Patents

Literature

82results about How to "Wide range of specifications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength steel plate with yield strength 1,000 MPa and production method thereof

InactiveCN102409261AIncreased cooling capacitySimple structureTemperature control deviceFurnace typesSteel platesElectromagnetic stirring

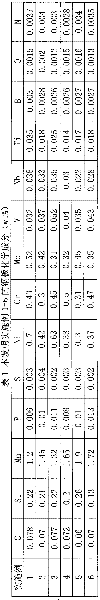

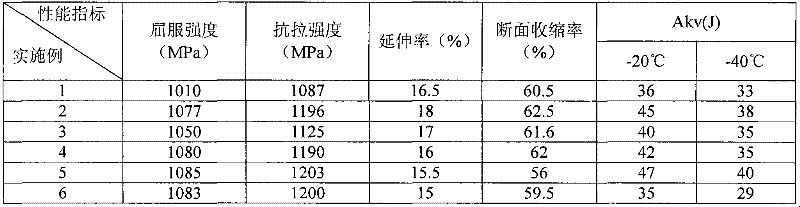

The invention discloses a high-strength steel plate with the yield strength 1,000 MPa and a production method thereof. The steel plate comprises the following chemical components in percentage by weight: 0.05-0.08 percent of C, 0.1-0.3 percent of Si, 1-2 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.007 percent of S, 0.3-0.7 percent of Ni, 0.3-0.5 percent of Cr, 0.3-0.6 percent of Mo, 0.02-0.04 percent of Nb, 0.03-0.055 percent of V, 0.01-0.035 percent of Ti, 0.002-0.0035 percent of B and the balance of Fe and inevitable impurities, wherein the gas content [O] is controlled to be less than or equal to 0.002 percent and [N] is controlled to be less than or equal to 0.004 percent, Ti / N is more than or equal to 3.2, and the carbon equivalent index Ceq is less than or equal to 0.56 percent. The production method comprises the following steps of: performing continuous casting with an electromagnetic stirring technology, wherein the thickness of a continuously cast bloom after casting is not less than four times that of a finished steel plate; and heating a steel blank at the temperature 1,100-1,200 DEG C, rolling in a recrystallization region and a non-recrystallization region at two stages, performing relaxation temperature waiting for 5-20 seconds, quickly cooling to 300-450 DEG C at the speed 10-30 DEG C per second, draining water, stacking, slowly cooling, tempering the steel plate at the tempering temperature 400-600 DEG C, and preserving heat for 2-3 minutes per millimeter. The steel plate has high comprehensive performance, large specification coverage and greatly-lowered production cost and raw material cost in comparison to the conventional product of the same level, and can be widely applied to the fields of mines, engineering machinery and the like.

Owner:ANGANG STEEL CO LTD

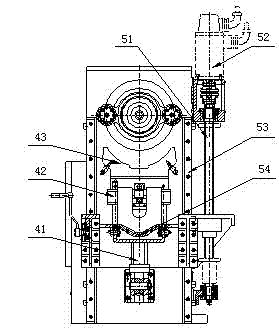

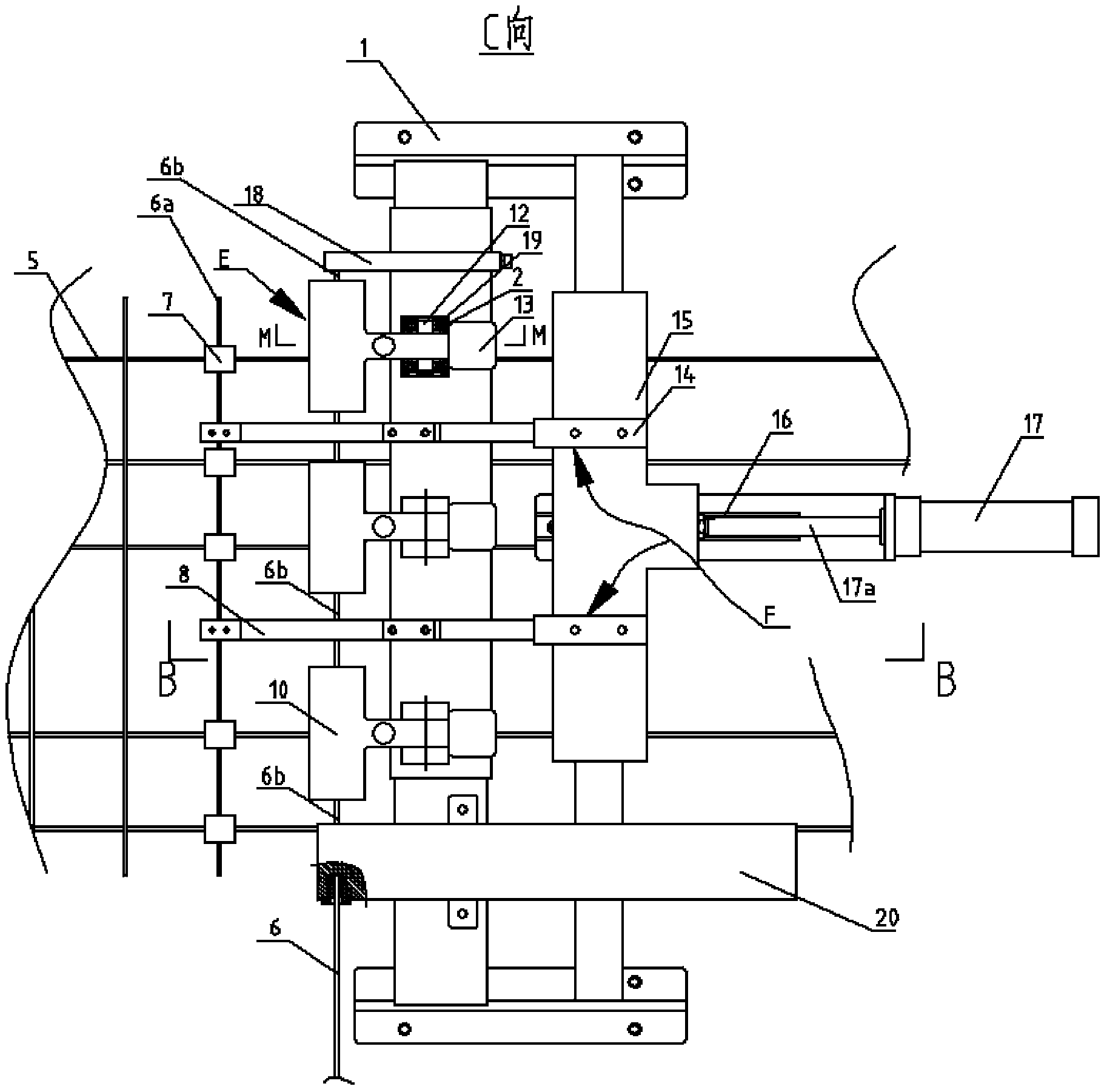

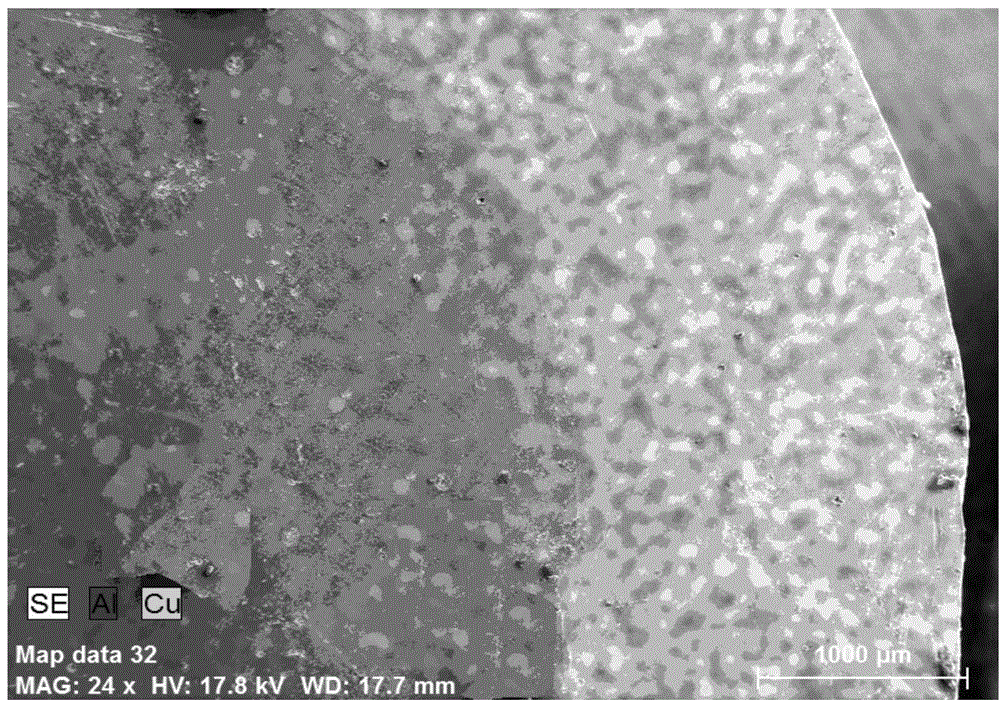

Full-automatic three-dimensional multipoint cold riveting assembly process engineering of die-casting aluminum alloy

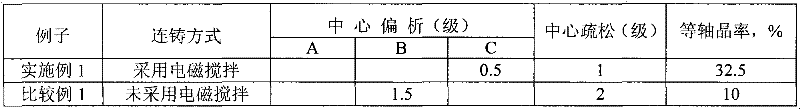

The invention discloses a full-automatic three-dimensional multipoint cold riveting assembly process engineering of die-casting aluminum alloy which relates to a full-automatic three-dimensional multipoint cold riveting special device. In the special device, a sliding table power mounting base and a workbench panel are respectively installed on a rack, a spin rivet power system is installed on a vertical Z-direction servo linear sliding table which is installed on the sliding table power mounting base, a workpiece spin rivet gripper is installed on a horizontal Y-direction servo linear sliding table which is installed on a horizontal X-direction servo linear sliding table, the X-direction servo linear sliding table is installed on the workbench panel, and the spin rivet power system is positioned above the workpiece spin rivet gripper. Compared with the prior art, the riveting speed of the invention is improved by 1.5-2 times, and the invention has the advantages of high riveting quality, high connection soundness, low error probability, wide adaptation range of product specification, high production efficiency, long life of snap heads, high riveting accuracy and the like.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

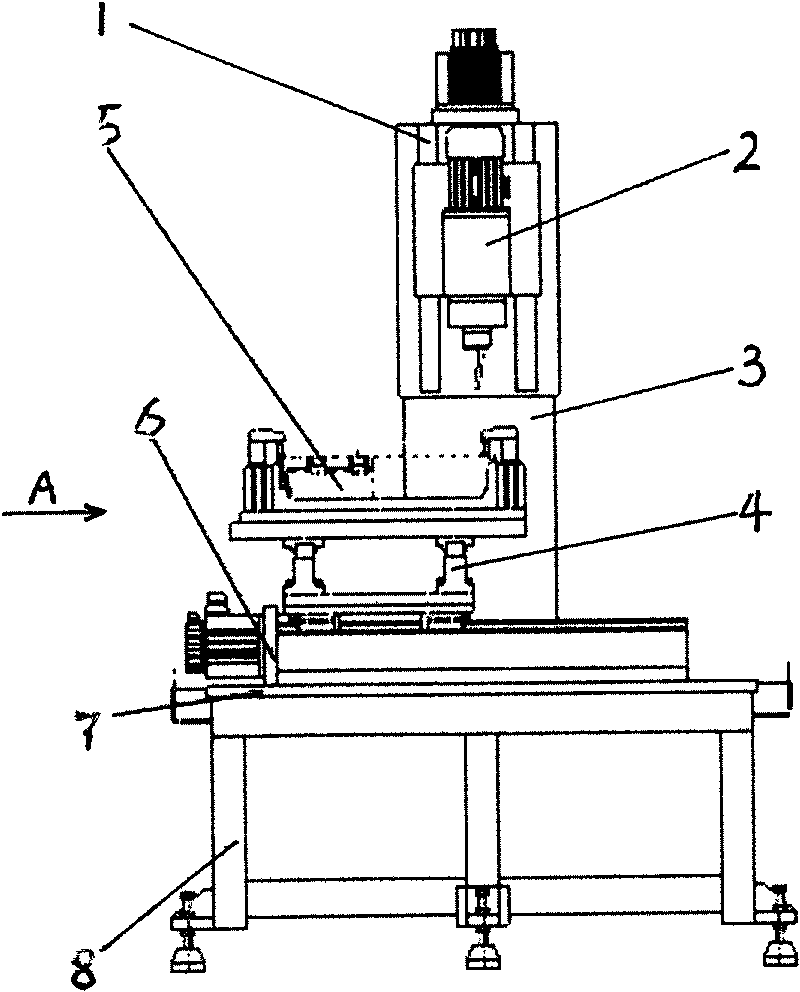

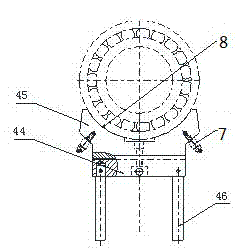

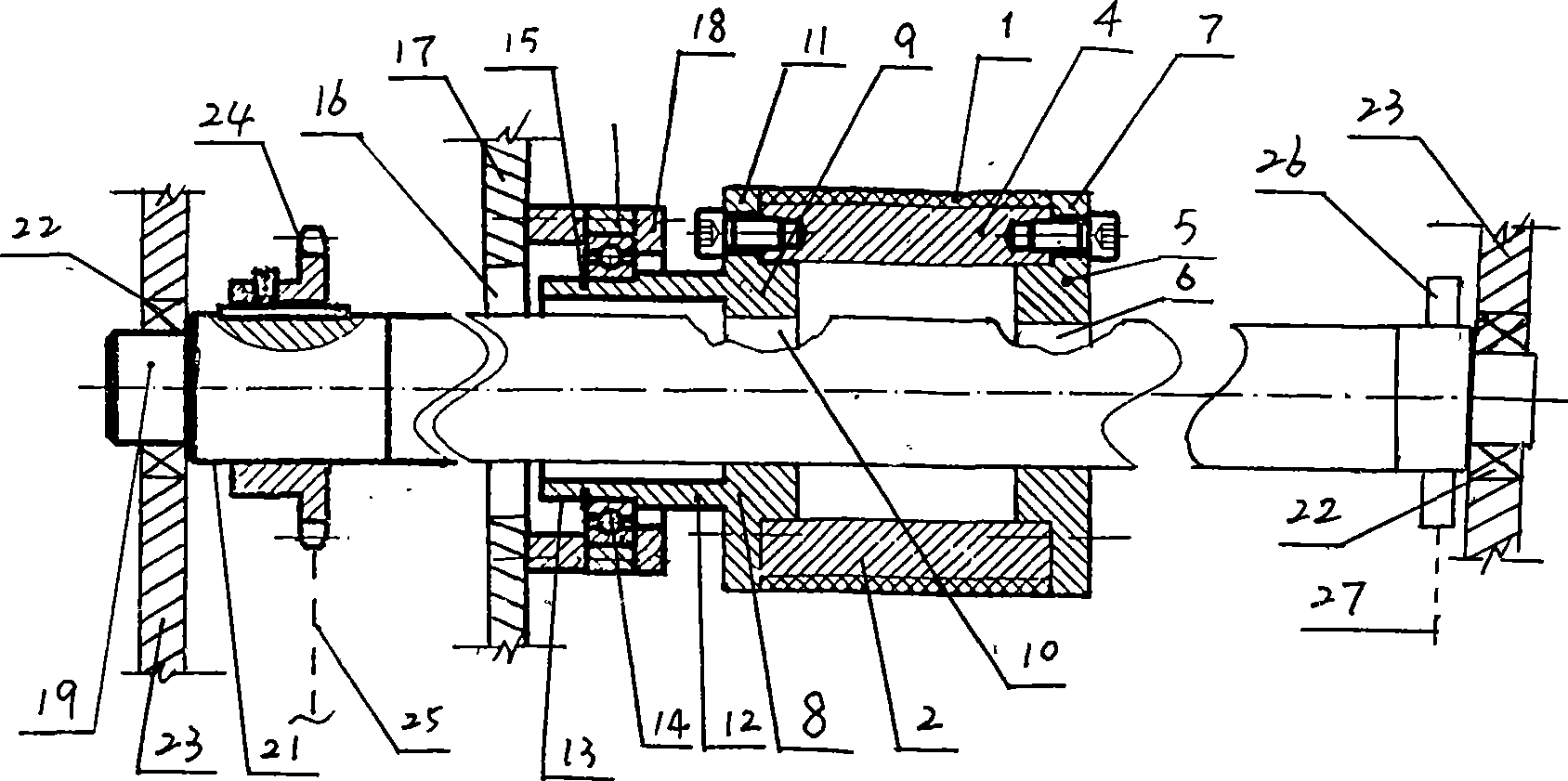

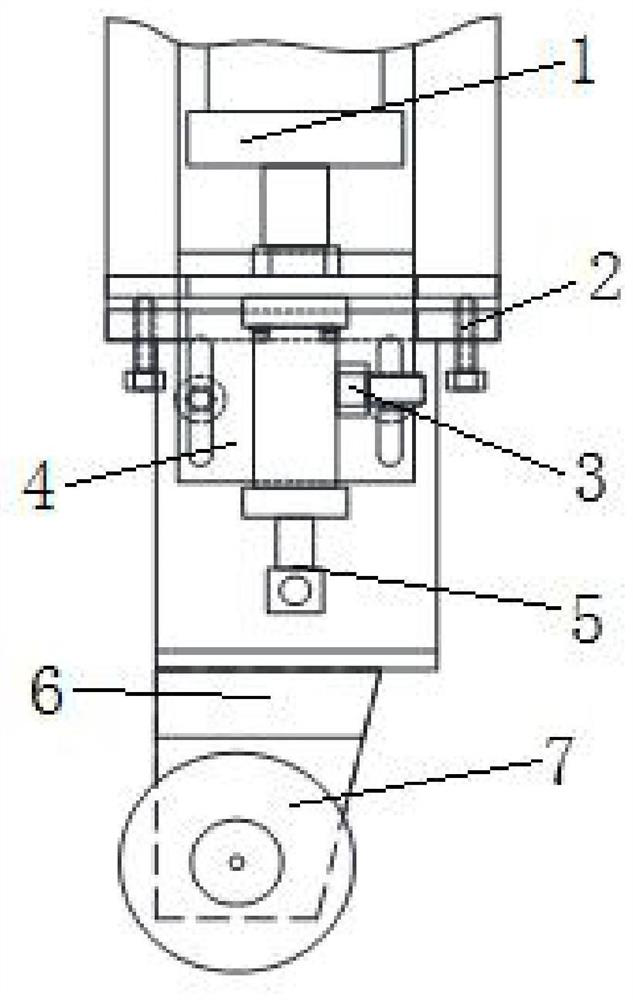

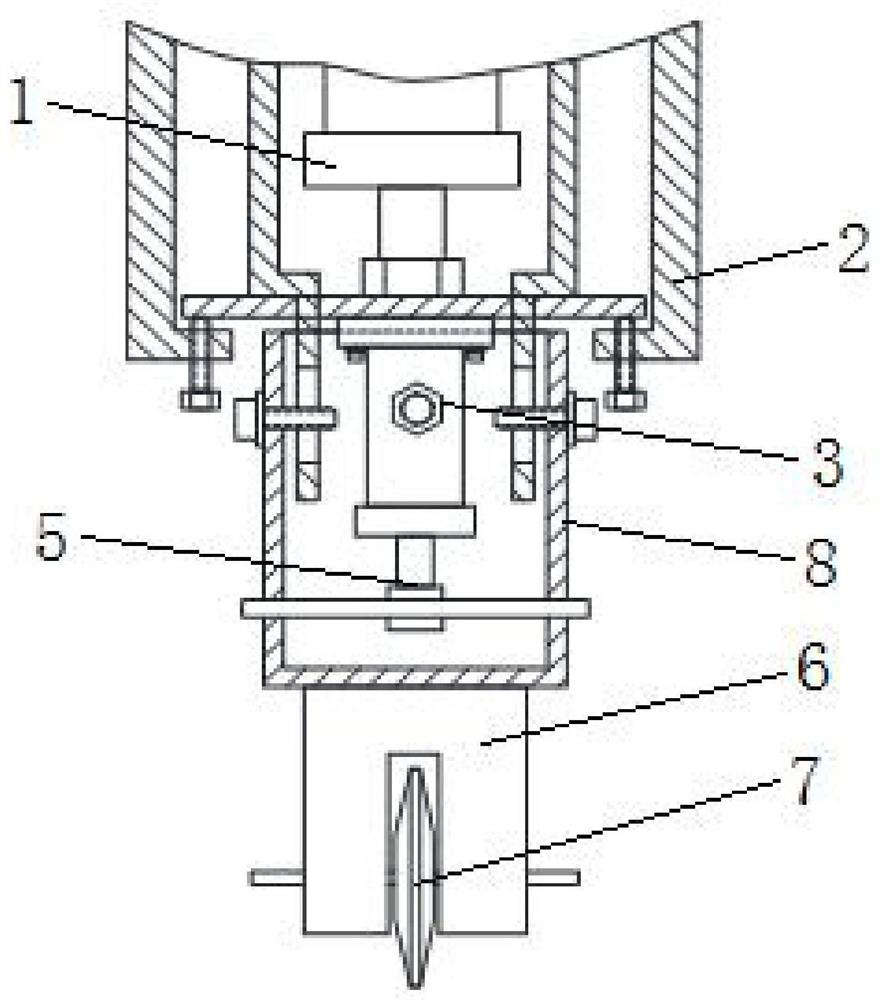

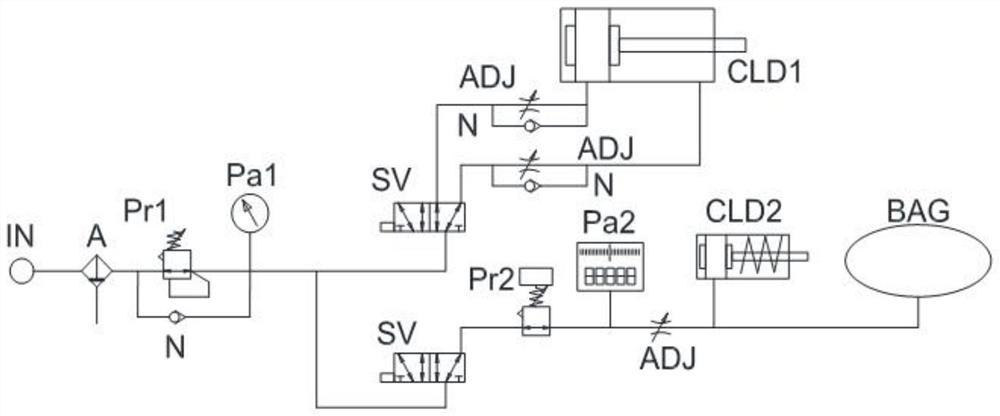

Rolling bearing fault detection device

InactiveCN103076173AWide range of specificationsImprove accuracyMachine bearings testingRolling-element bearingEngineering

The invention discloses a rolling bearing fault detection device, which comprises an engine base and a host machine fixed on the engine base, wherein the host machine comprises a main shaft system, an expanding-sleeve elastic chuck component, a loading component and a lifting platform; the expanding-sleeve elastic chuck component is arranged at one end of a main shaft of the main shaft system; the loading component is fixed just below the expanding-sleeve elastic chuck component and is contacted with a bearing; the lifting platform is arranged at one side of the engine base; and when the bearing is loaded, the bearing is driven to move up, and the bearing is loaded to the expanding-sleeve elastic chuck component. With the adoption of the rolling bearing fault detection device, the detection accuracy can be improved, the specification range of the detected rolling bearing is increased, and the automatic diagnosis of the bearing is realized.

