Patents

Literature

80results about How to "Improve fusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

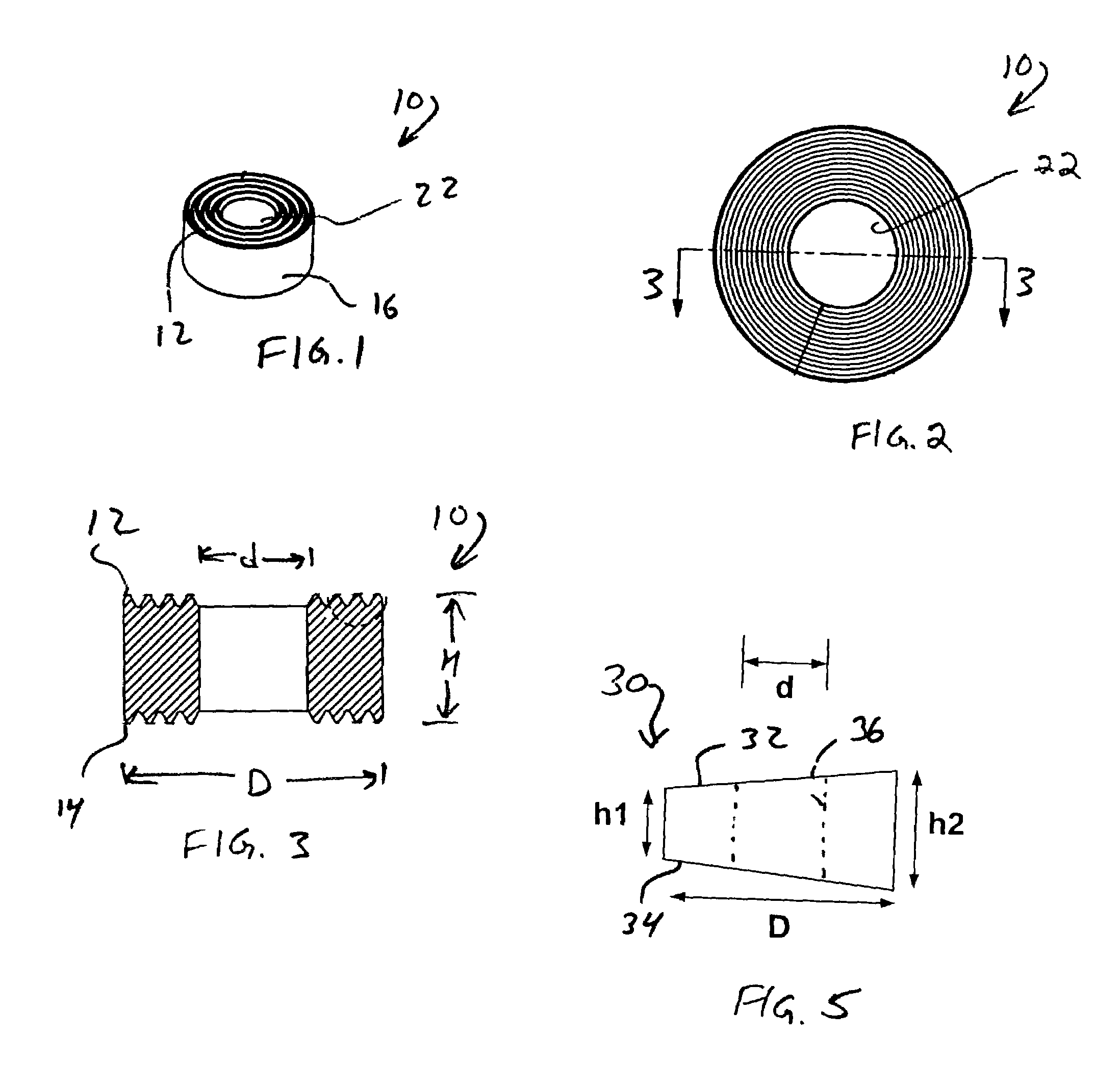

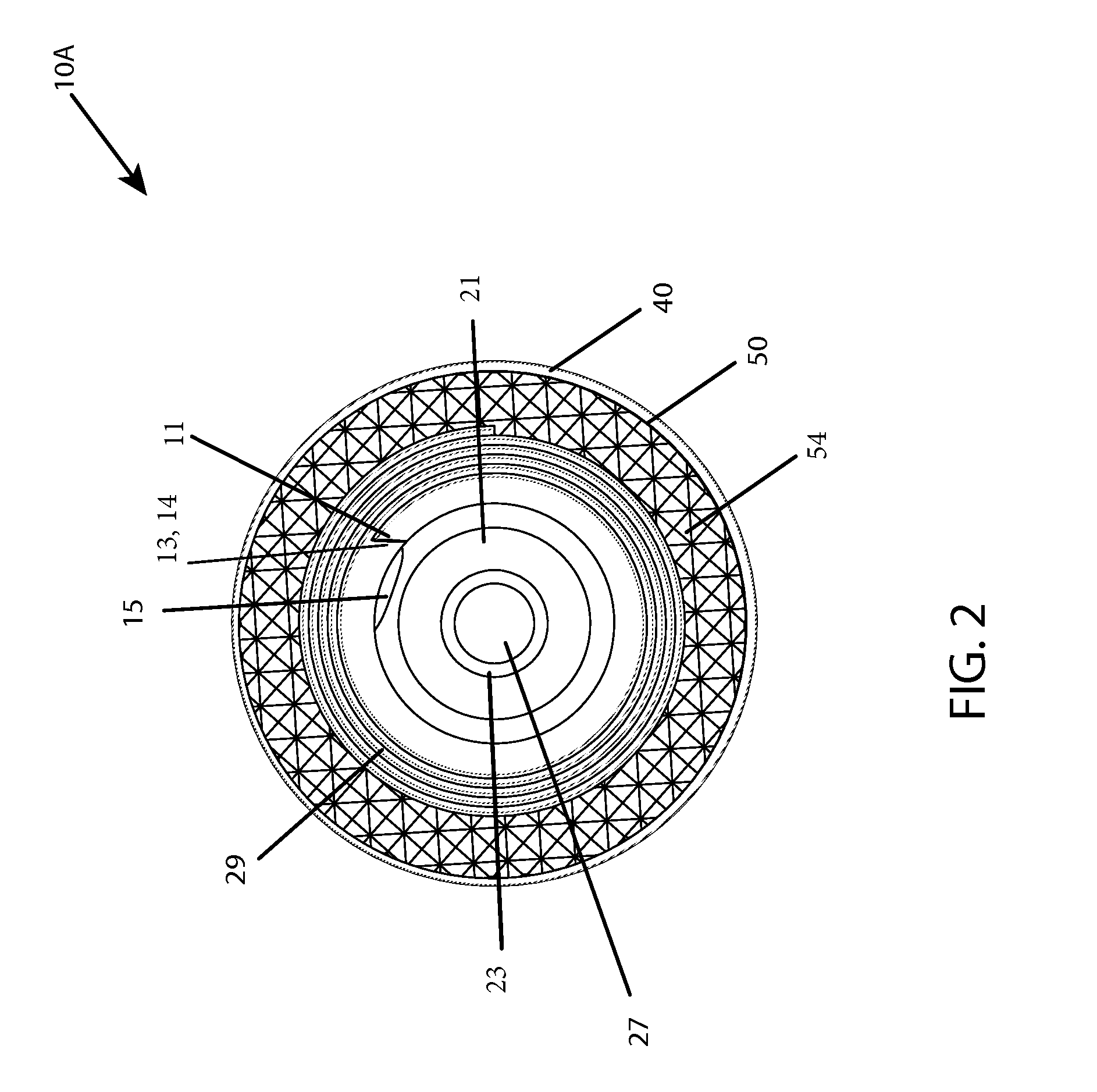

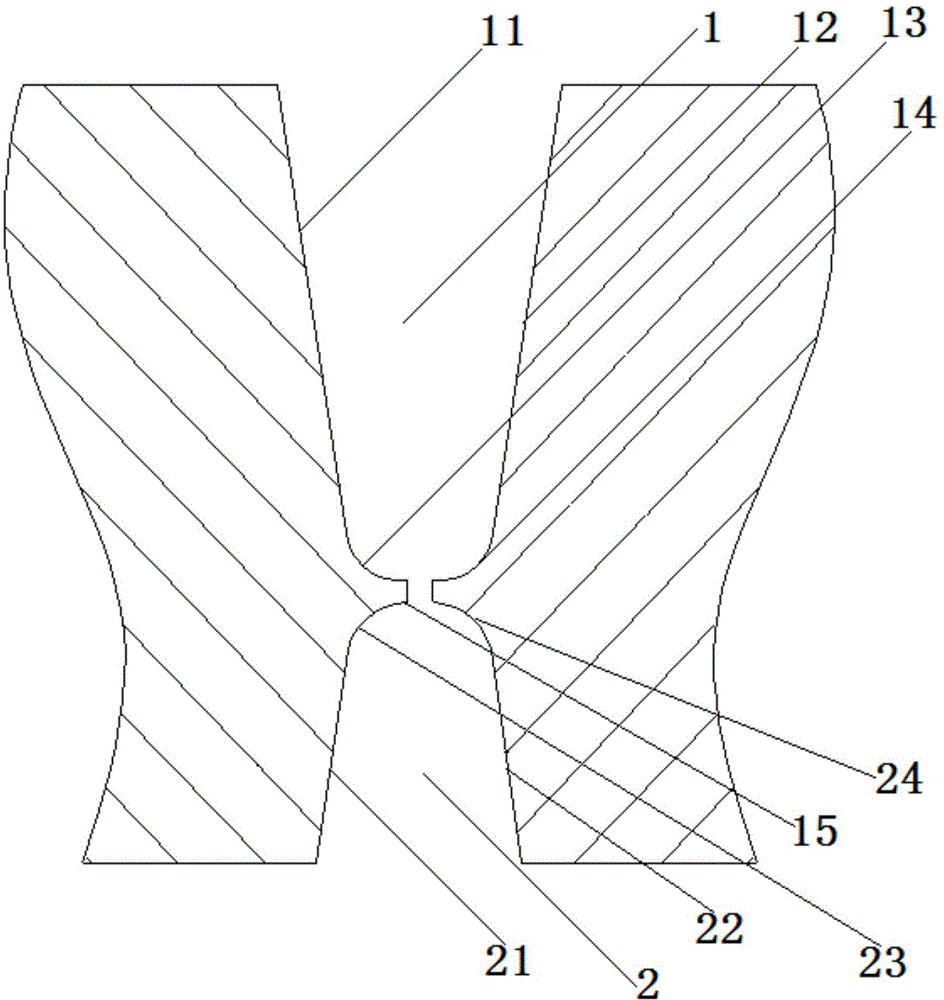

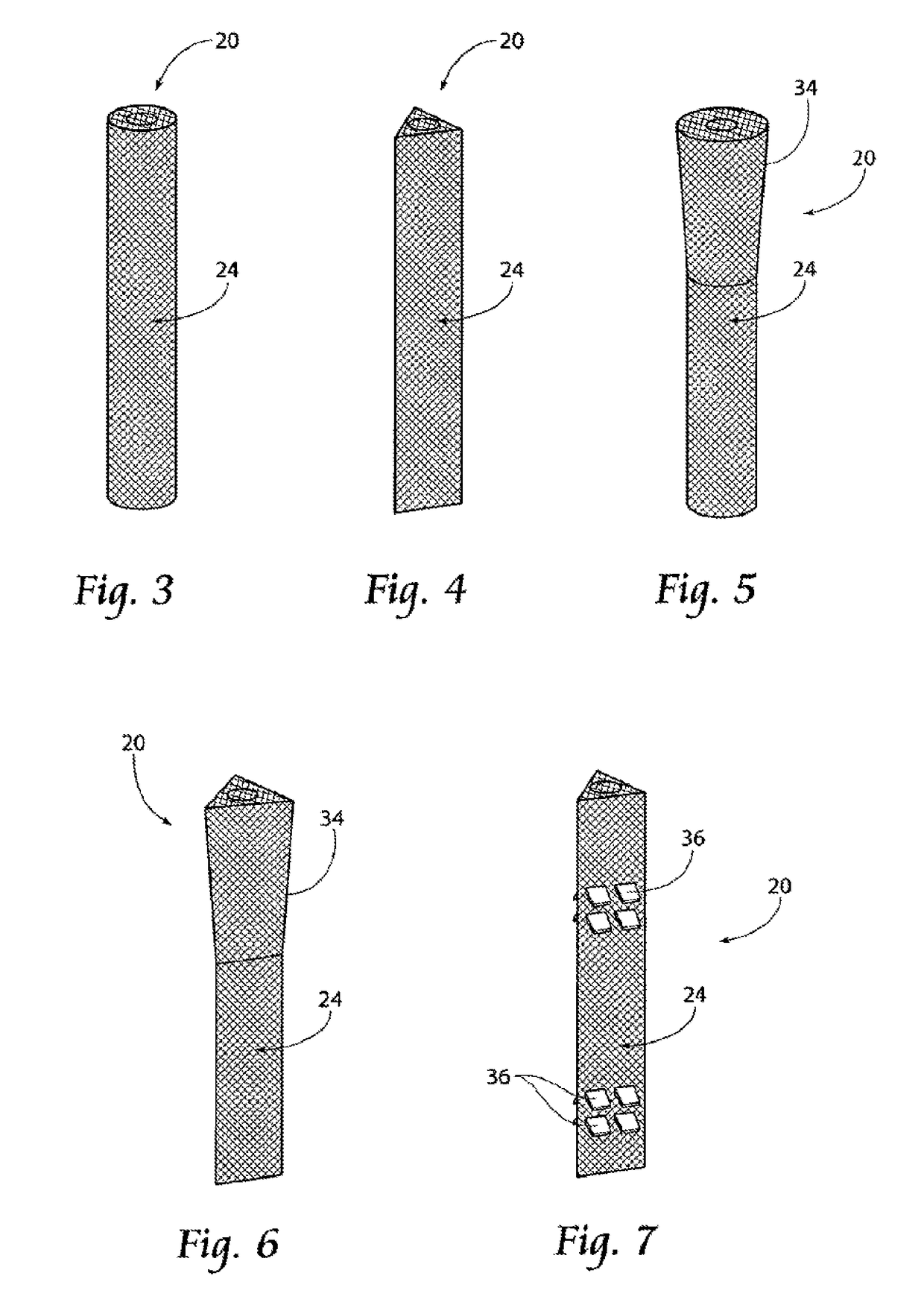

Allograft spinal implant

InactiveUS7018412B2Enhancing fusion of boneImprove fusionInternal osteosythesisBone implantSpinal implantBiomedical engineering

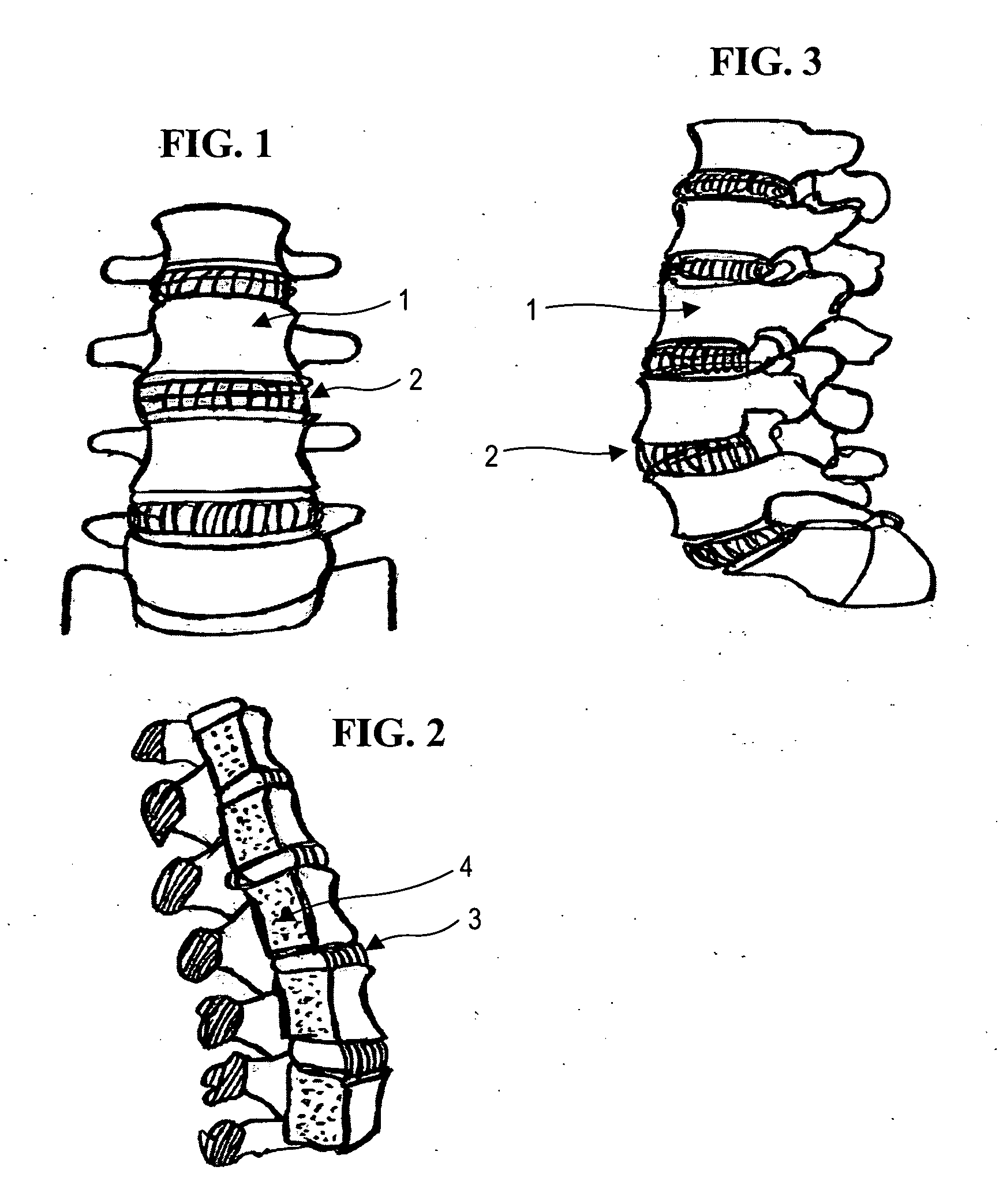

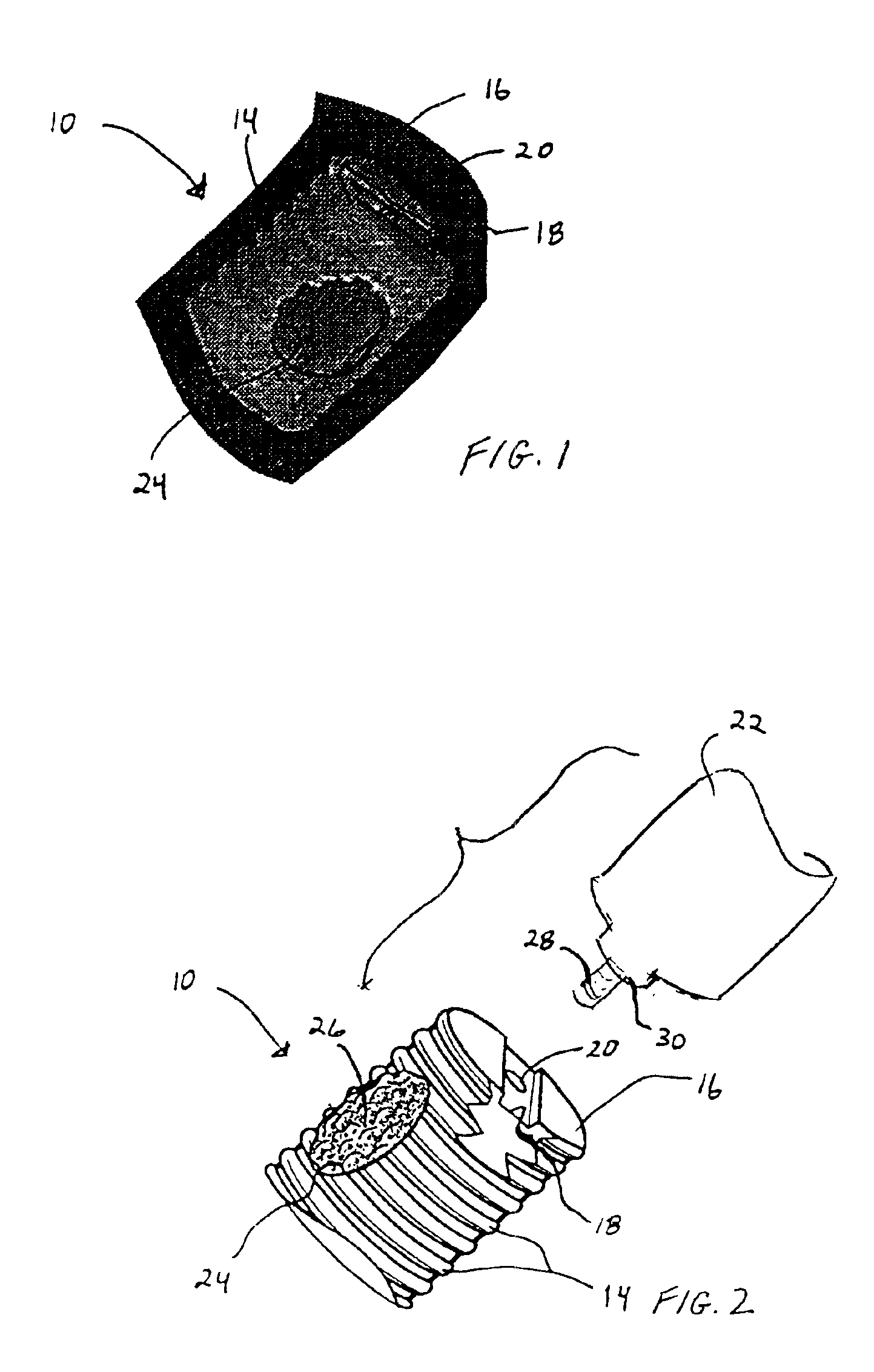

An allograft spinal implant includes a generally planar superior end face, a generally planar inferior end face and a generally cylindrical sidewall. The generally cylindrical sidewall extends between the superior end face and the inferior end face. At least one of the superior end face and the inferior end face includes a plurality of concentric circular ridges.

Owner:ZIMMER BIOMET SPINE INC

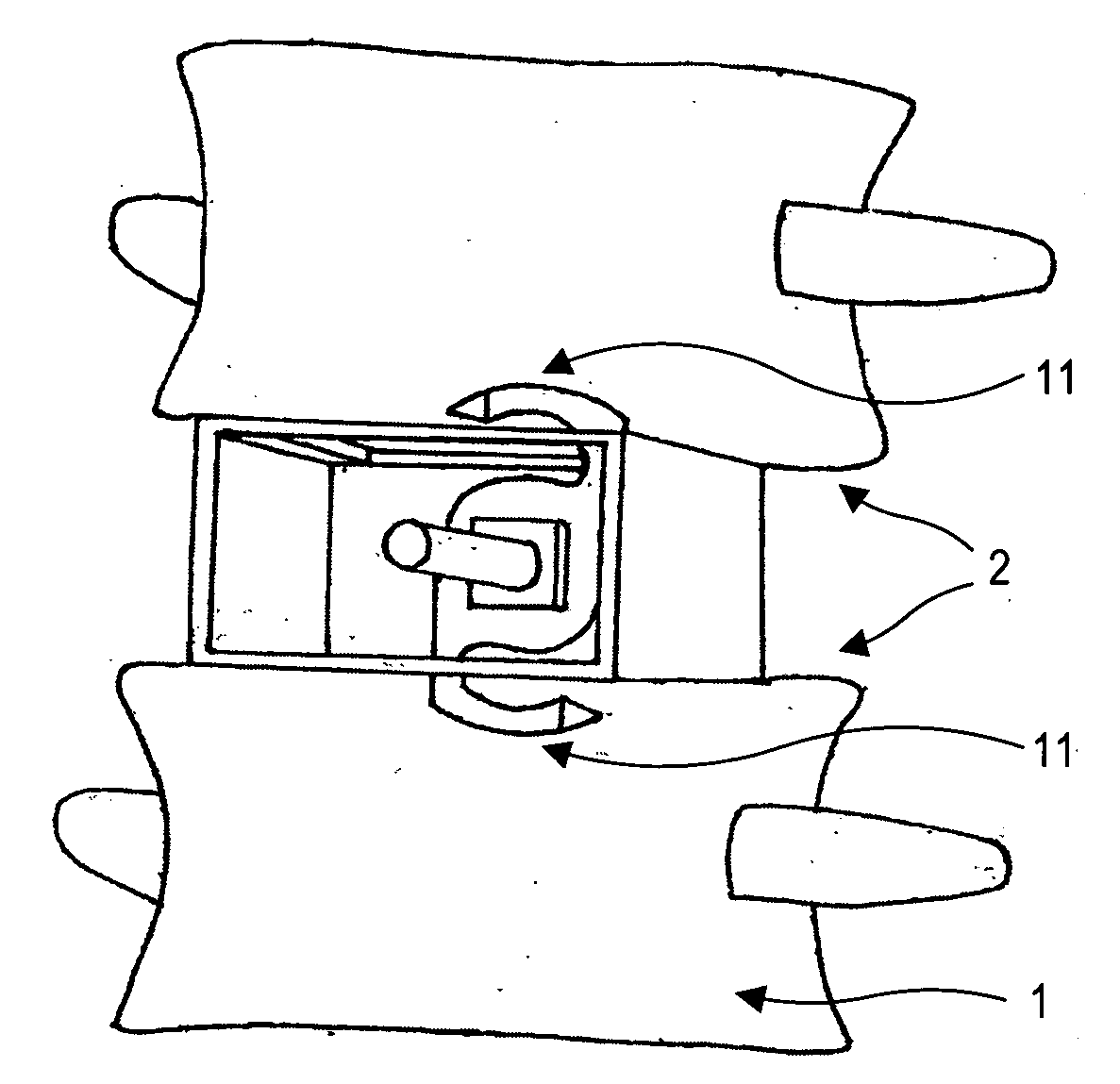

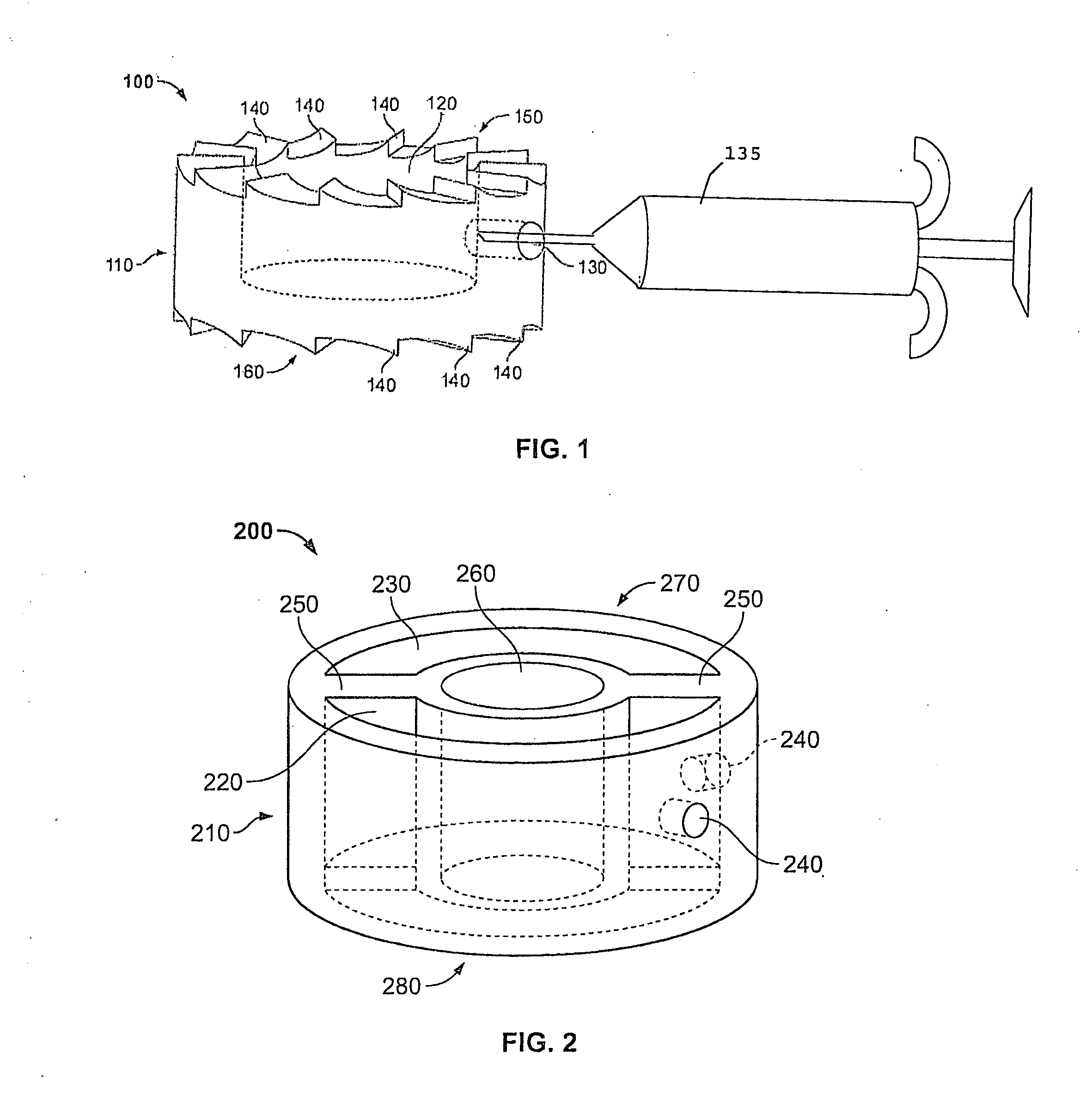

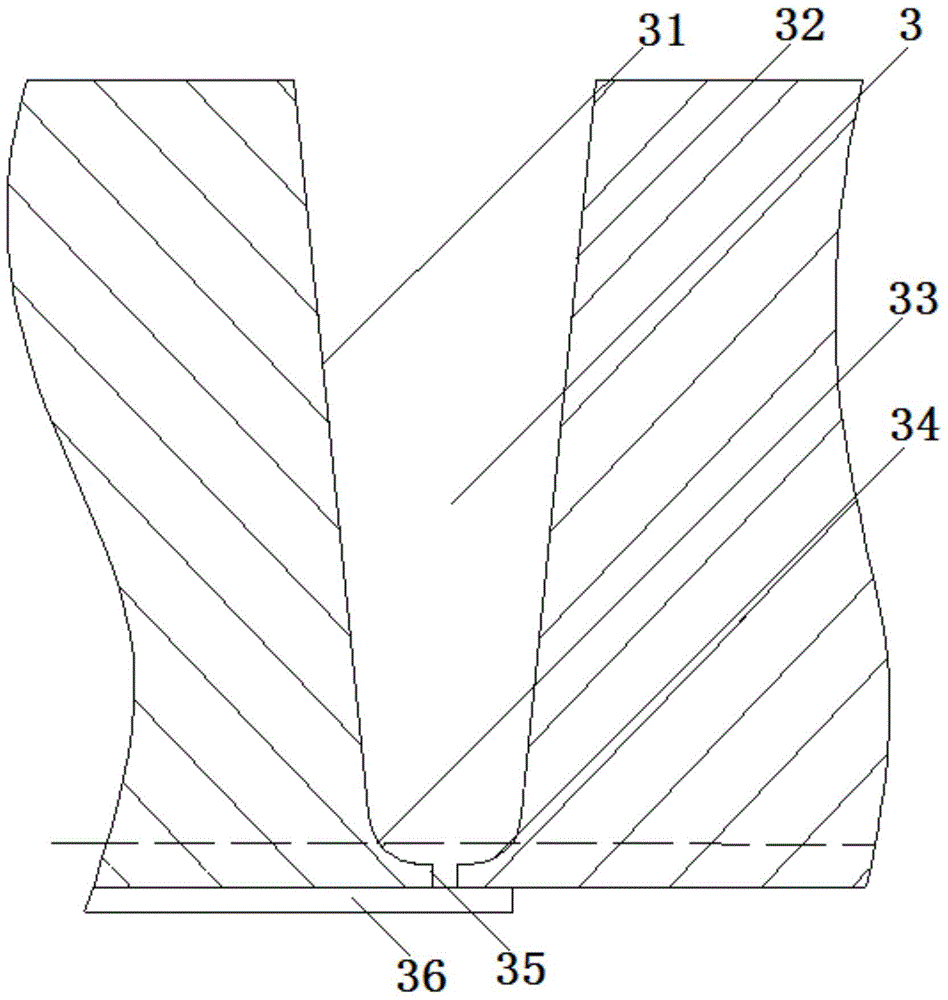

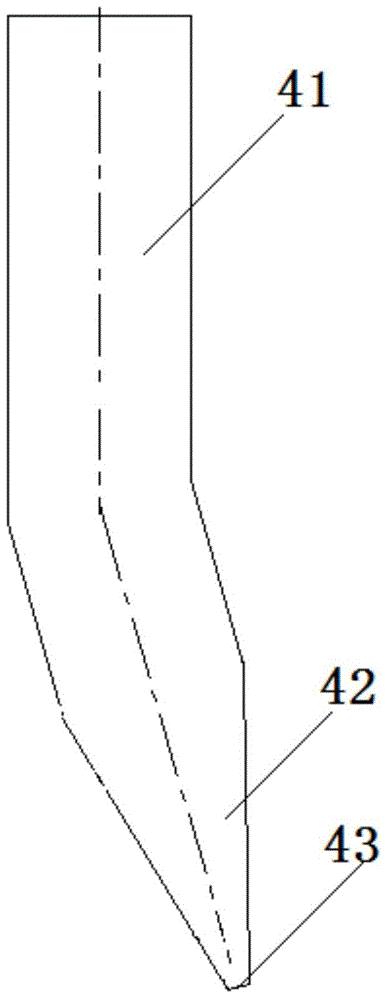

Apparatus and method for anterior intervertebral spinal fixation and fusion

ActiveUS20080132949A1Enhance bony fusionImprove fusionInternal osteosythesisJoint implantsVertebraSpinal locomotion

A spinal fixation and fusion device that includes a housing with leading deep surface conforming to the posterior aspect of the intervertebral disk and trailing outer surface conforming to the anterior surface of the disk, weight bearing sides and the top and bottom surfaces with plurality of openings enabling ingrowths of bone. The device further includes a shaft running from the center of the deep surface and perpendicular to the deep surface of the housing to the center of the outer surface of the housing and affixed at least to the deep surface of the housing, and a flat metal member threaded onto the shaft with sharp leading edge which upon clockwise or counterclockwise rotation about the axis of the shaft will break the endplate, hook into the vertebra and rigidly secure the vertebra to the entire device preventing separation of the vertebra from the device during spinal motion.

Owner:INT SPINAL INNOVATIONS +2

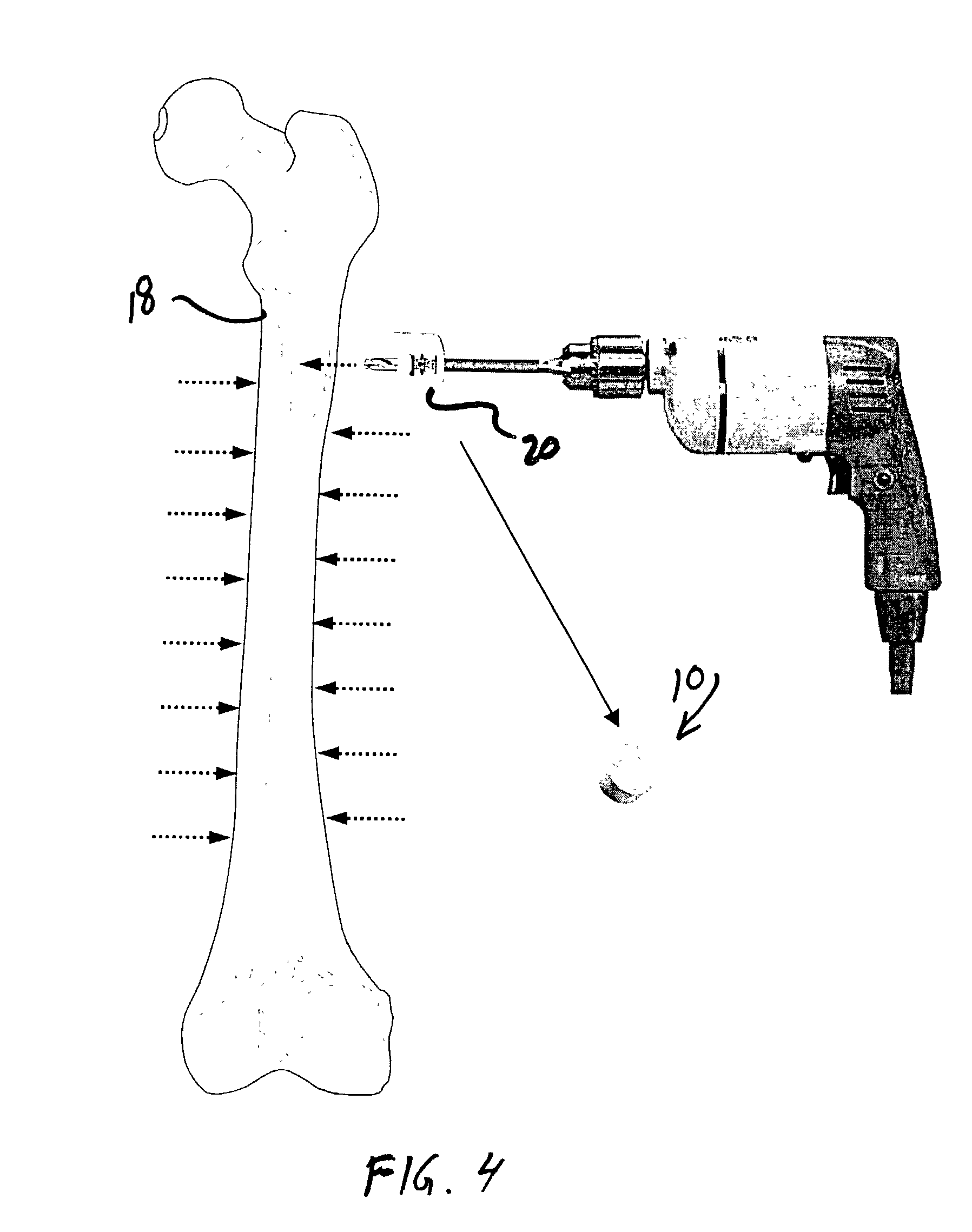

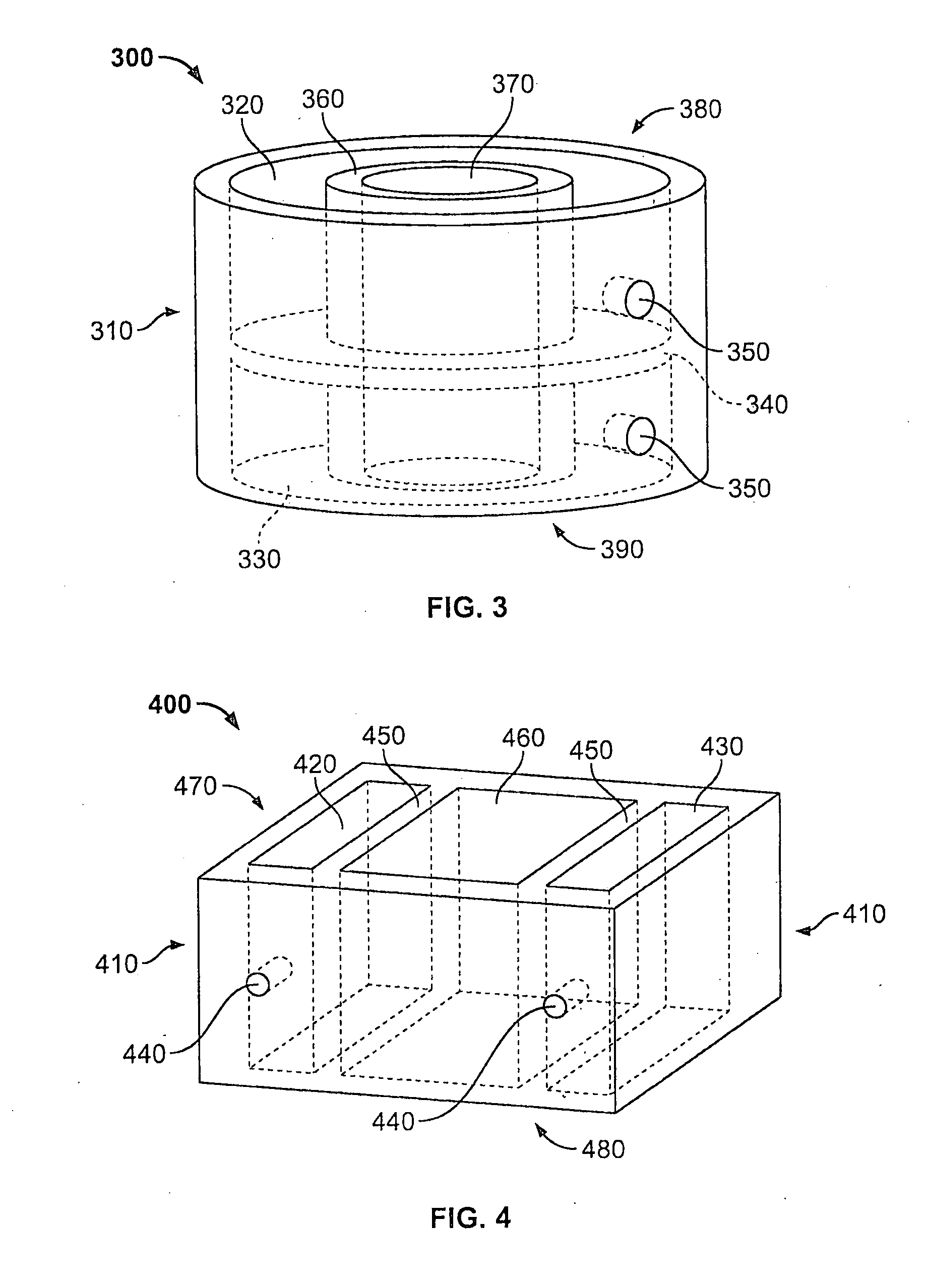

Radiolucent bone graft

InactiveUS6846327B2Enhanced bone ingrowthImprove fusionBone implantJoint implantsBone ingrowthVertebra

An improved ceramic bone graft is provided for human implantation, particularly such as a spinal fusion cage for implantation into the inter-vertebral space between two adjacent vertebrae. The improved spinal fusion cage includes a substrate block of high strength ceramic having a selected size and shape to fit the anatomical space, and a controlled porosity analogous to natural bone. The substrate block is coated with a bio-active surface coating material such as hydroxyapatite or a calcium phosphate to promote bone ingrowth and enhanced bone fusion. Upon implantation, the fusion cage provides a spacer element having a desired combination of mechanical strength together with osteoconductivity and osteoinductivity to promote bone ingrowth and fusion, as well as radiolucency for facilitated post-operative monitoring. The fusion cage may additionally carry one or more natural or synthetic therapeutic agents for further promoting bone ingrowth and fusion.

