Patents

Literature

164results about How to "Beautiful weld" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

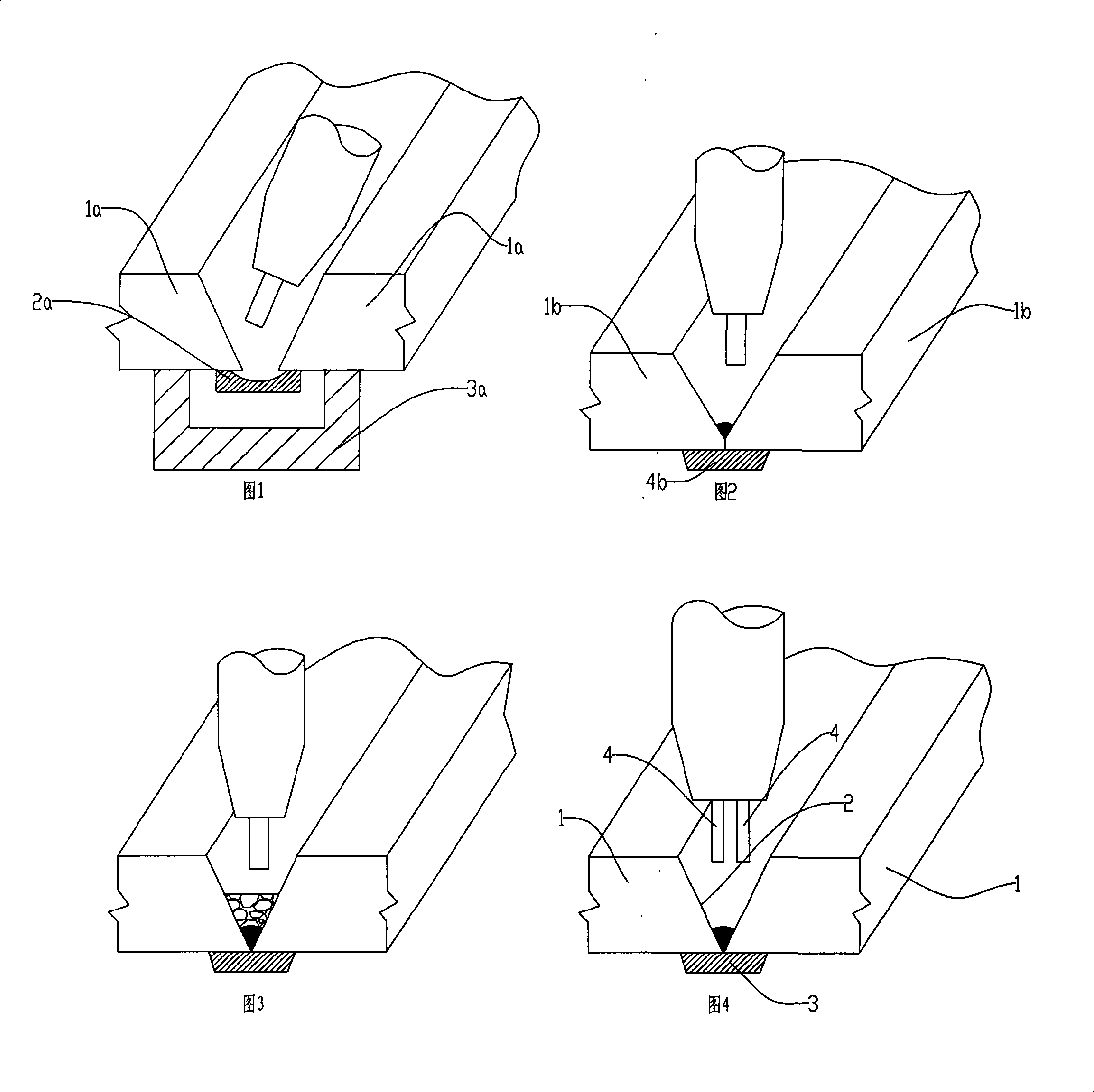

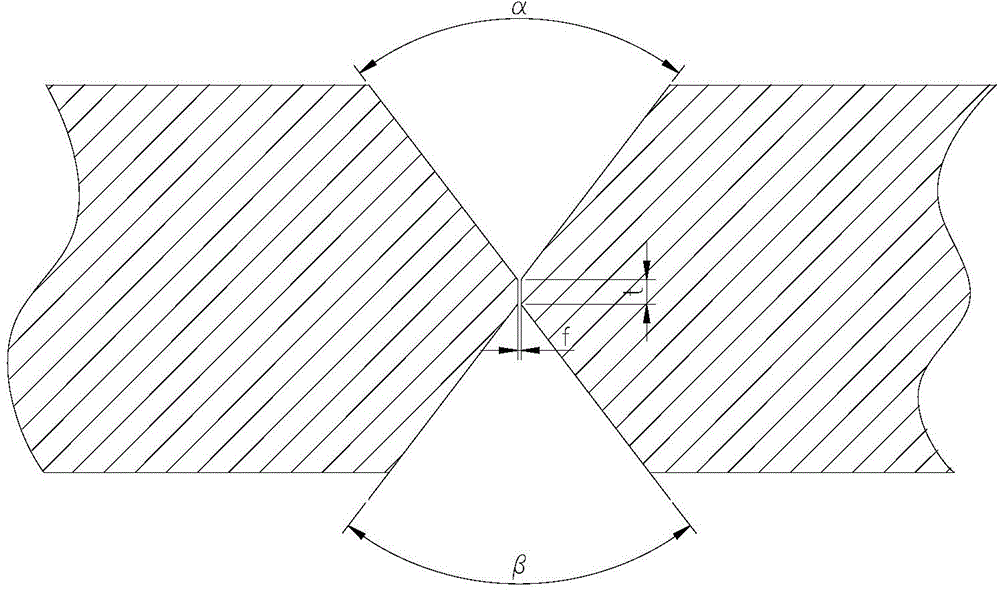

Main plate opposing connection welding method

InactiveCN101342629AFast meltingImprove deposition efficiencyArc welding apparatusButt jointActive force

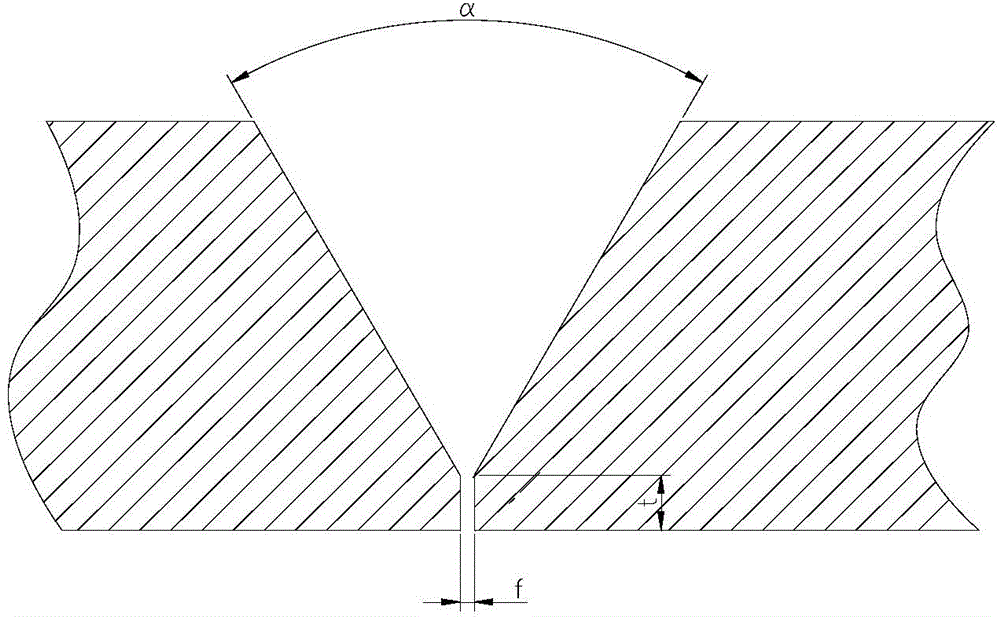

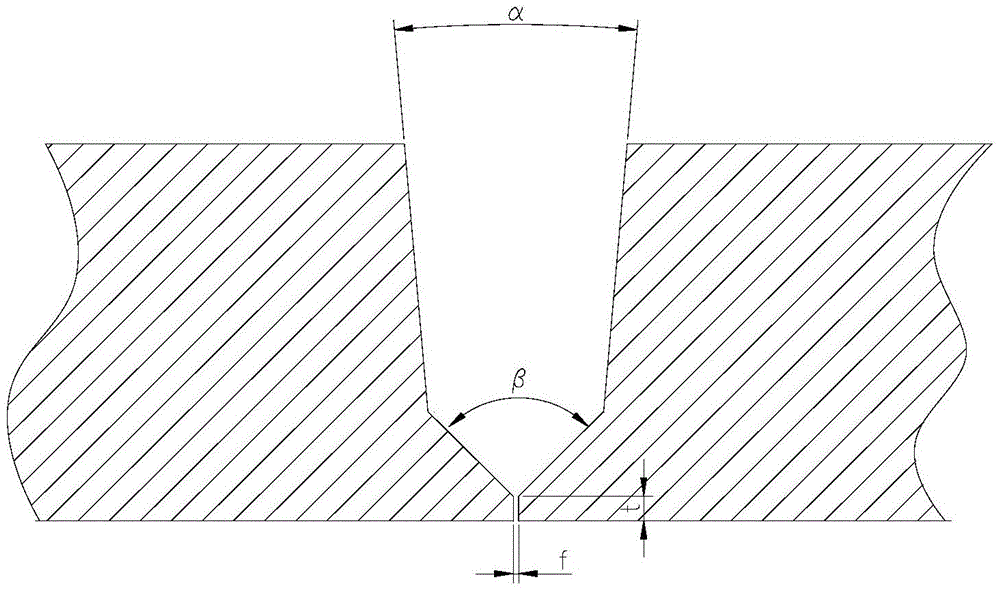

The invention discloses a butt-jointing and welding method of plates. The bases of the grooves of two plates which need to be welded are butt-jointed closely and are fixed in the groove through spot welding. A ceramic pad is stuck at the bottom of the butt-jointing place by an aluminum foil. Two parallel and separated thin welding wires are used to treat welding seam by submerged arc-welding. The butt-jointing and welding method effectively shunts the welding current to the two thin welding wires, not only improves the melting efficiency of the welding wire, but also avoids the excessive concentration of the active force of electric arc, not only has high welding efficiency, but also is easier to achieve a balance state to form the welding seam under the support of surface tension and the ceramic pad.

