Patents

Literature

52results about How to "Demagnetization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum bronze and preparation method thereof

The invention discloses an aluminum bronze. The aluminum bronze comprises the following components in percentage by weight: 9.0-18.0% of aluminum, 2.0-7.0% of iron, 1-5% of manganese, 0.01-1% of zinc and the balance of copper and inevitable impurities. The aluminum bronze has the following advantages that through utilizing specific element ratio, specific processing mode and composition, the tensile strength of the aluminum bronze can reach above 700 MPa, the Brinell hardness (HB) of the aluminum bronze is 300-400, and the compressive strength of the aluminum bronze is above 1000MPa; the aluminum bronze has high wear resistance; the friction coefficient of the aluminum bronze is less than 0.15, so that scratched products and adhered products cannot be caused; the alloy has good hot working character; the alloy has high anti-softening temperature; and the aluminum bronze is not added with noble elements such as Ag and Ni, does not need to be thermally treated, and the raw material and production costs are lowered.

Owner:NINGBO POWERWAY ALLOY MATERIAL

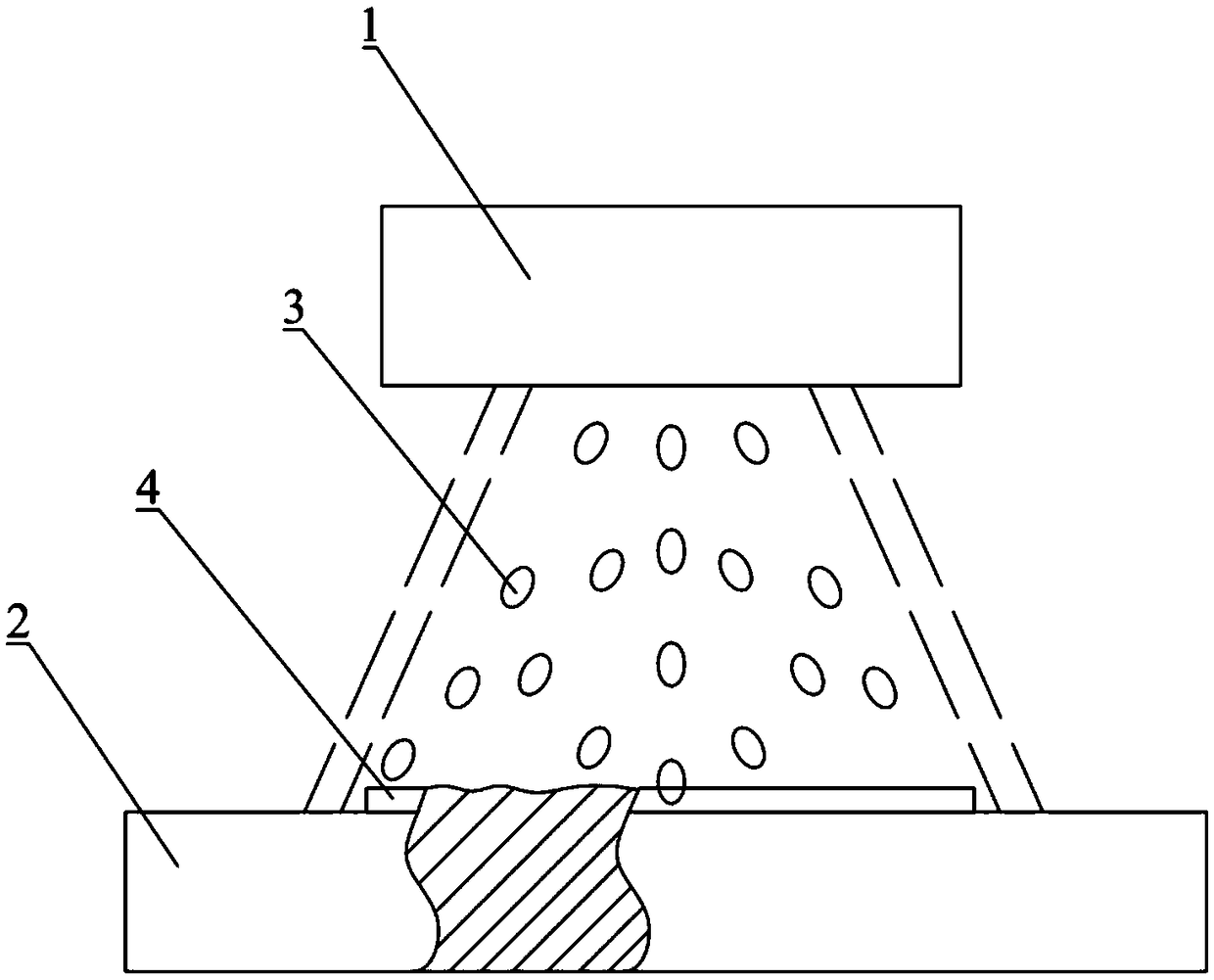

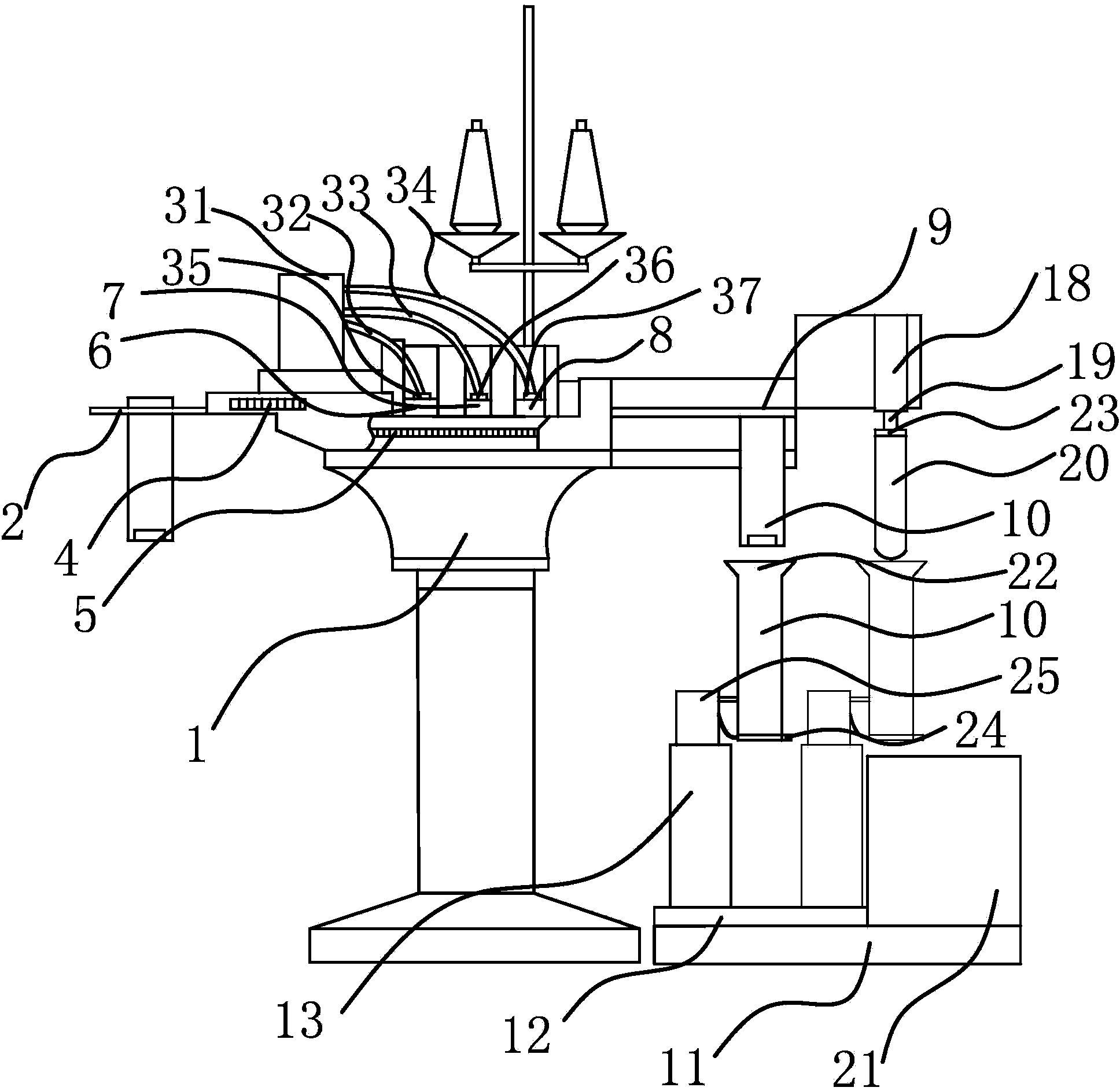

Preparation method of composite metal alloy coating layer and spraying equipment

InactiveCN109468570AImprove practicalityImprove surface qualityMolten spray coatingSuperimposed coating processPre treatmentMetal alloy

The invention discloses a preparation method of a composite metal alloy coating layer and spraying equipment, and belongs to the technical field of surface engineering. The composite metal alloy coating layer comprises a first coating and a second coating which are connected with each other. The preparation method comprises the following three steps: (1) adopting a Cu alloy, an Al alloy or a Zn alloy as thermal spraying raw material powder, and spraying the thermal spraying raw material powder in the molten state onto the surface of a pretreated substrate at a first preset speed so as to formthe first coating; (2) baking stainless steel powder in an oven for 2 hours or longer so as to eliminate magnetism between the stainless steel powder; and (3) adopting the stainless steel powder subjected to magnetism elimination as cold spraying raw material powder, and spraying the cold spraying raw material powder onto the outer surface of the first coating at a second preset speed so as to form the second coating. Consequently, the stainless steel powder can be sprayed onto the substrate through cold and thermal spraying method by utilizing the step (1) to the step (3), and then the surface properties of the substrate can be improved.

Owner:深圳市金中瑞通讯技术有限公司

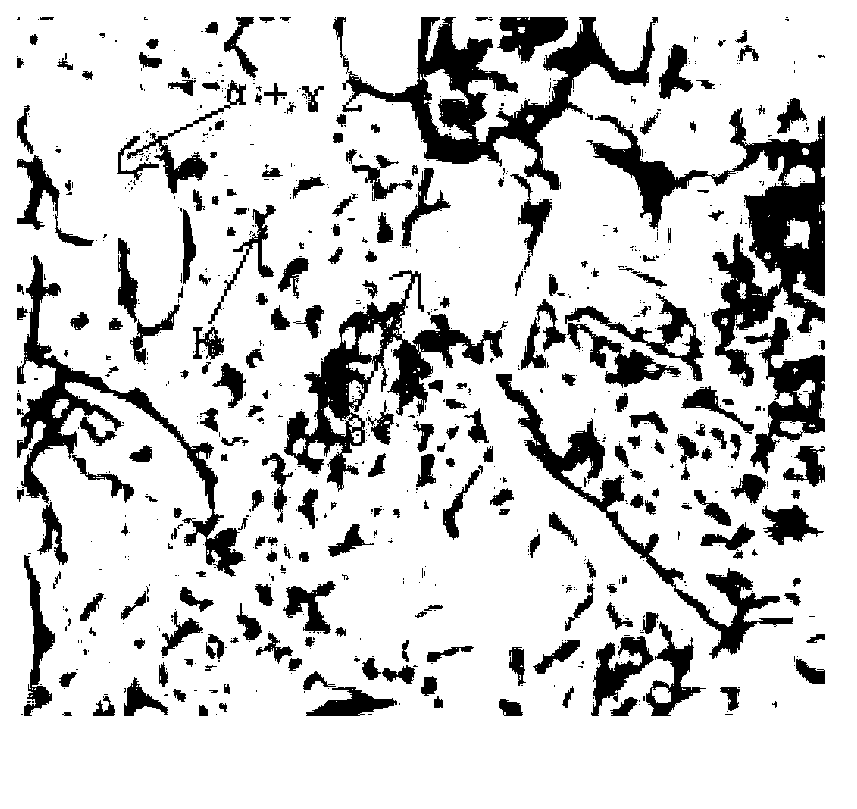

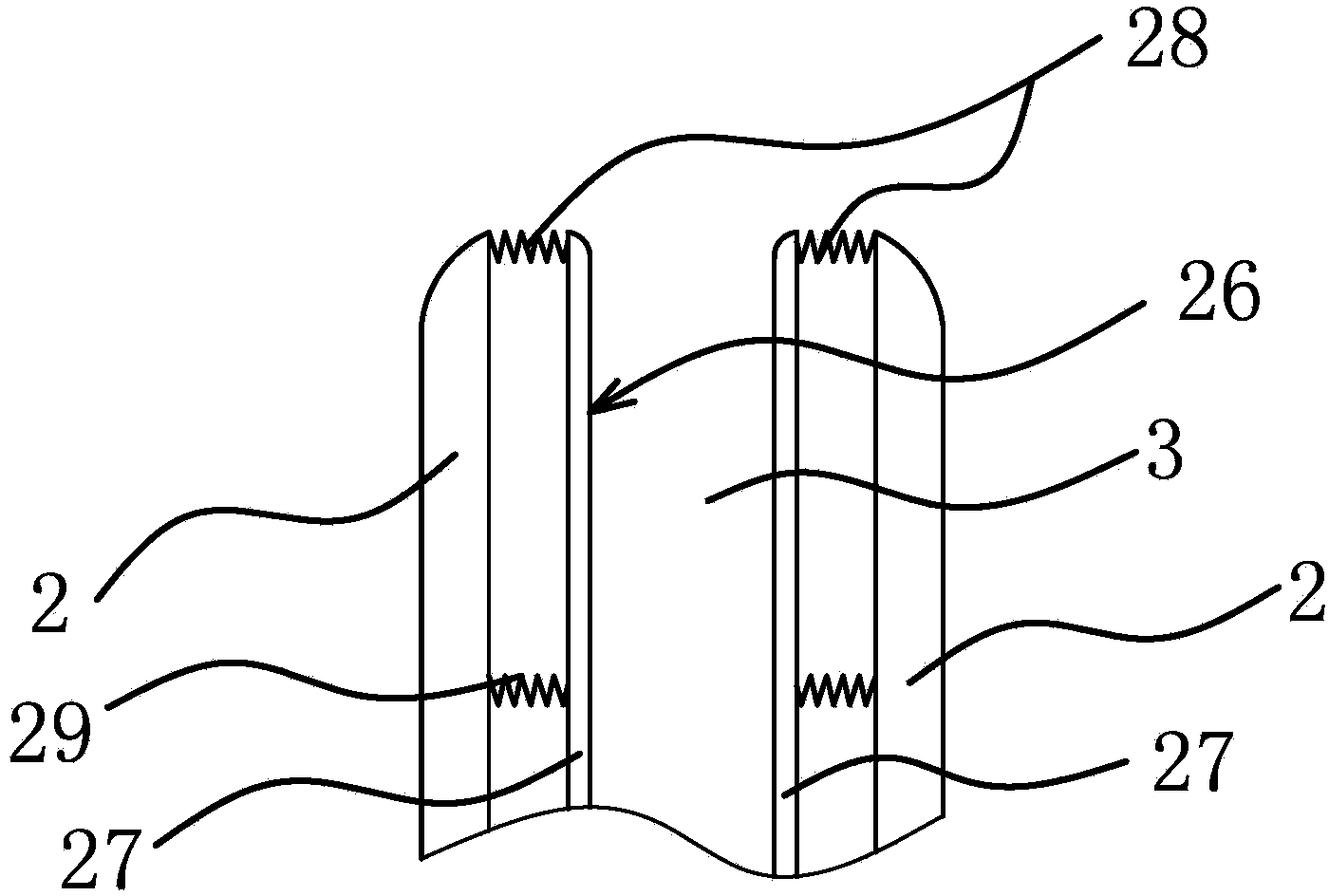

Production process of low-magnetic stainless steel band

ActiveCN103484647ADegaussing heat treatment process is simpleIncrease productivityFurnace typesHeat treatment furnacesShielding gasAustenite

A production process of a low-magnetic stainless steel band comprises the following steps that a finished stainless steel band is obtained after the austenite stainless steel band is preprocessed; the finished stainless steel band is placed in a distressing continuous-type annealing furnace for annealing, an inlet and an outlet of the distressing continuous-type annealing furnace are respectively provided with a tension device, the distressing continuous-type annealing furnace is filled with protective gas, the annealing condition comprises the aspects that tension ranges from 5 KN to 30 KN, the speed ranges from 4m / min to 10m / min, and the low-magnetic stainless steel band is obtained. The degaussing heat treatment process is simple and short in consumed time, only takes 3-5 minutes, and is high in production efficiency.

Owner:山东能源装备集团乾元不锈钢制造有限公司

Method for removing amorphous alloy iron core localized stress

The invention provides a method for removing a partial stress of an amorphous alloy iron core, which is characterized in that a hammer with a soft hammerhead is used to beat the amorphous alloy iron core which is processed through quenching. The beating refers to beating the upper end surface and the lower end surface, the surrounding side surfaces and the corners of the amorphous alloy iron core. The method for removing a partial stress of an amorphous alloy iron core has the advantages of effectively removing the magnetic performance of the amorphous alloy iron core through using the mode of manual beating, thereby improving the market competition of the amorphous iron core.

Owner:SHANGHAI RIGANG ZHIXIN AMORPHOUS METAL

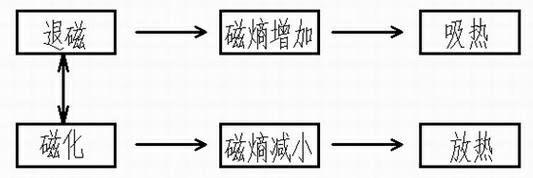

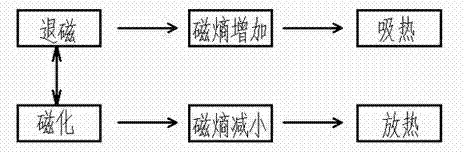

Electromagnetic refrigerating refrigerator

InactiveCN102331132AReduce volumeDemagnetizationLighting and heating apparatusDomestic refrigeratorsEngineeringHome appliance

The invention provides an electromagnetic refrigerating refrigerator, and belongs to household appliances; the refrigerator comprises a shell, a metal circulating pipeline section is arranged on the shell, a part of the circulating pipeline is arranged at the interior of the shell, and the other part of the circulating pipeline is arranged on the exterior of the shell; the external part of the shell is composed of an iron tube, the internal part of the shell is composed of a copper pipe or an aluminum pipe, the circulating pipeline is filled with a magnetic fluid, and the circulating pipeline is connected with a circulating pump in series; the circulating pipeline arranged on the exterior of the shell is wound with a solenoid, and a heat dissipation gap is left among circles of wires in the solenoid; and the refrigerator provided by the invention has the advantages that the refrigerator utilizes a magnetic refrigeration principle to refrigerate, the refrigerator has no refrigeration noise, the stoppage is not easy to occur, the volume is small, and the magnetizing efficient is high.