Owner:CTL MEDICAL CORP +1

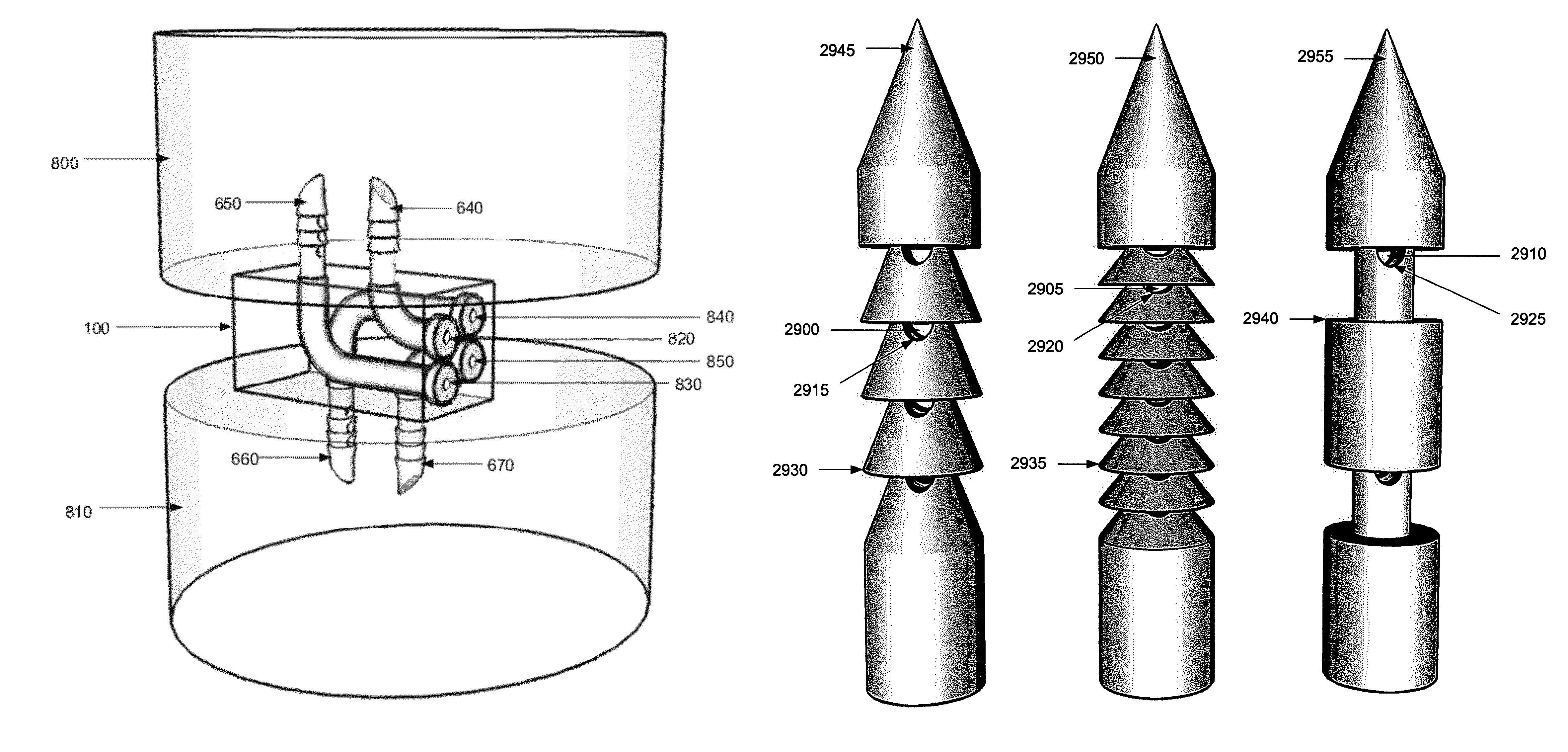

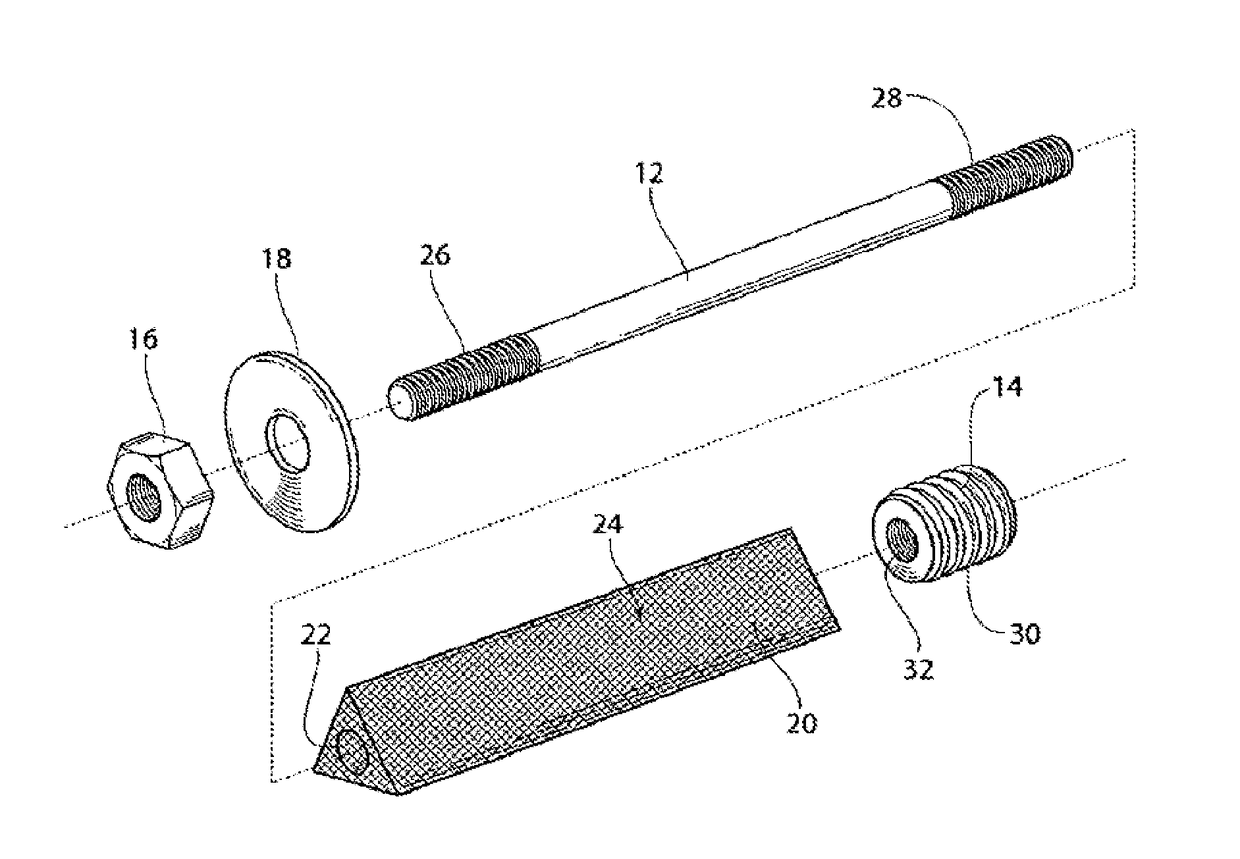

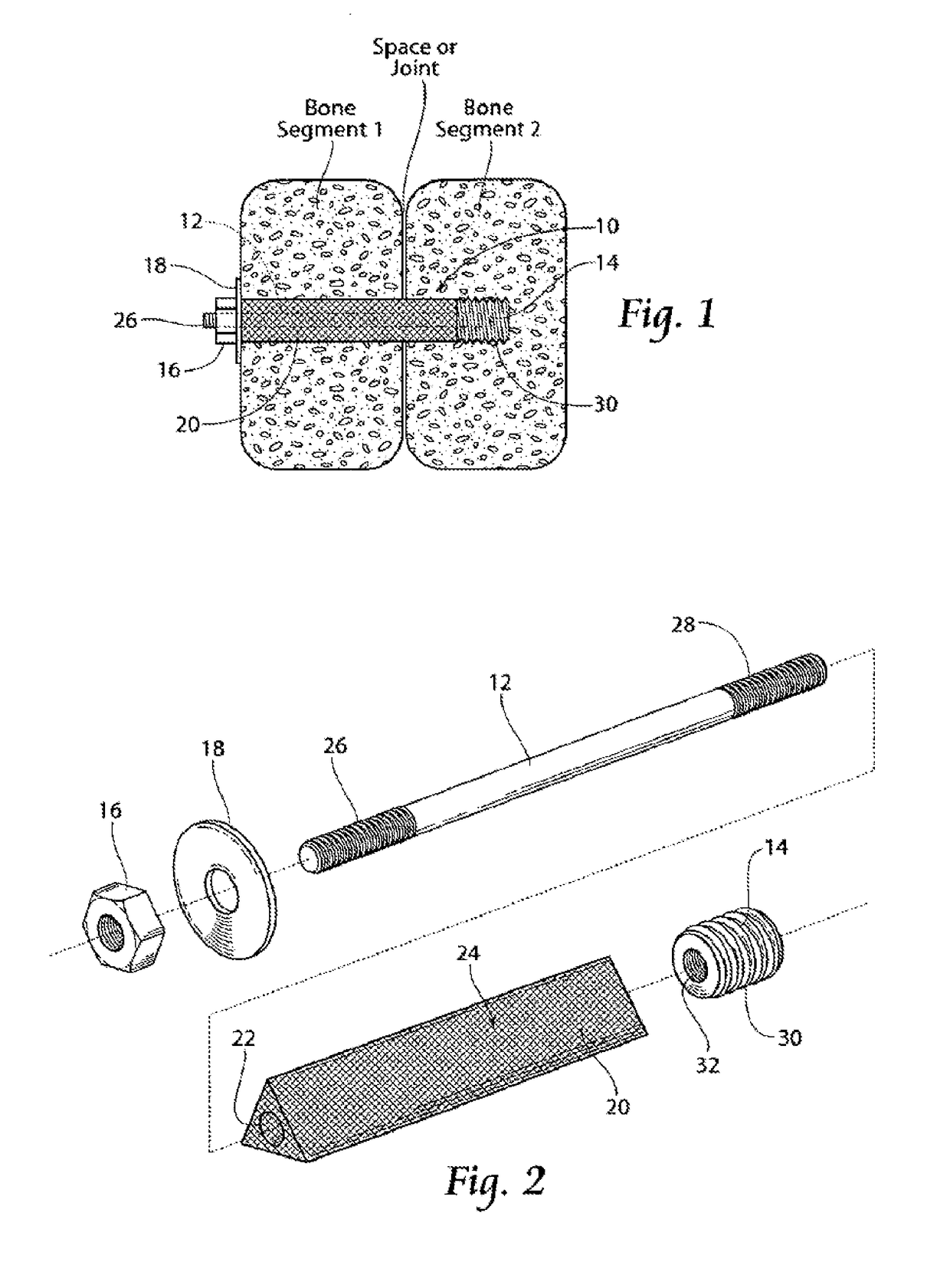

Intervertebral fusion device and method of use

InactiveUS8313528B1Improve stabilityEnhance bony fusionInternal osteosythesisBone implantIntervertebral fusionAdhesive materials

Some embodiments of the invention disclose an apparatus for achieving rapid mechanical fusion between two adjacent vertebral bodies by positioning a fusion member with one or more channels between the two vertebral bodies. Once the fusion member properly positioned, one or more needles are passed through the fusion member's channels and advanced into the marrow space of the adjacent vertebral bodies. Each needle has a lumen for receiving adhesive material and supplying said material to the marrow space of the adjacent vertebral bodies. The adhesive material is for adhesively bonding the needle to the adjacent vertebral bodies. In some embodiments, a needle also has various surface contours along its shaft, including angled teeth and backfacing ridges.

Owner:SPINELOGIK

Osteoconductive spinal fixation system

InactiveUS20060276788A1High strengthHigh mechanical strengthSuture equipmentsInternal osteosythesisPorositySpinal column

An improved spinal fixation system is provided for human implantation, including a set of screws with interconnecting rods for implantation into the pedicle and between two adjacent vertebrae or a plate with screws for fixating two adjacent vertebrae. The screws, rods, and plates include a substrate portion of high strength biocompatible material and a controlled porosity analogous to natural bone. The substrate portion may be coated with a bio-active surface coating material such as hydroxyapatite or a calcium phosphate to promote bone ingrowth and enhanced bone fusion. Upon implantation, the fixation system provides a desired combination of mechanical strength together with osteoconductivity and bio-activity to promote bone ingrowth and fusion, as well as radiolucency for facilitated post-operative monitoring. The fixation system may additionally carry one or more natural or synthetic therapeutic agents for further promoting bone ingrowth and fusion.

Owner:AMEDICA A DELAWARE

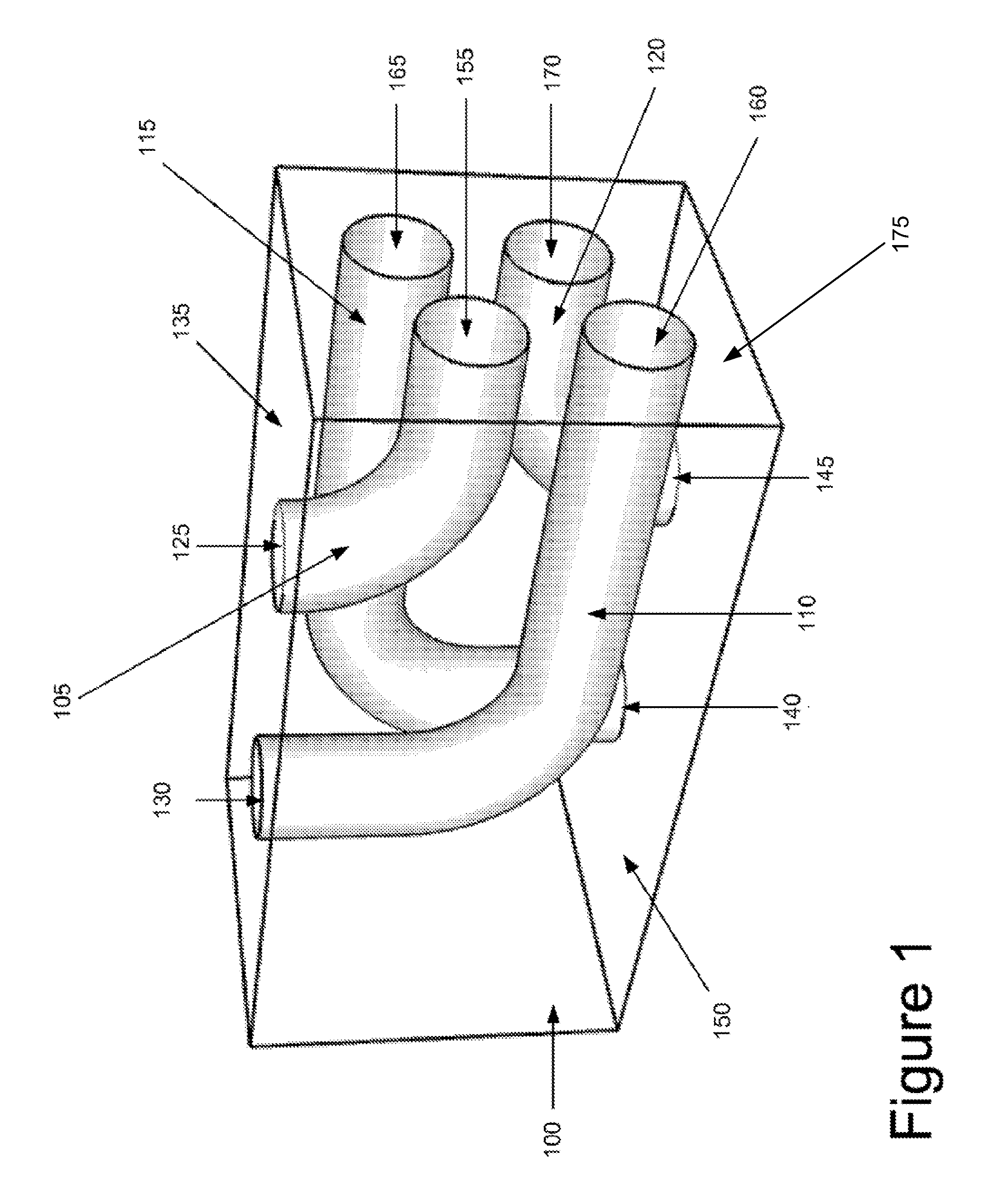

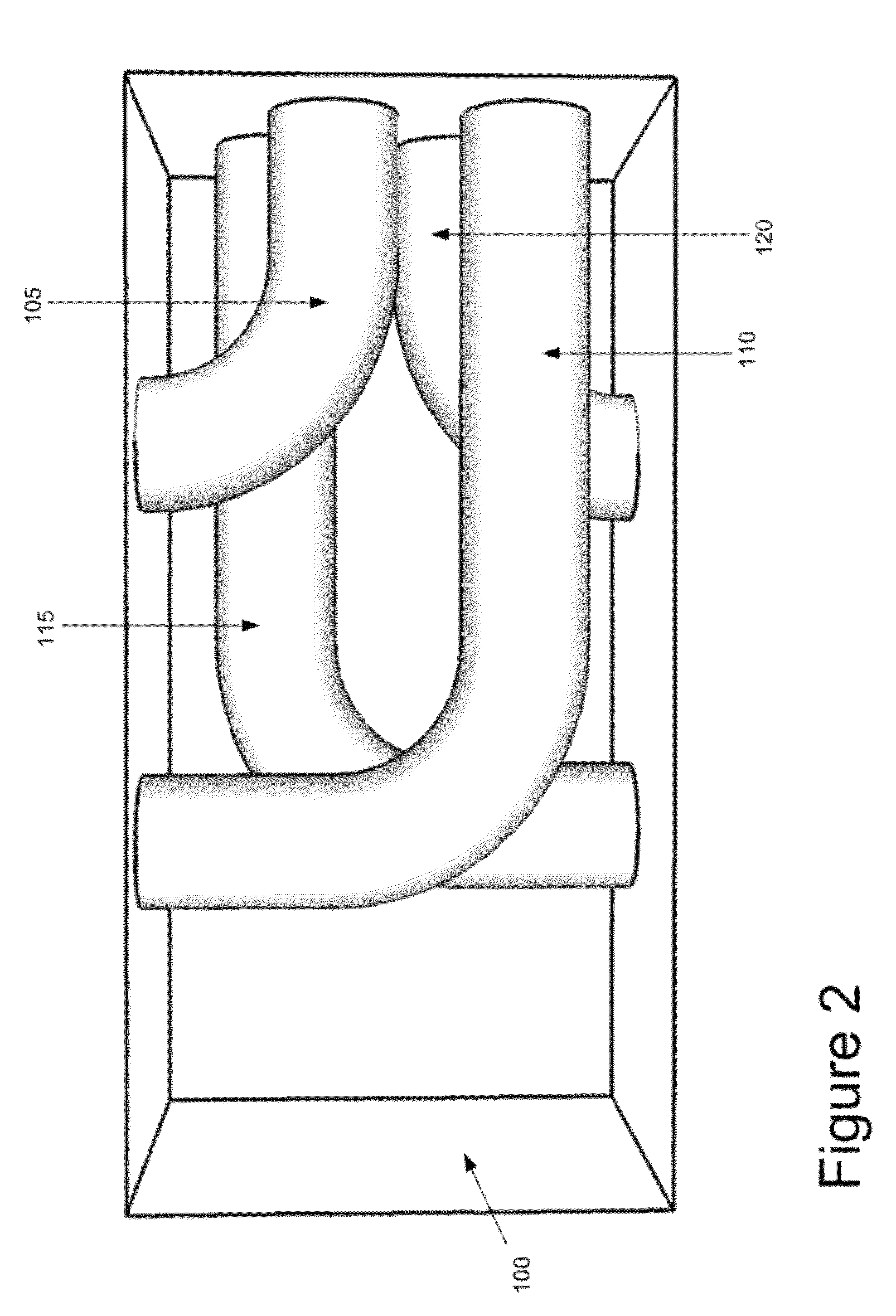

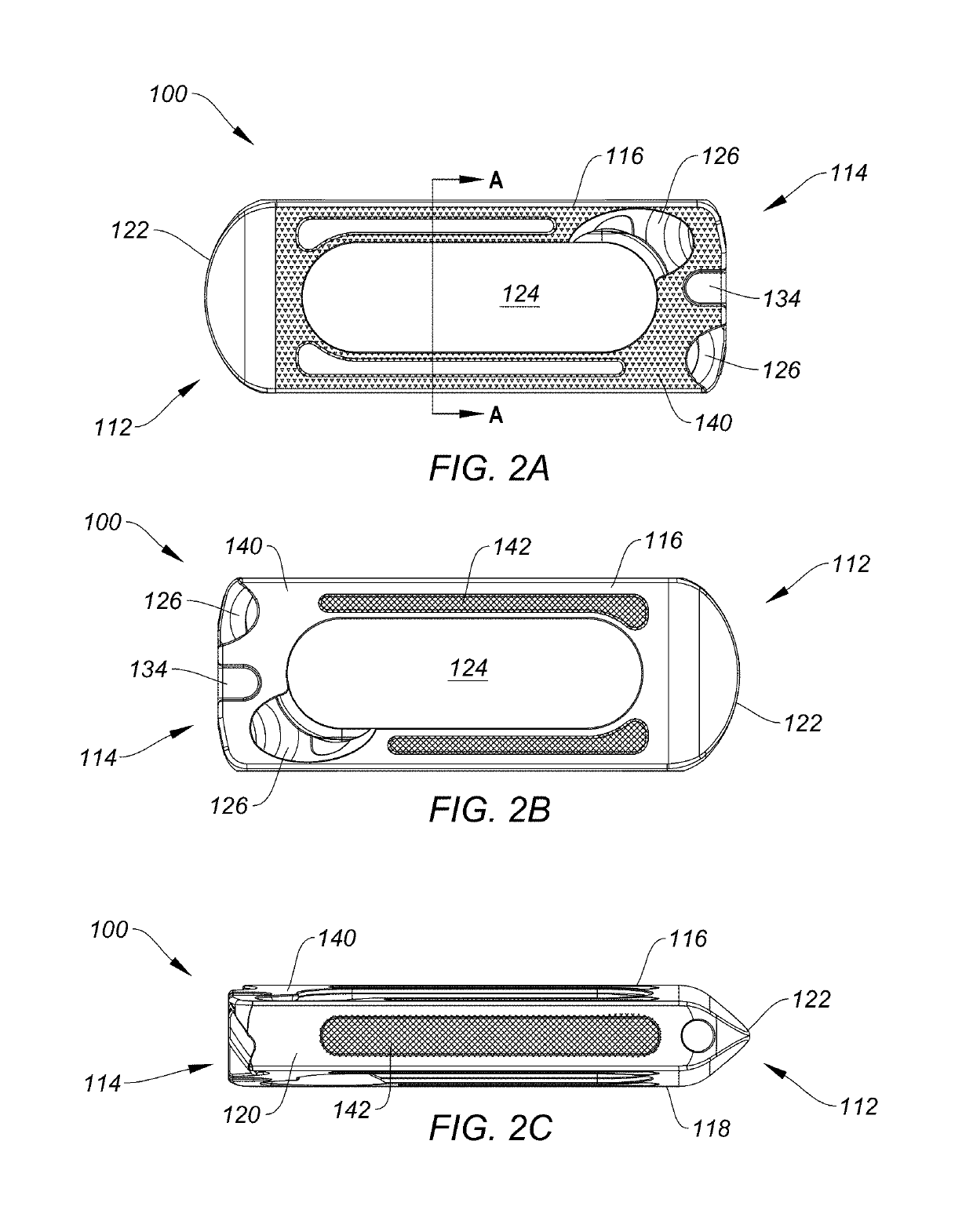

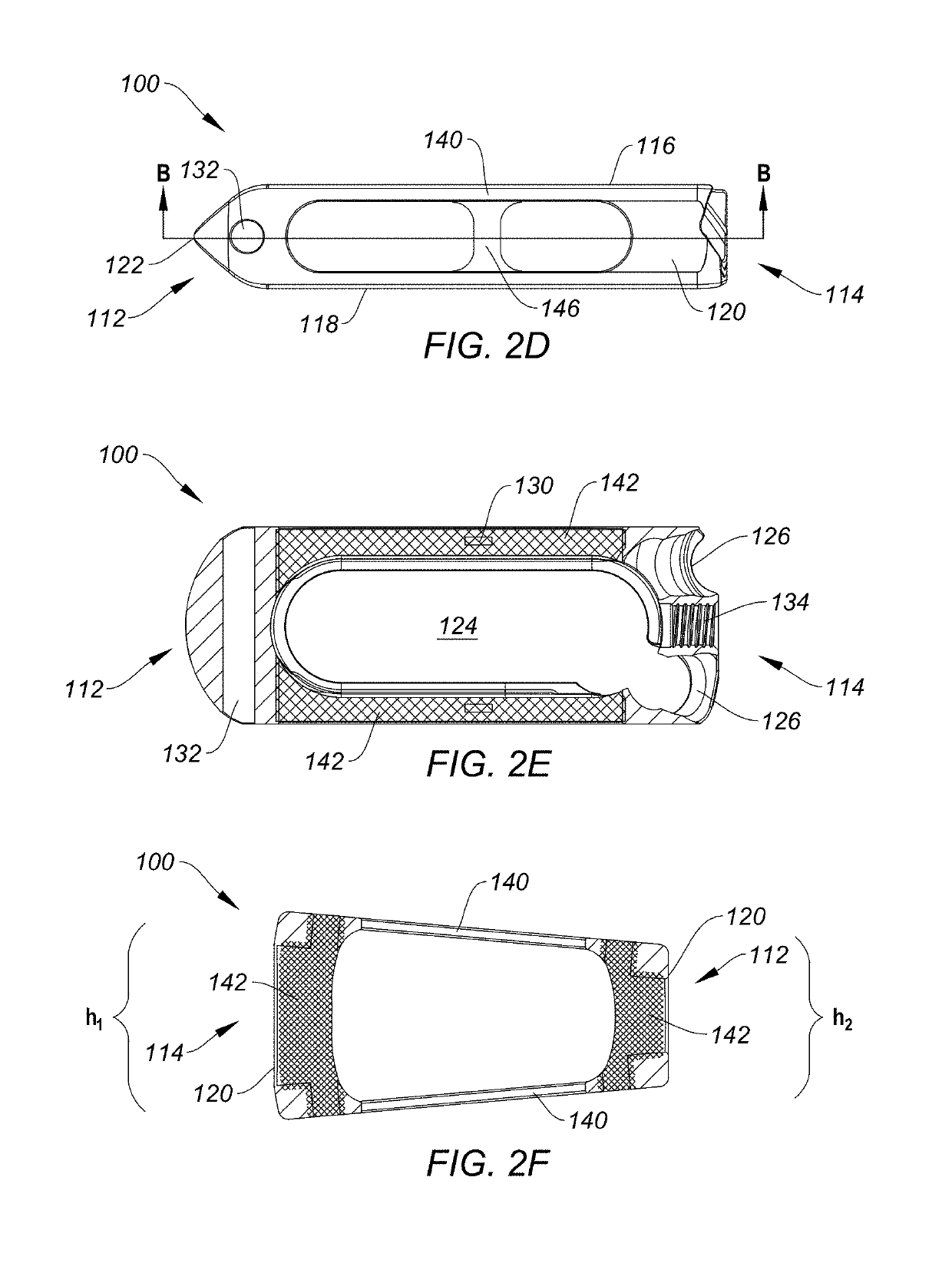

Fusion device, systems and methods thereof

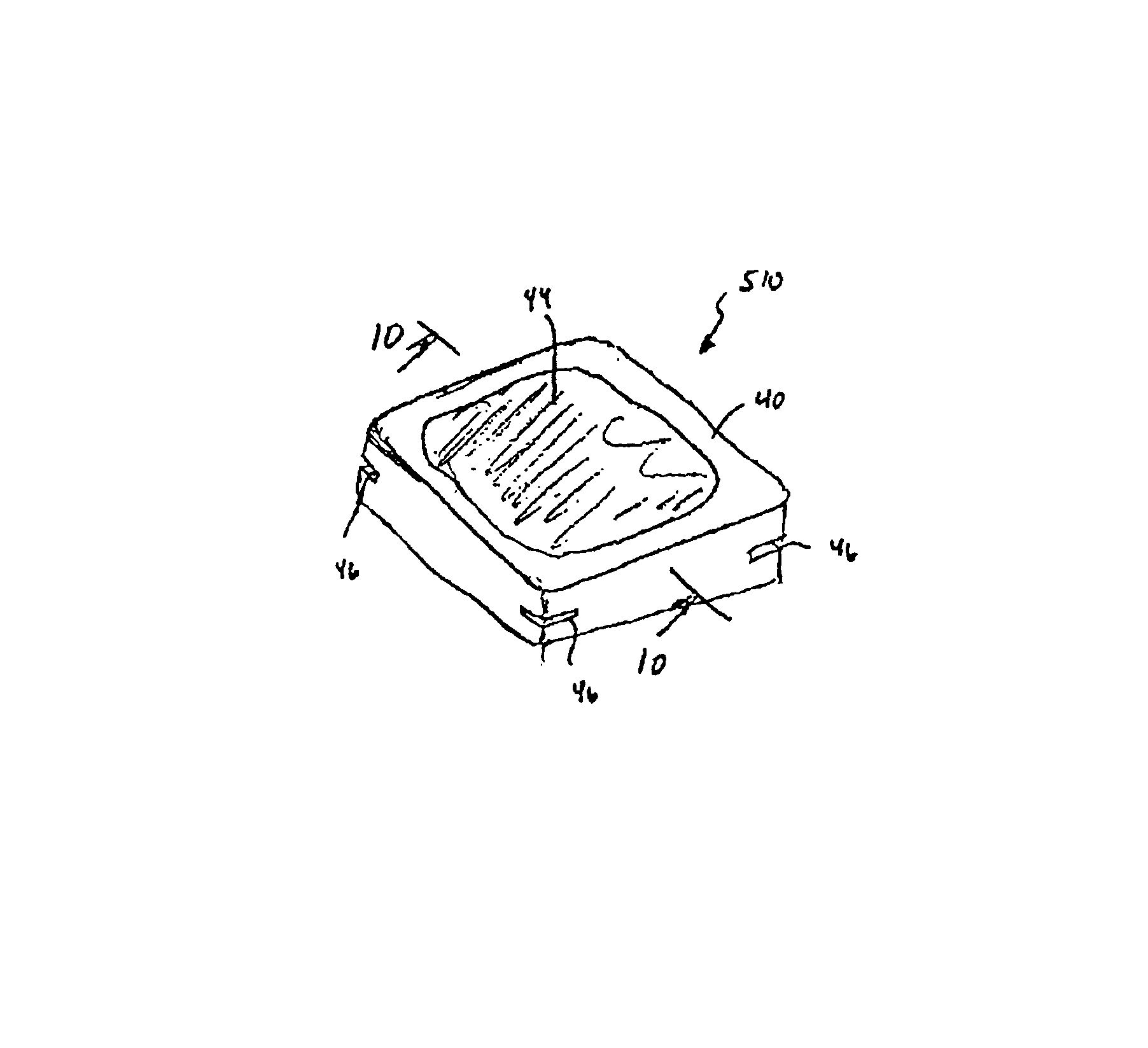

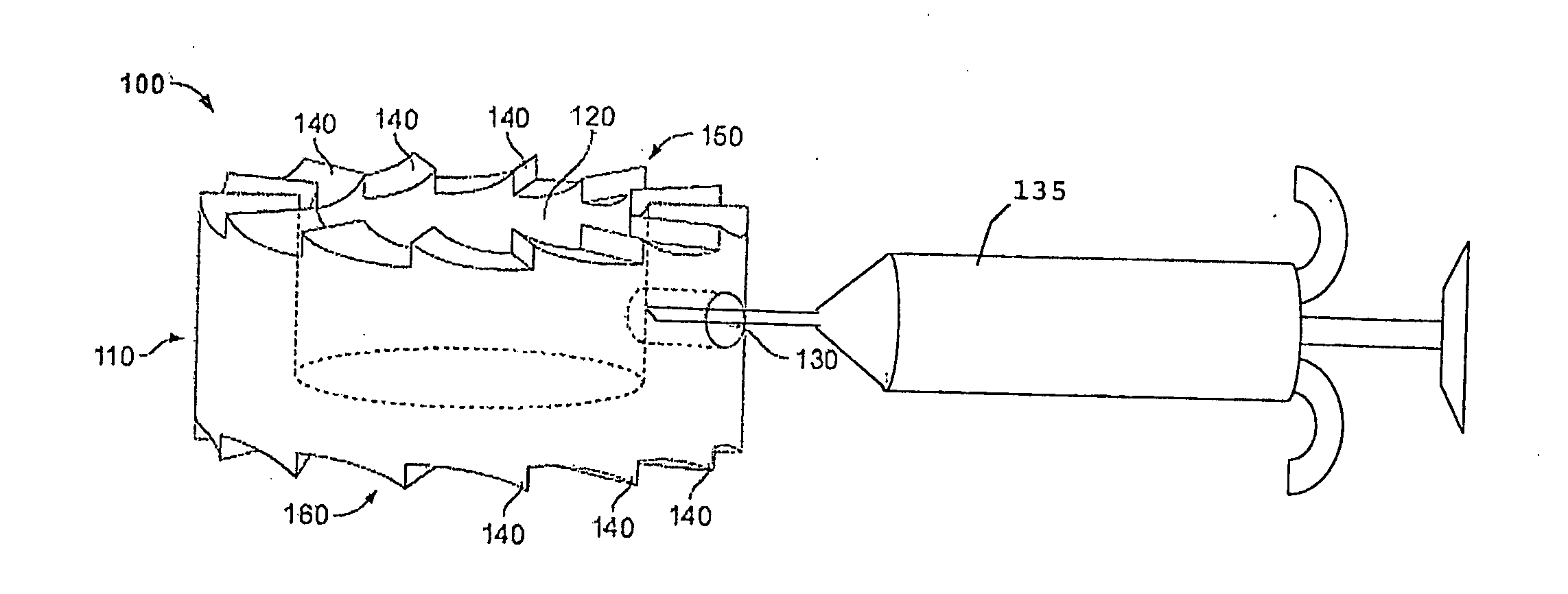

InactiveUS20110004307A1Reduce and eliminate needPrecise deliveryInternal osteosythesisBone implantVertebraIntervertebral space

The spinal fusion device (100) of the invention is implanted within an intervertebral space between adjacent upper and lower vertebrae and secured to the vertebrae with cement. The fusion device includes upper and lower endplate facing surfaces (150, 160) each having at least one opening (120) for delivering cement material to adjacent contact surfaces of the vertebrae above and below the implant. Utilizing quick-setting cement compositions with the device <:an allow for almost immediate fusion of the vertebrae, thus, reducing or eliminating the need for adjuvant fixation devices such as screws, plates, and / or rods, while also simultaneously providing precise delivery of cement to contact surfaces between the fusion device and vertebrae.

Owner:PIONEER SURGICAL TECH INC

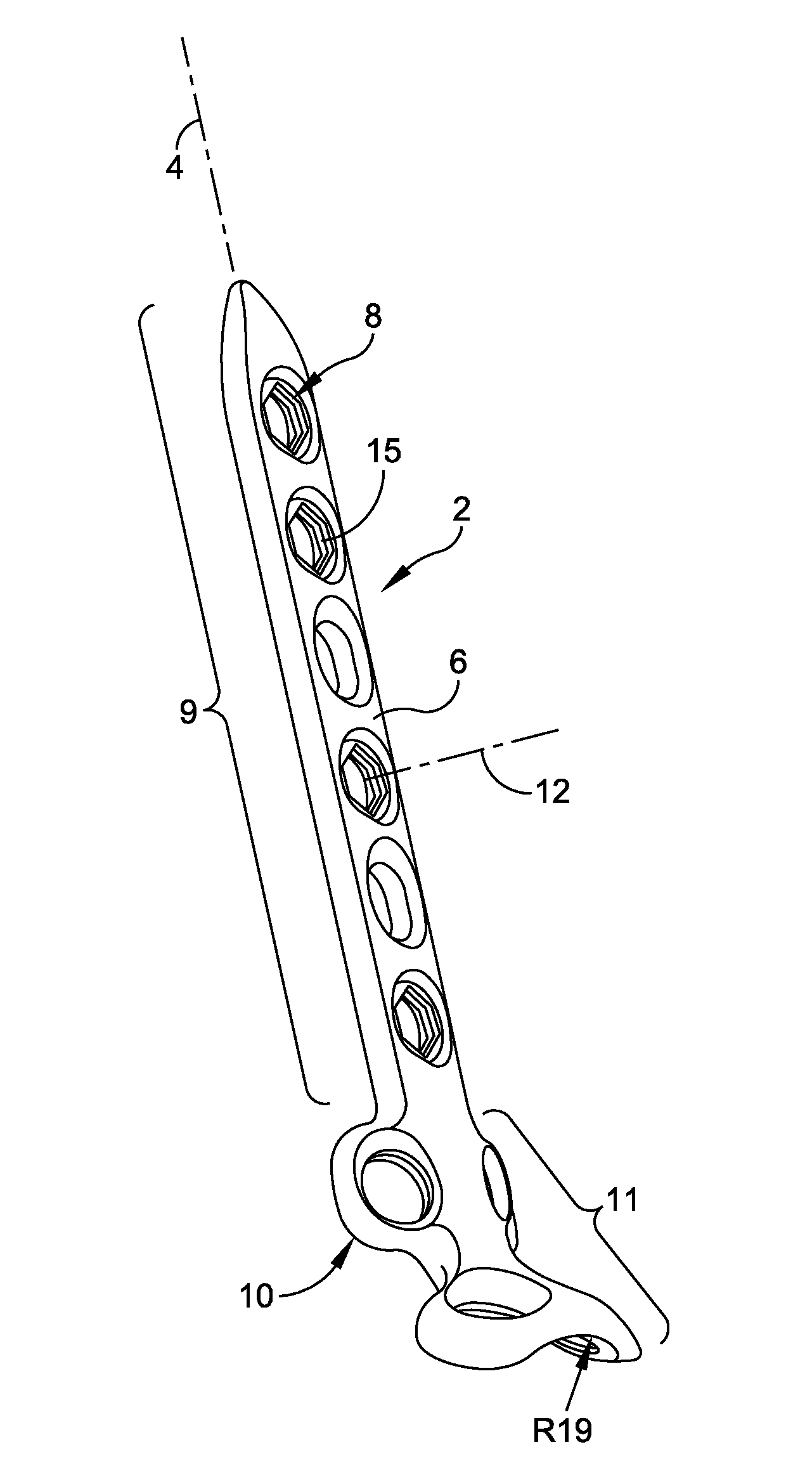

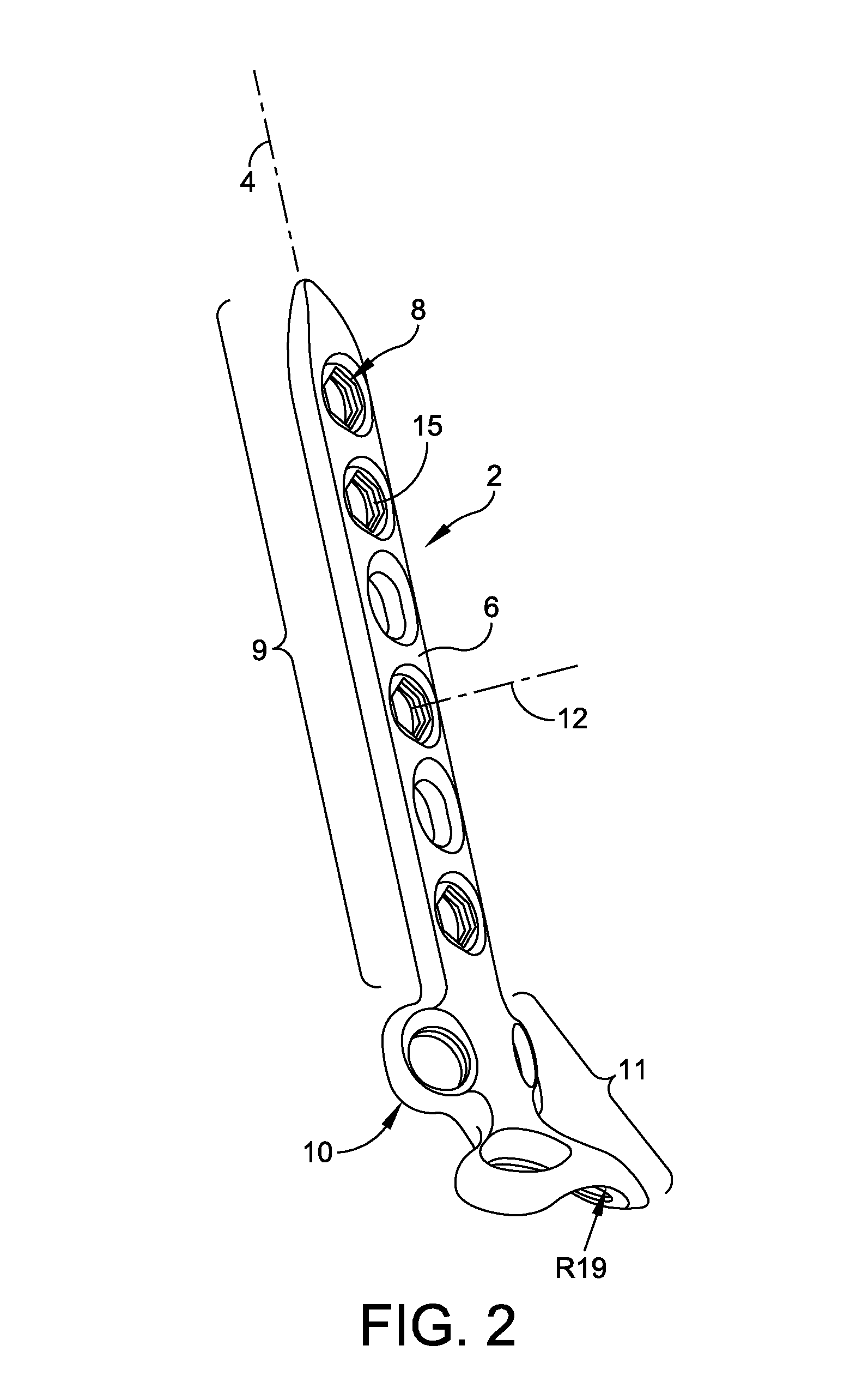

Posterior Ankle Fusion Plate

InactiveUS20140277178A1Effective positioningSecure tibiotalocalcaneal fixationBone platesJoint arthrodesisMedicine

An ankle arthrodesis fusion plate is provided that affords compression across the tibio-talar joint to promote bone fusion and joint stability.

