Stone cutter

A cutting machine, stone technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of motor stagnation, scratched work surface, uneven work surface, etc., to reduce friction and reduce scratches , Improve the effect of straightness and verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

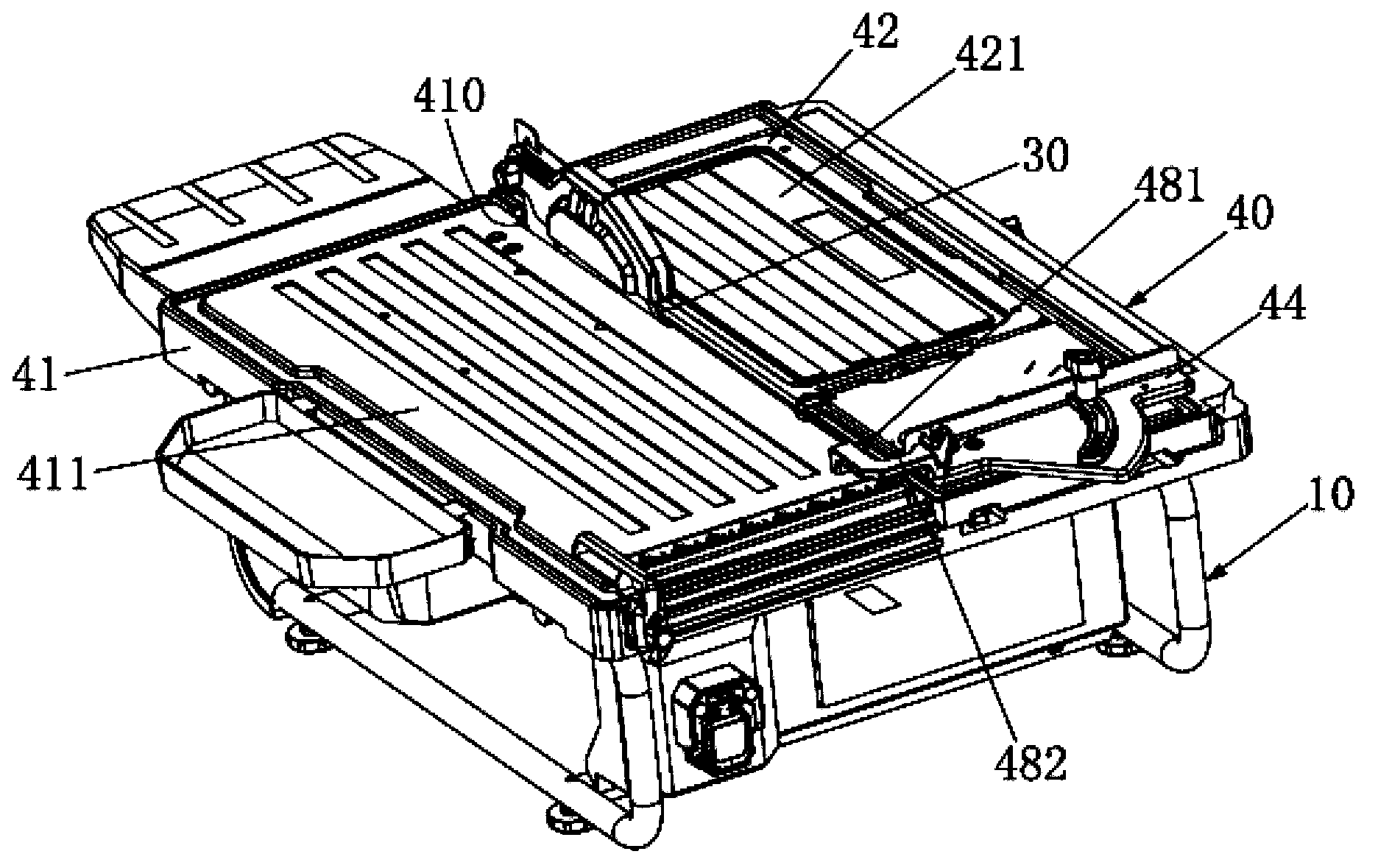

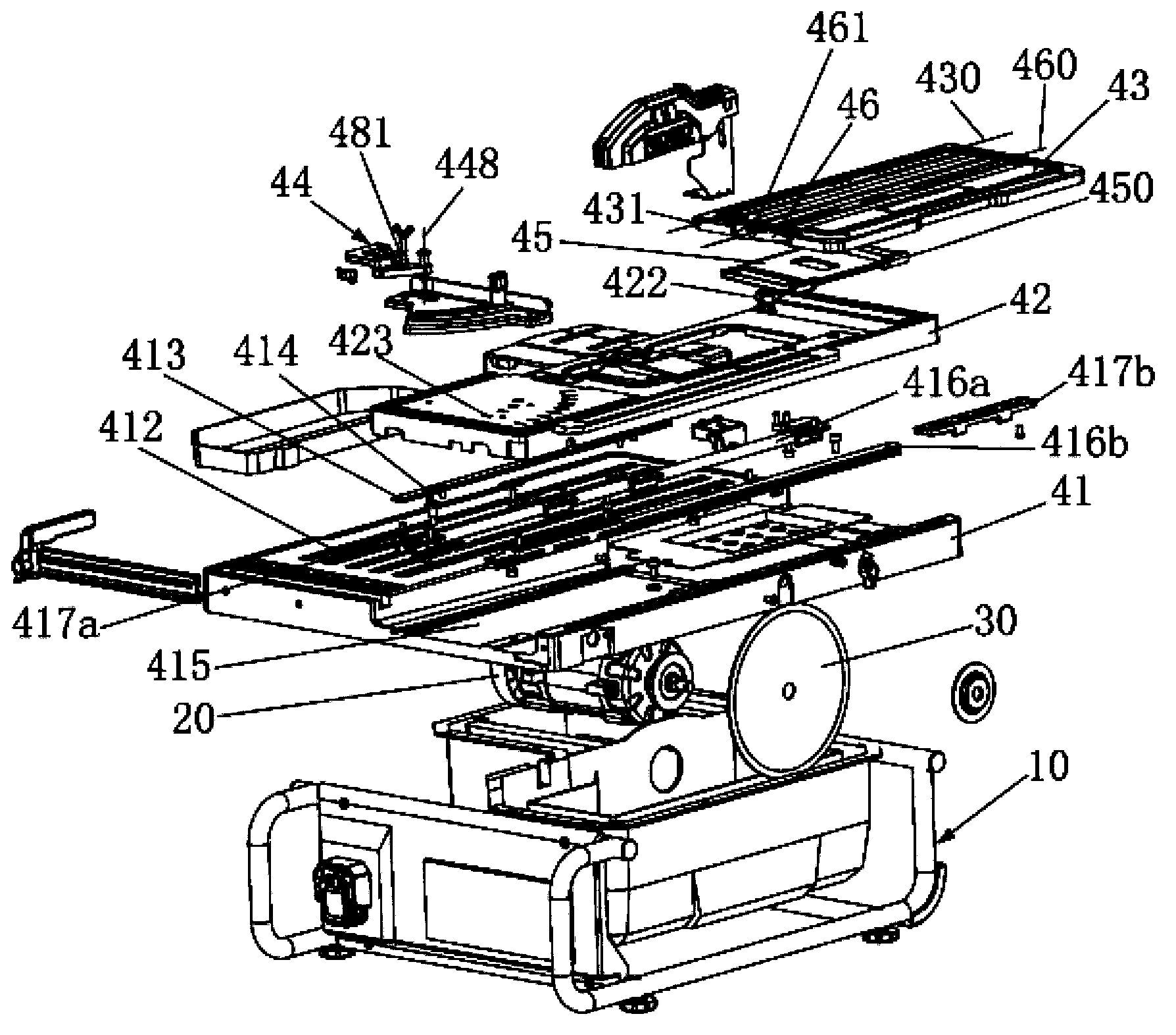

[0017] Such as figure 1 As shown, the stone cutting machine of the present invention comprises a base 10, a motor 20 accommodated in the base 10 (in figure 2 shown in ), the blade 30 driven by the motor 20 , and the workbench 40 supported on the base 10 .

[0018] Such as figure 2 As shown, the workbench 40 includes a fixed workbench 41 and a movable workbench 42 .

