Plate splitting device

A technology of plate separation and moving parts, which is applied in the directions of transportation and packaging, destacking of objects, etc., can solve the problems of cumbersome operation, large and complex mechanical structure of plate separation, affecting block bricks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

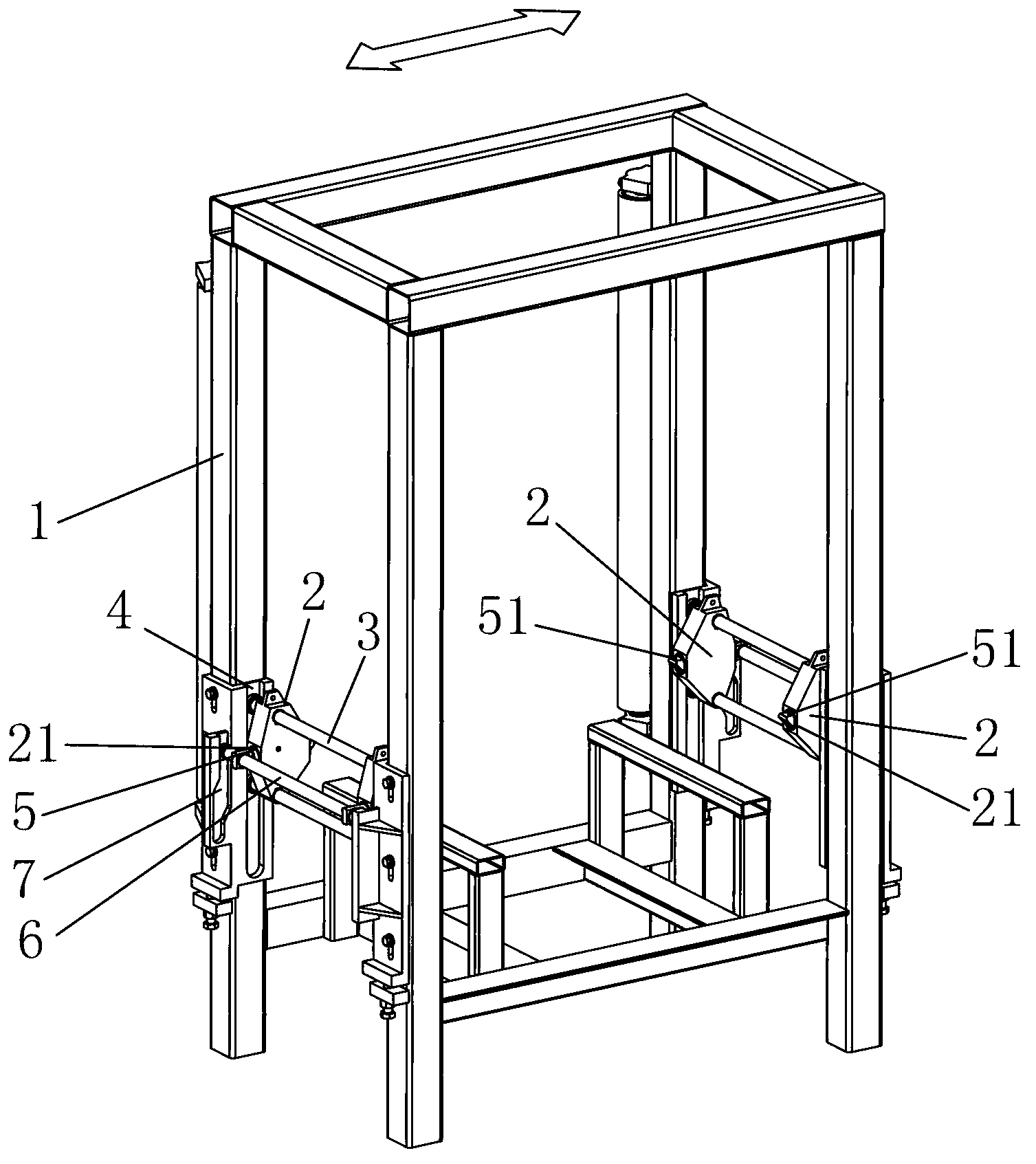

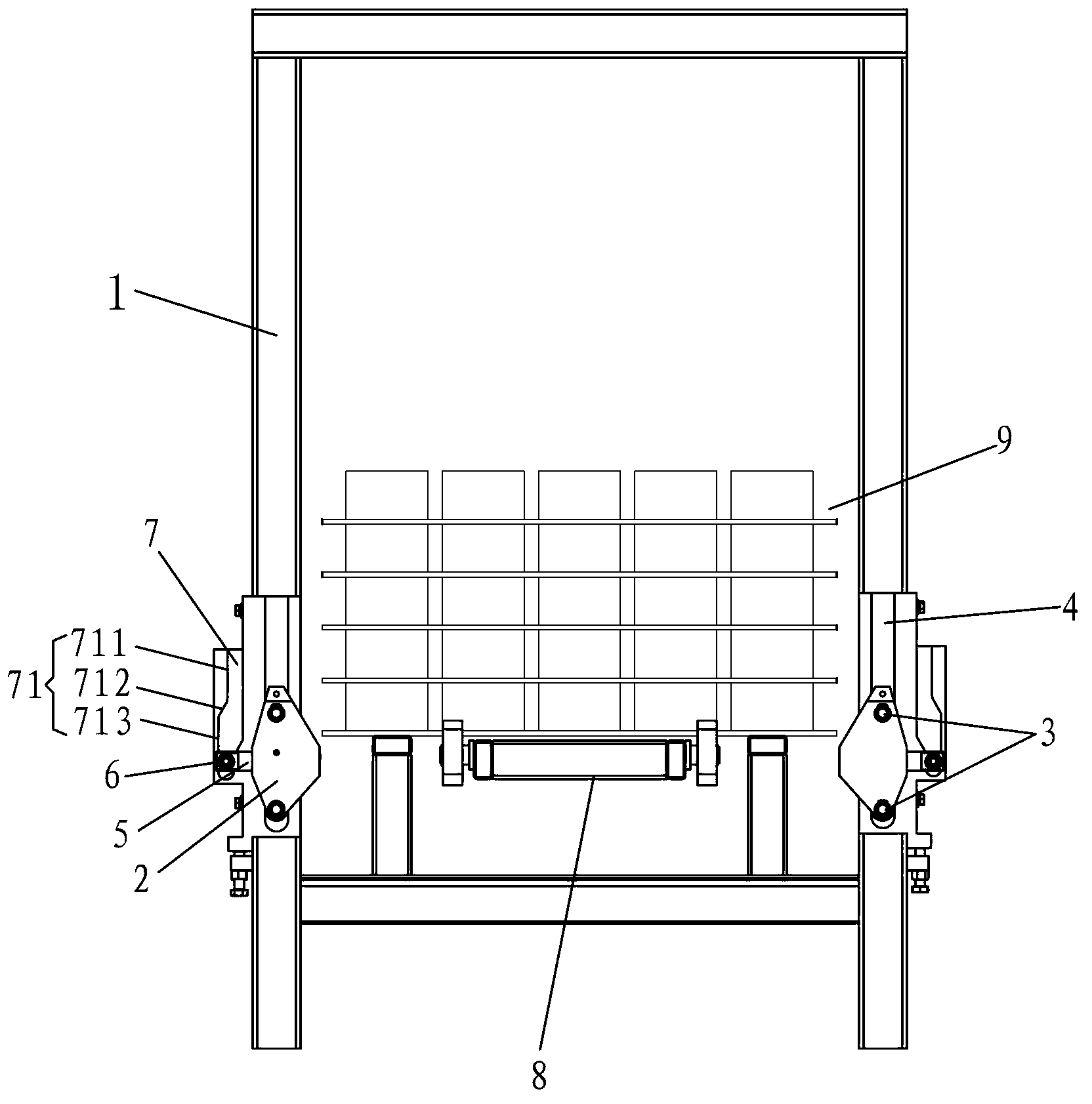