Owner:WRIGHT MEDICAL TECH

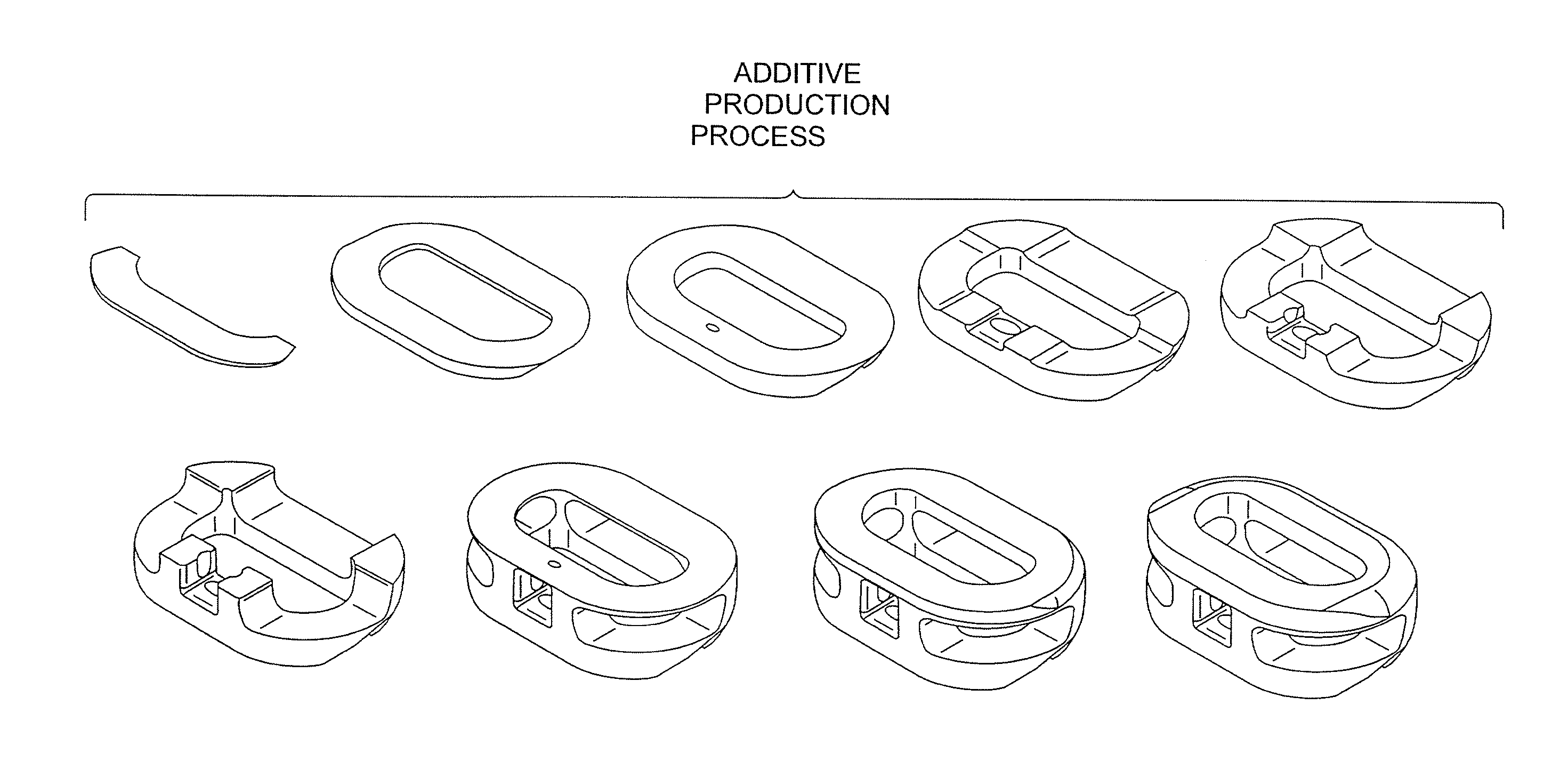

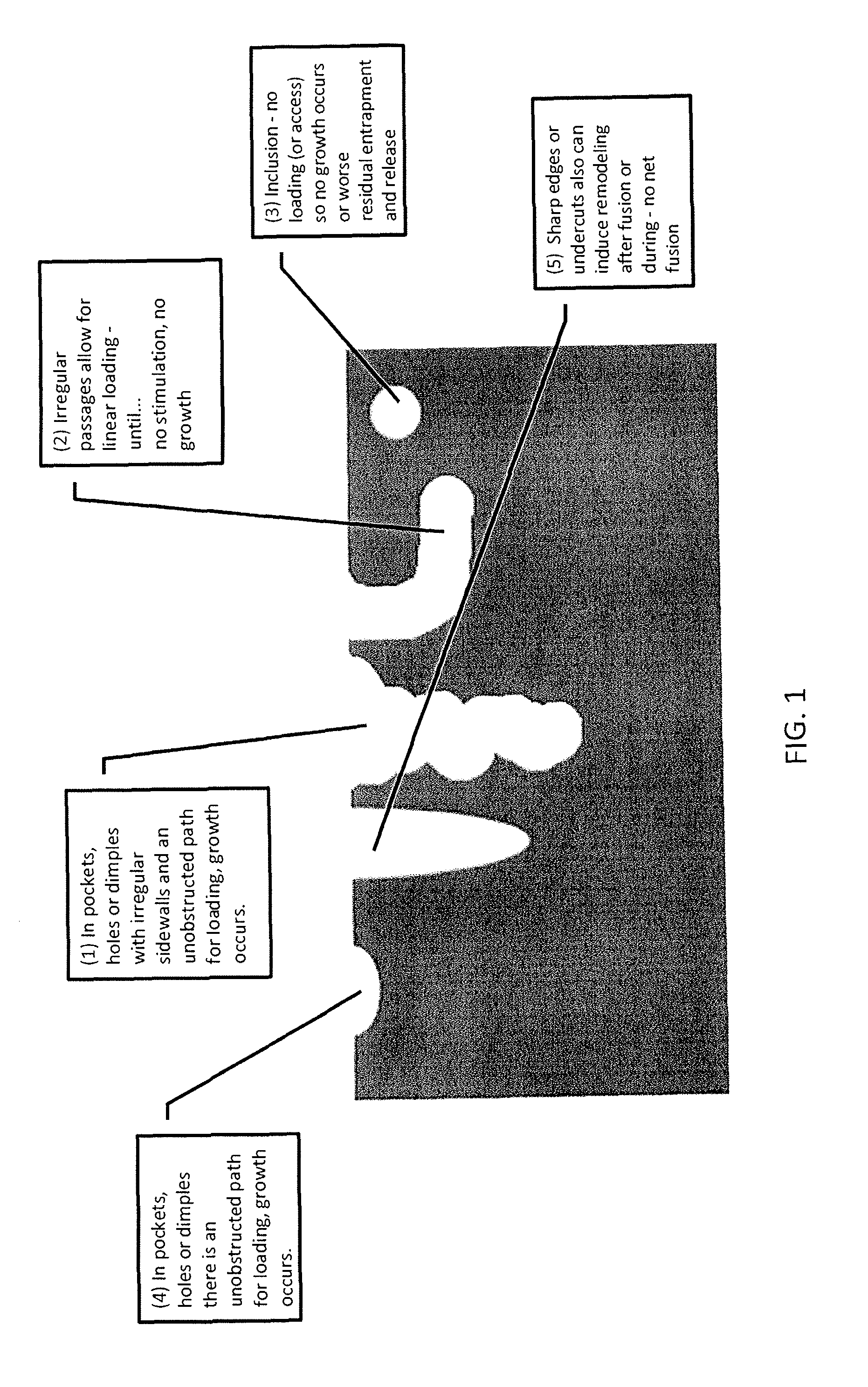

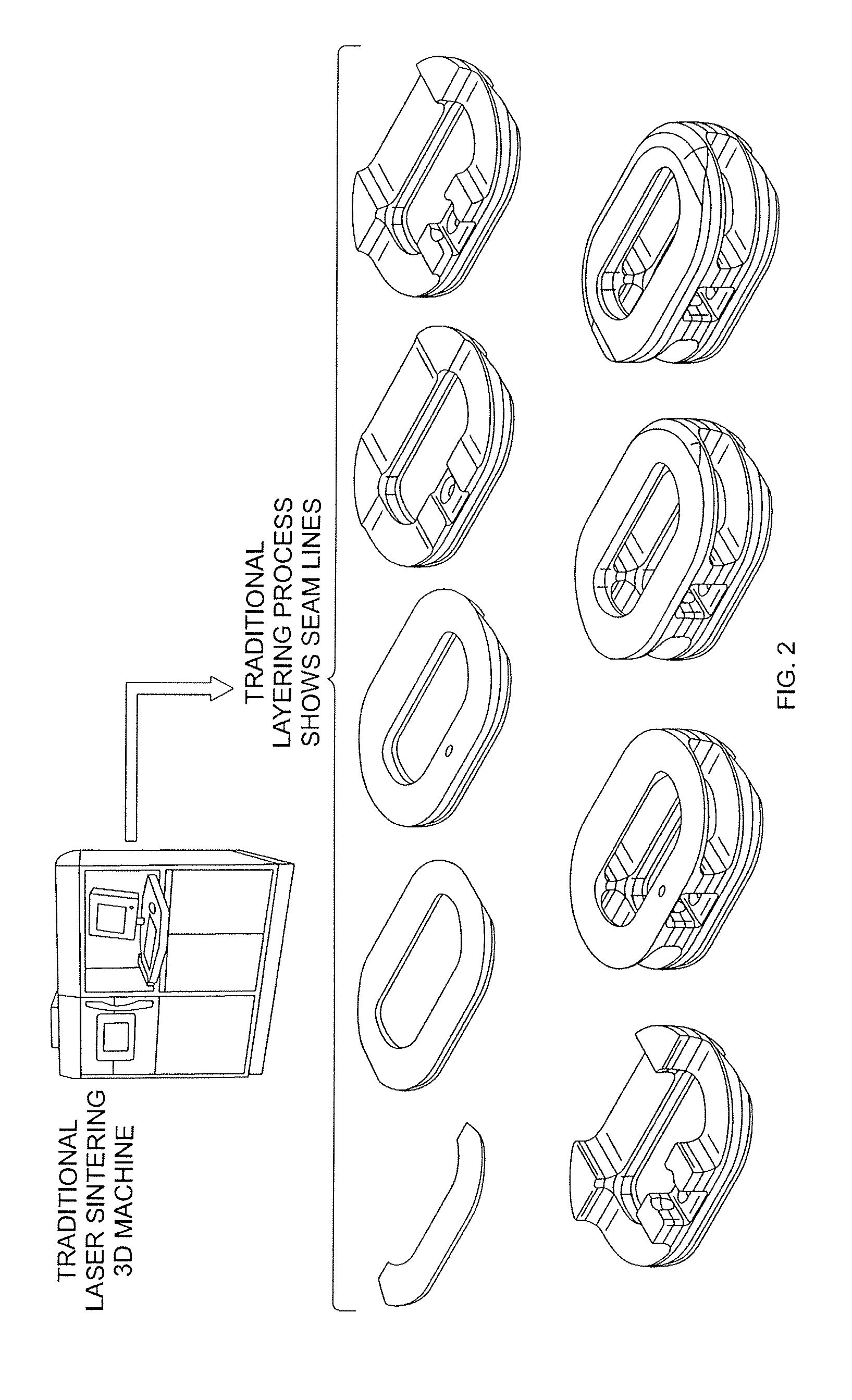

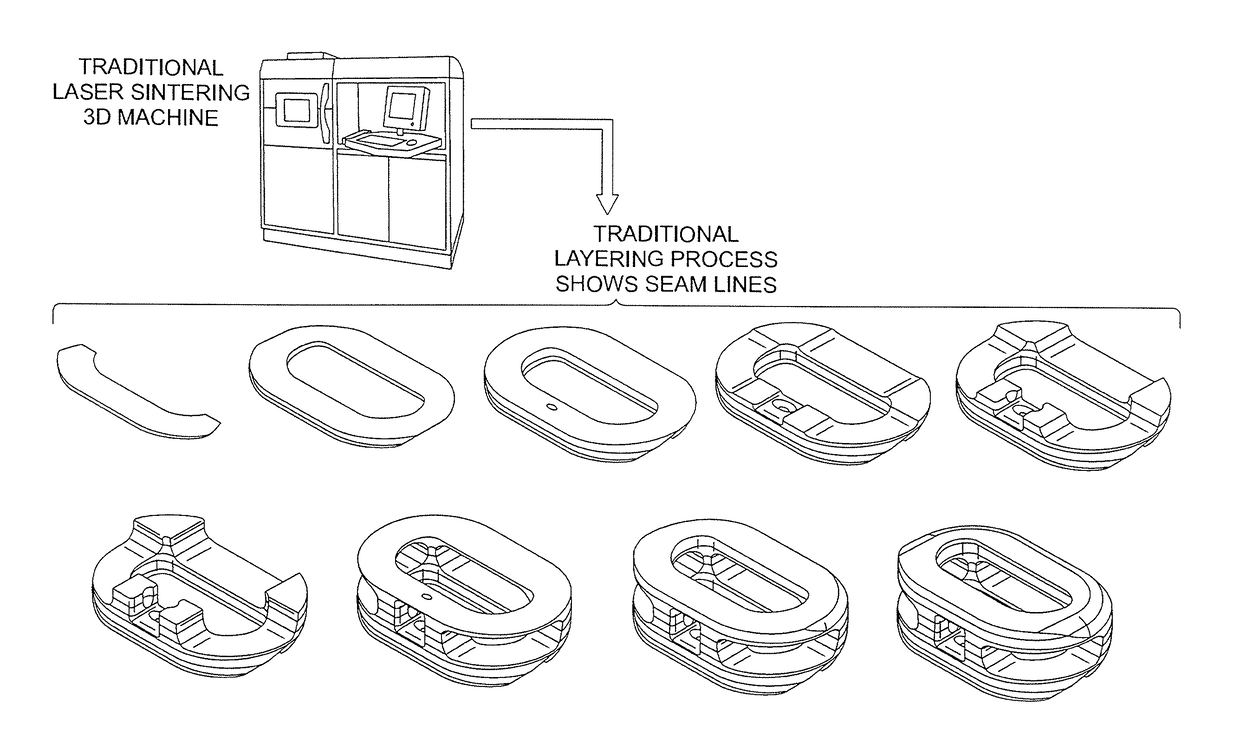

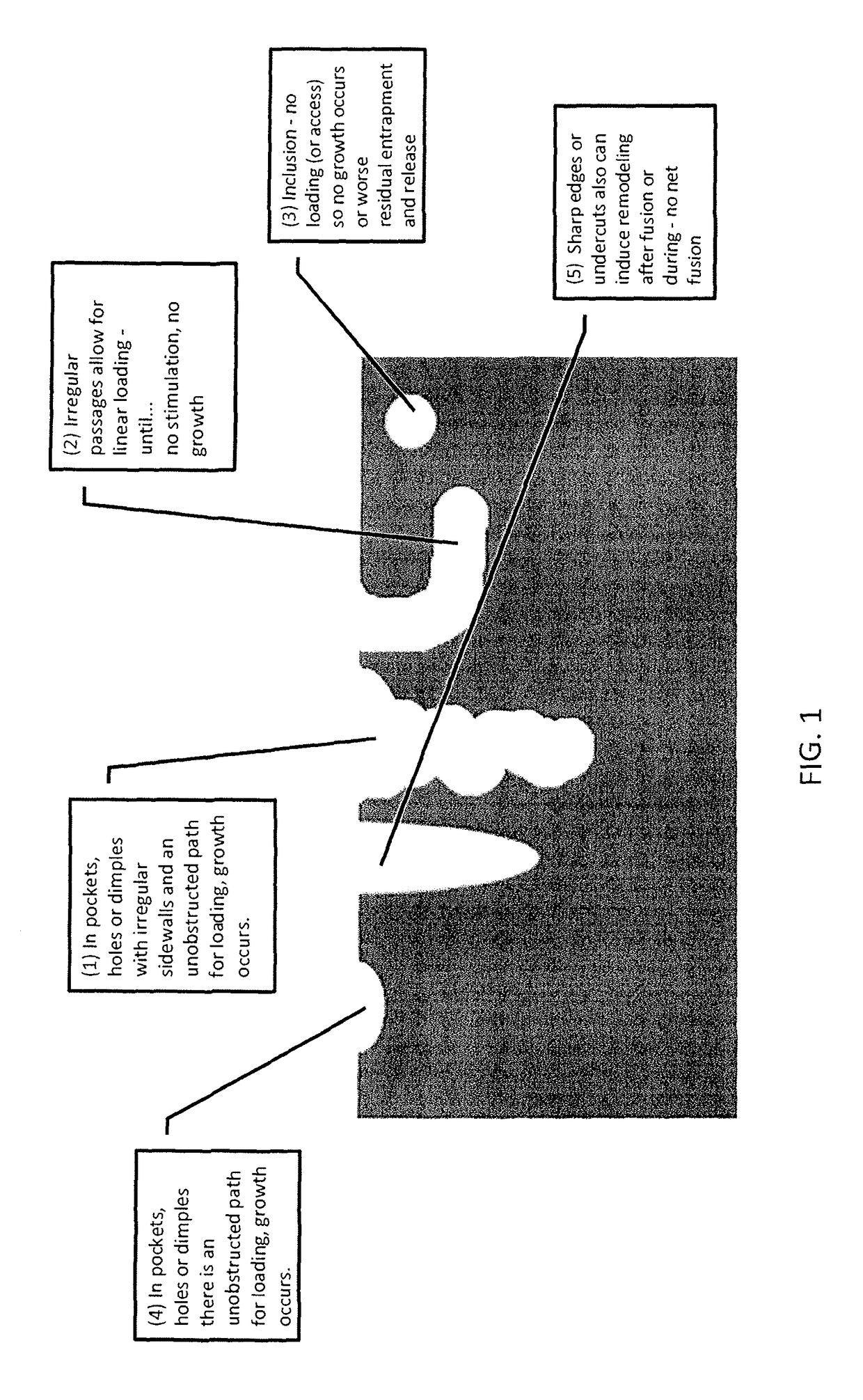

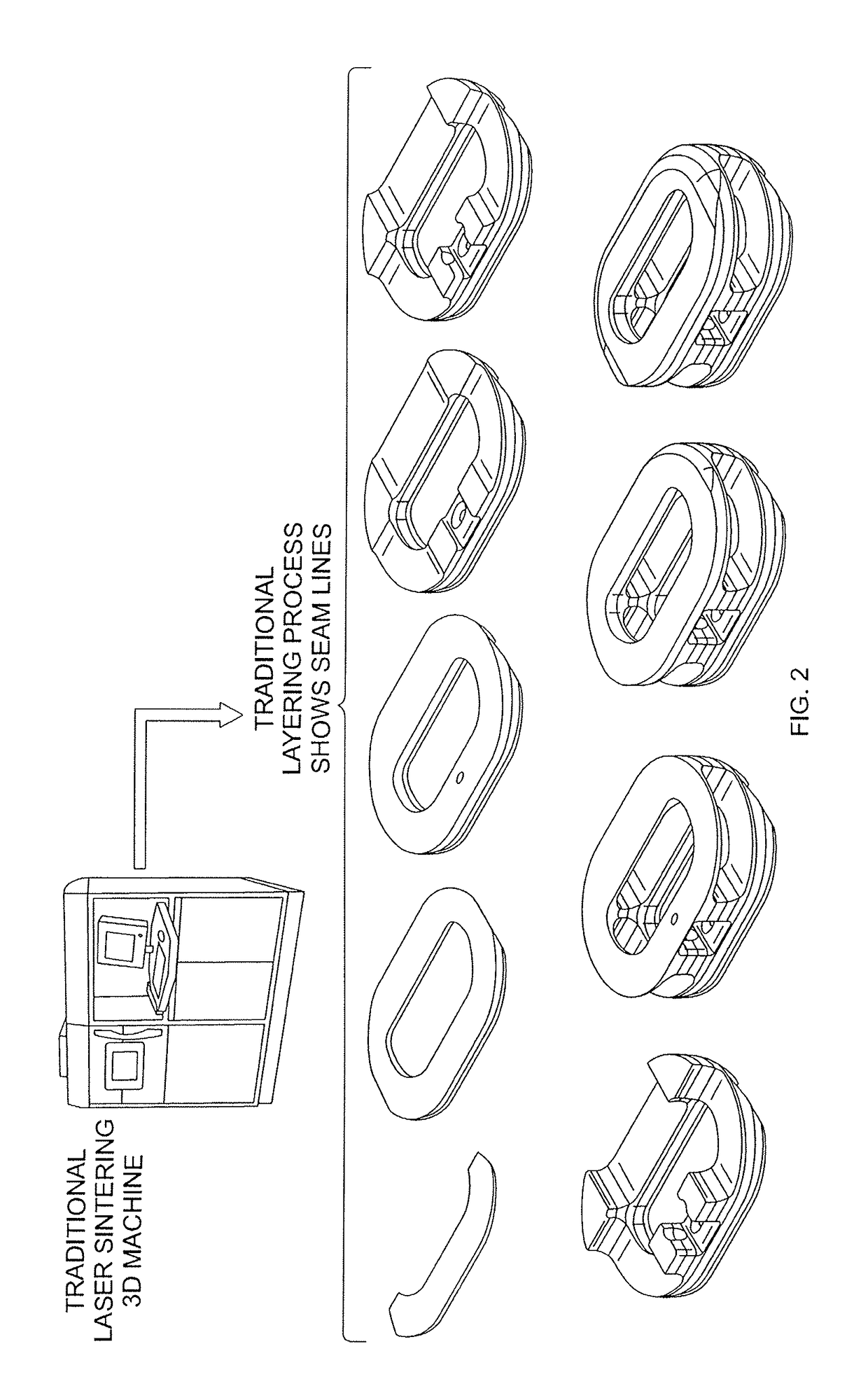

Additive and Subtractive Manufacturing Process for Producing Implants with Homogeneous Body Substantially Free of Pores and Inclusions

ActiveUS20150335434A1Enhance bone bone fusionEnhance bone growth boneAdditive manufacturing apparatusDecorative surface effectsBone growthNanostructure

Implants are formed from a multiple staged process that combines both additive and subtractive techniques. Additive techniques melt powders and fragments of a desired material, then successively layer the molten material into the desired implant shape, without compressing or remelting for homogenization of the layers, thereby producing an implant that is substantially free of pores and inclusions. Subtractive techniques refine implant surfaces to produce a bioactive roughened surface comprised of macro, micro, and nano structural features that facilitate bone growth and fusion.

