Full-automatic gang drilling device

A fully automatic drilling device technology, which is applied in woodworking safety devices, fixed drilling machines, wood processing equipment, etc., can solve the problems of subjective judgment error, inability to stop the conveyor belt in the work area, and high safety risk of manual operation, so as to reduce the The effect of friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

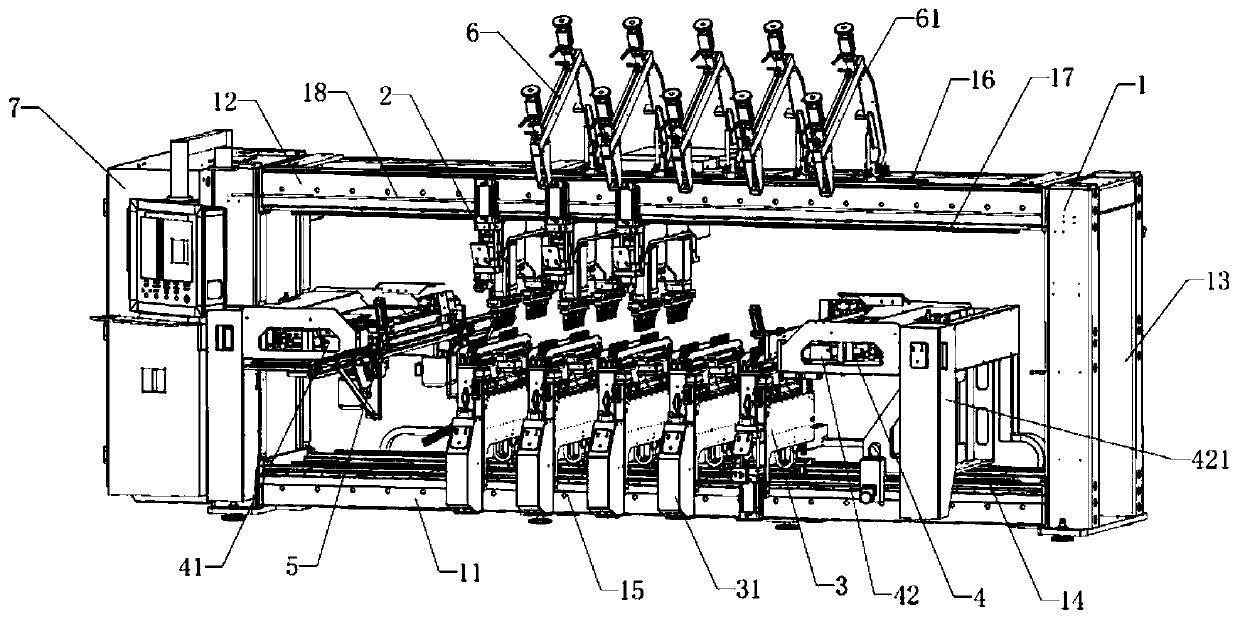

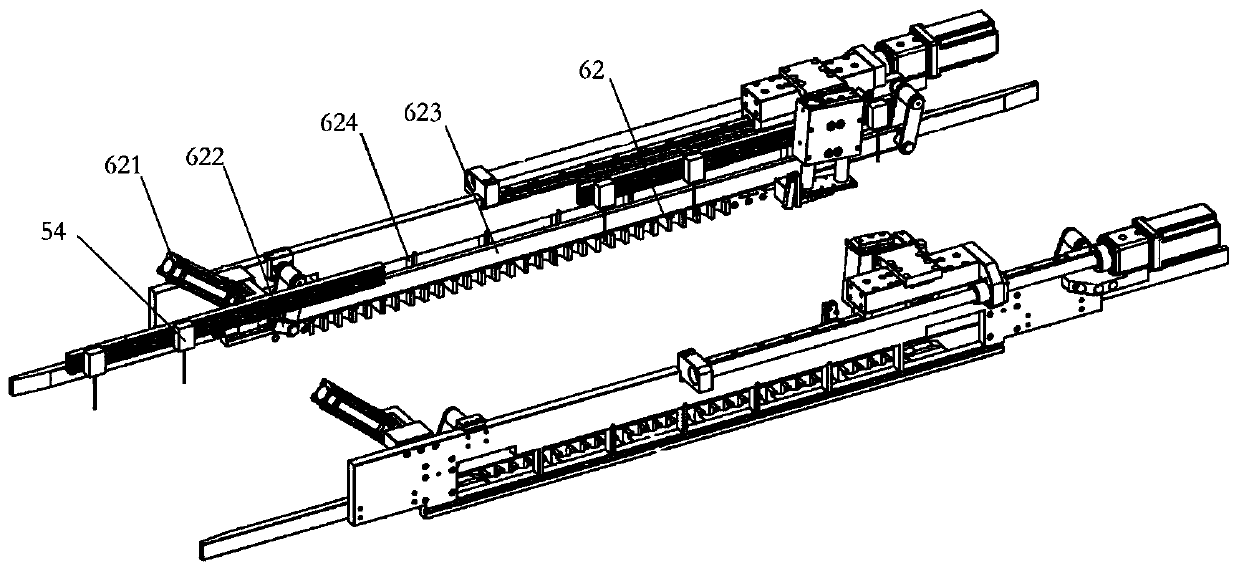

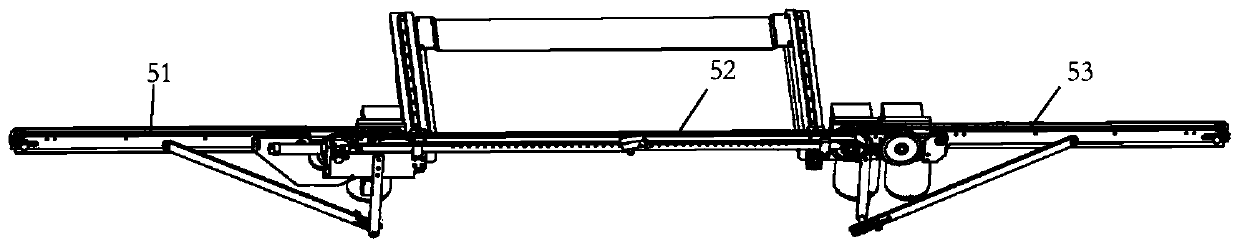

[0027] Such as Figure 1-6 As shown, a fully automatic drilling device includes a frame 1, a top drilling device 2, a bottom drilling device 3, a side drilling device 4, a conveying device 5, a positioning and fixing device 6, and a power supply device 7. The top drilling device 2, the bottom drilling device 3, the side drilling device 4, the positioning and fixing device 6, the conveying device 5 and the power supply device 7 are arranged in the frame 1.

[0028] The frame 1 is a rectangular parallelepiped frame as a whole, and the frame 1 includes a base 11, a cross beam 12 and a side column 13. The base 11 is a rectangular frame. There are four side posts 13 in total, and the four side posts 13 are respectively arranged at the four vertices of the base 11, and the side posts 13 are connected to the short bottom side of the base 11. The bottom of the side column 13 is provided with a foot, which can adjust the height of the corresponding side column 13 to adapt to uneven grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com