Patents

Literature

177results about "Linking machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

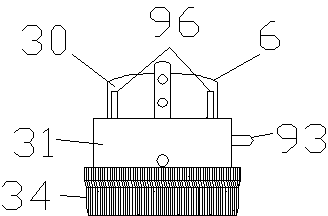

Sock production device

ActiveCN104233634ARealize automatic flippingBeautiful stitchesMechanical cleaningPressure cleaningSOCKSElectric machinery

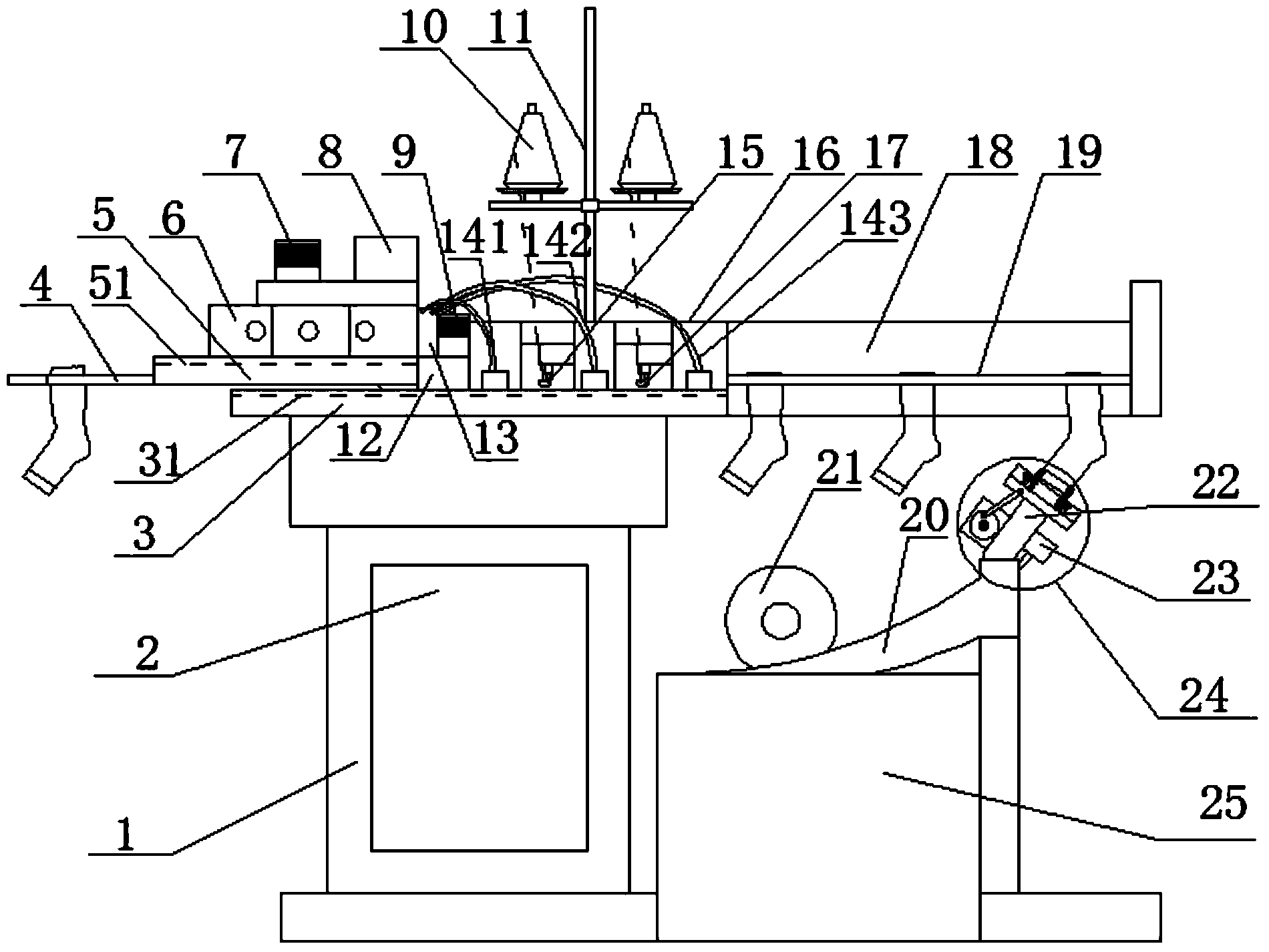

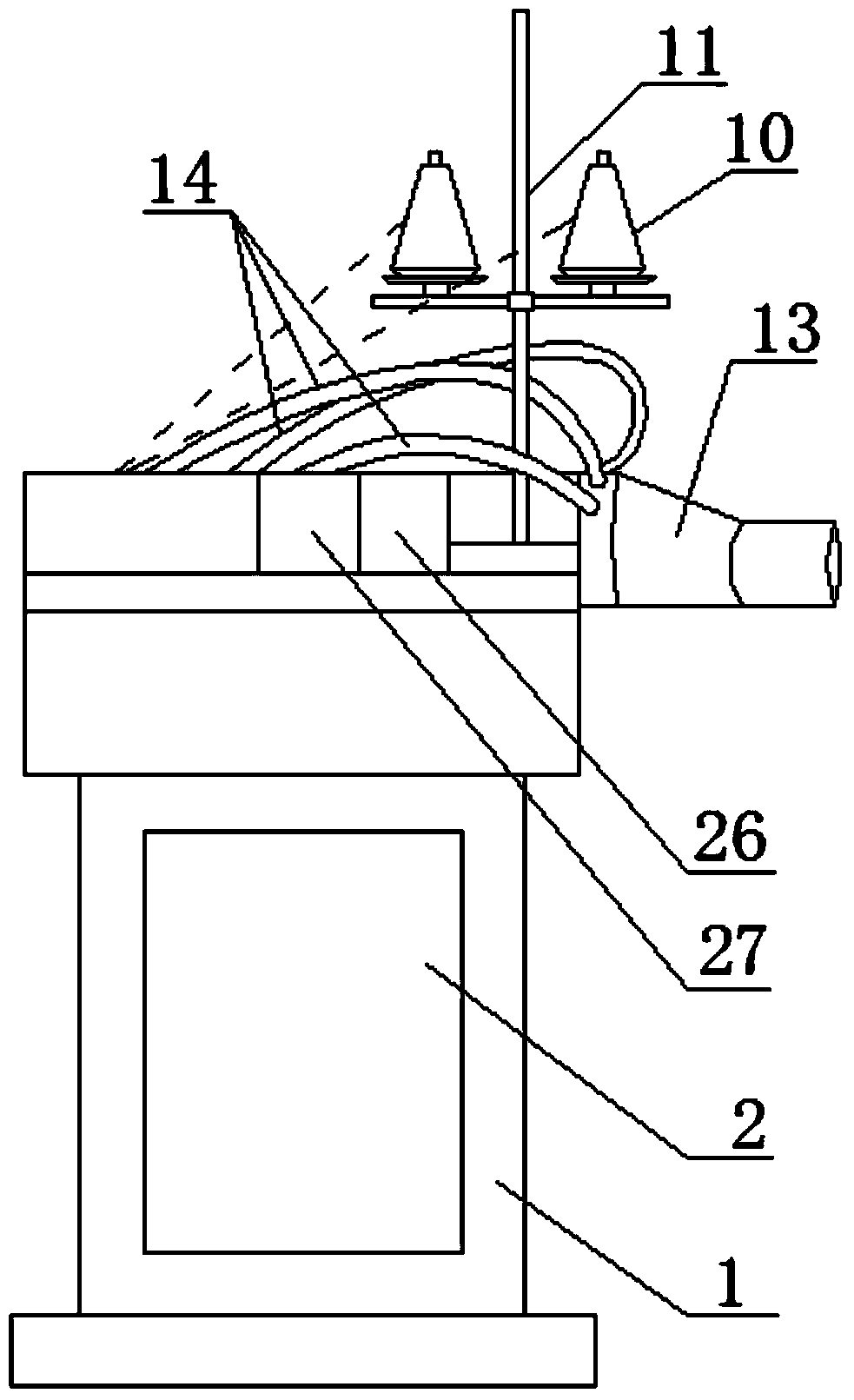

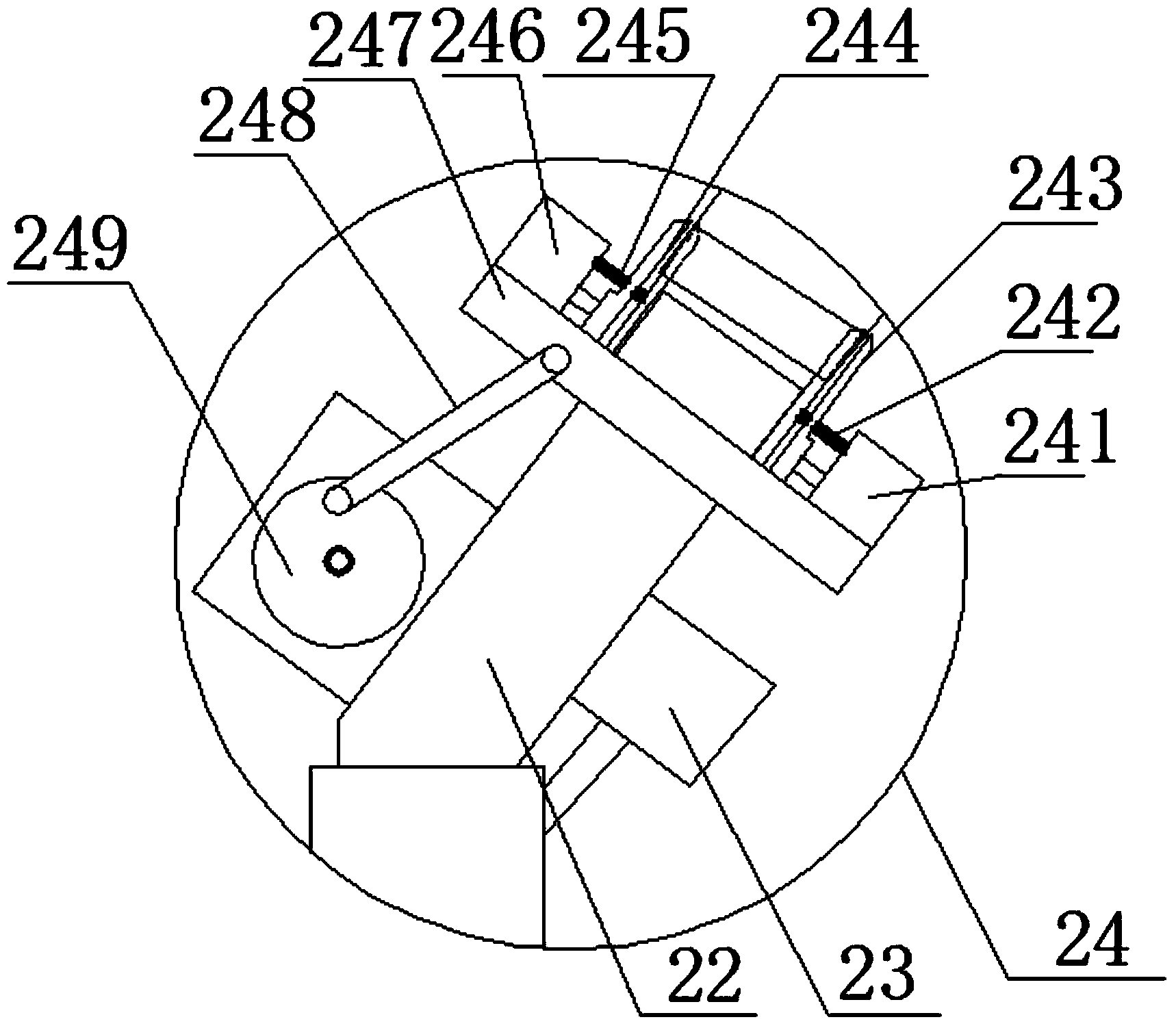

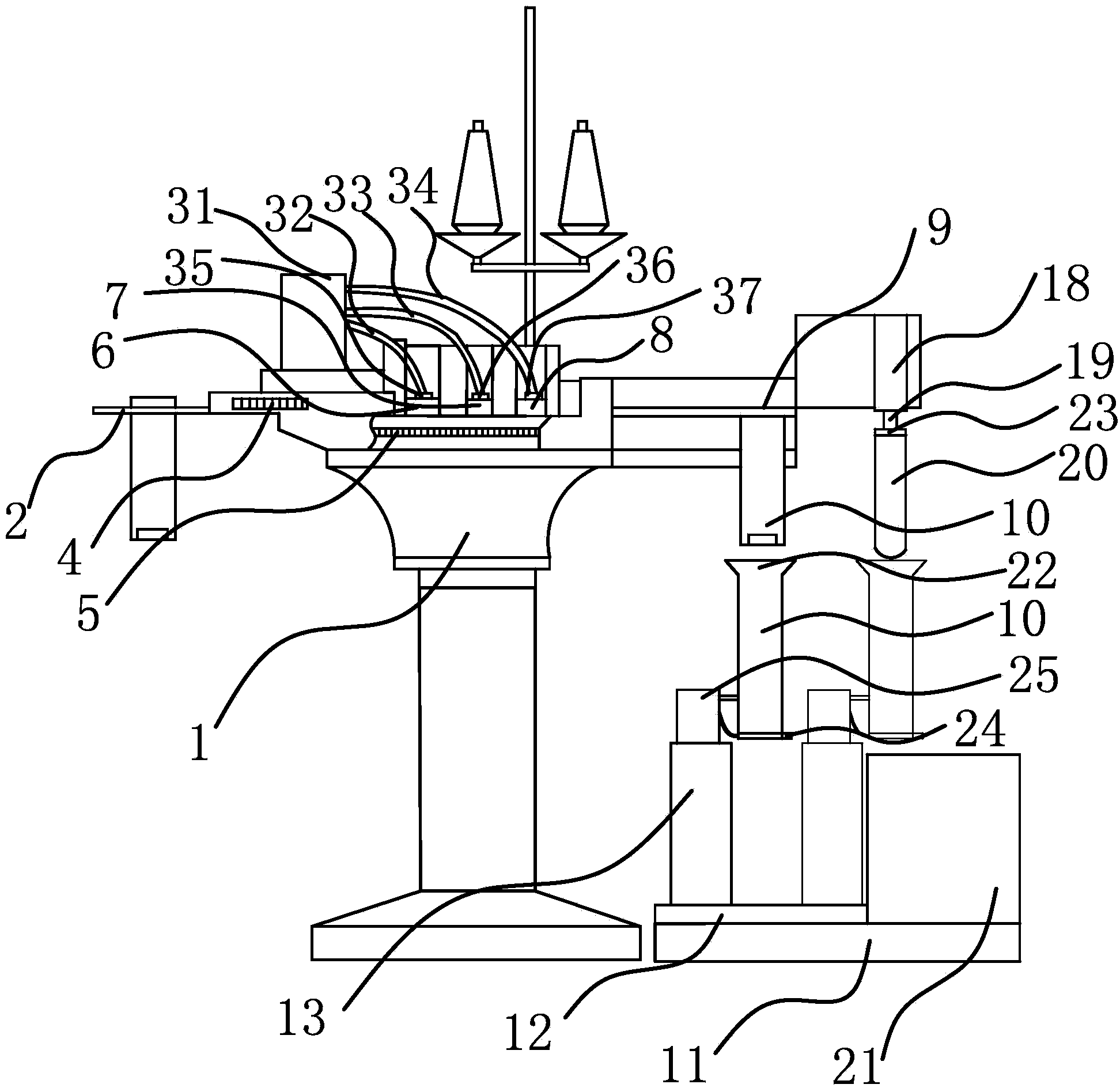

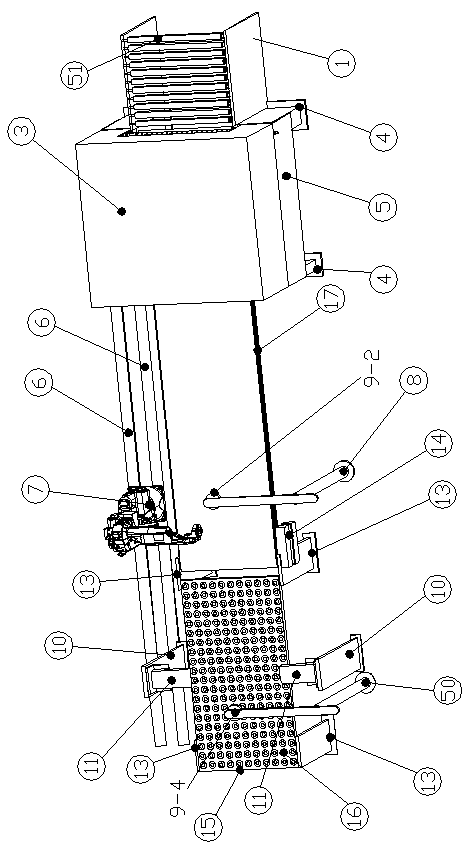

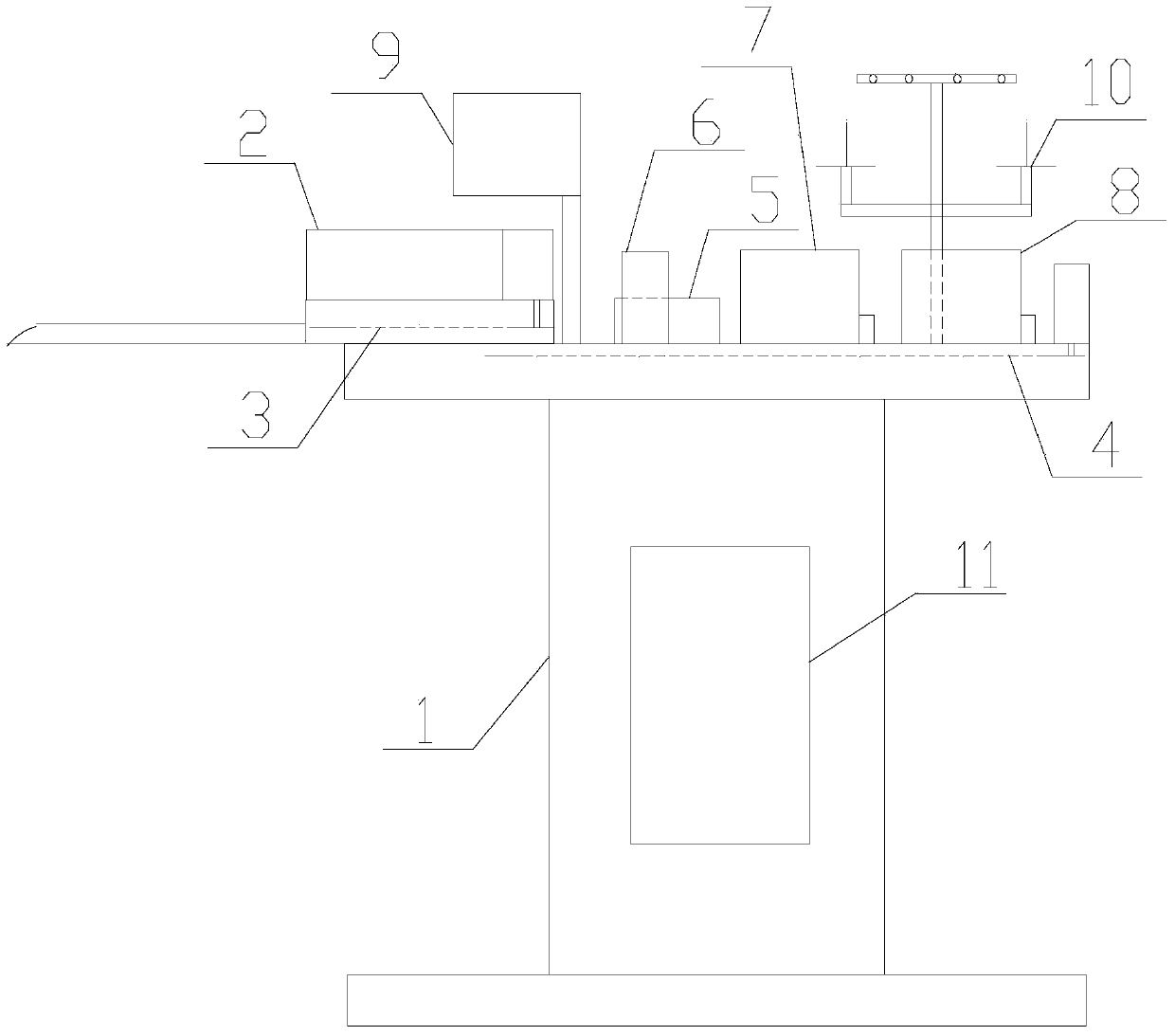

The invention discloses a sock production device. The sock production device comprises a rack, a feeding device, a waste material recovery device, a sewing box, a discharging device and a sock turning device, wherein the feeding device comprises a guide rail, a guiding frame, a guiding box, a feeding box and a first electric motor component; the waste material recovery device comprises a negative air pressure pumping device and a pipeline, the negative air pressure pumping device is arranged on the rack, and one end of the pipeline is connected to the negative air pressure pumping device; the sewing box is fixedly arranged on the rack and is sequentially and fixedly provided with a first sewing head and a second sewing head from left to right; the right end of the rack is fixedly provided with the discharging device, the discharging device is provided with a discharging guide rail, the lower part of the discharging guide rail is provided with a sock guiding pipe, and the sock guiding pipe is provided with the sock turning device. According to the sock production device disclosed by the invention, socks can be automatically turned after the socks are sewed when a seam of a sock point is completely sewed, meanwhile, the situation that waster materials which are generated by the first sewing head, the second sewing head and a sock point cutting mechanism can be collected is realized, the automation degree is high, the working efficiency is increased, and the labor cost is reduced.

Owner:浙江圣邦化纤针织有限公司

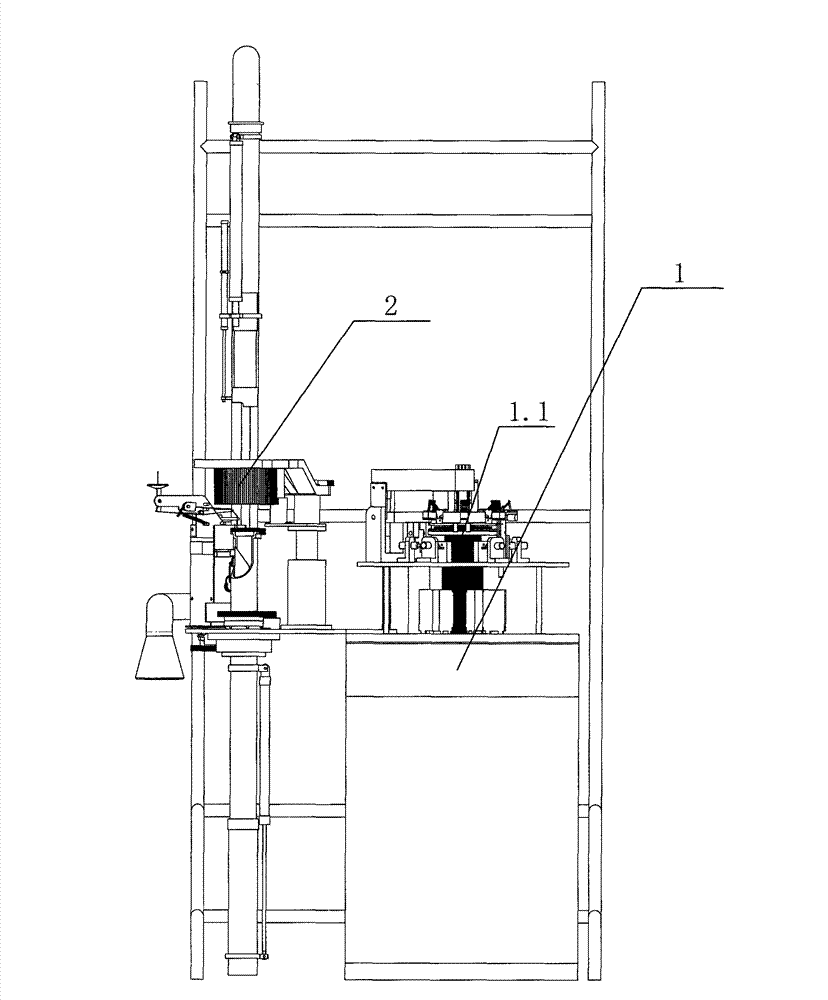

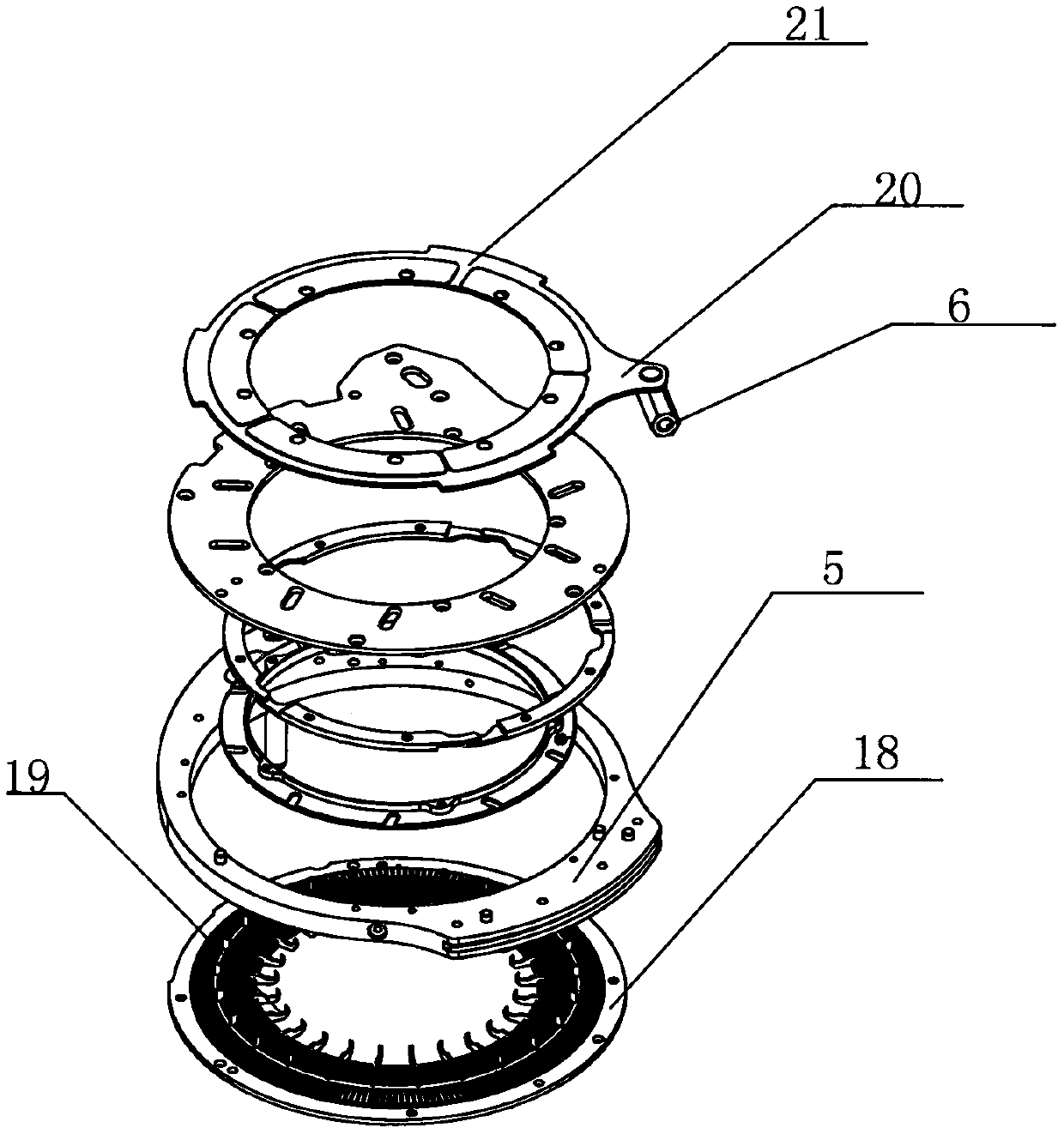

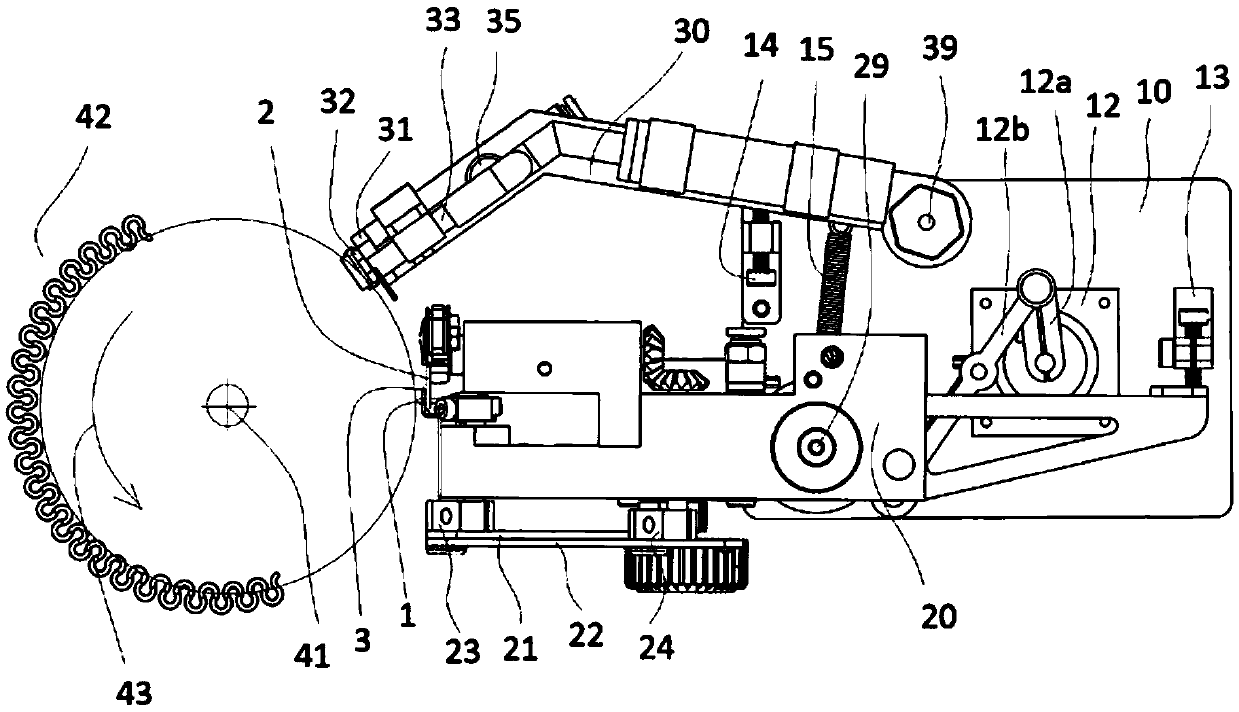

Stocking and sewing integrated hosiery machine

ActiveCN102885408ARealize modern developmentIncrease productivityWeft knittingLinking machinesEngineeringMechanical engineering