Owner:唐德尧

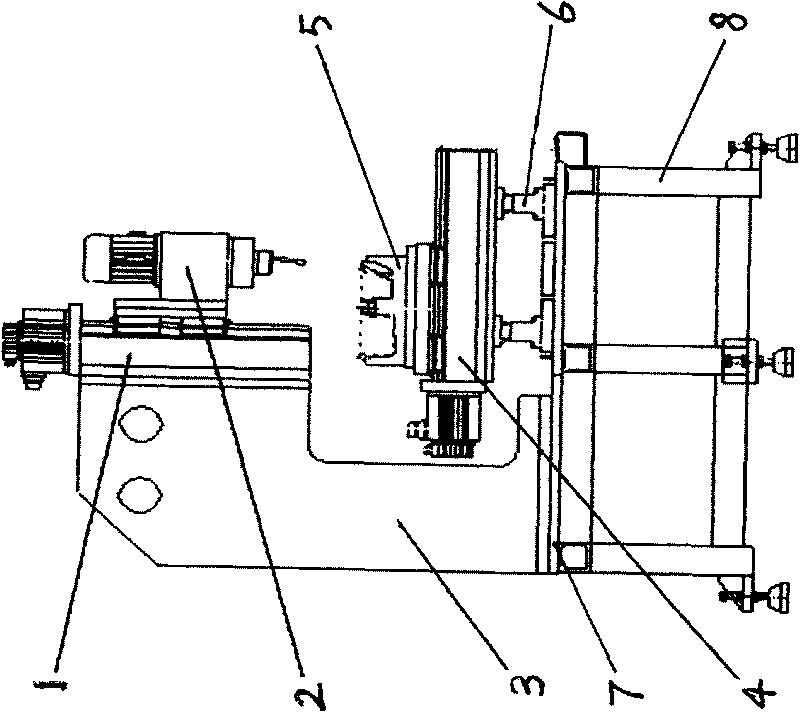

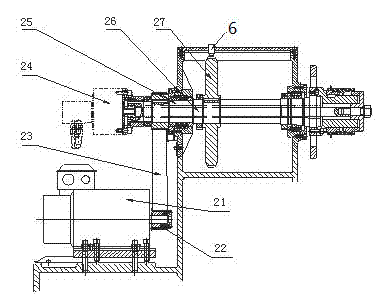

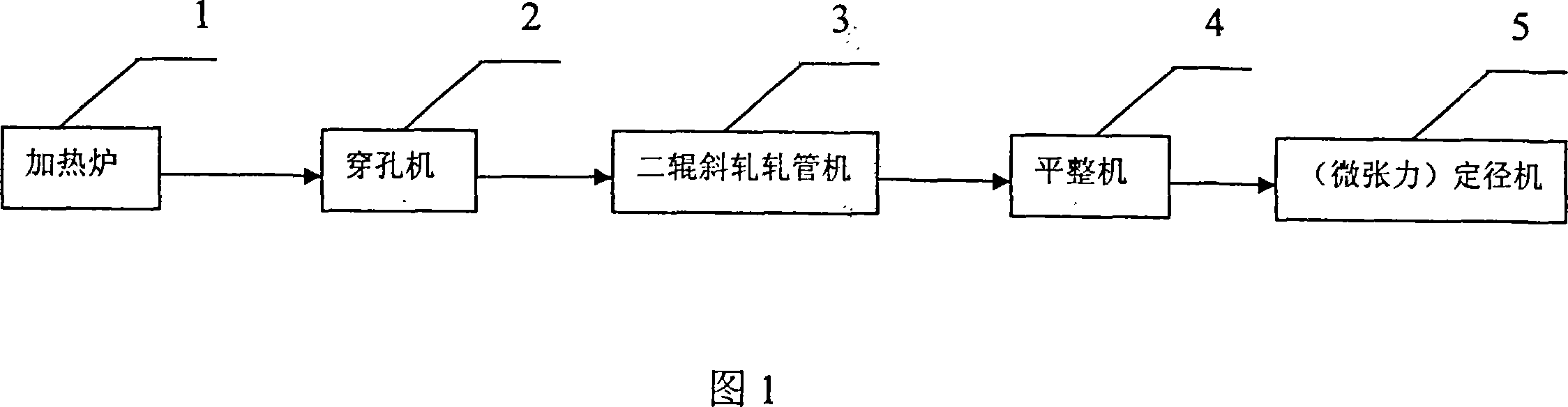

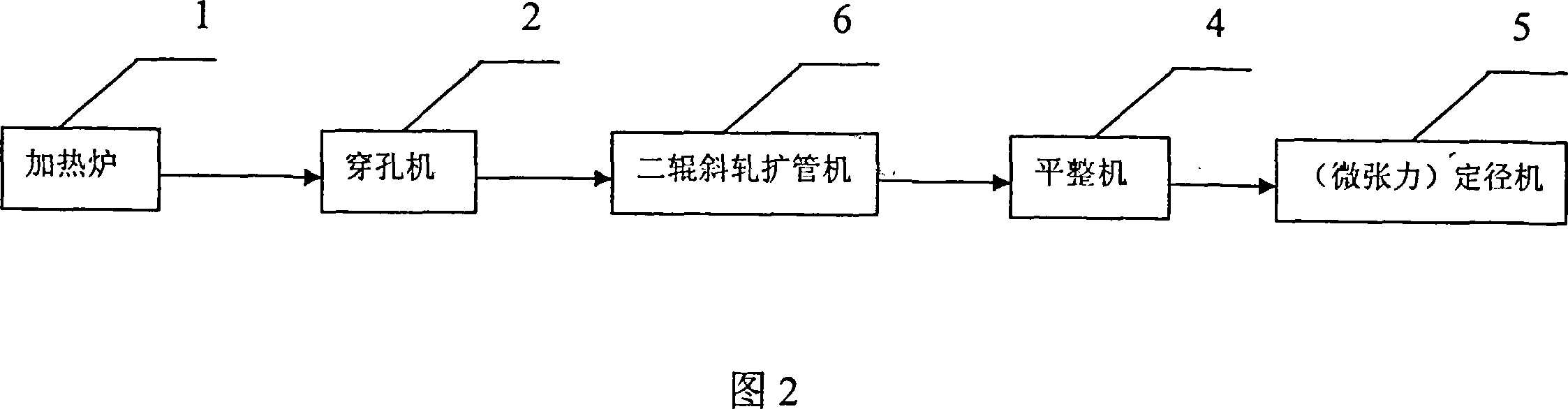

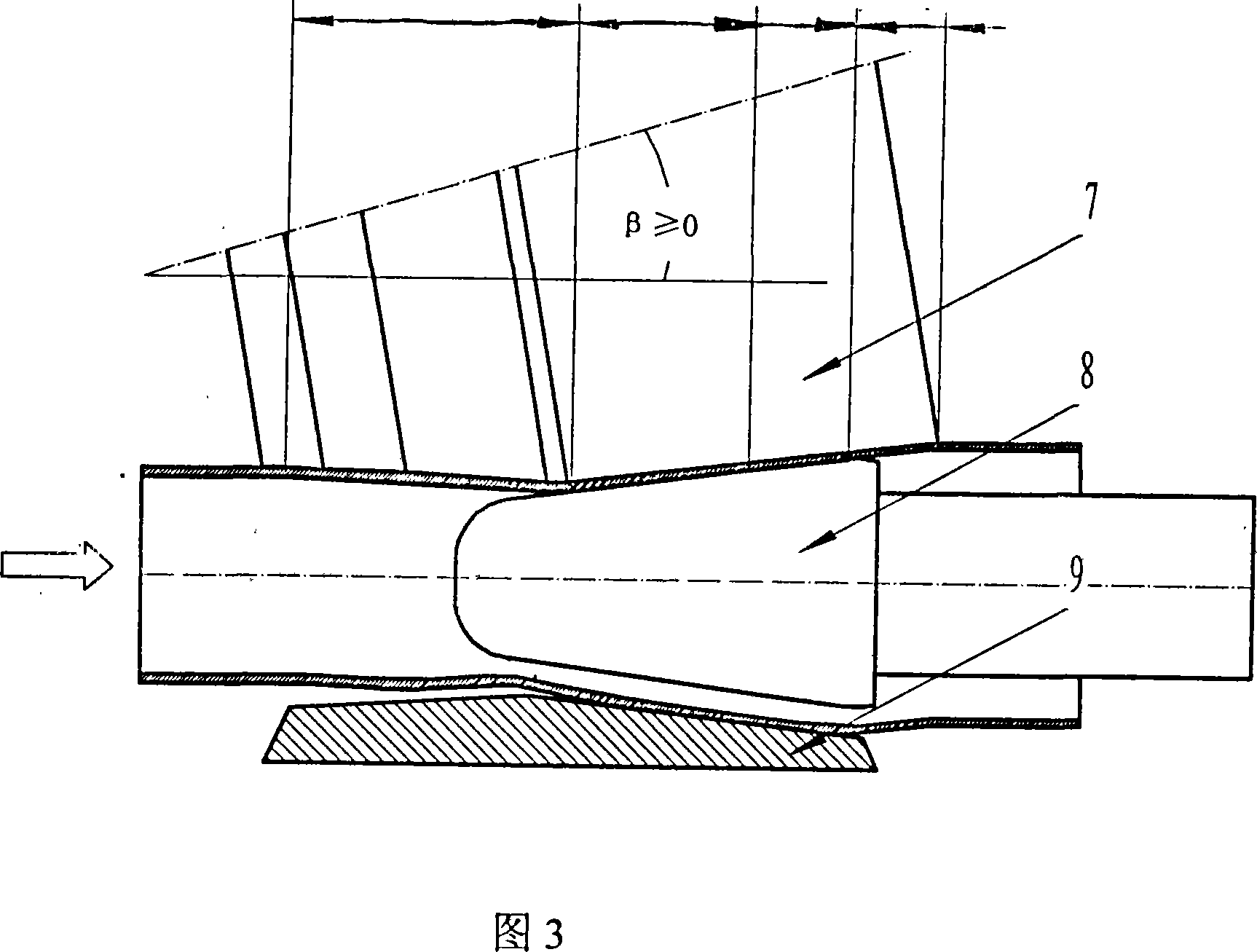

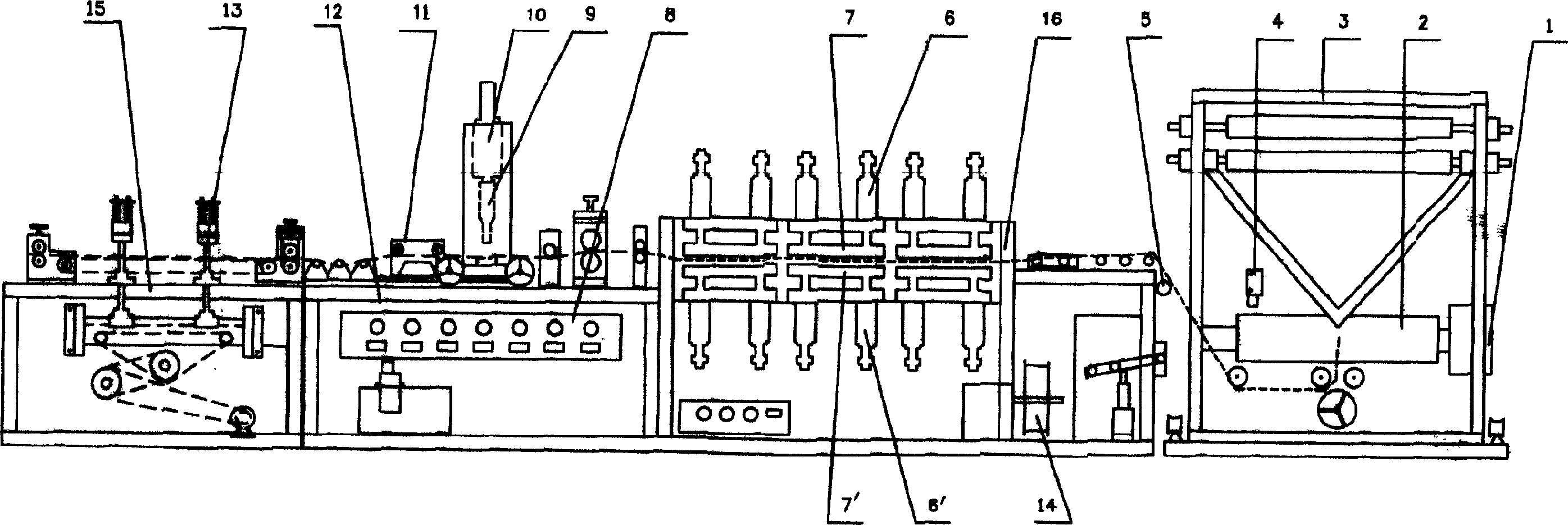

Technologic process and special apparatus for rolling seamless steel pipe

InactiveCN101066547AExpanded range of product specificationsMeet needsRoll mill control devicesMetal rolling arrangementsHeating furnaceMaterials science

The present invention discloses technological process and special apparatus for rolling seamless steel pipe. The technological process includes the steps of: heating in a heating furnace, perforating in a perforating machine, expanding in a two-roll skew rolling pipe expander, leveling in a leveling machine and sizing in a sizing mill. The two-roll skew rolling pipe expander therefor consists of two rolls, one forcer and two guide plates. The present invention has low apparatus investment, and can meet the requirement in rolling seamless steel pipe with wide size range and great batch.

Owner:烟台鲁宝钢管有限责任公司

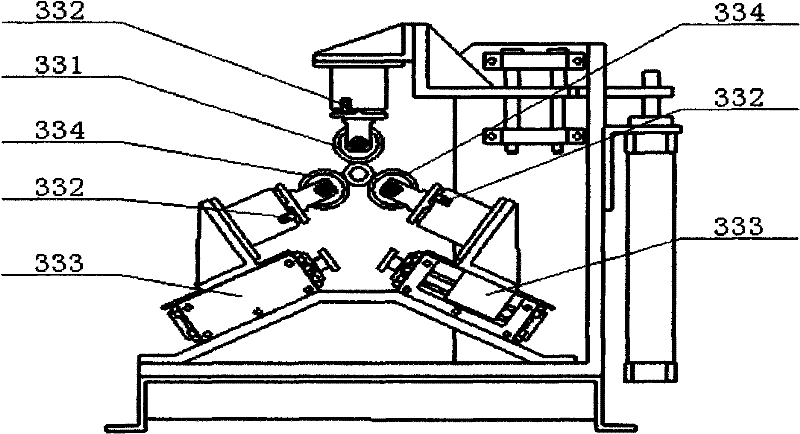

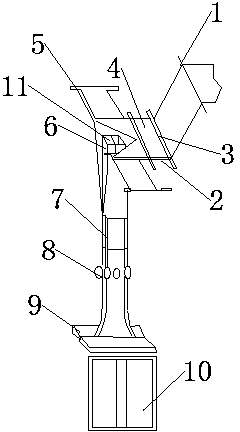

Flat plate heat collector single set slope type semiautomatic cover plate assembling machine

InactiveCN104708579AEasy to adjust the grabbing angleSmall footprintAssembly machinesMetal-working hand toolsAgricultural engineeringSmall footprint

