Adjustable mold heating and clamping platform for composite material pultrusion machine

A technology of mold heating and composite materials, which is applied in the field of adjustable mold heating and clamping platforms of composite pultrusion machines, can solve the problems affecting product quality and performance, and the straightness of mold center and traction center cannot be adjusted, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

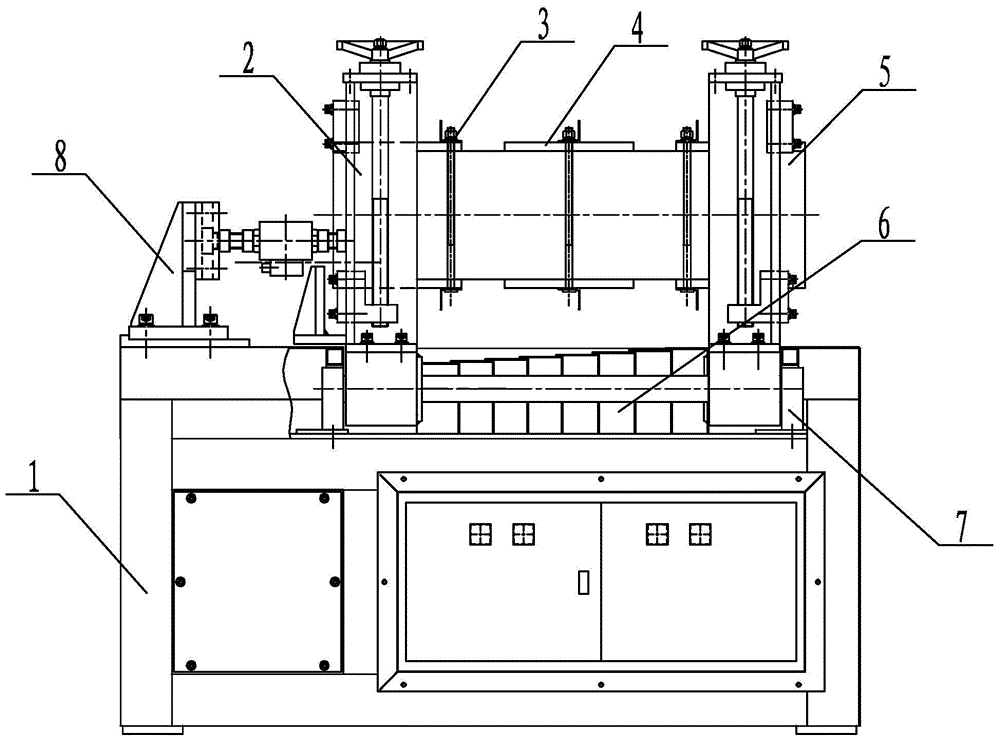

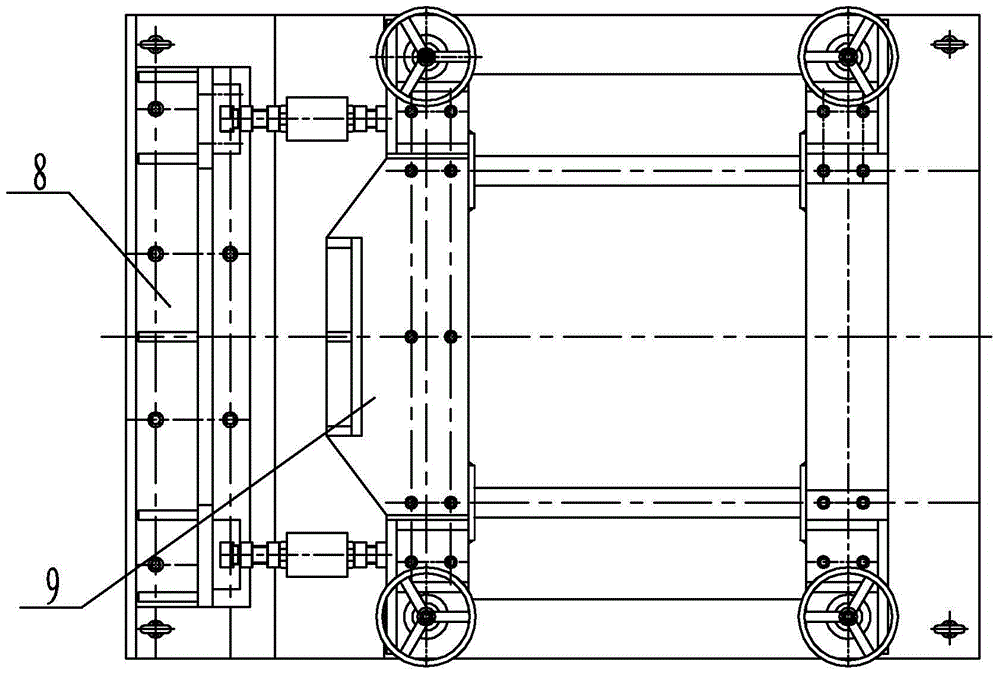

[0008] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 To illustrate this embodiment, an adjustable mold heating and clamping platform for a composite material pultrusion machine in this embodiment includes a mold heating and clamping platform 1, two adjustable mold clamping devices 2, a heating plate clamping fixture 3, and a heating plate 4. Pultrusion die 5, protective cover 6, support slide 7, tension detection and unloading support 8 and mold positioning bracket 9, tension detection and unloading support 8 is fixedly installed on the upper left side of the mold heating and clamping platform 1, and the mold is heated A sinking platform is provided on the clamping platform 1, and the supporting slide 7 is installed on the sinking platform of the mold heating clamping platform 1. Two adjustable mold clamping devices 2 are slidably arranged on the supporting slide 7, an...

specific Embodiment approach 2

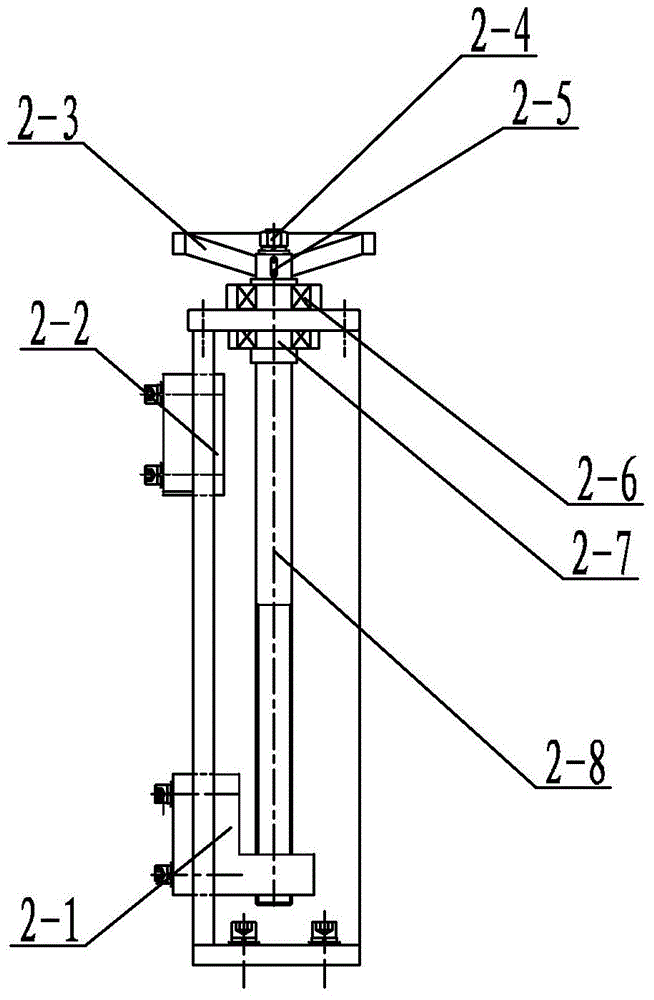

