Energy-saving and environment-protective welding rod

An energy-saving and environmentally friendly welding rod technology, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems that the pressure-coating property of the coating coating cannot be effectively solved, and achieve excellent welding process performance, Less toxic and side effects, stable arc effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Prepare 10kg of dry skin material, weigh 4.8kg of rutile, 0.7kg of medium carbon ferromanganese, 0.4kg of white clay, 0.6kg of feldspar, 0.5kg of mica, 0.7kg of dolomite, 0.8kg of ilmenite, 0.1kg of quartz and Sepiolite 0.4kg, attapulgite powder 1.0kg.

[0021] The welding core material is H08A low carbon steel.

[0022] The weighed material is pulverized and ball milled, passed through a 100-mesh sieve to make a powder with a certain particle size, and the carbon-manganese-ferroalloy powder in the material is subjected to passivation treatment. Then mix all kinds of ingredients evenly, slowly pour into water glass and wet mix evenly, and then the electrode coating coating will be prepared. Then use an electrode press coater to press-coat the prepared welding core, dry the press-coated wet electrode at 100-200°C and keep it warm for one hour, then it can be packaged and shipped.

[0023] The obtained welding rod has a smooth surface, no burr, and good appearance quali...

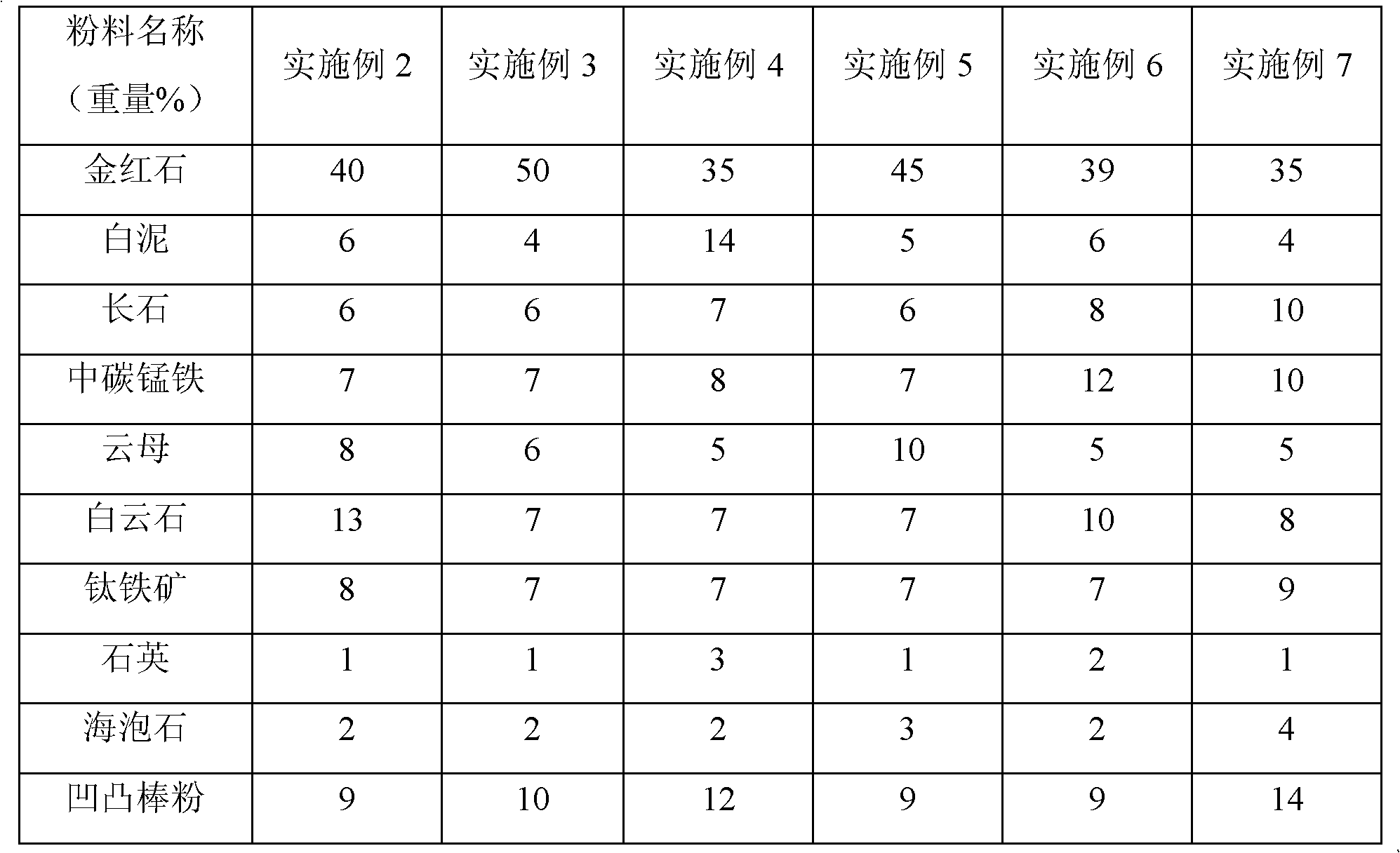

Embodiment 2~7

[0025]