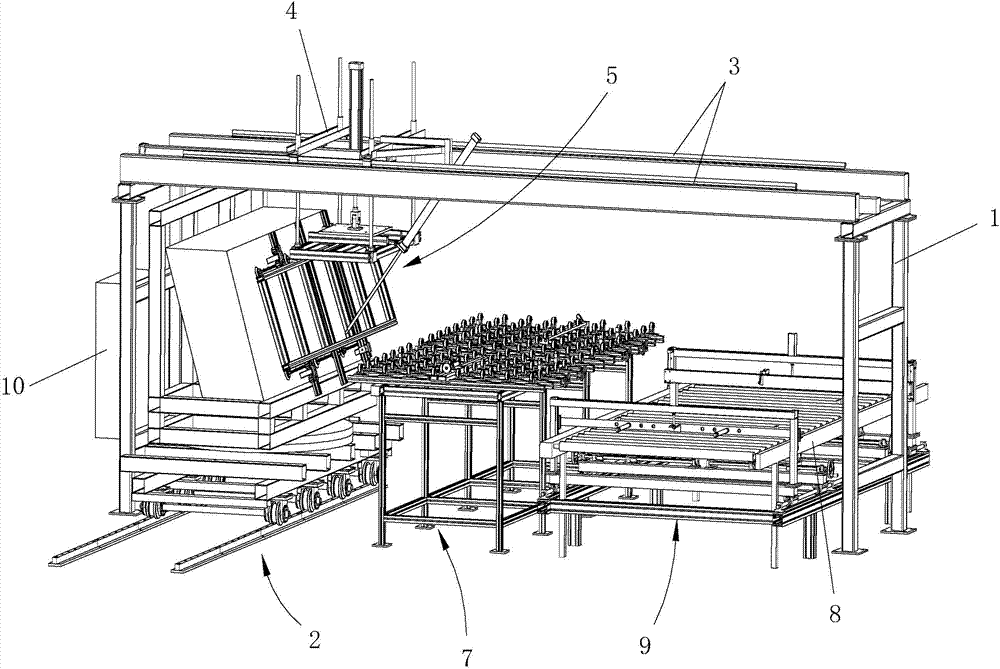

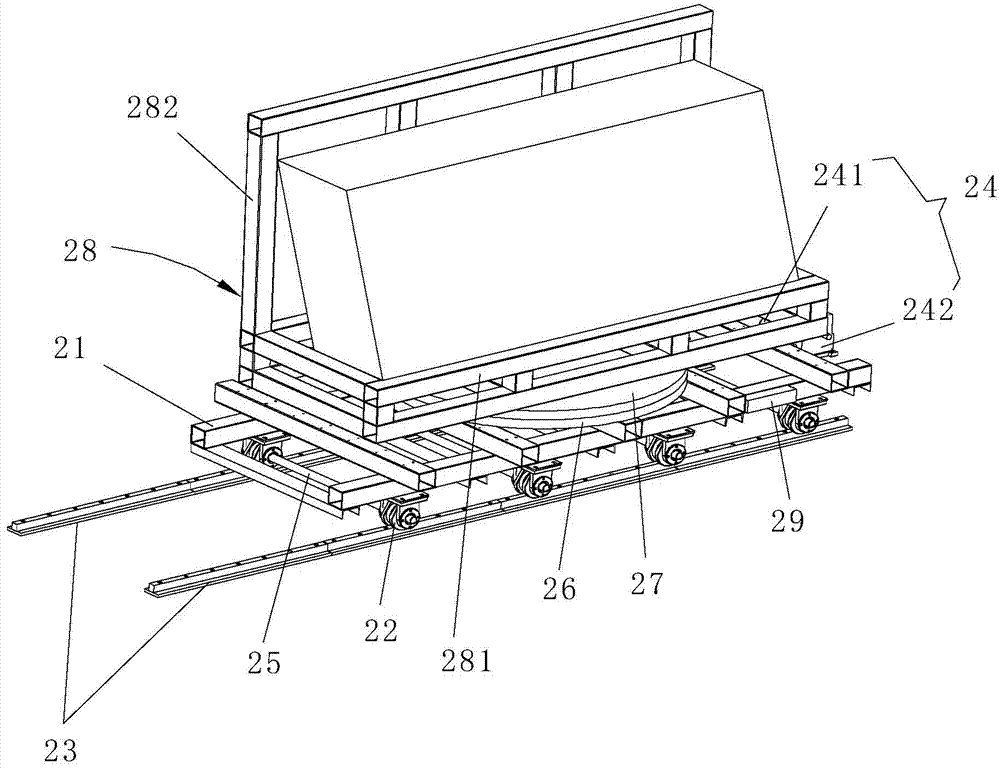

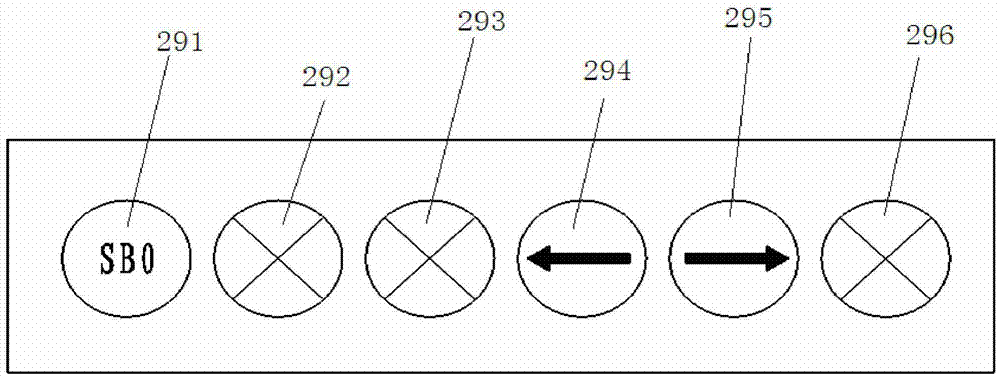

The invention discloses a flat plate heat collector single set slope type semiautomatic cover plate assembling machine which comprises a portal frame. An assembly area below the portal frame is sequentially provided with a slope type cover plate loader, a cover plate positioning mechanism and a frame positioning mechanism, the frame positioning mechanism is provided with a frame roller line, a main guide rail is arranged at the top of the portal frame and connected with a sliding bock seat in a sliding mode, and the sliding block seat is provided with a folding cover plate grab mechanism which moves on the main guide rail through the sliding block seat. The flat plate heat collector single set slope type semiautomatic cover plate assembling machine has the advantages that the operation is simple, the assembly efficiency is high, the productivity is high, the application range of production specifications is wide, the occupied area of equipment is small, the space is saved, the flat plate heat collector single set slope type semiautomatic cover plate assembling machine can be suitable for grabbing and assembling of a vertical packing cover plate, and the flexibility and the universality are higher.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

Single-film concave-convex chain clipped applying bag making machine

InactiveCN1541899AWide range of specificationsThe printing effect exceedsBox making operationsPaper-makingMicrocomputerPunching

The single-film concave-convex clip chain jointing machine is provided with upper and lower cylinders, ironing molds mounted on the pistons in the cylinders, bakelite board between the upper and lower ironing molds, and bag adhering mechanism with punching head mounted on the piston of one cylinder. The present invention has high bag making efficiency, convenient operation and stable performance, and the jointing machine is microcomputer controlled and provided with pneumatic mechanism.

Owner:郭明

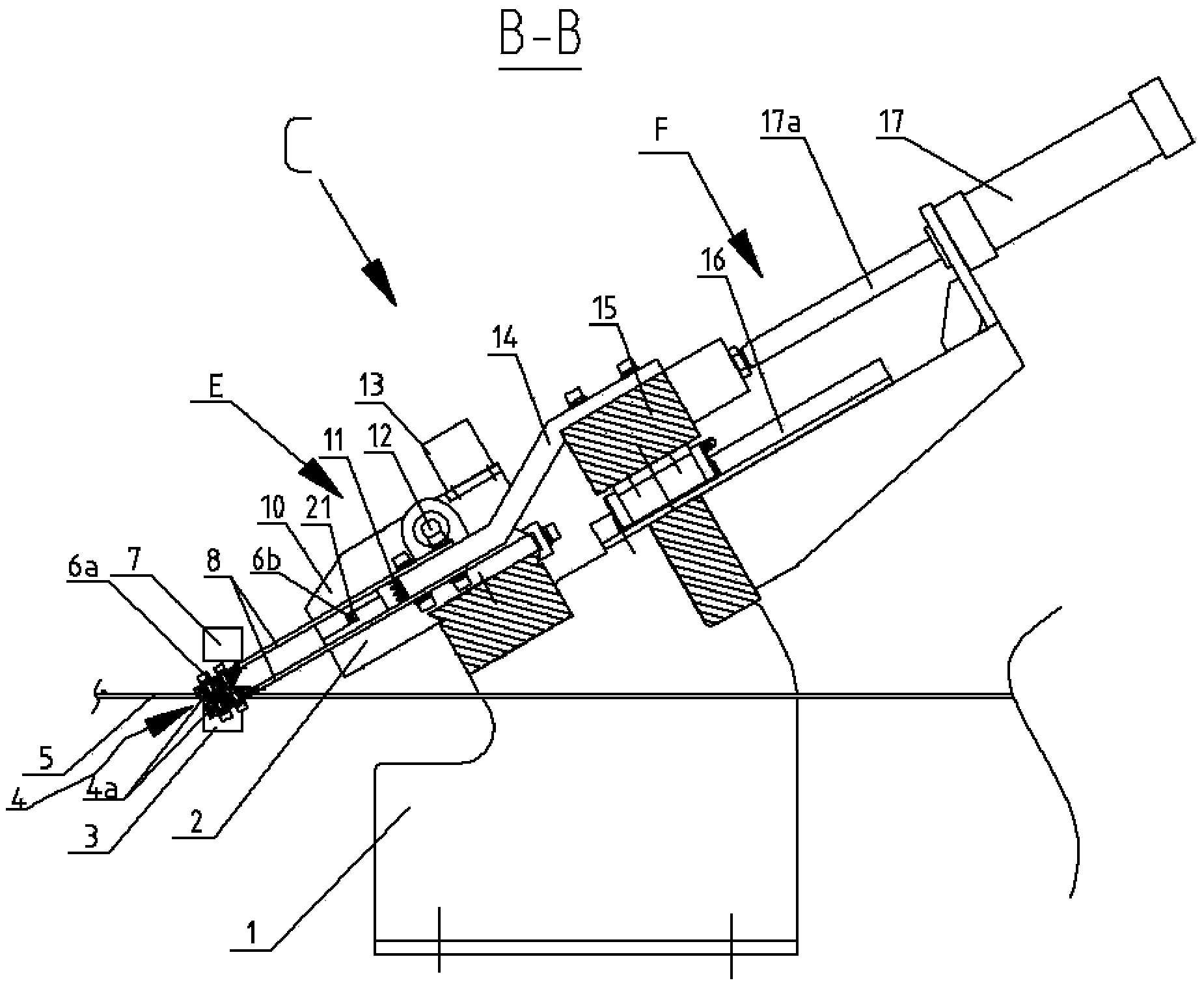

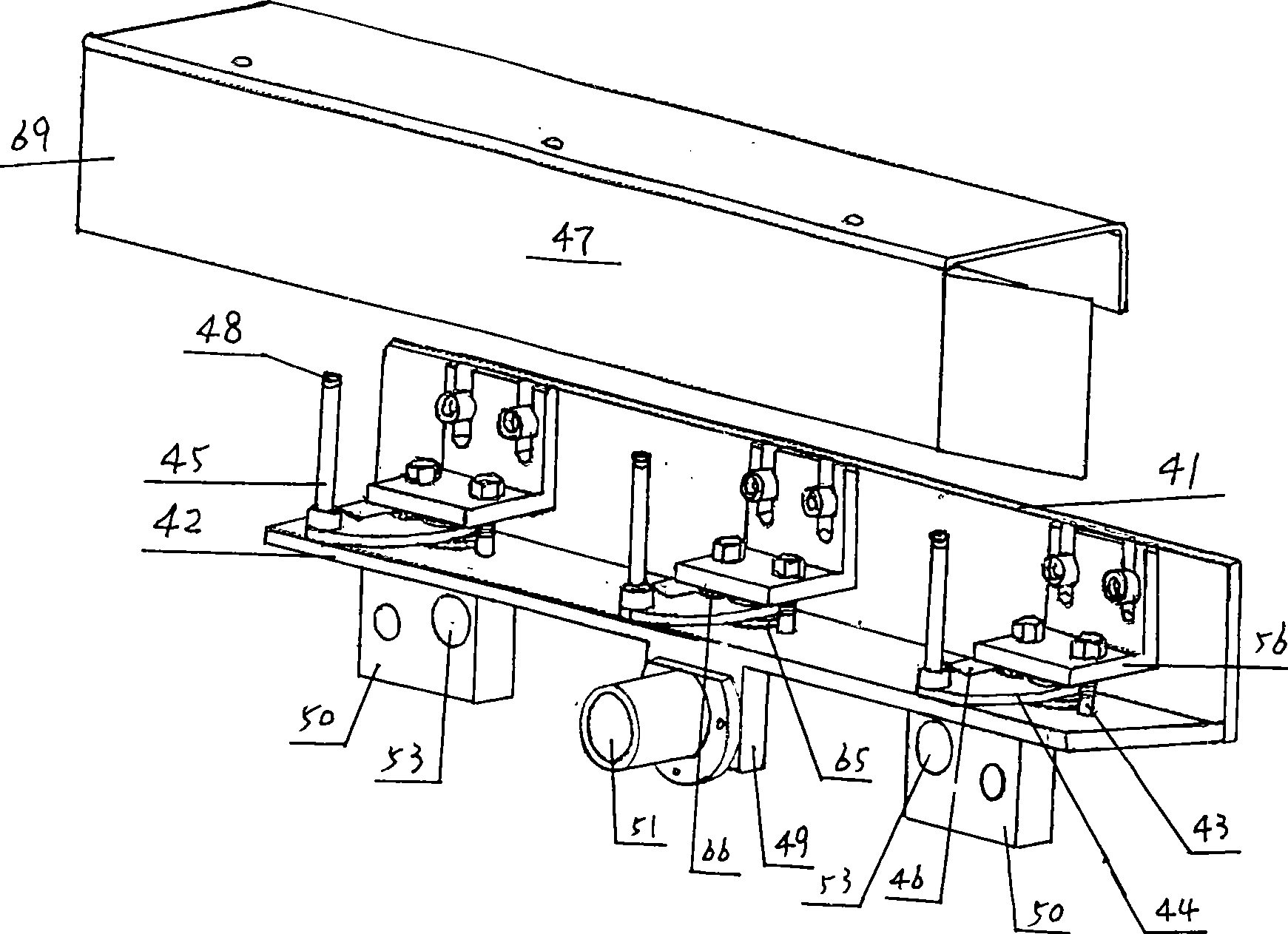

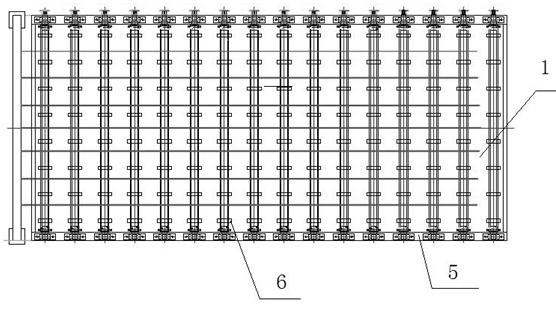

Novel transverse bar blanking mechanism of reinforcing mesh welding production line

ActiveCN104043762AWide range of specificationsApplicable to the requirements of high efficiency and energy savingWire networkWire rodProduction line

The invention discloses a novel transverse bar blanking mechanism of a reinforcing mesh welding production line. The novel transverse bar blanking mechanism structurally comprises multiple transverse bar wire feeding devices and multiple transverse bar positioning devices, wherein the multiple transverse bar wire feeding devices and the multiple transverse bar positioning devices are arranged in a direction vertical to the transverse bar axis direction; the transverse bar positioning devices comprise bases and movable bases; transverse bars pass through a transverse bar channel; when the transverse bar wire feeding devices drive clamping heads at the end parts of the transverse bar wire feeding devices to extend out to clamp and transfer the transverse bar to welding positions, the transverse bar channel is closed by the movable bases; when the transverse bar wire feeding devices drive the clamping heads at the end parts to retract so as to clamp the transverse bars, the transverse bar channel is opened by the movable bases, and the transverse bar wire feeding devices push the transverse bars to the welding positions. The novel transverse bar blanking mechanism has the beneficial effects that the transverse bar wire feeding devices and the transverse bar positioning devices are used for sequentially conveying the transverse bars to the welding positions and positioning and restricting the new input transverse bars; the specification range of processed transverse bars is wide, and the novel transverse bar blanking mechanism is simple in structure and easy to operate; steel wire rods are used as raw materials for the transverse bars, and the sizing requirements of the transverse bars are met by virtue of a simple-structure straightening and sizing device, so that the novel transverse bar blanking mechanism has the advantages of low cost and wide raw material application range.

Owner:TJK MACHINERY TIANJIN

Secondary impression device of corrugated case

InactiveCN101456261AWide range of specificationsQuality assuranceBox making operationsPaper-makingCardboardDrive shaft

The invention discloses a secondary indentation device for corrugated cases and belongs to the technical filed of corrugated case manufacturing equipment. The secondary indentation device comprises a paper conveying mechanism which is matched with an indentation mechanism and adopts a paper conveying structure driven by two synchronous small belts and a hexagonal steel type transmission shaft, a transversely positioning and arranging mechanism of the corrugated cardboards and a worm-and-gear indentation wheel pressure adjusting mechanism, wherein each synchronous small belt (1) is corresponding to a pair of a driving roller (2) and a driven roller (3) which are matched and arranged on a piece of wall plate (17), a hexagonal steel type rotating shaft (19) and a driven hexagonal steel type rotating shaft (20) which are arranged on a large wall plate (23) of a machine frame, and a threaded rod shaft driving the small wall plate (17) to adjust the axial positions of the rollers for standard and continuous paper conveying. One side of the transversely positioning mechanism has a plate type fixed compass (40) and the other side of the transversely positioning mechanism has a plate type elastic compass which is capable of carrying out micro limit adjustment freely and automatically. The transversely positioning device is arranged on a wall plate through a length bolt (55) at a position which can be adjusted. A pressure adjusting mechanism of an indentation wheel is of one-side worm-and-gear type. The axial positions of the small belts can be adjusted conveniently and rapidly. The transversely positioning and arranging mechanism has a function of free and automatic micro limit adjustment. Secondary indention is accurate. The pressure of the indention wheel can be adjusted accurately, conveniently and rapidly. Therefore, the quality of the secondary indentation is ensured and the production efficiency is improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Method for producing large-thickness lamination-crack-resistant tempered high-strength steel plate

The invention discloses a method for producing a large-thickness lamination-crack-resistant tempered high-strength steel plate. The method is characterized by comprising the steps: smelting, performing continuous casting, performing electroslag remelting, heating, rolling, annealing and performing heat treatment. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.18 percent of C, 0.20-0.50 percent of Si, 0.95-1.25 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.80-1.15 percent of Ni, 0.40-0.60 percent of Cr, 0.40-0.60 percent of Mo, 0.020-0.050 percent of Nb, 0.010-0.030 percent of Ti, 0.020-0.045 percent of TAl, and the balance of Fe and inevitable impurities. According to the method, electroslag remelting treatment is adopted, good overall performance of the large-thickness steel plate with the diameter of 30mm can be met due to the reasonable controlled rolling and heat treatment process, and the production cost is reduced; and the specification range is wide. The method adopts the steps of electric furnace smelting, continuous casting and electroslag remelting smelting, the contents of P and S in the obtained tempered high-strength steel plate are low, and the steel is pure; and moreover, a large-slab electroslag remelting technology is adopted, the round ingot hammer cogging process during electroslag remelting is reduced, the production period is shortened, and the cost is obviously reduced.

Owner:WUYANG IRON & STEEL

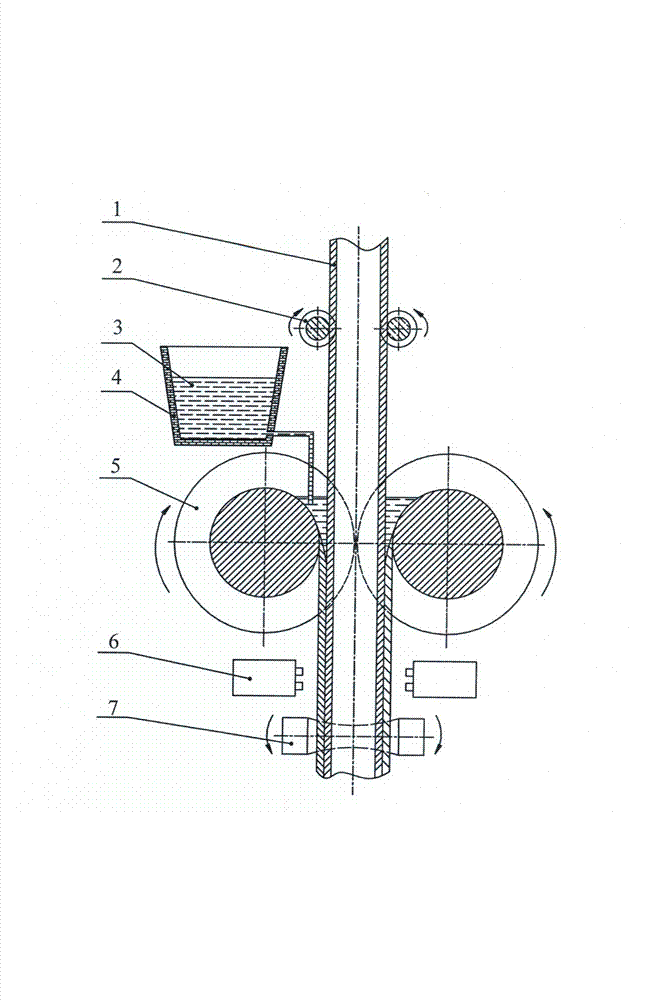

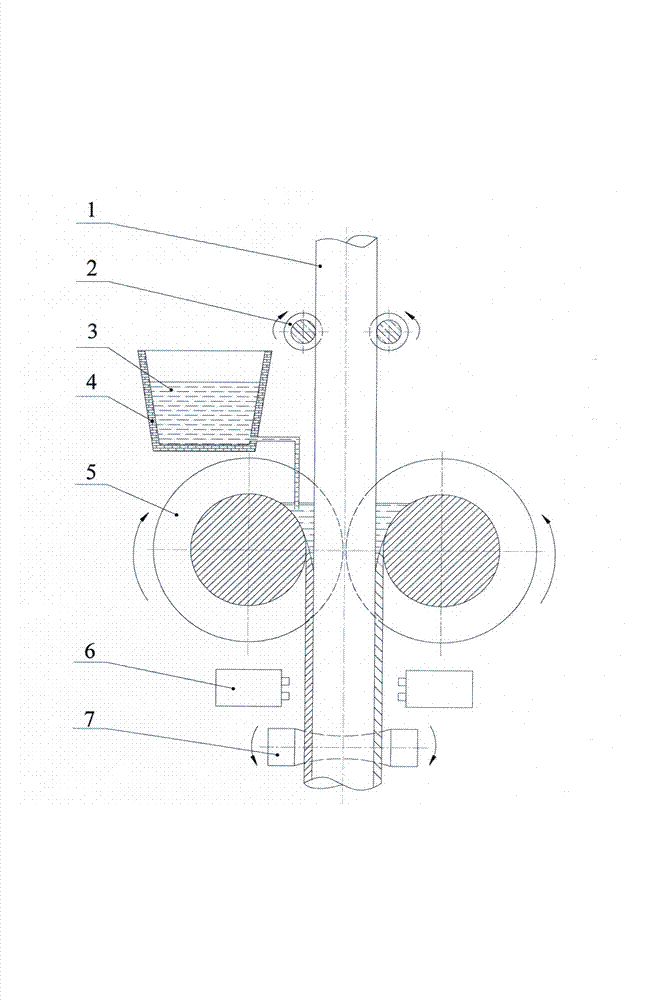

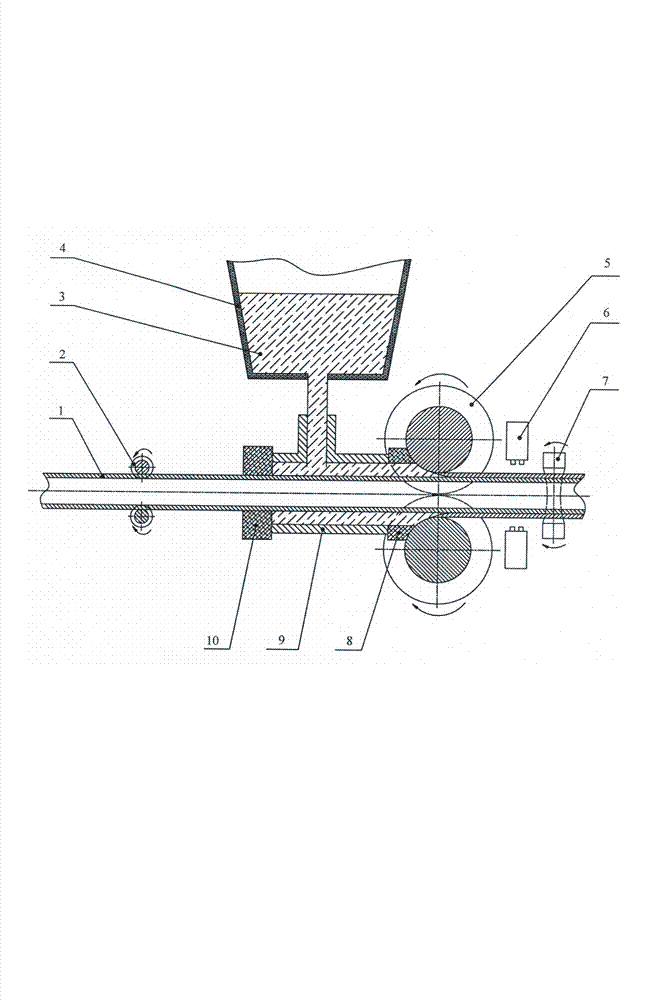

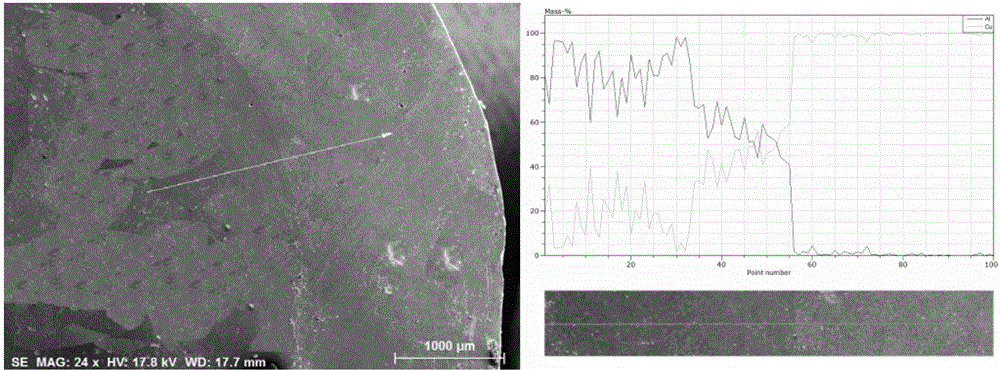

Method for producing bimetal composite material by adopting cold core continuous casting and rolling process