Owner:中船海洋与防务装备股份有限公司

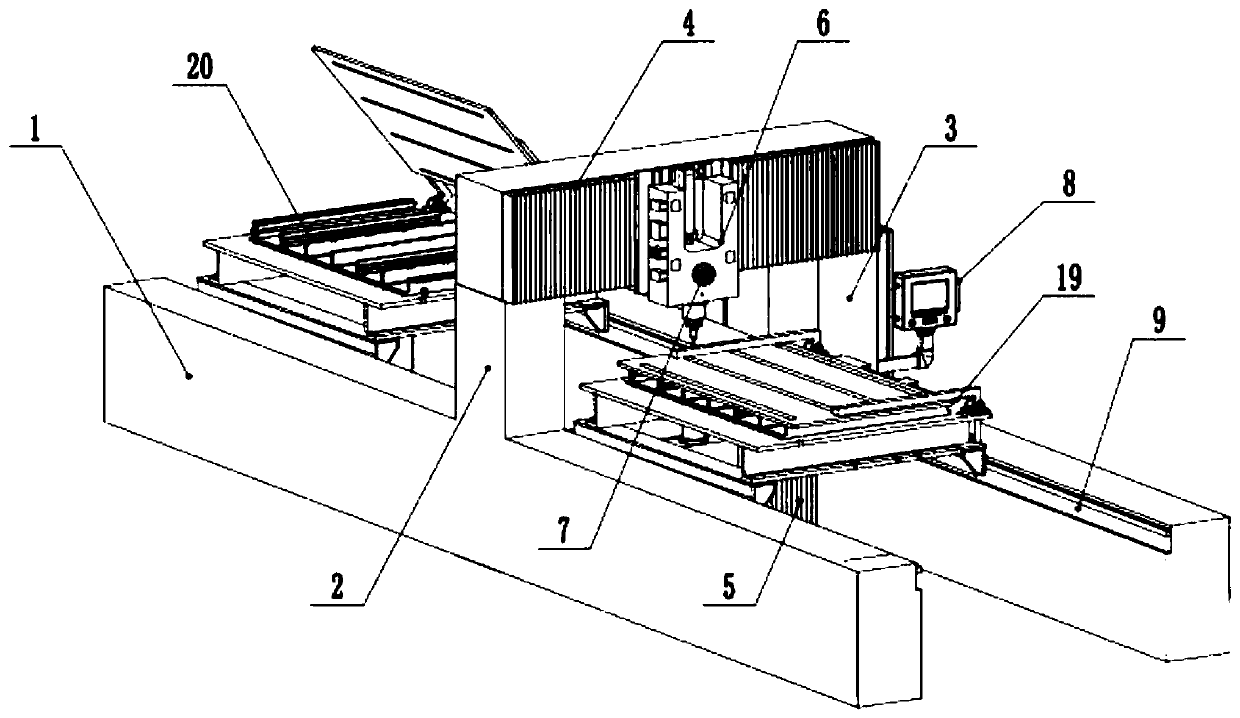

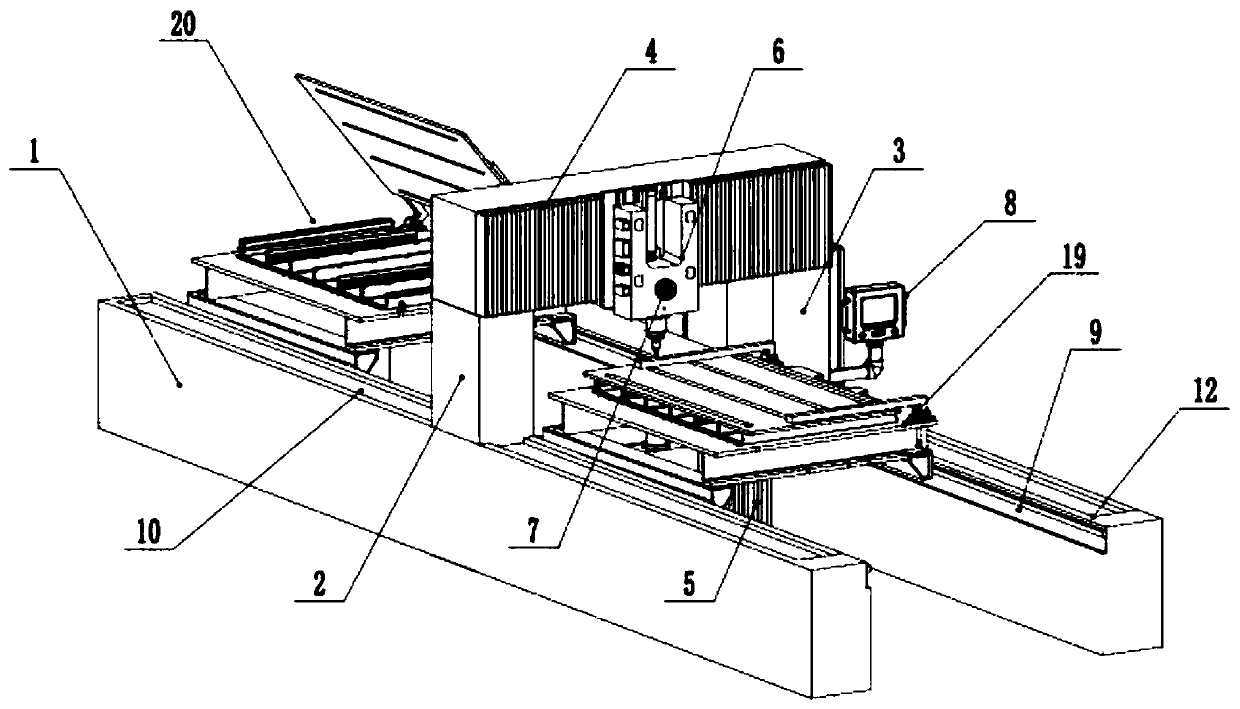

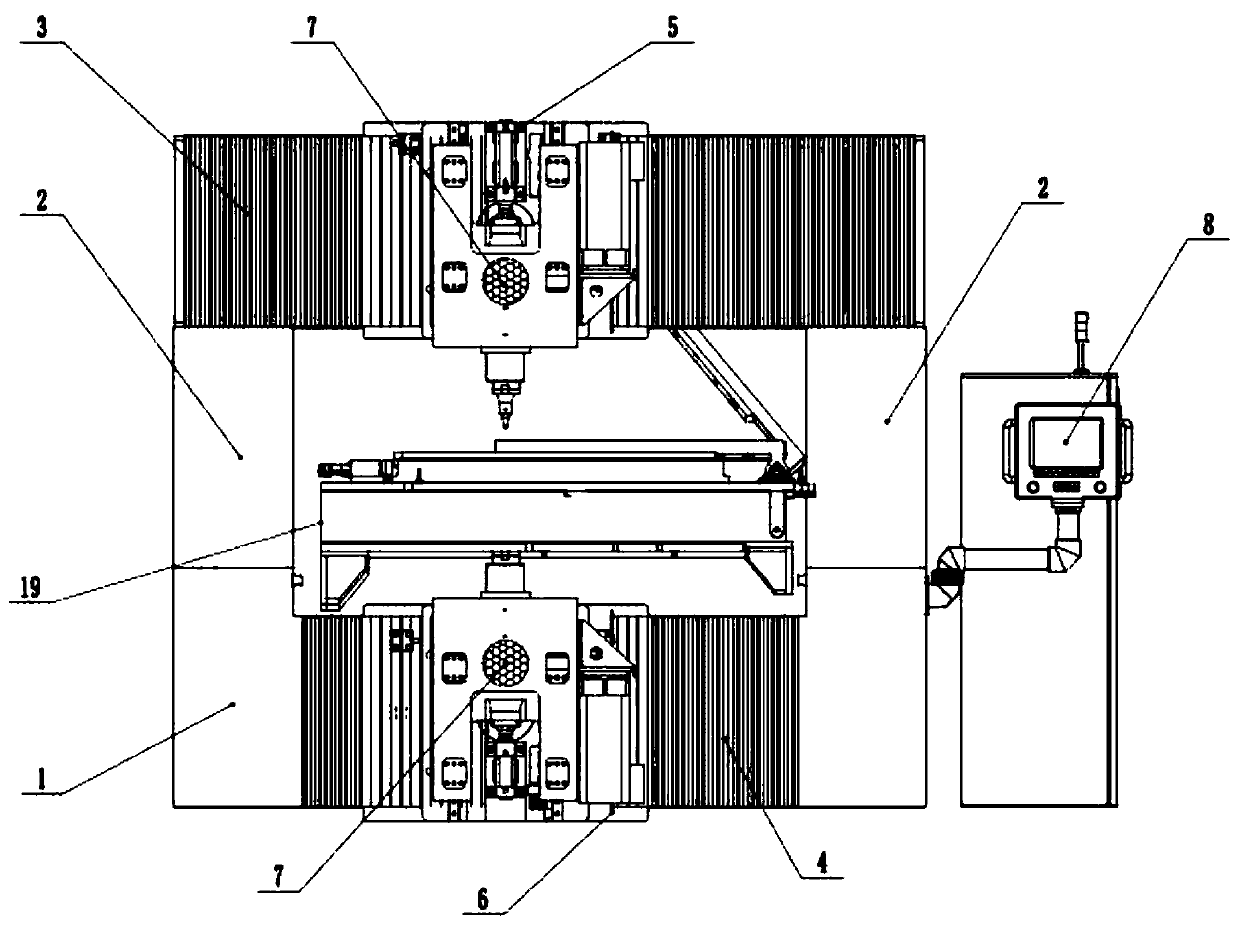

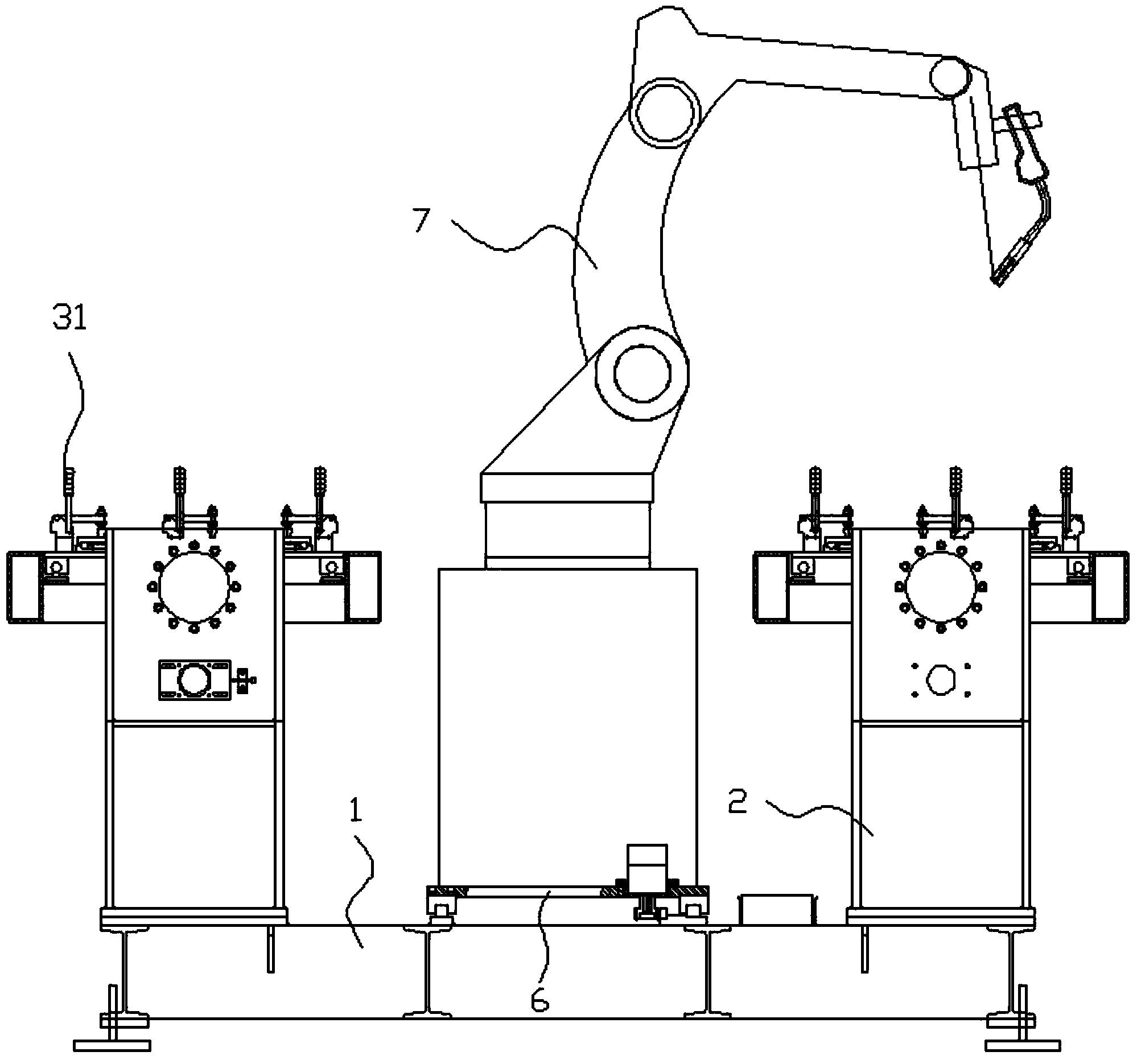

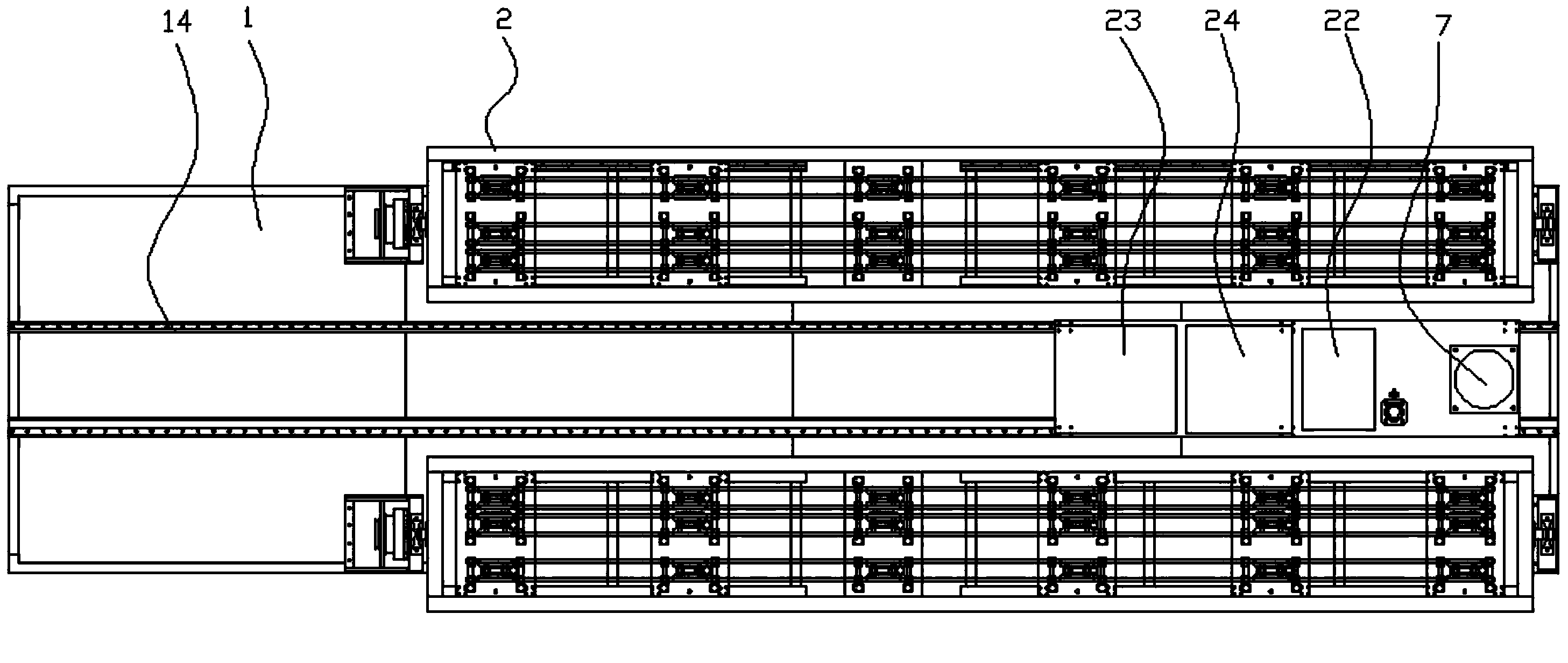

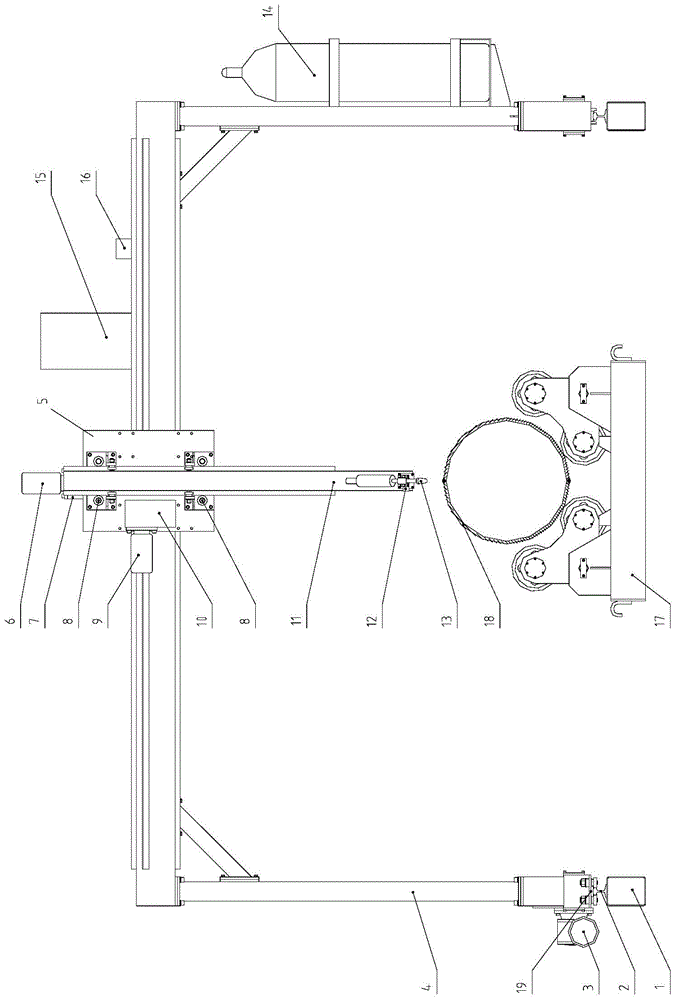

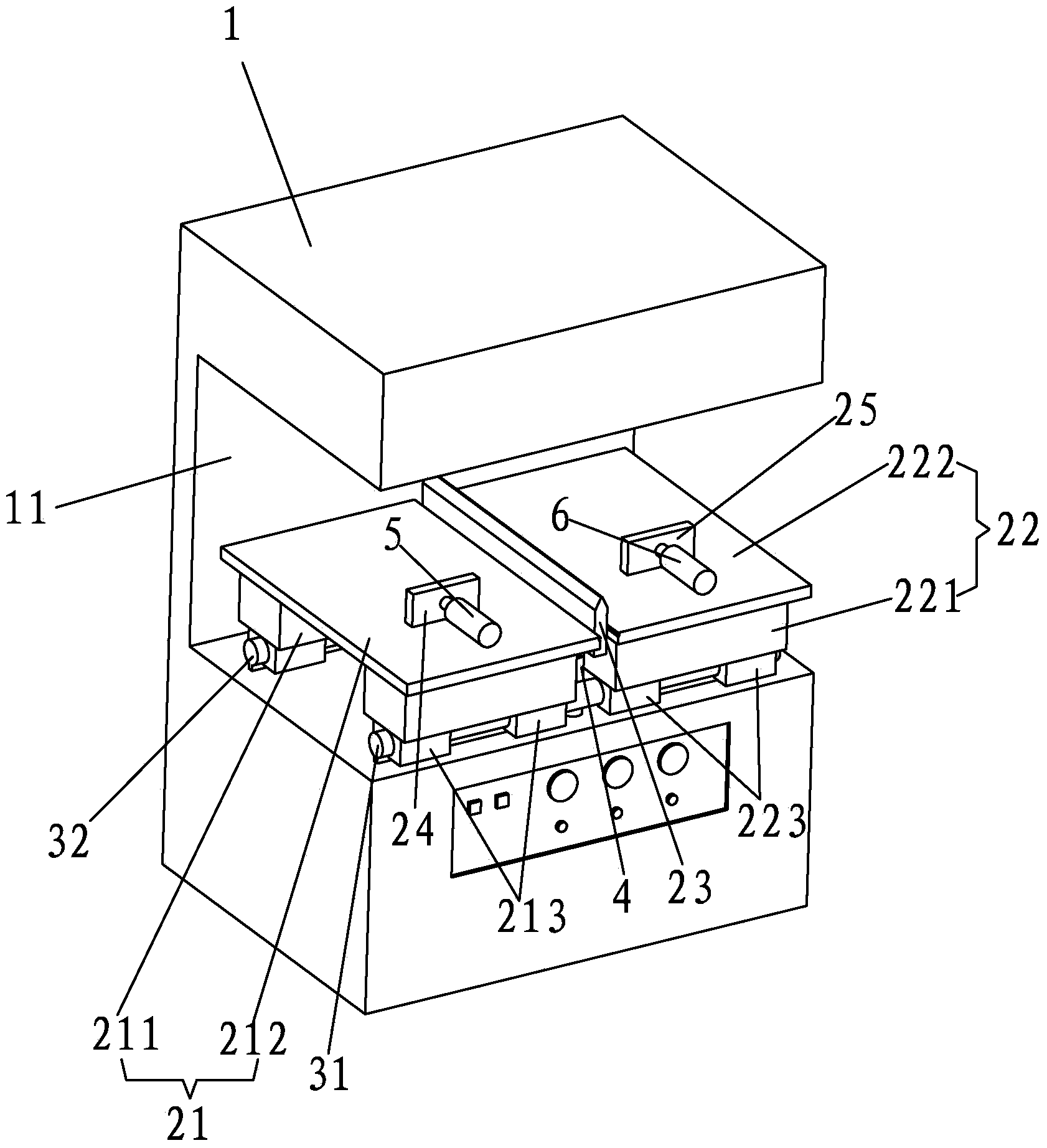

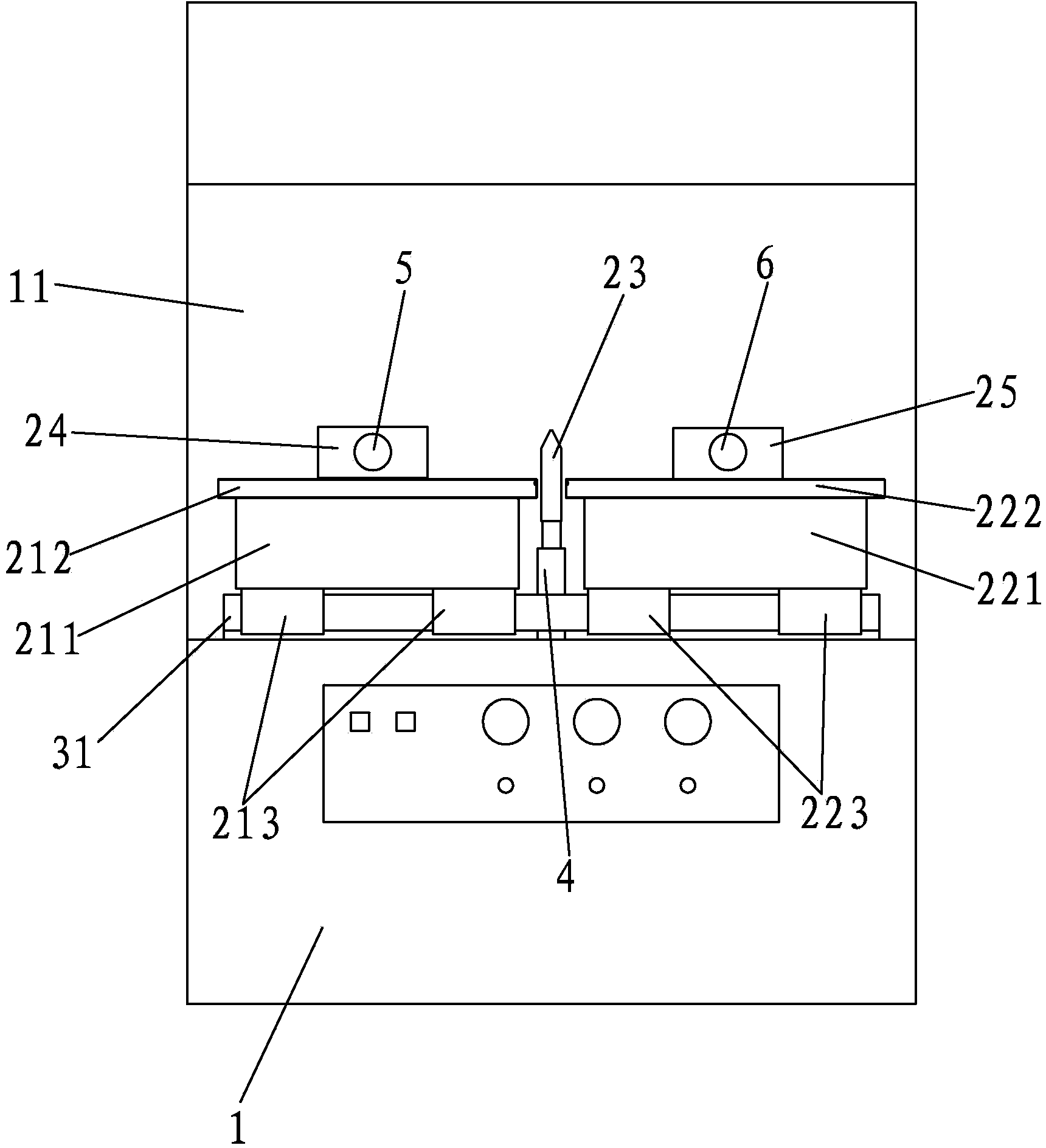

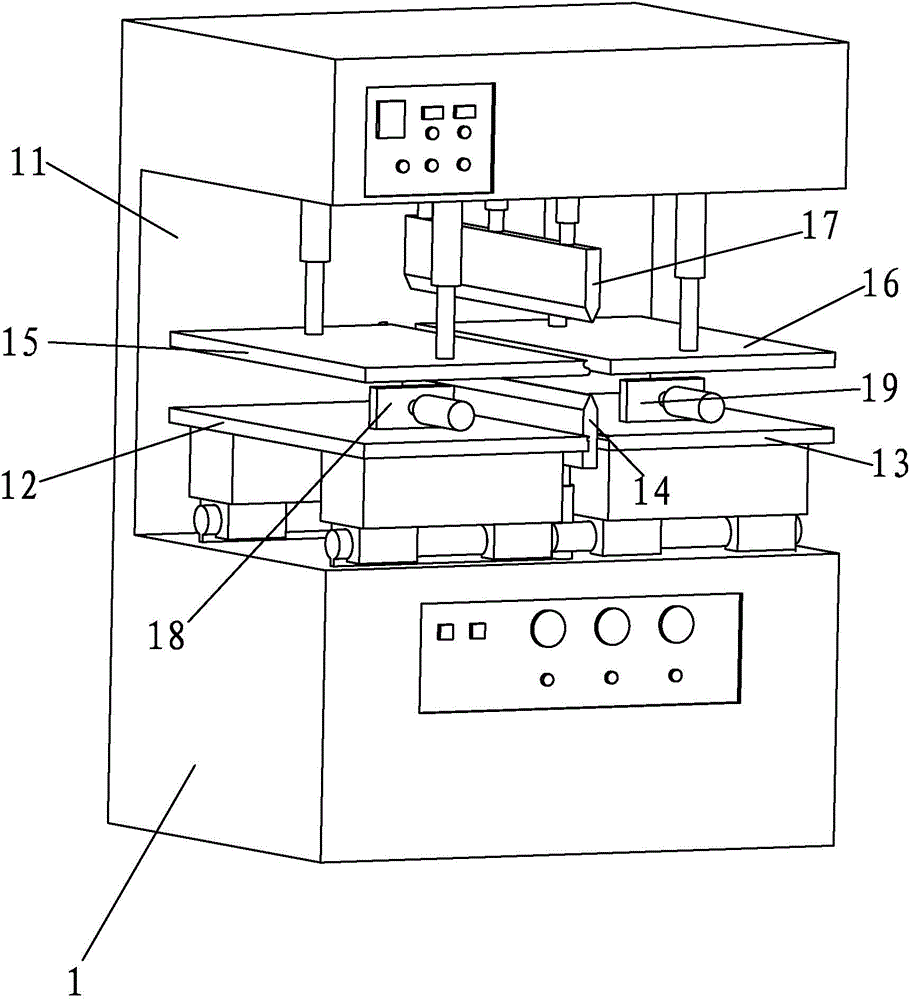

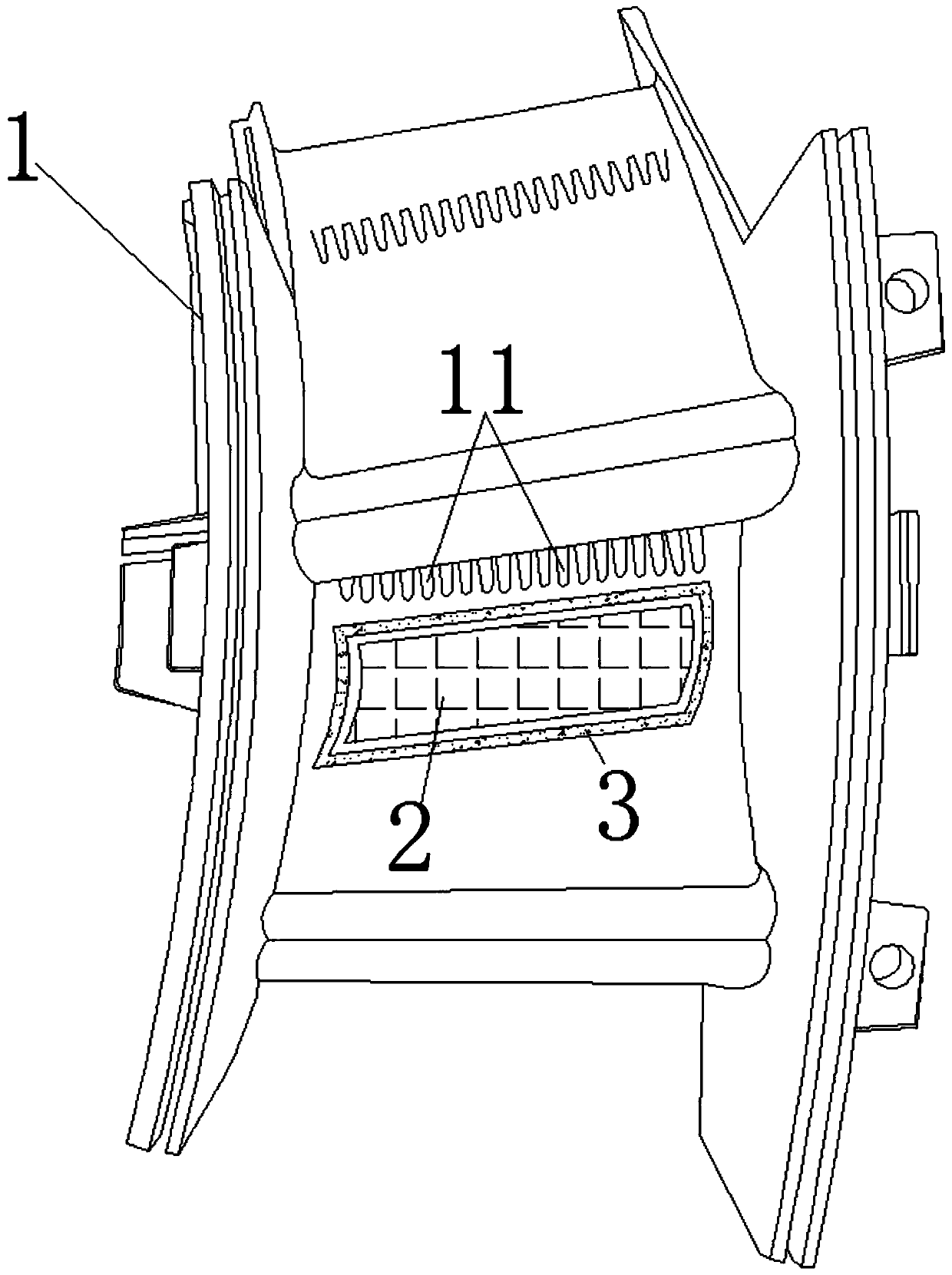

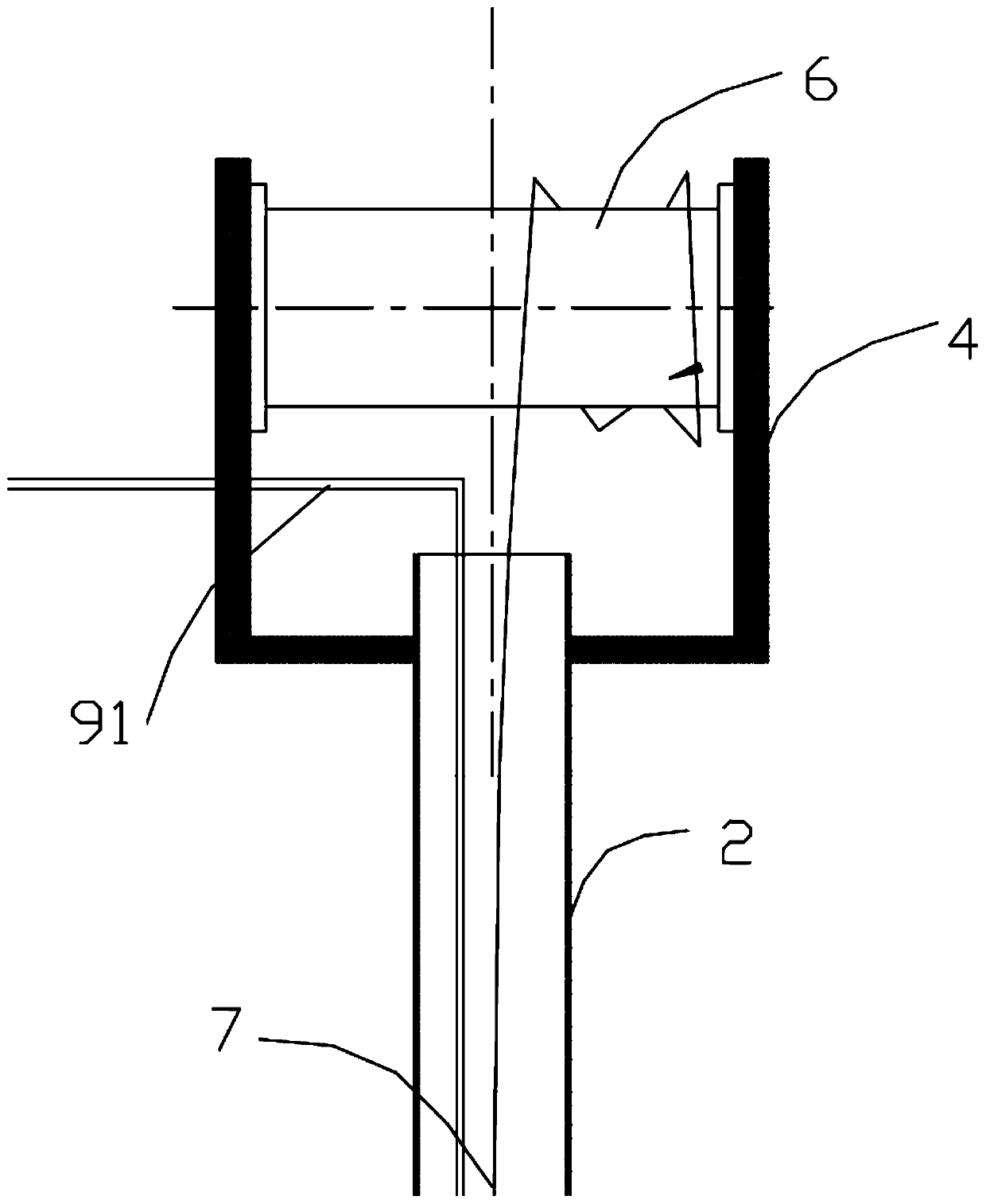

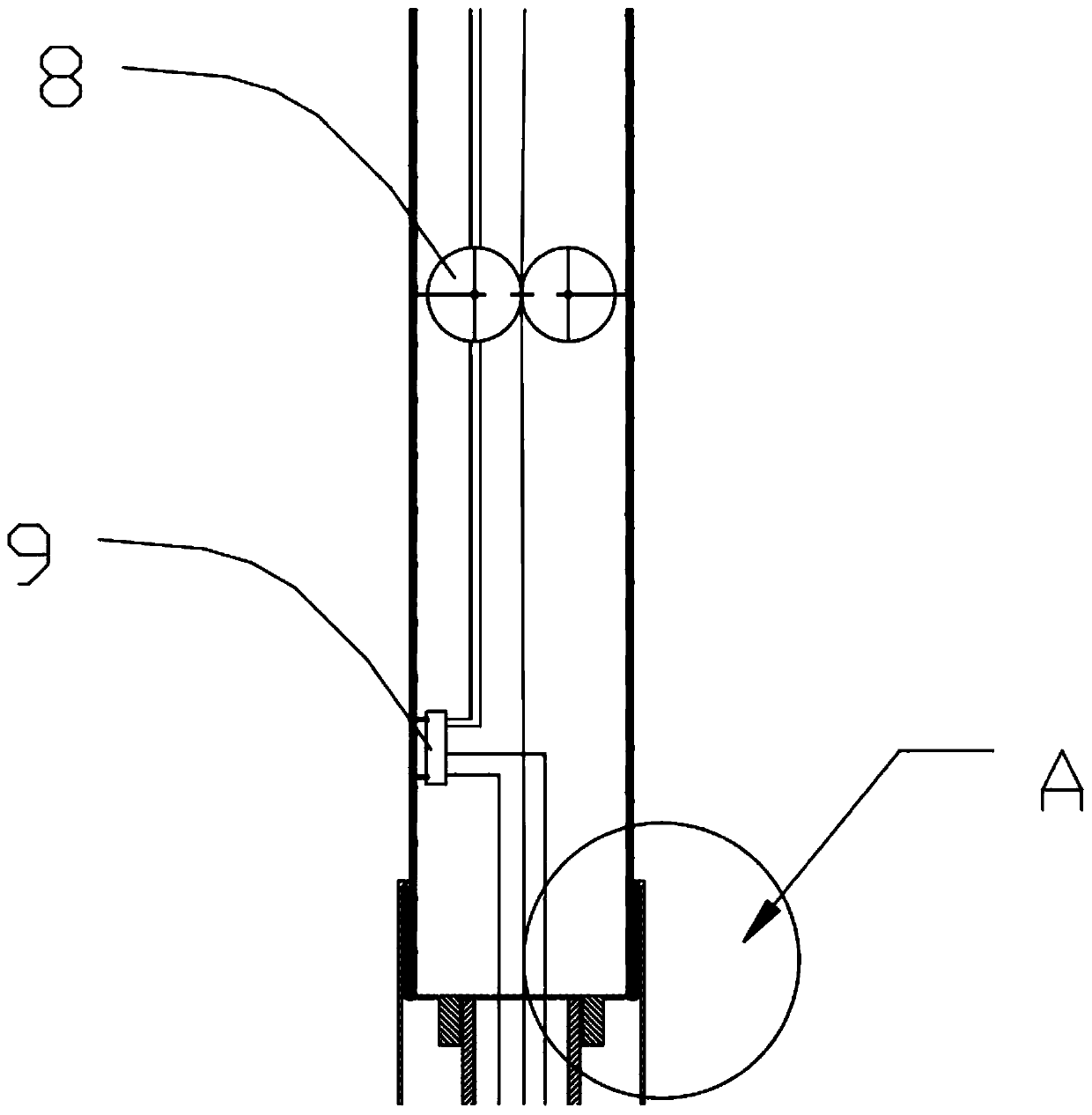

Double-head and double-sided friction stir welding equipment with high efficiency, and welding method thereof

