High-efficiency dial linking machine

A disc sewing machine, high-efficiency technology, applied to sewing machine components, sewing machine needle holders, sewing machine thread take-up devices, etc., can solve the problems of difficult oil control, inconvenient refueling, etc., to achieve smooth operation, good lubrication and cooling system, The effect of simple chassis structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

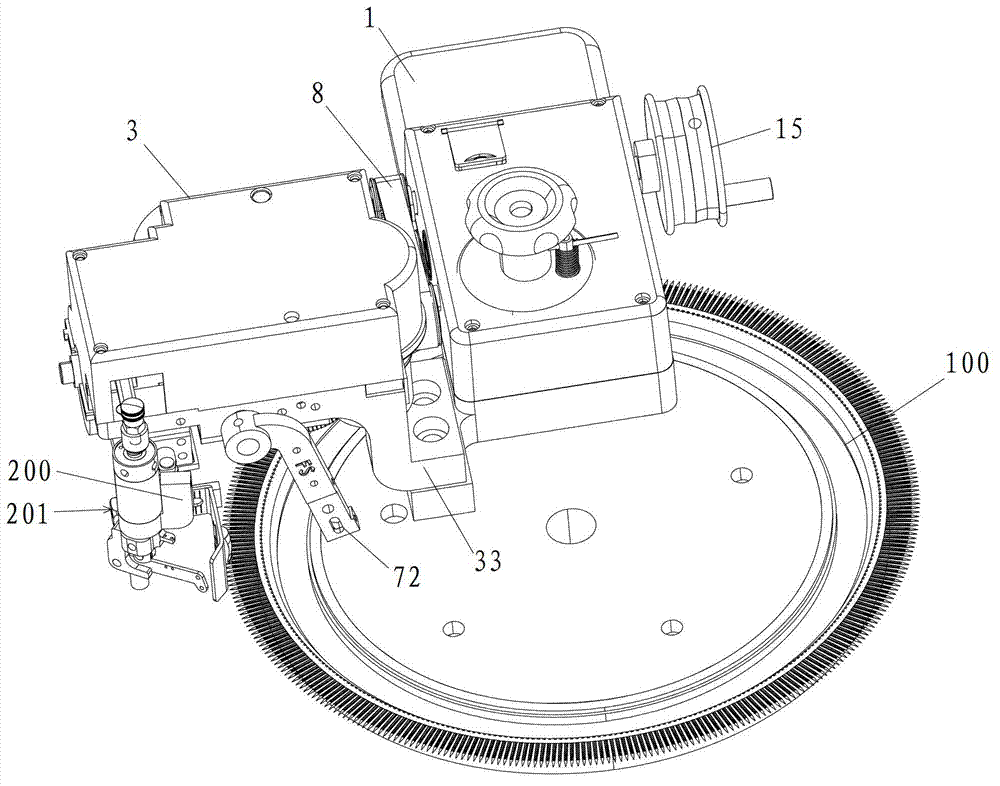

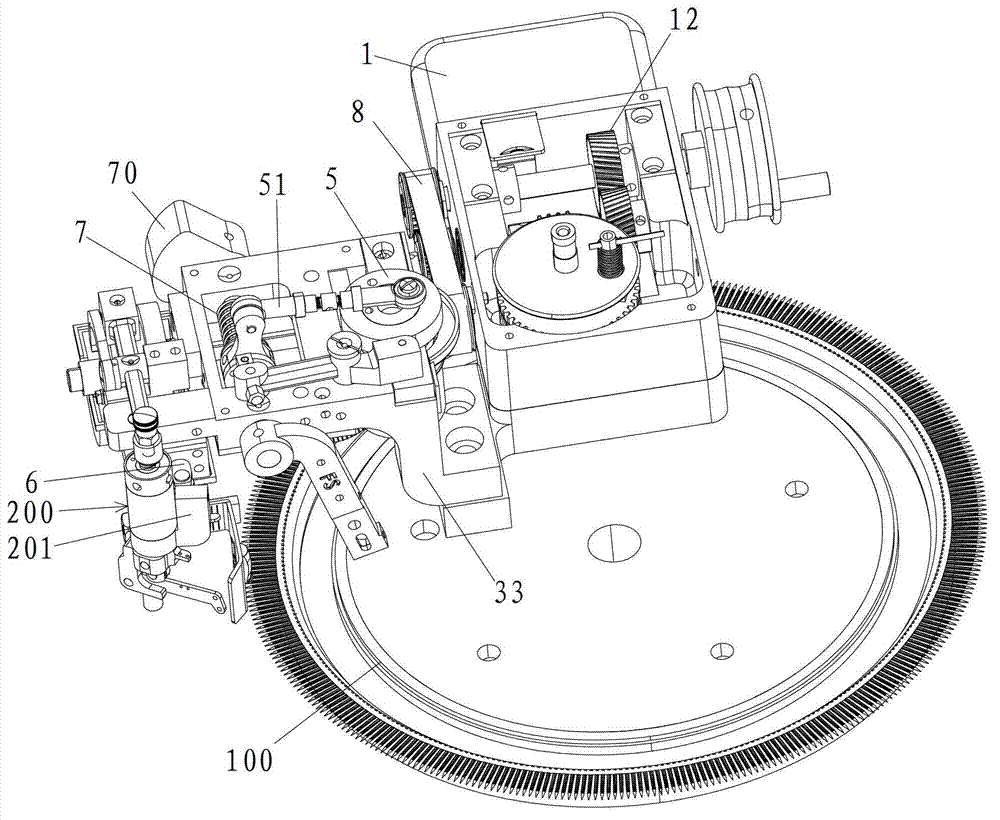

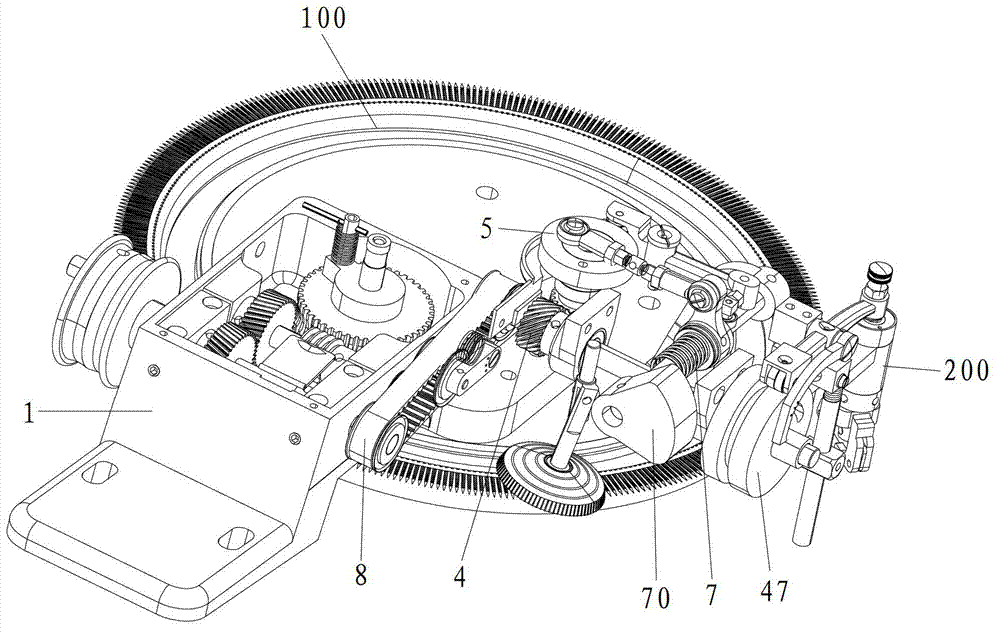

[0043] see Figure 1-14 Shown, a kind of high-efficiency disc seaming machine, it comprises: a car platform 1, and it comprises: box body 11, the box cover 13 that is installed in box body 11 upper ends, the gear assembly 12 that is installed in the box body 11 and gear assembly 12 interlocking adjustment handle 14, the gear assembly 12 includes: a first and second helical gears 1213, 1223 are installed respectively and the first and second gear assemblies 121, 122 are engaged and interlocked with each other; a speed regulating device 2, the The speed regulating device 2 cooperates with a motor and the gear assembly 12 through a frequency converter; a chassis 3 fixedly installed with the vehicle platform 1, the chassis 3 includes a mounting frame 33, which is installed on the upper and lower ends of the mounting frame 33 Shield 32 and lower shield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com