Multifunctional nut chip removal machine

A multifunctional, nut-to-nut technology, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as heavy workload, low cleaning efficiency, and poor use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

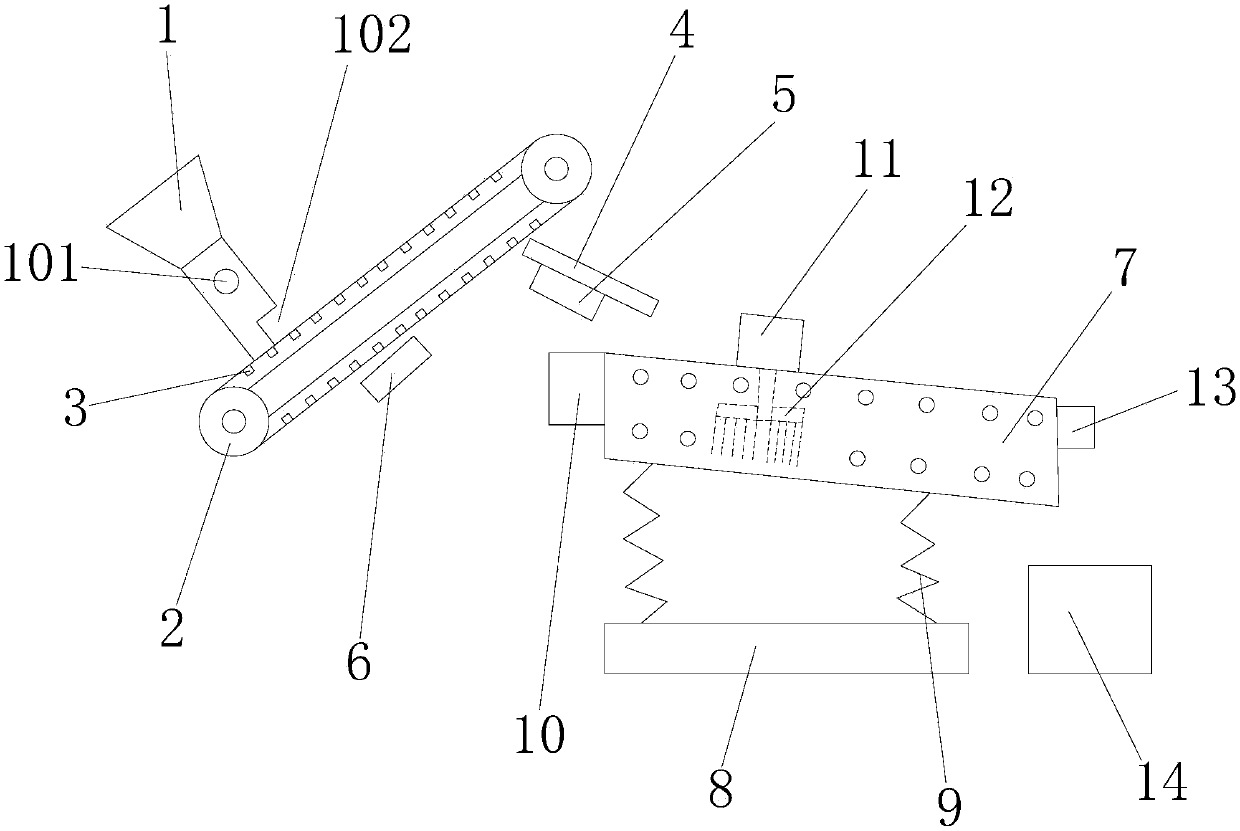

[0017] refer to figure 1 , a multifunctional nut chip removal machine of the present invention, comprising a lower hopper 1, a conveyor belt 2, a first magnet block 3, a scraper 4, a degausser 5, a second magnet block 6, a material sieve 7, a base 8, and a spring 9 , a vibrator 10, a motor 11, a hair brush 12, a blower 13 and a material receiving box 14, a conveyor belt 2 with an upturned output end is provided below the lower hopper 1, and the outlet end of the lower hopper 1 is located at the input of the conveyor belt 2 Directly above the end, the belt surface of the conveyor belt 2 is embedded with a number of equidistantly distributed first magnet blocks 3, and the output end of the conveyor belt 2 is provided with a scraper 4 arranged obliquely, and the scraper 4 The bottom is fixed with a degausser 5, the bottom of the conveyor belt 2 is located at the downstream of the scraper 4, and a second magnet block 6 is provided, and the lower end of the scraper 4 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com