Patents

Literature

166results about How to "Quality standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

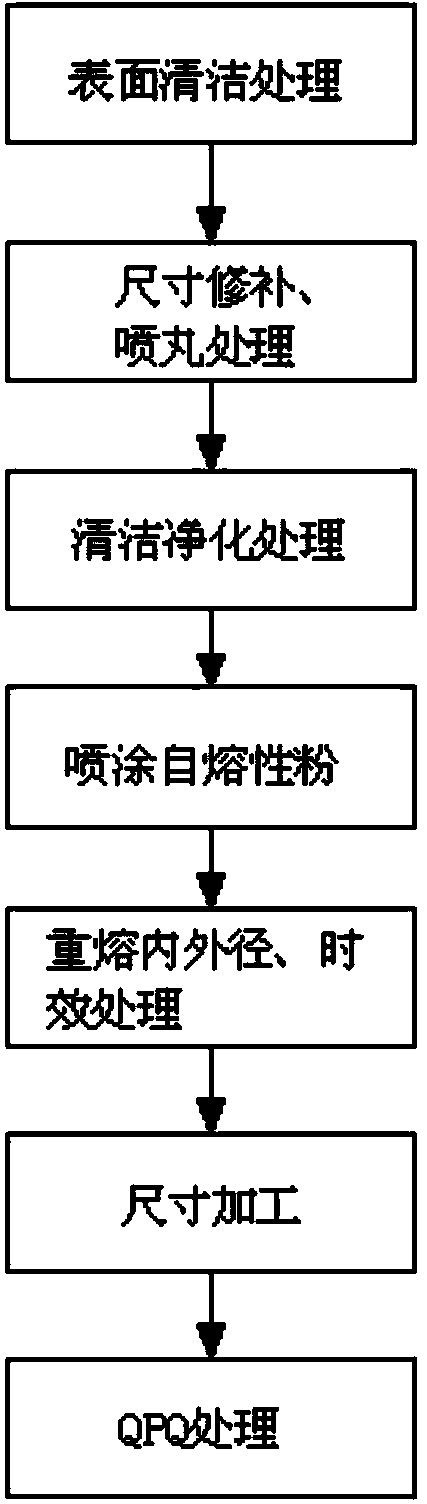

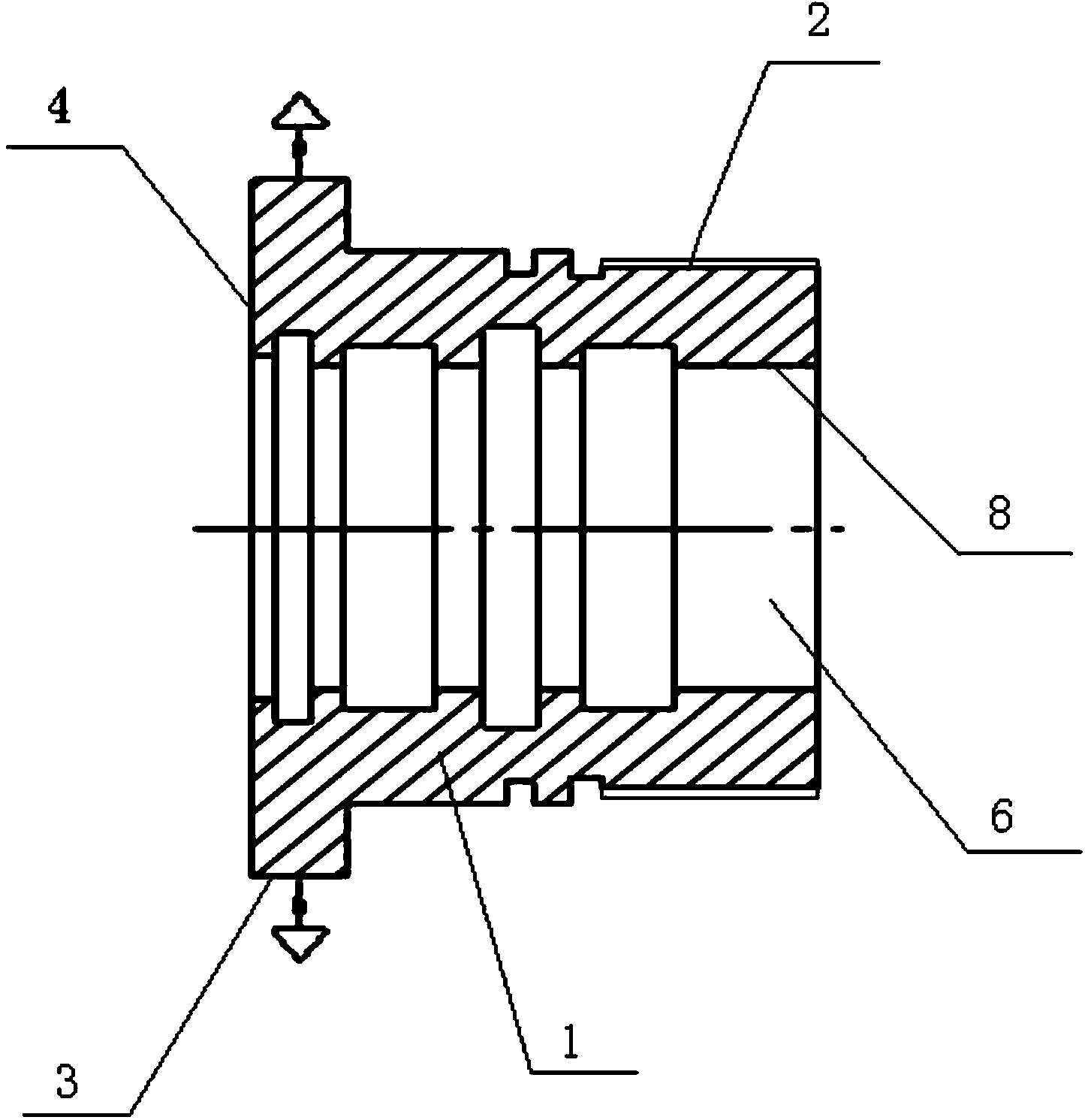

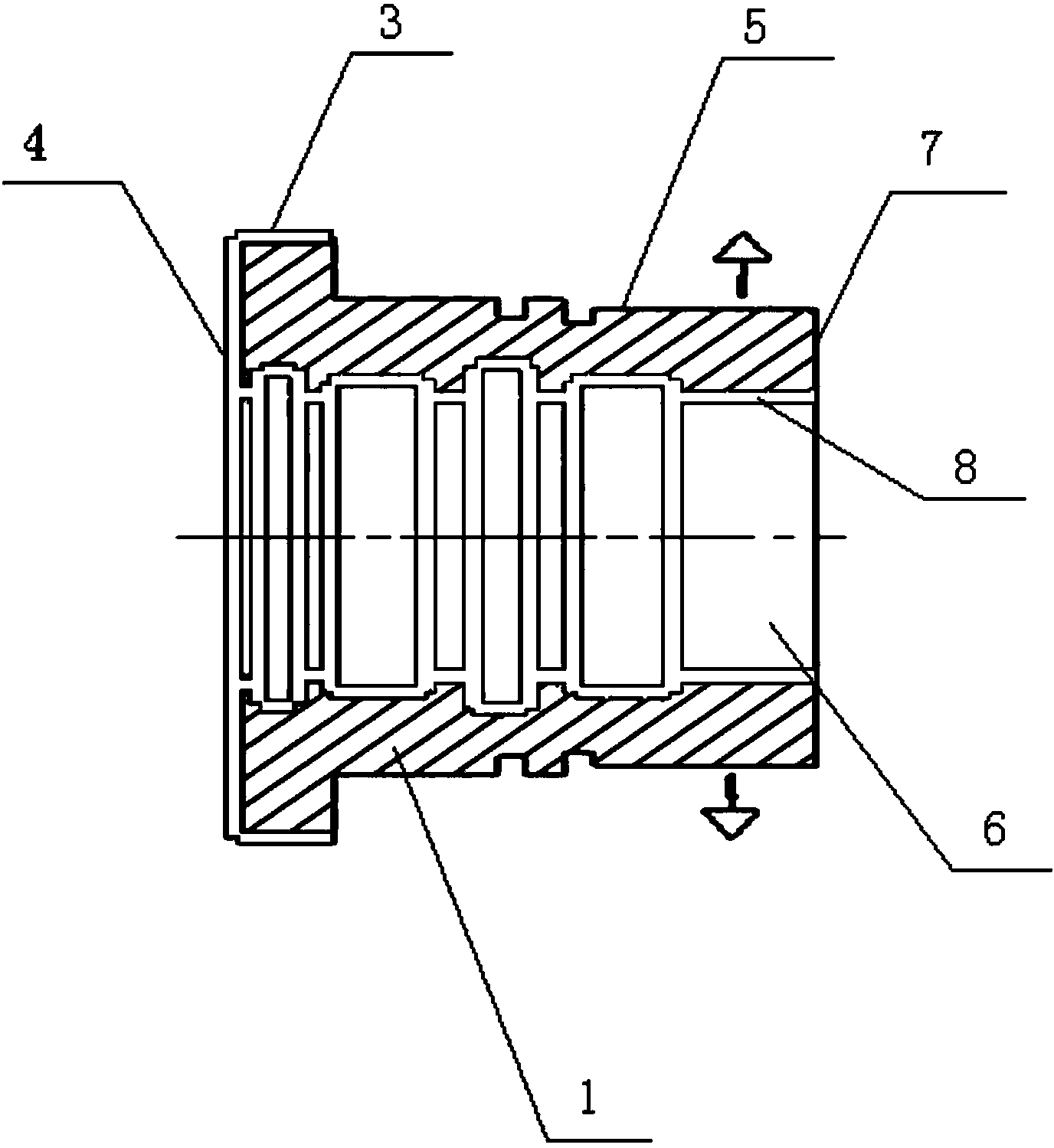

Re-manufacturing machining process of surface of inner hole of hydraulic cylinder scrap guide sleeve

InactiveCN104043941AExtended service lifeImprove anti-corrosion performanceHydraulic cylinderMedium frequency

The invention relates to a re-manufacturing machining process of the surface of an inner hole of a hydraulic cylinder scrap guide sleeve. The process comprises the following steps that the hydraulic cylinder guide sleeve is cleaned in the machining early period; size repair is carried out on the hydraulic cylinder guide sleeve, and shot blasting is carried on the inner surface and the outer surface of the hydraulic cylinder guide sleeve; the inner surface and the outer surface of the hydraulic cylinder guide sleeve are cleaned and purified through acetone; self-fluxing nature powder is sprayed on an outer thread, the outer surface, the wall surface of the inner hole and grooves of the hydraulic cylinder guide sleeve; the inner diameter and the outer diameter of the hydraulic cylinder guide sleeve are remelt through medium-frequency induction heating equipment, aging treatment is carried out after the inner diameter and the outer diameter of the hydraulic cylinder guide sleeve are remelt; size machining is carried out on the hydraulic cylinder guide sleeve; QPQ processing is carried out on the surface of the hydraulic cylinder guide sleeve. The re-manufacturing machining process of the surface of the inner hole of the hydraulic cylinder scrap guide sleeve has the advantages that the scrap hydraulic cylinder guide sleeve is re-machined to the original size and original structure, the thread can be machined in the original position, the anti-corrosion performance and anti-tension performance of the hydraulic cylinder guide sleeve are improved, the service life of a hydraulic cylinder is prolonged, and cost is lowered.

Owner:HENAN WEITONG TECH +1

Drying method for wood

InactiveCN106393342AFast dryingStable Quantitative ProductionRadiation/waves wood treatmentWood treatment detailsMicrowaveWood plank

The invention discloses a drying method for wood. The drying method comprises the following steps that A, the wood is pre-planed, and the wood is cut into boards with the same size; B, the pre-planed wood is soaked with brine; C, the wood soaked with the brine is wrapped with tin foil paper and baked; D, the baked wood is coated with a wood anti-cracking agent, and then the wood is subjected to microwave and ultrasonic drying; and E, the wood obtained after microwave and ultrasonic drying is performed is subjected to thermal convection drying. By the adoption of the drying method for the wood, the moisture in the wood can be dried effectively, and the moisture content of the wood is less than 8.5% and meets the dry standard; the phenomena of cracking, deformation, bending and warping of the wood and the like can be avoided; the drying speed of the wood can be increased effectively, the time is shortened, the cost is lowered, and the stable mass production of the wood is achieved; and the quality of the obtained wood is stable, and the error between the moisture content and the target moisture content of dried products is small.

Owner:玉溪万德能源技术有限公司

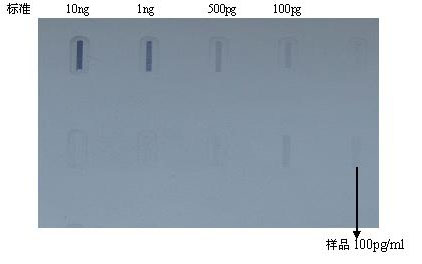

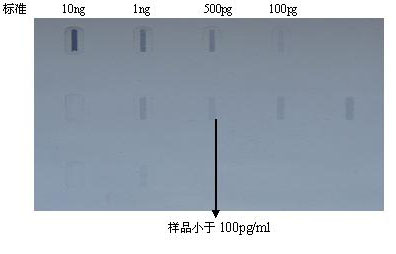

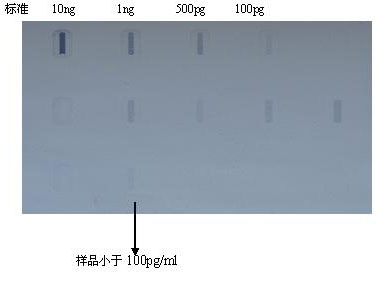

Method for preparing Vero cell influenza virus vaccine

ActiveCN102078605ASimple purification processQuality standardsAntiviralsAntibody medical ingredientsInfluenza virus vaccineIon exchange

The invention provides a method for preparing a Vero cell influenza virus vaccine. Seasonal trivalent influenza vaccines and pandemic influenza storage vaccines with qualified quality can be prepared by improving a vaccine purification process, combining hydrophobic chromatography with ion exchange and auxiliarily adopting other purification methods.

