Patents

Literature

77results about How to "No relative movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

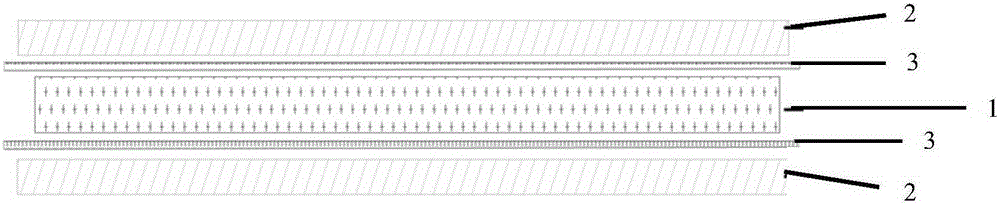

Lithium ion battery lamination unit, battery cell, battery cell preparing method and lithium ion battery

InactiveCN105336976AIncrease productivityAvoid misalignmentLarge-sized flat cells/batteriesFinal product manufactureElectrical polarityEngineering

The invention relates to a lithium ion battery lamination unit, a battery cell, a battery cell preparing method and a lithium ion battery and belongs to the technical field of lithium ion batteries. The lithium ion battery lamination unit comprises an inner electrode slice, membranes and outer electrode slices, wherein the polarity of the inner electrode slice and the polarity of the outer electrode slices are opposite, the membranes are attached to the two side faces of the inner electrode slice respectively through a binder, and the outer electrode slices are attached to the outer side faces of the membranes through the binder. According to the lithium ion battery lamination unit, on one hand, dislocation of the membranes relative to the electrode slices can be prevented, and a short circuit between a positive plate and a negative plate can not be formed; on the other hand, during battery cell manufacturing, due to the fact that part of procedures of clamping membranes in the electrode slices are omitted, battery cell manufacturing time is shortened greatly, and the production efficiency of the lithium ion battery is improved.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

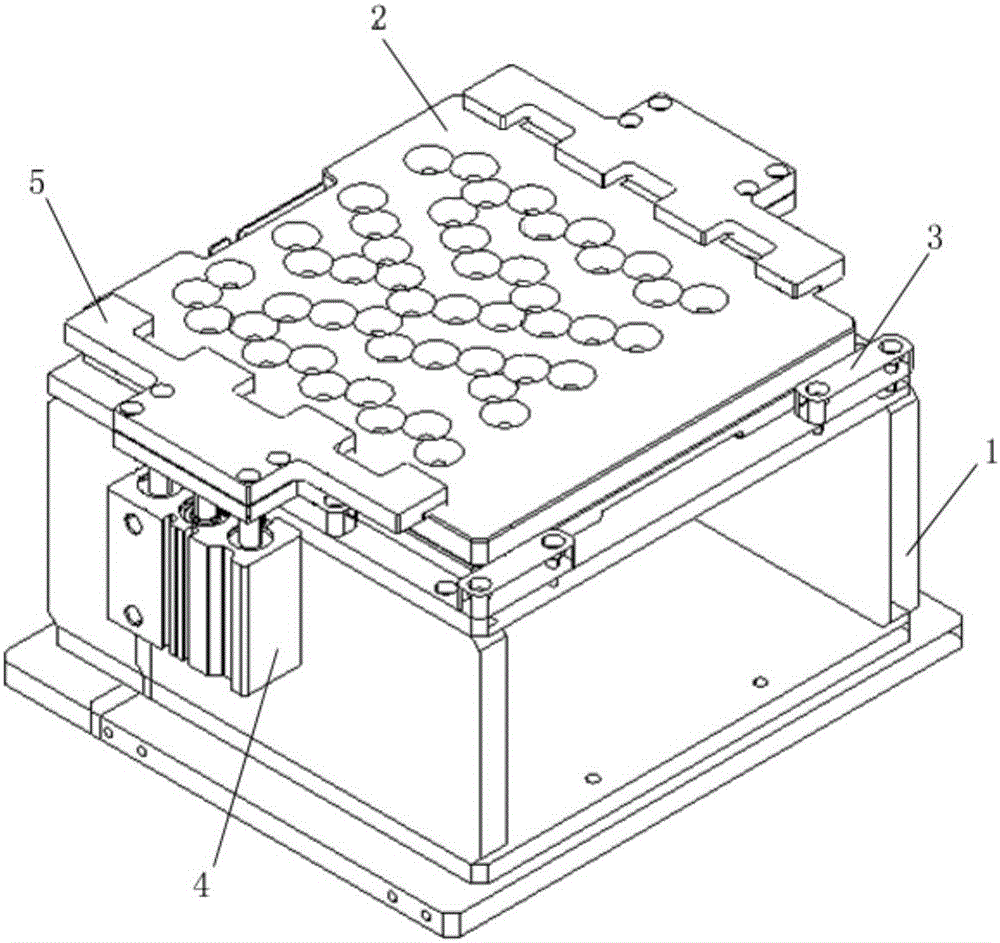

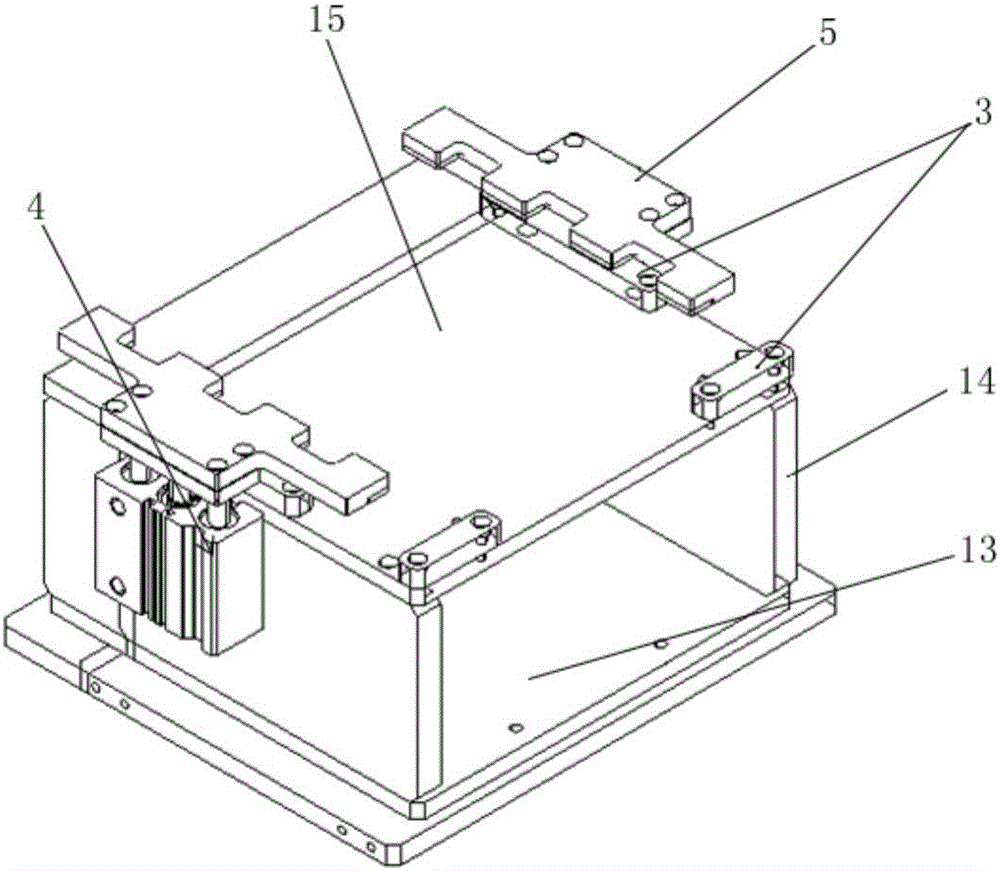

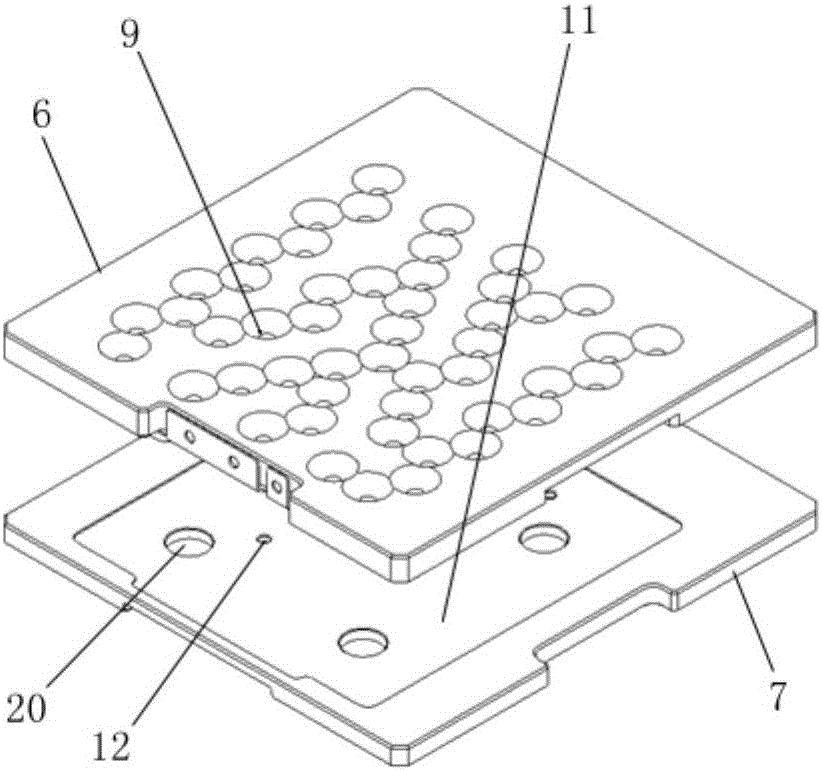

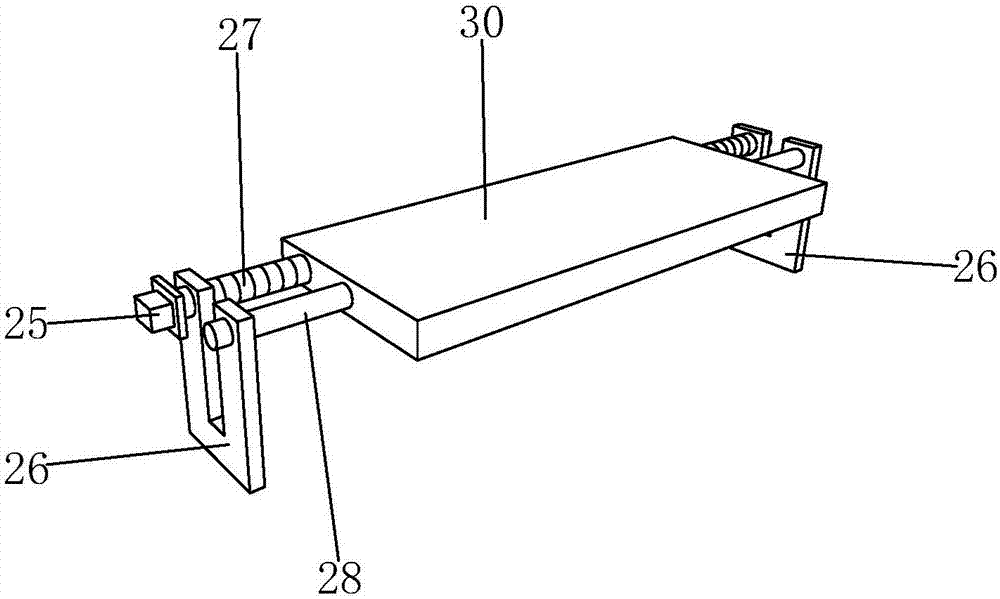

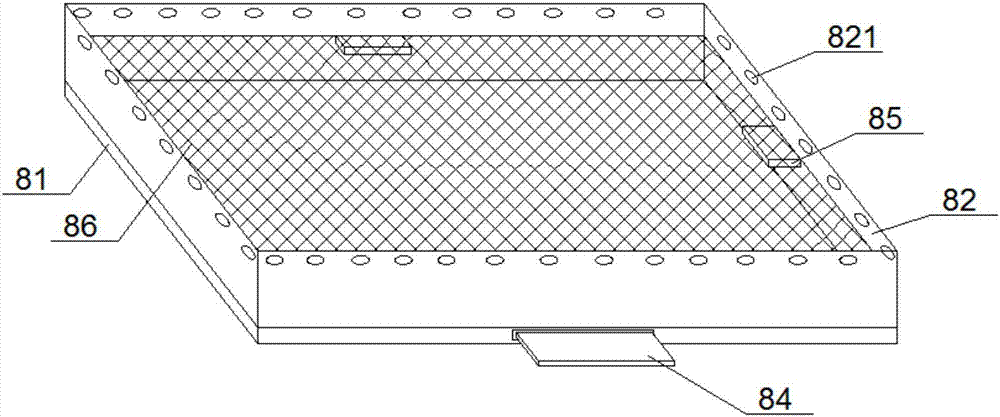

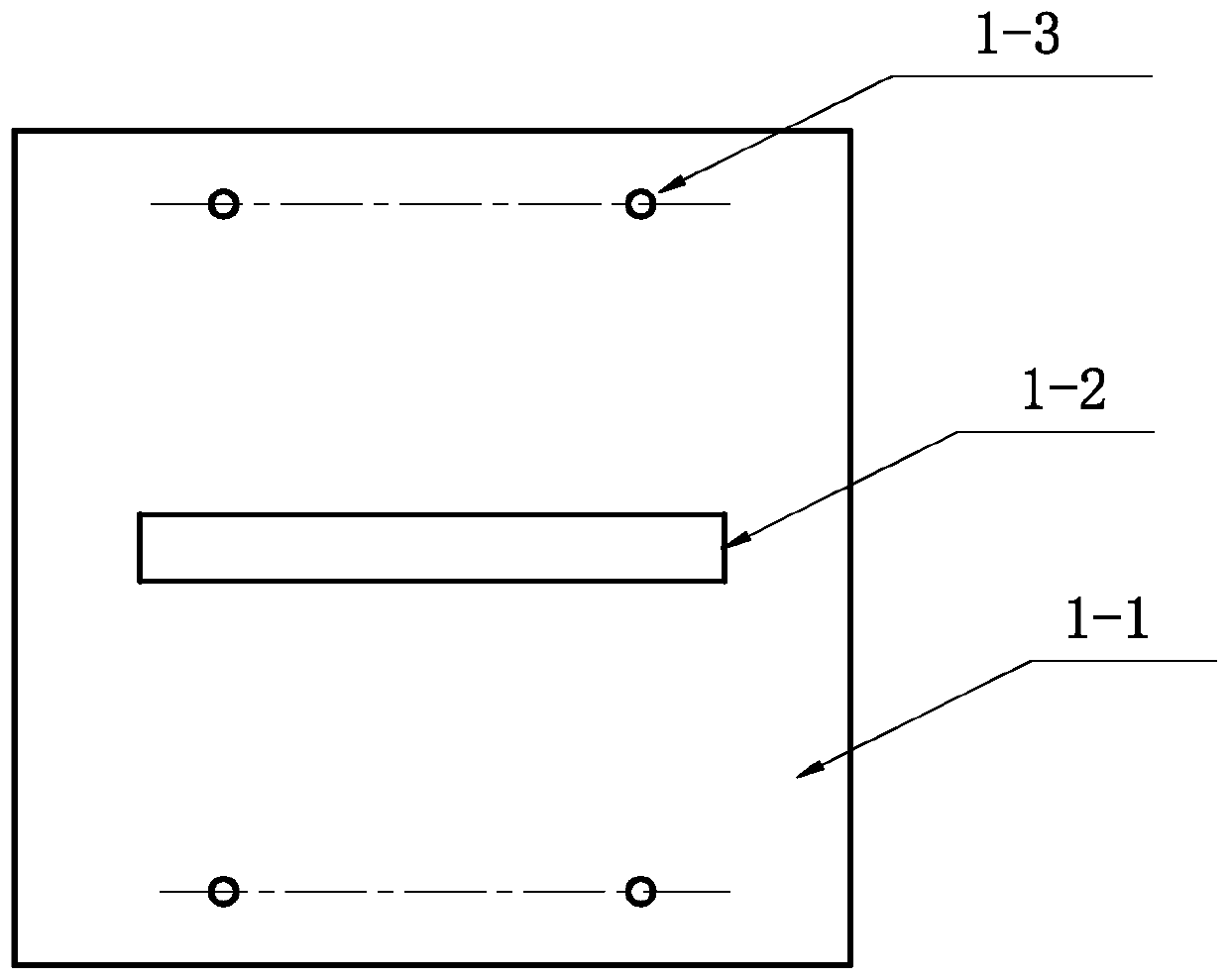

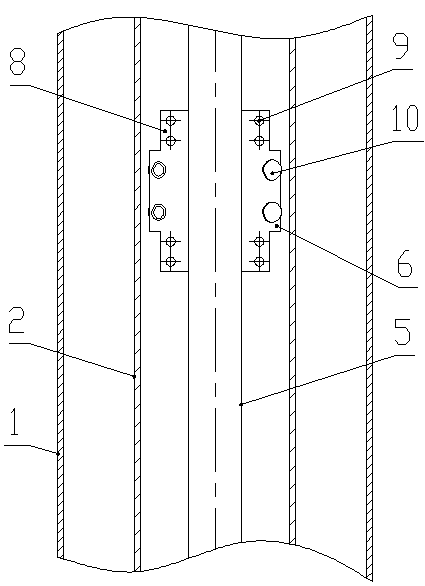

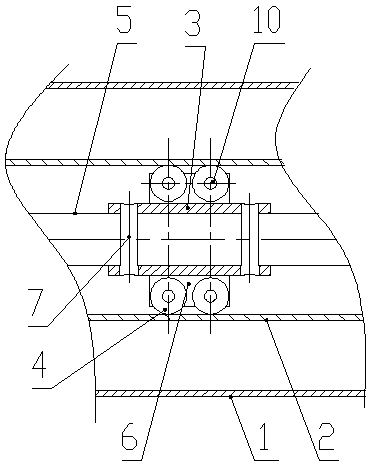

Laser welding tool for new energy resource power battery connecting piece

InactiveCN106624361APrecise positioningWeld firmlyLaser beam welding apparatusPower batteryNew energy

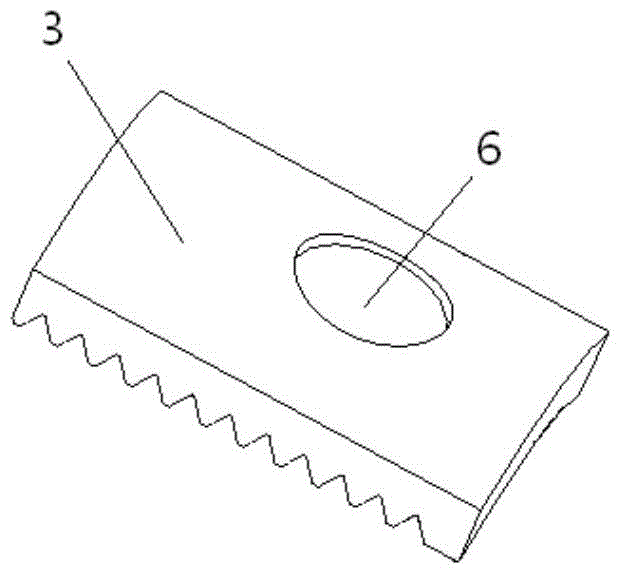

The invention relates to a laser welding tool for a new energy resource power battery connecting piece. The laser welding tool comprises a tool table and a clamp, wherein a clamp positioning block is arranged on the tool table, air cylinders and press plates are arranged on two sides of the tool table, and the press plates are fixed to the head ends of piston rods of the air cylinders. The clamp consists of a base plate and a cover plate, wherein a plurality of rows of tab avoiding grooves are formed in the base plate, distribution positions of the tab avoiding grooves correspond to the positions of die-sunken nickel piece tabs, and laser transmitting holes are formed among the tab avoiding grooves and correspond to welding positions. Two positioning pins are further arranged on the base plate, an accommodating groove is formed in the cover plate, and two positioning holes are further formed in the cover plate and correspond to the positioning pins. The laser welding tool can accurately position nickel pieces and copper bars and perform firm clamping to ensure that the two parts are fit tightly and have no relative movement, and the welding quality and efficiency are improved.

Owner:FIRST NEW ENERGY GRP CO LTD

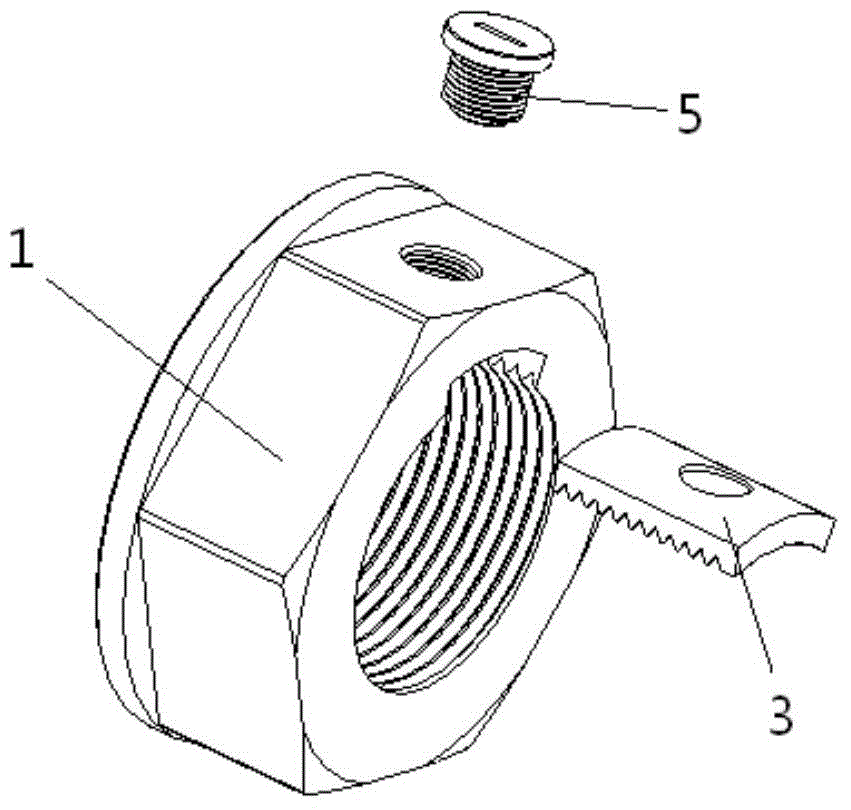

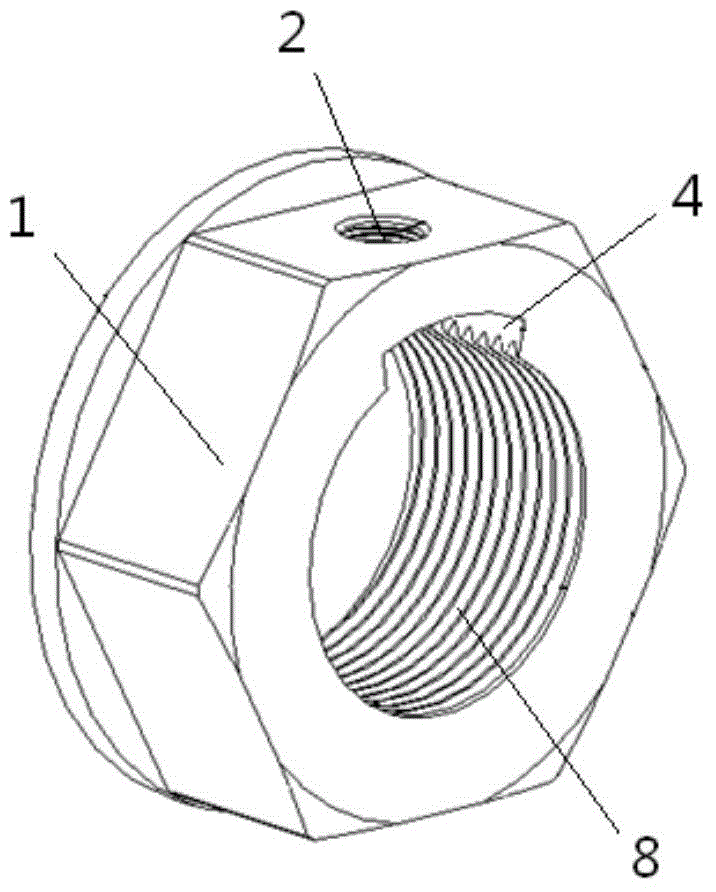

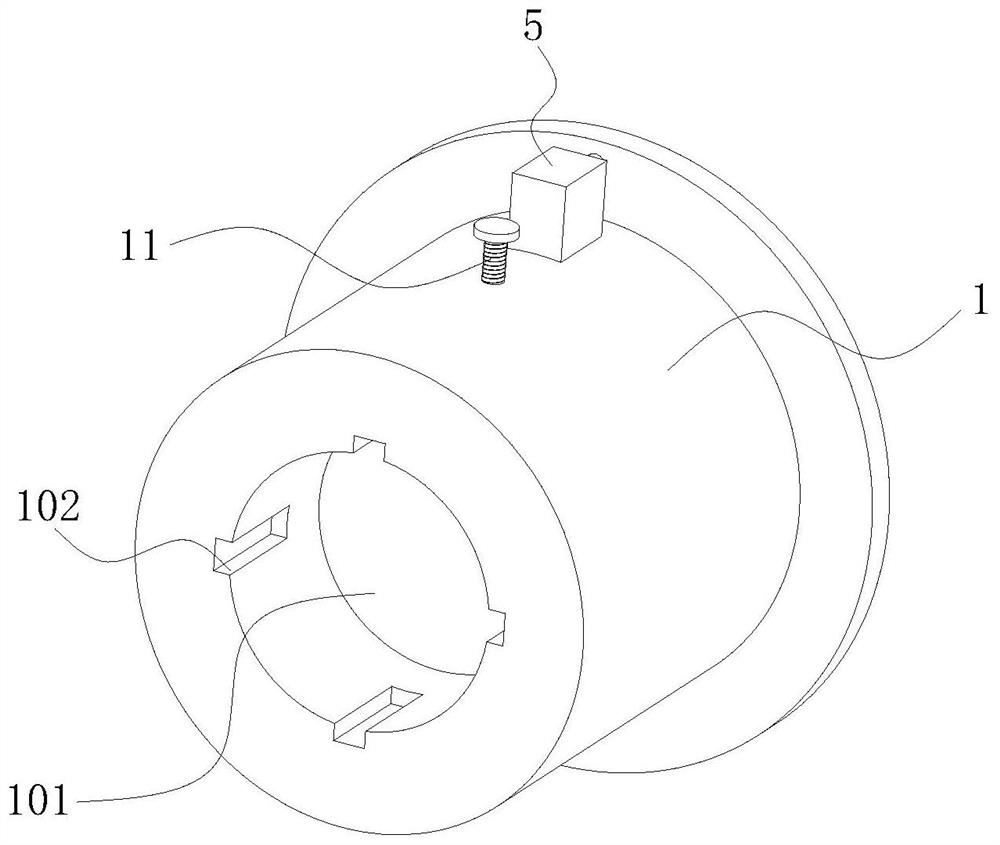

Anti-loose internal threaded part and screw joint device

The invention discloses an anti-loose internal threaded part and a screw joint device. The anti-loose internal threaded part comprises a body, wherein a first screw hole is formed in the body, an axial groove is formed in the inner wall of the first screw hole, and a locking piece is embedded in the axial groove; a second screw hole is formed in the side wall of the body, a locking screw is arranged in the second screw hole in a screw joint mode, and the tail end of the locking screw abuts against the locking piece. According to the anti-loose internal threaded part, when an external threaded part is screwed in the first screw hole, the locking screw is screwed down to press the locking piece, so that the locking piece located on the first screw hole presses the external threaded part and large static friction force is generated between the locking piece and the external threaded part, and then it is guaranteed that relative movement of the anti-loose internal threaded part and the external threaded part is avoided under vibration. Compared with a spring washer in the prior art, the anti-loose internal threaded part has the advantage that due to the fact that the locking piece and the locking screw are fixed to the body of the anti-loose internal threaded part, the application range is wider.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

