Three-dimensional printer and printing method and three-dimensional printing head

A three-dimensional printer and three-dimensional printing technology, which is applied in the printing field of printers, can solve the problems of not very smooth surface of printed objects, uneven shrinkage of molded objects, warping of three-dimensional printed objects, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

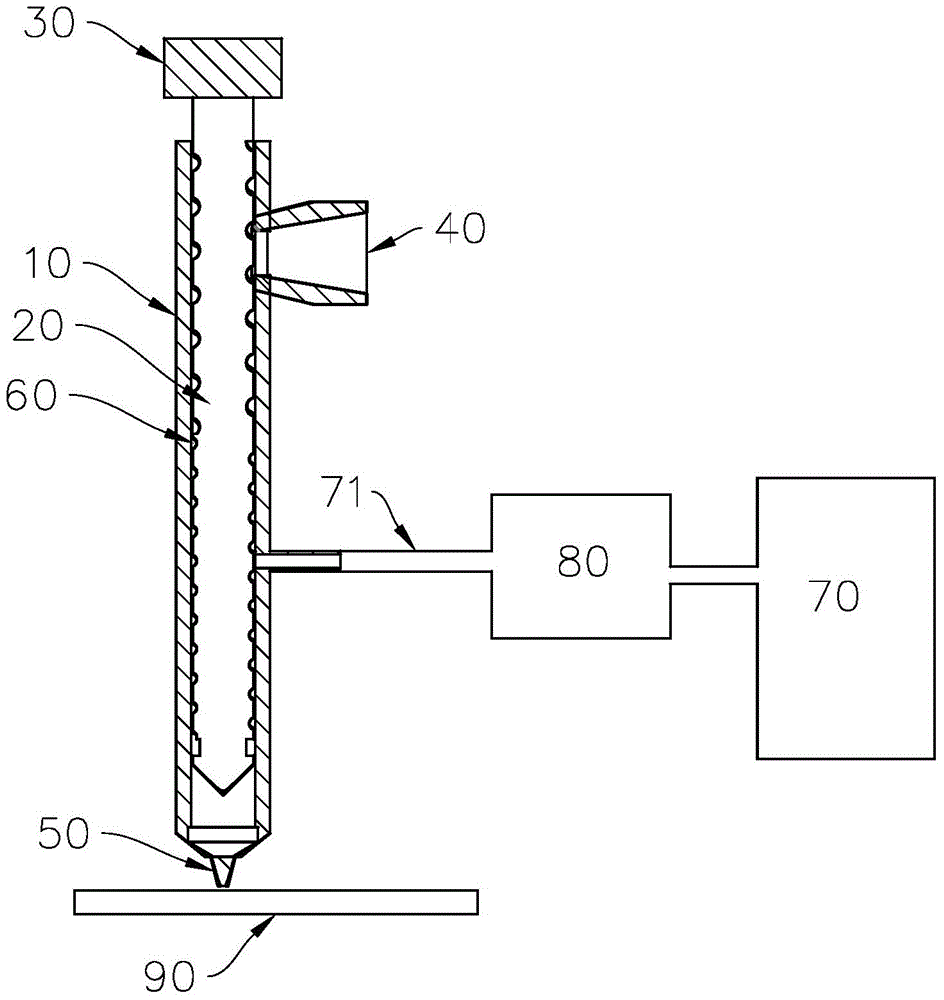

[0027] The three-dimensional printing head of this embodiment includes a material volume chamber 10 , a screw 20 , a motor 30 , a feeding device 40 , a printing nozzle 50 , a heater 60 , a supercritical fluid supply system 70 and a flow control device 80 .

[0028] The screw 20 is arranged inside the material volume chamber 10 , and the diameter of the screw 20 is slightly smaller than the inner wall of the material volume chamber 10 . There is a motor 30 at the upper end of the screw 20, and the motor 30 can drive the screw 20 to rotate clockwise or counterclockwise. A feeding device 40 is arranged on the right side of the upstream area of the material volume chamber 10, and the feeding device 40 communicates with the material volume chamber 10, and the operator or robot adds powdery or fragmented polylactic acid to the feeding device 40 (PLA) material. A printing nozzle 50 is detachably arranged at the lower end of the material volume chamber 10 . Between the feeding dev...