Owner:吉林亚泰生物药业股份有限公司

Preparation method for grapefruit tea and drinking method of grapefruit tea

The invention relates to the technical field of tea products, in particular to a preparation method for grapefruit tea and a drinking method of the grapefruit tea. The preparation method comprises the following steps: preparing materials, preprocessing, blending, filling, binding, drying, performing filling, binding and drying again, and cycling for 3 to 4 times in sequence until a dried grapefruit is plump to obtain finished grapefruit. The drinking method for the grapefruit tea prepared by the preparation method comprises the following step: brewing more than one of a grapefruit cover, grapefruit peel or dried tea leaves with boiling water for drinking, or decocting more than one of the grapefruit cover, the grapefruit peel or the dried tea leaves for drinking. The grapefruit tea prepared by the method is standard in quality and good in taste, does not contain a preservative or an essence, and contains the components of traditional Chinese medicaments with the functions of clearing away lung-heat and wetting throat, and has the effects of tea leaves, and the special thick flavor of the grapefruit; the prepared grapefruit tea has the effects of clearing away lung-heat, wetting throat, relieving cough, reducing sputum, reducing blood sugar and the like.

Owner:仙游县楼峰种养殖专业合作社

Method for manufacturing micropores for electric conduction among copper foil of high-density multilayer circuit boards

InactiveCN101588679AQuality standardsGood repeatabilityPrinted element electric connection formationHigh densityDielectric substrate

The invention discloses a method for manufacturing micropores for electric conduction among copper foil of high-density multilayer circuit boards. The method comprises: depositing a tin-containing metal layer in a position where a micropore is to be drilled on surface copper foil of a high-density multilayer circuit board by a local electroplating method; using a pulsed carbon dioxide laser microbeam to drill a hole in the position plated with the tin-containing metal layer so as to ensure that the surface copper foil on the bottom of the tin-containing metal layer is melted to form a copper-foil micropore; and aiming the pulsed carbon dioxide laser microbeam at the copper-foil micropore of the surface copper foil to drill a substrate medium hole on a substrate medium under the copper-foil micropore up to interlayer copper foil. The method integrates a drilling process for copper conductive layers with a drilling process for dielectric substrates in the manufacture of the high-density circuit boards, thereby greatly simplifying production process, avoiding the emission of a large number of acidic and organic pollutants and achieving the aims of reducing cost and protecting environment.

Owner:XI AN JIAOTONG UNIV

Skin disease lotion composition and preparation method thereof

ActiveCN101732632AStable production processExtended shelf lifeAntimycoticsInorganic boron active ingredientsDiseaseSophora Root

The invention relates to a skin disease lotion composition and a preparation method thereof. The skin disease lotion composition consists of bottled liquor and bagged realgar granules, wherein the liquor is prepared by extracting and processing lightyellow sophora root, sessile stemona root, pricklyash peel and densefruit pittany root-bark; and the realgar granules are prepared by processing, drying and granulating realgar.

Owner:王疆宏

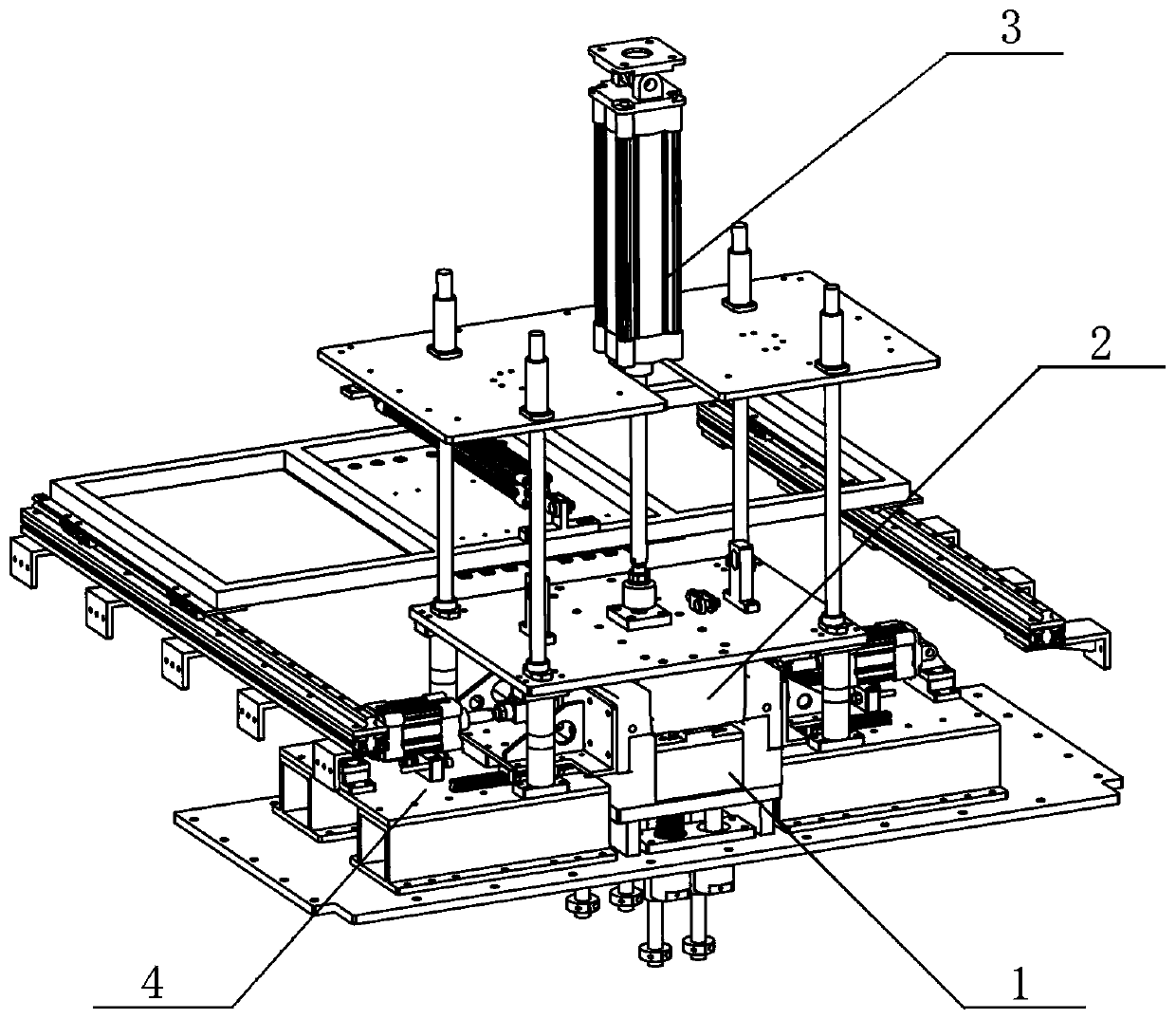

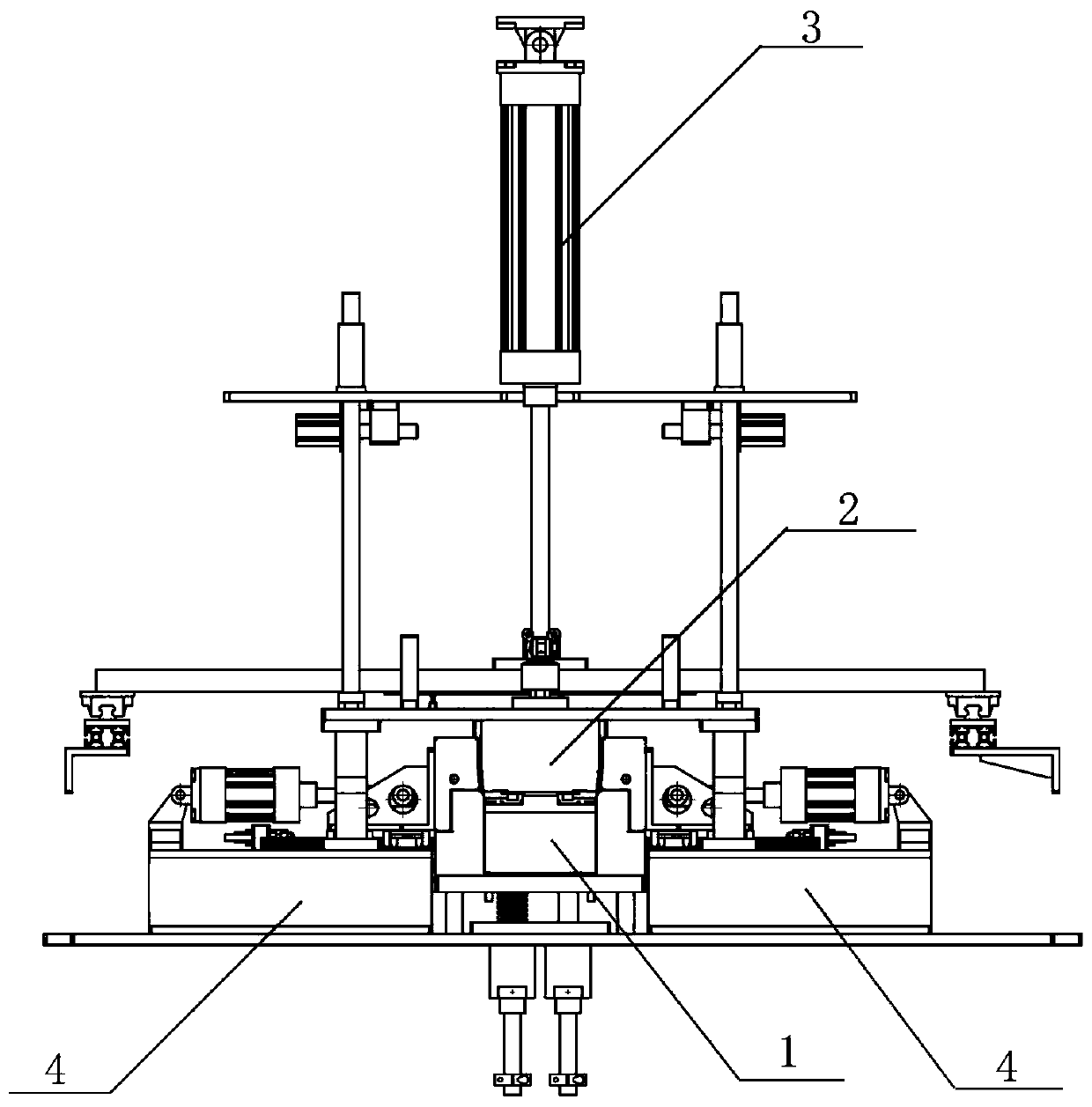

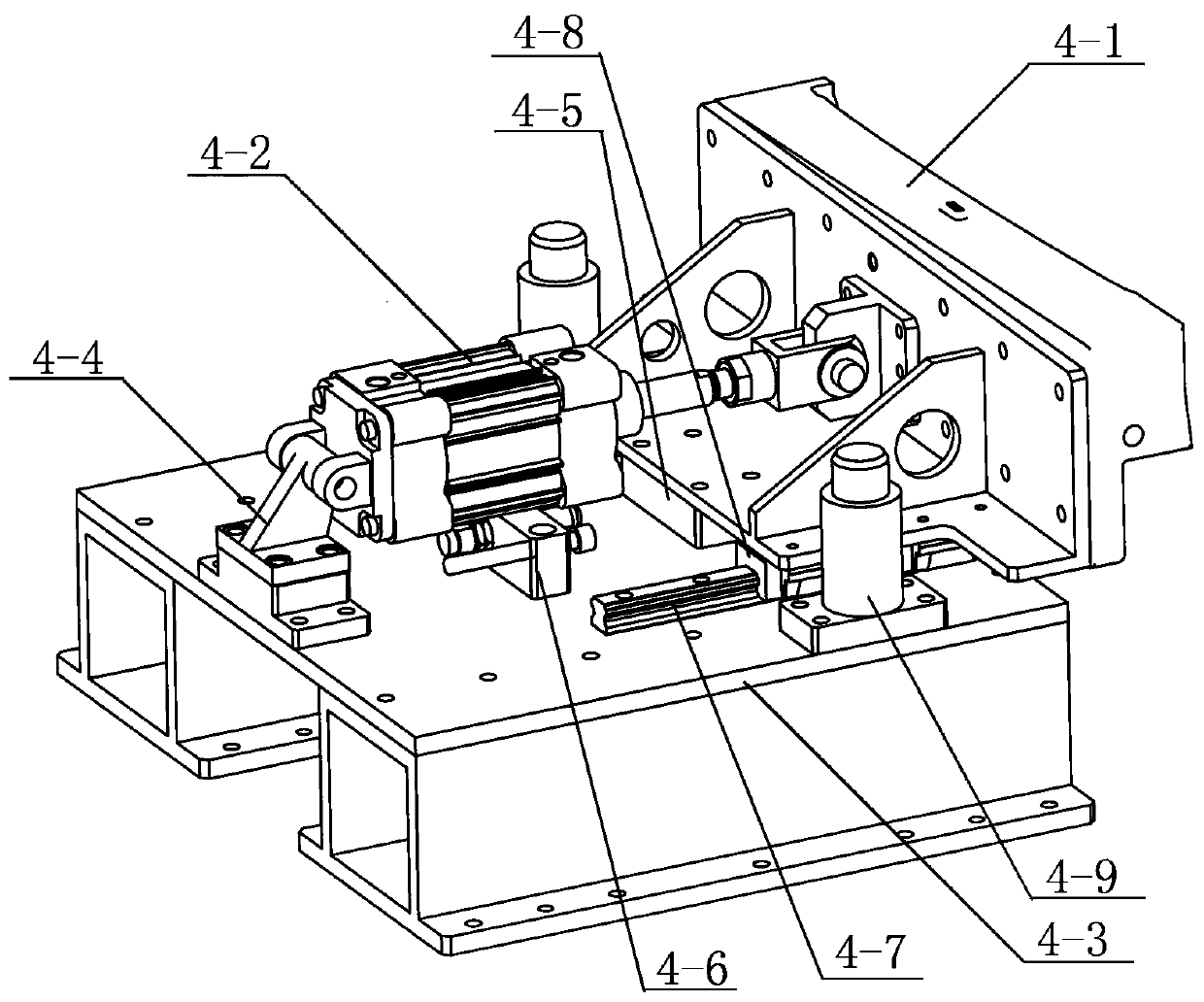

Automatic automobile trim coating device with sewing thread

PendingCN110219105AGuaranteed positionWarranty requirementsThread-break detectorsMechanical engineeringQuality standard