ActiveCN109822208AShorten the timeImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPortal frame

The invention discloses double-head and double-sided friction stir welding equipment with high efficiency, and a welding method thereof. The equipment comprises a base, upright columns, an upper crossbeam, a lower cross beam, at least one working table, visual sensors and a CNC controller; the upper cross beam is provided with an upper head, and the lower cross beam is provided with a lower head;the upright columns, the upper cross beam and the lower cross beam form a portal frame of an integral structure, and the upper head and the lower head can be moved along an X axis, a Y axis and a Z axis, and rotated along the Z axis through a driving device and a transmission mechanism; the working table is connected with the horizontal plane of the base, and the working table is located betweenthe upper head and the lower head; the working table and the portal frame can be moved relatively for achieving welding, and the visual sensors are installed on the upper head and the lower head, andused for navigation and identification of weld joints; and the CNC controller is used for controlling the portal frame, the upper head, the lower head, the working table and the visual sensors to work.

Owner:BEIJING FSW TECH

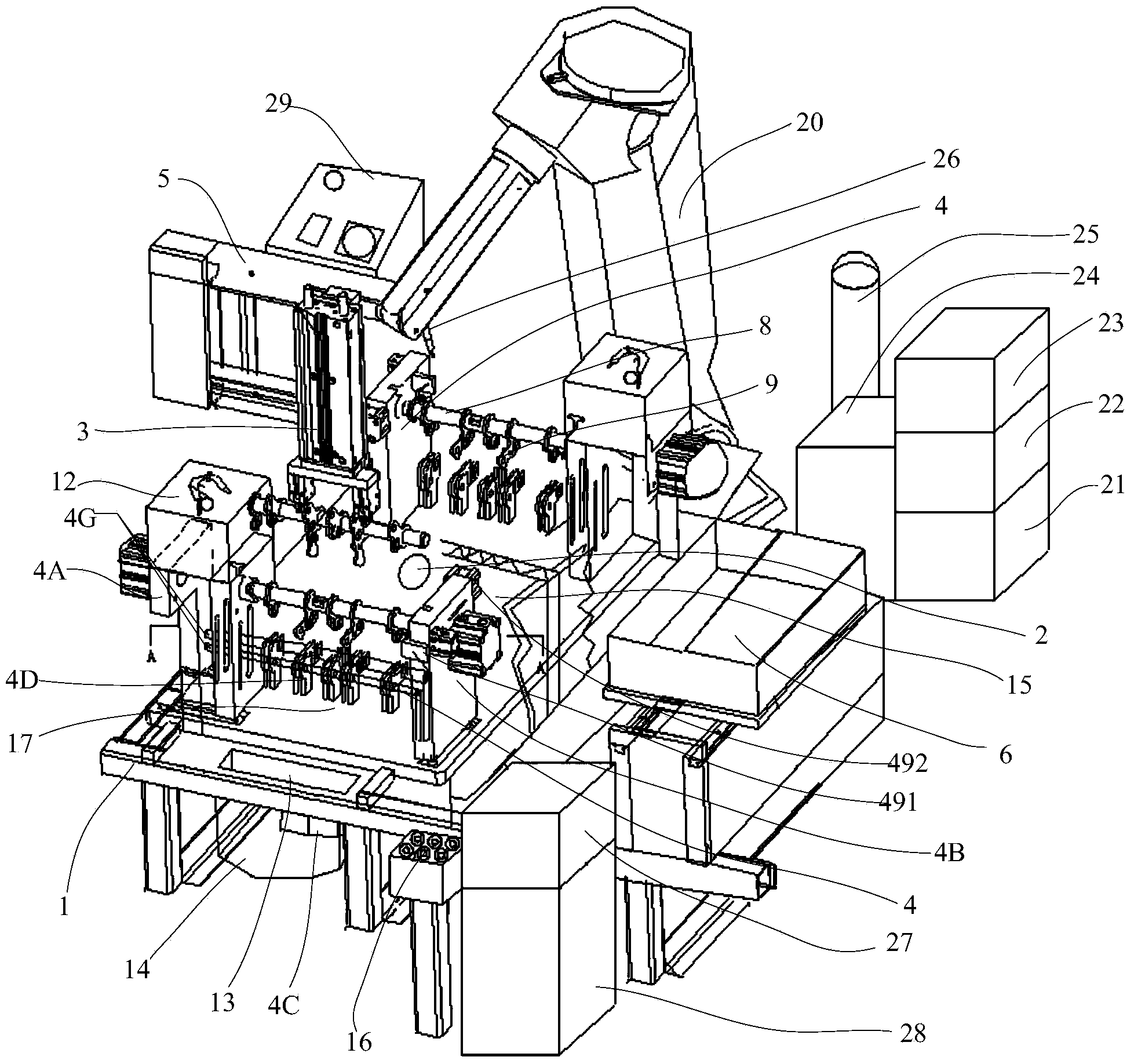

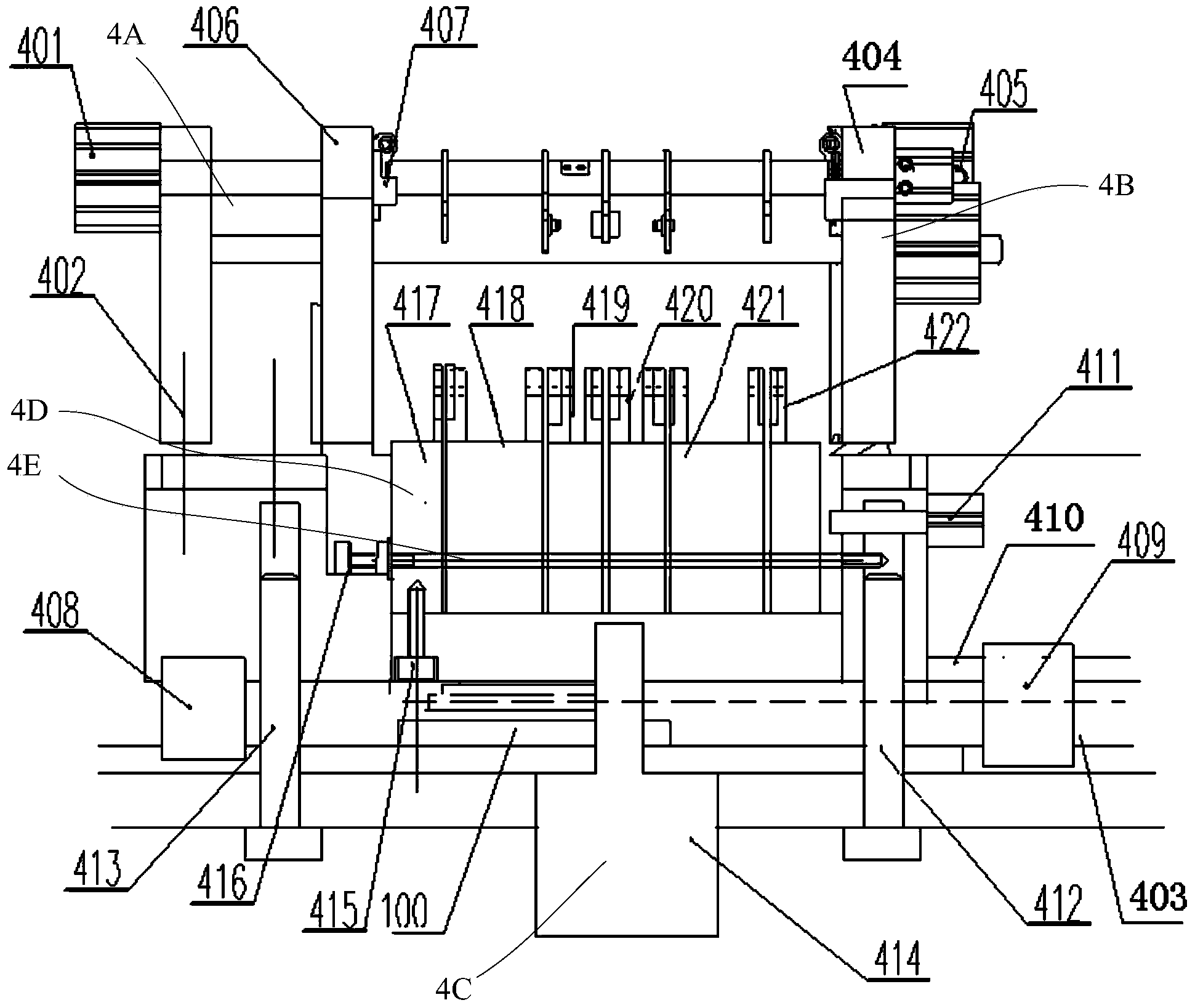

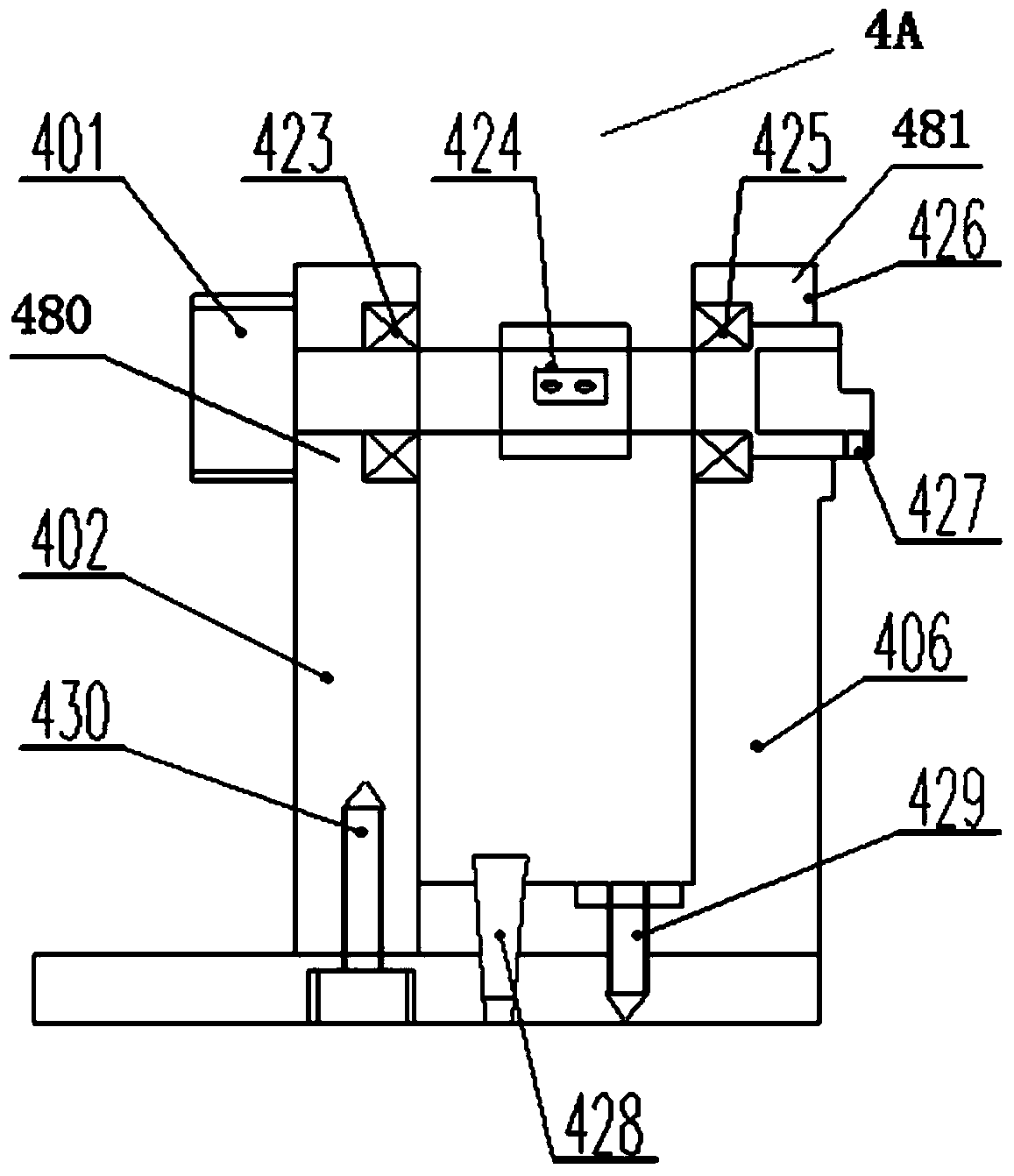

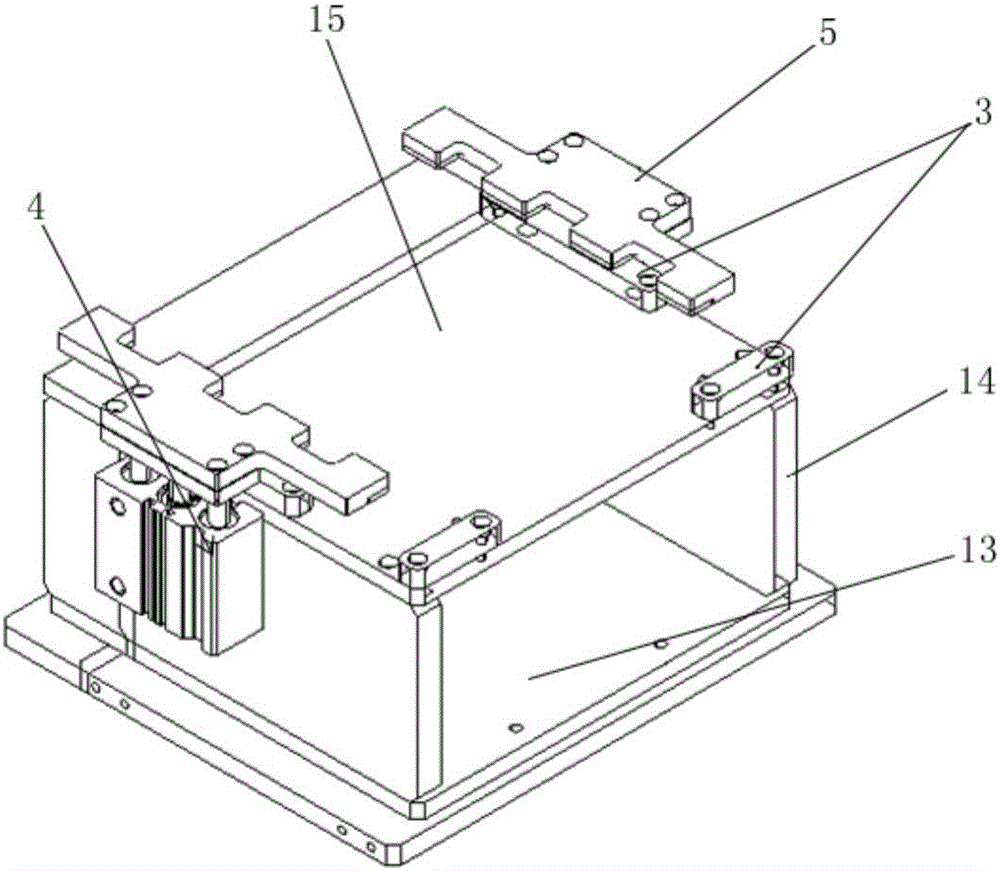

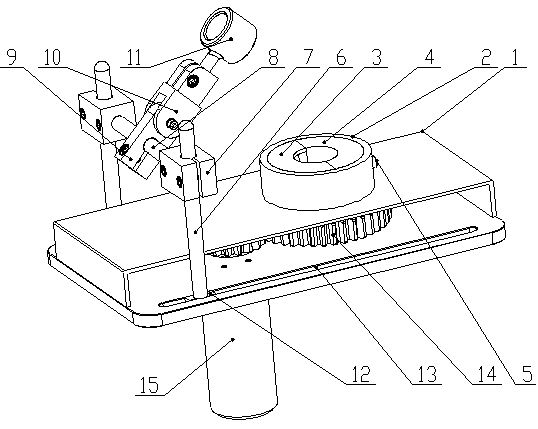

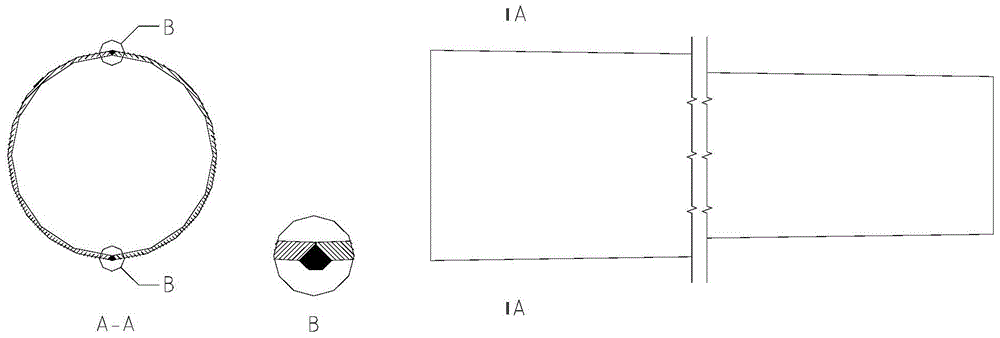

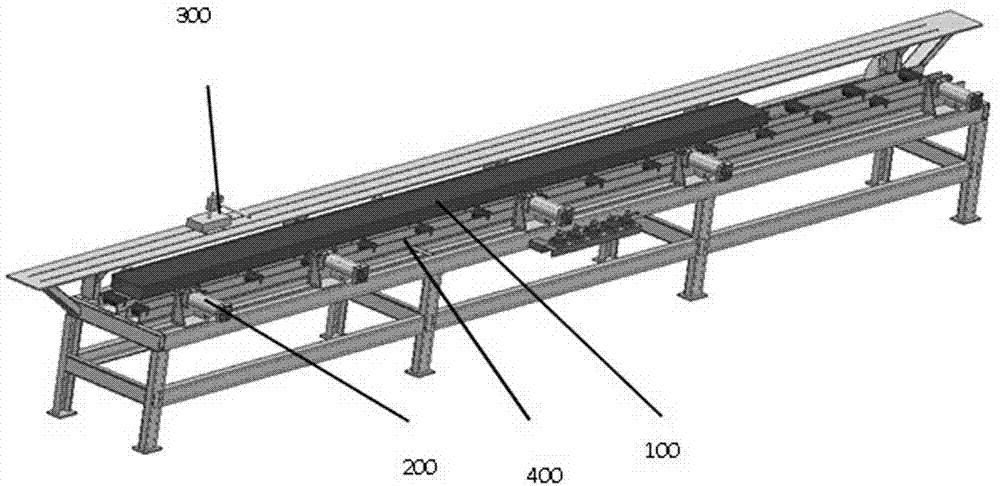

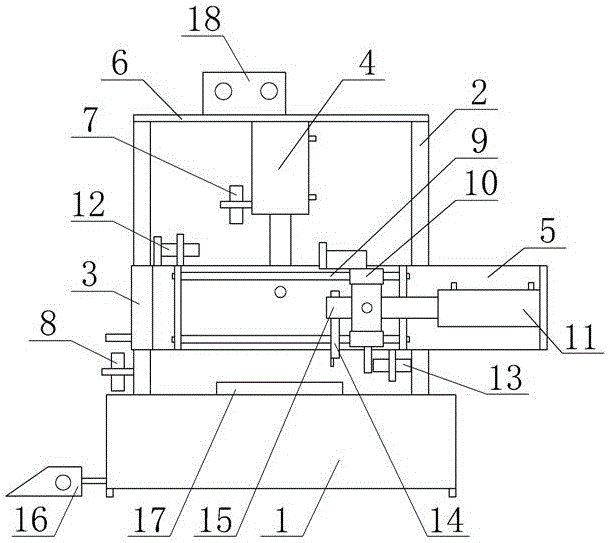

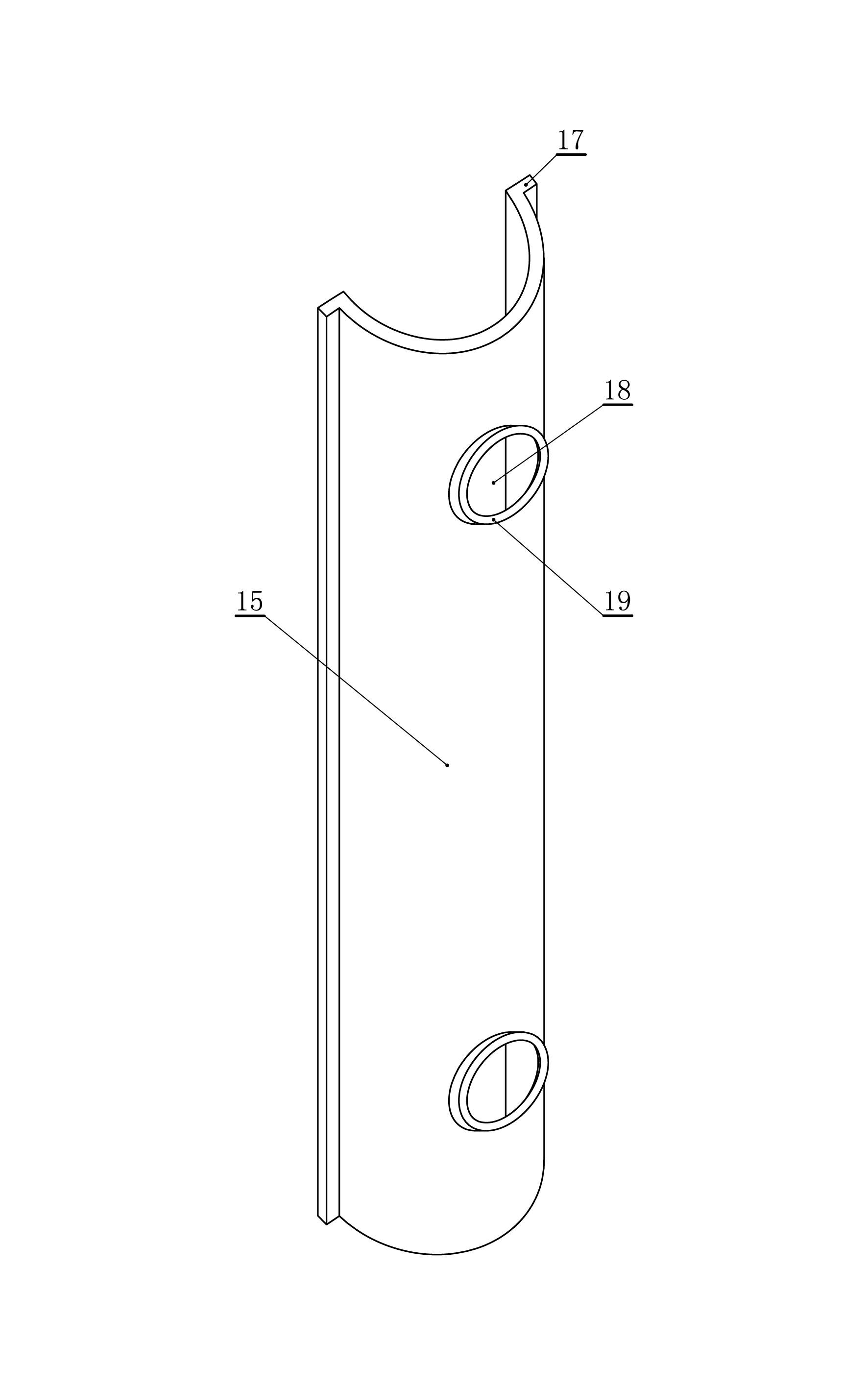

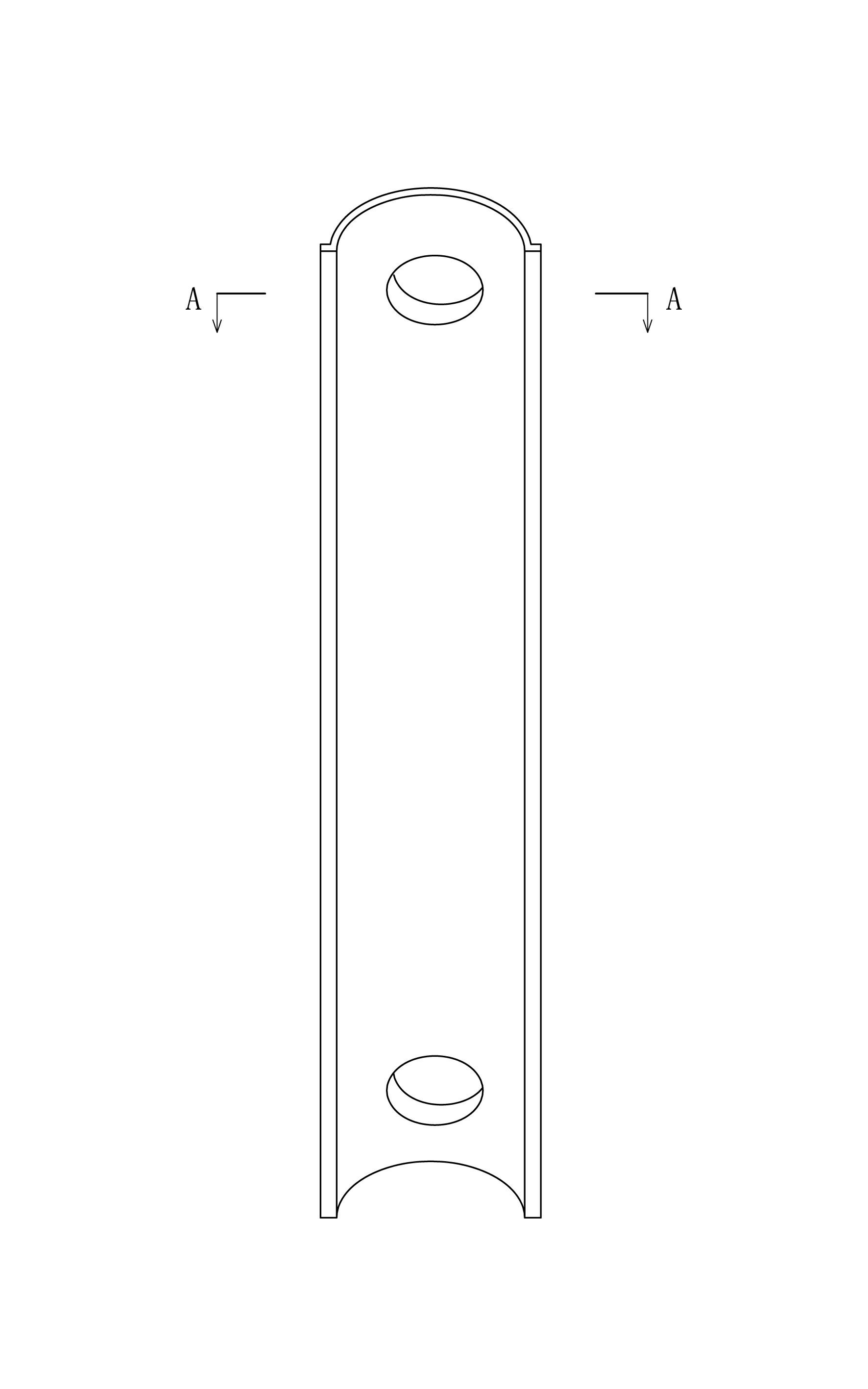

Rotating shaft welding jig, rotating shaft welding worktable and automatic rotating shaft welding system

ActiveCN103506797ASimple structurePrecise control of shape and positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a rotating shaft welding jig, a rotating shaft welding worktable and an automatic rotating shaft welding system. The rotating shaft welding jig comprises a rotating shaft clamp and a component fixing device, wherein the rotating shaft clamp is used for clamping a rotating shaft, and the component fixing device is used for fixing a rotating shaft component which needs to be welded to the rotating shaft. The rotating shaft clamp comprises a rotating shaft supporting and rotating mechanism and a rotating shaft supporting and clamping mechanism, wherein the rotating shaft supporting and rotating mechanism and the rotating shaft supporting and clamping mechanism are used for clamping the two ends of the rotating shaft respectively. The component fixing device is arranged between the rotating shaft supporting and rotating mechanism and the rotating shaft supporting and clamping mechanism and comprises a rotating shaft component clamping part and a clamping driving part. The rotating shaft component clamping part comprises a plurality of bases which are arranged on a base plate side by side, wherein the bases include at least one fixed locating base and a plurality of sliding bases. The clamping driving part is connected with the rotating shaft component clamping part and can drive the sliding bases to slide towards the locating base so that the adjacent bases can clamp and loosen the rotating shaft component. The rotating shaft welding jig can clamp the rotating shaft and the rotating shaft component at a time.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