Owner:SUZHOU JIAYAN ENERGY EQUIP

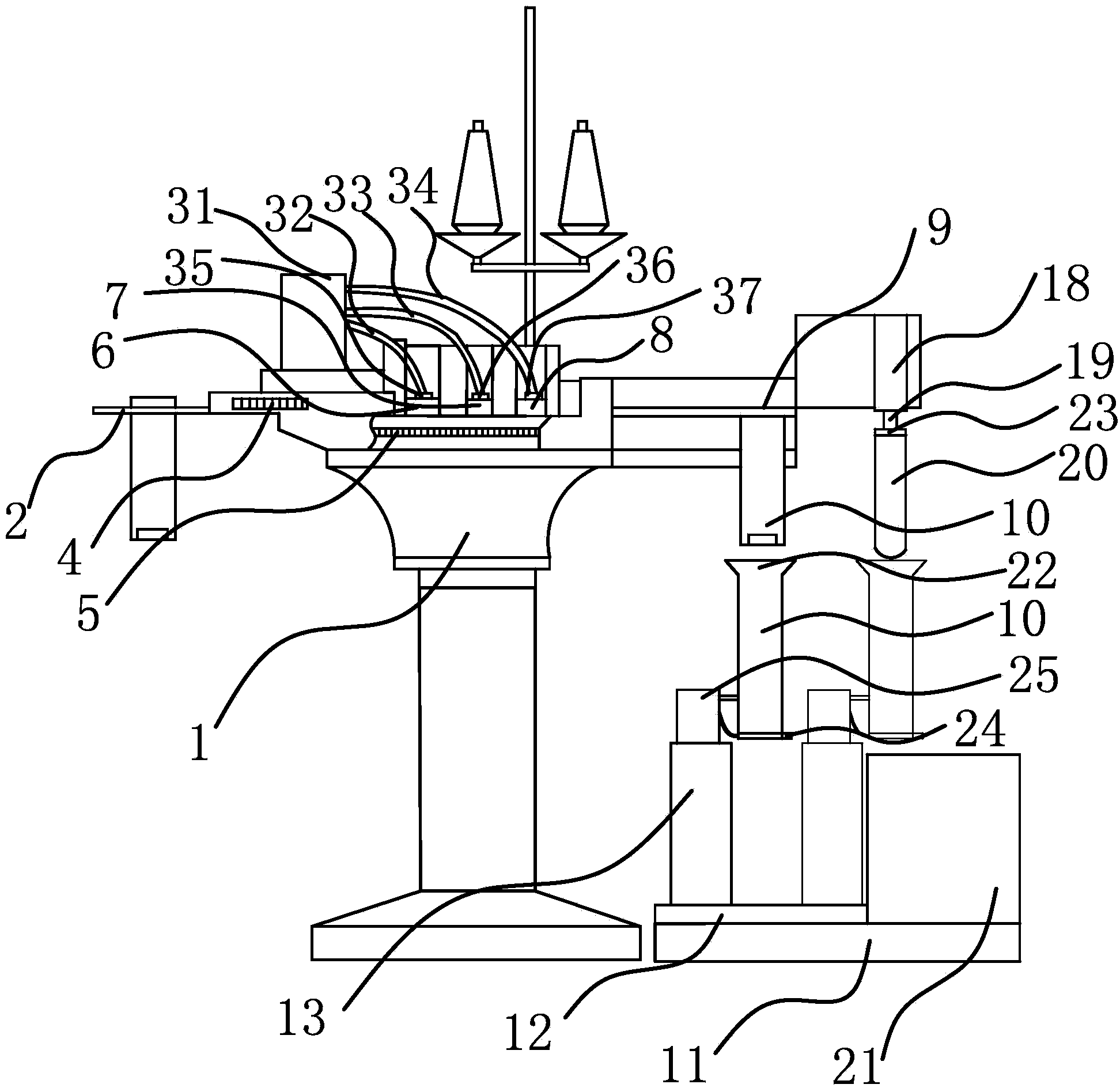

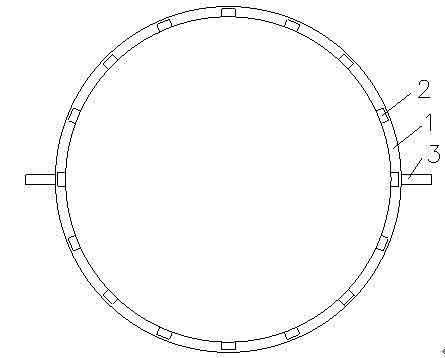

Head stitching machine for sock

InactiveCN103485079ADemagnetizationReduce adsorptionWork-feeding meansLinking machinesEngineeringElectromagnet

The invention provides a head stitching machine for a sock, belongs to the technical field of textile machinery and solves the technical problems that in the prior art, after the head of the sock is sewn, the sock cannot be automatically turned over, and the like. The head stitching machine comprises a rack; the right end of the rack is the discharge end of the sock; the bottom end of the sock is provided with a rubber magnetic sheet 1 and a rubber magnetic sheet 2; the bottom of a sock guide cylinder is provided with a discharge port for the sock to pass through, and is further fixedly provided with an electromagnet; an air cylinder is further fixed at the right end of the rack; the cylinder body of the air cylinder is fixed on the rack; the lower end of a piston rod is fixedly connected with a telescopic arm; a material containing basket is arranged right below the telescopic arm and is fixed on a material containing seat; the telescopic arm can be inserted in a material containing cylinder and can push the sock, so that the sock falls into the material containing basket. By adopting the head stitching machine for the sock, after the head of the sock is sewn, the sock can be automatically turned over, and the production efficiency of the sock is high.

Owner:HAINING SUNSHINE SOCKS MFG

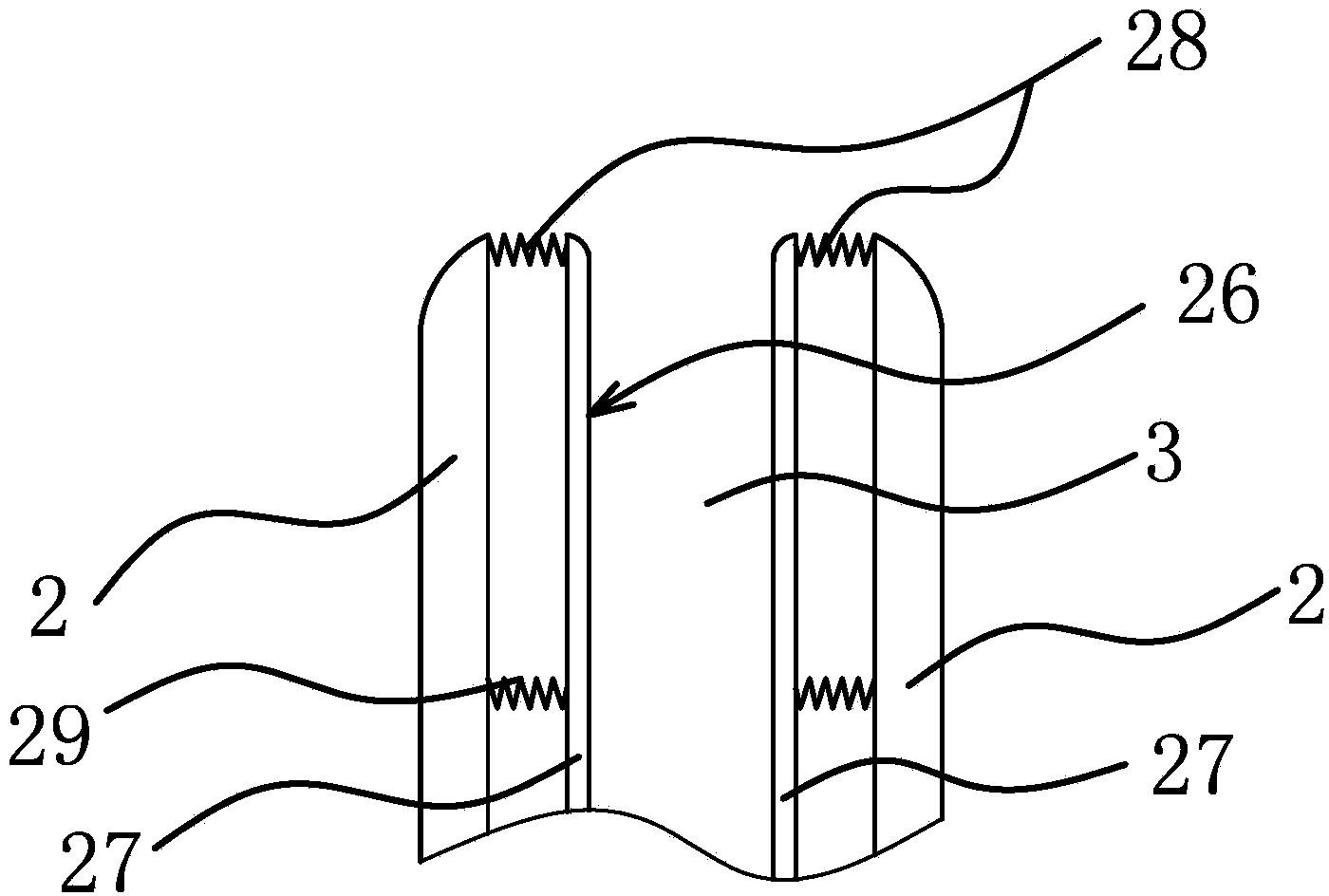

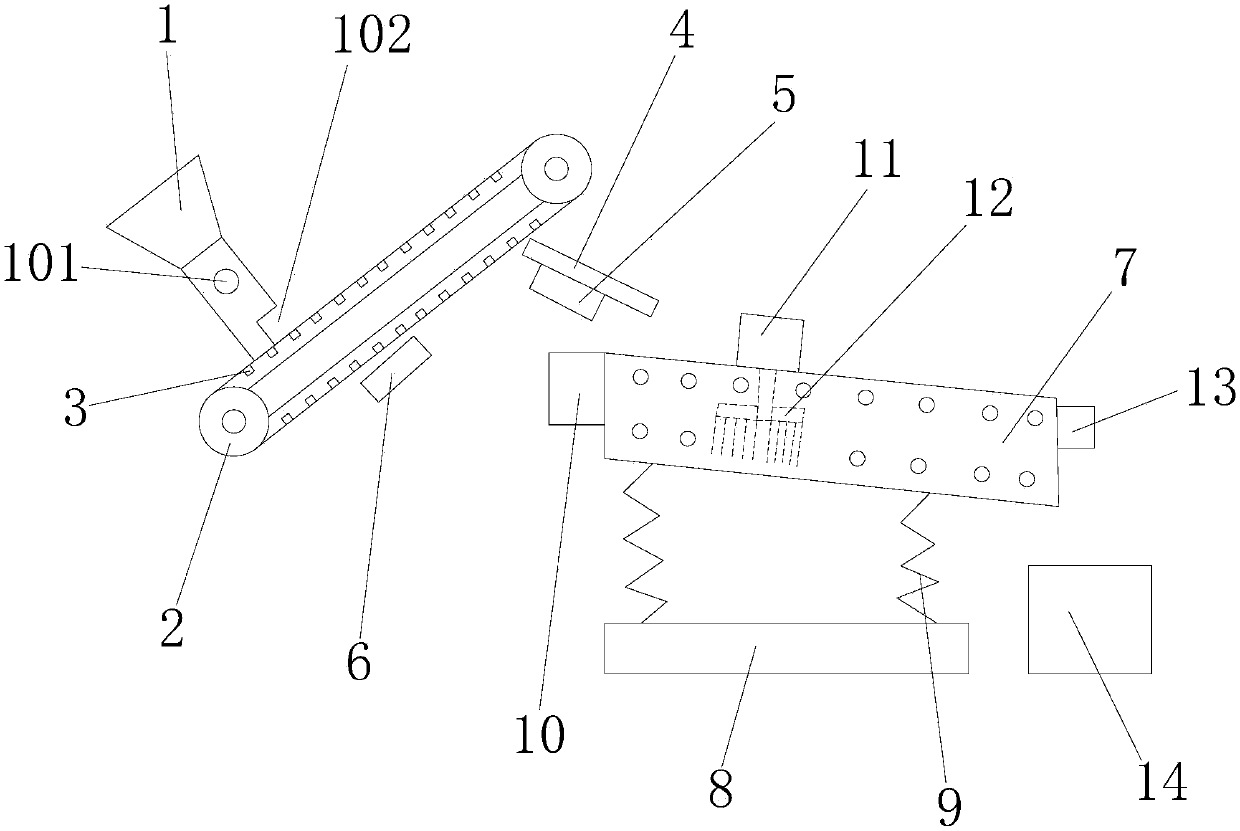

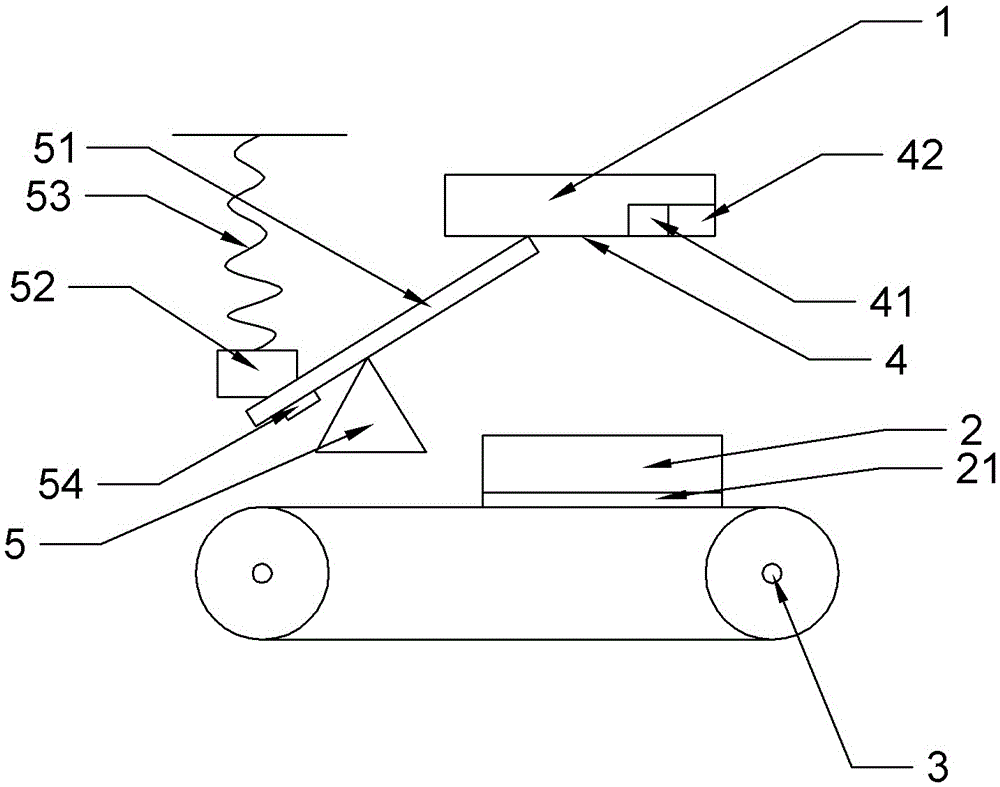

Multifunctional nut chip removal machine

PendingCN107716472ADemagnetizationEfficient removalCleaning using toolsCleaning using gasesElectric machineryEngineering

The invention discloses a multifunctional nut chip removal machine which comprises a discharging hopper, a conveying belt, first magnets, a scraping plate, a magnetic eraser, a second magnet, a containing screen, a base, springs, a vibrator, a motor, brushes, an air blower and a collection box. The conveying belt with the upwarped output end is arranged below the discharging hopper. The outlet endof the discharging hopper is located over the input end of the conveying belt. The multiple first magnets distributed at equal distance are embedded on the belt face of the conveying belt. The obliquely-arranged scraping plate is arranged below the output end of the conveying belt. The magnetic eraser is fixedly arranged at the bottom of the scraping plate. The second magnet is arranged at the position, located on the downstream portion of the scraping plate, below the conveying belt. The containing screen with the outlet end arranged obliquely downwards is arranged under the lower end of thescraping plate. Compared with the prior art, chip removal can be fast and efficiently carried out on a nut, the chip removal efficiency and effect to the nut are improved, the labor intensity of workers is reduced, and great convenience is brought to nut machining.

Owner:海盐晋悦五金制品有限公司

Magnetic fluid refrigerating refrigerator

InactiveCN102331133AReduce volumeDemagnetizationEnergy efficient heating/coolingDomestic refrigeratorsEngineeringCopper

The invention provides a magnetic fluid refrigerating refrigerator, and belongs to household appliances; the refrigerator comprises a shell, a metal circulating pipeline section is arranged on the shell, a part of the circulating pipeline is arranged at the interior of the shell, the other part of the circulating pipeline is arranged on the exterior of the shell, and the external part of the shell is composed of an iron pipe; the internal part of the shell is composed of a copper pipe or an aluminum pipe, the circulating pipeline is filled with a magnetic fluid, and the circulating pipeline is connected with a circulating pump in series; and the circulating pipeline arranged on the exterior of the shell is tightly attached to a permanent magnet along the circulating pipeline. The refrigerator abandons a compressor refrigeration system of a traditional refrigerator and adopts a magnetic refrigeration system; compared with a refrigerating ring type magnetic refrigeration system, the refrigerator provided by the invention has the advantages of small volume, good magnetization effect, and good refrigerating efficient.

