Patents

Literature

898 results about "Integrated optics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

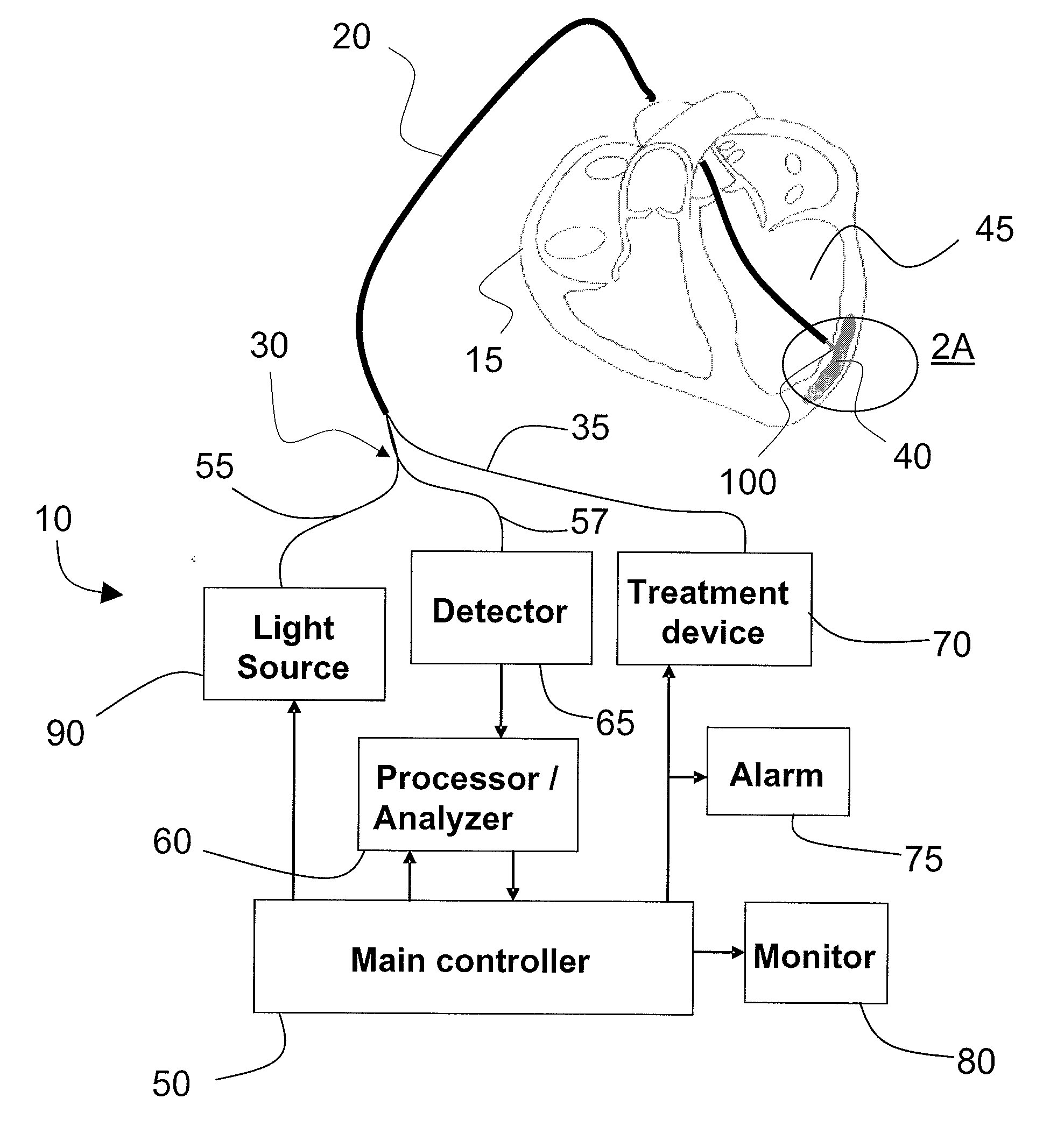

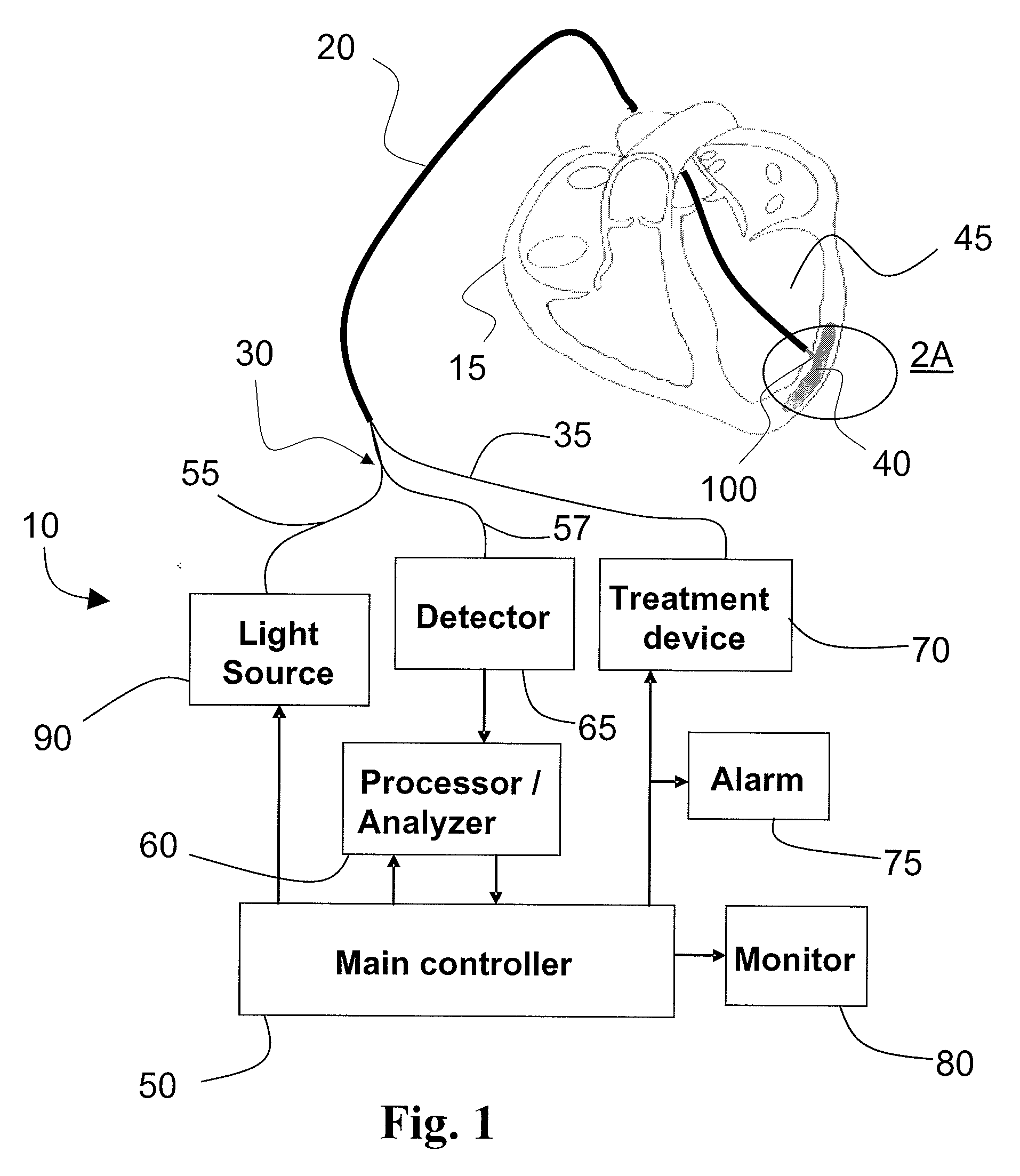

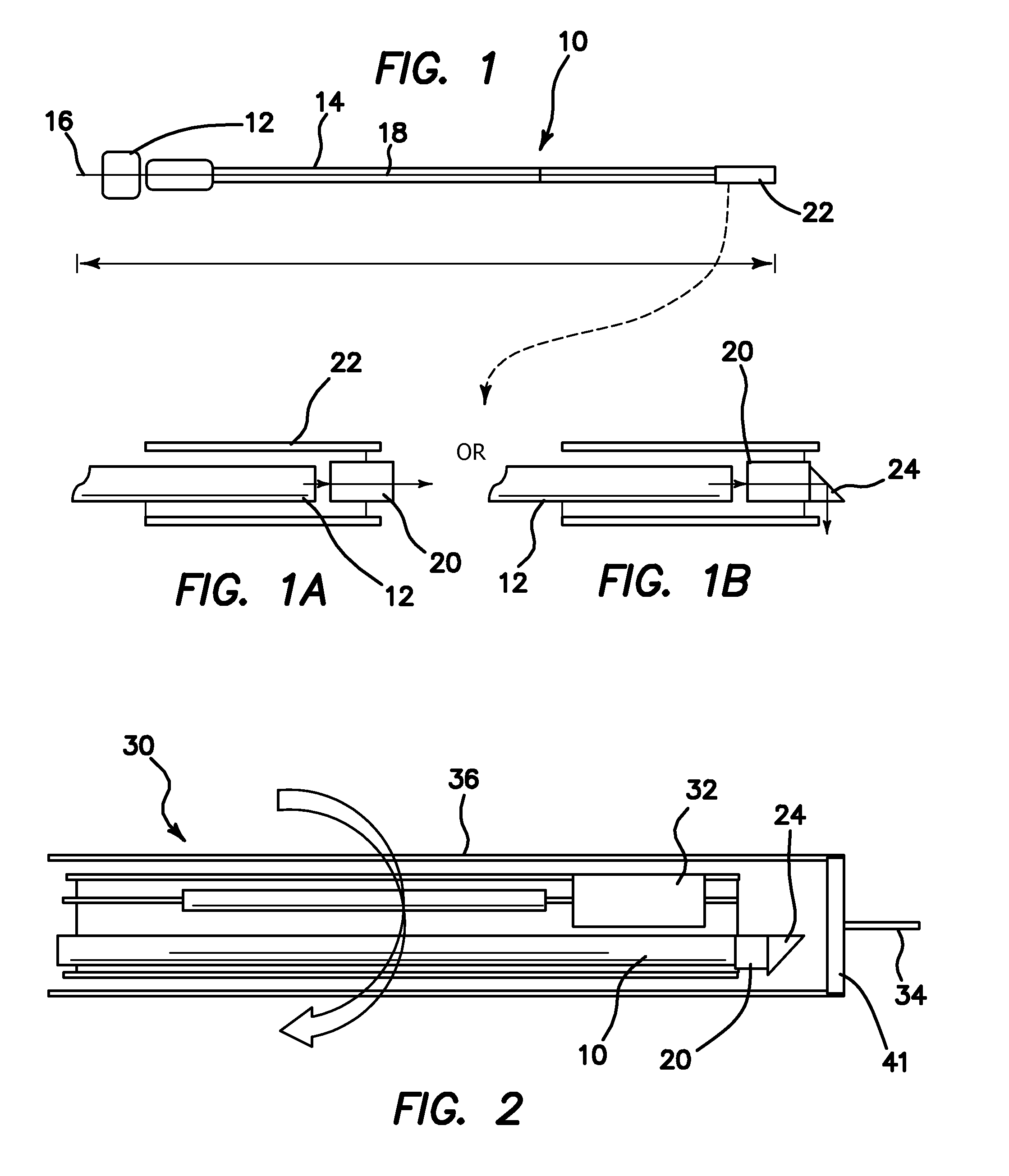

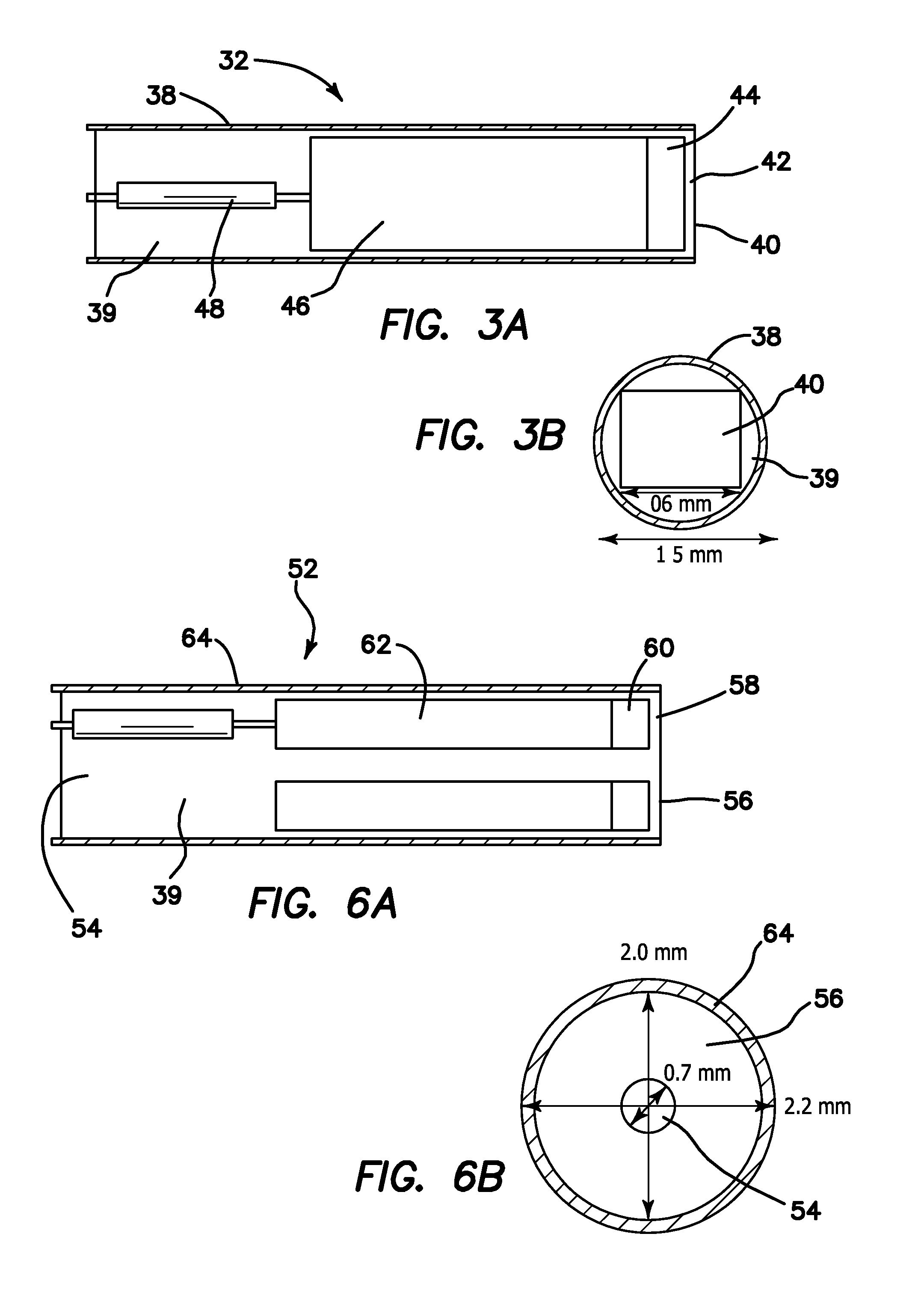

Method and apparatus for identifying and treating myocardial infarction

InactiveUS20080125634A1Safe and effectiveAccurate locationGuide needlesSurgical needlesVisual perceptionVisual feedback

A method and apparatus for analyzing and treating internal tissues and, in particular, tissues affected by myocardial infarct. The apparatus includes a catheterized device integrating an optical probe and treatment delivery system. The probe component includes fiber optic lines that can be used in conjunction with infrared spectroscopy to analyze various characteristics of tissues, including chemical, blood, and oxygen content, in order to locate those tissues associated with myocardial infarct, to determine the best location for applying treatment, and to monitor treatment and its effects. Physically integrated with the probe component is a treatment component for delivering treatments including stem cell and gene therapy, known for having beneficial effects on tissues associated with myocardial infarct. A control system coordinates operation of the catheter, including performing chemometric analysis with the use of model data, and for providing control and visual feedback to an operator.

Owner:CORNOVA

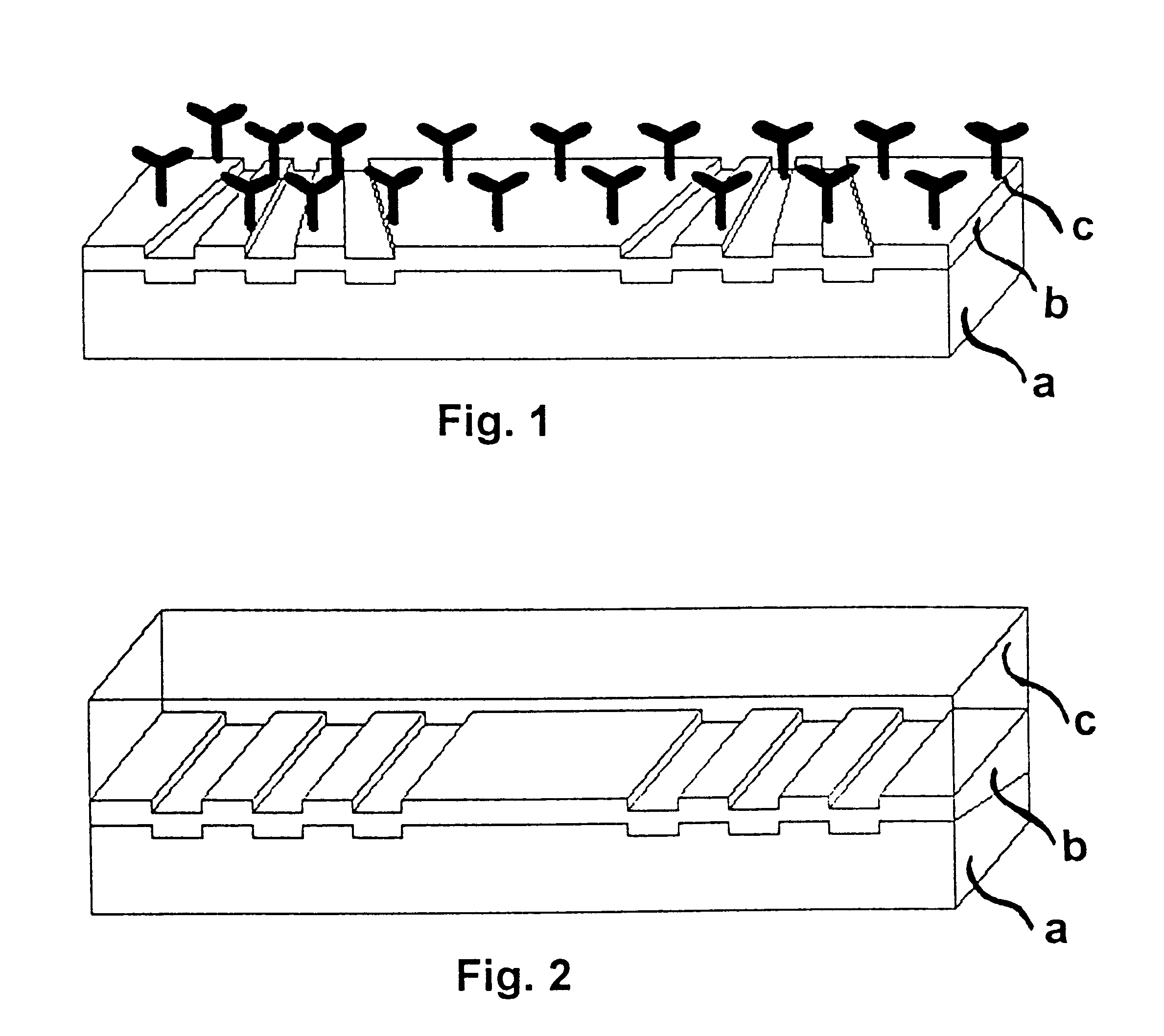

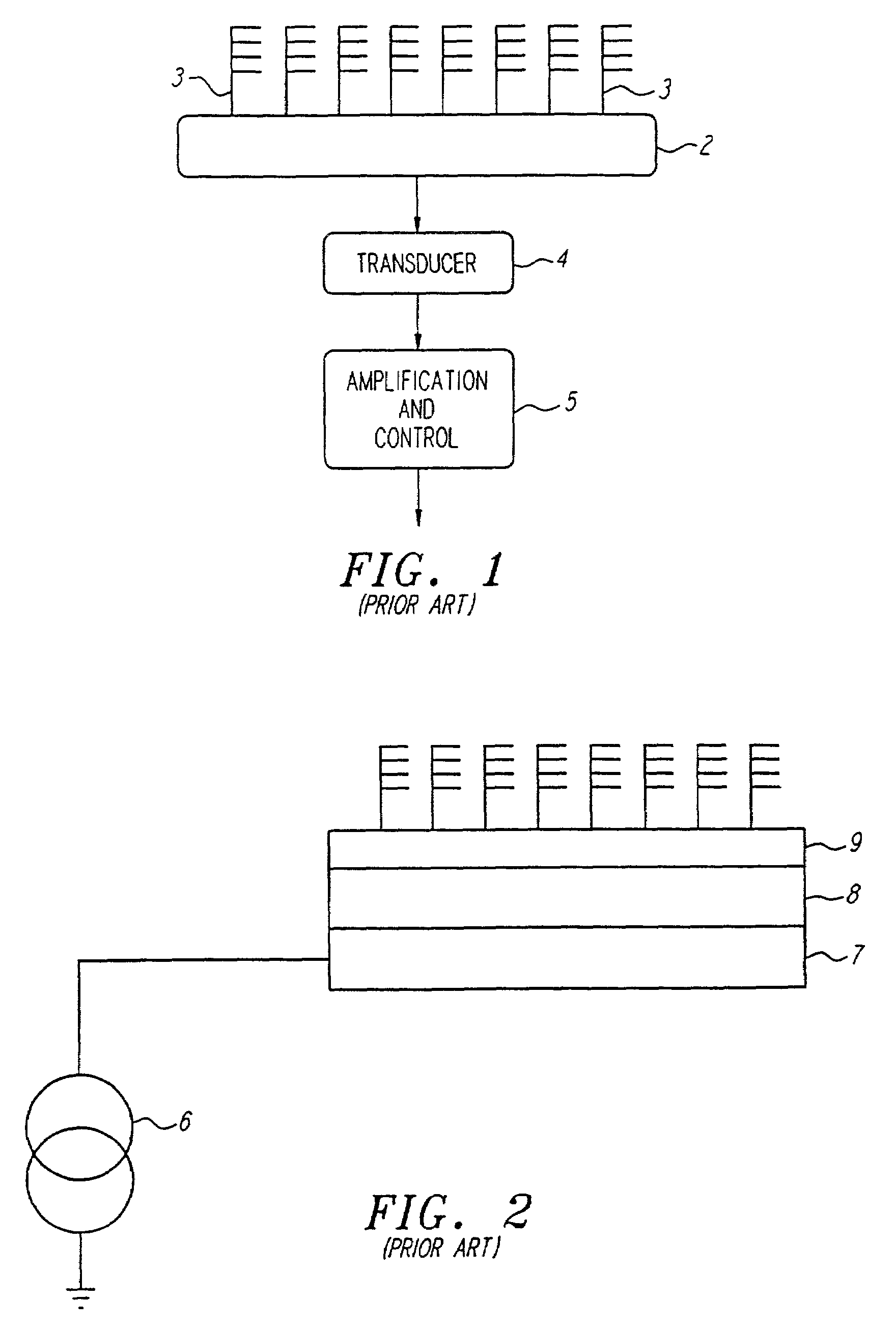

Optical chemical/biochemical sensor

InactiveUS6395558B1Radiation pyrometryMaterial analysis by observing effect on chemical indicatorTransducerLuminescence

The invention relates to a planar ATR and evanescently exited luminescence optical sensor platform, consisting of a transducer and a recognition layer, wherein changes in the effective refractive index of the recognition layer are converted into a measurable variable in accordance with the integrated-optical light pointer principle. The invention relates also to the use of the method and to the method itself using the sensor platform, for example in label-free biosensory analysis.

Owner:ZEPTOSENS

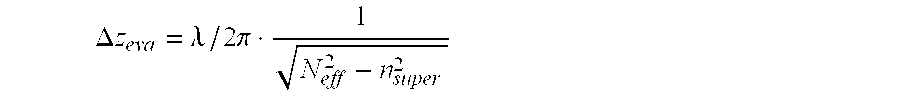

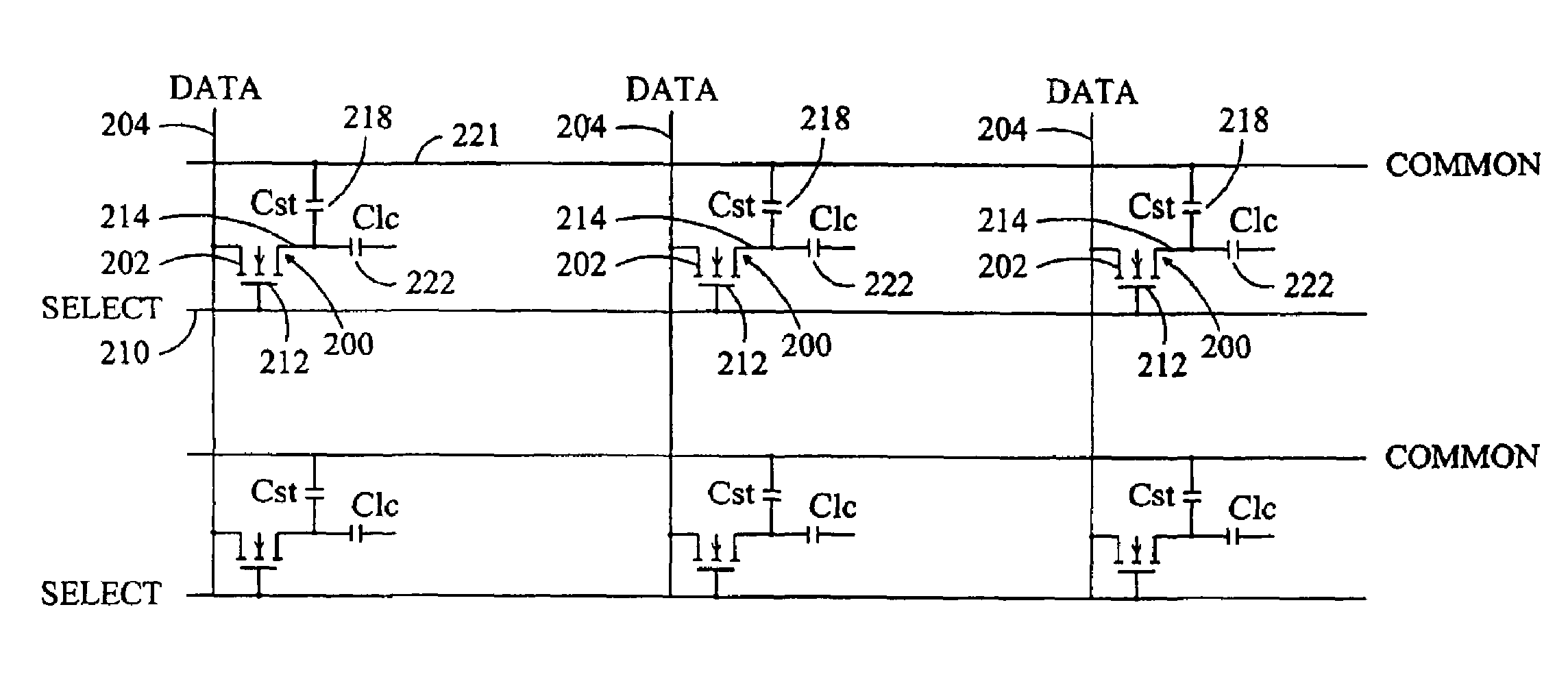

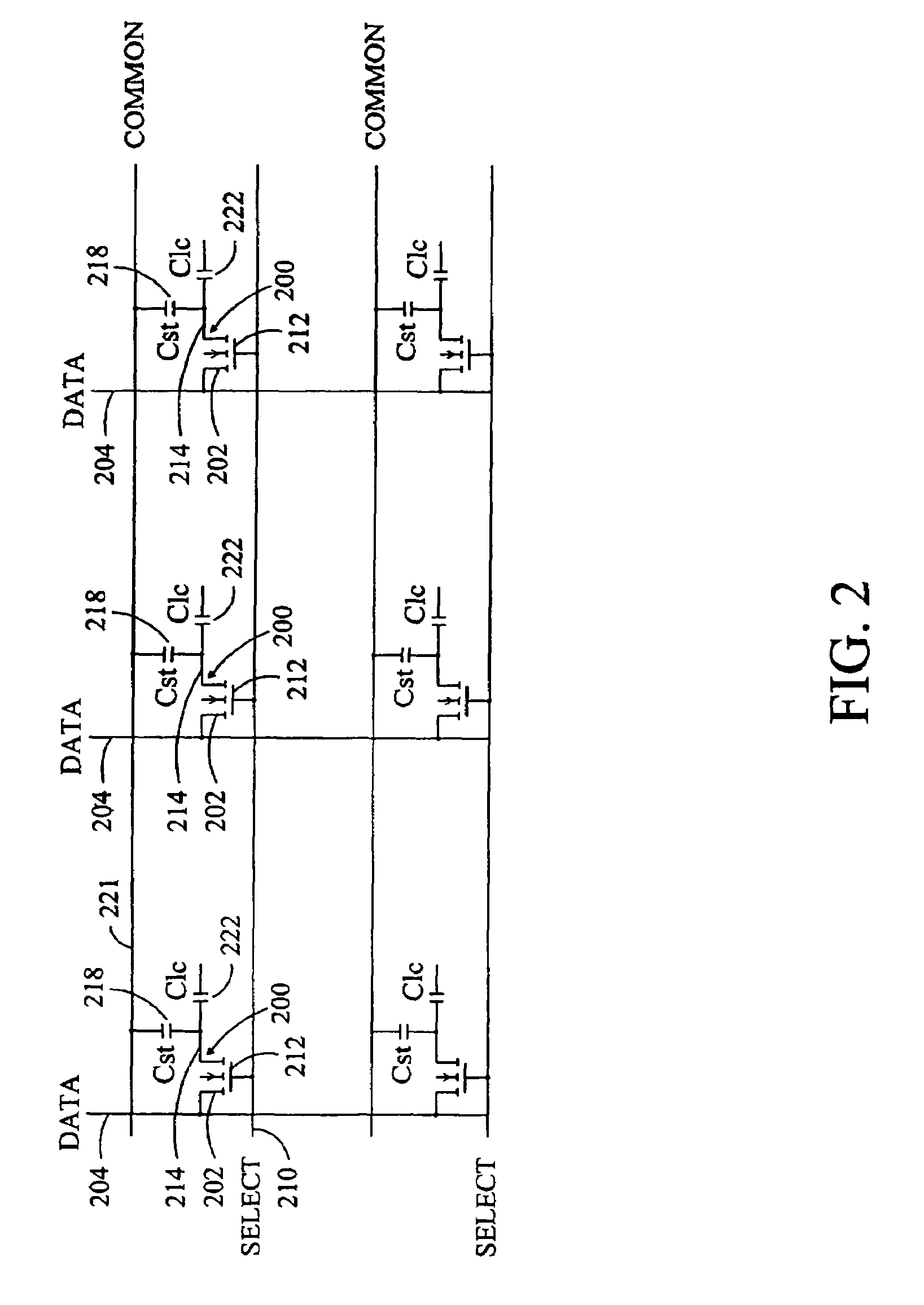

Integrated optical light sensitive active matrix liquid crystal display

ActiveUS7009663B2Static indicating devicesNon-linear opticsActive-matrix liquid-crystal displayLiquid-crystal display

A liquid crystal device including a front electrode layer, rear electrode layer, a liquid crystal material located between the front electrode layer and the rear electrode layer. A polarizer is located between the liquid crystal material and the front electrode layer and changing an electrical potential between the rear electrode layer and the front electrode layer modifies portions of the liquid crystal material to change the polarization of the light incident thereon. A plurality of light sensitive elements are located together with the rear electrode layer and a processor determines the position of at least one of the plurality of light sensitive elements that has been inhibited from sensing ambient light.

Owner:APPLE INC

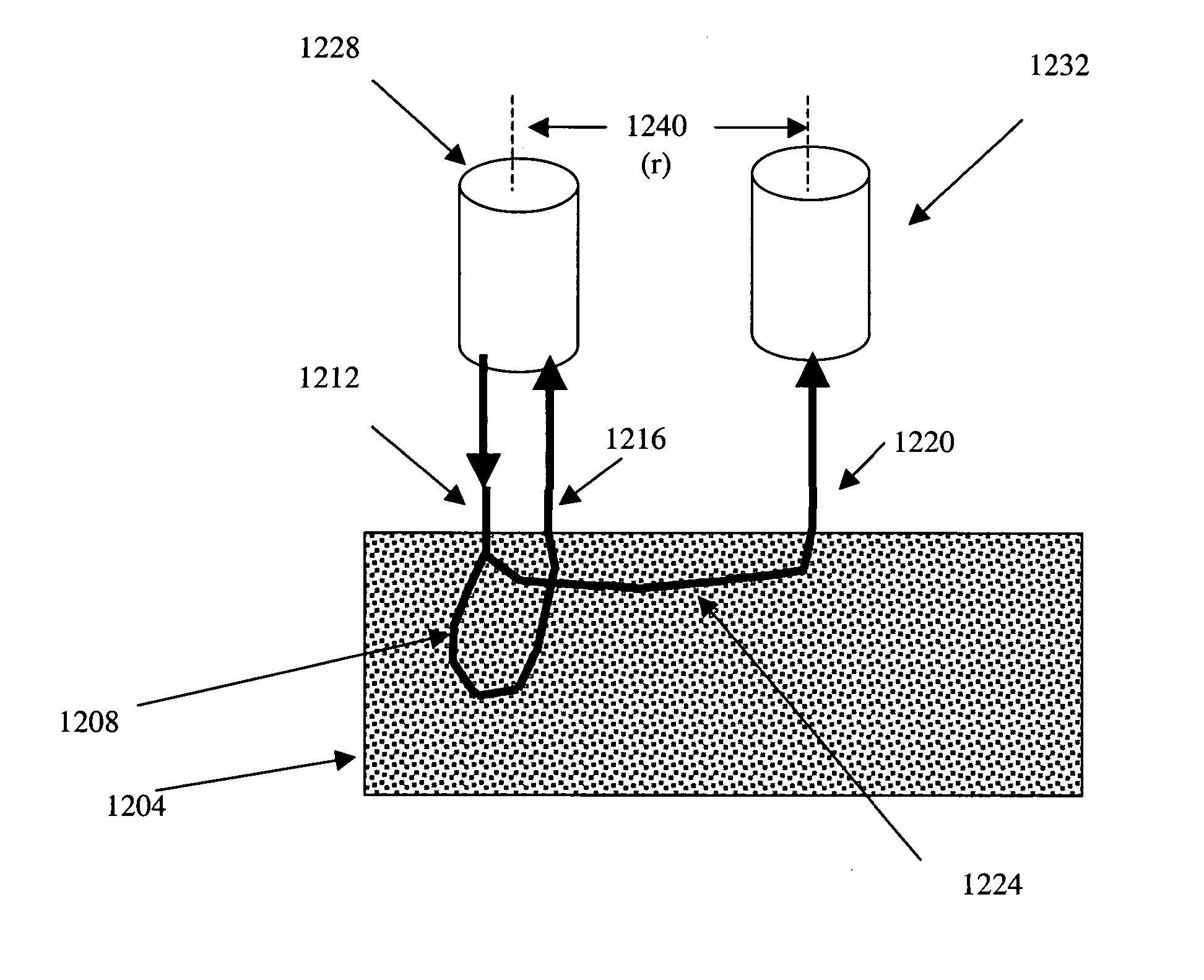

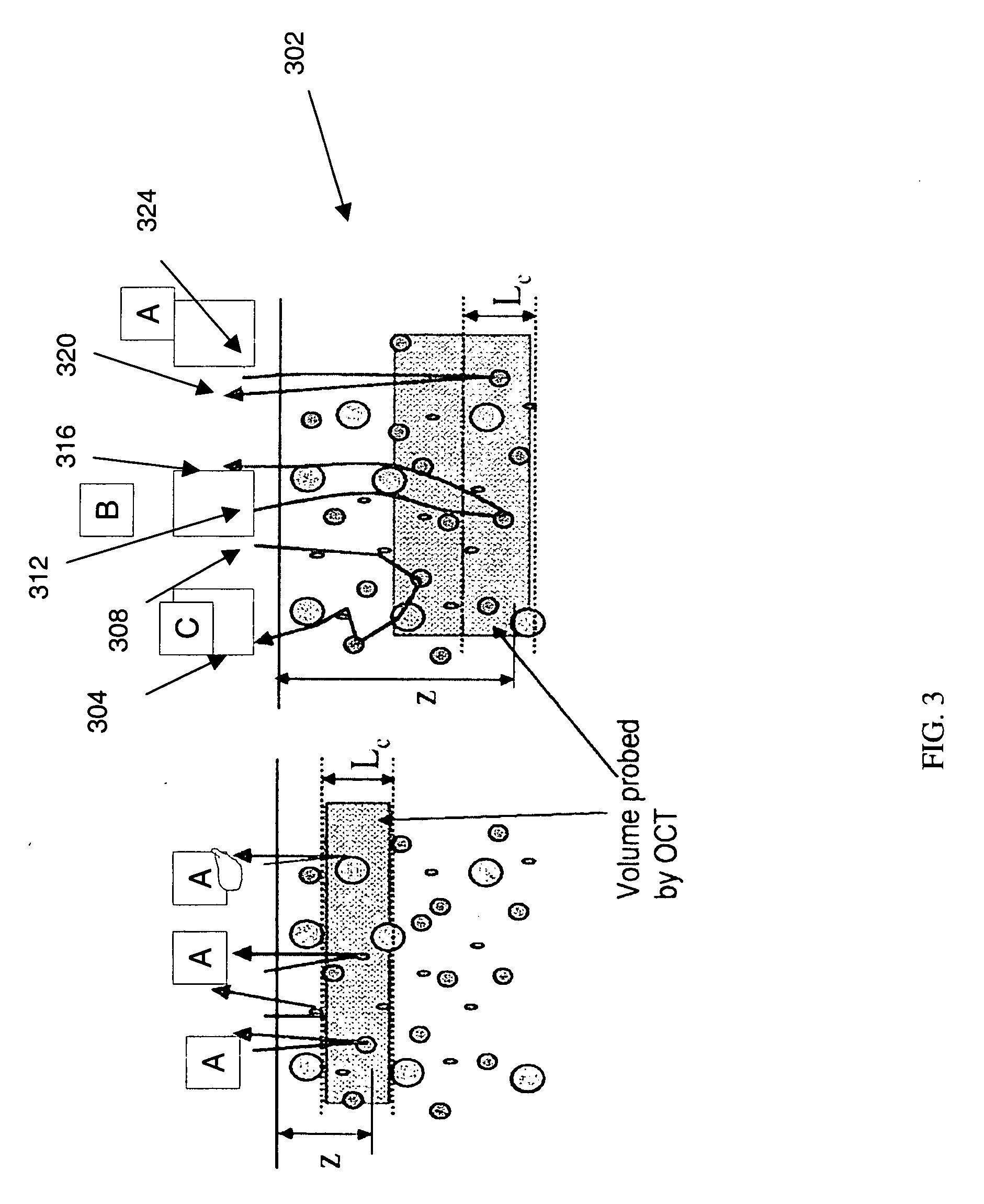

Interferometric sensor for characterizing materials

ActiveUS20050190372A1Fast and inexpensiveRobust designScattering properties measurementsDiagnostic recording/measuringFiberInterferometric sensor

An integrated optical sensor, using low coherence interferometry, is capable of determining analyte concentration in a material sample based on absorption, scattering and polarization. The sensor includes one or more light collectors, with each collector having a separation distance from the region where the sample is illuminated by the source. The light backscattered from the sample is combined with reference arm light at the same optical path length for each light collector. The intensity of interference may be correlated with the concentration of an analyte in the material, for example the glucose concentration in a turbid medium like skin. The sensor operation can be based on fiber optics technology, integrated optics, or a combination of these. The operation is such that the spectrally resolved scattering and absorption coefficients can be measured simultaneously. In addition, the operation of the sensor can be synchronized with other sensors, for example temperature, pressure, or heartrate.