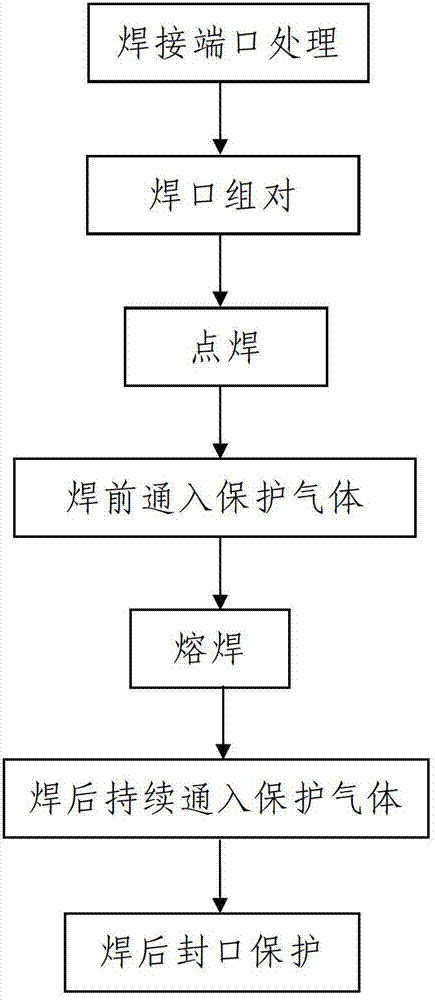

Automatic traceless fusion welding technology of thin-wall stainless steel clean pipeline

The invention discloses an automatic traceless fusion welding technology of a thin-wall stainless steel clean pipeline. The technology comprises the following steps of: step 1, treating a welding port: milling pipe end welding surfaces of two welded pipeline segments into planes; step 2: assembling welded junctions; step 3: carrying out point welding; step 4: carrying out fusion welding: carrying out fusion welding on the two pipeline segments by adopting an argon tungsten-arc welding machine, wherein the fusion welding process comprises the following steps of: introducing a protective gas before welding, welding the two welded pipeline segments by adopting the argon tungsten-arc welding machine, and introducing argon continuously during the welding process and introducing a protective gas continuously after welding; and step 5: sealing and protecting after welding. The automatic traceless fusion welding technology of the thin-wall stainless steel clean pipeline provided by the invention is reasonable in design, is simple and convenient to operate, is convenient to achieve, has a good pipeline cleanness control effect, is high in welding quality, and can effectively solve the problems of high labor intensity, low efficiency, high production cost, severe welding junction oxidation, poor formation inside and outside a welding line, difficulty in controlling cleanness in pipelines, poor cleanness control effect and the like in an existing welding method.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

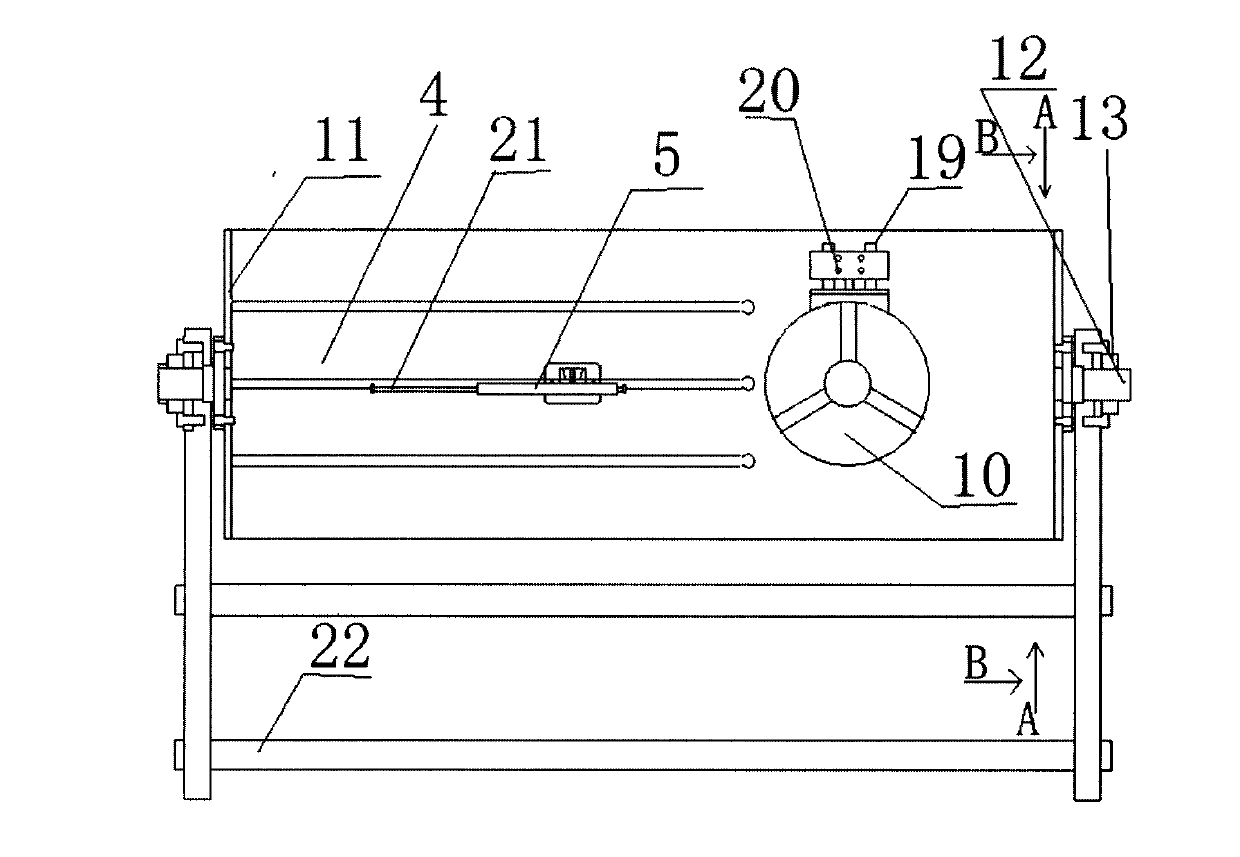

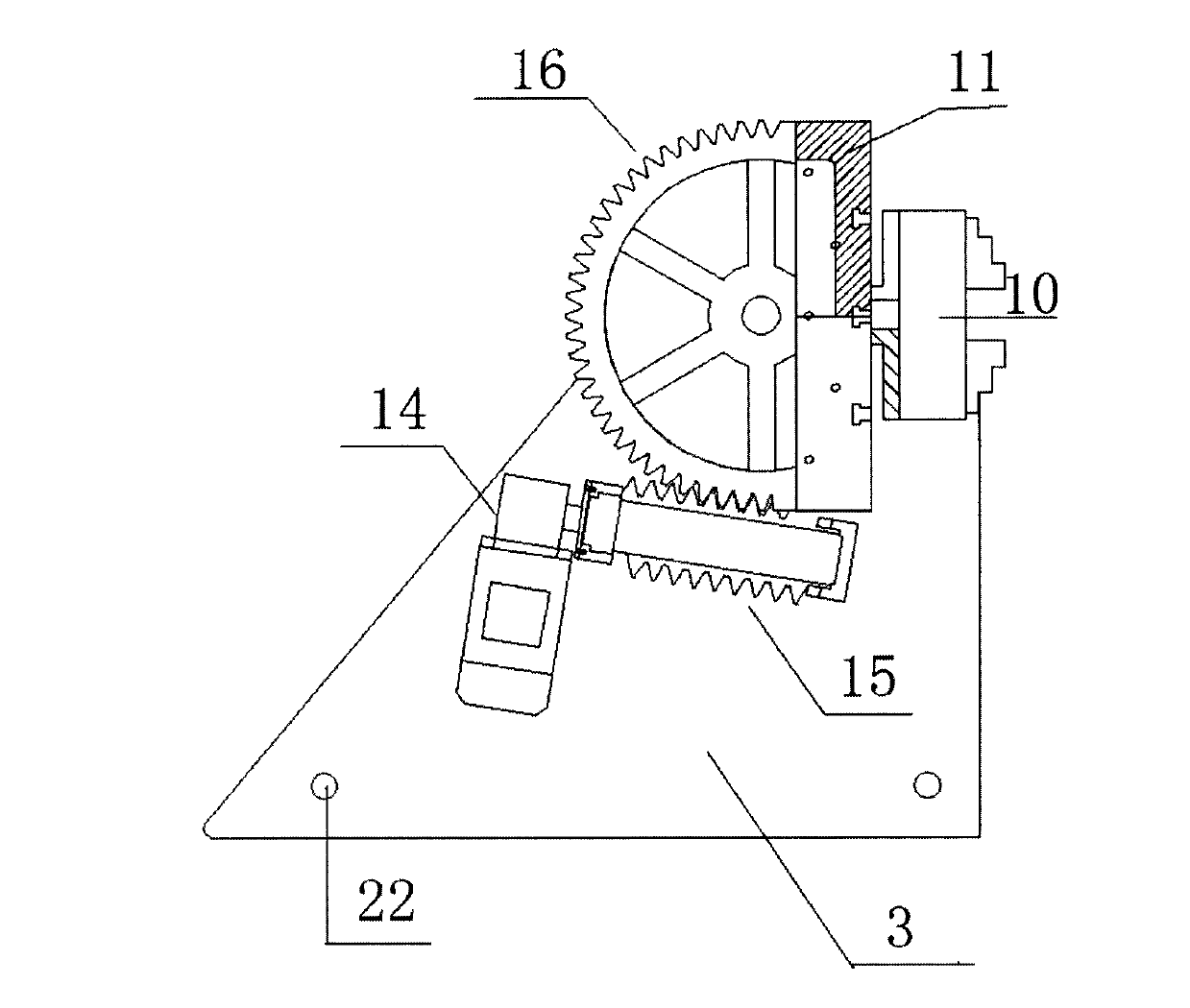

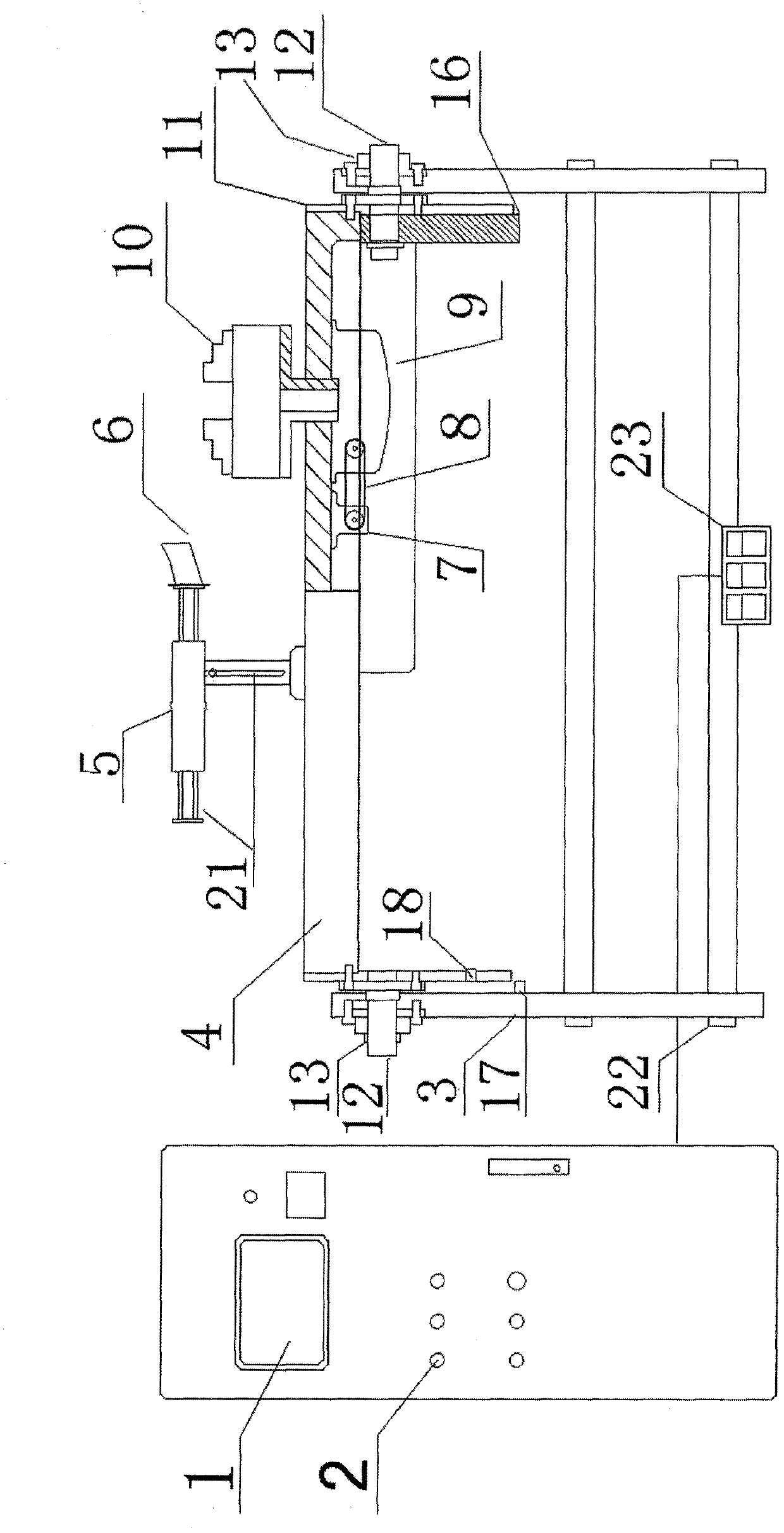

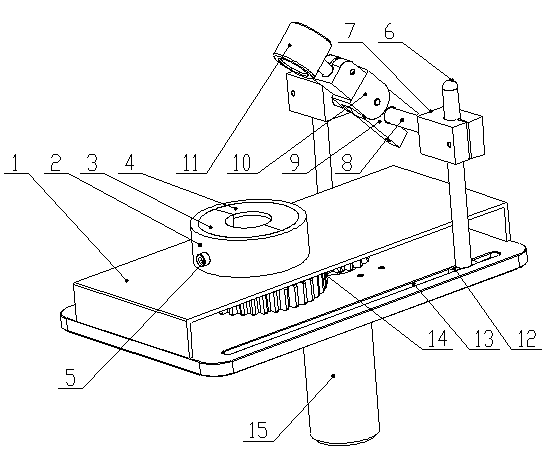

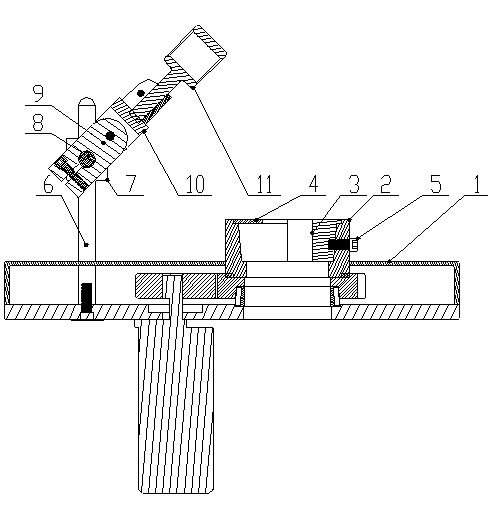

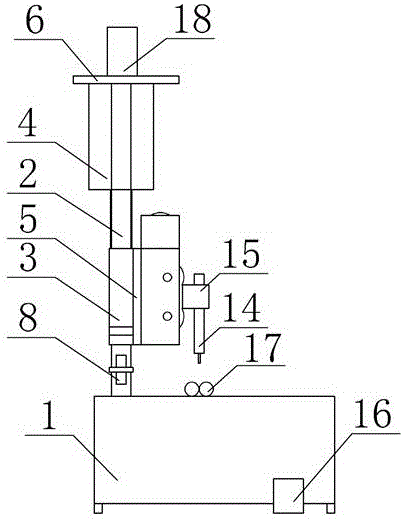

Device and technology of automatic impeller indexing weld

InactiveCN103128467AWeld firmlyBeautiful weldWelding/cutting auxillary devicesAuxillary welding devicesImpellerEngineering

The invention discloses a device and a technology of automatic impeller indexing weld, and belongs to the technical field of impeller weld in the fan industry. The device controls walk steps of a splitting motor by setting a splitting procedure of a controller, and can equally divide an impeller at any angle through a decelerating machine. A further improvement is flip type weld, and the flip type weld is characterized by instructing a flipping motor to drive a decelerating mechanism to achieve flipping at any angle by setting a flipping procedure of the controller, and thereby facilitating reinforced welding. The weld technology includes: firstly clamping an impeller rear disc and fastening, and fixing blades for spot welding; then using the device for indexing weld on each blade, and placing an impeller front disc and fastening; afterwards turning over a working table to a target position and then performing indexing weld reinforcing on each blade; and finally turning over the working table to an initial point to finish the weld. The device and the technology can achieve equally dividing the impeller accurately, are simple and convenient to manipulate, and enable the weld to be stable and beautiful.