Owner:SUZHOU JIAYAN ENERGY EQUIP

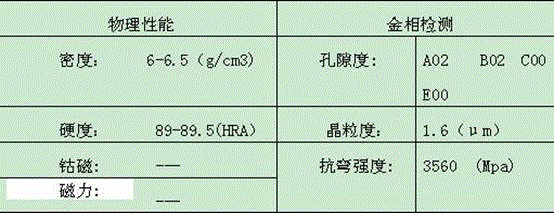

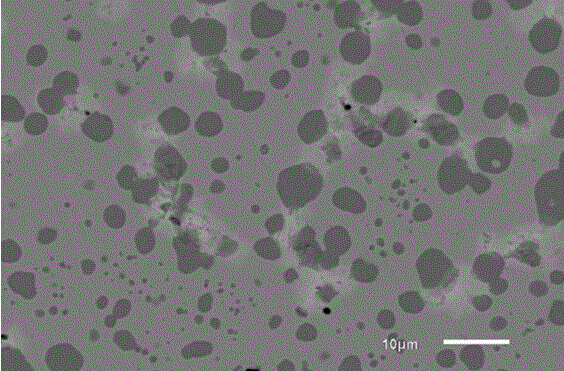

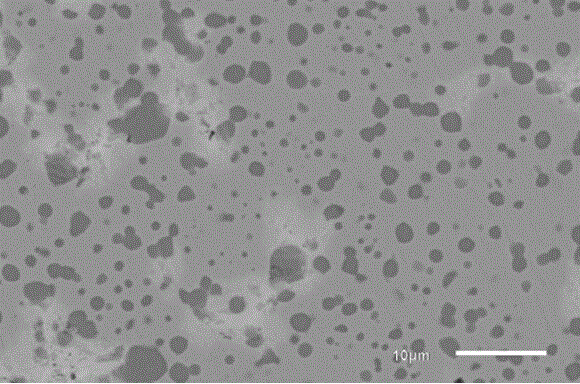

High-strength metal ceramic used for cutting nonferrous metal sheet and preparation method thereof

ActiveCN106756411AHigh hardnessLight weightTransportation and packagingMetal-working apparatusAviationAlcohol

The invention discloses high-strength metal ceramic used for cutting a nonferrous metal sheet and a preparation method thereof. The preparation method includes the following steps that a, original TiC powder, original Mo powder, original Ni powder and NbC powder are taken and ground through a ball milling medium for 48-64 h, and then slurry is obtained, specifically, the average fisher particle size of the original TiC powder is not greater than 1.0 [mu]m, and the mass ratio of the original TiC powder is 44%-46%; the average fisher particle size of the original Mo powder is not greater than 1.0 [mu]m, and the mass ratio of the original Mo powder is 14%-16%; the average fisher particle size of the original Ni powder is not greater than 1.0 [mu]m, and the mass ratio of the original Ni powder is 38%-40%; the average fisher particle size of the NbC powder is not greater than 1.0 [mu]m, and the mass ratio of the NbC powder is 0.8%-1.2%; the ball milling medium comprises hard alloy bar balls and absolute ethyl alcohol, or comprises hard alloy bar balls and No.120 aviation gasoline; b, the slurry obtained through the step a enters a stainless steel container through a stainless steel screen; and c, after the slurry is subjected to standing in the stainless steel container for 24 hours and under the condition that the ball milling medium comprises the hard alloy bar balls and the absolute ethyl alcohol, the absolute ethyl alcohol on the upper layer of the slurry is taken out.

Owner:株洲精特硬质合金有限公司

Steel wire material without magnetism and copper-clad wire without magnetism used for electric wire and cable

InactiveCN101016601AHigh tensile strengthDemagnetizationSingle bars/rods/wires/strips conductorsManufacturing cost reductionIntermediate frequency

The invention discloses a non-magnet wire material and a non-magnet copper-clad steel wire of electric wire and cable in new material technical domain, which comprises the following steps: allocating non-magnet wire material with mass percent at 72-96.2% ferroferrite with carbon content lower than 0.005%, 0.5-5% copper, 0.3-13% nickel and 3-10% manganese; smelting the ferroferrite through intermediate frequency furnace; adding the other component into hot iron; injecting the alloy solution into mold; clotting; forming; getting the product. This material can be used to produce electric wire and cable non-magnet copper-clad steel wire.

Owner:常计章

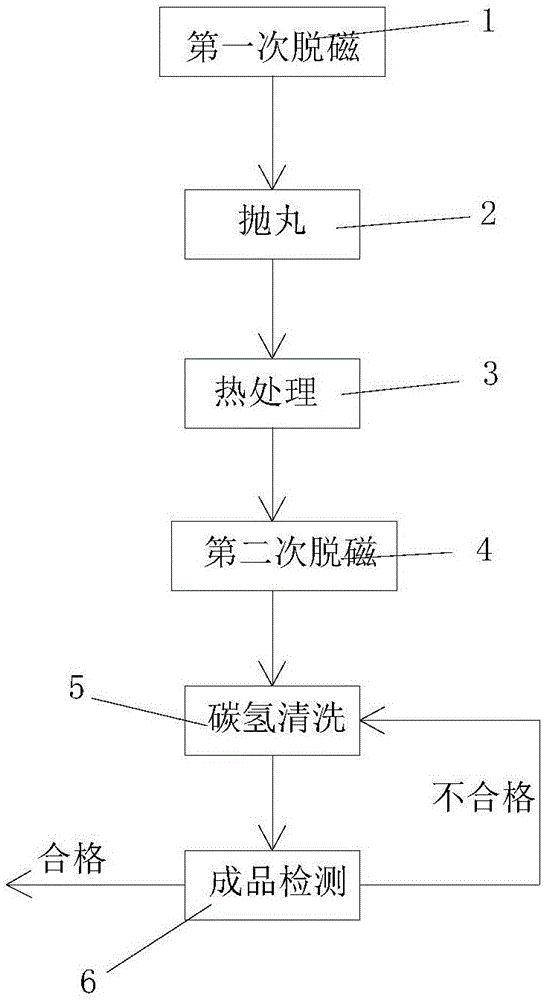

Method for improving surface cleanliness of spring

InactiveCN107520186ADemagnetizationReduce residual stressMagnetic bodiesAbrasion apparatusSurface oxidationEconomic benefits

The invention discloses a method for improving the surface cleanliness of a spring. The method comprises the following steps that demagnetizing is conducted for the first time, specifically, the spring is demagnetized through a demagnetizing machine; shot blasting is conducted, specifically, the spring is subjected to shot blasting through a shot blasting machine; heat treatment is conducted, specifically, the shot-blasted spring is tempered; demagnetizing is conducted for the second time, specifically, the spring is demagnetized through the demagnetizing machine; and hydrocarbon cleaning is conducted, specifically, the spring is cleaned through a hydrocarbon cleaning machine. According to the method, magnetism, residual stress and a surface oxidation layer, grease and dirt of the spring can be eliminated timely, and blind hole parts, concave parts, small gaps and other parts of springs and special-shaped golden parts are effectively cleaned; meanwhile, pollution and noise are avoided, batch assembly-line operation can be achieved, the machining efficiency is high, the cleaning quality is high, the requirement for the cleanliness standard is met; and meanwhile, damage to the spring is avoided, product performance is improved, the appearance requirement is met, a large amount of labor is saved, labor intensity is reduced, and the economic benefits are improved.

Owner:安庆谢德尔汽车零部件有限公司

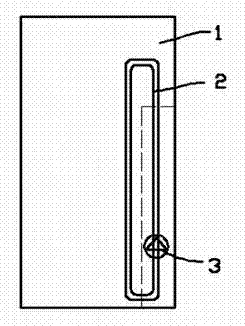

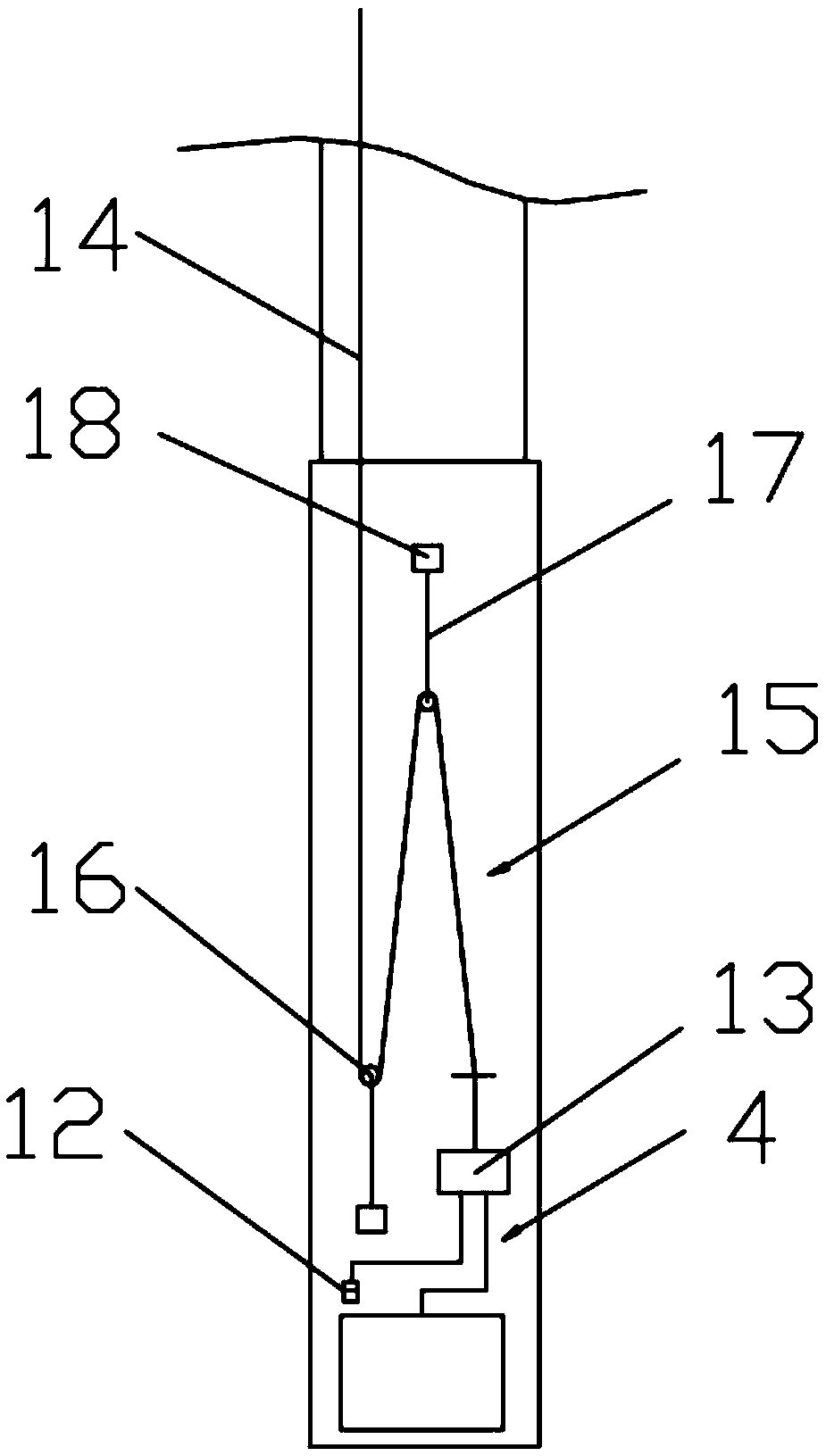

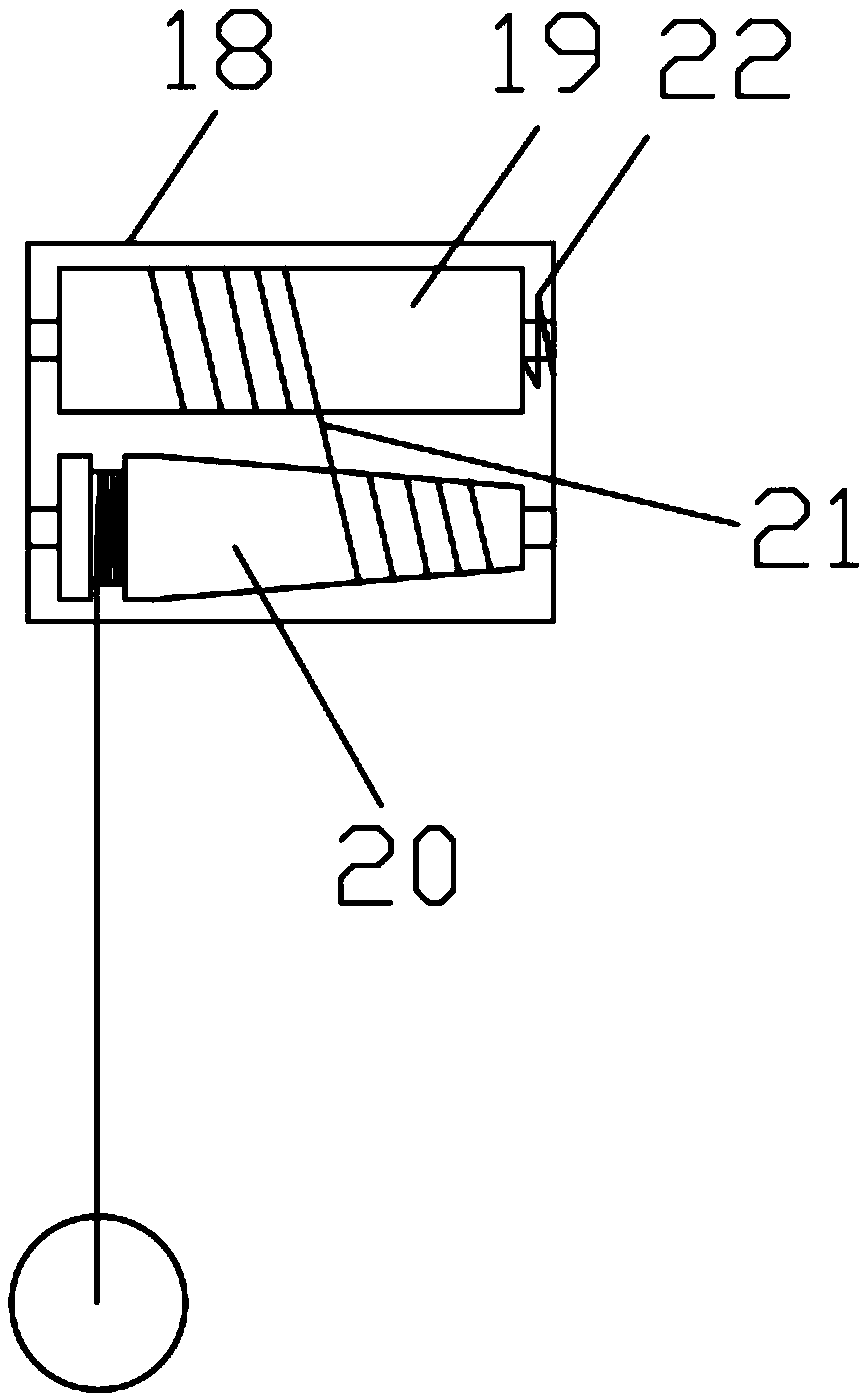

Fast dismounting ground wire

ActiveCN108963483ADemagnetizationFirmly connectedElectric connection structural associationsControl theoryGround line

The invention discloses a fast dismounting ground wire comprising a telescopic rod, a forward and reverse motor, an electromagnet, a control module, a rotating disk, a clamping head and a ground wire;the ground wire is connected with the clamping head; the forward and reverse motor and the telescopic rod are rotatably connected; the rotating disk is fixed on the output shaft of the forward and reverse motor; the electromagnet is used for magnetizing the rotating disk; the rotating disk is provided with a limit slot; the clamping head is detachably connected with the limit slot; the forward and reverse motor and the electromagnet are respectively connected with the control module. The fast dismounting ground wire can fast mount and dismount clamping heads of different heights and angles.

Owner:海南电力产业发展有限责任公司

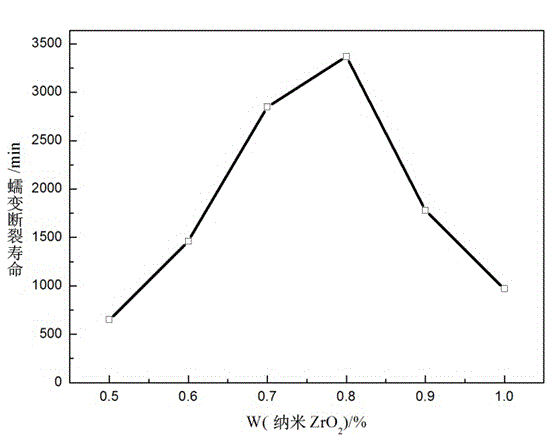

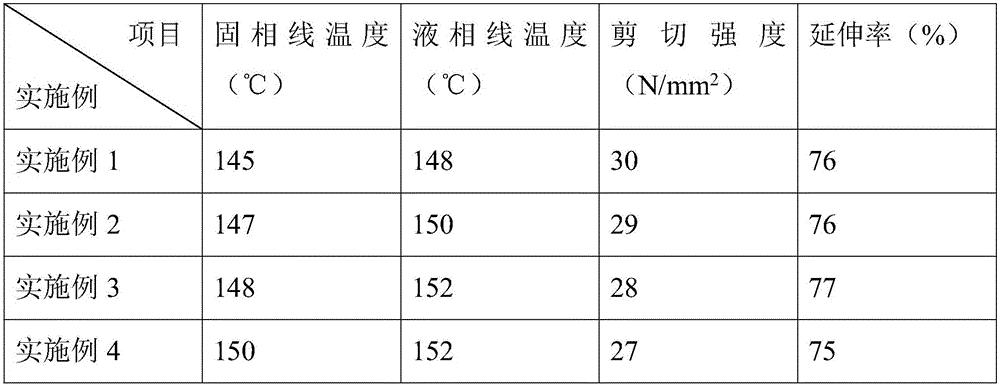

Submerged-arc welding high-moisture oxidation-resistant lead-free solder and preparation method thereof

ActiveCN104476006AGood for spreadingLower wetting angleWelding/cutting media/materialsSoldering mediaSubmerged arc weldingCrucible

The invention relates to a welding material, in particular to a lead-free solder in the field of submerged-arc welding. The lead-free solder comprises, in weight percent, 0.2-0.8% of Cu, 0.075-0.5% of Ni-V alloy particles, 0.1-1.2% of nano ZrO2 particles and the balance Sn. The invention further relates to a preparation method which includes the steps: uniformly mixing components of the lead-free solder according to the mass ratio and then placing the components into an Al2O3 crucible; placing the crucible in a 400-600 DEG C resistance furnace for smelting; keeping the temperature for 100min to 200min after complete smelting; sufficiently stirring the components after keeping the temperature; discharging the components and pouring the components into a solder bar mould; cooling the components to obtain a lead-free solder bar. The lead-free solder has the advantages that wetting property is fine, electromagnetic induction is not generated, the lead-free solder has a fine creep performance and resistant to oxidation and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