The invention provides an automatic automobile trim coating device with a sewing thread. The coating device comprises a lower mold and an upper mold. The upper mold is provided with a lifting mechanism, and side pushing mechanisms for clamping workpieces on the lower mold are arranged on both sides of the lower mold. The lower mold comprises a lower mold body, lateral lower molds, a lower mold mounting plate, sewing thread middle jacking molds, a main spring component and an auxiliary spring component. Two symmetrical sewing thread middle jacking mold mounting grooves are formed in edge positions, close to both sides, of the lower mold body. The sewing thread middle jacking molds are mounted in the sewing thread middle jacking mold mounting grooves. The automatic automobile trim coating device has the advantages that the sewing thread middle jacking molds with positioning and suction functions and the side pushing mechanisms are added to the lower mold, automatic coating of trim products can be realized; front and back edges of a cover are sucked by vacuum suckers to guarantee the shape stability of the sewing thread during coating, the position degree and flatness of the sewing thread after coating are also ensured, and accordingly, the products meet quality standards.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

Method for recycling sulfosalicylic acid from doxycycline production waste liquid

ActiveCN105348154AHigh purityReduce consumptionOrganic compound preparationSulfonic acids salts preparationAlcohol ethylSodium salicylate

The invention discloses a method for recycling sulfosalicylic acid from doxycycline production waste liquid and belongs to the field of medicinal chemistry separation and purification. The method includes the following steps that alkali is added to doxycycline production waste liquid, the alkali reacts with sulfosalicylic acid in the doxycycline production waste liquid, sulfosalicylic acid sodium salt is formed, then ethyl alcohol is recycled, crystallization is conducted, and sodium sulfosalicylate is obtained; the recycled sulfosalicylic acid sodium salt is added to an alcohol solution and an acid solution, after a reaction is ended, filtering is conducted, sodium chloride is removed, filter liquor is concentrated, solvent is recycled, crystallization is conducted, sulfosalicylic acid is obtained, the recycling rate reaches 80% or more, and a product is acceptable in quality. Compared with a traditional recycling process, the sulfosalicylic acid is recycled from the doxycycline production waste liquid, emission of pollutants is reduced, environmental protection is facilitated, the sulfosalicylic acid can be recycled, the production cost is lowered, and the economic and social benefits of doxycycline are raised.

Owner:开封豫港制药有限公司 +2

Air-jet loom weaving method with polyester cotton wrap yarn fabric

InactiveCN101418489AOvercoming the Disadvantages of DeformationReduce untwisting phenomenonLoomsWoven fabricsInsertion timeAir-jet loom

The invention discloses an air jet loom weaving method for a polyester cotton core-spun yarn fabric with a polyester filament as a core and cotton fiber wrapped outside polyester, which orderly comprises working procedures such as doubling, twist stabilization after twisting, warping and rebeaming, reeding, loom beam on-hook, adjustment of process parameters and so on. In the working procedure of batch warping, the rebeaming is performed on a sizing machine, and the sizing is not performed; during the reeding after the rebeaming, 50 to 100 percent of harness frame numbers are increased than the prior species according to the warp density; the weft-insertion time is adjusted to ensure that the weft-insertion time of previous group of auxiliary nozzles is longer than that of next group of the auxiliary nozzles and the weft-insertion time is orderly shortened in a step shape, and the entire auxiliary nozzles are synchronously closed at the same angle position. The working procedures after the adjustment effectively solve the problem that the dyeing of the polyester cotton core-spun yarn fabric has color difference after the polyester cotton core-spun yarn fabric is woven on an air jet loom, and ensure that the polyester cotton core-spun yarn fabric can be fully and normally woven on the air jet loom. The weaving efficiency can reach 96 percent, the rate of first-grade products when getting off the loom can reach more than 93 percent, woven cloth has qualified various indicators and fully satisfies the normal production of the dyeing and finishing, and no quality problem exists after the dyeing.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

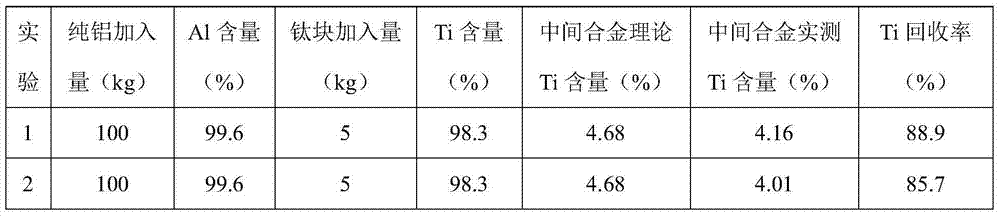

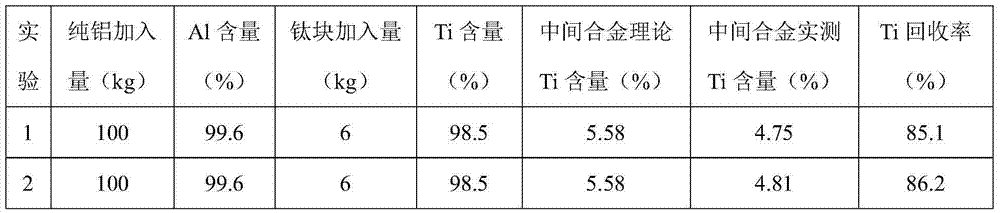

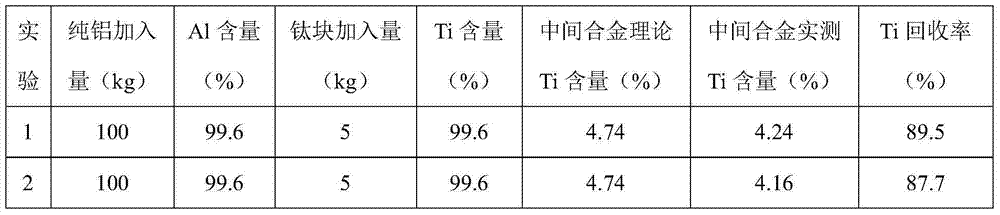

Method for preparing aluminum-titanium intermediate alloy by recycling titanium scrap or titanium leftover material

The invention relates to a method for preparing an aluminum-titanium intermediate alloy by recycling titanium scrap and titanium leftover material, relates to a method for preparing an aluminum-titanium intermediate alloy, and aims at solving the problem of low recycling rate of the titanium scrap or titanium leftover material generated in the production process of existing titanium products. The preparation method comprises the following steps: (I) grinding the titanium scrap or titanium leftover material on a grinder, removing oil and drying, and packaging with aluminum foil into bags to obtain titanium blocks in bags; (II) melting pure aluminum in a smelting furnace to obtain molten aluminum; (III) increasing the temperature of the molten aluminum, adding part of the titanium blocks in bags by a bell jar press-in way, stirring for a period of time, adding the rest titanium blocks in bags, and continuously stirring to obtain the molten aluminum; (IV) removing gas by use of a rotary degasser, and performing slagging-off and casting and ingot formation to obtain the aluminum-titanium intermediate alloy. According to the method provided by the invention, the waste titanium scrap and titanium leftover material generated in the machining process of the titanium product are recycled, and then, the recycling rate of the titanium element reaches 85-90%.

Owner:HARBIN UNIV OF SCI & TECH

200 million live spore/g lichen Bacillus subtilis medical fertilizer granule and preparation method thereof

InactiveCN102167641AAvoid spreadingImprove stress resistanceFertilizer mixturesBiotechnologyBacillus licheniformis

The invention provides 200 million live spore / g lichen Bacillus subtilis medical fertilizer granule and a preparation method thereof. The granule consists of the following raw materials by weight percent: 0.5% of 30 billion live spore / g Bacillus subtilis wettable powder, 0.5% of 30 billion live spore / g Bacillus licheniformis wettable powder, 1% of stabilizer, diffusant and suspending agent and 98% of organic fertilizer. In the preparation method of the granule, after Bacillus licheniformis is compounded with Bacillus subtilis, the mixture is mixed with organic fertilizer to produce a high-quality medical fertilizer product. The granule is used for effectively preventing and controlling soil-borne diseases when farmers apply fertilizer.

Owner:CHONGQING ZHONGLI BIOENG

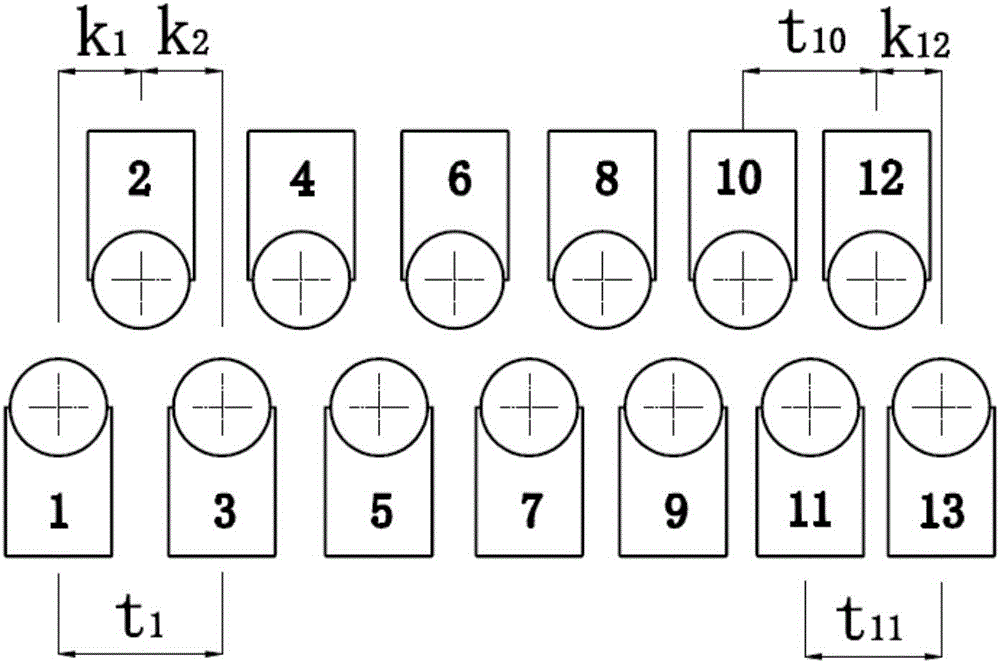

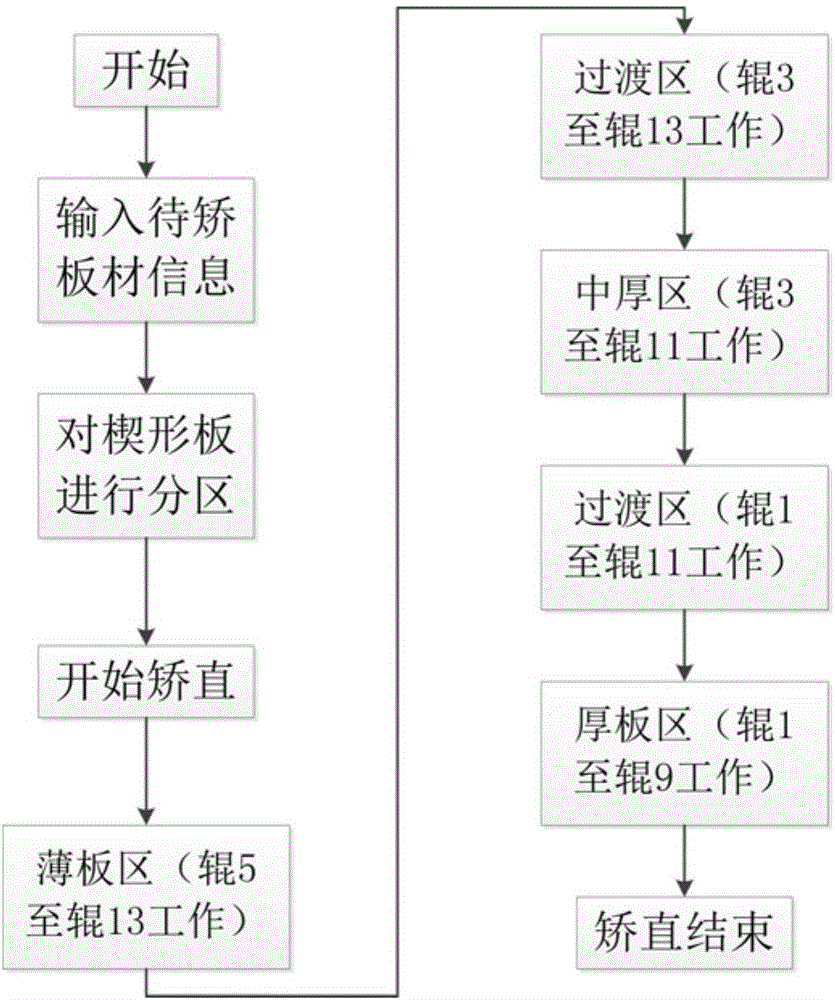

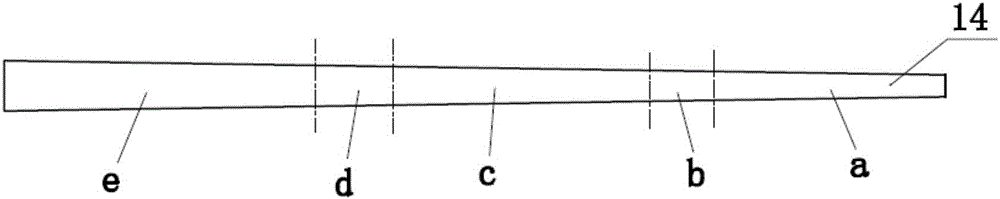

Straightening process for wedge-shaped plate

ActiveCN106391760AMeet the requirements of straightening process parametersQuality standardsCamWedge shape