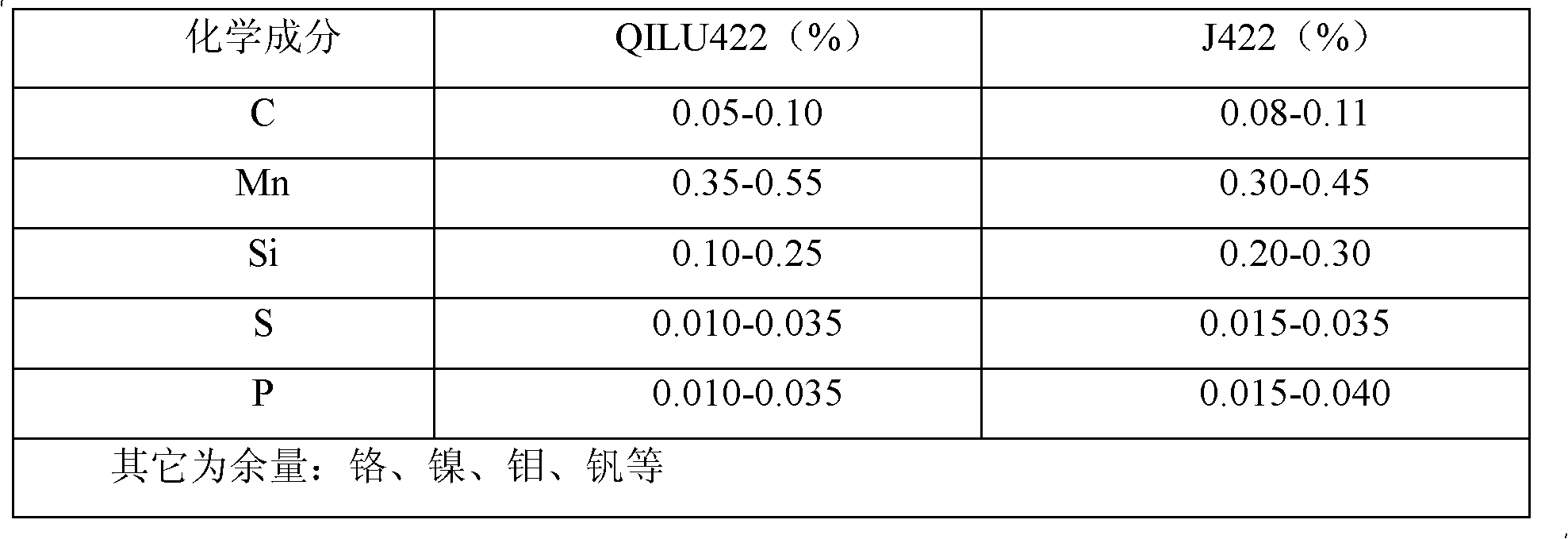

[0026] After welding, compared with the impurity components of the deposited metal of the QILU422 rutile-coated carbon steel electrode compared with the impurity components of the ordinary J422 carbon steel electrode, each impurity component is basically smaller than that of the ordinary J422 carbon steel electrode. The comparison data are shown in Table 1. Show:

[0027] Table 1 Comparison of deposited metal composition between QILU422 rutile carbon steel electrode and ordinary J422 carbon steel electrode

[0028]

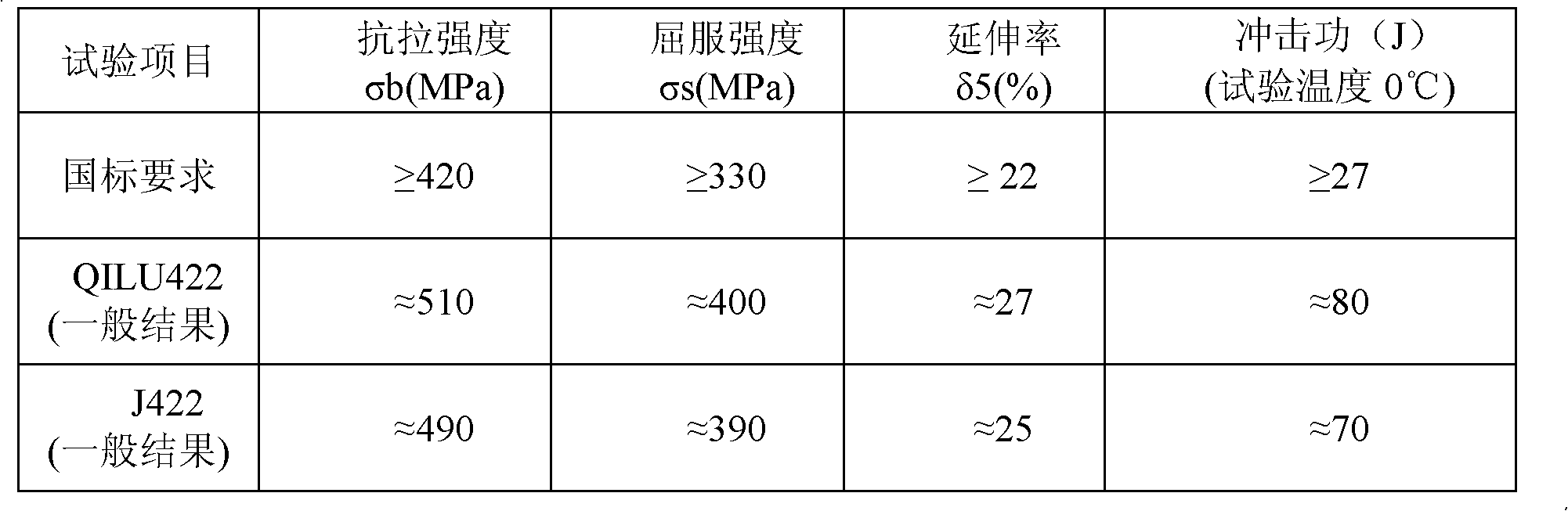

[0029] Comparing the yield strength and tensile strength of the QILU422 rutile-coated carbon steel electrode with the ordinary J422 electrode and the national standard electrode, it is found that the yield strength and tensile strength of the QILU422 rutile-coated carbon steel electrode are larger Improvement, welding process performance is more excellent, the comparison results are shown in Table 2:

[0030] Table 2 Comparison of yield strength an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com