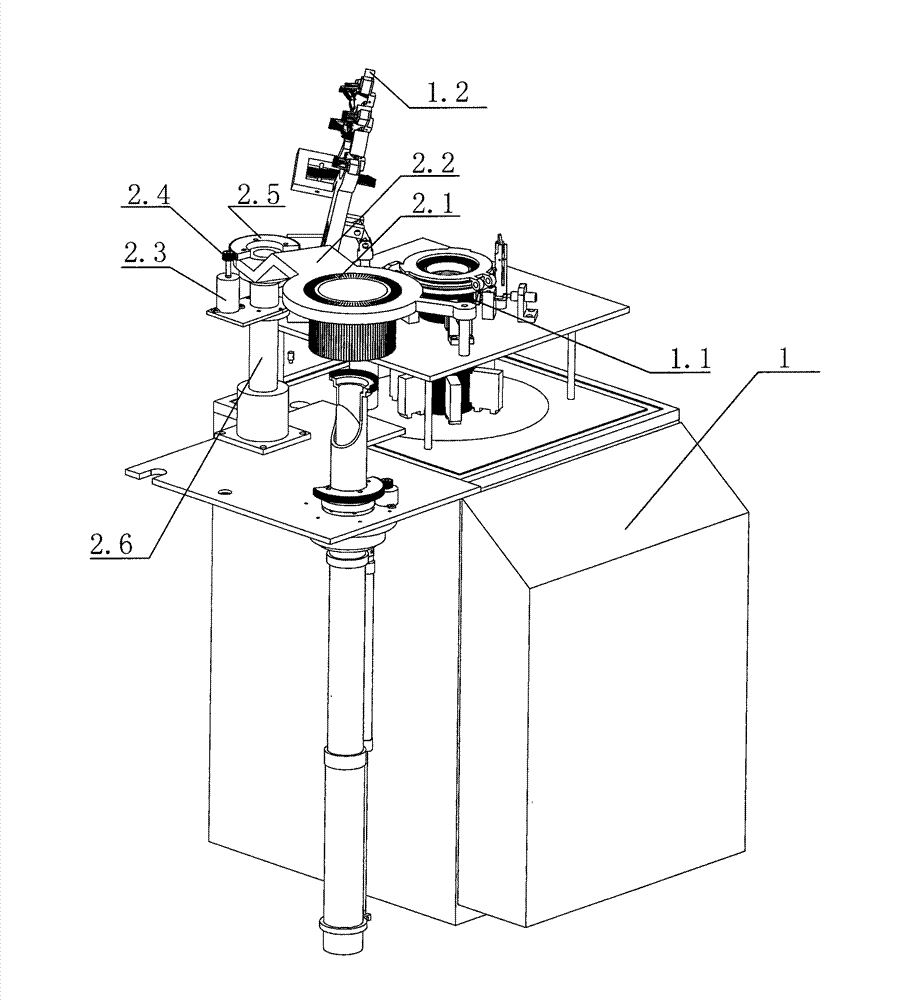

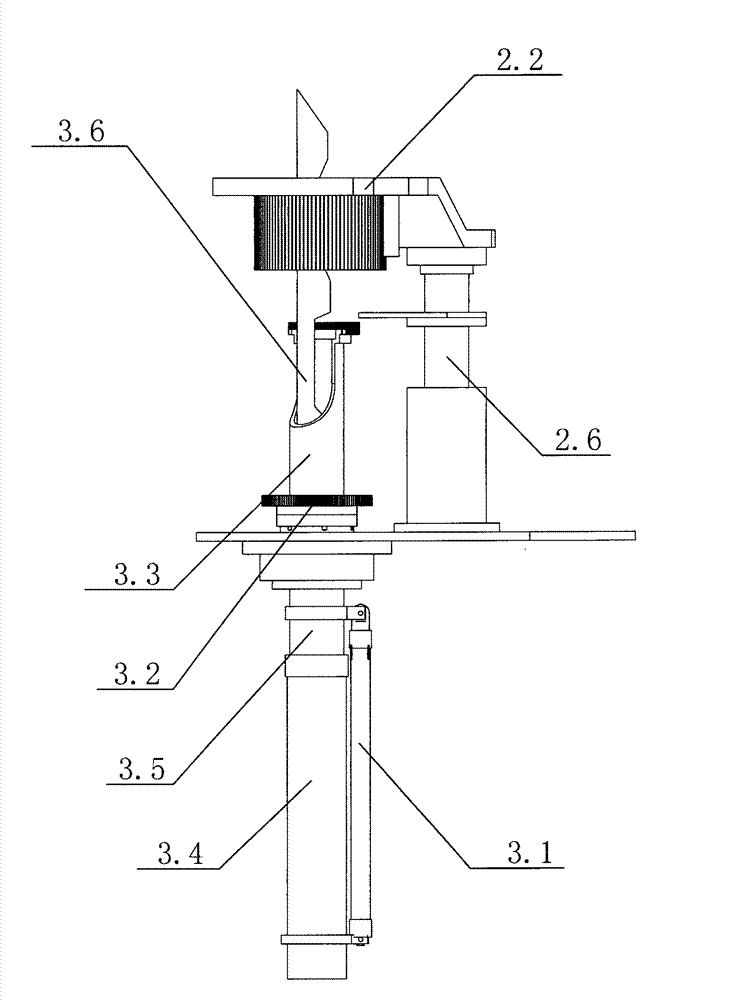

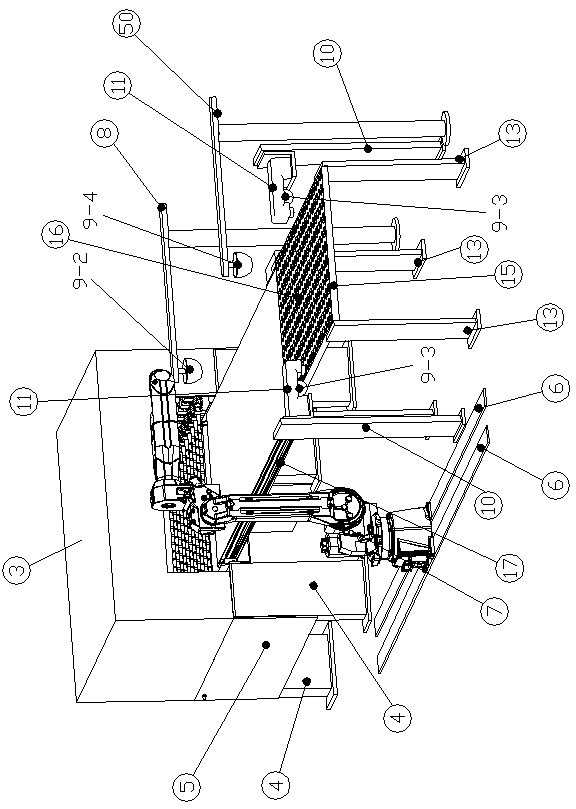

The invention discloses a stocking and sewing integrated hosiery machine. The stocking and sewing integrated hosiery machine comprises a stocking machine provided with a needle cylinder and an upper plate, wherein the stocking head of a stocking body which is woven by the stocking machine is picked up by a pickup device, and the stocking body is transferred to a stocking turning and sewing device at a side edge of the stocking machine to finish stocking turning and sewing process steps. Through the continuously operated device integrating the stocking machine, stocking turning and sewing, continuous operations of the stocking body from weaving to stocking to sewing are realized, and the stocking body is sucked away from a needle frame and is placed in a material frame through a stocking discharging mechanism, so that the production efficiency is greatly improved, the manufacturing cost is saved, and the modernized development of stocking weaving is realized.

Owner:ZHEJIANG ROSSO EQUIP MFG

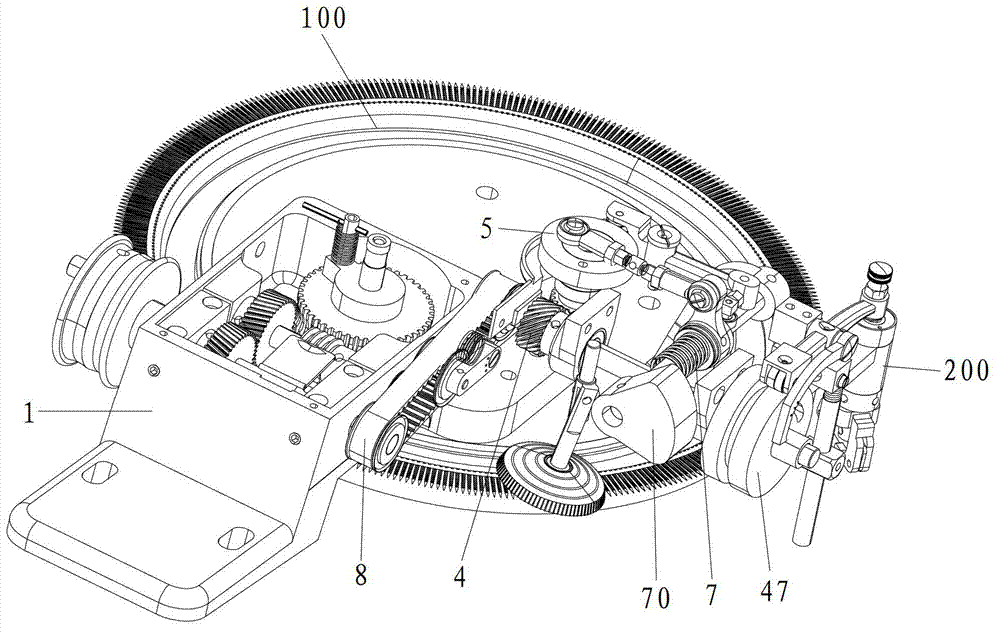

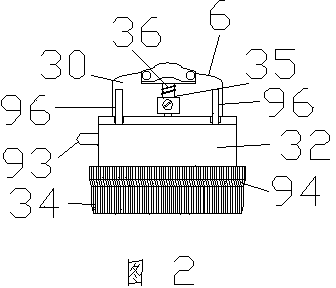

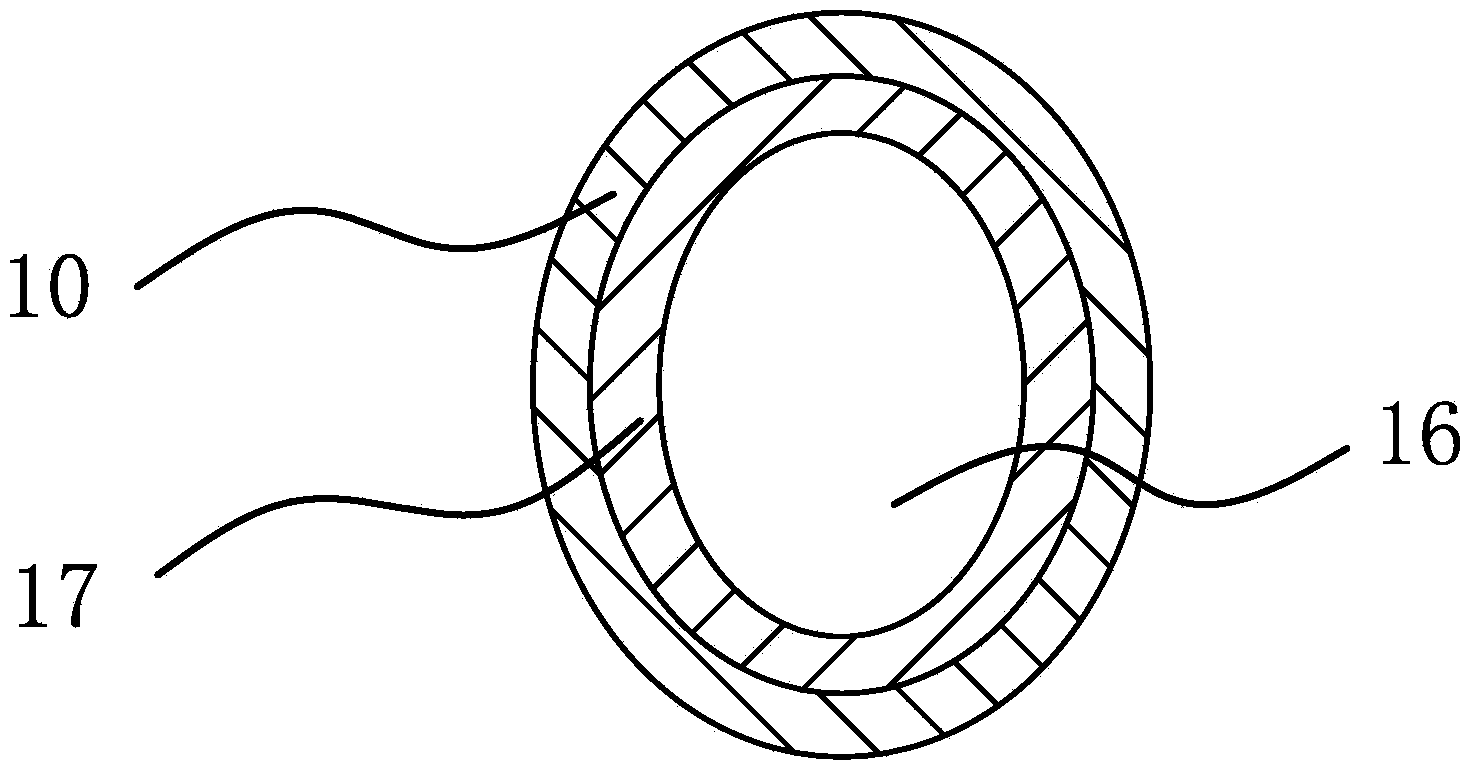

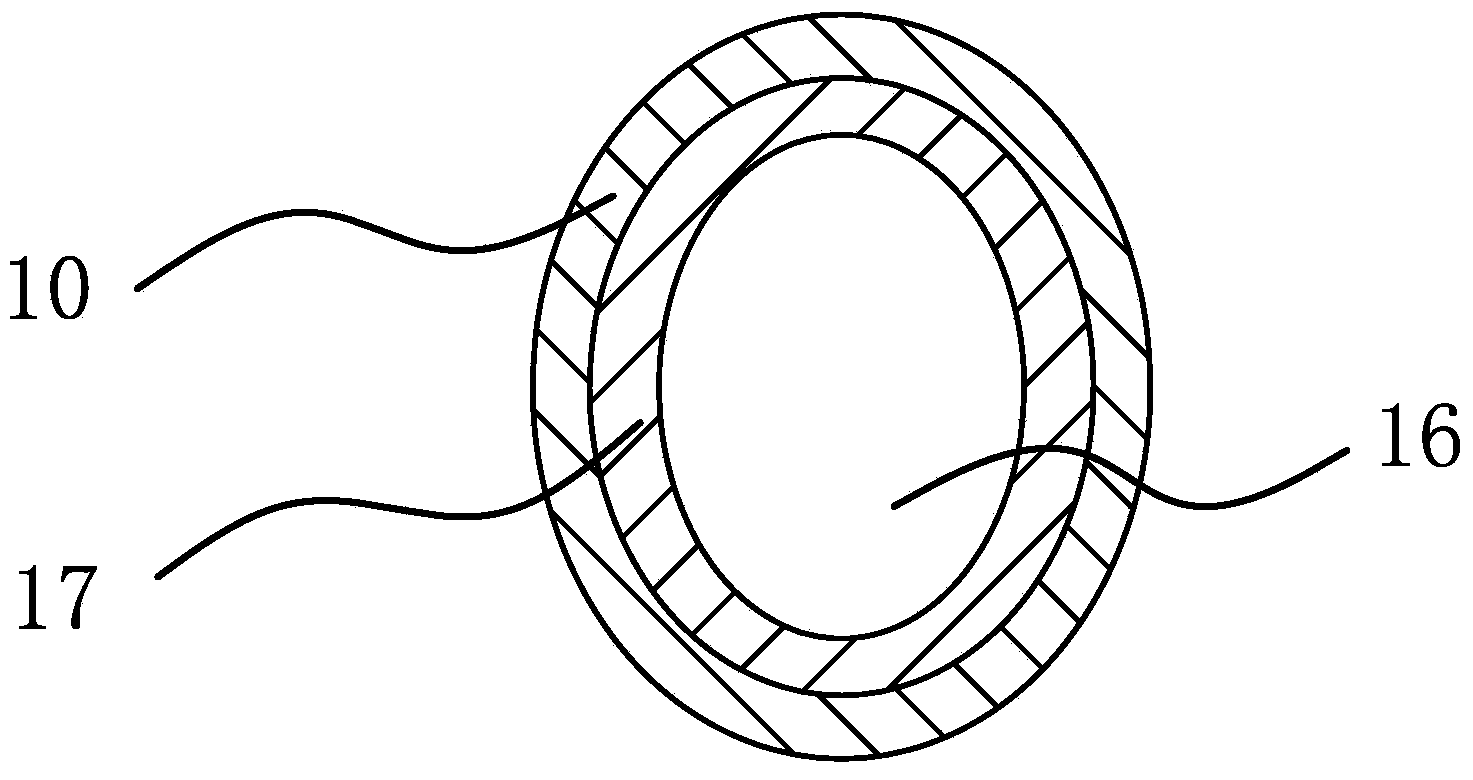

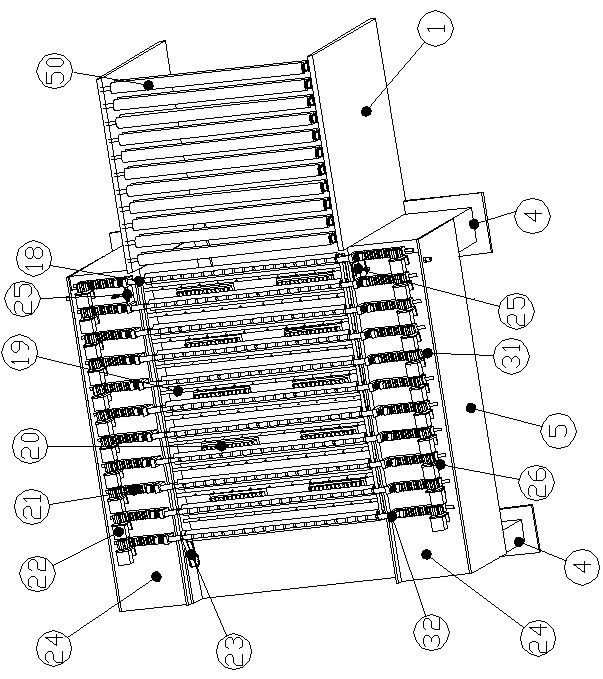

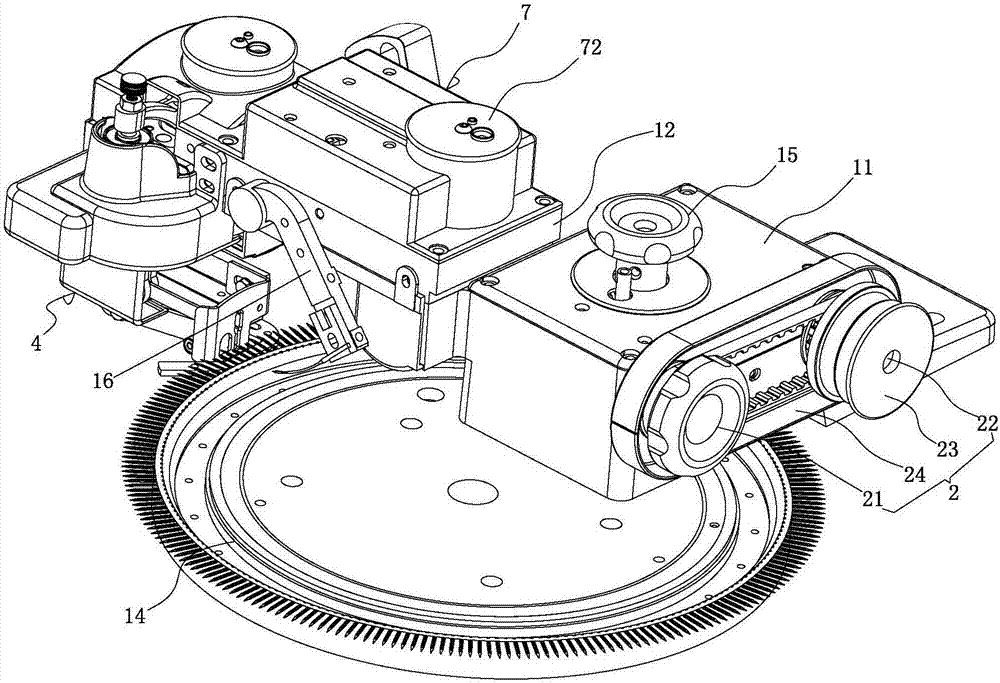

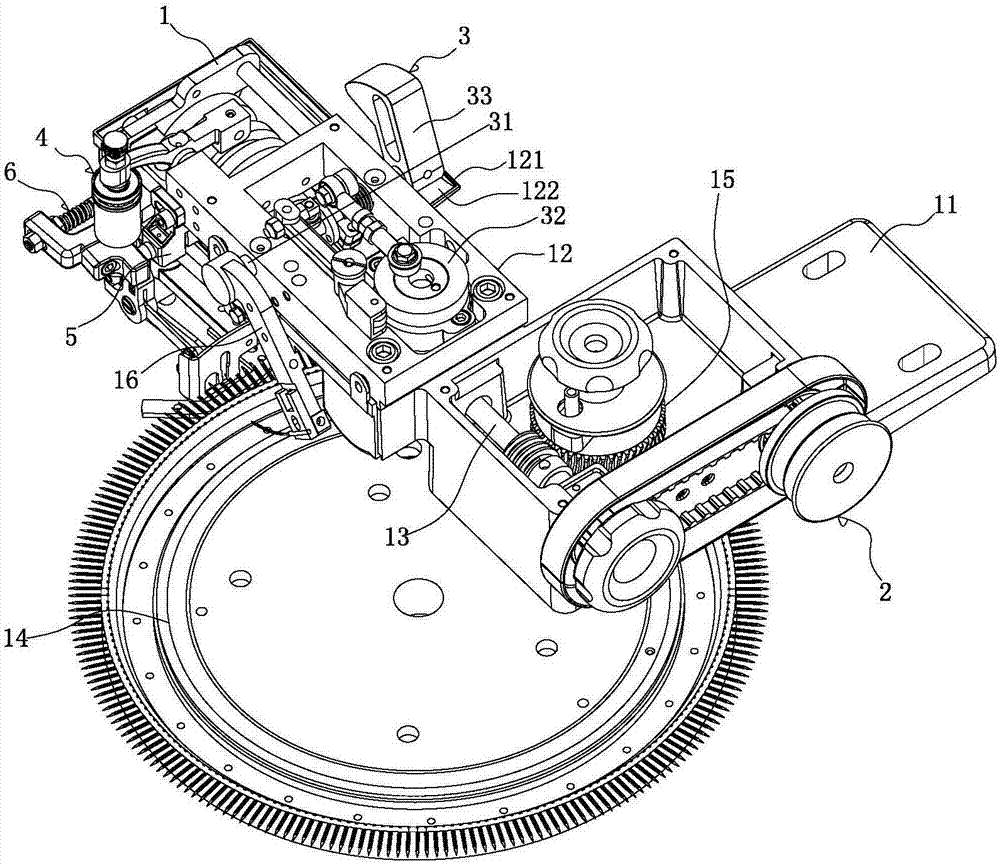

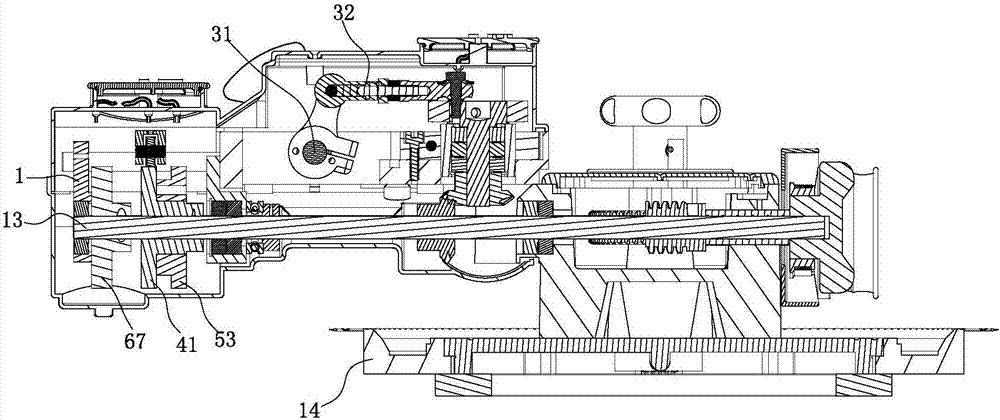

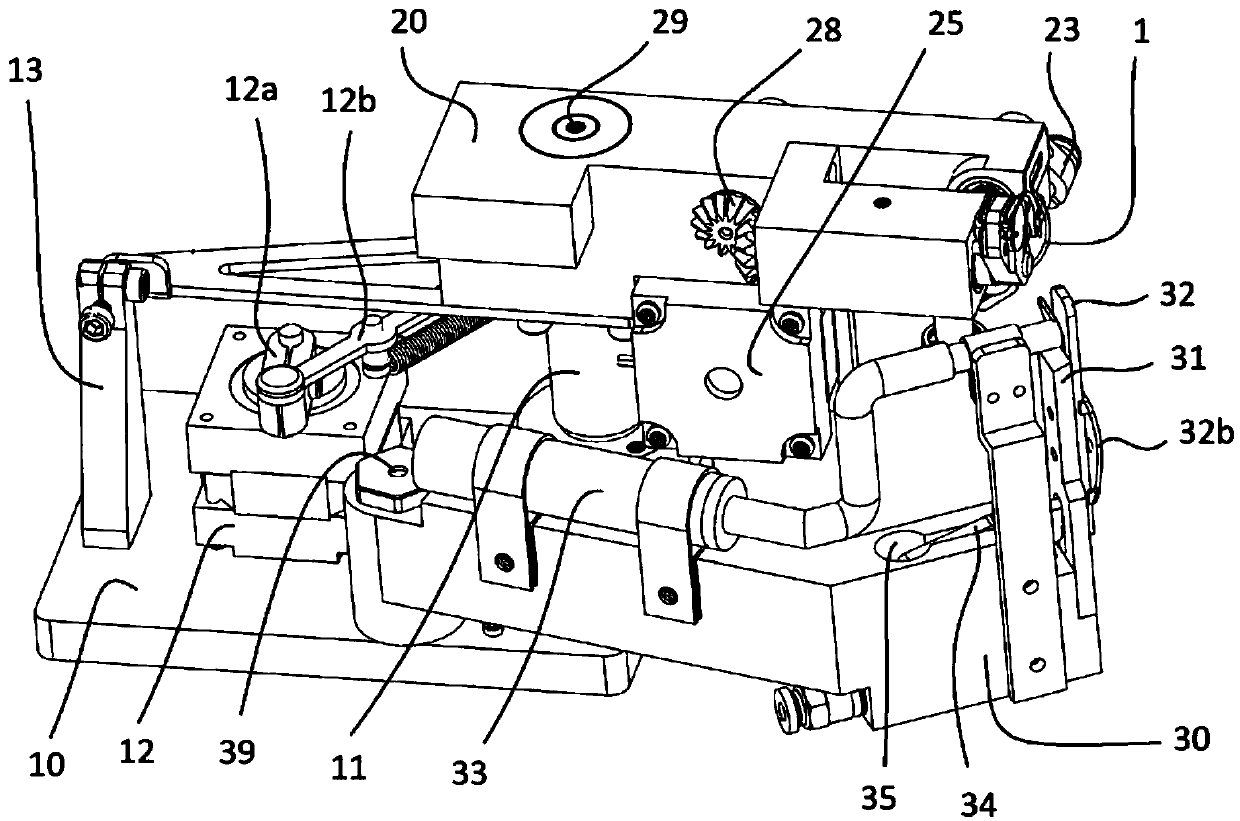

High-efficiency dial linking machine

ActiveCN102953234AStable structureGuaranteed uptimeLubrication/cooling devicesSewing-machine control devicesElectric machineryEngineering

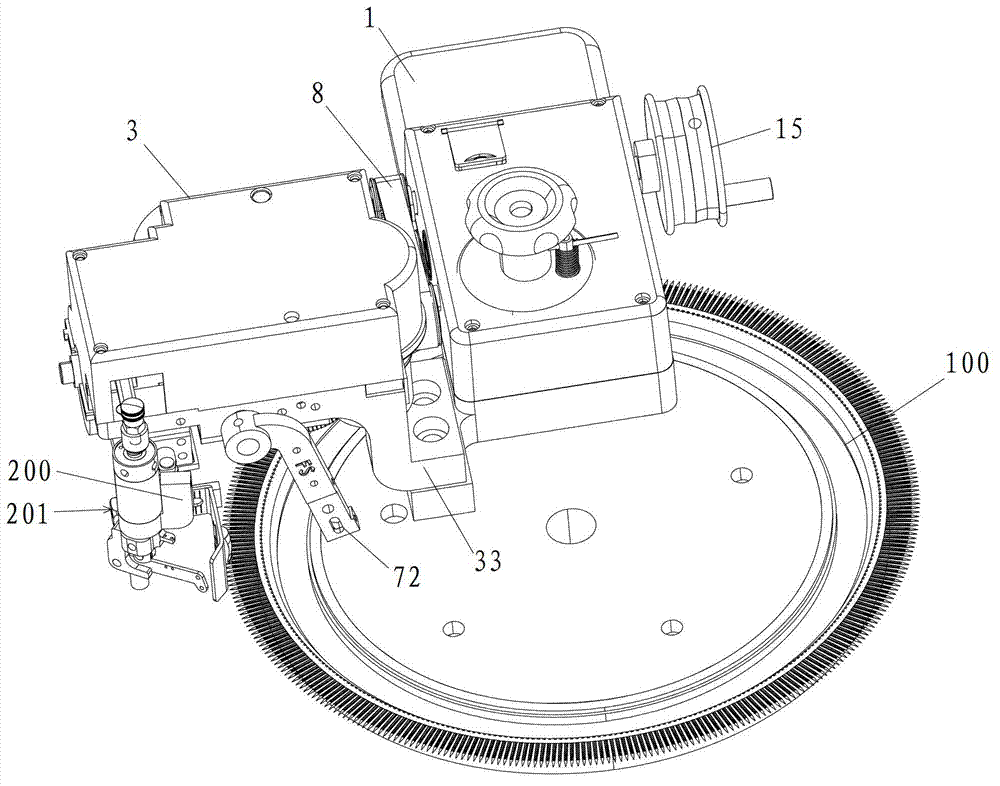

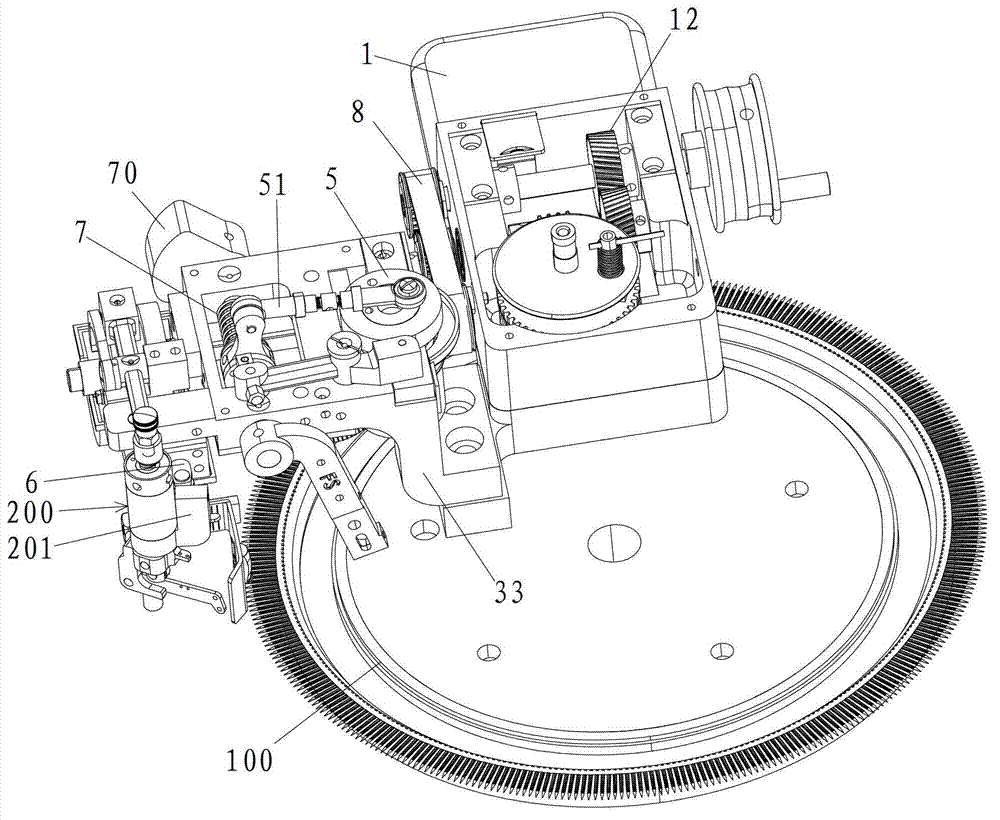

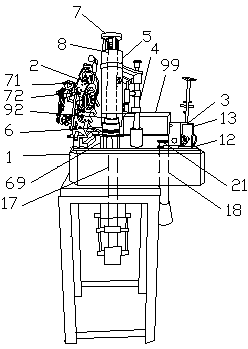

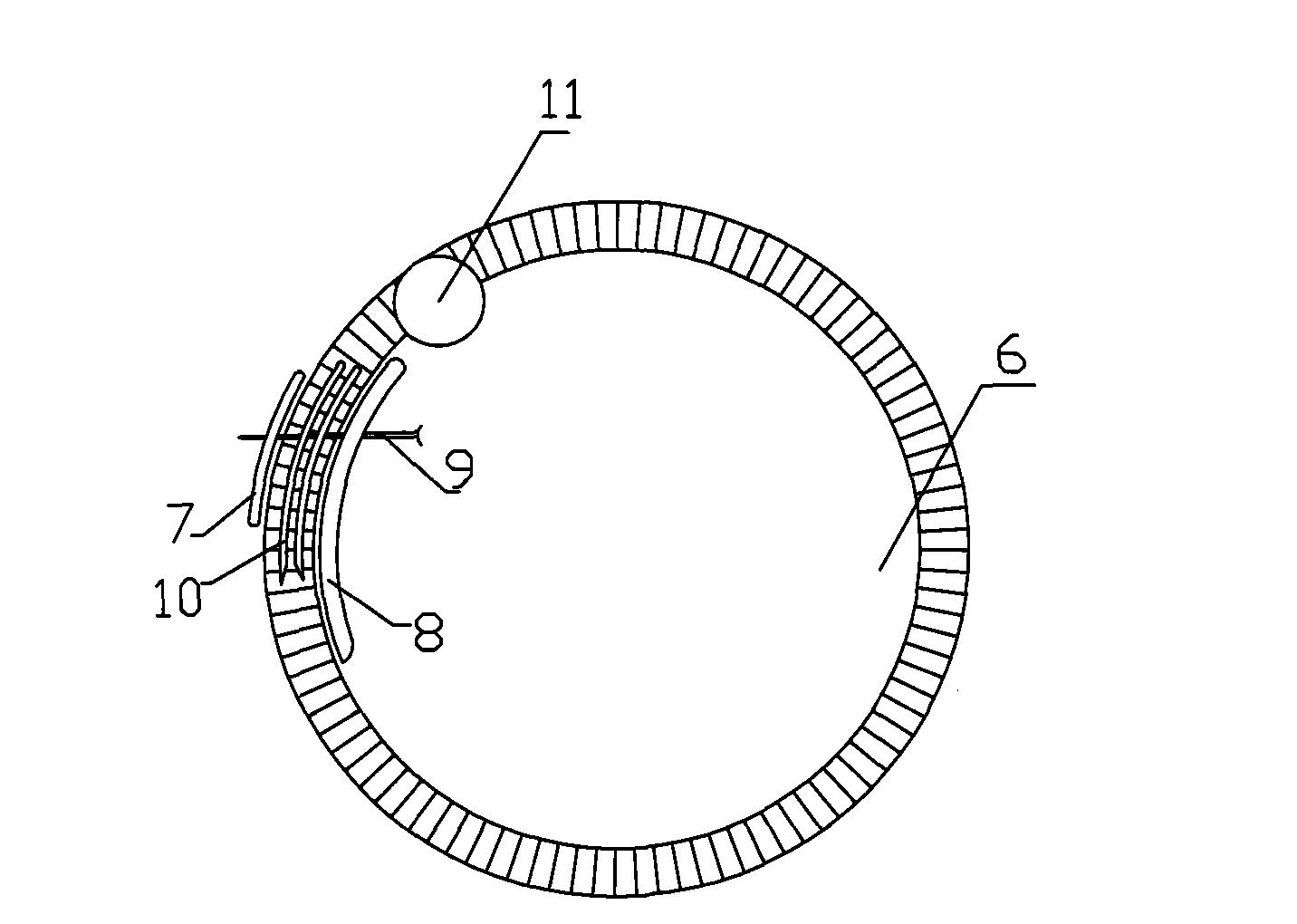

The invention discloses a high-efficiency dial linking machine. The high-efficiency dial linking machine comprises a headstock, a speed-regulating unit, a case and a dial; the headstock comprises a box, a box cover, a gear assembly and an adjusting handle, wherein the box cover is mounted on the top of the box, the gear assembly is mounted in the box, the adjusting handle is linked with the gear assembly, and the gear assembly comprises a first gear assembly and a second gear assembly which are respectively provided with a first helical gear and a second helical gear and are engaged with each other; the speed-regulating unit is linked with the gear assembly through a transmission by being matched with a motor; the case comprises a mounting bracket, an upper shield and a lower shield, and the upper shield and the lower shield are jointly formed into an automatic oil filling device; a helical tooth drive unit, a cam drive mechanism linked with the helical tooth drive unit, a striping unit, a push rod drive mechanism and a dividing unit linked with the cam drive mechanism are mounted in the case, wherein the helical tooth drive unit is linked with the gear assembly through a synchronous drive mechanism; and a debuggable counterweight is mounted on the dividing unit. The high-efficiency dial linking machine has the advantages of stable and smooth operation, good sewing quality, long service life and the like.