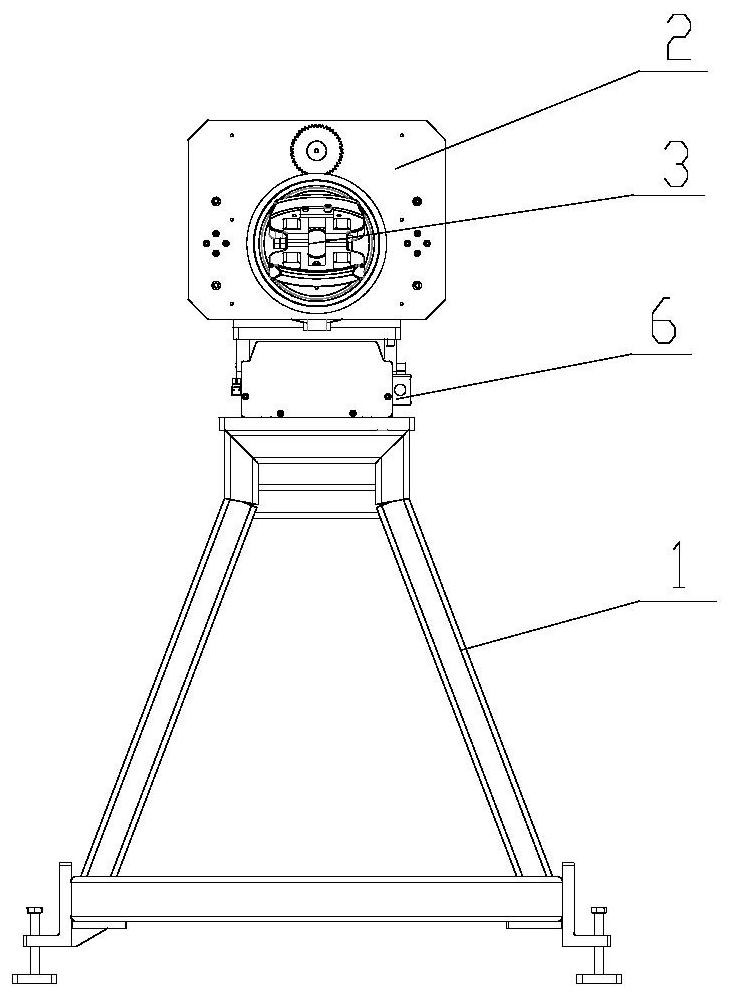

Mechanical drive dual-disc development device for development machine

InactiveCN102052080AReduce fuel consumptionImprove tunneling efficiencySlitting machinesTunnelsCircular discHydraulic cylinder

The invention discloses a mechanical drive dual-disc development device for a development machine, which consists of development heads, a development arm and a drive mechanism, wherein the development arm is arranged on a supporting mechanism; one end of the development arm is connected with the development heads by a diverter, and the other end of the development arm is connected with the drive mechanism by a universal coupling; the drive mechanism consists of a motor, a speed reducer and a drive shaft; and a hydraulic cylinder is also arranged on the supporting mechanism, and is connected with the development arm. The dual-disc development device adopts a unique design, realizes the mechanical drive of the development heads, has stable working performance and improves the development efficiency by over 50 percent.

Owner:兰海宽

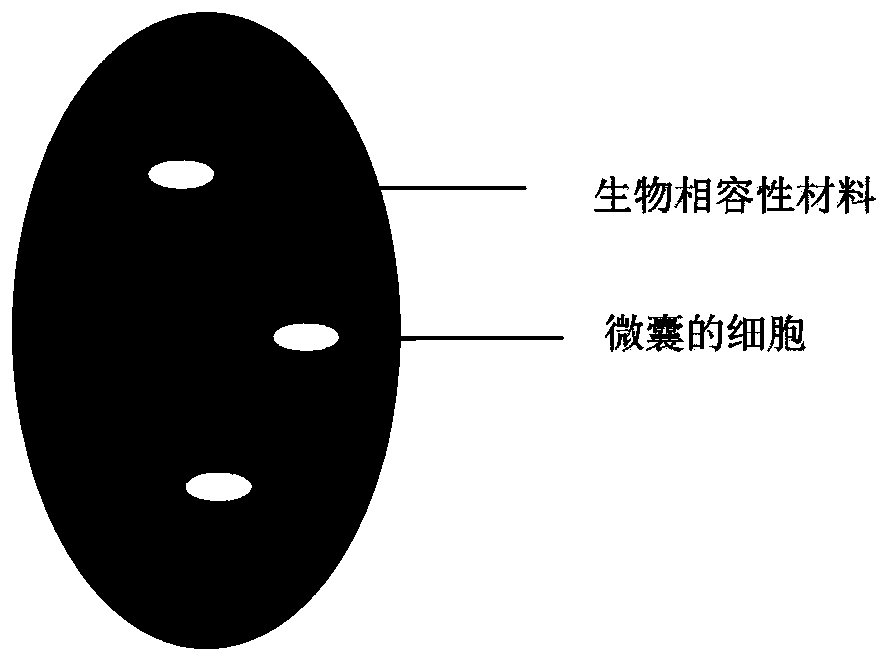

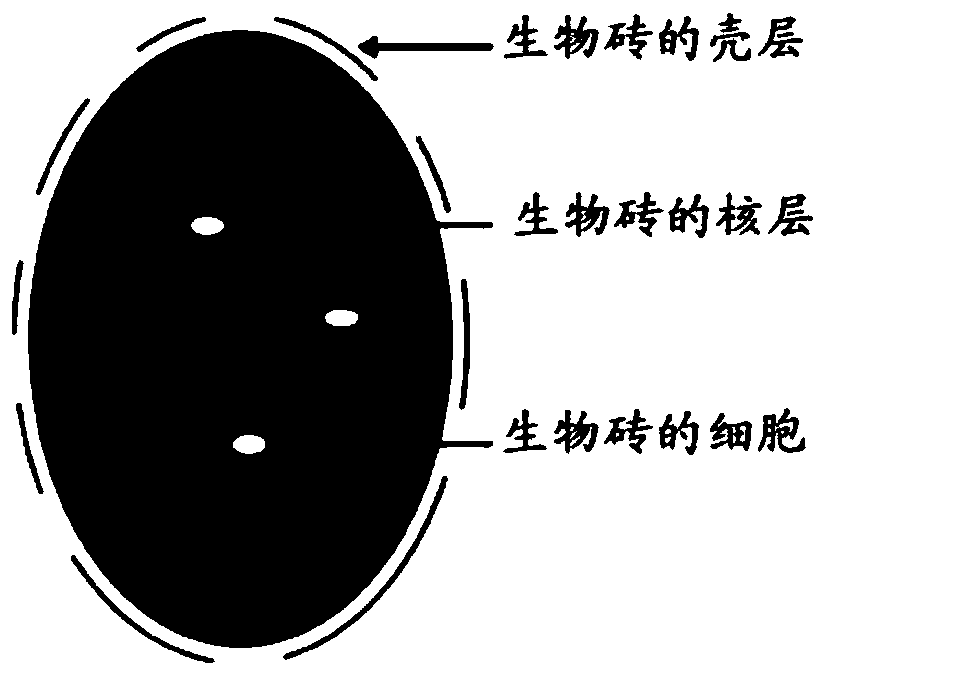

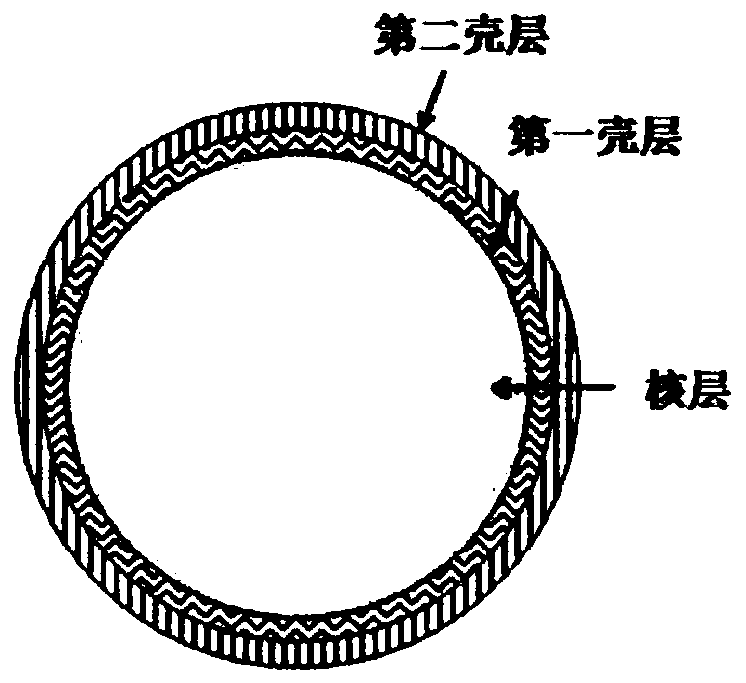

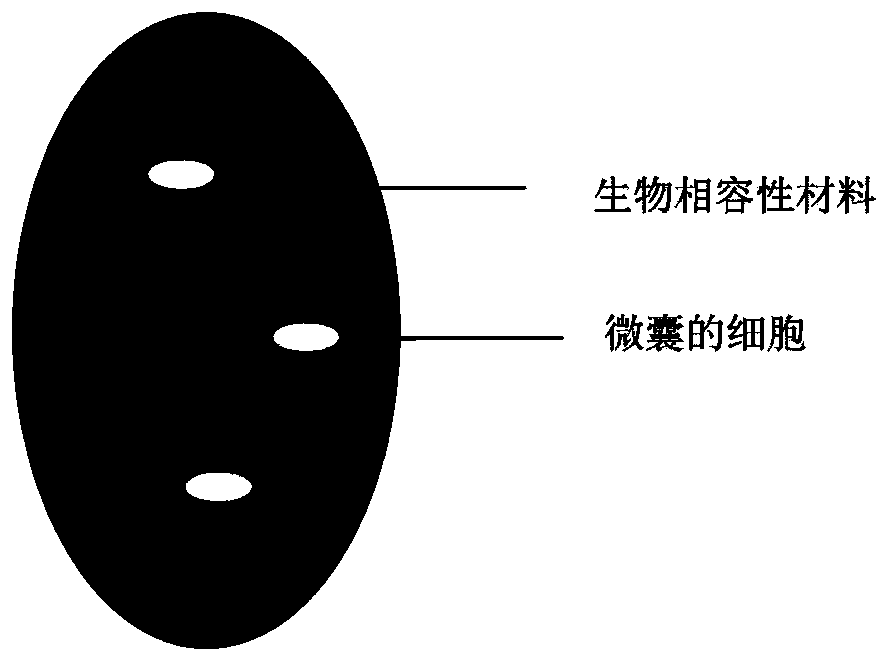

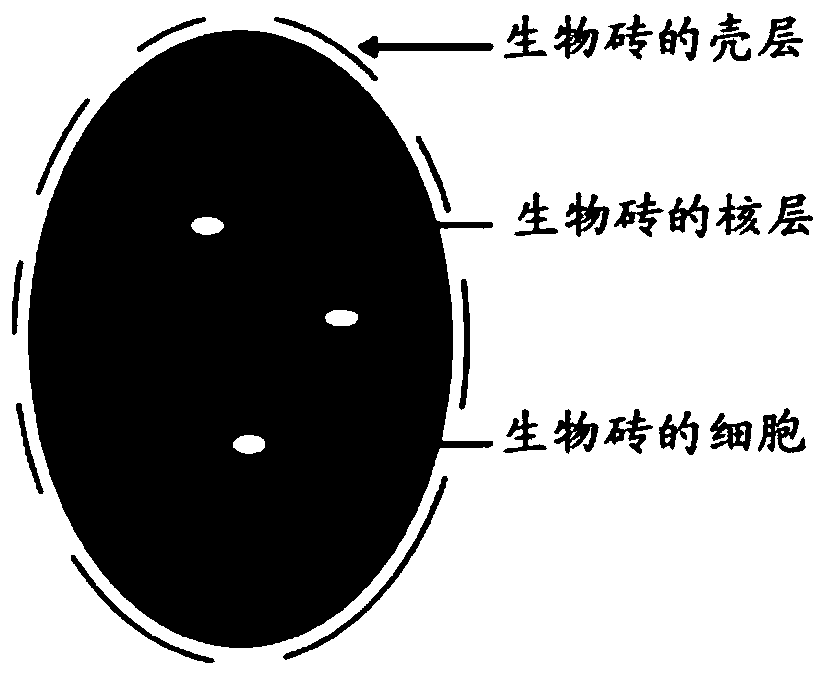

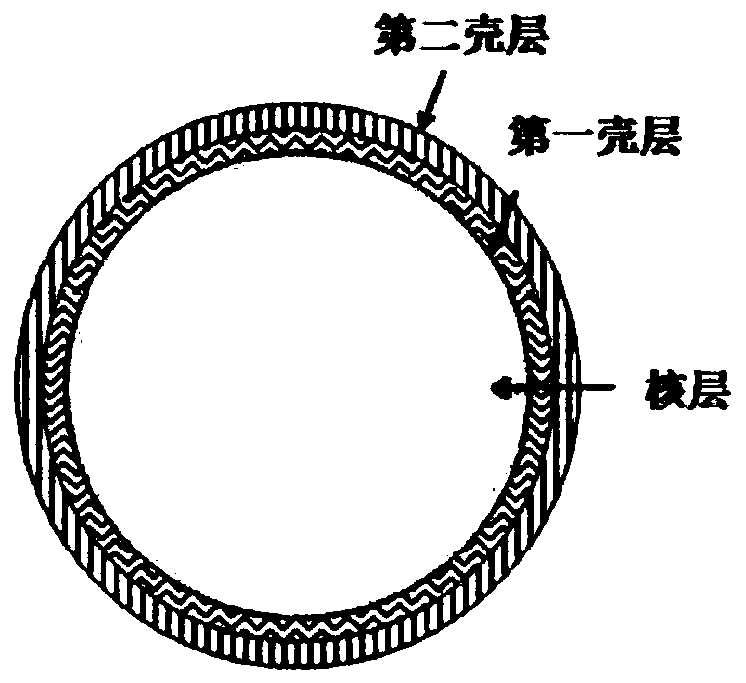

Artificial tissue precursor and preparation method thereof

ActiveCN109735434AComplete structureFunction increaseBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemistryBiomedical engineering

Owner:SICHUAN REVOTEK CO LTD

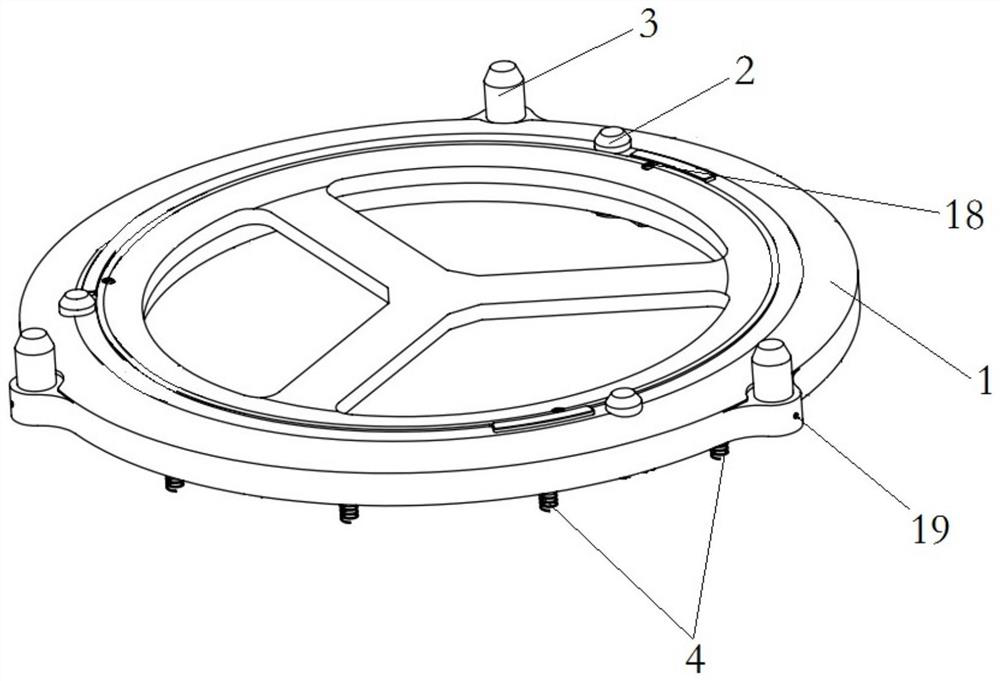

Bearing platform with wafer positioning function

ActiveCN111805416ANo offsetNo relative movementSemiconductor/solid-state device manufacturingLapping machinesWaferMechanical engineering

The invention provides a bearing platform with a wafer positioning function, and belongs to the technical field of semiconductors. The bearing platform comprises a substrate, the front surface of thesubstrate is provided with a clamping platform for supporting wafers, the periphery of the clamping platform is uniformly provided with a plurality of wafer positioning columns, polishing head positioning columns for positioning a polishing head are also arranged at the positions, on the outer sides of the wafer positioning columns, on the substrate, the bottom face of the substrate is suitable for being connected with a driving device through bolts, and the substrate is suitable for being elastically connected with the driving end of the driving device in an up-down sliding mode through the bolts. According to the bearing platform with the wafer positioning function, the wafer positioning precision is accurate, only one driving device is needed, and the reliability of the wafers in the loading and unloading process is improved.

