Patents

Literature

1116results about "Needle bars" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

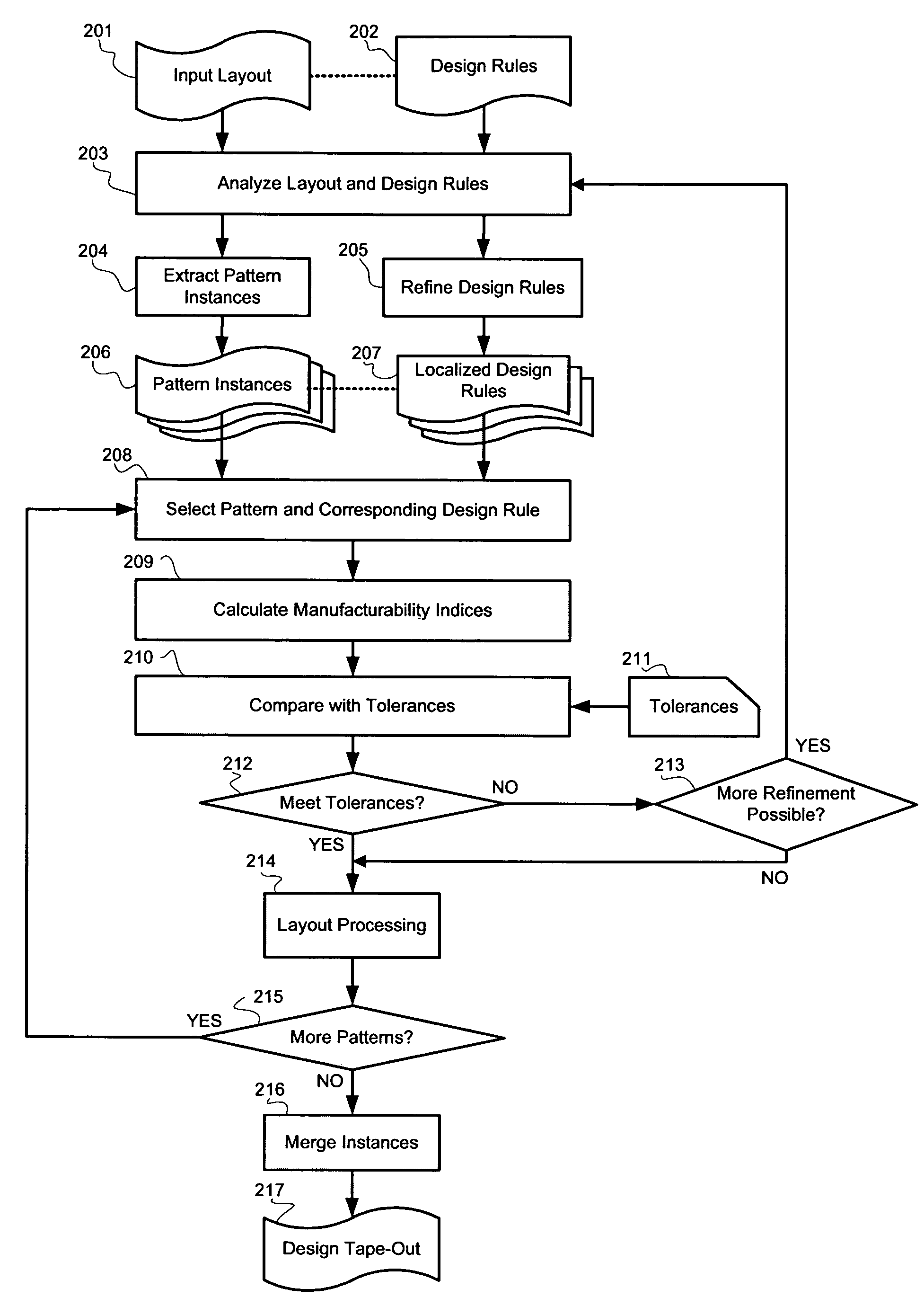

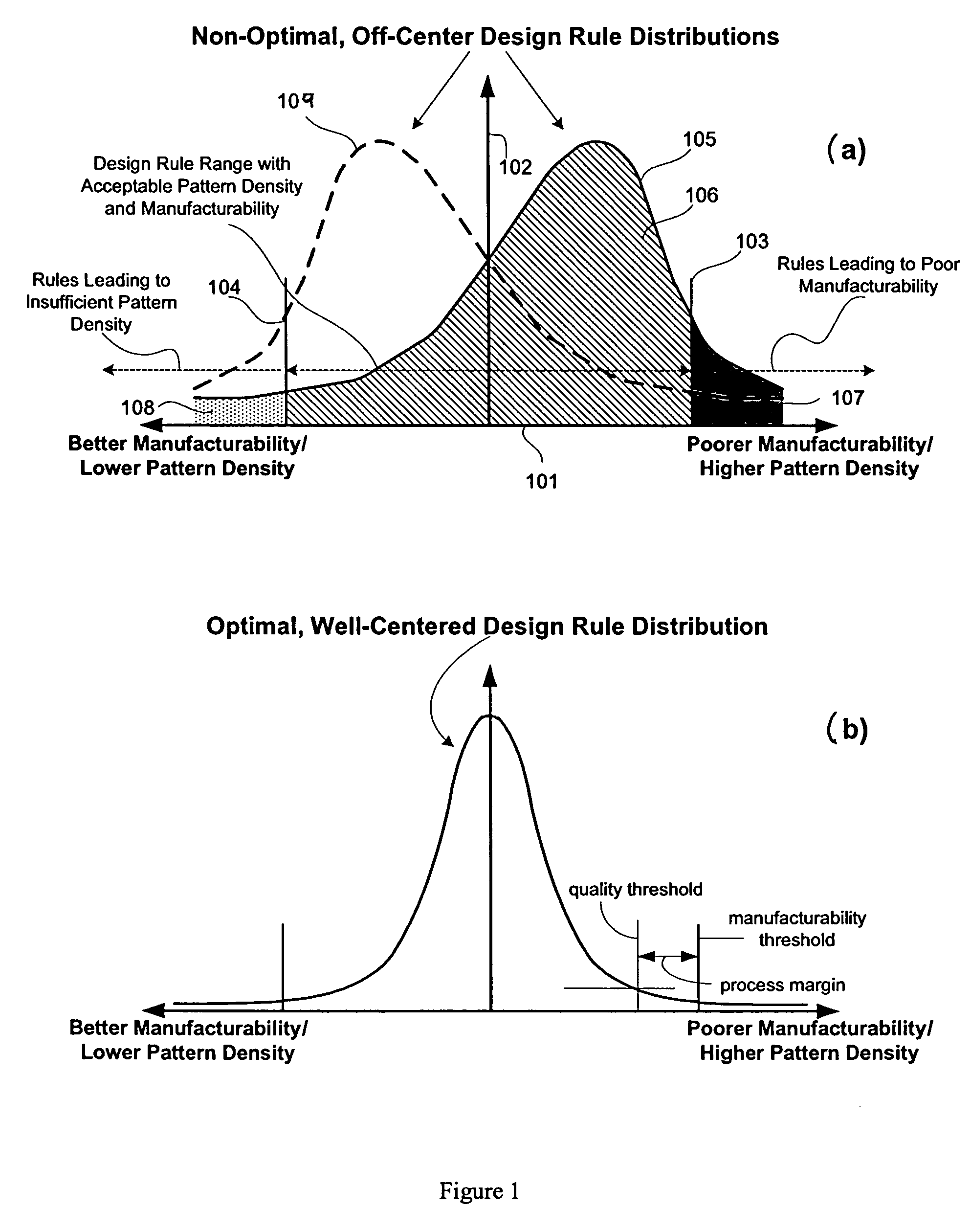

System for designing integrated circuits with enhanced manufacturability

ActiveUS7523429B2Improve manufacturabilityLittle interferencePressersMattress sewingGranularityEngineering

A system and method for integrated circuit design are disclosed to enhance manufacturability of circuit layouts through generation of hierarchical design rules which capture localized layout requirements. In contrast to conventional techniques which apply global design rules, the disclosed IC design system and method partition the original design layout into a desired level of granularity based on specified layout and integrated circuit properties. At that localized level, the design rules are adjusted appropriately to capture the critical aspects from a manufacturability standpoint. These adjusted design rules are then used to perform localized layout manipulation and mask data conversion.