Owner:东莞市缝神机械设备有限公司

Automatic silk stocking toe sewing machine and use method thereof

InactiveCN102433689ANo missing stitchesDoes not produce uniformityWorkpiece carriersWork-feeding meansMan machineCrowds

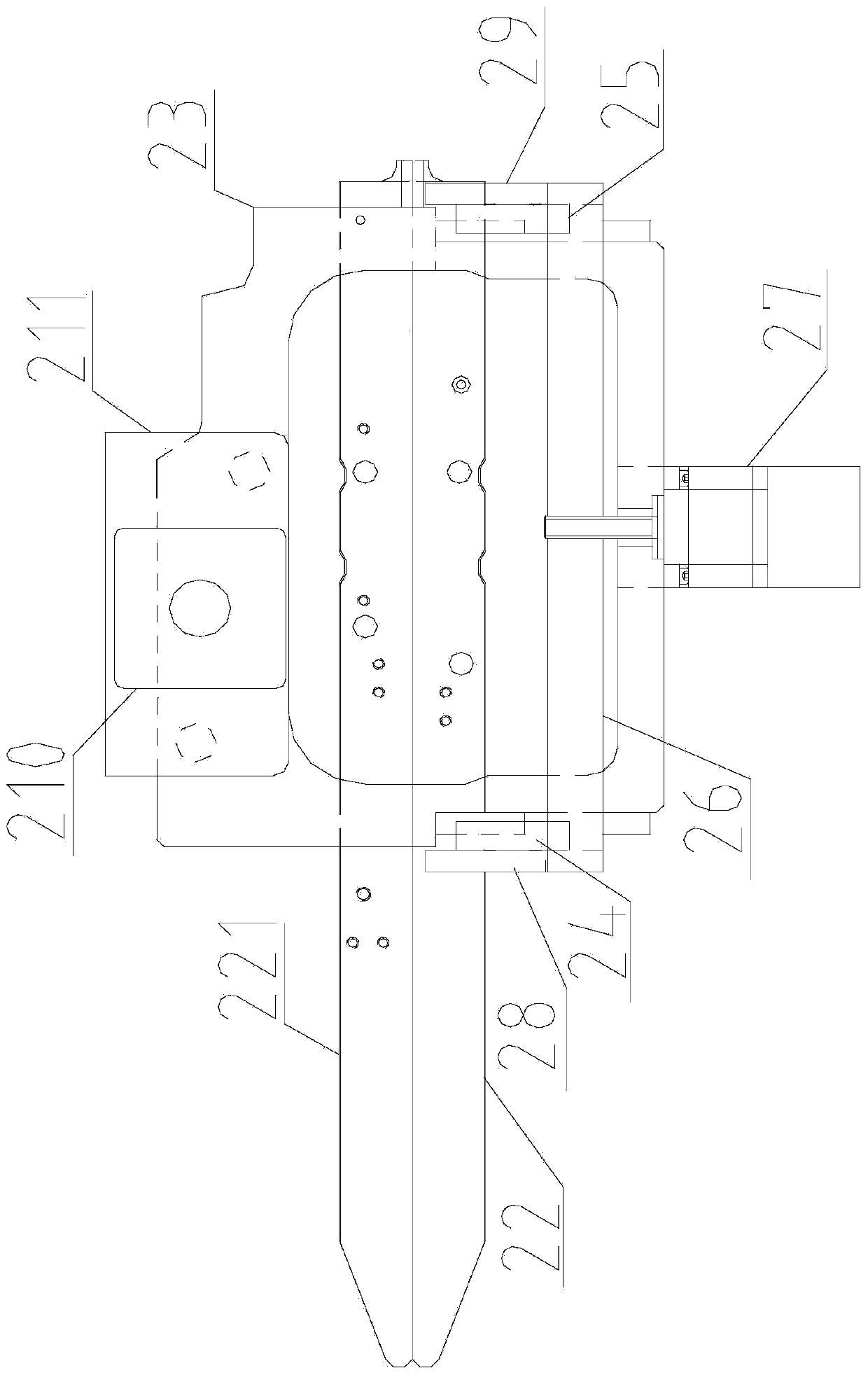

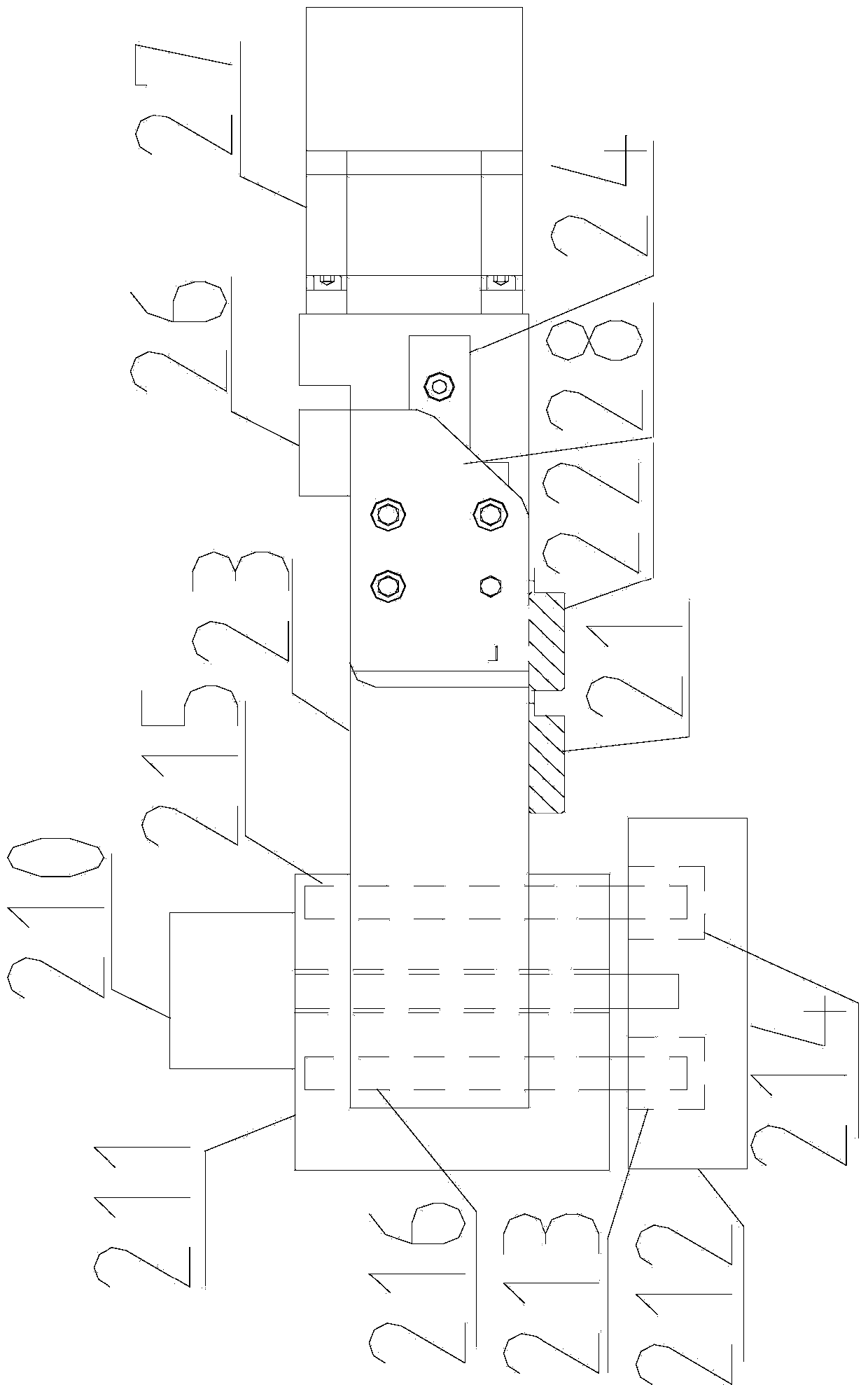

The invention discloses an automatic silk stocking toe sewing machine and a use method thereof. The automatic silk stocking toe sewing machine comprises a host machine, a movable socking plate, a machine head support, a machine head, a crotch cutting system, a stocking clamping system and the like, wherein the machine head support is independently driven by a lead screw motor, and the machine head support drives the machine head to change the sewing track; because the stocking casing is stationary when the stocking toe is sewn, a movable support drives the machine head to adopt an active sewing mode, thus the rotation speed of the machine head is reduced; and the stocking clamping system is used for clamping the stocking casing, so that the crotch cutting system carries out crotch cutting on the sewn stocking casing. In the invention, through simple man-machine conversation, multiple processes and multiple persons required by stocking toe sewing are changed into one-person operation; when ultra-thin or ultra-thick stockings are sewn, the problems of missed sewing, nonuniform spacing and the like are not generated, and the sewn stockings can accord with the toe arc lines of different crowds; and the crotch cutting is carried out under the state of clamping and tightening the stocking casing, thus the cut is straight and accurate, the artificial crotch cutting error is reduced, the working efficiency is greatly improved, the product quality is guaranteed and the raw materials are saved.

Owner:韶关市新时韵针织有限公司

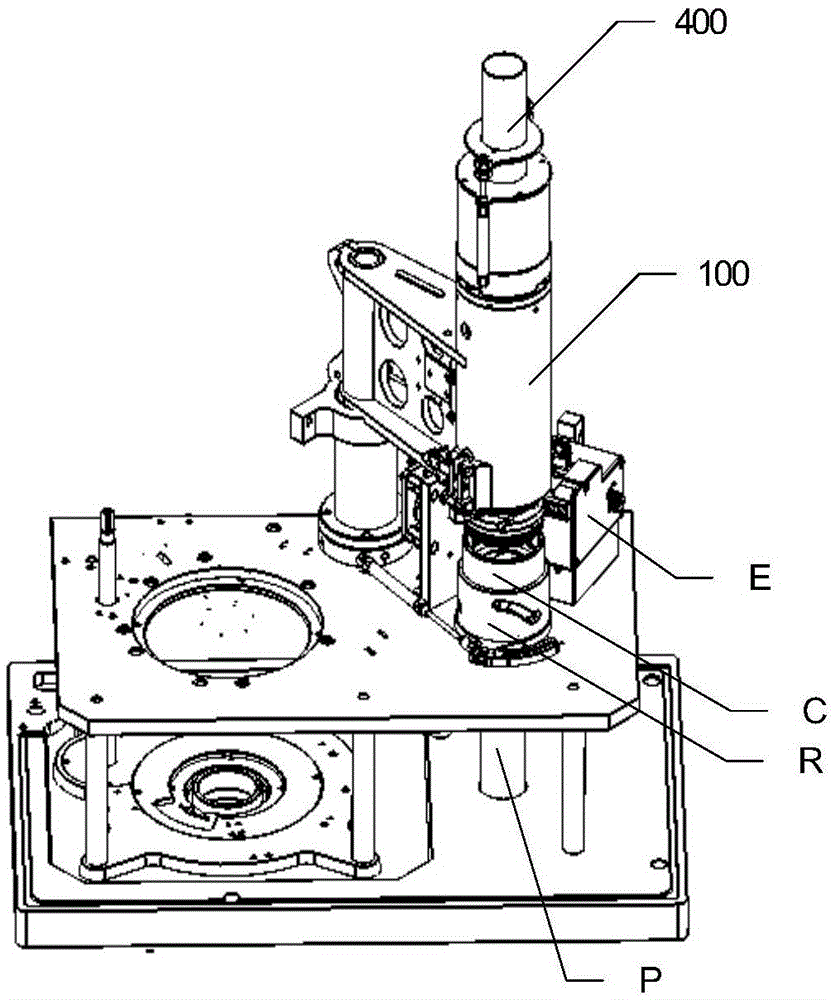

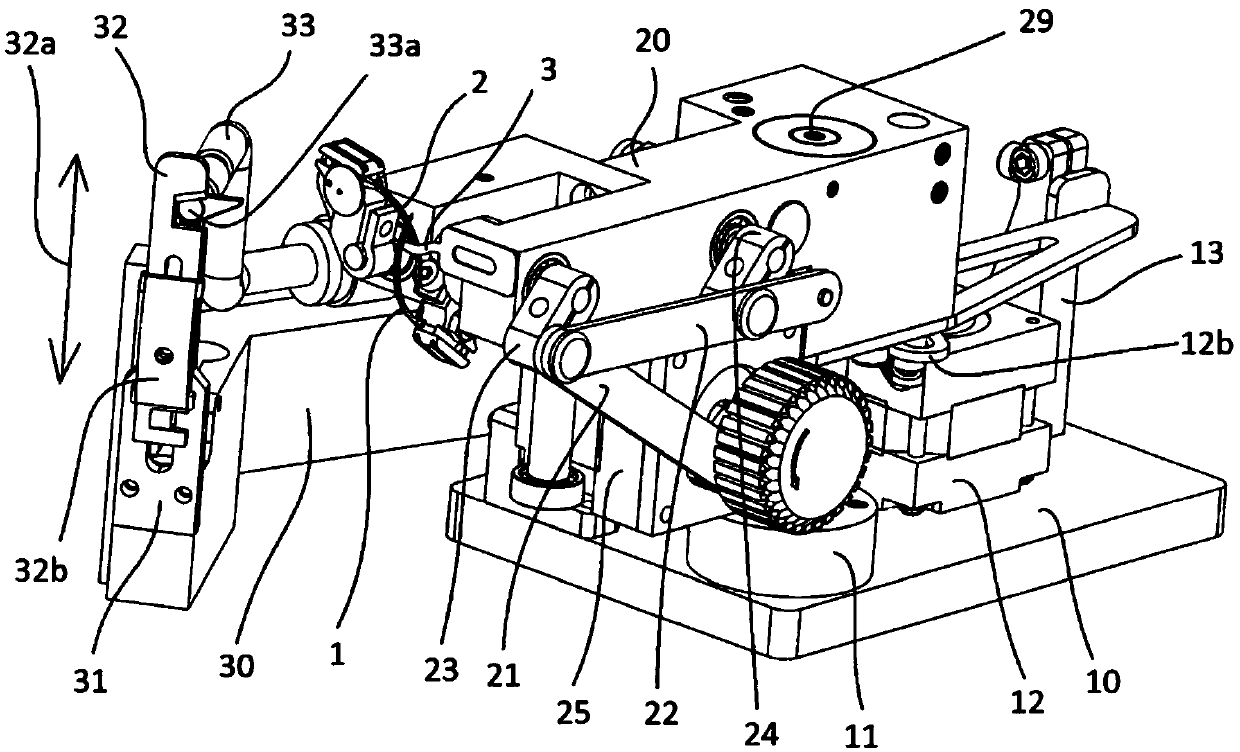

Toe end closing apparatus

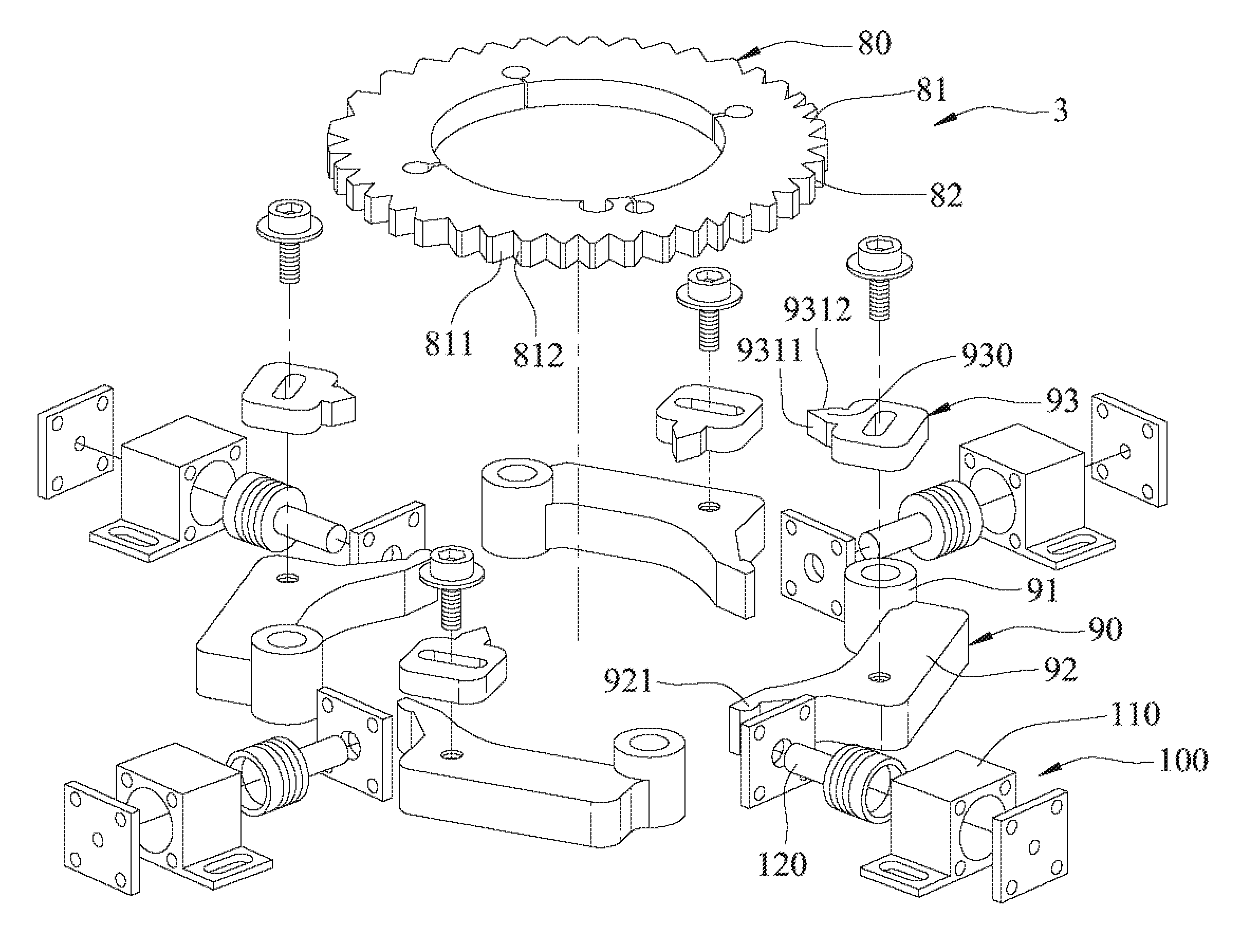

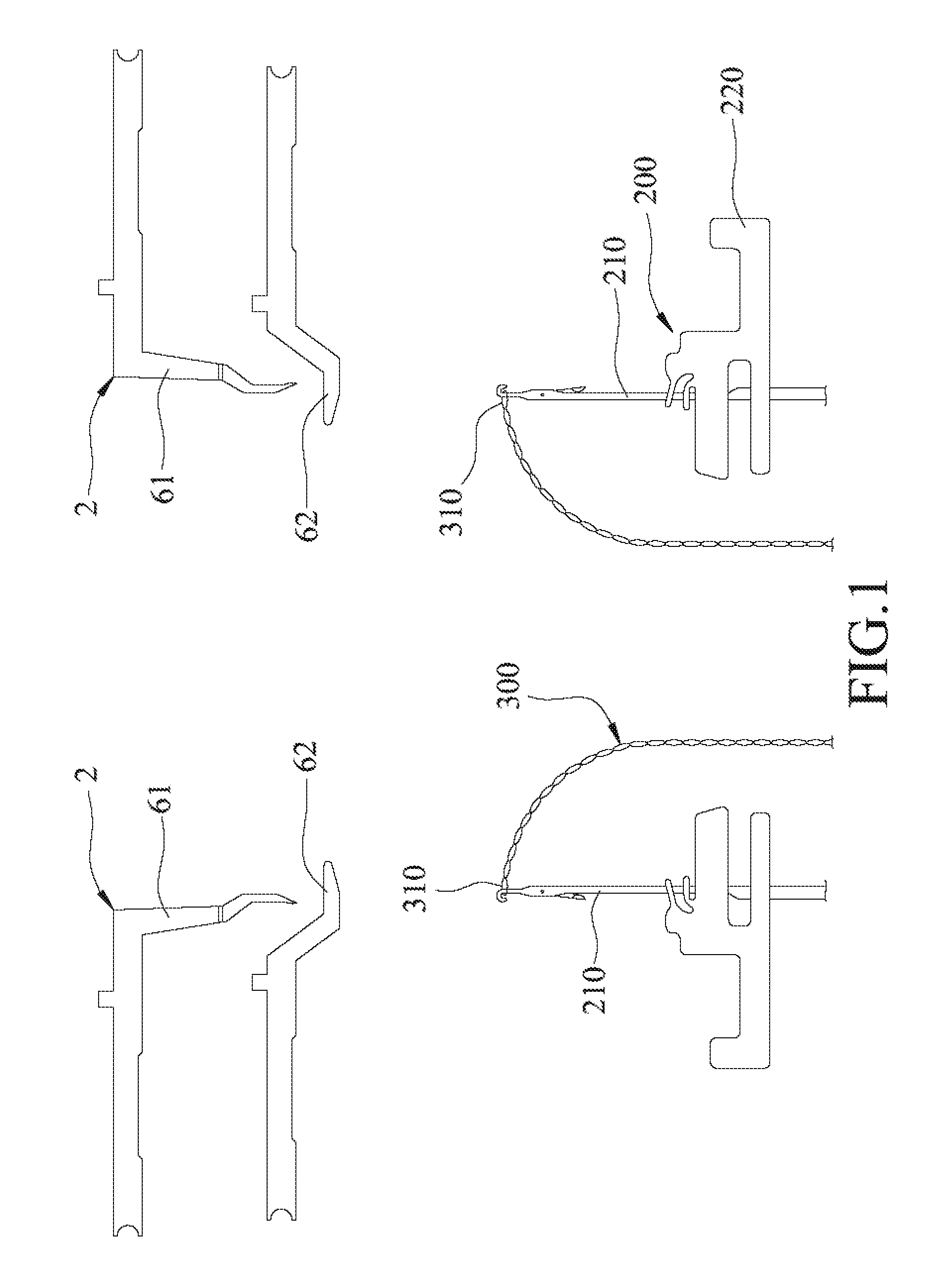

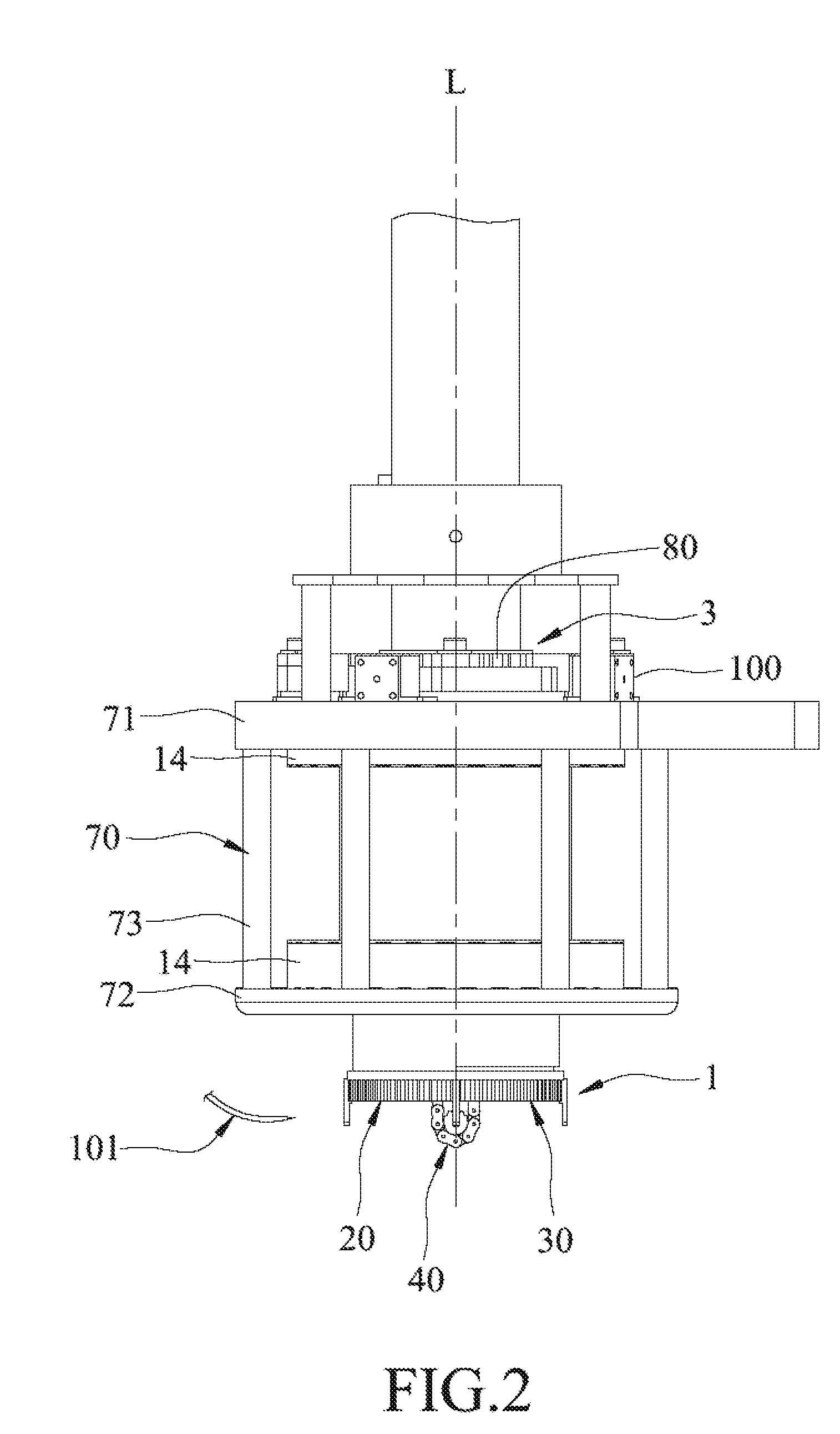

ActiveCN104652043ASimple structureReduce volumeProgramme-controlled sewing machinesSewing-machine control devicesRotation controlControl unit

