Aluminium alloy laser welding method by powder reinforced absorption

A laser welding and absorption enhancement technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the requirements of high critical power density, reduced output power and beam quality, and difficult to control the welding process of aluminum alloy deep penetration welding And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation and effects of the present invention will be described in detail below in conjunction with a specific example.

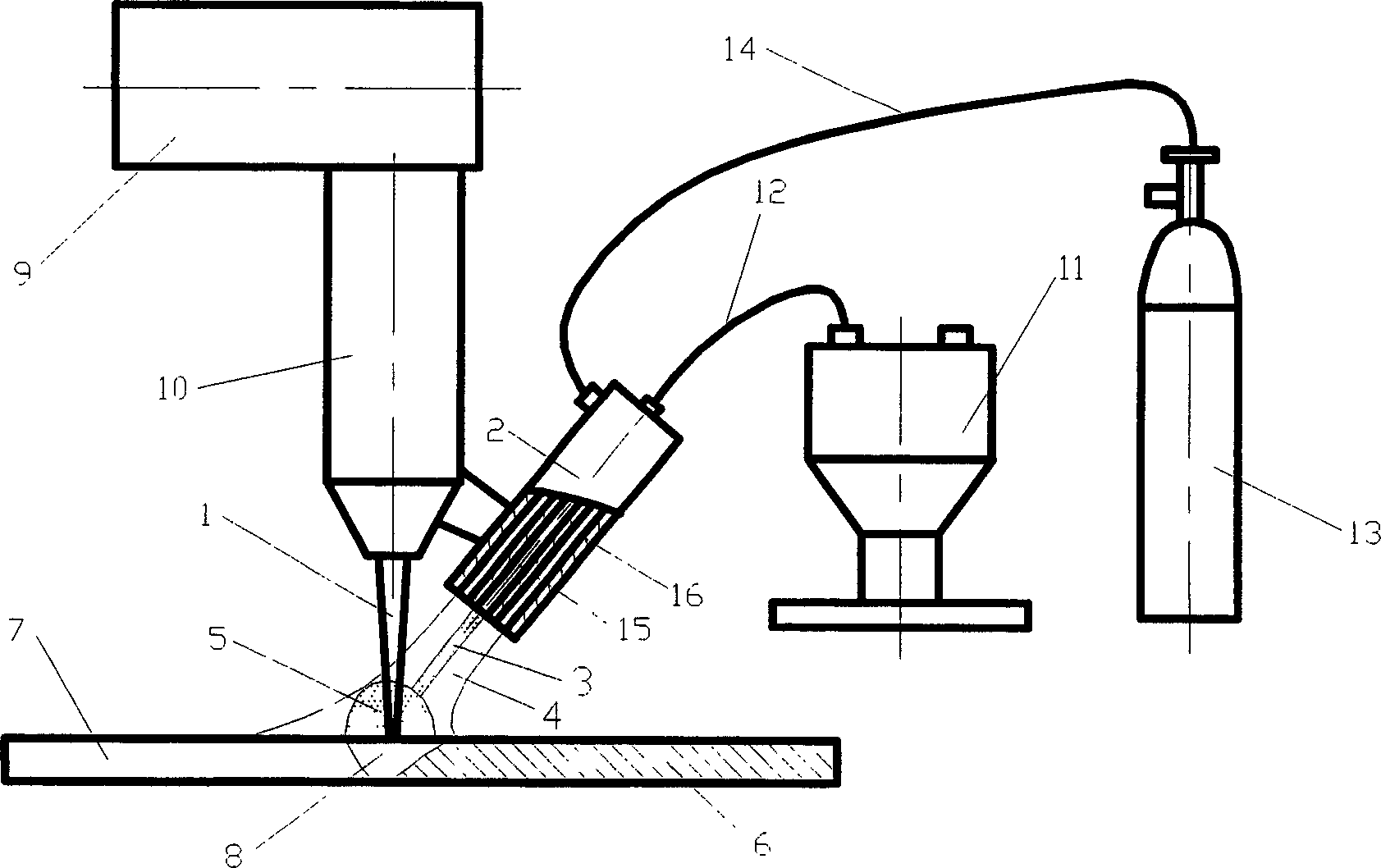

[0018] See attached figure 1 . The laser beam 1 emitted by the laser 9 is focused on the workpiece 7 through the laser welding head 10, and the powder feeding and shielding gas nozzle 2 is installed and fixed on the laser welding head 10 sideways, and the included angle with the surface of the workpiece is between 25 and 75 degrees . The powder feeding and protective gas nozzle 2 is connected to the powder feeder 11 through the powder feeding pipeline 12 , and is connected to the protective gas cylinder 13 through the gas feeding pipeline 12 at the same time. The powder feeder 11 is a general powder feeder for laser cladding or powder molding. Through the above method, during laser welding, the metal powder is continuously blown to the laser action area.

