Patents

Literature

88results about How to "Increase engine power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

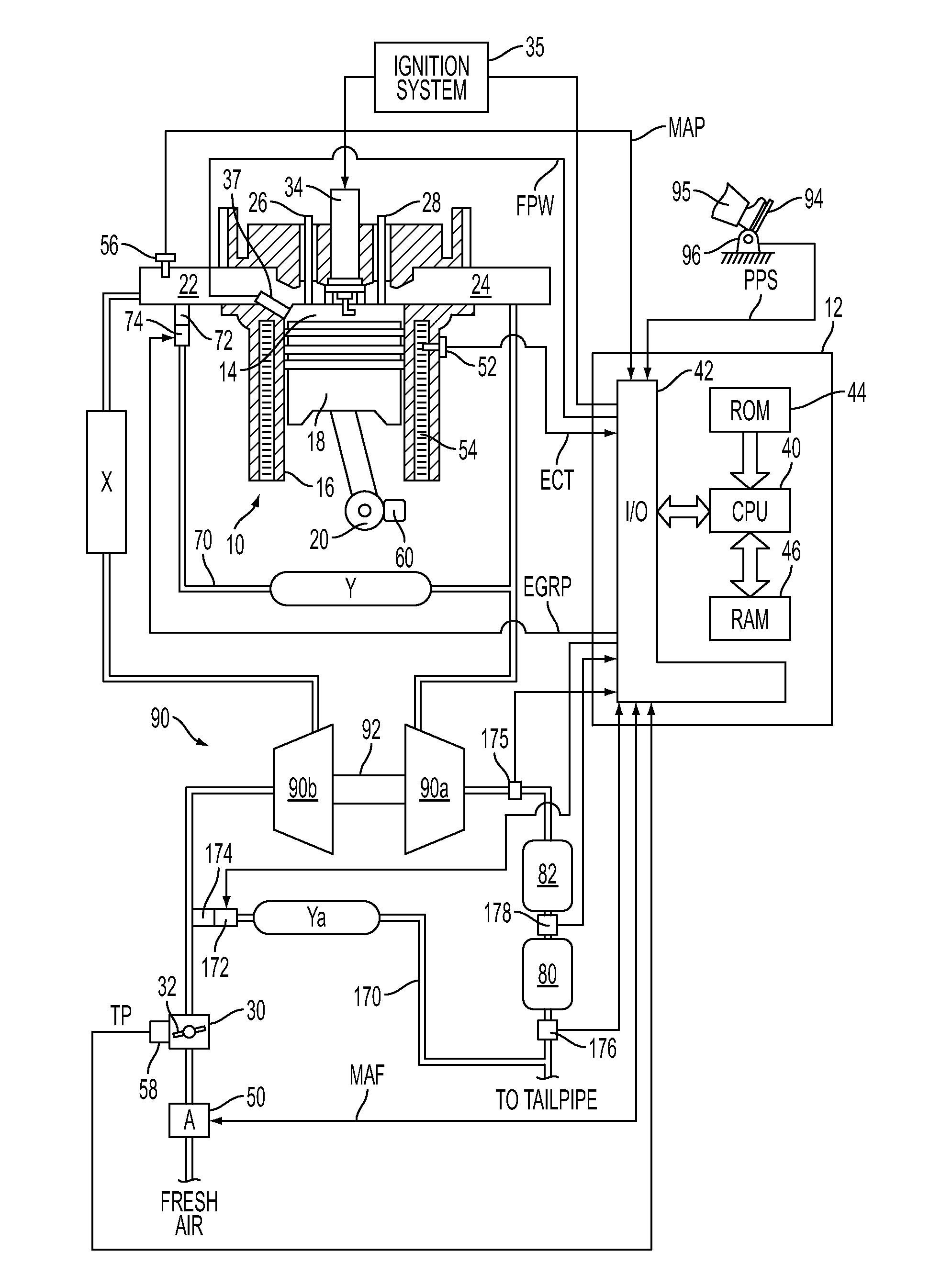

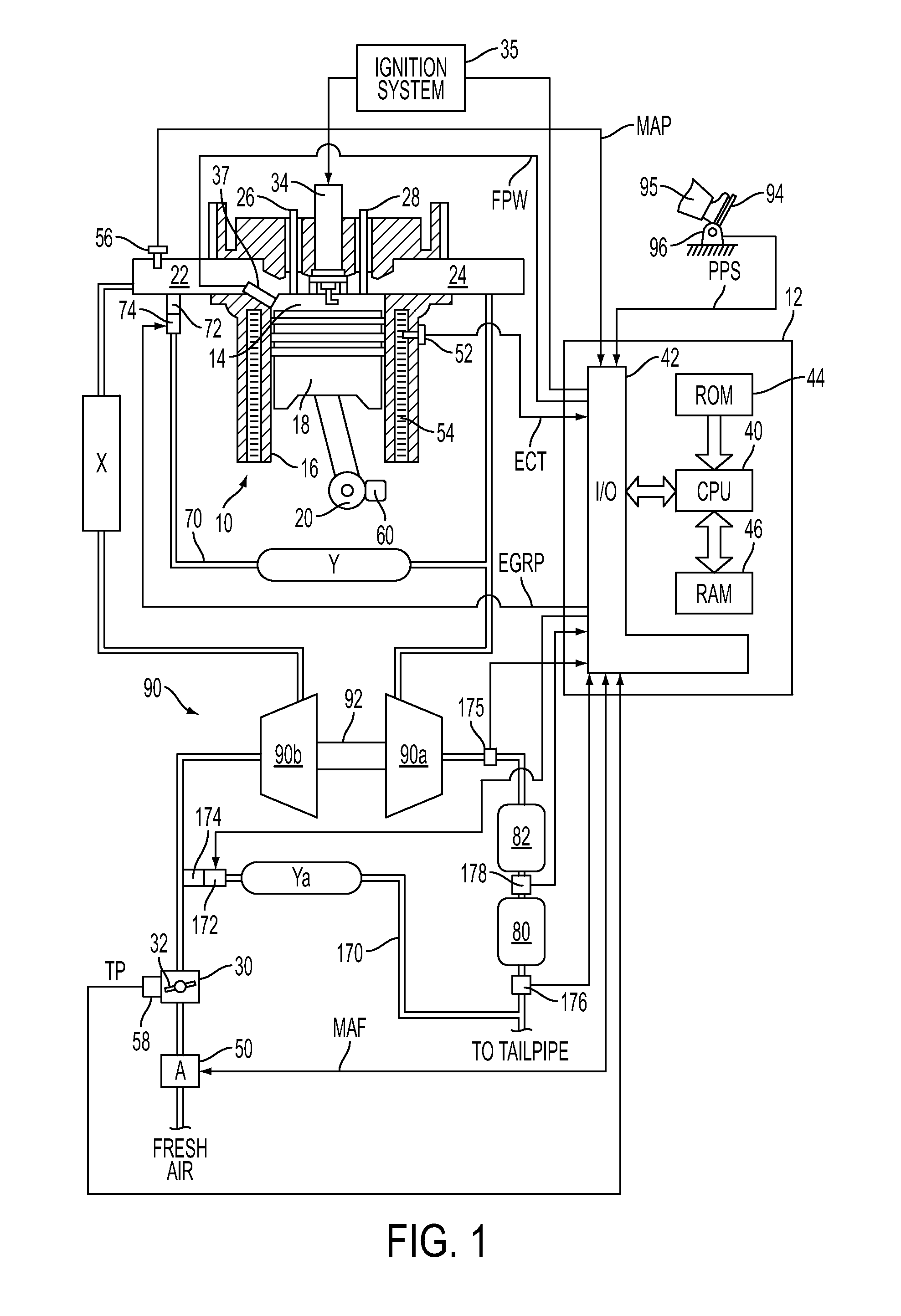

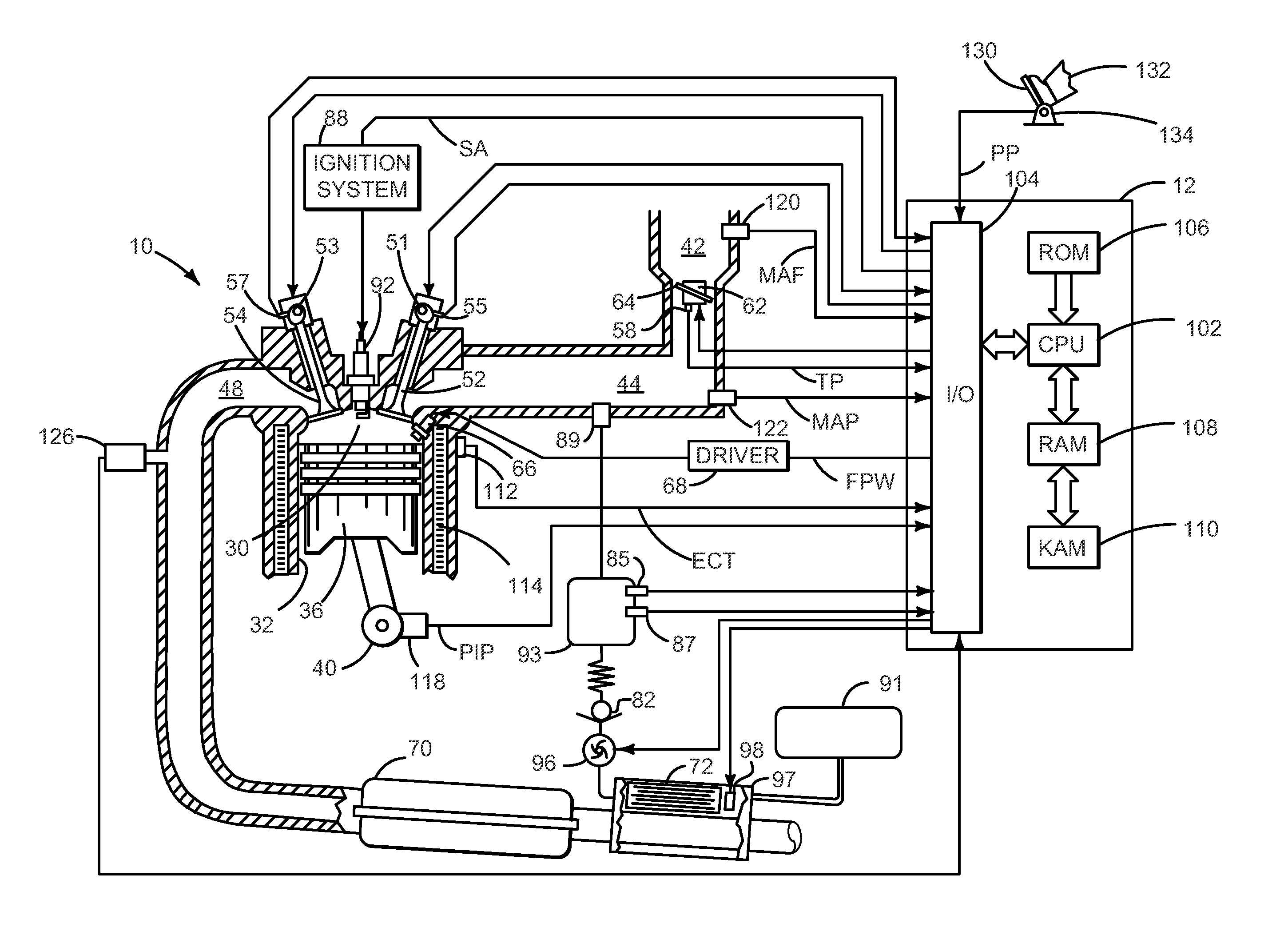

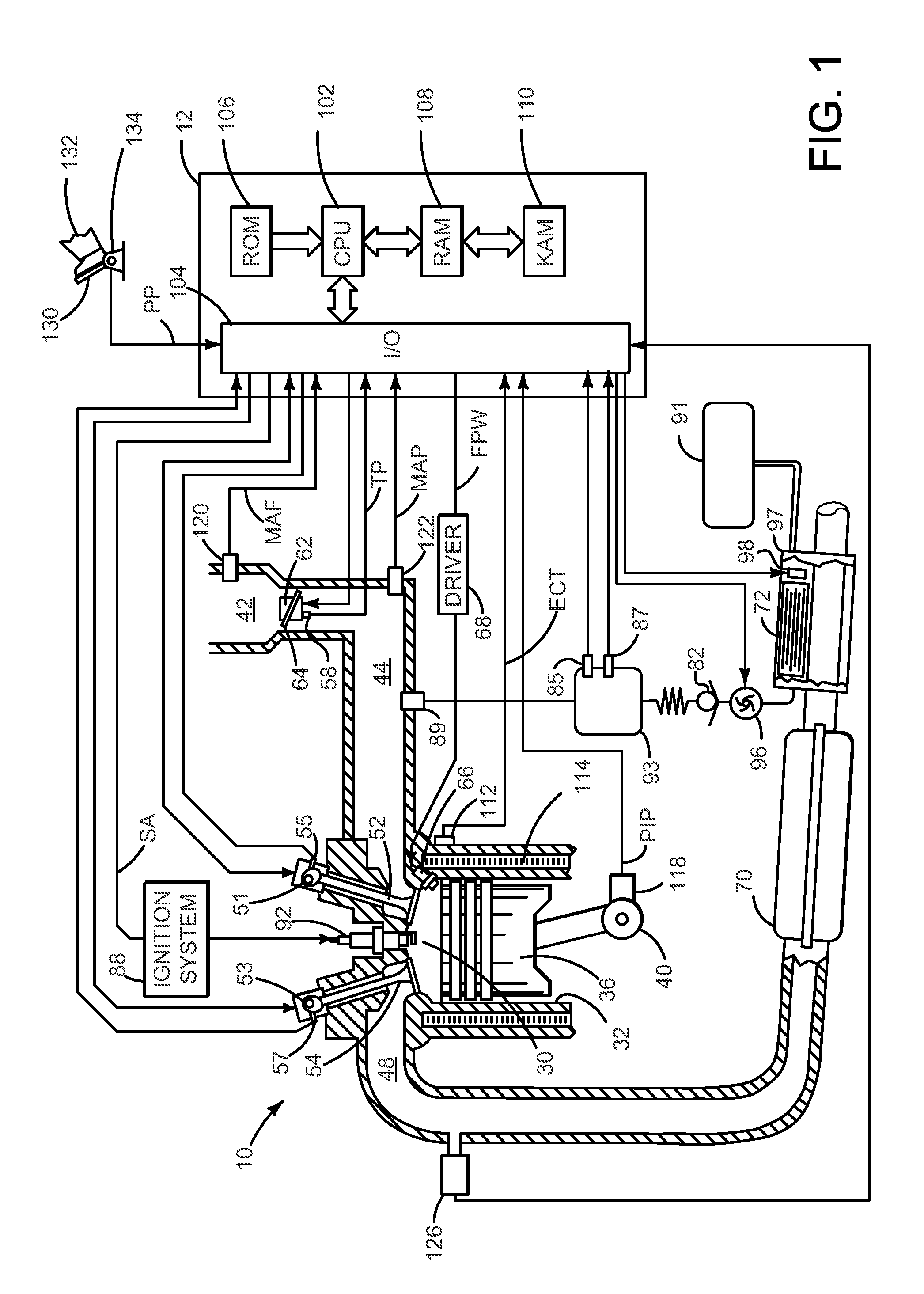

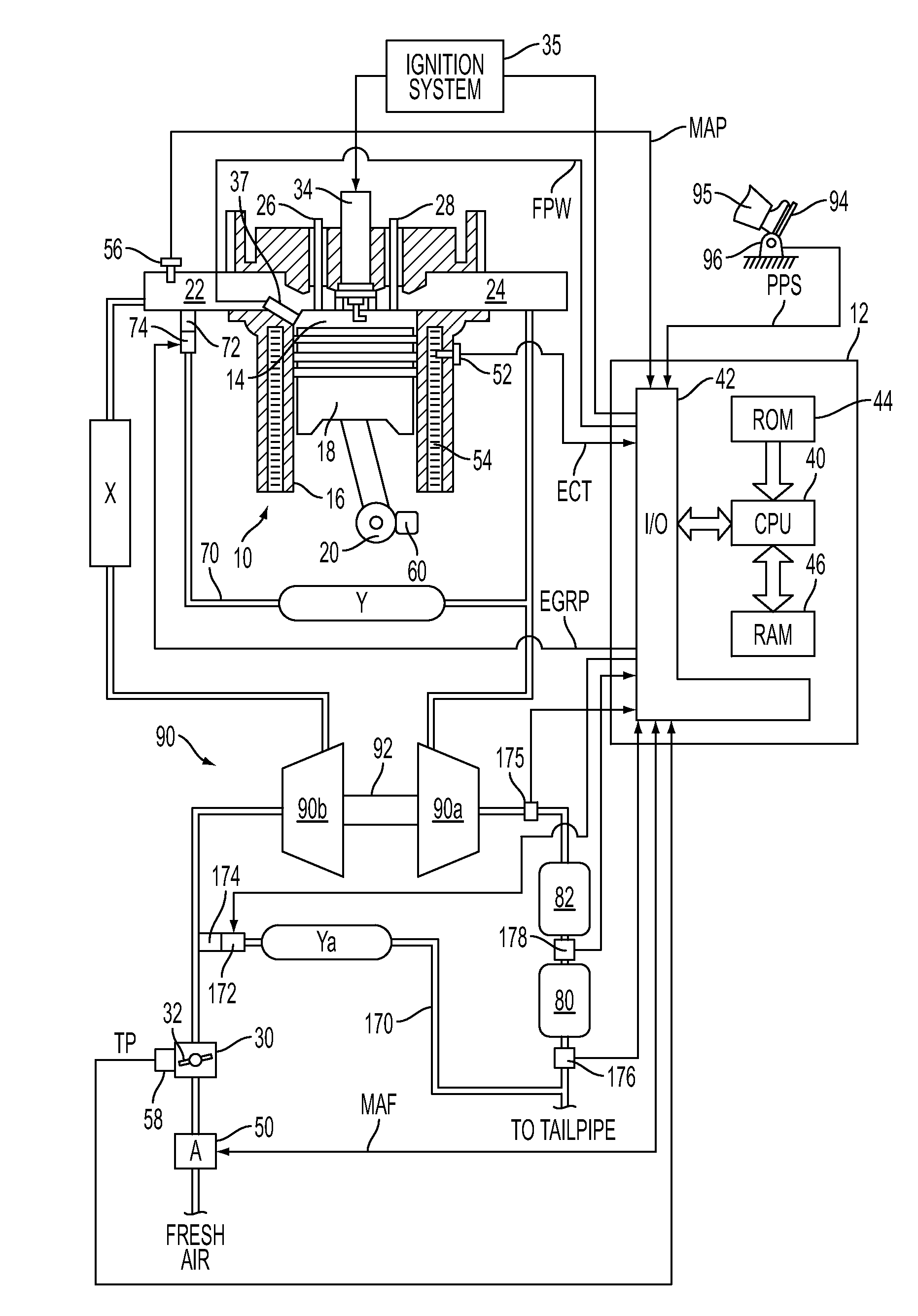

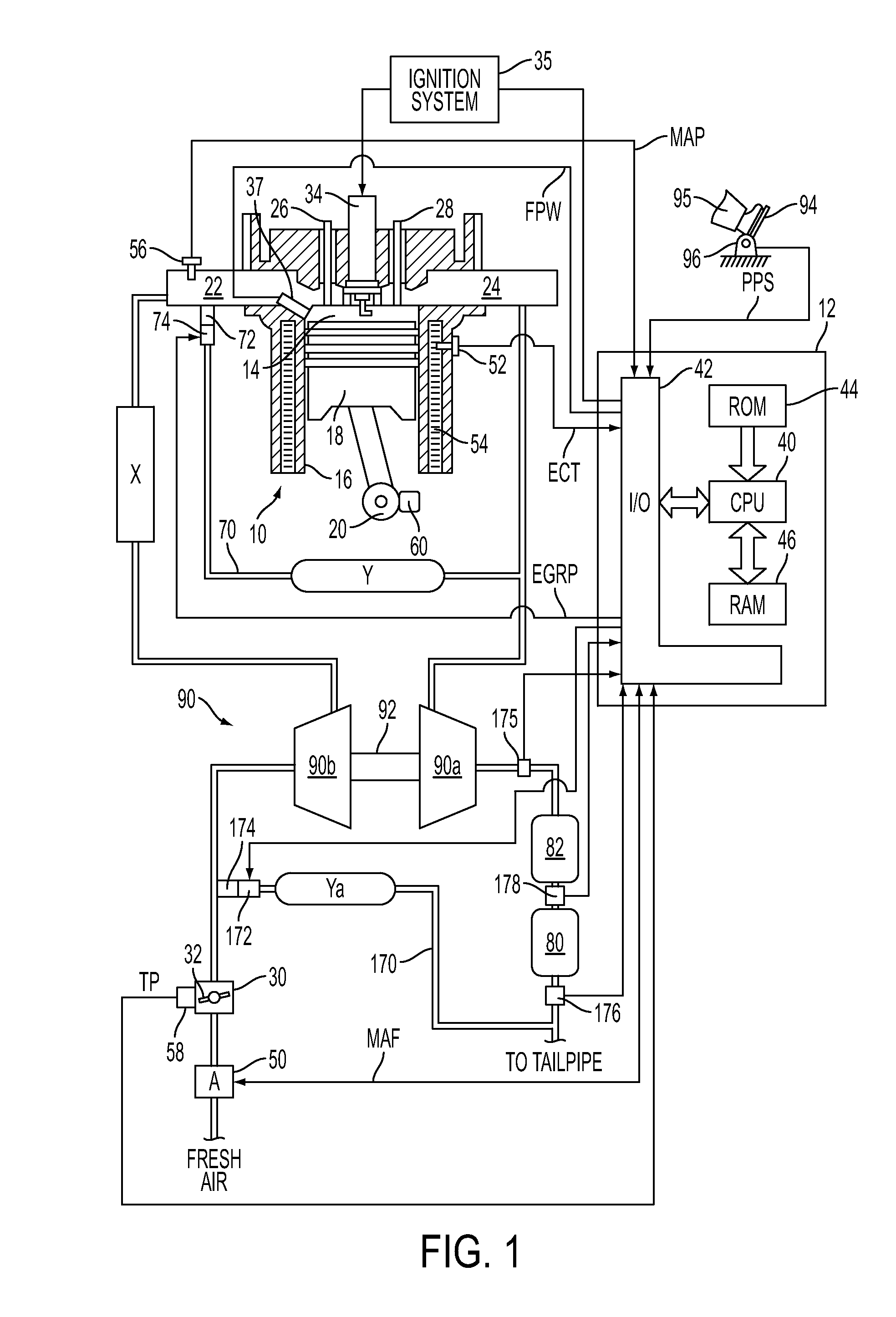

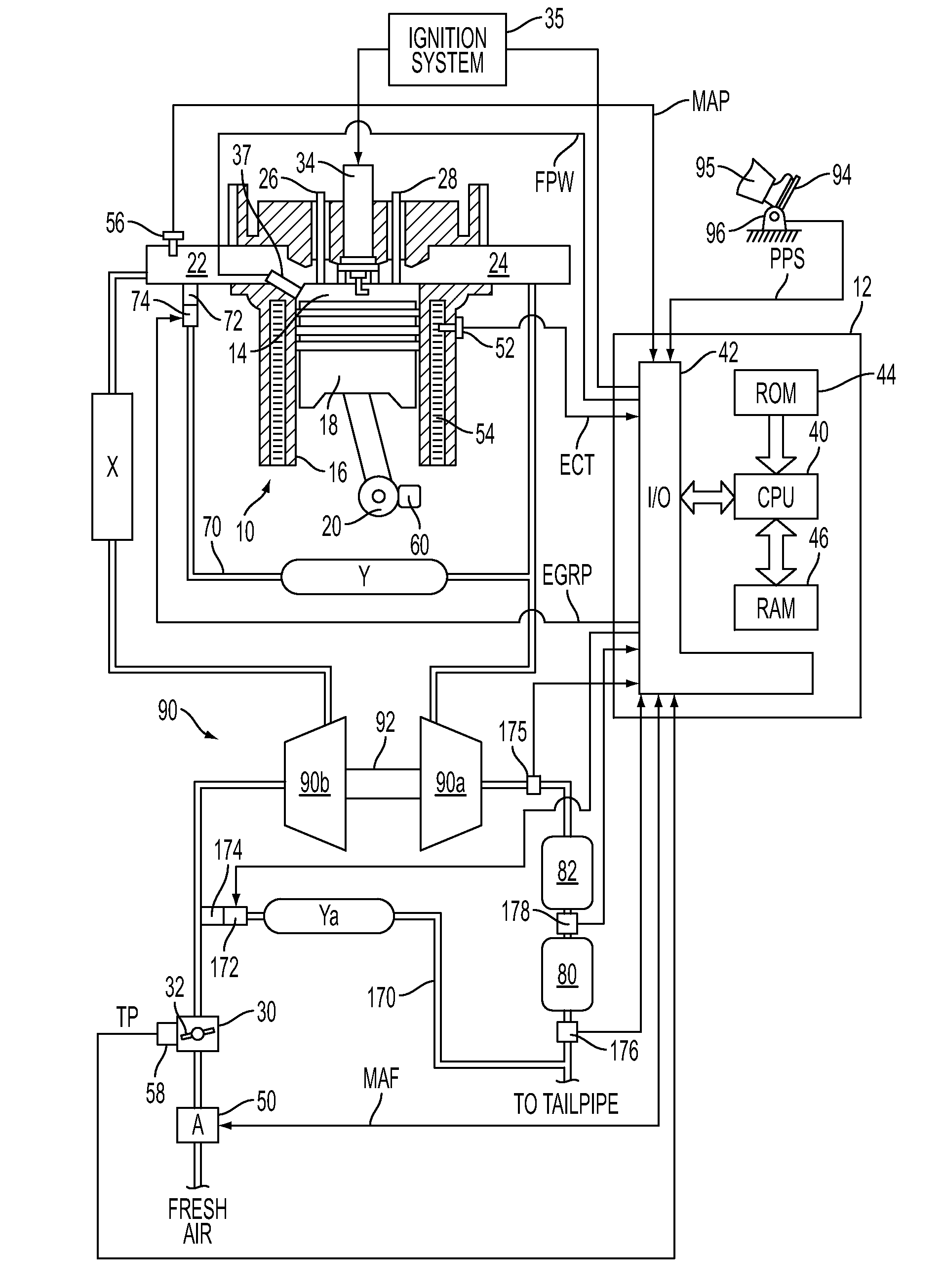

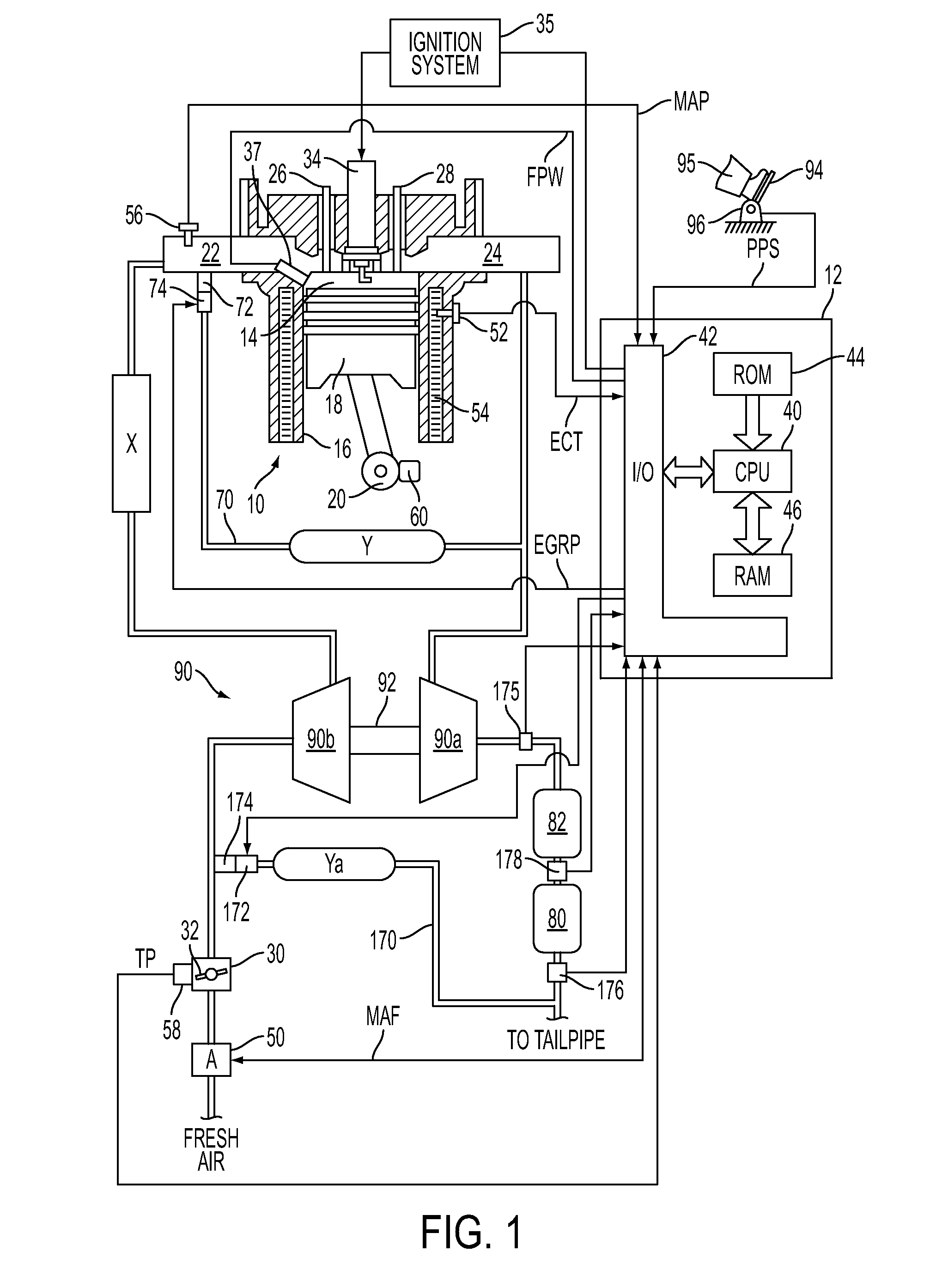

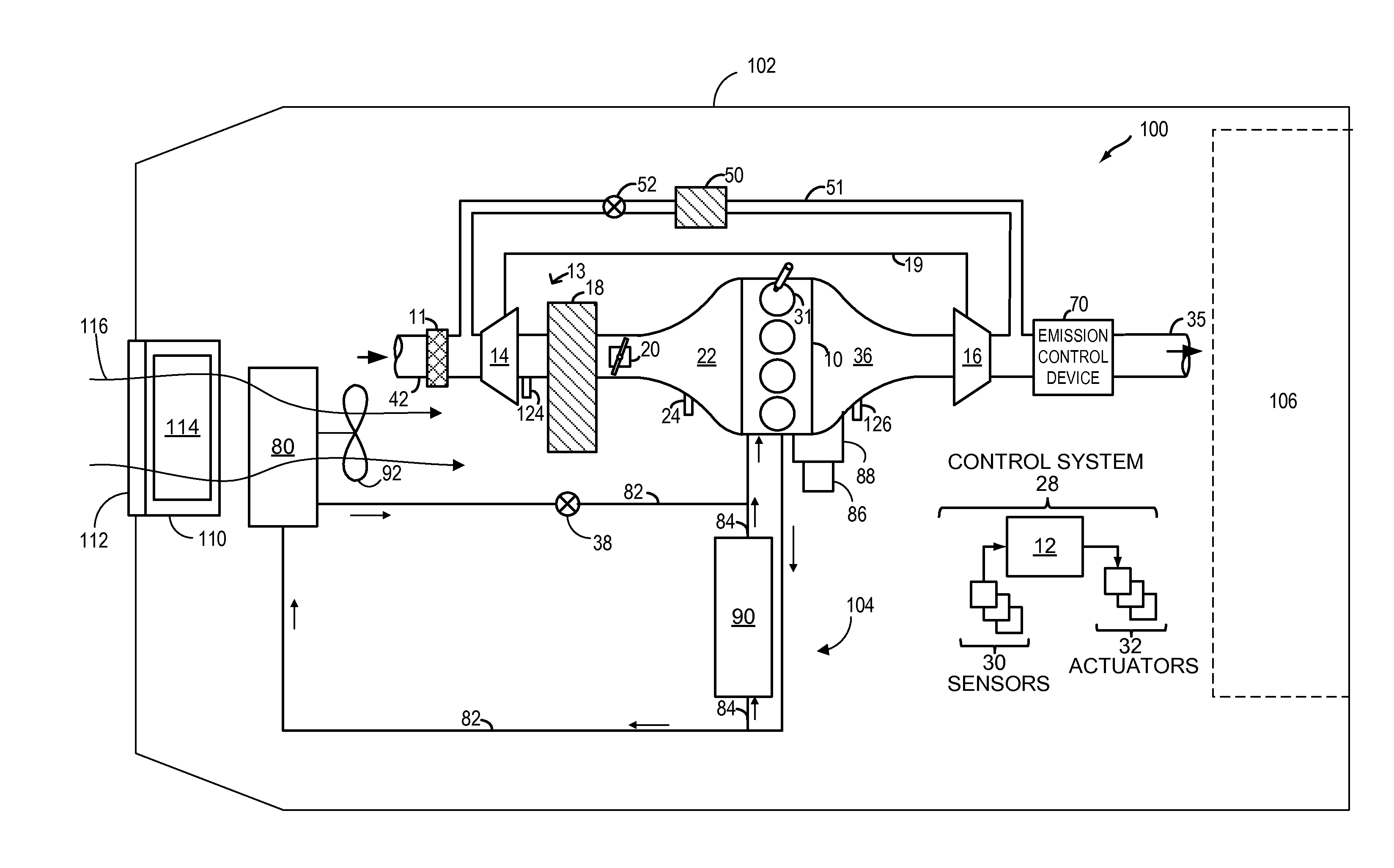

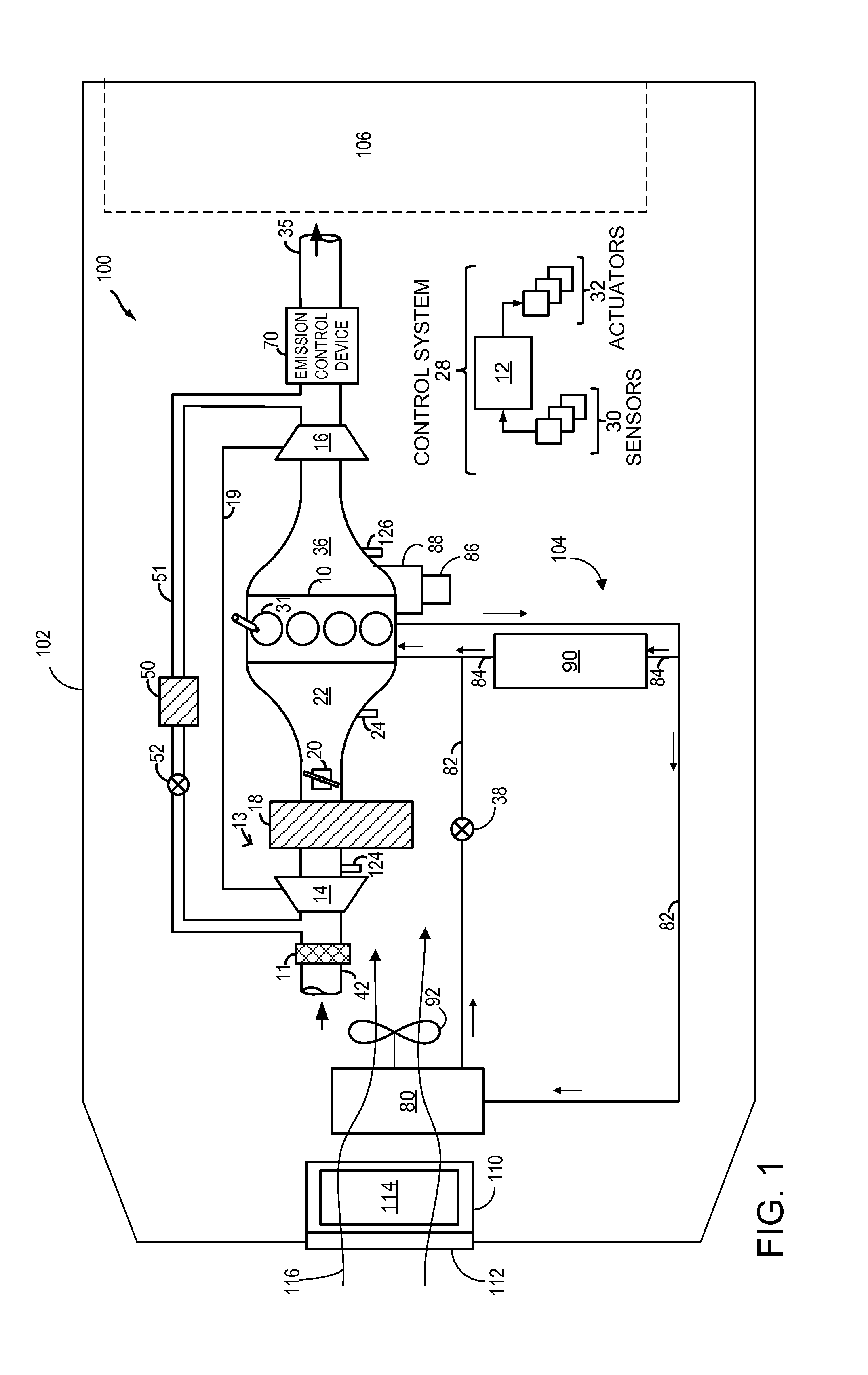

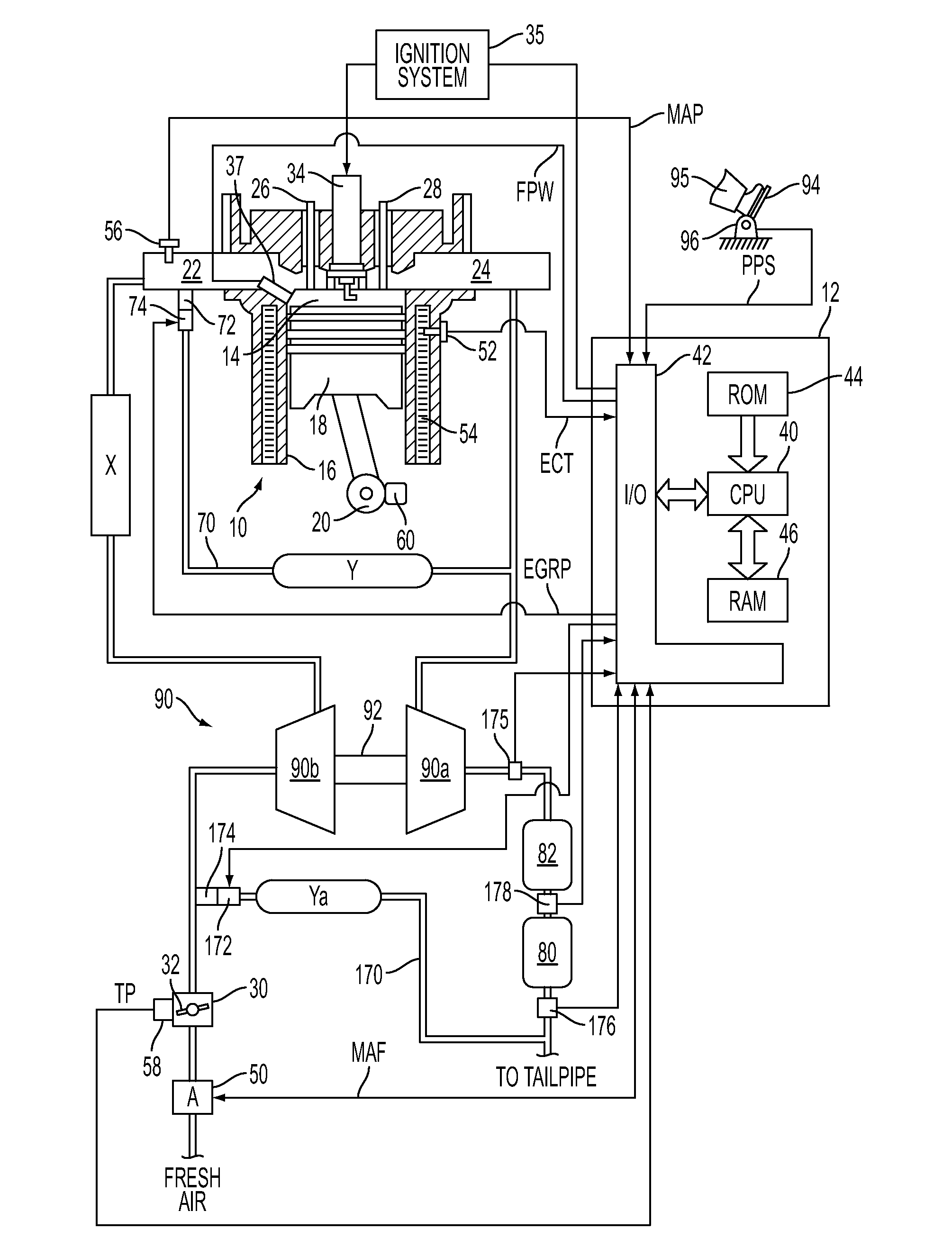

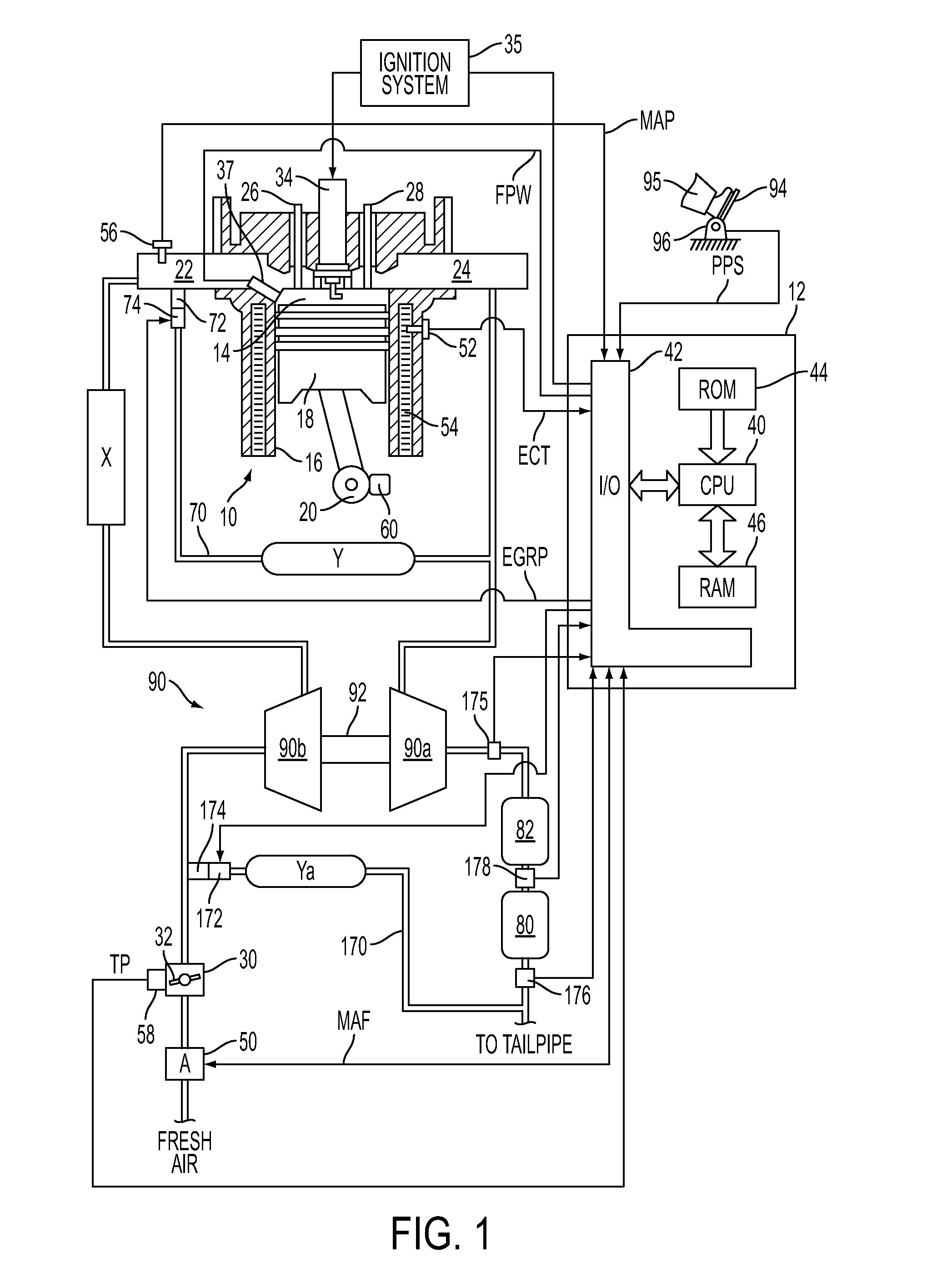