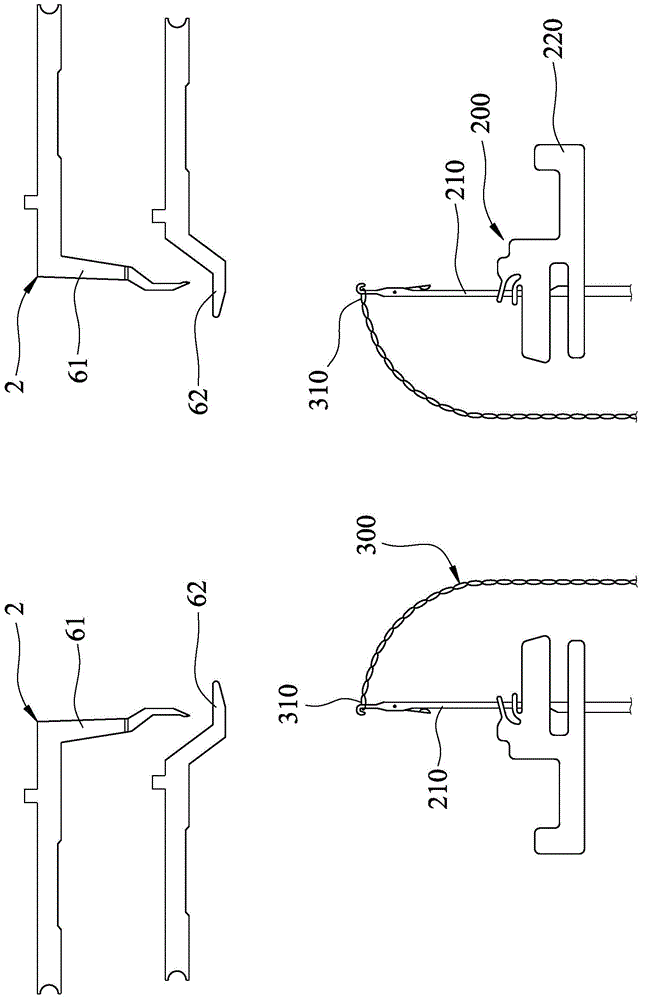

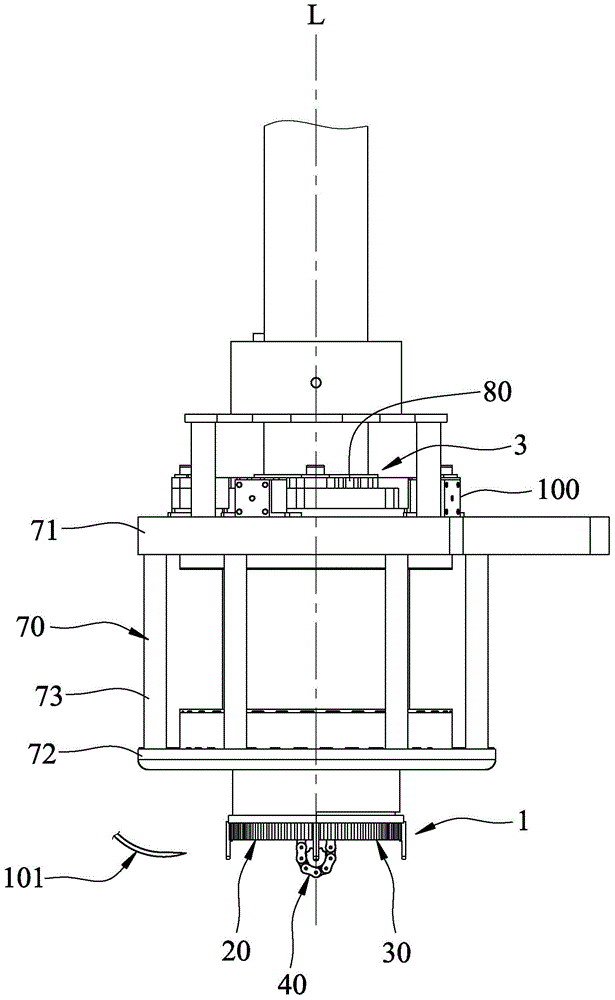

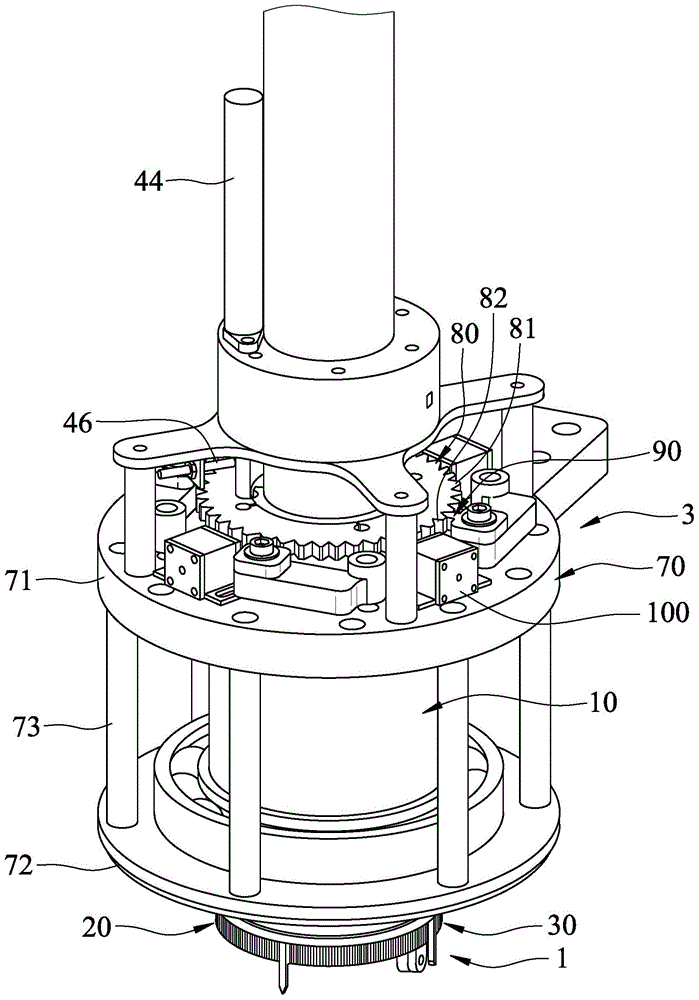

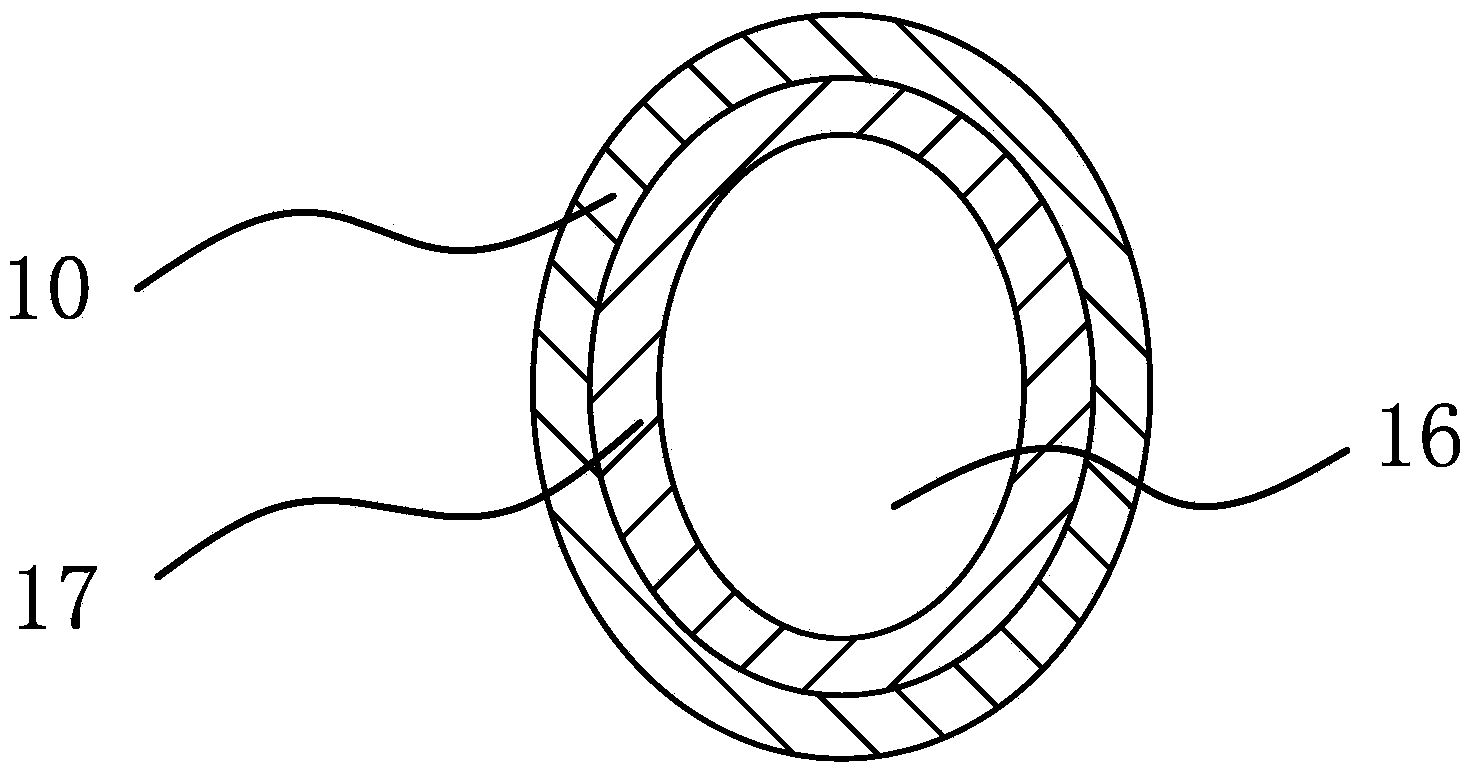

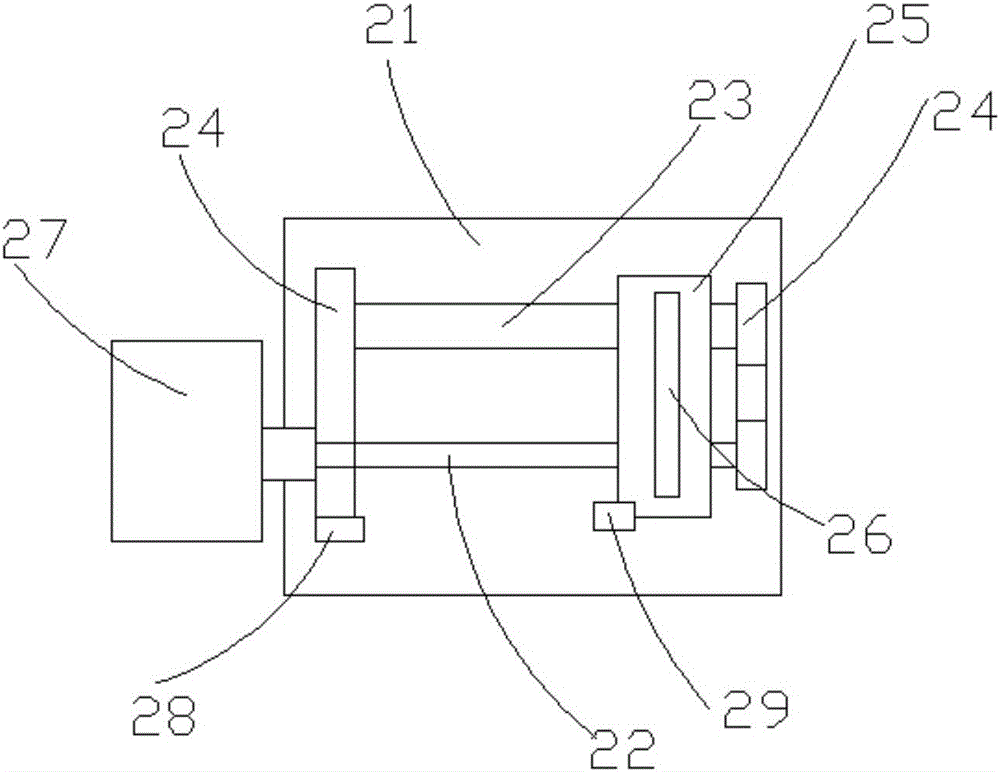

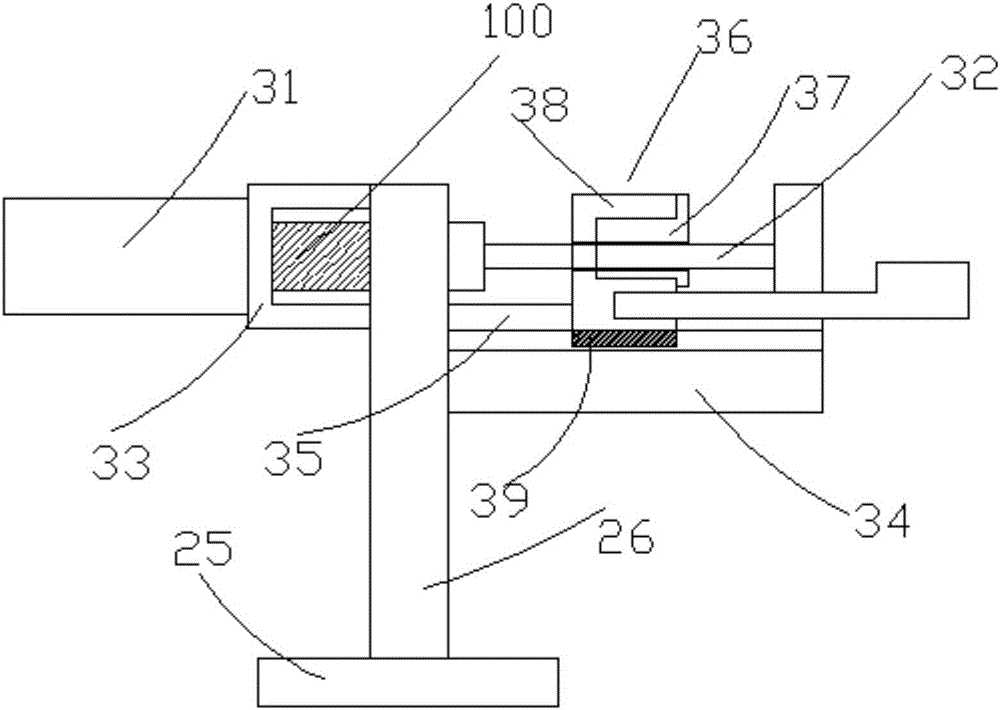

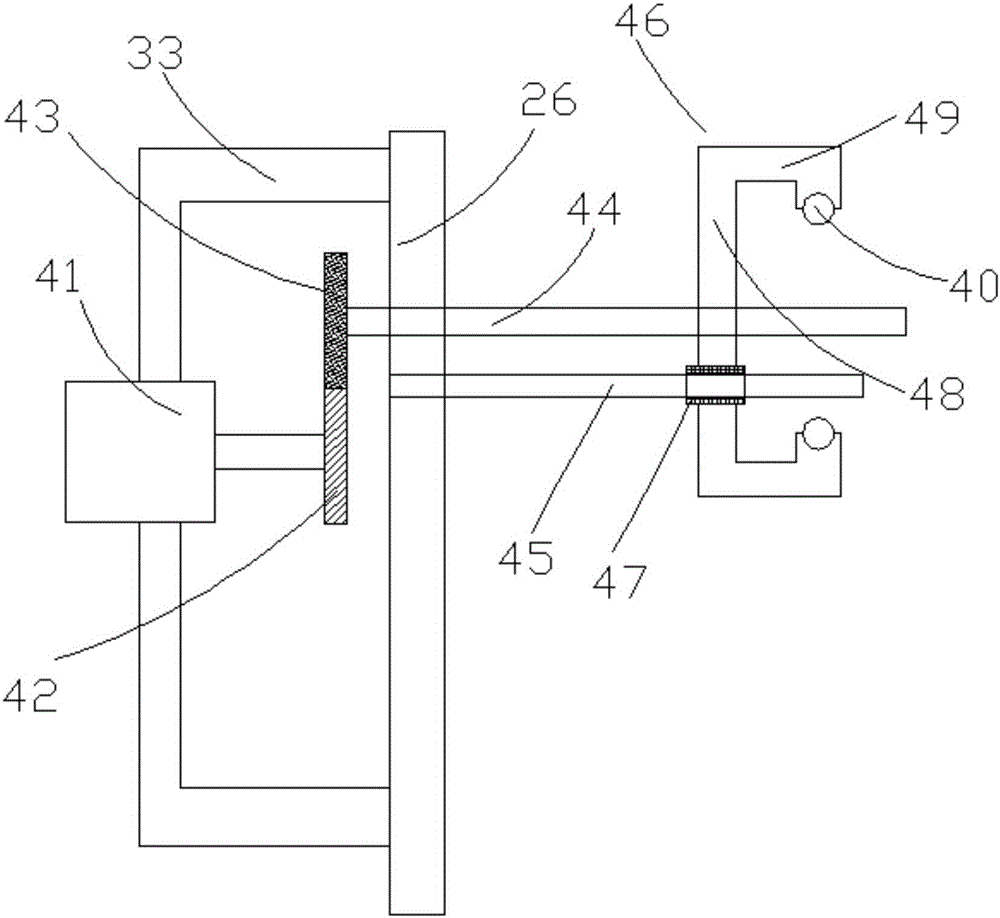

An apparatus for closing a toe end (310) of a tubular hosiery body (300) includes a stitching device (1) having a main body (10), a fixed reed (20), a movable reed (30) pivoted to the fixed reed (20), and a main drive assembly (40) for driving the movable reed (30) to rotate relative to the fixed reed (20) between juxtaposed and stacked positions. A rotary control unit (3) includes a support frame (70) supporting the main body (10), a rotary disc (80) attached to the main body (10), a plurality of detent members (90) disposed around the rotary disc (80), and a plurality of control drive members (100) respectively driving the detent members (90). The control drive members (100) consecutively operate to consecutively actuate the respective detent members (90) such that the rotary disc (80) together with the stitching device (1) consecutively produces a limited amount of rotation in an intermittent manner.

Owner:KONG ENTERPRISE

Integrated sock making machine with binding-off function

ActiveCN103966760AWith sock sewing functionIncrease productivityLinking machinesSpool-pin assembliesMagnetic valveManufacturing engineering

The invention discloses an integrated sock making machine with a binding-off function. The integrated sock making machine comprises a work table and a sock weaving machine installed on the work table, the work table is further provided with a binding-off machine, a rotary stand column, a work plate, a sock discharging platform and an electromagnetic control box, a sock turning ejecting rod is matched with the work plate, a sock discharging cylinder is matched with the sock discharging platform, and the sock weaving machine, the binding-off machine, the rotary stand column, a sock absorbing cylinder, the sock turning ejection rod and the sock discharging cylinder are all connected with the electromagnetic control box. The integrated sock making machine has a sock sewing function and has the advantages that only one work procedure is needed from sock production to a finished product, production efficiency is effectively improved and labor and materials are saved.

Owner:浙江海润精工机械有限公司

Flat seaming machine for socks end

InactiveCN101270535AReduce temperature riseExtend your lifeProgramme-controlled sewing machinesWorkpiece carriersSOCKSLiquid-crystal display

The invention discloses a stocking toe seamer which includes a power supply part, a motor drive part, a PC control part and a signal detecting part. The seamer also includes a feed device, a cutting device, a belt lifting seaming device and a transmission device. The seamer is characterized in that the motor drive part is provided with a main motor drive circuit and a lifting motor drive circuit of the belt lifting seaming device; the PC control part includes a touch screen or a keyboard, an LCD and a micro-controller. Each motor drive circuit, the touch screen or the keyboard, the LCD and the signal detecting part are all electrically connected with the micro-controller; the feed device, the cutting device, the belt lifting seaming device, the transmission device and the main motor are connected in transmission. The stocking toe seamer has the advantages of precise control, flat and beautiful stocking toe seaming line, etc.

Owner:何伟斌

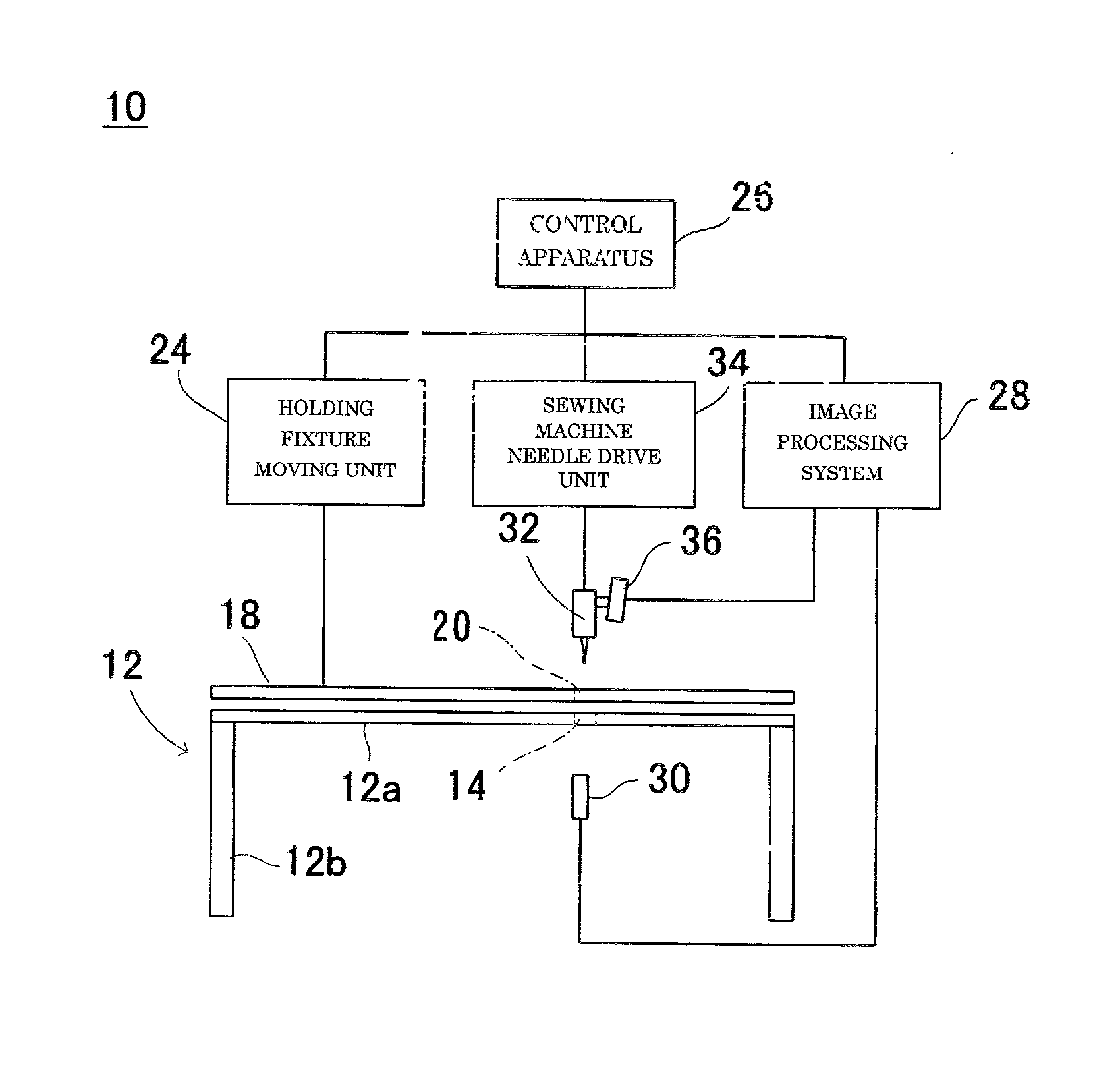

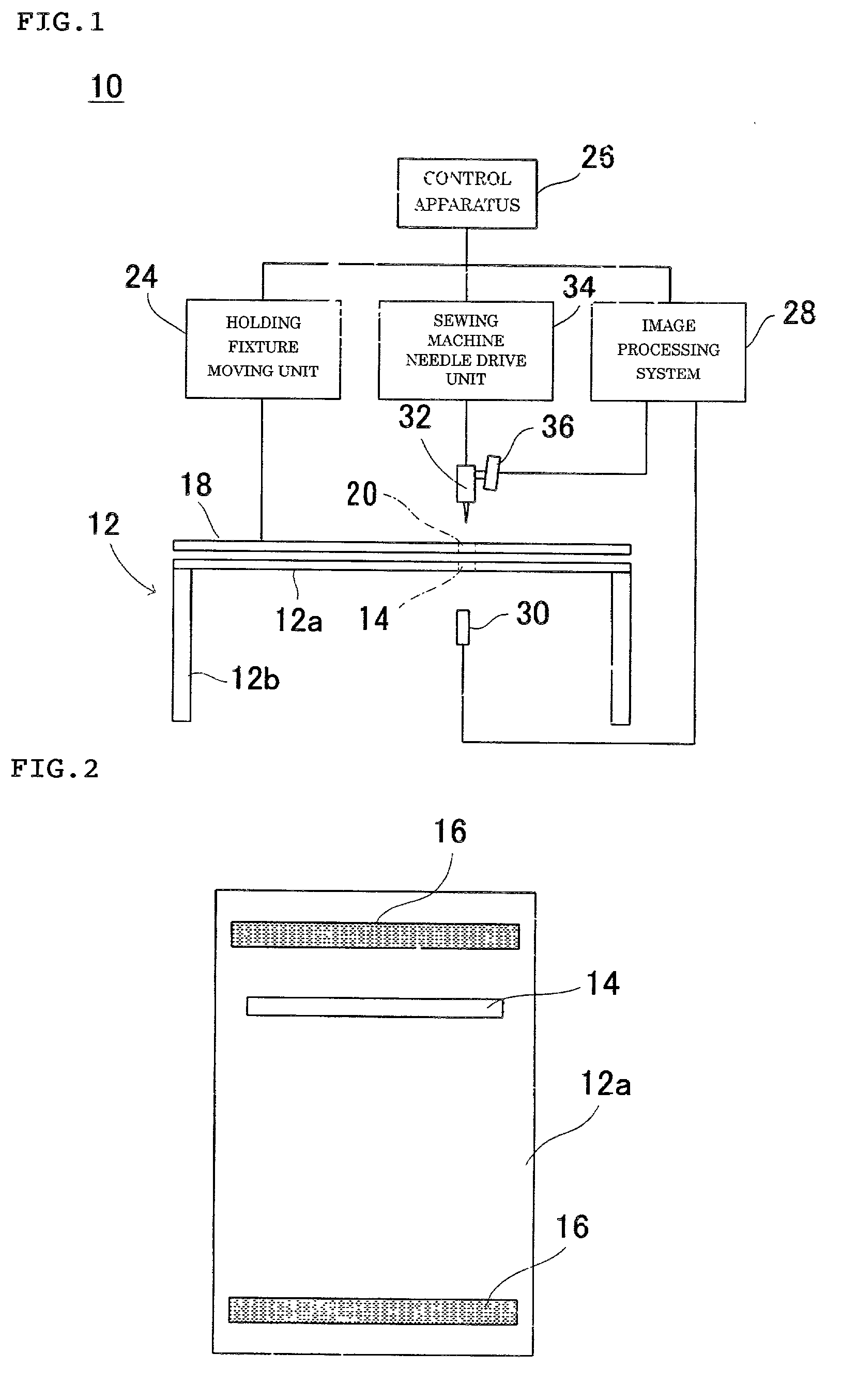

Method and apparatus for linking plain knitted fabrics

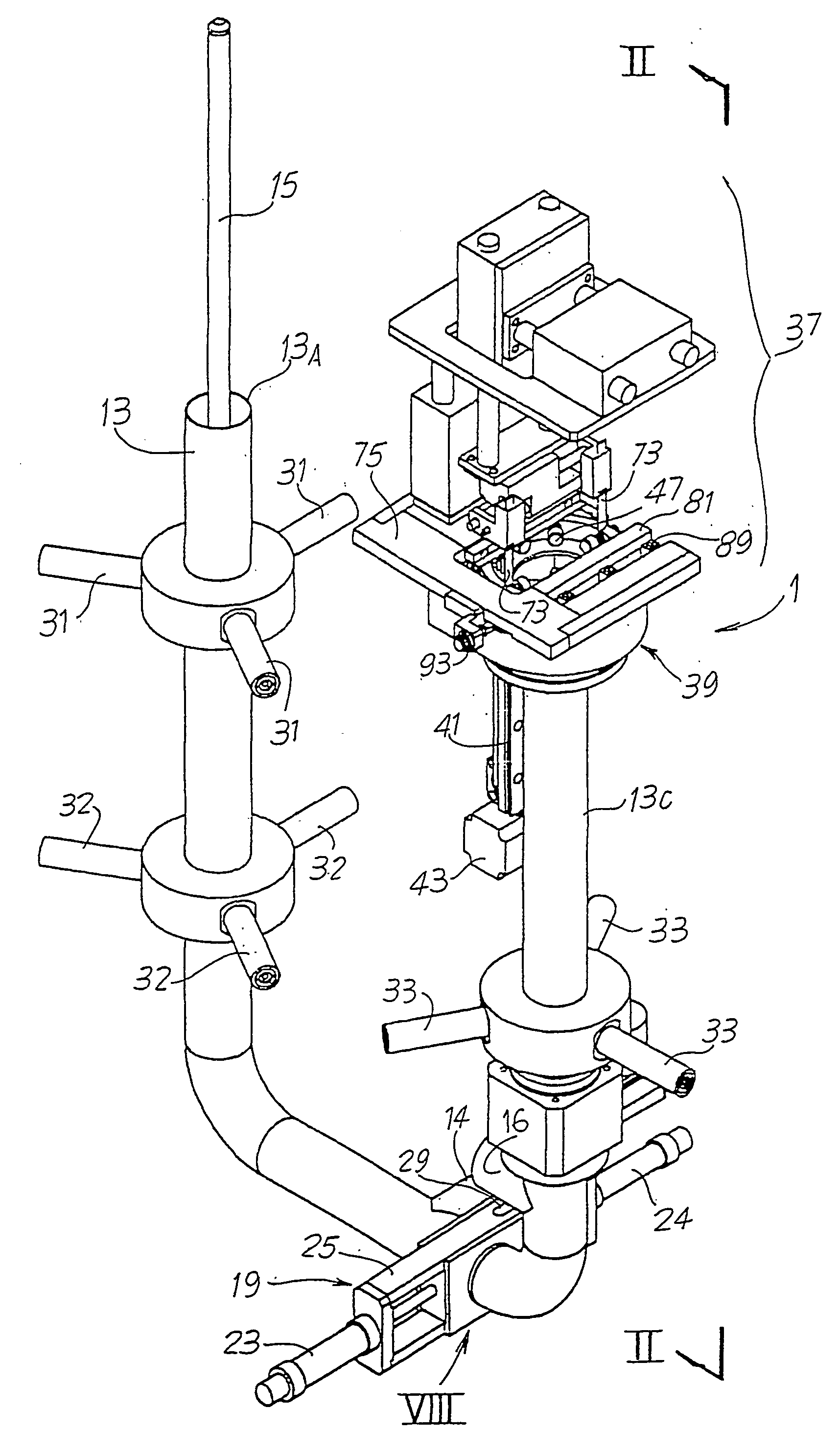

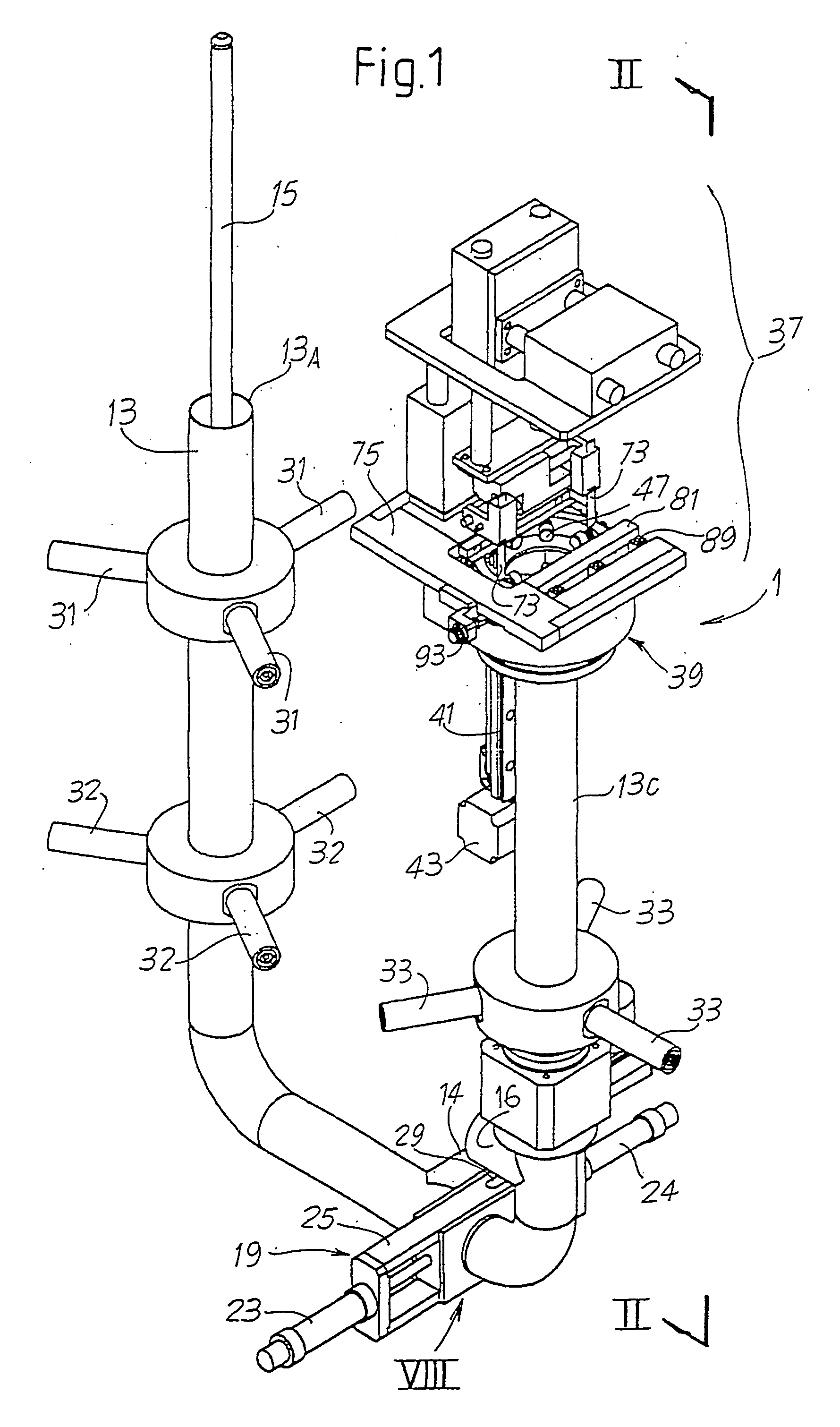

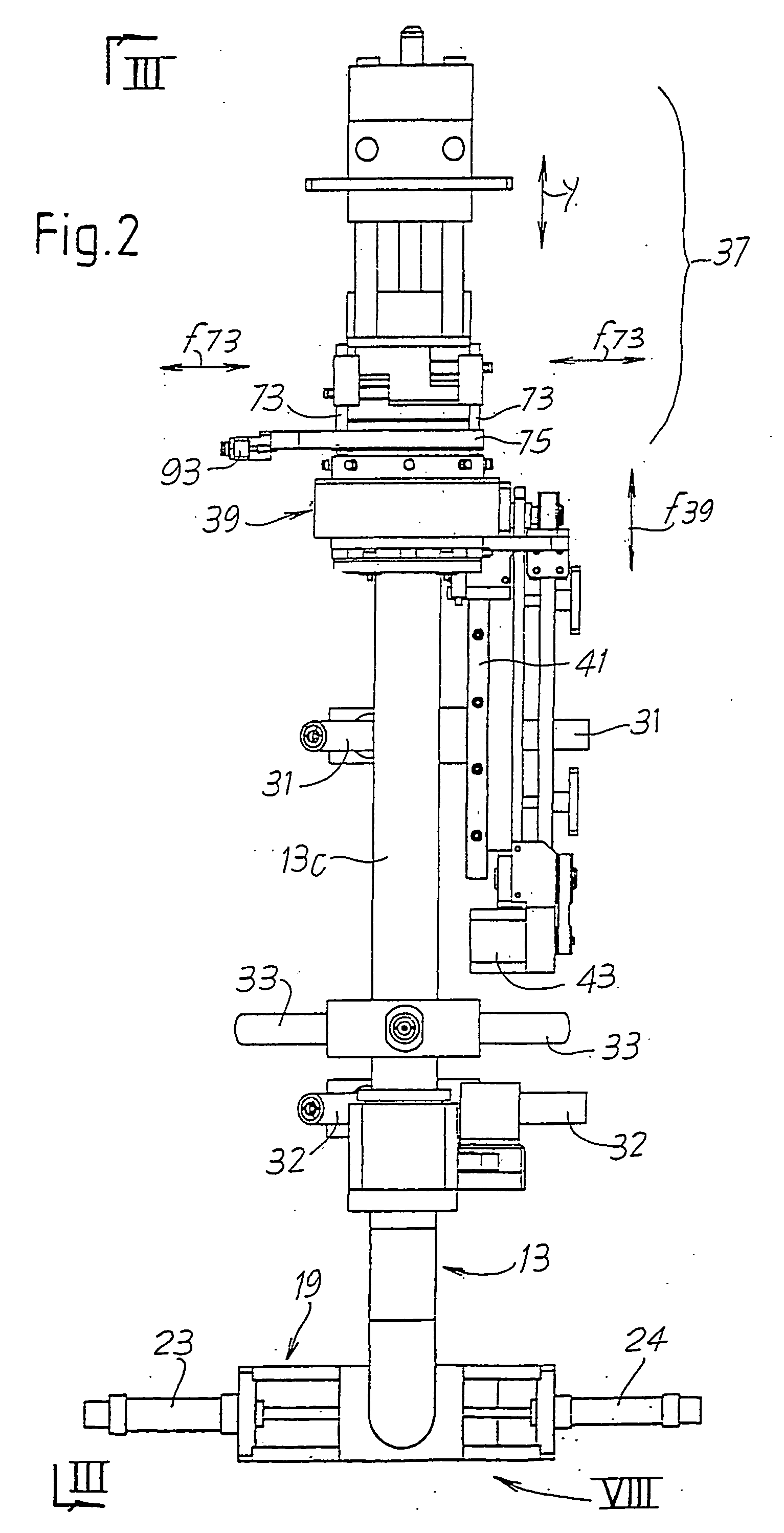

InactiveUS20020129626A1Reduce amountAccurate and efficient dockingWork-feeding meansLinking machinesEngineeringSewing machine

A method for linking plain knitted fabrics includes the steps of fixing a first plain knitted fabric in a stretched state, obtaining an image including an image of a darning stitch of the first plain knitted fabric in the stretched state, calculating a location of the darning stitch of the first plain knitted fabric from the obtained image, holding a second plain knitted fabric in a stretched state, obtaining an image including an image of a darning stitch of the second plain knitted fabric in the stretched state, calculating a location of the darning stitch of the second plain knitted fabric from the obtained image, moving the first plain knitted fabric and the second plain knitted fabric relative to each other to align the darning stitch of the second plain knitted fabric with the darning stitch of the first plain knitted fabric, moving a sewing machine needle of a sewing machine mechanism to the location of the darning stitch of the first plain knitted fabric, and linking together the darning stitch of the first plain knitted fabric and the darning stitch of the second plain knitted, fabric with the sewing machine needle.

