Patents

Literature

165results about How to "Reduce heating efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

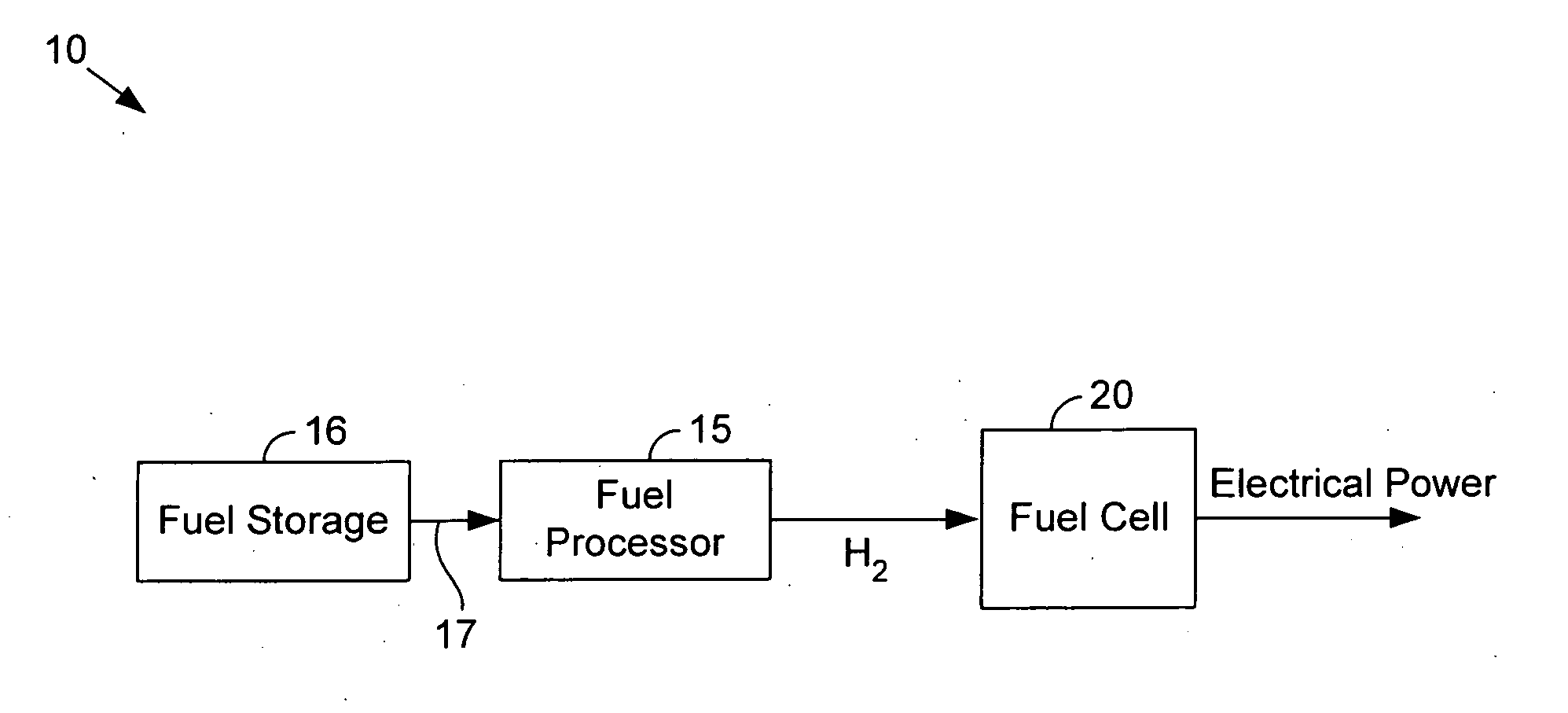

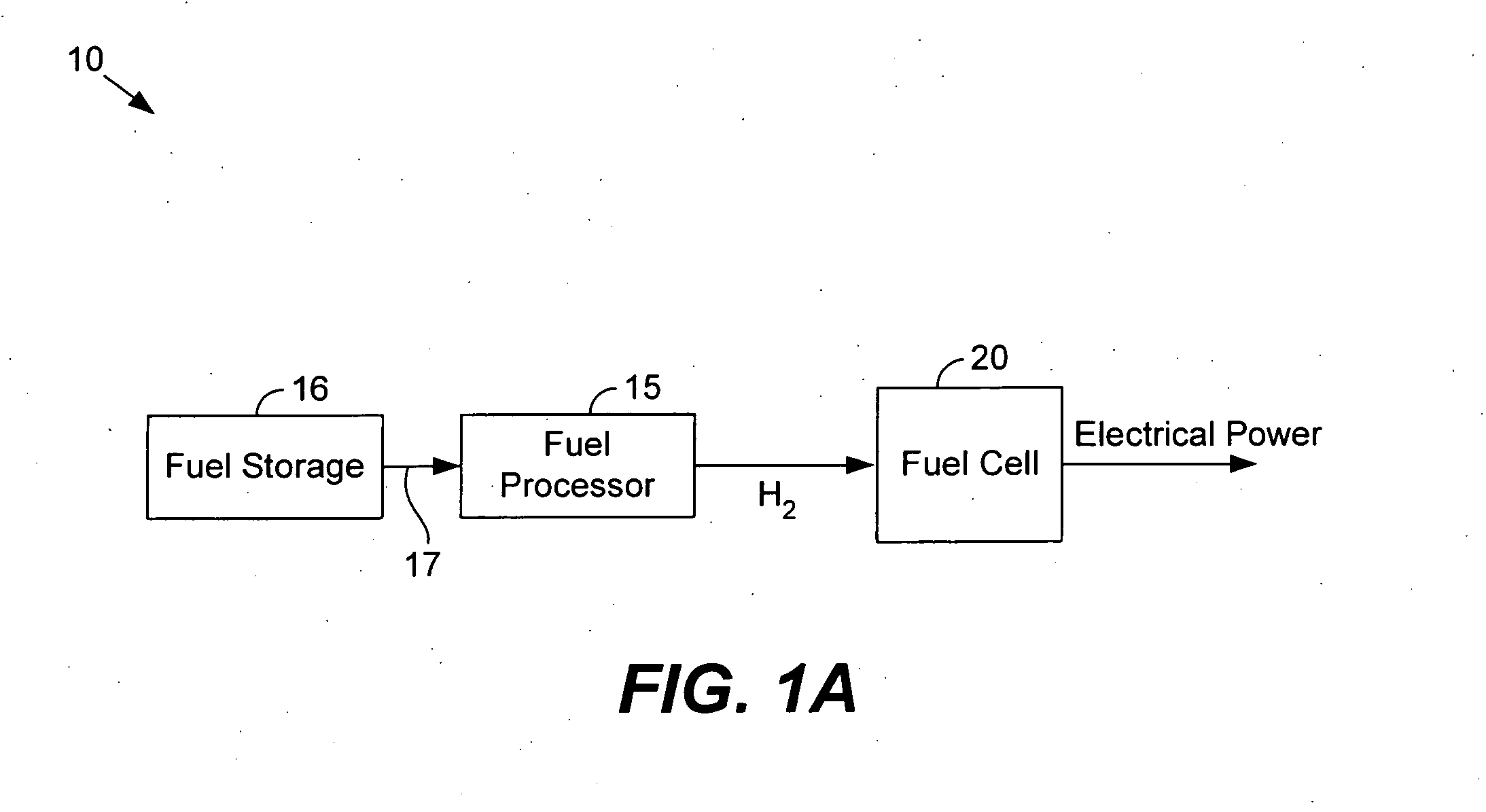

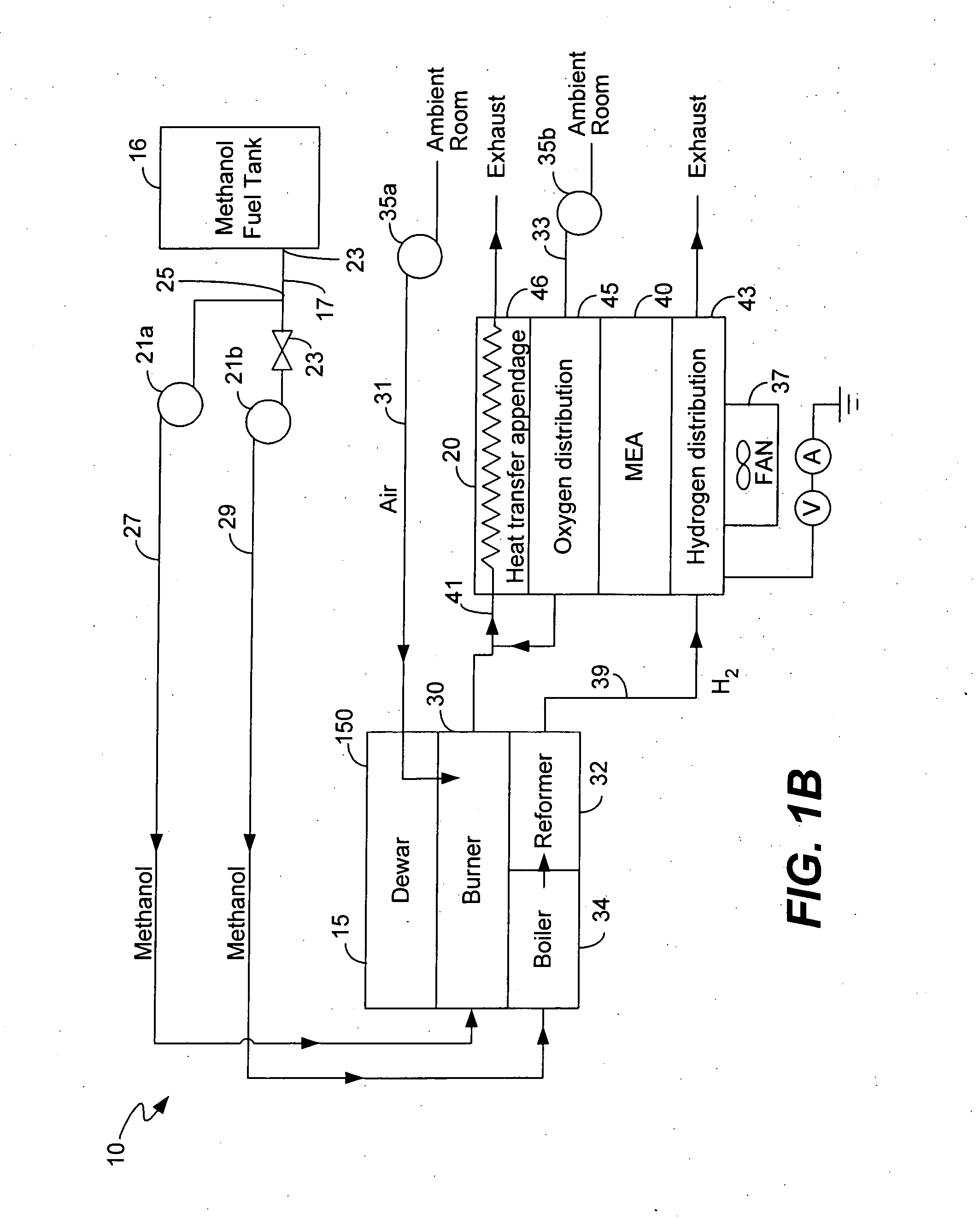

Annular fuel processor and methods

ActiveUS20050011125A1Promote productionIncreased hydrogen productionPressurized chemical processLevel controlCombustorHydrogen

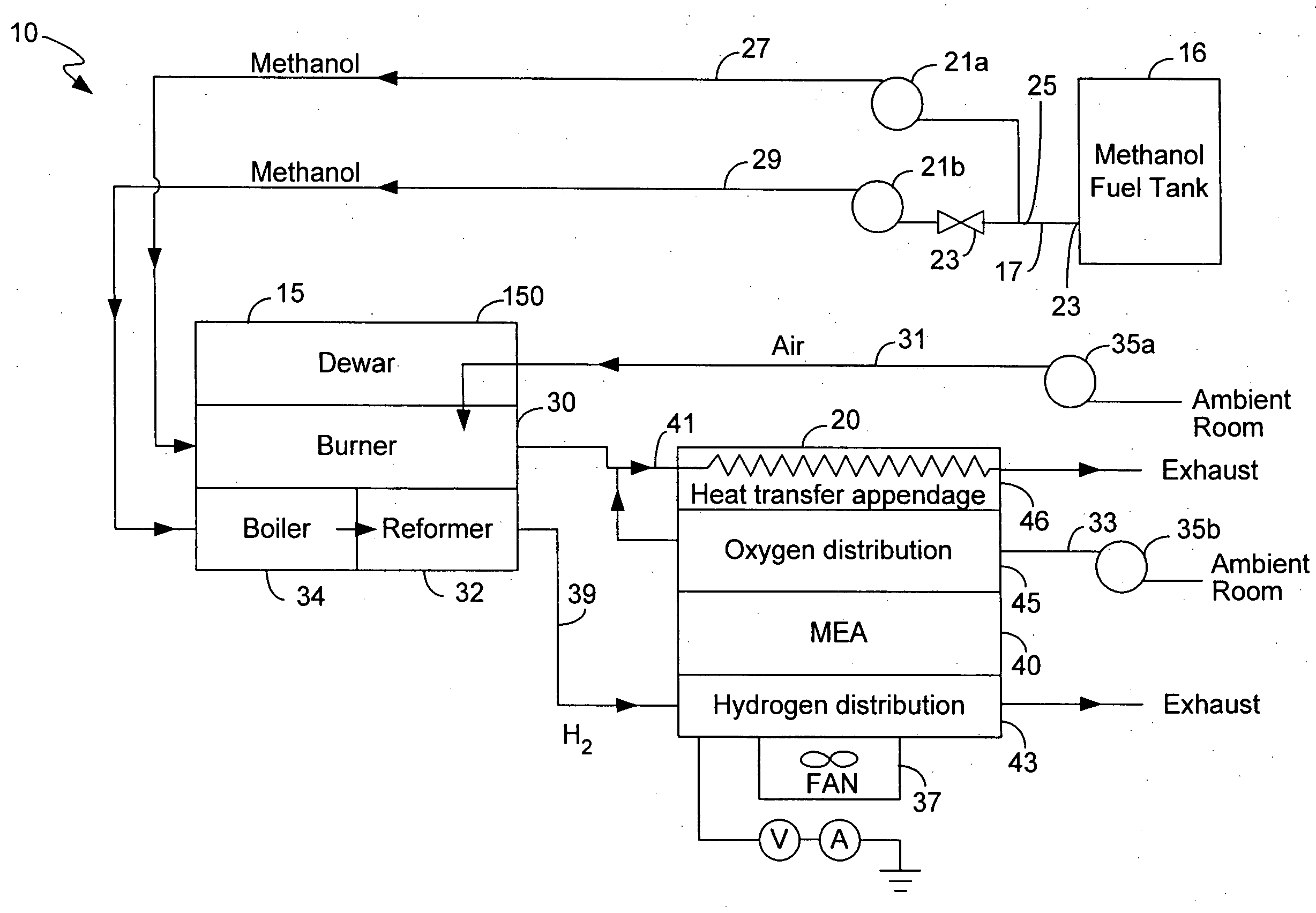

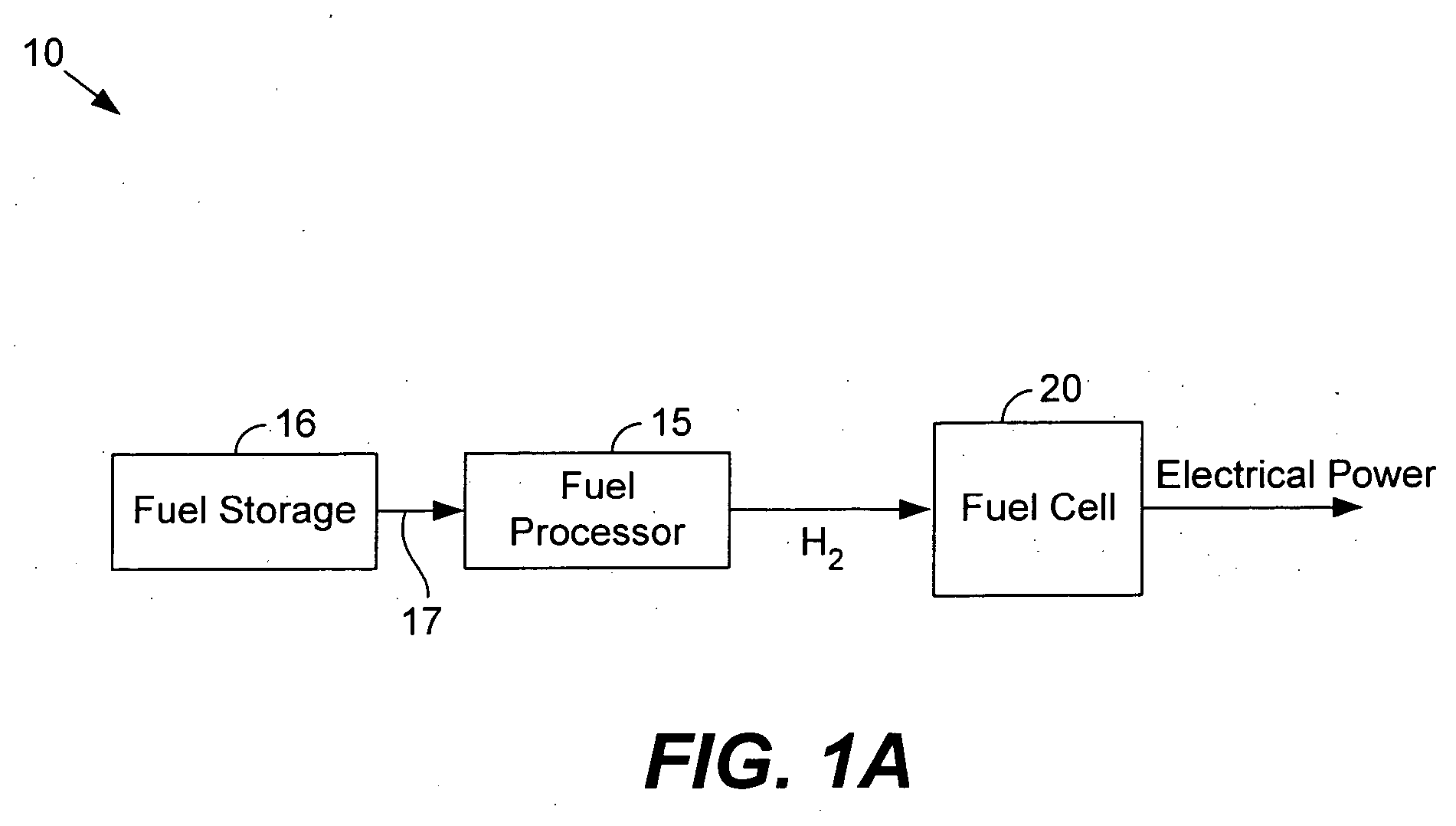

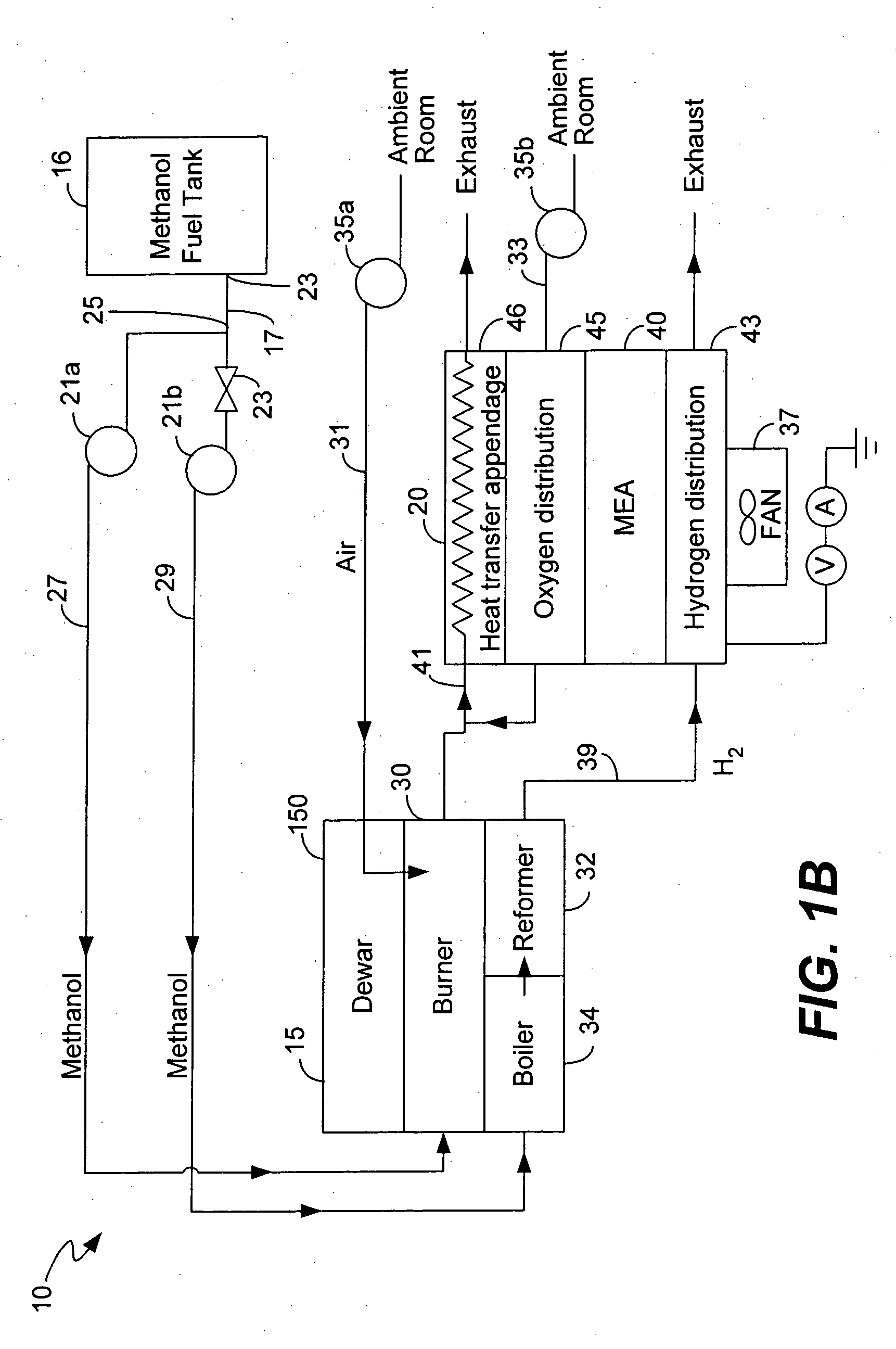

Described herein is a fuel processor that produces hydrogen from a fuel source. The fuel processor comprises a reformer and burner. The reformer includes a catalyst that facilitates the production of hydrogen from the fuel source. Voluminous reformer chamber designs are provided that increase the amount of catalyst that can be used in a reformer and increase hydrogen output for a given fuel processor size. The burner provides heat to the reformer. One or more burners may be configured to surround a reformer on multiple sides to increase thermal transfer to the reformer. Dewars are also described that increase thermal management of a fuel processor and increase burner efficiency. A dewar includes one or more dewar chambers that receive inlet air before a burner receives the air. The dewar is arranged such that air passing through the dewar chamber intercepts heat generated in the burner before the heat escapes the fuel processor.

Owner:ADVENT TECH LLC

Rare earth-doped semiconductor infrared radiation thick-film electronic paste and preparation method therefor

InactiveCN105472791AExtensive selectionLower your temperatureHeating element materialsScreen printingSemiconductor materials

The present invention discloses rare earth-doped semiconductor infrared radiation thick-film electronic paste and a preparation method therefor. The electronic paste comprises, in percentage by weight, 10%-90% of an organic vehicle and 10%-90% of a functional phase. The organic vehicle comprises, in percentage by weight, 50%-95% of an organic solvent,1%-40% of a thickening agent, and 0%-5% of an organic additive. The functional phase comprises, in percentage by weight, 40%-95% of a rare earth-doped infrared radiation semiconductor material, 5%-60% of a conductive material, and 0%-20% of a functional additive. According to the electronic paste, the selecting range of a base material is wide, the heating temperature range is wide, the heating efficiency is high, the temperature of a heating body itself is low, and the bidirectional thermoelectric conversion can be achieved. The preparation method comprises: a, mixing the thickening agent, the organic additive and the organic solvent to prepare the organic vehicle; b, mixing and grinding the organic vehicle and the functional phase to prepare the electronic paste; c, printing the electronic paste on a substrate by means of screen printing, and performing curing or sintering to form a film.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

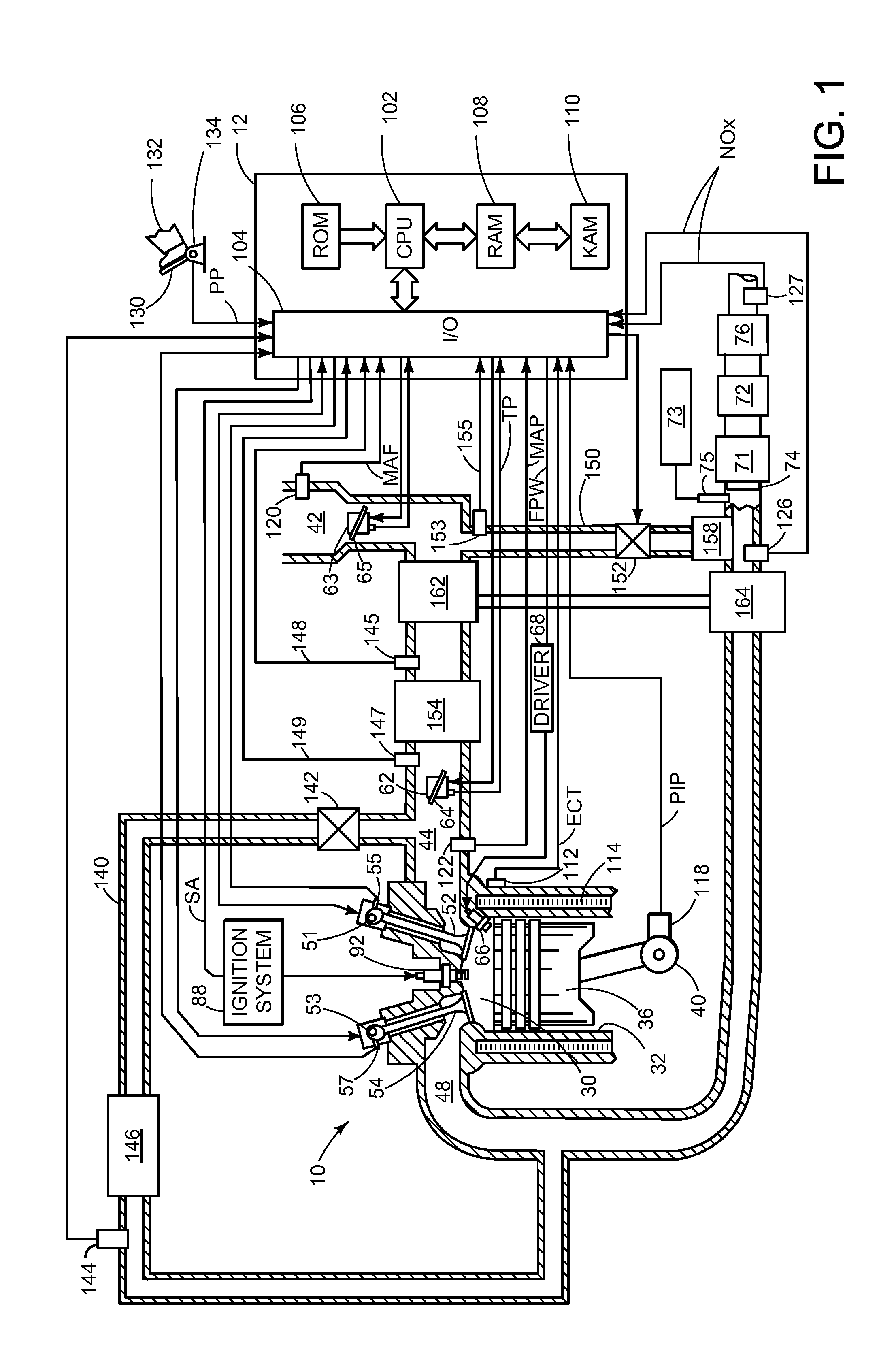

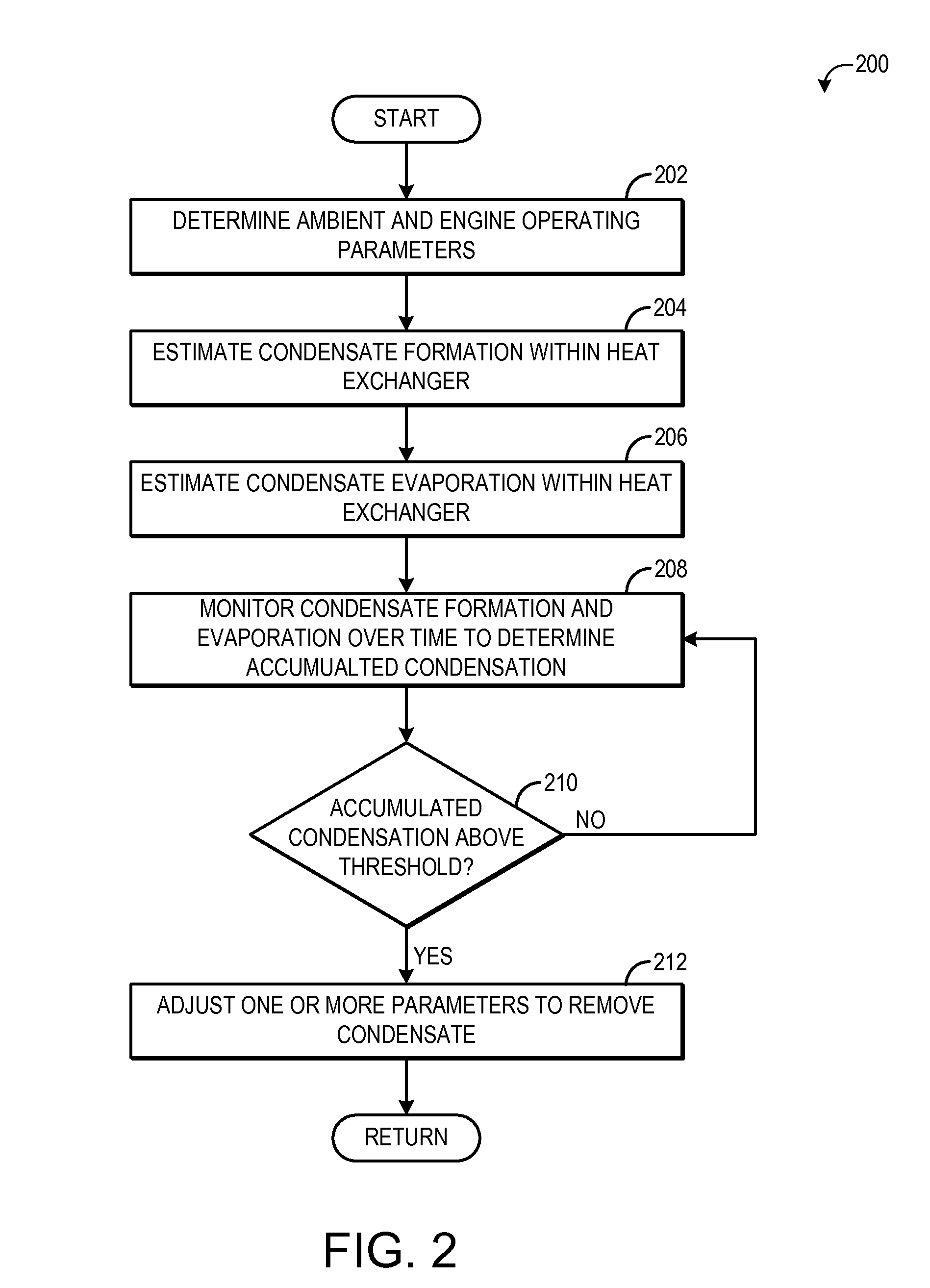

Condensate accumulation model for an engine heat exchanger

ActiveUS20140102428A1High densityReduce heating efficiencyElectrical controlInternal combustion piston enginesEngineeringExhaust gas recirculation

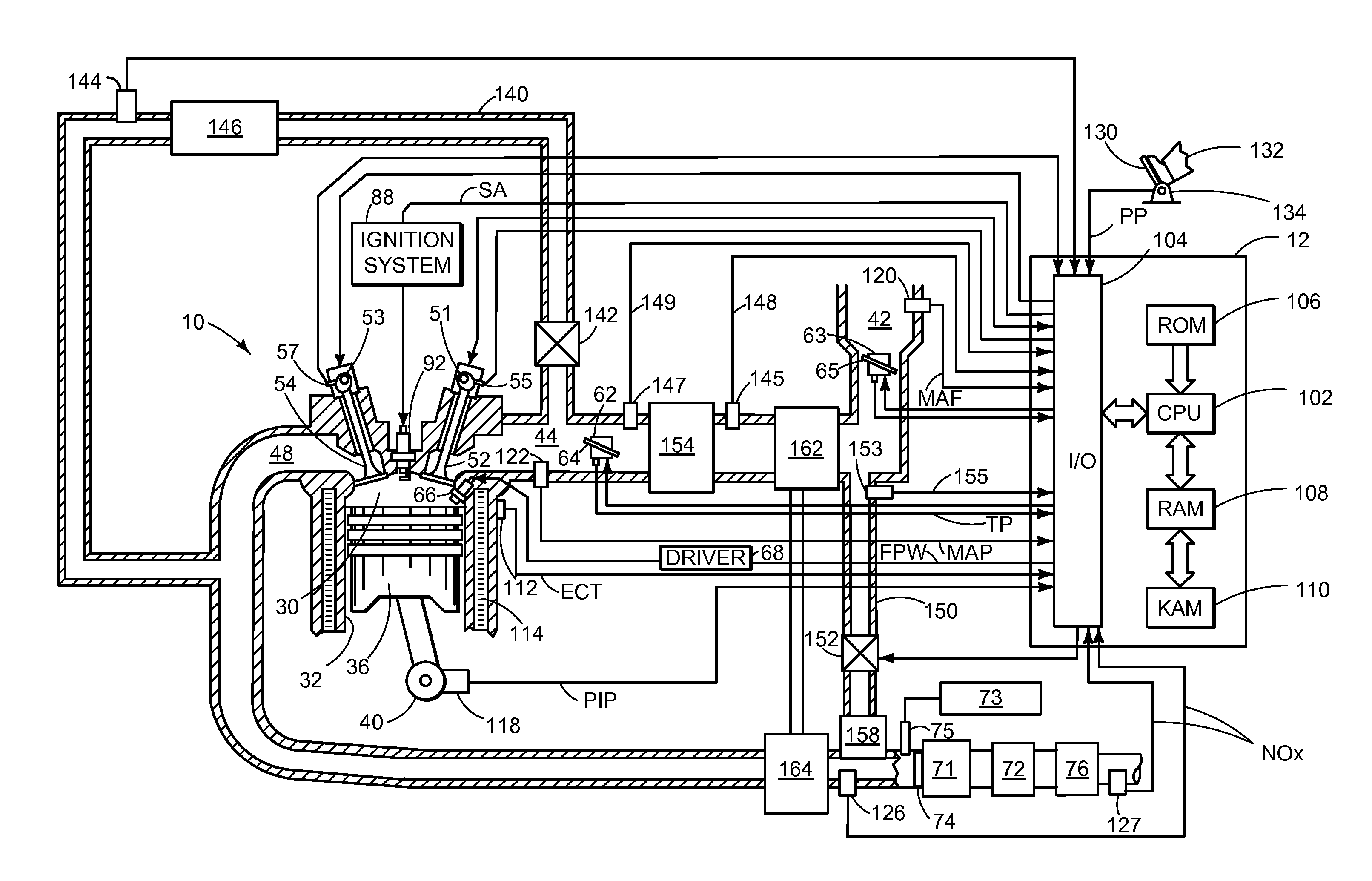

Embodiments for controlling condensate in an engine heat exchanger are disclosed. In one example, a method for an engine comprises increasing exhaust gas recirculation (EGR) flow responsive to condensation in an EGR cooler. In this way, condensate in the EGR cooler may be controlled via modulation of EGR flow.

