Patents

Literature

90results about How to "Will not cause scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

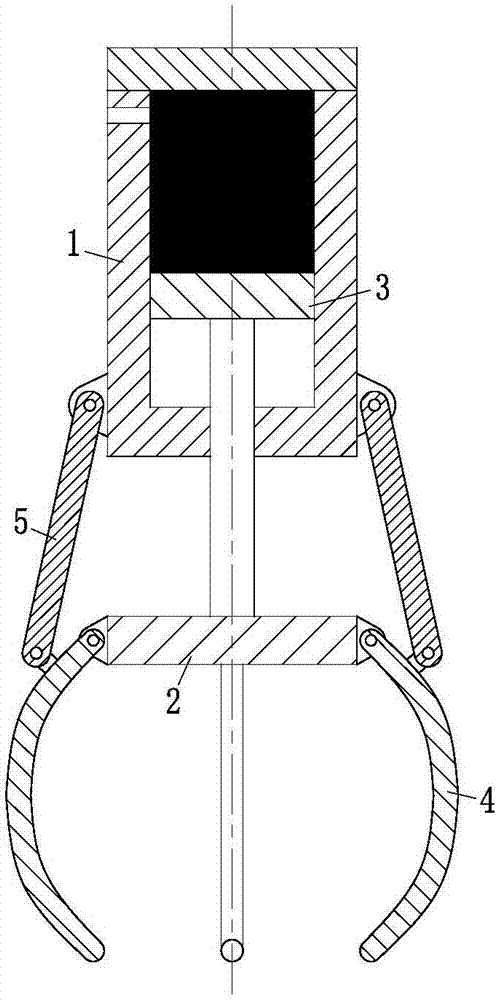

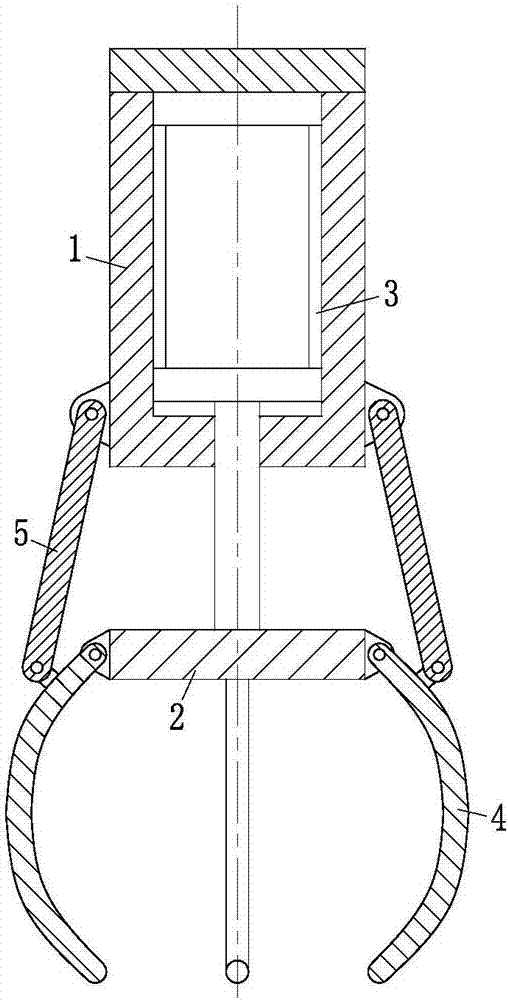

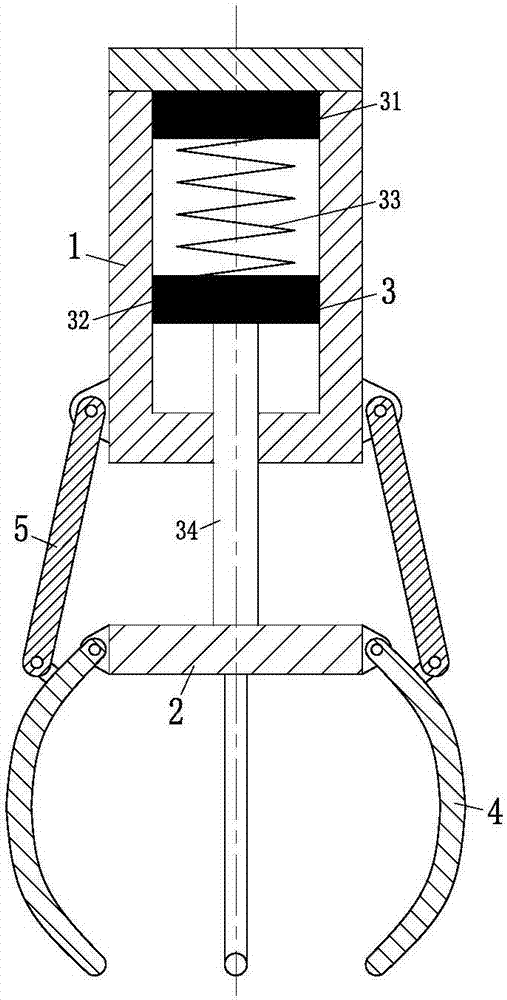

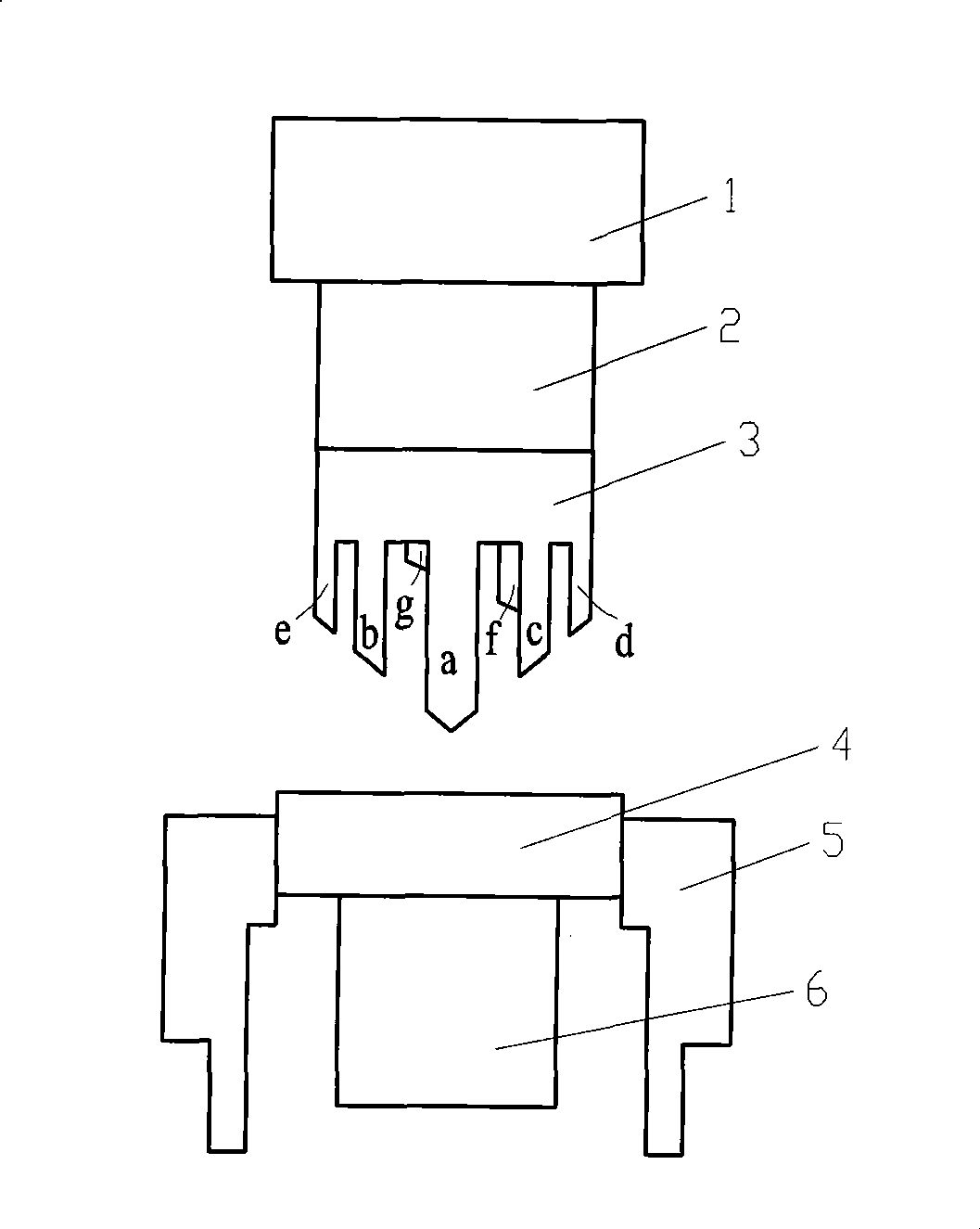

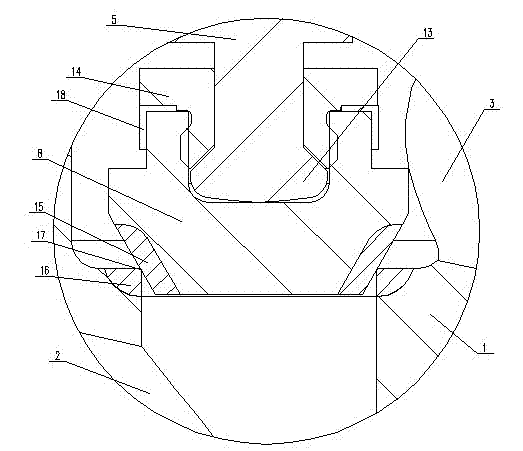

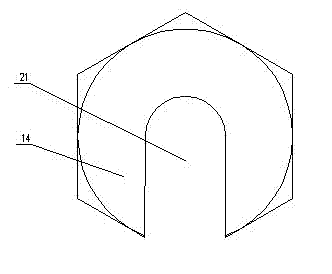

Three-claw manipulator for doll catcher

InactiveCN106861178ARealize clamping workAdapt to a wide rangeIndoor gamesGripping headsHydraulic cylinderEngineering

The invention relates to the field of toys for children, in particular to a three-claw manipulator for a doll catcher. The manipulator comprises a cylinder and further comprises a bottom plate, a pushing mechanism, clamping claws and connection rods. The pushing mechanism can be a micro hydraulic cylinder or a micro pneumatic cylinder or a pen type electric push rod or an electromagnetic element. The clamping claws can be rigid elastic clamping claws or air bag type elastic clamping claws. A layer of foaming cotton can be wound around each clamping claw, each clamping claw can be wrapped by a layer of pure cotton soft cloth, and clamping electromagnets can be installed on the clamping claws. The clamping claws can be various combinations of rigid clamping claws, elastic clamping claws and electromagnetic clamping claws. The three-claw manipulator for the doll catcher can be suitable for clamping toys made from one of or various materials such as common stuffing, hard plastic, soft plastic, wood and iron, and can greatly enrich the varieties of toys in the doll catcher.