Owner:TITAN SPINE

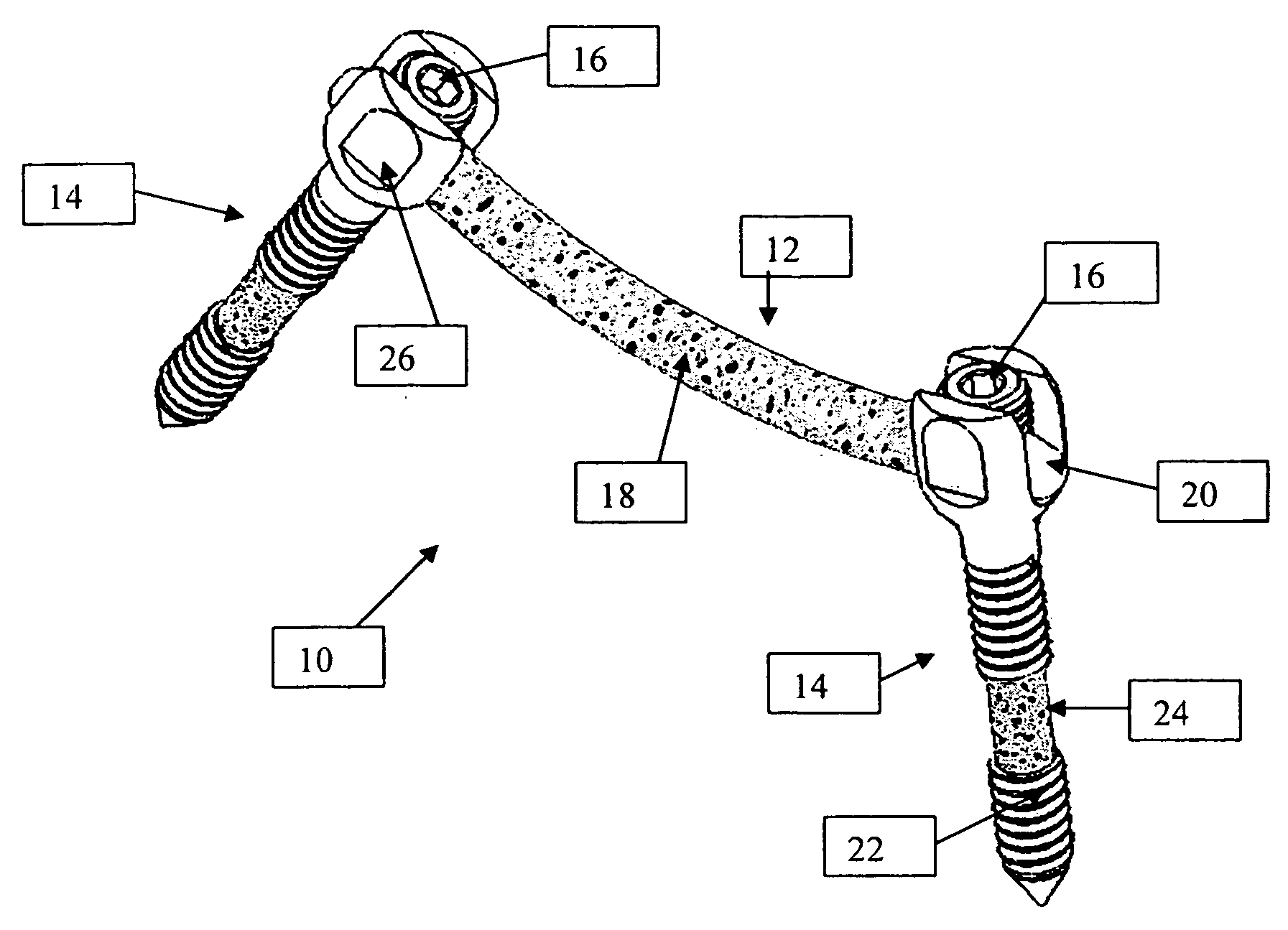

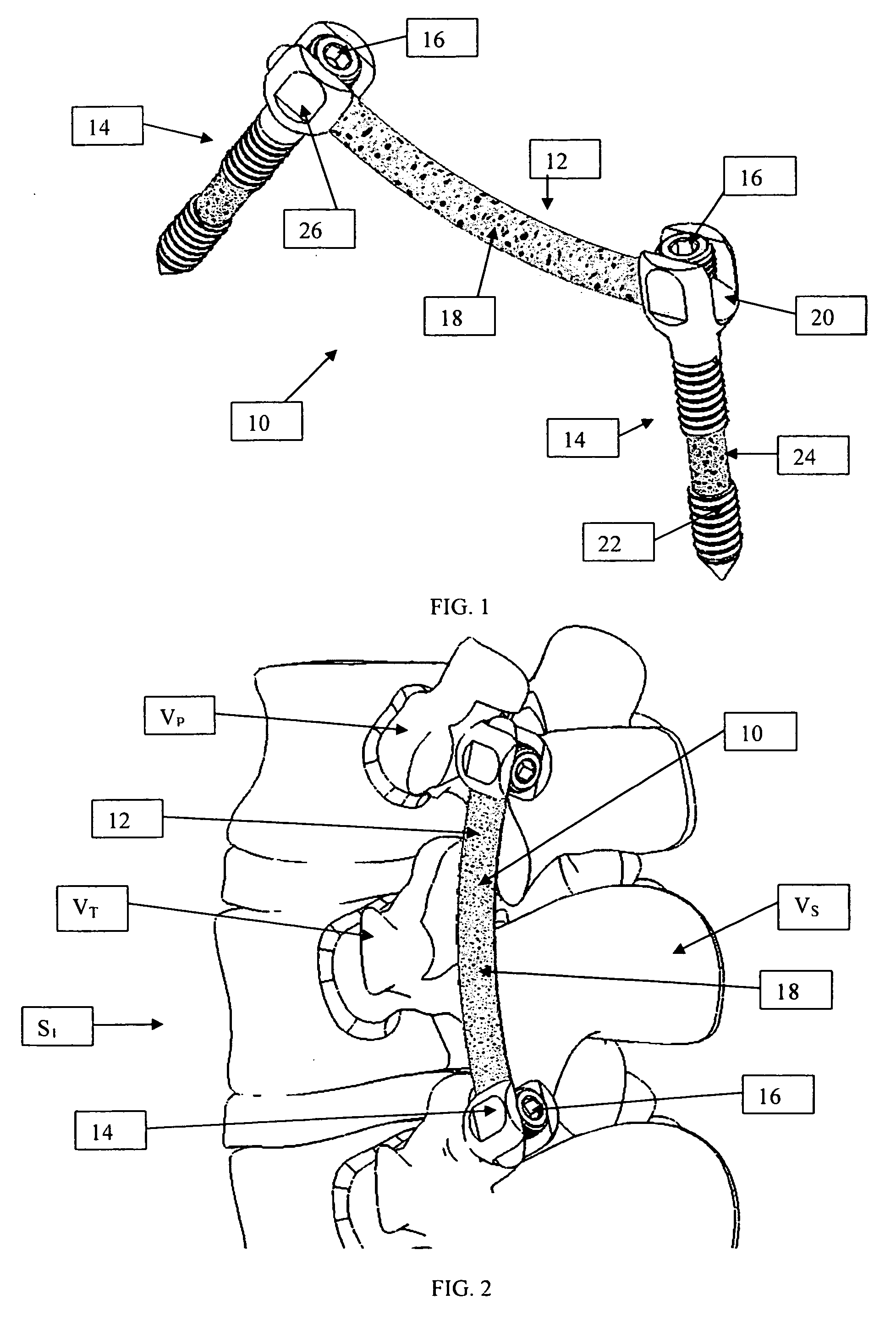

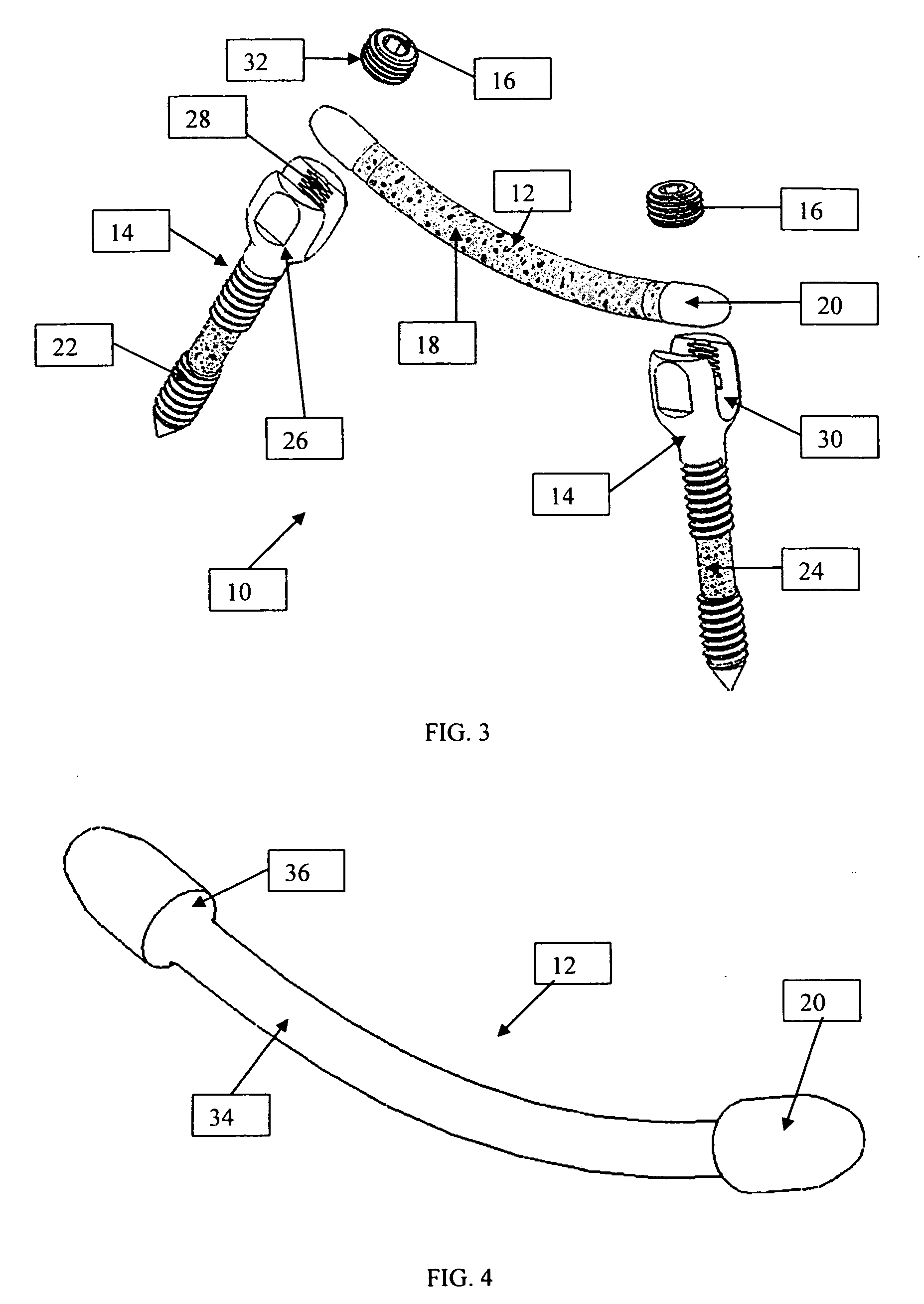

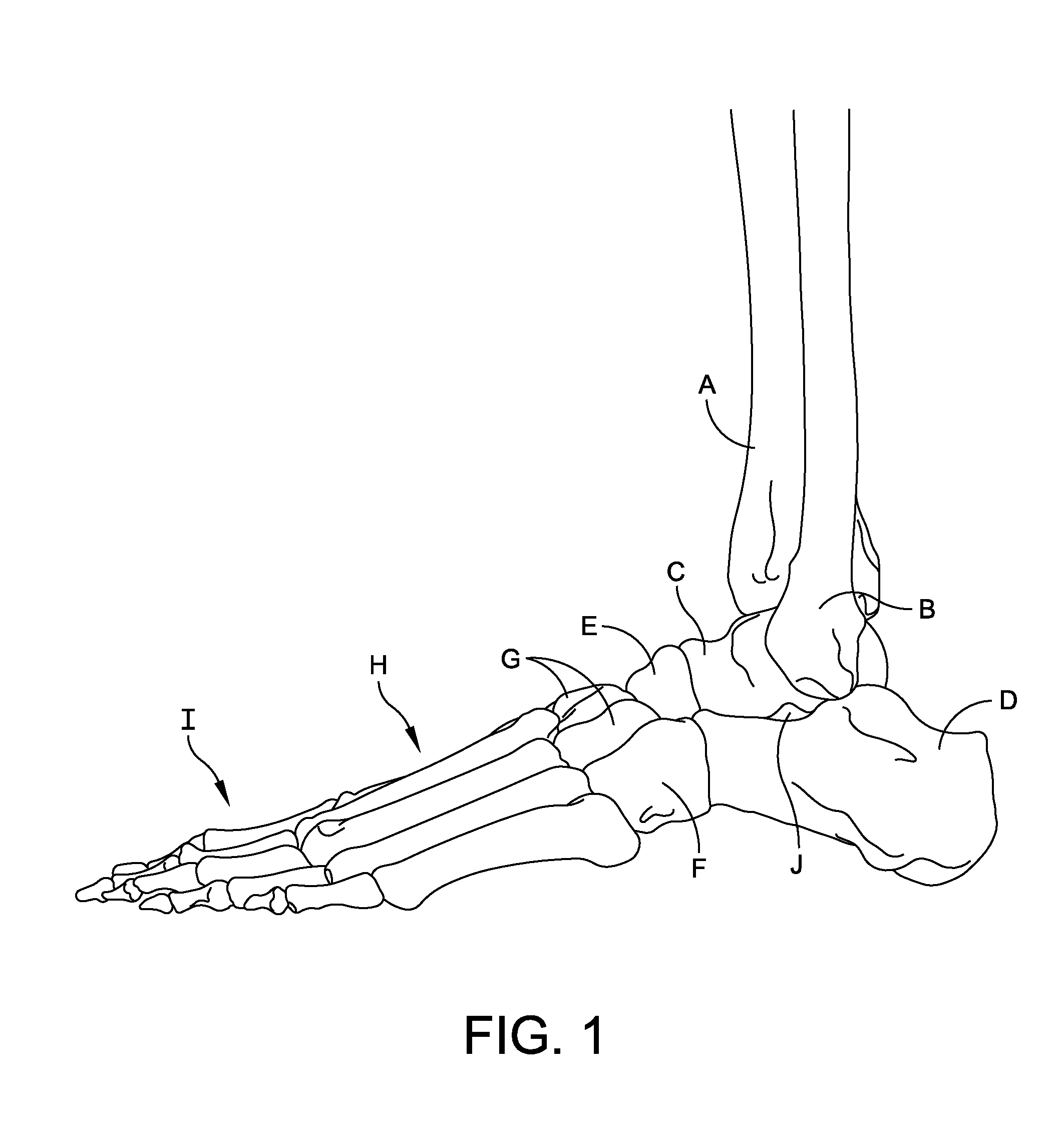

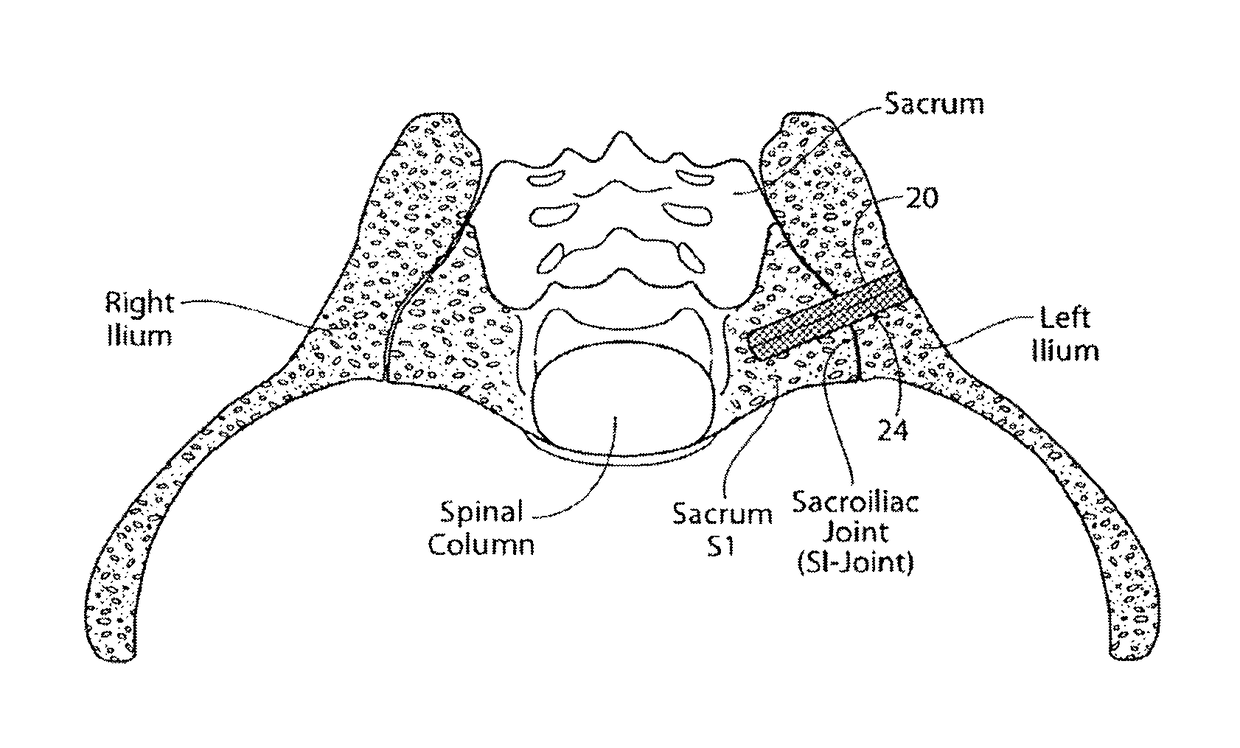

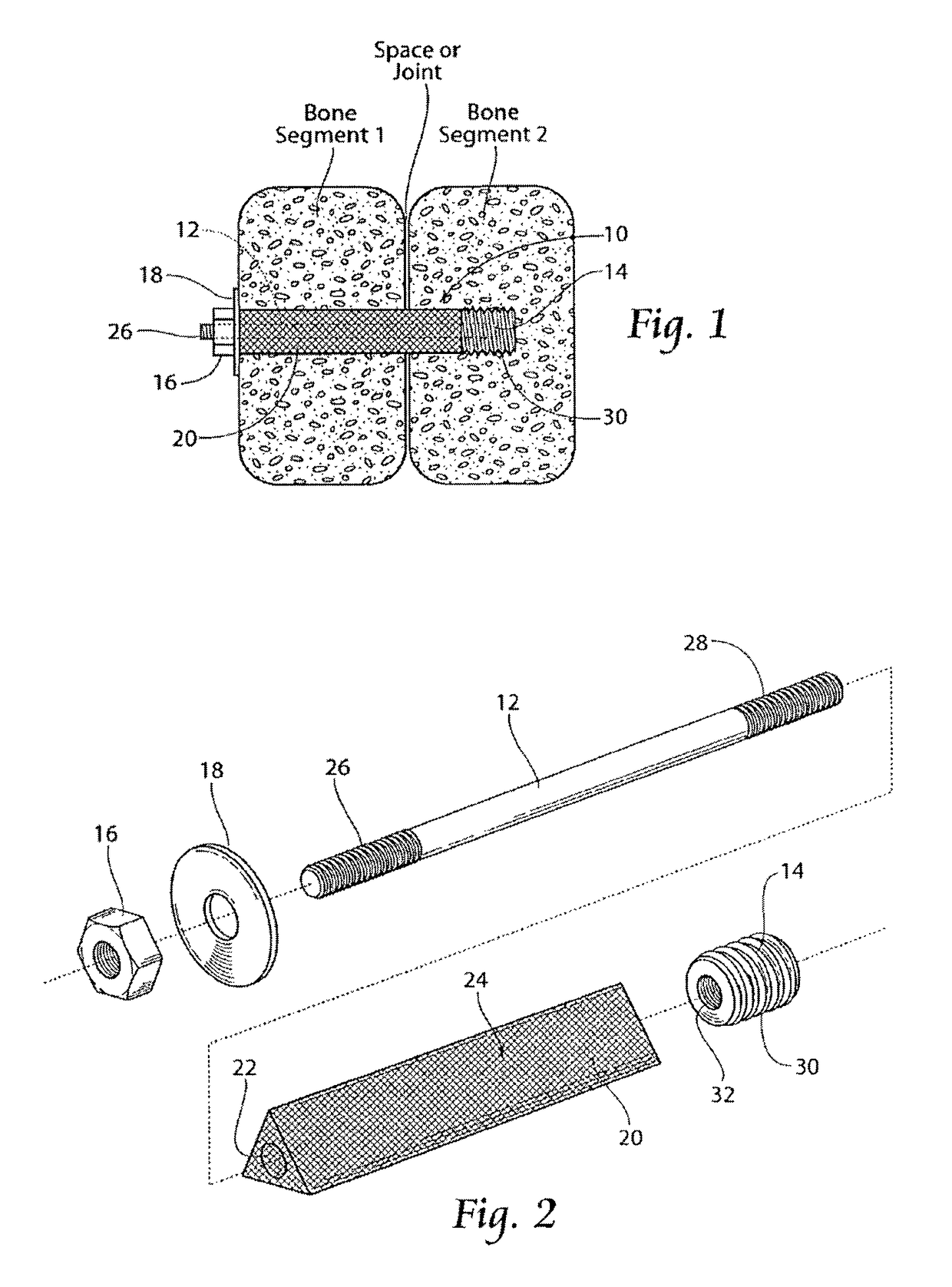

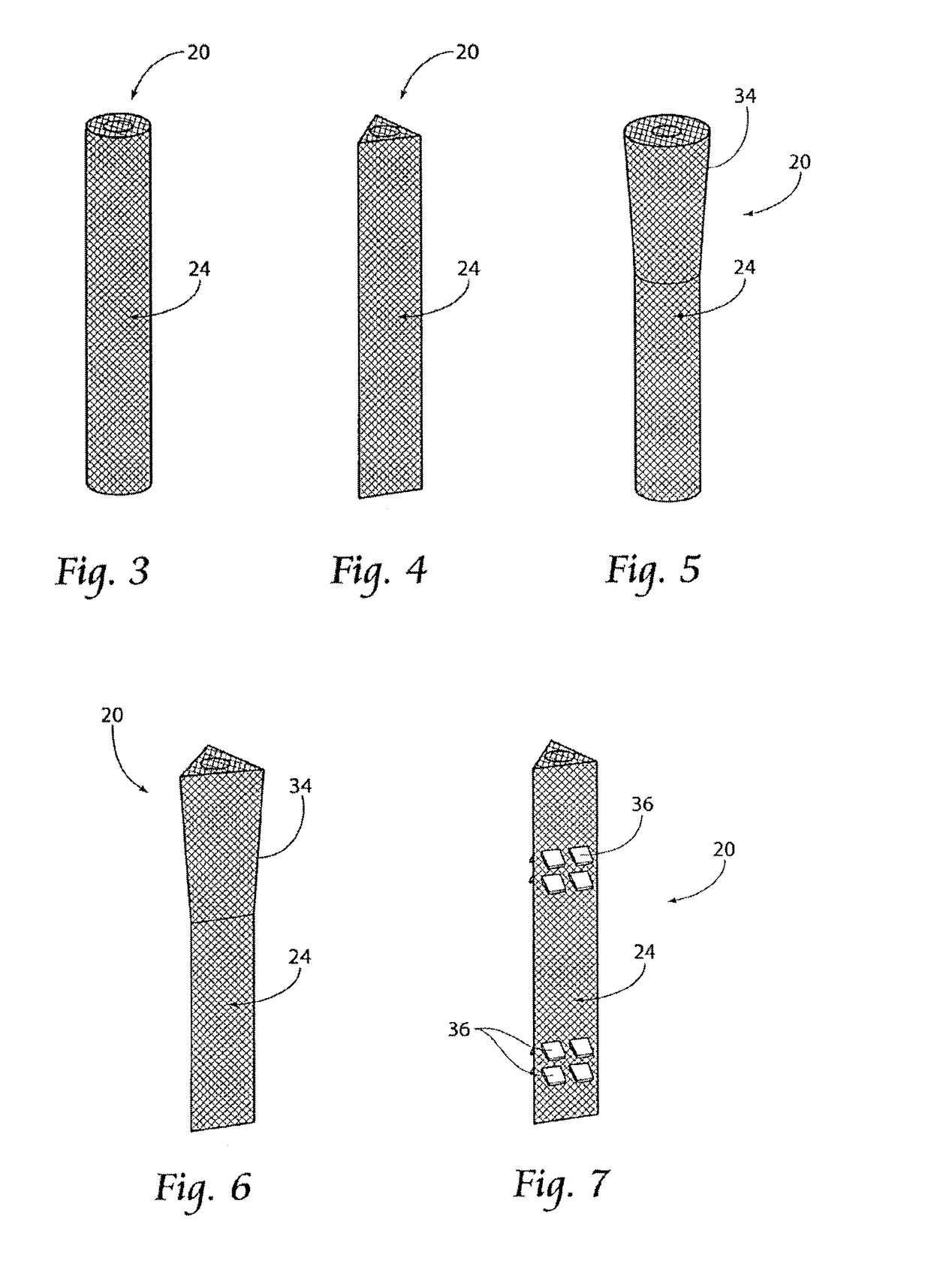

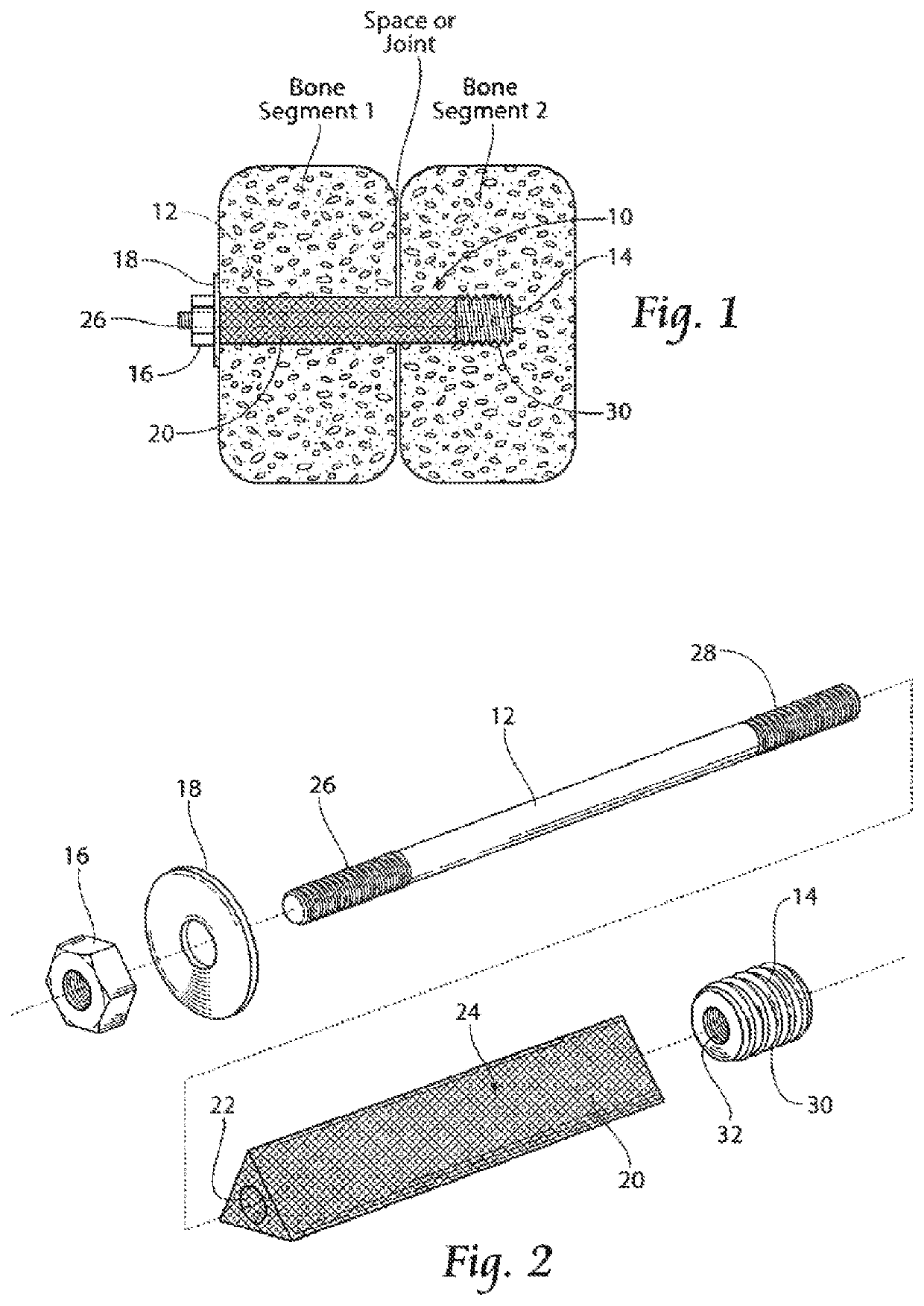

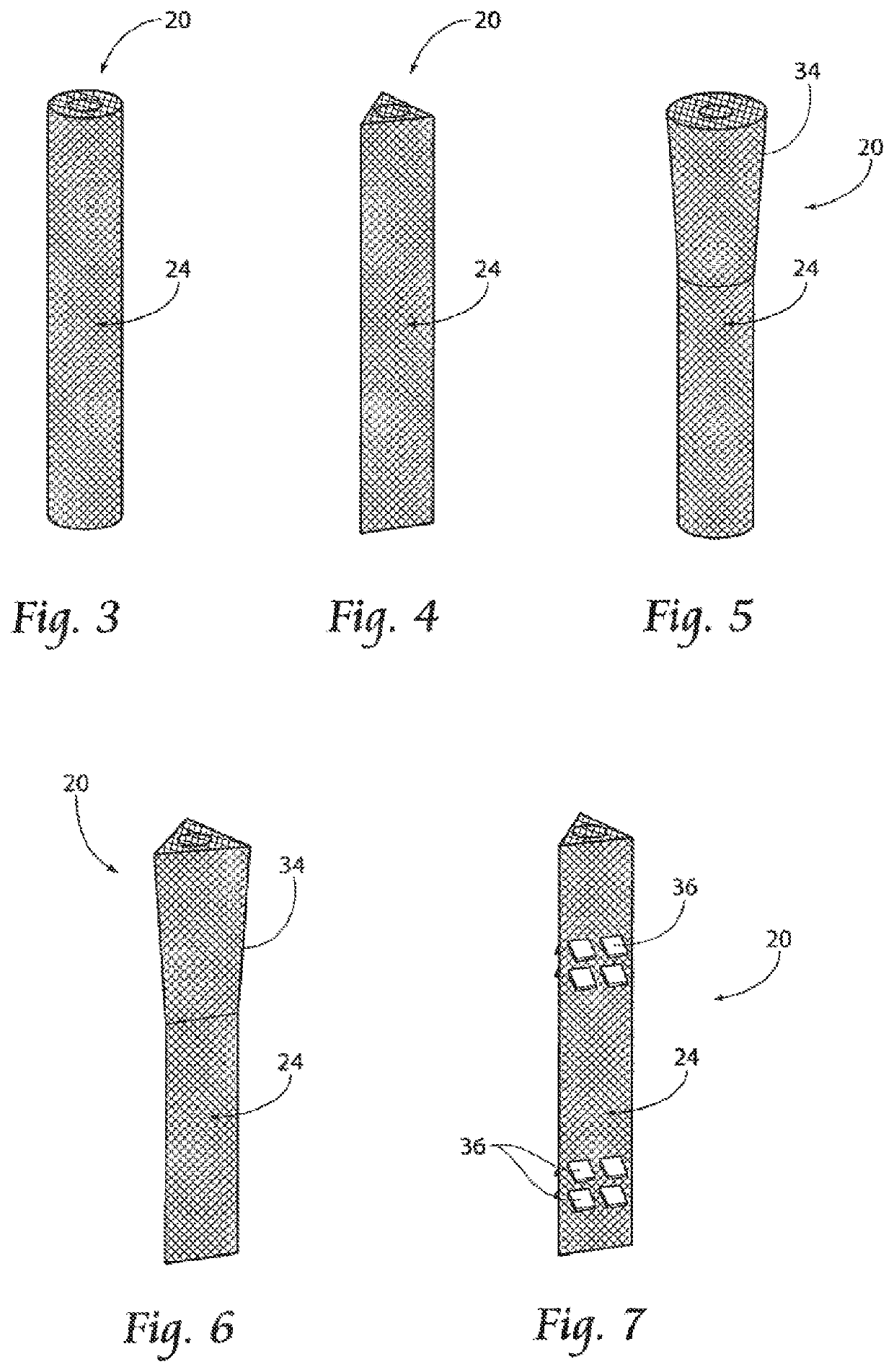

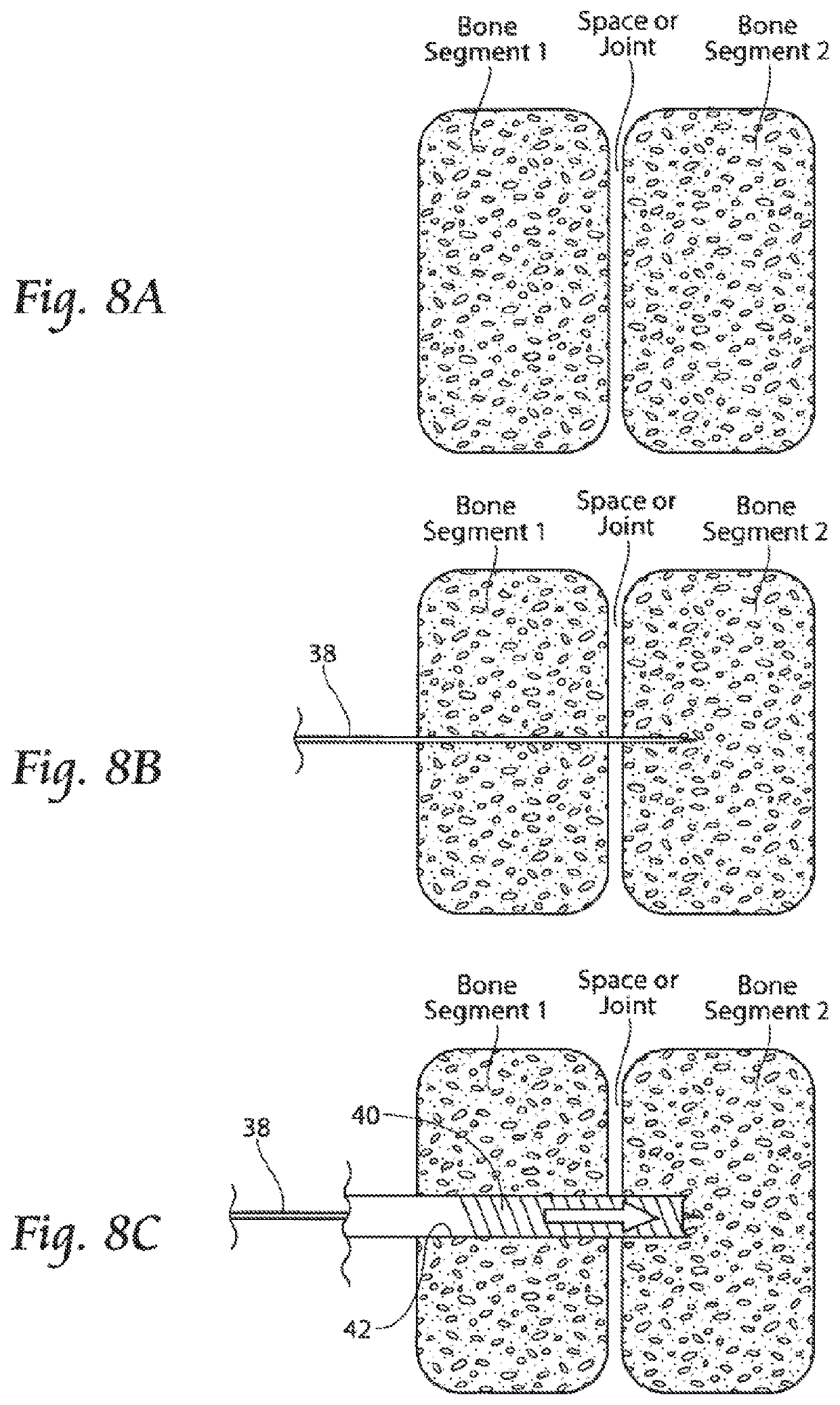

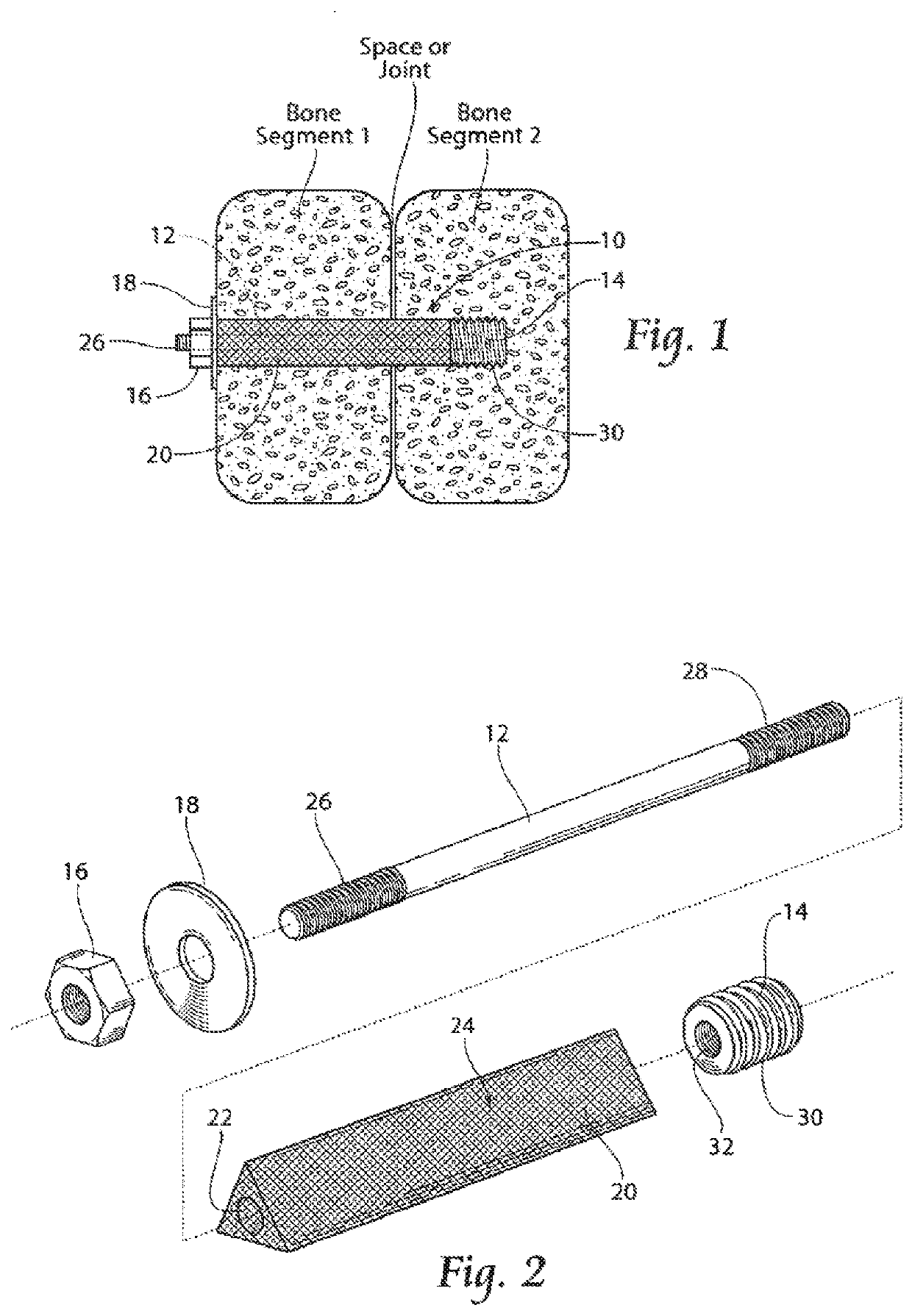

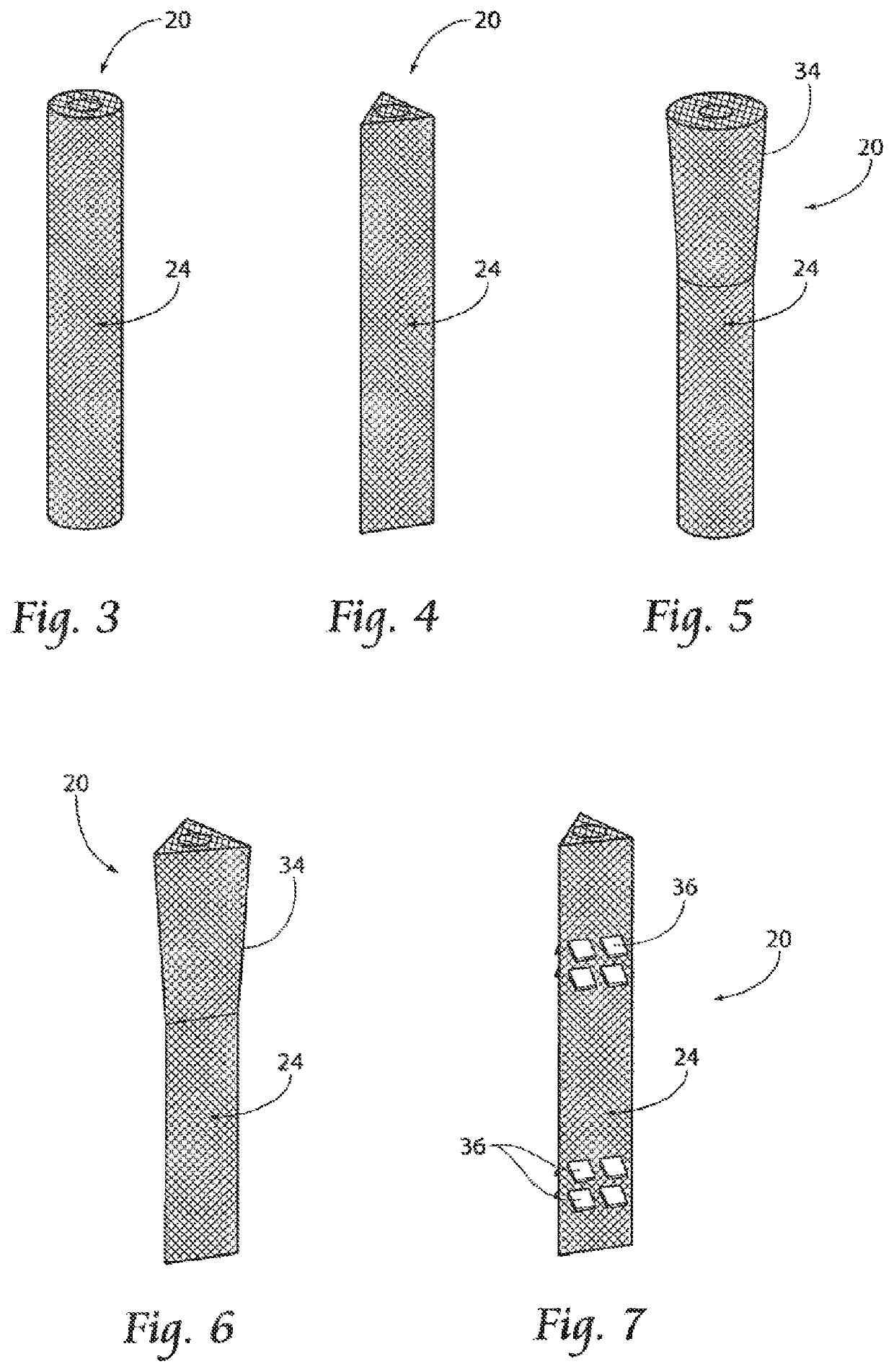

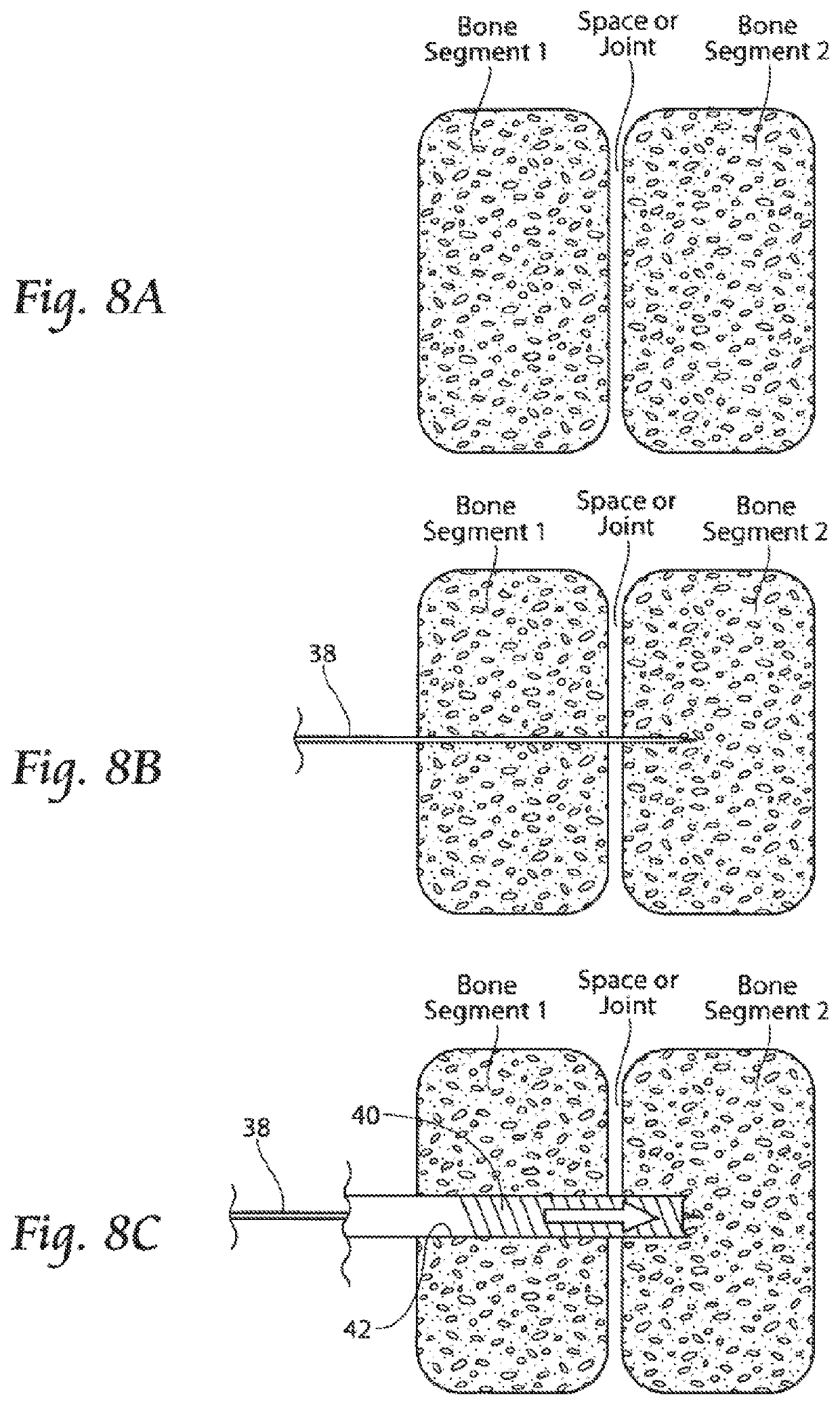

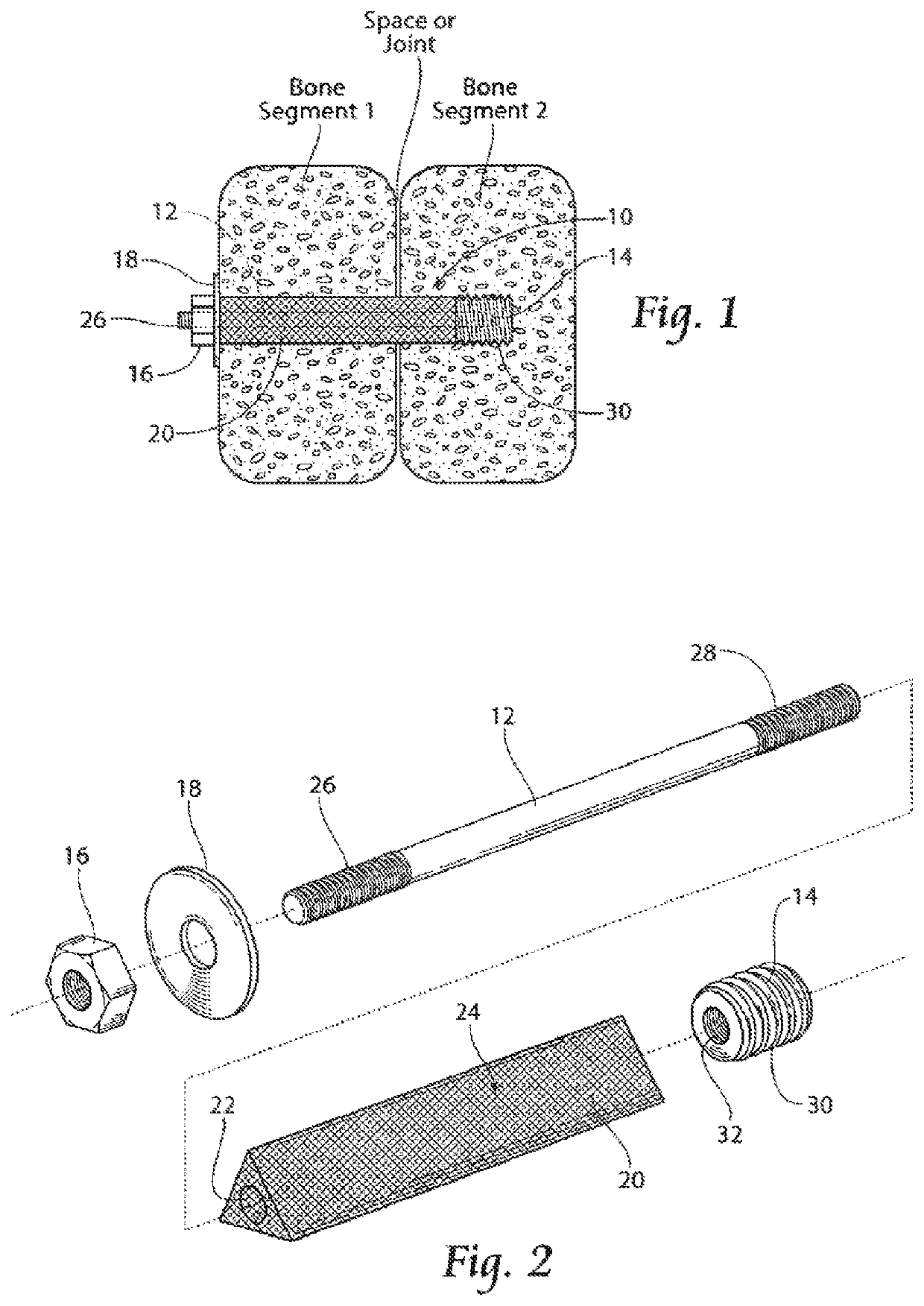

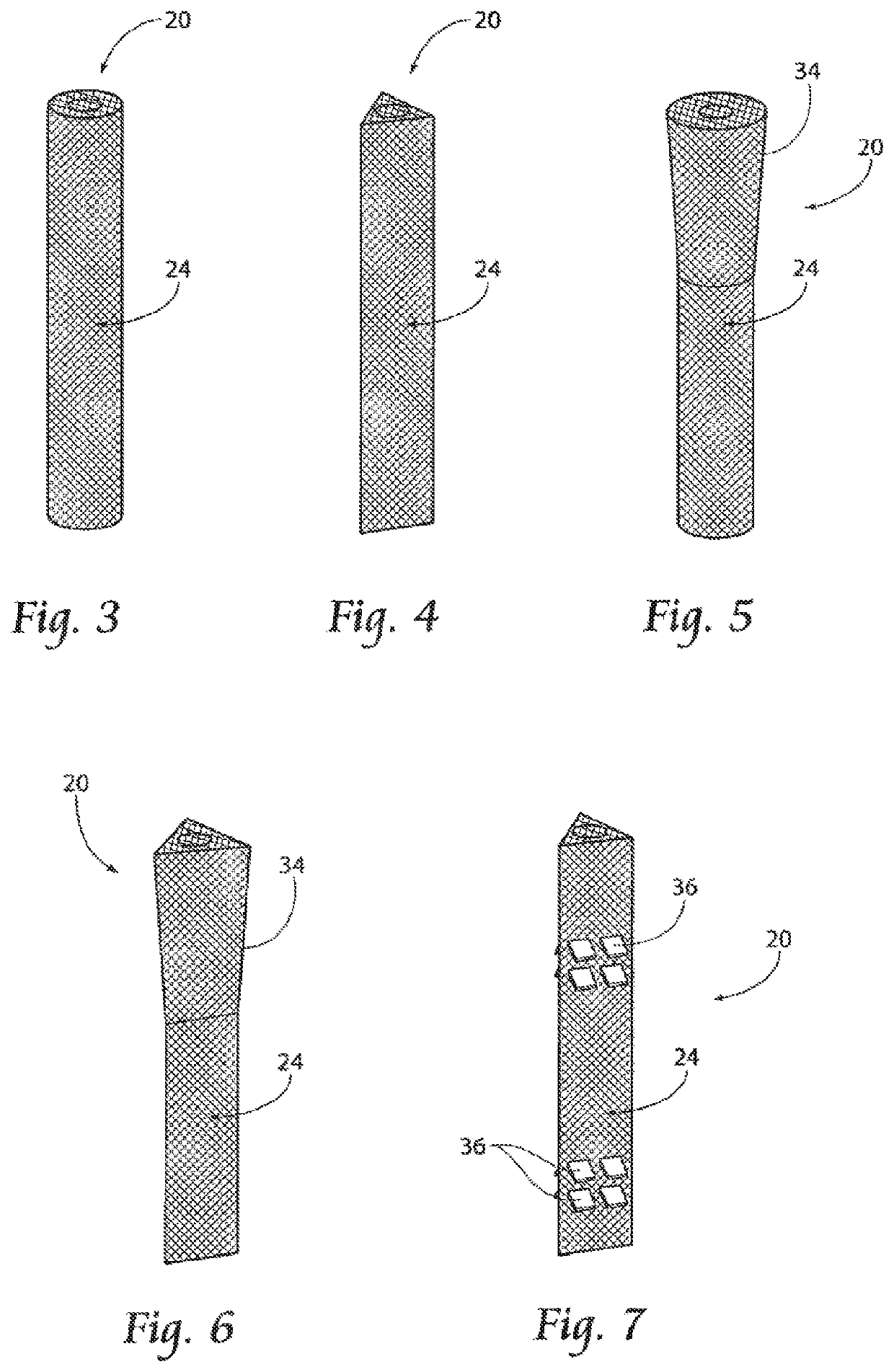

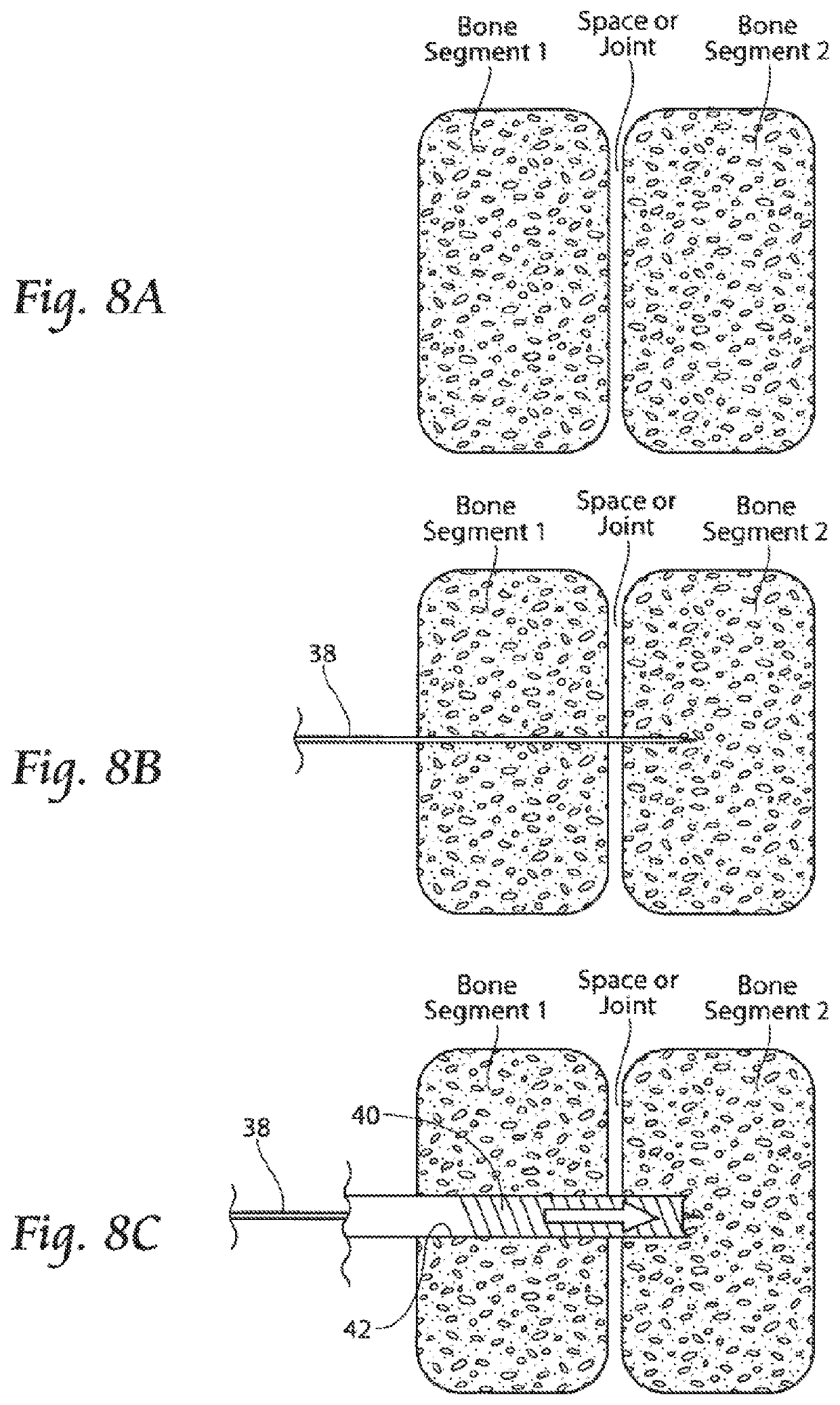

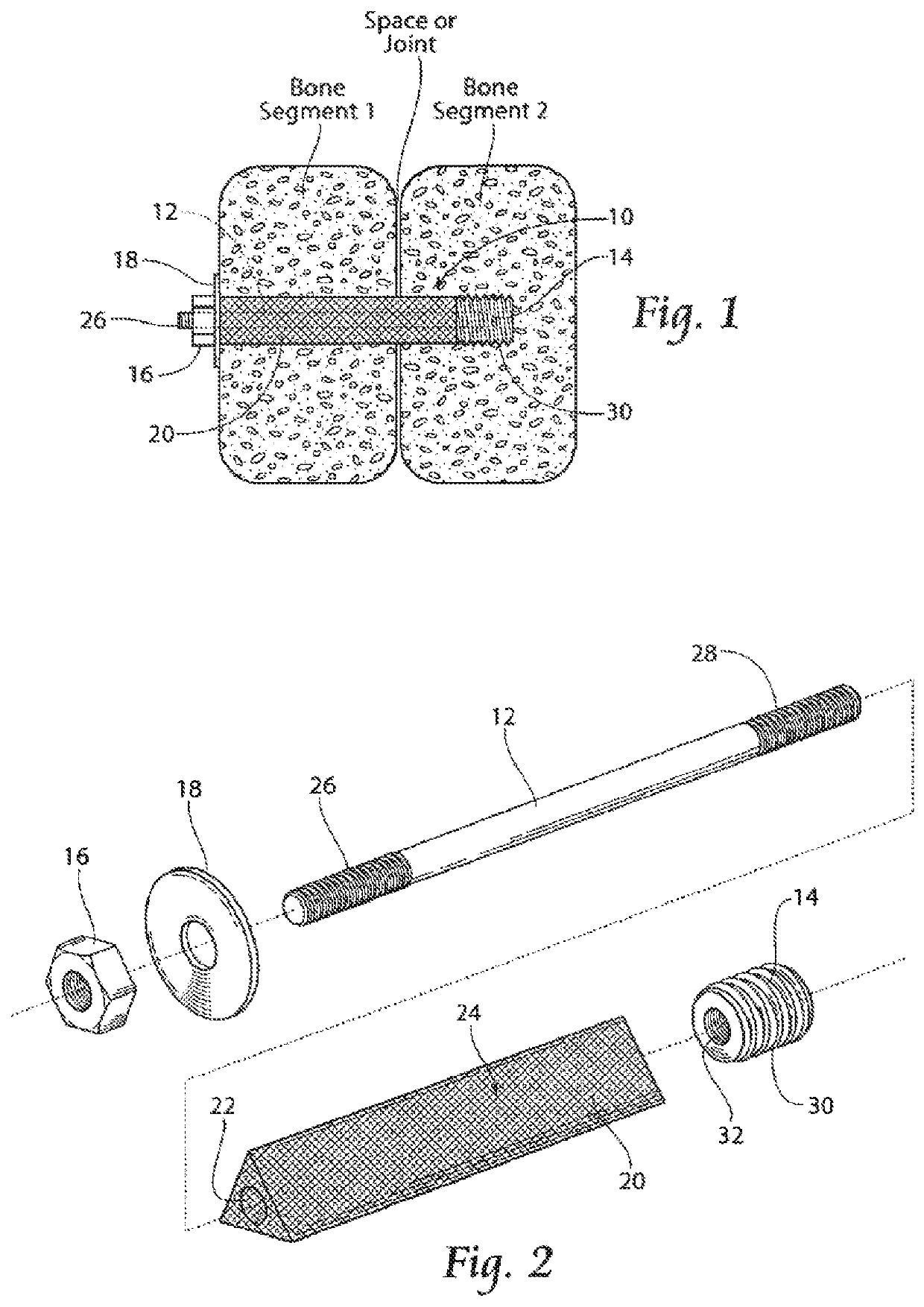

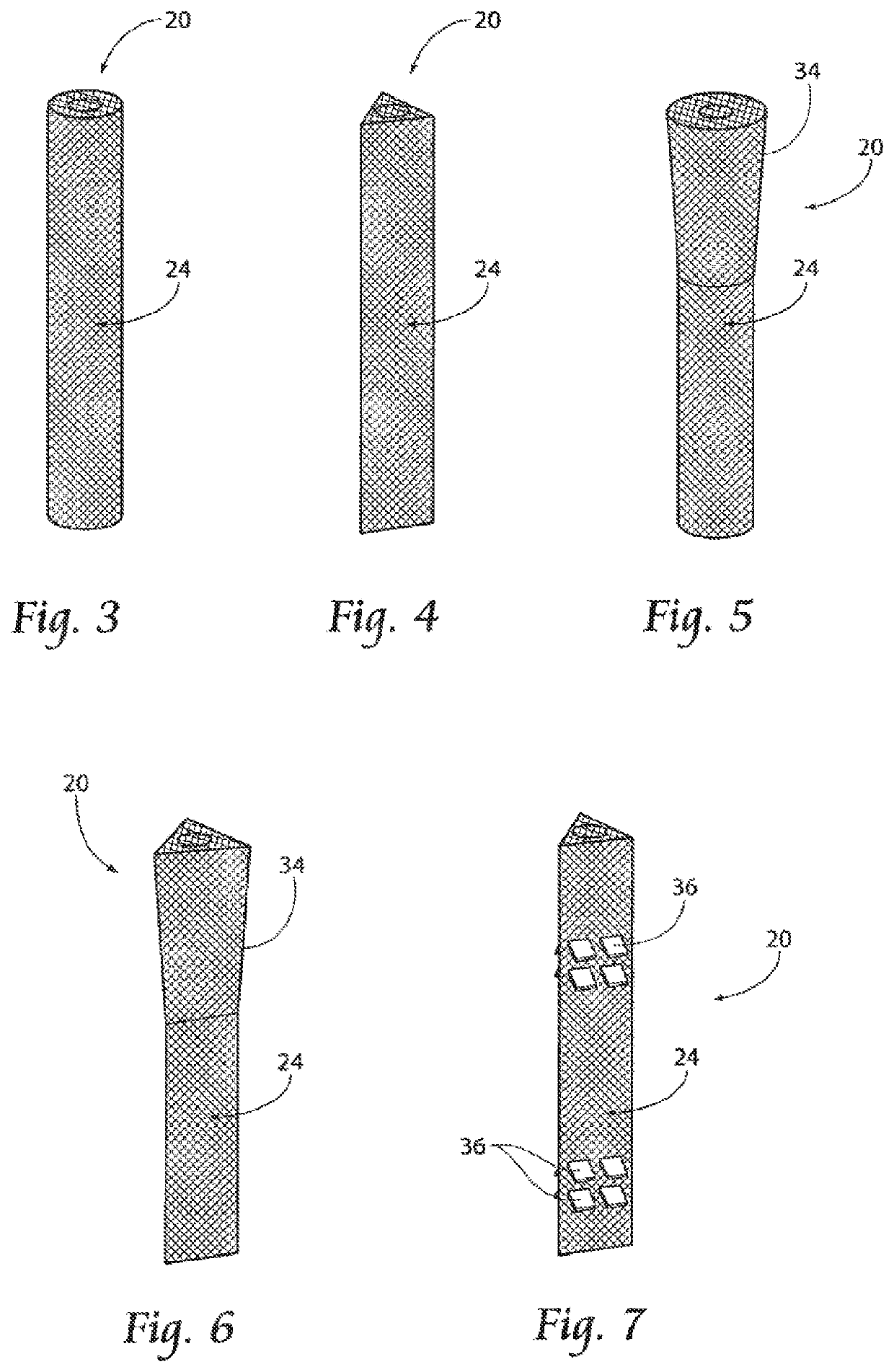

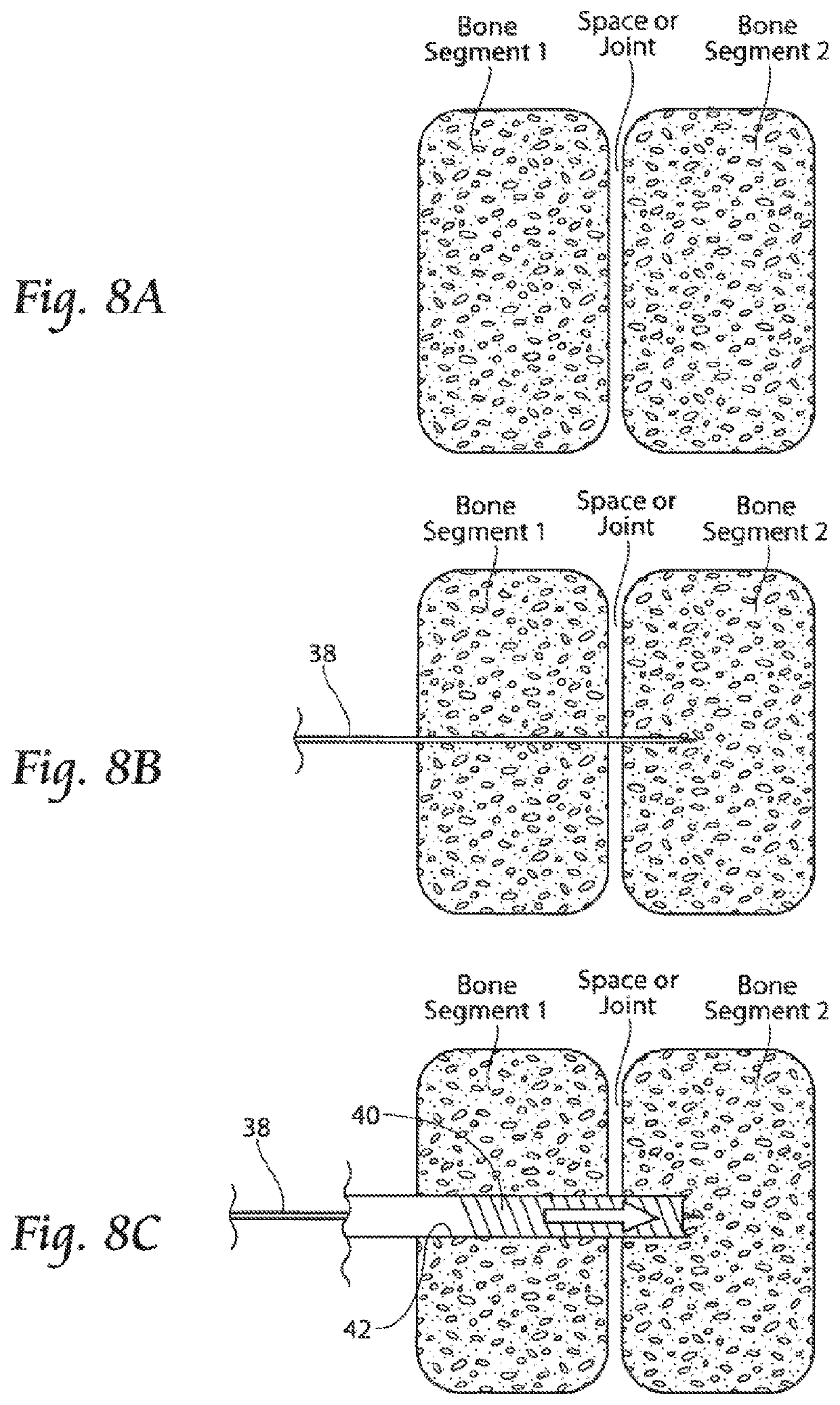

Apparatus, systems, and methods for the fixation or fusion of bone

ActiveUS9949843B2Easy to fixImprove fusionInternal osteosythesisAnkle jointsLumbar facet jointIntervertebral disc

Assemblies of one or more implant structures make possible the achievement of diverse interventions involving the fusion and / or stabilization of the SI-joint and / or lumbar and sacral vertebra in a non-invasive manner, with minimal incision, and without the necessitating