Coating equipment and method for tube-type PERC solar cells

A technology of solar cells and coating equipment, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve problems affecting the uniformity of Al2O3 coating, affecting the qualified rate of finished batteries, affecting the EL yield of batteries, etc., to achieve the reduction of EL Scratch ratio, good self-lubricating performance, and the effect of saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132] (1) Put the graphite boat into the tubular PECVD coating equipment for drying, the drying temperature is 300 degrees, and the drying time is 20 minutes;

[0133] (2) After drying the boat, put the graphite boat into the tubular PECVD coating equipment again, and coat at least one layer of silicon carbide film on the surface of the graphite boat. The coating method of the silicon carbide film is as follows:

[0134] Raise the temperature to 380°C, inject ammonia gas, the plasma power is 2000w, the flow rate is 1slm, and the time is 2min;

[0135] Feed methane and silane, the methane flow rate is 2slm, the silane flow rate is 200sccm, and the time is 5s;

[0136] Methane and silane are introduced, the plasma power is 3000w, the time is 1 hour, the methane flow rate is 2slm, and the silane flow rate is 200sccm;

[0137] Cool down to 350°C and leave the boat.

[0138] (3) Place the treated silicon wafer on a graphite boat, and send it to the tubular PECVD coating equipmen...

Embodiment 2

[0144] (1) Put the graphite boat into the tubular PECVD coating equipment for drying, the drying temperature is 350 degrees, and the drying time is 25 minutes;

[0145] (2) After drying the boat, put the graphite boat into the tubular PECVD coating equipment again, and coat at least one layer of silicon carbide film on the surface of the graphite boat. The coating method of the silicon carbide film is as follows:

[0146] Raise the temperature to 400°C, inject ammonia gas, the plasma power is 3000w, the flow rate is 2slm, and the time is 3min;

[0147] Feed methane and silane, the methane flow rate is 4slm, the silane flow rate is 400sccm, and the time is 10s;

[0148] Methane and silane are introduced, the plasma power is 5000w, the time is 2 hours, the flow rate of methane is 3slm, and the flow rate of silane is 300sccm;

[0149] Cool down to 360°C and leave the boat.

[0150] (3) Place the treated silicon wafer on a graphite boat, and send it to the tubular PECVD coating ...

Embodiment 3

[0156] (1) Put the graphite boat into the tubular PECVD coating equipment for drying, the drying temperature is 370 degrees, and the drying time is 30 minutes;

[0157] (2) After drying the boat, put the graphite boat into the tubular PECVD coating equipment again, and coat at least one layer of silicon carbide film on the surface of the graphite boat. The coating method of the silicon carbide film is as follows:

[0158] Raise the temperature to 420°C, inject ammonia gas, the plasma power is 4000w, the flow rate is 5slm, and the time is 5min;

[0159] Feed methane and silane, the methane flow rate is 5slm, the silane flow rate is 500sccm, and the time is 15s;

[0160] Methane and silane are introduced, the plasma power is 6000w, the time is 1.5 hours, the methane flow rate is 4slm, and the silane flow rate is 500sccm;

[0161] Cool down to 380°C and leave the boat.

[0162] (3) Place the treated silicon wafer on a graphite boat, and send it to the tubular PECVD coating equi...

PUM

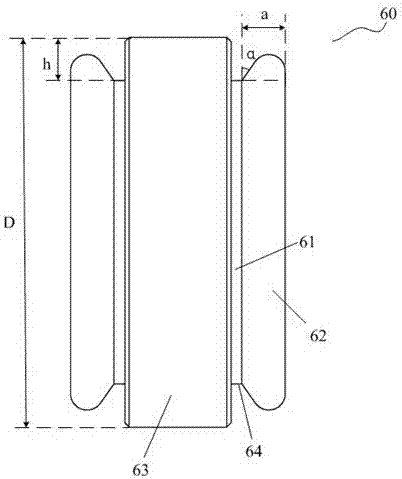

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com