Owner:武伟

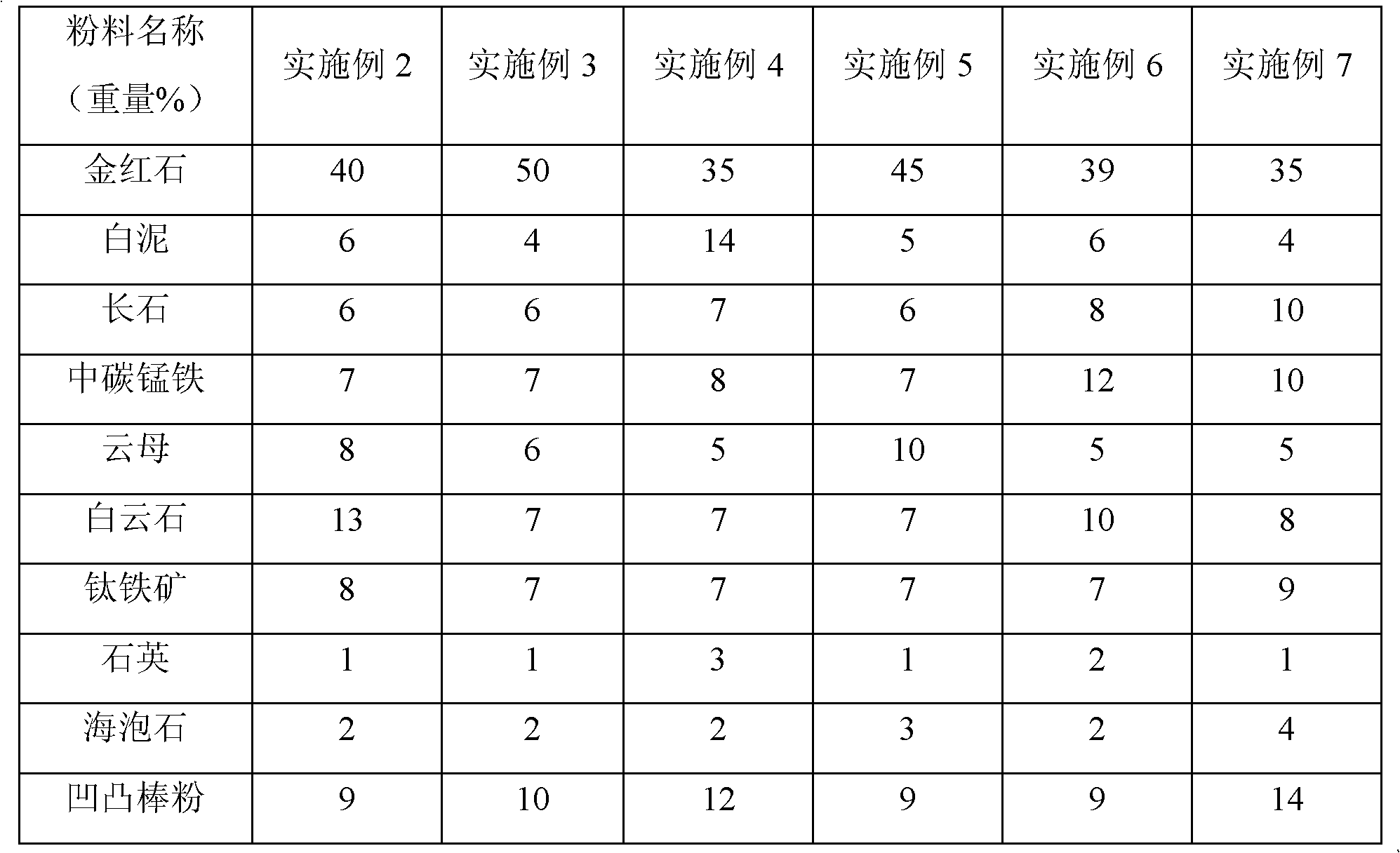

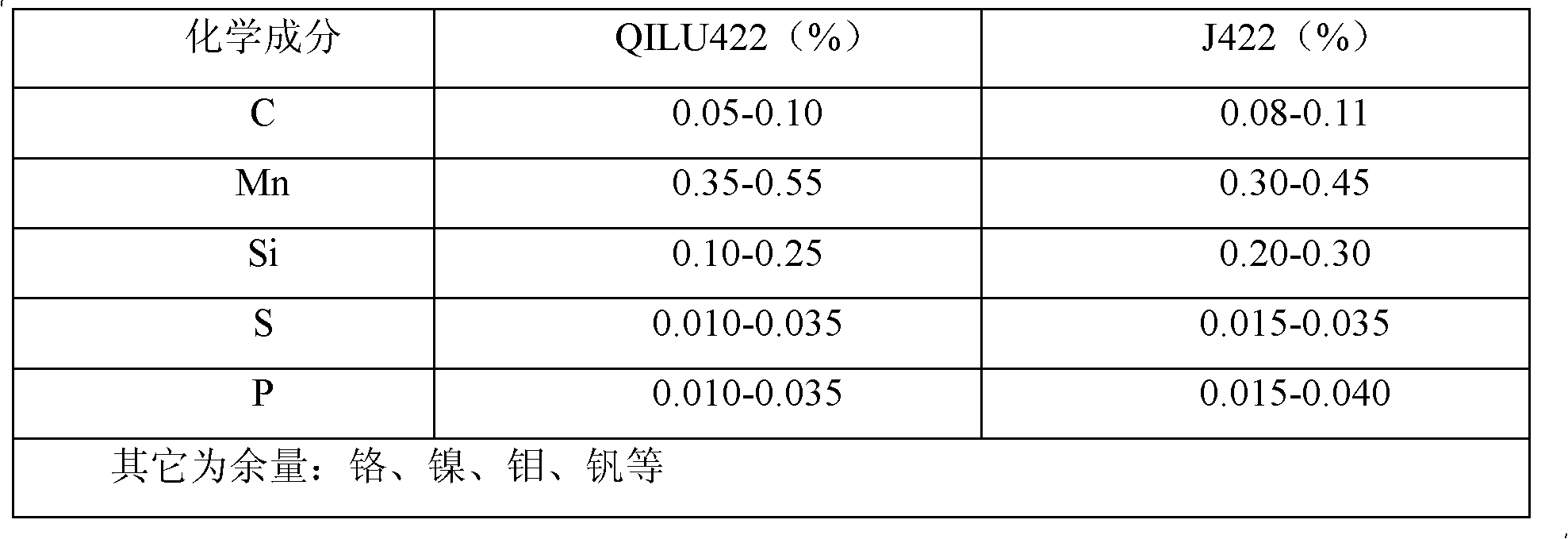

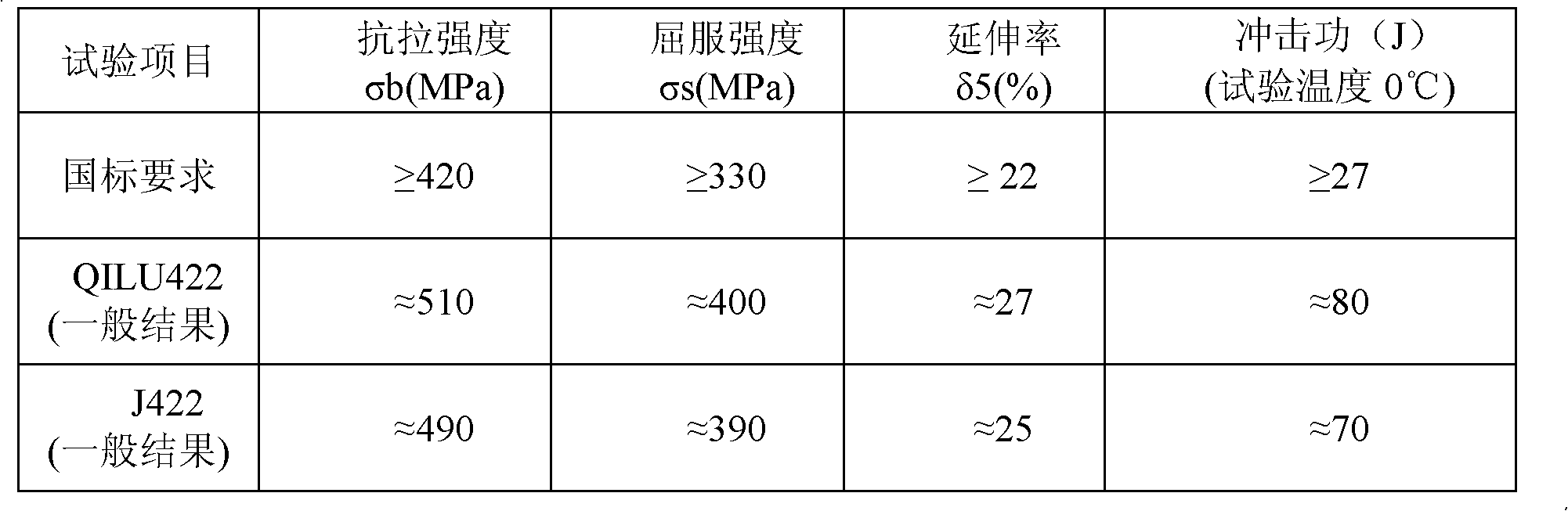

Energy-saving and environment-protective welding rod

ActiveCN101934442AReduce energy consumptionSmall side effectsWelding/cutting media/materialsSoldering mediaAlternating currentDolomite

The invention relates to an energy-saving environment-friendly welding rod belonging to the field of welding materials. The energy-saving environment-friendly welding rod comprises a coating and a welding core. The energy-saving environment-friendly welding rod is characterized in that the coating comprises the following matters in percentage by weight: 35-50 percent of rutile, 7-12 percent of mid-carbon ferromanganese, 4-14 percent of white slime, 6-12 percent of feldspar, 5-10 percent of mica, 7-13 percent of dolomite, 7-9 percent of ilmenite, 1-3 percent of quartz, 2-4 percent of meerschaum and 9-14 percent of attapulgite powder. For selecting raw materials, the rutile is adopted instead of titanium pigment and reduced titanium, which has low energy consumption and low pollution; and the meerschaum is used instead of organic matters of wood flour, cellulose, and the like, which almost does not generate dust when being used, is environment-friendly and does not damage the health of operating staff. The invention is the carbon steel welding rod with the rutile type coating, has the advantages of excellent welding process property, stable electric arc, beautiful welding seams, low splash, little dust and dual purposes of alternating current and direct current, and can carry out all-position welding.

Owner:淄博齐鲁焊业有限公司

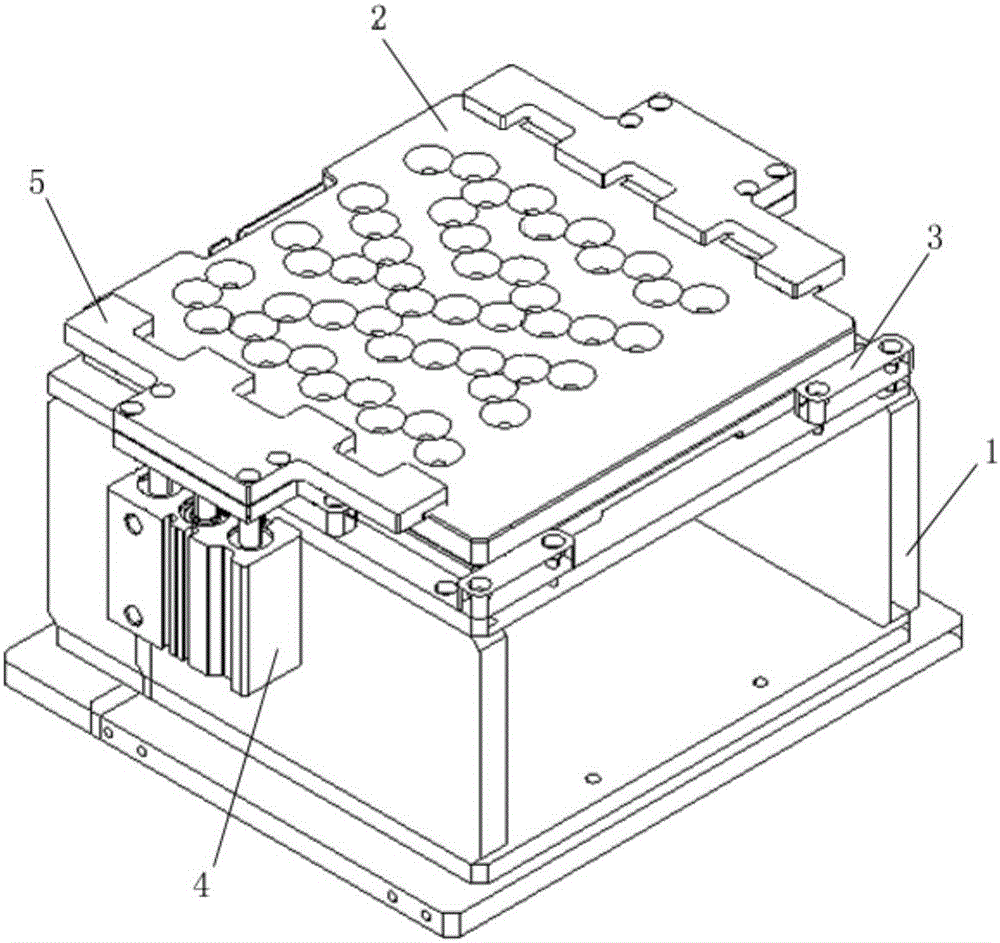

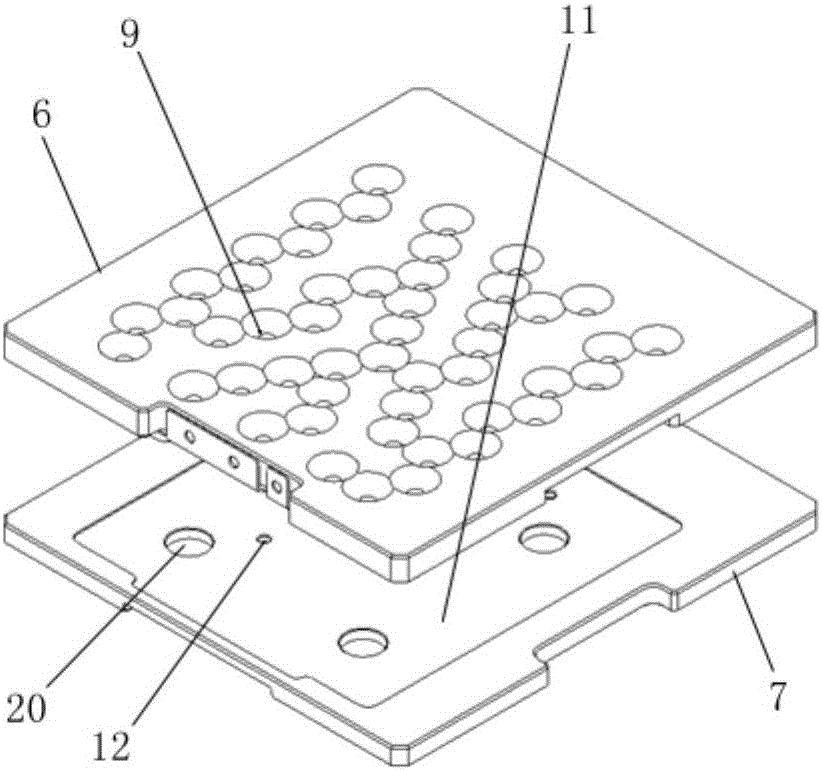

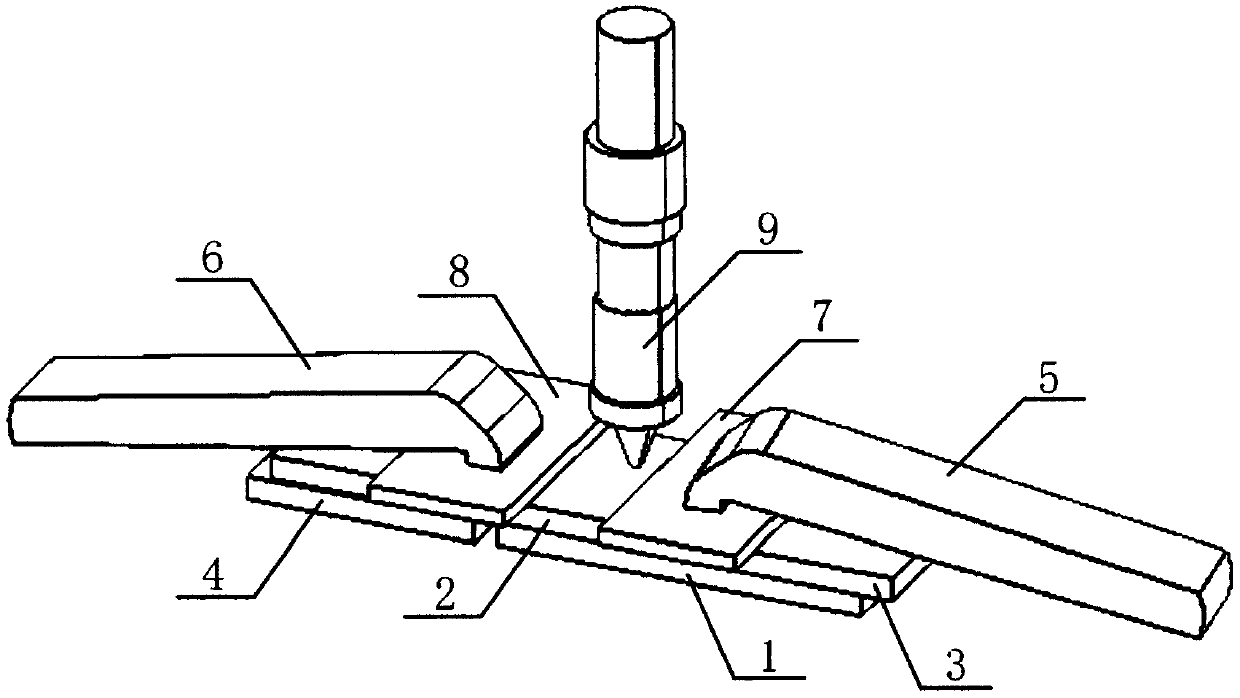

Laser welding tool for new energy resource power battery connecting piece

InactiveCN106624361APrecise positioningWeld firmlyLaser beam welding apparatusPower batteryNew energy

The invention relates to a laser welding tool for a new energy resource power battery connecting piece. The laser welding tool comprises a tool table and a clamp, wherein a clamp positioning block is arranged on the tool table, air cylinders and press plates are arranged on two sides of the tool table, and the press plates are fixed to the head ends of piston rods of the air cylinders. The clamp consists of a base plate and a cover plate, wherein a plurality of rows of tab avoiding grooves are formed in the base plate, distribution positions of the tab avoiding grooves correspond to the positions of die-sunken nickel piece tabs, and laser transmitting holes are formed among the tab avoiding grooves and correspond to welding positions. Two positioning pins are further arranged on the base plate, an accommodating groove is formed in the cover plate, and two positioning holes are further formed in the cover plate and correspond to the positioning pins. The laser welding tool can accurately position nickel pieces and copper bars and perform firm clamping to ensure that the two parts are fit tightly and have no relative movement, and the welding quality and efficiency are improved.

Owner:FIRST NEW ENERGY GRP CO LTD

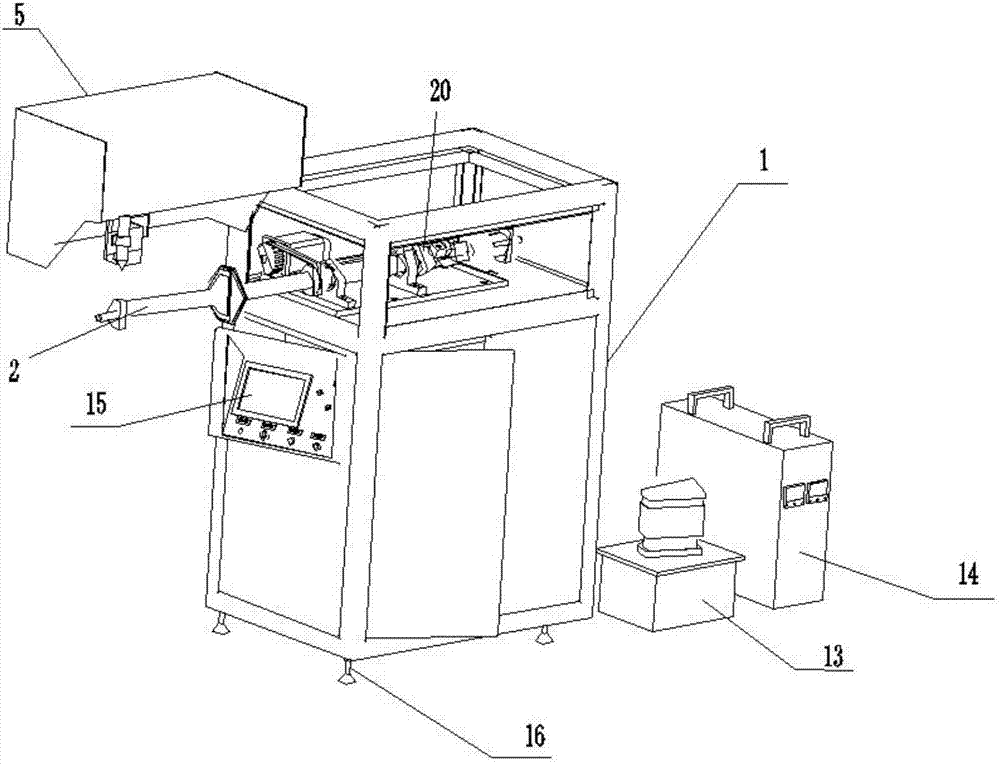

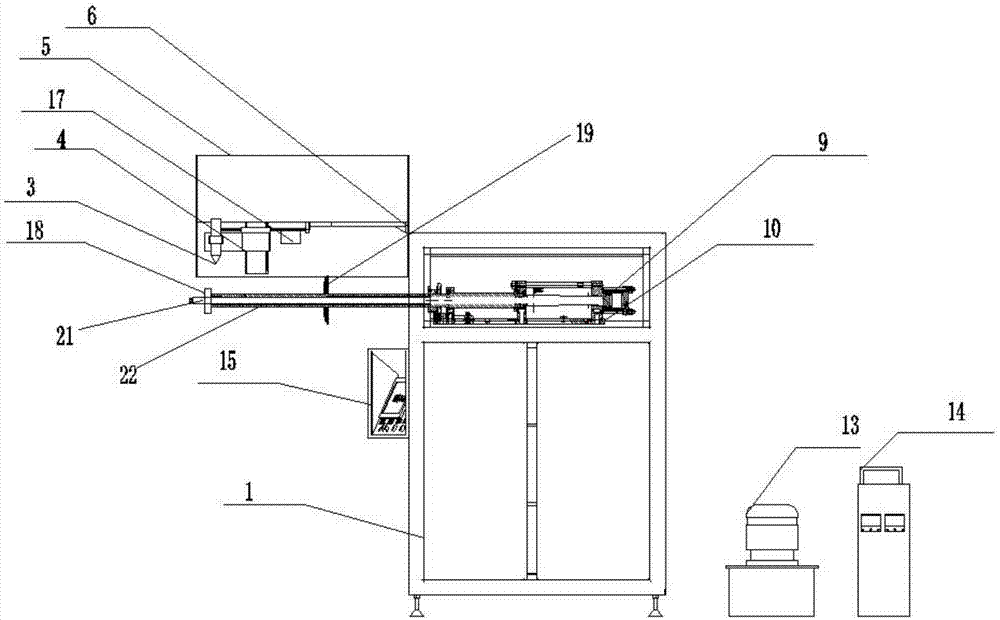

Device used for welding copper tube and aluminum tube in refrigeration equipment and welding method thereof

ActiveCN104191081ANo consumptionNice appearanceHigh frequency current welding apparatusWelding/soldering/cutting articlesMagnetic tension forceTransformer

The invention discloses a device used for welding a copper tube and an aluminum tube in refrigeration equipment and a welding method of the device. The device comprises a main device body and a working table, wherein the main device body comprises a main box, an alternating-current power source, a transformer, a high-voltage rectifier, a capacitor set, vacuum switches and a triggering device; the working table comprises a rack and a welding head, the welding head comprises an electric conducting coil and a magnetic flux concentrator, and the electric conduction coil is connected with all the vacuum switches through coaxial cables. The welding method includes the following steps that (1), one end of an outer tube is inserted in the magnetic flux concentrator, and one end of an inner tube is inserted into the magnetic flux concentrator; (2), a pulser is started, when a charging voltage reaches a set value, the system control triggering device turns on a discharging switch, and the outer tube and the inner tube are welded through magnetic force in the magnetic flux concentrator. The device used for welding the copper tube and the aluminum tube in the refrigeration equipment achieves normal-temperature welding, and is more convenient and faster to use, more environmentally friendly and lower in welding cost.