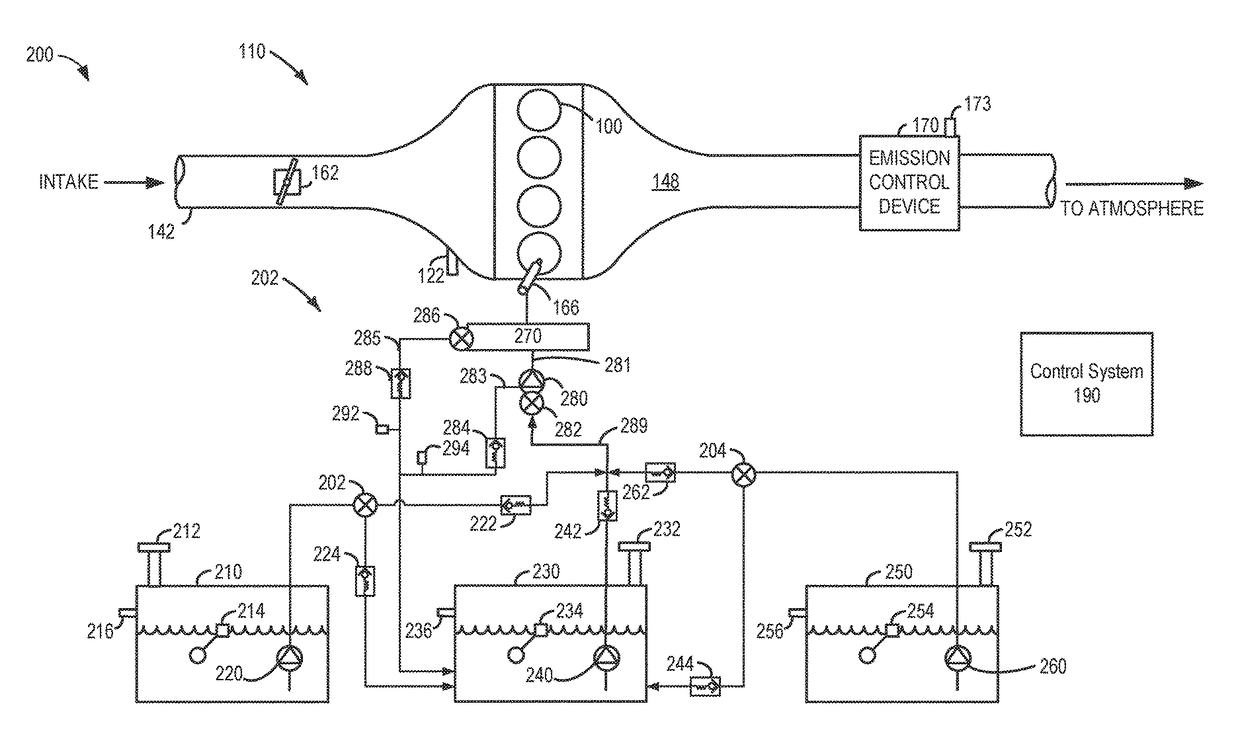

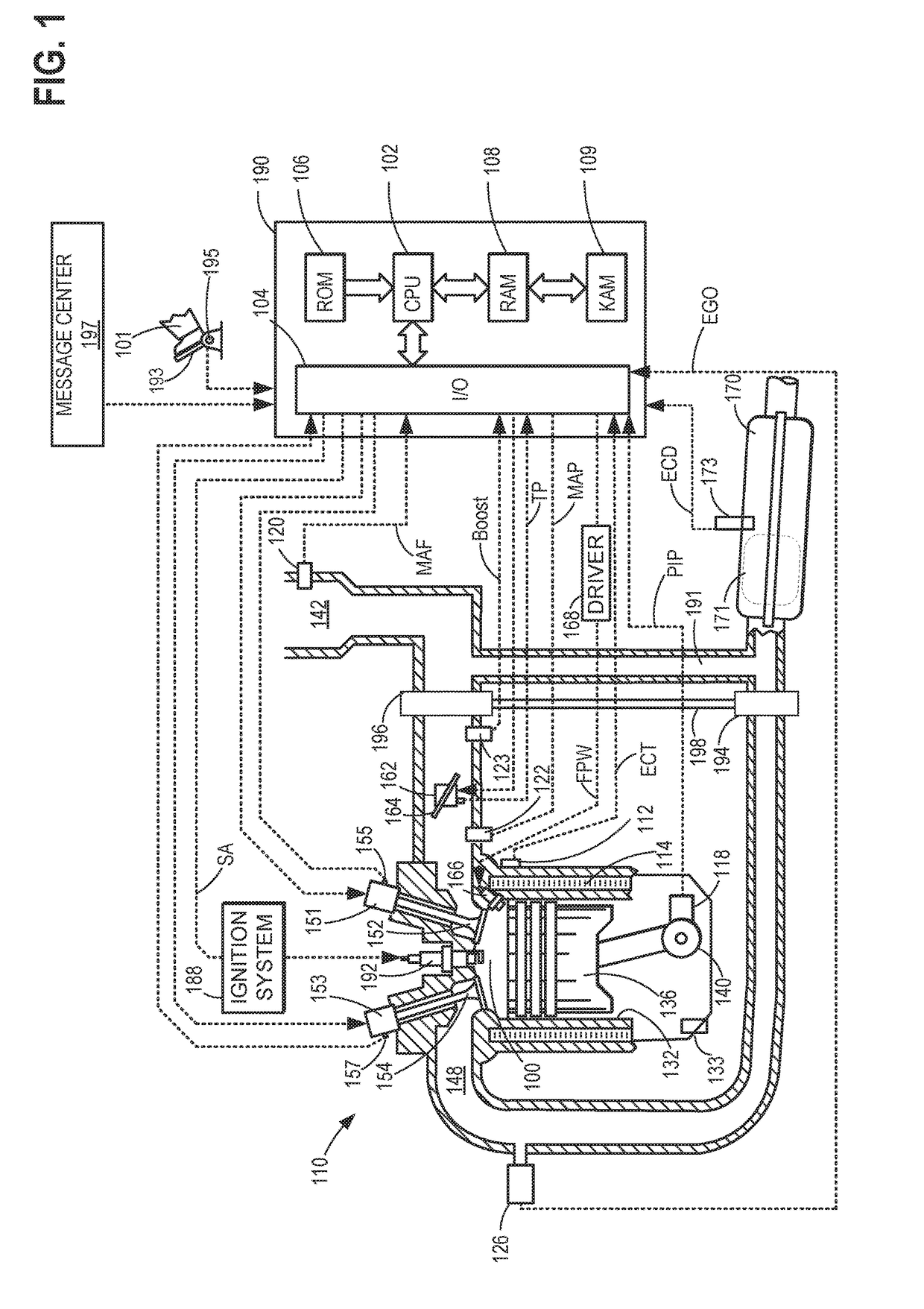

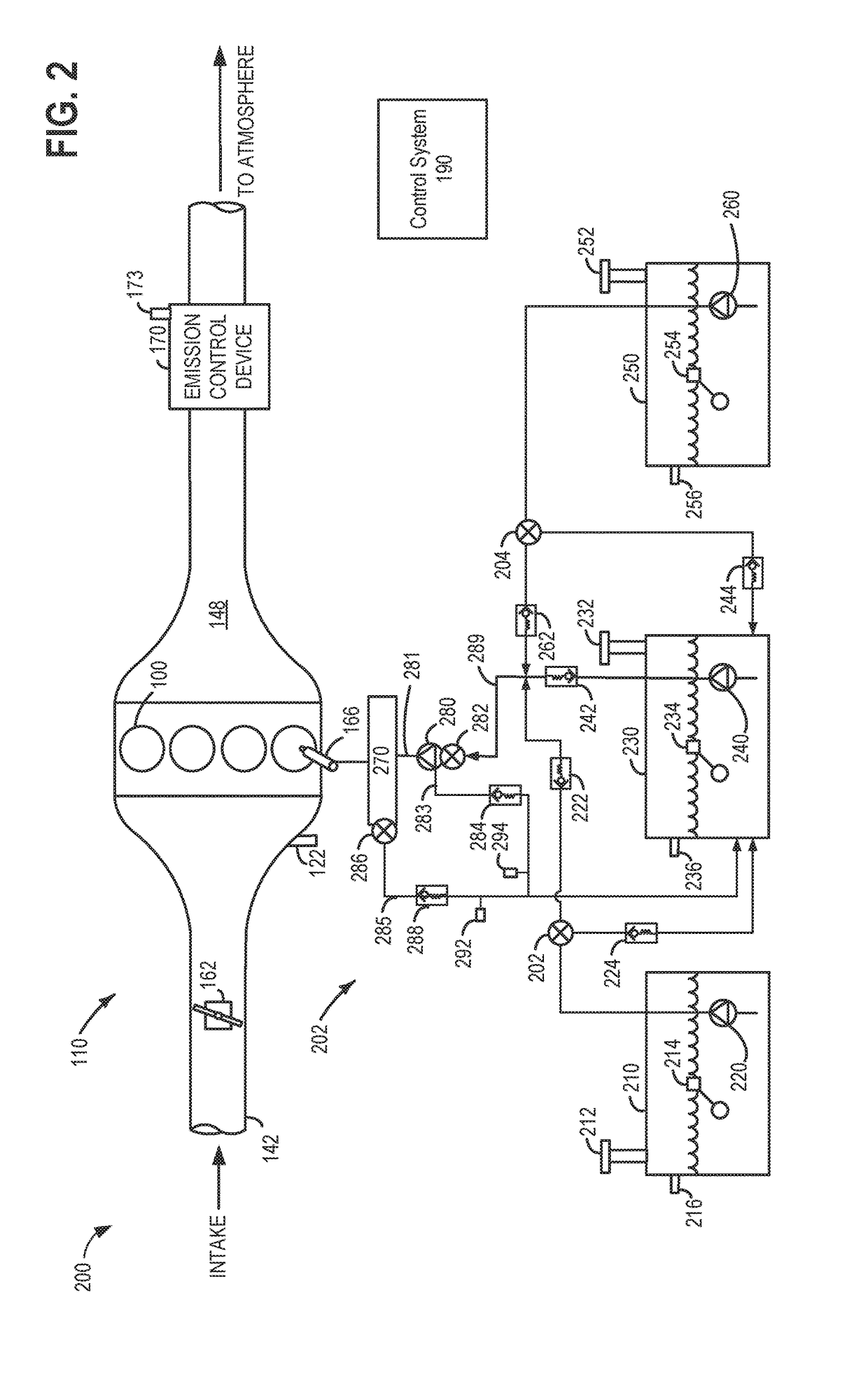

Fuel control for spark ignited engine having a particulate filter system

ActiveUS20110072787A1Improve efficiencyLess tendencyElectrical controlNon-fuel substance addition to fuelGasoline direct injectionFilter system

A system for filtering and oxidizing particulate matter produced by a gasoline direct injection engine is disclosed. In one embodiment, engine cylinder air-fuel is adjusted to allow soot to oxidize at an upstream particulate filter while exhaust gases are efficiently processed in a downstream catalyst.