Owner:张新

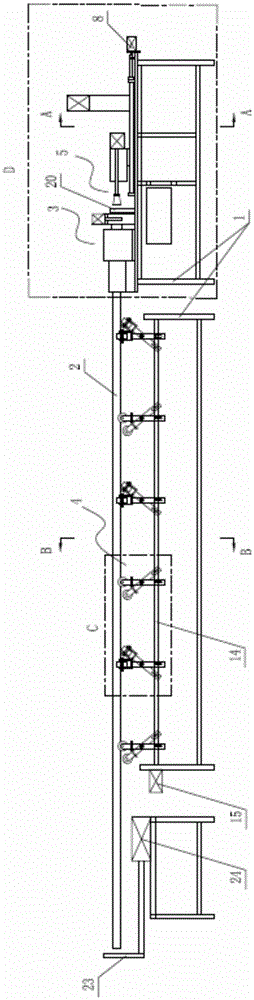

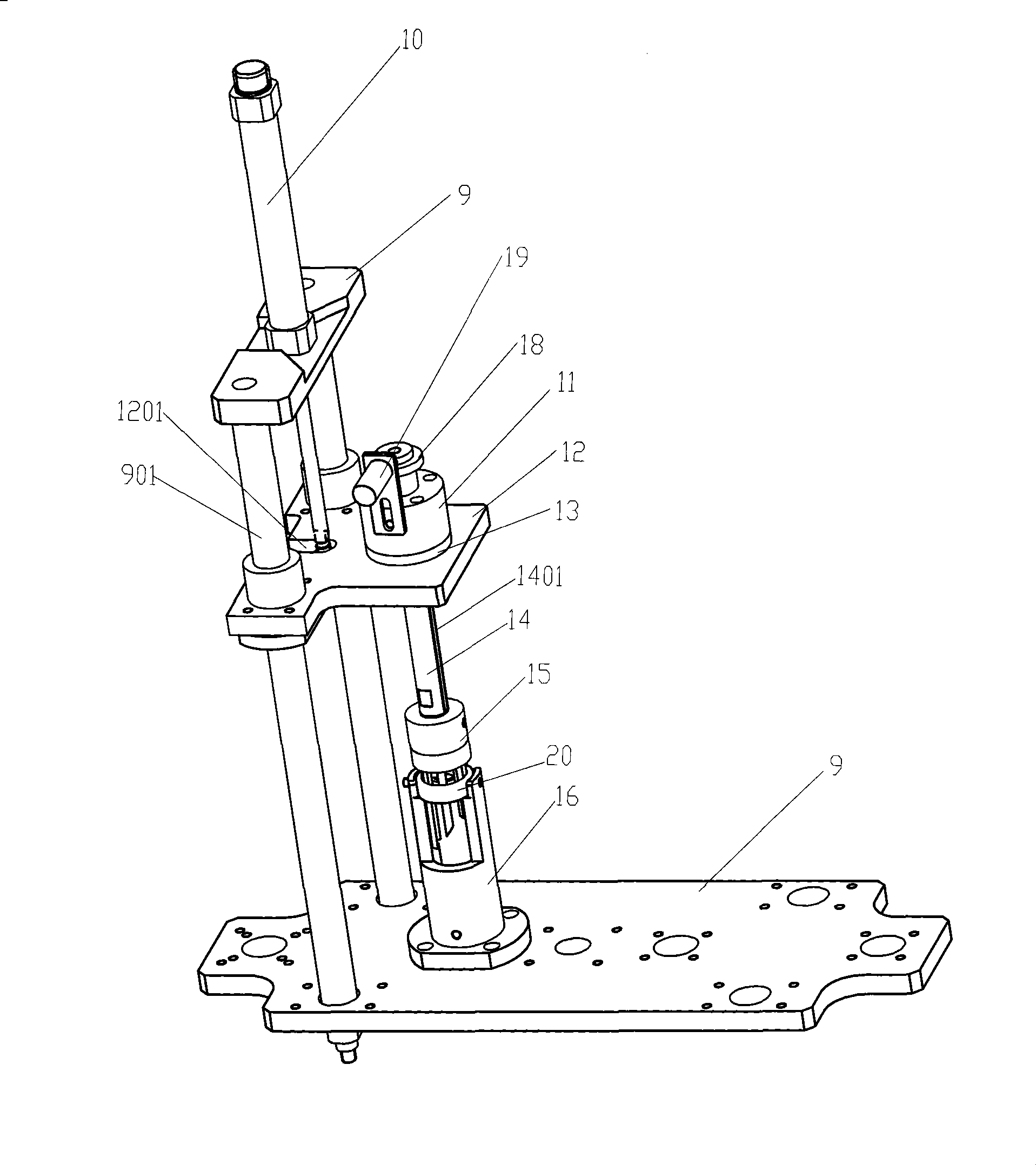

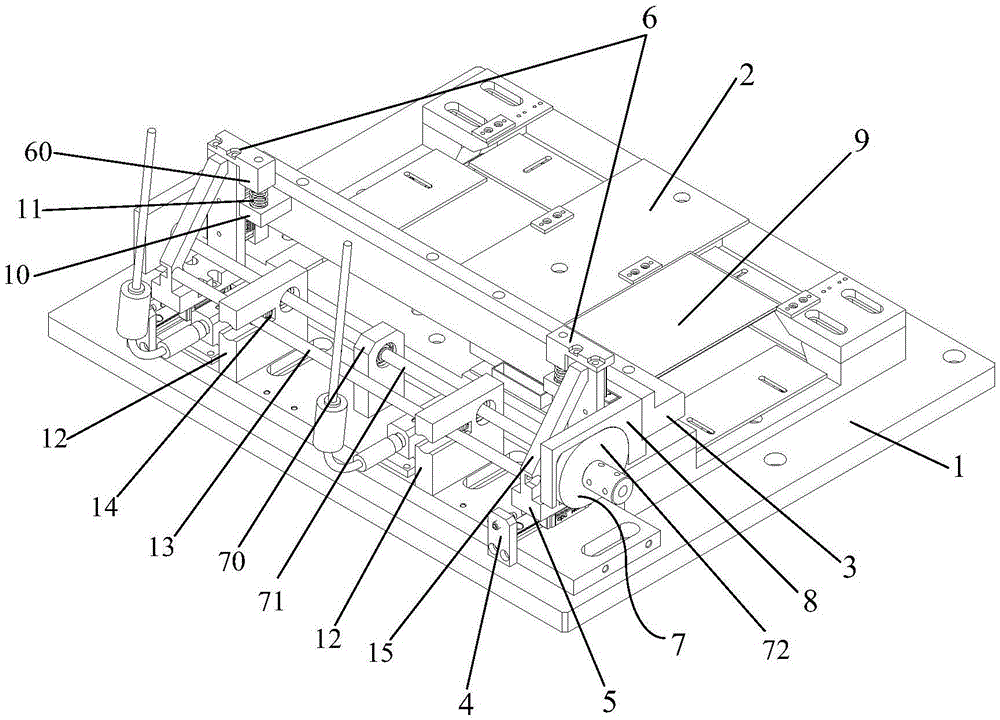

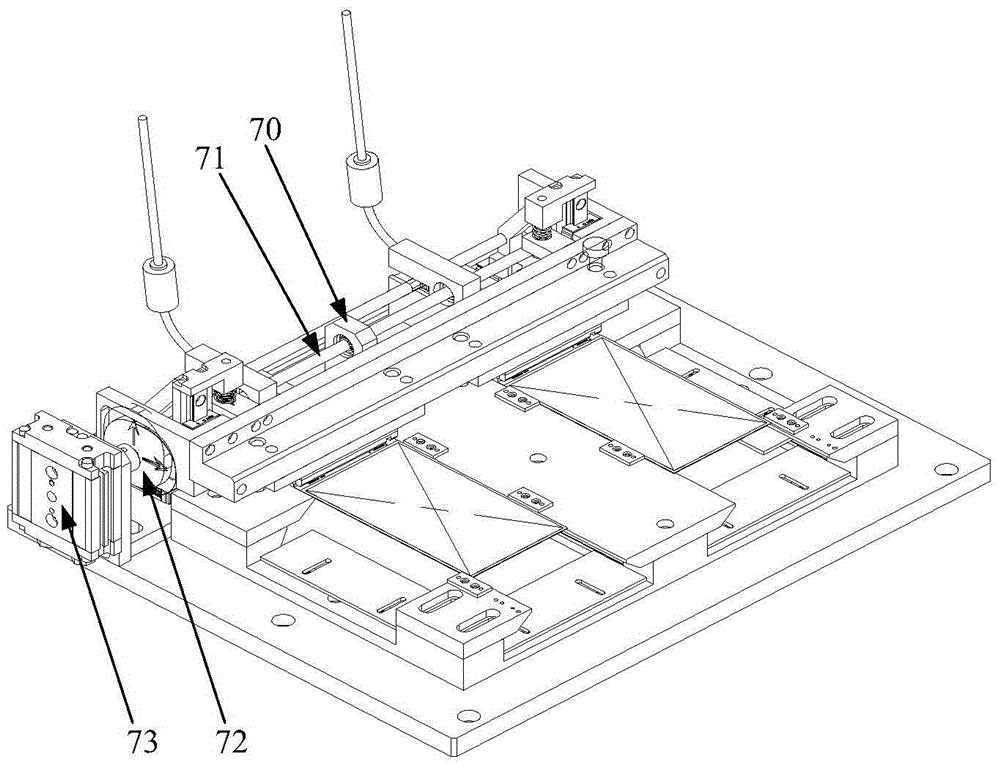

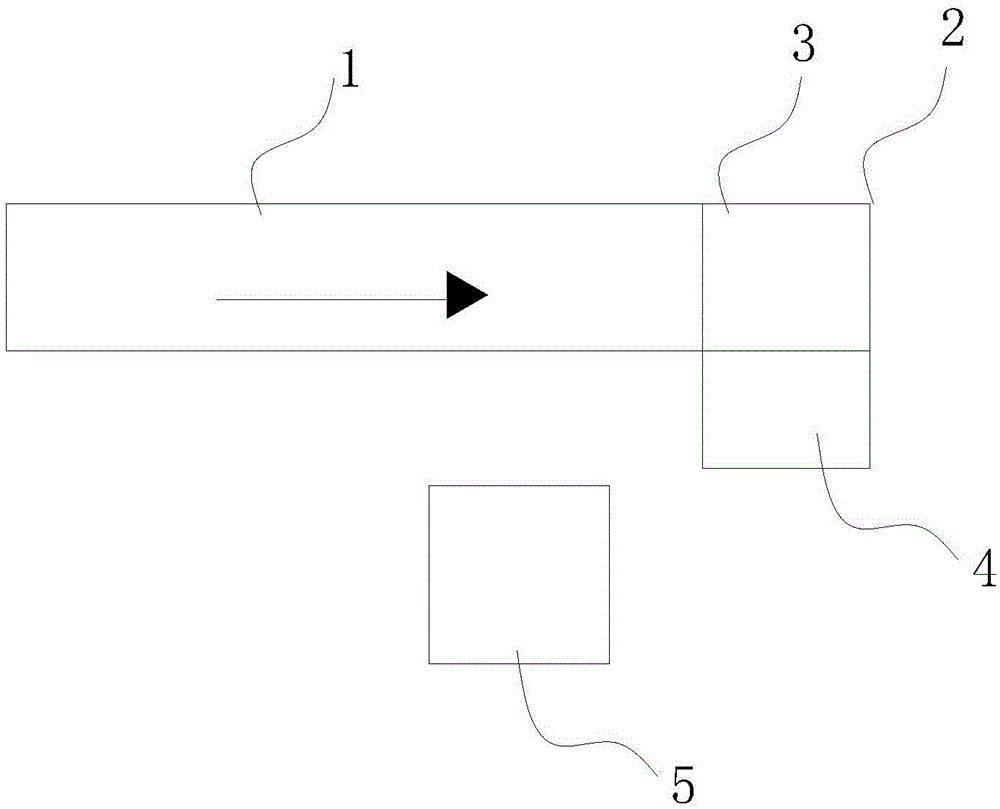

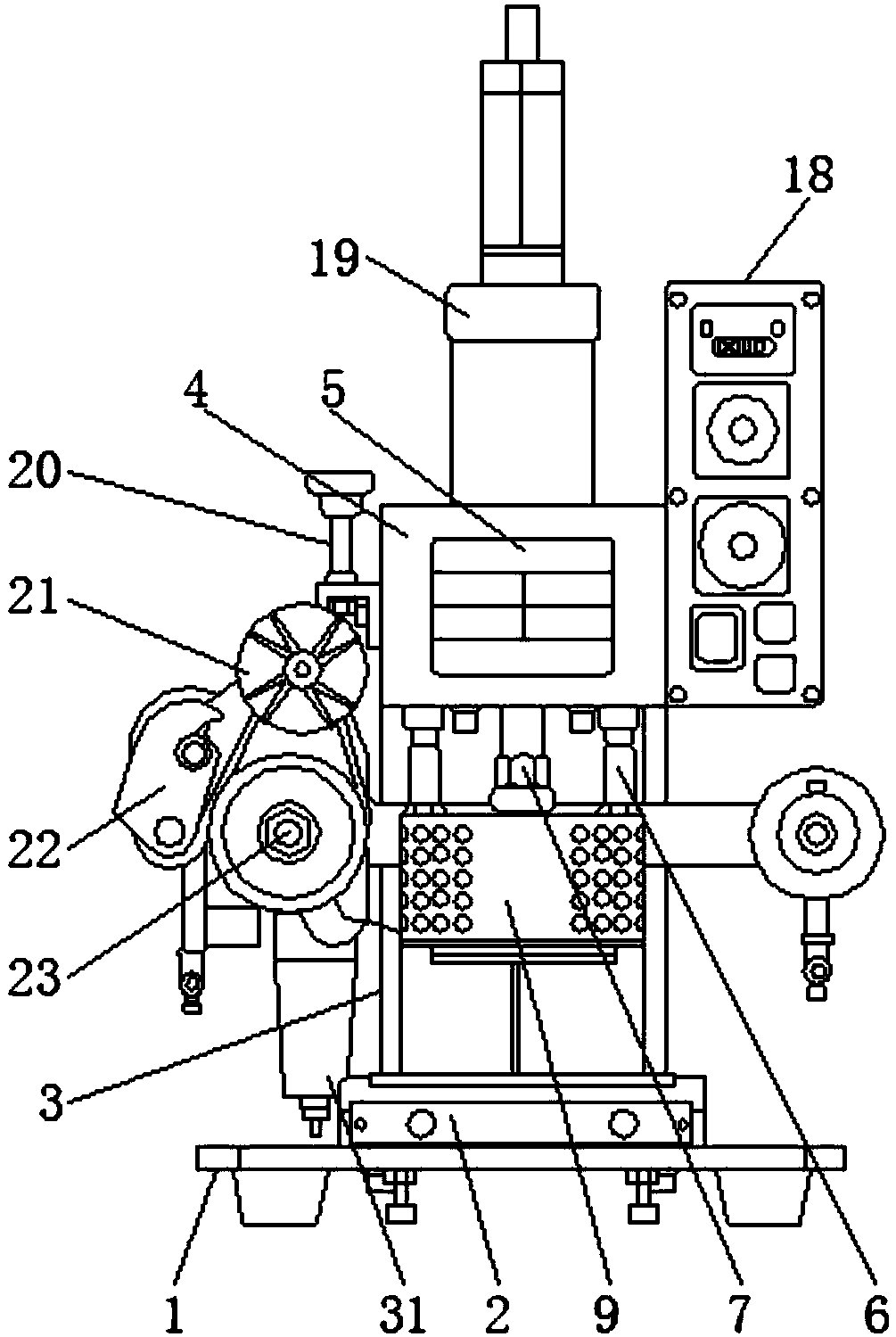

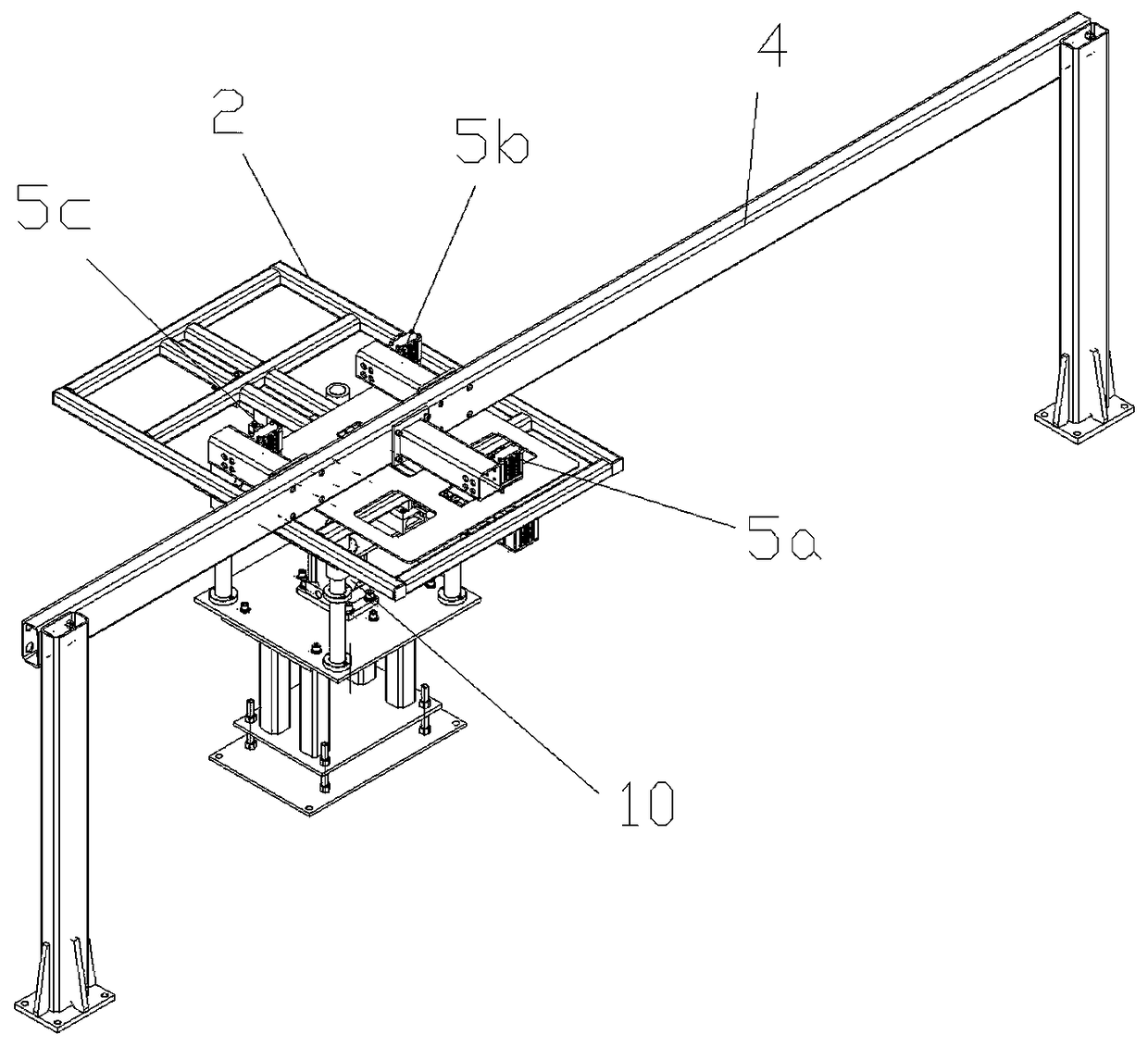

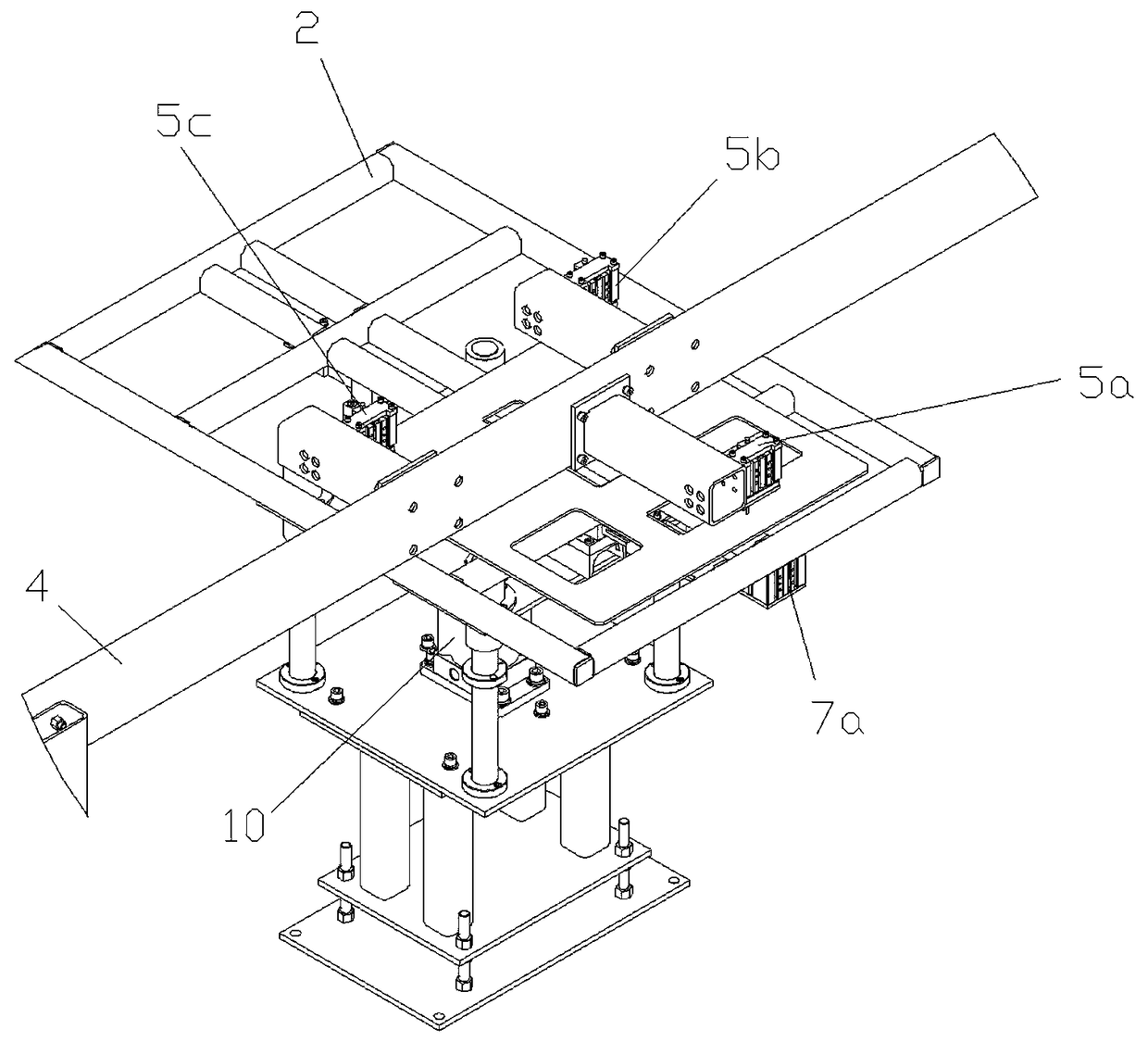

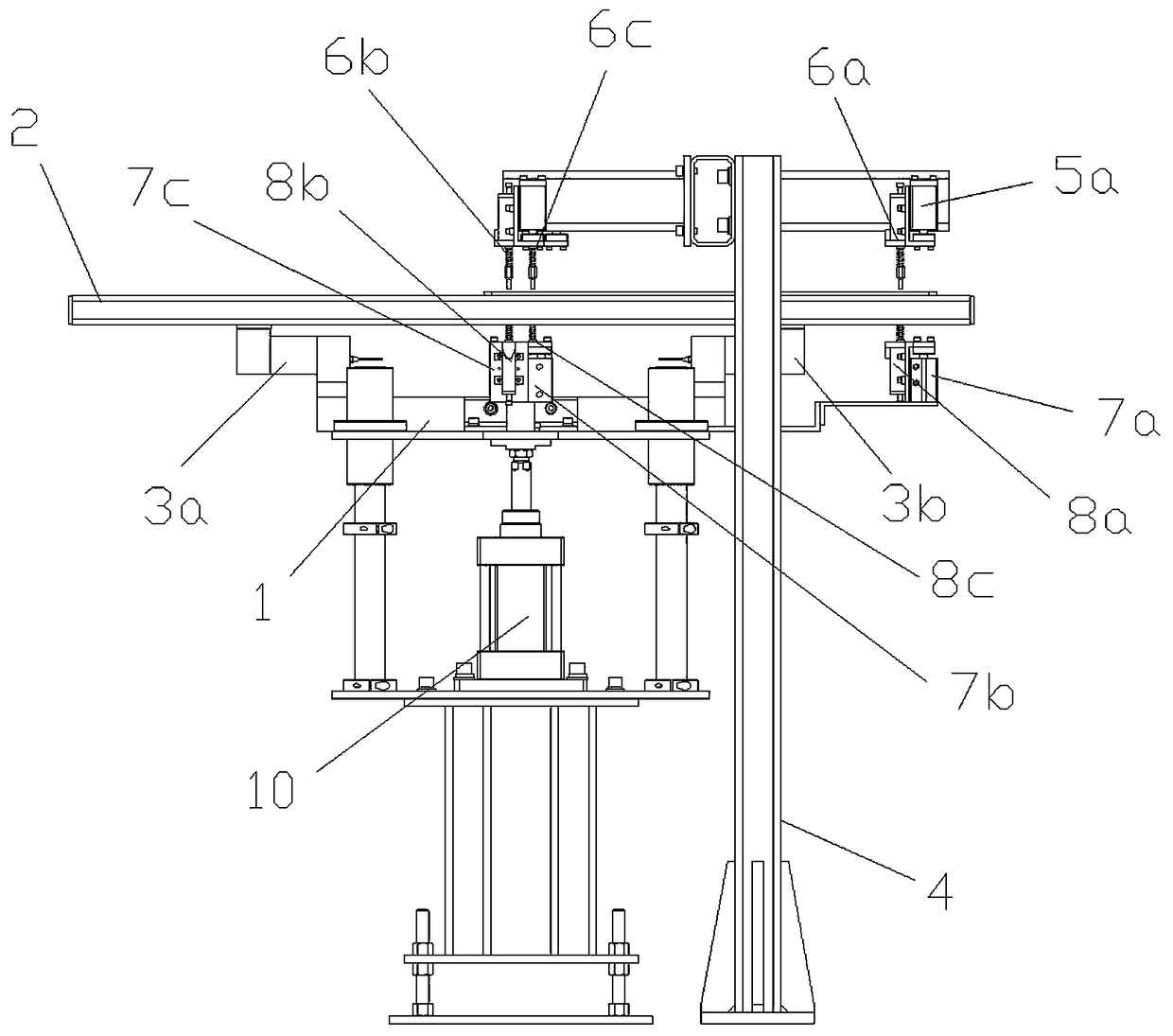

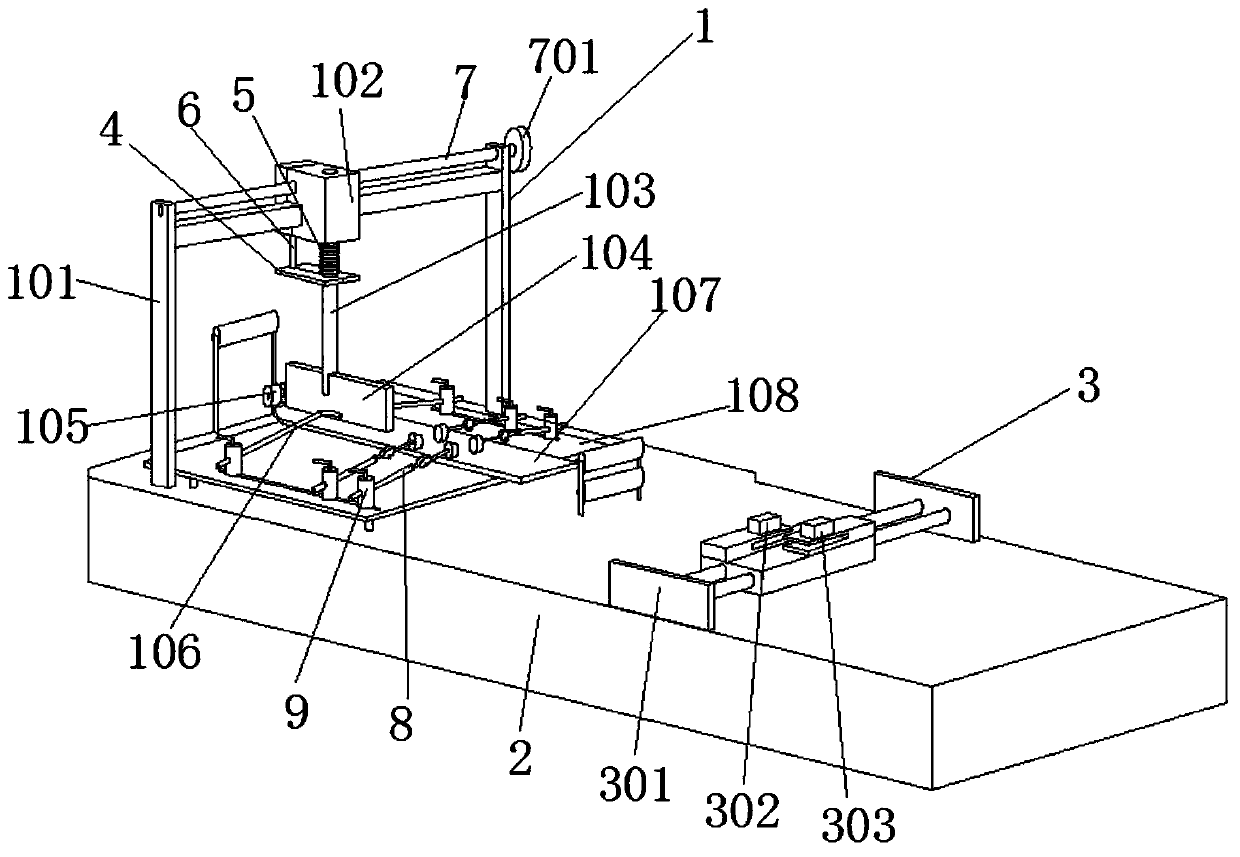

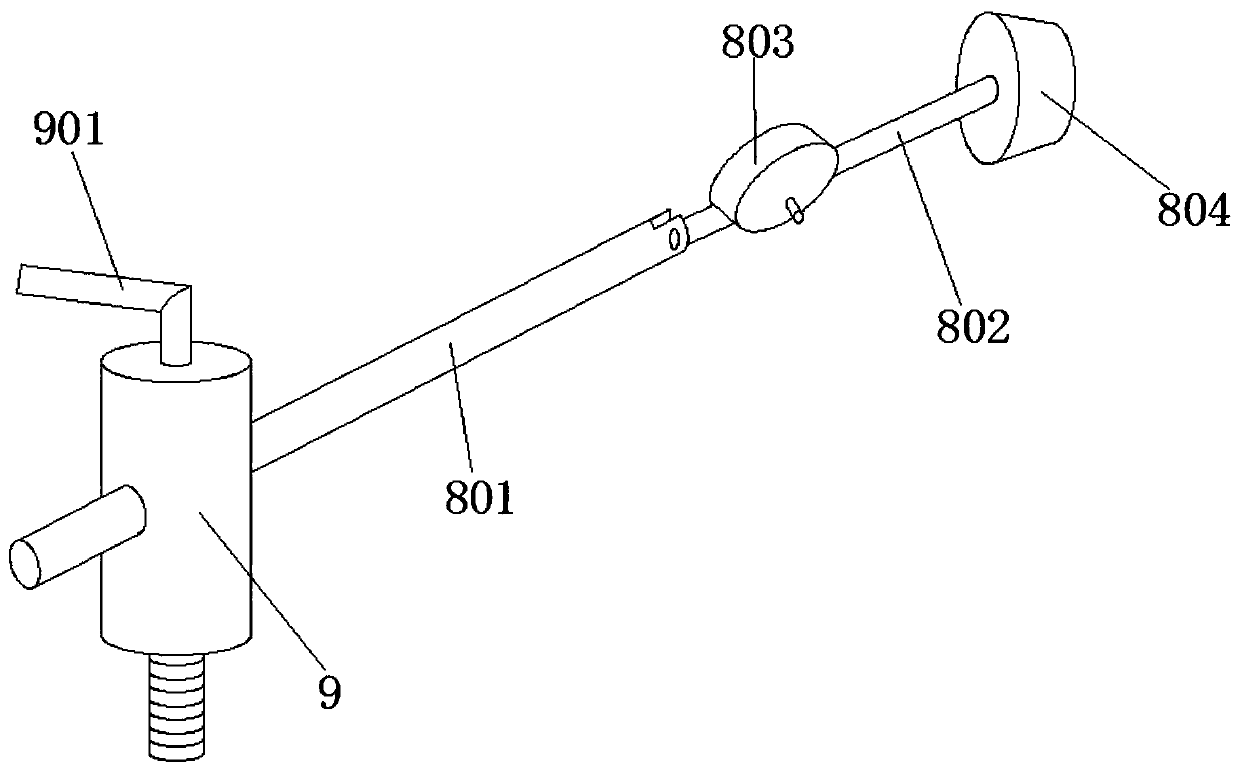

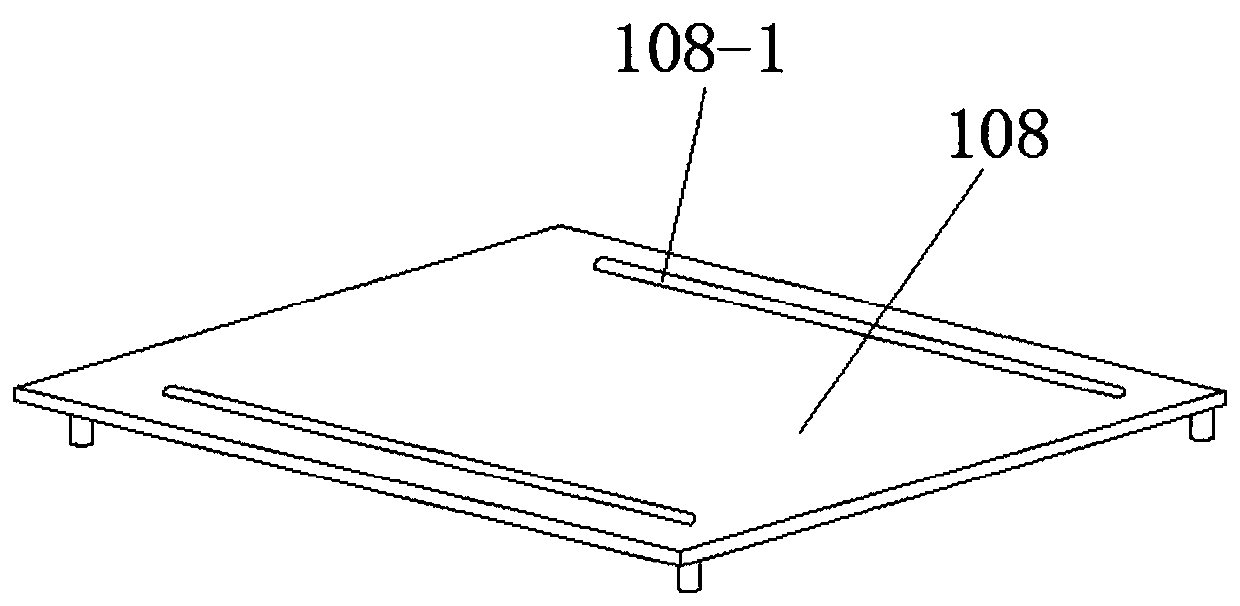

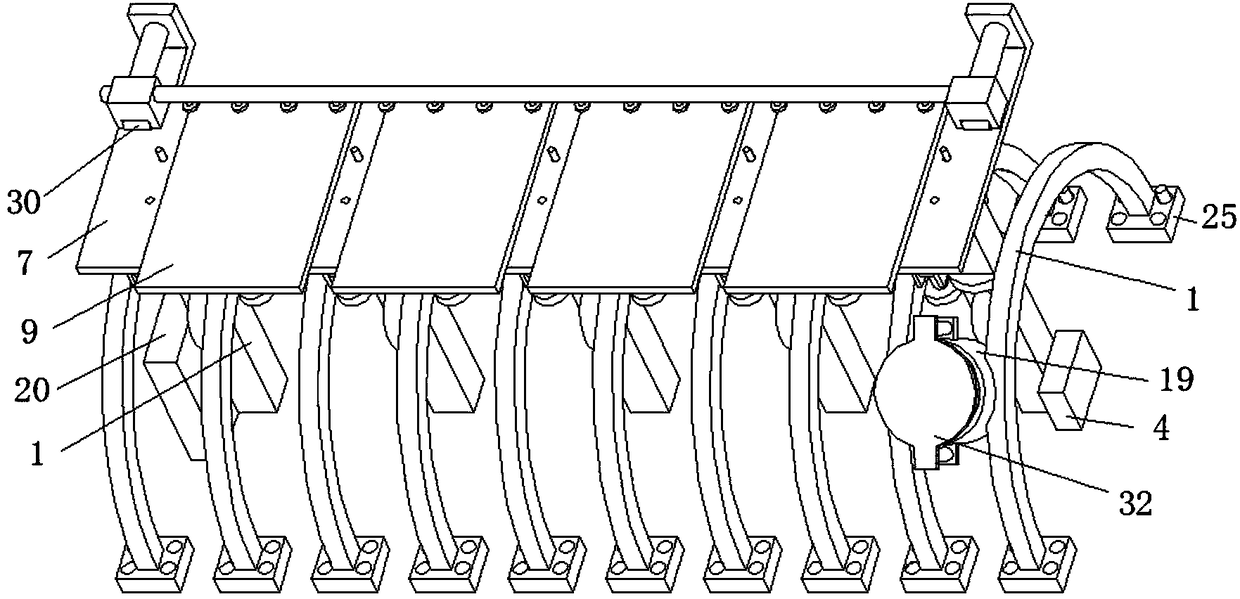

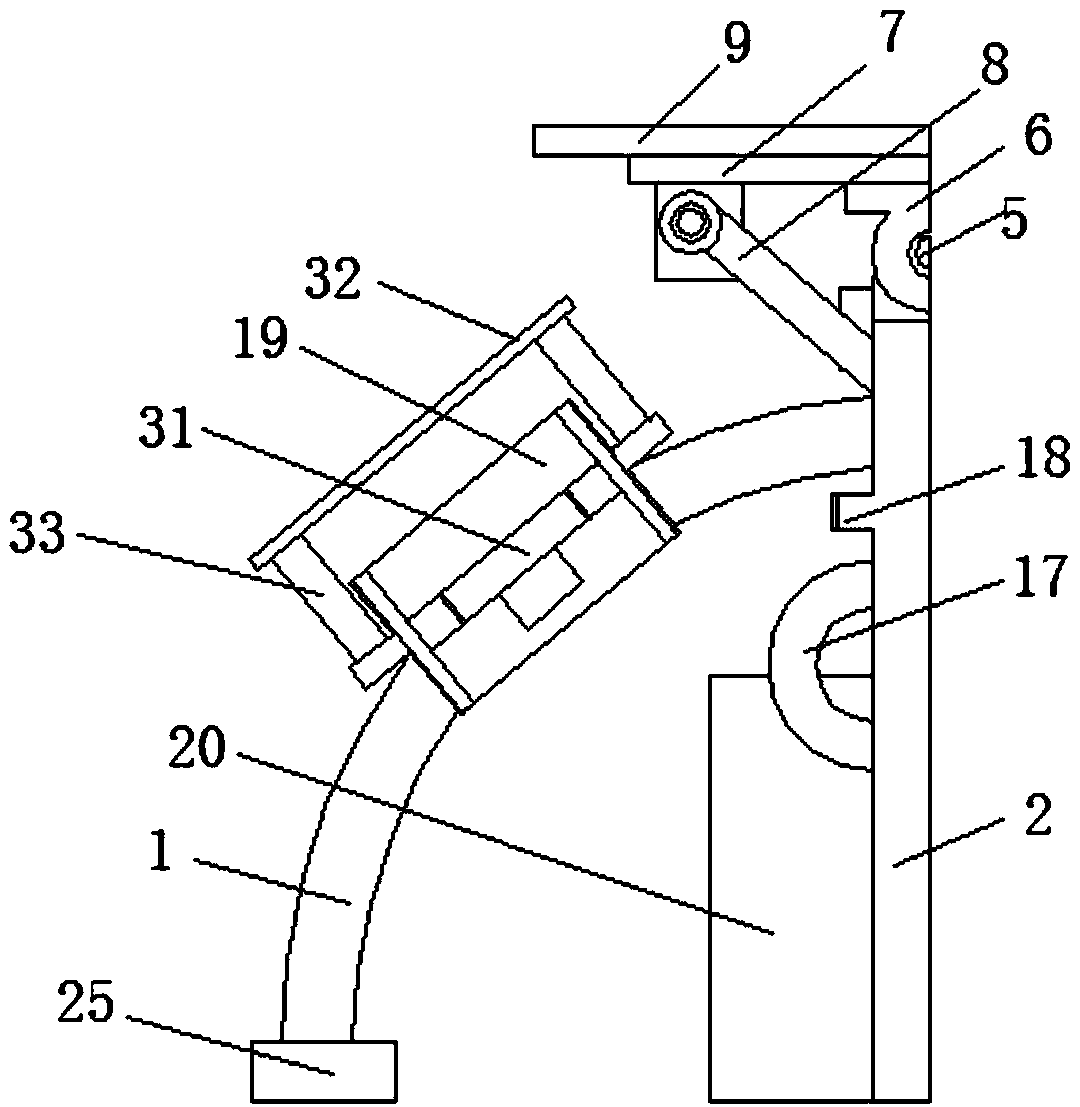

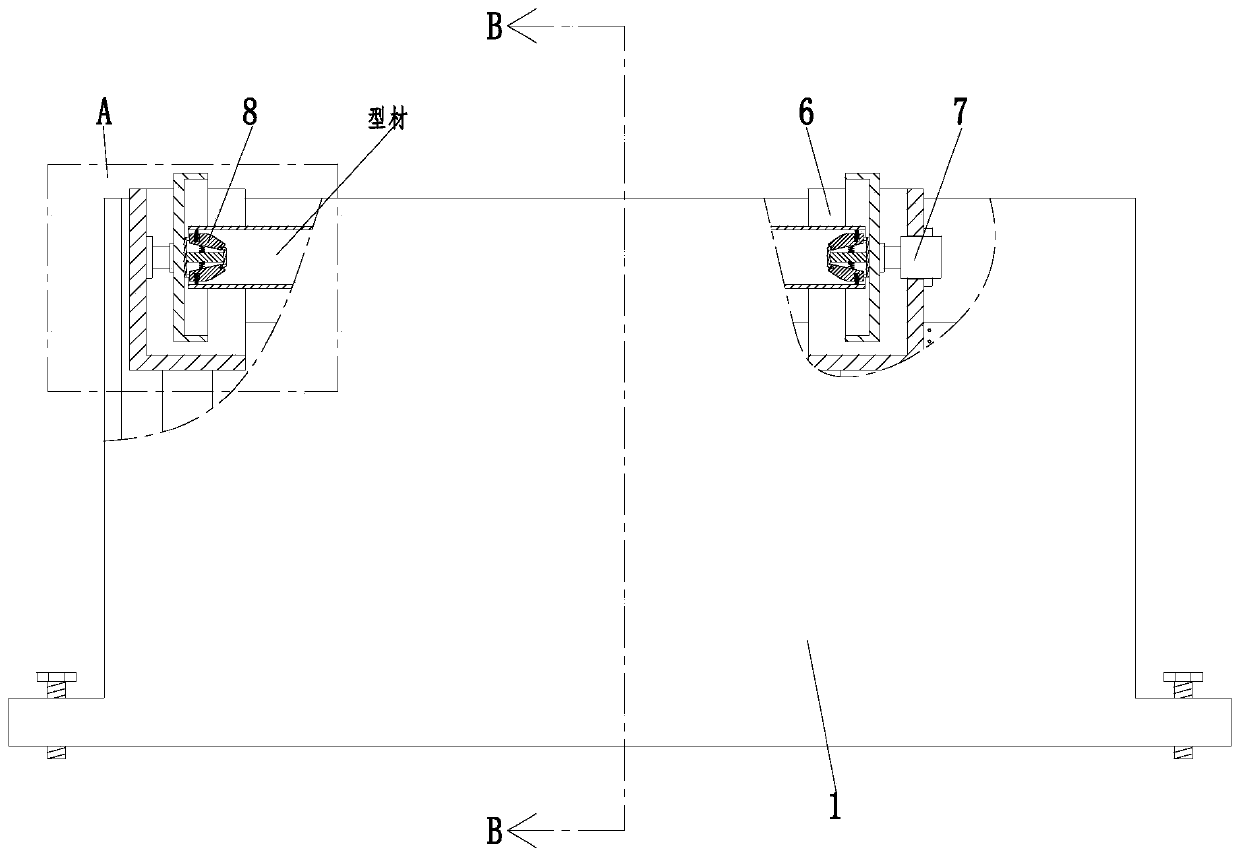

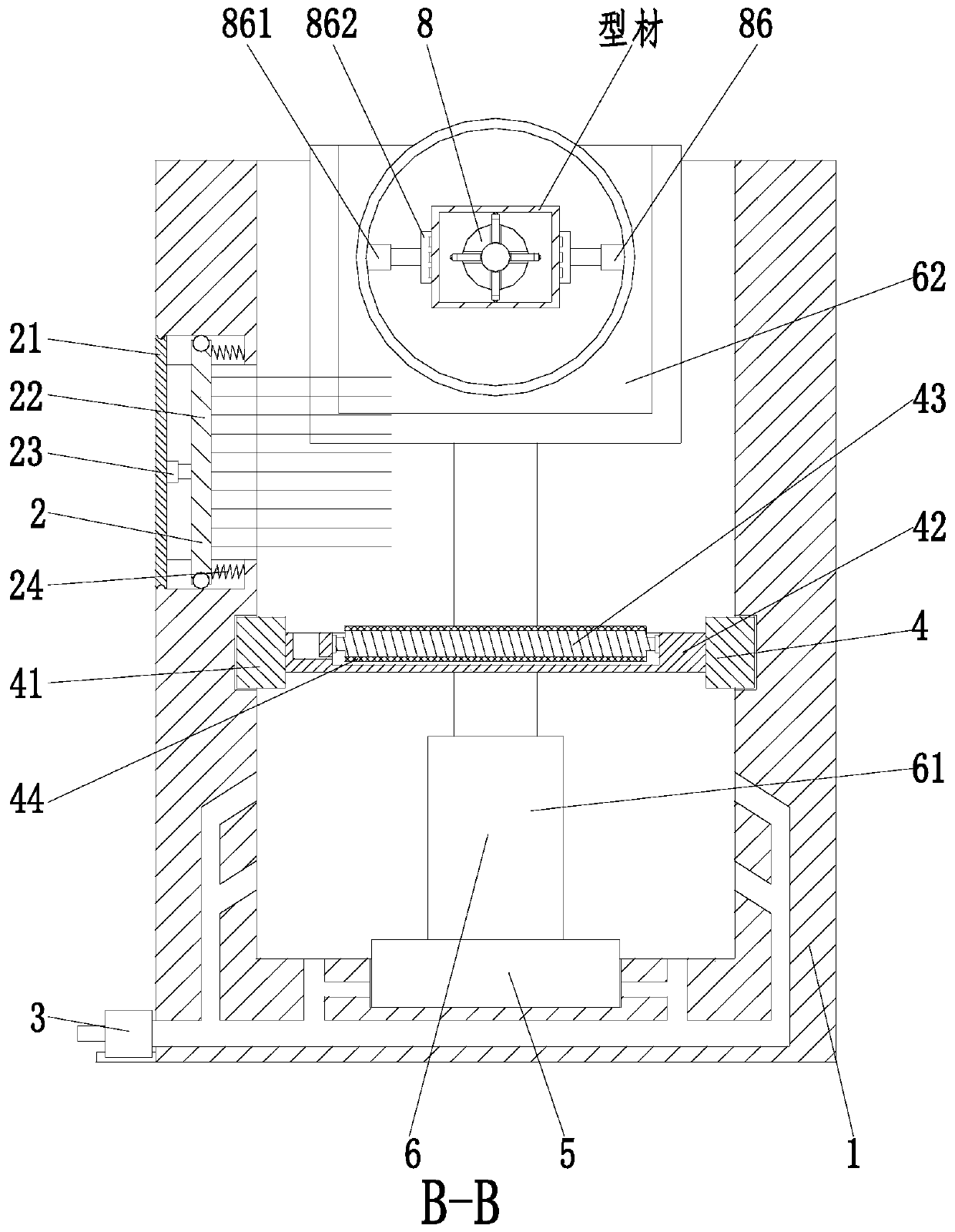

Automatic pipe cutter

ActiveCN105345128ARealize multiple continuous cuttingFacilitate continuous productionTube shearing machinesMetal working apparatusPipe fittingEngineering

The invention discloses an automatic pipe cutter. The automatic pipe cutter comprises a machine frame (1), wherein a cutting device (3) for cutting off pipe fittings (2) is arranged on the machine frame (1). The automatic pipe cutter disclosed by the invention is characterized in that a guiding mechanism (4) for lifting the pipe fittings (2) is arranged at the feeding end, which is close to the machine frame (1), of the machine frame (1), and a feeding mechanism (5) which pulls the ends to be cut of the pipe fittings (2) to move in the axial direction to a position to be processed when the cutting device (3) resets is arranged at the discharging end, which is close to the cutting device (3), of the machine frame (1). The automatic pipe cutter provided by the invention can automatically feed the pipe fittings after the pipe fittings are cut off in a disposable manner, so that the automatic continuous cutting-off processing of the pipe fittings is realized.