Owner:APPLIED MATERIALS INC

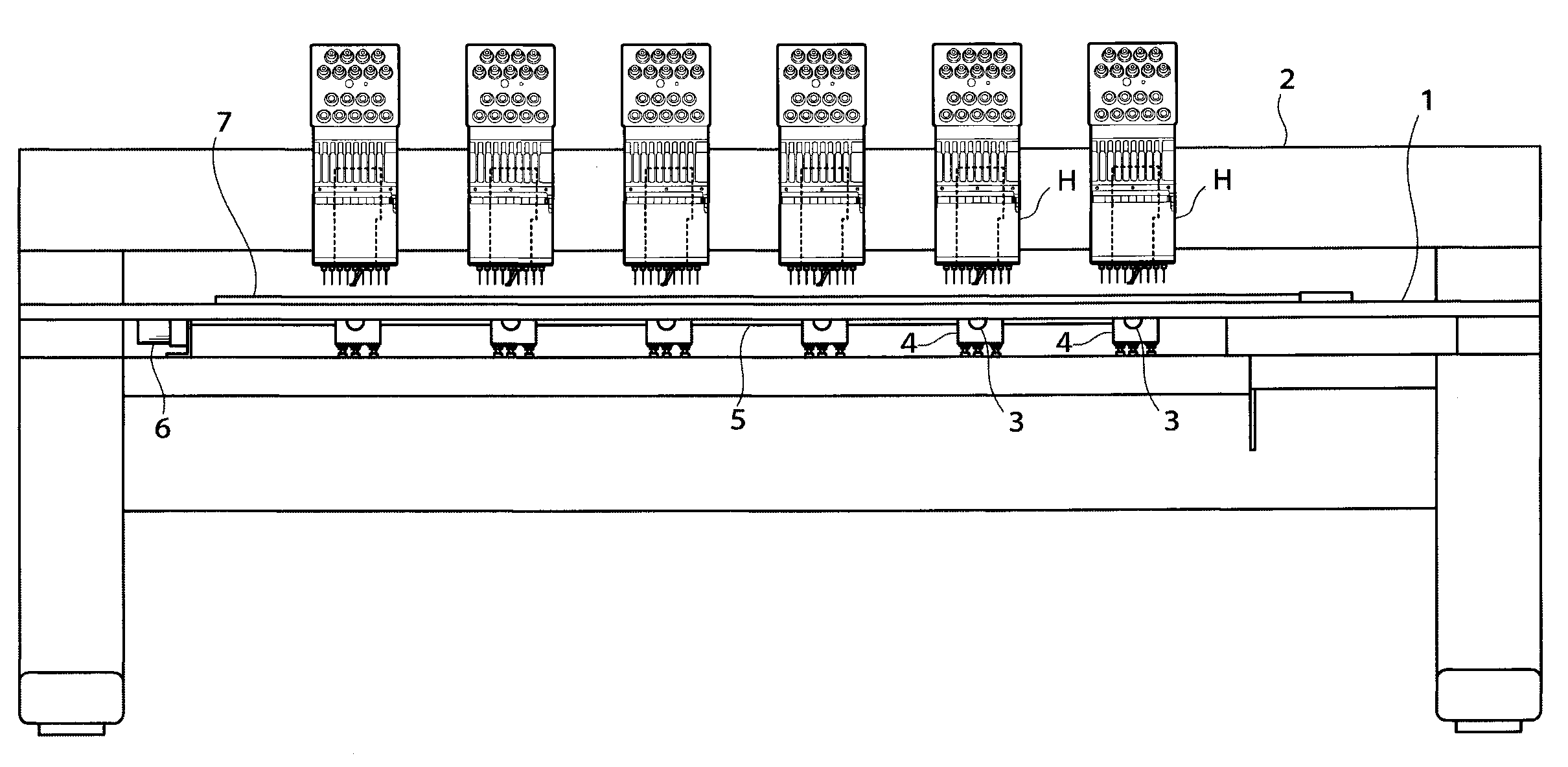

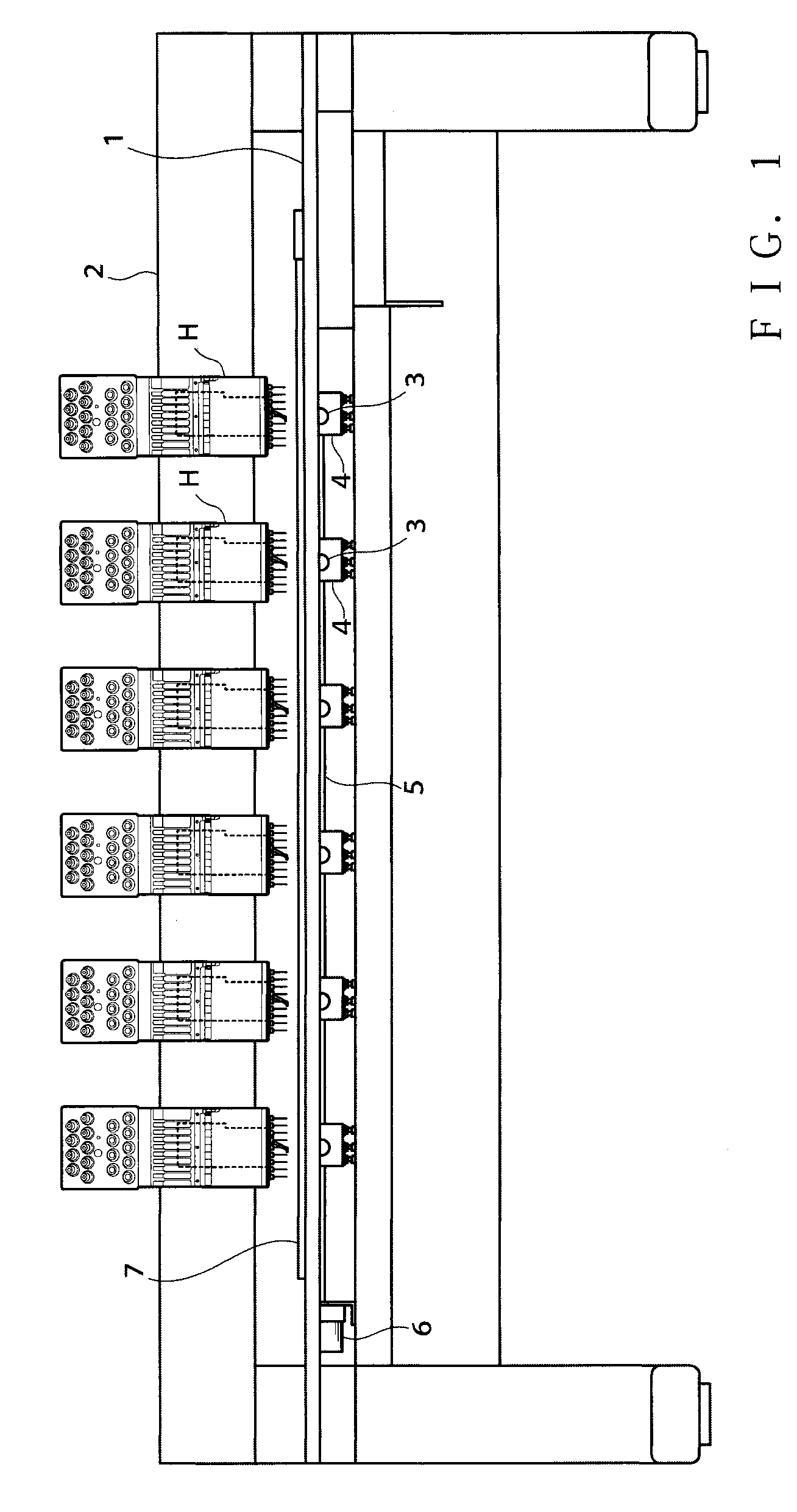

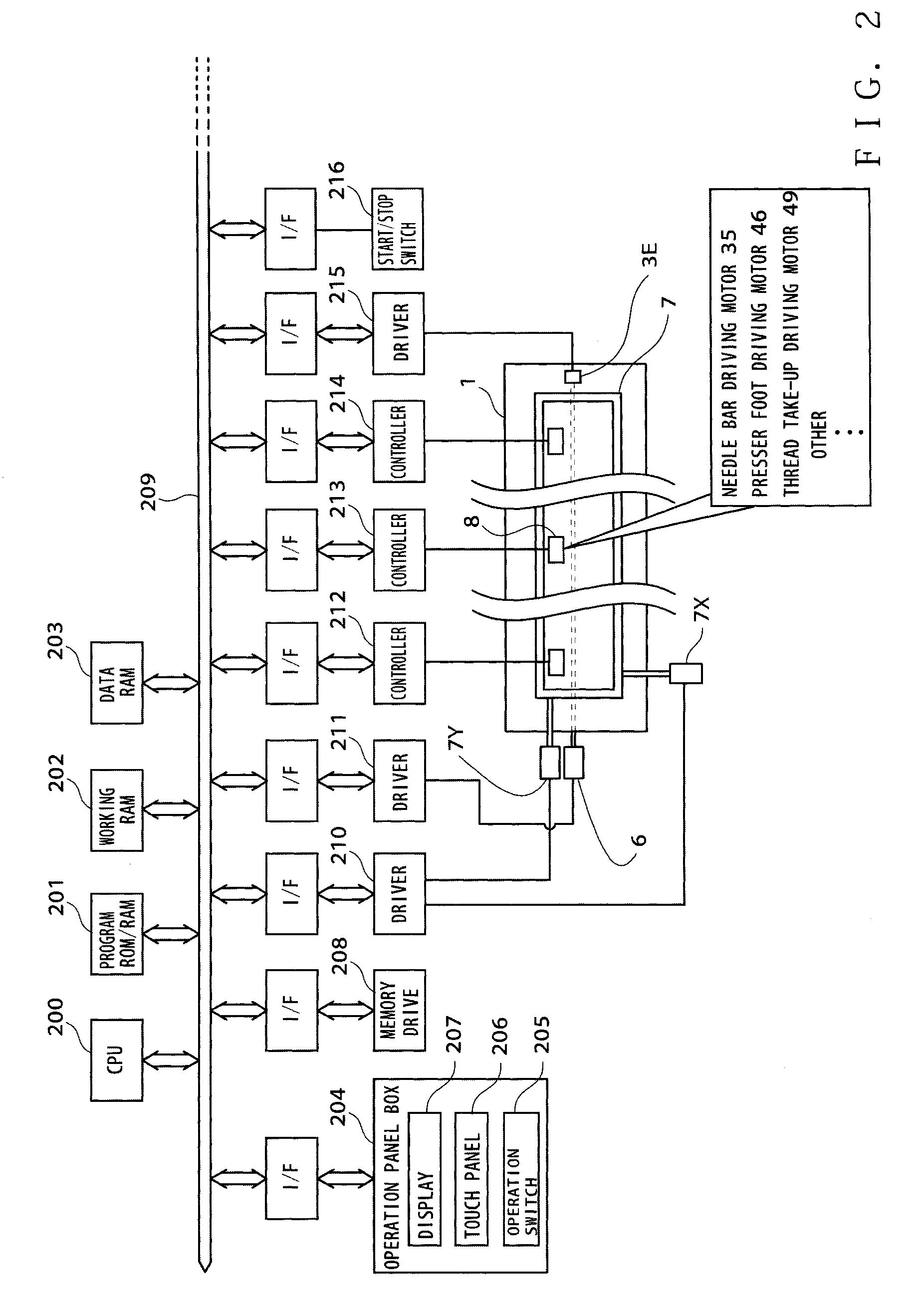

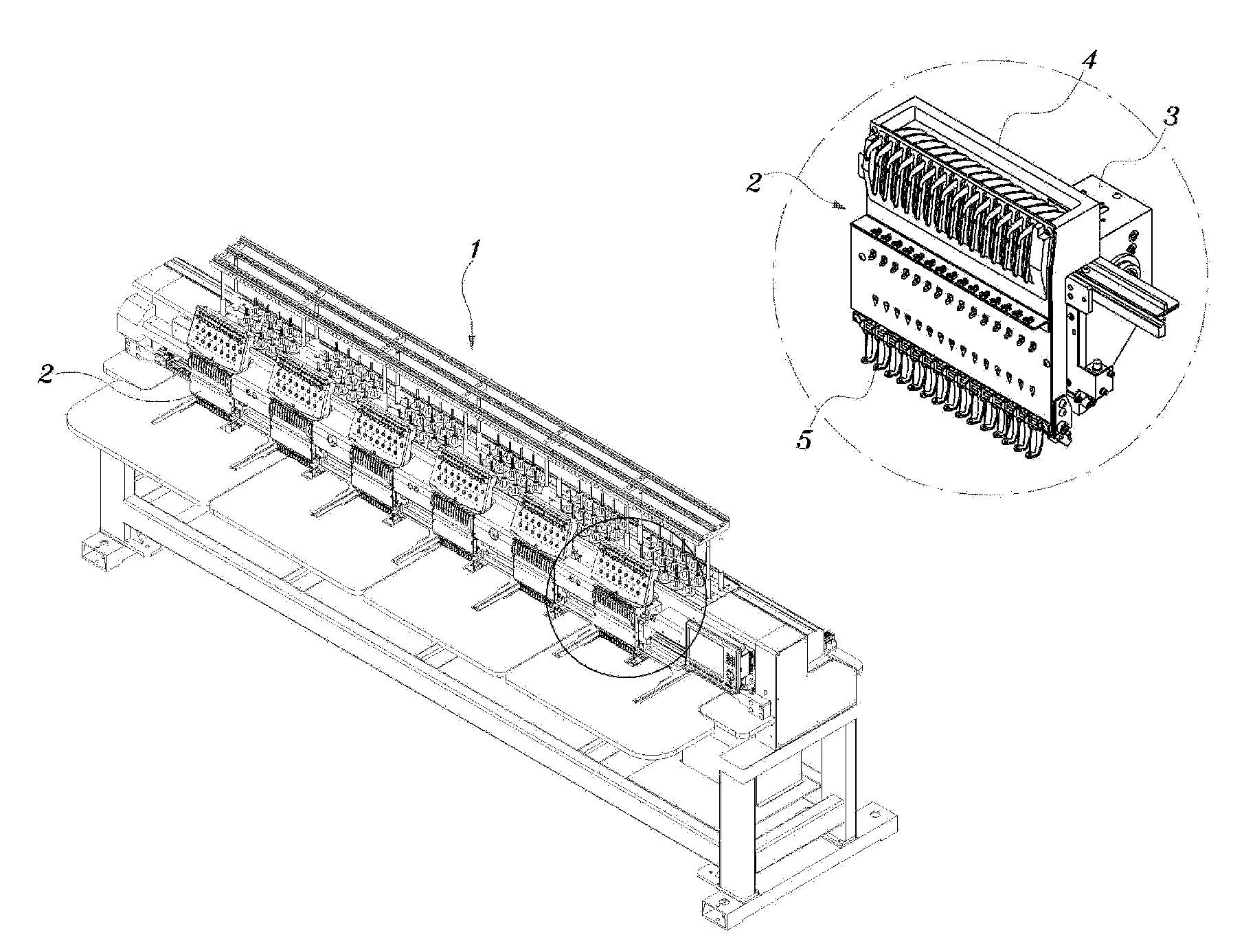

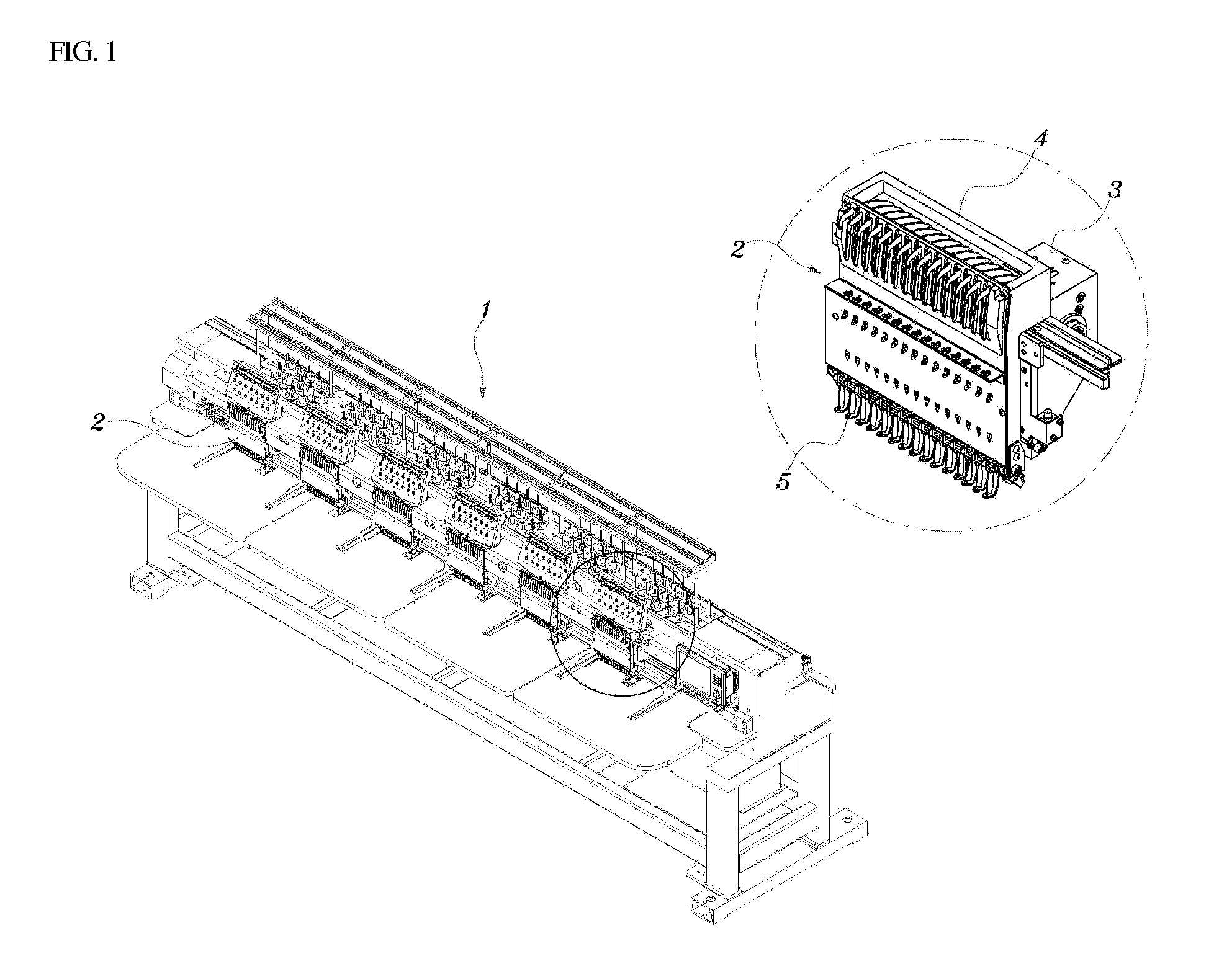

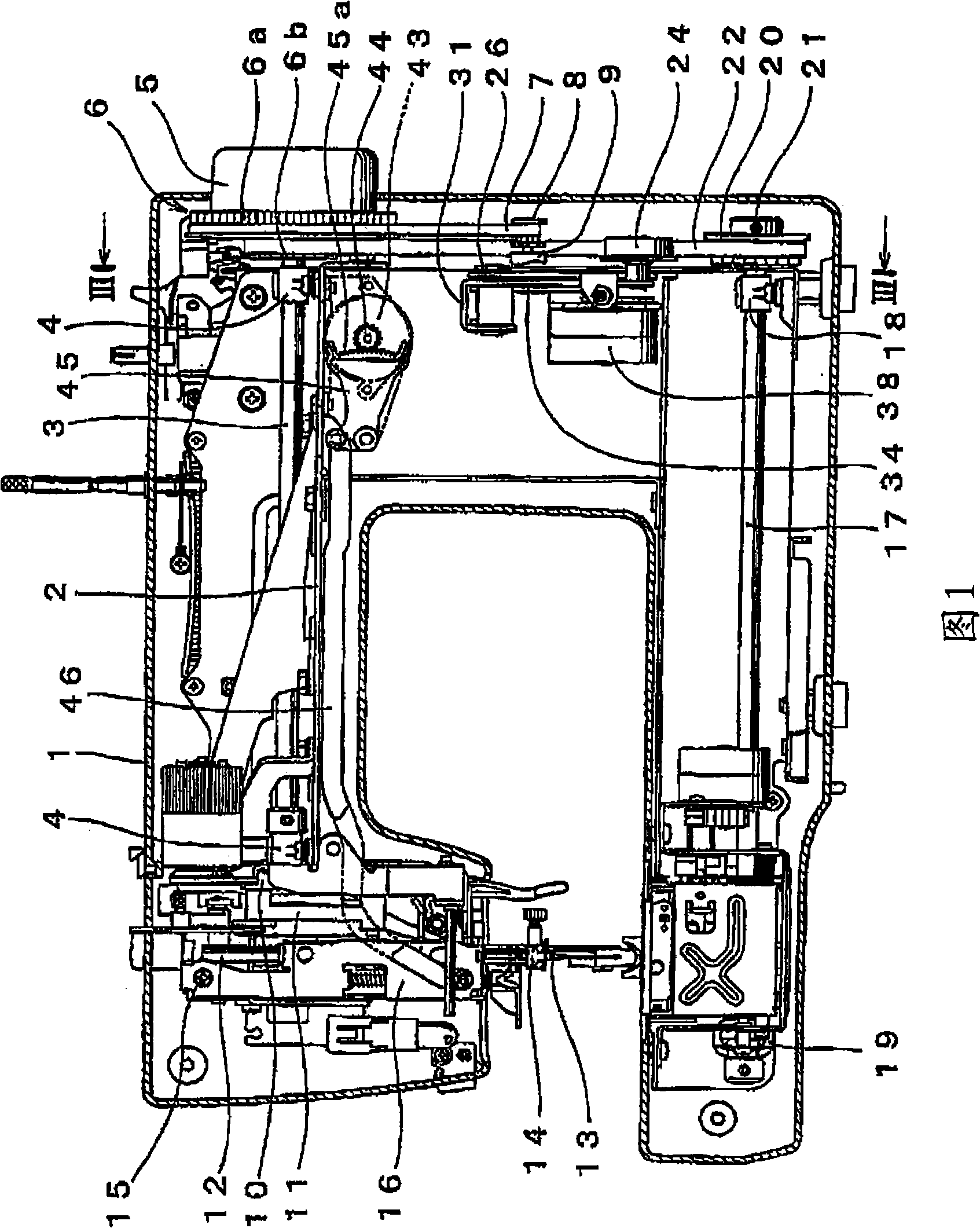

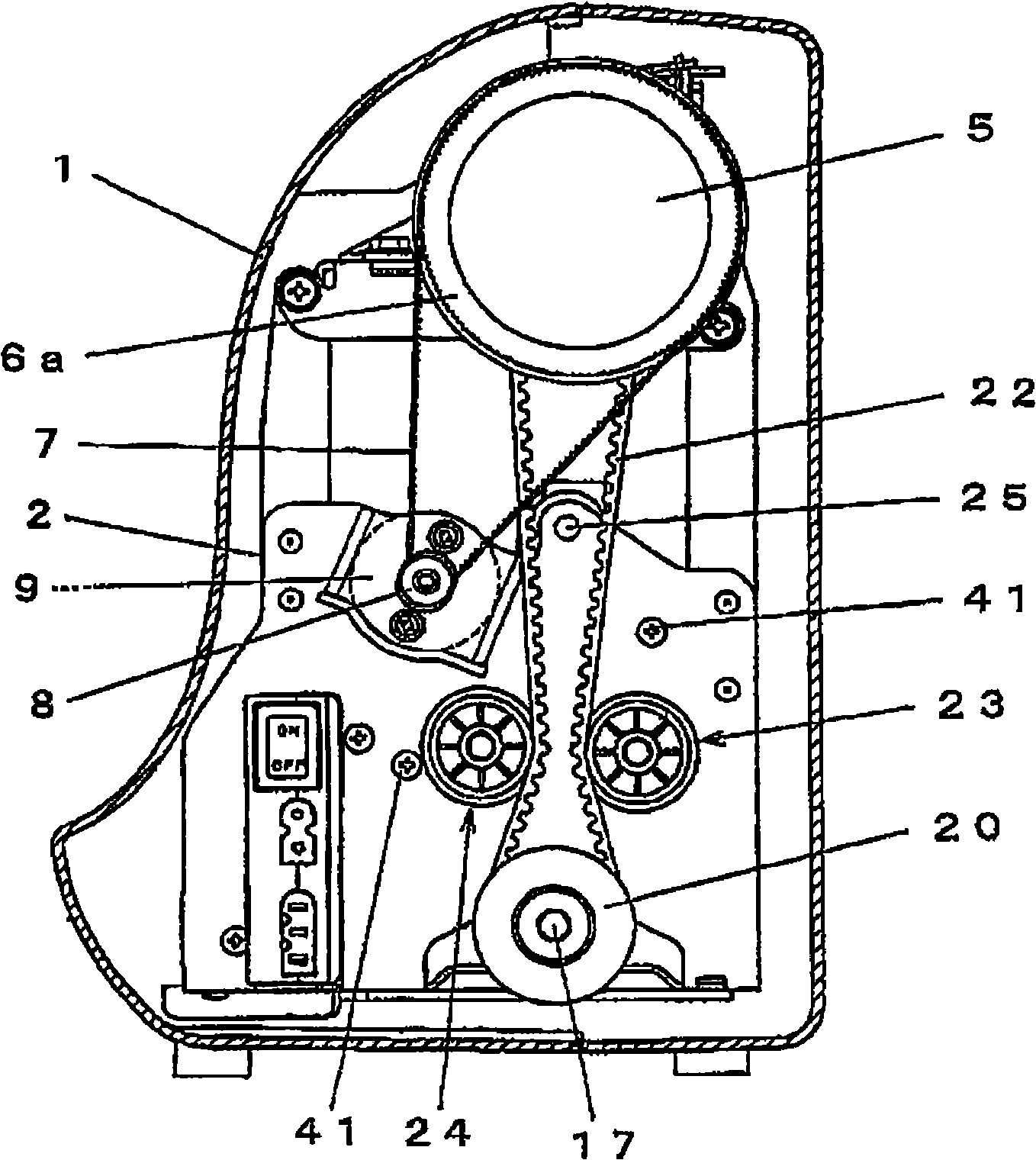

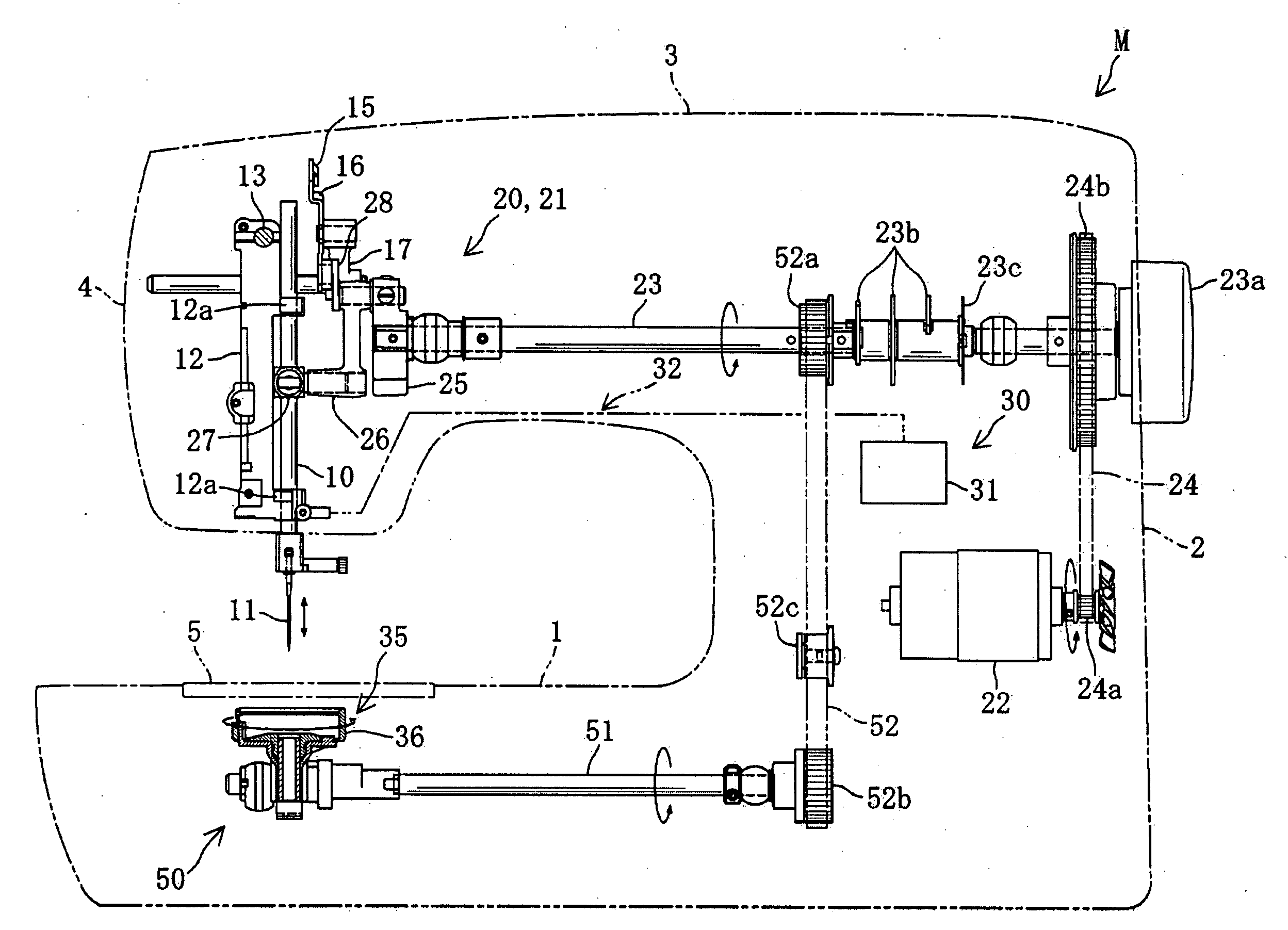

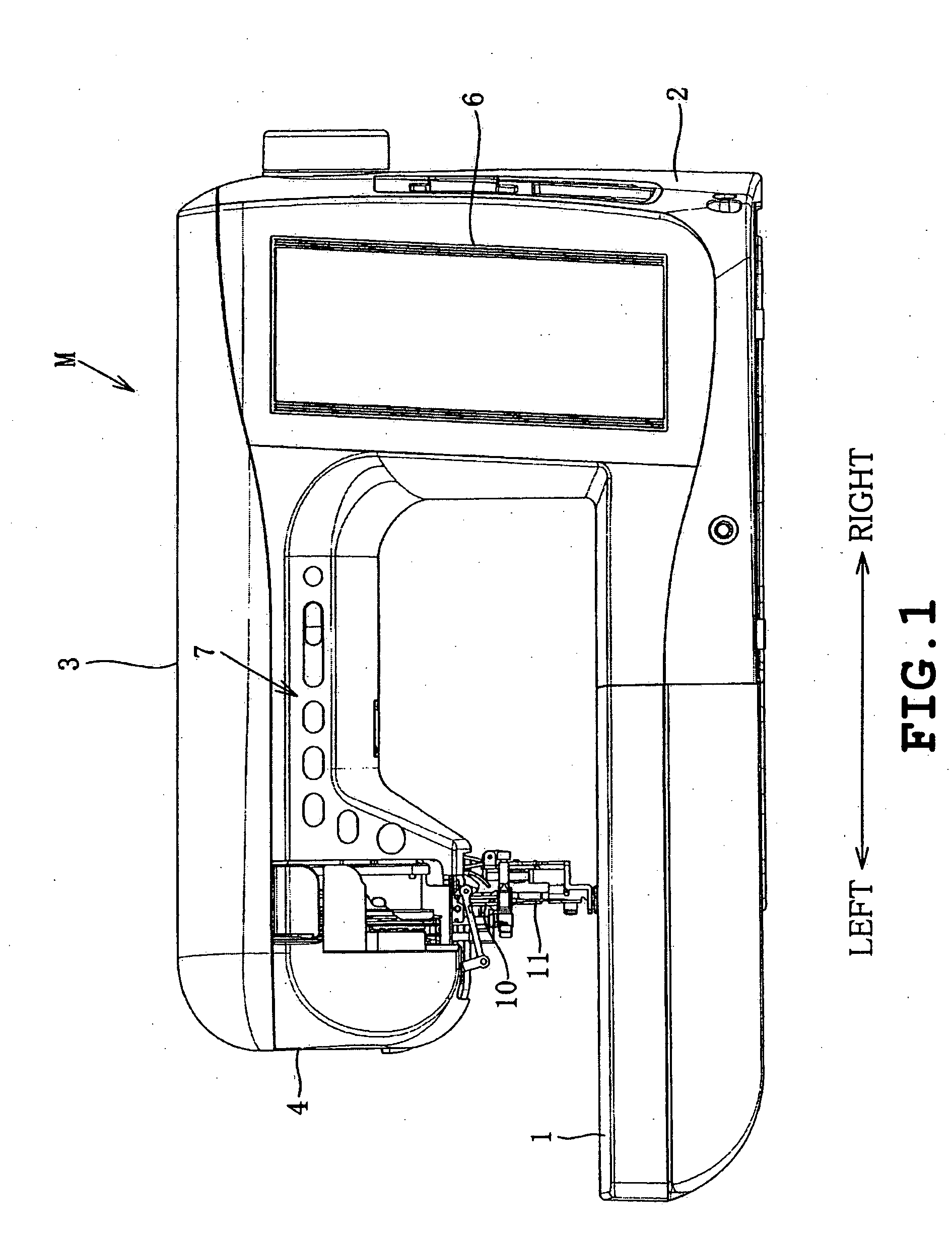

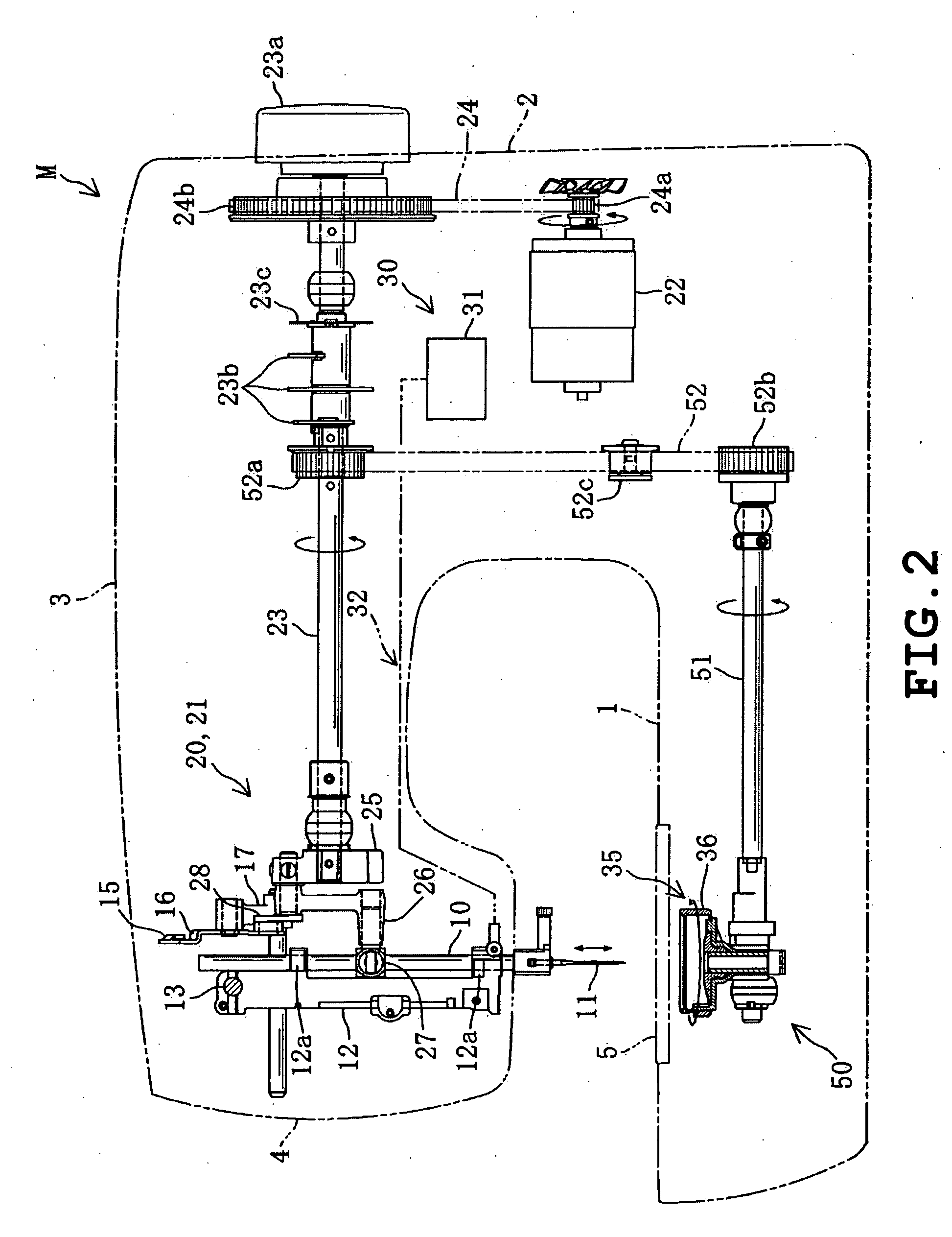

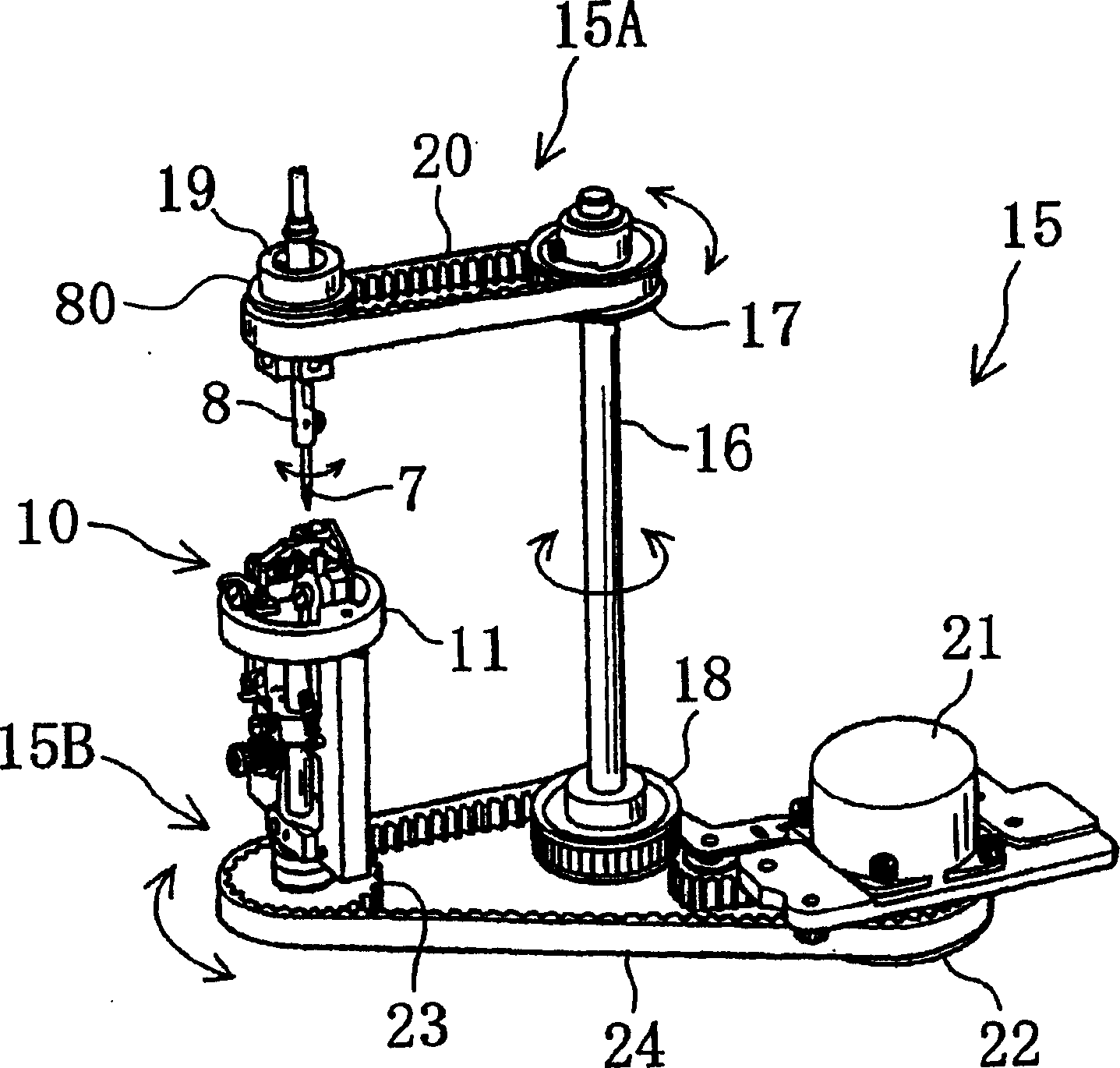

Multi-head embroidery sewing machine

InactiveUS20070261621A1Avoid unevennessEasy to switchPressersSewing-machine control devicesMechanical componentsEngineering

Individual motors in a sewing machine of the invention are provided, for each of a plurality of machine heads, for individually driving respective mechanical components, such as a needle bar driving mechanism, thread take-up lever and presser foot mechanism. A plurality of rotary hooks are driven by a common motor. Even in a case where embroidering workpieces set on the individual machine heads differ in material between the heads and upper threads used for the machine heads differ in characteristic between the heads, the sewing machine can make, in a concurrent, parallel fashion, embroidery products of different texture suited for the respective materials, characteristics, etc., by setting independent stitch formation per machine head.

Owner:TOKAI IND SEWING MACH CO LTD

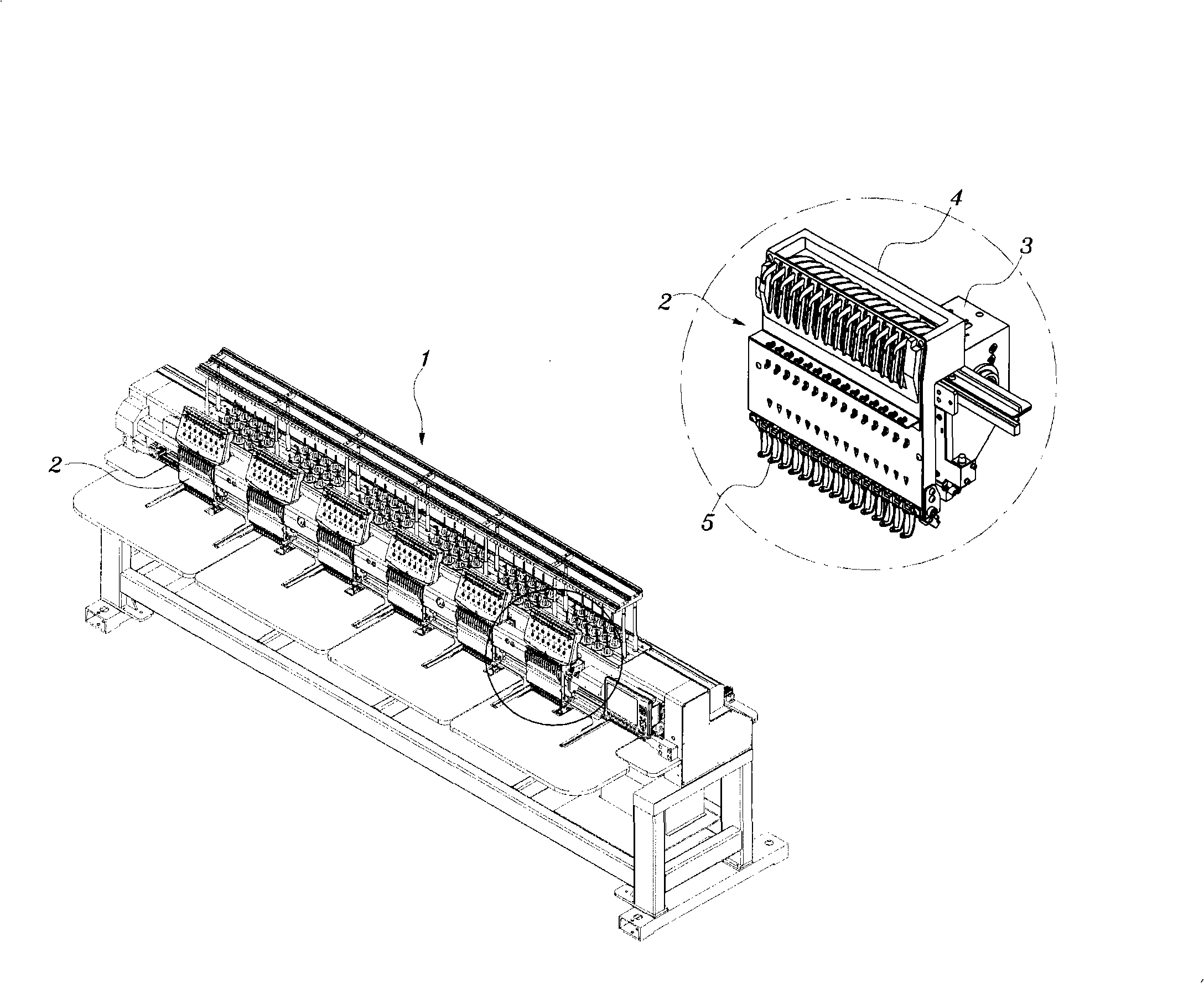

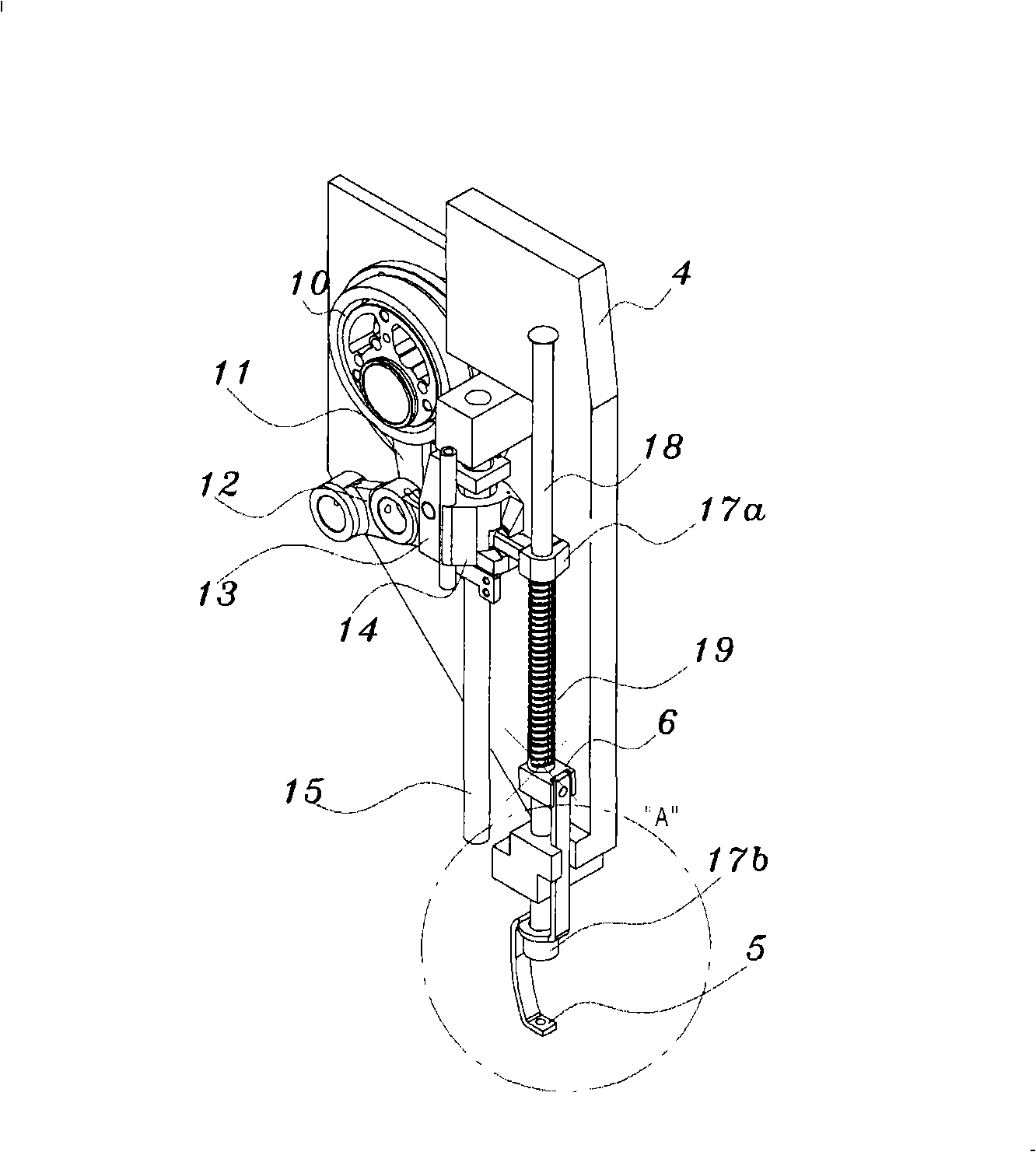

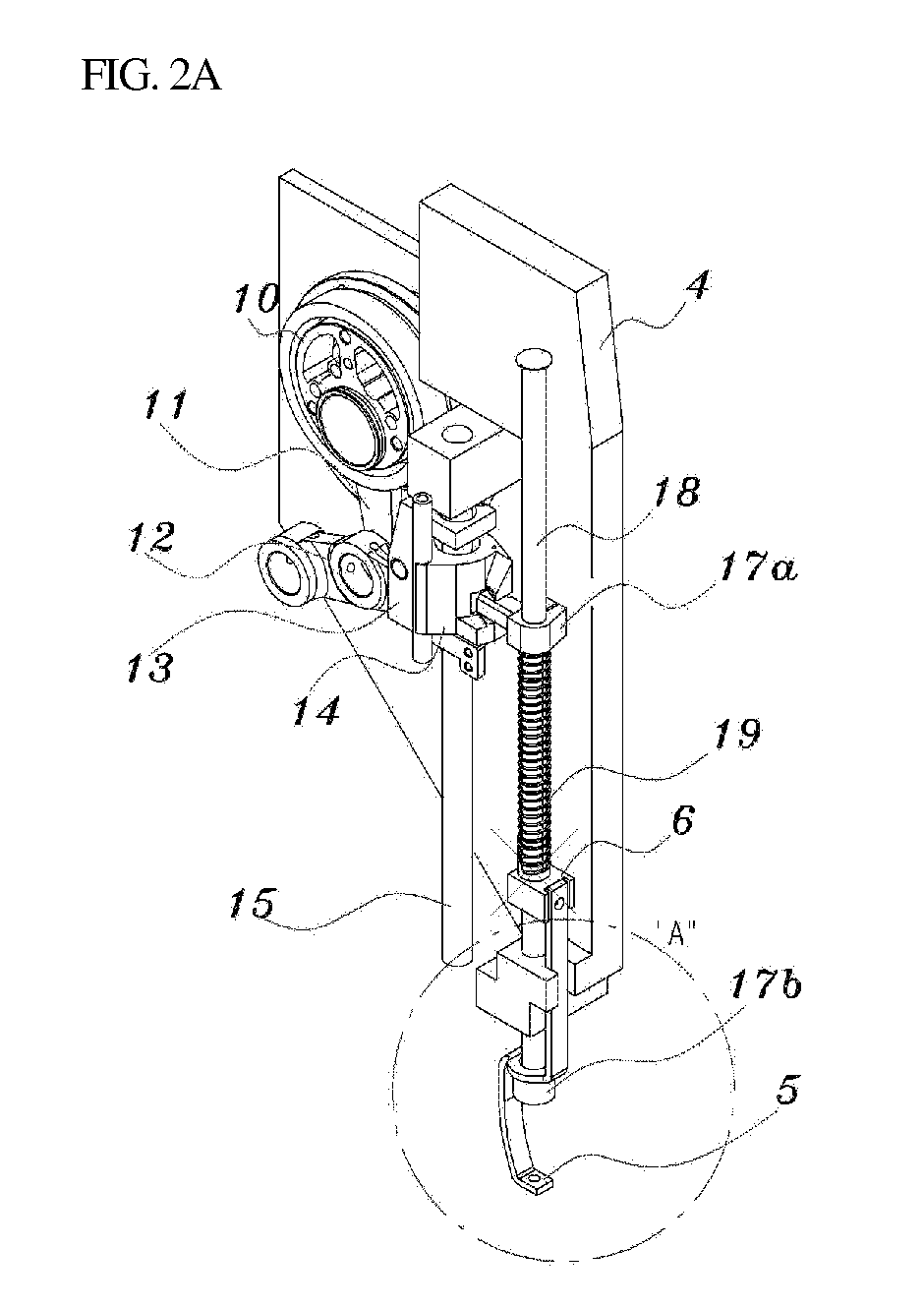

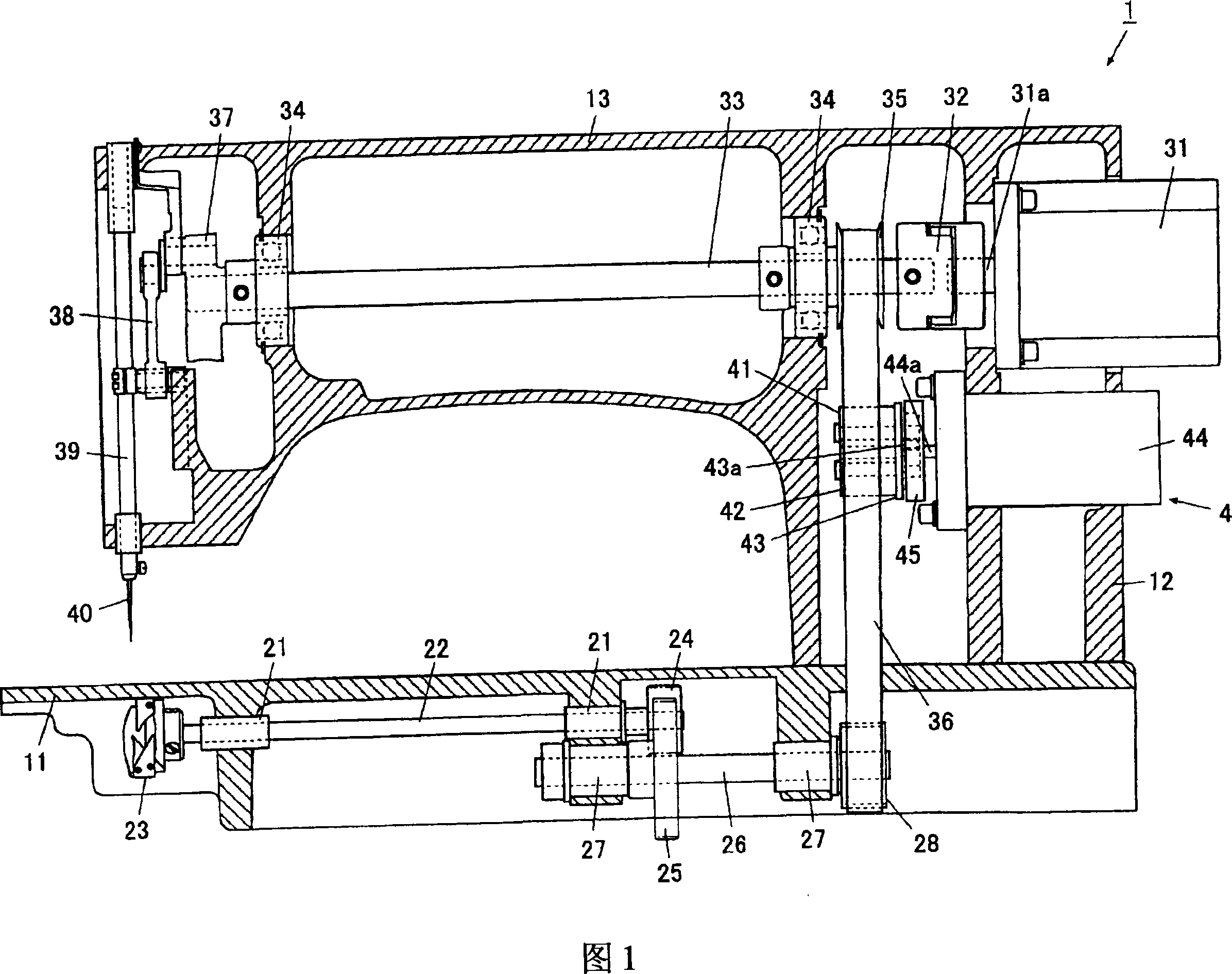

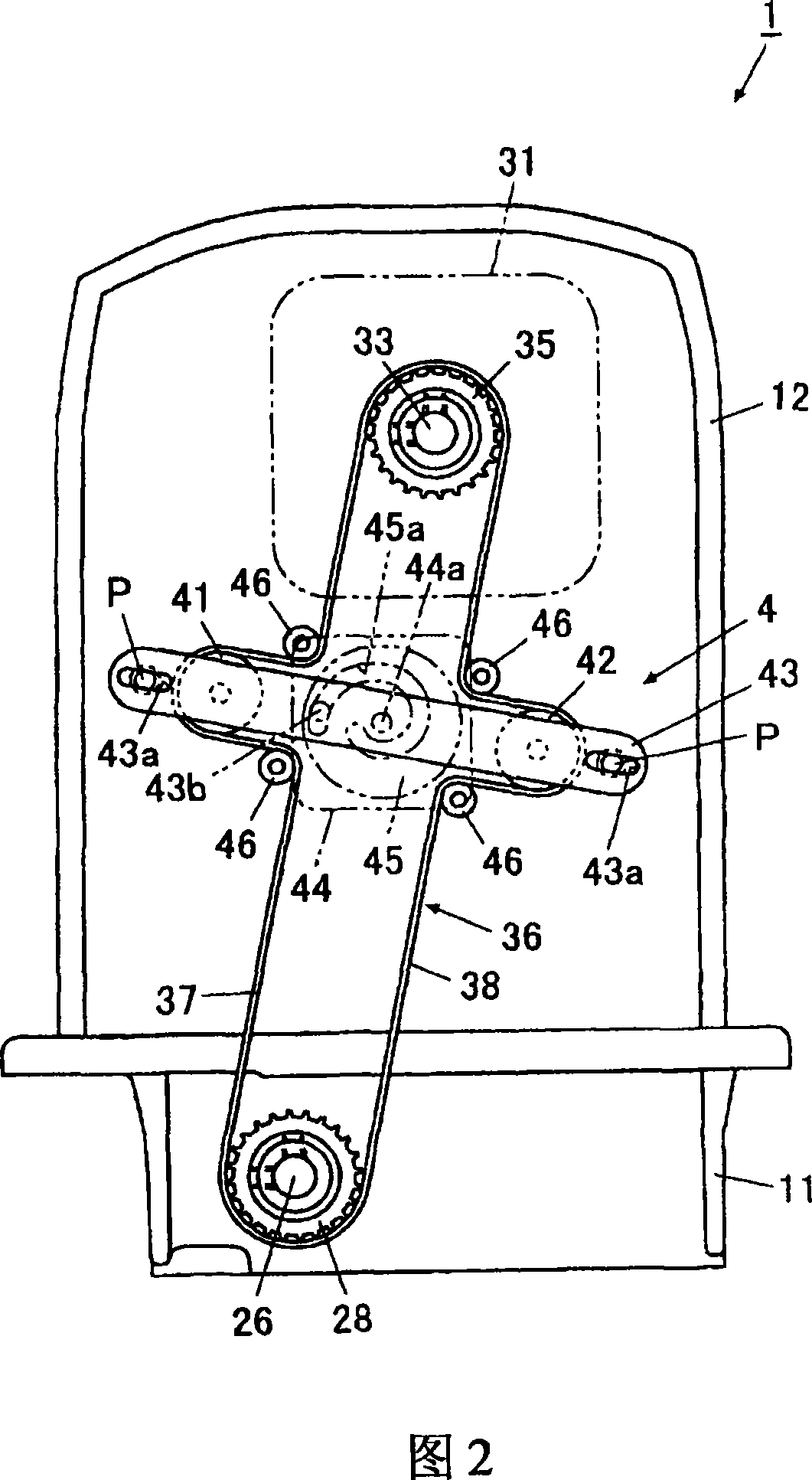

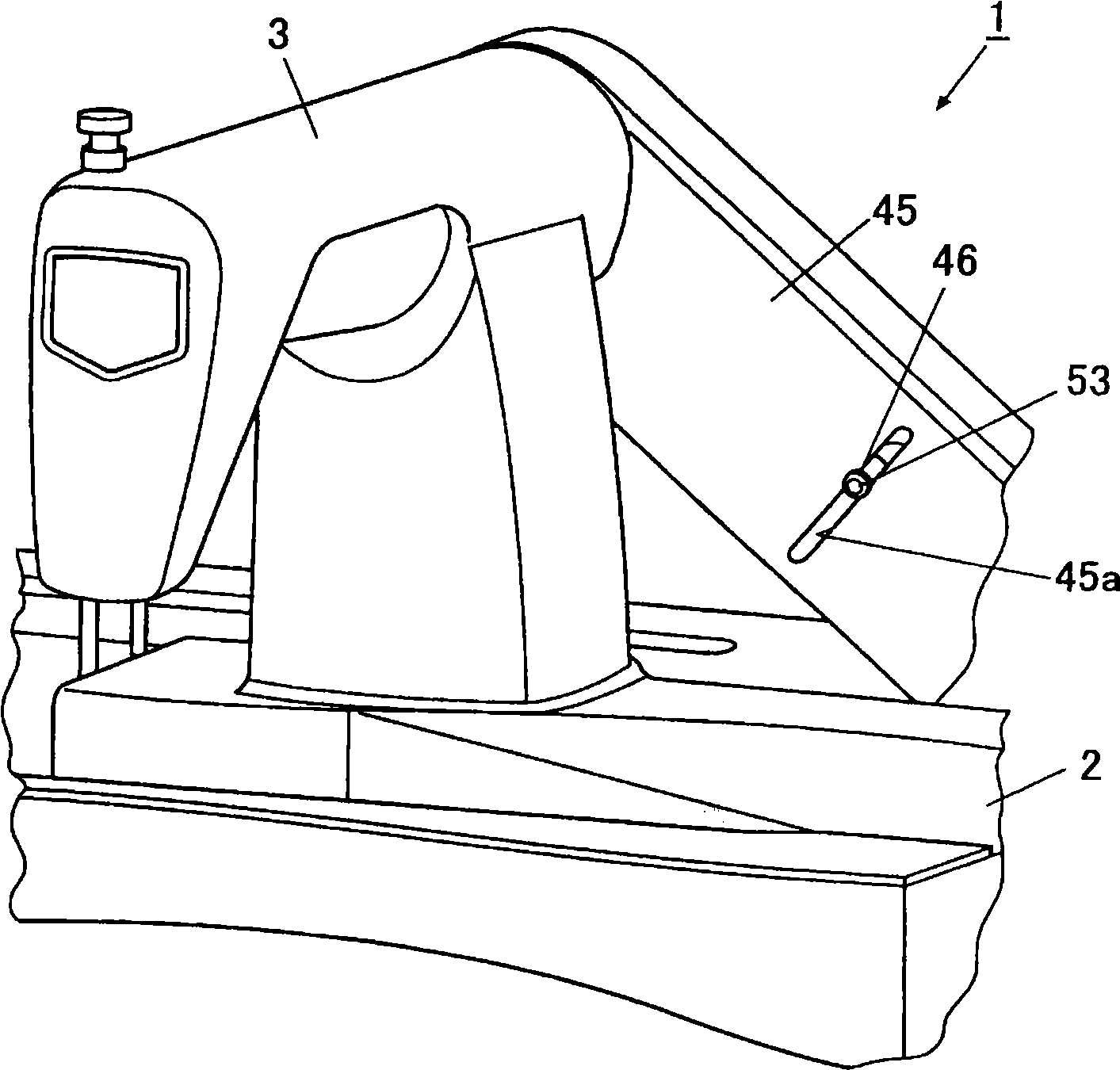

Embroidery machine

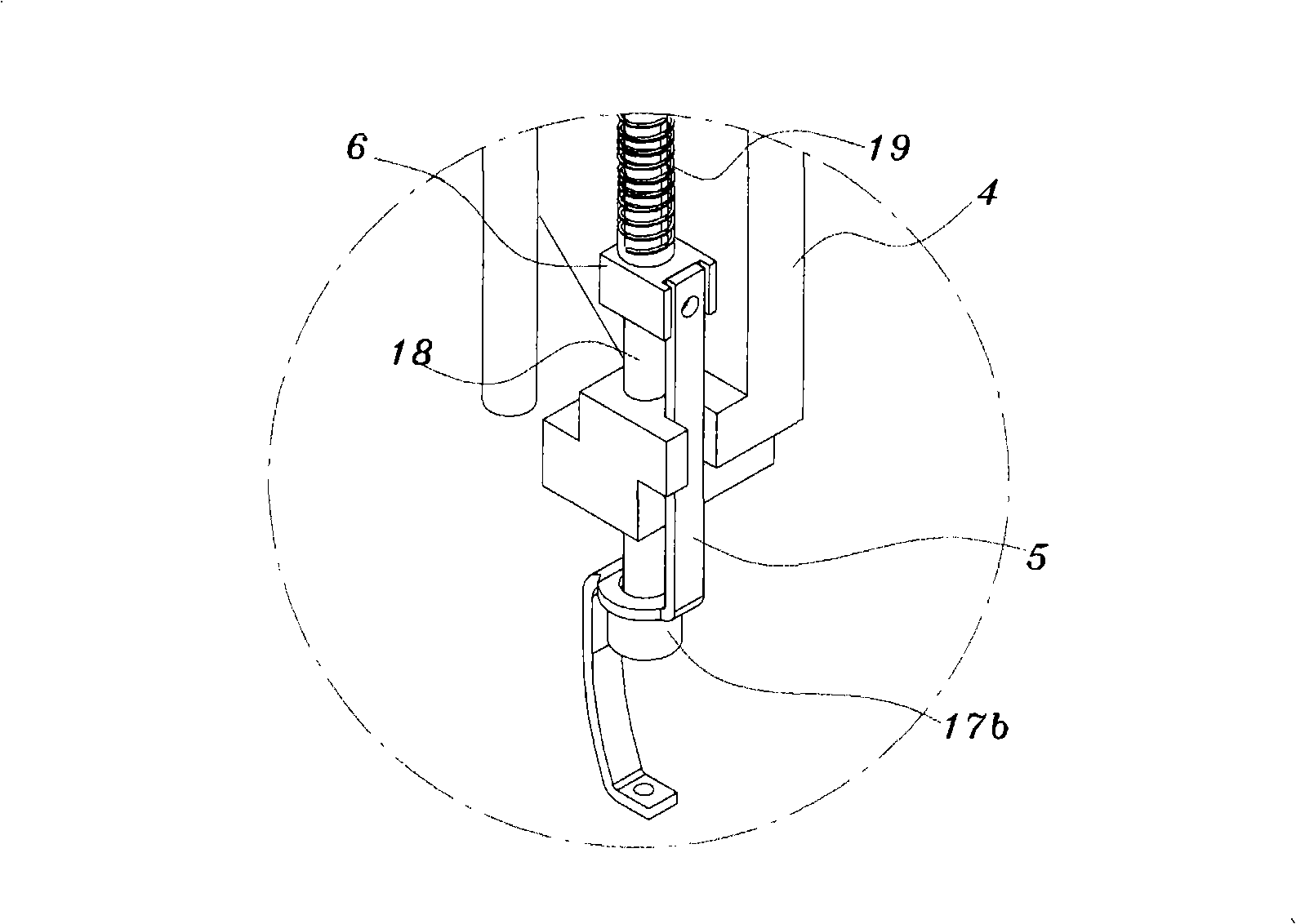

InactiveCN101260601AChange itineraryProgramme-controlled sewing machinesPressersEngineeringPRESSURE FEET

An embroidery machine includes a sewing arm having an upper shaft for providing a driving force, a needle bar support case, which is assembled to a front portion of the sewing arm so as to be laterally movable, a needle bar provided in a needle bar support case, the needle bar having a needle at a lower end thereof and vertically carrying the needle using a rotation driving force of the upper shaft, and a presser foot, which is provided in the needle bar support case so as to be vertically movable, characterized in that each of the needle bar and the presser foot is operated by an individual drive mechanism. The presser foot is separately driven by its own drive source, independent of the drive source of the needle bar.