the removing the intervertebral disc. The representative lumbar spine interventions, which can be performed on adults or children, include, but are not limited to, SI-joint fusion or fixation; lumbar interbody fusion; translaminar lumbar fusion; lumbar facet fusion; trans-iliac lumbar fusion; and the stabilization of a spondylolisthesis.

Owner:SI BONE INC

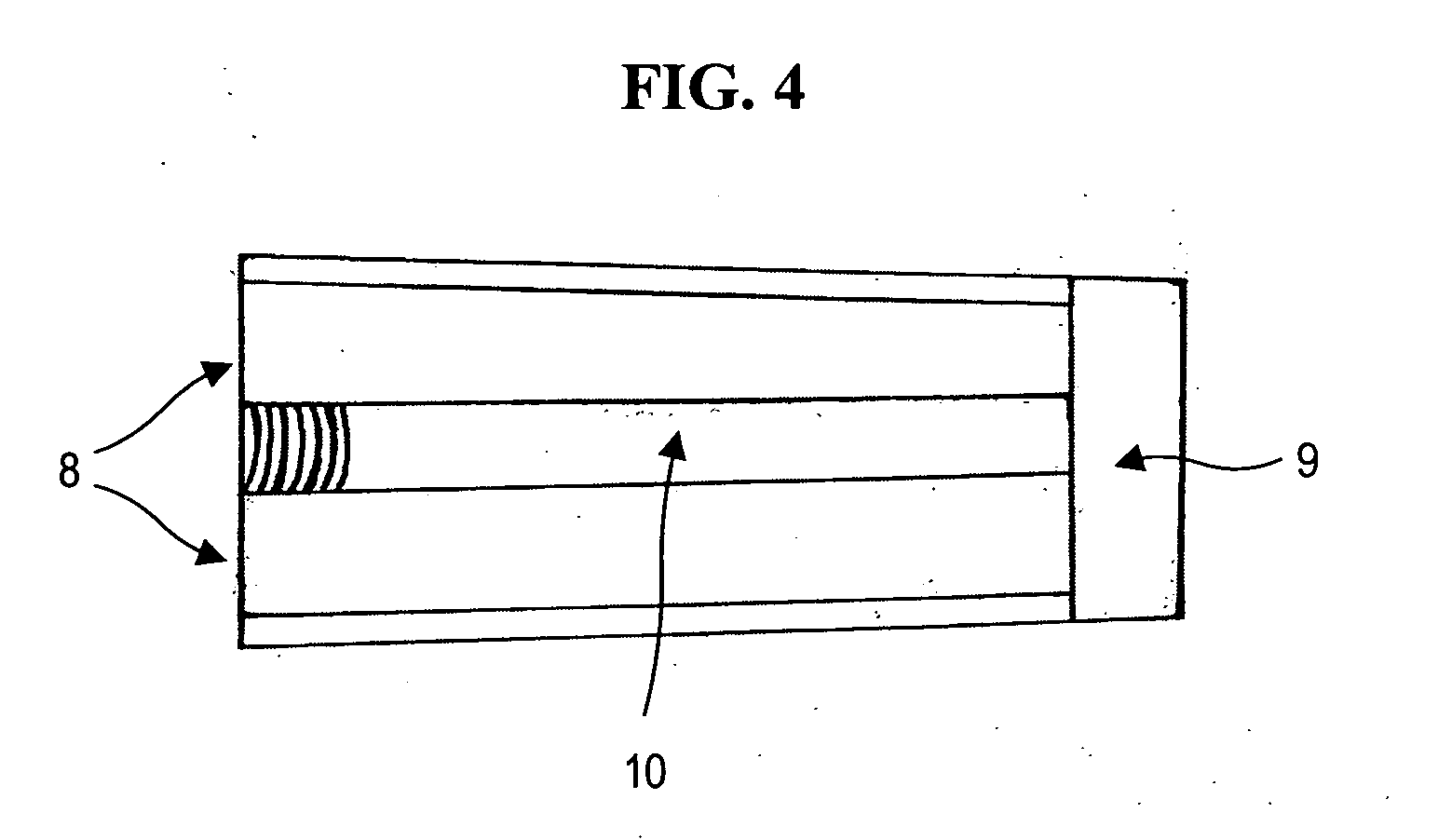

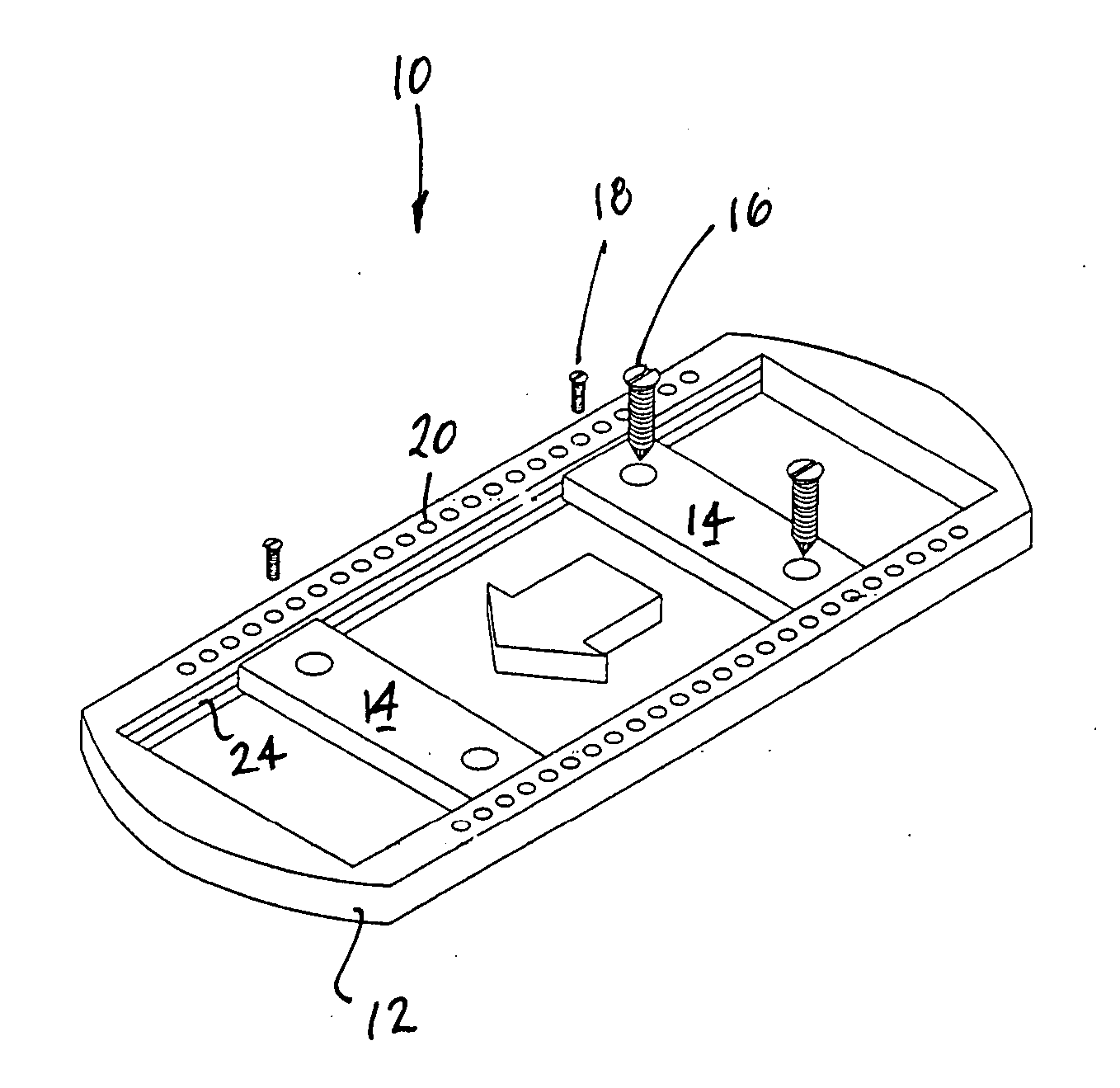

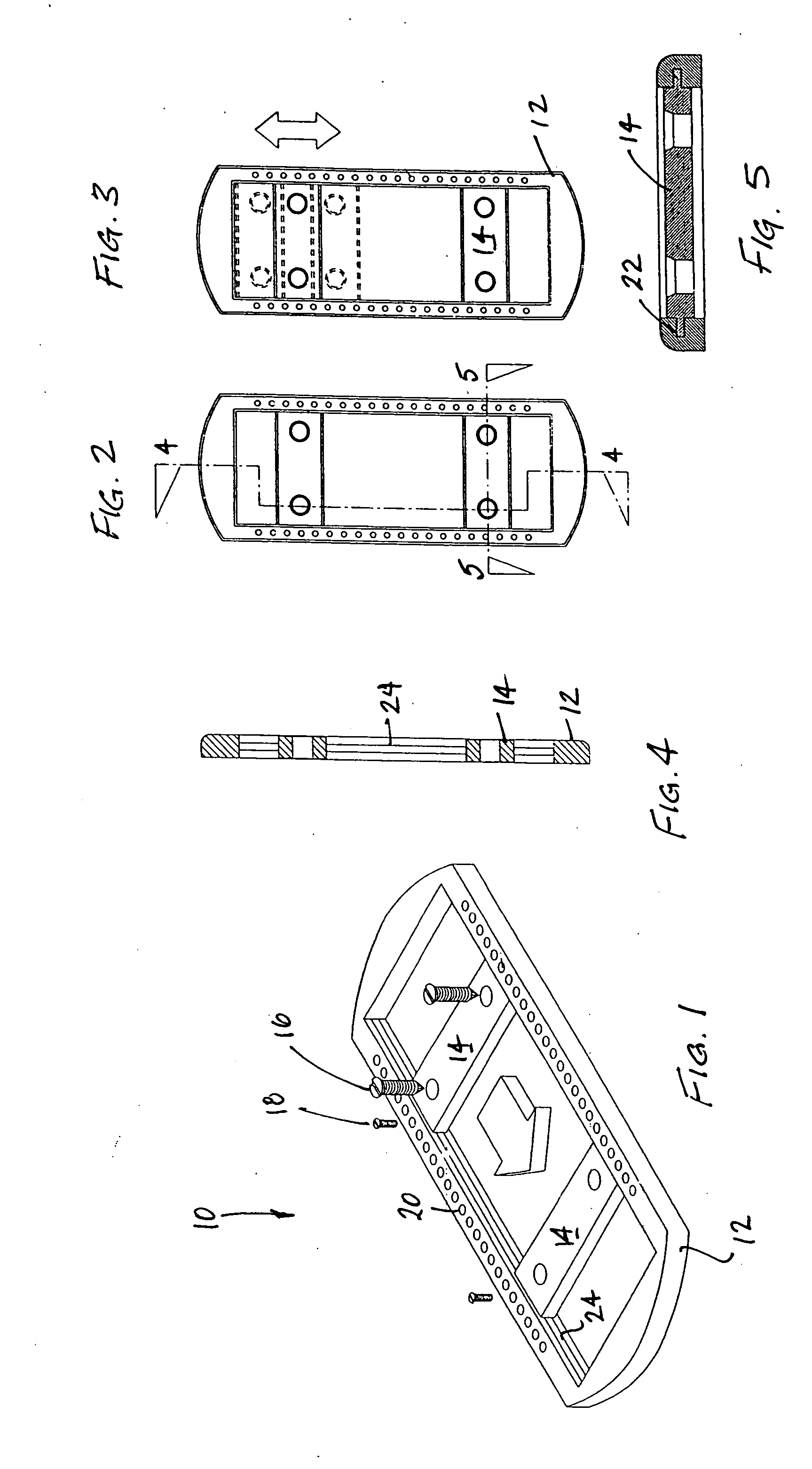

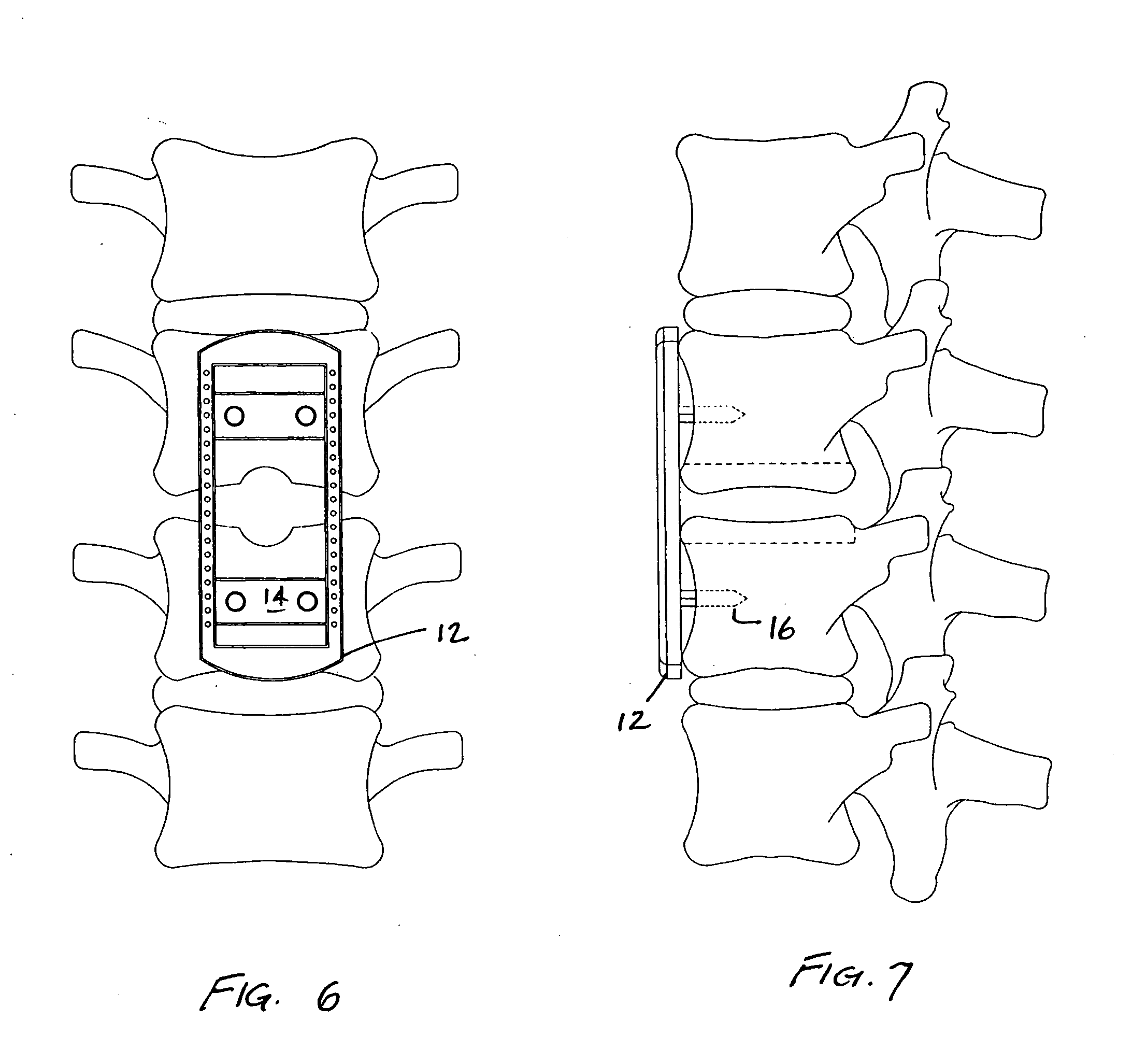

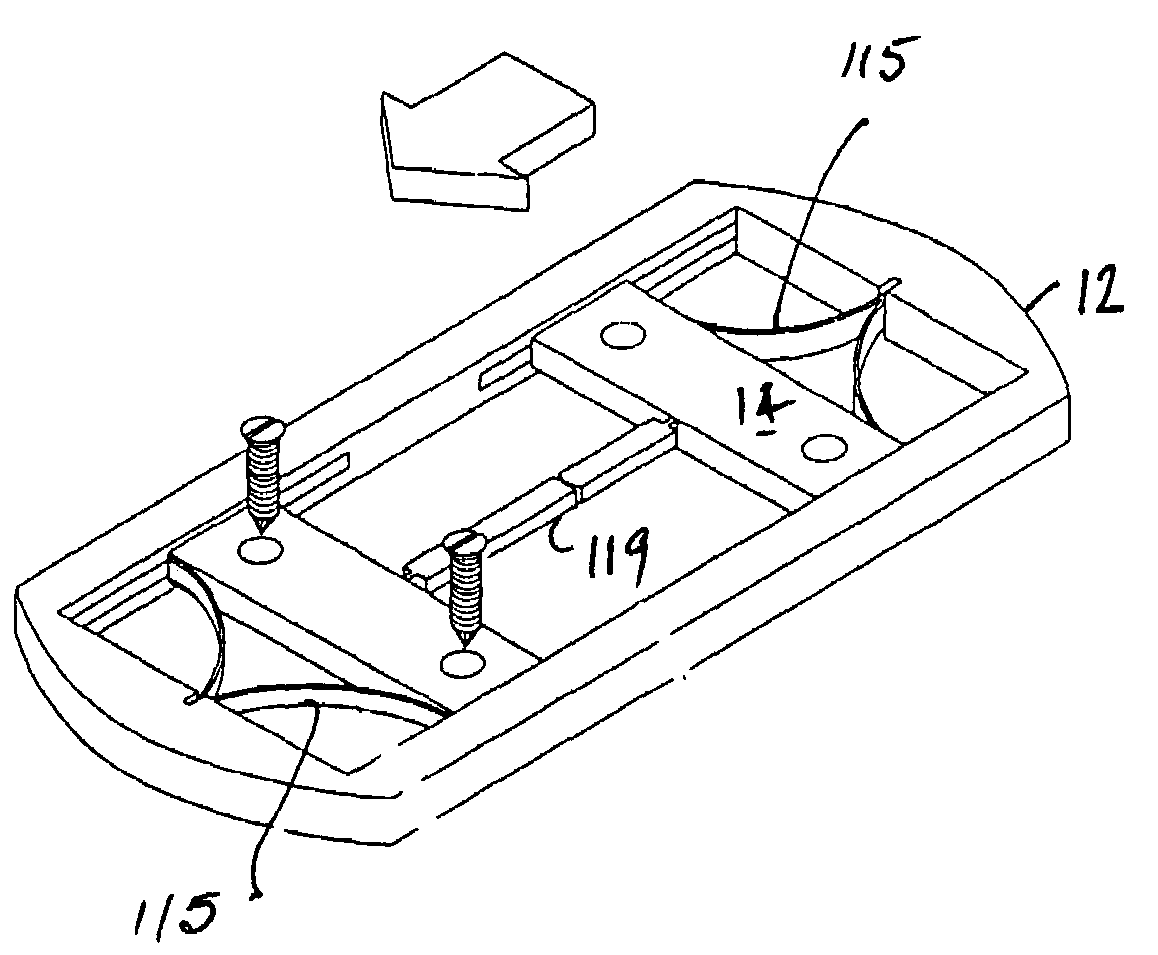

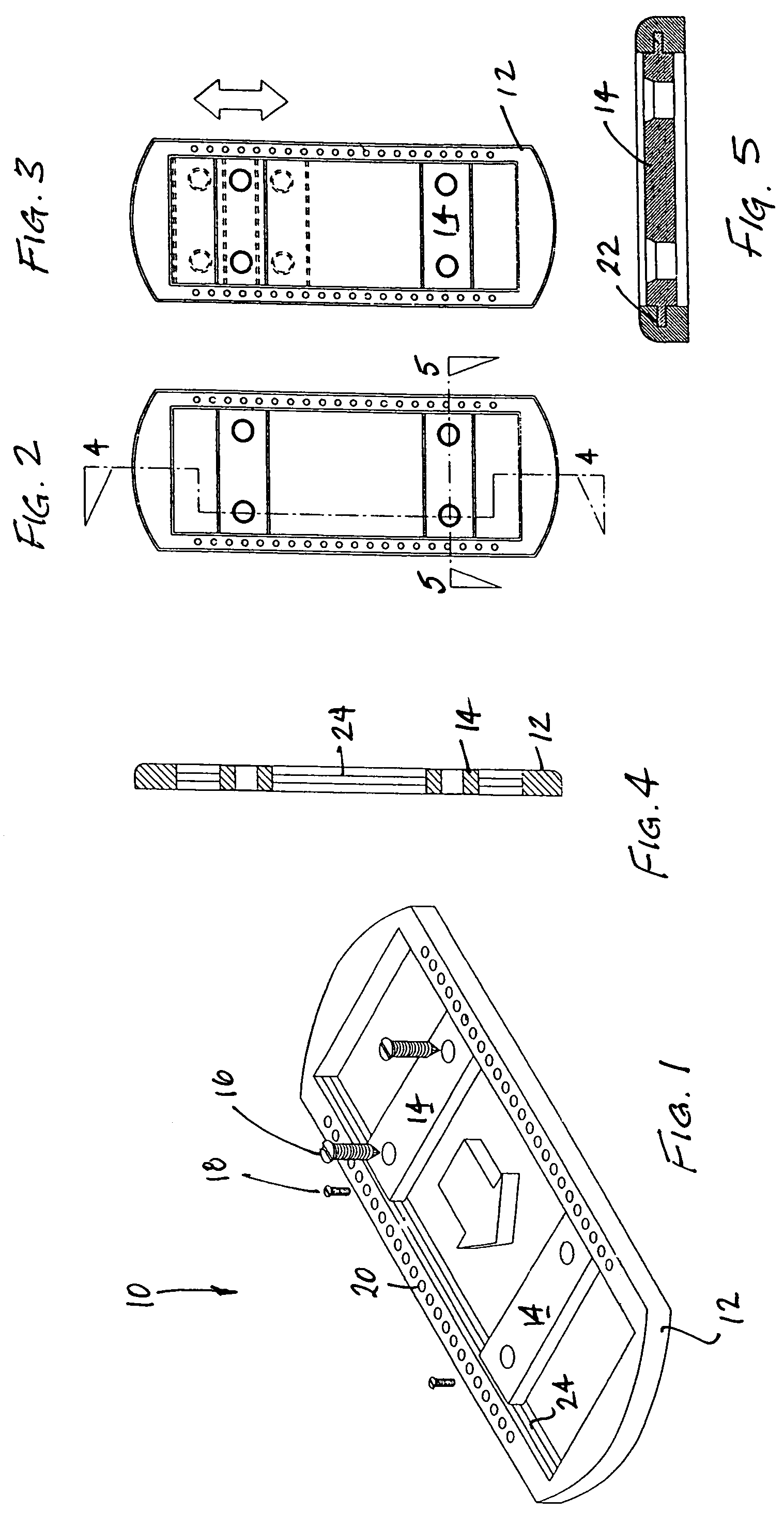

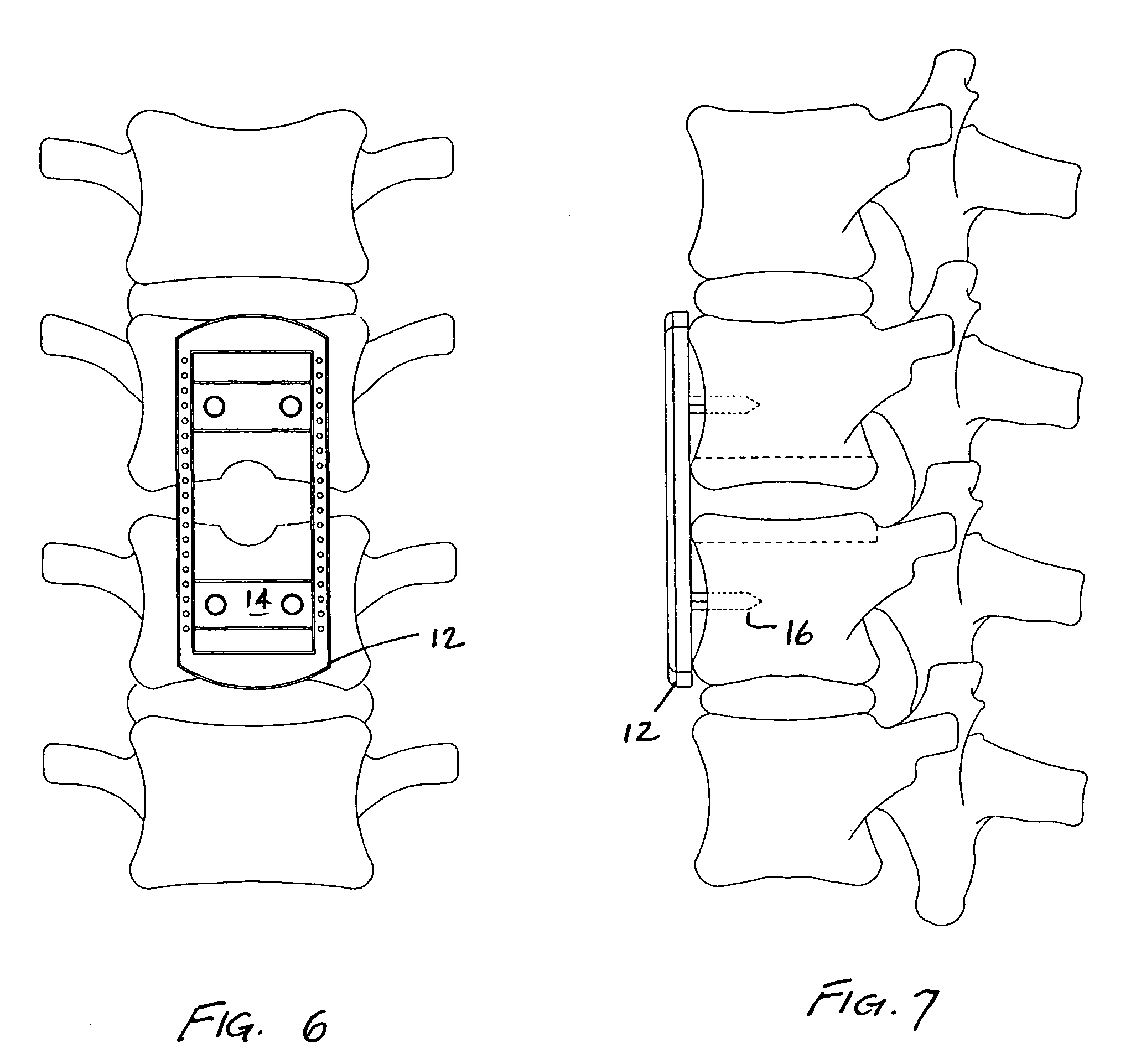

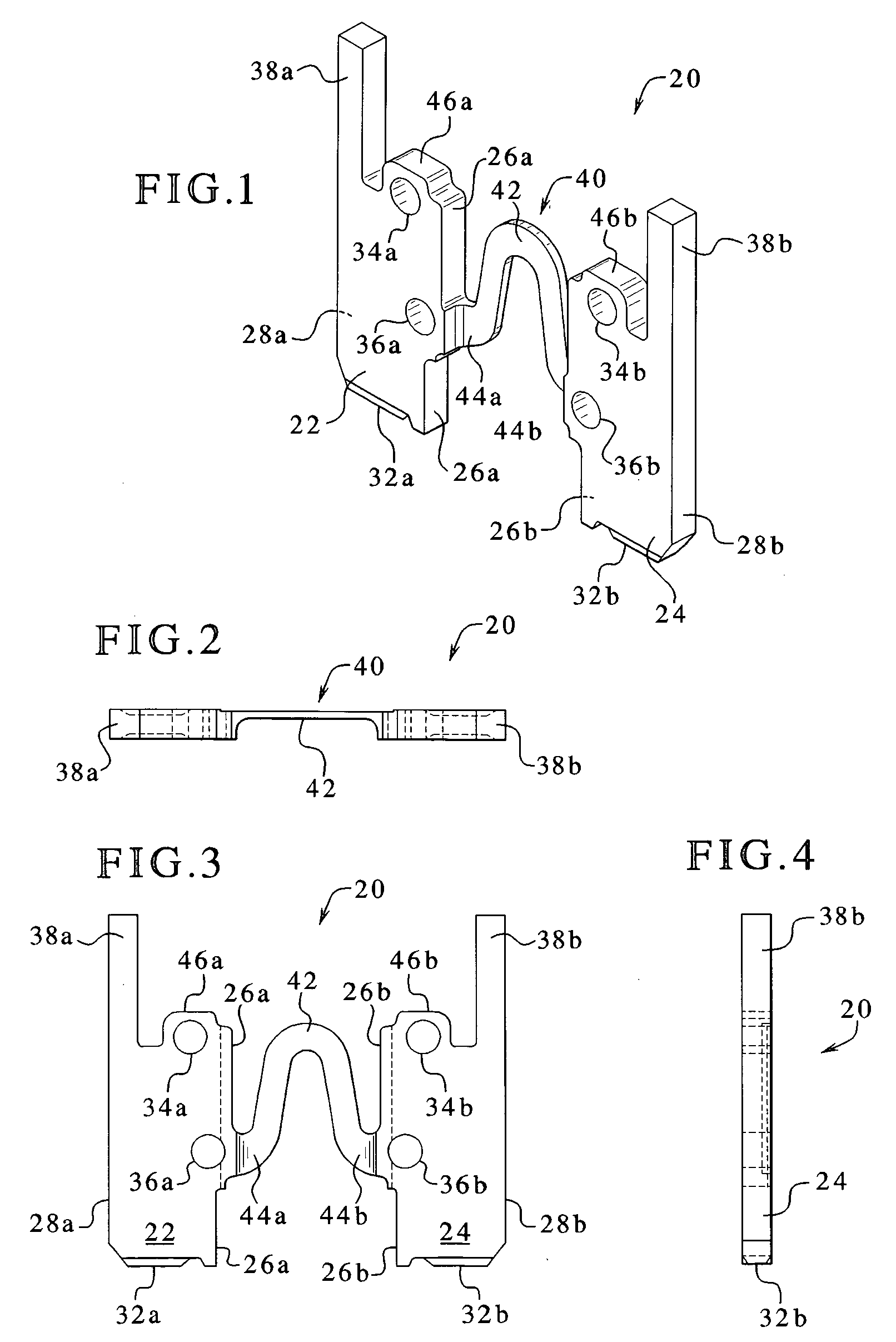

Orthopedic fusion plate having both active and passive subsidence controlling features

ActiveUS20060167457A1Deleterious effectPrevent movementInternal osteosythesisJoint implantsEngineeringTongue and groove

An orthopedic fusion plate device has a rigid perimetral frame which embraces a pair of plates retained within the frame by a tongue and groove mechanism so that the plates can move in only a single dimension, toward and away from another. The device is intended to mitigate the effects of bone graft resorption and settling through either active or passive mechanisms.

