Patents

Literature

197 results about "Pipe layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pipelayer (or pipe-layer or drain layer) is a skilled tradesman who lays pipe, such as for storm sewers, sanitary sewers, drains, and water mains. Pipelayers may grade (i.e., level) trenches and culverts, position pipe, or seal joints. The Standard Occupational Classification System code for pipelayers is 47-2151.

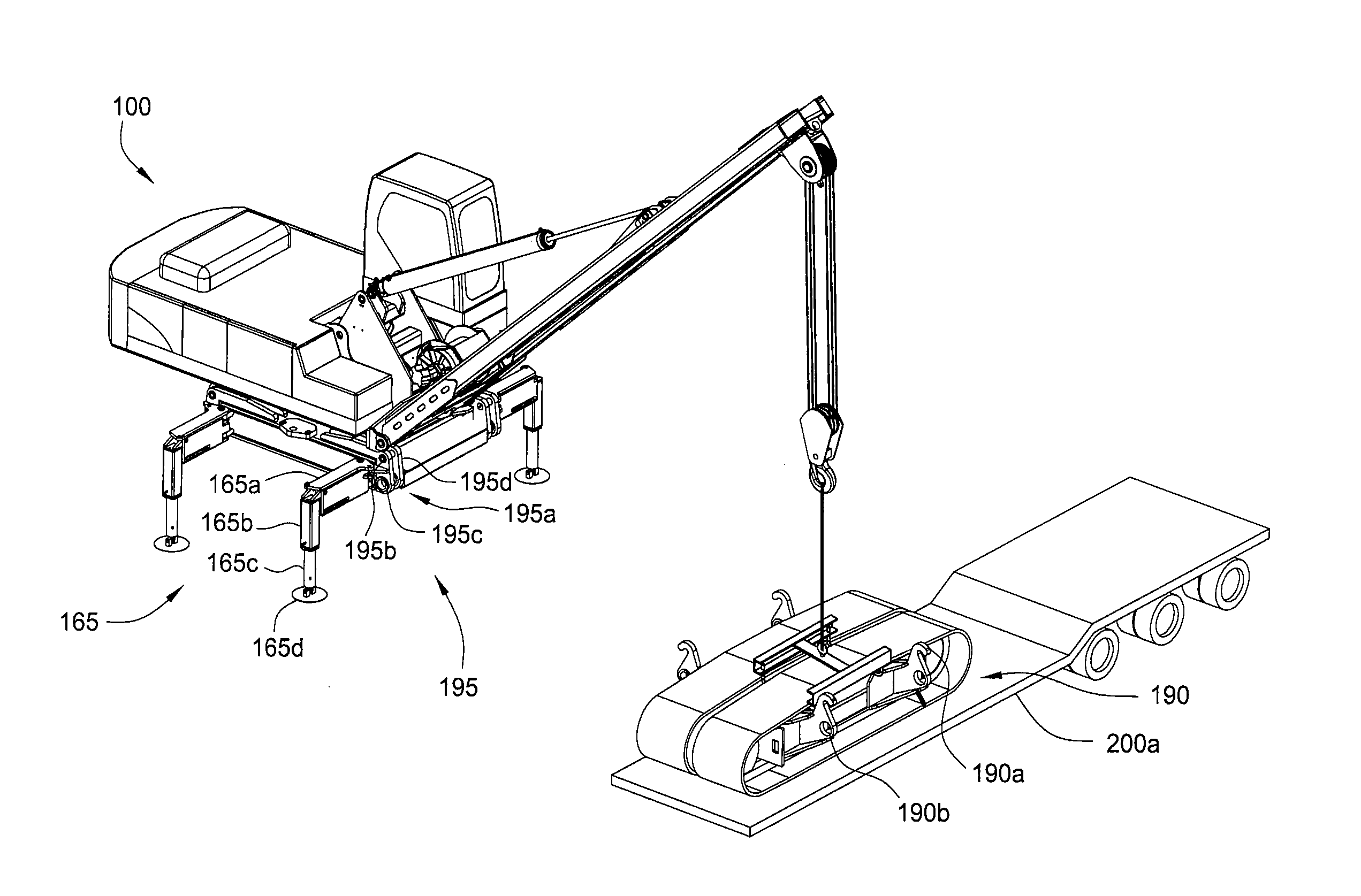

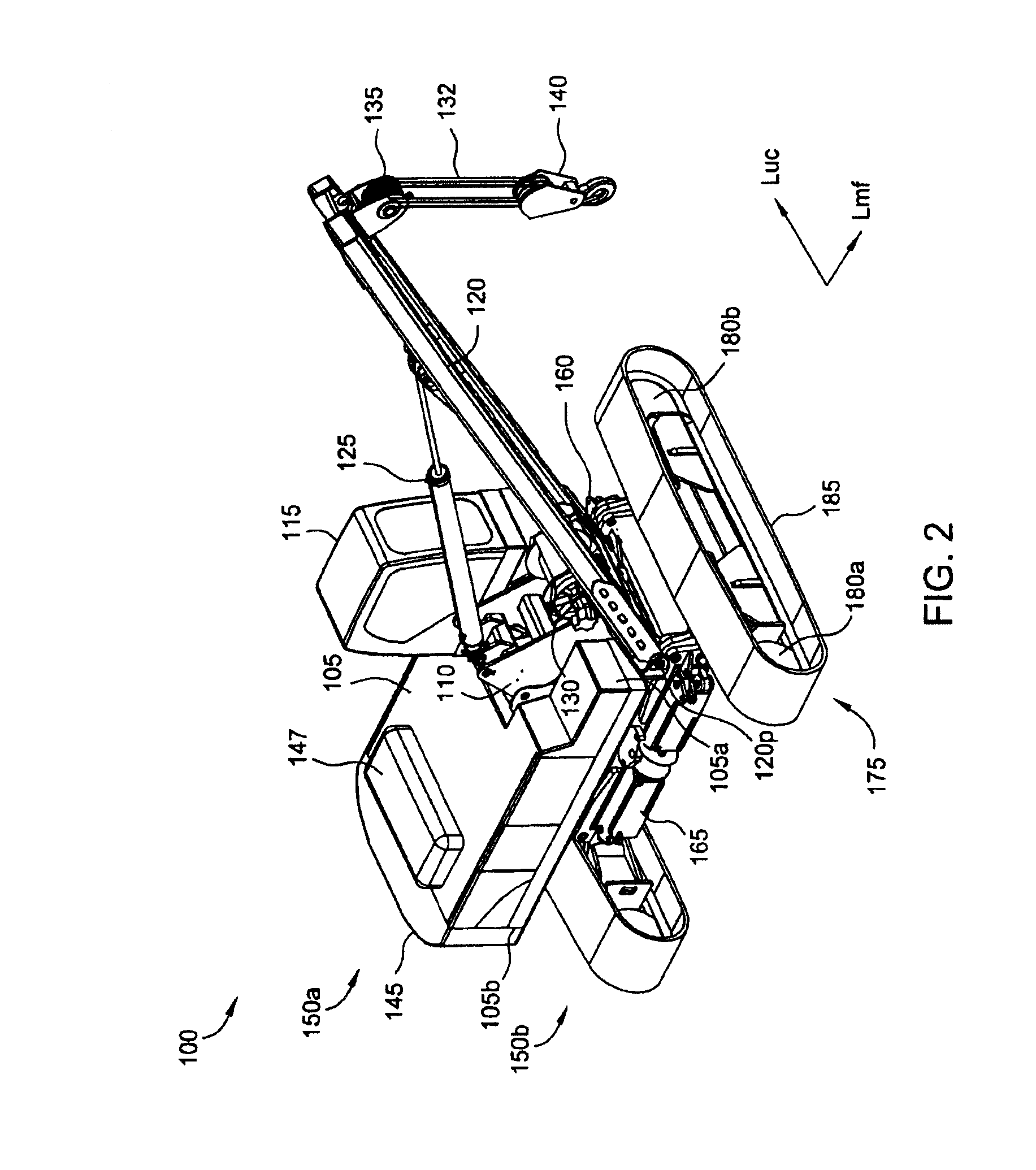

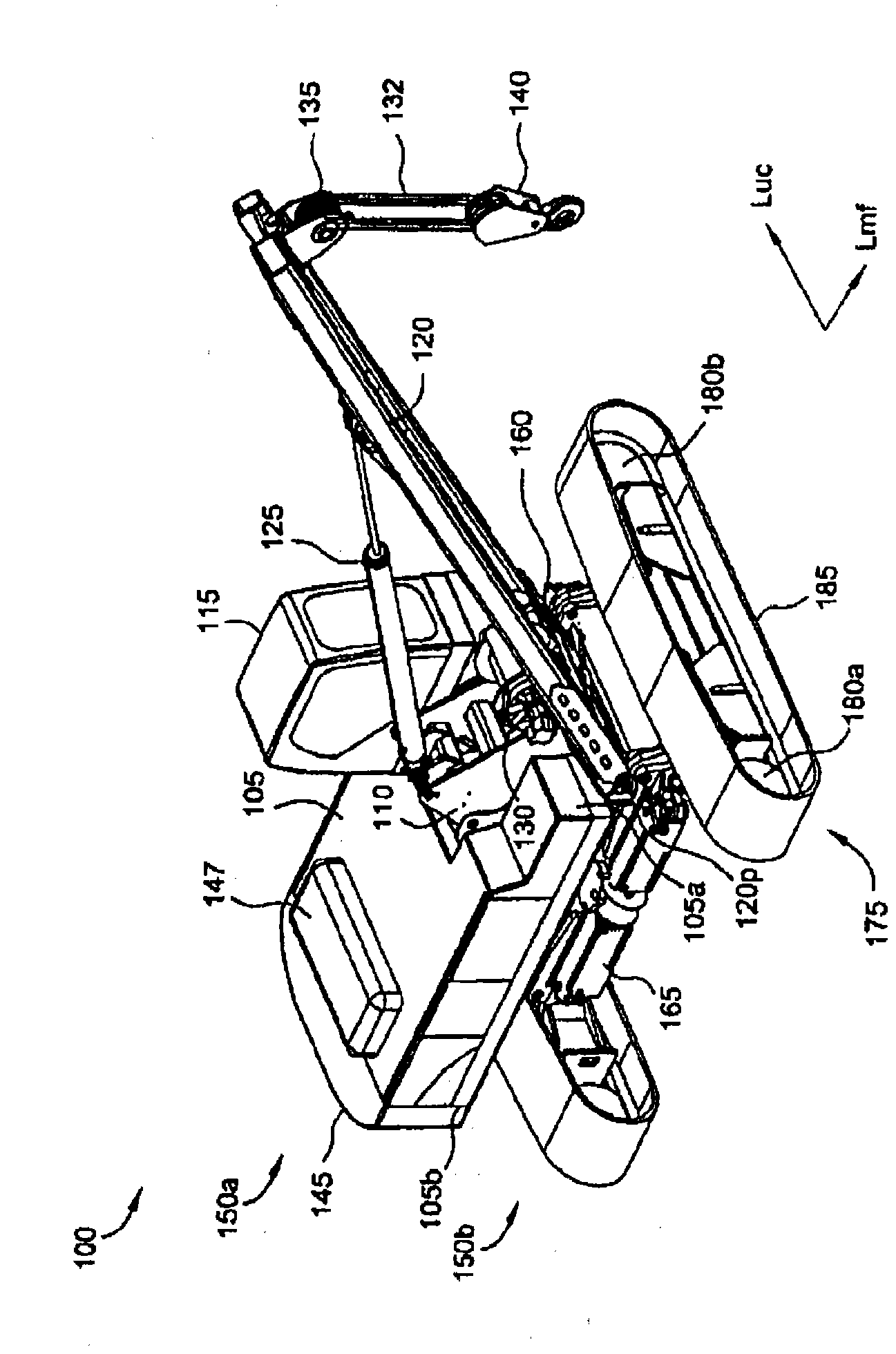

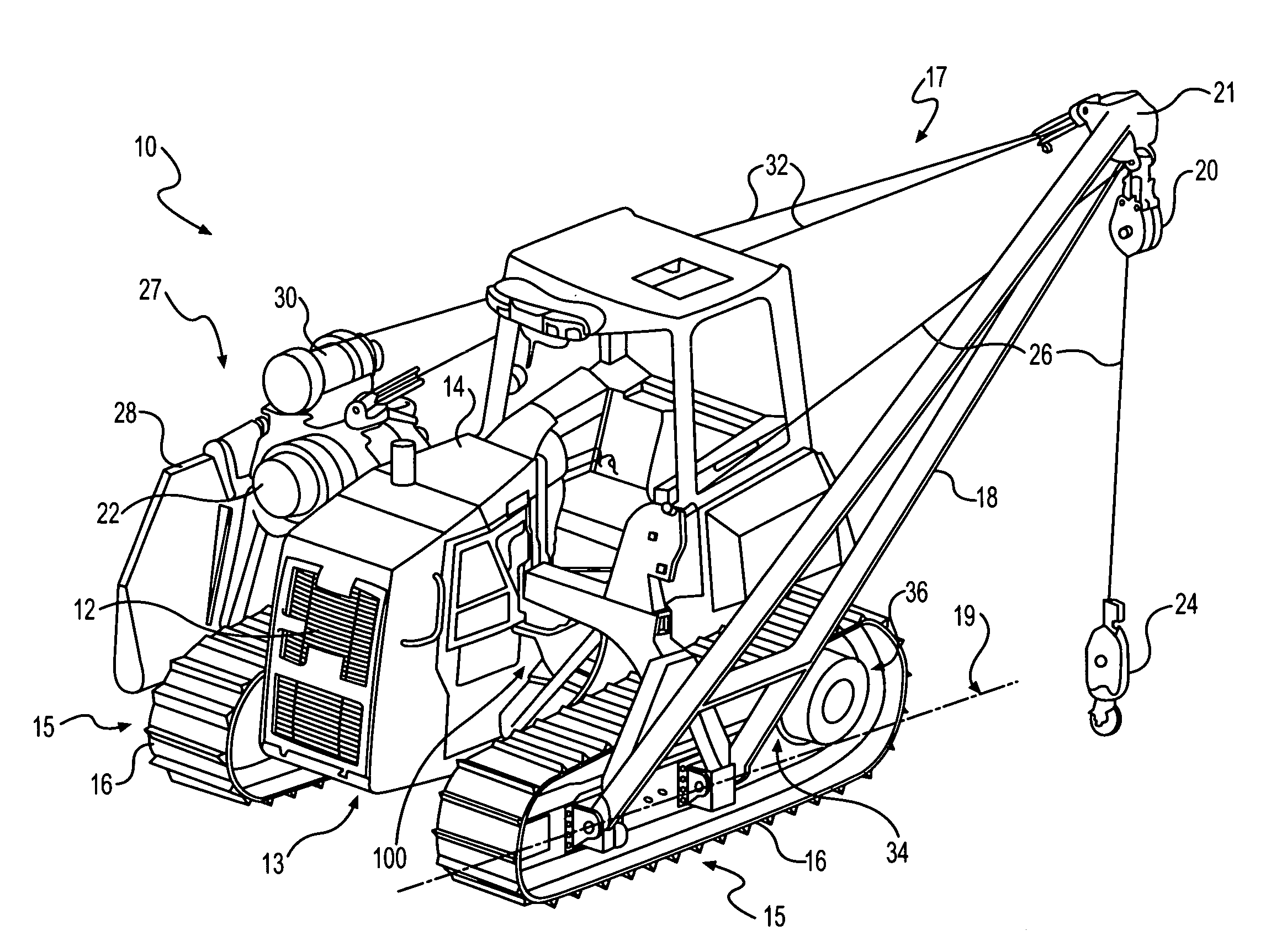

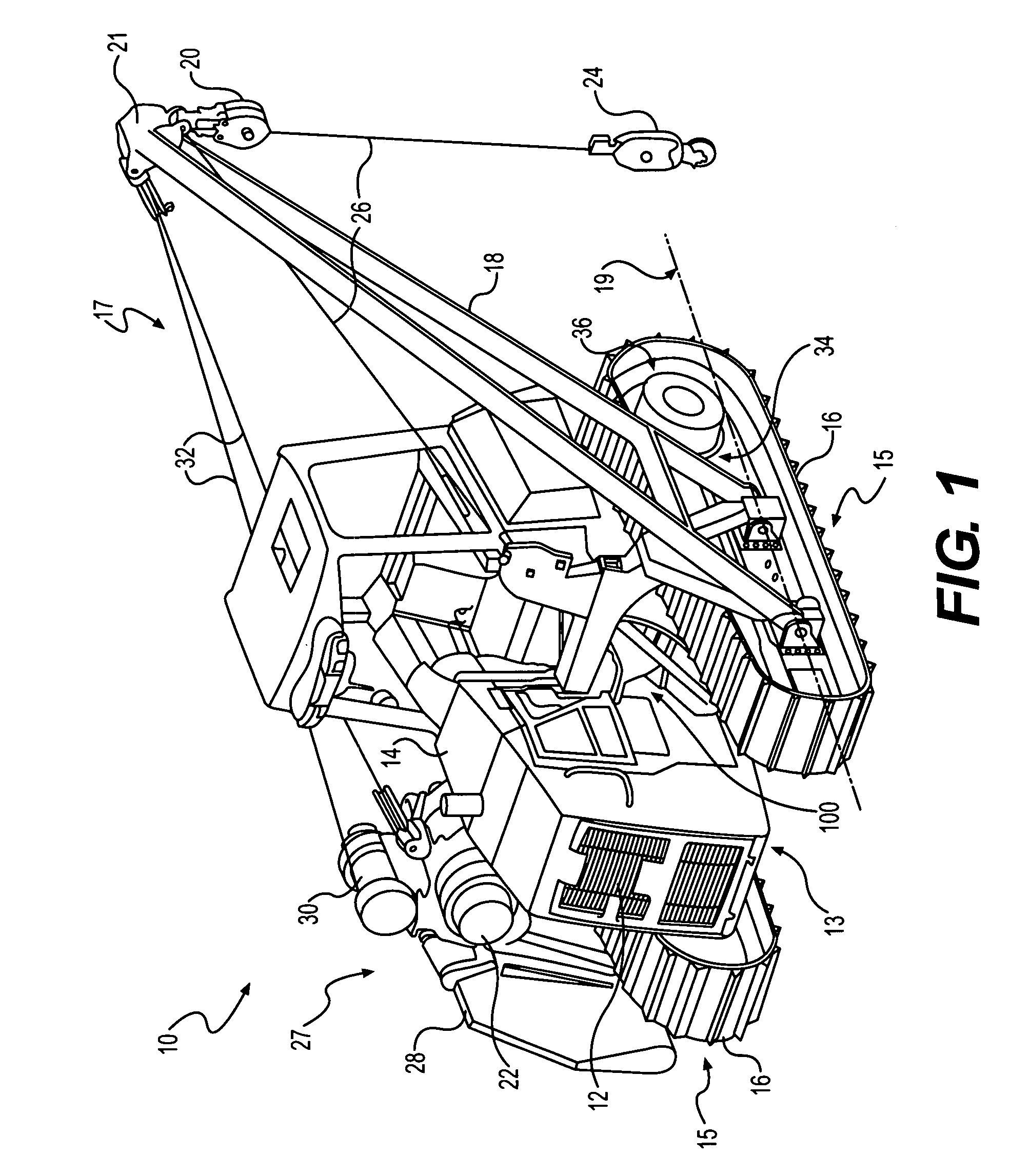

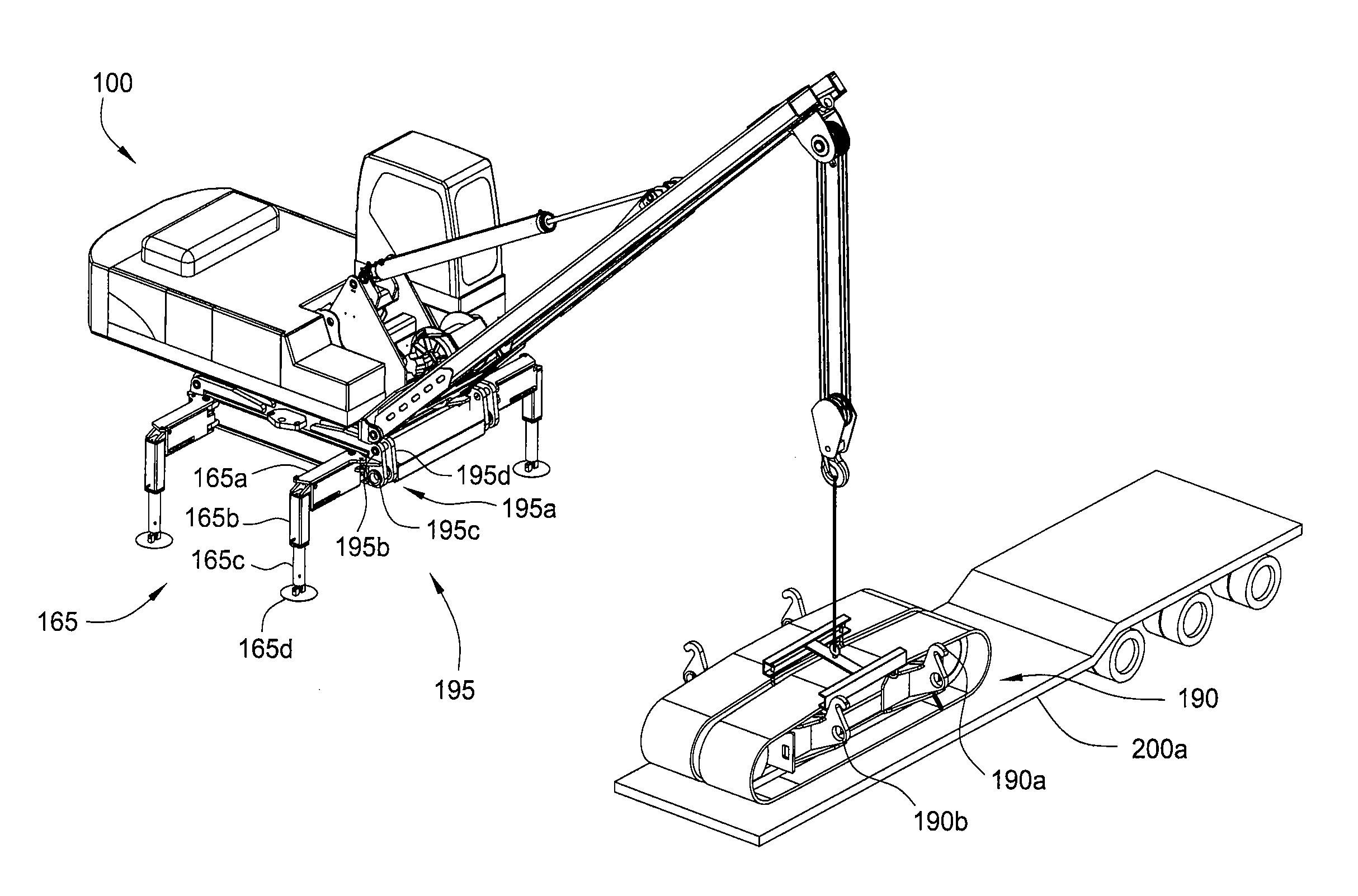

Pipelayer and method of loading pipelayer or excavator for transportation

Embodiments of the present invention generally relate to a pipelayer and a method for of loading a pipelayer or excavator for transportation. One embodiment includes a method for transporting a pipelayer or excavator from a first work site to a second worksite via a public road. The method includes acts of: raising the pipelayer or excavator off of track shoes of the pipelayer or excavator; removing a first track assembly from the pipelayer or excavator using a boom of the pipelayer or a boom assembly of the excavator; loading the first track assembly onto a first trailer of a first tractor-trailer using the boom of the remaining pipelayer or the boom assembly of the remaining excavator; removing the second track assembly from the pipelayer using the boom of the remaining pipelayer or the boom assembly of the remaining excavator; and loading the second track assembly onto the first trailer using the boom of the remaining pipelayer or the boom assembly of the remaining excavator.

