Method for manufacturing silicone micro-nano optical structure by using imprinting technology

An optical structure, micro-nano technology, applied in the manufacture of microstructure devices, microstructure devices, optics, etc., can solve problems such as high pressure, and achieve the effects of low transmission loss, excellent optical properties, and improved environmental resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

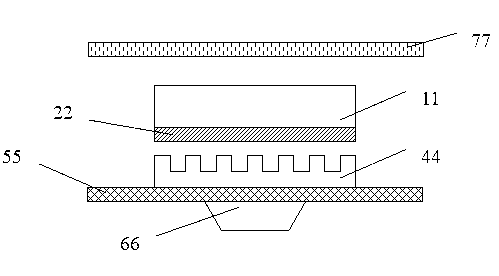

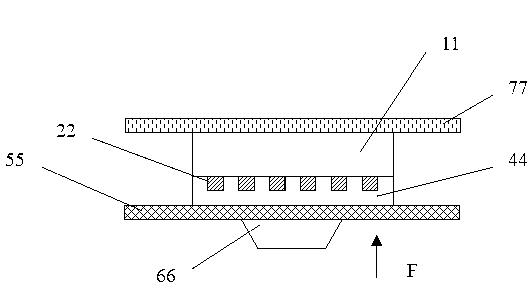

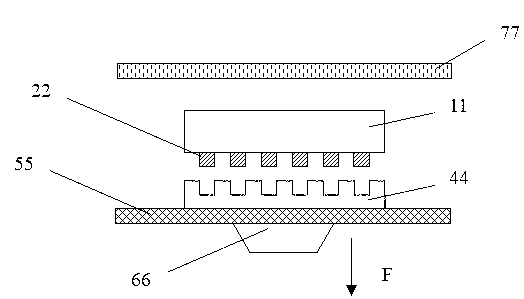

Image

Examples

Embodiment 1

[0033] The silicone micro-nano optical structure is prepared by hot embossing method, and the specific steps include:

[0034] 1. Use photonic device simulation software to design and optimize optical waveguide devices, then use computer-aided design tools to draw the mask layout according to the design results, and transfer the designed pattern files to professional photolithography mask manufacturers for customization;

[0035] 2. Expose the photoresist, and then perform ICP etching to obtain a stamp made of silicon or other materials for imprinting; if the minimum line width of the device is relatively high, electron beam exposure or other advanced lithography equipment can be used to customize.

[0036] 3. Hydroxylation treatment is carried out on the surface of silicon stamp or other hard template surface, and then it is placed in a petri dish in an anhydrous environment, and an appropriate amount of perfluorotetrahydrooctylsilane is injected with a microliter syringe, ...

Embodiment 2

[0042] 1. Use photonic device simulation software to design and optimize optical waveguide devices, then use computer-aided design tools to draw the mask layout according to the design results, and transfer the designed pattern files to professional photolithography mask manufacturers for customization;

[0043] 2. Expose the photoresist, and then perform ICP etching to obtain a stamp made of silicon or other materials for imprinting; if the minimum line width of the device is relatively high, electron beam exposure or other advanced lithography equipment can be used to customize.

[0044] 3. Hydroxylation treatment is carried out on the surface of silicon stamp or other hard template surface, and then it is placed in a petri dish in an anhydrous environment, and an appropriate amount of perfluorotetrahydrooctylsilane is injected with a microliter syringe, and heated from room temperature to 250°C , keep the temperature for 2 hours after the temperature stabilizes, and wash of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com