Bifilar optical fiber stowage for fiber-optic gyroscope

a fiber-optic gyroscope and optical fiber technology, applied in the direction of instruments, optical elements, bundled fibre light guides, etc., can solve the problems of reducing the performance of the gyroscope, causing the degraded lorentz reciprocity of the approach, and easy degrading of the lorentz reciprocity of the environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

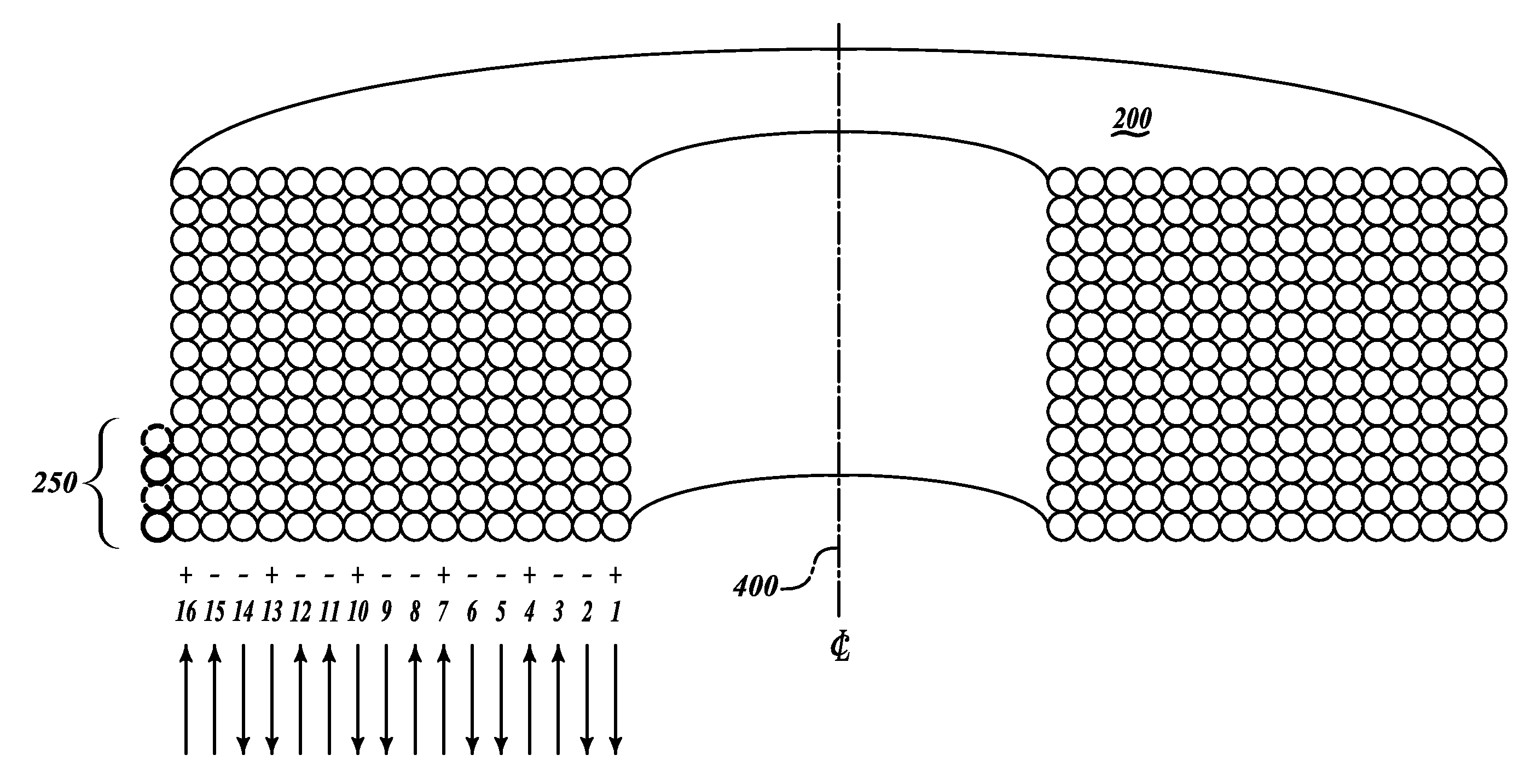

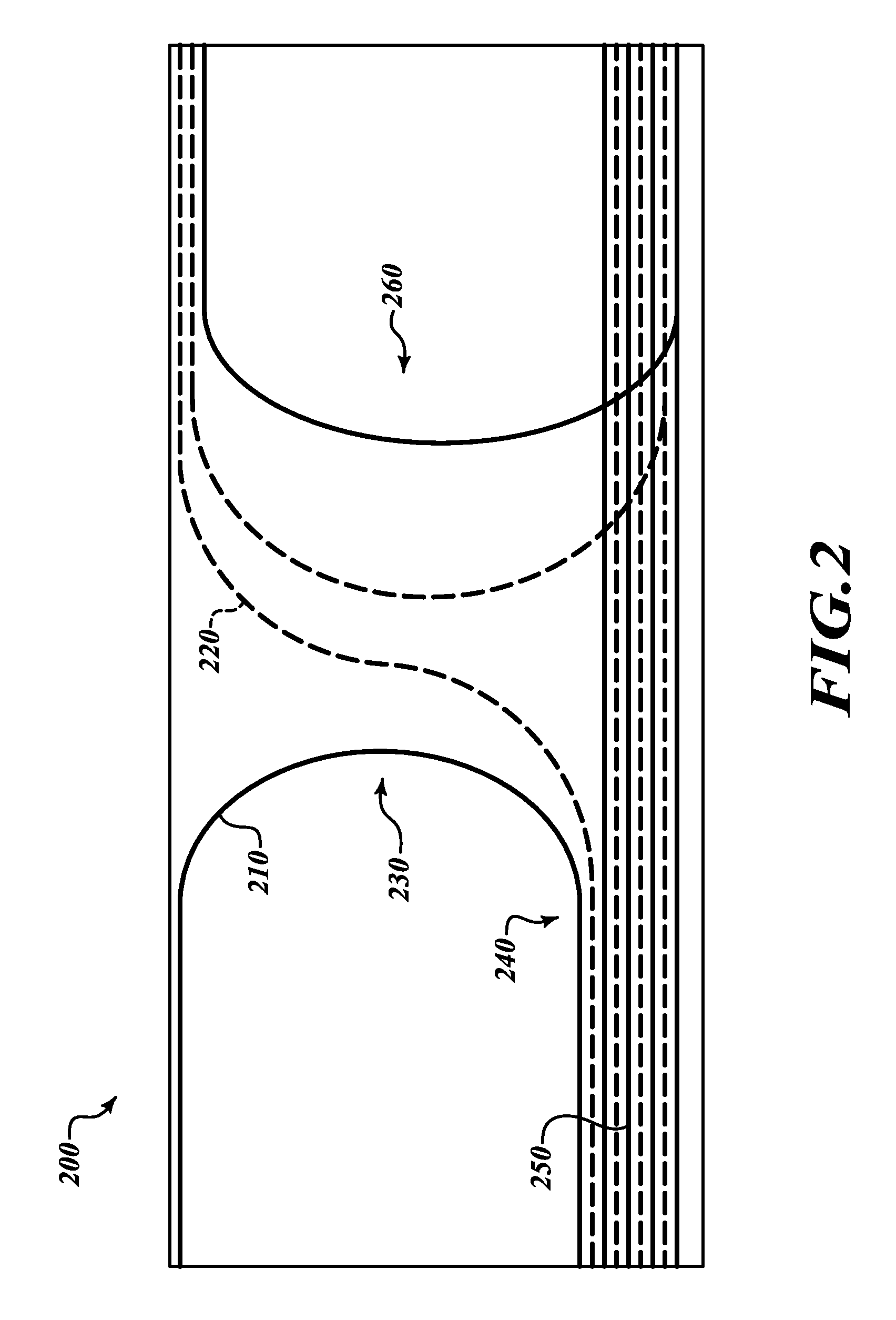

[0010]An embodiment provides for a service-lead stowage location on the outer layer of an interferometric fiber coil, thereby providing improved performance as compared to a separate compartment storage.

[0011]An embodiment of a bifilar service-lead routing method provides improved performance under time-varying thermal gradients and reduces the Shupe effect of these service leads.

[0012]An embodiment provides bifilar fiber routing method that ensures service leads are confined to a single outer layer of a coil and not additional layers, which would be subject to more stress over temperature changes.

[0013]An embodiment provides a reduction of the number of points where optical fiber crosses over itself, as well as twists in the fiber, thereby improving gyroscope bias stability.

[0014]By routing the fibers in such a bifilar-pair fashion, points equal and opposite in the sensing loop are physically adjacent to each other and see the same effects over varying environments.

[0015]Referring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com