Owner:VOLVO CONSTR EQUIP AB

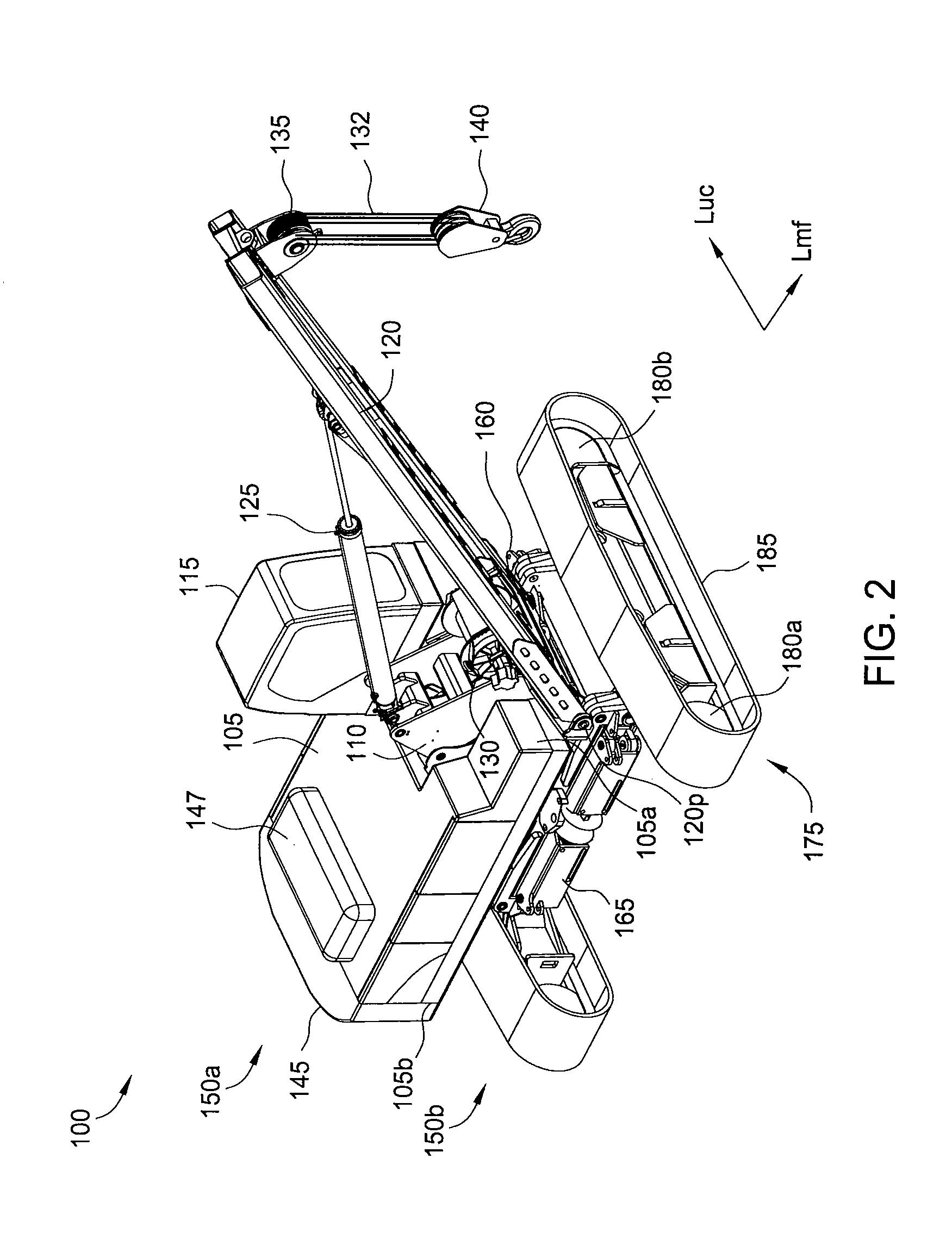

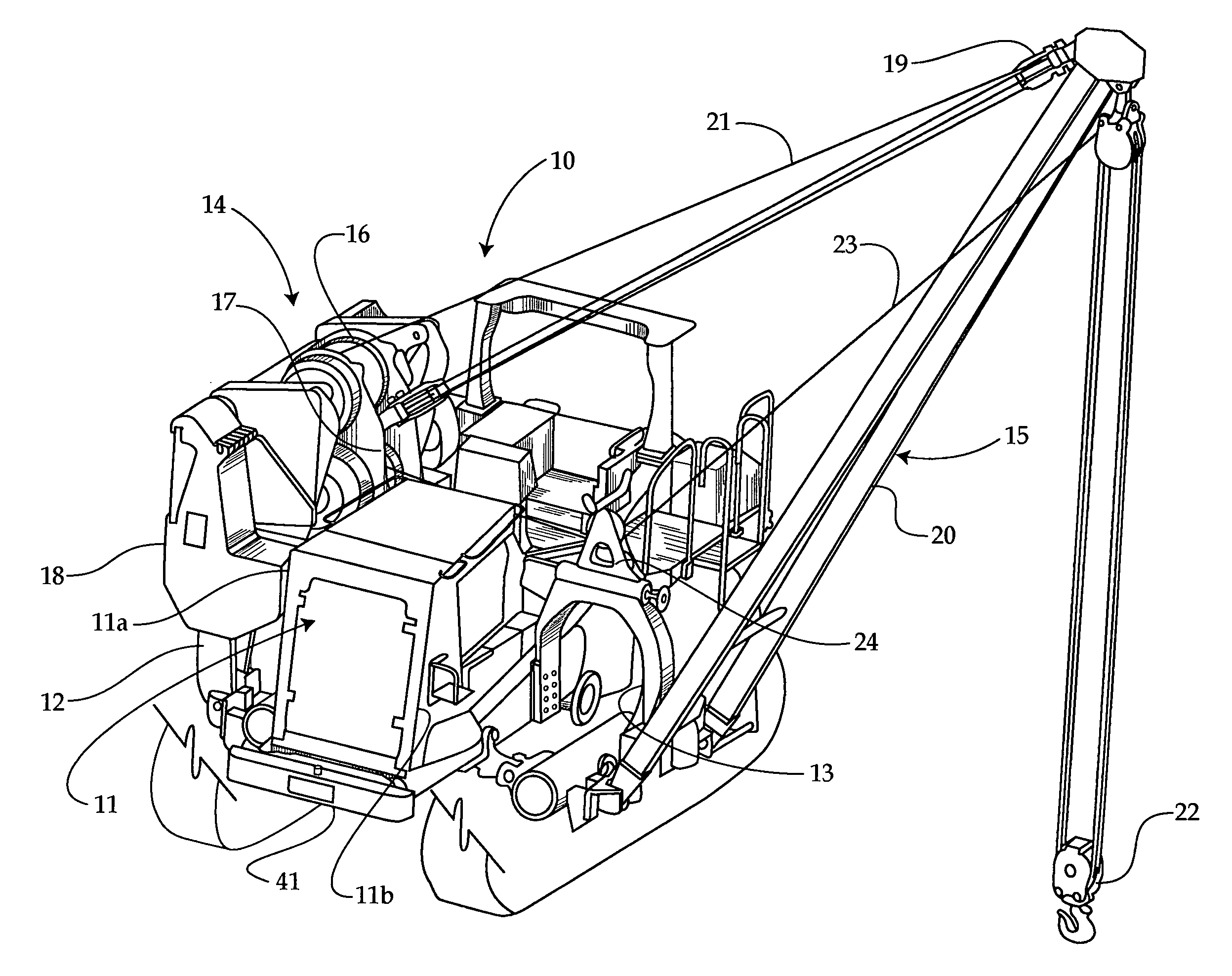

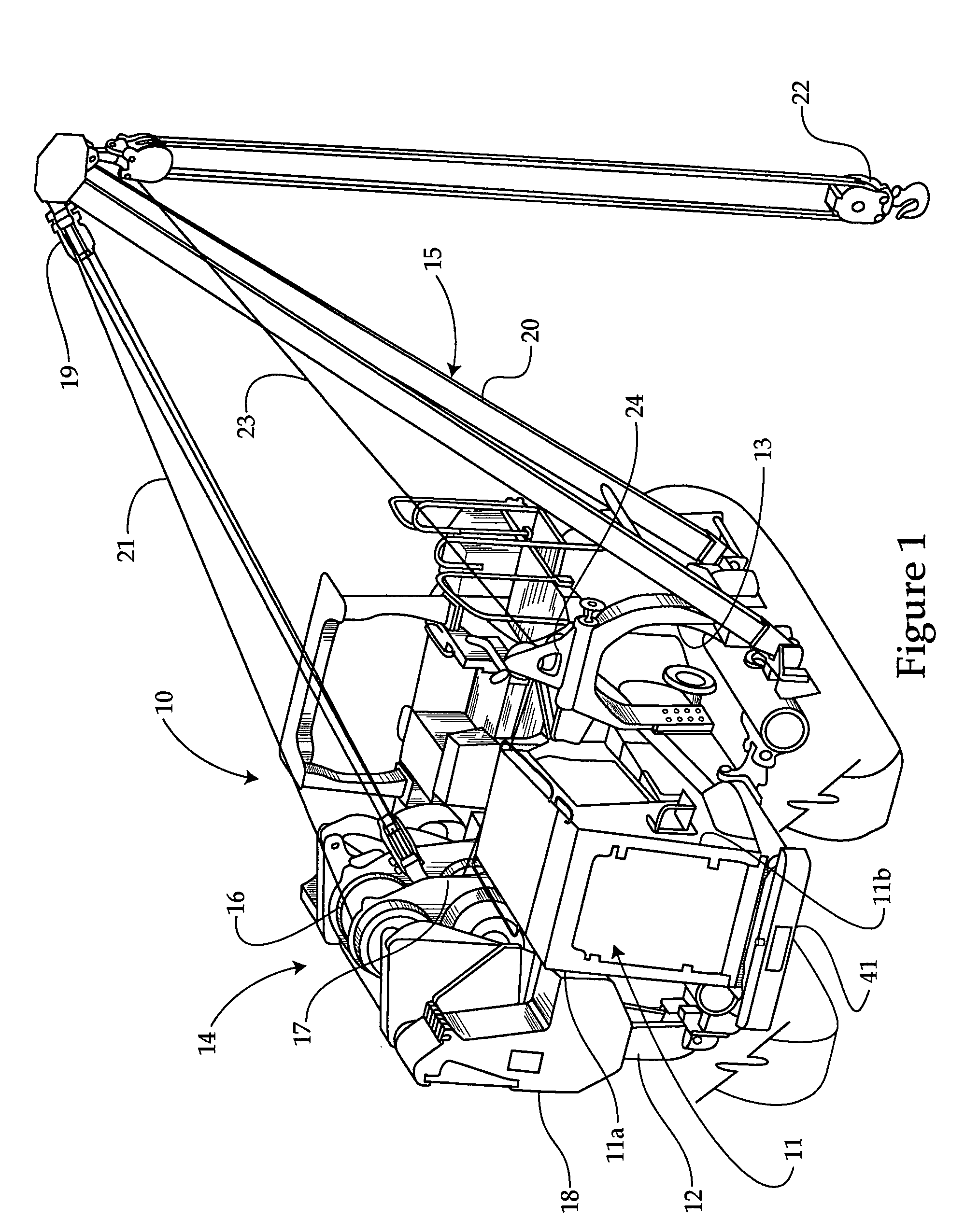

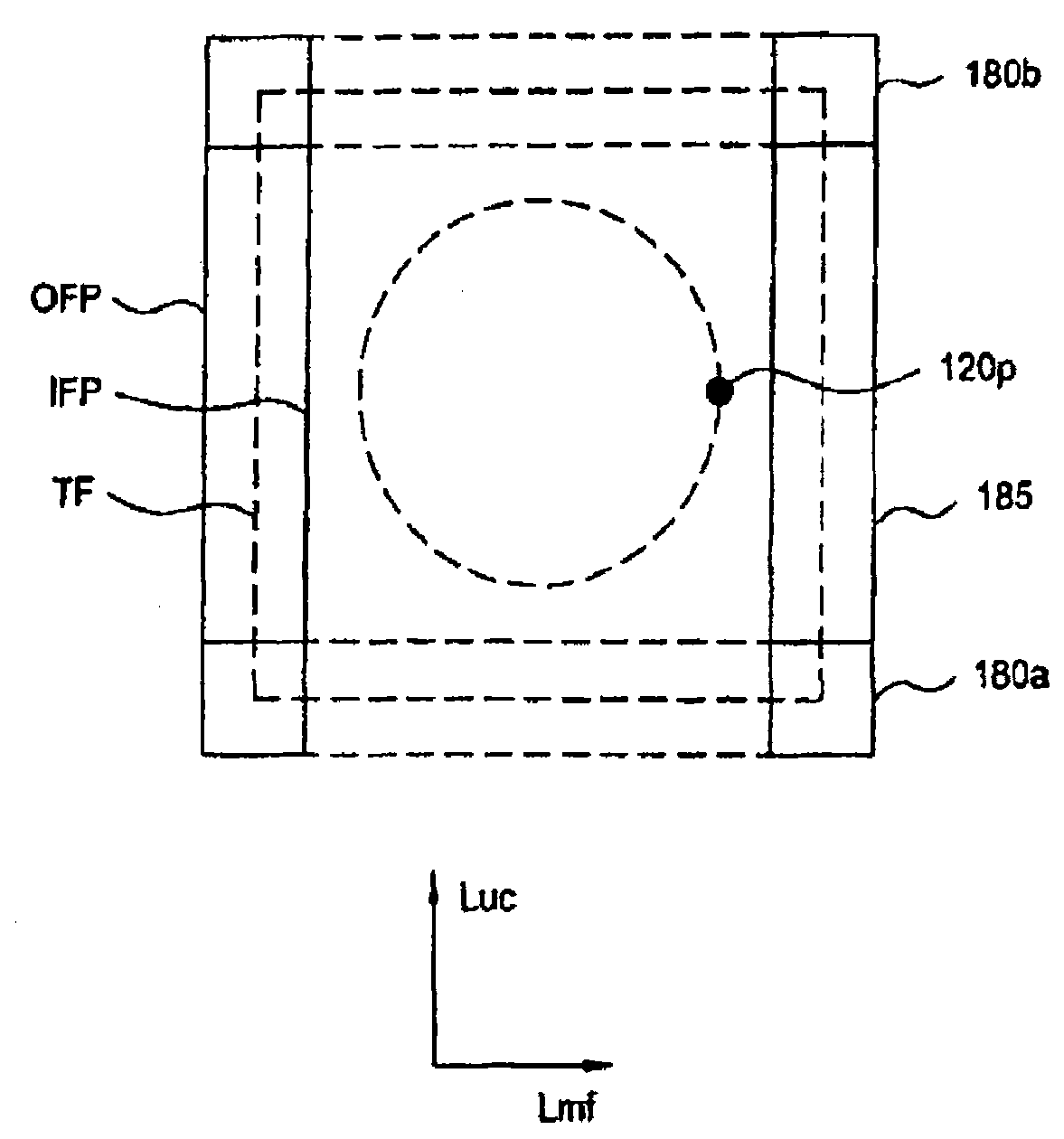

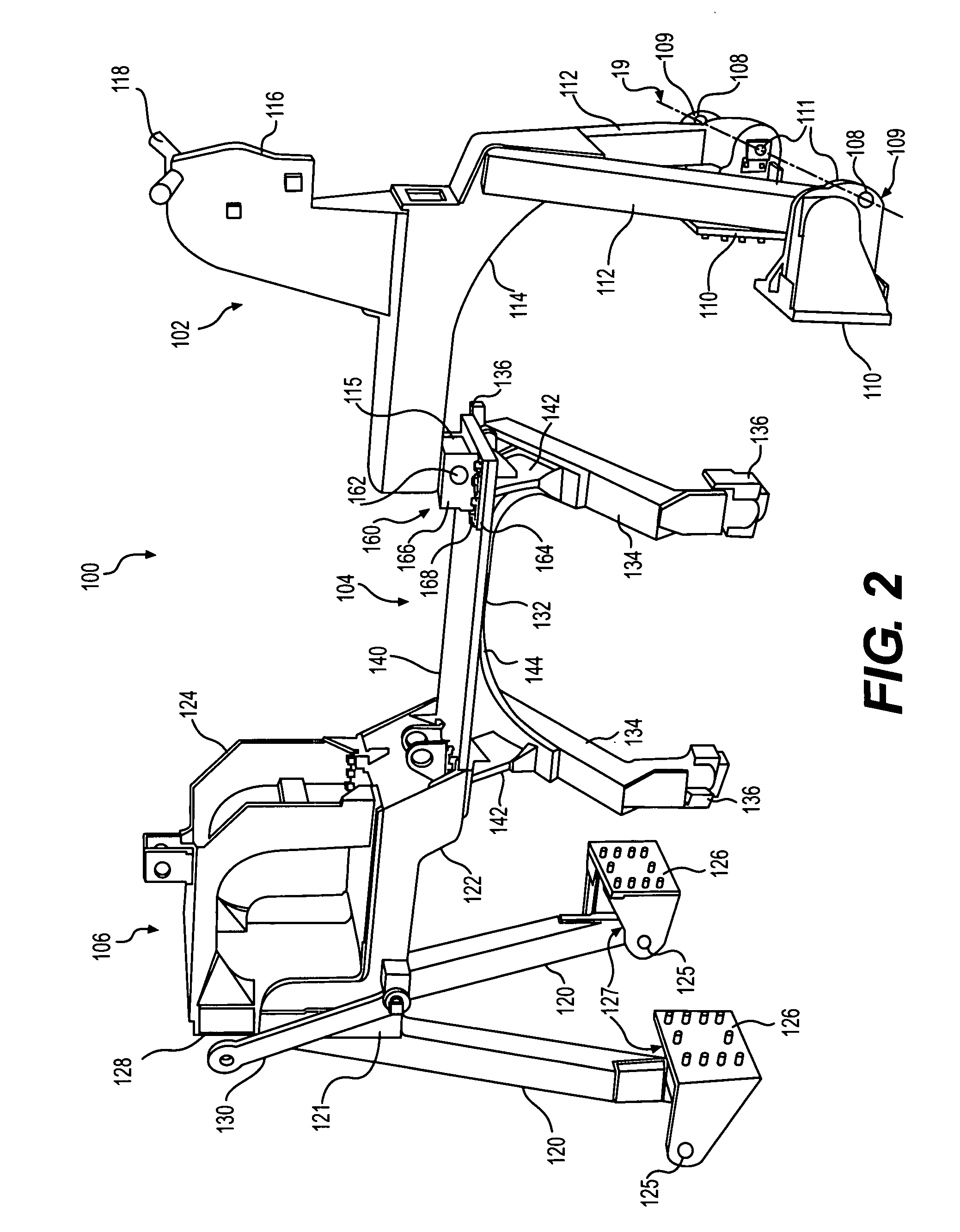

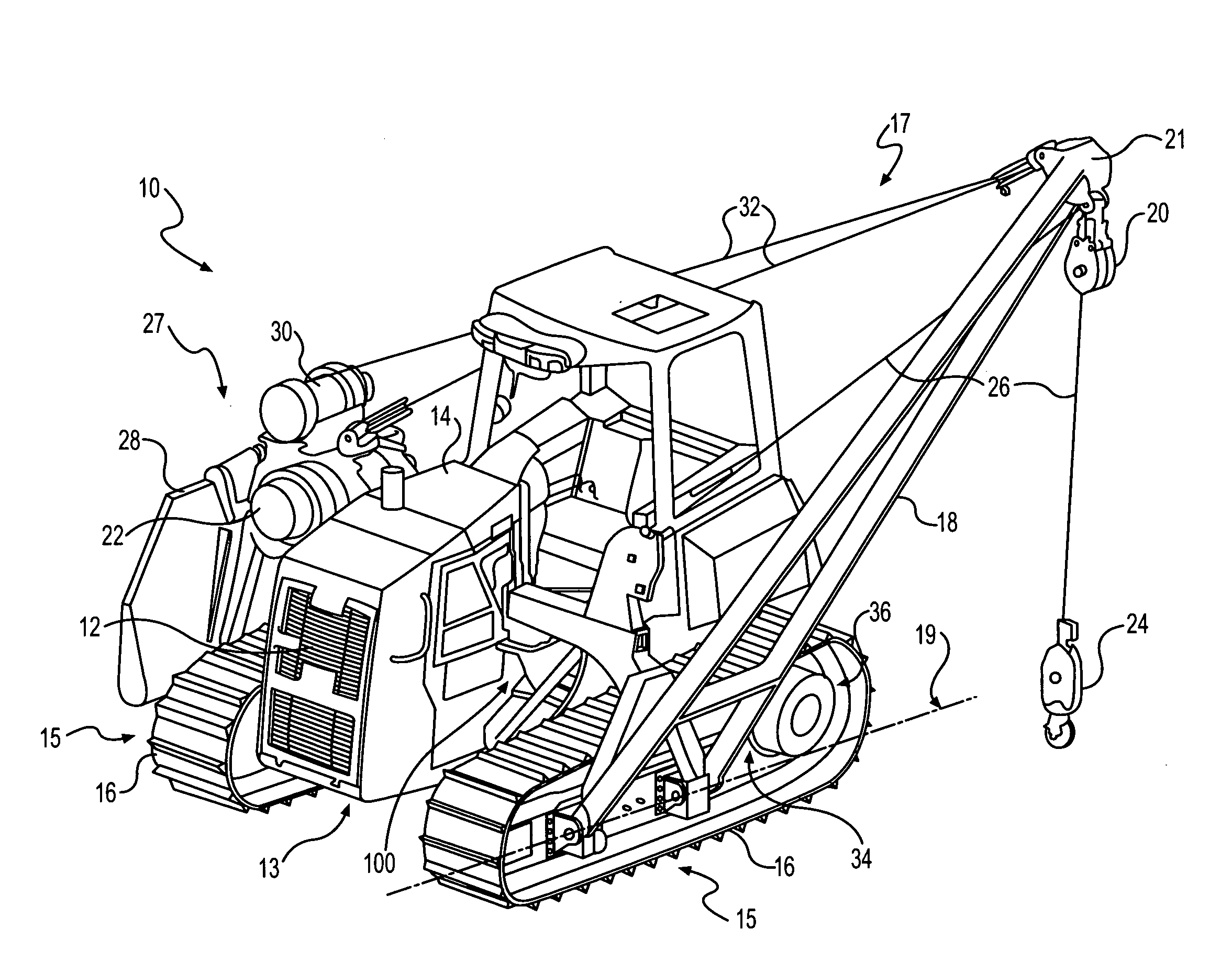

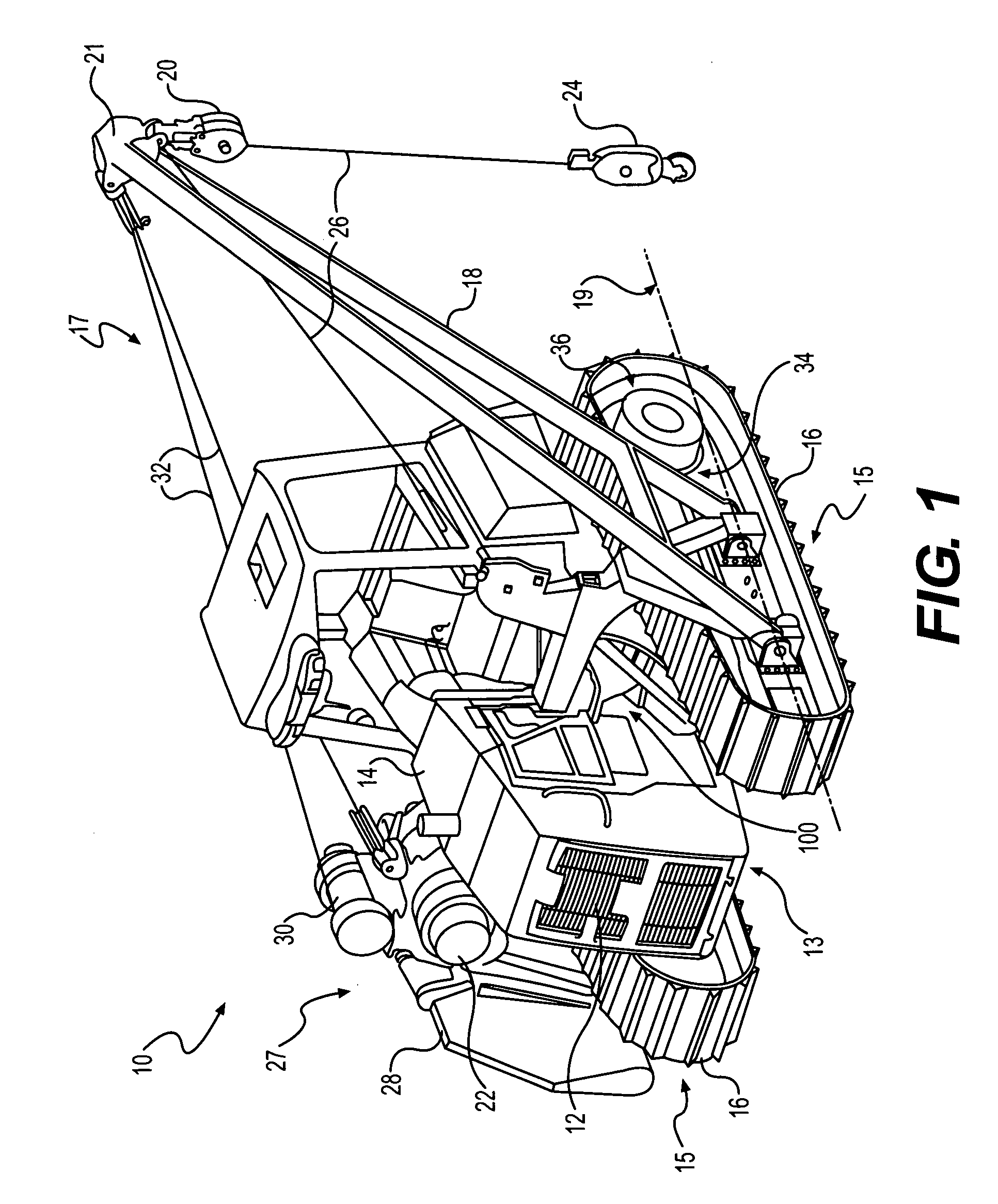

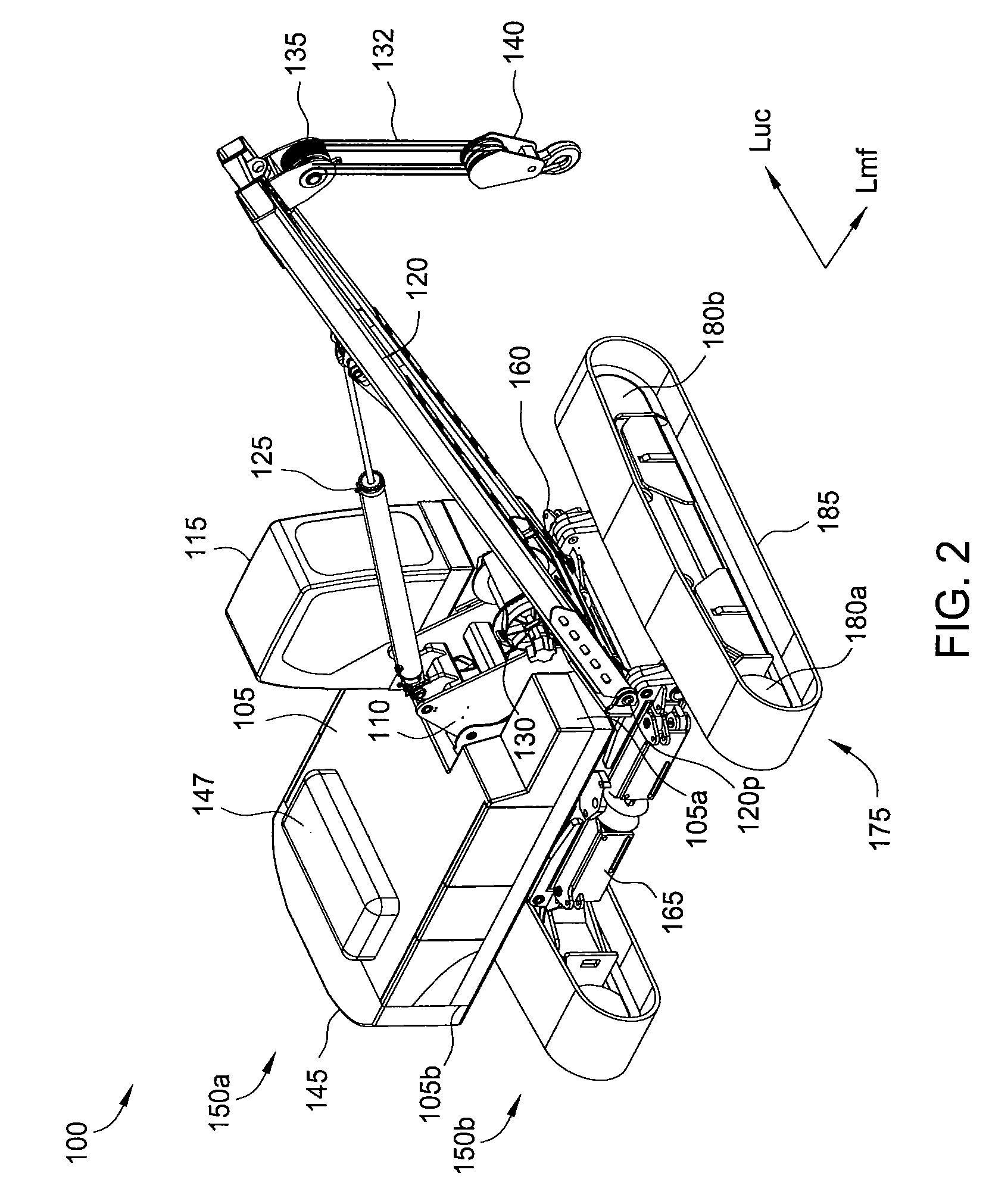

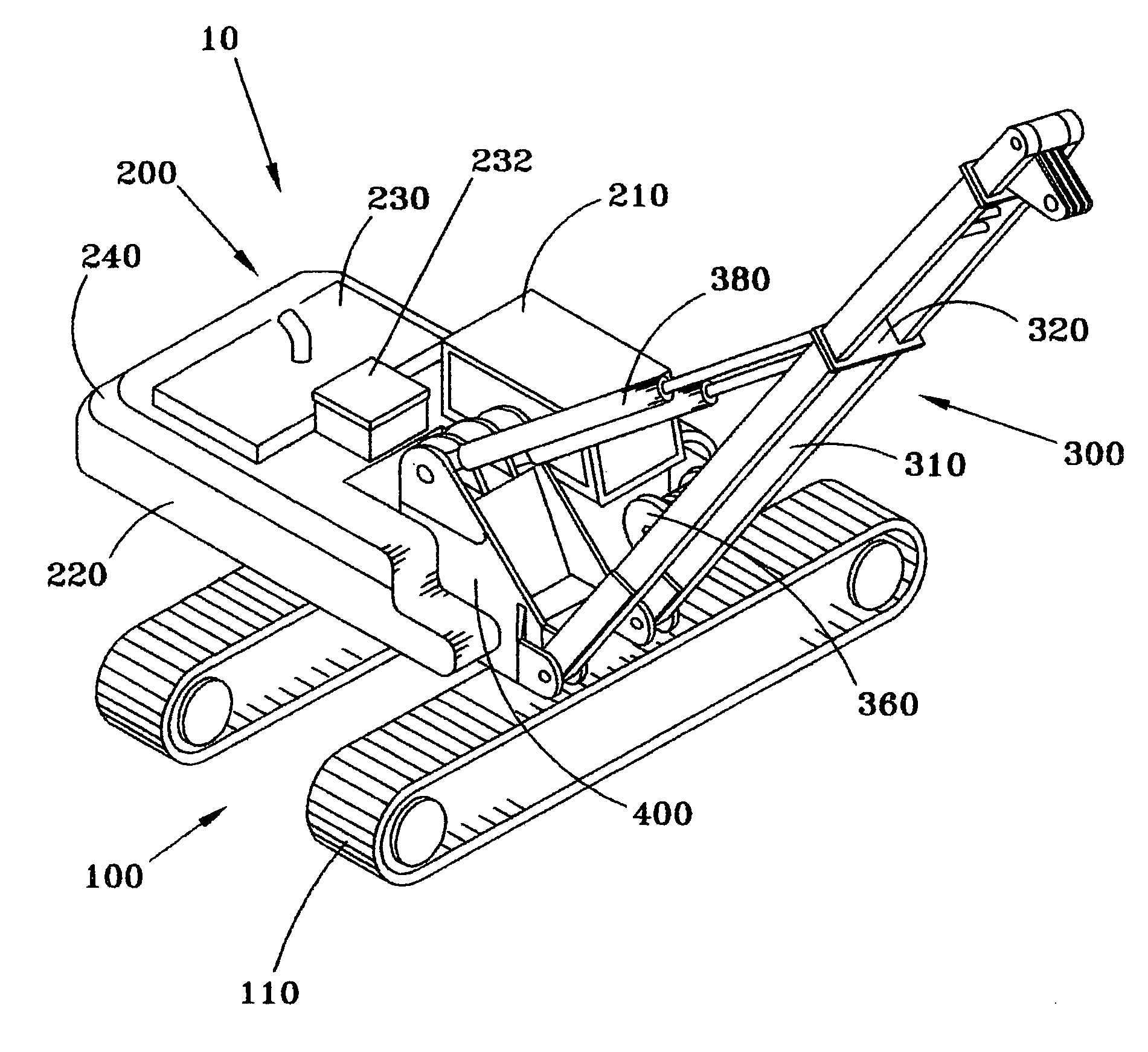

Pipelayer With Cab Riser

A pipelayer having an undercarriage with at least two tracks and a main assembly. Each track has a track frame coupled to the undercarriage and a track shoe supported by and movable around the track frame. The main assembly is supported by and rotatable relative to the undercarriage, and has a main frame, a boom pivotally mounted to the main frame, an operator cab, and a cab riser connecting the operator cab to the main frame. The cab riser is operable to selectively raise and lower the operator cab relative to the main frame. Also provided is a movable cab assembly having an operator cab, an adjustment mechanism to connect the cab to a vehicle frame and move to change the operator's view, and a guide to align the cab. A method for laying pipe using a pipelayer having a movable cab is also provided.

Owner:VOLVO CONSTR EQUIP

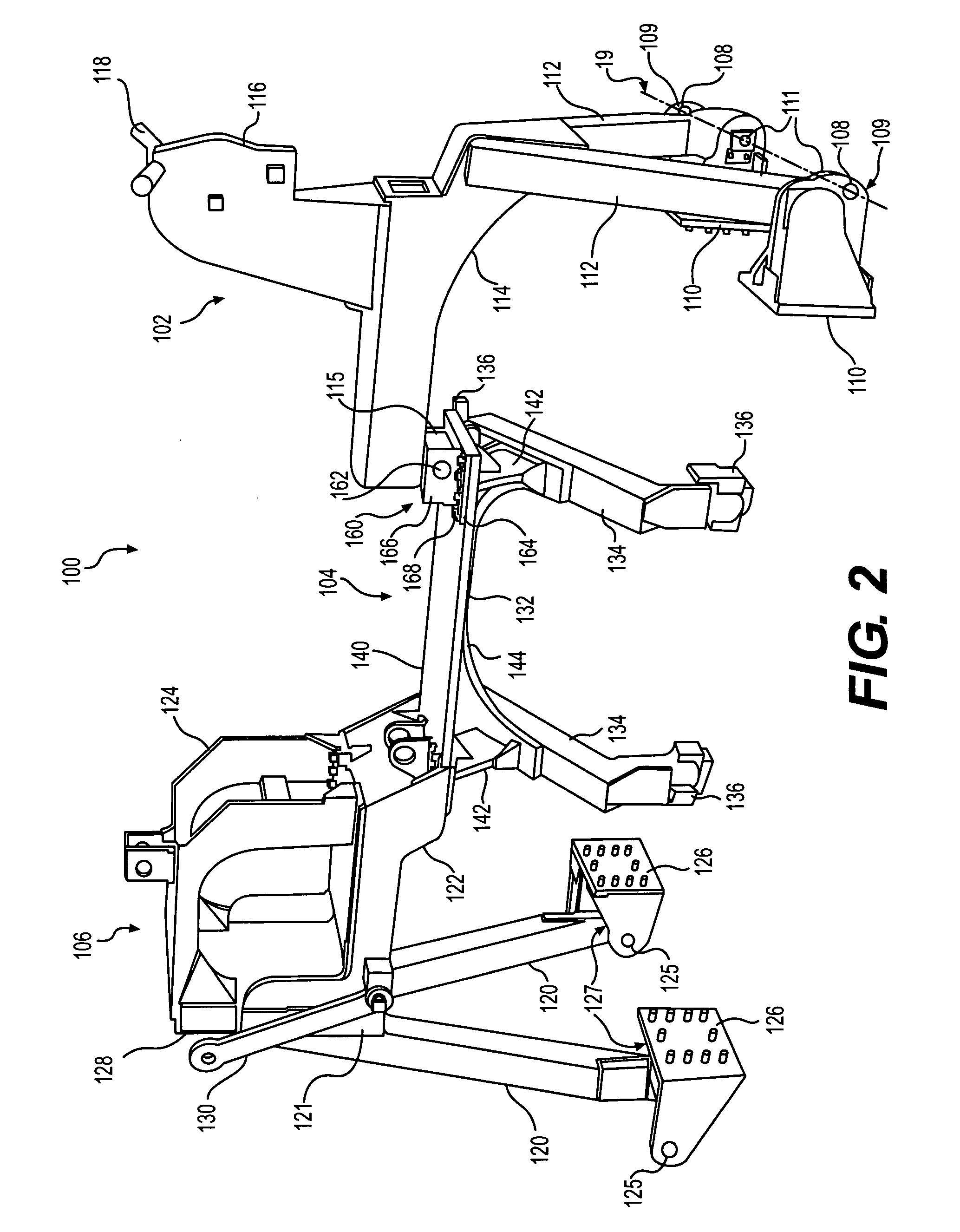

Pipelayer subframe and work machine with same

In order to reduce production and maintenance costs, it is desirable that application-specific machines, such as pipelayers, include common parts with standard track-type work machines, such as a counterpart bulldozer. According to the present disclosure, a pipelayer is assembled by attaching a winch frame and a boom frame to a first and second side of a chassis, respectively. The attached boom frame and the attached winch frame are interconnected by extending a cross-bar between the boom and winch frames.

Owner:CATERPILLAR INC

Electromagnetic inductive welding method of steel-plastic compound pipe

InactiveCN101852323AEasy to implementSuitable for weldingPipe connection arrangementsPipe fittingWater leak

The invention discloses an electromagnetic inductive welding method of a steel-plastic compound pipe, which belongs to a pipeline connecting method. The traditional methods can not realize welding of steel-plastic compound pipes of all specifications. In the method, firstly, the steel-plastic compound pipe is inserted into a connecting port of a pipe fitting; secondly, a steel pipe layer of the steel-plastic compound pipe in the inserting position is heated by an electromagnetic inductive heater to fuse plastics on both sides of the steel pipe layer; and finally, the plastics are cooled to realize welding of the steel-plastic compound pipe and the pipe fitting. Because the steel-plastic compound pipe is inserted into the connecting port of the pipe fitting at first, and then the inserting position is heated for welding, the method is easy. The structures of the pipe fitting and the pipe are not changed, and thus the pipe is easy to be manufactured. The method is suitable for welding of steel-plastic compound pipes of all specifications and the pipe fitting, and is easy to realize double-face seal. In case of water leak or water seepage caused by bad welding quality, the inserting part can be heated again for improvement.