Owner:FORD GLOBAL TECH LLC

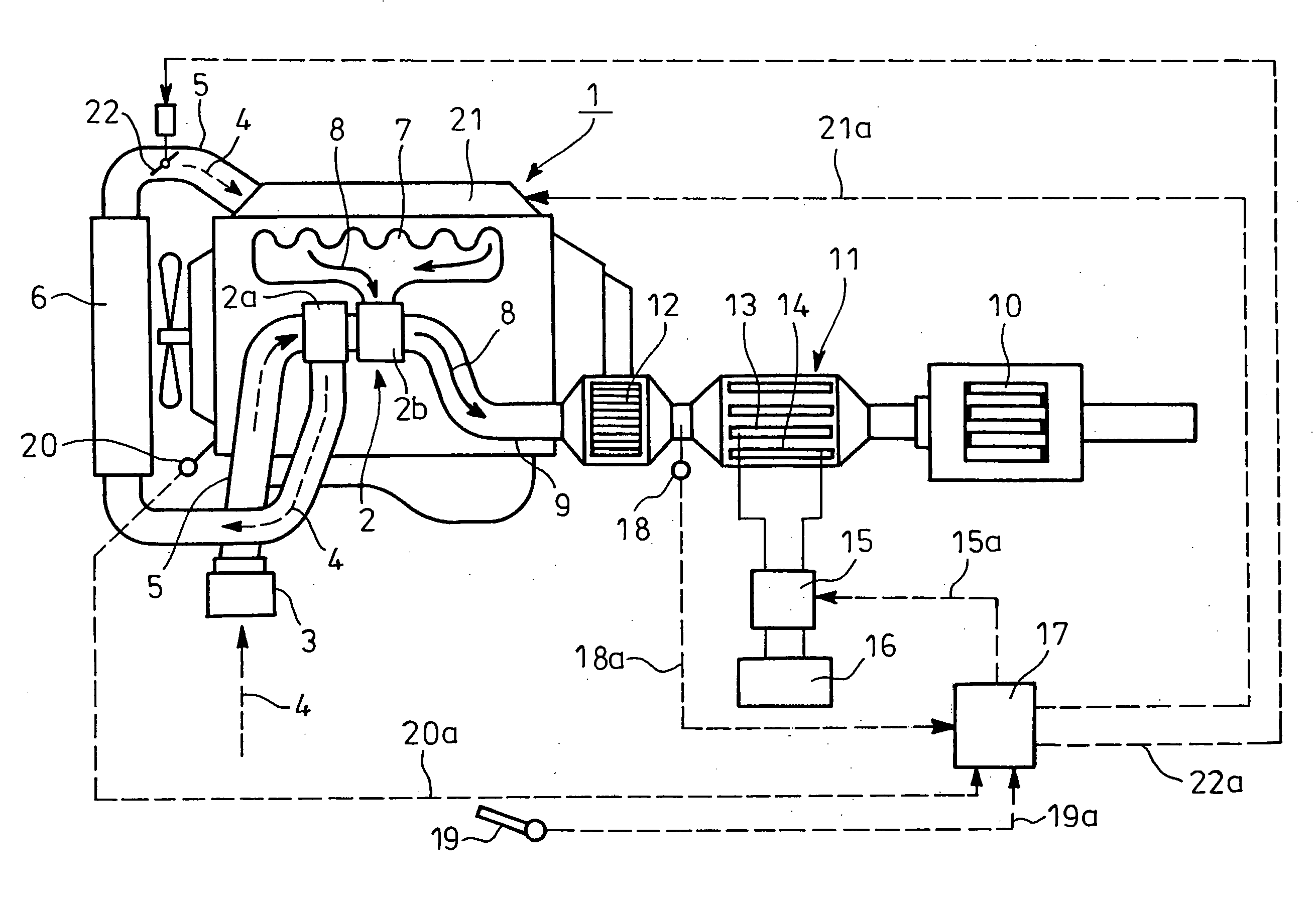

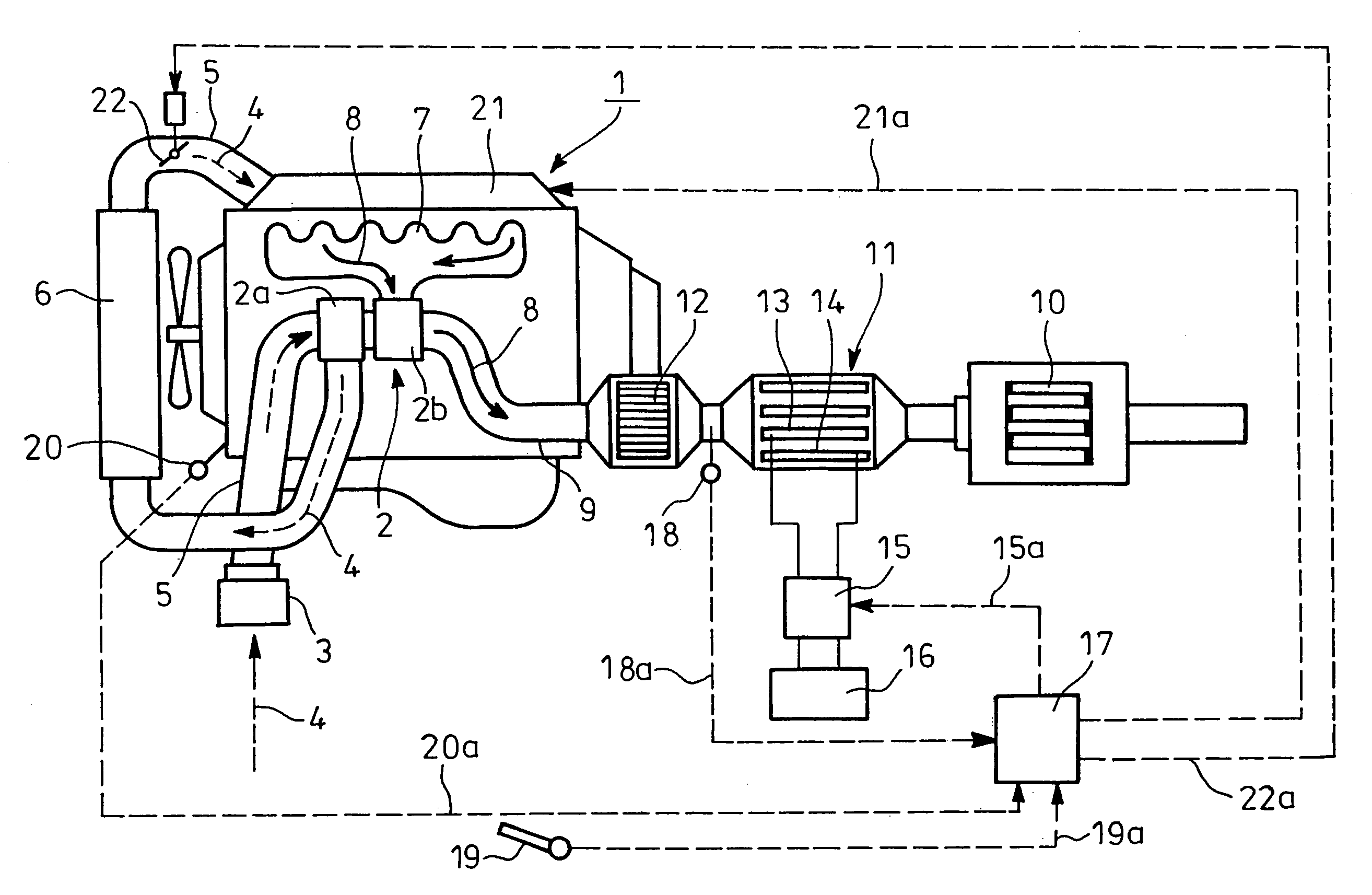

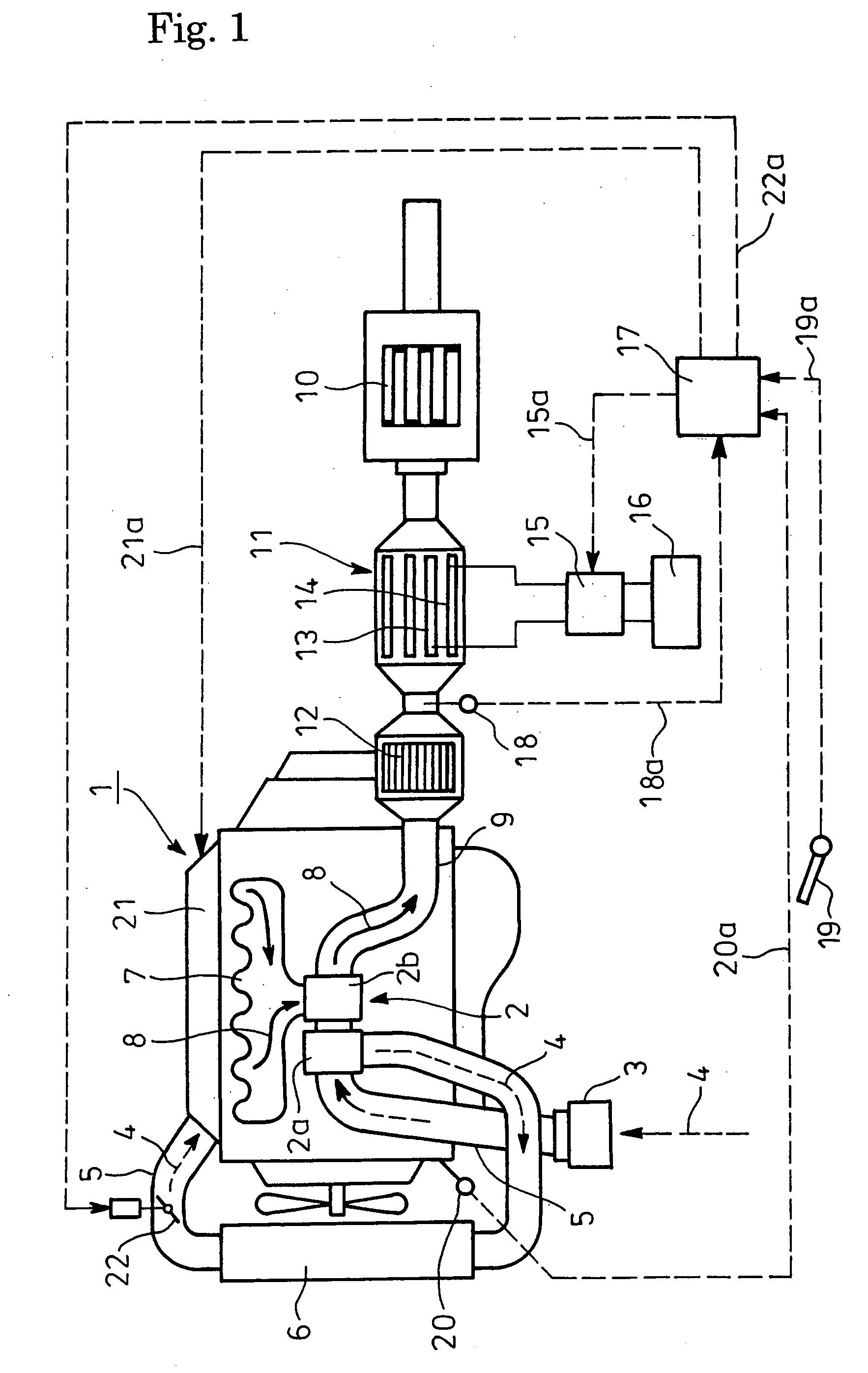

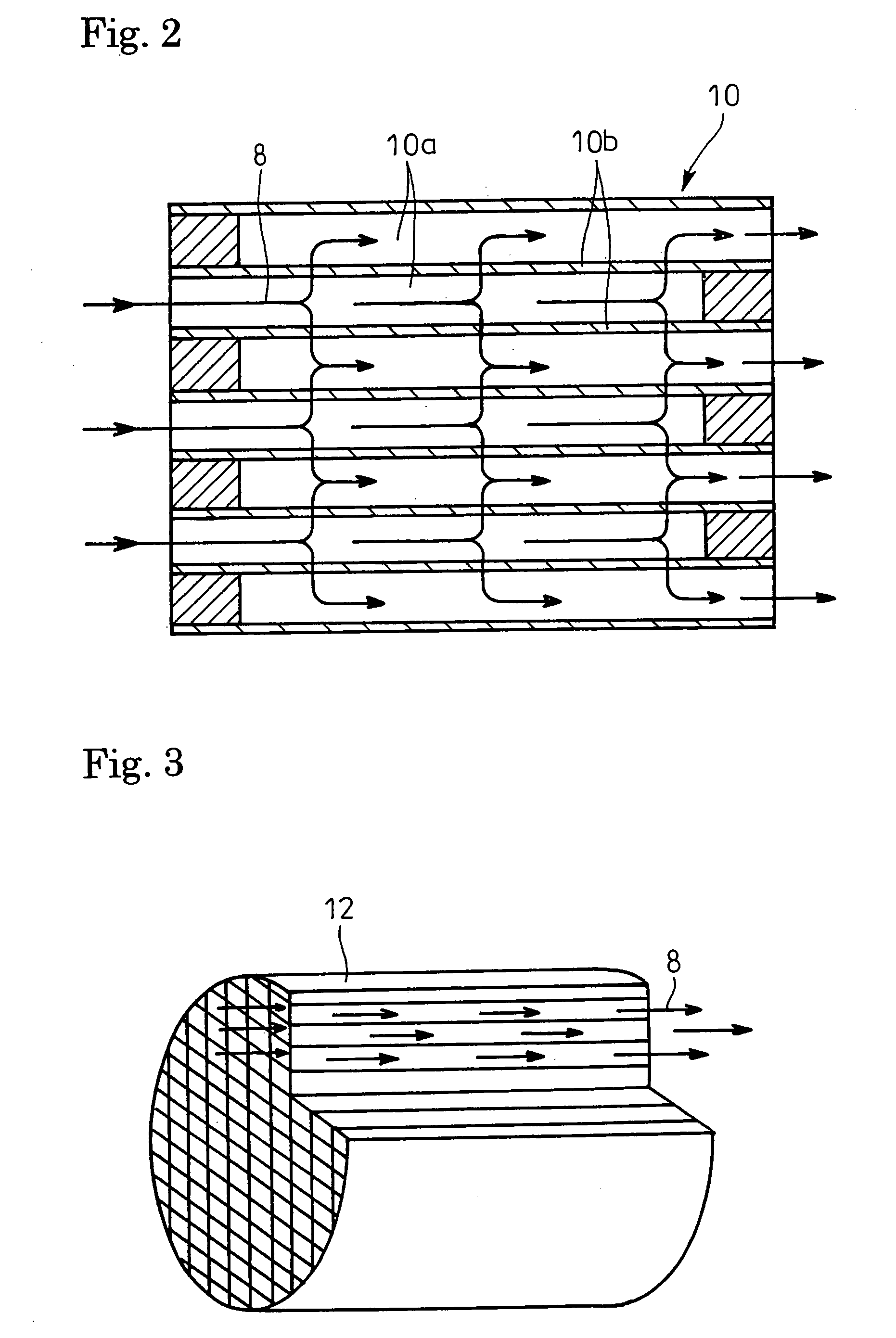

Exhaust gas purifier

InactiveUS20060288689A1Good effectIncrease exhaust temperatureElectrical controlInternal combustion piston enginesParticulatesPlasma generator

Provided is an exhaust emission control device which can properly burn off soot and soluble organic fraction attached to and accumulated on electrodes of a plasma generator. The exhaust emission control device with a post-processing device (catalyst regenerative particulate filter 10) for allowing exhaust gas to pass therethrough for gas purification incorporated in an exhaust pipe 9 of an internal combustion engine (diesel engine 1) comprises a plasma generator 11 arranged upstream of the post-processing device for discharging electricity in the exhaust gas 8 to generate plasma, flow-through type oxidation catalyst 12 arranged upstream of the plasma generator 11, fuel adding means (controller 17) arranged upstream of the oxidation catalyst 12 for adding fuel into the exhaust gas 8, temperature increasing means (suction throttling valve 22 or controller 17) for increasing the exhaust temperature to a level enough for oxidation reaction on the oxidation catalyst 12 of the fuel added by said fuel adding means.

