Patents

Literature

436results about How to "Improve competitive advantage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

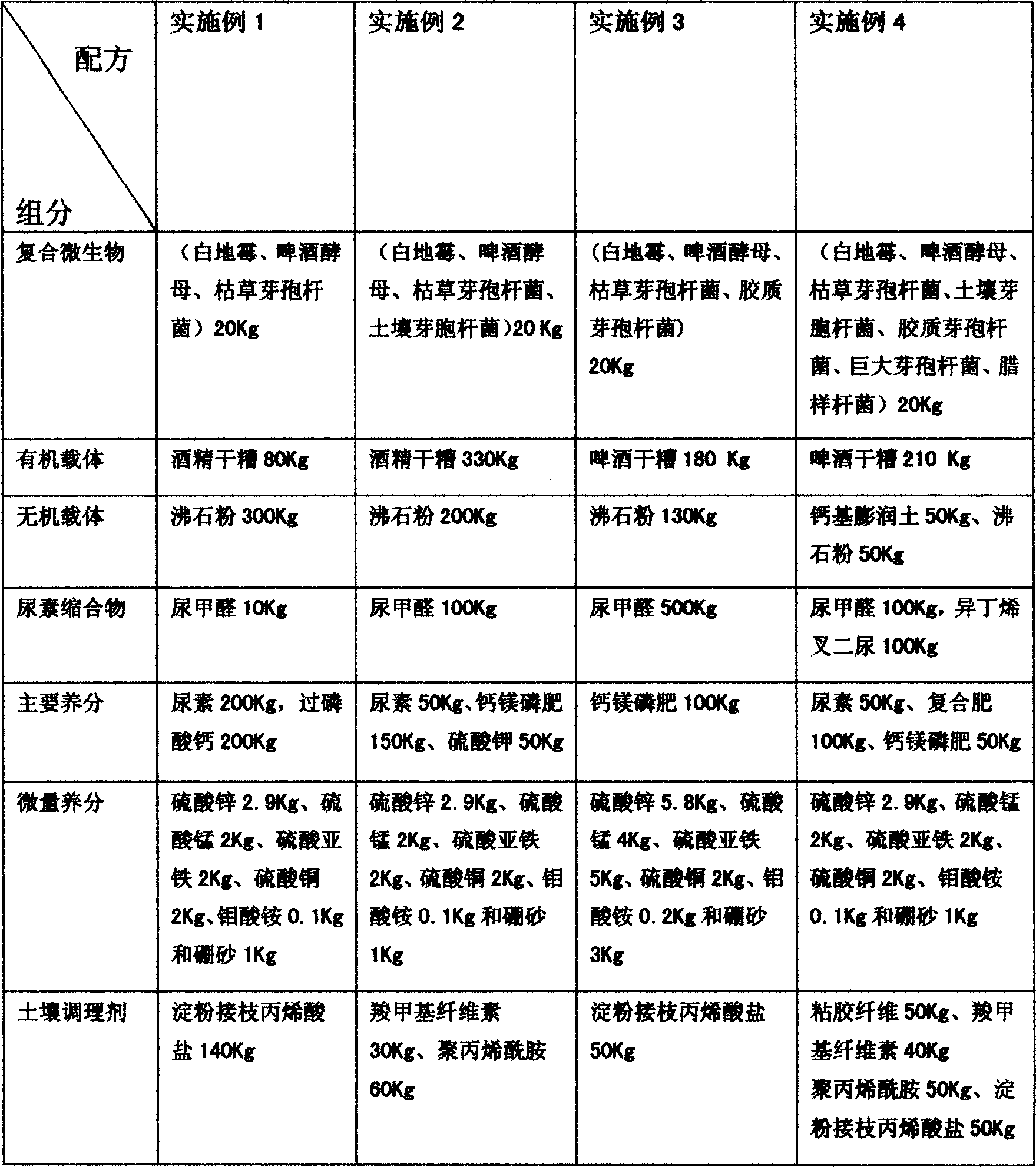

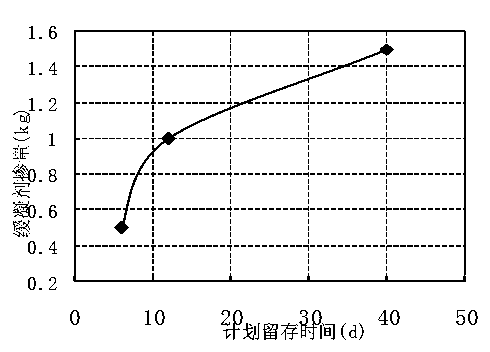

Organic slow-release fertilizer additive

InactiveCN1569758AAdapt to needsImprove microbial activityOrganic fertilisersFertilizer mixturesMicroorganismTrace element

The invention relates to a fertilizer and soil conditioner, wherein the compound fertilizer contains a slow-release fertilizer additive adjustable based on soil and plant requirement, which comprises compound microorganism - organic carrier 2-50%, inorganic carrier 1-30%, ureacondensate 1-50%, primary nutrient 1-60%, trace element 1-10%, and inorganic soil conditioner 1-50%.

Owner:朱绍林

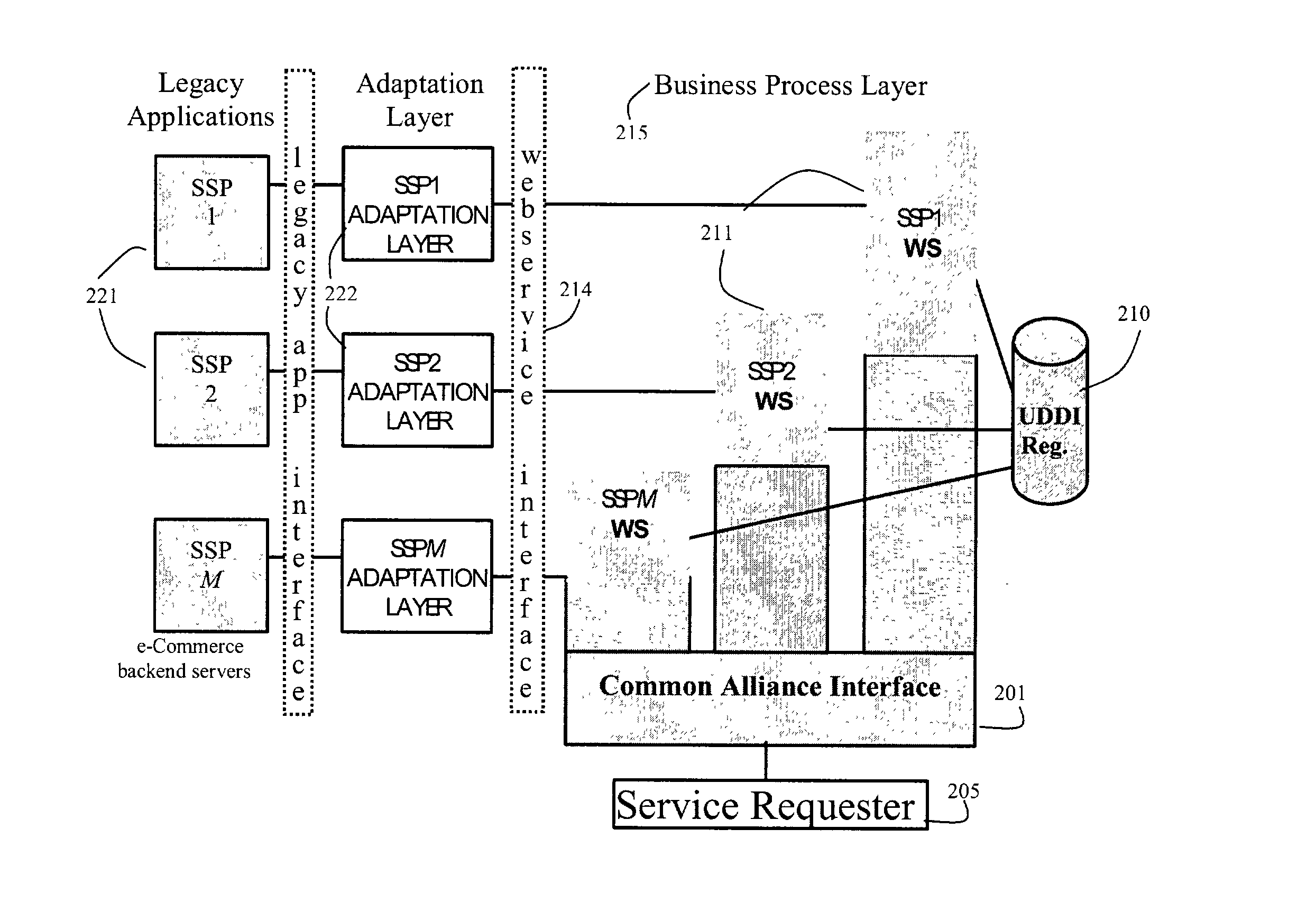

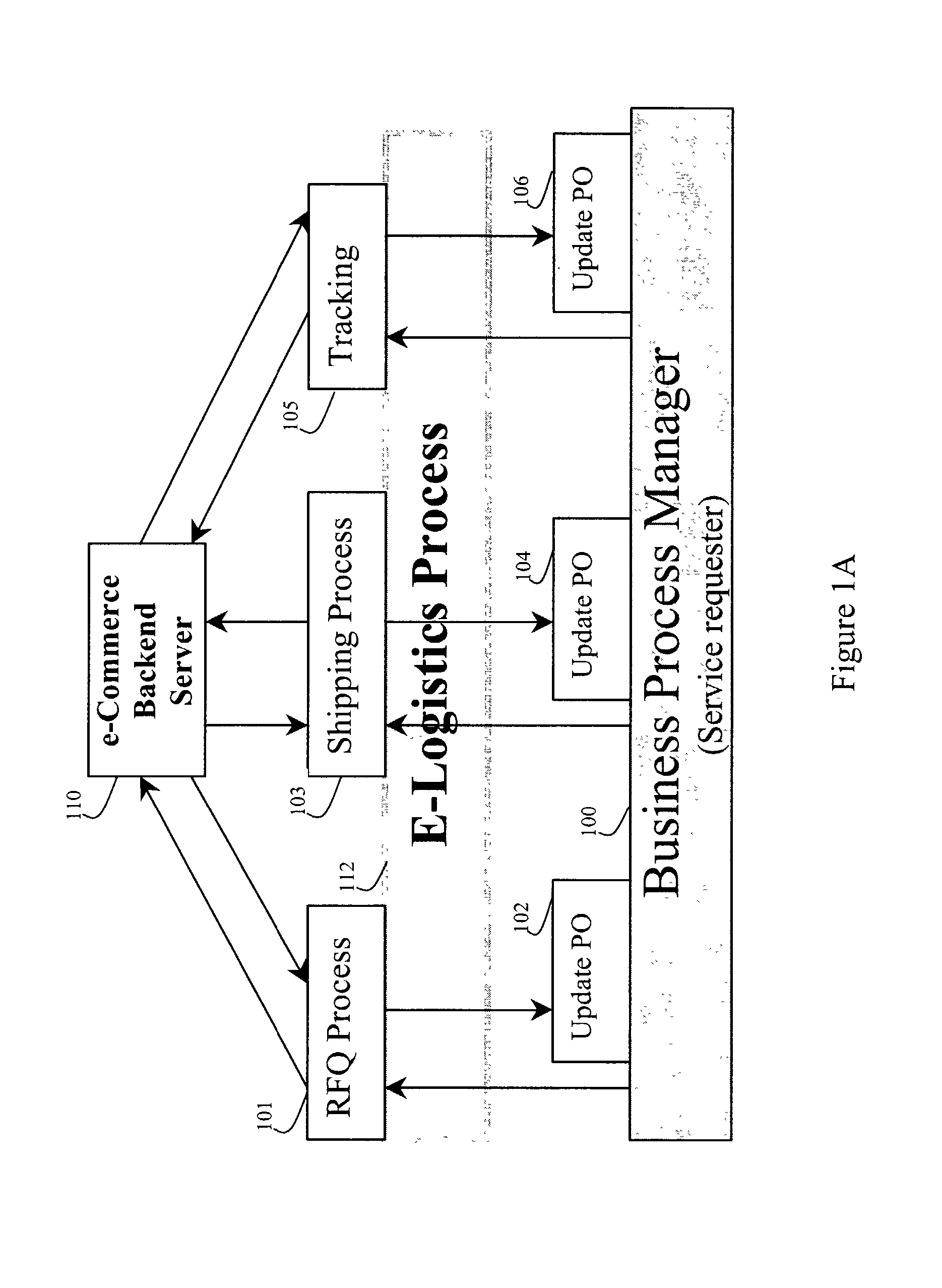

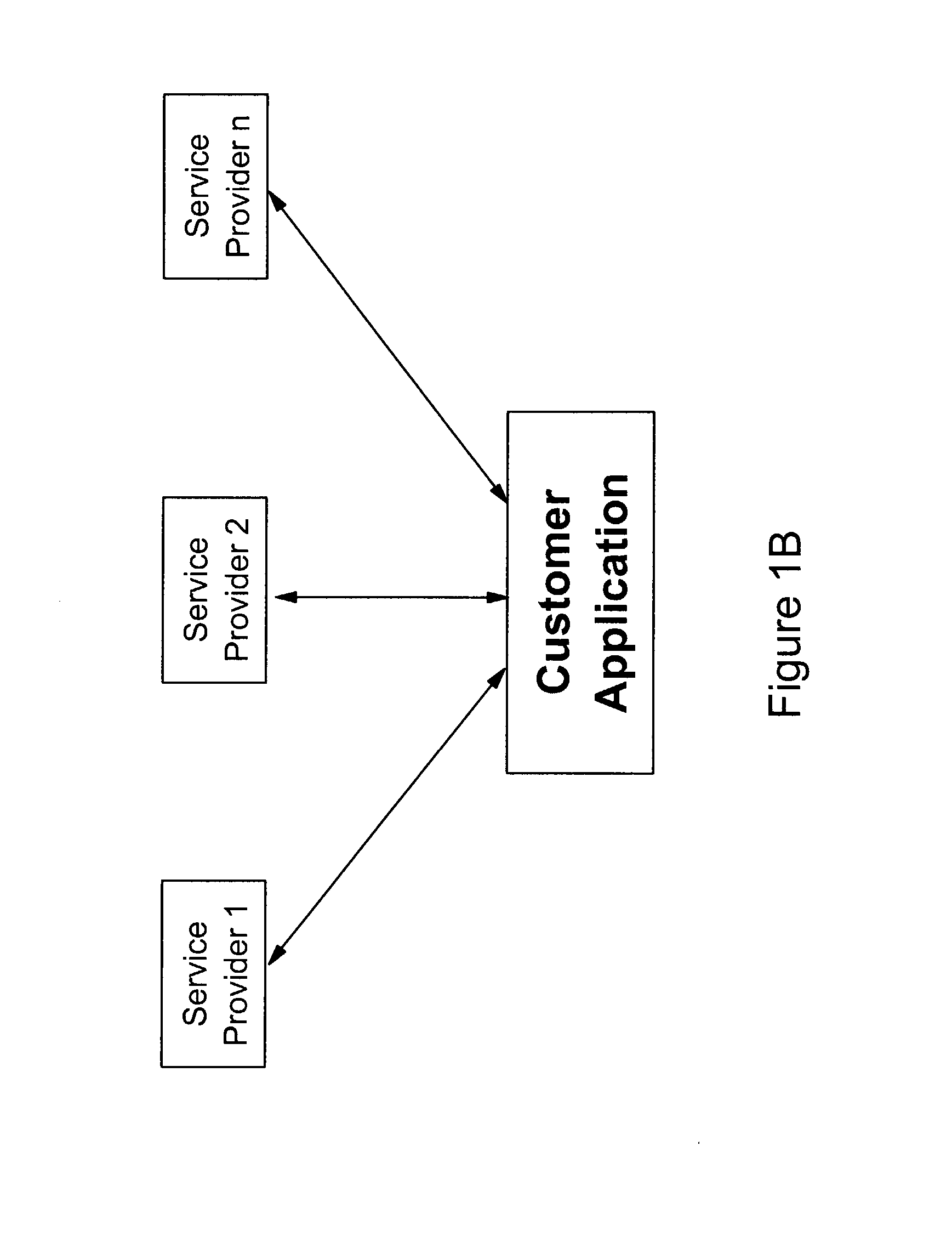

Method and system for integrating e-Logistics processes into a user/provider interface using Web Services

InactiveUS20030191677A1Avoiding high cost and complexityImprove efficiencyResourcesLogisticsLogistics managementProcess integration

A system and method for providing specified electronic commerce services to users, in particular e-Logistics services, services which are available in the marketplace from a variety of service providers whose electronic commerce systems are incompatible. There is provided a user / customer interface to the specified electronic commerce services, called a Common Alliance Interface, and a distinct interface for service providers of the specified electronic commerce services. Between the two interfaces is a business process layer which integrates one or more components of the specified electronic commerce services, these integrated components thereby being transparent to users. The service provider obtains access to users of the Common Alliance Interface by updating entries in a UDDI registry. There is further provided a service template which the service provider can modify to provide an adaptation layer between their legacy application and the business process layer. There is disclosed a business process layer of e-Logistics services comprised of RFQ, shipping and tracking processes.

Owner:IBM CORP

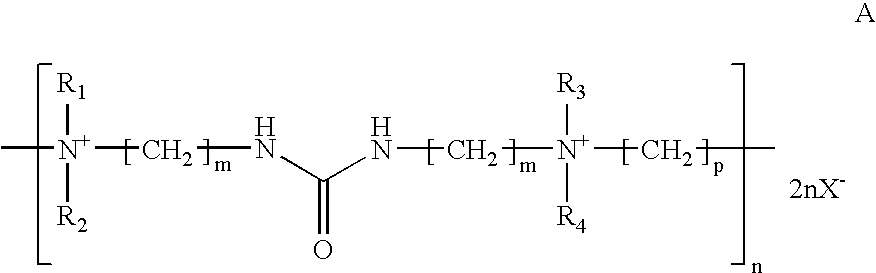

Alkaline zinc-nickel alloy plating compositions, processes and articles therefrom

InactiveUS20050133376A1Easy to handleImprove ductilityAnti-corrosive paintsLiquid/solution decomposition chemical coatingZinc ionNickel alloy

The present invention relates to an aqueous zinc-nickel electroplating bath, including water; nickel ion; zinc ion; at least one complexing agent; and at least one non-ionogenic, surface active polyoxyalkylene compound, wherein the bath has an alkaline pH. In one embodiment, the zinc ion, the nickel ion and the non-ionogenic surface active polyoxyalkylene compound are present at concentrations sufficient to deposit a zinc-nickel alloy comprising a substantially gamma phase.