Owner:中科华飞管业(东莞)有限公司

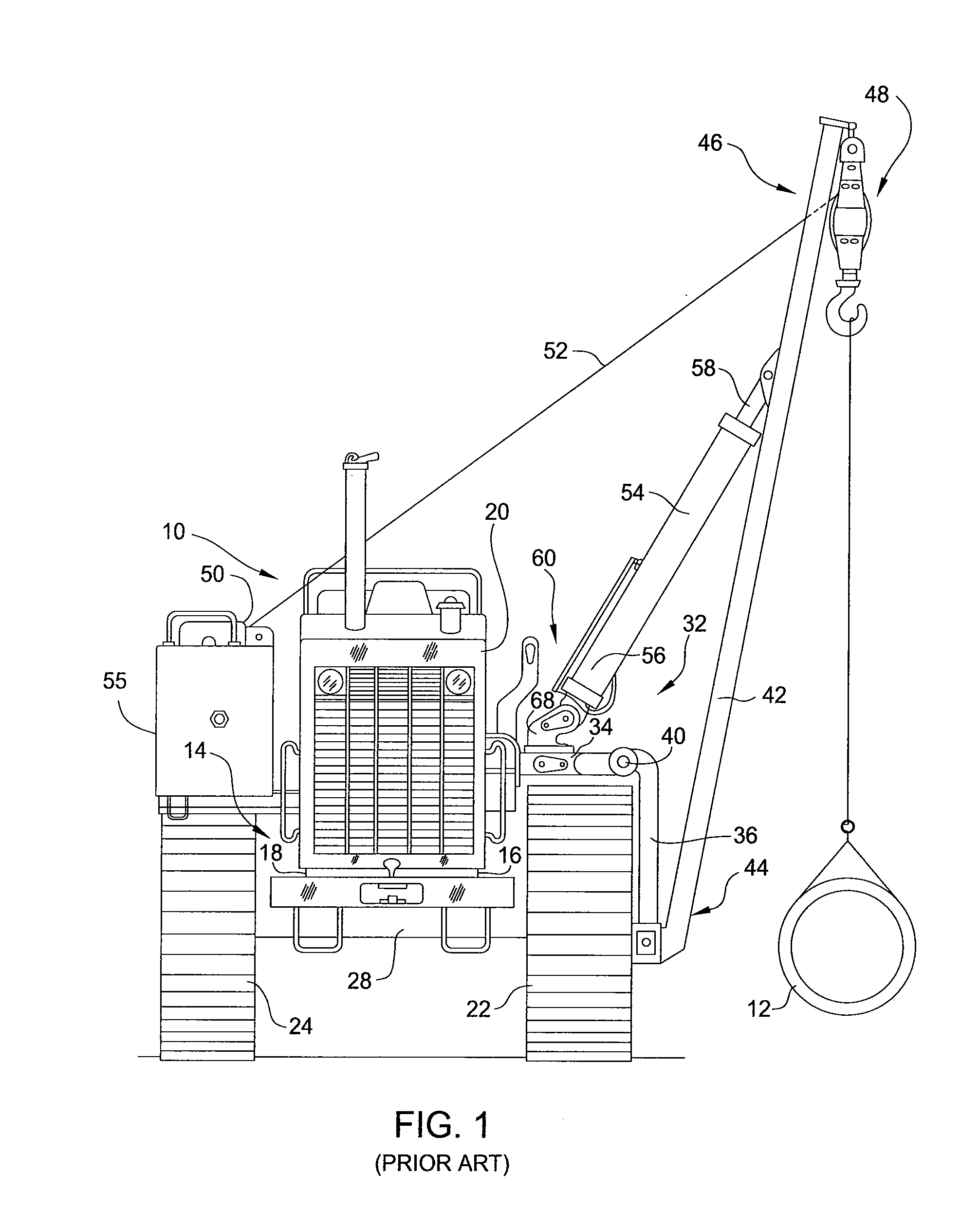

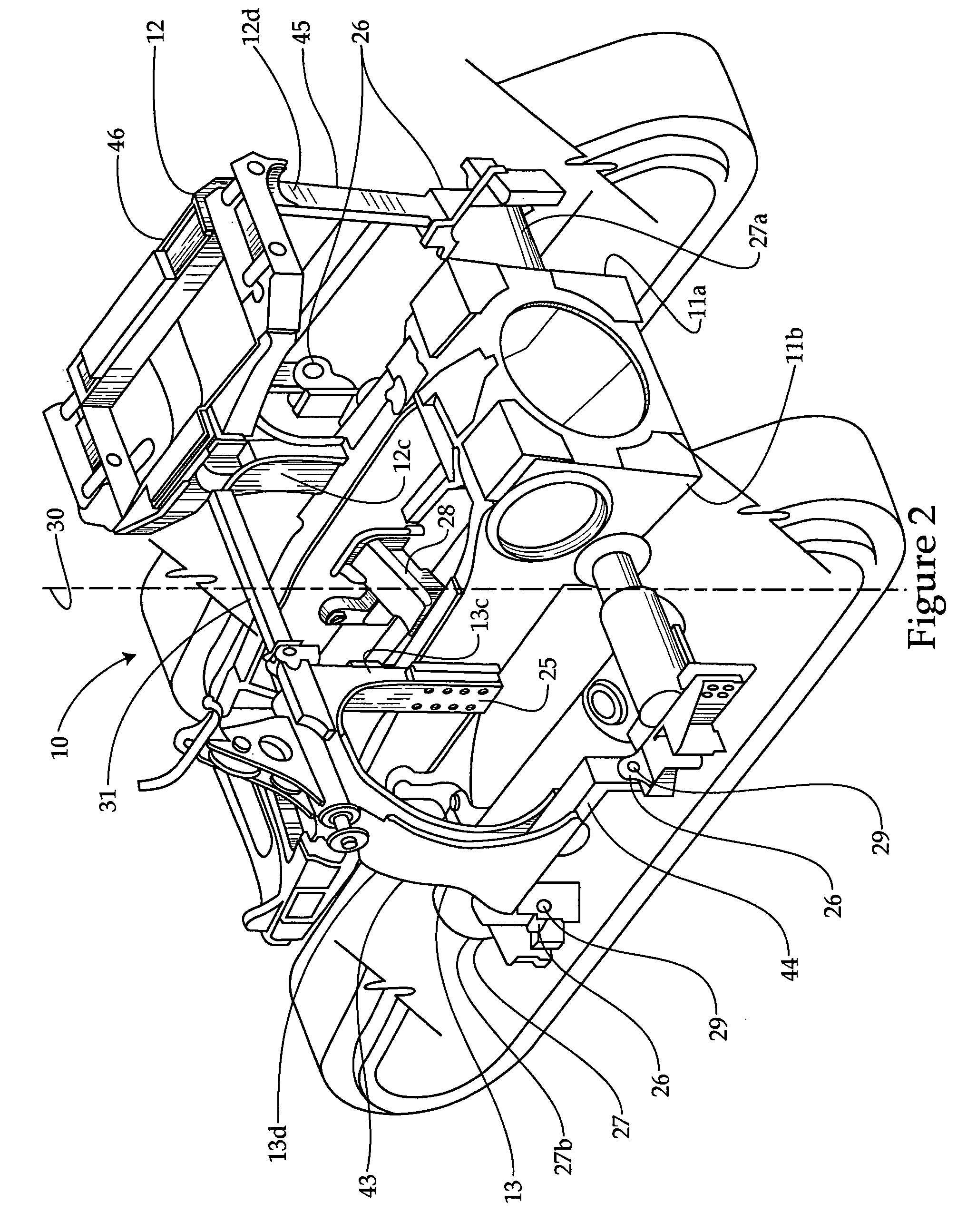

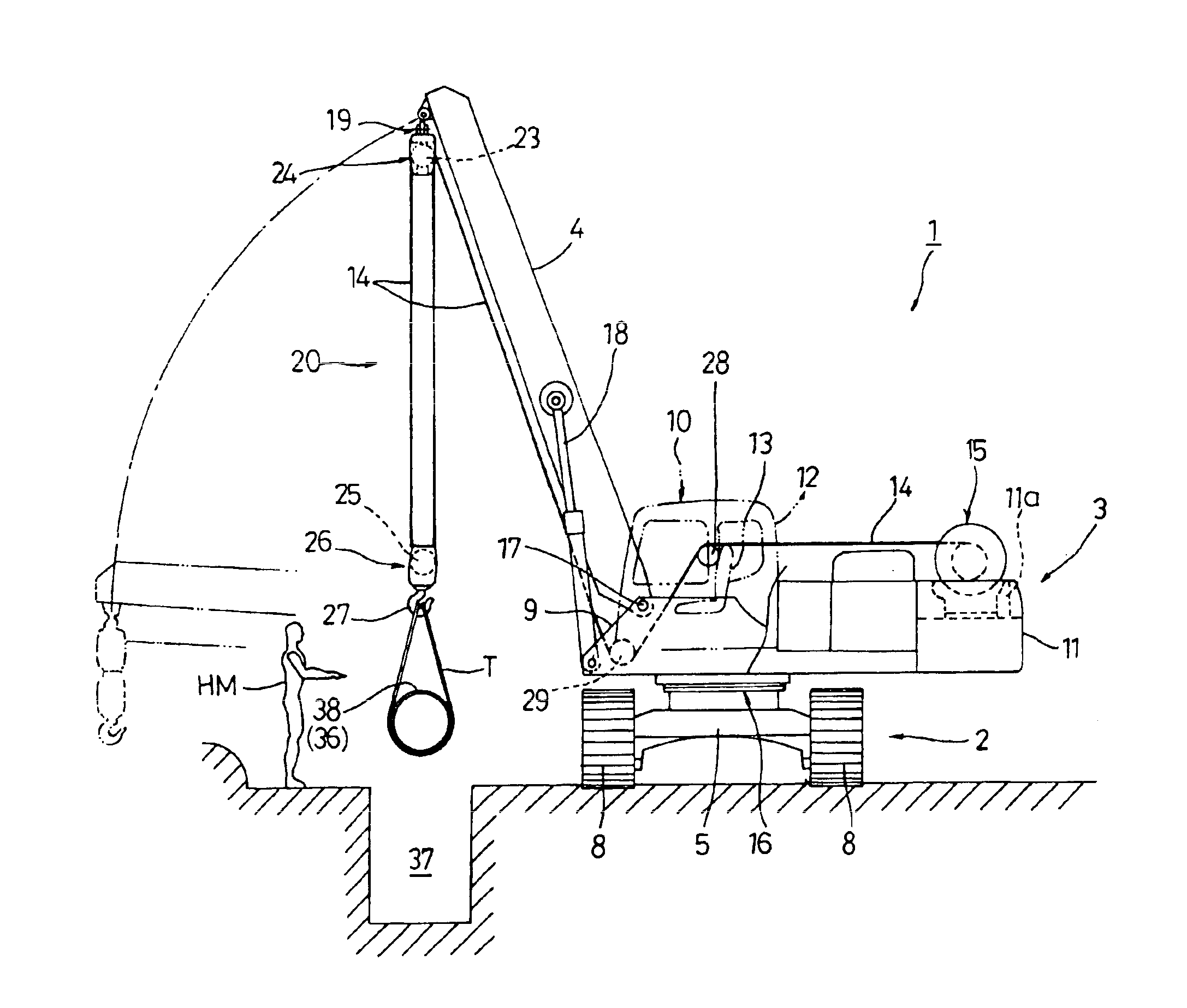

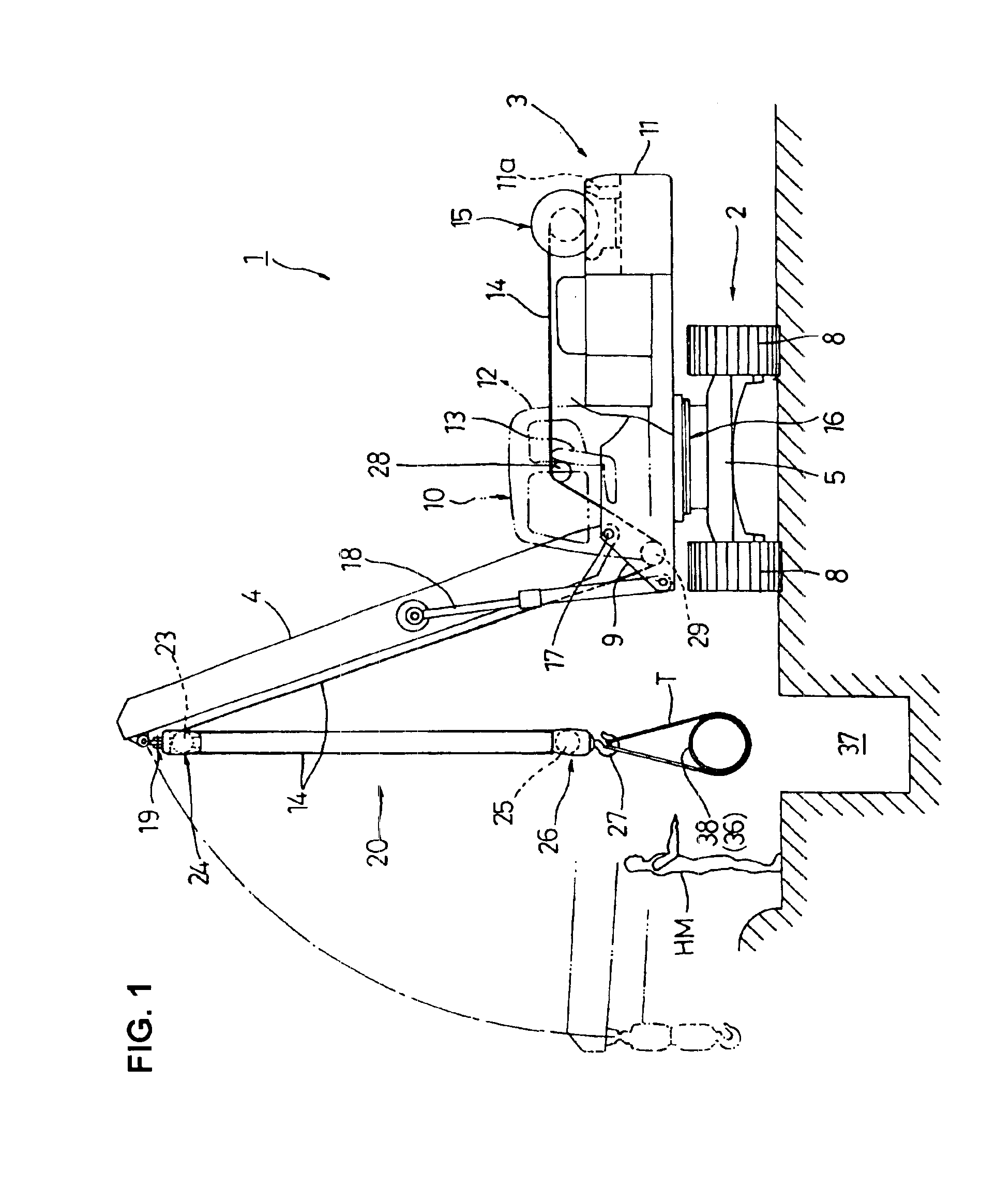

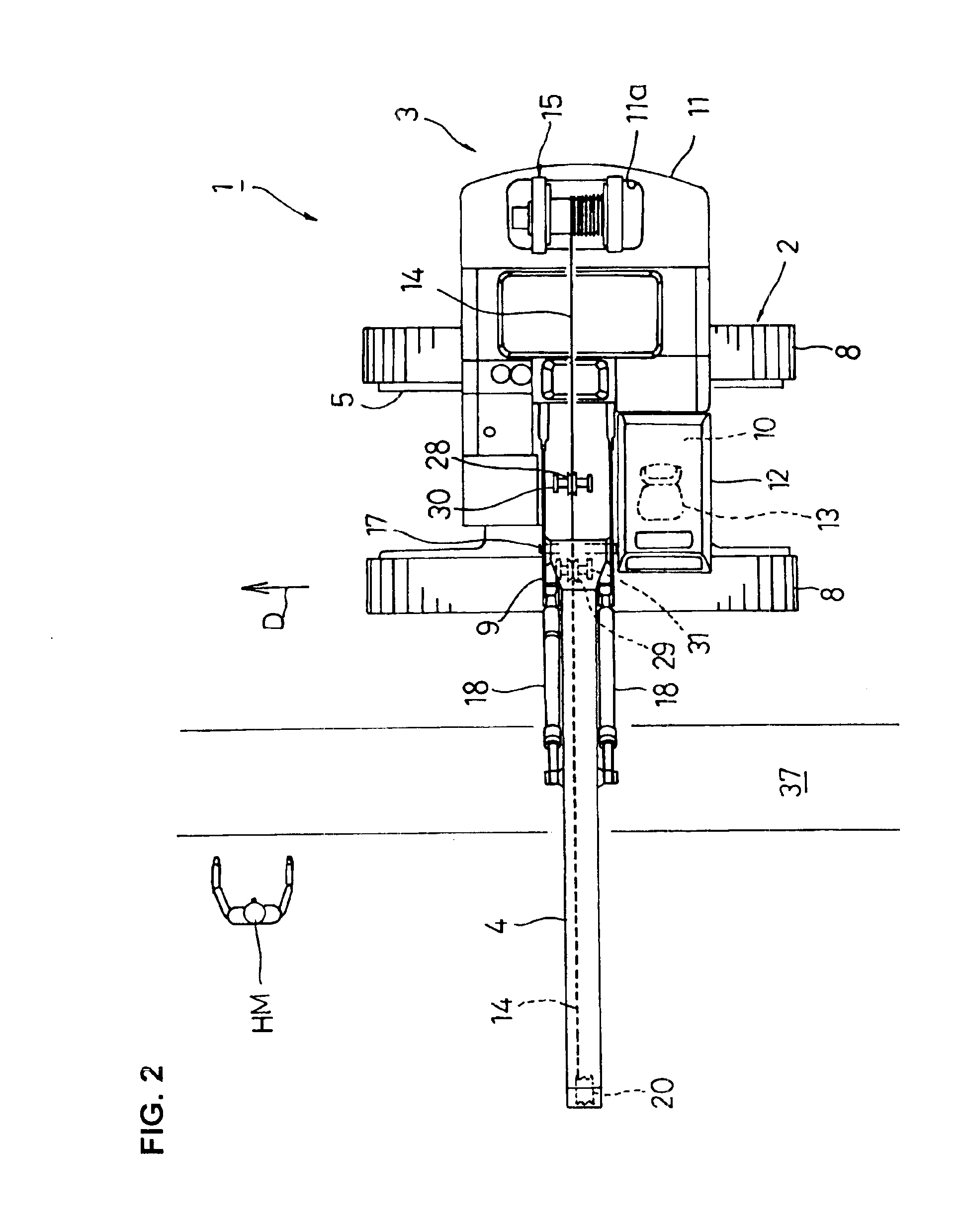

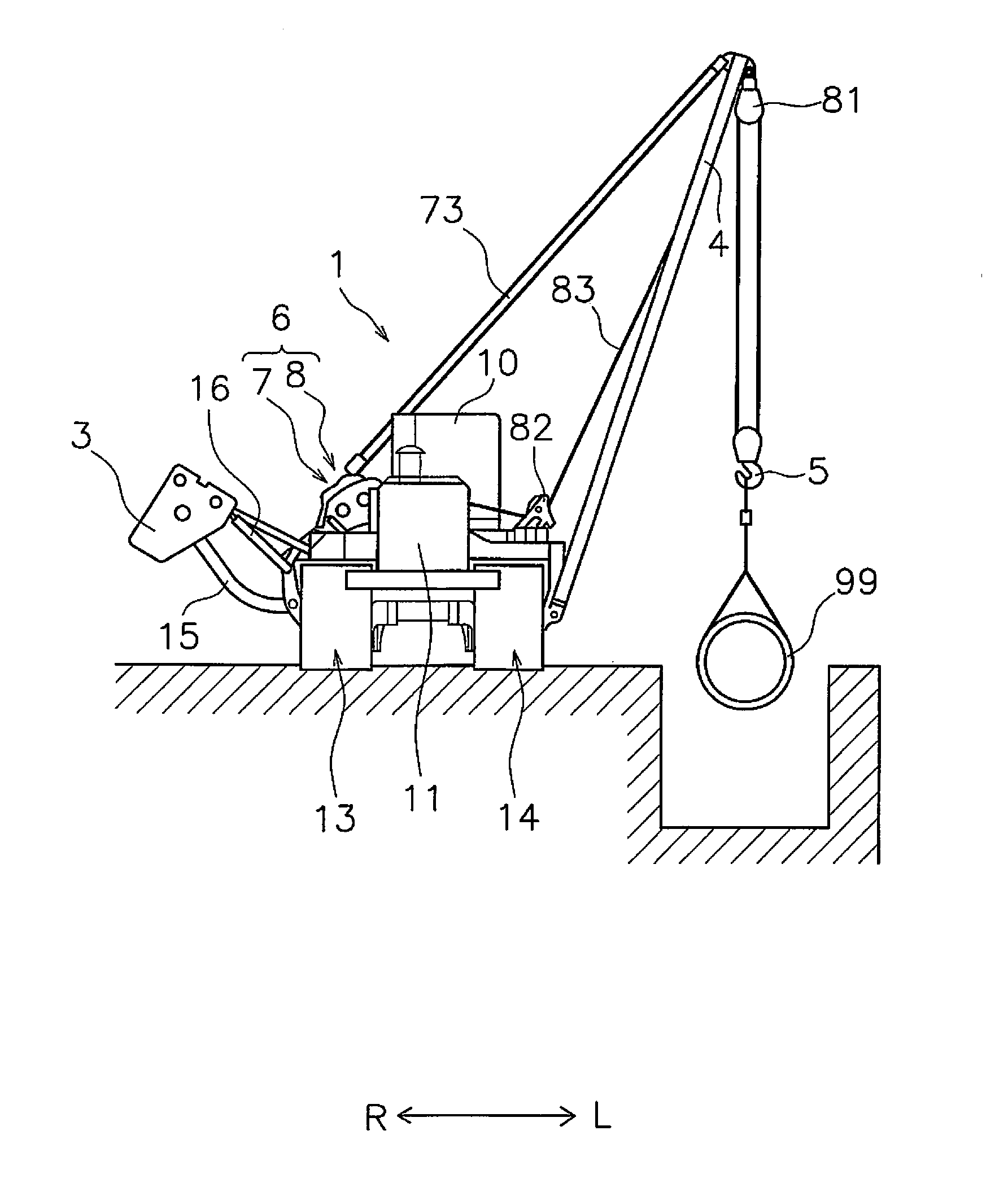

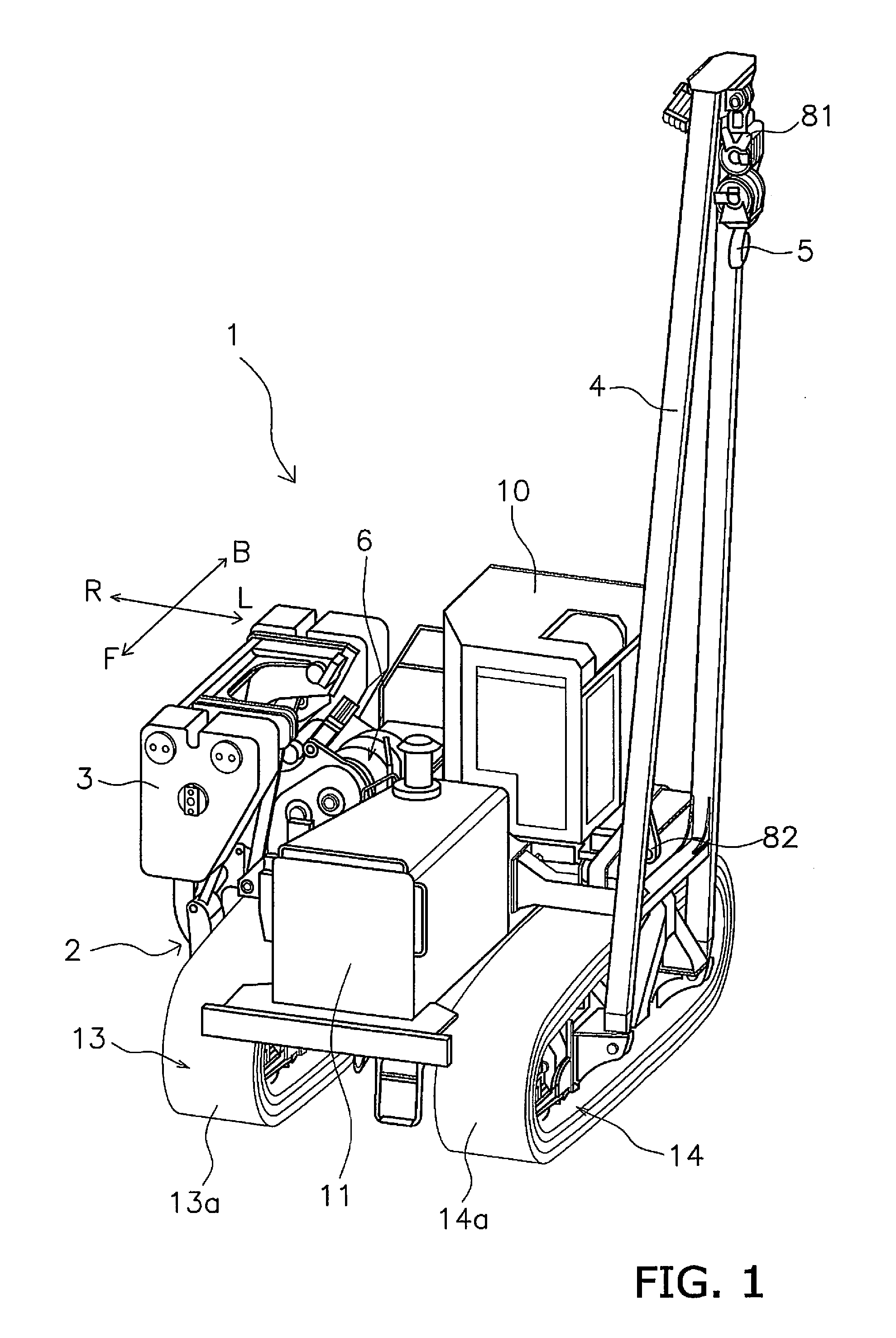

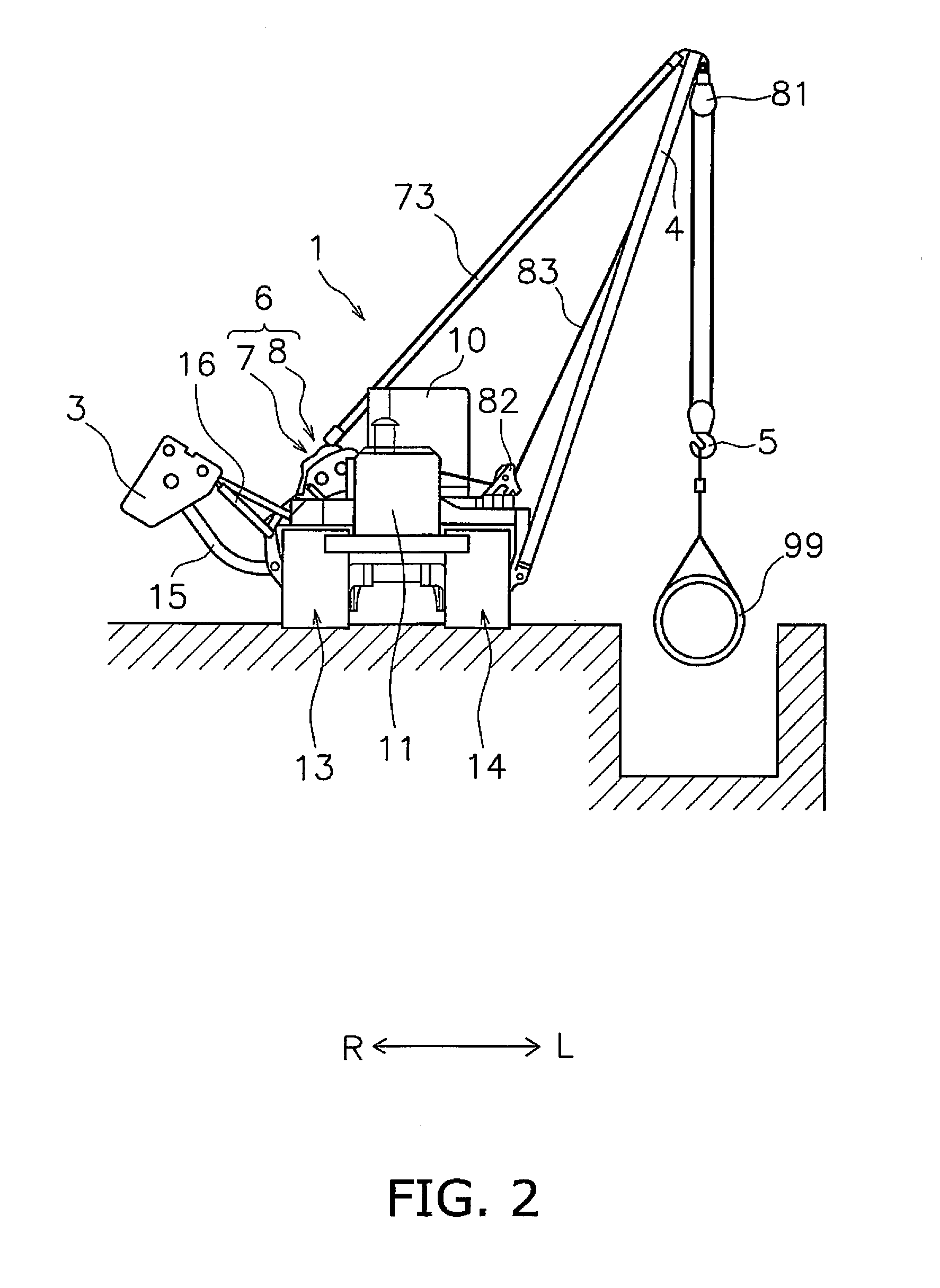

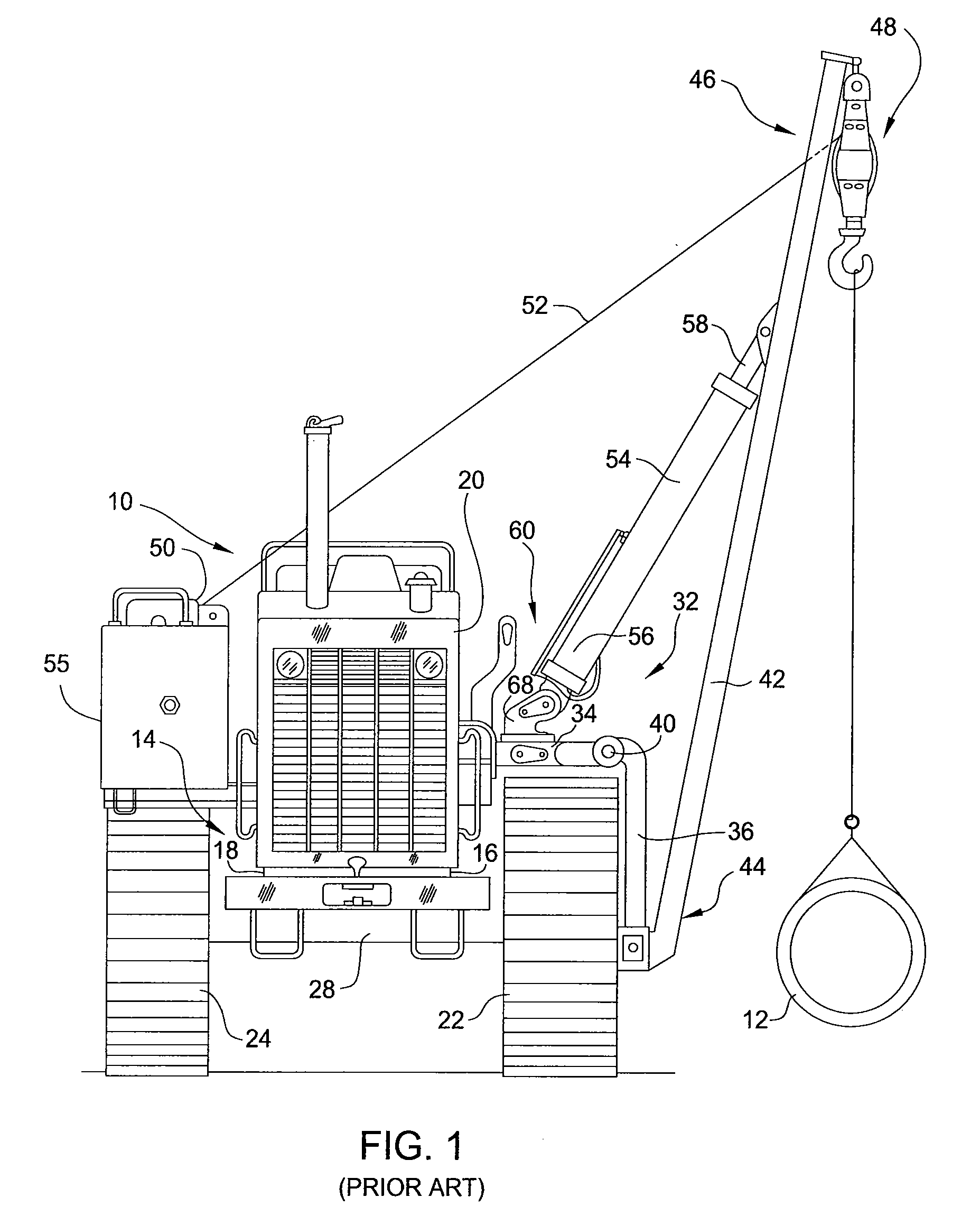

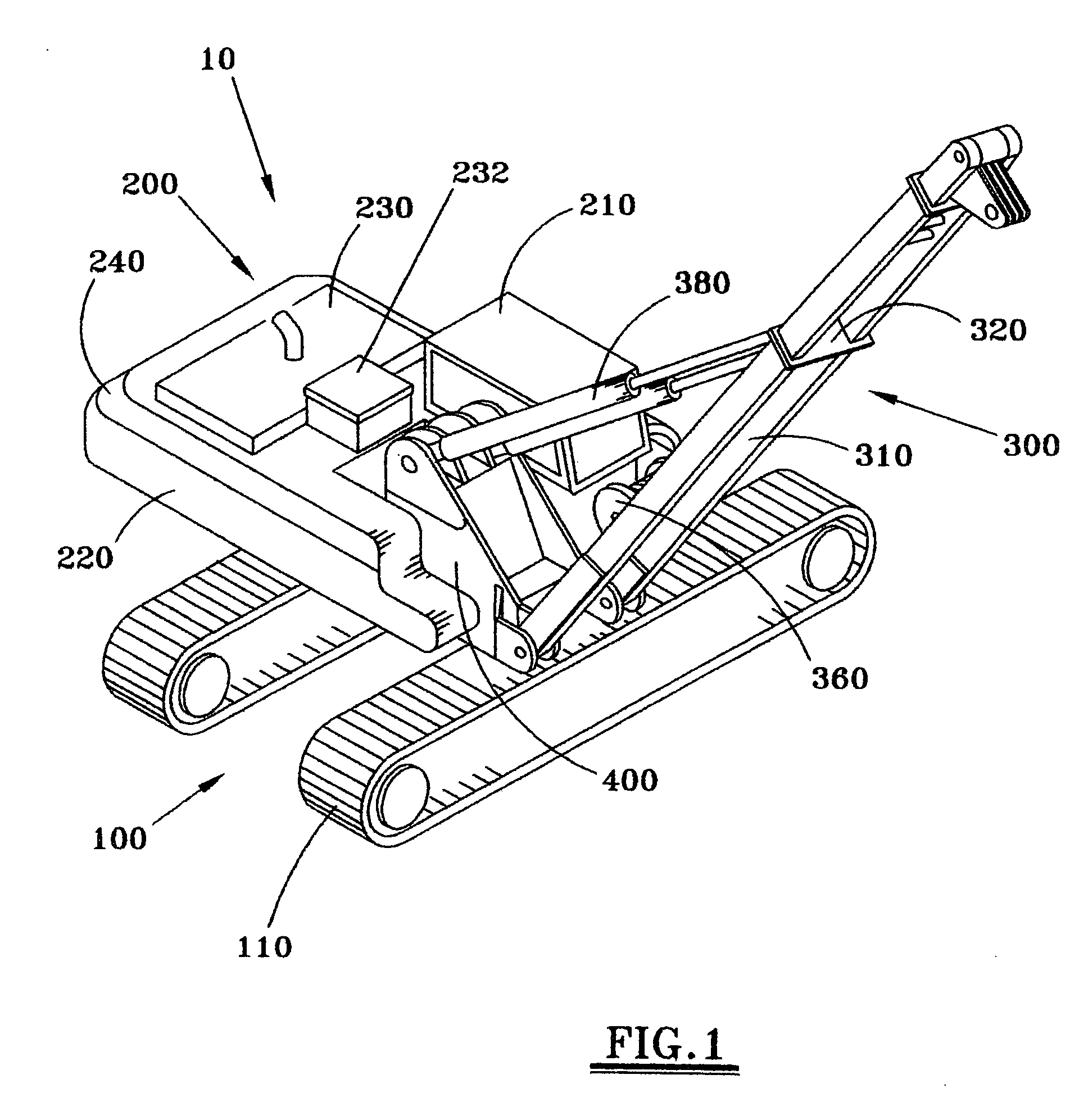

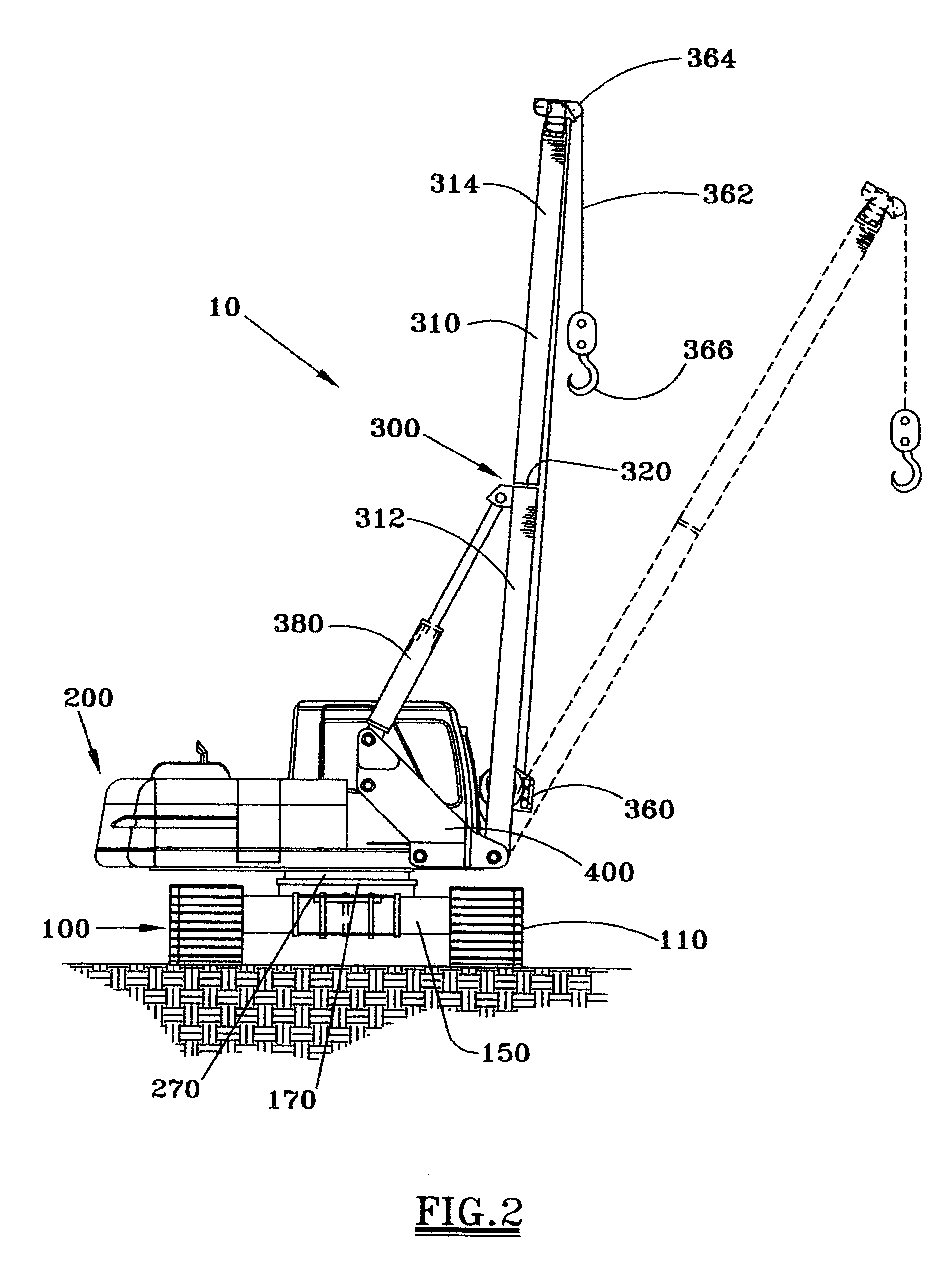

Pipelayer

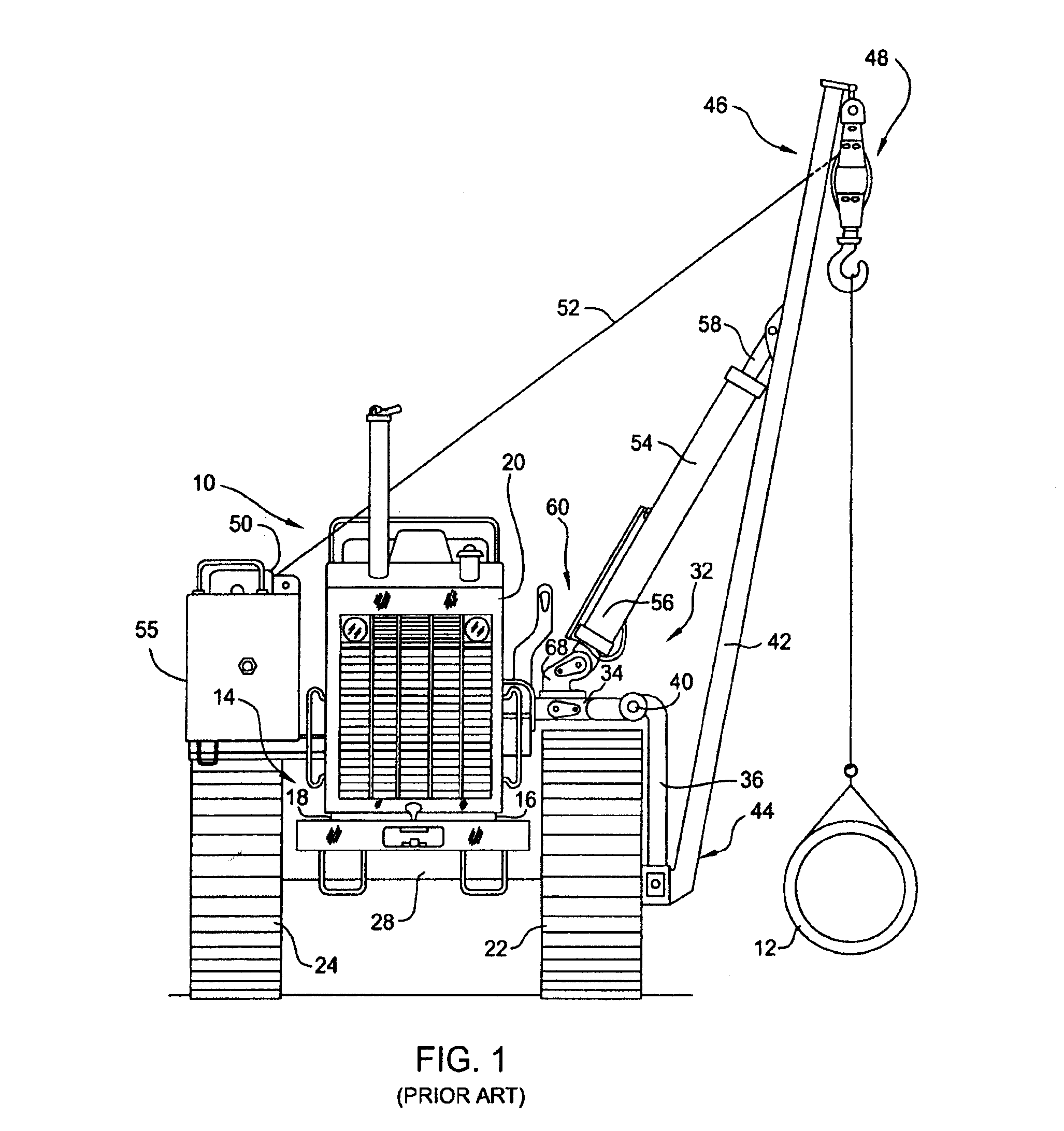

InactiveUS6893189B2Load hoistingEfficient transportPipe laying and repairLifting devicesUniversal jointBlock and tackle

A pipelayer is provided which is capable of effectively transporting pipes or the like and stably carrying out load hoisting operation on a slope. The pipelayer comprises: an undercarriage; an upper revolving superstructure mounted on the undercarriage so as to turn around freely upon the undercarriage; a boom supported by the upper revolving superstructure so as to be freely raised and lowered; a pulley block attached to the boom through a universal joint; a hoist mounted on the upper revolving superstructure; a hoist hook hung by a wire rope that is paid out from the hoist and wound around the pulley block.