Owner:SUDDABY LOUBERT

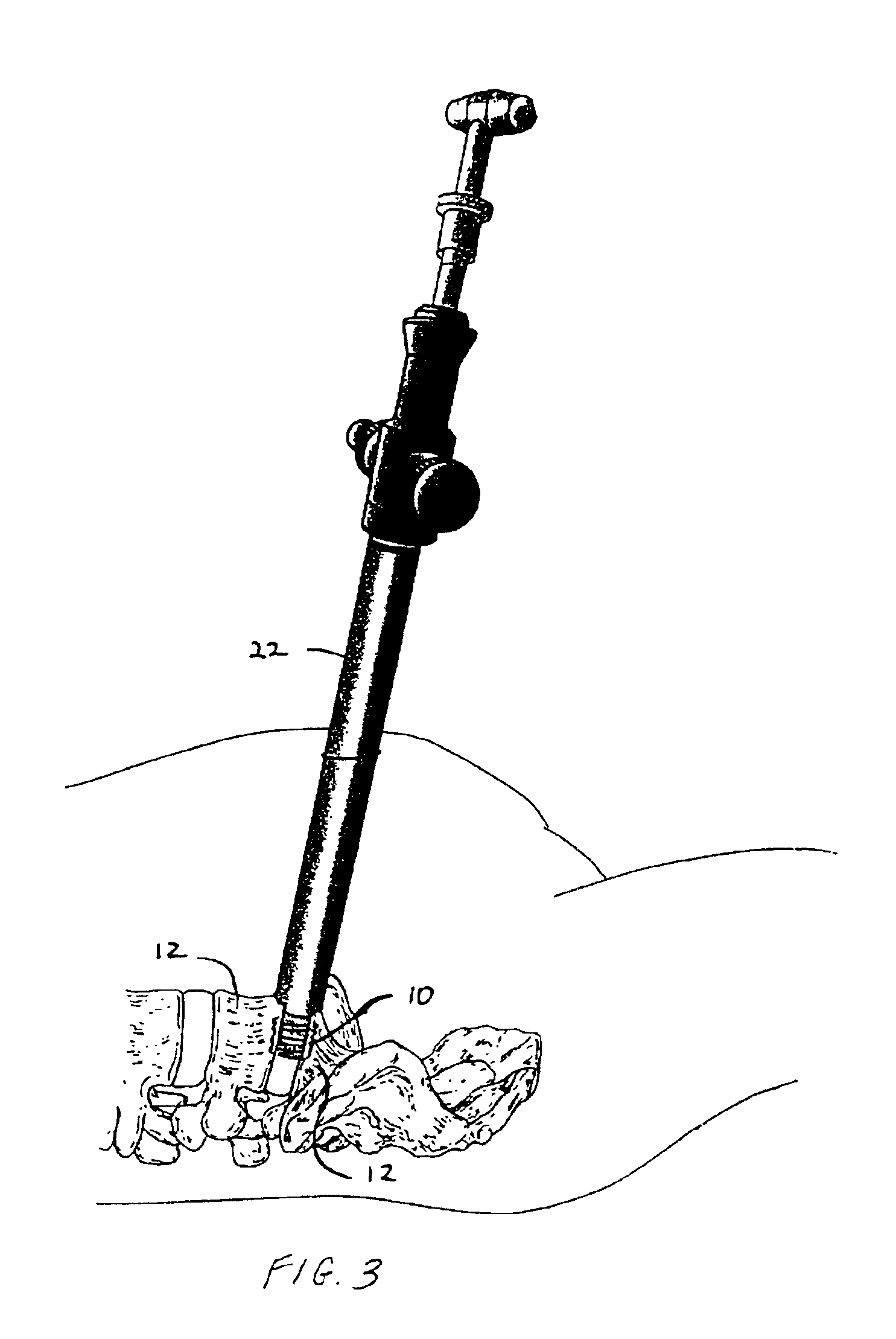

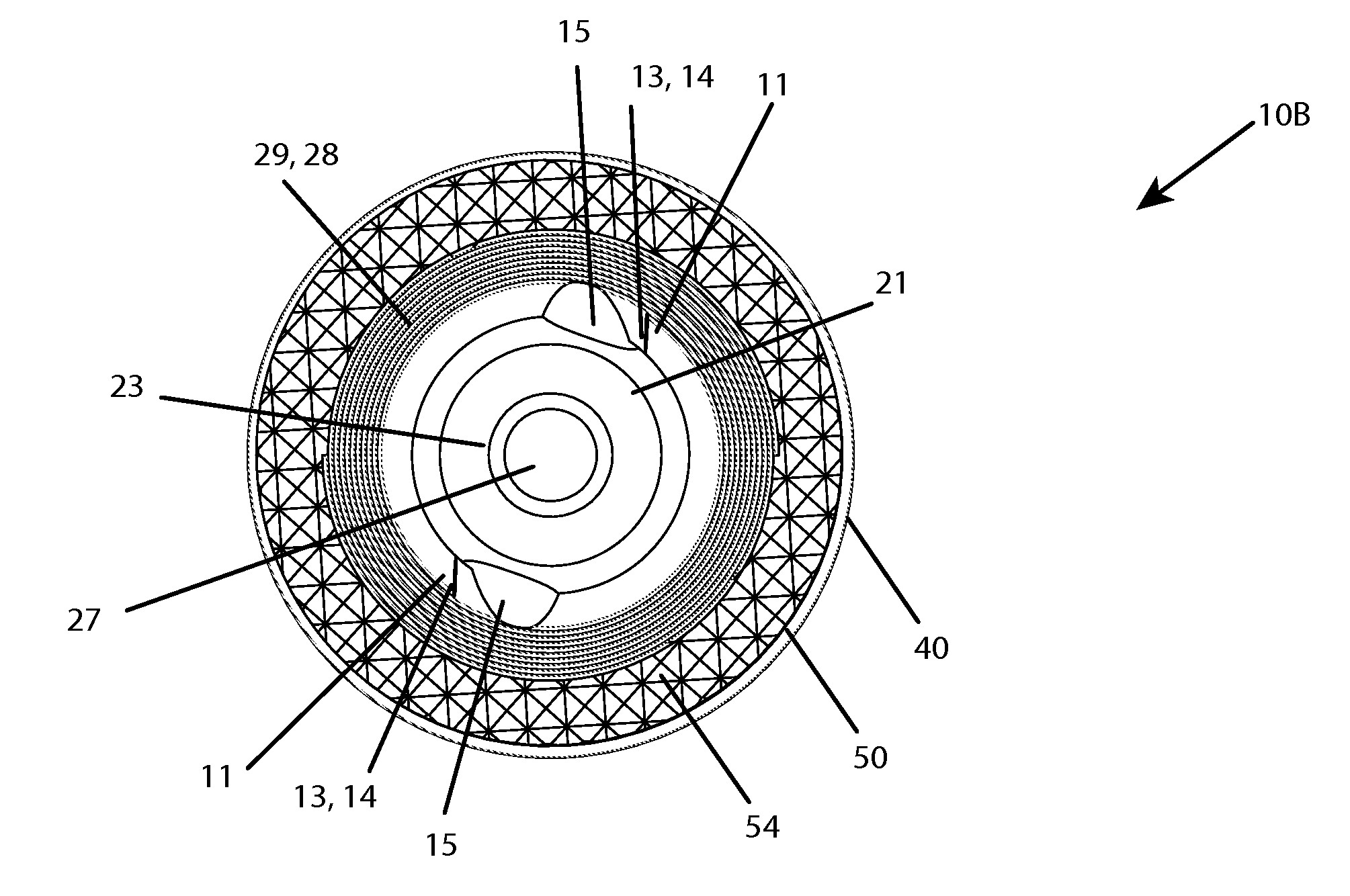

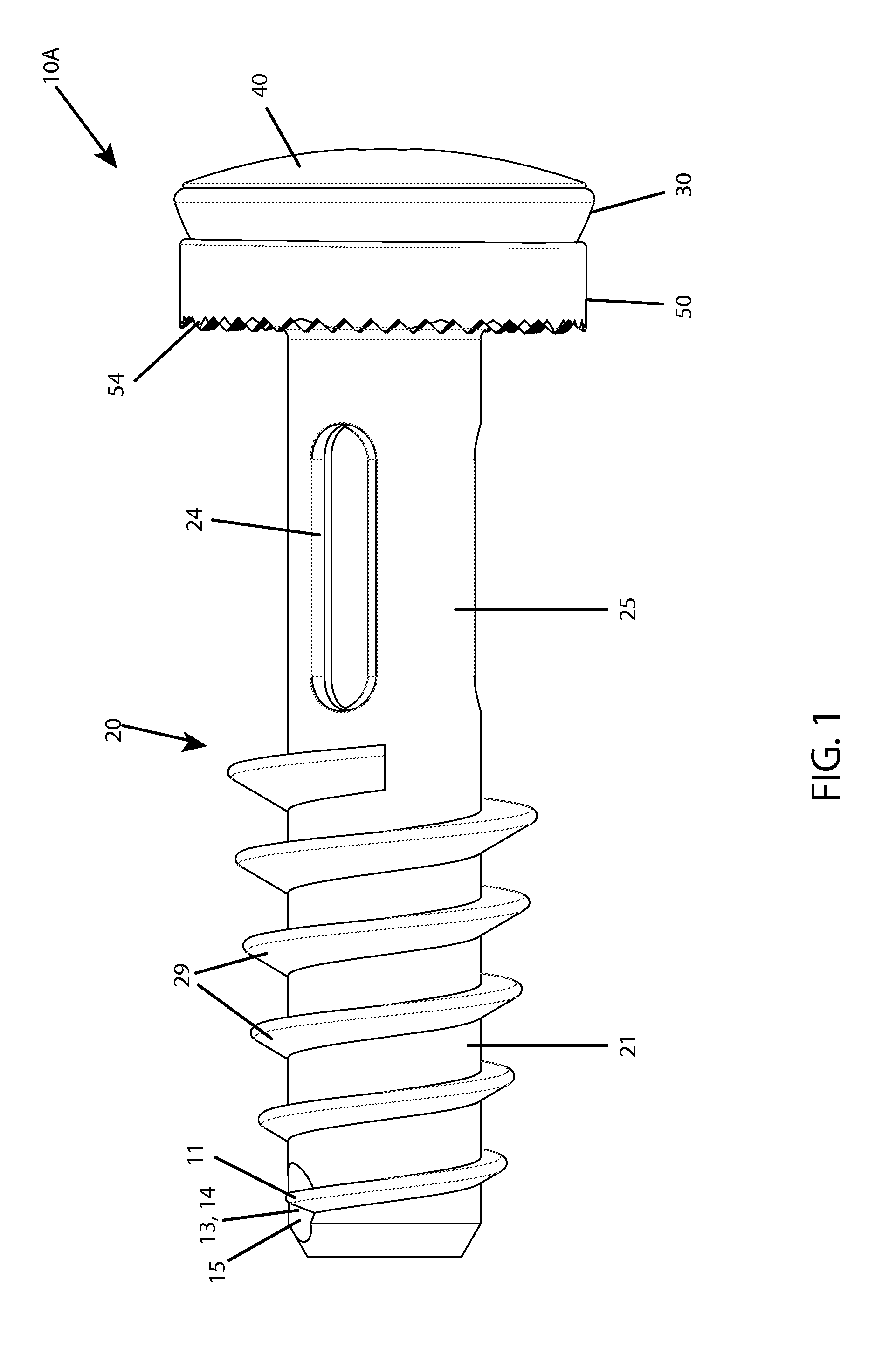

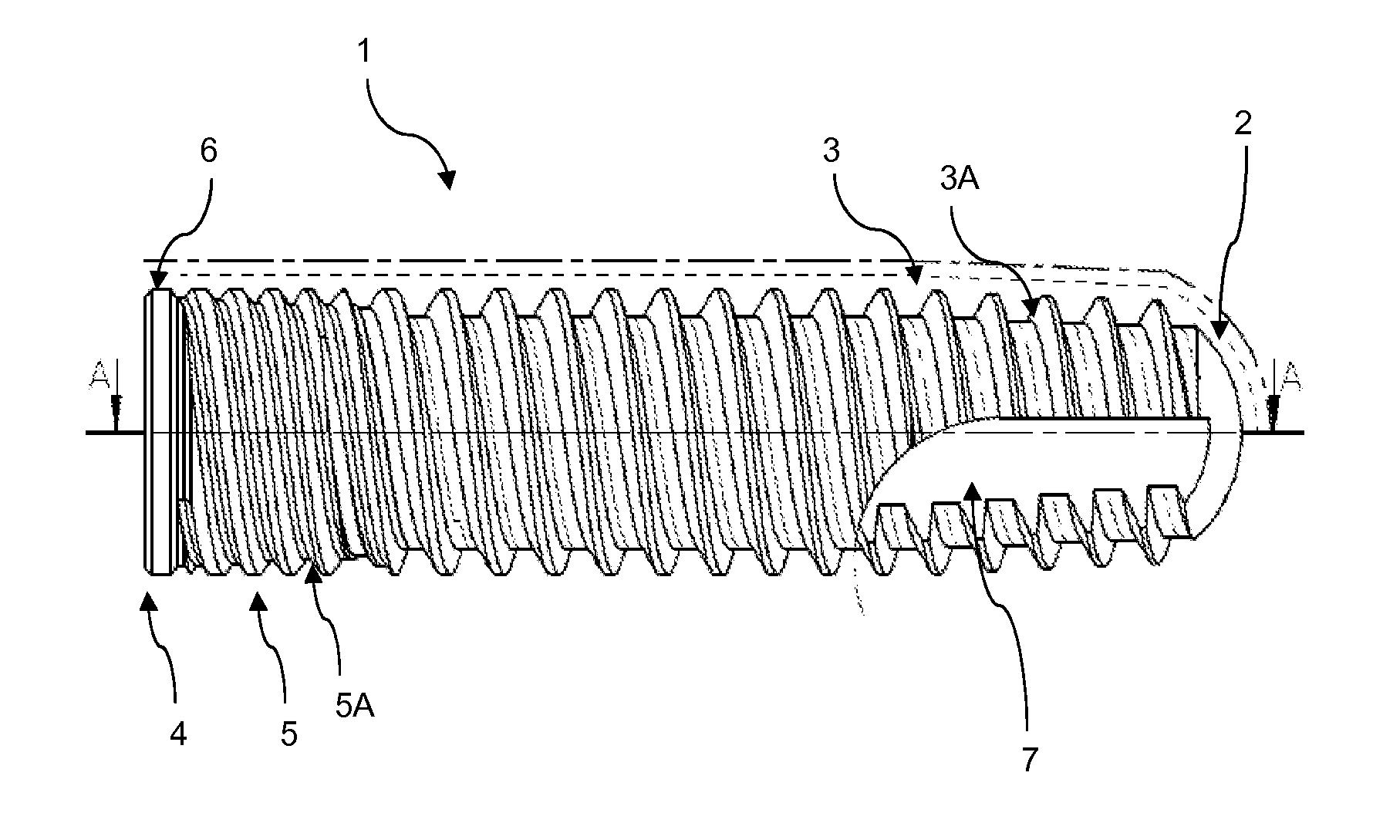

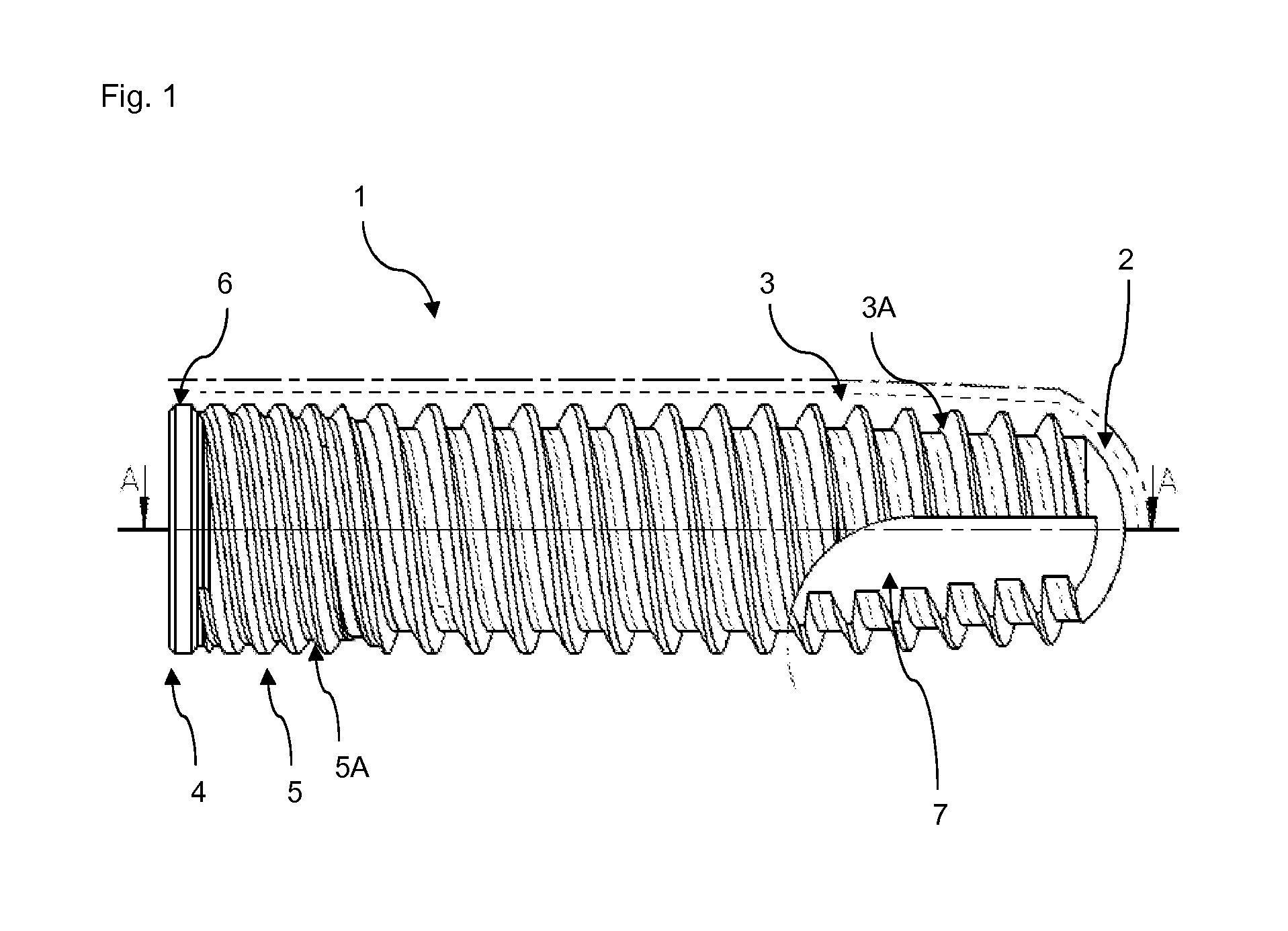

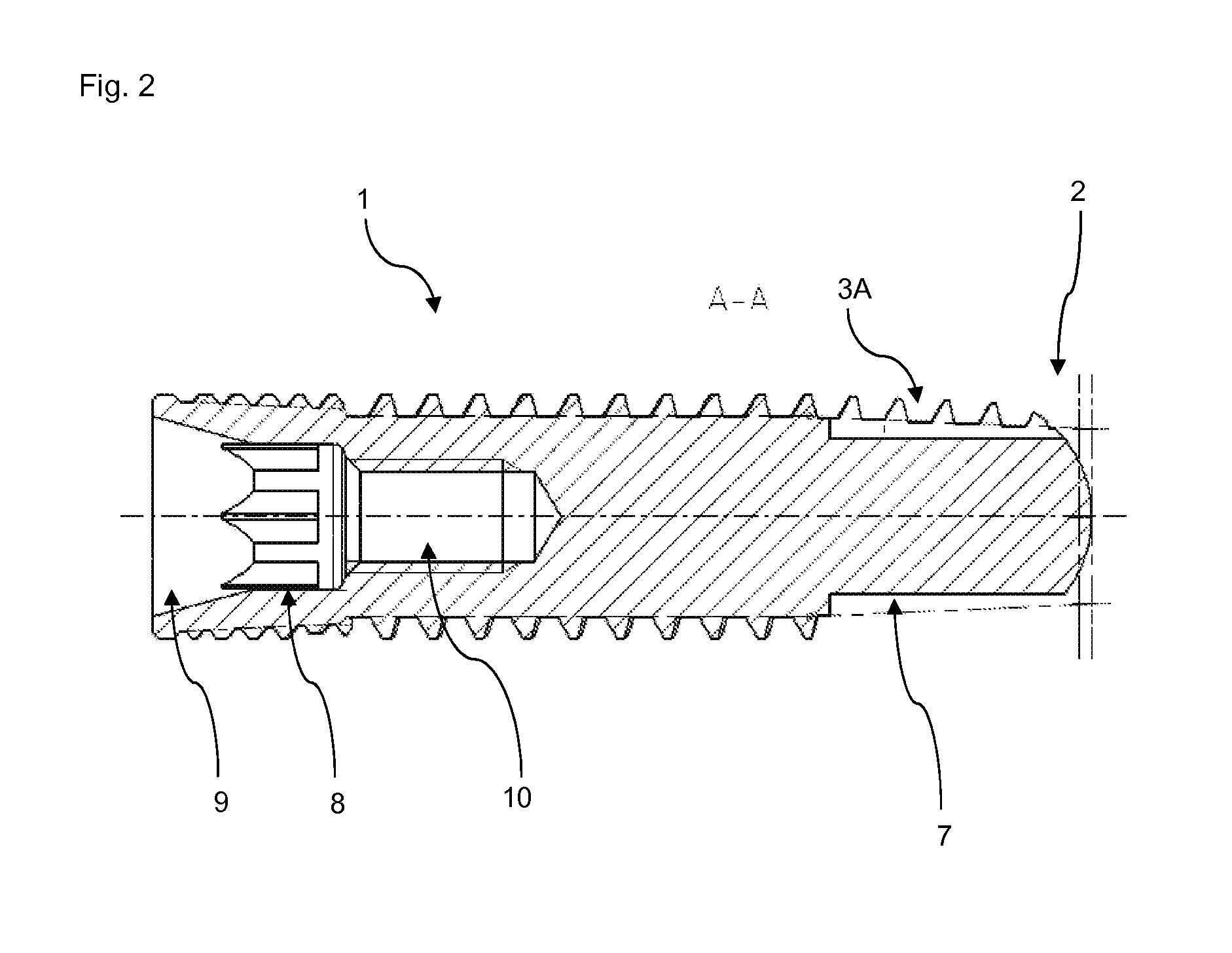

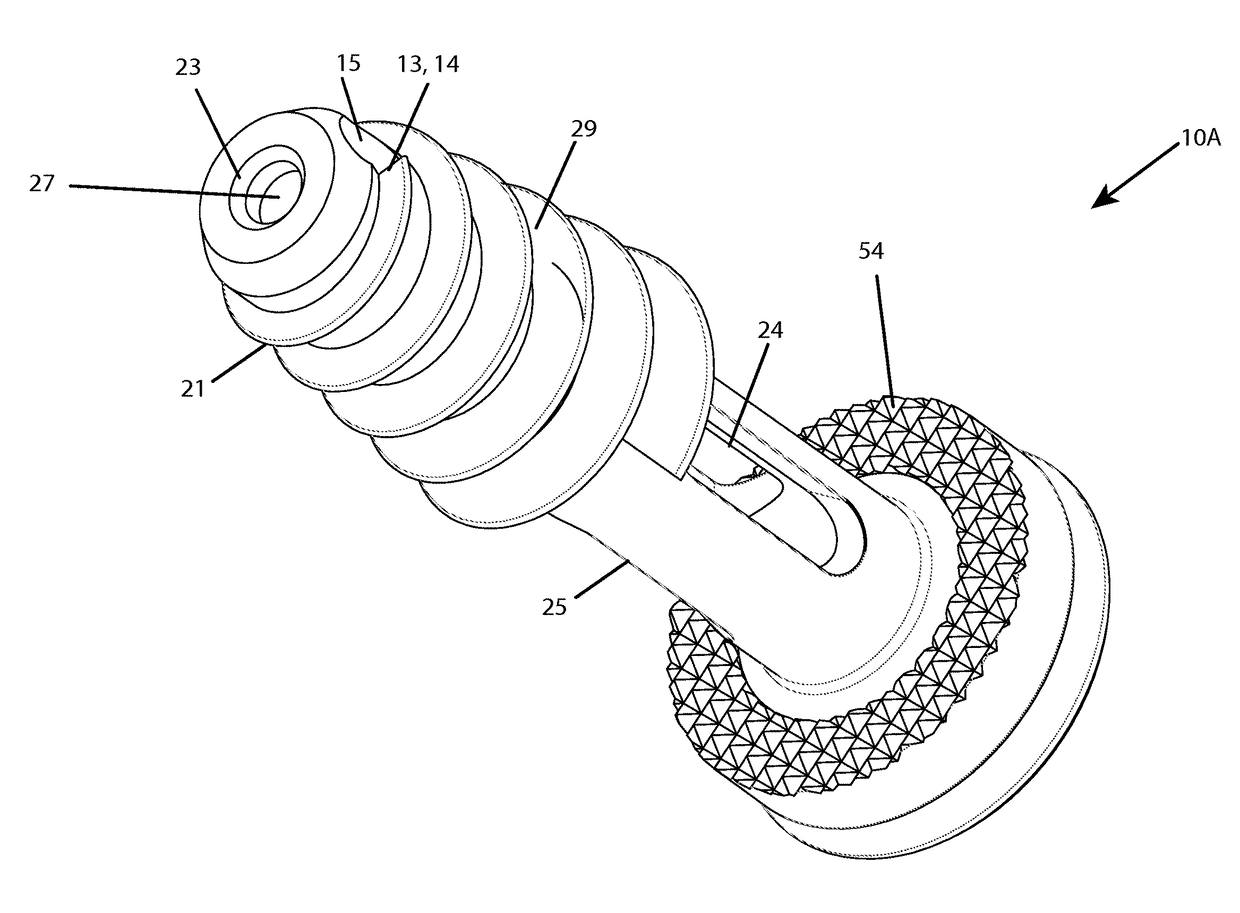

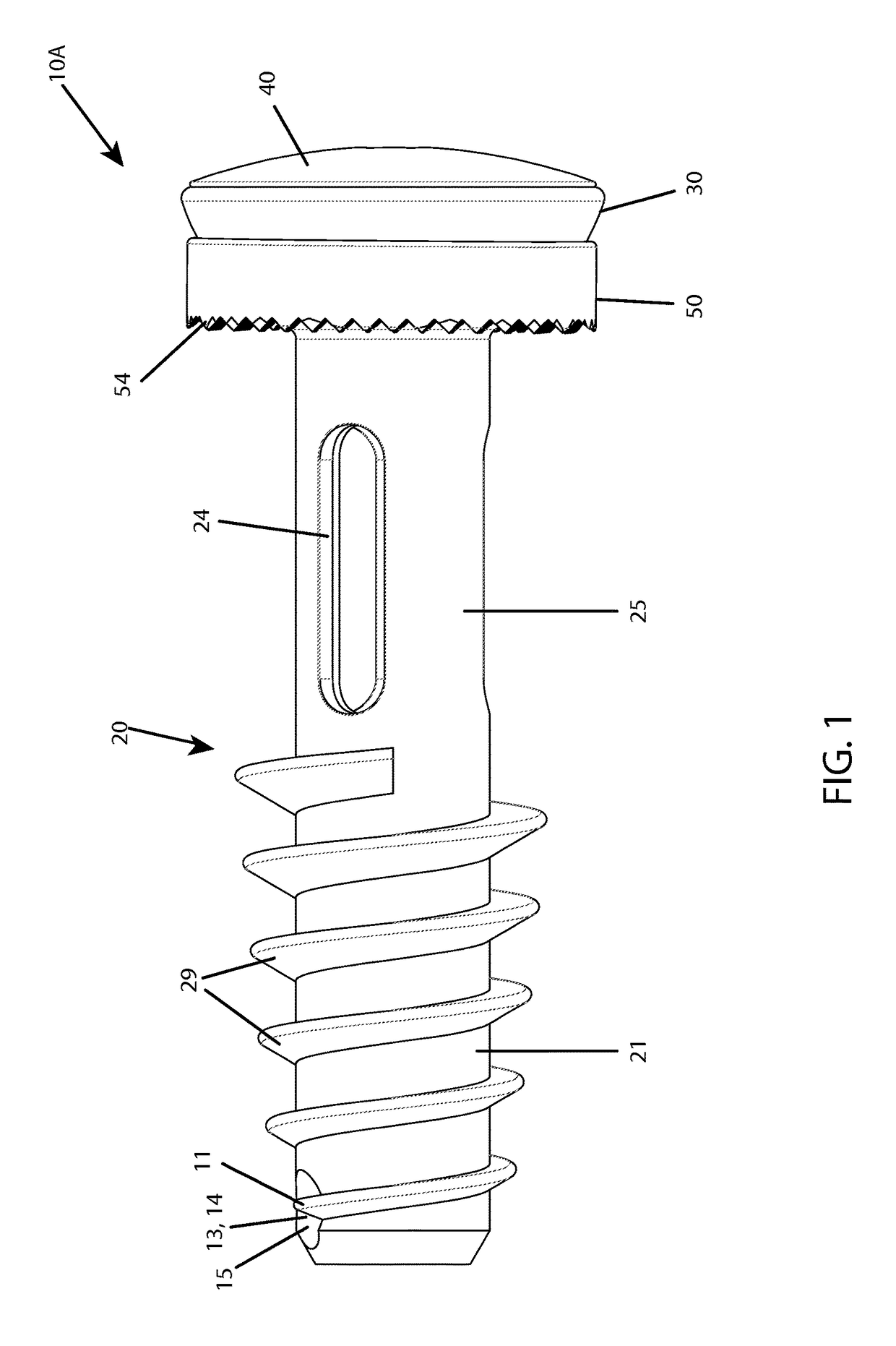

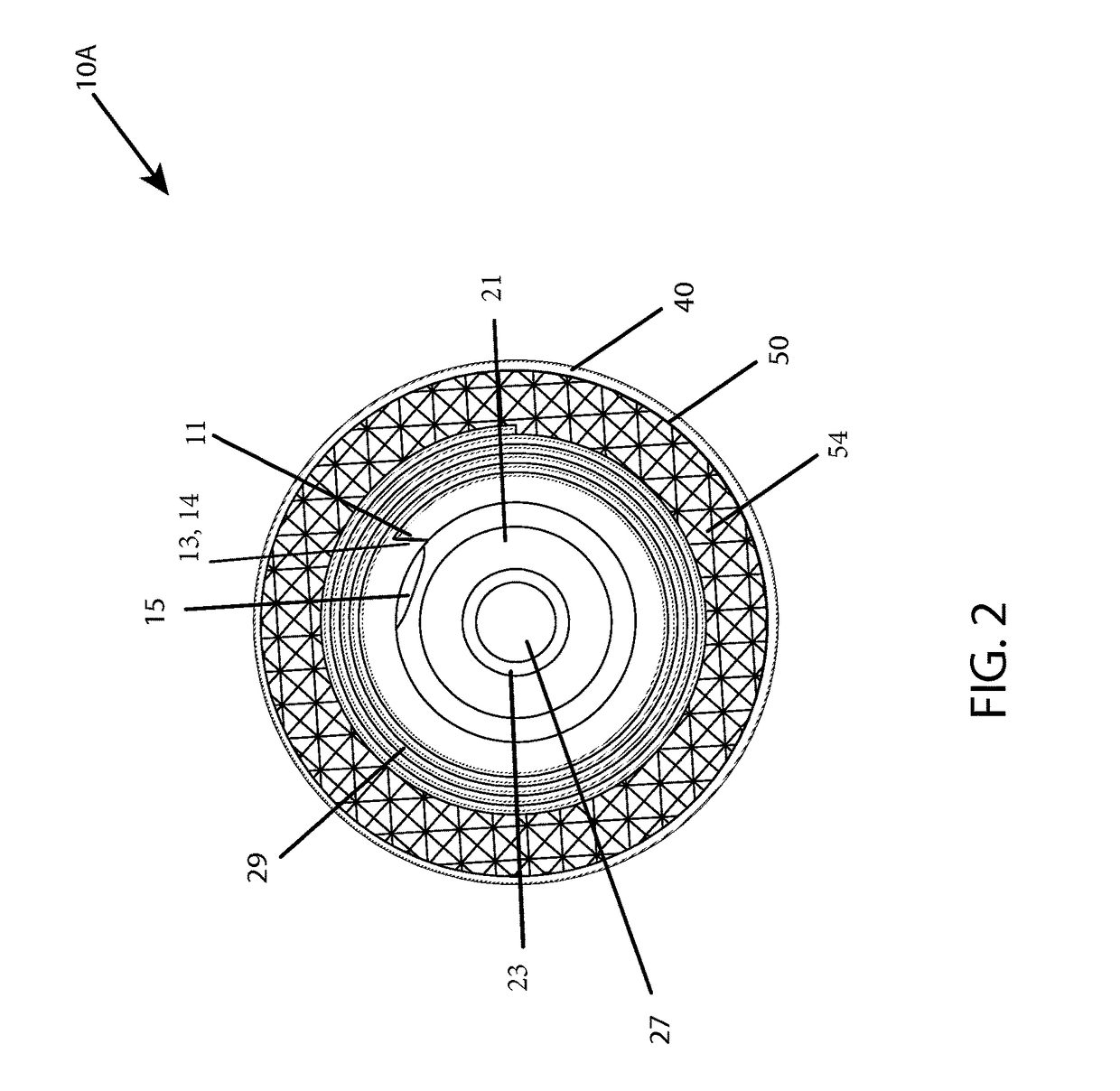

Sacroiliac screw

ActiveUS20160242820A1Easy to integrateAdvancing screwInternal osteosythesisFastenersFluteWindow opening

An improved joint fusion screw for transiliac fixation has a screw head and extending therefrom an elongate hollow shaft. The hollow shaft has an externally threaded end portion extending to a tip end and a non-externally threaded shank portion having a plurality of window openings. At or near the tip end is a start of a thread with a bone cutting flute. The bone cutting flute has a cutting edge on a circumferential exterior of the threaded tip to cut bone and directs the cut bone internally into a bone receiving opening in the hollow shaft directly in front of the cutting flute. The cutting edge lies at the start of the thread extending radially above the bone receiving opening at least partially overhanging the opening configured to cut bone.

Owner:SPINAL ELEMENTS INC

Orthopedic fusion plate having both active and passive subsidence controlling features

An orthopedic fusion plate device has a rigid perimetral frame which embraces a pair of plates retained within the frame by a tongue and groove mechanism so that the plates can move in only a single dimension, toward and away from another. The device is intended to mitigate the effects of bone graft resorption and settling through either active or passive mechanisms.