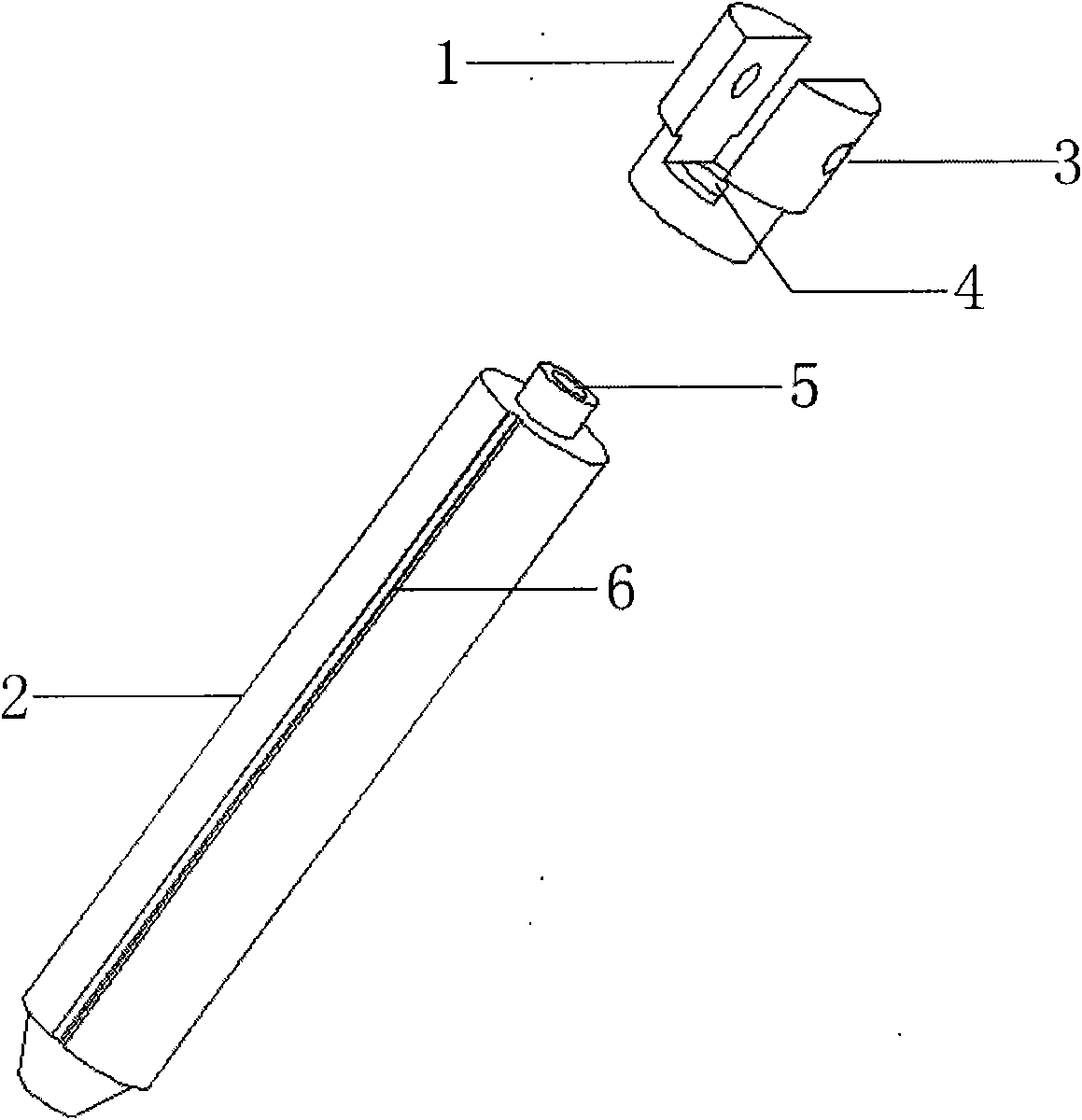

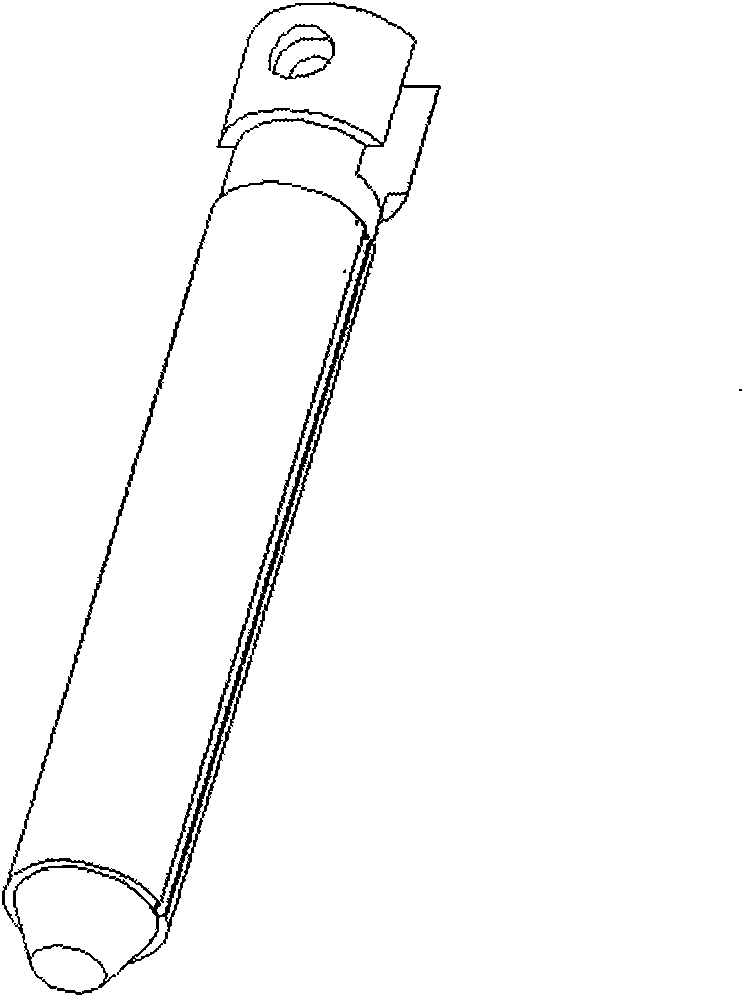

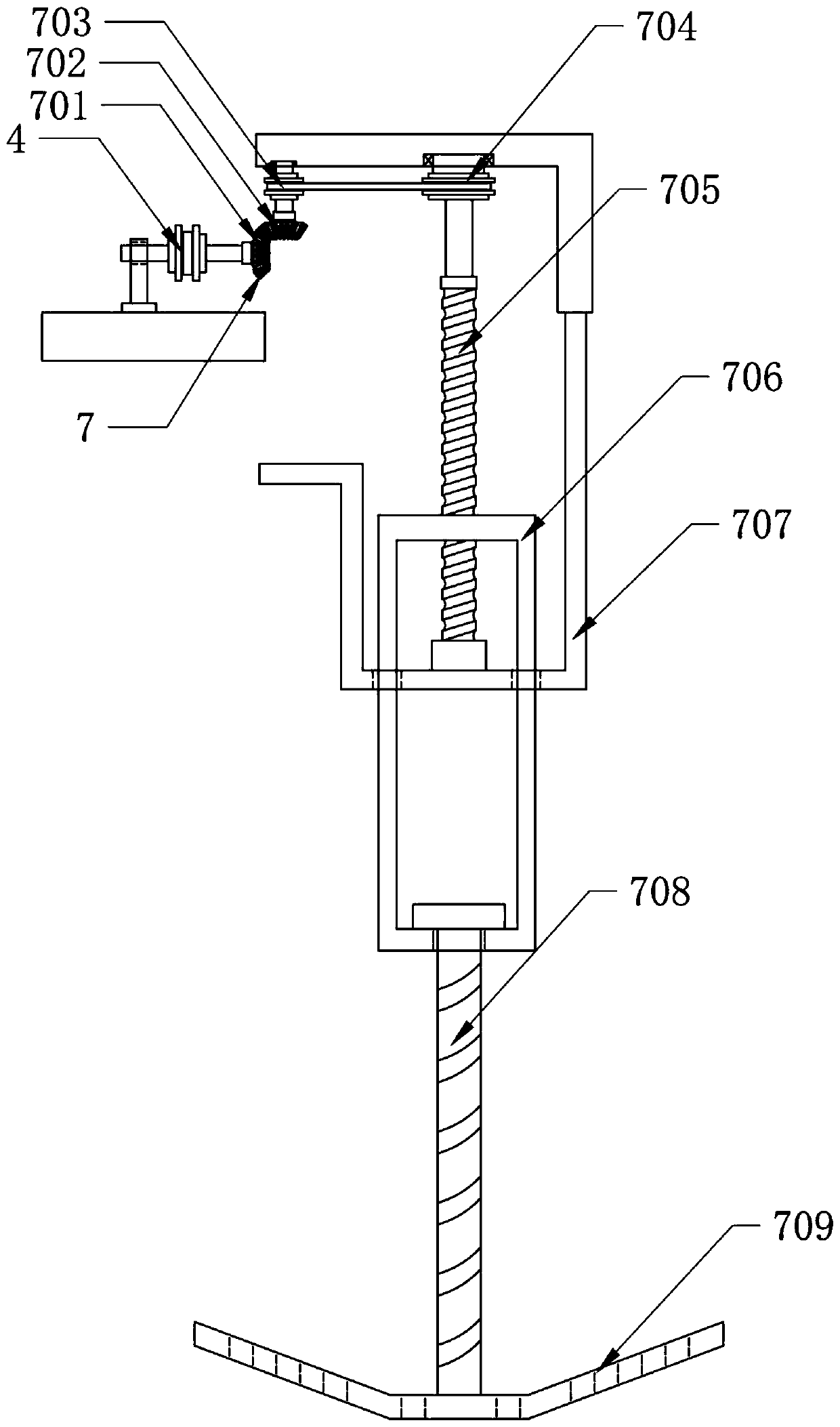

Push rod device for electromagnet

The invention relates to a push rod device for an electromagnet, in particular to a push rod device for the electromagnet, which can eliminate residual magnetism instantly without remaining the residual magnetism after power turn-off and effectively control the flexibility and the stability of the electromagnet. The push rod device for the electromagnet comprises two separated sections, namely thepush rod is divided into a push rod main body and a connector, wherein the push rod main body is made of a high-carbon steel material, the head of the main body is provided with a fixed column, and the push rod main body is provided with an air discharge duct from top to bottom; and the connector is made of a copper material, the lower end of the connector is provided with a connecting hole, thefixed column is arranged in the connecting hole, and the push rod main body and the connector are fixed together by stamping. Thus, the push rod device for the electromagnet has the advantages of reasonable structure, high stability and strong reliability, can eliminate the residual magnetism instantly, and can effectively control the flexibility of the electromagnet.

Owner:敬德元

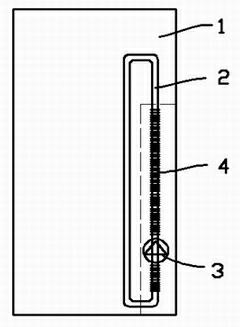

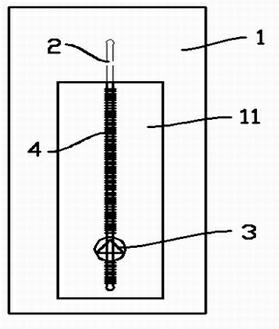

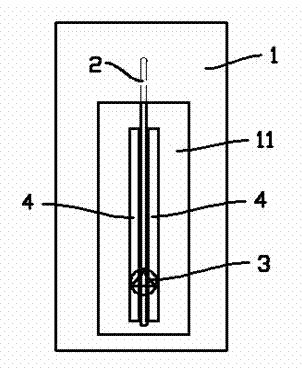

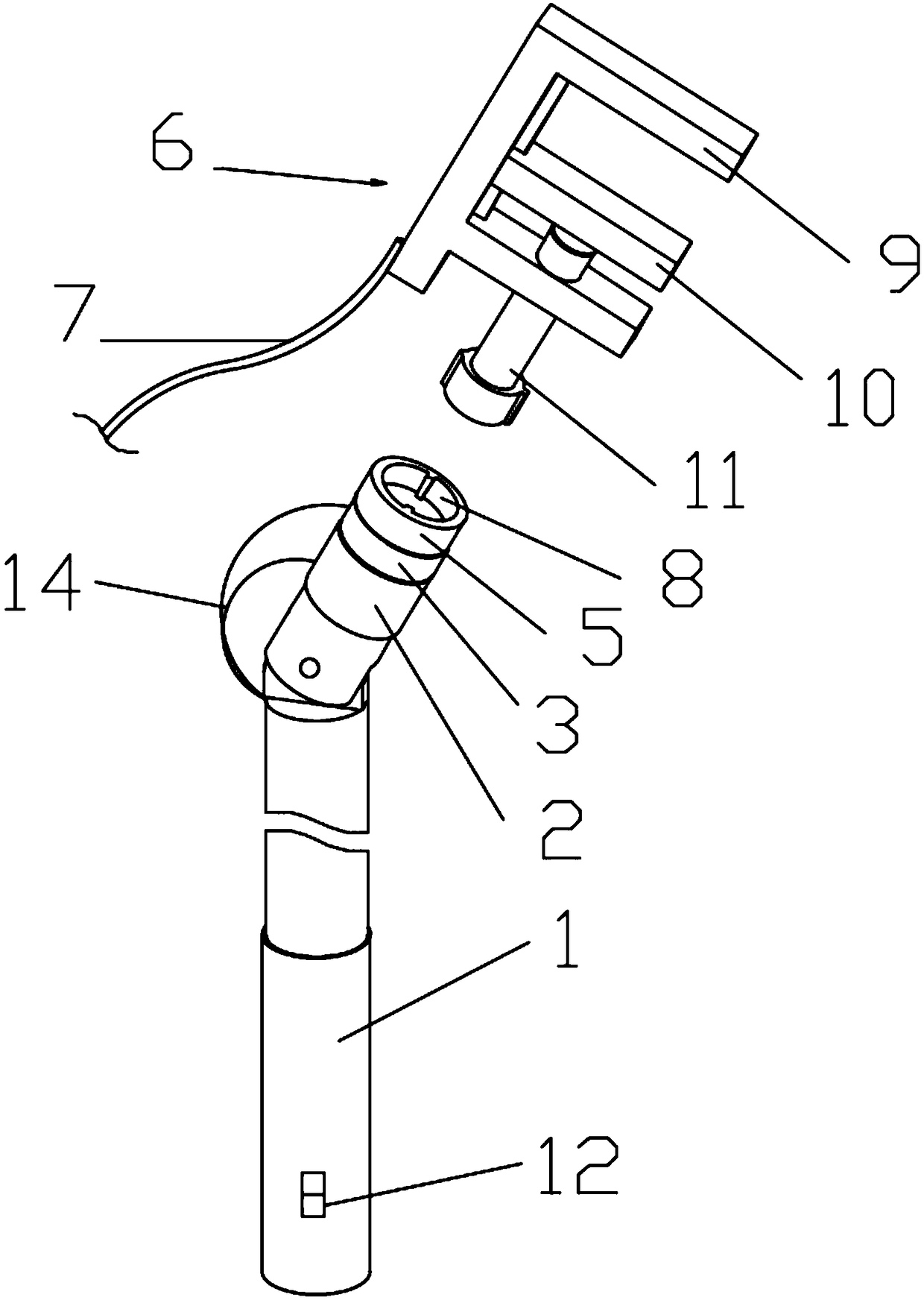

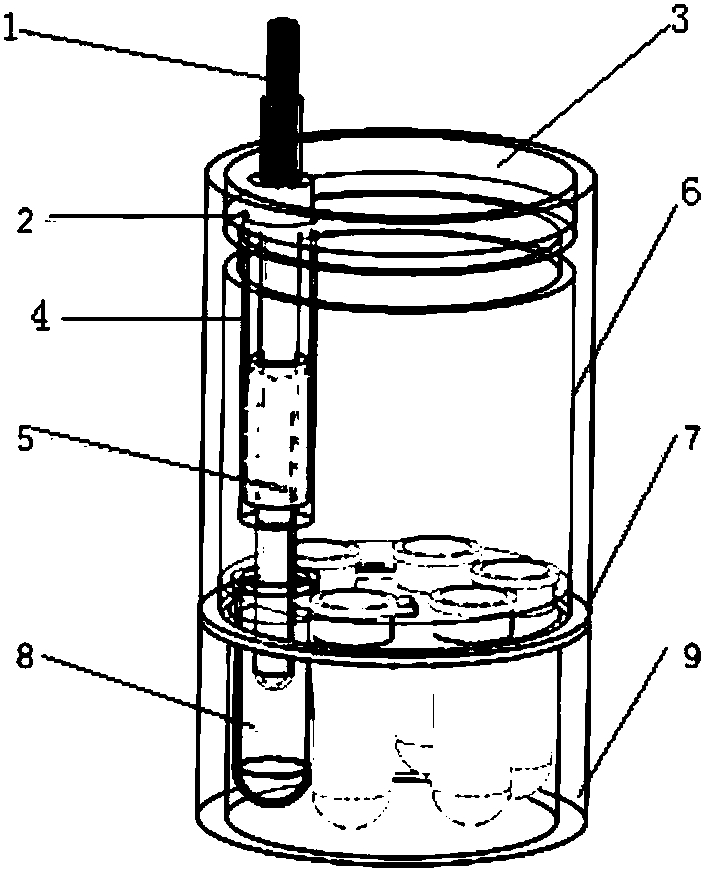

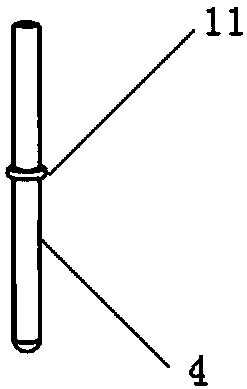

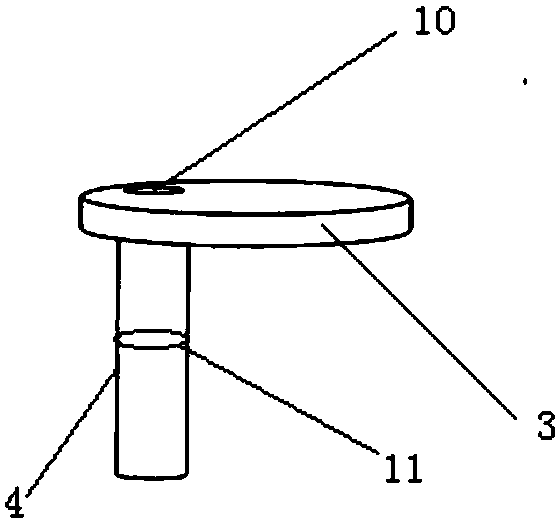

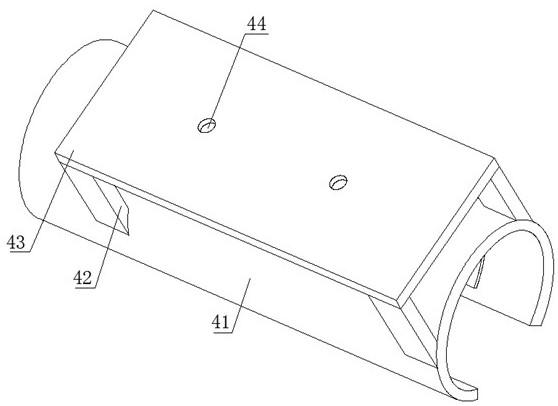

Cartridge for purifying PCR product

InactiveCN107760602ADemagnetizationBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic beadEngineering

The invention discloses a cartridge for purifying a PCR product. A through hole is formed in an upper cover of the cartridge, a magnetic sheath is arranged in the through hole, an annular bulge is arranged in the middle of the magnetic sheath, a spring is sheathed on the magnetic sheath on the lower part of the annular bulge, a metal bar is arranged in the magnetic sheath, a sphere with the diameter slightly smaller than the inner diameter of the magnetic sheath is arranged at the bottom of the metal bar, the upper end of the metal bar extends out of the upper cover, the lower end of the metalbar is inserted in the bottom of the magnetic sheath, and the metal bar can drive the magnetic sheath to move up and down; and a plurality of centrifugal pipes are arranged on a base. Under the action of an outside magnetic field, the metal bar can generate magnetism which can be completely eliminated after the outside magnetic field is removed. Through the up-down movement of the metal bar and the magnetic sheath, the grab and release of magnetic beads can be completed, the capture, washing and rinsing of nucleic acid can be realized through simple operation, and finally, the purified PCR product can be obtained, the influence of aerosol escape generated during the purification process of the PCR product on the environment can be avoided.