[0009] Specific implementation mode two: combination image 3 with Figure 4 To illustrate this embodiment, each of the two adjustable mold clamping devices 2 of this embodiment includes two lower clamping blocks 2-1, two upper clamping blocks 2-2, two A lifting hand wheel 2-3, two axial lock nuts 2-4, two flat keys 2-5, four bearings 2-6, two bearing seats 2-7, two lifting screw 2-8 , two clamping brackets 2-9, upper clamping plate 2-10 and lower clamping plate 2-11, each lifting screw 2-8 is installed on a bearing seat 2-7 through two bearings 2-6, and a lifting hand The wheel 2-3 is installed on the top of a lifting screw 2-8 through a flat key 2-5 and is axially fixed through an axial lock nut 2-4, and each bearing seat 2-7 is installed on a clamping On the bracket 2-9, each upper clamping block 2-2 is fixed on the upper part of a clamping bracket 2-9, and the upper parts of the two clamping brackets 2-9 are connected by an upper splint 2-10, and each lower clamping bloc...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 5 Describe this embodiment, the heating plate clamping fixture 3 of this embodiment comprises clamping angle steel 3-1 below, two screw rods 3-2, six locking nuts 3-3 and upper clamping angle steel 3-4, and clamping angle steel 3-4 of lower clamping The tight angle steel 3-1 is fixed on the bottom of two screw rods 3-2 by four lock nuts 3-3, and the upper clamp angle steel 3-4 is fixed on the heating plate 4 when in use and is fixed by two lock nuts 3-2. 3 is fixed on the screw rod 3-2. In this way, according to the heating power and heating area required by the pultrusion process, the heating plate 4 is placed at the corresponding position of the pultrusion die 5, and the upper clamping angle steel 3-4 and the lower clamping angle steel 3-1 are used to clamp respectively The heating plate 4 on the upper and lower surfaces of the pultrusion die 5 is locked with lock nuts 3-3, so that the heating plate 4 is closely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com