Owner:HINO MOTORS LTD

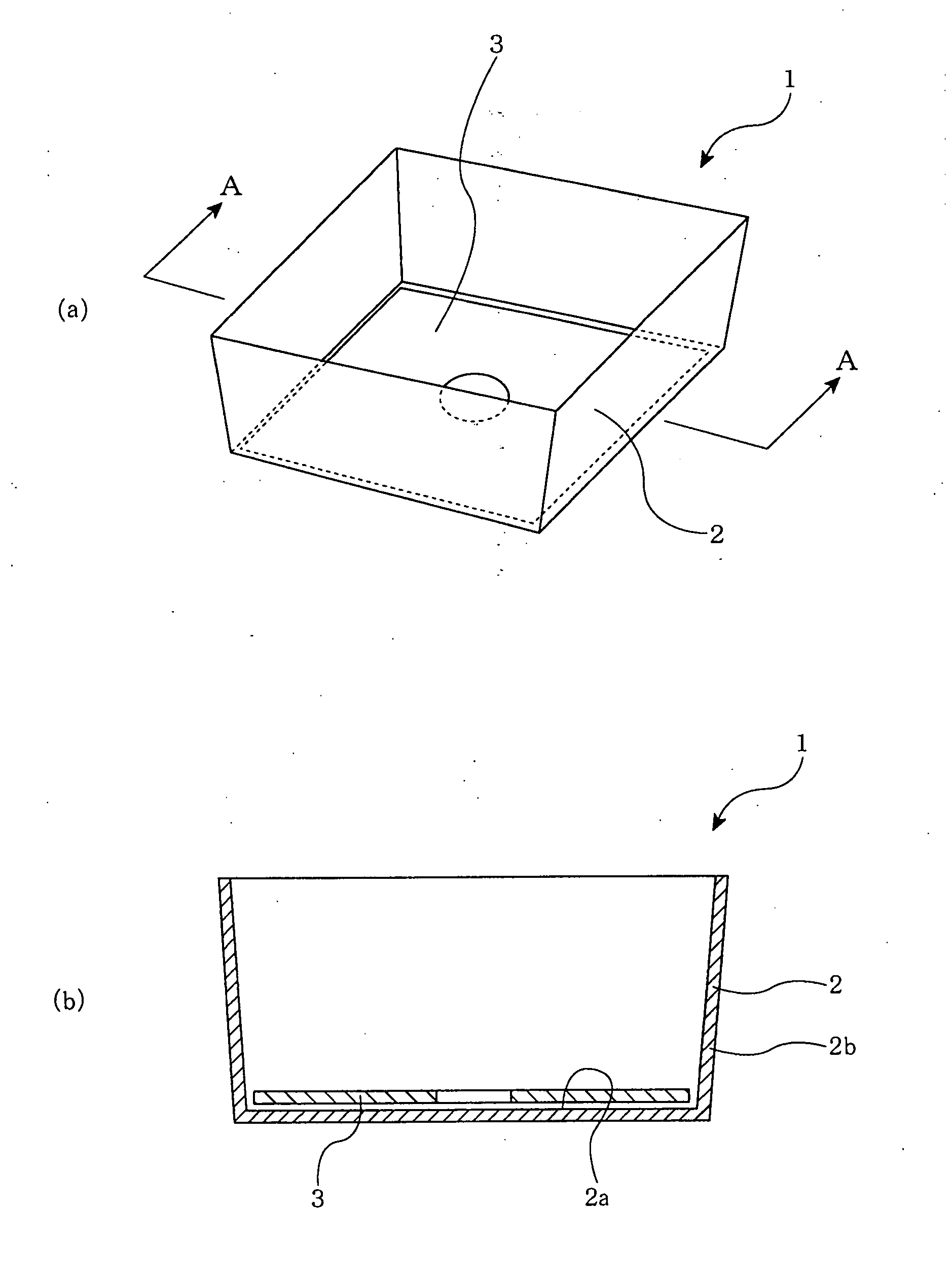

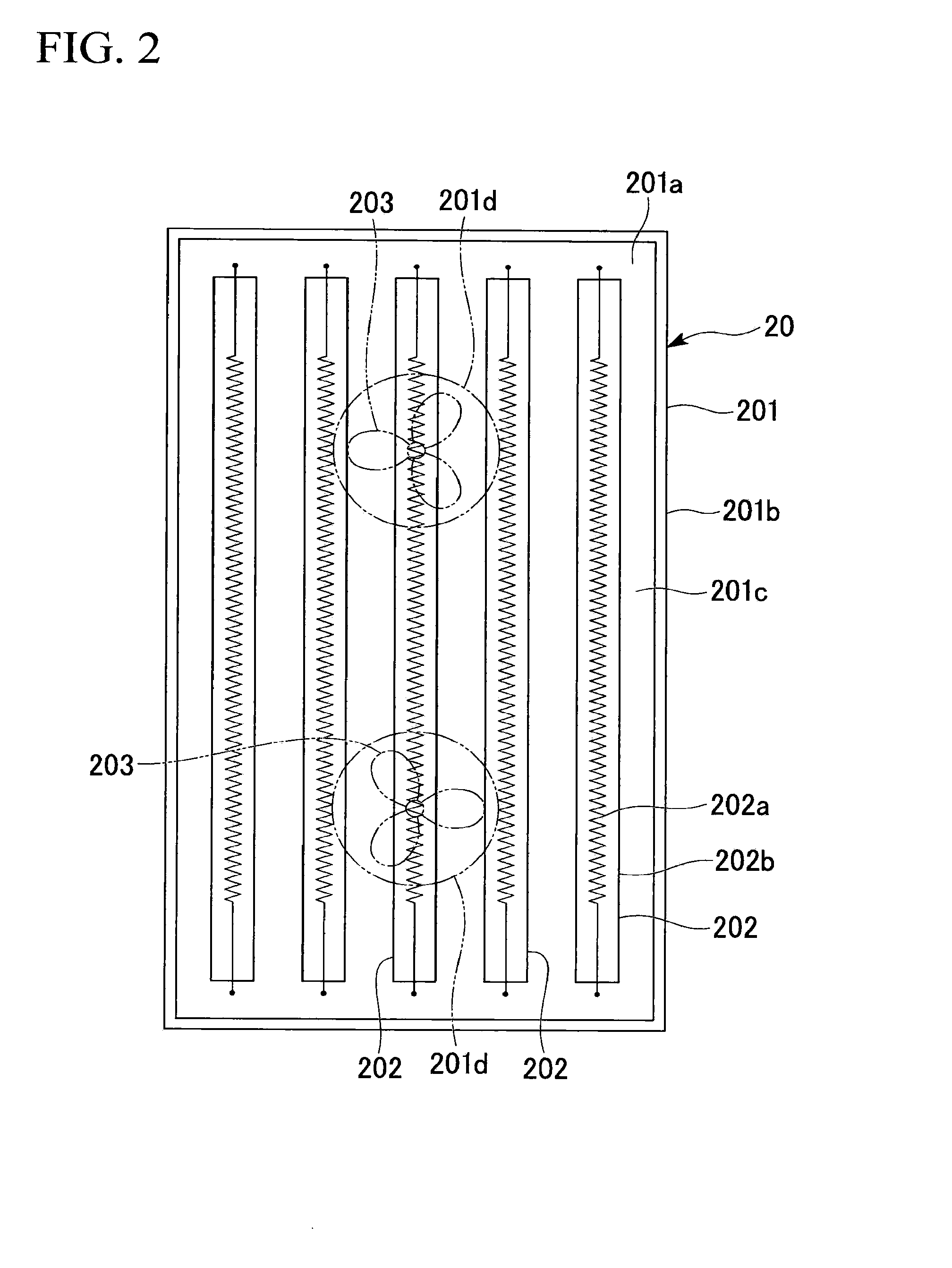

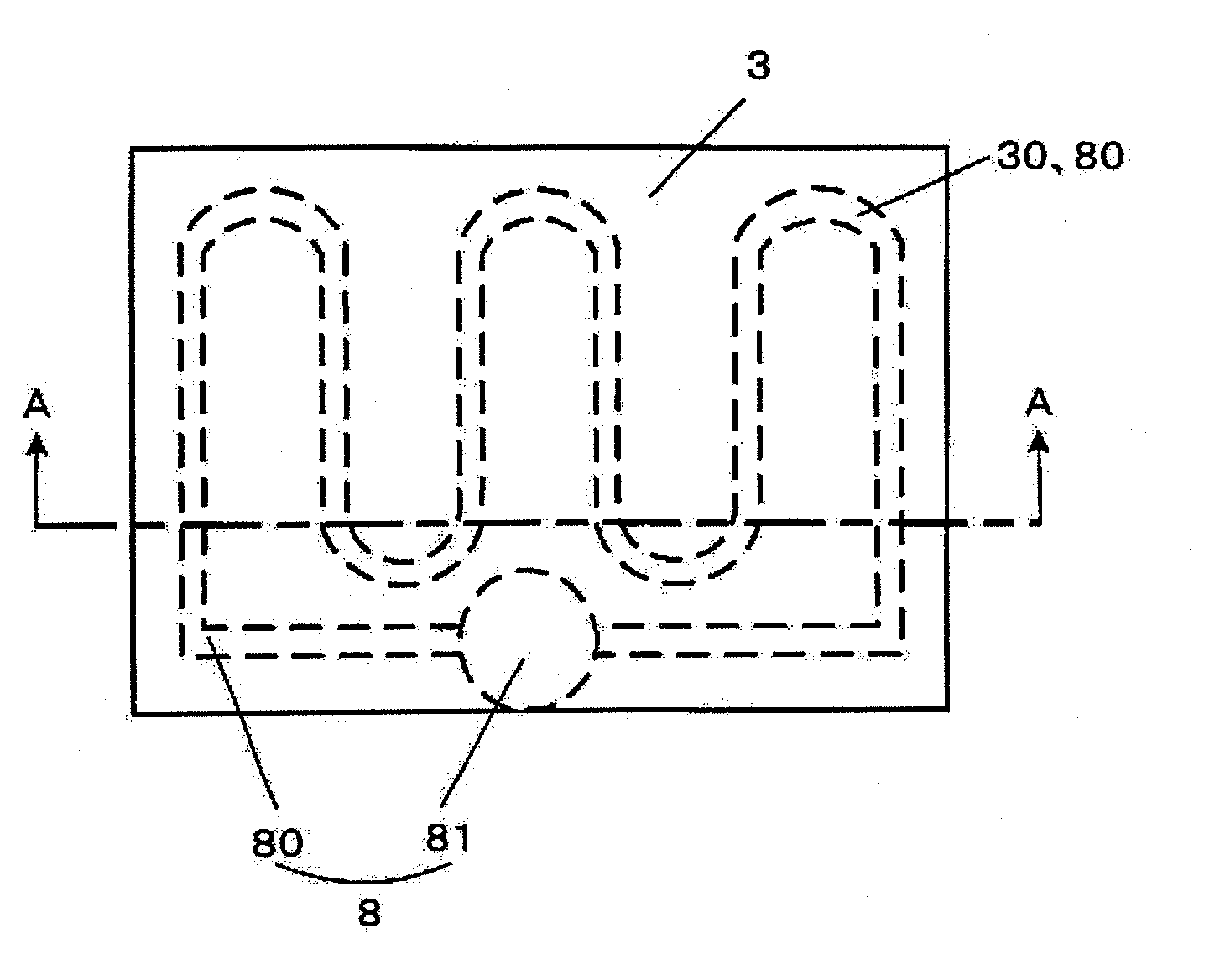

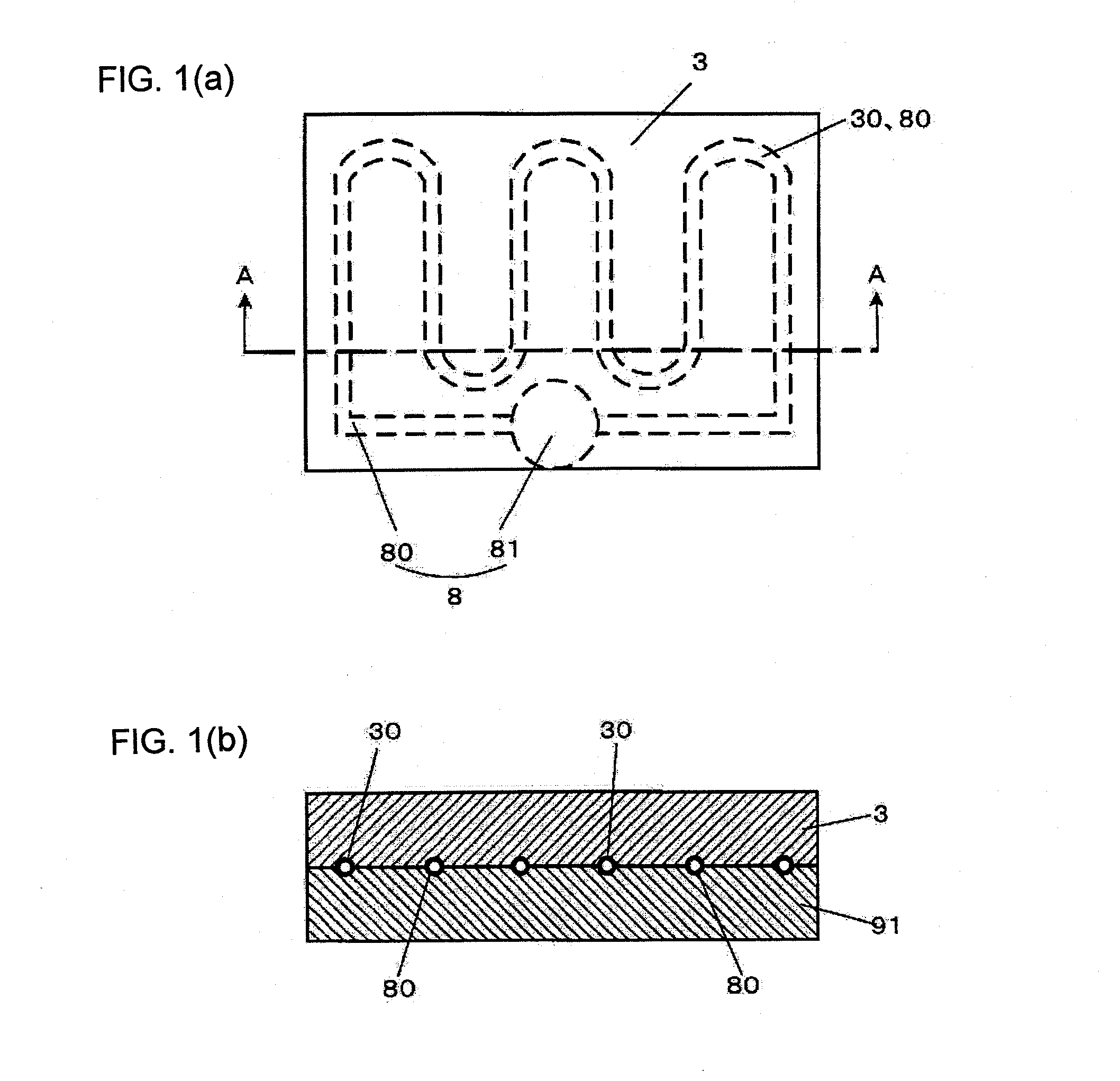

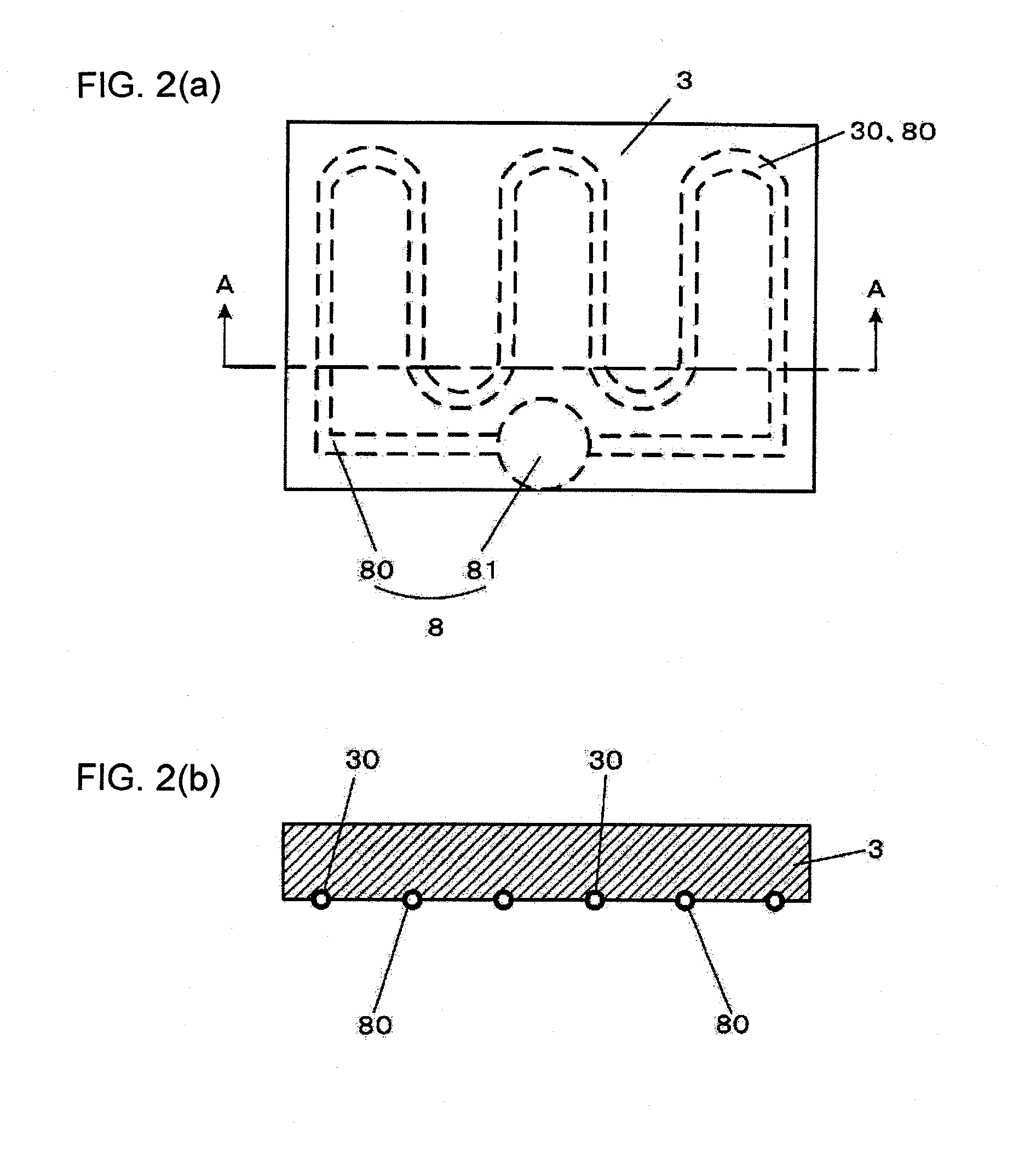

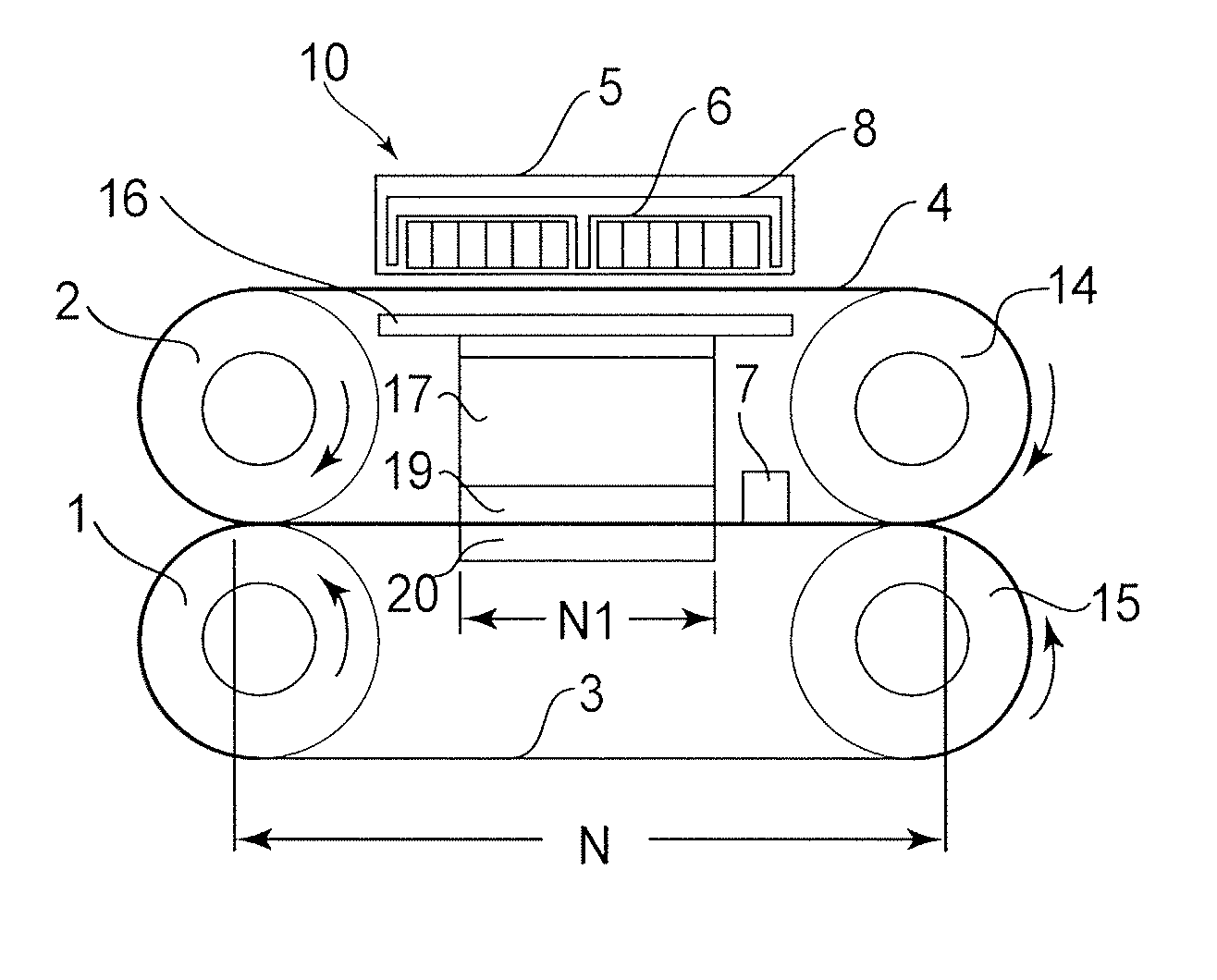

Induction heating body and indcution heating container

InactiveUS20100320195A1Enhancing safety in heatingHeating efficiency can be suppressedFurnaces without endless coreCooking-vessel materialsEddy currentMagnetic field

In an induction heating body 1 in which heat is generated by eddy current induced by a high-frequency magnetic field, when forming a radially-directed separation section 31 separated from the center to the outer periphery, one of end brim parts 31a1 is superimposed on the other end brim parts 31a2 or they are close to each other with the end surfaces thereof 31b1 and 31b2 being abutted.

Owner:TOYO SEIKAN KAISHA LTD

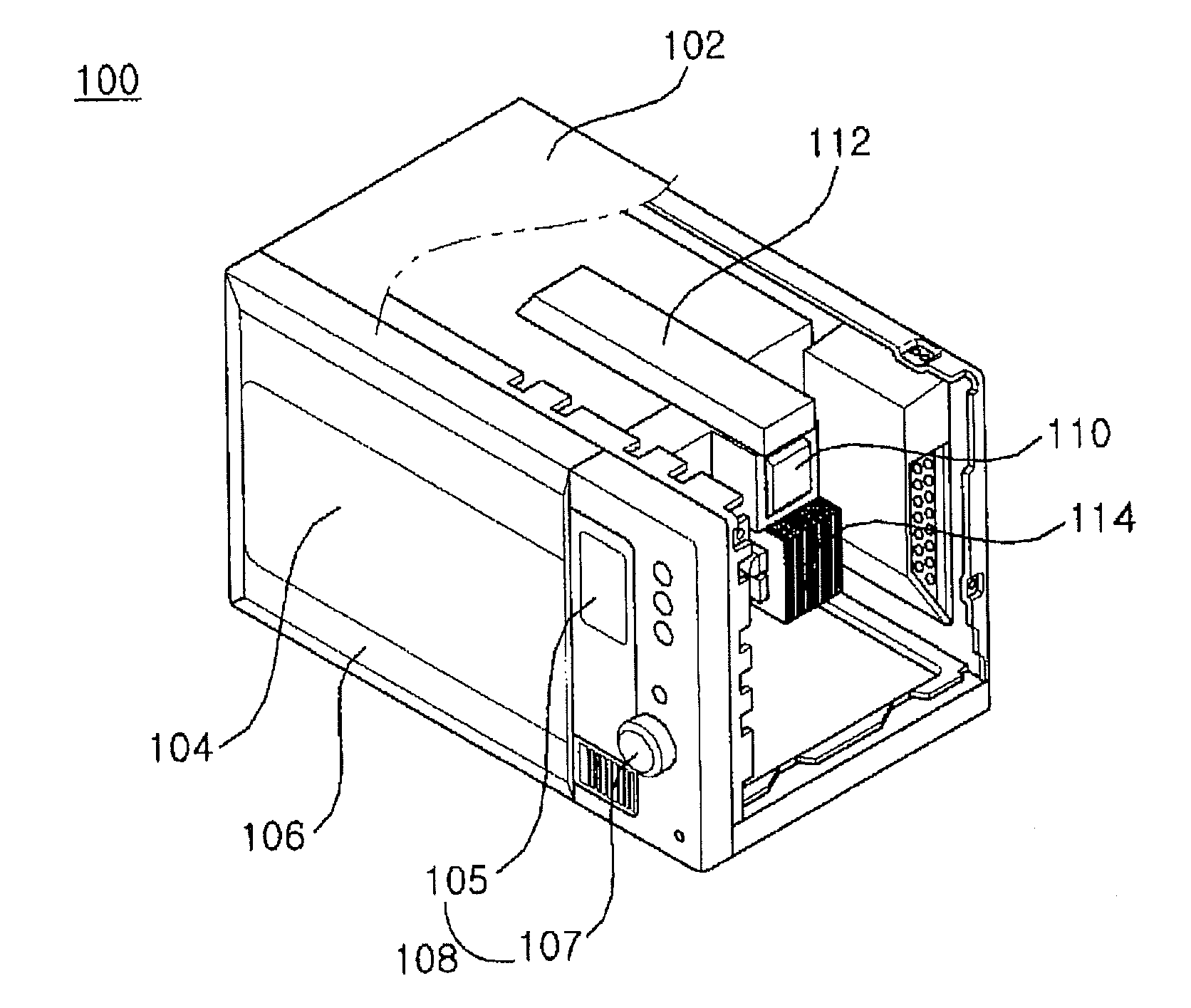

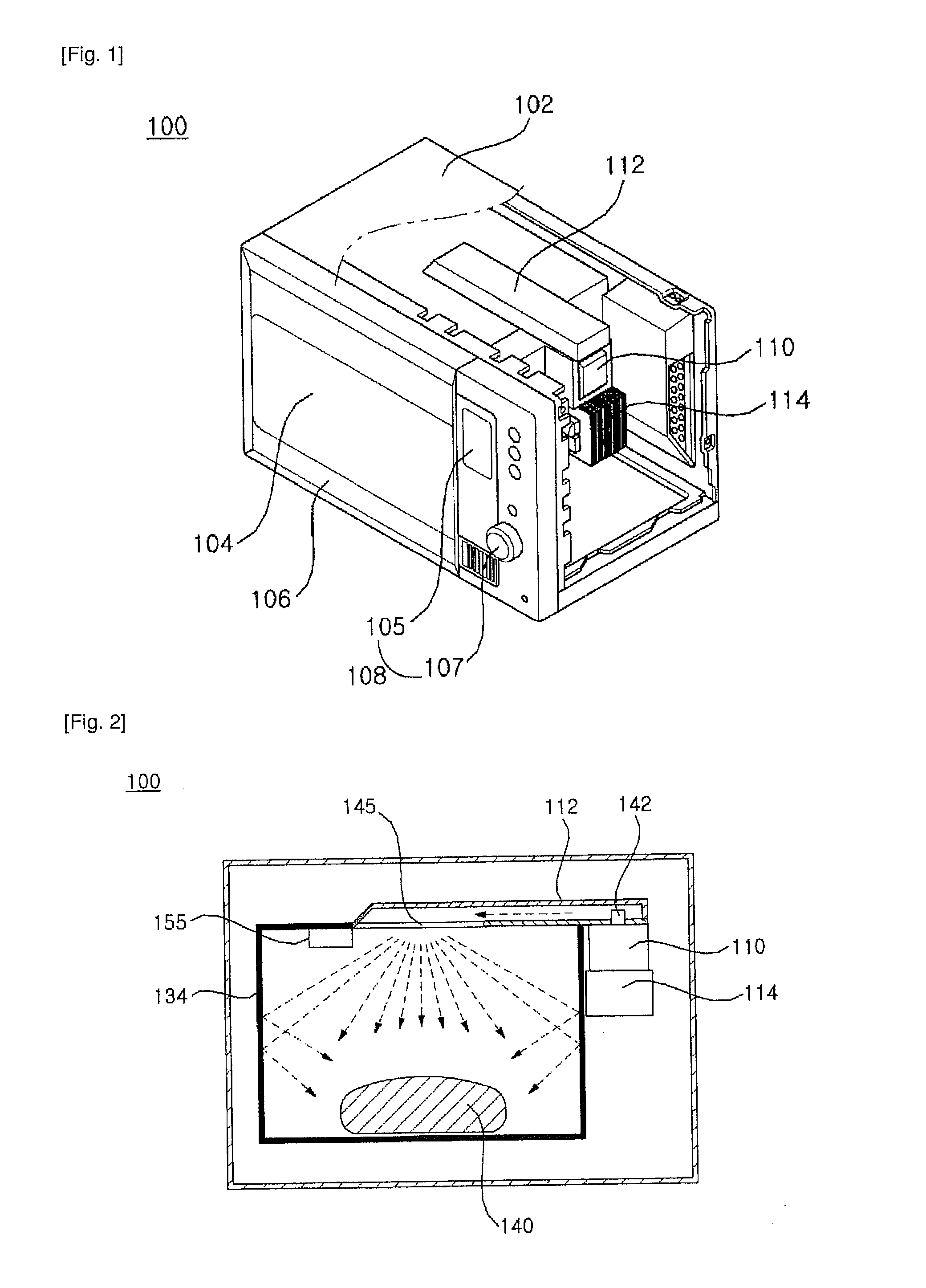

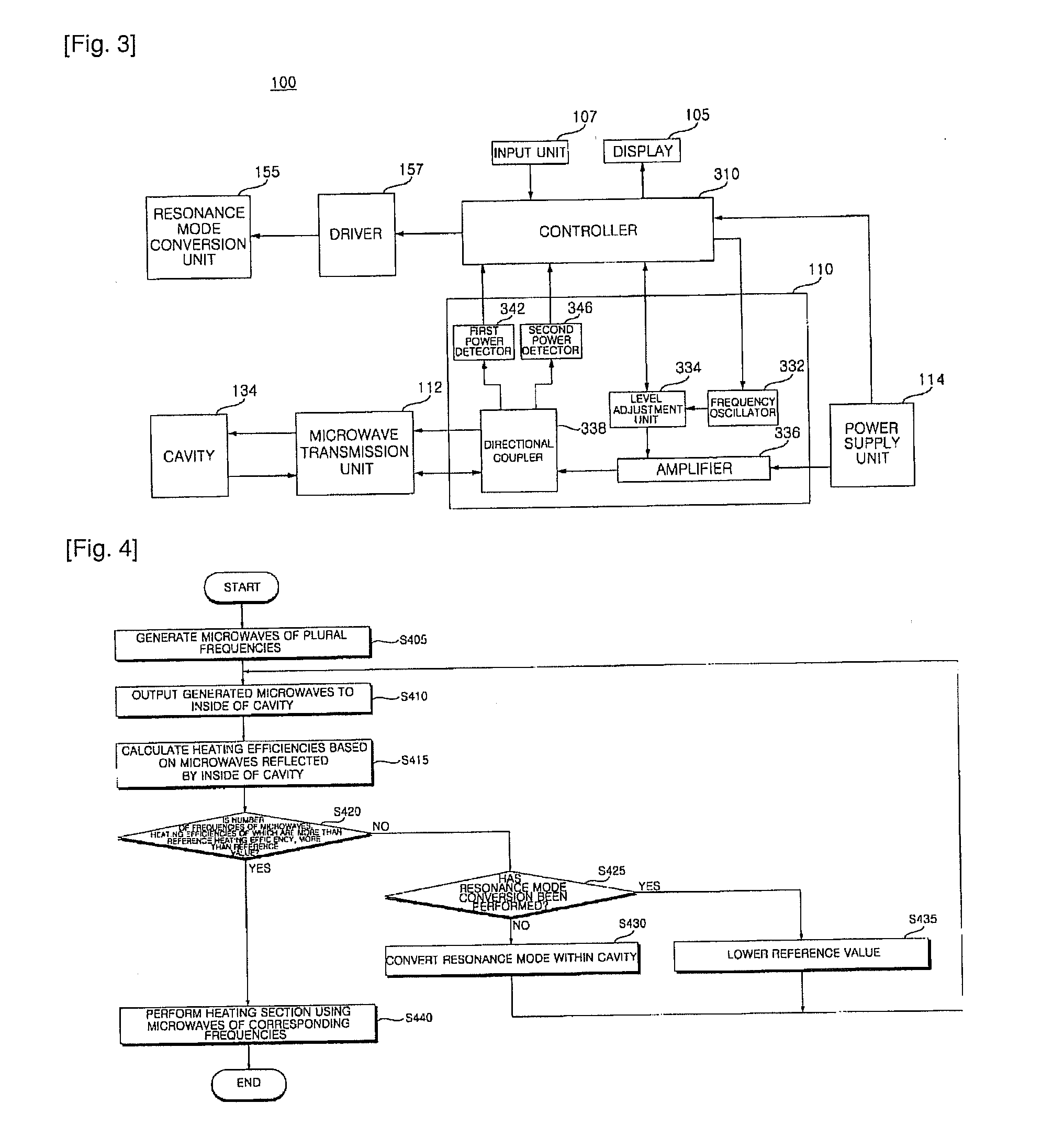

Cooking apparatus

InactiveUS20130206752A1Effectively enter heating sessionPerforming heatingMicrowave heatingDomestic cooking appliancesMicrowaveResonance

Provided herein are a cooking apparatus and an operating method thereof. The cooking apparatus includes a microwave generator to generate and output microwaves of a plurality of frequencies to heat an object within a cavity, a resonance mode conversion unit to convert a resonance mode by varying at least one of progressing direction, power or frequency of the microwaves output to the inside of the cavity, and a controller to operate the resonance mode conversion unit, if the number of frequencies of microwaves, the heating efficiencies of which are more than a reference heating efficiency, is below a reference value, based on heating efficiencies calculated according to microwaves reflected by the inside of the cavity from among the output microwaves. Thereby, operating efficiency of the cooking apparatus is improved.

Owner:LG ELECTRONICS INC

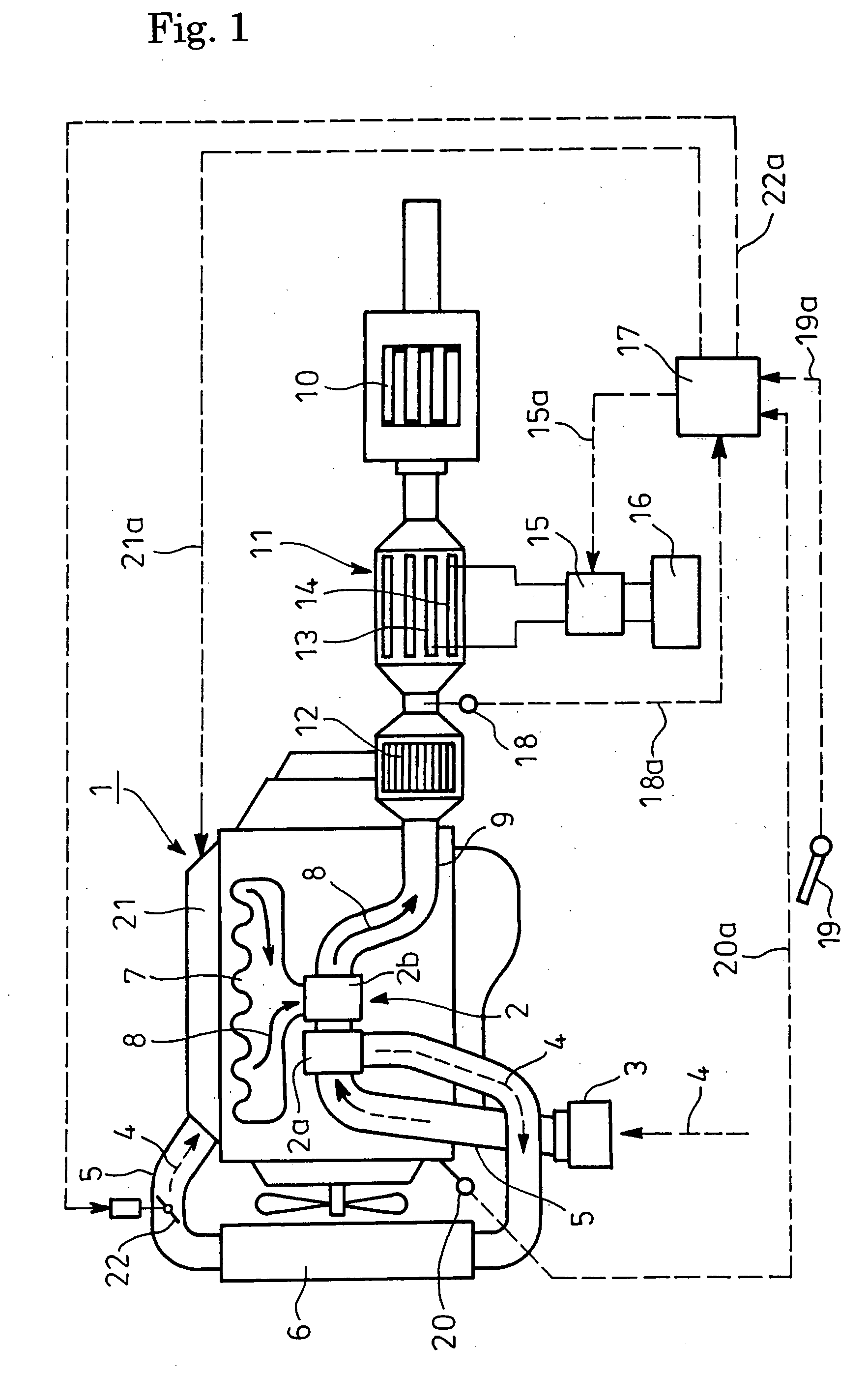

Exhaust emission control device

InactiveUS7331170B2Increase exhaust temperaturePrevent leakageElectrical controlInternal combustion piston enginesParticulatesPlasma generator

Provided is an exhaust emission control device which can properly burn off soot and soluble organic fraction attached to and accumulated on electrodes of a plasma generator. The exhaust emission control device with a post-processing device (catalyst regenerative particulate filter) for allowing exhaust gas to pass therethrough for gas purification incorporated in an exhaust pipe of an internal combustion engine (diesel engine) comprises a plasma generator arranged upstream of the post-processing device for discharging electricity in the exhaust gas to generate plasma, flow-through type oxidation catalyst arranged upstream of the plasma generator, fuel adding means (controller) arranged upstream of the oxidation catalyst for adding fuel into the exhaust gas, temperature increasing means (suction throttling valve or controller) for increasing the exhaust temperature to a level enough for oxidation reaction on the oxidation catalyst of the fuel added by said fuel adding means.

Owner:HINO MOTORS LTD

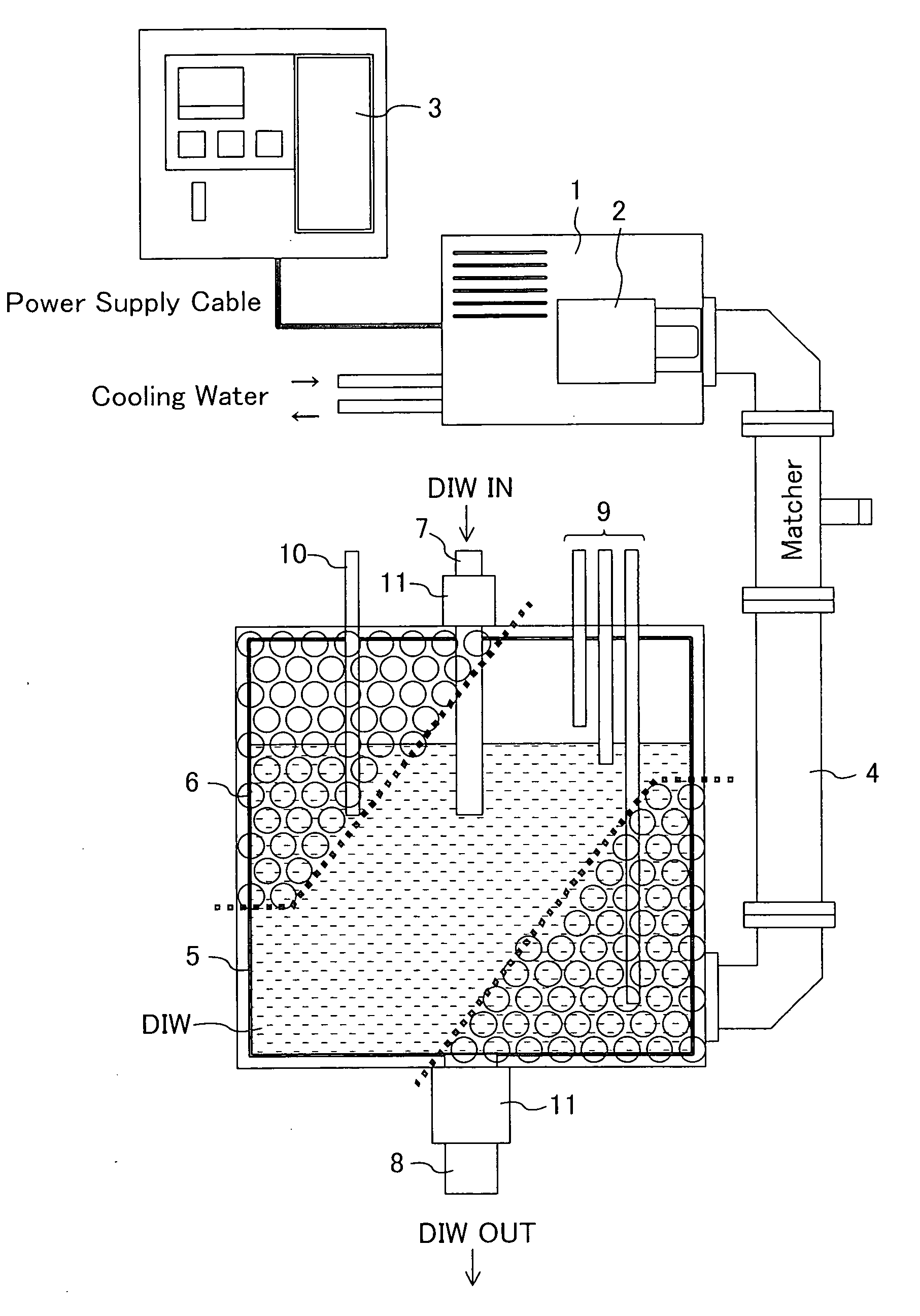

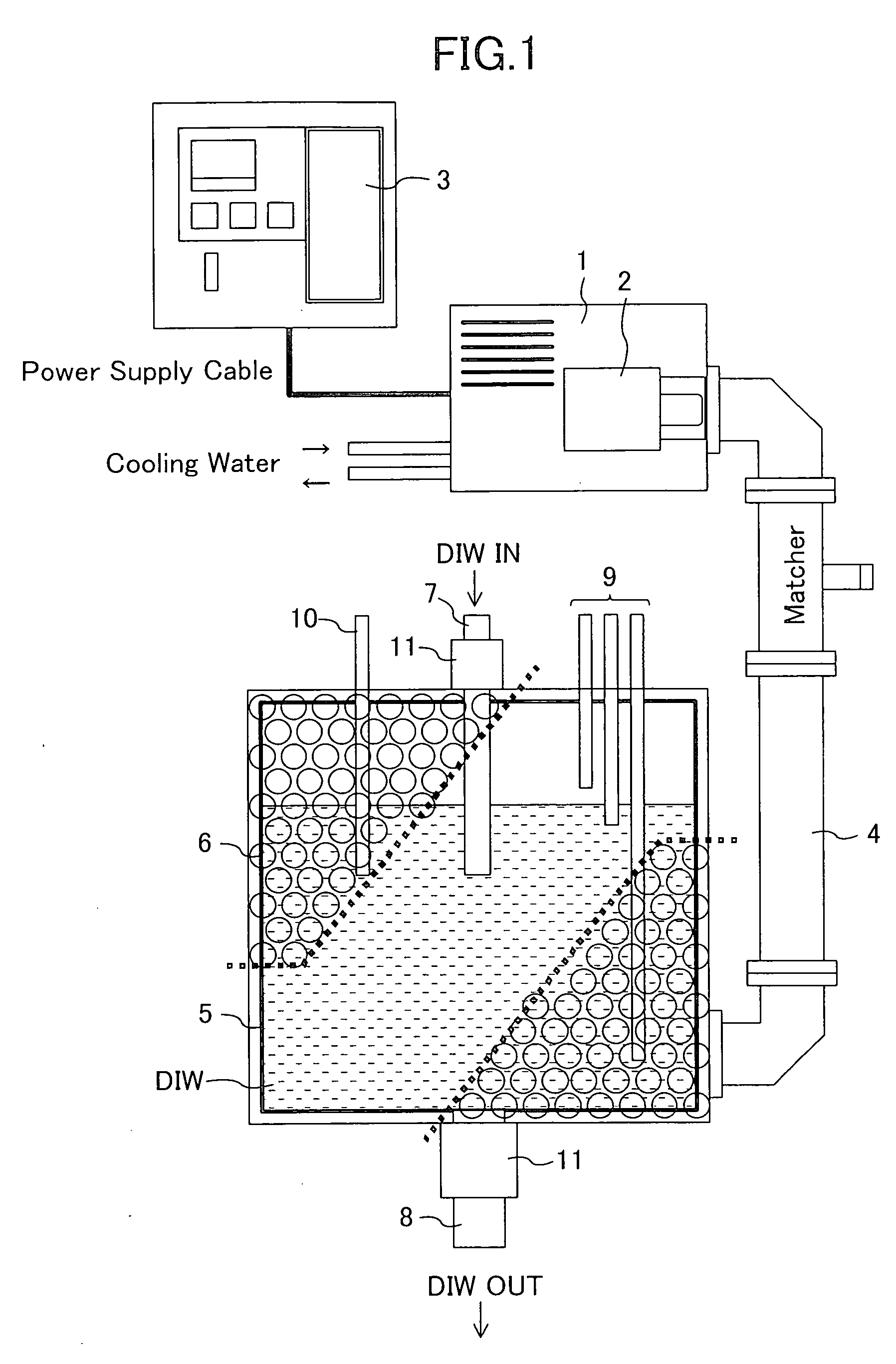

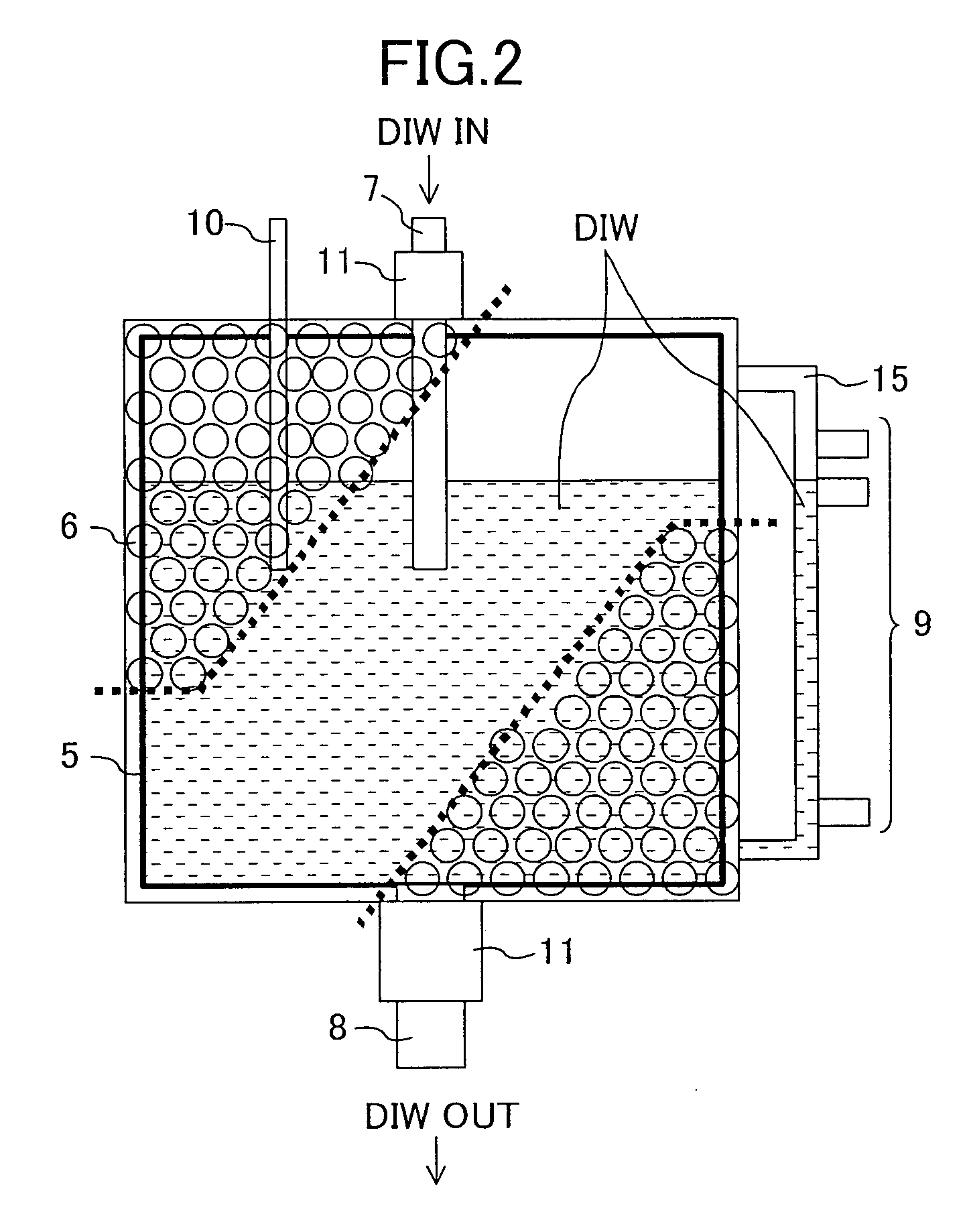

Liquid heating apparatus and cleaning apparatus and method

InactiveUS20060027571A1Large heatReduce heating efficiencySemiconductor/solid-state device manufacturingMicrowave heatingMicrowaveChemical engineering