Owner:DAN

Toe closing apparatus

An apparatus for closing a toe end of a tubular hosiery body includes a stitching device having a main body, a fixed reed, a movable reed pivoted to the fixed reed, and a main drive assembly for driving the movable reed to rotate relative to the fixed reed between juxtaposed and stacked positions. A rotary control unit includes a support frame supporting the main body, a rotary disc attached to the main body, a plurality of detent members disposed around the rotary disc, and a plurality of control drive members respectively driving the detent members. The control drive members consecutively operate to consecutively actuate the respective detent members such that the rotary disc together with the stitching device consecutively produces a limited amount of rotation in an intermittent manner.

Owner:KONG ENTERPRISE

Bar tacking machine with needle position safety detection sensor, control method and sensing plate thereof

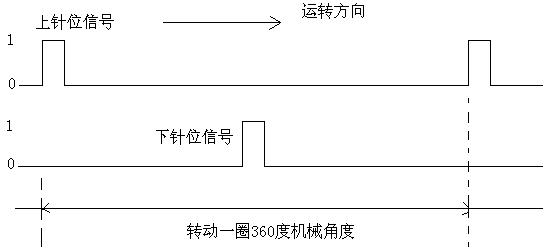

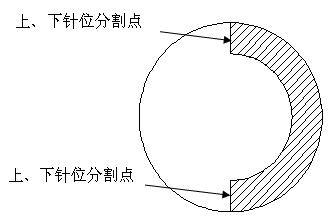

InactiveCN102162177AEfficient detection of absolute physical locationSimple signalProgramme-controlled sewing machinesLinking machinesElectricityNeedle position

The invention discloses a method for controlling a bar tacking machine with a needle position safety detection sensor, which comprises the steps of firstly, detecting the actual position of a needle bar through a position sensor corresponding to a needle position induction sheet; secondly, judging the parking position through the edge detection method for a needle position signal, according to the corresponding relationship between the needle position induction sheet and the needle position signal; thirdly, judging the absolute position of the machine needle according to the needle position signal; fourthly, selecting the rotation direction of a motor according to the absolute position of the machine needle, and performing the needle lifting action for the first time after power on; fifthly, adopting the above needle feeding position as a mechanical phase zero and outputting the edge detection jump of the pulse signal and the needle position signal so as to realize the counting within 0-360 mechanical angles as phases. Due to the adoption of the method, the absolute physical position of a needle bar can be effectively detected, so that the safe operation direction of first needle lifting after power on is judged according to the position of the needle bar.

Owner:ZHEJIANG MAQI SEWING MACHINE

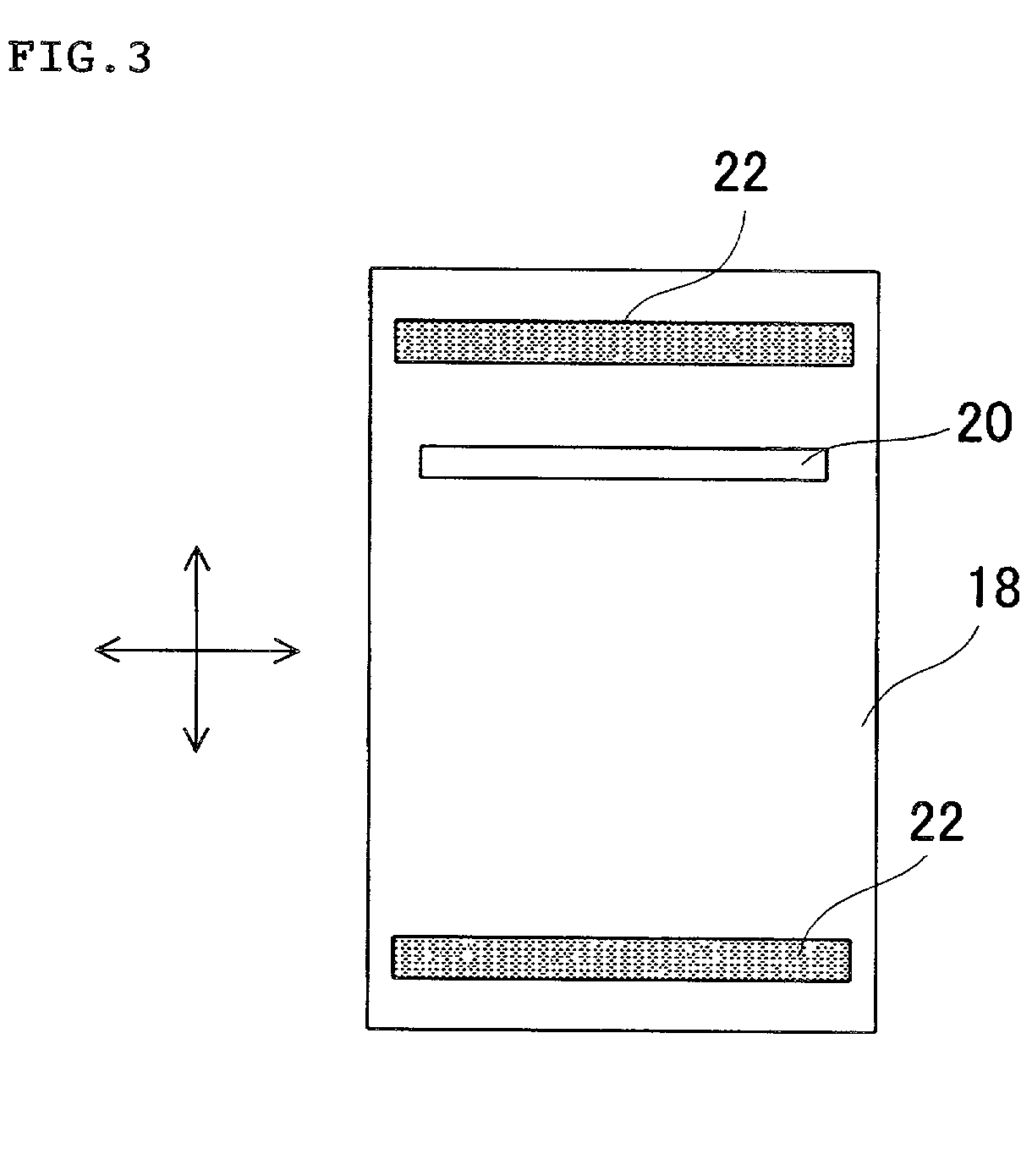

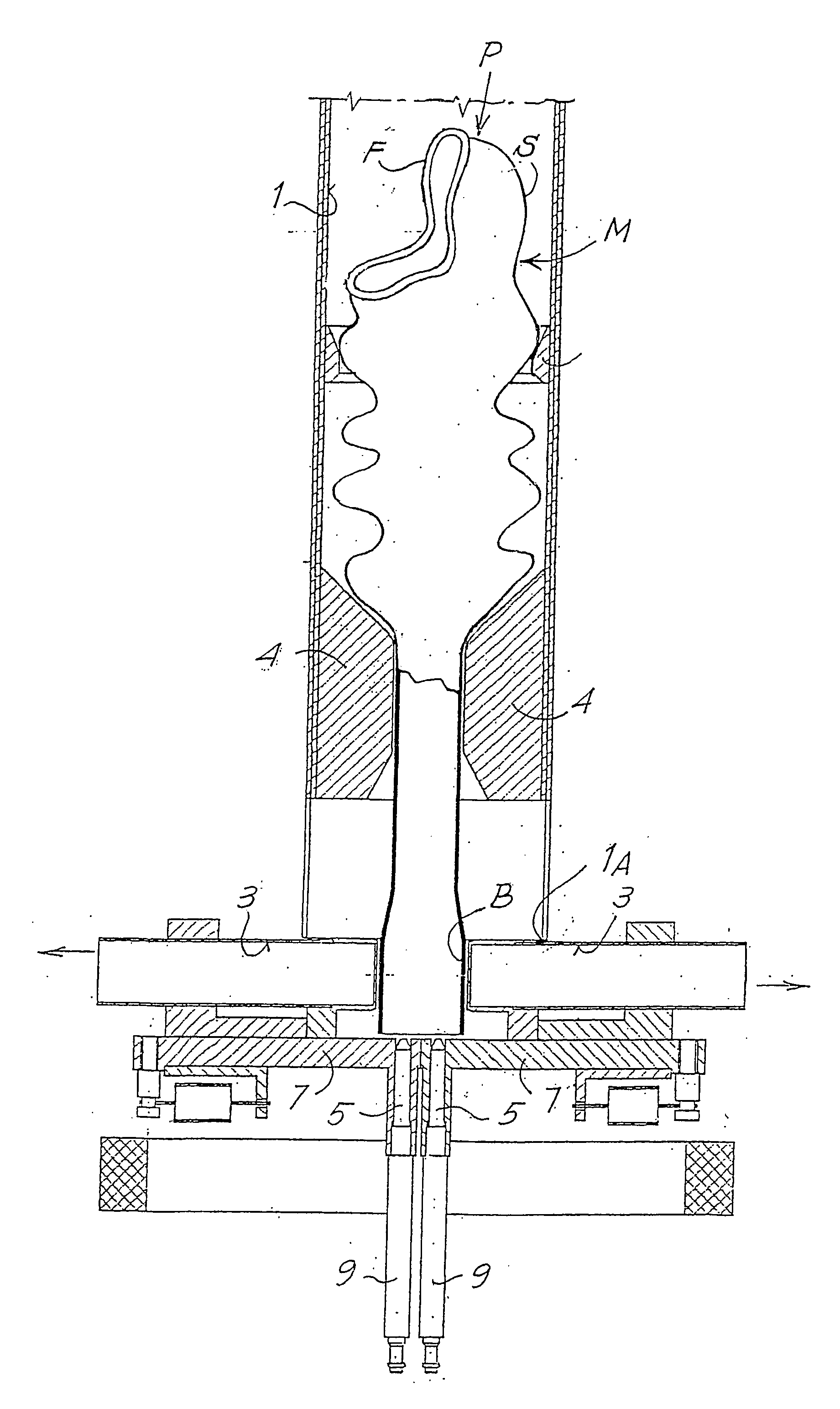

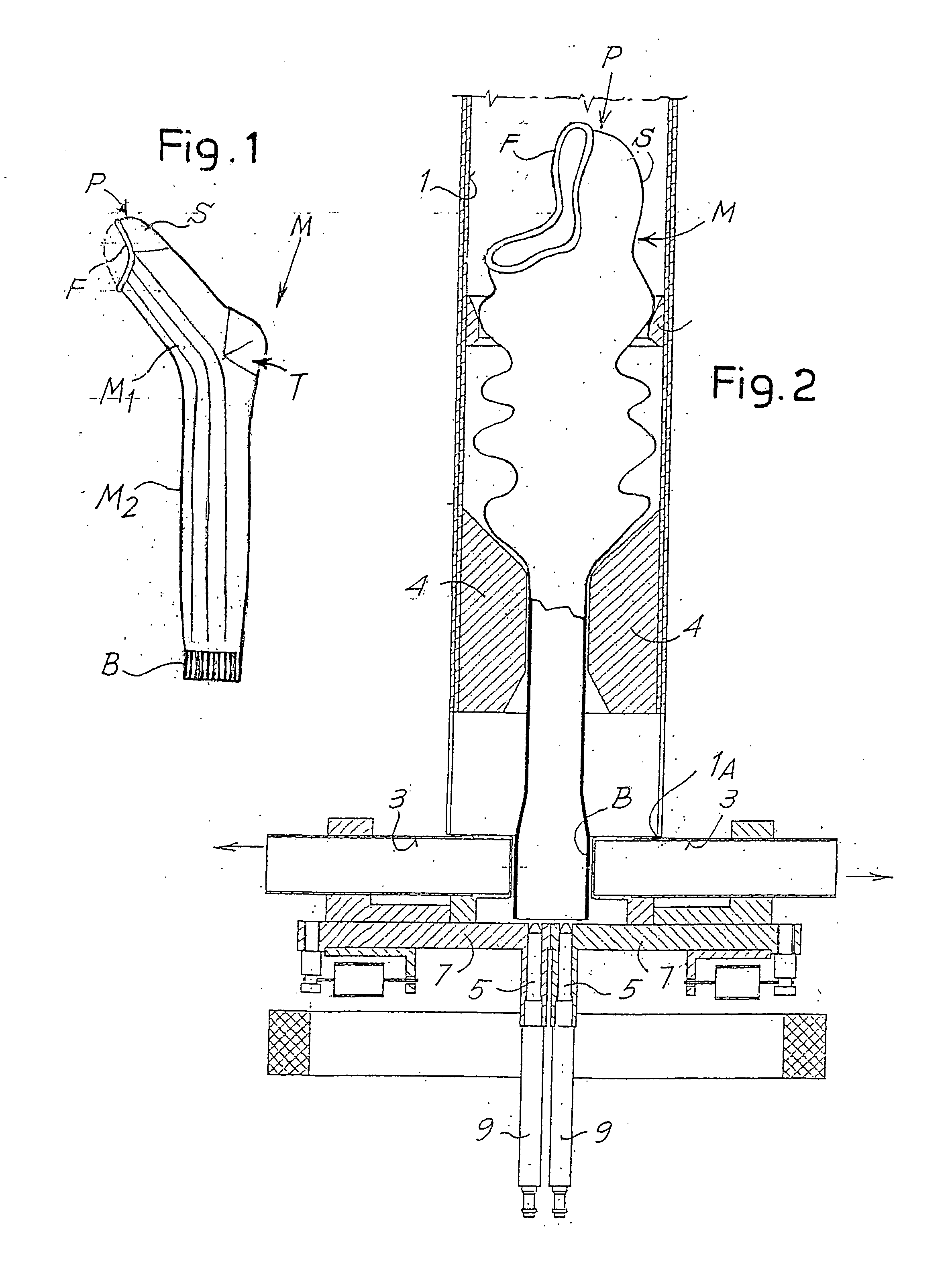

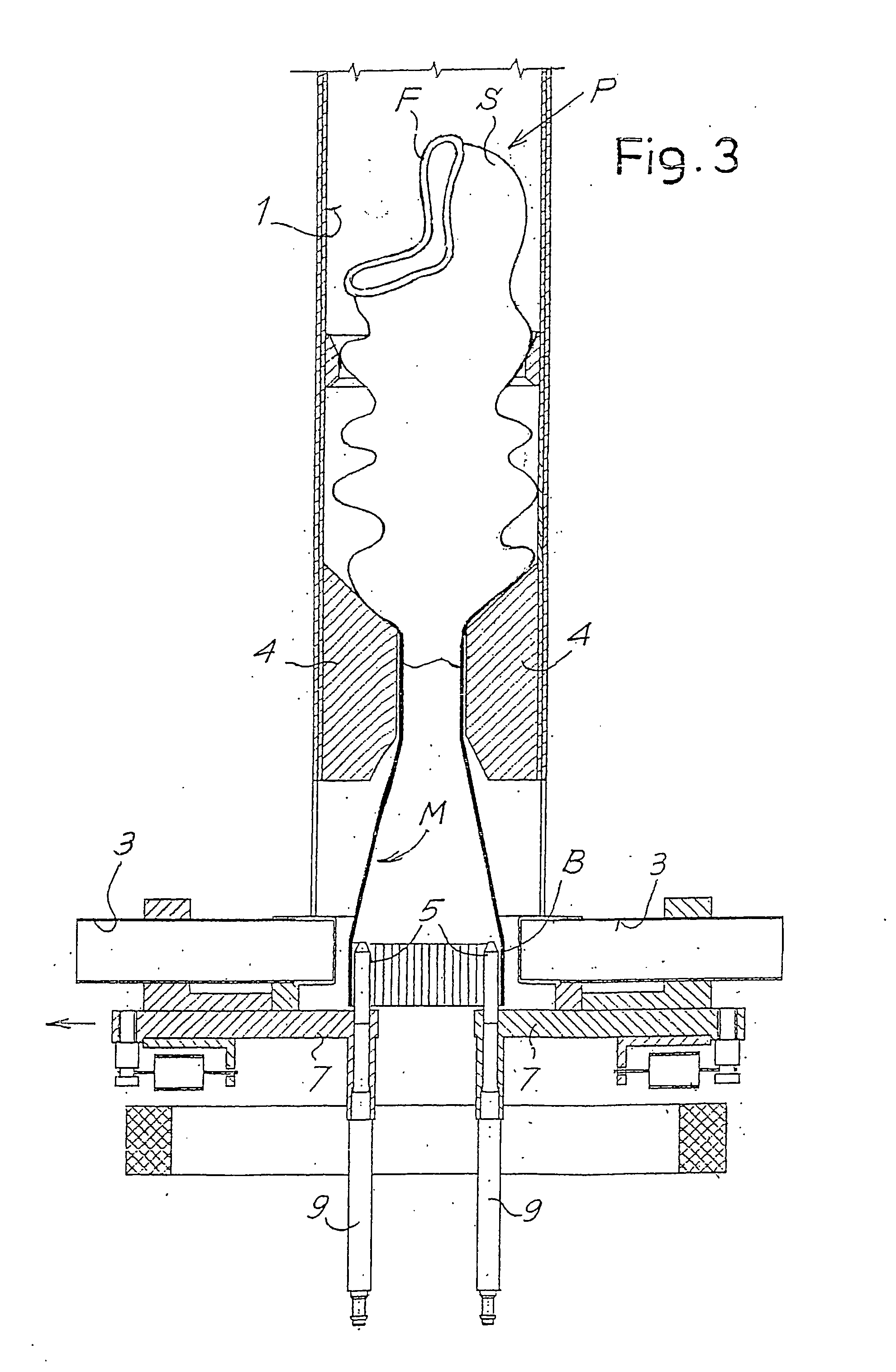

Method and device for the production of tubular knitted articles and in particular for closing the toe

InactiveUS20040168478A1Improve automationProduct qualityLinking machinesCircular knitting machinesBiomedical engineeringMechanical engineering

Described herein is a method for forming a closed toe in a tubular knitted article, for example a sock, comprising the steps of: setting two end flaps (L1, L2) of the article (M) alongside one another; inserting, inside the loops of at least one first row (X2) of stitches of the flaps set alongside one another, a comb-like structure comprising a plurality of teeth (85); sewing (C) together the loops of at least one second row of stitches, which is set between the first row of stitches (X2) and the body of the tubular article (M); and opening the loops of the first row of stitches.

Owner:GOLDEN LEDI CO SPA

Hosiery seamer

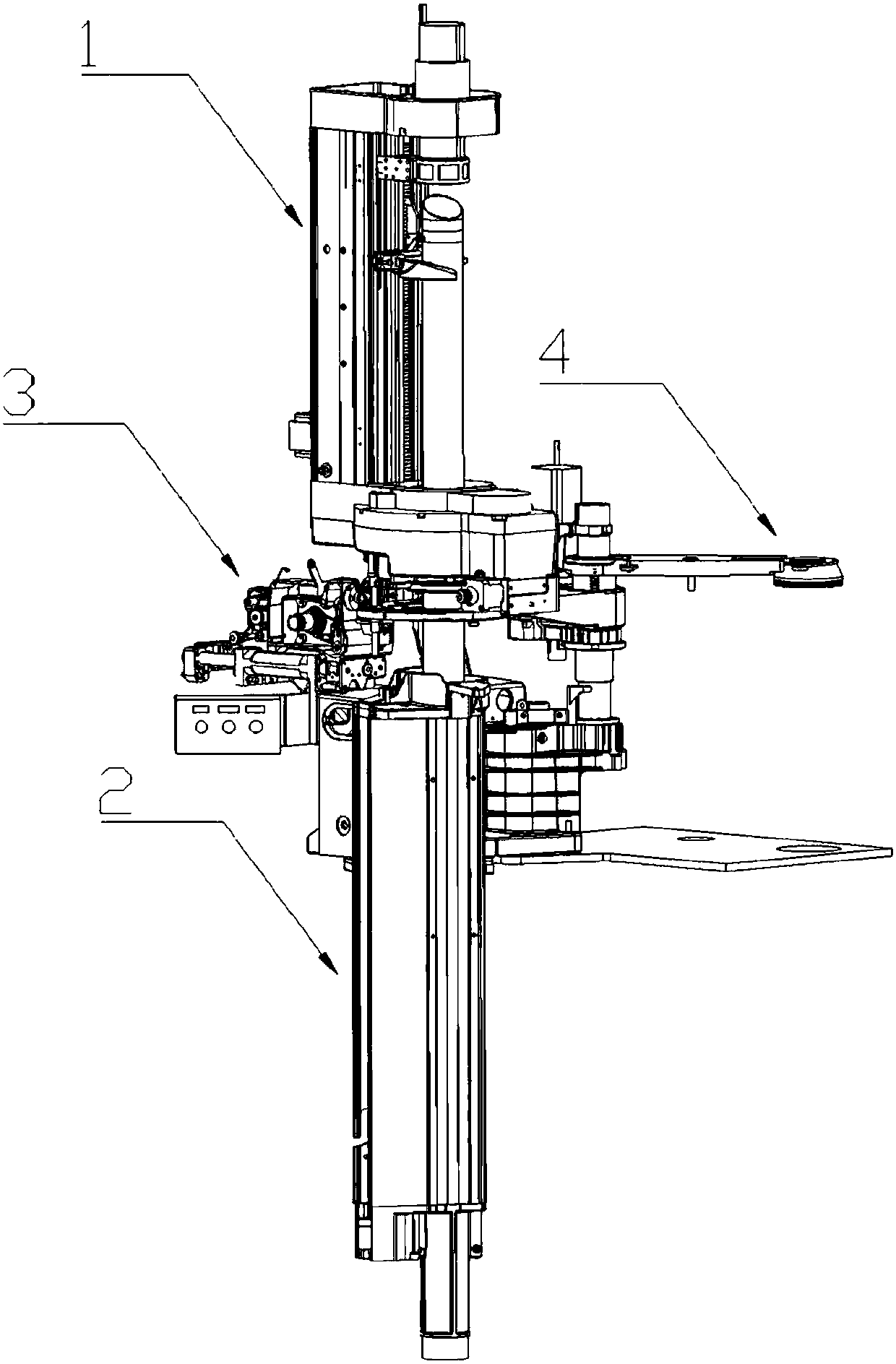

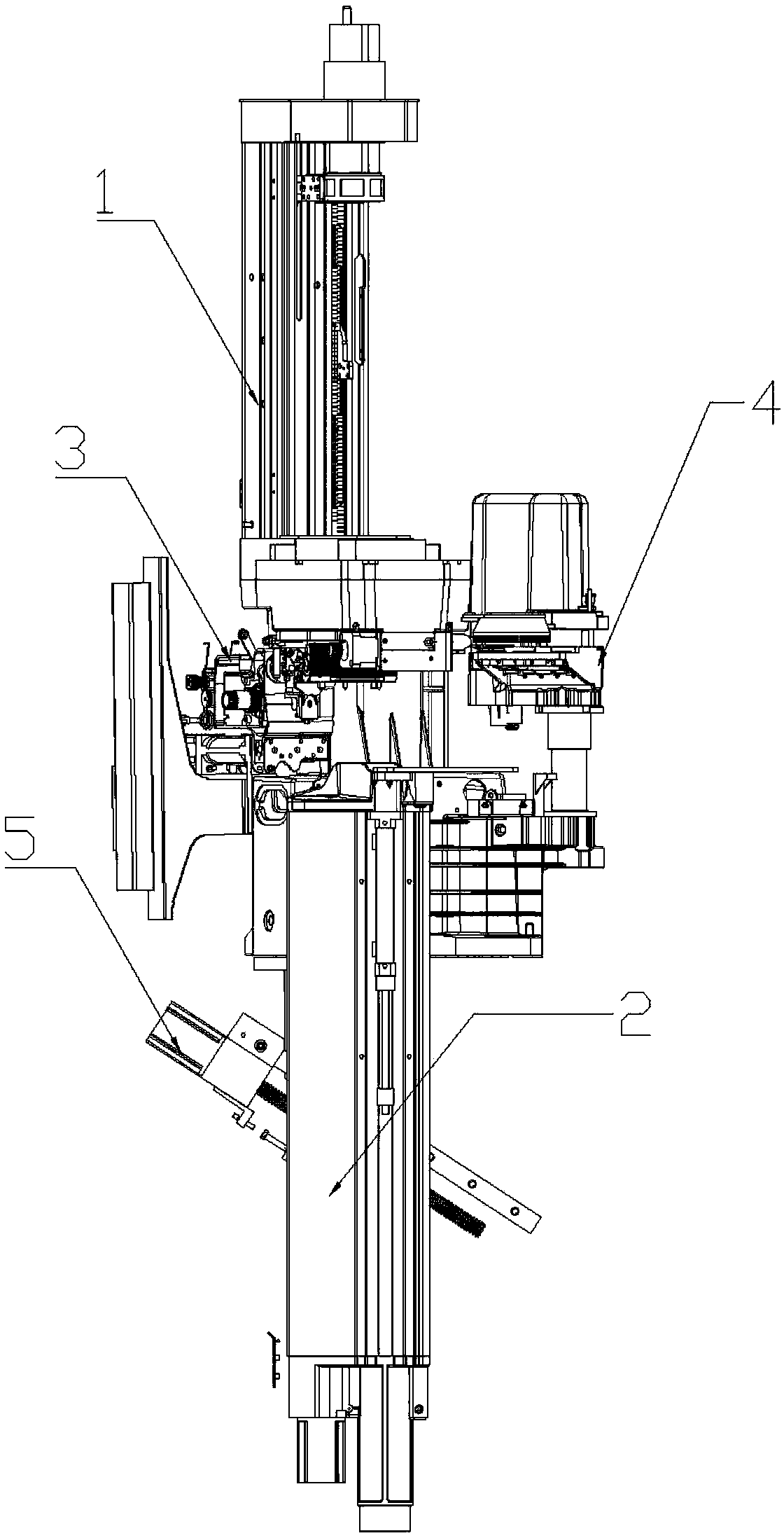

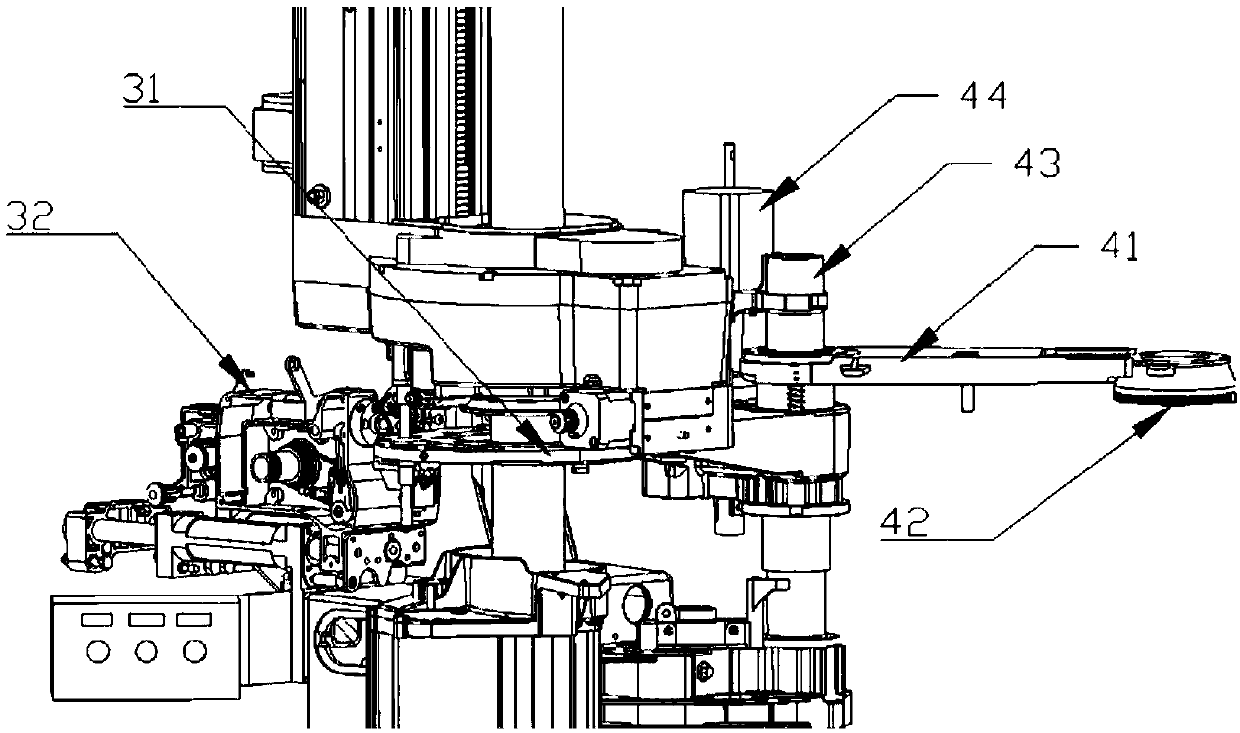

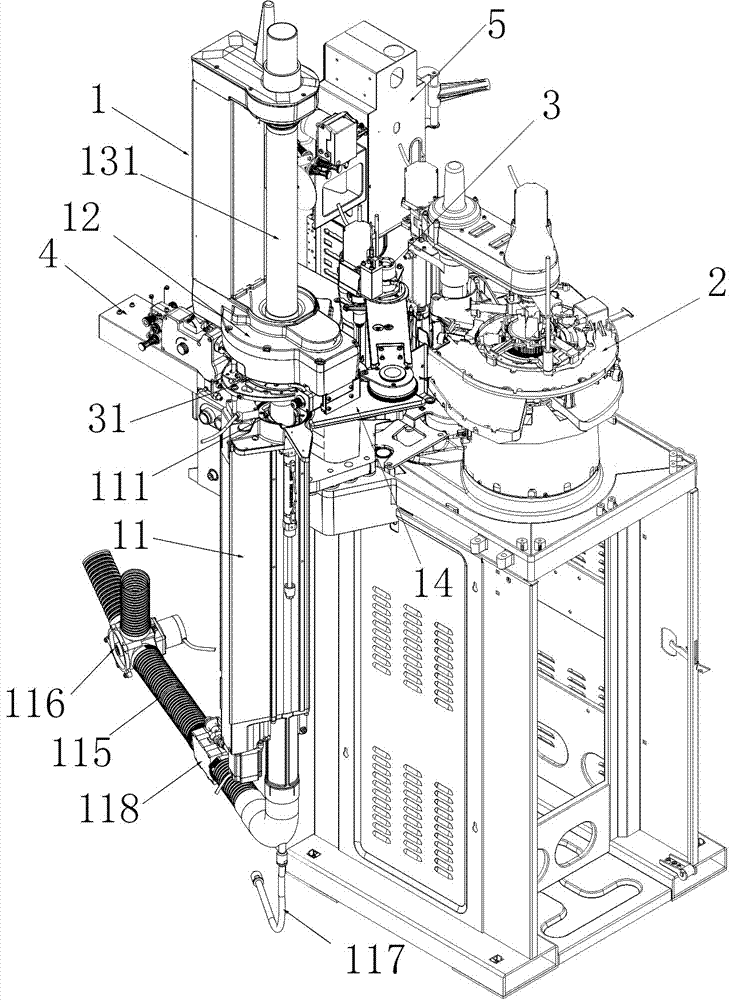

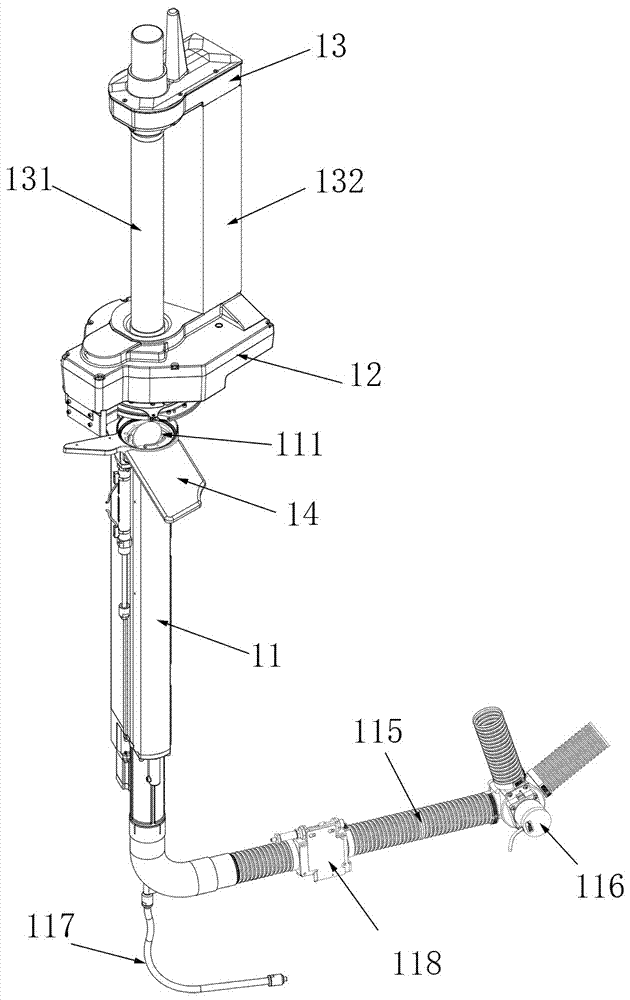

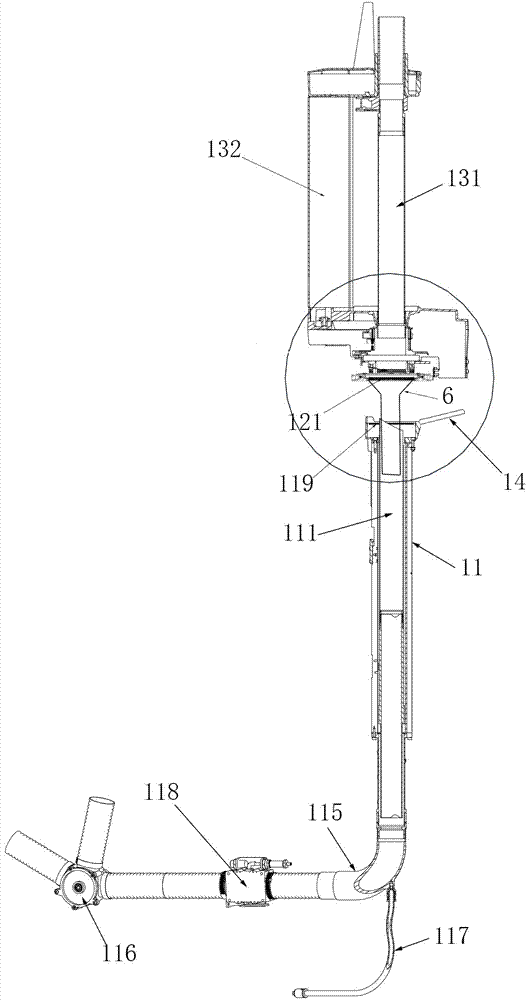

PendingCN110144672AIncrease distanceAvoid failureMechanical cleaningPressure cleaningMechanical engineeringEngineering