ActiveCN102825067ALow requirements for billet size and shape accuracyHigh yield and metal utilizationMetal rolling arrangementsManufacturing engineeringPipe

The invention relates to a method for producing a bimetal composite material by adopting a cold core continuous casting and rolling process. The method is characterized by comprising the following steps of: using an inlet pinch and guide device to feed a cold core base material into a groove of a casting and rolling roller, continuously pouring a molten-state covering material in a ladle into an annular crystallizer constituted by the base material and the groove of the casting and rolling roller, driving the casting and rolling roller, continuously and uniformly coating the molten-state covering material on the surface of the cold core base material, and arranging a secondary cooling device and an outlet pinch and guide device on the outlet side so as to realize cold core continuous casting and rolling composite molding of a bimetal composite pipe or rod. The method has the advantages that the bimetal composite pipe or rod produced by the technological method has the advantages of low requirements on size and shape precision of a stock, no need of pre-assembly, high finished product rate, high metal utilization rate, no limitations on length and thickness of a covering layer of a product, a wide range of specifications of the product and the like, and the method is of a high-efficient production technological method. The product can be directly used as a finished product or be used as the stock for pipe rolling, cold drawing and other process steps.

Owner:YANSHAN UNIV

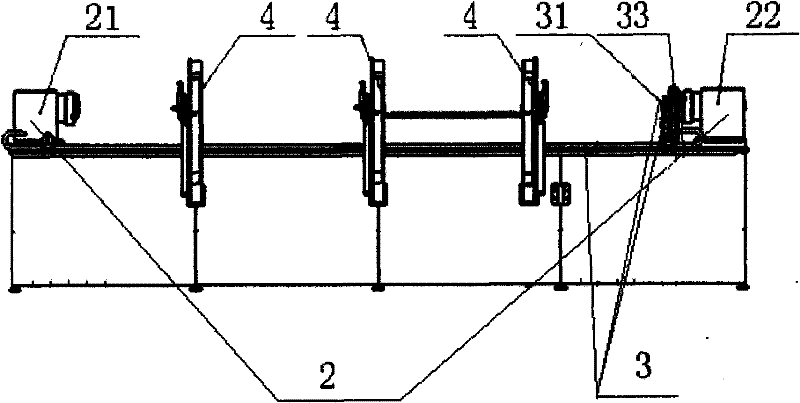

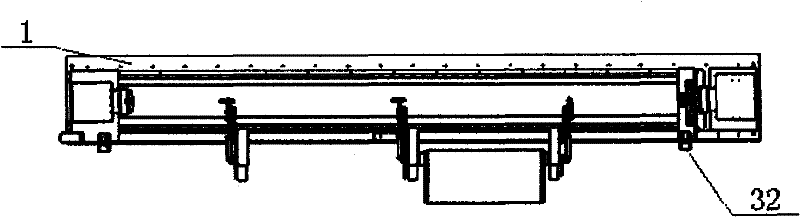

Movable high-accuracy silk material ultrasonic detection system

ActiveCN102221577AWide range of specificationsBroad requirementsAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringFalse alarm

The invention discloses a movable high-accuracy silk material ultrasonic detection system, which consists of a substrate platform (1), a clamping mechanism (2) and a detection mechanism (3), wherein the clamping mechanism (2) and the detection mechanism (3) are arranged on the substrate platform (1). The system is characterized in that: the detection mechanism (3) consists of a detection unit (31) and an axial moving unit (32); and the detection unit (31) is flexibly connected with the axial moving unit (32), has a degree of freedom in the radial direction of a silk material, and axially rigidly moves along with the radial movement of the silk material when the silk material moves radially. The movable high-accuracy silk material ultrasonic detection system changes the structural form of a conventional detection apparatus, effectively reduces a missed alarm rate and a false alarm rate, and realizes the digital operations of clamping, rotation and scanning and defect signal acquisition and processing by using private control detection software, thereby realizing the high-flexibility and high-efficiency automatic detection, recording and evaluation of internal defects, surface defects and near surface defects of the silk material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Medium carbon alloy high-strength quenched and tempered steel plate and production method thereof

The invention discloses a medium carbon alloy high-strength quenched and tempered steel plate, which consists of the following components in percentage by weight: 0.38 to 0.45 percent of C, less than or equal to 0.35 percent of Si, 0.60 to 0.90 percent of Mn, less than or equal to 0.035 percent of P, less than or equal to 0.025 percent of S, 0.15 to 0.25 percent of Mo, 0.90 to 1.20 percent of Cr and the balance of Fe and inevitable impurities. The detection proves that the mechanical properties of the steel plate meet the following requirements that: (1) Re is more than or equal to 650MPa, Rmis more than or equal to 900-1,100MPa, A is more than or equal to 12 percent, Z is more than or equal to 50 percent, AKV at the temperature of 20 DEG C is more than or equal to 35J, and the surface hardness is 270 to 330HB; and (2) Rp0.2 is more than or equal to 550MPa, Rm is more than or equal to 800-1,100MPa, A is more than or equal to 12 percent, Z is more than or equal to 50 percent, AKV at the temperature of 20 DEG C is more than or equal to 35J, and the surface hardness is 270 to 330HB.

Owner:WUYANG IRON & STEEL +1

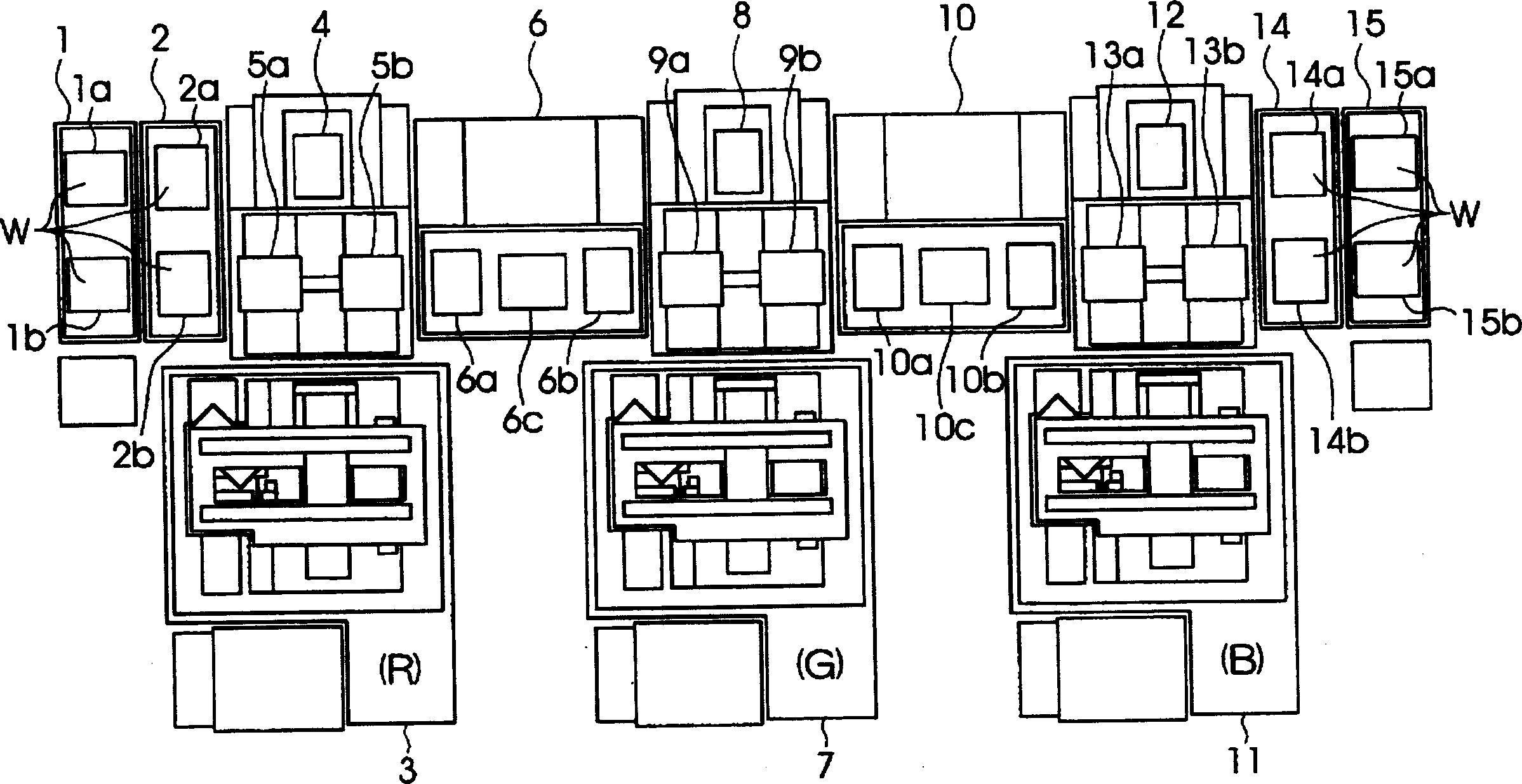

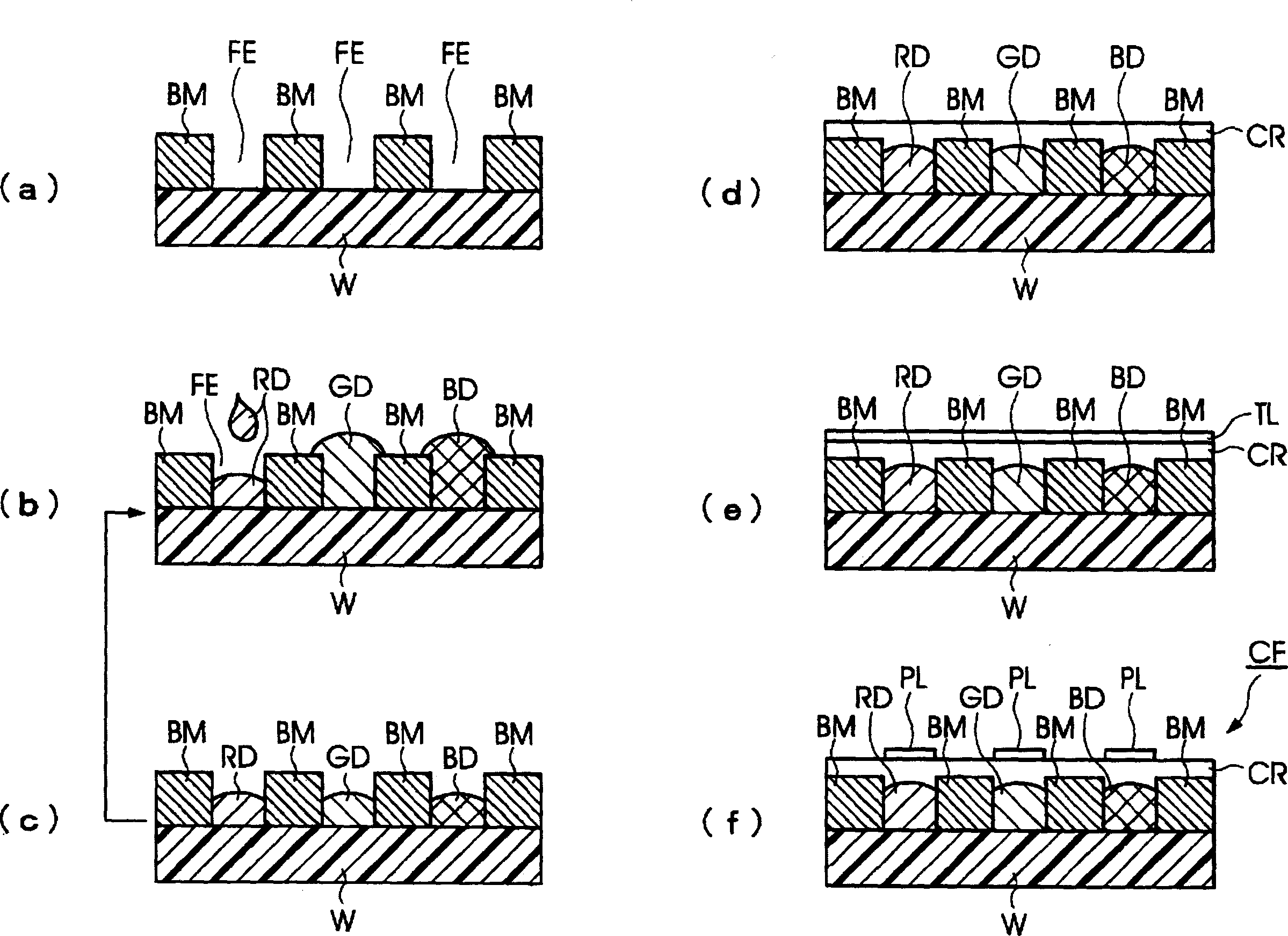

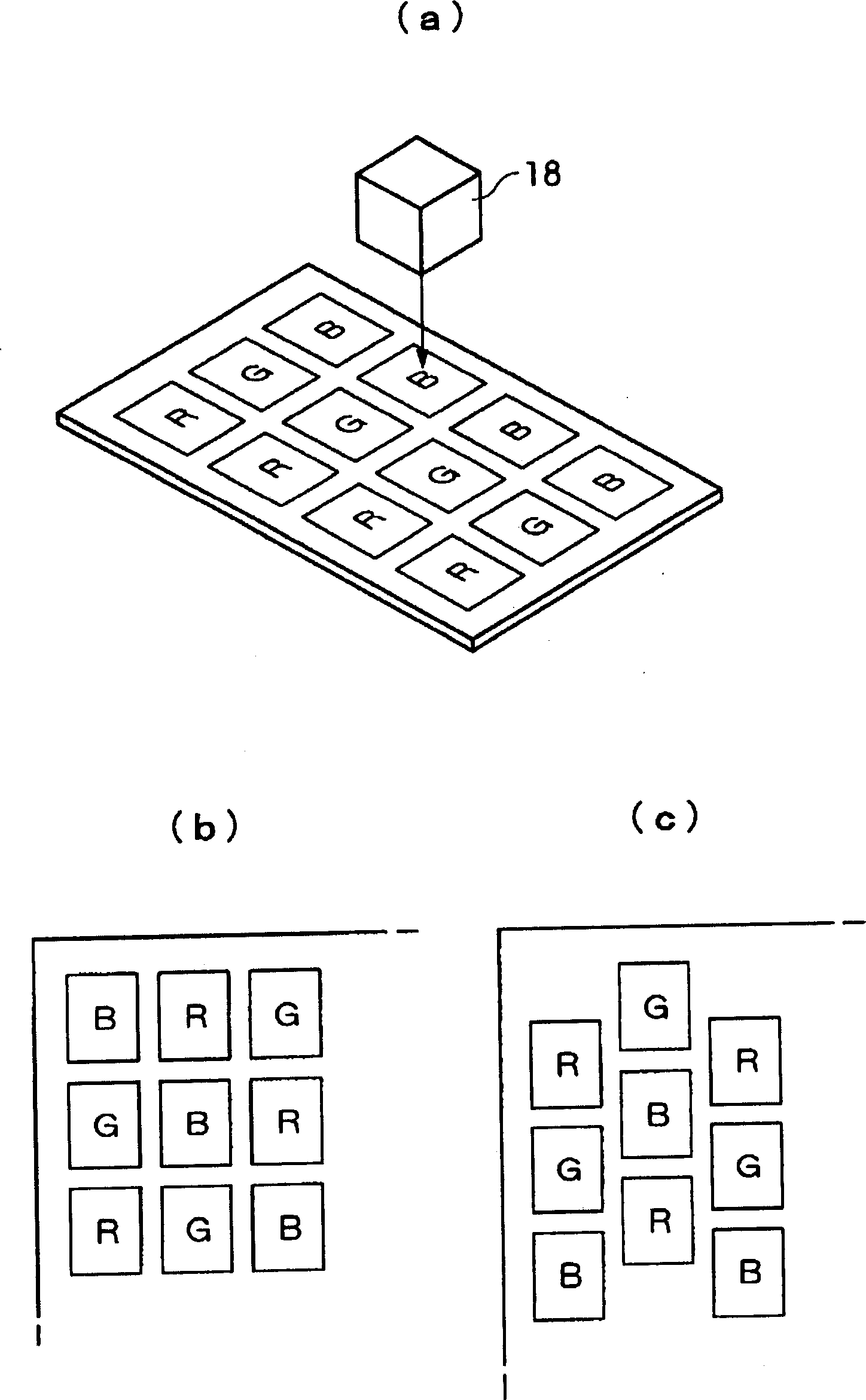

Driving device, method and procedure of spray nozzle, liquid drop spray out device and its manufacturing method

InactiveCN1442291AThe deformation rate per unit time can be freely controlledWide range of specificationsLiquid surface applicatorsInking apparatusSpray nozzleVIT signals

To provide a head drive device and method capable of discharging a required amount of viscous material from a head having a pressure generating element such as a piezoelectric element, a droplet discharge device having the head drive device, a head driver program, and a manufacturing process One of them is a device manufacturing method having a step of ejecting the viscous body using this method. The driving signal (COM) is a signal applied to a pressure generating element such as a piezoelectric element provided on the head. Furthermore, the clock signal (CLK2) is a signal supplied to a drive signal generation circuit that generates a drive signal (COM), and the drive signal generation circuit generates the drive signal (COM) in synchronization with the clock signal (CLK2). The present invention changes the rate of change of the voltage value per unit time of the drive signal (COM) by changing the frequency of the clock signal (CLK2) in accordance with the rate of deformation of the pressure generating element per unit time.