Owner:南京中科拜尔医学技术有限公司

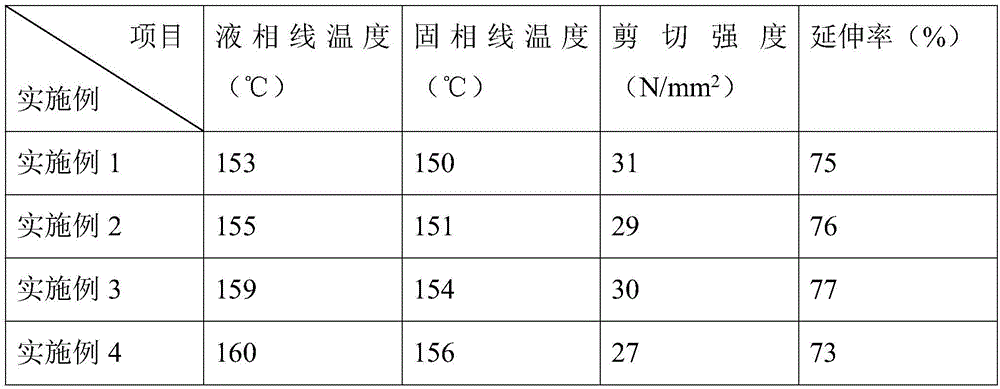

Low-melting-point lead-free solder alloy

InactiveCN106624433ALow melting pointLow costWelding/cutting media/materialsSoldering mediaSesquioxideDiiron Trioxide

The invention provides low-melting-point lead-free solder alloy. The low-melting-point lead-free solder alloy comprises, by weight, 10%-30% of bismuth, 0.6%-1.8% of silver, 0.3%-0.8% of nano iron sesquioxide particles, 0.02%-0.1% of vanadium and the balance tin. The low-melting-point lead-free solder alloy is very low in melting point, good in wetting performance and shearing resistance and low in silver content and cost.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

Low-melting-point tin bismuth solder alloy

InactiveCN106624432AImprove shear resistanceDemagnetizationWelding/cutting media/materialsSoldering mediaSesquioxideTitanium

The invention provides low-melting-point tin bismuth solder alloy. The low-melting-point tin bismuth solder alloy is prepared from the following raw materials in percentages by weight: 10-30% of bismuth, 2.0-3.0% of titanium, 0.3-0.8% of nano iron sesquioxide particles, 0.02-0.1% of vanadium, 0.002-0.006% of RE and the balance of tin. The solder alloy not only has a very low melting point, but also has good wetting property and anti-shearing property.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

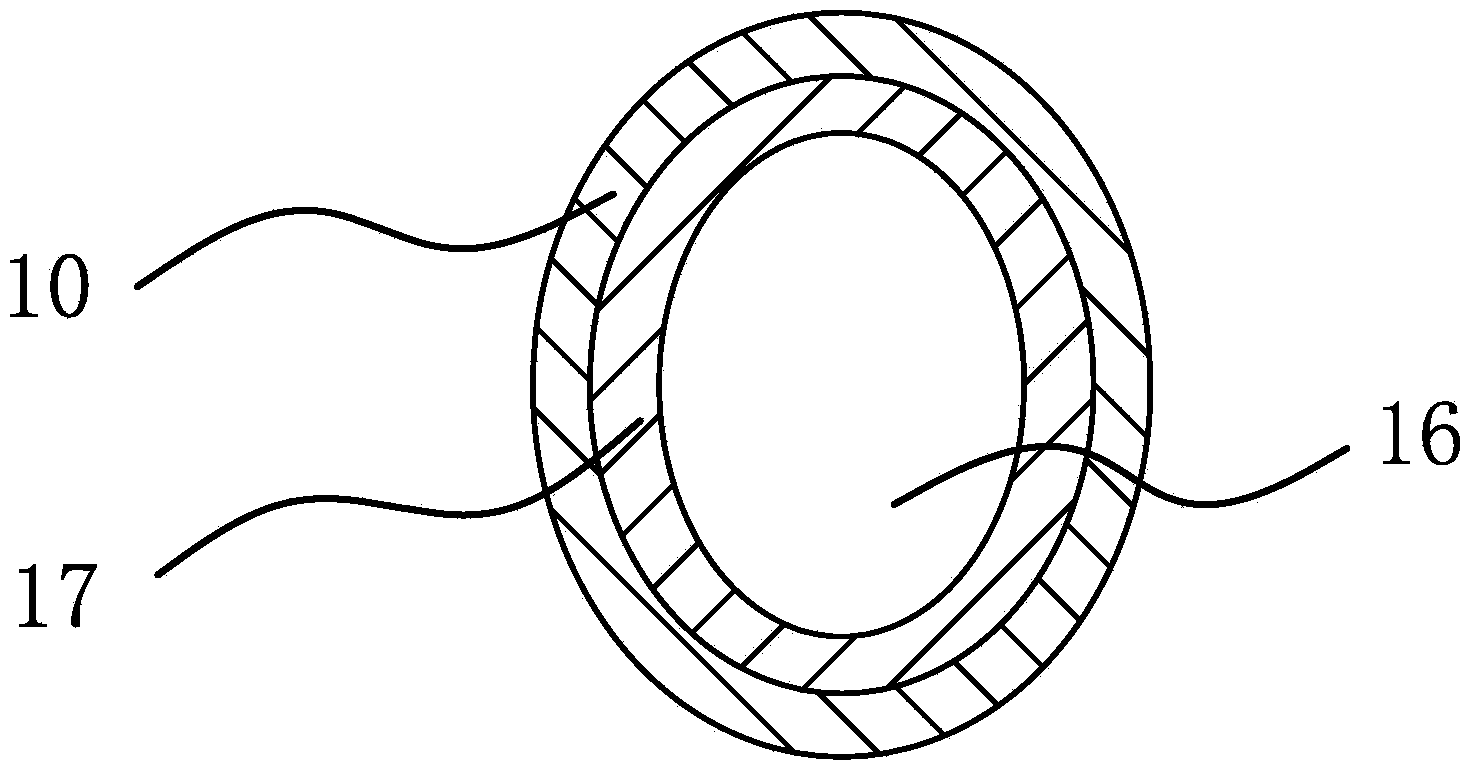

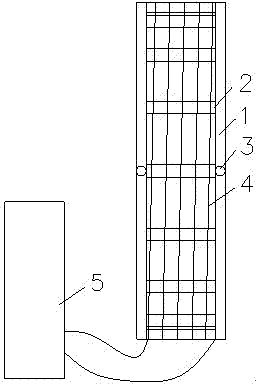

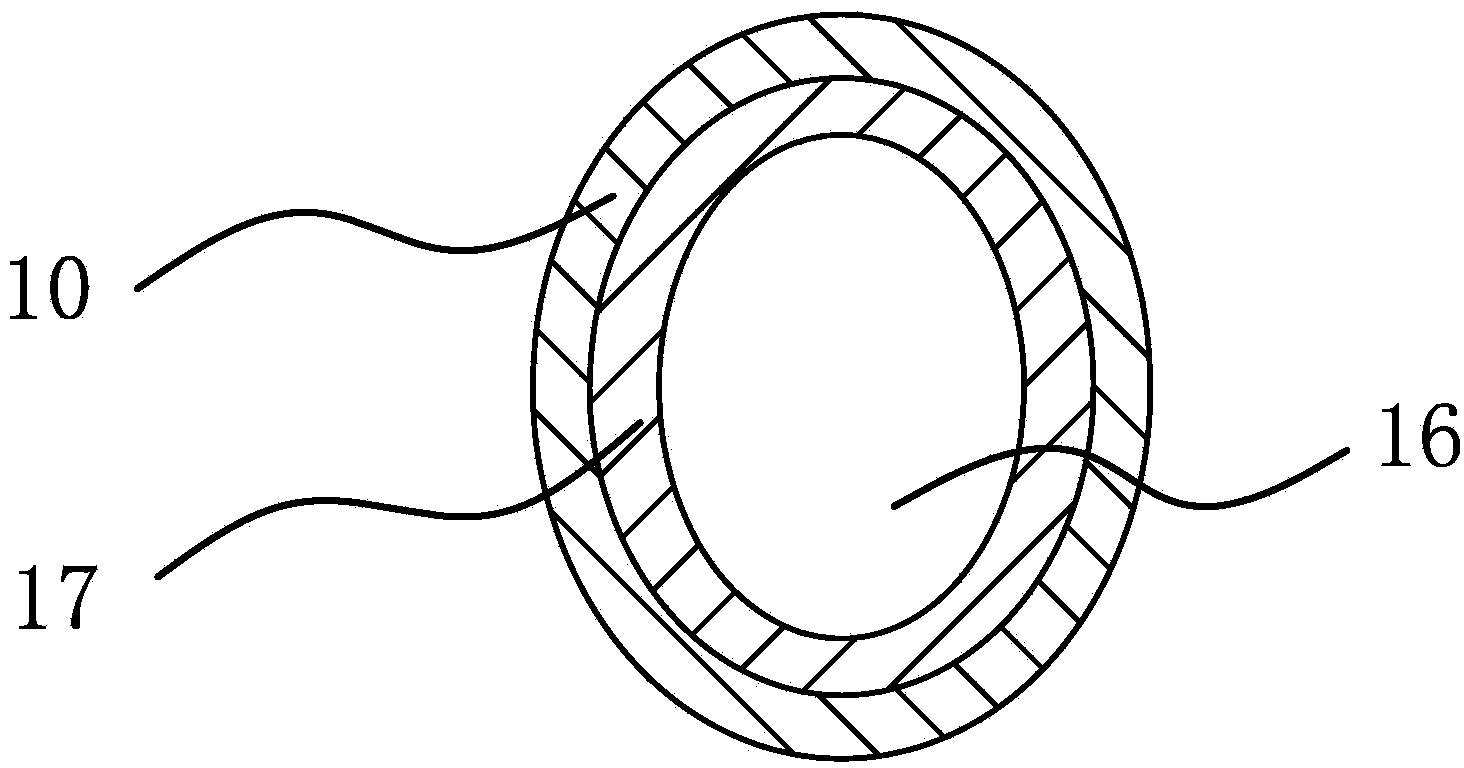

Orifice degaussing device for long-distance pipeline

InactiveCN104842049ADemagnetizationEasy to useMagnetic bodiesWelding accessoriesArc stabilityWelding

The invention discloses an orifice degaussing device for a long-distance pipeline. The orifice degaussing device comprises a cylindrical support, the internal diameter of the cylindrical support is slightly greater than the external diameter of an orifice of a pipeline, so that the cylindrical support can be conveniently sleeved on or taken out from the periphery of the orifice of the pipeline. A cable for welding is spirally winded on the periphery of the cylindrical support, and a joint of the cable is connected with a DC welding machine. The cable spirally winded on the cylindrical support forms 8 to 10 loops without crossover and overlap. The orifice degaussing device for the long-distance pipeline can degauss a welded orifice when the pipeline is welded, magnetic blow can be avoided, the arc stability will not be interfered, and a problem that the orifice cannot be normally welded because strong magnetism at the periphery of a groove attracts a welding wire to generate flutter or adhesion can be solved.

Owner:中石化胜利油建工程有限公司

Sock head sewing device with air power source

The invention provides a sock head sewing device with an air power source, belonging to the technical field of textile machinery. The sock head sewing device solves the technical problem that the surfaces of socks cannot be automatically turned over after the heads of the socks are sewn. The sock head sewing device with the air power source comprises a rack, a sock discharging end is the right end of the rack, the rubber magnetic sheets I and rubber magnetic sheets II are arranged at the bottom ends of the socks, a discharging opening allowing the socks to penetrate through is formed in the bottom of a sock guide barrel, an electromagnet is further fixed to the bottom of the sock guide barrel, an air cylinder is fixed to the right end of the rack, a cylinder body of the air cylinder is fixed on the rack, a telescopic arm is fixedly connected to the lower end of a piston rod, a material storage basket is just under the telescopic arm and is fixed onto the material storage base, and the telescopic arm can be inserted into the material storage barrel and pushes the socks to fall into the material storage basket. The surfaces of the socks can be automatically turned over after the heads of the socks are sewn, accordingly, the production efficiency of socks is high.

Owner:HAINING SUNSHINE SOCKS MFG

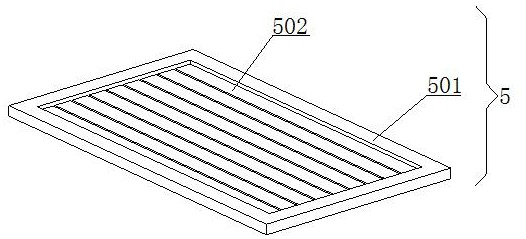

Automatic dried tofu collecting device

The invention relates to the field of dried tofu processing equipment, in particular to an automatic dried tofu collecting device. The automatic dried tofu collecting device comprises a collection box, a transmission mechanism and a containing box located on the upper face of the transmission mechanism. The collection box is located on the upper portion of the containing box, and a movable overturning plate in hinged joint with the collection box is arranged at the bottom of the collection box. The automatic dried tofu collecting device is characterized in that a pressure sensor and a control circuit are arranged on the upper face of the movable overturning plate, and an automatic adjusting part is arranged at the lower end of the movable overturning plate; the automatic adjusting part comprises a supporting frame serving as a supporting point, an adjusting plate located on the upper face of the supporting frame, and a metal balance block; an elastic piece is arranged on the upper face of the metal balance block, and an electromagnet is arranged at the end, located below the metal balance block, of the adjusting plate; and the electromagnet is electrically connected with the pressure sensor and the control circuit. By means of the lever principle, the adjusting plate moves vertically around the supporting frame, and thus the effect of automatically collecting dried tofu is achieved.

Owner:重庆乐嚼食品有限公司

Manufacturing method for remanence-free mold steel

InactiveCN108893583ADemagnetizationMeet the requirements of no residual magnetismRemanenceMetallurgy

The invention discloses a manufacturing method for remanence-free mold steel and relates to the technical field of metallurgy. The method comprises the following steps: performing normalizing thermaltreatment on a rolled steel plate, wherein the heating temperature is 880-900 DEG C, the heating rate is 1-1.5 min / mm and the insulating time is 0.6-1.0 min / mm; setting reasonable heating temperature,heating rate and insulating time of tempering thermal treatment according to different mold steel types; adopting a vacuum chuck or jig for performing all the transporting processes after thermal treatment, and meanwhile performing remanence test on head, middle and tail parts of the steel plate, thereby meeting the magnetic requirement of the steel plate. According to the invention, the thermaltreatment technology for the rolled mold steel is optimized for eliminating the magnetism of the mold steel, and meanwhile, the devices, such as the vacuum sucker and the jig, are equipped in the hoisting and transporting processes, and the requirement for remanence-free performance is met.