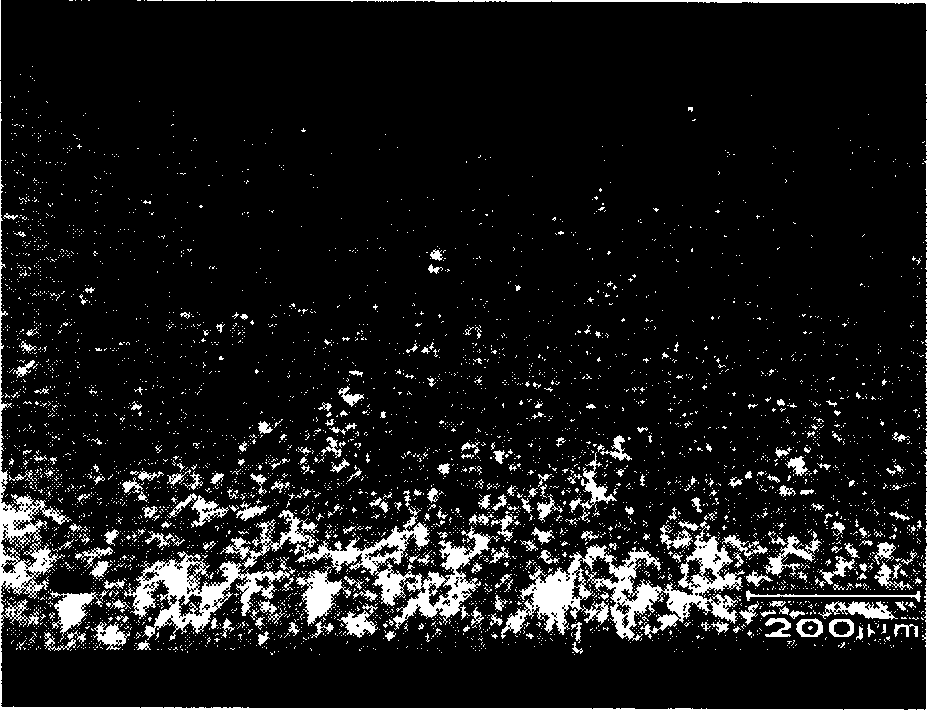

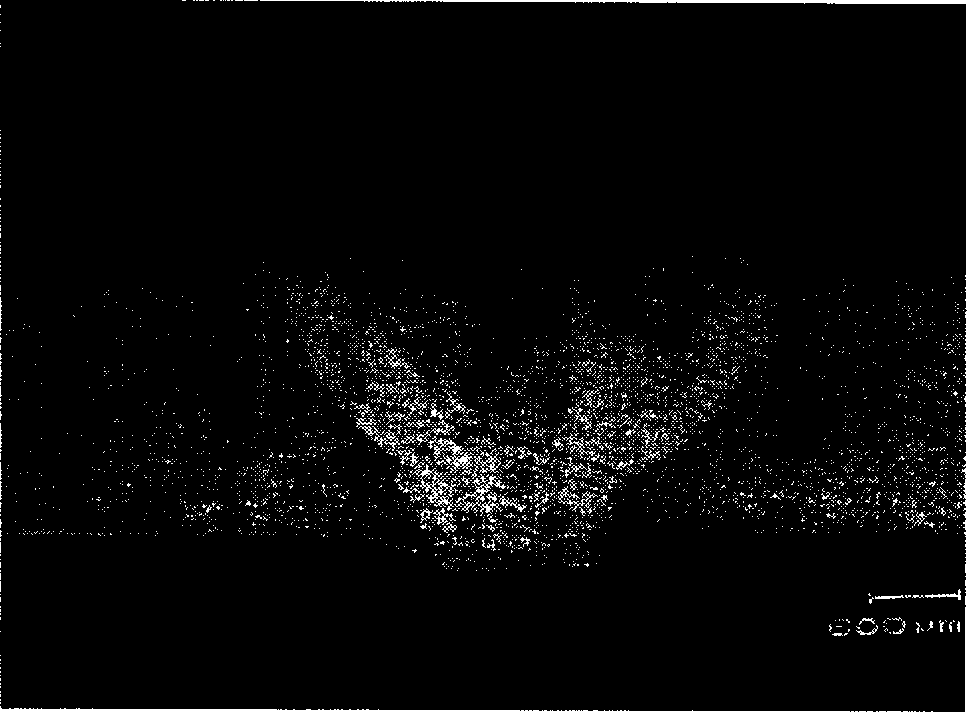

[0019] In order to illustrate the implementation effect of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com