Full-position connecting pipe and safety end circular seam welding method achieved through tungsten electrode inert gas arc welding

A technology of tungsten inert gas and welding method, which is applied in the direction of welding equipment, arc welding equipment, workpiece edge, etc., can solve problems such as lack of fusion, difficult welding quality, high thermal crack sensitivity, etc., to reduce welding deformation and avoid Weld bead defects, effect of good weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

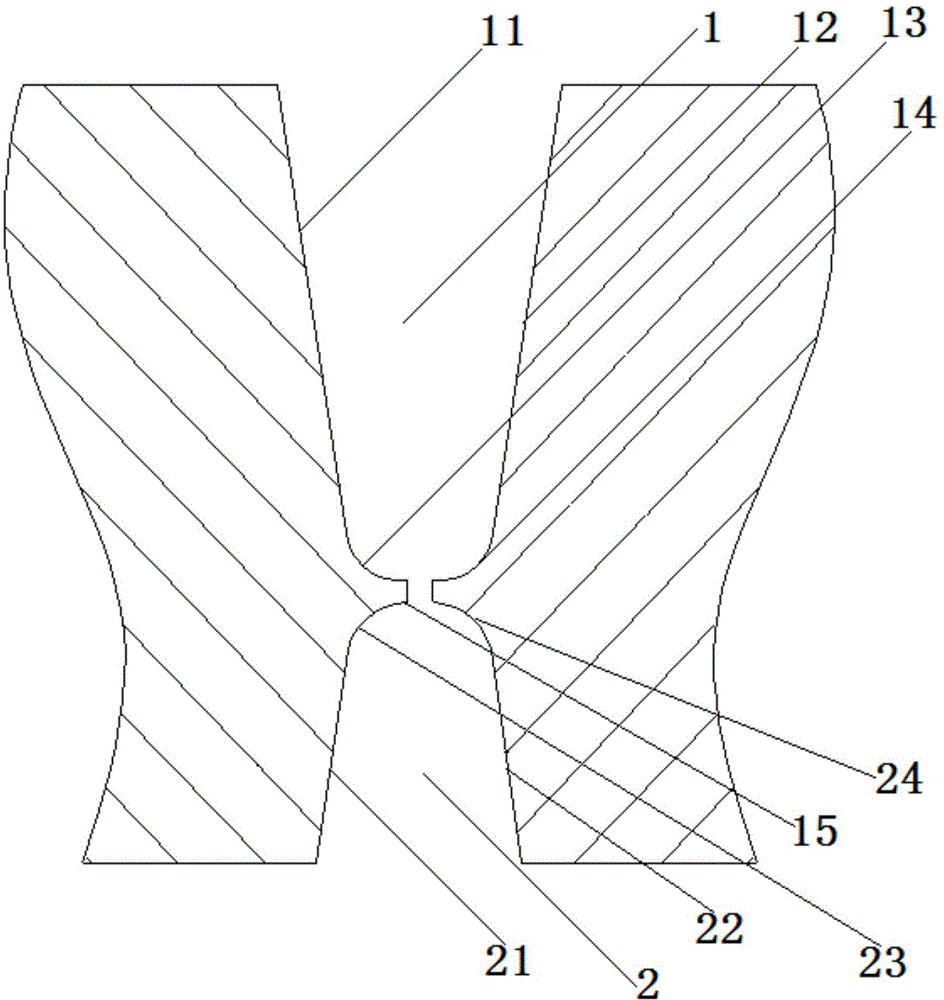

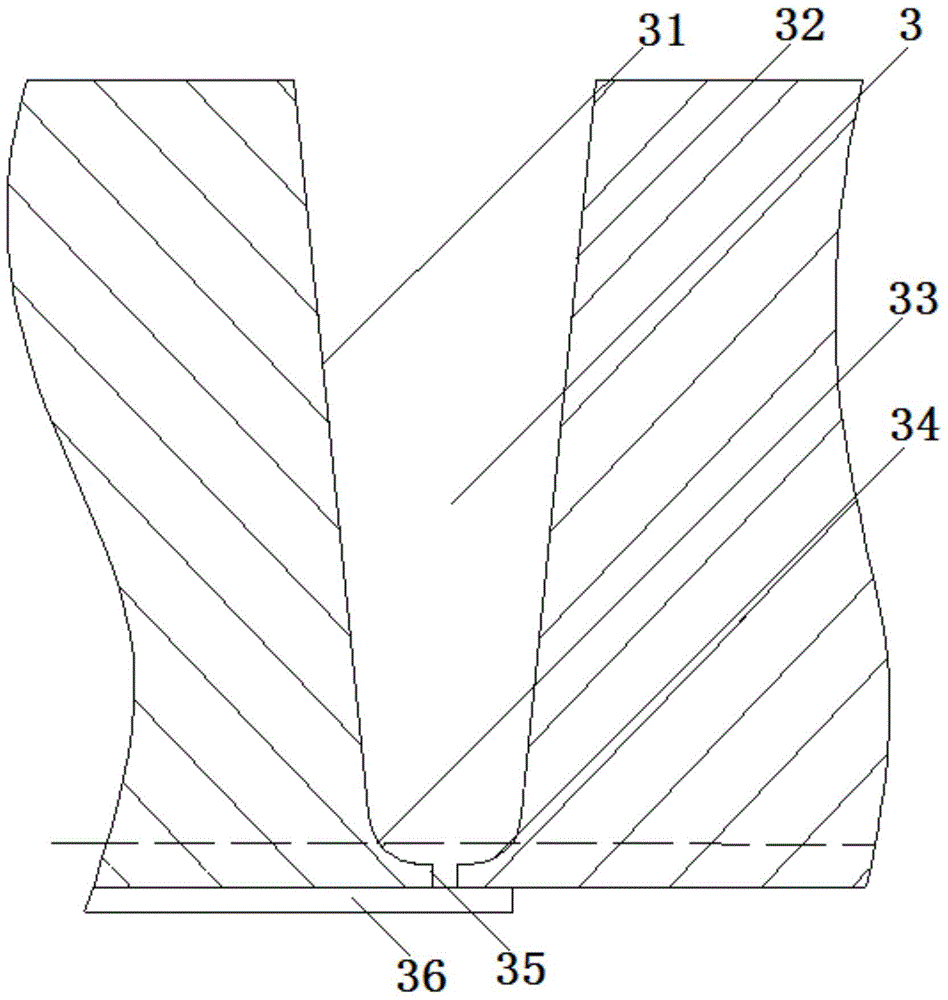

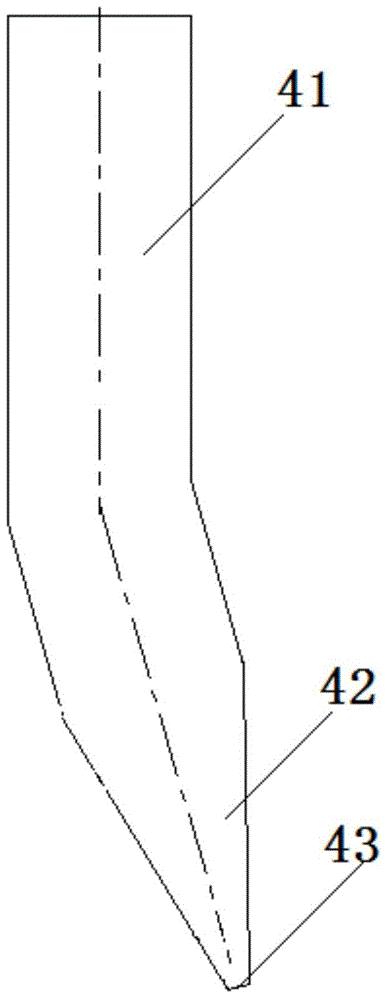

[0110] For the welding of the connecting pipe with an outer diameter of 900mm and a wall thickness of 140mm, the welding groove is selected as a double-sided U-shaped narrow gap groove, and the method provided by the present invention and its welding parameters are used to weld the connecting pipe and the safety end girth seam. One weld bead is cleaned before welding. Each weld bead is first welded on one side of the part to be welded, and then welded on the other side. The two arc starting points are slightly overlapped, and the two arc terminating points are also slightly overlapped; first Weld the outer groove, after the welding depth is 40mm, stop the welding of the outer groove, carry out root cleaning operation on the inner groove, then weld the inner groove completely, and finally weld the outer groove completely.

[0111] Among them, the welding parameters are: the welding wire is ERNiCrFe-7A welding wire with a diameter of 0.9mm, the welding base current is 110A, the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com