Owner:SEIKO EPSON CORP

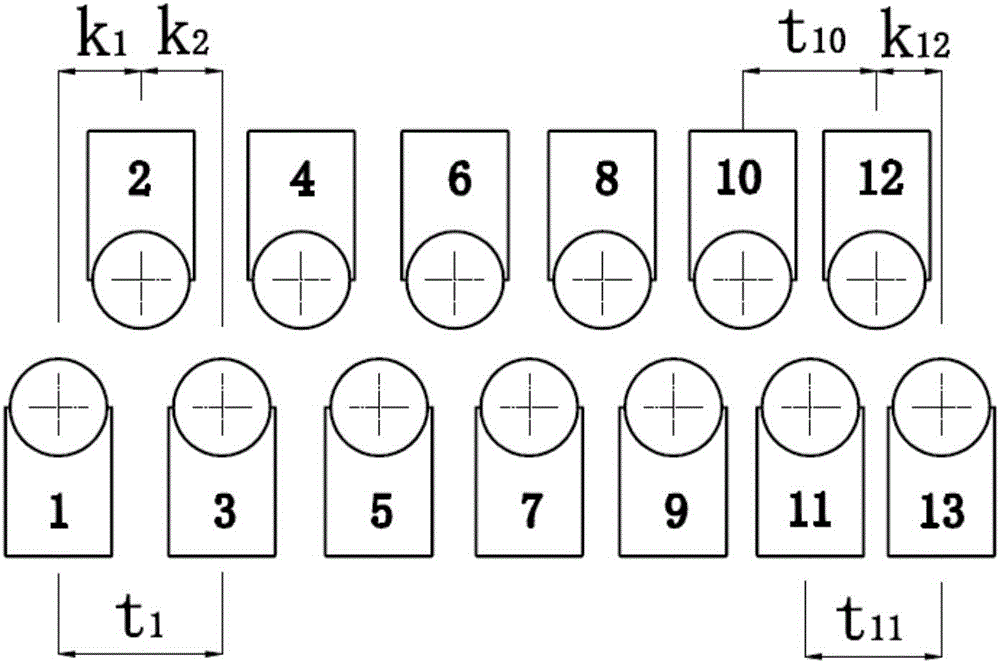

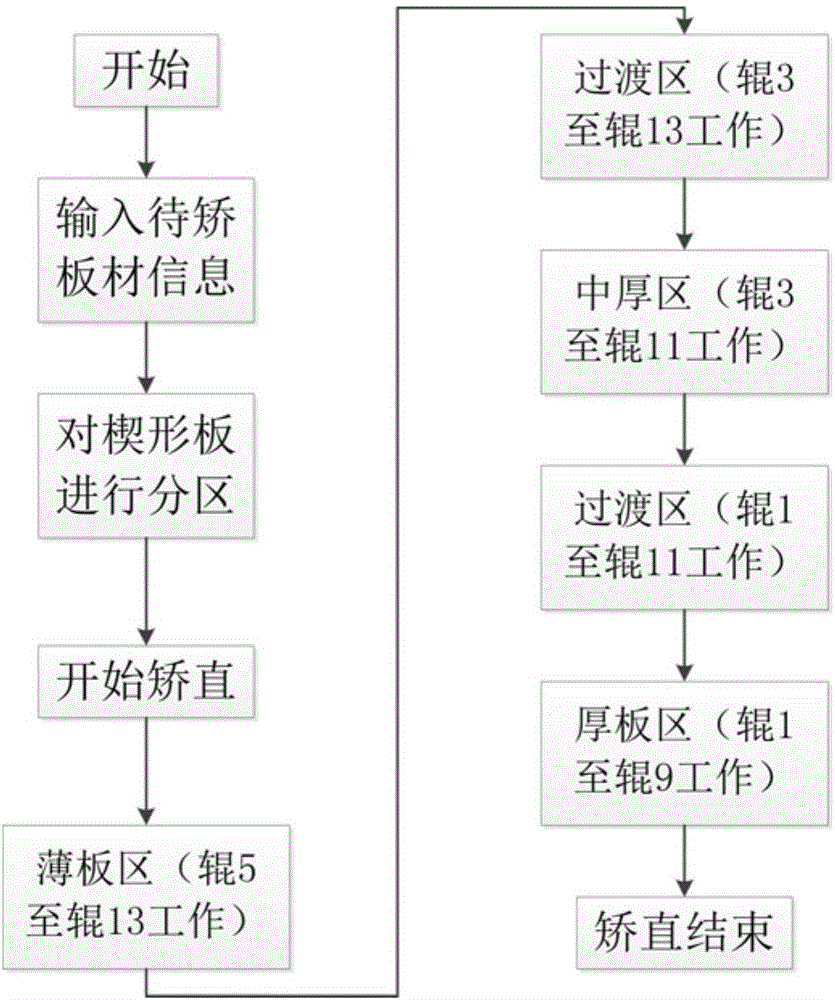

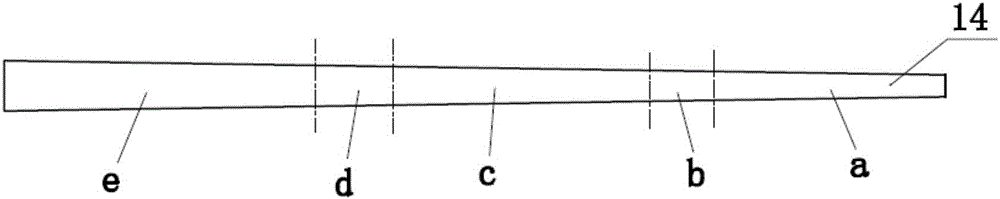

Straightening process for wedge-shaped plate

ActiveCN106391760AMeet the requirements of straightening process parametersQuality standardsCamWedge shape

The invention discloses a straightening process for a wedge-shaped plate. A 13-roller straightener is adopted. The roller spaces of a straightening roller system are arranged from large to small in a progressive decreasing mode. Four front rollers and four rear rollers of the straightening roller system are rising-falling straightening rollers. The straightening process comprises the specific steps that (1) the wedge-shaped plate serves as a variable thickness plate, and according to the parameters of the wedge-shaped plate, the roller space ti and rolling reduction hi corresponding to different plate thicknesses are calculated; (2) according to the parameters of the wedge-shaped plate, the wedge-shaped plate is subjected to plate thickness zoning; and (3) according to plate thickness zoning, different plate segments are straightened through roller sets, during straightening, the thin plate zone enters the straightener first, the four front rollers and the four rear rollers of the straightening roller system enters or leaves work according to the change of the plate thickness of the wedge-shaped plate during straightening, and thus the roller space is adjusted according to the change of the plate thickness until straightening is finished. Through the straightening process, the problem that straightening rollers of a traditional plate belt straightener cannot be adjusted on line under pressure during straightening is solved, thus rolling reduction and the roller spaces cam meet straightening process parameter requirements of the wedge-shaped plate, and the wedge-shaped plate with acceptable quality is obtained through straightening.

Owner:YANSHAN UNIV

Preparation method for double-metal compound wire

InactiveCN105710154AWide range of adaptationLarge amount of depressionMetal rolling arrangementsSurface finishingAluminium

The invention relates to a preparation method of a bimetal composite wire, belonging to the field of bimetal composite wire preparation. In this method, two metal pipes and bars of different materials are surface-treated and nested together, and then the pipes and bars nested together are rolled by a three-roller planetary rolling mill, so that the pipes and bars are combined together. , to obtain a bimetallic composite billet; the bimetallic composite billet is rolled again with a multi-stand Y rolling mill or a vertical roller mill, and rolled into a bimetallic composite wire rod with a diameter of 4.5-5.5mm; The metal composite wire is drawn and processed to prepare a bimetal composite wire with a diameter of 0.5 mm to 3 mm. A series of bimetallic composite wires such as titanium-clad copper bimetallic composite wires, titanium-clad steel bimetallic composite wires, and copper-clad aluminum bimetallic composite wires can be prepared. The bimetallic composite wires obtained by this method have high bonding strength between the two metals. The production equipment is simple, flexible and low in cost.

Owner:有研科技集团有限公司

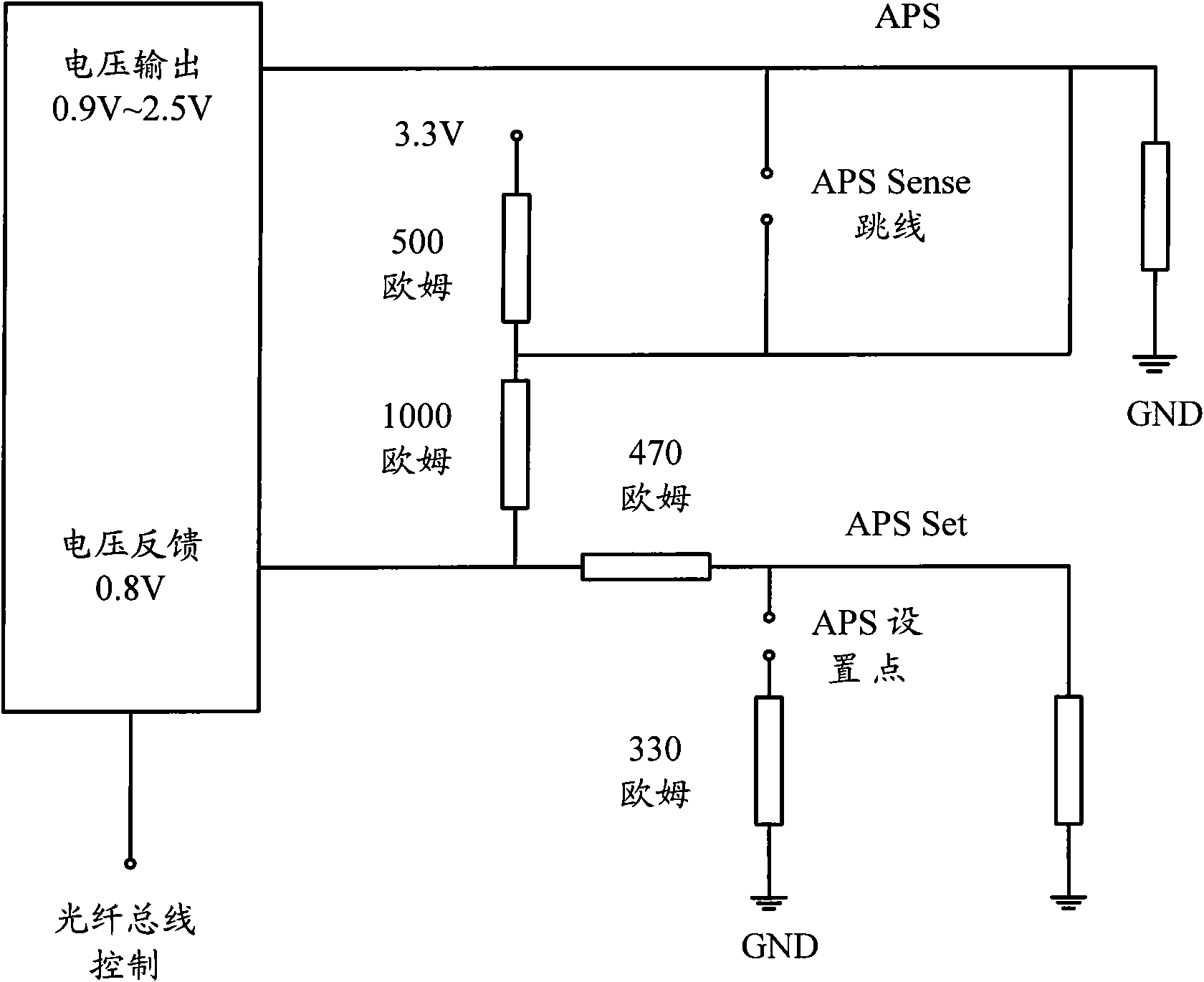

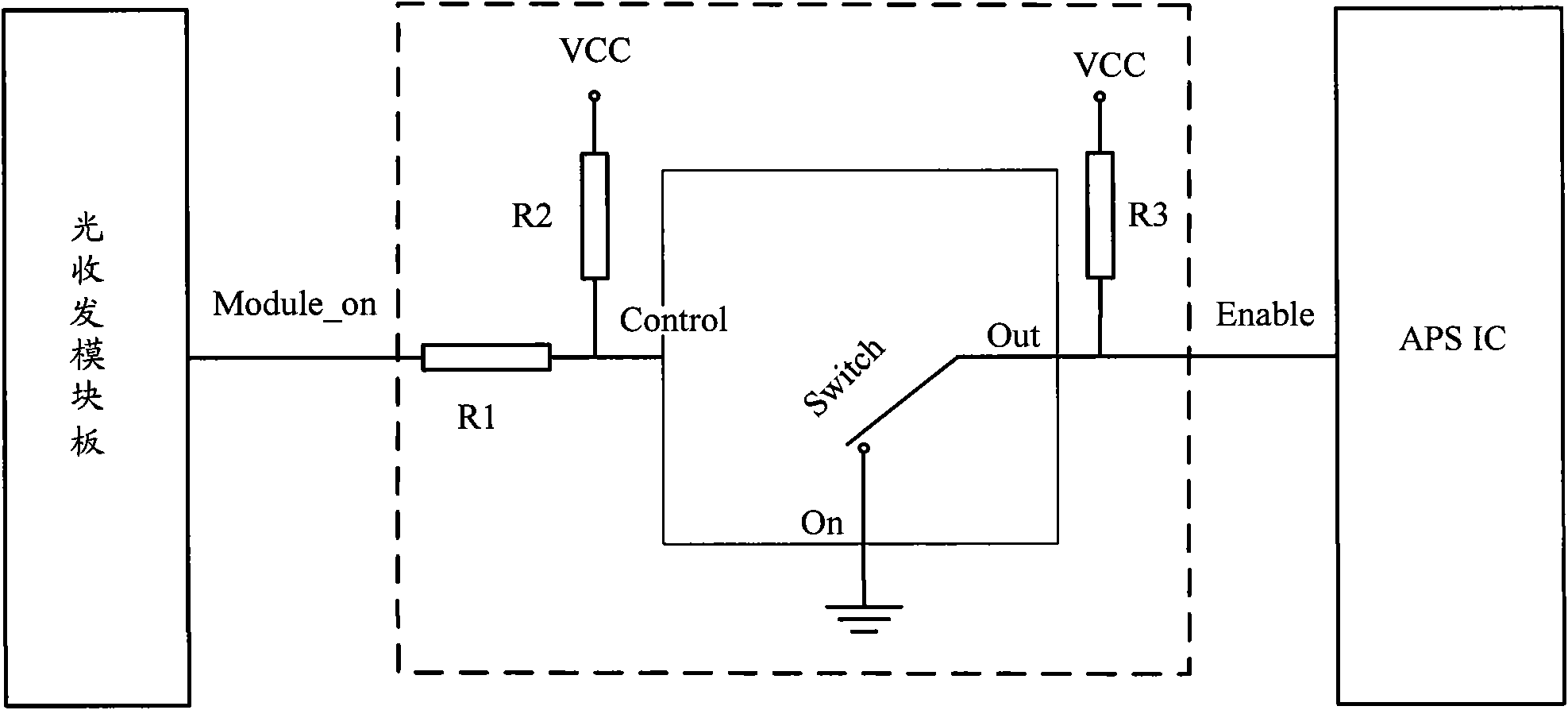

Power controller with adaptation power supply

InactiveCN101572482AImprove adaptabilityImprove compatibilityApparatus without intermediate ac conversionPower controllerElectricity

The invention discloses a power controller with adaptation power supply. A power supply control circuit is additionally arranged so that a single plate can control a power supply of an adaptation power supply (APS) integrated circuit (IC) chip to supply electricity; when the single plate is not at a position, the output voltage of the APS control IC is 0 V; and when the single plate is at the position, the APS control IC normally works. The power controller with the adaptation power supply can effectively reduce the consumption of the electricity energy of communication equipment when the singe plate of the communication equipment is not at the position and can also enhance the compatibility of the APS power supply on optical single plates of different factories.

Owner:宋华华

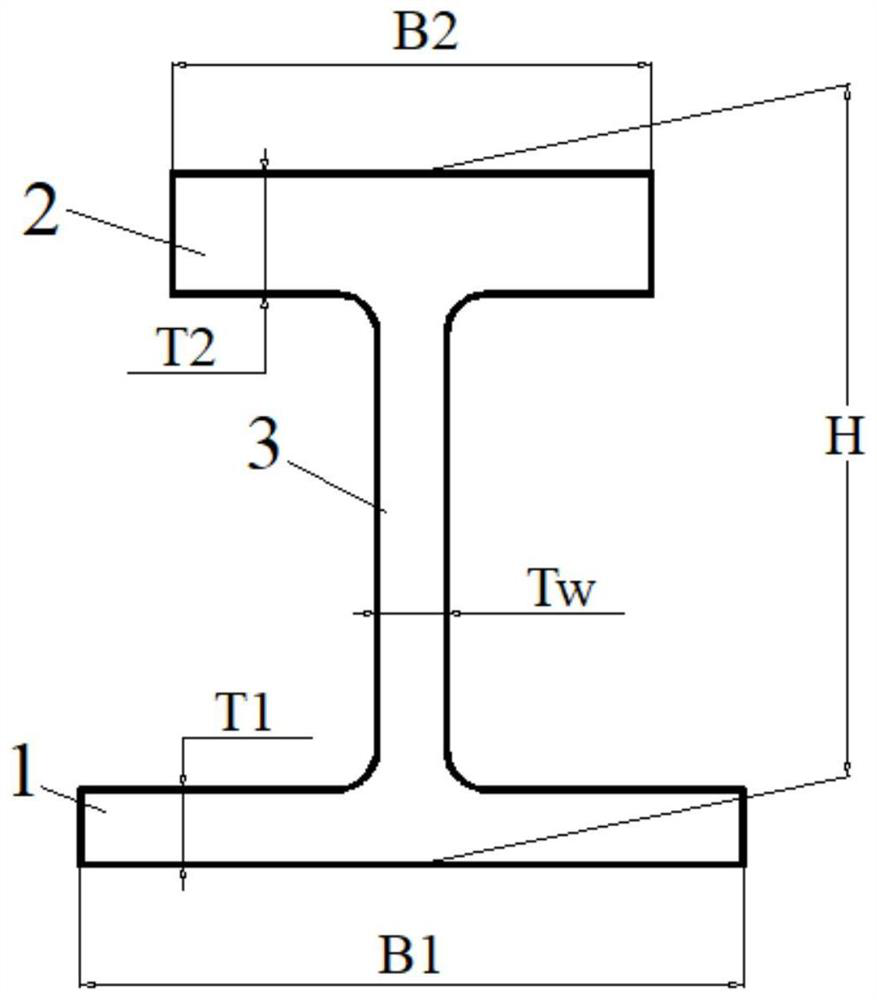

Hot-rolled H-shaped steel and production method thereof

ActiveCN113399453AMeet production requirementsStable Production RequirementsElongated constructional elementsMass flow control deviceMetallurgyEngineering