Owner:PANASONIC CORP

Fuel processor dewar and methods

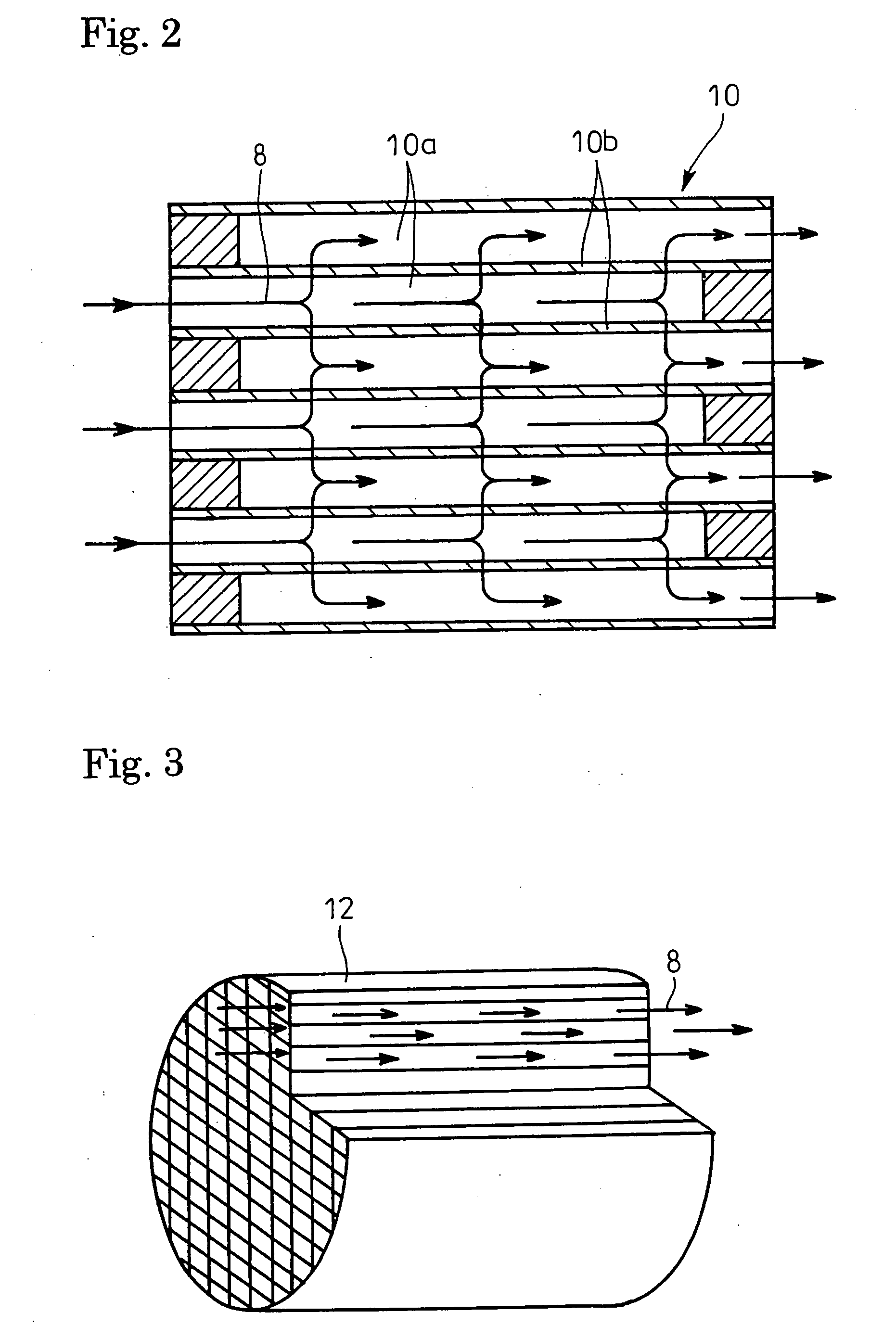

ActiveUS20050005521A1Promote hydrogen productionIncreased hydrogen productionPressurized chemical processLevel controlCombustorHydrogen

Described herein is a fuel processor that produces hydrogen from a fuel source. The fuel processor comprises a reformer and burner. The reformer includes a catalyst that facilitates the production of hydrogen from the fuel source. Voluminous reformer chamber designs are provided that increase the amount of catalyst that can be used in a reformer and increase hydrogen output for a given fuel processor size. The burner provides heat to the reformer. One or more burners may be configured to surround a reformer on multiple sides to increase thermal transfer to the reformer. Dewars are also described that increase thermal management of a fuel processor and increase burner efficiency. A dewar includes one or more dewar chambers that receive inlet process gas or liquid before a burner receives the process gas or liquid. The dewar is arranged such that process gas or liquid passing through the dewar chamber intercepts heat generated in the burner before the heat escapes the fuel processor.

Owner:ADVENT TECH LLC

Method for preparing polymer electrothermal film

ActiveCN102932974ASolve the shortcomings of not being resistant to high temperature and not being flame retardantSolve uneven heating temperatureChemical industryOhmic-resistance heatingPolymer scienceHeating temperature

The invention discloses a method for preparing a polymer electrothermal film. The method comprises the following steps: according to the weight percentage of raw materials, weighing 10 to 36 percent of colloidal graphite micro powder, 8 to 33 percent of conductive carbon black micro powder, 0.1 to 15 percent of nano carbon powder, 0.1 to 18 percent of zinc oxide powder, 0.1 to 13 percent of silver powder and 0.1 to 13 percent of magnesium hydroxide powder to prepare conductive composite filling powder; then preparing conductive composite filling glue by utilizing the conductive composite filling powder; preparing a heating thin film and simultaneously preparing insulating composite filling glue; preparing an insulating film by utilizing the insulating composite filling glue; and finally, preparing the polymer electrothermal film. The invention solves the problems of nonuniform heating temperature and high heating efficiency of a conventional electrothermal film. The invention also overcomes the defects of power attenuation, short working service life and the like of the conventional electrothermal film in the using process.

Owner:苏州威泰克斯新材料科技有限公司

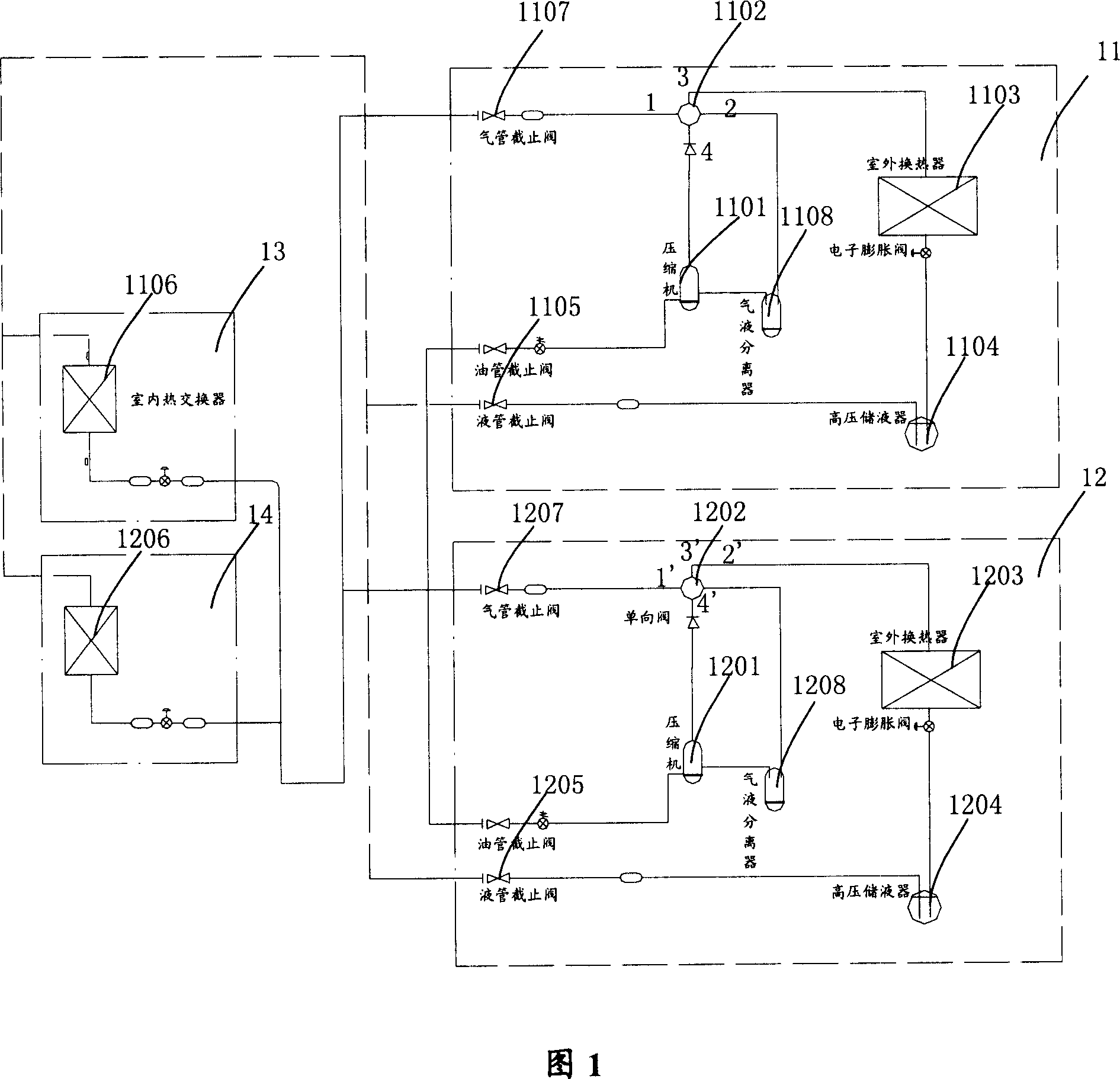

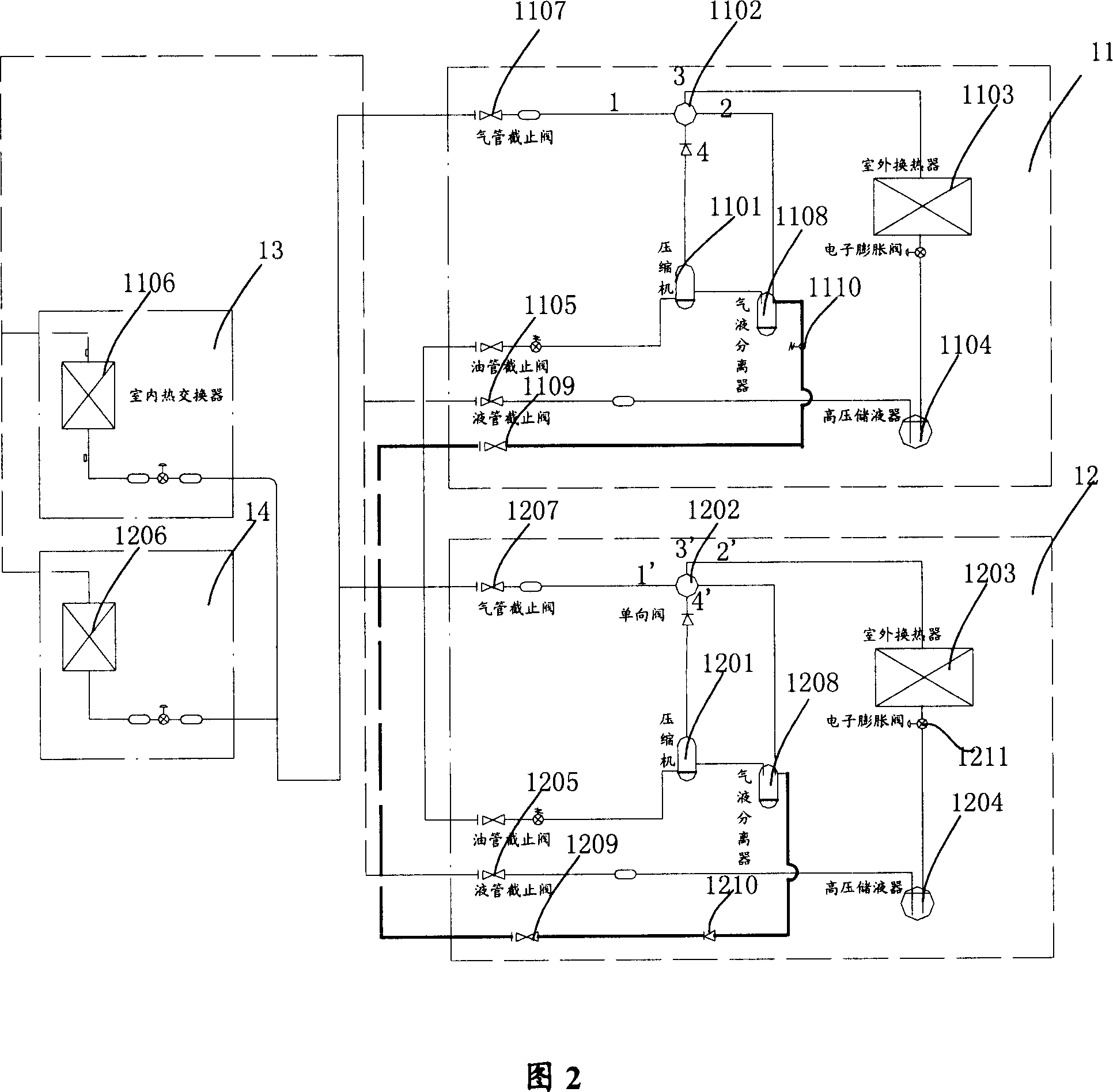

Multiple air-conditioning unit pipe device

InactiveCN101063567AAvoid starting difficulties or even damageAvoid harmFluid circulation arrangementVapor–liquid separatorMagnetic valve

The invention discloses a pipe line of a multiple air conditioner group, comprising an air pipe, a liquid pipe, an oil pipe and a balance pipe communicated with every outer low pressure side, the special communicated location is every outer air-liquid separator. The balance pipe is arranged in the magnetic valve located at the main device side of the multiple air conditioner groups. The magnetic valve is started when the multiple air conditioner groups is producing heat and is shut down in the heat producing oil modification process. The balance pipe is arranged with a single direction valve arranged at the child device side of the multiple air conditioner groups, the cooling liquid could only be flow out from the child device. The balance pipe is arranged with balance pipe cutoff valve arranged on the balance pipe at the main device side and every child device side of the multiple air conditioner groups. The problem that the device is hard to start or being damage caused by the accumulation of the cooling liquid when the multiple air conditioner groups are producing heat and the child device is shut down could be avoided.

Owner:HAIER GRP CORP +1

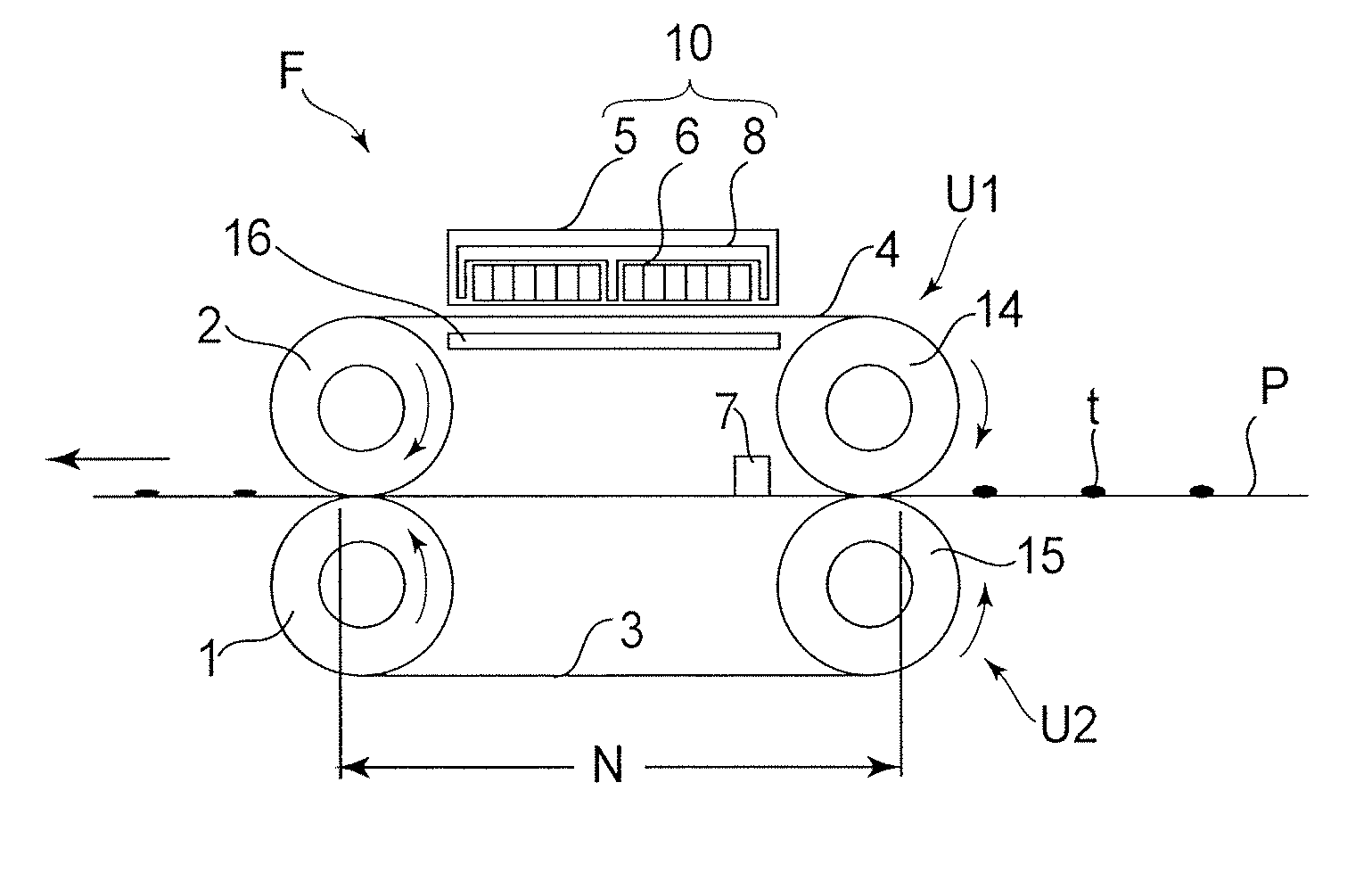

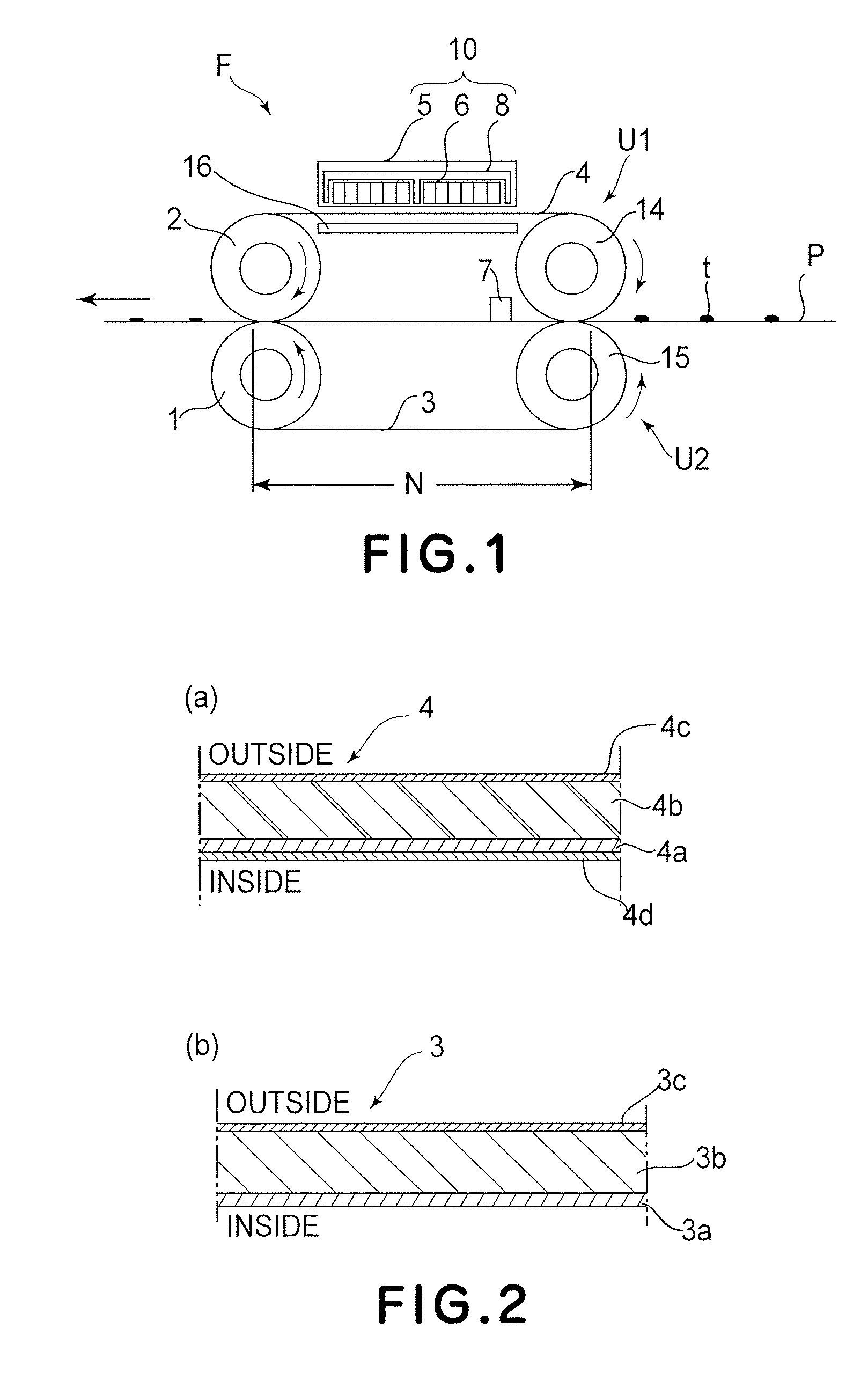

Toner fixing apparatus and electrophotographic printing device

InactiveUS20100086336A1Keep dryEasy to useElectrographic process apparatusElectrographic processes using charge patternImage formationEngineering

A toner fixing apparatus characterized by provision of a provisional fixing portion provided with a provisional fixing component having an infrared heater irradiating infrared radiation onto a printed surface of the web and a main fixing portion provided downstream in the web flow in the provisional fixing portion and nipping the web with heat rollers performing a main fixing operation or having a plurality of main fixing units. According to this invention, a toner fixing apparatus and an electrophotographic printing device including the toner fixing apparatus are provided which display excellent fixing properties during multicolor image formation, excellent heating efficiency and excellent economy with respect to installation space.

Owner:MIYAKOSHI PRINTING MACHINERY

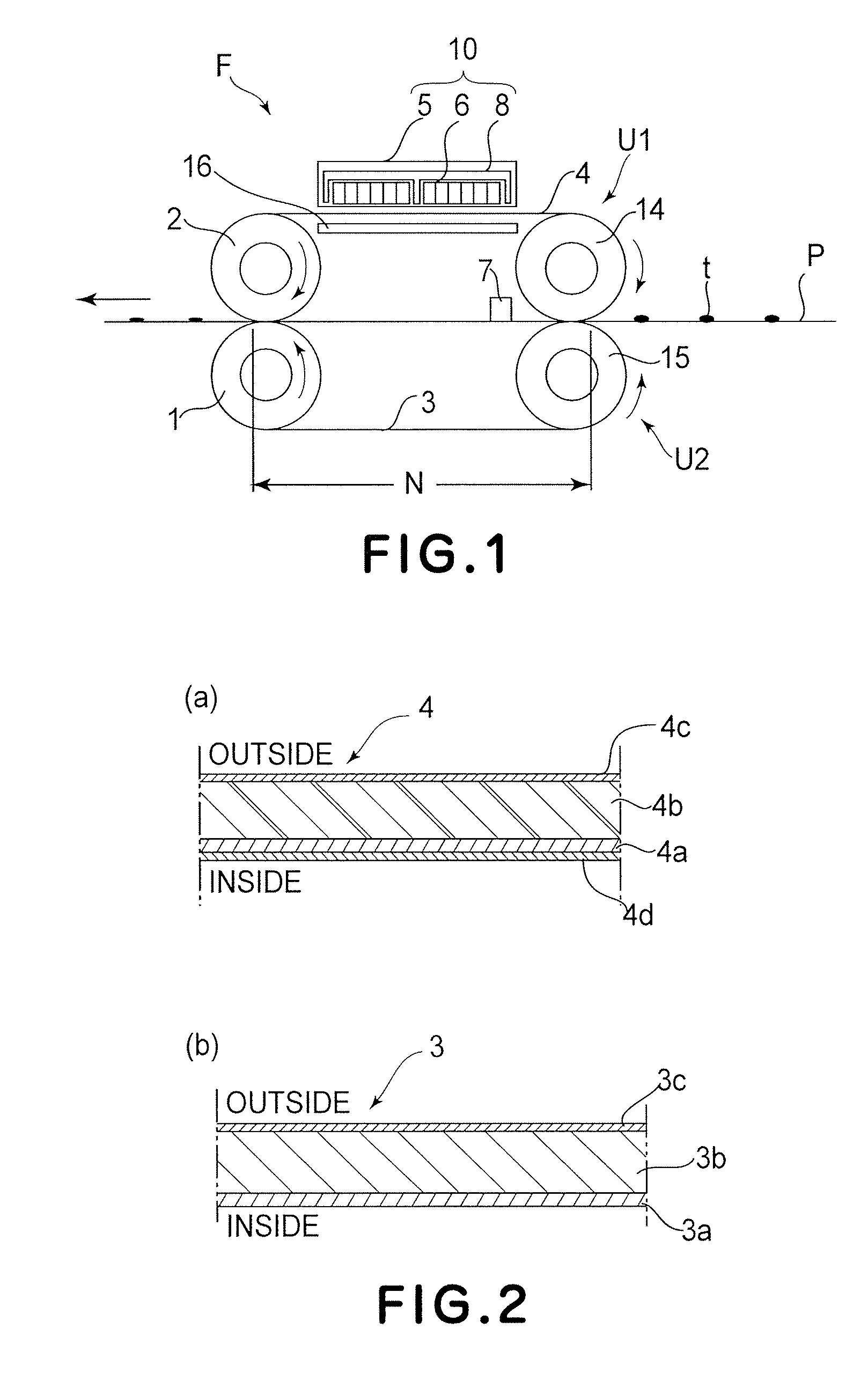

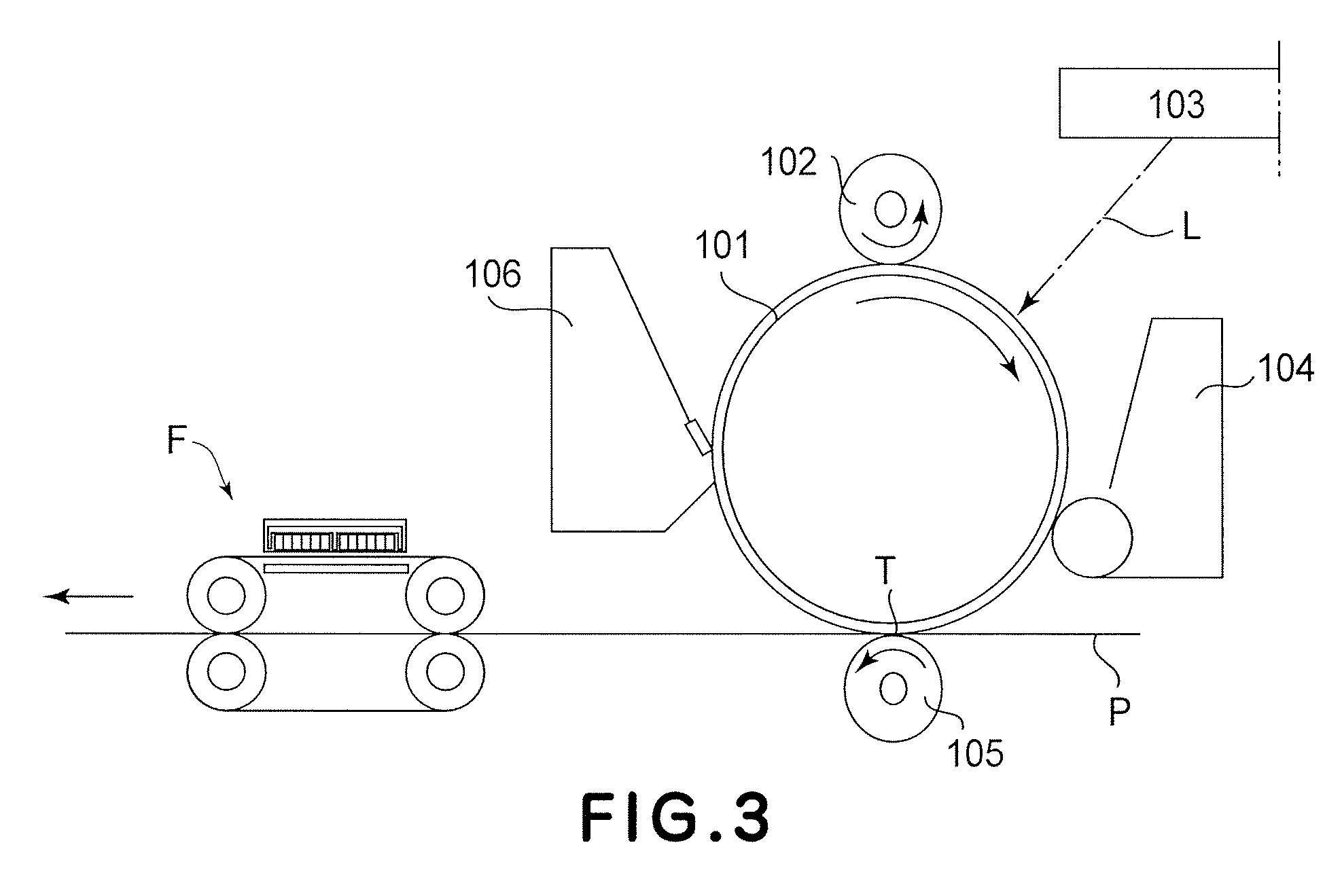

Image heating apparatus

ActiveUS20070071523A1Reduce heating efficiencyOhmic-resistance heatingElectrographic process apparatusEngineeringMagnetic flux

An image heating apparatus includes an endless belt for heating an image on a recording material at a nip; magnetic flux generating means, disposed opposed to an outer surface of the endless belt, for generating a magnetic flux to cause the belt to generate heat; a metal member disposed inside the belt and supporting a member which is disposed inside the belt; and a magnetic flux reducing member, disposed between the metal member and an opposing portion of the belt which is opposed to the magnetic flux generating means, for reducing a magnetic flux actable on the metal member.