Owner:FORD GLOBAL TECH LLC

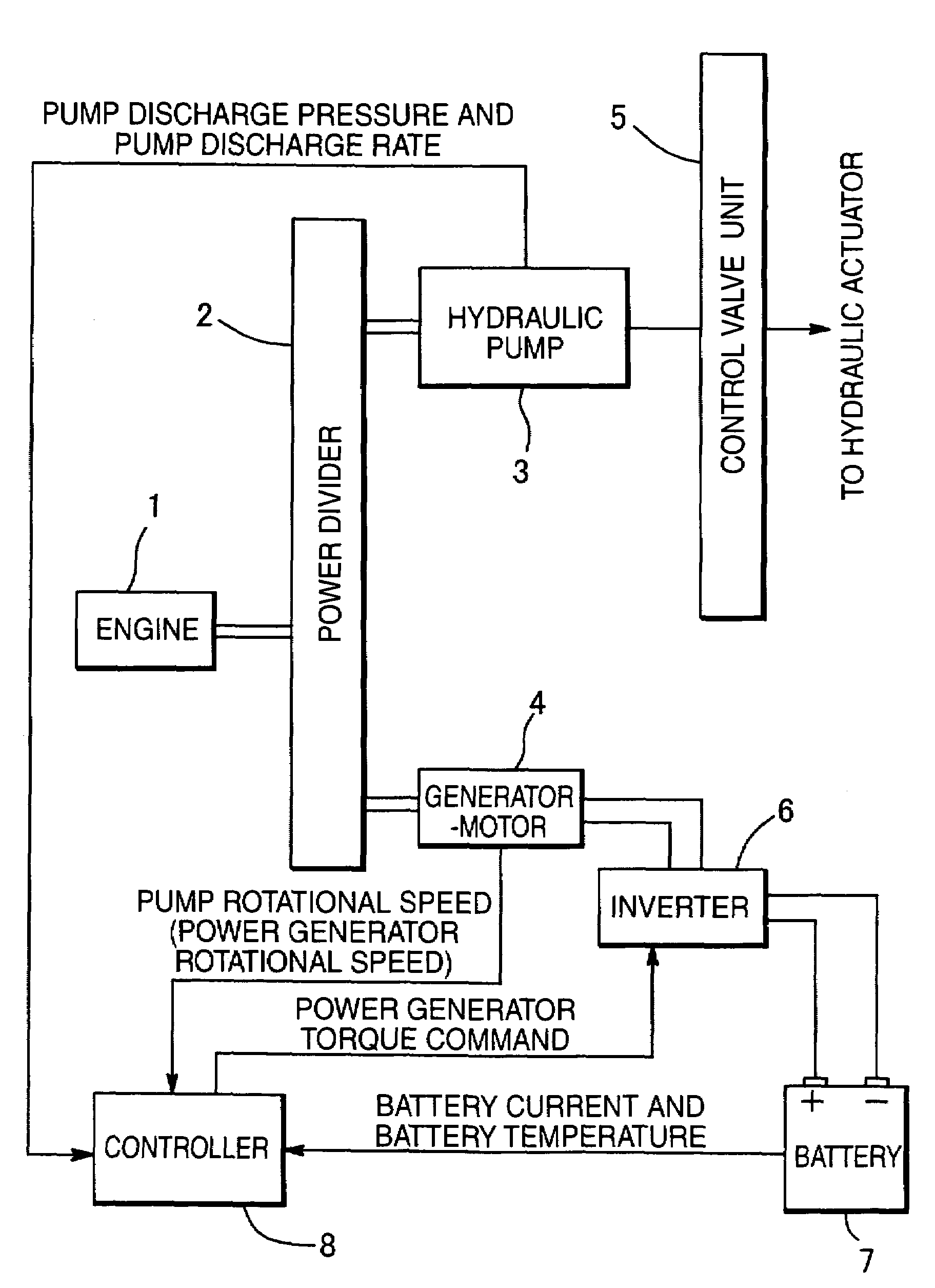

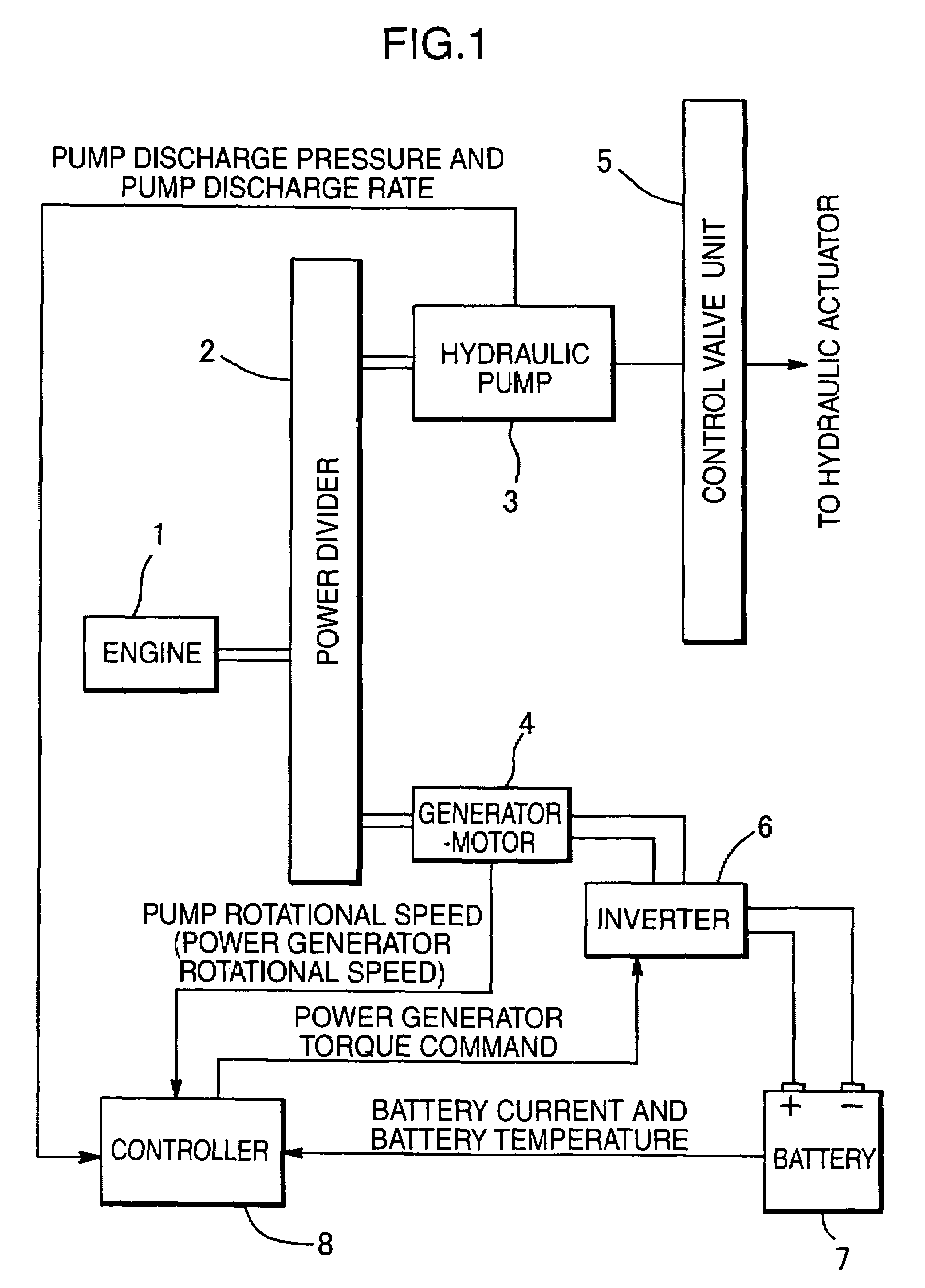

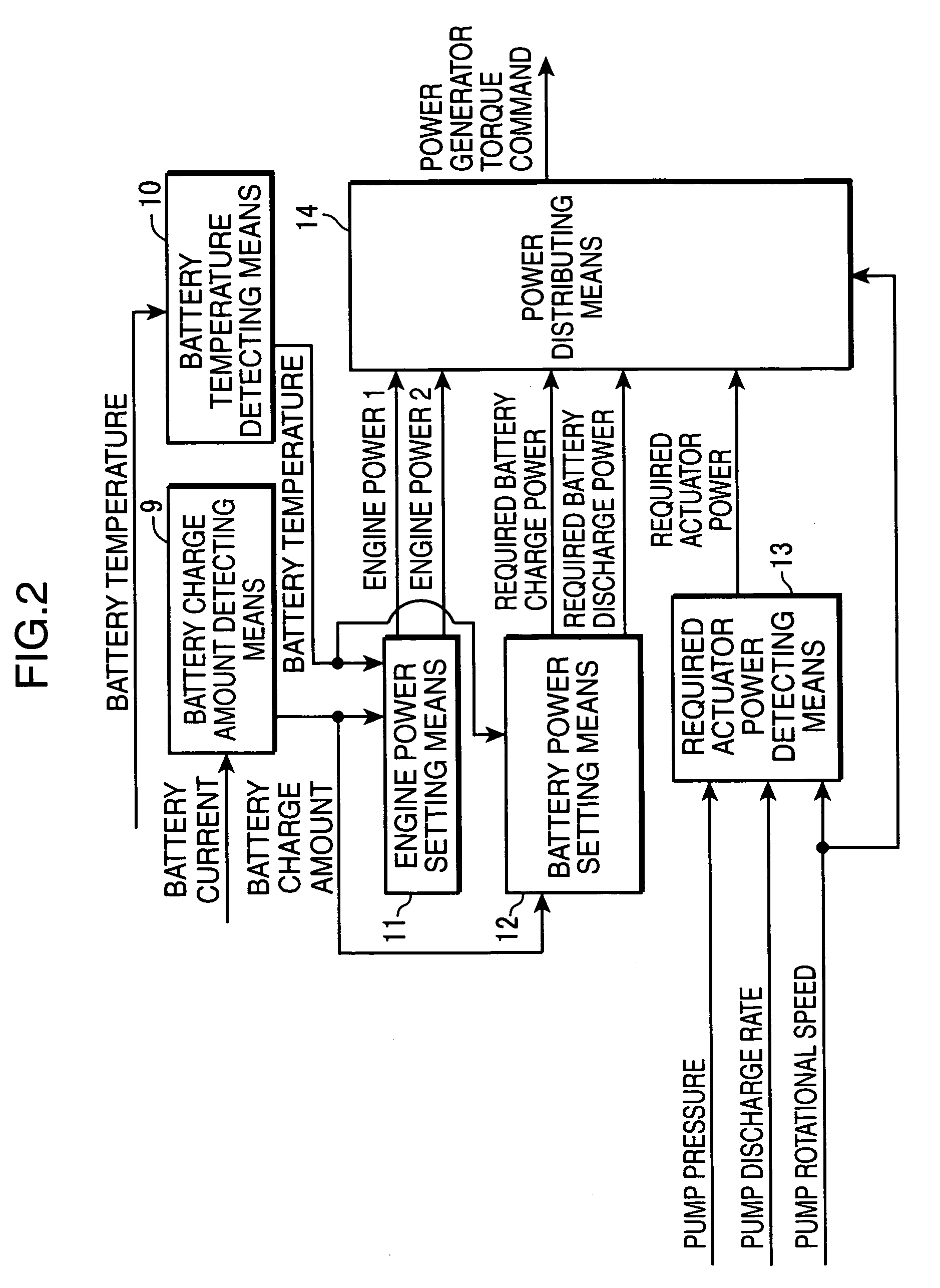

Power source device for working machine

ActiveUS7525206B2More powerPrevent degradationSafety beltsCircuit arrangementsBattery chargeElectrical battery

Power distribution of an engine and an electric power storage device is determined according to a charge amount of the power storage device, and the charge amount of the power storage device is maintained in an adequate range. A power source device for working machines includes a hydraulic pump, a generator-motor, an engine, serving as a common power source, to which the hydraulic pump and the generator-motor are connected parallel, and a battery, serving as an electric power storage device, for storing a power thereof by the generator function of the generator-motor. The generator-motor is driven by a discharge power of the battery to perform the motor function. Using a controller, the power distribution of the engine and the generator-motor is determined based on the required actuator power, the charge power and the discharge power of the battery which are set according to the battery charge amount in such a way that the battery charge amount is maintained in a predetermined range, and on the preset engine power.

Owner:KOBELCO CONSTR MASCH CO LTD +1

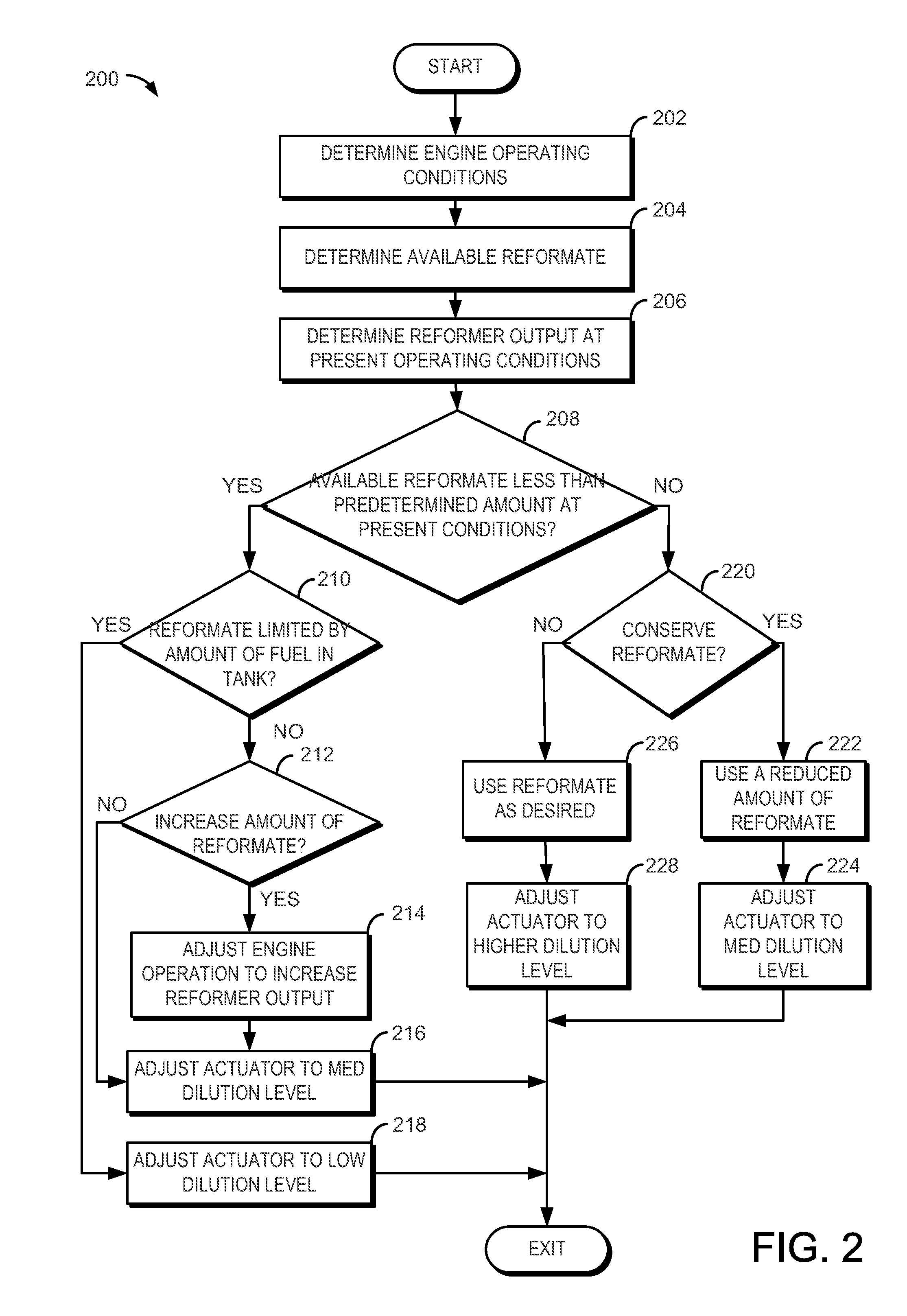

Method for operating an engine

InactiveUS8037850B2Reduce fossil fuel consumptionIncrease engine powerInternal combustion piston enginesElectric ignition installationPresent methodAlcohol

A method for operating an engine with a fuel reformer is presented. In one embodiment a first fuel is reformed into a gaseous fuel comprising H, CO, and CH4, or the fuel may change state to vaporized alcohol. The present method provides for ramping injection of the gaseous fuel so that stoichiometric combustion may be maintained while gaseous fuel is injected to the engine.

Owner:FORD GLOBAL TECH LLC

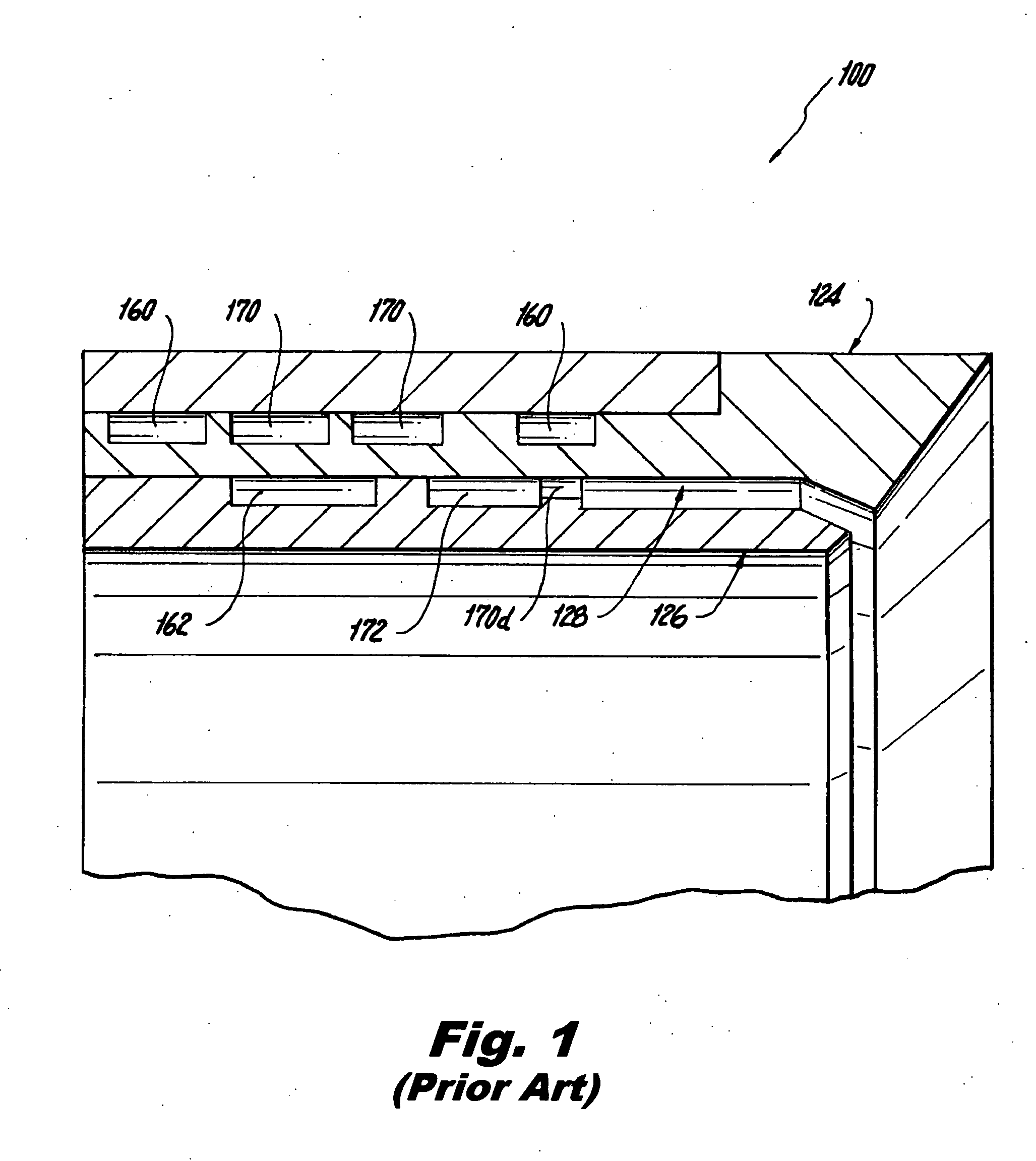

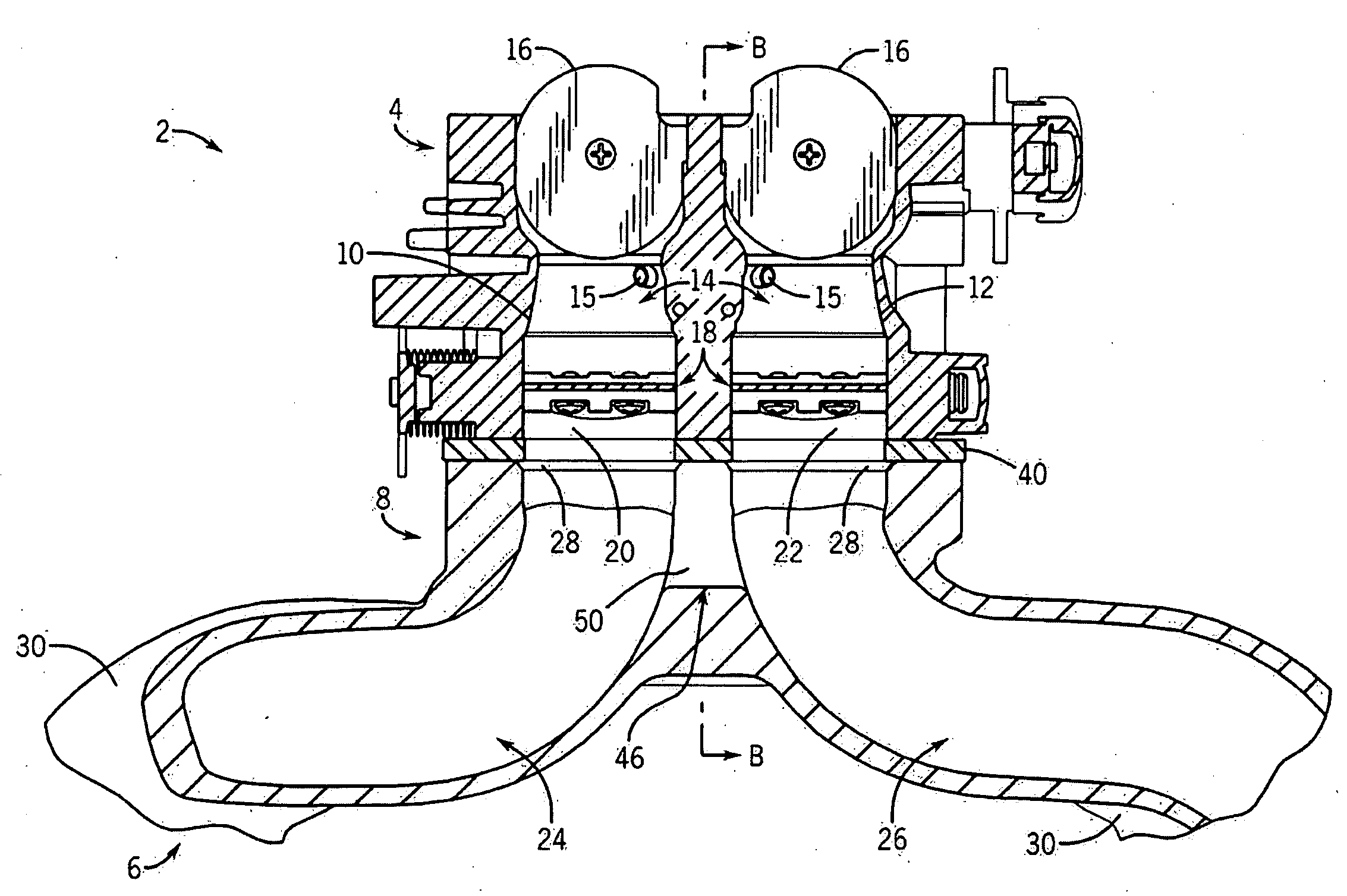

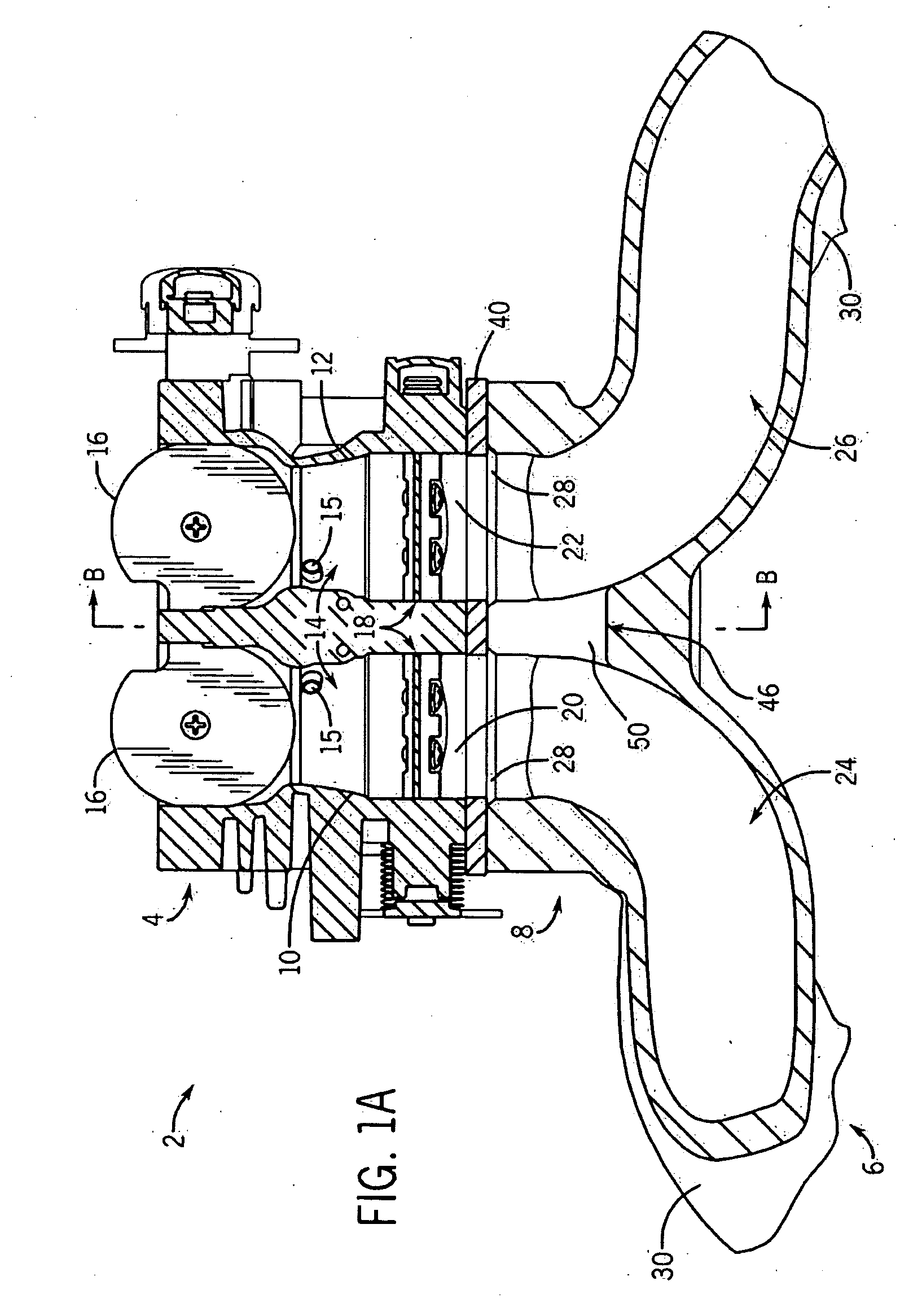

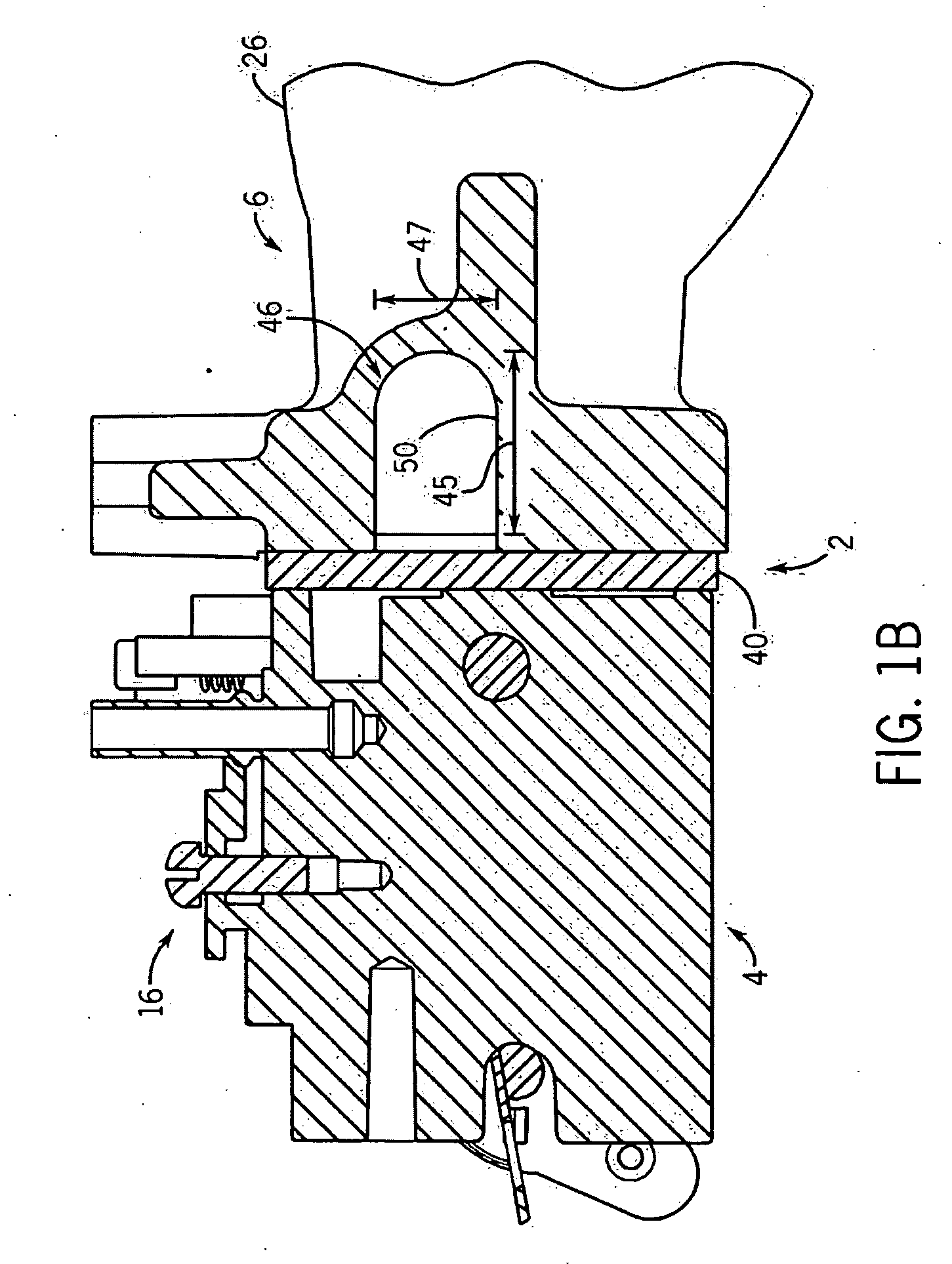

Systems and method for cooling a staged airblast fuel injector

ActiveUS20120228397A1High engine powerAvoid scorchingBurnersContinuous combustion chamberInjectorEngine power

The present invention is directed to a staged fuel injector that includes, inter alia, a main fuel circuit for delivering fuel to a main fuel atomizer and a pilot fuel circuit for delivering fuel to a pilot fuel atomizer which is located radially inward of the main fuel atomizer. The main fuel atomizer includes a radially outer prefilmer and a radially inner fuel swirler. Portions of the main fuel circuit are formed in the prefilmer and portions of the pilot fuel circuit are formed in the prefilmer and the fuel swirler and are positioned proximate to and in thermal contact with fuel exit ports associated with the main fuel circuit and formed in the prefilmer. As a result, the pilot fuel circuit cools the stagnant fuel located in main fuel circuit, including the exit ports, even when performing at engine power levels of up to 60% of the maximum take-off thrust.

