Device and technology of automatic impeller indexing weld

A welding device and impeller technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of affecting the appearance, large welding deformation, inconsistent angles, etc.

Inactive Publication Date: 2013-06-05

武伟

View PDF7 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, in the fan industry, the impeller is the key component of the fan, and the welding quality and precision of the blades are particularly important. The traditional welding method is still to fix the impeller rear plate on the welding mold, use a compass ruler to mark the line manually or use a fixed The indexing plate of the scale is used to determine the position and angle of the blade, but the number, angle and direction of the impeller blades are different due to the different uses of the fan. When the number of blades is different, the indexing plate with different scales needs to be replaced, so that the traditional indexing welding method The speed is slow, there is no homogeneity in mass production, and the impeller is placed in a flat position during welding. Welding spatter will easily affect the appearance and cause false welding. There are defects such as uneven welding, inconsistent angles, and large welding deformation, which makes the impeller When doing static balance and dynamic balance, the deviation is large and unstable, which directly affects the performance of the fan

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

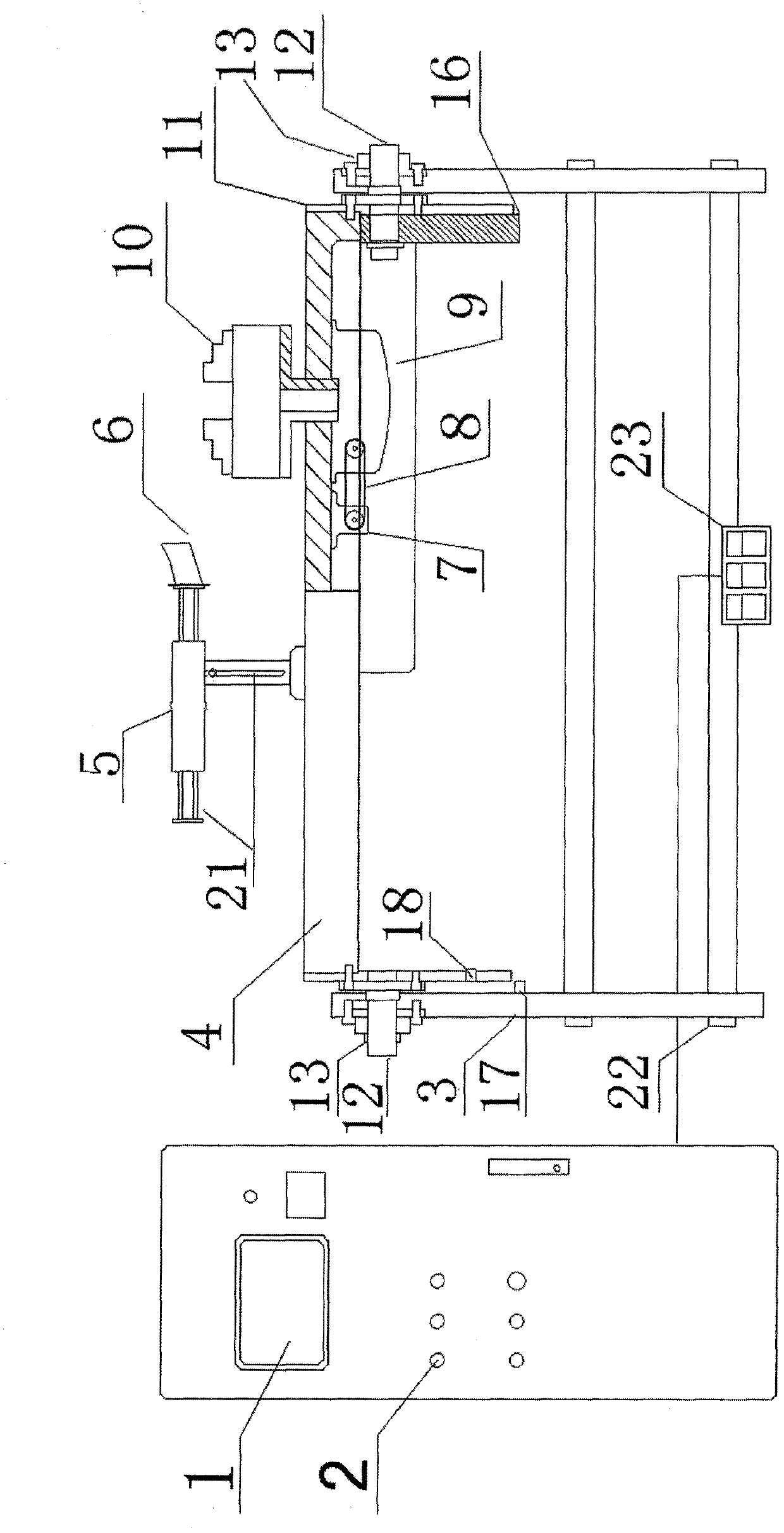

[0014] ②Set up the cutting program of the controller 1, start the controller 1 with the cutting button in the pedal triple switch 23, and the controller instructs the cutting motor 7 and the reducer 9 to each target cutting position to pre-weld each blade, and the welding is completed Finally, put the front disc of the impeller and press and fasten it with the pressure plate;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