Owner:CANON KK

Rapid preprocessing method for measuring total phosphorus content in deposit

InactiveCN101251489AReduce energy consumptionEasy to carryMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationPretreatment methodFiltration

The invention discloses a quick pretreatment method for measuring the total phosphorus content in sediments, belonging to the environmental monitoring technical field. The invention comprises the following steps: A. pretreatment of a soil sample: the soil sample is weighed, dried to the constant weight, taken out, cooled and grinded to over 60 meshes under drying conditions, weighed and then transferred into a slaking pipe; B. slaking pretreatment: distilled water and potassium persulphate solution are added and placed into a slaking hole of a COD slaking instrument, and simultaneously blank solution is taken and processed together with a sample to be detected with the same method; C. slaking; D. filtration: after slaking is finished, the sample in the slaking pipe is leached out by the distilled water, filtered to a container by a filter paper or a filter membrane, diluted, colored and finally measured and calculated according to the general spectrophotography. Compared with the prior pretreatment method, the quick pretreatment method for measuring the total phosphorus content in the sediments has the advantages of quick measurement, few equipment used, low energy consumption, simple experimental conditions, easy carryover of experimental equipment, suitability for on-scene monitoring, and safe experimental process.

Owner:NANJING UNIV

Organic matter self-energy-supply drying and pyrolysis and full-component recycling system and technology method

ActiveCN105841160AReduce energy consumptionImprove energy utilizationIncinerator apparatusWater contentZero emission

The invention provides an organic matter self-energy-supply drying and pyrolysis and full-component recycling system and a technology method, and belongs to the technical field of solid waste recycling and environments. The system comprises a feeding bin, a drying device, a condenser, a water treatment device, a pyrolyzing furnace, an oil storage tank set, a gas storage tank, a combustion furnace and the like. Before original organic matter is subjected to pyrolysis, the original organic matter enters the drying device to be dried, the water content of the organic matter is reduced, and therefore the pyrolysis effect of the organic matter is enhanced, and the water content in product oil is low. Semicoke and noncondensing combustible gas generated through pyrolysis are conveyed into the combustion furnace to be combusted, energy is recycled, pollution to the environment from waste residues and waste gas is prevented, accordingly, the effect of zero emission of pollutants is achieved, and therefore the emission standard for the pollutants can be met. Due to the fact that drying and pyrolysis in the technology are separated, energy all comes from the combustion heat of pyrolysis residues, consumption of auxiliary fuel is reduced, and the organic matter self-energy-supply drying and pyrolysis and full-component recycling system and the technology method have high economic efficiency in the aspects of solid waste treatment and energy recycling.

Owner:DALIAN UNIV OF TECH

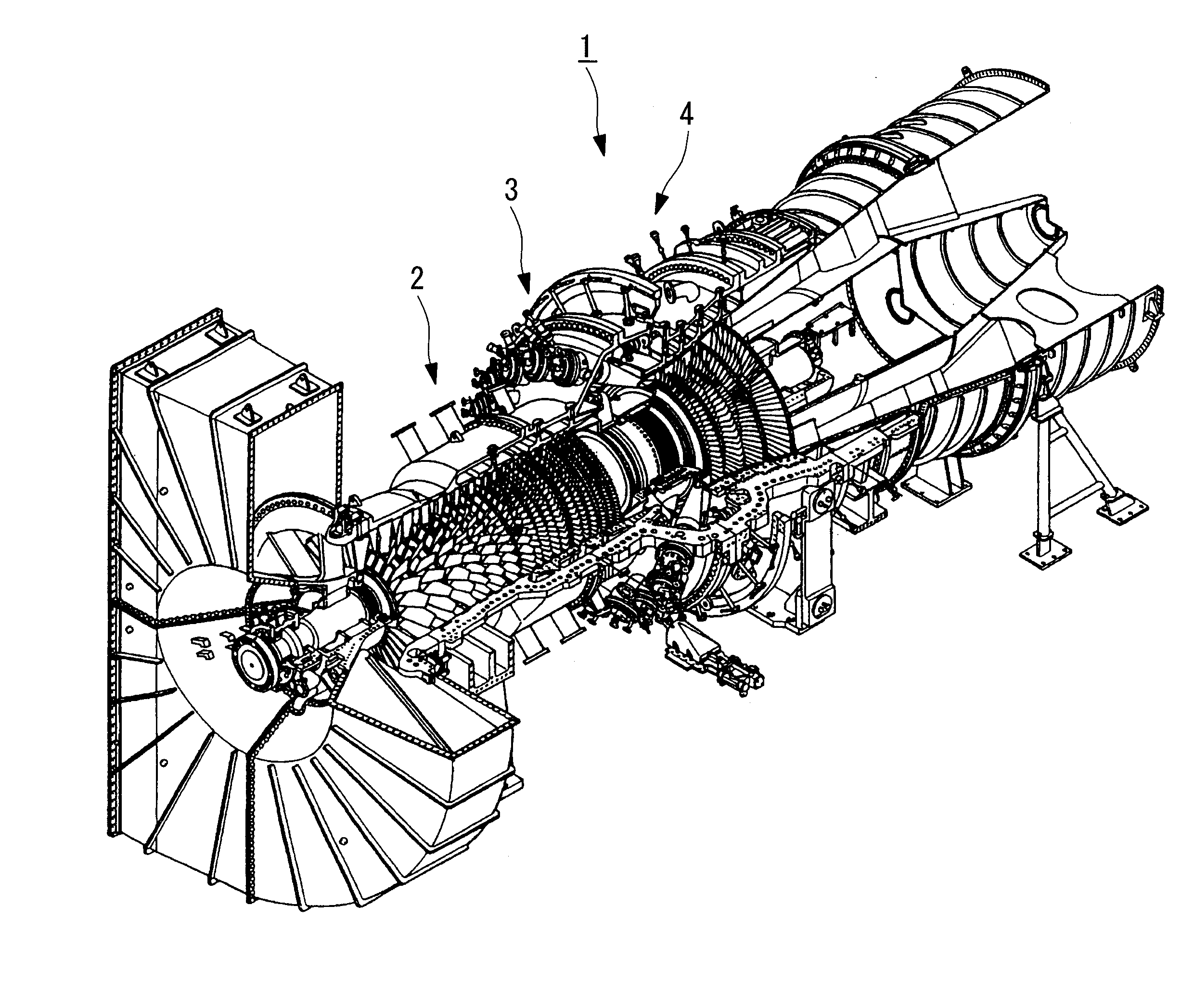

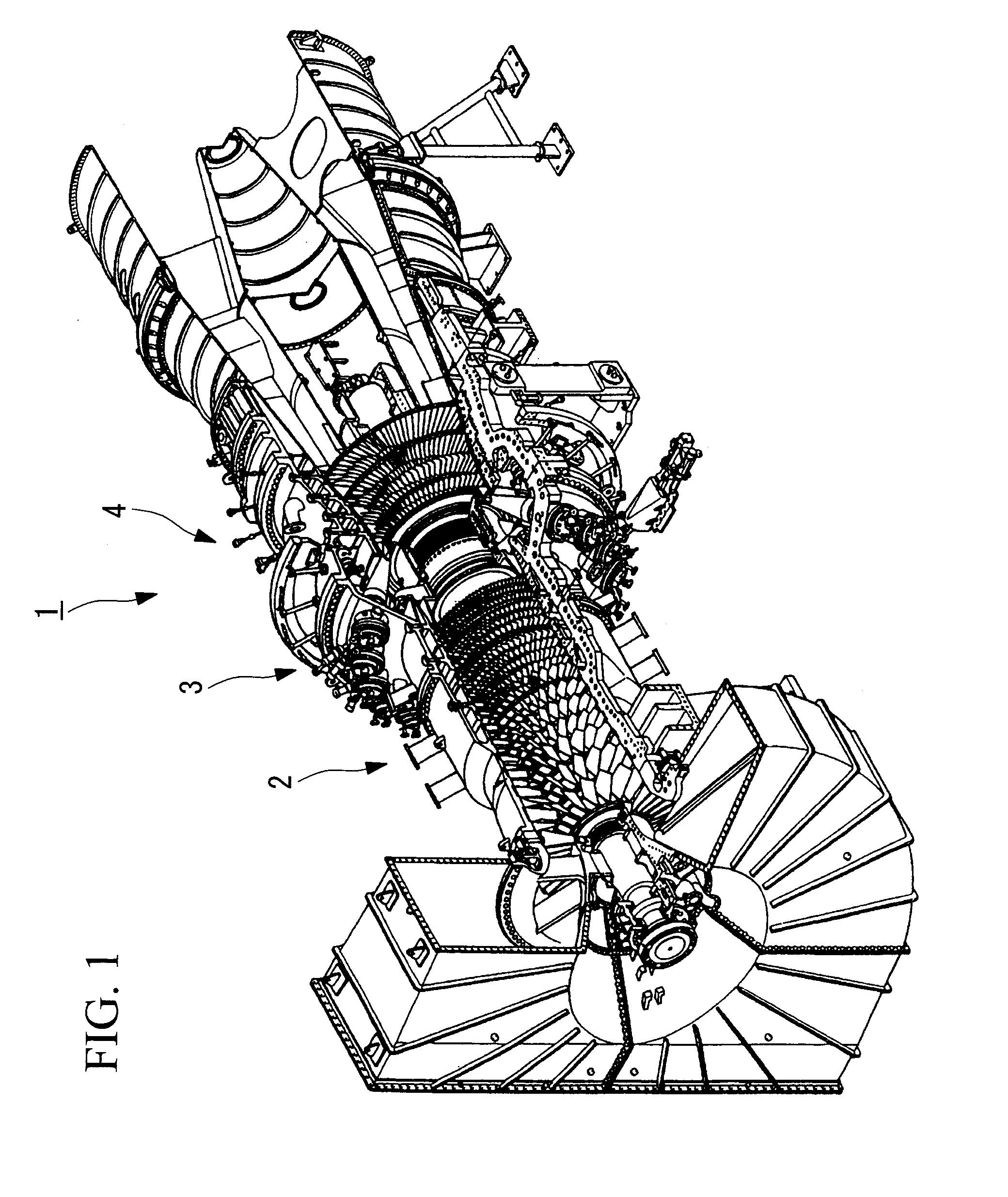

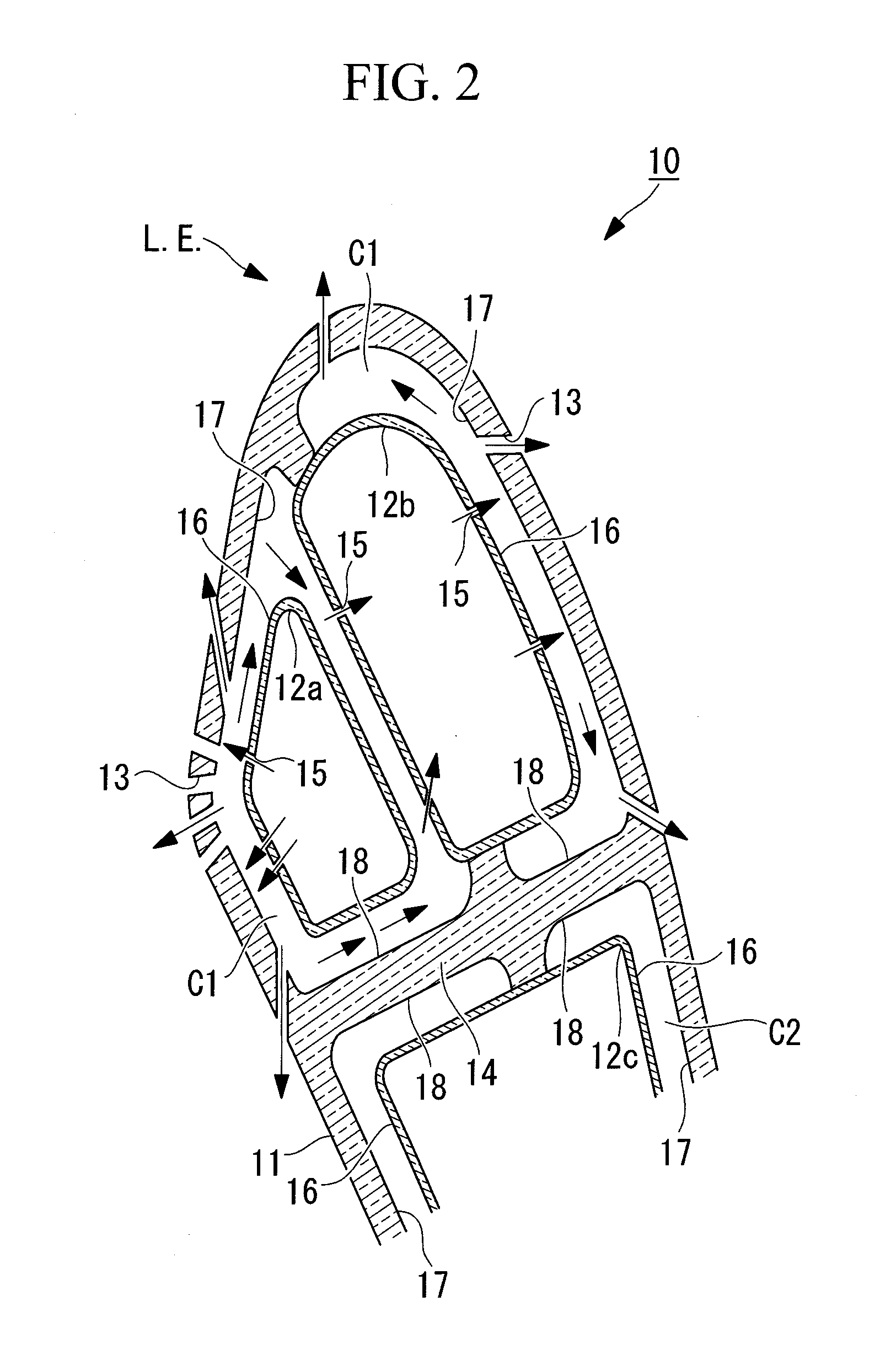

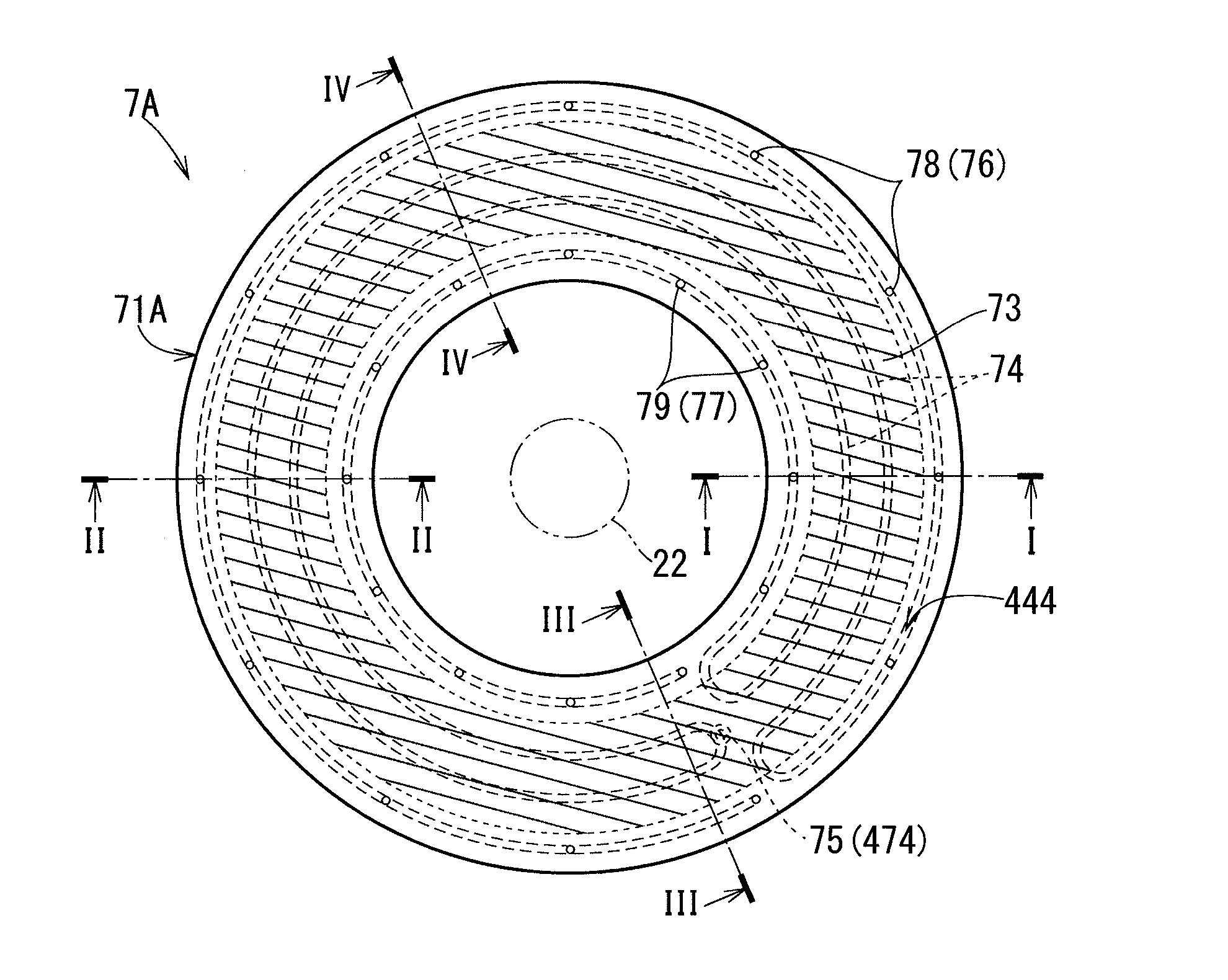

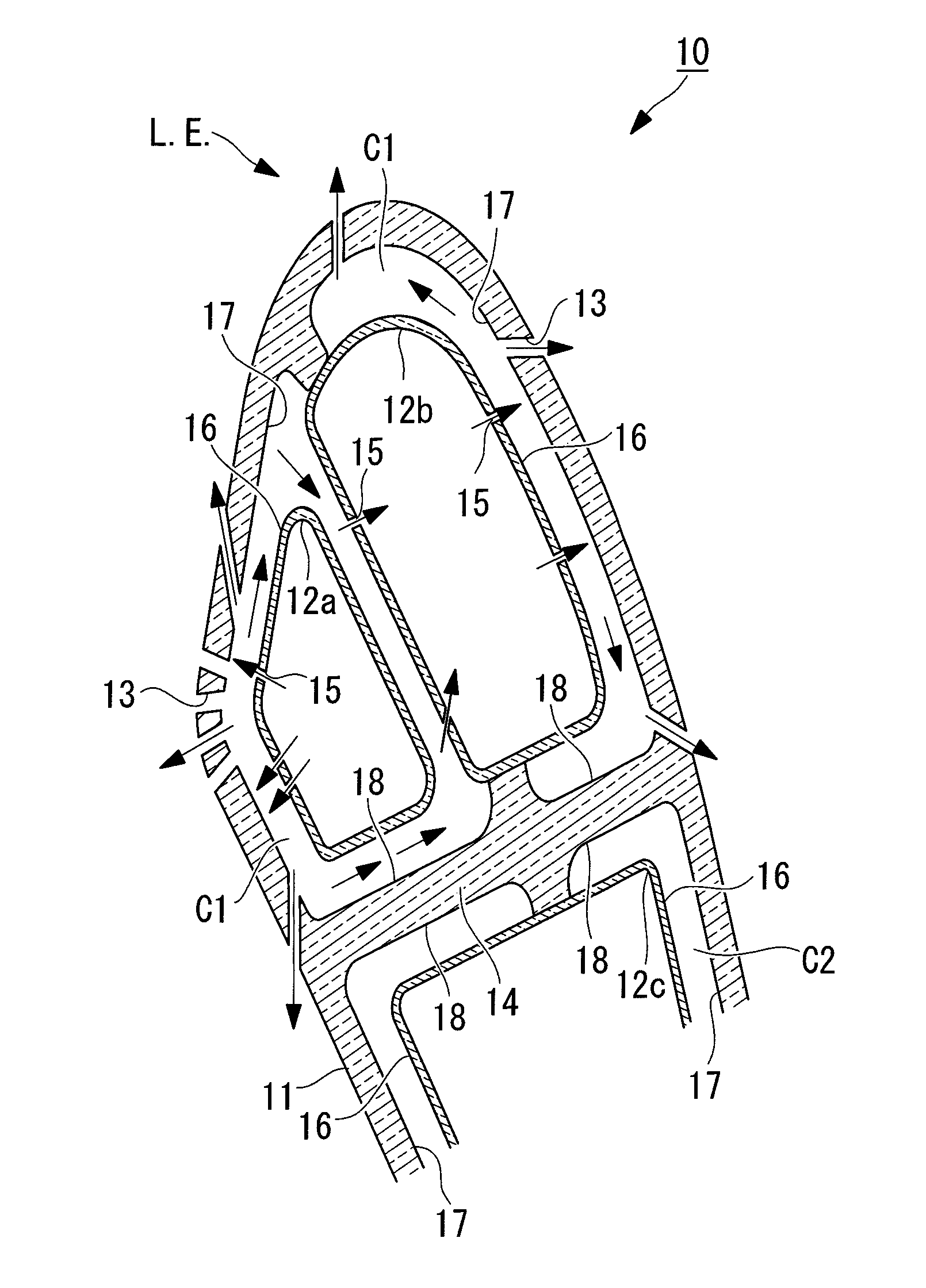

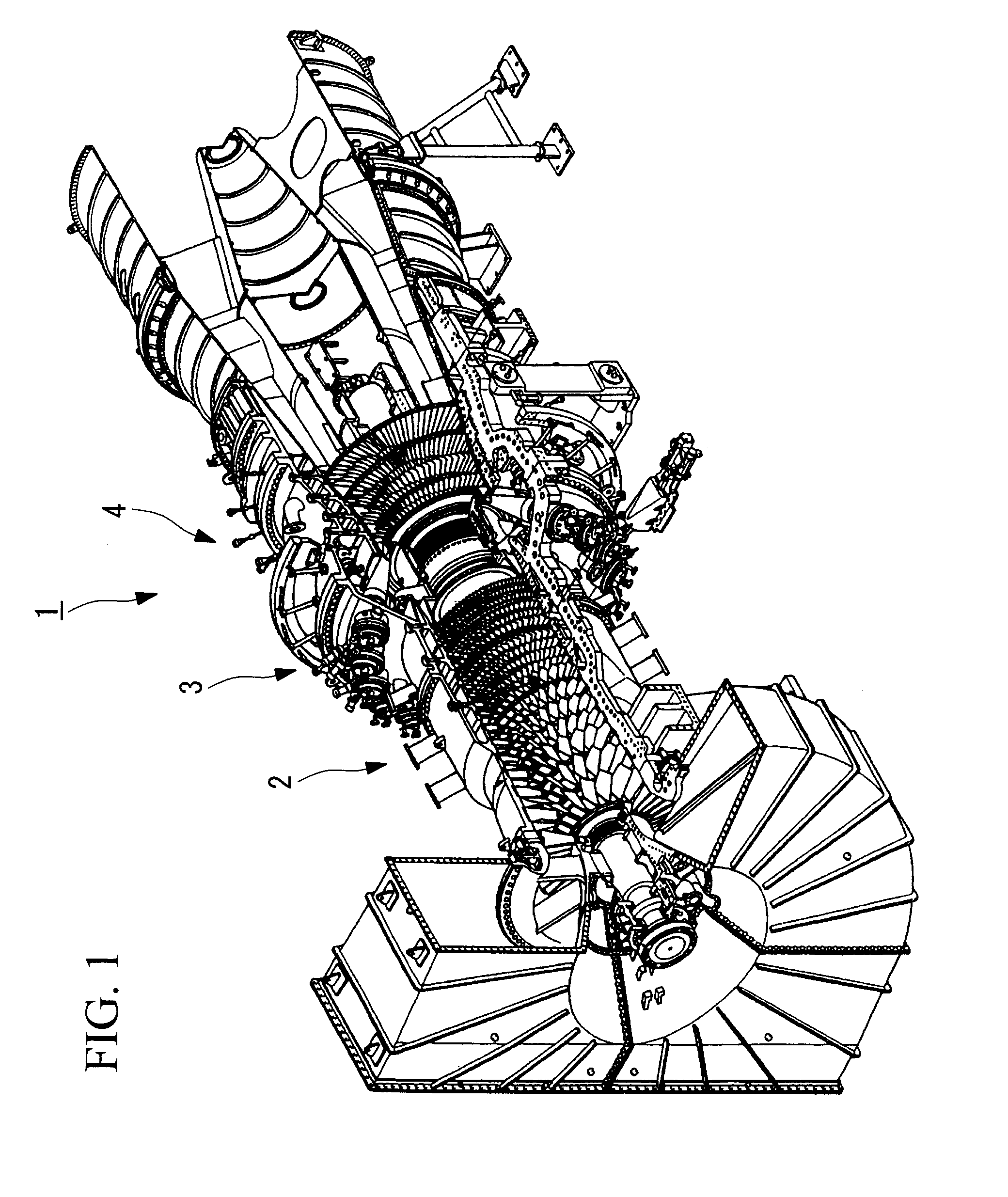

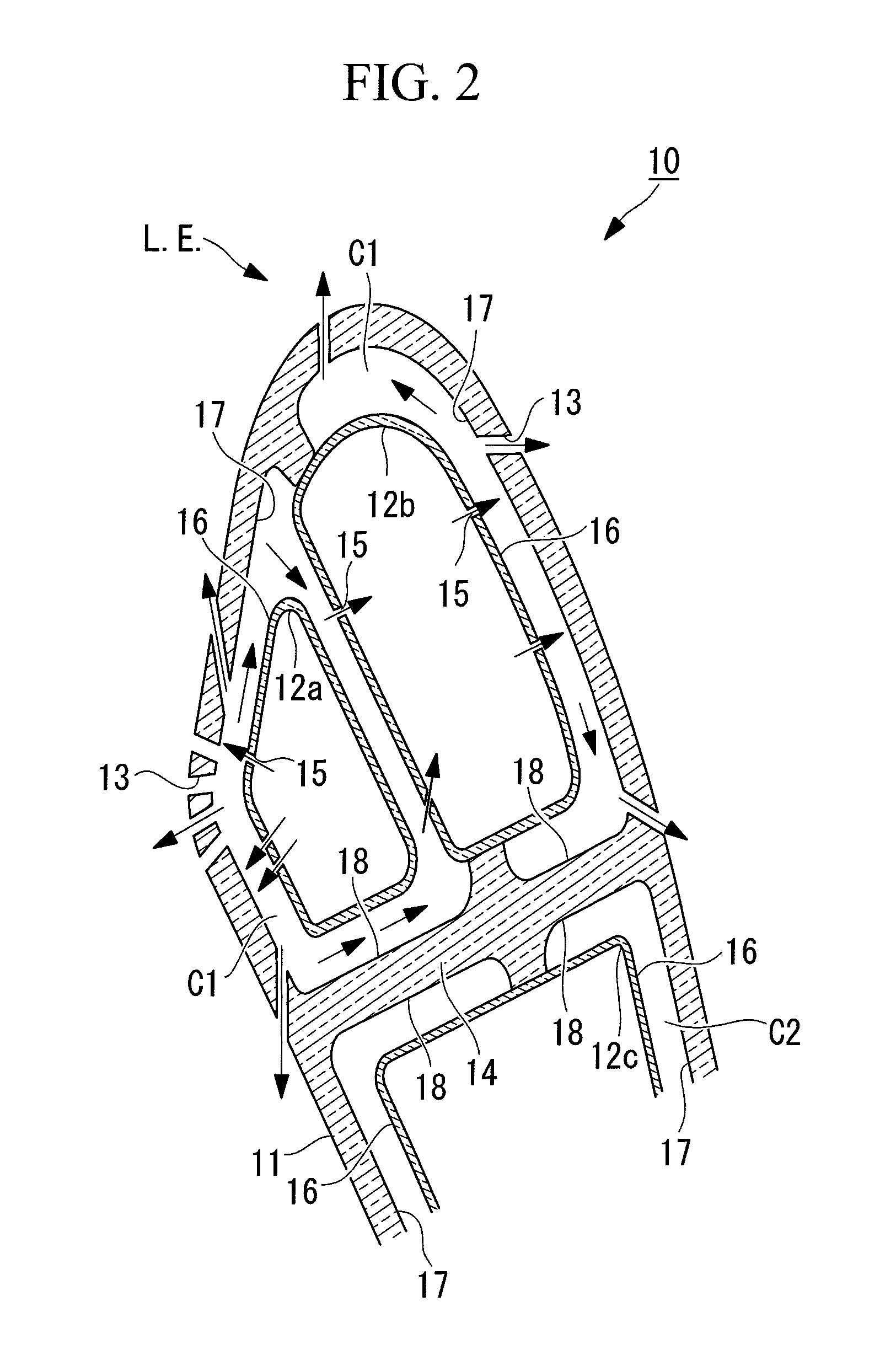

Turbine blade

ActiveUS20110103971A1Reduce the amount requiredPrevent low-temperature cooling airPropellersPump componentsTurbine bladeShock cooling

The amount of cooling air (cooling medium) can be reduced, and low-temperature cooling air is prevented from being blown out through film cooling holes. Part of a cooling medium impingement-cooling an inner circumferential surface of a blade main body located on a ventral side further impingement-cools the inner circumferential surface of the blade main body located on a dorsal side and is blown out through film cooling holes in the blade main body that are located on the dorsal side.