Owner:PINGXIANG WEIDA IND CO LTD

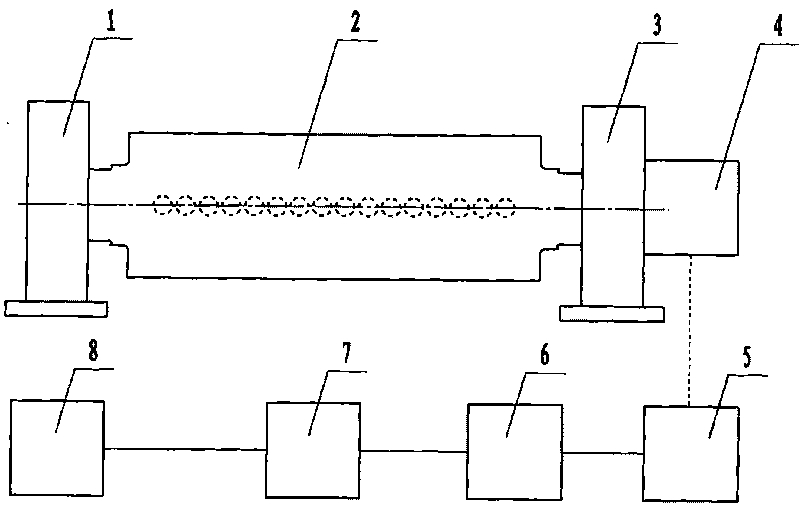

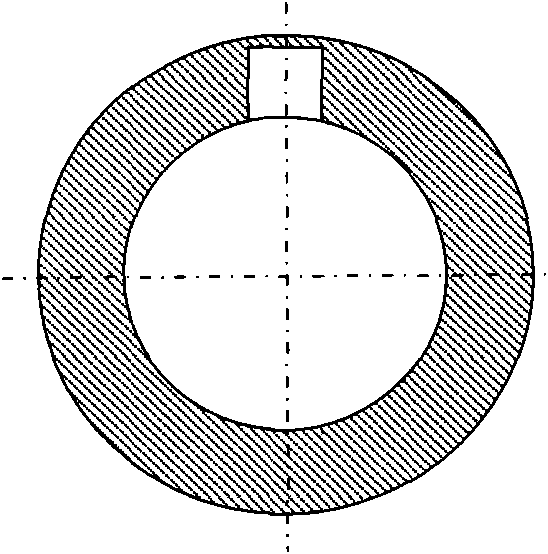

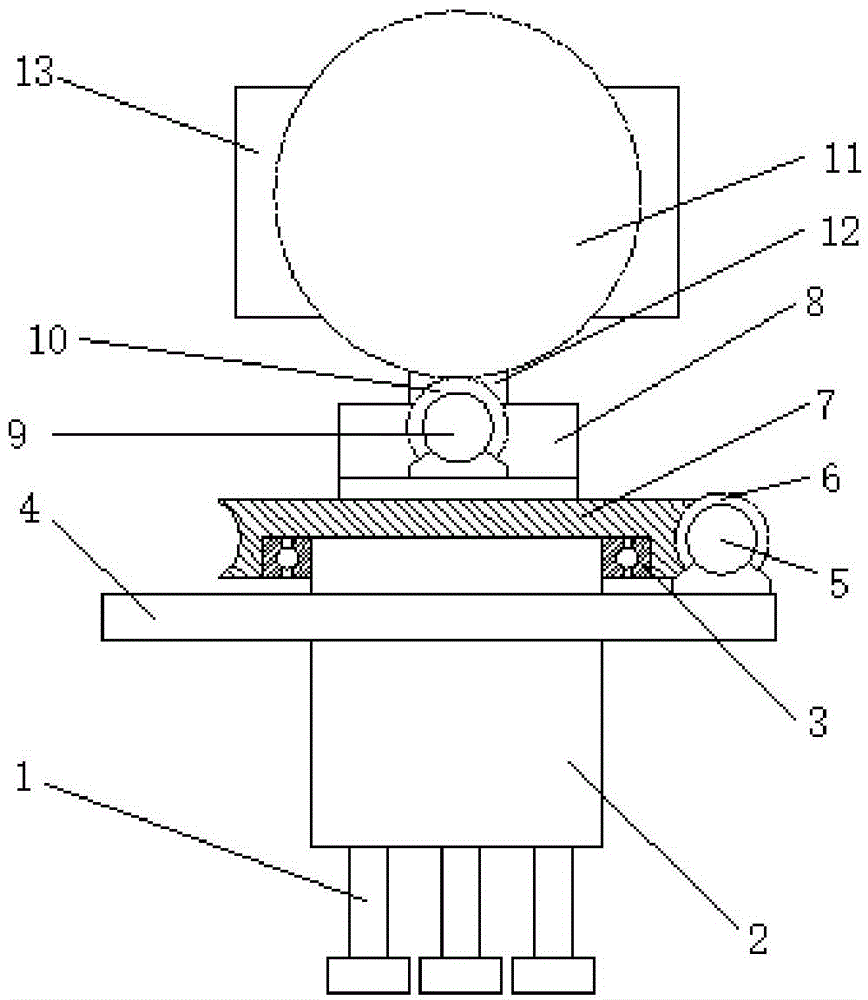

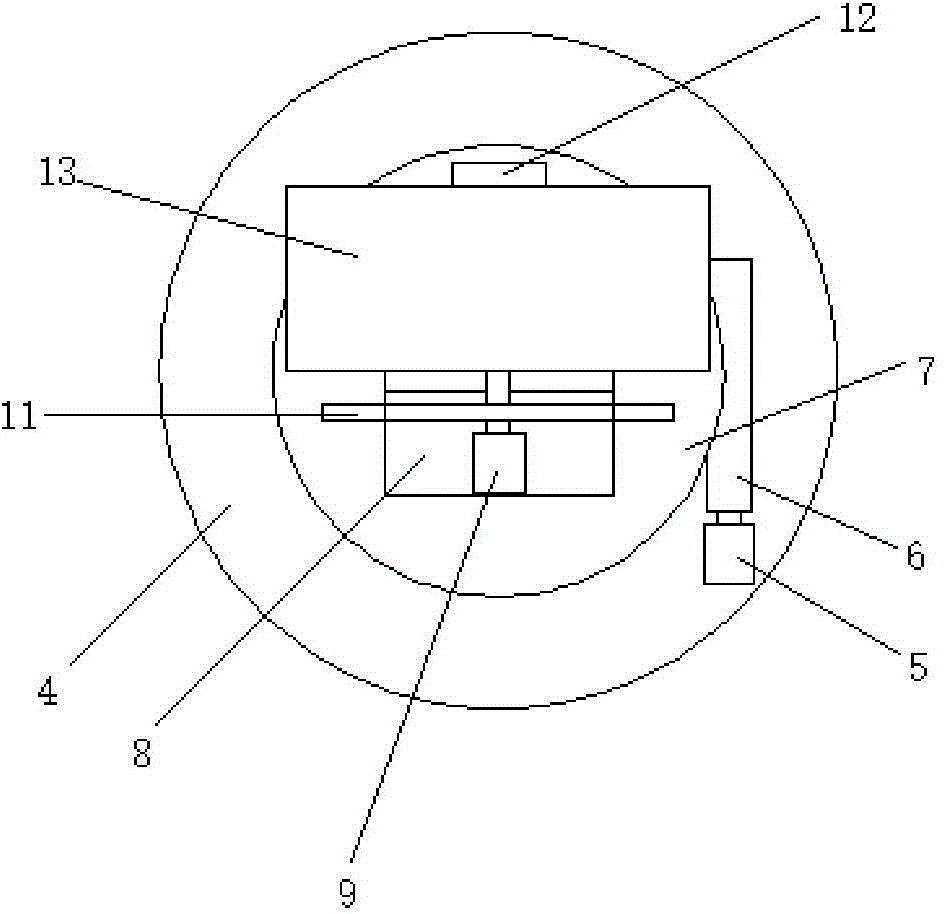

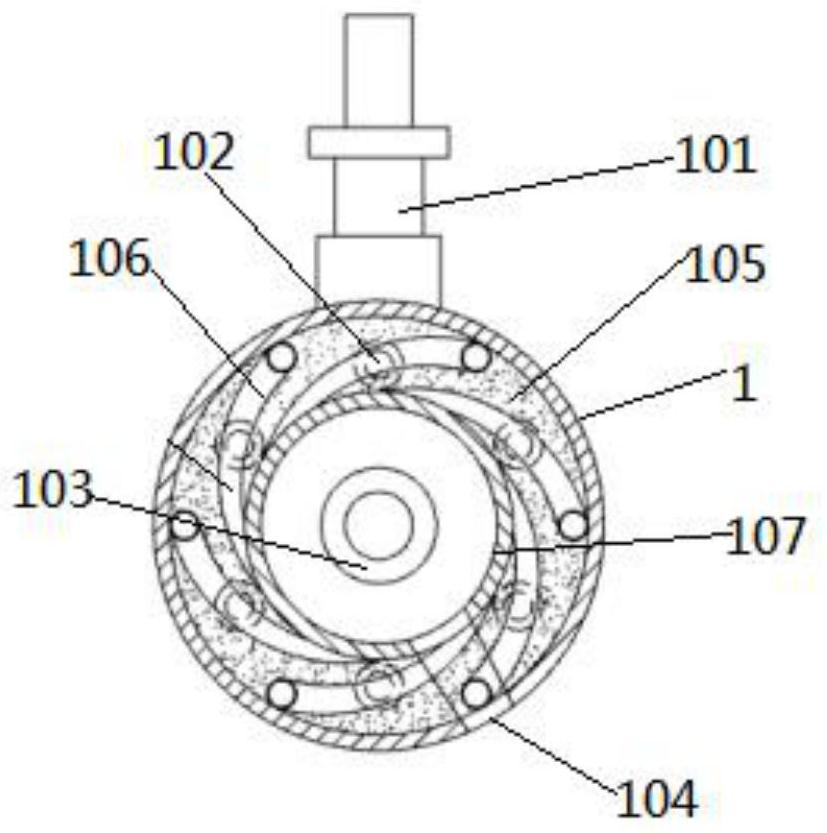

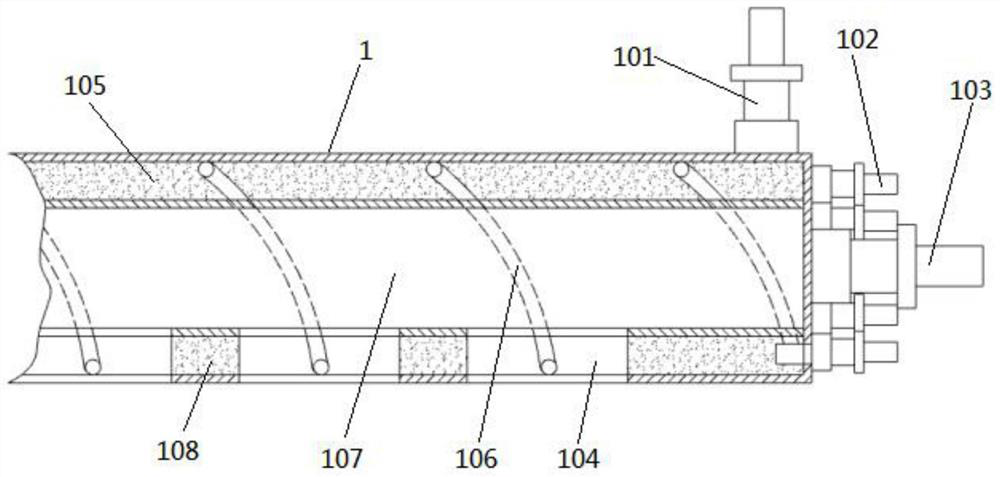

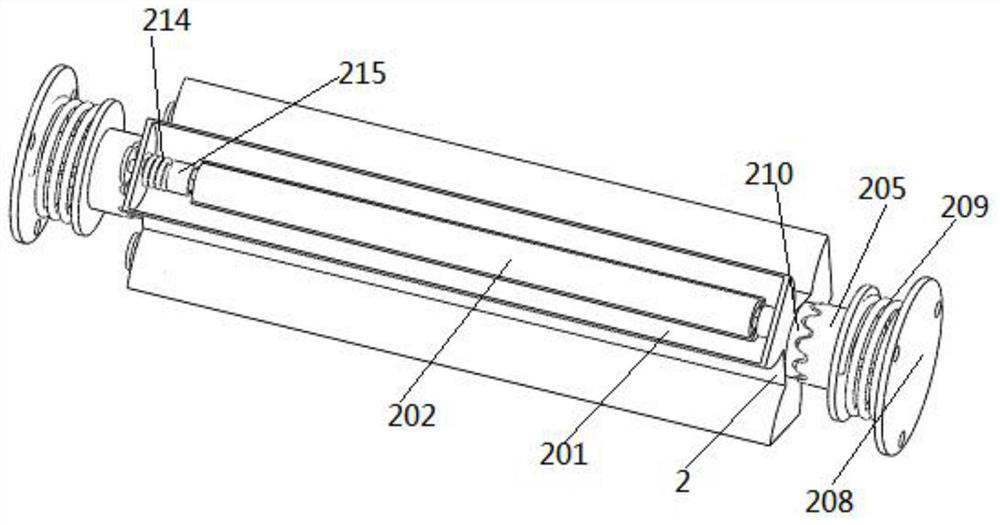

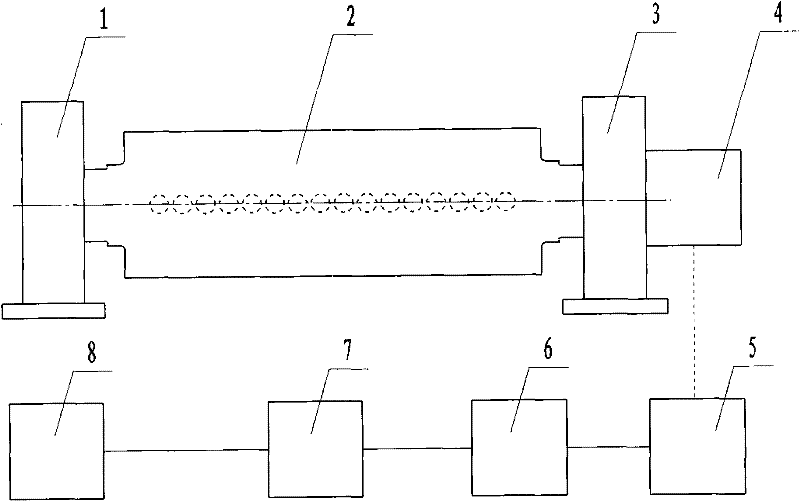

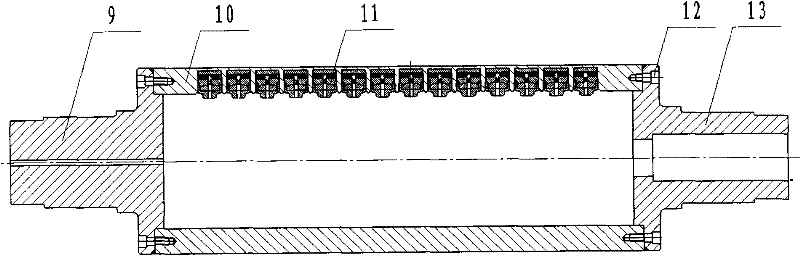

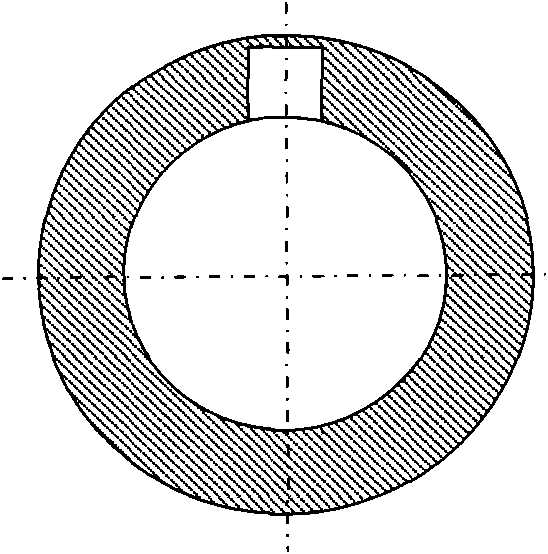

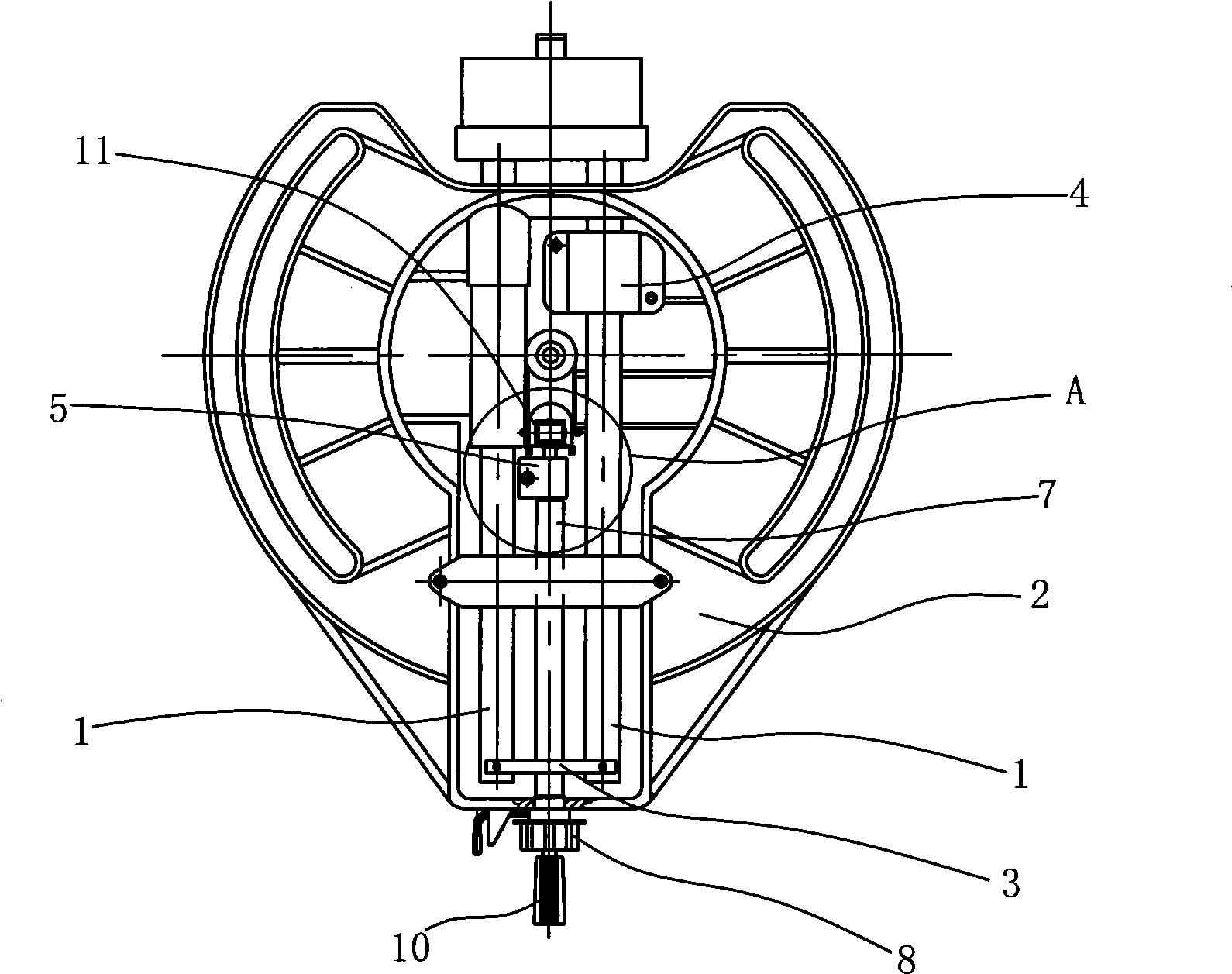

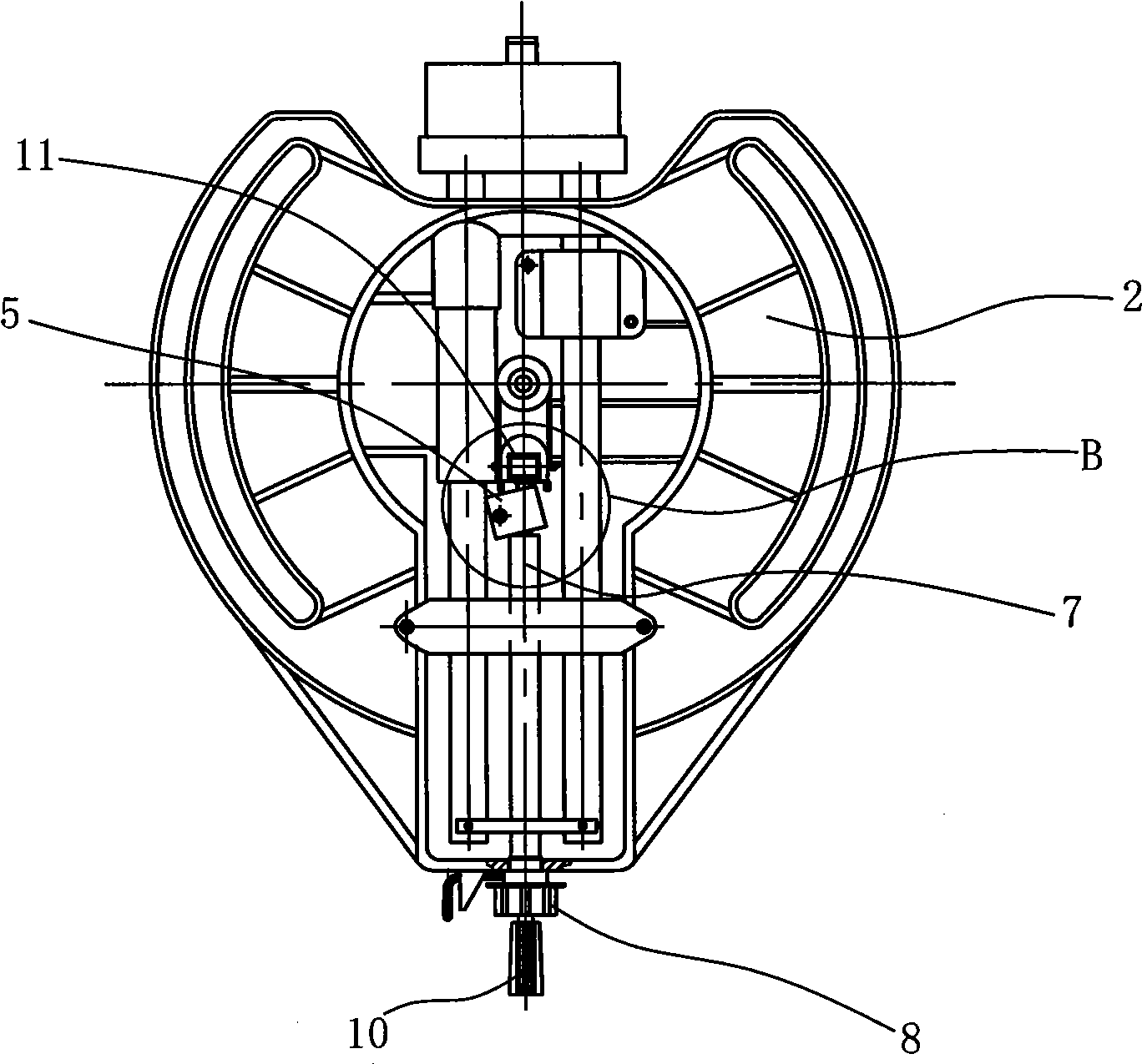

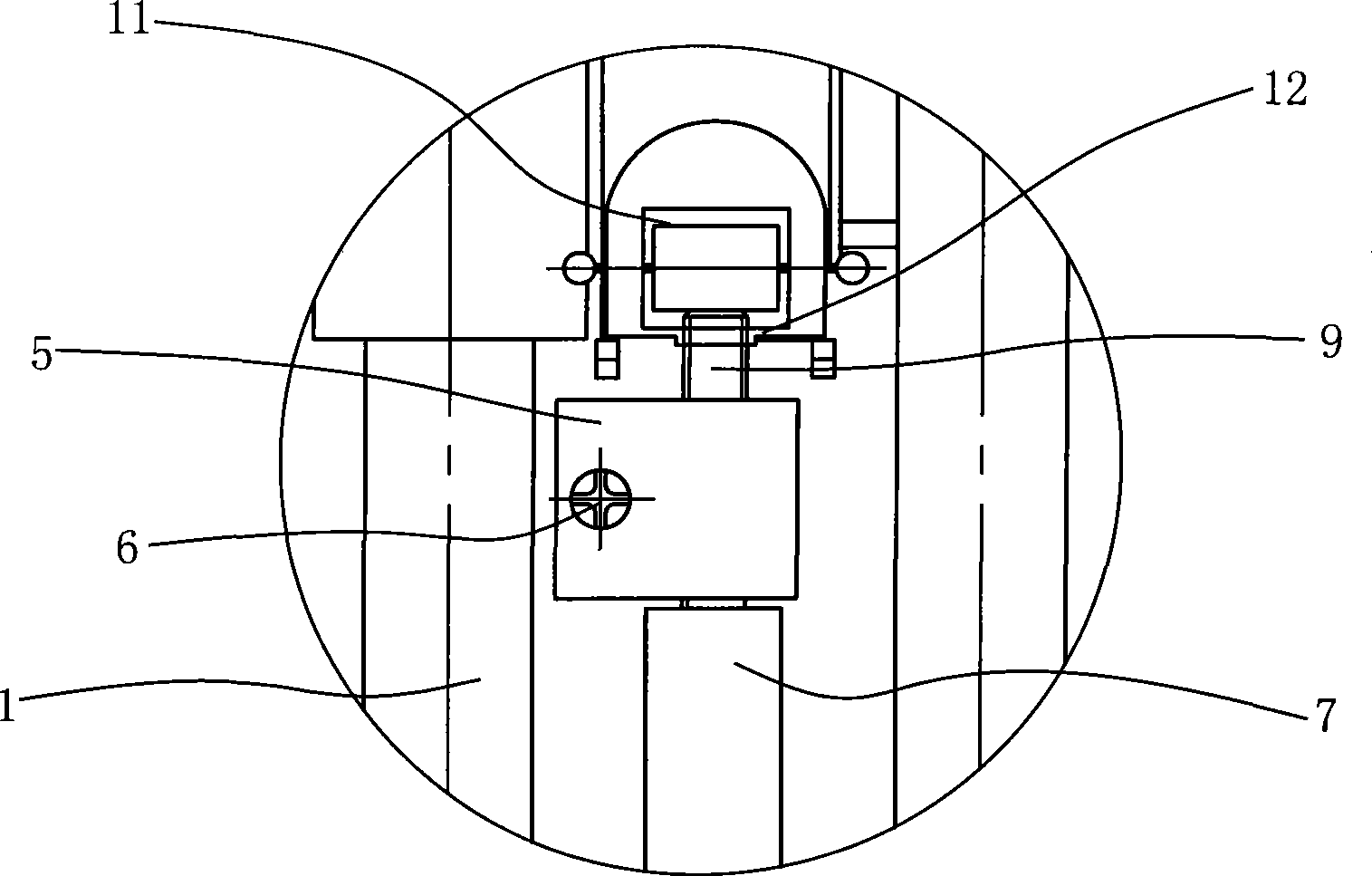

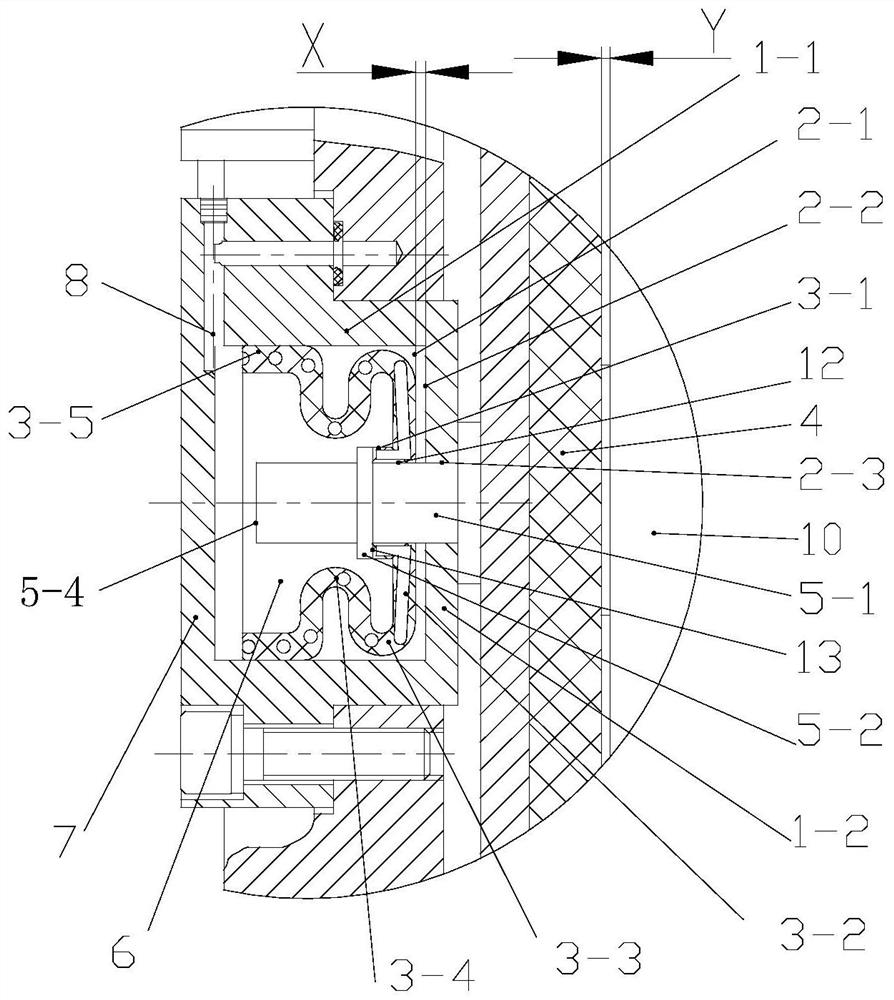

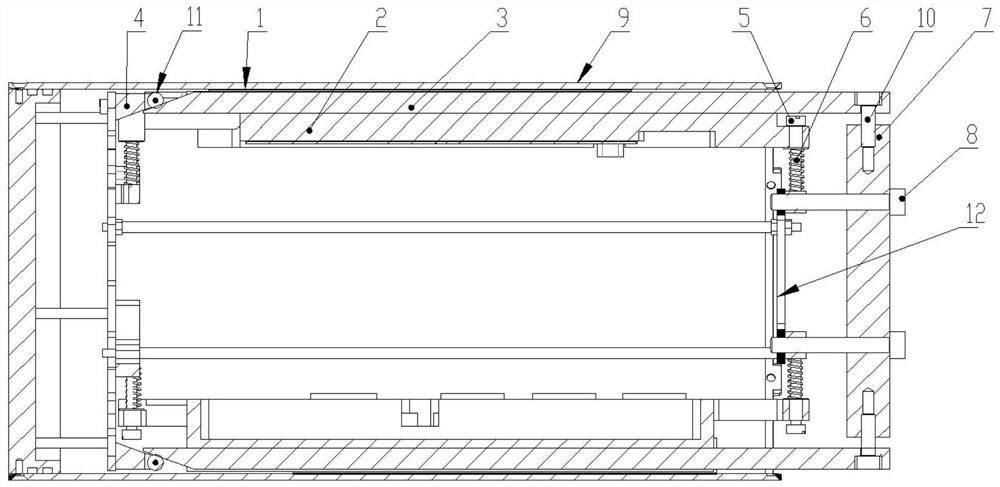

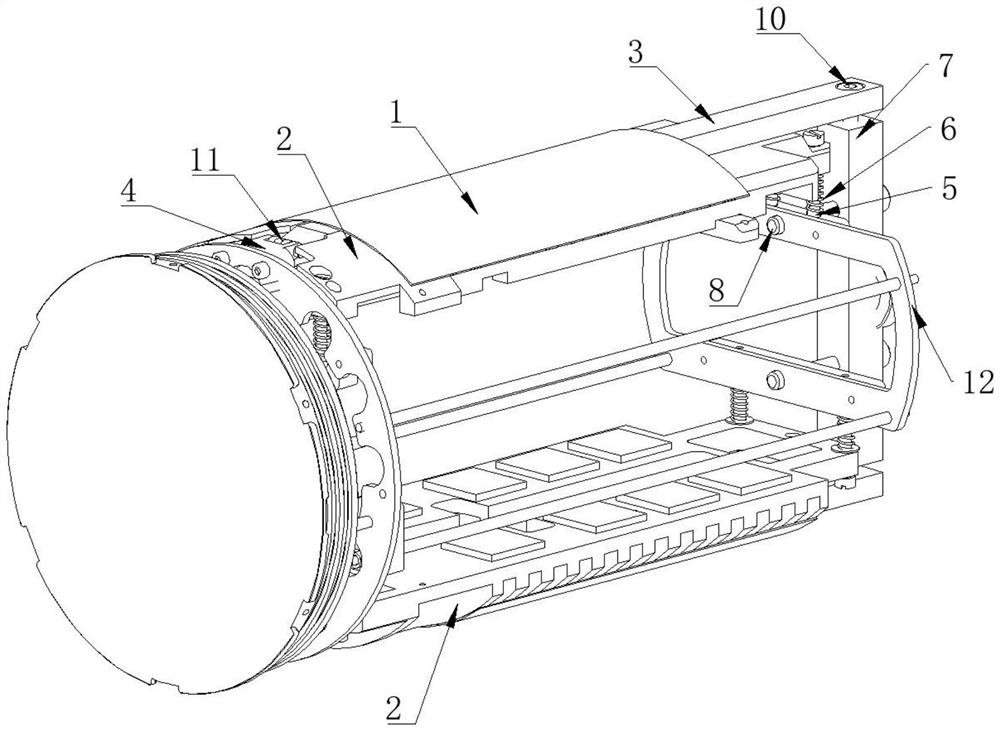

Seamless wireless type plate shape gauge of entire roller

InactiveCN101694368AAvoid Zero Drift ProblemsExcellent high frequencyElectric/magnetic contours/curvatures measurementsLinear/angular speed measurementShielded cableSignal processing circuits

The invention discloses a seamless wireless type plate shape gauge of an entire roller, which is characterized in that a plate shape gauge detecting roller (2) detects an original plate shape signal which is transmitted to a signal processing circuit board (31) in a power self-generating signal processing and wireless emitting device (4) through a coaxial high shielded cable; and after being processed by a DSP chip, a coded digital signal packet is output by a wireless emitter (36) in the power self-generating signal processing and wireless emitting device (4) in a wireless way. After the wireless receiver (5) receives the data packet, a decoder (6) restores the received data packet and delivers the data packet a software processing system (7) for carrying out digital filtration, signal compensation, and the like on the plate shape signal so as to obtain real online plate shape data. The invention avoids scratching the surface of a band steel; a differential charge amplifier is adopted so that the plate shape gauge has fine high frequency and low frequency response characteristics; all circuits are completely sealed inside a roller body, the data packet of the plate shape signal is emitted in real time through antennae and the plate shape gauge has excellent shielding property, realizes wireless emitting and receiving of the signal, avoids slip ring type wired transmission, effectively eliminates the influence of interference factors on plate shape detecting signals and accurately detects the signal in real time so that the plate shape gauge can stably run for a long time under the a serious working condition.

Owner:YANSHAN UNIV

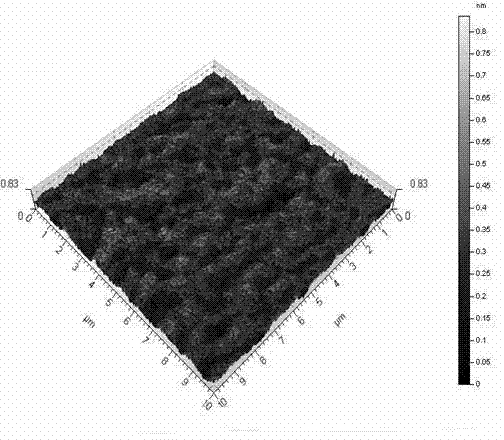

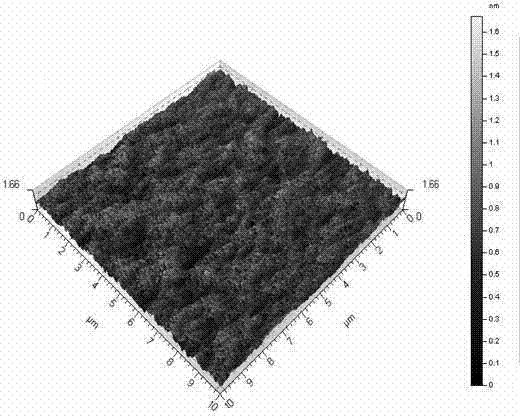

CMP (Chemical-Mechanical Polishing) polishing liquid with mixed grinding materials for alkaline sapphire substrate and preparation method thereof

ActiveCN103571333ASolve pollutionSolve many disadvantages such as easy gelPolishing compositions with abrasivesNano sio2SURFACTANT BLEND

The invention relates to a CMP (Chemical-Mechanical Polishing) polishing liquid with mixed grinding materials for an alkaline sapphire substrate and a preparation method thereof. The CMP polishing liquid consists of the following components in percentage by weight: 0.5-35% of a main grinding material, 0.015-0.09% of an auxiliary grinding material, 0.005-0.05% of a chelating agent, 0.005-0.05% of a surfactant, 0.01-0.5% of a pH adjustor, and the balance of deionized water, wherein the main grinding material is a nano SiO2 sol and the auxiliary grinding material is an Al2O3 sol. The auxiliary grinding material, the chelating agent, the surfactant and the alkaline pH adjustor are sequentially added into a nanosilicon sol suspension. In the polishing liquid, as the content of the main grinding material SiO2 sol is reduced, the phenomenon that the polishing liquid residue on the surface of the substrate after CMP is relatively severe is reduced to facilitate subsequent cleaning. A less amount of the auxiliary grinding material Al2O3 is added, so that the polishing speed is remarkably increased, and the roughness of the substrate after CMP is reduced.

Owner:江西伟嘉创展企业管理有限公司

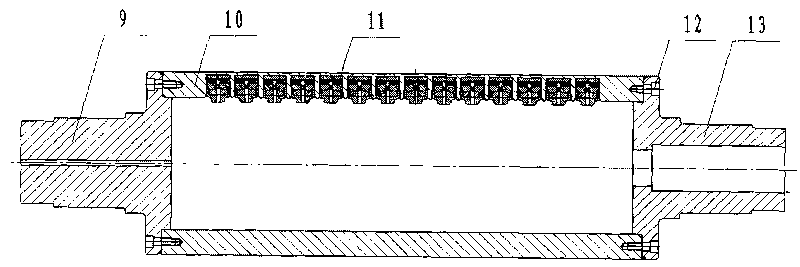

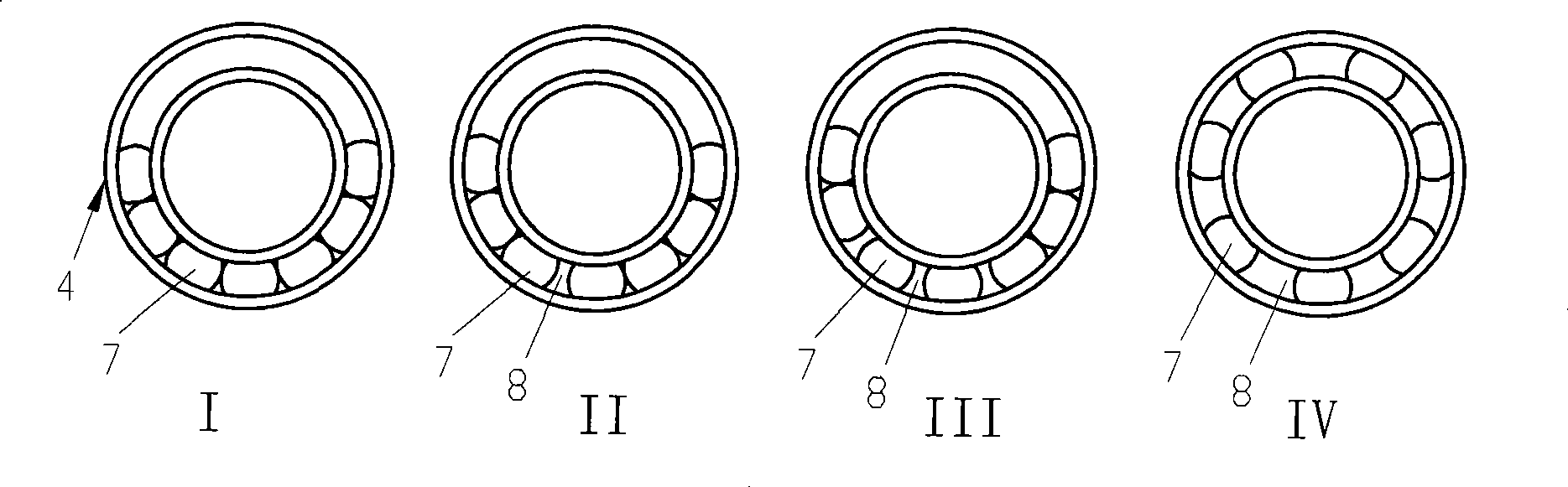

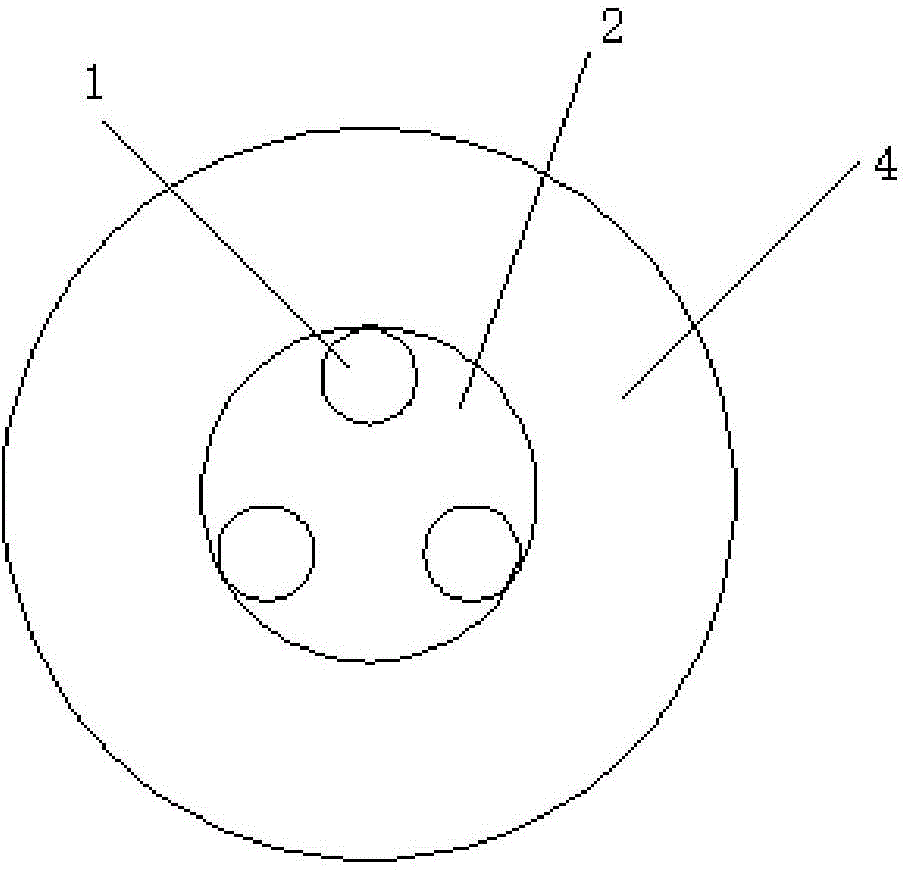

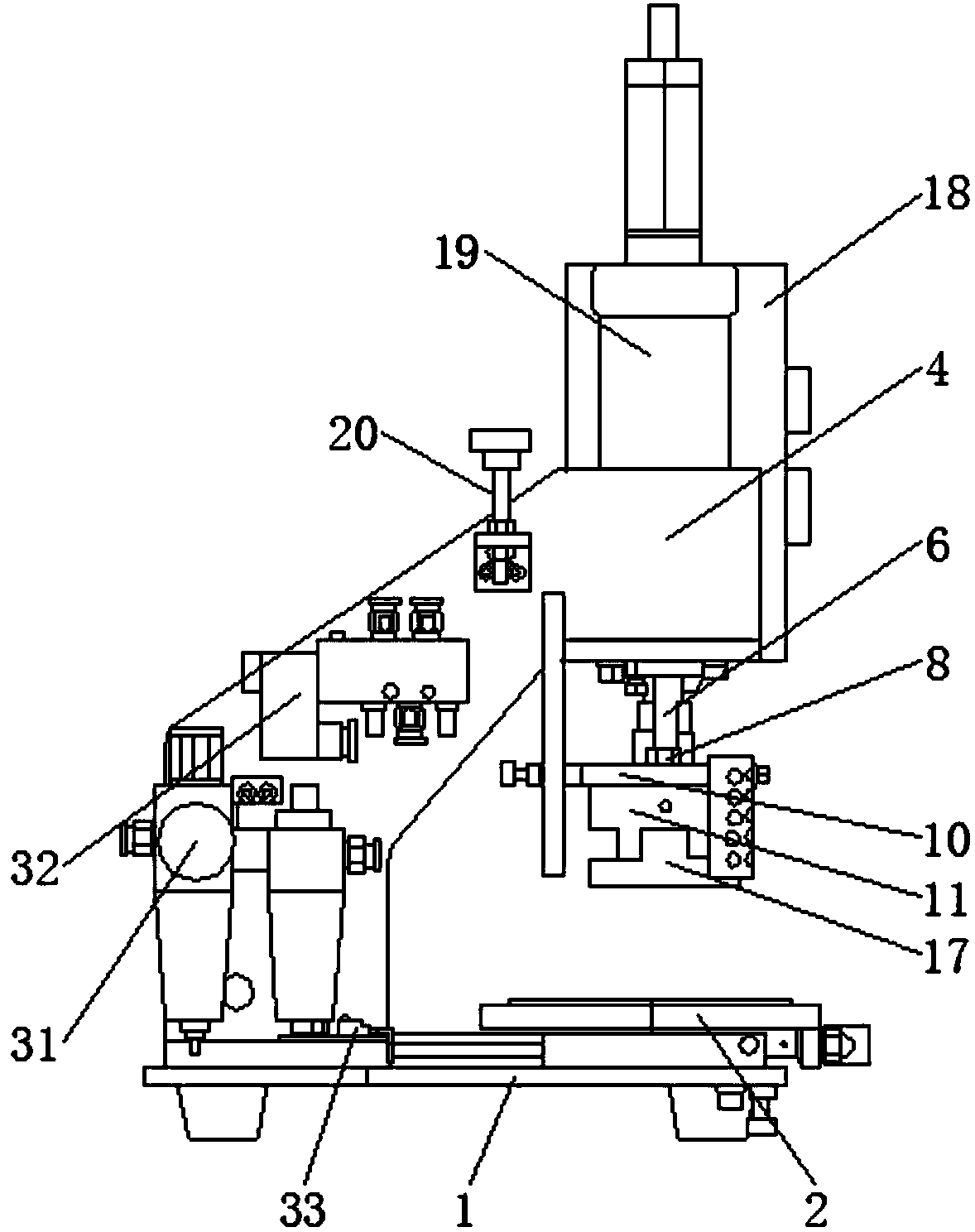

Ball separating device of bearing ball separating holder assembly machine