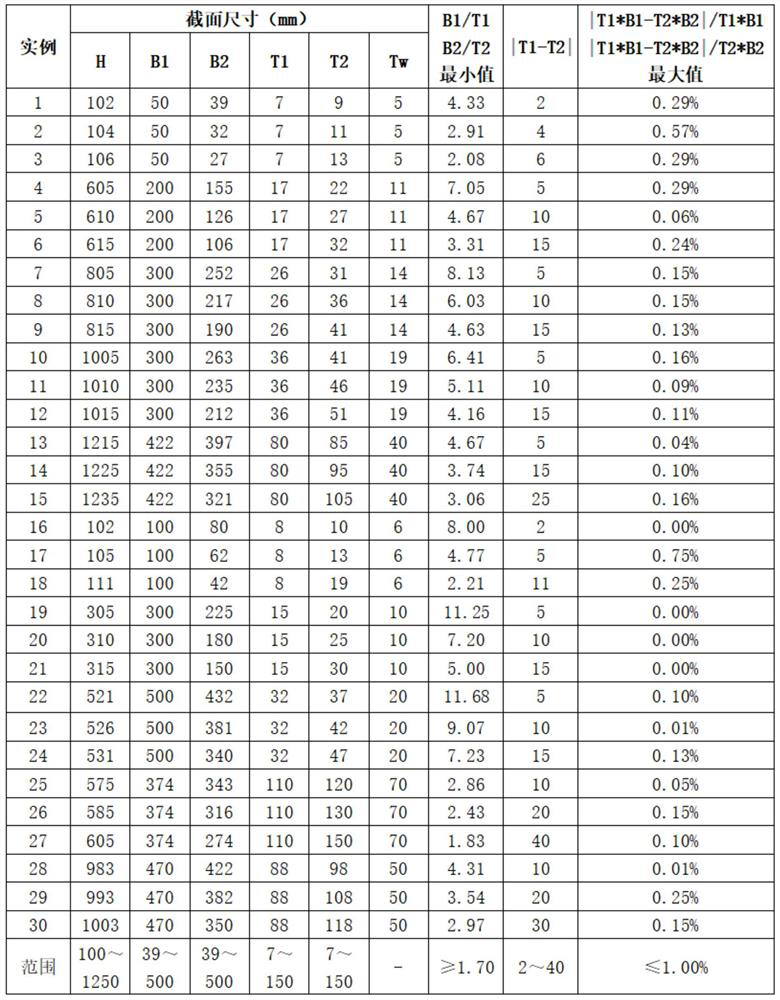

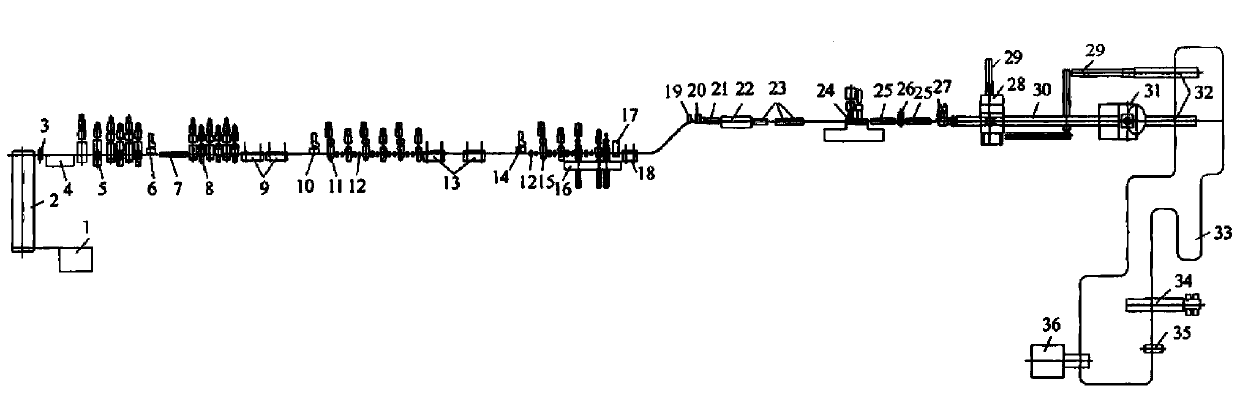

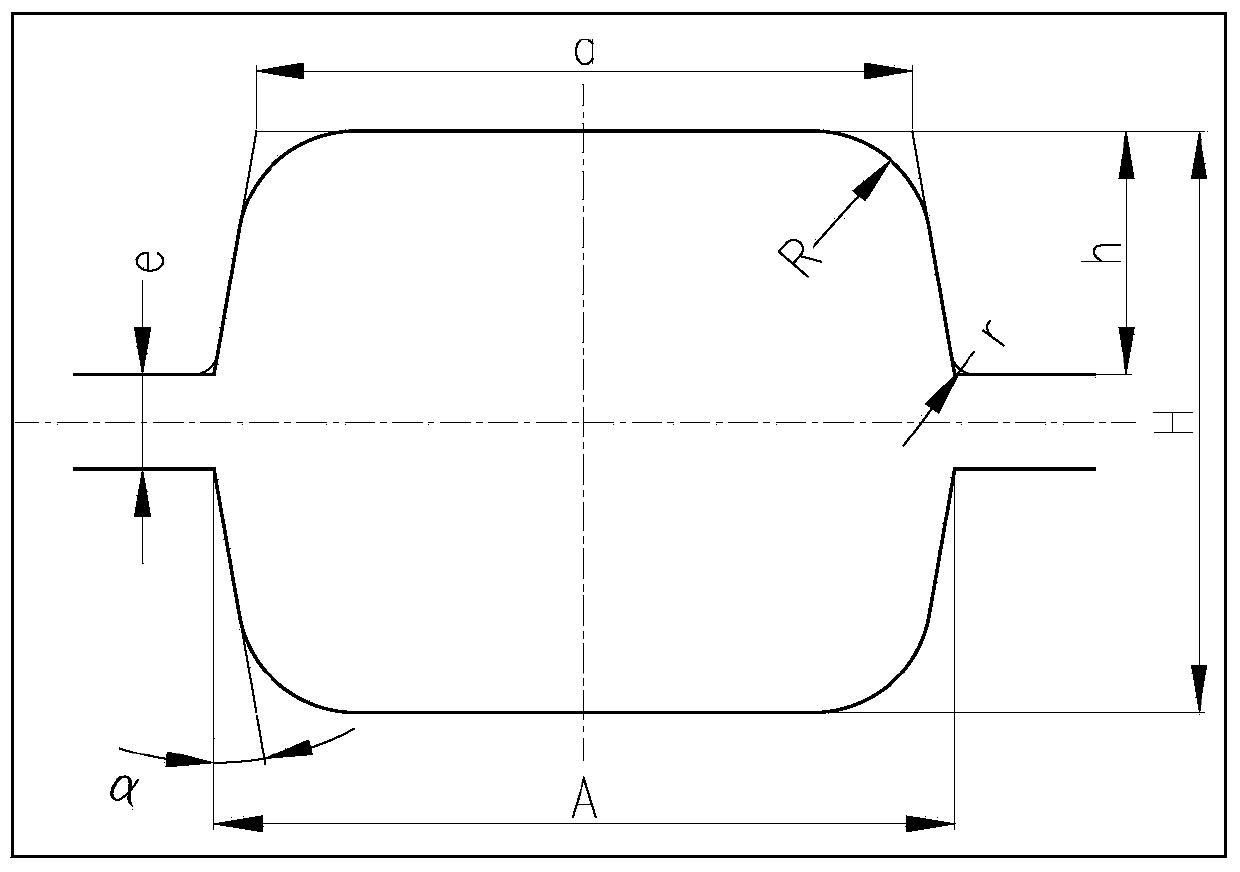

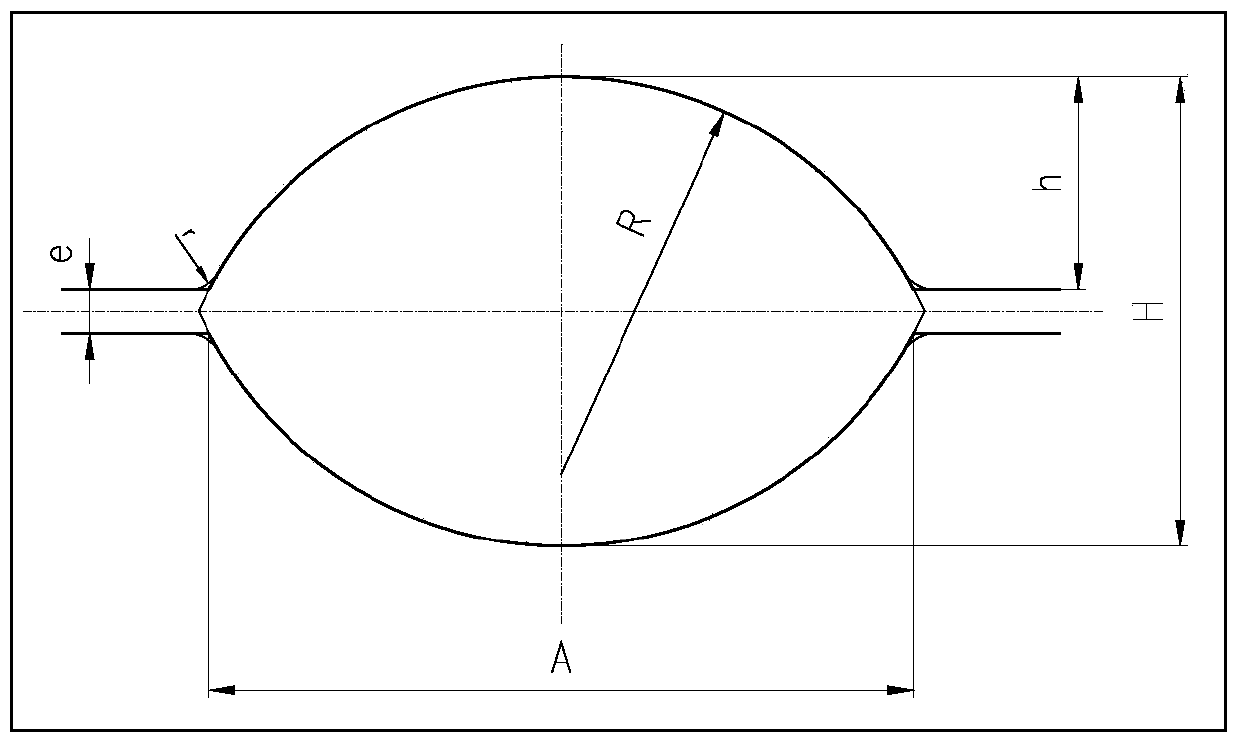

The invention discloses hot-rolled H-shaped steel, which comprises a web plate, a first flange plate and a second flange plate; the difference value T1-T2 between the thickness value of the first flange plate and the thickness value of the second flange plate is larger than 0; the ratio of the area difference S1-S2 of the first flange plate and the second flange plate to the area S1 of the first flange plate is not larger than 1, or the ratio of the area difference S1-S2 of the first flange plate and the second flange plate to the area S2 of the second flange plate is not larger than 1. According to the hot-rolled H-shaped steel provided by the invention, the production requirement that the flanges on the two sides of various specifications are different in thickness can be met, meanwhile, lateral bending in the rolling process can be avoided, the metal second flow difference of the flanges on the two sides in the rolling process is controlled within a certain range, and therefore the hot-rolled H-shaped steel with the flanges on the two sides being different in thickness is stably produced. The invention further discloses a production method of the hot-rolled H-shaped steel.

Owner:MAANSHAN IRON & STEEL CO LTD

Method for producing titanium and titanium alloy wires through hot continuous rolling

ActiveCN104174649AMeet the small batchMeet the characteristicsTemperature control deviceMetal rolling arrangementsStructure propertyTitanium

The invention relates to a method for producing titanium and titanium alloy wires through hot continuous rolling, belongs to the technical field of metal plastic working, and aims to solve the technical problems and provide a method for producing titanium and titanium alloy wires on a traditional steel hot continuous rolling unit. According to the method for producing the titanium and titanium alloy wires through hot continuous rolling, a heating system, blooming temperature, rolling speed and hole pattern are controlled, processes including shearing, cooling and spinning to form coils are performed, and titanium and titanium alloy square billets are discharged from a furnace through single heating and rolled into wires with the diameter ranging from phi 5.5 mm to phi 20 mm. According to the method for producing the titanium and titanium alloy wires through hot continuous rolling, titanium and titanium alloy wire products with large single wire coil weight, good surface quality and roundness and uniform structure property can be produced quickly and efficiently on the hot continuous rolling unit.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

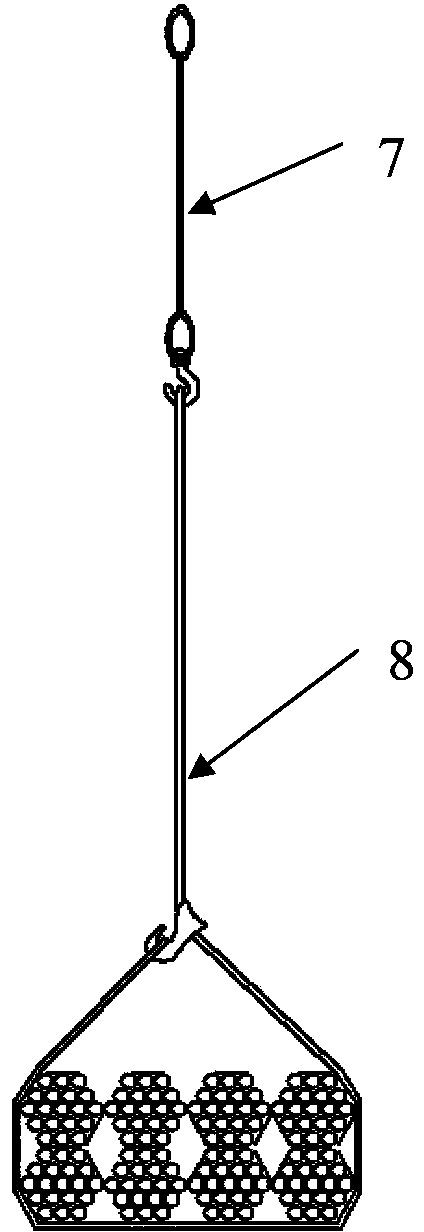

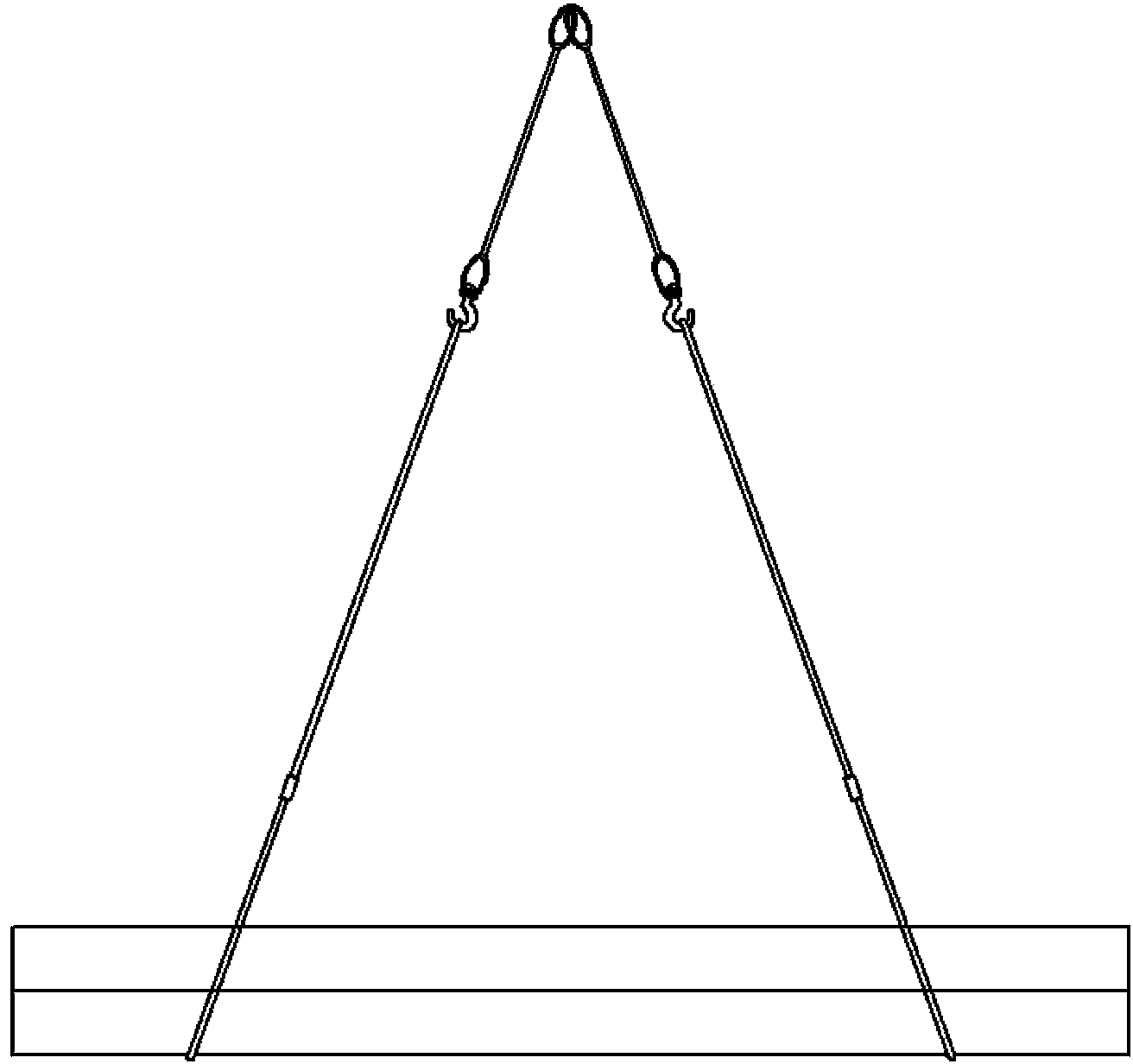

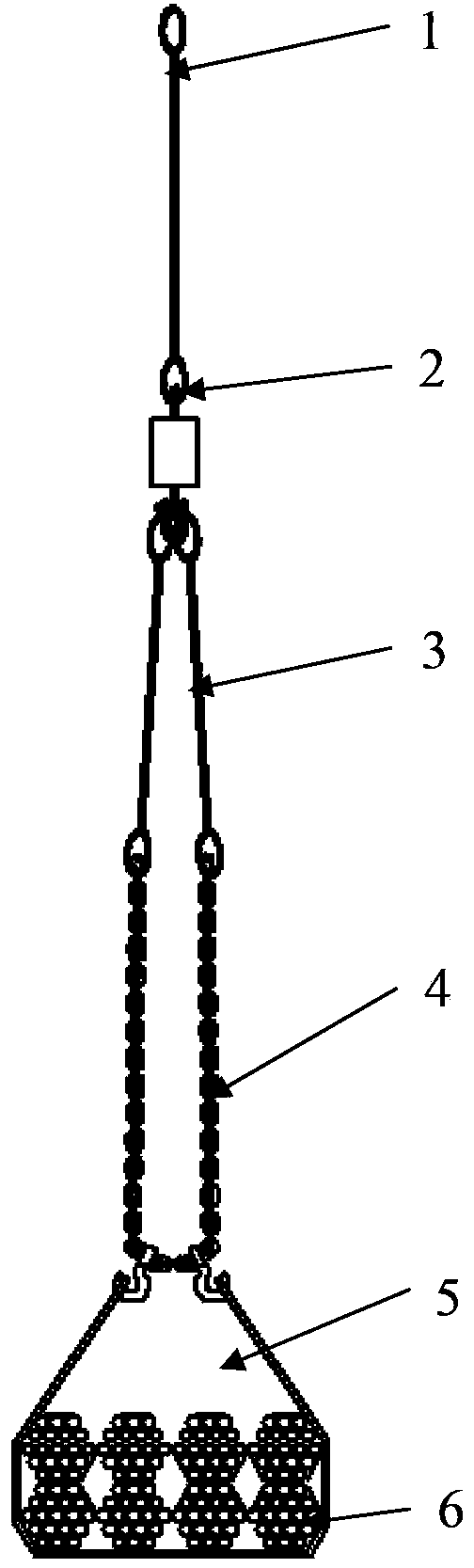

Steel tube cargo shipping accessory and operating method employing same

InactiveCN103407874AGuaranteed stabilityOvercome the problem of unequal perimeter of each section of goodsLoading/unloadingLoad-engaging elementsWork performanceEngineering

The invention provides a steel tube cargo shipping accessory. A supporting bar of the accessory is hung on the shackle of a supporting bar suspension system; a short suspension system is hung on the suspension centre at the lower part of the supporting bar; two ends of a chain are hung on the shackles of the short suspension system; a slip hook is hung on the chain in a sliding manner; a steel wire lock catch is connected onto the chain through the slip hook; meanwhile, the invention provides an operating method employing the steel tube cargo shipping accessory. The steel tube cargo shipping accessory and the operating method employing the same have the benefits that after cargos are lifted and suspended in the air, stability during the process of operation is guaranteed by employing the method, the problem that the peripheral perimeters of the cargos in each car of a pallet truck are unequal due to unequal diameters of steel tube cargos is solved, the accessory is applied to steel tube cargos with wide specification ranges, time for changing tools due to specification change of the cargos is reduced, the potential safety hazards are reduced, the working performance is improved, the operation is convenient, and the accessory has remarkable application effects at a general cargo terminal which regards 25 tonne portal cranes as main operation machinery.