Owner:ATOTECH DEUT GMBH

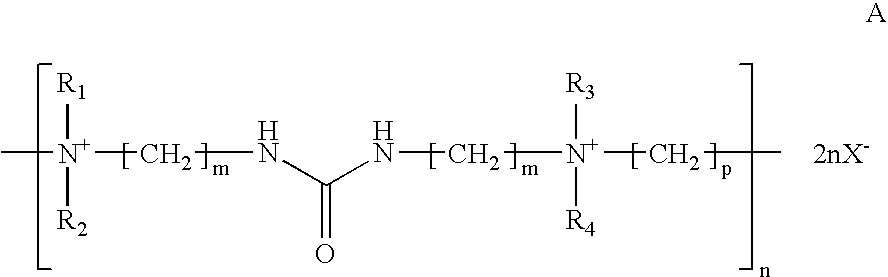

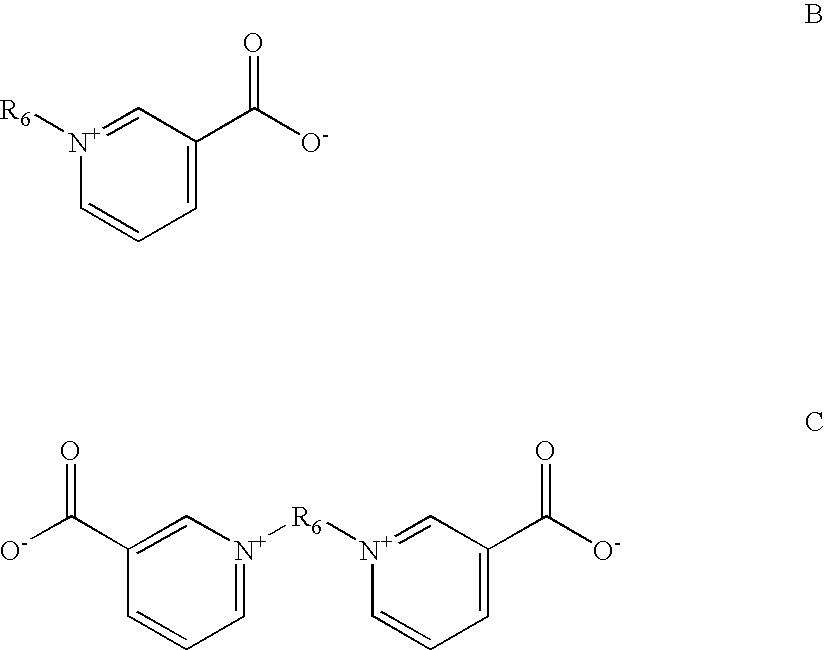

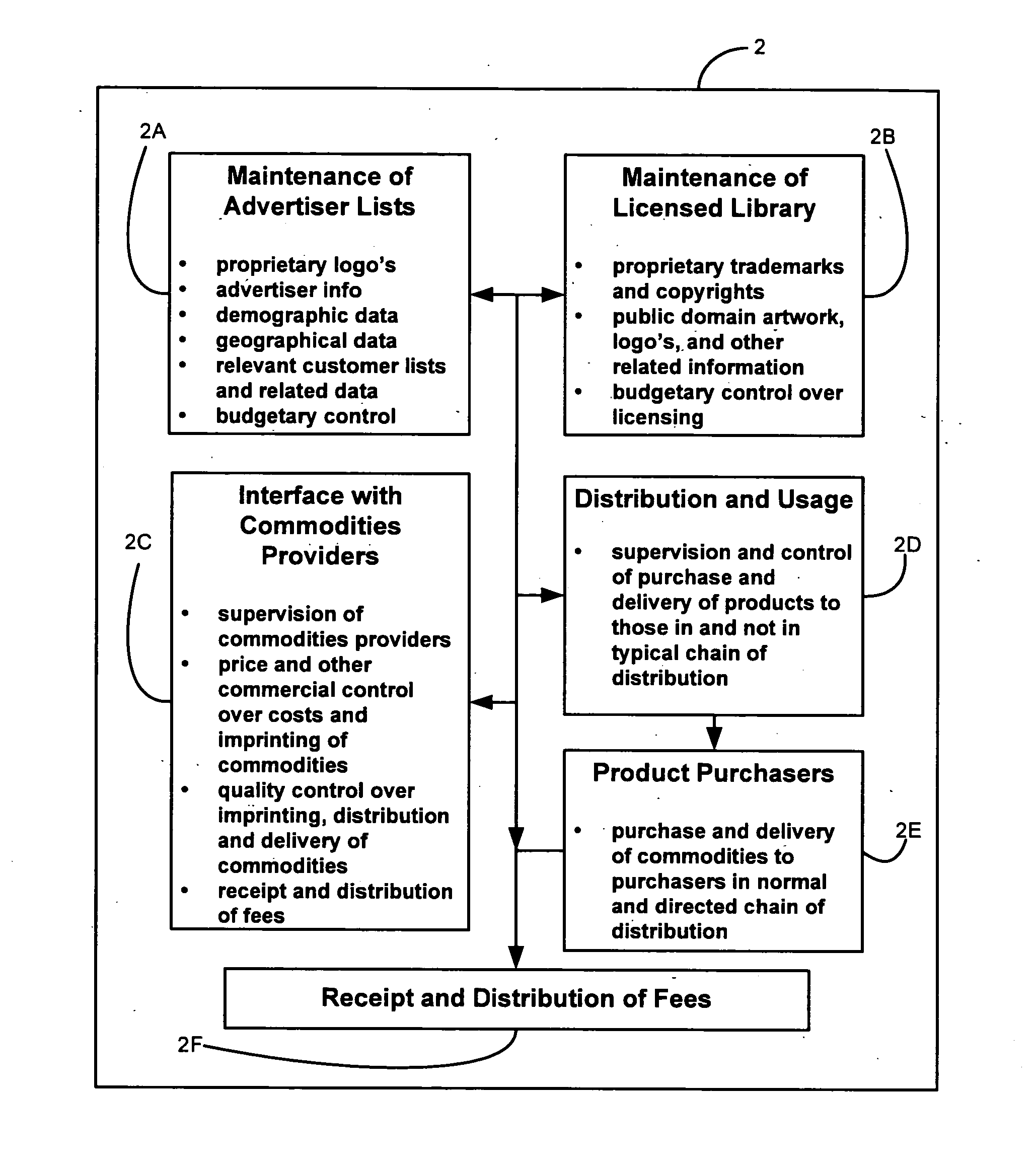

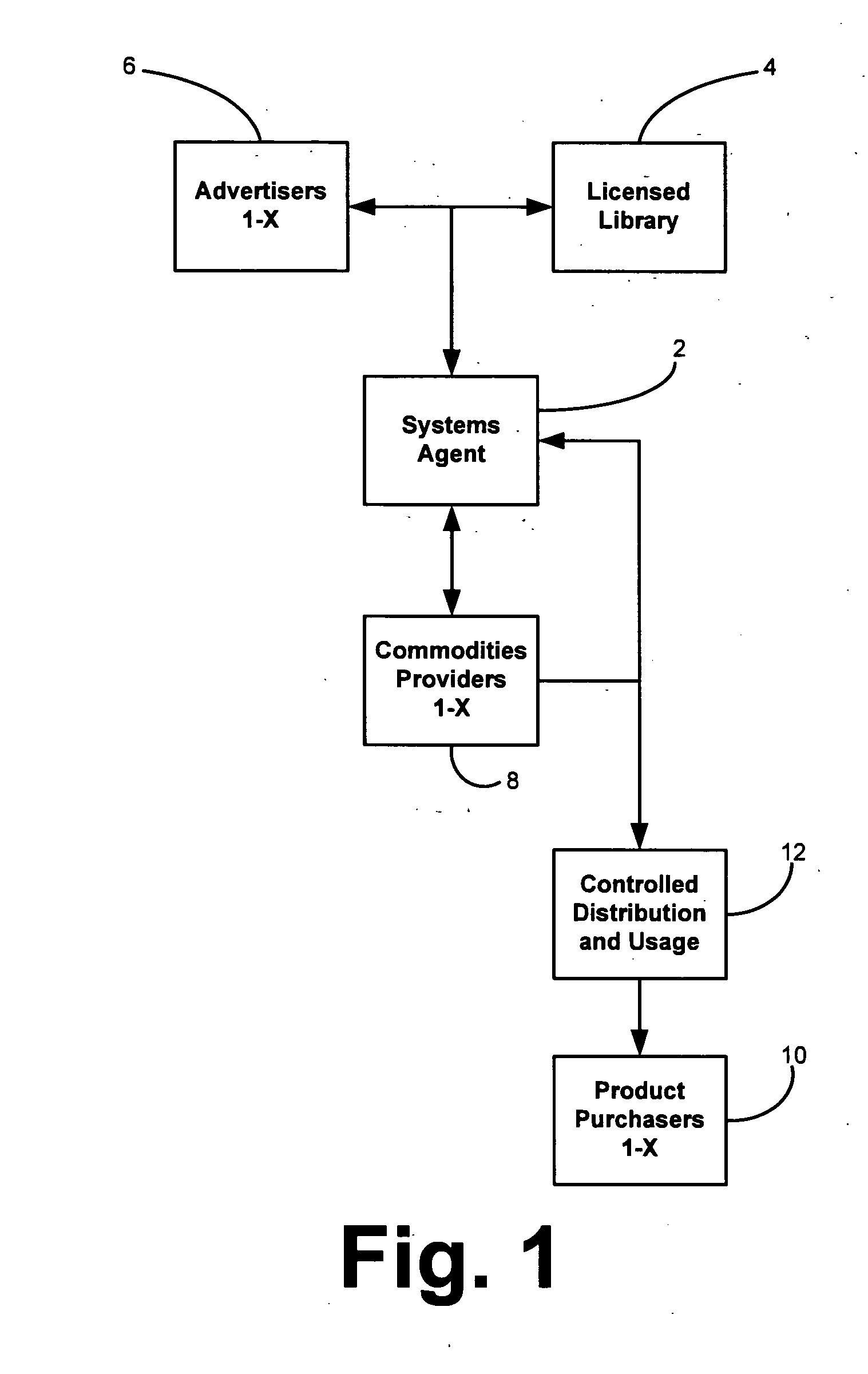

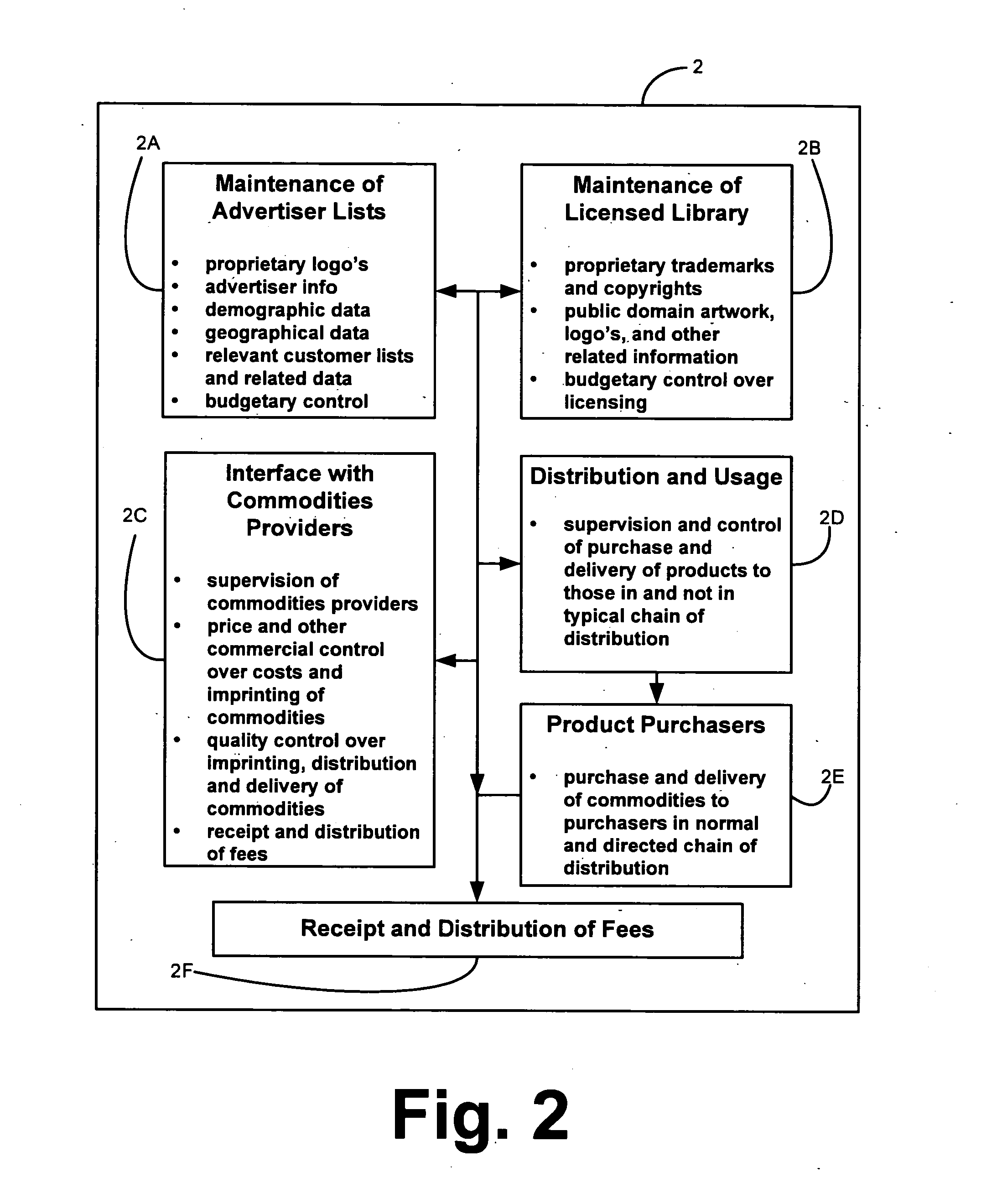

Method and system for the determination and dissemination of brand-related artwork on commodity-based products

InactiveUS20050144063A1Low costImprove competitive advantageAdvertisementsSpecial data processing applicationsDisposable cupDemographic data

A method and system for utilizing impressions, including advertising logo's and other licensable advertisements, for placement upon commodity-based products (like disposable cups, packaging, plates, utensils and the like), such that licensing revenue or other advertising revenue offset the cost of manufacture of such commodity-based products as well as the cost of purchase of such commodity-based products (to the point of potentially zero) by those non-franchised entities like delicatessens, diners, restaurants, and the like, and even potentially the ultimate purchaser of the food or beverage therein contained, by which a library of licensable impressions are maintained and a system and method is employed to control the library, commodity-based manufacturers and commodity-based purchasers, including demographic data, geographical data, customer lists, and / or data related to a targeted audience of potential purchasers of materials to whom advertisements are thereby directed.

Owner:SPECTOR DONALD

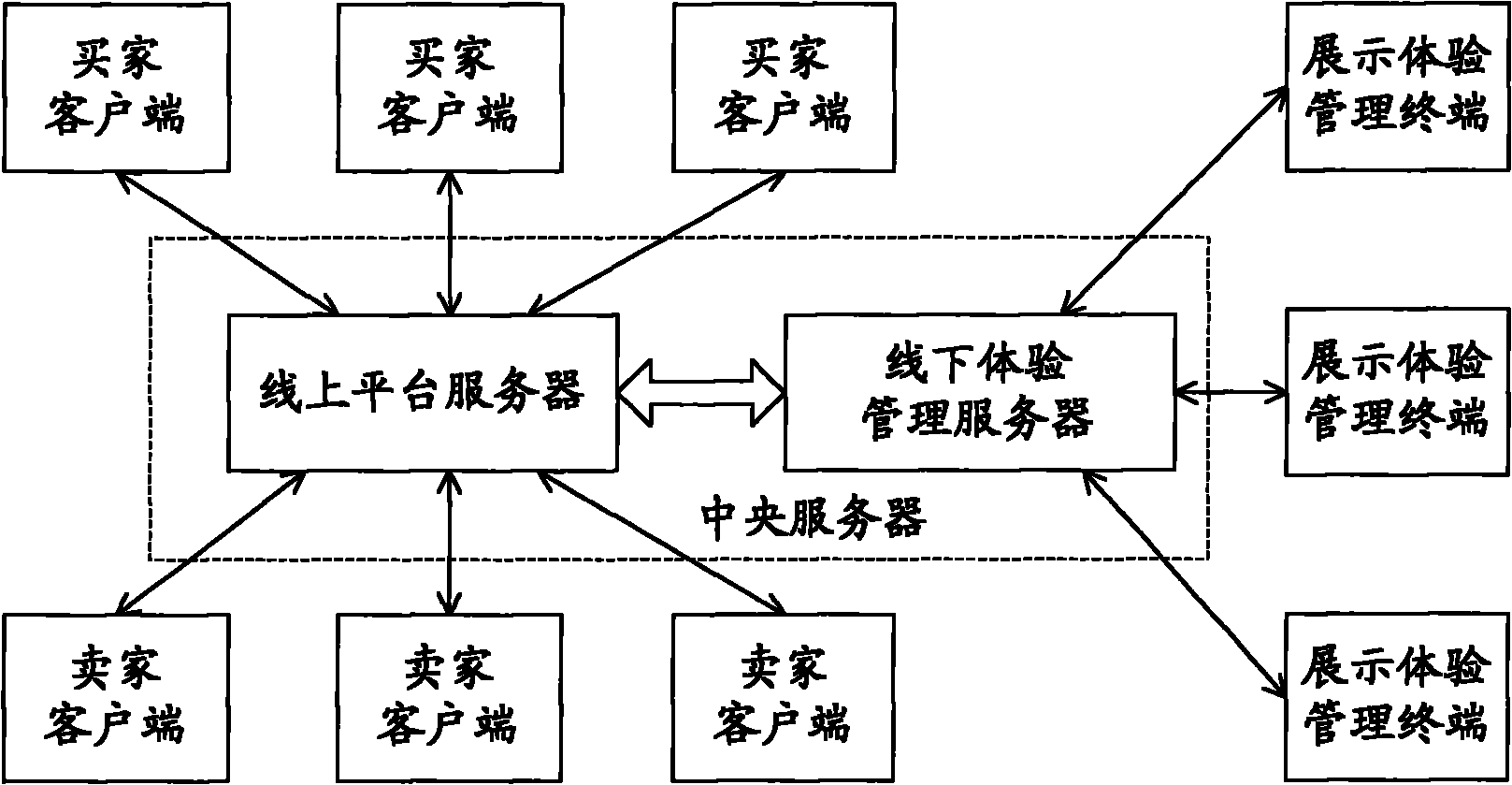

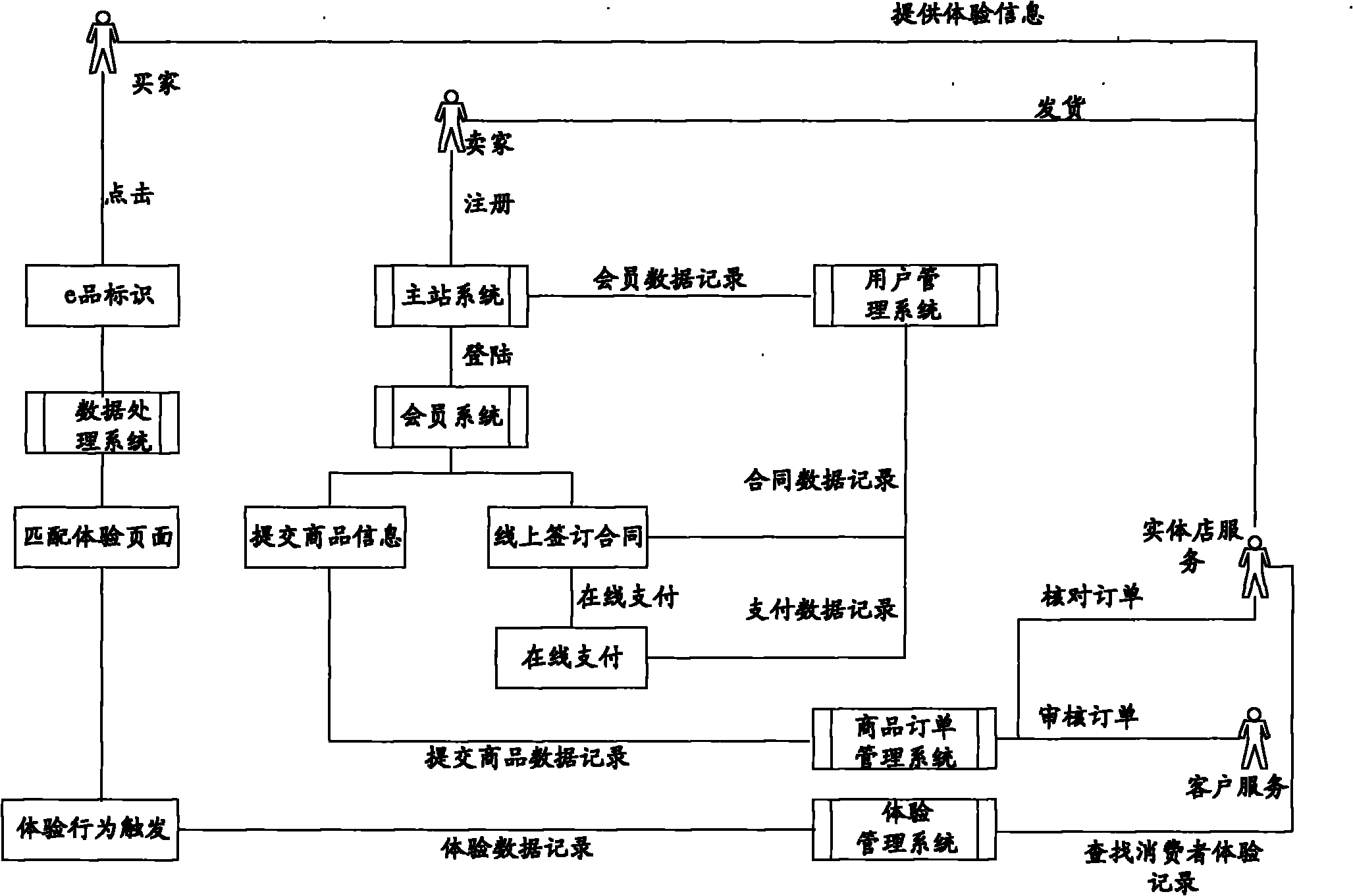

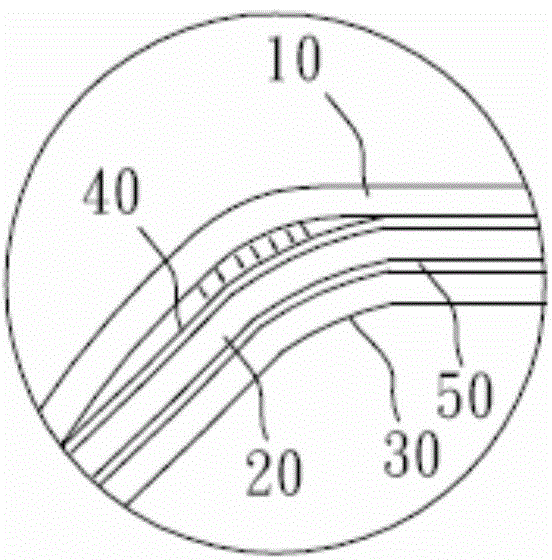

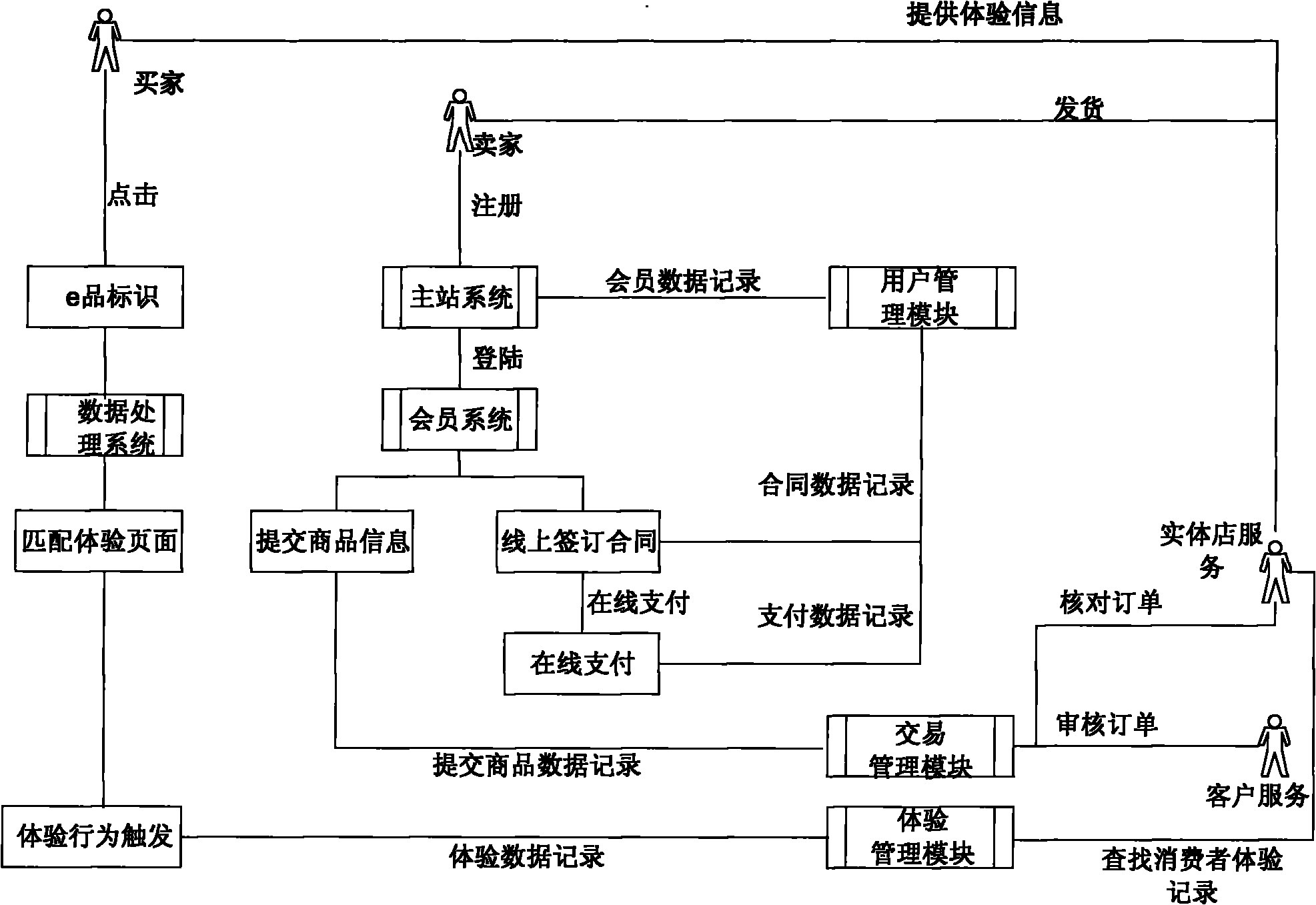

System and method for combining online and offline exhibition

InactiveCN101901438AExpand application spaceMeet operating costsMarketingCommunication interfaceTransaction management

The invention discloses a service system for combining online and offline exhibition, which comprises a central server, a seller client communicated with the central server, a purchaser client and an exhibition experience management terminal which is communicated with the central server, wherein the central server comprises a server database and a management system; the management system comprises a user management module, a transaction management module, an experience management module and a communication module; the communication module is used for providing corresponding data exchange service; the transaction management module matches the supply and demand of goods, generates goods orders and manages the orders; the experience management module queries corresponding information of an exhibition experience shop according to the goods orders, transmits the experience goods information to the experience management terminal, and carries out experience reservation; and the exhibition experience management terminal provides a communication interface between the worker of the exhibition experience shop and the central server, and manages the goods storage and delivery of the exhibition experience shop and the purchaser experience.