Owner:北京晶亦精微科技股份有限公司

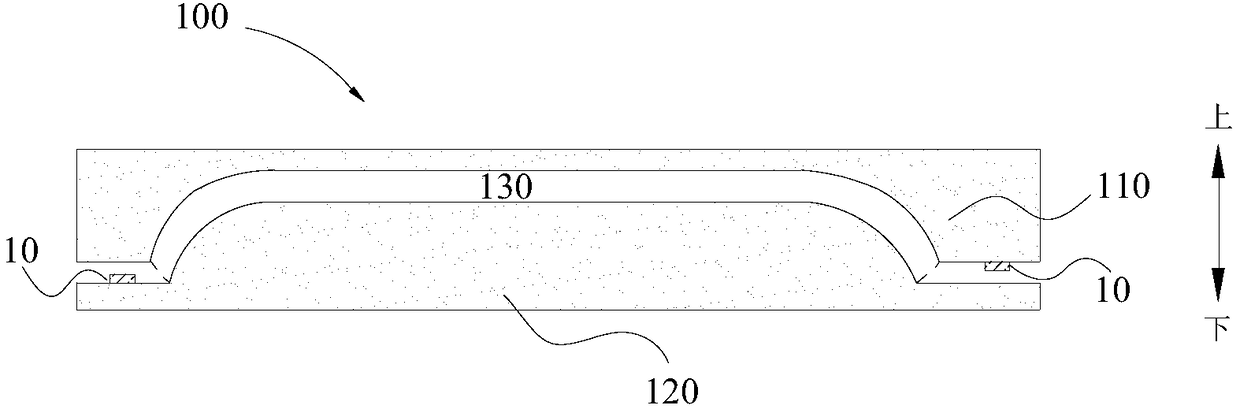

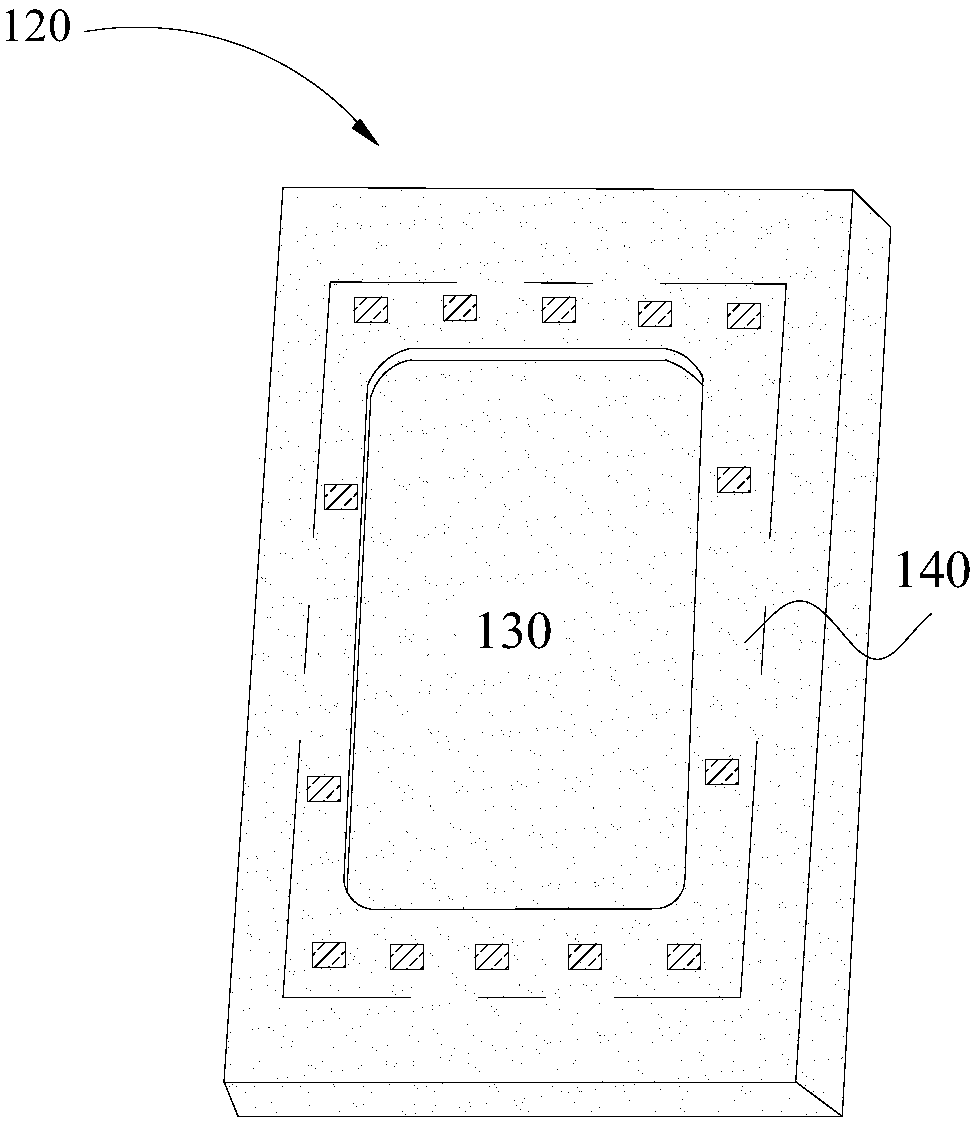

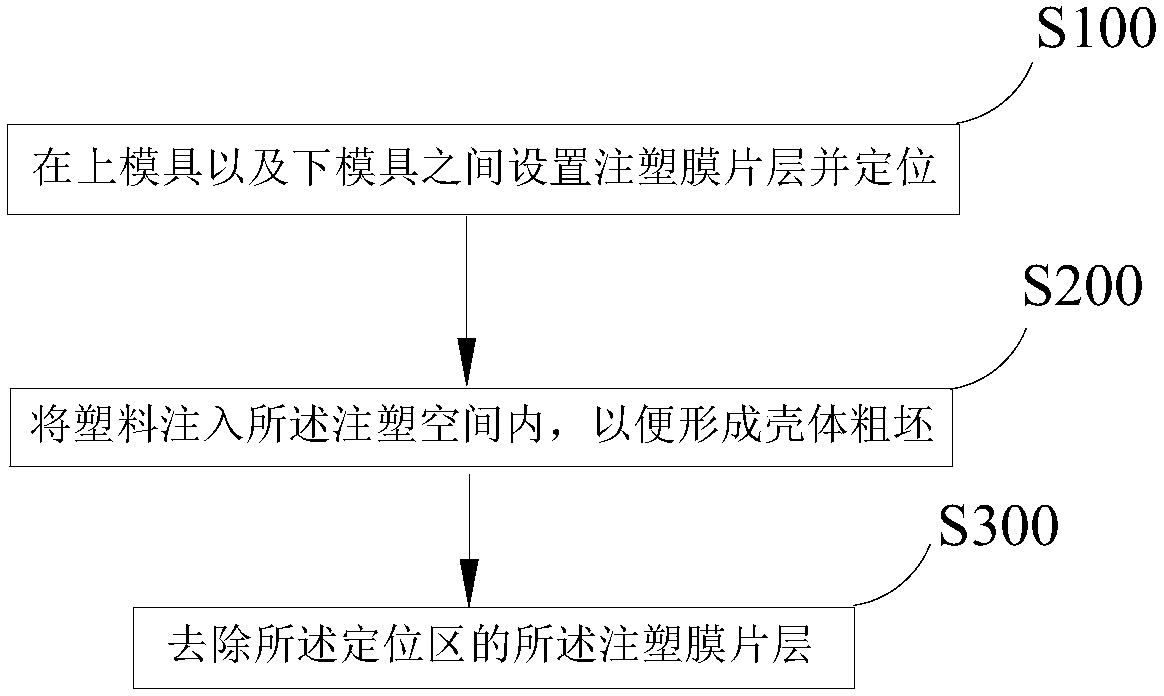

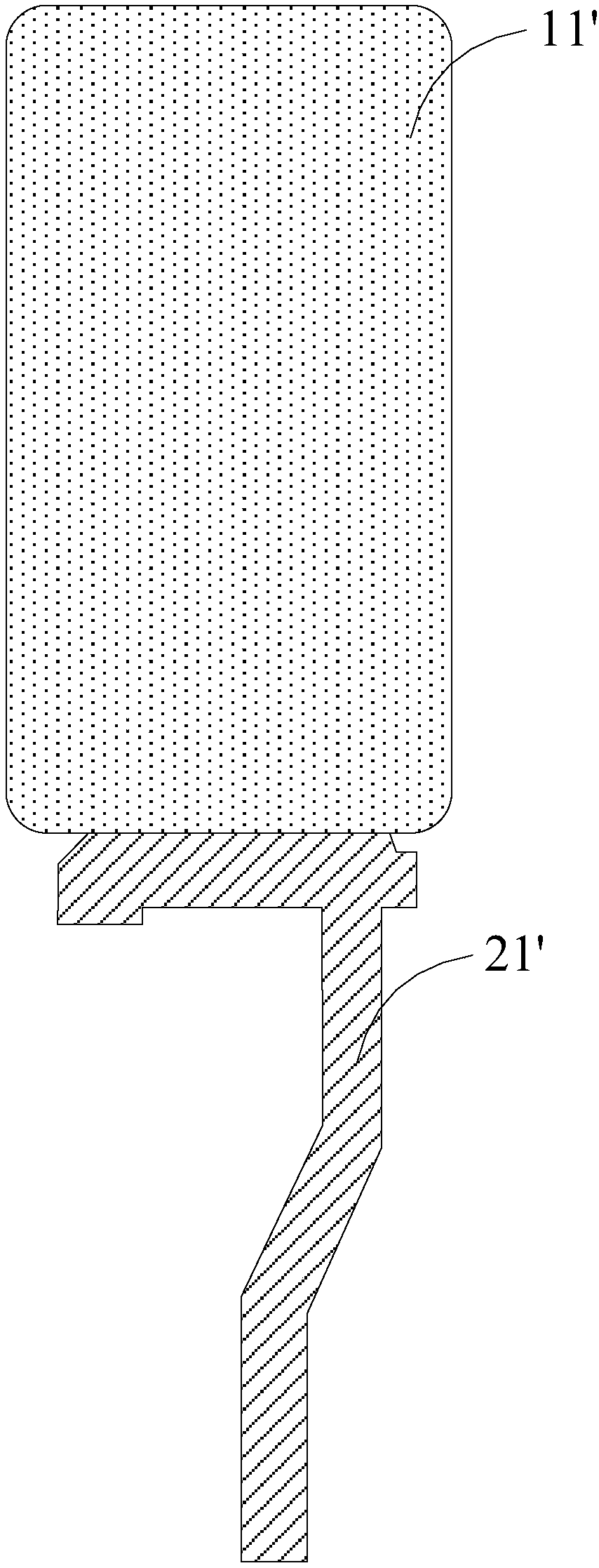

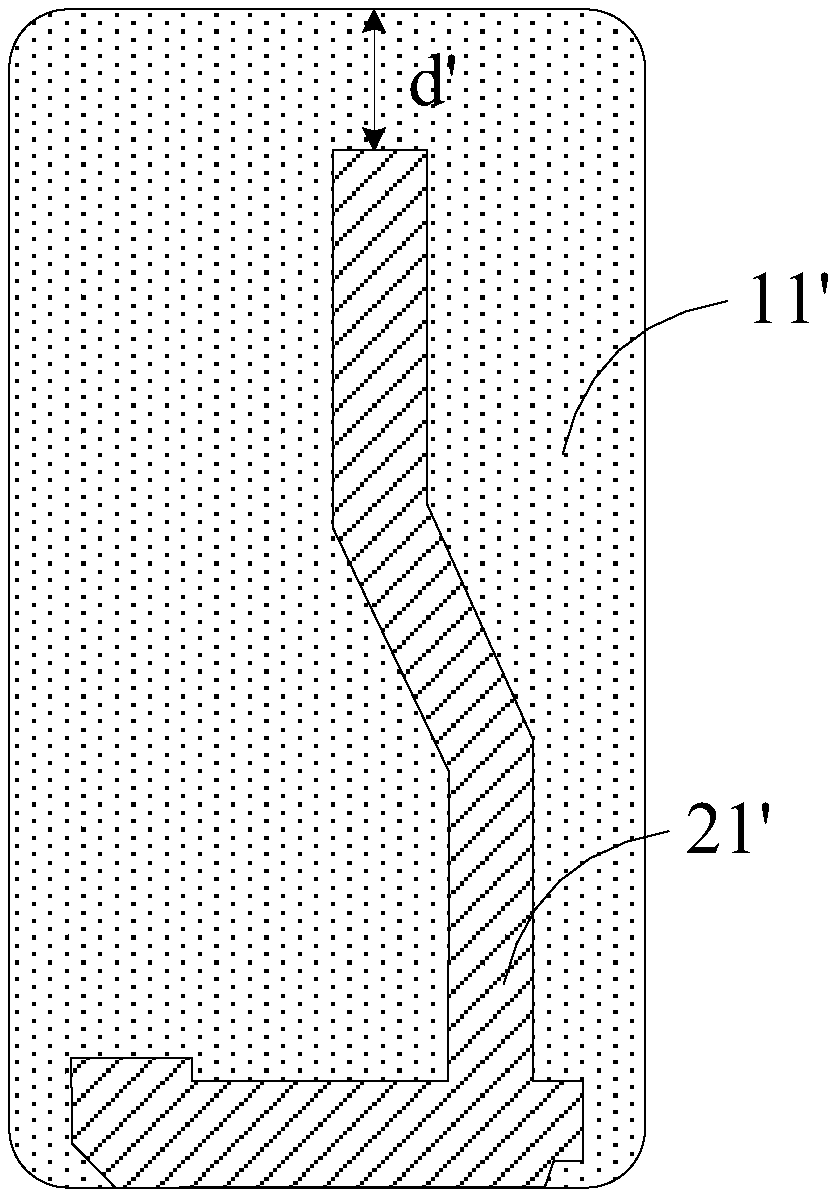

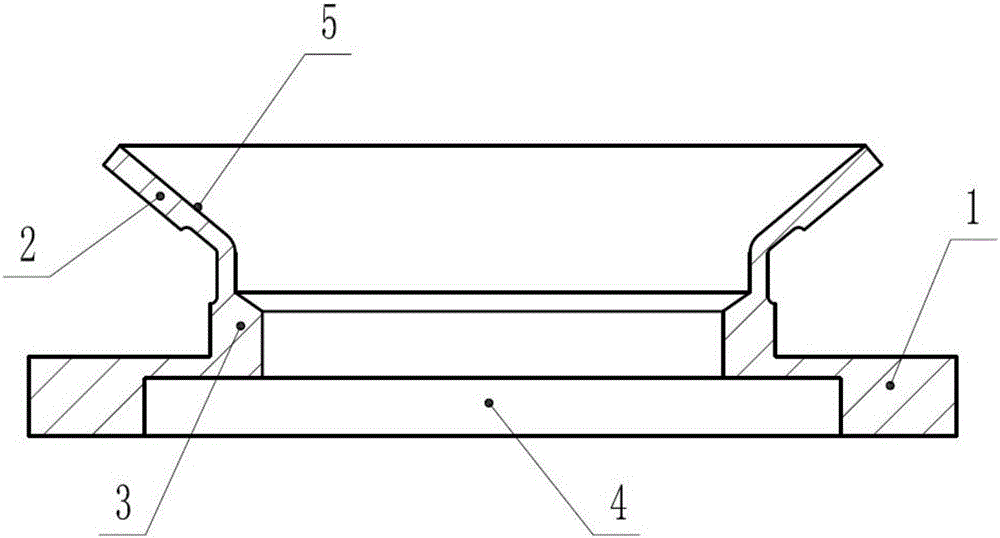

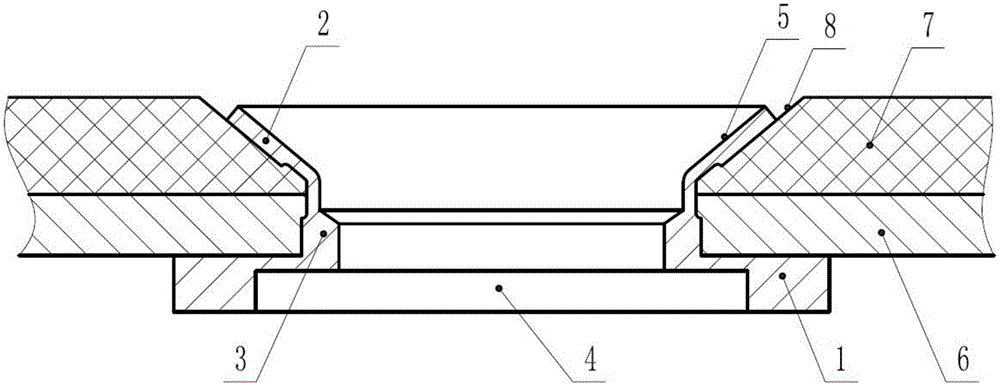

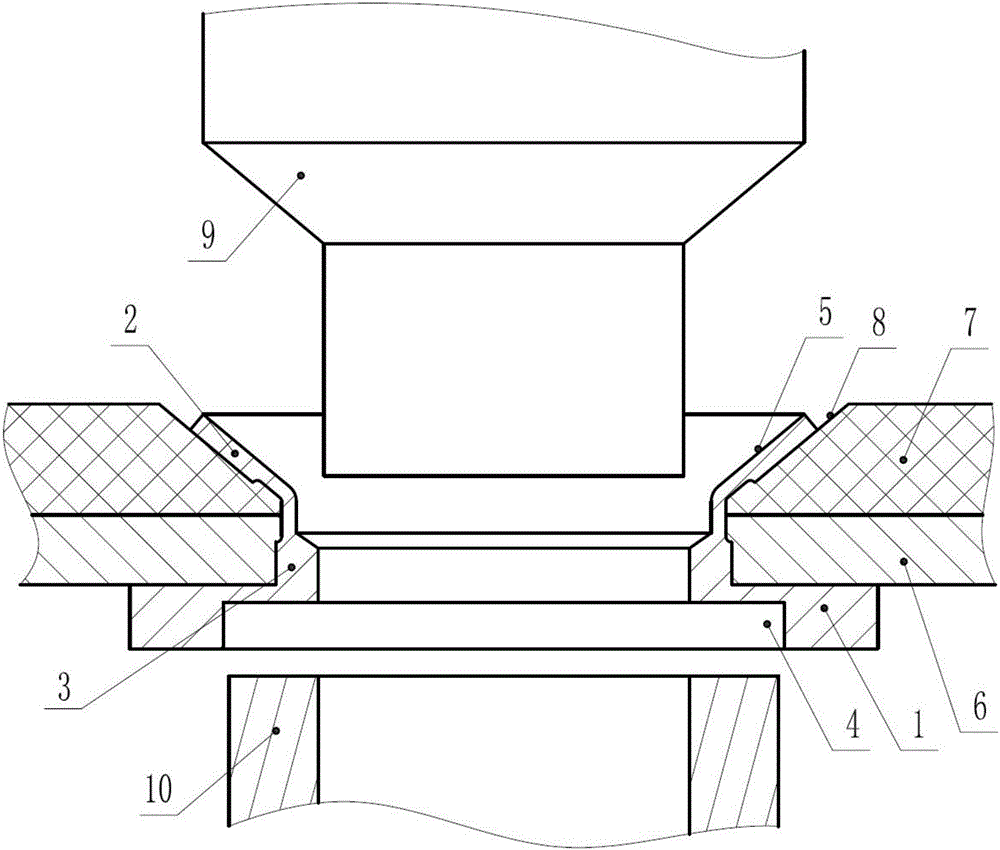

Mould for in-mould decoration (IMD), shell, preparation method thereof, and mobile terminal

InactiveCN108058327ANo relative movementCasings/cabinets/drawers detailsDomestic articlesInjection mouldingMaterials science

The invention provides a mobile terminal shell, a preparation method thereof, a mould for IMD, and a mobile terminal. Specifically, the mould comprises an upper mould and a lower mould. The upper mould and the lower mould form an injection moulding space between the upper mould and the lower mould and an external positioning area that surrounds the injection moulding space. At least one of the upper mould and the lower mould is arranged on a position corresponding to the external positioning area and is provided with a membrane positioning member. Through abovementioned technical scheme, during the injection moulding process, an injection moulding membrane will not move relative to the mould, and thus the change of the membrane position is effectively prevented during the process of injection moulding. The mould can realize a positioning function without arranging a positioning member on the shell body.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

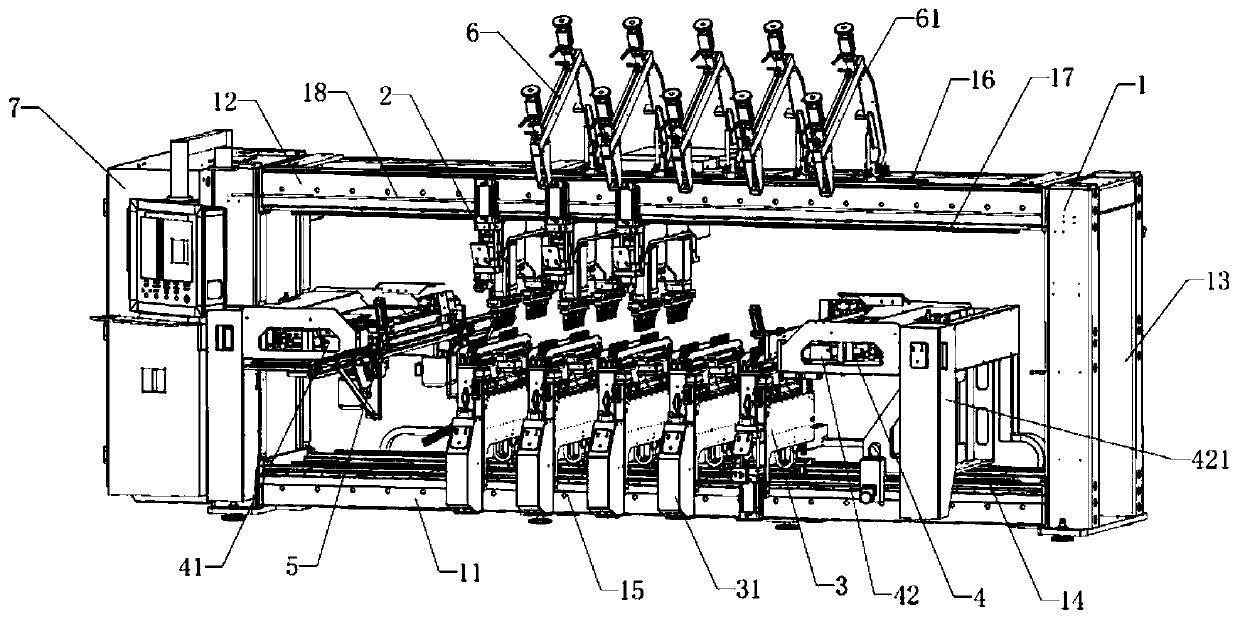

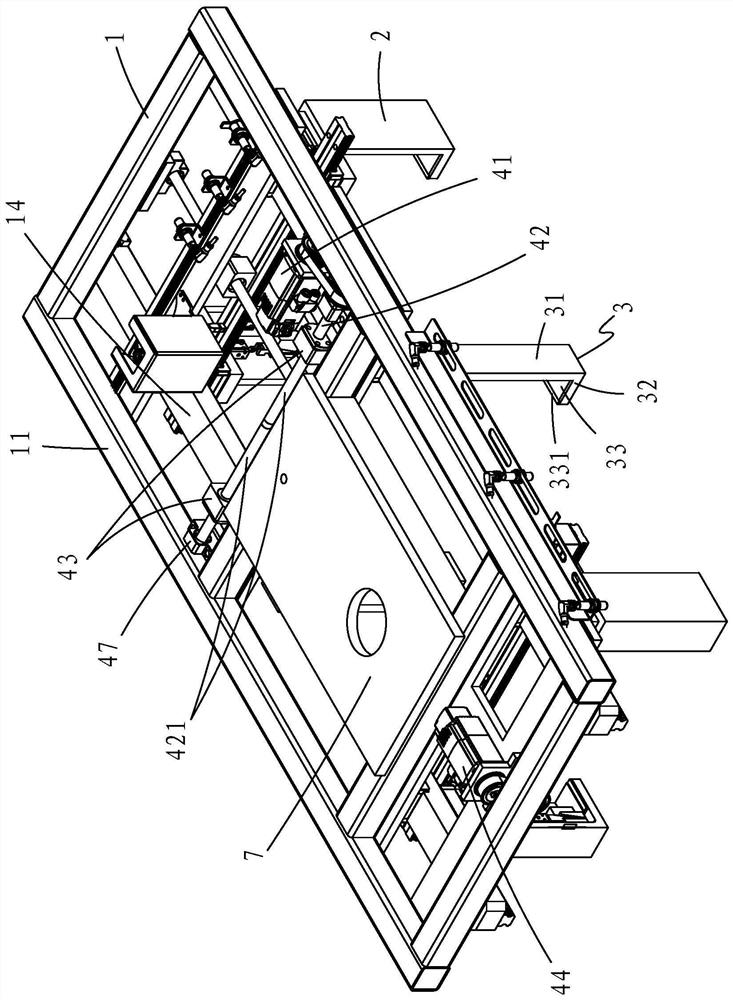

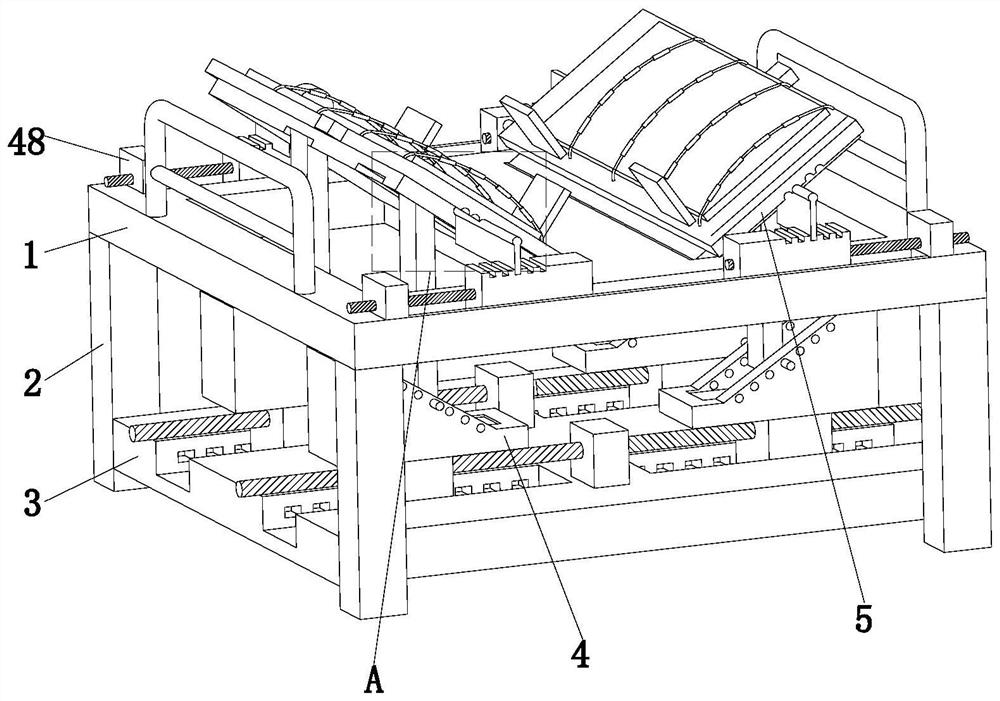

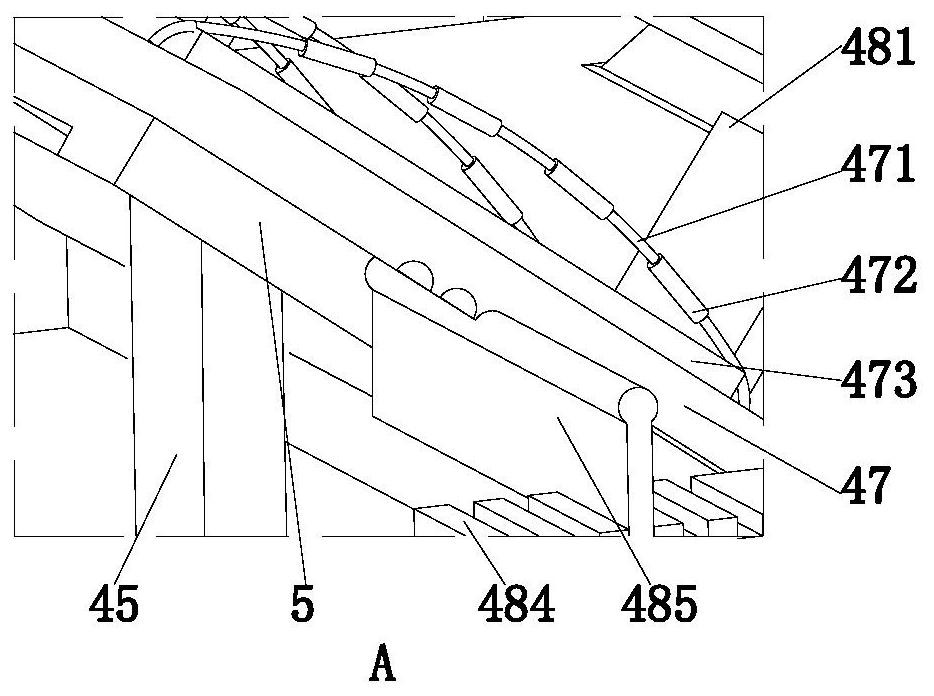

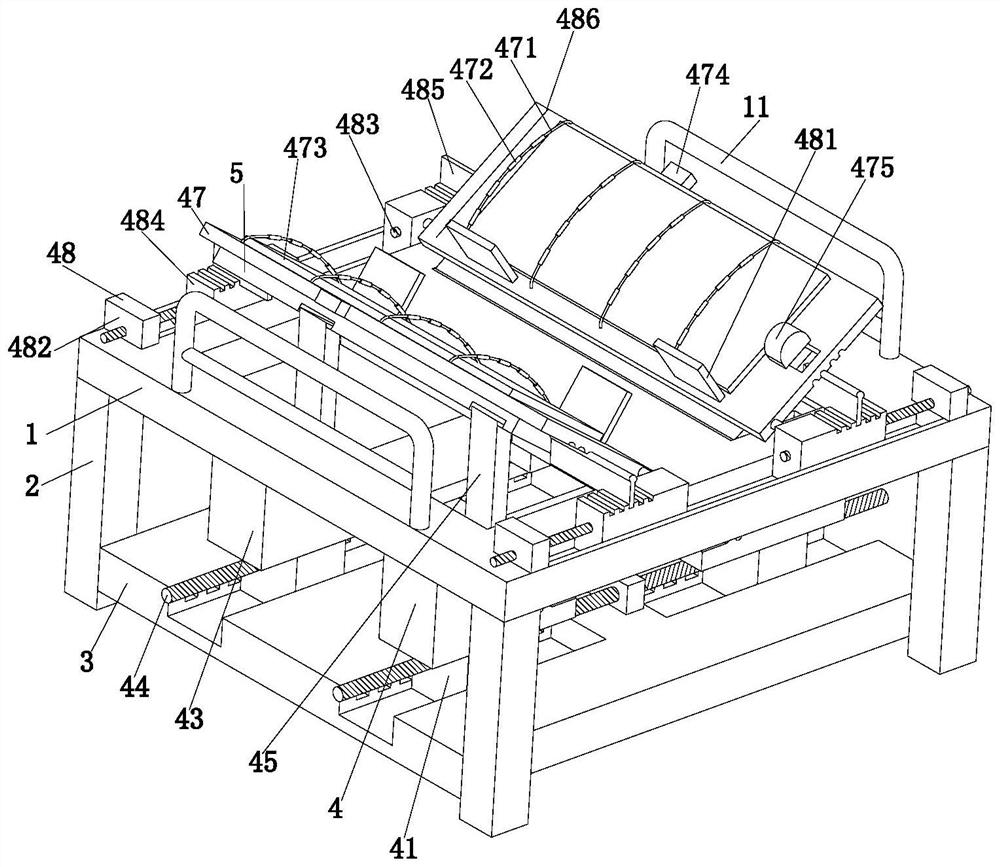

Full-automatic gang drilling device

PendingCN110653886AGuaranteed adjustabilityWon't get in the wayStationary drilling machinesWood working safety devicesTransmission beltConveyor belt

A full-automatic gang drilling device is characterized by includes a rack, a top drilling device, a bottom drilling device, a side drilling device, a positioning and fixing device, a transmission device, and a power supply device, wherein the top drilling device, the bottom drilling device, the side drilling device, the positioning and fixing device, the transmission device and the power supply device are arranged at the rack; the transmission device includes a first section power conveyor belt, a second section power conveyor belt and a third section power conveyor belt; the positioning andfixing device includes an overturned pressing device, a clamping device and a positioning device. The overturned pressing device is arranged to effectively guarantee the adjustment of the top drillingdevice, and hindering is not caused by the movement of the top drilling device and the overturned pressing device; besides, hems are arranged on the upper surface of the support plate, and a scratch-proof strip is arranged on the mounting plate, and frictional loss of the plate during transmission of a conveyor belt is reduced.