Owner:UNIV OF CENT FLORIDA

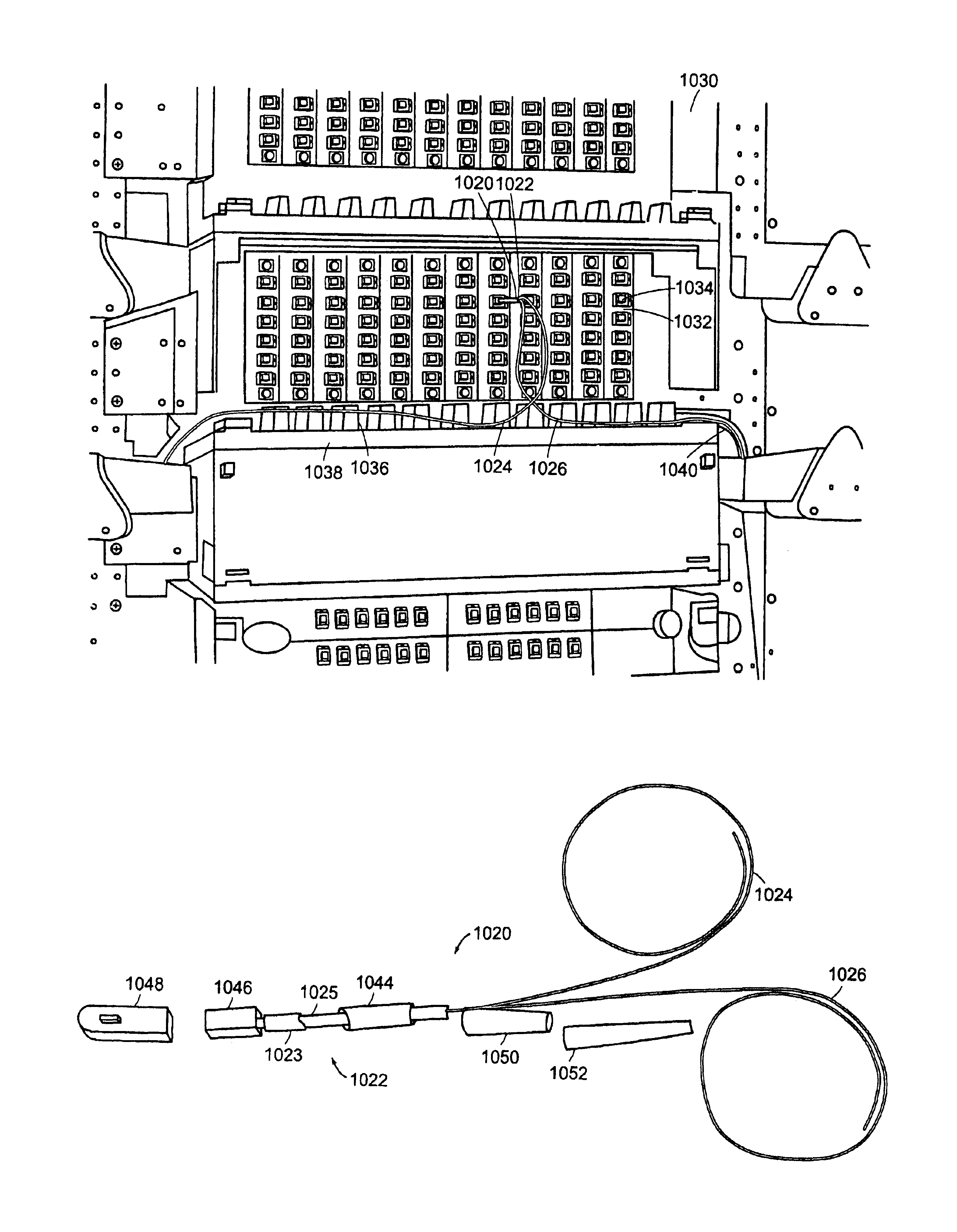

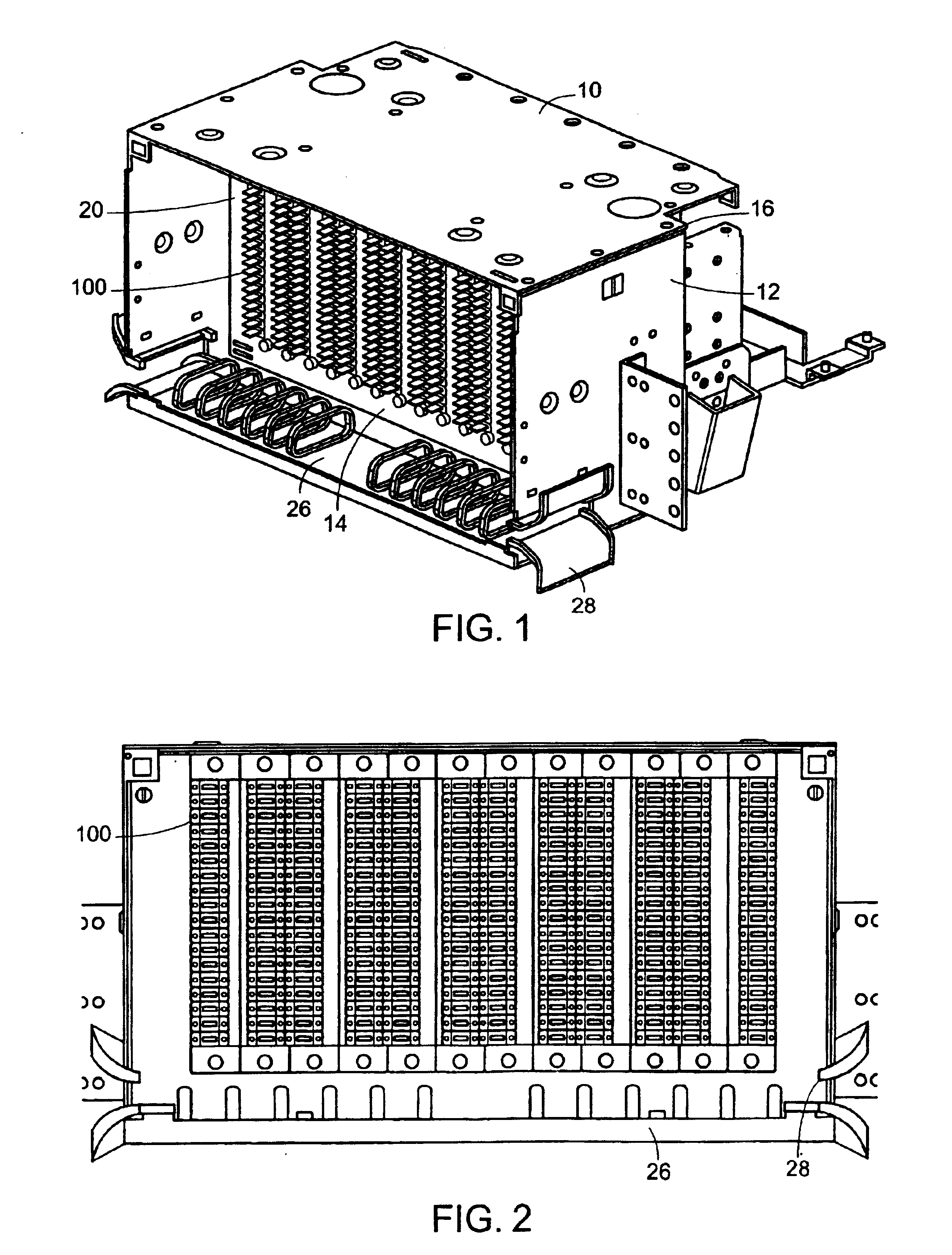

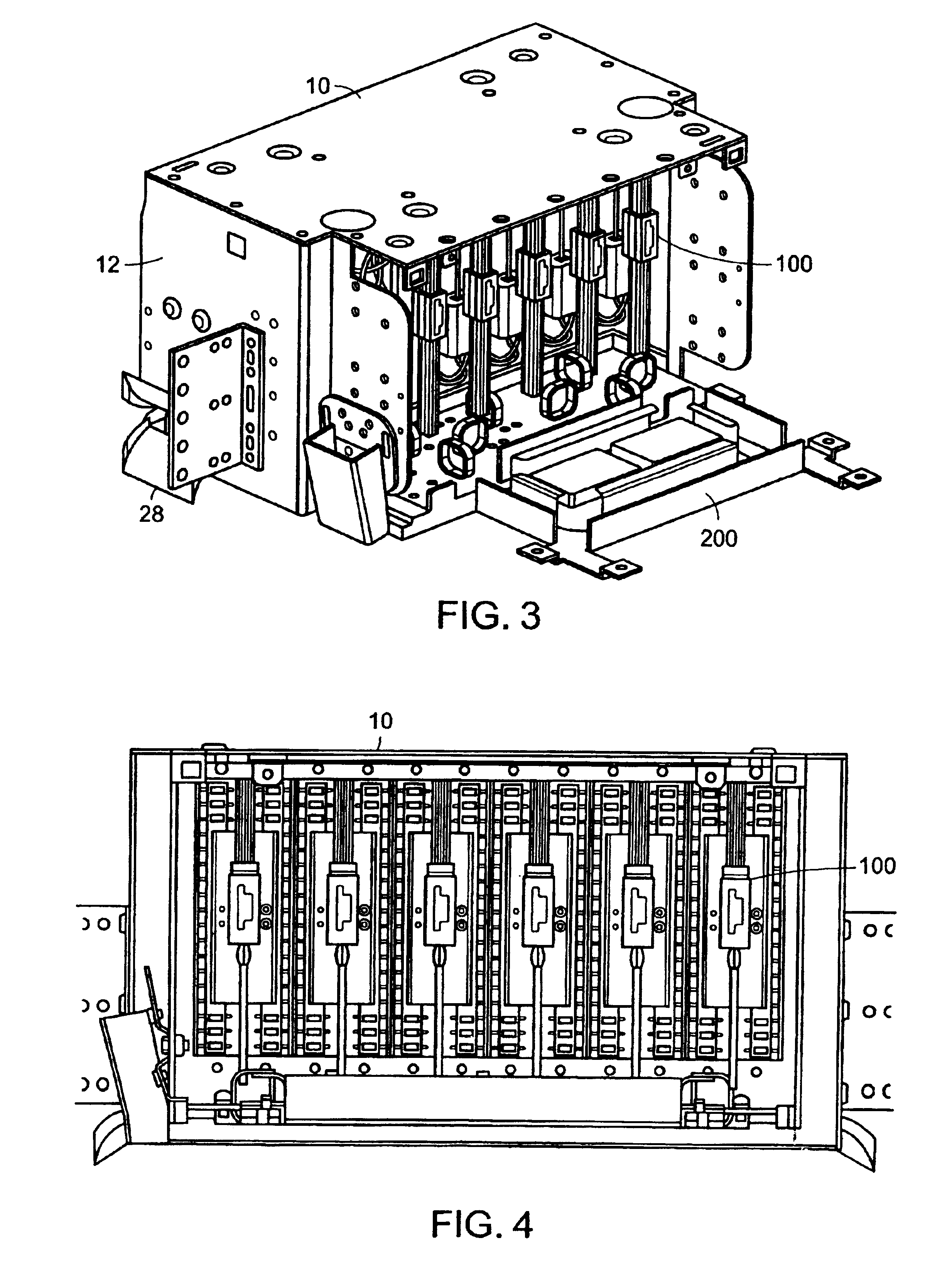

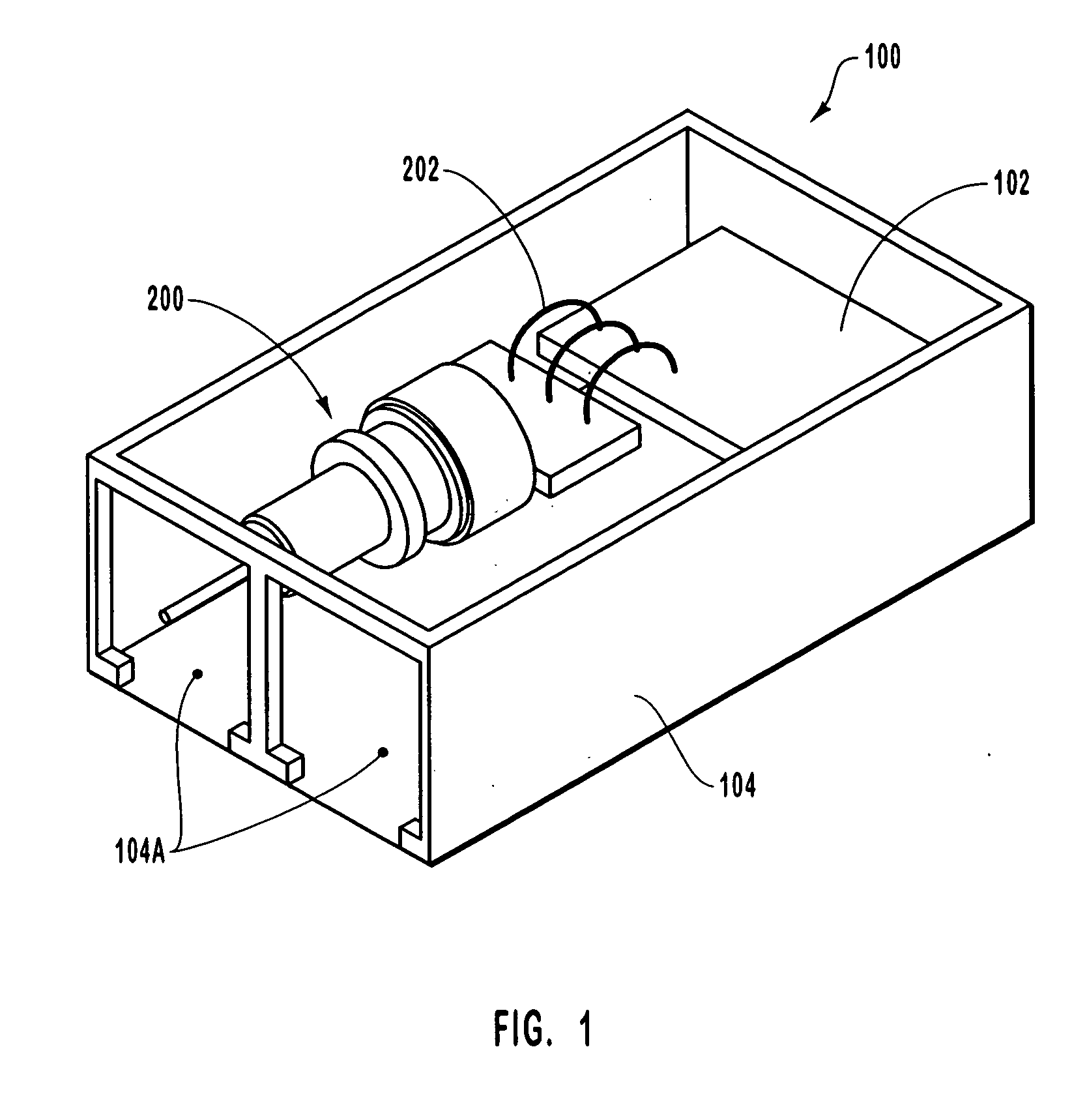

Optical fiber enclosure system using integrated optical connector and coupler assembly

InactiveUS6909833B2Precise positioningEfficient administrationCoupling light guidesFibre mechanical structuresFiberEngineering

An optical fiber enclosure system includes a plurality of integrated optical connector and coupler assemblies. The first optic coupler is integrated adjacent to the ferrule in the connector. In a preferred embodiment, the integrated optical connector coupler is constructed in a compact package such that when installed in the optical fiber enclosure no part of the coupler connector assembly protrudes beyond the footprint of the fiber enclosure and yet maintains an industry recommended minimum bend radius of 1.5 inches on the output cable ports thus allowing the fiber enclosure front panel to close without impinging on the cables of the assembly.

Owner:COMMSCOPE TECH LLC

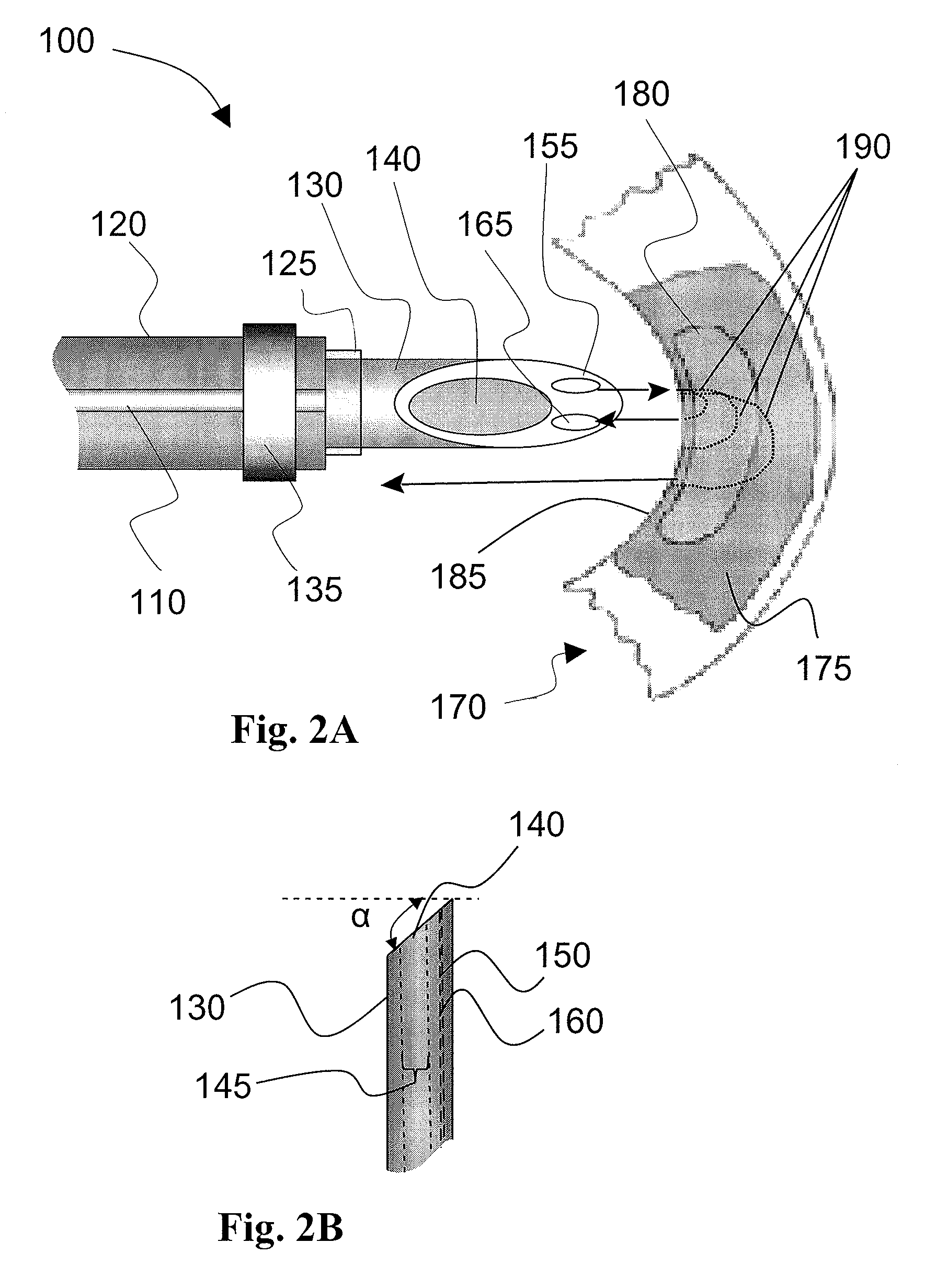

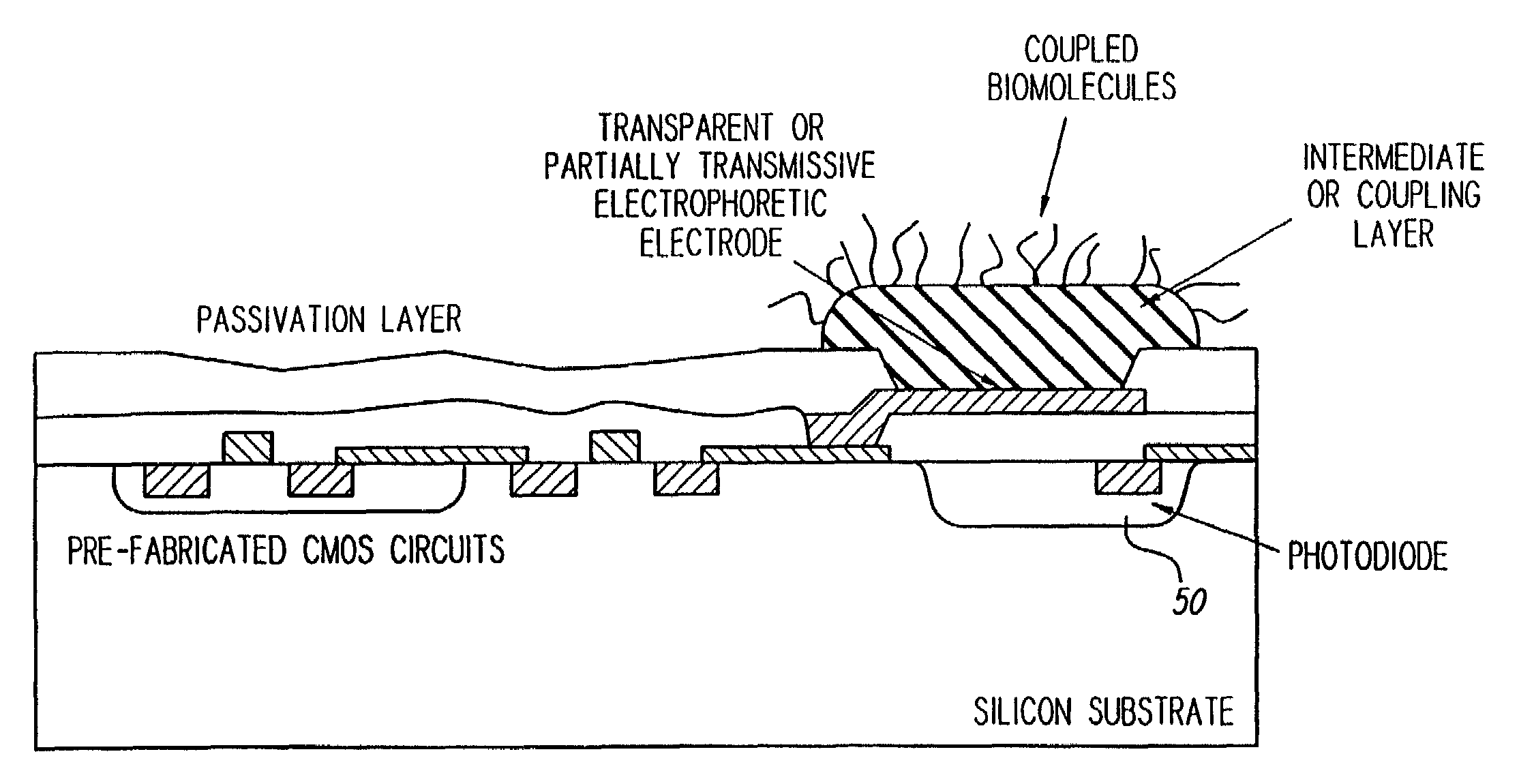

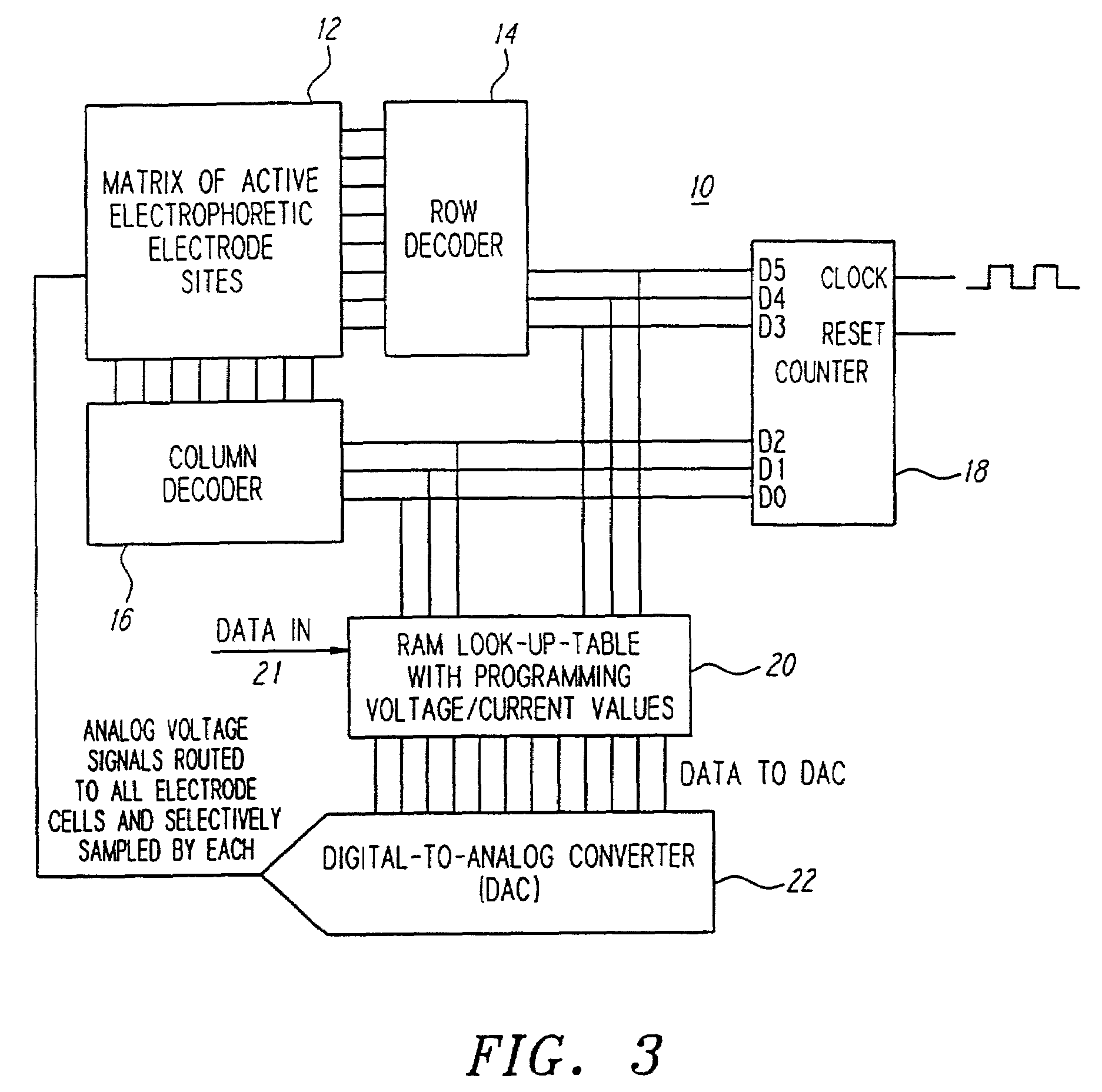

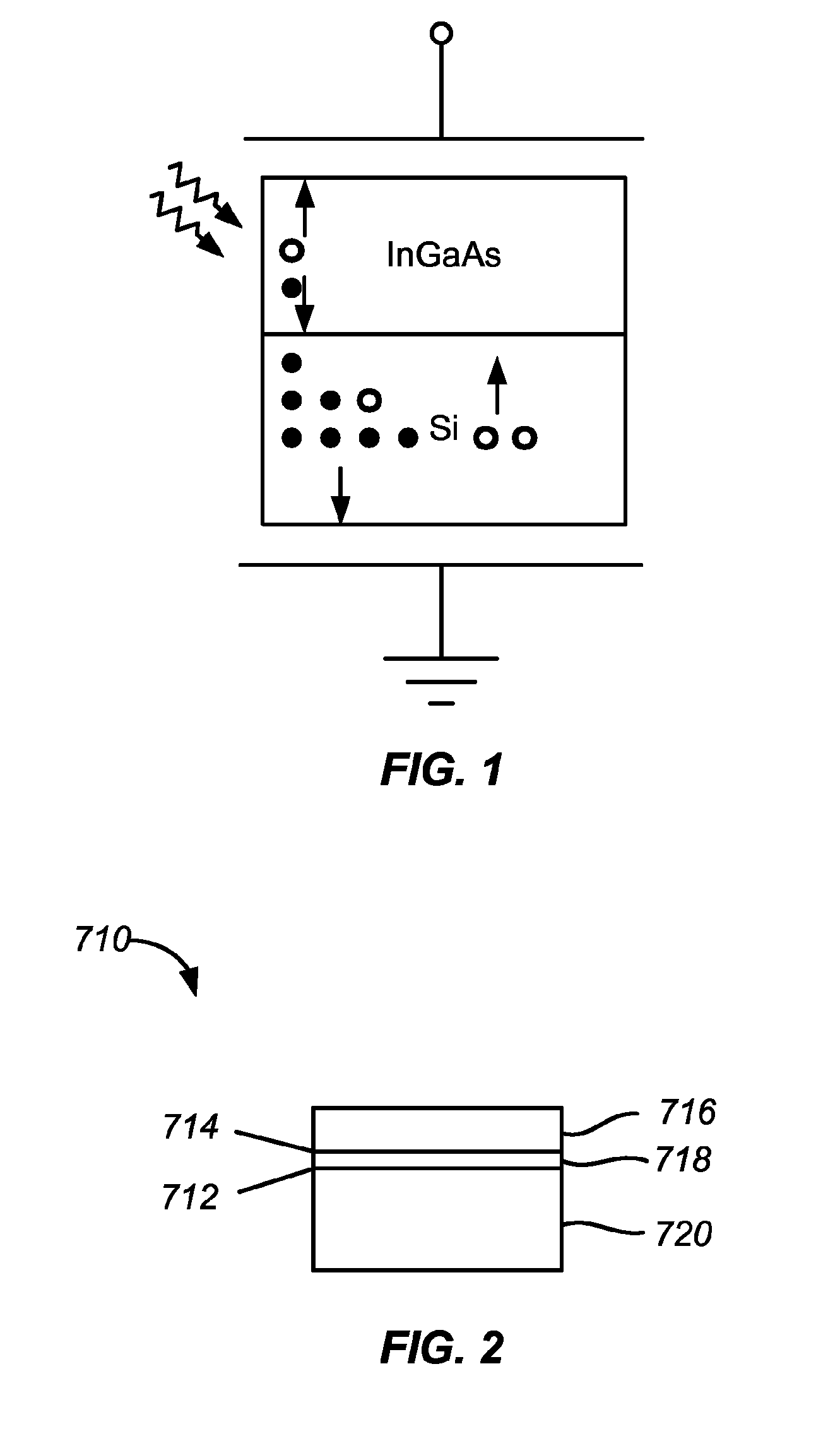

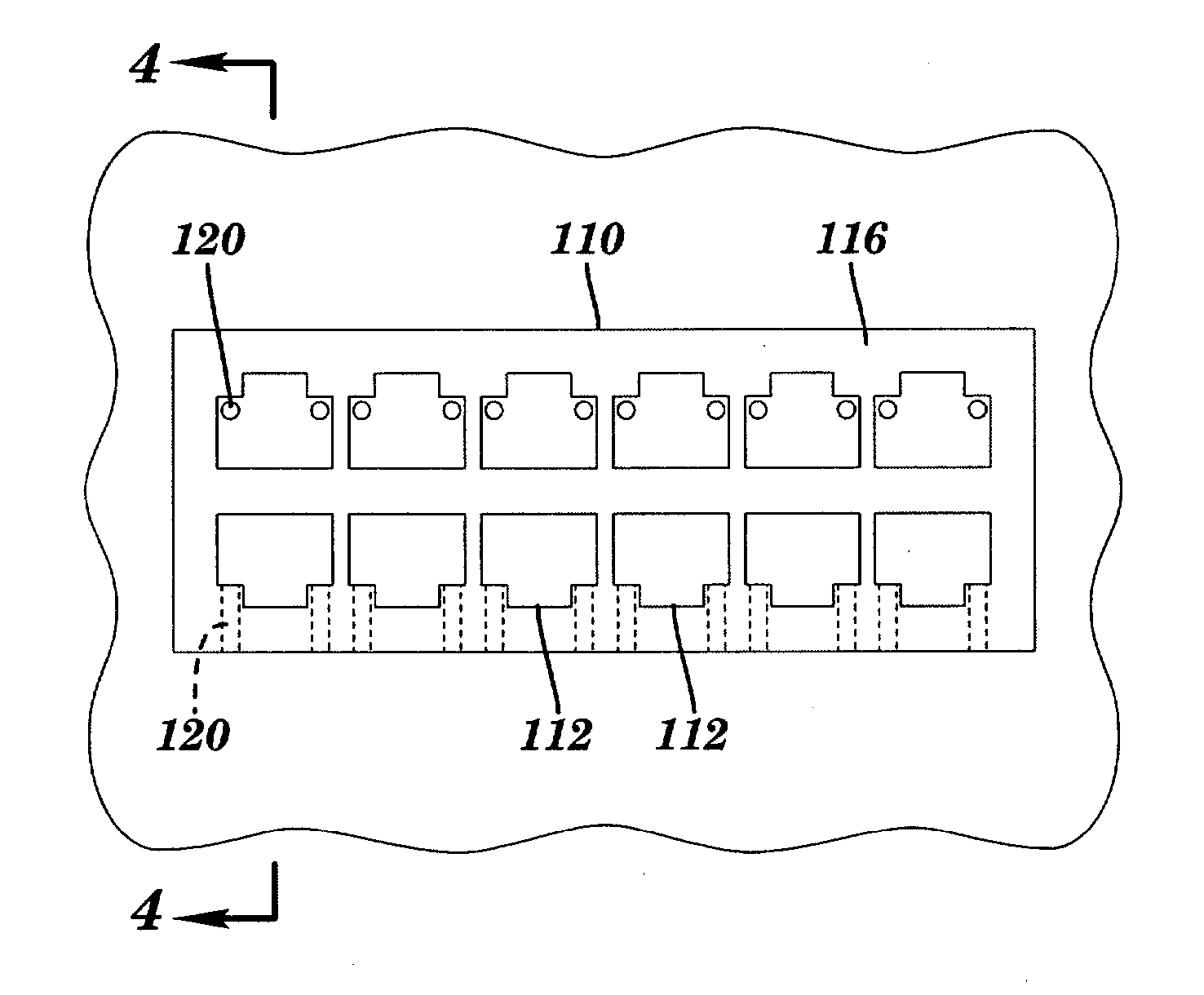

Biologic electrode array with integrated optical detector

InactiveUS7045097B2Easy to controlLow costSequential/parallel process reactionsChemiluminescene/bioluminescenceElectrode arraySemiconductor

A biologic electrode array is formed on a semiconductor substrate. A matrix of electrode sites is disposed on the semiconductor substrate. A matrix of optical detectors is disposed beneath the electrode sites in the semiconductor substrate, wherein each electrode site is associated with a corresponding optical detector. The optical detectors are coupled to detection circuitry formed on the semiconductor substrate. The electrode sites may include slitted electrodes, punctuated electrodes, or optically transparent electrodes.