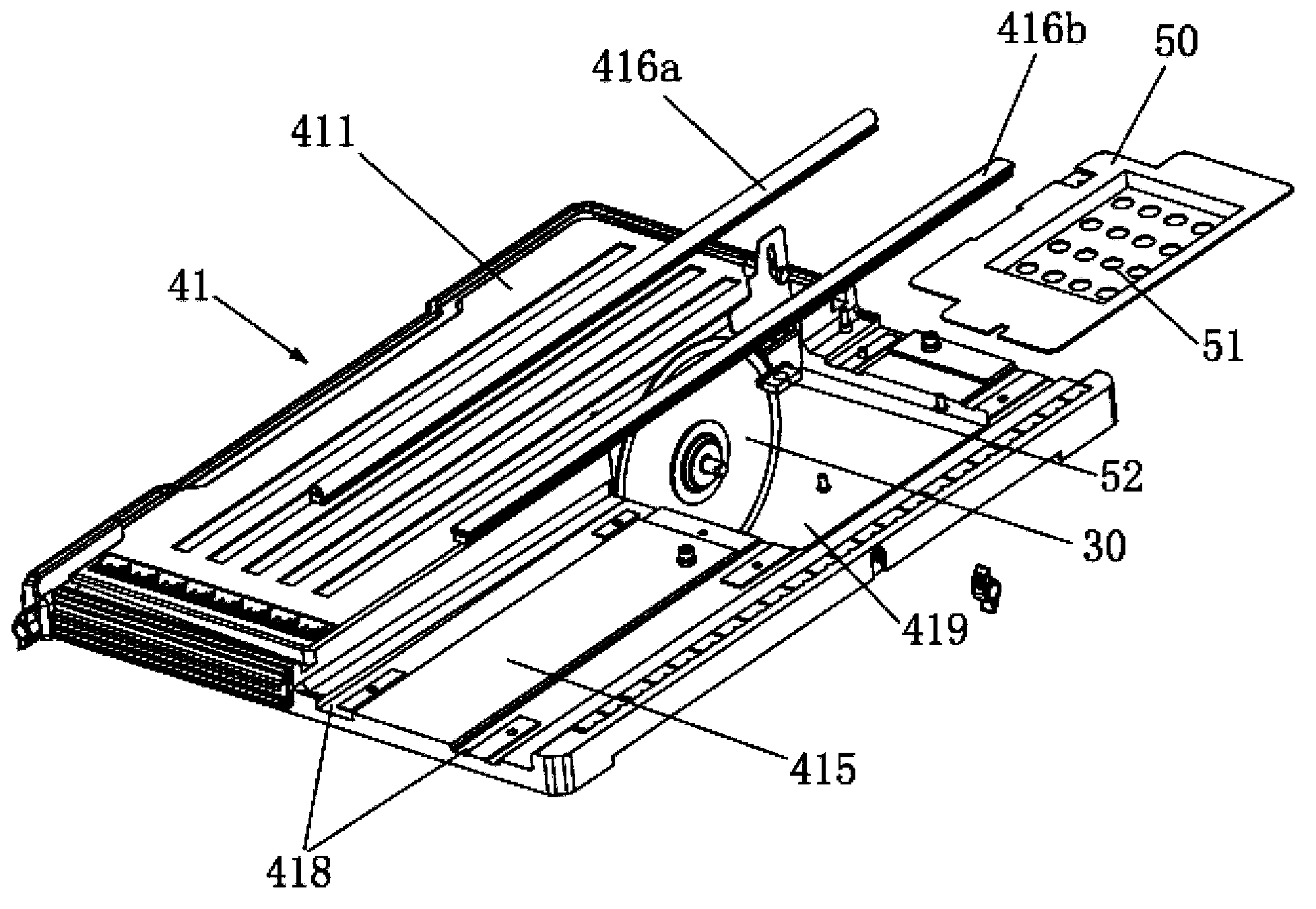

[0019] The fixed workbench 41 covers the entire base 10 . An elongated hole 410 is opened in the middle of the fixed workbench 41 , and the blade 30 protrudes from the elongated hole 410 and is partially located above the fixed workbench 41 . The fixed table 41 forms a first support surface 411 on the upper surface of one side of the blade 30 for supporting the piece to be cut (not shown). A plurality of grooves 412 for accommodating the adjusting pieces 413 are formed on the first supporting surface 411 , and the grooves 412 extend along a direction parallel to the plane of the blade 30 and are parallel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com