Owner:安徽信诺家具有限公司

Artificial tissue precursor and method for preparing same

InactiveCN109880795AComplete structureFunction increaseSkeletal/connective tissue cellsBiological material testing proceduresBiochemistryBiomedical engineering

Owner:SICHUAN REVOTEK CO LTD

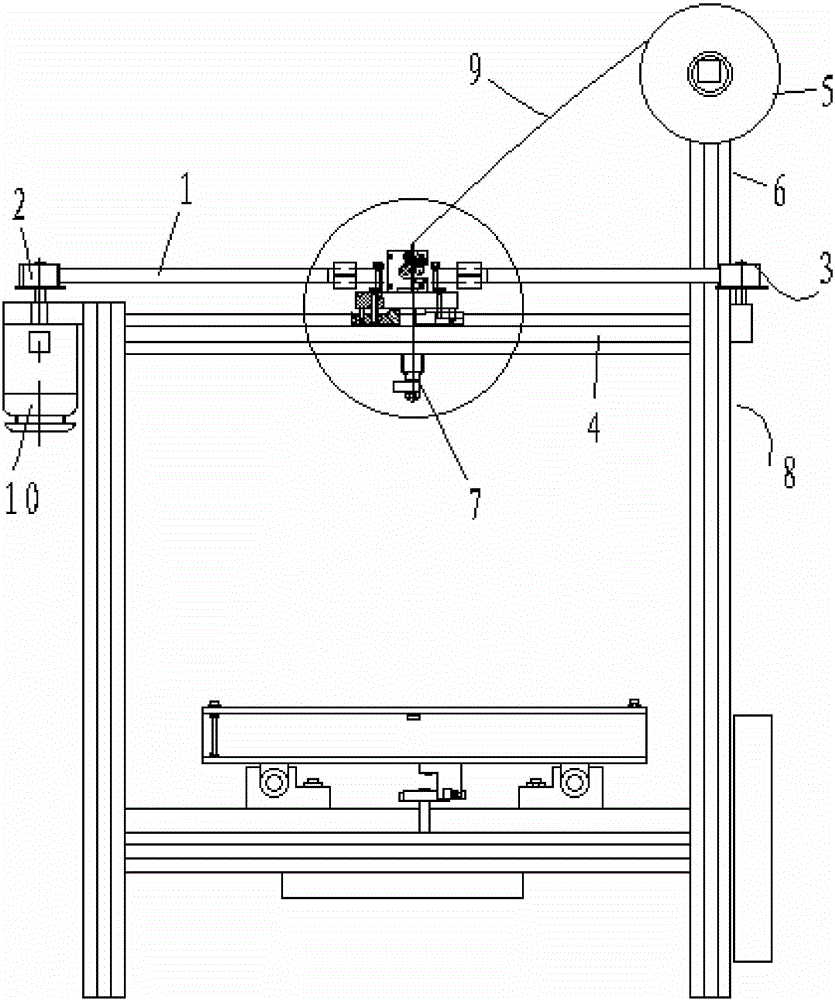

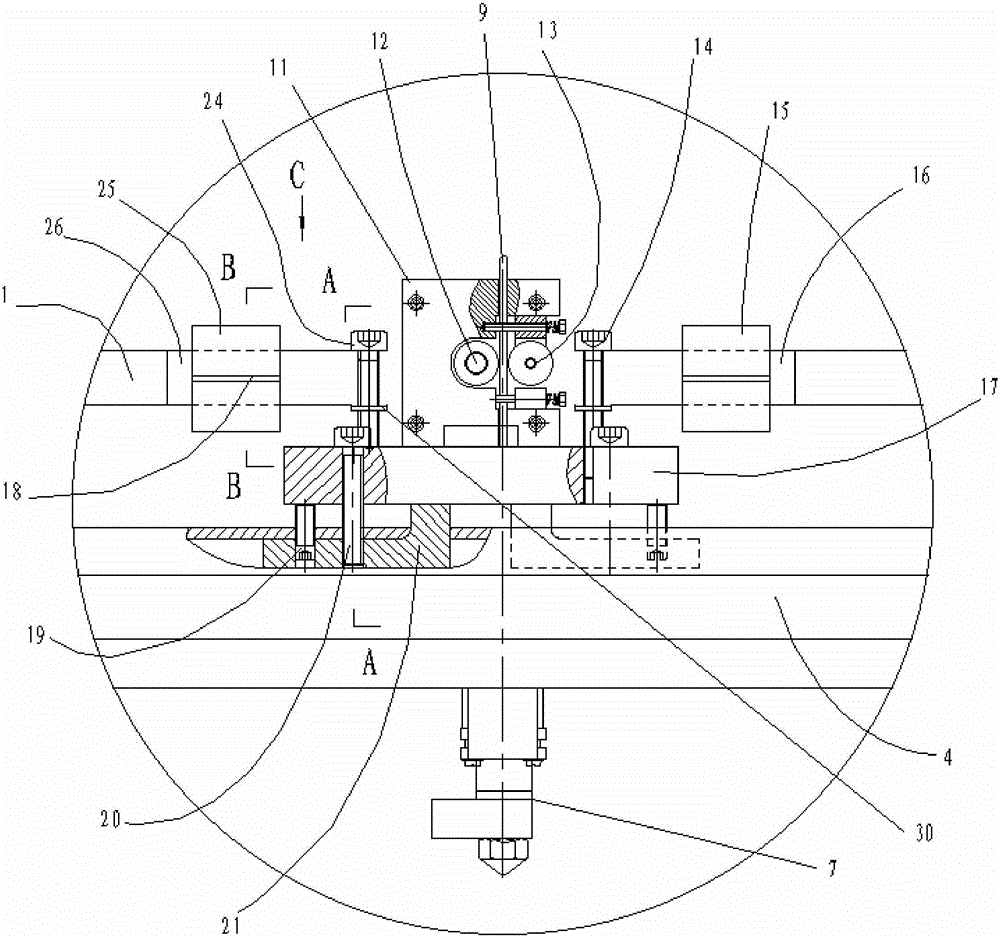

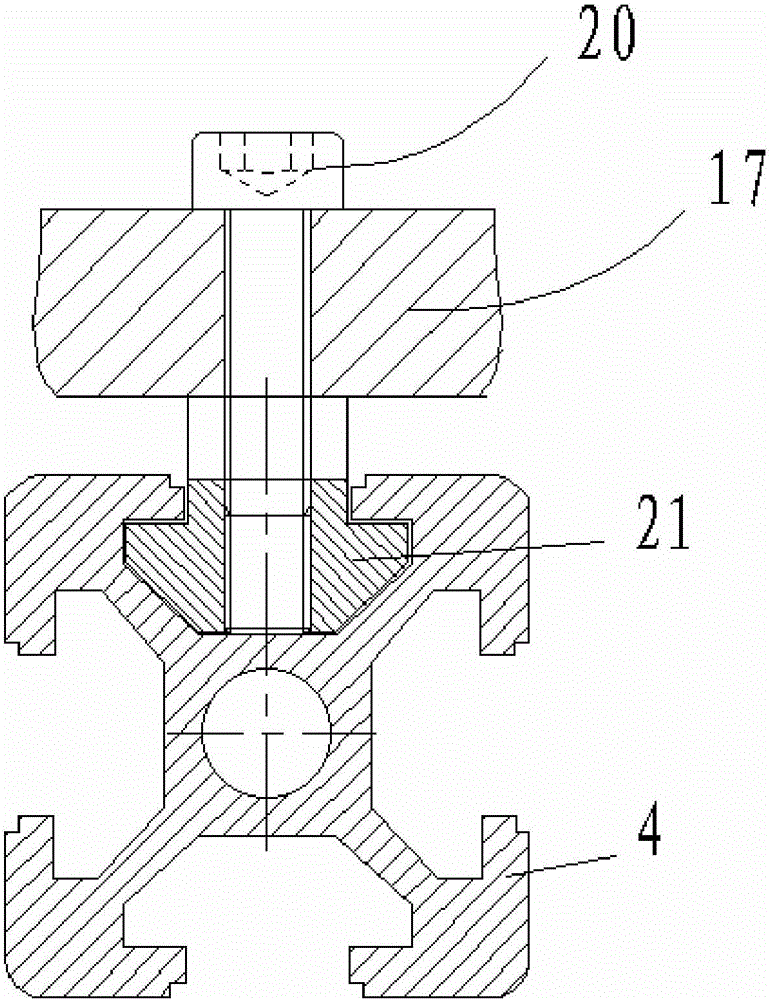

Printing head walking structure of 3D printer

InactiveCN105014969AEasy tension adjustmentExtended service lifeAdditive manufacturing apparatus3d printAgricultural engineering