The invention discloses a straightening process for a wedge-shaped plate. A 13-roller straightener is adopted. The roller spaces of a straightening roller system are arranged from large to small in a progressive decreasing mode. Four front rollers and four rear rollers of the straightening roller system are rising-falling straightening rollers. The straightening process comprises the specific steps that (1) the wedge-shaped plate serves as a variable thickness plate, and according to the parameters of the wedge-shaped plate, the roller space ti and rolling reduction hi corresponding to different plate thicknesses are calculated; (2) according to the parameters of the wedge-shaped plate, the wedge-shaped plate is subjected to plate thickness zoning; and (3) according to plate thickness zoning, different plate segments are straightened through roller sets, during straightening, the thin plate zone enters the straightener first, the four front rollers and the four rear rollers of the straightening roller system enters or leaves work according to the change of the plate thickness of the wedge-shaped plate during straightening, and thus the roller space is adjusted according to the change of the plate thickness until straightening is finished. Through the straightening process, the problem that straightening rollers of a traditional plate belt straightener cannot be adjusted on line under pressure during straightening is solved, thus rolling reduction and the roller spaces cam meet straightening process parameter requirements of the wedge-shaped plate, and the wedge-shaped plate with acceptable quality is obtained through straightening.

Owner:YANSHAN UNIV

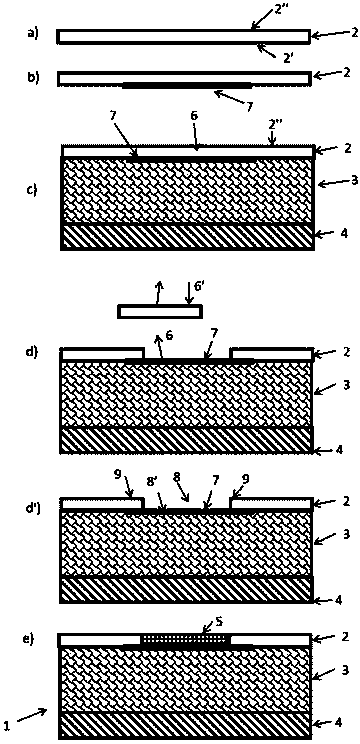

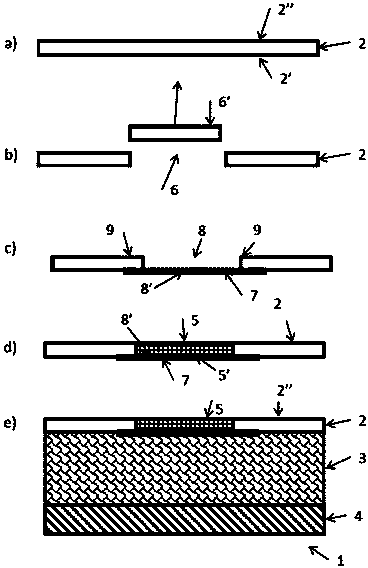

Method for manufacturing an interior lining part and corresponding part

InactiveCN104386000AQuality standardsLamination ancillary operationsLaminationComposite materialManufacturing engineering

A method for manufacturing an interior lining part, includes producing a skin; placing the skin in a foaming mold with a support layer; foaming an intermediate layer; cutting out an area of the skin producing a cutout area of the skin; placing a piece of adhesive tape or film in the cutout area, the piece of adhesive tape or film being placed in between the skin and the intermediate foam layer; and placing an insert in the cut out area of the skin. A method for manufacturing an interior lining part, includes producing a skin by rotational molding; placing a piece of adhesive tape or film in the cutout area, the piece of adhesive tape or film being placed in between the skin and the intermediate foam layer; placing the skin in a foaming mold with a support layer; foaming an intermediate layer; cutting out an area of the skin producing a cutout area of the skin; and placing an insert in the cut out area of the skin.

Owner:VISTEON GLOBAL TECH INC

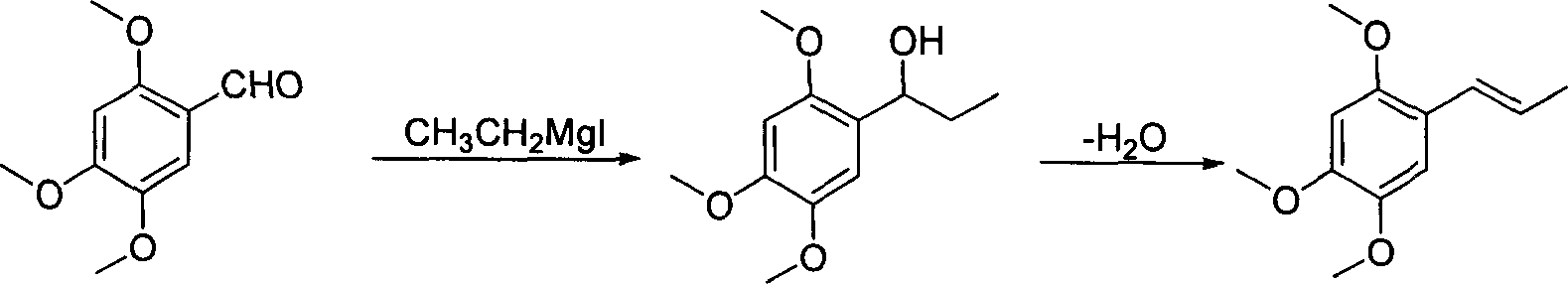

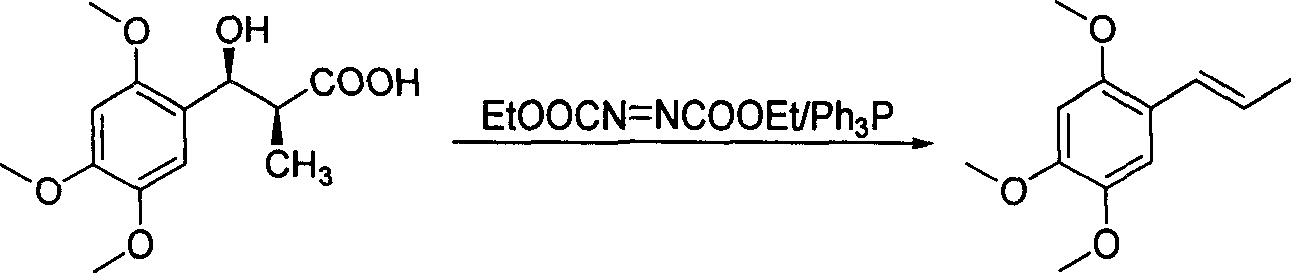

Method of preparing alpha-asarone

InactiveCN101012159ALow costControl contentNervous disorderOrganic chemistryAntiepileptic drugLigroin

The invention discloses a making method of antiepileptic drug alpha-asaryl, which comprises the follwoig steps: dissolving cistron-asaryl in the solvent; adding certain quantity of palladium compound as catalyst; stirring under indoor temperature or heating condition; filtering catalyst; decompressing; condensing the reacting liquid; recrystallizing residual through ligroin or skellysolve B to obtain the product.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG +1

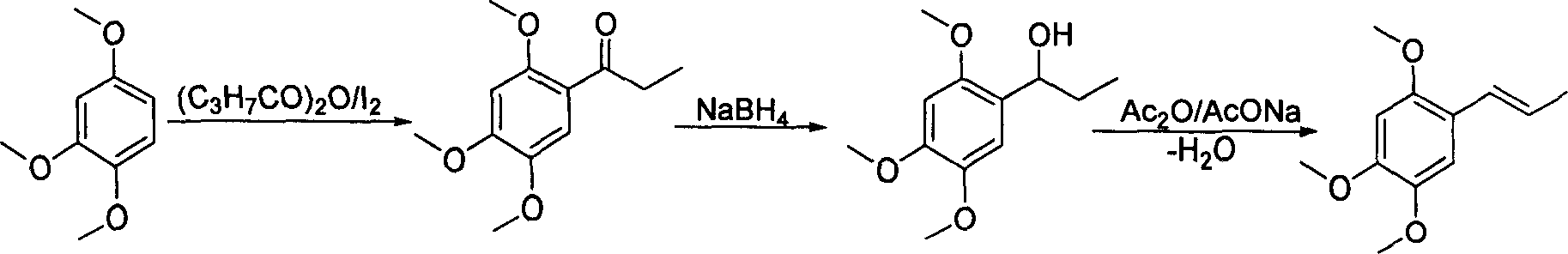

Production process for producing high-grade coated white manila board by using ONP (Old News Paper) pulp instead of DIP (Deinked Pulp) pulp

InactiveCN109056407AHigh yieldLow whiteness requirementPaper/cardboardSecondary cellulose fibresFiberSurface layer

The invention provides a production process for producing high-grade coated white manila board by using ONP (Old News Paper) pulp instead of DIP (Deinked Pulp) pulp, relates to the technical field ofpulp paper production, and in particular to the production process for producing high-grade coated white manila board by using ONP pulp instead of DIP pulp. The high-grade coated white manila board isproduced by using the following process steps: using the ONP pulp as a surface layer, using an OCC (Old corrugated container) pulp as a lining layer, using a mixture of sawdust pulp and OCC staple fiber and filament fiber pulp as a core layer, and using OCC pulp middle-length fiber pulp as a bottom layer; performing base paper making via a net portion, a pressing portion, a pre-drying portion, asurface sizing portion, and a hard calendaring portion; coating the raw paper after the papermaking by pre-coating, curtain-coating, back-coating, and top-coating; and then being subjected to soft calendering, coiling, rewinding, and storing to a warehouse. The high-grade coated white manila board produced by the production process provided by the invention has the following properties: a whiteness of 70-72 ISO, a dirt count the paper surface of 30-60 mm<2> / m<2>, a surface strength (IGT) of 1.5 to 2.0 m / s, a glossiness of the finished paper of 40%, an ink absorbency of 26-28%, and a smoothnessof 130-150S, wherein the covering performance of the coated white manila board meets the quality requirements of traditional high-grade coated white manila board, and the coated white manila board can be offset as many as 4 or 5 times and can be folded as many as 15-20 times.

Owner:LIANSHENG PAPER IND LONGHAI

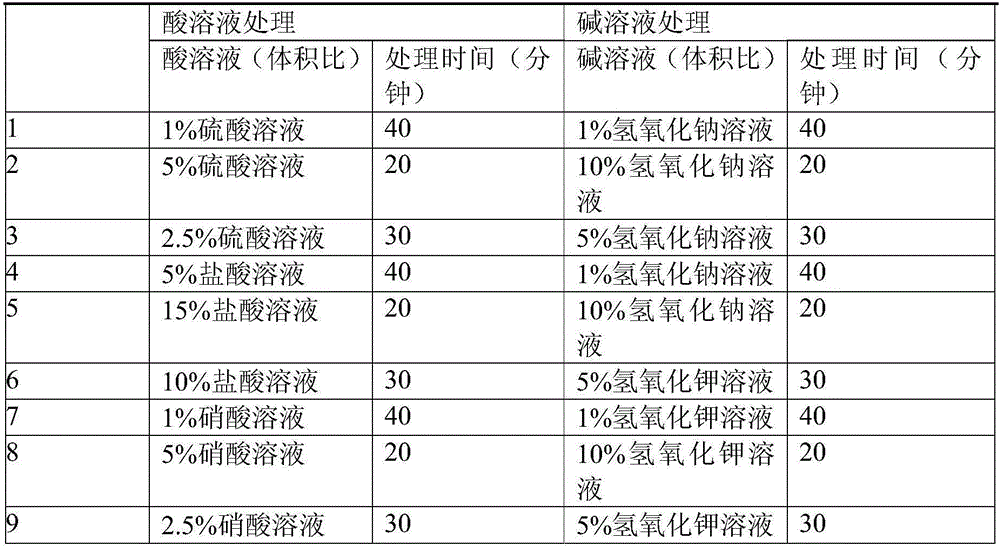

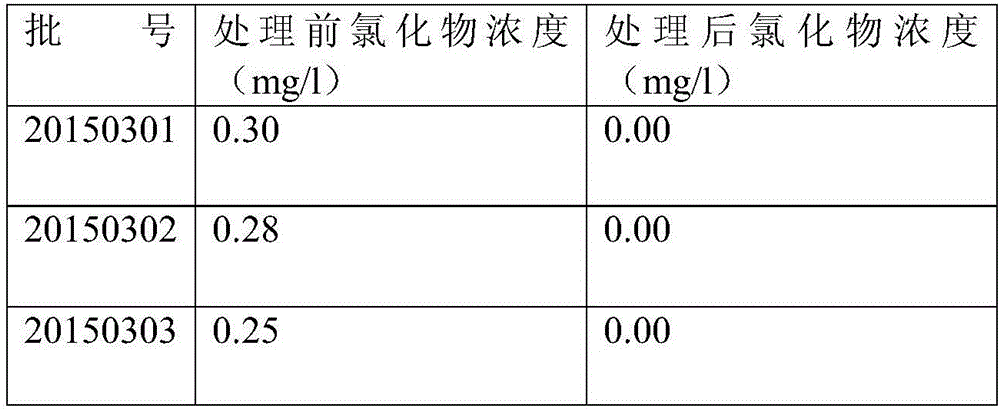

Penicillin bottle handling method, penicillin bottle obtained through handling, and penicillin-bottled water for injection