Owner:BEIJING HUSNG CHUANGZHAN TECH

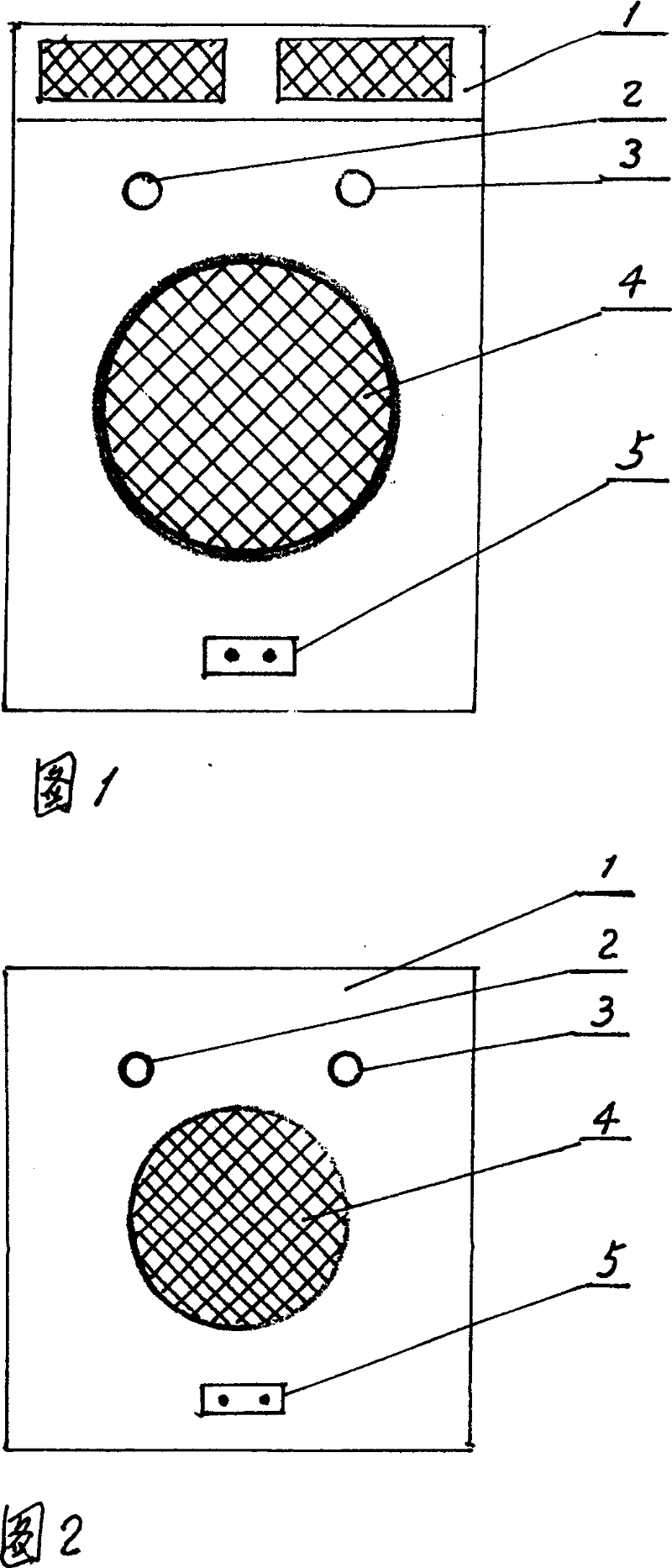

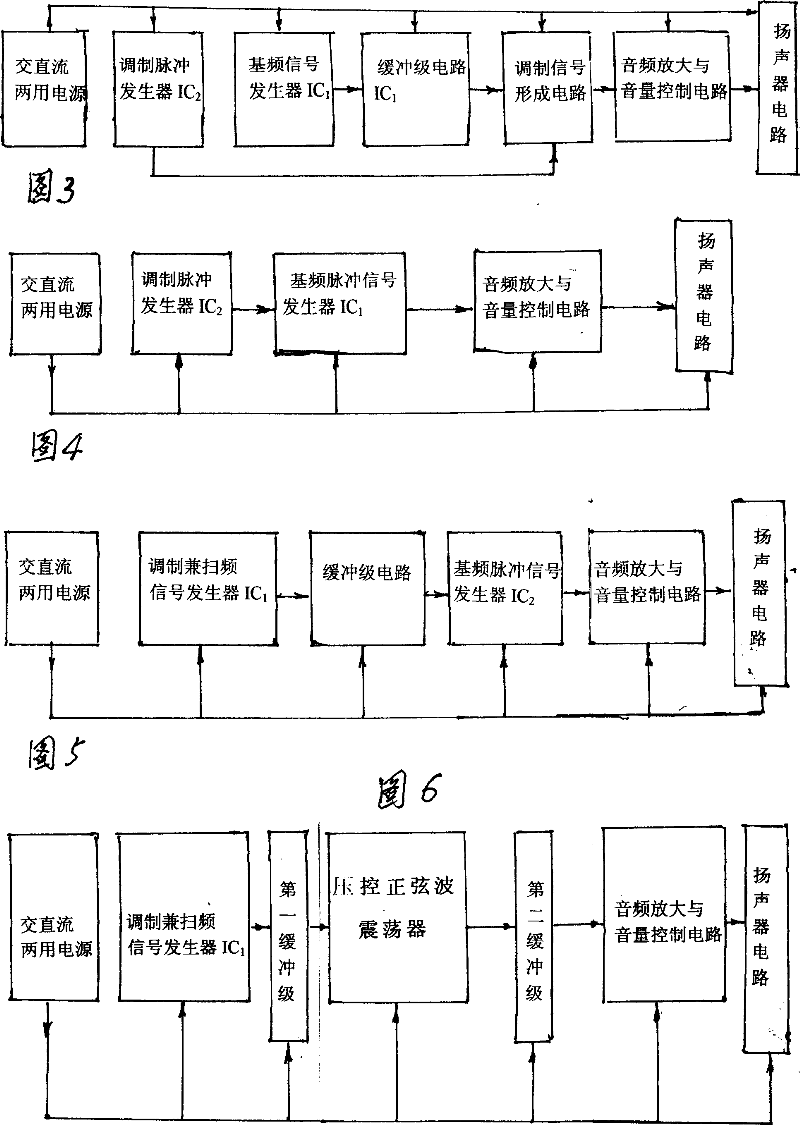

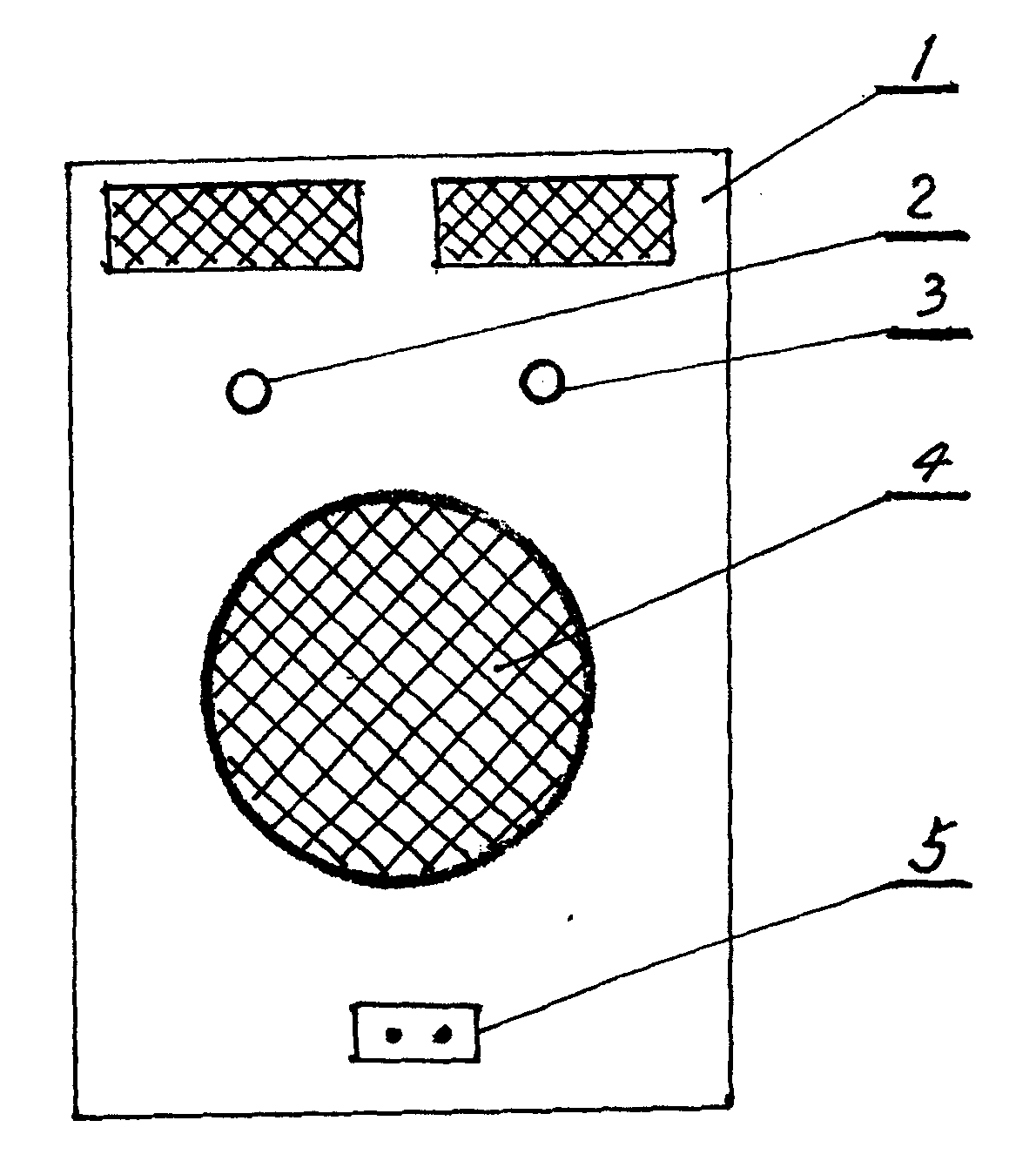

Multifunctional sonic wave processing technology and sonic wave generator for increasing quality plant production with protection

InactiveCN100356836CMeet the needs of useIncreased dose of sonicationElectrophonic musical instrumentsHorticulture methodsFrequency spectrumEngineering

A multifunctional sonic treating techinque for increasing the yield of plant and improving its quality and its sound wave generator are disclosed. The pulse modulated sound waves and sweep-frequency sound waves, which have strong force energy and information actions, are emitted toward the plant to promote the sequential activity of mass, energy and information, resulting in high yield and quality.

Owner:仇剑锋

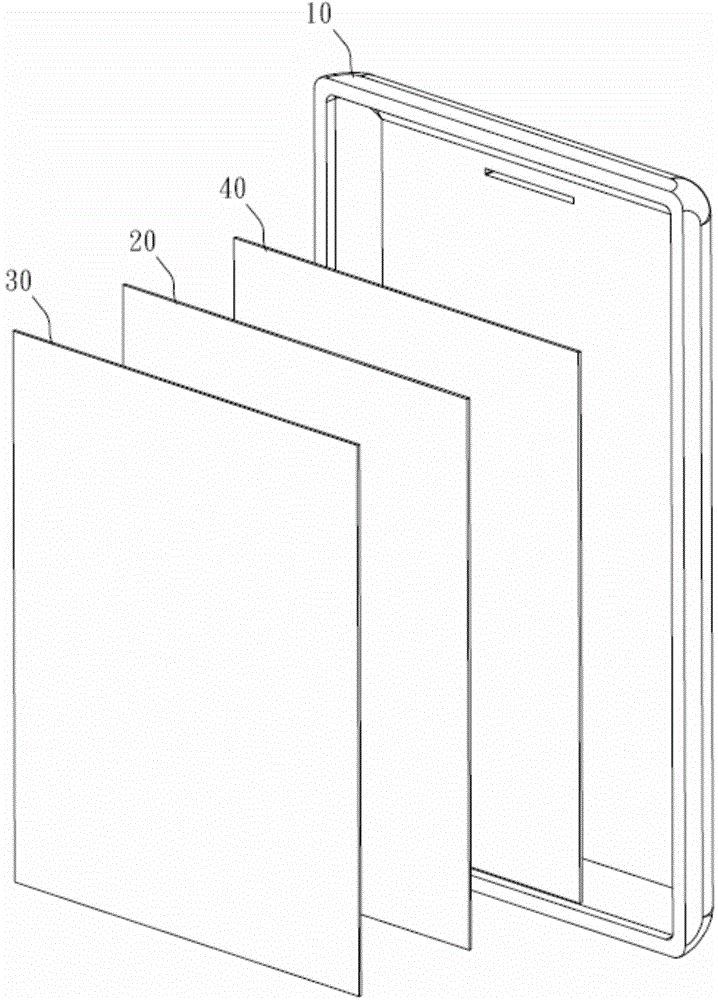

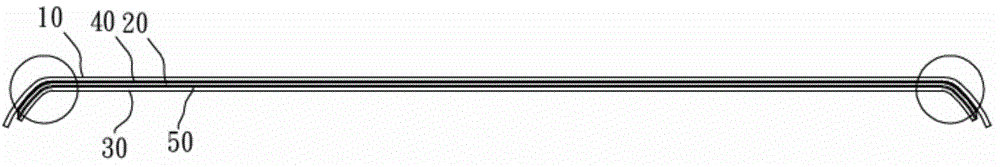

Three-dimension curve surface touch control panel

InactiveCN103955306AImprove yieldReduce processing costsInput/output processes for data processingEngineeringFilm structure

The invention discloses a three-dimension curve surface touch control panel. The surface of a protection panel of the three-dimension curve surface touch control panel is provided with a three-dimension curve surface and is pasted with an optical film, the optical film is in contact with a bending part formed by the three-dimensional curve surface of the protection panel, and at least one hole is formed in a position, corresponding to the bending part of the three-dimensional curve surface, of the optical film, so the region becomes a stress release region, and the air bubble problem and the peeling phenomenon caused by stress action during the curve surface pasting can be respectively solved and avoided, wherein the holes at the bending part of the optical film can be designed to penetrate or not penetrate through the optical film, in addition, the optical film is of a one-layer or multilayer film structure and can comprise a touch control sensing film, optical cement or anti-explosion film, and in addition, the three-dimension curve surface touch control panel is applicable to protection panels with three-dimensional curve surfaces such as inner curve surfaces, outer curve surfaces or irregular curve surfaces.

Owner:INTERFACE OPTOELECTRONICS SHENZHEN +1

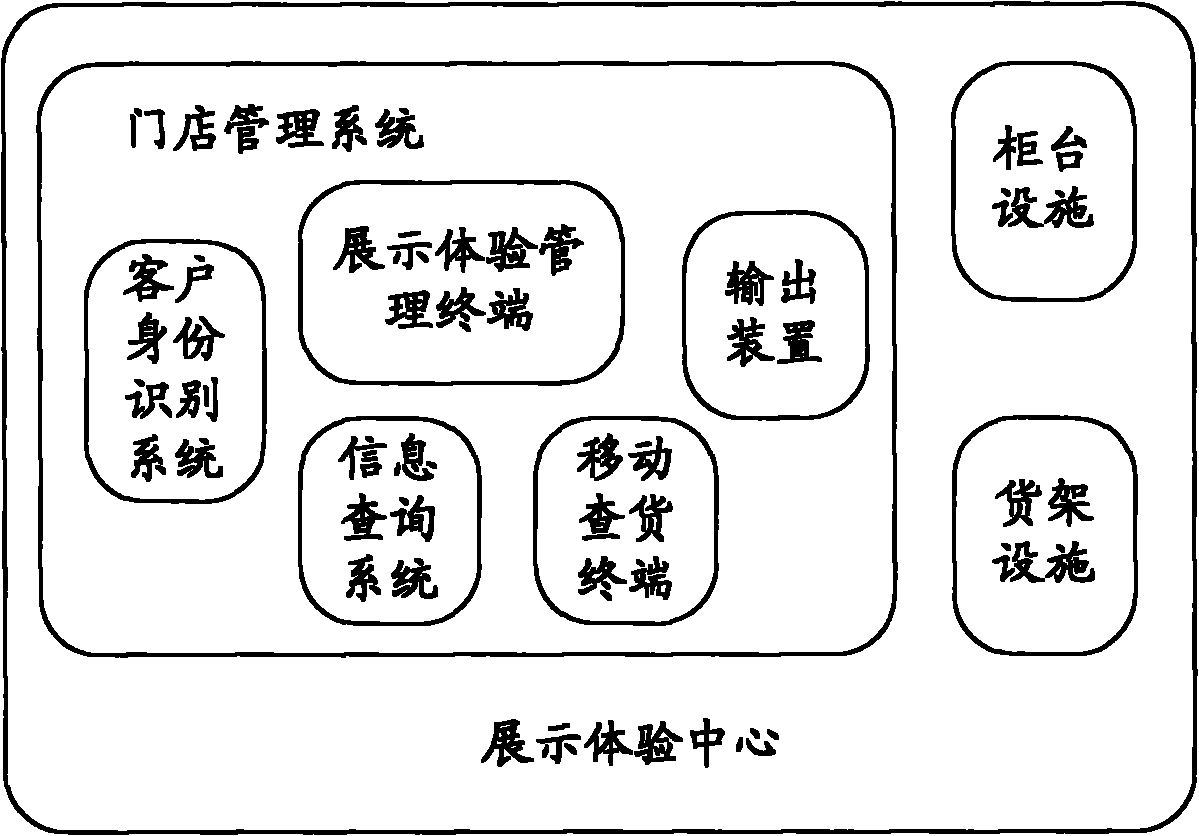

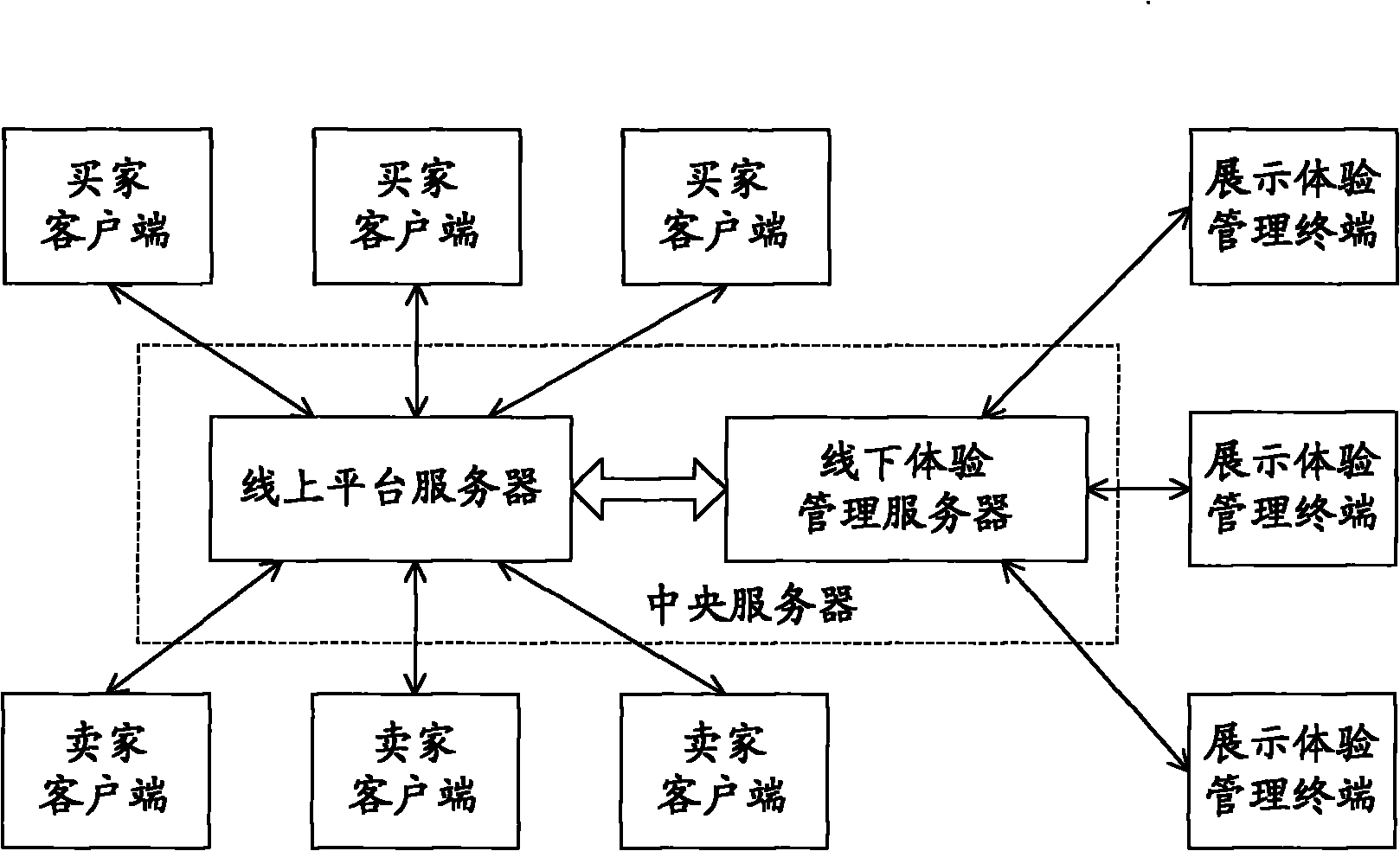

Off-line experience store management system and method

The invention relates to an off-line experience store management system. The system comprises an experience management system terminal and a client identification system, an information query system, a mobile query terminal and an output device which are connected with the experience management system terminal in a communication way, wherein the experience management system terminal is connected with a remote central server in a communication way and performs data interaction and the synchronization of an experience goods database; the client identification system is used for identifying experience sheet numbers of clients coming into a store, transmits the experience sheet numbers to the experience management system terminal and generates experience serial numbers of the clients; the output device is used for displaying information to users in the store according to instructions of the experience management system terminal; the information query system is communicated with the experience management system terminal and is used for providing real-time query of store inventories and experience information for the clients or salesclerks; and the mobile query terminal is used for reading all the goods information of the store and uploading the goods information to the experience management system terminal. Therefore, the system can realize mutual combination of an on-line system and an off-line system and provides an integrated shopping platform.

Owner:BEIJING HUSNG CHUANGZHAN TECH

Alkaline zinc-nickel alloy plating compositions, processes and articles therefrom

The present invention relates to a process for electroplating a zinc-nickel alloy on a substrate, including electroplating the substrate in an aqueous zinc-nickel electroplating bath, including water; nickel ion; zinc ion; at least one complexing agent; and at least one non-ionogenic, surface active polyoxyalkylene compound, wherein the bath has an alkaline pH. In one embodiment, the zinc ion, the nickel ion and the non-ionogenic surface active polyoxyalkylene compound are present at concentrations sufficient to deposit a zinc-nickel alloy comprising a substantially gamma phase.