InactiveCN101363478AImprove work efficiencyNot easy to break or bend out of shapeBearing componentsEngineeringPiston rod

The invention relates to a ball separating device of a bearing ball separating retainer assembly machine, and is characterized in that the ball separating device comprises a frame and an electric control system; a cylinder is arranged above the frame, a piston rod of the cylinder passes through a hole of a support plate, the front end of the piston rod is provided with a lifting and pulling head, the lower end of a mandrel is provided with a ball separating head, the upper end thereof is provided with an axle cap, a lower die of a locating bearing is arranged on the frame below the mandrel; the ball separating head includes a base which is arranged at the lower end of the mandrel, and a plurality of ball separating pins are sequentially arranged on the base by a sleeve chuck; the outer layer of the ball separating pin is made of metaformaldehyde or nylon, and the center thereof is embedded with a metal strip. By adopting the deadweight of the mandrel and a guide block to realize ball separating, the ball separating device does not cause damage to steel balls and the grooves on inner and outer rings and has high work efficiency. In addition, with the structure, the ball separating pin is not likely to snap, bend or deform during use, thus prolonging the service life of the ball separating pin and causing no scratch to the surfaces of the steel balls.

Owner:无锡市江益轴承自动化设备有限公司

Automatic lighting fixture for liquid crystal screen

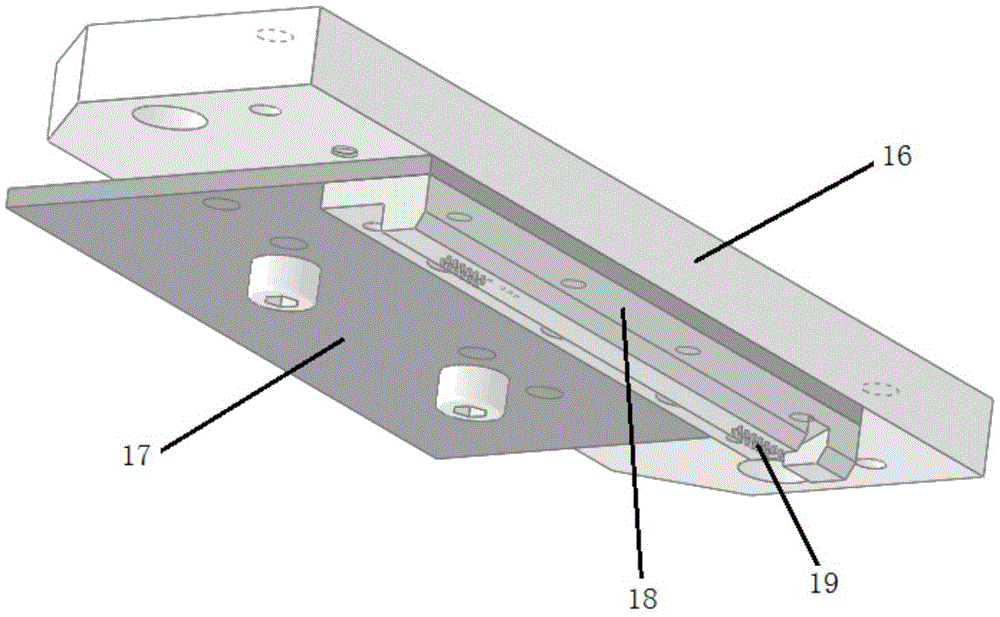

The embodiment of the invention discloses an automatic lighting fixture for a liquid crystal screen. The automatic lighting fixture comprises a bottom plate, a liquid crystal screen bracket, a probe pressing block for fixing probes, two horizontal sliding guide rails, horizontal sliding seats, two perpendicular fixing plates, a cam structure and a U-shaped lifting support; the horizontal sliding guide rails are both located on the outer side of the edge, close to a lighting switch, in the liquid crystal screen bracket, and the length directions of the horizontal sliding guide rails are both perpendicular to the edge, close to the lighting switch, in the liquid crystal screen bracket; the horizontal sliding seats are arranged on the corresponding sliding guide rails and can move on the sliding guide rails; each perpendicular fixing plate is perpendicular to the corresponding horizontal sliding seat; the cam structure is fixedly arranged on the bottom plate, the U-shaped lifting support comprises two side plates and the bottom plate, one side plate is located above a cam of the cam structure and provided with a cam groove matched with the cam, the inner side face of the bottom plate is connected with vertical sliding guide rails arranged on the two perpendicular fixing plate in a sliding mode respectively, and the probe pressing block is arranged on the outer side face of the bottom plate. The automatic lighting fixture for the liquid crystal screen can effectively avoid a liquid crystal screen from colliding with the probes.

Owner:BEIJING LUSTER LIGHTTECH

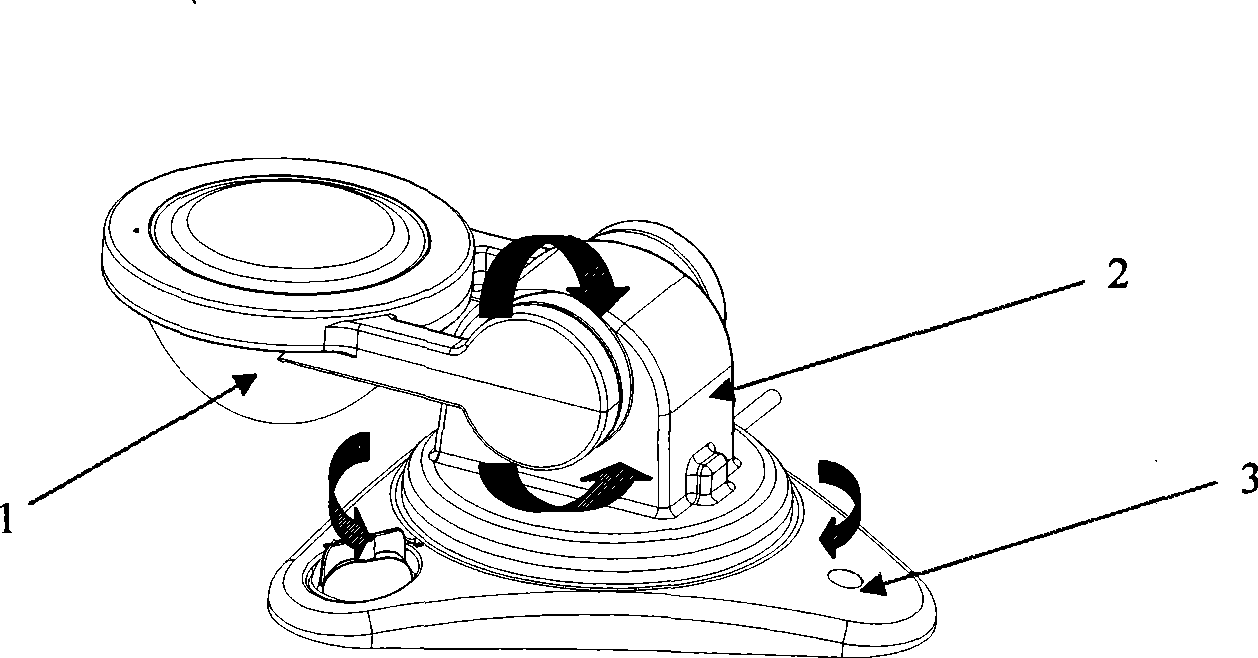

Non-contact type specially-shaped surface detection device

InactiveCN105737755AWill not cause extrusionWill not cause scratchesUsing optical meansElectric machineContact type

The invention discloses a non-contact special-shaped surface detection device, which belongs to the technical field of parts detection device design, including a foot, a base, a horizontal scanning stepping motor, a worm, a worm wheel, a longitudinal scanning stepping motor, a pinion and a large gear 1. Laser length measuring instrument. There are three legs connected to the lower end of the base. The worm is fixedly connected to the motor shaft of the horizontal scanning motor. Fixedly connected with the big gear, the non-contact special-shaped surface detection device designed by the present invention can ensure that the whole device is horizontal before measurement, and the horizontal and longitudinal scanning angles are controlled accurately. It is non-contact measurement and will not cause surface tissue damage Being squeezed and scratched has guiding significance for the adjustment of the processing technology of special-shaped parts.

