Elastic expansion pipe and production technology thereof

A technology of elastic stretching and elastic tubes, which is applied in the direction of hoses, pipes, tubular objects, etc., can solve the problems of shortening the service life of water pipes, easy entrainment of soil in pipes, and difficult folding of outer pipes, etc., and achieves good self-cleaning performance and is not easy to entrain , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

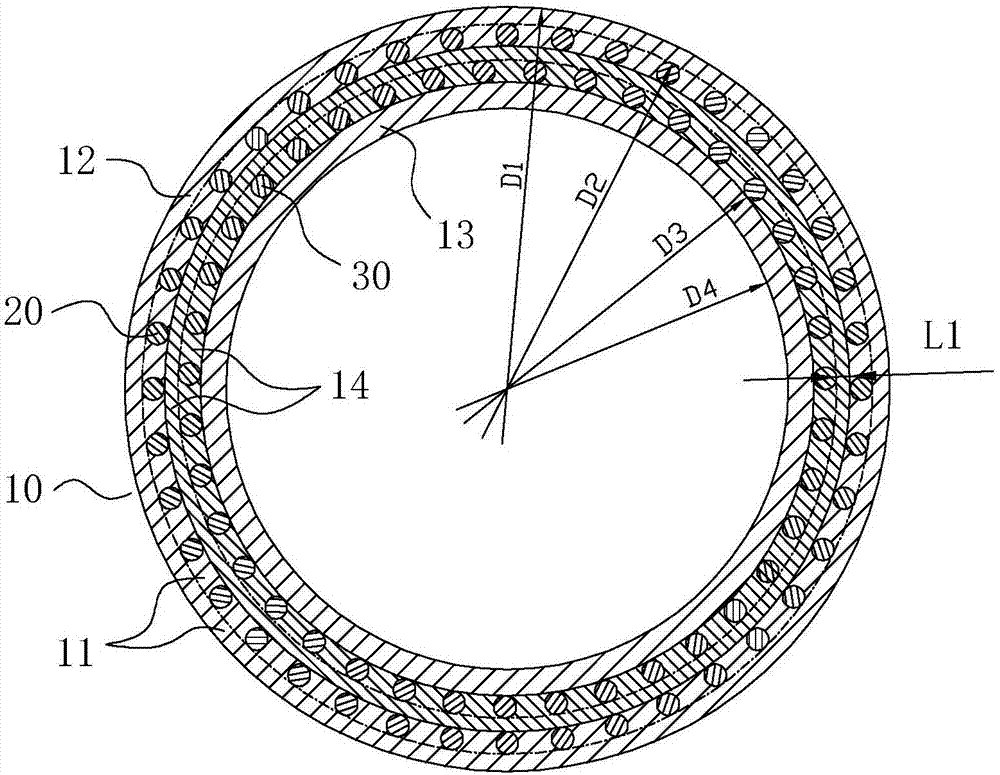

[0023] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 :

[0024] An elastic telescopic tube, comprising an elastic tube 10 made of an elastic body. The elastic tube 10 is provided with more than two layers of helical wire layers 20, 30 or braided mesh layers that can expand and contract with the expansion and contraction of the elastic tube 10. In the helical layer, the helical direction of the two adjacent helical layers 20, 30 is opposite, the outer diameter D2 of the outermost helical layer 20 or the braided net layer is smaller than the outer diameter D1 of the elastic tube 10, and the innermost helical layer The inner diameter D3 of the line layer 13 or the braided mesh layer is less than the inner diameter D4 of the elastic tube 10; when the elastic tube 10 is filled with pressurized water to promote the radial deformation of the elastic tube 10, due to the gap between the adjacent tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com