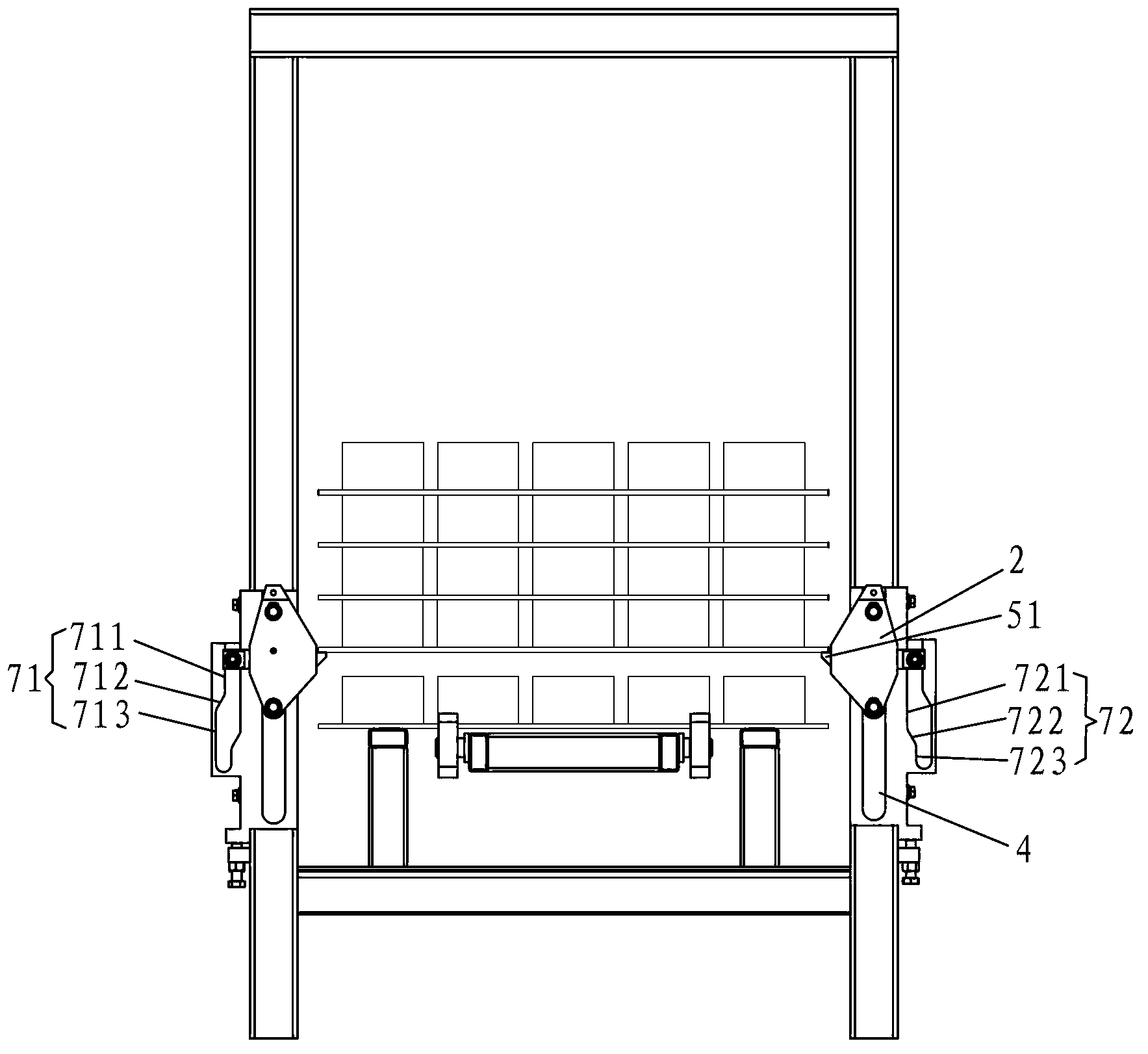

[0027] The invention relates to a splitting device, such as figure 1 As shown, a bracket 1 is included. Taking the direction of an opposite side of the bracket 1 as a reference direction (the direction of the arrow in the figure), the opposite sides of the bracket 1 are respectively provided with movable parts 2. The movable part 2 is connected with a driving mechanism (not shown in the figure) through a chain (not shown in the figure), and the driving mechanism drives the movable part 2 to move up and down within a proper range. The movable part 2 is horizontally provided with a guide rod 3 extending perpendicular to the reference direction, and the frame 1 is vertically provided with two guide grooves 4 for inserting two free ends of the guide rod 3 respectively. In the specific design, the movable part 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com