Owner:SUSR PRECISION CO LTD

Embroidery Machine

An embroidery machine includes a sewing arm having an upper shaft for providing a driving force, a needle bar support case, which is assembled to a front portion of the sewing arm so as to be laterally movable, a needle bar provided in a needle bar support case, the needle bar having a needle at a lower end thereof and vertically carrying the needle using a rotation driving force of the upper shaft, and a presser foot, which is provided in the needle bar support case so as to be vertically movable, characterized in that each of the needle bar and the presser foot is operated by an individual drive mechanism. The presser foot is separately driven by its own drive source, independent of the drive source of the needle bar.

Owner:SUSR PRECISION CO LTD

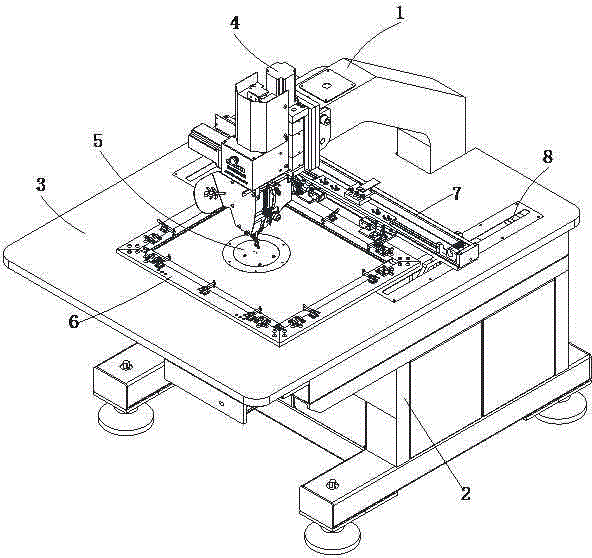

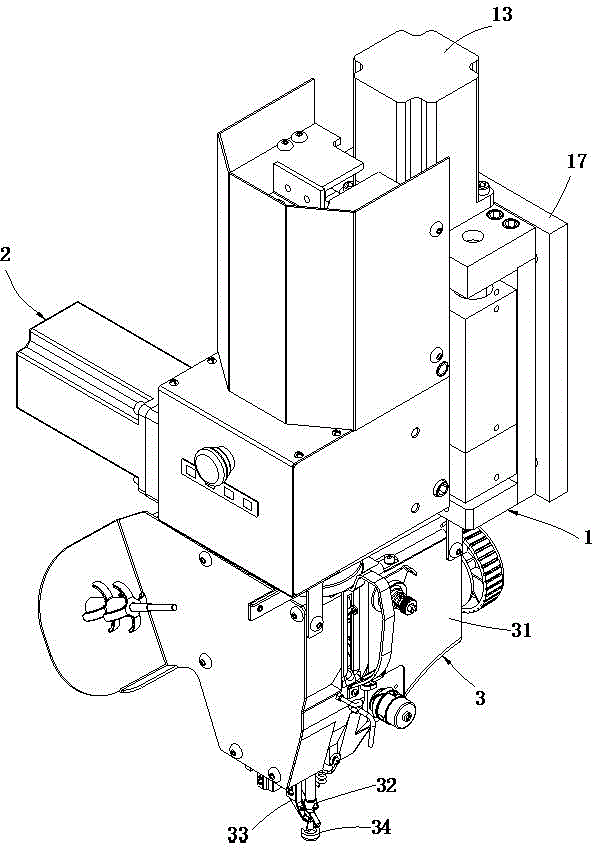

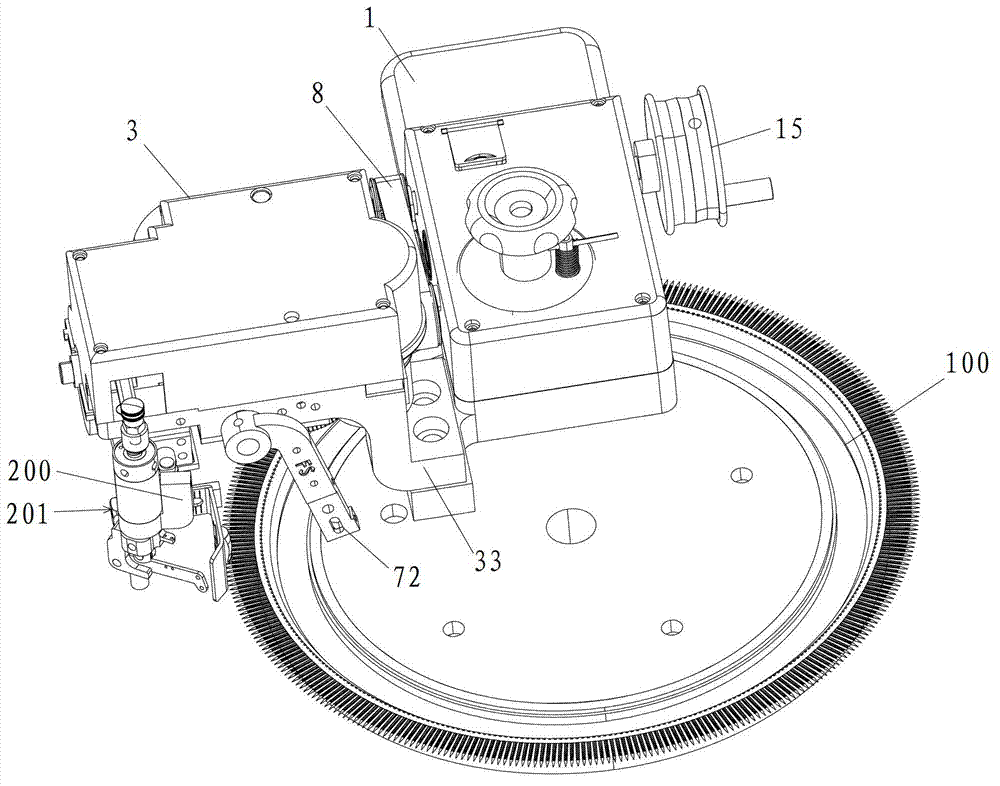

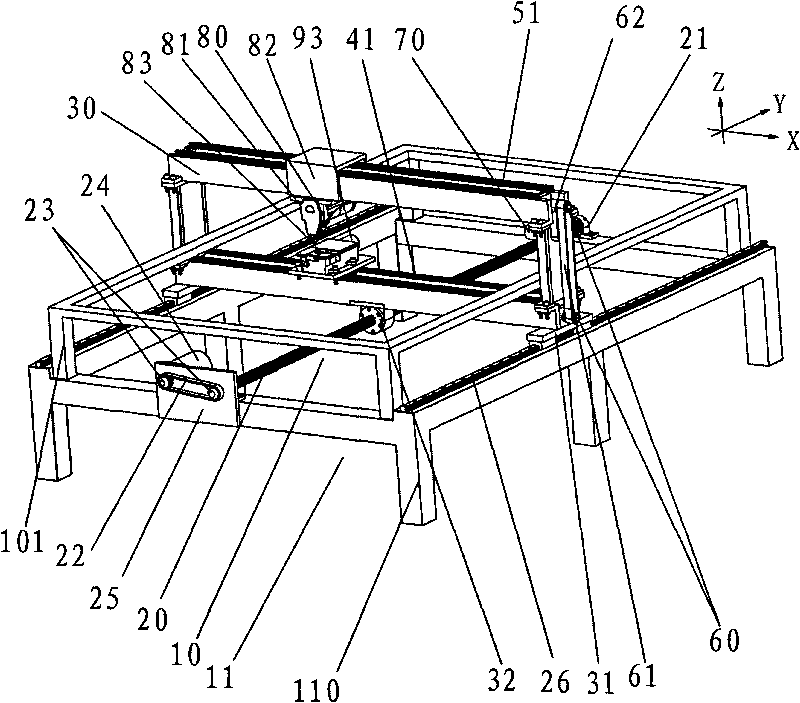

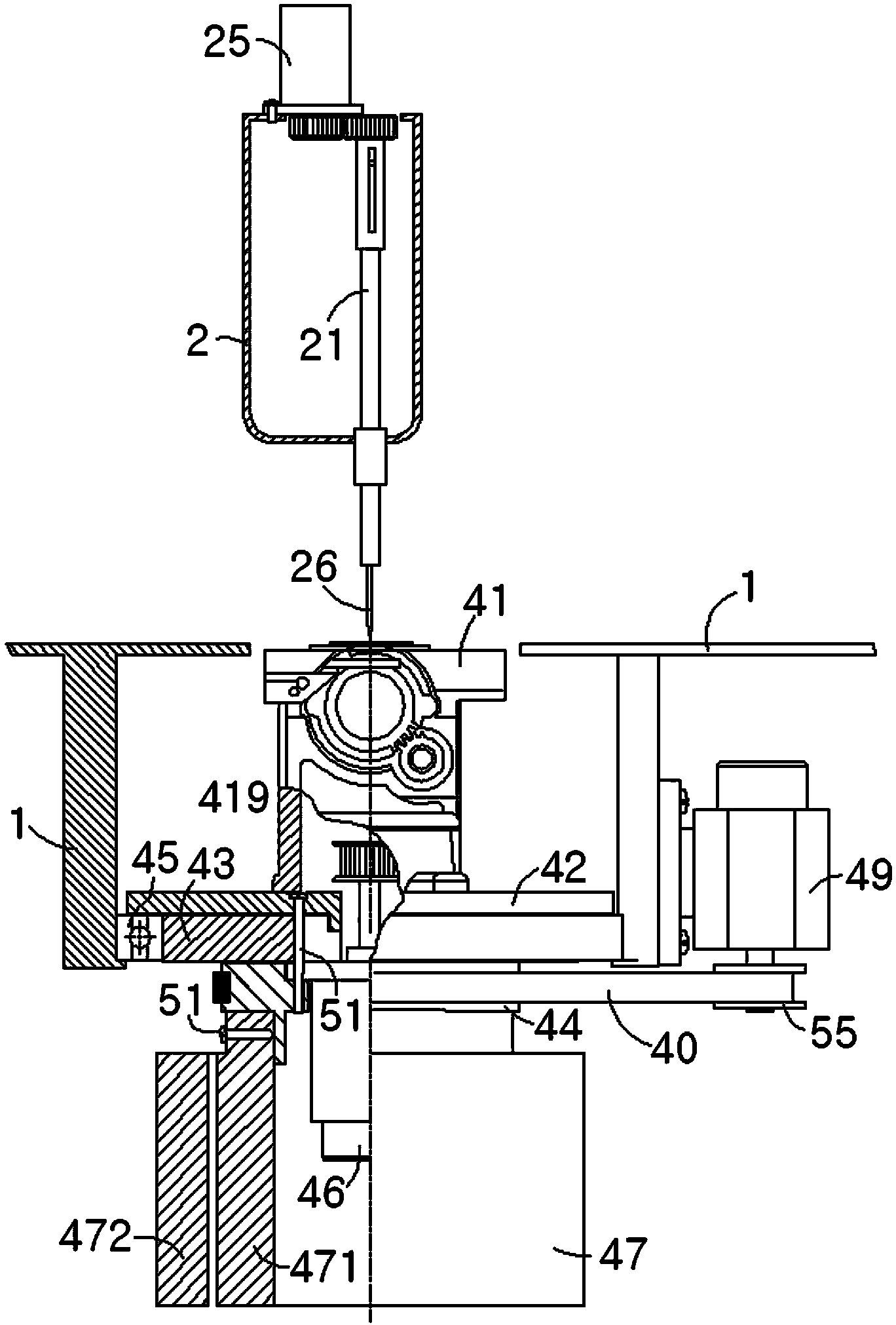

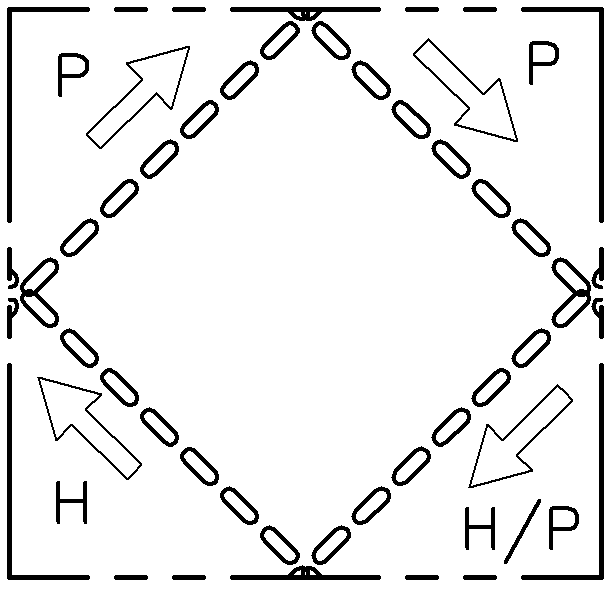

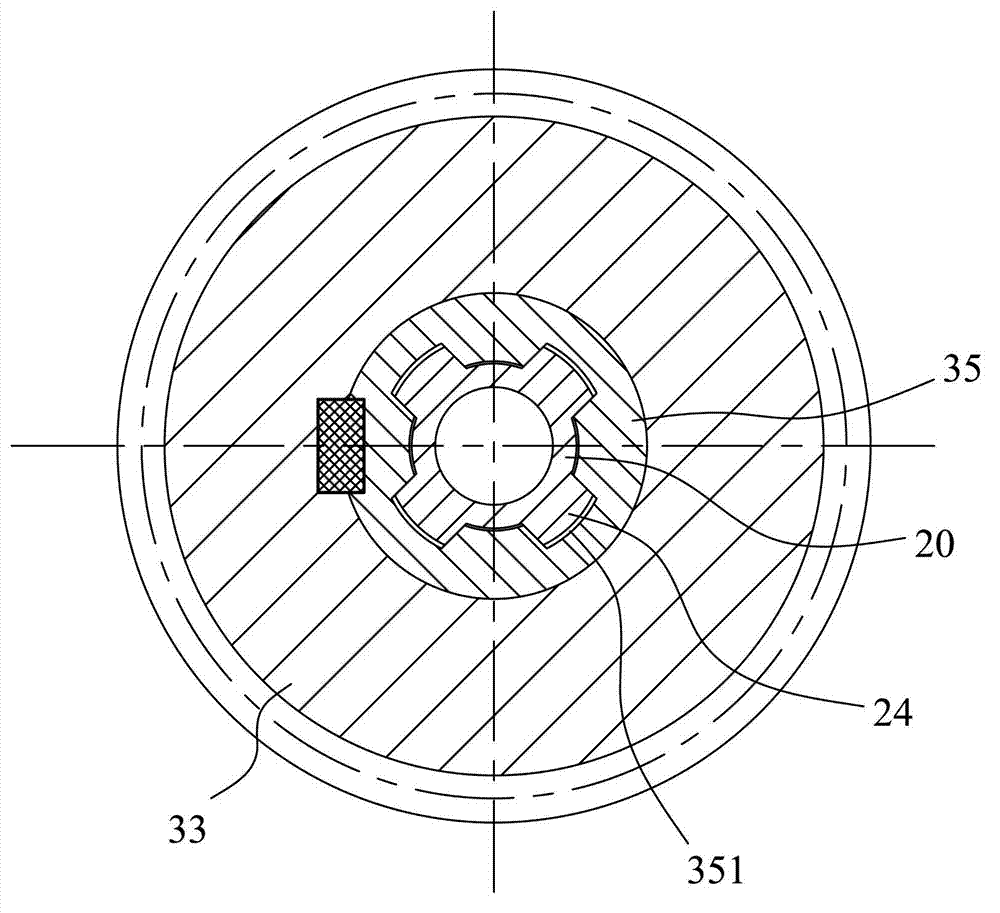

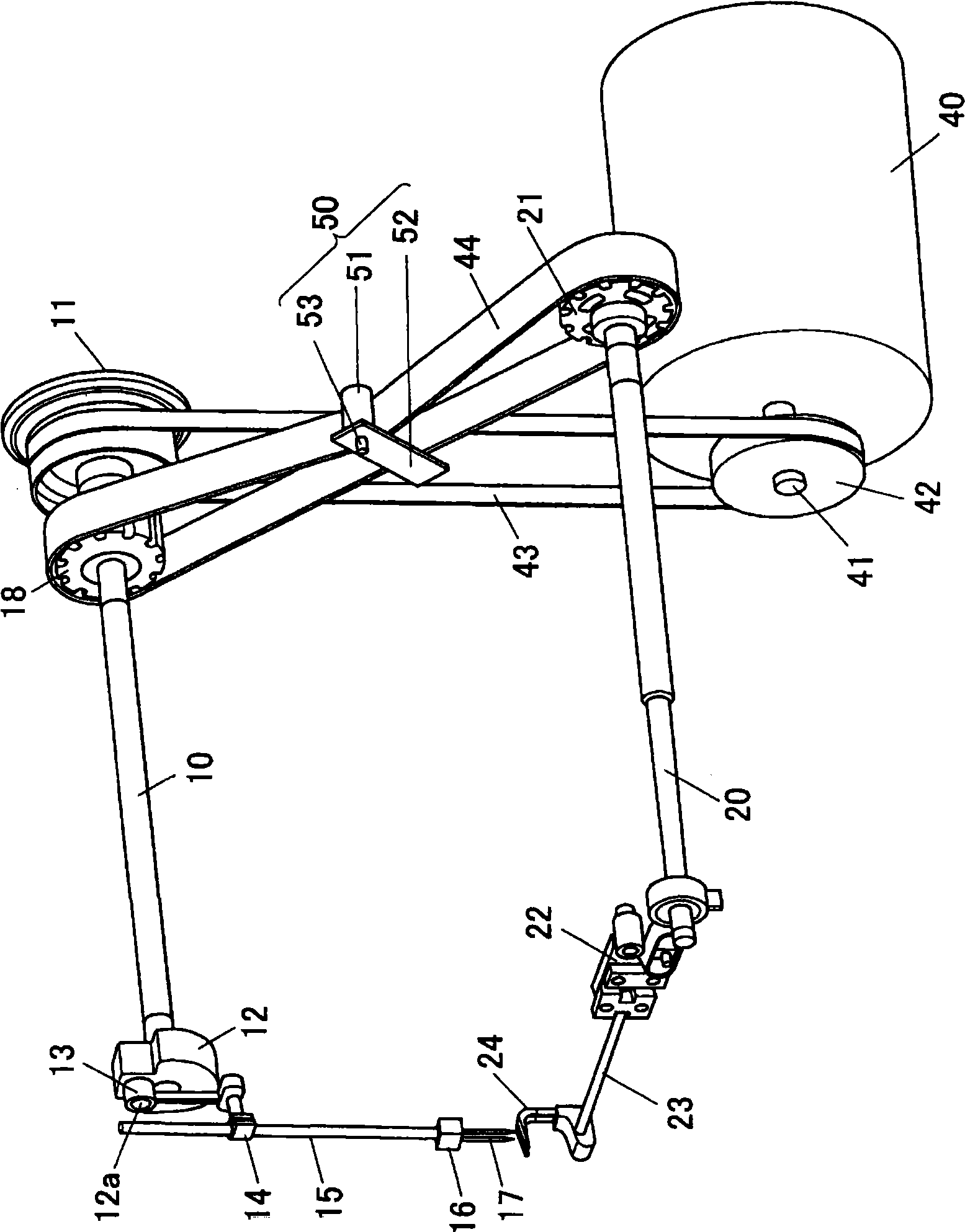

Outrigger rotating type independently-driven automatic sewing equipment

ActiveCN103981638AMeet processing needsPowerfulPressersNeedle barsFailure rateAutomatic test equipment

The invention relates to outrigger rotating type independently-driven automatic sewing equipment. The equipment comprises an upper machine head and a lower machine head which are independently driven respectively, wherein the upper machine head comprises a machine head lifting assembly, a machine head rotating assembly and a machine head assembly, the machine head rotating assembly is fixedly arranged on the machine head lifting assembly, the machine head assembly is fixedly arranged at the lower part of the machine head rotating assembly, and the upper machine head can rise / fall and can also adaptively rotate synchronously with the lower machine head; the lower machine head comprises a bottom line rotating assembly and a bottom shuttling system, the bottom shuttling system is arranged at the upper part of the bottom line rotating assembly, and the bottom line rotating assembly drives the bottom shuttling system to rotate in 360 degrees in any direction; each of the upper and lower machine heads is further provided with a servo-control system, and the servo-control systems control the steering of a bottom line rotating shaft and control the bottom line rotating shaft and machine head rotating shafts to correspond to each other and be in the same rotating speed. The equipment has the advantages that various machining needs can be met, the scope of application is greatly enlarged, and the function is powerful; the stability is high, the failure rate is low, and the maintenance is simple and convenient.

Owner:浙江锦上智控科技有限公司

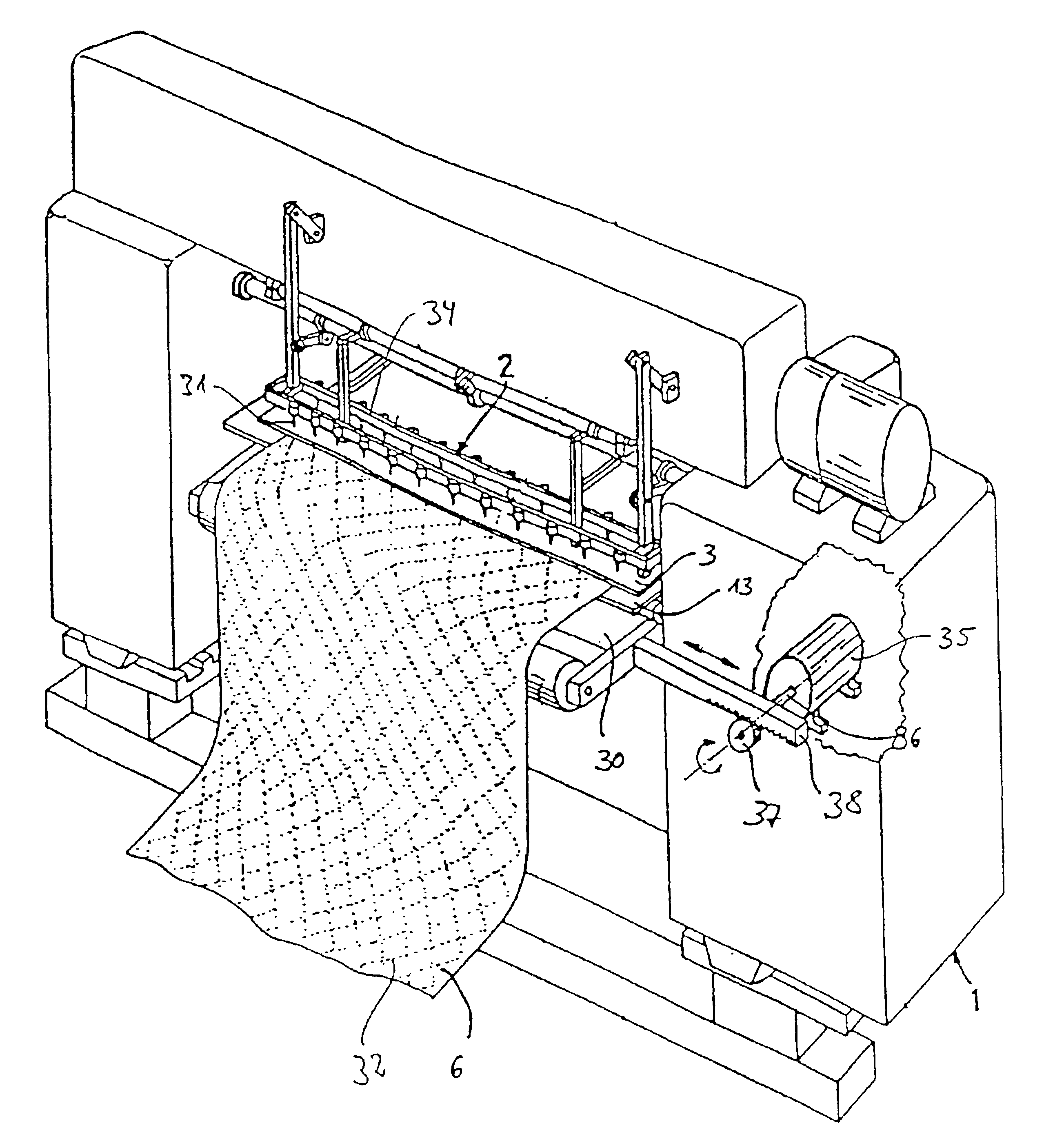

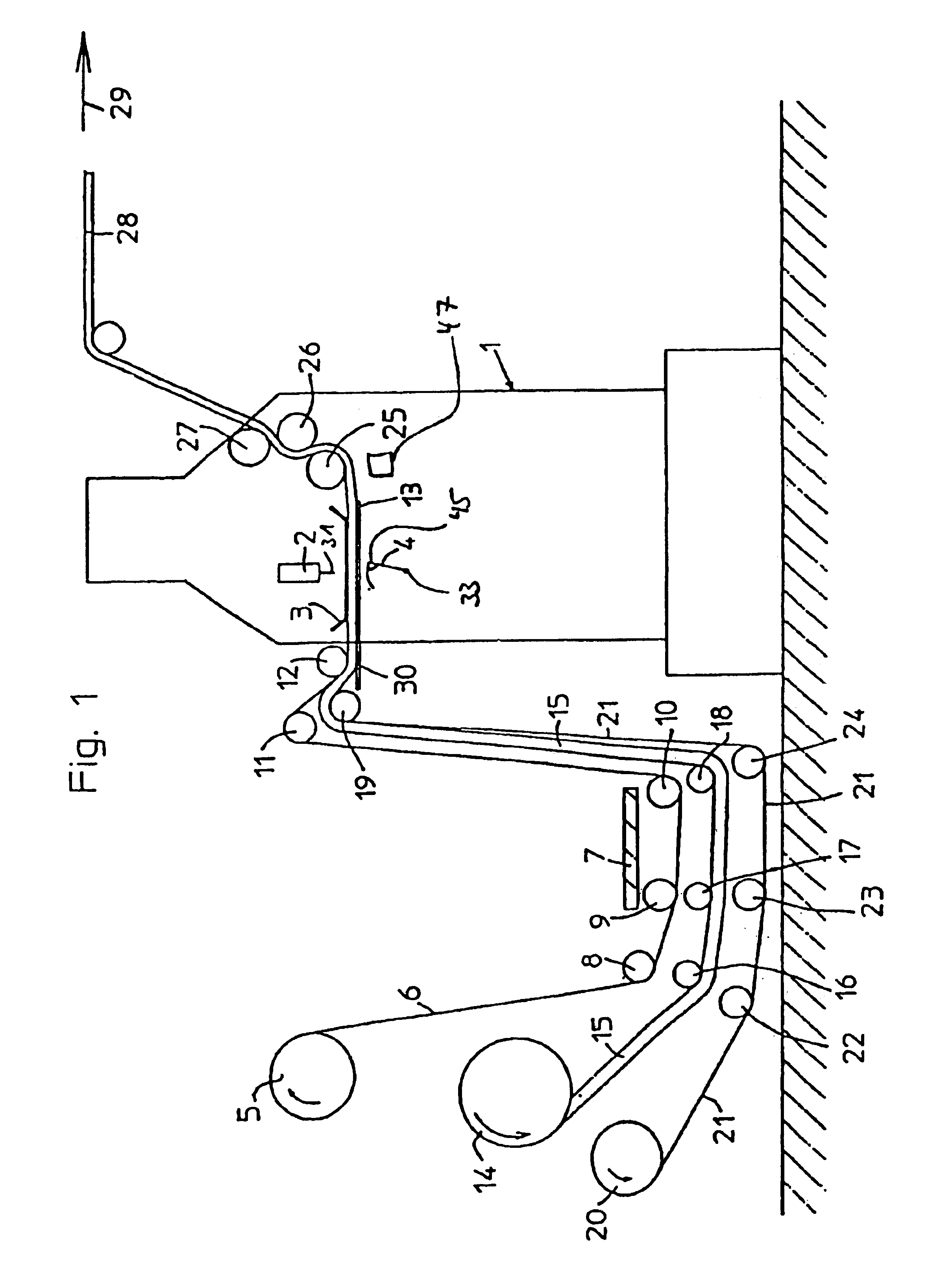

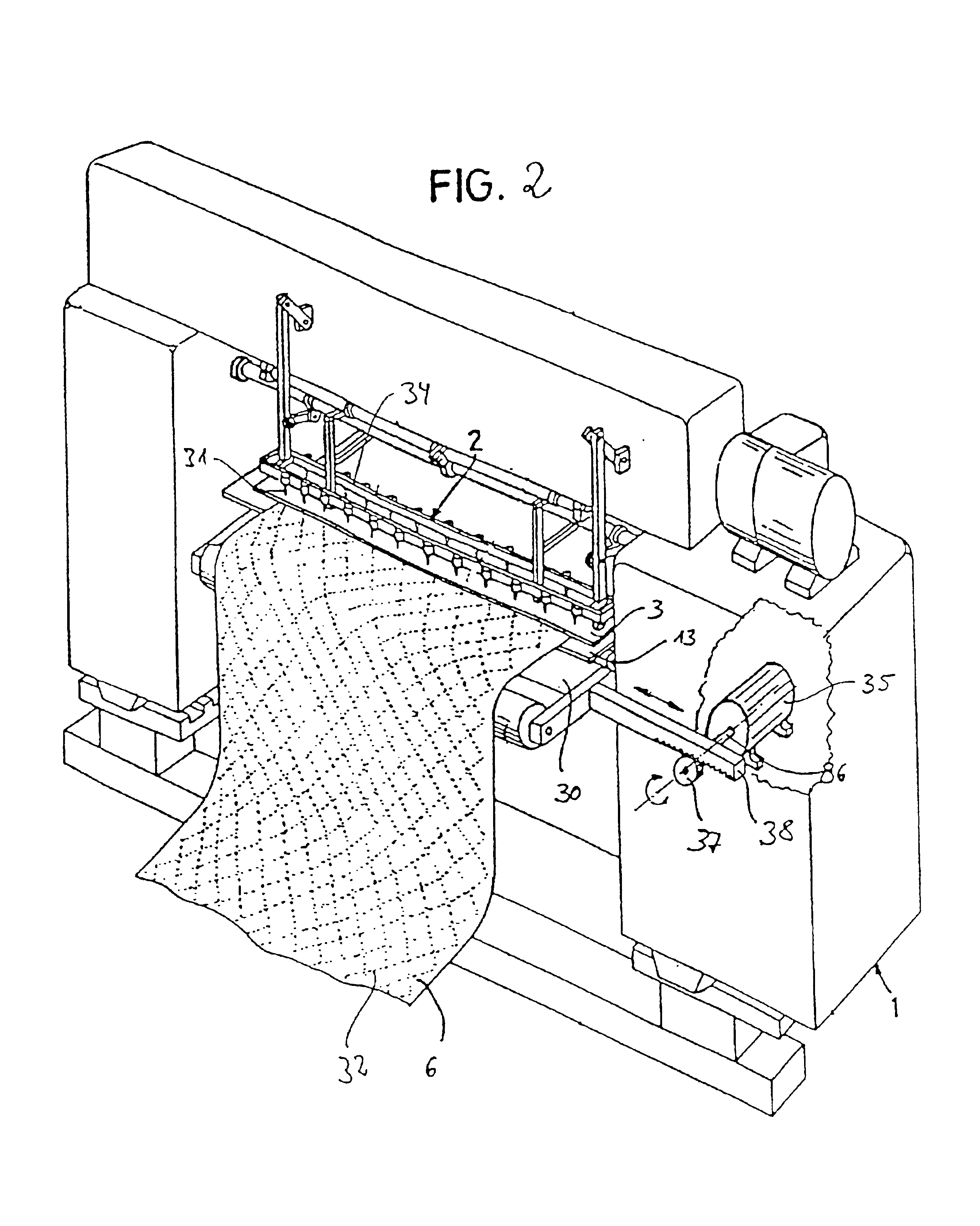

Chain stitch multi-needle quilting machine and method to create a pattern in a quilting material

InactiveUS6895878B2Cut shortAvoid insufficient lengthWork-feeding meansNeedle severing devicesEngineeringBiomedical engineering

The invention relates to a chain stitch multi-needle guilting machine with stitch-forming quilting elements and a method for creating a pattern in a guilting material. The elements of the quilting machine are comprised of at least one needle bar with attached needles and at least one looper shaft with attached loopers. Each of the needles and the loopers have a corresponding needle thread and looper thread associated therewith, form quilting element pairs, and are driven to build chain stitches in a quilting material. At least one of the needles is adjustable between two positions and participates in the quilting procedure in a first position and does not prick into the quilting material in the second position during the quilting procedure. The quilting machine can be made to have a device to knot the needle thread with the looper thread, or a device to cut the looper thread, or both.