Owner:KOMATSU LTD

Pipelayer with cab riser

A pipelayer having an undercarriage with at least two tracks and a main assembly. Each track has a track frame coupled to the undercarriage and a track shoe supported by and movable around the track frame. The main assembly is supported by and rotatable relative to the undercarriage, and has a main frame, a boom pivotally mounted to the main frame, an operator cab, and a cab riser connecting the operator cab to the main frame. The cab riser is operable to selectively raise and lower the operator cab relative to the main frame. Also provided is a movable cab assembly having an operator cab, an adjustment mechanism to connect the cab to a vehicle frame and move to change the operator's view, and a guide to align the cab. A method for laying pipe using a pipelayer having a movable cab is also provided.

Owner:VOLVO CONSTR EQUIP AB

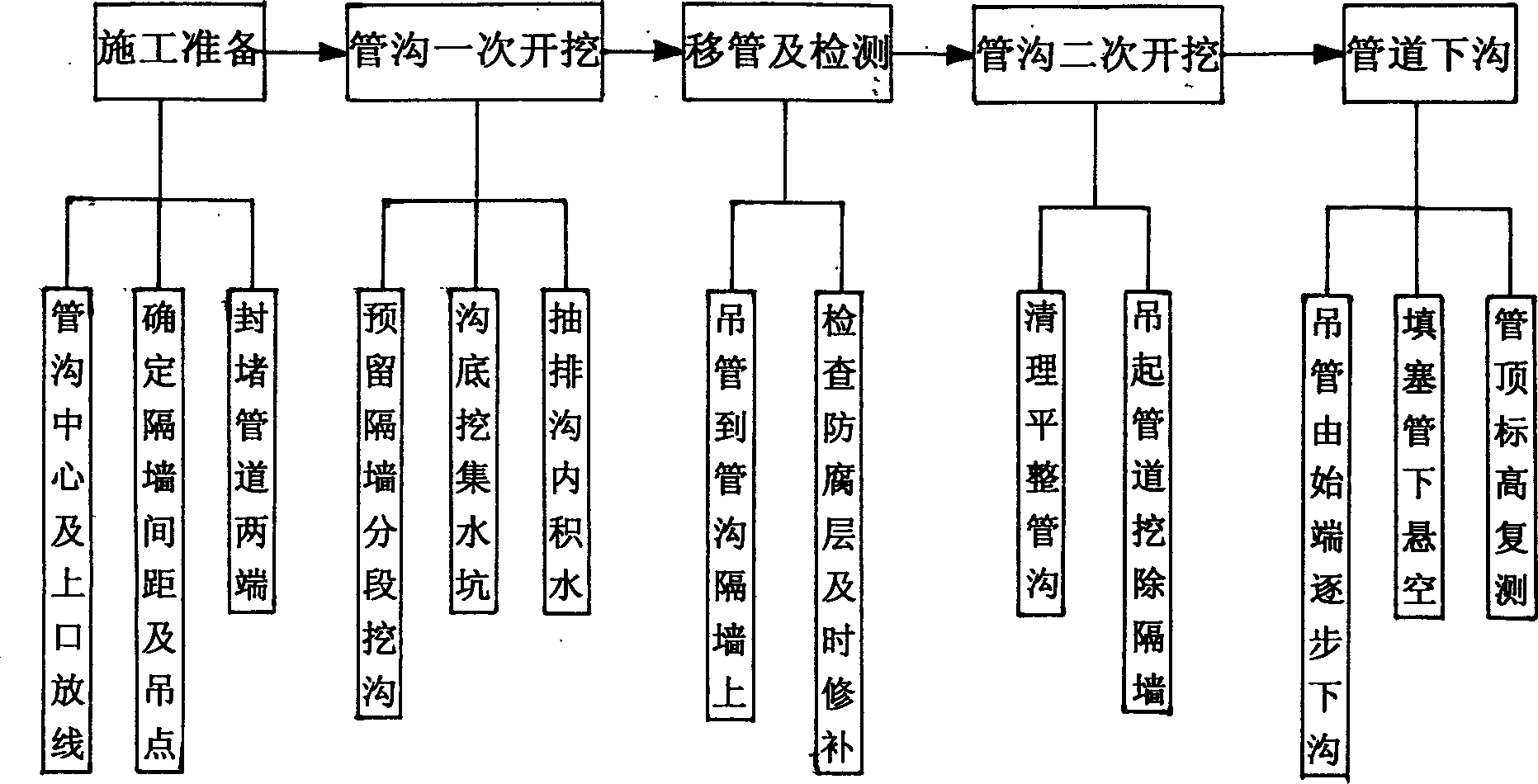

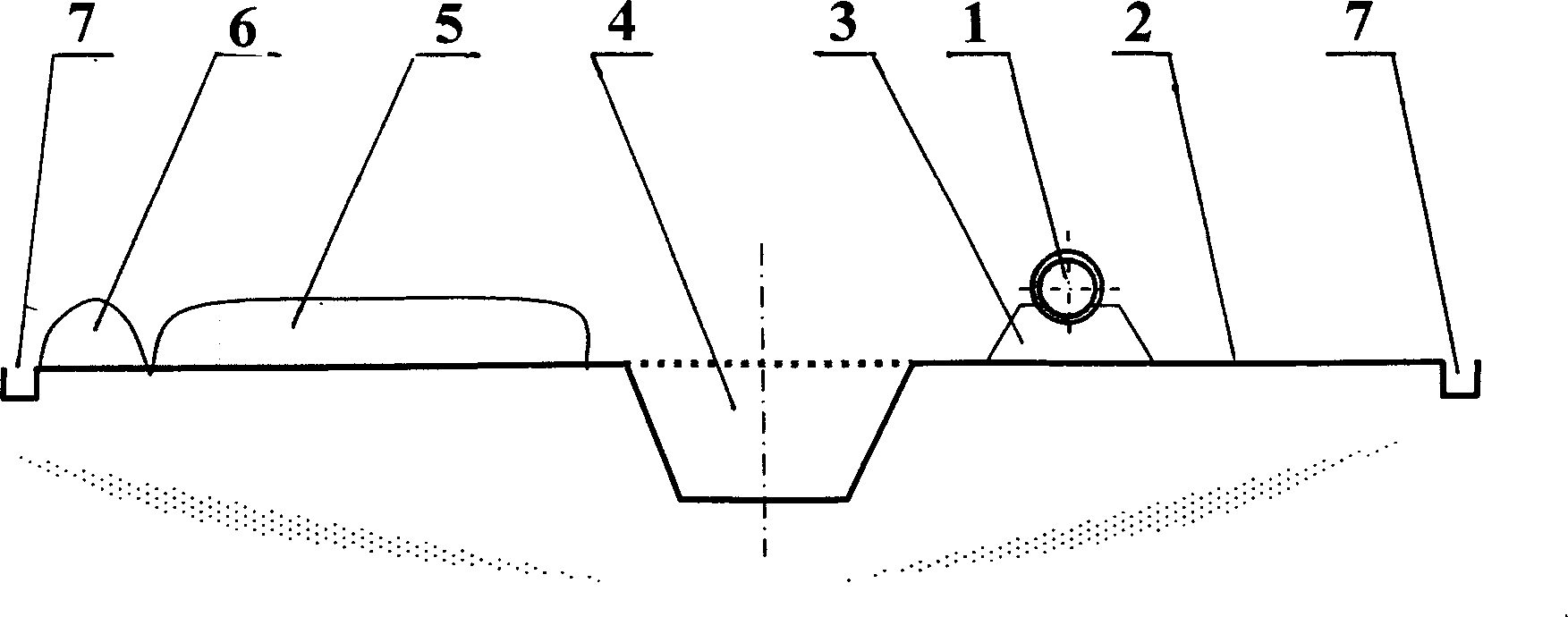

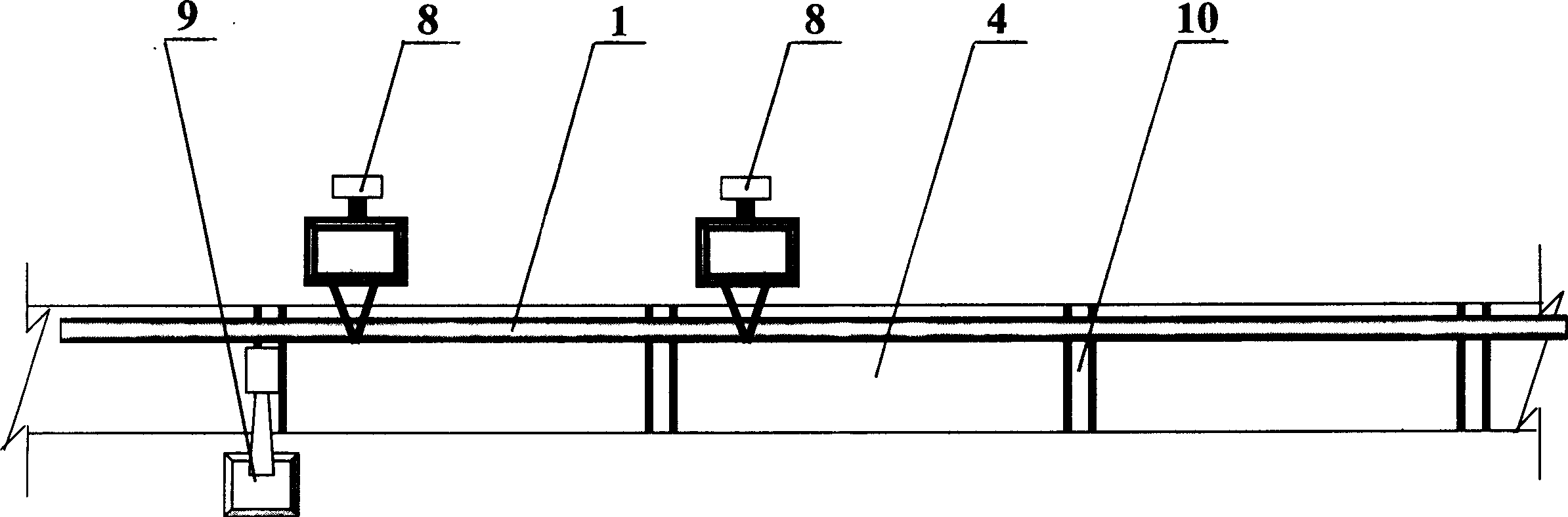

Down-ditch construction method for laying heavy caliber pipeline

InactiveCN1558130AAvoid tipping accidentsGuarantee the quality of workPipe laying and repairDitchPipe layer

The present invention is the construction process of laying wide bore pipe into pipe canal and relates to one important pipeline construction step. The present invention features that during excavating pipe canal, one soil partition wall is preserved in each certain distance; the pipe is first hoisted with two pipe layers and settled on the partition walls, and the initial end of the pipe is lifted before the soil partition wall is dug out with excavator and then settled slowly into the pipe canal; and all the partition walls are dug out successively and the pipes are settled in the pipe canal. The construction process includes the main steps of: preparation, the first pipe canal excavation, shifting pipes and detection, the second pipe canal excavation, and laying the pipes. The main advantages includes using two pipe layers only, low cost, low power consumption, simplified construction process, short construction period, etc.

Owner:NO 3 BRANCH OF SHENGLI PETROCHEM BUILDING CO LTD SHENGLI OIL FIELD

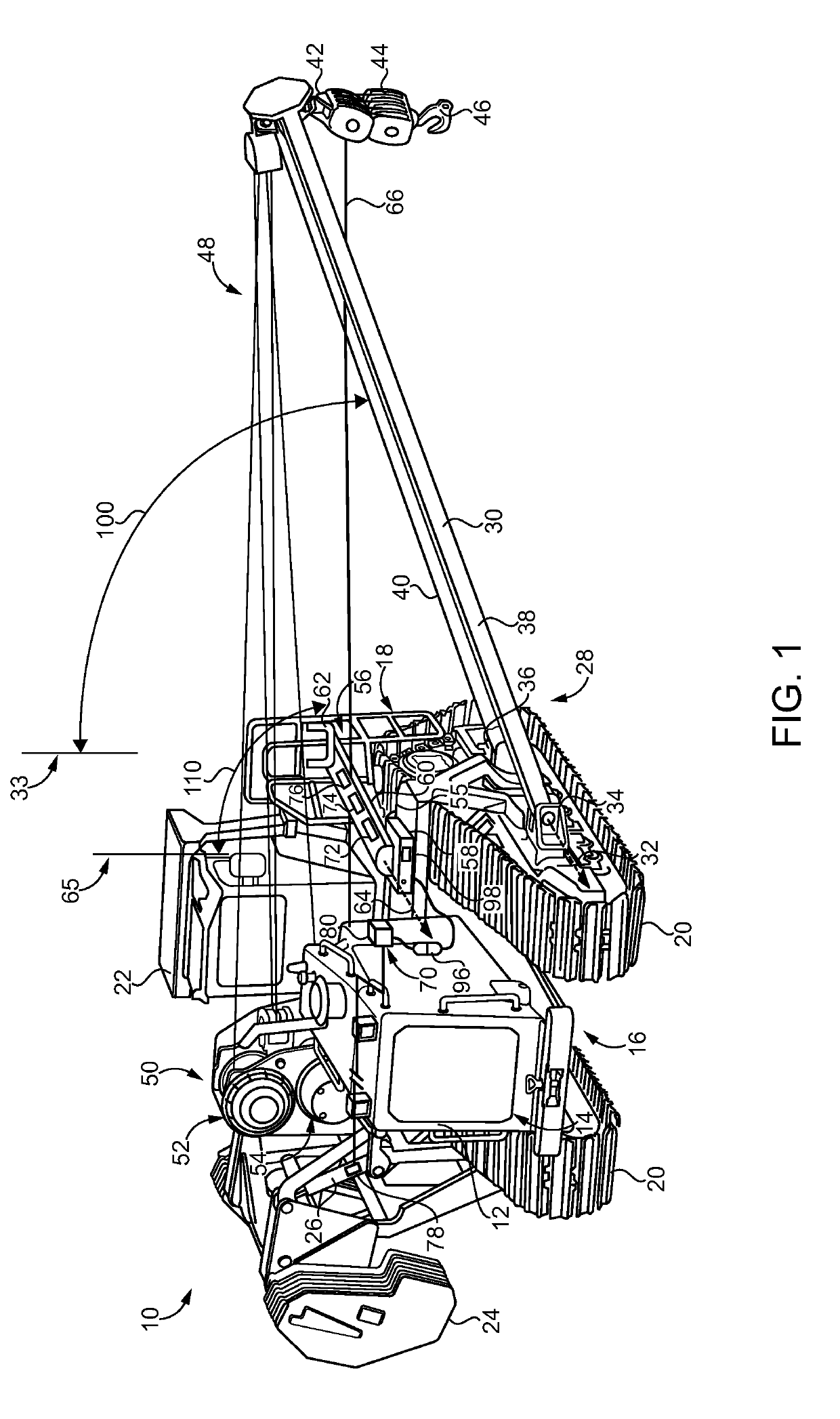

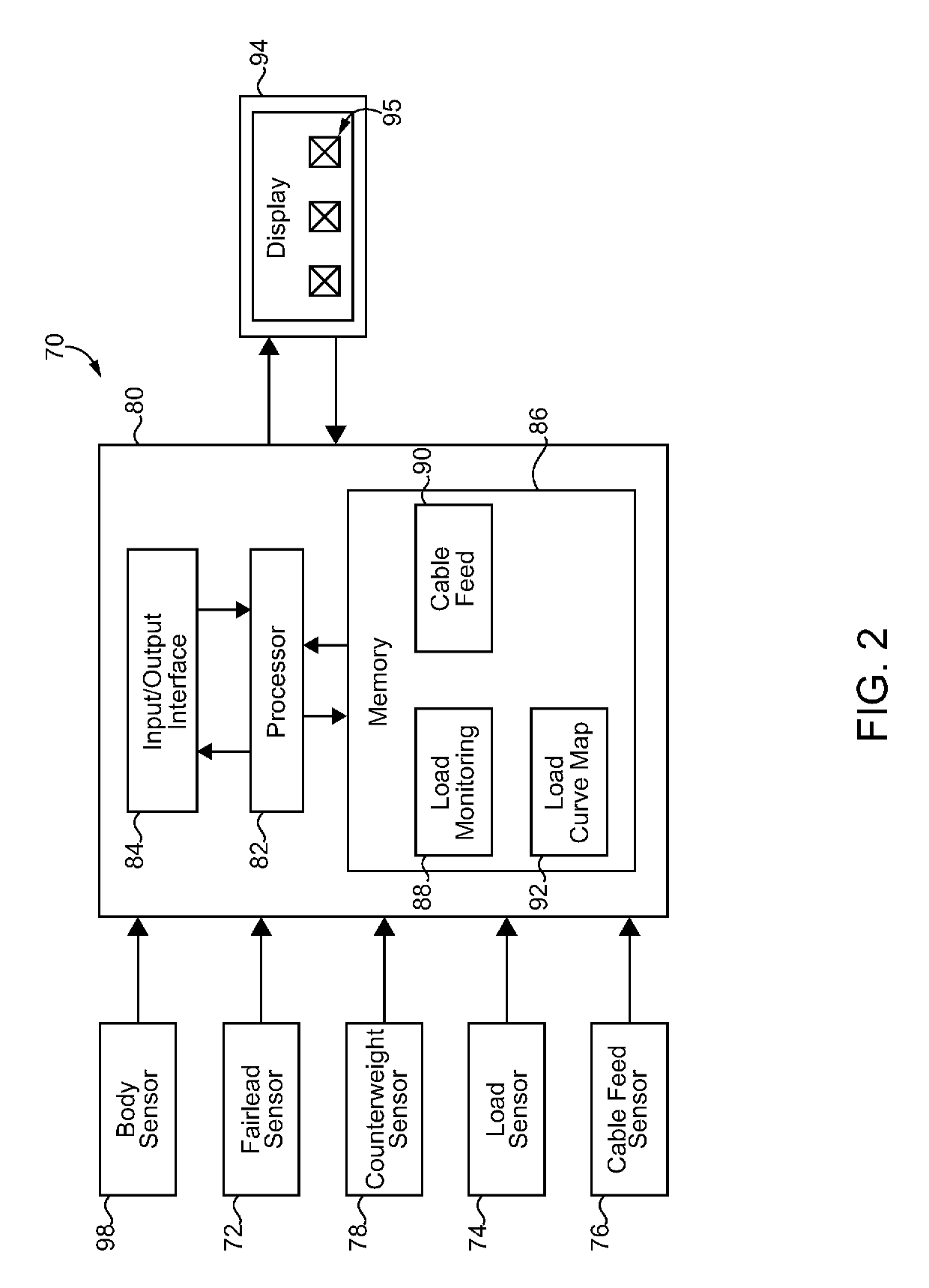

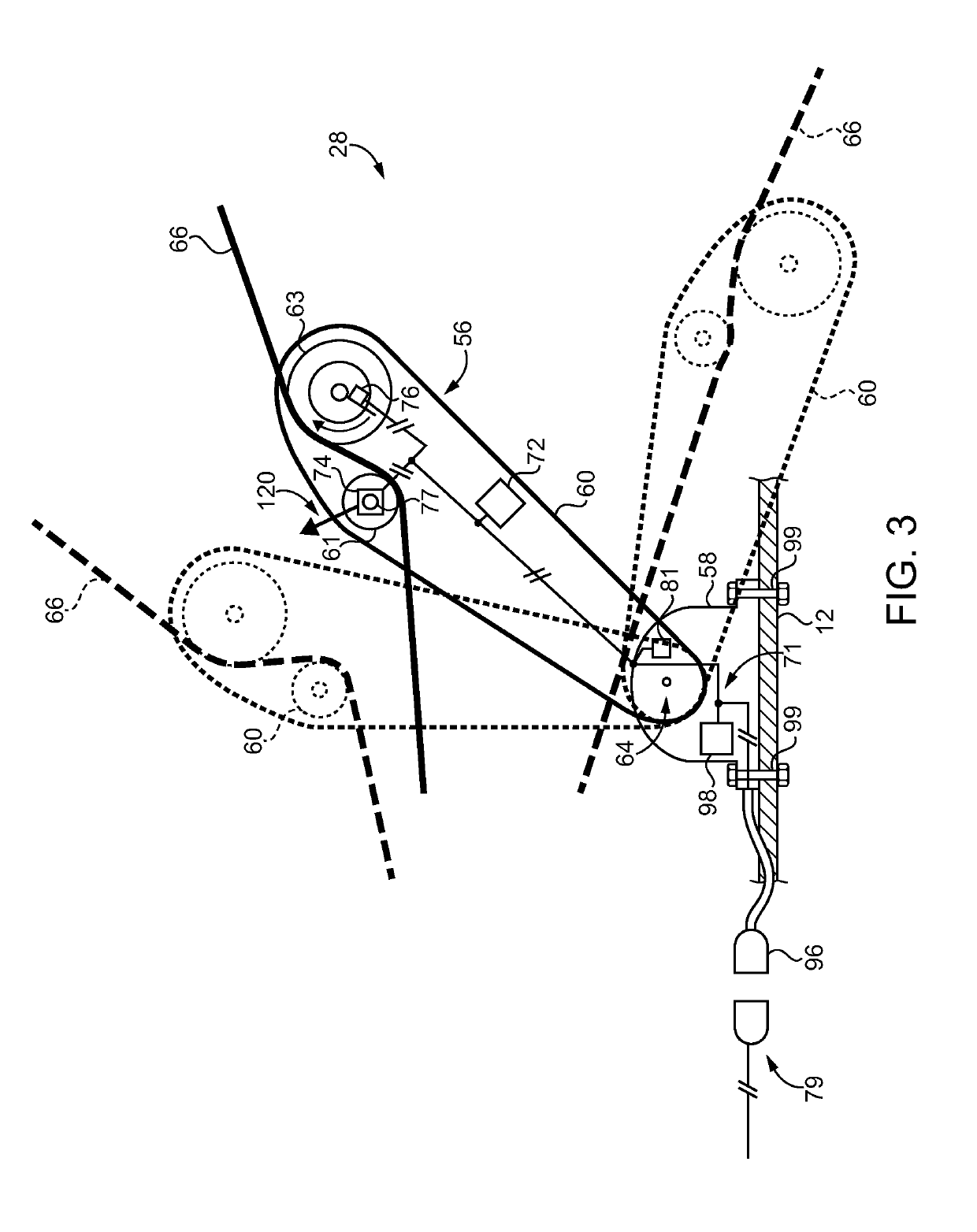

Pipelayer machine having hoisting system with pivotable fairlead

A machine includes a frame, ground-engaging elements coupled to the frame, and a hoisting system having a sideboom and a fairlead. The hoisting system also includes a hook pulley block and a hoisting cable extending through the fairlead and the hook pulley block and held in tension such that the hoisting cable couples pivoting of the fairlead to pivoting of the sideboom. The pivotable fairlead may be instrumented with position, cable loading, and cable feed sensors.

Owner:CATERPILLAR INC

Winch for pipelayer and pipelayer equipped with same

A restraining roller (100) of a hook winch (8) has a roller middle part (101), a first roller end part (102) and a second roller end part (103). The roller middle part (101) is formed in a columnar shape, and each of the first roller end part (102) and the second roller end part (103) is formed in a roughly circular truncated cone shape. The widths of the first roller end part (102) and the second roller end part (103) are greater than the diameter of a wire rope (83). A difference in diameter between an inner end and outer end of each of the first and second roller end parts (102) and (103) is less than the diameter of the wire rope (83). Where a taper angle is defined as an angle formed between a line arranged in parallel to the surface of the roller middle part (101) and a line arranged in parallel to the surface of each of the first and second roller end parts (101) and (103) in a plane view seen in a direction perpendicular to a center axis of the restraining roller (100), a taper angle θ3 of the first roller end part (101) and a taper angle θ4 of the second roller end part (102) are different from each other.

Owner:KOMATSU LTD

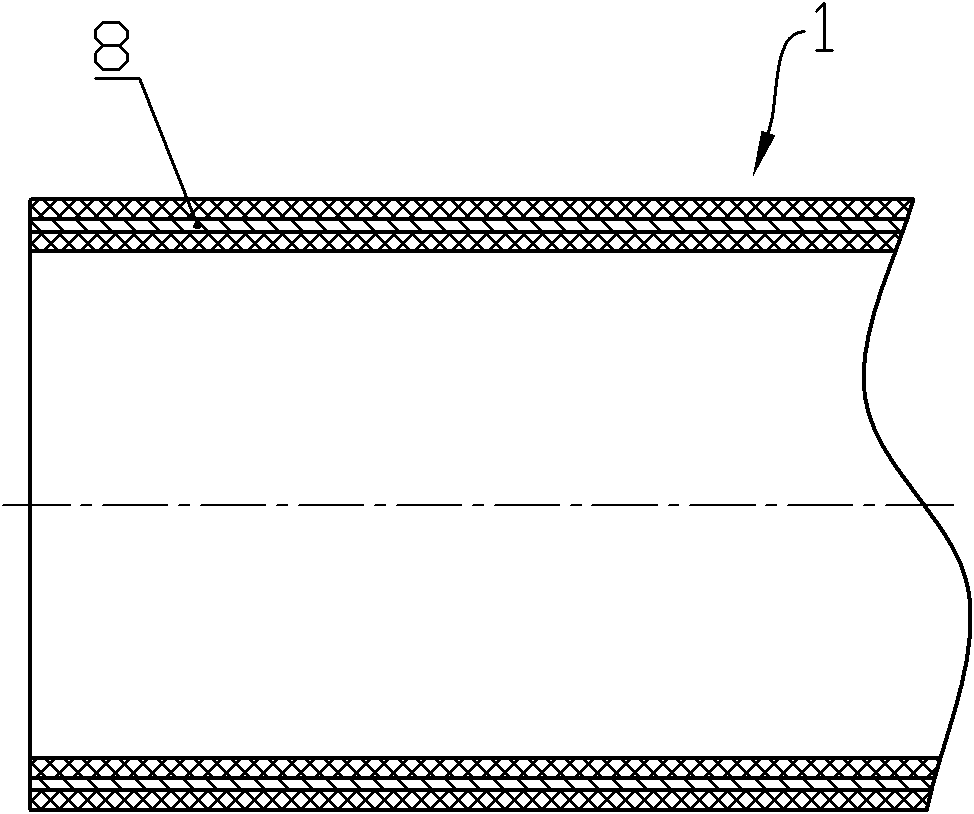

Ceramic and glass reinforced plastic composite tube and preparing method thereof

This invention relates to a kind of ceramics, glass steel compound pipe which is composed of ceramic inner layer, middle connection layer and glass steel layer. The process method comprises the following steps: spraying resin middle connection layer on the inner ceramic pipe layer; then compounding glass steel outer layer. The compound pipe middle connection layer and the ceramic layer and the glass steel outer layer are tightly combined, which makes best use of the ceramic characteristics and the glass steel materials. The invention are most used in transmission of liquid medium with solid particles and the powders.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