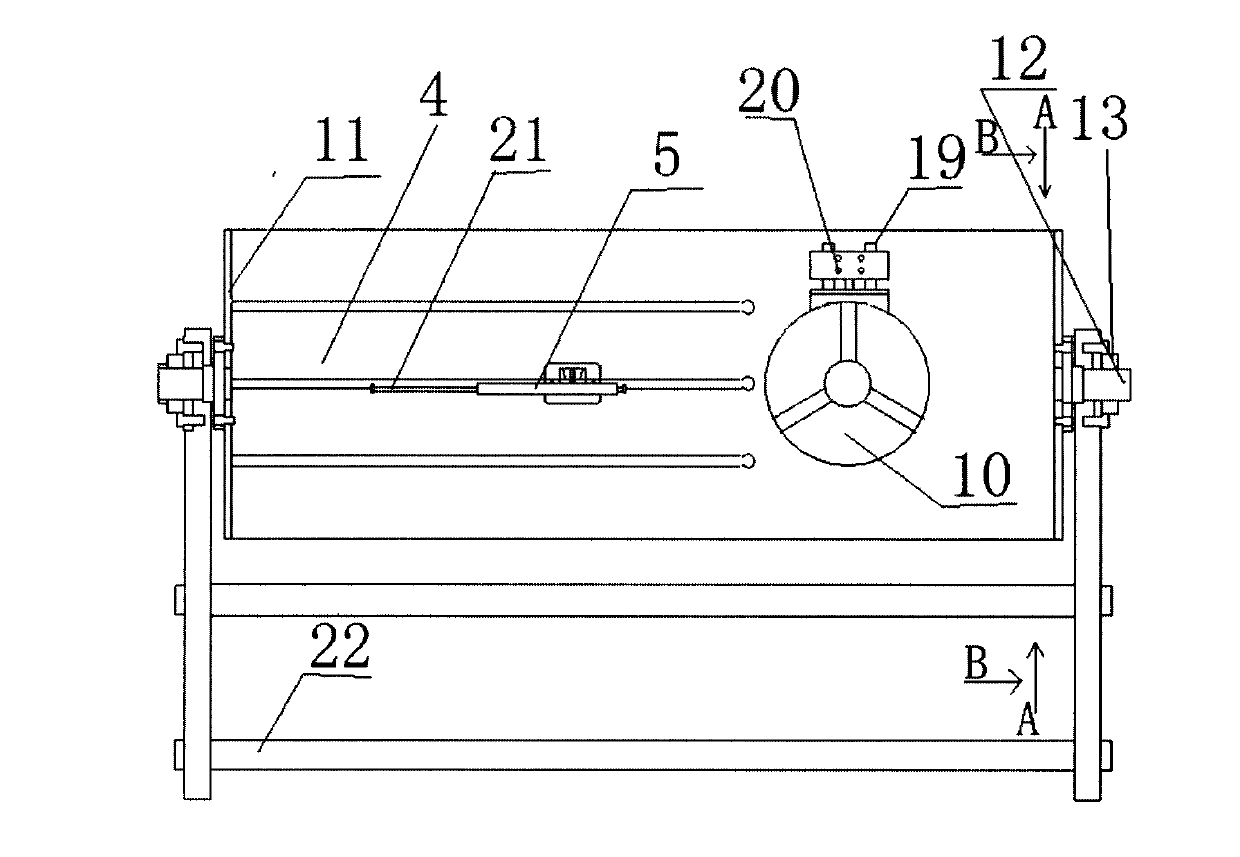

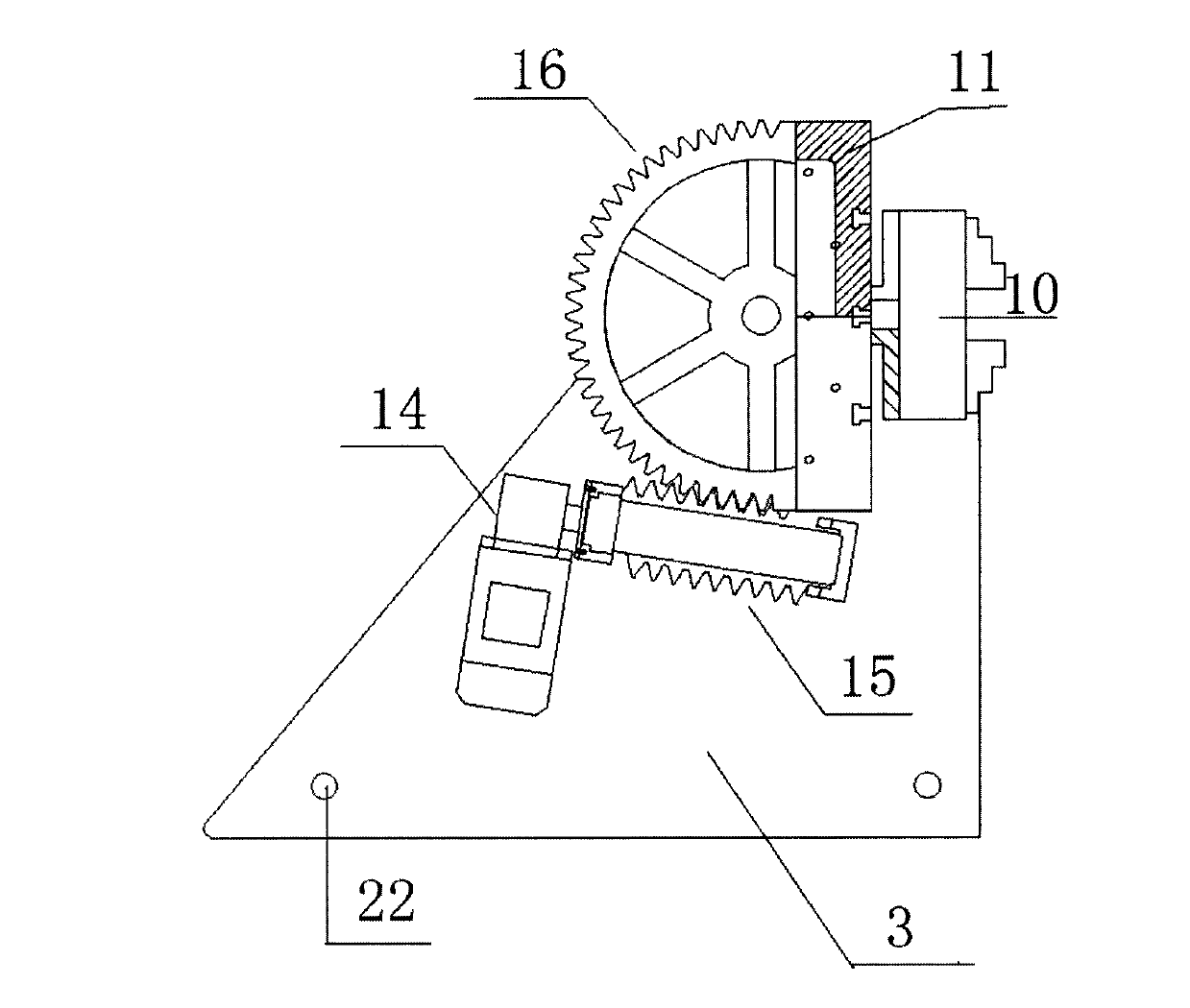

The invention discloses a device and a technology of automatic impeller indexing weld, and belongs to the technical field of impeller weld in the fan industry. The device controls walk steps of a splitting motor by setting a splitting procedure of a controller, and can equally divide an impeller at any angle through a decelerating machine. A further improvement is flip type weld, and the flip type weld is characterized by instructing a flipping motor to drive a decelerating mechanism to achieve flipping at any angle by setting a flipping procedure of the controller, and thereby facilitating reinforced welding. The weld technology includes: firstly clamping an impeller rear disc and fastening, and fixing blades for spot welding; then using the device for indexing weld on each blade, and placing an impeller front disc and fastening; afterwards turning over a working table to a target position and then performing indexing weld reinforcing on each blade; and finally turning over the working table to an initial point to finish the weld. The device and the technology can achieve equally dividing the impeller accurately, are simple and convenient to manipulate, and enable the weld to be stable and beautiful.

Description

technical field [0001] The invention belongs to the technical field of impeller welding in the fan industry, and in particular relates to a welding device and process for determining the positions of blades by dividing the impeller into equal parts at any degree. Background technique [0002] At present, in the fan industry, the impeller is the key component of the fan, and the welding quality and precision of the blades are particularly important. The traditional welding method is still to fix the impeller rear plate on the welding mold, use a compass ruler to mark the line manually or use a fixed The indexing plate of the scale is used to determine the position and angle of the blade, but the number, angle and direction of the impeller blades are different due to the different uses of the fan. When the number of blades is different, the indexing plate with different scales needs to be replaced, so that the traditional indexing welding method The speed is slow, there is no ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K37/00

Inventor 武伟

Owner 武伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com