Owner:NAHMASCHFAB EMIL STUTZNACKER

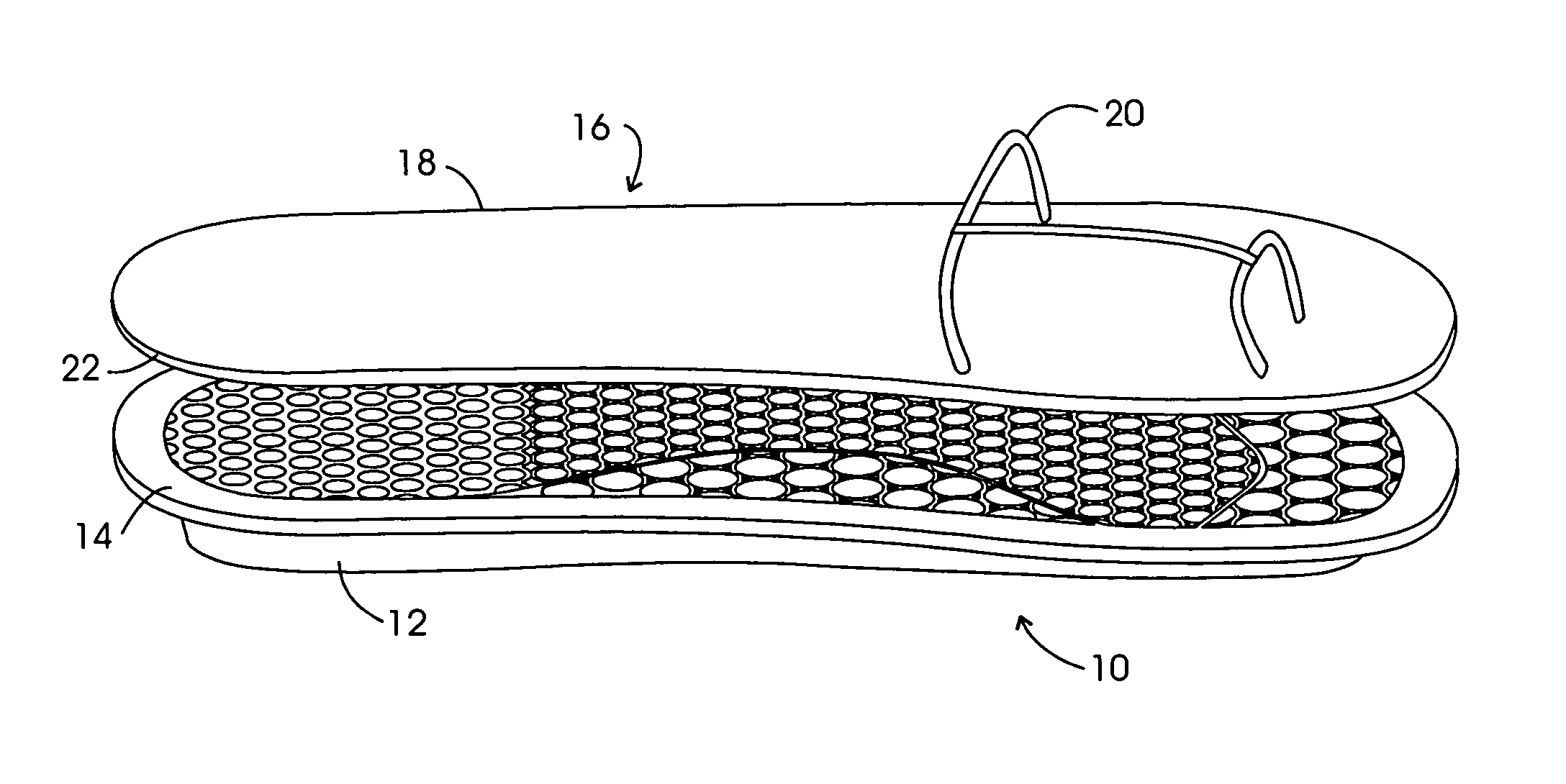

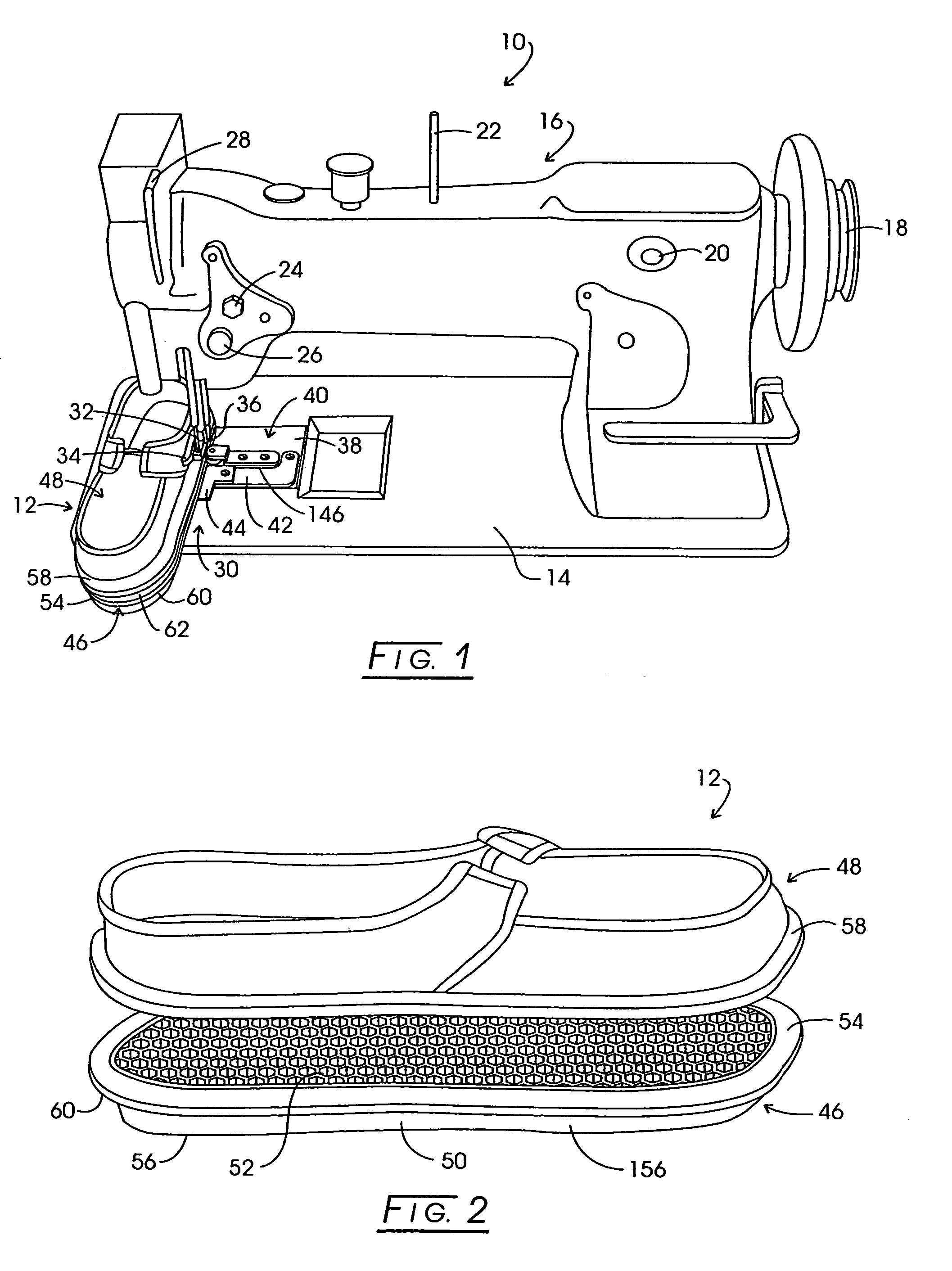

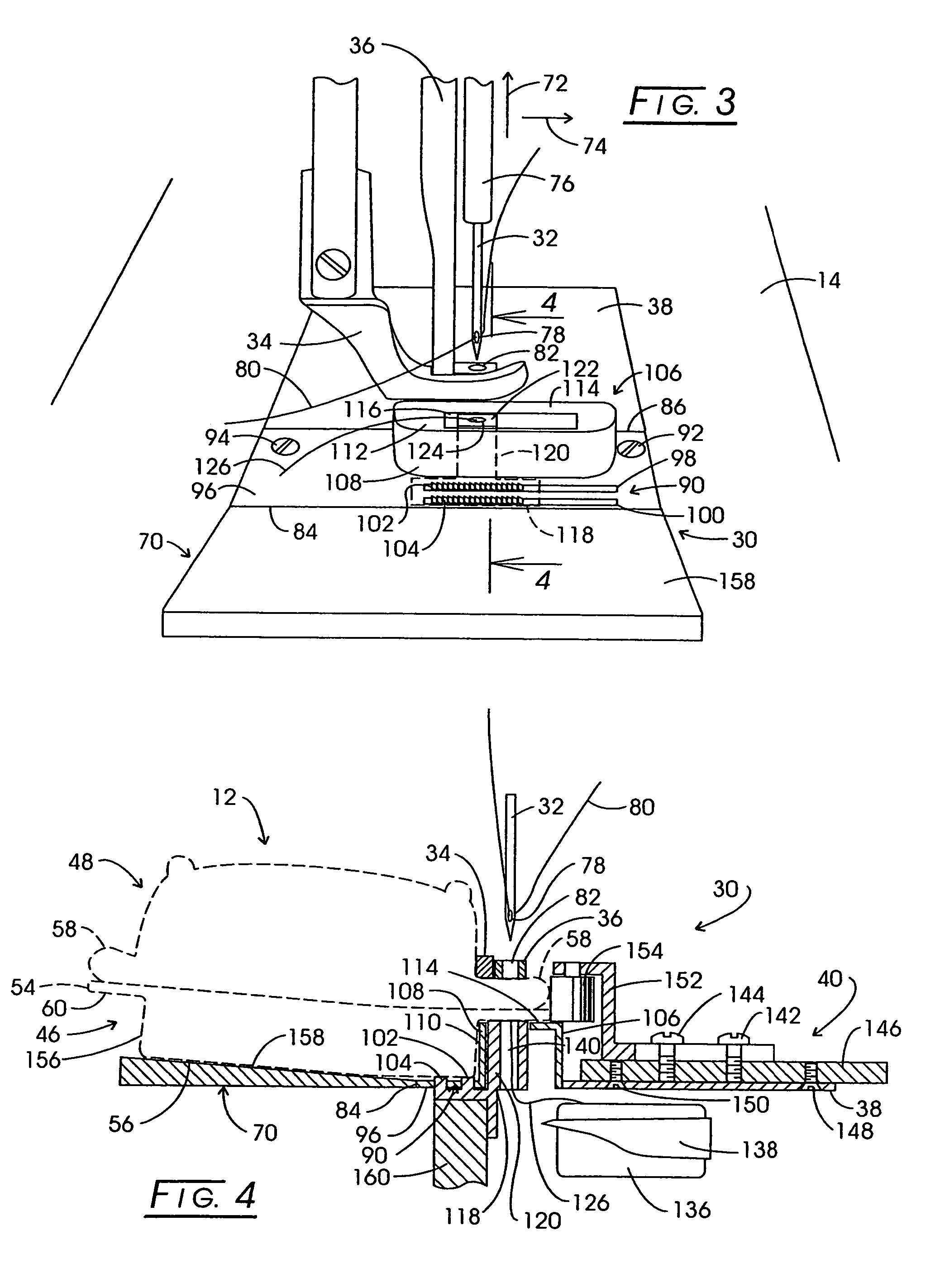

Elastomeric sole for use with converted flatbed sewing machine

The present invention addresses an elastomeric sole having a sidewall with a height less that 0.625 inch, forming a cavity and a horizontally disposed rim extending from the top surface of the sidewall. The sole includes at least two upstanding regions extending upwardly from the cavity lower surface, each region formed from elastomer and having a different effective modulus of elasticity. The invention also includes the combination of an elastomeric sole and an upper and a method for sewing an elastomeric sole to an upper by means of a converted sewing machine.

Owner:SEWING INNOVATIONS & MACHINE COMPANY

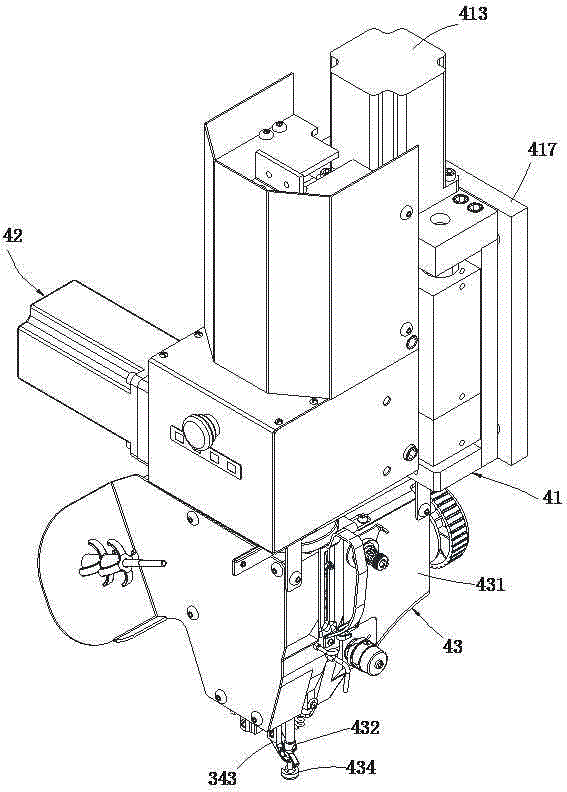

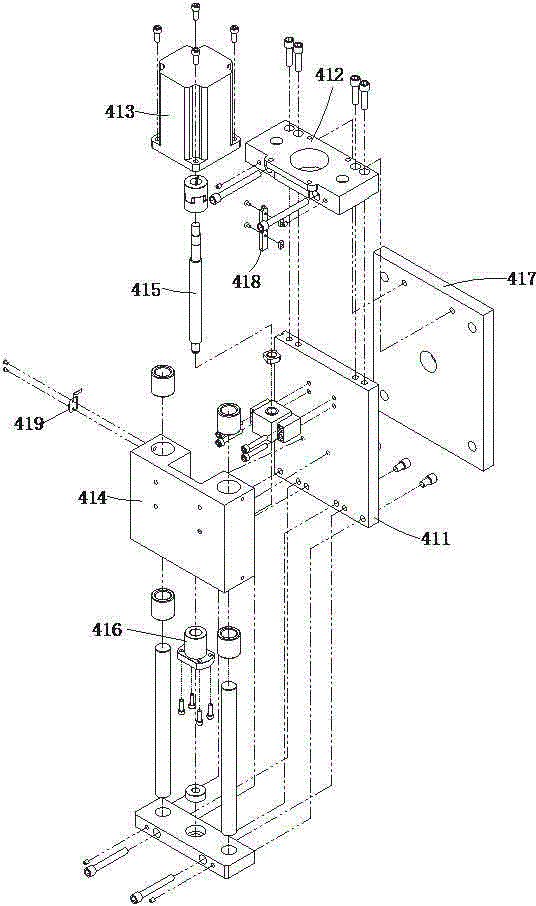

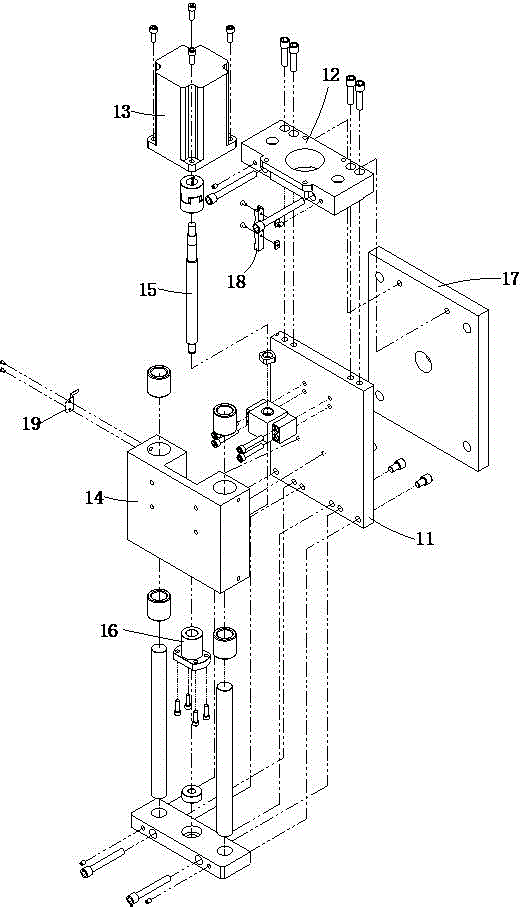

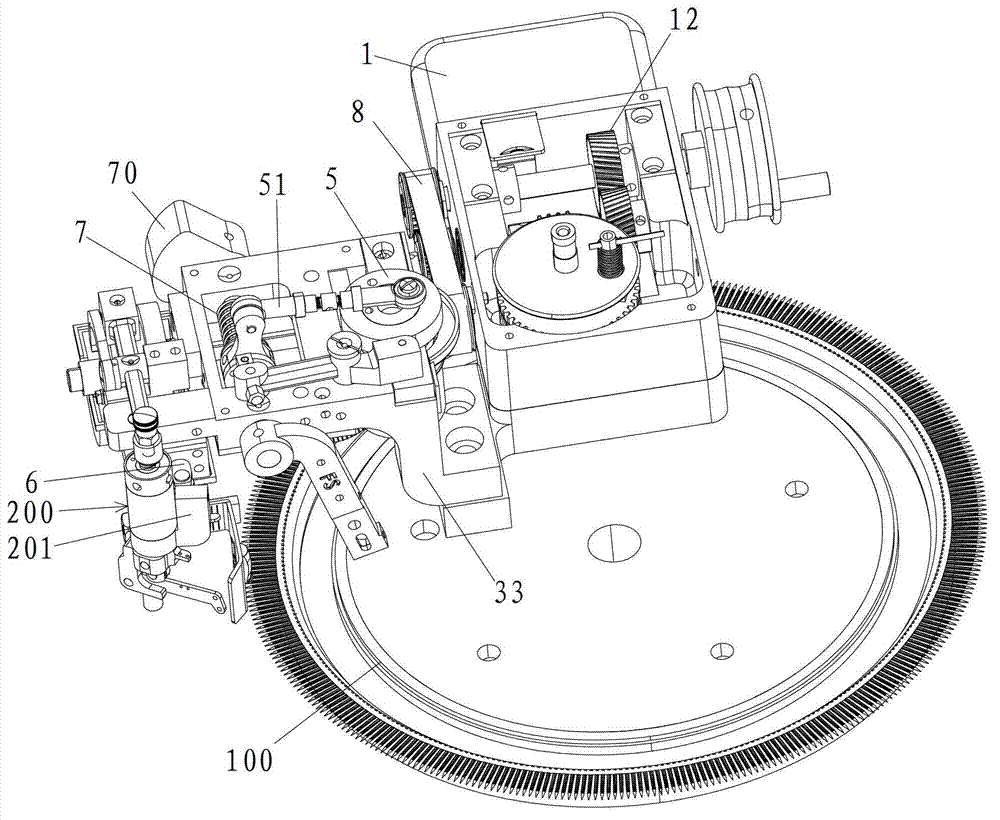

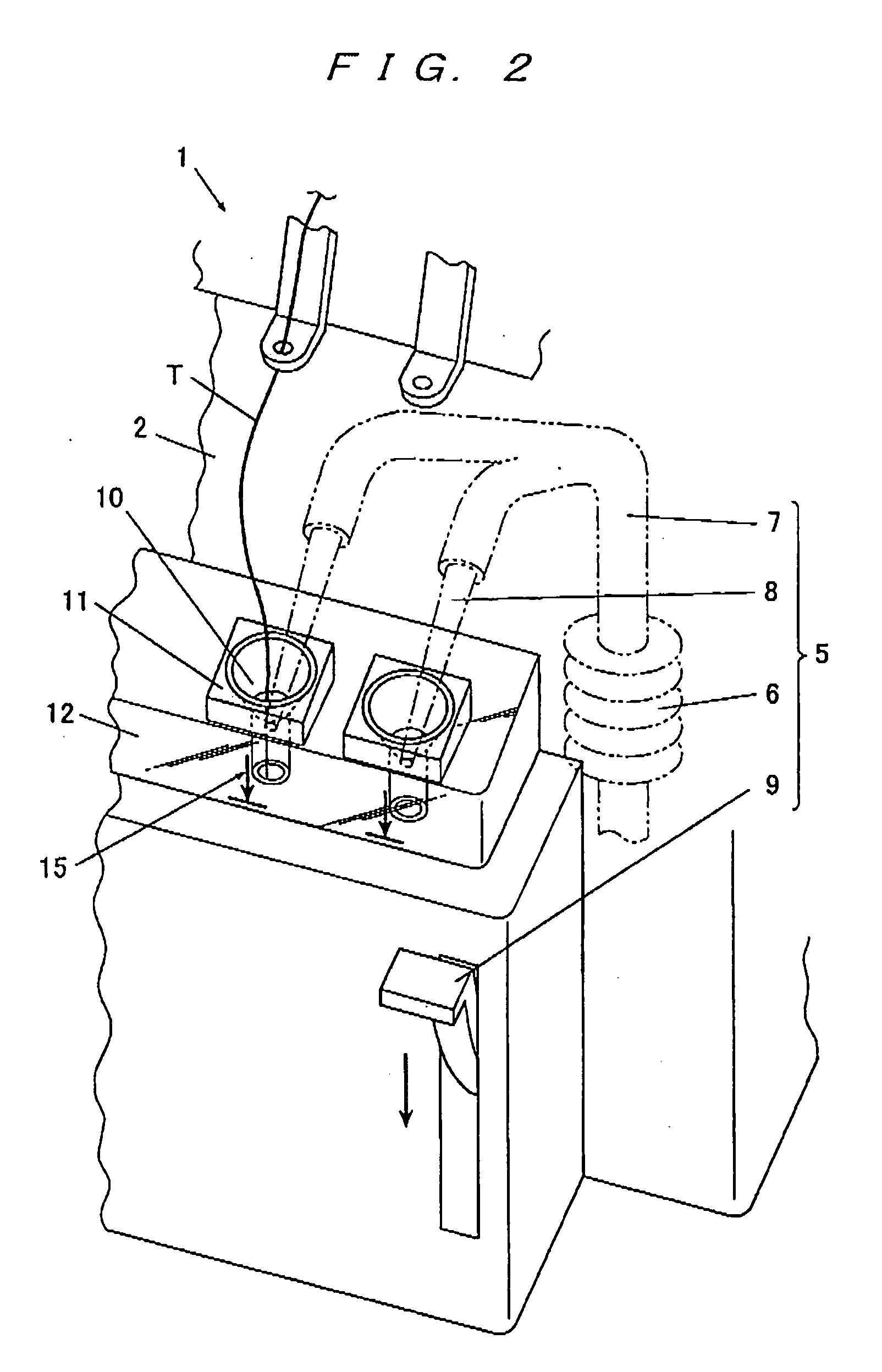

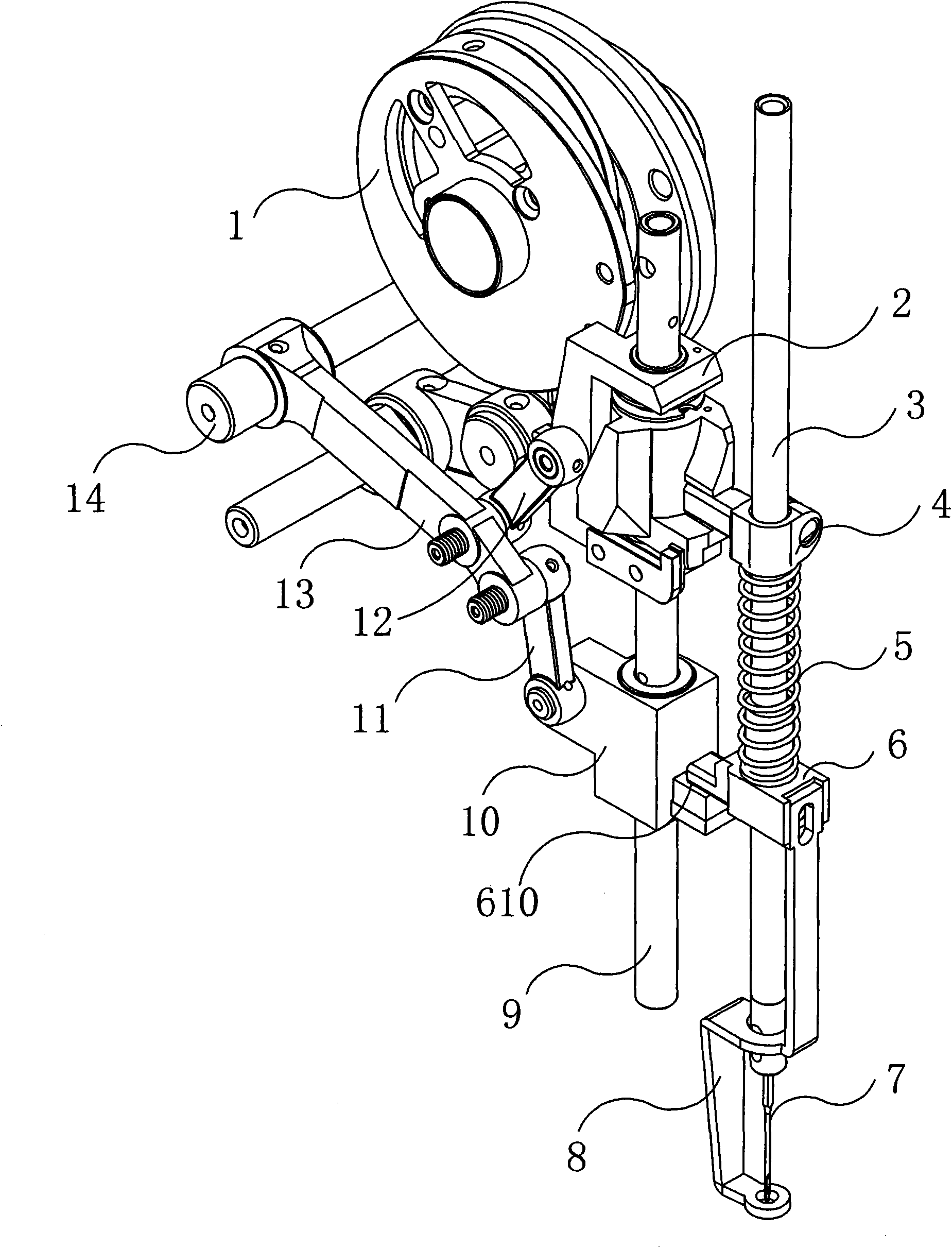

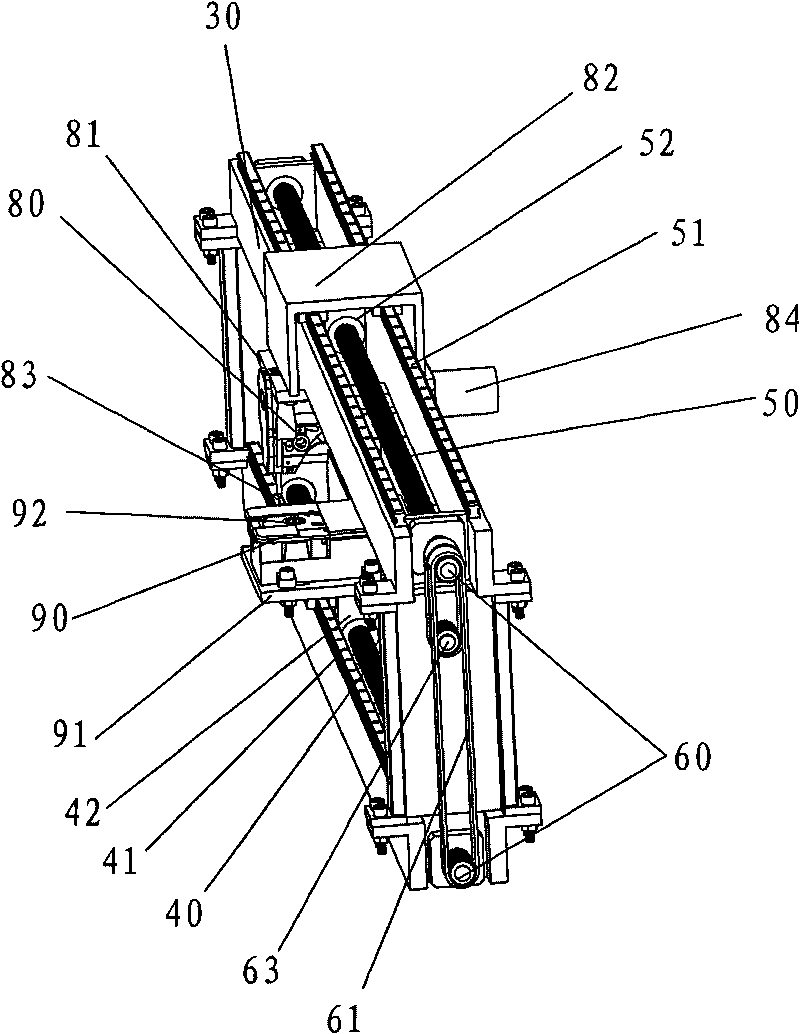

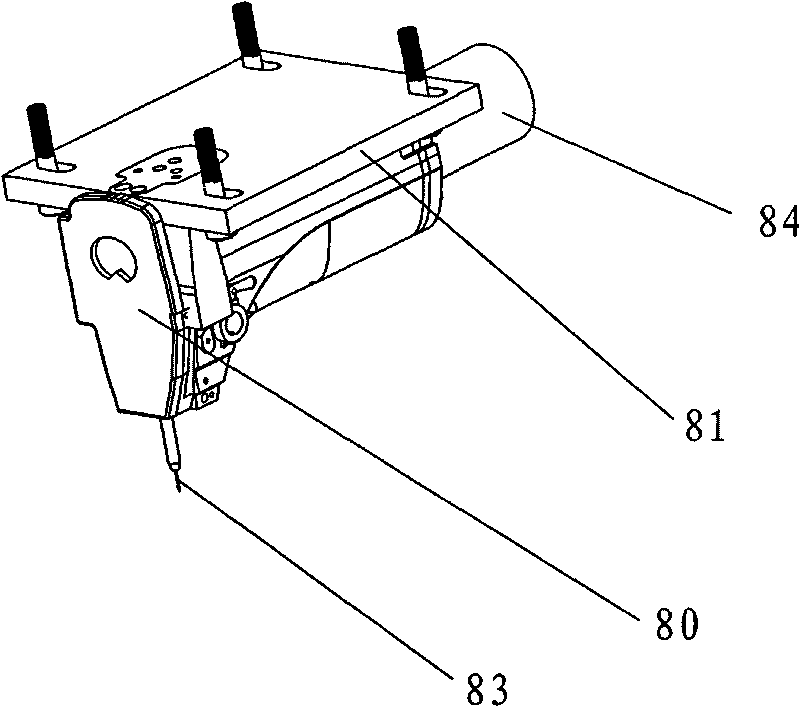

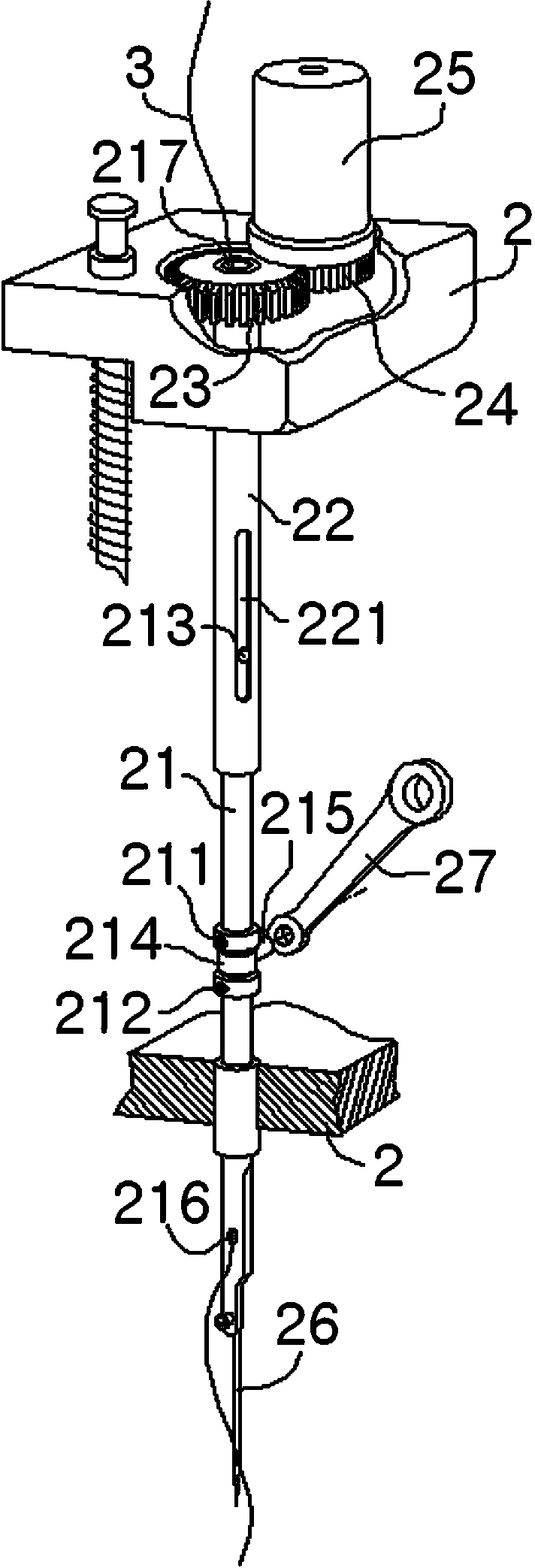

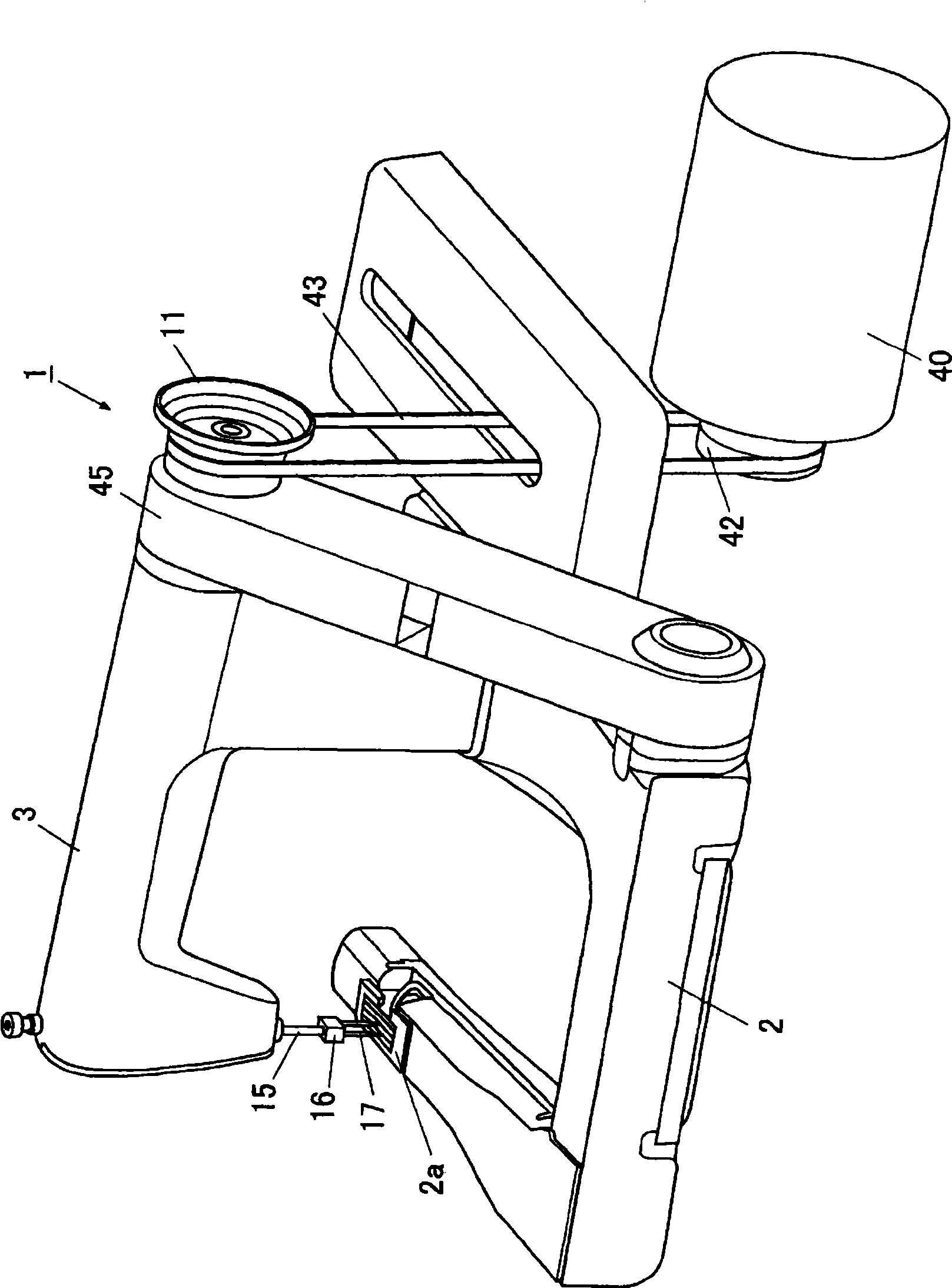

Upper machine head of independently-driven rotary type automatic sewing device

ActiveCN103981649AReduce volumeHigh degree of integrationPressersSewing-machine control devicesFailure rateMachining

The invention relates to an upper machine head of an independently-driven rotary type automatic sewing device. The upper machine head comprises a machine head lifting assembly, a machine head rotating assembly and a machine head assembly, wherein the machine head rotating assembly is fixedly arranged on the machine head lifting assembly; the machine head assembly is fixedly arranged at the lower part of the machine head rotating assembly; the machine head rotating assembly comprises a conductive slip ring, a slip ring fixing seat, a machine head installation plate, a machine head rotating motor, a gearbox and a rotating shaft, the upper end of the rotating shaft is connected with the conductive slip ring for driving the conductive slip ring to rotate, and the rotating shaft can drive the machine head assembly to rotate clockwise or anticlockwise by 360 degrees; the machine head lifting assembly can drive the machine head assembly to move up and down through the machine head rotating assembly. The upper machine head disclosed by the invention can be lifted and can be rotated as well, various machining needs can be met, and the application range is greatly enlarged; the size is small, the integration degree is high, the upper machine head can be matched with a lower machine head for realizing synchronous high-speed rotating, the stability is high, the failure rate is low, and the maintenance is simple and convenient.

Owner:浙江锦上智控科技有限公司

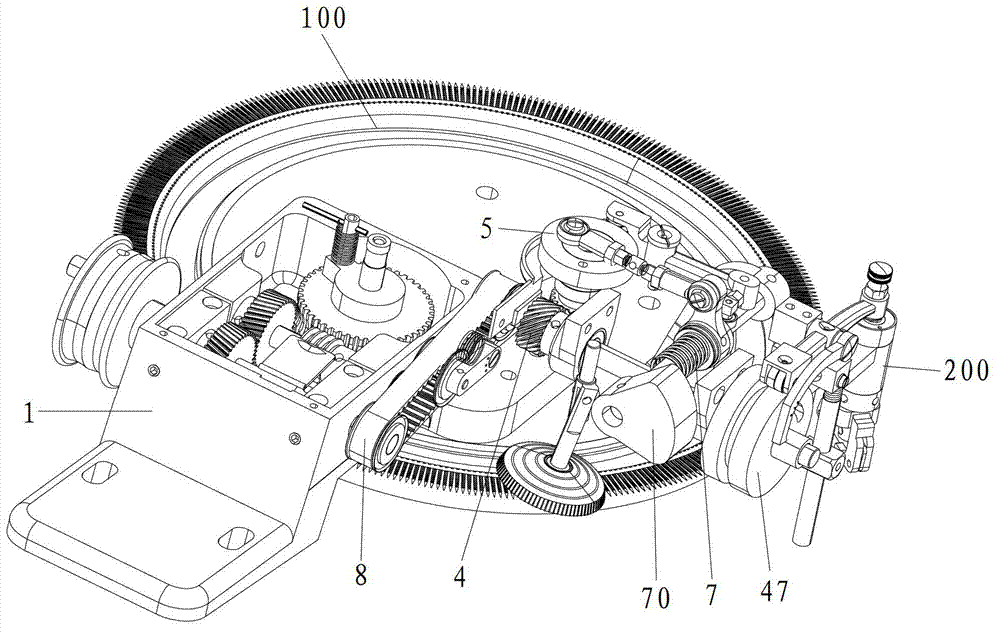

High-efficiency dial linking machine

ActiveCN102953234AStable structureGuaranteed uptimeLubrication/cooling devicesSewing-machine control devicesElectric machineryEngineering

The invention discloses a high-efficiency dial linking machine. The high-efficiency dial linking machine comprises a headstock, a speed-regulating unit, a case and a dial; the headstock comprises a box, a box cover, a gear assembly and an adjusting handle, wherein the box cover is mounted on the top of the box, the gear assembly is mounted in the box, the adjusting handle is linked with the gear assembly, and the gear assembly comprises a first gear assembly and a second gear assembly which are respectively provided with a first helical gear and a second helical gear and are engaged with each other; the speed-regulating unit is linked with the gear assembly through a transmission by being matched with a motor; the case comprises a mounting bracket, an upper shield and a lower shield, and the upper shield and the lower shield are jointly formed into an automatic oil filling device; a helical tooth drive unit, a cam drive mechanism linked with the helical tooth drive unit, a striping unit, a push rod drive mechanism and a dividing unit linked with the cam drive mechanism are mounted in the case, wherein the helical tooth drive unit is linked with the gear assembly through a synchronous drive mechanism; and a debuggable counterweight is mounted on the dividing unit. The high-efficiency dial linking machine has the advantages of stable and smooth operation, good sewing quality, long service life and the like.