Owner:CHIZHOU UNIV

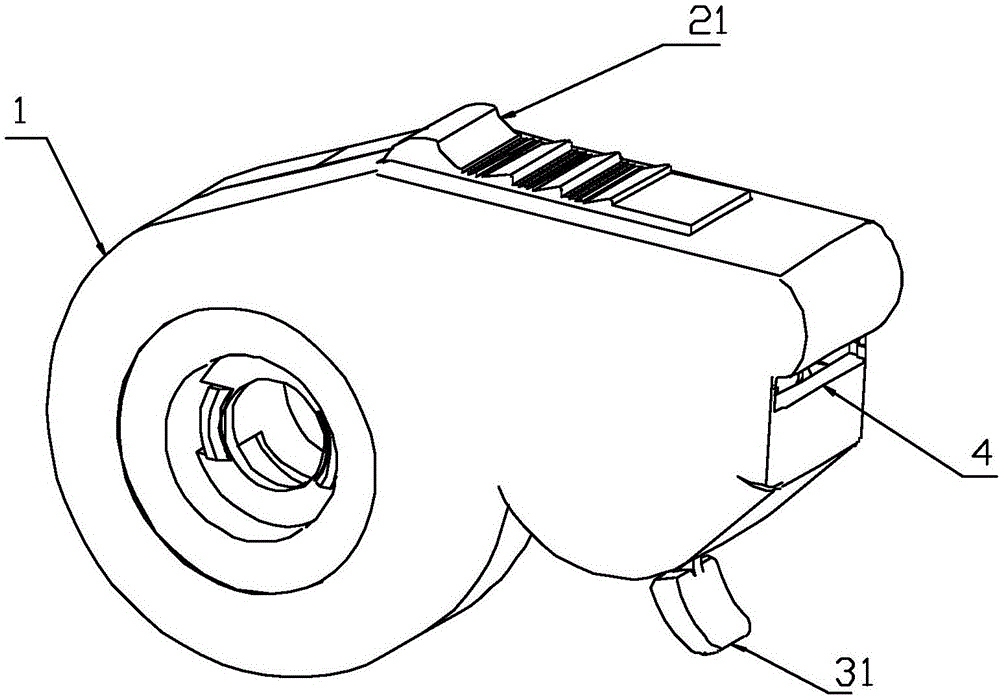

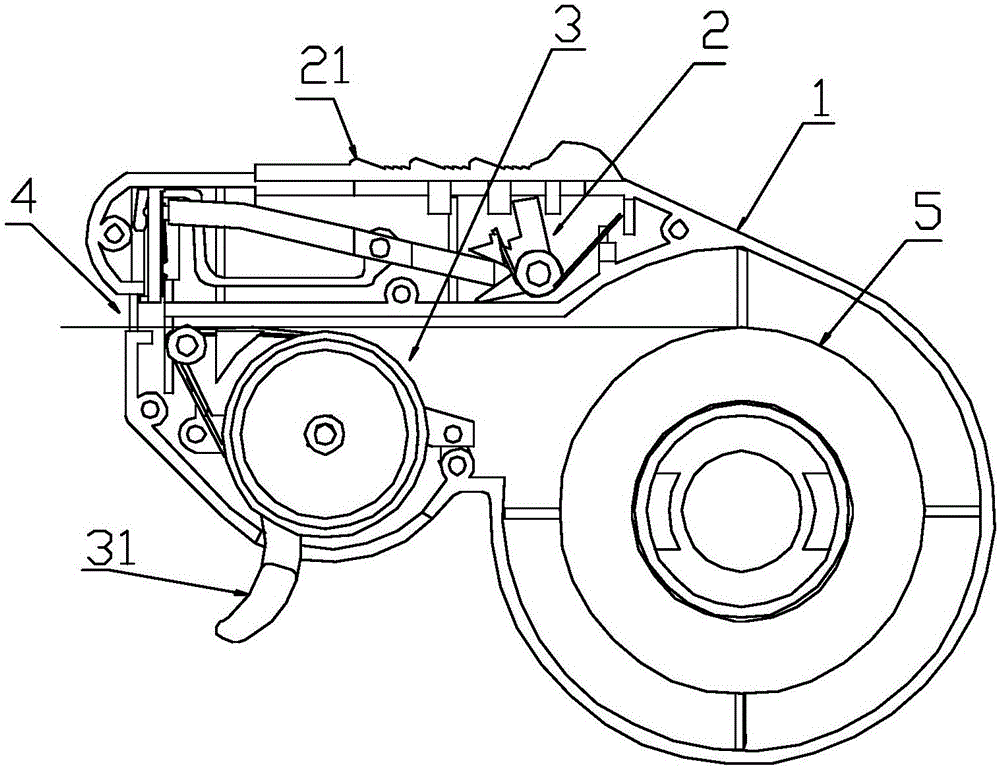

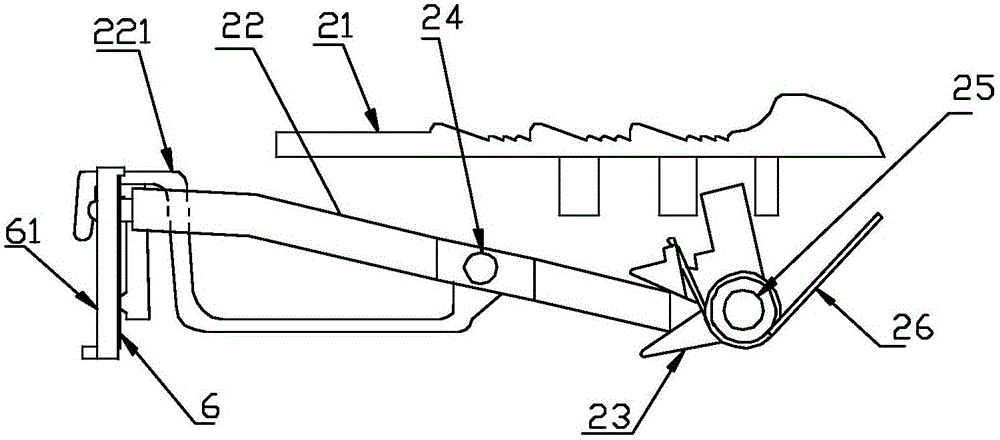

Automatic adhesive tape device

InactiveCN106219304AOutput tape is accurateNot easy to get dirtyArticle deliveryMechanical engineeringEngineering

The invention relates to an automatic adhesive tape device. The automatic adhesive tape device comprises a shell, wherein an adhesive tape outlet is arranged on one side of the shell; a cavity for assembling an adhesive tape is formed in the shell; the automatic adhesive tape device further comprises an adhesive tape cutting mechanism and an adhesive tape output mechanism; the adhesive tape cutting mechanism comprises a cutter arranged in the shell and a cutter driving mechanism which drives the cutter to move to cut off the adhesive tape; and the adhesive tape output mechanism is arranged at the adhesive tape outlet and is in contact with the adhesive tape, so that the adhesive tape is output through the adhesive tape outlet. According to the automatic adhesive tape device, the adhesive tape output mechanism is adopted for outputting the adhesive tape; manual pulling is not needed; the adhesive tape is output more accurately; meanwhile, the adhesive tape cutting mechanism is internally arranged; use is convenient; and a safe protection effect is realized for users.

Owner:QINGDAO YATAN STATIONERY CO LTD

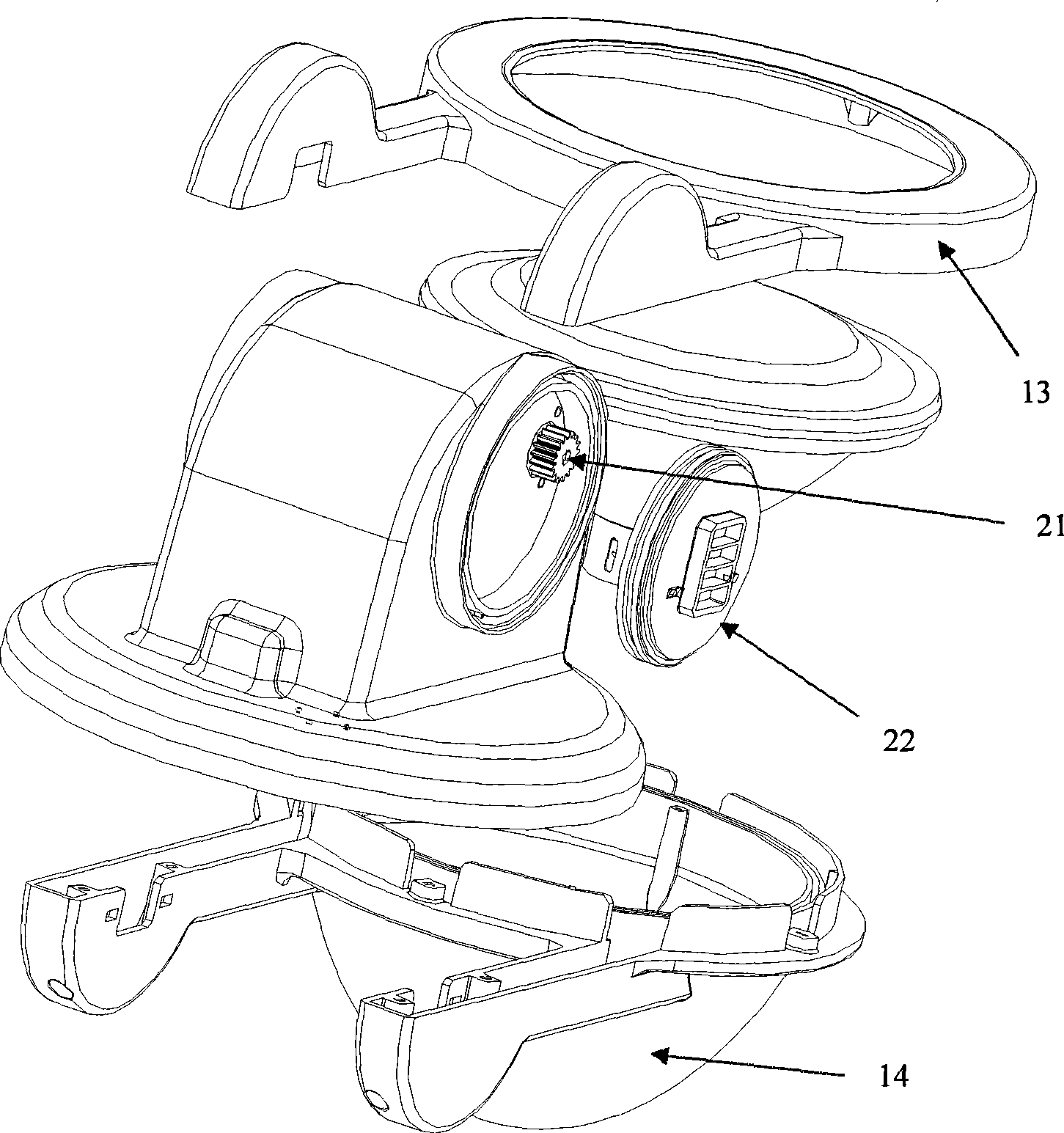

Magnetic adhesion apparatus and searchlight including the same

InactiveCN101469847AWon't scratchWill not cause scratchesLighting support devicesMagnetic tension forceClosed loop

The invention relates to a magnetic adsorption device and a searchlight comprising the magnetic adsorption device. The magnetic adsorption device comprises a magnet, a fixing base and a magnetic switch for enabling / disabling the magnet to produce adsorptive force; the searchlight comprises a lamp cap, a main body, a chassis and at least a magnet arranged on the chassis, at least a part of the magnet is equipped with a magnetic switch for enabling / disabling the magnet to produce adsorptive force. The magnetic switch comprises two magnetic conductors fixed on the fixing base and a rotary member arranged on the magnet for rotating the magnet; a non-closed loop which has circular inner wall with two symmetrical notches is formed by arranging symmetrically the two magnetic conductors at a certain distance; the magnet, being cylindrical, is capable of rotatably being installed on the fixing base and positioned in a cavity formed by the inner wall of the non-closed ring. The invention is capable of disassembling the magnetic adsorption device or the searchlight from a carrier without scratching or deforming the surface of the carrier.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

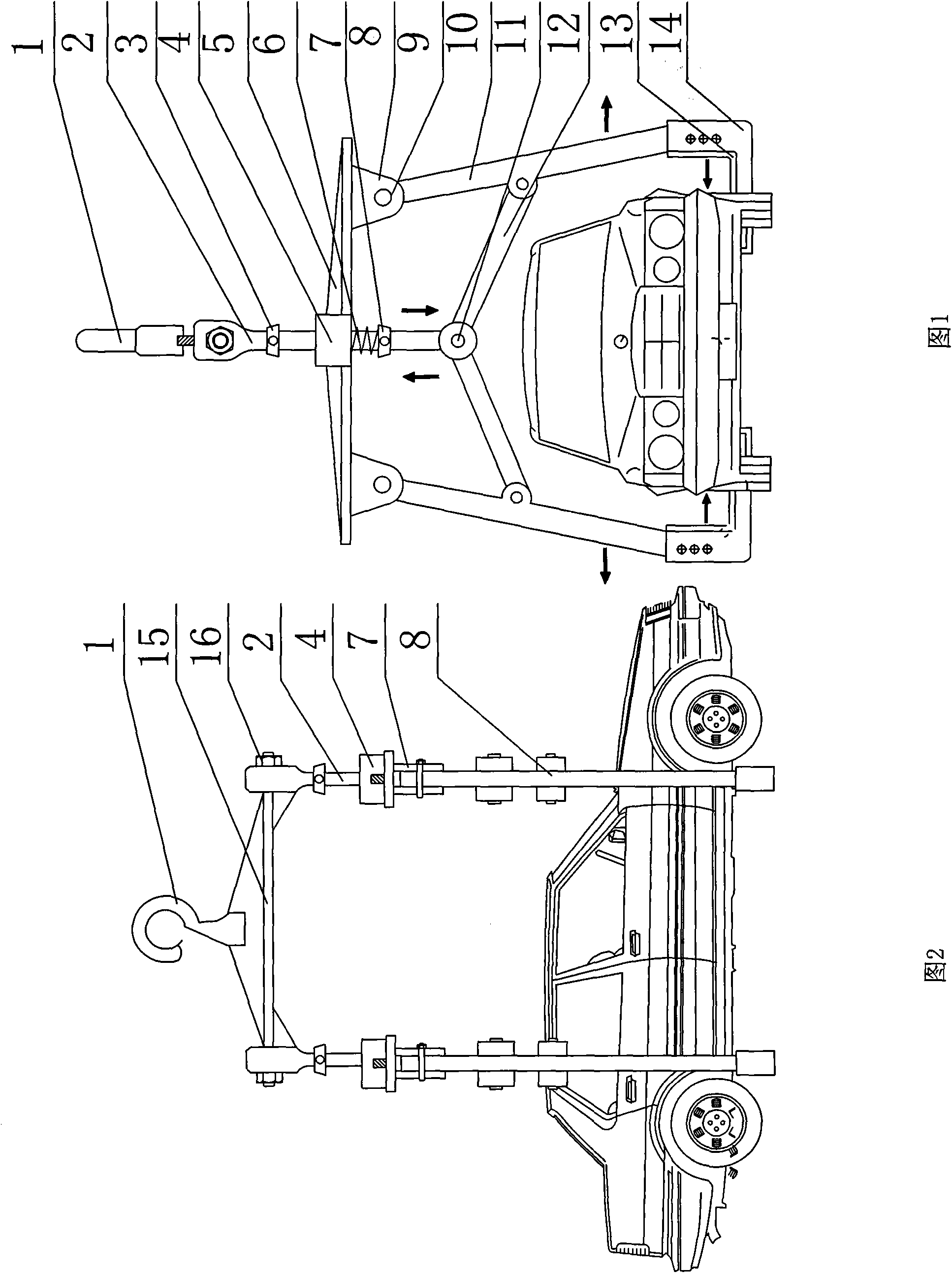

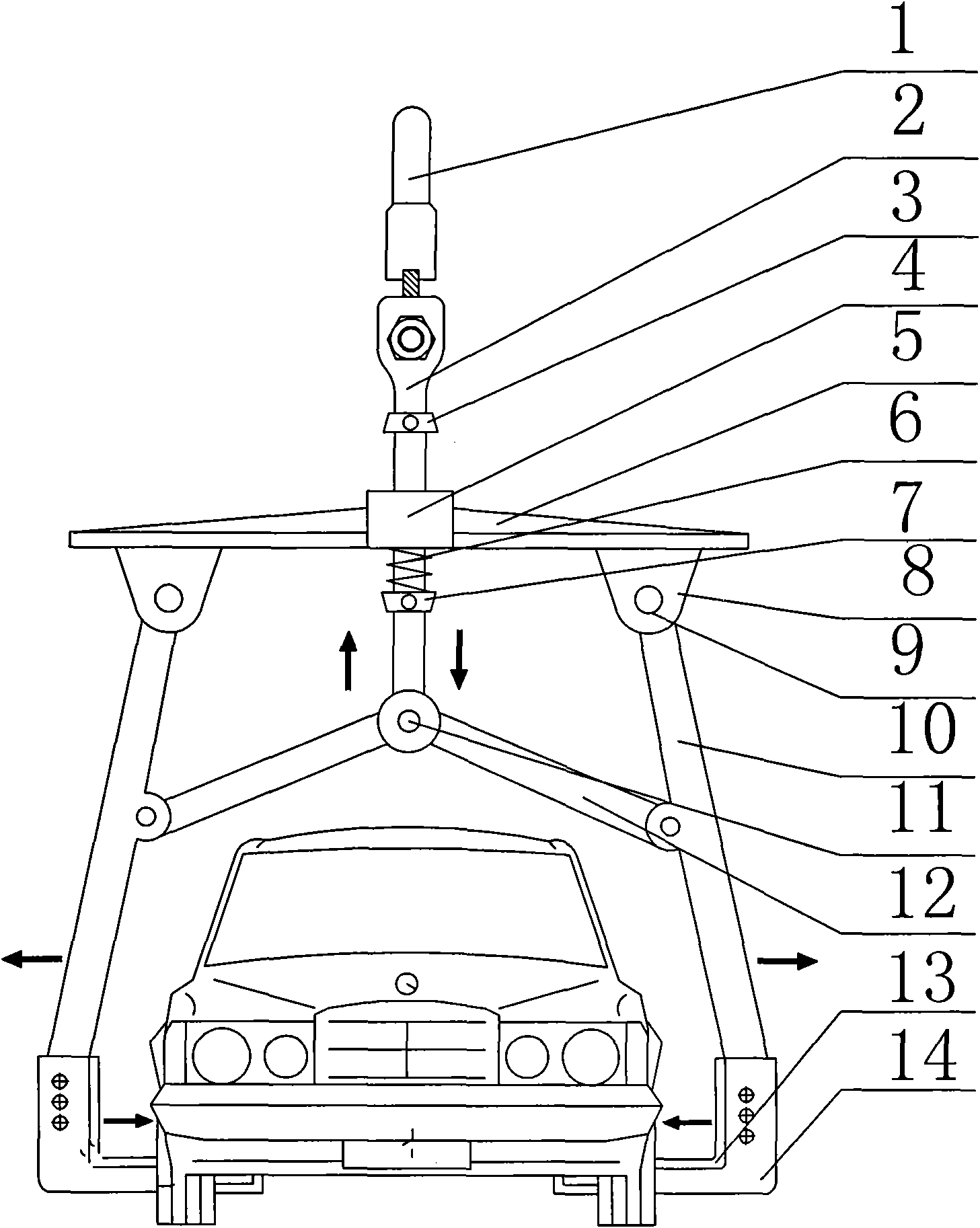

Semi-automatic motor vehicle unloading and lifting device

InactiveCN102464263AWill not cause scratchesIncreased load-bearing capacityLoad-engaging elementsProduction lineSemi automatic

The invention discloses a semi-automatic motor vehicle unloading and lifting device, belonging to motor vehicle unloading and lifting equipment on a coating production line. The semi-automatic motor vehicle unloading and lifting device is designed through optimal combination by adopting the lever principle. The semi-automatic motor vehicle unloading and lifting device comprises a lifting hook, a movable rod, an upper position-limiting block, a guide sleeve, a small lifting frame, a spring, a lower position-limiting block, a connecting lug, a pin shaft, a large support arm, a center shaft, a small support arm, a rubber protective pad, a support foot, a large lifting frame and a screw nut. The semi-automatic motor vehicle unloading and lifting device is applicable to the unloading and the lifting of different motor vehicles, and has the advantages of good bearing load, simplicity in manufacture, convenience and rapidness for unloading and lifting, safe operation and saved labor; the appearance of a vehicle body is not damaged through being scratched by a lifting device, the product quality is ensured, and the production efficiency is also improved.

Owner:孙中华

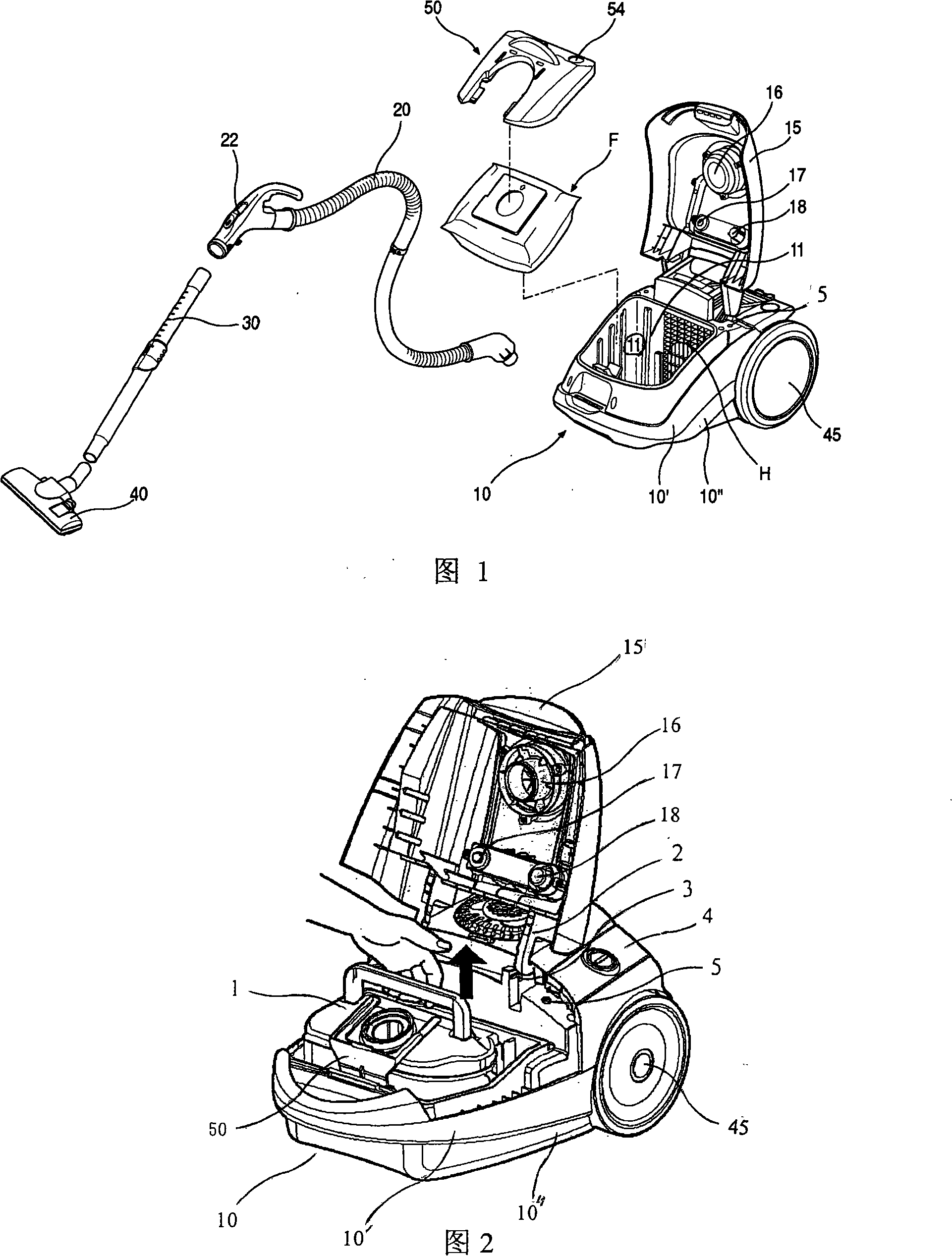

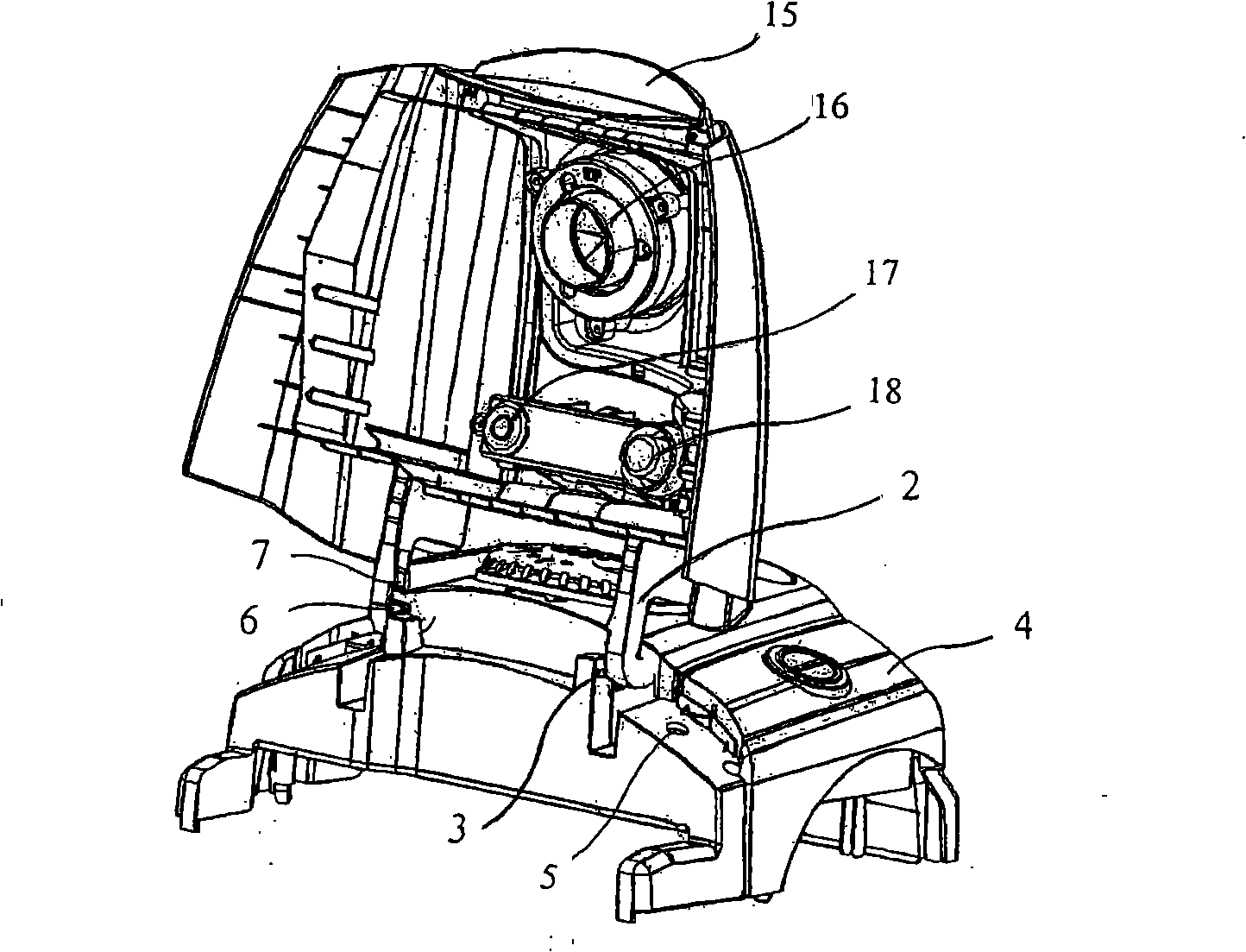

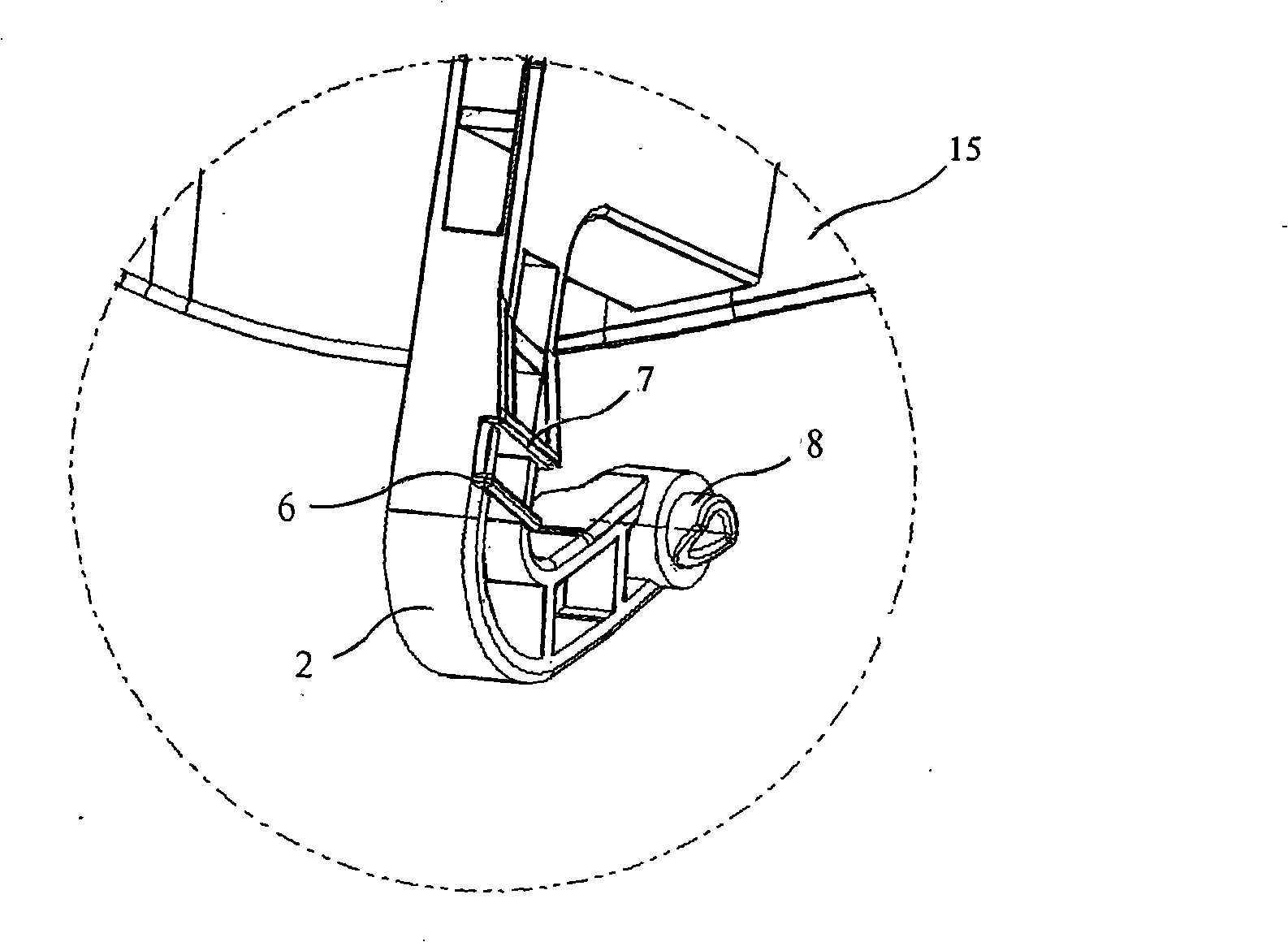

Vacuum cleaner front cover switching-on two-position spacing structure

InactiveCN101278815AImprove versatilityImprove competitivenessSuction cleanersFront coverEngineering