Owner:GAMIDA FOR LIFE

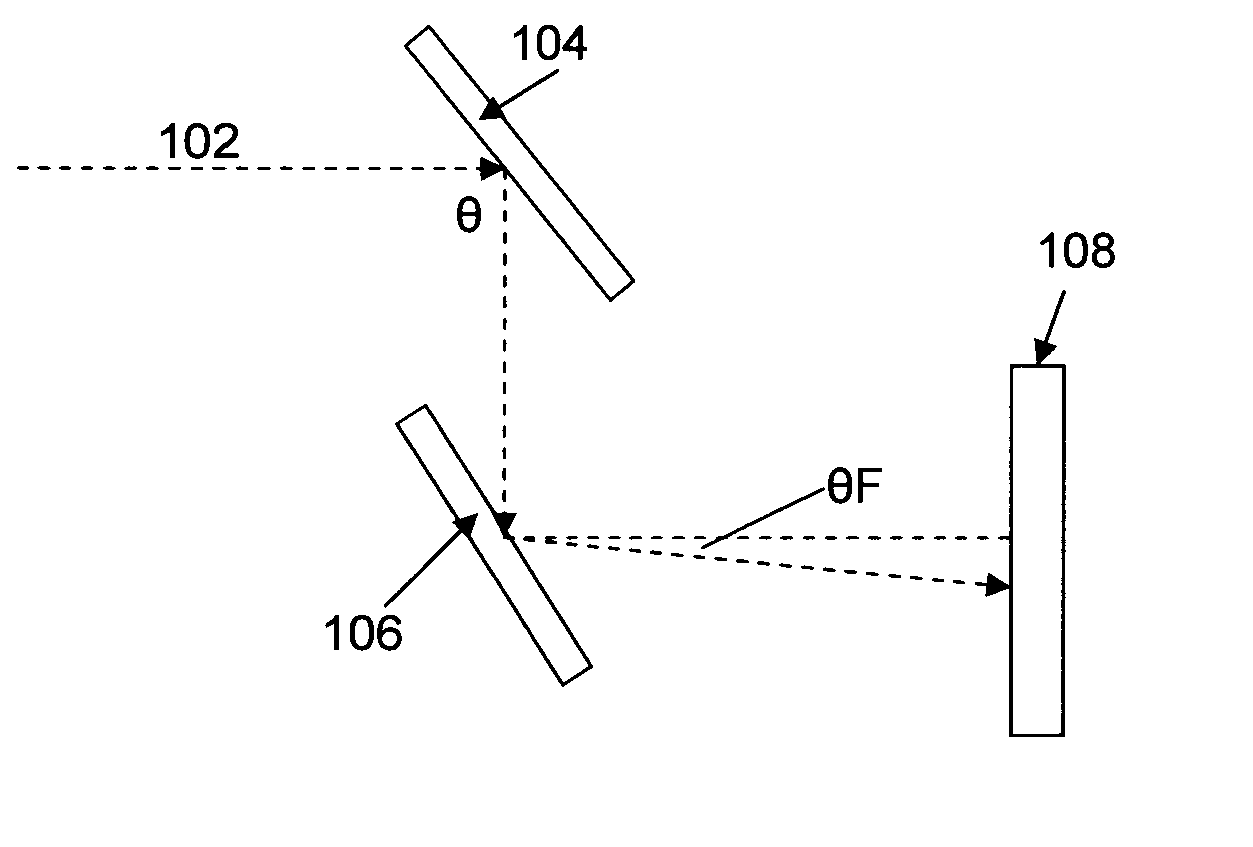

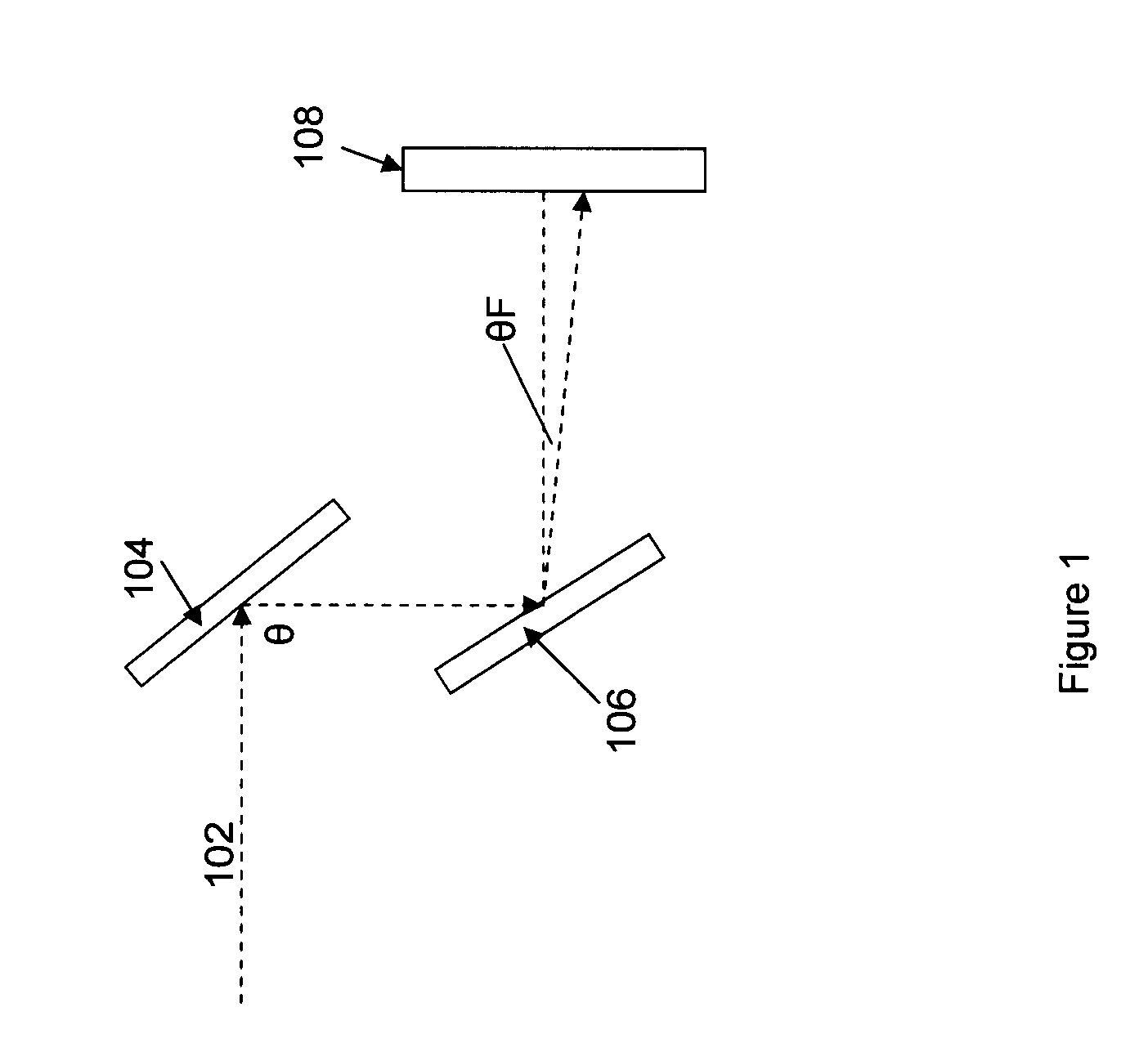

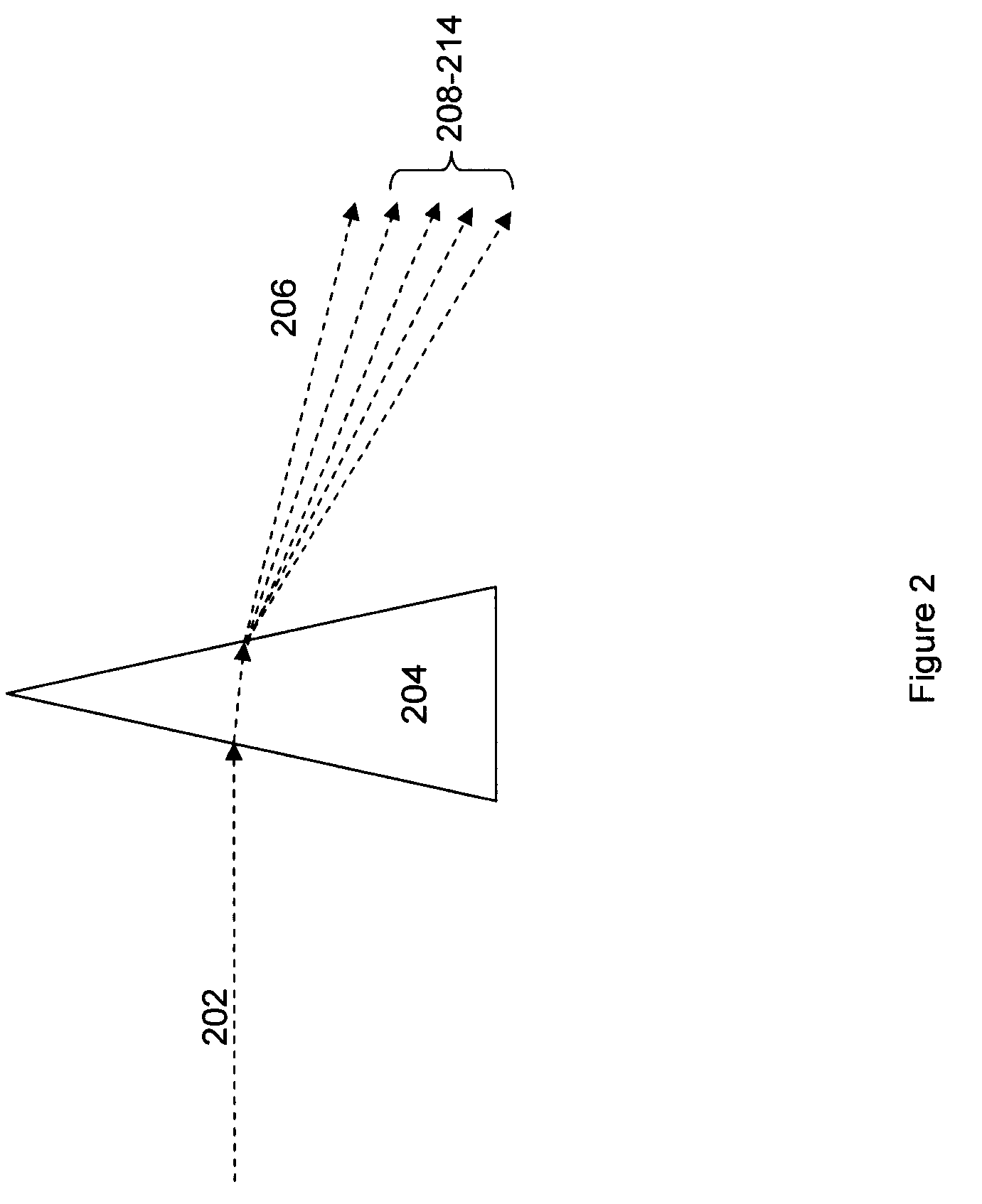

Solid state optical phased array lidar and method of using same

ActiveUS20150293224A1Instruments for comonautical navigationMaterial analysis by optical meansOptical delay lineRadiation pattern

A lidar-based apparatus and method are used for the solid state steering of laser beams using Photonic Integrated Circuits. Integrated optic design and fabrication micro- and nanotechnologies are used for the production of chip-scale optical splitters that distribute an optical signal from a laser essentially uniformly to an array of pixels, said pixels comprising tunable optical delay lines and optical antennas. Said antennas achieve out-of-plane coupling of light.As the delay lines of said antenna-containing pixels in said array are tuned, each antenna emits light of a specific phase to form a desired far-field radiation pattern through interference of these emissions. Said array serves the function of solid state optical phased array.By incorporating a large number of antennas, high-resolution far-field patterns can be achieved by an optical phased array, supporting the radiation pattern beam forming and steering needed in solid state lidar, as well as the generation of arbitrary radiation patterns as needed in three-dimensional holography, optical memory, mode matching for optical space-division multiplexing, free space communications, and biomedical sciences. Whereas imaging from an array is conventionally transmitted through the intensity of the pixels, the optical phased array allows imaging through the control of the optical phase of pixels that receive coherent light waves from a single source.

Owner:QUANERGY SOLUTIONS INC

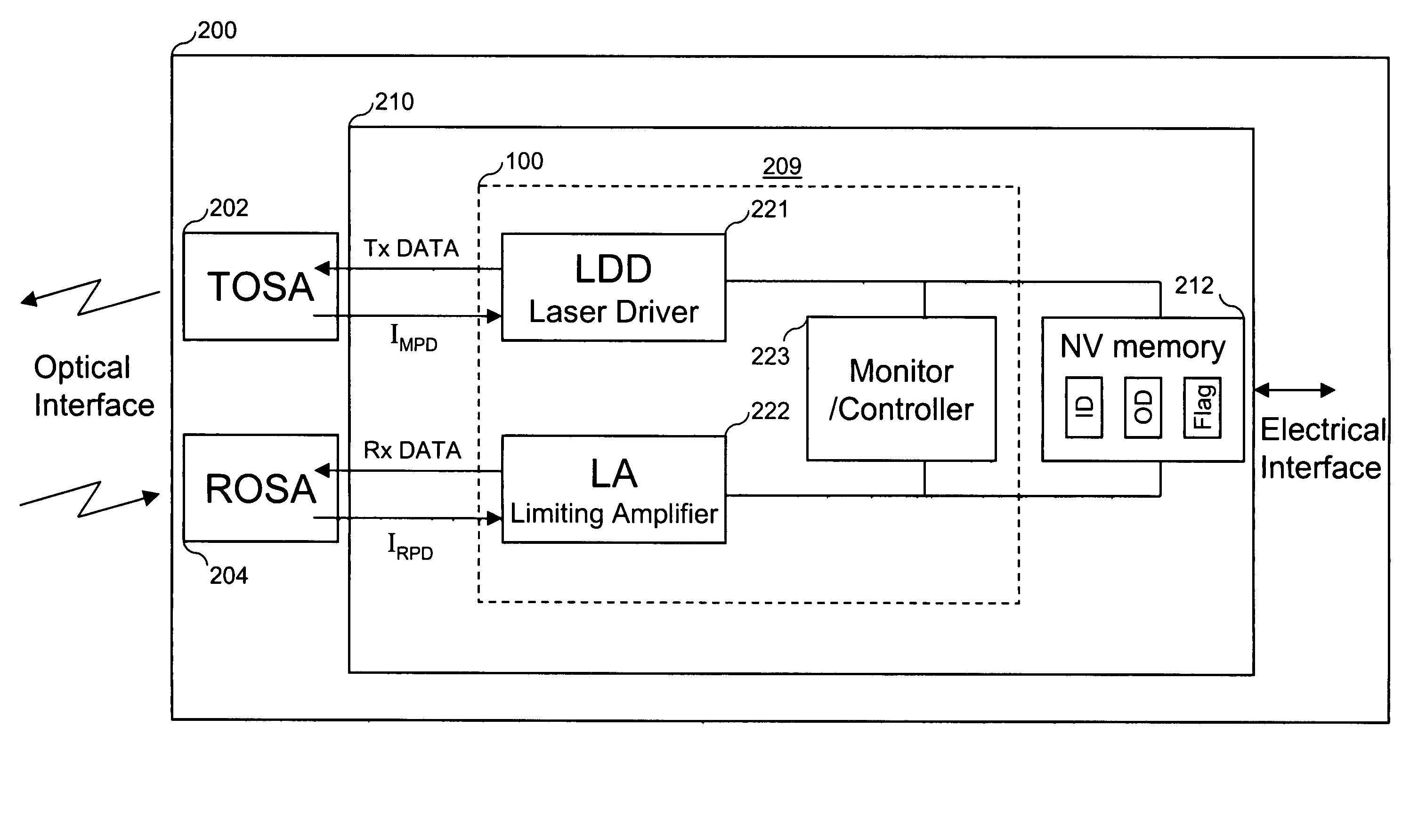

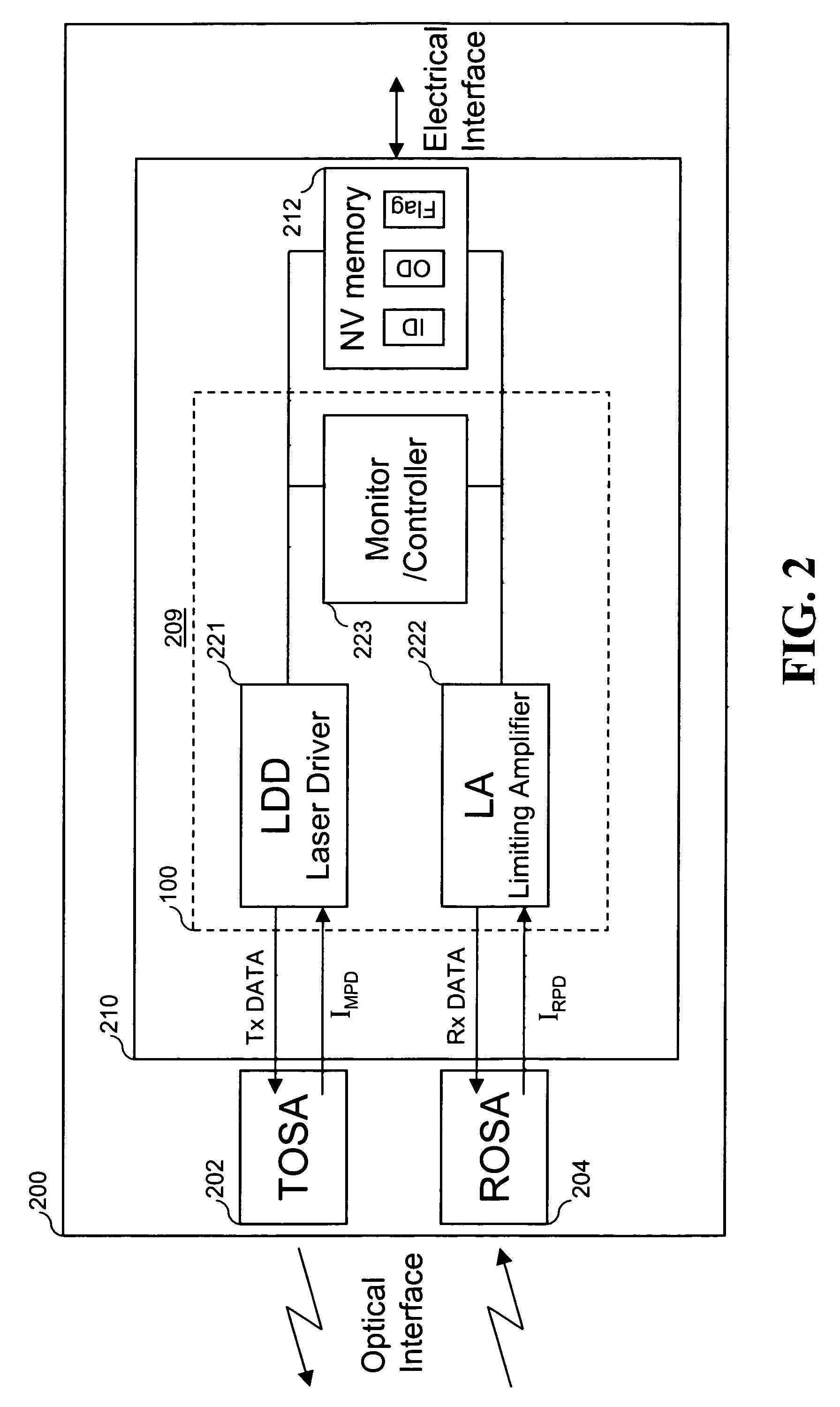

Integrated driving, receiving, controlling, and monitoring for optical transceivers

ActiveUS7215891B1Wide driving flexibilityElectromagnetic transmittersElectromagnetic transceiversTransceiverOpto electronic

An optical transceiver includes a single integrated circuit chip to integrate the drive, receive, control, and monitoring functions of the optical transceiver. The single chip may further have an advance replacement algorithm and monitoring algorithm for the opto-electronic devices of the optical transmitter and receiver to generate flags and / or an advance replacement indication. Methods, apparatus, and systems are disclosed.

Owner:NASA +1

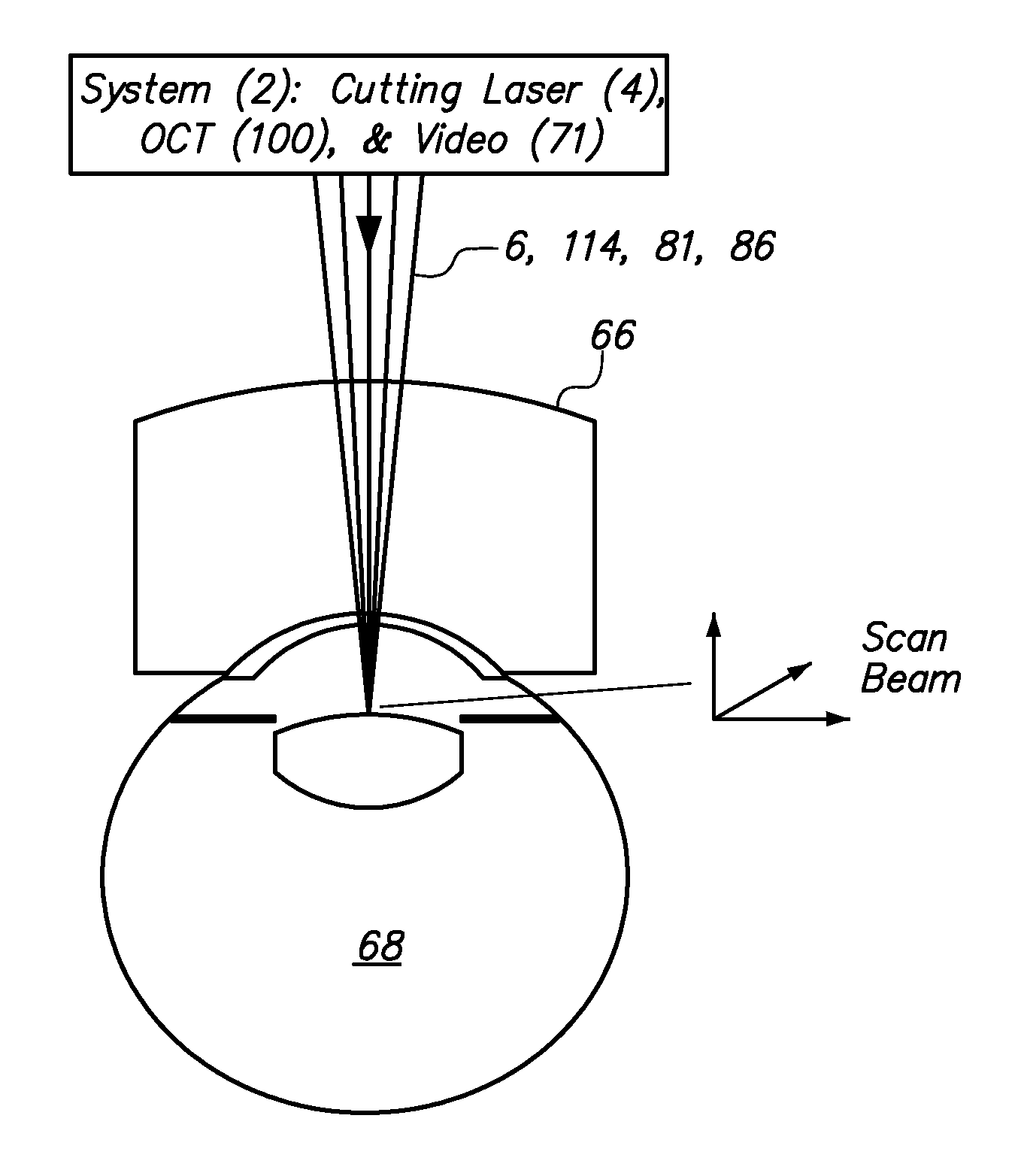

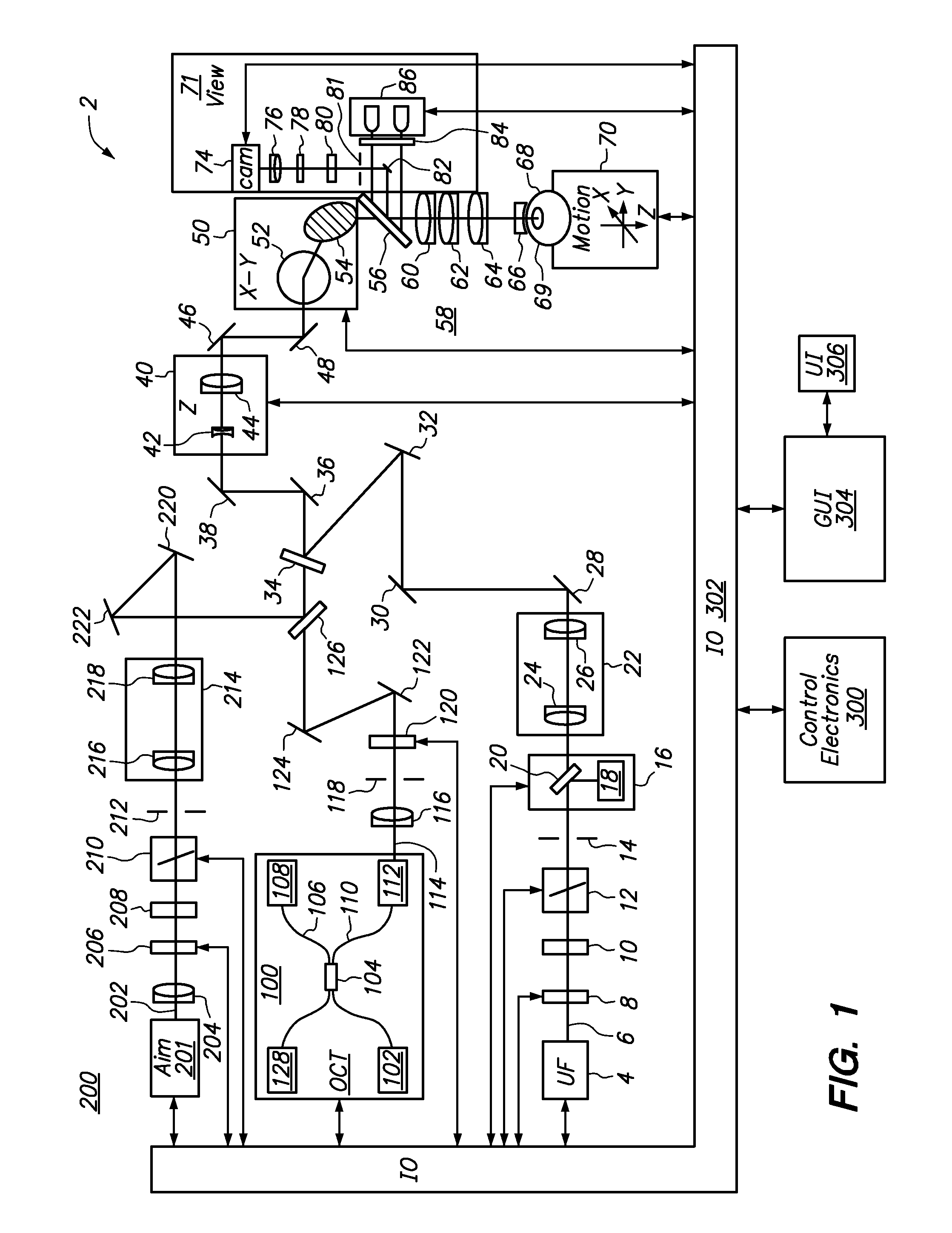

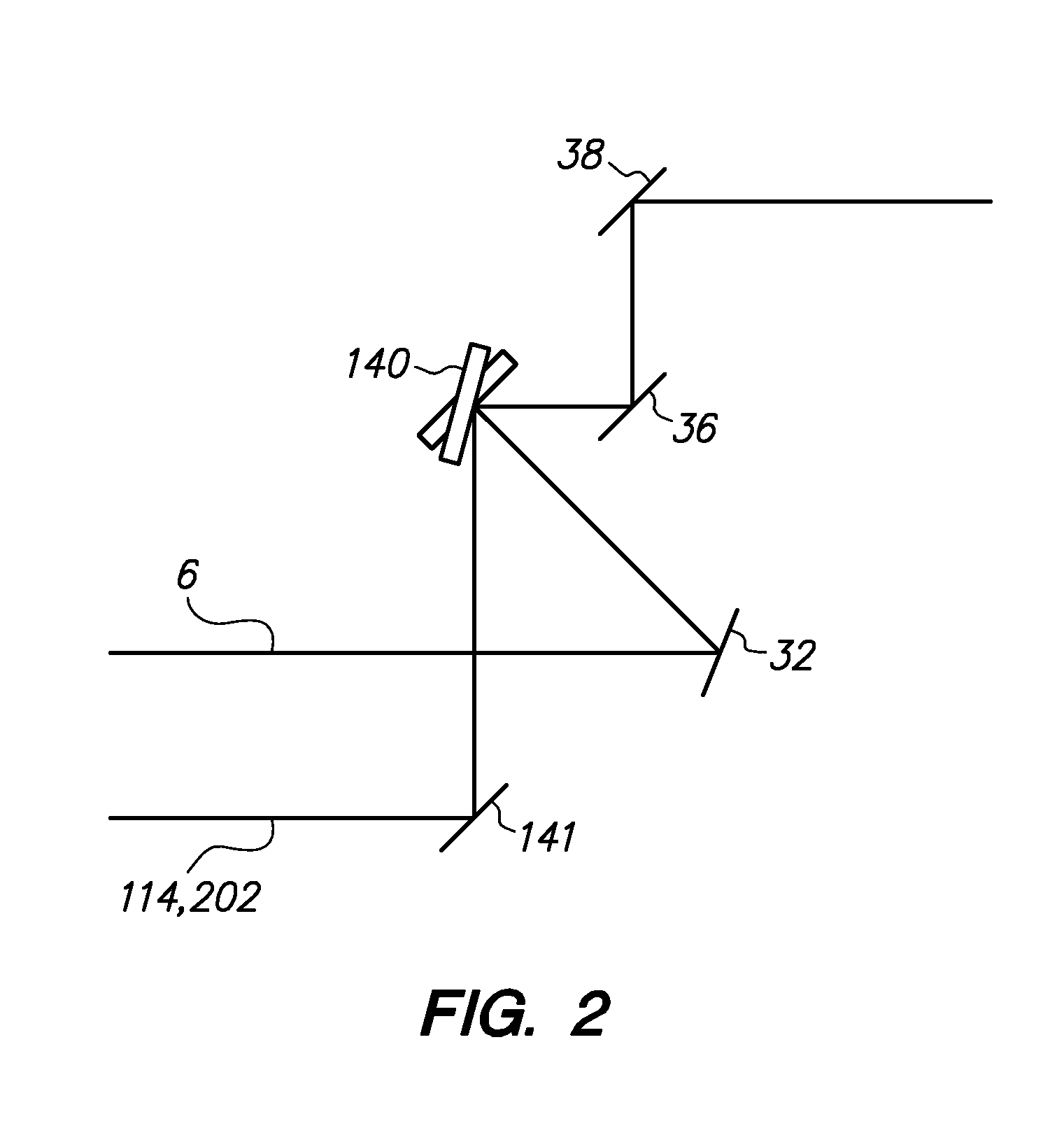

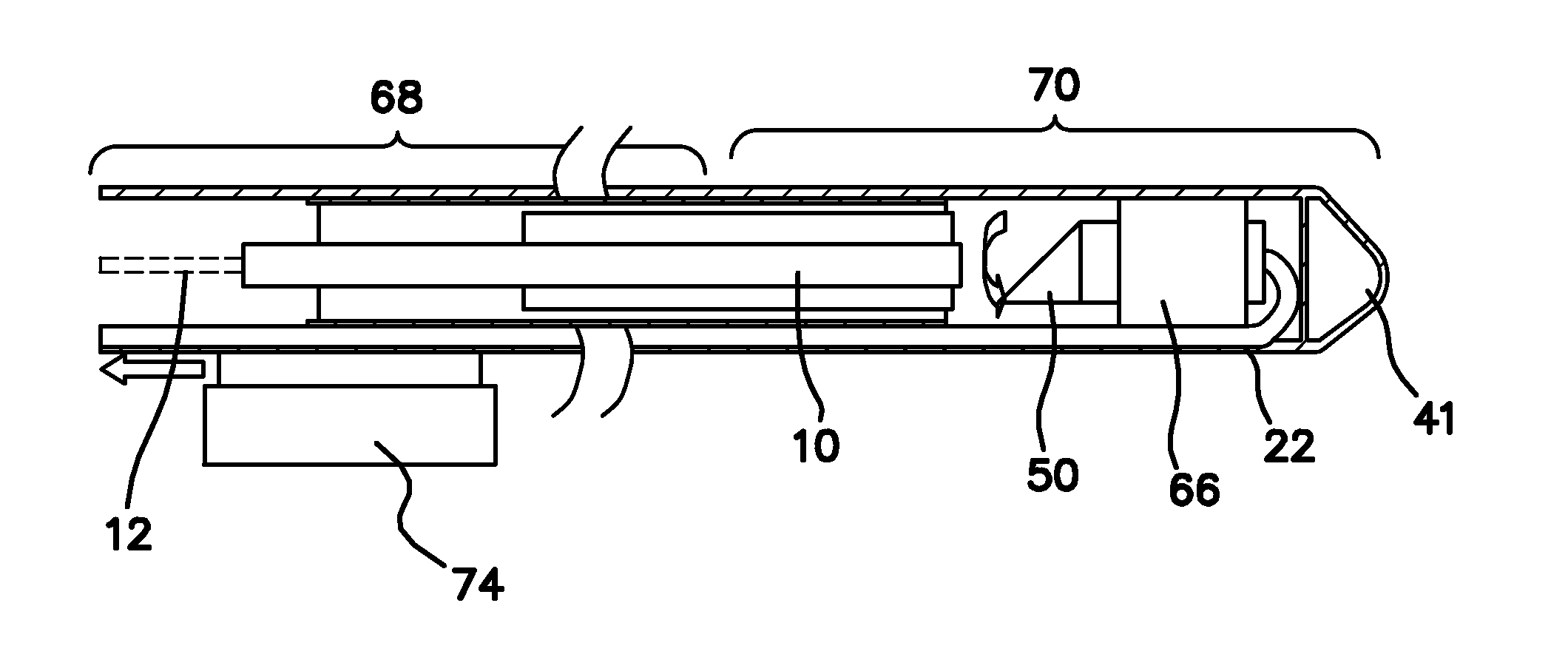

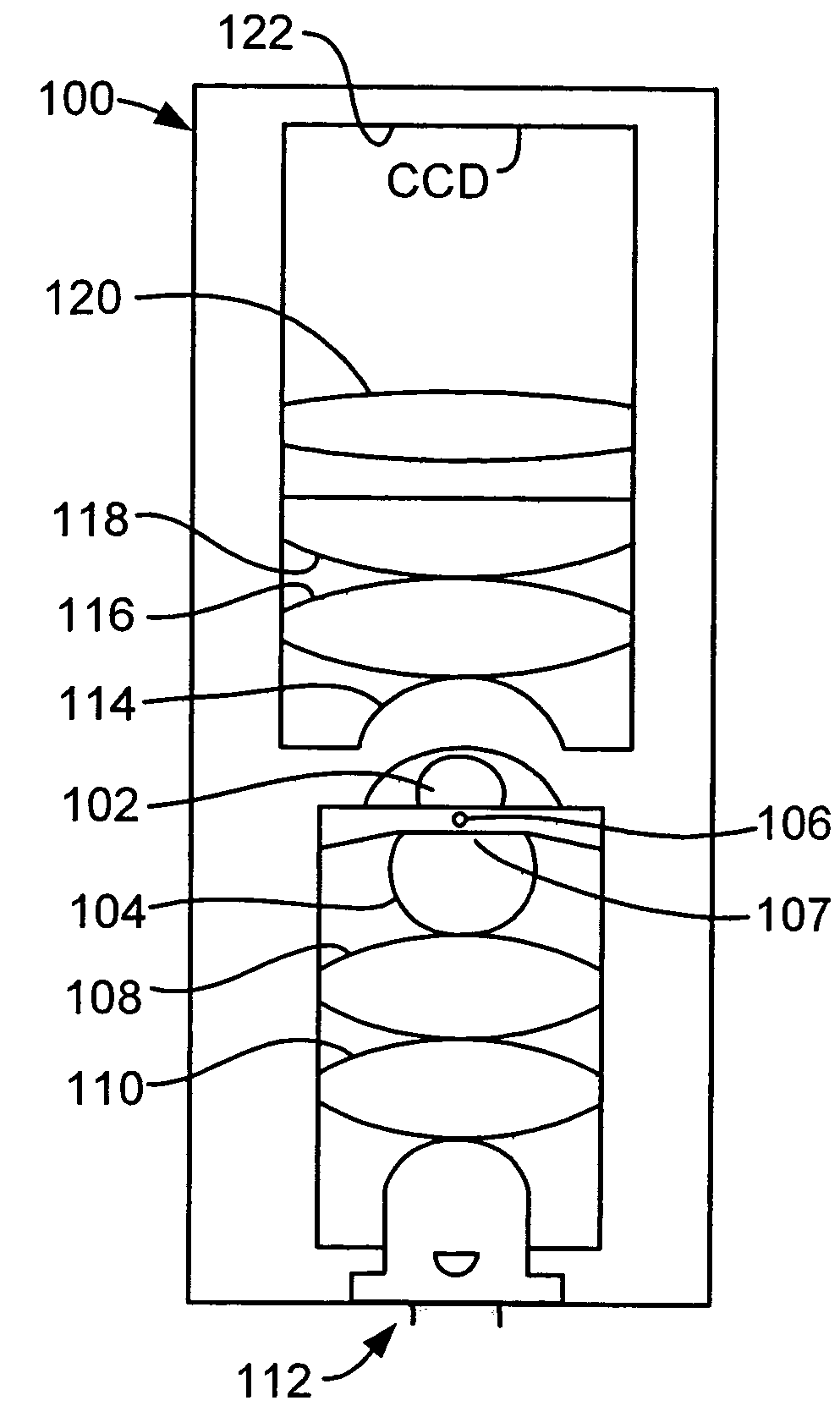

Method and apparatus for automated placement of scanned laser capsulorhexis incisions

ActiveUS20110202046A1Easy to implantLaser surgeryImage enhancementAnatomical structuresRobust least squares

Systems and methods are described for cataract intervention. In one embodiment a system comprises a laser source configured to produce a treatment beam comprising a plurality of laser pulses; an integrated optical system comprising an imaging assembly operatively coupled to a treatment laser delivery assembly such that they share at least one common optical element, the integrated optical system being configured to acquire image information pertinent to one or more targeted tissue structures and direct the treatment beam in a 3-dimensional pattern to cause breakdown in at least one of the targeted tissue structures; and a controller operatively coupled to the laser source and integrated optical system, and configured to adjust the laser beam and treatment pattern based upon the image information, and distinguish two or more anatomical structures of the eye based at least in part upon a robust least squares fit analysis of the image information.

Owner:AMO DEVMENT

Ultrasound guided optical coherence tomography, photoacoustic probe for biomedical imaging

ActiveUS20110098572A1High resolution imagingEasy accessUltrasonic/sonic/infrasonic diagnosticsCatheterDiagnostic Radiology ModalityHigh resolution imaging

An imaging probe for a biological sample includes an OCT probe and an ultrasound probe combined with the OCT probe in an integral probe package capable of providing by a single scanning operation images from the OCT probe and ultrasound probe to simultaneously provide integrated optical coherence tomography (OCT) and ultrasound imaging of the same biological sample. A method to provide high resolution imaging of biomedical tissue includes the steps of finding an area of interest using the guidance of ultrasound imaging, and obtaining an OCT image and once the area of interest is identified where the combination of the two imaging modalities yields high resolution OCT and deep penetration depth ultrasound imaging.