Owner:东莞市缝神机械设备有限公司

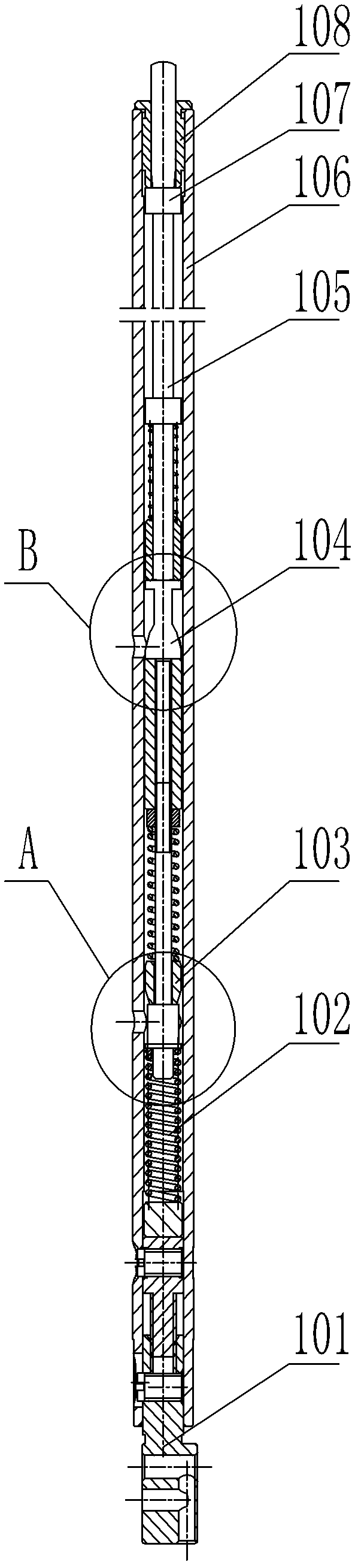

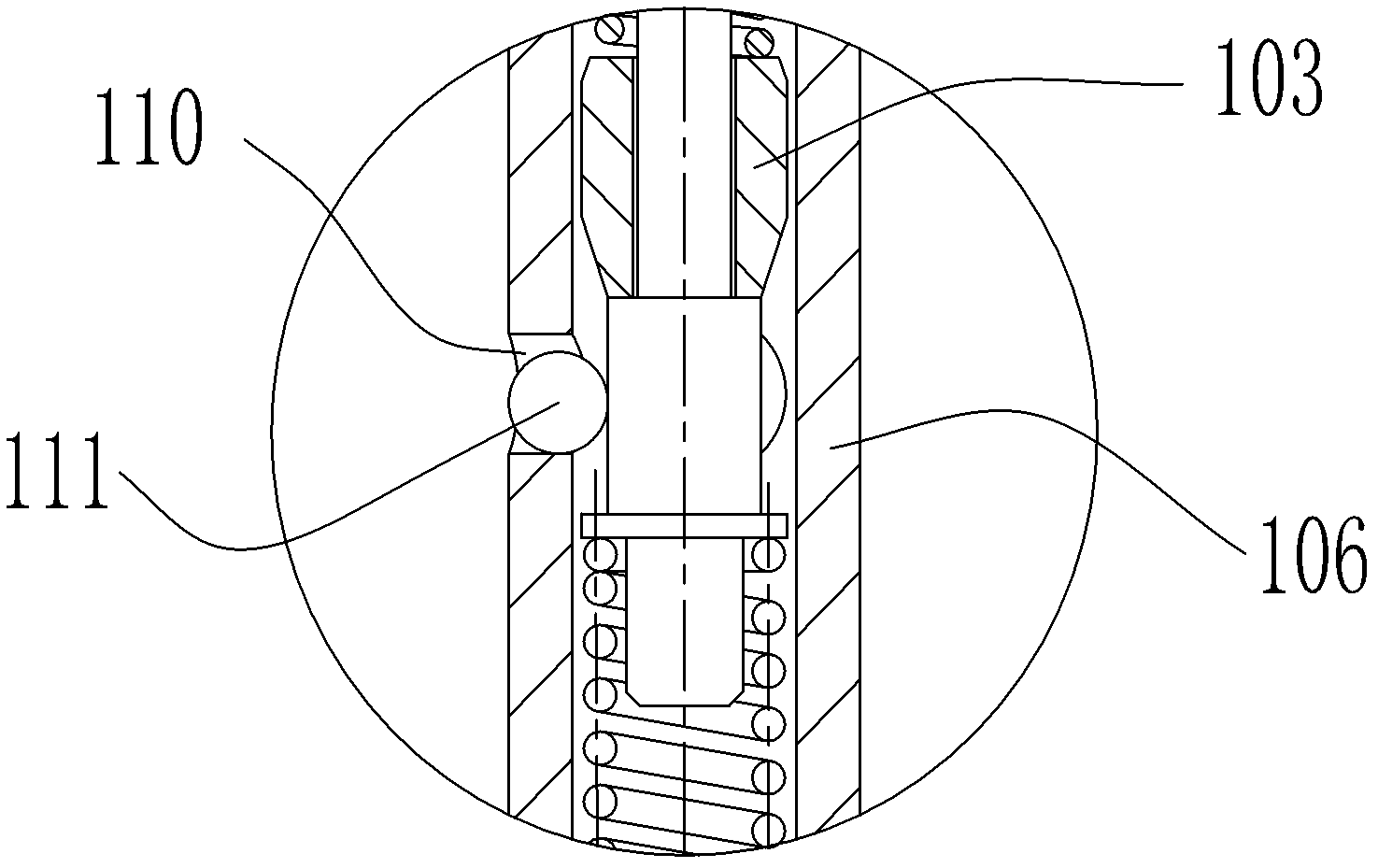

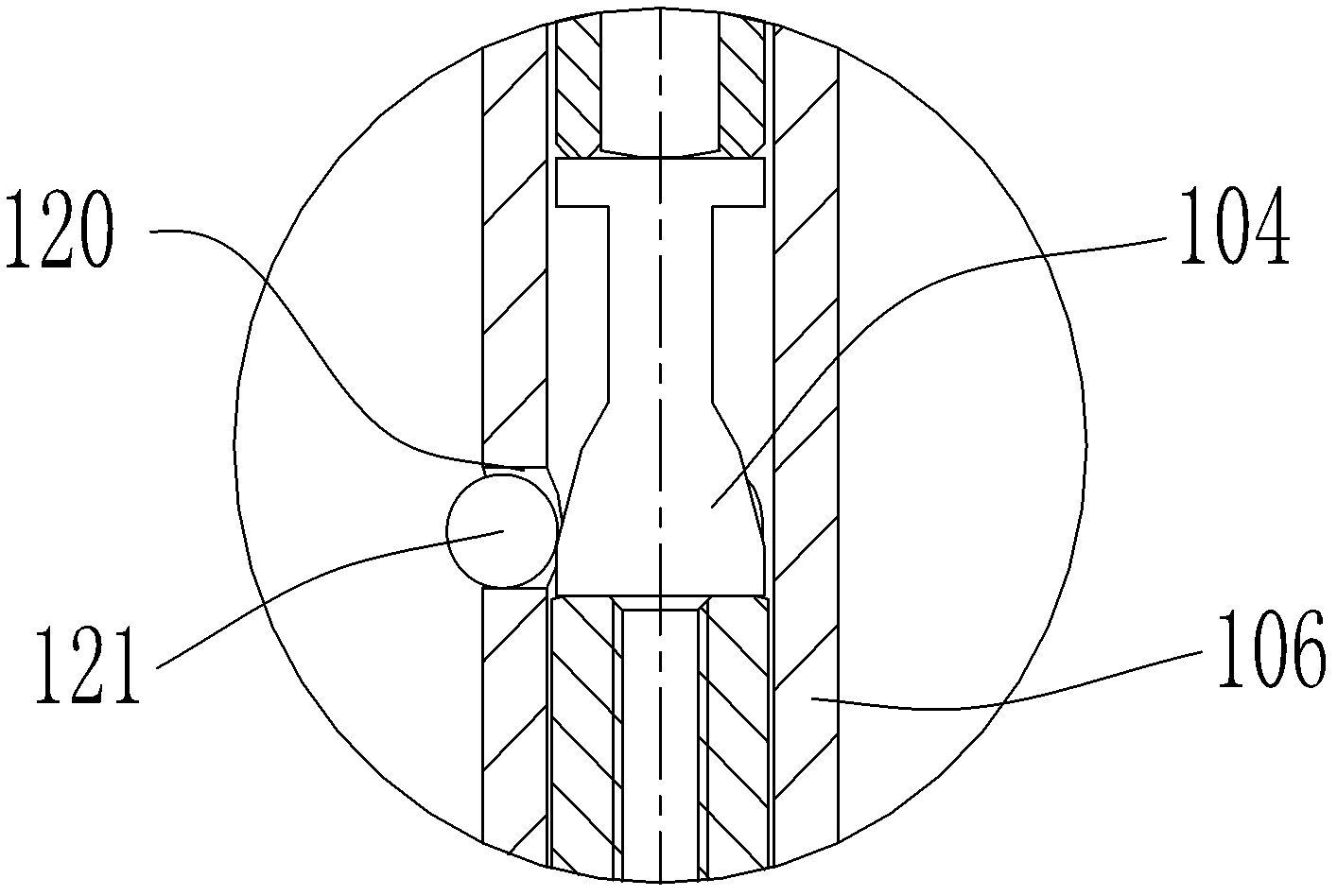

Needle rod for two-needle sewing machine, and switching mechanism for needle rod

ActiveCN102409489ASimple structure and appearanceEasy to processNeedle barsEngineeringBiomedical engineering

The invention discloses a needle rod for a two-needle sewing machine, and a switching mechanism for the needle rod. The needle rod comprises a hollow needle rod body; the lower end of the needle rod body is fixedly connected with a needle rod head which is used for installing a frame needle; a returning spring, a first wedge block, a second wedge block and a switching compression lever are arranged in the needle rod body sequentially; the upper end of the switching compression lever is exposed out of the needle rod body; a tip of the first wedge block faces upward; the tip of the second wedgeblock faces upward; a first through hole is formed on the side wall, corresponding to the first wedge block, of the needle rod body; a first sliding block is arranged in the first through hole; and the side wall, corresponding to the second wedge block, of the needle rod body is provided with a second through hole, and a second sliding block is arranged in the second through hole. The switching mechanism for the needle rod comprises the needle rod, a needle rod frame, a needle rod sleeve, a needle rod drive mechanism and a switching compression block; the needle rod sleeve is connected with the needle rod drive mechanism; and the needle rod frame is also connected with a translation device.

Owner:JACK SEWING MASCH CO LTD

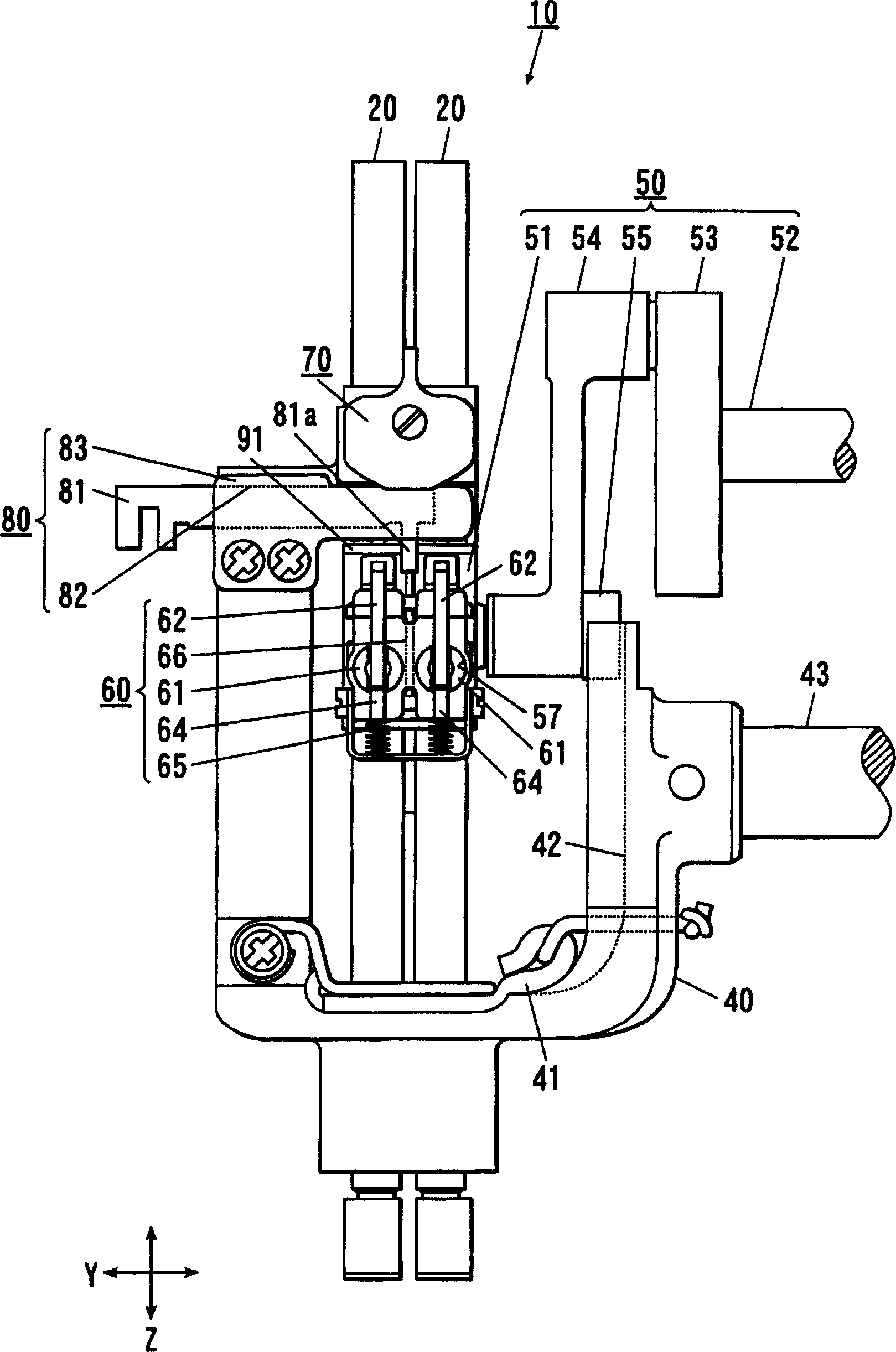

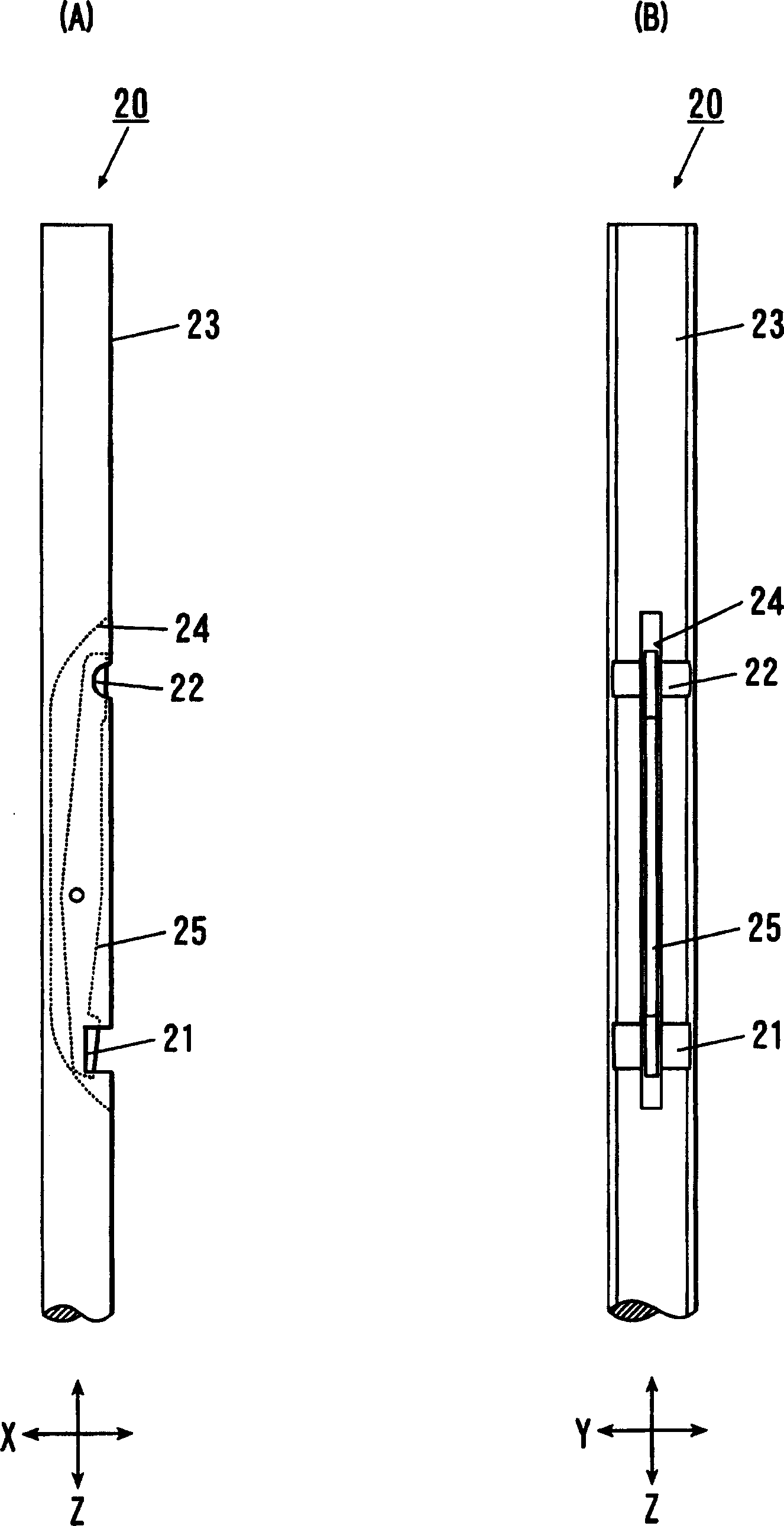

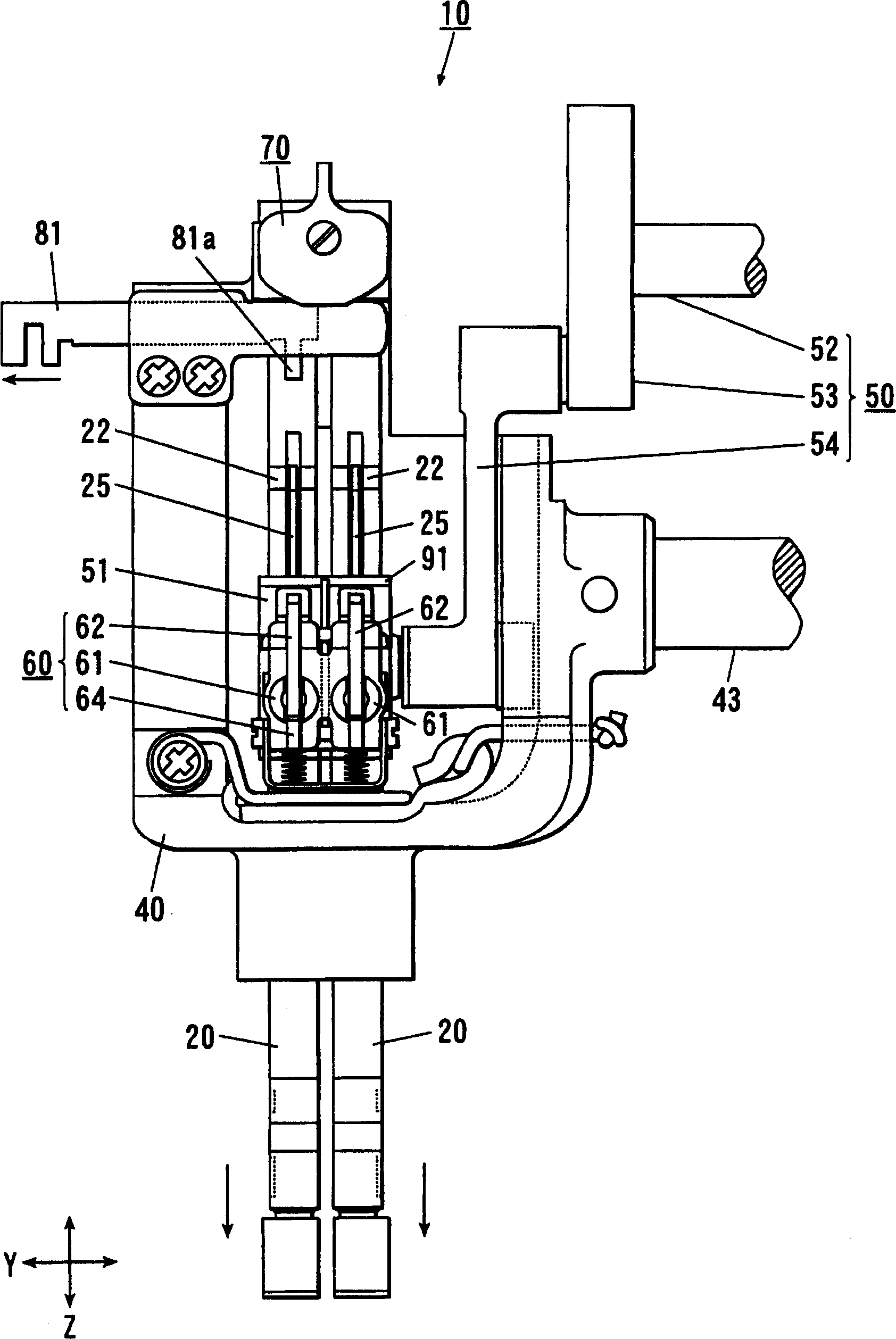

Needle stem mechanism of double-needle sewing machine

InactiveCN1776066AEven sewingSmooth up and down movementLubrication/cooling devicesNeedle barsBiomedical engineeringClutch

A needle bar mechanism for a double-needle sewing machine, comprising: a needle bar support body (40) supporting a pair of needle bars (20) capable of moving up and down; A needle bar up and down movement mechanism (50) for each needle bar to move up and down; a clutch mechanism (60) equipped with a plurality of input parts (62, 66) that accept the holding and release input of each needle bar; a switching part (81), the switching Parts (81) are selectively docked on each input part that carries out the lifting action and carry out the switching of holding or releasing the needle bar; and also have a grease supply mechanism (91), and the grease supply mechanism (91) is set On the needle bar abutment, at the same time, it is used to supply grease to the sliding parts of the needle bar abutment and each needle bar. The needle bar mechanism of this double needle sewing machine increases the durability of the unit.

Owner:JUKI CORP

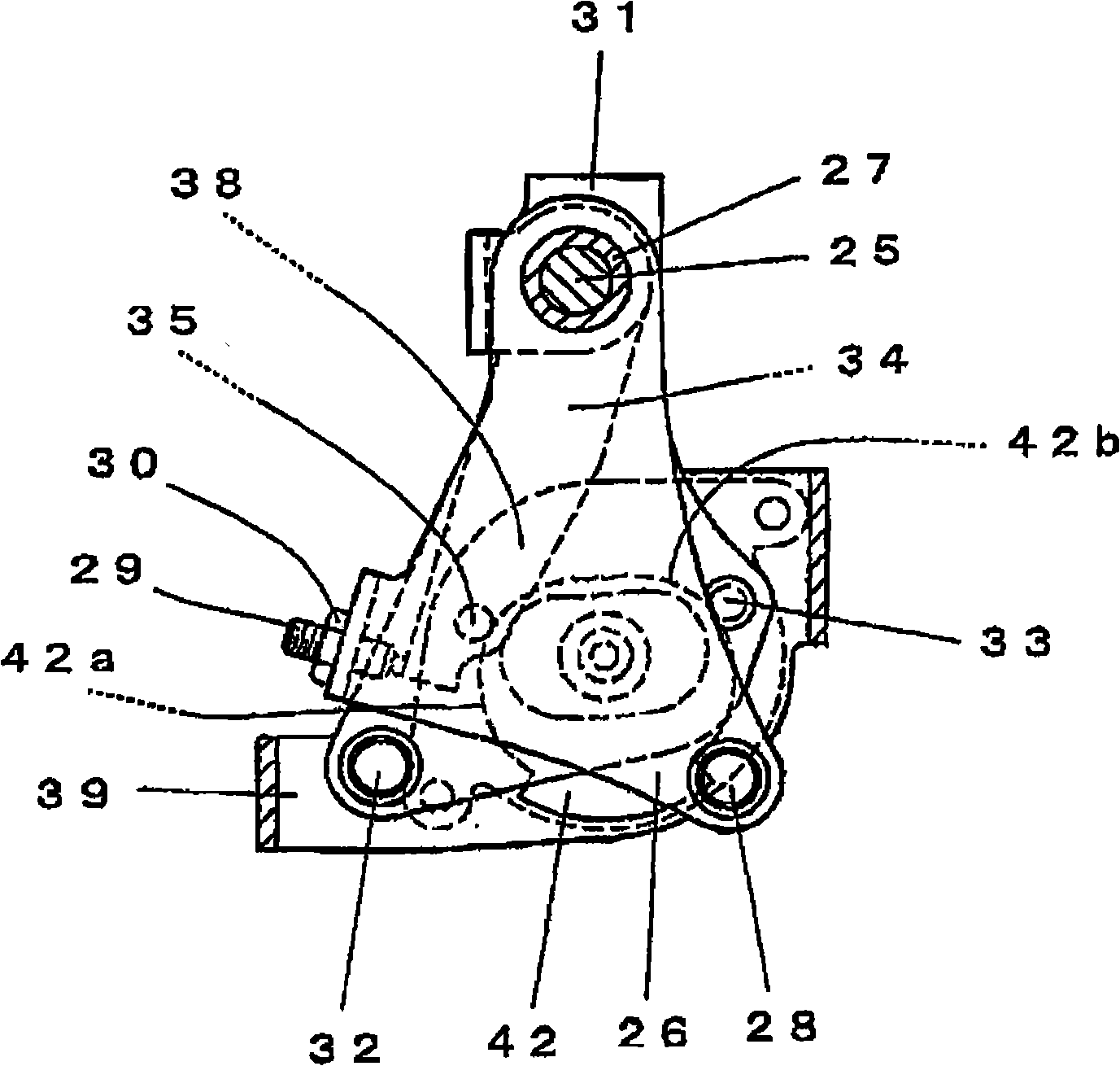

Apparatus for adjusting timing of needle and looptaker of sewing machine

An apparatus for adjusting a timing of a needle and a looptaker of a sewing machine provided at a zigzag sewing machine having an upper shaft for driving a needle bar, a lower shaft for driving a looptaker, a machine frame, and a timing belt for connecting and synchronizing the shafts includes a cam member including a first cam surface and a second cam surface, a first arm member and a second arm member supported by the machine frame and a first pulley and a second pulley mounted to the first arm member and the second arm member respectively and always contacting the timing belt, the first pulley following the first cam surface and the second pulley following the second cam surface.

Owner:SINGER SOURCING LTD LLC

Threading device of sewing machine

InactiveUS20080257241A1Easily and visually recognizeReduce stepsFilament handlingLightening equipmentEngineeringScrew thread

A threading device of a sewing machine includes a thread inserting base formed with a thread path hole having a thread inserting port opened toward an outer side of a sewing machine frame, and further formed with an air path hole which joins the thread path hole in the vicinity of the thread inserting port, an air supply device coupled to the air path hole to supply compressed air, and illuminating means provided on the sewing machine frame to irradiate a joining portion of the thread path hole and the air path hole. The thread inserting base includes a transparent member through which at least the joining portion of the thread path hole and the air path hole can be visually recognized.