Owner:NANJING IRON & STEEL CO LTD

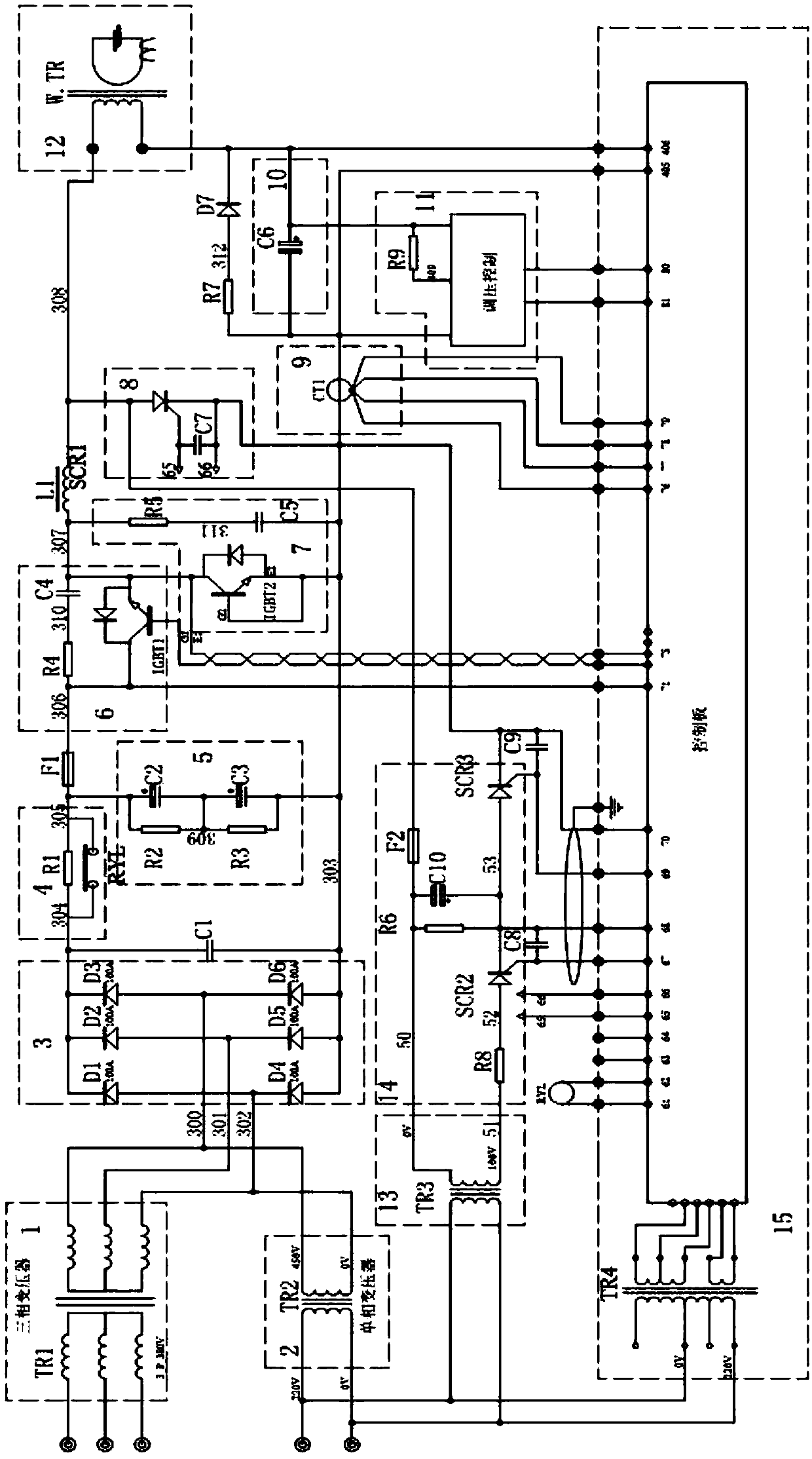

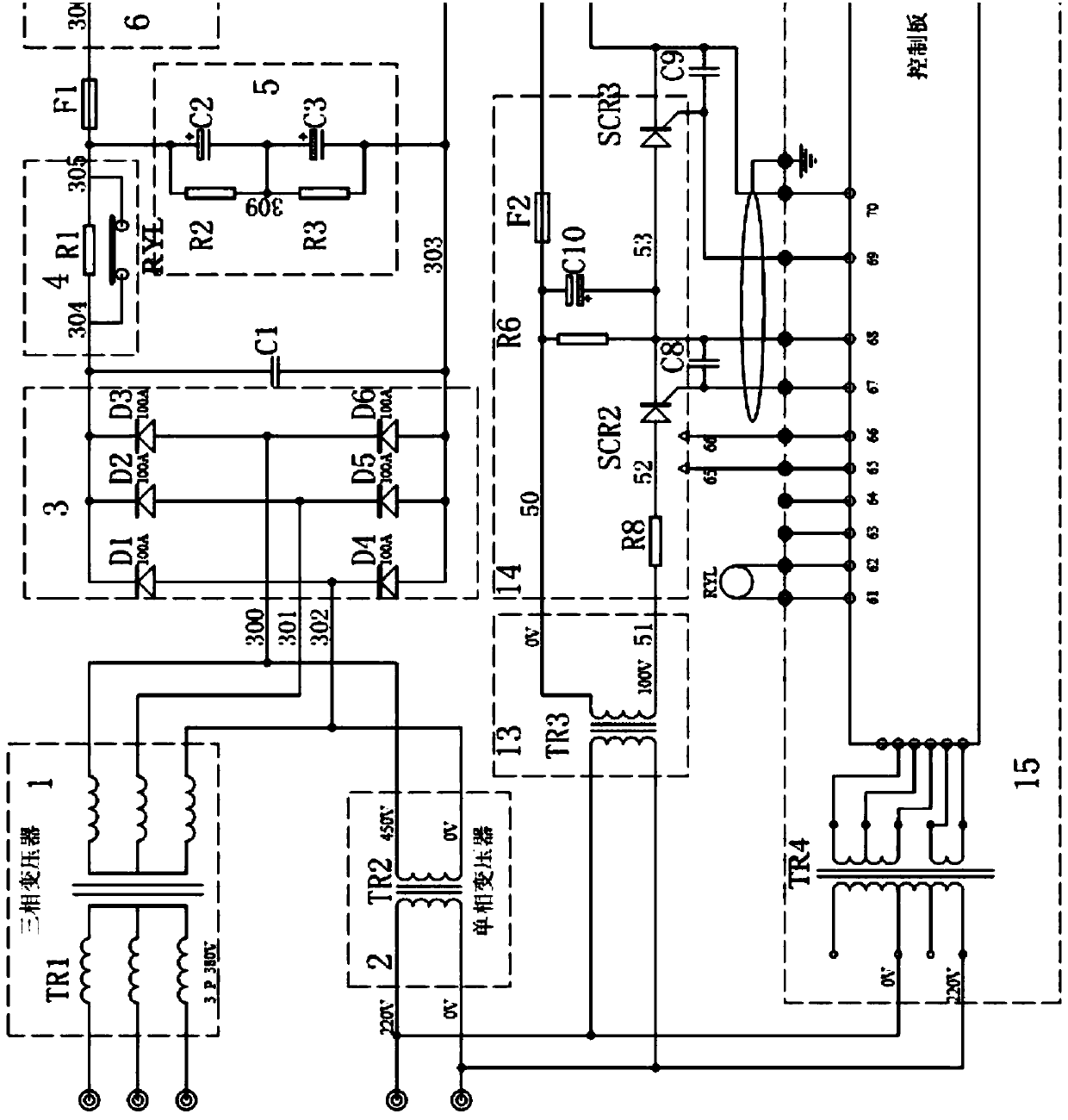

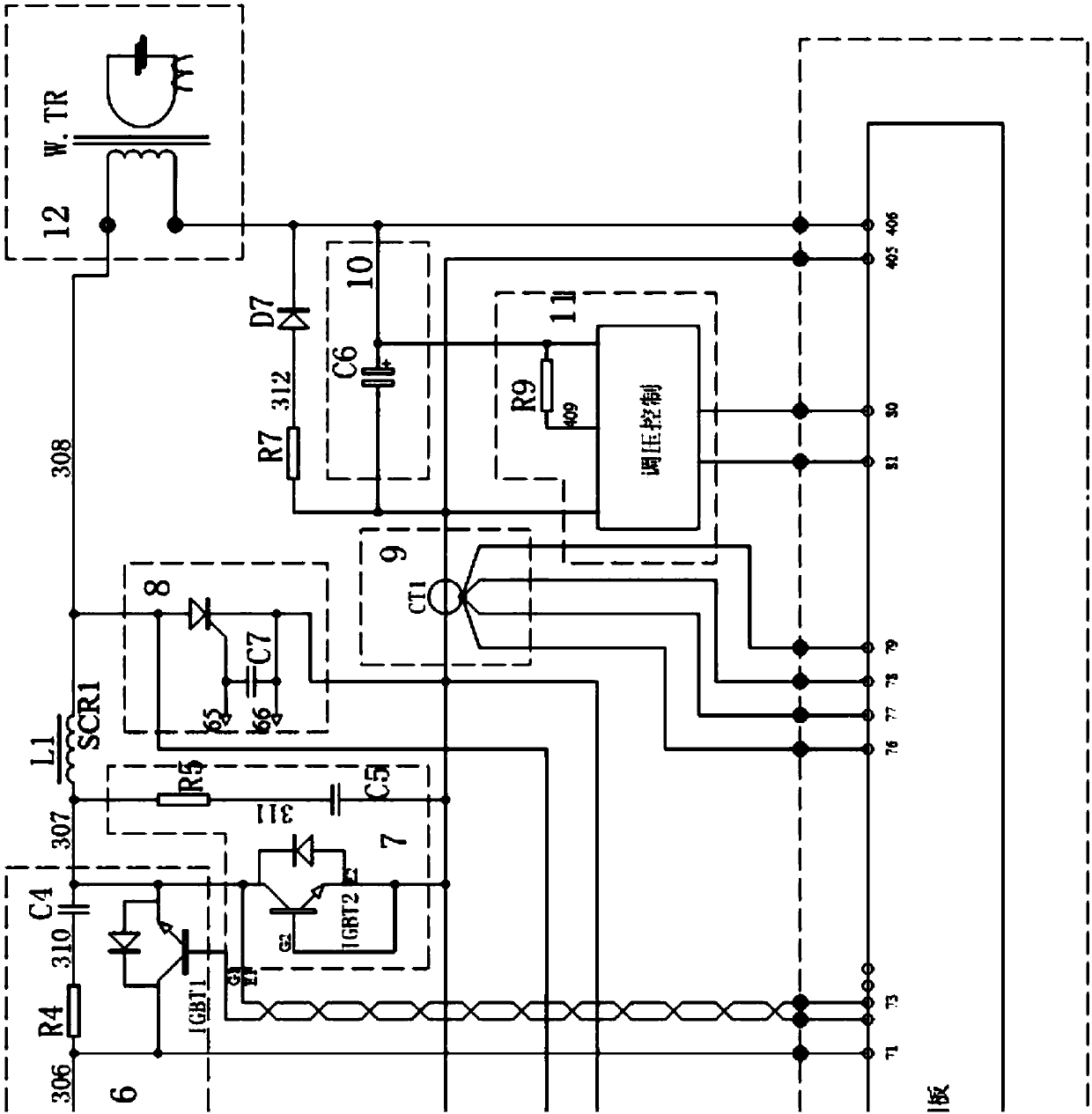

PWM pulse width type constant current charging type capacitor energy storage welding charging control system

ActiveCN107707003ADemagnetizationImprove welding qualityElectric powerBattery load switchingCapacitanceTransformer

The invention relates to the technical field of a welding machine, particularly a PWM pulse width type constant current charging type capacitor energy storage welding charging control system. The charging control system comprises a three-phase charging transformer, a single-phase charging transformer, a rectifying circuit, a DC-LINK filtering circuit, a PWM charging control part, a charging current detection part, a welding transformer, a discharging circuit, a discharging switch-off circuit, a discharging current detection part, a discharging control part and a capacitor bank; no matter the input power supply is in single phase or three phases, the input power supply can be controlled by the same controller; by adoption of the PWM pulse width modulation mode the precision can be improvedby 10 times or more (counted by 1,000HZ) compared with an SCR adjustment mode; by adoption of a hall current sensor, the charging current can be sampled in real time, and then the PWM pulse width is adjusted, thereby realizing constant current control; and charging and discharging are both realized by adopting the welding transformer, and the charging current direction and the discharging currentdirection are opposite, so that magnetization of the transformer can be prevented effectively.

Owner:广州双穗电气设备有限公司

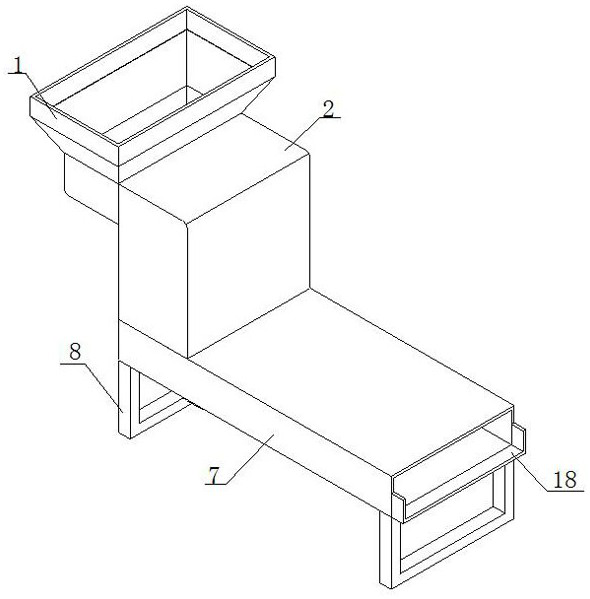

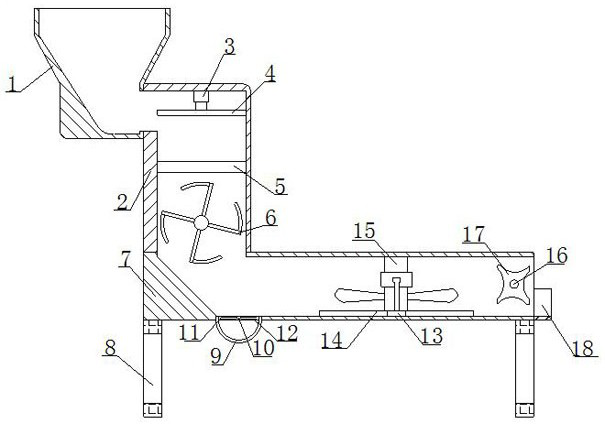

Spinning cotton cleaner capable of adjusting material quantity

InactiveCN112226854AAvoid Metal ResidueControl outputFibre cleaning/opening by toothed membersFibre cleaning/opening machinesAgricultural engineeringMaterial storage

The invention discloses a spinning cotton cleaner capable of adjusting the material quantity, and belongs to the technical field of spinning. The spinning cotton cleaner capable of adjusting the material quantity comprises a feeding bin, a material storage box and an operation case, wherein the outer wall of the feeding bin is fixedly connected with the outer wall of the material storage box; a telescopic column is arranged in the material storage box; one end of the telescopic column is fixedly connected with the inner wall of the material storage box; a squeezing plate is fixedly installed at the other end of the telescopic column; a discharging device is arranged at the bottom of the squeezing plate; the outer wall of the discharging device is fixedly connected with the inner wall of the material storage box; and a material conveying wheel is movably installed on the inner wall of the material storage box. The discharging amount and the discharging speed of cotton can be controlledthrough the rotating opening and closing degree of rotating blades; cotton feeding can be controlled according to the actual situation; the cotton feeding speed can be further controlled through the material conveying wheel, and the cotton is opened; and the squeezing plate squeezes the cotton to increase the discharging amount of the cotton in the material storage box, so that the cotton is prevented from remaining on the discharging device.

Owner:浙江申久金属制品有限公司

Square tube cutting machine

ActiveCN105057761AAvoid bendingAvoid driveFeeding apparatusTube shearing machinesEngineeringUniversal joint

The invention discloses a square tube cutting machine. The square tube cutting machine comprises a worktable. The worktable is provided with a drive device, a double-cross universal joint and a shearing device. The drive device is connected with the shearing device through the double-cross universal joint. The drive device comprises a supporting block and a motor located on the supporting block, and the supporting block is arranged on the worktable in a sliding mode. The shearing device comprises a shearing piece, a rotary shaft and a lifting component, the rotary shaft is located in the center of the shearing piece, and the lifting component is located at the upper end of the shearing piece and connected with the rotary shaft. The lifting component comprises a shell, an iron plate is arranged in the shell and matched with the inner wall of the shell, and two connection columns are arranged between the lower surface of the iron plate and the rotary shaft. The two connection columns are located on the two sides of the shearing piece respectively and connected with the iron plate and the rotary shaft. A spring is disposed between the upper surface of the iron plate and the upper wall of the shell. An electromagnetic block is arranged on the upper wall of the shell and connected with an electric control box through a circuit. Square tubes are prevented from being bent after being cut off, cost is reduced, and work efficiency is improved.

Owner:CHENGDU MATSUKAWA METAL MATERIALS

Asbestos ore tailings treatment device

ActiveCN111437962AOvercome expensiveIncrease valueMagnetic separationGrain treatmentsFiberMining engineering

The invention relates to the field of ore, in particular to an asbestos ore tailings treatment device. The technical aim of the asbestos ore tailings treatment device is that the asbestos ore tailingstreatment device is provided. The asbestos ore tailings treatment device comprises a tailings refinement device, a temporary storage transfer tank, an air cylinder, a block-powder separation device,a special magnetic separation device and a miscellaneous material collection box; the tailings refinement device is arranged on the right side of the top of a top plate; and the right side of the bottom of the top plate is connected with the block-powder separation device. The use of the own weight of tailings to press the bottom ore to frictionally break the ore is achieved, the probability of long asbestos fibers being destroyed into short asbestos fibers is reduced, and the value of recycling asbestos fibers is improved; and a bowl-shaped separating plate is used for intercepting unbroken tailings and high-value long asbestos fibers, the fibers are collected, and the unbroken ore is crushed again to increase the utilization rate of tailings; after magnetic separation, heating and impactare used for eliminating the magnetite magnetism and improving the effect of mineral collection.

Owner:马立刚 +1

Forming and detecting integrated equipment used for high-end equipment manufacturing

ActiveCN113500179ASize effectPrevent splashEdge grinding machinesUsing optical meansCompression moldingMetallic materials

The invention discloses forming and detecting integrated equipment used for high-end equipment manufacturing, and relates to the technical field of equipment manufacturing. The forming and detecting integrated equipment used for high-end equipment manufacturing specifically comprises an operation bottom plate and an upper mold assembly, wherein a lower mold assembly is arranged at the left side of the surface of the operation bottom plate, sliding push rods are arranged in a sliding rail, the upper mold assembly is arranged at the bottom of a driving motor, the bottom of a mold cover is connected with a cavity bottom mold plate, a side mold plate is fixed to the outer side of a spring rod, the top of the mold cover is connected with a water supply pipe, and laser contour projection equipment is arranged at the middle portion of the operation bottom plate. According to the forming and detecting integrated equipment used for high-end equipment manufacturing, burrs on the side faces of the edges of a metal material are polished and eliminated after injection molding and compression molding of the metal material, the polishing degree is limited, thus the burrs are completely eliminated, meanwhile, the situation that the size of a shell is affected by excessive polishing is avoided, and metal scraps generated by polishing are magnetically adsorbed and collected so that the scraps can be prevented from sputtering, and meanwhile, the scraps can be conveniently recycled in the later period.