Owner:RGT UNIV OF CALIFORNIA

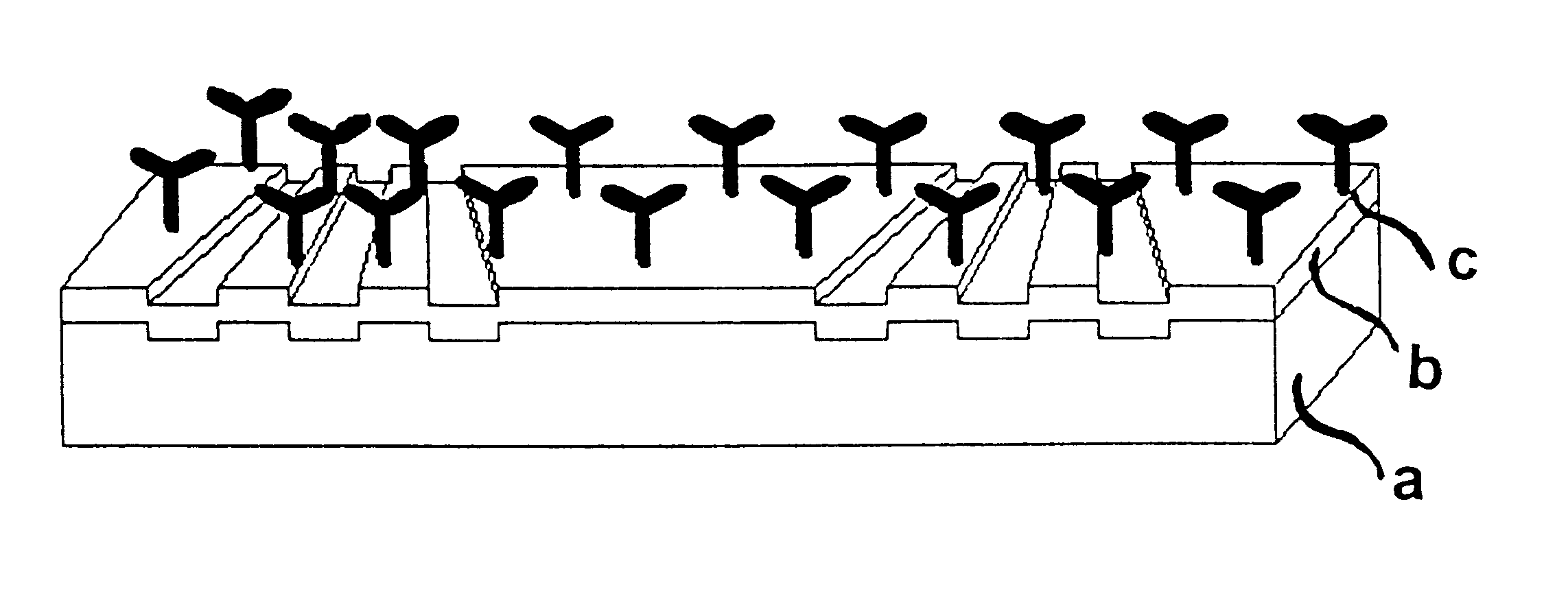

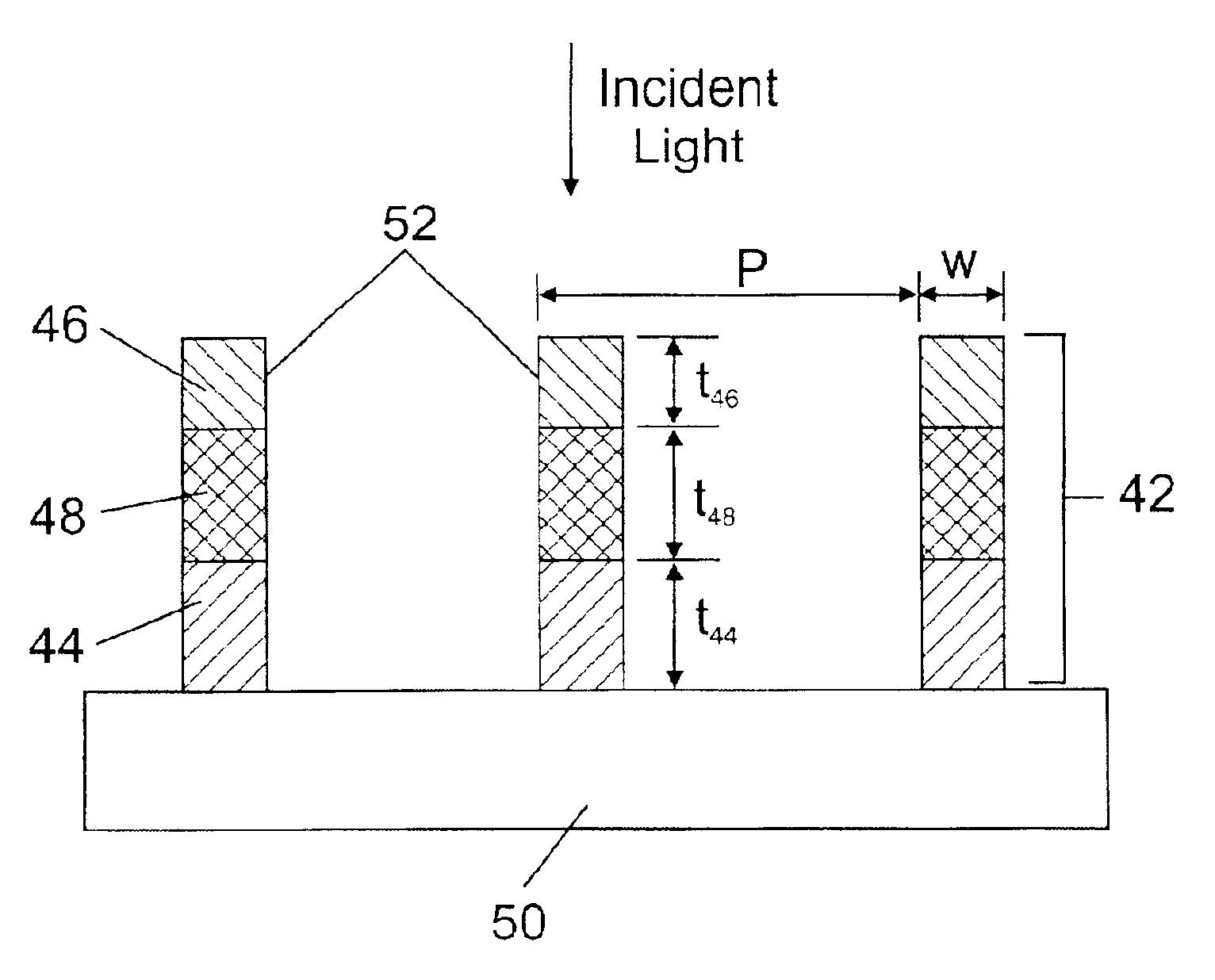

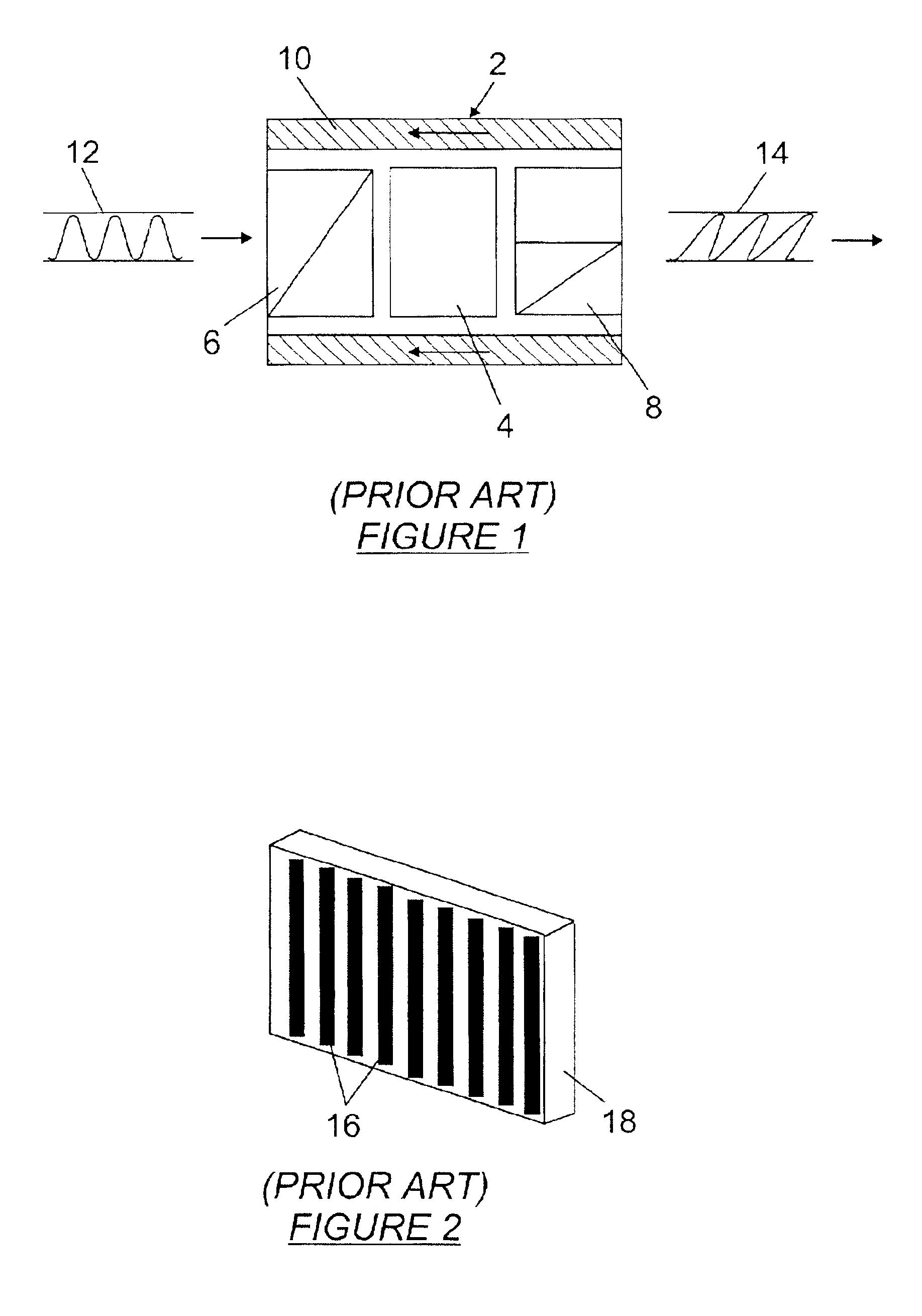

Method for fabricating an integrated optical isolator and a novel wire grid structure

InactiveUS6813077B2Inhibition reflexLow cost without sacrificing performanceDecorative surface effectsPolarising elementsResistWire grid

A method for fabricating an integrated optical isolator includes depositing a wire grid material on a magneto-optical substrate and depositing a resist film on the wire grid material. The method further includes bringing a mold with a wire grid pattern on contact with the resist film and compressing the mold and resist film together so as to emboss the wire grid pattern in the resist film. The method further includes transferring the wire grid pattern in the resist film to the wire grid material on the magneto-optical substrate by etching.

Owner:CORNING INC

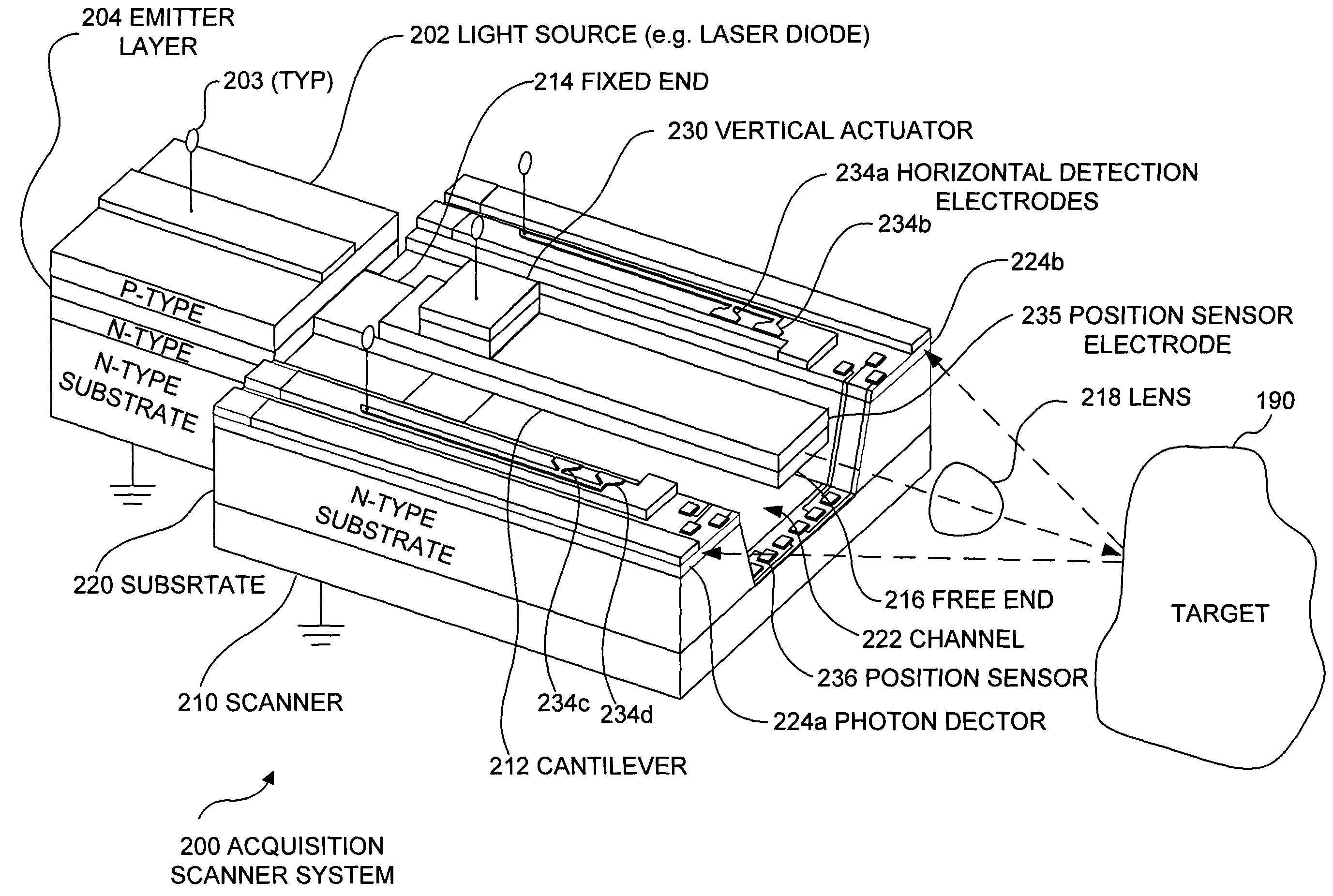

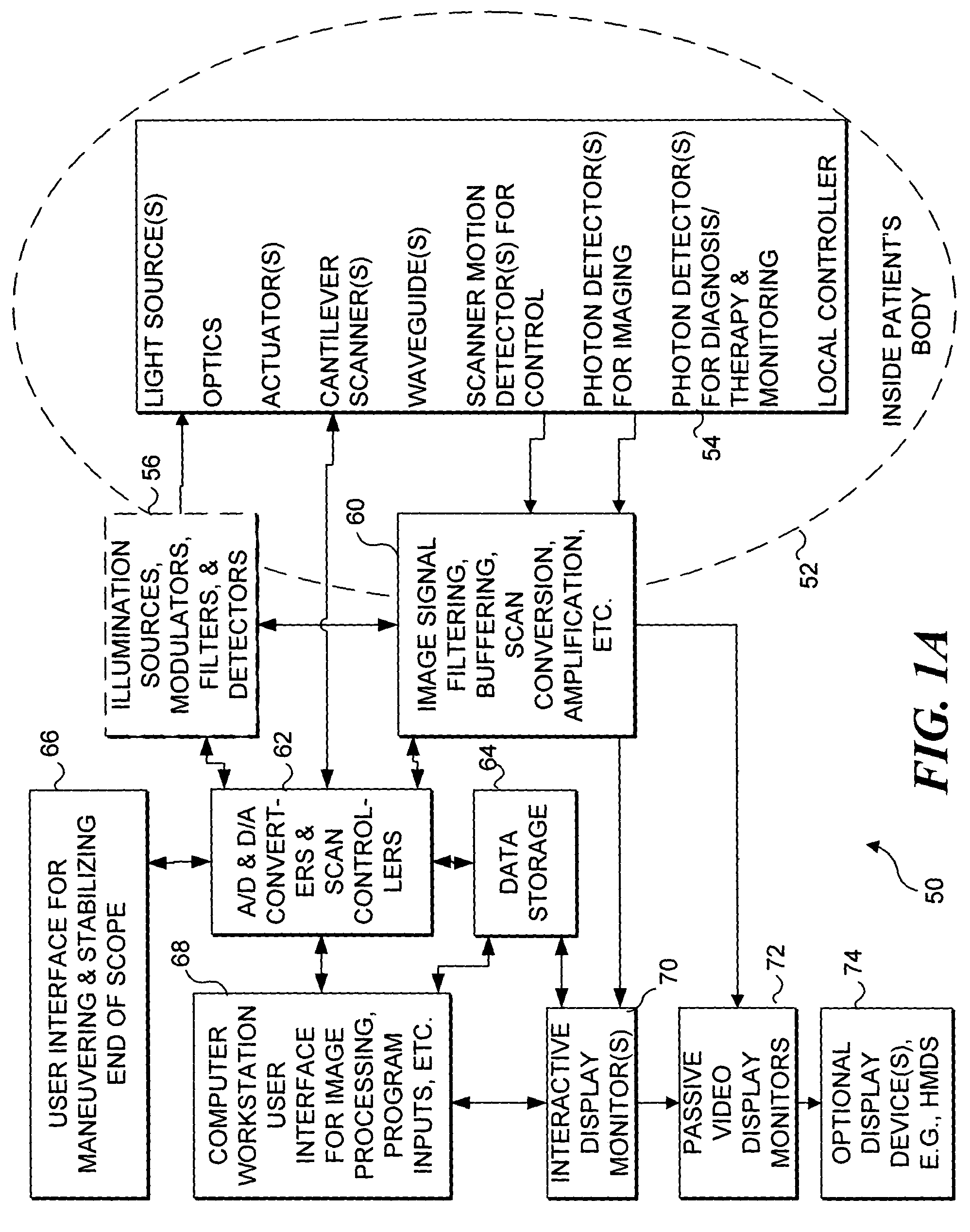

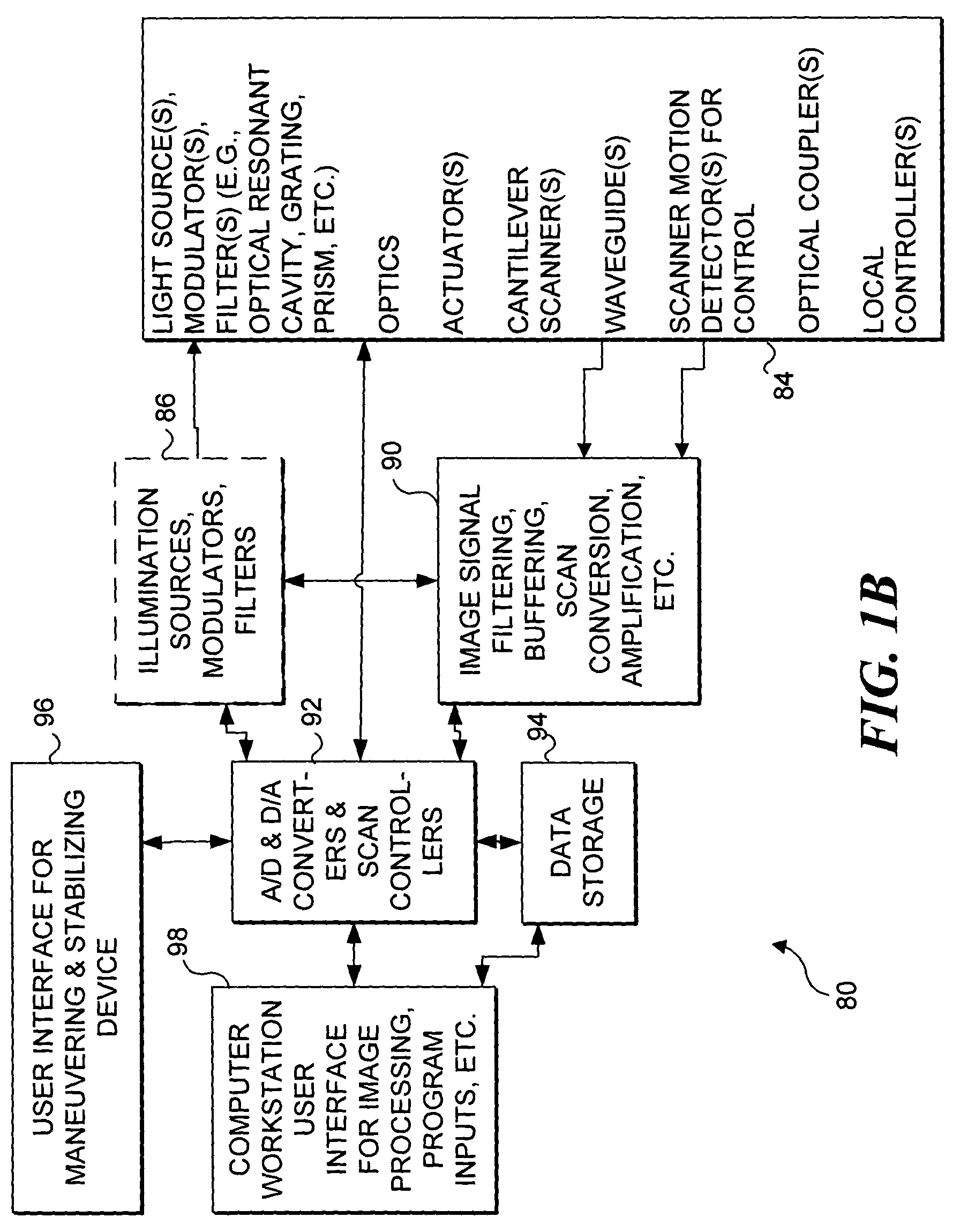

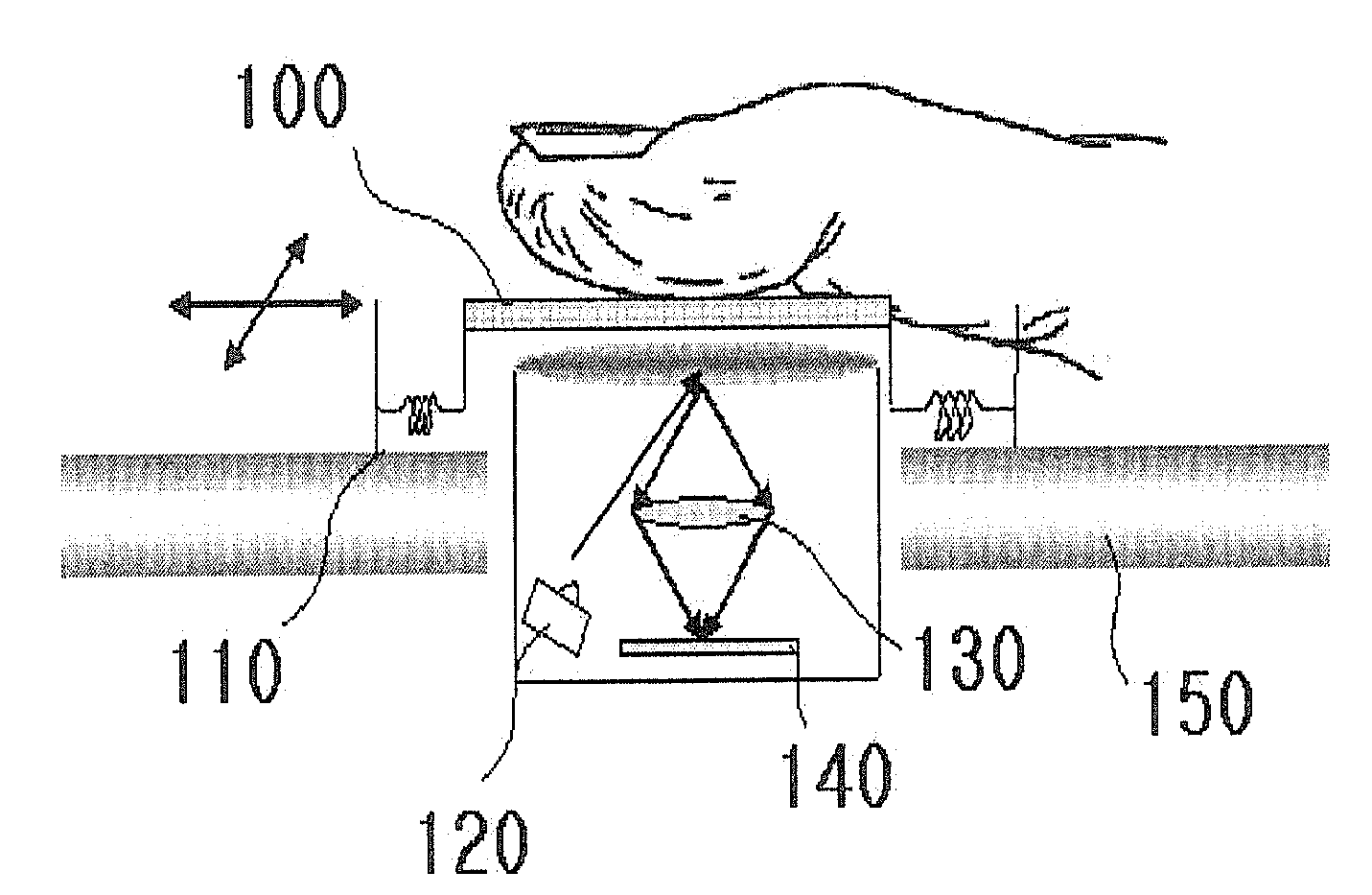

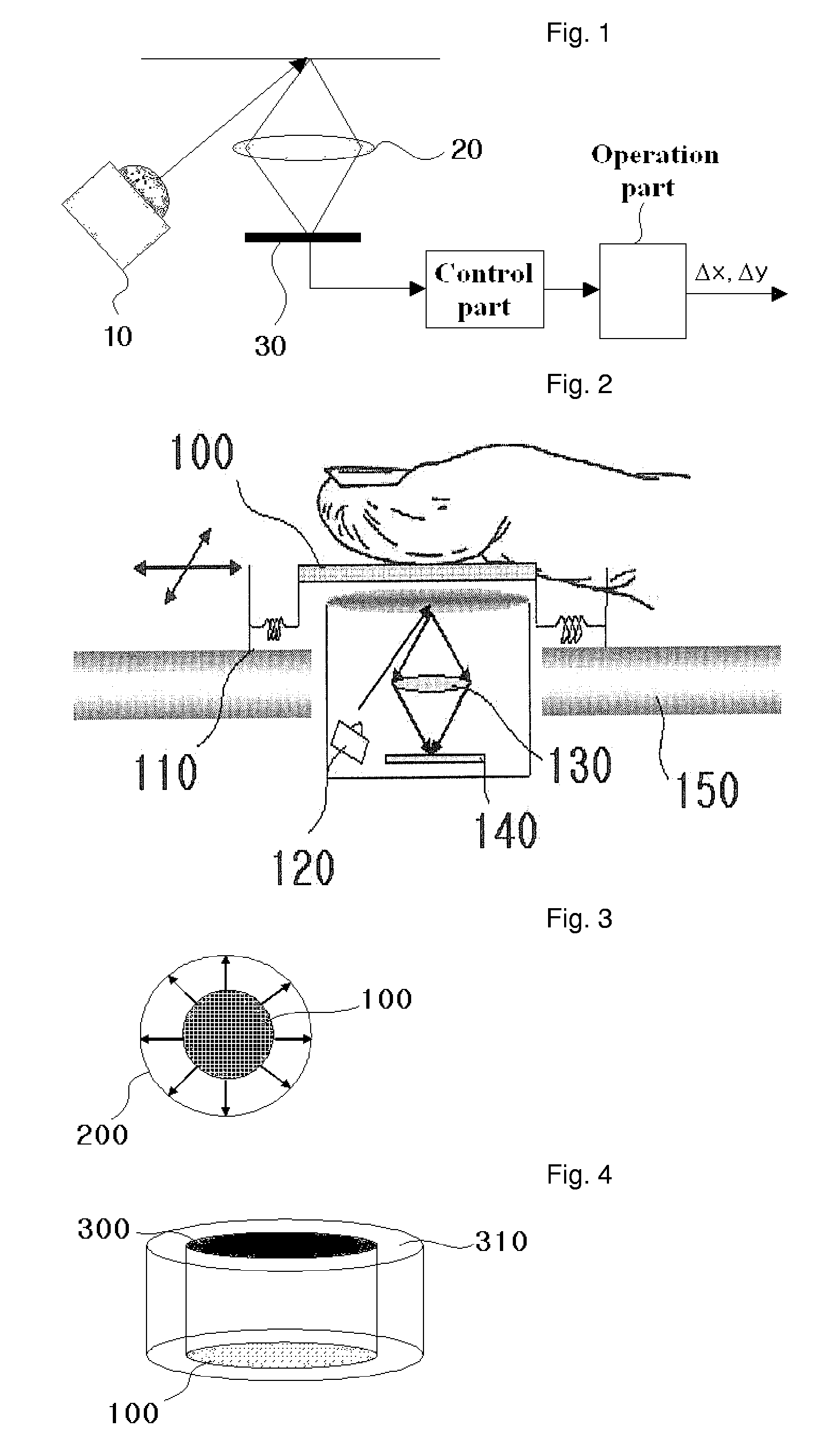

Integrated optical scanning image acquisition and display

An apparatus and method for providing image acquisition and / or image display in a limited region of interest (ROI). The apparatus comprises a micro electro-mechanical system (MEMS), preferably integrating a light source, a cantilever, a lens, an actuator, a light detector, and a position sensor. The light source provides light for illuminating the ROI, displaying an image, providing a therapy, and / or performing other functions. The cantilever comprises a resin waveguide with a fixed end attached to a substrate that supports many or all other components. A free end of the cantilever is released from the substrate during fabrication and includes the lens. The actuator scans the free end in orthogonal directions to illuminate the ROI or display an image. The position sensors detect the position of the free end for control. The light detector receives light backscattered from the ROI separate from, or at the fixed end the cantilever.

Owner:UNIV OF WASHINGTON +1

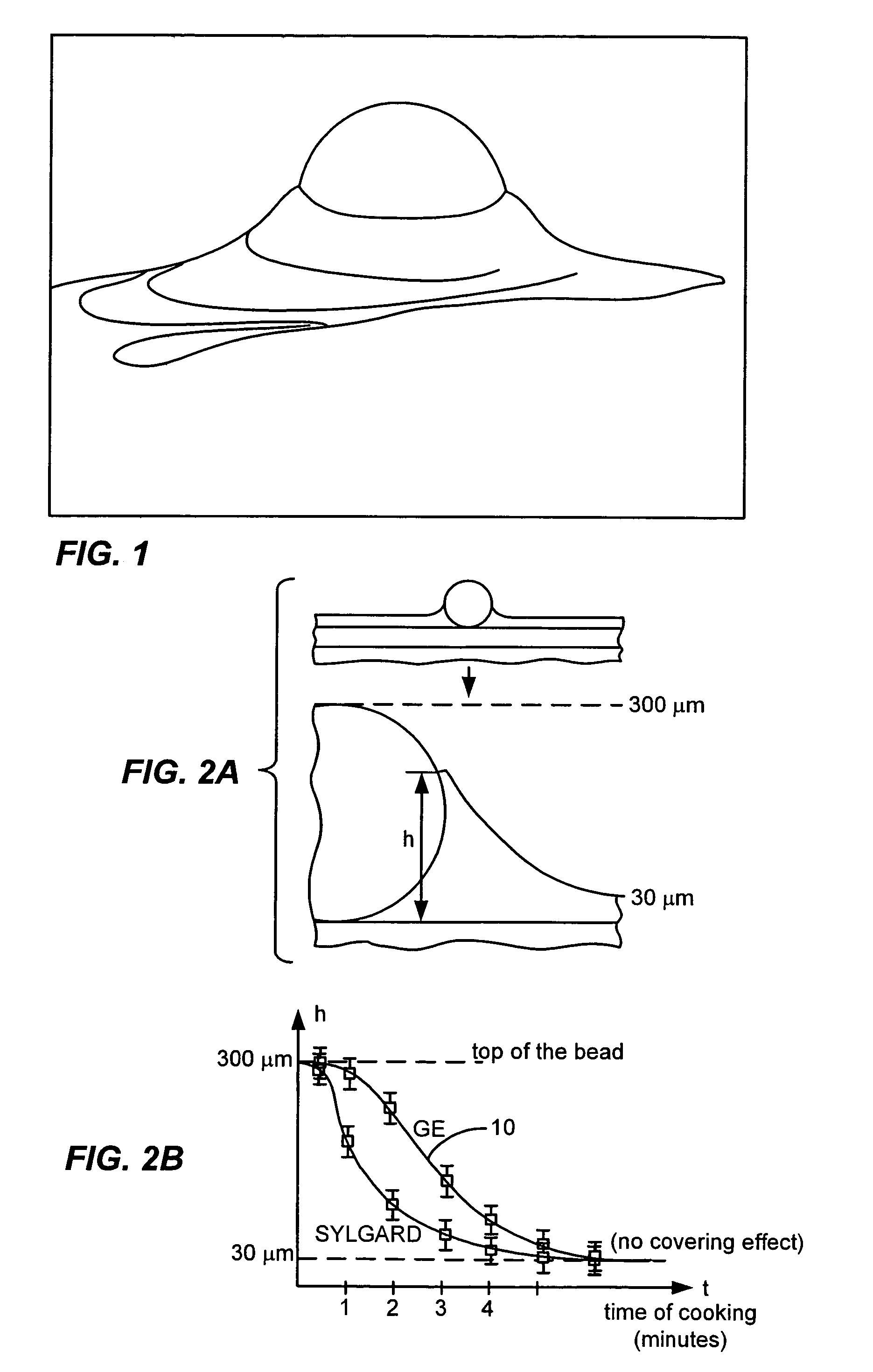

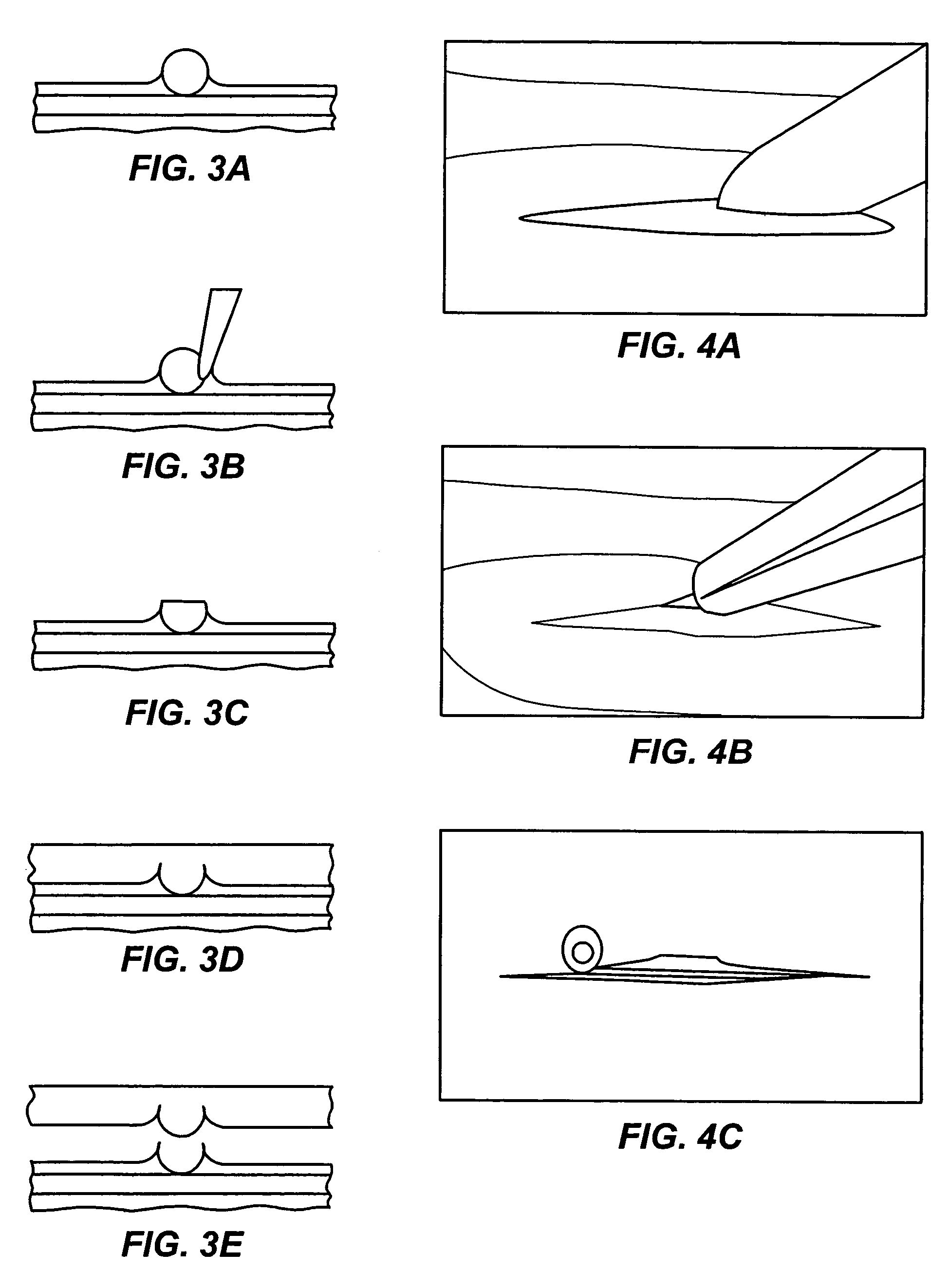

Microfabricated rubber microscope using soft solid immersion lenses

Soft lithography with surface tension control is used to microfabricate extremely efficient solid immersion lenses (SILs) out of rubber elastomeric material for use in microscope type applications. In order to counteract the surface tension of the mold material in a negative mold that causes creep on a positive mold, material such as RTV is partially cured before use in order to allow the reticulation of polymer chains to change the viscosity of the uncured material in a controllable manner. In a specific embodiment, the techniques of soft lithography with surface tension control are used to make molded SILs out of the elastomer polydimethylsiloxane. The lenses achieve an NA in the range of 1.25. The principle of compound lens design is used to make the first compound solid immersion lens, which is corrected for higher light gathering ability and has a calculated NA=1.32. An important application of these lenses is integrated optics for microfluidic devices, specifically in a handheld rubber microscope for microfluidic flow cytometry.

