Preparation method of bacterial cellulose based carbon nanofibers

A bacterial cellulose and nano-carbon fiber technology, applied in fiber processing, natural fiber, fiber chemical characteristics, etc., can solve the problems of cumbersome preparation parameters, affect the preparation cost and application field of nano-carbon fiber, and cannot form three-dimensional network nanofibers, etc., to achieve The preparation process is simple and easy, the effect of good spatial network structure and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

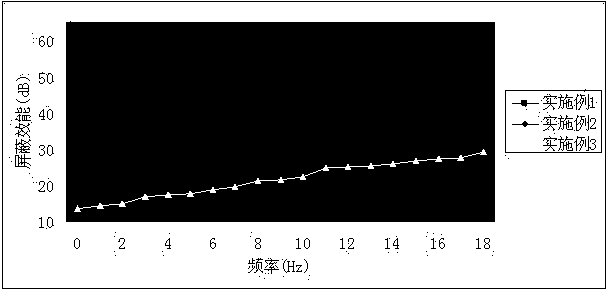

Embodiment 1

[0022] The bacterial cellulose fermented by Alcaligenes and Aerobacter was placed in 10wt% sodium hydroxide aqueous solution and cooked at high temperature for 1 hour, and washed with deionized water until neutral. The material was frozen at -80 °C for 24 h, and then dried under vacuum for 24 h.

[0023] The dried bacterial cellulose material is placed in an atmosphere furnace under the protection of nitrogen and heated from room temperature to 800°C for carbonization treatment. The heating rate in the range of 100-300°C is 5°C / min, and the heating rate in the range of 300-500°C is 1°C / min, the heating rate in the range of 500-800°C is 30°C / min; when the temperature reaches 800°C, continue to heat up to 3000°C, the heating rate is 30°C / min; after the heating is completed, the material is slowly cooled to room temperature in the atmosphere furnace to obtain the diameter A bacterial cellulose-based carbon nanofiber material with a thickness of about 30nm and a three-dimensional...

Embodiment 2

[0025] The bacterial cellulose fermented by Acetobacter xylinum was placed in 5wt% sodium hydroxide aqueous solution and cooked at high temperature for 1 hour, and washed with deionized water until neutral. The material was frozen at −20° C. for 24 h, and then dried under vacuum for 24 h.

[0026] The dried bacterial cellulose material is placed in an atmosphere furnace and heated from room temperature to 600°C under vacuum for carbonization treatment. The heating rate in the range of 100-300°C is 5°C / min, and the heating rate in the range of 300-500°C is 1°C. / min, the heating rate in the range of 500-600°C is 30°C / min; when the temperature reaches 600°C, continue to heat up to 2000°C, the heating rate is 50°C / min; after the heating is completed, the material is slowly cooled to room temperature in the atmosphere furnace to obtain the diameter A bacterial cellulose-based carbon nanofiber material with a size of about 10nm and a three-dimensional network space structure.

Embodiment 3

[0028] The bacterial cellulose fermented by Sarcina and Pseudomonas was placed in 6wt% sodium hydroxide aqueous solution and cooked at high temperature for 0.6h, and washed with deionized water until neutral. The material was frozen at -30 °C for 12 h and then dried in vacuo for 48 h.

[0029] The dried bacterial cellulose material is placed in an atmosphere furnace and heated from room temperature to 800°C under vacuum for carbonization treatment. The heating rate in the range of 100-300°C is 6°C / min, and the heating rate in the range of 300-500°C is 2°C / min, the heating rate in the range of 500-800°C is 30°C / min; when the temperature reaches 800°C, continue to heat up to 2200°C, the heating rate is 50°C / min; after the heating is completed, the material is slowly cooled to room temperature in the atmosphere furnace to obtain the A bacterial cellulose-based carbon nanofiber material with a size of about 10nm and a three-dimensional network space structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com