Flexible light-emitting diode (LED) lamp band and manufacturing method thereof

A technology of LED light strips and LED light sources, which is applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., to achieve good heat dissipation performance, high stability, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

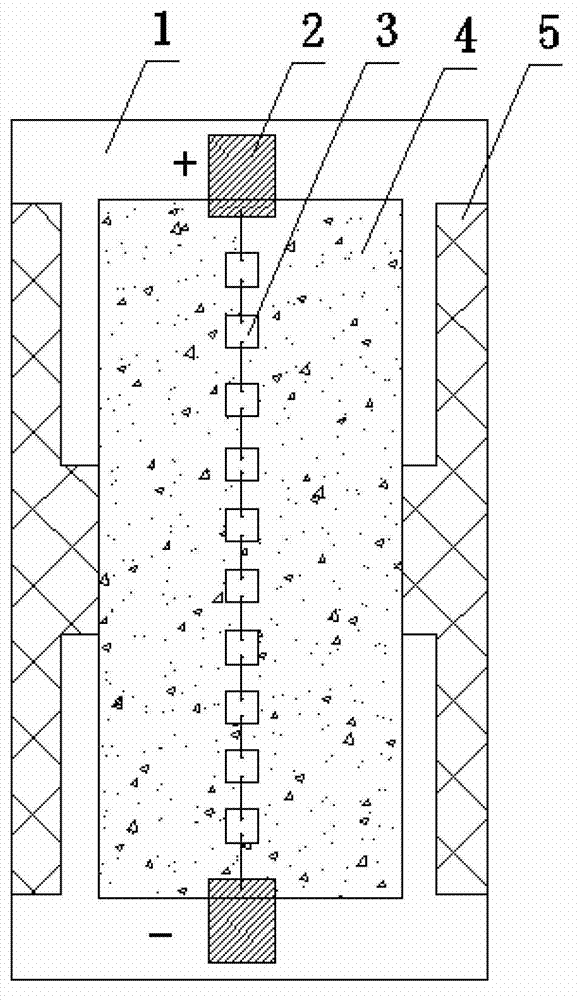

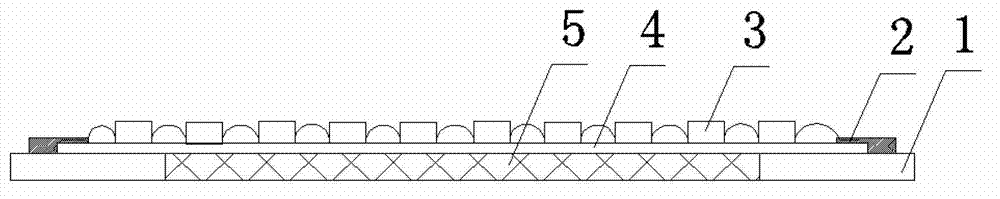

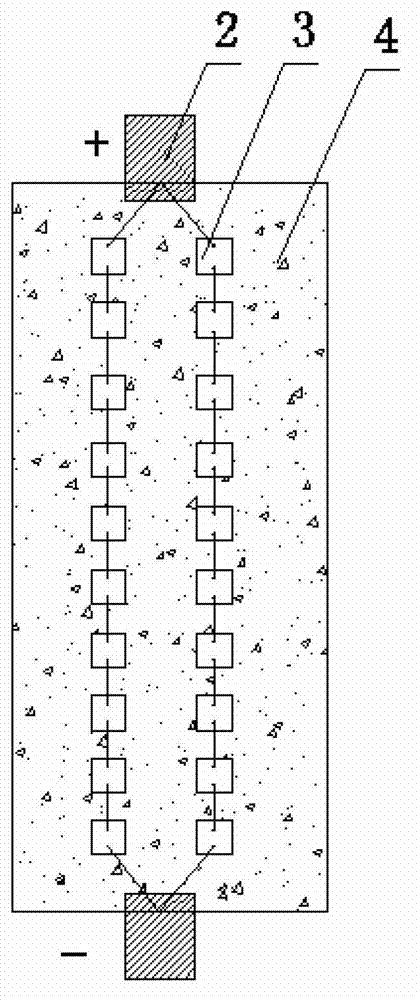

[0030] Such as figure 1 , figure 2 As shown, a flexible LED light strip is formed by arranging a plurality of LED light source modules. The LED light source module includes two isolated upper and lower copper sheets 1 and a copper sheet connected between the upper and lower two copper sheets 1. An insulating sheet 5, the upper surfaces of the copper sheet 1 and the insulating sheet 5 are coated with a heat-conducting layer 4, and at least one string of LED chips 3 are mounted on the heat-conducting layer 4, and on the upper and lower two copper sheets 1 Electrode welding points 2 are respectively provided, and the LED chips 3 are connected in series between the upper and lower electrode welding points 2 .

[0031] During the implementation process, the LED light source module is designed as a small rectangular box, and the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com