Rolling bearing fault detection device

A technology for fault detection and rolling bearings, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of low accuracy, heavy workload, low accuracy of rolling bearing fault detection, etc., and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

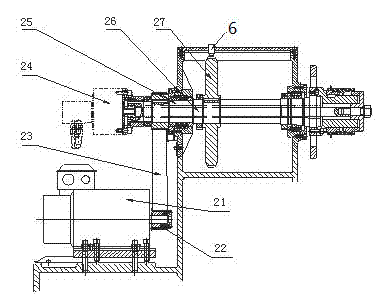

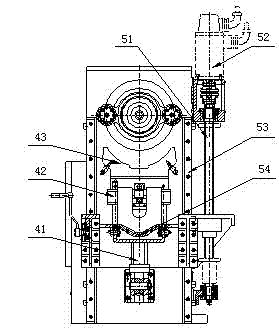

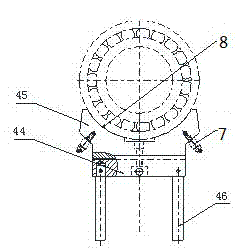

[0028] Such as figure 1 As shown, an embodiment of the present invention includes an automatic control detection and diagnosis system III, a hydraulic station II, a base 1 and a host I fixed on the base 1, and the host I transmits a fault detection signal to the automatic control Detection and diagnosis system III, the automatic control detection and diagnosis system III is connected to the hydraulic station II, the main engine includes a spindle system 2, an expansion sleeve type collet assembly 3, a loading assembly 4 and a lifting platform 5, the expansion sleeve Type collet assembly 2 is installed on one end of the main shaft 25 of the main shaft system 2; the loading assembly 4 is fixed directly below the expansion sleeve type collet assembly 3 and is in contact with the bearing; the lifting platform 5 It is arranged on one side of the machine base 1 , and when the bearing is loaded, it drives the bearing to move upwards, and loads the bearing onto the expansion sleeve ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com