Owner:JUKI CORP

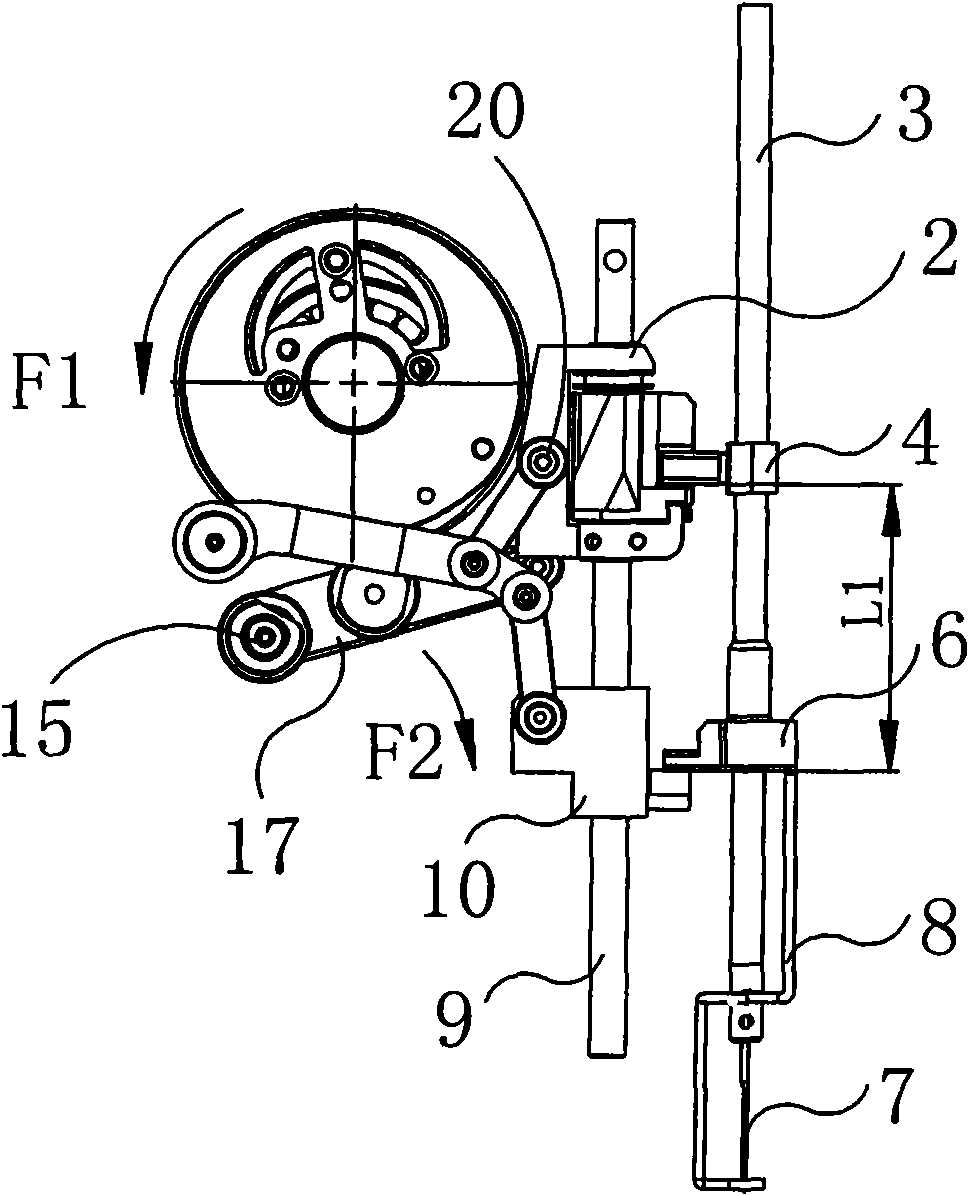

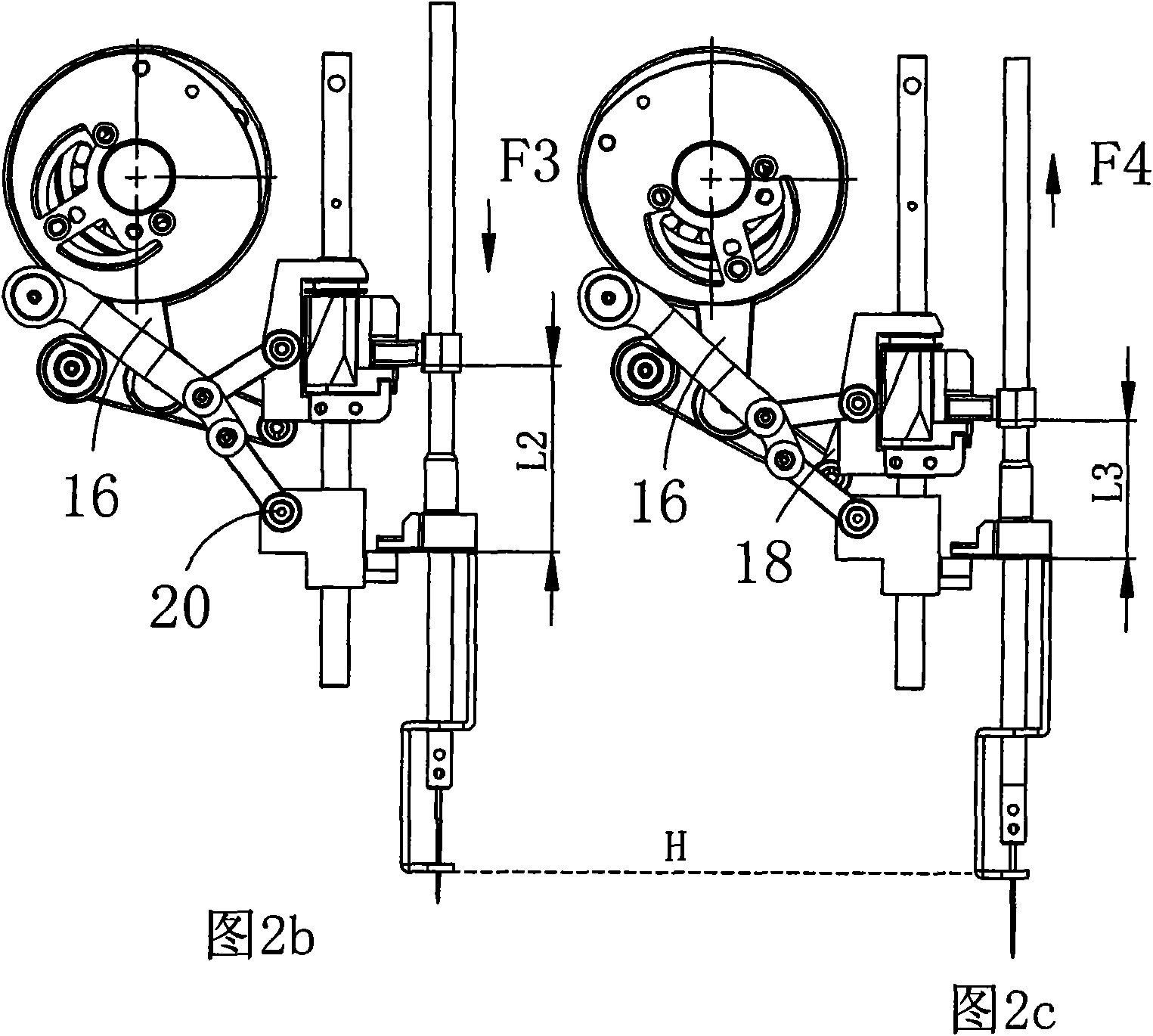

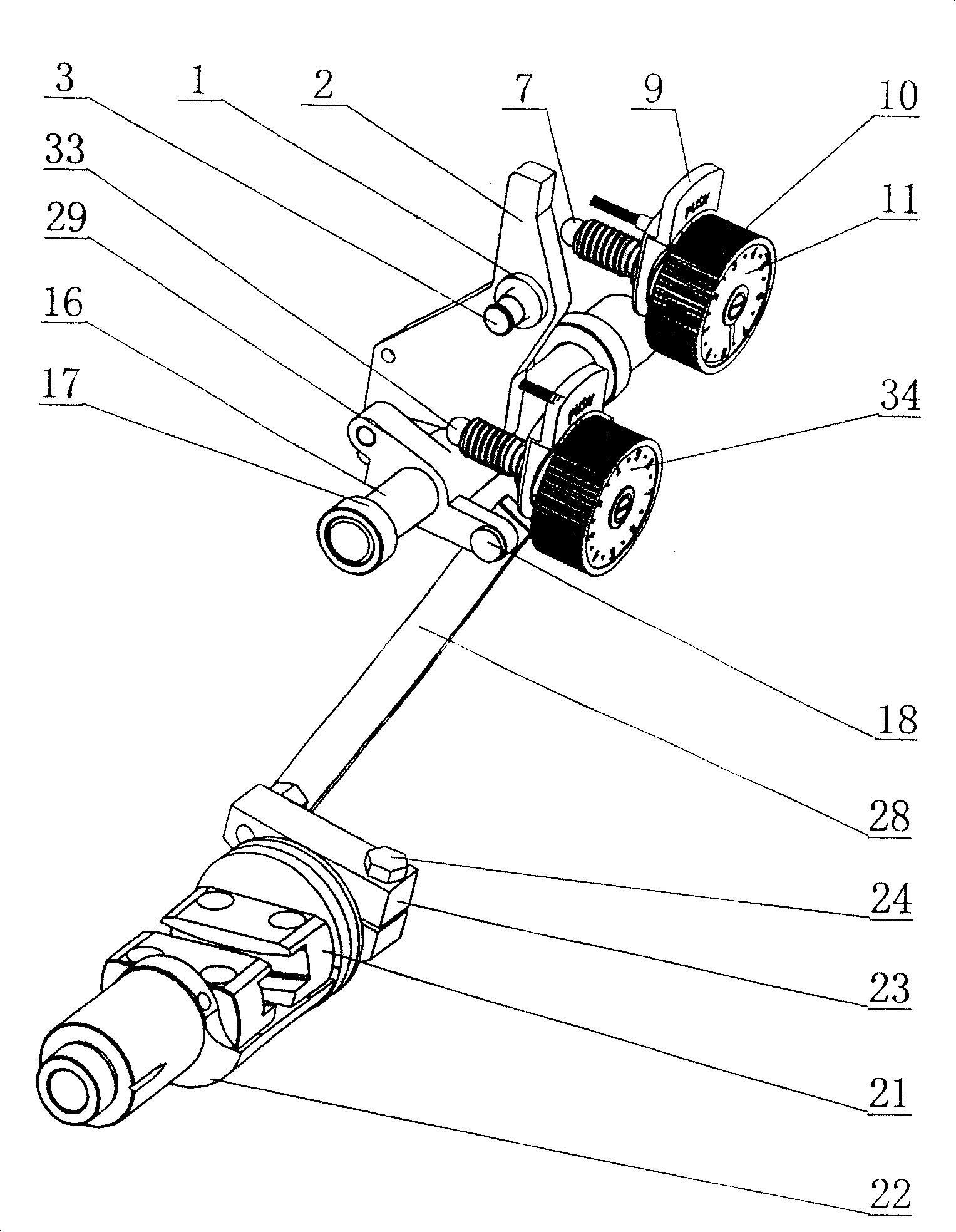

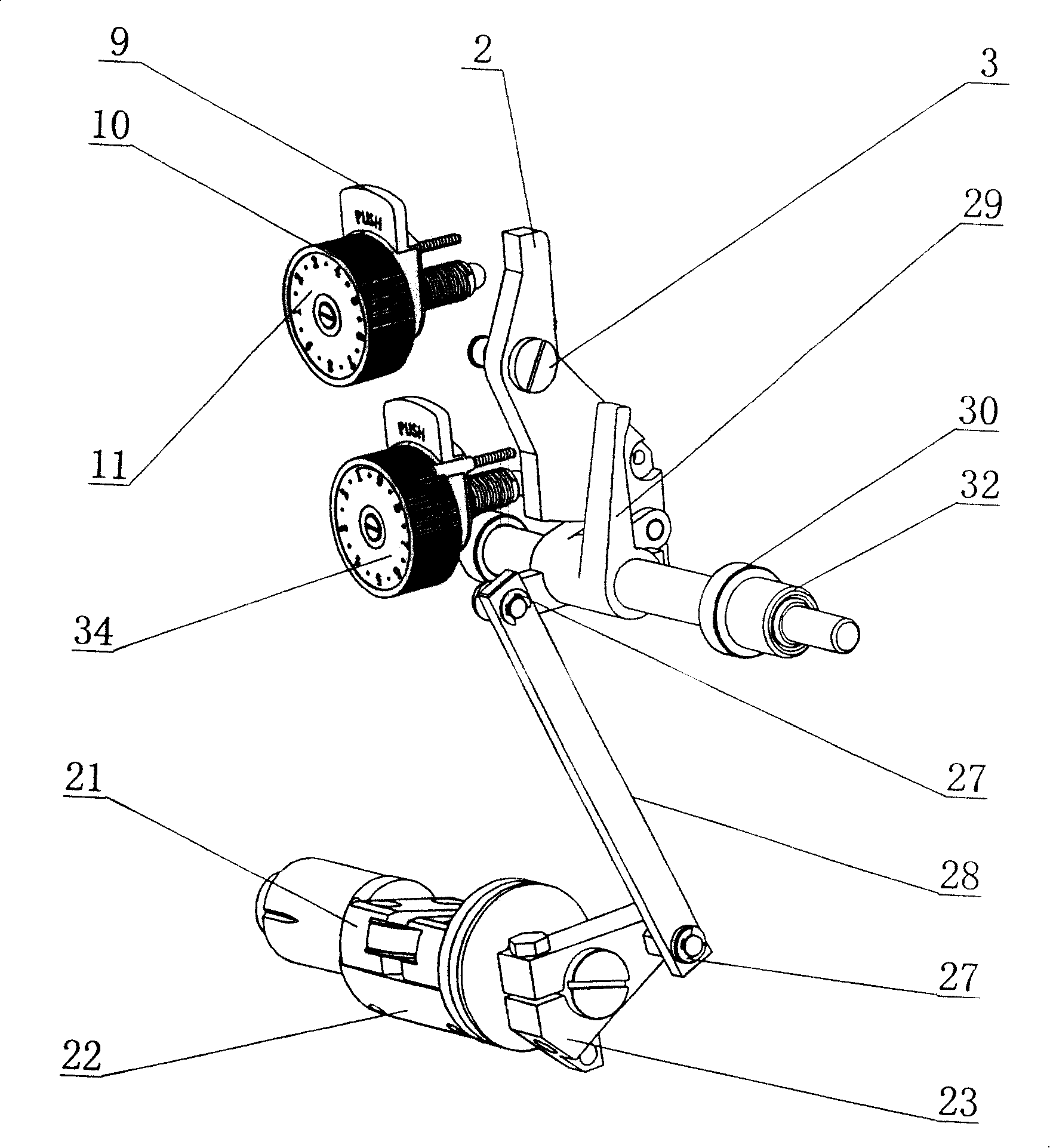

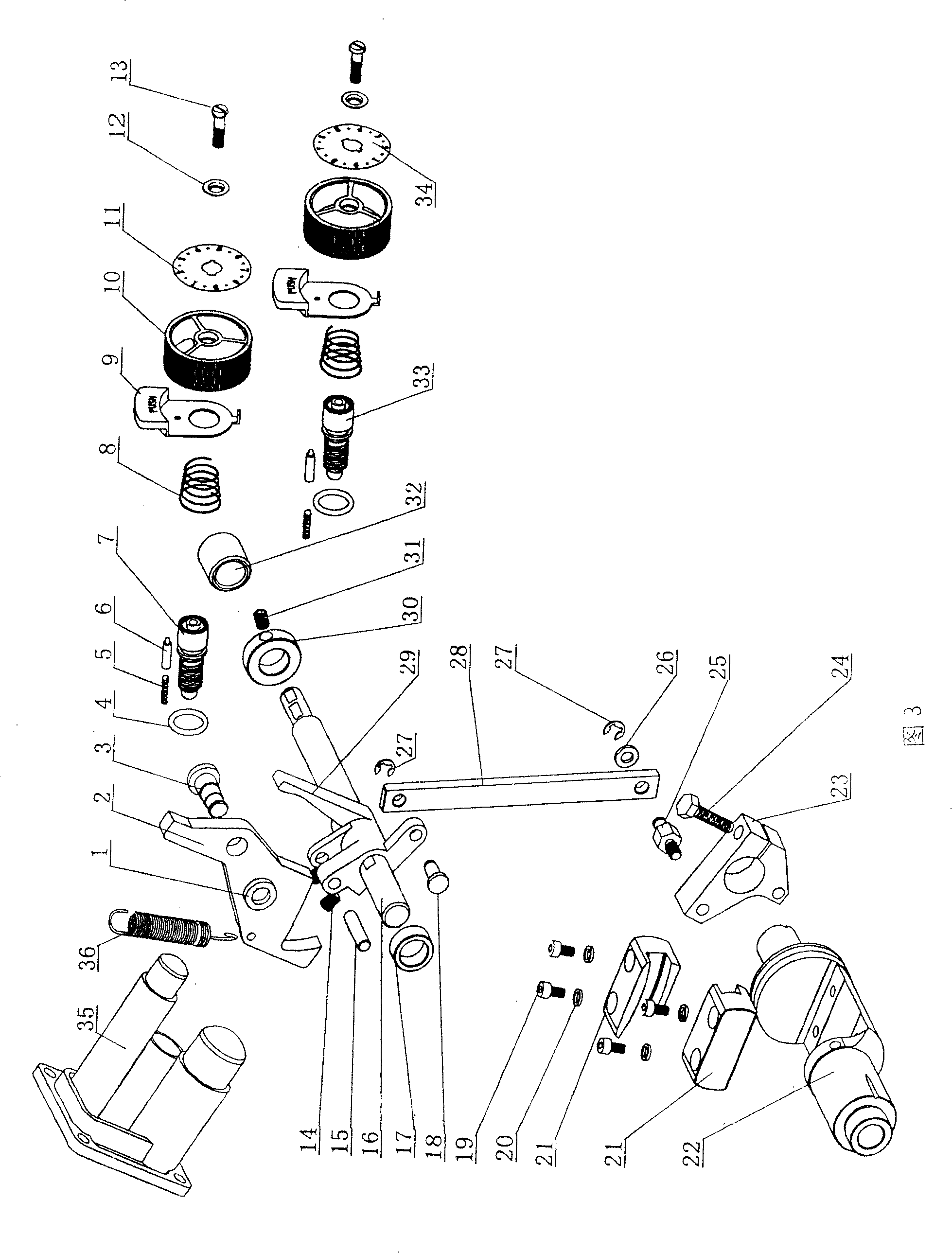

Auxiliary lifting mechanism of presser foot of computerized embroidery machine

InactiveCN101775716AReasonable designSimple structurePressersEmbroidering machines apparatusMechanical engineeringSynchronism

The invention relates to an auxiliary lifting mechanism of a presser foot of a computerized embroidery machine, which is designed aiming at the technical problem of poor structure of the auxiliary lifting mechanism (a cam mechanism) of the presser foot of the computerized embroidery machine. A link mechanism adopting three connecting rods is arranged in the auxiliary lifting mechanism of the presser foot and is in a Y shape, one end of the link mechanism is fixed in a casing of a machine head by a shaft A, and the other two ends are respectively fixed at a slide block A and a slide block B. In a group of link mechanism comprising a three-hole connecting rod A, a two-hole connecting rod B and a two-hole connecting rod C, the three-hole connecting rod A is bent in an arc shape; and a hole C1 of the three-hole connecting rod A is connected with a hole A2 of the two-hole connecting rod B by a pin shaft, and a hole A1 of the three-hole connecting rod A is connected with a hole A3 of the two-hole connecting rod C by a pin shaft. The invention has high running accuracy, small noise, convenient maintenance, assembly and use, good movement matching synchronism and stability, low production cost and extensive application range and is suitable for a high-speed computerized embroidery machine and similar tailoring equipment.

Owner:冯品牛

Sewing machine

ActiveUS20080216722A1Reliably prevent stitch skippingAccurate synchronizationSewing-machine control devicesNeedle barsGear wheelEngineering

A sewing machine includes a rotating hook, a lower shaft rotating the rotating hook in synchronization with vertical movement of the needlebar, a lower shaft gear including a helical gear and slidably mounted on the lower shaft, a hook gear including a helical gear capable of mesh engagement with the lower shaft gear and mounted on the rotating hook, a drive force transmission mechanism supporting the lower shaft so that the lower shaft is axially moveable and transmits rotation of the lower shaft to the lower shaft gear, a cam mechanism axially moving the lower shaft gear to adjust at least one of a left encounter timing for seizure of the needle thread loop by the hook beak when the needle occupies a left needle location and a right encounter timing for seizure of the needle thread loop by the hook beak when the needle occupies a right needle location.

Owner:BROTHER KOGYO KK

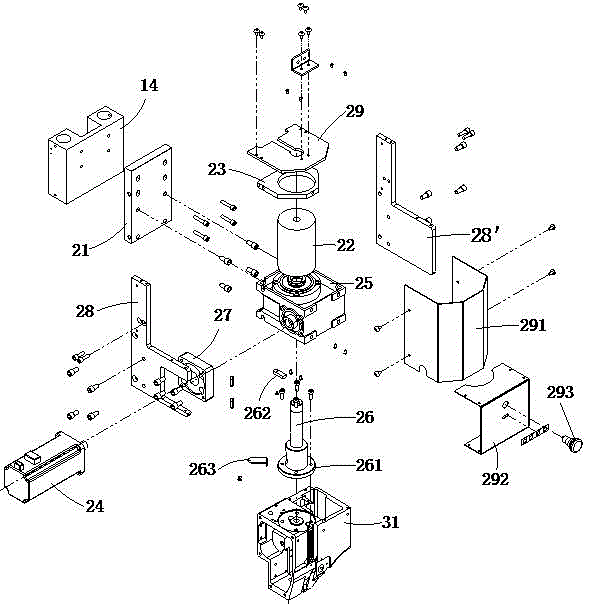

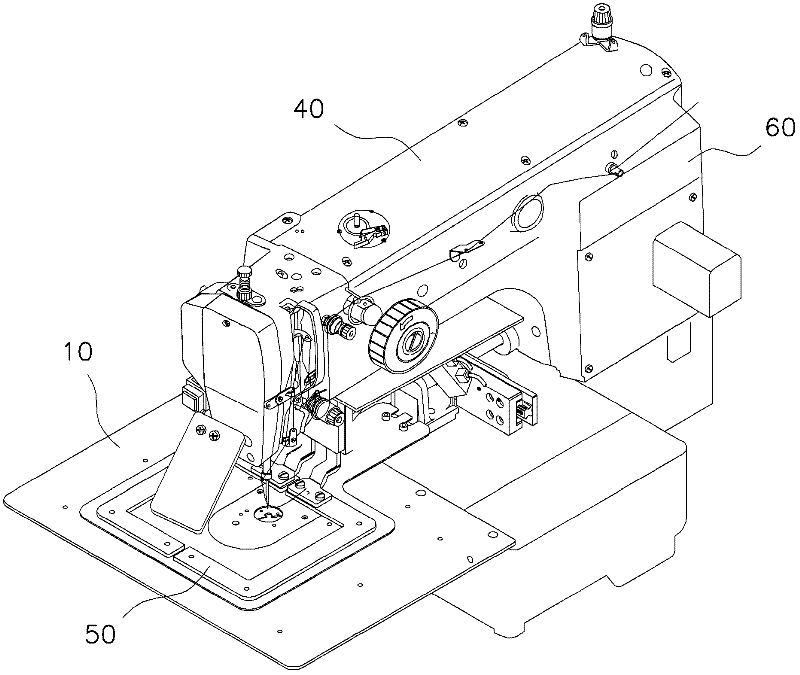

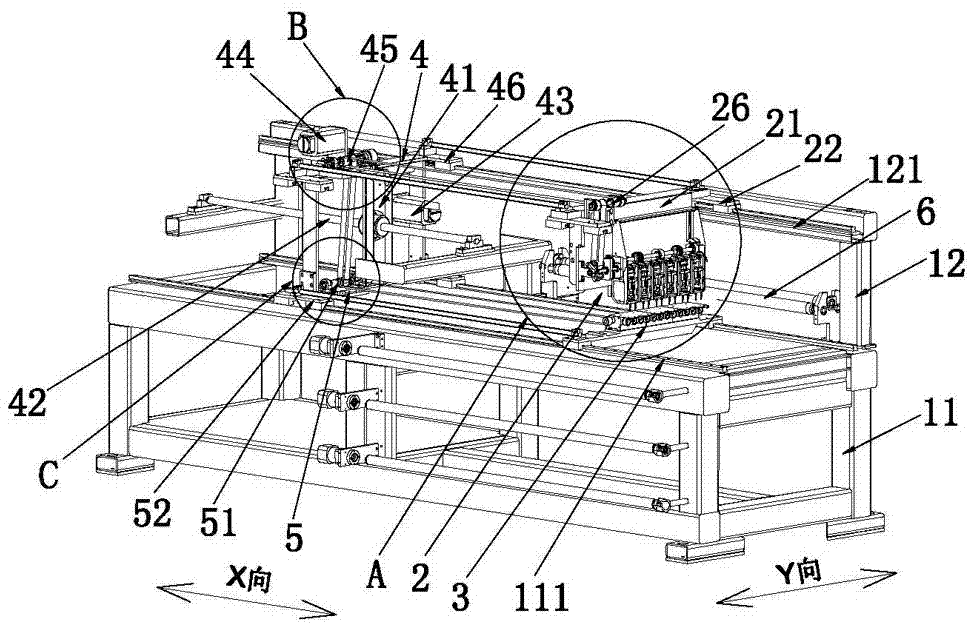

Machine head and machine base split type pattern sewing machine

InactiveCN101696534ASimple structureEasy to operateSewing-machine casingsWork-feeding meansBall screwElectric machinery

The invention relates to a machine head and machine base split type pattern sewing machine belonging to the technical field of sewing machines. The machine head and machine base split type pattern sewing machine comprises an X-direction feed device, a Y-direction feed device, a machine head, a machine base and a stand, wherein the X-direction feed device and the Y-direction feed device are driven by respectively independent motors; the Y-direction feed device drives the X-direction feed device to move along a Y direction; the X-direction feed device is provided with a double-ball screw, and the synchronous feed of the double-ball screw is realized through a synchronous belt so that the machine base and the machine head which are arranged on the X-direction feed device can synchronously move. The invention has simple structure and easy operation and can move along an X direction and the Y direction and achieve the purposes of sewing patterns with large areas and enhancing the work efficiency; in addition; the pattern sewing machine can more stably work through the double-ball screw arranged on the X-direction feed device.

Owner:JACK SEWING MASCH CO LTD

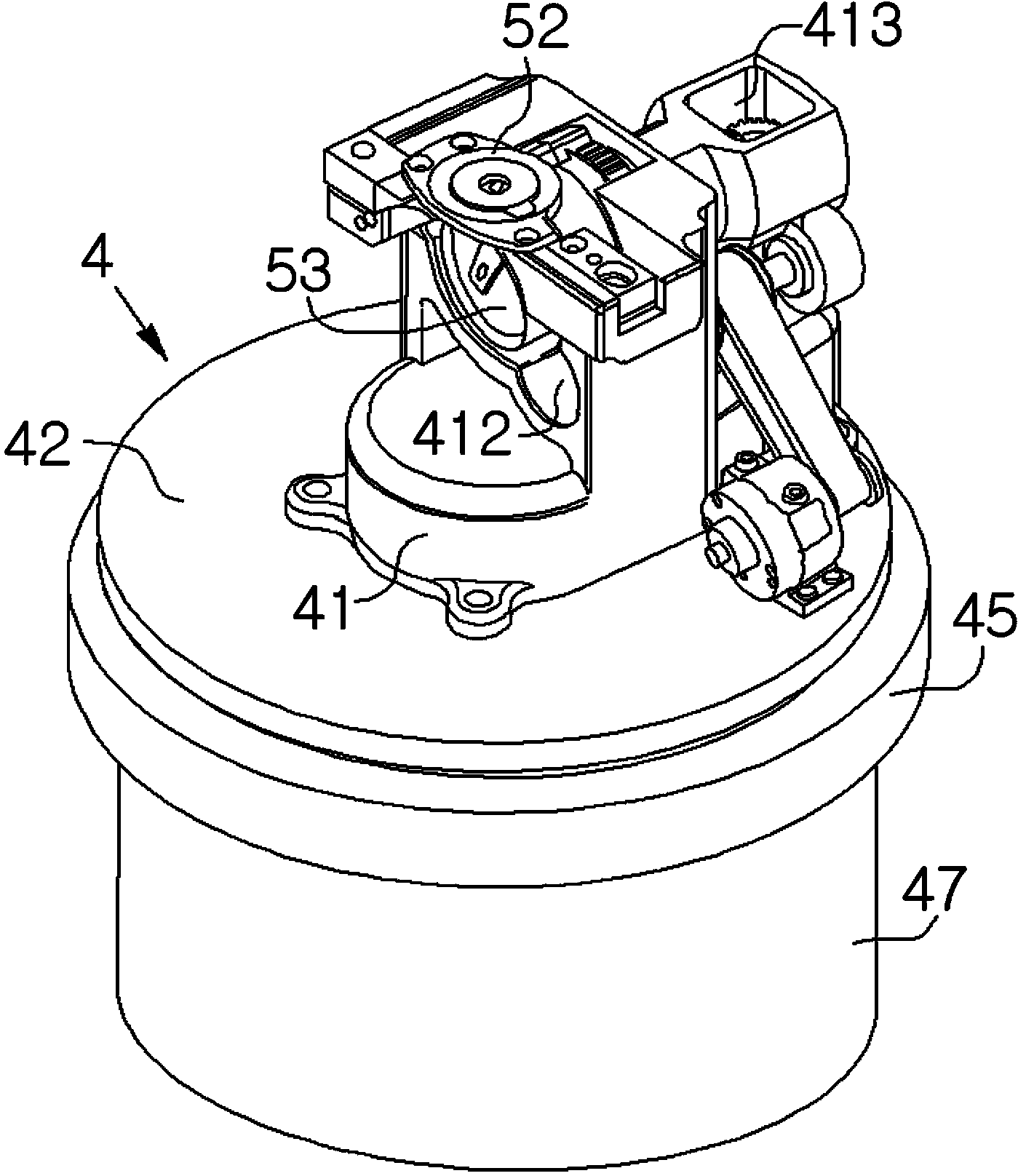

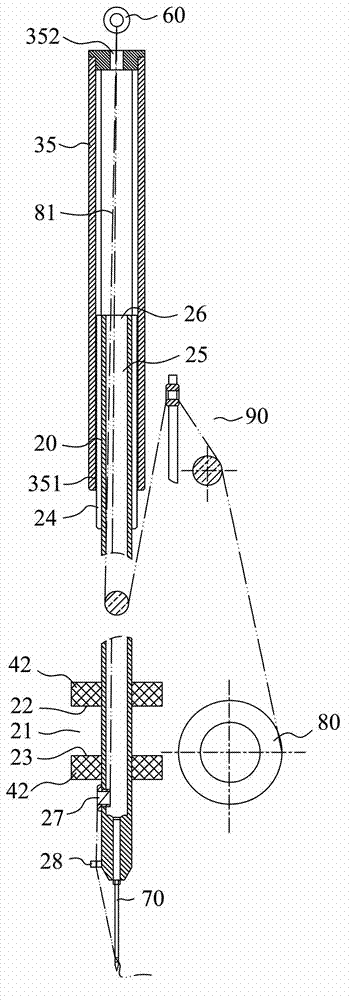

Industrial sewing machine

ActiveCN104141201ASuitable for sewingThe stitches are strong and beautifulProgramme-controlled sewing machinesNeedle severing devicesProgrammable logic controllerReciprocating motion

The invention belongs to the technical field of machinery and discloses an industrial sewing machine. A needle holder is driven to do vertical reciprocation by a swing rod and is driven to rotate around the needle holder axis by a needle holder rotation motor. A rotary hook and a hook carrier are mounted on a hook carrier assembly which comprises a shell, a rotary disc, a circular rotary seat, a belt pulley ring, a rotary hook motor, an assembly bearing and a slip ring. The rotary hook assembly is driven to do horizontal rotation by a rotary hook motor. Cloth to be sewn is clamped by a cloth feeding mechanism to do plane moving between the needle holder and the rotary hook. The needle holder rotation motor, the rotary hook carrier motor and the rotary hook motor are connected to a programmable logic controller on a table through the slip ring. The programmable logic controller drives the needle holder and the rotary hook carrier assembly to do rotation with same phase and same angular velocity. Products sewn by the industrial sewing machine have stable and firm stitches, and the industrial sewing machine is particularly suitable for sewing leather / cloth products in variable curved shapes.

Owner:广州明志电脑花样缝纫机械有限公司

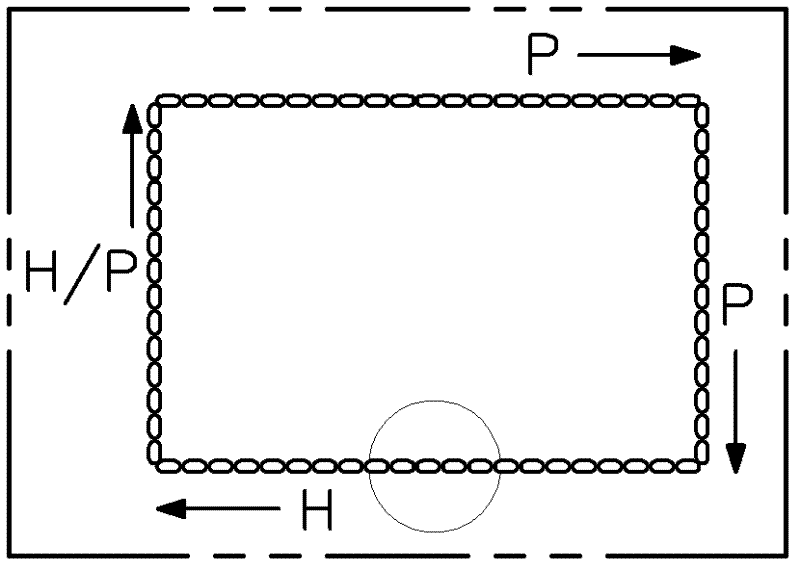

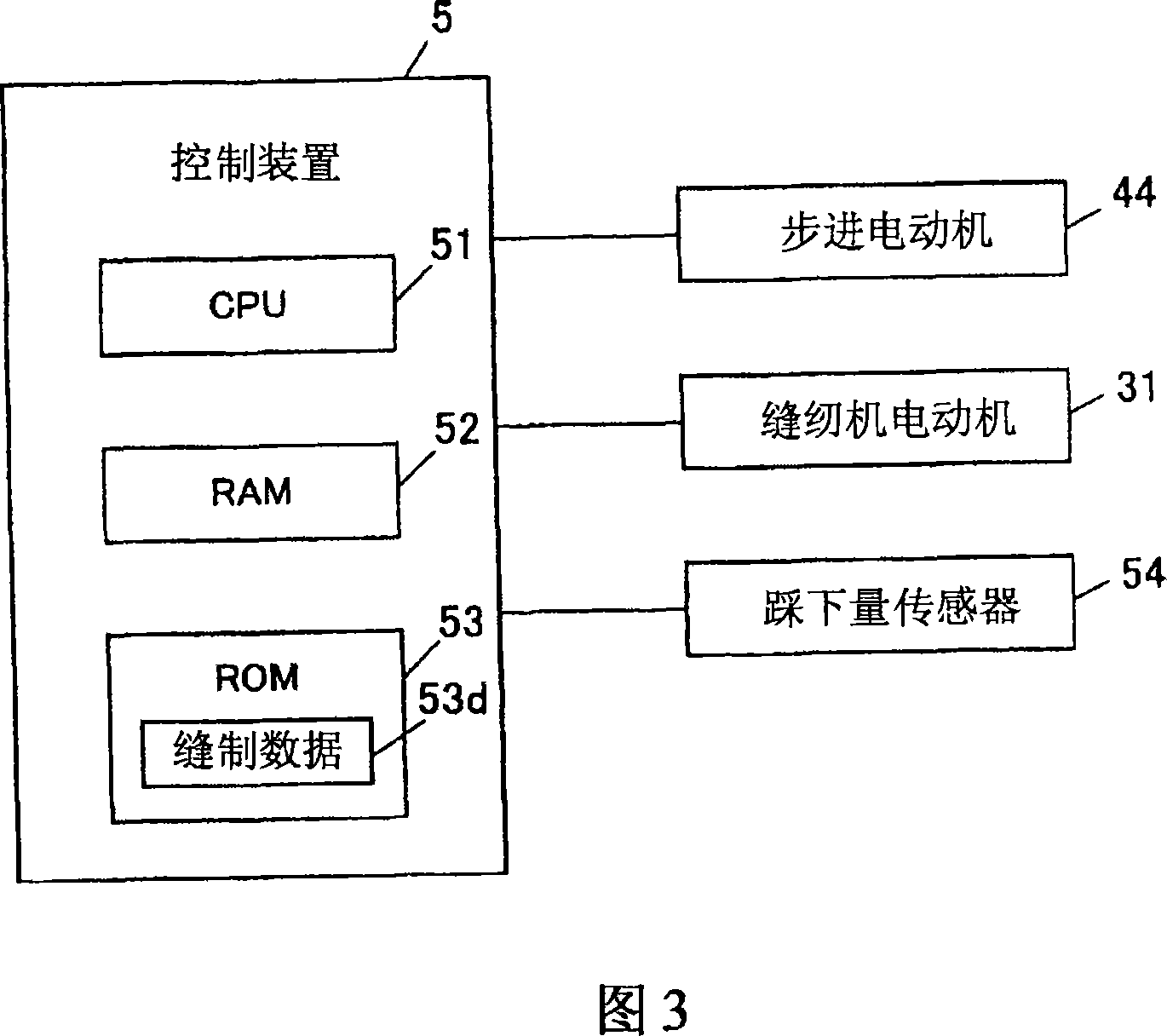

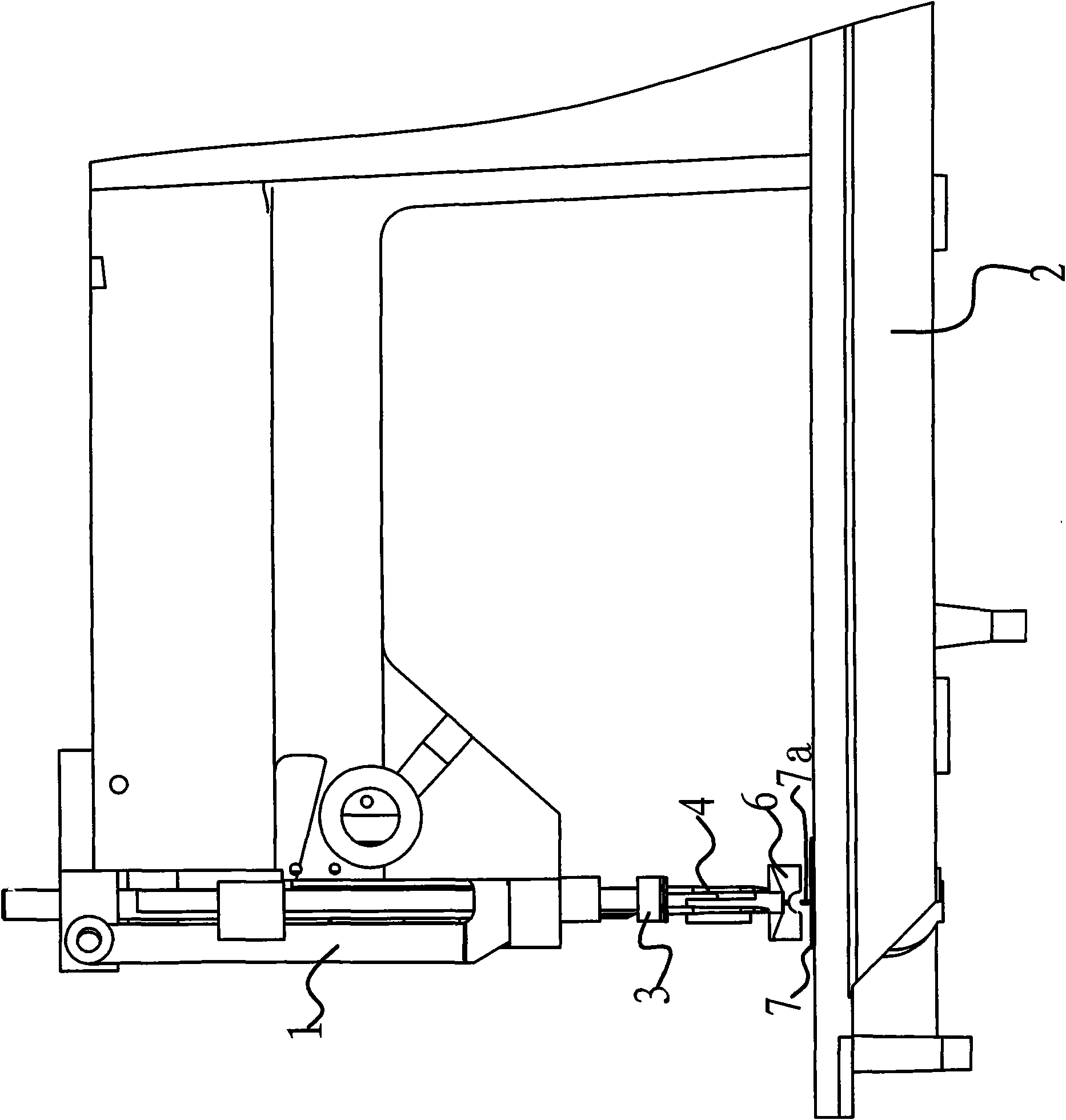

Sewing machine and method of controlling operation of the same

ActiveCN102560915AAchieving perfect stitchesExpand the operating areaProgramme-controlled sewing machinesLeather sewingEngineeringSewing machine

A sewing machine is provided, which includes a table, support posts, upper and lower frames, a head unit, a bed unit, an X-axial head-unit-transport means and an X-axial bed-unit-transport means. An object is placed on the table. The support posts are provided on opposite sides of the table. The upper and lower frames connect the support posts to each other. The head unit is provided on the upper frame so as to be movable in an X-axis direction. The head unit has a head-unit-rotating means for rotating a sewing head. The bed unit is provided on the lower frame so as to be movable in the X-axis direction. The bed unit has a bed-unit-rotating means for rotating a sewing bed. The X-axial head-unit-transport means moves the head unit on the upper frame horizontally. The X-axial bed-unit-transport means moves the bed unit on the upper frame horizontally.

Owner:SUNSTAR KK

Sewing machine

ActiveCN101100793AImprove sewing qualityImprove sewing efficiencySewing-machine control devicesNeedle barsRing deviceTime transfer

The present invention is to improve sewing efficiency through omitting the regulating work of the installation position of a kettle (or a beating ring device) generated through the thickness of the matter to sewing or the rotation delay of sewing speed as well as a kettle (or a beating ring device). A sartorius comprises an upper axis, which keeps a needle of a sewing needle move up and down; a lower axis, driving a sewing catching unit which catches the upper thread of the sewing needle to swing with the lower thread; a drive source, applying rotary drive on the upper axis and the lower axis; an upper axis rotary part, rotating along with the upper axis; a lower axis rotary part, rotating along with the lower axis; a drive transferring part, which loop shaped frames set on the upper axis rotary part and the lower axis rotary part, at the same time transfers the rotary drive of a rotary part rotated by means of the drive source to another rotary part, the drive transferring part ensures the length rate of two frame parts connecting with the position between the upper axis and the lower axis rotary part to be alter automatically through outside force.

