Ceramic membrane, preparation method of lithium ion secondary battery and battery

A ceramic diaphragm and diaphragm technology, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of the influence of the pore structure of the diaphragm substrate, it is difficult to meet industrial production, and the preparation process is complicated, and achieve excellent thermal stability. , easy industrial production, simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of lithium ion secondary battery of the present invention comprises:

[0029] 1) Preparation of positive electrode sheet: Lithium cobaltate, conductive carbon, and binder polyvinylidene fluoride were mixed uniformly in N-methylpyrrolidone solvent to make positive electrode slurry, and then coated on aluminum foil and dried for cooling Pressing, slitting, trimming, and tab welding to make positive plates;

[0030] 2) Preparation of negative electrode sheet: Mix graphite, conductive carbon, thickener sodium carboxymethyl cellulose, and binder styrene-butadiene rubber in deionized water to make negative electrode slurry, and then coat it on copper foil and bake After drying, carry out cold pressing, slitting, trimming, and tab welding to make negative electrodes;

[0031] 3) Diaphragm substrate: made of PE or PP microporous film;

[0032] 4) Preparation of the ceramic diaphragm: Add the main chain substance into the mixed solvent of ethanol and dei...

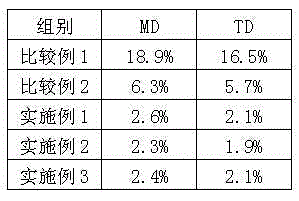

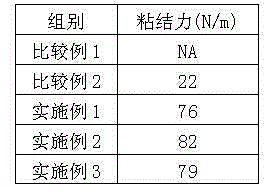

Embodiment 1

[0048] Preparation of positive electrode sheet: mix lithium cobaltate, conductive carbon, and binder polyvinylidene fluoride in N-methylpyrrolidone (NMP) solvent at a mass ratio of 96:2.2:1.8 to make positive electrode slurry, and then coat On the aluminum foil and dried at 110°C, cold pressing, slitting, trimming, and tab welding are carried out to make a positive electrode sheet.

[0049] Preparation of negative electrode sheet: Mix graphite, conductive carbon, thickener sodium carboxymethyl cellulose, and binder styrene-butadiene rubber in deionized water at a mass ratio of 95:1.5:1.5:2.0 to make a negative electrode slurry, and then After being coated on copper foil and dried at 85°C, cold pressing, slitting, trimming, and tab welding are carried out to make negative electrode sheets.

[0050] Diaphragm: Take a polyethylene microporous film with a thickness of 9um as the isolation membrane.

[0051] Preparation of ceramic diaphragm: Add methyl methacrylate (MMA) into a mi...

Embodiment 2

[0054] Preparation of positive electrode sheet: mix lithium cobaltate, conductive carbon, and binder polyvinylidene fluoride in N-methylpyrrolidone (NMP) solvent at a mass ratio of 96:2.2:1.8 to make positive electrode slurry, and then coat On the aluminum foil and dried at 110°C, cold pressing, slitting, trimming, and tab welding are carried out to make a positive electrode sheet.

[0055] Preparation of negative electrode sheet: Mix graphite, conductive carbon, thickener sodium carboxymethyl cellulose, and binder styrene-butadiene rubber in deionized water at a mass ratio of 95:1.5:1.5:2.0 to make a negative electrode slurry, and then After being coated on copper foil and dried at 85°C, cold pressing, slitting, trimming, and tab welding are carried out to make negative electrode sheets.

[0056] Diaphragm: A polypropylene microporous film with a thickness of 12um is used as a diaphragm.

[0057] Preparation of ceramic diaphragm: Add methyl methacrylate (MMA) into a mixed so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com