Owner:OPASKAR VINCENT C +1

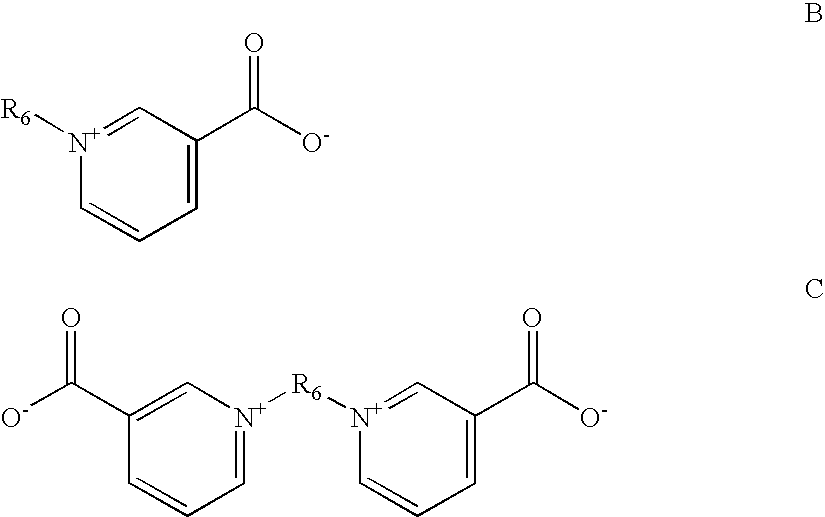

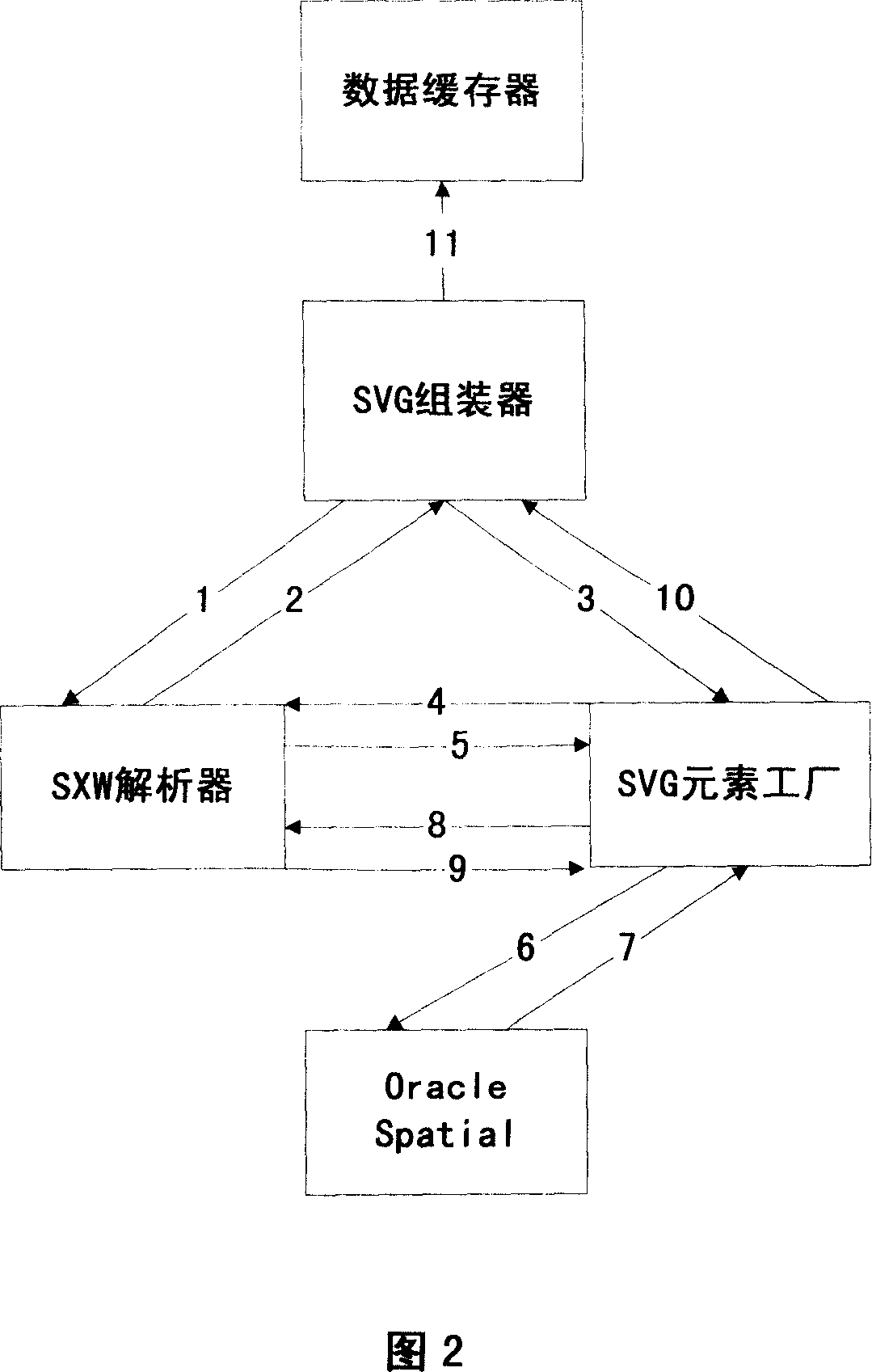

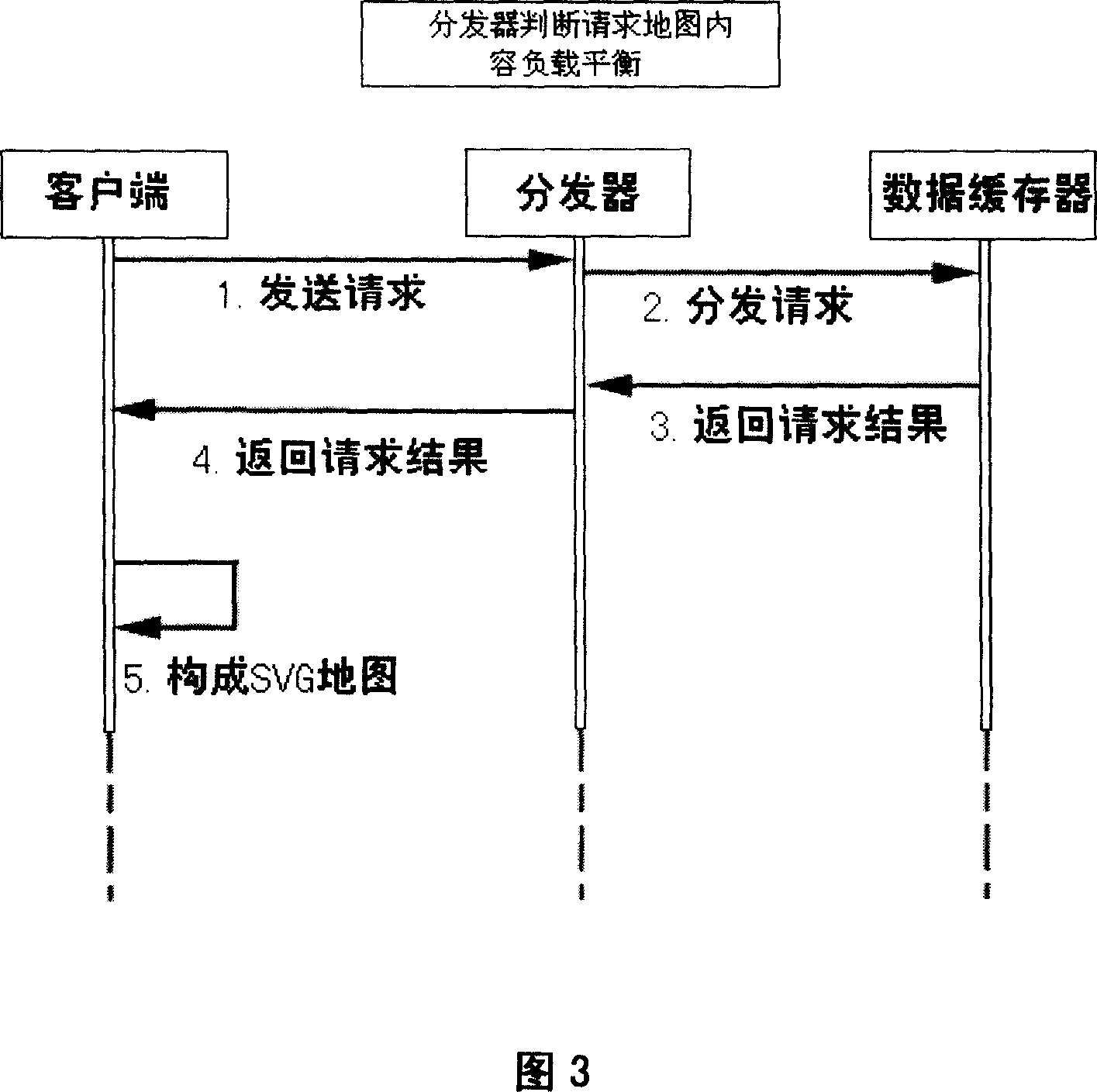

Method for forming and applying high speed Wcb electronic map based on space data base and SVG

InactiveCN1945578AHigh speedImprove the development effectSpecial data processing applicationsSpatial managementThe Internet

The invention relates to a database structure that is constructed or arranged by the use of the internet map data, especially belonging to a generation and application method of high speed Web electric map based on the space database and SVG, which is composed of server and client end that is named foreground control module. The server contains the data permanent layer that includes SXW documents and Oracle Spatial, and the application logic layer that includes data storage, SXW analysis device, data updating device, SVG packaging device, SVG element plant, distribution device and client end. The effect of the invention is: the efficient and independent Oracle Spatial management and calculating spatial system. Because the space data performance and space dada calculation are separated, the terminal user greatly improves speed in space inquiry and map examination, so that it is beneficial in the user experience.

Owner:福州开睿动力通信科技有限公司

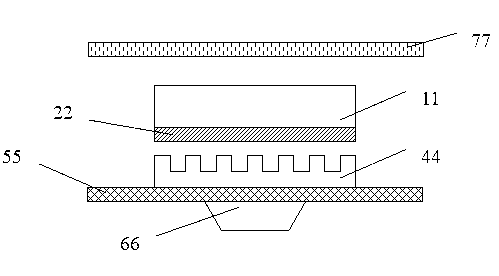

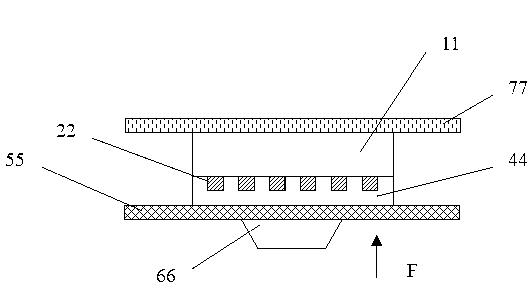

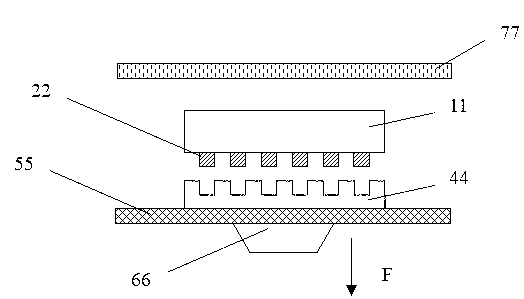

Method for manufacturing silicone micro-nano optical structure by using imprinting technology

InactiveCN102707378AGood thermal stabilityGood light transmissionDecorative surface effectsPhotomechanical apparatusWeather resistancePolymer

The invention discloses a method for manufacturing a silicone micro-nano optical structure by using an imprinting technology. Firstly, a template serving as a seal during the imprinting is designed and processed according to the requirements of the structure of a device; secondly, an appropriate substrate material is selected and used according to the requirements of the micro-nano optical structure of the device, and then covered with imprinting glue; afterwards, structural patterns on the template are transferred to the imprinting glue by adopting an imprinting process, the imprinting glue is solidified and molded, the template is released after the template and the substrate are both cooled, and then a micro-nano optical structure with embossed figures is obtained; and finally, a polymeric optical bounding layer covers above imprinted lines according to the design of the device, and then the whole micro-nano optical structure is formed. By adopting the method, optical devices whichhave good weatherability and strong thermal stability and cause low loss can be prepared; and besides, the process is simple, so that the method has a cost advantage.

Owner:SOUTH CHINA NORMAL UNIVERSITY

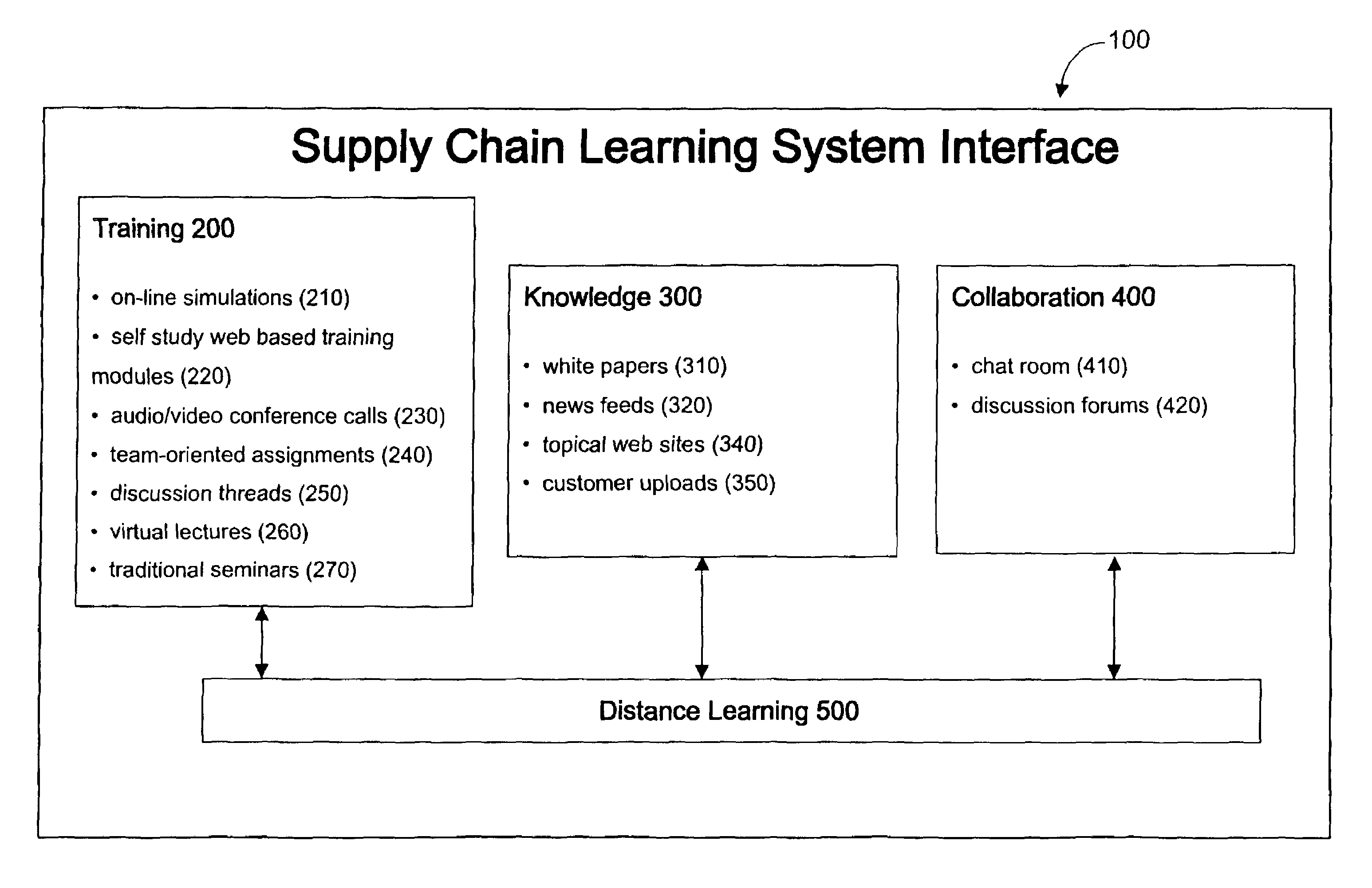

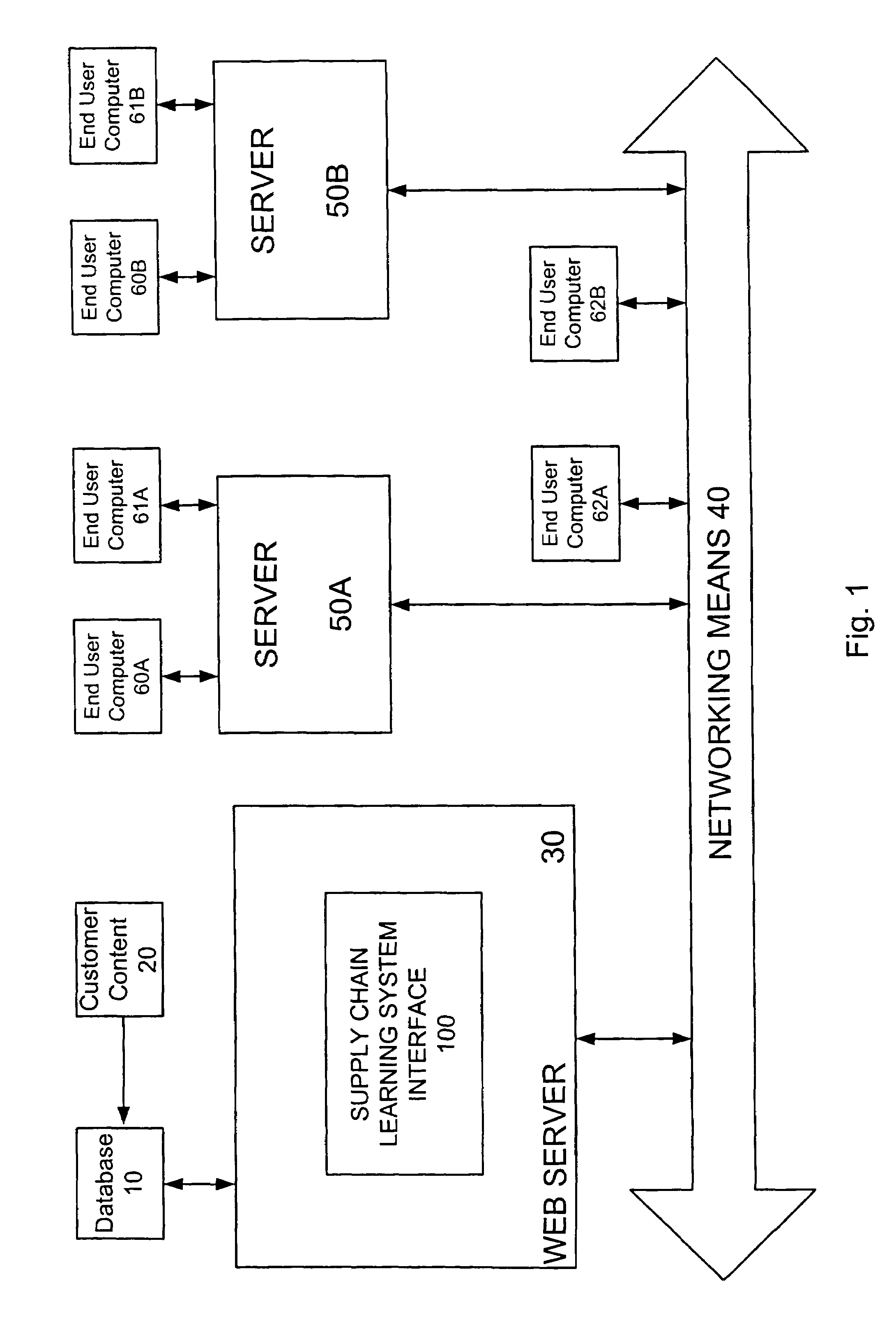

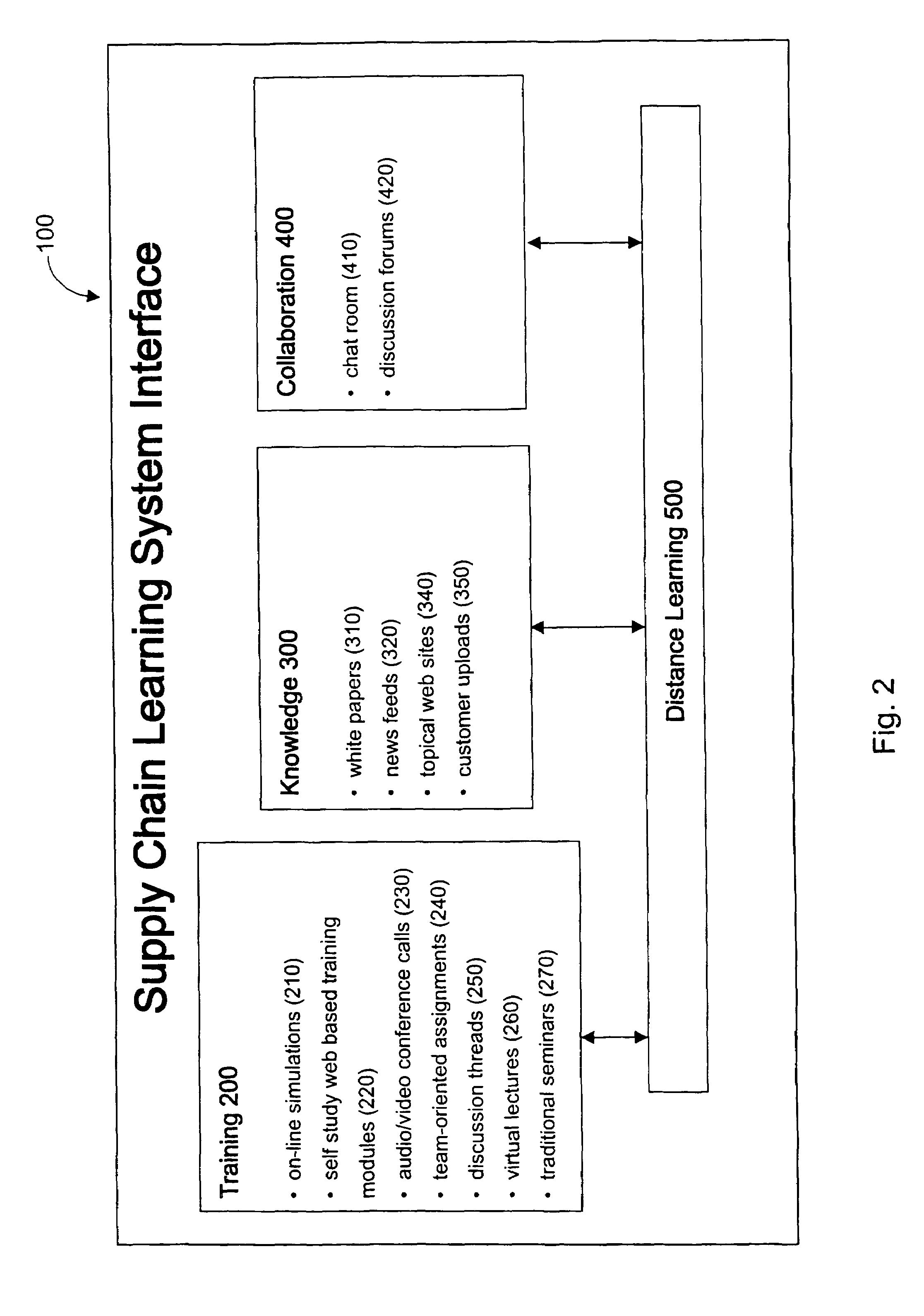

Learning system and related methods particularly suitable for an organization's supply chain

ActiveUS7300287B2Improve competitive advantageImprove abilitiesOffice automationElectrical appliancesSkill setsKnowledge management

The invention disclosed relates to a learning system and related methods for providing training and continuing education to members of an organization's supply-chain workforce. A learning system utilizes a blended learning approach that matches various educational delivery techniques to the appropriate learning materials, time constraints, and skill level of the end user. The system is simultaneously accessible to multiple organizations in order to provide uniformity of learning among a wide variety of participants within the supply-chain workforce, while remaining adaptable to the unique learning needs of each organization. Thus, the invention captures the benefits of distance learning techniques while minimizing the isolationist learning environment typically associated with those leaning delivery methods. Furthermore, the invention seeks to capture the benefits associated with traditional learning delivery methods such as team-oriented learning and personal instructor feedback.