Owner:SUDDABY LOUBERT

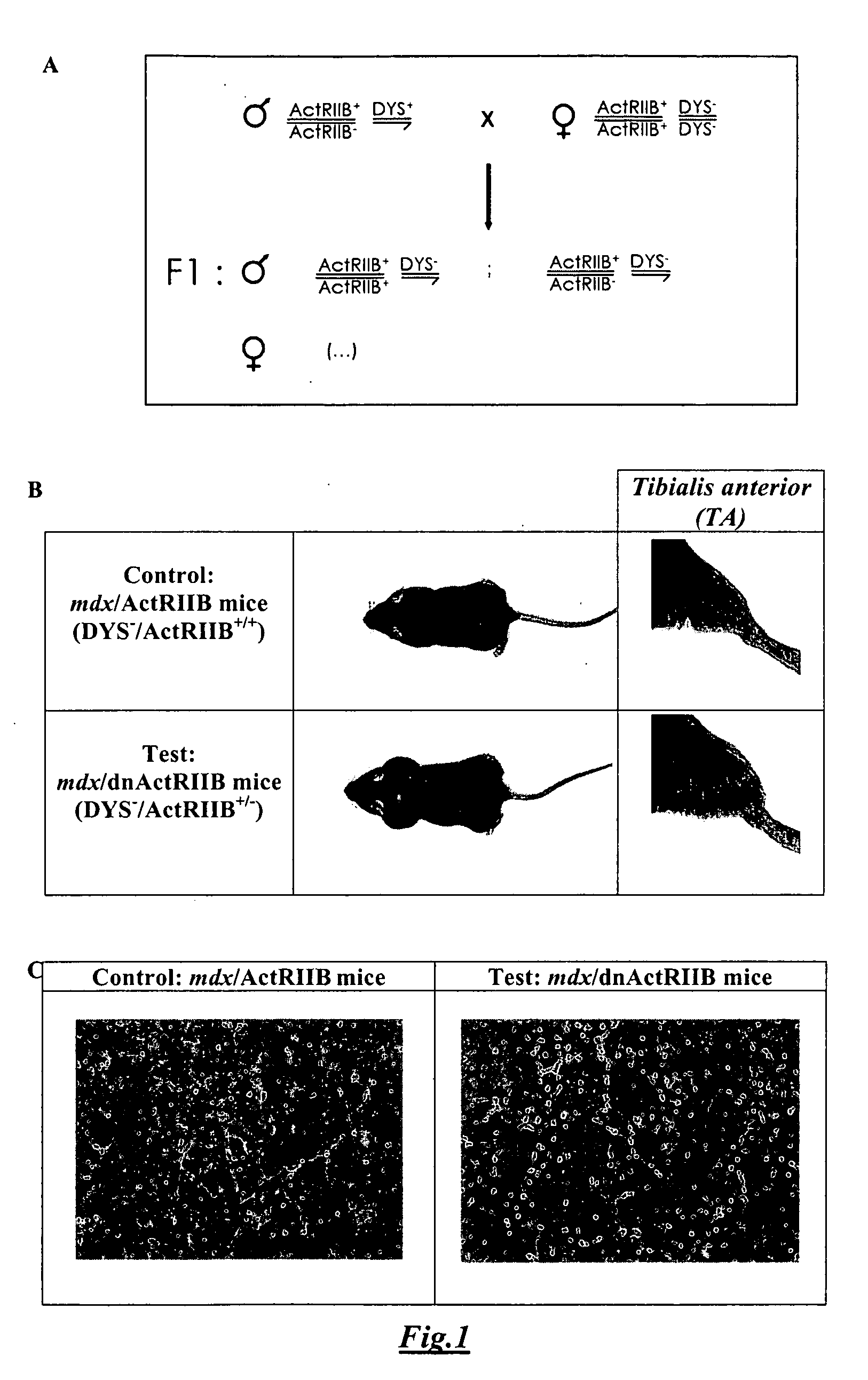

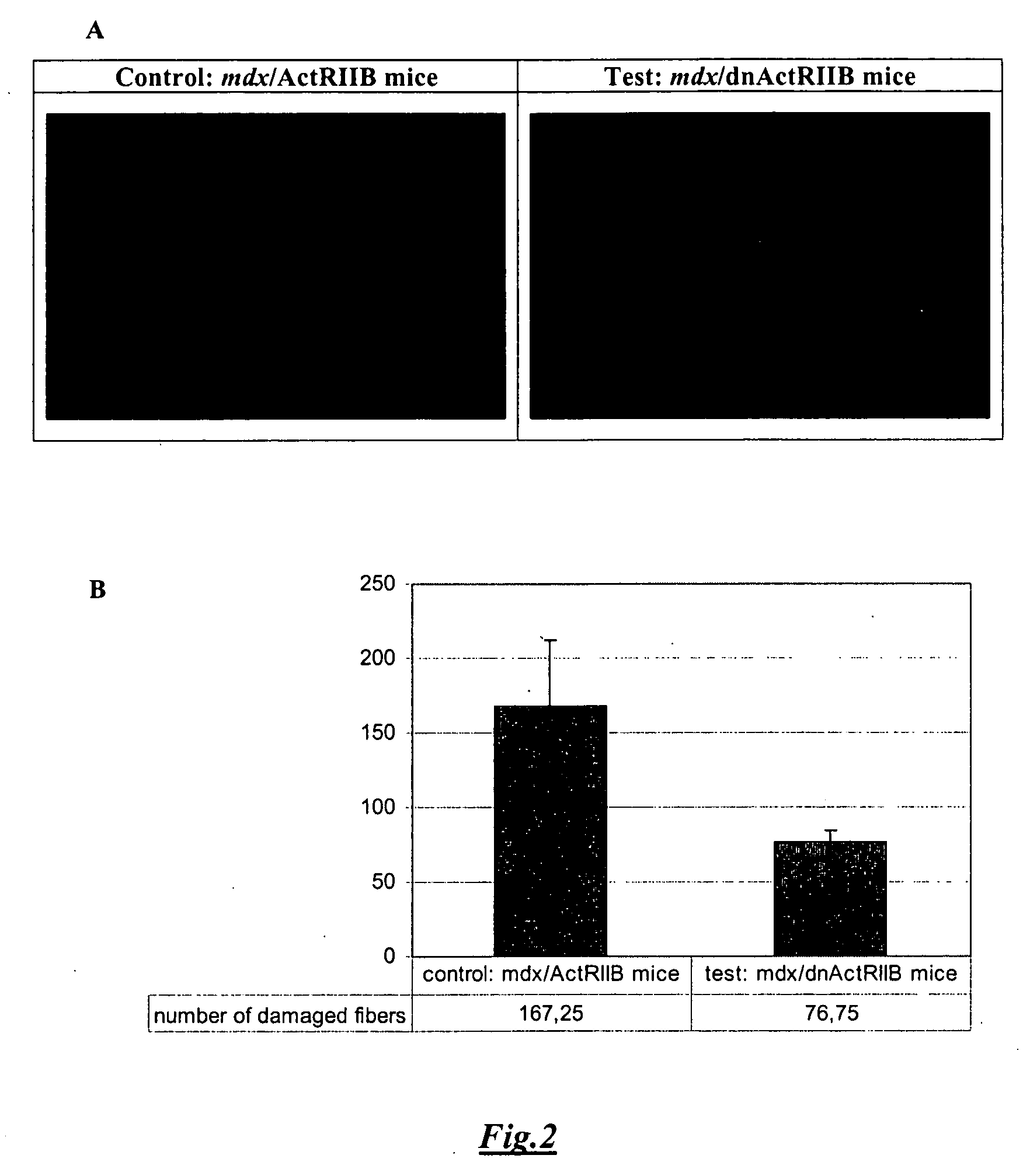

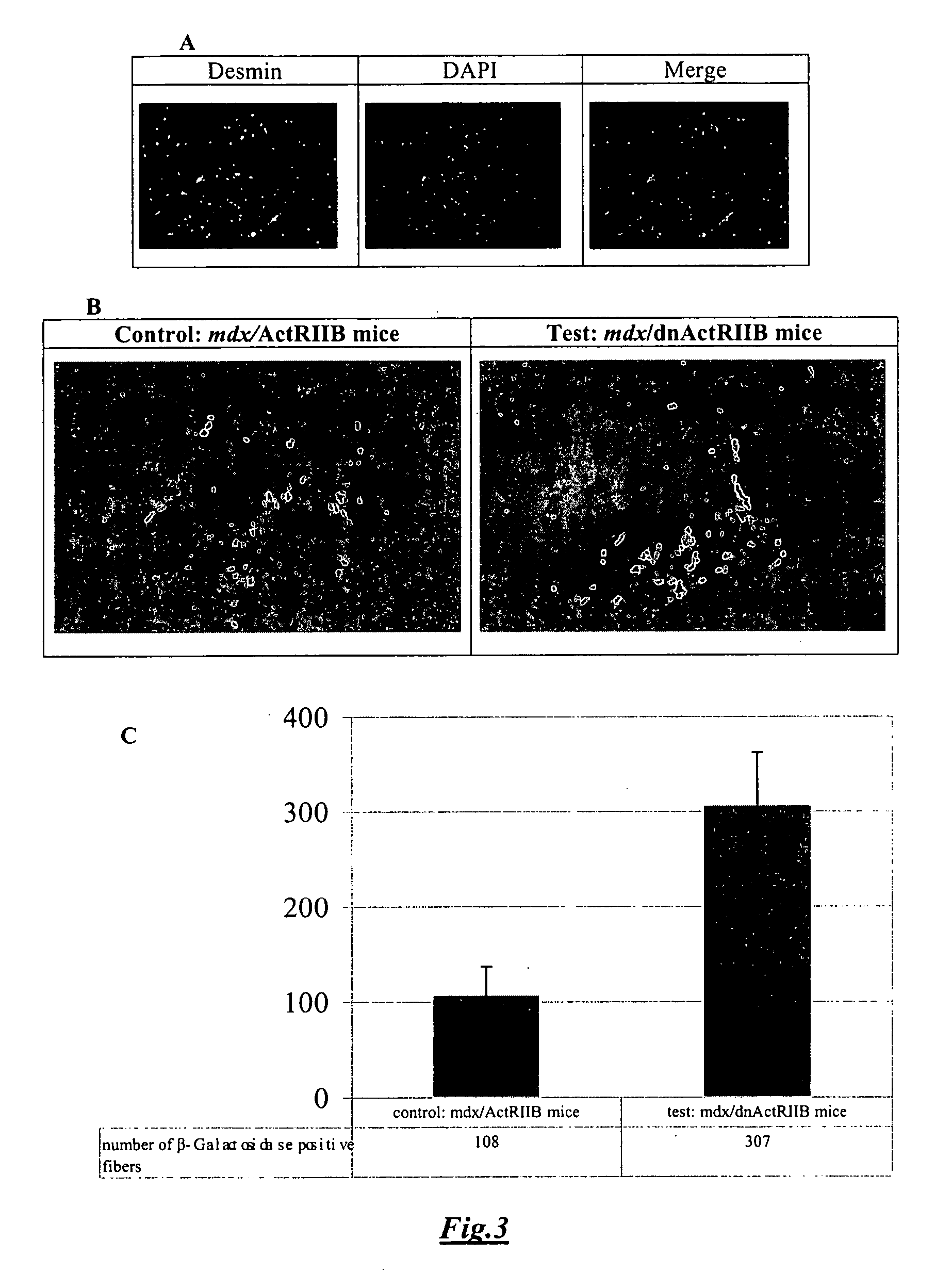

Modulation of myostatin and use thereof in cell transplantation-based treatment of muscle disease

InactiveUS20060251632A1Improve fusionIncreased proliferationBiocideAnimal repellantsMyostatinDisease

Owner:UNIV LAVAL

Full-position connecting pipe and safety end circular seam welding method achieved through tungsten electrode inert gas arc welding

ActiveCN104084678AImprove welding efficiencyReduce welding distortionArc welding apparatusWorkpiece edge portionsSpin weldingArchitectural engineering

The invention discloses a full-position connecting pipe and safety end circular seam welding method achieved through tungsten electrode inert gas arc welding. According to the method, nickel base alloy serves as an isolating layer to carry out machining on a connecting pipe and a safety end so that a welding groove can be formed by the connecting pipe and the safety end during assembling, and the welding groove is welded. A plurality of weld beads are welded during welding, the bottom end of a part to be welded is arced during welding, spin welding is carried out along one side of the part to be welded to the top end of the part to be welded, arcing is stopped, the bottom end of the part to be welded is arced again, spin welding is carried out along the other side of the part to be welded to the top end of the part to be welded, and arcing is stopped. When the welding groove is a double-faced U-shaped narrow gap groove, an outer groove is welded but not completely welded, back chipping and complete welding are carried out on an inner groove, and then complete welding is carried out on the outer groove. When the welding groove is a single-faced narrow gap groove, the groove is completely welded, a cushion plate is removed, and back chipping is carried out.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

Apparatus, systems, and methods for the fixation or fusion of bone

InactiveUS20180228621A1Easy to fixImprove fusionInternal osteosythesisToe jointsLumbar facet jointIntervertebral disc

Assemblies of one or more implant structures make possible the achievement of diverse interventions involving the fusion and / or stabilization of the SI-joint and / or lumbar and sacral vertebra in a non-invasive manner, with minimal incision, and without the necessitating the removing the intervertebral disc. The representative lumbar spine interventions, which can be performed on adults or children, include, but are not limited to, SI-joint fusion or fixation; lumbar interbody fusion; translaminar lumbar fusion; lumbar facet fusion; trans-iliac lumbar fusion; and the stabilization of a spondylolisthesis.

Owner:SI BONE

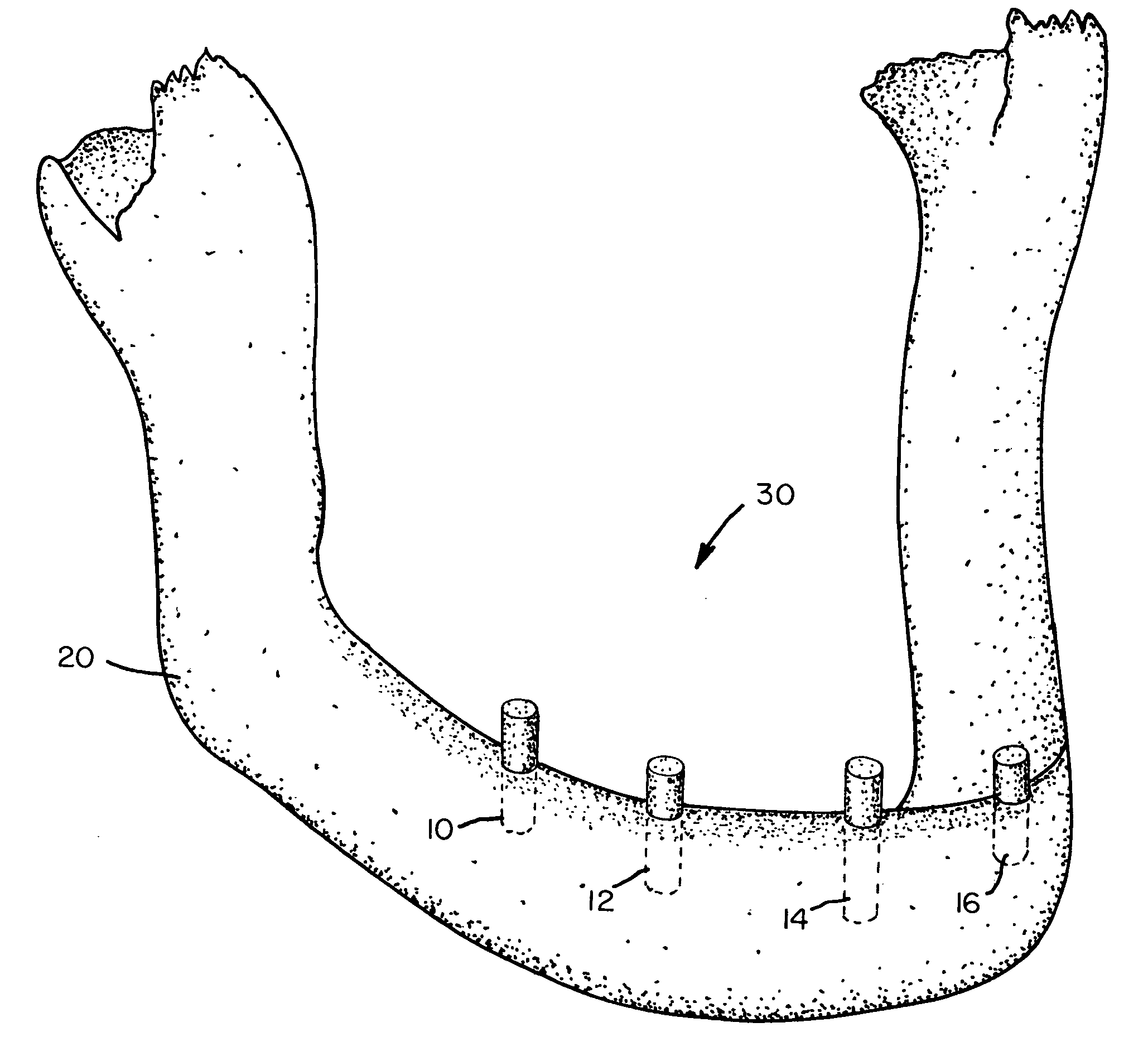

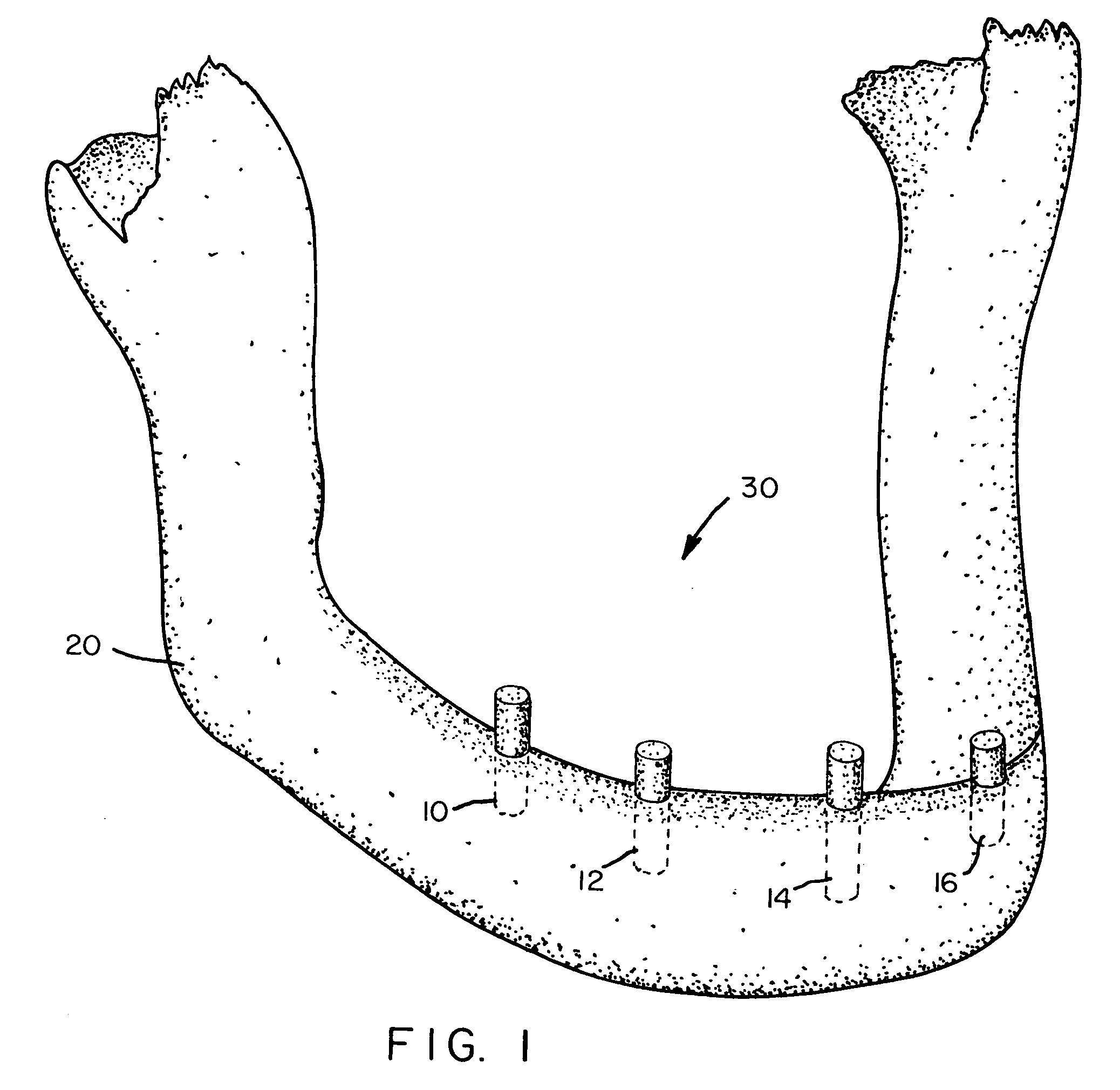

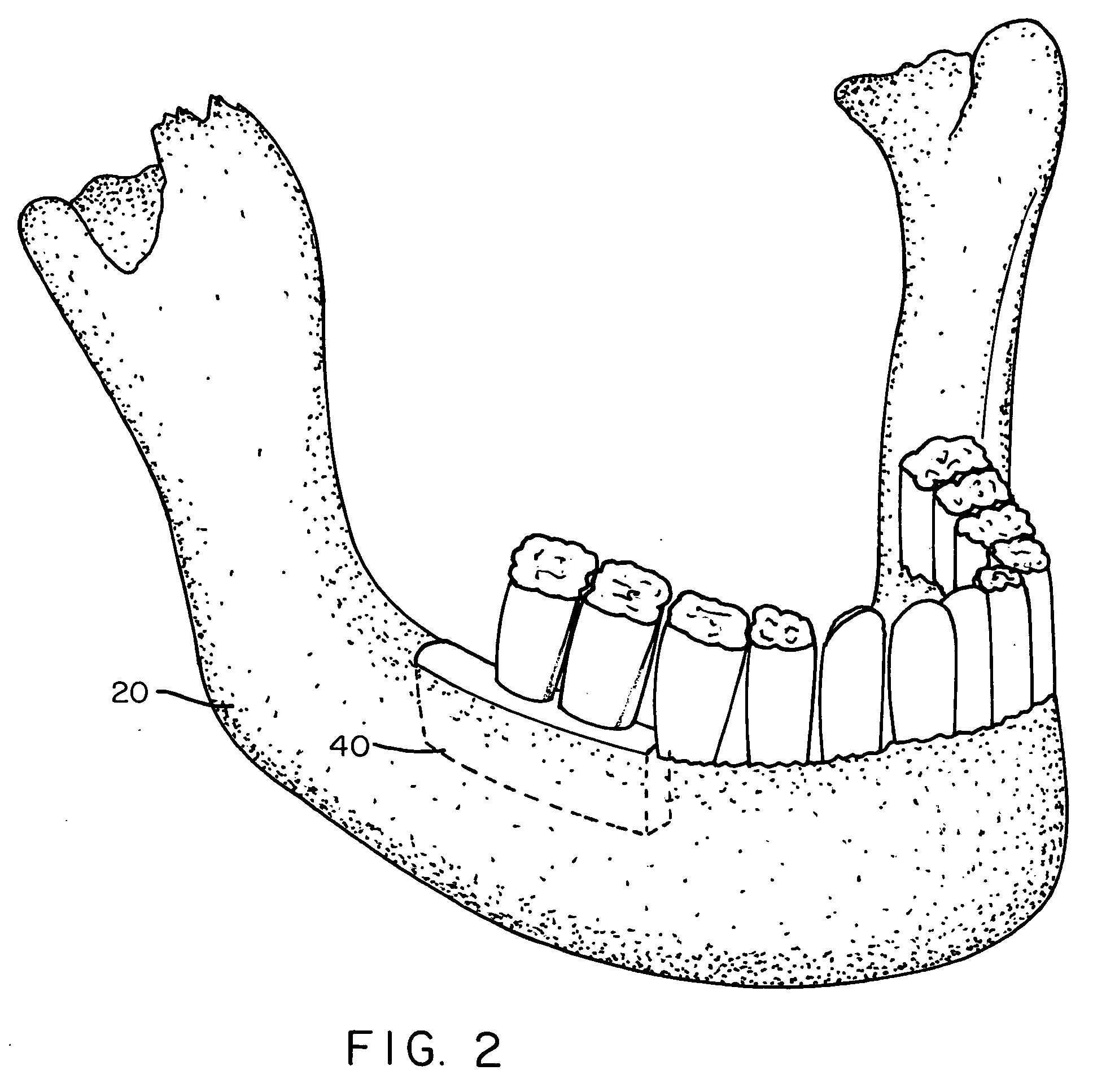

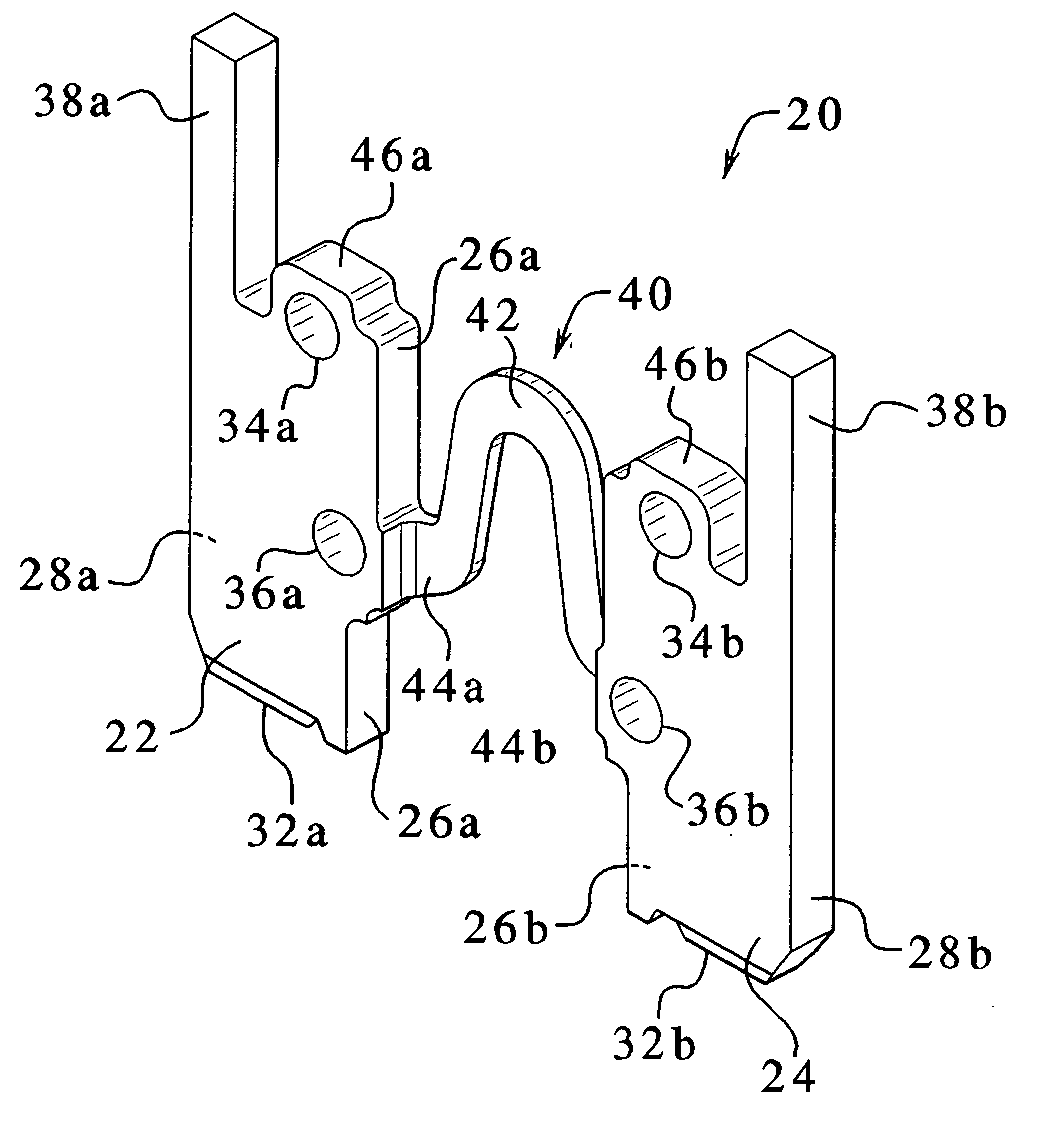

Dental implant having a first, conical, screw part and a second, cylindrical, screw part

InactiveUS20140087331A1Simple introductionEasily screwed into jawboneDental implantsImpression capsScrew threadDental implant

The invention relates to a dental implant having a first conical screw part and a second cylindrical screw part, wherein the first screw part has a progressive thread and the second screw part has a fine thread and there is a circumferential groove at the thread termination of the fine thread, wherein the implant has a hexagon socket at the cervical end, the hexagon socket being arranged in a conical recess.

Owner:RIEMSER PHARMA

Magnetically implantable prosthetic device and method to shorten healing time, enhance bone fusion, and retard bacterial growth

ActiveUS20090029316A1Improve fusionShorten healing timeDental implantsTeeth fillingMedicineBones fusion

Disclosed is a prosthetic implant comprising an implantable magnetic base structure that supports or couples with a prosthetic suprastructure for implantation in a mammal to fulfill a prosthetic need. The implantable base more quickly fuses with surrounding tissue or bone with the aid of a magnetic field. The suprastructure abuts and is supported by the implantable base, and each comprises a biocompatible magnetic material to establish a magnetic field in the region of the tissue surrounding the implantable base. An anchoring arrangement may be employed to fasten the suprastructure to the base. Together, the magnetic base, suprastructure, and / or anchoring arrangement are positioned relative to each other to concentrate a magnetic field in the region of the implant in order to facilitate fusion of the base structure with surrounding bone or tissue. Advantageously, the magnetic field shortens the healing time and retards bacterial growth whereby to quickly fuse the base structure with the surrounding bone or tissue.

Owner:DUNN FREDERIC B

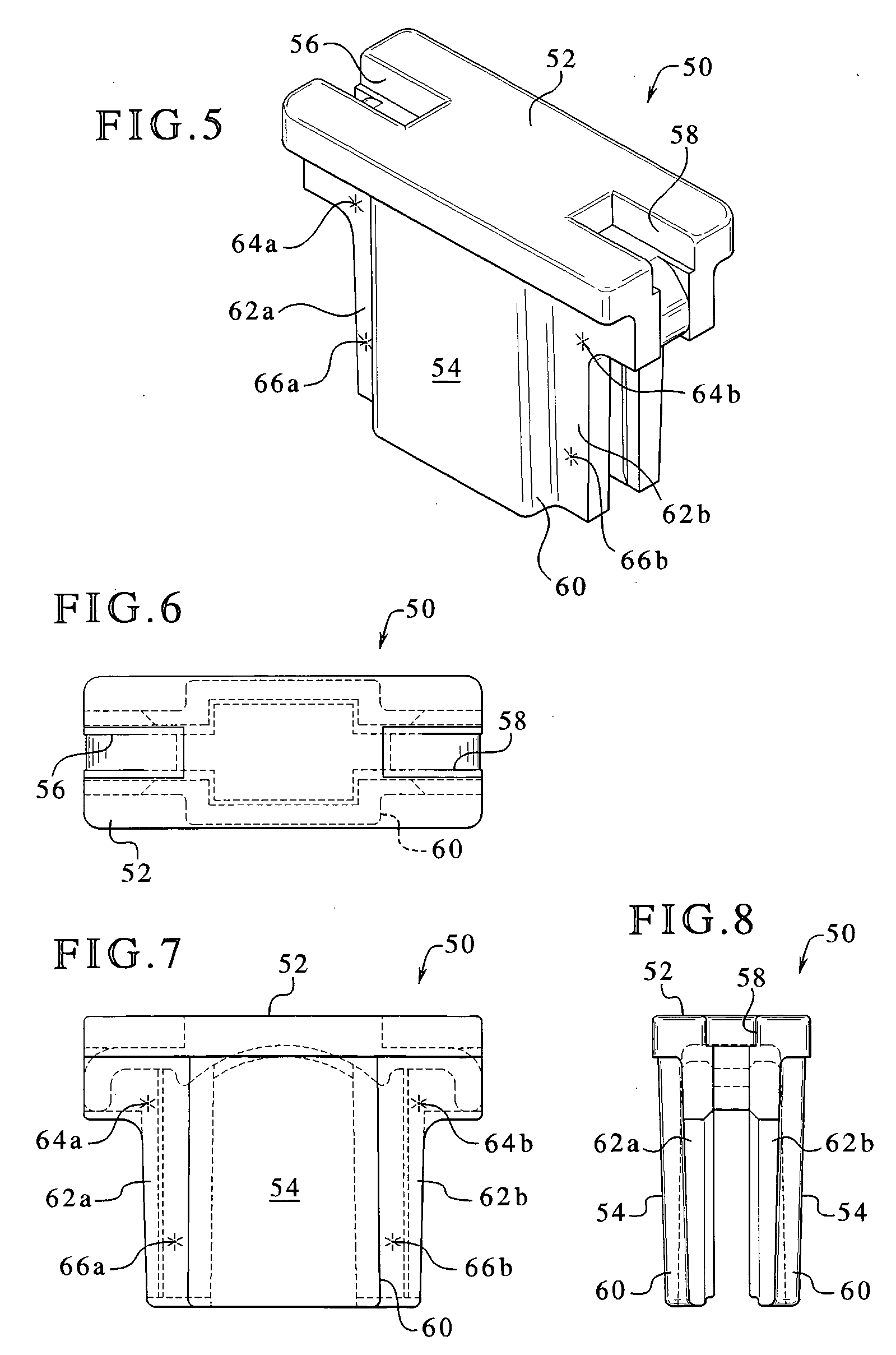

Low profile automotive fuse

ActiveUS20050212647A1Easy to integrateSimple methodEmergency protective devicesMechanical engineeringFuse cutout

An automotive blade-type fuse and method of manufacturing same are provided. The fuse includes a pair of metallic terminals separated by and in electrical communication with a fuse element. An insulative housing is provided that covers at least a portion of the of an inner edge of each of the terminals and exposes the outer edges of the terminals-and at least a portion of the upper edges of the terminals. The terminals can define grooves that interface with projections extending inwardly from the housing to hold the terminal firmly within the housing. Also, the upper edges of the terminals are bent inward to crimp the housing between an intermediate portion of the terminals and the bent upper end edges.

Owner:LITTELFUSE INC

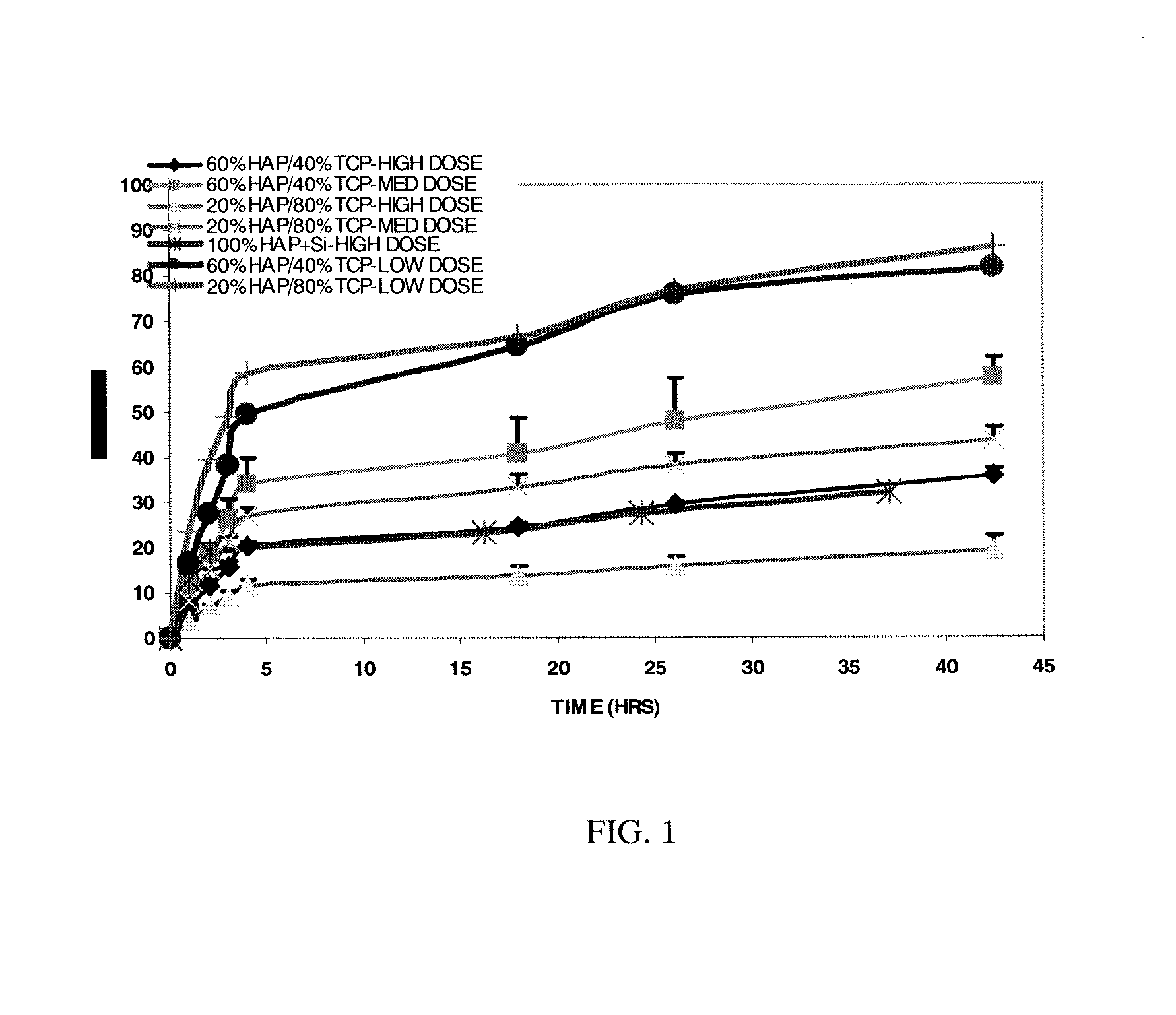

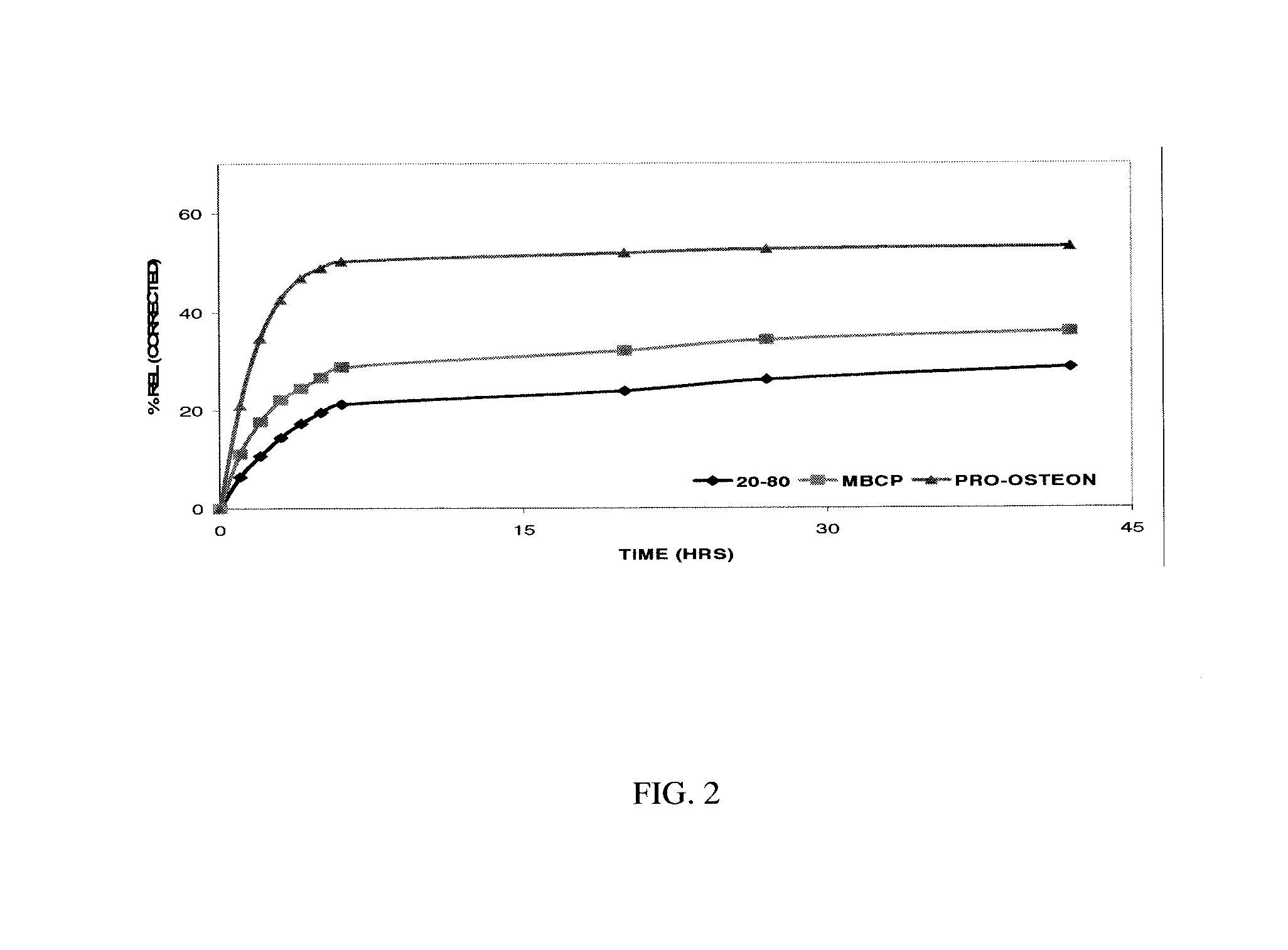

Composition and Method for Delivery of BMP-2 Amplifier/Co-Activator for Enhancement of Osteogenesis

ActiveUS20080063622A1Enhance osteoinductionAccelerate bone repairOrganic active ingredientsPeptide/protein ingredientsReceptor degradationCo activator

A composition comprising a synthetic growth factor analogue comprising a non-growth factor heparin binding region, a linker and a sequence that binds specifically to a cell surface receptor and an osteoconductive material where the synthetic growth factor analogue is attached to and can be released from the osteoconductive material and is an amplifier / co-activator of osteoinduction.

Owner:FERRING BV +1

Method for improved melt flow rate fo filled polymeric resin

InactiveUS20060020056A1Increased melt flow rateImprove fusionPigment pastesPolymer resinPolymer chemistry

Fillers used in polymer applications are surface modified with an amine prior to compounding with a polymeric resin thus improving the melt flow rate and fusion times of the polymeric resin composition when compounded.

Owner:SPECIALITY MINERALS (MICHIGAN) INC

Apparatus, systems, and methods for the fixation or fusion of bone

PendingUS20200345508A1Easy to fixImprove fusionInternal osteosythesisBone implantLumbar facet jointLumbar spinal fusion

Assemblies of one or more implant structures make possible the achievement of diverse interventions involving the fusion and / or stabilization of the SI-joint and / or lumbar and sacral vertebra in a non-invasive manner, with minimal incision, and without the necessitating the removing the intervertebral disc. The representative lumbar spine interventions, which can be performed on adults or children, include, but are not limited to, SI-joint fusion or fixation; lumbar interbody fusion; translaminar lumbar fusion; lumbar facet fusion; trans-iliac lumbar fusion; and the stabilization of a spondylolisthesis.

Owner:SI BONE INC

Apparatus, systems, and methods for the fixation or fusion of bone

PendingUS20200345507A1Easy to fixImprove fusionInternal osteosythesisToe jointsLumbar facet jointLumbar spinal fusion

Assemblies of one or more implant structures make possible the achievement of diverse interventions involving the fusion and / or stabilization of the SI-joint and / or lumbar and sacral vertebra in a non-invasive manner, with minimal incision, and without the necessitating the removing the intervertebral disc. The representative lumbar spine interventions, which can be performed on adults or children, include, but are not limited to, SI-joint fusion or fixation; lumbar interbody fusion; translaminar lumbar fusion; lumbar facet fusion; trans-iliac lumbar fusion; and the stabilization of a spondylolisthesis.

Owner:SI BONE INC

Apparatus, systems, and methods for the fixation or fusion of bone

ActiveUS20200345509A1Easy to fixImprove fusionInternal osteosythesisToe jointsLumbar facet jointLumbar spinal fusion

Assemblies of one or more implant structures make possible the achievement of diverse interventions involving the fusion and / or stabilization of the SI-joint and / or lumbar and sacral vertebra in a non-invasive manner, with minimal incision, and without the necessitating the removing the intervertebral disc. The representative lumbar spine interventions, which can be performed on adults or children, include, but are not limited to, SI-joint fusion or fixation; lumbar interbody fusion; translaminar lumbar fusion; lumbar facet fusion; trans-iliac lumbar fusion; and the stabilization of a spondylolisthesis.

Owner:SI BONE INC

Apparatus, systems, and methods for the fixation or fusion of bone

PendingUS20200345510A1Easy to fixImprove fusionInternal osteosythesisBone implantLumbar facet jointLumbar spinal fusion

Assemblies of one or more implant structures make possible the achievement of diverse interventions involving the fusion and / or stabilization of the SI-joint and / or lumbar and sacral vertebra in a non-invasive manner, with minimal incision, and without the necessitating the removing the intervertebral disc. The representative lumbar spine interventions, which can be performed on adults or children, include, but are not limited to, SI-joint fusion or fixation; lumbar interbody fusion; translaminar lumbar fusion; lumbar facet fusion; trans-iliac lumbar fusion; and the stabilization of a spondylolisthesis.