Owner:MITSUBISHI POWER LTD

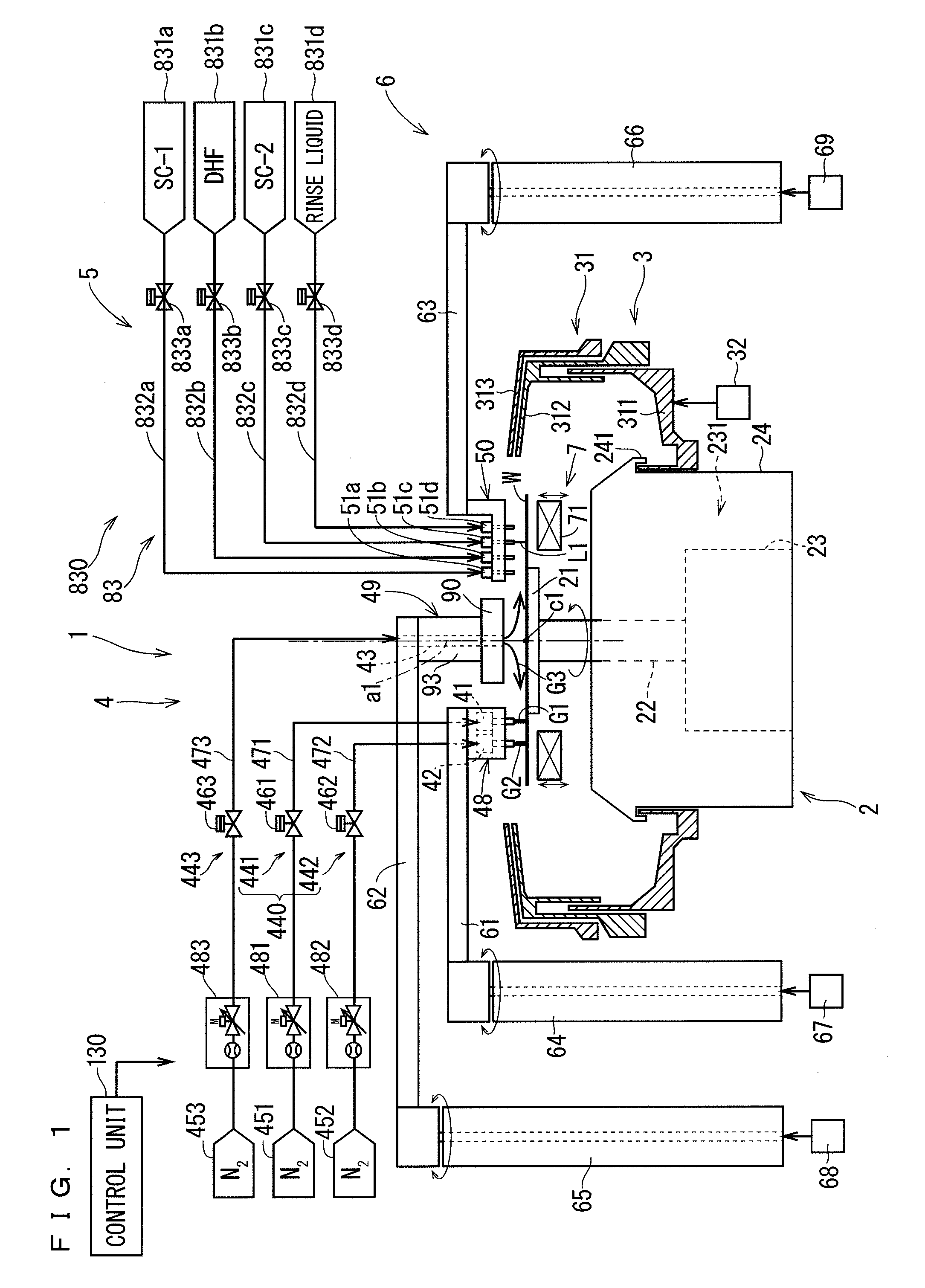

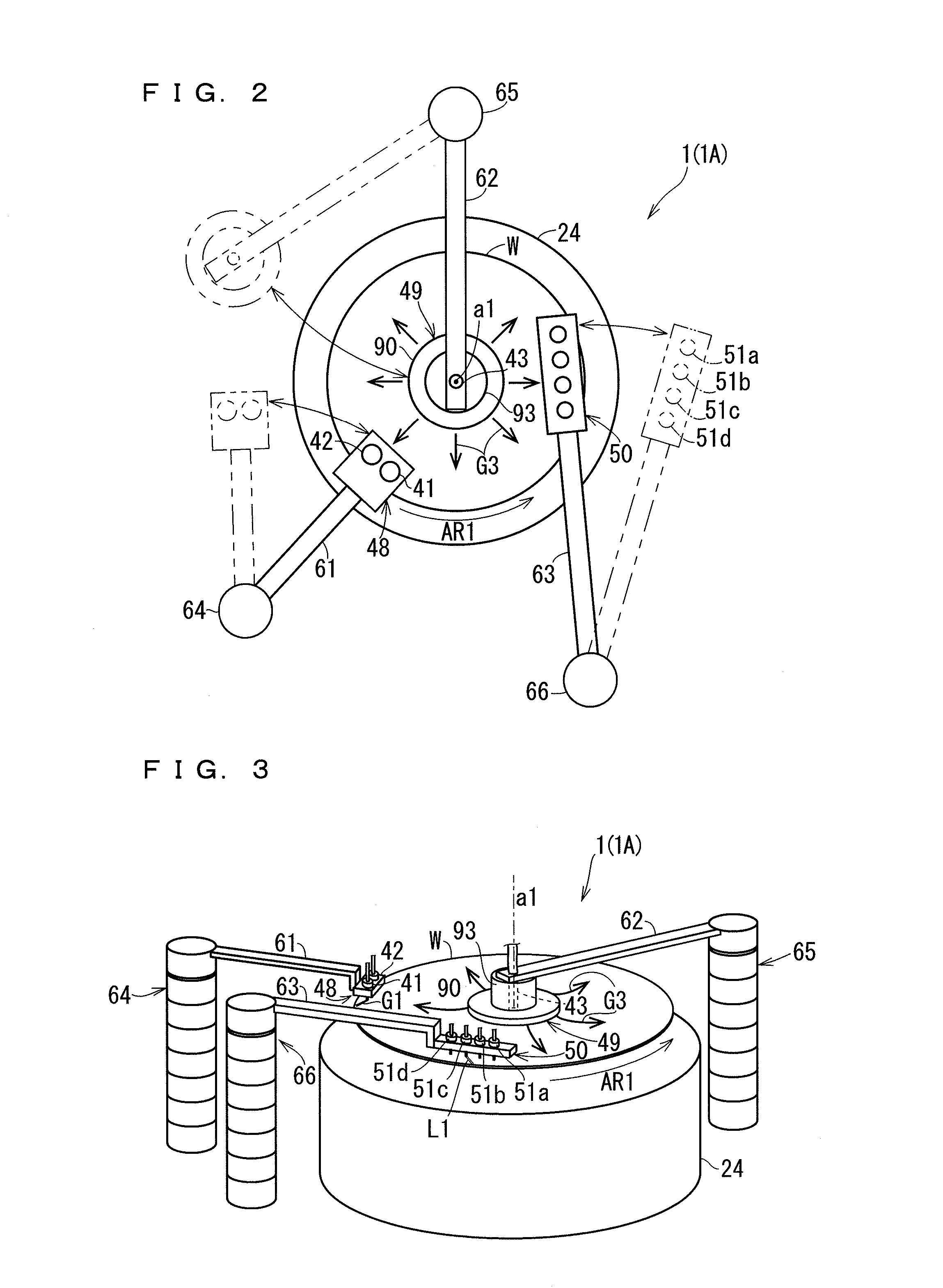

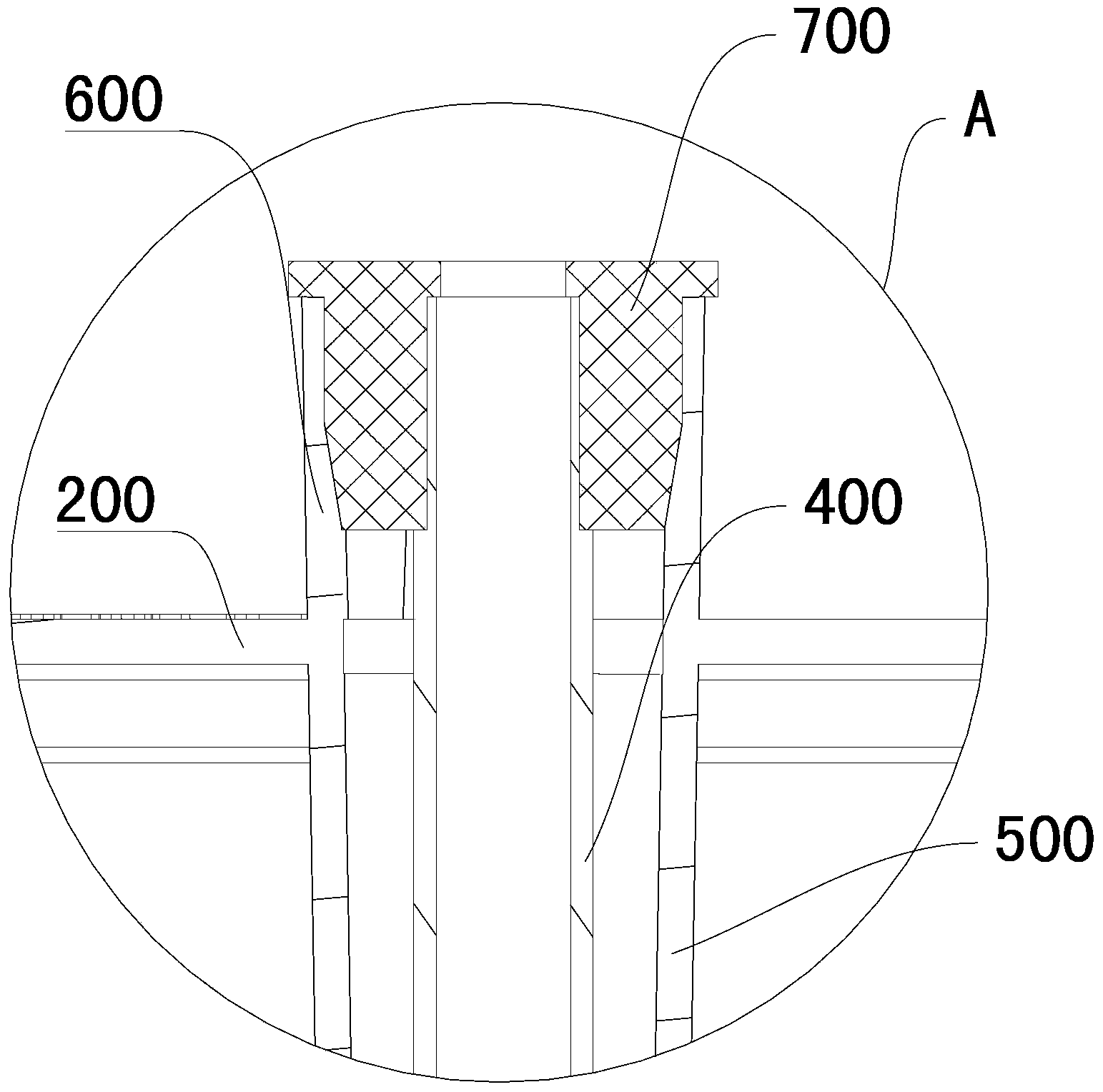

Substrate processing apparatus

ActiveUS20160372340A1Avoid dilutionSolve the real problemSemiconductor/solid-state device manufacturingAirflowEngineering

A substrate processing apparatus includes a substrate holder, a rotating mechanism, a processing liquid discharge unit, and a gas discharge unit. The processing liquid discharge unit discharges a liquid flow of a processing liquid such that the liquid flow comes into contact with a landing position in a rotation path of a peripheral portion of an upper surface of the substrate being rotated. The gas discharge unit discharges a first gas flow of an inert gas from above toward a first position upstream from the landing position in a direction of rotation of the substrate in the rotation path, and discharges a second gas flow of the inert gas from above toward a second position upstream from the first position in the direction of rotation of the substrate in the rotation path. The kinetic energy of the second gas flow is lower than the kinetic energy of the first gas flow.

Owner:DAINIPPON SCREEN MTG CO LTD

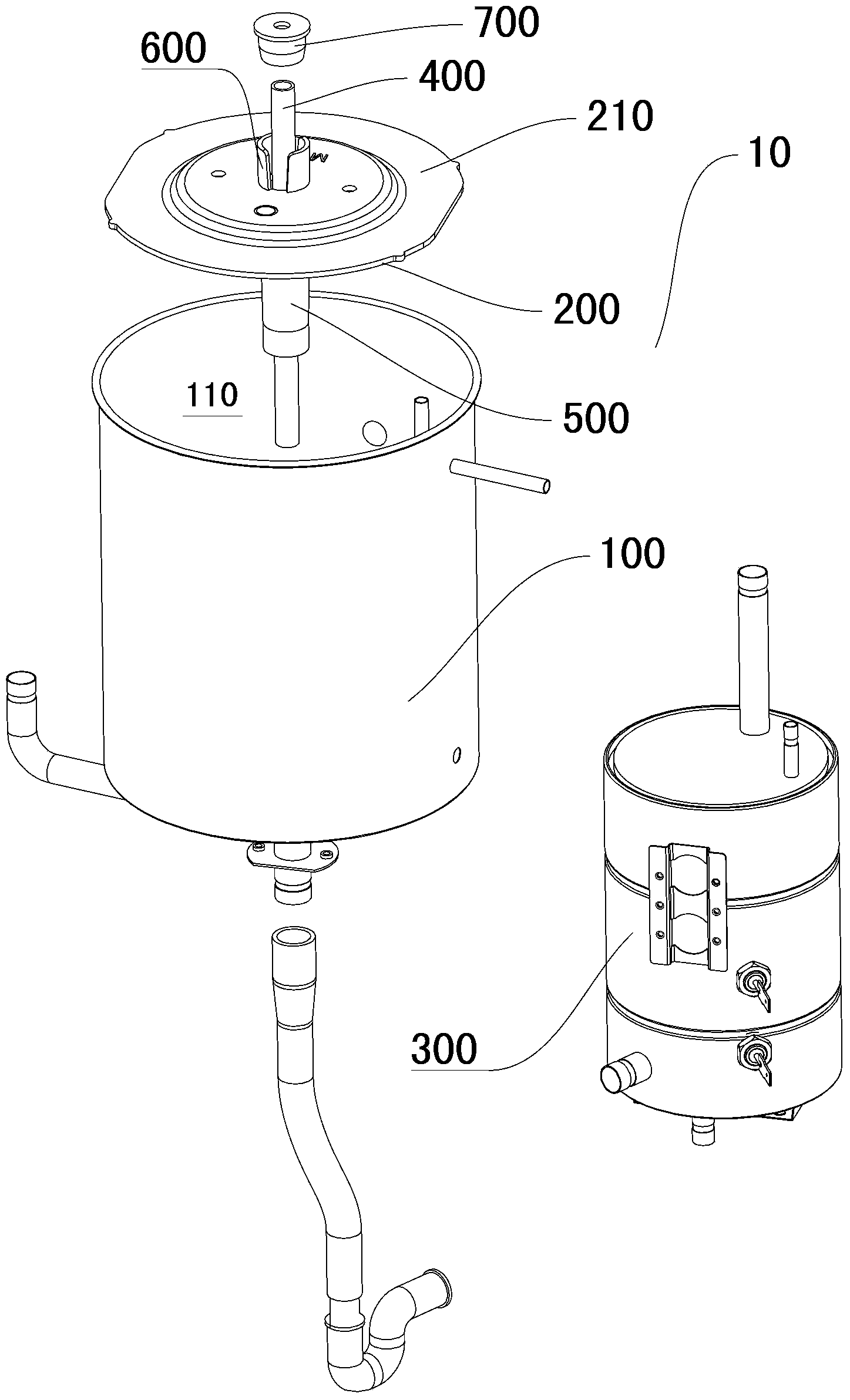

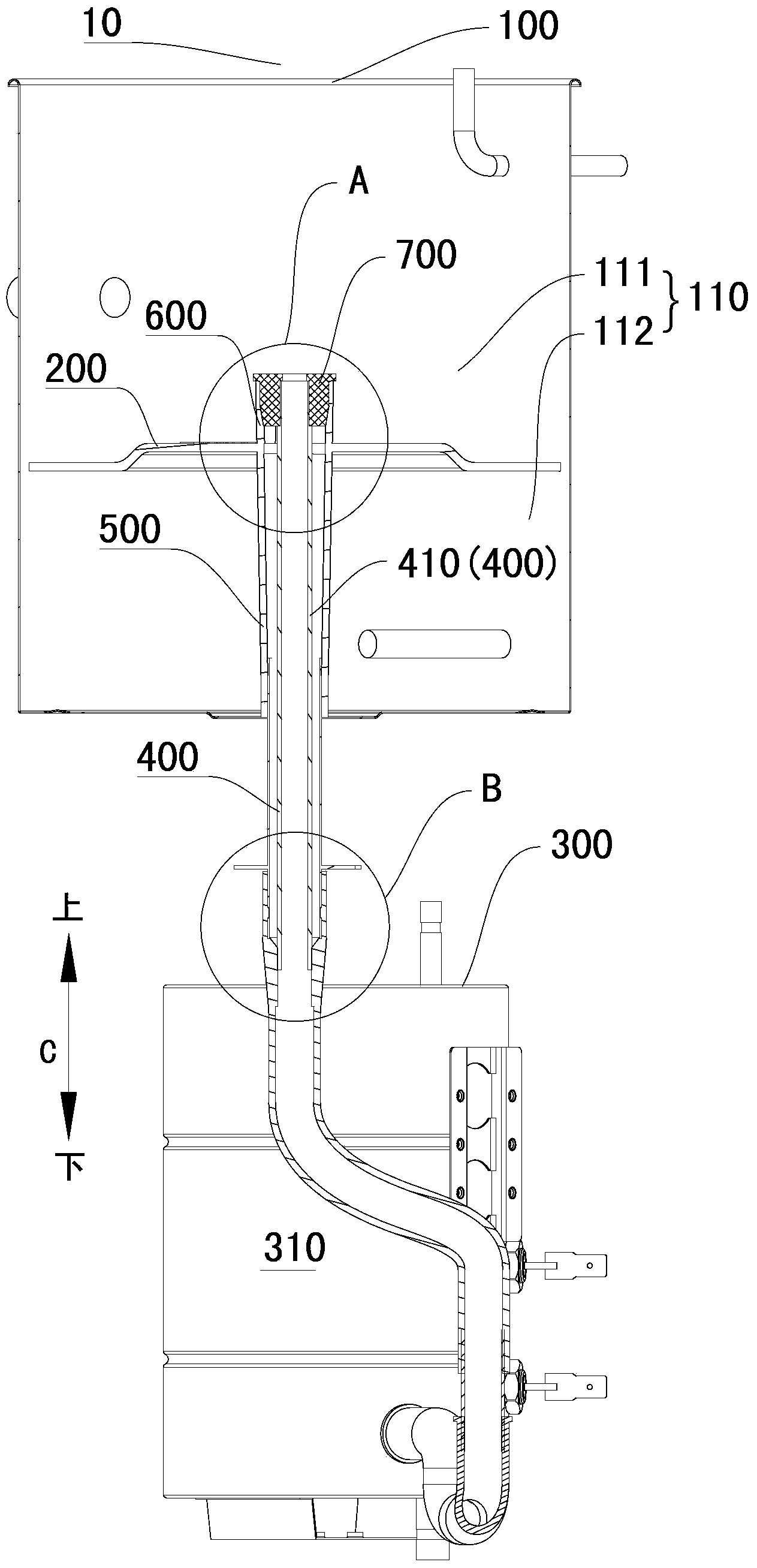

Water dispenser

ActiveCN104337403AReduce heating efficiencyImprove heating efficiencyBeverage vesselsWarm waterThermal insulation

The invention discloses a water dispenser. The water dispenser comprises a water storage tank, a flow distribution disk, a hot water tank and a water pipe, wherein a containing cavity is formed in the water storage tank; the flow distribution disk is arranged in the containing cavity, so that the containing cavity can be divided into a warm water cavity and a cold water cavity; a hot water cavity is formed in the hot water tank; one end of the water pipe is communicated with the warm water cavity while the other end of the water pipe is communicated with the hot water cavity; a thermal insulation layer is formed between space in the water pipe and the cold water cavity. According to the embodiment, the water dispenser has the advantages of being low in energy consumption, high in heating efficiency and the like.

Owner:MIDEA GRP CO LTD +1

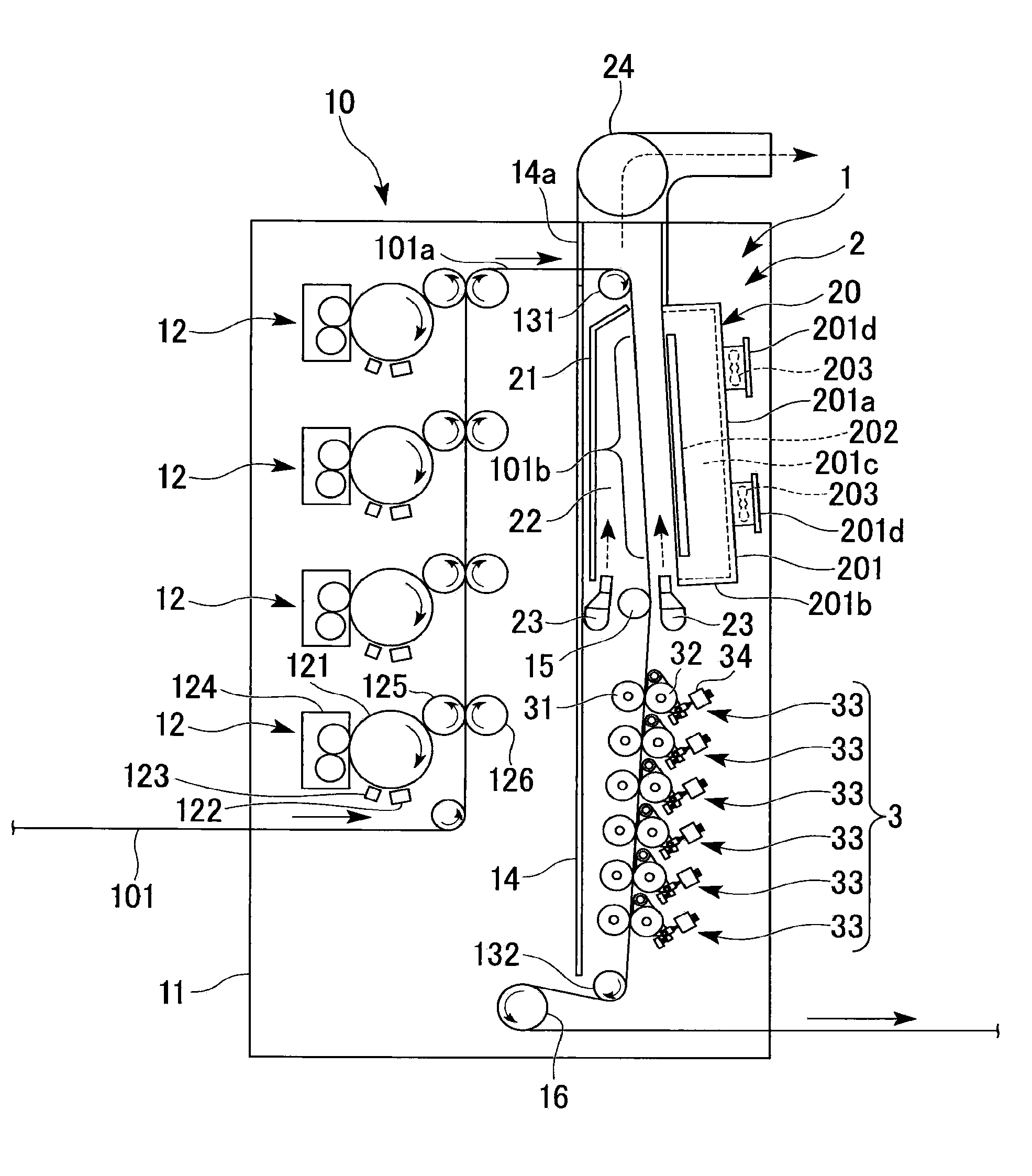

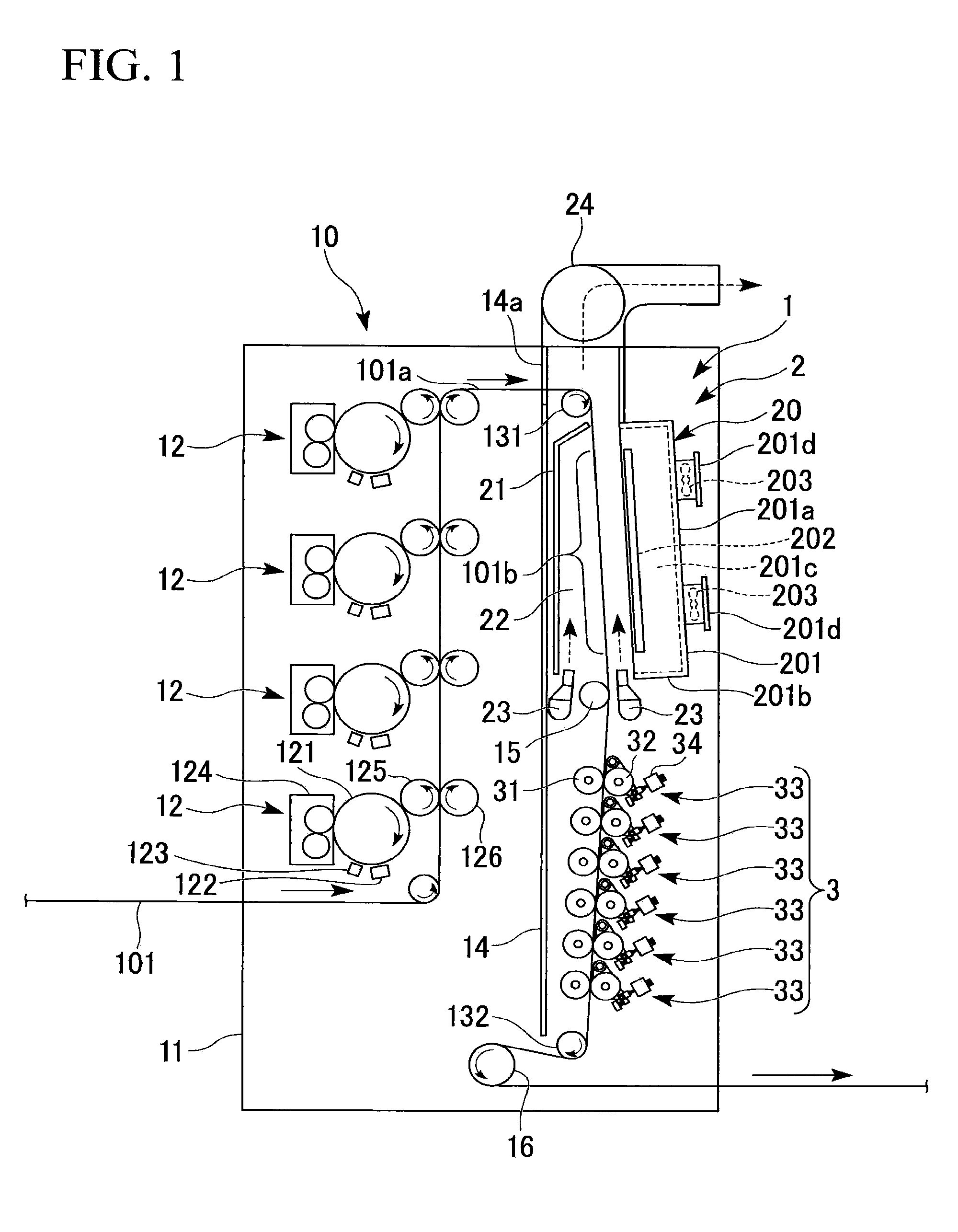

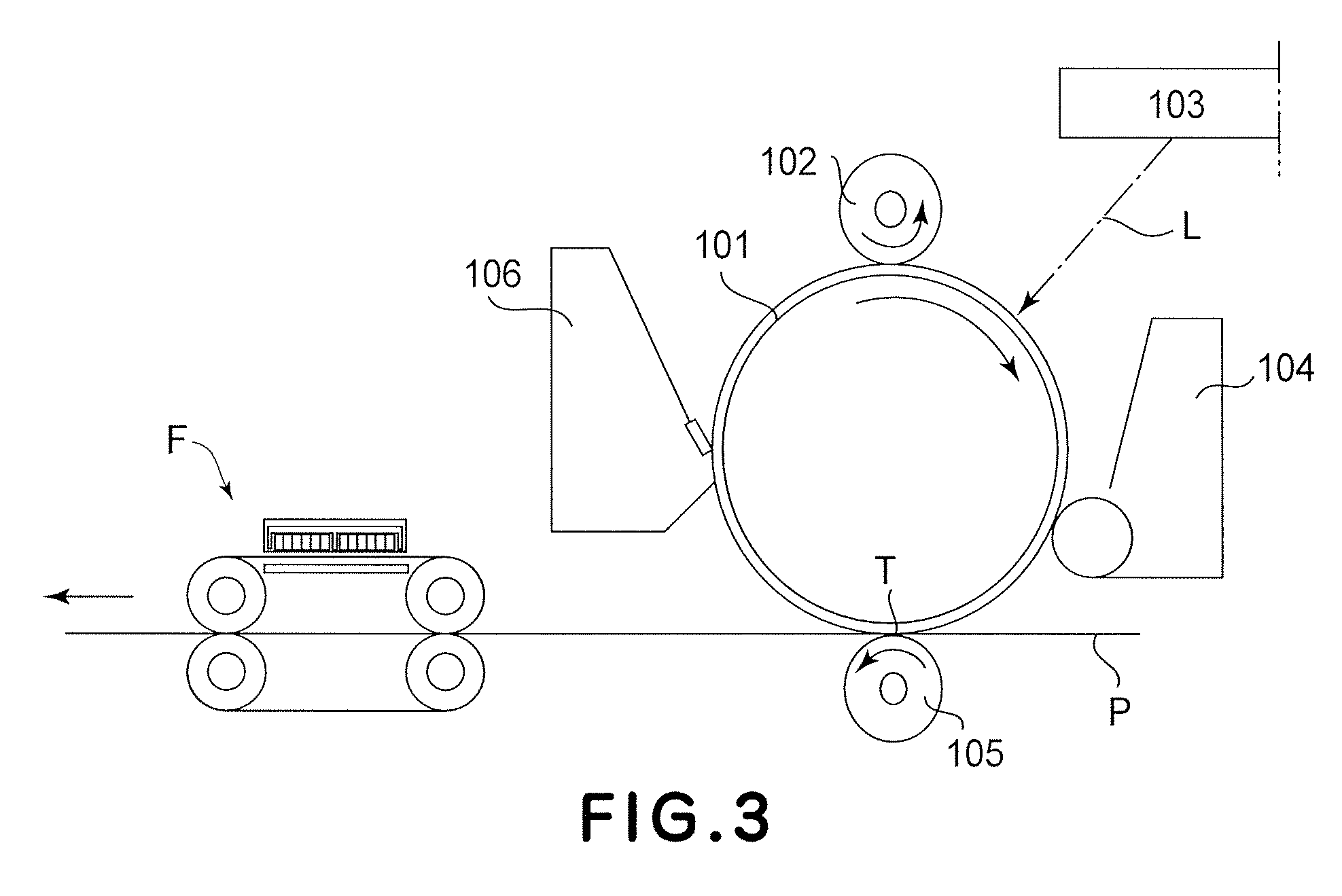

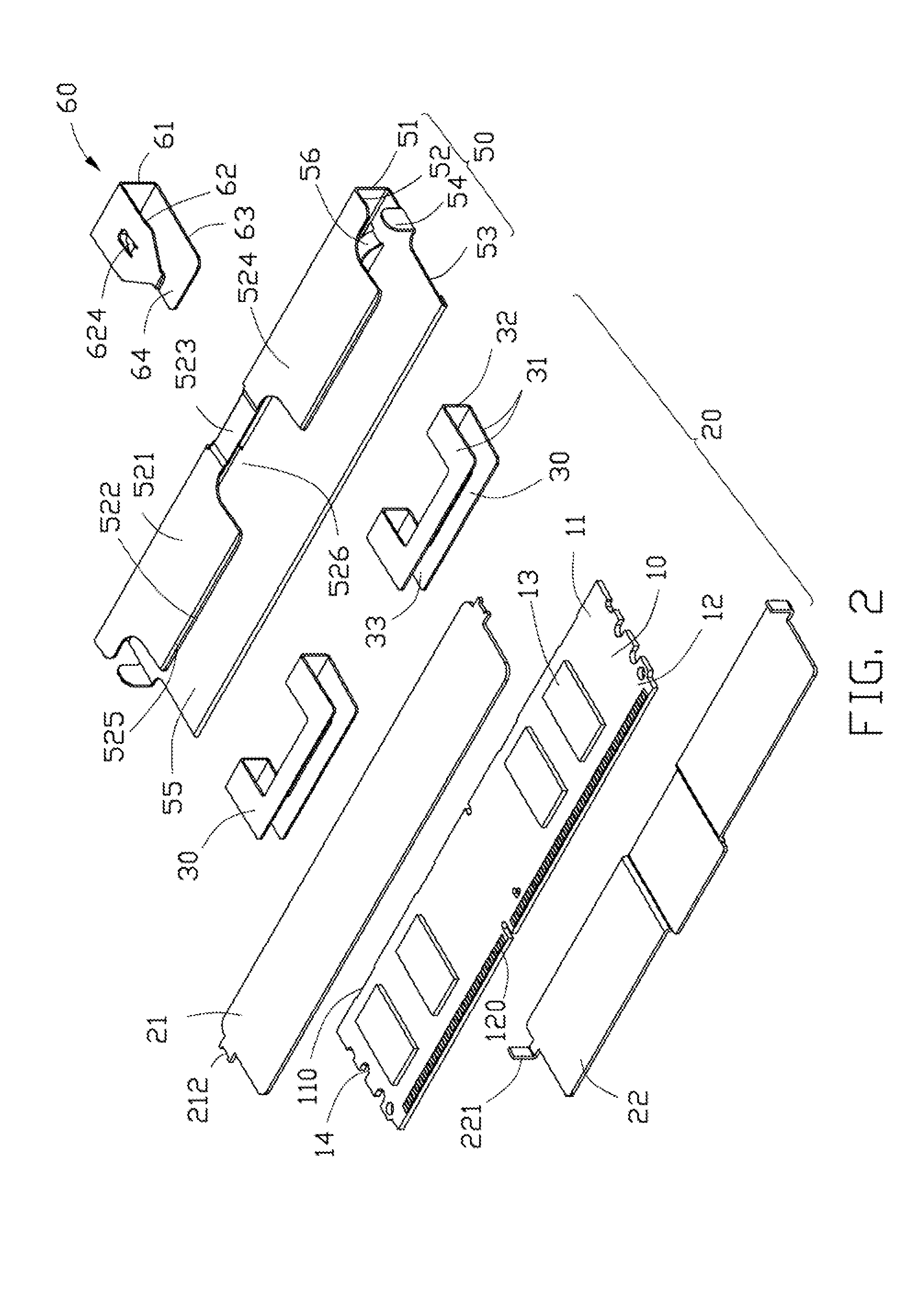

Apparatus for Producing Three-Dimensional Shaped Product

ActiveUS20110256253A1Reduce cooling efficiencyReduce heating efficiencyAdditive manufacturing apparatusConfectioneryEngineeringThermal dissipation

An apparatus for producing a three-dimensional shaped product capable of decreasing thermal dissipation due to thermal conduction of a heating device or a cooling device loading a base plate, in which powder is sequentially sintered on a table and a base plate a inside a shaping tank wherein a space of vertical direction is formed on the table or the space is formed and a heat insulating material is filled into the thus formed region, a heating device or a cooling device which loads the base plate a supporting the sintered layer is firmly fixed.