Owner:TIANJIN PORT HUISHENG TERMINAL

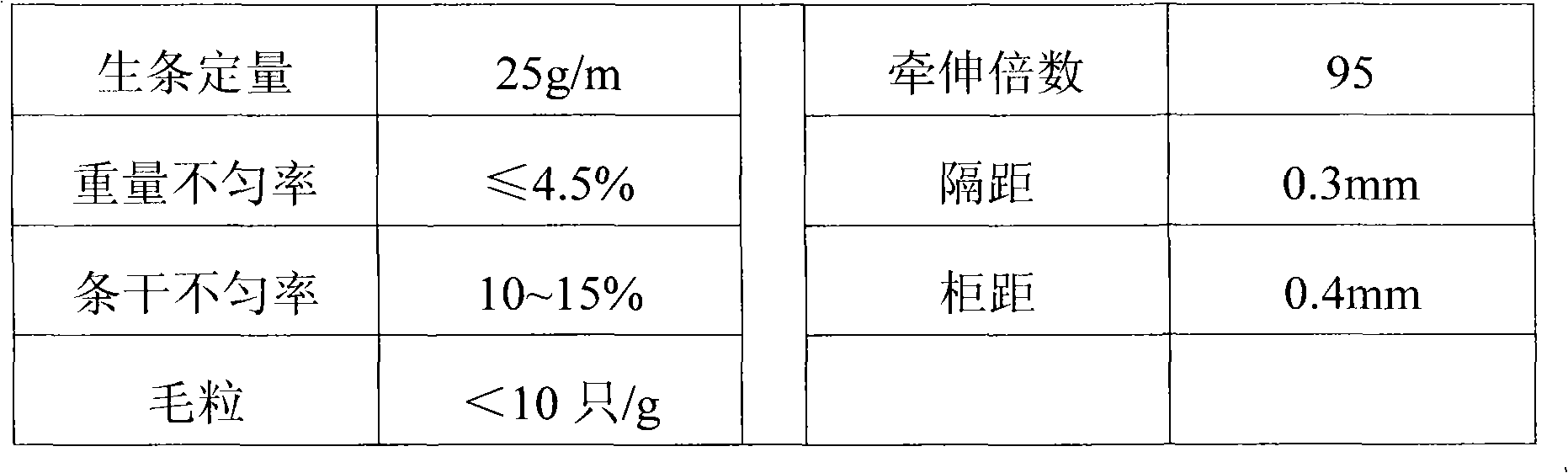

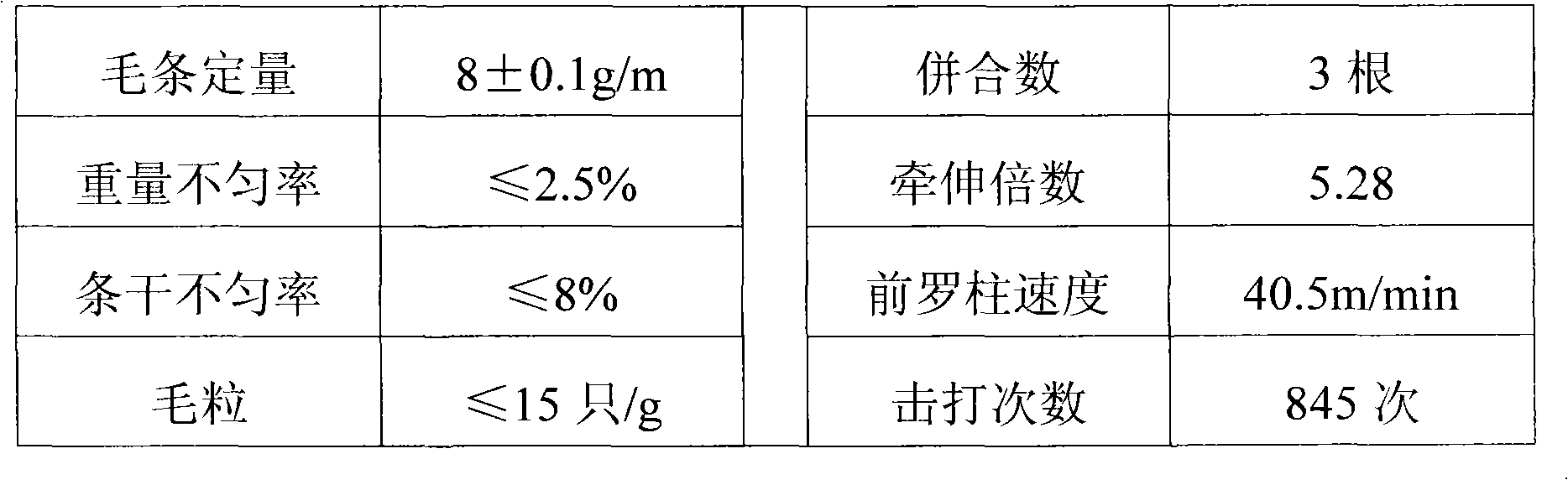

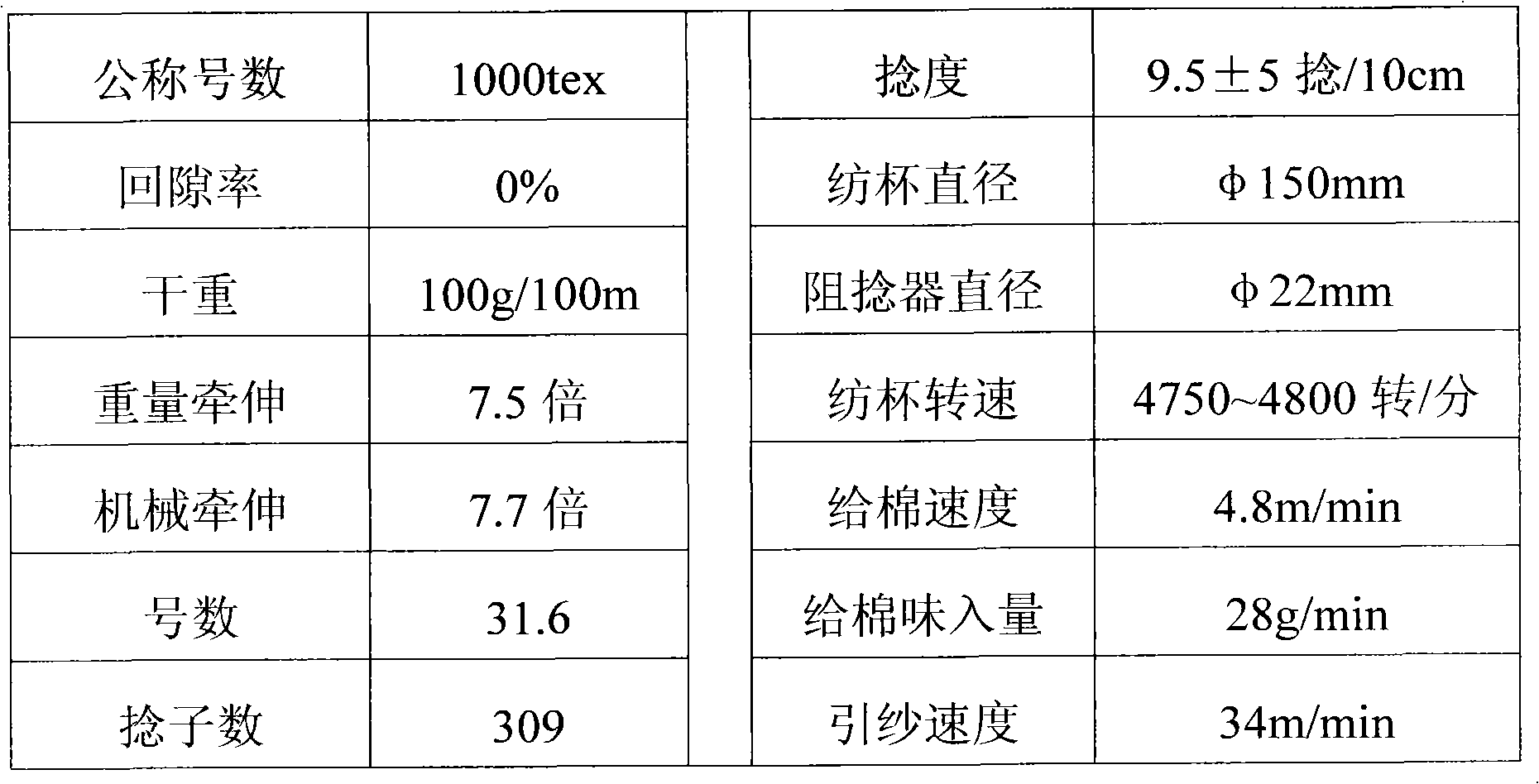

Revolving cup spinning profiled polypropylene fiber rough yarn and its spinning method

InactiveCN101343800APenetrating and denseImprove filtering effectContinuous wound-up machinesOpen-end spinning machinesYarnPenetration force

Owner:扬州华美丙纶纺织有限公司

Preparation method and product of napping veneer exterior dry-hanging ceramic plate

InactiveCN103696554ANo ubiquinol problemImprove safety and reliabilityCovering/liningsClaywaresBrickAdditive ingredient

The invention discloses a preparation method of a napping veneer exterior dry-hanging ceramic plate. The ingredients of the napping veneer exterior dry-hanging ceramic plate comprises 10-30% of high plastic clay dry powder, 20-40% of white clay dry powder, 10-30% of feldspar powder, 15-30% of coarse aggregate with the fineness of 8-20 meshes, and 0.2-7.0% of additives. According to the napping veneer exterior dry-hanging ceramic plate, a product capable of hanging in a dry-hanging manner such as back-hanging or side-hanging can be produced through a mold, is integrated with curtain wall keel, is already been widely applied in various middle-high buildings, and is high in safety reliability; as dry-hanging construction is adopted, no saltpetering problem of split bricks exists because of no cement contact; as a napping face ceramic plate is large in decorative face and is simple and efficient to mount, the labor cost and the construction time are reduced; as the plate is convenient to replace later through dry-hanging, unlike a split brick, a large-area brick does not need to be knocked off and paved again on the whole face, a broken brick is pulled out and a new brick is hung.

Owner:瑞高(浙江)环保新材料科技有限公司

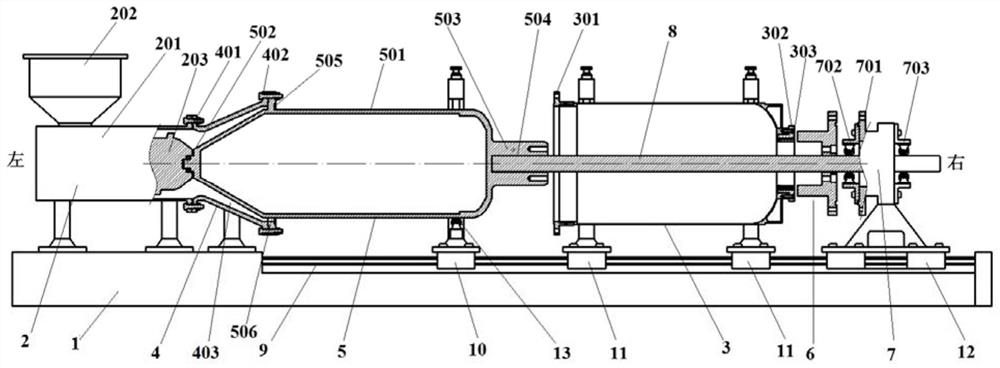

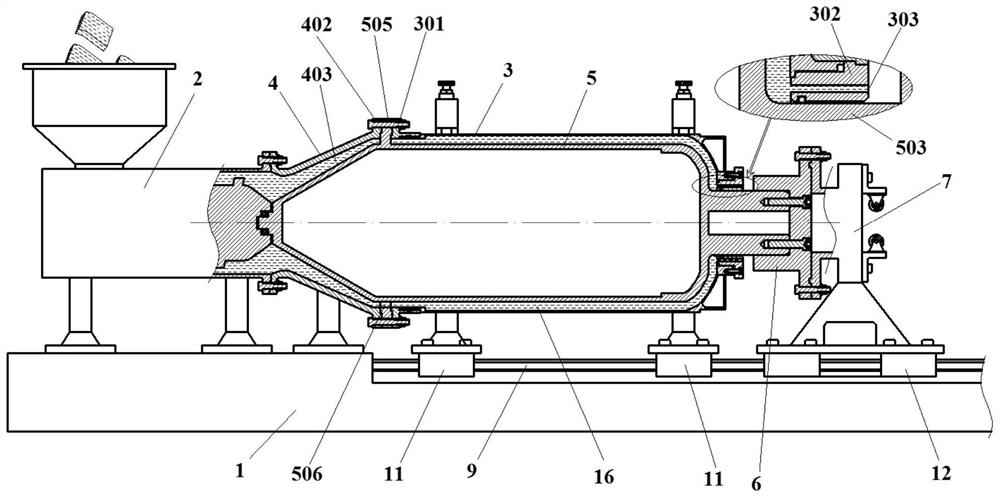

Combustion chamber cylinder section-seal head heat insulation layer integrated extrusion molding system and method

ActiveCN112497699ARealize all-in-one rapid prototypingLow costDomestic articlesCoatingsCombustion chamberInsulation layer

The invention provides a combustion chamber cylinder section-seal head heat insulation layer integrated extrusion molding system and method. The combustion chamber cylinder section-seal head heat insulation layer integrated extrusion molding system comprises a base, an extruder and a combustion chamber shell, and the combustion chamber shell is of a cylinder section-seal head integral structure, and the system further comprises a transition sleeve, a core mold, a core mold adapter flange and a support, wherein the extruder, the transition sleeve, the core mold, the combustion chamber shell, the core mold adapter flange and the support are coaxially arranged in sequence from left to right; the method specifically comprises the following steps of 1, a preparation stage; 2, a mold-shell buttjoint stage; 3, an extrusion molding stage; and 4, a dismounting and post-processing stage. Based on the mature process of extrusion in the civil field, the integrated rapid molding function of the cylinder section-seal head heat insulation layer is achieved, meanwhile, the cost of equipment, the process, a mold and the like can be greatly reduced, and meanwhile the application range of a heat insulation sizing material system is very wide.

Owner:XIAN MODERN CHEM RES INST

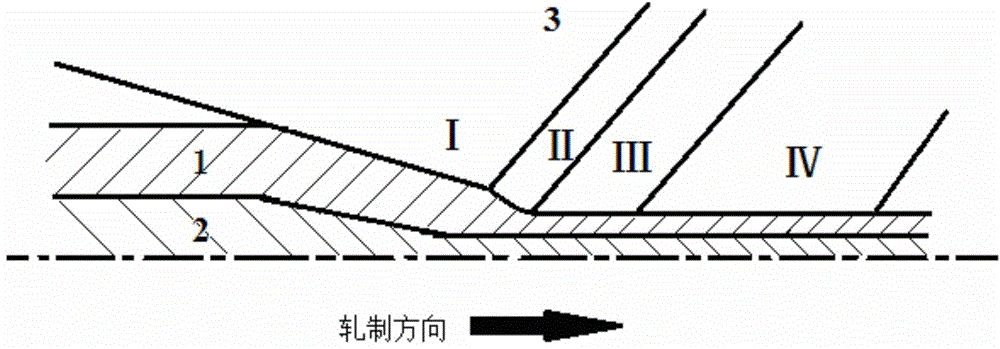

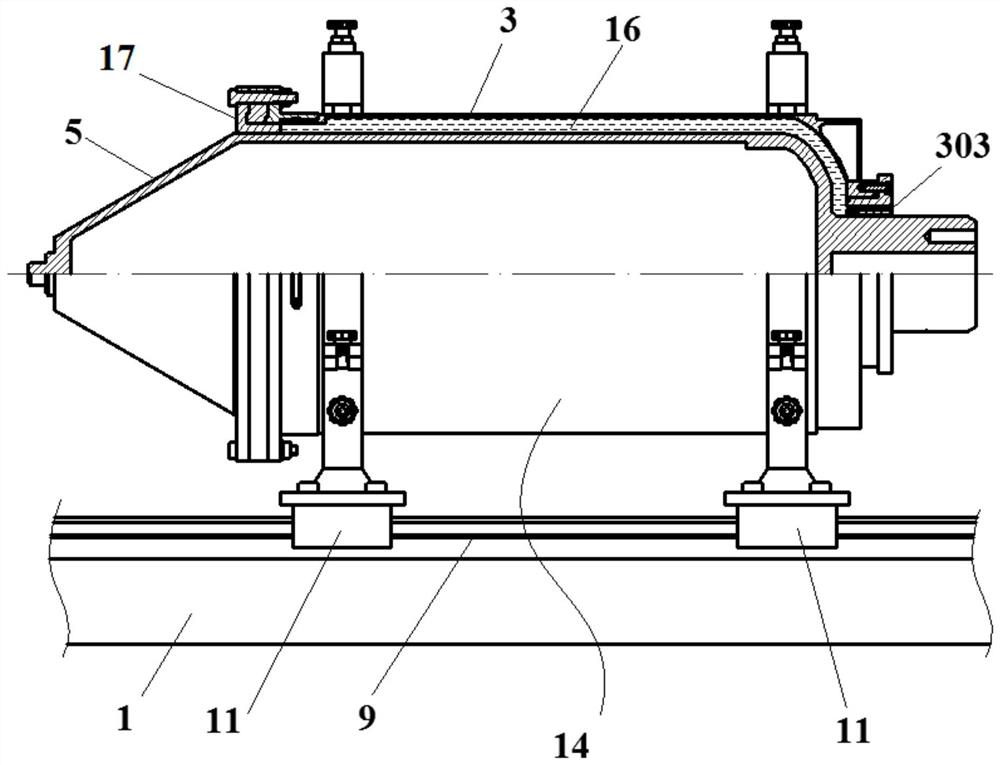

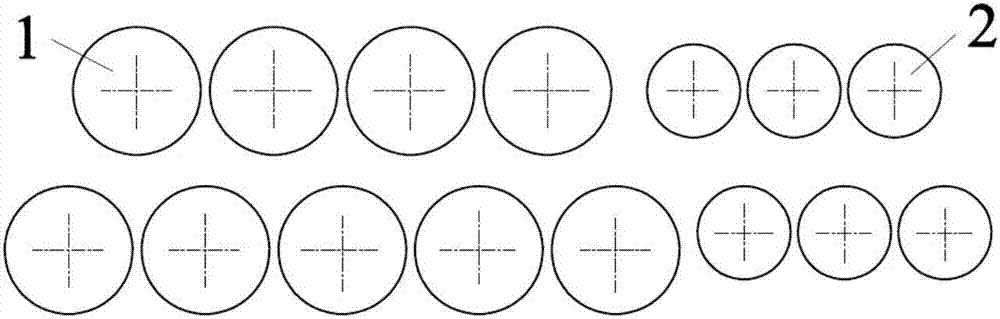

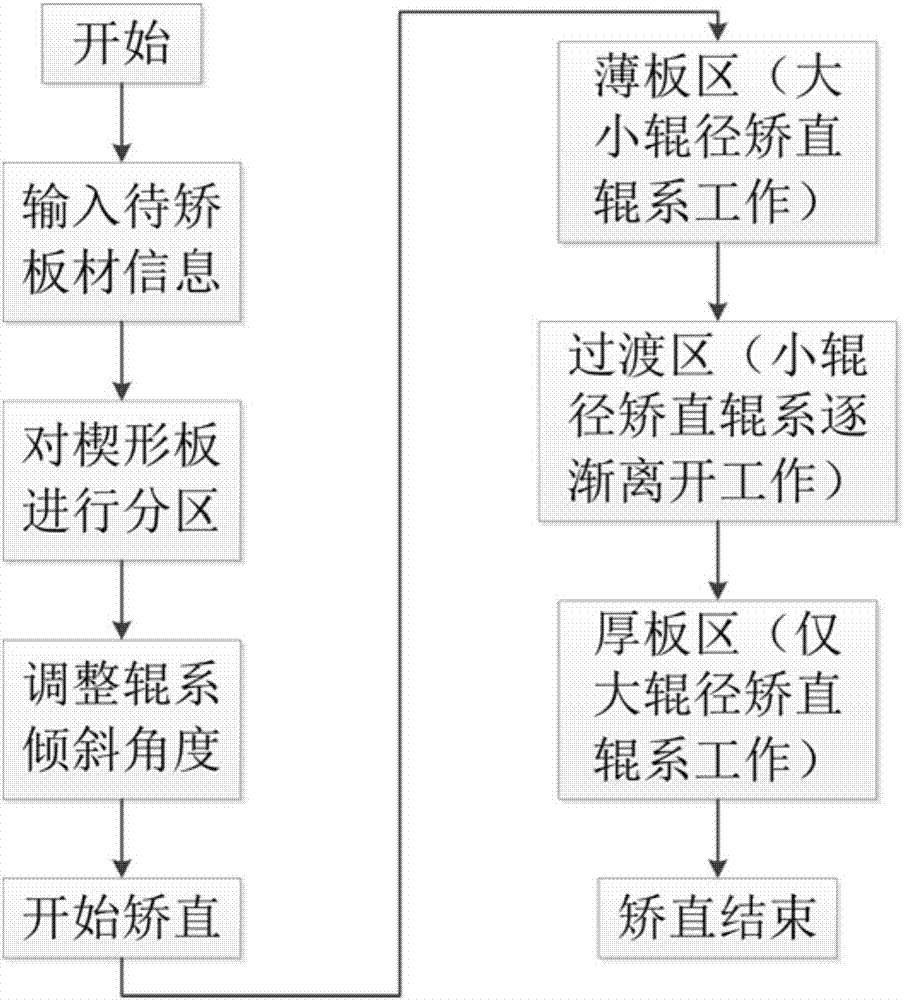

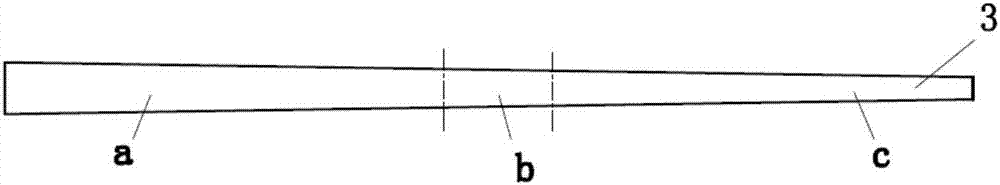

Wedge-shaped plate straightening technology based on cooperating roll systems

InactiveCN107413891AMeet the straightening process requirementsQuality standardsEngineeringMechanical engineering

The invention discloses a wedge-shaped plate straightening process based on a matching roller system. A double-roll system straightening machine is adopted, and the roller systems with large and small roll diameters are respectively arranged on the entrance side and the exit side. The specific steps are: 1. According to the parameters of the wedge-shaped plate Calculate the reduction corresponding to different plate thicknesses; 2. Adjust the inclination angle of the lower roll and the upper roll of the straightening roll system with large and small roll diameters of the straightening machine according to the slope of the wedge plate; 3. Adjust the inclination angle of the wedge plate according to the parameters of the wedge plate Carry out plate thickness division, and divide the wedge-shaped plate into three plate sections: thin plate area, transition area and thick plate area; 4. According to the plate thickness division of the wedge-shaped plate, different roll systems are used to straighten different plate sections. When straightening, The thin plate area of the wedge-shaped plate enters the straightening machine first, and the straightening rollers with large and small diameter rolls work together to complete the straightening of different sections of the wedge-shaped plate. The invention solves the problem that the number of rolls and the diameter of the rolls should be changed according to the thickness of the plate when straightening the wedge-shaped plate, so that the reduction and the number of rolls and the diameter of the rolls meet the technical requirements for straightening the wedge-shaped plate, and the wedge-shaped plate with qualified quality can be straightened.