Owner:CALIFORNIA INST OF TECH

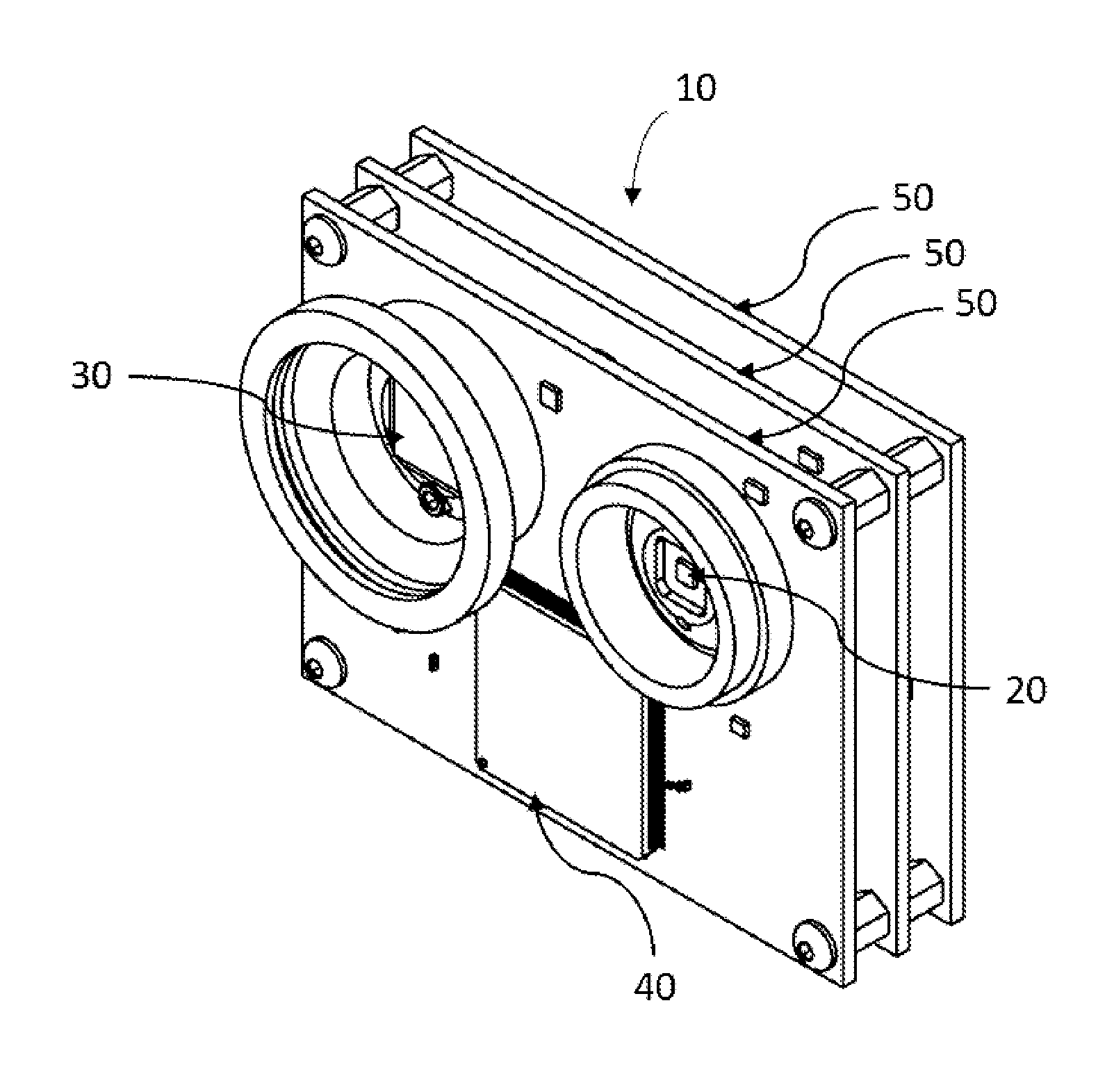

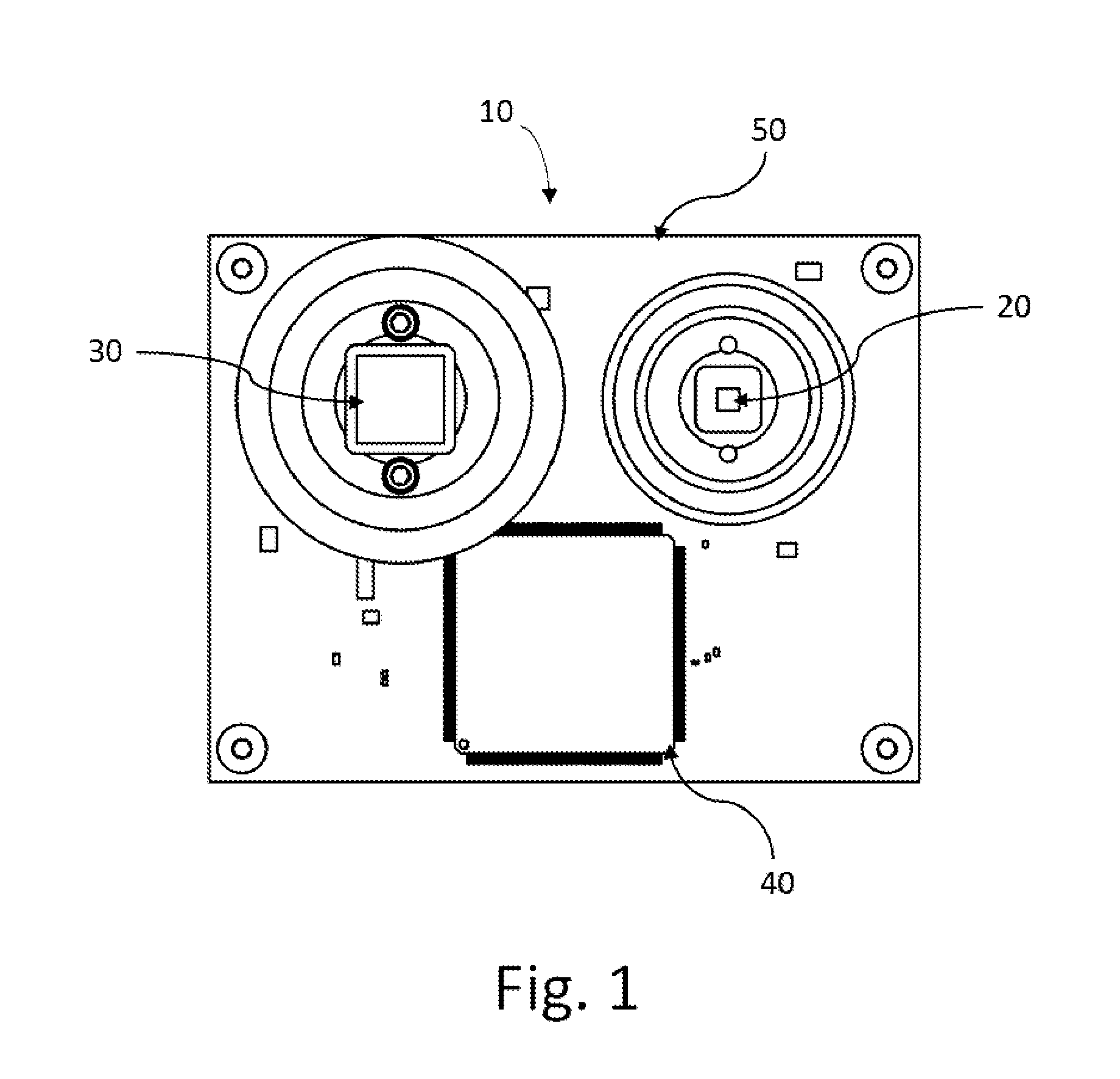

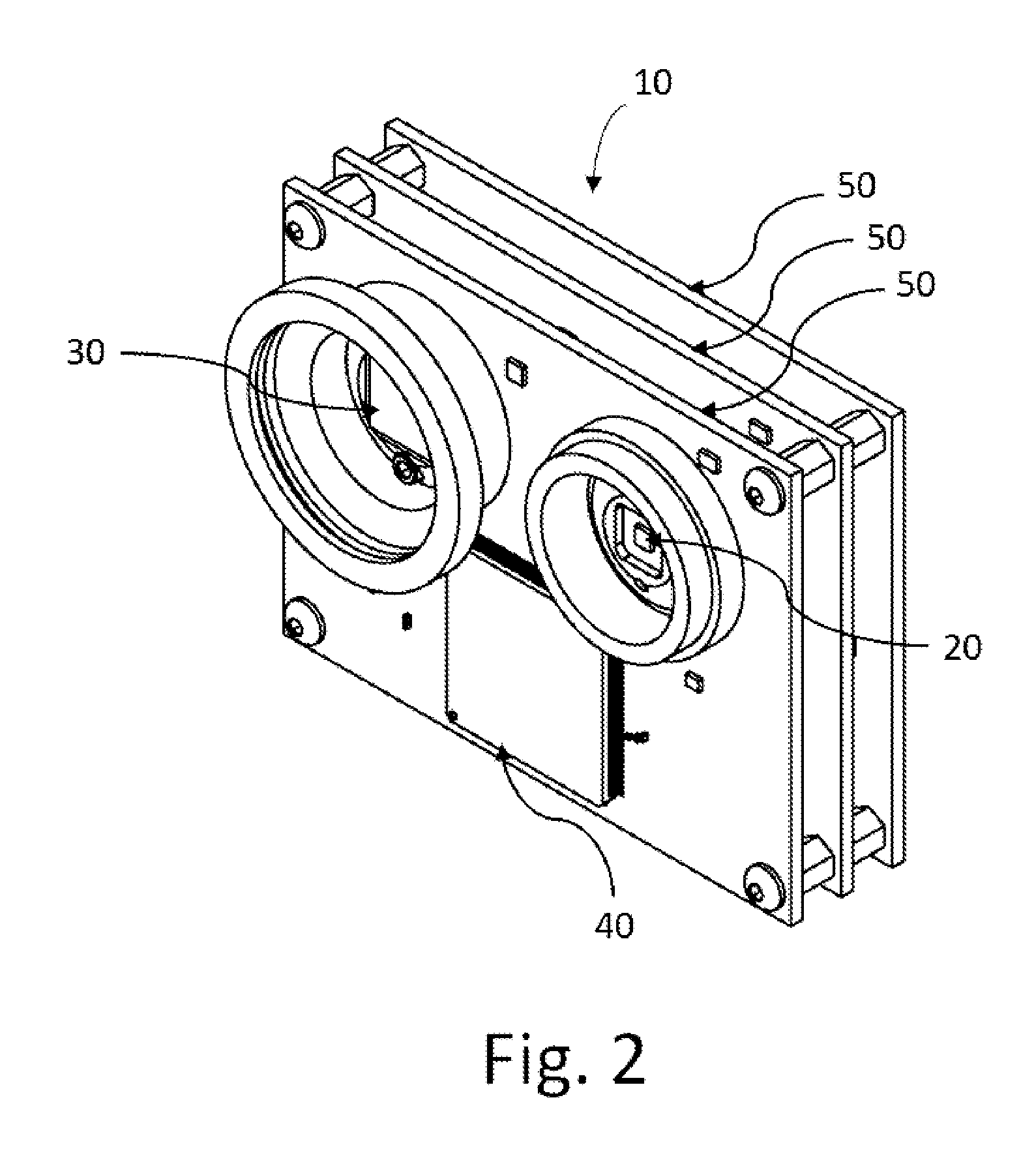

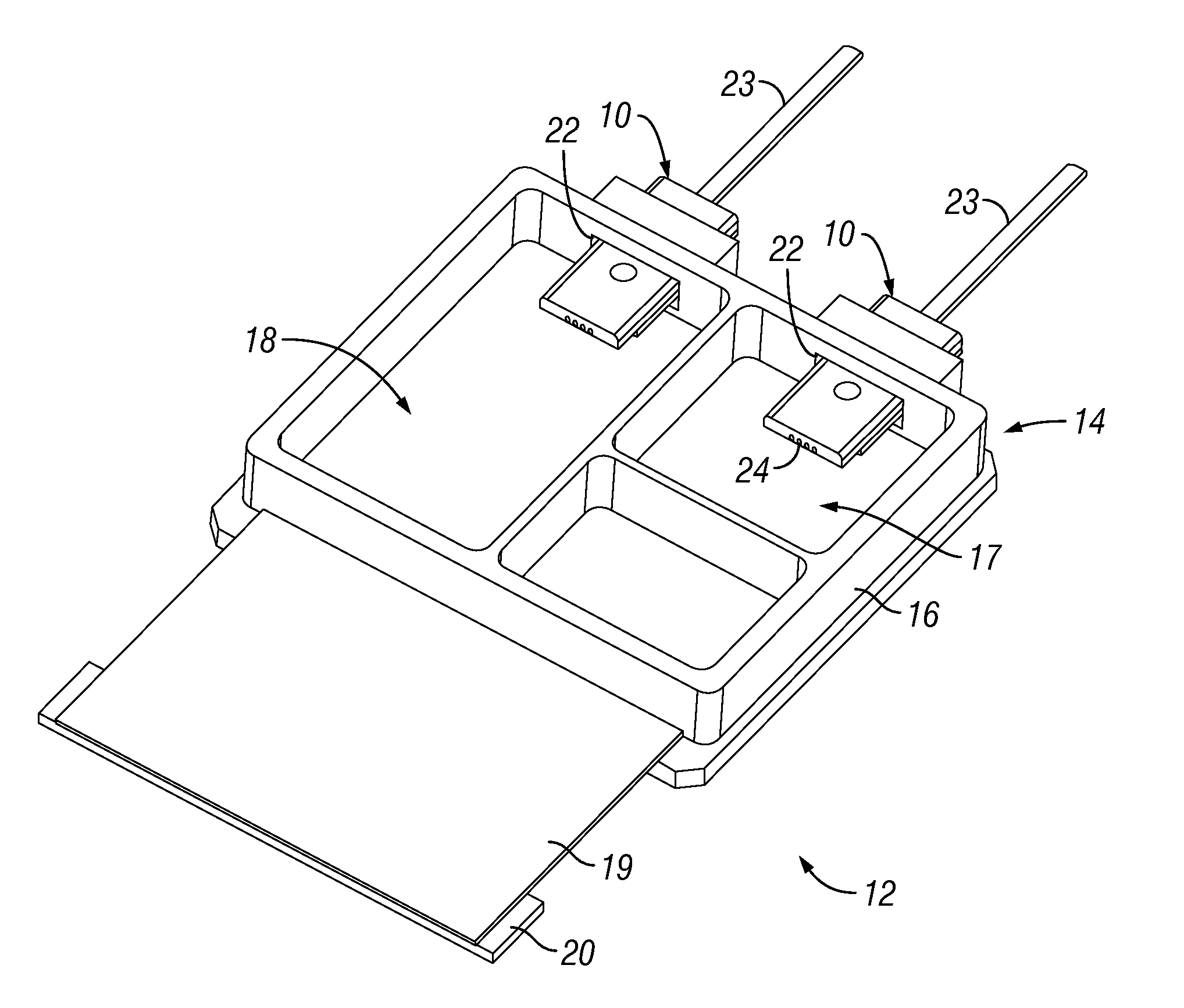

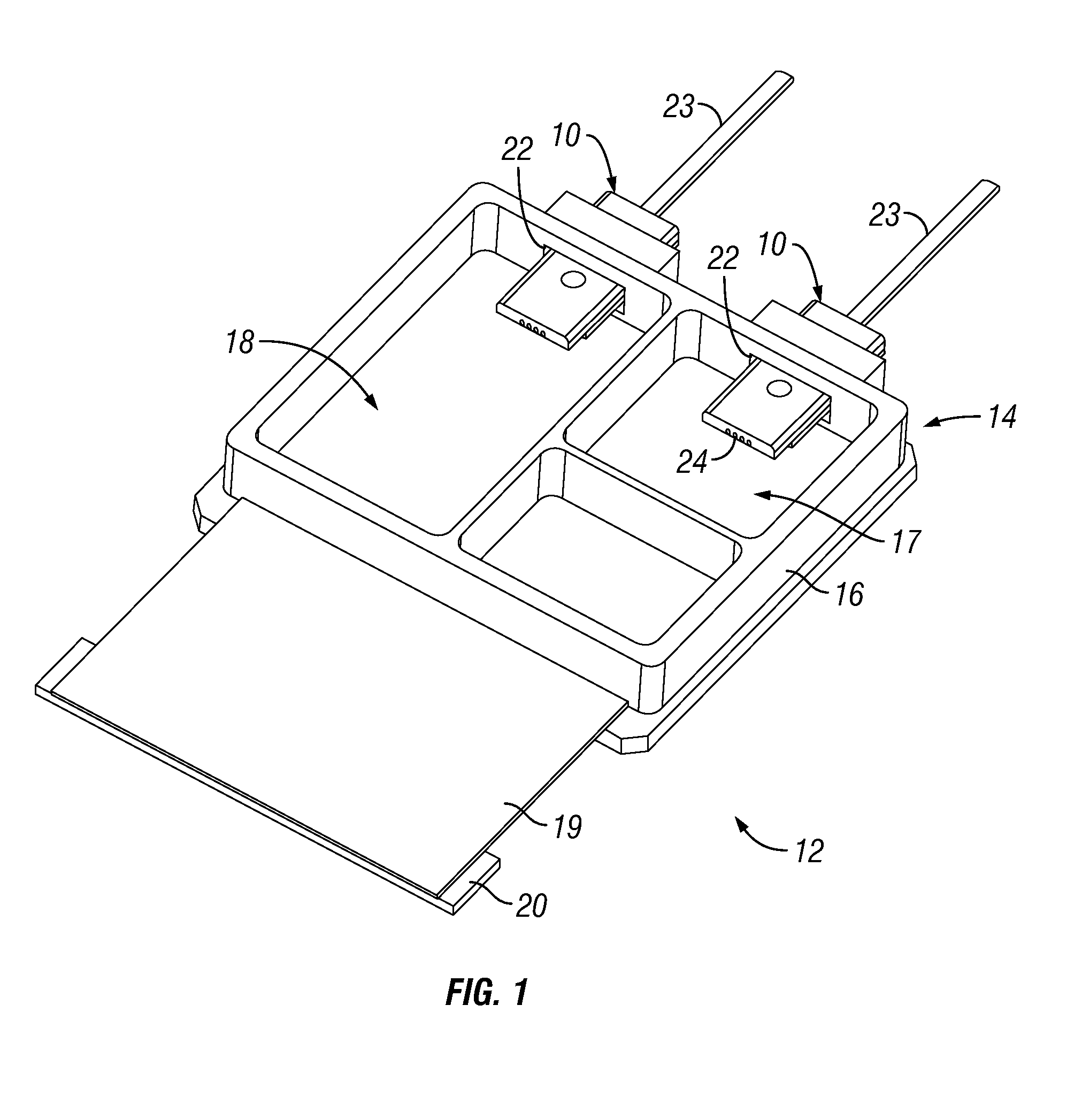

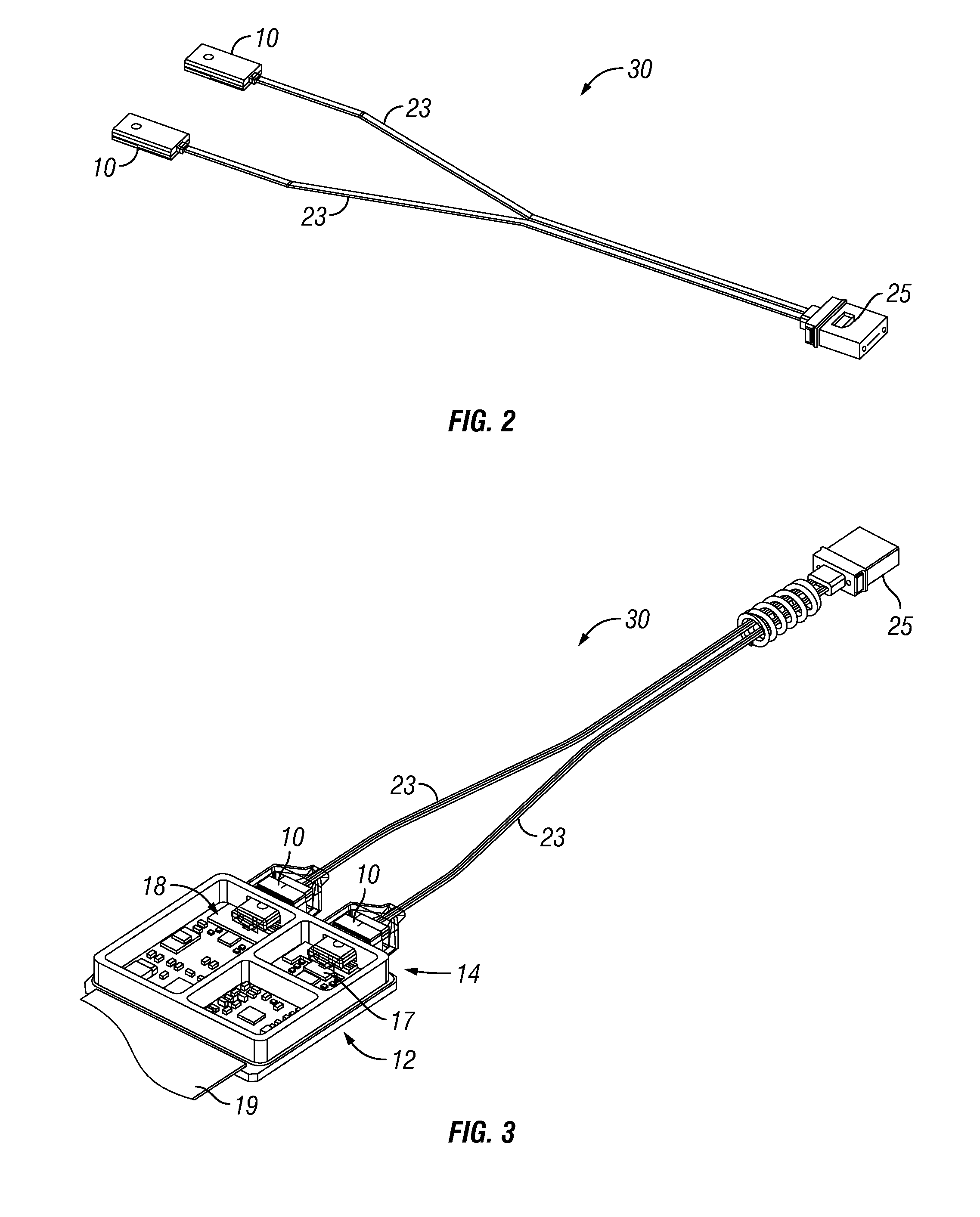

Modular optical components and systems incorporating same

InactiveUS20080080059A1Simplified and robustPrevents and minimizes optical aberrationMaterial analysis by optical meansOptical elementsOptical ModuleFluorescence

Modular optical systems employing integrated optical plates, prisms, reflective and semireflective layers that provide less complex, more robust optical systems. The modular systems provide single, or double component optical modules for the redirection, deflection and separation of optical energy for use in optical systems, and particularly optical detection systems for, e.g., fluorescence analysis tools used in the biochemical and chemical analysis industries.

Owner:PACIFIC BIOSCIENCES

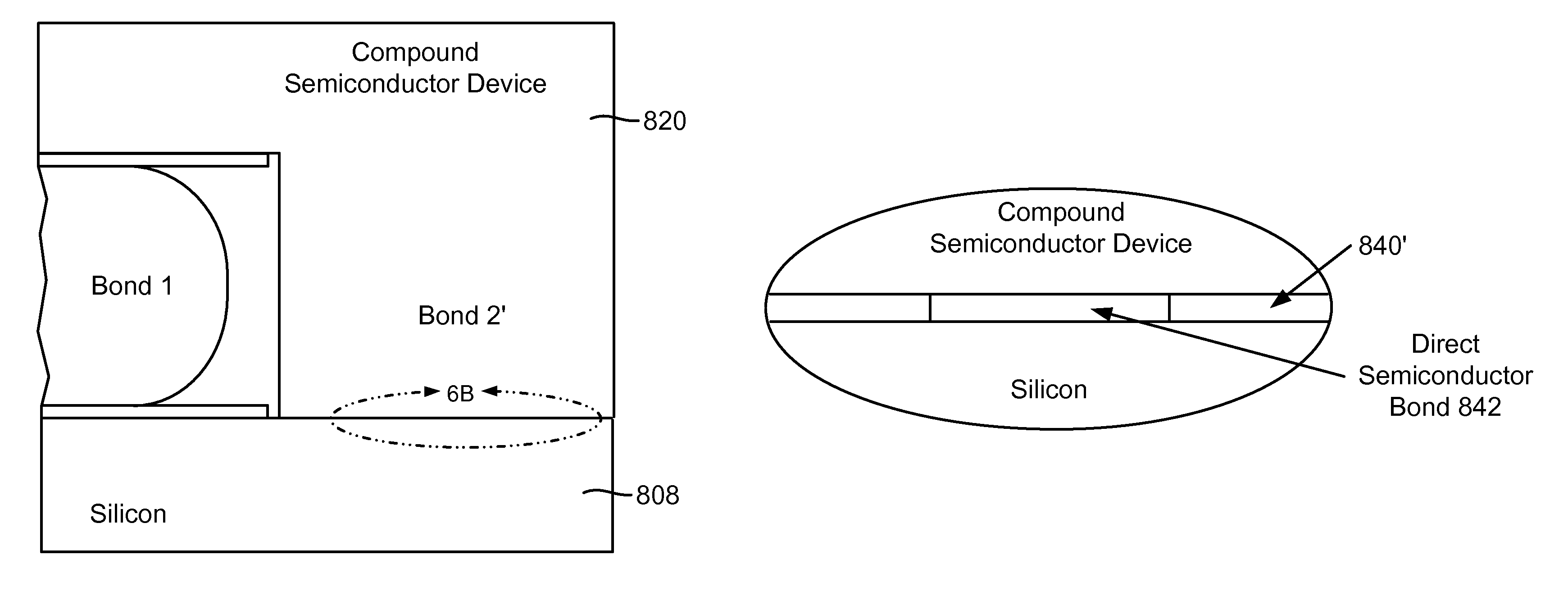

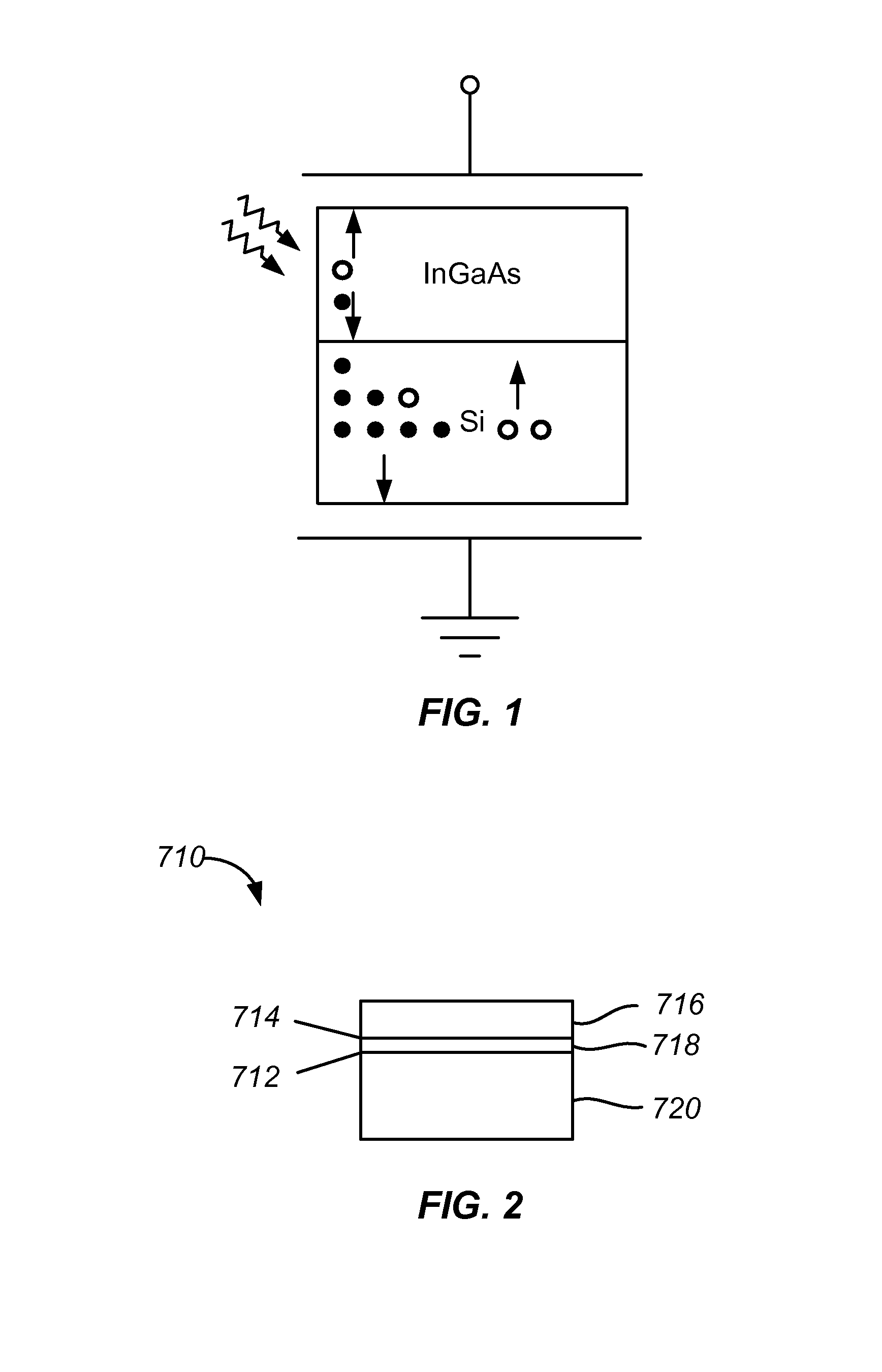

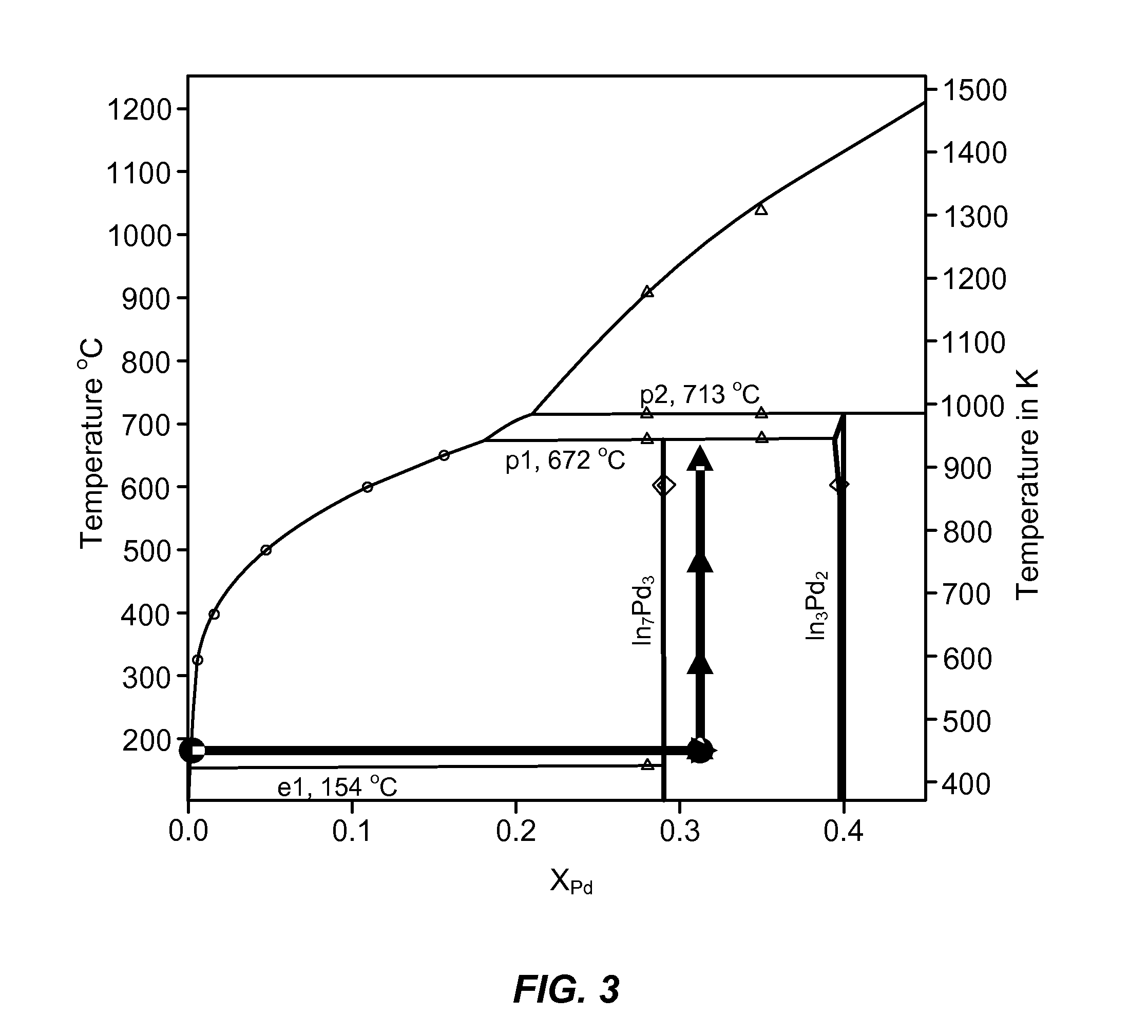

Method and system for heterogeneous substrate bonding of waveguide receivers

InactiveUS8611388B2Semiconductor/solid-state device detailsSolid-state devicesInterface layerWaveguide

A composite integrated optical device includes a substrate including a silicon layer and a waveguide disposed in the silicon layer. The composite integrated optical device also includes an optical detector bonded to the silicon layer and a bonding region disposed between the silicon layer and the optical detector. The bonding region includes a metal-assisted bond at a first portion of the bonding region. The metal-assisted bond includes an interface layer positioned between the silicon layer and the optical detector. The bonding region also includes a direct semiconductor-semiconductor bond at a second portion of the bonding region.

Owner:SKORPIOS TECH

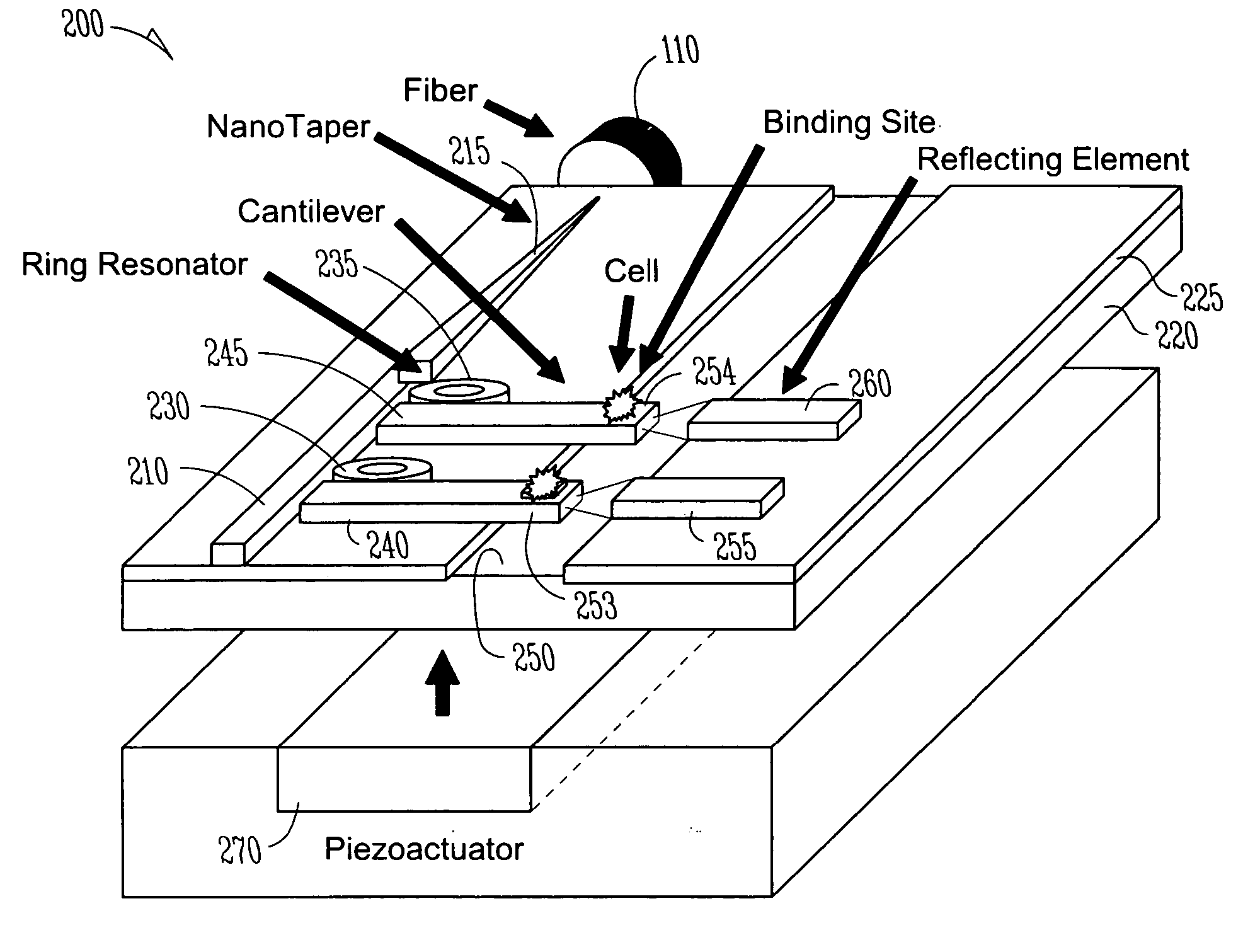

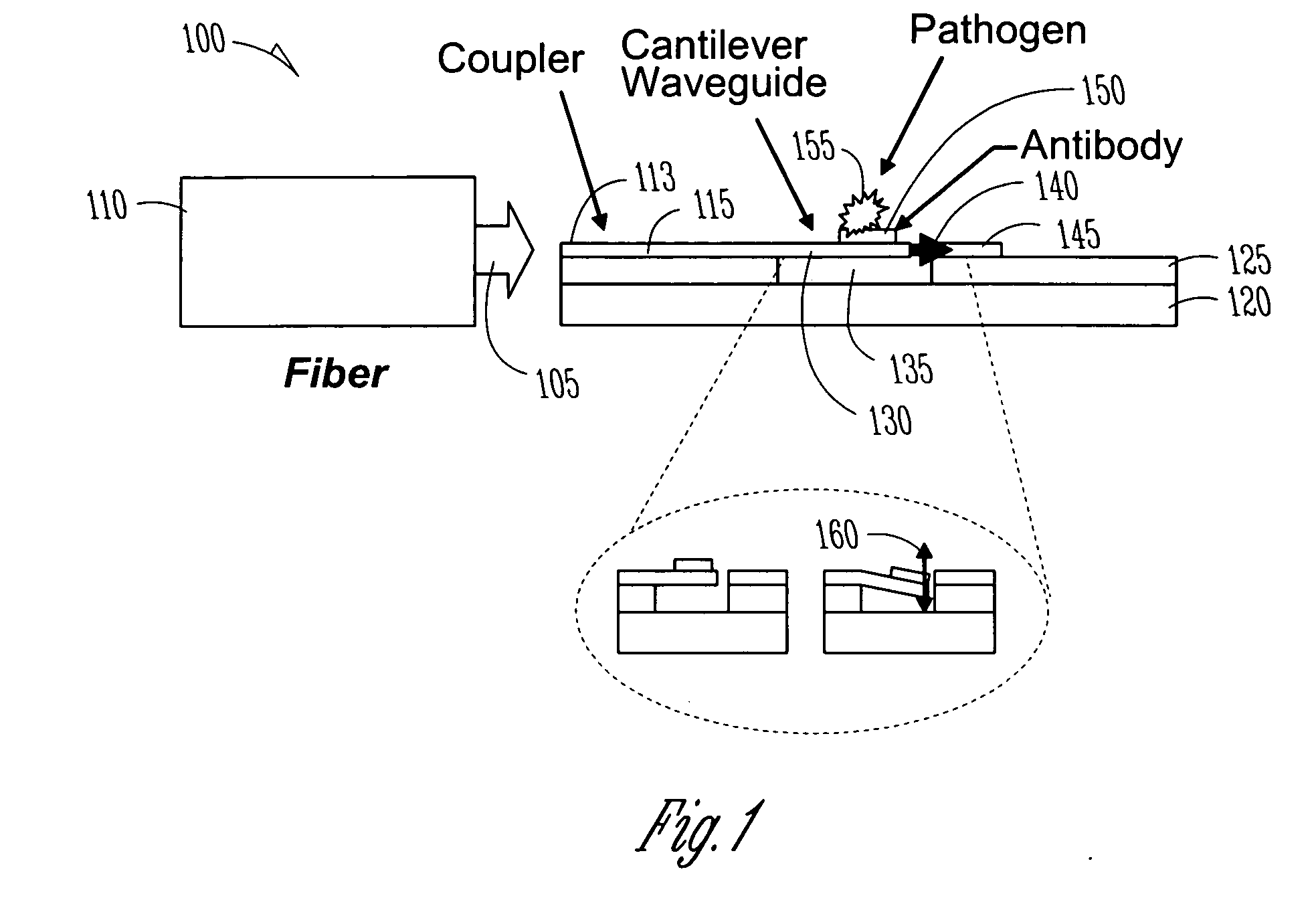

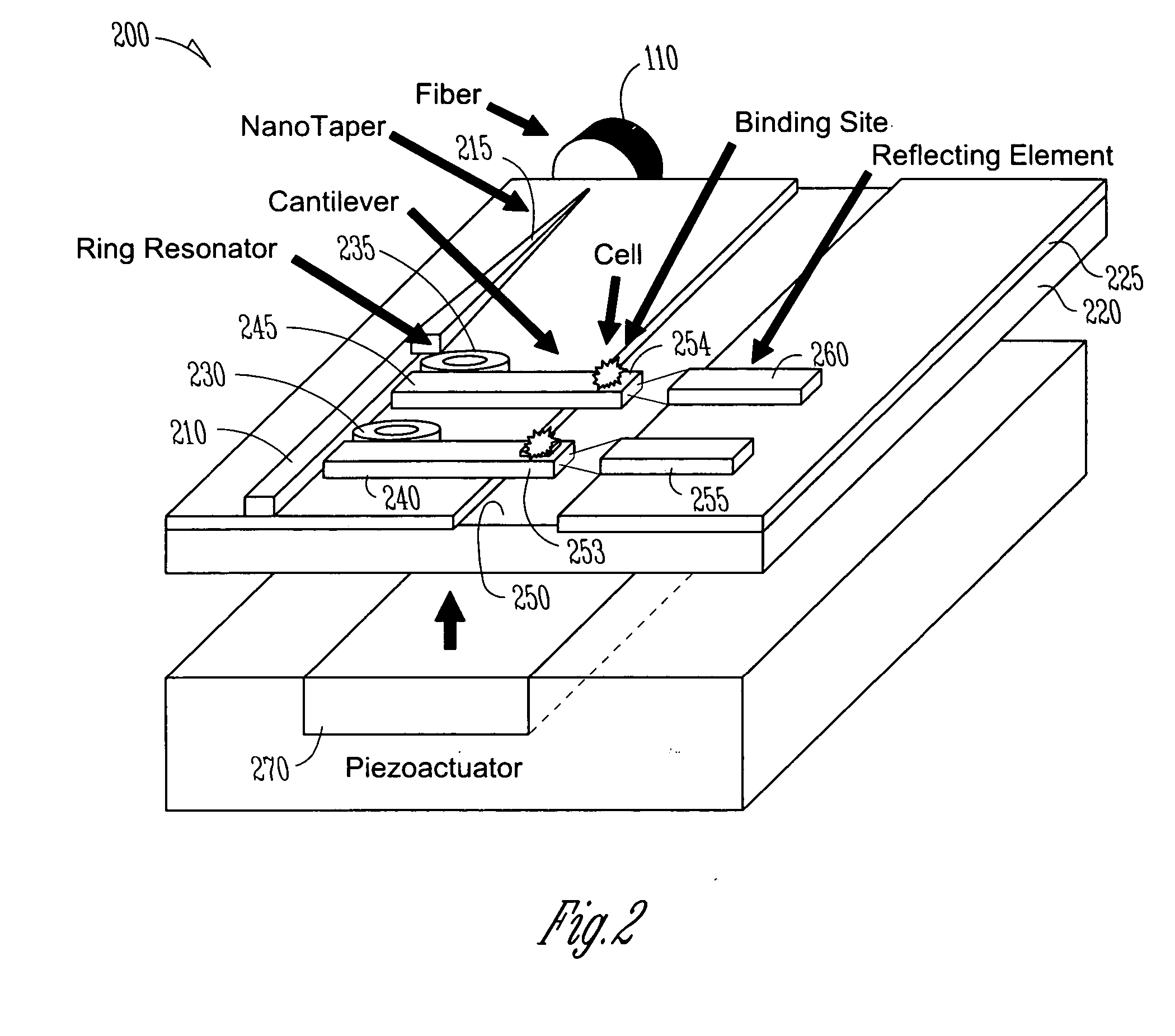

Optical waveguide displacement sensor

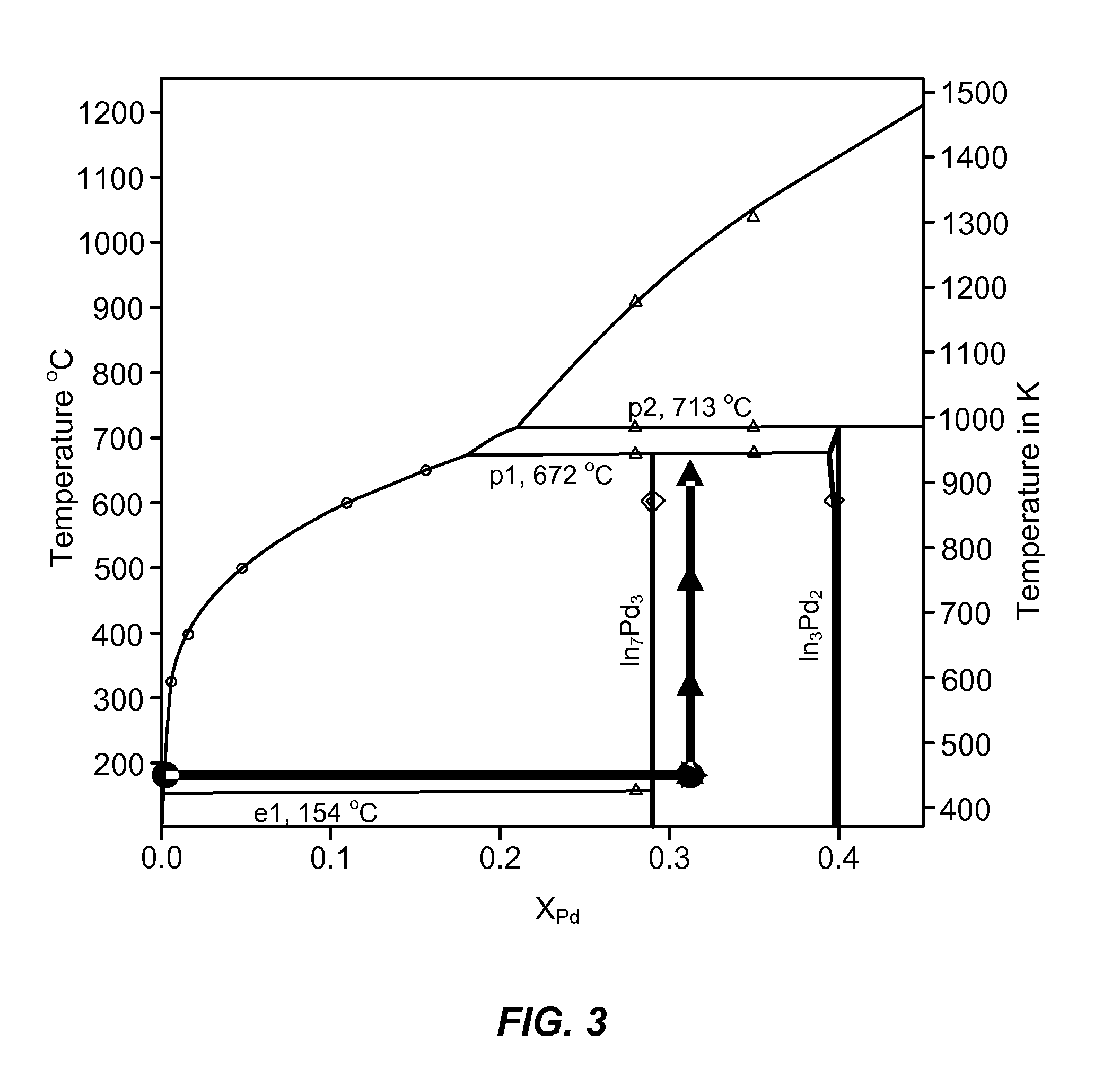

A substrate incorporates a mechanical cantilever resonator with passive integrated optics for motion detection. The resonator acts as a waveguide, and enables optical detection of deflection / displacement amplitude, including oscillations. In one embodiment, the cantilever comprises a silicon waveguide suspended over a substrate. A reflector structure faces a free end of the suspending cantilever, or a waveguide is supported facing the free end of the suspended cantilever to receive light transmitted through the silicon waveguide cantilever. Deflection / displacement of the cantilever results in modulation of the light received from its free end that is representative of the displacement. Ring resonators may be used to couple different wavelength light to the waveguides, allowing formation of an array of cantilevers.

