Production process of aluminum alloy liquid tank truck

A production process and technology for liquid tank trucks, which are applied in the field of aluminum alloy liquid tank truck production processes, can solve the problems of unsightly molding of the surface of the tank body, low work efficiency, and difficulty in docking the heads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

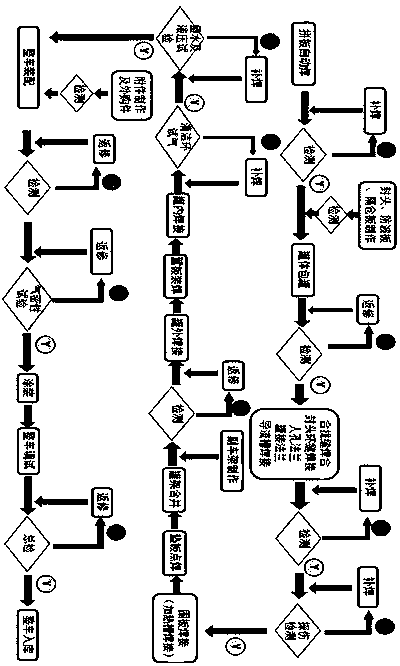

Image

Examples

Embodiment 1

[0071] A production process of an aluminum alloy liquid tank car, comprising the following process steps:

[0072] (1) Jigsaw automatic welding;

[0073] (2) The tank body wraps the tank;

[0074] (3) Circular seam welding of the tank body;

[0075] (4) Production of plugs for sedimentation tanks;

[0076] (5) Steel frame and sub-frame assembly;

[0077] (6) Steel frame assembly;

[0078] (7) Production of head and anti-wave board;

[0079] (8) Final assembly.

[0080] The concrete process of described step 1 jigsaw puzzle automatic welding is:

[0081] (1) Use the raw material boards according to the requirements of the drawings, check whether the material, thickness, length and width of the material boards are consistent with the requirements of the drawings, clean up the burrs and dirt on the edges of the boards after confirmation, and splice them in sequence according to the jigsaw puzzle of the tank body;

[0082] (2) Compact with automatic welding briquetting, pre...

Embodiment 2

[0090] A production process of an aluminum alloy liquid tank car, comprising the following process steps:

[0091] (1) Jigsaw automatic welding;

[0092] (2) The tank body wraps the tank;

[0093] (3) Circular seam welding of the tank body;

[0094] (4) Production of plugs for sedimentation tanks;

[0095] (5) Steel frame and sub-frame assembly;

[0096] (6) Steel frame assembly;

[0097] (7) Production of head and anti-wave board;

[0098] (8) Final assembly.

[0099] The specific process of said step 3 tank body girth welding is:

[0100] (1) When receiving the tank body, strictly check and accept the amount of seam misalignment, forming flatness, the gap between the head and the tank body, and the amount of misalignment. After confirmation, hang the tank body on the positioner with a sling and fix it. Pay attention In the case of bumps on the tank body and scratches on the board surface, pay attention to protecting the tank body board surface;

[0101] (2) Welding o...

Embodiment 3

[0109] A production process of an aluminum alloy liquid tank car, comprising the following process steps:

[0110] (1) Jigsaw automatic welding;

[0111] (2) The tank body wraps the tank;

[0112] (3) Circular seam welding of the tank body;

[0113] (4) Production of plugs for sedimentation tanks;

[0114] (5) Steel frame and sub-frame assembly;

[0115] (6) Steel frame assembly;

[0116] (7) Production of head and anti-wave board;

[0117] (8) Final assembly.

[0118] The concrete process of described step 6 steel vehicle frame assembly is:

[0119] (1) Positioning of the left and right longitudinal beams: place the left and right longitudinal beams of the frame on the left and right sides of the tooling, stick to the left and right positioning beams, and the rear end of the longitudinal beams is close to the positioning angle steel at the rear end of the tooling;

[0120] (2) Rear crossbeam positioning: place the rear crossbeam on the lateral positioning seat of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com