Owner:管艳芳

Automatic iron nail and scrap iron dispersing and collecting device used after iron nail polishing

The invention discloses an automatic iron nail and scrap iron dispersing and collecting device used after iron nail polishing. The device comprises a machine body, wherein a feeding port is formed in the top end of the machine body, a controller is arranged on the side wall of the machine body, an inspection window is formed in the front face of the machine body, an iron nail discharging box and an scrap iron discharging box are arranged at the bottom end of the machine body; the controller is connected with a generator arranged on the inner wall of the machine body, a bidirectional moving rod is arranged at the bottom end of the generator, and a pushing rod matched with the bidirectional moving rod is arranged on the bidirectional moving rod. The device has the beneficial effects that the iron nail polishing process is completed through the electromagnetic induction technology and several separation devices, iron nail and scrap iron mixture is separated, iron nails and scrap iron are still attracted together through static electricity after separation, the magnetism between the iron nails and the scrap iron is eliminated through heating of the electromagnetic induction technology, then better separation is carried out, the flow of the iron nails and the scrap iron can be controlled in the separation process, the automation degree is high, and the better separation effect is achieved.

Owner:况雨晴

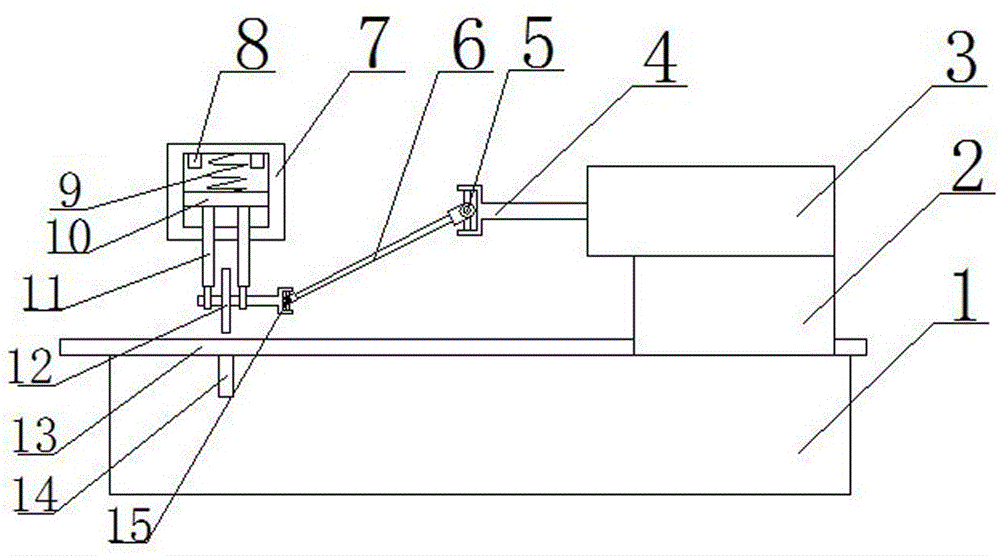

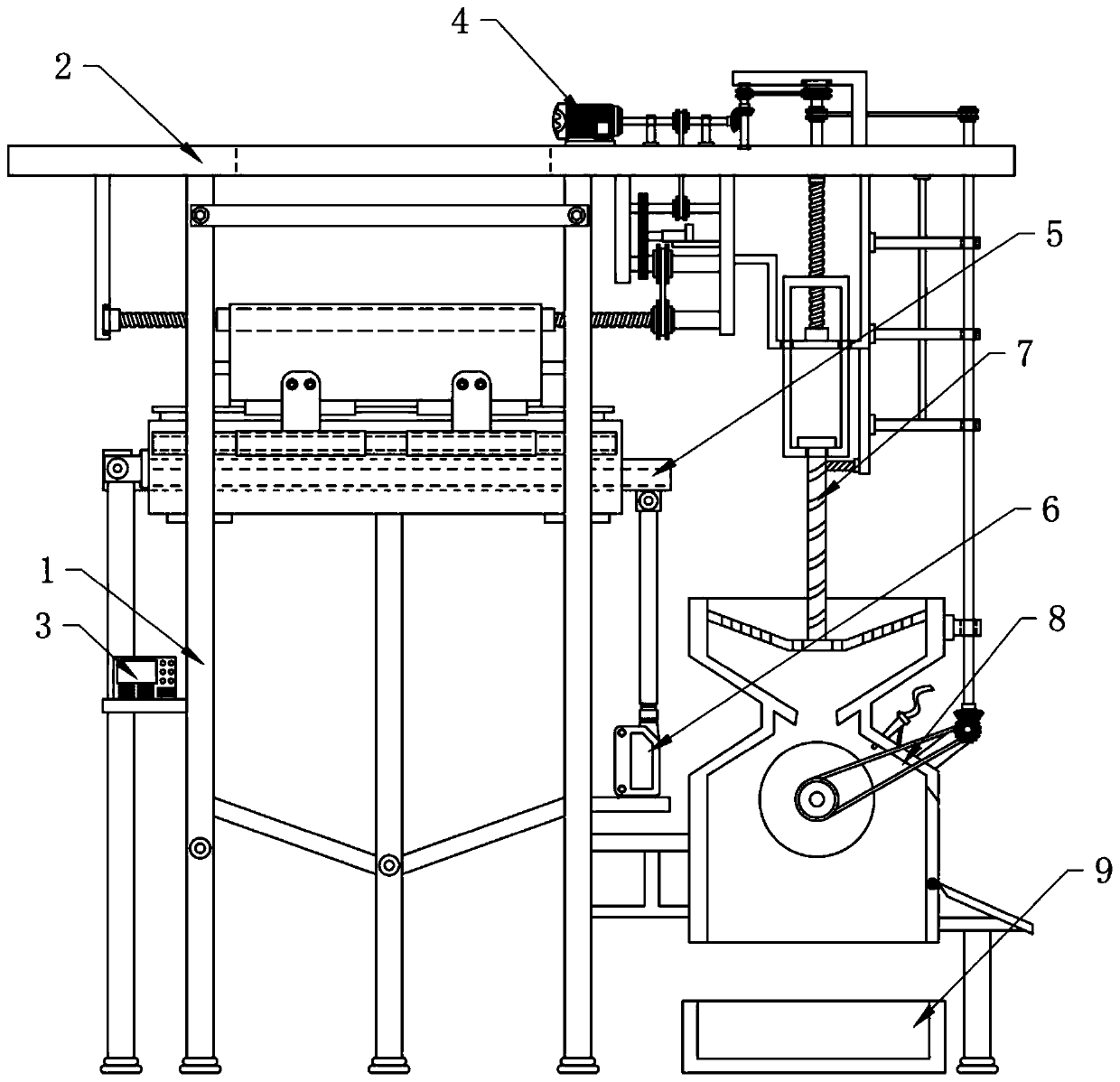

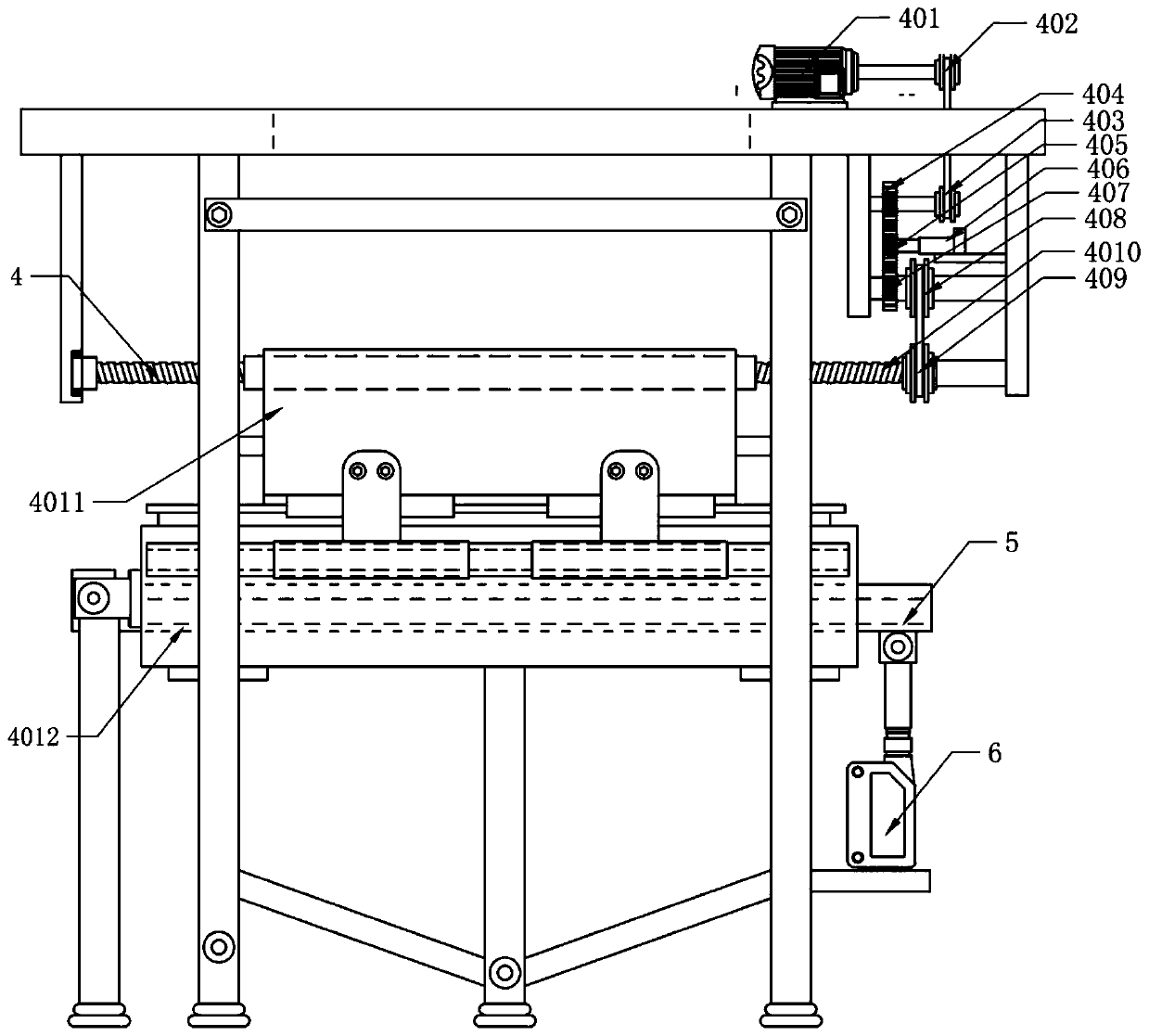

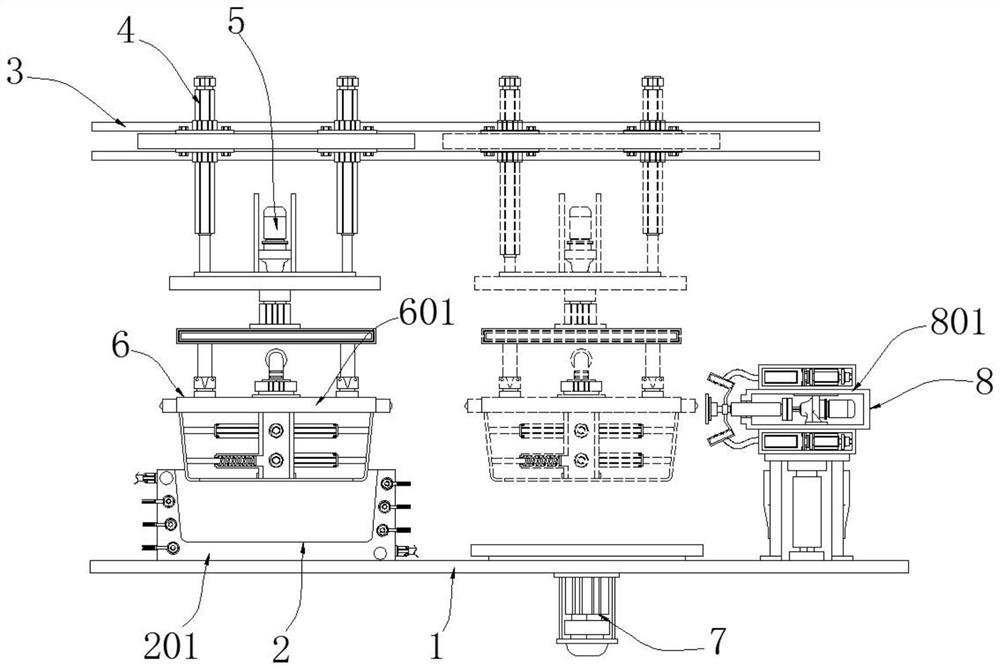

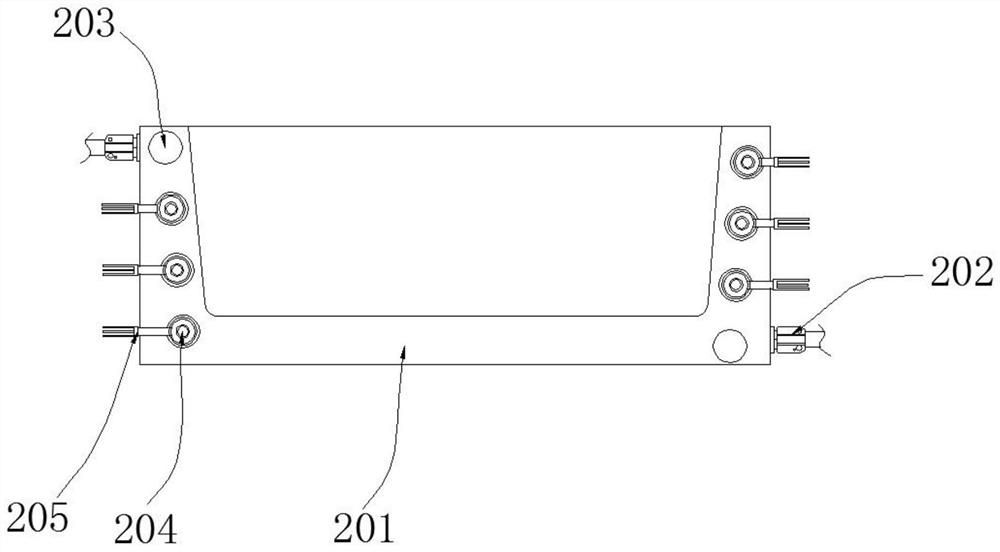

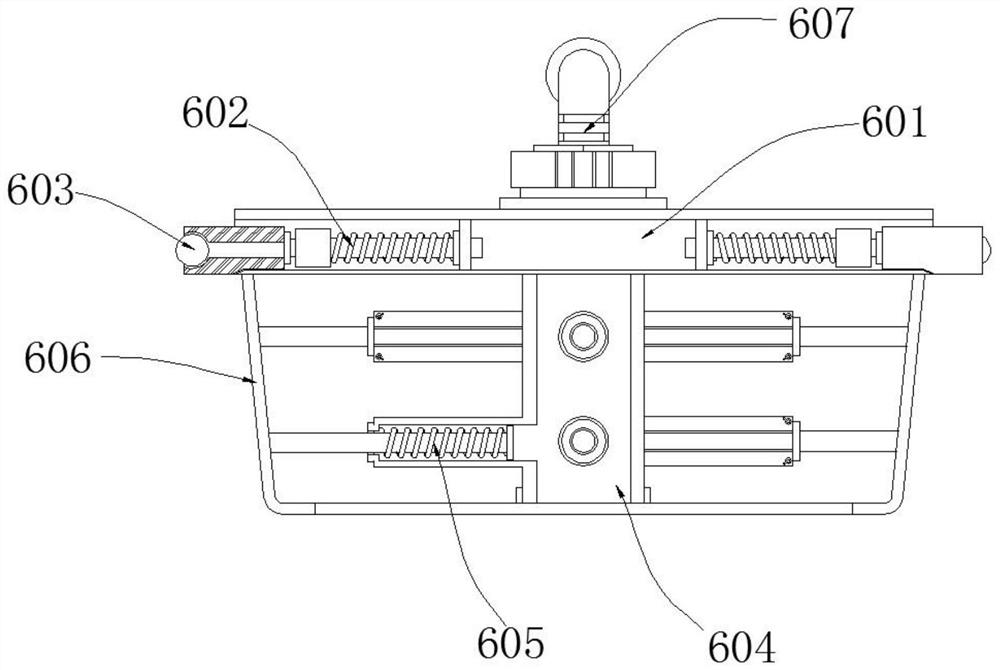

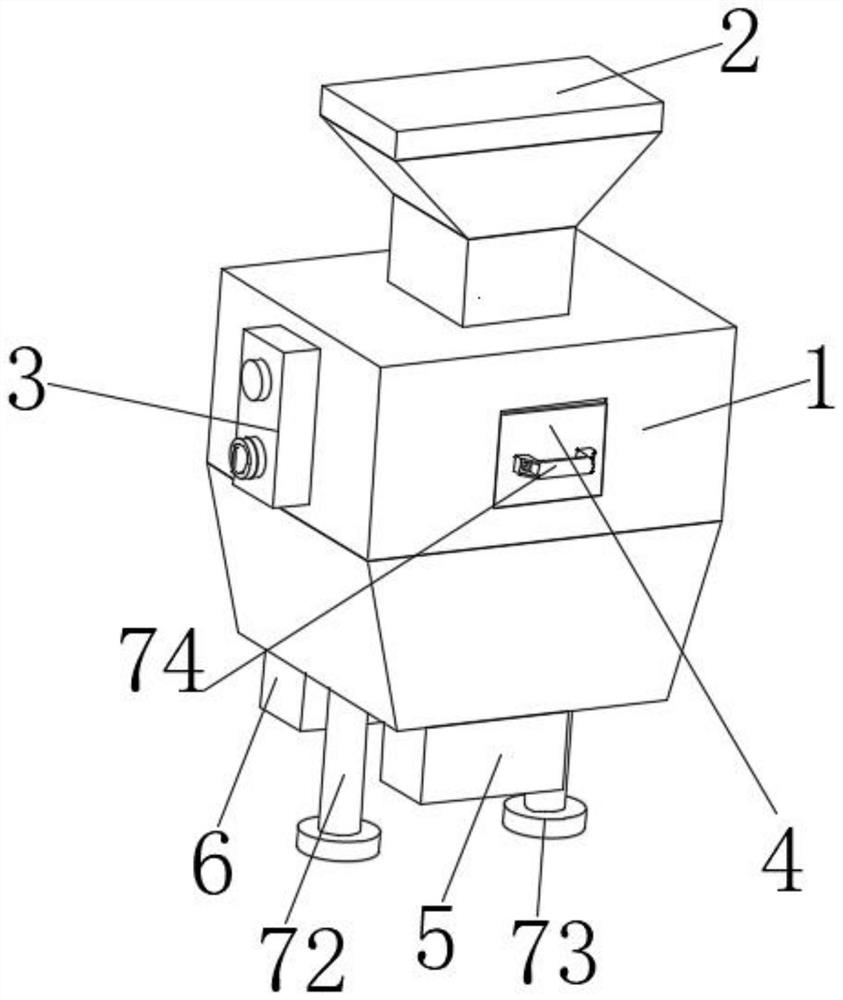

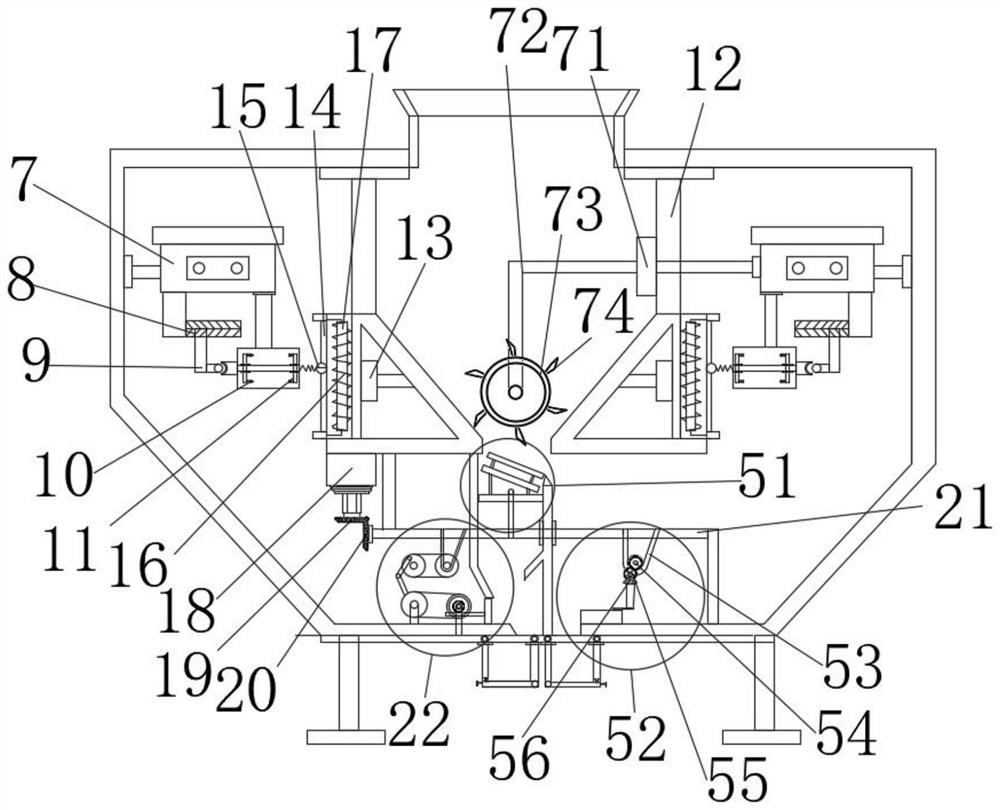

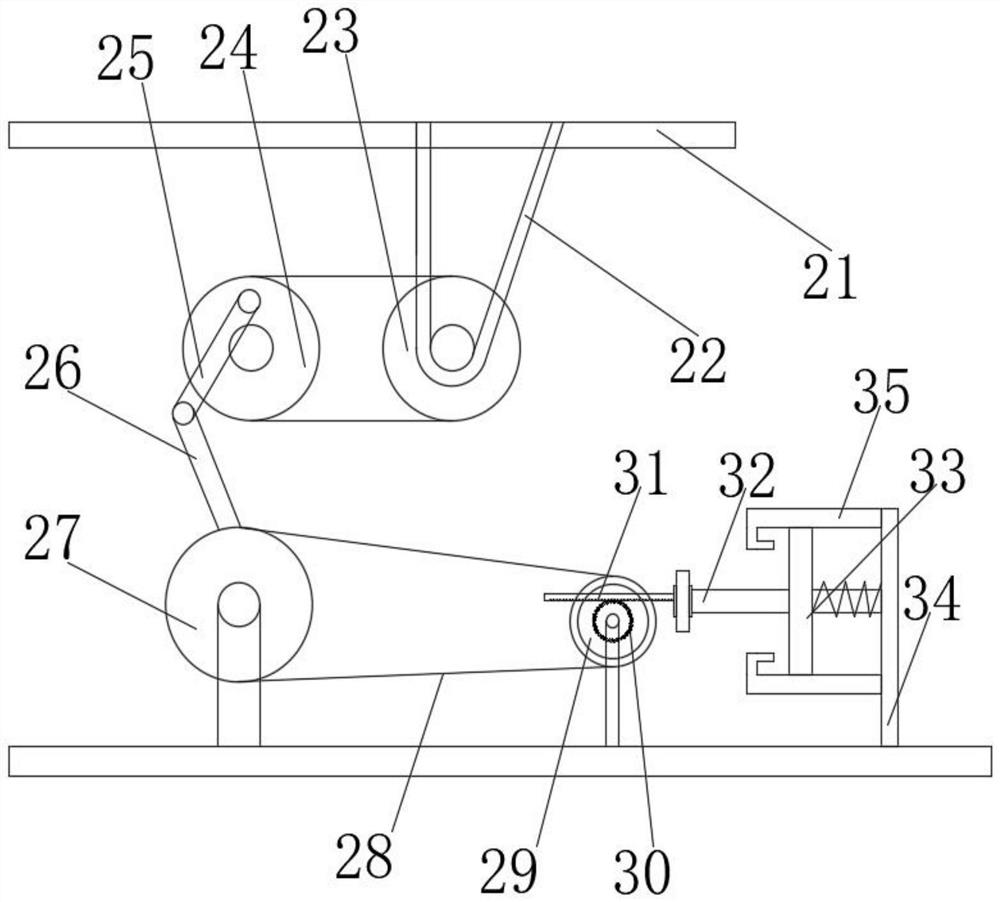

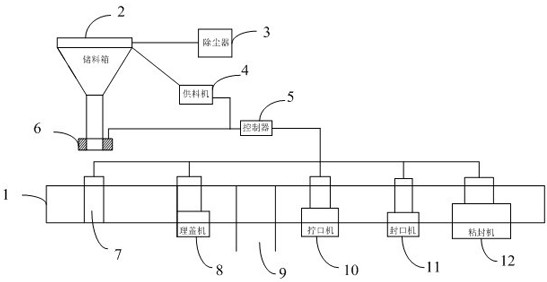

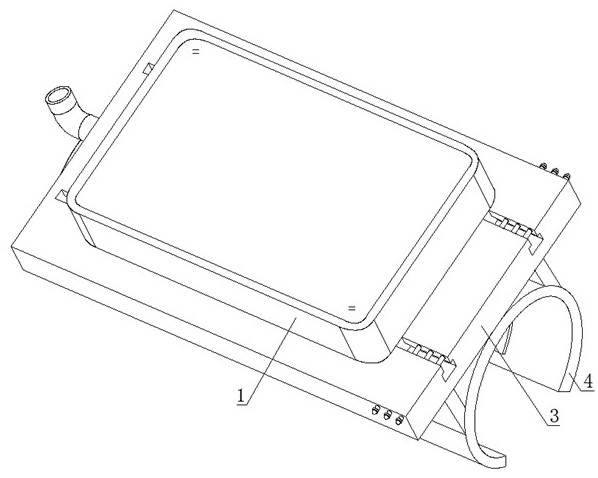

A special packaging line for laser printer toner

ActiveCN104423209BNo pollutionDemagnetizationElectrographic process apparatusComputer printingProcess engineering

The invention discloses a special packaging line for laser printer toner, comprising: a storage box, the storage box includes a powder inlet and a powder outlet; a feeder for feeding materials into the storage box machine, the discharge port of the feeder is connected to the powder inlet of the storage box; the electromagnetic anti-drip device arranged at the powder outlet of the storage box; the assembly line workbench, the assembly line workbench A positioning system for positioning the toner bottle is arranged on the top; a controller is used for controlling the power-on or power-off of the electromagnetic anti-drip device. The electromagnetic anti-drip device of the present invention utilizes the principle of electromagnetic induction to prevent the raw materials from the powder outlet from leaking, which will not cause waste and environmental pollution. The electromagnetic anti-drip device is suitable for the packaging of most magnetic powder objects.