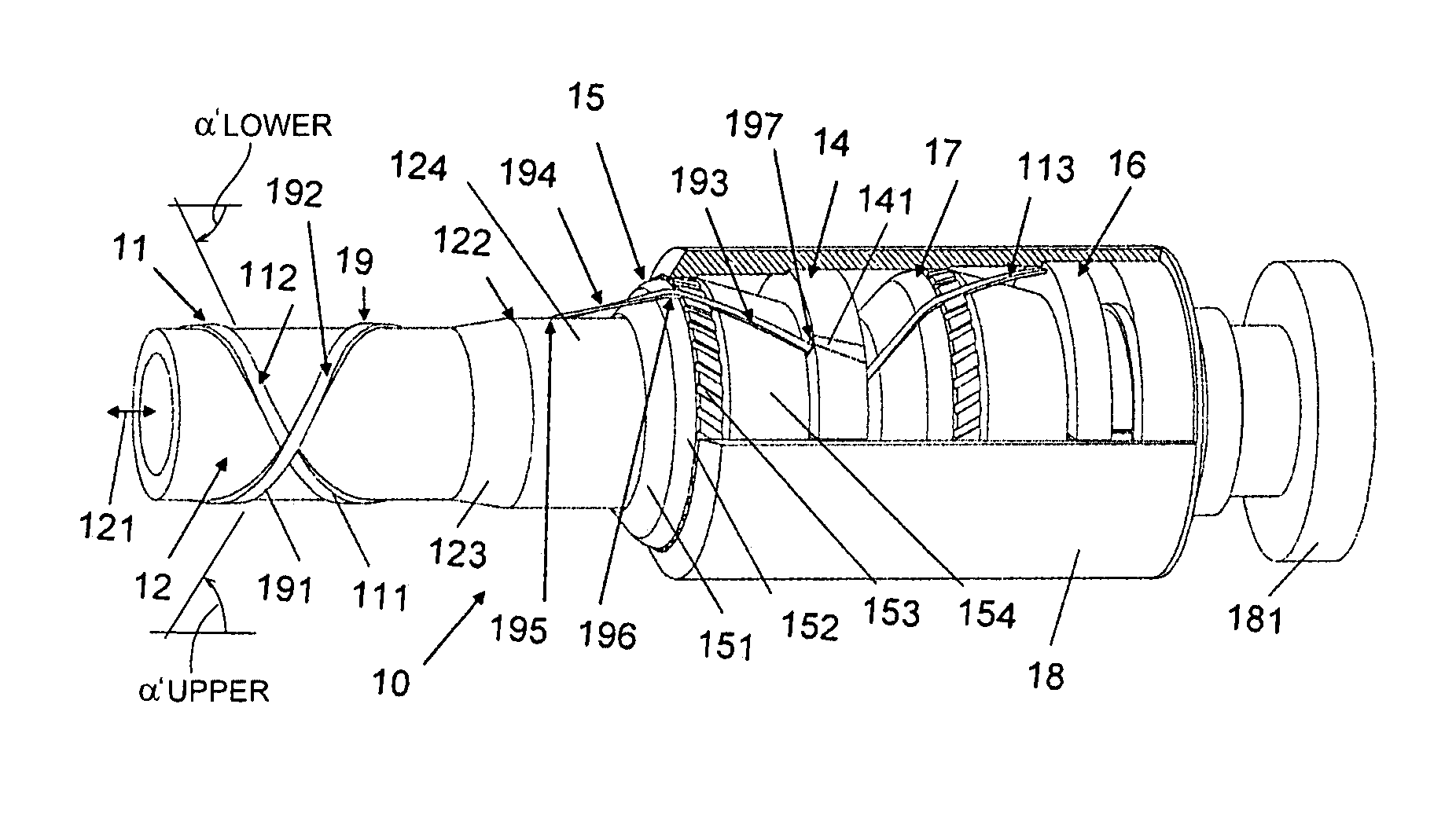

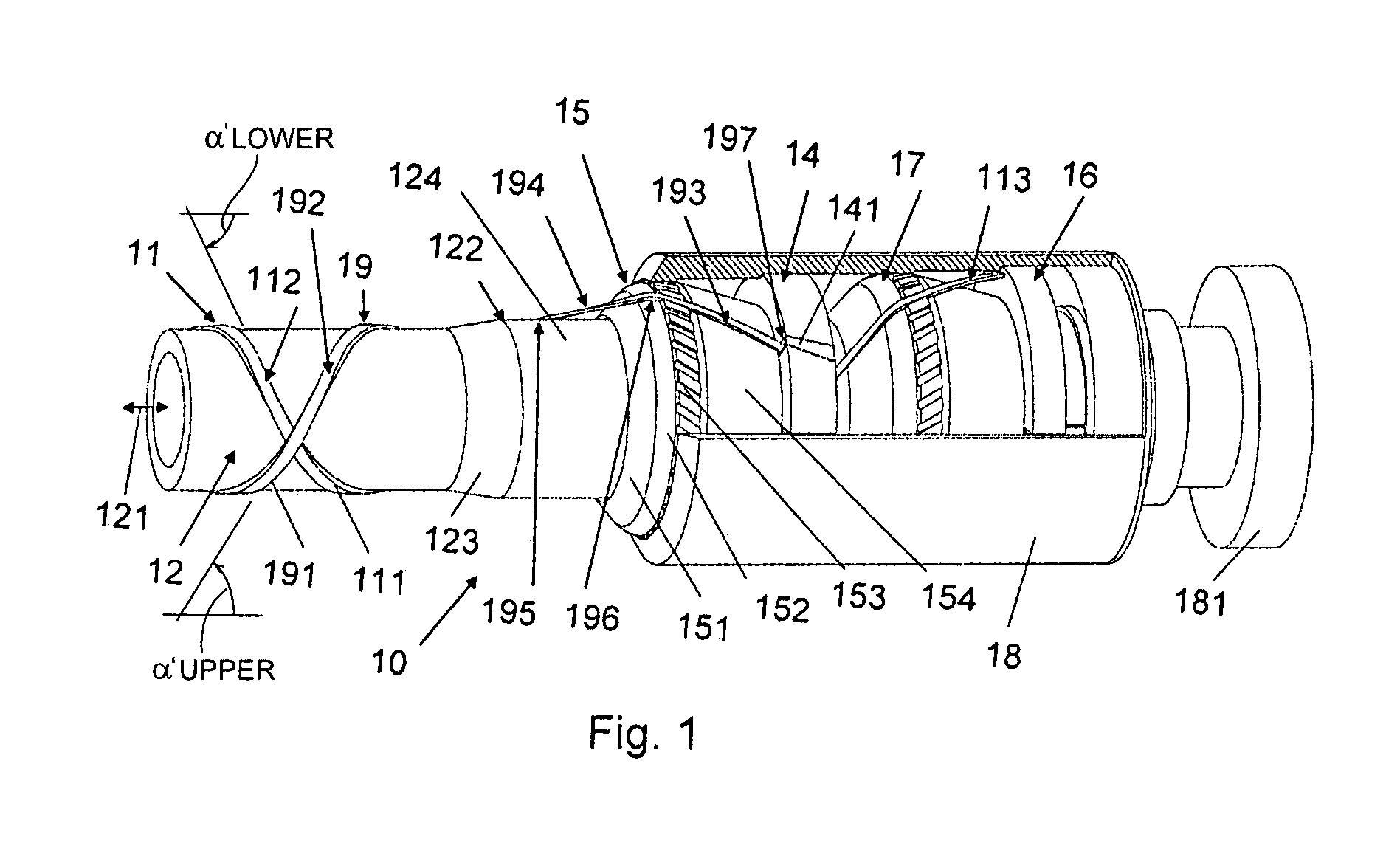

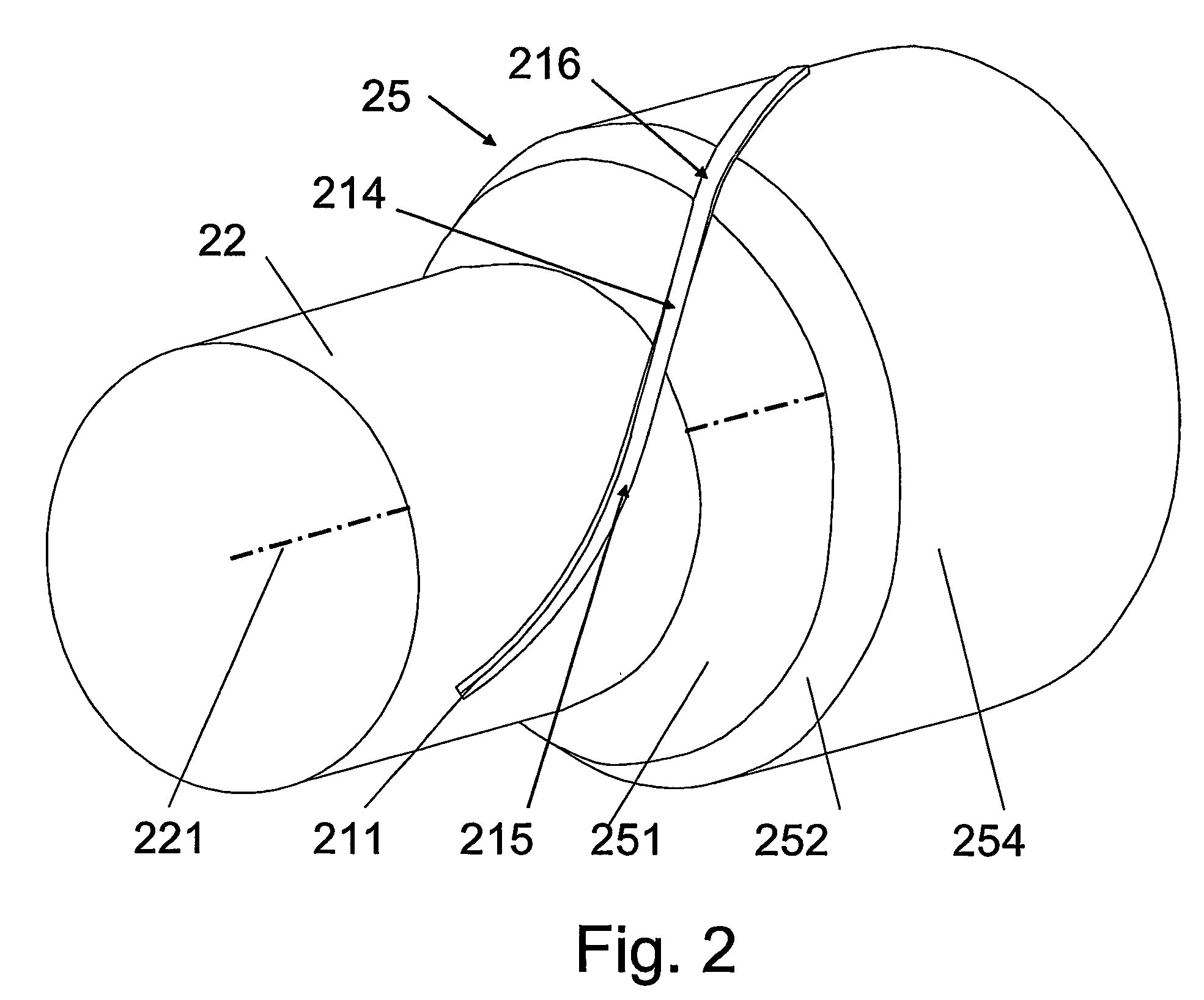

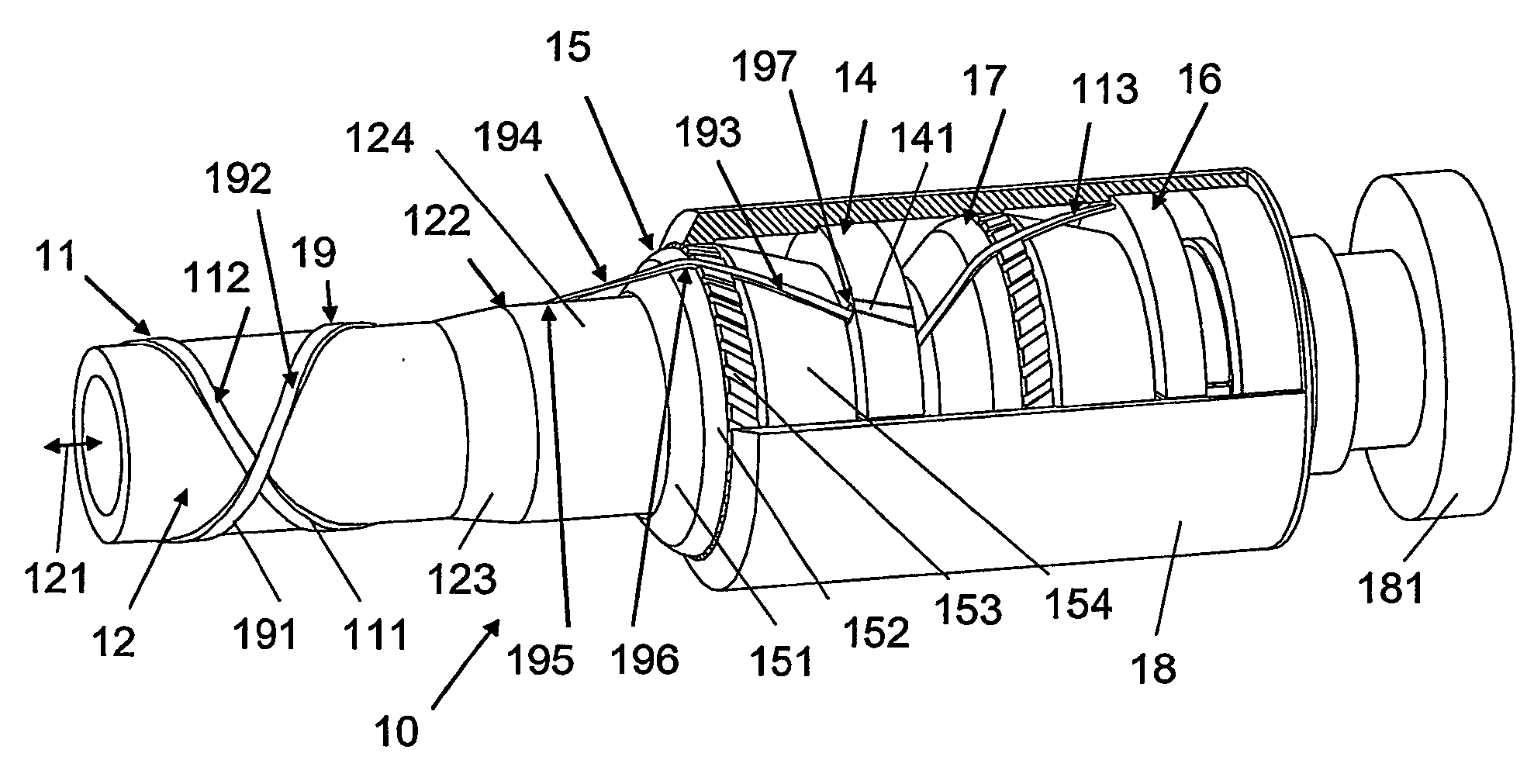

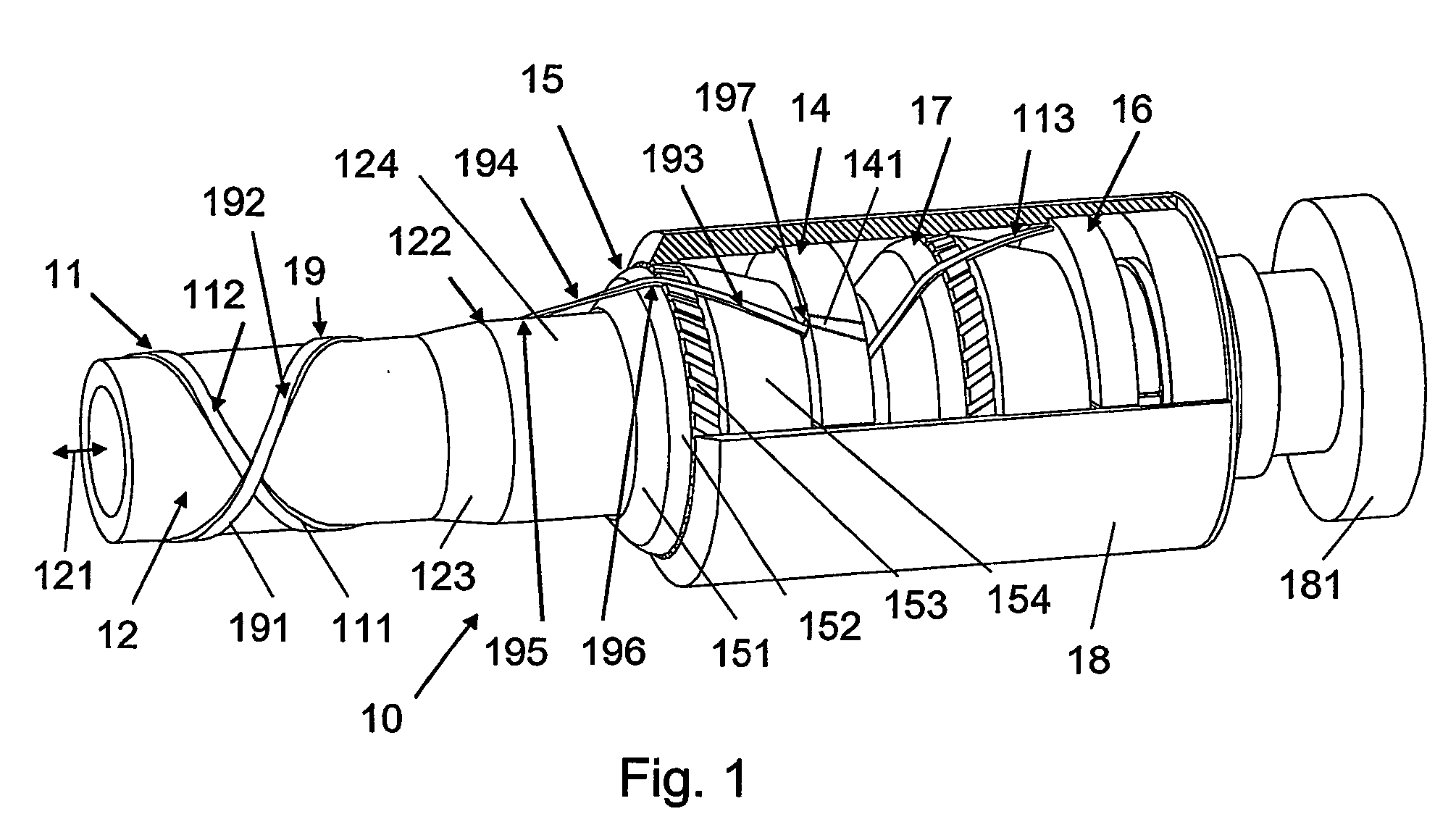

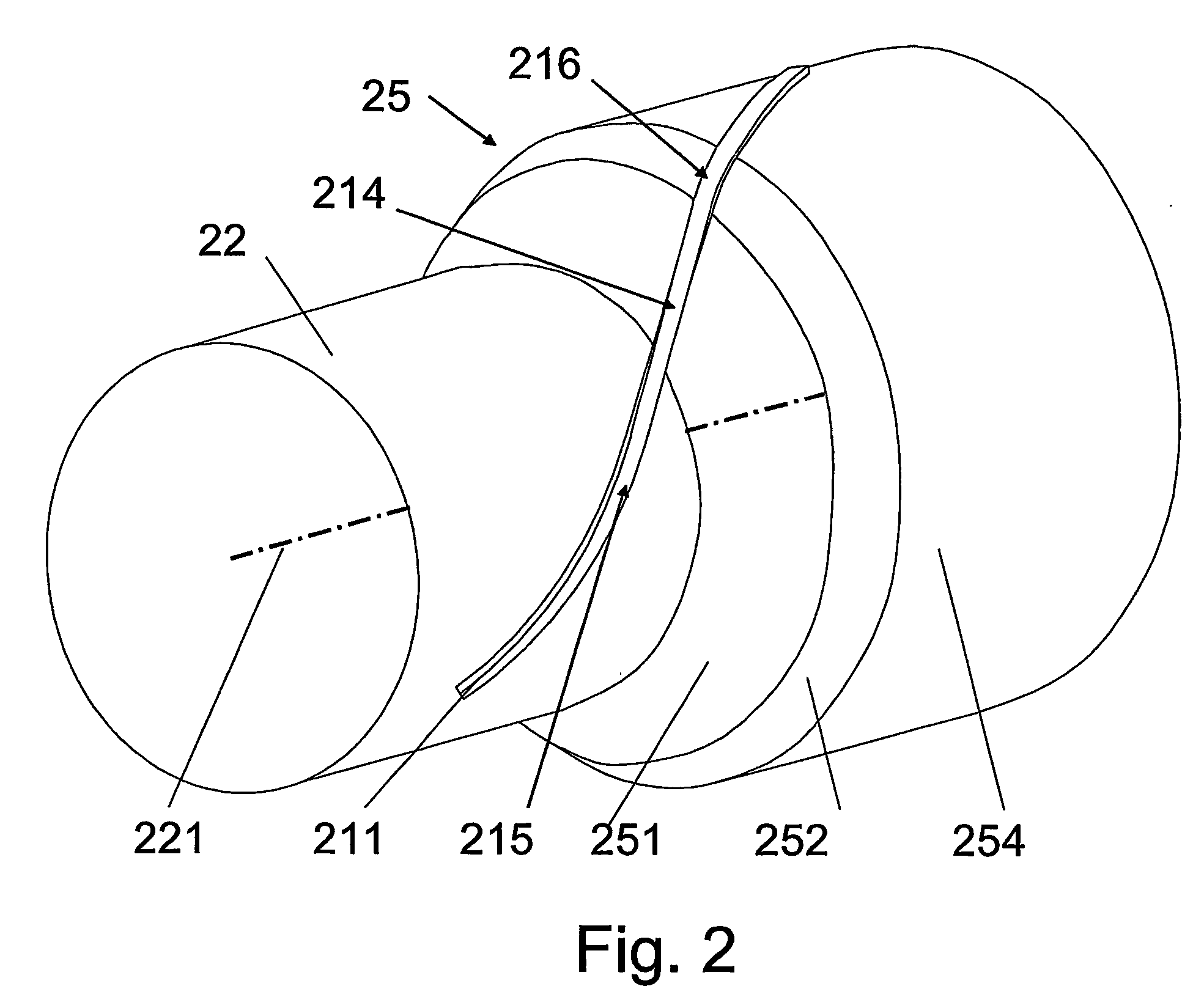

Flexible pipe connected to an end fitting

A pipe structure comprising a length of a flexible pipe connected to an end fitting, the flexible pipe comprising an armour layer and an underlying pipe layer the armour layer, the underlying pipe layer having an outer surface around which armouring wires of an armouring layer are helically wound. The pipe structure provides a coupling between a flexible pipe comprising armouring wires and an end fitting, the coupling exerting a relatively low bending or flexure strain on the wires during normal operation of the flexible pipe. The transition path of an armouring wire between the flexible pipe and the end fitting comprises a straight-line-section between a wire-pipe-exit-point where the wire extends away from its underlying pipe layer and a straight-line-end-point on a support unit of the end fitting where the armouring wire in question has its first tangential point of contact. This has the advantage that in a loaded situation where the armouring wires will elongate elastically leading to a change in the helical angle of the armouring wires, the pipe structure will experience a slight twist and a controlled bending of the armouring wires on the surface of the support unit (due to a possible change in the base point of contact of the armouring wire with the support unit induced by the change of helical angle), thereby avoiding substantial bending of the individual armouring wires, which is of particular importance when the armouring wires are formed of a composite material. The pipe structure may be used in flexible pipes for the off shore transport of fluids (e.g. oil).

Owner:NKT FLEXIBLES IS

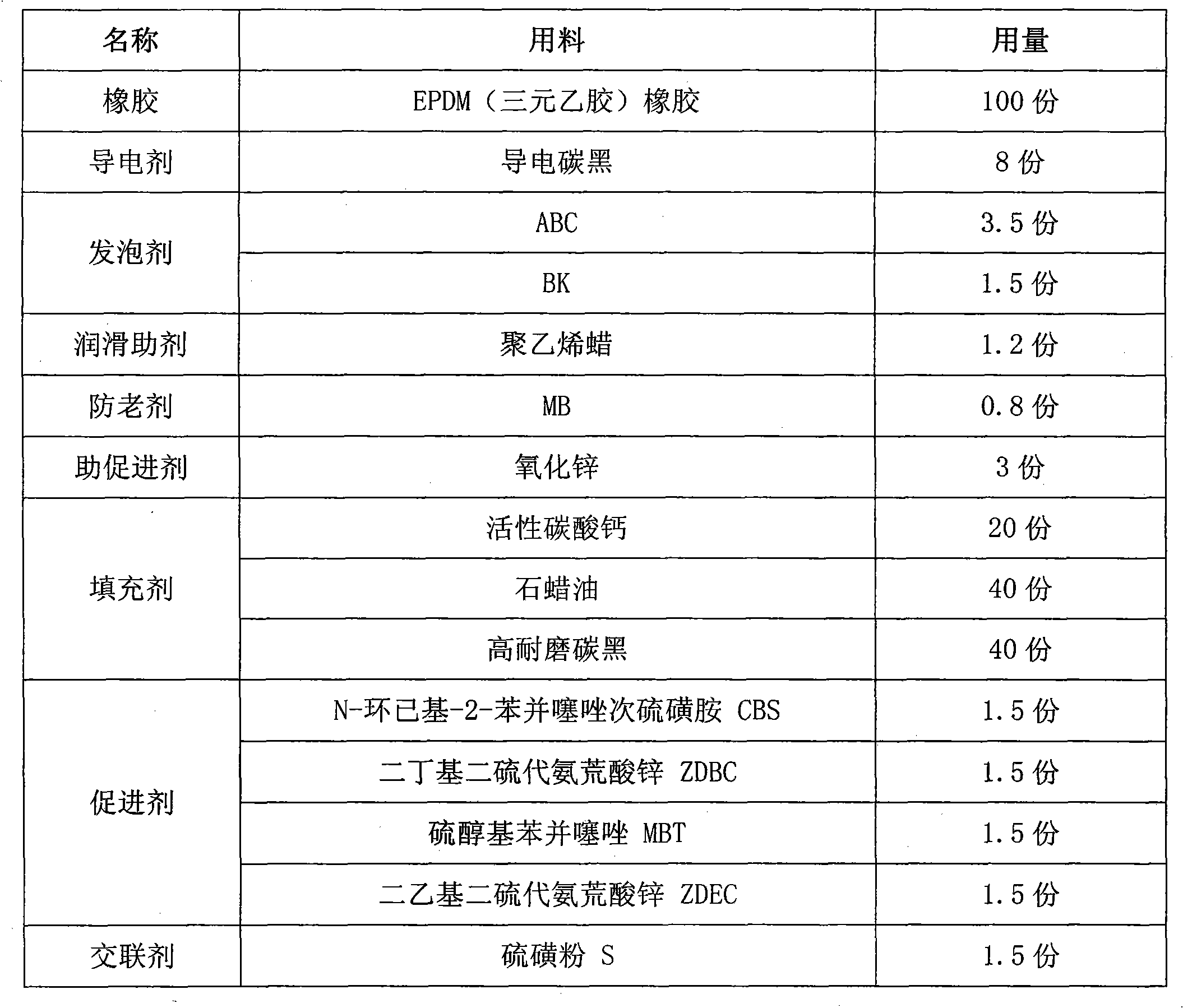

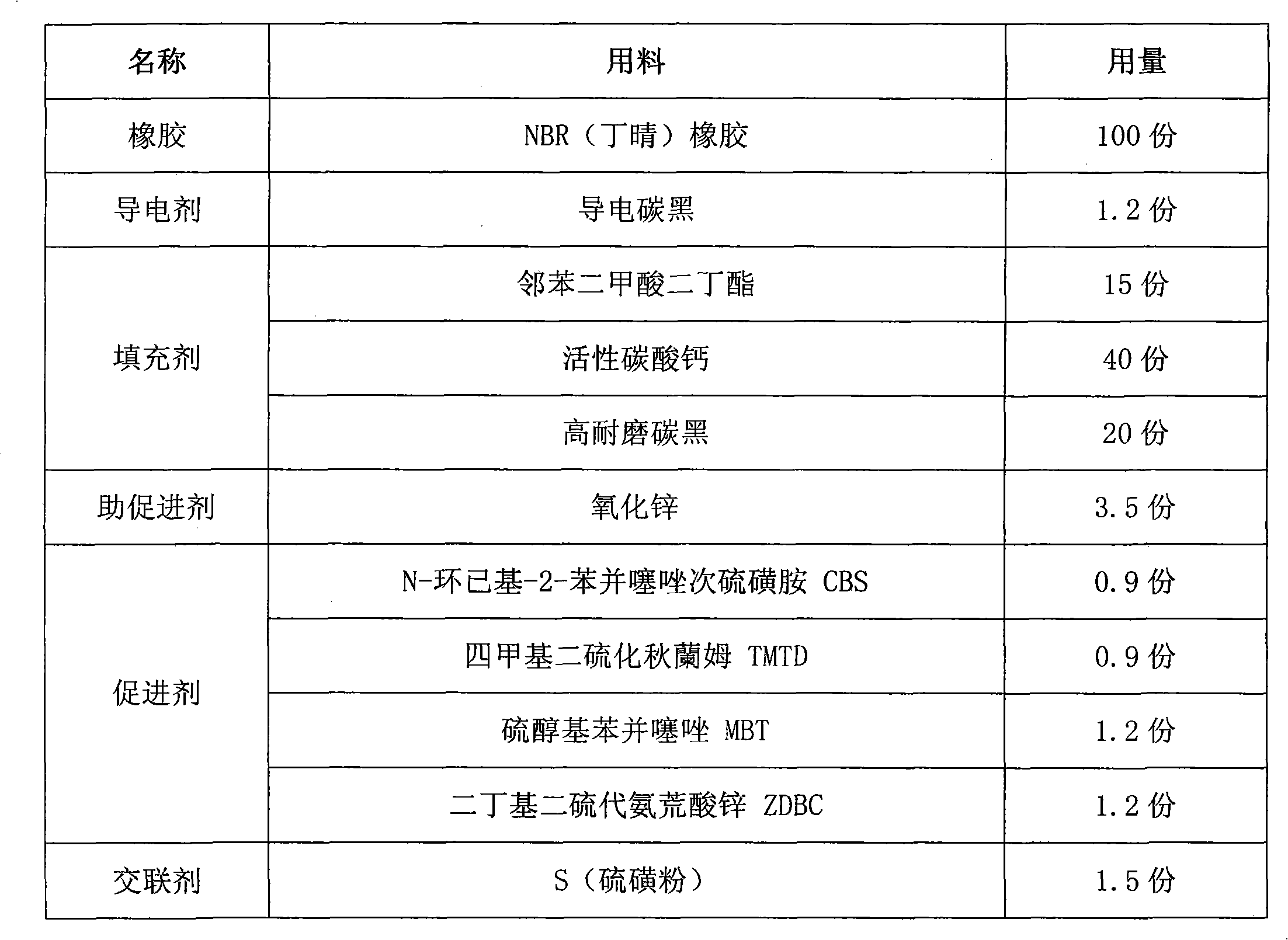

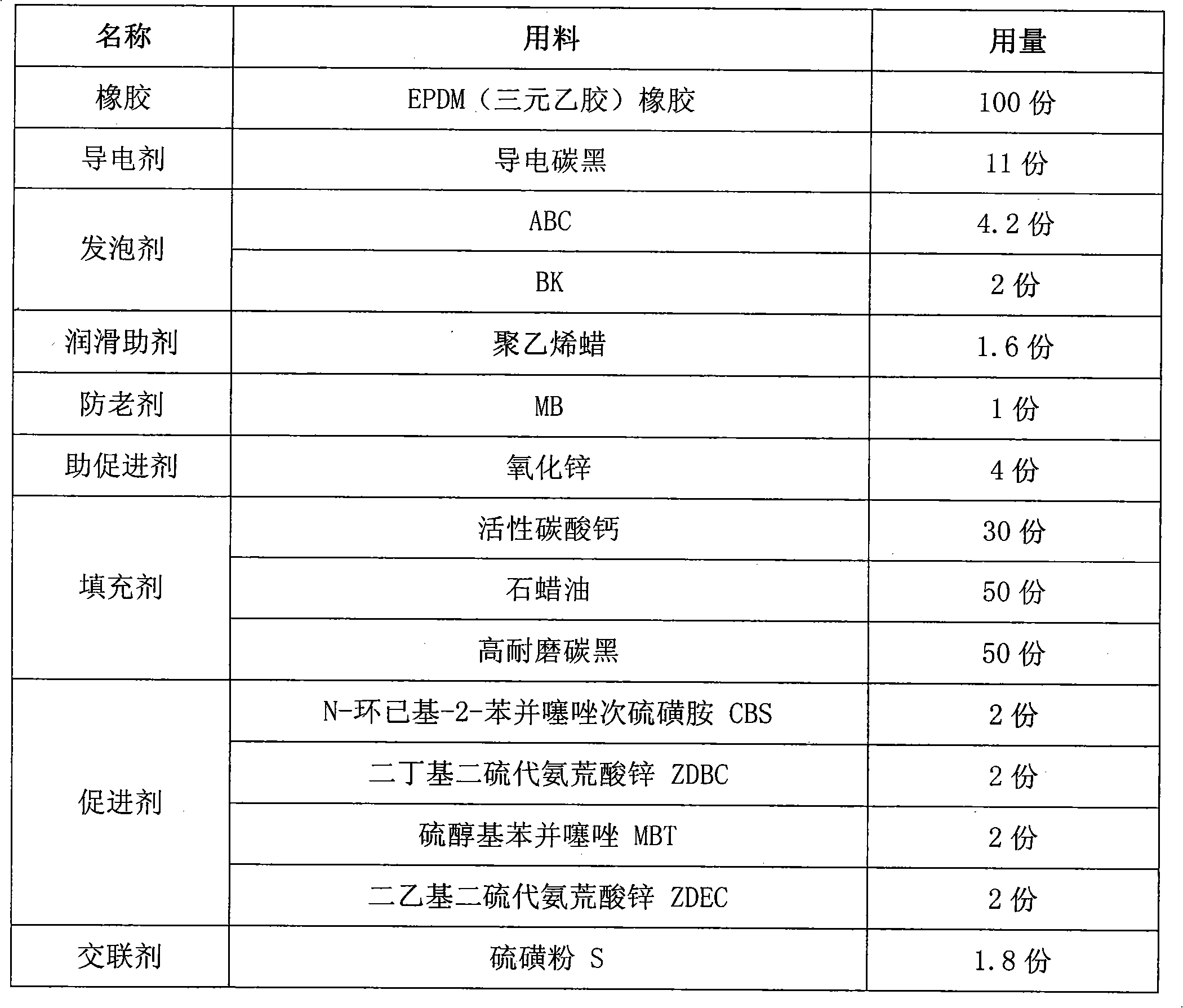

Conductive foam rubber charging roller and preparation method thereof

InactiveCN101968614AAvoid influenceStain-resistant photosensitive drum for a short timeCorona dischargeEnvironmental resistanceNitrile rubber

The invention discloses a conductive foam rubber charging roller and a preparation method thereof. The conductive foam rubber charging roller comprises a metal shaft center, a foaming pipe layer and a conductive rubber hose layer which is sleeved outside the foaming pipe layer, wherein the foaming pipe layer is prepared by nitrile rubber buna (NRB) with conductive black, and the weight part ratio of the conductive black to the NRB is 1.2-2:100; and the conductive rubber hose layer is prepared by ternary B glue rubber with conductive black, and the weight part ratio of the conductive black to the ternary B glue rubber is 8-15:100. In the invention, the influence of climatic temperature on the charging roller is solved; due to the existence of an elastic sponge layer, abnormal sound in the printing process is avoided and a photosensitive drum is not polluted; at the same time, printing life can be improved by one to two periods, thus further being beneficial for environmental protection.

