Electromagnetic inductive welding method of steel-plastic compound pipe

A steel-plastic composite pipe and electromagnetic induction technology, which is applied in the direction of pipeline connection layout, pipe/pipe joint/pipe fittings, mechanical equipment, etc. Easy double-sided sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings of the description.

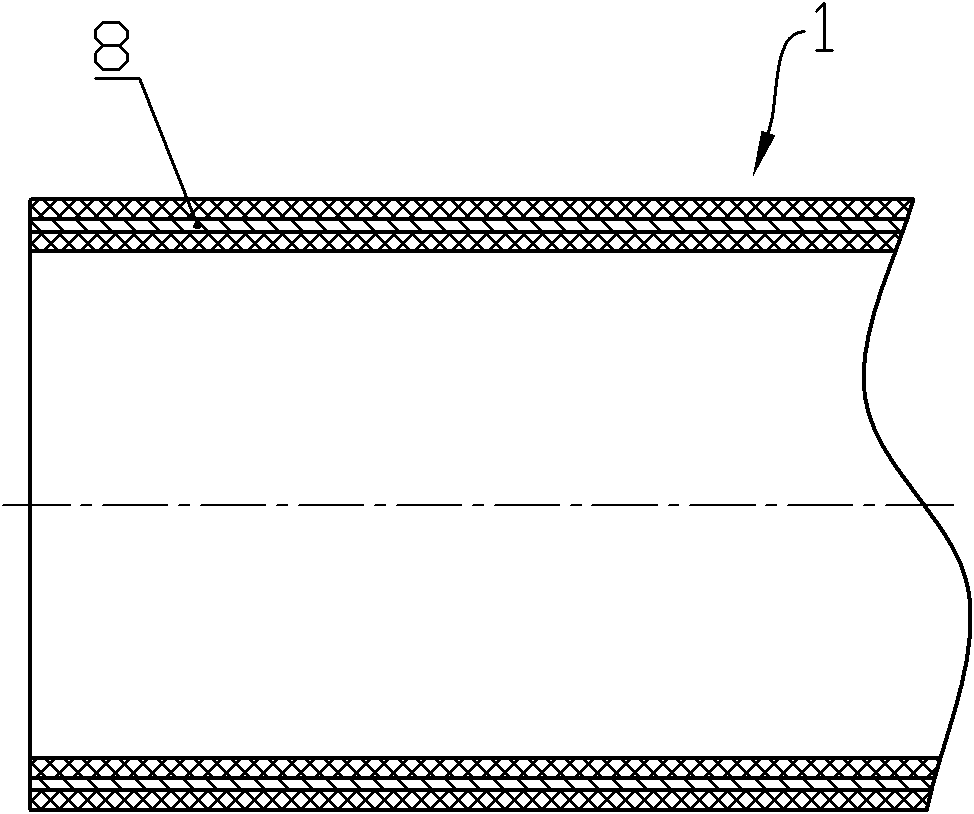

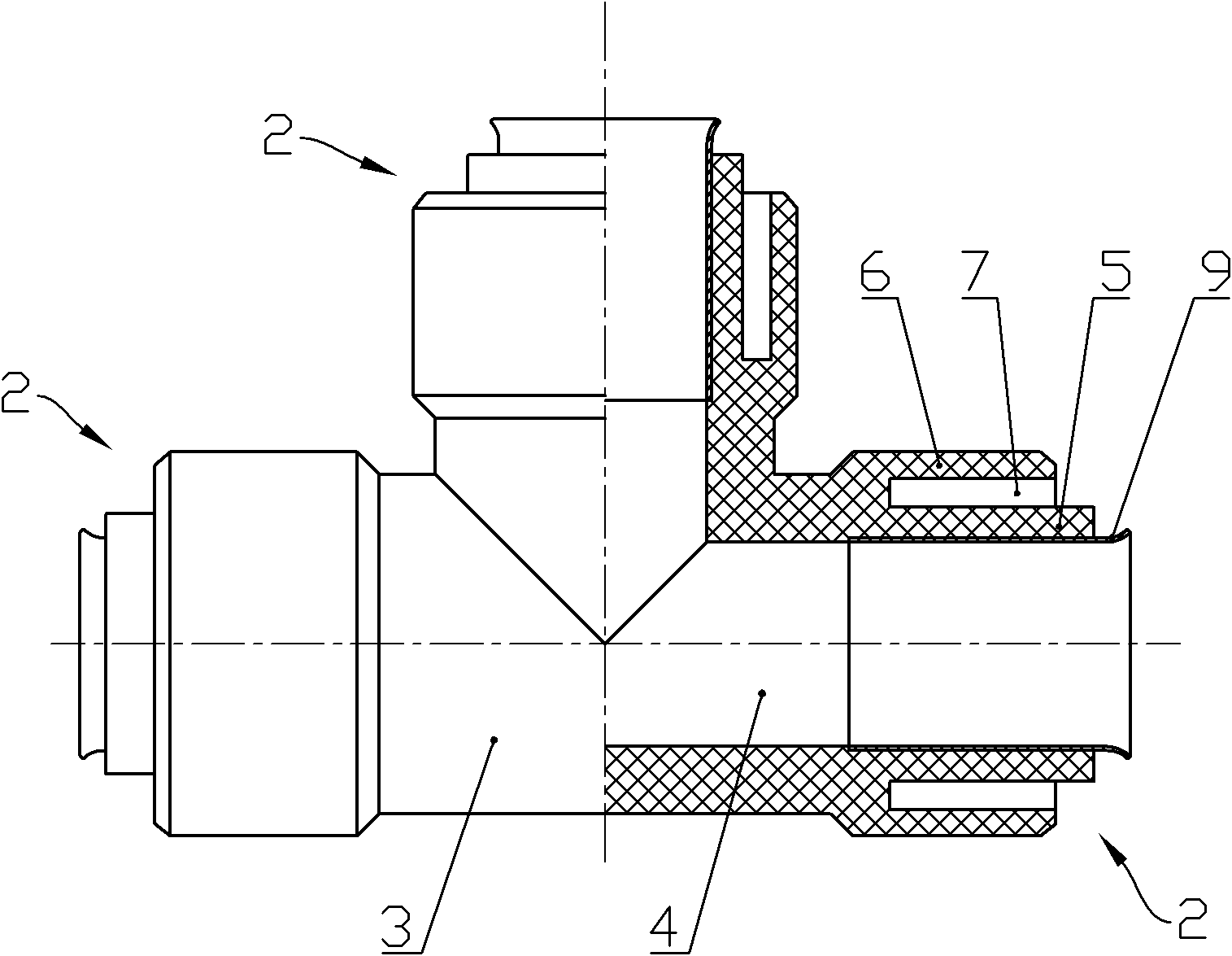

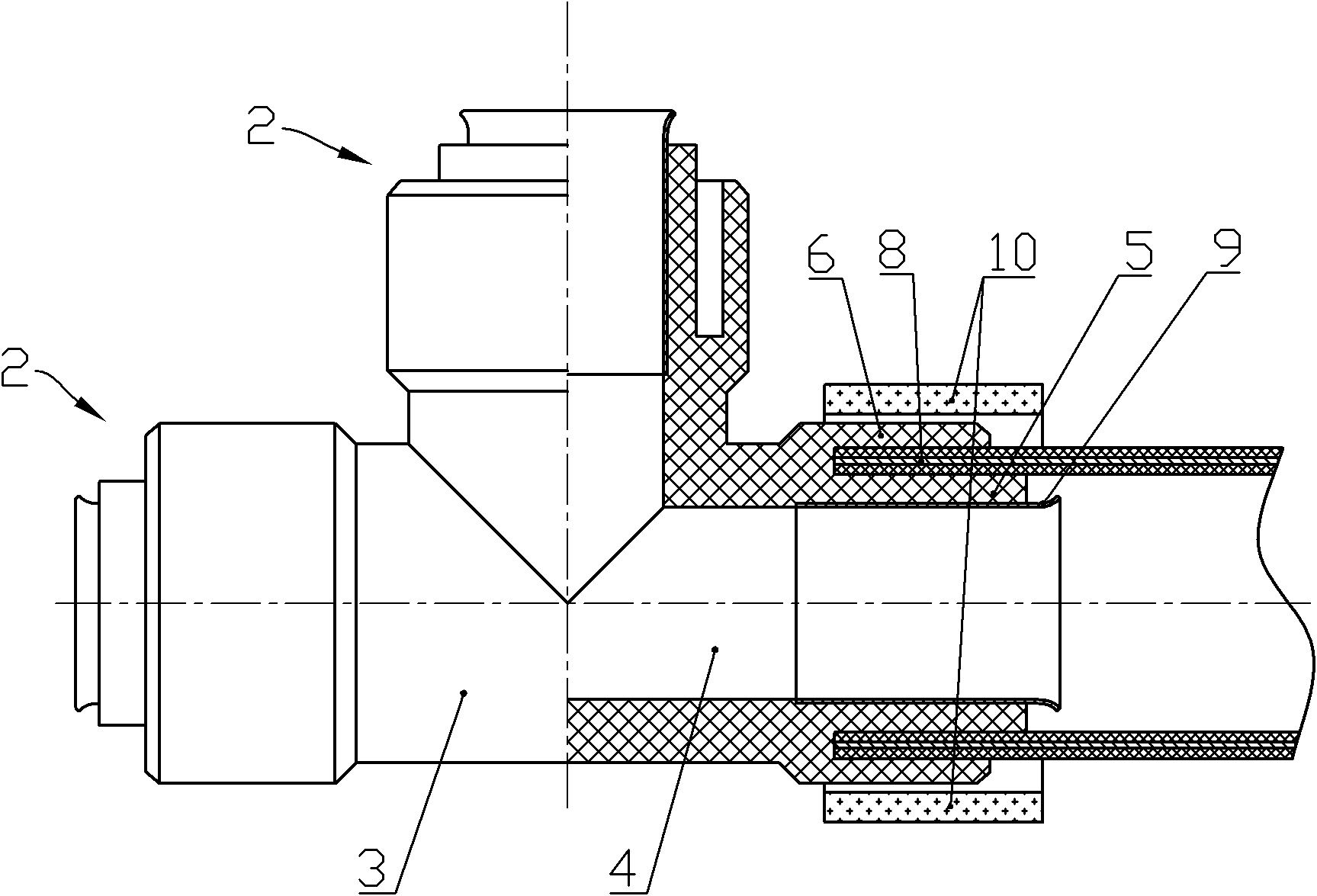

[0025] First of all, the steel-plastic composite pipe 1 and the pipe fitting 3 involved in the present invention are described: the steel-plastic composite pipe 1 involved in the present invention can be as follows figure 1 As shown, it is composed of an inner plastic layer, an intermediate steel pipe layer, and an outer plastic layer; it may also be composed of an inner plastic layer and an outer steel pipe layer or an outer plastic layer and an inner steel pipe layer. The pipe fitting 3 involved in the present invention can be as figure 2 As shown, it has at least two connecting ends 2 (the pipe fitting shown in the figure is a tee, so it has three connecting ends, but in practice, the pipe fitting can be in specific structural forms such as straight-through, elbow, cross, etc., and can also be yes Figure 6 As shown in the sealing sleeve 11), e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com