ActiveCN106428817AQuality standardsImprove stabilityPackage sterilisationBottle-handling machinesPenicillinWarm water

The invention provides a penicillin bottle handling method, a penicillin bottle obtained through handling, and penicillin-bottled water for injection, and belongs to the technical field of medicine. The penicillin bottle comprises a bottle body and a butyl rubber plug. The penicillin bottle handling method comprises the following steps in any sequence: (1) handling the bottle body by utilizing an acid solution and an alkaline solution sequentially, carrying out cleaning till the pH value reaches 5.0-7.0, and carrying out drying and sterilization for standby application; and (2) handling the butyl rubber plug by utilizing the acid solution, the alkaline solution and warm water sequentially, carrying out cleaning till the pH value reaches 5.0-7.0, and carrying out sterilization for standby application. The invention further provides a preparation method of the penicillin-bottled water for injection. The preparation method comprises the following step: filling the penicillin bottle obtained through handling with the water for injection. The water or liquid medicine for injection accommodated in the penicillin bottle obtained according to the penicillin bottle handling method, or the penicillin-bottled water or liquid medicine for injection obtained according to the preparation method not only is qualified and high in stability, but also can be protected from chloride leakage, chloride out-of-specification and the like after standing for a long time, and is suitable for long-term preservation.

Owner:SANCAI SHIQI PHARMA CO LTD

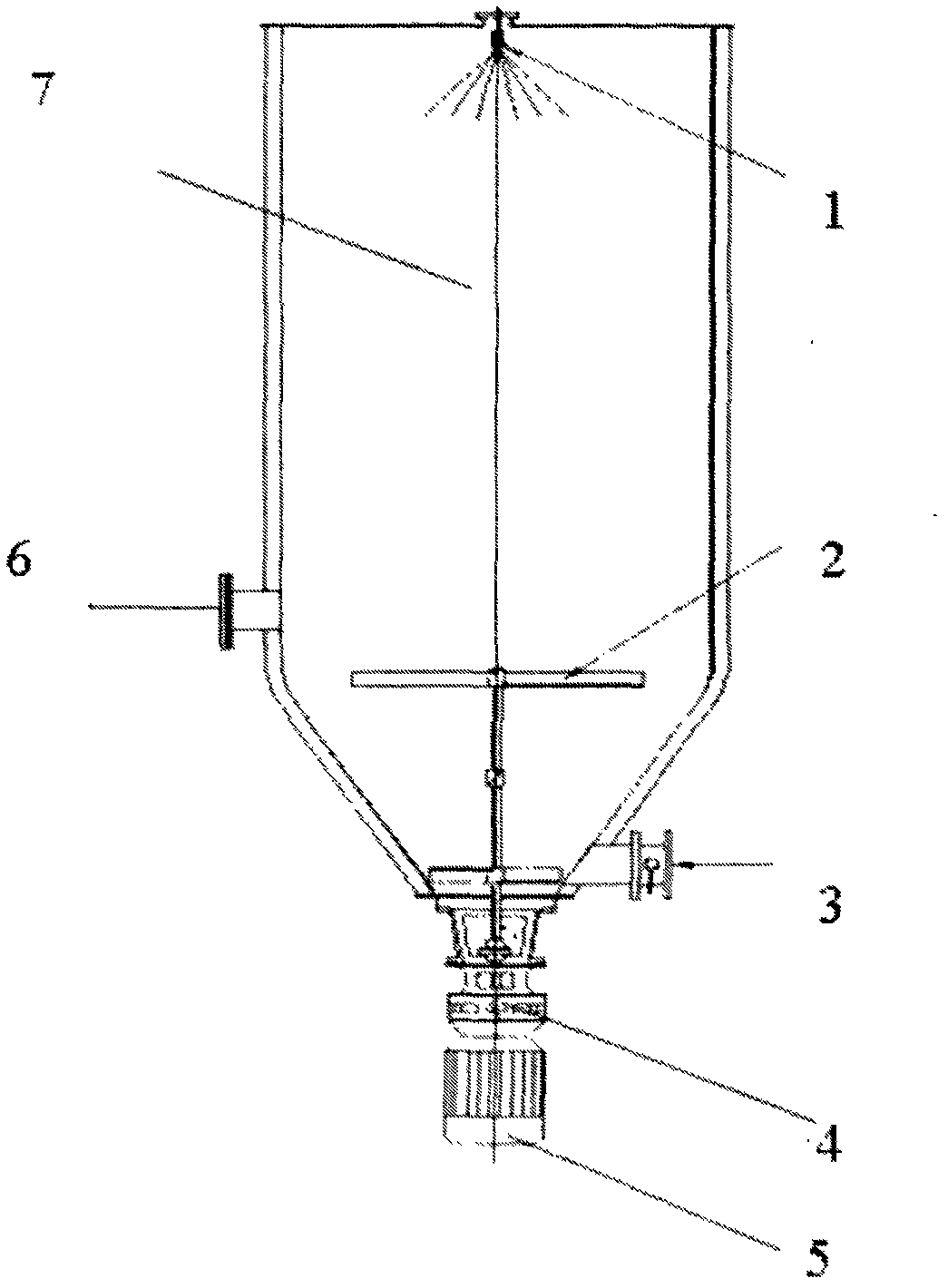

Drying and producing process of traditional Chinese medicine through one-step granulating

InactiveCN103292587ADry fastQuality standardsDrying solid materials with heatDrying chambers/containersFluidized bed dryingSpray nozzle

A drying and producing process of traditional Chinese medicine through one-step granulating is mainly characterized in that quantitative dried auxiliary material particles are added from a particle outlet and enter a drying chamber from a hot air inlet after heated by filtered air; the added dried particles form a fluidized bed through hot air; after the auxiliary material particles are heated to a designated temperature, a pressurized liquid medicine is mixed and atomized with compressed air through a nozzle in a storage tank; the sprayed liquid medicine is absorbed in materials of the fluidized bed, an agitating blade agitates the mixture continuously, particles are increased gradually on a fluidized bed layer dried by the hot air to the particle outlet; and finally, the particles are discharged out of a drying tower. According to the drying and producing process of traditional Chinese medicine through one-step granulating, a spray drying method, a fluid bed drying technique and an agitating method are combined, a one-step drying and granulating process of a traditional Chinese liquid medicine is realized.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

Feeding system for spraying viscous material

The invention discloses a feeding system for spraying a viscous material. The feeding system comprises a storage tank, a feeding pipe, a discharge pipe, a feeding pump, a spray pipe and a pressure adjusting pump, wherein the feeding inlet of the storage tank is communicated with the feeding pipe, the discharge hole of the storage tank is communicated with one end of the discharge pipe, the other end of the discharge pipe is communicated with the inlet end of the feeding pump and the outlet end of the feeding pump is communicated with the inlet of the spray pipe; the spray pipe is communicated with the pressure adjusting pump and then is communicated with a spray device, the pressure adjusting pump is electrically connected with a pressurizer, and the pressurizer is used for adjusting the pressure adjusting pump to keep the material be ejected from the spray device in a constant pressure state. Two pump bodies can be arranged to provide enough power to convey the viscous materials, so as to prevent all connections, pump bodies and pipe fittings from being blocked by the material; furthermore, the pressure can be kept to be constant by the pressurizer when the material is ejected, the discharged materials of the spray device are uniform, the materials sprayed on all surfaces of work-pieces are uniform and attractive and are qualified in quality.

Owner:FOSHAN KINGPENG ROBOT TECH CO LTD

Earthen flywheel target and method for making same

InactiveCN1884184ALow costNo pollution in the processCeramic shaping apparatusMovable targetsCoalKiln

The invention discloses a material composition of ceramic flying saucer target and preparing method, which consists of 80-120 clay and 2-10 coal powder. The preparing method comprises the following steps: (1) preparing paste according to certain rate of raw material and water through grinding; (2) sieving the paste; (3) removing most of water in the paste through mud-expelling machine; (4) pugging to prepare mould material through vacuum pugging machine; (5) placing certain quantity of mould in the flying saucer target mould; putting the mould on the chassis; rotating chassis and roller inversely through eccentric roller to roll the mould into flying saucer mould; (6) trimming the flying saucer target; demoulding; (7) sintering the flying saucer target mould in the high-temperature kiln; cooling to obtain ceramic flying saucer target.

Owner:陈兹明

Breeding method for Hypsizygus marmoreus strains

InactiveCN109182450AExcellent amino acid contentGood fertilizer for cultivating edible fungiMicrobiological testing/measurementPotassiumBiology

The invention discloses a breeding method for Hypsizygus marmoreus strains. The specific breeding method comprises the following steps: 1) adding residue of sophora japonica, mixture of Chinese herbalmedicine, sophora japonica powder, potassium hydrogen phosphate, pig bile salt, glucose, lactose and agar into a culture medium; 2), adding clean water into the culture medium of the step 1, shakingevenly, and pouring into a petri dish; 3), drawing a black line on the bottom cover of each petri dish to divide the area into two equal part, and inoculating mother species and antagonistic bacteriaof Hypsizygus marmoreus at two opposite points 3cm away from the center of the plate respectively; 4), controlling the temperature of the inoculated Petri dish to 22 DEG C, and culturing the inoculated Petri dish in a light-shielding and airtight manner; and 5), after culturing, calculate that bacteriostasis rate of the H. maritima strains to antagonistic bacteria in each culture dish, and selecting the H. maritima strains in the culture dish with high bacteriostasis rate as the selected target strain. The breeding method for Hypsizygus marmoreus strains is simple and convenient, and is easy to popularize. And basically does not consume energy, no pollution to the environment, in line with the national energy-saving and environmental protection industrial policy.