Owner:MATSUURA MACHINERY

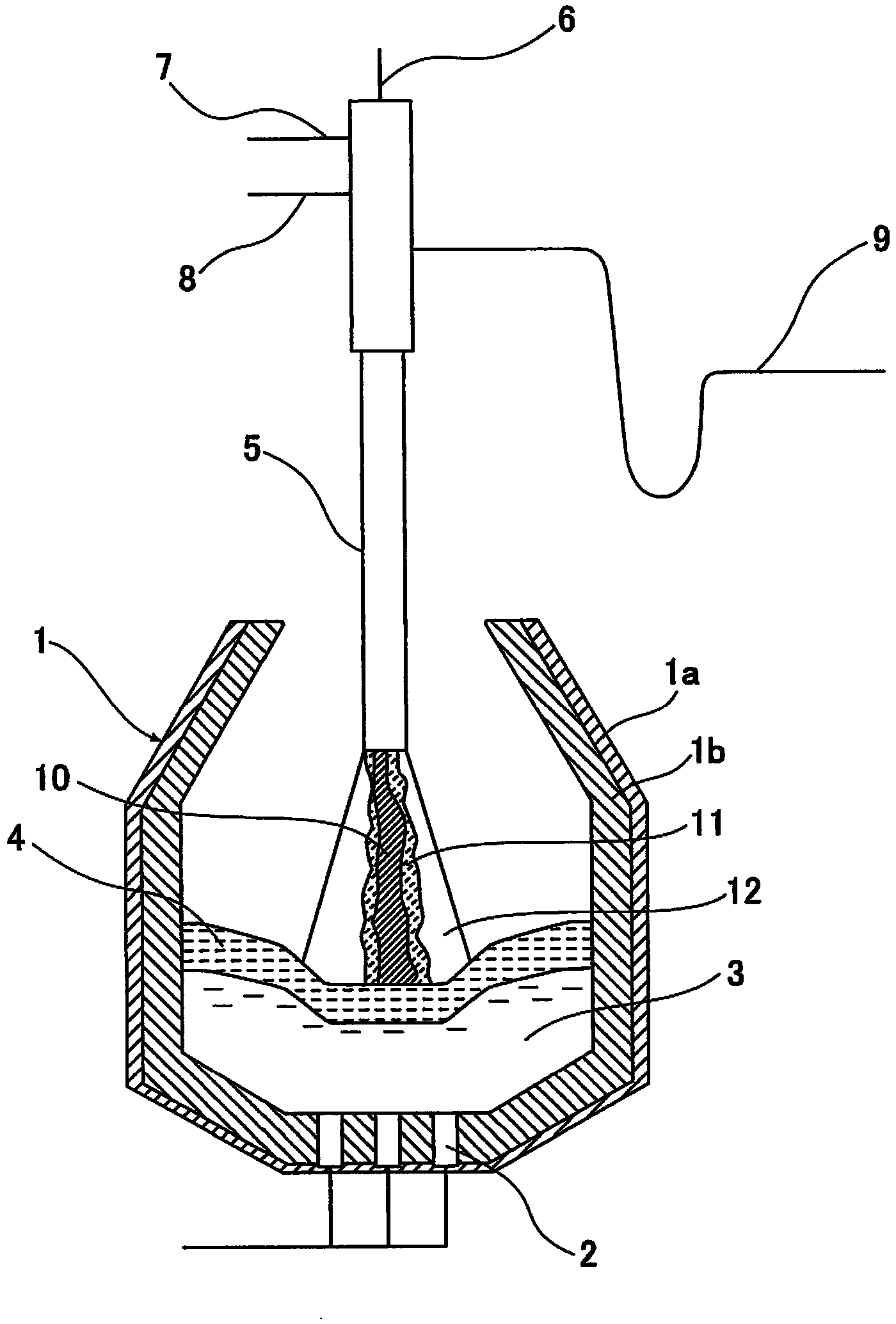

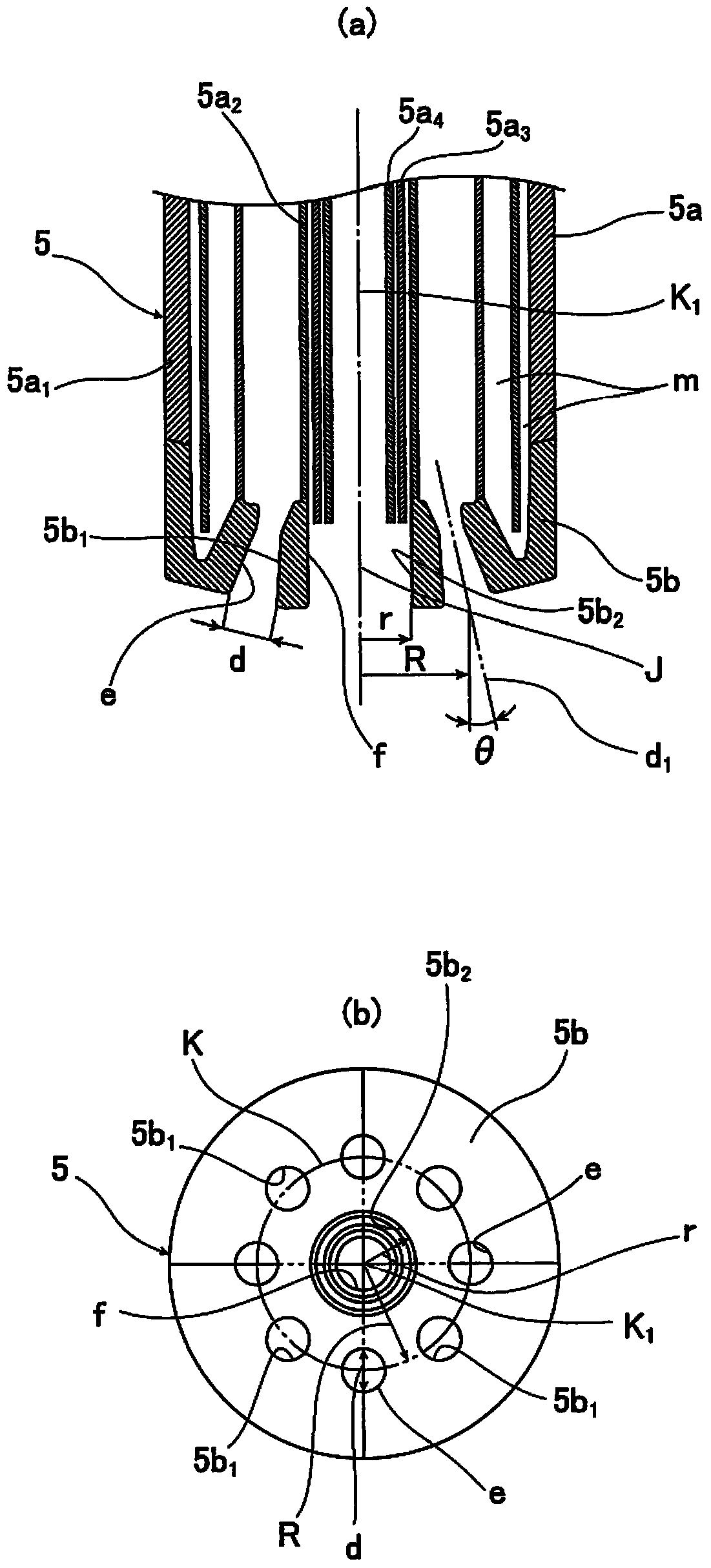

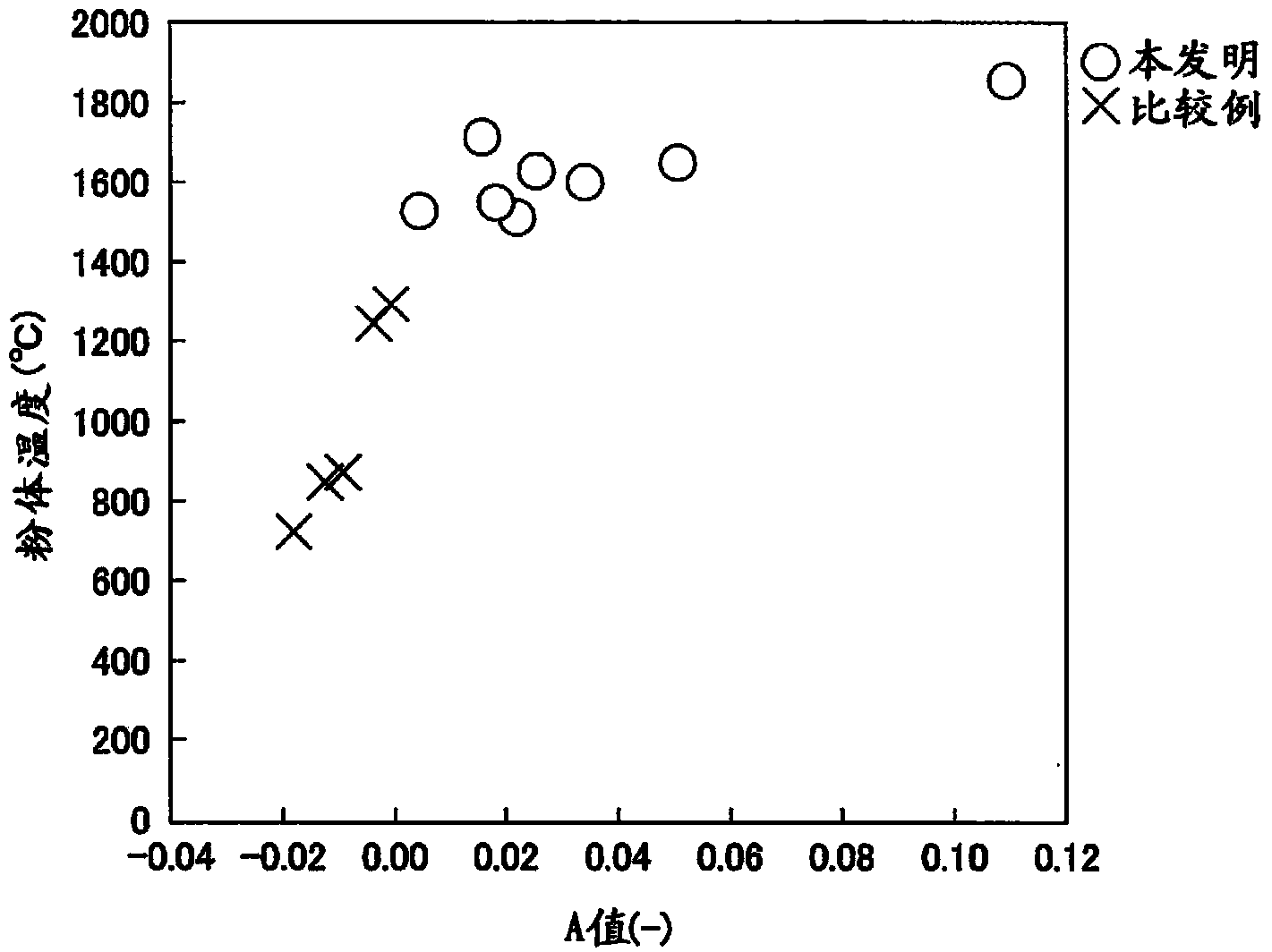

Powder injection lance and method of refining molten iron using the powder injection lance

ActiveCN103890199AReduce distractionsImprove heat transfer efficiencyManufacturing convertersProcess efficiency improvementMaterials scienceHeat transfer

A powder injection lance is provided with: a refining oxygen gas injection nozzle which has multiple ejection openings that are arranged at intervals along a circular trajectory and inject an oxygen gas into an iron bath housed in a reaction vessel; and a burner nozzle which has an axial center coaxial with the central axis of the circular trajectory, and which has an ejection opening which forms a flame on the inside of the refining oxygen gas injection nozzle and which injects into the iron bath a powder to which heat has been transferred by the flame. An indicator showing the positional relation between the ejection opening of the refining oxygen gas injection nozzle and the ejection opening of the burner nozzle fulfills A=1.7(R-r-d / 2) / L+tan(theta-12 DEG )-0.0524>0. Here, R is the radius (mm) of the circular trajectory, r is the radius (mm) of the ejection opening of the burner nozzle, d is the diameter (mm) of the ejection openings of the refining oxygen nozzle, theta is the inclination angle (DEG) of the axial center of the refining oxygen gas injection nozzle, and L is the lance height (mm). By this means, the efficiency of heat transfer to the iron bath is improved.

Owner:JFE STEEL CORP

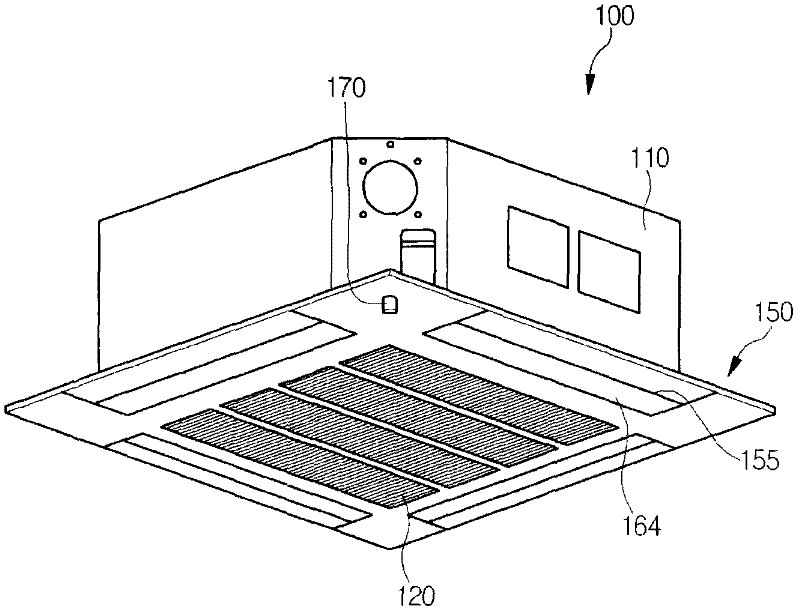

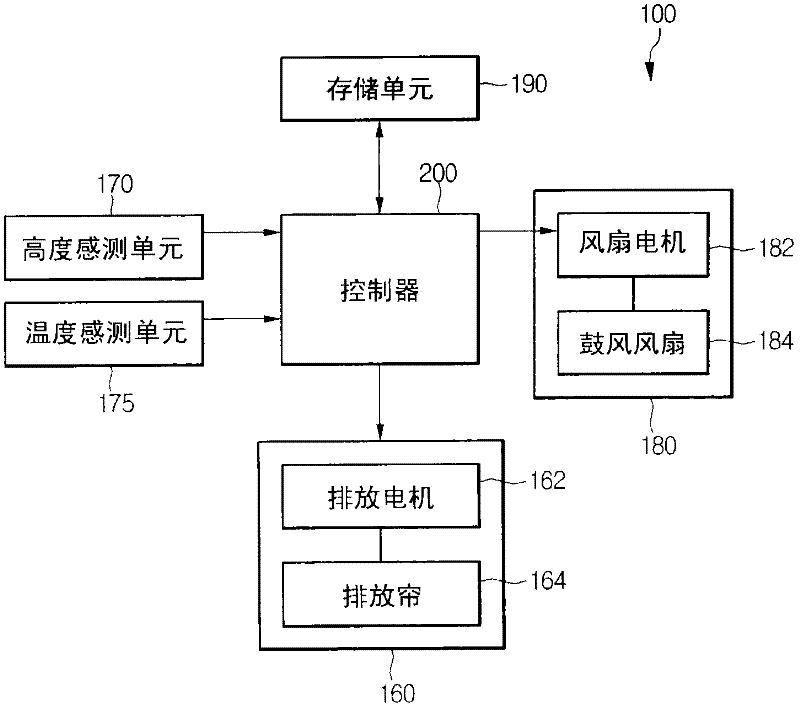

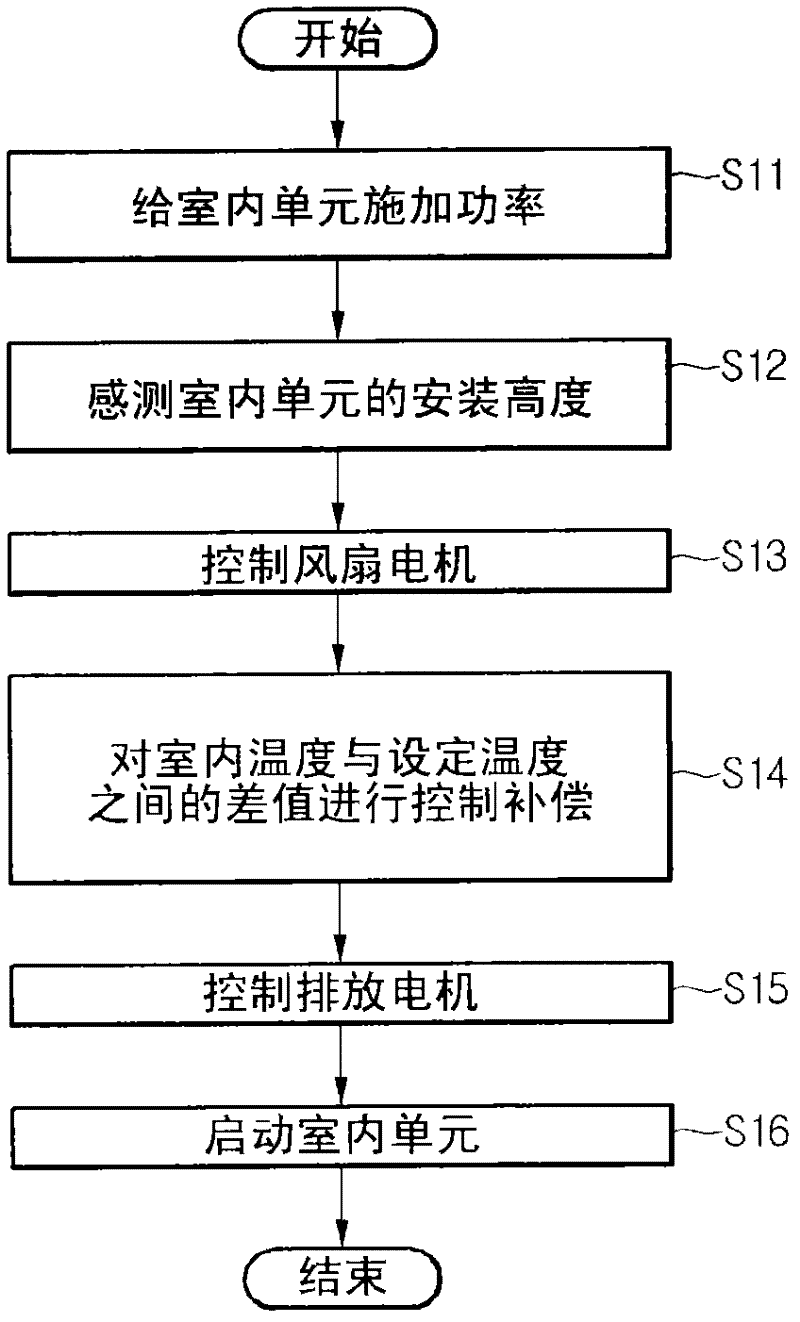

Indoor unit for air conditioner and control method thereof

InactiveCN102374590AEmission controlImprove cooling effectMechanical apparatusSpace heating and ventilation safety systemsMarine engineeringFront panel

Provided is an indoor unit for an air conditioner buried in a ceiling and including a heat exchanger with respect to an indoor space defined by a bottom surface, the ceiling, and a plurality of wall surface, including: a front panel where a suction part suctioning air of the indoor space; a discharge hole placed on at least one side of the suction part and discharging heat-exchanged air from the heat exchanger; an opening member provided movably to selectively open the discharge hole; a distance sensing unit sensing at least one of a distance up to the bottom surface from the front panel or the indoor unit and a distance up to the wall surface from the indoor unit; and a controller controlling the opening degree of the opening member based on a sensing result sensed by the distance sensing unit.

Owner:LG ELECTRONICS INC

Solar battery piece series welding method

InactiveCN106903389AFully meltedShorten heating timeFinal product manufactureSoldering apparatusEngineeringSolar battery

The invention provides a solar battery piece series welding method. When solar battery pieces and a welding strip are welded, a preheating mode is adopted, the solar battery pieces and the welding strip are heated preliminarily, and thus the heating efficiency of a subsequent welding station is reduced; and vacuum heat insulation and vacuum heat preservation principles are adopted, so that the welding efficiency and welding quality are improved.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Image heating apparatus including a belt member for heating an image on a recording material

ActiveUS7970329B2Reduce heating efficiencyOhmic-resistance heatingElectrographic process apparatusEngineeringMagnetic flux

Owner:CANON KK

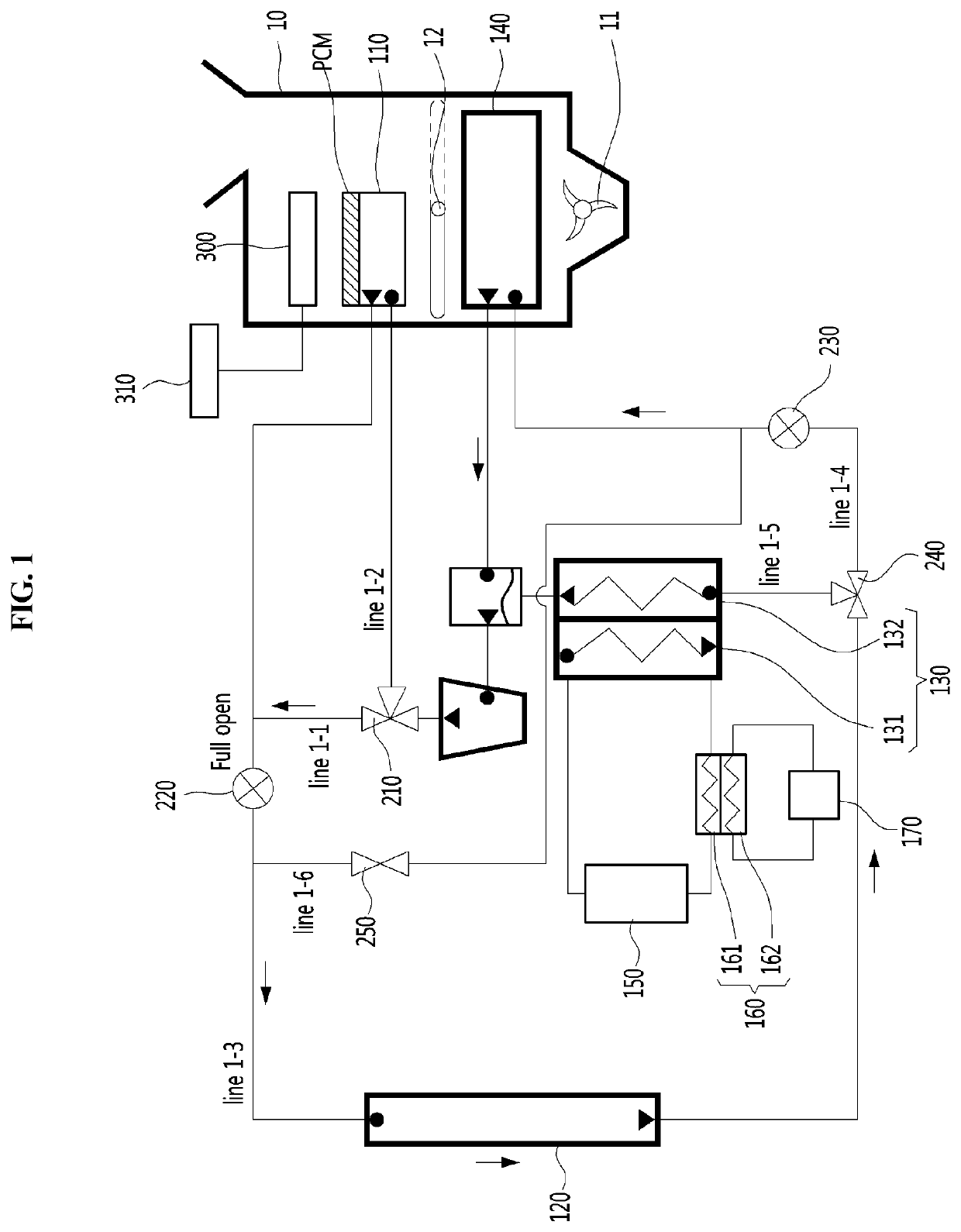

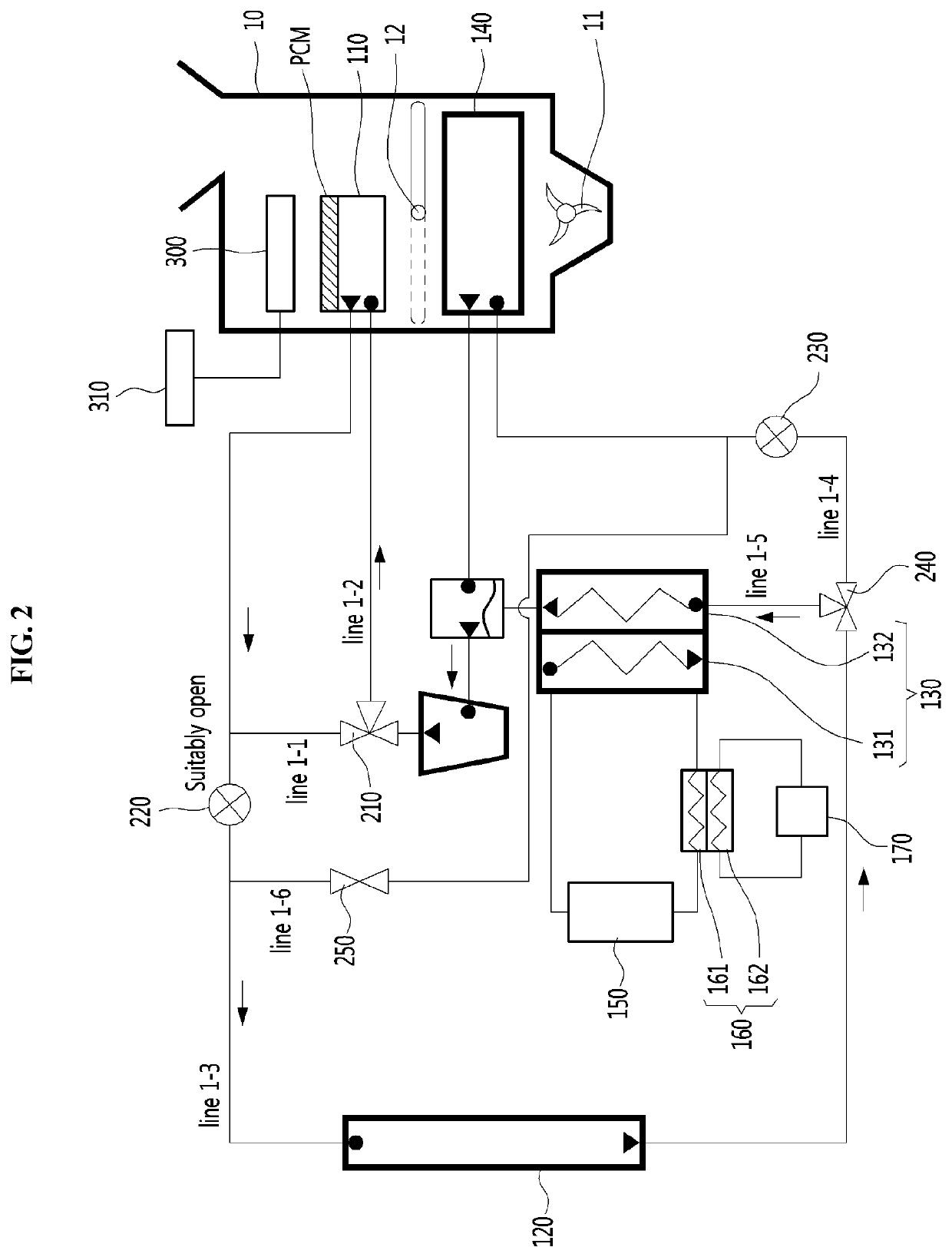

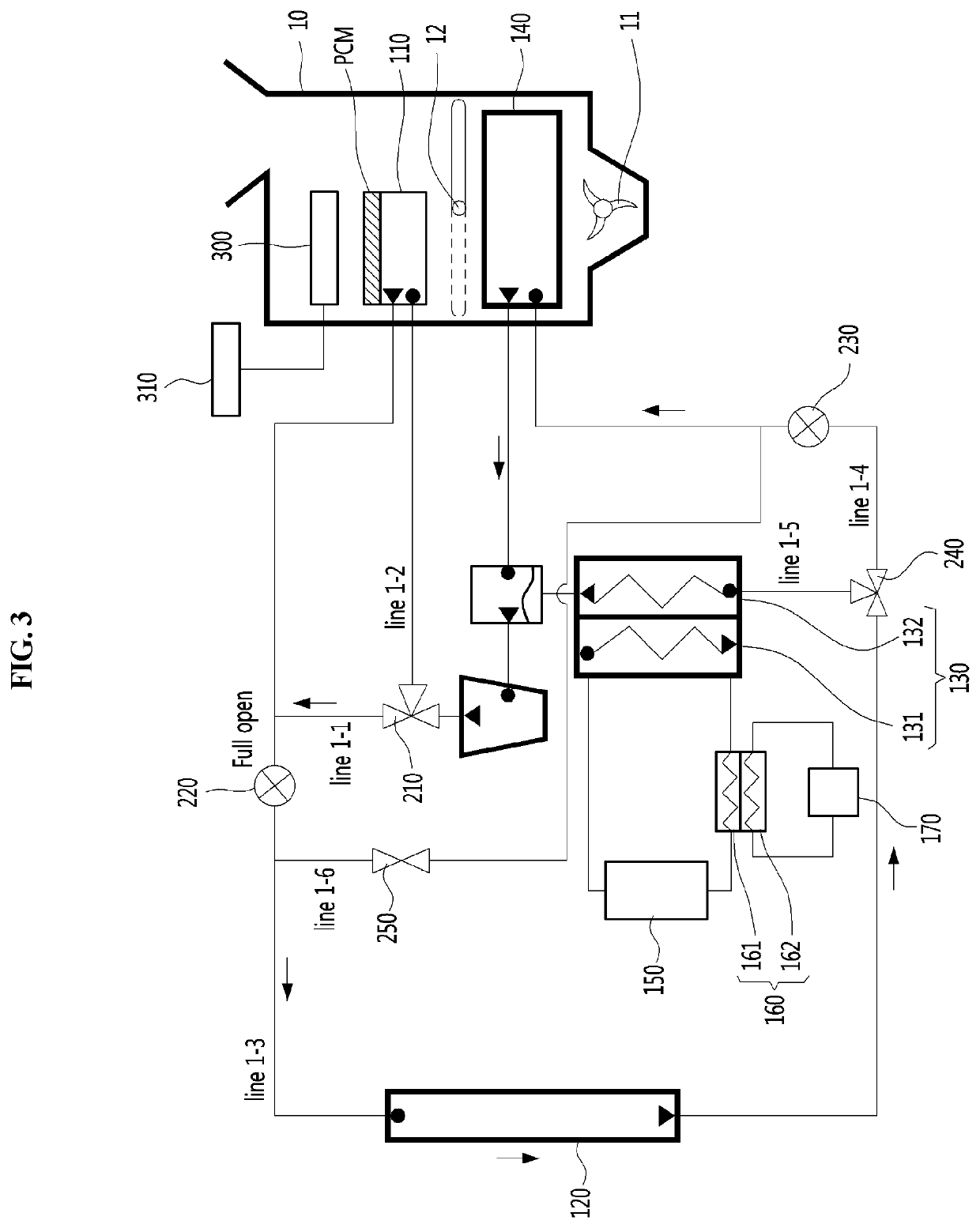

Heat pump for automobile

ActiveUS20190351739A1Reduce heating efficiencySame heating efficiencyAir-treating devicesMechanical apparatusEngineeringRefrigerant

A heat pump for a vehicle is provided in which the heat pump includes a compressor, an inner heat exchanger, an outer heat exchanger, a first expansion unit, a second expansion unit, an evaporator, an accumulator, a third heat exchanger, a first directional control valve, a second directional control valve, and a dehumidification line, and performs cooling, heating, defrosting, and dehumidifying operations according to the flow of a refrigerant.