Owner:CHONGQING PULSAR TECH

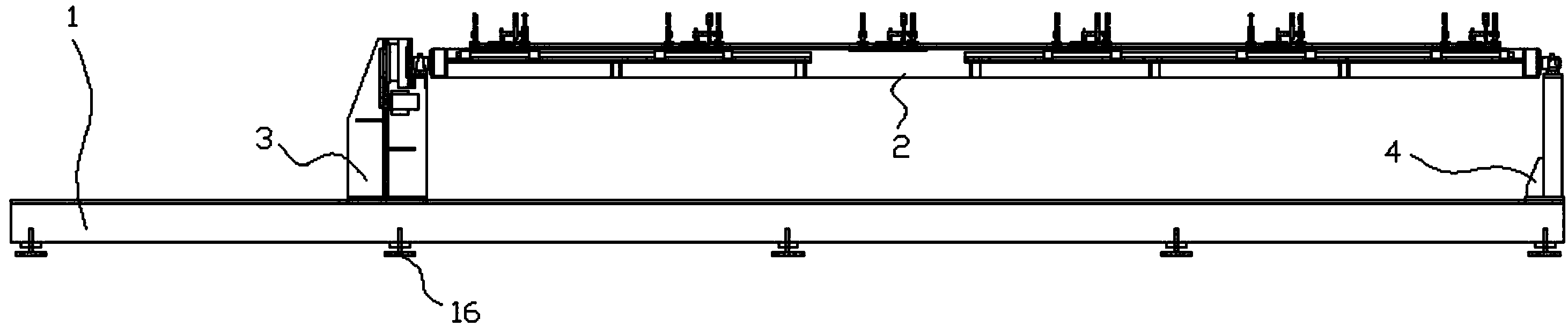

Special robot welding machine for joist

ActiveCN104014900AImprove welding efficiencySimple inputWelding/cutting auxillary devicesAuxillary welding devicesJoistReducer

The invention relates to joist welding, and discloses a special robot welding machine for a joist. The special robot welding machine comprises a main engine base, a rotating frame and a moving trolley, a main support and an auxiliary support are arranged on the main engine base, the two ends of the rotating frame are arranged on the main support and the auxiliary support through bearings respectively, and a welding robot is arranged on the moving trolley; a controller is further arranged on the main engine base, a harmonic speed reducer is arranged on the main support, a first servo motor is arranged below the harmonic speed reducer and synchronously connected with the harmonic speed reducer, and one end of the rotating frame is connected with the harmonic speed reducer. The moving trolley and the servo motor on the main support are controlled through the PLC, and the welding robot is taught to simulate a welding track, so that full automation is achieved, labor is liberated completely, only feeding and discharging procedures need to be finished manually, other procedures are automatic, labor intensity of workers is greatly reduced, welding efficiency is improved, and welding is even.

Owner:江苏沃达电子科技有限公司

Efficient shape welding machine and using method thereof

InactiveCN103008942AQuick welding jobConvenient welding workWelding/cutting auxillary devicesAuxillary welding devicesDrive motorEngineering

The invention relates to an efficient shape welding machine and a using method thereof. The efficient shape welding machine comprises a working platform, wherein a rotary barrel is arranged on the working platform; a magnet of which the section is circular-arc-shaped is arranged in the rotary barrel, so that the outer circumferential wall of a welded part is fixed on the inner side arc face of the magnet; and a support frame for fixing a welding gun is arranged beside the rotary barrel. The method comprises the following steps of: I, adsorbing a welded part onto the inner circumferential wall of the magnet to realize fixing of the welded part; II, covering a separation blade for matching the separation blade with the magnet to sleeve the outer circumferential wall of the welded part; III, adjusting relative positions of a vertical rod, a first slide block and a swing stem to make a circular tube reach a corresponding position and position the welding gun erected on the circular tube at a welding position; and IV, starting the welding gun and a driving motor, wherein the driving motor is used for driving the rotary barrel to rotate for driving the welded part to rotate, and the welding gun is used for welding the welded part at the welding position through the driving motor, so that welding work of bent parts can be finished conveniently and rapidly.

Owner:江苏冠赛达工贸有限公司

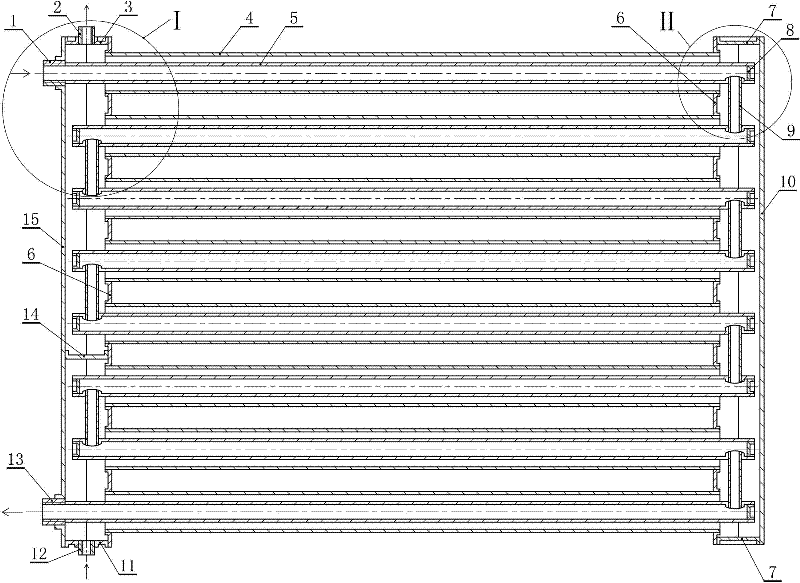

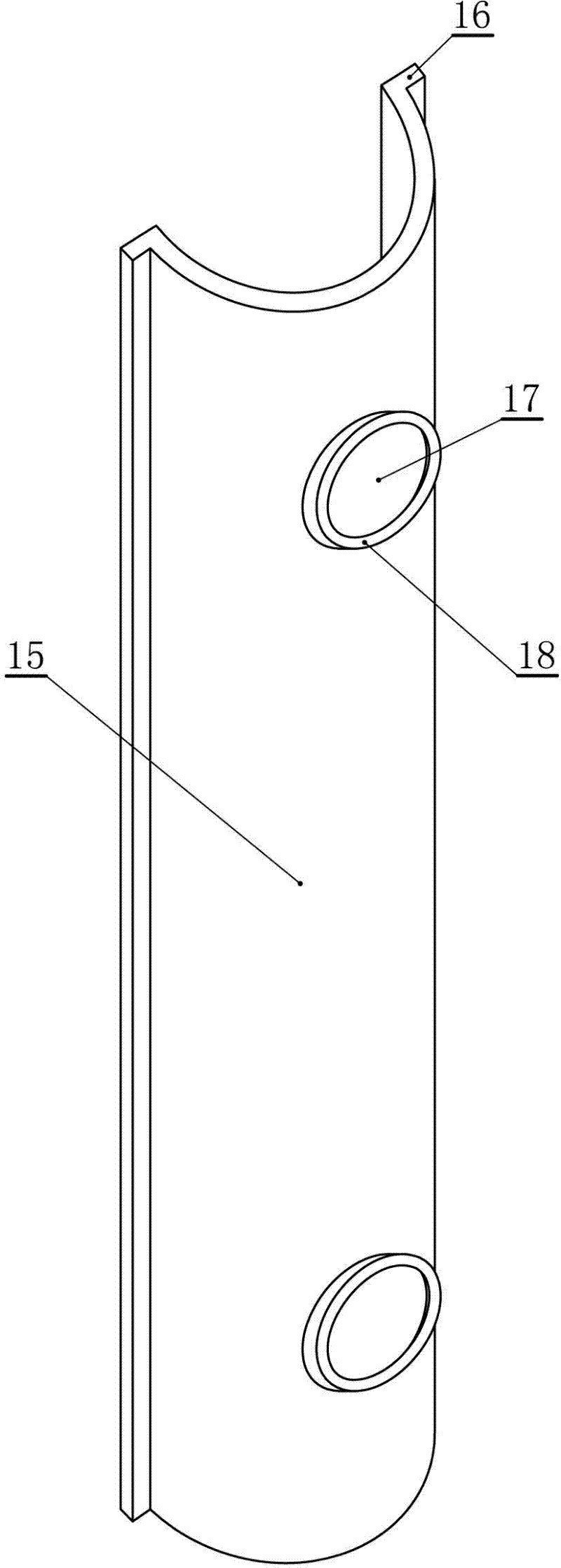

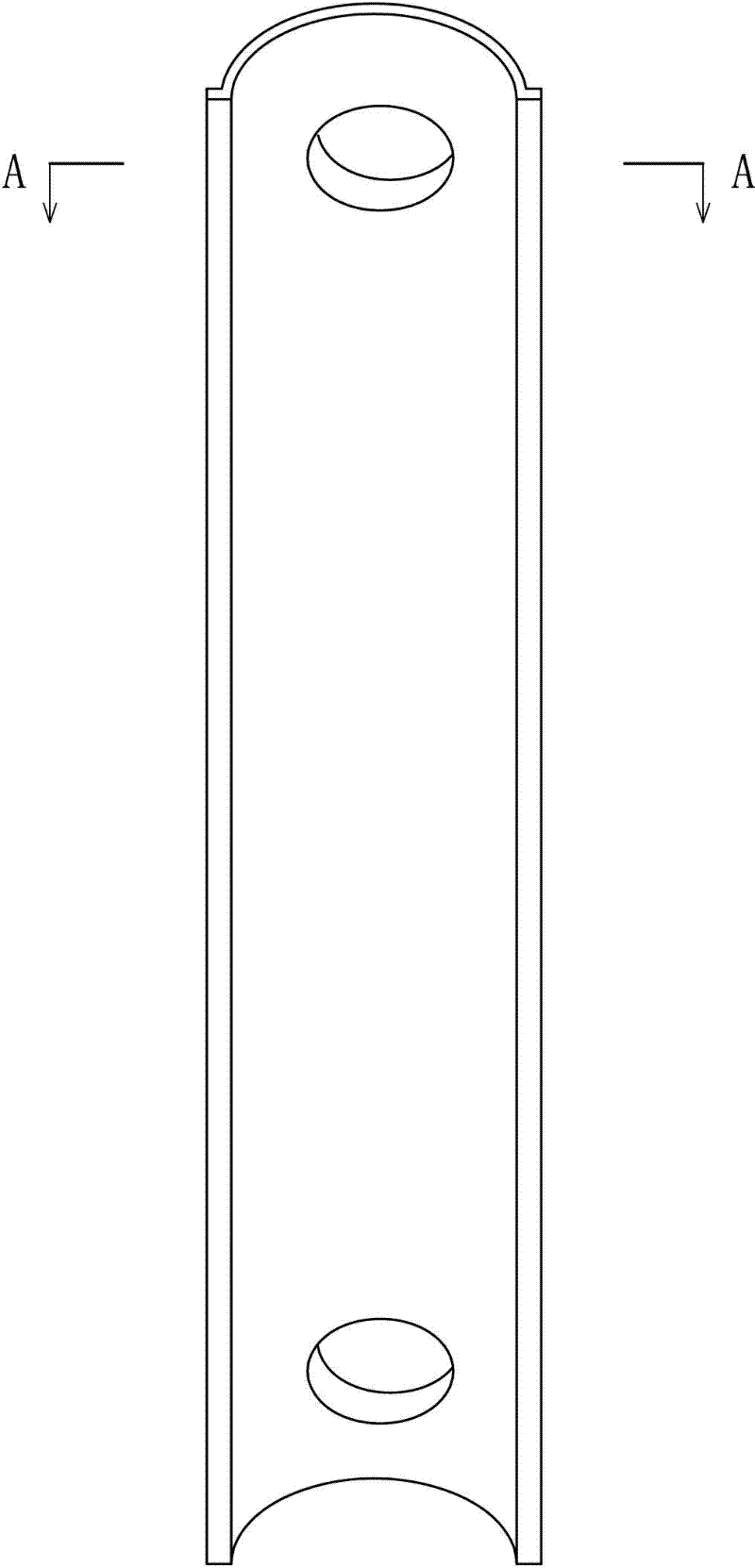

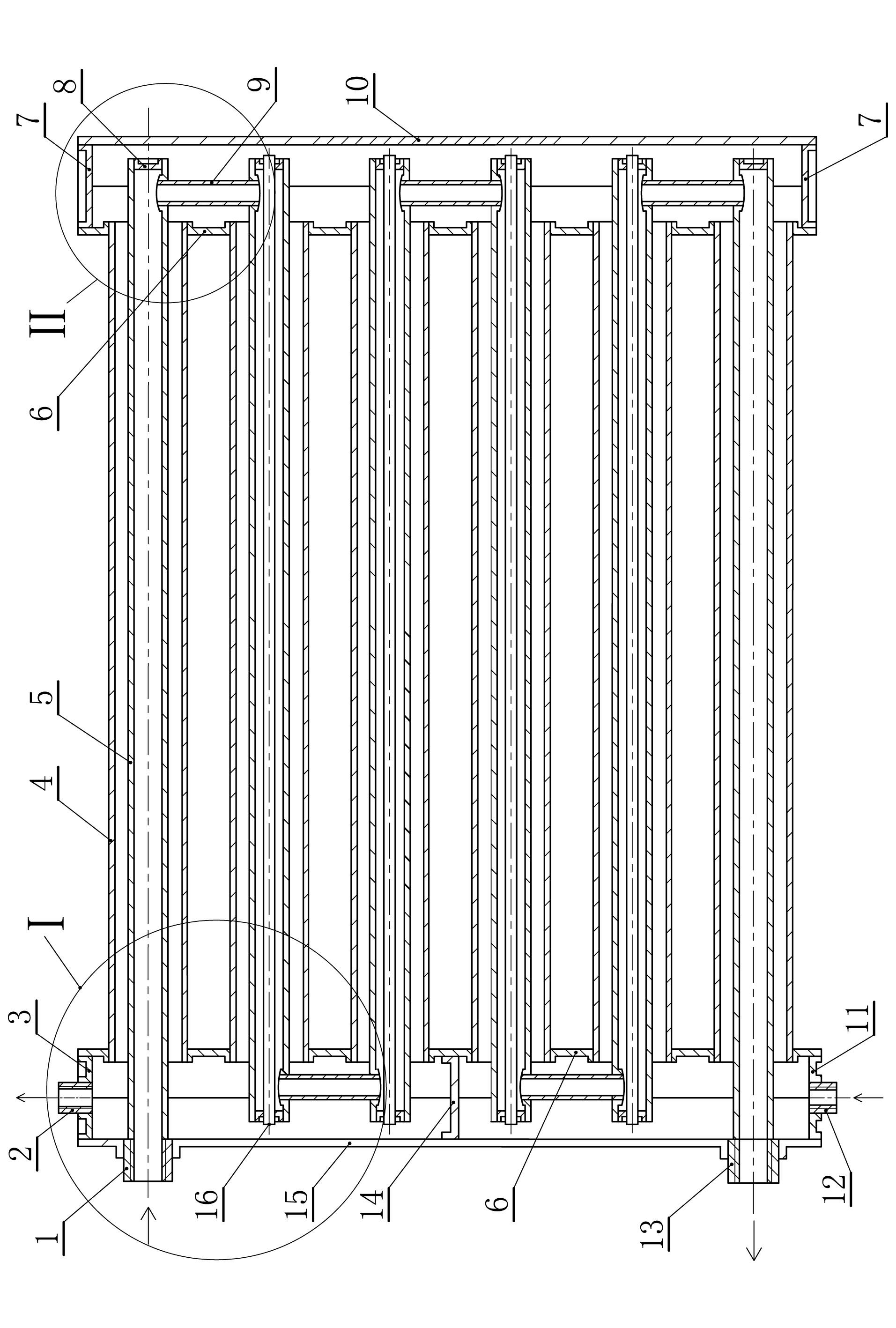

Circular pipe communicated, spliced, edge-pinched, and welded pressure-bearing heat exchanger, and manufacturing process thereof

ActiveCN102418956ASolve the problem of water leakage under pressureReduce difficultySpace heating and ventilation detailsHeat exchanger casingsPlate heat exchangerWater leakage

The invention discloses a circular pipe communicated, spliced, edge-pinched, and welded pressure-bearing heat exchanger, and a manufacturing process thereof. The heat exchanger comprises two headers, wherein a tap water communication pipe is fixedly connected between the two headers; a hot air heat supply pipe passes through the tap water communication pipe; each header is formed by welding two arc plates; the plate edges of the arc plates are flanged outwards; the plate edges of the two arc plates are aligned with each other and are subjected to edge-pinching and self-fluxing welding to form a circular tubular header cylinder body; head blocking plates of the headers are flanged outwards and are embedded at two ports of the circular tubular headers; and the two edges are aligned with a pipe wall surface, are spliced and are subjected to the edge-pinching and the self-fluxing welding to form the headers. An installation hole is punched on each arc plate; the installation hole is stretched inward an arc to form an edge; the aperture and the height of are stretched according to the arc plates; and the end surfaces of the two ends of the tap water communication pipe are subjected to R-angle cutting according to the stretching hole diameter and the stretching height of the arc plates, and then the tap water communication pipe is inserted into the installation holes stretched from the arc plates, are matched with each other, are spliced and are subjected to edge-pinching and self-fluxing welding connection. In the heat exchanger, welding seams are spliced, the edge-pinching welding is easy to realize, and water leakage is avoided; and the heat exchanger is good in pressure-bearing performance, and low in maintenance cost.

Owner:张伟

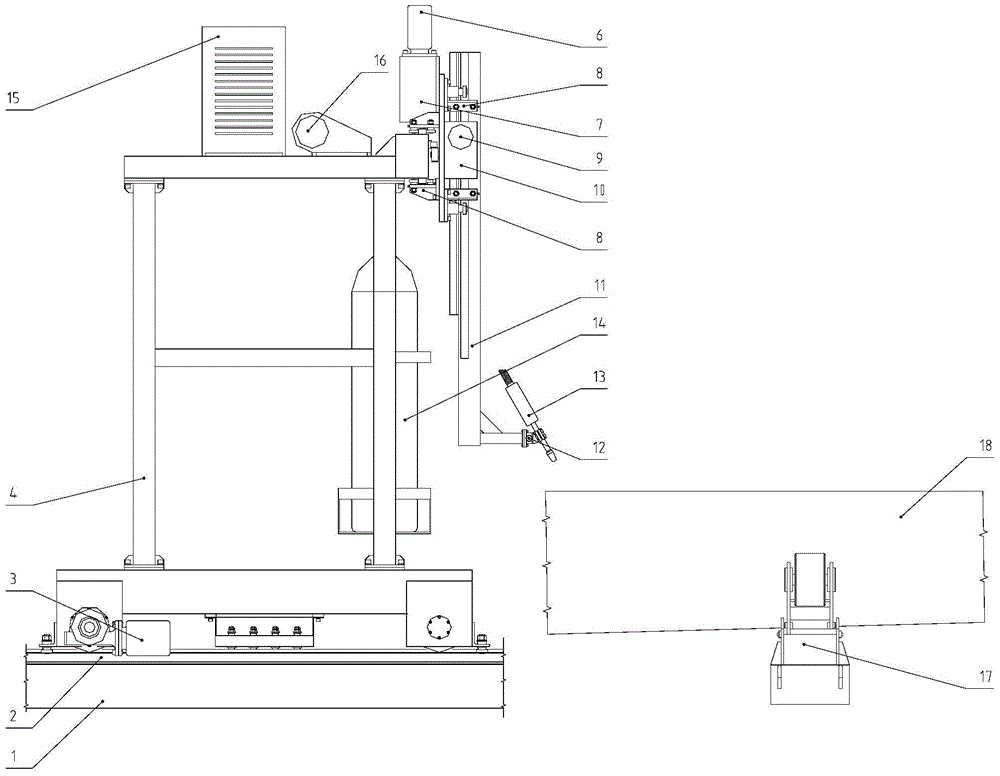

Gantry-type automatic welding and gouging integrated machine for welding steel pipe rods

ActiveCN104475918ALower skill requirementsReduce labor costsWelding/cutting auxillary devicesArc welding apparatusEngineeringReducer

The invention discloses a gantry-type automatic welding and gouging integrated machine for welding steel pipe rods, wherein the gantry frame is a door frame type rack formed by two vertical posts and one cross beam; the cross beam of the gantry frame is provided with a welding machine and a solder wire feeding machine. A crosswise cast iron convex guide rail on a crosswise dragging plate is in sliding match connection with a protruded grooved track on lateral side of the cross beam of the gantry frame; and the cross beam of the gantry frame is provided with a welding arm crosswise walking motor and a welding arm crosswise reducer, so as to provide power for the crosswise movement of the welding arm. Supporting guide rails on bilateral sides of the welding arm are in sliding match connection with vertical sliding chutes on the crosswise dragging plate; and the crosswise dragging plate is provided with a welding arm vertical walking motor and a welding arm vertical reducer, so as to provide power for the vertical movement of the welding arm. Compared with the prior art, the provided gantry-type automatic welding and gouging integrated machine for welding steel pipe rods is able to increase the comprehensive welding efficiency, quality and aesthetic measure of the product, and reduce the cost thereof.