Owner:ROLLS ROYCE PLC

System and method for regenerating a particulate filter accompanied by a catalyst

ActiveUS20110072783A1Improve efficiencyLess tendencyElectrical controlInternal combustion piston enginesGasoline direct injectionExhaust fumes

A system for filtering and oxidizing particulate matter produced by a gasoline direct injection engine is disclosed. In one embodiment, engine cylinder air-fuel is adjusted to allow soot to oxidize at an upstream particulate filter while exhaust gases are efficiently processed in a downstream catalyst.

Owner:FORD GLOBAL TECH LLC

System and method for regenerating a particulate filter

ActiveUS20110072784A1Improve efficiencyLess tendencyElectrical controlInternal combustion piston enginesGasoline direct injectionEnvironmental engineering

A system for filtering and oxidizing particulate matter produced by a gasoline direct injection engine is disclosed. In one embodiment, engine cylinder air-fuel is adjusted to allow soot to oxidize at an upstream particulate filter while exhaust gases are efficiently processed in a downstream catalyst.

Owner:FORD GLOBAL TECH LLC

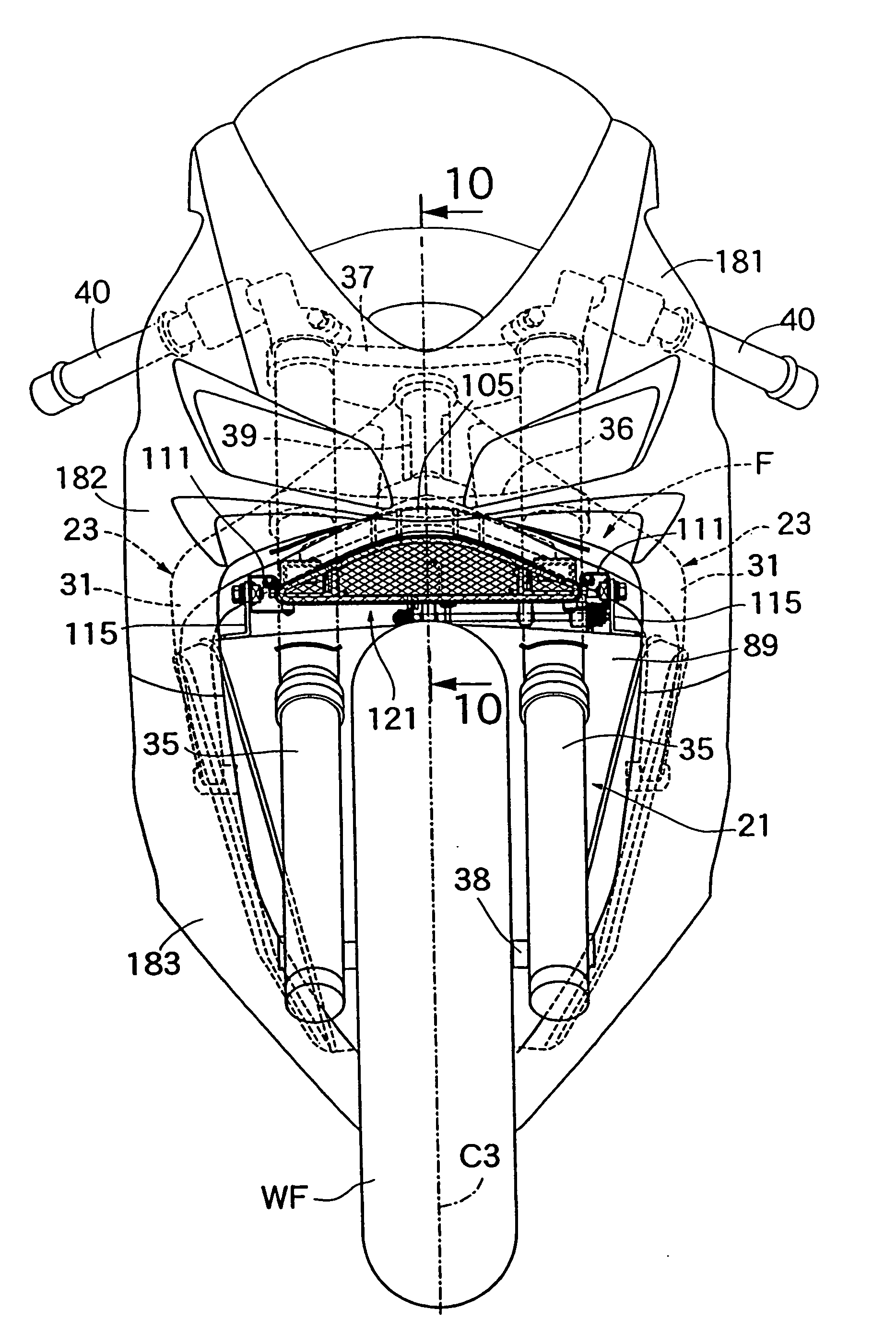

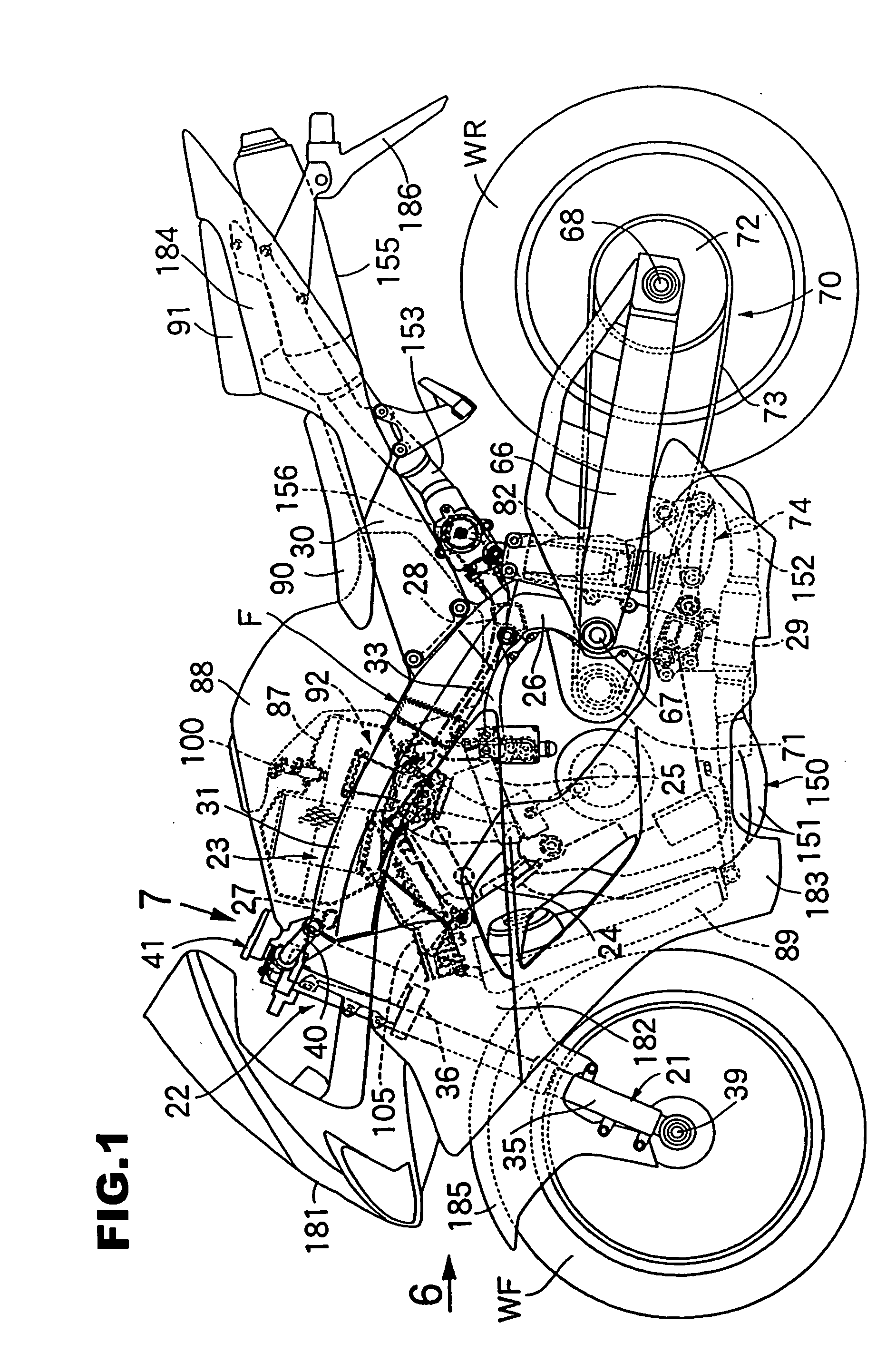

Intake apparatus for engine

InactiveUS20050150703A1Efficiently obtainedEfficient use ofCombination devicesInternal combustion piston enginesLow speedEngineering

In an intake duct, a first intake passage arranged in a width direction of the front wheel and a second intake passage arranged on a side of the first intake passage are formed such that a flow area of the first intake passage is set larger than a flow area of the second intake passage. An intake control valve closes the first intake passage when the engine rotates at low speed and opens the first intake passage when the engine rotates at high speed.

Owner:HONDA MOTOR CO LTD

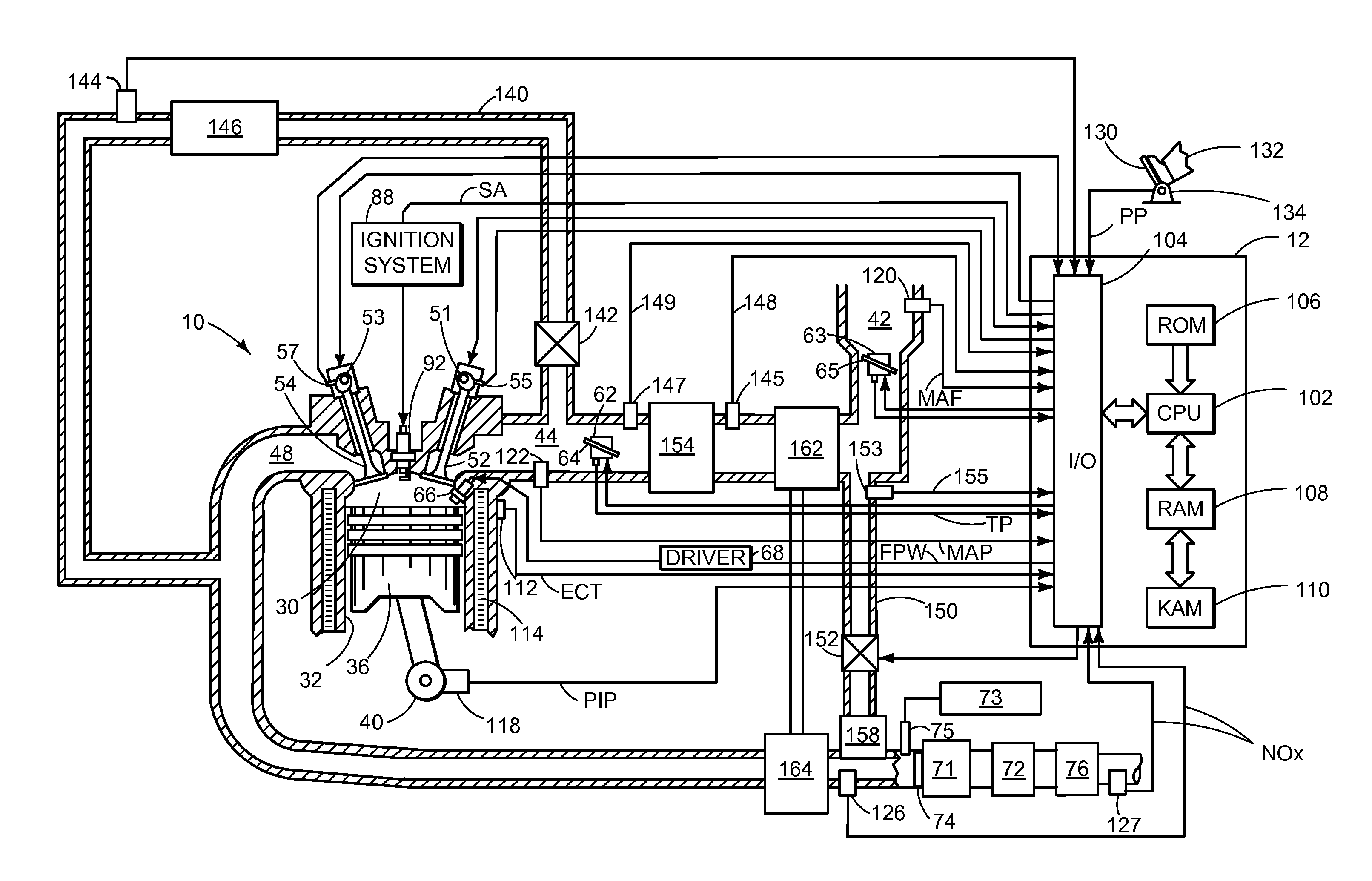

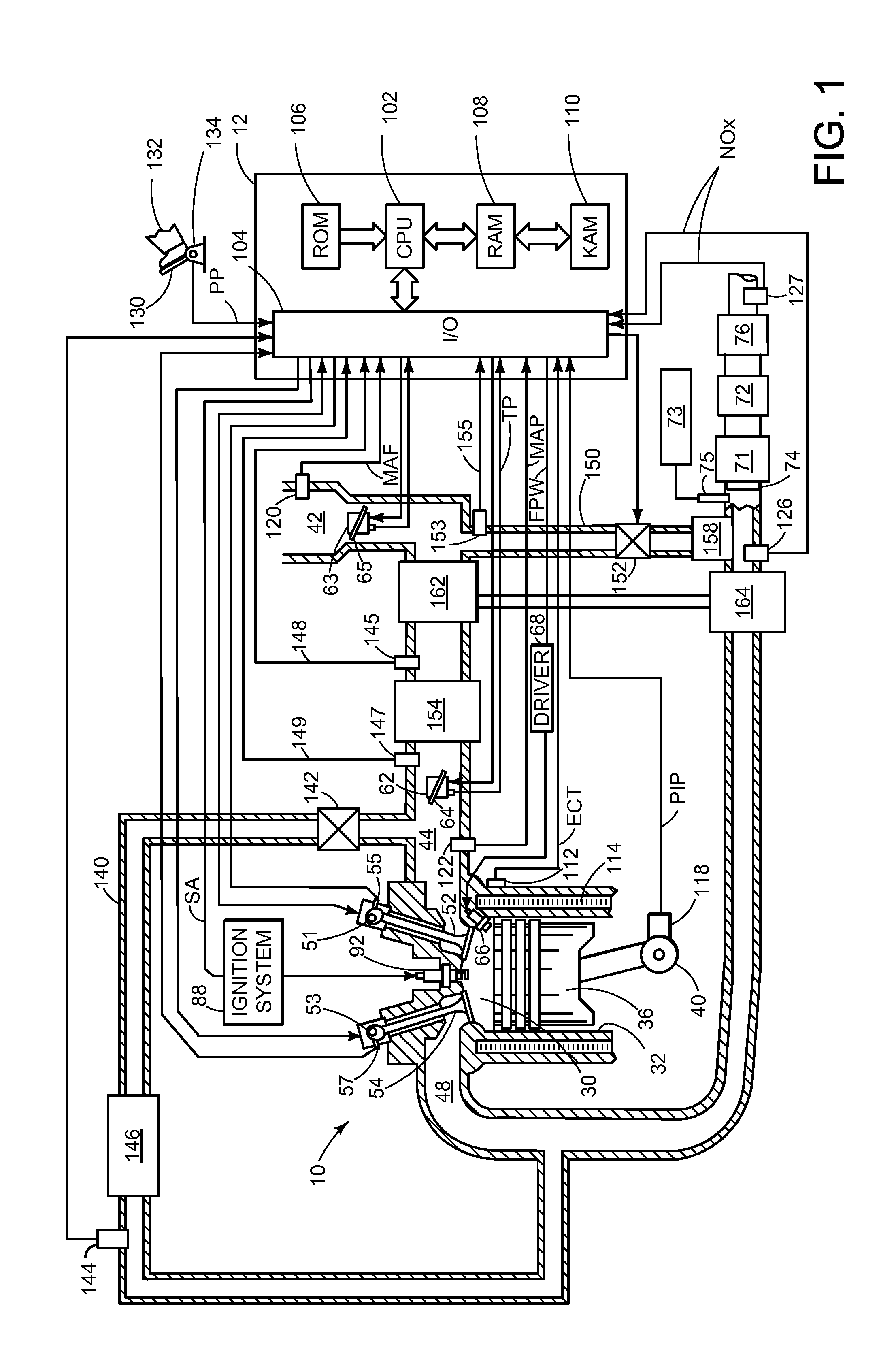

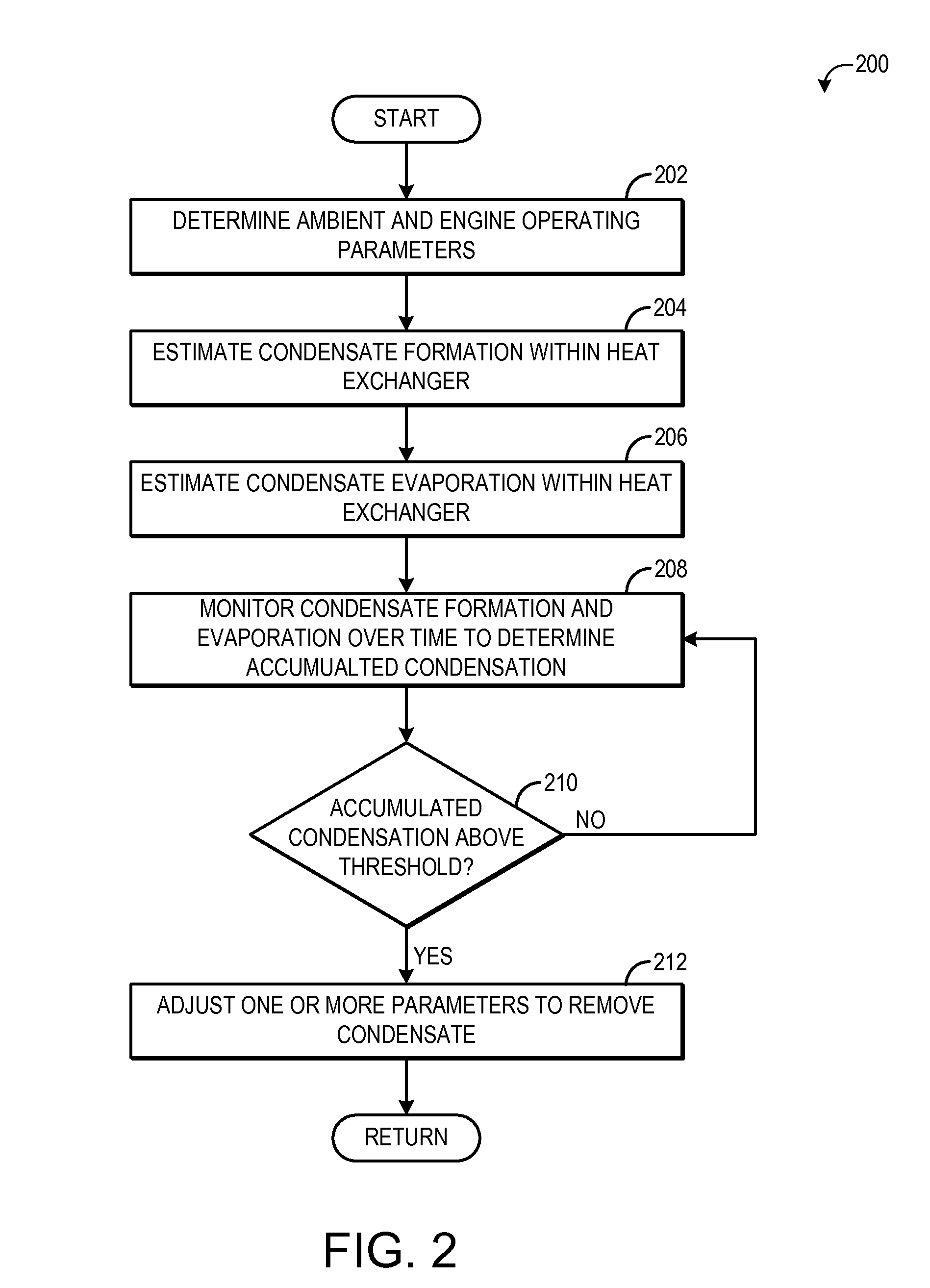

Condensate accumulation model for an engine heat exchanger

ActiveUS20140102428A1High densityReduce heating efficiencyElectrical controlInternal combustion piston enginesEngineeringExhaust gas recirculation

Embodiments for controlling condensate in an engine heat exchanger are disclosed. In one example, a method for an engine comprises increasing exhaust gas recirculation (EGR) flow responsive to condensation in an EGR cooler. In this way, condensate in the EGR cooler may be controlled via modulation of EGR flow.

Owner:FORD GLOBAL TECH LLC

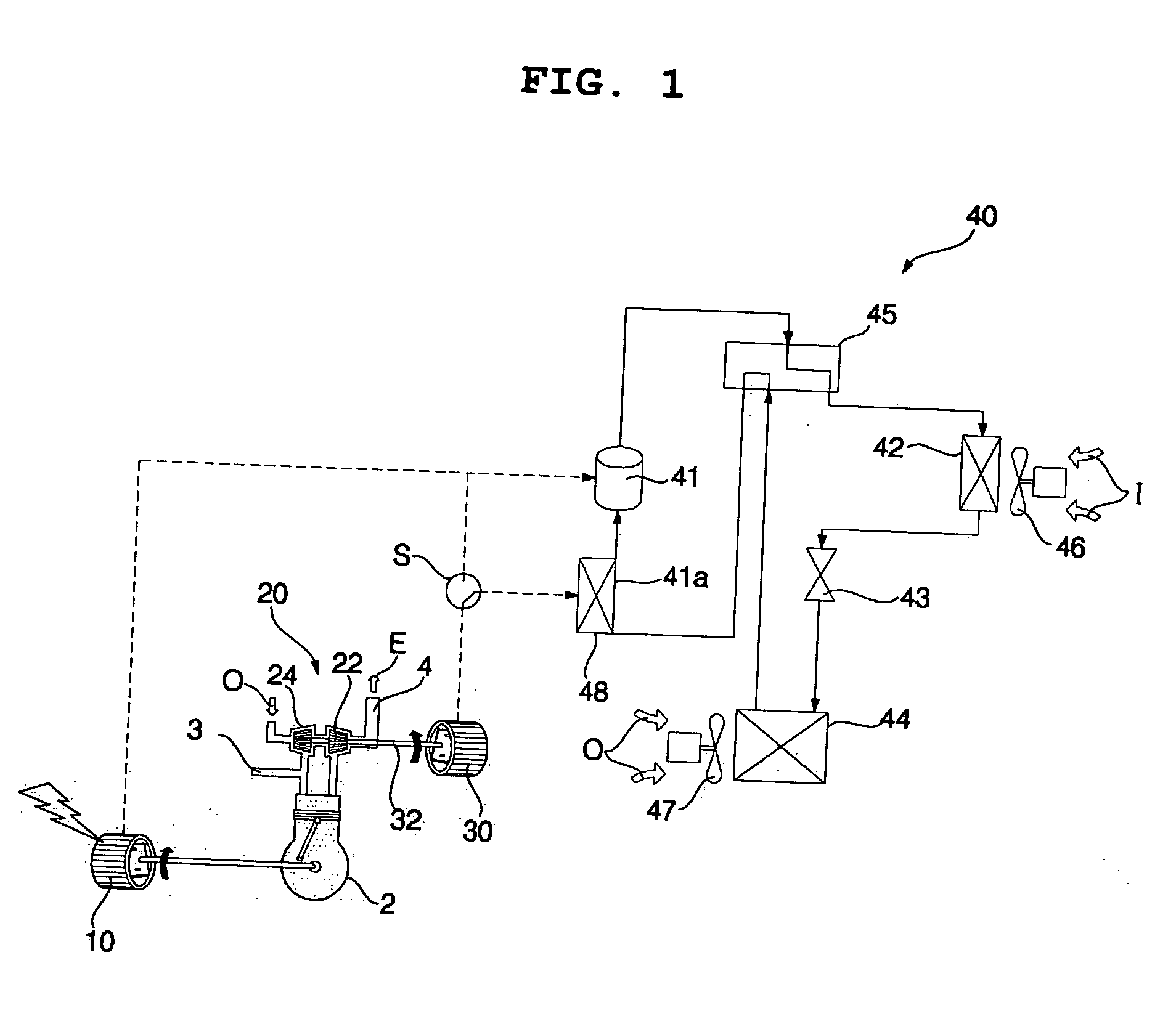

Control Method of Direct Injection Engine, Controller for Implementing the Control method, and Control Circuit Device Used for the Controller

InactiveUS20080208438A1Improve volumetric efficiencyIncrease engine powerElectrical controlInternal combustion piston enginesTime changesEvaporation

An object of the present invention is to provide a fuel injection control technique which maximizes engine power according to fuel evaporation characteristics. The fuel injection timing in the intake stroke is delayed according as a physical quantity affecting the fuel evaporation time changes such that the fuel evaporation time decreases. Further, the fuel injection timing when a physical quantity affecting the fuel evaporation time is such that the fuel evaporation time decreases is set closer to the end of the intake stroke than the fuel injection timing when the physical quantity is such that the fuel evaporation time increases. The fuel injection timing is controlled so as to maximize engine power according to fuel evaporation times.