Owner:江苏品品鲜生物科技股份有限公司

An intelligent tobacco leaf purchasing method and system

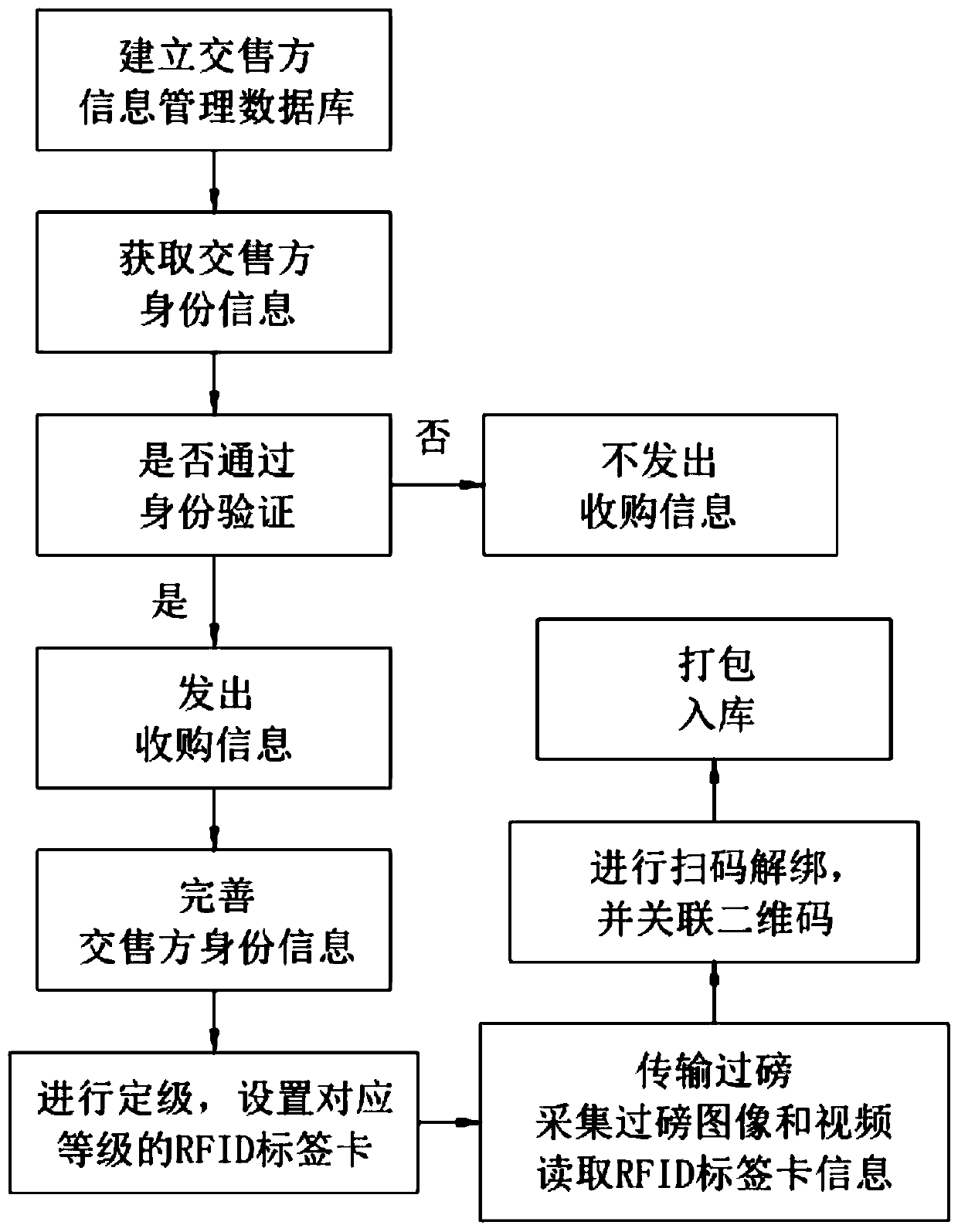

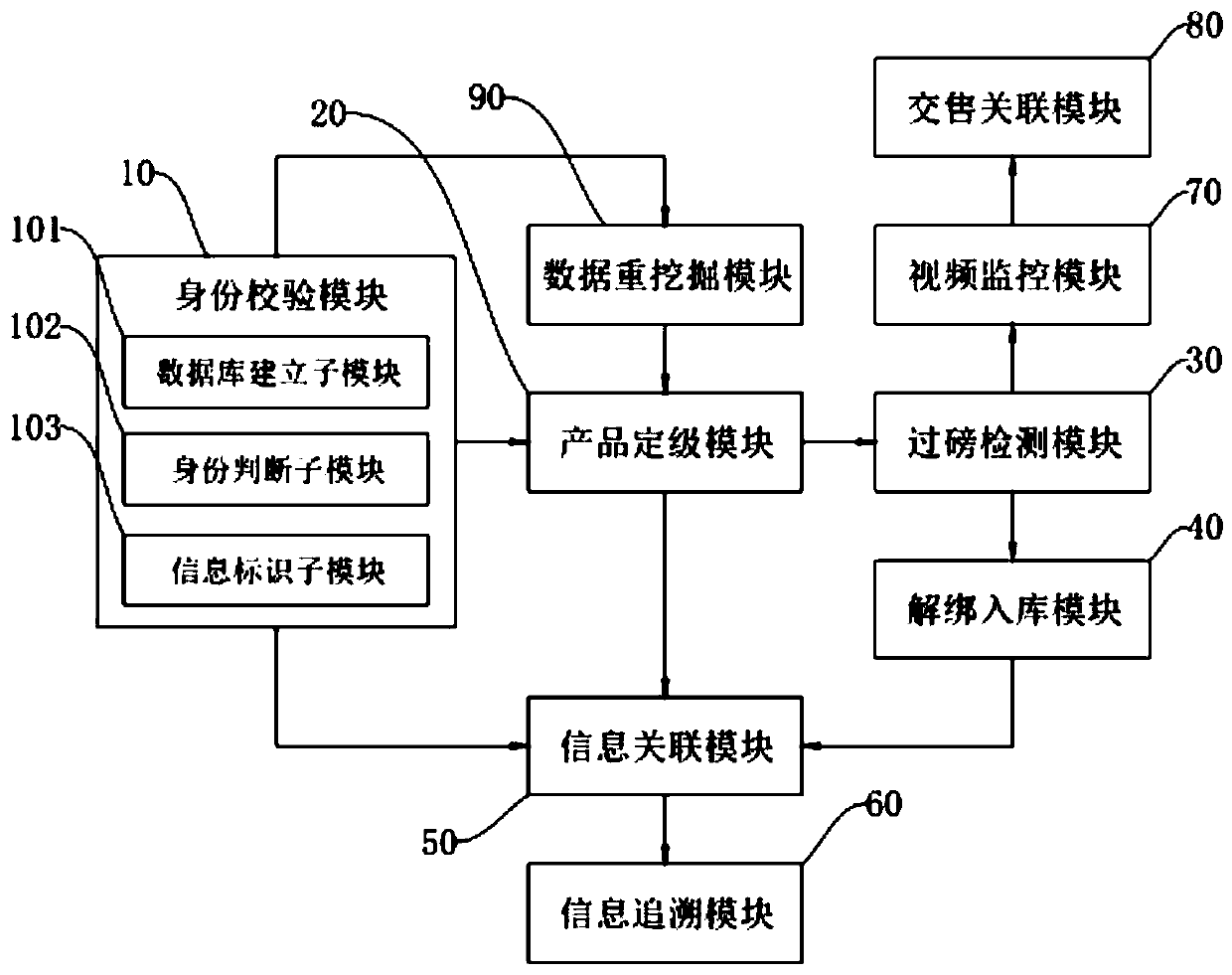

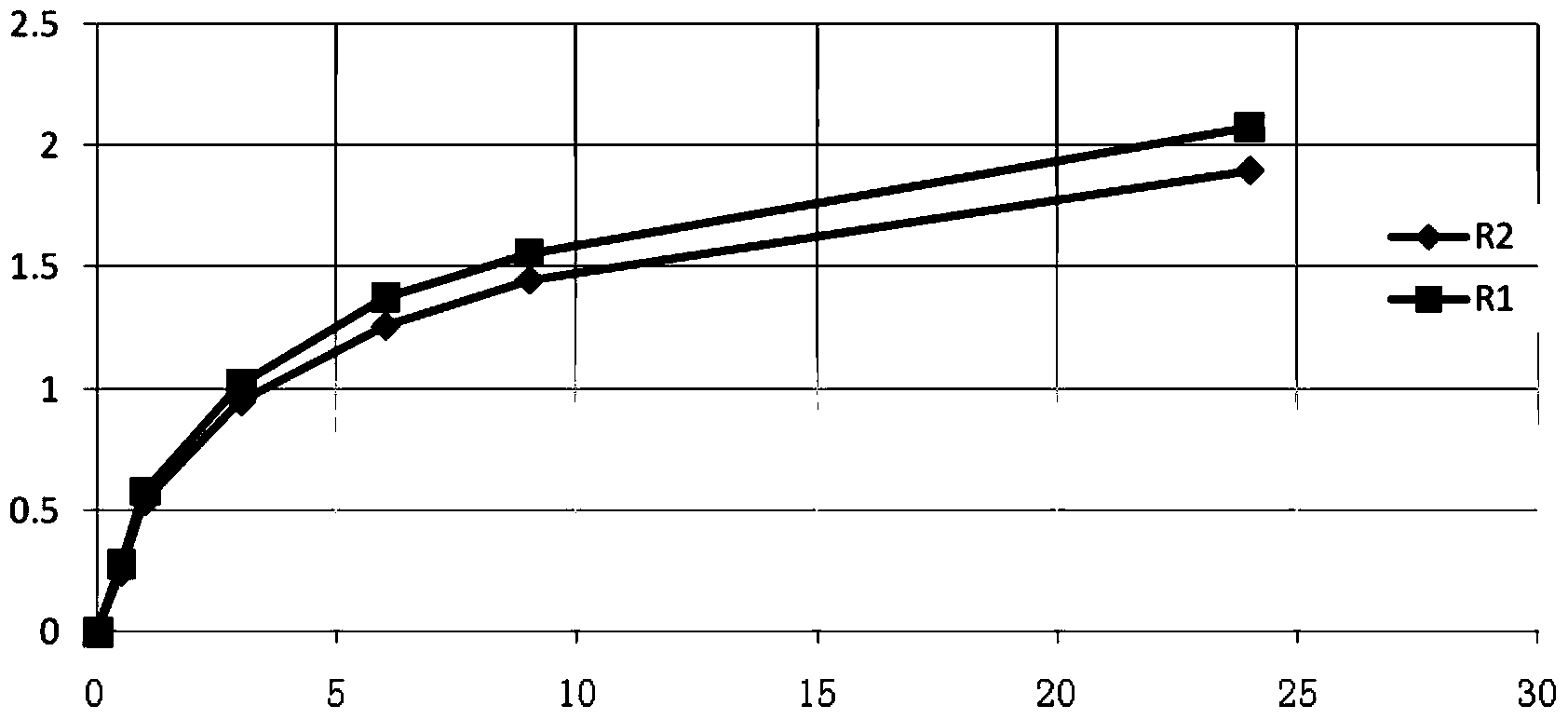

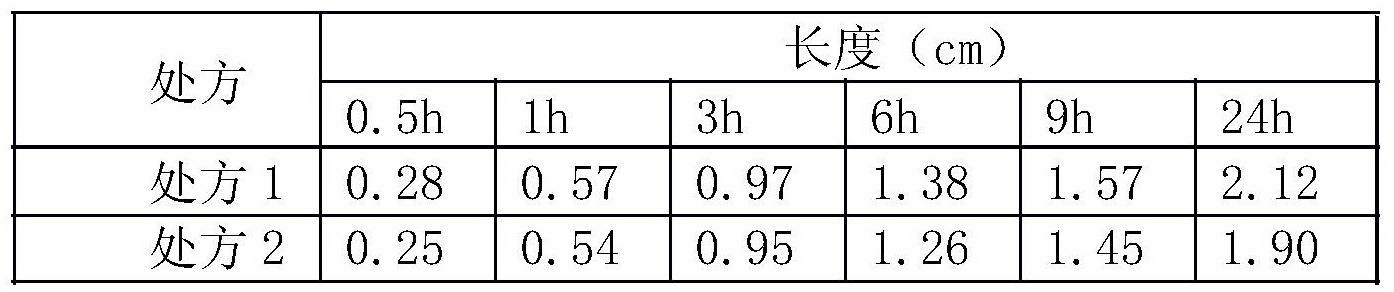

PendingCN109727020AQuality standardsImprove flow and orderCo-operative working arrangementsCash registersEmbedded systemManagement level

The invention discloses an intelligent tobacco purchasing method. The method comprises the following steps: acquiring and verifying identity information of a seller; Primarily inspecting the tobacco leaf products, grading the primarily inspected tobacco leaf products, and setting RFID label cards with corresponding grades; Automatically transmitting and weighing, acquiring a current weighing image, and reading the information of the RFID tag card; And after the two-dimensional code is associated, carrying out packaging and warehousing. The invention further discloses an intelligent tobacco purchasing system which comprises an identity verification module, a product grading module, a weighing detection module and an unbinding warehousing module. According to the invention, a traceability system which is convenient and fast to carry out informatization recording and quality tracking is established, automatic purchasing and intelligent control are realized, purchasing efficiency and safety management level are improved, stations are reduced, and cost is reduced.

Owner:CAS OF CHENGDU INFORMATION TECH +1

Tannin paste and preparation method

InactiveCN104000774AFacilitated releaseGood flexibilityOrganic active ingredientsAerosol deliverySolubilitySulfite salt

The invention discloses tannin paste and a preparation method thereof. The paste is composed of the following components in parts by weight: 100 parts of tannin, 150 parts of glycerol, 73.8 parts of lanolin, 664.2 parts of vaseline, 2 parts of anhydrous sodium sulfite and 10 parts of purified water. When the tannin paste is prepared, the vaseline and the lanolin are heated and mixed to form a component A; the purified water, the glycerol and the anhydrous sodium sulfite are heated and mixed to form a component B; and after the component B and the tannin are mixed to obtain a mixture, the mixture is added into the component A to obtain the tannin paste. The anhydrous lanolin in the formula can adsorb free moisture in preparation, so that the stability of products is increased; the tannin paste does not contain anticorrosives and beewax which are replaced by the vaseline and the lanolin which are easily smeared, so that the softness of the preparation is improved, and the tannin paste is easily smeared; in the preparation process of the tannin paste, materials are easily blocked, according to the preparation method provided by the invention, after a little water is added, the solubility is improved; and through an extracorporeal drug release test, the drug release performance is better than that of a preparation prepared by a national standard prescription.

Owner:CHONGQING ZHULIU BIOENG

Effervescent tables for treating thrombus, and its prepn. method

InactiveCN1723971AEasy to takeShort disintegration timeOrganic active ingredientsPill deliverySodium bicarbonatePolyethylene glycol

A medicine Xuesaitong in the form of effervescent tablet for treating thrombus is proportionally prepared from arasaponin, lactose, rebaudiose, tartaric acid, sodium dicarbonate, phlyethanediol, and magnesium stearate. Its preparing process is also disclosed.