Owner:CORNELL RES FOUNDATION INC

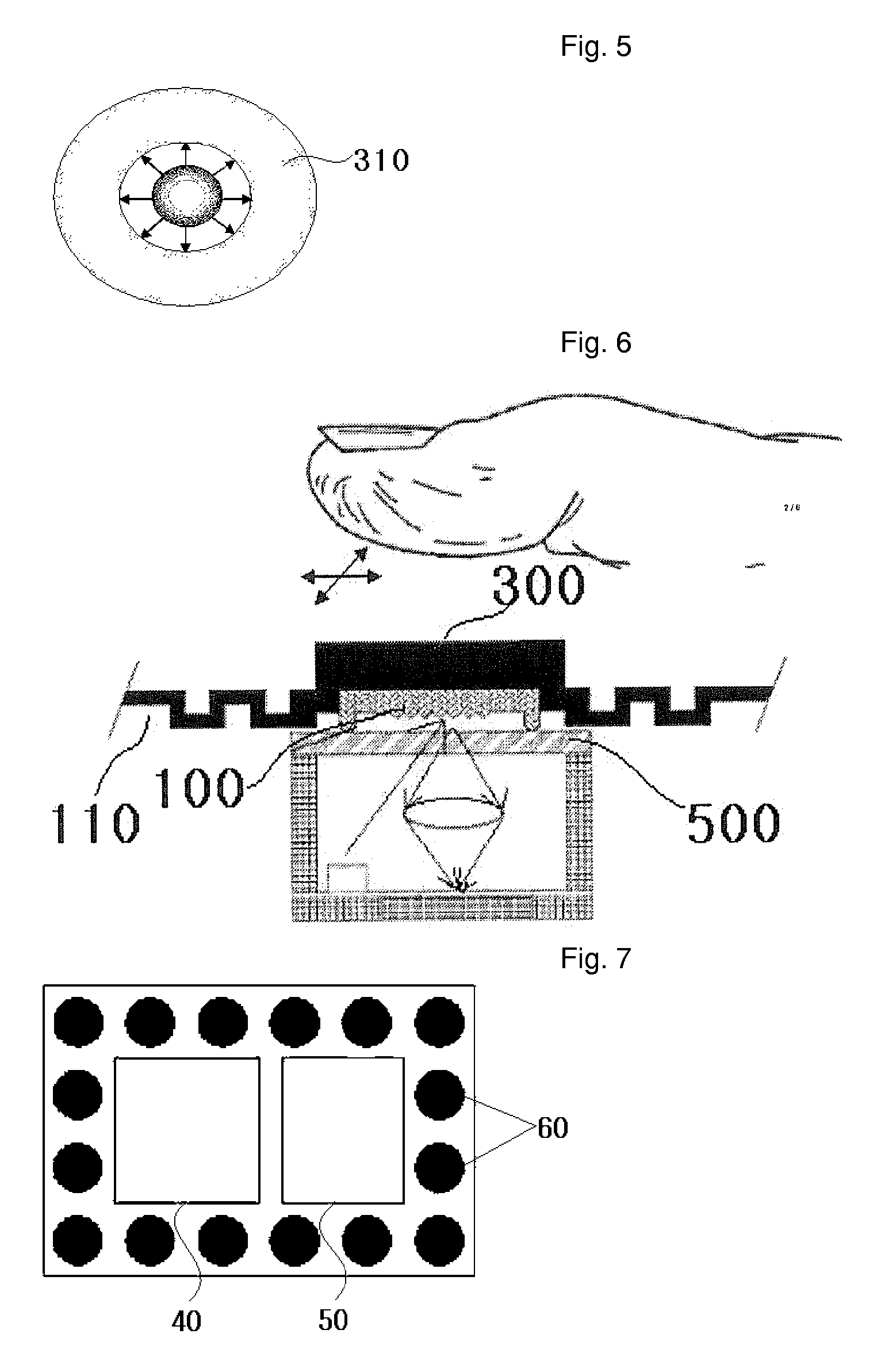

Pointing device with an integrated optical structure

InactiveUS20070146318A1Reduce spendingImprove mobilityCathode-ray tube indicatorsInput/output processes for data processingPrismImaging lens

The present invention relates to a micro-optical pointing device suitable for mobile terminals such as a cellular phone and PDA. A disclosed pointing device includes a light source emitting light rays to a subject; a contact member comprising a lattice type or perceivable pattern, which reflects an image of the moving subject; and an automatic transfer device restoring the contact member moved by a finger. The pointing device may further include a flip chip containing an image sensor, which converts the acquired image into an electronic signal, and a circuit for signal processing. The pointing device may include an integrated optical structure comprising a condensing lens, a specular surface, a light output part, and an image-formation lens. The pointing device may include a light guide structure that a parallel light prism lens, an image-formation lens, and a mask for blocking disturbance ray are formed into a single part.

Owner:MOBISOL +1

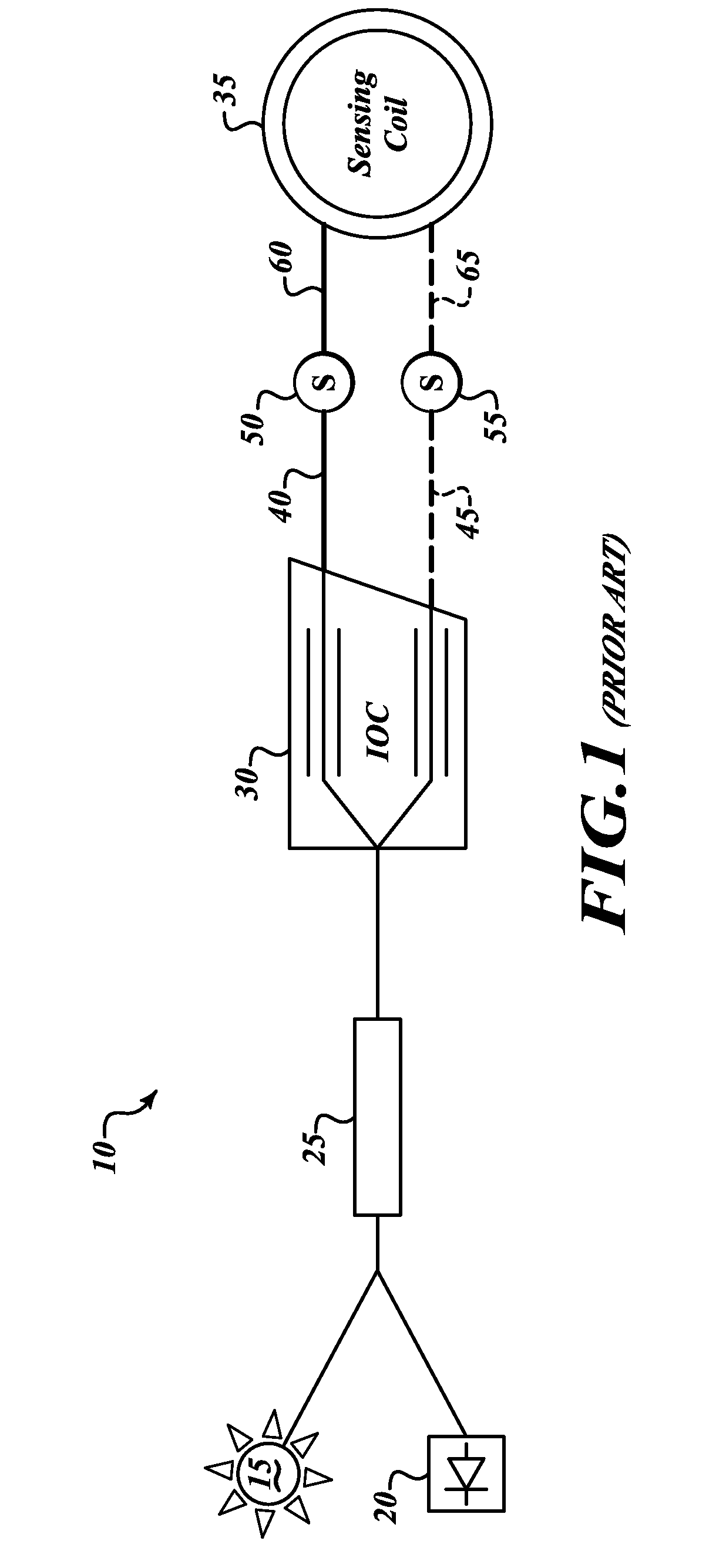

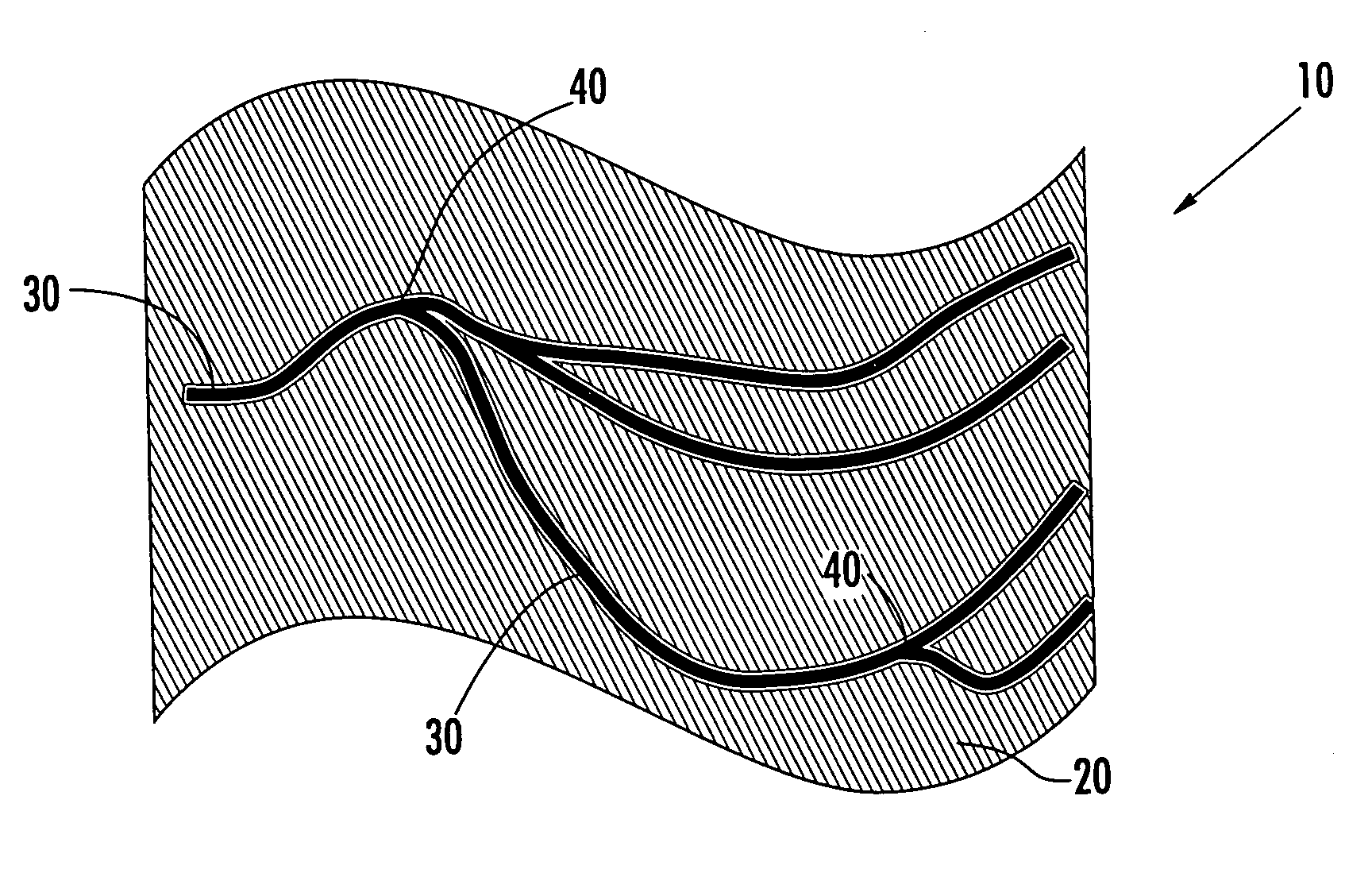

Bifilar optical fiber stowage for fiber-optic gyroscope

ActiveUS20100092126A1Speed measurement using gyroscopic effectsSagnac effect gyrometersFiberGyroscope

Owner:HONEYWELL INT INC

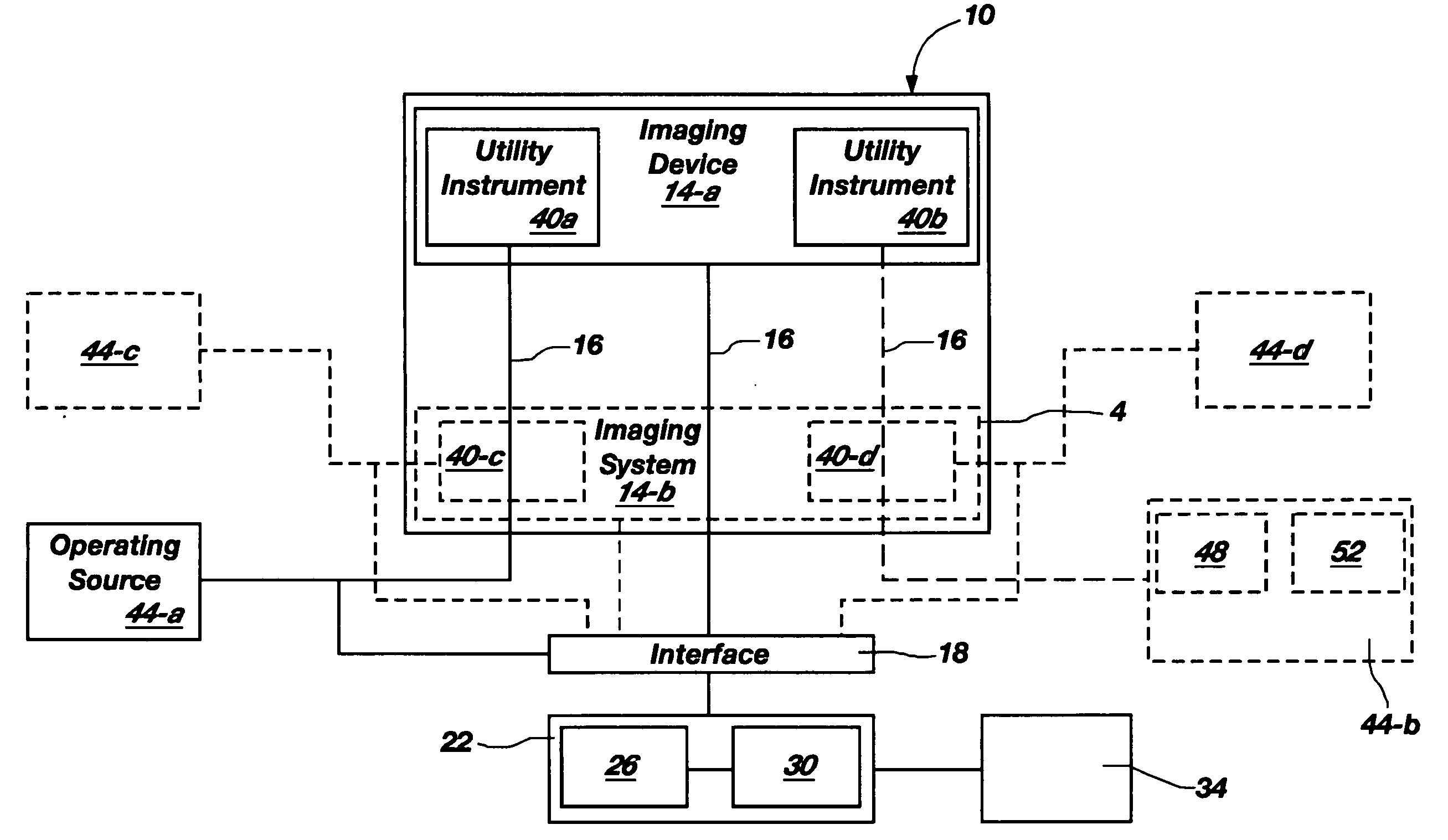

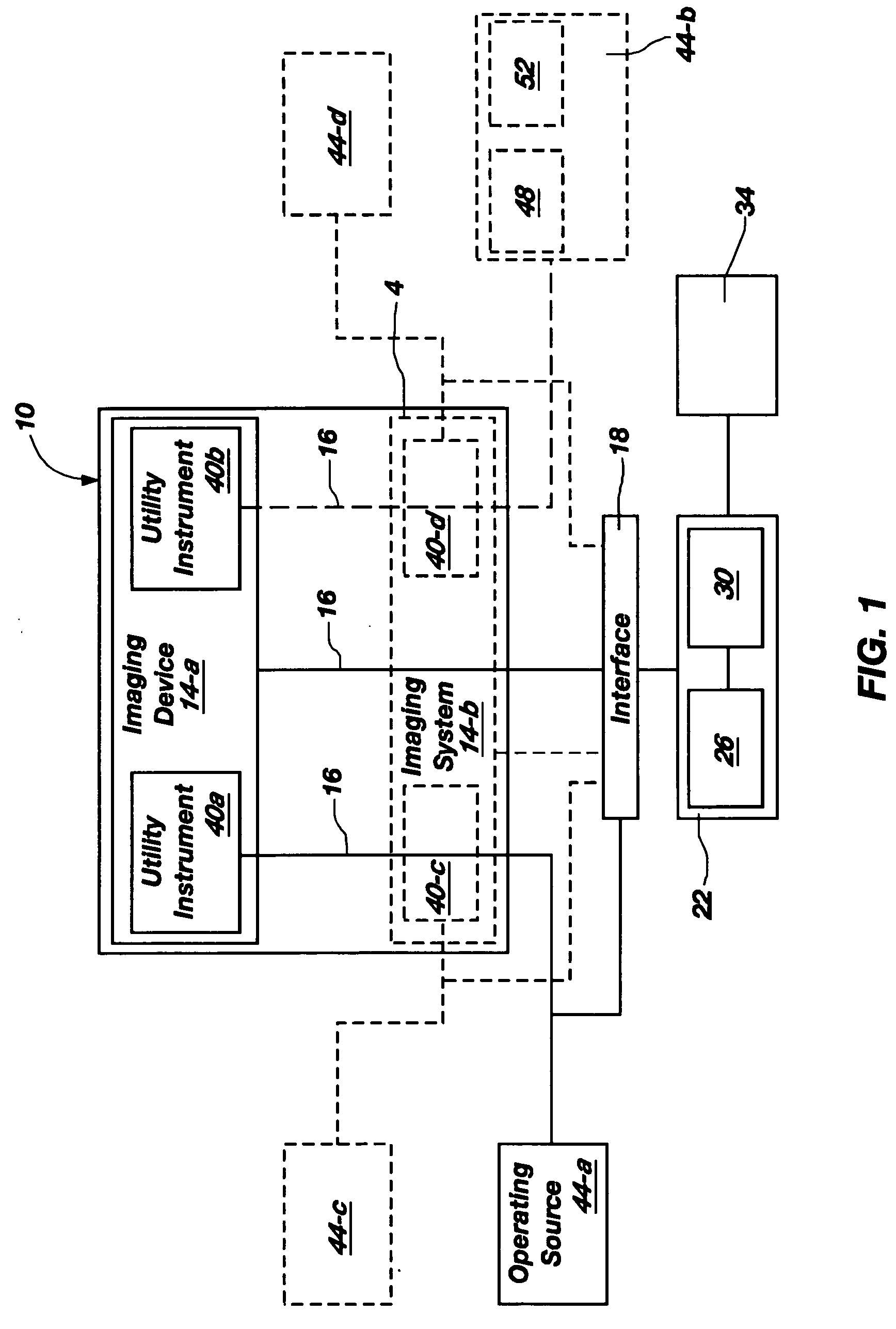

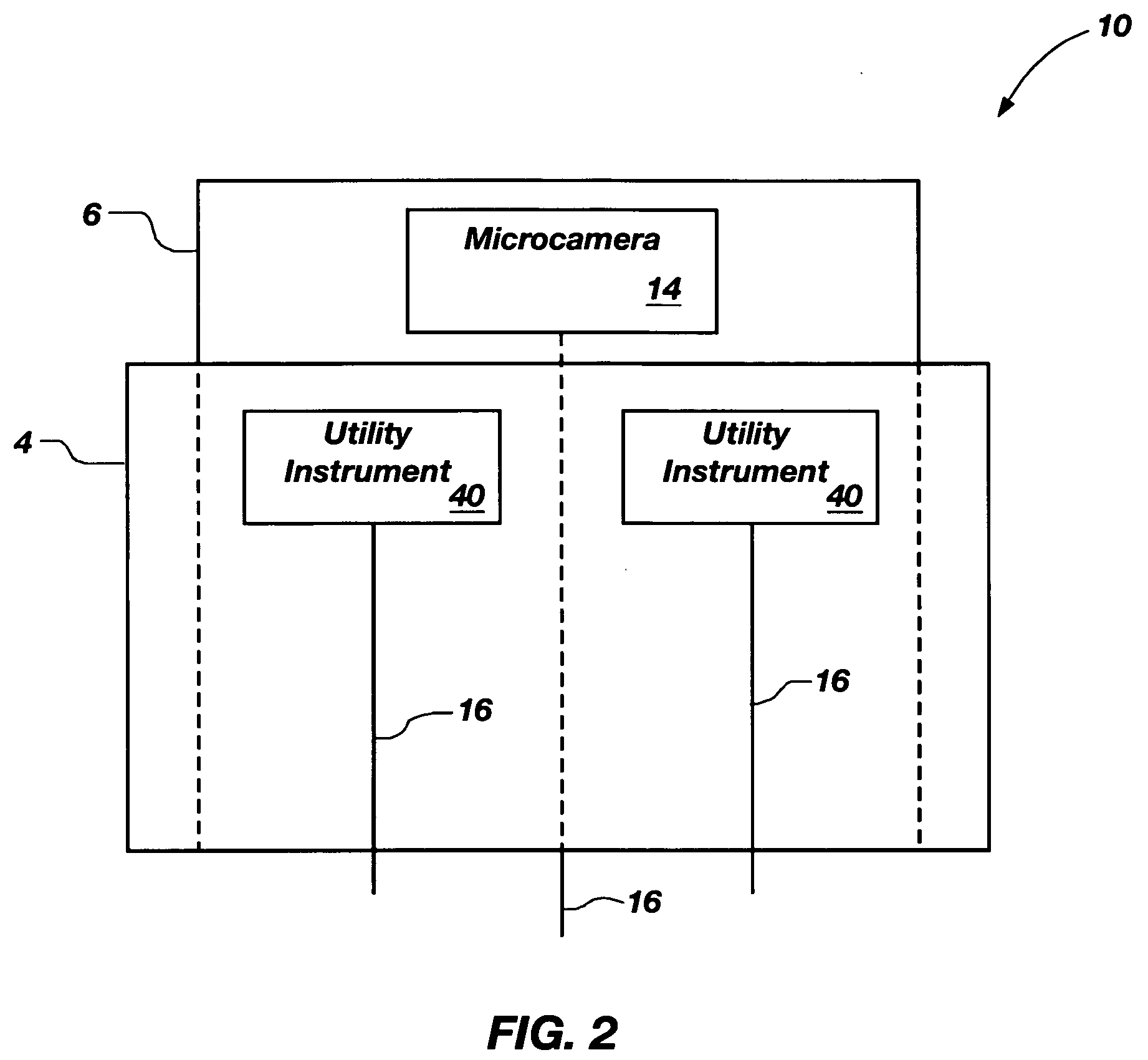

Miniaturized utility device having integrated optical capabilities

InactiveUS20060146172A1High aspect ratioTelevision system detailsEndoscopesMicro imagingCamera image

A miniaturized utility device having integrated optical capabilities for use on a high aspect ratio system, wherein the miniaturized utility device comprises: (a) a micro camera comprising a solid state micro imaging device including, as an integral structure, an imaging array electrically coupled to a conductive pad, wherein the solid state imaging device further includes at least one utility aperture passing therethrough, and a lens optically coupled to the imaging array; and (b) a micro utility instrument configured for coordinated operation with the imaging device at a common local site, wherein the micro utility instrument is configured to perform a designated function viewable, preferably in real-time, via a camera image generated by the micro camera.

Owner:STERLING L C

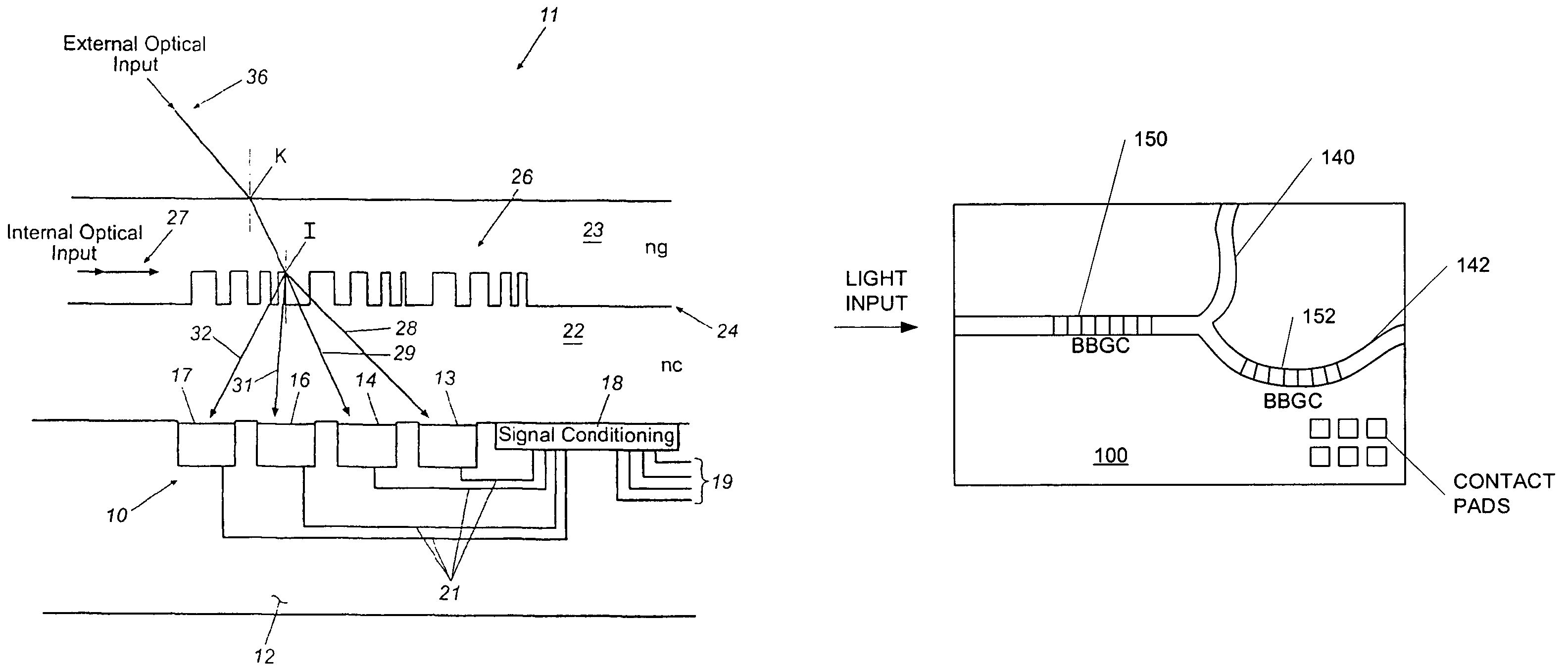

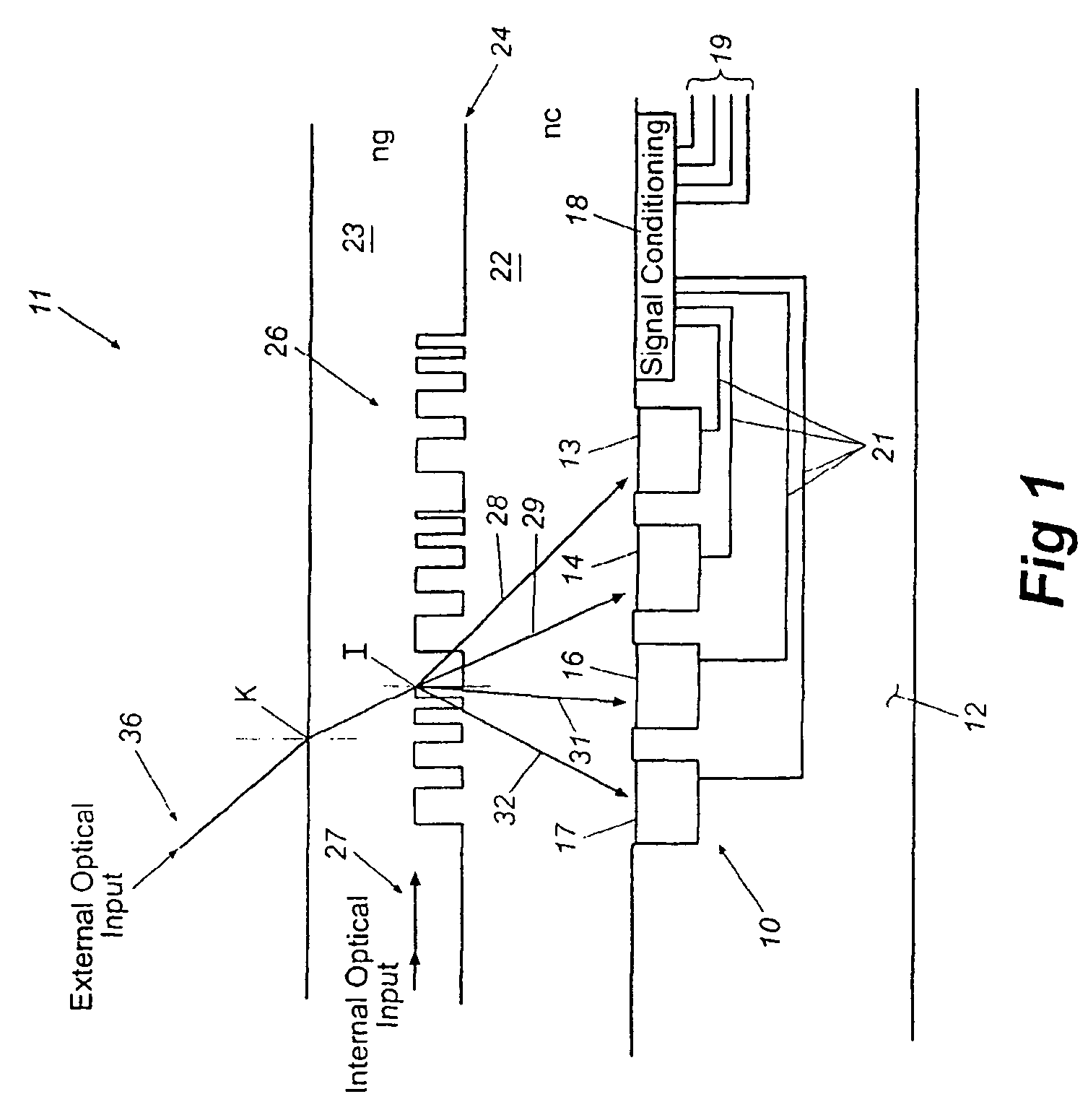

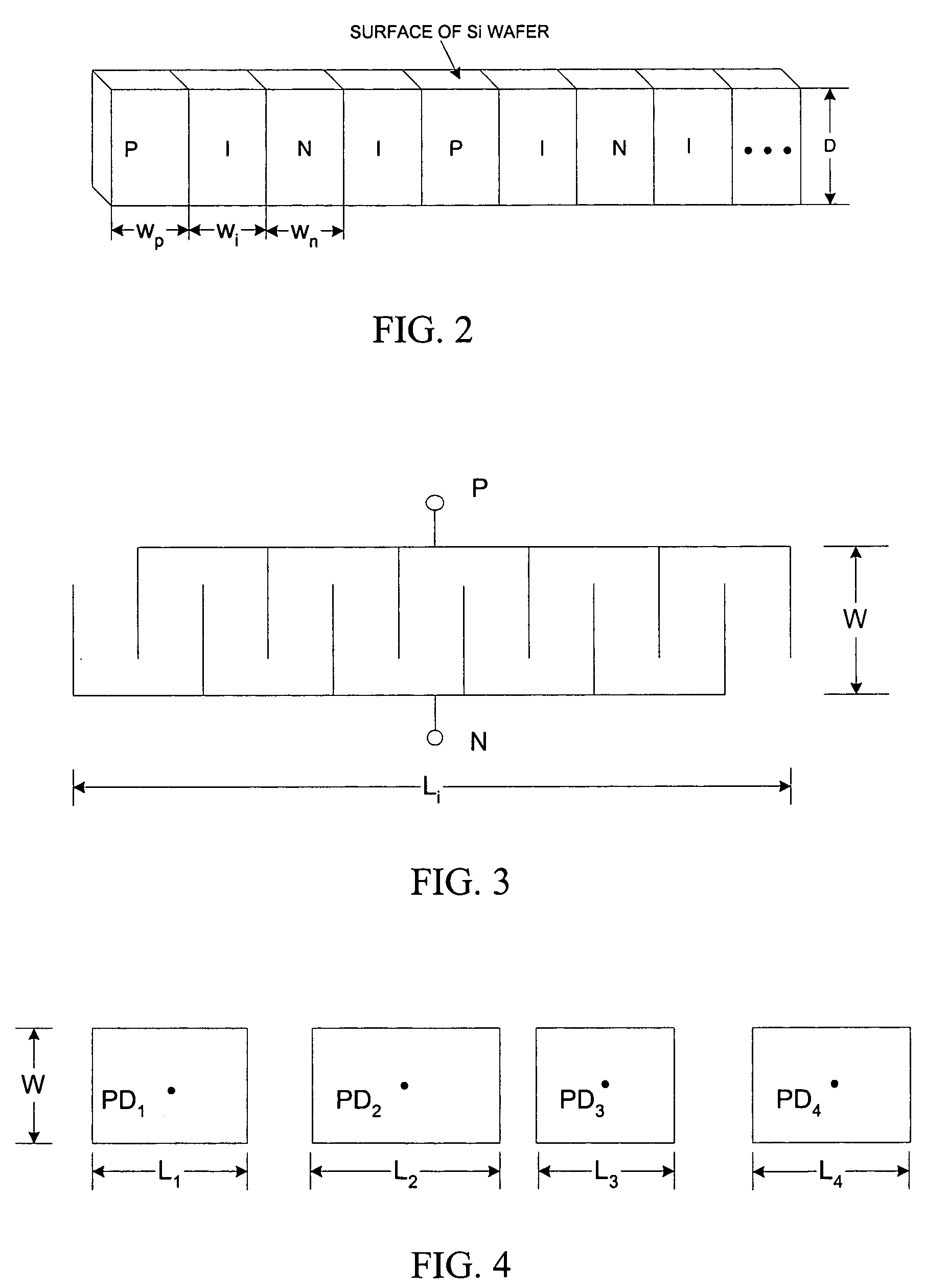

Integrated optical multiplexer and demultiplexer for wavelength division transmission of information

InactiveUS7050675B2High intensity optical signalFast data throughputRadiation pyrometryFinal product manufactureGratingWaveguide

A multiplexer / demultiplexer is provided for optical interconnection between electronic components on an integrated circuit chip. The multiplexer / demultiplexer includes a substrate formed with an array of photo emitters / detectors and conditioning electronics coupled thereto. A first layer of optically transparent material is formed on the substrate overlying the emitters / detectors and a second layer of optically transparent material, functioning as an optical waveguide, is formed on the first layer. A binary blazed grating is formed at the interface of the two layers. For multiplexing, discrete wavelength optical signals are modulated with data, emitted by the emitters, intercepted by the binary blazed grating, and multiplexed into a polychromatic beam for transmission through the waveguide. For demultiplexing, the discrete wavelengths are separated by the binary blazed grating and directed to corresponding detectors. The conditioning electronics receive and demodulate the output of the detectors to extract data, and format the data for communication with electronic components.

