Double-wire efficient perpendicular water-cooling electrogas welding gun

A welding torch and high-efficiency technology, which is applied in the field of double-wire high-efficiency vertical gas-electric water-cooled welding torch, can solve the problems of reducing the mechanical properties of formed welds, poor heat dissipation, and welding torch burnout, so as to reduce heat input, avoid welding torch short circuit, and weld The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the drawings and embodiments.

[0024] The main purpose of the concept of the present invention is: during the butt welding operation of vertical plates using a vertical gas-electric automatic welding device (such as a vertical gas-electric welding trolley), the welding wire deposition rate can be increased while the welding heat input to the molten pool can be reduced. Therefore, the welding efficiency and the mechanical properties of the formed weld are greatly improved, and the barrier of the previous gas-electric vertical welding to meet the performance requirements of the weld by improving the performance of the welding material is solved.

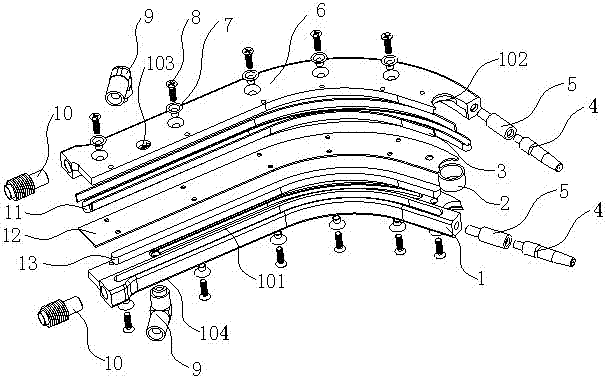

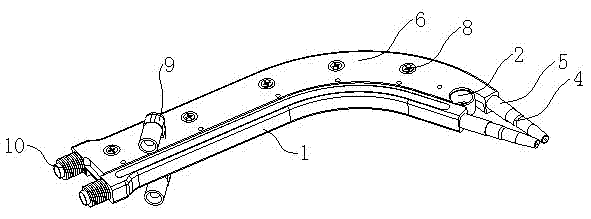

[0025] Refer to Figure 1-2 As shown, the present invention provides a double-wire high-efficiency vertical gas-electric water-cooled welding gun. The double-wire high-efficiency vertical gas-electric water-cooled welding gun includes an integrated first welding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com