Owner:福寿堂制药有限公司 +1

Bismuth brass alloy material and preparation process and hot stamping process thereof

The invention discloses a bismuth brass alloy material, which comprises the following components by mass percent: 35.0-45.0% of zinc, 0.4-1.5% of bismuth, 0.3-0.9% of titanium, 0.05-0.5% of selenium and the balance of copper. The invention also discloses a preparation process and a hot stamping process of the bismuth brass alloy material. According to the invention, the bismuth brass alloy material contains fewer metal elements, and the preparation method is simple; the prepared bismuth brass alloy has good mechanical property, cutting property and hot processing property; and the hot stamping process is adopted to directly stamp castings into pipe joints in various models, so that the compactness of the pipe joints can be improved, the process can be simplified, the production efficiency is improved, and the production cost is reduced.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

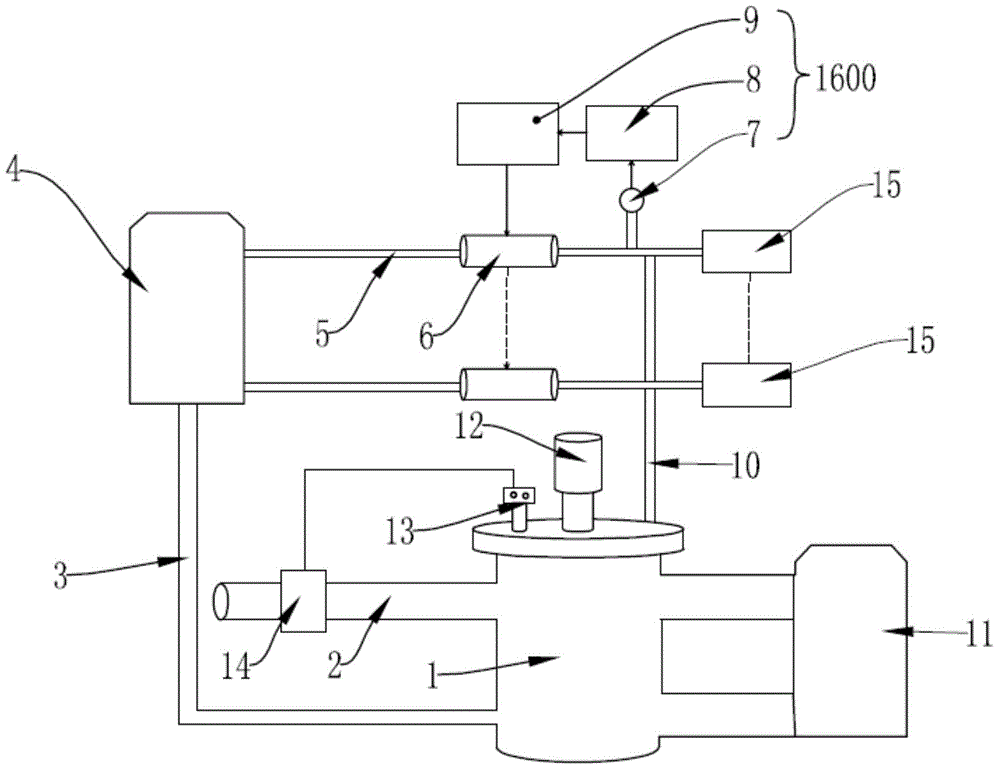

Automatic spraying and curing system and spraying method

PendingCN107775786AImprove work efficiencyGuaranteed continuityCeramic shaping apparatusWater useSediment Filter

The invention provides an automatic spraying and curing system and a spraying method. The system comprises a spraying system, a water supply system and a spraying control system, wherein the inlet ofa fixed sediment filtering tank of the water supply system is connected with pedestal drainage ditch gathering openings; a water supply tank of the water supply system is connected with a water inletof the spraying system through a pressure pump and a water supply main pipeline; the spraying control system is connected with a liquid level meter in the water supply tank of the water supply system,spraying switches of the spraying system and a water supplementing switch of the water supply system. Compared with the prior art, the automatic spraying and curing system and the spraying method arecapable of automatically spraying and curing prefabricated parts without dead corners in 24 hours; the water used by the system can be recycled and reused; the curing effect is improved; the water resource is saved.

Owner:CHINA THIRD METALLURGICAL GRP

Method for preparing high-purity glucomannan

ActiveCN105669877ALow content of related substancesHigh purityOrganic active ingredientsPharmaceutical non-active ingredientsBletilla striataFiltration membrane

The invention discloses a method for preparing high-purity glucomannan. The method comprises main steps as follows: a solution with the concentration of 0.5%-10.0% is prepared from homogeneous polysaccharide raw materials which have the molecular weight in a range of 10-1,000 kD and are selected from naturally sourced konjac polysaccharides, Bletilla striata polysaccharides or hydrolysates of the konjac polysaccharides or Bletilla striata polysaccharides; a filter aid is added to the solution for treatment, an obtained mixture is filtered and is sequentially filtered with a 100-1,000-nm micro-filtration membrane and concentrated with an ultrafiltration membrane with the molecular weight cut off of 2-100 kD, an obtained product is concentrated and dried, and the high-purity glucomannan with the purity of 90% or higher or a liquid preparation of the high-purity glucomannan is obtained. The method has the advantages that the preparation process is concise and controllable, and enlarged production is realized easily; the obtained glucomannan has high purity and low content of related substances and can meet the quality standard for medicinal bulk pharmaceutical chemicals, thereby being applicable to preparation of drugs and related medical products such as pharmaceutical excipients, medical equipment and the like.

Owner:SUZHOU QIUSHI HERBAL HEALTH TECH CO LTD

Furosemide injection and preparation process thereof

InactiveCN103371967AQuality standardsOrganic active ingredientsPharmaceutical delivery mechanismDrug productMedical prescription

The invention provides a furosemide injection and a preparation process thereof. Each 10000ml of furosemide injection contains the following raw materials: 100g of furosemide, 60-90g of sodium chloride, 120-180ml of 10% (mass concentration) of sodium hydroxide and injection water for supplementing to 10000ml. The preparation process comprises the following steps of: adding the injection water which accounts for 70 percent of the total amount of preparation into a burdening tank; adding the furosemide, the sodium chloride and the 10% (mass concentration) of sodium hydroxide to the burdening tank; stirring till the furosemide is dissolved; cooling the solution to be below 30 DEG C; adjusting the pH value of the solution to 9.1-9.4; adding the injection water to reach total preparation amount and uniformly stirring; filtering the solution; and introducing N2 to the filtered solution to realize encapsulation. The furosemide injection and the preparation process thereof have the advantages that the problem that related substances in an original formula of the furosemide injection are unqualified is solved, and the furosemide injection can meet the quality standard of the furosemide injection in China Pharmacopoeia (2010 Edition 2) and provision of notification related to release of basic technical requirements of chemical injection and multi-component biochemical medicine injection.

Owner:上海禾丰制药有限公司

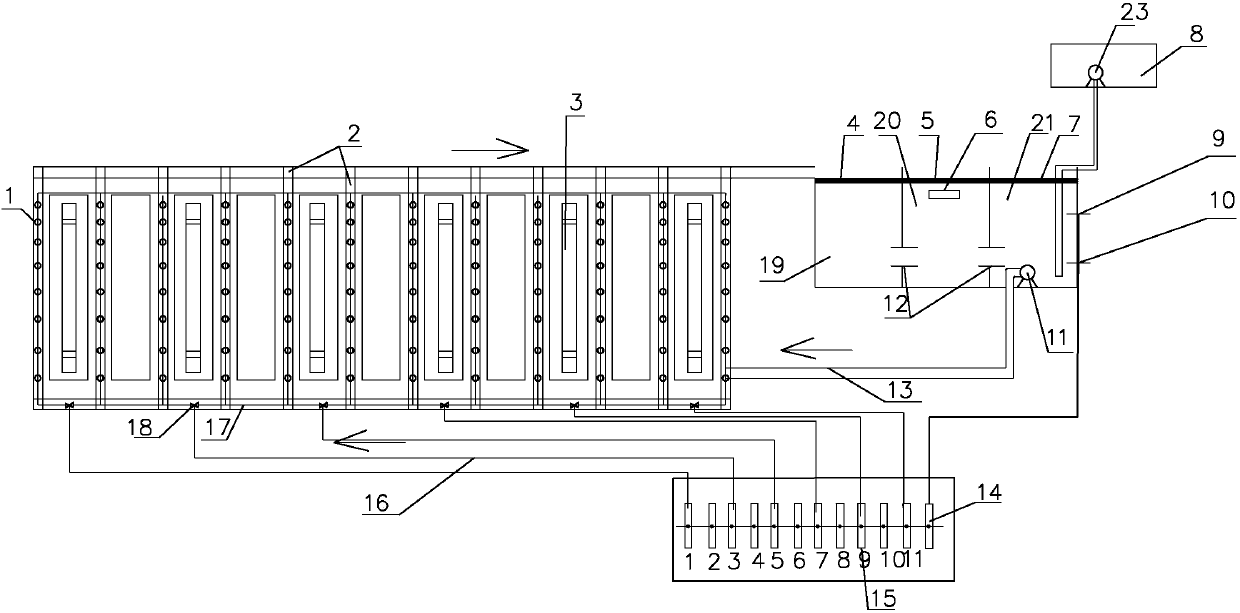

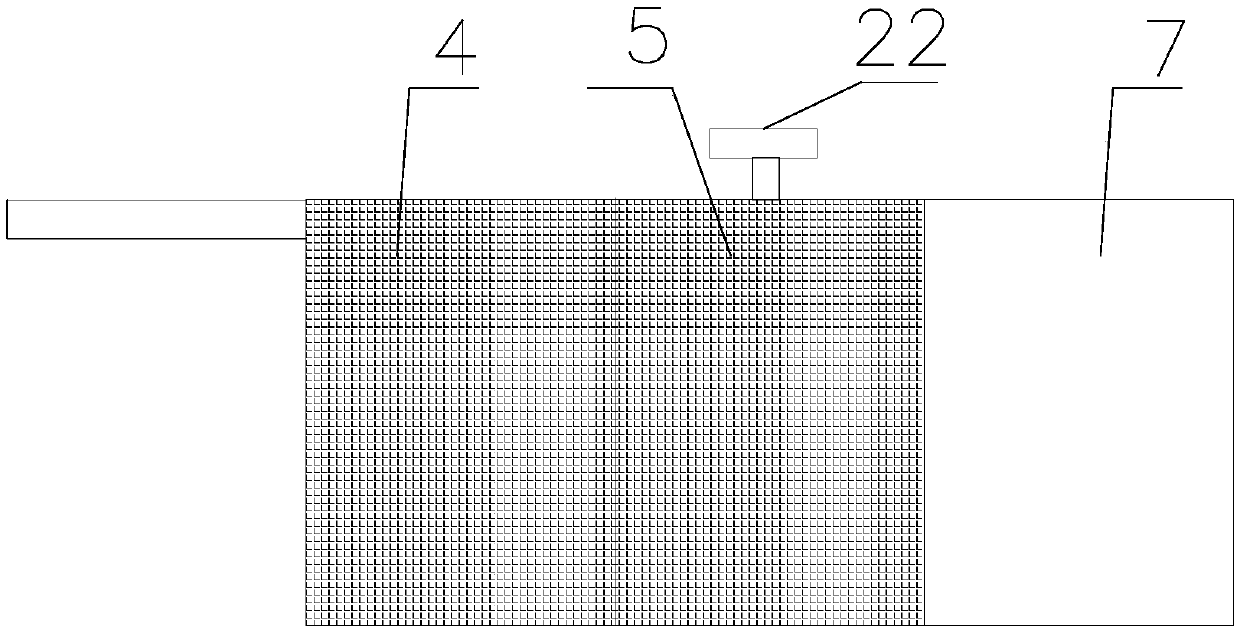

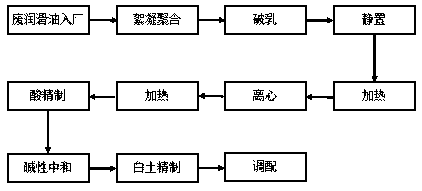

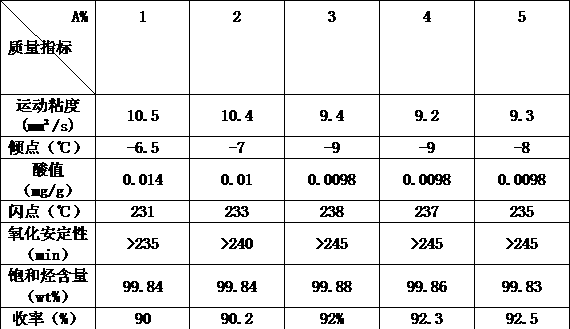

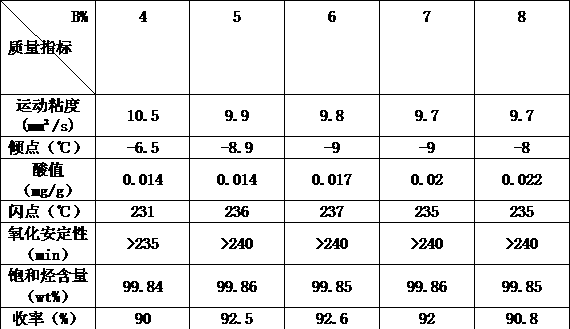

Method for regenerating waste lubricating oil

InactiveCN109280575AHigh yieldShorten the distillation processLubricant compositionFlocculationDistillation

The invention belongs to the technical field of lubricating oil, and relates to a method for regenerating waste lubricating oil. The method comprises the following steps: 1) feeding waste lubricatingoil into a plant; 2) carrying out flocculation and aggregation; 3) carrying out demulsification; 4) carrying out standing; 5) carrying out heating, 6) carrying out centrifugation; 7) carrying out heating; 8) carrying out acid refining; 9) carrying out alkaline neutralization; 10) carrying out clay refining; and 11) carrying out blending. According to the method disclosed by the invention, the yield of the lubricating oil is increased by reducing a distillation process, and the yield of the lubricating oil is increased to 89%-95%, which is increased by 10-15% compared with a yield in a common regeneration technology, and certain social and economic benefits are achieved.