Owner:ANHUI JIXI JIADE STEEL STRUCTURE

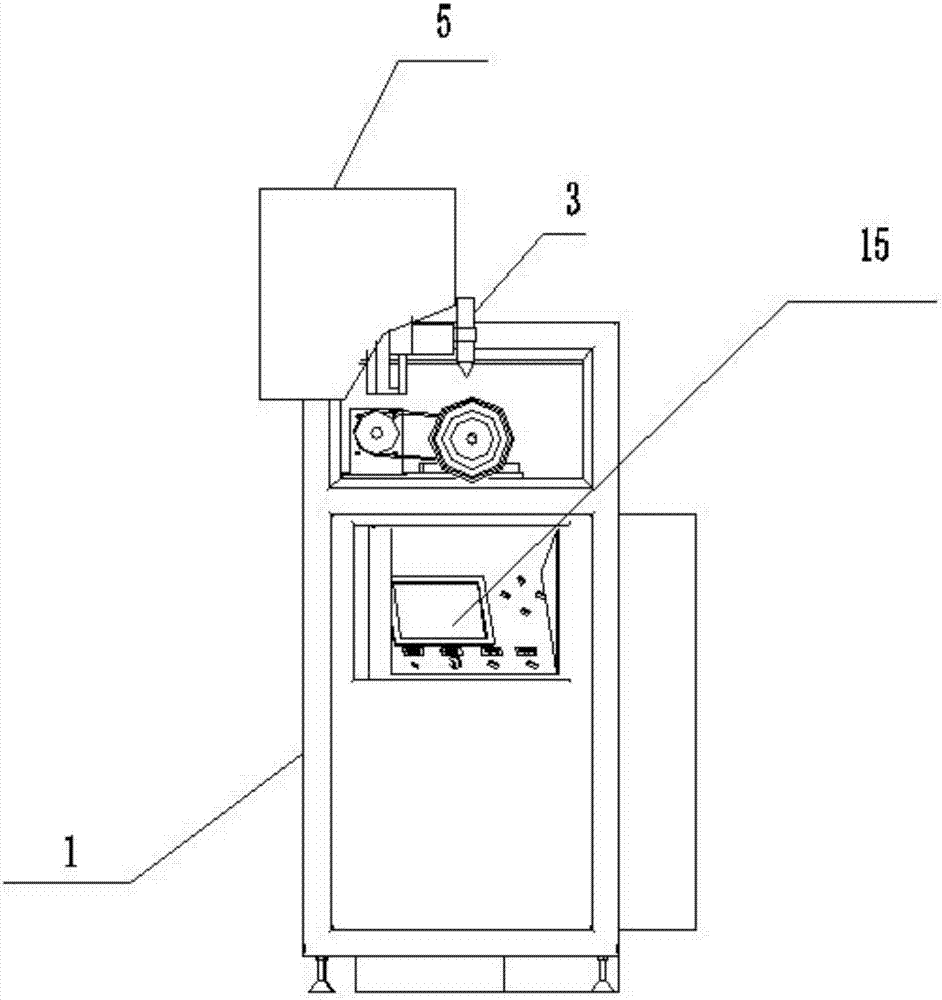

Stainless steel automatic pipe welding machine

InactiveCN107252953AGuaranteed normal rotationGuaranteed positioningWelding/cutting auxillary devicesAuxillary welding devicesElectrical controlPipe welding

Owner:襄阳顺特阳光科技有限公司

Welding device for longitudinal beam of underframe of carriage of dumper truck

InactiveCN103753036ASmall amount of welding deformationBeautiful weldWelding/cutting auxillary devicesAuxillary welding devicesTruckWeld line

A welding device for a longitudinal beam of an underframe of a carriage of a dumper truck is used for changing the welding mode of the longitudinal beam of the underframe of the carriage. The welding device of the longitudinal beam of the underframe of the carriage of the dumper truck comprises an air cylinder used to tightly clamp the longitudinal beam of the underframe, a welding tractor used to weld a welding line on the longitudinal beam of the underframe, and an electric device to control the moving of the welding tractor, wherein the electric device is used to protect the welding tractor to automatically move and weld. According to this arrangement, the welding mode is changed; therefore, the deformation of the welding is small, the welding line is beautiful, and the welding efficiency is improved.

Owner:LIUZHOU CHENGLONG SPECIAL PURPOSE VEHICLE CO LTD

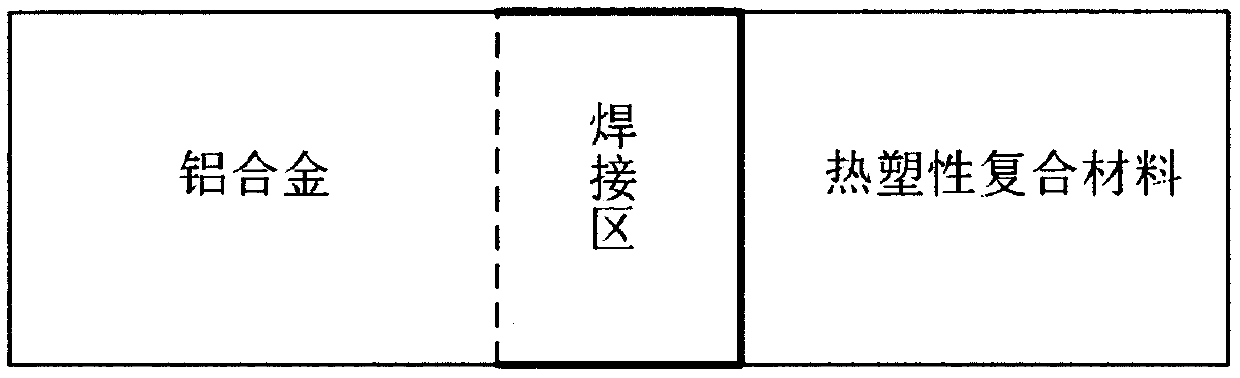

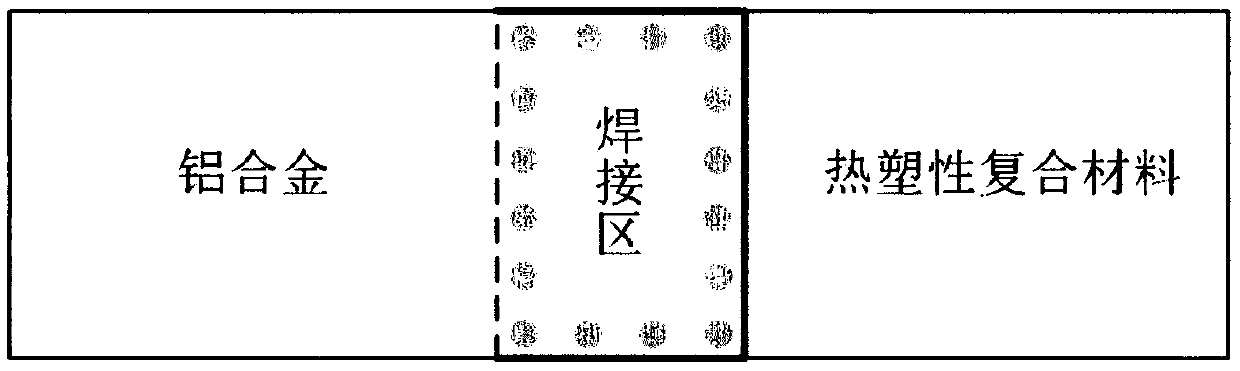

Laser swing welding method for lap joint structure of thermoplastic composite material and aluminum alloy

The invention relates to the technical field of dissimilar material connection, and discloses a laser swing welding method for a lap joint structure of a thermoplastic composite material and an aluminum alloy. The method comprises the steps that S1, sand blasting treatment is conducted on the laser welding surface of the aluminum alloy, and a nail hook structure is machined on the connecting surface through laser; S2, the interface of a lap joint between the thermoplastic composite material and the aluminum alloy is filled with a certain thickness of resin material; S3, a linear or dot-matrixclamping mode is selected according to the thickness of a to-be-welded part, and a stable lap joint is obtained; S4, the size, shape and defocusing amount of a light spot are determined according to the size and requirement of the to-be-welded part, and a laser swing track and a scanning path are designed; and S5, a laser device is started to weld the lap joint, a cooling device is used for cooling weld joints after the welding of each weld joint is completed, and then subsequent welding is conducted. The method can effectively improve the mechanical property of the connecting joint between the thermoplastic composite material and the aluminum alloy, is good in weld joint forming and high in quality, and has a wide application prospect in the aerospace field.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

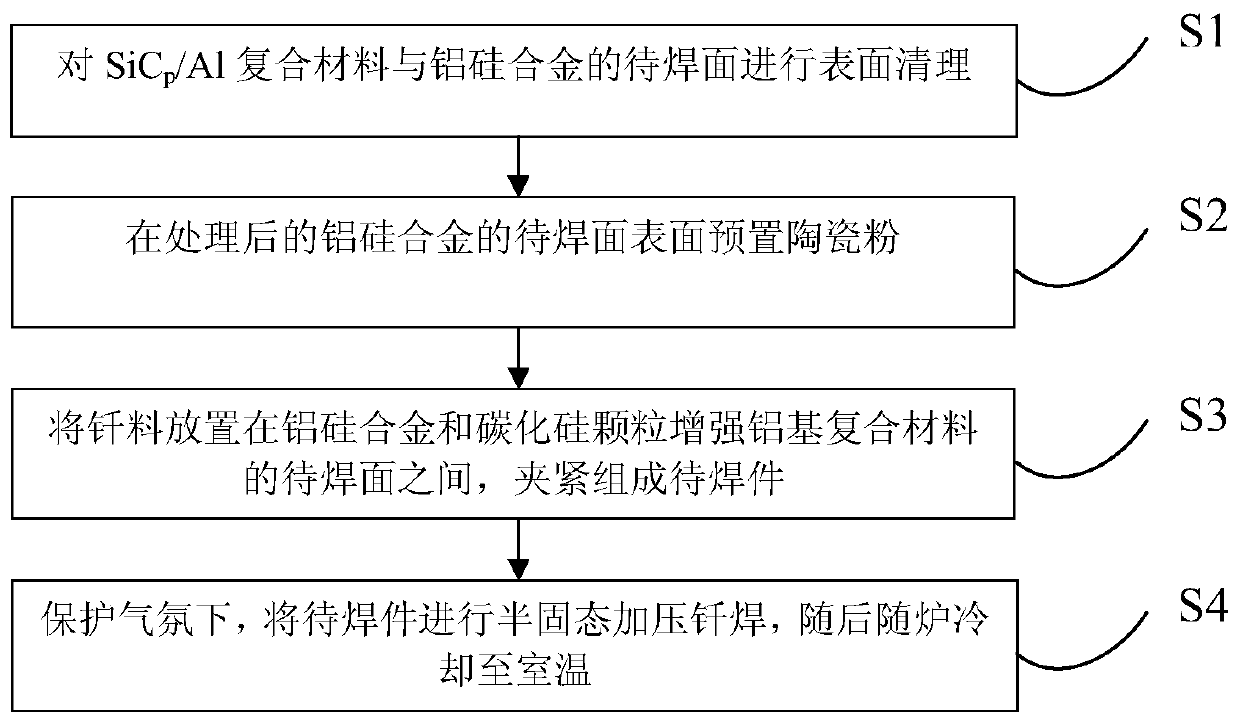

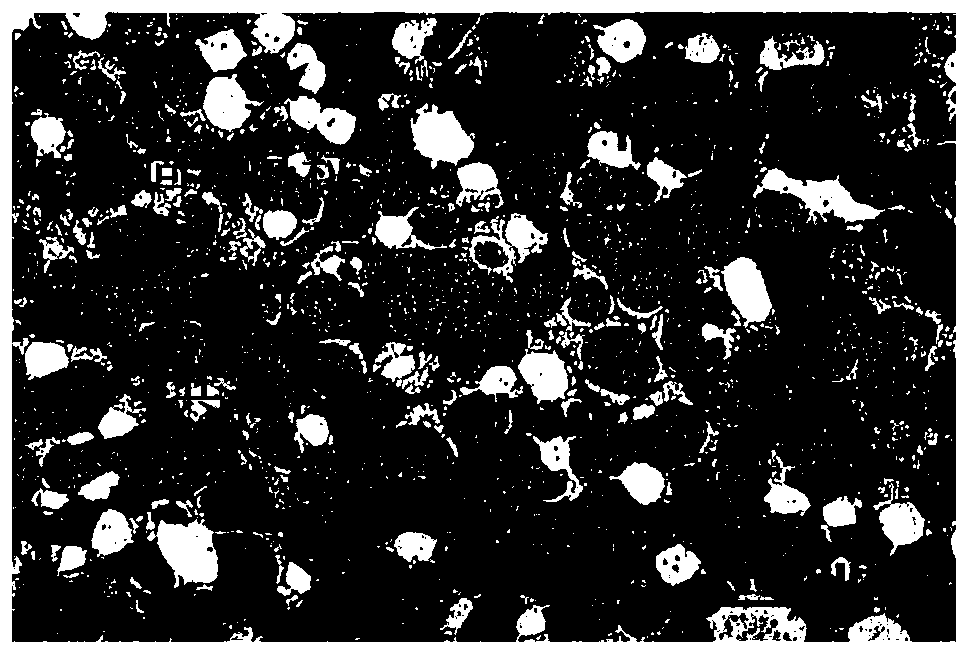

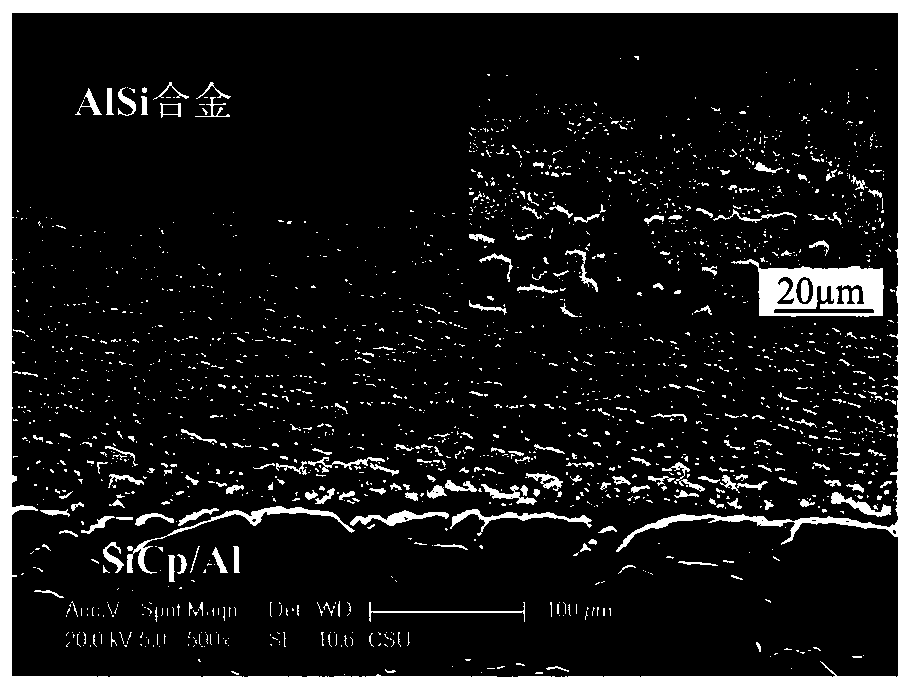

Brazing method of high-volume-fraction silicon carbide particle reinforced aluminum matrix composite material and aluminum-silicon alloy

ActiveCN110576232AReduce residual stressHigh strengthSoldering apparatusAfter treatmentSilicon alloy

The invention discloses a brazing method of a high-volume-fraction silicon carbide particle reinforced aluminum matrix composite material and an aluminum-silicon alloy. The brazing method includes thefollowing steps that S1, the to-be-welded surfaces of the silicon carbide particle reinforced aluminum matrix composite material and the aluminum-silicon alloy are subjected to surface clearing; S2,ceramic powder is prearranged on the to-be-welded surface of the aluminum-silicon alloy after treatment in the S1; S3, a brazing filler metal is placed between the to-be-welded surfaces of the aluminum-silicon alloy and the silicon carbide particle reinforced aluminum matrix composite material to form a to-be-welded part; and S4, under the protective atmosphere, the to-be-welded part is heated up,kept warm and pressurized to 5-20 MPa, and continuous heat preservation and pressure maintaining are conducted, and then the to-be-welded part is furnace-cooled to the room temperature. According tothe brazing method, oxide films on the surfaces of the silicon carbide particle reinforced aluminum matrix composite material and the aluminum-silicon alloy are broken by using the hard ceramic powderto assist the metal brazing filler metal, the brazing filler metal is fully wetted and spreads on the surfaces of the silicon carbide particle reinforced aluminum matrix composite material and the aluminum-silicon alloy, and metallurgical bonding of the connection surface of the silicon carbide particle reinforced aluminum matrix composite material and the aluminum-silicon alloy is induced.

Owner:HUNAN HARVEST TECH DEV

Self-protection flux-cored wire for strengthening surface of large hot-forging die and production method of self-protection flux-cored wire

ActiveCN107175426AExtended service lifeEasy to processWelding/cutting media/materialsSoldering mediaNiobiumManganese

The invention discloses a self-protection flux-cored wire for strengthening the surface of a large hot-forging die and a production method of the self-protection flux-cored wire. The flux-cored wire comprises, by mass percentage, 26-30% of chromium, 8-10% of molybdenum, 1.8-3% of tungsten, 1.5-2.5% of nickel, 0.8-1.2% of silicon, 0.6-1.0% of manganese, 0.15-0.3% of niobium, 1.2-1.6% of carbon, not larger than 0.02% of phosphorus, not larger than 0.02% of sulfur and the balance cobalt and impurities. By the adoption of the self-protection flux-cored wire for strengthening the surface of the large hot-forging die, overlaying of the flux-cored wire is conducted on the surface of the working region of a die cavity of the large hot-forging die, the surface strengthened layer is formed, the temperature of the surface layer of the die cavity of the large hot-forging die is below 500-700 DEG C, the wear, deformation and crack are not likely to generate under the extreme working condition that the load is above 40,000 tons, the service life of the large hot-forging die is prolonged by over 10 times, and the manufacturing cost of large forgings is lowered remarkably.

Owner:CHONGQING JIEPIN TECH +2

Full-automatic welding method for metal powder-cored wire pipeline girth welding joints

InactiveCN105583499ASolve defects such as uneven welding thickness and even unwelded weldingIncreased weld thicknessArc welding apparatusTubular articlesEngineeringMetal powder

The invention discloses a full-automatic welding method for metal powder-cored wire pipeline girth welding joints. The full-automatic welding method is characterized by comprising the following steps: S1, grooves are machined; S2, pipe openings are pretreated; S3, root welding layer welding, hot welding layer welding, packing layer welding and cover surface welding are performed by adopting metal powder-cored wires, wherein the method M1 for root welding layer welding comprises the step of welding according to root welding layer welding parameters; the method M2 for hot welding layer welding comprises the step of welding according to hot welding layer welding parameters; the method M3 for packing layer welding comprises the step of welding according to packing layer welding parameters; and the method M4 for cover surface welding comprises the step of welding according to cover surface welding parameters. By adopting the full-automatic welding method for metal powder-cored wire pipeline girth welding joints, during welding of pipelines, the detect that side walls are not fused is not easily caused; and the method is high-efficient and environment-friendly.

Owner:廊坊市管道人机械设备有限公司

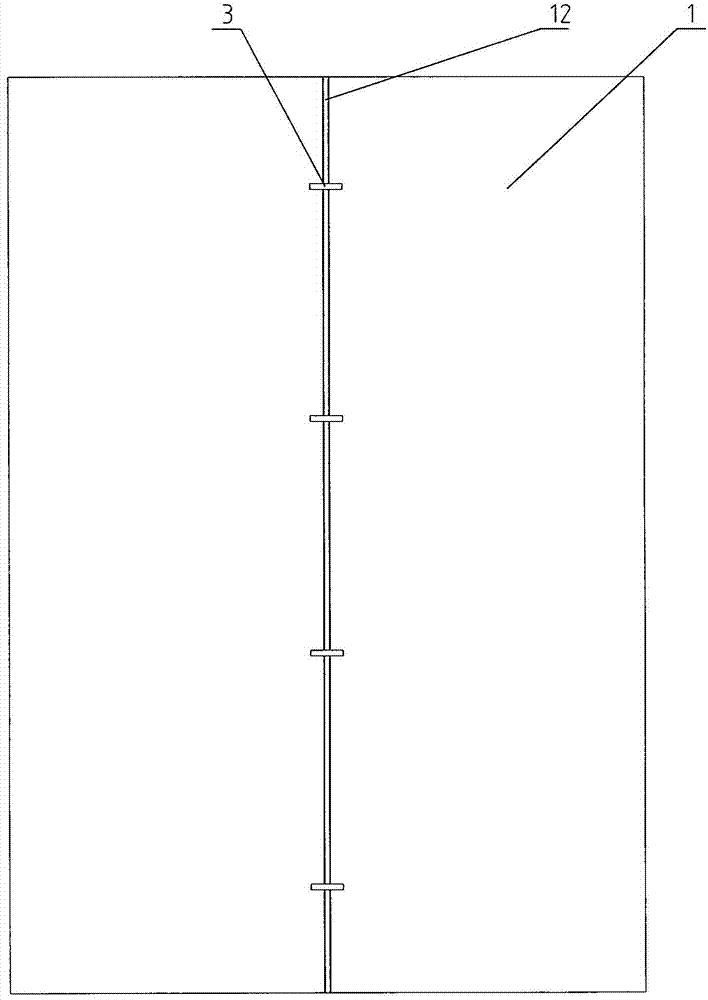

Butt joint positioning device and butt joint positioning method of welding surfaces of concrete mold plates

The invention discloses a butt joint positioning device and a butt joint positioning method of welding surfaces of concrete mold plates, which can perform butt joint positioning for welding surfaces of two to-be-welded concrete mold plates, and are high in butt joint precision and positioning degree. The butt joint positioning device comprises an engine base and a positioning device, wherein the positioning device comprises a left placing table, a right placing table, a middle positioning plate, a left front backup plate and a right front backup plate, wherein the left placing table and the right placing table can move left and right; the middle positioning plate can vertically lift between the left placing table and the right placing table; the left front backup plate and the right front backup plate can move back and forth; the left placing table and the right placing table can be matched closely; the engine base is provided with left and right translation driving devices which respectively control the translation of the left and right placing tables as well as a lifting driving device capable of controlling the middle positioning plate to lift; the left and right front backup plates are respectively placed on the upper surfaces of the left and right placing tables correspondingly; the left placing table and the right placing table are respectively provided with left and right back and forth translation driving devices which respectively control the left and right front backup plates to move back and forth.

