High-reflection and high-stiffness light reflecting film

A technology of light reflective film and high stiffness, applied in the field of reflective film, can solve the problems of scratching, wrinkling, affecting the brightness and picture quality of the backlight and the display, and achieving reduced difficulty, high stiffness, and reduced scratches and the effect of wrinkle loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

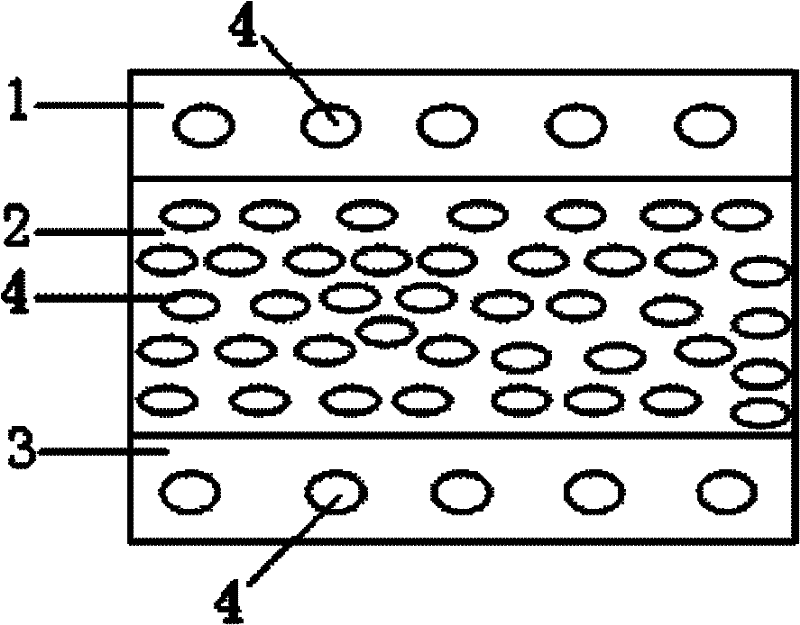

Image

Examples

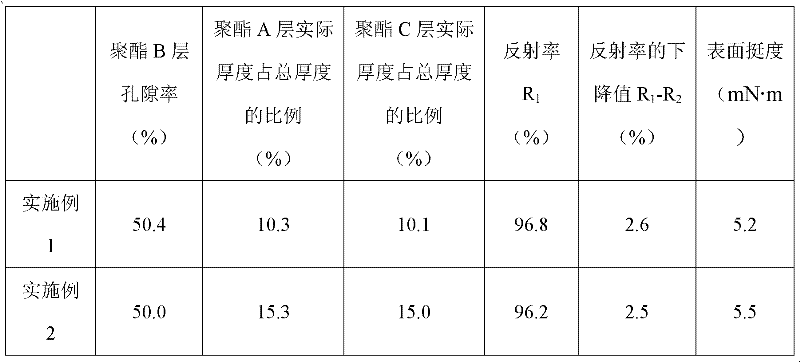

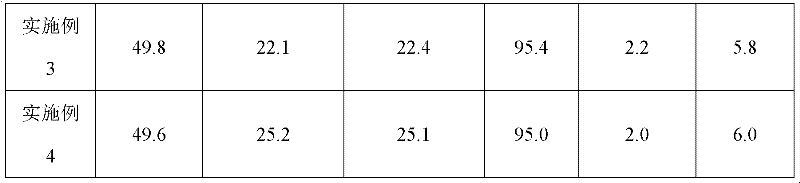

Embodiment 1

[0044] Pre-crystallize and dry polyester raw materials at 180°C, mix inorganic and organic particles or (and) incompatible polymers and other additives according to the formula, and transport them to the extruder at a temperature of about 285°C Melt extrusion, filtered through a filter and extruded from a multi-layer die to obtain a sheet-like melt. Wherein the polyester layer A raw material is 100 parts polyester and 12wt% TiO2 and BaSO4 mixture (mass ratio 1: 2), 0.01wt% 2,4-dihydroxybenzophenone and 0.01wt% 4-benzoyl Oxy-2,2,6,6-tetramethylpiperidine, and additives such as antioxidant, heat stabilizer, and light stabilizer. The average particle size of TiO2 and BaSO4 is 0.7μm, and the surface is treated with polyethylene glycol. Polyester B layer raw material is 100 parts of polyester and 10wt% BaSO4 (average particle diameter is 0.7 μm, the surface is treated with polyethylene glycol), 5wt% polymethacrylic acid particles (average particle diameter 1.2 μm), 8wt% polyformal...

Embodiment 2

[0048] Except that the thicknesses of the polyester A layer and the polyester C layer are adjusted to be about 15% of the total thickness respectively, other steps are the same as in Example 1.

Embodiment 3

[0050] Except that the thicknesses of the polyester A layer and the polyester C layer are adjusted to be about 22% of the total thickness respectively, other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com