The present invention relates to a dust collector, in particular to a front-cover opening two-gear spacing structure of a vacuum dust collector, which solves the problem of a dust collecting box and the universalization of a dust collecting bag of the dust collector, and the problem is also that the front cover is easily damaged when screws are fastened in the production and assembling of the dust collector. The collector comprises a main body which is provided with a sucking fan arranged inside; caster wheels are arranged on the two sides of a main body; a sucking nozzle is communicated with the inner part of the main body by a hose and an expansion pipe; an upper-part shell, a lower-part shell, a front cover and a rear cover form the appearance of the main body; a dust collecting part is caved to the inner part of the main body; a fixing clip of the dust collecting bag is blocked on the front edge of the dust collecting part; and the dust collecting bag or the dust collecting box is arranged in the dust collecting part. The dust collector is characterized in that in order to lead the loading and unloading of the dust collecting box and the production and assembling of the dust collecting box to be convenient and not damage the front cover, the front cover and the rear cover of the main body are designed as that a convex shaft of a shaft rack is rotationally connected with an axle hole and the front cover and the rear cover of the main body are provided with a double spacing and a blocking boss of the front-cover opening two-gear spacing structure. The dust collector achieves the universality of the dust collecting device of the dust collector and increases the convenience of product assembling and use and the market competitiveness.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

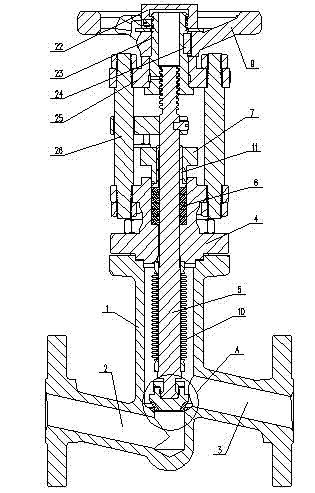

Chlorine stop valve

InactiveCN102966744AReduces the accumulation of dirtExtended service lifeSpindle sealingsLift valveVertical distanceFlange

The invention provides a chlorine stop valve which relates to a valve. The chlorine stop valve comprises a valve body, and an inlet passage and an outlet passage at the lower end of the valve body, wherein a valve cover is arranged at the upper end of the valve body; a valve rod penetrates through the valve cover; the upper end of the valve rod is connected with a hand wheel assembly; the lower end of the valve rod is connected with a valve clack assembly; a gland packing and a pressing plate are arranged between the valve rod and the valve cover; a corrugated pipe is arranged at the lower section of the valve rod; one end of the corrugated pipe is welded on the valve cover and the other end thereof is welded on the valve rod; and a valve clack is matched with a valve port sealing surface between the inlet passage and the outlet passage. The chlorine stop valve is characterized in that the valve cover is short; the valve body adopts a long neck design; the total height of the short valve cover is less than the maximum outside diameter of the valve cover; and the vertical distance from an upper plane of a middle flange of the long neck valve body to the highest point of a side flange of the valve body exceeds 1.5 times the diameter of a flow passage. The chlorine stop valve has the advantages that the chlorine stop valve is self-cleaning, long in service life, higher in overall safety, and convenient to dismount, maintain and replace.

Owner:JIANGSU DINGSHENG VALVE

Production process of aluminum alloy liquid tank truck

The invention relates to a production process of an aluminum alloy liquid tank truck. The process mainly comprises the steps of automatic welding of jointed boards, tank wrapping, tank body ring seamwelding, manufacturing of a sedimentation tank plug, assembling of a steel truck frame and an auxiliary truck frame, steel frame assembling, manufacturing of an end socket and an anti-wave plate and final assembly. The tank wrapping process adopts automatic welding of the jointed boards, the welding speed is high, the welding quality is good, the weld seam is attractive after molding, the problemsof assembling gaps and misalignment of a tank body and the end socket and attaching gaps of partition plates and cylinder plates are solved, and the welded tank body is better in straightness and more attractive in appearance.

Owner:SHANDONG SANXING MACHINERY MFG

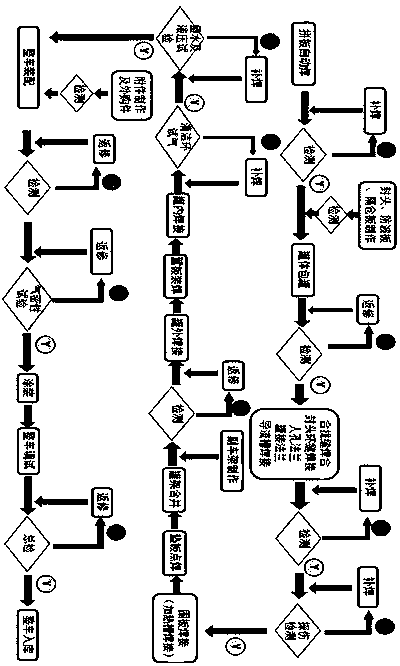

Automatic optics testing device and method for PCBs

InactiveCN105129408AHigh split efficiencyWill not cause scratchesOptically investigating flaws/contaminationConveyor partsInductorEngineering

The invention provides an automatic optics testing device and method for PCBs. The automatic optics testing device comprises a conveying acceleration section, a steering corner temporary storage machine, a conveying storage position, an inductor and AOI equipment. The steering corner temporary storage machine is arranged at the conveying tail end of the conveying acceleration section. The inductor is arranged at the inner side of the steering corner temporary storage machine. The conveying storage position is arranged at one side of the steering corner temporary storage machine. The AOI equipment is arranged beside the conveying storage position. The invention further provides an automatic optics testing method for the PCBs. The method is implemented through the automatic optics testing device for the PCBs. The method comprises the following steps that 1, the PCBs are sequentially conveyed to the conveying acceleration section after being treated through a copper etching technology; 2, whether the PCBs reach the steering corner temporary storage machine is judged by means of the inductor, and when the PCBs reach the steering corner temporary storage machine, the steering corner temporary storage machine enables the PCBs to be steered and conveys the PCBs into the conveying storage position; the PCBs in the conveying storage position are conveyed into the AOI equipment; automatic optics testing is carried out on the PCBs by means of the AOI equipment.

Owner:HUANGSHI HUSHI ELECTRONICS CO LTD

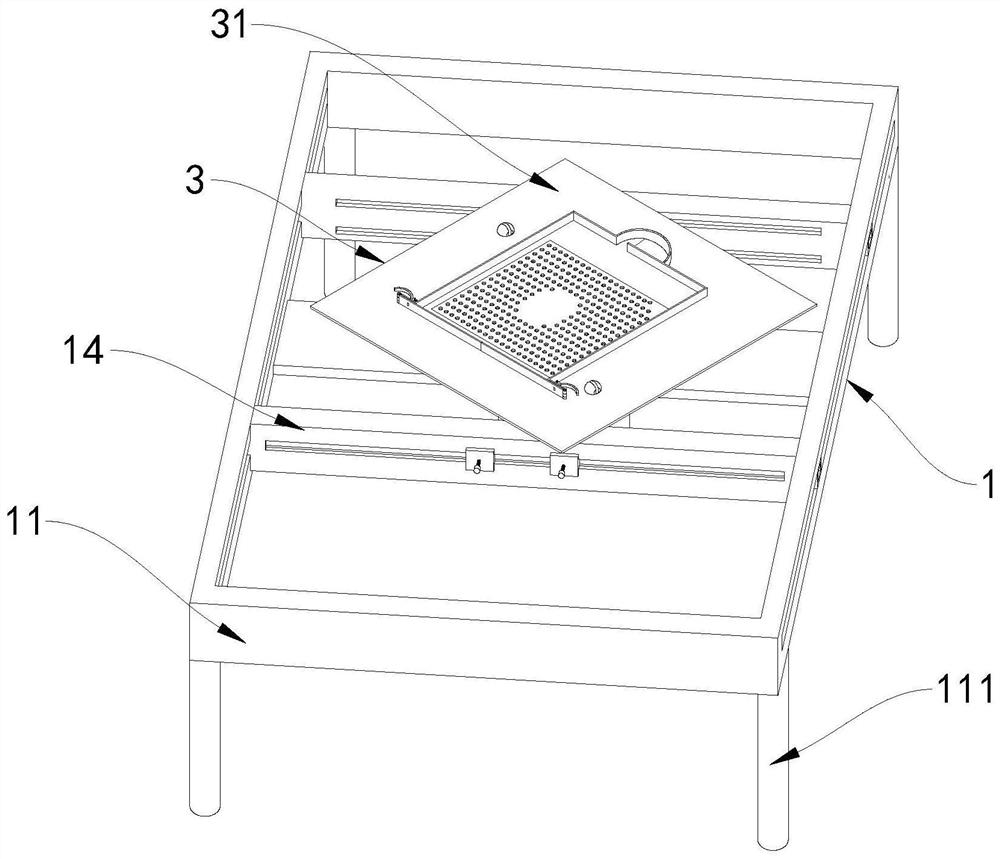

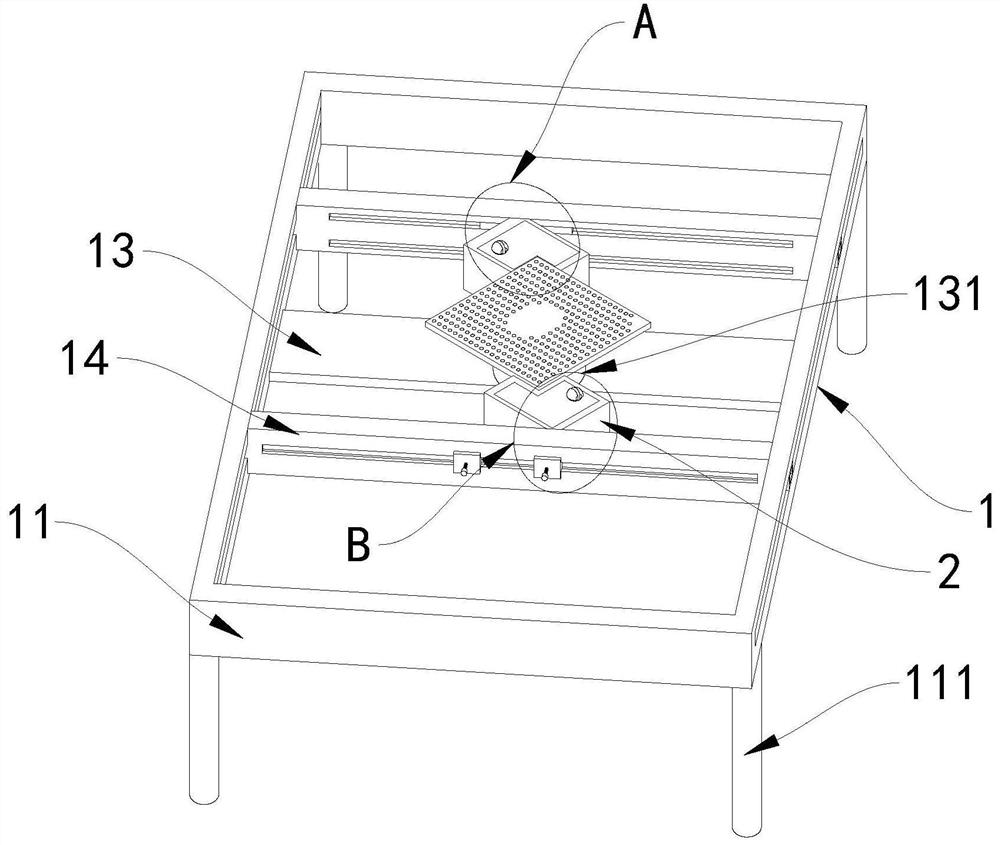

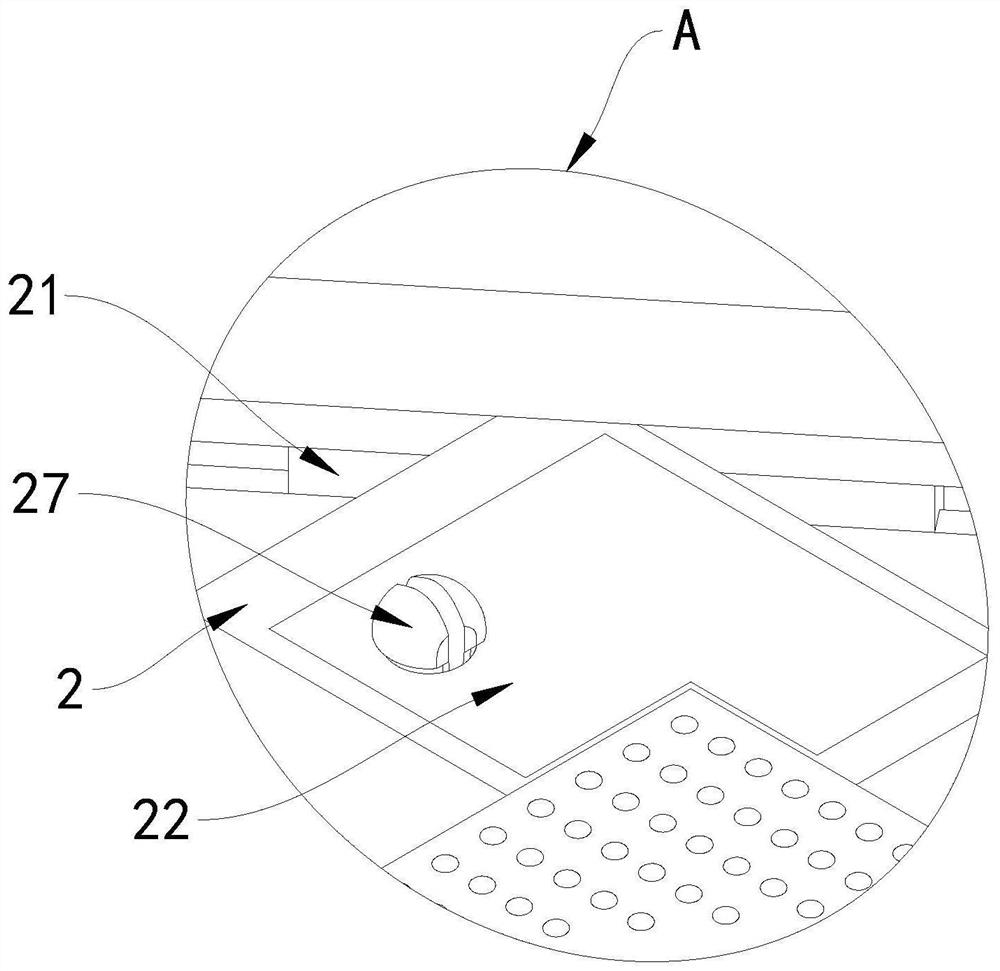

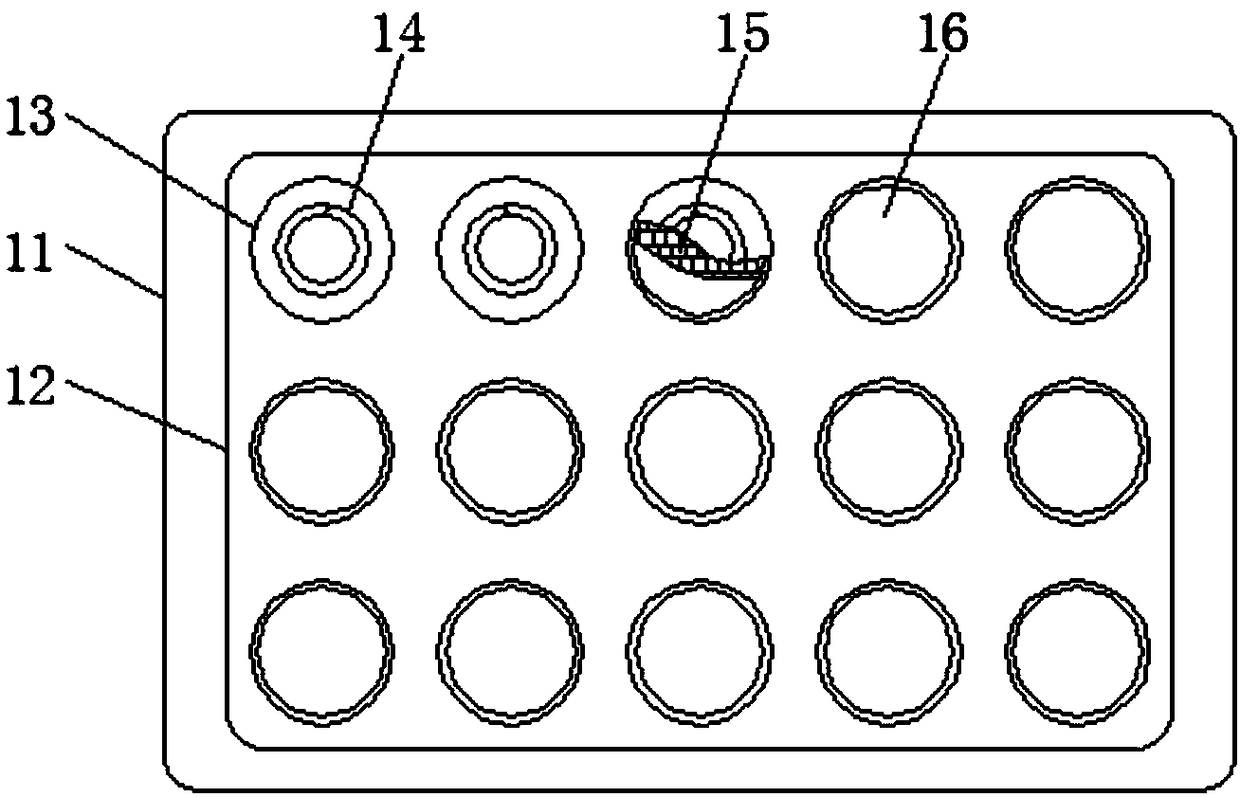

Chip ball mounting tool and method based on computer whole machine manufacturing process

InactiveCN114068338AUniform coatingWill not cause scratchesSolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologyEngineering

The invention discloses a chip ball mounting tool and method based on a whole computer manufacturing process, and relates to the technical field of chip ball mounting. The tool comprises a chip positioning jig used for positioning a chip to be subjected to ball mounting, the chip positioning jig comprises a positioning frame, sliding holes are formed in the two sides of the positioning frame, a supporting table used for placing the chip is arranged in the positioning frame, at least two sliding rods are movably arranged in the positioning frame, and movable grooves, movable cavities and movable holes are sequentially formed in the sliding rods. The chip positioning jig, the height adjusting block and the chip ball mounting jig are arranged, the chip positioning jig is used for clamping and positioning a chip, the height adjusting block is used for adjusting according to the thickness of the chip, and finally, the chip ball mounting jig is used for assisting in solder paste coating and ball mounting operation on the chip, so that the operation mode is simple and rapid. In the process, the chip is not scratched, tin paste coating is uniform and rapid, and the method has a wide application prospect.

Owner:深圳市美祺科技有限公司

TFT cutting and separating device

InactiveCN112551880AEasy to replaceRapid cooling downGlass severing apparatusCutting glassClean environment

The invention discloses a TFT cutting and separating device which comprises a cooling and quenching device, a heating and radiating device and a cutting and separating quality detection module, a glass substrate at the cutting and scribing position is rapidly heated through the heating and radiating device, and the glass substrate at the cutting and scribing position is rapidly cooled through thecooling and quenching device; the cut glass is subjected to stress change from the scribing part and is broken in the scribing direction, the effect that the cut glass can be broken off along the scribing part is achieved, separation is not conducted in a hard breaking mode, and stress change breaking is started from the interior of the glass body in the separation process; therefore, mechanical broken and cracked glass chippings cannot be generated at the moment of separation, equipment pollution and product pollution are well prevented in a clean environment, and the device can be widely applied to glass cutting and thermal separation after lineation of different thicknesses and lengths. High-precision equipment does not need to align to a scribing part, and scribing position changes ofdifferent similar sizes can be conveniently compatible.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

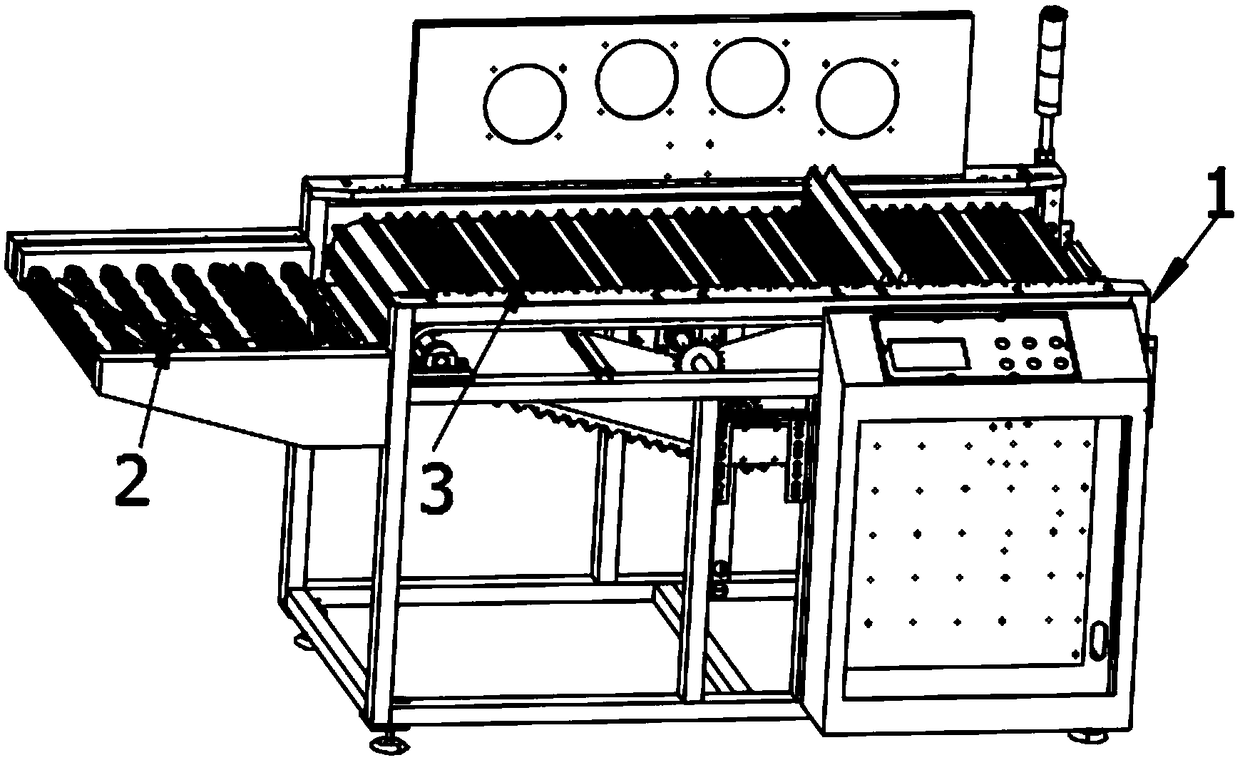

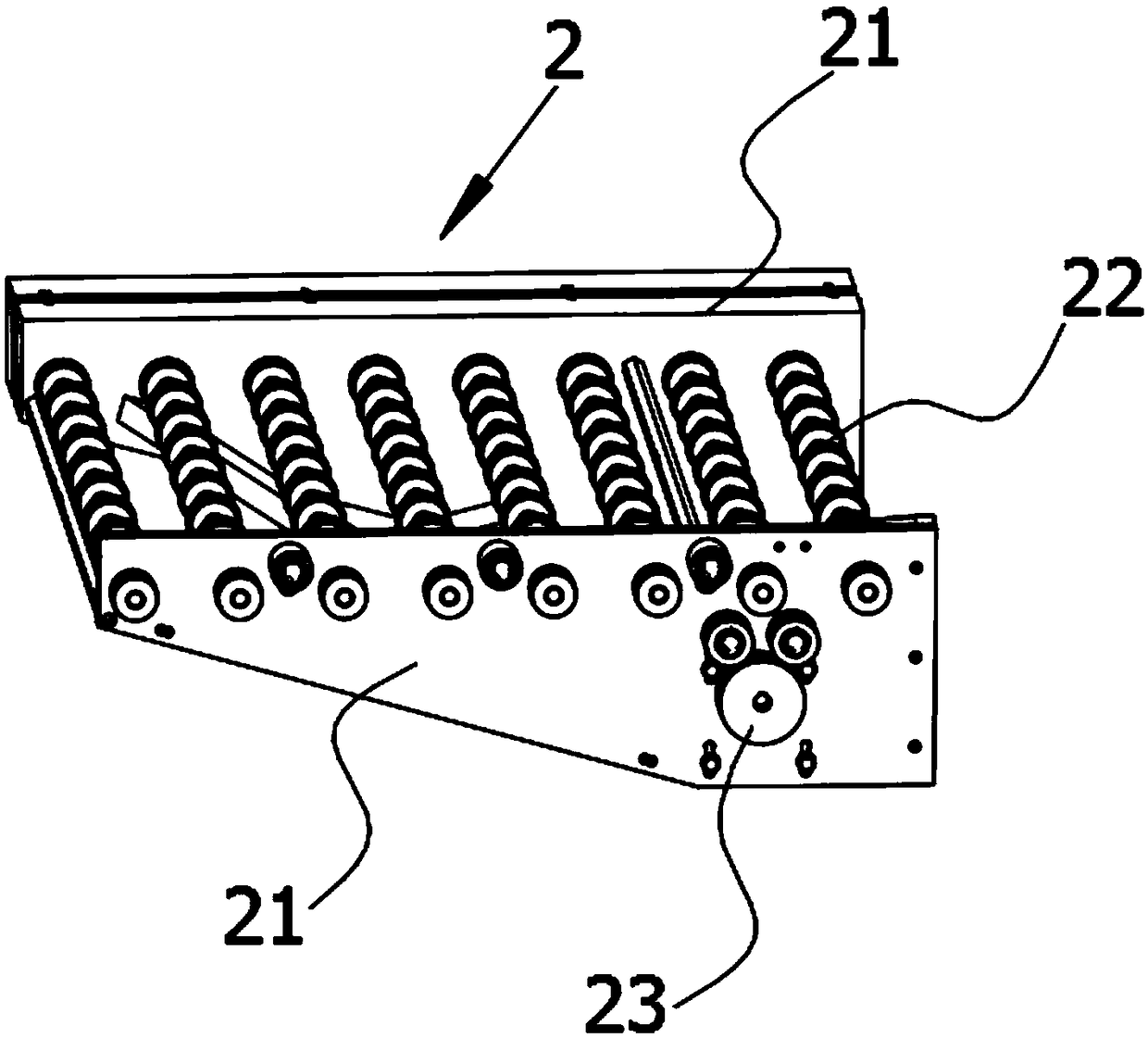

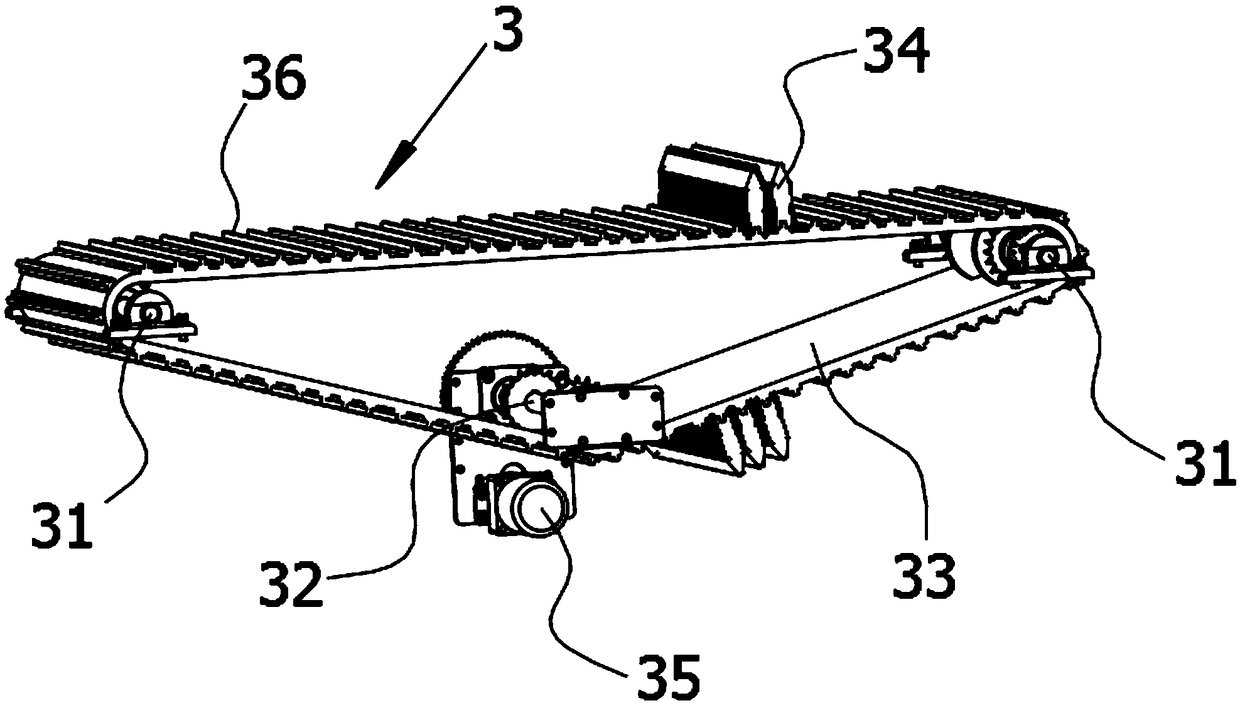

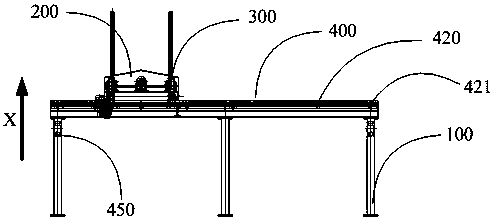

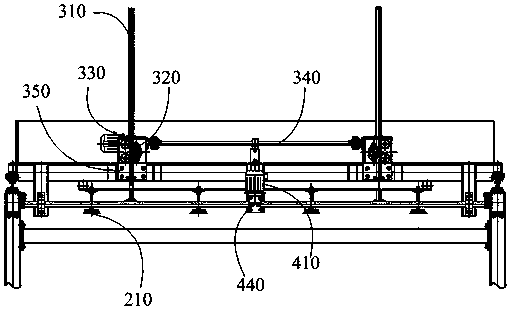

Universal type plate placing machine

InactiveCN109051525AWill not cause scratchesIncrease frictionConveyorsConveyor partsMechanical engineeringEngineering

The invention discloses a universal type plate placing machine. The universal type plate placing machine comprises a machine frame, a drive mechanism and a conveying turnover mechanism, wherein the drive mechanism and the conveying turnover mechanism are fixed on the machine frame. The conveying turnover mechanism comprises two driven rollers and a drive roller which are fixed on the machine frame, a conveying belt which are connected with the driven roller and the drive roller, and a turnover clamping plate which are detachably connected with the conveying belt. The drive roller is located between the two driven rollers, and a first motor is connected to one end of the drive roller. A plurality of clamping blocks are arranged on the peripheral surface of the conveying belt, and the lengthdirection of the clamping blocks is parallel to the width direction of the conveying belt. Clamping grooves connected with the clamping blocks in a clamping mode are formed in the lower end of the turnover clamping plate, anti-skid structures are arranged on the left and right side walls of the turnover clamping plate separately, and the anti-skid structures are formed by connecting a plurality of anti-skid protruded strips in sequence. The universal type plate placing machine can realize efficient and stable conveying of PCB with different thickness and perform 180 degrees turnover, and canfurther avoid the scratch of PCB surface.