Owner:DONGGUAN UNIV OF TECH

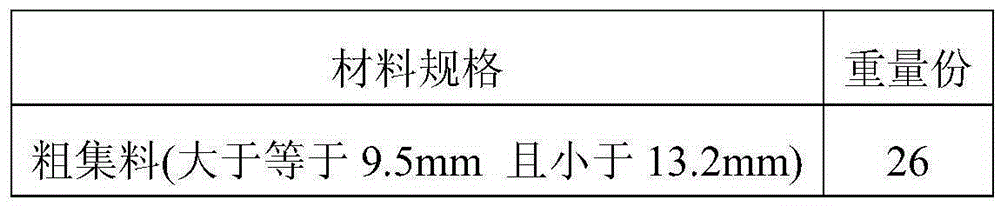

Dense-graded bitumen surface layer concrete

The invention provides dense-graded bitumen surface layer concrete which is prepared from stone and bitumen. The mass of the bitumen accounts for 4-5 wt% of the mass of the stone; the stone is prepared from, by weight, 49-53 parts of coarse aggregate, 42-47 parts of fine aggregate and 4-5 parts of mineral powder. According to the scheme, the steel slag mineral powder and the fine aggregate are adopted as dense-graded bitumen concrete aggregate, the grain gradation of the adopted materials is low, and therefore the problem of instability caused by unstable ingredients such as free calcium oxide and free magnesium oxide contained in large-grain steel slag in the prior art is solved; meanwhile, according to the technical scheme, the use range of the steel slag is enlarged greatly, and the maximum content of free calcium in the steel slag is increased to be 5% from 1.5-2% in the prior art.

Owner:SHANGHAI MCC ENVIRONMENTAL ENG TECH CO LTD +1

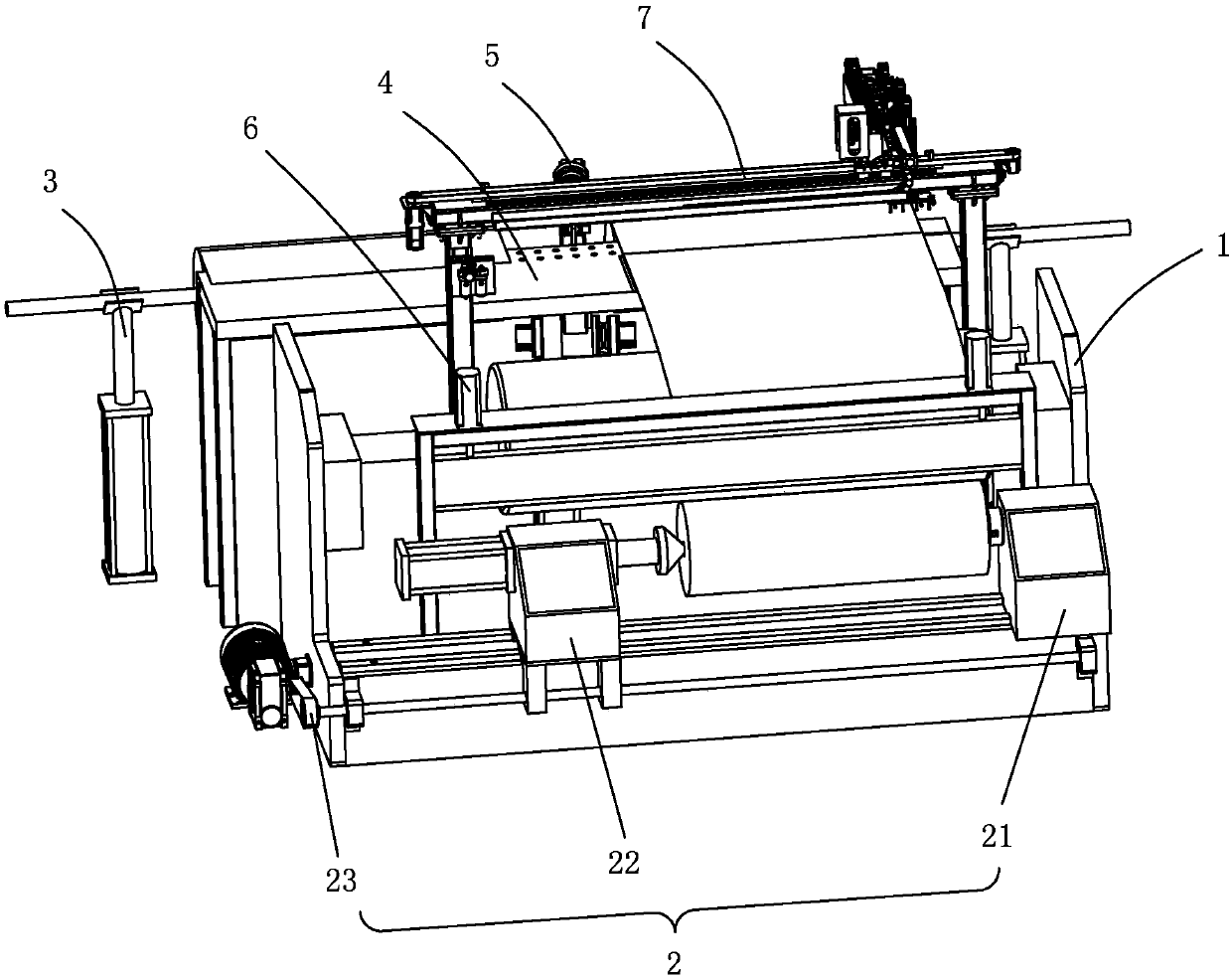

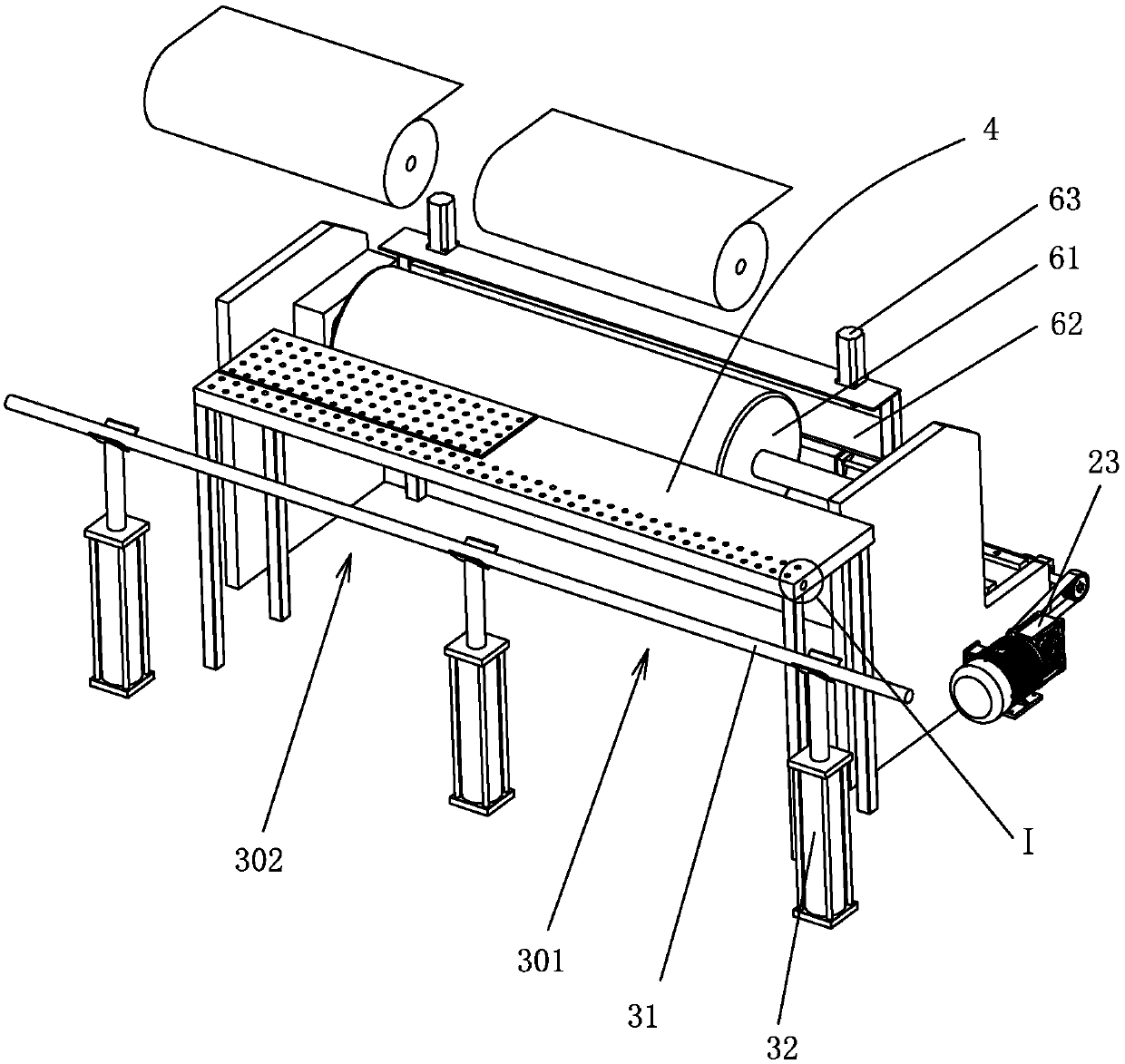

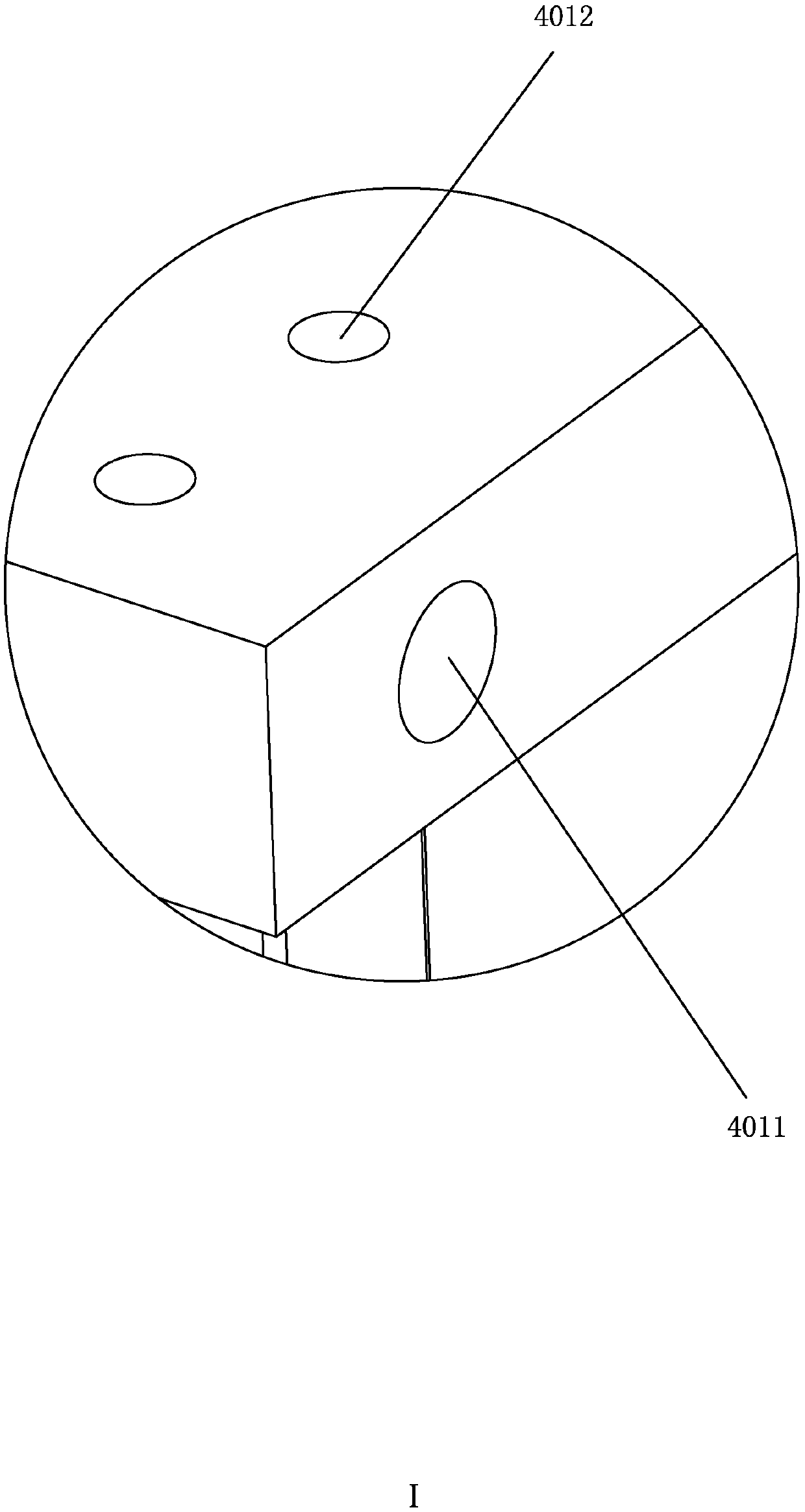

Automatic continuous film wrapping equipment

PendingCN109665134AImprove stitching qualityReduce manufacturing costWrapping material feeding apparatusWrappingEngineeringRoll film

The invention discloses automatic continuous film wrapping equipment. The automatic continuous film wrapping equipment comprises a frame, a workpiece rotation driving device arranged on the frame, a support carrying device arranged on the back side of the workpiece rotation driving device and provided with a placing station and a working station, a film strip positioning device arranged on the front side of the support carrying device and provided with a first positioning area and a second positioning area, a pushing device arranged on the back side of the support carrying device, and a pressing roller device arranged between the support carrying device and the workpiece rotation driving device, and a cutting assembly device arranged between the pressing roller device and the film strip positioning device. The automatic continuous film wrapping equipment not only can realize automatic material change and automatic assembly of roll film strips, but also can greatly improve the assemblyquality and the assembly stability, can prevent the local release or breakage phenomenon in the film strip assembly place, can improve the production efficiency to the greatest extent, can greatly reduce the production cost of enterprises, facilitates large-scale standard production of the enterprises, and improves the competitiveness.

Owner:ZHONGSHAN DONGYUN PLATEMAKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com