Owner:JUKI CORP

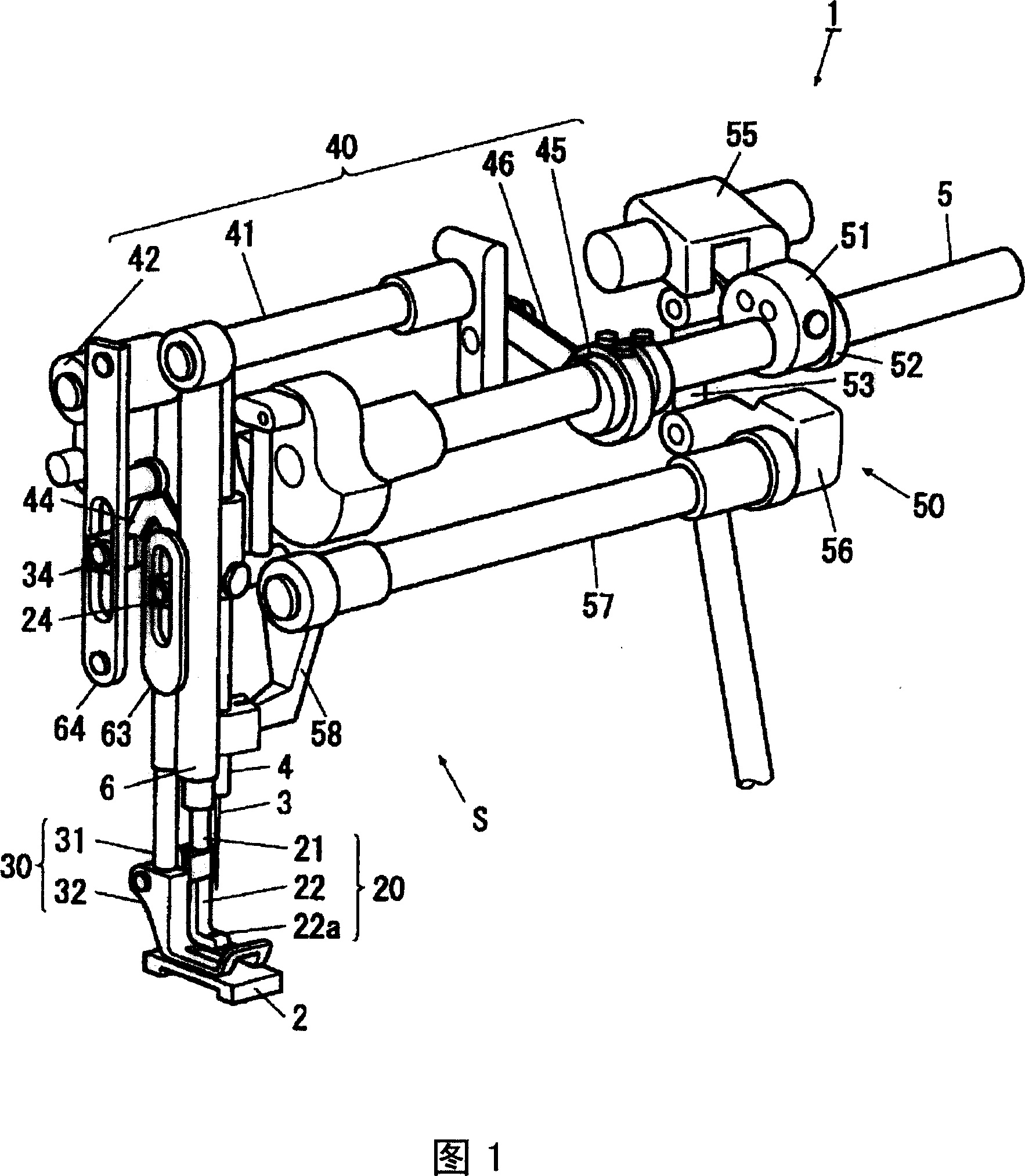

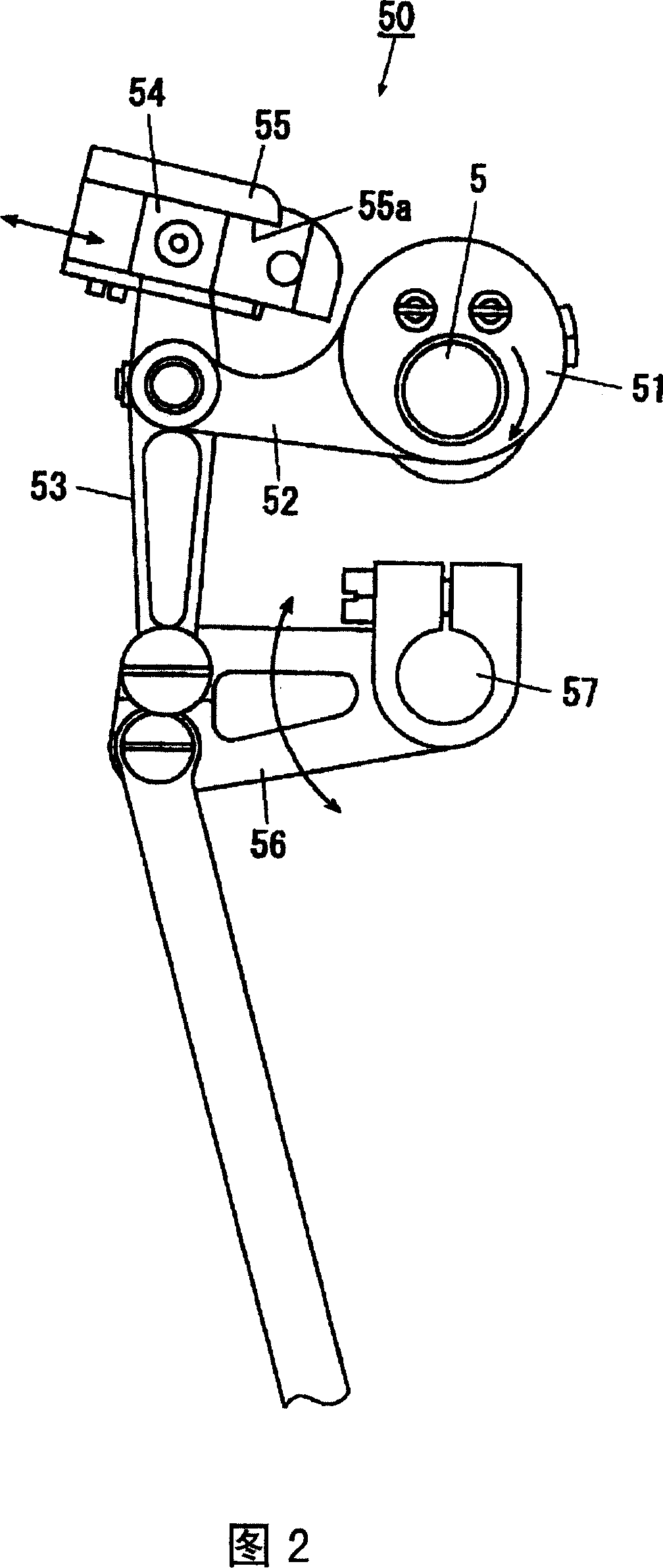

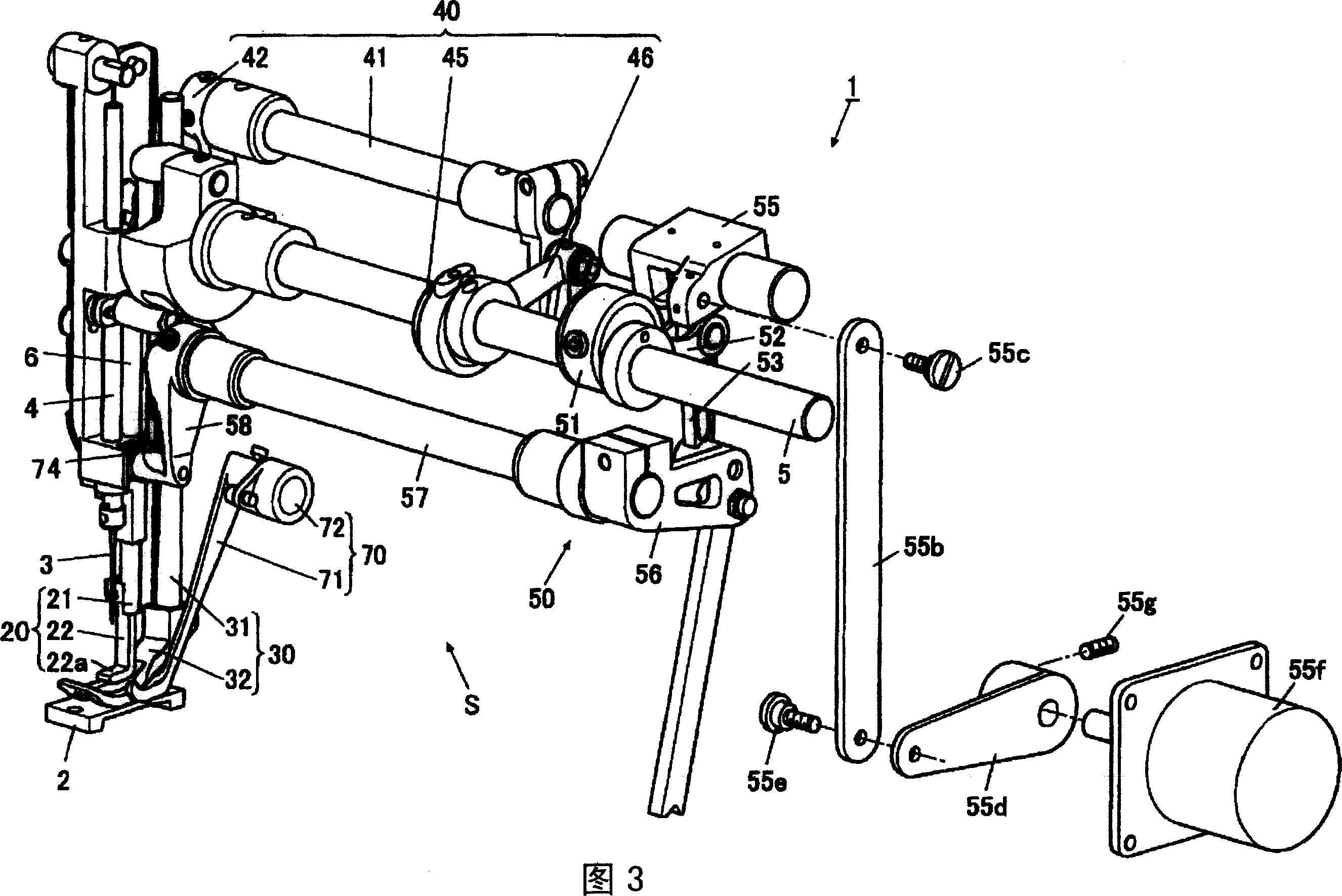

Cloth-feeding device of sewing machine

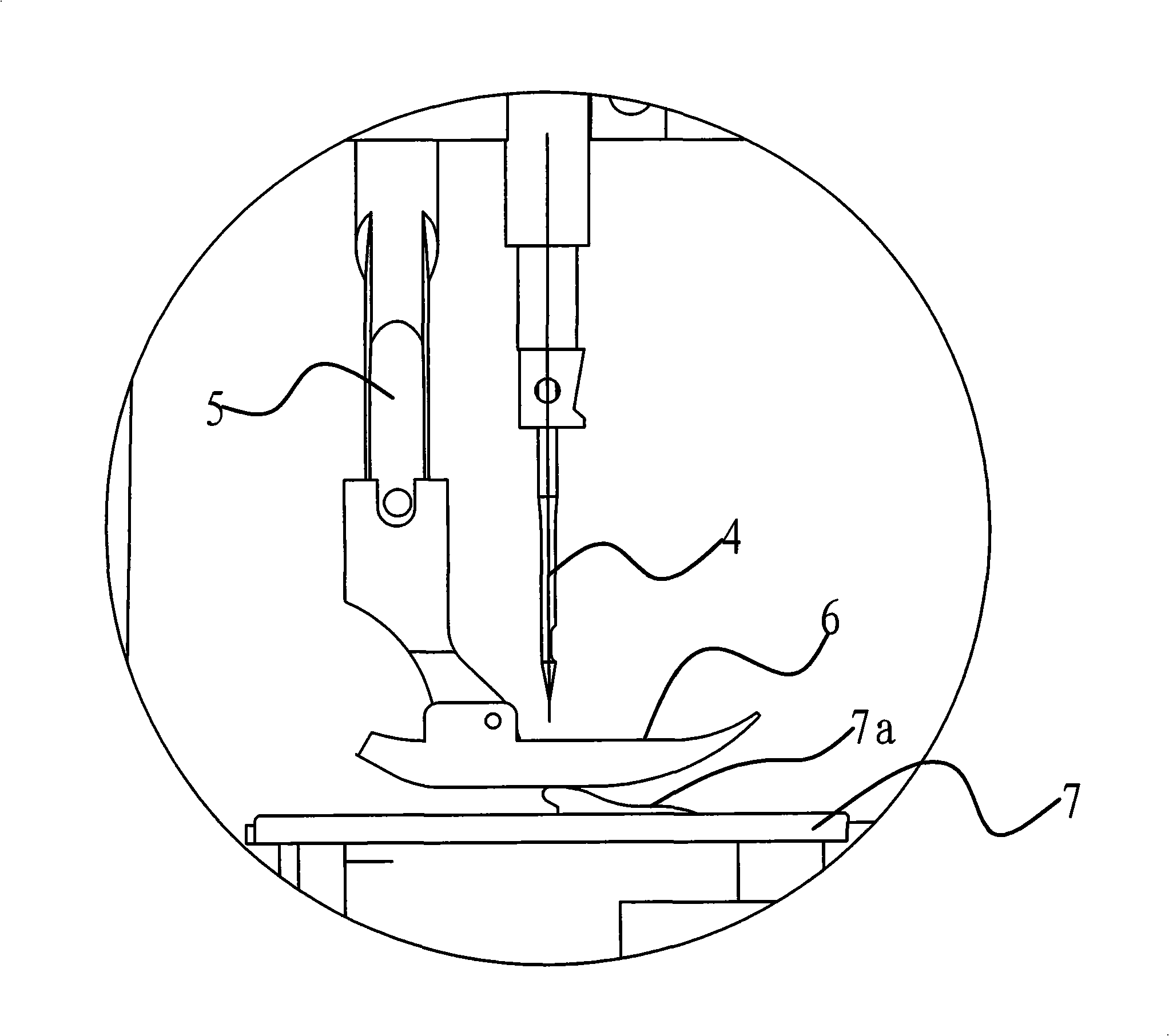

InactiveCN1995519ASewing spacing is about the sameSame sewing pitchProgramme-controlled sewing machinesWork-feeding meansTranslation tableSewing machine

The present invention provides a fabric feeding apparatus of sewing machine capable of providing approximately same distance of sewing. The fabric feeding apparatus of sewing machine comprises a fabric frame (S), which moves synchronously with a needle bar (4) moving up and down driven by a motor of the sewing machine, and feeds fabric on a needle plate (2) by feeding tooth; a fabric feeding quantity input apparatus, which inputs fabric feeding quantity based on the fabric frame (S); a drive control apparatus (70), which measures fabric thickness fed by the fabric frame (S); a storing apparatus, which stores fabric feeding quantity translation table of relationship between fabric thickness and fabric feeding quantity suiting for the fabric thickness; and a fabric feeding quantity correction apparatus, which selects the fabric feeding quantity corresponding with fabric thickness measured by the drive control apparatus (70) from the fabric feeding quantity translation table and corrects the data of fabric feeding quantity with the fabric feeding quantity input apparatus such that the fabric feeding quantity is that selected.

Owner:JUKI CORP

Sewing machine needle distance regulating mechanism

InactiveCN101168888AEasily convert between each otherEasy to operateNeedle barsEngineeringBiomedical engineering

The invention discloses a needle distance adjusting mechanism of a sewing machine, which comprises a needle distance adjusting device, a needle distance adjusting swinging rod, a back sewing crank, and a back sewing table. The needle distance adjusting device has two groups, namely, a large needle distance adjusting device and a small needle distance adjusting device, wherein, the large needle distance adjusting device consists of a large needle distance adjusting threaded rod, a needle distance index disc positioning plate, a needle distance index disc, and a large needle distance index disc panel; the small needle distance adjusting device consists of a small needle distance adjusting threaded rod, a needle distance index disc positioning plate, a needle distance index disc, and a small needle distance index disc panel; the needle distance adjusting swinging rod is driven by a back sewing full needle cylinder and respectively contacted with the large needle distance adjusting threaded rod and the small needle distance adjusting threaded rod. Through the driving of the back sewing full needle cylinder, the product of the invention easily realizes the mutual conversion between the large needle distance adjusting device and the small needle distance adjusting device, and has the advantages that the operation is simple, the sewing efficiency is improved, etc.

Owner:SHANGHAI HUIGONG NO 3 SEWING MACHINE FACTORY CHINA TYPICAL SEWING MACHINE

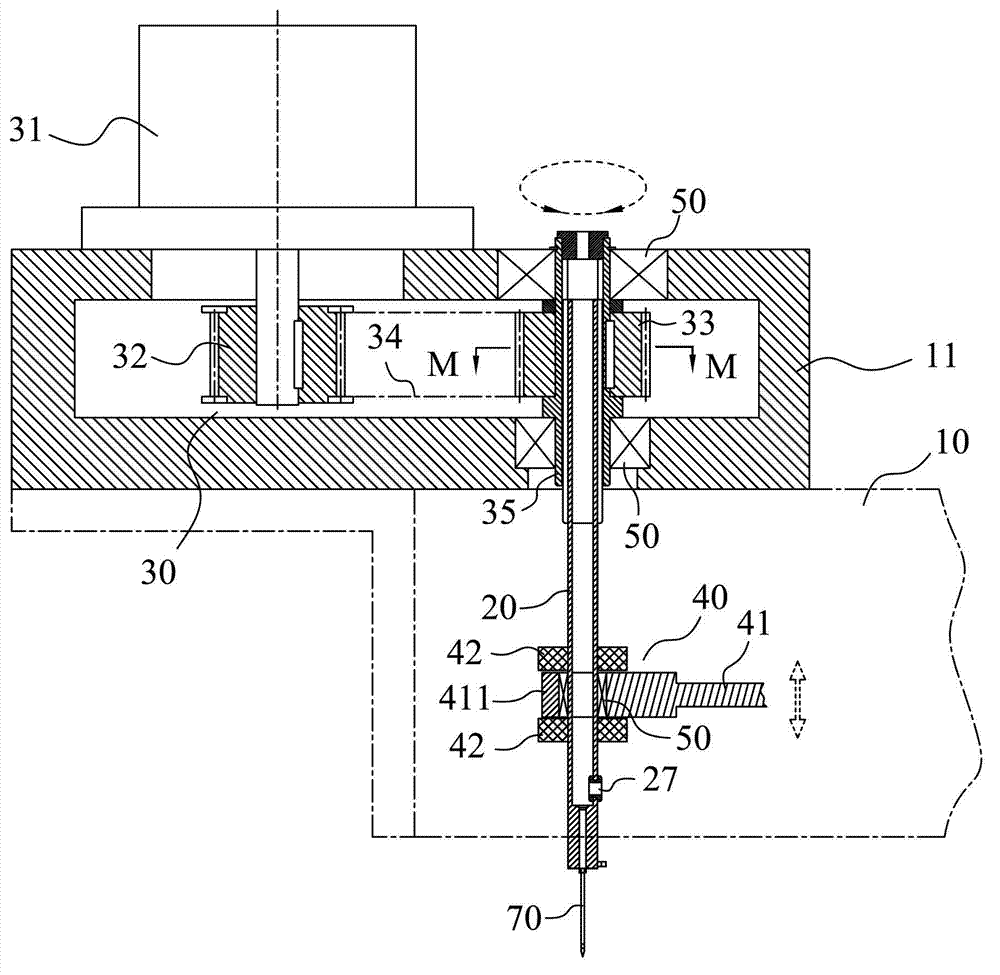

Needle-bar-rotating pattern sewing machine

InactiveCN102776722AGuaranteed aestheticsThere will be no twisting phenomenonHem-stitch machinesNeedle barsYarnElectric machinery

The invention disclosed a needle-bar-rotating pattern sewing machine, which comprises a needle bar, a needle bar rotating mechanism and a needle bar up-and-down movement mechanism, wherein the needle bar rotating mechanism comprises a needle bar sheath; the needle bar moves up and down relative to the needle bar sheath; an axial thread inlet is arranged at the top of an axial thread hole formed in the hollow part of the needle bar; and a thread outlet is arranged at the lower end of the axial thread hole. As the needle bar up and down motion mechanism drives the needle bar into up-and-down movement to conduct stitching action, the needle bar rotating mechanism drives the needle bar to rotate; through regulating sewing stitches and directions, the changes of patterns and design directions are adaptive, and stitch esthetic appearance is ensured; and as the yarn passes through the axial thread hole of the needle bar, the phenomenon of twisted threads does not occur during the process of rotation of the needle bar. Therefore, the needle-bar-rotating pattern sewing machine provided by the invention has the beneficial effect that by replacing the way of large-volume machine head rotation with thin and small-volume needle bar rotation, stitches can be formed along the tangential direction of designs and patterns in sewing, the rotation inertia is reduced, the vibration is reduced, the rotation speed is improved, and the motor power is greatly reduced.

Owner:颜新宁

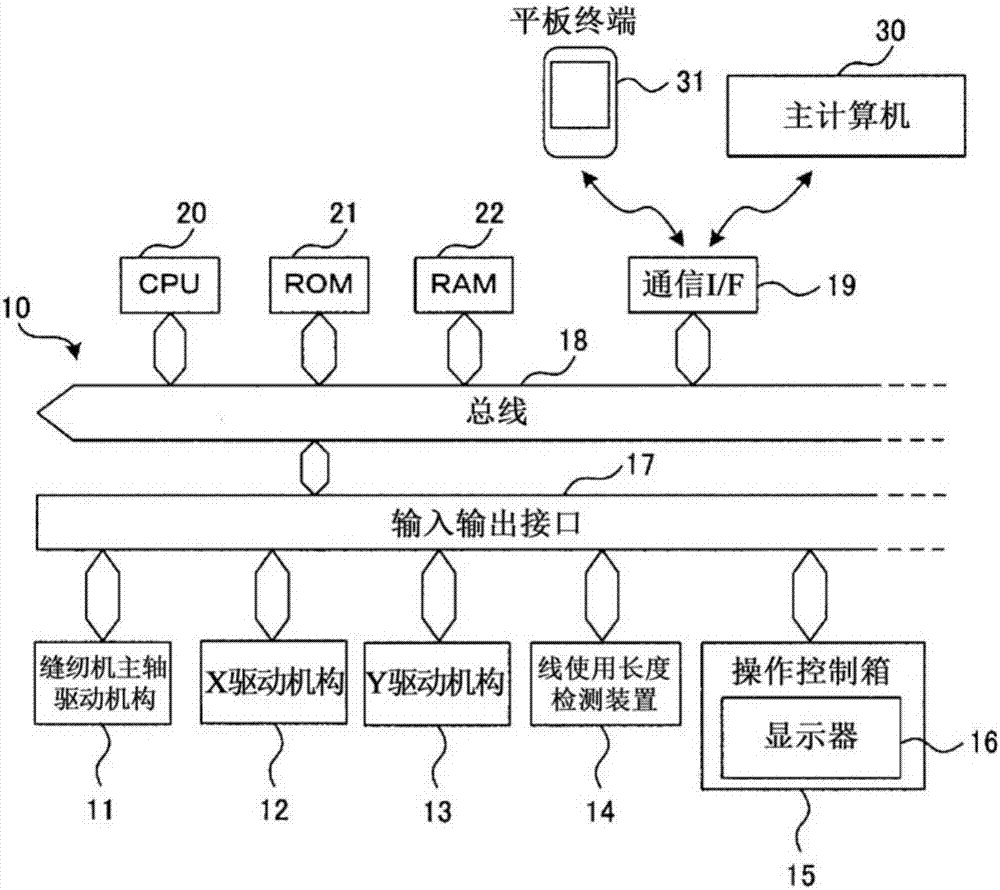

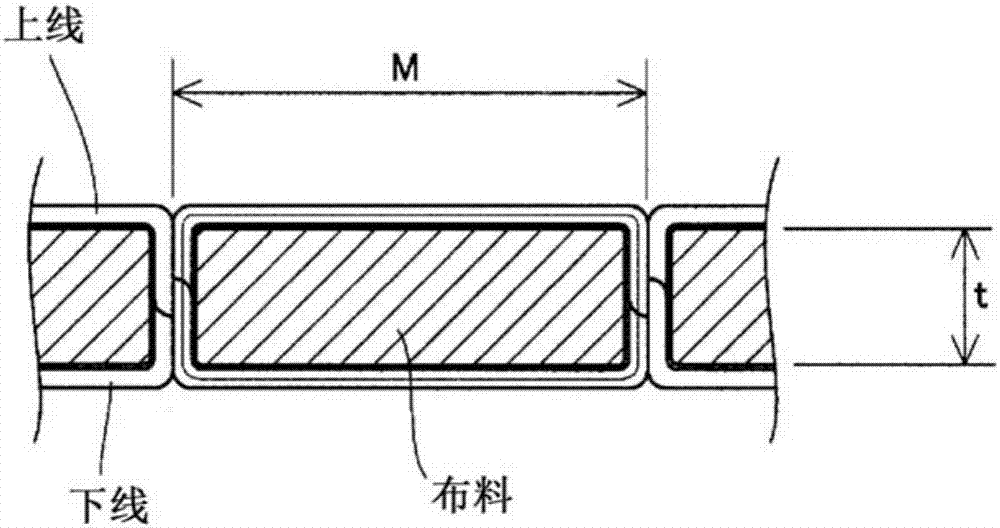

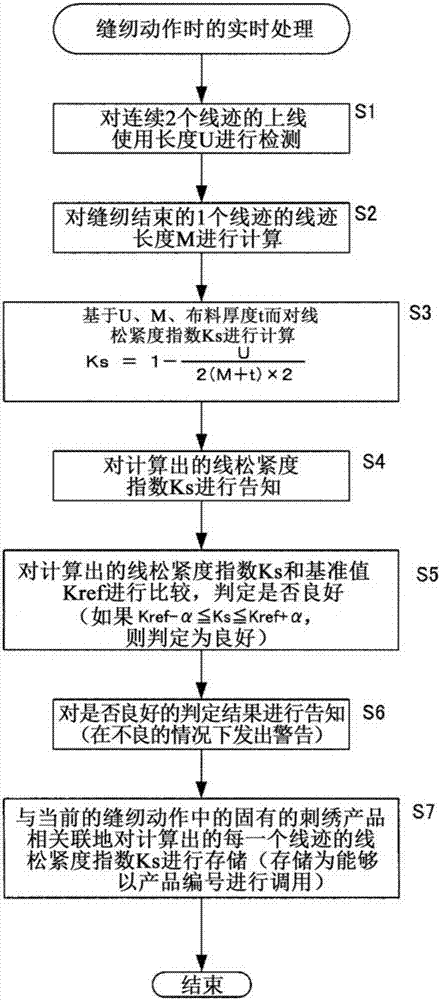

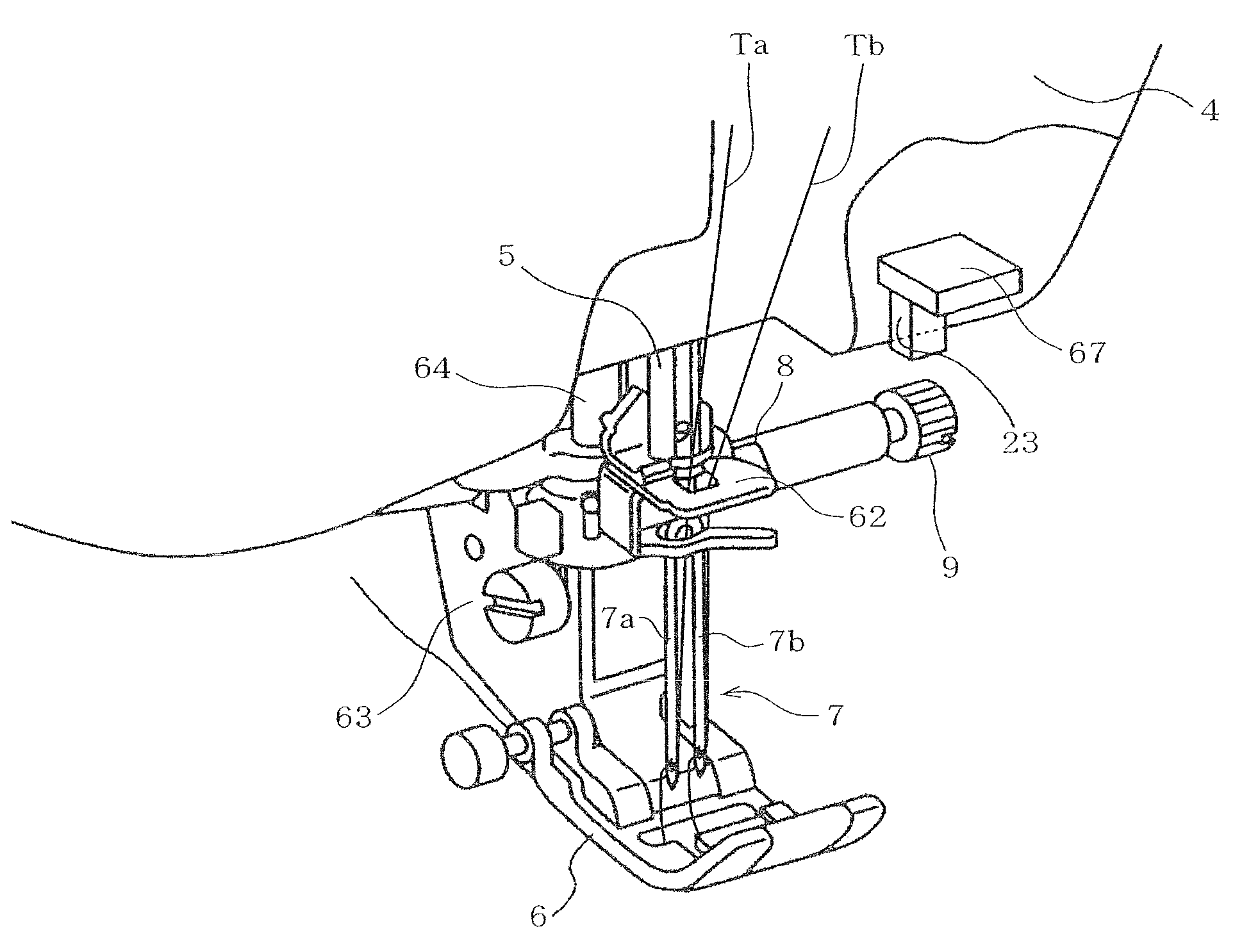

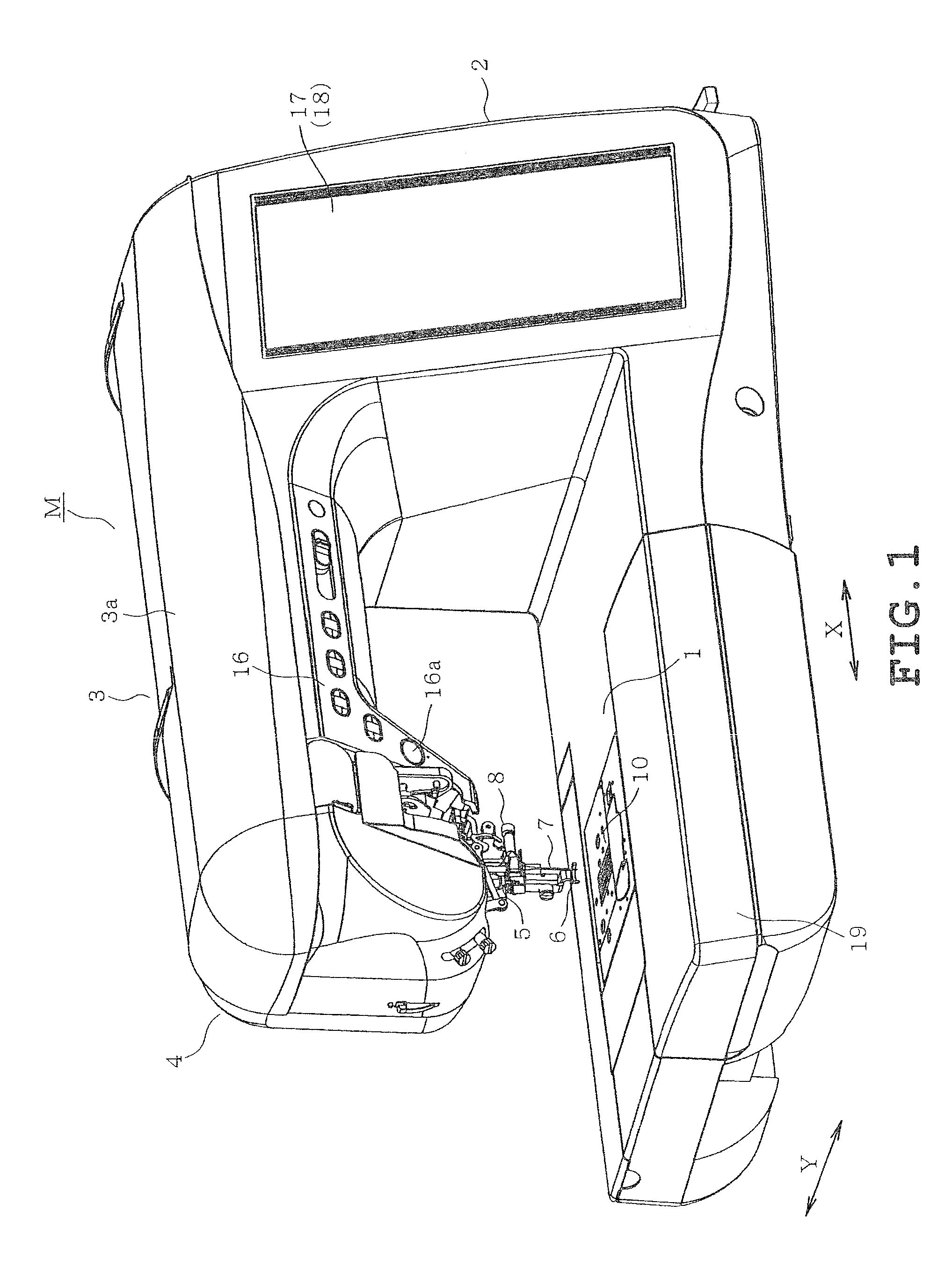

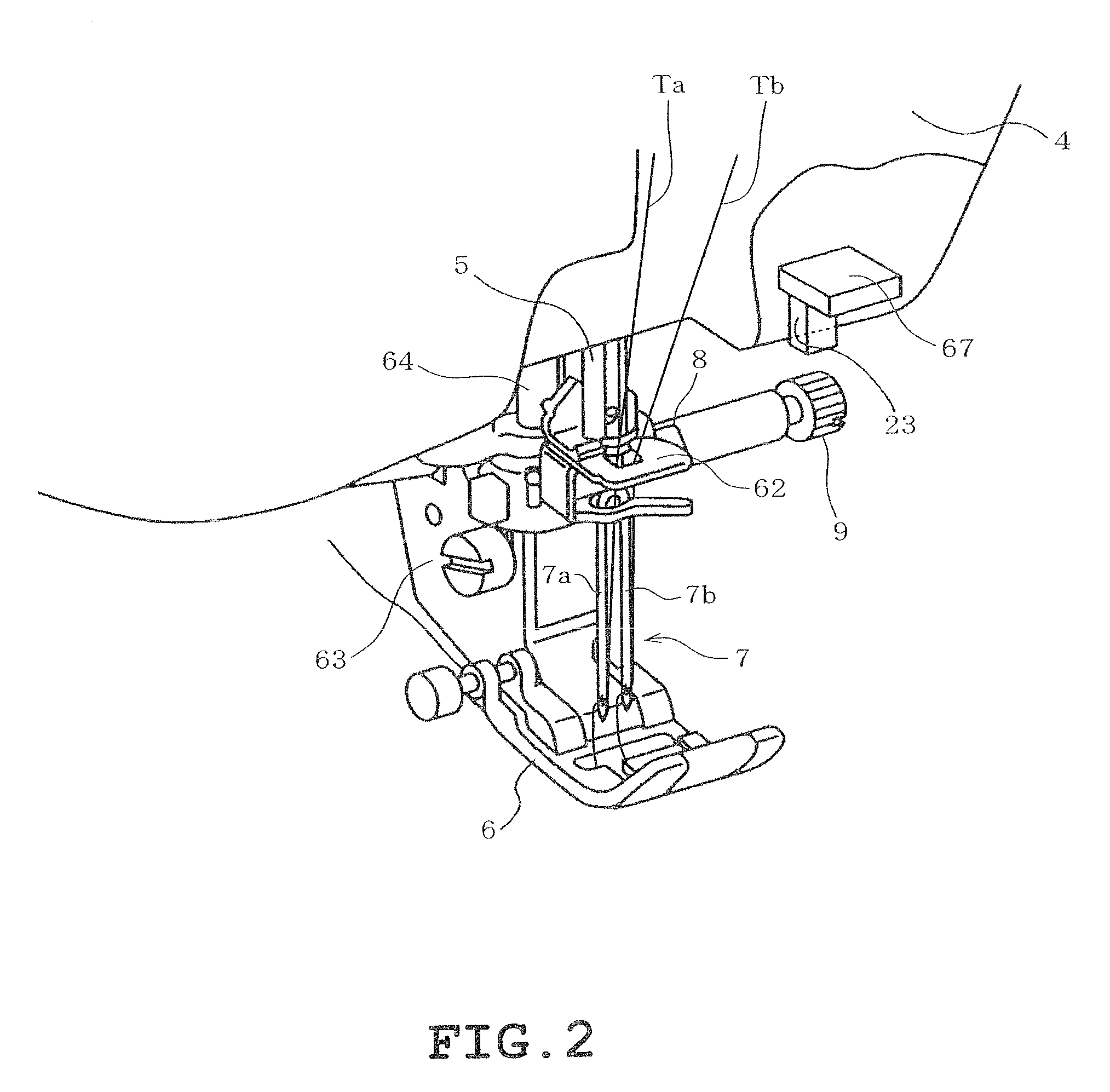

Sewing quality control in sewing machine

ActiveCN107407030AImprove sewing qualityCentralized management of production progressProgramme-controlled sewing machinesSewing measuring devicesQuality controlEngineering

The present invention relates to a sewing machine which evaluates sewing quality using a thread tightening index. During a sewing operation, an upper thread used length (U) used for each stitch is detected, and a thread tightening index (Ks) for each sewn stitch is calculated on the basis of a stitch length (M) for each stitch, defined in accordance with sewing pattern data, a fabric thickness (t) of the object being sewn, and the detected upper thread used length (U) data. A report (for example a display of the thread tightening index Ks) corresponding to the thread tightening index (Ks) calculated for each sewn stitch is issued. By comparing the thread tightening index (Ks) calculated for each sewn stitch with a reference value (Kref), the acceptability of the thread tightness for each sewn stitch can be assessed, and the assessment results can be reported.

Owner:TISM CO LTD +1

Sewing machine provided with needle bar rocking mechanism

ActiveUS20100224111A1Optimize locationProgramme-controlled sewing machinesWork-feeding meansBiomedical engineeringSewing machine

A sewing machine includes a needle bar to which a needle is attached, a needle bar rocking mechanism which rocks the needle bar, a needle plate having a needle hole through which the needle is passed, an imaging device which images a lower part of the needle bar, a setting section which sets a range of rocking motion of the needle bar based on an image obtained by the imaging device, and a control device which controls the needle bar rocking mechanism based on the range of rocking motion set by the setting section.