Owner:吴声立

Conversion kit for adjusting pipelayer frame width

Owner:CATERPILLAR INC

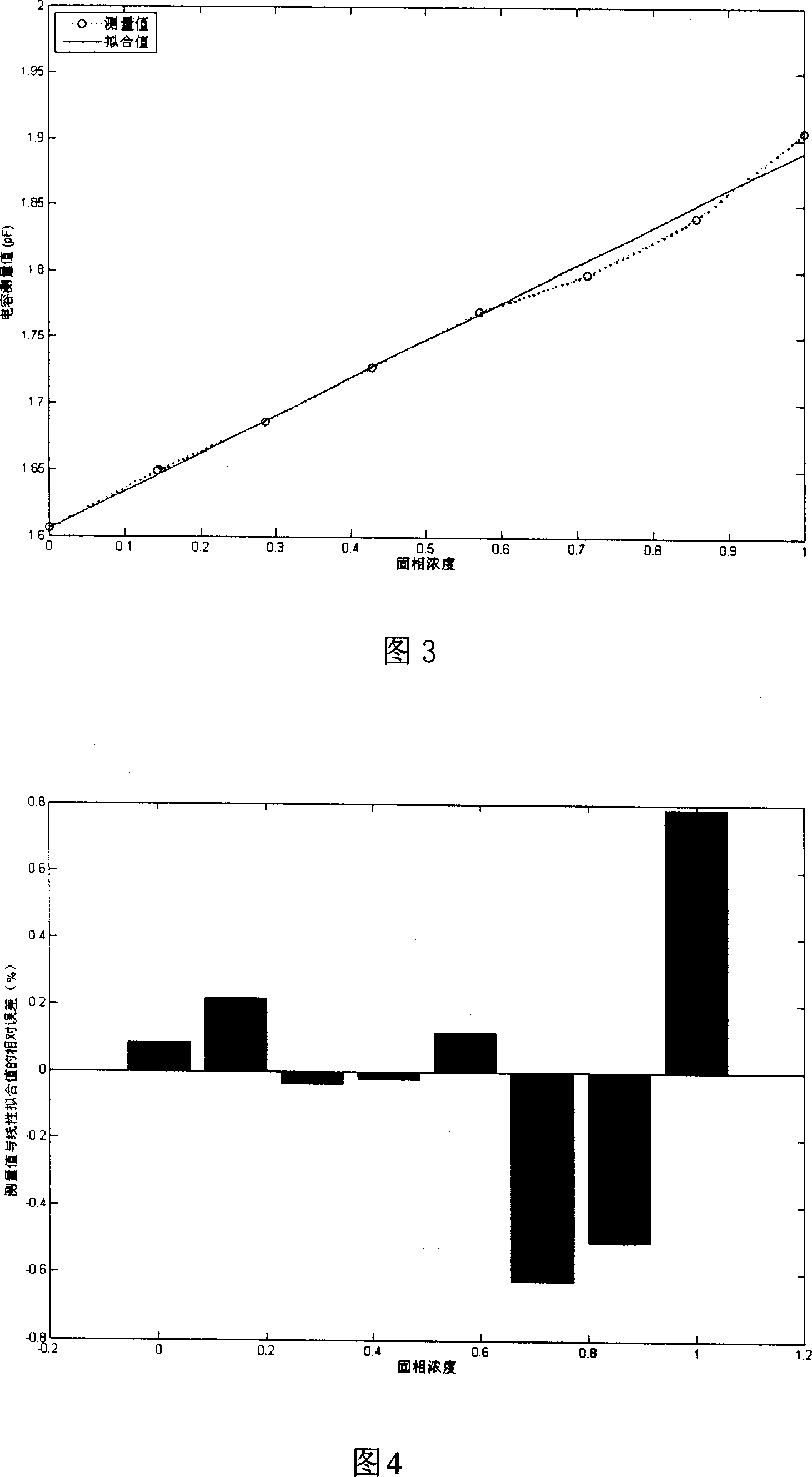

Impedance sensor of split phase ratio of two phase flows, and method for optimizing structural parameter

InactiveCN101093207AOvercome narrow turndownOvercome precisionMaterial resistanceSpecial data processing applicationsFast measurementInter layer

An impedance transducer of mobile phase content in two-phase is prepared for applying metal shielding layer as external layer for enabling to regulate thickness to support structure, applying insulation material layer as intermediate layer for isolating excitation electrode and measurement electrode from metal shielding layer, applying insulation pipe layer with excitation electrode and measurement electrode as internal layer and setting two said electrodes on pipe wall of insulation pipe layer radially and symmetrically in mode of 180degree -angle spiral distribution. The method for optimizing structure parameter of said transducer is also disclosed.

Owner:TIANJIN UNIV

High-pressure hydraulic oil pipe and production method thereof

InactiveCN103062526AImprove pass rateImprove pressure resistanceNon-macromolecular adhesive additivesFlexible pipesHydraulic equipmentHigh pressure

The invention belongs to the technical field of hydraulic oil pipes and particularly discloses a high-pressure or super-high-pressure hydraulic oil pipe suitable for cranes especially heavy machinery and a production method thereof. According to the technical scheme, the high-pressure hydraulic oil pipe comprises an inner rubber pipe layer, an outer rubber pipe layer, a plurality of wound or braided pressure-resistant steel wire layers disposed between the inner rubber pipe layer and the outer rubber layer, and a rubber pipe layer disposed between two pressure-resistant steel wire layers. A cloth layer is wound on the outer wall of the inner rubber pipe layer or the rubber pipe layer. The inner rubber pipe layer or the rubber pipe layer are wound or braided by the pressure-resistant steel wire layers. The cloth layer is integrated with the inner rubber pipe layer or the rubber pipe layer by means of adhering. By the high-pressure hydraulic oil pipe, diameter of wound steel wires can be increased, pressure resistance of the prepared high-pressure hydraulic oil pipe is improved greatly, and the pressure resistance requirements of the high-pressure hydraulic oil pipe for hydraulic equipment such as a large crane are satisfied.

Owner:河北省景县飞龙橡塑制品有限公司

Common pipelayer frame for multiple machine configurations

A pipelayer frame for a track-type machine having an engine compartment, a first track frame, and a second track frame is disclosed. The frame has a center frame removably attachable within the engine compartment, a first side frame removably attachable to the first track frame and to the center frame, and a second side frame removably attachable to the second track frame and to the center frame. The frame also has a spacer assembly removably attachable to the first side frame. The frame further has an adjustable assembly located between the second side frame and the center frame, the adjustable assembly being configured to adjust a distance between the second side frame and the center frame.

Owner:CATERPILLAR INC

Casing pipe type water conveying pipeline applied to crossing bridge and installation and construction method thereof

ActiveCN109323049AGuaranteed stabilityNot easy to seepagePipe supportsPipe laying and repairCross bridgePipe layer

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

Flexible pipe connected to an end fitting

InactiveUS20060082140A1Small twistLimit bendingFlexible pipesHose connectionsCouplingTangential contact

The invention relates to a pipe structure (10) comprising a length of a flexible pipe connected to an end fitting, the flexible pipe comprising an armour layer (11; 19) and an underlying pipe layer (12; 11) to said armour layer, said underlying pipe layer having an outer surface around which armouring wires (111; 191) of an armouring layer are helically wound. The object of the present invention is to provide a coupling between a flexible pipe comprising armouring wires and an end fitting, the coupling exerting a relatively low bending or flexure strain on the wires during normal operation of the flexible pipe. The problem is solved in that the transition path of an armouring wire between the flexible pipe and the end fitting comprises an straight-line-section (194) between a wire-pipe-exit-point (195) where the wire extends away from its underlying pipe layer and a straight-line-end-point (196) on a support unit (15) of the end fitting where the armouring wire in question has its first tangential point of contact. This ahs the advantage that in a loaded situation where the armouring wires will elongate elastically leading to a change in the helical angle of the armouring wires, a pipe structure according to the invention will experience a slight twist and a controlled bending of the armouring wires on the surface of the support unit (due to a possible change in the base point of contact of the armouring wire with the support unit induced by the change of helical angle), thereby avoiding substantial bending of the individual armouring wires, which is of particular importance when the armouring wires are formed of a composite material. The invention may be used in flexible pipes for the off shore transport of fluids (e.g. oil).

Owner:NKT FLEXIBLES IS

Pipelayer and method of loading pipelayer or excavator for transportation

Embodiments of the present invention generally relate to a pipelayer and a method for of loading a pipelayer or excavator for transportation. One embodiment includes a method for transporting a pipelayer or excavator from a first work site to a second worksite via a public road. The method includes acts of: raising the pipelayer or excavator off of track shoes of the pipelayer or excavator; removing a first track assembly from the pipelayer or excavator using a boom of the pipelayer or a boom assembly of the excavator; loading the first track assembly onto a first trailer of a first tractor-trailer using the boom of the remaining pipelayer or the boom assembly of the remaining excavator; removing the second track assembly from the pipelayer using the boom of the remaining pipelayer or the boom assembly of the remaining excavator; and loading the second track assembly onto the first trailer using the boom of the remaining pipelayer or the boom assembly of the remaining excavator.

Owner:VOLVO CONSTR EQUIP AB

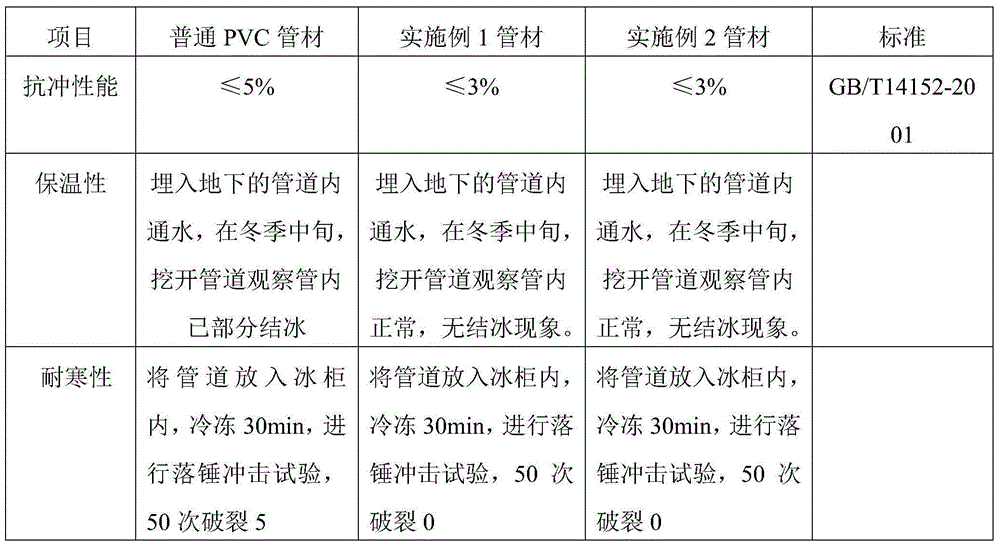

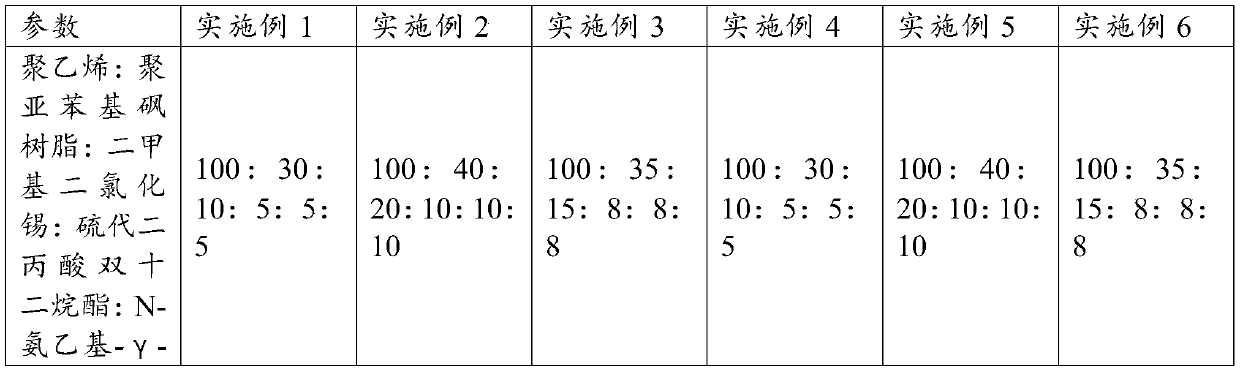

Cold-resistant high impact strength unplasticized polyvinyl chloride (PVC-U) composite pipe and preparation method thereof

InactiveCN105065792AImprove cold resistanceImprove impact resistanceThermal insulationFlexible pipesProduction lineThermal insulation

The invention relates to a cold-resistant high impact strength unplasticized polyvinyl chloride (PVC-U) composite pipe and a preparation method thereof. The pipe is of a three-layer structure which sequentially includes an inner PVC layer, a middle foaming polyethylene (PE) layer and an outer PE layer. The preparation method includes the following steps that raw materials of the PVC layer are uniformly mixed, added into a PVC pipe production line and subjected to extrusion, setting, cooling, pulling, cutting and the like, so that an inner pipe layer is obtained; the middle foaming PE layer is composited on the inner PVC layer through a composite production line; meanwhile, the outer PE layer is composited on the middle layer, and a finished product is obtained. By means of the cold-resistant high impact strength PVC-U composite pipe and the preparation method thereof, cold resistance, shock resistance and thermal insulation property of the pipe are extremely improved; the adaptability of the plastic pipe to the environment is enhanced; meanwhile, the defect of poor cold resistance of the PVC-U pipe is overcome; excellent properties of PVC and PE pipes are integrated.

Owner:大禹节水(天津)有限公司

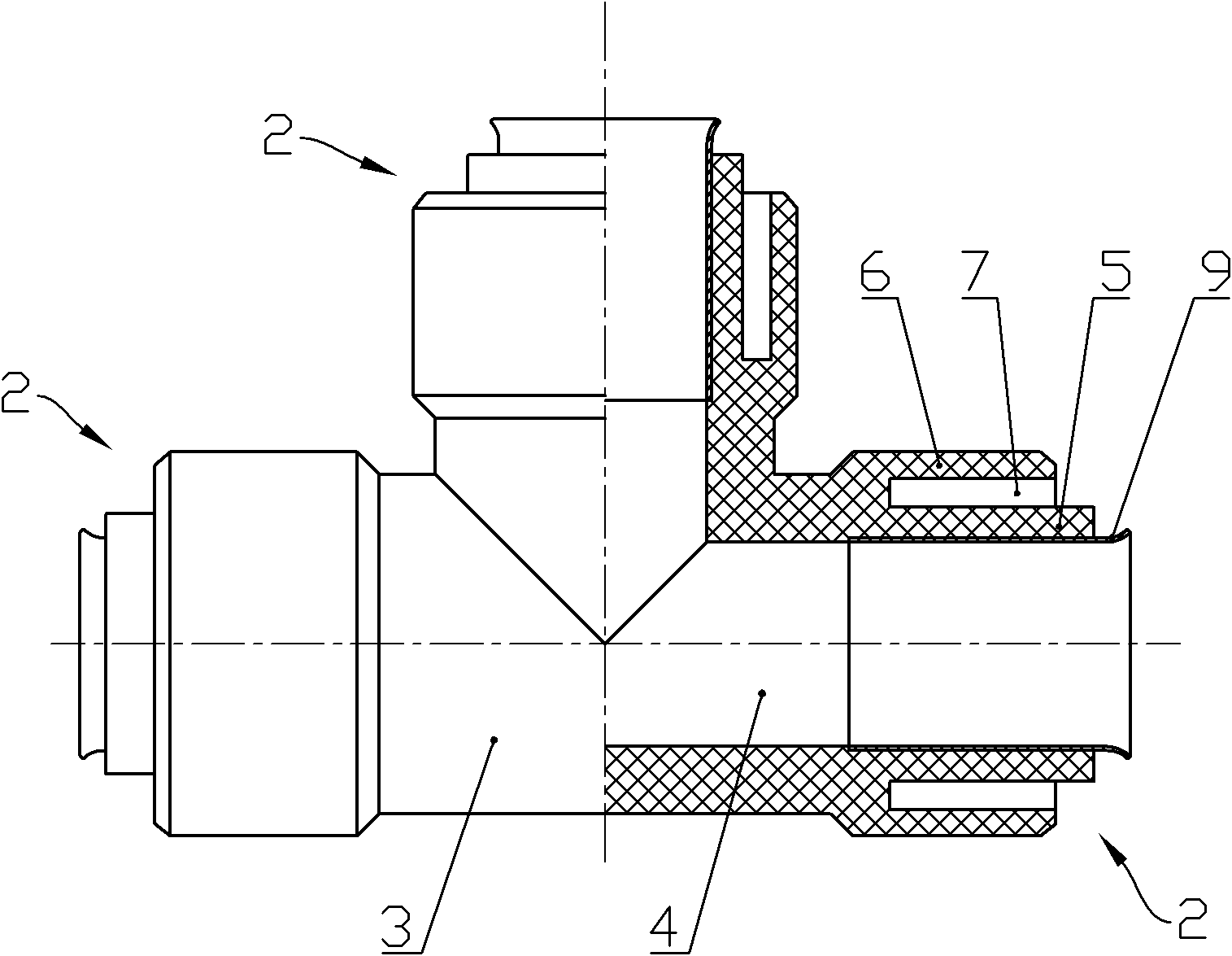

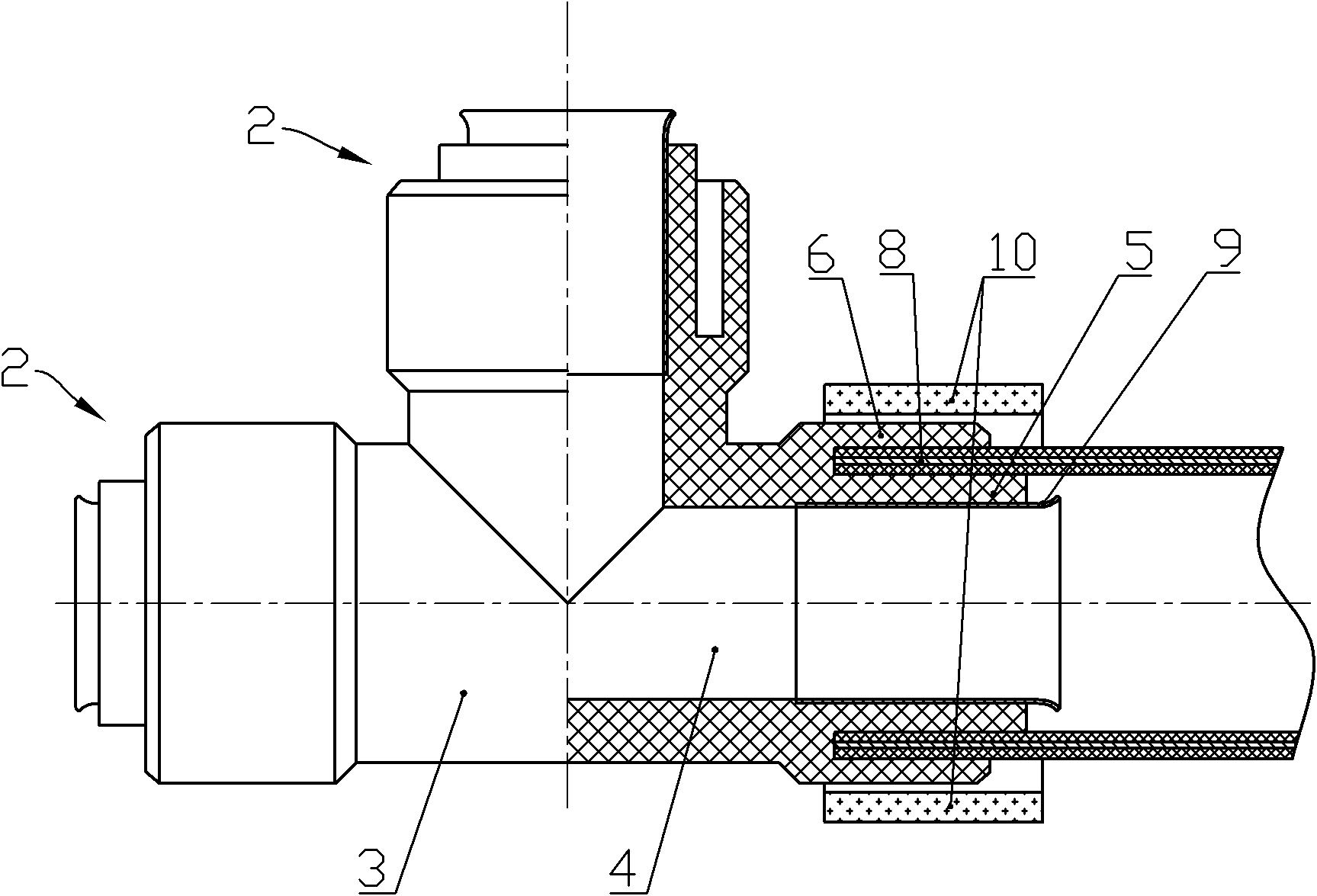

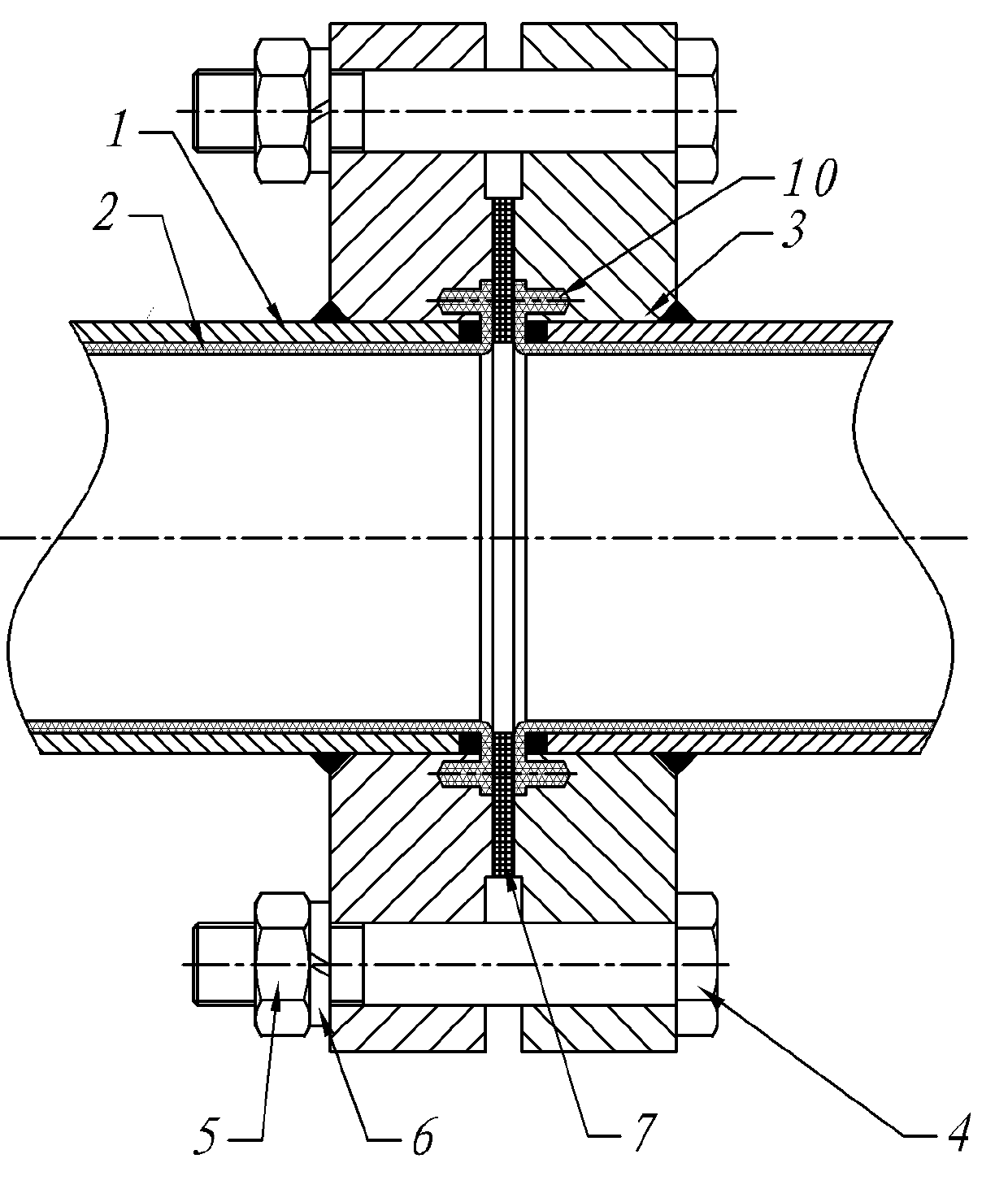

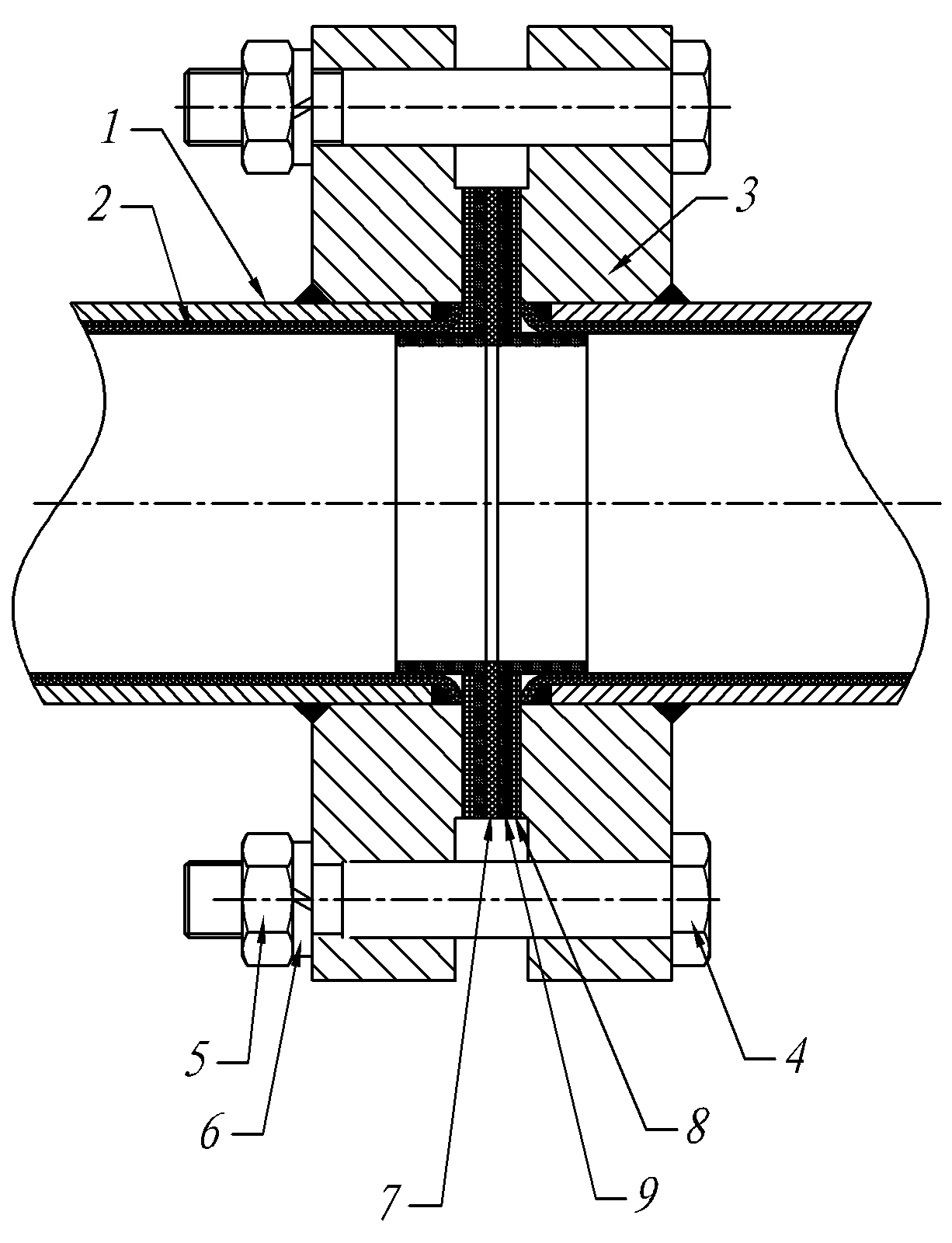

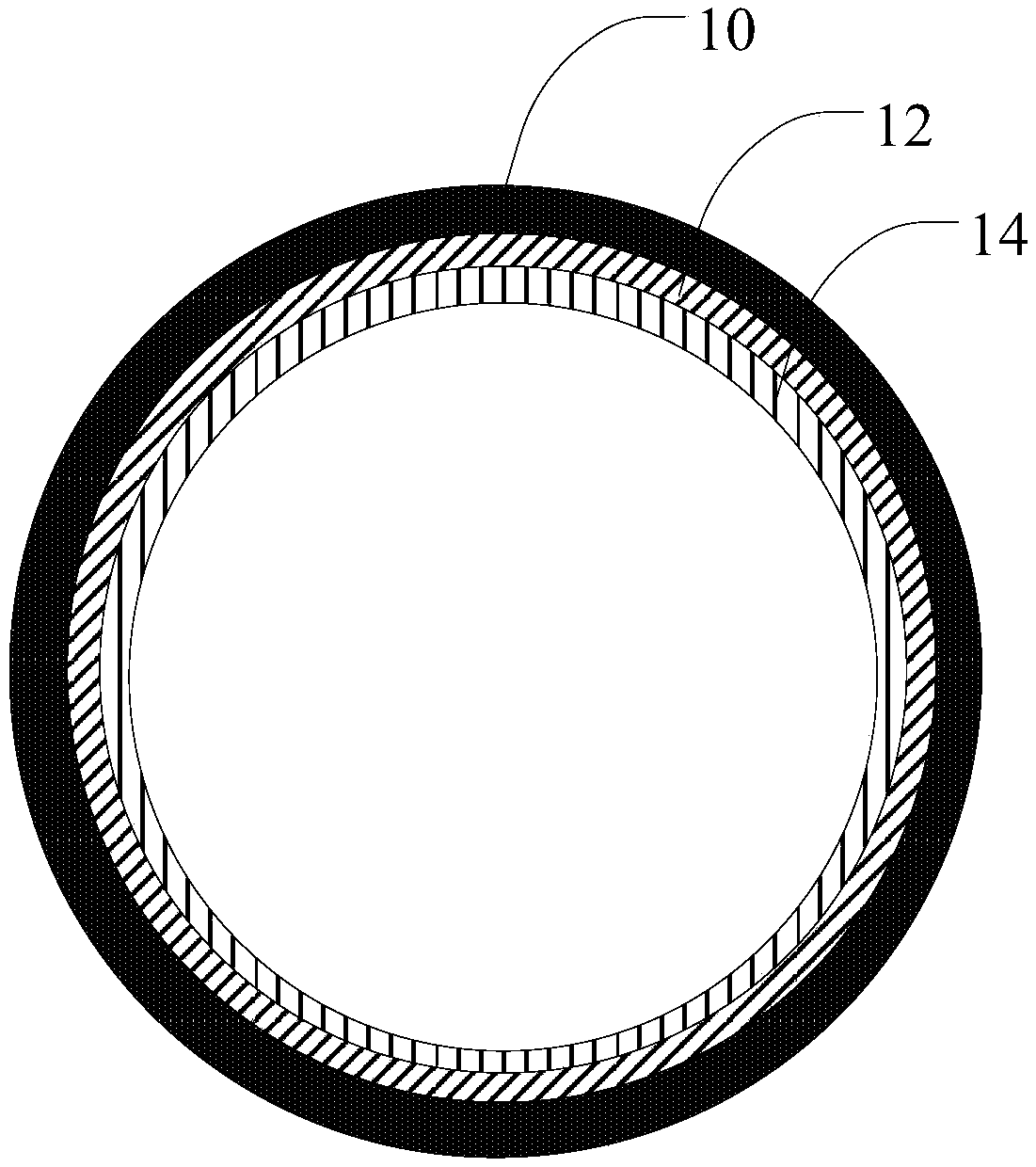

Device and method for connecting and sealing steel-plastic composite steel pipe, flange metal pipe and pipe fitting

ActiveCN103123024AImprove sealingEasy to installFlanged jointsCorrosion preventionIndustrial constructionPipe fitting

The invention provides a method for connecting and sealing a steel-plastic composite steel pipe, a flange metal pipe and a pipe fitting, and further provides a device for connecting and sealing the steel-plastic composite steel pipe, the flange metal pipe and the pipe fitting. The method comprises that at least one rabbet is formed on the periphery of the outer end surfaces of flange gaskets of the steel-plastic composite steel pipe; hot melt adhesive is coated on the outer layer of an inner liner plastic pipe layer of the steel-plastic composite steel pipe; the steel-plastic composite steel pipe with the hot melt adhesive coated on the outer layer of the steel-plastic composite steel pipe is embedded in an outer layer pipeline, and the inner liner plastic pipe layer is extended and coated on the end surface of the outer layer pipeline; and a silica gel gasket is arranged between end surfaces of two flange gaskets. The device for connecting and sealing the steel-plastic composite steel pipe, the flange metal pipe and the pipe fitting is simple in sealing and connecting method, reliable, stable and strong in sealing ability, and has prominent and active effects for engineering applications in the fields such as subways, industrial architecture and drinking water.

Owner:JIANGDONG SHENGFENG STEEL PLASTIC PIPE MFG FACTORY NINGBO

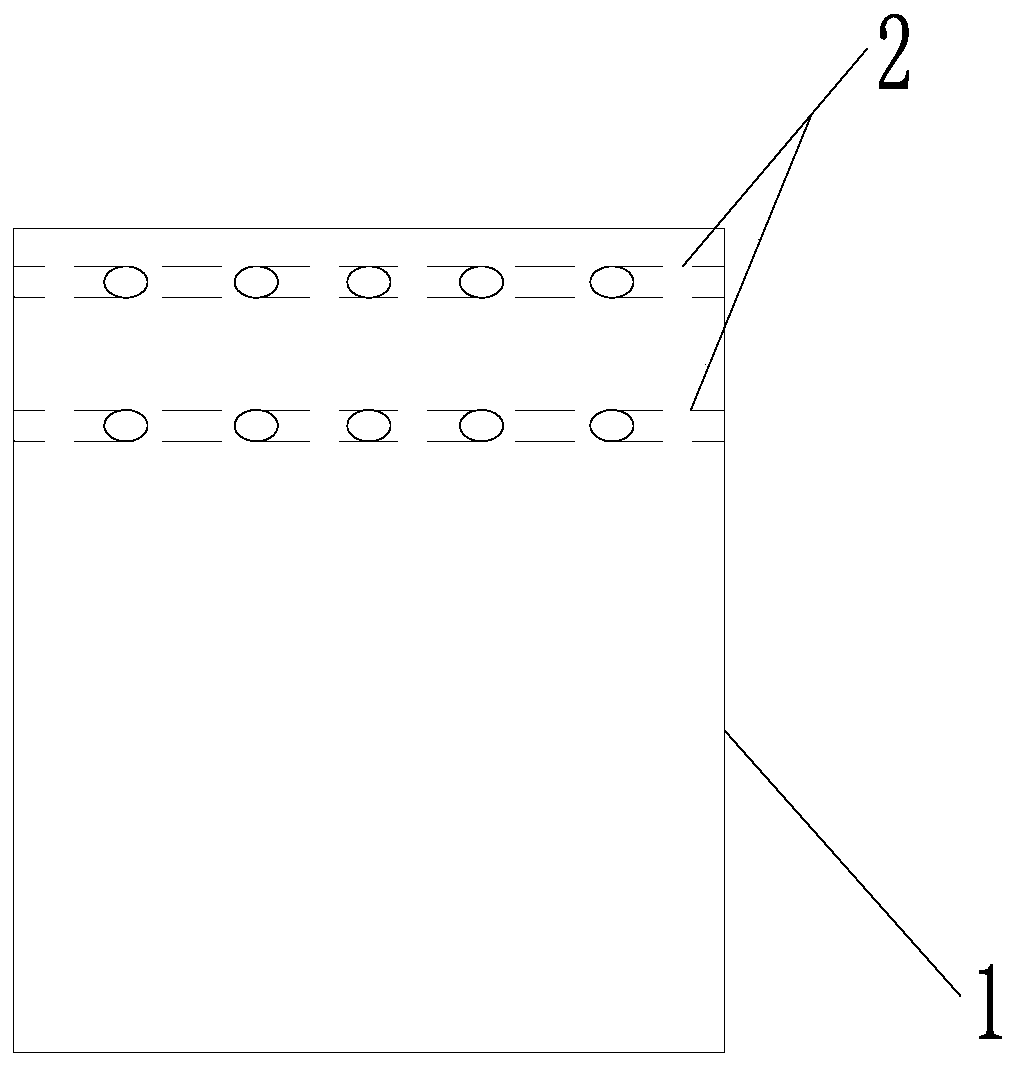

PE pipe and preparation method thereof

ActiveCN111300911AImprove performanceHigh mechanical strengthSynthetic resin layered productsTubular articlesPipe layerMechanical engineering

The invention provides a PE pipe and a preparation method thereof. The PE pipe comprises at least two pipe layers. Any two adjacent pipe layers are connected with each other in a forming mode of co-extrusion in a multi-layer co-extrusion mold; and any at least one pipe layer comprises an antibacterial material. The PE pipe has excellent performance and is particularly suitable for manufacturing ofdomestic water supply pipelines.