Owner:HITACHI LTD

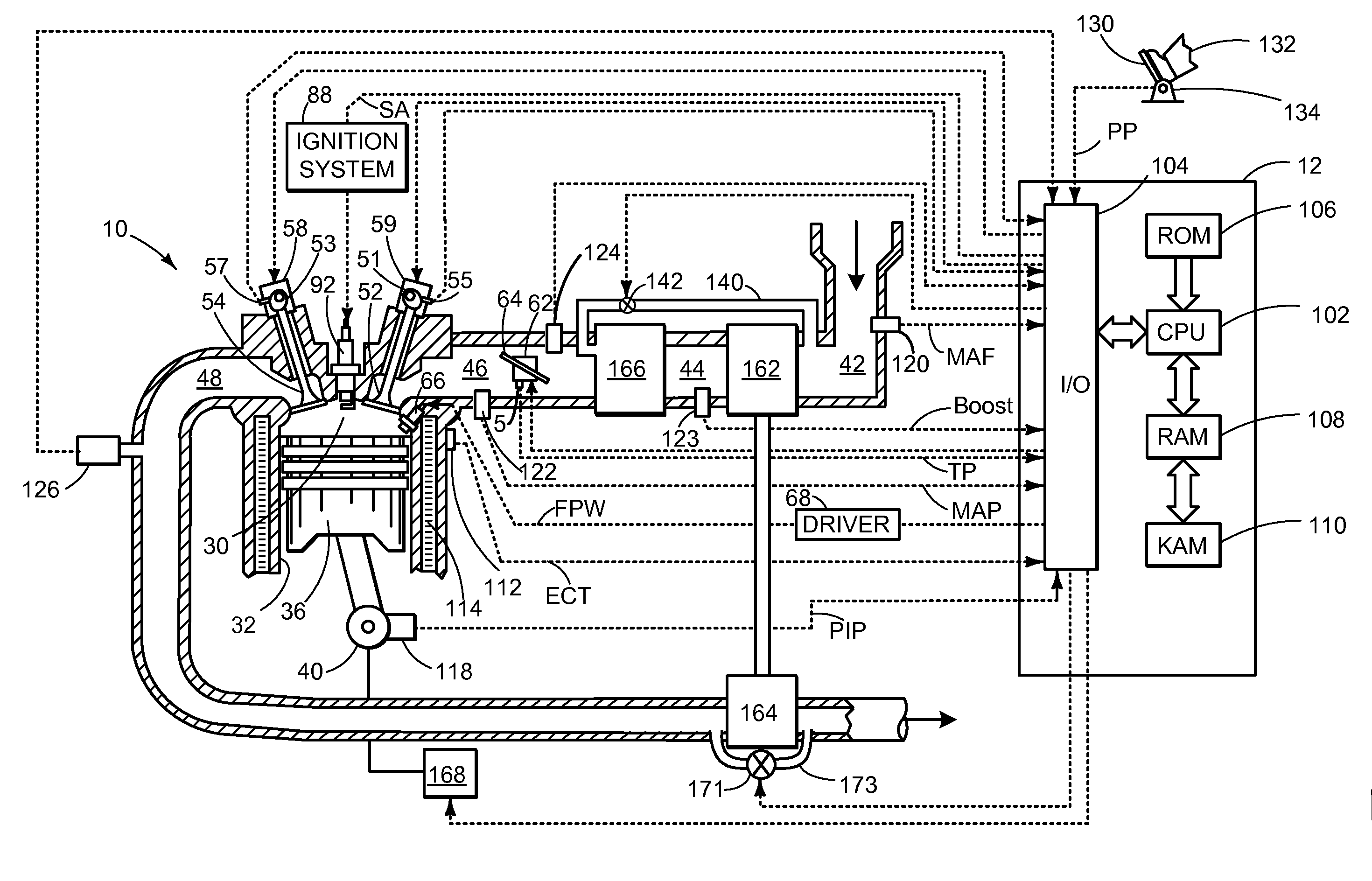

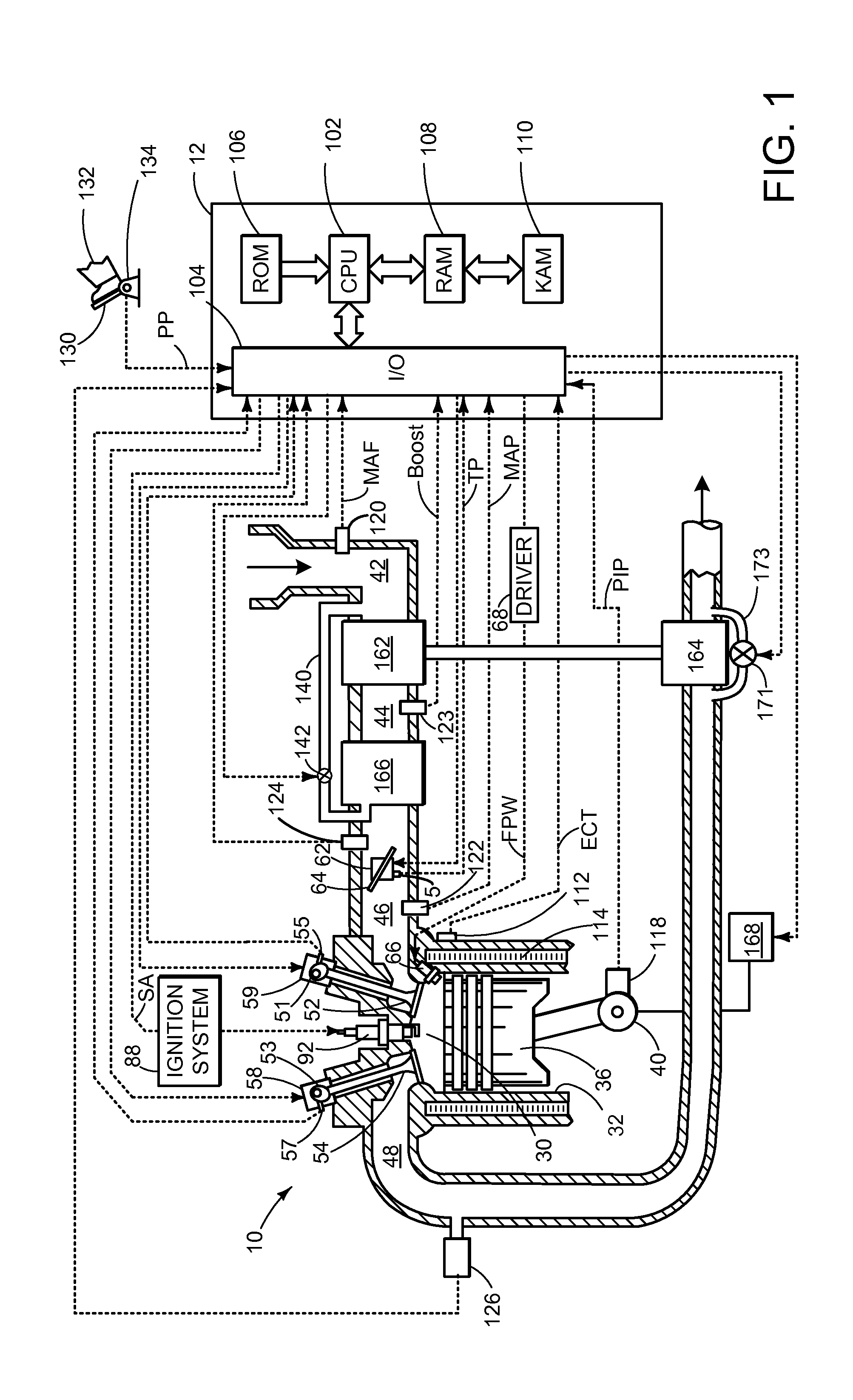

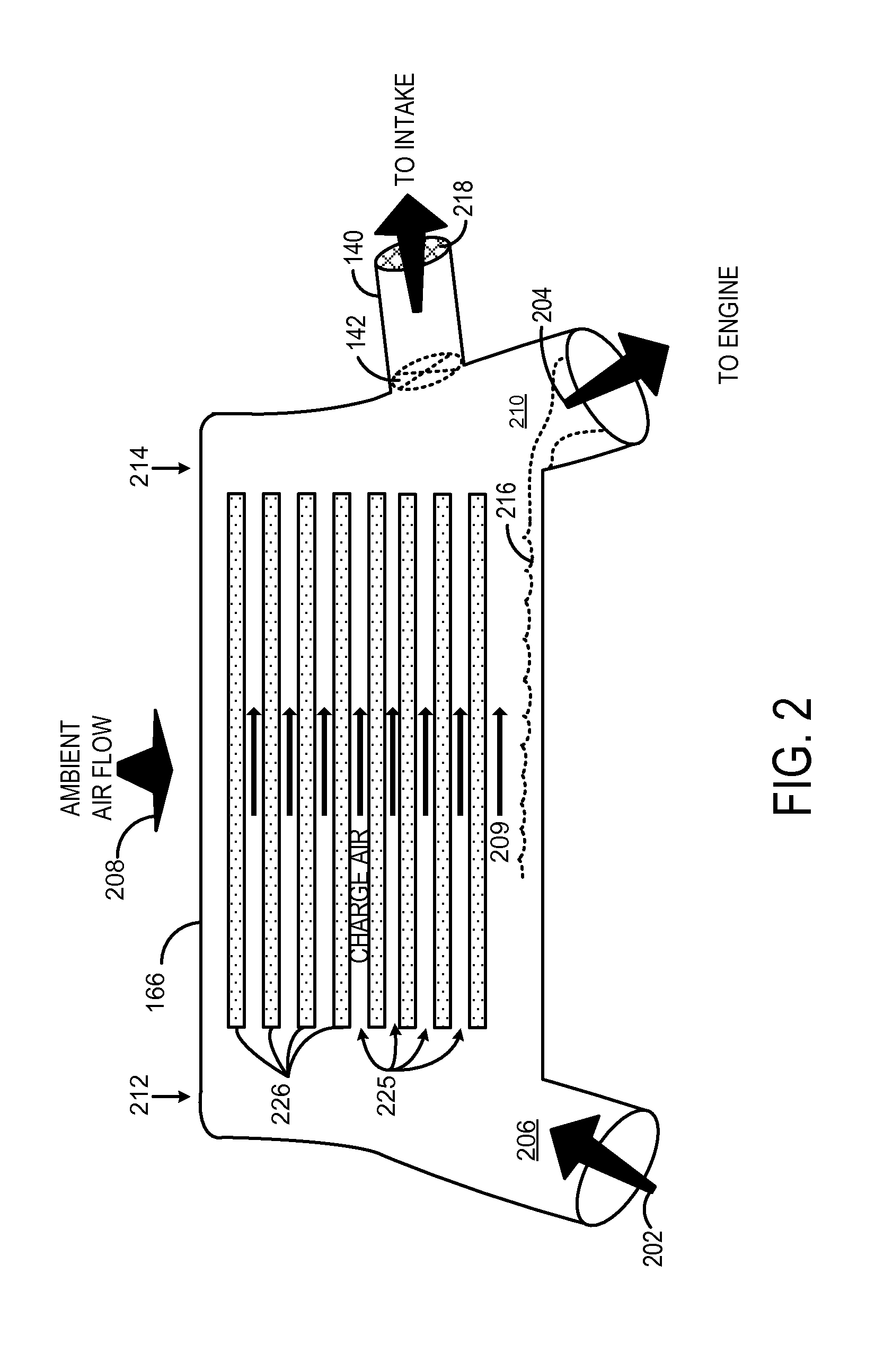

Charge air cooler component diagnostics

ActiveUS20140150756A1Increase powerHigh densityInternal combustion piston enginesExhaust gas recirculationTemperature differenceEngineering

Embodiments for a charge air cooler are provided. In one example, a method comprises adjusting an operating parameter in response to a degraded grille shutter, the degraded grille shutter determined based on a temperature difference across a charge air cooler. In this way, degradation of the charge air cooler or engine may be reduced.

Owner:FORD GLOBAL TECH LLC

Cerium dioxide nanoparticle-containing fuel additive

InactiveUS20100199547A1Increase engine powerFacilitate fuel combustionMaterial nanotechnologyRotary stirring mixersNanoparticleCerium

A fuel additive composition includes: a) a reverse-micellar composition having an aqueous disperse phase that includes cerium dioxide nanoparticles in a continuous phase that includes a hydrocarbon liquid, a surfactant, and optionally a co-surfactant and b) a reverse micellar composition having an aqueous disperse phase that includes a cetane improver effective for improving engine power during fuel combustion. A method of making a cerium-containing fuel additive includes the steps of: a) providing a mixture of a nonpolar solvent, a surfactant, and a co-surfactant; and b) combining the mixture with an aqueous suspension of stabilized cerium dioxide nanoparticles.

Owner:CERION

Method for controlling spark for particulate filter regenerating

ActiveUS20110073070A1Improve efficiencyLess tendencyElectrical controlInternal combustion piston enginesGasoline direct injectionEngineering