Owner:ACCENTURE GLOBAL SERVICES LTD

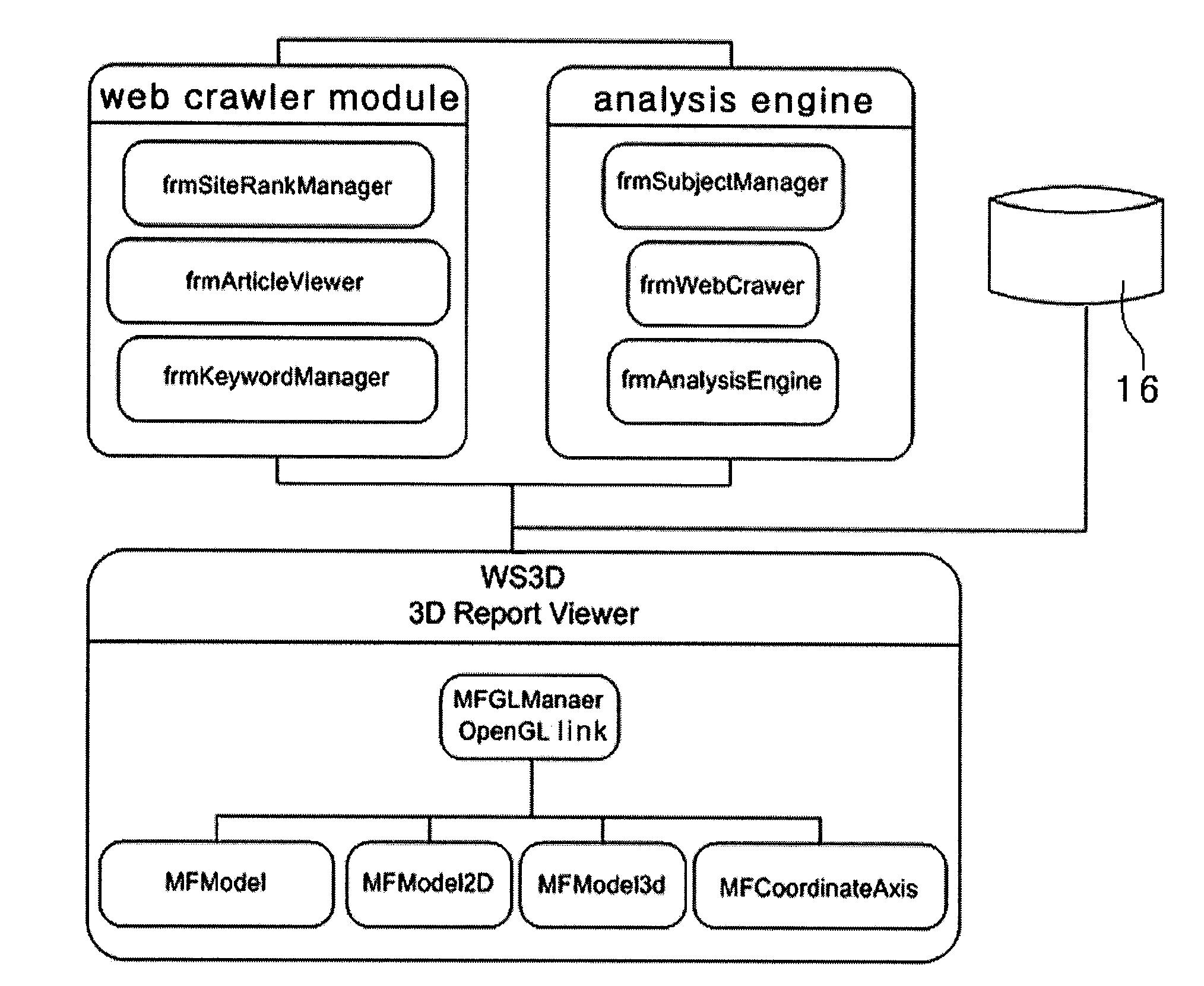

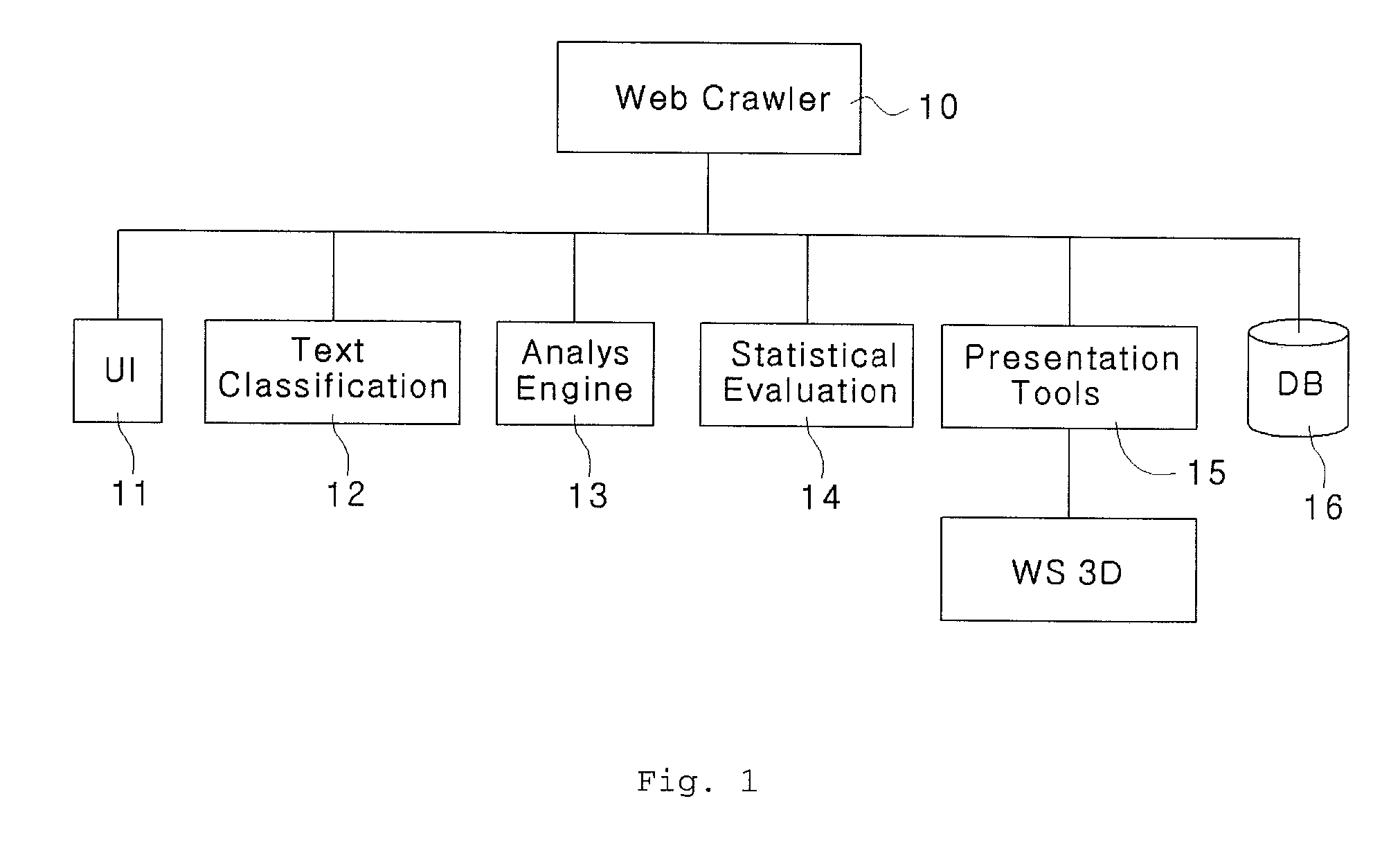

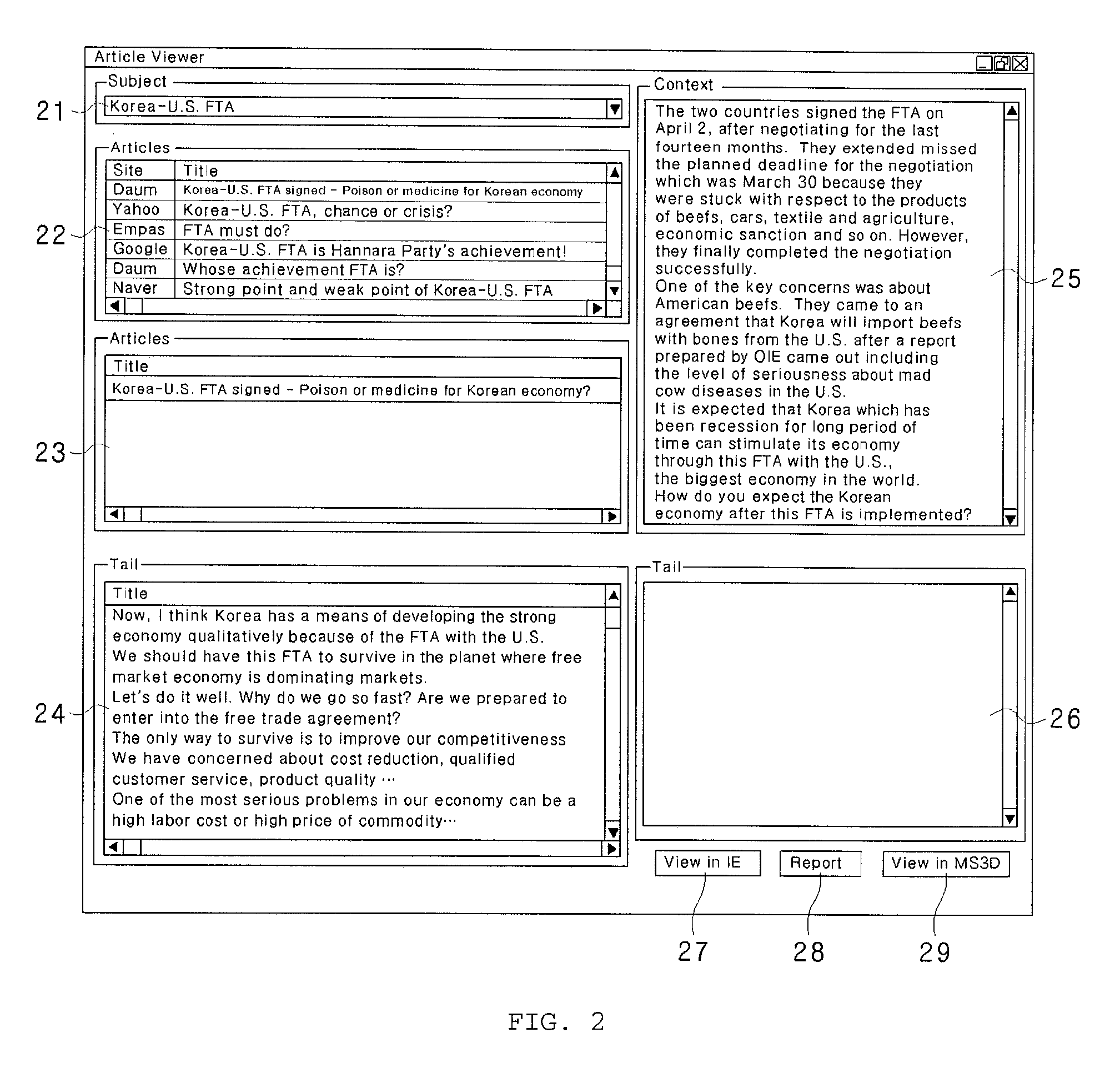

3D visualization system for web survey

InactiveUS20100153372A1Easy to understandImprove abilitiesWeb data indexingDigital data processing detailsFixed starsReal-time web

The present disclosure relates to a three-dimensional visualization system for internet-based web surveys which can collect in real time web articles about specific companies, products or public figures from specific websites, blogs or knowledge-search web pages, process and analyze collected articles and display survey results with a planetary system having a three-dimensional fixed star and planets such that the user can understand easily and accurately the survey results. The system can include a user interface, a database server configured to store collection conditions, a web crawler module a text classification module, an analysis engine module, a statistical evaluation module, and store rate values of the web articles and a presentation tool configured to display three-dimensional graphics of the rate values of the web articles stored in the statistical evaluation module symbolizing a planetary system having a fixed star and planets.

Owner:KIM SEA WOO

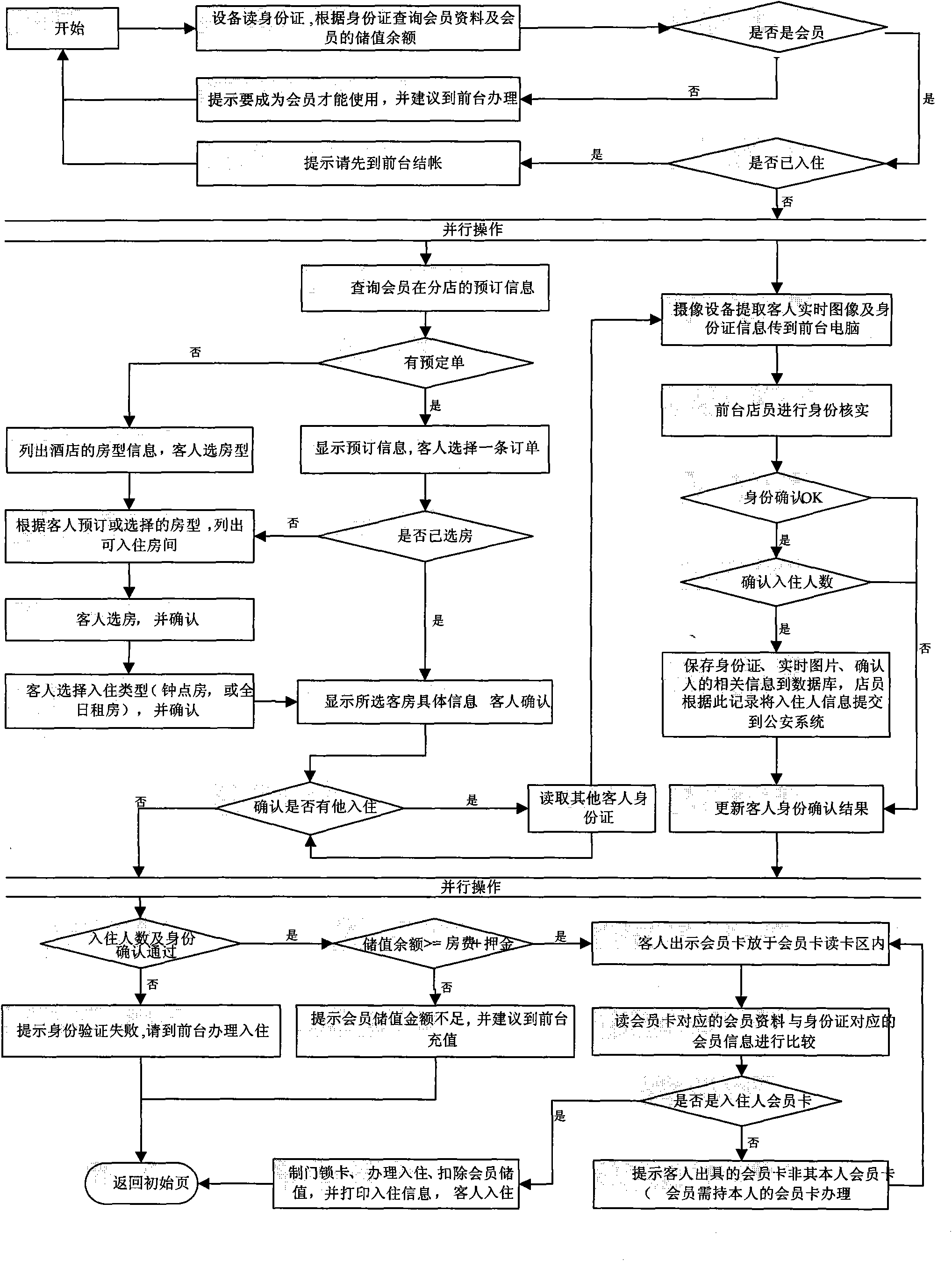

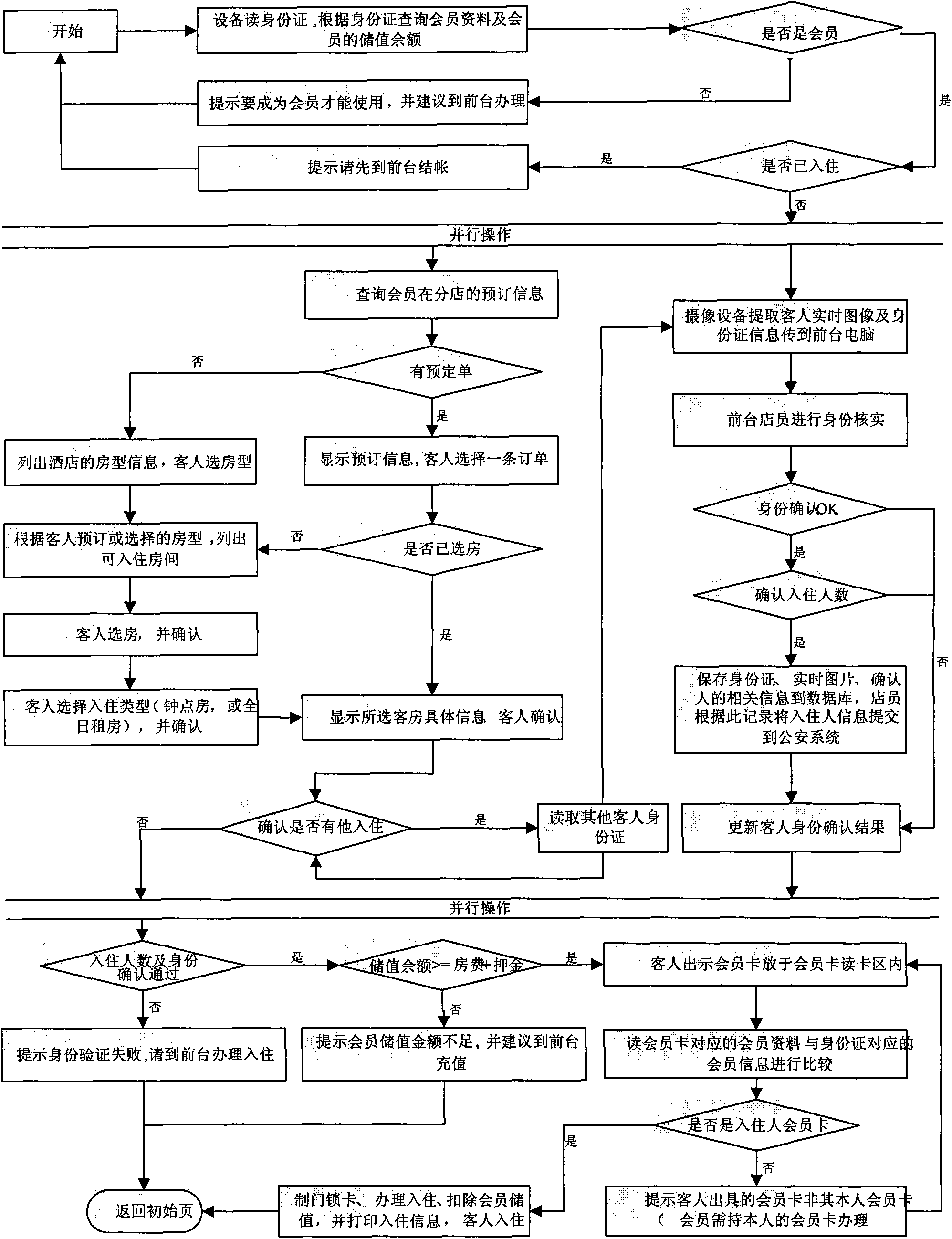

Self-service check-in management system and method for hotels

InactiveCN101957952ASimplify check-inExpress check-inData processing applicationsIndividual entry/exit registersService personnelRecovery period

The invention relates to a self-service check-in management system and method for hotels, which can simplify the check-in procedure, shortens the investment recovery period of the hotels, reduces the operating risk, reduces service staff of a main station, and reduces the operating cost of the hotels. In the process that the system imports the application, the identity authentication of a guest, settlement of articles consumed by the guest and check-out are relatively processed, and the measures basically meet the requirements of the public security sector for hotel management.