Owner:FUYUAN FUJIAN ENVIRONMENTAL PROTECTION TEMPLATE

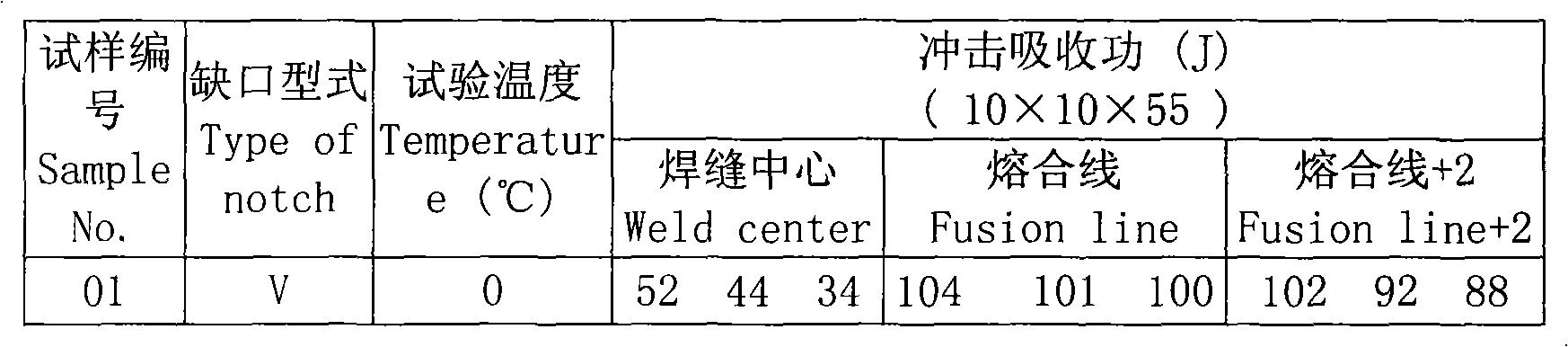

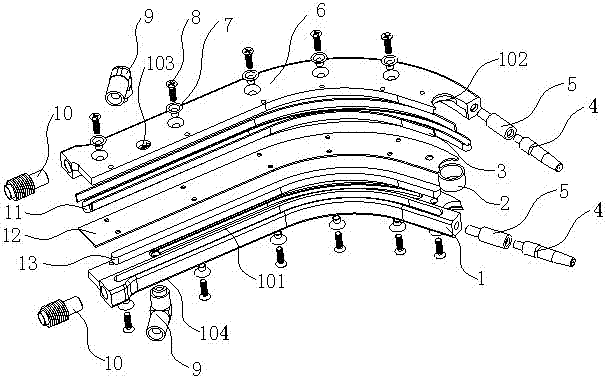

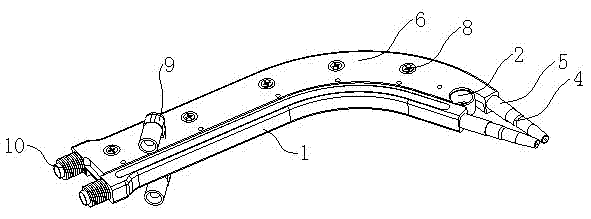

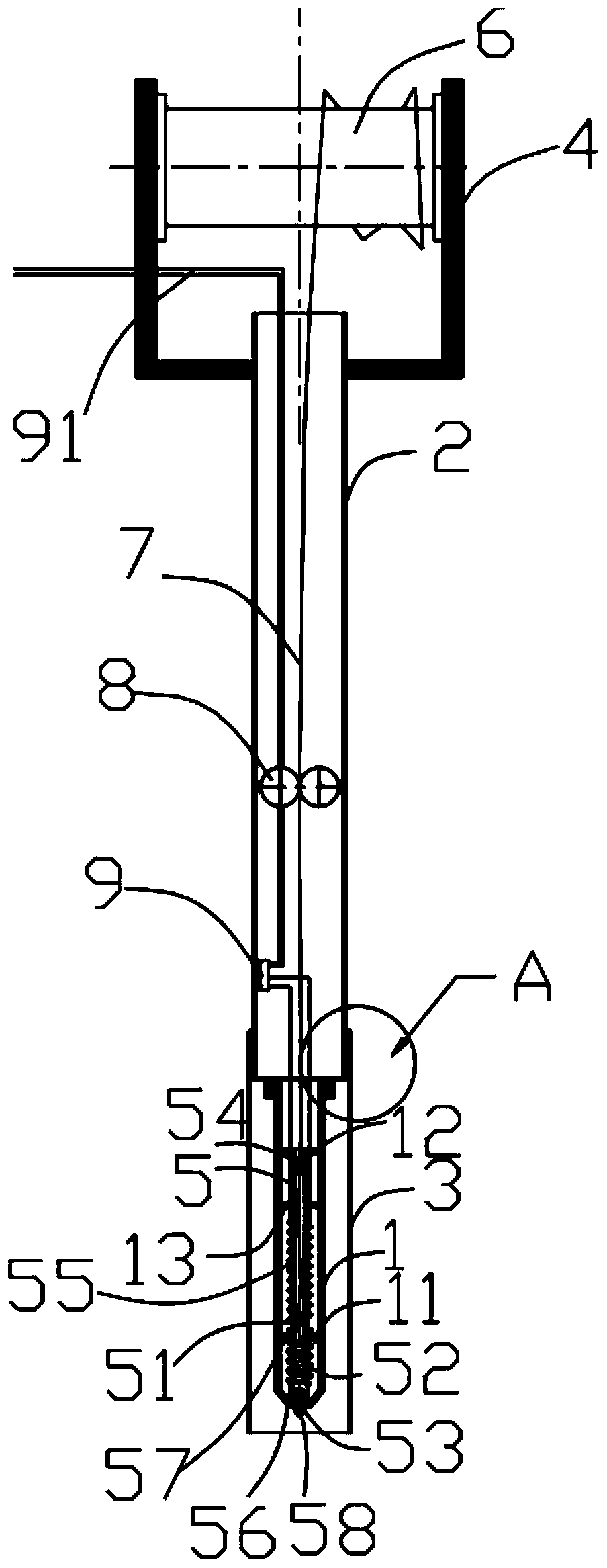

Double-wire efficient perpendicular water-cooling electrogas welding gun

InactiveCN102773597AImprove mechanical propertiesThe overall thickness is thinElectrode supporting devicesElectrode accessoriesEngineeringMechanical property

The invention relates to a double-wire efficient perpendicular water-cooling electrogas welding gun which is good in radiating effect in a welding process and is high in quality of weld joints. The double-wire efficient perpendicular water-cooling electrogas welding gun comprises a first welding gun and a second welding gun which are integrated, and a cooling circuit is arranged on the double-wire efficient perpendicular water-cooling electrogas welding gun. The double-wire efficient perpendicular water-cooling electrogas welding gun is provided with the cooling circuit, and the cooling circuit, an external water-cooling slider and a water tank can form a welding circulating water cooling system, so that the service life of the double-wire efficient perpendicular water-cooling electrogas welding gun is longer. In addition, owing to the integral structural design, a gun body is thin and is compact in structure, welding efficiency is improved, economical benefit is greatly increased, and mechanical properties of the molded weld joint are high.

Owner:KUSN RUILING WELDING TECH

Method for welding multilayer cable conductors

InactiveCN103474858AHigh tensile strengthImprove impact performanceLine/current collector detailsElectrical conductorGas metal arc welding

The invention discloses a method for welding multilayer cable conductors. Stepped slope cutting is conducted on the multilayer cable conductors, and then the multilayer cable conductors are welded from the inner layer to the outer layer in a gas metal arc welding mode to form a high-quality welding connector. The method for welding the multilayer cable conductors is simple in technology, strong in controllability and attractive, smooth and even in welding seam; a finished cable has very high tensile resisting strength and fault current impact resisting capability and has certain mechanical performance and corrosion prevention performance.

Owner:KUNSHAN AODELU AUTOMATION TECH

Laser no-filling penetration weld seal welding process for T-shaped welding head of steel plate

The invention discloses a laser no-filling penetration weld seal welding process for a T-shaped welding head of a steel plate. The laser no-filling penetration weld seal welding process comprises the steps as follows: carrying out laser no-filling penetration weld on a weld joint overlapping part of a first workpiece and a second workpiece from the rear surface of the first workpiece by adopting a laser welding machine so as to form a weld joint; carrying out laser no-filling penetration weld in the perpendicular direction of the weld joint for multiple times so as to form a plurality of perpendicular weld joints perpendicular to the weld joint, wherein a gap exists between the adjacent perpendicular weld joints; and carrying out weld joint leak detection on the weld joint, and when a weld joint leak point is found, manually repairing the weld joint between the adjacent perpendicular weld joints in a position where the weld joint leak point is. With the adoption of the laser no-filling penetration weld seal welding process, the phenomenon of welding the whole weld joint is avoided, the difficulty and the workload of manual repair welding are lowered, and the welding deformation of manual repair welding when the whole weld joint is weld is also reduced at the same time, thereby enabling the weld joint to be beautiful.

Owner:TAIPINGYANG POWER EQUIP GROUP CHANGZHOU

Production process of aluminum alloy liquid tank truck

The invention relates to a production process of an aluminum alloy liquid tank truck. The process mainly comprises the steps of automatic welding of jointed boards, tank wrapping, tank body ring seamwelding, manufacturing of a sedimentation tank plug, assembling of a steel truck frame and an auxiliary truck frame, steel frame assembling, manufacturing of an end socket and an anti-wave plate and final assembly. The tank wrapping process adopts automatic welding of the jointed boards, the welding speed is high, the welding quality is good, the weld seam is attractive after molding, the problemsof assembling gaps and misalignment of a tank body and the end socket and attaching gaps of partition plates and cylinder plates are solved, and the welded tank body is better in straightness and more attractive in appearance.

Owner:SHANDONG SANXING MACHINERY MFG

Concrete formwork welding technology

The invention discloses a concrete formwork welding technology, which is realized by the following steps: (1) setting a welding machine; (2) ascending a middle positioning plate; (3) positioning a first concrete formwork to be welded and a second concrete formwork to be welded; (4) descending the middle positioning plate; (5) outward moving a left placement plate and a left pressure plate or a right placement plate and a right pressure plate; (6) descending and heating a middle heating plate; (7) inward moving, extruding and fusing the left placement plate and the left pressure plate or the right placement plate and the right pressure plate, to realize the welding of the two concrete formworks; and (8) ascending the left pressure plate and the right pressure plate, thus being capable of taking out the welded concrete formworks. Compared with the prior art, the welding of the two concrete formwork waste can be realized, the cut concrete formwork wastes can be welded together to form an available concrete formwork meeting the standard, so that the concrete formwork wastes can be recycled to prevent resource waste; and the welding precision is high, and the welded concrete formwork is attractive.

Owner:FUYUAN FUJIAN ENVIRONMENTAL PROTECTION TEMPLATE

Automatic steel bar lap joint and welding device

PendingCN106735965AFully automatedEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesControl engineeringSteel bar

The invention discloses an automatic steel bar lap joint and welding device. Lifting sliding columns and lifting sliding sleeves are fixed to a base. The lifting sliding sleeves are mutually connected through a connecting plate and extend rightwards. Transverse moving sliding rods are vertically fixed to the connecting plate, a left limiting switch is arranged at the upper left portion of the connecting plate, and a right limiting switch is arranged at the right lower portion of the connecting plate. A lifting air cylinder and an upper limiting switch are fixed to the lower face of a fixing plate. A lower limiting switch is arranged on the outer side of the left lifting sliding column. The telescopic end of the lifting air cylinder is hinged to the center of the connecting plate. The extending end of the connecting plate is fixed to the fixing end of a transverse moving air cylinder. The telescopic end of the transverse moving air cylinder is hinged to the middles of transverse moving sliding sleeves. The transverse moving sliding rods are arranged in sliding openings of the transverse moving sliding sleeves correspondingly. A welding gun is arranged on the side face of one transverse moving sliding sleeve. The automatic steel bar lap joint and welding device overcomes the defects existing in the process of manual lap joint and welding operation of steel bars, and professional technique welders are not needed; and operation is simple, convenient and fast, the welding speed is high, efficiency is high, welding lines are full, uniform and attractive, and automation of the electric welding technology is achieved.

Owner:NO 3 ENG LIMITED OF CR20G

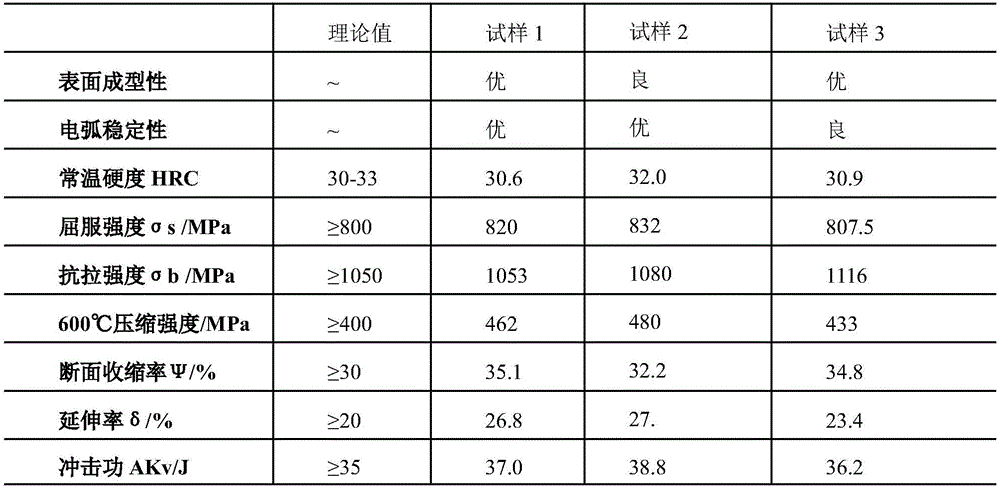

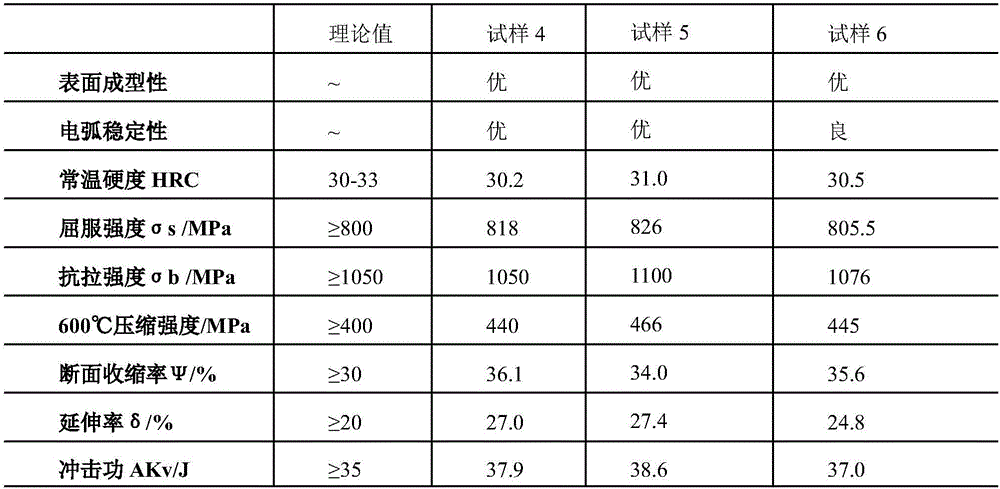

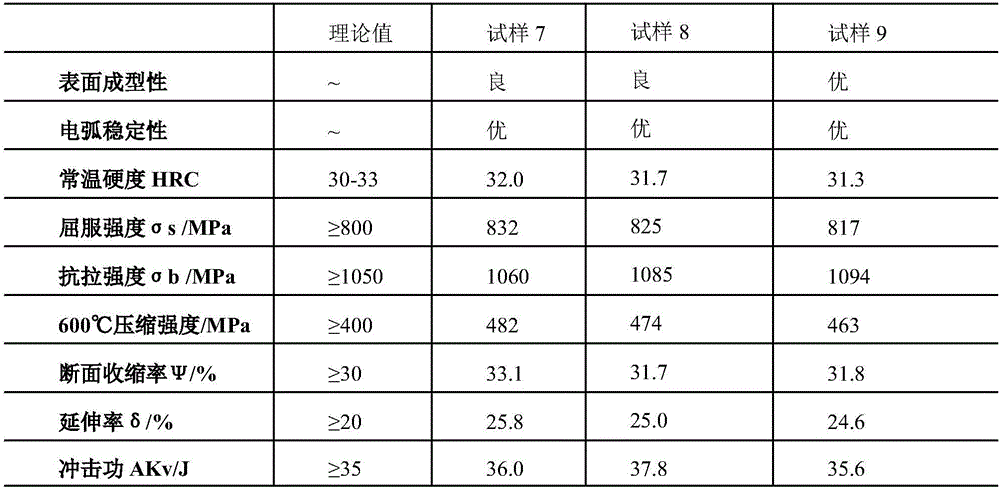

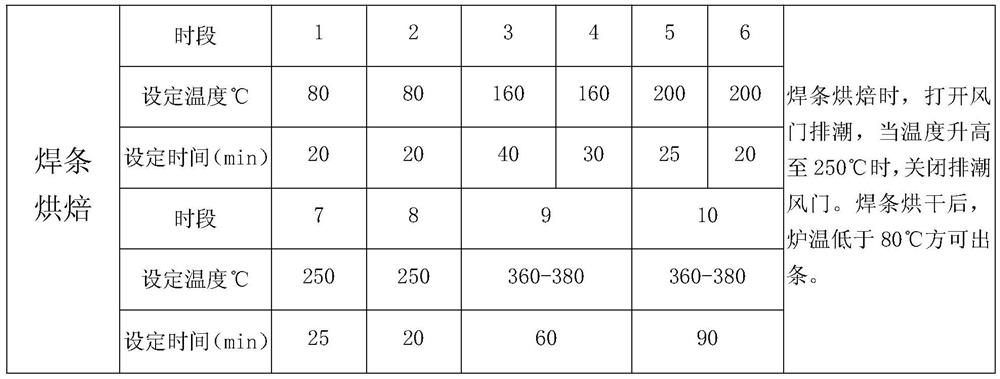

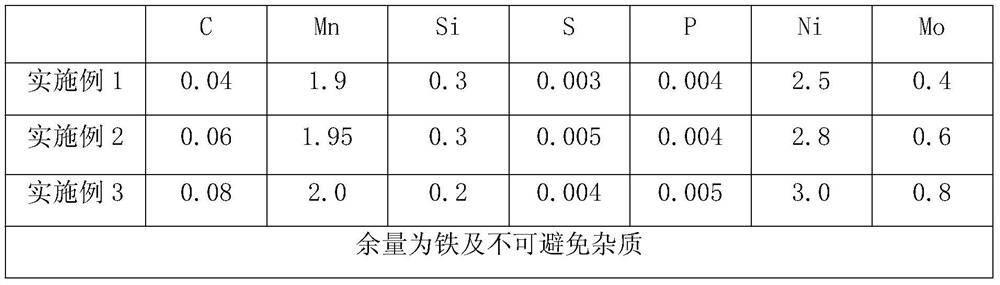

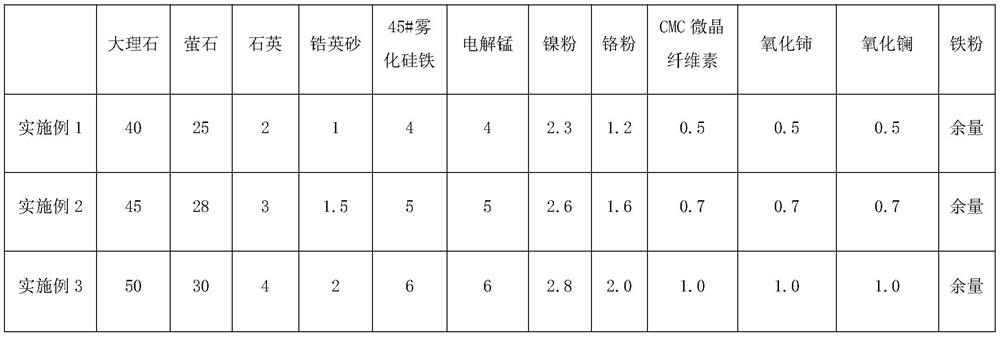

800MPa high-strength steel welding rod and preparation method

InactiveCN111644775ABeautiful weldReduce splashWelding/cutting media/materialsSoldering mediaHydrogen contentMechanical property

The invention provides an 800MPa high-strength steel welding rod. The 800MPa high-strength steel welding rod comprises a core wire and a coating, and the core wire comprises the following components of, in percentage by mass, 0.04%-0.08% of C, 1.9%-2.0% of Mn, less than or equal to 0.4% of Si, less than or equal to 0.005% of S, less than or equal to 0.005% of P, 2.5%-3.0% of Ni, 0.4%-0.8% of Mo, less than or equal to 93.5% of iron and the balance inevitable impurities. The 800MPa high-strength steel welding rod has the advantages of being good in all-position welding process performance, attractive in weld joint and excellent in mechanical property, and the diffusible hydrogen content of deposited metal reaches an ultralow hydrogen level.

Owner:昂科万德(武汉)科技有限公司

Heat transfer side kneading welding heat exchanger with headers and double dividing walls and manufacturing process of heat transfer side kneading welding heat exchanger

ActiveCN102564173AGood corrosion resistanceAnti-corrosion performance, durable and prolonging lifeHeat exchanger casingsStationary tubular conduit assembliesConvective heat transferHeating efficiency

Disclosed are a heat transfer side kneading welding heat exchanger with headers and double dividing walls and manufacturing process of the heat transfer side kneading welding heat exchanger. The heat transfer side kneading welding heat exchanger comprises two headers, and the headers are round tube headers or D-shaped headers. A warm air inlet, a warm air outlet, a tap water inlet and a tap water outlet are fixedly connected onto each header, two or more tap water through outer tubes are fixedly connected between the two headers and are communicated with each other via the headers, warm air heat supply tubes penetrate into the tap water through outer tubes and are through, one end of each warm air heat supply tube is connected to the corresponding warm air inlet while the other end of the warm air heat supply tube is connected with the corresponding warm air outlet, and tap water heat absorbing inner tubes are disposed in parts or all of the warm air heat supply tubes and communicated with the headers. Cold water tube channels are added in cavities of the heat supply tubes to form the double dividing walls to realize convection heat transfer, a cold fluid double-pass channel is formed to realize pure backflow, average temperature difference is increased, and heat efficiency is improved.

Owner:张伟

Brazing process of turbine stator blade of gas turbine

ActiveCN110919289AImprove repairabilityExtended service lifeSoldering apparatusWelding apparatusTurbineGas turbines

The invention discloses a brazing process of a turbine stator blade of a gas turbine. The whole surface of the stator blade is cleaned to ensure that the surface is clean, and then, the stator blade is brazed. The brazing process comprises the following steps: flaw detection is conducted on the turbine stator blade of the gas turbine through FPI, detected penetrating cracks are repaired through argon arc welding, detected non-penetrating fine cracks are removed through grinding, and a to-be-brazed area is formed after repairing and grinding; a plurality of square lattices in the to-be-brazed area are fully coated with a brazing material, and the height of the brazing material is larger than the height of a welding seam formed by 0.5mm argon arc build-up welding; the coated blade is put into a vacuum furnace, the vacuum furnace is heated to a certain temperature and then slowly cooled, and the blade is taken out after the furnace body is cooled; the area higher than the blade is removedby grinding, and flaw detection is carried out on the welding area by using FPI; and the area with insufficient plate thickness or more fine cracks is repeatedly brazed, and thus, a brazing process is finished.

Owner:华瑞(江苏)燃机服务有限公司

Welding device

PendingCN111590159AEasy to weldBeautiful weldMetal working apparatusSolder feeding devicesEngineeringMaterials science

The invention relates to a welding device. A hollow portion is arranged in the welding device, a welding wire is conveyed through the hollow portion, a heating portion is arranged to heat and melt thewelding wire, the melted welding wire flows into a welding storage cavity through a welding draining groove, a welding head is pressed, so that a gap is formed between the welding head and an opening, and welding flux flows out. The welding device is convenient to operate, and welding work can be finished through single-hand control. The size of a welding point can be conveniently controlled, thewelding success rate is improved, and the welding attractiveness is improved. According to the scheme with a heat insulation shell, when the welding device is temporarily placed in the welding process, the welding head cannot scald objects, people and the like. Compared with a traditional welding device, the welding device is more convenient for welding; the flow of the welding point can be controlled according to the pressure, and the welding point is more attractive; and a telescopic protection sleeve is used for temporarily accommodating an electric soldering iron, and thus, the welding device is safer to use.

Owner:ZHUHAI GREE PRECISION MOLD CO LTD +1

Technology method for welding brass H62 and low-alloy cast steel G20Mn5 dissimilar materials

The invention discloses a technology method for welding brass H62 and low-alloy cast steel G20Mn5 dissimilar materials. A manual argon tungsten-arc welding method and an S211 silicon bronze welding wire with the diameter of phi 2.5 are adopted, preheating is performed at 150-200 DEG C before welding, the situation that the interlayer temperature is higher than the preheating temperature in the welding process is guaranteed, heat is preserved for 2 hours after welding, and then dye penetrant inspection is performed. The argon tungsten-arc welding method is adopted, the technological means is simple, welding forming is attractive, the fusion quality of the root of a welding joint is good, the requirement for the skill level of workers is not high, the welding quality is stable, the production efficiency is improved, and the production cost is reduced.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com