Owner:FORD GLOBAL TECH LLC

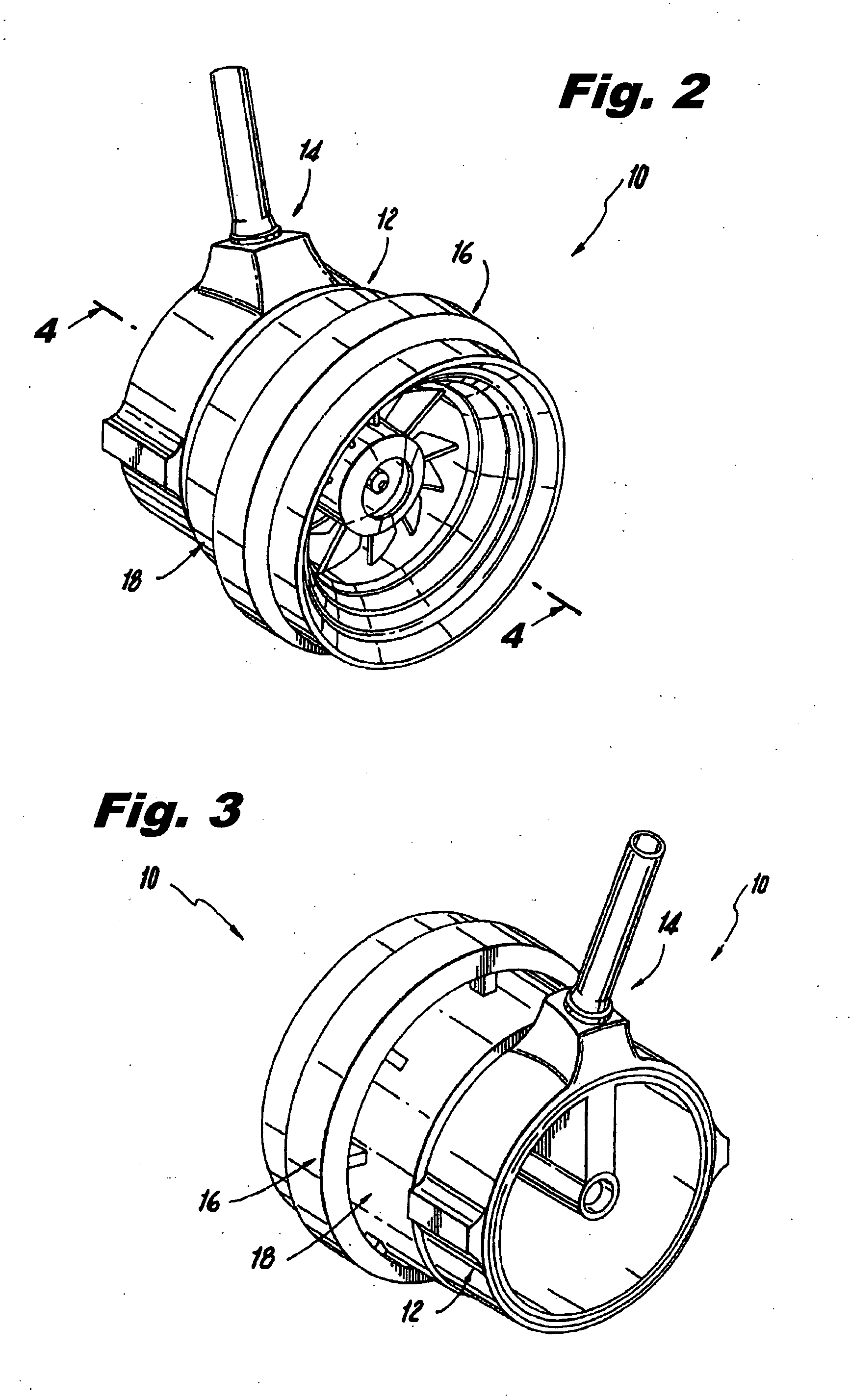

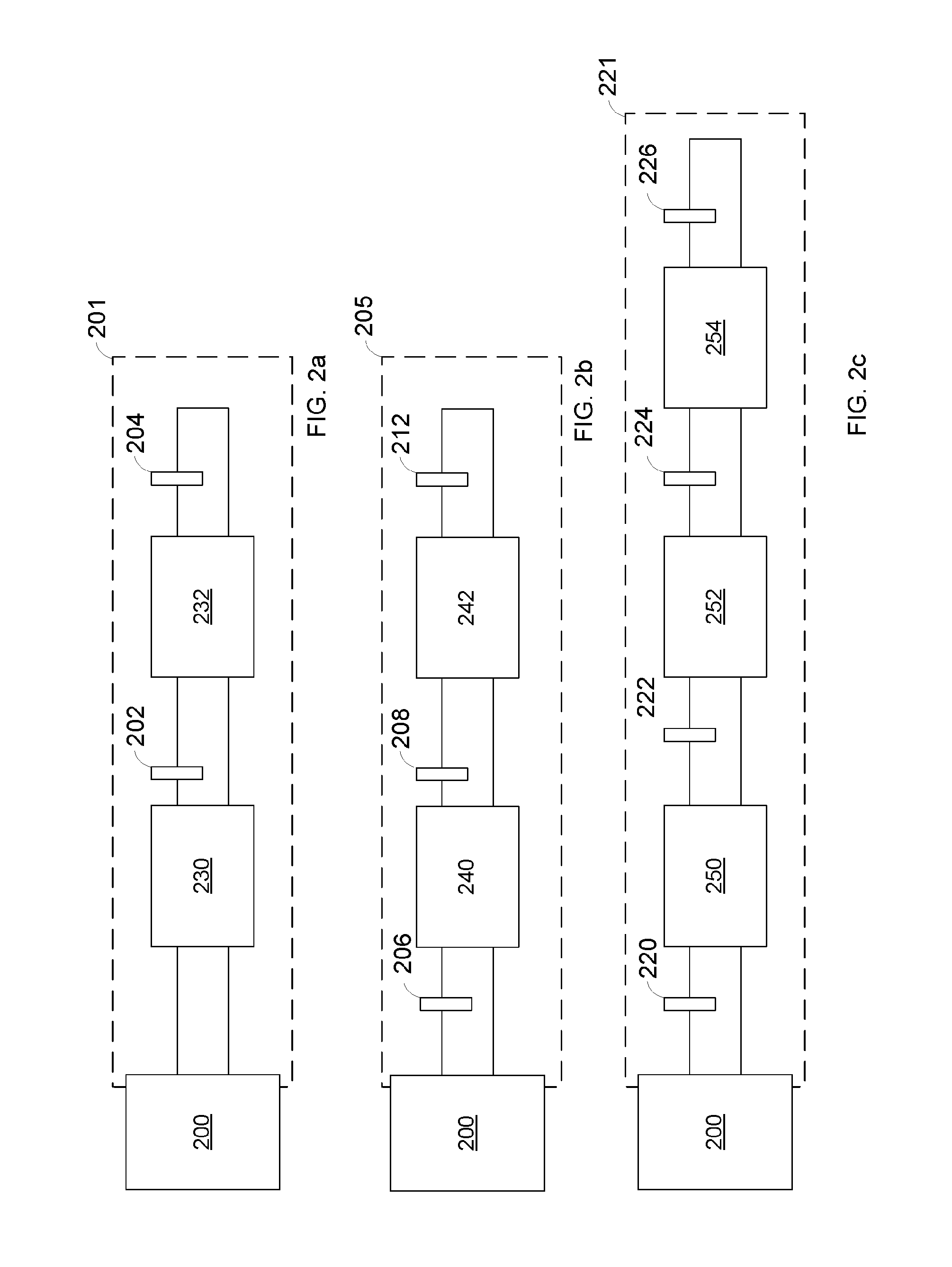

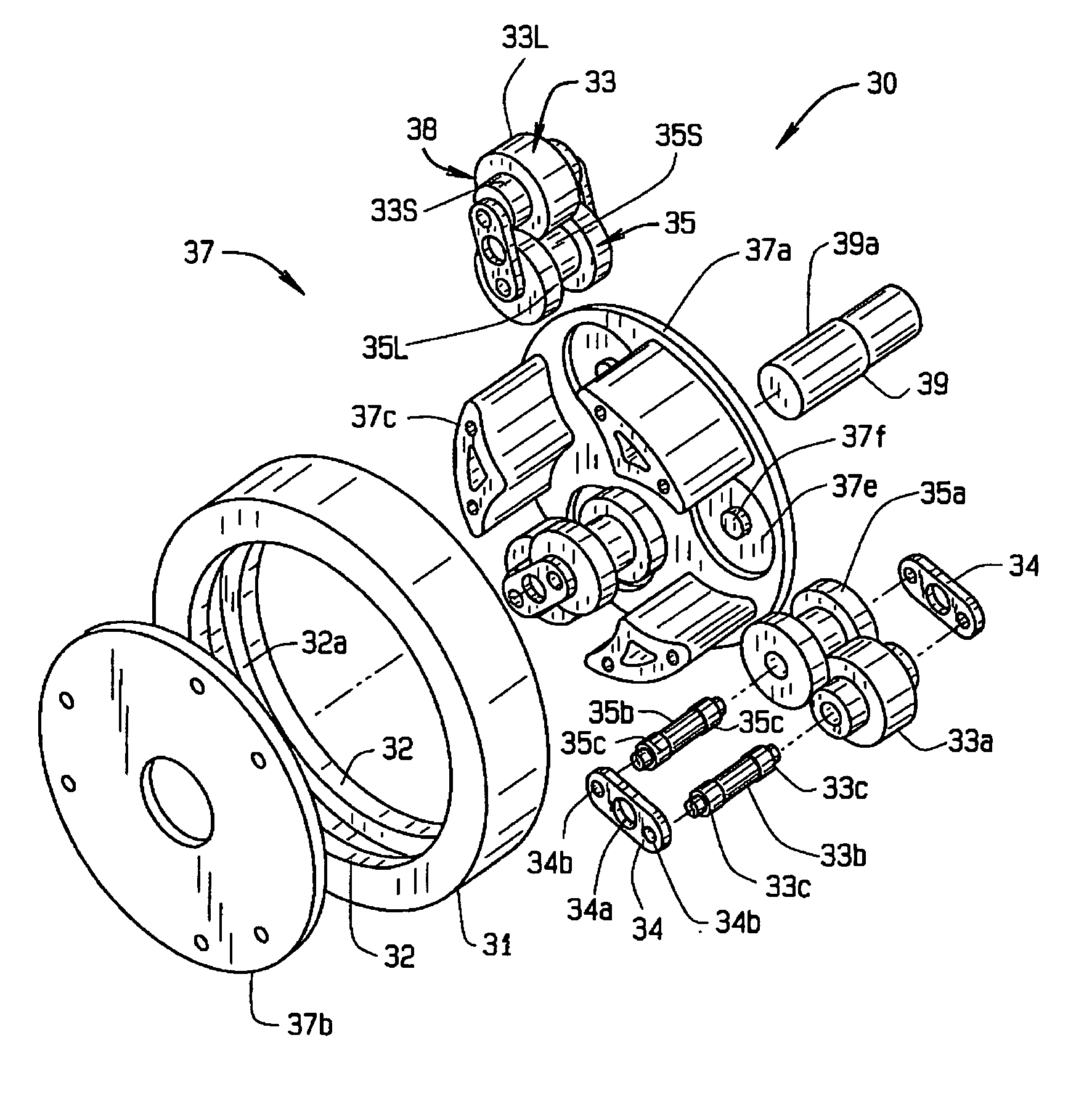

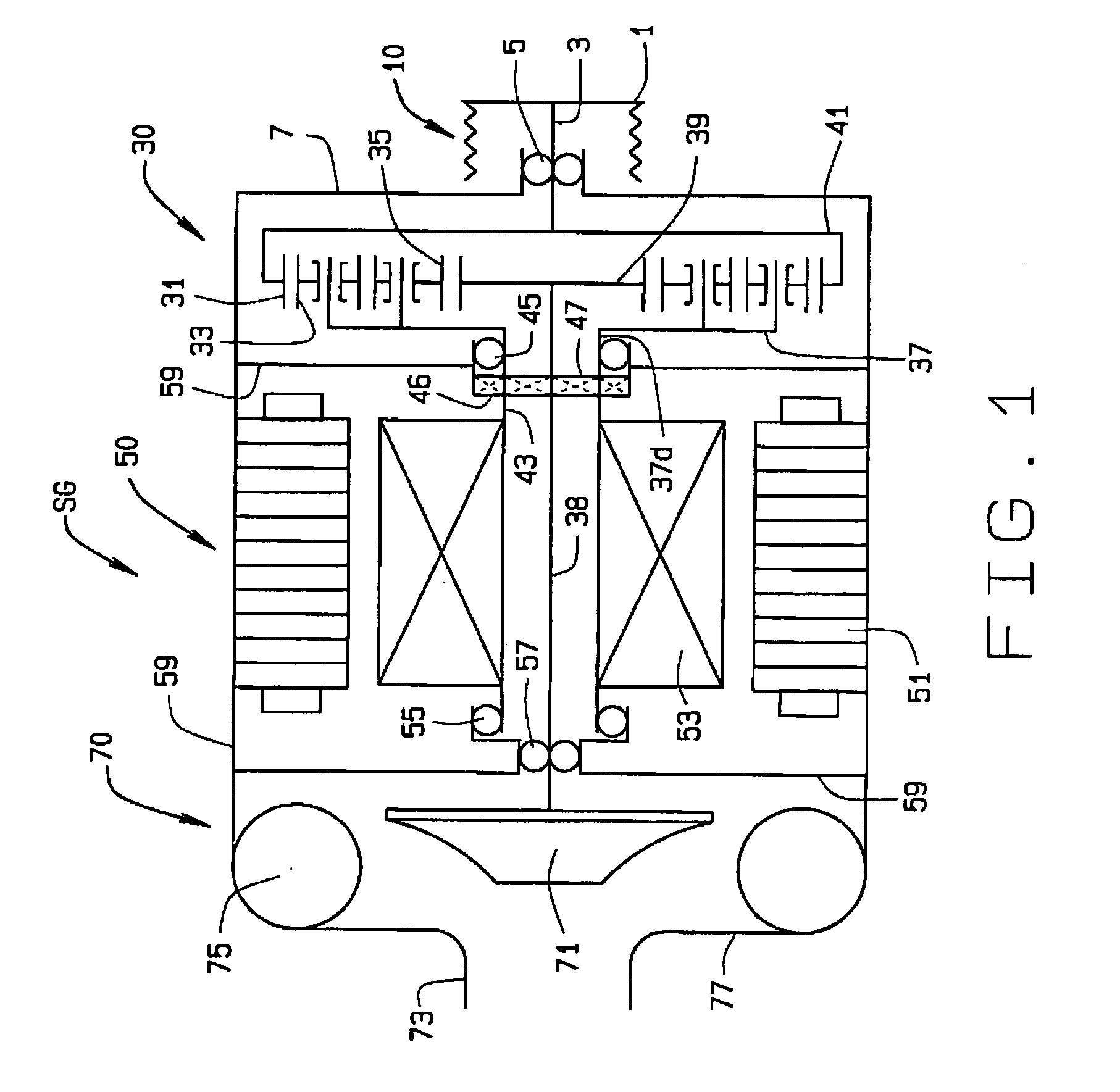

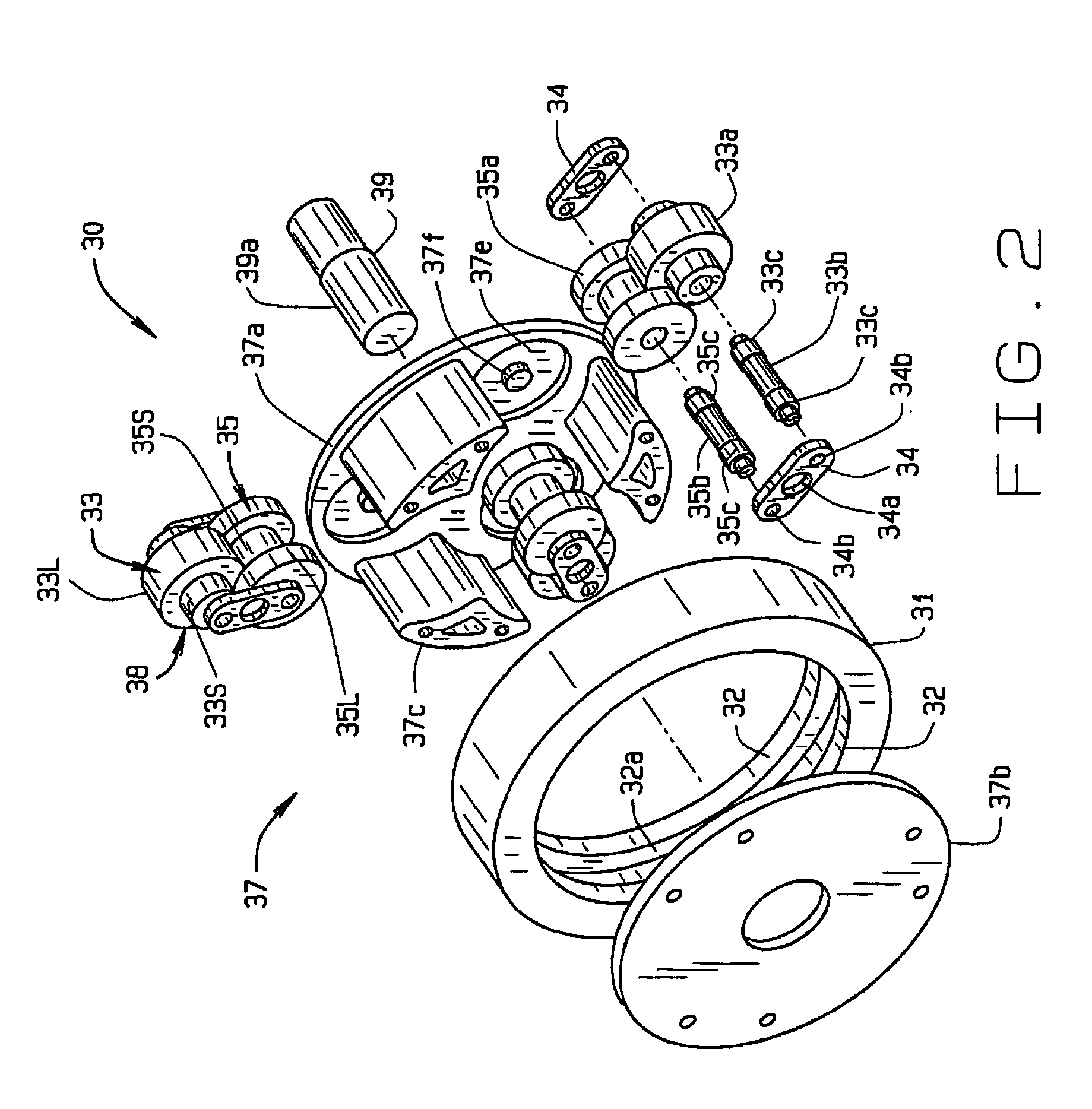

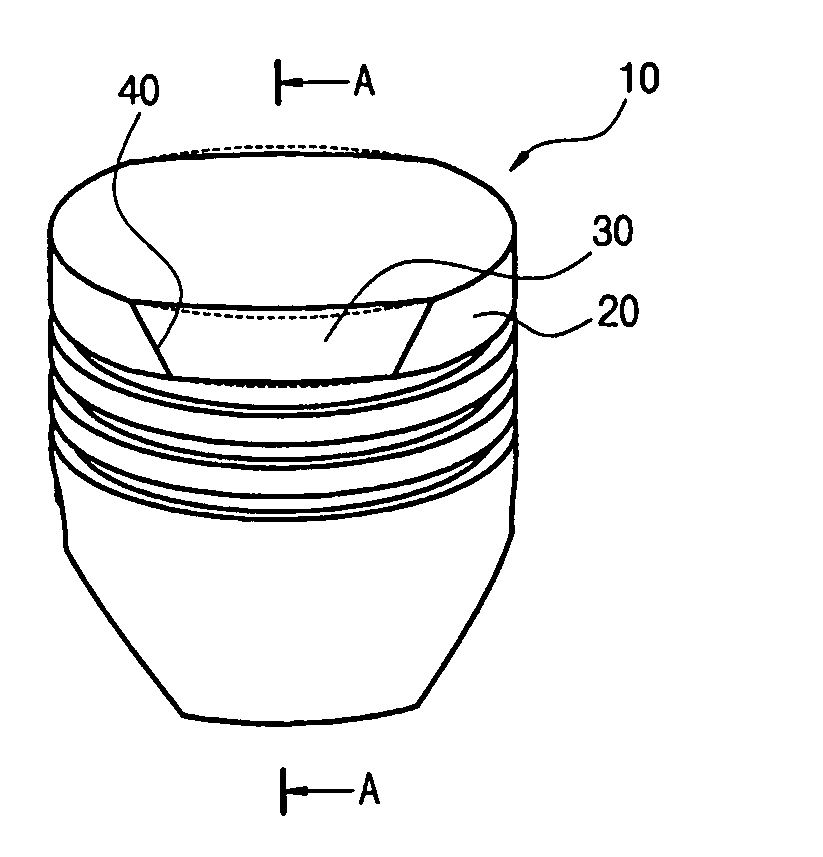

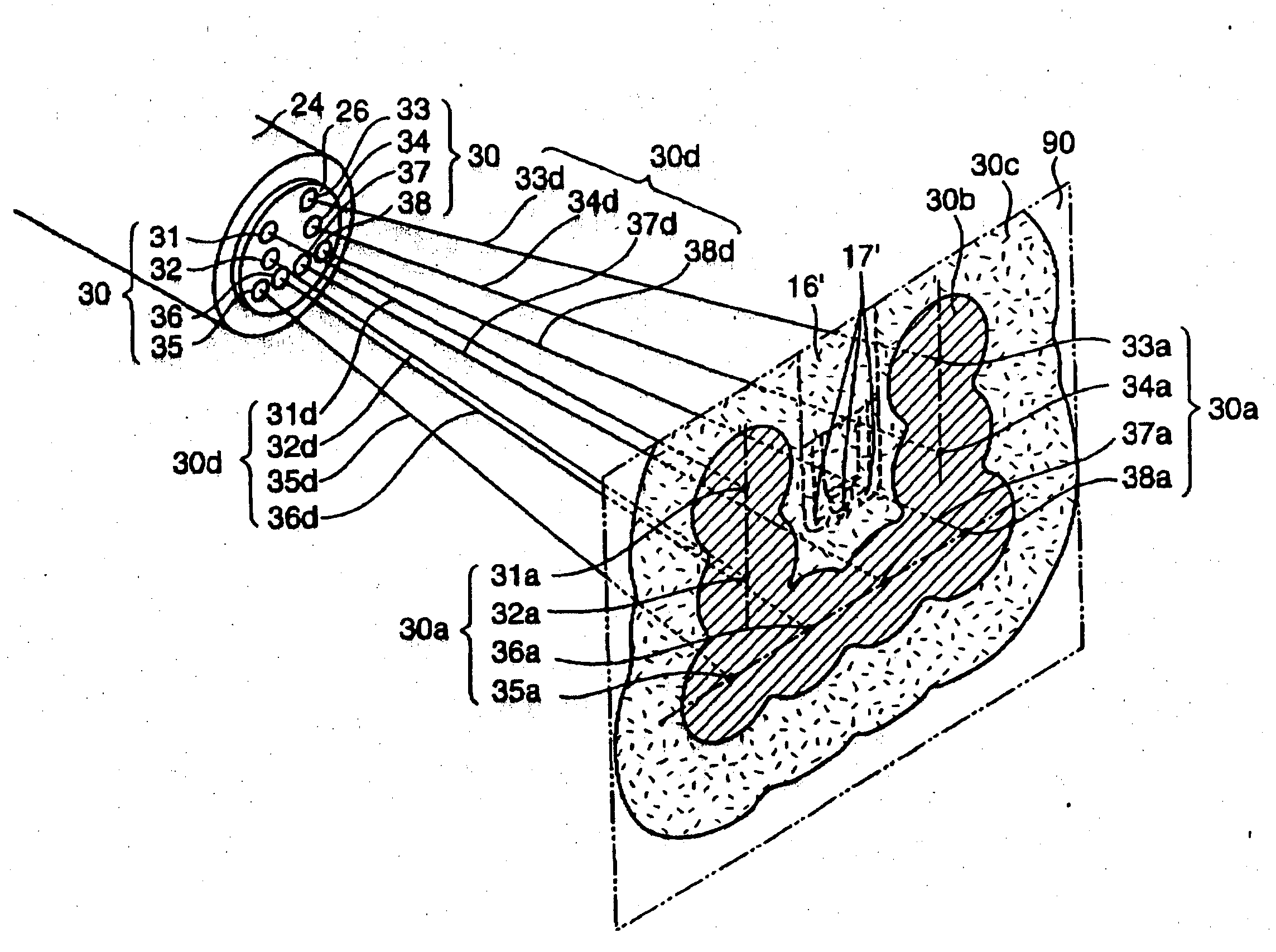

Variable Speed Supercharger With Electric Power Generation

ActiveUS20100050998A1Increase the speed ratioIncrease engine powerCombustion enginesToothed gearingsImpellerElectric machine

A supercharger for boosting intake manifold pressure in an internal combustion engine and producing electrical energy comprises an input shaft (3), a electric machine (50) including a stator (51) and a rotor (53), a compressor (70) including an impeller (71), and a planetary transmission (30) located between the input shaft (3) and the rotor (53) of the electric machine (50) and the impeller (71) of the compressor (70), all such that the input shaft 3 can drive both the impeller (71) and the rotor (53), or the rotor (53) and input shaft (3) can drive the impeller (71). The planetary transmission (30) includes an outer ring (31) operatively coupled to the input shaft (3), a sun member (39) operatively coupled to the impeller (71), planetary clusters (38) located between the outer ring (31) and sun member (39), and a carrier (37) operatively coupled to the planet clusters (38) and the rotor (53). Each planetary cluster (38) comprises an inner roller (35) and an outer roller (33).

Owner:THE TIMKEN CO

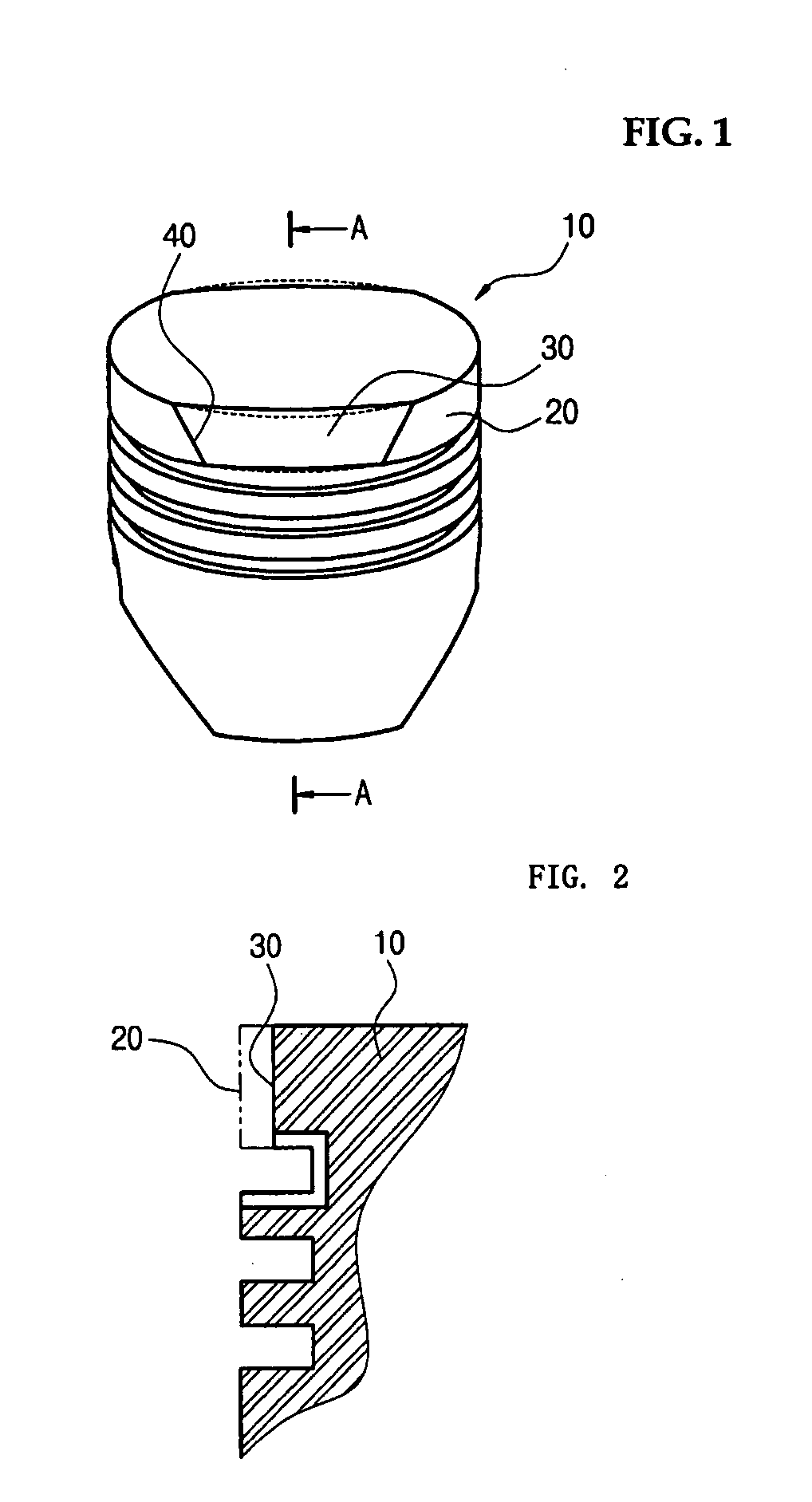

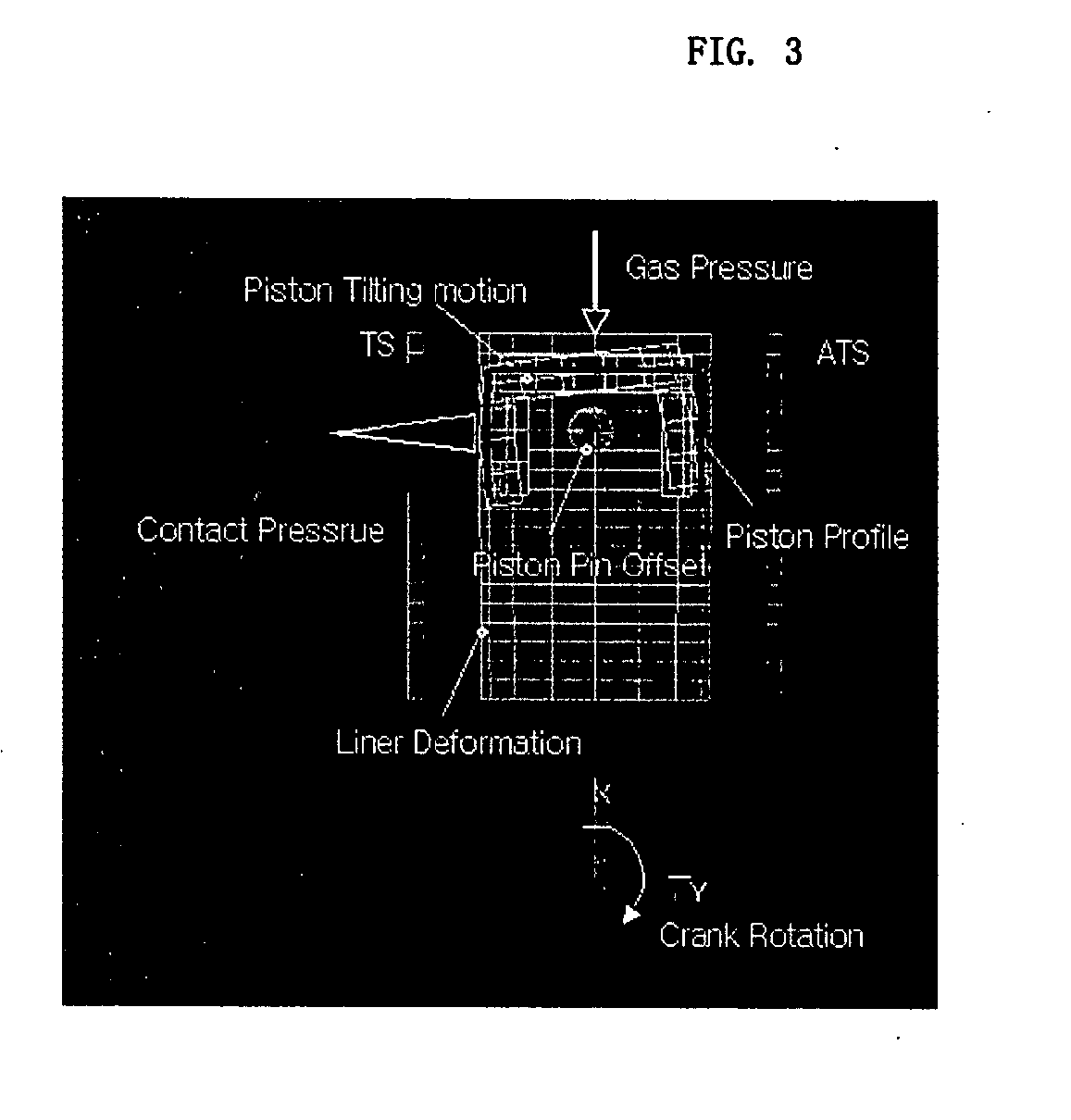

Piston structure for reducing friction losses

InactiveUS20050051128A1Reduce friction lossEnhancing fuel consumption ratePlungersMachines/enginesFriction reductionContact pressure

The present invention relates to a piston for decreasing a frictional losses by receiving a part of the expanding gas during the power stroke of an engine and reducing contact pressure on a piston applied from the expanding gas, thereby enhancing fuel consumption and engine power. The piston for decreasing such friction includes a recess for receiving expanding gas formed in a circumferential section of a top land part of the piston head.

Owner:HYUNDAI MOTOR CO LTD +1

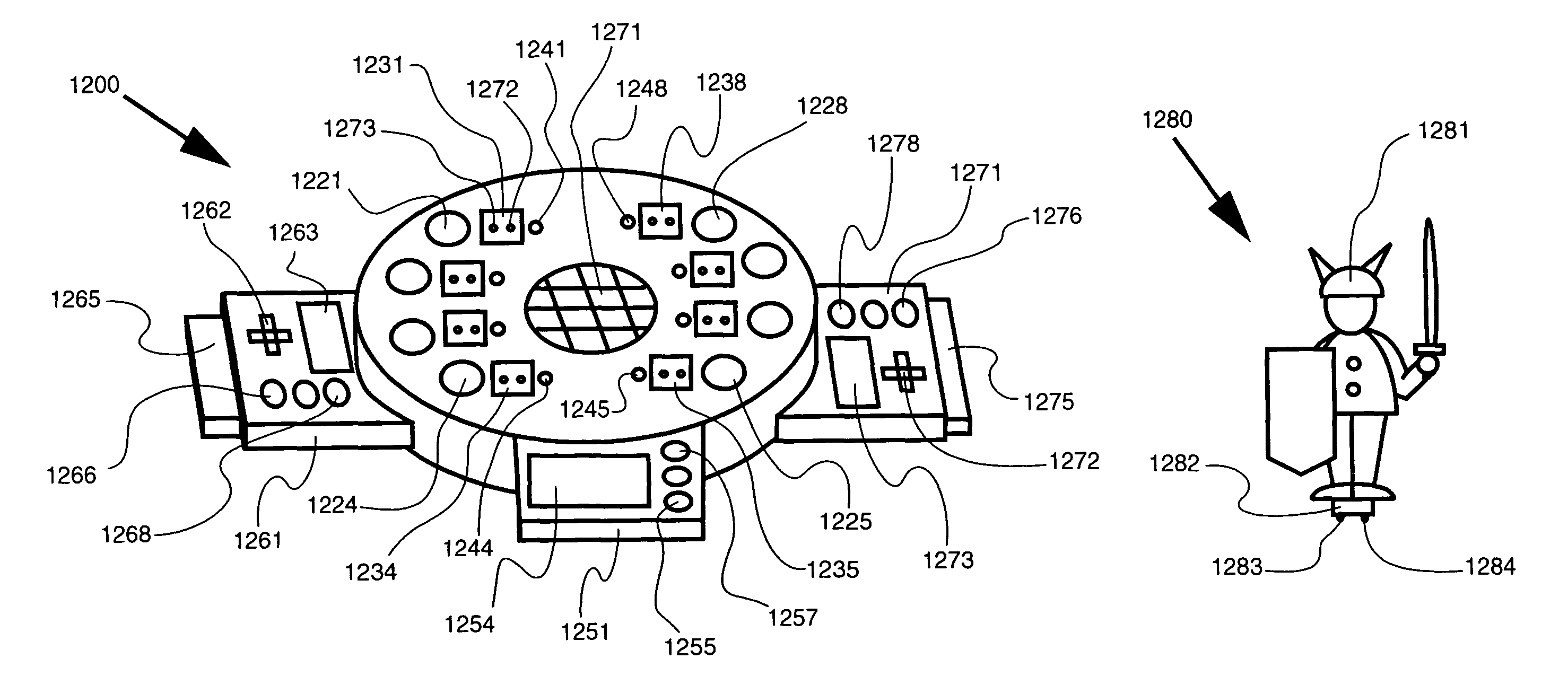

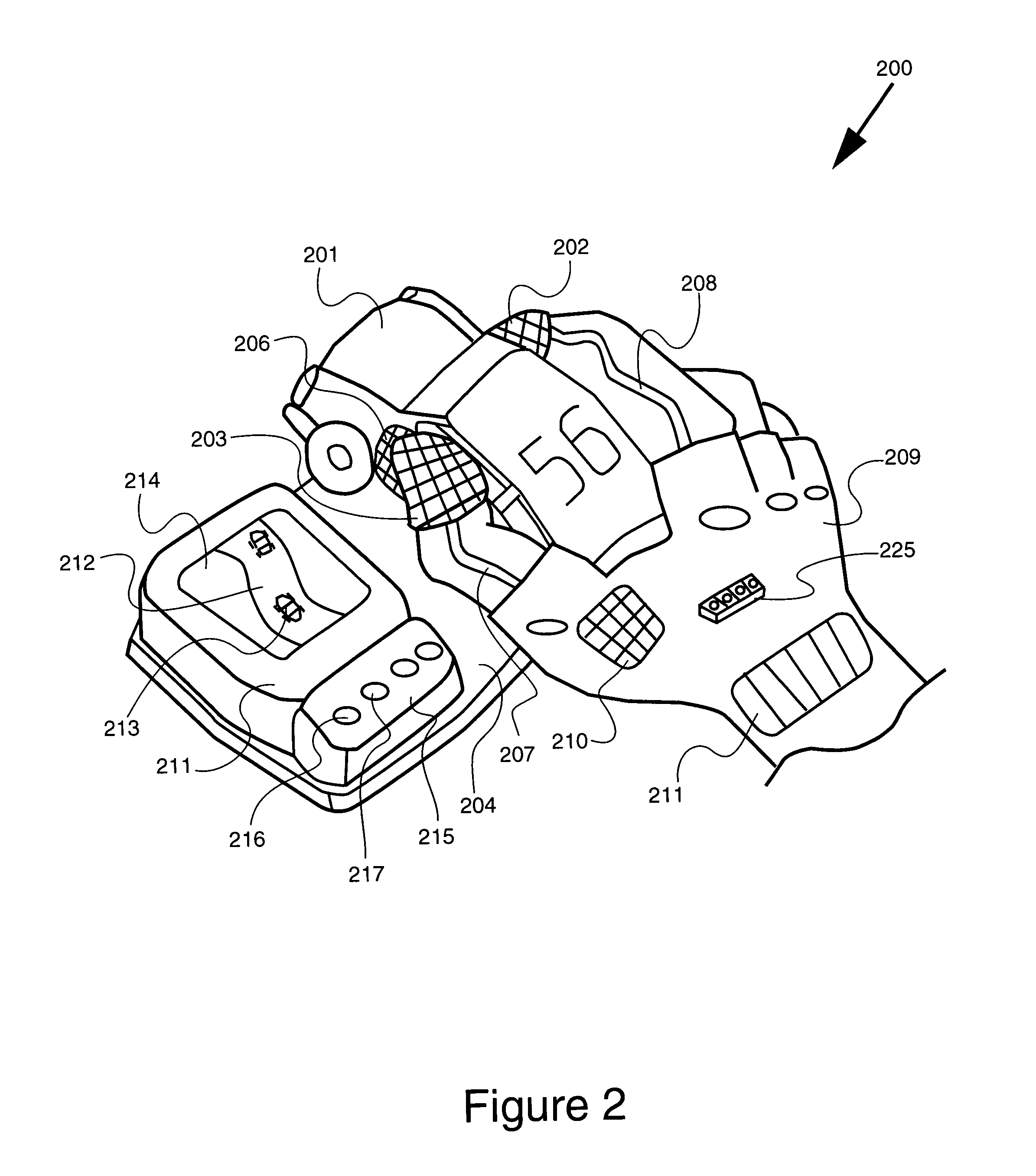

Electronics toy play set

InactiveUS9457281B1Enhance game play valueEnhanced play valueEmergency casingsComputerized toysEngineeringGame play

A toy play set comprising a master toy member structured to interface with a family of accessory toy members. Each accessory toy member comprises an electronics identification means to be recognized by said master toy member. Each accessory toy member is also programmable to modify the personal characteristics of said accessory toy member according to a game play.

Owner:PEOPLE INNOVATE FOR ECONOMY FOUND

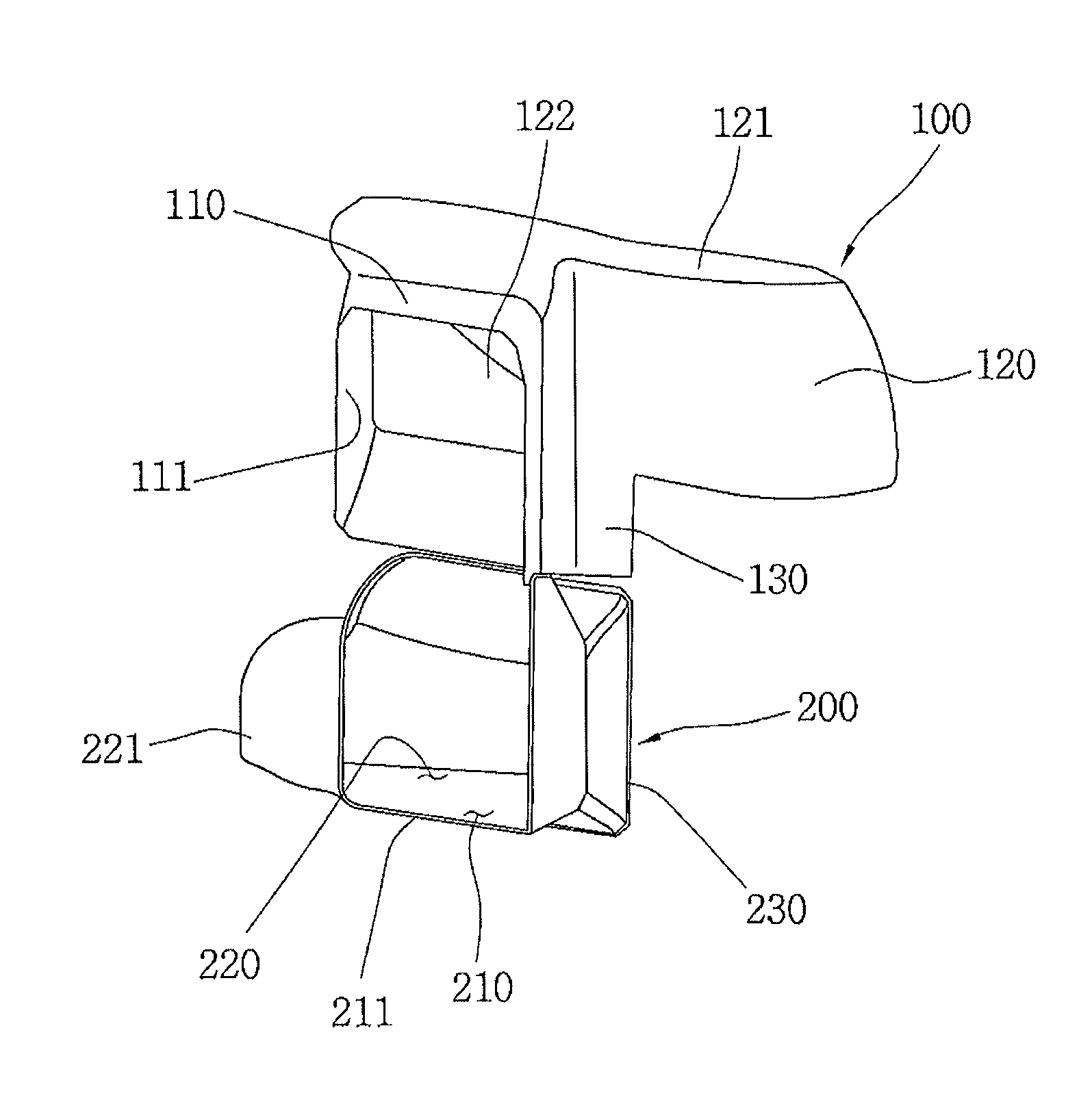

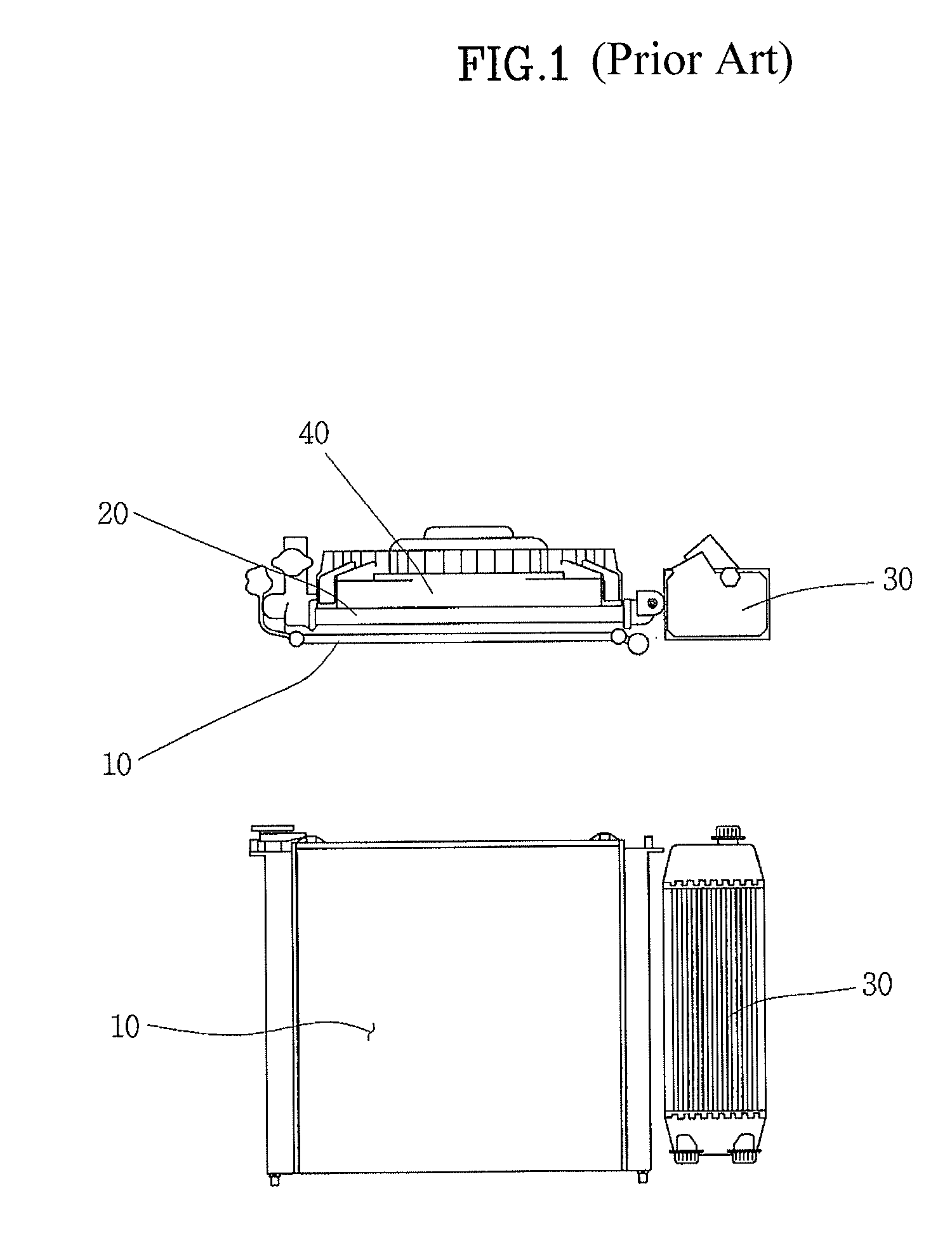

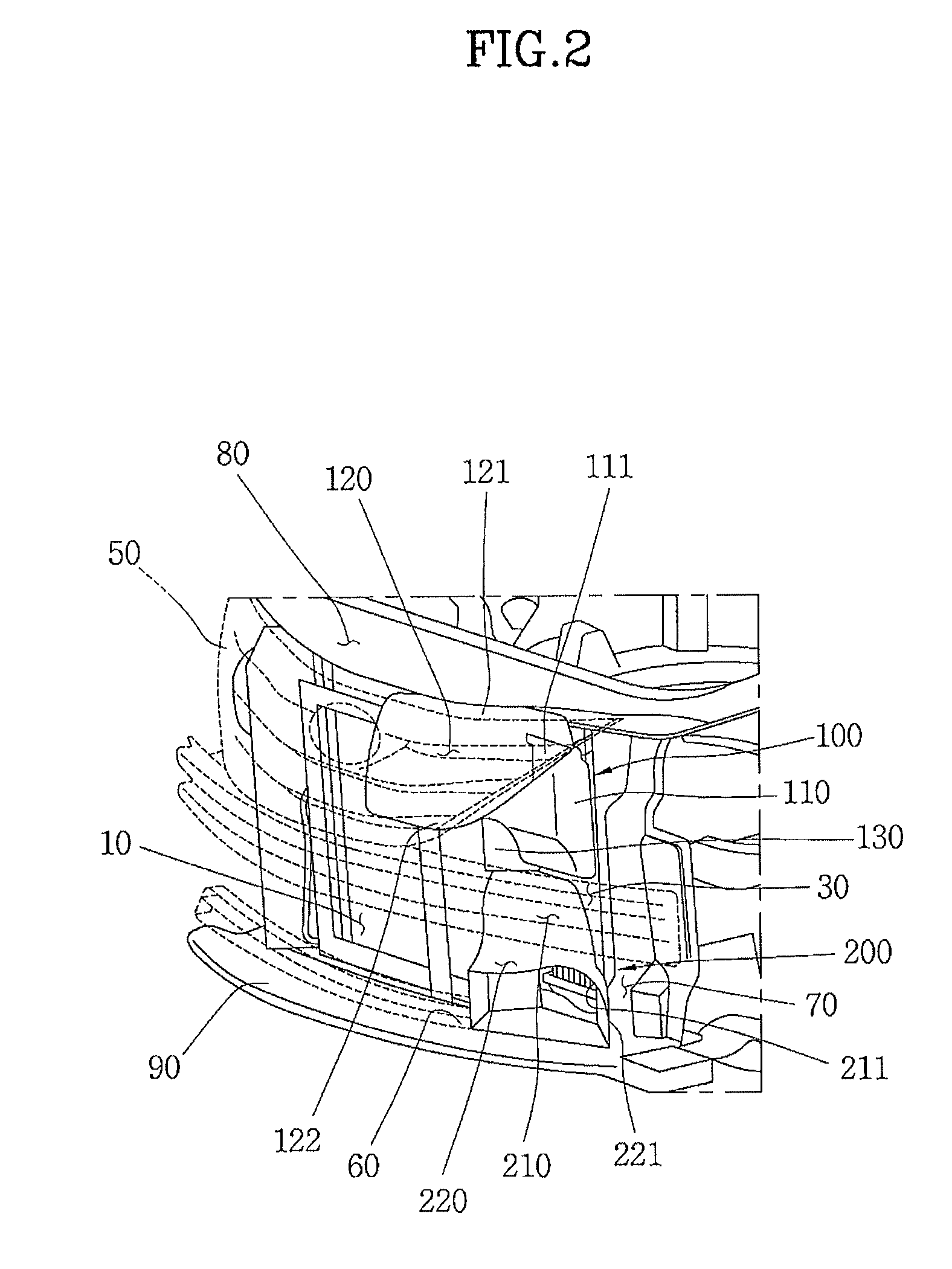

Dual air duct for front end of vehicle

ActiveUS8365854B2Improve cooling effectIncrease engine powerSuperstructure subunitsPropulsion coolingIntercoolerHeat spreader

A dual air duct of a vehicle may include an upper duct that guides running wind flowing outside an intercooler through a radiator grill to upper portion of the intercooler and a lower duct that guides running wind flowing outside the intercooler through a hole of a bumper cover to lower portion of the intercooler.