The invention relates to a hosiery seamer. The hosiery seamer comprises an upper assembly, a lower assembly, a stitching assembly and a pickup assembly, wherein the upper assembly and the lower assembly are arranged at the upper and lower ends of the stitching assembly respectively, the pickup assembly is arranged at the lateral part of the stitching assembly, the lower assembly comprises a hosiery suction cylinder and a hosiery turning and lifting cylinder nested in the hosiery suction cylinder; the hosiery turning and lifting cylinder is connected with a negative pressure air source and canupwards extend toward the upper assembly on a vertical shaft; a lower assembly moving device for driving the lower assembly to reciprocate in the oblique direction is arranged on the outer side of thehosiery suction cylinder. The distance between the hosiery suction cylinder and the pickup assembly is increased, the technical problems of faults and lower production efficiency caused by the fact that hosiery cannot be successfully sent into the hosiery suction cylinder are solved, and the hosiery seamer is particularly suitable for turning stockings.

Owner:ZHEJIANG YEXIAO KNITTING MACHINERY

Technology for producing deodorant socks

InactiveCN106498602ASoft and delicateImprove comfortLinking machinesHeating/cooling textile fabricsYarnDeodorant

The invention relates to the technical field of production technology of socks and particularly relates to a production technology of deodorant socks. The production technology of the deodorant socks comprises the following steps: (1) preparing yarns, (2) dyeing and deodorizing, (3) softening, (4) weaving socks, (5) jointing, (6) setting, (7) pairing and packaging. The yarn of the technology for producing deodorant socks adopts the proportion of cotton yarn 70%, nylon 25% and spandex 5% to be matched. The technology for producing deodorant socks has the advantages of being reasonable in design, delicate, soft, comfortable and good in handfeel, more deodorant, more wear-resisting, capable of reducing friction, thin in air permeability, capable of being better in elasticity, better in sweat moisture conductivity, not stuffy in feet, easy in washing and quick drying, durable in wearing, and not easy to deformed.

Owner:浙江欧美特袜业有限公司

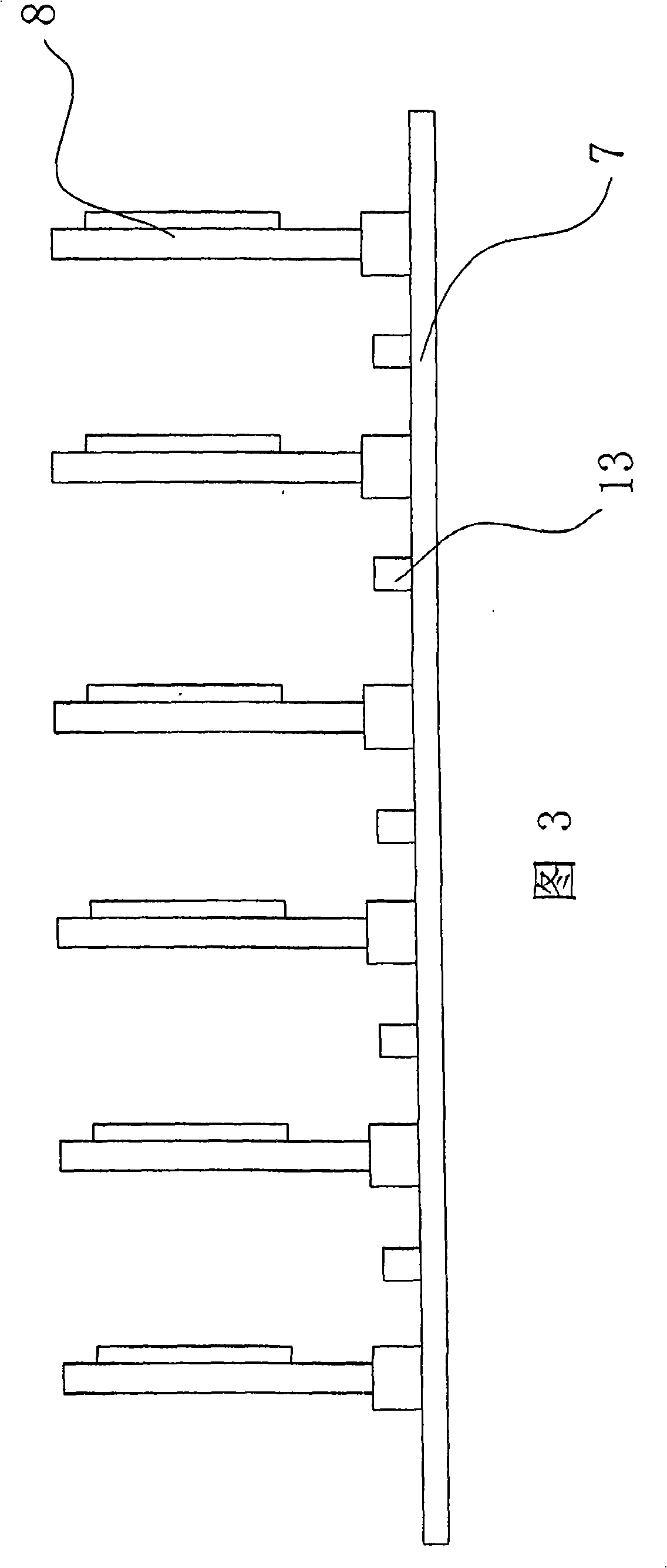

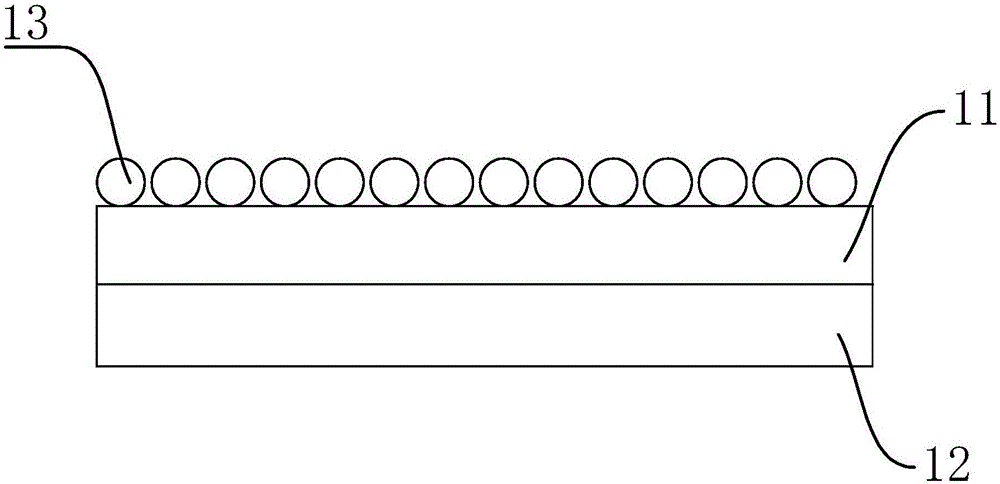

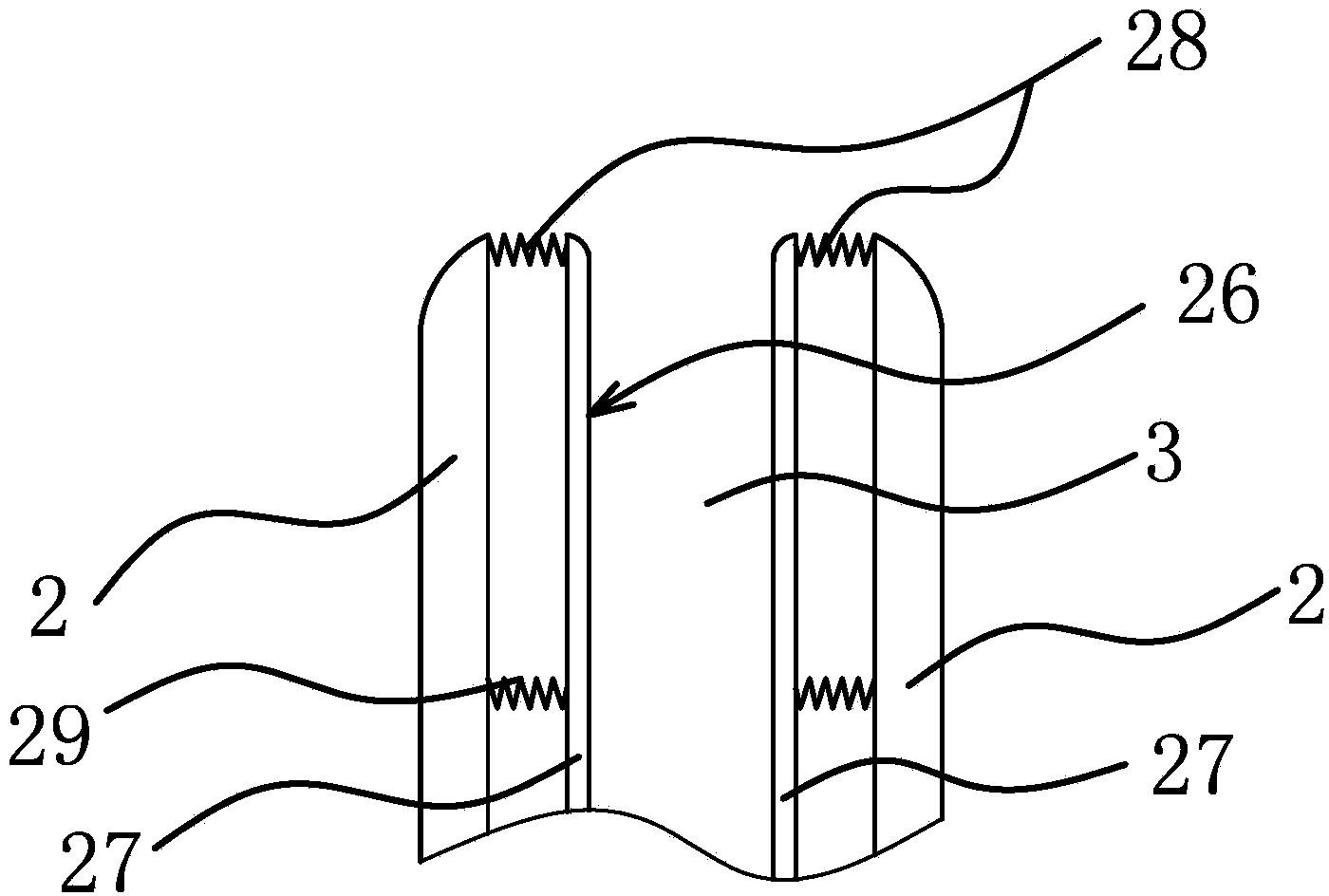

Fabric tiling device capable of fabricating looping of linking machine

InactiveCN105603632AImprove work efficiencySolve the error phenomenonWork-feeding meansLinking machinesInstabilityPlough

The invention discloses a fabric tiling device capable of fabricating looping of a linking machine. The fabric tiling device comprises a work bench and two traveling ploughs, wherein a strip gap is formed in the work bench; a cover board is arranged on the work bench; a fence structure is arranged at one side of the cover board; a plurality of rake teeth are arranged on the bottom surface of each traveling plough; sawteeth are arranged on the bottom surface of each rake tooth; the rake teeth of the traveling ploughs are matched with the fence structure at the left side of the cover board; and the traveling ploughs can move up and down and left and right relative to the work bench. The fabric is tiled on the work bench; a line fault is not easy to generate in a looping process; the overall fabric tiling device is precise to work; the line fault phenomenon caused by instability when the fabric is looped can be effectively avoided; and the cut piece sewing quality and the work efficiency of the linking machine are improved.

Owner:叶军忠 +2

Woollen sweater linking machine

A woollen sweater linking machine mainly comprises a rack main body, a linking disc, a left protective plate and a right protective plate disposed on the linking disc, a bending needle for sewing, and a dial wheel for removing the sewed braided fabrics on the linking disc, wherein the left and right protective plates are respectively provided with a gap where the bending needle can pass through; the linking disk is further provided with a pair of splints which are located between the pair of left and right protective plates; the pair of splints are respectively provided with a cambered hole where the bending needle can pass through; the braided fabrics are passed through a gap between the pair of splints and sewed up.