Owner:大江南电子科技(昆山)有限公司

Full-automatic rotary type indentation gold stamping equipment

The invention discloses full-automatic rotary type indentation gold stamping equipment. The full-automatic rotary type indentation gold stamping equipment comprises a workbench, an object printing frame and a conveying wheel, wherein a horizontal substrate is installed on the workbench, and a support is fixed above the rear side of the horizontal substrate; a bearing seat is welded to the front side of the upper part of the support, and a sign is arranged on the front side of the bearing seat; the left side and the right side of the lower part of the bearing seat are correspondingly provided with fixed printing shafts, a supporting shaft is arranged between the fixed printing shafts, and a is installed below the fixed printing shafts; a protective plate is arranged below the supporting shaft, a heating block is arranged below the object printing frame, and the object printing frame is located on the back side of the protective plate; and a wheel middle shaft is fixed in the middle of the conveying wheel, and the conveying wheel is located at the right lower part of a traction wheel. When gold paper is transmitted by the full-automatic rotary type indentation gold stamping equipment, the gold paper can be subjected to synchronous smoothing operation, heating is uniform, heating uniformity can be ensured after the equipment is used for a long period of time, and the service lifeis relatively long.

Owner:方圆塑胶彩印制品(江西)有限公司

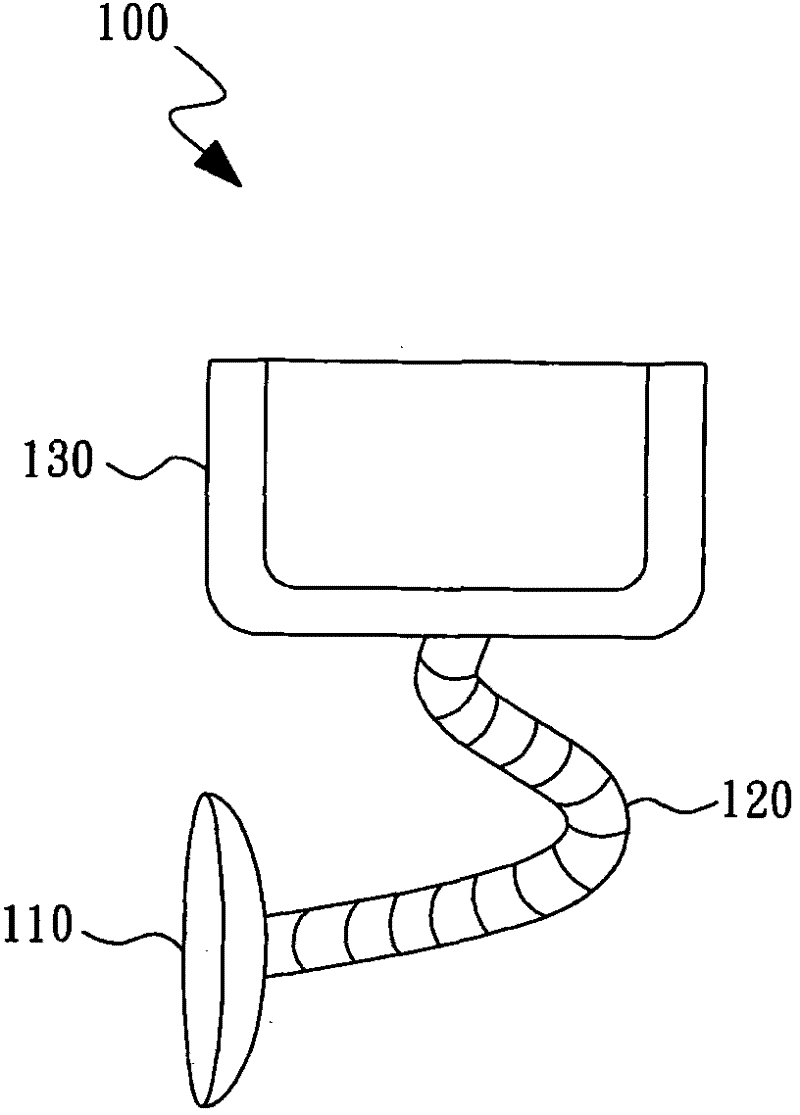

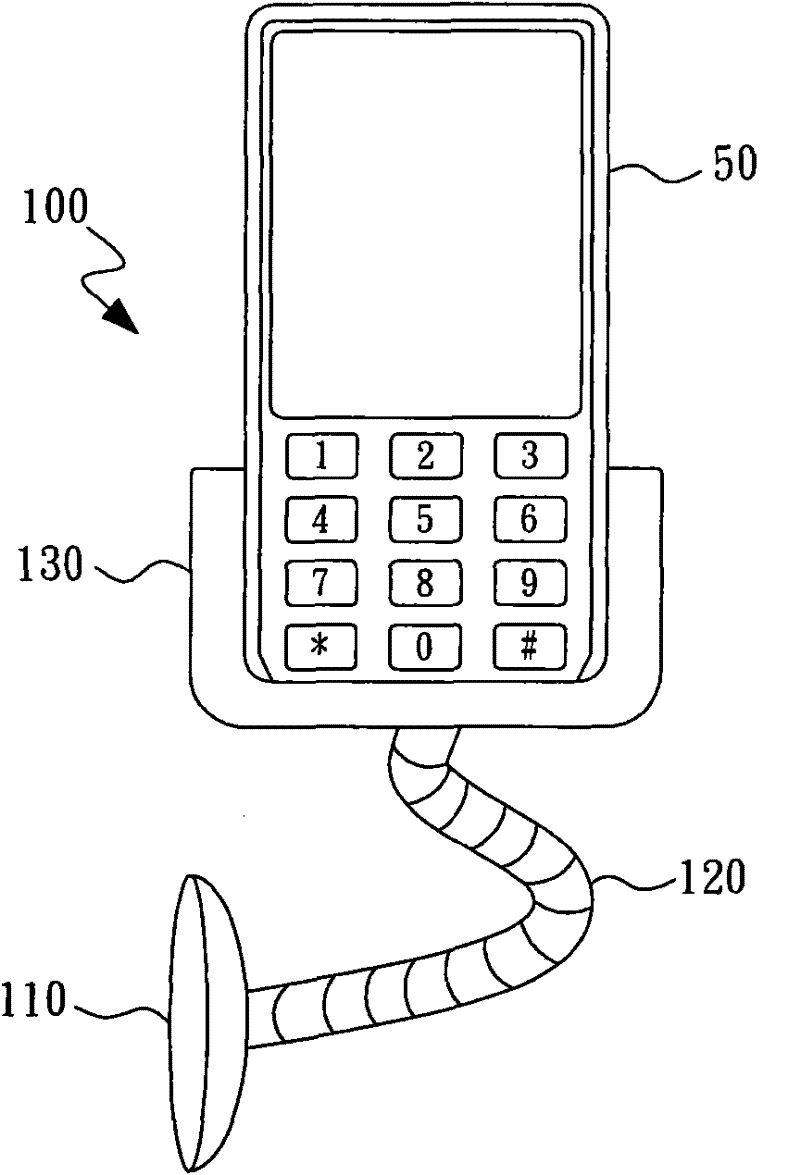

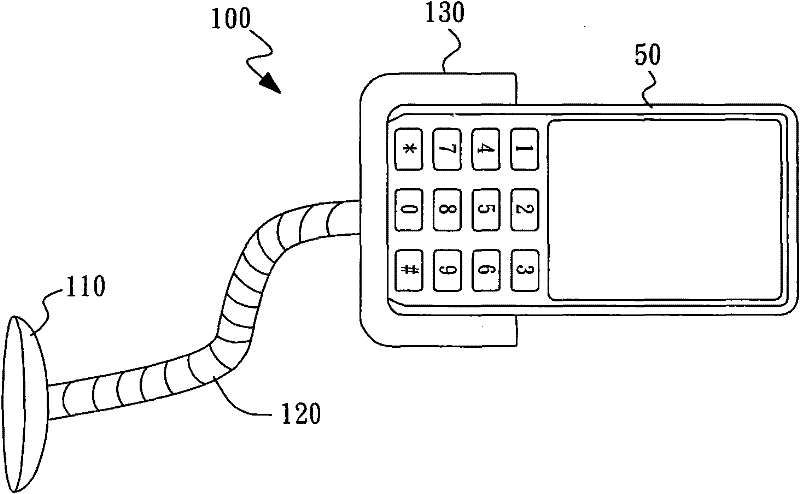

Fixing frame of electronic device

InactiveCN102242856AMeet needsWill not cause scratchesStands/trestlesVehicle componentsFixed frameEngineering

Owner:TAIDING TECH

Automatic and on-line method for weighing and measuring thickness of plate glass

InactiveCN109000768AWill not cause scratchesLoose requirementsSpecial purpose weighing apparatusProduction lineFlat glass

The invention discloses an automatic and on-line method for weighing and measuring thickness of plate glass. The automatic and on-line method comprises the following steps of arranging a parallel beamweighing sensor between a glass split table support rack and a glass split table; arranging three upper measurement air cylinders, and connecting the three upper measurement air cylinders to an upperdisplacement sensor; arranging three lower measurement air cylinders, and connecting the three lower measurement air cylinders to a lower displacement sensor; controlling a glass split table supportair cylinder to ascend by a glass production line PLC when glass runs at the glass split table so that the glass is raised from a transmission roller; sending acquired weight data to the glass production line PLC by the parallel beam weighing sensor, subtracting weight of the split table from the weight data to obtain glass weight by the glass production line PLC; and controlling the three upper measurement air cylinders to descend and simultaneously controlling the three lower measurement air cylinders to ascend by the glass production line PLC, and performing calculation to obtain glass thickness of a measurement point by the glass production line PLC according to displacement data fed back by a displacement sensor. By the automatic and on-line method, the working efficiency is improved,the labor cost is reduced, and the detection accuracy is improved.

Owner:海控三鑫(蚌埠)新能源材料有限公司

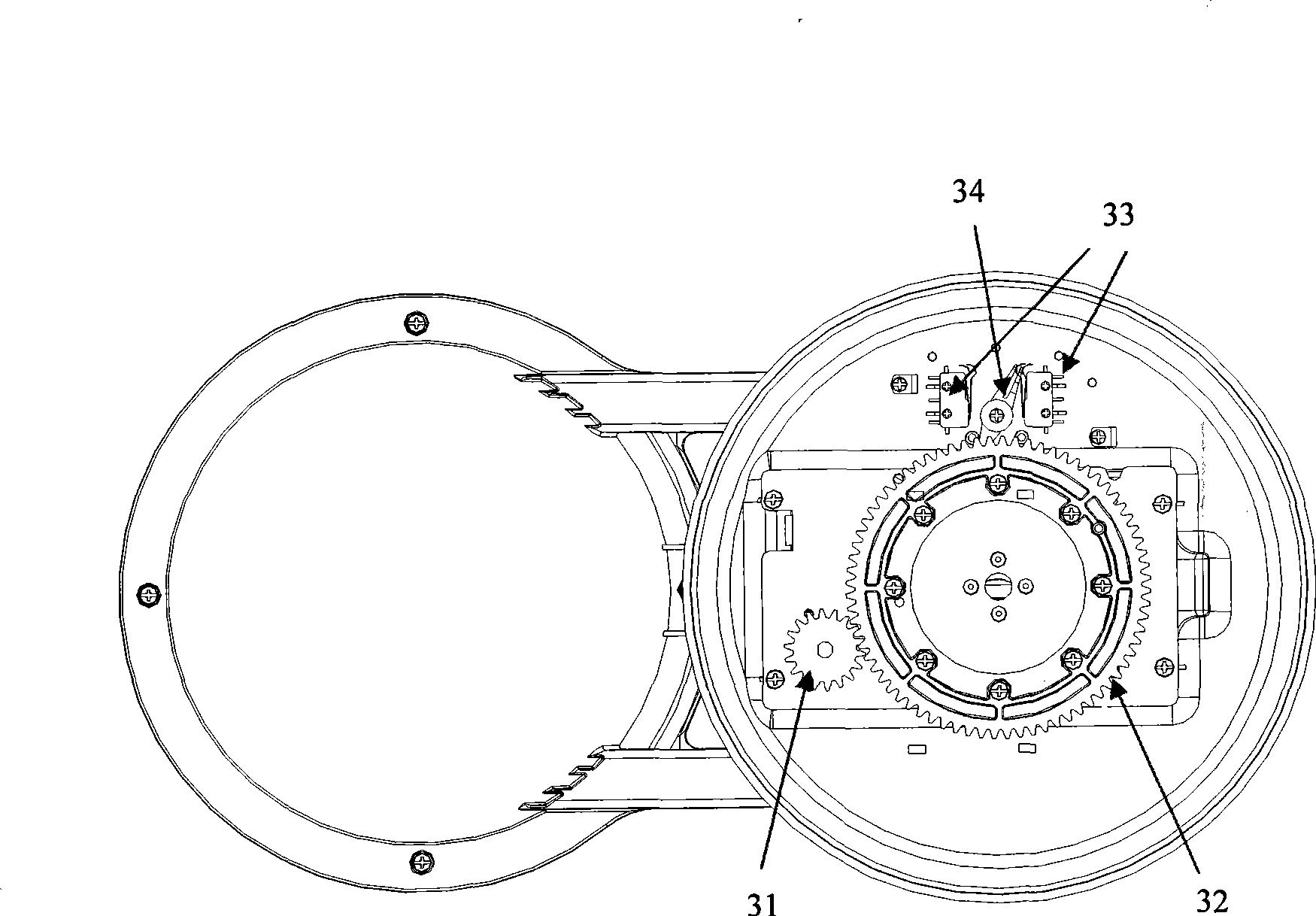

Seamless wireless type plate shape gauge of entire roller

InactiveCN101694368BAvoid Zero Drift ProblemsExcellent high frequencyUsing electrical meansLinear/angular speed measurementShielded cableLow noise

The invention discloses a seamless wireless type plate shape gauge of an entire roller, which is characterized in that a plate shape gauge detecting roller (2) detects an original plate shape signal which is transmitted to a signal processing circuit board (31) in a power self-generating signal processing and wireless emitting device (4) through a low noise coaxial high shielded cable(30); and after being processed by a DSP chip, a coded digital signal packet is output by a wireless emitter (36) in the power self-generating signal processing and wireless emitting device (4) in a wireless way. After the wireless receiver (5) receives the data packet, a decoder (6) restores the received data packet and delivers the data packet a software processing system (7) for carrying out digital filtration, signal compensation, and the like on the plate shape signal so as to obtain real online plate shape data. The invention avoids scratching the surface of a band steel; a differential charge amplifier is adopted so that the plate shape gauge has fine high frequency and low frequency response characteristics; all circuits are completely sealed inside a roller body, the data packet of the plate shape signal is emitted in real time through antennae and the plate shape gauge has excellent shielding property, realizes wireless emitting and receiving of the signal, avoids slip ring type wired transmission, effectively eliminates the influence of interference factors on plate shape detecting signals and accurately detects the signal in real time so that the plate shape gauge can stably run for a long time under the a serious working condition.

Owner:YANSHAN UNIV

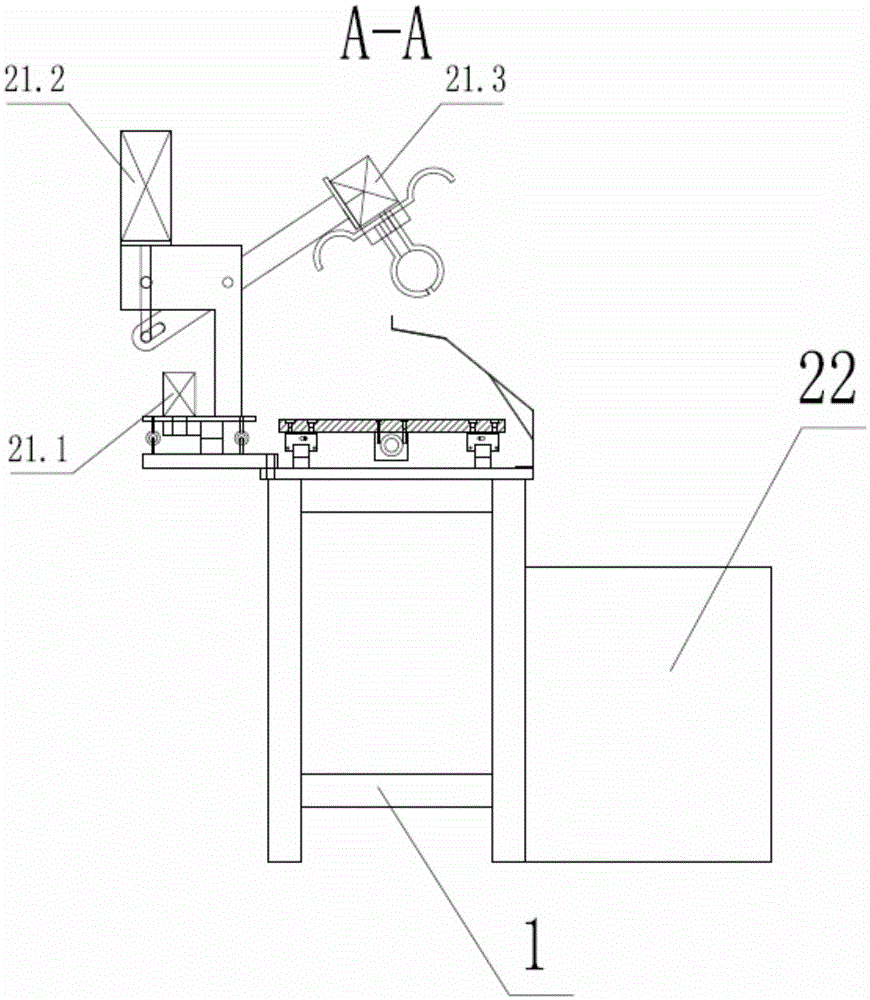

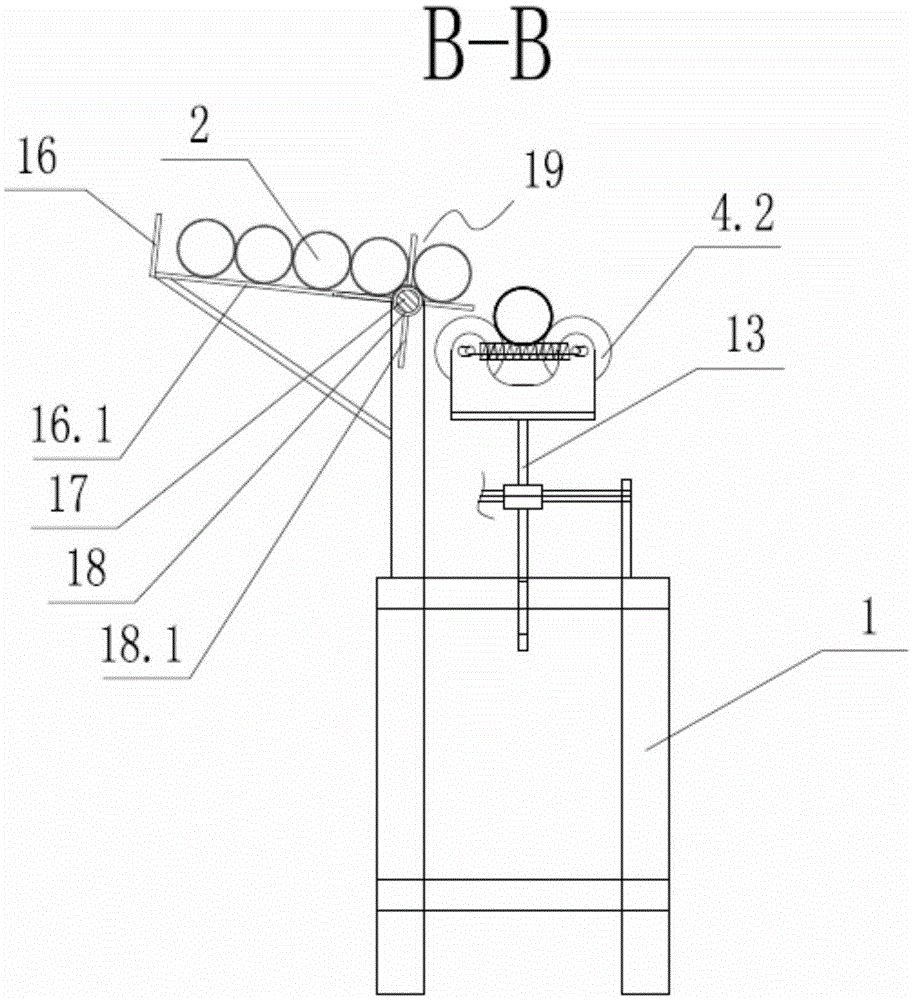

Bottom sealing strip edge-folding and punching device of bag making machine

PendingCN110802875AEffective protectionWill not cause scratchesBag making operationsPaper-makingPunchingStructural engineering

The invention discloses a bottom sealing strip edge-folding and punching device of a bag making machine. The device comprises a bottom strip edge folding assembly and a bottom strip punching assembly,wherein the bottom strip edge folding assembly comprises a door-shaped frame and a bottom plate, the door-shaped frame and the bottom plate are arranged on a bag making machine body, a cross beam ofthe door-shaped frame is provided with a connecting base, the connecting base is connected with an edge folding vertical plate through a connecting rod at the lower side, two bottom strip guide wheelsare arranged at the front end of the edge folding vertical plate, edge folding ejector rods are arranged on the two sides of the edge folding vertical plate, an edge folding pressing plate is connected to the bottom surface of the edge folding vertical plate, the edge folding pressing plate and the bottom plate form a bottom sealing strip guide space, the bottom strip punching assembly comprisesa sliding rod frame arranged on the bag making machine body, and a first punching assembly and a second punching assembly are arranged on the sliding rod frame in a staggered mode. The bottom sealingstrip edge-folding and punching device is simple in operation and ingenious in structure, a bottom sealing strip is effectively protected in the edge folding process, and the bottom sealing strip is prevented from being scratched in the edge folding process.

Owner:张家口通达纸塑彩印有限公司

Cutting machine

The invention relates to a cutting machine, in particular to the improved guideway locking structure and the turnplate locking structure of the cutting machine. A guideway locking piece is arranged near one of two guideways and is hinged with the turnplate; the guideway locking piece comes in contact with one end of a brake shaft, and the other end of the brake shaft comes in contact with the inner end of a guideway tight locking rotary knob which is in threaded connection with the turnplate; when the guideway tight locking rotary knob is tightly screwed, the brake shaft is pushed by the guideway tight locking rotary knob in a forward shaft direction, the front end of the brake shaft pushes the guideway locking piece to rotate so as to cause the guideway locking piece to tightly press the surface of the guideway, thereby relatively locking the guideway and the turnplate; and when the tight locking rotary knob is screwed to be loosened, the brake shaft loses the push force of the guideway tight locking rotary knob, the guideway locking piece is separated from the surface of the guideway to be reset, and the guideway and the turnplate can be relatively slid. The guideway tight locking rotary knob is convenient to be arranged, and the invention has the advantages of convenient locking operation, reliable locking and no surface scratch of the guideway.

Owner:王骥

Photovoltaic agricultural science and technology greenhouse with roof cleaning device

InactiveCN108738905AEasy to useWill not cause scratchesClimate change adaptationRenewable energy machinesWater sourceGreenhouse

The invention discloses a photovoltaic agricultural science and technology greenhouse with a roof cleaning device. The greenhouse comprises skeletons and supporting pillars, the ten or more skeletonsare distributed at equal intervals, the supporting pillars are arranged among the skeletons, the skeletons are arranged to be of semicircular structures, first spraying nozzles are arranged at the topends inside the skeletons and connected with water pumps through pipelines, the water pumps are connected with an external water source through pipelines, and an installing plates is rotatably connected to the top ends of the supporting pillars. When the photovoltaic agricultural science and technology greenhouse with the roof cleaning device is cleaned, a user only needs to control the work of second electric telescopic rods through a PLC, the spraying nozzles move, the water pumps work, and then water is jetted from the spraying nozzles to clean solar panels; the photovoltaic agricultural science and technology greenhouse with the roof cleaning device is easy to operate, will not scratch the surfaces of the solar panels, and is quite convenient to use for users.