Owner:UNIV OF JINAN

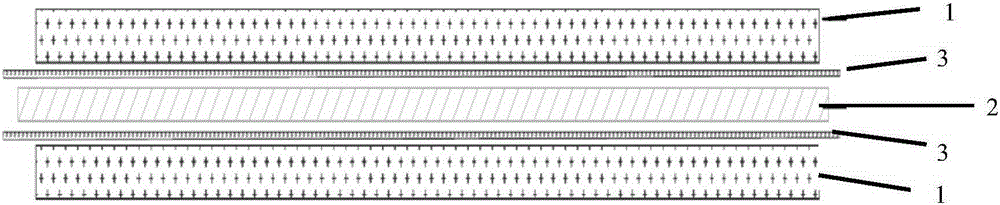

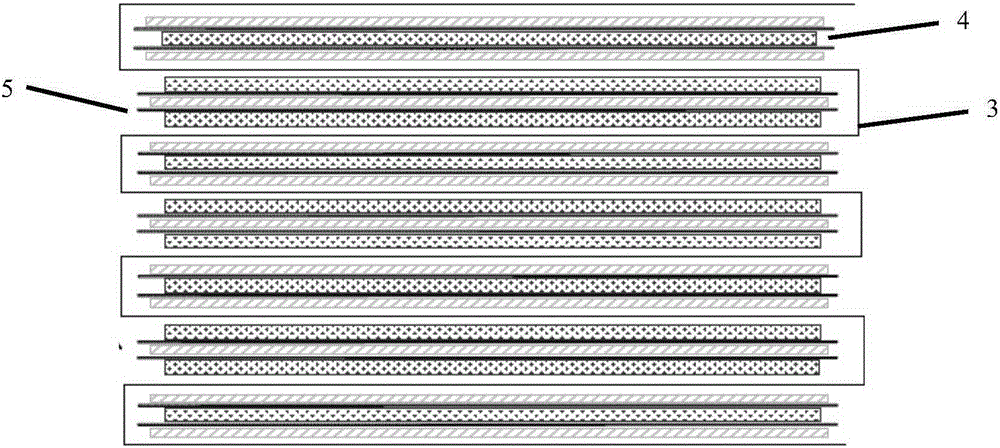

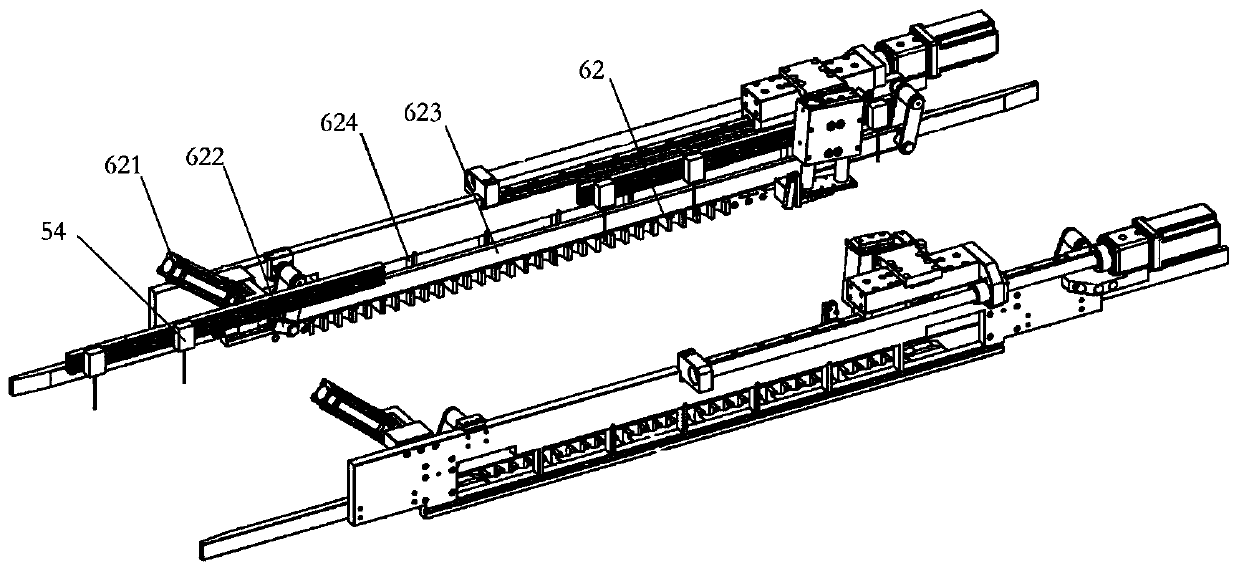

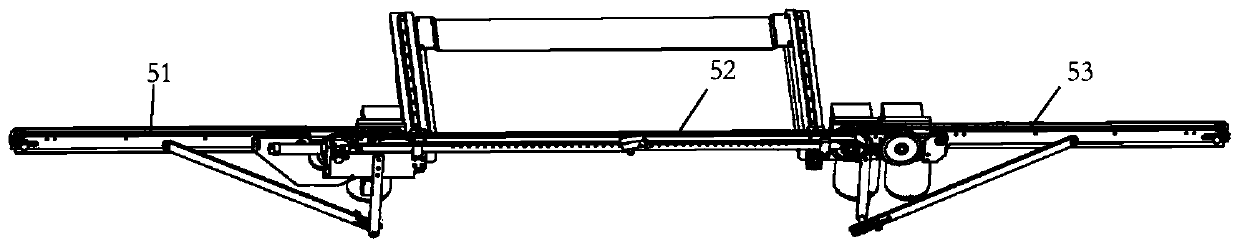

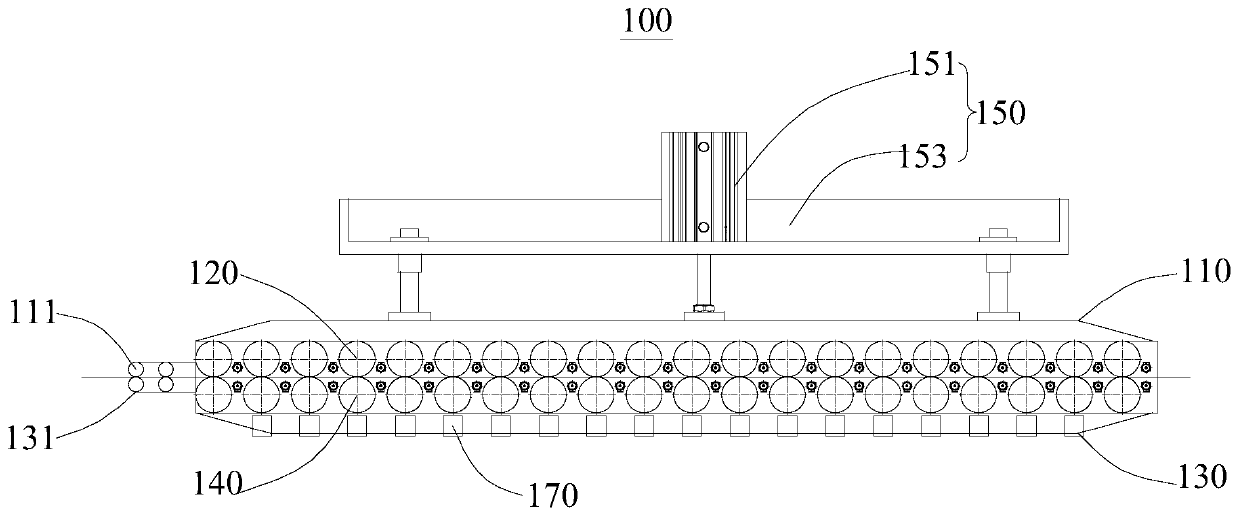

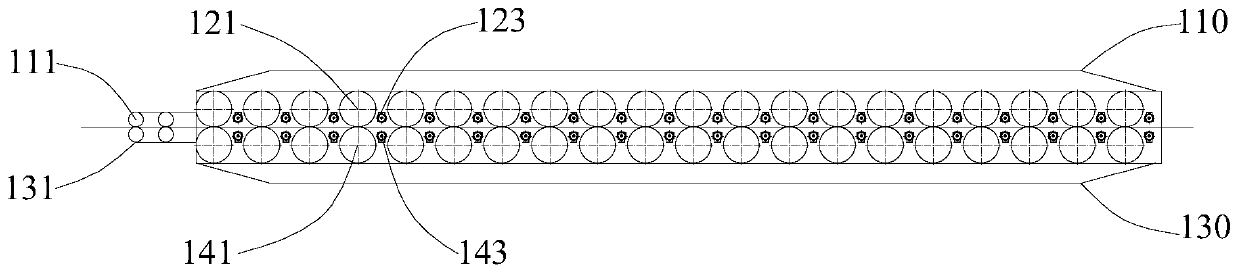

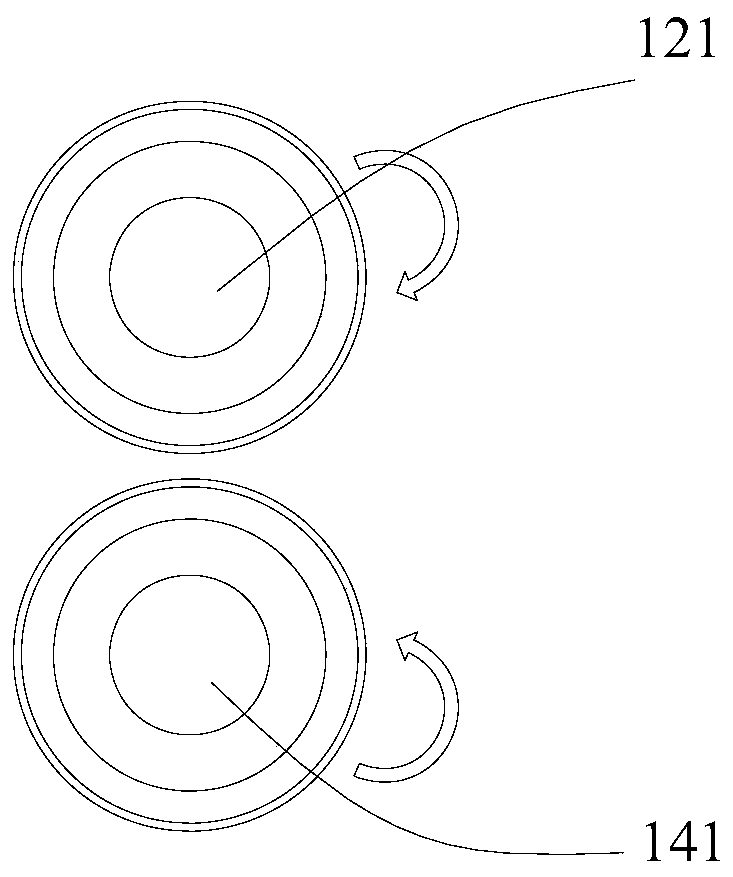

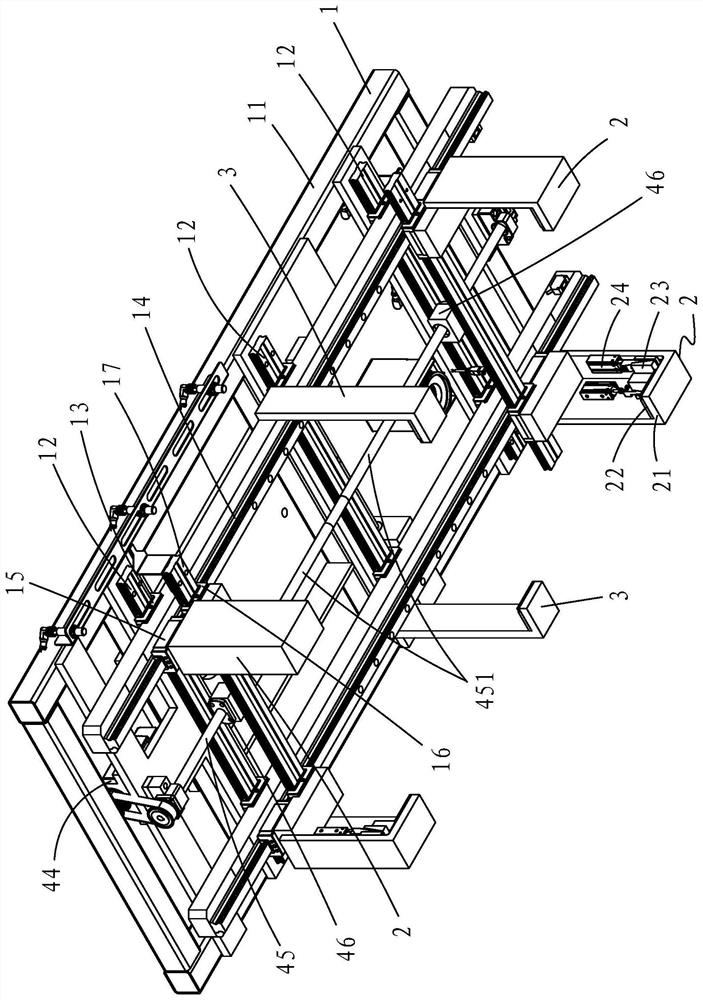

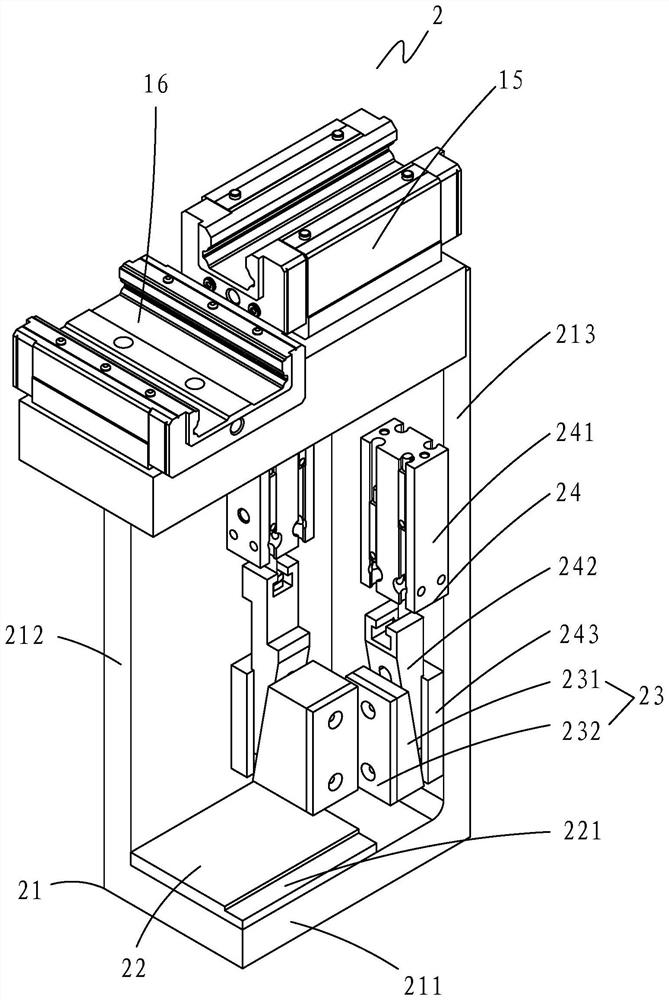

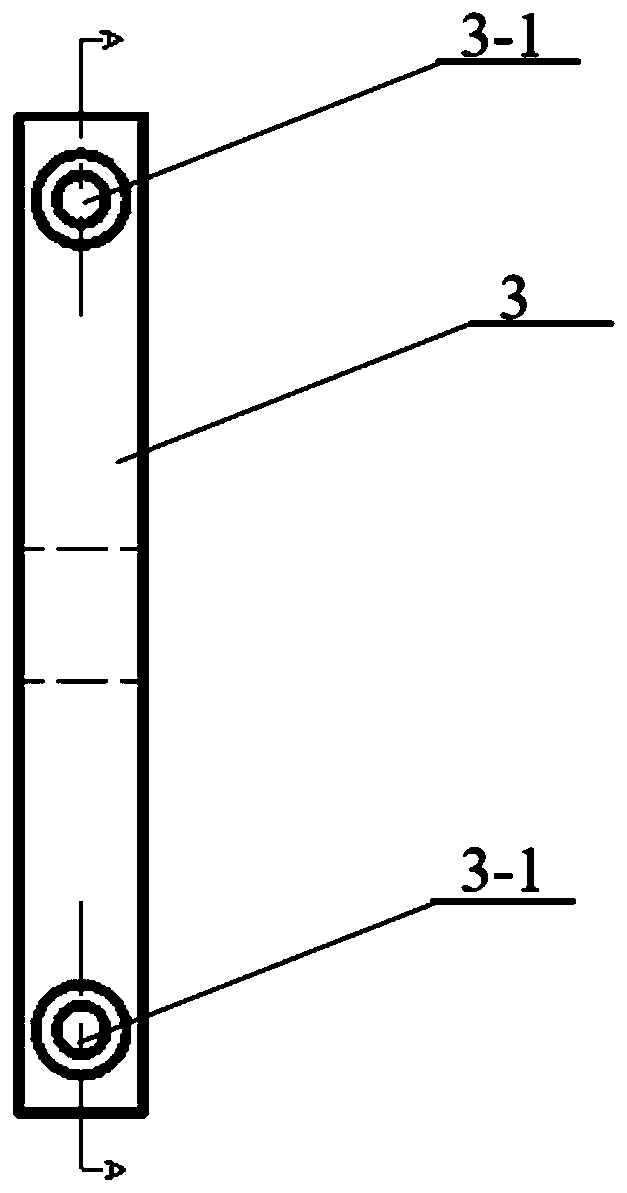

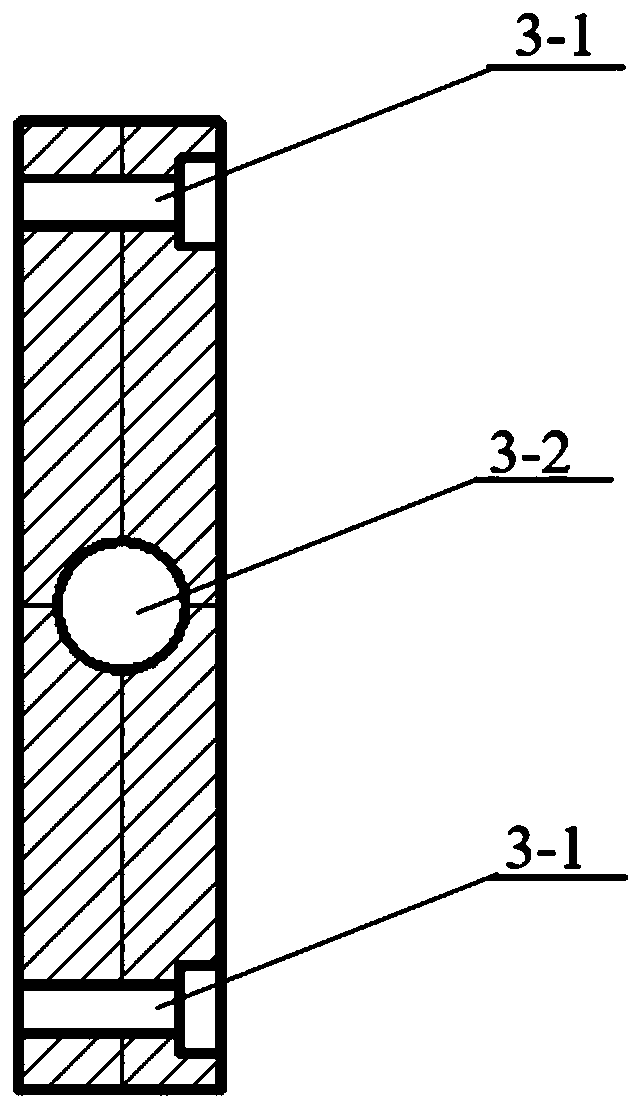

Composite pole piece conveying device and composite pole piece conveying system

PendingCN111162321AReduced footprint and operating costsAchieve clampingPrimary cell manufactureAssembling battery machinesEngineeringPole piece

The invention provides a composite pole piece conveying device and a composite pole piece conveying system and relates to the technical field of lithium battery manufacturing. The composite pole piececonveying device comprises a first frame body and a second frame body which are oppositely arranged, wherein a first hot-pressing roller assembly is arranged on the first frame body, a second hot-pressing roller assembly is arranged on the second frame body, a pressing channel for a composite pole piece to pass through is formed between the first hot-pressing roller assembly and the second hot-pressing roller assembly, and the first hot-pressing roller assembly and the second hot-pressing roller assembly are used for being pressed on the upper side and the lower side of the composite pole piece respectively. Compared with the prior art, the composite pole piece conveying device provided by the invention has the advantages that the composite pole piece is clamped and conveyed by the hot-pressing roller assembly instead of a mylar film, so that an MYLAR film can be prevented from being used, extra equipment is not needed for compounding, and the overall occupied space and the operationcost are reduced.

Owner:GEESUN AUTOMATION TECH

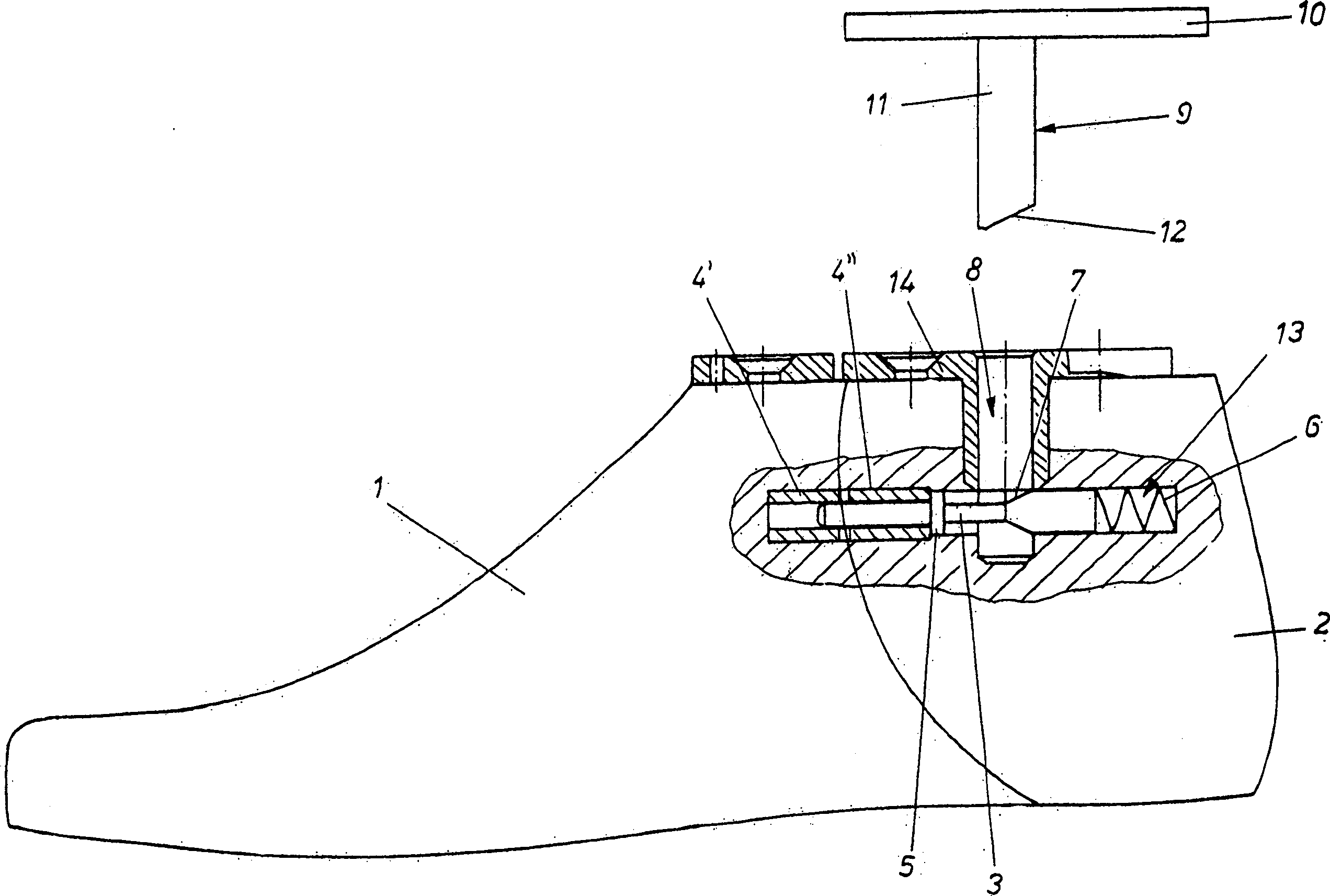

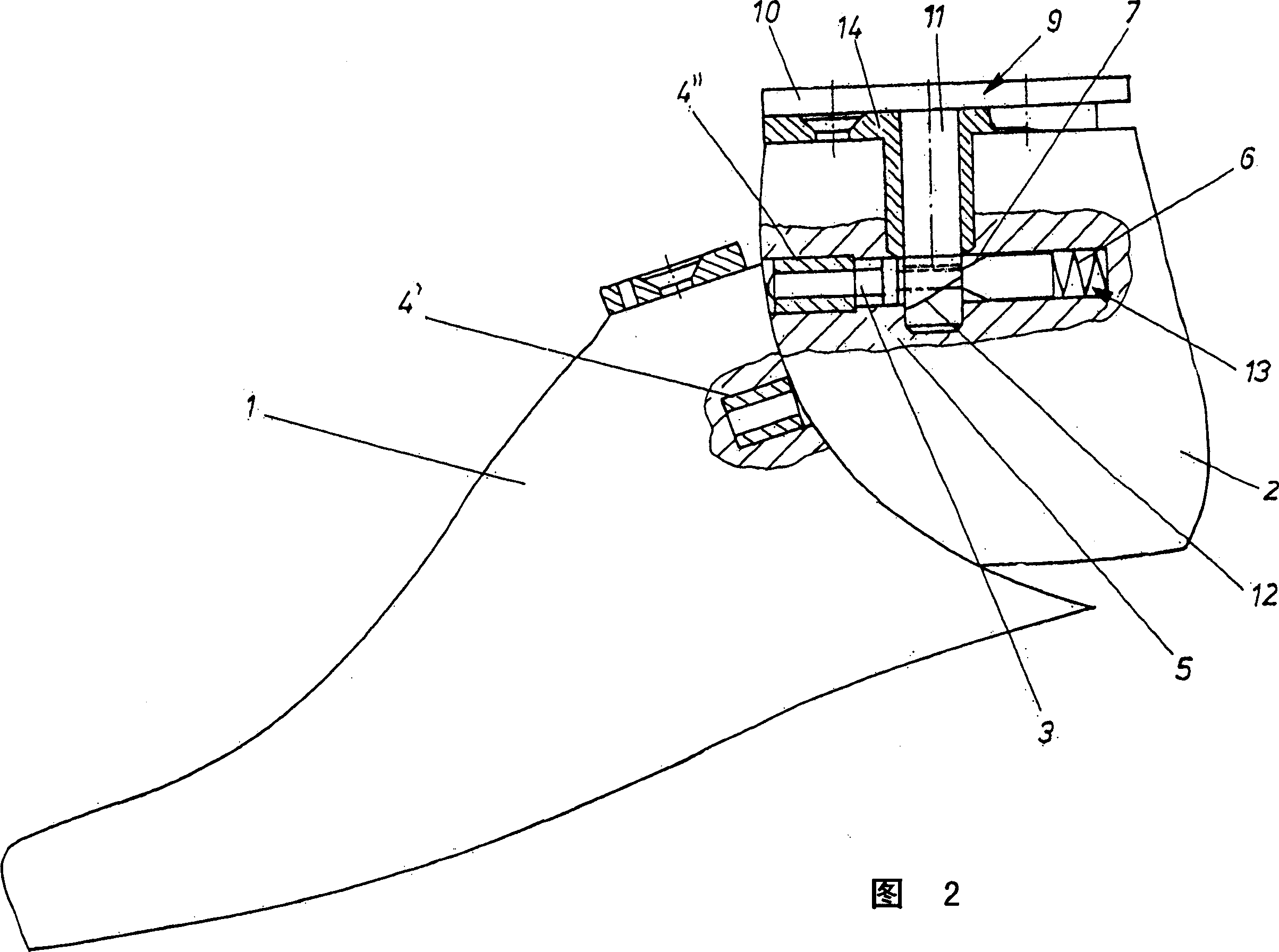

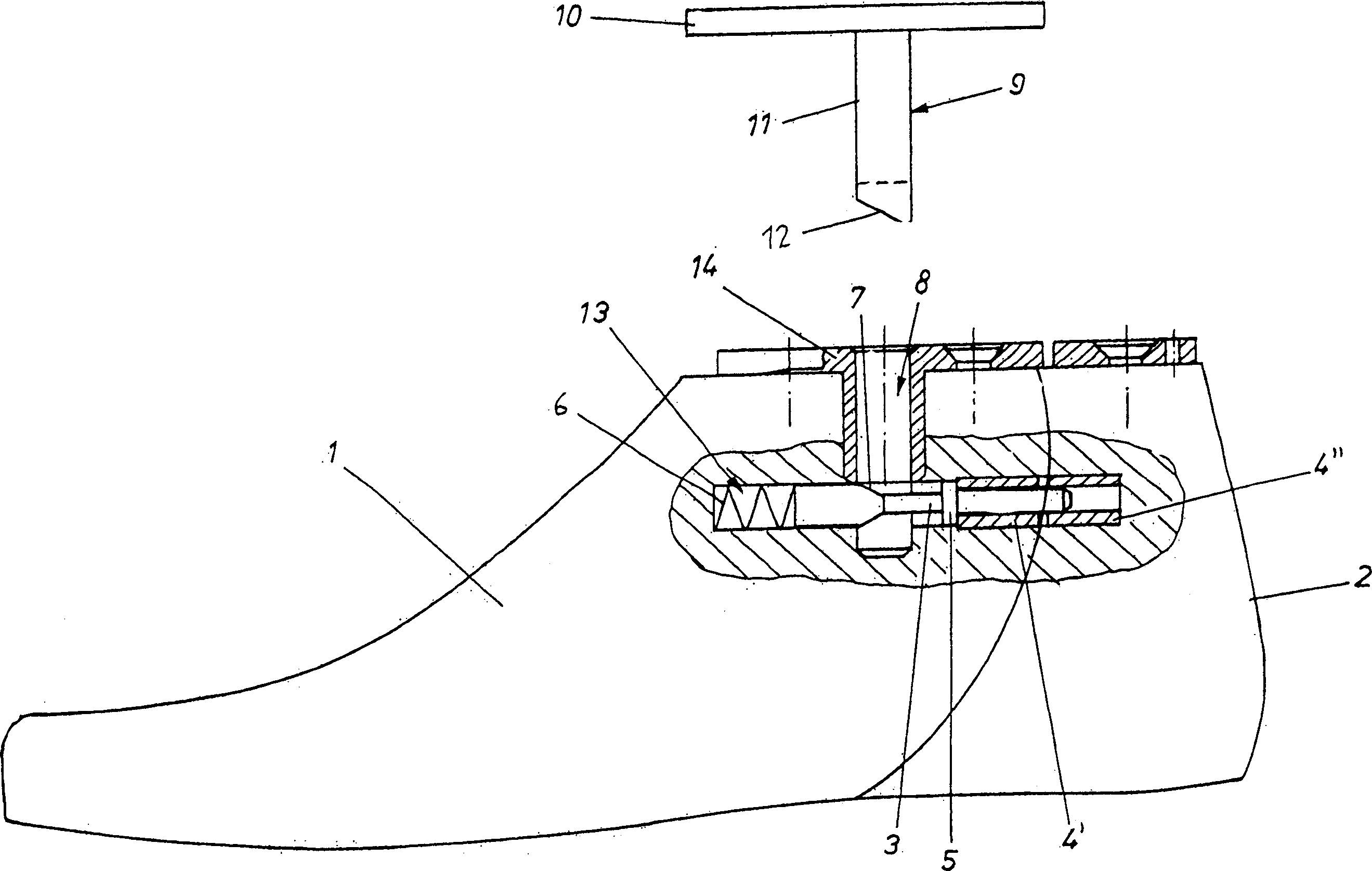

Shoe tree of multi-component

Owner:FAGUS GRECON GRETEN

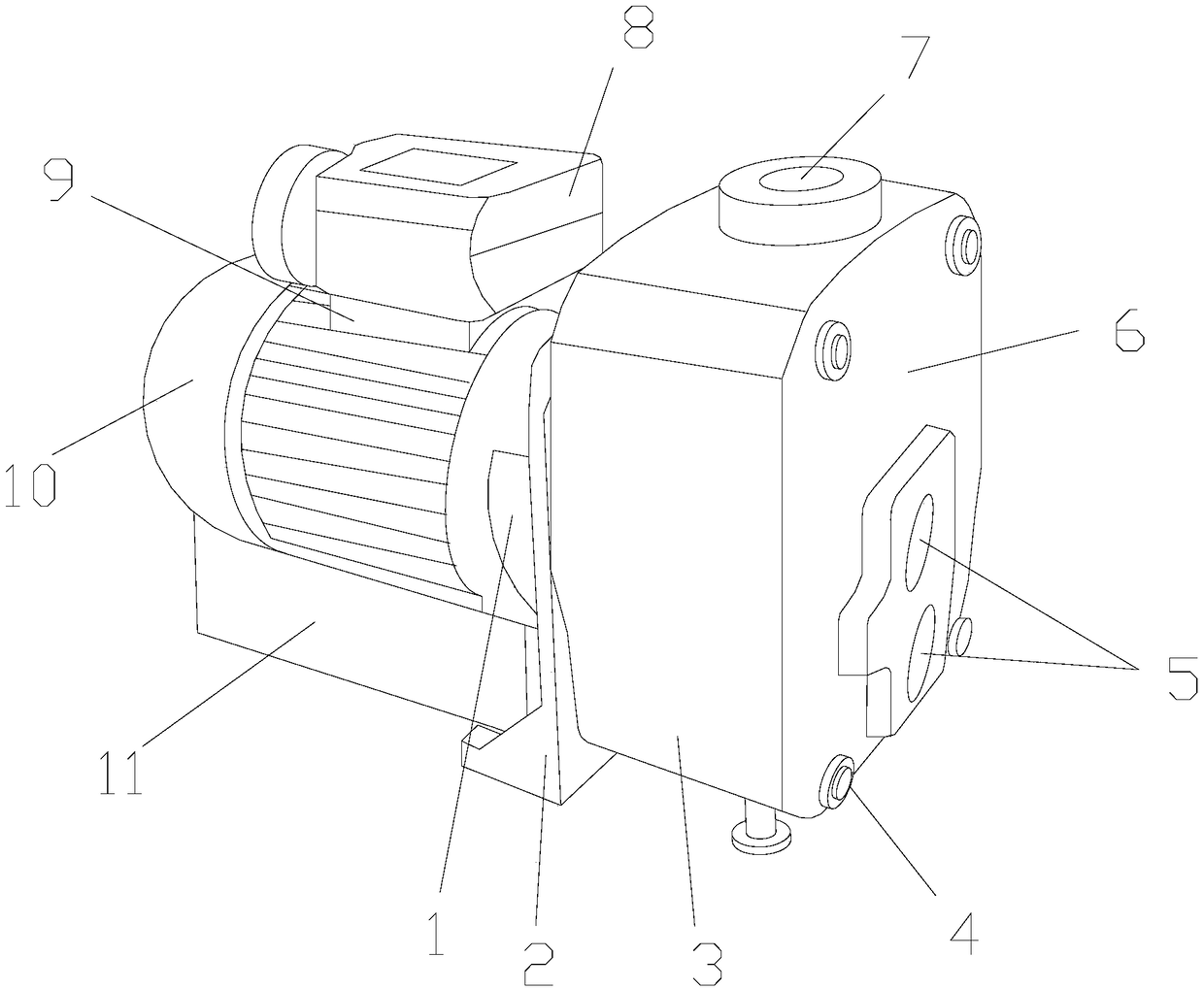

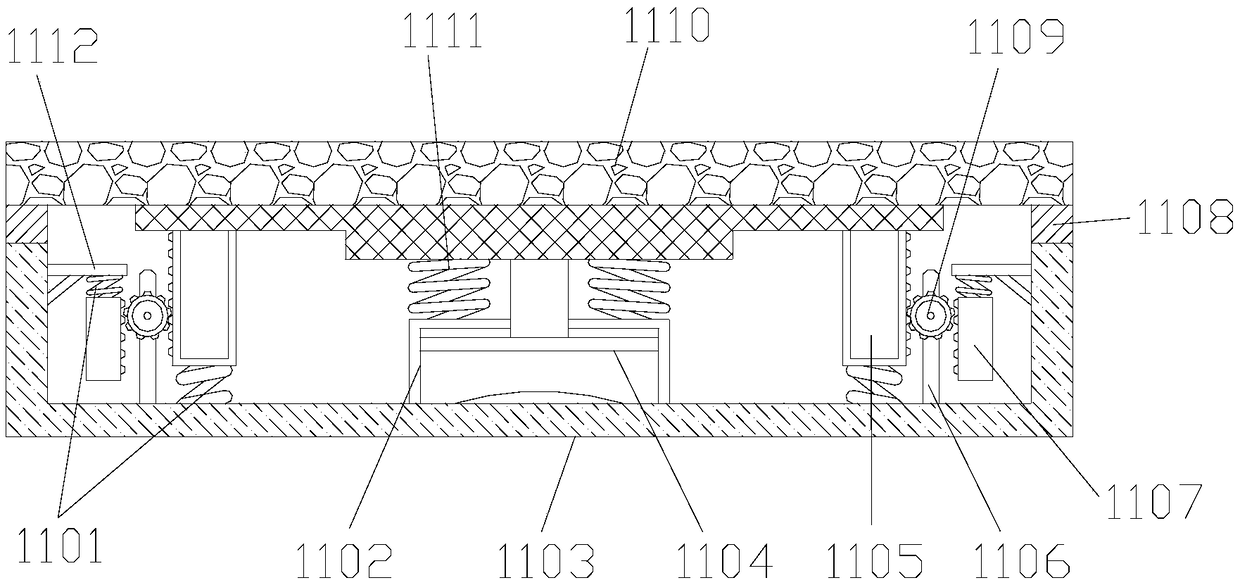

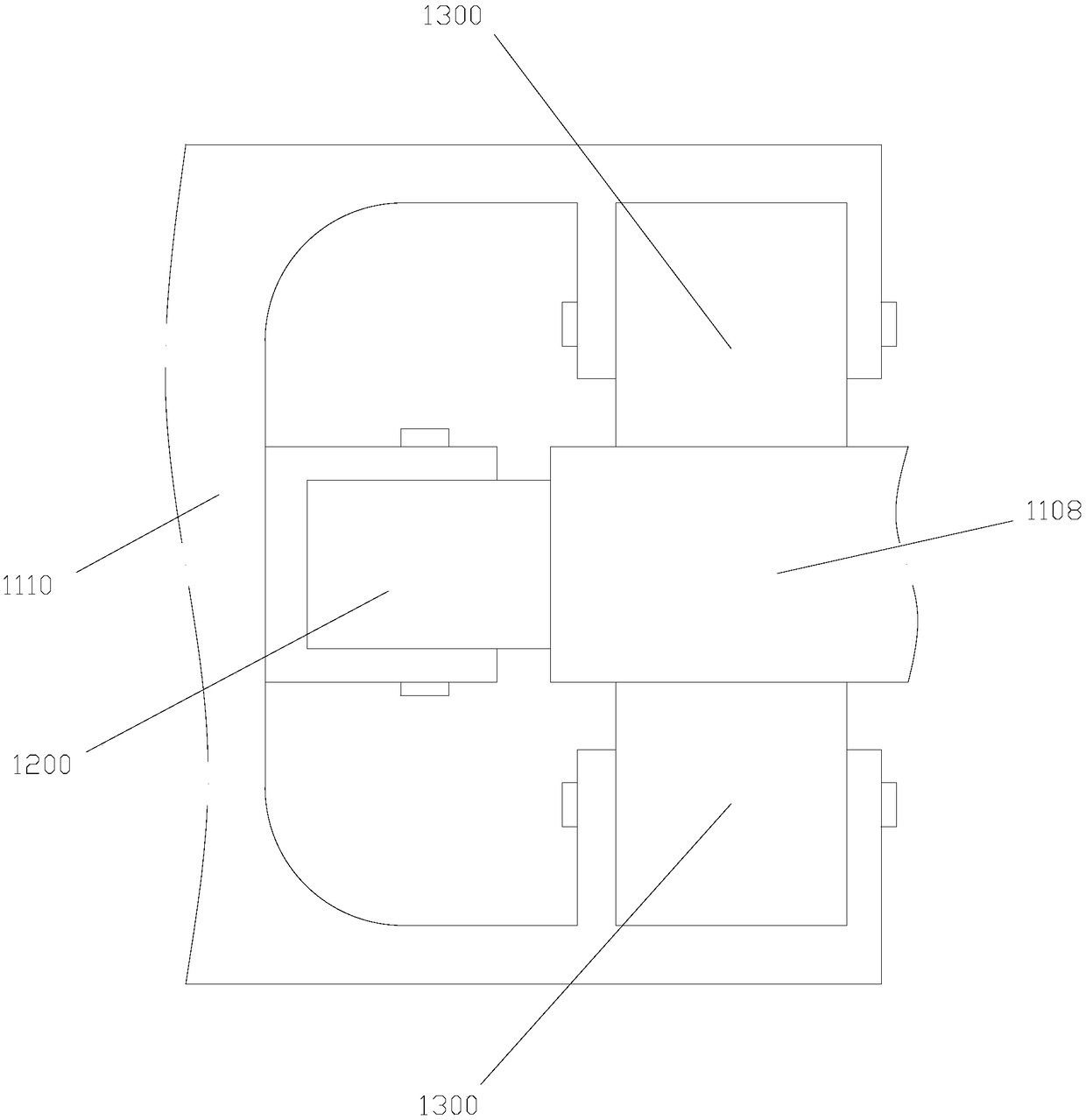

Underground water drawing device

ActiveCN108894279AExtended service lifeNo relative movementPump componentsPumpsEngineeringGroundwater