no. 2 example

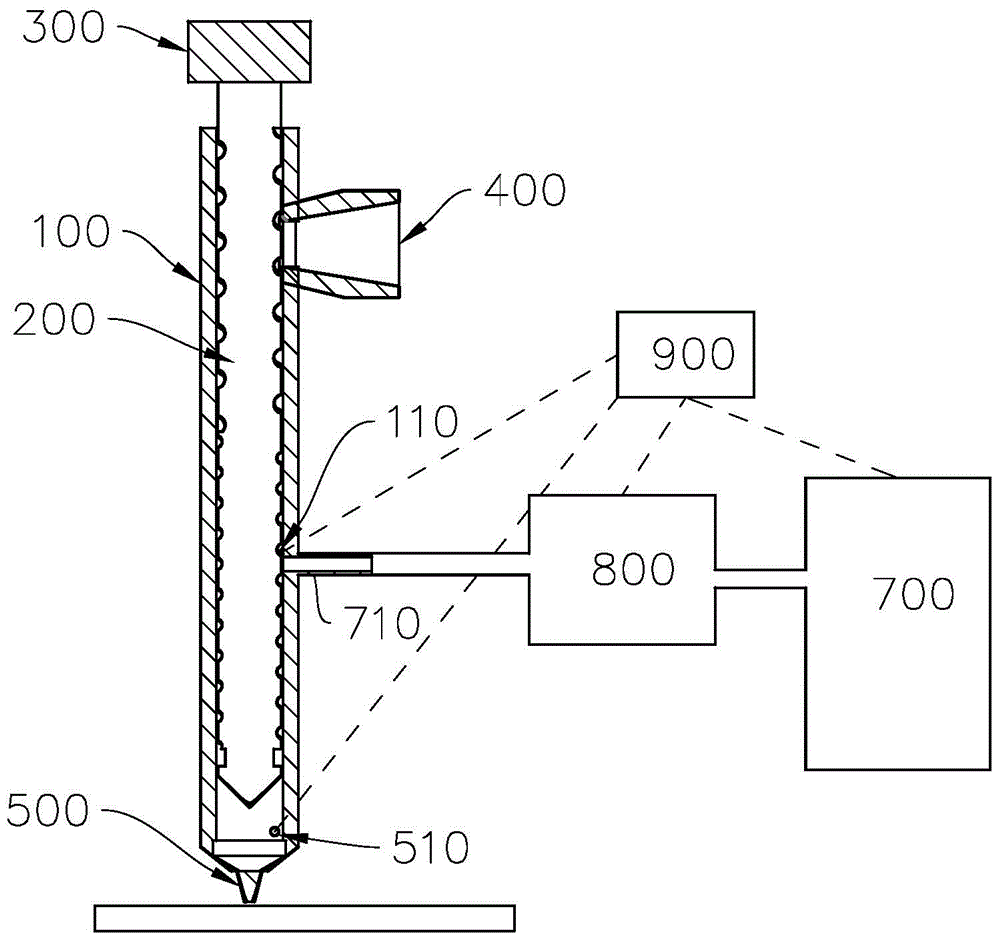

[0031] The three-dimensional printing head of this embodiment includes a material volume chamber 100, a screw 200, a motor 300, a feeding device 400, a printing nozzle 500, a heater, a supercritical fluid supply system 700, and a flow control device 800. The structural features and connections of these components The relationship has been described in detail in the first embodiment and will not be repeated here.

[0032]The three-dimensional printing head of this embodiment further includes a control system 900 , and a density sensor 510 is provided at a position adjacent to the printing nozzle 500 . A temperature sensor 110 is provided at a position where the connecting pipe 710 of the supercritical fluid supply system 700 communicates with the material volume chamber 100 . The control system 900 is electrically connected to the fluid supply system 700 , the density sensor 510 , the flow control device 800 , and the temperature sensor 110 .

[0033] The density value of the ...

no. 3 example

[0036] The three-dimensional printer of this embodiment includes a material volume chamber, the screw is arranged in the material volume chamber, the motor is connected to the screw, the feeding device is connected to the material volume chamber, the printing nozzle is arranged at the end of the material volume chamber, and the printing platform is used to accept the For the molten material produced by the printing nozzle, the heater is arranged on the material volume chamber, and is located between the feeding device and the printing nozzle, and the supercritical fluid supply system communicates with the material volume chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com