Owner:无锡蝶尚酒店管理有限公司

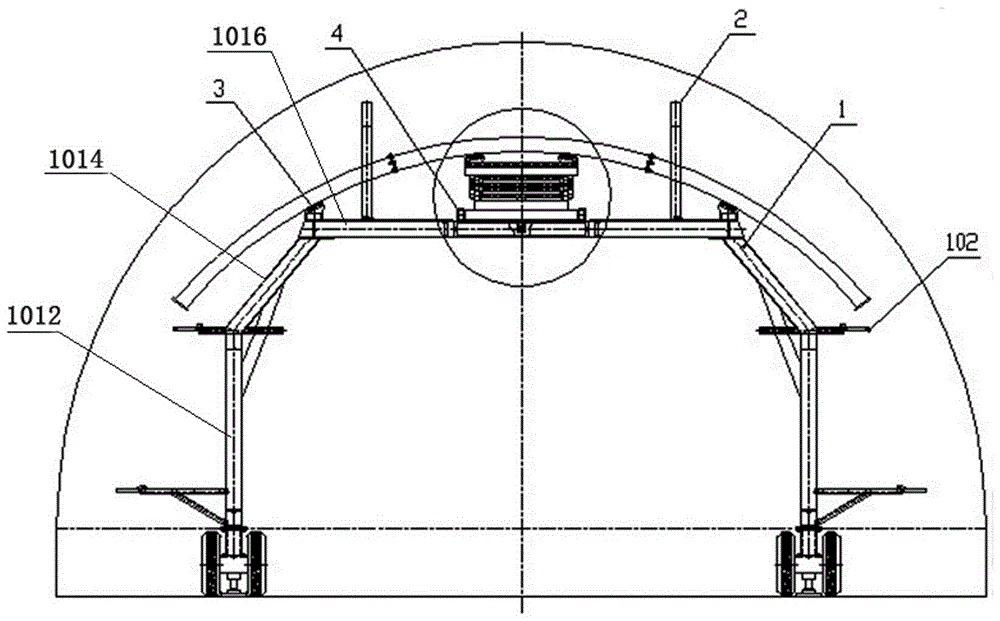

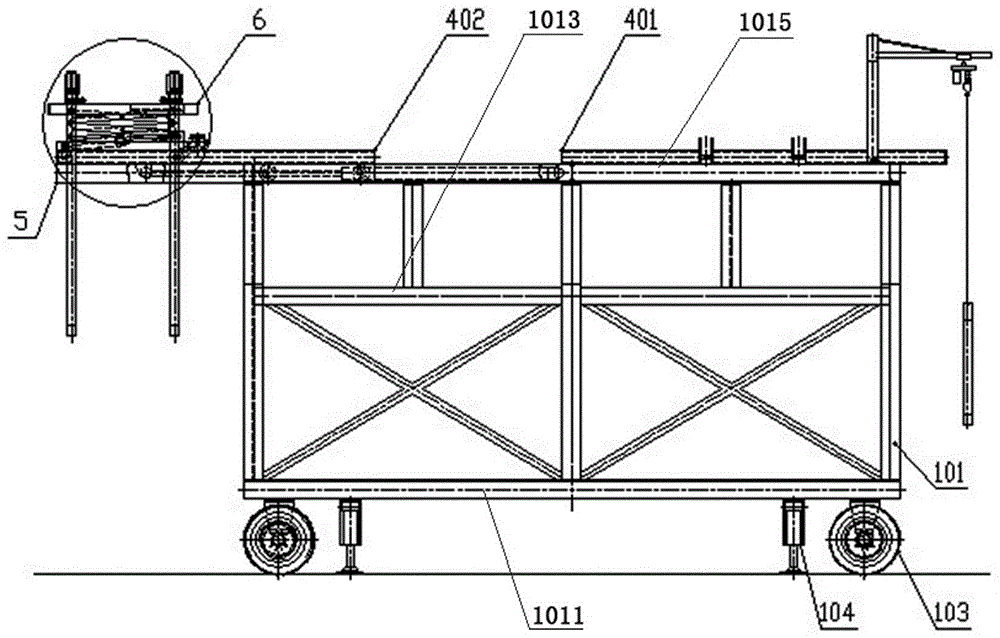

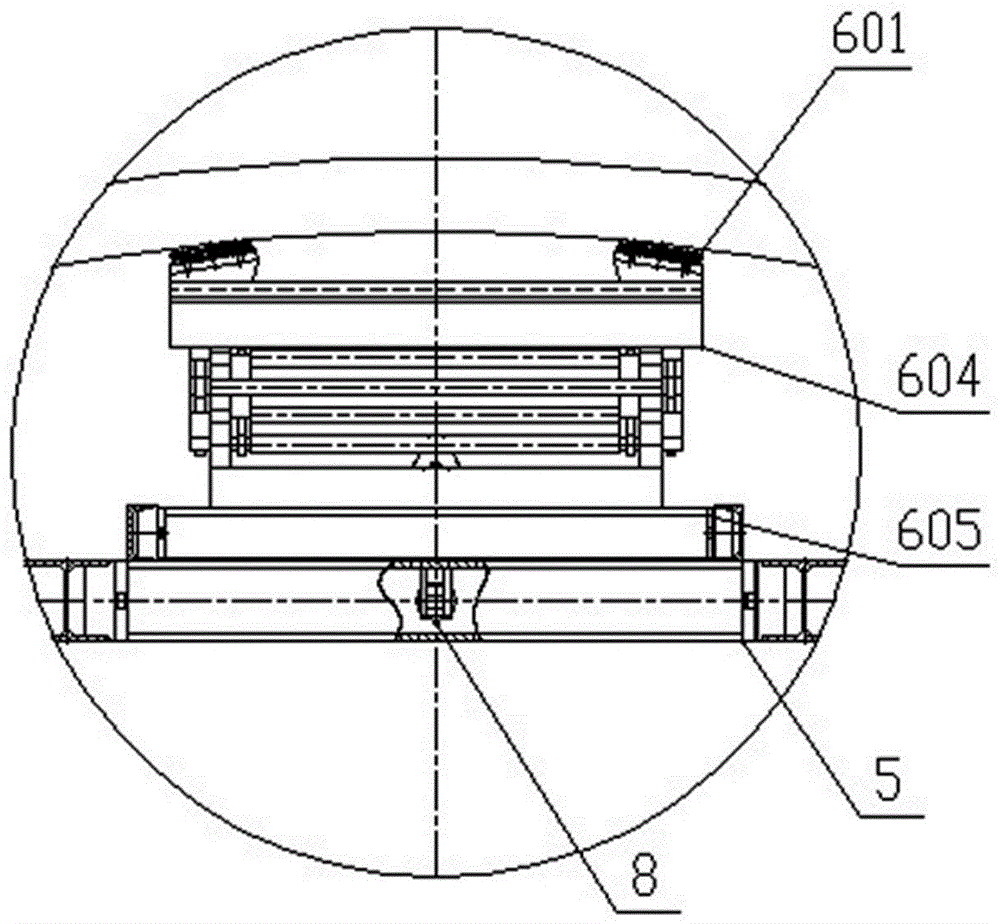

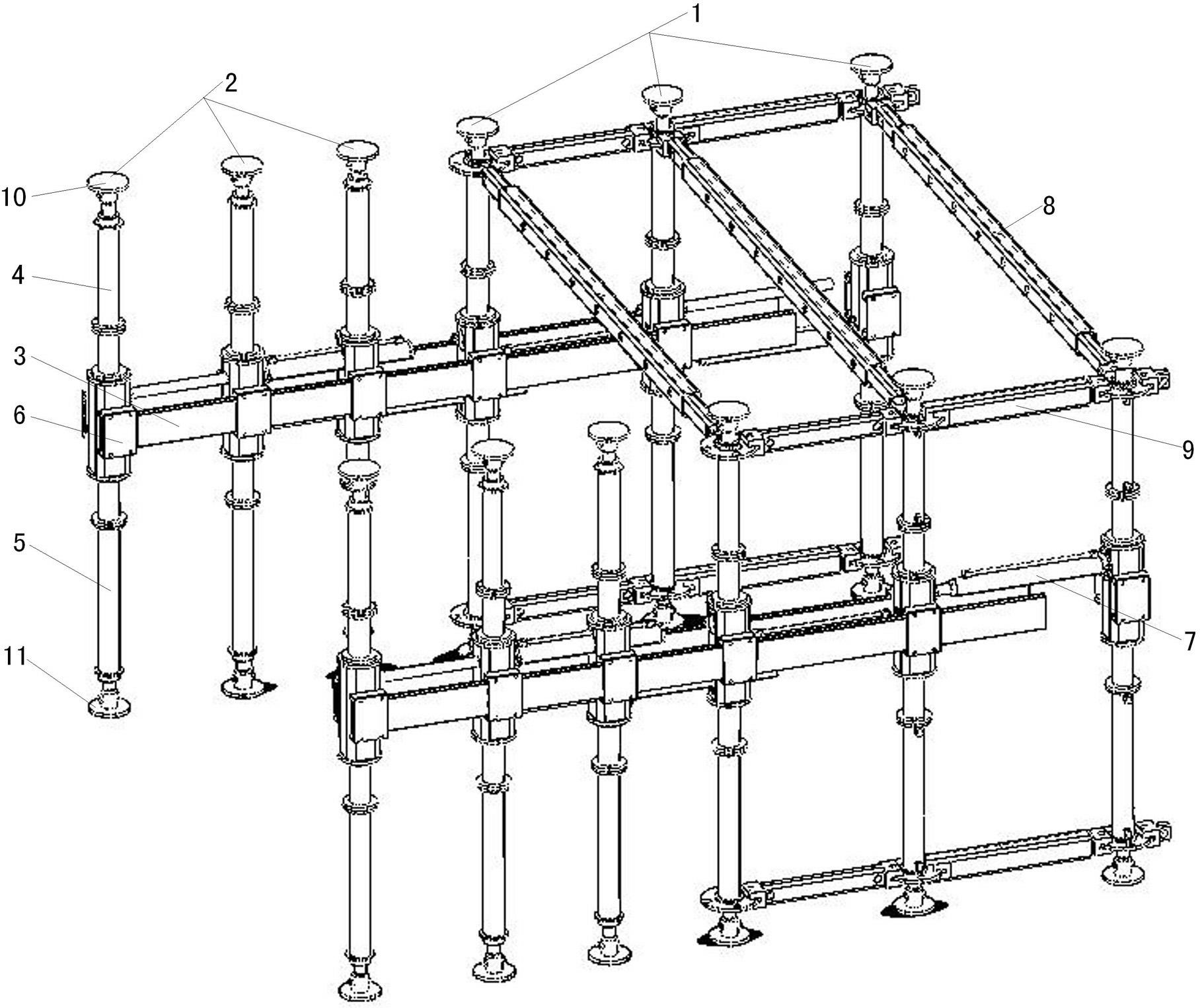

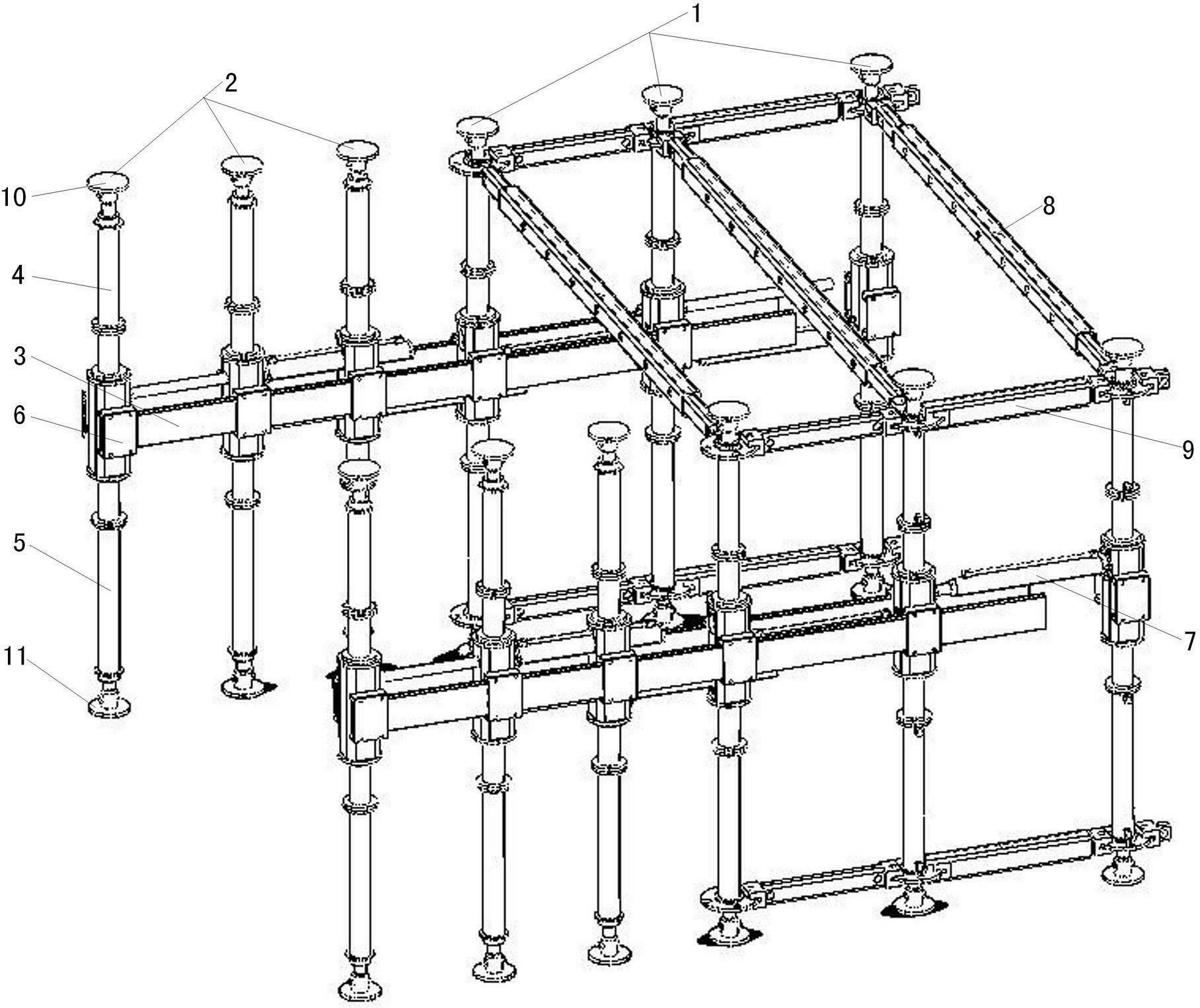

Door frame type multi-functional support trolley for tunnel

ActiveCN106837392AStable supportMeet the installation requirementsUnderground chambersTunnel liningBogieEngineering

The invention discloses a door frame type multi-functional support trolley for a tunnel. The door frame type multi-functional support trolley for the tunnel comprises a door frame and a working platform. The top end of the door frame is provided with a sliding groove track and an arch centering mounting device. The arch centering mounting device comprises a traveling bogie and a lifting device, wherein the traveling bogie is capable of moving backward and forward on the sliding groove track. The lower side of the lifting deviceis fixed to the traveling bogie. The left side and the right side of the lifting device are provided with left-right moving mechanisms and left-right moving tracks for the left-right moving mechanisms to move correspondingly. The left-right moving mechanisms are provided with transportation supports. The sliding groove track comprises a fixed sliding groove track and a movable sliding groove track with the same gauge. The fixed sliding groove track is fixed to the rear of the top end of the door frame and the tail end of the fixed sliding groove track is beyond the tail end of the door frame. The movable sliding groove track is fixed to a sliding platform in the middle of the front of the top end of the door frame. The rear end of the sliding platform is hinged to one end of a sliding cylinder, and the other end of the sliding cylinder is hinged to the door frame. According to the door frame type multi-functional support trolley for the tunnel, the arch centering mounting requirements of a micro-step excavation and support construction method of very weak surrounding rock can be met, and the working procedure time occupied by the arch centering mounting is shortened.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

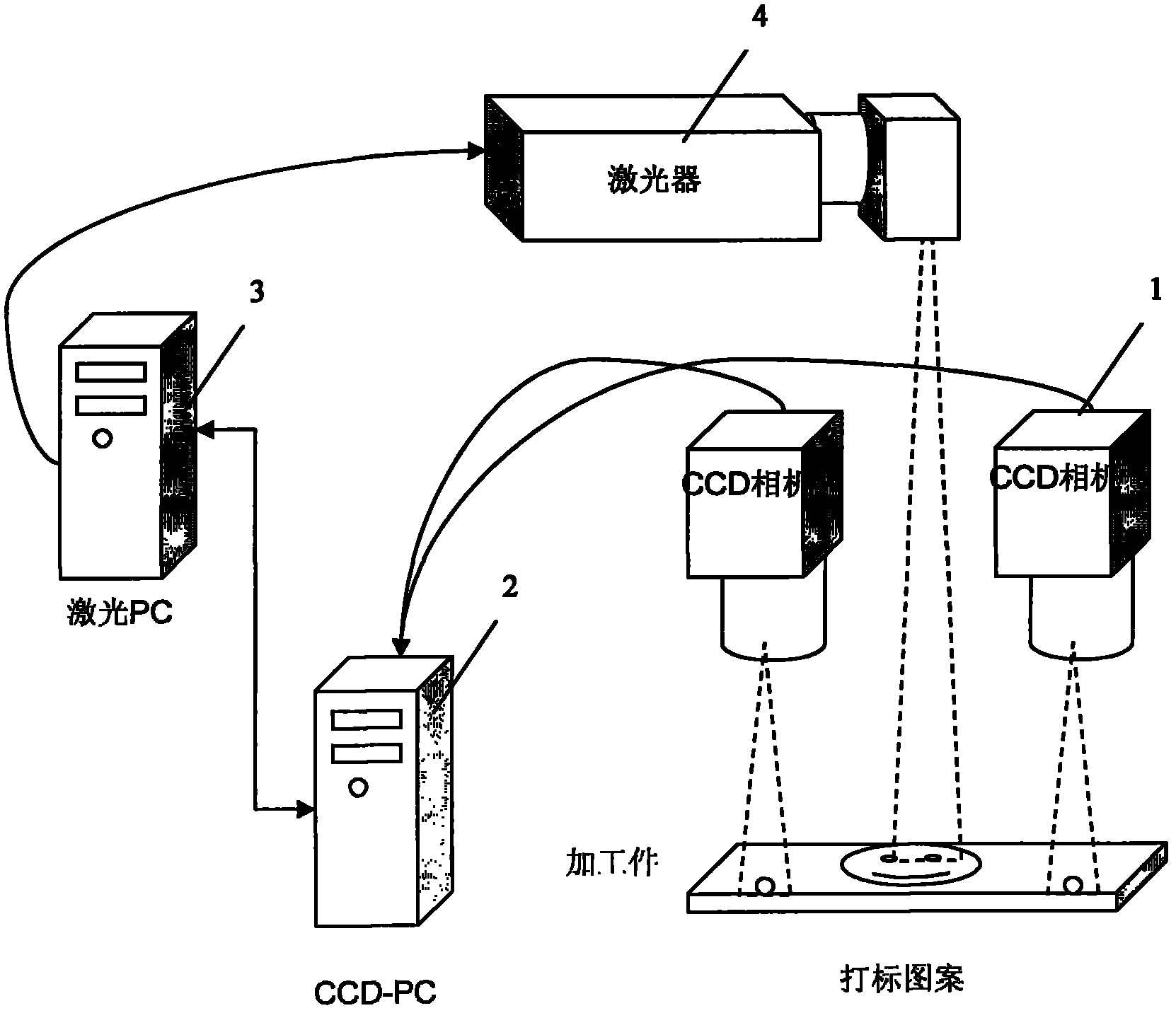

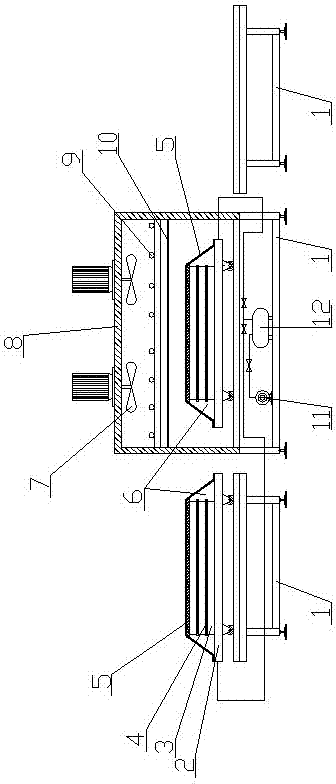

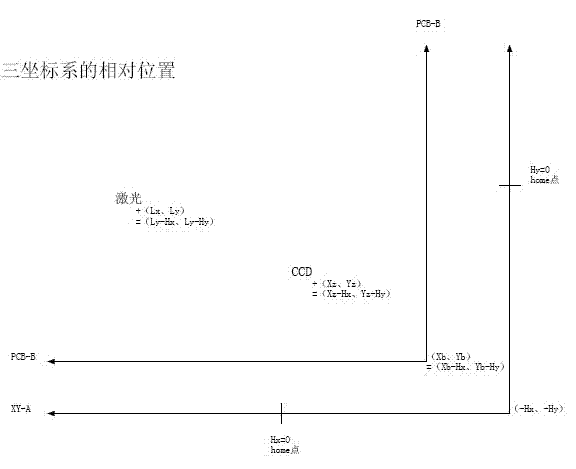

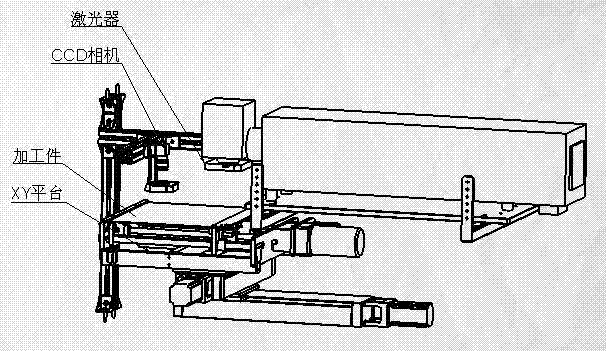

Laser marking method and device based on CCD (Charge Coupled Device) image navigation

The invention relates to a laser marking method based on CCD (Charge Coupled Device) image navigation, comprising the following steps: 1) inputting a product position parameter into CCD-PC (Personal Computer), correcting a marking pattern position by the CCD-PC; 2) putting a product in; 3) respectively collecting and detecting characteristic images on the left position and the right position of the product by a CCD camera, and transferring the characteristic images to the CCD-PC; 4) comparing the product position parameter set in step 1) by the CCD-PC, calculating by the CCD-PC to obtain the absolute displacement coordinate value of the product, and transmitting the value to a laser PC; 5) overlaying the absolute displacement coordinate value of the product to the marking coordinate valueof a laser; positioning a marking pattern onto the corresponding position of the product; and printing. Compared with the prior art, the laser marking method has the advantages of low cost and the like and is convenient to use.

Owner:上海功源电子科技有限公司

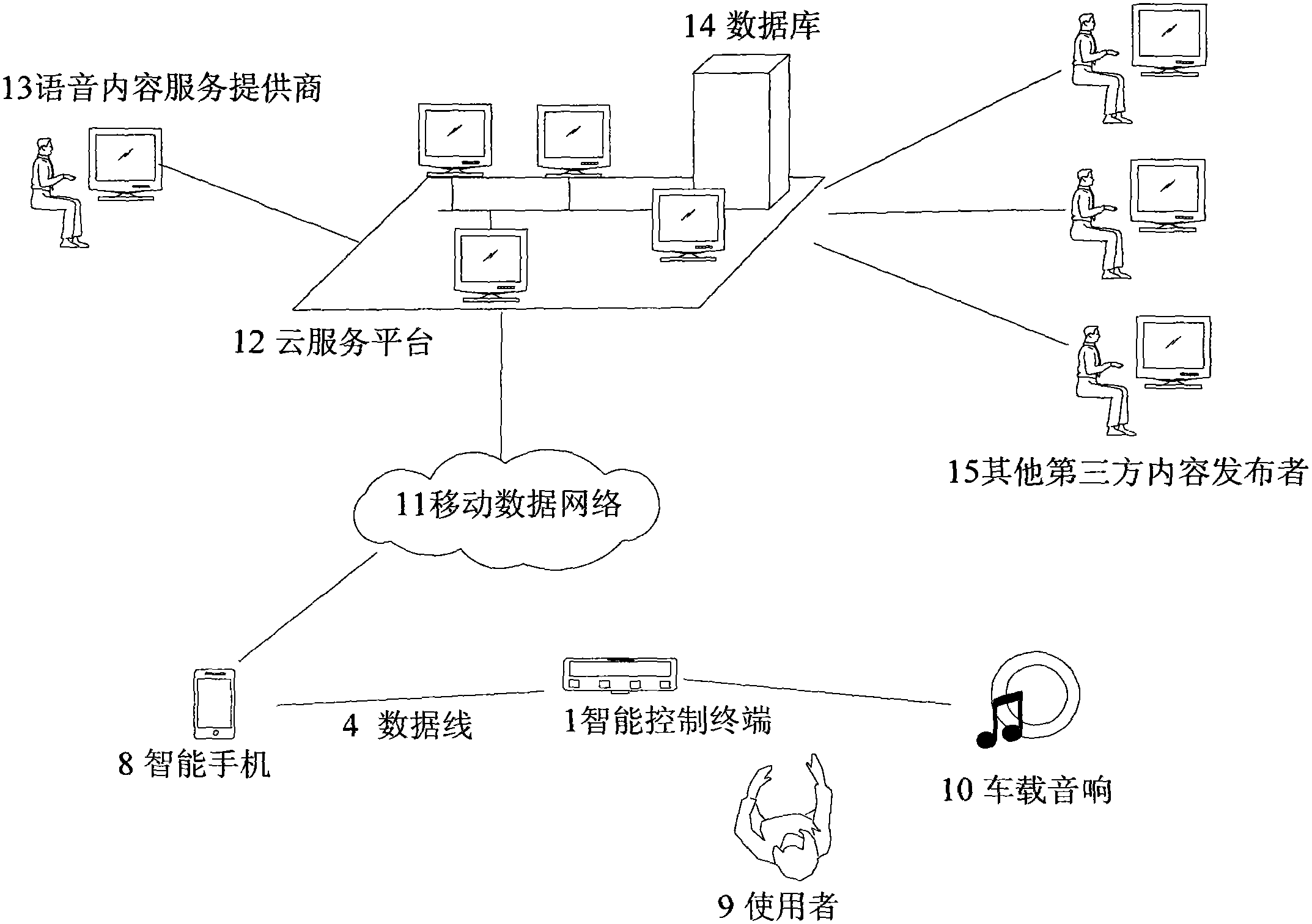

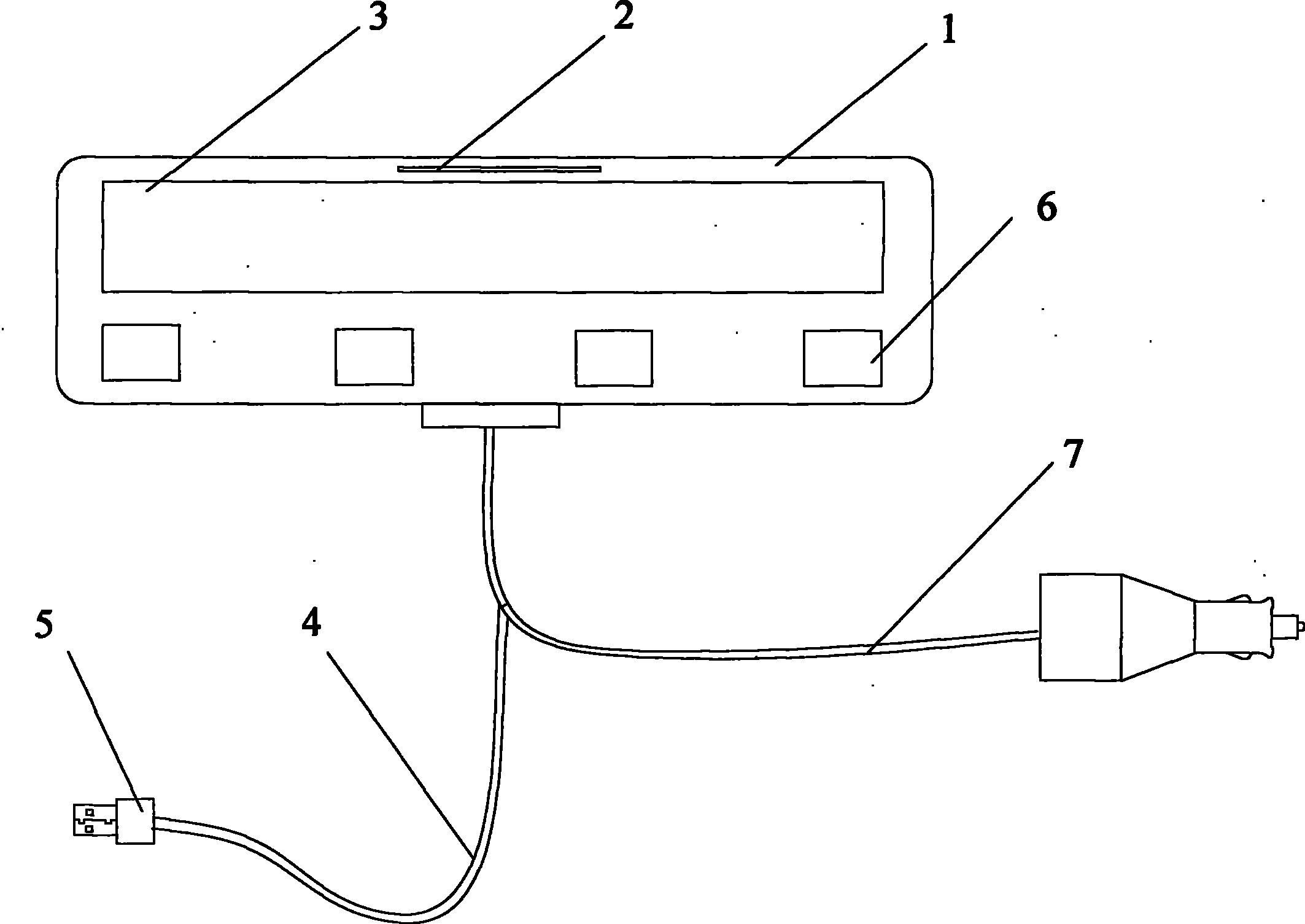

A method for controlling a vehicle-mounted intelligent system through voices

ActiveCN103676826AEasy to operateLow service chargeProgramme total factory controlHandsetSpeech control

The invention provides a method for controlling a vehicle-mounted intelligent system through voices. The method comprises the following steps: S1, an intelligent control terminal is arranged inside an automobile, and the intelligent control terminal is connected with an intelligent handset and vehicle-mounted sound equipment inside the automobile; S2, the mode that the intelligent control terminal is in is selected from the following four modes: a voice content mode, a communication and short message mode, an interphone mode and a position service mode; and S3, a user emits voice commands to the intelligent control terminal, and the control terminal converts the voice commands into digital signals, and the digital signals are compared with the voice commands stored by the intelligent control terminal, and then the intelligent handset or the vehicle sound equipment are controlled to carry out operation. The control method brought forward by the invention has the characteristics of voice control, convenient operation and safe driving. Time spent on driving is turned by the method into a happy, relaxed and valuable driving experience. The method is applicable to any vehicle model; a plug-and-play function is realized; the service cost is relatively low; and the method has very large competition advantages and market popularization advantages. As for the method, a market can be bound together with a mobile communication service provider; and the method has mature market channels and huge client bases.

