Continuous winding machining technology of bamboo wound composite tube

A processing technology and composite pipe technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of low production efficiency, unstable quality, low degree of automation, etc., and achieve high production efficiency and stability. Good, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

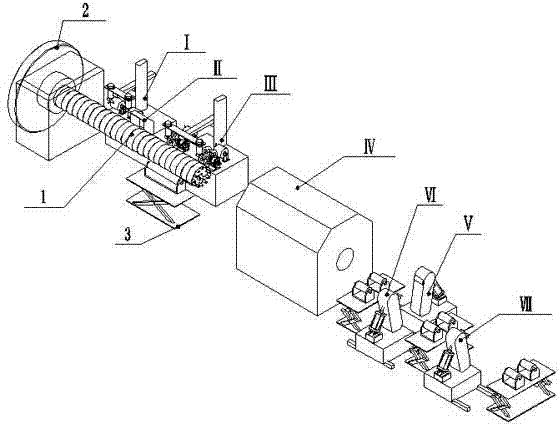

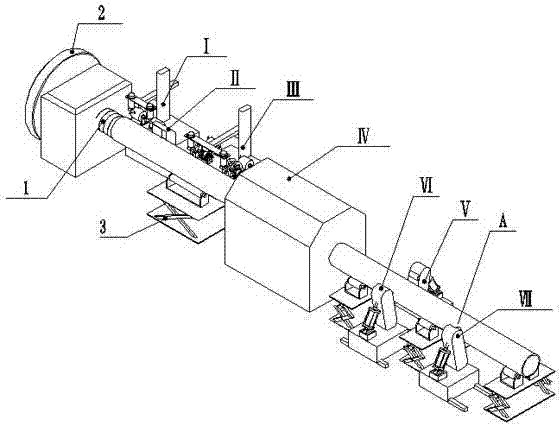

[0019] See Figure 1~3 , The above technical scheme is applied to DN600 bamboo composite pipe, the implementation steps are as follows:

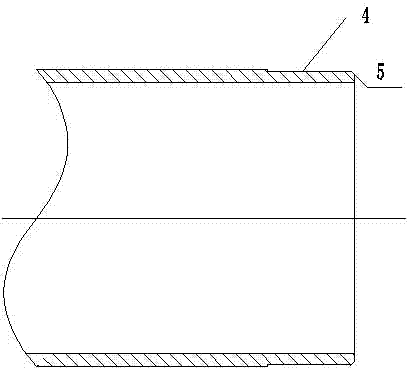

[0020] 1) On a steel mold with an outer diameter of 600mm and a length of 3M-8M, a steel strip with a width of 10~30mm and a thickness of 0.5~1.5mm is continuously wound in parallel to form a steel strip mold 1, which is added on the steel strip mold 1. Release layer (release agent or film) and dry quickly.

[0021] 2) The rotation of the steel mold drives the steel belt to advance spirally. In the lining making zone I, a layer of 20~50mm and 20~30g / is wound on the surface of the steel strip covered with the mold release layer through the fixed position feeding device in the liner making zone. ㎡ non-woven fabric (non-woven fabric can be made of bamboo viscose, pp, glass fiber, etc.). The non-woven fabric is soaked by dipping or dipping, with a glue content of 90%wt or more.

[0022] 3) The steel belt spirally advances, driving the non-woven fab...

Embodiment 2

[0033] See Figure 1~3 , The above technical solution is applied to DN1000 bamboo composite pipe, the implementation steps are as follows:

[0034] 1) On a steel mold with an outer diameter of 1000mm and a length of 3M-8M, a steel strip with a width of 10-30mm and a thickness of 0.5-1.5mm is continuously wound in parallel to form a steel strip mold 1. Add a release layer (release agent or film) on the steel belt mold 1 and dry quickly.

[0035] 2) The rotation of the steel mold drives the steel belt to advance spirally. In the lining making zone I, a layer of 20~50mm and 20~30g / is wound on the surface of the steel strip covered with the mold release layer through the fixed position feeding device in the liner making zone. ㎡ non-woven fabric (non-woven fabric can be made of bamboo viscose, pp, glass fiber, etc.). The non-woven fabric is soaked by dipping or dipping, with a glue content of 90%wt or more.

[0036] 3) The steel belt spirally advances, driving the non-woven fabric lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com