Owner:YANSHAN UNIV

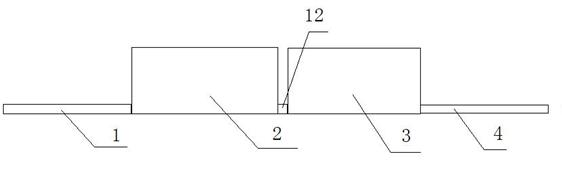

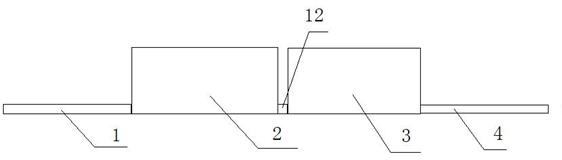

On-line solid solution furnace

ActiveCN102383073ASuitable for mass productionImprove compatibilityFurnace typesHeat treatment furnacesHigh volume manufacturingSolid solution

The invention discloses an on-line solid solution furnace, which comprises a heating furnace and a quenching chamber, wherein the heating furnace and the quenching chamber are arranged horizontally; a feeding end on the front end of the heating furnace is provided with a feeding roller bed; a transition roller is arranged between the discharging end of the heating furnace and the feeding end of the quenching chamber; and the discharging end on the rear end of the quenching chamber is provided with a discharging roller bed. The equipment disclosed by the invention has the advantages of strong compatibility, wide product specification coverage range and short quenching transfer time and is suitable for the large-batch production of large plates.

Owner:南京年达炉业科技有限公司

Automatic packaging machine achieving equal cutting and opposite combination forming bag-making for washing powder

InactiveCN105460255AGuaranteed to workWide range of specificationsSuccessive articlesHobbingThin membrane

The invention discloses an automatic packaging machine achieving equal cutting and opposite combination forming bag-making for washing powder and relates to the field of packaging mechanical equipment. The automatic packaging machine comprises a forming device. A feeding barrel is connected to the upper side of the forming device. A steering guide roller is connected to the feeding barrel. A slitting hobbing cutter is arranged on the steering guide roller. A notch guide pipe and a compression roller are arranged at one end of the slitting hobbing cutter and are parallel to each other. A guide roller is arranged at the other end of the slitting hobbing cutter. A plurality of longitudinal sealing rolling wheels are arranged on the forming device. A transverse sealing roller is connected to the lower side of the forming device. A thin film raw material is jointly guided by the feeding barrel and the forming device to form an opposite combination barrel type, the thin film raw material is continuously pulled by the longitudinal sealing rolling wheels to achieve longitudinal sealing, the thin film is equally divided from the center by the longitudinal sealing rolling wheels, and bag shapes of double-row bags are formed; a longitudinally sealed bag barrel enters the transverse sealing roller, and thus material filling and packaging are conducted. By the adoption of the equal cutting and opposite combination forming technology, the attractive four-side-sealed bag shape can be produced, the bag shape specification variation range is wide, and specifications are complete.

Owner:天津市天亨洗涤剂有限公司

Hardening and tempering high-strength steel plate for wood based panel equipment and production method of tempering high-strength steel plate

The invention relates to a hardening and tempering high-strength steel plate for wood based panel equipment and a production method of the steel plate, and belongs to the field of manufacturing low-alloy high-strength structural steel. The steel plate consists of the following chemical components in percentage by weight: 0.18 to 0.24 percent of C, 0.20 to 0.50 percent of Si, 0.80 to 1.20 percent of Mn, more than or equal to 0.02 percent of P, more than or equal to 0.01 percent of S, 0.20 to 0.50 percent of Mo, 0.20 to 0.50 percent of Ni, 0.70 to 1.00 percent of Cr, more than or equal to 0.003percent of B, 0.017 to 0.030 percent of Nb, 0.040 to 0.050 percent of V, 0.017 to 0.026 percent of Ti, and the balance of Fe and inevitable impurities. The production method of the steel plate comprises the following steps of: electric furnace smelting, vacuum decarburization / vacuum arc decarburization (VD / VOD) furnace vacuum decarburization, ladle furnace (LF) furnace refining, continuous casting (die casting), billet steel (ingot) clearing, heating, plate rolling, hardening and tempering, steel plate checking and polishing, tempering, sampling inspection, and warehousing. The hardening andtempering high-strength steel plate for the wood based panel equipment adopts Cr-Ni-Mo-B system micro-alloy elements for composite strengthening, and acquires good obdurability matching through a reasonable heat treatment process, and simultaneously the welding performance of a thick plate is not reduced.

Owner:WUYANG IRON & STEEL +1

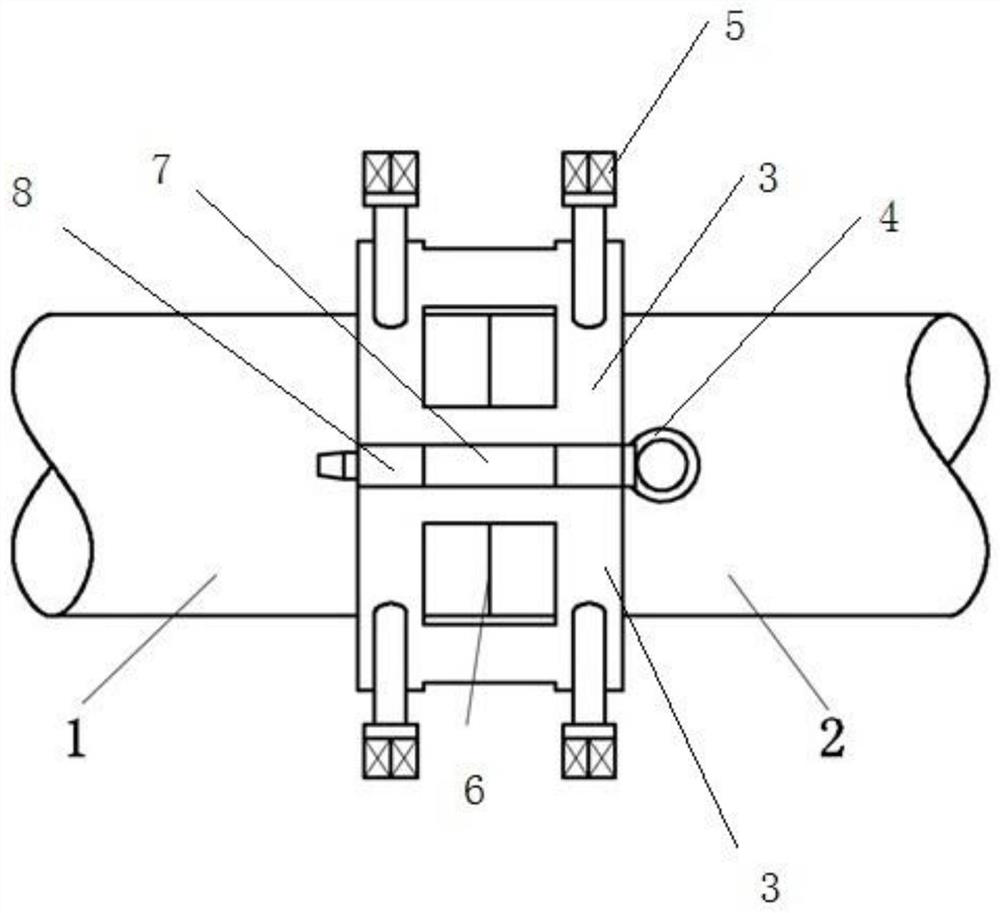

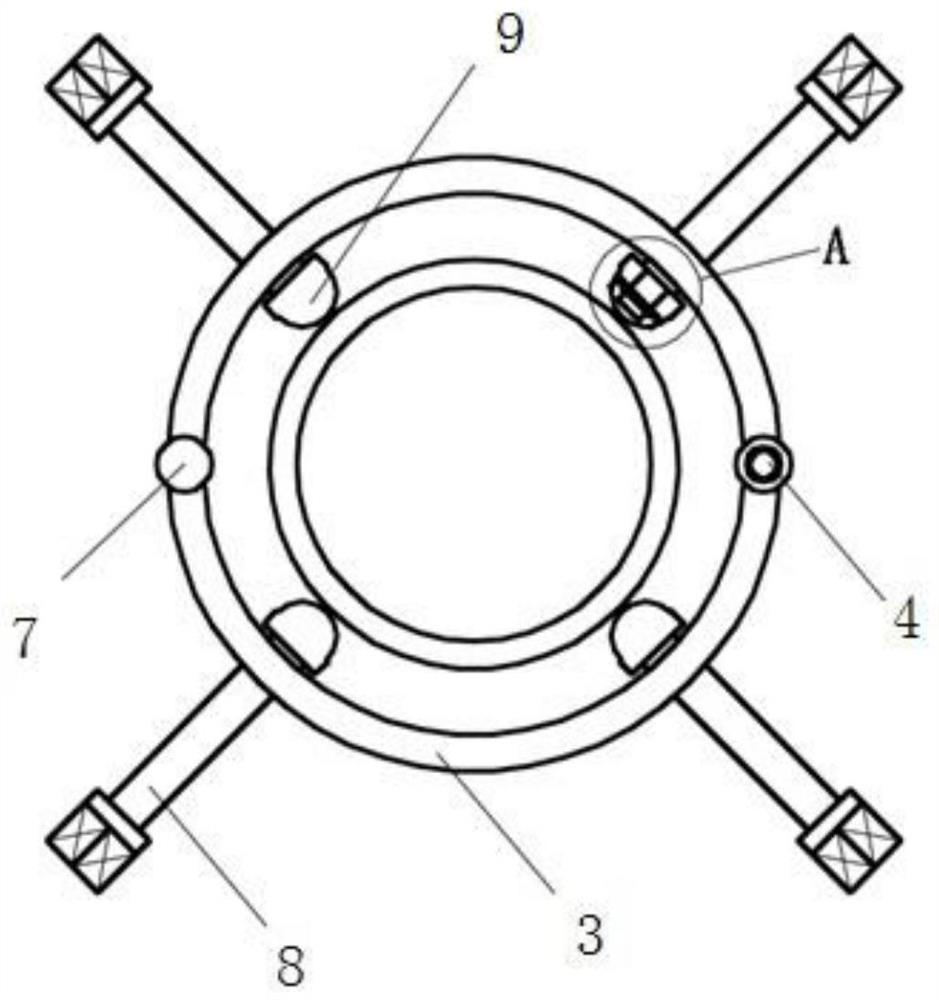

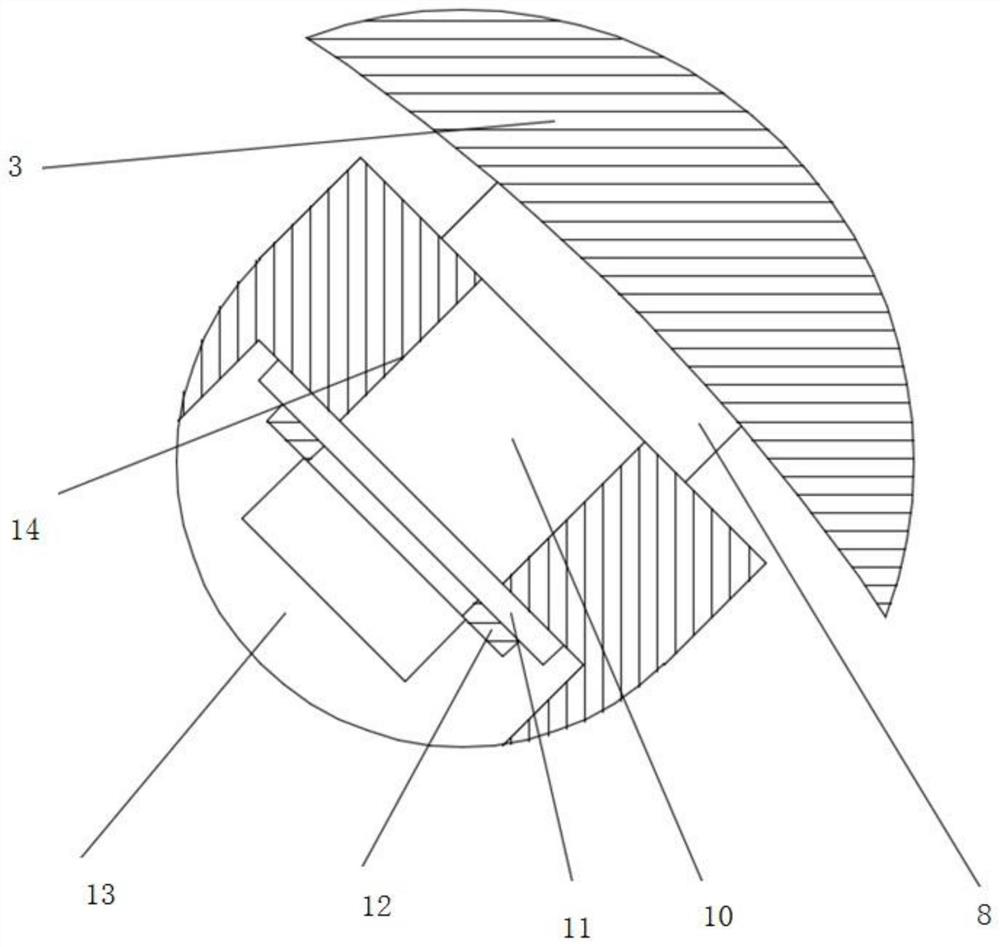

Pipe butt welding positioning tool and method

ActiveCN111992968AImprove accuracyWide range of specificationsWelding/cutting auxillary devicesAuxillary welding devicesButt weldingStructural engineering

The invention relates to a pipe butt welding positioning tool. The pipe butt welding positioning tool comprises two movably-mounted half shells, wherein welding holes are formed in the side walls of the half shells; fastening adjusting pieces are further arranged on the side walls of the half shells; each fastening adjusting piece comprises a screw rod and a top strip; the screw rods are in threaded connection with the side walls of the half shells; and one ends of the screw rods are movably connected with the top strips. By means of the pipe butt welding positioning tool, positioning of buttwelding of two pipes can be achieved, the pipe butt welding accuracy is improved, and then the butt welding quality is improved. The positions of the top strips relative to the half shells can be changed by adjusting the fastening adjusting pieces, so that the pipe butt welding positioning tool can be wider in specification range suitable for pipes.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

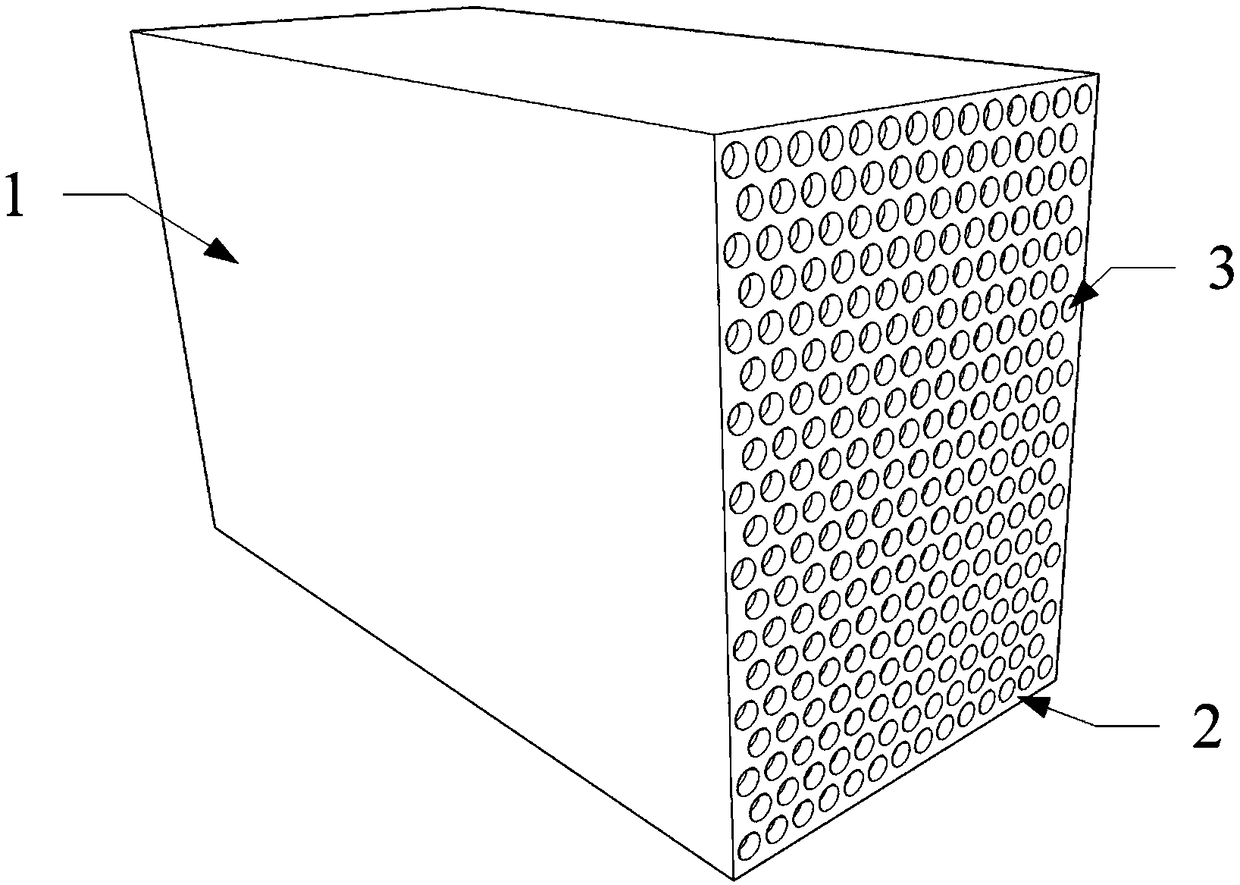

Forming method for precast concrete member bonding surface

InactiveCN108638300ALow priceWide range of specificationsMouldsMould auxillary partsPrecast concreteAir bubble

The invention relates to a forming method for a precast concrete member bonding surface. The method comprises the following steps that a concrete member is precast; an air bubble film is attached, specifically, the air bubble film is mounted on the inner surface, corresponding to the bonding surface of the precast concrete member, of a template; and the air bubble film is peeled off, specifically,after the template is dismounted, the air bubble film is peeled off, and concave pits which are consistent with the air bubble film in size and arrangement rule are formed in the precast concrete member bonding surface. According to the technical scheme, through the forming method for the precast concrete member bonding surface, the roughness requirement for the precast concrete member bonding surface is met through the air bubble film, the construction process is simple and convenient, the surface quality is good, in addition, materials of the air bubble film are easy to take, the price is low, and the advantages of customization and easy demolding are achieved.

Owner:NANJING UNIV OF TECH

Easy-weld hardening high-strength steel plate and production method thereof

InactiveCN100467652CReduce manufacturing costFine tissue structureRoll force/gap control deviceTemperature control deviceImpurityMaterials science

The invention relates to an easily welded, hardened and tempered high-intensity steel plate and its producing method, which comprises the following part: C<=0.15%, 0.15%-0.50% Si, 0.80%-1.80% Mn, P<=0.02%, S<=0.01%, Mn<=0.6%, Nb<=0.07%, B<=0.003%, Ni<=1.20%, Cr<=0.80%, Ti<=0.03%, V<=0.08%, the rest Fe and unavoidable impurity. The invention smelts with the electric furnace, which is provided with the low quantity P, S and the pure steel, gets the users' favor, has the low cost and the market competitive ability, solves the problem of big crystal grain and low dynamic ductility, and is fit for producing the high-intensity steel with low draught pressure rolling mill in the other steel factory. The invention also reduces the labor strength, which saves the time of the work, improves the availability ratio of the material, and reduces the leveling expense of making the steel plate.

Owner:WUYANG IRON & STEEL

Accurate and automatic pressurizing system for TFT knife

InactiveCN112456778AExtended service lifeImprove utilizationGlass severing apparatusTool bitControl system

The invention discloses an accurate automatic pressurizing system of a TFT cutting knife, which comprises an automatic pressurizing system equipment unit, a cutting knife automatic pressurizing gas circuit unit and an electrical control system unit, when the accurate automatic pressurizing system is used, a cutting cylinder is connected with a cutting arm, and when substrate glass is cut, the cutting cylinder acts to drive the cutting arm to descend; a cutting knife wheel directly installed on the cutting knife head makes contact with a substrate glass, in the walking process of the knife head, the cutting knife wheel cuts the surface of the substrate glass, the pressure of the pressurizing air cylinder is adjusted, the pressure influences the acting force of the cutting knife wheel on glass cutting, and on the basis of original equipment, the cutter head mechanism can be directly replaced, the cutter head mechanism can be transformed and upgraded and transformed into an accurate automatic pressurizing function of the cutter, the shutdown frequency of cutter wheel replacement can be reduced, the equipment utilization rate can be increased, the service life of the cutter wheel can be prolonged, and the production cost can be reduced.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com