Owner:时代云英(重庆)科技有限公司

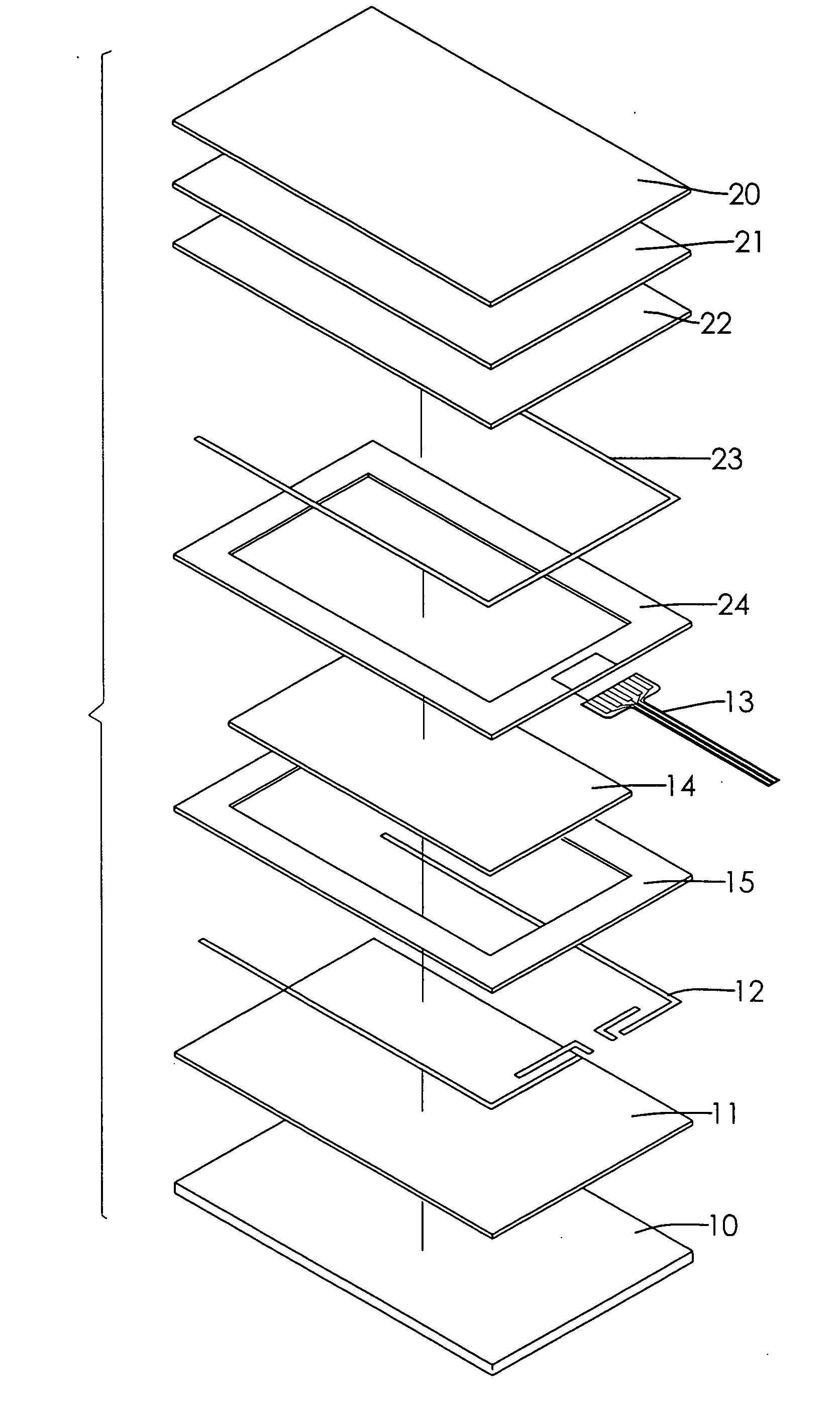

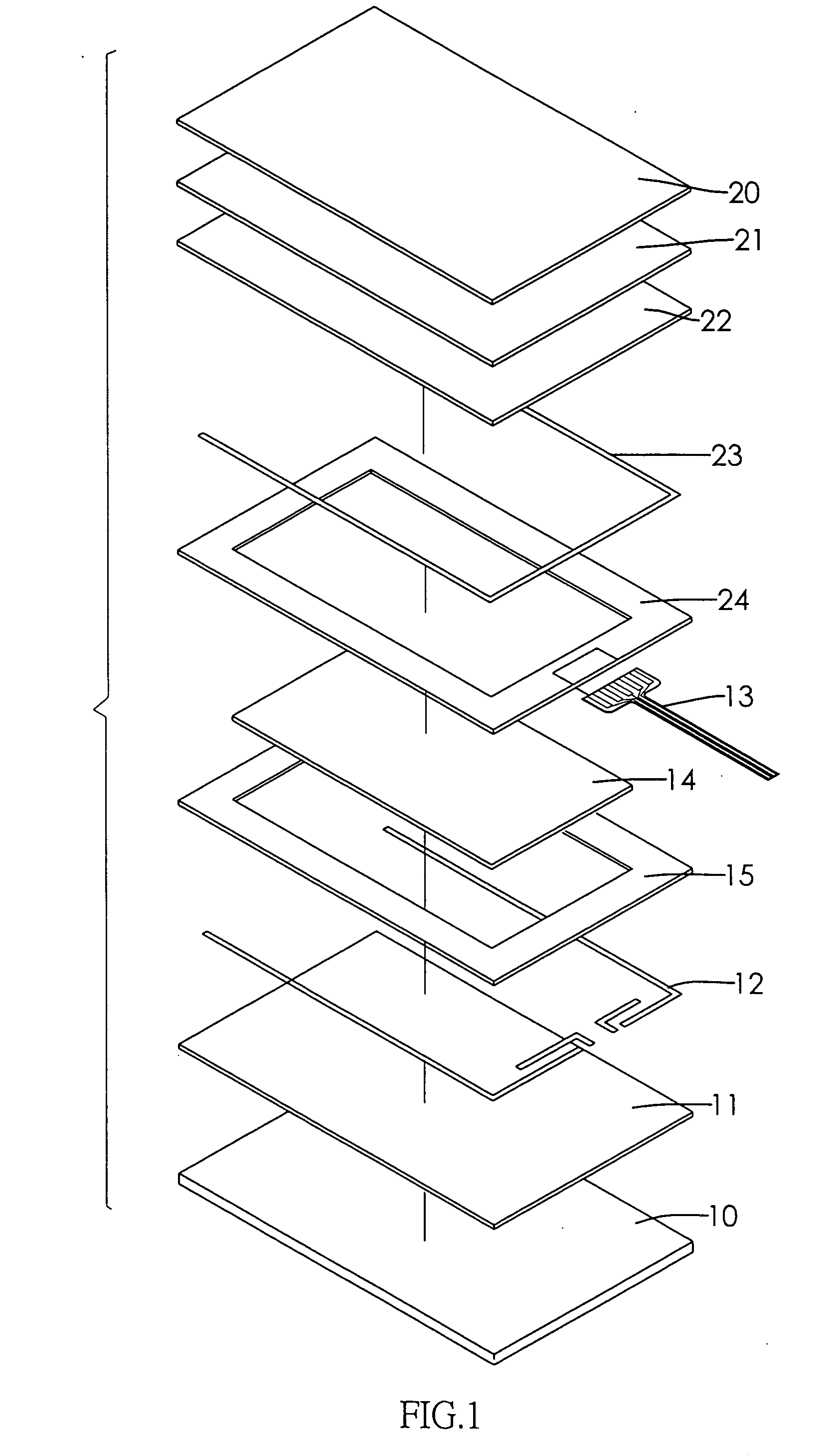

Resistive touch panel

InactiveUS20100283755A1Increase productionEliminates fabricating stepNon-linear opticsInput/output processes for data processingTectorial membraneFlexible circuits

A resistive touch panel has a lower panel module and an upper panel module, an adhesive layer, a separating layer and a flexible circuit board. The lower panel module has a substrate, a lower conducting layer and a plurality of electrodes. The upper panel module has a protective film, an upper conducting layer, a pattern layer, an ink electrode mounted to electrically connect with the flexible circuit board, and an insulation layer. One end of the flexible circuit board and the separating layer are sandwiched between the top surface of the lower conducting layer and the top surface of the upper conducting layer. Given the foregoing structure, the components and steps for fabricating the resistive touch panel can be reduced since the pattern layer is directly printed on the bottom surface of the upper conducting layer. Therefore, fabricating yields are increased.

Owner:MINLEAD

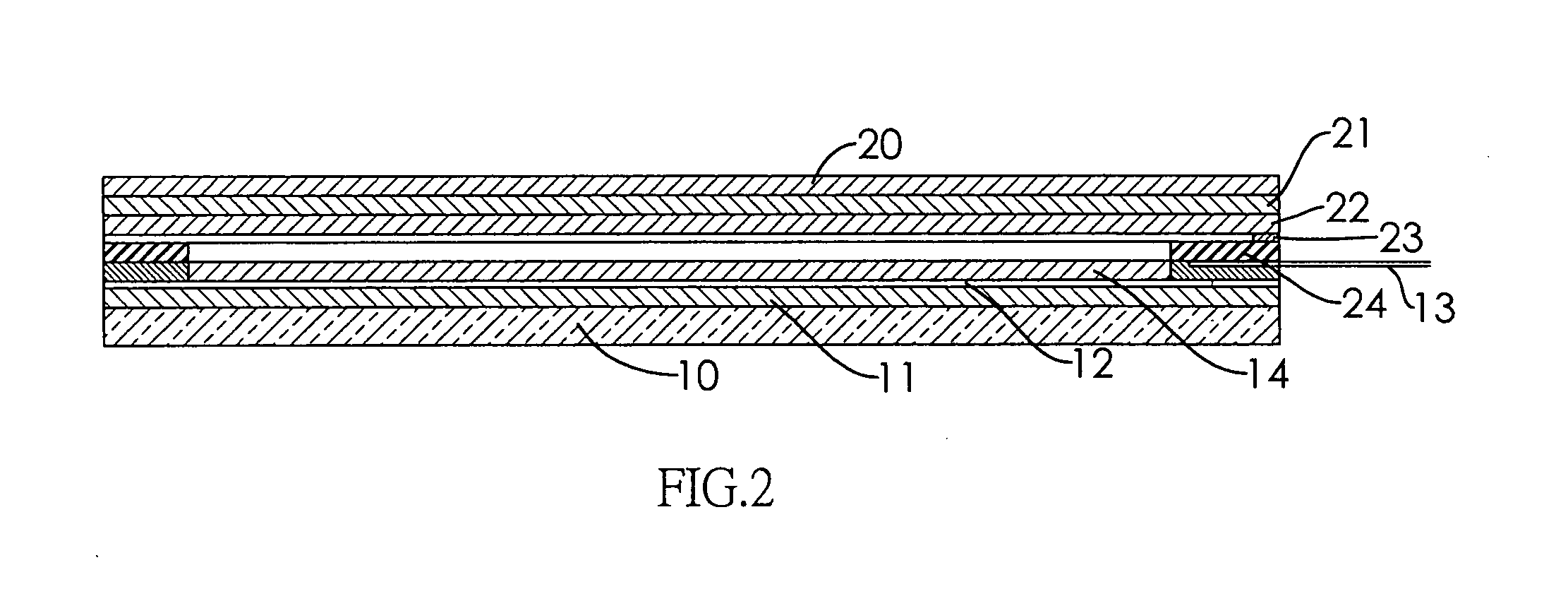

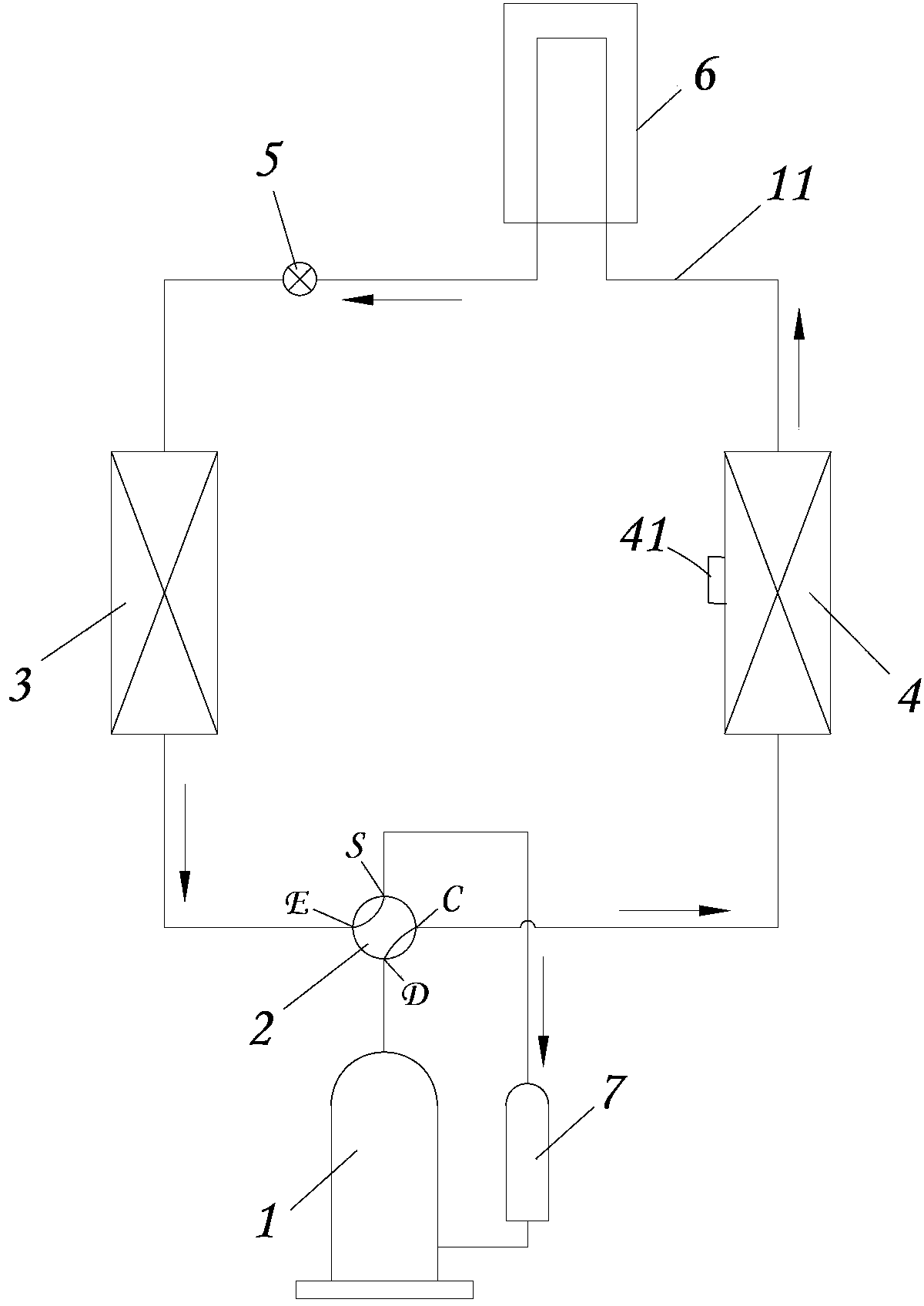

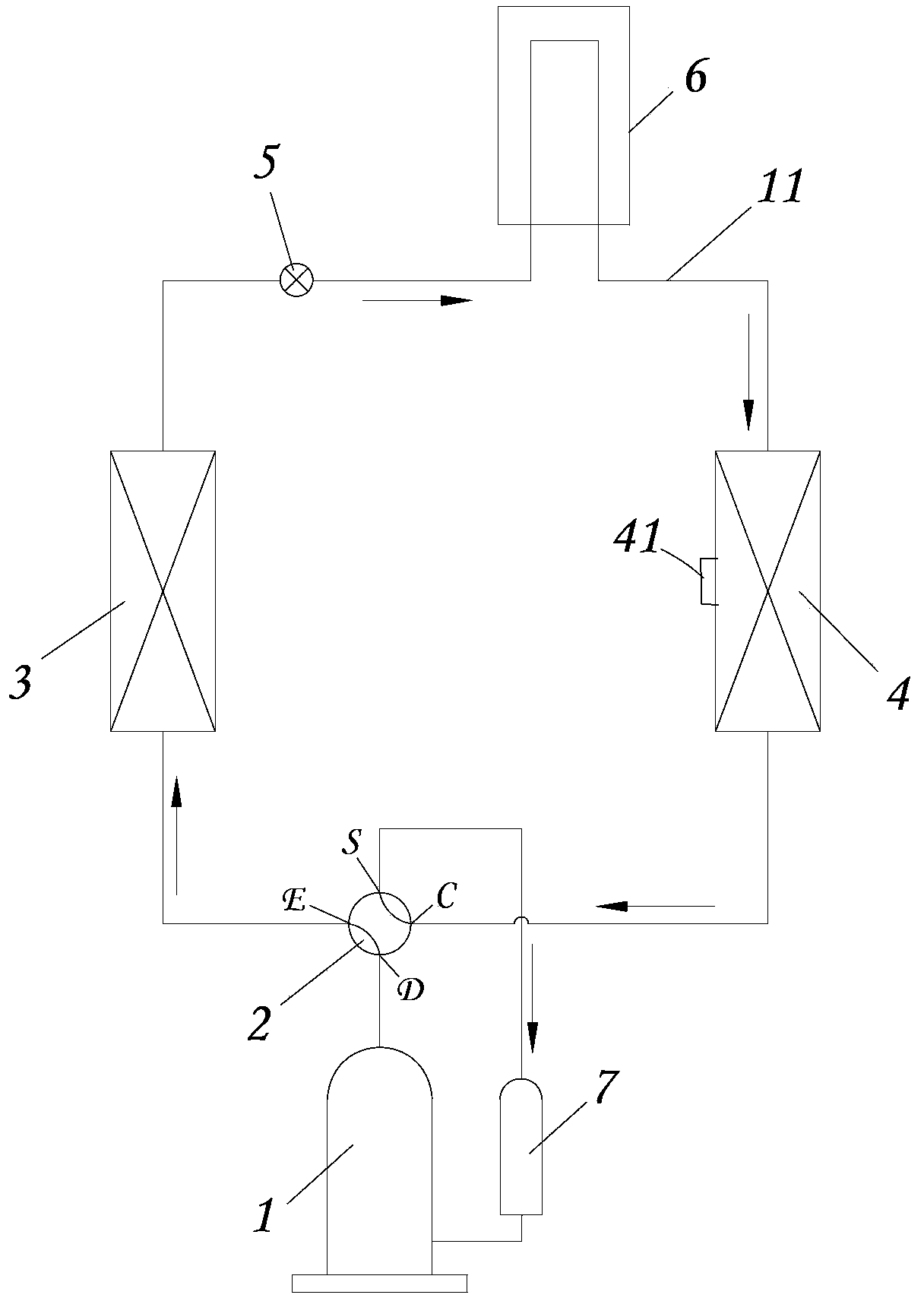

Air-conditioning system and control method thereof

InactiveCN103388944AImprove user experienceSimple structureSpace heating and ventilation safety systemsSpace heating and ventilation control systemsThermodynamicsEngineering

The invention provides an air-conditioning system and a control method thereof. The air-conditioning system comprises a refrigerant circulating loop and a controller, wherein the refrigerant circulating loop is mainly formed by connecting a compressor, a reversing valve, an indoor heat exchanger, an outdoor heat exchanger and an electronic expansion valve through a refrigerant pipeline; and the controller is used for controlling the air-conditioning system to operate. By virtue of the air-conditioning system provided by the invention, a refrigerant heater is additionally arranged between the outdoor heat exchanger and the electronic expansion valve of a throttling device; the refrigerant heater is controlled to be started, and the frequency of the compressor and the openness of the electronic expansion valve are correspondingly controlled according to actual working conditions, so that under the condition of non-reversing of the reversing valve in a heating mode, a frost layer on the outdoor heat exchanger can be molten; and meanwhile, the indoor heat exchanger continuously supplies heat to a room, the comfort of the air-conditioned room is ensured, and the air-conditioner using experience of a user under the low-temperature working condition is improved. The air-conditioning system is simple in structure, easy to control, reliable to operate and easy to implement. Compared with like products, the air-conditioning system has higher competitive advantages.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Preparation process of urea-formaldehyde resin adhesive

InactiveCN100999652AReduce manufacturing costReduce packageAldehyde/ketone condensation polymer adhesivesReaction temperatureResin adhesive

The present invention is process of preparing urea-formaldehyde resin adhesive. The preparation process includes the following steps: 1. adding formaldehyde in 420-600 weight portions into a reaction kettle and regulating pH value to 7.0-9.0 with alkali; 2. adding liquid urea from a urea synthesizing apparatus in 185-395 weight portions into the reaction kettle, reaction at 90-95 deg.c for 0.5-1.5 hr, regulating pH value to 4.0-5.5 with acid and further reaction until the solution becomes turbid and has viscosity of 15-20 CP; 3. regulating pH value to 7.0-7.6 with alkali and adding liquid urea of other 10-15 weight portions; 4. decompression dewatering, adding liquid urea of other 5-10 weight portions and modifier of 3-30 weight portions at temperature not higher than 70 deg.c and absolute pressure of 0.08-0.19 atm; and 5. regulating pH value to 7.5-8.5 with alkali, cooling to below 50 deg.c, discharging and packing.

Owner:水煤浆气化及煤化工国家工程研究中心

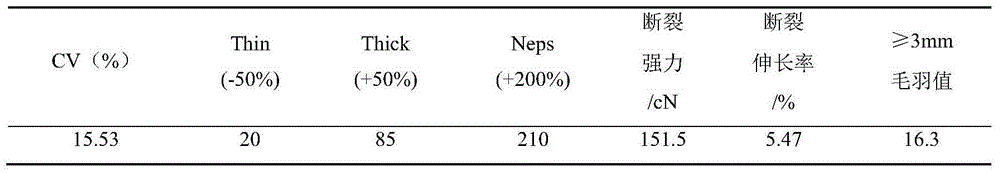

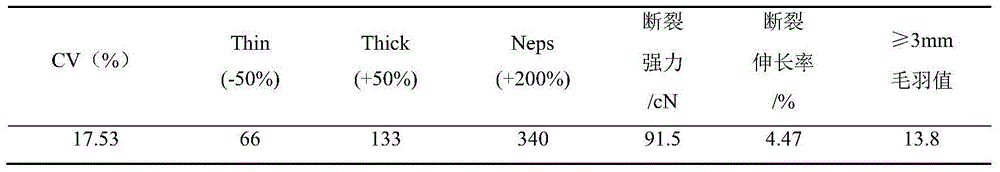

Method of spinning high-count spun silk yarns

The invention relates to a method of spinning high-count spun silk yarns; the method comprises the steps: pretreatment of spun silk fiber material; spraying of antistatic agent and water; cotton opening and cleaning procedure; cotton carding procedure; preparation procedure for combing; combing procedure; drawing procedure; roving procedure and spinning procedure. The production cost of spun silks in the present spun silk enterprises is very high and the produced spun silk products are lack of competitiveness; in order to solve the problems, the method of spinning the high-count spun silk yarns in cotton spinning equipment is searched in the combination of the characteristics of the spun silk fiber material; and finally, the high-count spun silk yarns with yarn fineness of 240-300Nm are spun on a four-roller and three-section draft ring spinning machine modified by grid ring type compact spinning; the method not only changes the situation that the present silk spinning equipment is only capable of spinning low-count spun silk yarns, but is improved in the utilization of the spun silk material; the competitive advantage of the spun silk products in the market is promoted and the benefits are brought to enterprises.

Owner:苏州京正新材料科技有限公司

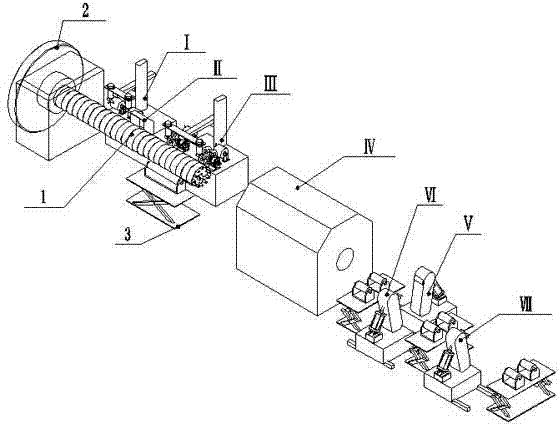

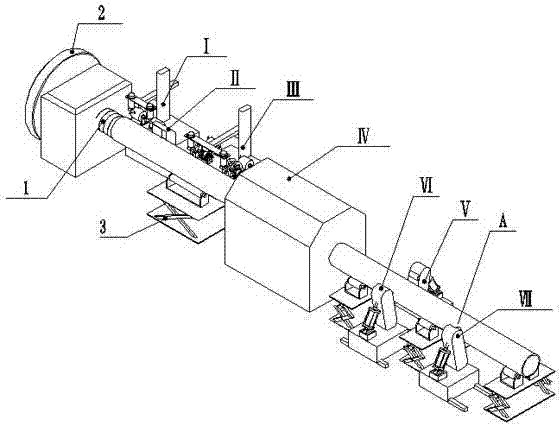

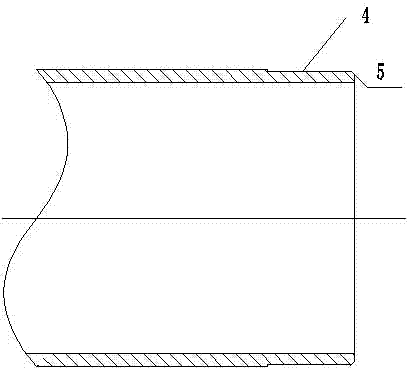

Continuous winding machining technology of bamboo wound composite tube

ActiveCN104325257AHigh degree of automationIncrease productivityRigid pipesWinding machineWoven fabric

The invention relates to continuous winding machining technology of a bamboo wound composite tube. A circulating steel strip is wound outside a hollow steel die; the rotation of the steel die drives the steel strip to advance helically; gum-containing non-woven fabric is wound on the surface of the steel strip layer by layer through a lining manufacturing zone feeding device, so that a lining layer is manufactured; the helical advancing of the steel strip drives the lining layer above to rotate and advance; the heated and initially cured lining layer is separated from the steel die from the tail end of the steel die; the steel strip outside the steel die returns to the head end of the steel die through the axial cavity of the steel die, so that lining layers are continuously prepared again; meanwhile the initially cured lining layer advances continuously; bamboo skin fabric is wound outside the lining layer through a plurality of winding zone feeding devices till designed thickness is achieved; with the continuous circulation of the steel strip, tubes wound by the bamboo skin fabric advance continuously; the tubes are cured, polished and finished, and then are subjected to cutting and segmentation; outer protective layers are painted on the tubes; ports of the tubes are machined, so that the tubes can be connected in a sealed way. The technology is efficient in production and stable in quality.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

Three-dimensional cultivation method for grape vines and Chinese herbs

InactiveCN103999727ATake advantage ofIncrease profitCultivating equipmentsHorticultureVitis viniferaAdditive ingredient

The invention relates to the technical field of agriculture planting, in particular to a three-dimensional cultivation method for grape vines and Chinese herbs. Long-cane grape vine planting is adopted, reasonable distribution is performed on the density of grape vine planting, the Chinese herbs which are sciophilous and resistant to moisture are planted in a grape vine forest in an interplanting mode, a drip tube mode is adopted for replenishing nutrients, and through the reasonable combination between the grape vines and the Chinese herbs, the reasonable combination between grape vines and grape vines and the reasonable combination between the Chinese herbs and Chinese herbs, and it is ensured that growth density between the grape vines and the Chinese medicine herbs is appropriate. Nutritional ingredients in the forest are sufficiently used for improving the quality of the grape forests and the Chinese herbs. Through reasonable preparation of base fertilizers, nutrient replenishing between the grape vines and the Chinese herbs is guaranteed, and the base fertilizers are used for meeting the requirement for adding elements into the glucose component, and meanwhile the nutrient requirement of the Chinese herbs in the forest is met; through the reasonable arrangement of a built shed formwork and reasonable relay interplanting of intercropping in the forest, the aesthetics value of a base is greatly enhanced, and the base has significant ornamental value and practical value.