Owner:BROTHER KOGYO KK

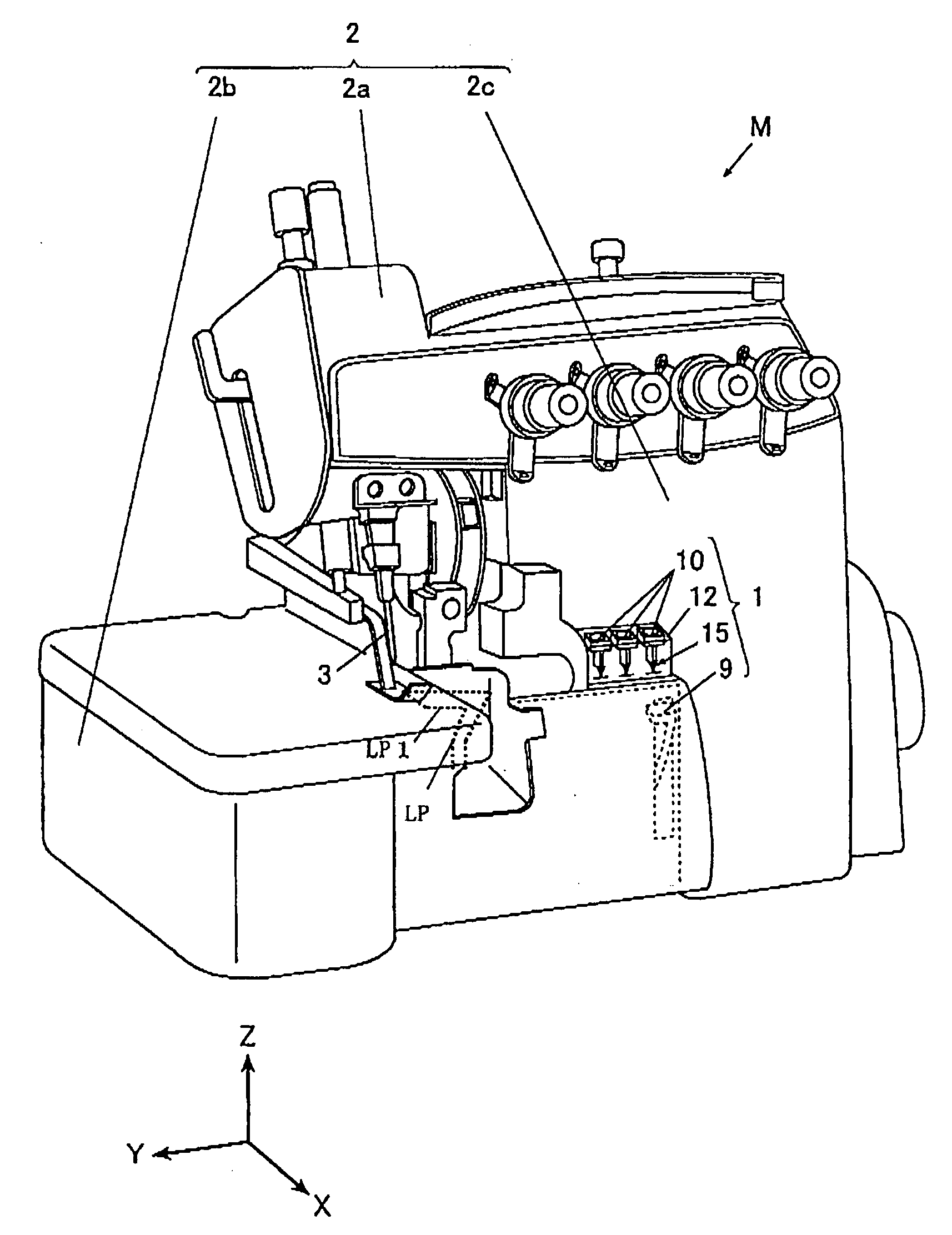

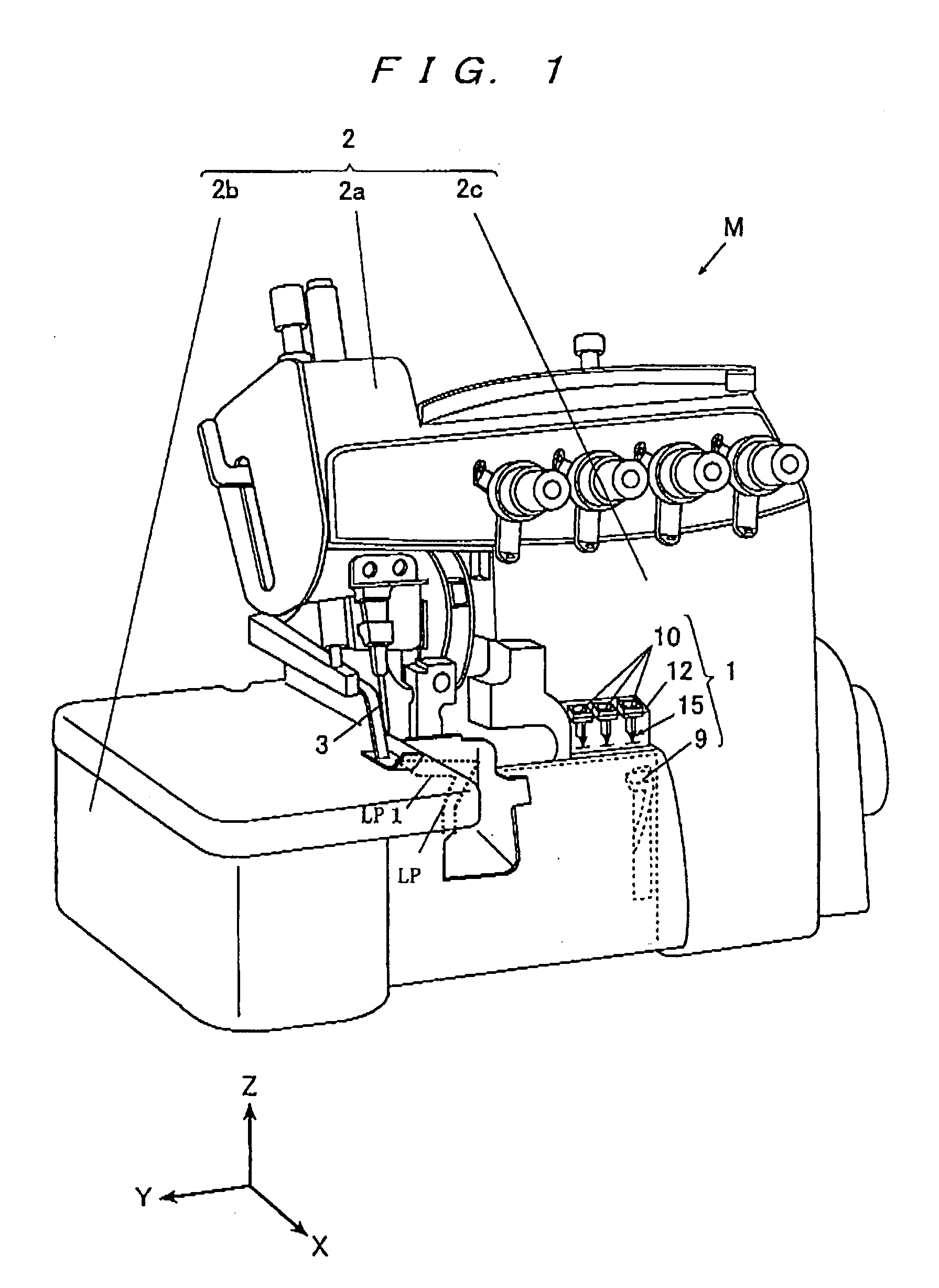

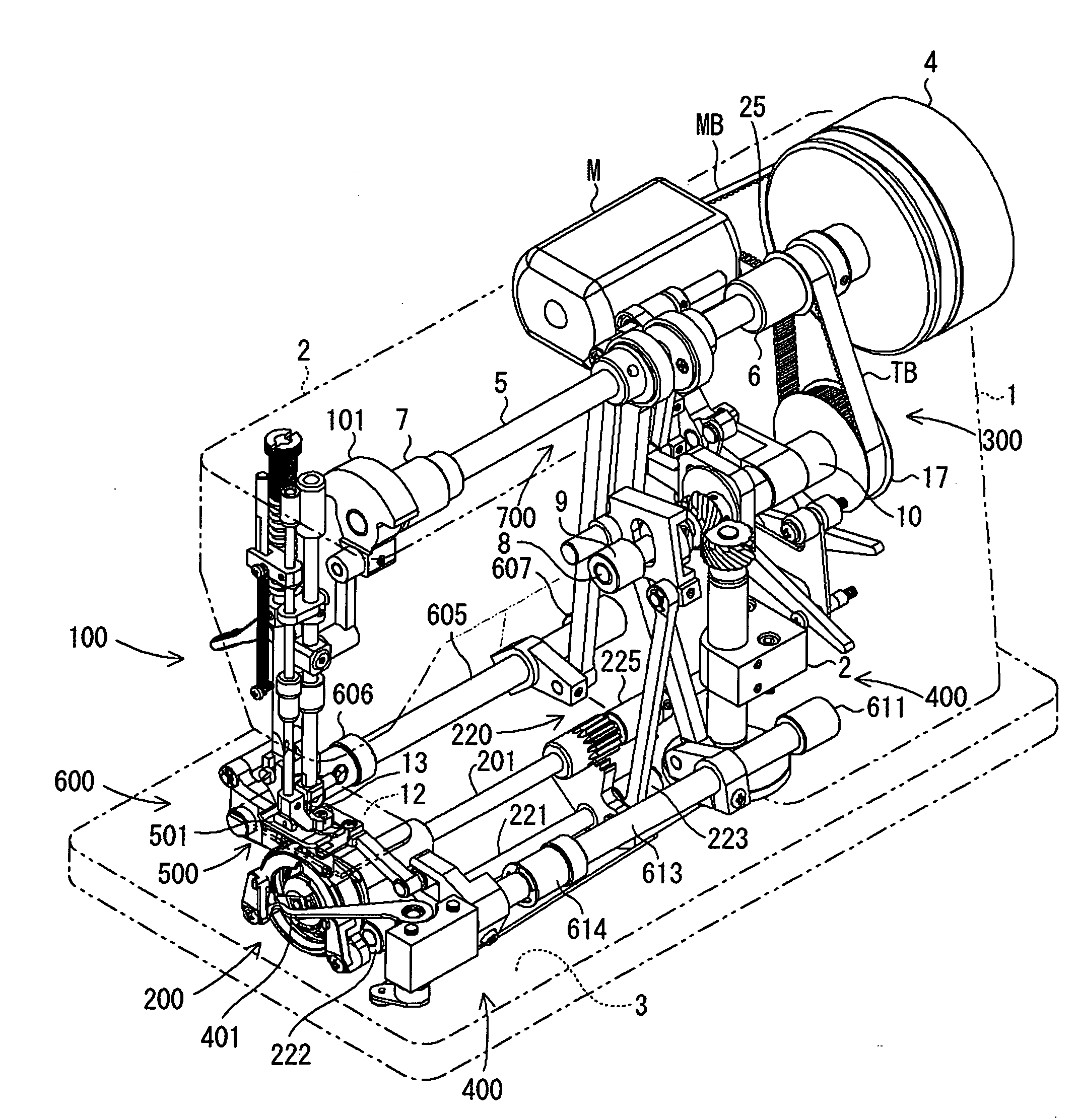

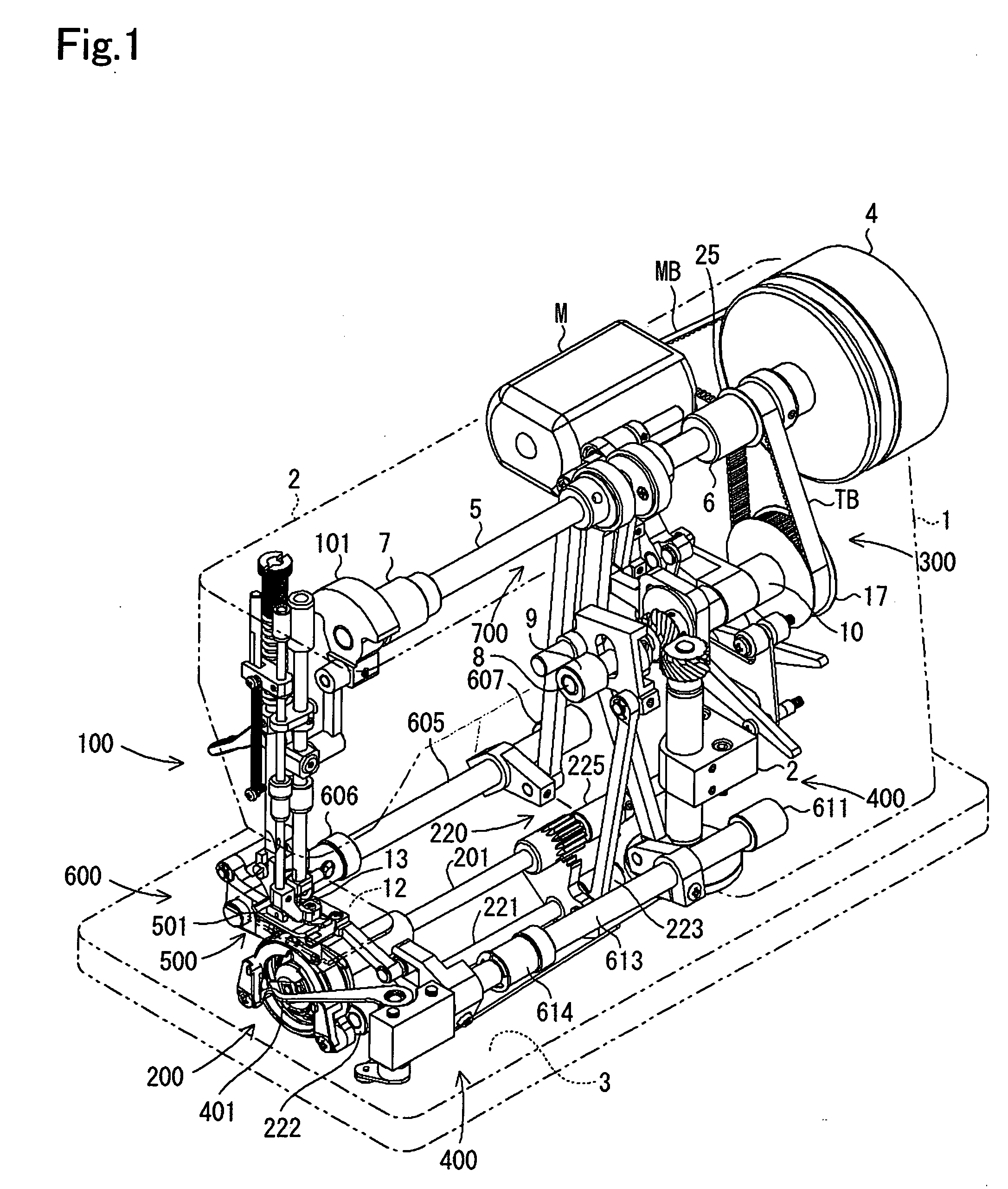

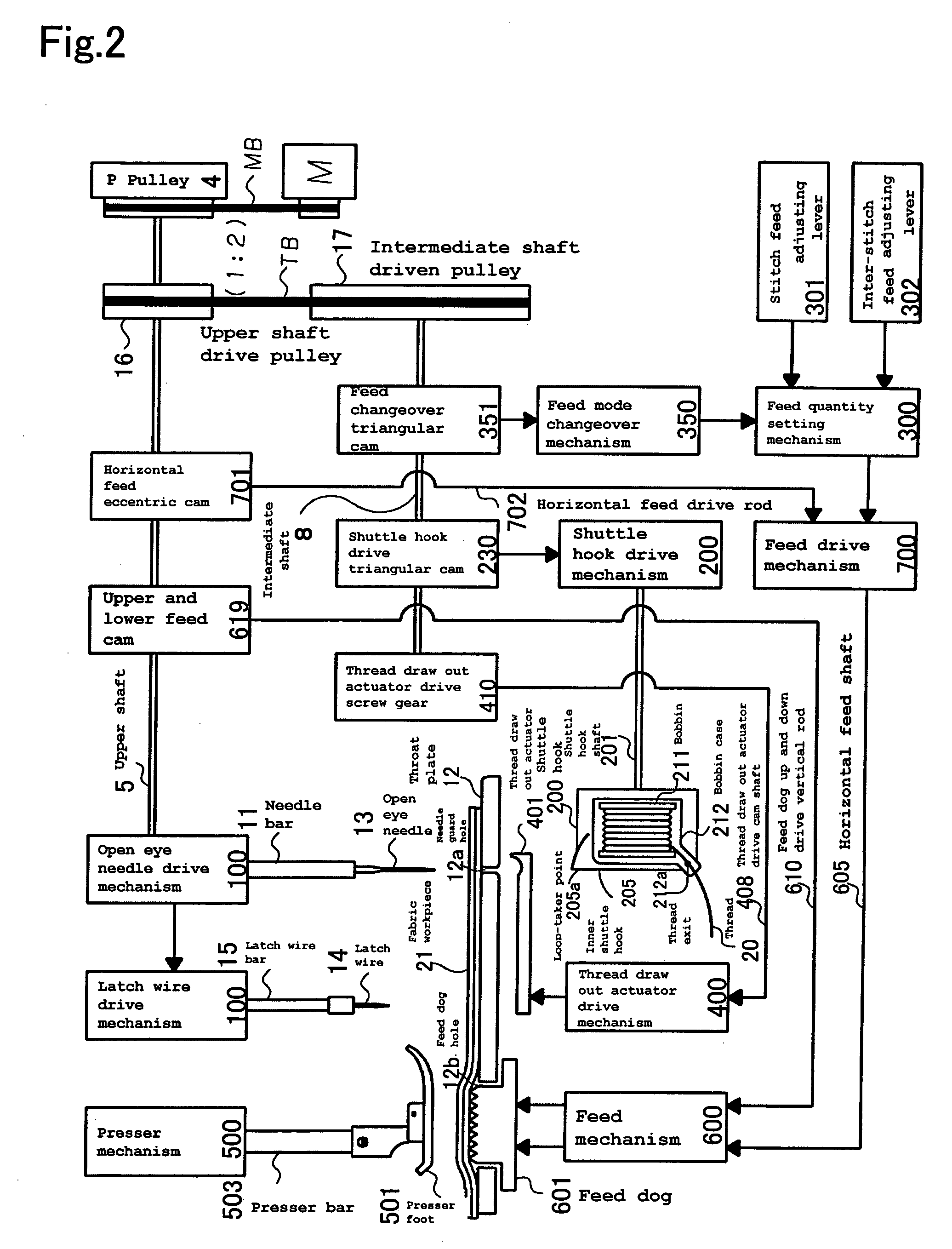

Method and Sewing Machine for Forming Single-Thread Locked Handstitches

ActiveUS20090007830A1Confirm positionAccurate sewingProgramme-controlled sewing machinesWork-feeding meansEye needlesEngineering

A sewing thread (20) can be captured certainly with a thread capturing open eye (13a) of an open eye needle (13) and the stitches are formed in the inner space of a sewing machine bed (3). A handstitch and a locked stitch are formed, respectively, on the front surface and the back surface of a fabric workpiece (21) as a skip stitch set through cooperation of the open eye needle (13), a shuttle hook (200) and a thread draw out actuator (401). A feed dog (601) feeds the fabric workpiece by a stitch length (P1) for handstitch during a first stroke of the open eye needle (13), and feeds the fabric workpiece by an inter-stitch pitch (P2) between the handstitches during a second stroke of the open eye needle (13).

Owner:SUZUKI MFG CO LTD

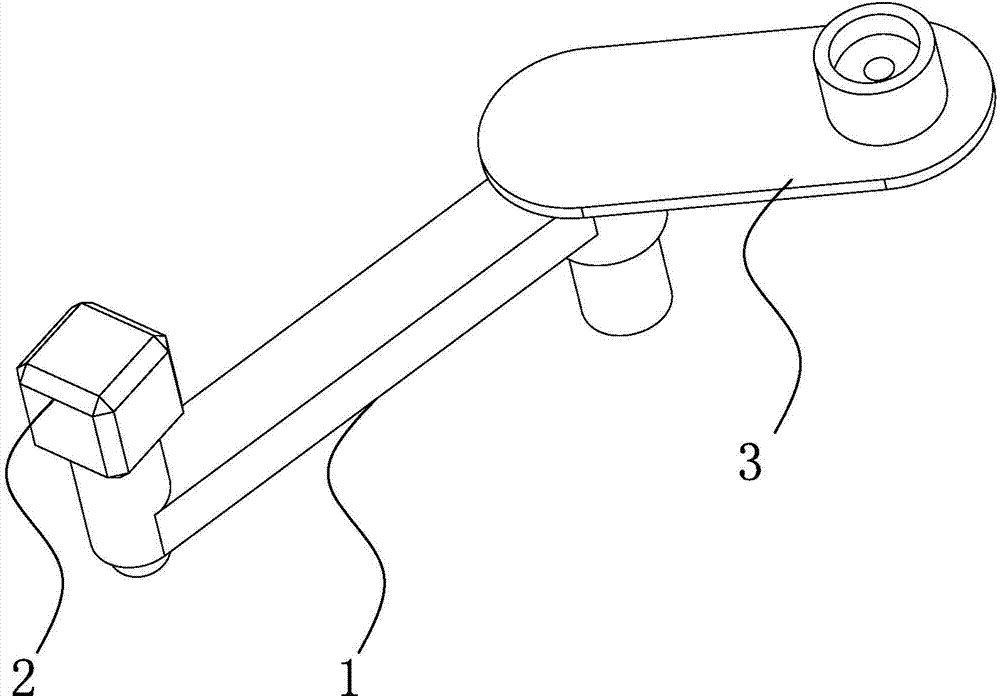

Connecting rod of sewing machine and preparation method thereof

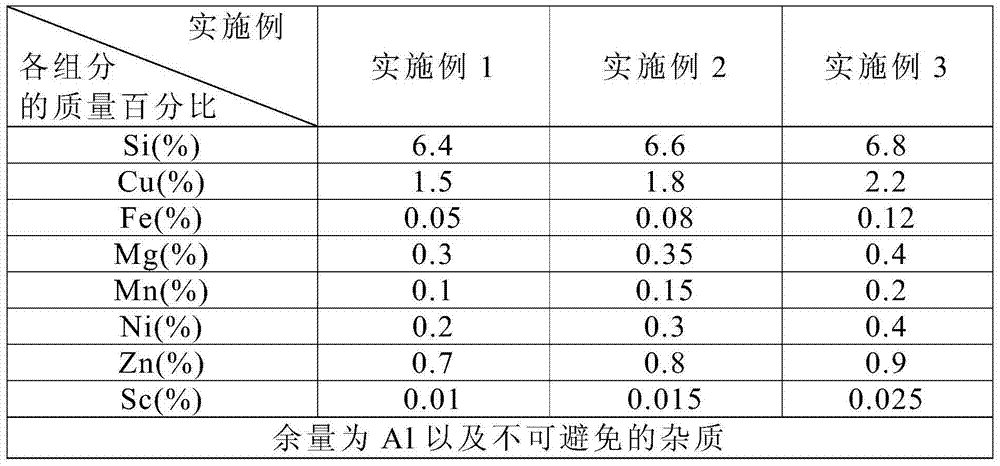

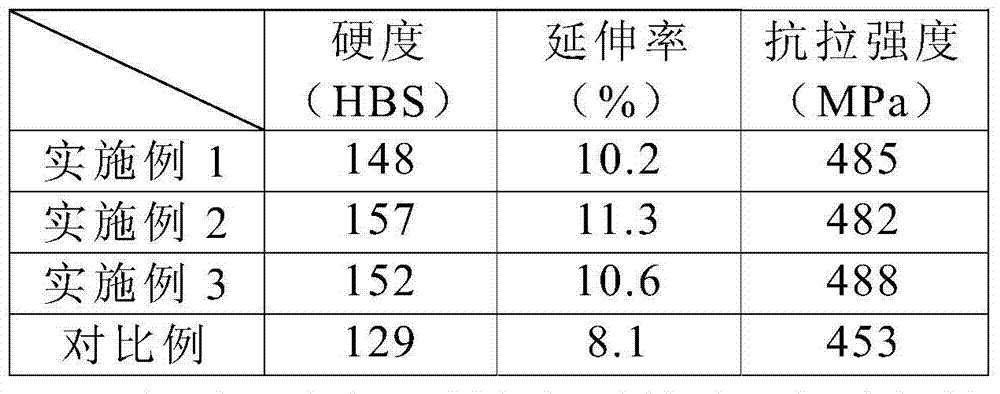

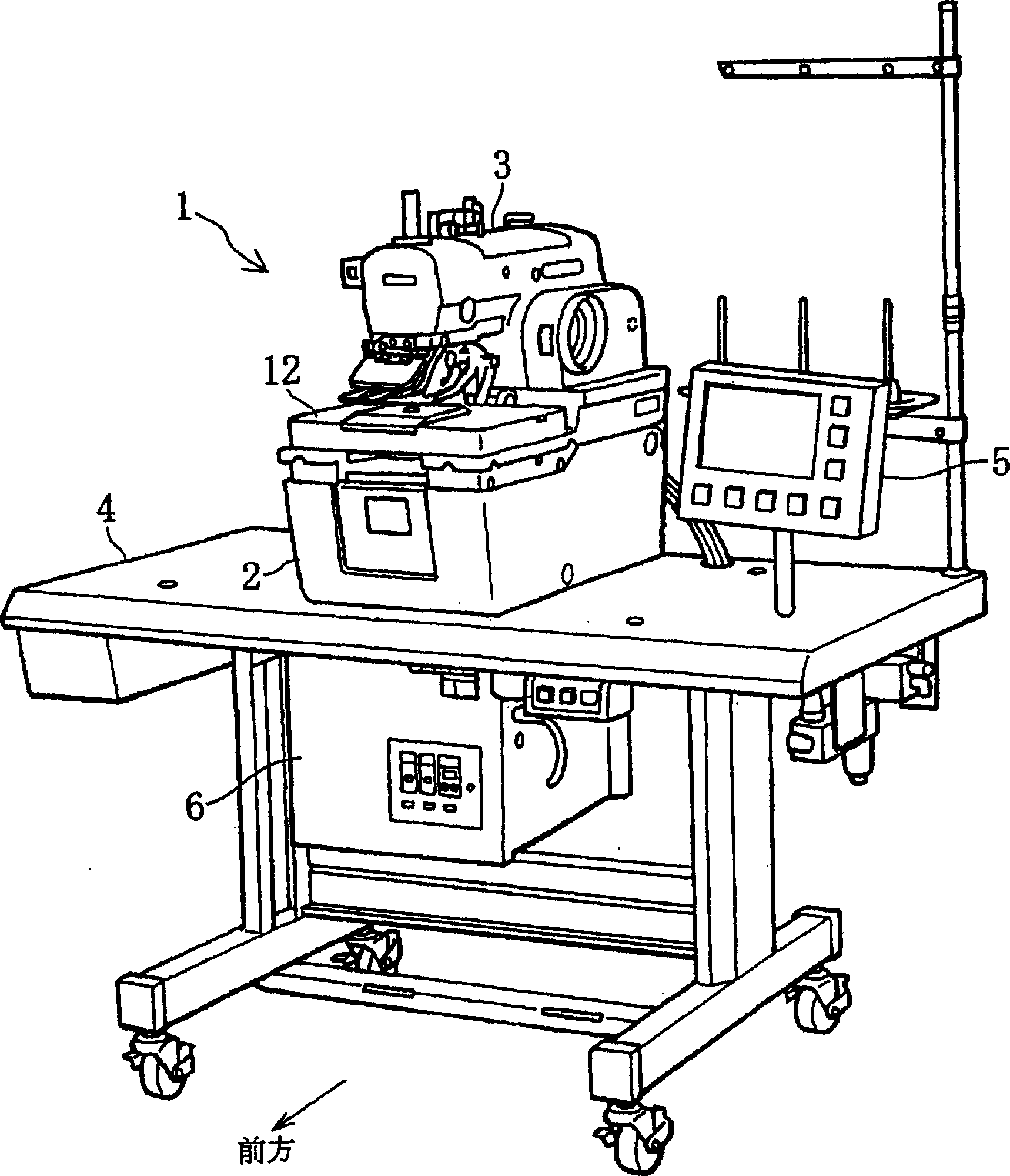

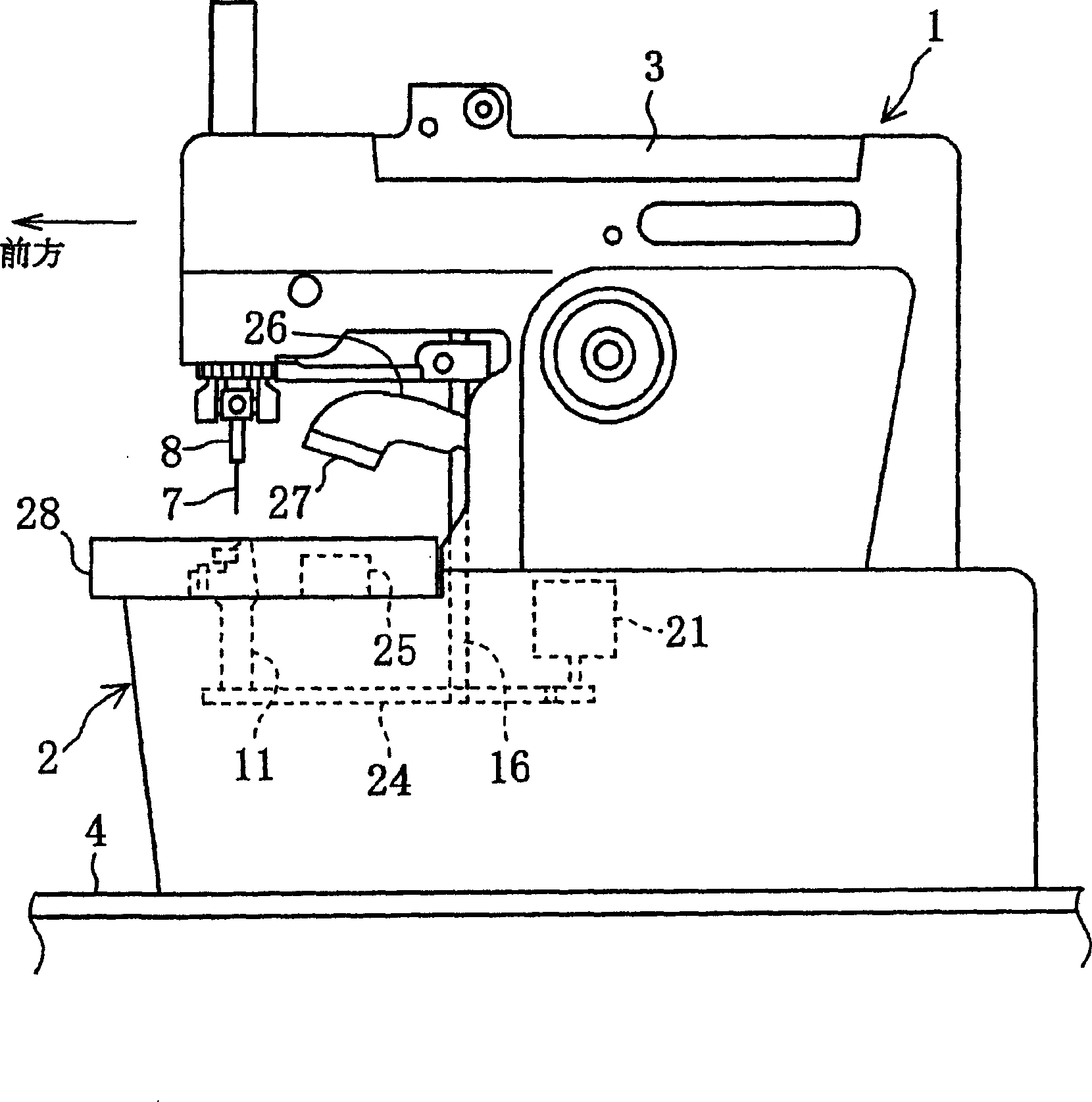

The invention relates to a connecting rod of a sewing machine and a preparation method thereof. The connecting rod is composed of a needle stem crankshaft bar, a needle bar column and a needle bar holding part and made of an aluminum alloy, wherein the aluminum alloy comprises, by weight, 6.2 to 7.0% of Si, 1.0 to 2.5% of Cu, 0.05 to 0.15% of Fe, 0.3 to 0.4% of Mg, 0.1 to 0.2% of Mn, 0.1 to 0.5% of Ni, 0.7 to 1.0% of Zn and 0.01 to 0.025% of Sc, with the balance being Al and unavoidable impurities. The preparation method comprises the following steps: fusing the above-mentioned metals and carrying out stirring and slag removal; then carrying out stamping and die casting so as to obtain blanks of the needle stem crankshaft bar, the needle bar column and the needle bar holding part; and finally, subjecting the blanks to post-treatment and carrying out assembling to obtain the connecting rod of the sewing machine. The connecting rod of the sewing machine has good strength, hardness, plasticity, toughness, wear resistance, elongation, tensile strength, etc. and high quality.

Owner:NINGBO RUIMING MACHINERY

Sewing machine

ActiveCN1824872AAvoid unreasonable forceIncreased durabilityNeedle barsLoop takersEngineeringVertical motion

The sewing machine of the present invention has a needle bar crank linked to a main shaft, a vertical movement transmission mechanism linked to the needle bar crank, and a needle swing mechanism for swinging the needle bar. The up and down movement transmission mechanism includes: a ring-shaped member having a space defined by a ring-shaped inner peripheral surface, through which the needle bar passes; and a pair of upper and lower needle bar frame members, which are fixed on the outside of the needle bar, and Arranged on the upper and lower sides of the ring member. The ring member is journally connected to the needle bar crank. A clearance for swinging is ensured between the annular inner peripheral surface of the space of the annular member and the outer periphery of the needle bar. The needle bar can swing without being in contact with the annular inner peripheral surface within the swing gap.

Owner:BROTHER KOGYO KK

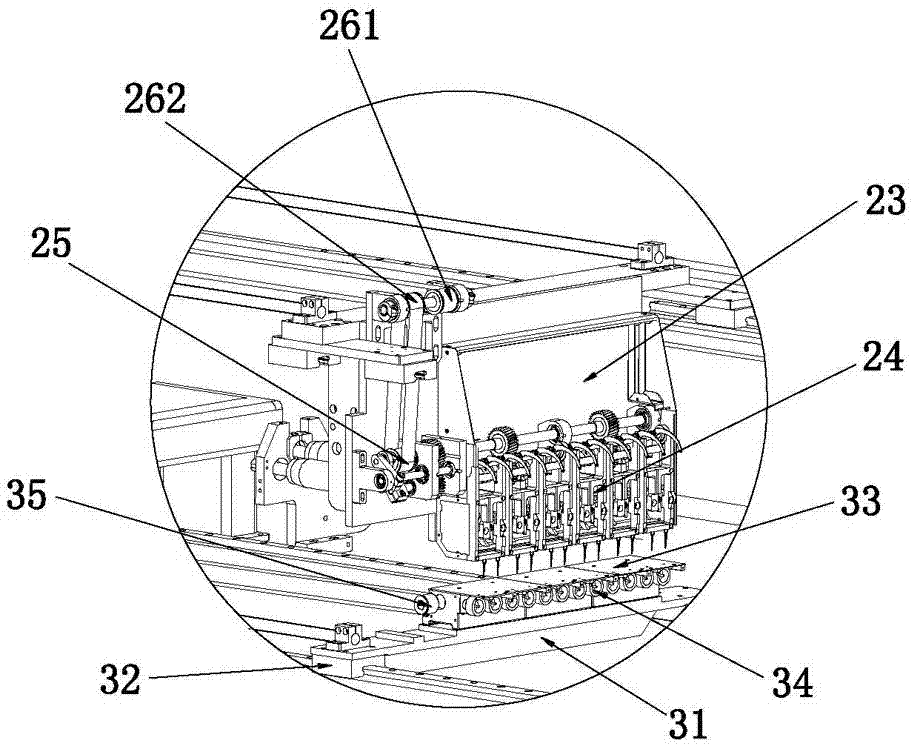

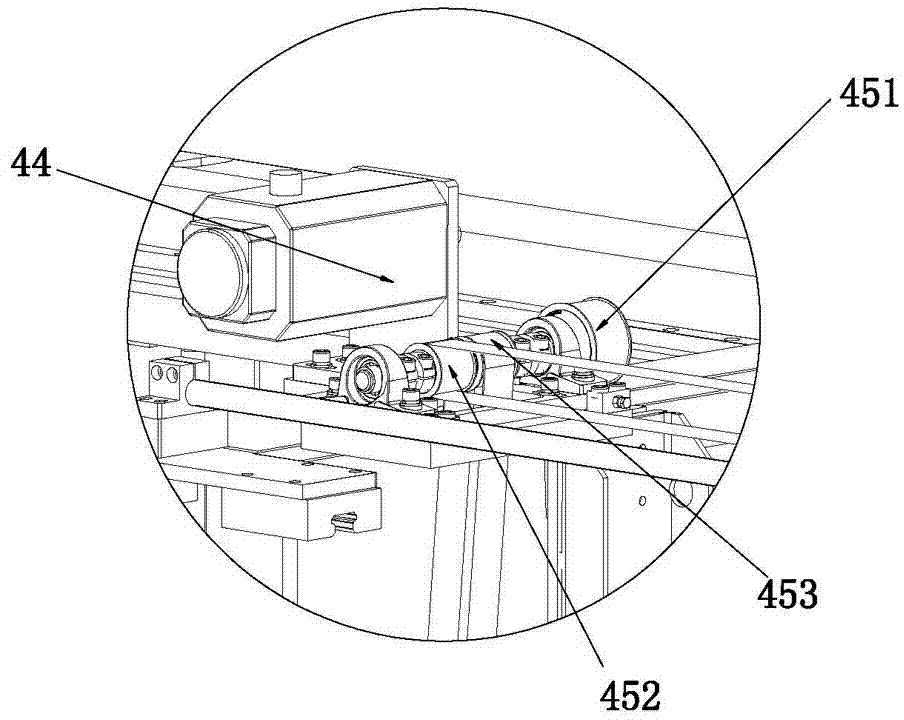

Numerical-control sewing and embroidering quilting machine provided with horizontal multi-needle machine head

InactiveCN104499188ANo mutual interferenceEasy offlineWork-feeding meansMattress sewingNumerical controlMechanical engineering

The invention belongs to the technical field of quilting machines, and particularly relates to a numerical-control sewing and embroidering quilting machine provided with a horizontal multi-needle machine head. The numerical-control sewing and embroidering quilting machine comprises a frame, wherein the frame comprises a rack and an upper frame which is arranged at the upper end of the rack; the frame is provided with the multi-needle machine head capable of moving longitudinally; a rotating shuttle mechanism is arranged under the multi-needle machine head; the frame is provided with a first driving mechanism for driving the multi-needle machine head and the rotating shuttle mechanism to move synchronously; the multi-needle machine head is connected with the upper frame in a sliding manner; the rotating shuttle mechanism is connected with the rack in the sliding manner; the frame is also provided with a second driving mechanism for driving a fabric to be fed horizontally. The multi-needle machine head of the numerical-control sewing and embroidering quilting machine is arranged in a direction vertical to the feeding direction of the fabric, so that two adjacent needles have no interference in sewing trace during sewing, no wired node is formed in a spliced point, and thus the node is unlikely to loosen, and the quality and the attractive appearance of the product are guaranteed; a plurality of sewing needles work simultaneously, so the production efficiency is improved.

Owner:DONGGUAN UNIV OF TECH +1

Ring sewing machine

InactiveCN101545182AImprove workabilityEliminate loosenessNeedle barsLoop takersEngineeringSewing machine

The invention provides a ring sewing machine which preventing loosening of looper, and enhancing workability of threading through looper in the mean time. The ring sewing machine comprises an upper shaft and a lower shaft which are disposed parallel to each other; a ring shaped synchronous belt, which is disposed between the upper shaft and the lower shaft and delivers rotation thereof to the lower shaft; a needle rod, which is connected to the upper shaft and swings cooperatively with the rotation of the upper shaft; and a looper shaft, which is connected to the lower shaft, and swings cooperatively with the rotation of the lower shaft. The ring sewing machine comprises a tension applying means including two belt wheels, which are arranged on external side of the synchronous belt with the synchronous belt clamped therein; and a substrate for supporting two belt wheels, which is capable of moving on the direction intersecting the line formed by connecting the upper shaft core and lower shaft core.

Owner:JUKI CORP

Bent two-needle sewing machine

InactiveCN101525814AHigh precisionEasy to replaceSewing-machine casingsPressersEngineeringSewing machine

The invention provides a bent two-needle sewing machine, belongs to the mechanical technical field, and solves the technical problems that the existing bent two-needle sewing machine can not be conveniently installed and maintained, and can not manufacture different three-dimensional stripes. The bent two-needle sewing machine comprises a sewing machine head, a bottom board, a needle clamp and two needles fixedly connected on the needle clamp, wherein, the sewing machine head is fixedly connected on the bottom board; the needle clamp is connected with the sewing machine head; and a detachable mechanism is arranged between the needle clamp and the sewing machine head. The bent two-needle sewing machine has the advantages of high positioning precision of needles, convenient disassembly, assembly, replacement and maintenance, etc.

Owner:新通宇缝纫机股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com