Owner:保定莱盛办公设备有限公司

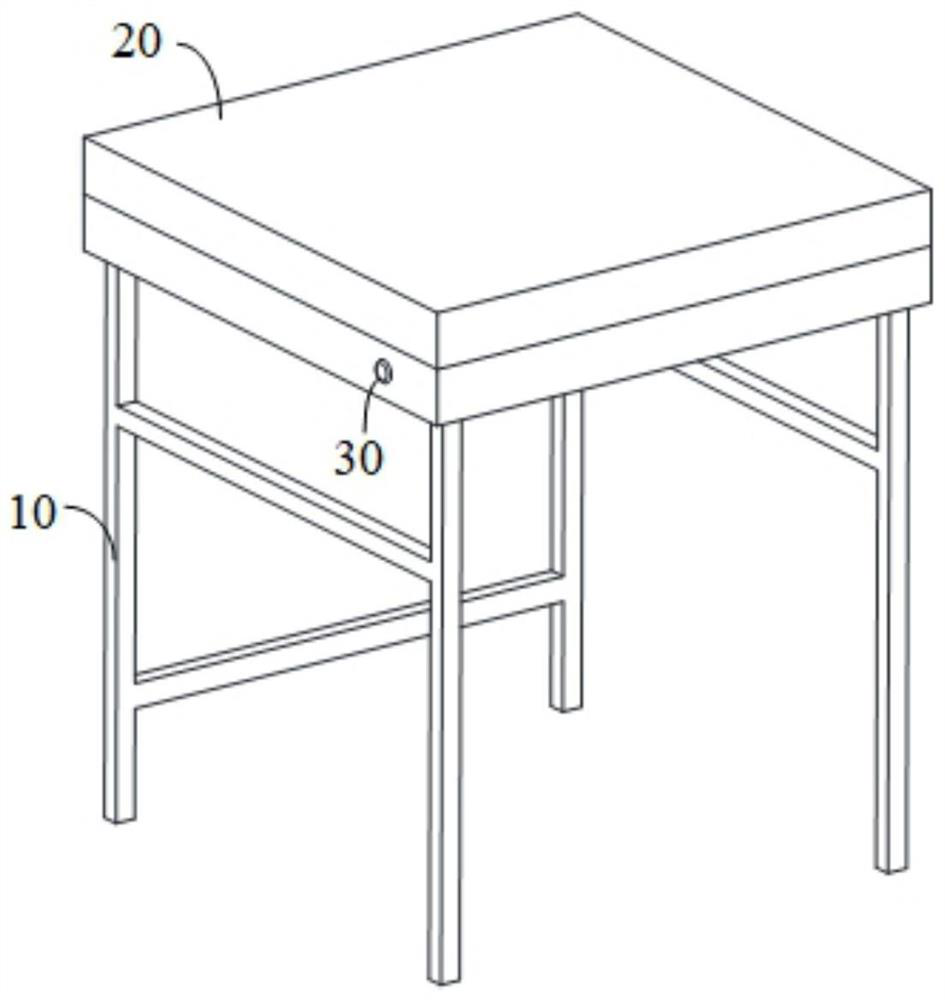

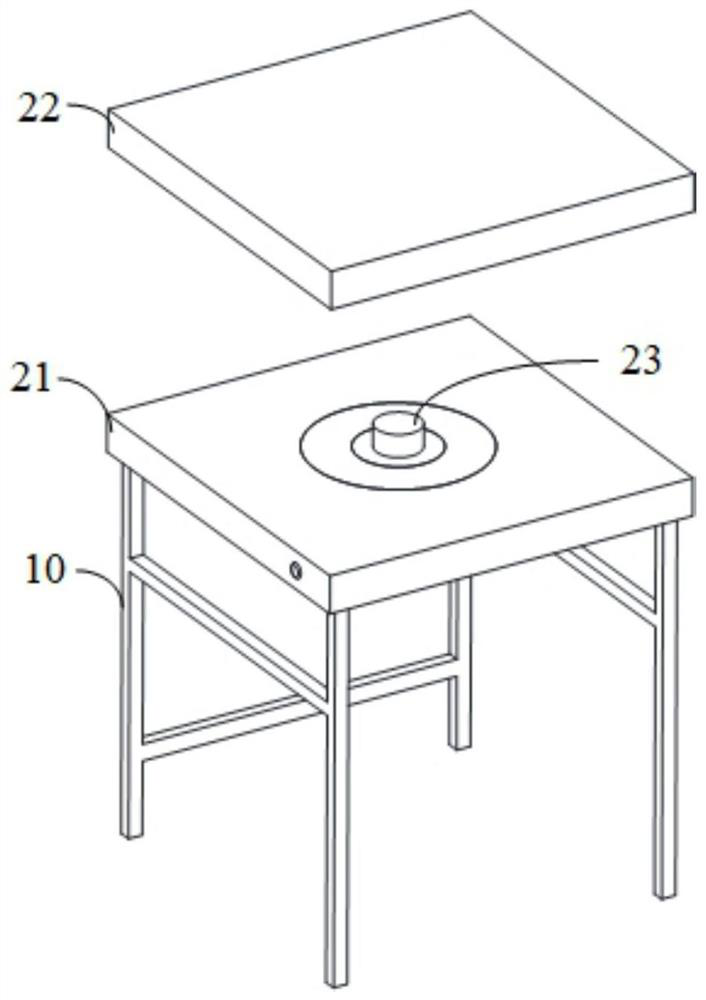

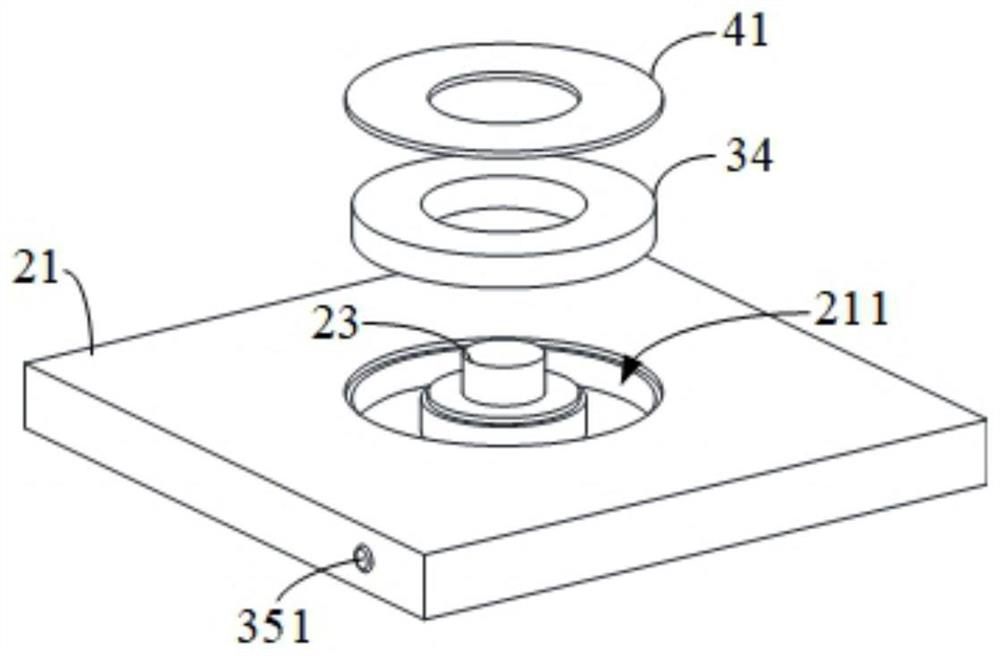

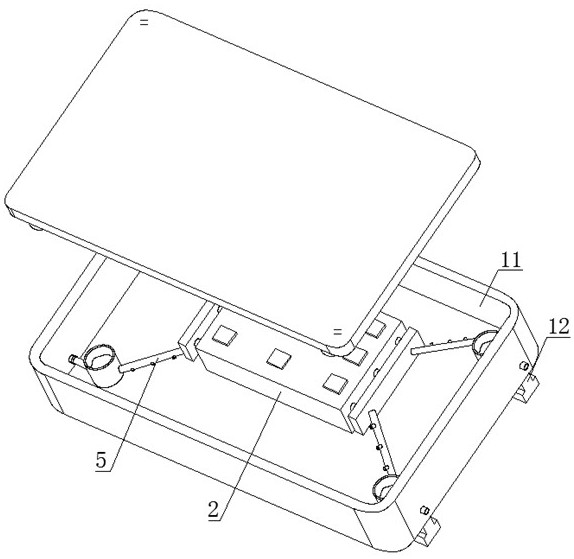

interior design drafting workbench

ActiveCN112716147BEasy to drawUnlock rotation restrictionsDrawing boardsDrawing desksHemt circuitsInterior design

The invention discloses an indoor design drawing workbench, which includes a support, a drawing board and a limiting device, wherein the drawing board includes a base plate and a panel, the base plate is arranged on the support, the panel and the base plate are stacked, and the panel and the base plate are rotatably connected; The device includes a first electromagnet, a first circuit, a normally closed circuit breaker, a first magnetic part and a controller, wherein the first electromagnet and the first circuit are arranged on the substrate, and the first electromagnet is connected to the first circuit; The normally closed circuit breaker is connected to the first circuit to conduct the first circuit; the first magnetic part is arranged on the panel and opposite to the first electromagnet; the controller is electrically connected to the normally closed circuit breaker, and the controller is used to control Opening and closing of normally closed circuit breakers. The indoor design drawing workbench of the technical solution of the present invention has the advantage of being convenient for users to use.

Owner:HENAN POLYTECHNIC INST

Multi-index physical fitness integration evaluation device and method based on Internet

PendingCN114281153AImprove efficiencyEasy to useTechnology managementDigital processing power distributionControl engineeringThe Internet

The invention discloses a multi-index physical fitness integration evaluation device and method based on the Internet, belongs to the technical field of physical fitness evaluation, and aims at solving the problems that in the existing integration evaluation process, efficiency is low, and heat generated by the whole is difficult to dissipate. Through the auxiliary receiving mechanism, the external connection mechanism, the internal connection mechanism and the processing module, the auxiliary receiving mechanism is connected with the external connection mechanism, the main shell is connected with the internal connection mechanism, and the electronic element is connected with the processing module; to-be-queried target information is input through the information manual input module, the result is displayed through the information display module, intelligent voice query can be carried out through the intelligent question and answer module, the result is broadcasted through the voice broadcast module, the efficiency of the whole evaluation process is improved, and the user experience is improved. And meanwhile, personal query can be carried out according to the information manual input module and the intelligent question and answer module, so that later use is facilitated.

Owner:奥美医健(北京)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com