Owner:SI BONE INC

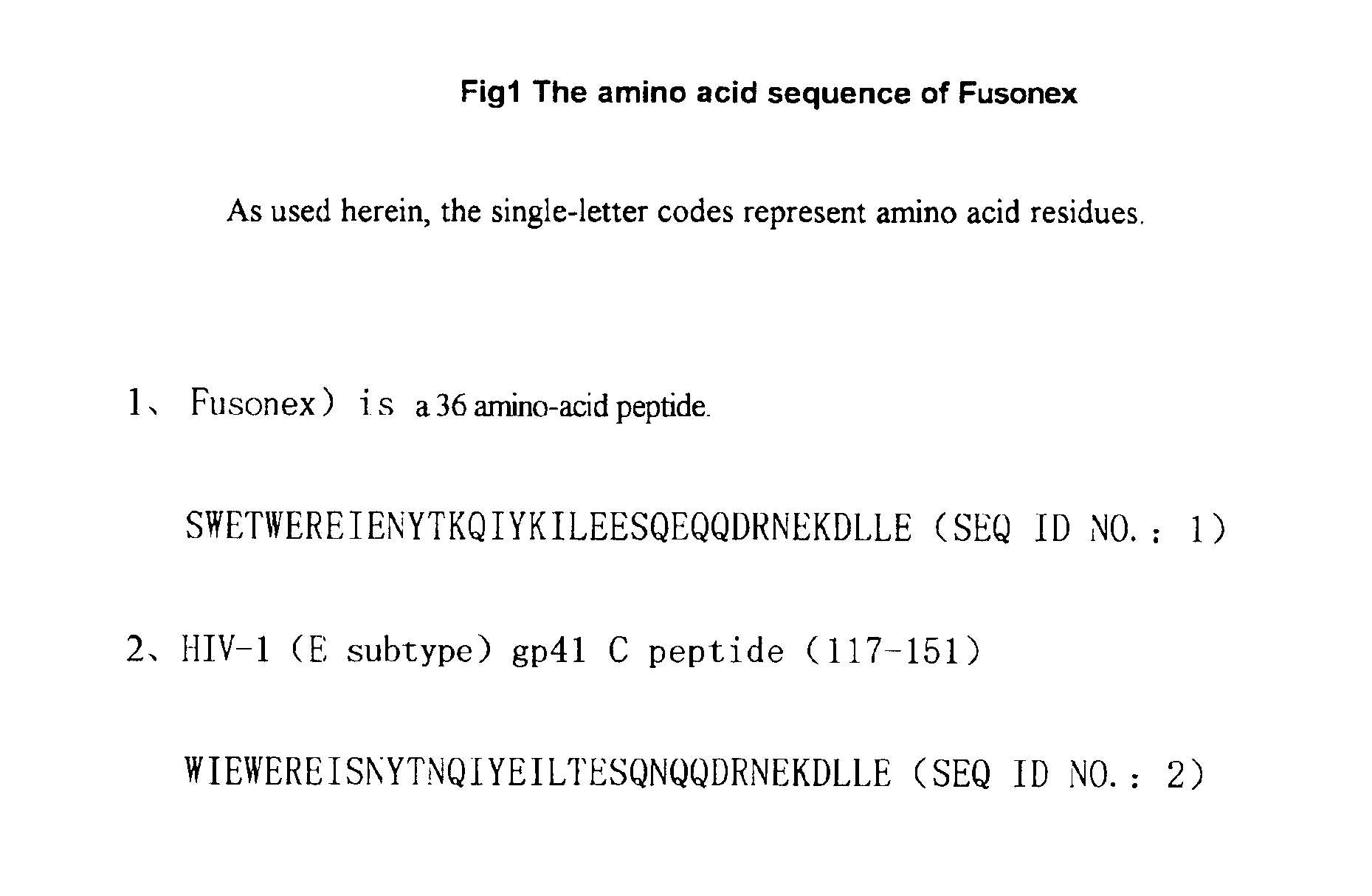

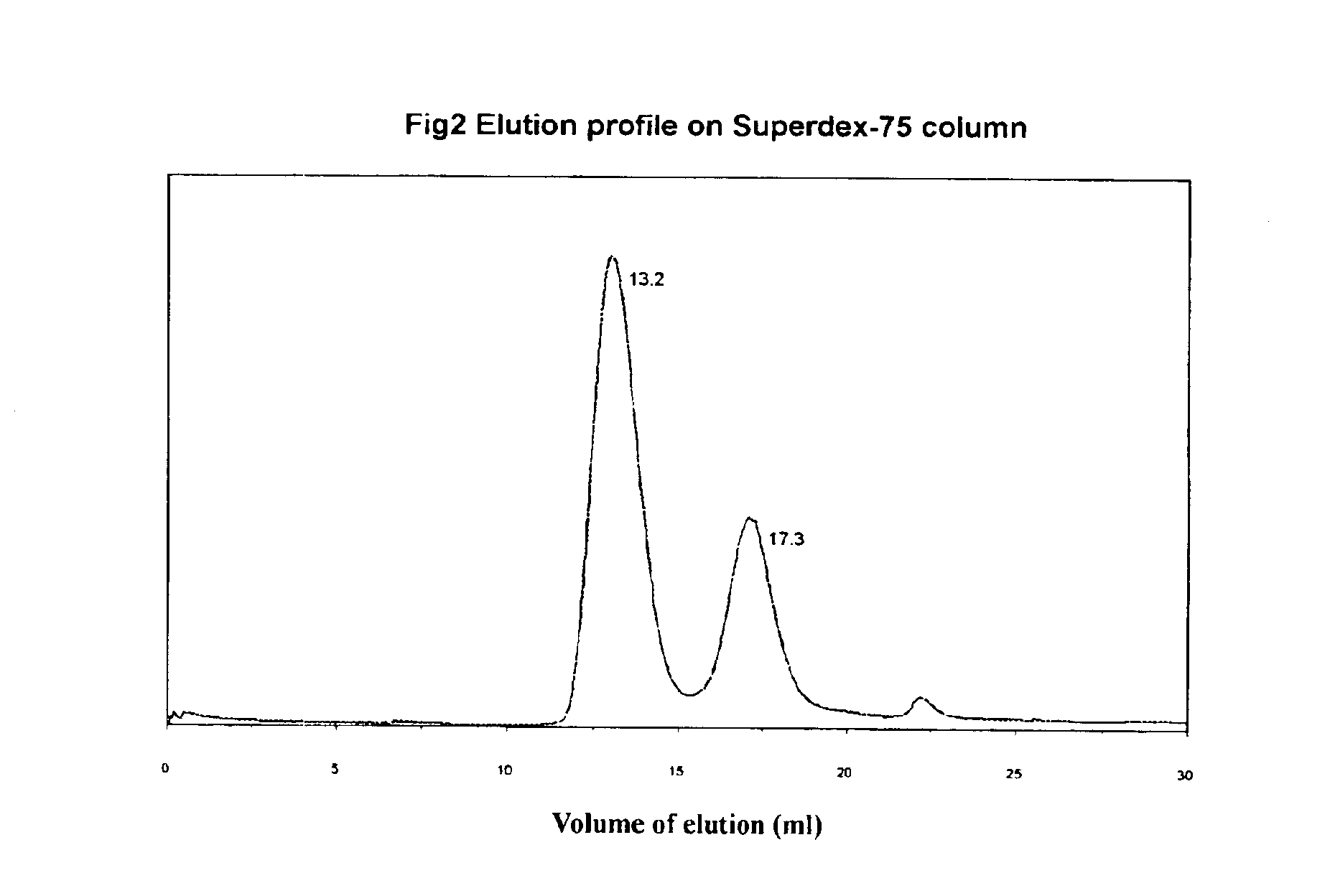

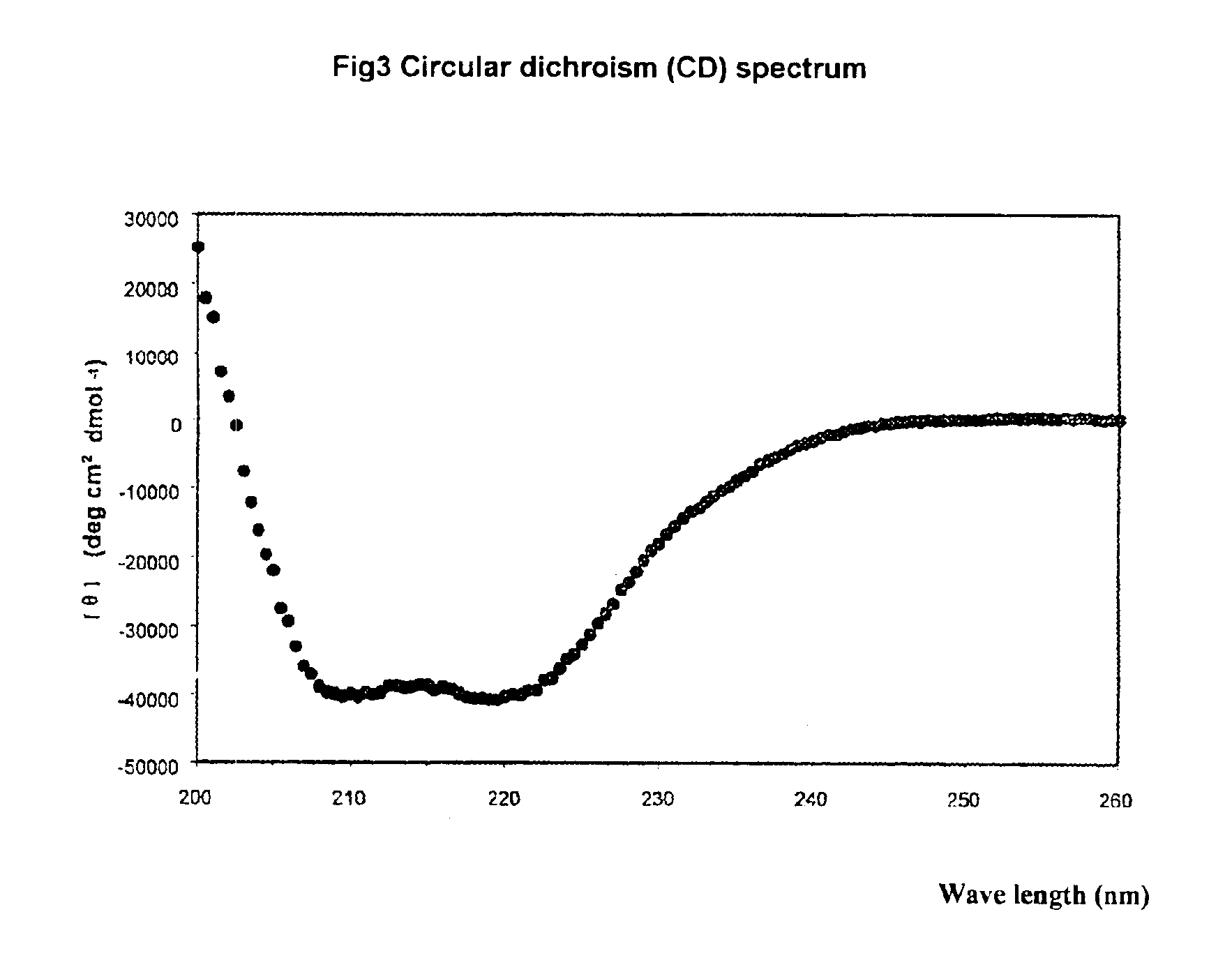

Pharmaceutical being used for treating HIV infection, the composition and uses thereof

InactiveUS6962900B2Reduce loadMaintain antiviral activityBiocideOrganic active ingredientsChemistryPeptide sequence

A pharmaceutical being used for treating HIV infection is provided which has the following peptide sequence: X-SWETWEREIENYTKQIYKILEESQQDRN-EKDRNEKDLLE-Z, where S is Serine, W is Trytophan, E is Glutamate, T is Threonine, R is Argine, I is Isoleucine, N is Asparagine, Y is Tyrosine, K is Lysine, Q is Glutamine, L is Leucine, D is Aspartic acid, X is amino group, acetyl-hydrophobic group, or macromolecule carrier group, Z is carboxyl group, amino group, amido group, tert-nutyloxycarbonyl group, hydrophobic group, or macromolecule carrier group. The drug inhibits strongly the infection of HIV.

Owner:TIANJIN FUSOGEN BIOTECH CO LTD

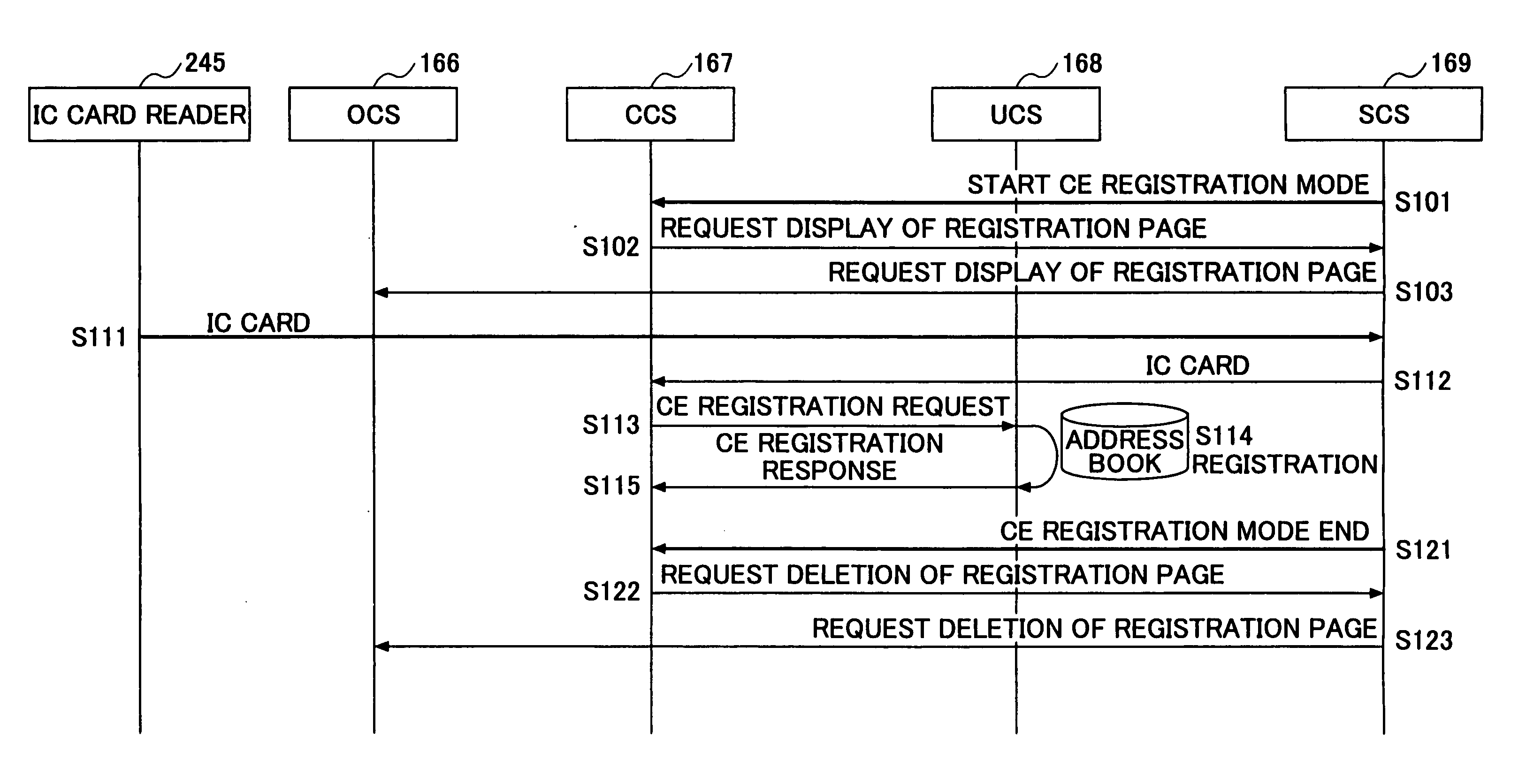

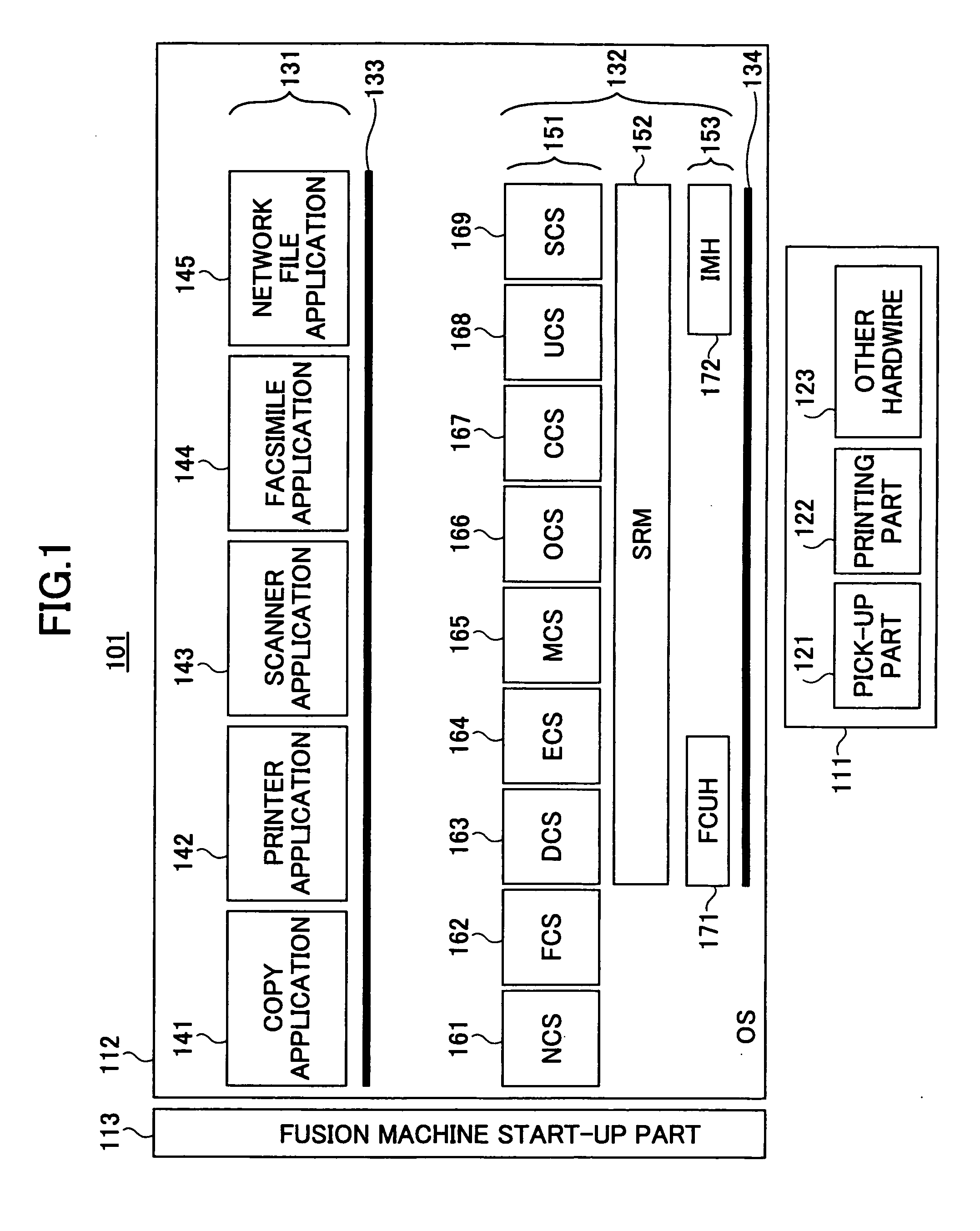

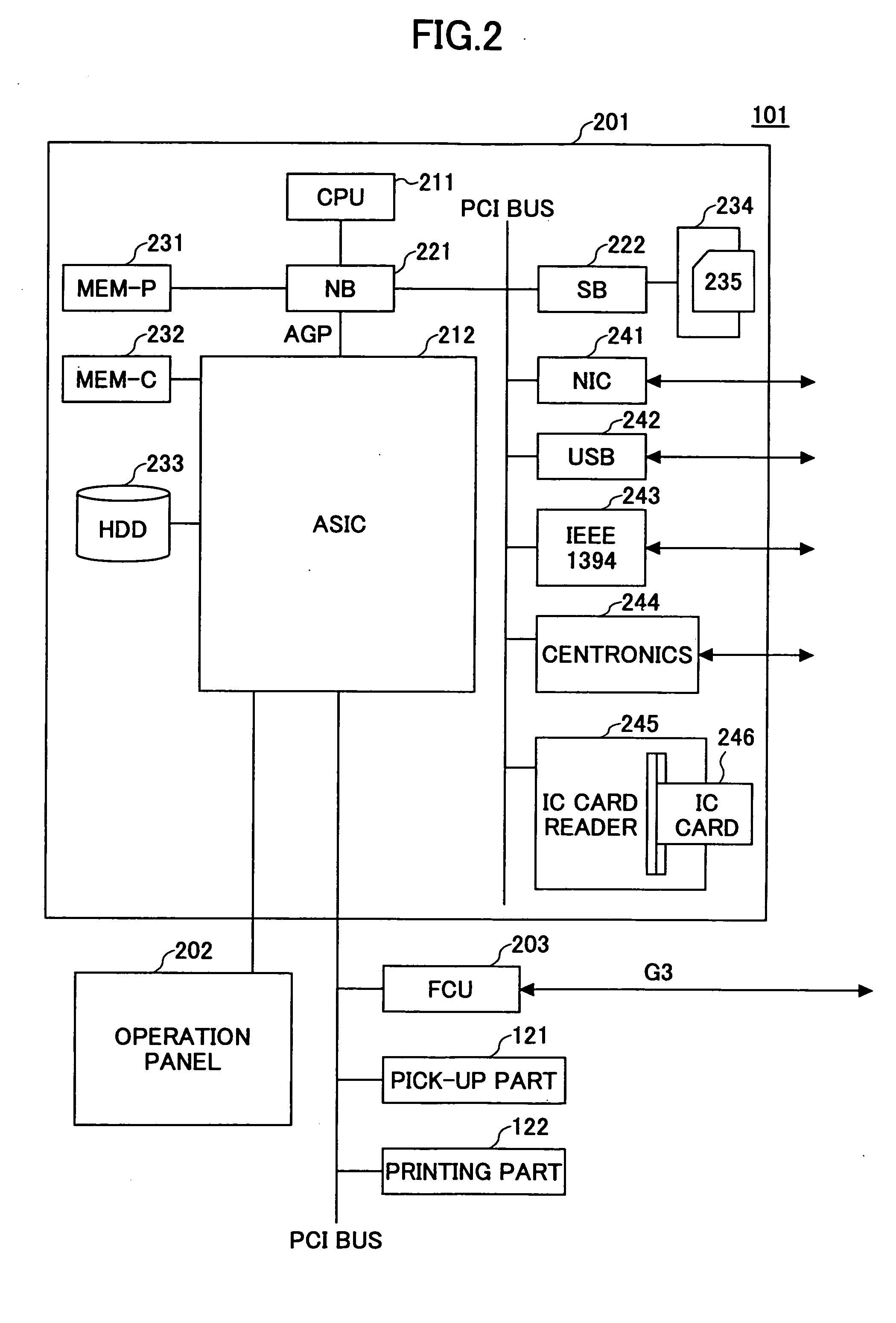

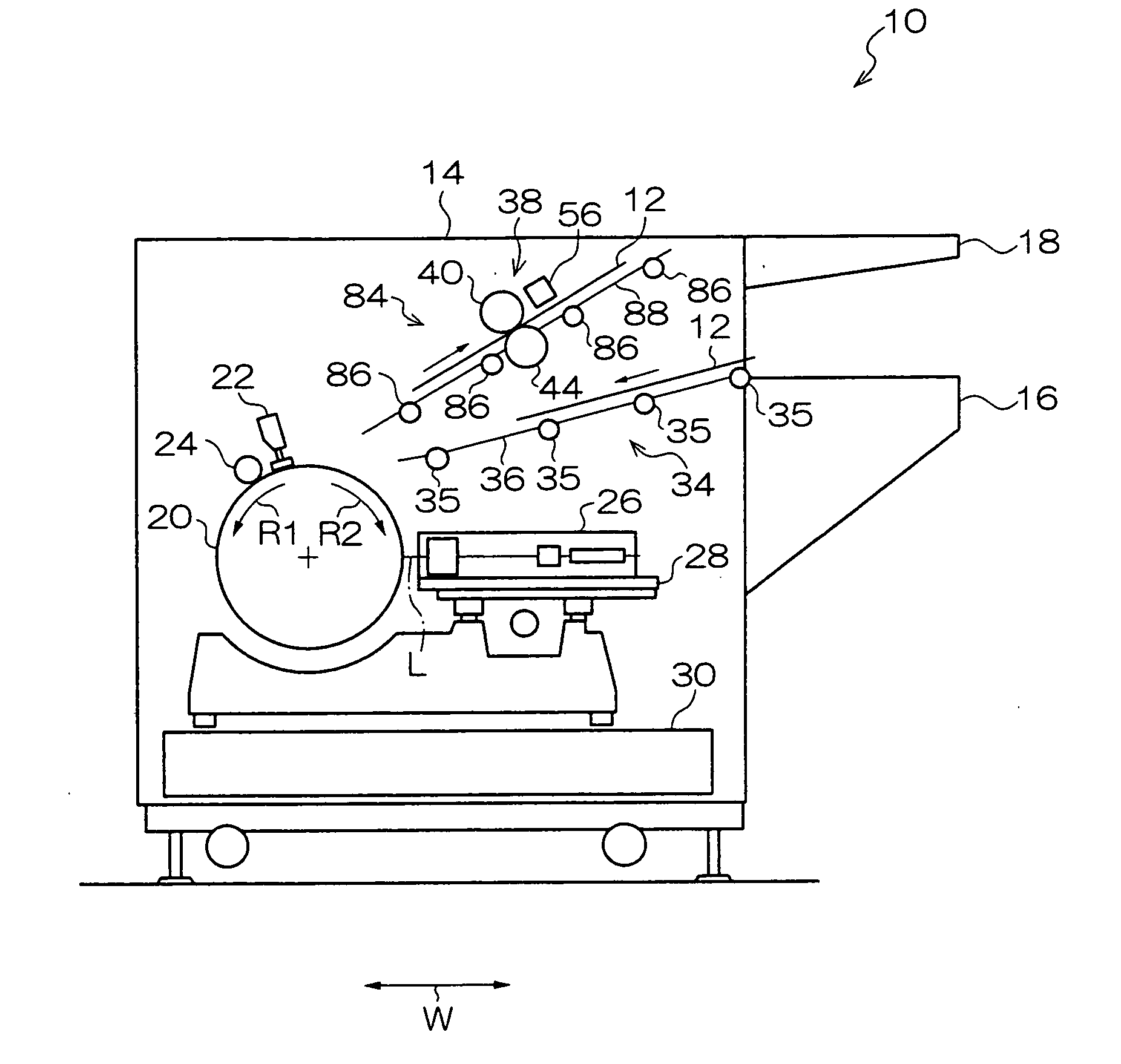

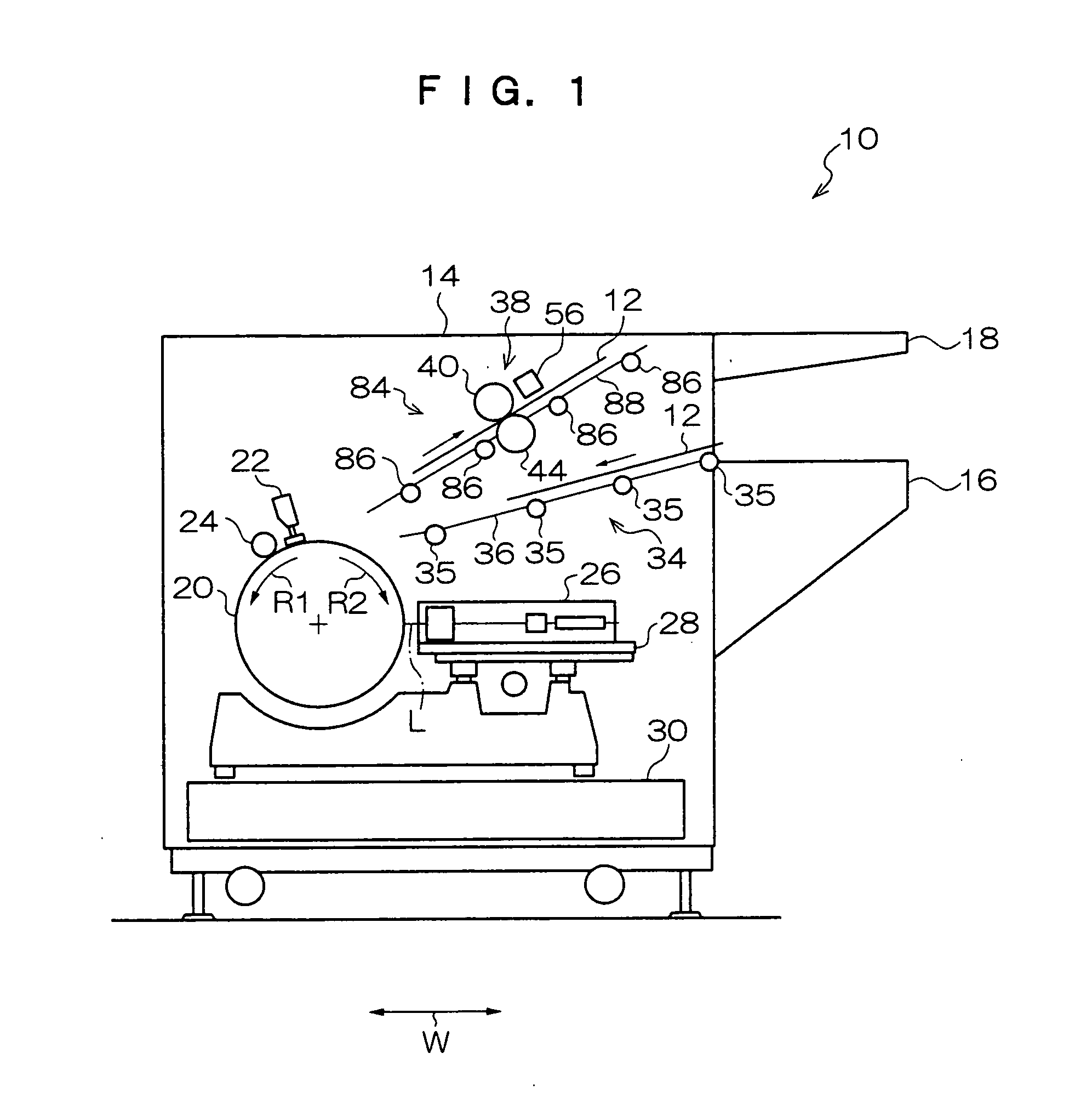

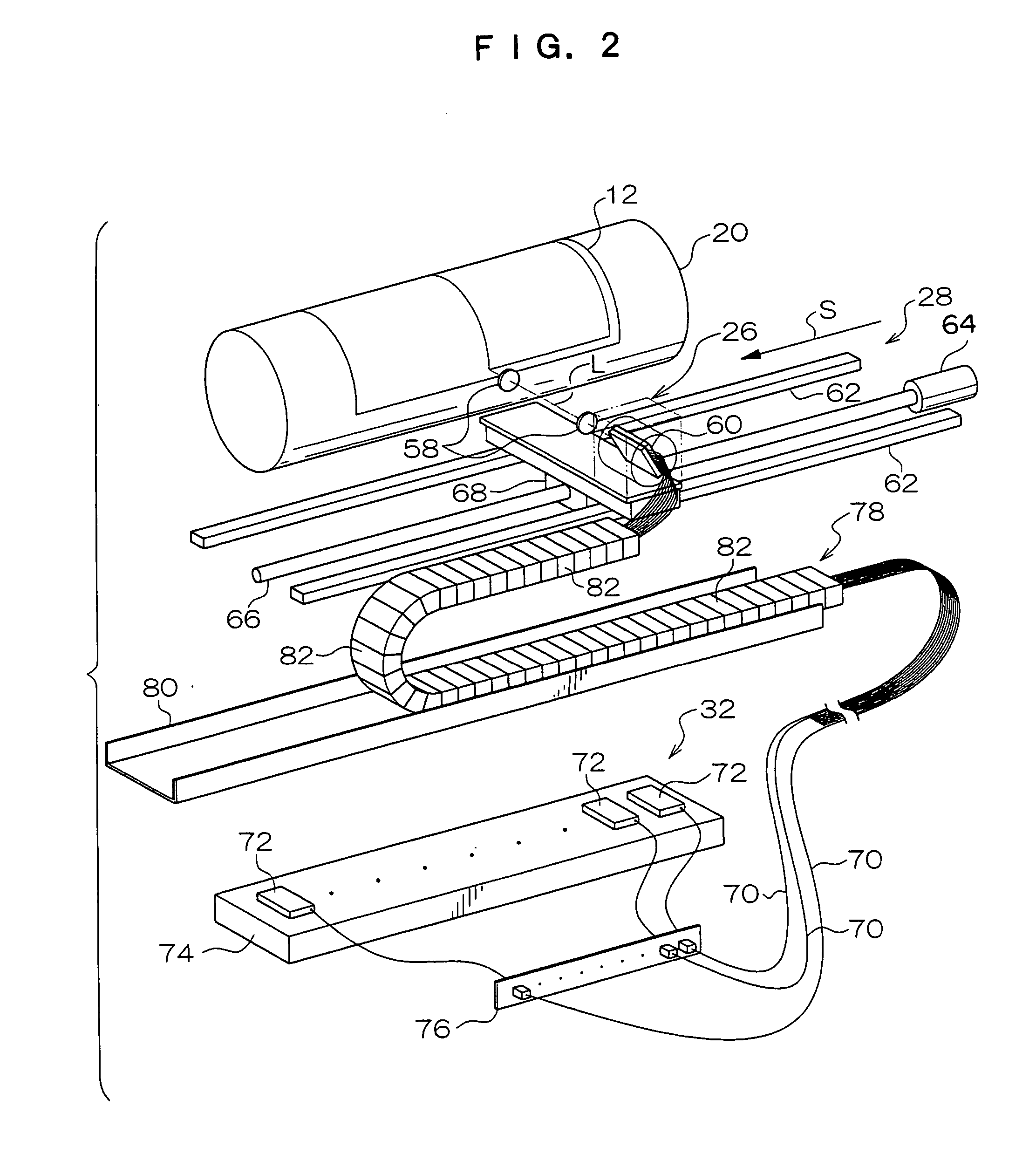

Information processing apparatus, information processing method, information processing program and computer readable recording medium

InactiveUS20050259288A1Interest be increaseInformation leakageElectric signal transmission systemsDigital data processing detailsService workerOperating system

In an information processing apparatus having a service mode for a service person to carry out maintenance of the apparatus enters for carrying out the maintenance, a registration page is provided for registering the service person as a service person in charge of the maintenance of the apparatus, and an input page is provided for inputting authentication information required for the service person that is registered in the registration page as a person in charge of the maintenance of the apparatus to enter the service mode.

Owner:RICOH KK

Sacroiliac screw

An improved joint fusion screw for transiliac fixation has a screw head and extending therefrom an elongate hollow shaft. The hollow shaft has an externally threaded end portion extending to a tip end and a non-externally threaded shank portion having a plurality of window openings. At or near the tip end is a start of a thread with a bone cutting flute. The bone cutting flute has a cutting edge on a circumferential exterior of the threaded tip to cut bone and directs the cut bone internally into a bone receiving opening in the hollow shaft directly in front of the cutting flute. The cutting edge lies at the start of the thread extending radially above the bone receiving opening at least partially overhanging the opening configured to cut bone.

Owner:SPINAL ELEMENTS INC

Additive and subtractive manufacturing process for producing implants with homogeneous body substantially free of pores and inclusions

ActiveUS10111753B2Improve fusionPromote growthAdditive manufacturing apparatusBone implantBone growthNanostructure

Implants are formed from a multiple staged process that combines both additive and subtractive techniques. Additive techniques melt powders and fragments of a desired material, then successively layer the molten material into the desired implant shape, without compressing or remelting for homogenization of the layers, thereby producing an implant that is substantially free of pores and inclusions. Subtractive techniques refine implant surfaces to produce a bioactive roughened surface comprised of macro, micro, and nano structural features that facilitate bone growth and fusion.

Owner:TITAN SPINE

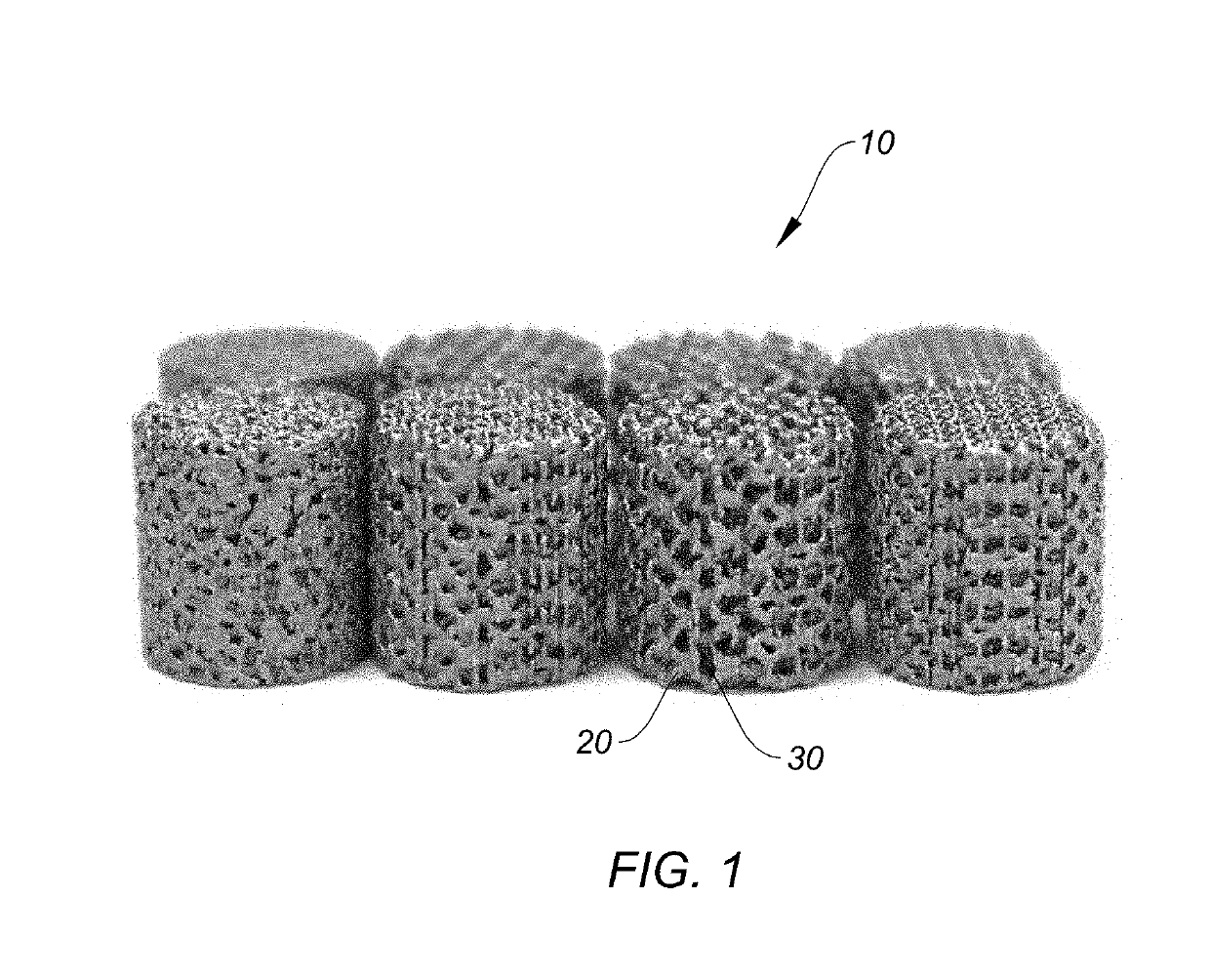

Porous implantable interbody devices

PendingUS20190117410A1Enhancing fusion of boneImprove fusionJoint implantsSpinal implantsWound healingBone regeneration

Various porous implantable interbody or spinal fusion devices, which may be formed of metal, metal alloy or polymer are provided. These porous implantable interbody devices may be engineered to have a porous network or scaffold structure for repairing and / or replacing damaged bone segments in the spine while allowing better fusion for improved bone healing and bone regrowth.

Owner:CENTINEL SPINE LLC

Image forming method and image exposure device

InactiveUS20050064337A1Improve mobilityIncrease heightPhotomechanical apparatusLithographyImage recordingImage formation

A method for forming an image on a planographic printing plate precursor including a substrate and an image recording layer disposed thereon, the layer including a hydrophobic precursor and a light-to-heat converting agent. The method includes an image exposing process of exposing the planographic printing plate precursor to infrared radiation to form an image on the image recording layer of the planographic printing plate precursor, and a post-heating process of heating the planographic printing plate precursor to a predetermined heating temperature.

Owner:FUJIFILM HLDG CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com