Owner:WUJIANG CITY XIESHI GARMENT

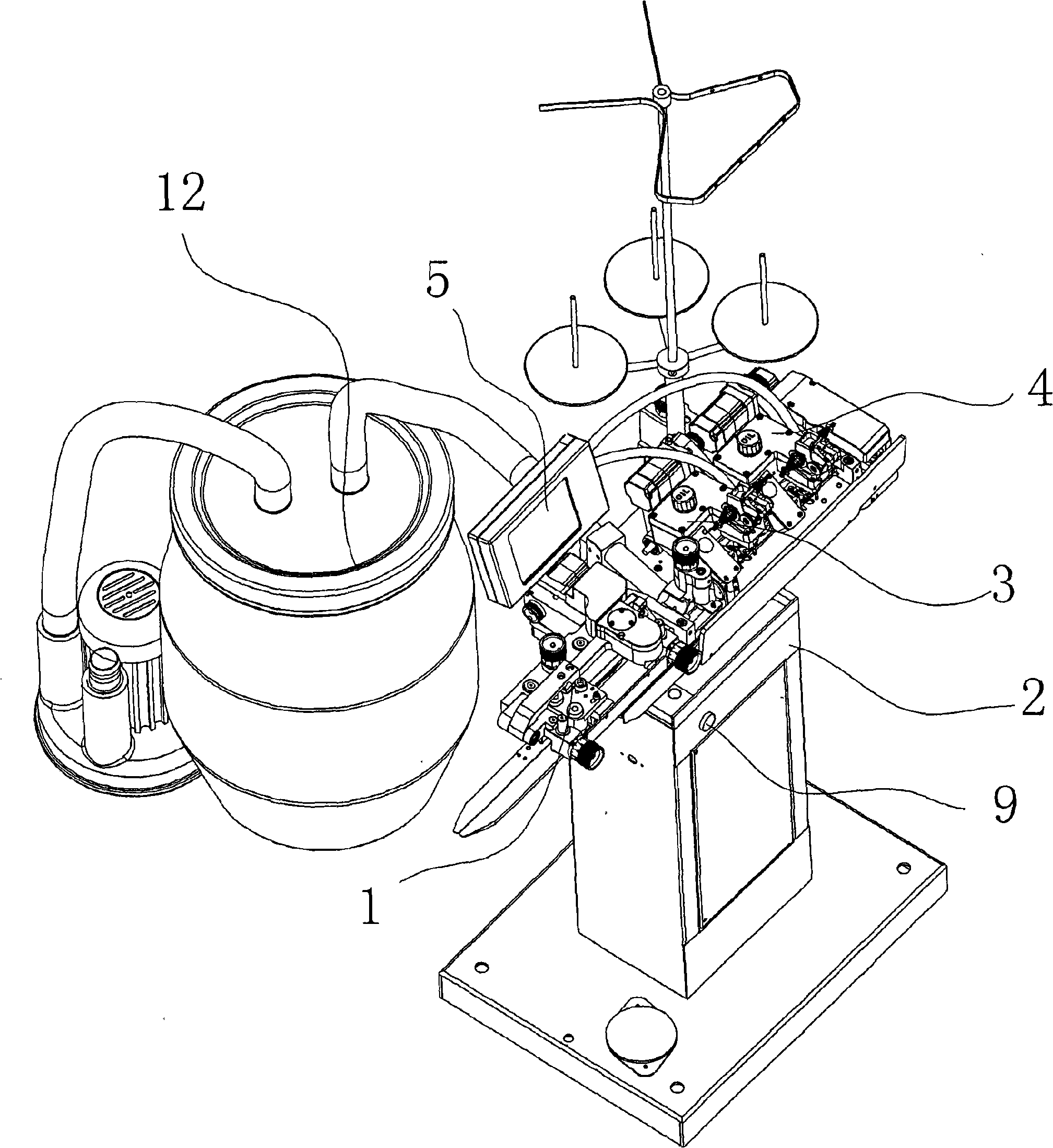

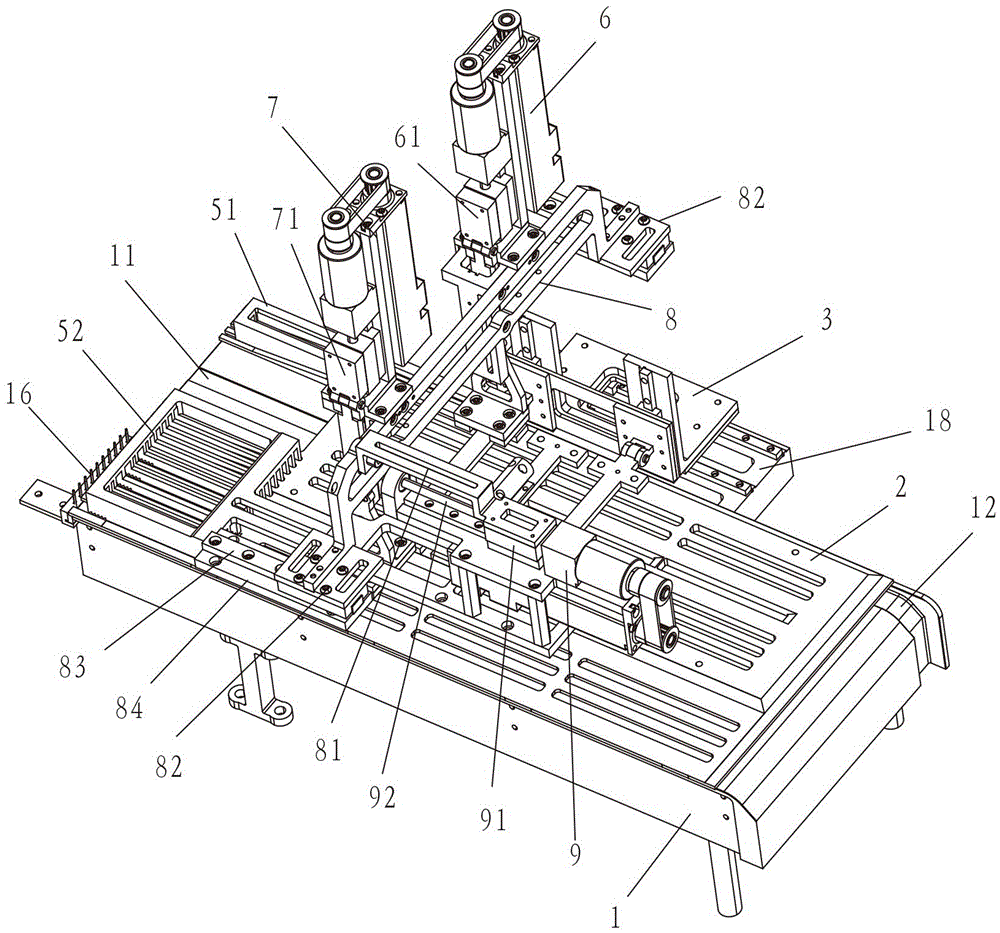

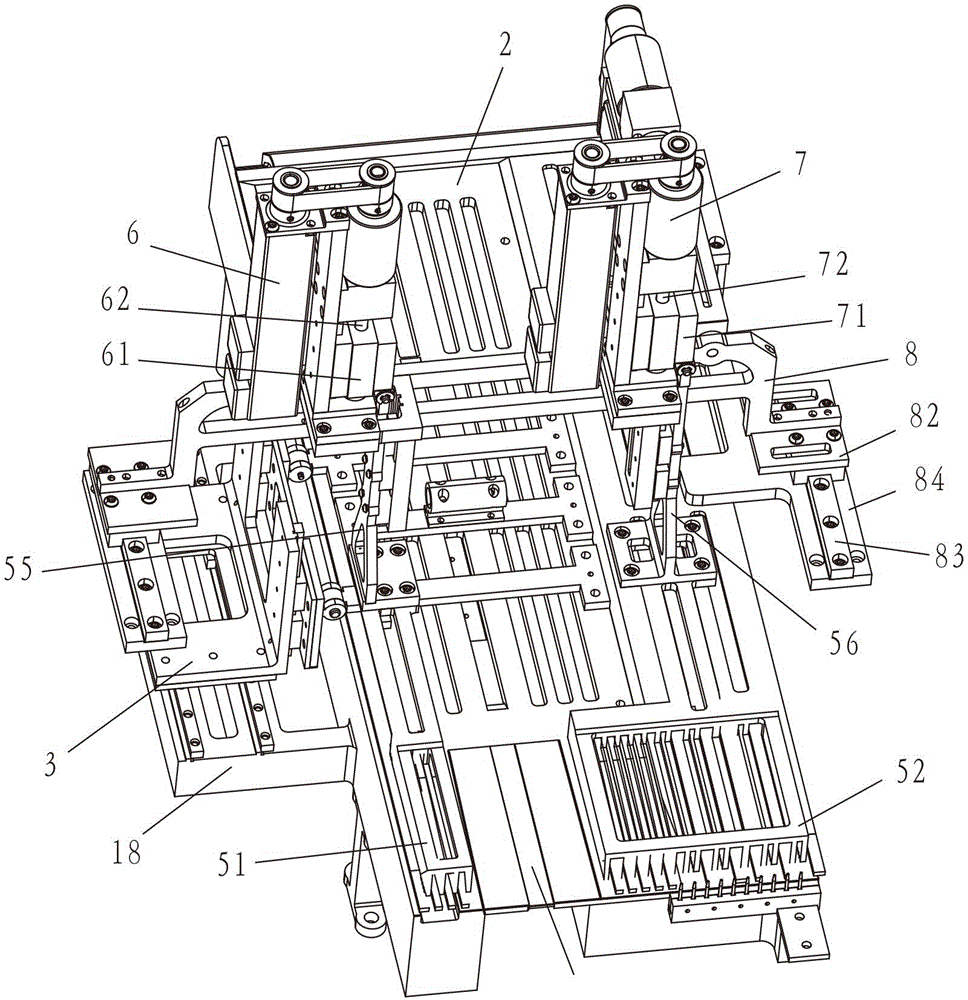

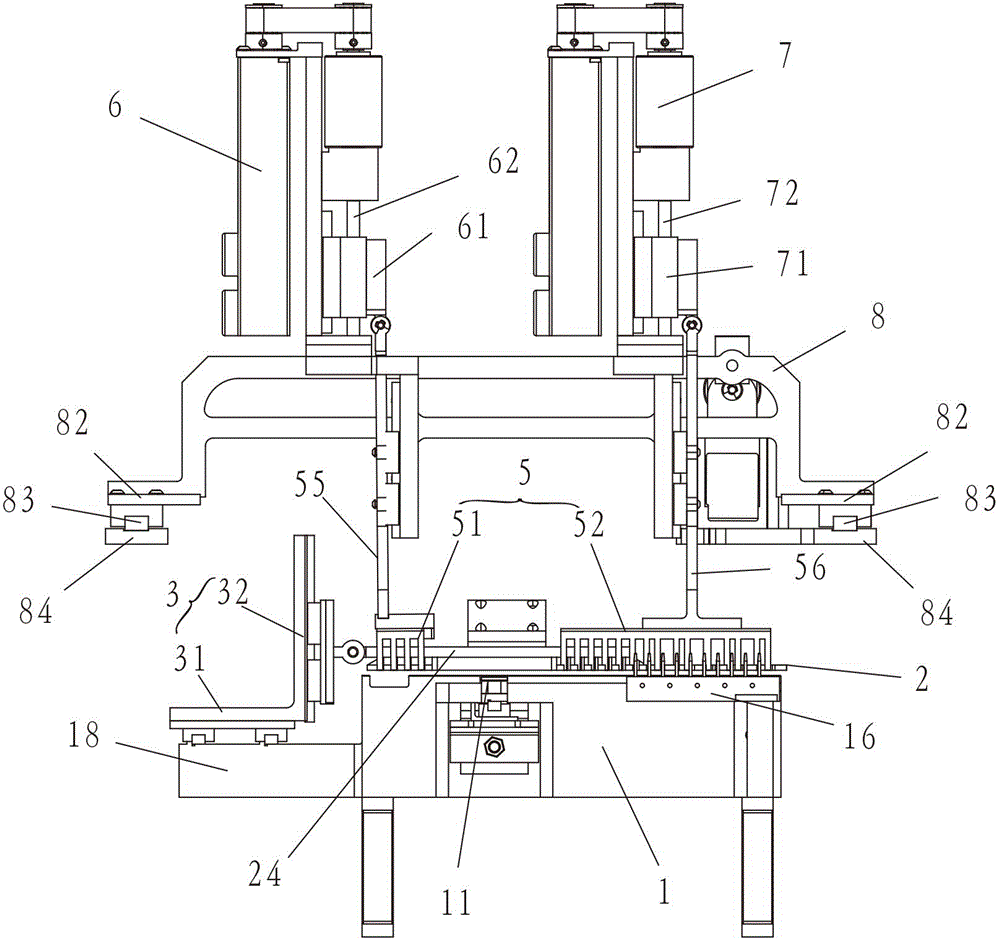

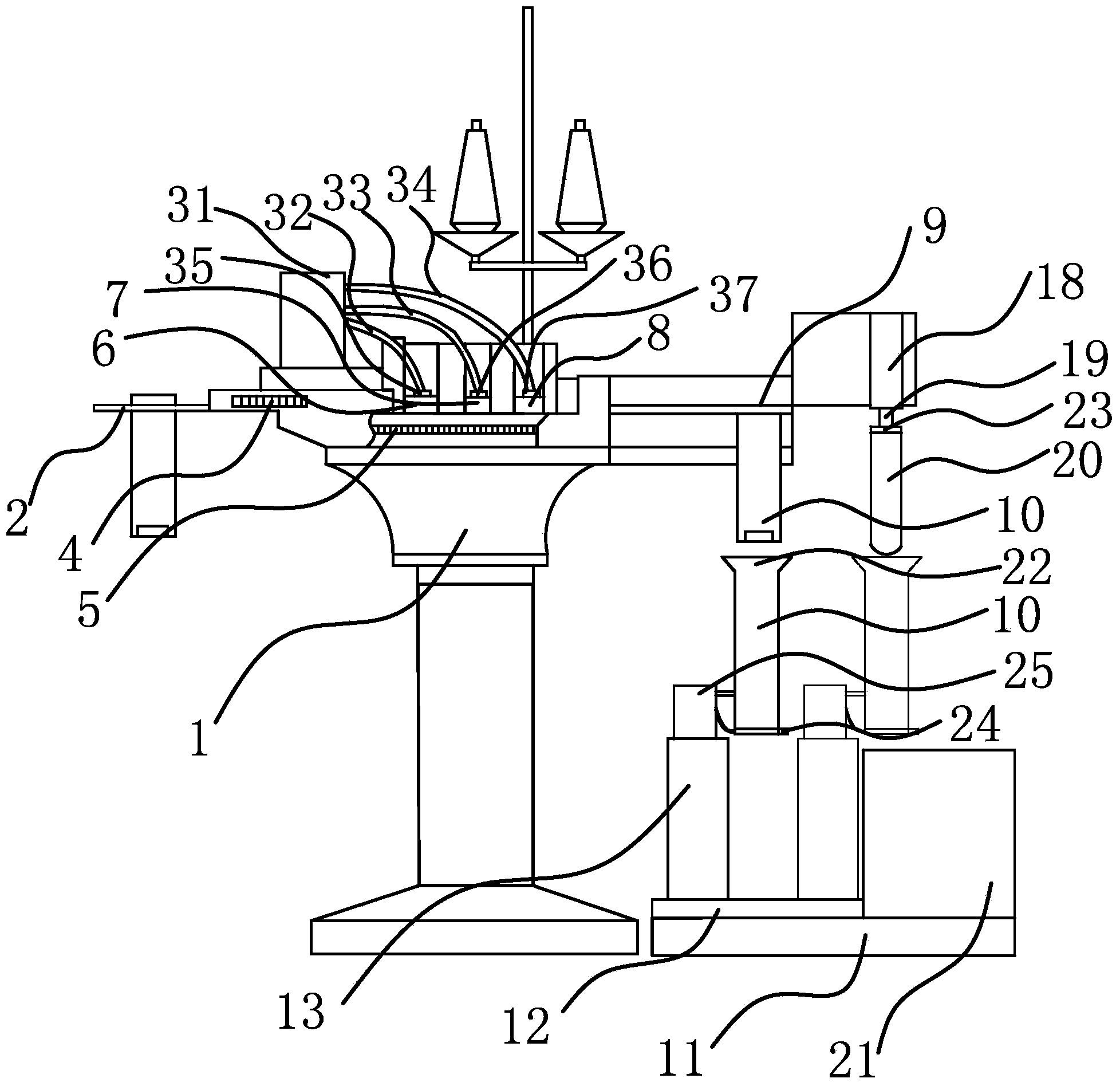

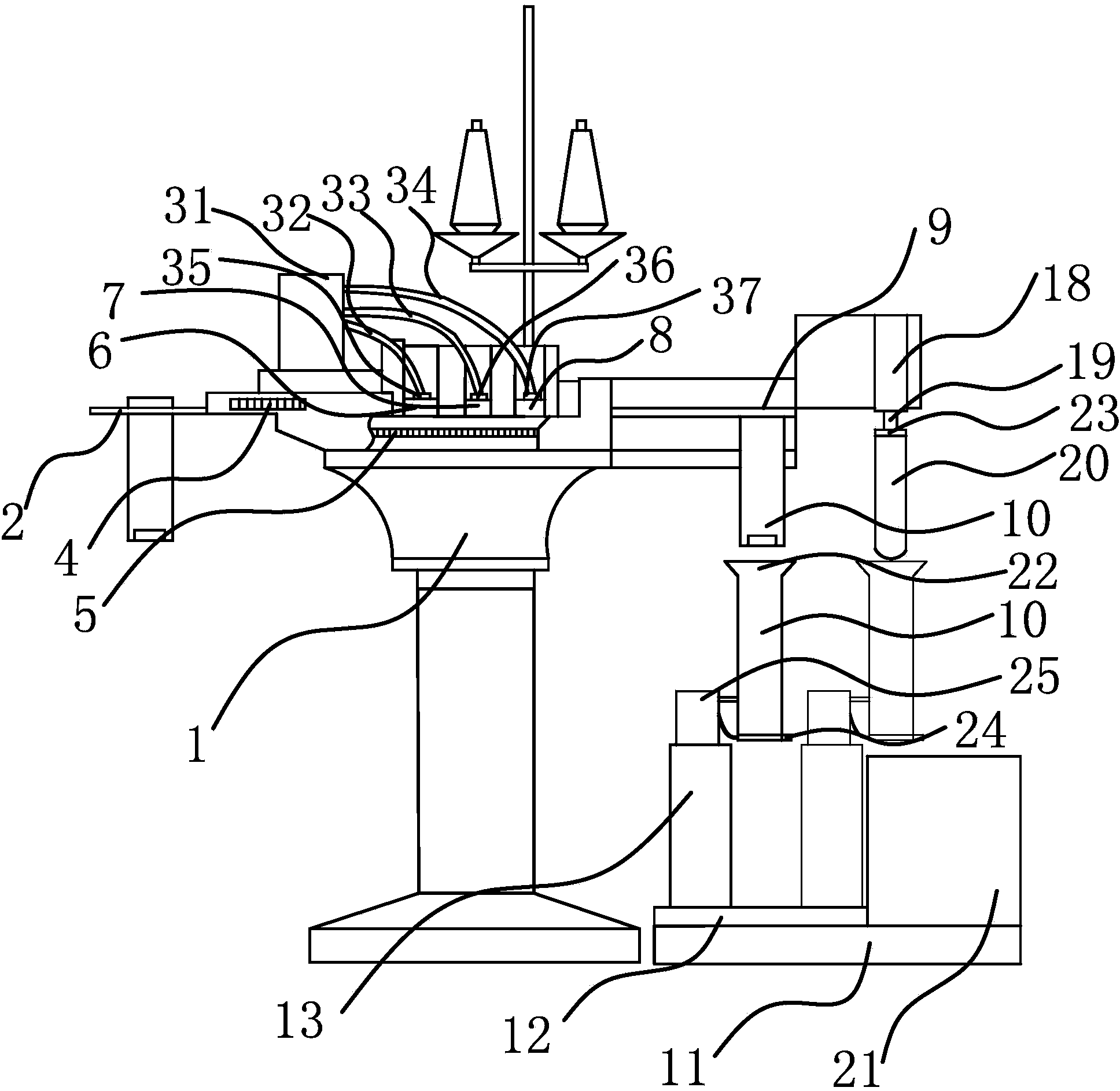

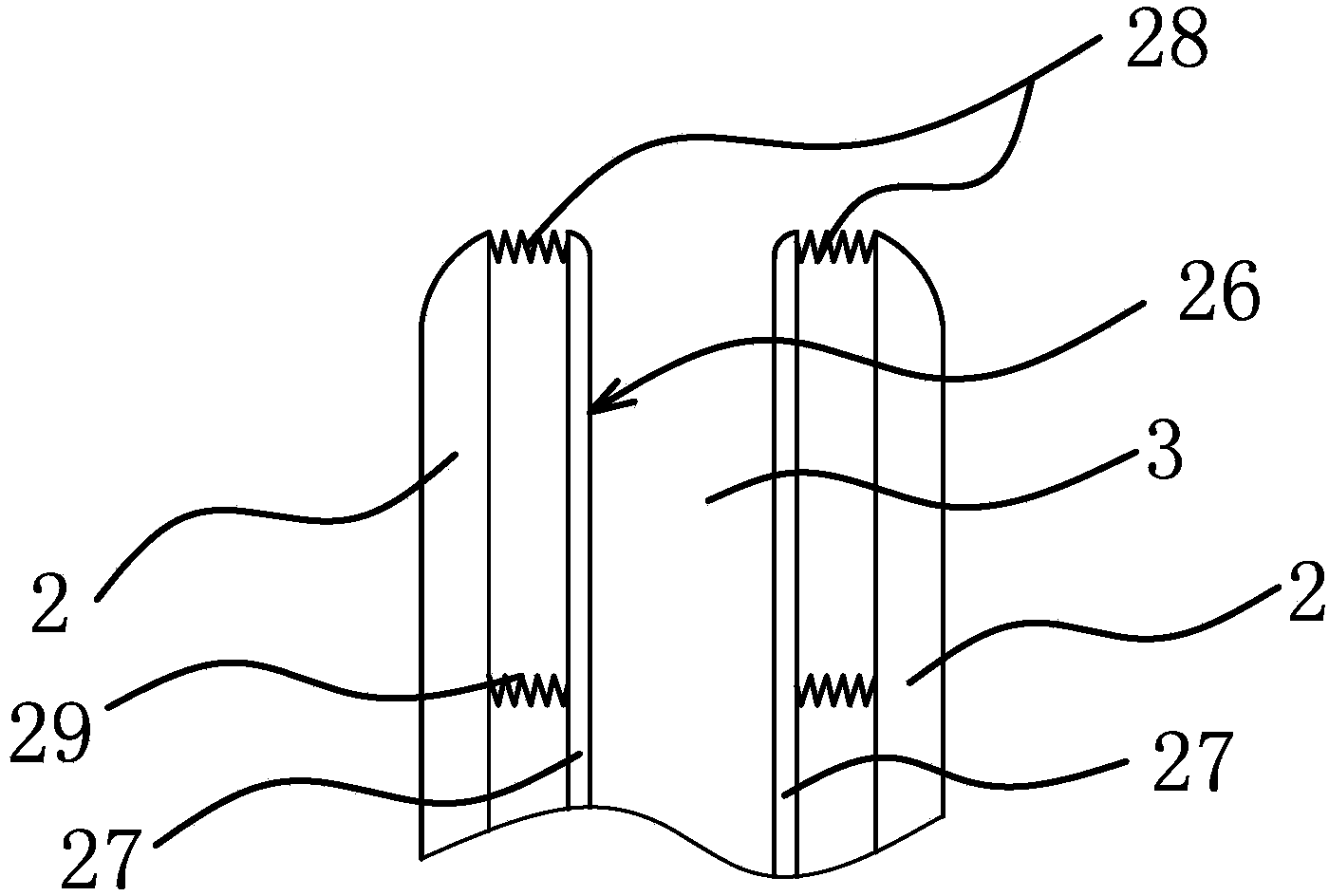

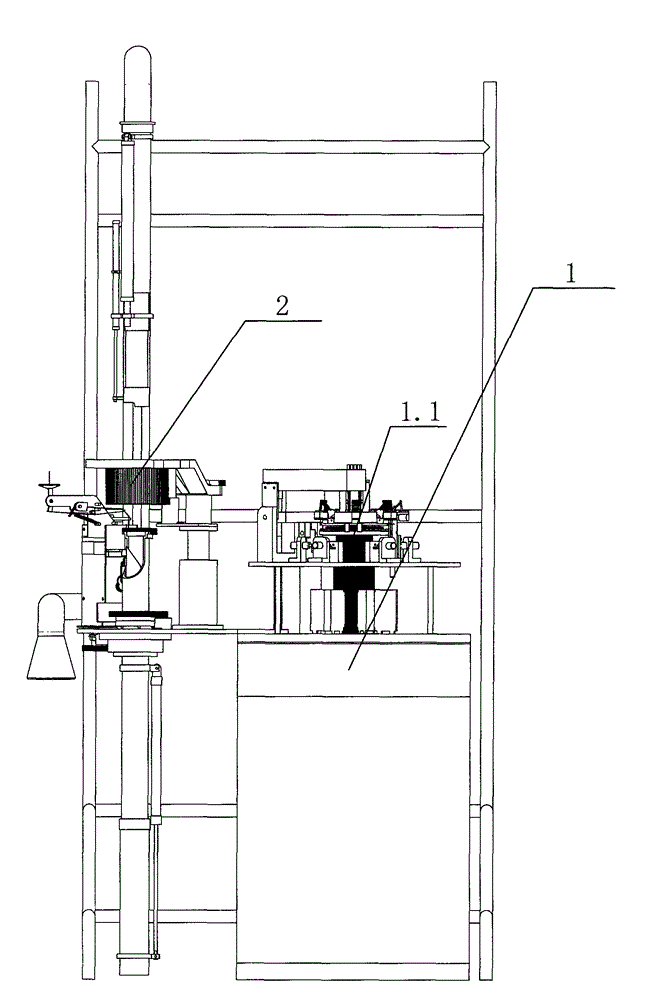

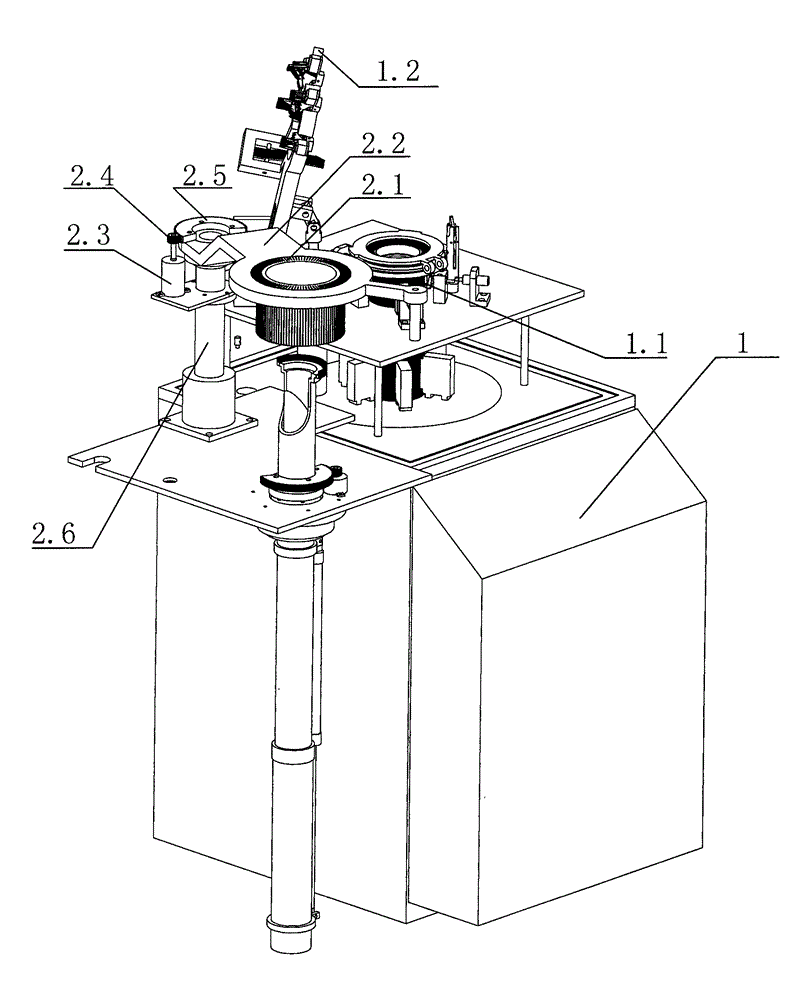

Hollow fiber cool healthcare socks and full-automatic linking machine

The invention provides a pair of hollow fiber cool healthcare socks and a full-automatic linking machine, and belongs to the technical field of textiles. Each hollow fiber cool healthcare sock comprises a sock body; the sock body is formed by weaving blended yarns; the blended yarns include yarns prepared from porous polyester fibers and special fibers by adopting hollow spinning; the sock body comprises a sock opening, a sock leg, a sock heel, the sock body and a sock toe; the front end of the sock body is the sock toe; the turning joint of the sock leg and the sock body is the sock heel; the upper end of the sock leg is the sock opening; the sock body comprises a sock surface and a sock bottom; the sock toe and the sock surface are linked by adopting the full-automatic linking machine; the sock bottom is embedded with viscose fibers; the full-automatic linking machine comprises a machine frame; the machine frame comprises a base and a working table; and a first conveying mechanism, a second conveying mechanism, a guide hole mechanism, a trimming mechanism, a first machine head, a yarn frame and a second machine head are arranged on the working table. The healthcare socks are good in moisture absorbing and sweat releasing property, have a cool feeling, are high in comfort level, and are suitable to be worn in summer.

Owner:海宁威尔斯针织股份有限公司

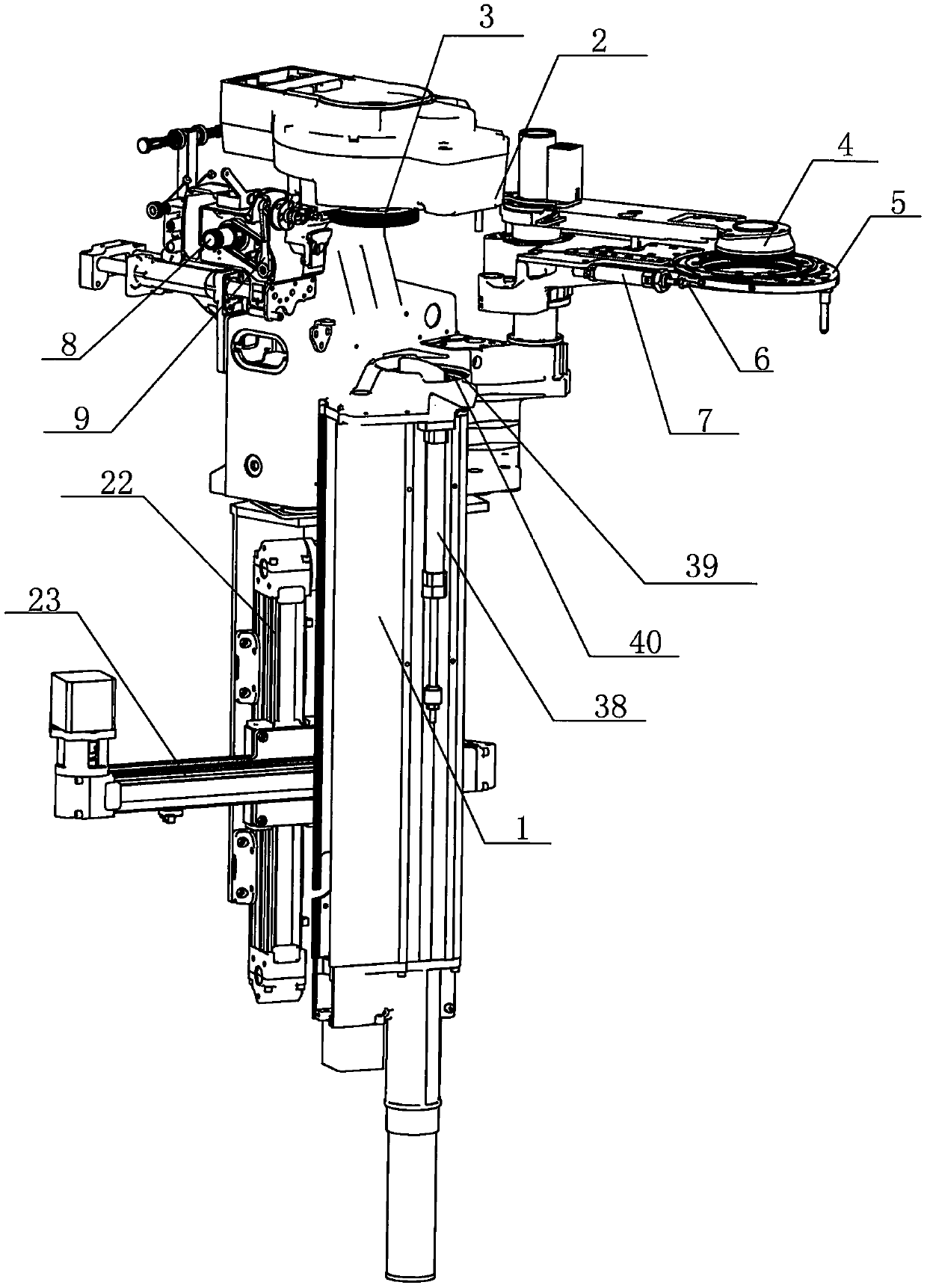

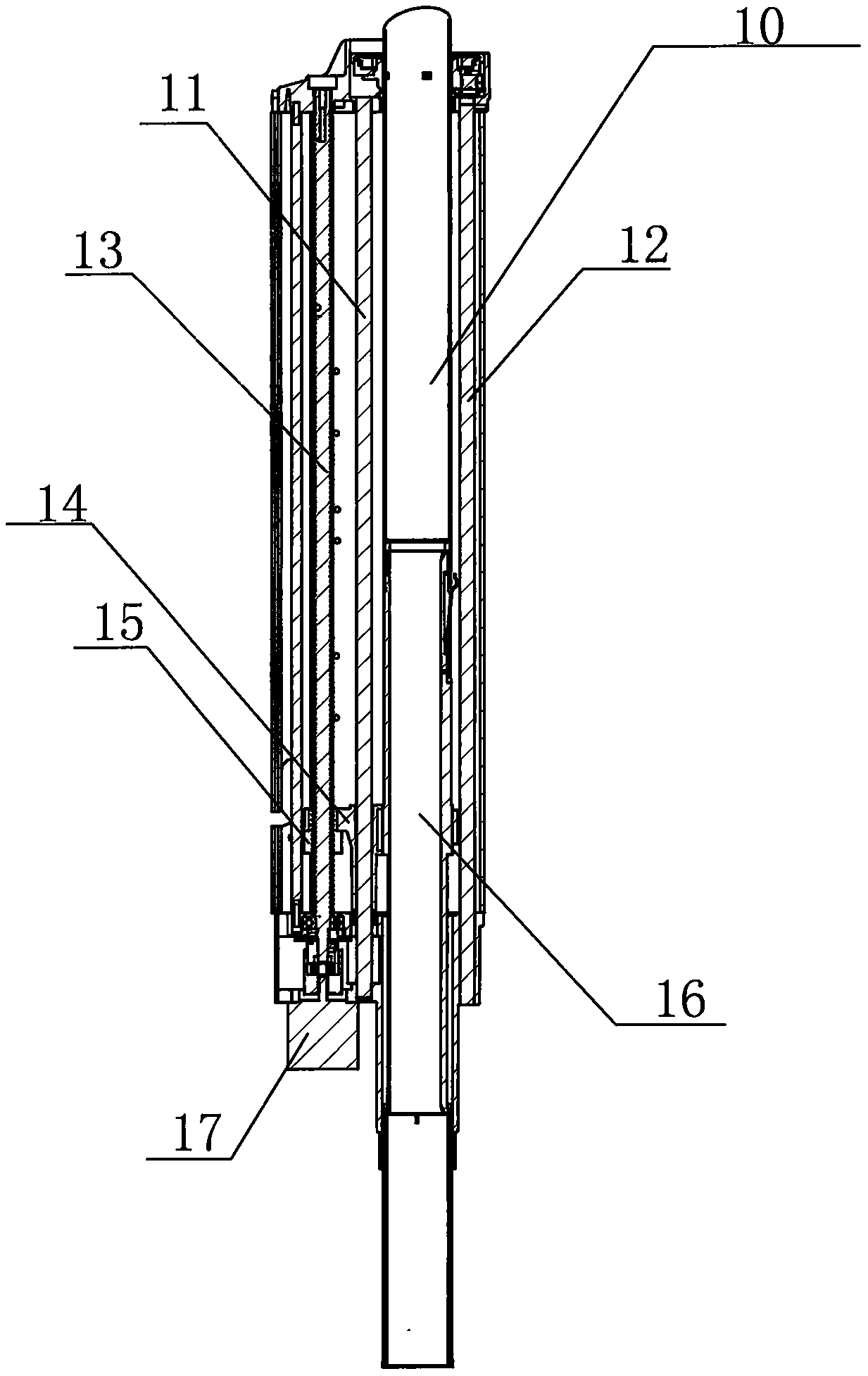

Automated sock turn-over and end sewing device capable of moving downwards-turned stocking cylinder in multiple directions and application method

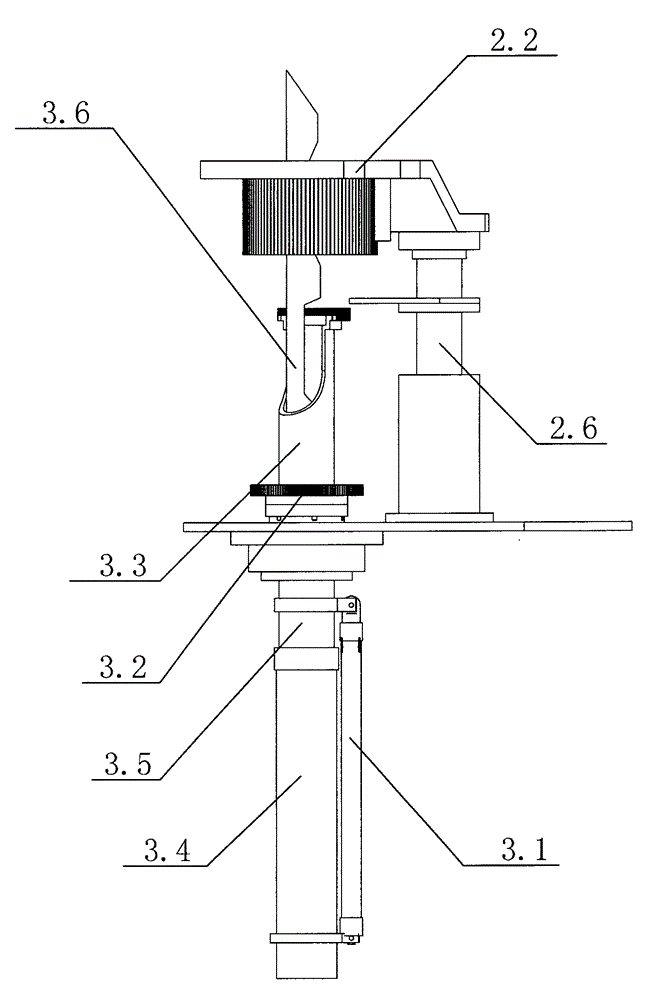

PendingCN109778420AReduce difficultyHigh degree of automationMechanical cleaningPressure cleaningEngineeringAutomation

The invention discloses an automated sock turn-over and end sewing device capable of moving a downwards-turned stocking cylinder in multiple directions. The device comprises a sock knitting device, asock turn-over device, an end sewing device and a sewing disc. A mechanical swing arm is arranged between the sock knitting device and the sewing disc, grabs one end of a stocking leg on the sock knitting device below the mechanical swing arm and horizontally swings the stocking leg to the sewing disc above the mechanical swing arm, the sock turn-over device comprises the downwards-turned stockingcylinder, the downwards-turned stocking cylinder is moved to the other end of the stocking leg through a driving mechanism, and an air suction port is formed in the top of the downwards-turned stocking cylinder; the air suction port conducts suction through a suction device, makes the stocking leg fall in the downwards-turned stocking and then makes the downwards-turned stocking cylinder move tothe position below the sewing disc through the driving mechanism, the downwards-turned stocking cylinder and the sewing disc are located on the same straight line, the stocking leg on the sewing discis subjected to end sewing through the end sewing device, the driving mechanism comprises a horizontal guide rail and a vertical guide rail, the downwards-turned stocking cylinder is moved in multipledirections, and all work of sock turn-over and end sewing of the device is high in automation degree.

Owner:赵镭

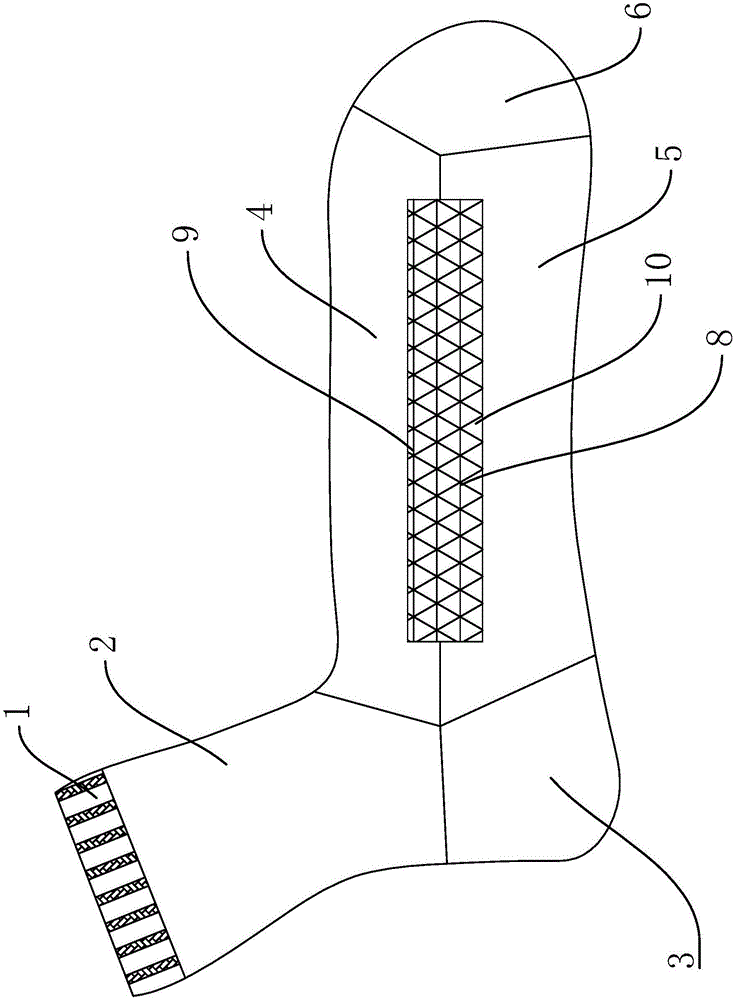

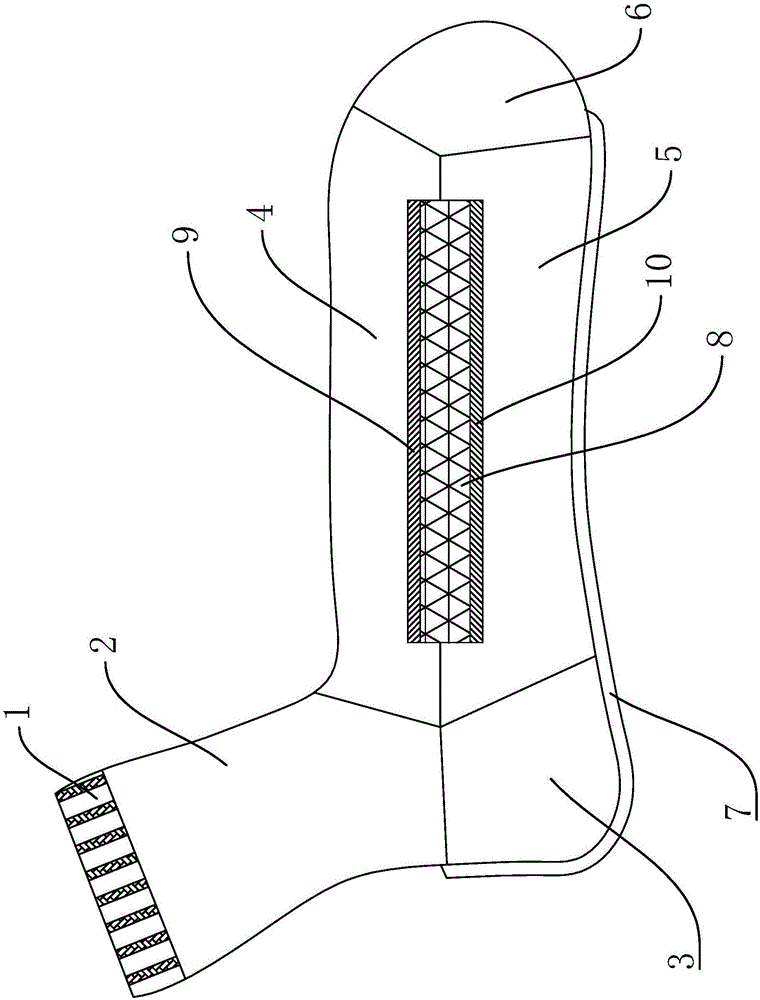

Head stitching machine for sock

InactiveCN103485079ADemagnetizationReduce adsorptionWork-feeding meansLinking machinesEngineeringElectromagnet

The invention provides a head stitching machine for a sock, belongs to the technical field of textile machinery and solves the technical problems that in the prior art, after the head of the sock is sewn, the sock cannot be automatically turned over, and the like. The head stitching machine comprises a rack; the right end of the rack is the discharge end of the sock; the bottom end of the sock is provided with a rubber magnetic sheet 1 and a rubber magnetic sheet 2; the bottom of a sock guide cylinder is provided with a discharge port for the sock to pass through, and is further fixedly provided with an electromagnet; an air cylinder is further fixed at the right end of the rack; the cylinder body of the air cylinder is fixed on the rack; the lower end of a piston rod is fixedly connected with a telescopic arm; a material containing basket is arranged right below the telescopic arm and is fixed on a material containing seat; the telescopic arm can be inserted in a material containing cylinder and can push the sock, so that the sock falls into the material containing basket. By adopting the head stitching machine for the sock, after the head of the sock is sewn, the sock can be automatically turned over, and the production efficiency of the sock is high.

Owner:HAINING SUNSHINE SOCKS MFG

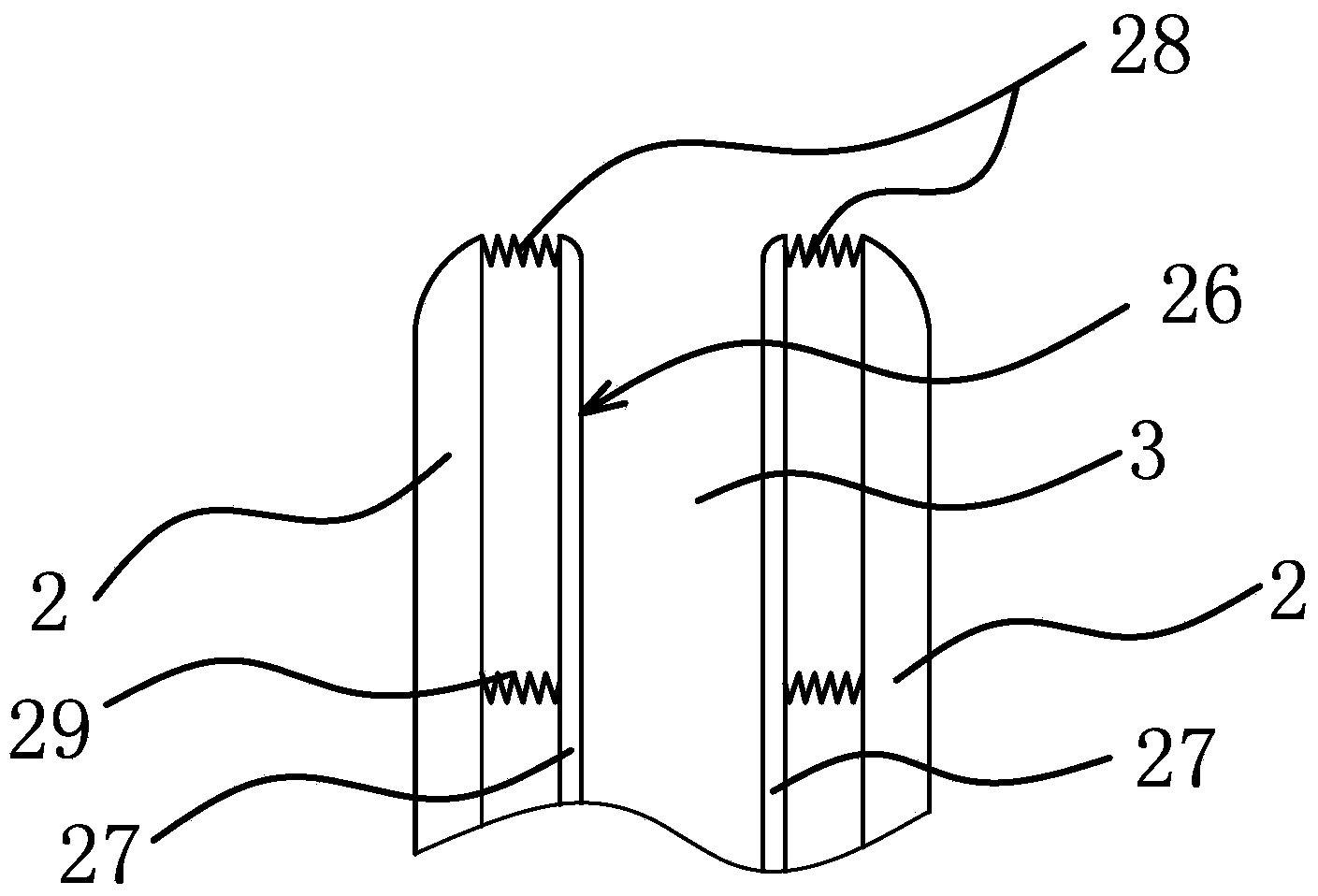

Device and method used for seaming tubular fabric

ActiveCN107385685AAvoid vacuumingSmooth entryMechanical cleaningPressure cleaningBiomedical engineeringFault rate

The invention discloses a device and method for seaming a tubular fabric. The device comprises a transfer device, a clamping plate, an overturn device and a seaming device. The transfer device comprises a transfer plate used for taking the knitted tubular fabric down and transferring the knitted tubular fabric to the clamping plate for clamping; the clamping plate comprises two semicircle ring sewing disks which can be folded in half; the seaming device is located on the side face of the clamping plate; the overturn device comprises a first tubular part and a second tubular part, the first tubular part is coaxially located under the clamping plate, and the second tubular part is coaxially located over the clamping plate; the first tubular part and the second tubular part are both connected with a negative-pressure air source. The overturn of the tubular fabric is achieved by using a pneumatic device, a device which turns over the fabric by using the mechanical principle in the prior art is replaced, and the structural complexity and fault rate are reduced.