Owner:ERAE AUTOMOTIVE SYST

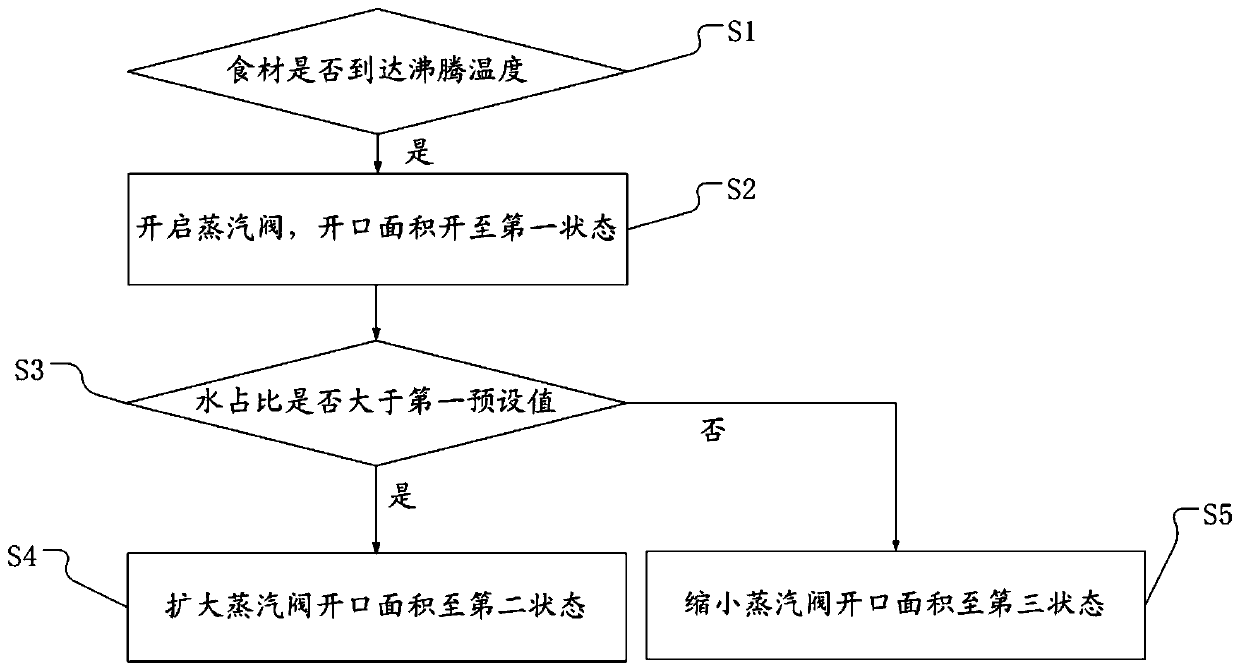

Cooking equipment and control method thereof

The invention provides cooking equipment and a control method thereof. The control method comprises the steps of judging whether foods reach a boiling temperature or not; if yes, opening a steam valve, wherein the opening area of the steam valve reaches a first state; after continuously heating for first preset time, judging that whether a water ratio is more than a first preset value or not; if yes, expanding the opening area of the steam value to a second state; and if no, reducing the opening area of the steam valve to a third state. Due to such a design, the opening area of the steam valveis automatically adjusted according to the detected temperature, the water ratio and working time; quick dissipation of heat and quick escape of vapor are avoided while generation and overflowing ofbubbles are avoided, the contradictory relation between the opening area of the steam valve and heating power is solved, and heating efficiency and user experience are improved.

Owner:GREE ELECTRIC APPLIANCES INC

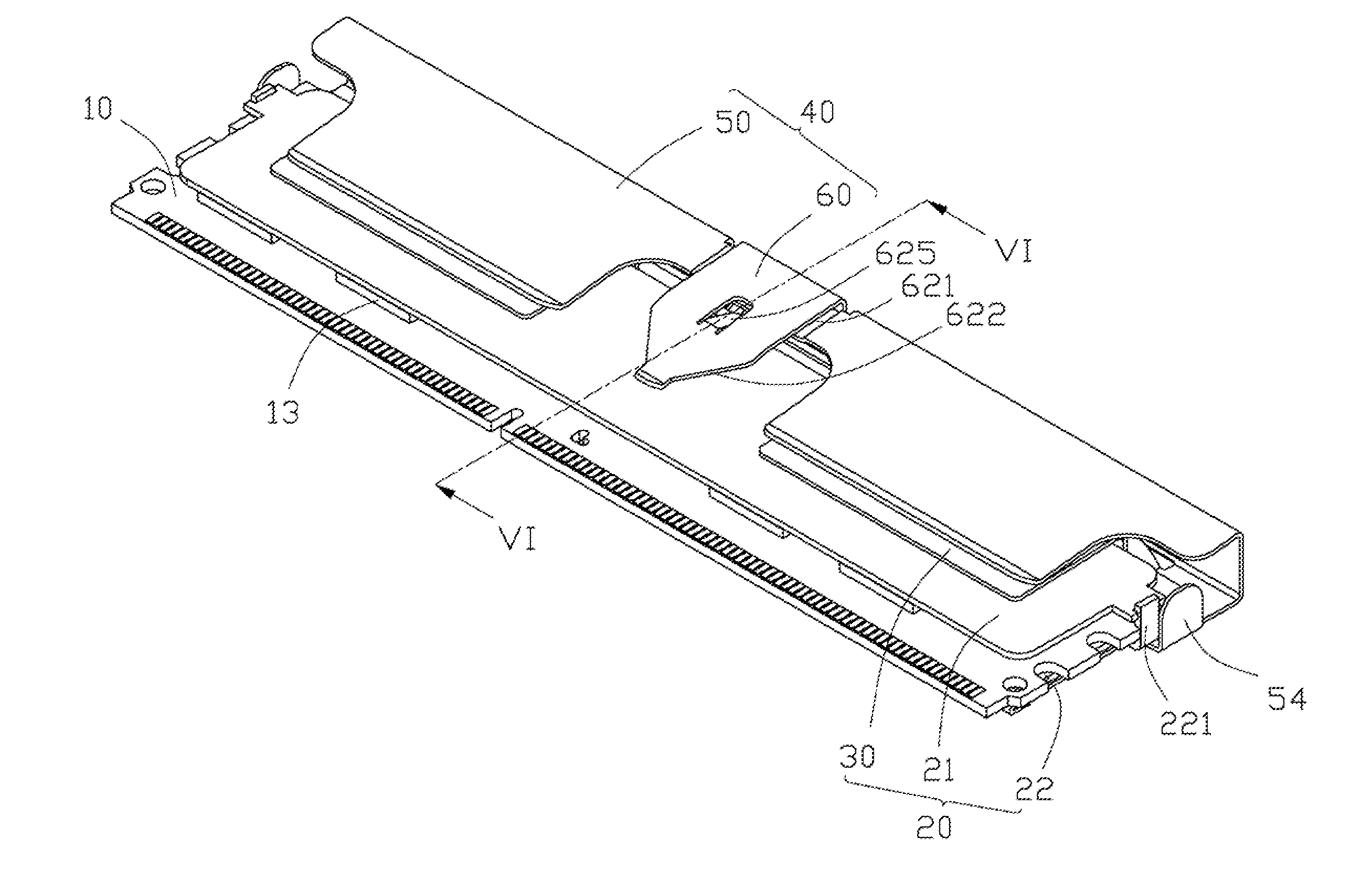

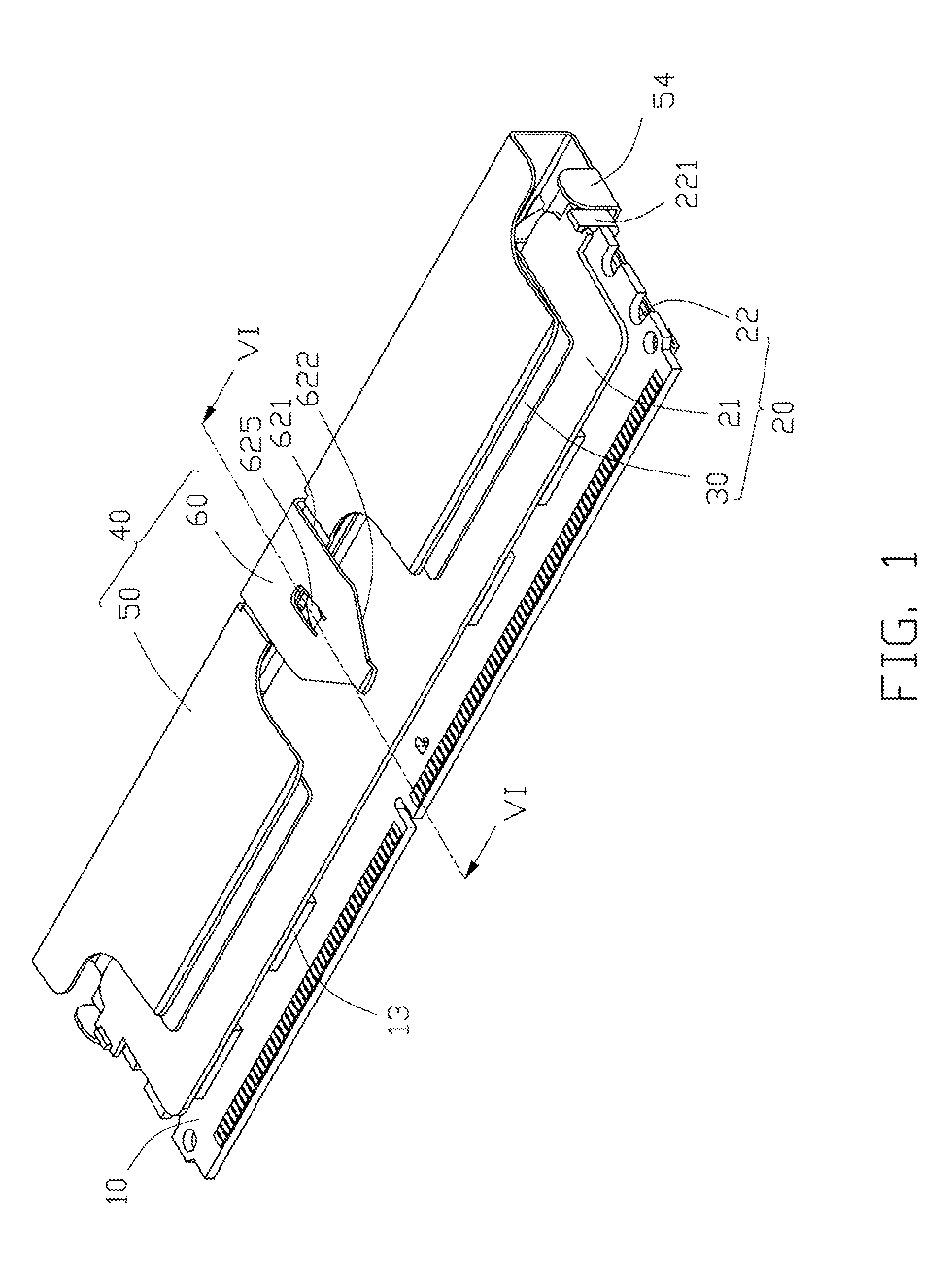

Cooling device for add-on card

InactiveUS20100243203A1Reduce heating efficiencyReduce cooling efficiencyDigital data processing detailsHeat transfer modificationEngineeringHeat spreader

A cooling device for cooling an add-on card includes a heat absorption member attached to the add-on card to absorb heat therefrom, a heat sink and a clip for clasping the heat sink onto the heat absorption member. The heat sink includes a supporting plate, and a first plate and a second plate respectively extending from opposite sides of the supporting plate and attached to the heat absorption member tightly. The clip includes an operation board, and an engaging board and a supporting board respectively extending from opposite sides of the supporting plate. The engaging board and the supporting board respectively abut the first plate and the second plate of the heat sink. A tongue extends from the engaging board rearwards and downwards toward the operation board. The tongue is provided for blocking a separation of the clip from the heat sink.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

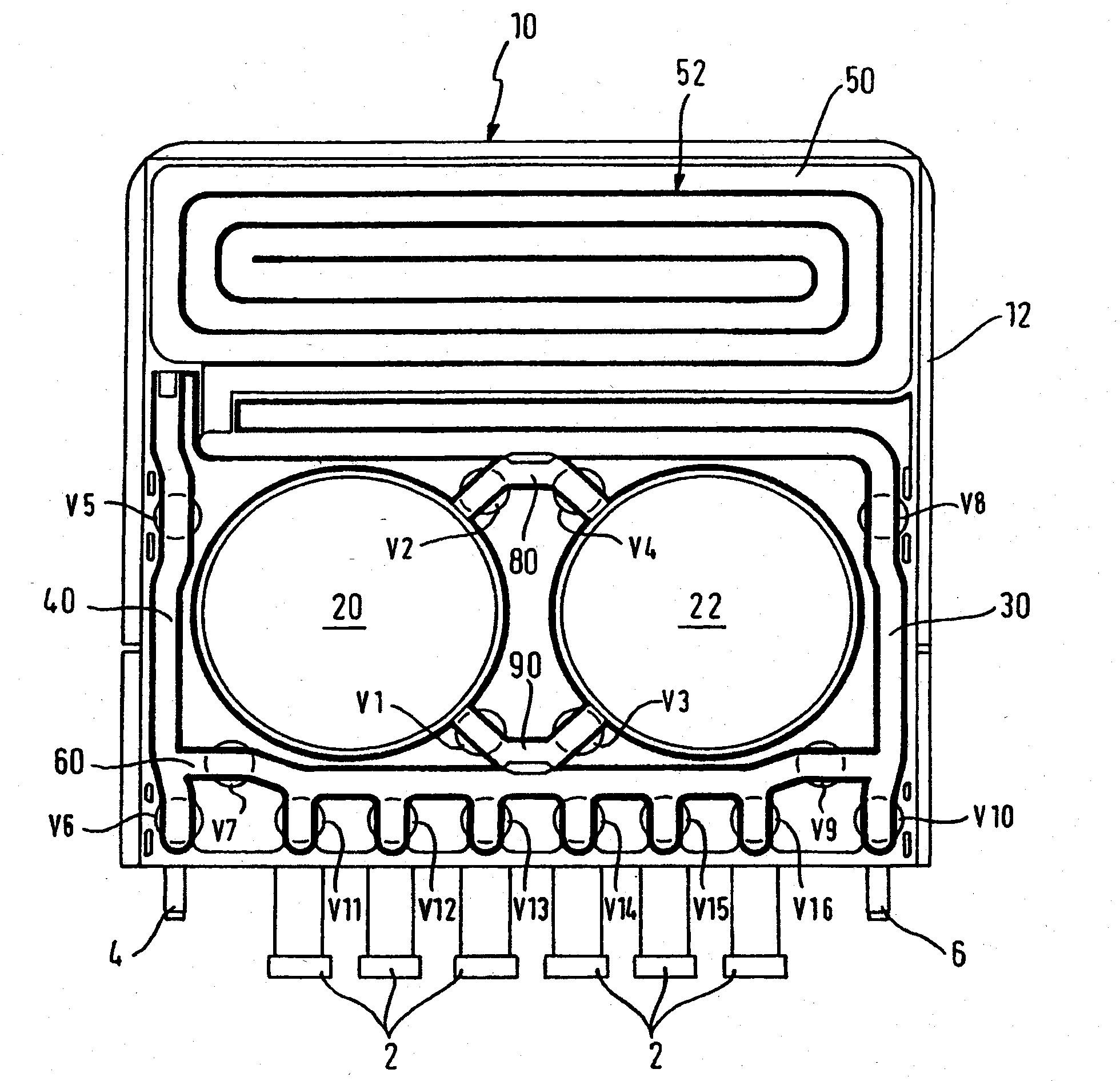

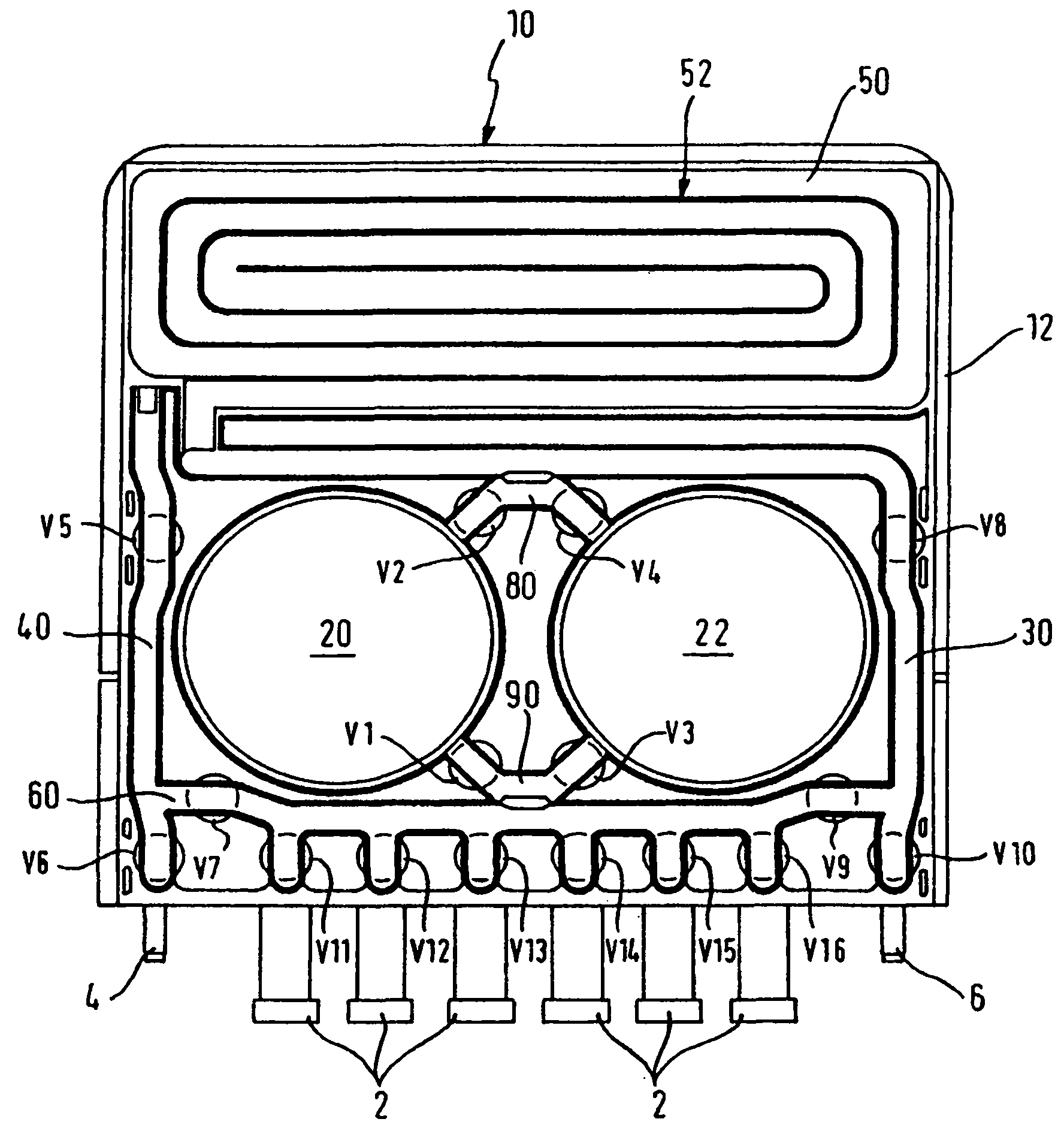

Cartridge for conveying fluids, particularly dialysis fluids

ActiveCN102123754AReduce heating efficiencyMedical devicesIntravenous devicesEngineeringDialysis fluid

The invention relates to a cartridge for conveying fluids, having connection elements for connecting fluid bags and lines leading to the patient or the dialysis device. According to the invention the cartridge has a controller for guiding fluid that is heated to above the target temperature, said controller being effective until the target temperature has again been reached. The invention further relates to a dialysis device having a unit for accommodating said cartridge, and to a method for controlling the temperature of the fluid guided in the cartridge.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

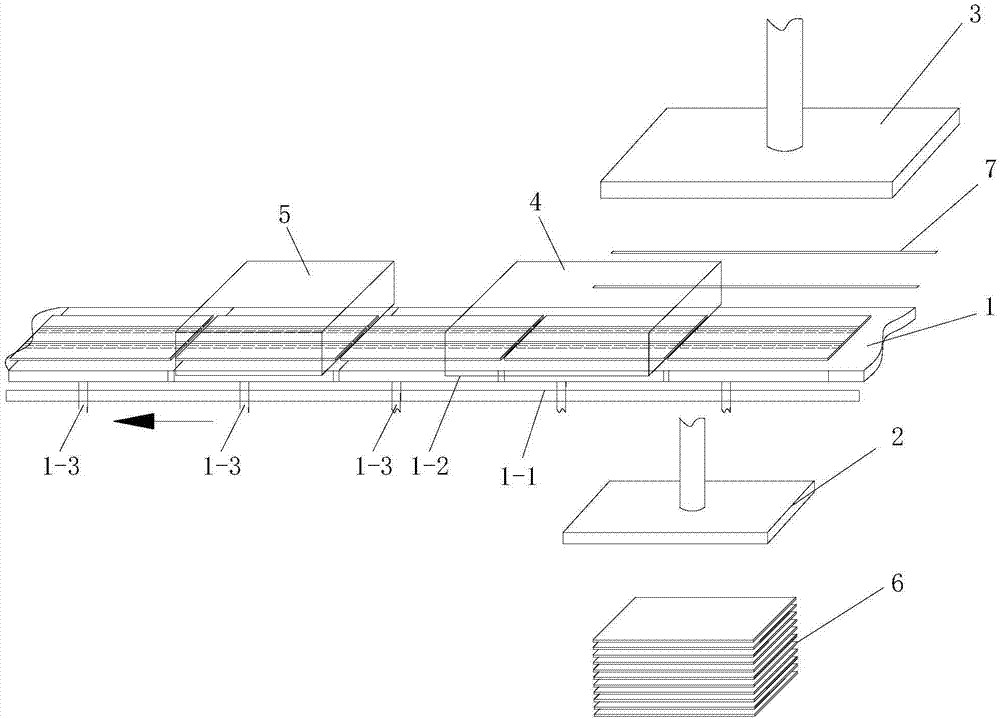

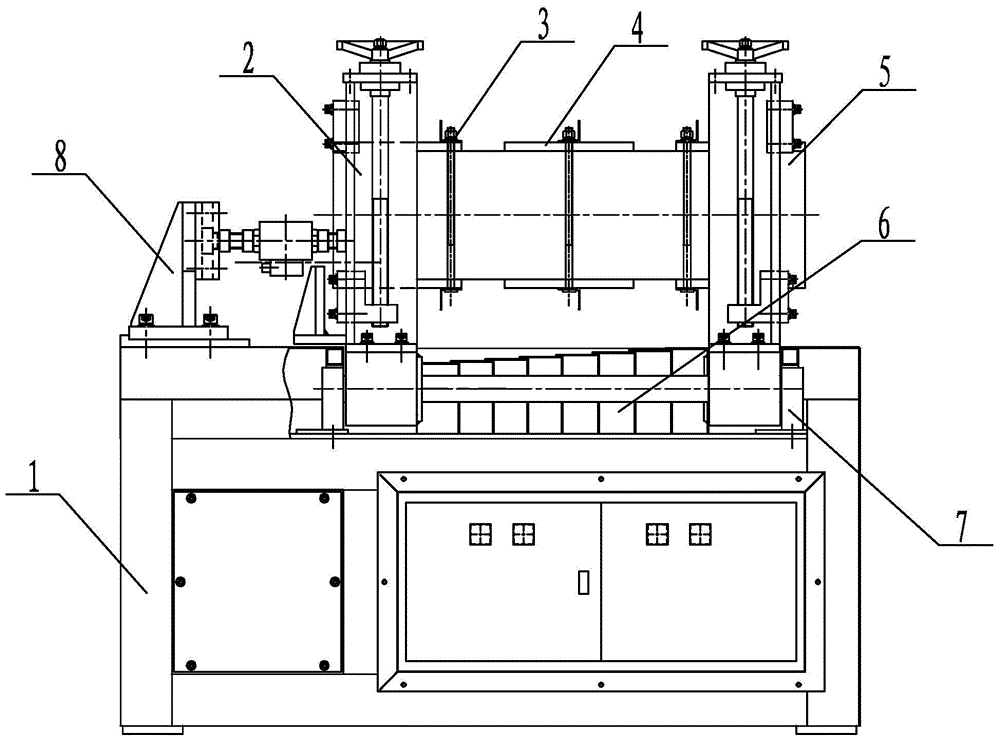

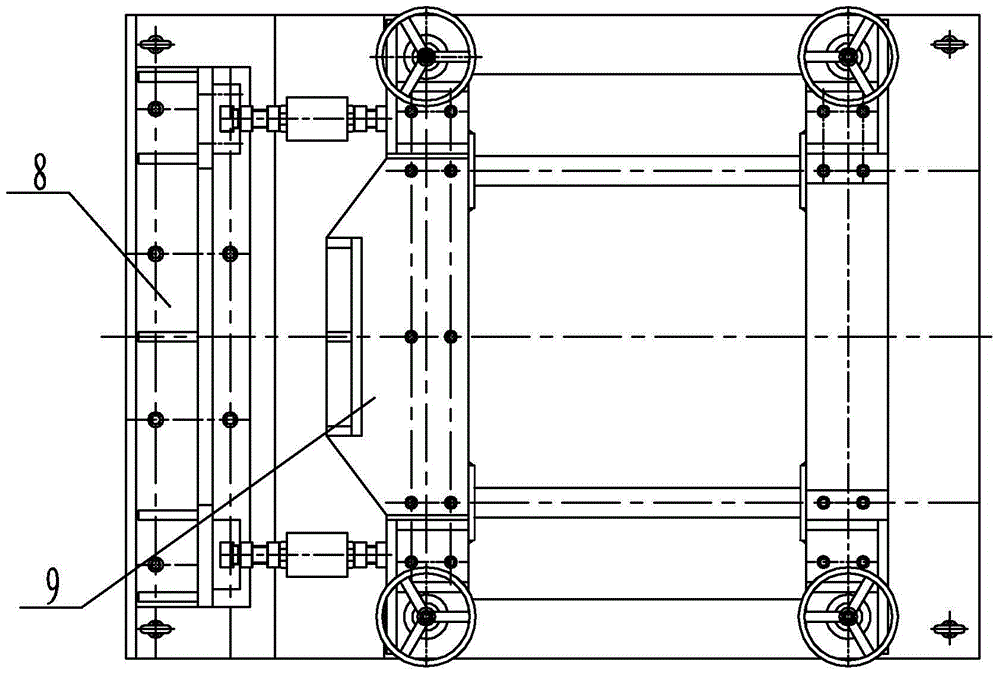

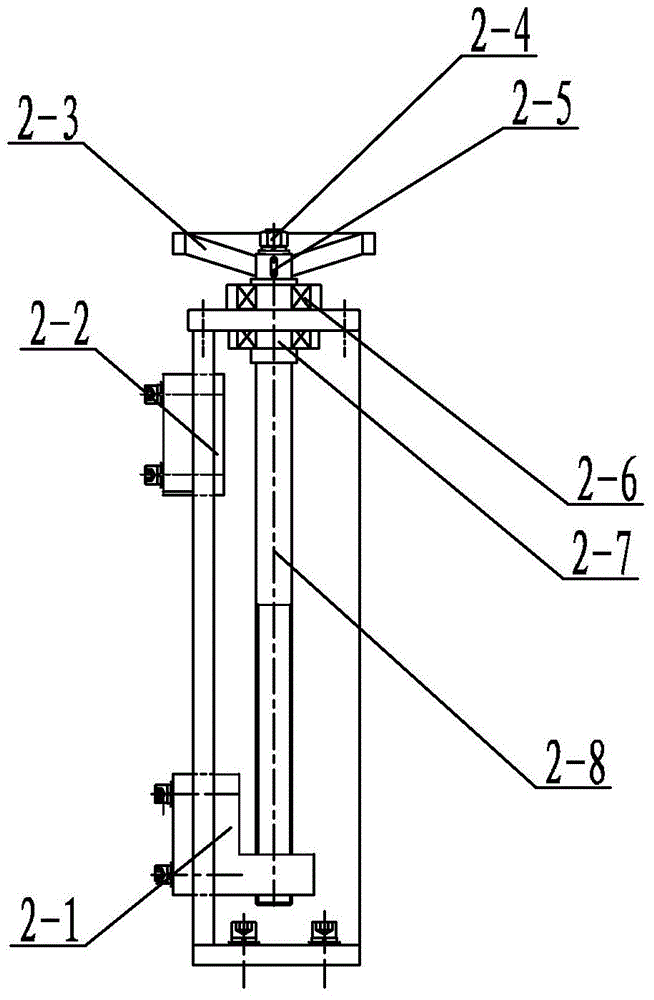

Adjustable mold heating and clamping platform for composite material pultrusion machine

The invention discloses an adjustable mold heating and clamping platform for a composite material pultrusion machine, relates to an adjustable mold heating and clamping platform, and aims to solve the problems that quality and performance of a product are directly influenced due to the fact that the straightness of the mold center and a traction center cannot be adjusted with a conventional pultrusion machine mold fixing and heating manner. A tension detecting and unloading support is fixedly mounted on the left side of the upper end of a mold heating and clamping platform, a sinking platform is arranged on the mold heating and clamping platform, a support sliding table is mounted on the sinking platform of the mold heating and clamping platform, two adjustable mold clamping devices are glidingly arranged on the support sliding table, a protecting cover is mounted in the middle of the support sliding table, a mold positioning bracket is mounted on one adjustable mold clamping device close to one side of the tension detecting and unloading support, a pultrusion mold is mounted between the two adjustable mold clamping devices and is positioned by the mold positioning bracket, and a heating plate is mounted on the pultrusion mold. The adjustable mold heating and clamping platform applies to composite material pultrusion.

Owner:HARBIN COMPOSITE EQUIP

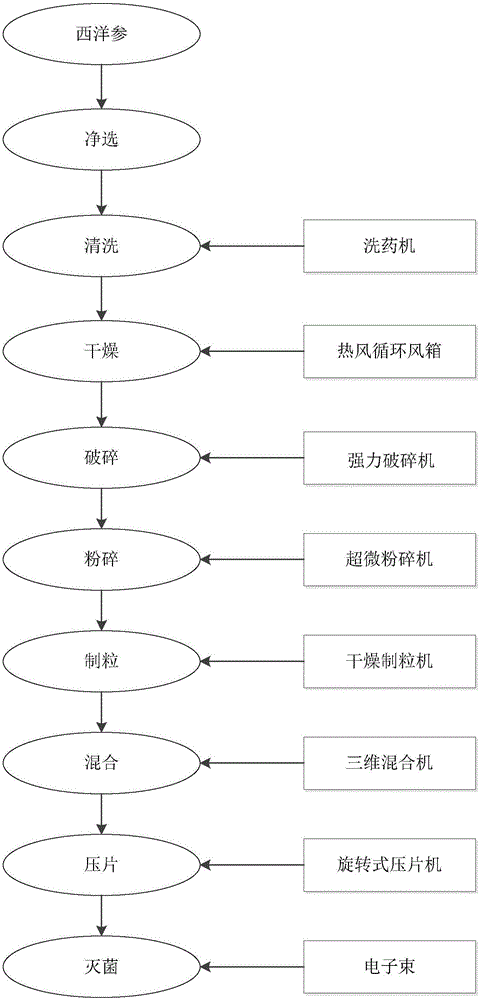

Preparation method of panax quinquefolius raw powder tablets

InactiveCN105902587ADisintegrates quicklySpeed up entryNervous disorderPill deliveryBioavailabilityProcessing cost

The invention discloses a preparation method of panax quinquefolius raw powder tablets, and belongs to the technical field of health care products. The method comprises nine steps: sorting, cleaning, drying, crushing, grinding, granulating, mixing, tabletting and sterilizing. The panax quinquefolius raw powder tablets do not contain any auxiliary materials; the bioavailability of product is increased; the product is more convenient to use, with longer guarantee period, lower processing cost, good dispersibility, miscibility and absorbability, thus the effective constituents of panax quinquefolius enter human body quickly; the original taste is reserved, and the health care function is increased; moreover, the dosage can be exponentially reduced, thereby effectively increasing utilization ratio of rare resources.

Owner:HEBEI LIN YITANG MEDICAL CO LTD

Turbine blade

ActiveUS8596976B2Improve cooling effectIncrease volumePropellersRotary propellersTurbine bladeBlow out

The amount of cooling air (cooling medium) can be reduced, and low-temperature cooling air is prevented from being blown out through film cooling holes. Part of a cooling medium impingement-cooling an inner circumferential surface of a blade main body located on a ventral side further impingement-cools the inner circumferential surface of the blade main body located on a dorsal side and is blown out through film cooling holes in the blade main body that are located on the dorsal side.

Owner:MITSUBISHI POWER LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com