Pipe butt welding positioning tool and method

A positioning tooling and butt welding technology, applied in auxiliary devices, manufacturing tools, metal processing, etc., can solve the problems of inaccurate positioning, single pipe system specifications, poor welding quality, etc., to achieve improved accuracy, low processing costs, and improved The effect of butt weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention is further described below in conjunction with specific embodiments:

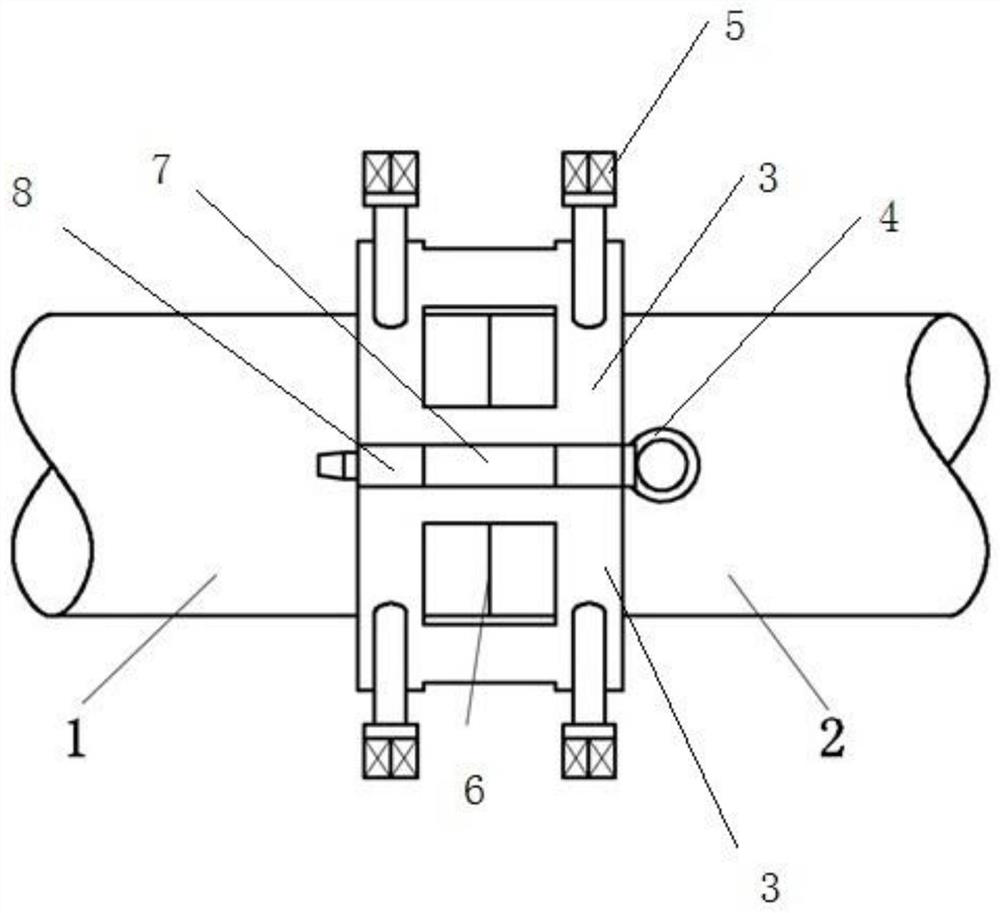

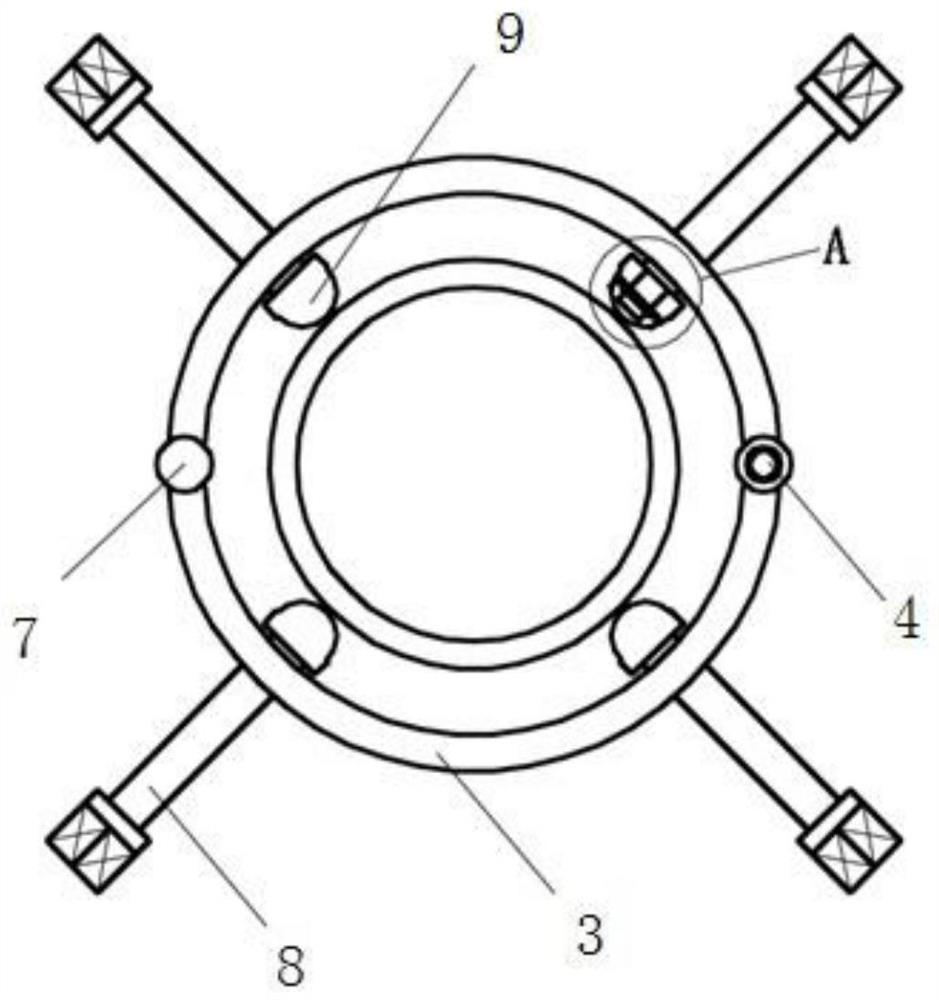

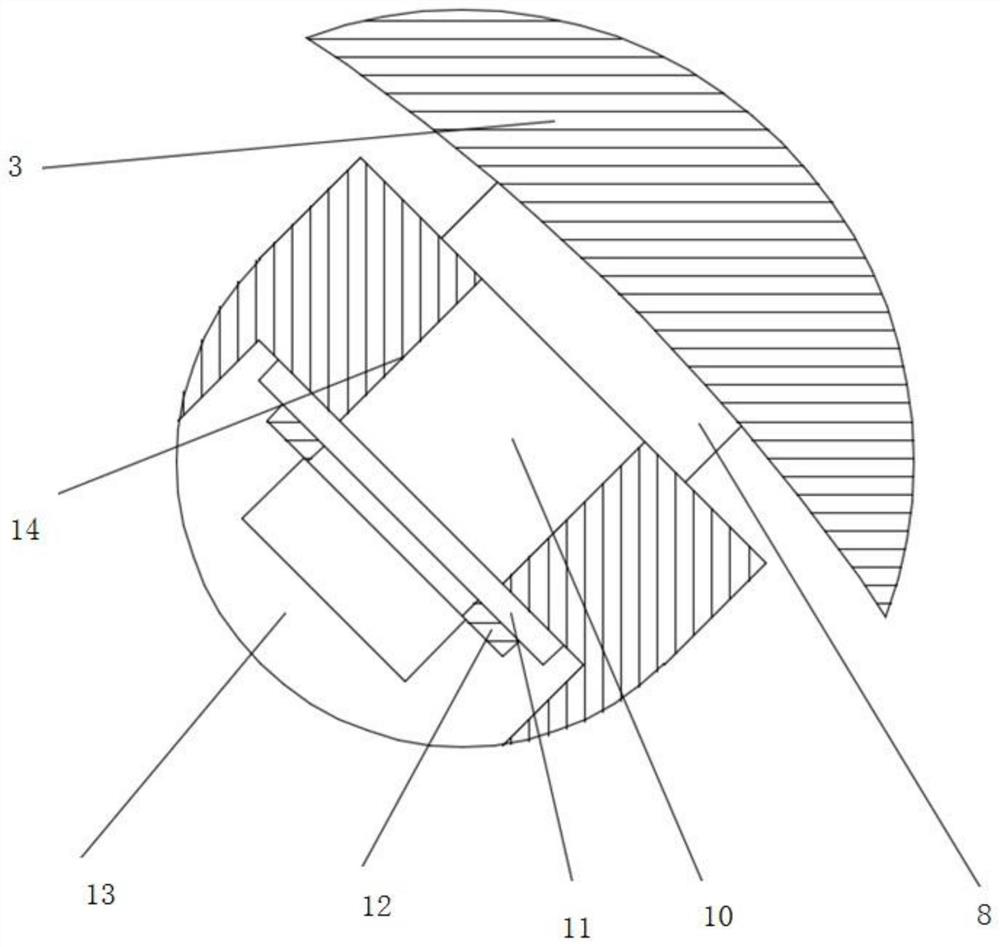

[0034] A pipe butt welding positioning tool, such as Figure 1-9 Shown, comprise two arc-shaped half-shells 3, the two half-shells 3 have the same structure, and are provided with welding holes 17 on the side walls of the half-shells 3, so that welding rods can be inserted into the welding holes 17 for welding; One end of the housing 3 is provided with a first pin hole 15, and the other end of the half shell 3 is provided with a second pin hole 16. When the two half shells 3 are spliced together, it is always the first pin hole of one half shell. The pin hole 15 is dislocated to match the second pin hole 16 of the other half shell, wherein the first pin hole 15 of one half shell is connected with the second pin hole 16 of the other half shell with the revolving pin 7, Respin 7 is made up of respin rod 20 and resell cap 21, after being connected by re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com