Dense-graded bitumen surface layer concrete

A technology of concrete and dense grading, which is applied in the field of asphalt dense grading surface concrete, which can solve the problems of high cost and unstable quality, achieve excellent performance, expand the scope of use, save time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

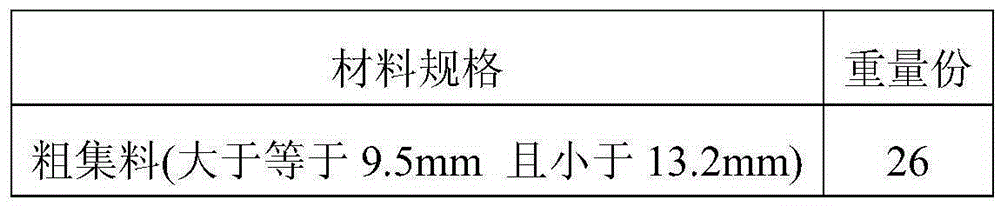

[0042] This example is a comparative example, which is the common AC-13 dense-grade asphalt concrete in the prior art, wherein the coarse aggregate, fine aggregate and mineral powder are all made of limestone, and the asphalt is SBS modified asphalt, which belongs to I-D category. Concrete content of each raw material component is shown in the following table:

[0043] Material specification

[0044] In this embodiment, asphalt accounts for 4.9% of the total mass of the stone.

Embodiment 2

[0046] In this example, steel slag AC-13 dense-grade asphalt concrete is used, in which limestone is used as the coarse aggregate, steel slag is used as the fine aggregate and mineral powder, and SBS modified asphalt is used as the asphalt, and it is I-D type.

[0047] Material specification

parts by weight

Coarse aggregate (greater than or equal to 9.5mm and less than 13.2mm)

25

Coarse aggregate (greater than or equal to 4.75mm and less than 9.5mm)

27

Fine aggregate (less than 4.75mm)

44

steel slag powder

4

[0048] The content of particles with a particle size not greater than 0.075mm in the steel slag ore powder is greater than 80wt%.

[0049] In this embodiment, asphalt accounts for 4.5% of the total mass of the stone.

Embodiment 3

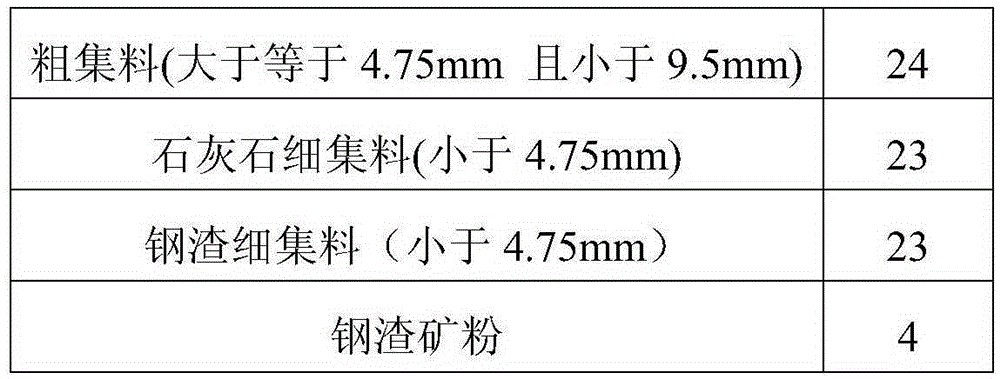

[0051] In this embodiment, it is steel slag AC-13 dense grade asphalt concrete, wherein the coarse aggregate is limestone, the fine aggregate is 50wt% steel slag and 50wt% limestone, the mineral powder is all steel slag, and the asphalt is SBS modified asphalt, and it is I-D kind.

[0052]

[0053]

[0054] The content of particles with a particle size not greater than 0.075mm in the steel slag ore powder is greater than 80wt%.

[0055] In this embodiment, asphalt accounts for 4% of the total mass of the stone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com