Automatic optics testing device and method for PCBs

A PCB board and automatic optical technology, applied in the field of PCB automatic optical inspection device, can solve problems such as low efficiency of operation, scratches on PCB board lines, and hidden quality problems, and achieve the effect of high board separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

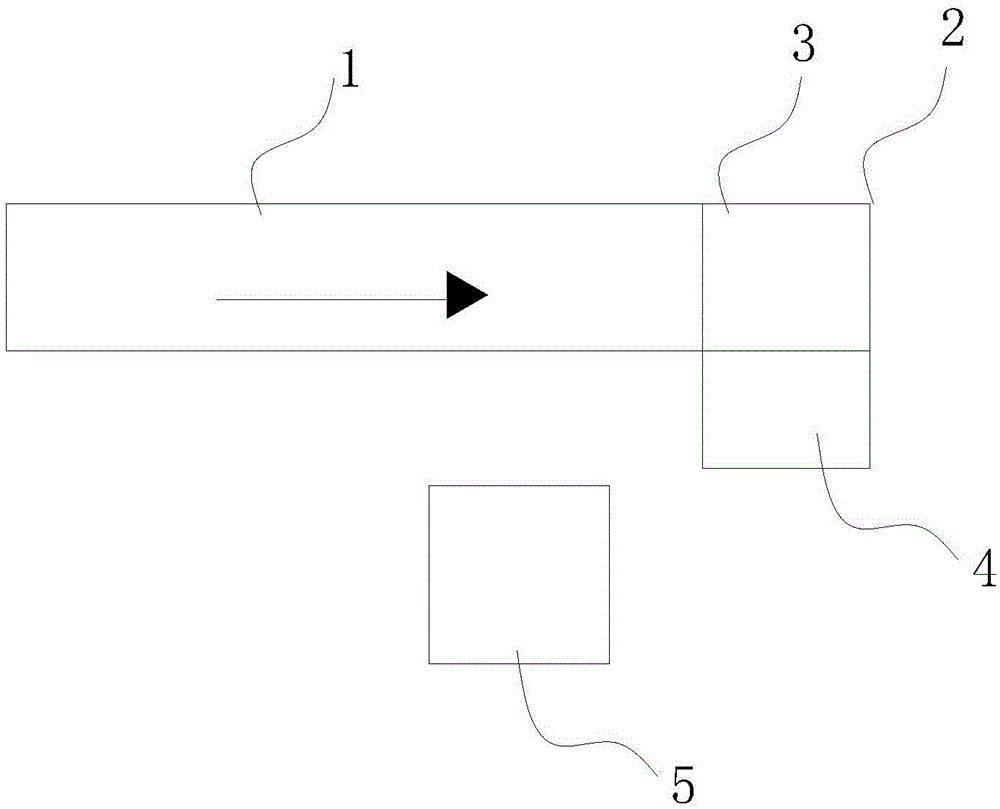

[0016] Such as figure 1 As shown, an automatic optical inspection device for PCB boards includes a conveying acceleration section 1 , a steering angle temporary storage machine 2 , a conveying storage position 4 , a sensor 3 , and an AOI device 5 .

[0017] The steering angle temporary storage machine 2 is set at the conveying end of the conveying acceleration section 1; the sensor 3 is set inside the steering angle temporary storage machine 2; the conveying storage position 4 is set on the side of the steering angle temporary register; the AOI equipment 5 is set at the conveying storage next to bit 4. figure 1 The direction of the middle arrow is the direction of PCB board transmission.

[0018] Optionally, the AOI equipment 5 and the delivery storage position 4 are located on the same side relative to the steering angle temporary register.

[0019] Optionally, in the automatic optical inspection device for PCB boards according to the embodiment of the present invention, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com