Owner:HEBEI UNIV OF ENG

Device and method for preventing two objects from shifting in carrying process

PendingCN112589403ANo relative movementWill not have the opposite effectGripping headsMetal working apparatusEngineeringMechanical engineering

The invention provides a device for preventing two objects from shifting in the carrying process. The device for preventing the two objects from shifting in the carrying process comprises a connectingassembly and at least four clamping jaws, wherein all the clamping jaws are symmetrically arranged in a rectangular shape and are connected to the connecting assembly in a sliding manner; and all theclamping jaws are synchronously opened and closed. A method for preventing the two objects from shifting in the carrying process comprises the following steps that firstly, all the clamping jaws aresynchronously and oppositely closed, first L-shaped positioning grooves in all the clamping jaws are driven to be flush with the four side faces of the second object, and four-side positioning of thesecond object is completed; secondly, pressing pieces of all the clamping jaws synchronously press the four side faces of the first object; and finally, all the clamping jaws synchronously move to carry the two objects. According to the device and the method, the clamping jaws which are symmetrically arranged and connected into a whole are adopted for synchronously clamping the objects, so that the objects do not move relatively in the moving process, internal forces formed by counter-acting forces borne by the clamping jaws are offset, and the counter-acting effect is avoided.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

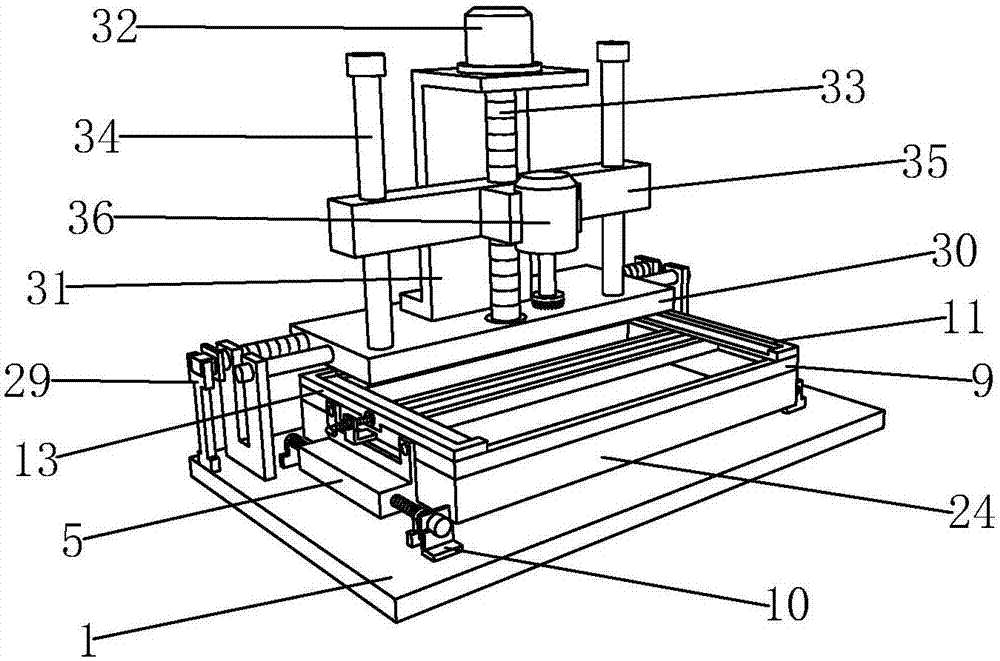

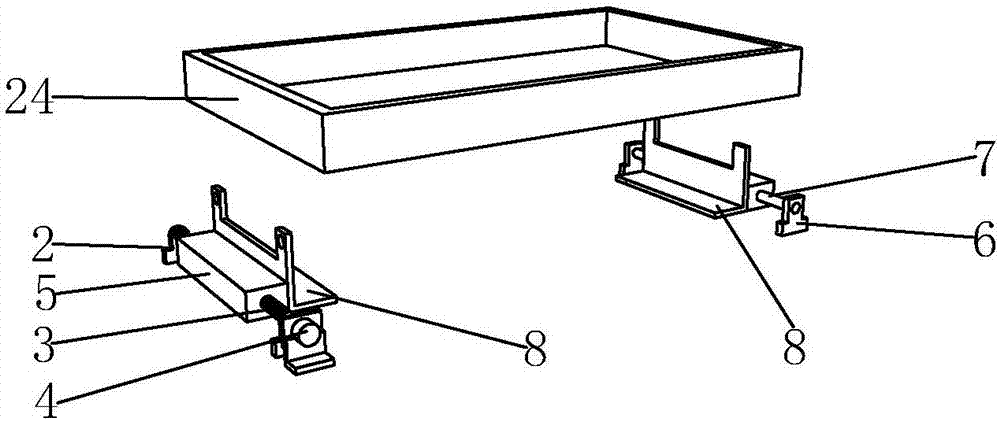

Drilling device for laminated glass production

InactiveCN106956371AGuaranteed to collect completelyImprove work efficiencyWorking accessoriesFine working devicesElectric machineryWorking environment

The invention discloses a drilling device for the production of laminated glass, which comprises a working platform, on which a driving mechanism, a screw mechanism and a fixing mechanism are respectively arranged, and a supporting block is arranged on the screw mechanism and the fixing mechanism, and the supporting block There is a storage table between them, a receiving box is movably connected between the L-shaped support parts, a sliding seat is provided on the driving mechanism, a support frame is provided on the sliding seat, a stepping motor is provided on the top of the supporting frame, and the stepping motor and the A first screw is provided between the sliding seats, a fixed rod is provided on the sliding seat, a support plate is provided between the fixed rod and the first screw, a drilling motor is provided on the support plate, and a drilling shaft is connected to the drilling motor. One end of the drilling shaft is provided with a drill piece, and drill teeth are distributed around the bottom of the drill piece. The invention has the advantages of simple structure, strong flexibility, large drilling range, and can complete rows of drilling in the horizontal direction, with high working efficiency, simple collection of waste materials, and protection of the working environment.

Owner:嵊州市赫利玻璃制品有限公司

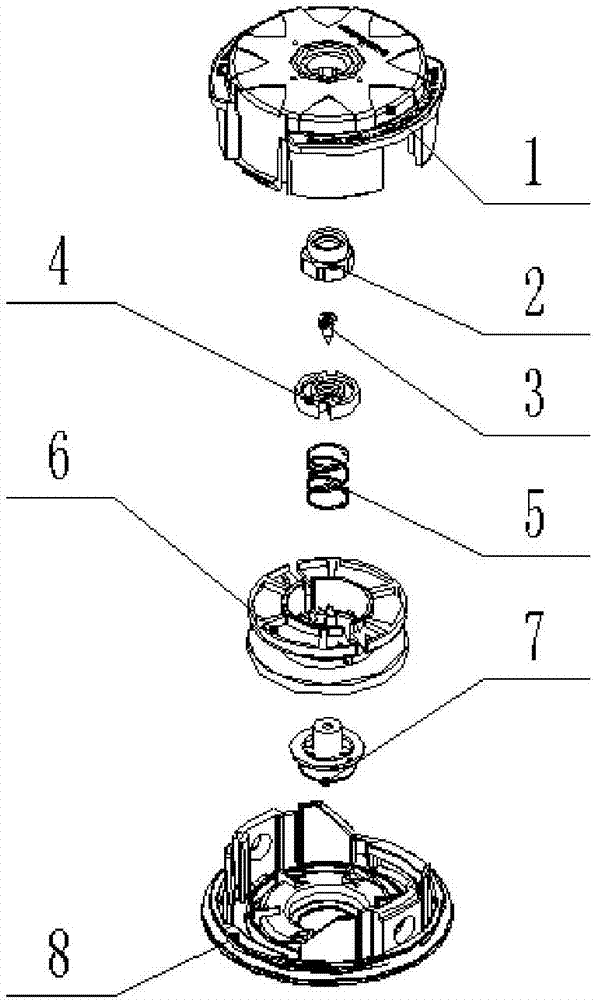

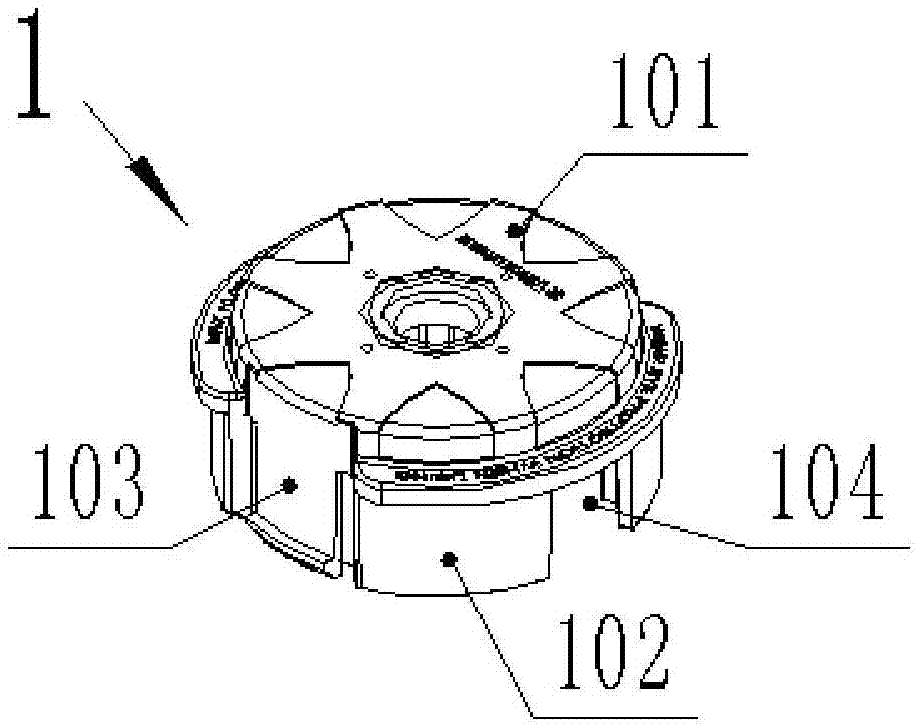

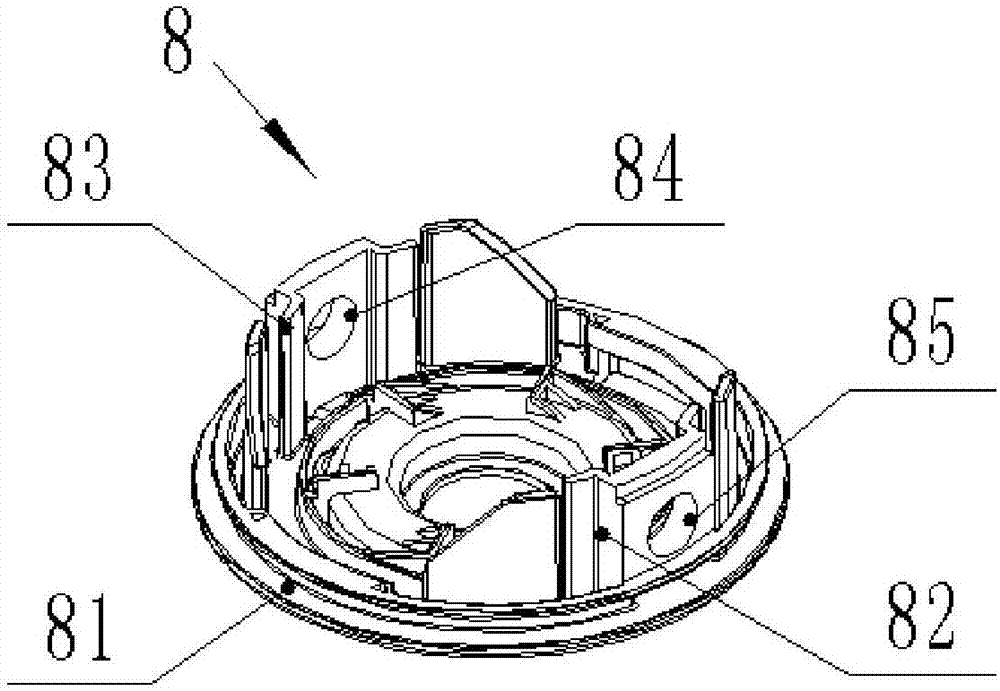

Connecting structure and grass trimmer head device

The invention provides a connecting structure and a grass trimmer head device, and relates to the field of garden equipment. The connecting structure comprises a rope wheel box and a big cover which are mutually buckled from top to bottom, a small cover is arranged between the rope wheel box and the big cover, a rope wheel and a connecting block are arranged between the small cover and the big cover, a left-handed nut is arranged between the small cover and the rope wheel box and pressed and mounted on the rope wheel box, and the left-handed nut is in interference fit with the rope wheel box; the connecting structure further comprises a rotating compression spring and a self-tapping screw, the rotating compression spring is arranged in the center of the rope wheel and connected to a protruding structure of the connecting block in a sleeving mode, the self-tapping screw penetrates through the small cover, and the rotating compression spring is in thread connection with the protruding structure of the connecting block. The invention further relates to the grass trimmer head device which comprises the connecting structure, a grass trimmer rope, two rope outlet clamping pieces, an impact compression spring, a leaf spring and an impact head. According to the technical scheme, the big cover and the rope wheel box can be stably buckled, and the service life of a grass trimmer head is prolonged.

Owner:ZHEJIANG TITAN MACHINERY

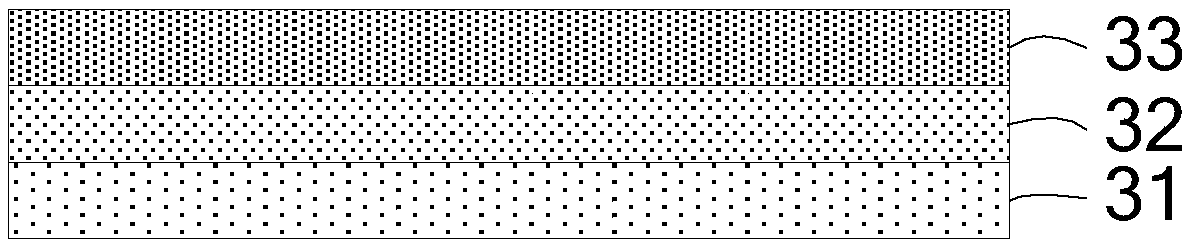

Magnetic adhesive tape and display device

ActiveCN108251007AFirmly connectedFlexible position adjustmentFilm/foil adhesivesPhotovoltaic energy generationFlexible circuitsDisplay device

The invention discloses a magnetic adhesive tape and a display device. The display device comprises a display panel, a flexible circuit board, a first film layer, a first magnetic adhesive tape and asecond magnetic adhesive tape, wherein the flexible circuit board is bound on the display panel; the first film layer is arranged on the side, far away from the light outgoing surface of the display device, of the display panel; the first magnetic adhesive tape is fixed on one side, far away from the display panel, of the first film layer; the second magnetic adhesive tape is fixed on the flexiblecircuit board; each of the first magnetic adhesive tape and the second magnetic adhesive tape comprises a magnetic layer, a first viscous layer positioned on one side of the magnetic layer and a protective film positioned on the side, far away from the magnetic layer, of the first viscous layer; the first viscous layer of the first magnetic adhesive tape is positioned on the side, far away from the first film layer, of the first magnetic adhesive tape; and the first viscous layer of the second magnetic adhesive tape is positioned on the side, far away from the flexible circuit board, of the second magnetic adhesive tape. Through the magnetic adhesive tape and the display device, the assembling process of the flexible circuit board of the display device and a mainboard can be simplified, and implementation is facilitated.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

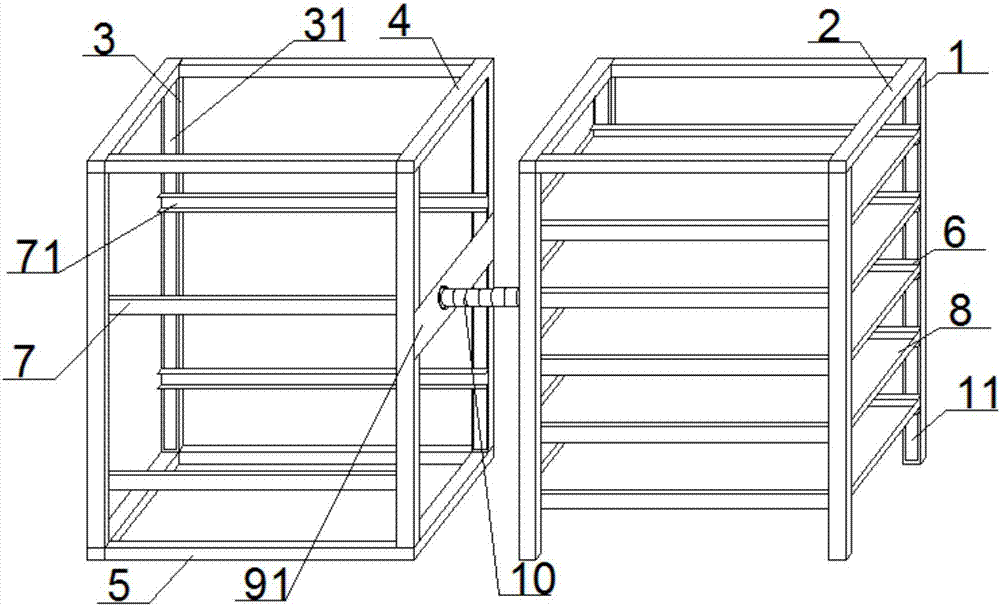

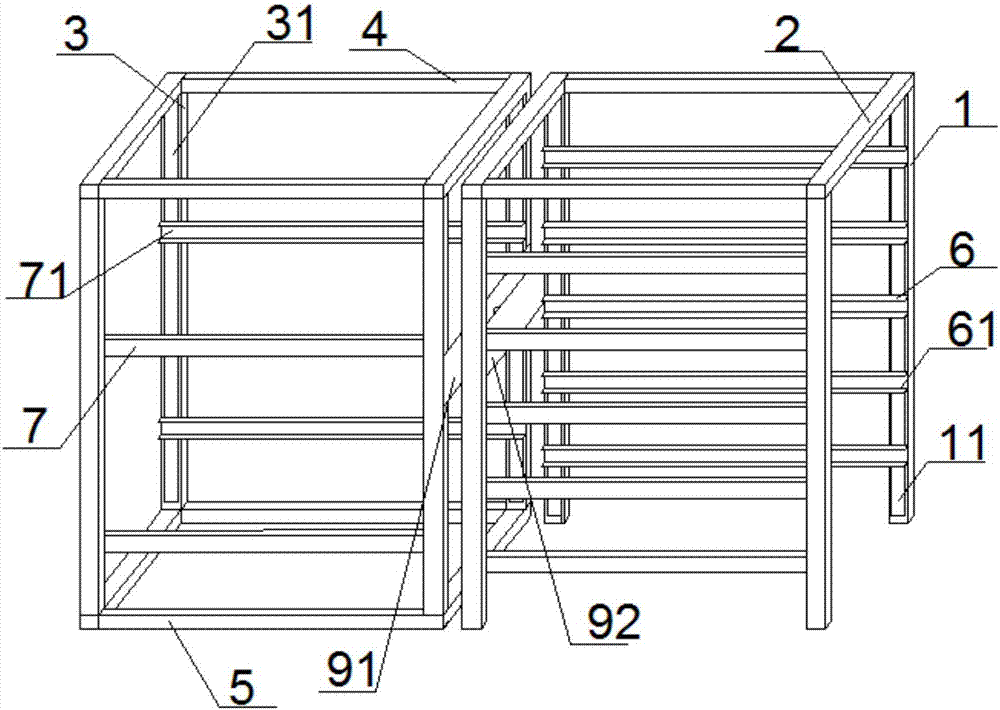

Stack-up sericulture device

ActiveCN107439497AAdjust vertical heightImprove space utilizationAnimal husbandryMechanical engineeringEngineering

The invention discloses a stack-up sericulture device. The stack-up sericulture device comprises a feeding tray frame, a bracket, a first connecting plate, a second connecting plate, a telescopic rod, multiple pairs of connecting bars and multiple pairs of transverse bars, wherein the feeding tray frame comprises four first upright columns and four first crossbeams; the bracket is located at the left side of the feeding tray frame, is rotatably connected with the feeding tray frame and comprises four second upright columns, four second crossbeams and four third crossbeams; the first connecting plate and the second connecting plate are separately arranged on two opposite side faces of the feeding tray frame and the bracket; the telescopic rod is horizontally arranged between the first connecting plate and the second connecting plate and is vertical to the first connecting plate; the multiple pairs of connecting bars are arranged among the four first upright columns from top to bottom; the multiple pairs of transverse bars are arranged between the second crossbeams and the third crossbeams from top to bottom. According to the stack-up sericulture device, procedures of rapid, timesaving, laborsaving and silkworm-direct-contact-avoided bed cleaning and mulberry leaf replacing can be achieved, the sericulture effect is improved, and thus, the stack-up sericulture device has a relatively high practical value.