Owner:HYUNDAI MOTOR CO LTD +1

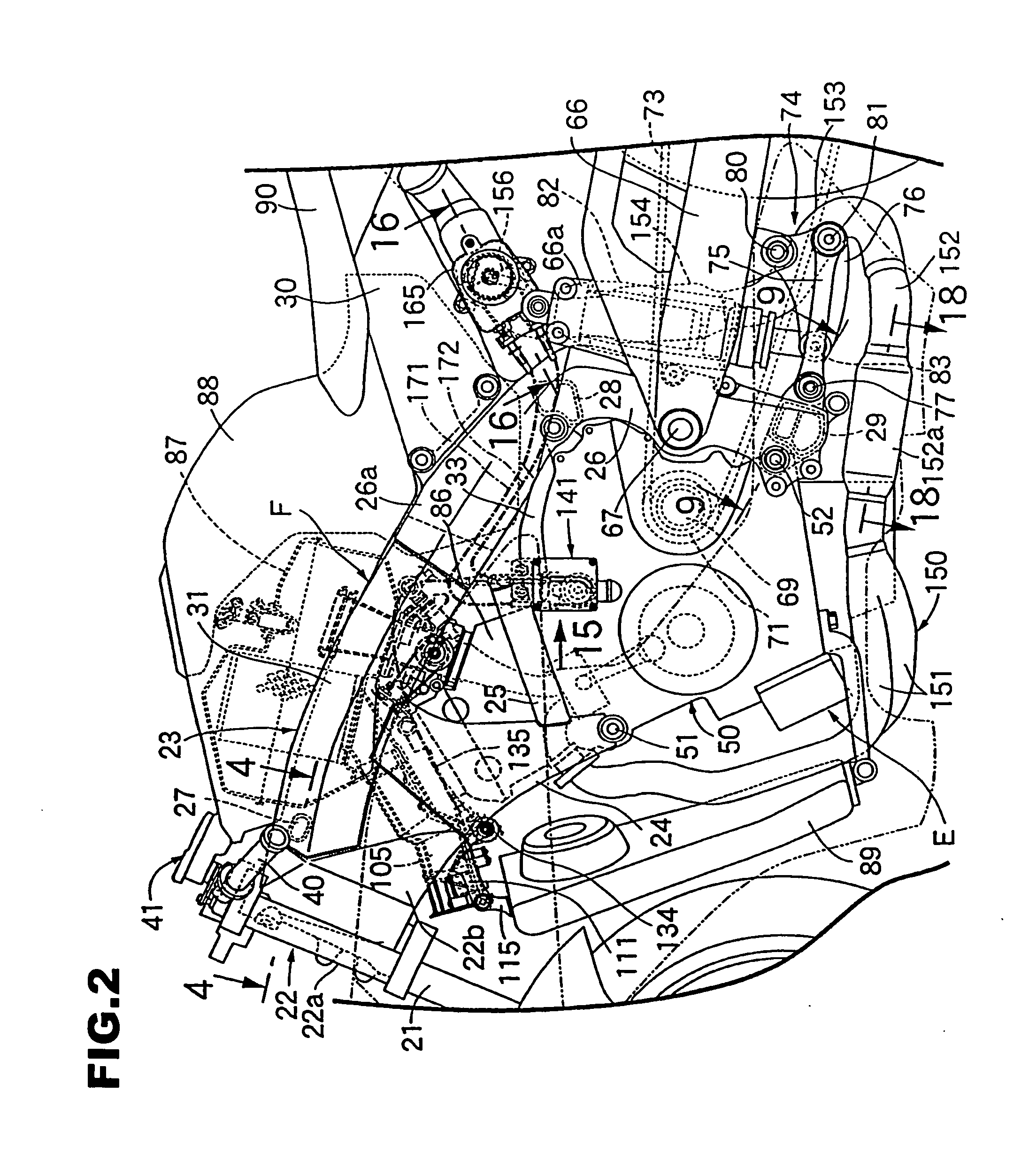

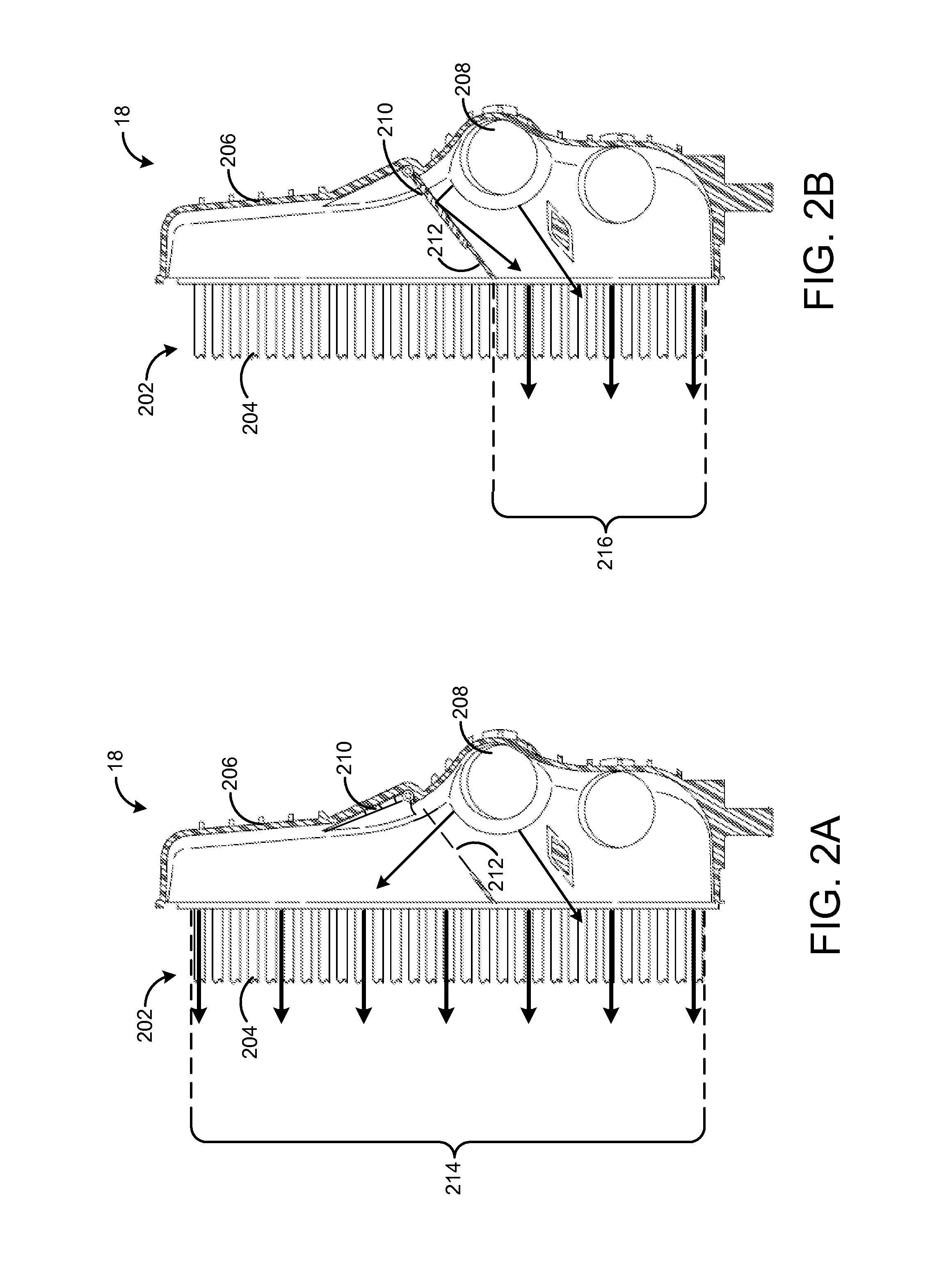

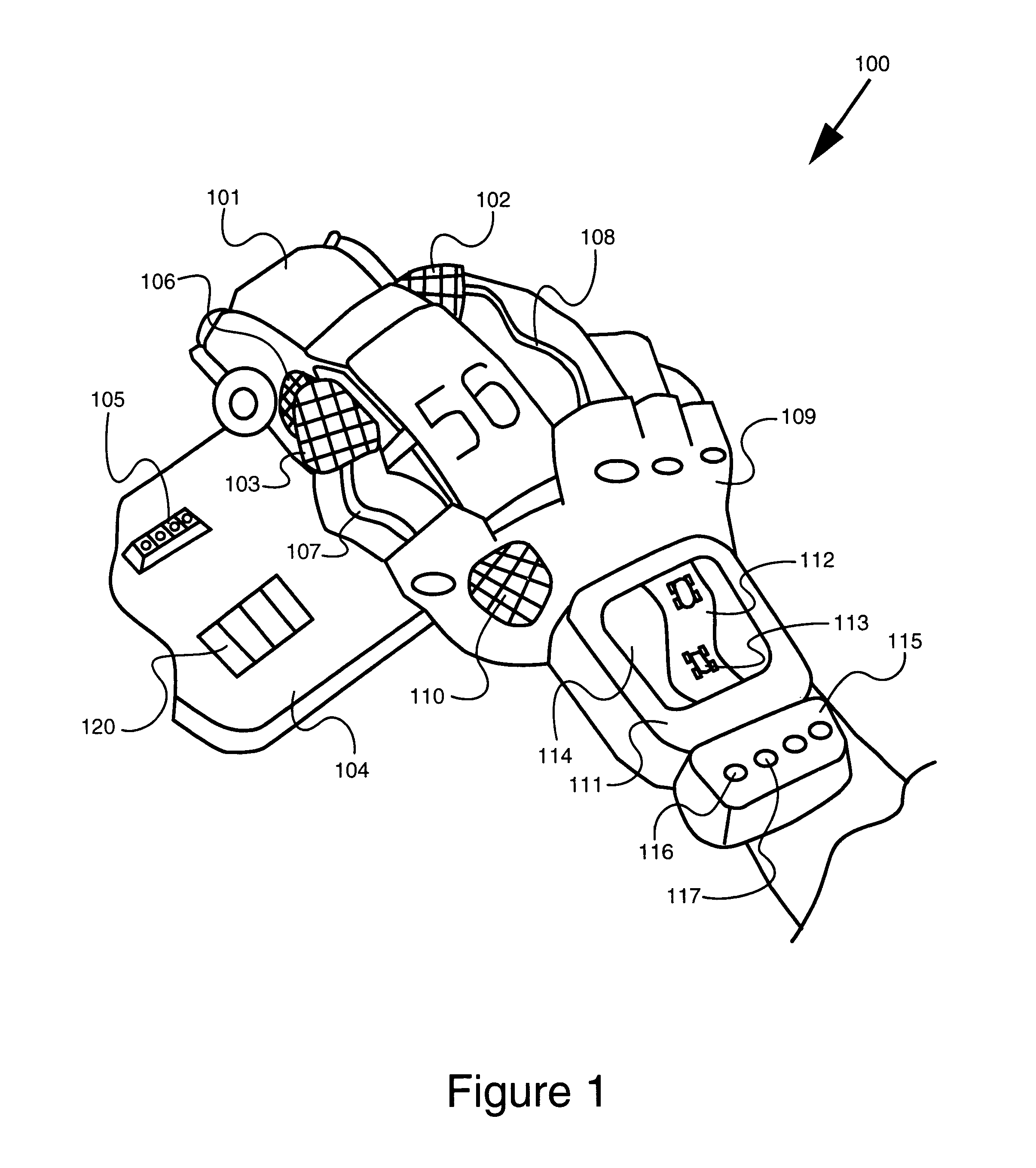

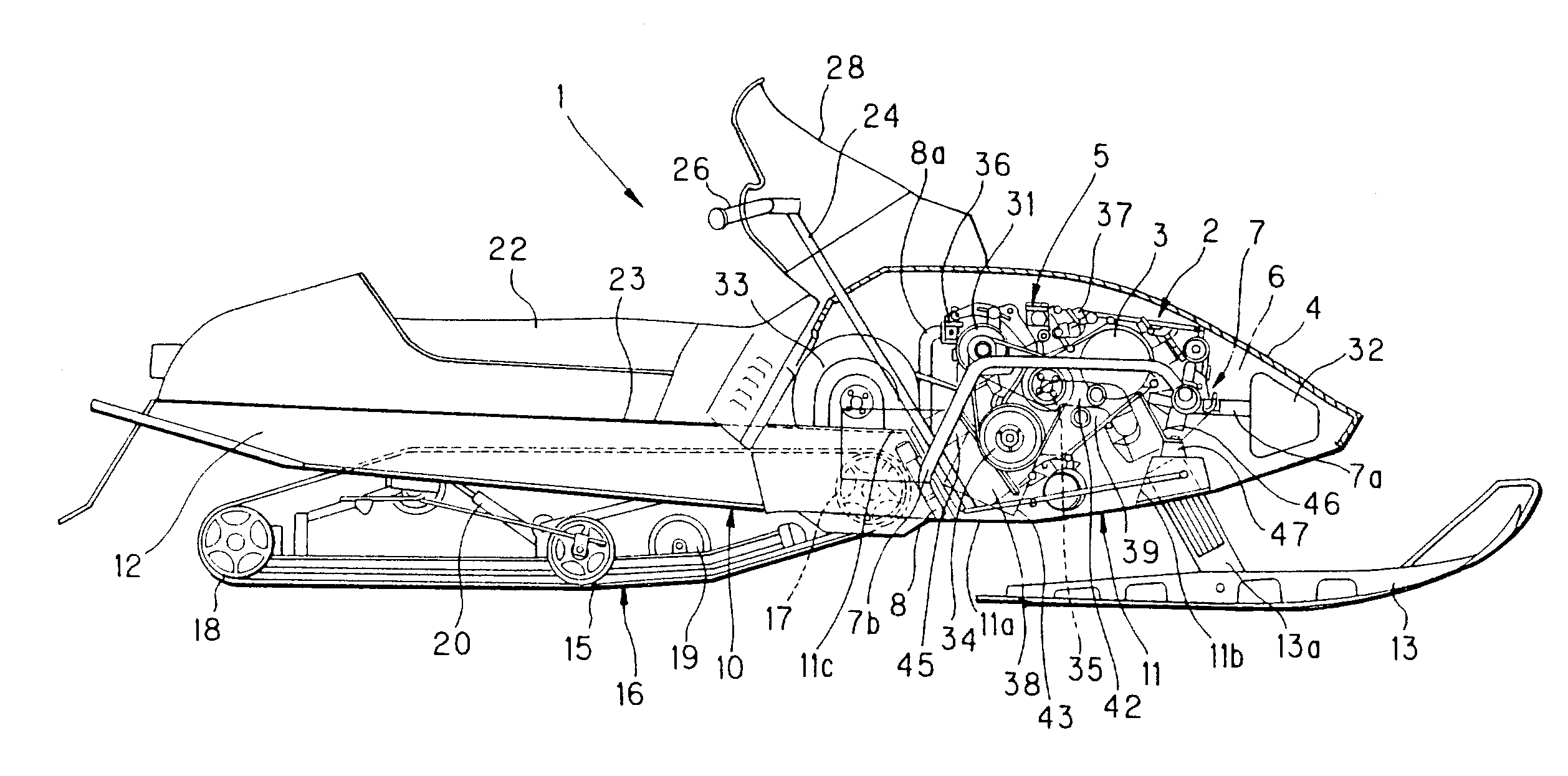

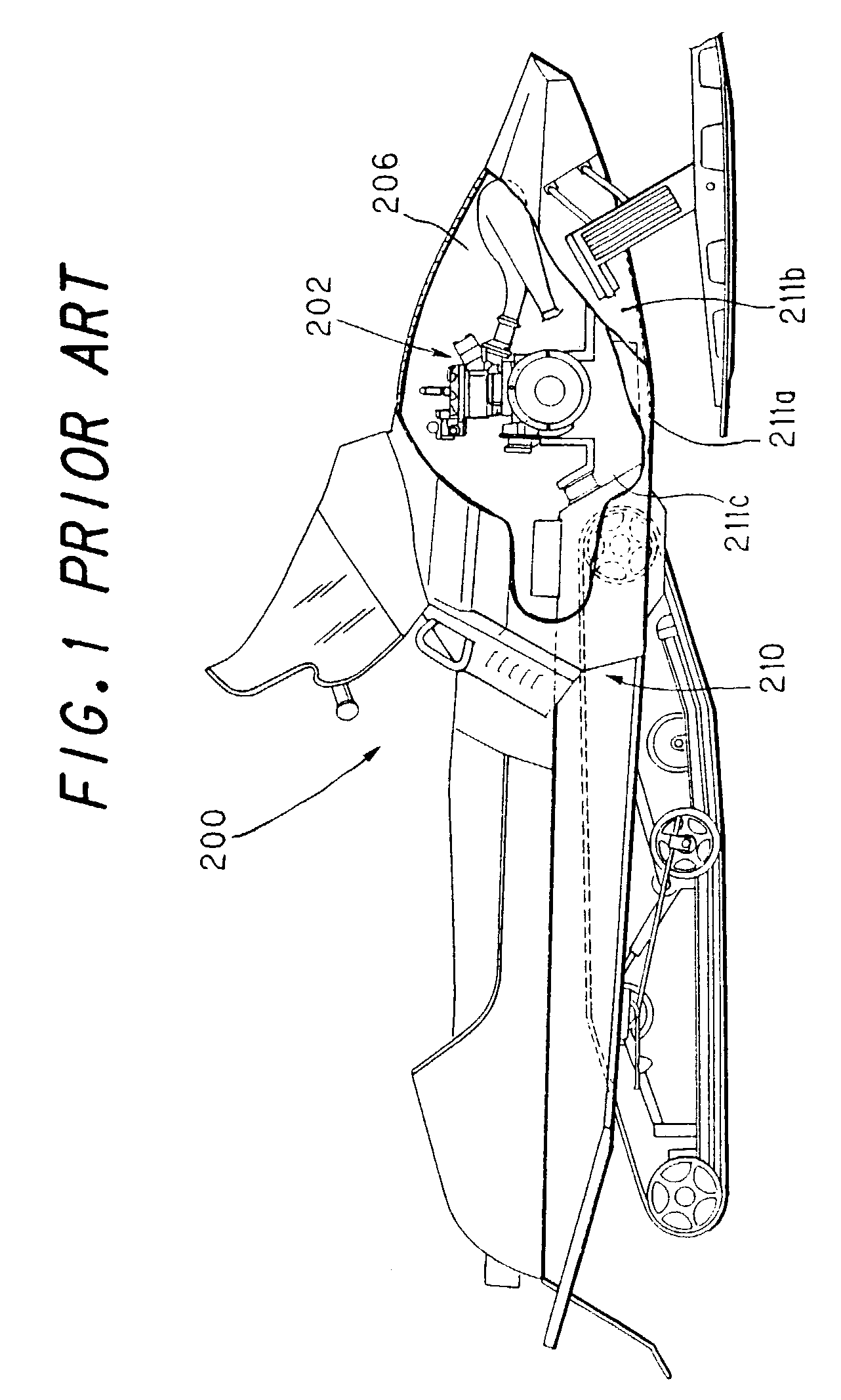

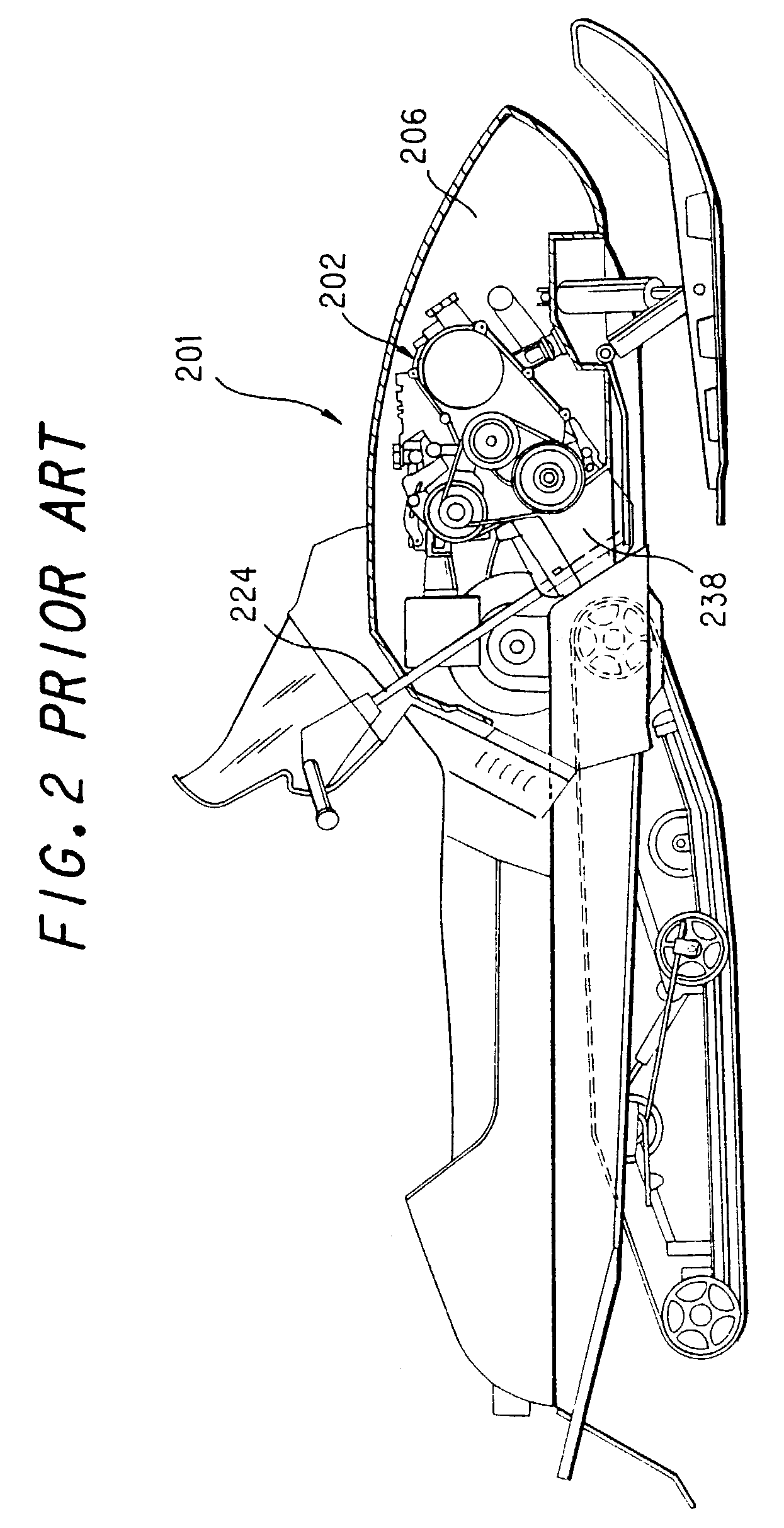

Snowmobile four-cycle engine arrangement

InactiveUS7036619B2Simplify communication pathLow costMachines/enginesRider propulsionCylinder headFuel tank

A snowmobile four-cycle engine arrangement, includes: a four-cycle engine arranged in an engine compartment formed in the front body of a snowmobile with its crankshaft laid substantially parallel to the body width and having a cylinder case inclined forwards with respect to the vehicle's direction of travel. The engine employs a dry sump oil supplying system and an oil tank separate from the engine is provided. Another snowmobile four-cycle engine arrangement includes: a four-cycle engine having a cylinder head at its top, arranged in the engine compartment and inclined forwards with respect to the vehicle's direction of travel with an intake path provided on the upper portion of the engine body. An intercooler for cooling the intake air is arranged in a tunnel created inside the body frame for accommodating a track belt.