Owner:ZHEJIANG JIAZHILI INTELLIGENT TECH CO LTD

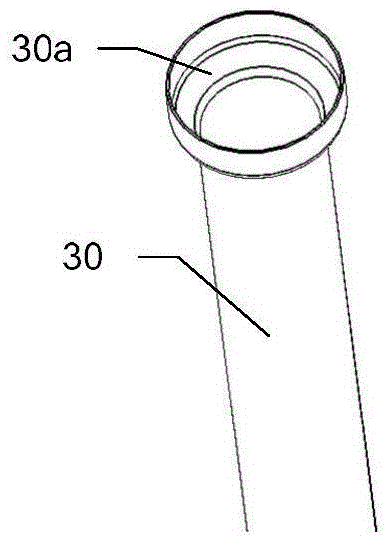

Integral sock kitting machine with sock reversing function

The invention discloses an integral sock kitting machine with a sock reversing function. The integral sock kitting machine comprises a needle cylinder, a sewing machine and a transferring device, wherein the transferring device comprises a central mounting pipe, and a transferring head is mounted on the central mounting pipe; the transferring head comprises a fixed half tooth frame and a reversed half tooth frame, wherein one or more first function teeth are formed on the fixed half tooth frame, and one or more second function teeth are formed on the reversed half tooth frame. The integral sock kitting machine further comprises a produced sock reversing cylinder, a produced sock reversing cylinder driving device and a produced sock reversing cylinder maintaining device, wherein the produced sock reversing cylinder can be perpendicularly and movably mounted on one side of the needle cylinder; the produced sock reversing cylinder driving device drives the produced sock reversing cylinder to move up and down, so that the produced sock reversing cylinder has a first position positioned under a transferring and seaming device and a second position positioned in the transferring and seaming device; the produced sock reversing cylinder maintaining device is connected with the produced sock reversing cylinder at the second position. The integral sock kitting machine disclosed by the invention has the benefits that after socks are seamed, the seamed socks are removed out of a sock cylinder and are reversed at the same time, so that the structure of the sock kitting machine is simplified, working procedures are simplified, and the production efficiency is improved.

Owner:浙江海润精工机械有限公司

Sock sewing device

The invention provides a sock sewing device and belongs to the technical field of textile machinery. The sock sewing device solves the technical problem that after a sock is sewn, the sock cannot be automatically turned in the prior art. The sock sewing device comprises a machine frame. The right end of the machine frame is a discharging end of the sock. The bottom end of the sock is provided with a first rubber magnetic piece and a second rubber magnetic piece. A discharging port enabling the sock to pass through is formed in the bottom of a sock guiding cylinder. The bottom of the sock guiding cylinder is further provided with an electromagnet. An air cylinder is further fixed to the right end of the machine frame. A cylinder body is fixed to the machine frame. The lower end of a piston rod is fixedly connected with a telescopic arm. A material holding basket is arranged under the telescopic arm. The material holding basket is fixed to a material holding base. The telescopic arm can be inserted into a material holding cylinder and the sock is pushed to fall into the material holding basket. After the sock is sewn, the sock can be automatically turned and the sock production efficiency is high.

Owner:HAINING SUNSHINE SOCKS MFG

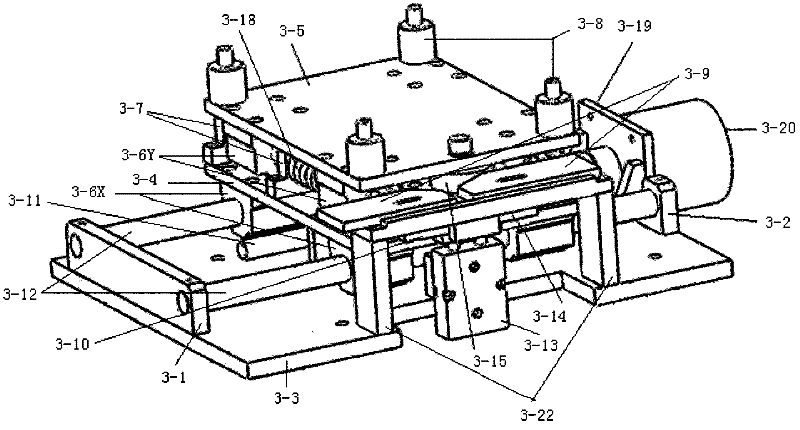

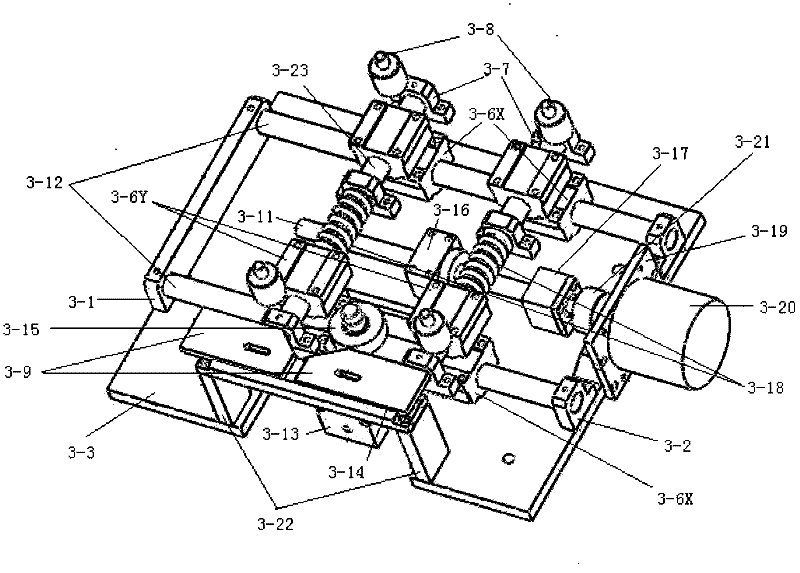

Automatic sweater sewing method based on machine vision perception

ActiveCN109457398AFacilitate automatic sewingRealize automatic stitchingProgramme-controlled sewing machinesWork-feeding meansMachine visionEngineering

An automatic sweater sewing method based on machine vision perception comprises the following steps of: (1) starting automatic sweater sewing equipment; (2) conveying a sweater weaving piece into a stretching and freezing device from front to back from an input flattening device; (3) stretching the sweater weaving piece and freezing the sweater weaving piece into a rigid body convenient for sewingin the stretching and freezing device; (4) conveying the sweater weaving piece which is stretched and frozen into the rigid body to a sewing preparation device; and (5) finishing turning, carrying, sewing auxiliary pushing and sorting of the frozen sweater weaving piece by a carrying robot, and sewing an upper sweater weaving piece and lower sweater weaving piece which are correspondingly arranged up and down by using a sewing device. The method can replace prior manual sweater sewing, improves the processing efficiency, achieves the improvement of the sewing quality, achieves the stable consistency of products in batch production, and further improves the added value of the products; and the method has certain significance for promoting the development of equipment in the sweater weavingindustry in China.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

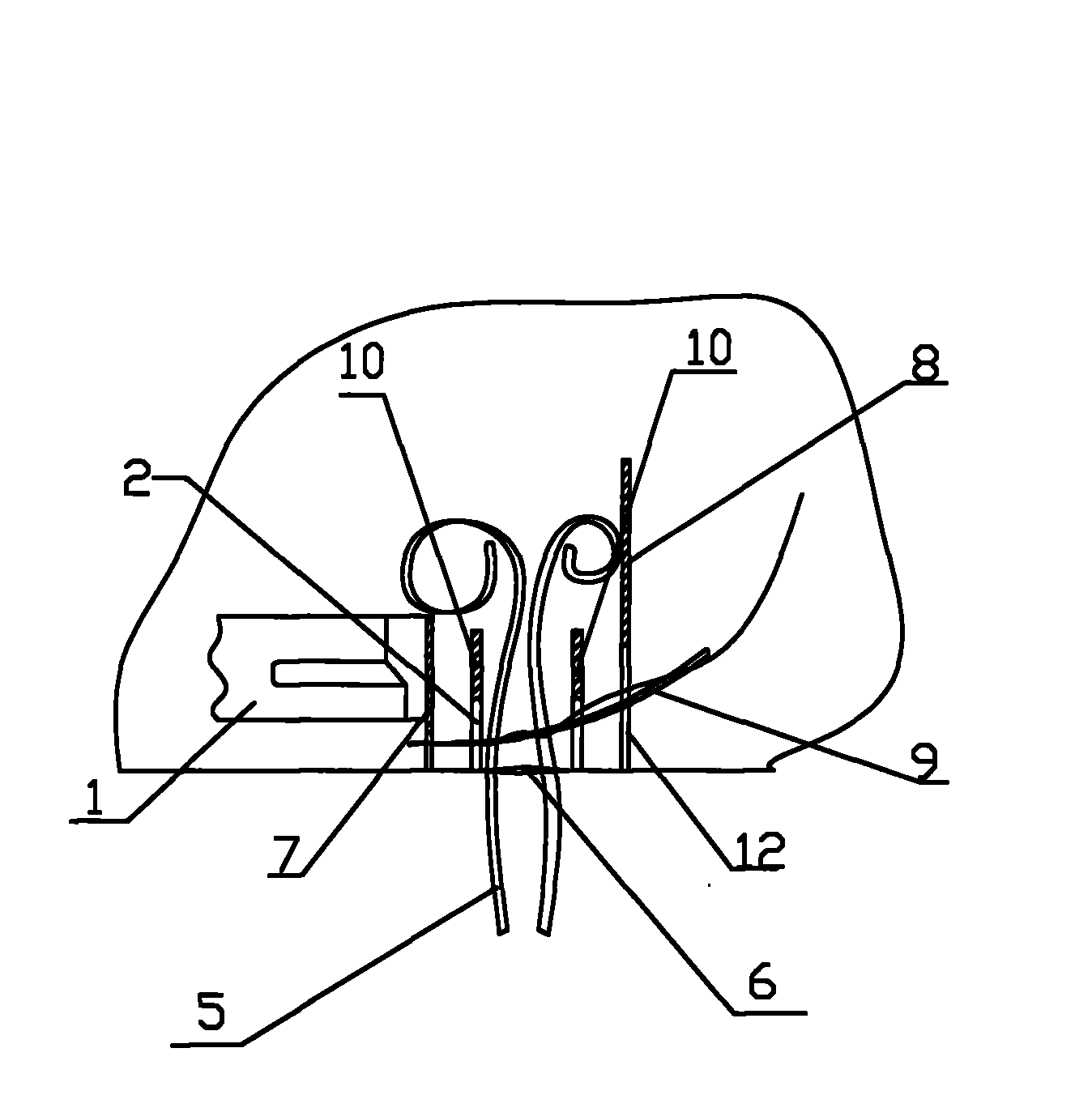

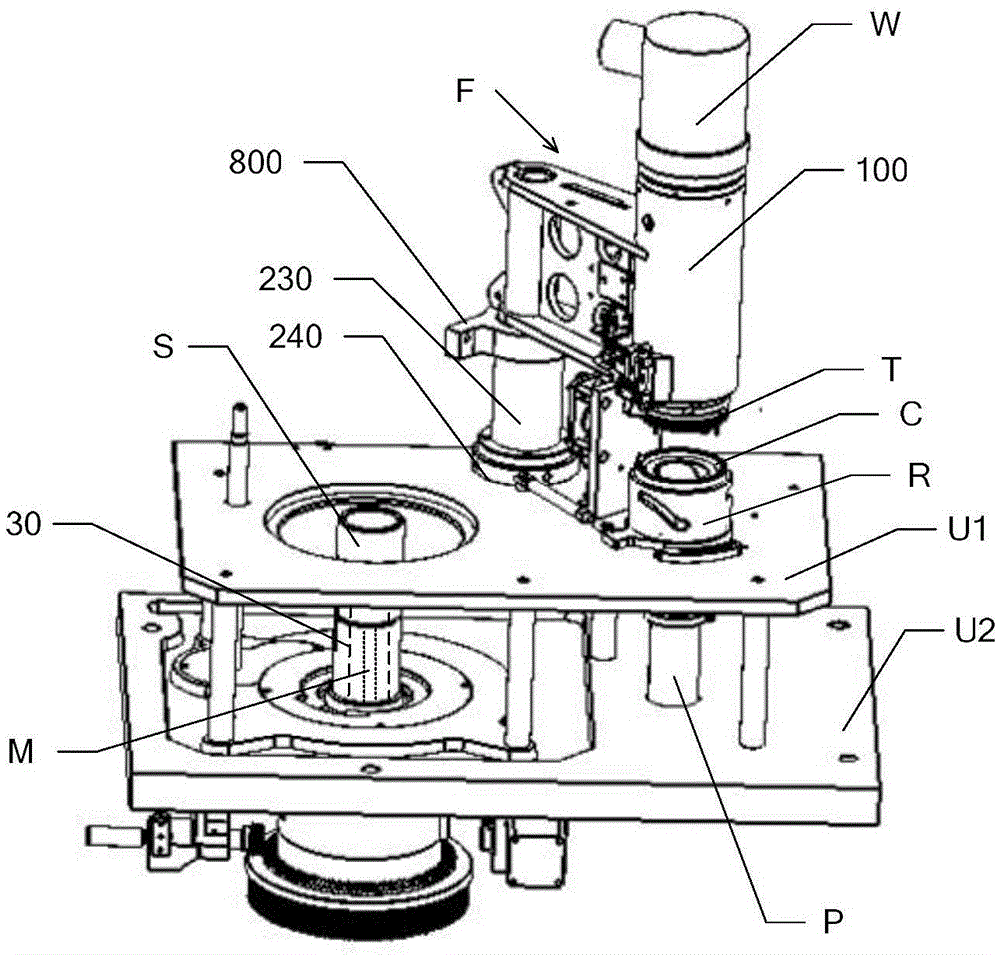

Method and device for handling a tubular knitted article, in particular a sock

InactiveUS20070101770A1Easy to identifyLinking machinesCircular knitting machinesEngineeringStructural engineering

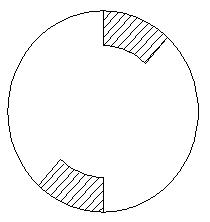

A method to orient a tubular knitted article, such as a sock or the like, with respect to a pocket of fabric, for example the heel or toe pocket of said article. The method comprises the phases of: stretching an article on a tubular member (1) so that an intermediate part of the band (F) surrounding an end to be sewn of said article (M) is positioned along a line intersecting in two points the end edge of the tubular member and the remaining part is disposed along the outer side surface of the tubular member; detecting the angular position of said band on the tubular member; identifying the position of a pocket of fabric of the article on the basis of the angular position of said band with respect to the tubular member.

Owner:GOLDEN LEDI CO SPA

Sock toe sewing machine with air power source

InactiveCN104073977ADemagnetizationReduce adsorptionLinking machinesPulp and paper industryElectromagnet

The invention provides a sock toe sewing machine with an air power source, and belongs to the technical field of textile machines. The technical problem that a sock cannot be automatically turned over after a sock toe is sewn in the prior art is solved. The sock toe sewing machine with the air power source comprises a rack, the right end of the rack is a sock discharging end, a first rubber magnetic sheet and a second rubber magnetic sheet are arranged at the bottom end of a sock, a discharge opening allowing the sock to penetrate through is formed in the bottom of a sock guide barrel, an electromagnet is further fixedly arranged at the bottom of the sock guide barrel, an air cylinder is further fixedly arranged at the right end of the rack, a cylinder body is fixedly arranged on the rack, a telescopic arm is fixedly connected with the lower end of a piston rod, a material containing basket is arranged under the telescopic arm, the material containing basket is fixedly arranged on a material containing seat, and the telescopic arm can be connected in a material containing barrel in an inserted mode and push the sock to fall into the material containing basket. The sock can be automatically turned over after the sock toe is sewn, and sock production efficiency is high.

Owner:HAINING SUNSHINE SOCKS MFG

Deviation rectifying mechanism

ActiveCN105714479ACompliant with blankingAchieve fixationWork-feeding meansLinking machinesVisual inspectionEngineering

The invention relates to a deviation rectifying mechanism. The deviation rectifying mechanism comprises a linear guide rail component, a visual inspection component and a control chip, wherein two deviation rectifying components which are arranged vertically and symmetrically are arranged on the linear guide rail component; an opening component is arranged between the two deviation rectifying components; an uncoiling component is arranged at the end part of each deviation rectifying component; the control chip is connected with the linear guide rail component, the deviation rectifying components, the opening component and the visual inspection component. According to the deviation rectifying mechanism, the disadvantages in the prior art can be overcome; whether an upper garment piece is aligned with a lower garment piece can be inspected, and the garment pieces can be adjusted until the garment pieces are aligned; the labour cost is reduced; the overall work efficiency is improved.

Owner:王贤虎

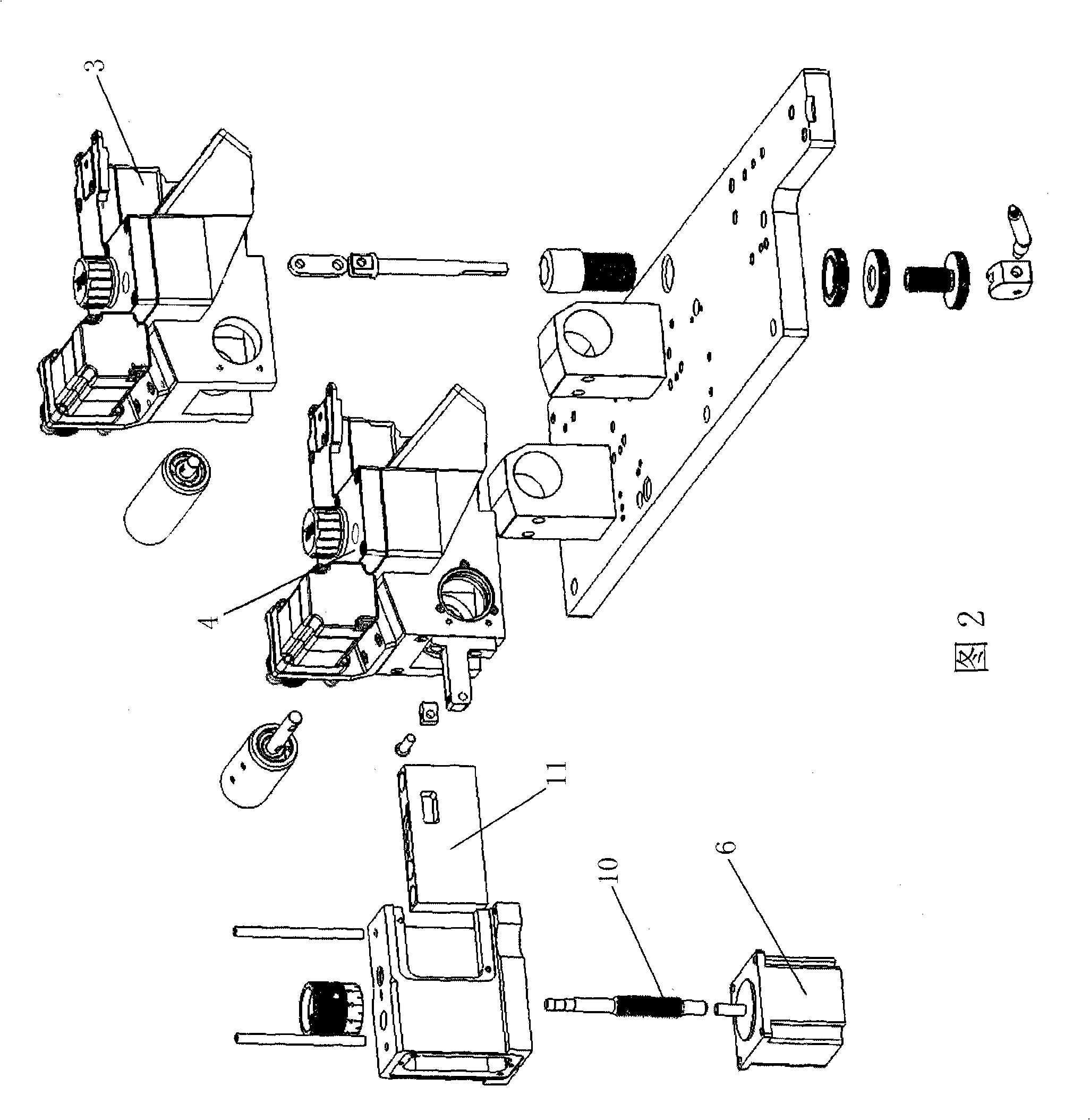

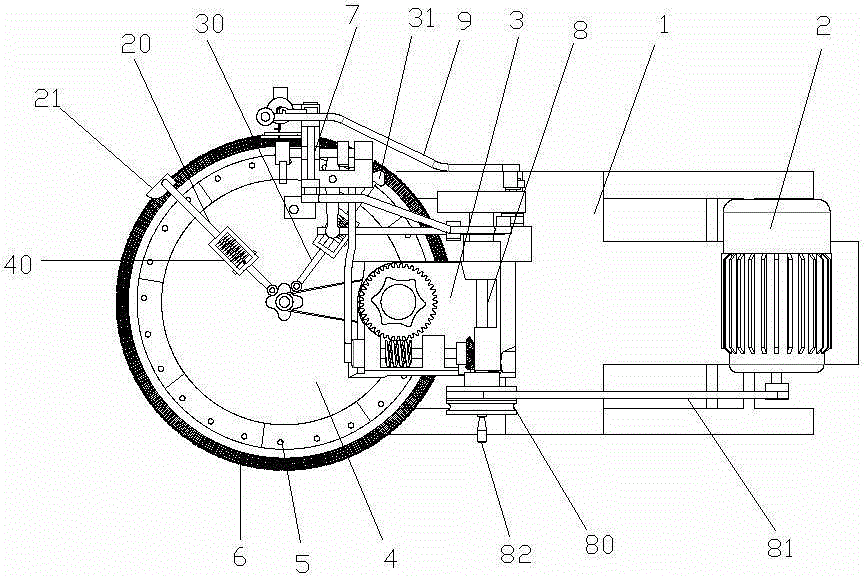

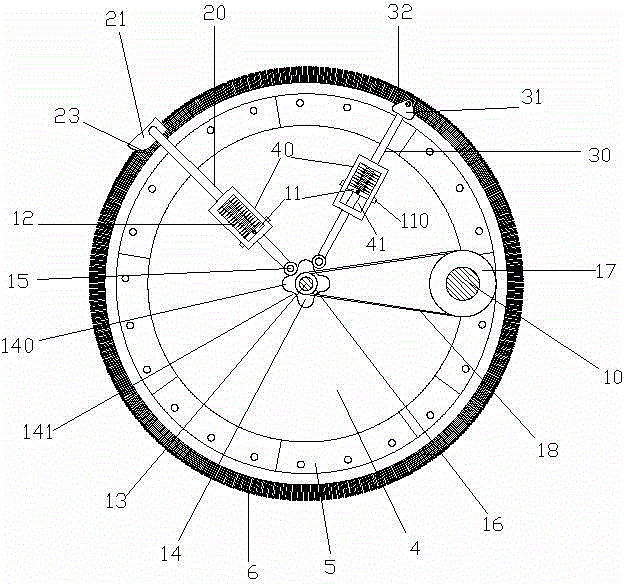

Oil-storage high-speed dial linking sewing machine

ActiveCN107475908AGuaranteed uptimeSimple structureLubrication/cooling devicesSewing-machine control devicesGear driveEngineering

The invention discloses an oil-storage high-speed dial linking sewing machine. The oil-storage high-speed dial linking sewing machine comprises a bed, a support, a transmission main shaft, a power device, a needle dial, a worm and gear assembly, a crochet hook assembly, an eccentric gear driving device, a thread take-up device and an ejector pin device, wherein the support is installed beside the bed; the transmission main shaft is arranged in the bed and the support in a penetrating mode; the power device is installed on the outer side of the bed and used for driving the transmission main shaft to rotate; the needle dial is installed below the bed; the worm and gear assembly is installed in the bed and used for driving the needle dial to rotate; the crochet hook assembly is installed on the outer side of the support and matched with the needle dial; the eccentric gear driving device is installed in the support and used for driving the crochet hook assembly to swing; the thread take-up device is installed in the support; the ejector pin device is installed in the support and matched with the thread take-up device; the worm and gear assembly, the eccentric gear driving device, the thread take-up device and the ejector pin device are linked with the transmission main shaft; a pressure-adjustable spring mechanism is installed between the support and the thread take-up device, and an oil-storage lubricating device used for oiling the thread take-up device and / or the eccentric gear driving device is arranged on the support.

Owner:东莞市缝神机械设备有限公司

Sewing machine and method for closing open end of tubular knitted article

A sewing machine and the method for closing open end of tubular knitted articles. The sewing machine is configured to knit and close the open end of a tubular knitted article, comprising a frame, a knitting head and a thread cutter. The knitting head and the thread cutter are disposed rotatable on the frame, the knitting head has a needle, a needle-shaped hook and a knot making peg to form threadknots, and the thread cutter is configured to cut the knitting thread, wherein the thread cutter is configured in a fashion of making a relative movement to the knitting head.

Owner:KONG ENTERPRISE

Stocking and sewing integrated hosiery machine

ActiveCN102885408BRealize modern developmentIncrease productivityWeft knittingLinking machinesMechanical engineeringContinuous operation

The invention discloses a stocking and sewing integrated hosiery machine. The stocking and sewing integrated hosiery machine comprises a stocking machine provided with a needle cylinder and an upper plate, wherein the stocking head of a stocking body which is woven by the stocking machine is picked up by a pickup device, and the stocking body is transferred to a stocking turning and sewing device at a side edge of the stocking machine to finish stocking turning and sewing process steps. Through the continuously operated device integrating the stocking machine, stocking turning and sewing, continuous operations of the stocking body from weaving to stocking to sewing are realized, and the stocking body is sucked away from a needle frame and is placed in a material frame through a stocking discharging mechanism, so that the production efficiency is greatly improved, the manufacturing cost is saved, and the modernized development of stocking weaving is realized.

Owner:ZHEJIANG ROSSO EQUIP MFG

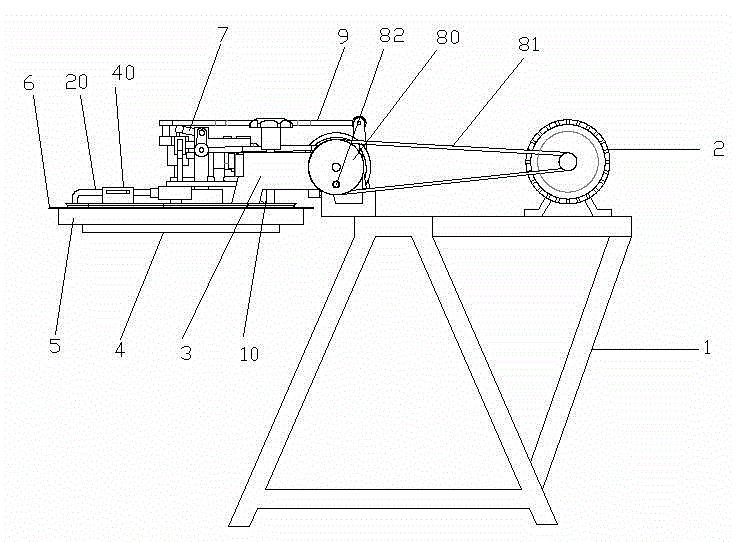

Automatic feeding type disc sewing machine

InactiveCN104911825ARealize automatic positioningRealize automatic unloadingLinking machinesCircular discDrive shaft

The invention relates to the technical field of sewing equipment and discloses an automatic feeding type disc sewing machine. The automatic feeding type disc sewing machine comprises a machine frame, a motor is arranged at one end of the machine frame, a disc connecting base is arranged at the other end of the machine frame, a horizontal disc is fixed at the lower end of the disc connecting base, the outer circle of the disc is provided with a needle dial rotationally connected with the disc, the outer circle of the needle dial is provided with needles, a sewing mechanism is arranged on the needle dial, and the disc connecting base is provided with a main shaft driven by the motor to rotate. The disc connecting base is further provided with a needle dial driving shaft perpendicular to the disc, a pull rod is arranged on the disc and located at the feeding end of the sewing mechanism, a pressing block is arranged at the outer end of the pull rod, the inner side of the pressing block is provided with a U-shaped groove buckled to the two sides of the needles, an arc-shaped guide surface is arranged on the pressing block and located at the feeding end of the U-shaped groove, a push rod is arranged on the disc and located at the discharging end of the sewing mechanism, and a push block is arranged at the outer end of the push rod. Thus, the automatic feeding type disc sewing machine has the advantages of being capable of automatically achieving complete feeding and positioning of materials, shortening waiting time during prepositioning, and improving sewing efficiency.

Owner:ZHEJIANG SCI-TECH UNIV

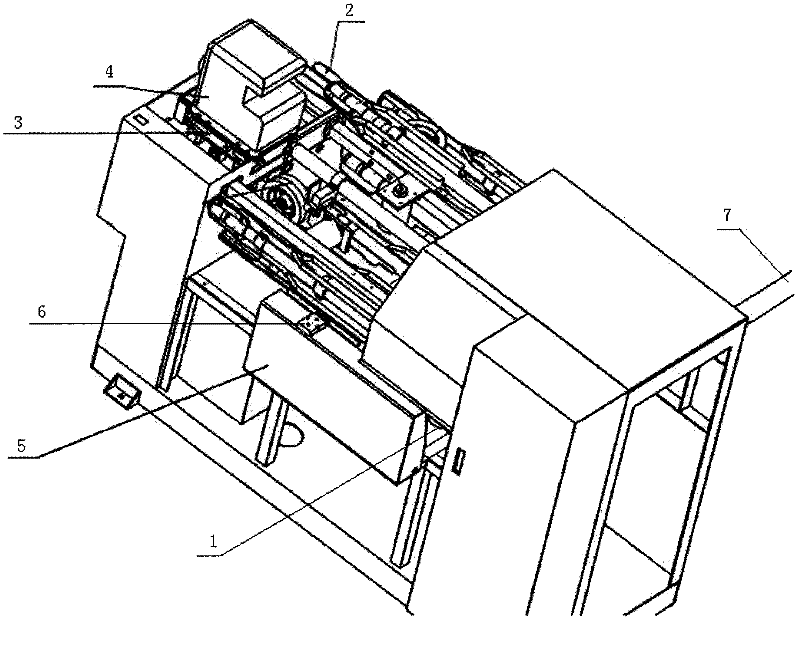

Full-automatic straight type sock stitching machine

ActiveCN103789932AShorten the timeImprove work efficiencyProgramme-controlled sewing machinesLinking machinesElectric machineryChain device

The invention discloses a full-automatic straight type sock stitching machine. The full-automatic straight type sock stitching machine comprises a rack, an opening guiding device, a first conveying chain device, a second conveying chain device, a main motor, a cutter device, a first machine head, a second machine head, a computer, a thread stand and an electrical box, wherein the opening guiding device, the cutter device, the first machine head and the second machine head are arranged on the upper portion of the rack and are sequentially arrayed; the first conveying chain device is arranged on the bottom of the opening guiding device; the second conveying chain device is positioned below the cutter device, the first machine head and the second machine head; the rack is provided with the computer, the main motor and the thread stand; the computer is arranged in front of the main motor; the thread stand is arranged at the rear of the main motor; and the rack is provided with the electrical box. Compared with the prior art, the full-automatic straight type sock stitching machine has the advantages that the time is saved, the work efficiency is improved, the production quality is guaranteed, and the full-automatic straight type sock stitching machine is easy to operate.

Owner:ZHUJI SHIGAN KNITTING MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com