Owner:NANJING ZHIQIAO AGRI CO LTD

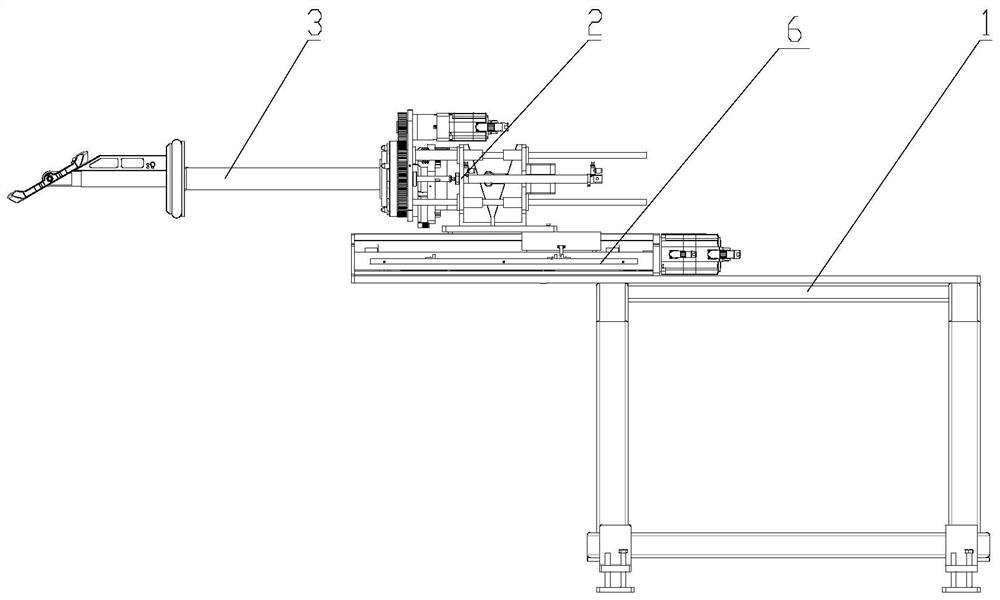

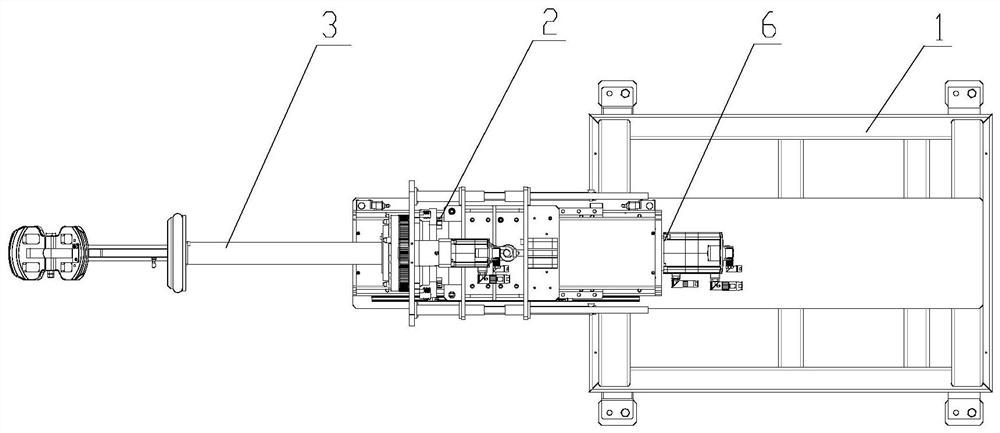

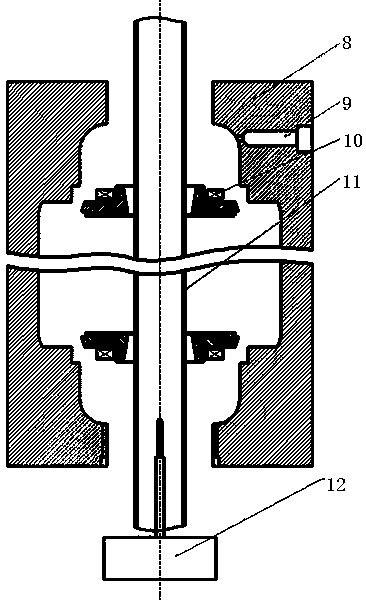

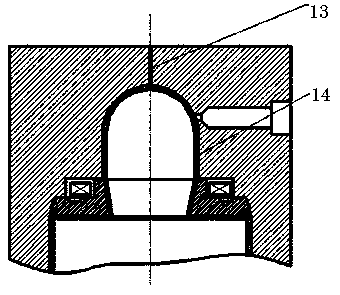

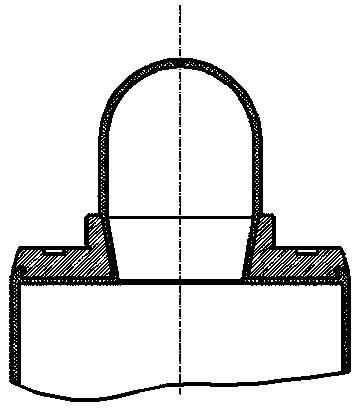

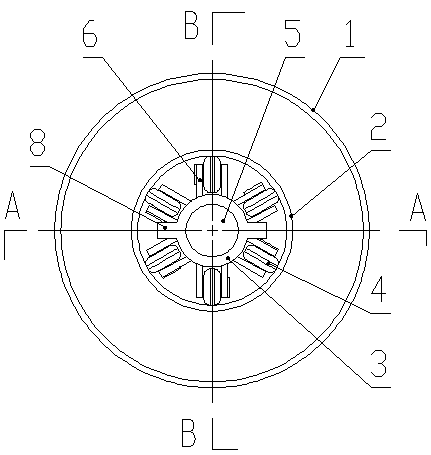

Full-automatic self-adaptive aligning and plugging mechanism for throats of large cavity type workpieces

ActiveCN112378586ACorrect pluggingEfficient pluggingFluid-tightness measurement using fluid/vacuumEngineeringMechanical engineering

The invention relates to the technical field of airtight experiments of large cavity type workpieces, in particular to a full-automatic self-adaptive aligning and plugging mechanism for throats of thelarge cavity type workpieces. The mechanism comprises a base, a driving mechanism, a plugging mechanism and a horizontal transferring module, wherein the horizontal transferring module is arranged onthe base; the driving mechanism is arranged on the horizontal transferring module; the plugging mechanism is arranged at the output end of the driving mechanism; and the plugging mechanism can be driven by the driving mechanism to plug the throat of the large cavity type workpiece. In the product airtightness detection process, full-automatic self-adaptive alignment plugging of the throat of thelarge cavity horn-mouth-shaped workpiece in the horizontal state can be achieved, plugging is reliable and free of leakage, and then the airtightness detection accuracy and reliability are guaranteed.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Electric safety window device and use method thereof

An electric safety window device is disclosed. The device includes a doors and glass. A sliding cavity is arranged in the door. A sliding groove communicating with the outside is arranged at the rearend of the top wall of the slide cavity. A slide block is slidably installed up and down in the sliding cavity, the glass is slidably mounted in the sliding groove, the low end of the glass is fixedlyconnected with the slide block, a transmission cavity is arranged below the sliding cavity, a first rotating chamber is arranged below the transmission cavity, a first rotating shaft is rotatably mounted in the upper and lower end walls of the transmission cavity, the first rotating shaft is provided with a first rotating hole passing through the first rotating shaft vertically, the first rotating hole is provided with a second rotating shaft extending vertically, the upper end of the second rotating shaft penetrates the top wall of the transmission cavity and extends into the sliding cavity,the low end extends downward and is rotatably mounted in the bottom wall of the first rotating chamber, a first internal screw groove passing through the slide block is arranged in the slide block, and a first screw shaft extending upward and downward is threadably fitted in the first internal screw groove.

Owner:韩巧女

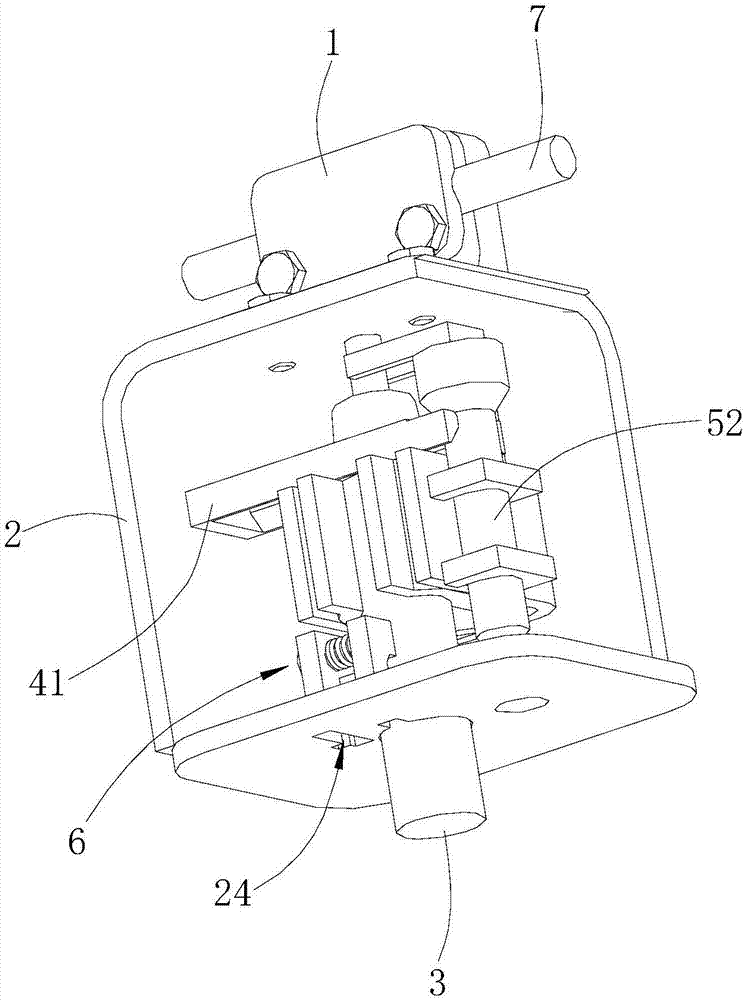

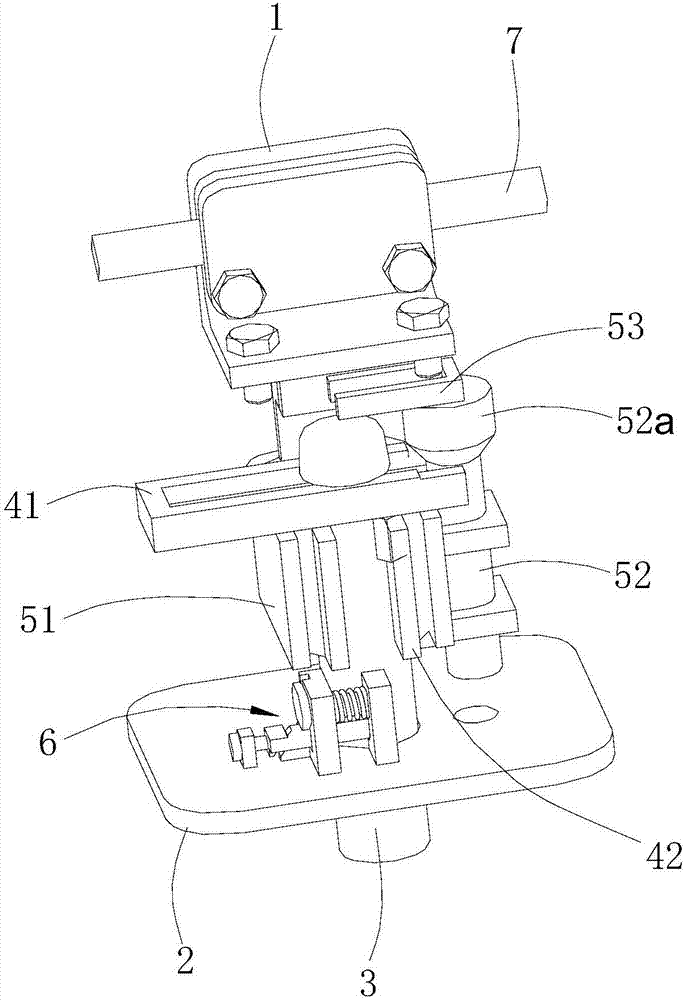

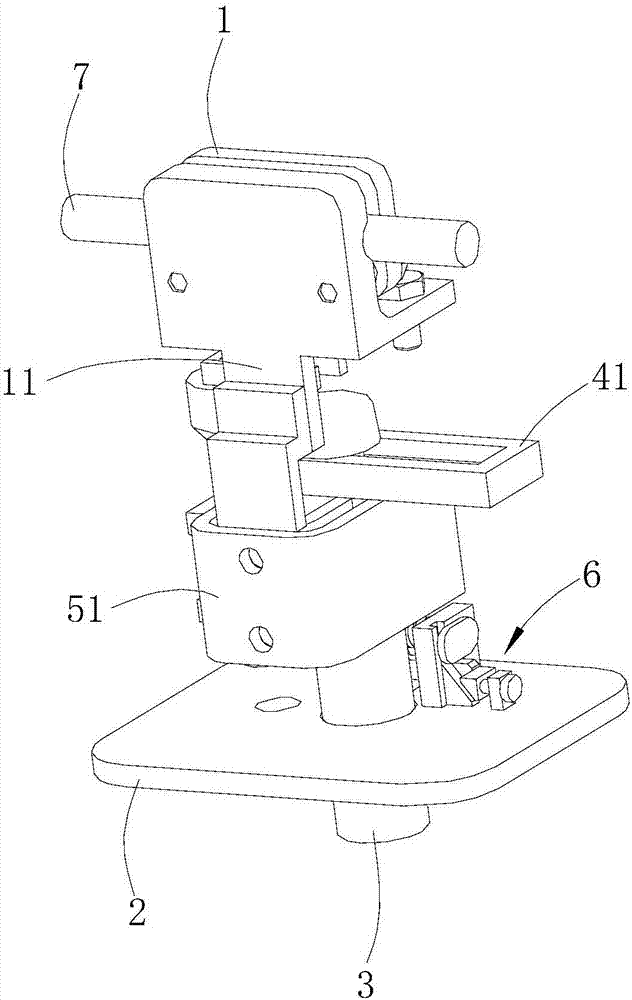

Overhead line plug-pull connection device

ActiveCN106972293AShorten repair timeQuickly complete on-site security measuresElectric connection structural associationsClamped/spring connectionsEngineeringOverhead line

The invention discloses an overhead line plug-pull connection device, which comprises an insulation shell, a wire clamp, a connection wire plug-pull connector and a clamping assembly, wherein the insulation shell is internally provided with a cavity; the lower end surface of the insulation shell is provided with a plugging hole for enabling the connection wire plug-pull connector to extend to the cavity; the wire clamp is fixedly connected onto the outer side wall of the insulation shell; the wire clamp and a power line are connected and fixed; the contact part of the wire clamp extends to the cavity of the insulation shell; the clamping assembly is fixed in the cavity of the insulation shell; the clamping assembly comprises at least one clamping part matched with the connection wire plug-pull connector; and the clamping part is connected with the contact part of the wire clamp. The overhead line plug-pull connection device has the beneficial effects that the distribution network rush repair time is reduced, the nearby device arranged in the surrounding line can be selected, a plug-and-pull connection device (a wire plug-pull connector and a grounding plug-pull connector) can be exchanged, field safety measures can be quickly completed, and the device is safe and efficient.

Owner:BENGBU POWER SUPPLY COMPANY STATE GRID ANHUI ELECTRIC POWER +2

Size-adjustable pressurizing, fixing and centering device and centering method

InactiveCN111122303AIncrease contactIncrease contact surfaceAngles/taper measurementsPreparing sample for investigationContact pressureStructural engineering

The invention discloses a size-adjustable pressurizing, fixing and centering device and a centering method and belongs to the field of sample pretreatment. The centering device comprises a base and centering clamping plate units, centering guide grooves are arranged on the surface of the base, the two centering clamping plate units are slidably connected onto the centering guide grooves, two baffle plates are parallelly arranged on two sides of each centering guide groove, and fastening screws are arranged on the baffle plates. Certain contact pressure can be generated between sample pieces through the baffles and the fastening screws arranged on the two sides of the centering guide grooves, and good contact between the sample pieces is guaranteed; the two centering clamping plate units can do relative motion in the groove direction of the centering guide grooves, and therefore the centering clamping plate units can adapt to centering, pressurizing and fixing of sample pieces of different sizes by adjusting the sliding positions of the two centering clamping plate units on the centering guide grooves. The device is simple in structure, easy to operate and high in practicability.

Owner:XI AN JIAOTONG UNIV

Nursing bed with lateral turning-over assisting function

ActiveCN113975020AAvoid the risk of secondary injuryRisk of secondary injuryNursing bedsAmbulance serviceNursing careEngineering

The invention relates to the technical field of medical nursing beds, in particular to a nursing bed with a lateral turning assisting function, which comprises a bed body, a support frame, a turning rack, a turning mechanism and a turning plate, in the turning mechanism, a moving block drives an adjusting plate to move in opposite directions so as to drive the turning plate to rotate through an inclined surface; a moving plate and moving branch chains are matched with each other to drive a patient to conduct auxiliary turning, and the labor intensity of complete manual turning is reduced; in the moving branch chains, the turning plate synchronously drives the moving plate on the right side to turn in the rotating process so as to ensure that the patient is in a turning posture, then a lead screw is rotated to drive the patient to move to the moving plate on the left side through mutual cooperation of a moving sliding block and the moving plate, and then the moving plate on the left side is manually reset, so that the patient can turn over; and the danger of secondary injury of the patient caused by high working intensity and uneven stress due to complete manual turning is avoided.

Owner:滑县中医院

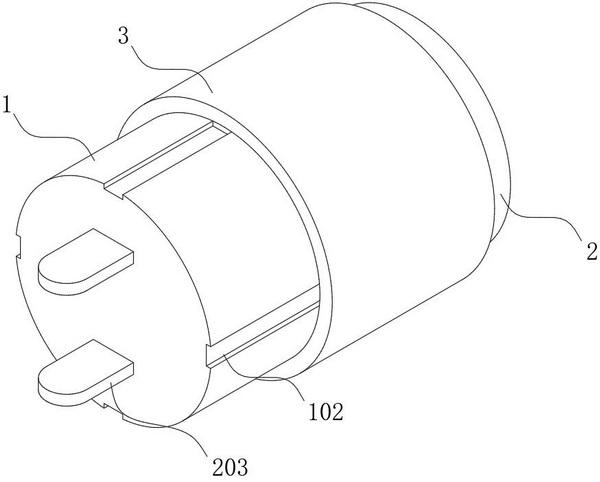

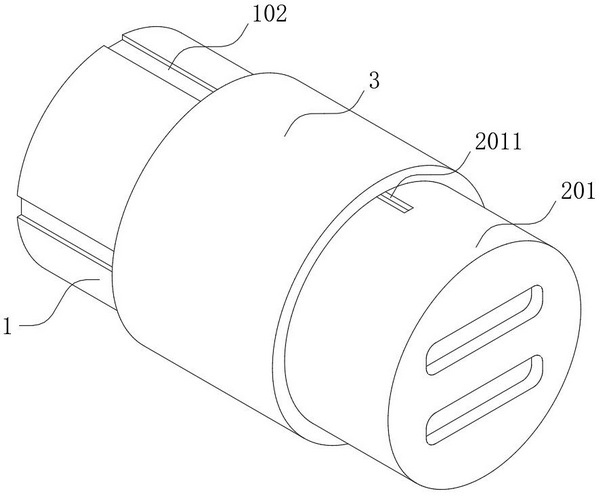

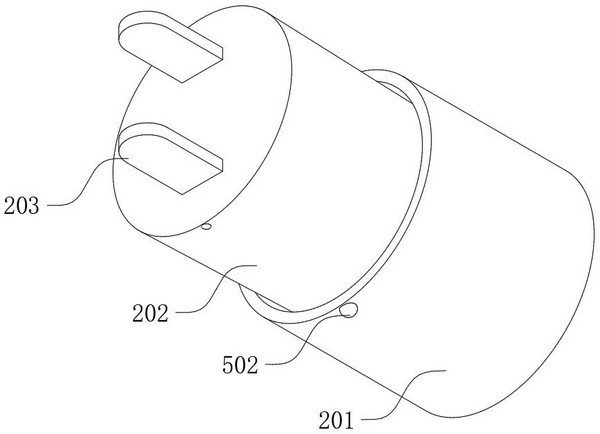

Split type adapter

The invention belongs to the technical field of adapters, and particularly relates to a split type adapter which comprises a fixed shell, a connecting piece, a limiting assembly, a guiding assembly and a fastening assembly, a movable plug is arranged in the fixed shell, and the connecting piece is arranged on the outer side of the fixed shell and the outer side of the movable plug. The limiting assembly is arranged at the joint of the fixed shell and the connecting piece and used for assembling the fixed shell and the connecting piece, the guiding assembly is arranged at the joint of the movable plug and the connecting piece and used for limiting the displacement direction of the movable plug, and the fastening assembly is arranged in the connecting piece and used for fixing the fixed shell. And the fastening assembly is used for fixing the limiting assembly at the joint of the fixed shell and the connecting piece. According to the invention, the fixed shell, the connecting piece or the movable plug can be replaced without the assistance of an external tool, so that the convenience of replacement of parts of the adapter is effectively improved.