Owner:ADVANCED INTERFACES GEORGIA

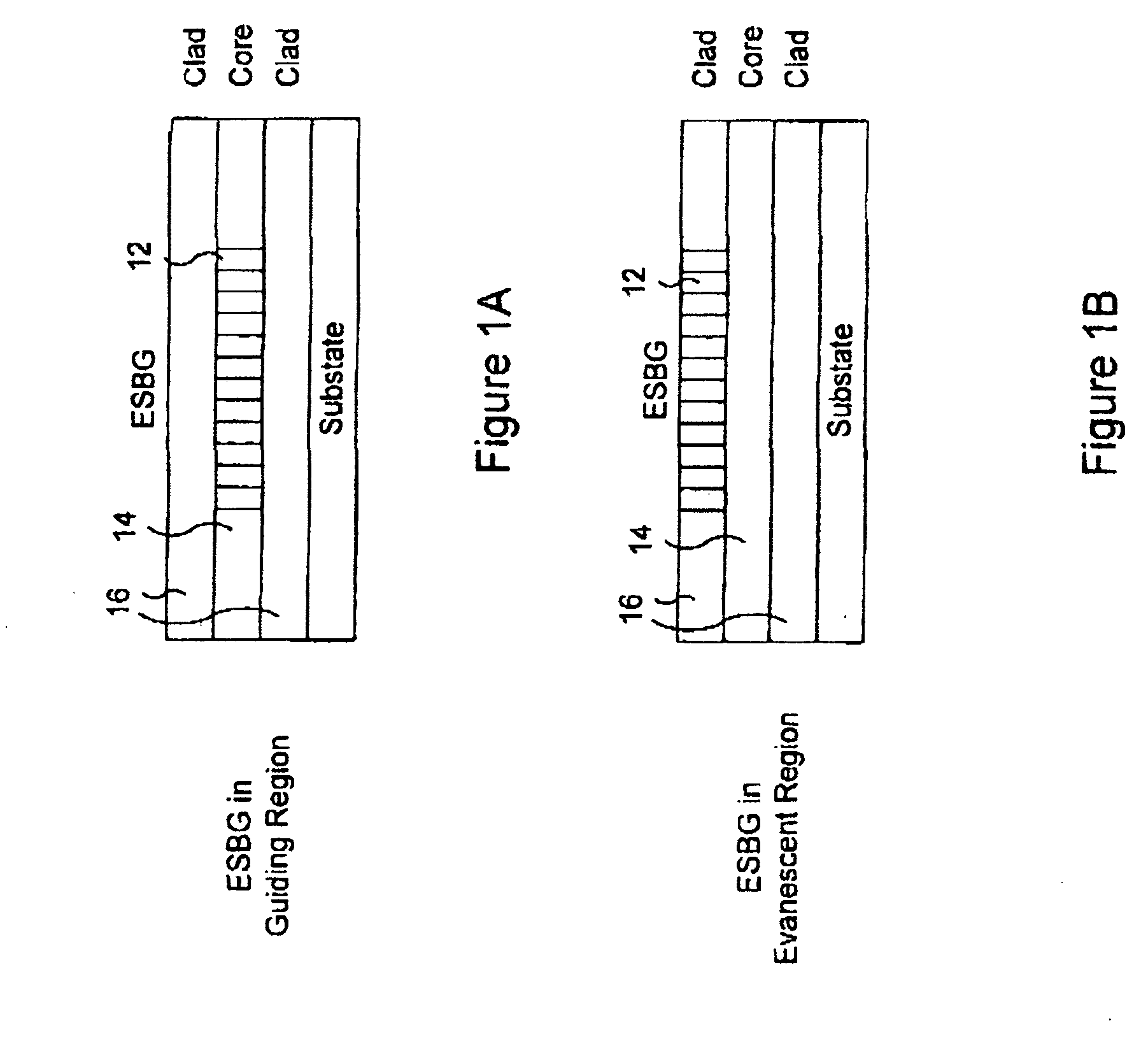

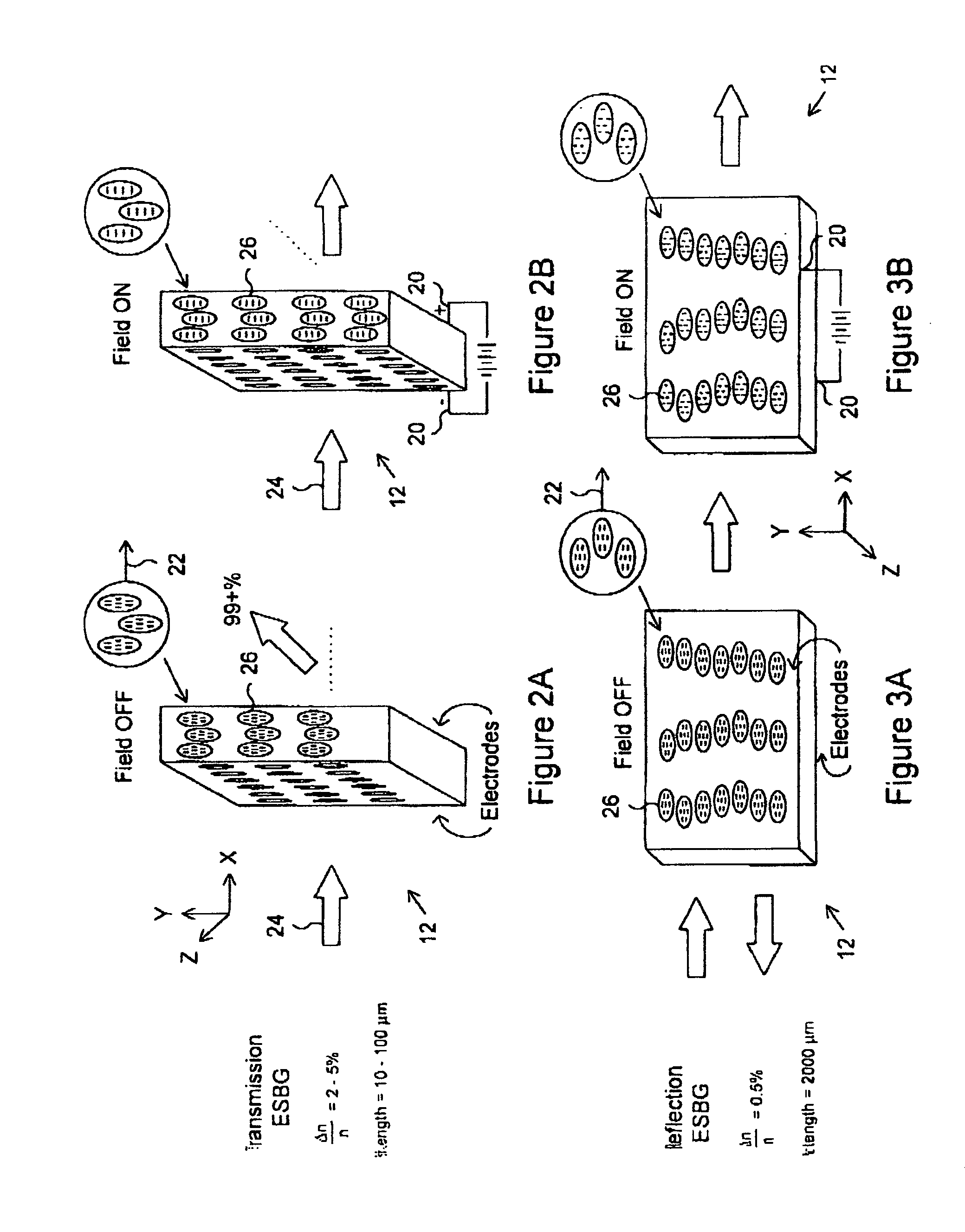

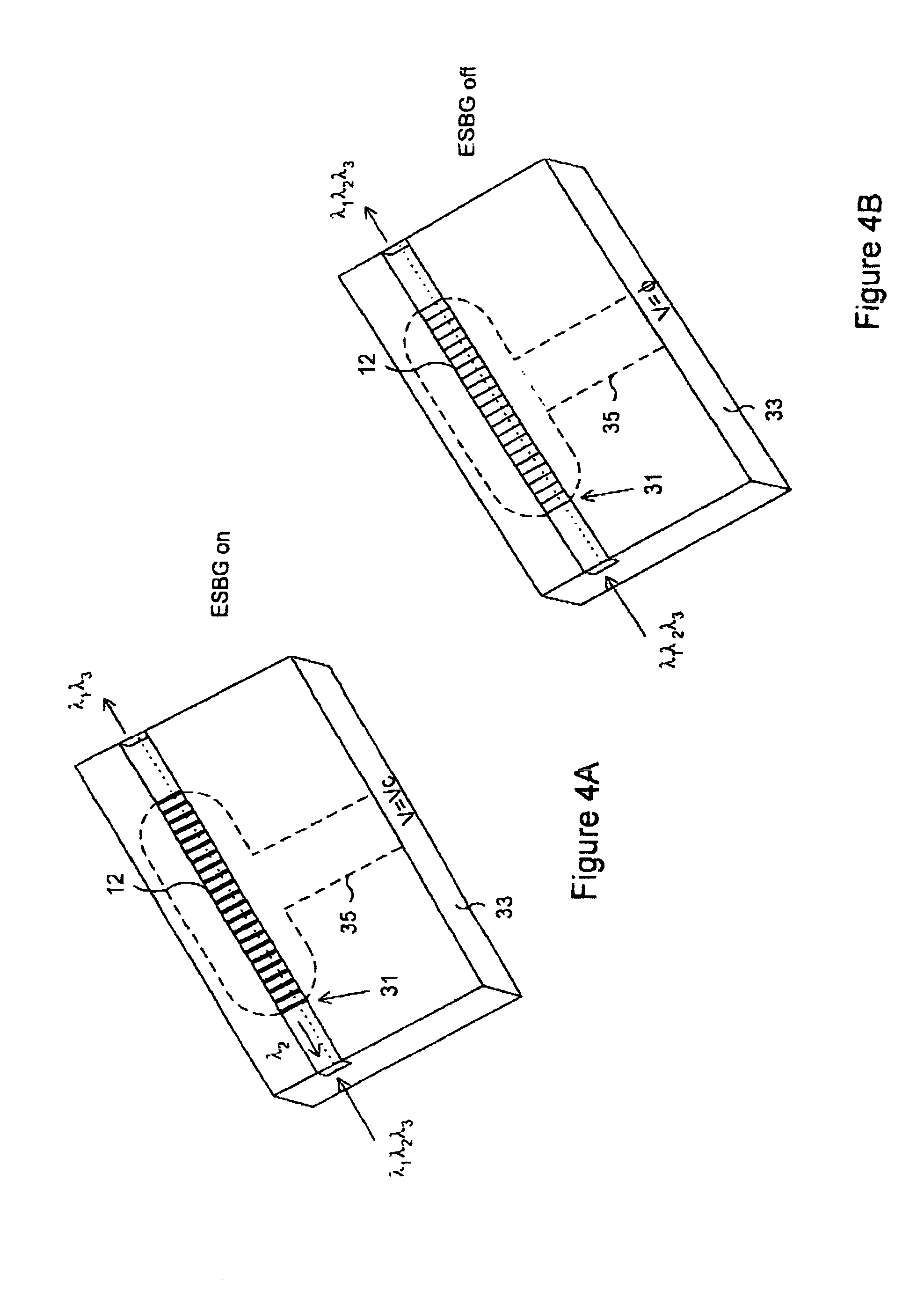

Switchable optical components

This invention relates to a number of components, devices and networks involving integrated optics and / or half coupler technology, all of which involve the use of electronically switchable Bragg grating devices and device geometries realized using holographic polymer / dispersed liquid crystal materials. Most of the components and devices are particularly adapted for use in wavelength division multiplexing (WDM) systems and in particular for use in switchable add / drop filtering (SADF) and wavelength selective crossconnect. Attenuators, outcouplers and a variety of other devices are also provided.

Owner:DOMASH LAWRENCE H +1

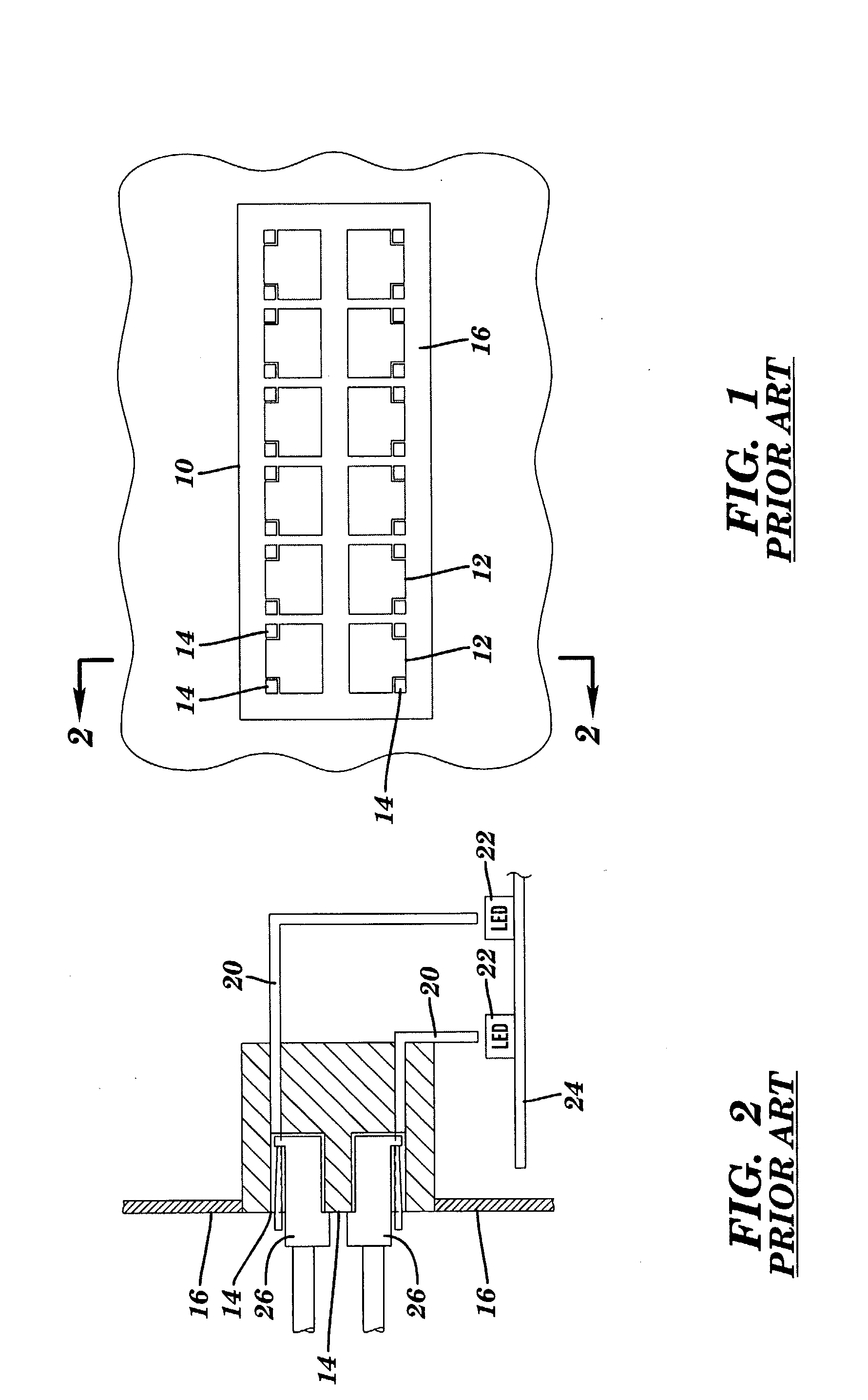

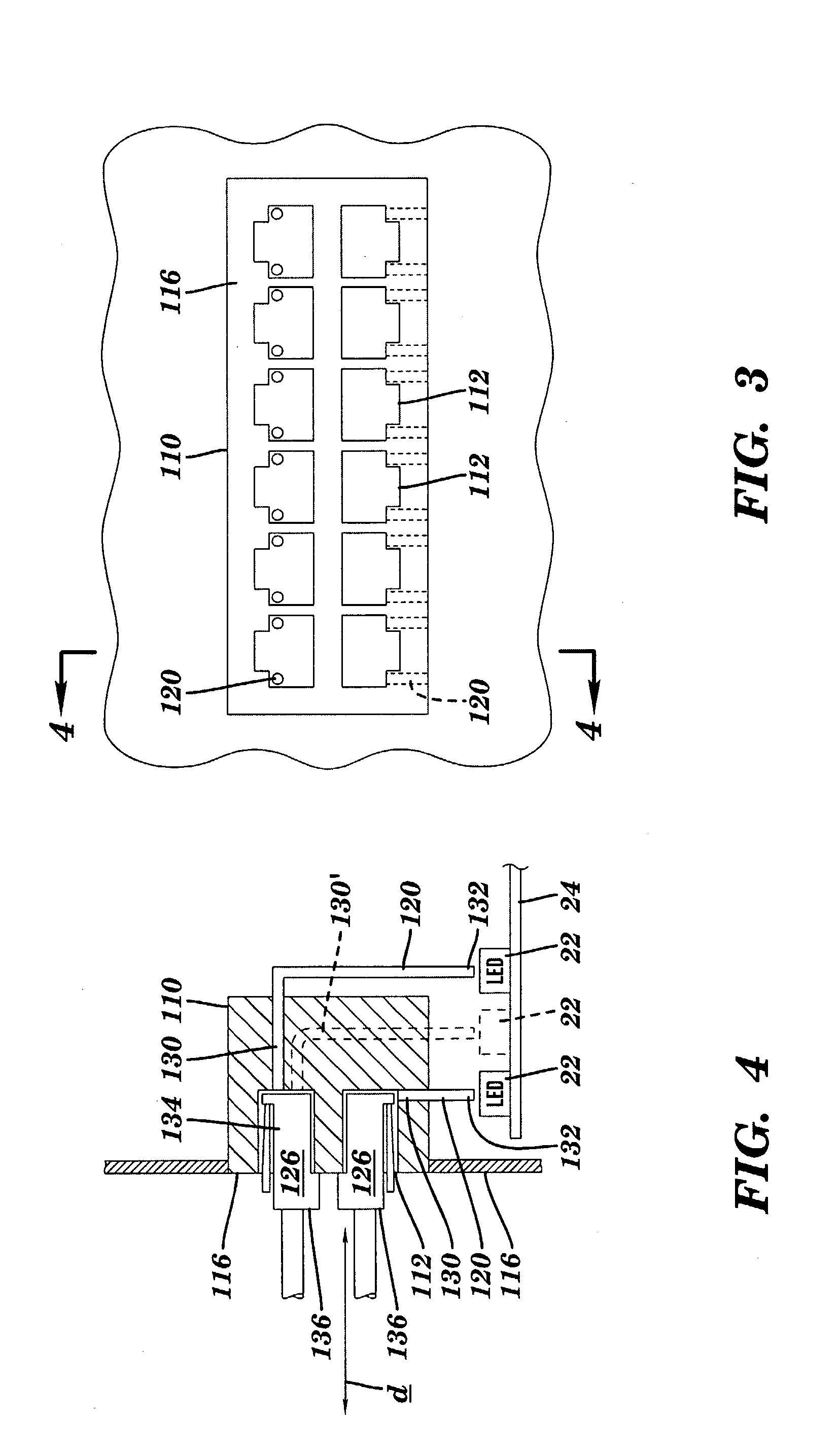

Modular receptacle assembly and interface with integral optical indication

ActiveUS20050063647A1Mechanical apparatusElectrically conductive connectionsLight pipeComputer module

A modular receptacle assembly includes integral optical indication. The receptacle assembly includes a module housing one or more receptacles configured to releasably receive, in an insertion direction, a leading portion of a modular plug. A light pipe having proximal and distal ends, is disposed in the footprint of the module. The proximal end is coupled to the receptacle, and the distal end is coupled to a light source. The proximal end is configured to radiate light onto the leading portion of a plug disposed within said receptacle. An actuator is configured to selectively operate the light pipe.

Owner:EXTREME NETWORKS INC

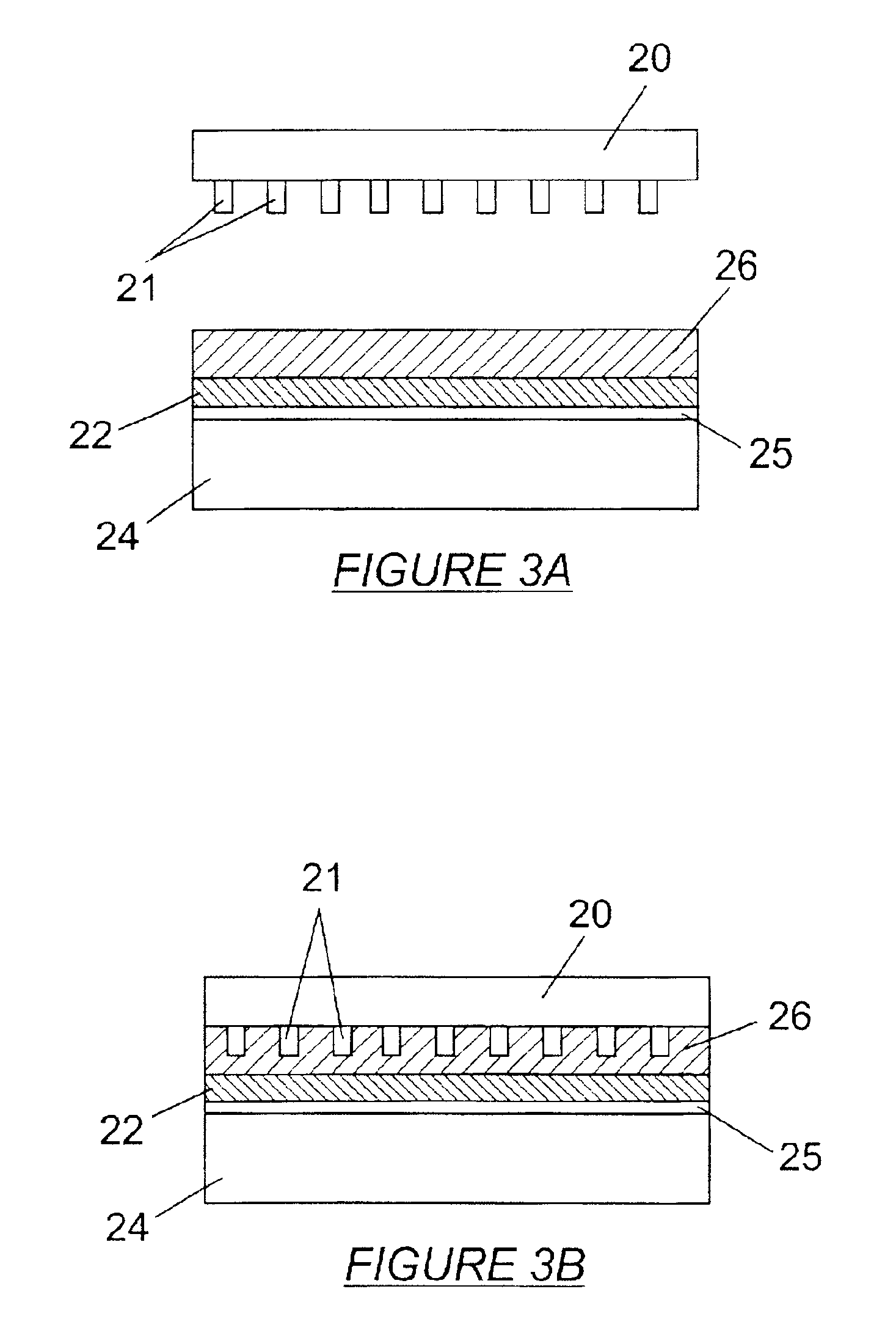

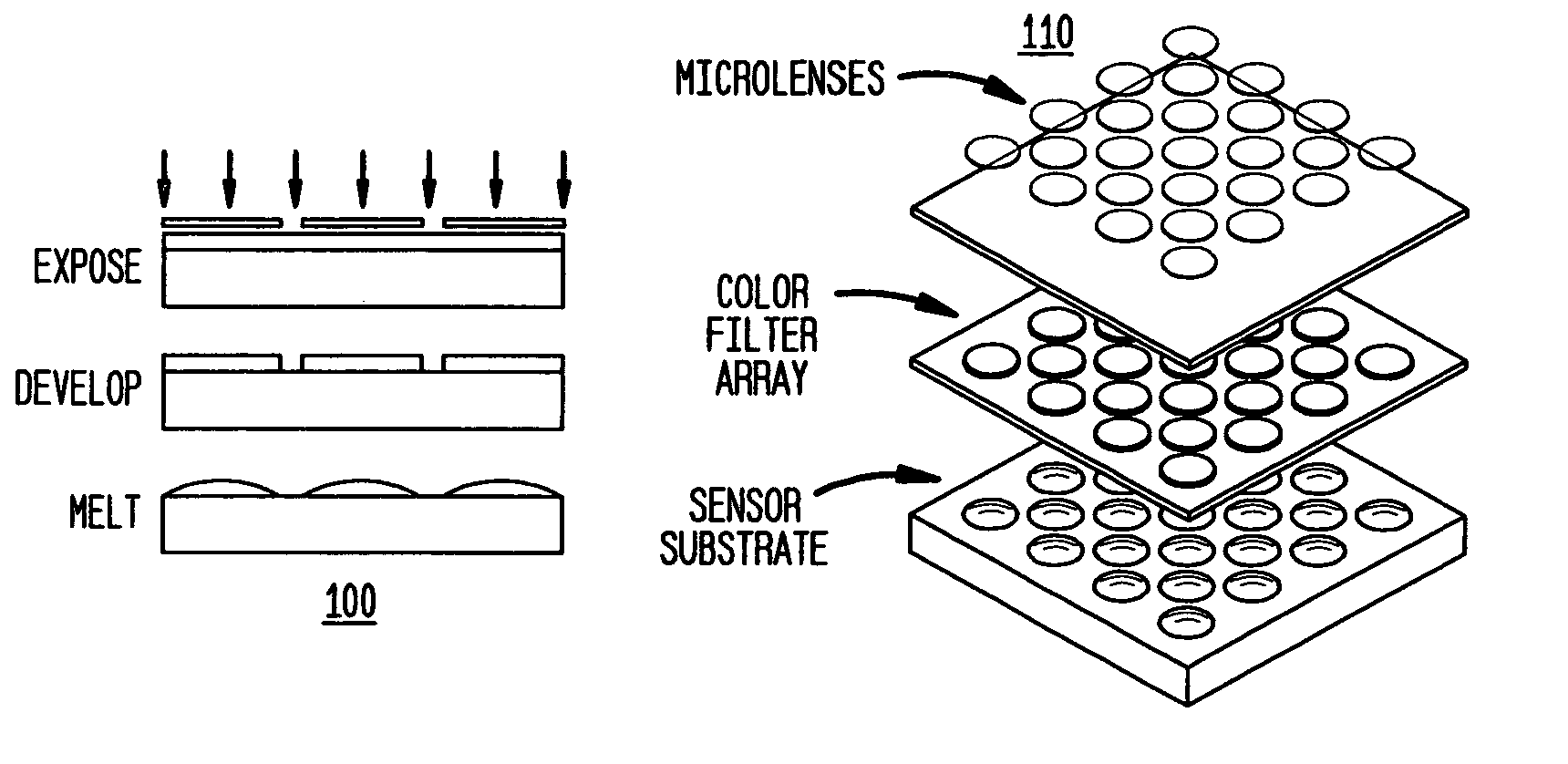

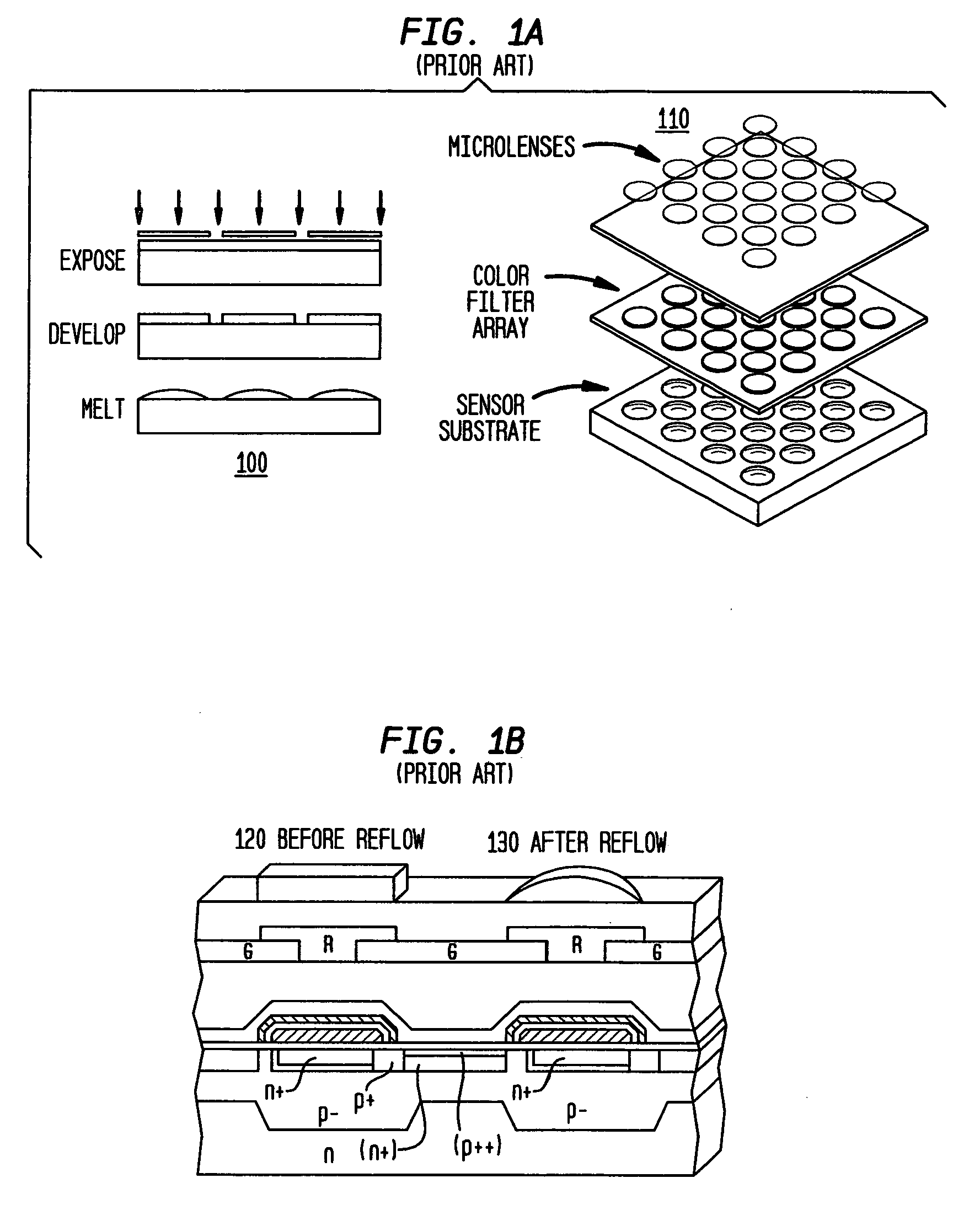

Injection molded microoptics

ActiveUS20070029277A1Minimizes number and task-timesReduces of semiconductor arraysMaterial nanotechnologySolid-state devicesFiberTransformer

A wafer-scale apparatus and method is described for the automation of forming, aligning and attaching two-dimensional arrays of microoptic elements on semiconductor and other image display devices, backplanes, optoelectronic boards, and integrated optical systems. In an ordered fabrication sequence, a mold plate comprised of optically designed cavities is formed by reactive ion etching or alternative processes, optionally coated with a release material layer and filled with optically specified materials by an automated fluid-injection and defect-inspection subsystem. Optical alignment fiducials guide the disclosed transfer and attachment processes to achieve specified tolerances between the microoptic elements and corresponding optoelectronic devices and circuits. The present invention applies to spectral filters, waveguides, fiber-optic mode-transformers, diffraction gratings, refractive lenses, diffractive lens / Fresnel zone plates, reflectors, and to combinations of elements and devices, including microelectromechanical systems (MEMS) and liquid crystal device (LCD) matrices for adaptive, tunable elements. Preparation of interfacial layer properties and attachment process embodiments are taught.

Owner:IBM CORP

Hermetic optical fiber alignment assembly having integrated optical element

A hermetic optical fiber alignment assembly includes a ferrule portion having a plurality of grooves receiving the end sections of optical fibers, wherein the grooves define the location and orientation of the end sections with respect to the ferrule portion. The assembly includes an integrated optical element for coupling the input / output of an optical fiber to the opto-electronic devices in the opto-electronic module. The optical element can be in the form of a structured reflective surface. The end of the optical fiber is at a defined distance to and aligned with the structured reflective surface. The structured reflective surfaces and the fiber alignment grooves can be formed by stamping.