Owner:ZHEJIANG LONGCAI PLASTIC IND

Nano antibacterial PP-R composite pipe and manufacturing method thereof

InactiveCN101725771AHigh strengthSmall coefficient of linear expansionRigid pipesWater qualitySilver ion

The invention relates to a nano antibacterial PP-R composite pipe and a manufacturing method thereof and belongs to the technical field of building materials. The traditional PP-R pipes, on one hand, has inadequate strength and large coefficient of inertia expansion, and, on the other hand, cannot suppress the growth of bacteria and deteriorates water as a bacterium film is on the inside surface of the pipe after long-term use. Aiming at overcoming the drawbacks, the invention designs a composite pipe, which comprises a common PP-R outer pipe layer and is characterized in that: an inner pipe layer is PP-R loaded with a silver ion antibacterial agent; and a composite reinforcing layer blended with glass fibers and the PP-R is arranged between the inner and outer pipe layers. The manufacturing method of the nano antibacterial PP-R composite pipe comprises: connecting three layers of composite molds and three plastic extruding machines; after the raw materials are heated to a corresponding temperature, sequentially starting the three extruding machines to co-extruding the three layers to make a pipe blank; and subjecting the pipe blank to vacuum sizing, spray cooling, surface drying, laser code spray, fixed length cutting and end milling to obtain the nano antibacterial PP-R composite pipe. Trial use shows that the nano antibacterial PP-R composite pipe of the invention has the advantages of high strength, small coefficient of inertia expansion and remarkable antibacterial effect.

Owner:朱智波

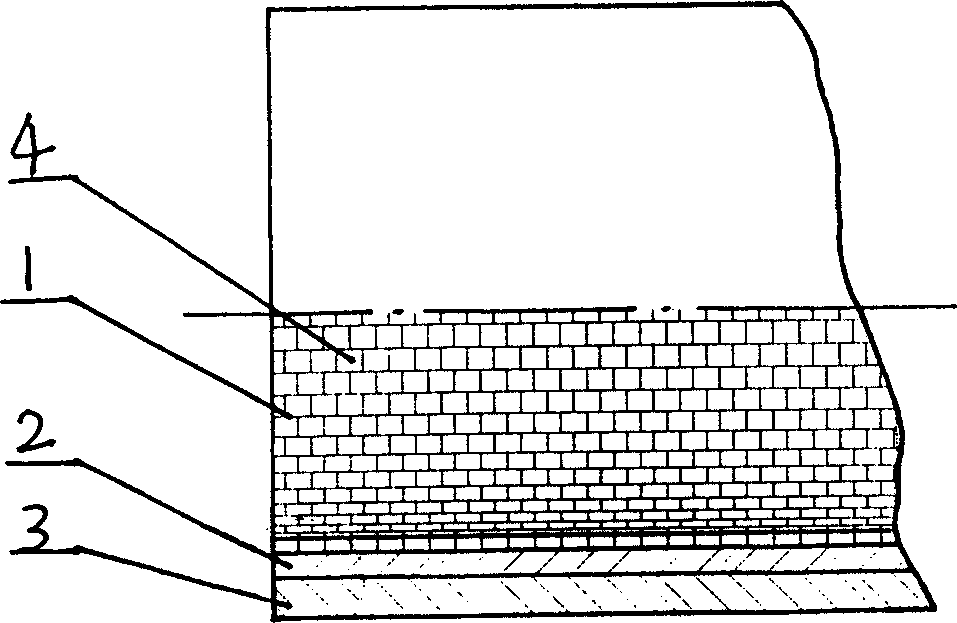

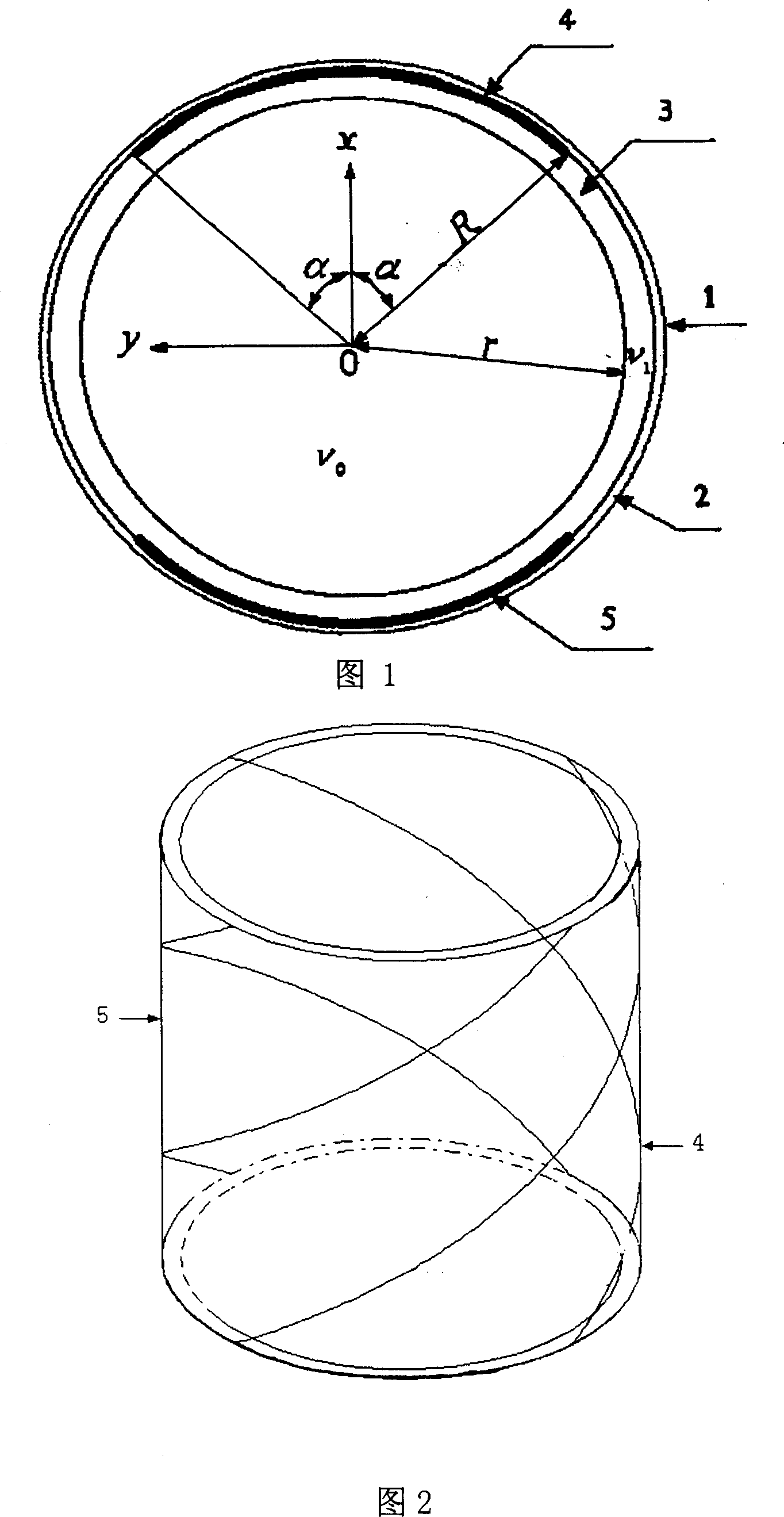

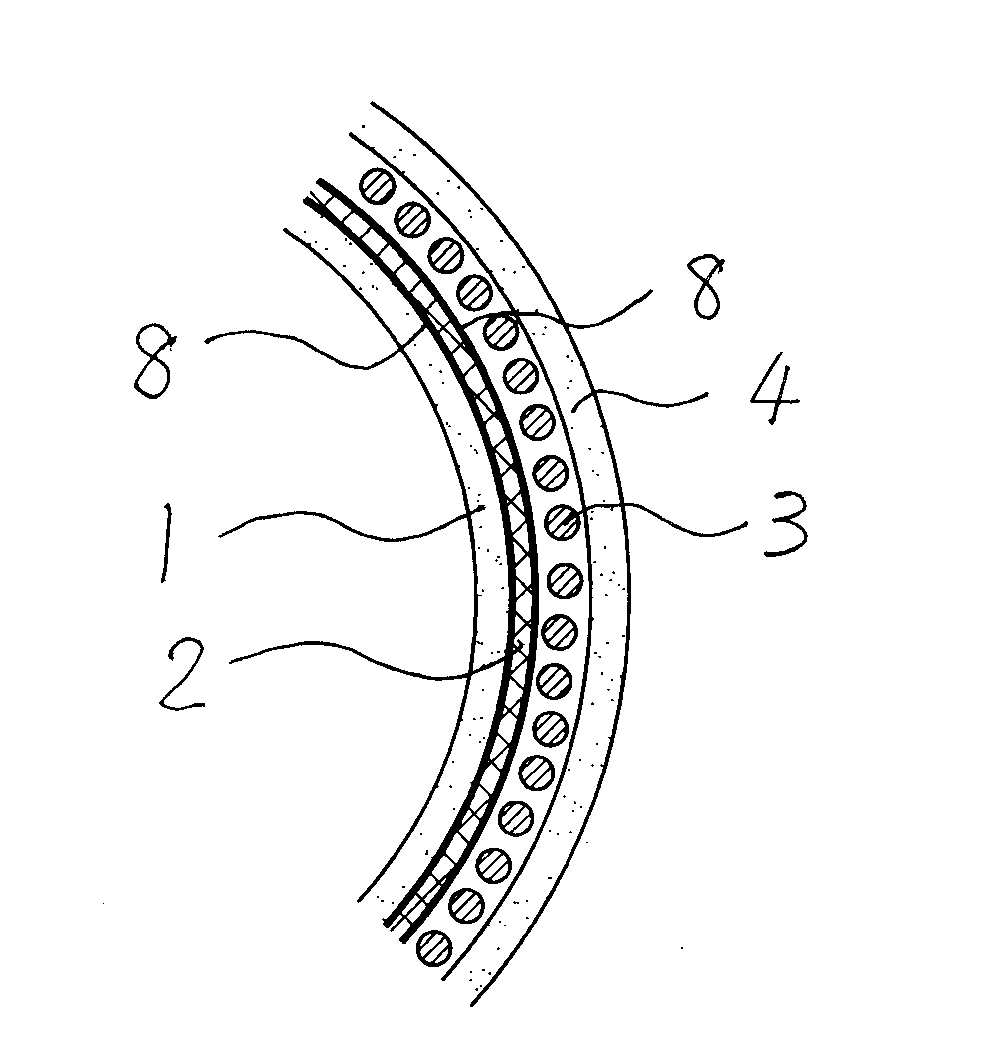

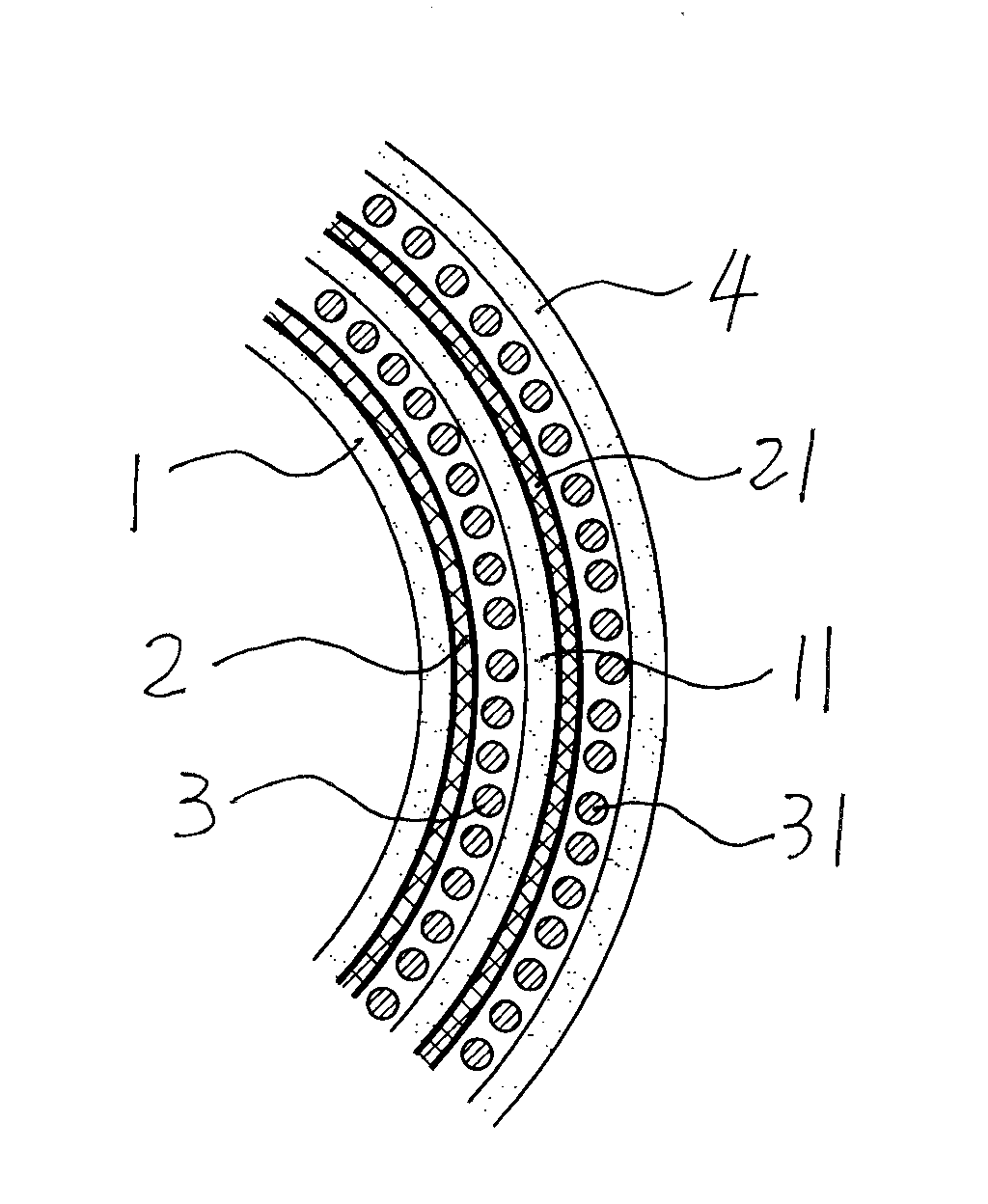

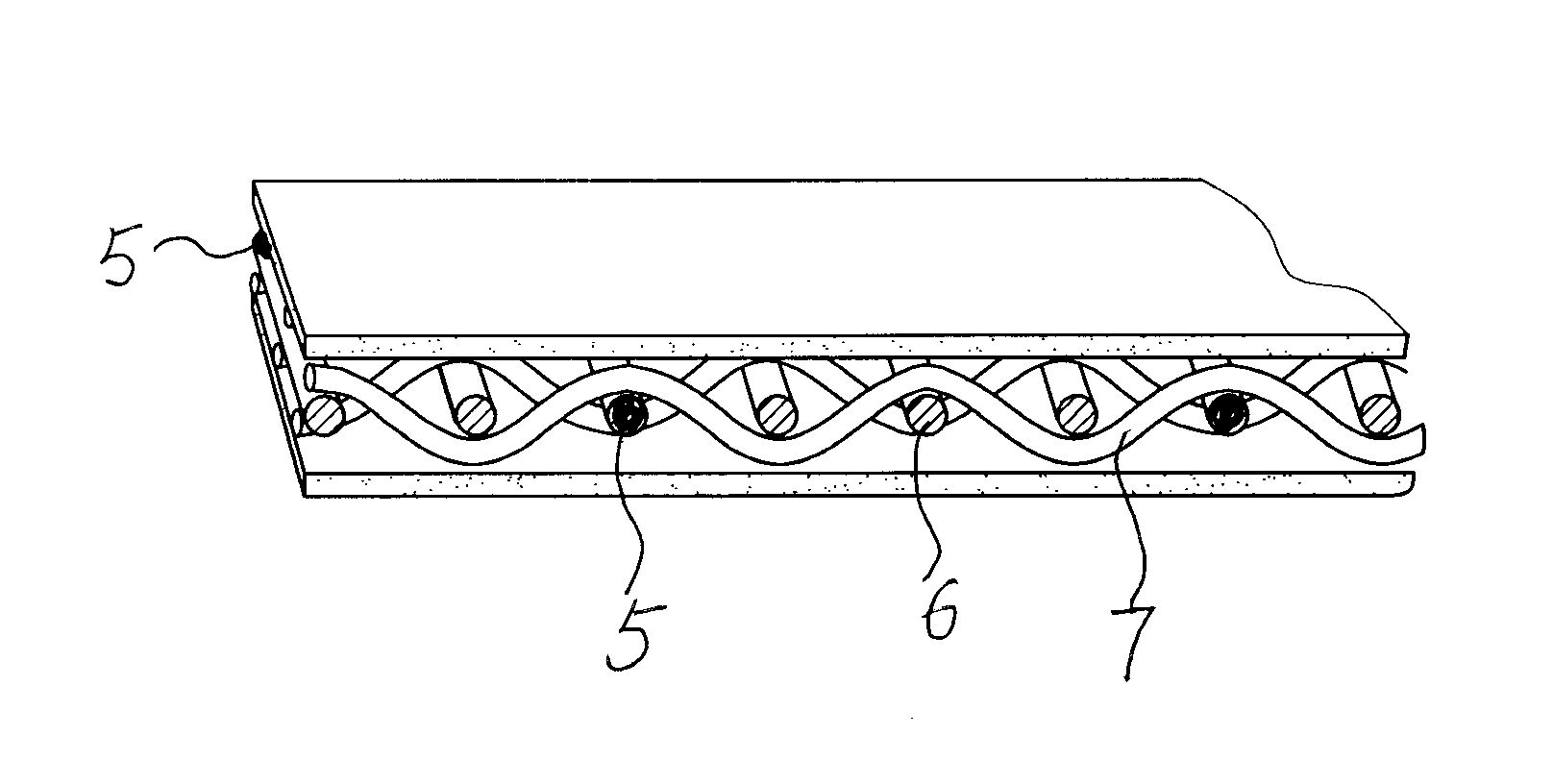

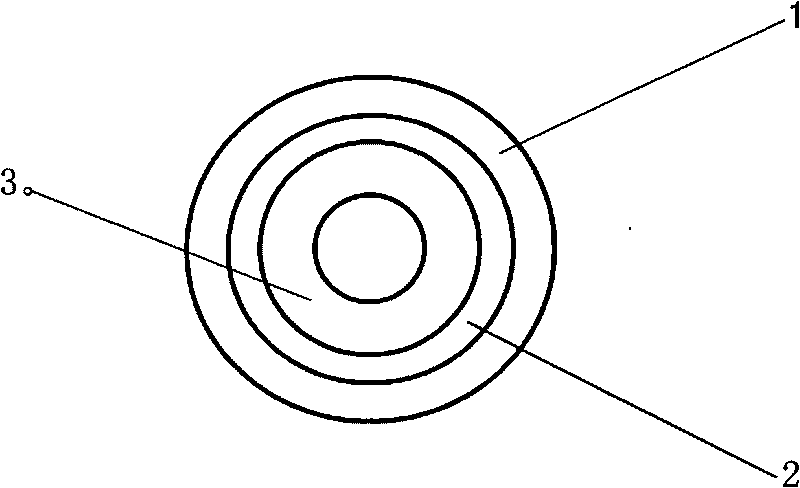

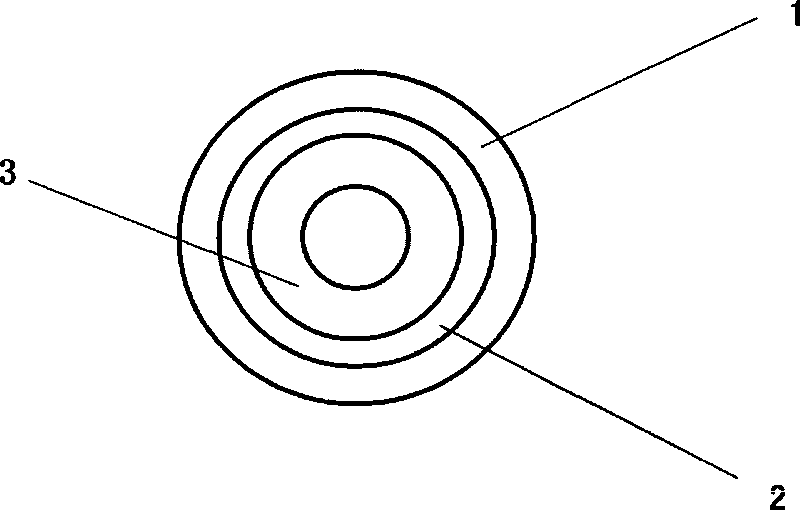

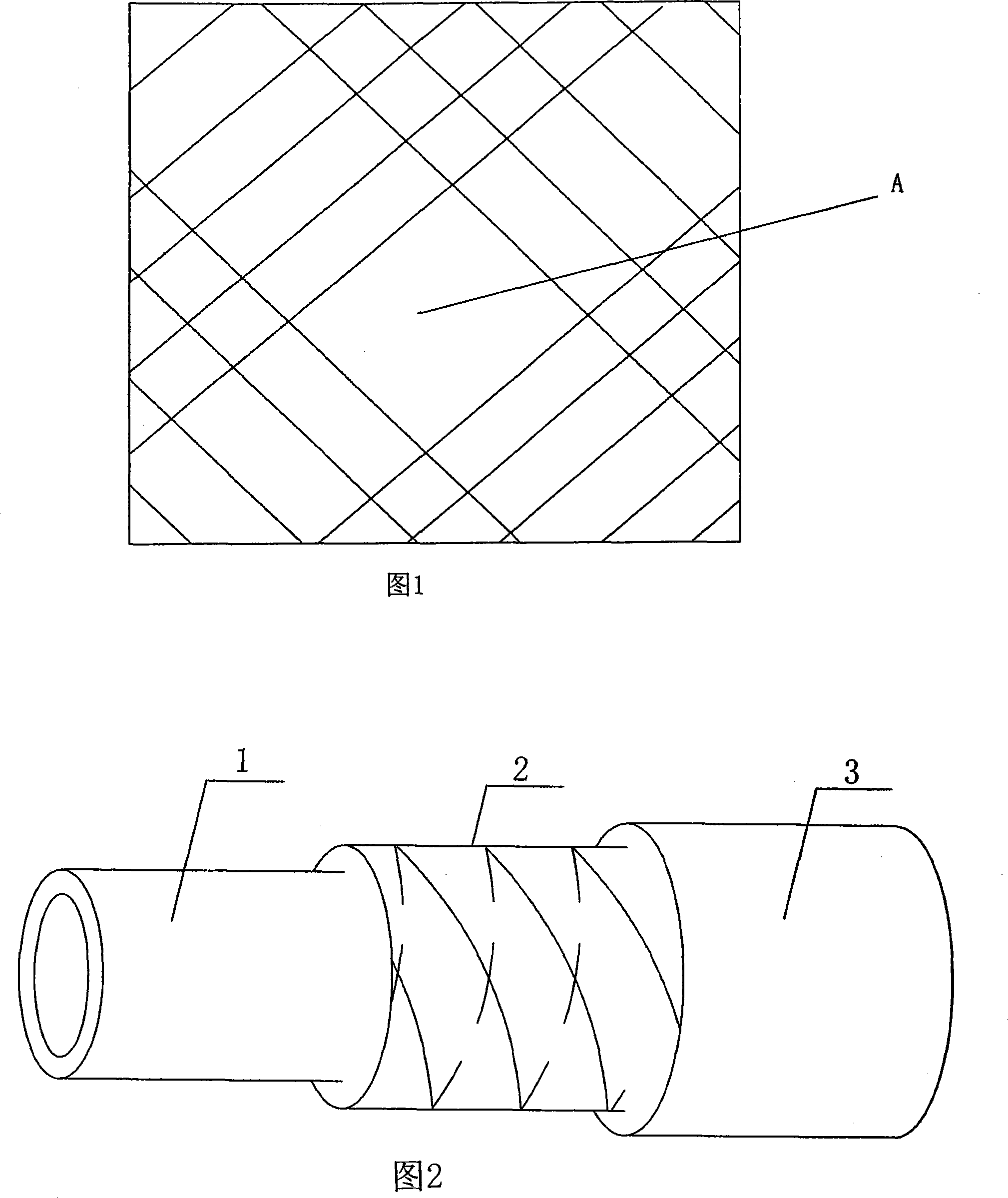

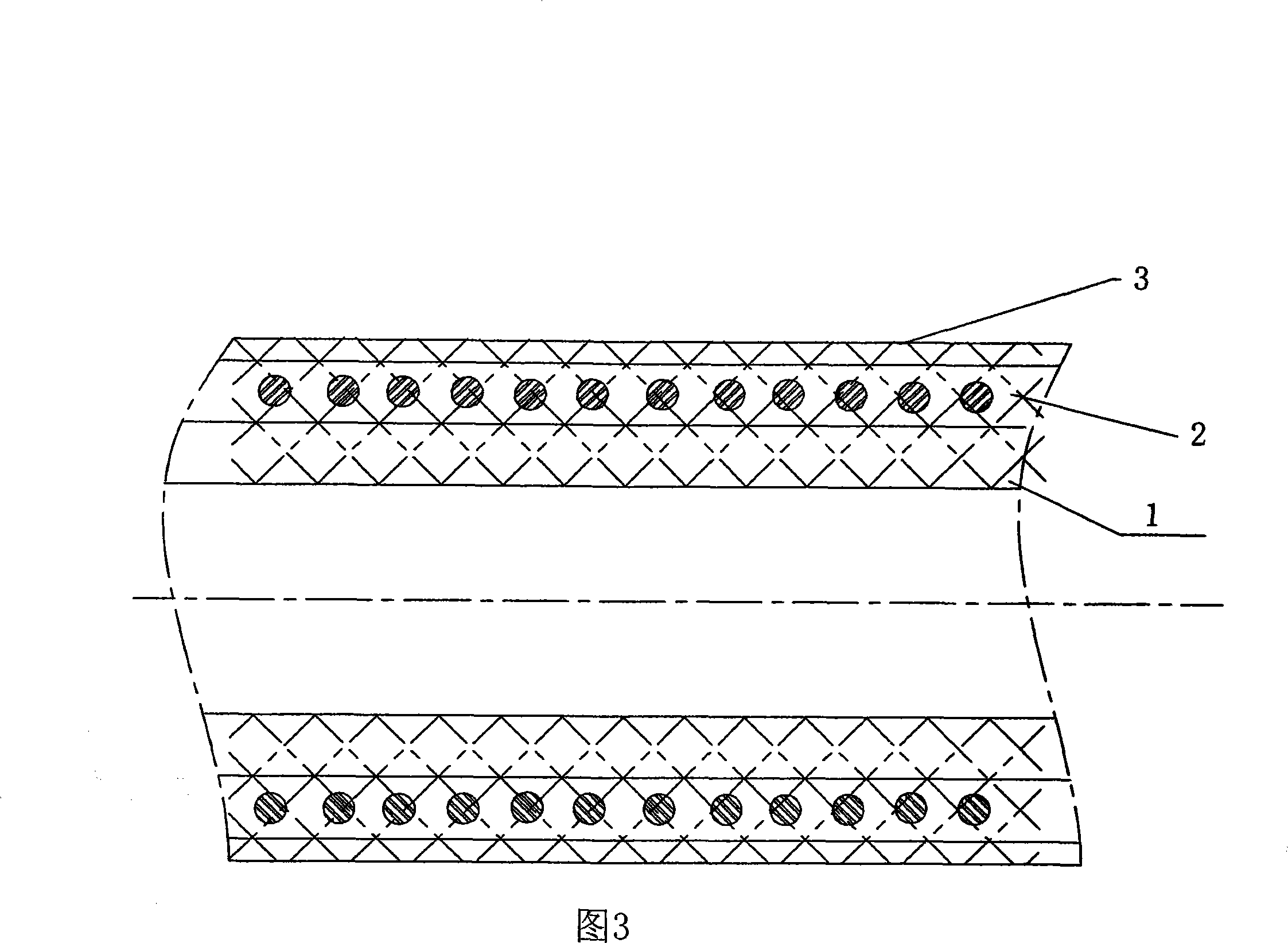

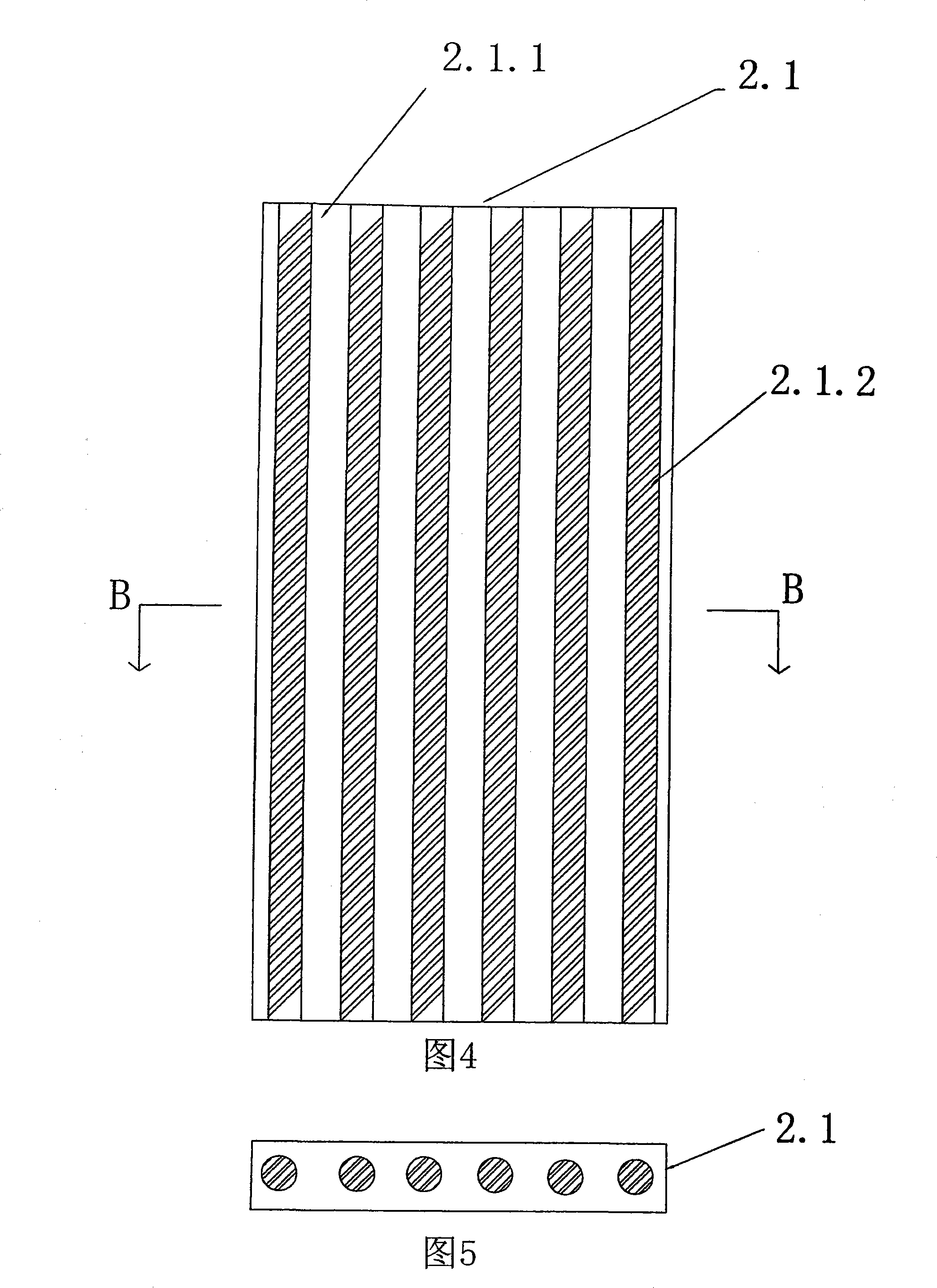

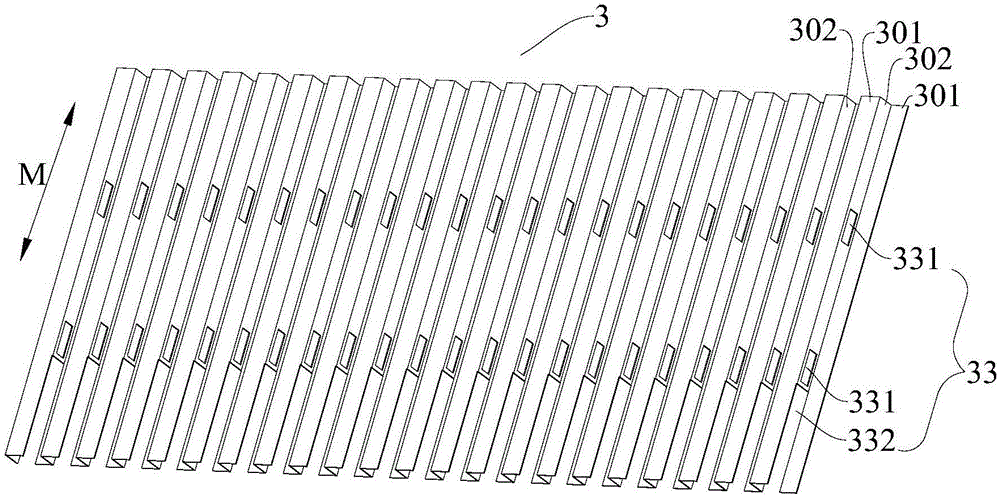

Metal mesh plastic composite pipe winded with reinforced structure and preparation method thereof

The invention relates to a wire mesh-plastic composited tube twined with reinforcing tape structure and the preparation method. The composited tube is formed by the combination of an inner layer blank pipe (1), a twined tape reinforcing body (2) and an outer layer pipe (3). The twined tape reinforcing body (2) is of reinforcing structure formed by cross twining n layers of twined tapes round the inner blank pipe layer, wherein, the n is a natural number more than or equal to two. The preparation method comprises the prefabrication of the twined tape and the preparation of the composited tube. The preparation of the composited tube comprises the following processes: a plastic inner layer blank pipe is first extruded. Then the prefabricated tape is cross twined round the inner layer blank pipe and the twined tape reinforcing body is heated with a high frequency heating ring. In the end, a layer of plastic is extruded to cover over the twined tape reinforcing body. The invention avoids uneven distribution of twined wire owing to self stress of the wire and the processing of an outer layer plastic pipe, improves the security of the composited tube, enhances the combining strength of the inner layer blank pipe, the twined tape reinforcing body and the outer layer pipe and the loading capacity of the multiple-unit tube.