Owner:遵义市李龙基葡萄种植农民专业合作社

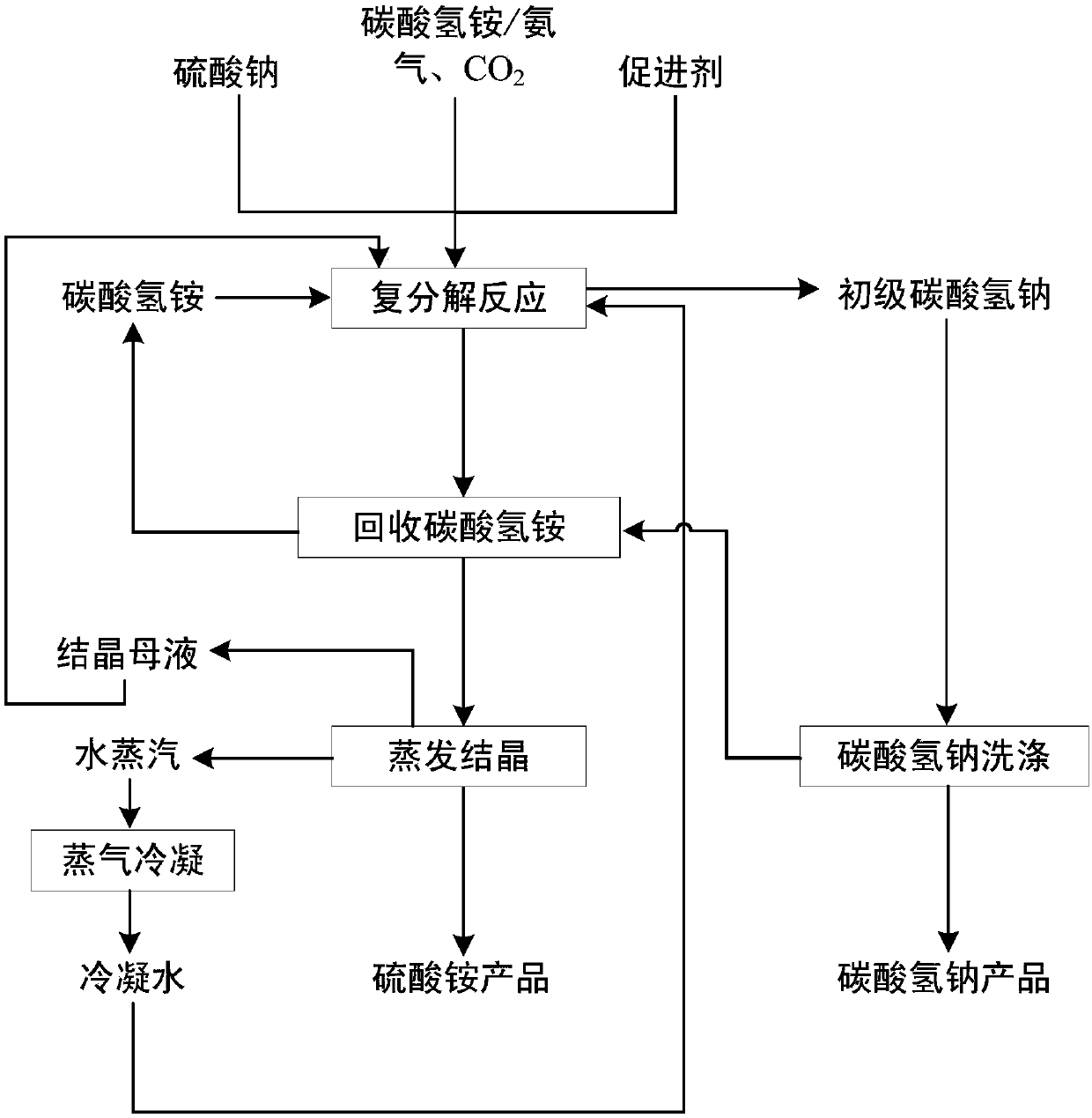

Method for co-producing sodium bicarbonate and ammonium sulfate from sodium sulfate

ActiveCN111039310ACrystallization zone expansionIncrease profitAmmonium salt fertilisersCarbonate preparationSodium bicarbonateSulfate

The invention provides a method for co-producing sodium bicarbonate and ammonium sulfate from sodium sulfate, which comprises the following steps: carrying out double decomposition reaction on sodiumsulfate and ammonium bicarbonate under the action of an accelerator to obtain the sodium bicarbonate and the ammonium sulfate. The method is simple in process and low in cost, the utilization rate ofsodium sulfate is higher than 85%, the purity of sodium bicarbonate is higher than 90%, and the purity of the ammonium sulfate product meets the requirements of GB535-1995.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Lining material for bottle cap and use in cap of plastic bottle of heat filling beverage

InactiveCN1465507AImprove performanceIncrease elasticitySealingLow-density polyethylenePolymer science

The present invention belongs to an improvement on lining material of bottle cap and its application in the thermofilled beverage plastic bottle cap. Said bottle cap lining material is made of EVA modified maleic acid, SEBS (hydrophenylethylene diene copolymer), hydrogenated paraffin oil, branching low-density polyethylene, polypropylene, polystyrene and low-molecular lubricant through a certain preparatino process. As compared with traditional lining material it has excellent performance and low cost.

Owner:上海紫日包装有限公司

Manufacturing method of ultra-large plate glass pattern and processing equipment thereof

InactiveCN102825939ASuitable for processingImprove competitive advantageTransfer printingDuplicating/marking methodsMaximum dimensionFlat glass

The invention discloses a manufacturing method of an ultra-large plate glass pattern and processing equipment thereof, and the method comprises the following steps: (1) coating a resin layer on a surface of cleaned glass, heating for drying and curing to form a resin layer on the glass surface; (2) putting the glass on a vacuum thermal transfer work bench with the glass resin layer facing upwards, paving thermal sublimation transfer paper on the glass resin layer, covering an air proof cloth on the glass and the transfer paper to form a vacuum chamber between the air proof cloth and the work bench surface, performing vacuum-pumping; (3) putting the work bench with the glass and the transfer paper into a heating furnace for heating so as to allow the printing ink on the transfer paper to be heated, sublimate and penetrate into the resin layer; (4) when the transfer printing finishes, cooling the glass, peeling the transfer paper after cooling, and coating protection paint on the surface of the resin layer to obtain the finished product. The product of the invention has a maximum dimension of up to 1830 mm*2440 mm; the method and equipment of the invention are suitable for processing of large-specification glass products, have good product quality and high working efficiency.

Owner:ZHENGZHOU YUHAI GLASS TECH

Hydraulic walking multi-level temporary supporting equipment for advancement of tunnel

InactiveCN102587945AImprove space utilizationEffective supportMine roof supportsSupport groupSingle support

The invention belongs to the technical field of equipment for advancement production of coal mines, and particularly relates to hydraulic walking multi-level temporary supporting equipment for advancement of a tunnel, which aims to realize safe and fast advancement of coal mine advancing tunnels. Single supports, which are located on the same side, of a walking support group and a temporary support group are serially connected onto a guide track and can slide relative to the guide track, and single supports located on the left side and the right side of the walking support group and single supports located on the left side and the right side of the temporary support group are connected with a pushing mechanism capable of pushing the single supports to move longitudinally. The hydraulic walking multi-level temporary supporting equipment has the advantages that safety of supporting operation is greatly improved; timely supporting of the supporting equipment can be guaranteed when the grade of the tunnel is changed; and the supporting equipment is an integral structure, runs independently and saves time, labor and space.

Owner:SHANXI DATONG UNIV

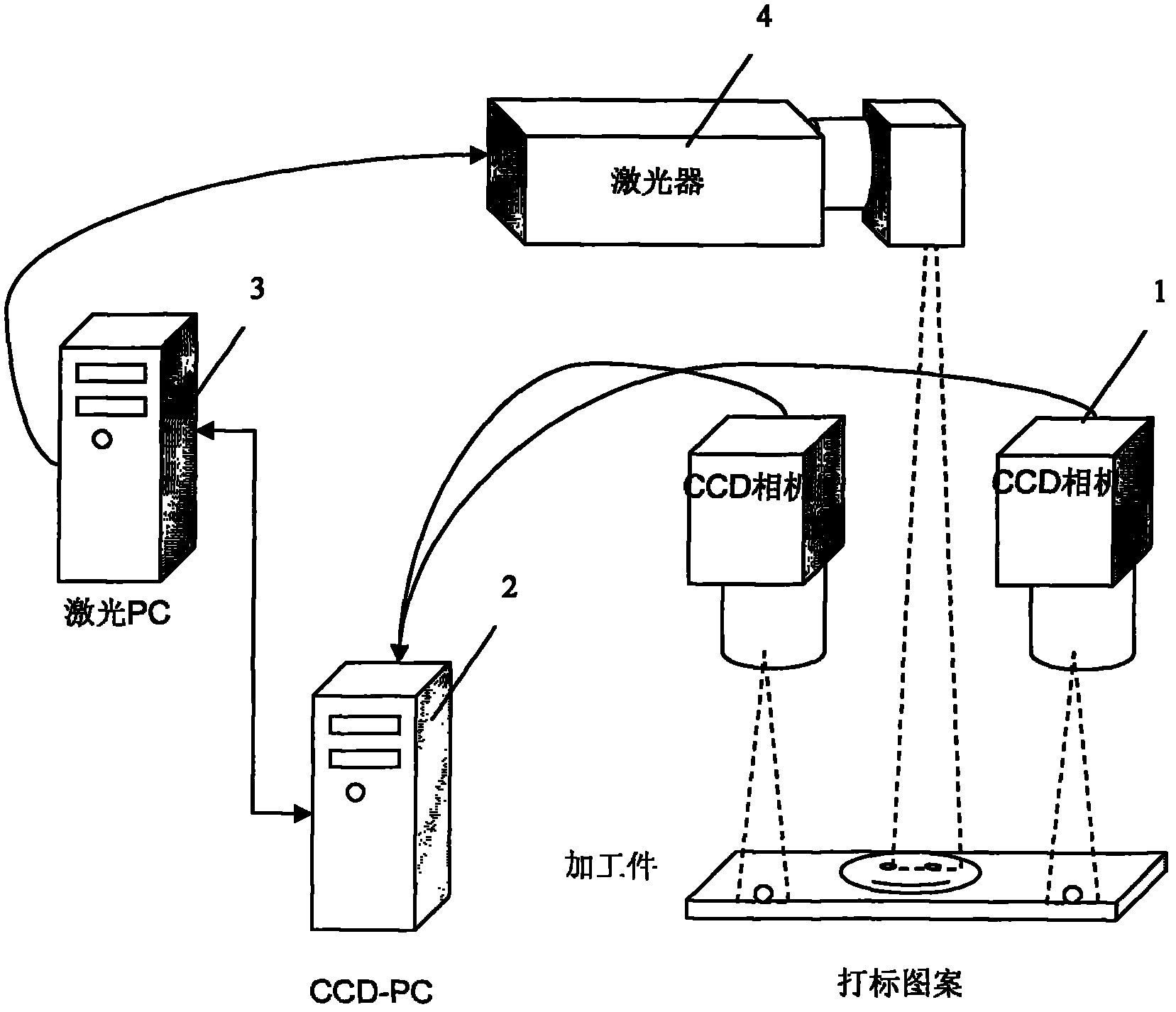

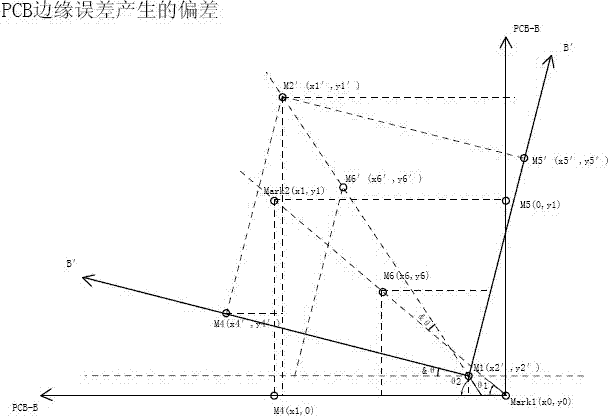

Novel positioning compensation method for PCB by single vision camera

InactiveCN102865815AImprove competitive advantageLow costUsing optical meansEngineeringPersonal computer

The invention relates to a novel positioning compensation method for a PCB (printed circuit board) of a single vision camera. The novel positioning compensation method mainly aims at PCB positioning. The positioning compensation method comprises the following steps of: detecting a center of a mark point of a product by a CCD (charge coupled device) camera, sending detecting data to a personal computer (PC); calculating a position difference between detected images by using a CCD alignment system (CAS) and recording a corresponding detecting result, thereby obtaining a position offset value; transmitting the result to a computer connected with a laser controller to perform automatic position compensation and correction marking. Compared with a conventional PCB positioning technique, the novel positioning compensation method has the advantages of low cost, convenience in use, high precision and the like; and furthermore, the novel positioning compensation method can support great majority of lasers in the market, the single vision camera can be mounted on an ordinary machine table, and therefore, possibility is provided for product upgrade and application upgrade of customers.

Owner:上海功源电子科技有限公司

Preparation process of concrete porous brick prepared from tubular pile residual slurry and waste incineration slag

ActiveCN103880464AReduce and eliminate emissionsReduce processing costsSolid waste managementCeramicwareBrickSlag

The invention relates to a preparation process of a concrete porous brick prepared from tubular pile residual slurry and waste incineration slag. The preparation process comprises the following steps: firstly, pretreating raw materials, including delayed coagulation of tubular pile residual slurry, sorting and grinding treatment of domestic waste incineration slag and direct use of fly ash, cement and stone chips; secondly, stirring and mixing according to a set ratio; thirdly, filling a brick mold cavity with the mixed material by adopting a brick making molder and molding in a ramming manner; and finally, carrying out standing curing the molded concrete porous bricks and a bottom supporting plate together in a standing curing chamber for not less than 1 day, then transferring to a maintenance chamber spraying water for maintenance for 10-14 days, and finally transferring to a concrete porous brick stacking field and naturally maintaining for 28 days to obtain a concrete porous brick finished product. By adopting effective components in the tubular pile residual slurry and the waste incineration slag to produce the tubular pile residual slurry-waste incineration slag concrete porous brick, the preparation process has the advantages of not only reducing and avoiding emission of waste slag and waste liquid left over in industrial production so as to prevent secondary pollution, but also saving lots of land stacking cost and treatment expenses.

Owner:TONGXIANG TONGDE WALL BUILDING MATERIALS +2

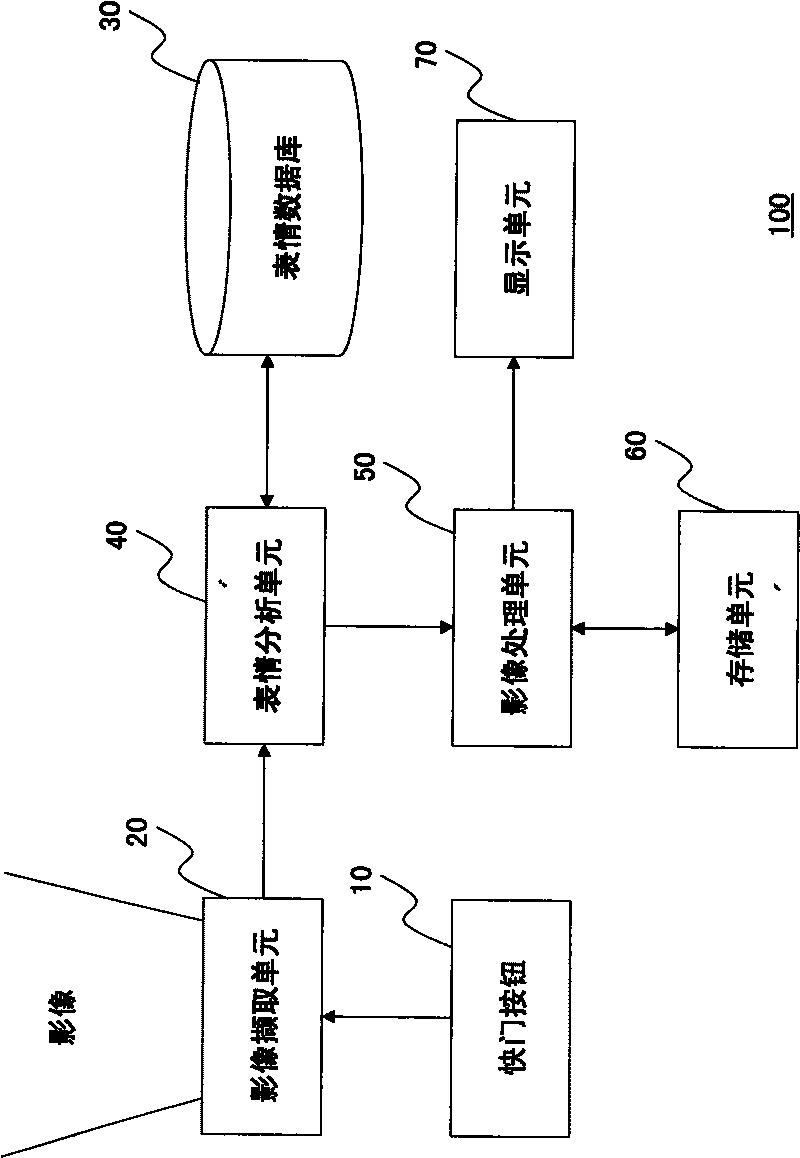

Emotive image processing device and image processing method

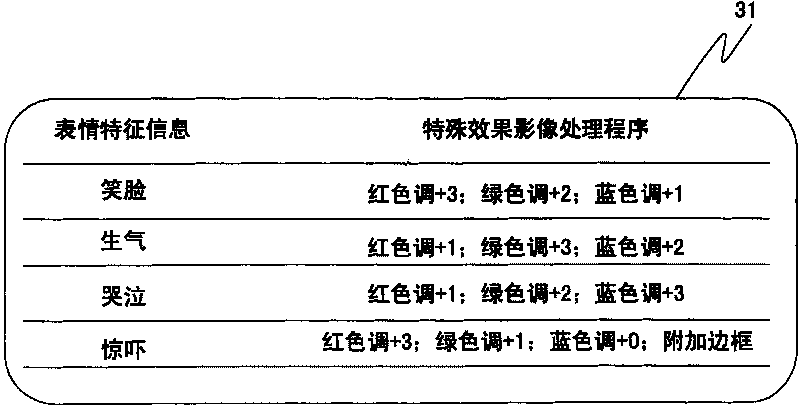

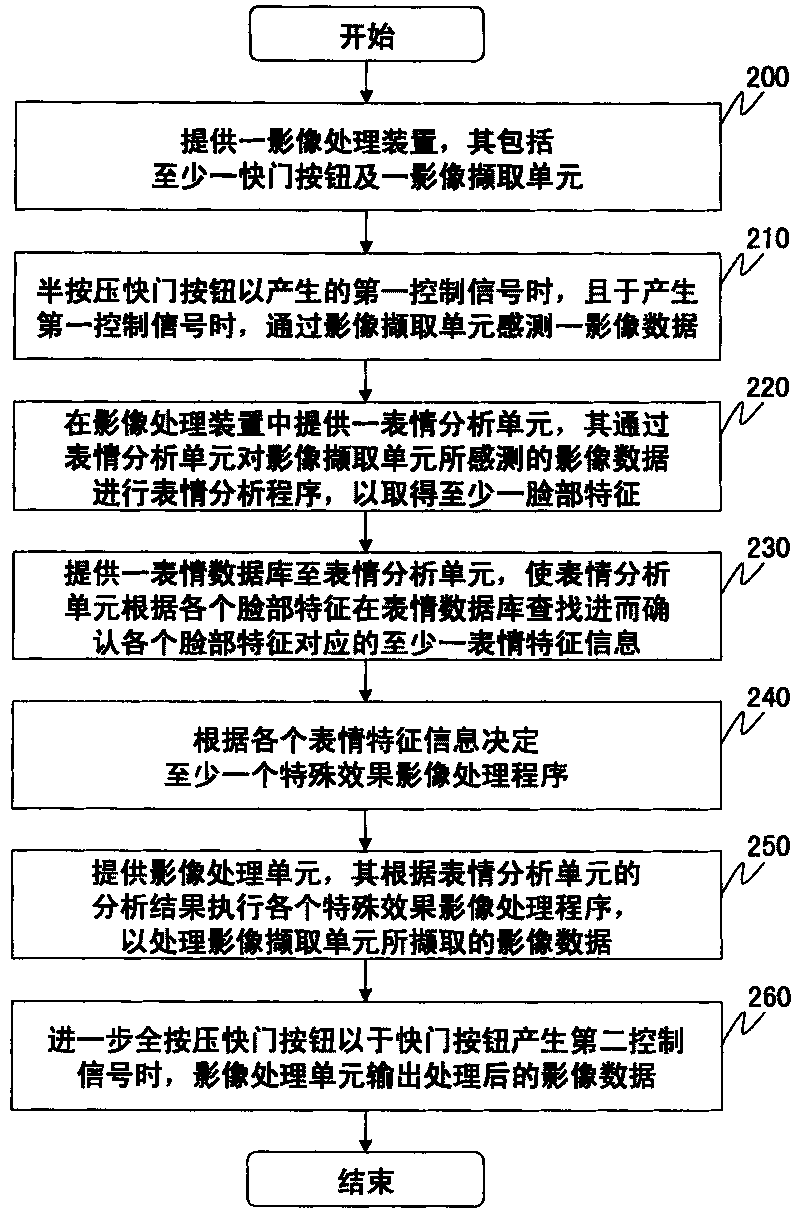

InactiveCN101753850AFunction increaseImprove competitive advantageTelevision system detailsColor television detailsImaging processingControl signal

The invention discloses an emotive image processing device and an image processing method which comprises a shutter button, an image acquisition unit, an expression data base, an expression analysis unit and an image processing unit, wherein the shutter button respectively generates a first control signal and a second control signal according to different pressed phases; the image acquisition unit is used for sensing image data while receiving the first control signal, sending out an expression analysis command and acquiring the image data while receiving the second control signal; the expression data base is used for storing expressive feature information and a corresponding image processing procedure; the expression analysis unit is used for receiving the expression analysis command to identify facial features in the image data and determine the expressive feature information corresponding to the facial features; and the image processing unit is used for executing the image processing procedure according to the determined expressive feature information to process the image data acquired by the image acquisition unit.

Owner:ALTEK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com