Owner:SENKO ADVANCED COMPONENTS

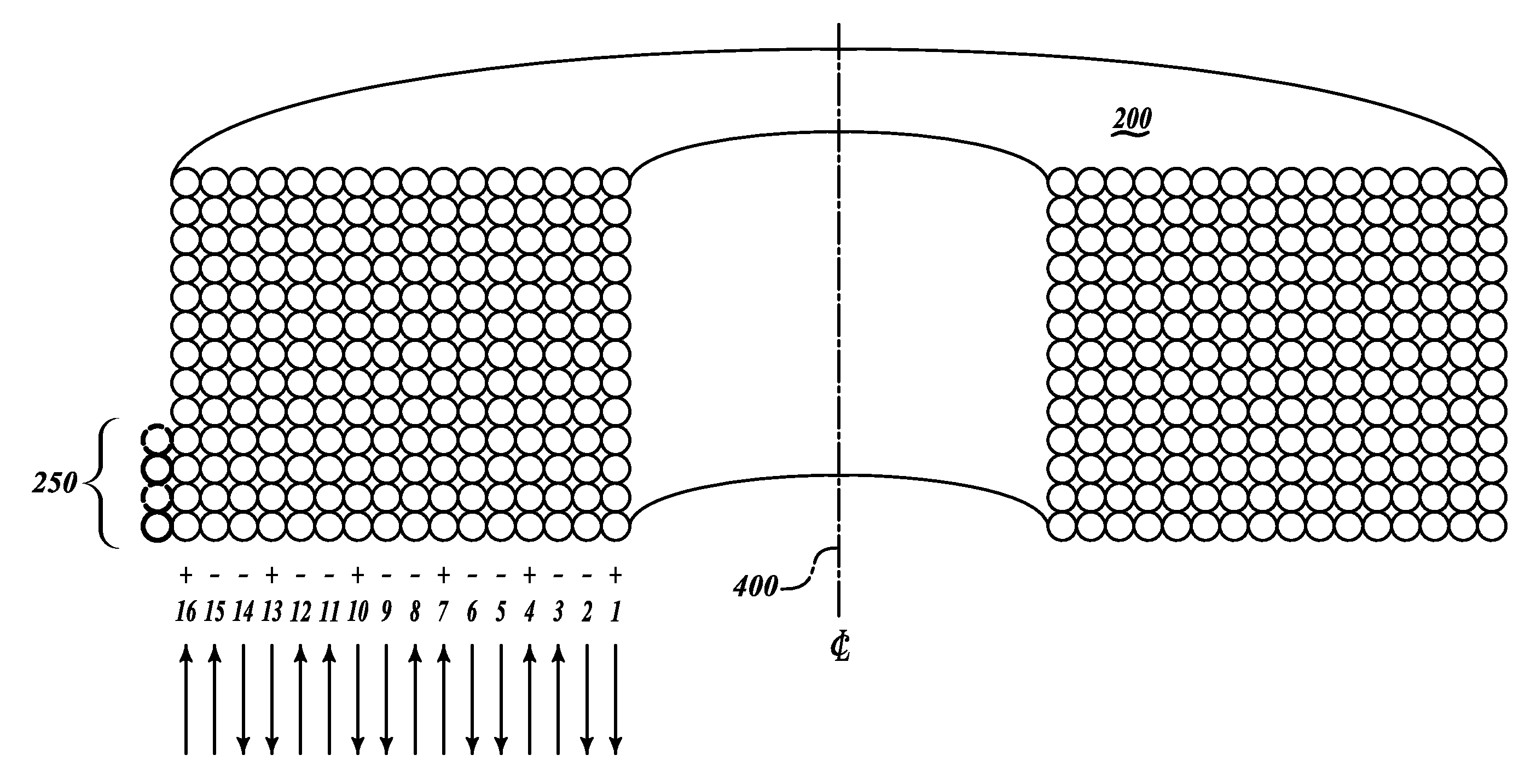

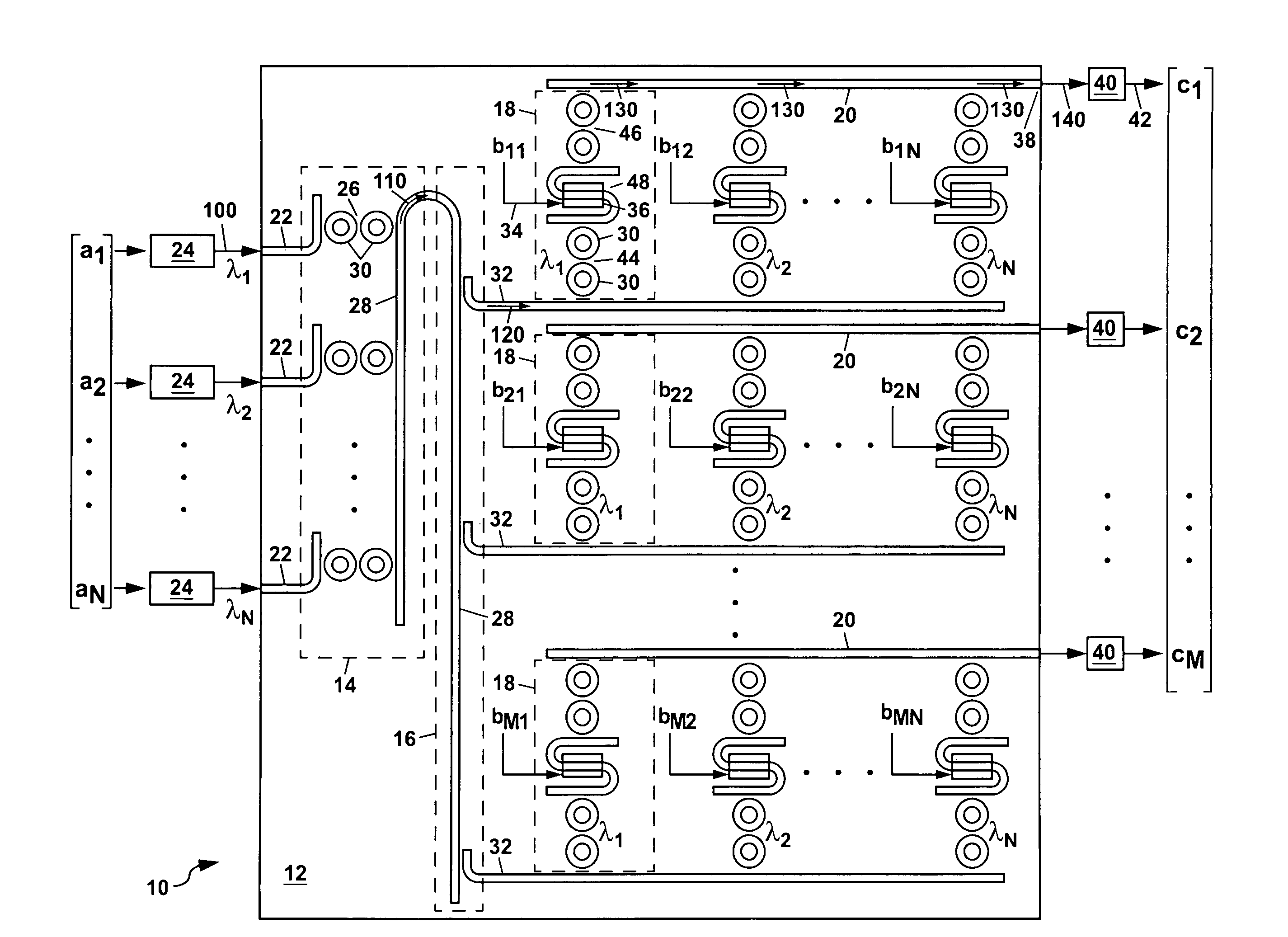

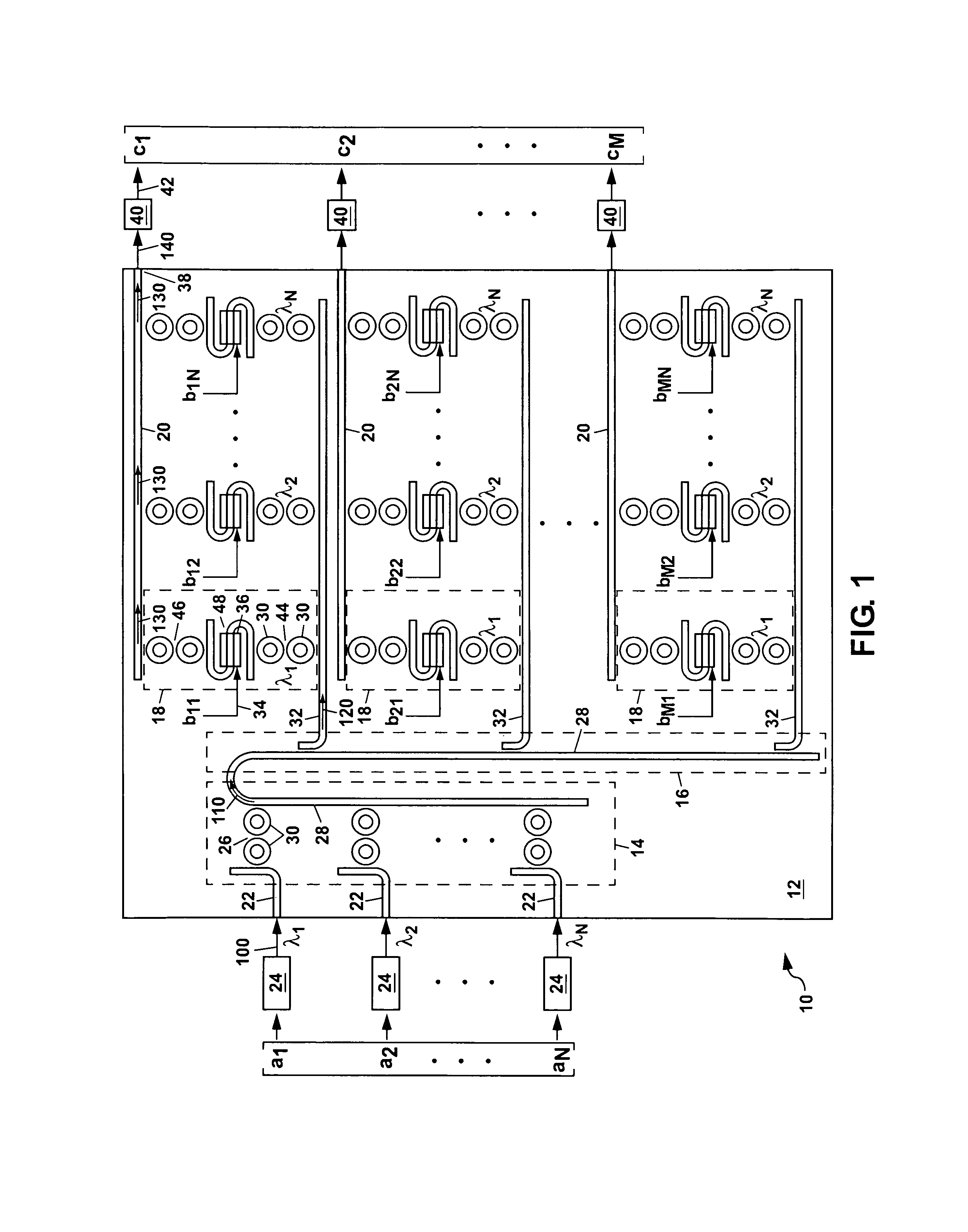

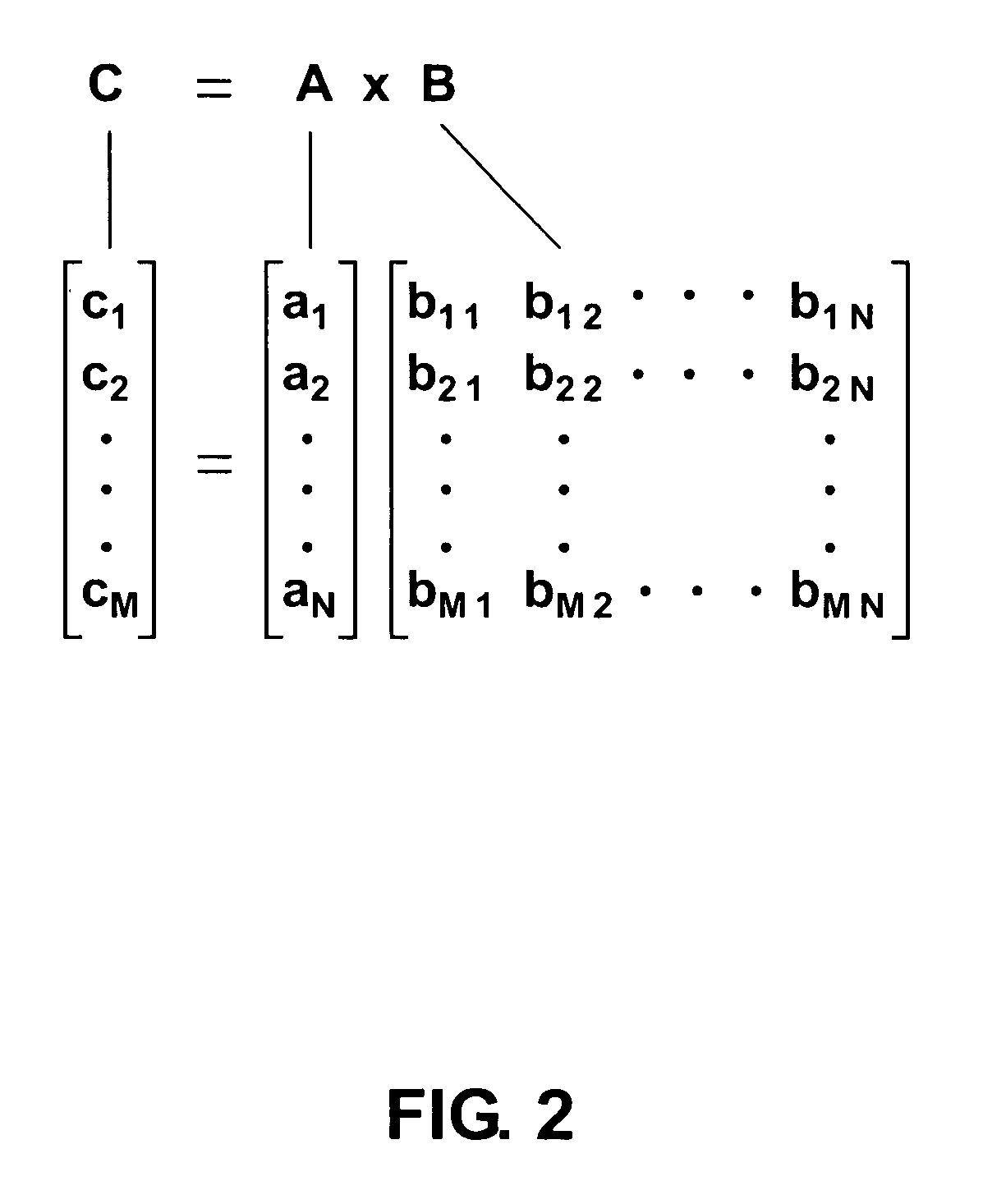

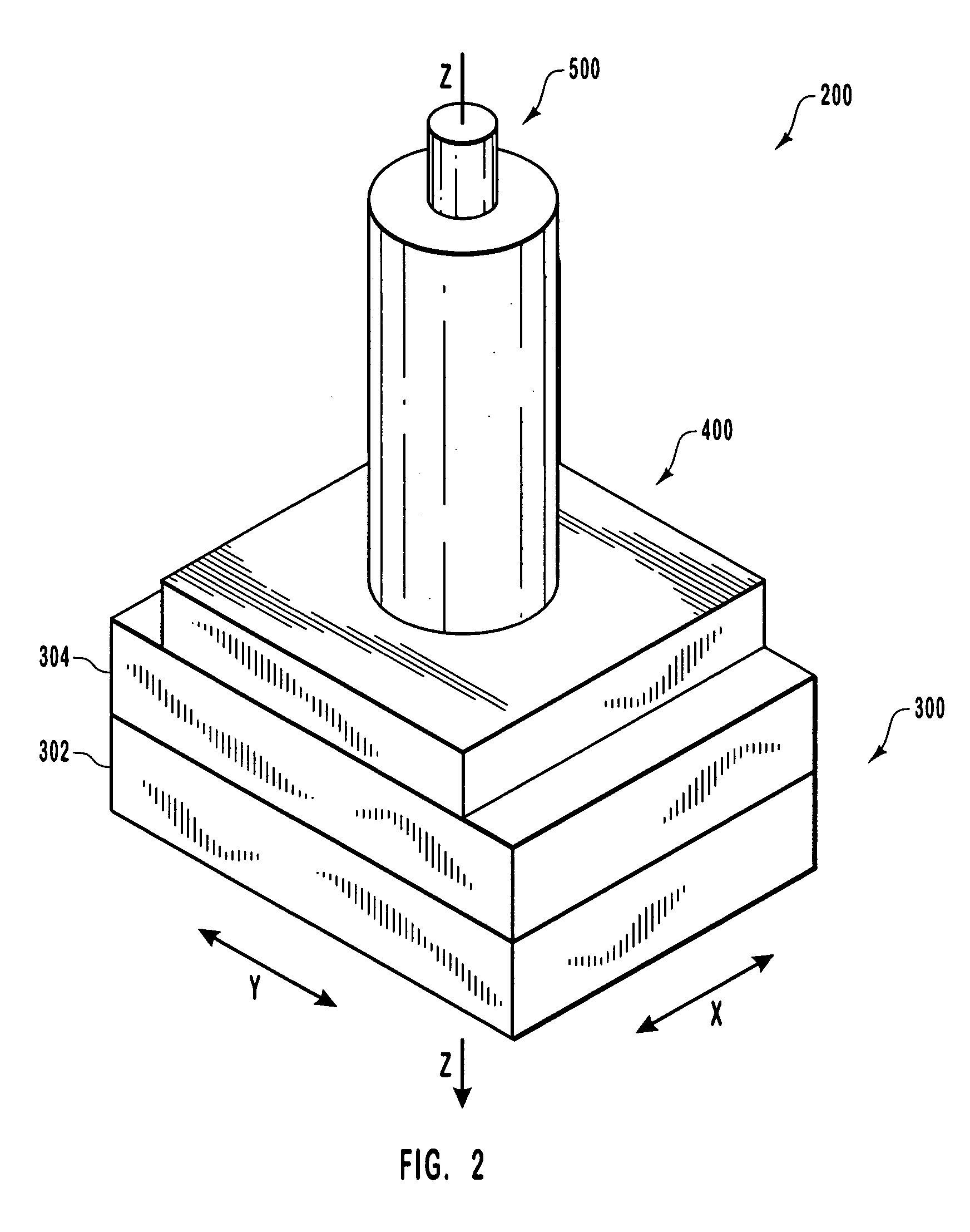

Integrated optic vector-matrix multiplier

ActiveUS8027587B1Computing operations for integration/differentiationWavelength-division multiplex systemsMatrix multiplierLength wave

A vector-matrix multiplier is disclosed which uses N different wavelengths of light that are modulated with amplitudes representing elements of an N×1 vector and combined to form an input wavelength-division multiplexed (WDM) light stream. The input WDM light stream is split into N streamlets from which each wavelength of the light is individually coupled out and modulated for a second time using an input signal representing elements of an M×N matrix, and is then coupled into an output waveguide for each streamlet to form an output WDM light stream which is detected to generate a product of the vector and matrix. The vector-matrix multiplier can be formed as an integrated optical circuit using either waveguide amplitude modulators or ring resonator amplitude modulators.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

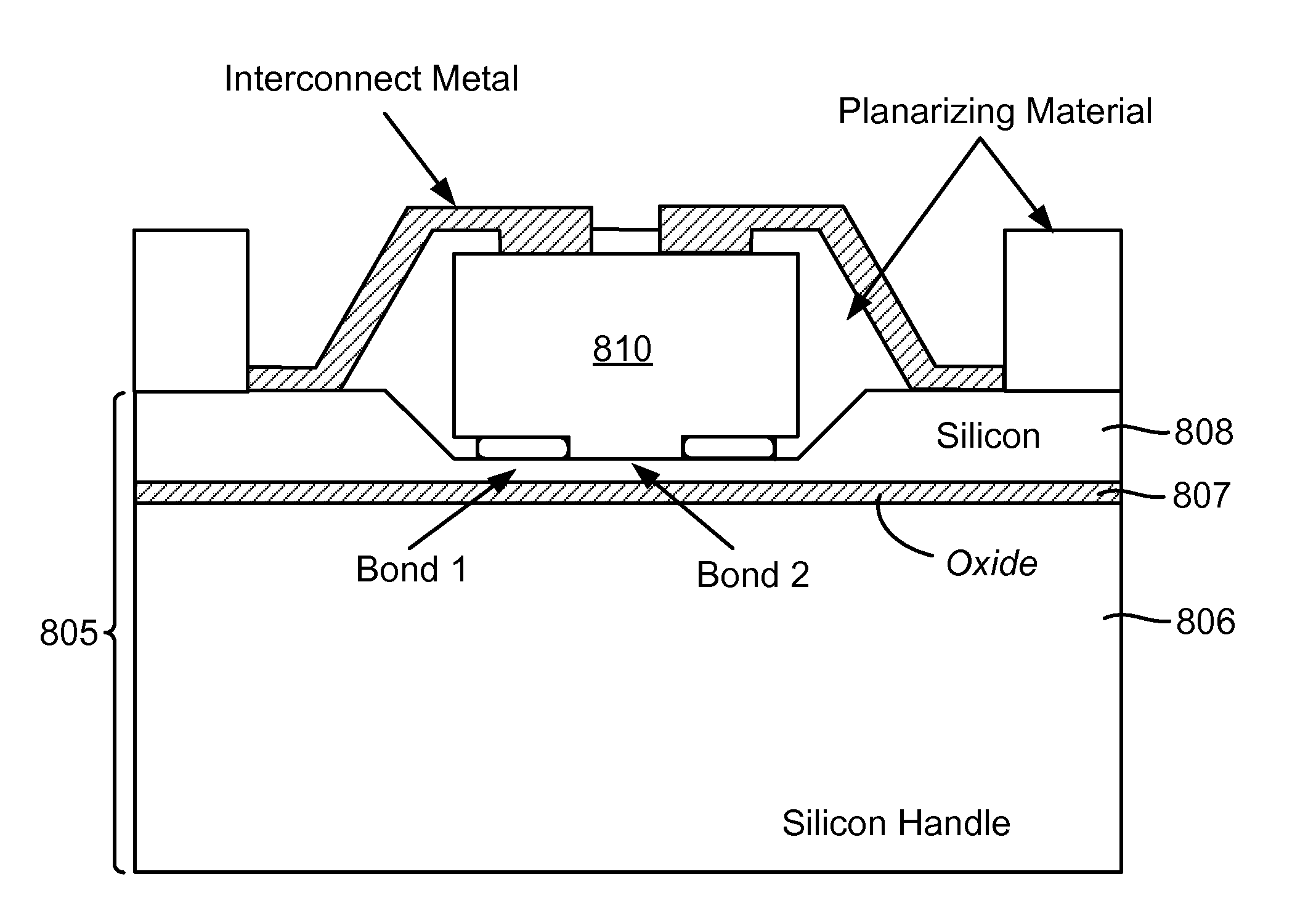

Method and system for heterogeneous substrate bonding of waveguide receivers

InactiveUS20120057816A1Good light transmissionImprove conductivityLaser detailsSemiconductor/solid-state device detailsInterface layerWaveguide

A composite integrated optical device includes a substrate including a silicon layer and a waveguide disposed in the silicon layer. The composite integrated optical device also includes an optical detector bonded to the silicon layer and a bonding region disposed between the silicon layer and the optical detector. The bonding region includes a metal-assisted bond at a first portion of the bonding region. The metal-assisted bond includes an interface layer positioned between the silicon layer and the optical detector. The bonding region also includes a direct semiconductor-semiconductor bond at a second portion of the bonding region.

Owner:SKORPIOS TECH

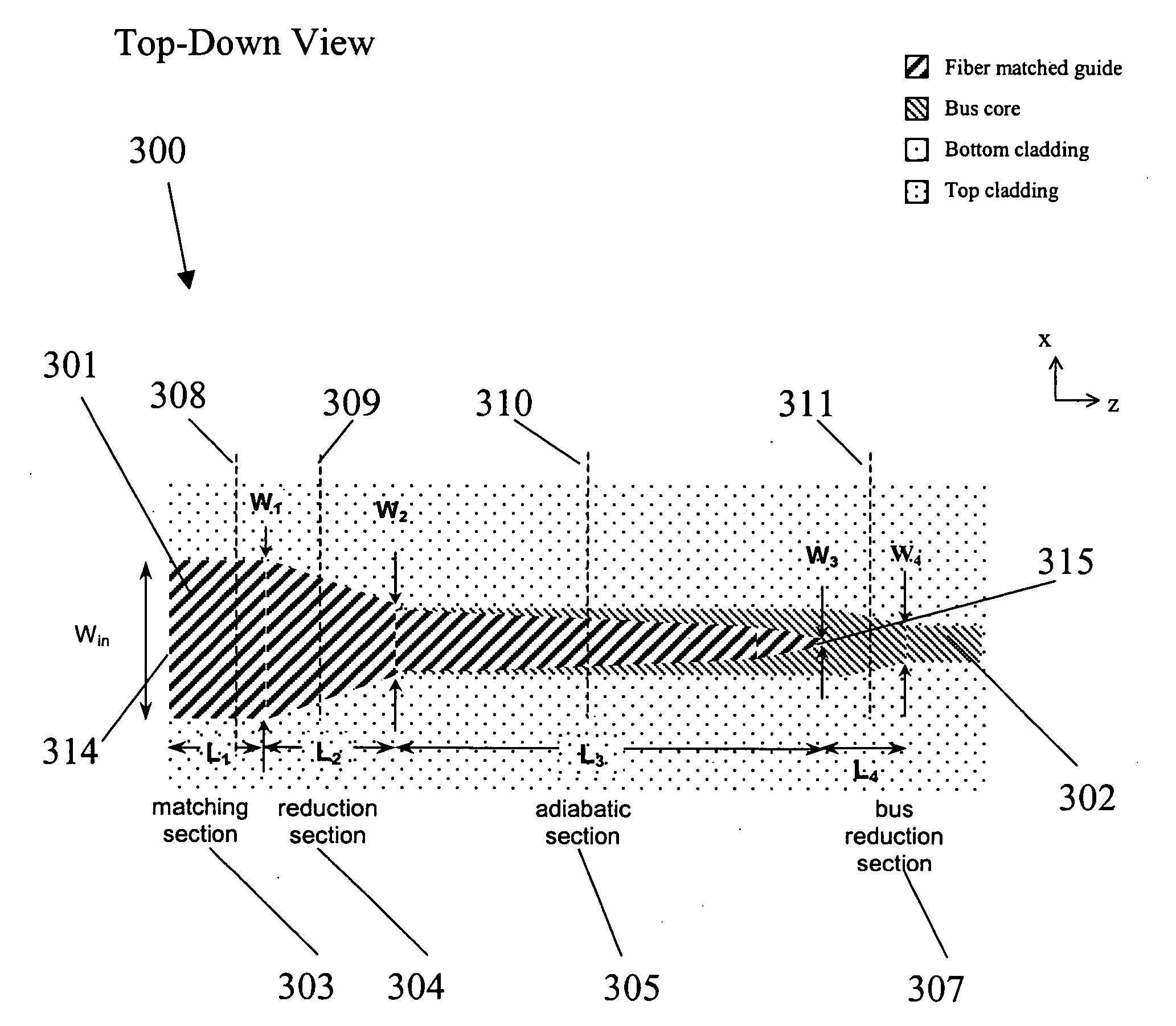

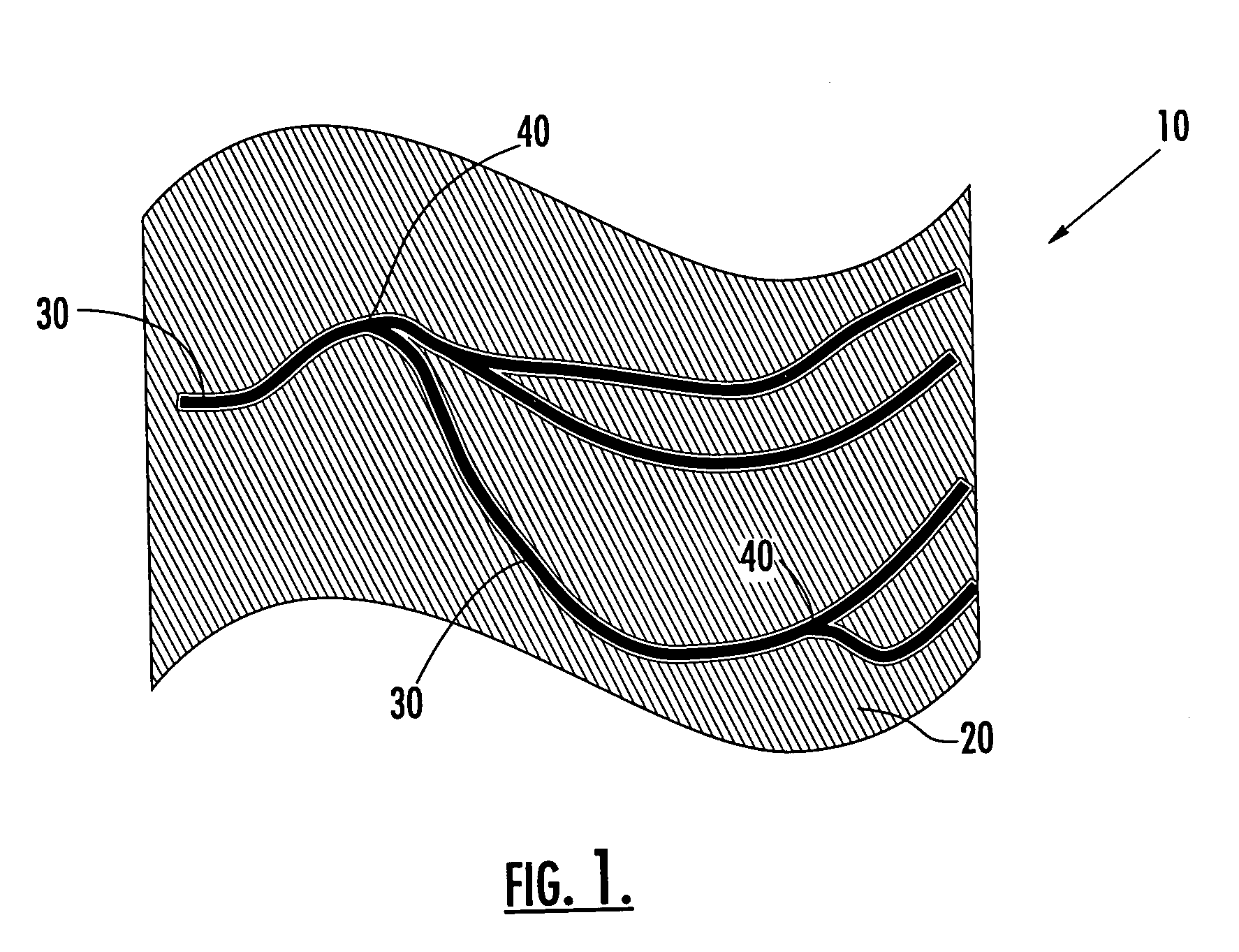

Integrated optical mode shape transformer and method of fabrication

An integrated optical mode transformer provides a low loss interconnection between an optical fiber and an integrated optic waveguide having a spot size different from that of the fiber. The mode transformer is comprised of two waveguide layers, an upper layer and a lower layer, with the upper layer being contiguous to the lower layer. The lower layer is the integrated optic waveguide layer forming the optical circuit. The input dimensions of the composite two-waveguide structure supports a fundamental mode that accepts all of the light present on the optical fiber. The upper waveguide layer is tapered down from an input width to an output width and then terminates in such a way that at the termination substantially all of the input optical power resides in the lower waveguide layer. The two-waveguide layer structure is fabricated by deposition and planarization techniques.

Owner:INFINERA CORP

Ultra-high multiplex analytical systems and methods

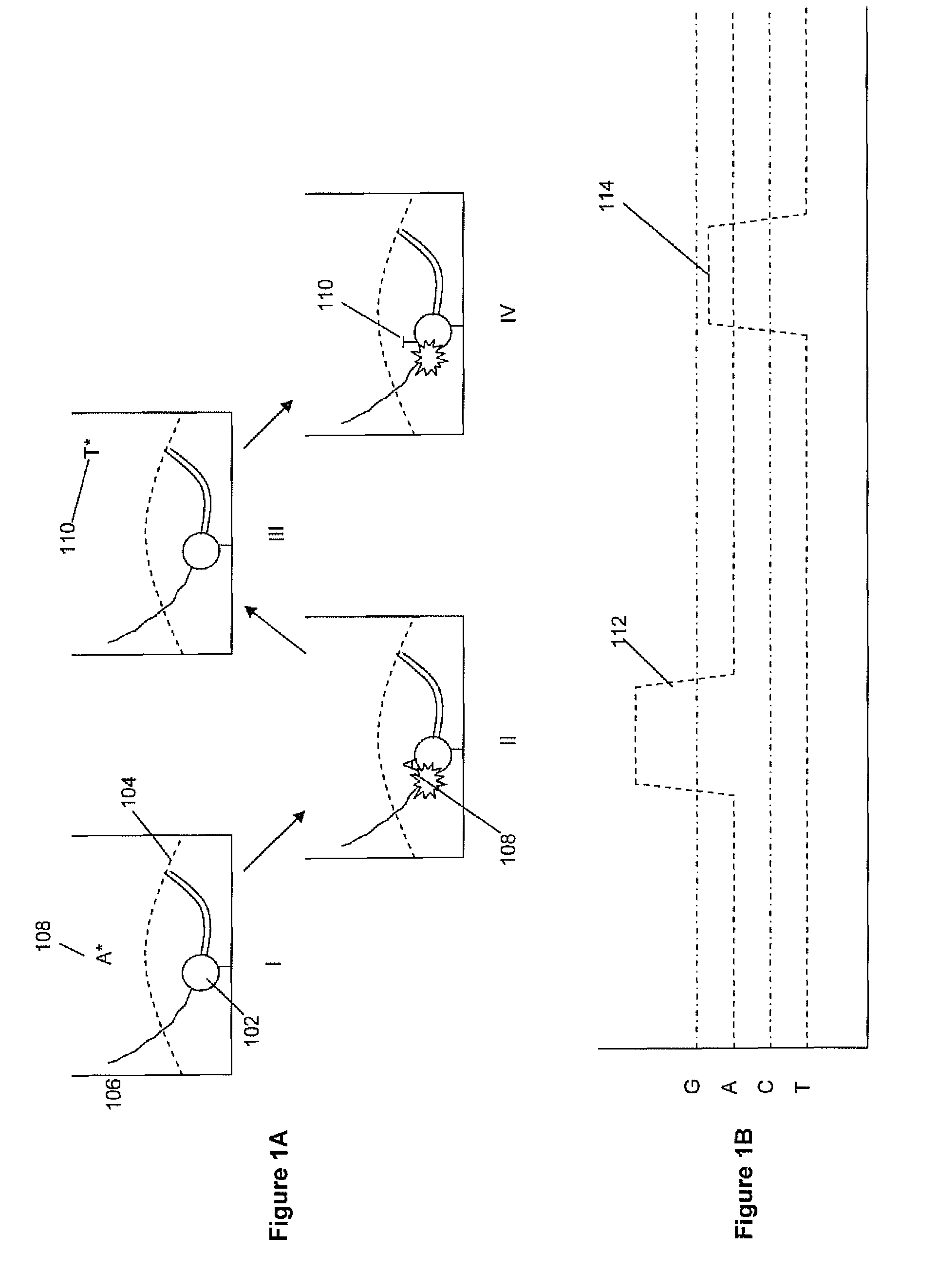

ActiveUS8247216B2Bioreactor/fermenter combinationsLiquid surface applicatorsDirect illuminationSequence determination

Apparatus, systems and methods for use in analyzing discrete reactions at ultra high multiplex with reduced optical noise, and increased system flexibility. Apparatus include substrates having integrated optical components that increase multiplex capability by one or more of increasing density of reaction regions, improving transmission of light to or collection of light from discrete reactions regions. Integrated optical components include reflective optical elements which re-direct illumination light and light emitted from the discrete regions to more efficiently collect emitted light. Particularly preferred applications include single molecule reaction analysis, such as polymerase mediated template dependent nucleic acid synthesis and sequence determination.

Owner:PACIFIC BIOSCIENCES

Integrated optical circuits

InactiveUS7058245B2Easy to makeLight loss is minimizedSemiconductor laser arrangementsLaser arrangementsEngineeringOpto electronic

An optoelectronic device having a flexible substrate and an optical interconnect (i.e. waveguide) comprising a sol-gel based material formed on the substrate. The sol-gel based waveguide is capable of being integrated into an all-optical system and provides for greater interconnect distance and lower signal loss. Other sol-gel based optical devices, such as filters, optical source, detectors, sensors, switches and the like, will be implemented in conjunction with the sol-gel based waveguides to provide for an integrated optical system. Methods of formulating the sol-gel based material and methods for fabricating the sol-gel based devices are also provided.

Owner:GULA CONSULTING LLC +1

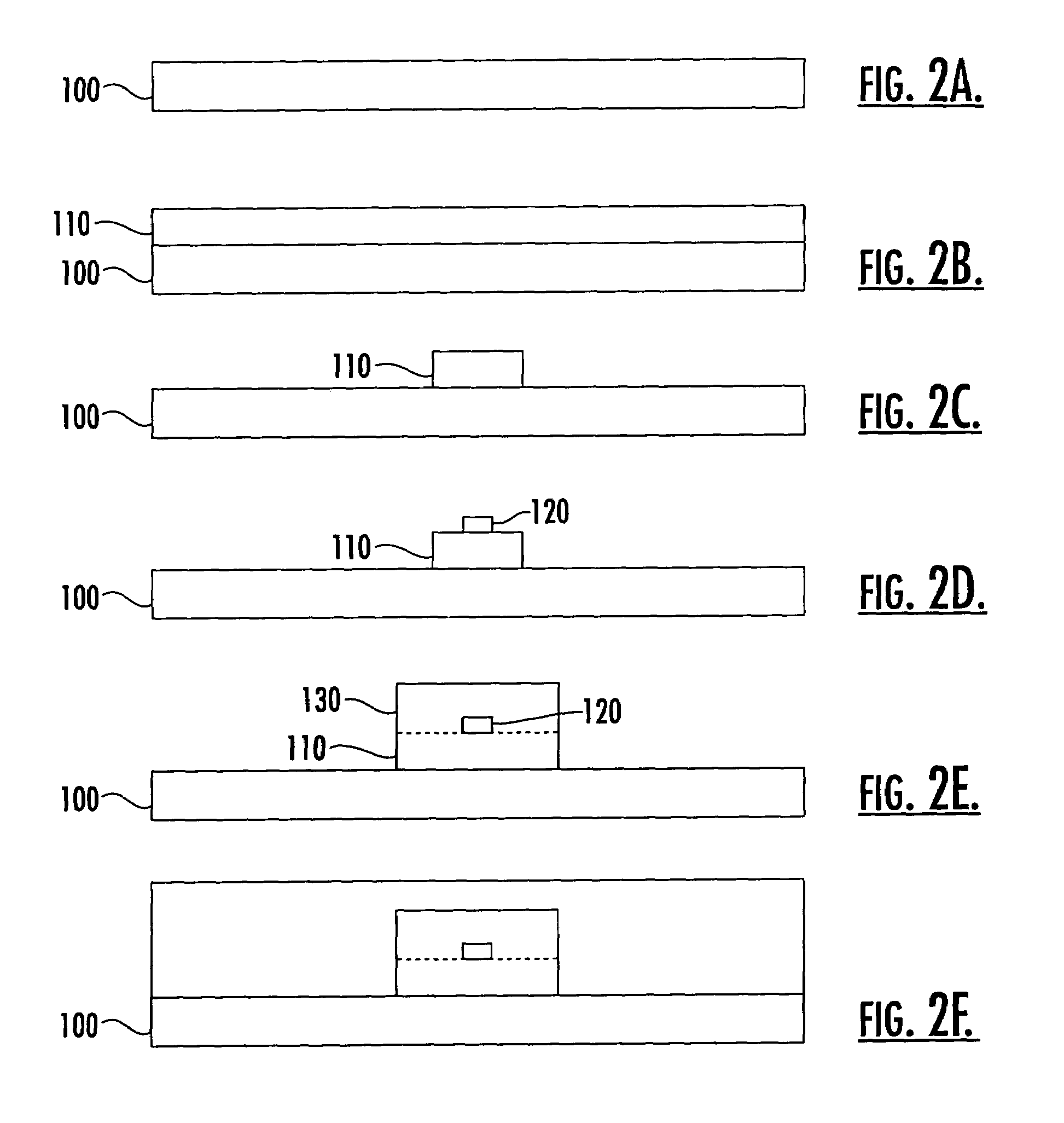

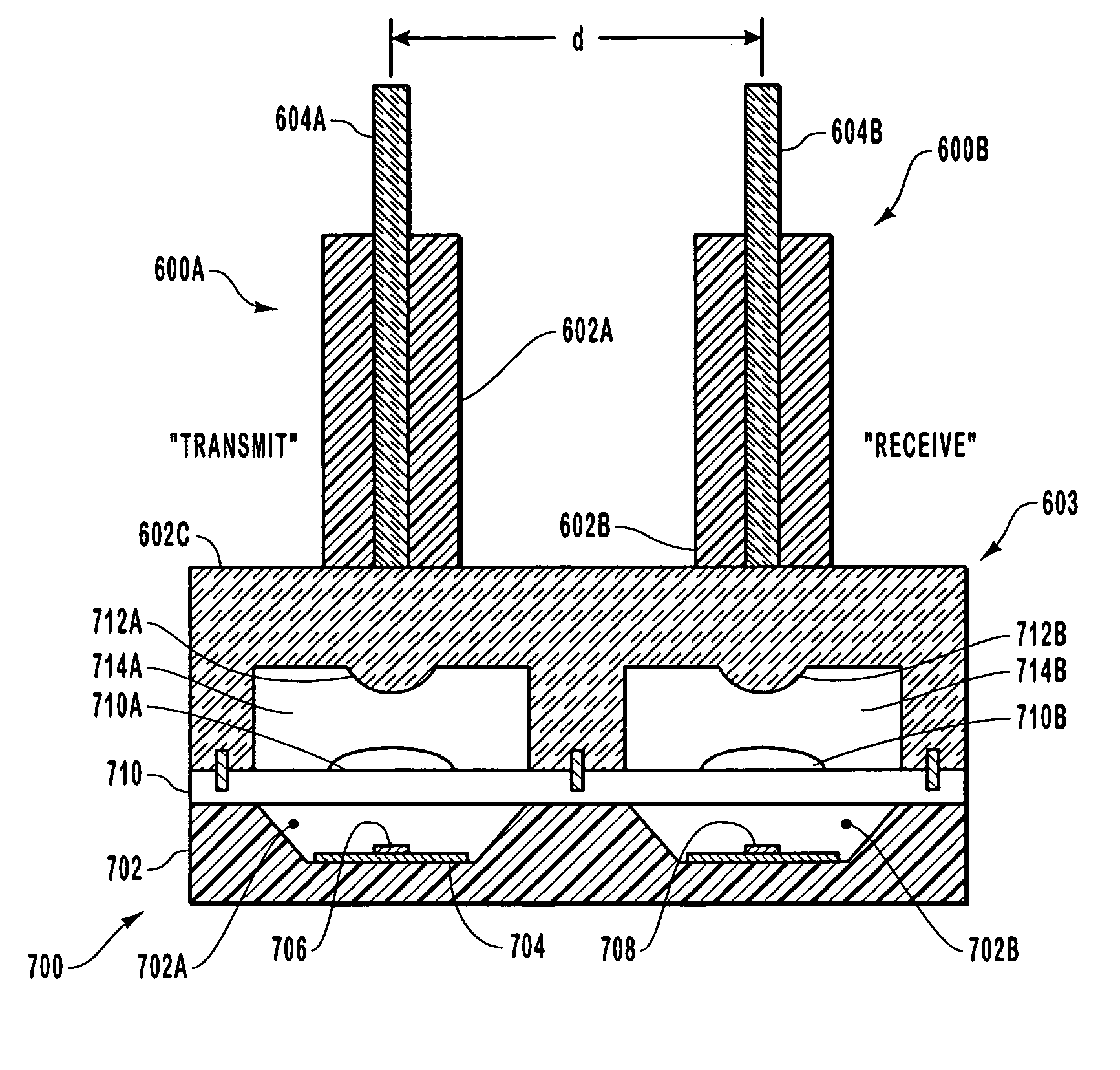

Integrated optical devices and methods of making same

ActiveUS20050185900A1Reduce in quantityRapid and inexpensive productionCoupling light guidesEngineeringOptical coupling

An optical subassembly is provided that includes an optical component mounted to a substrate. In addition, the optical subassembly includes a lens package having a lens that is optically coupled with the optical component. The lens package cooperates with the substrate to define a hermetic chamber within which the optical component is disposed. The optical subassembly can be made as an integrated subassembly having both transmit and receive components within the hermetic chamber. Methods in accordance with the present invention include techniques for producing hermetically sealed optical subassemblies in mass-production.

Owner:ELECTRONICS & TELECOMM RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com