Owner:江苏法尔胜新型管业有限公司

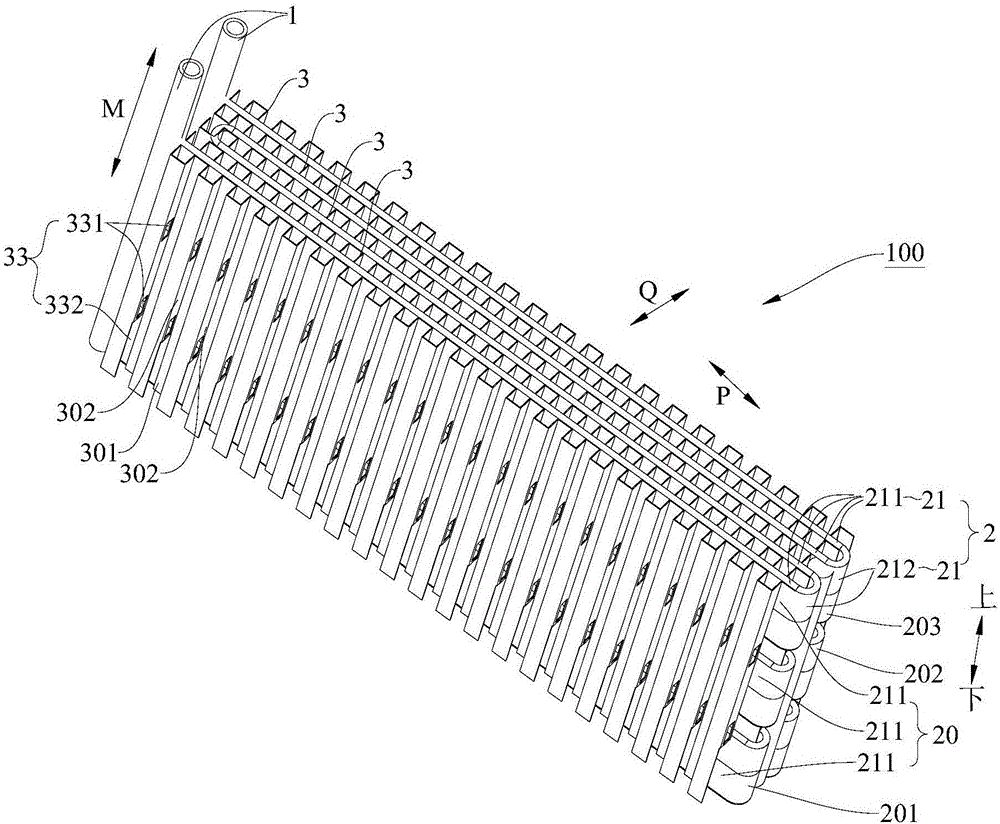

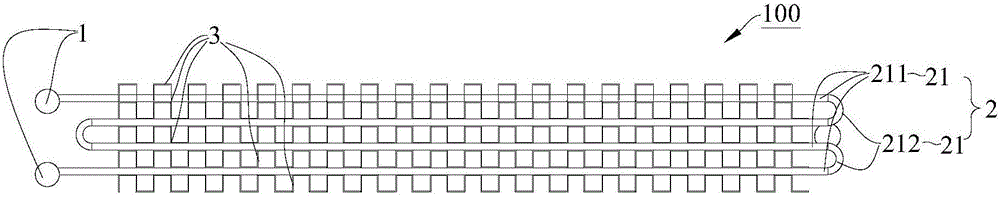

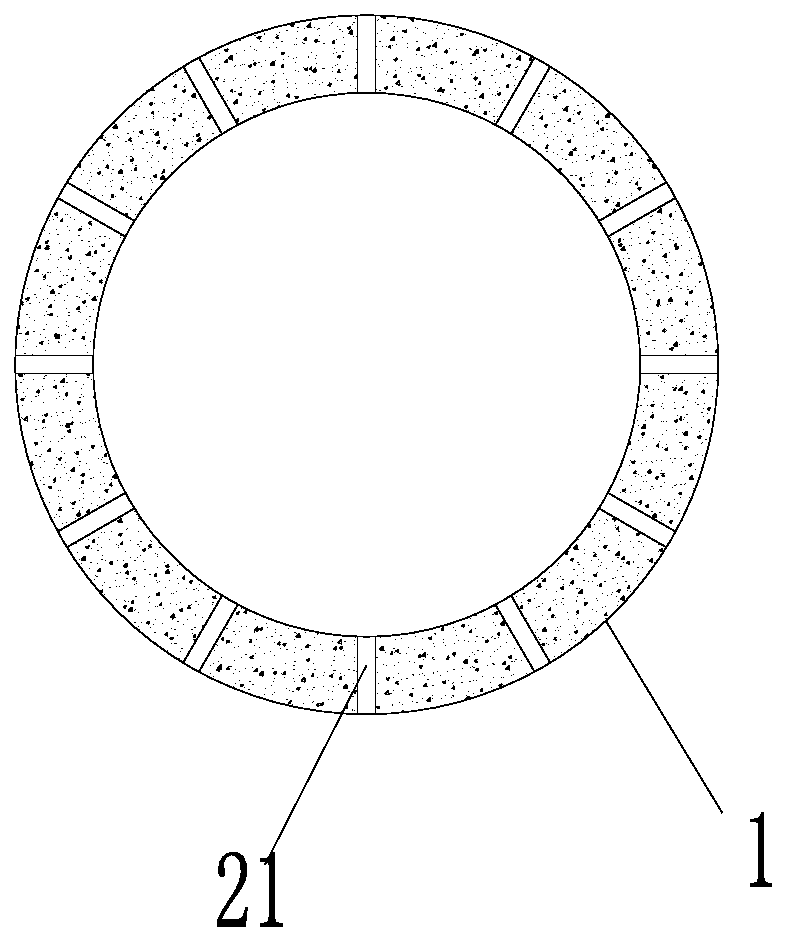

Microchannel heat exchanger, refrigerator and air-cooled refrigerator

InactiveCN106322850AImprove heat transfer effectSmall circulation resistanceEvaporators/condensersStationary conduit assembliesPipe layerRefrigerant

The invention discloses a microchannel heat exchanger, a refrigerator and an air-cooled refrigerator. The microchannel heat exchanger comprises two header pipes, multiple heat exchange pipes and fins. The two header pipes are arranged in parallel. The two ends of the multiple heat exchange pipes are connected with the two header pipes correspondingly. The multiple heat exchange pipes are bent in the length direction to form multiple pipe layers. The refrigerant circulation resistance of some heat exchange pipes is smaller than that of the rest of the heat exchange pipes. Each fin is arranged between every two adjacent pipe layers or arranged on the outer side of the outermost pipe layer. In the extending direction of the heat exchange pipes, each fin extends in a corrugate shape. In the extending direction of the heater pipes, each fin continuously extends. The fins are provided with air holes. According to the microchannel heat exchanger, the problem that a large amount of water is attached to fin surfaces and cannot be thoroughly drained is solved, and the phenomenon that dense ice is produced on the surface of the microchannel heat exchanger, and therefore heat exchange efficiency is affected can be prevented. In addition, the defrosting period can be prolonged, the refrigerant flow of the multiple heat exchange pipes is promoted to be uniform, and heat exchange performance is improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

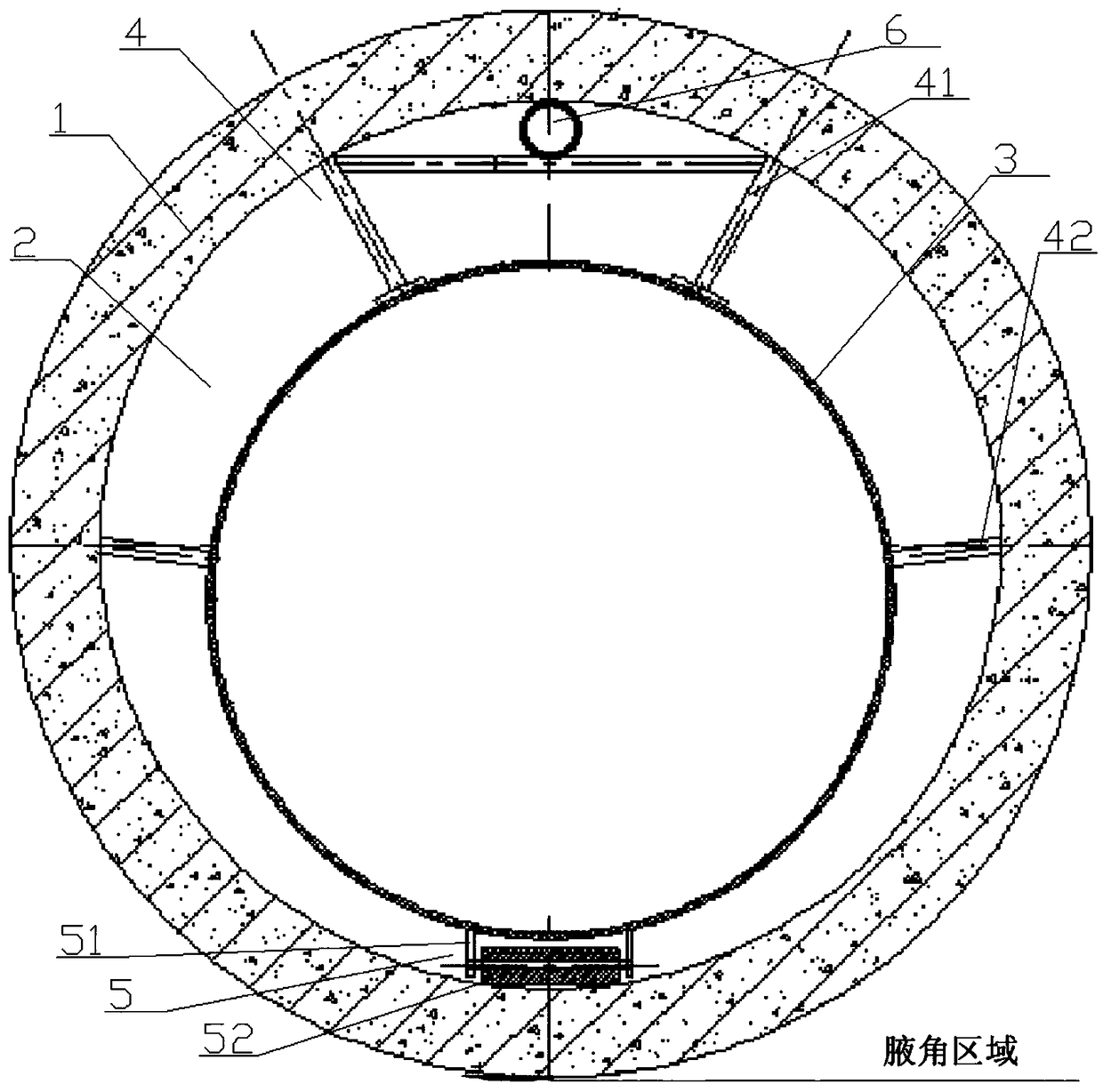

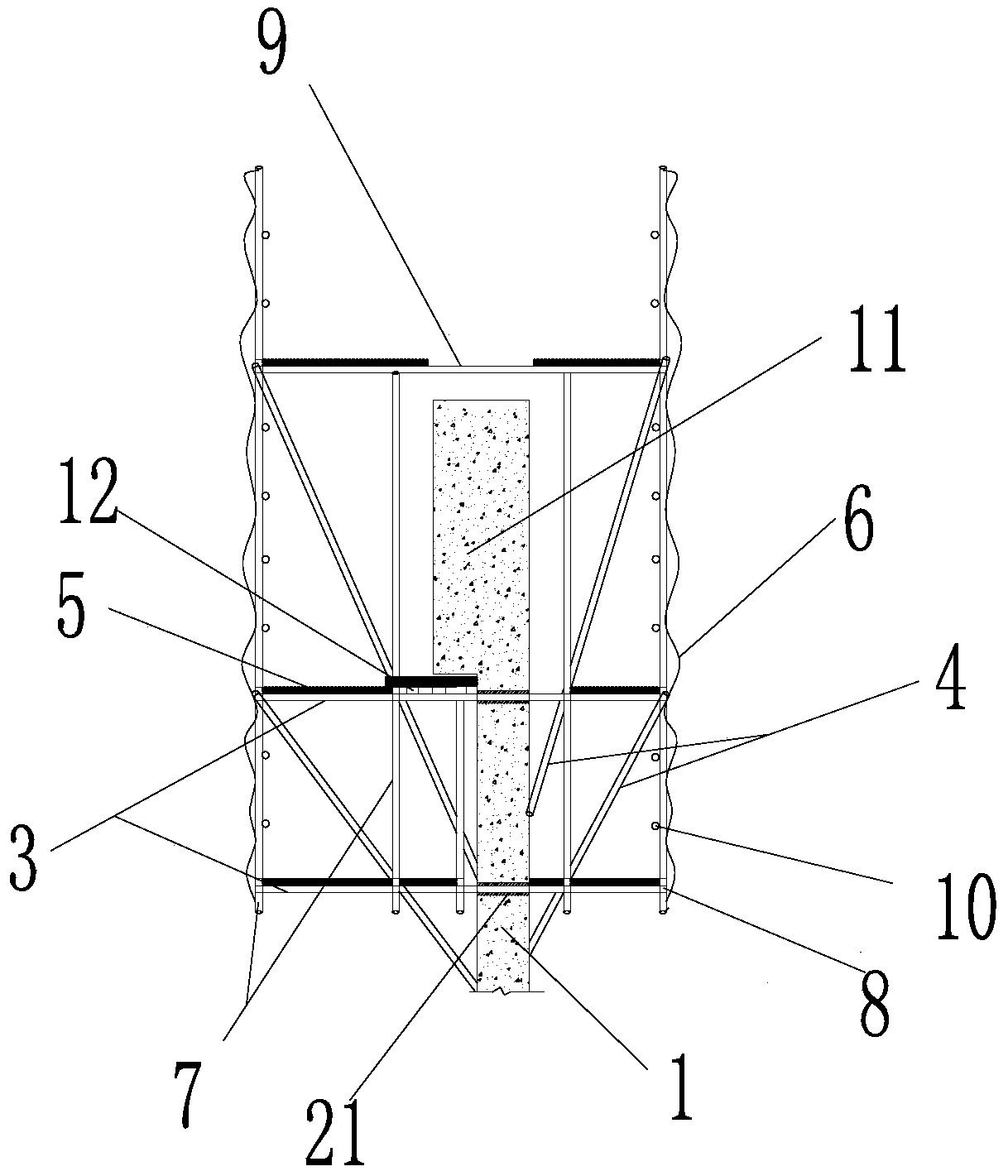

Erecting structure and erecting method for top ring beam construction platform of concrete silo

InactiveCN110725597ALess materialSimple structureBulk storage containerBuilding support scaffoldsArchitectural engineeringPipe layer

Owner:CHINA 19TH METALLURGICAL CORP

Elastic expansion pipe and production technology thereof

PendingCN107178665AOutstanding and Beneficial Technical EffectsLess contact with waterFlexible pipesTubular articlesElastomerEngineering

The invention belongs to the technical field of expansion pipes, and relates to an elastic expansion pipe and a production technology thereof. The elastic expansion pipe comprises an elastic pipe made of an elastic body; two or more spiral line layers or woven mesh layers which can expand and contract along with expanding and contracting of the elastic pipe are arranged in the elastic pipe; and when the spiral line layers are arranged, the spiral directions of every two adjacent spiral line layers are opposite, the outer diameter of the spiral line layer or the woven mesh layer located on the outermost layer is smaller than the outer diameter of the elastic pipe, and the inner diameter of the spiral line layer or the woven mesh layer located on the innermost layer is smaller than the inner diameter of the elastic pipe. According to the production technology, the inner spiral line layer or the inner woven mesh layer is arranged on the outer surface of an inner elastic pipe body, a first elastic body layer is formed on the outer surface of the inner spiral line layer or the inner woven mesh layer, then, the second spiral line layer or the second woven mesh layer is arranged, a second elastic body layer is formed on the outer surface of the second spiral line layer or the second woven mesh layer, the rest can be done in the same manner, and an outer elastic pipe layer is formed on the outermost layer. The elastic expansion pipe has the advantages of being low in weight, large in expansion amount, high in tensile strength, and long in service life.

Owner:ZHEJIANG HELEN PLASTIC

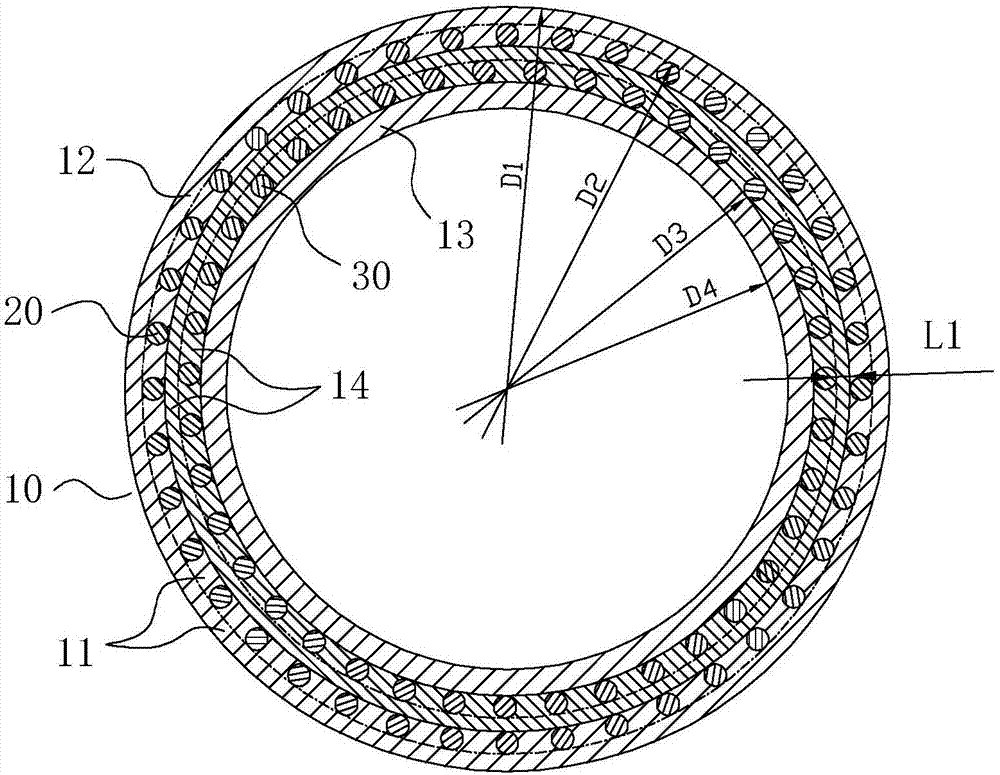

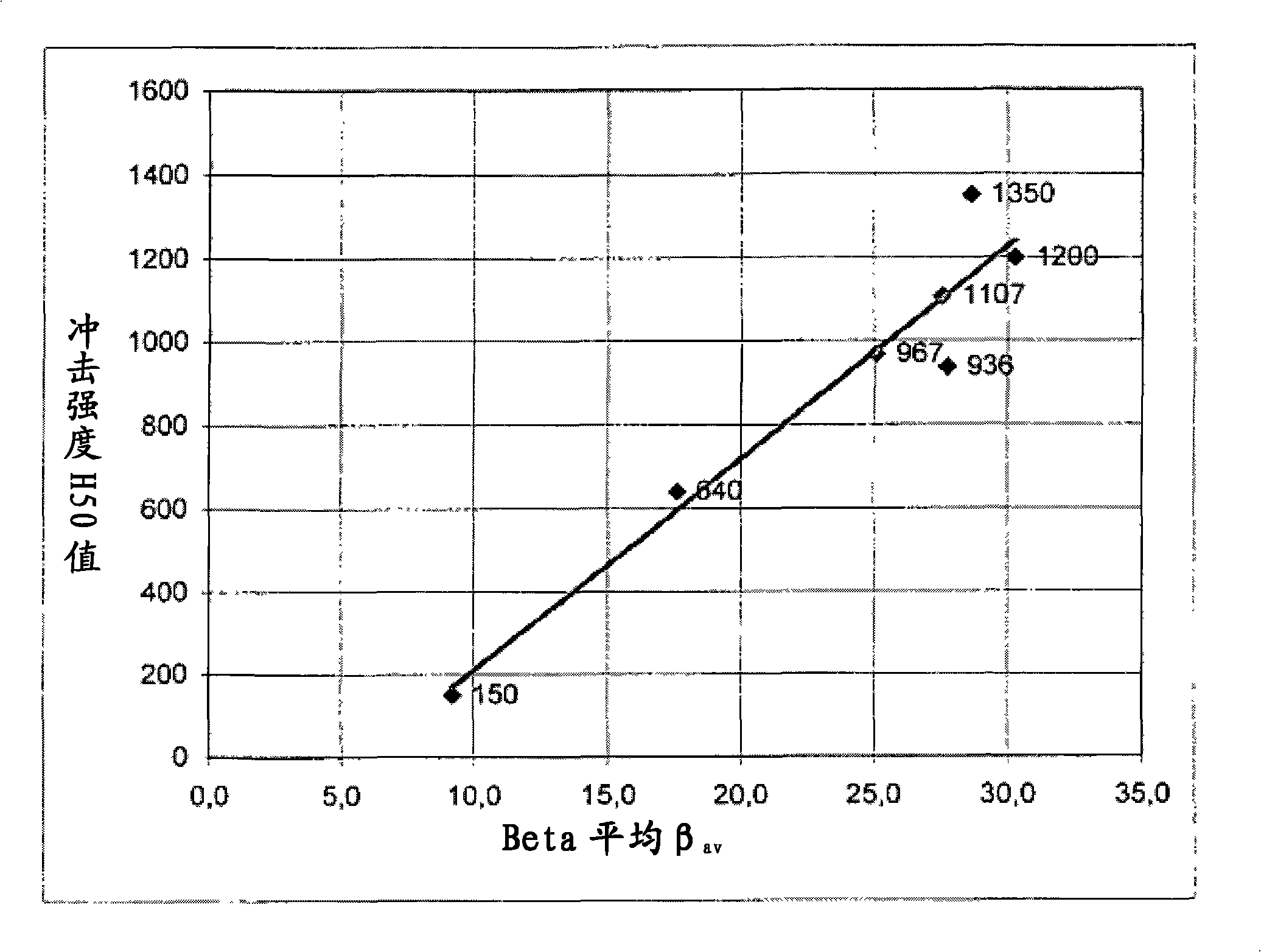

Process for the production of impact resistant pipe

The present invention relates to a process for producing a pipe comprising at least one layer made of a polypropylene composition comprising a beta nucleated polypropylene base resin, wherein the process comprises the steps of: a) extrusion of the polypropylene composition at a temperature of above 200 DEG C, b) subsequent cooling of the extruded product with a cooling medium having a temperature of above 5 DEG C, and c) subsequent annealing of the extruded product with an annealing medium having a temperature of at least the cooling medium temperature of step b), and to a pipe comprising at least one layer made of a propylene polymer composition, wherein the average beta-crystallinity of the pipe layer, beta av is higher or equal to 20 %.

Owner:ボレアリステクノロジーオイ

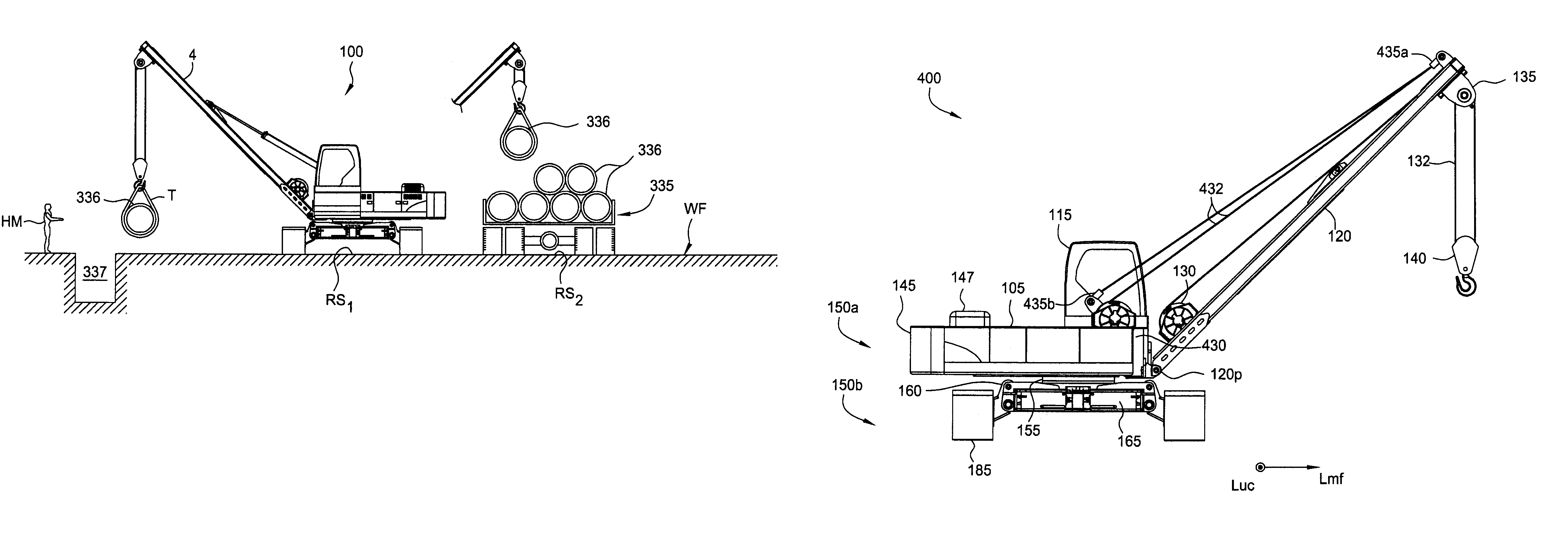

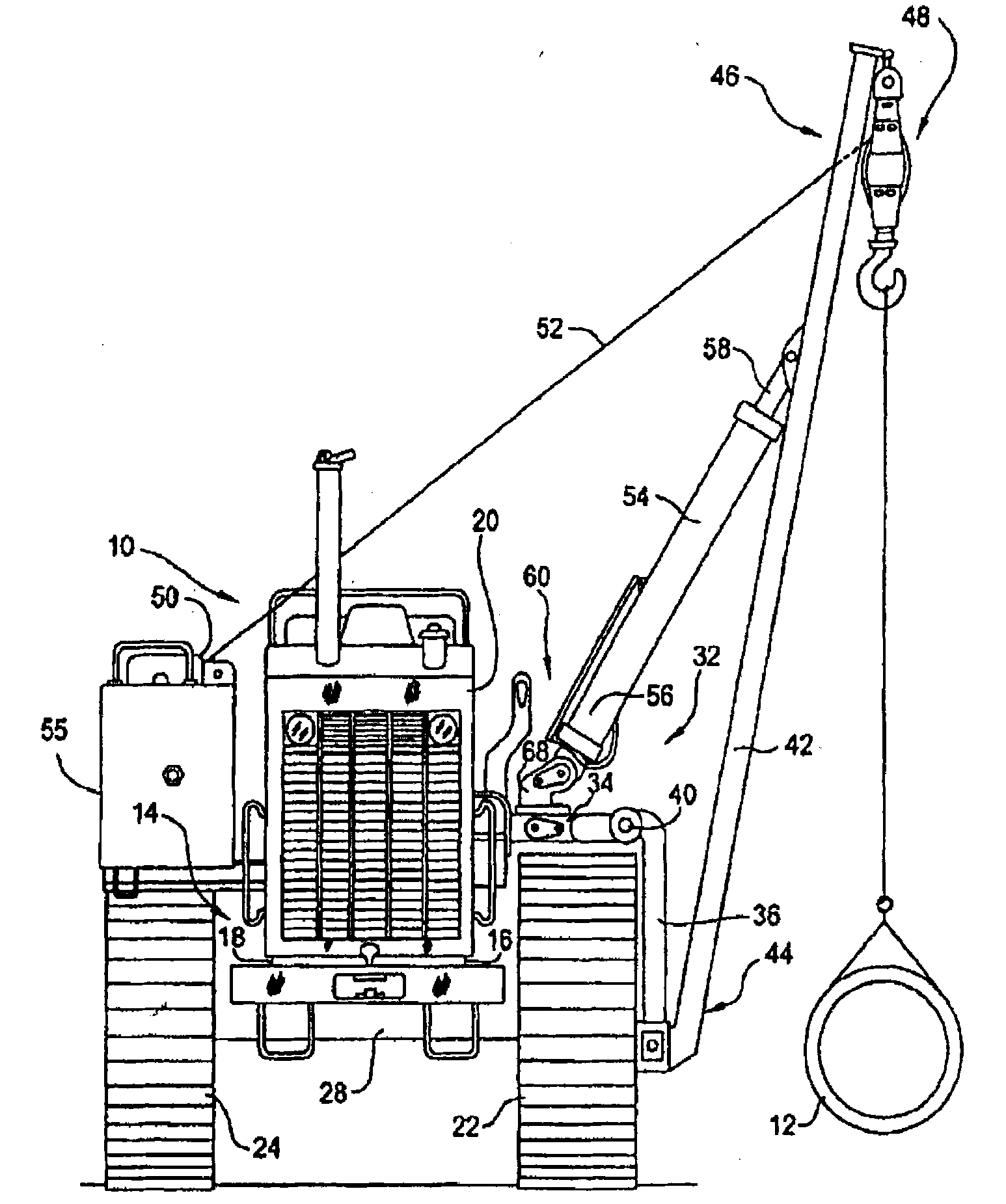

Pipelayer crane excavator apparatus and methods

The pipelayer crane apparatus comprises a lower, the lower comprising a lower frame, a pedestal, a lower bearing portion, a telescoping axle, a track roller, and a track shoe, an upper, the upper comprising a frame, a body, a cab, a pedestal, a upper bearing portion, and a counterweight, a lifting assembly, the lifting assembly comprising an adjacent portion, a remote portion, a joint, and a cylinder and a weldment, the weldment comprising a body, an extension, a winch, and securing members. A method for a pipelayer crane apparatus to rotate about the track shoes comprising a lower, the lower having a pedestal attached to a lower bearing surface; an upper, the upper having a pedestal attached to a upper bearing portion; bearing formed by the interaction of the upper bearing surface and the lower bearing surface; a pipe lifting assembly, the pipe lifting assembly attached to a weldment, the weldment attached to the upper; and the upper rotating about the bearing formed by the upper bearing surface and the lower bearing surface.

Owner:VOLVO CONSTR EQUIP

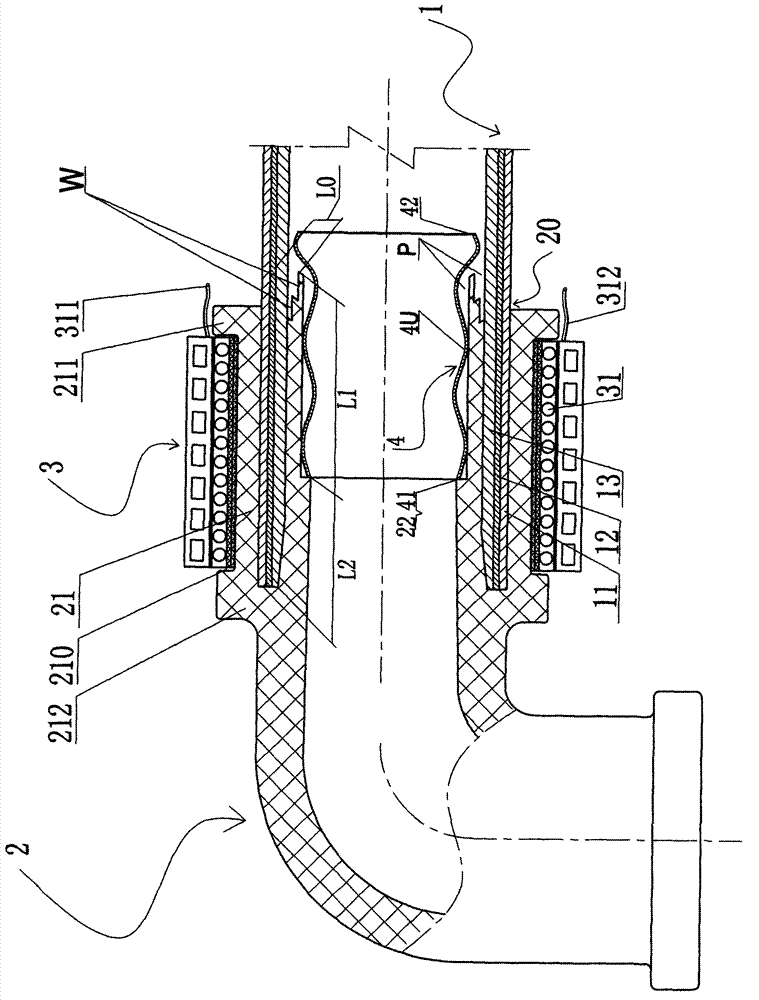

Electromagnetic induction heating type steel-plastic composite pipeline full fusion welding structure

InactiveCN102829276AGuarantee the quality of electromagnetic weldingImprove sealingPipe connection arrangementsPipe fittingWave shape

The invention discloses an electromagnetic induction full heating type steel-plastic composite pipeline connecting structure. The connecting structure comprises a wave-shaped lining ring, a pure plastic pipe fitting, and a steel-plastic composite pipe material with an inner plastic pipe layer, wherein the pure plastic pipe fitting is provided with an outer ring part, an annular bearing and inserting cavity, an inner ring body segment and an inner ring expanding segment; the steel-plastic composite pipe material is inserted into the annular bearing and inserting cavity; a transition step is formed by the inner ring body segment and the inner ring expanding segment; an electromagnetic induction coil wrapped at the outer ring part is used for the fusion welding of the steel-plastic composite pipe material and the pure plastic pipe fitting; the free end of the lining ring leaned against the inner wall of an inner ring part is positioned outside the end part of the inner ring expanding segment; a gap exists between the free end of the lining ring and the inner wall of the adjacent inner plastic pipe layer; fused plastic accumulated in a fused material placing space carries out the fusion welding for the end part of the inner ring expanding segment and the inner wall of the steel-plastic composite pipe material together in a sealing manner after being condensated; and the sum of the wall thickness of the inner ring expanding segment and the wall thickness of the inner plastic pipe layer is from 3mm to 20mm. According to the invention, reliable and gapless fusion welding in a tight sealing manner can be formed between the steel-plastic composite pipe material and the inner ring part, so that the seepage phenomenon between the steel-plastic composite pipe material and the inner ring part is avoided.

Owner:徐焕松 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com