Owner:深圳市祥弘瑞科技有限公司

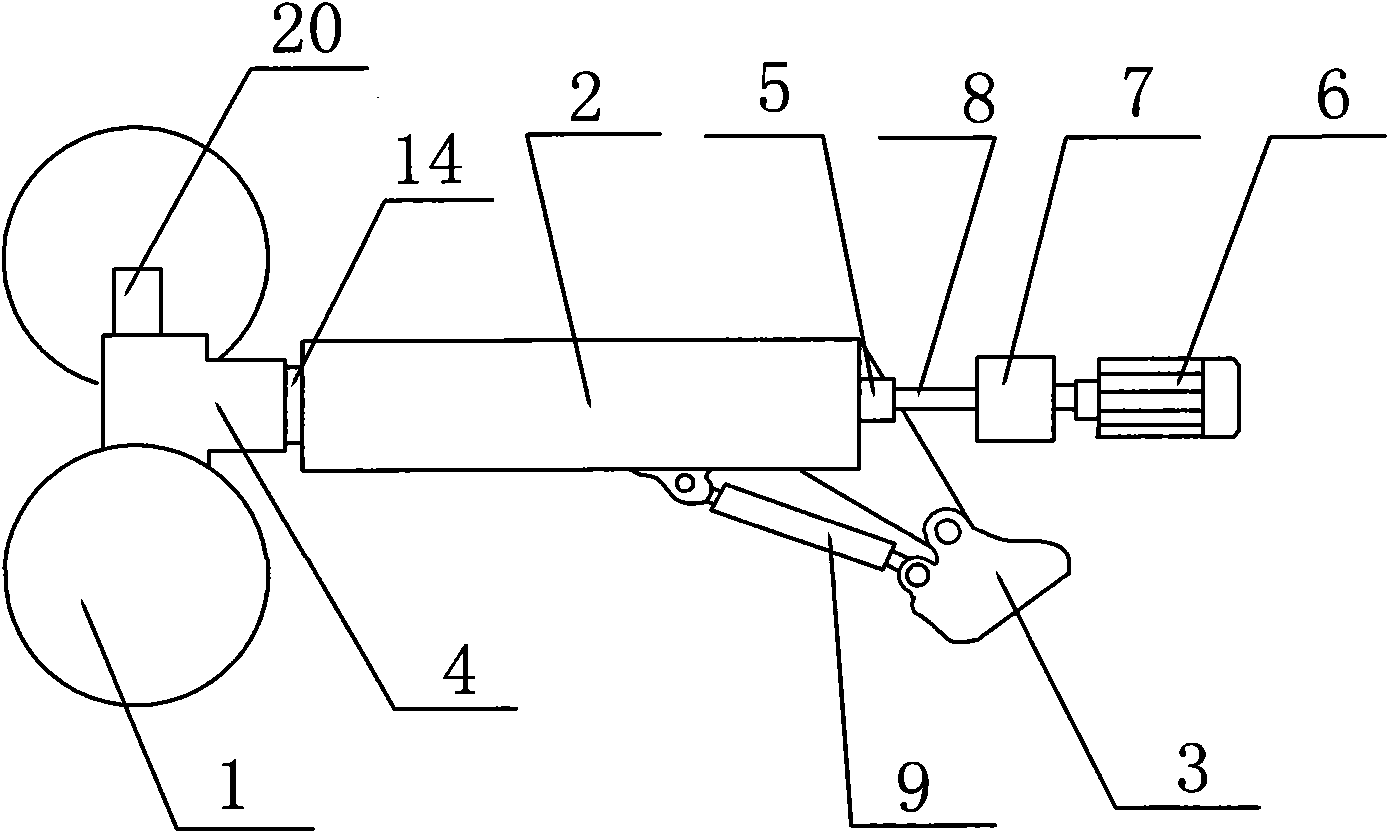

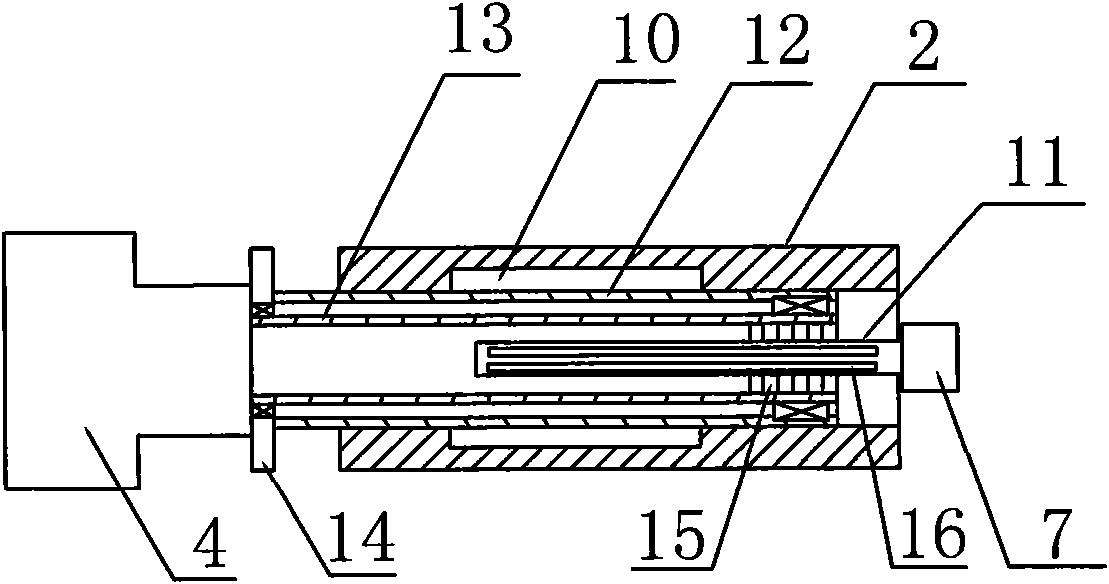

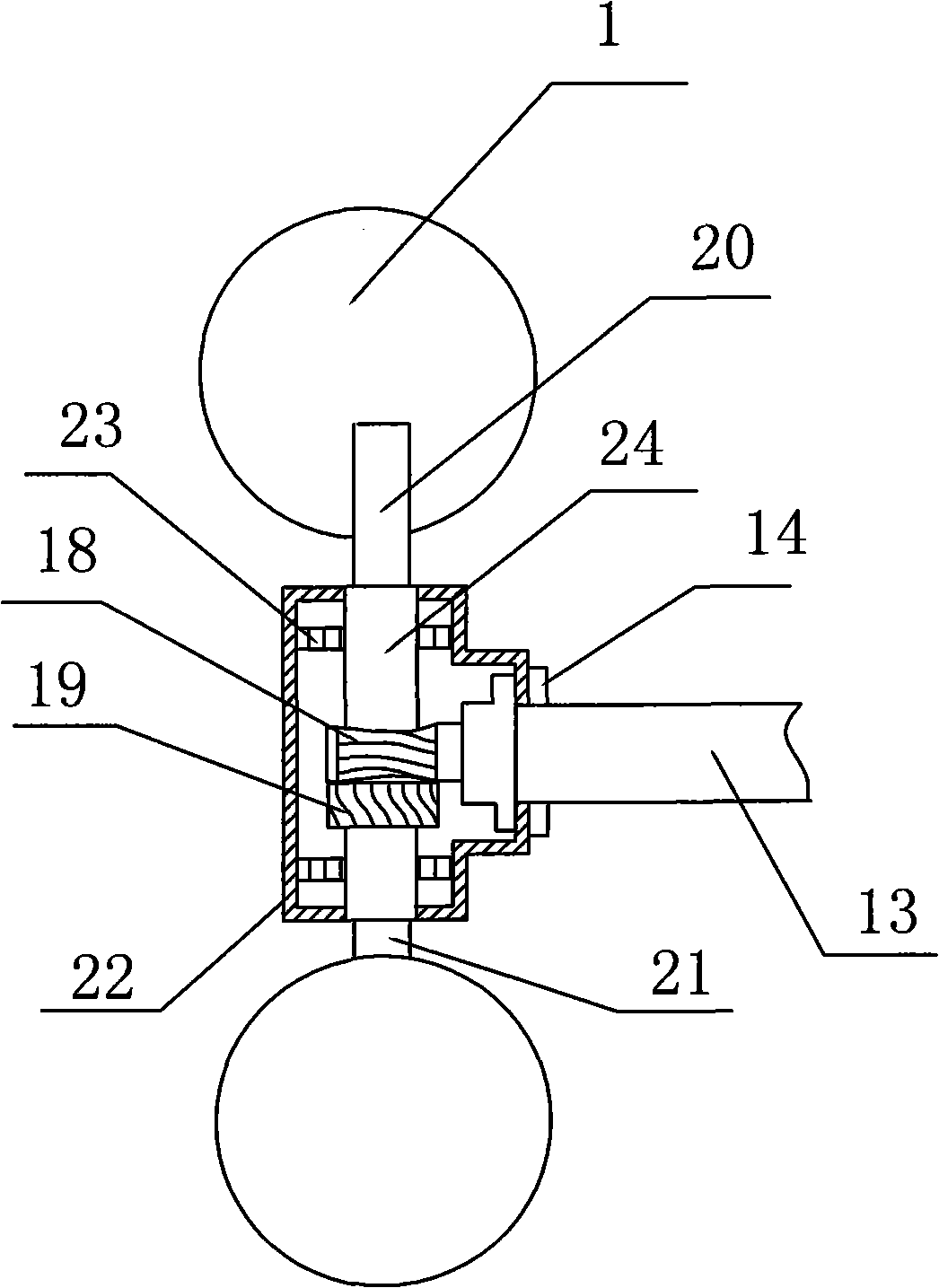

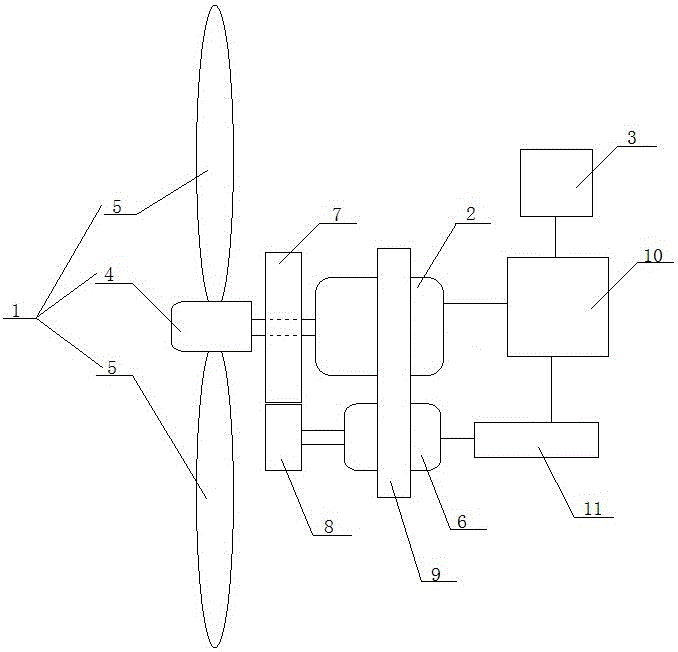

Intelligent electric fan having self power storage and supply functions

InactiveCN105065300AGuaranteed work efficiencyGuaranteed stabilityPump controlMechanical energy handlingElectric machineGear wheel

The invention relates to an intelligent electric fan having self power storage and supply functions. The intelligent electric fan having the self power storage and supply functions comprises a fan blade body (1), a rotation motor (2), an externally connected power supply (3), a rotating mechanical generator (6), a driving gear (7), a driven gear (8), a control module (10) and a power storage module (11). Based on the technical scheme, the hardware modules are connected, so that the intelligent electric fan with the self power storage and supply functions is formed; when the rotation motor (2) controls the fan blade body (1) to rotate, a driving end of the rotating mechanical generator (6) is driven by the fan blade body (1) through the driving gear (7) and the driven gear (8) to rotate, so that the rotating mechanical generator (6) generates power; the power is stored by the power storage module (11), and finally the power storage module (11) is controlled to supply power according to the power supply condition of the externally connected power supply (3); and in this way, stable power supply to the rotation motor (2) can be achieved, and normal work and work efficiency of the intelligent electric fan are guaranteed.

Owner:SUZHOU BROADLINE POWER SUPPLY TECH

Clamping fixing conical washer for multi-angle dispersion of electronic equipment panel load

The invention discloses a clamping fixing conical washer for multi-angle dispersion of an electronic equipment panel load and aims at providing the washer which is simple in structure, stable, reliable and capable of dispersing a load of a conical counter bore, and a multi-angle load dispersing method for combining and fixing a multilayer panel can be provided. According to the following technical scheme, the clamping fixing conical washer is characterized in that a base (1) and a sleeve (3) are integrally connected and fixedly connected to the base; the sleeve (3) penetrates through the conical counter bore (8) in the installation panel of electronic equipment, and the conical-surface washer (2) is formed in a spread out mode; and a lower-layer installation panel body (6) and an upper-layer installation panel body (7) are clamped between the conical-surface washer (2) and the step plane of the base (1), the conical-surface washer and a notch in the surface of the sleeve make contact with and interact with the upper-layer installation panel body and the lower-layer installation panel body, and thus an inlaid matching structure is formed. By means of the clamping fixing conical washer for multi-angle dispersion of the electronic equipment panel load, the pressure bearing area between a countersunk fastener and the equipment installation panel can be increased, so that the stress of the contact zone of the conical counter bore is dispersed to a certain extent.

Owner:10TH RES INST OF CETC

Forming method for end enclosure structure and lining of IV-type cylinder

The invention relates to a forming method for an end enclosure structure and a lining of an IV-type cylinder. The method comprises the following steps that (1), mechanical arms clamp an upper metal insert and a lower metal insert and place the metal inserts at corresponding positions in a mould, a blank is extruded out, and the lower end of the blank penetrates through polar holes of the upper metal insert and the lower metal insert; (2), the mold is closed; (3), parison blow molding and forming is ended, convective heat exchange cooling inside the mold is performed, the blank is cooled to a proper temperature, the mold is opened, the parison with the inserts is removed, blow molding burrs are removed, and then cooling and shaping are performed; (4), the cooled and shaped parison is placedon a rack to be fixed, and a blow molding false head is cut off with a blade; (5), a metal end cover is assembled, the metal end cover is connected with the metal inserts through threads, and a groove in the neck of a metal end head allows a torque wrench to exert force; (6), fiber winding is performed. By means of the forming method, the problem that the extruded and blow molding parison cannotpenetrate through the polar holes of the metal inserts is solved; and meanwhile, the process method for implementing the engineering is proposed targeted to the structure, and thus the advantages of the extrusion and blow molding process are played effectively.

Owner:YAPP AUTOMOTIVE PARTS (KAIFENG) CO LTD

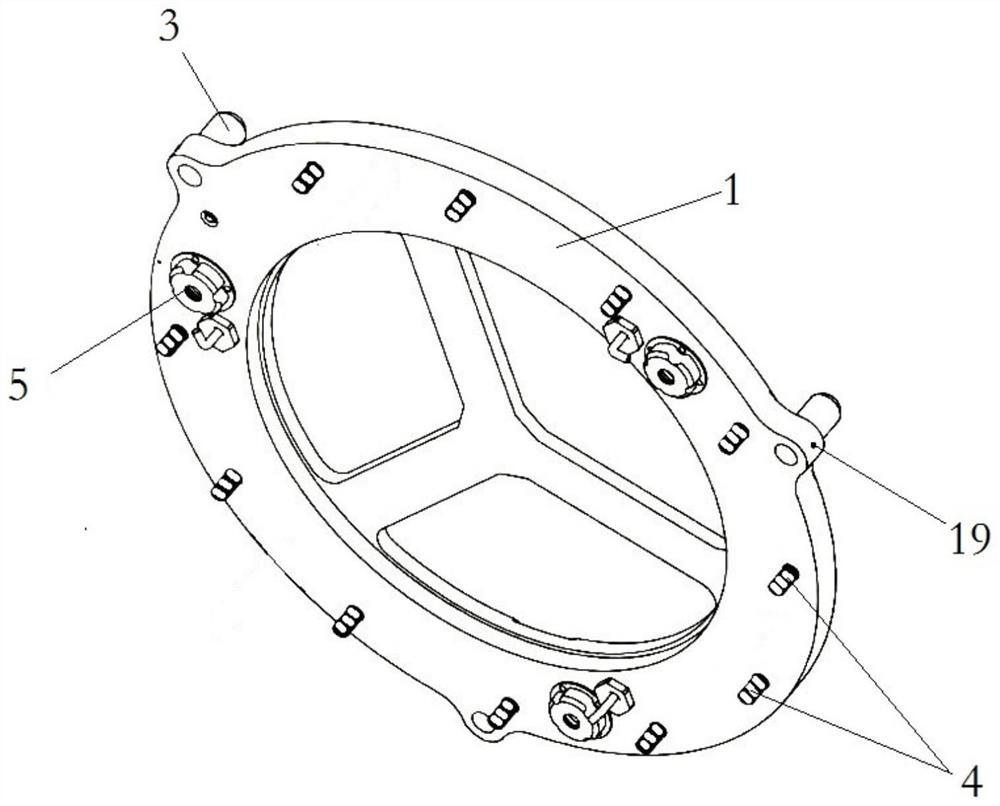

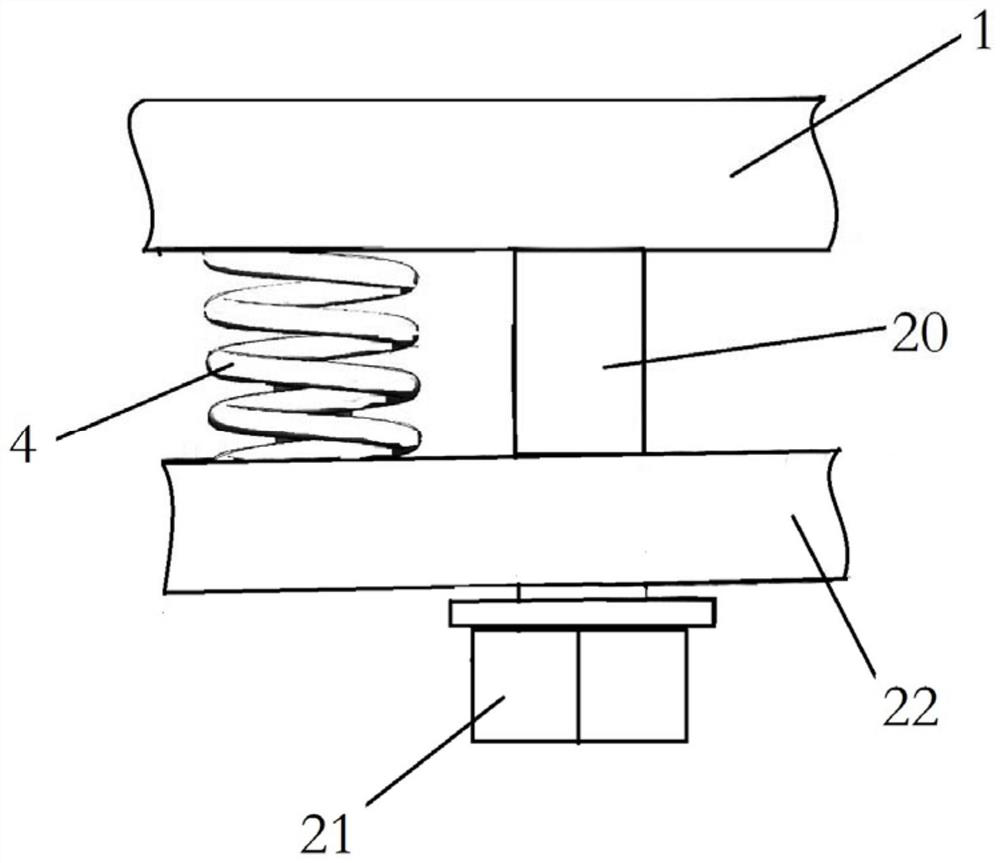

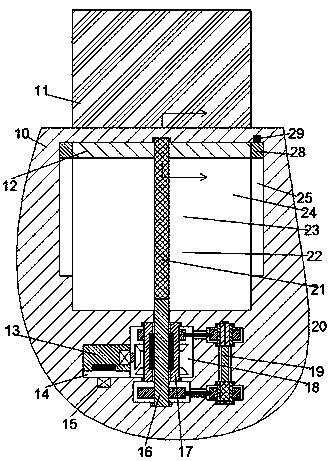

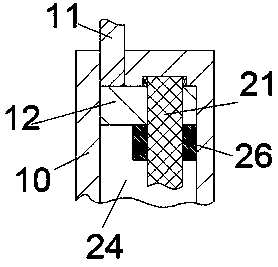

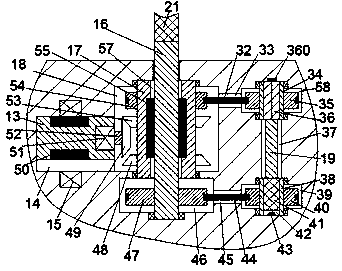

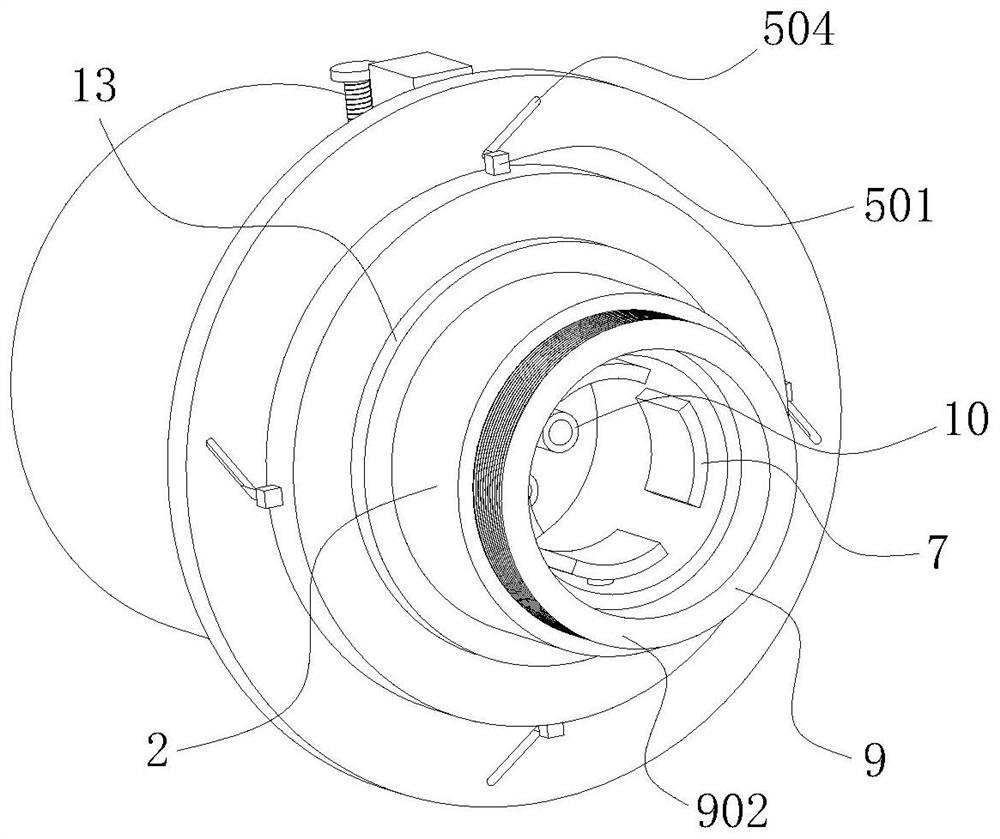

Sucker rod anti-eccentric grinding device for coal-bed gas well

InactiveCN103775005ANo relative movementEasy and convenient to installDrilling rodsDrilling casingsRolling resistanceEngineering

A sucker rod anti-eccentric grinding device for a coal-bed gas well comprises a centralizing mechanism; the center of the centralizing mechanism is provided with a mounting hole for inserting a sucker rod; a plurality of idler wheels are uniformly arranged at the periphery of the centralizing mechanism along the center of the mounting hole; the plane where the rotary direction of each idler wheel is positioned passes by the central line of the centralizing mechanism; the outer surfaces of all idler wheels are positioned on the same circle. The sucker rod anti-eccentric grinding device for the coal-bed gas well has the remarkable and beneficial effects that at the bent part of a shaft, when the sucker rod is bent along the shaft, firstly, the idler wheels arranged on the centralizing mechanism are directly contacted with an oil sucking pipe, and in the up and down motion of the sucker rod, the idler wheels roll along the inner wall of the oil sucking pipe, so the sliding friction of the existing centralizer and the pipe wall of the pipe is changed to be rolling friction, the friction resistance is greatly reduced, the abrasion of the centralizer and the pipe wall is reduced, and the service life of the centralizing device and that of the oil sucking pipe is prolonged. The work time of the air exhaust shaft is greatly shortened, and massive maintenance cost and maintenance time are saved.

Owner:HENAN POLYTECHNIC UNIV

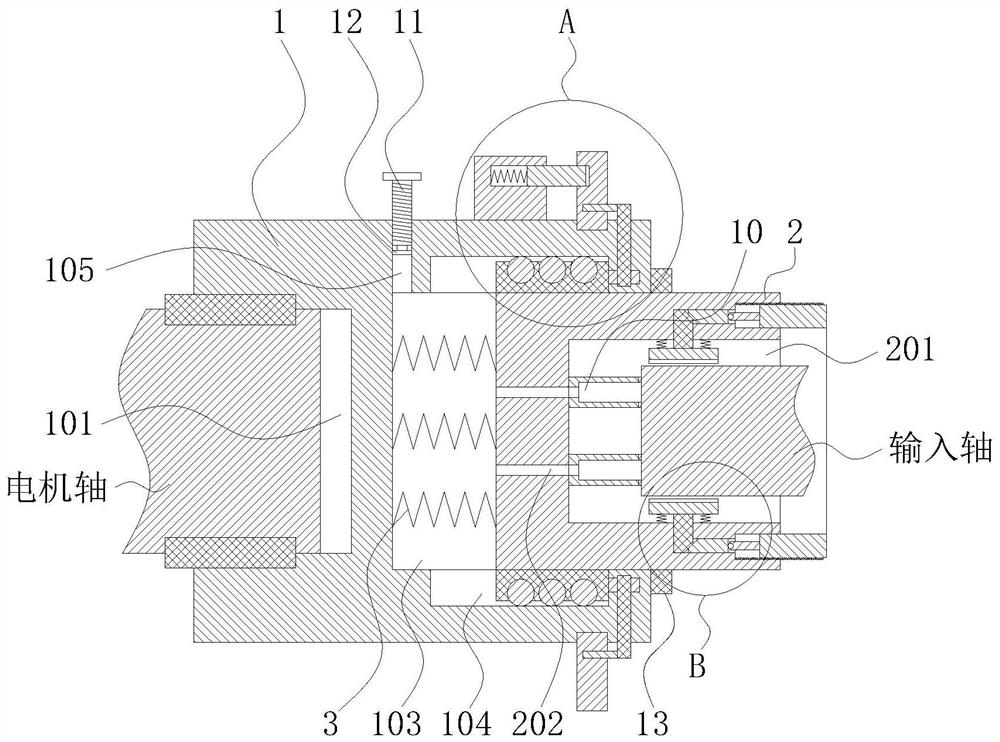

Quick connecting structure for rotating shaft of speed reducer

InactiveCN113404846ARotate synchronouslyImprove convenienceCouplings for rigid shaftsGearing detailsReduction driveCoupling

The invention belongs to the technical field of speed reducers, and particularly relates to a quick connecting structure for a rotating shaft of a speed reducer. The quick connecting structure comprises a mounting cylinder, a first circular groove, a key groove, a second circular groove and a guide groove are formed in the mounting cylinder, and a sleeve is arranged in the second circular groove in a sliding fit mode; a third circular groove is formed in the sleeve, a guide block is installed on the sleeve, a plurality of clamping blocks are installed on the third circular groove, a clamping plate is installed at the end of each clamping block, a reset spring is fixedly connected between each clamping plate and the third circular groove, and an auxiliary clamping mechanism is arranged on the sleeve. In the quality detection process of the speed reducer, compared with a split type coupler, the operation convenience is improved, and it can be guaranteed that a motor shaft and an input shaft of the speed reducer rotate synchronously.

Owner:武汉荣誉机电设备工程有限公司

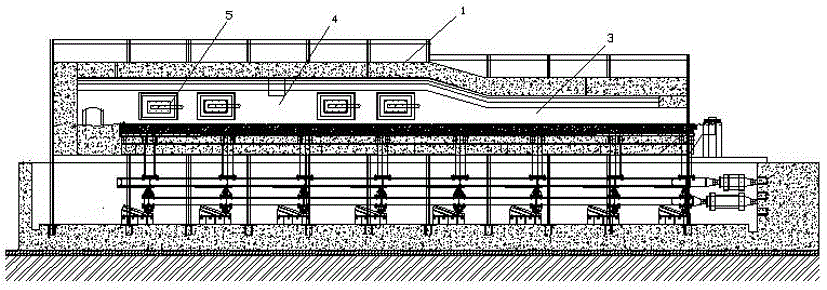

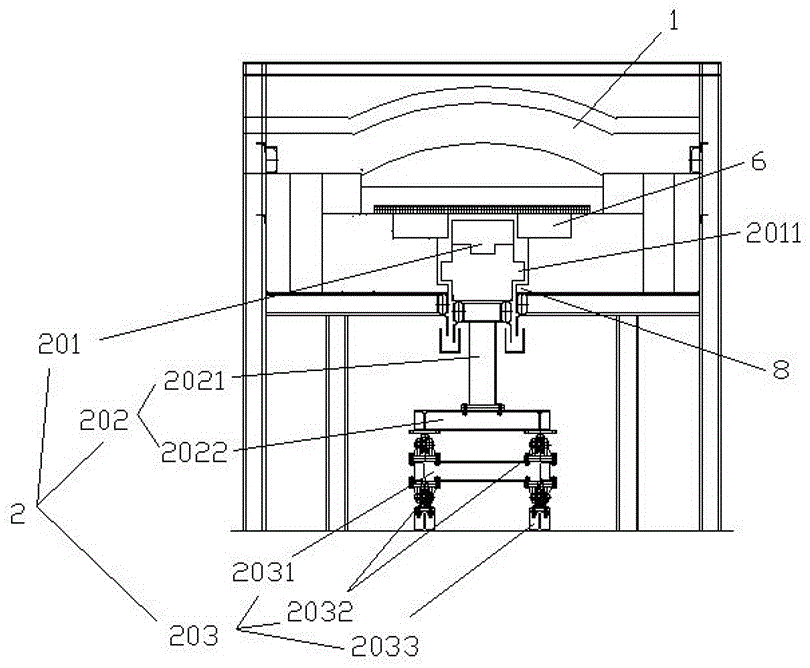

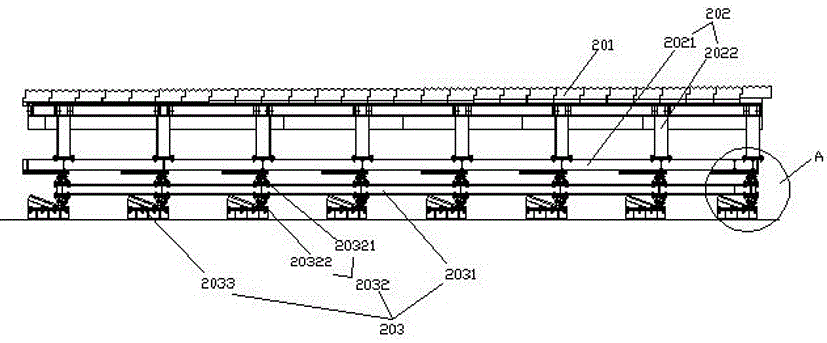

Walking beam furnace

InactiveCN106369999AReduce heating efficiencyMake sure the spacing is fixedFurnace typesEngineeringMechanical engineering

Owner:长兴吉成工业炉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com