Laser welding tool for new energy resource power battery connecting piece

A laser welding and power battery technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems affecting the quality of laser welding, offset the position of nickel sheets, reduce work efficiency, etc., and achieve high composite efficiency and good product rate , Satisfy welding performance, improve welding quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

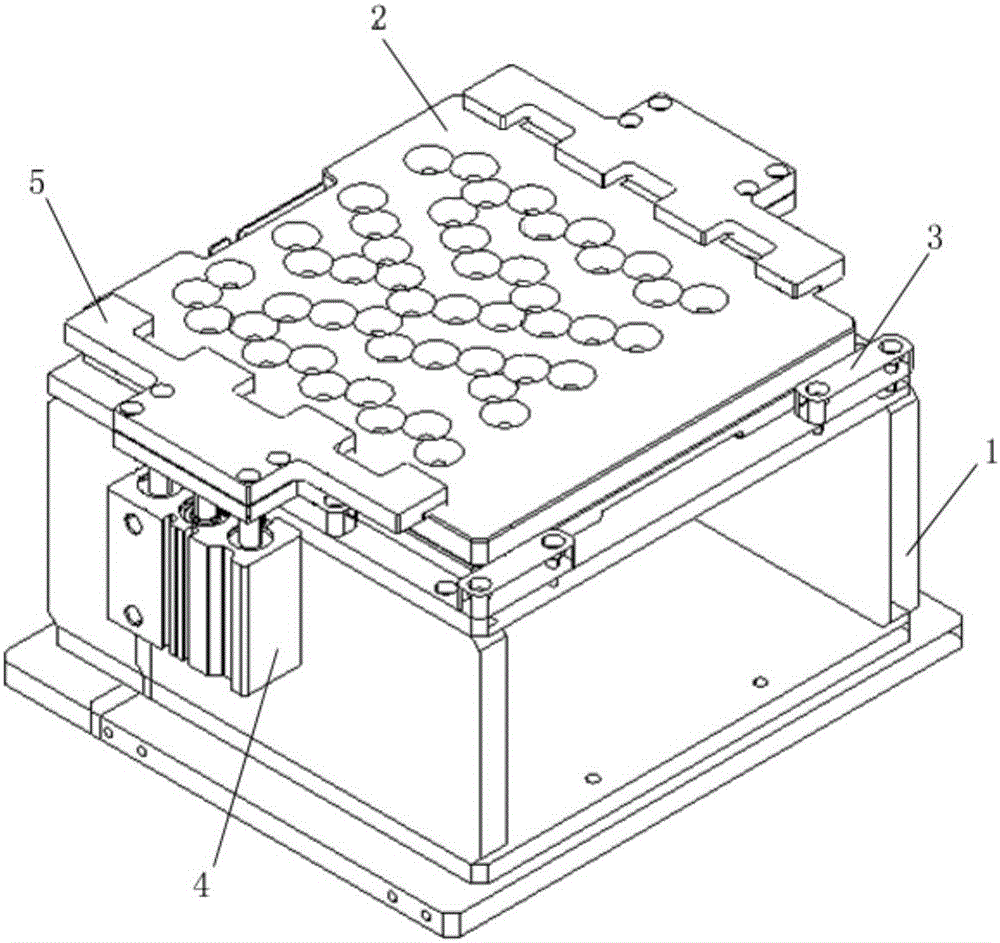

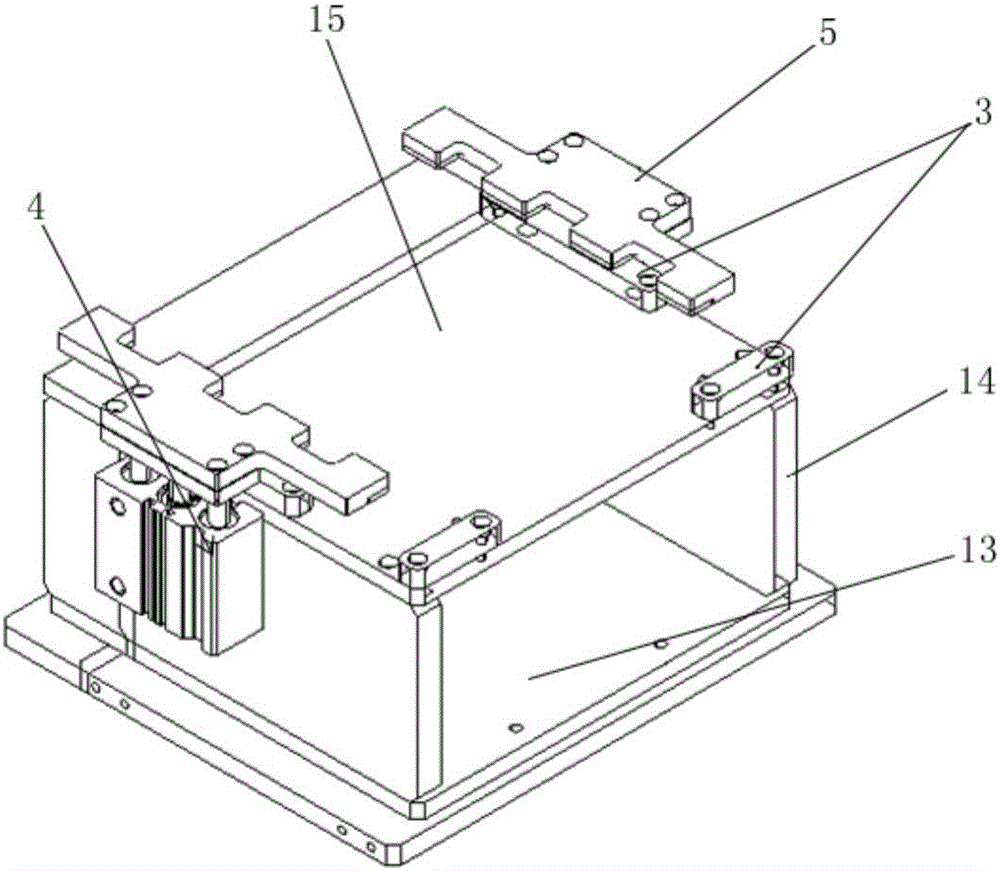

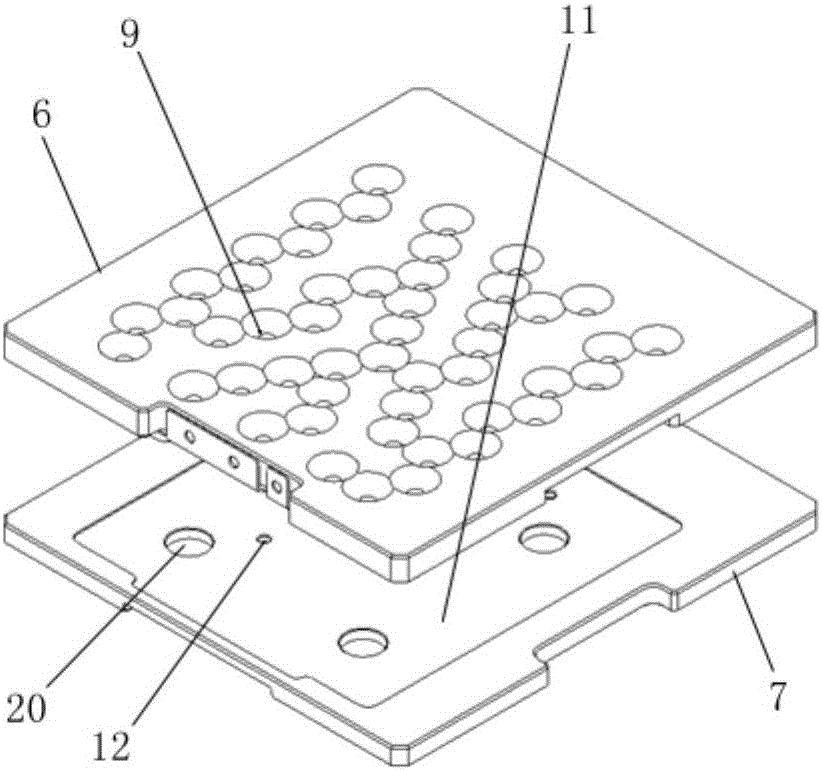

[0025] see figure 1 , image 3 , Figure 5 , Figure 7 , a new energy power battery connecting sheet laser welding tooling of the present invention, including a tooling table 1 and a fixture 2, the tooling table is provided with a fixture positioning block 3, and both sides of the tooling table are provided with a cylinder 4 and a pressure plate 5. The pressure plate is fixed on the head end of the piston rod of the cylinder; the clamp is composed of a bottom plate 6 and a cover plate 7, and the bottom plate is provided with ten rows of tab avoidance grooves 8, and the distribution positions of the tab avoidance grooves and The positions of the lugs on the molded nickel sheet 16 correspond to each other, and laser through holes 9 are arranged between the lug avoidance grooves, and the laser through holes are set correspondingly to the welding parts; The positioning pin 10 is provided with an accommodating groove 11 on the cover plate, and two positioning holes 12 are also p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com