Owner:阜阳市卓创科技服务生产力促进中心

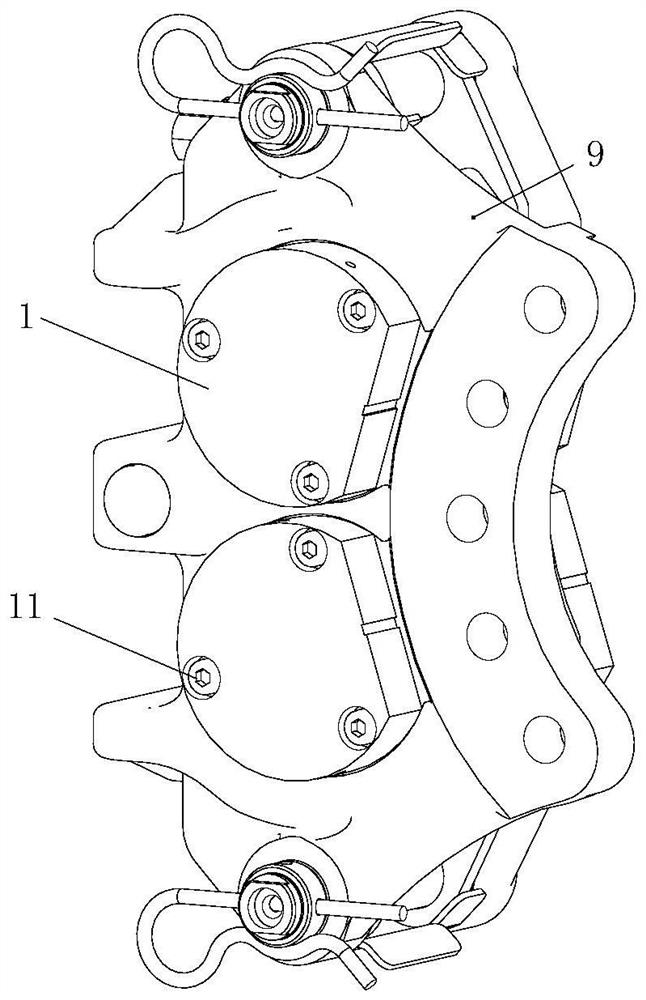

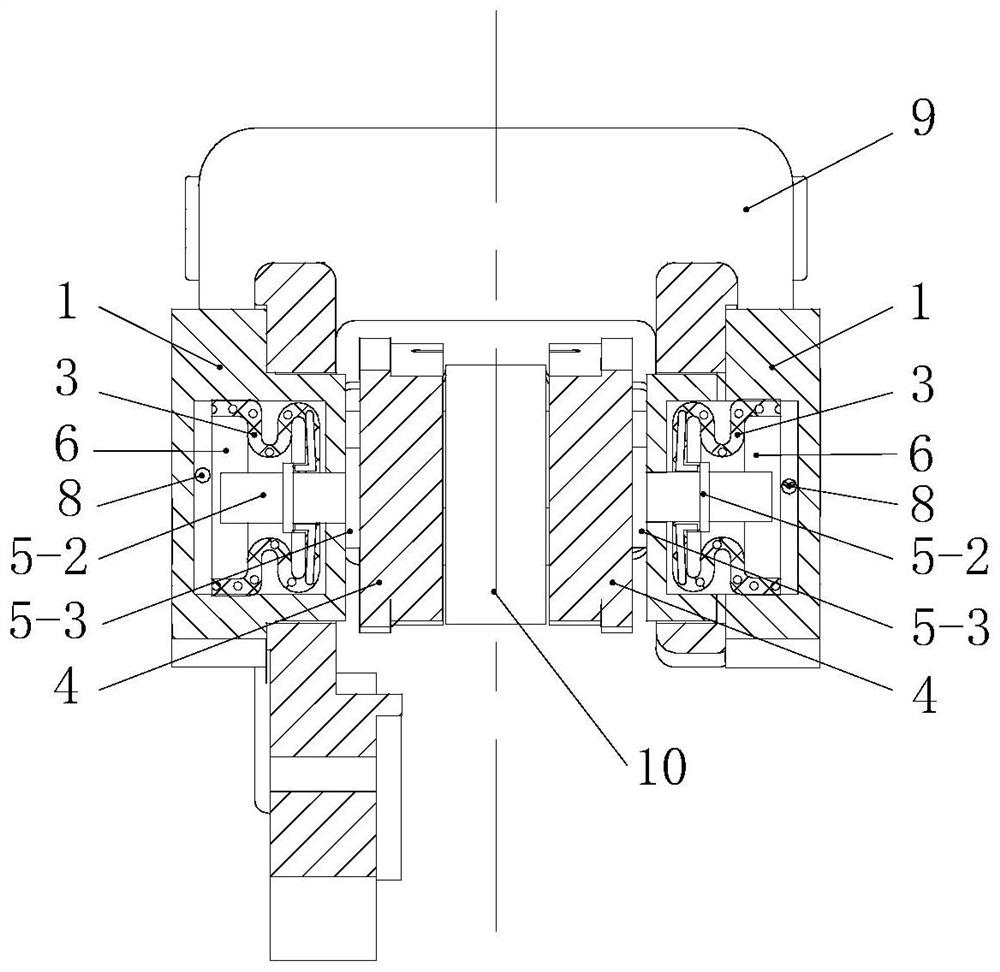

Brake oil cylinder for rail transit and brake clamp unit of brake oil cylinder

ActiveCN114233778ASolve the problem of not being able to reset automaticallyNormal clearanceBrake actuating mechanismsSlack adjustersThermodynamicsOil intake

The invention discloses a brake oil cylinder for rail transit and a brake clamp unit of the brake oil cylinder. The brake oil cylinder comprises an oil cylinder body (1), an oil inlet (8) is formed in the oil cylinder body, a piston (5-2) is arranged in the brake oil cylinder body, one end of a piston rod (5) of the piston extends out of the oil cylinder body, and an elastic sealing element (3) capable of generating elastic deformation in the axis direction of the oil cylinder body is contained in the oil cylinder body. A sealing oil cavity communicated with the oil inlet is formed in the elastic sealing element; the piston is sleeved with the elastic sealing element, one end of the elastic sealing element is connected with the inner cavity wall of the oil cylinder, and the other end of the elastic sealing element is connected with the piston; the distance between the elastic sealing element and the extending end of the piston rod of the oil cylinder is larger than or equal to the working stroke (X) of the elastic sealing element. According to the invention, a normal gap between the brake disc and the brake pad can be ensured after relieving, virtual attachment of the brake pad and the brake disc is avoided, and grinding particles generated by brake friction can be smoothly discharged.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

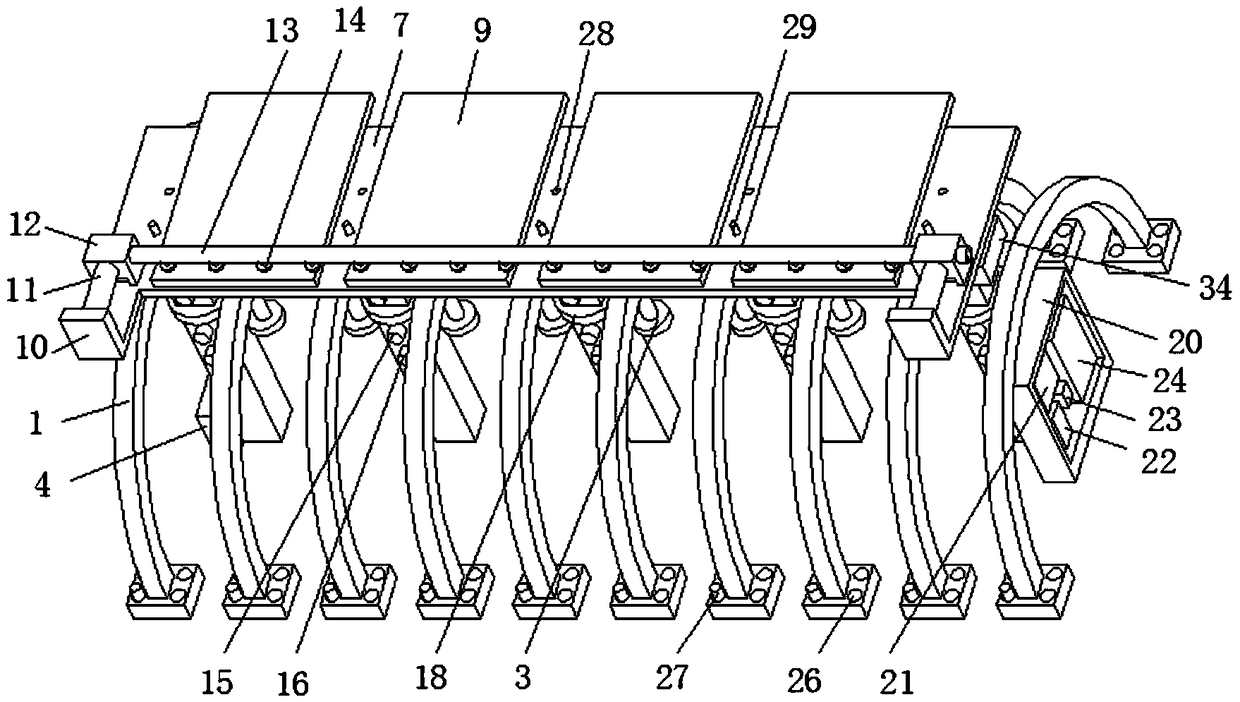

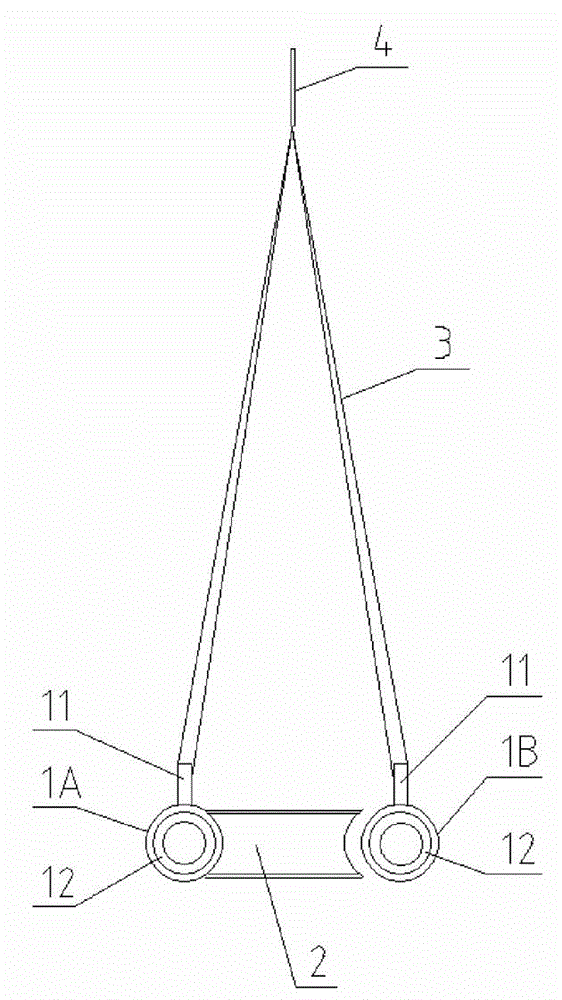

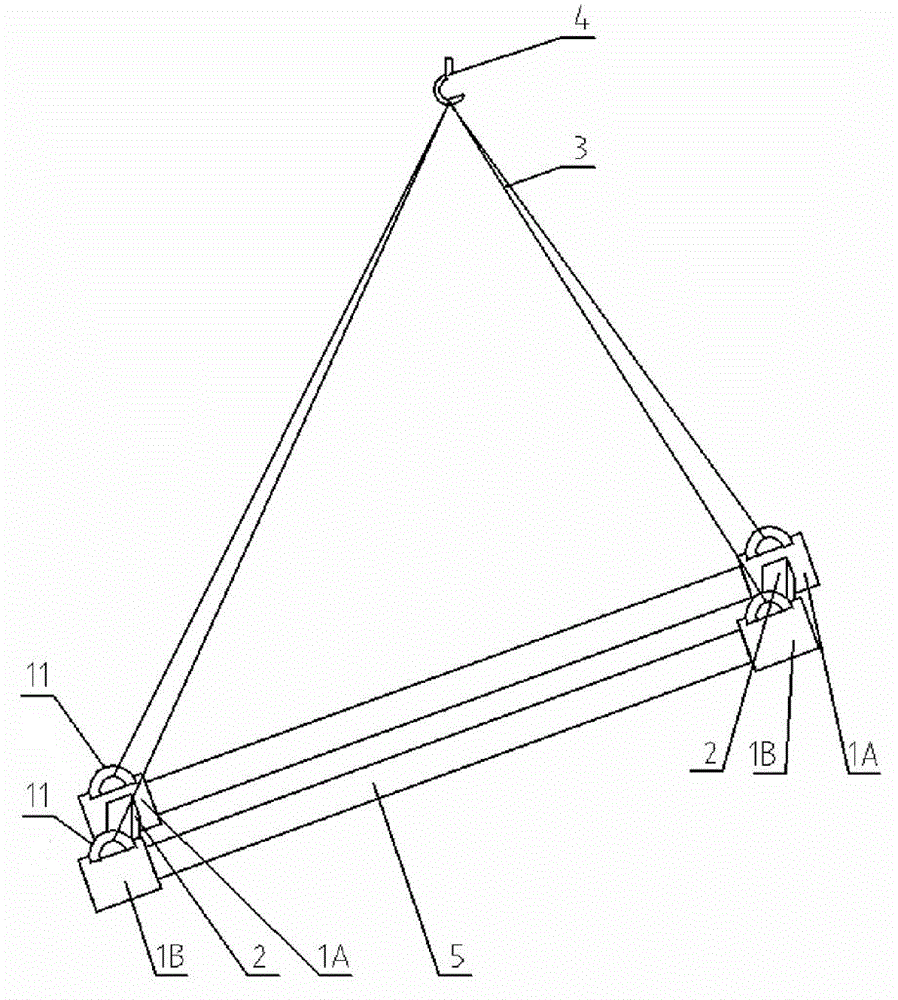

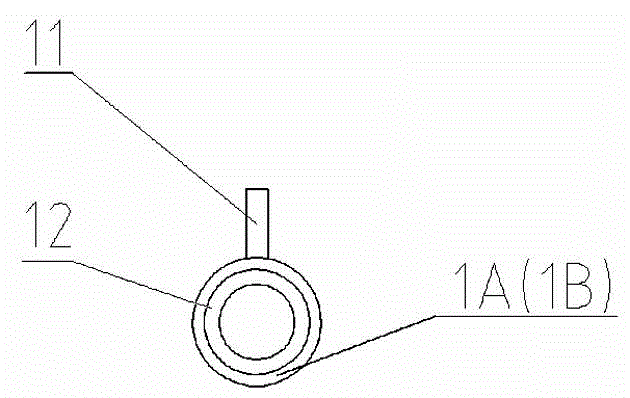

Double-roller hoisting device suitable for multi-roller rolling mill

ActiveCN103552906ASafe and efficient liftingWill not cause scratchesLoad-engaging elementsEngineeringRolling mill

The invention discloses a double-roller hoisting device suitable for a multi-roller rolling mill. The double-roller hoisting device comprises hoisting fasteners (1A-1B), a spacer bar (2) and a lifting rope (3), wherein one hoisting fastener (1A) and one hoisting fastener (1B) form a group of movable fasteners; two groups of movable fasteners form a pair of sling; an inner diameter of a cylinder (12) of each of the hoisting fastener (1A) and the hoisting fastener (1B) is 10-20 percent larger than the diameter of each roller neck of a roller to be hoisted; the hoisting fastener (1A) and the hoisting fastener (1B) are connected with roller necks at two ends of the hoisted roller; the spacer bar (2) is fixedly connected with the hoisting fastener (1A); two ends of the lifting rope (3) are respectively and fixedly connected with the hoisting fastener (1A) and the hoisting fastener (1B); the middle of the lifting rope (3) is connected with a crane hook. The hoisting fasteners with the spacer bar and the hoisting fasteners are used in pairs, and a pair of working rollers can be hoisted for one time, so that the hosting efficiency can be multiplied. The device is simple in structure, flexible to separate, stable to operate and easy and convenient to operate, and the rollers can be safely and efficiently hoisted.

Owner:WUKUN STEEL

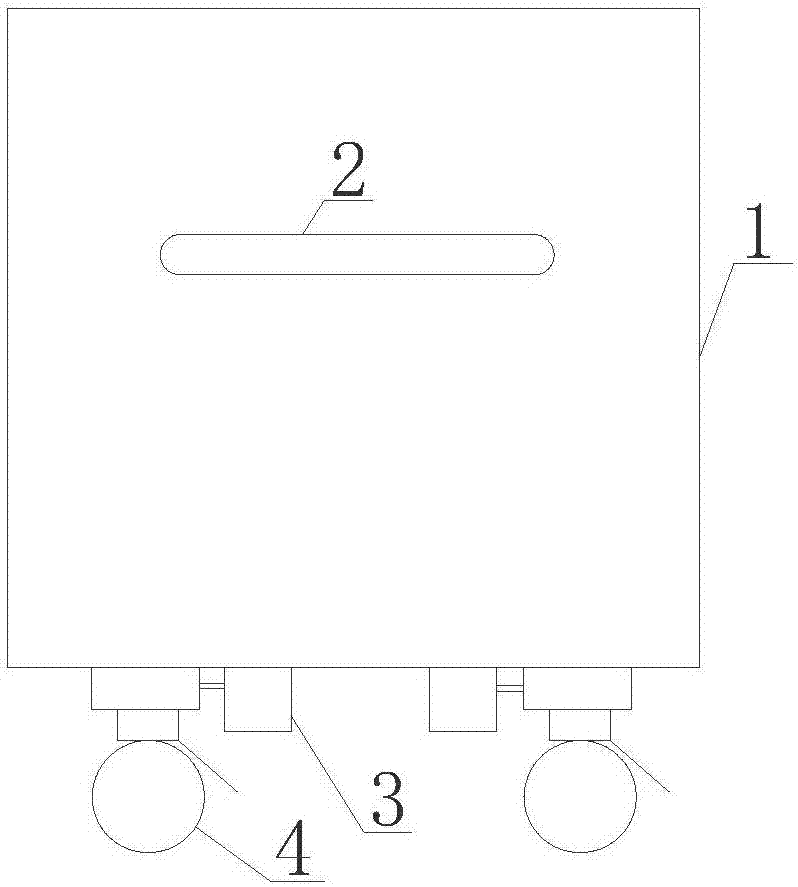

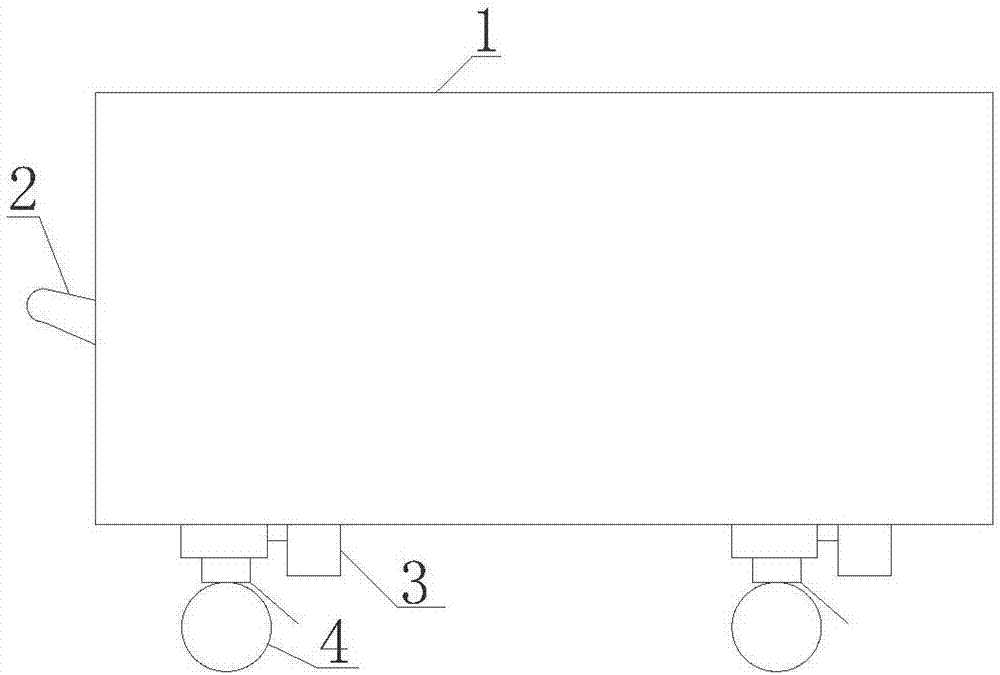

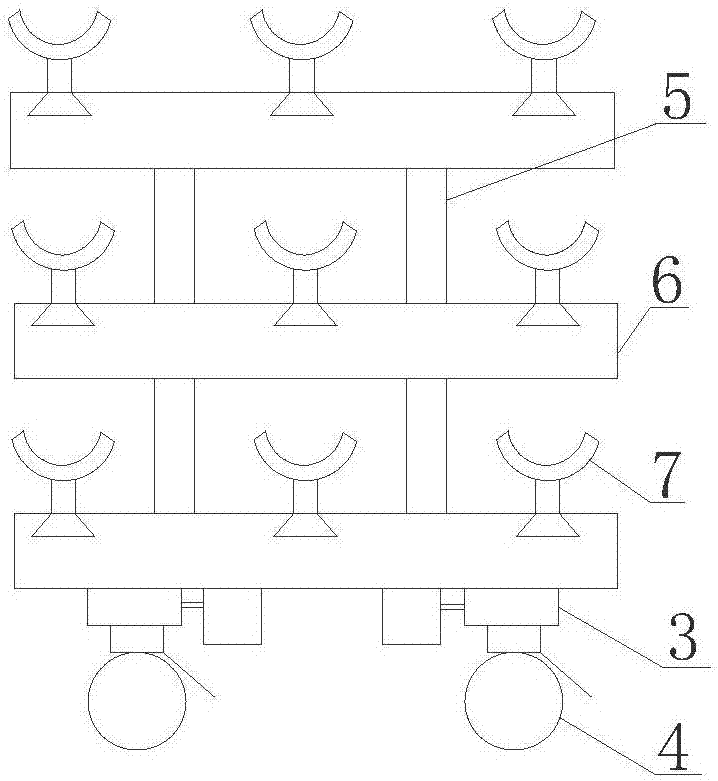

Conveying device for hydraulic prop

InactiveCN107380225AAvoid easy bumpsWill not cause scratchesHand carts with multiple axesHydraulic pumpEngineering

The invention provides a conveying device for a hydraulic prop and belongs to the technical field of a single hydraulic prop. The conveying device for the hydraulic prop comprises a box body, a handle, control devices, rollers, supporting rods, panel devices and supporting frame devices; the handle is fixedly mounted on one side of the surface of the oblong box body; the plurality of supporting frame devices are mounted on the plurality of panel devices; at least two supporting rods are mounted on the panel devices; the control devices and the rollers are fixedly mounted on the bottom surface of the panel device; the control devices comprise housings I, housings II, through holes I, through holes II, through holes III, keys I, keys II, keys III, power supplies and single chips; the panel devices comprise panels, guide rails and circular holes; and the supporting frame devices comprise protection pads, supporting frames, adjusting rods, screw rods, threaded grooves and dovetail grooves. The conveying device for the hydraulic prop has the advantages that multiple parts can be conveyed at one time without part surface scratches, the conveying device is suitable parts with any sizes, the use rate is high and the working efficiency of working personnel is enhanced.

Owner:XUZHOU ZHONAN SCI & TECH CO LTD

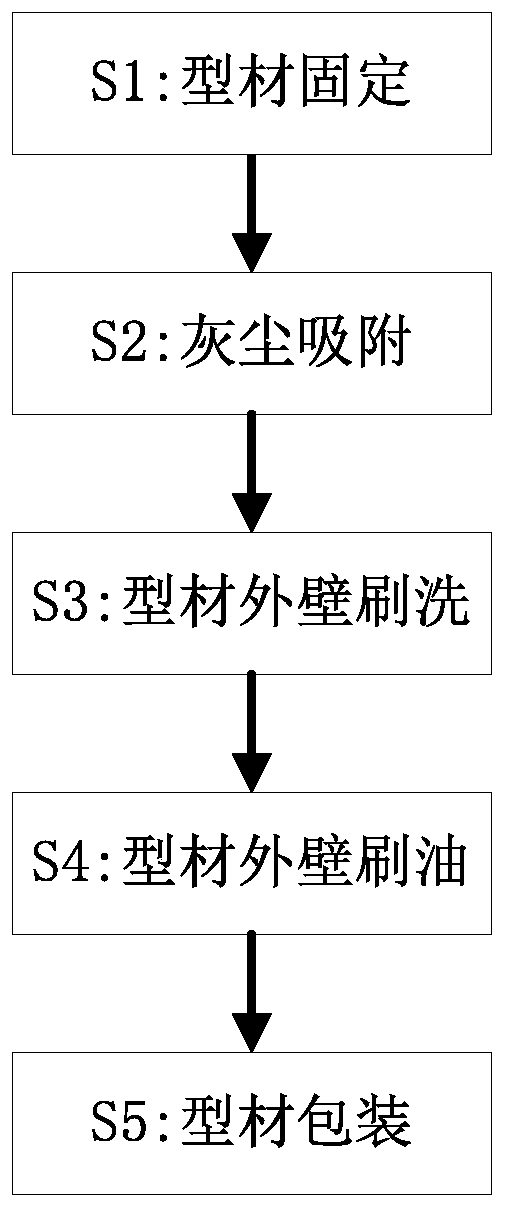

Thermal insulation aluminum alloy profile surface protection pretreatment process

ActiveCN111468446AImprove cleaning efficiencyAvoid harmLiquid surface applicatorsDirt cleaningLiquid wasteThermal insulation

The invention provides a thermal insulation aluminum alloy profile surface protection pretreatment process. Protection pretreatment of the surface of a thermal insulation aluminum alloy profile is completed through cooperation of a treatment basket, a scrubbing unit, a dust suction pump, an oil brushing unit, an electric sliding block, a supporting set, a driving motor and a clamping unit. The thermal insulation aluminum alloy profile surface protection pretreatment process can solve the main problems that when the surface of the aluminum alloy profile is subjected to protection treatment, a,metal chippings on the outer wall of the aluminum alloy profile are attached to the surface of the profile, and the surface of the profile is of a rectangular structure; during manual cleaning, the consumed time is long, and the arms of workers are easily punctured by metal chippings; b, manual oiling protection treatment on the outer wall of the aluminum alloy profile is prone to causing oil liquid dripping, the oiling quality of the outer wall of the profile is affected, and oil liquid waste is extremely likely to be caused; and the outer wall of the sectional material is manually oiled unevenly.

Owner:铭帝集团有限公司

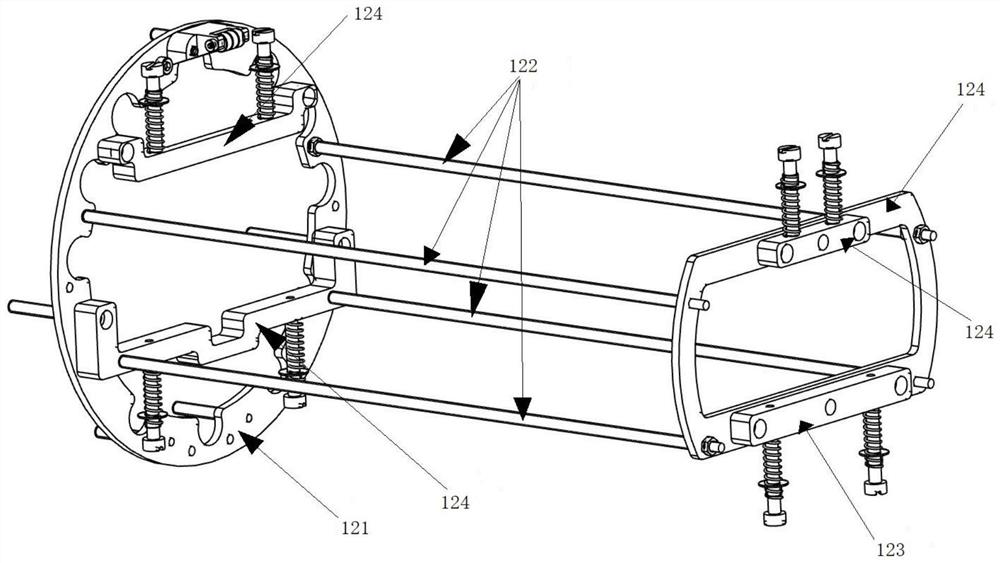

Cylindrical cabin pre-compression tensioning heat dissipation structure and sealed cabin

PendingCN111792006AWon't scratchWill not cause scratchesHull partsUnderwater vesselsPush outWedge shape

The invention provides a cylindrical cabin pre-compression tensioning heat dissipation structure and a sealed cabin and relates to the technical field of underwater sealed cabins, and aims at solvingthe problems that in the prior art, a heat dissipation plate cannot be in complete contact with a cylinder wall, and the cylinder wall is scratched. According to the characteristics of a cylindrical cabin body, a pre-compression mechanism and a tensioning mechanism are additionally arranged in an internal cabin structural part, and the tensioning mechanism can push out a heat dissipation plate ina radial direction; in the pre-compression mechanism, a wedge-shaped base and a pre-compression rod are installed at the tail end and the head end of the internal cabin structural part respectively, the heat dissipation plate is arranged between the wedge-shaped base and the pre-compression rod, the pre-compression rod can move in the axial direction, and the head end of a pre-compression push rodis connected with the pre-compression rod and can move in the radial direction. The tail end of the pre-pressing push rod is a wedge-shaped head, and the pre-pressing push rod is movably connected with the heat dissipation face of the heat dissipation plate in a pressing mode. When the pre-pressing rod moves towards the wedge-shaped base, the wedge-shaped head inclined face of the pre-pressing push rod can be matched with the wedge-shaped base, and the pre-pressing push rod and the heat dissipation plate can move inwards in the radial direction. The heat dissipation plate can be reasonably arranged to improve the heat dissipation efficiency, and the heat dissipation plate is prevented from scratching the cylinder wall.

Owner:BOYA GONGDAO BEIJING ROBOT TECH CO LTD

Double-station hoisting suction manipulator

InactiveCN107804709AReliable operationGood stabilityConveyorsControl devices for conveyorsManipulatorEngineering

The invention discloses a double-station hoisting suction manipulator. The double-station hoisting suction manipulator comprises a rack spanning two parallel stations, a hoisting suction frame arranged on the rack, a hoisting mechanism for driving vacuum suckers to move in the horizontal direction perpendicular to the rack and a walking mechanism for driving the hoisting suction frame to horizontally move along the rack, wherein the multiple vacuum suckers are arranged on the hoisting suction frame, and first position sensors for judging the hoisting heights of the vacuum suckers are arrangedon the hoisting mechanism. Buffer elastic pieces are correspondingly arranged at the two ends of the rack in the horizontal direction. The whole manipulator is easy and reliable to operate, good in stability and the like, the scratches, caused by the manipulator, on the surfaces of plates are avoided.

Owner:FOSHAN CITY SANSHUI DISTRICT MANYA ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com