Owner:SUZUKI MOTOR CORP

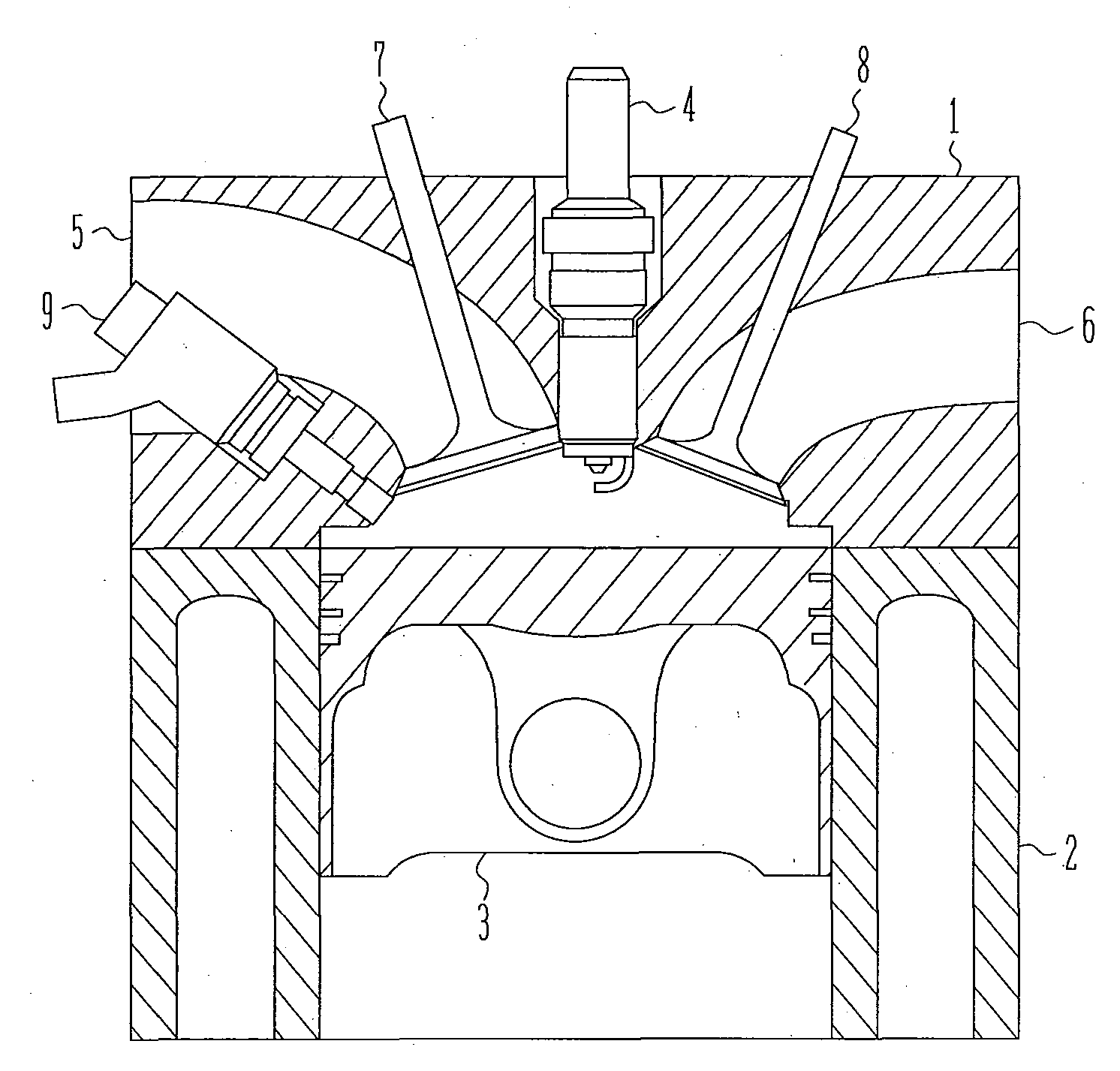

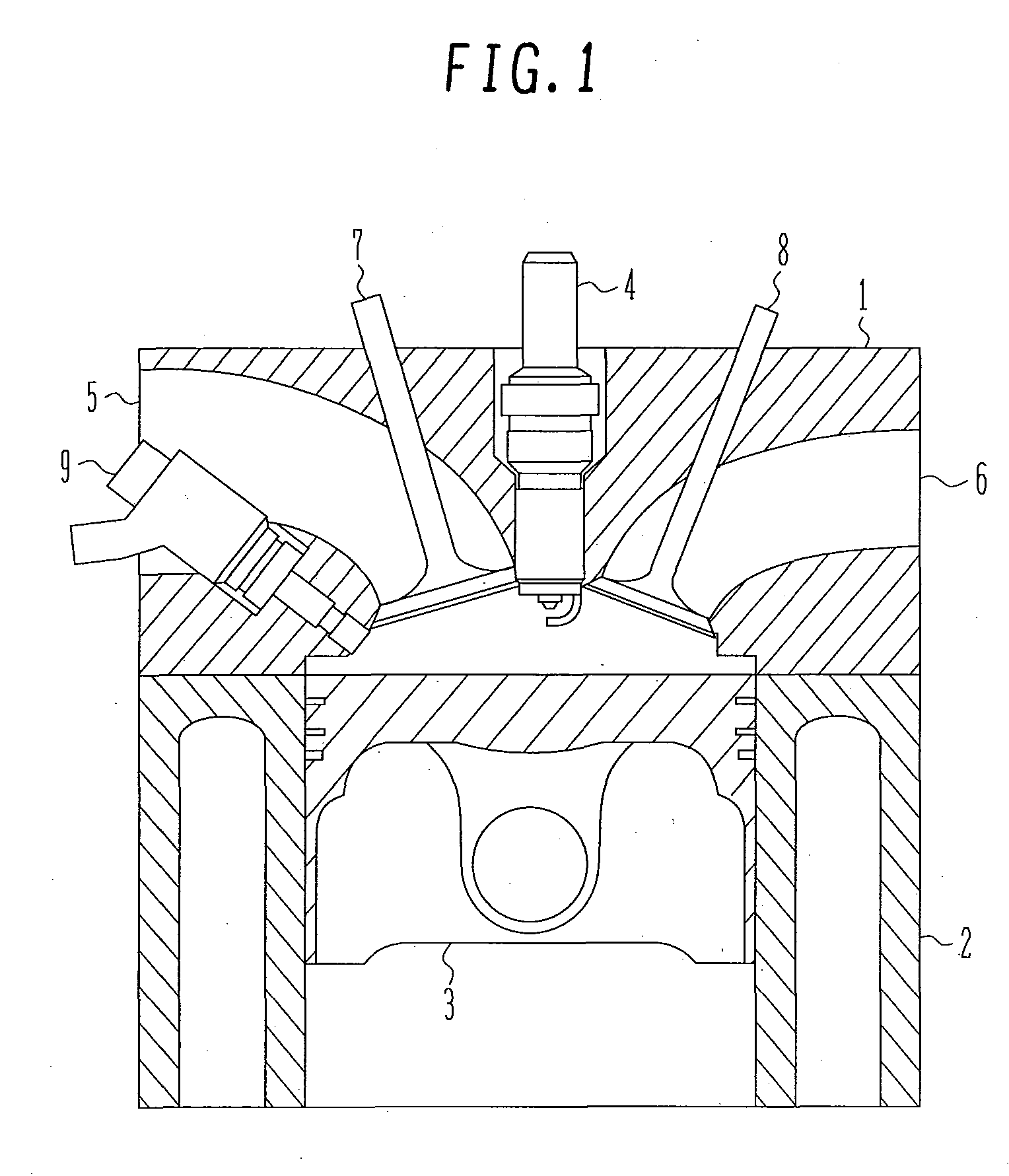

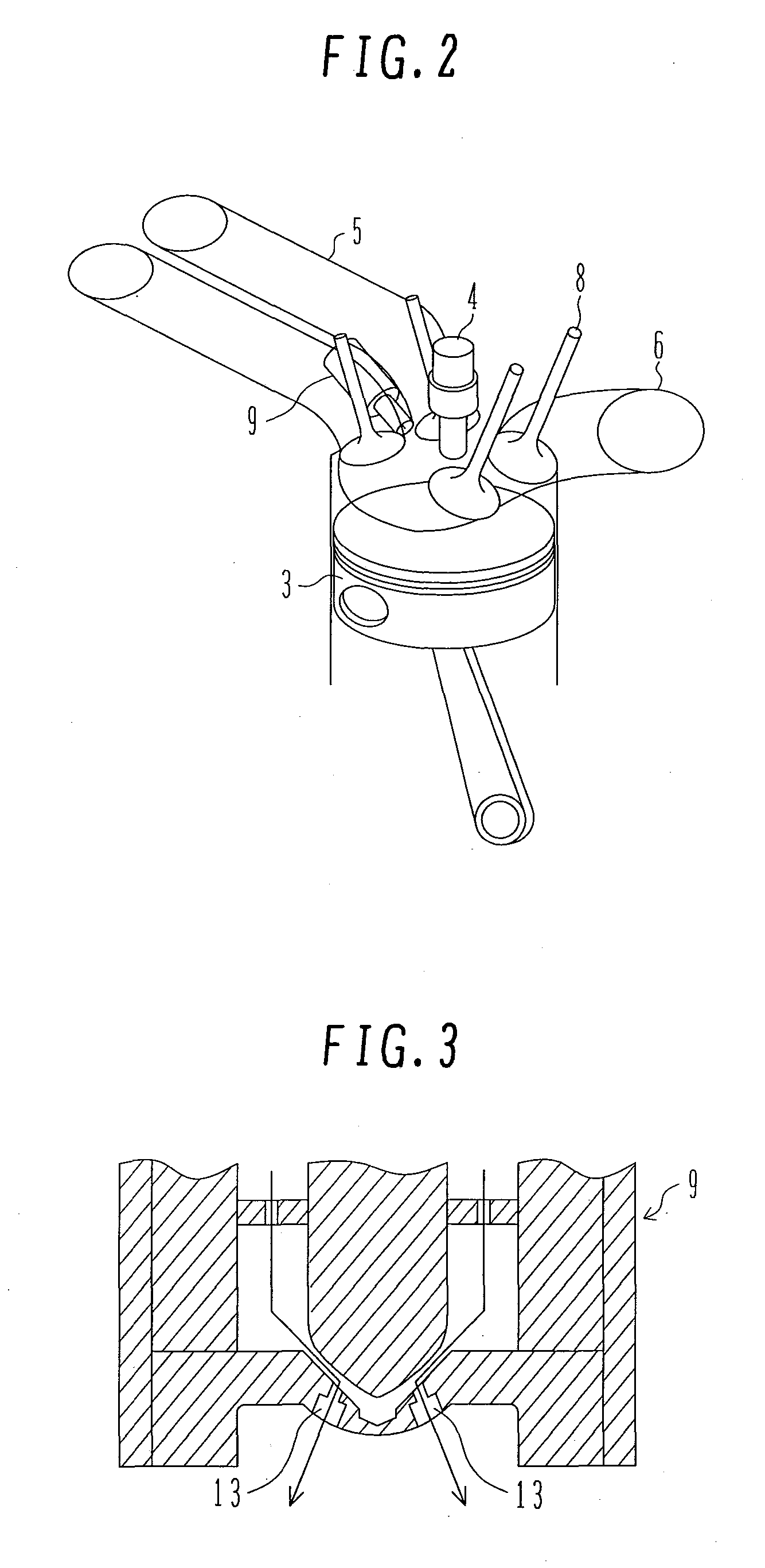

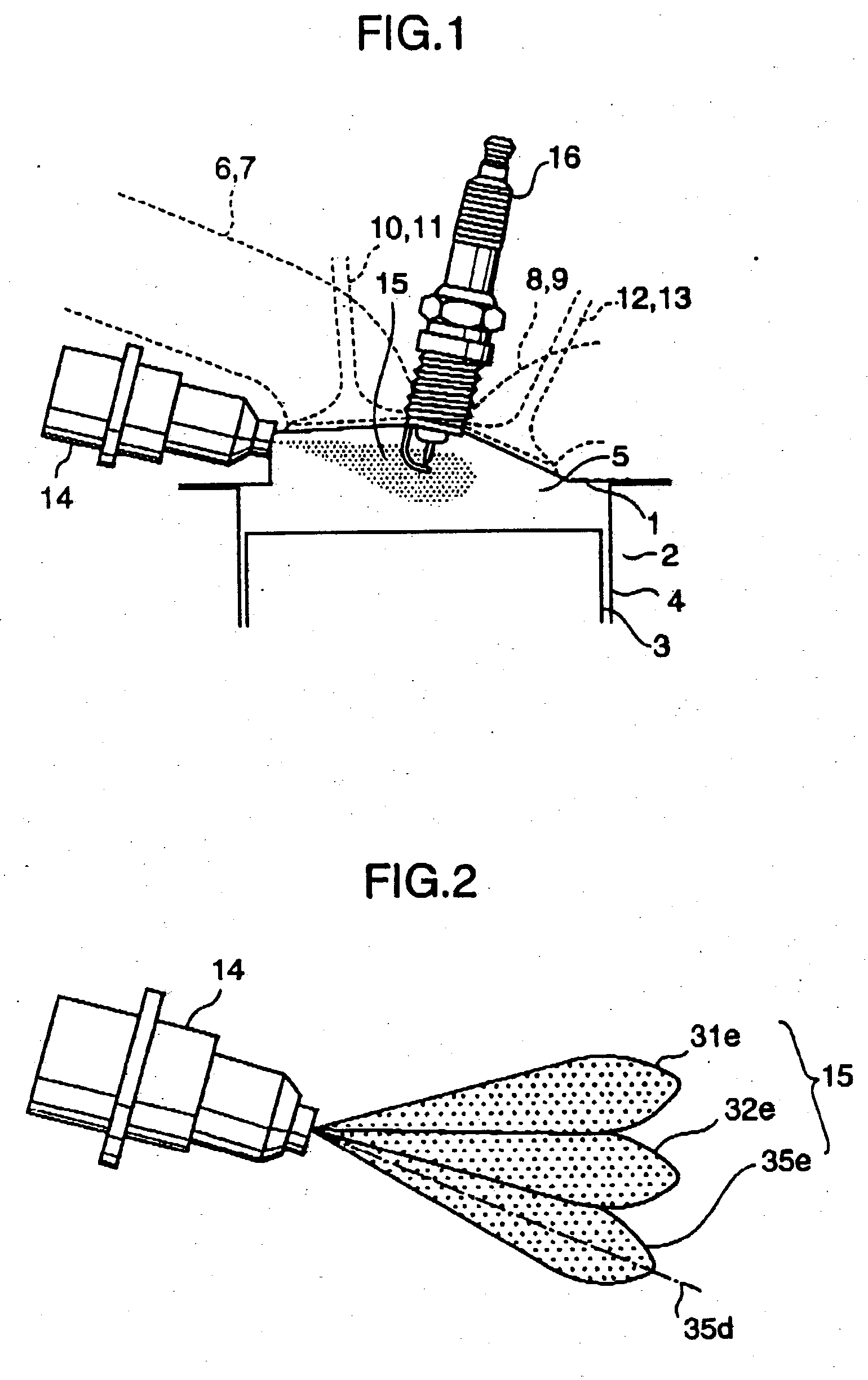

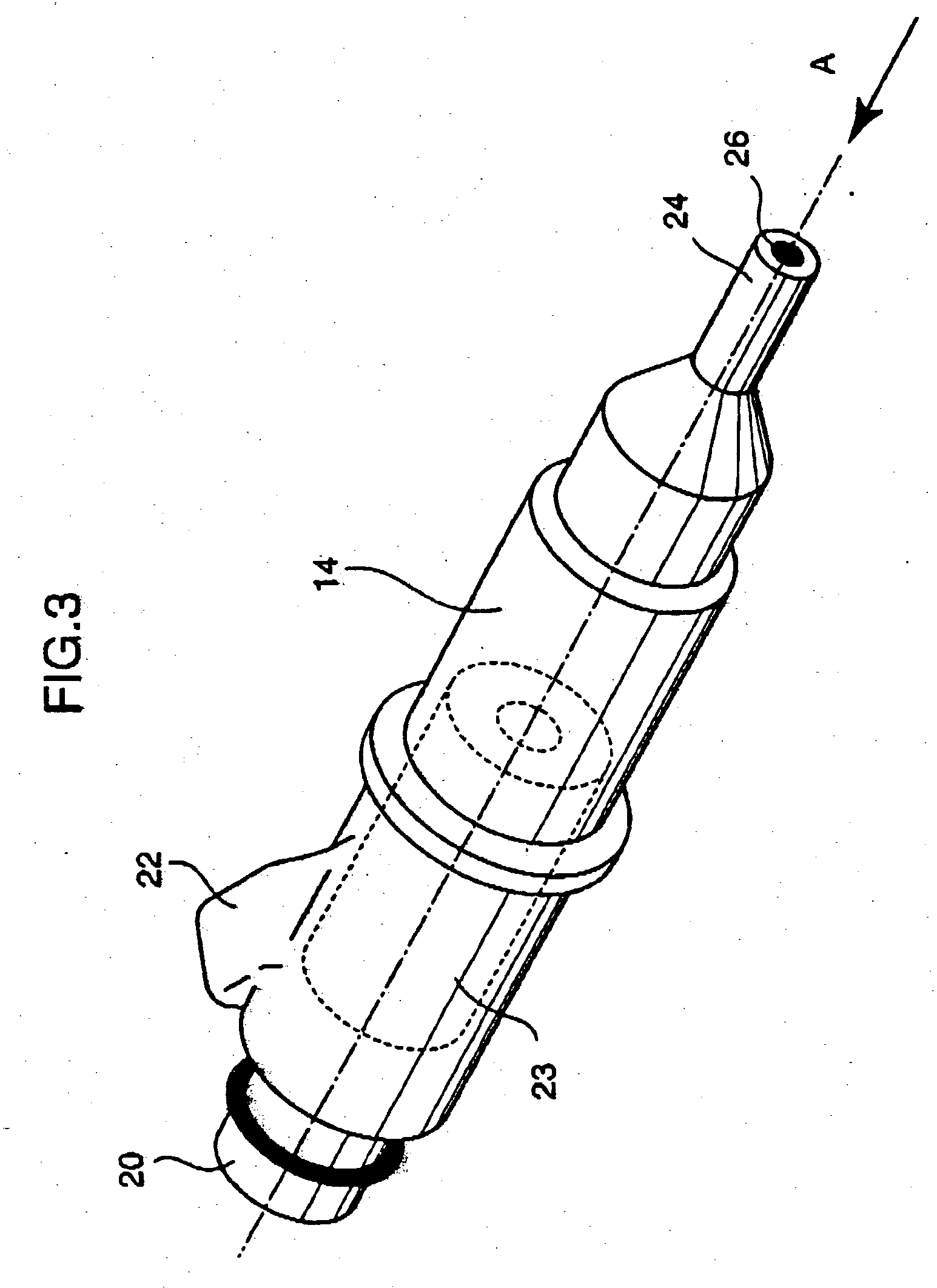

Direct-injection spark-ignition engine

InactiveUS20040011326A1Accelerate evaporationPromote atomizationInternal combustion piston enginesLow pressure fuel injectionCombustion chamberEngineering

A direct-injection spark-ignition engine includes a spark plug provided approximately at the center of the ceiling of a combustion chamber, and an injector having at its downstream end a nozzle which is located in an upper peripheral area of the combustion chamber, in which multiple openings are formed in the nozzle of the injector. Fuel is injected from the nozzle of the injector directly toward the proximity of an electrode of the spark plug. The directions of axis lines of the individual openings are set such that central points of fuel jets spewed out of the individual openings do not lie on the spark plug but are distributed around the electrode, slightly separated therefrom.

Owner:MAZDA MOTOR CORP

Manifold communication channel

ActiveUS20090013955A1Increase engine powerEngine controllersMulti-stage carburettorsExternal combustion engineEngineering

A manifold, such as an intake manifold or a fuel injection manifold, for use in an internal combustion engine, as well as a method of operating such an engine, are disclosed. In at least one embodiment, the manifold includes an input end capable of being coupled at least indirectly to an air input device, first and second intake tubes linking the input end to first and second exit ports, respectively, and a first communication channel linking the first and second intake tubes. The communication channel has a first width that is substantially less than a second width of at least one of the first and second intake tubes, and the communication channel links upper portions of the first and second intake tubes, while lower portions of the intake tubes remain separated by a wall.

Owner:KOHLER CO

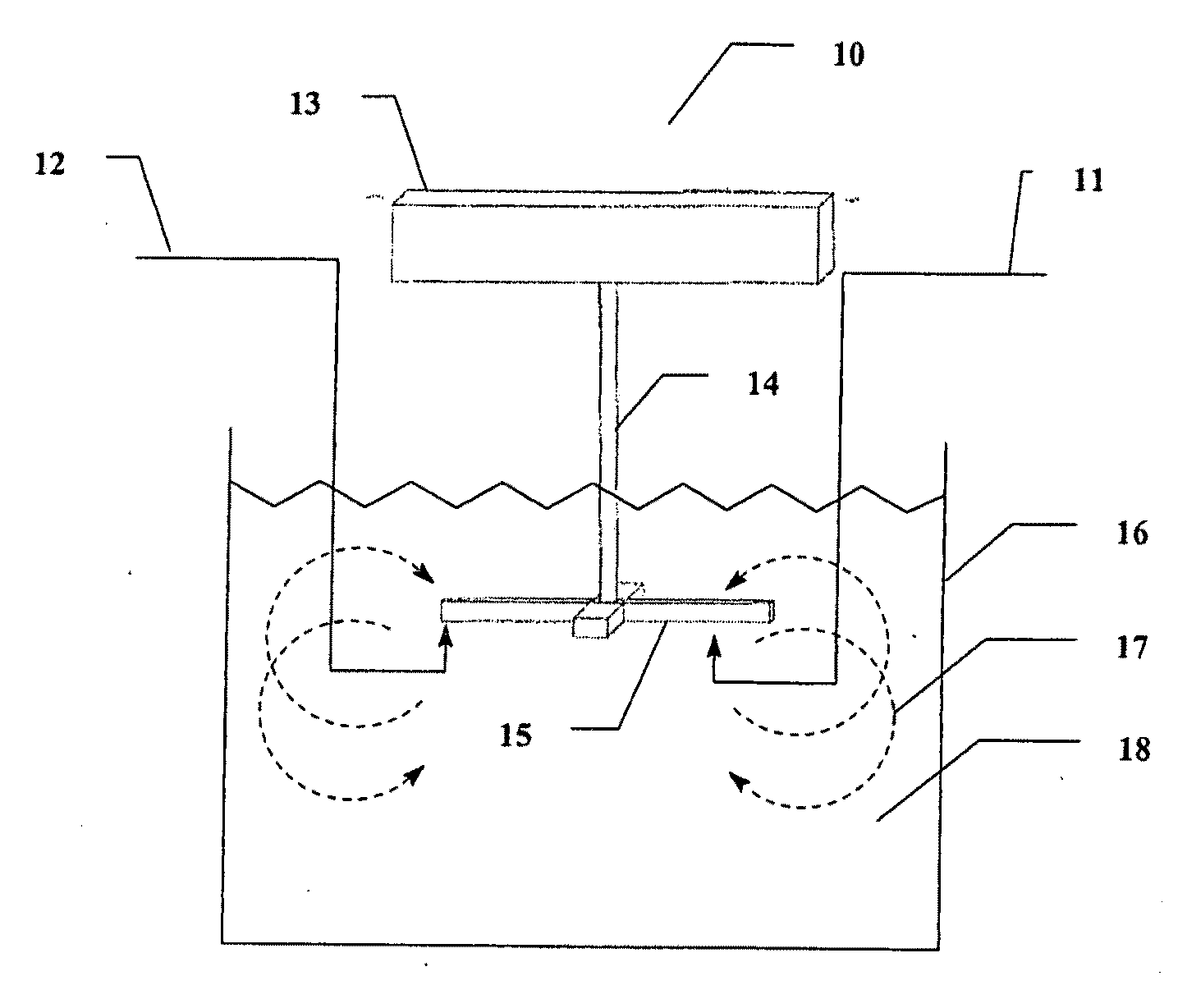

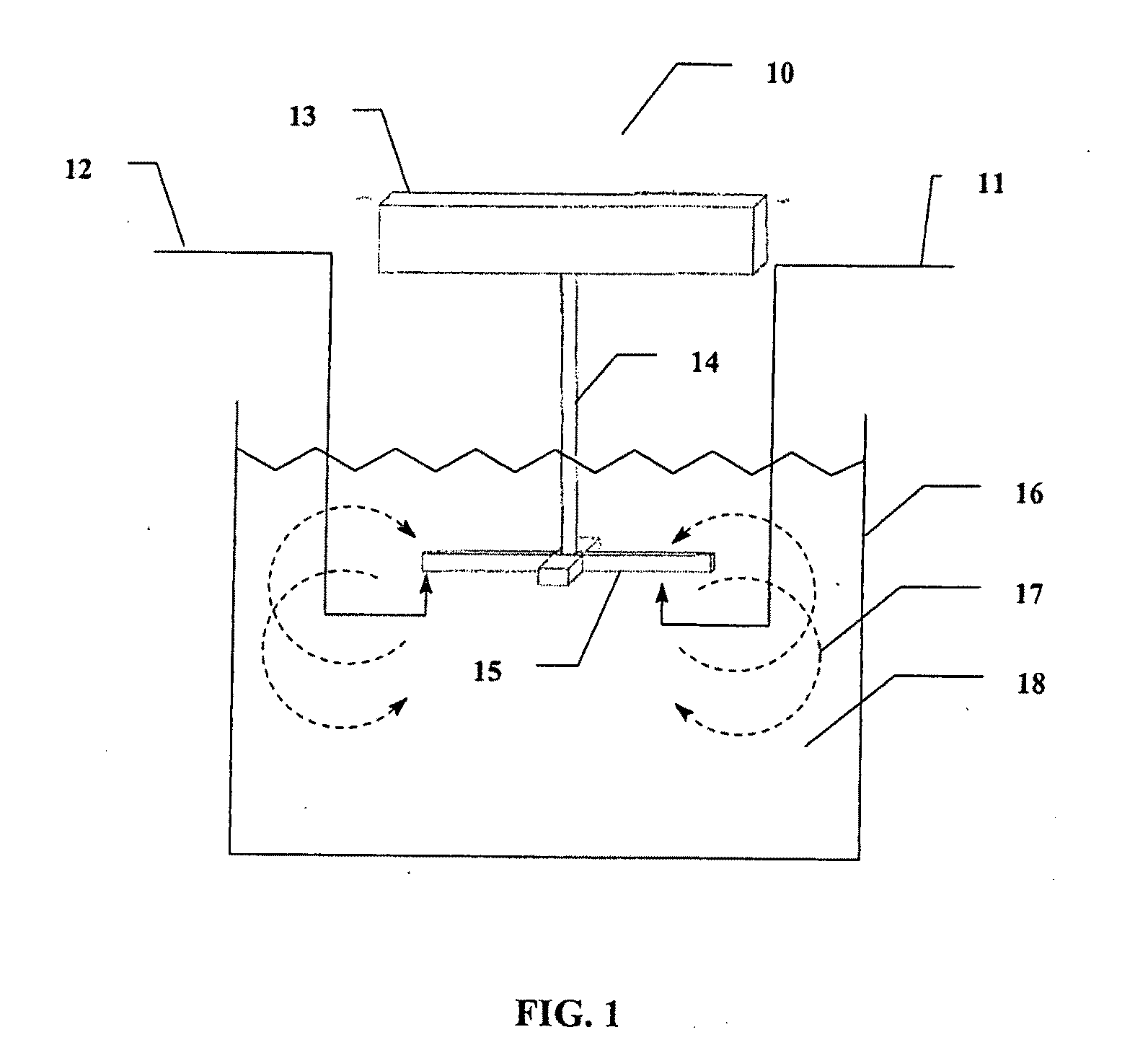

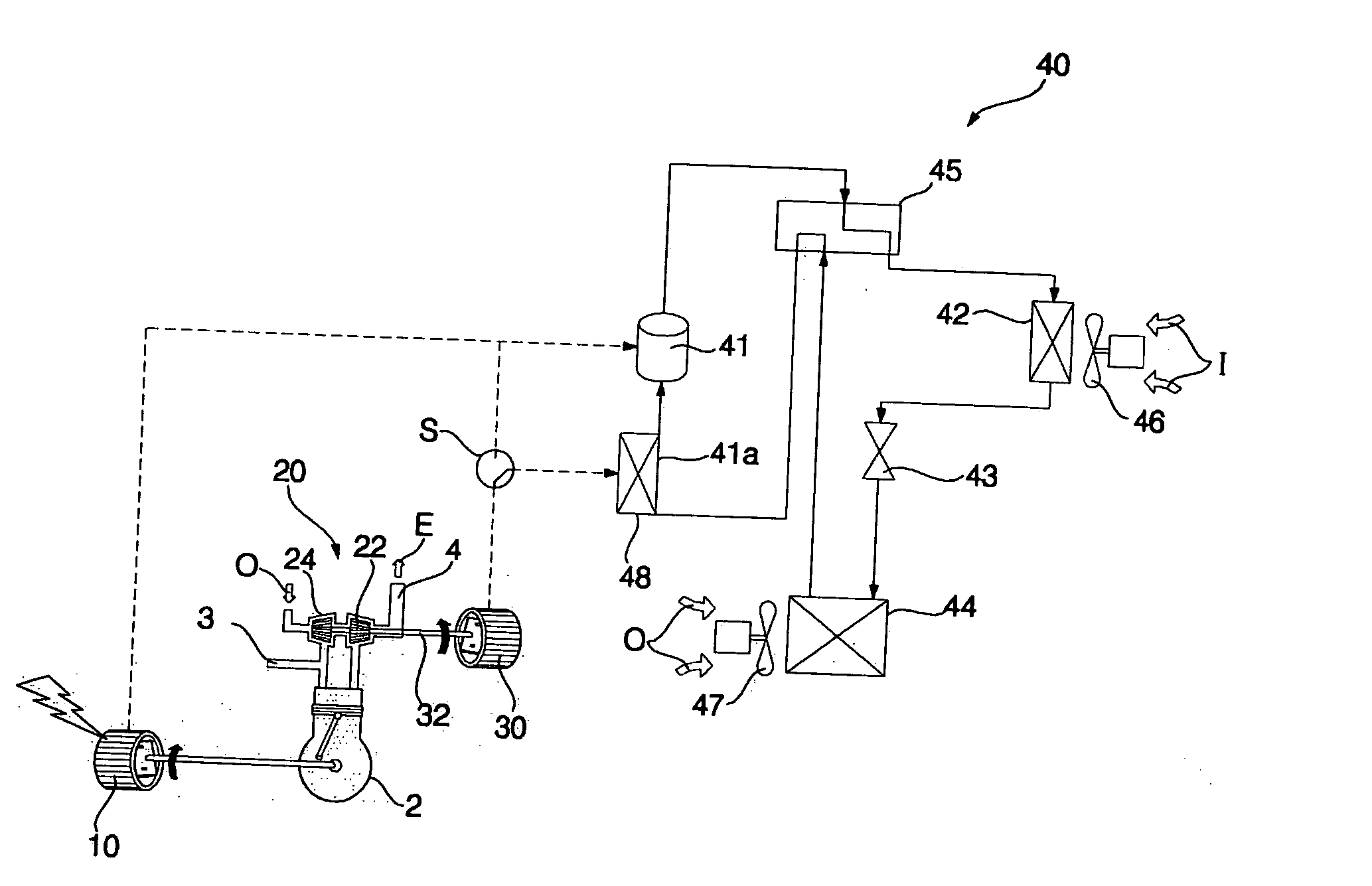

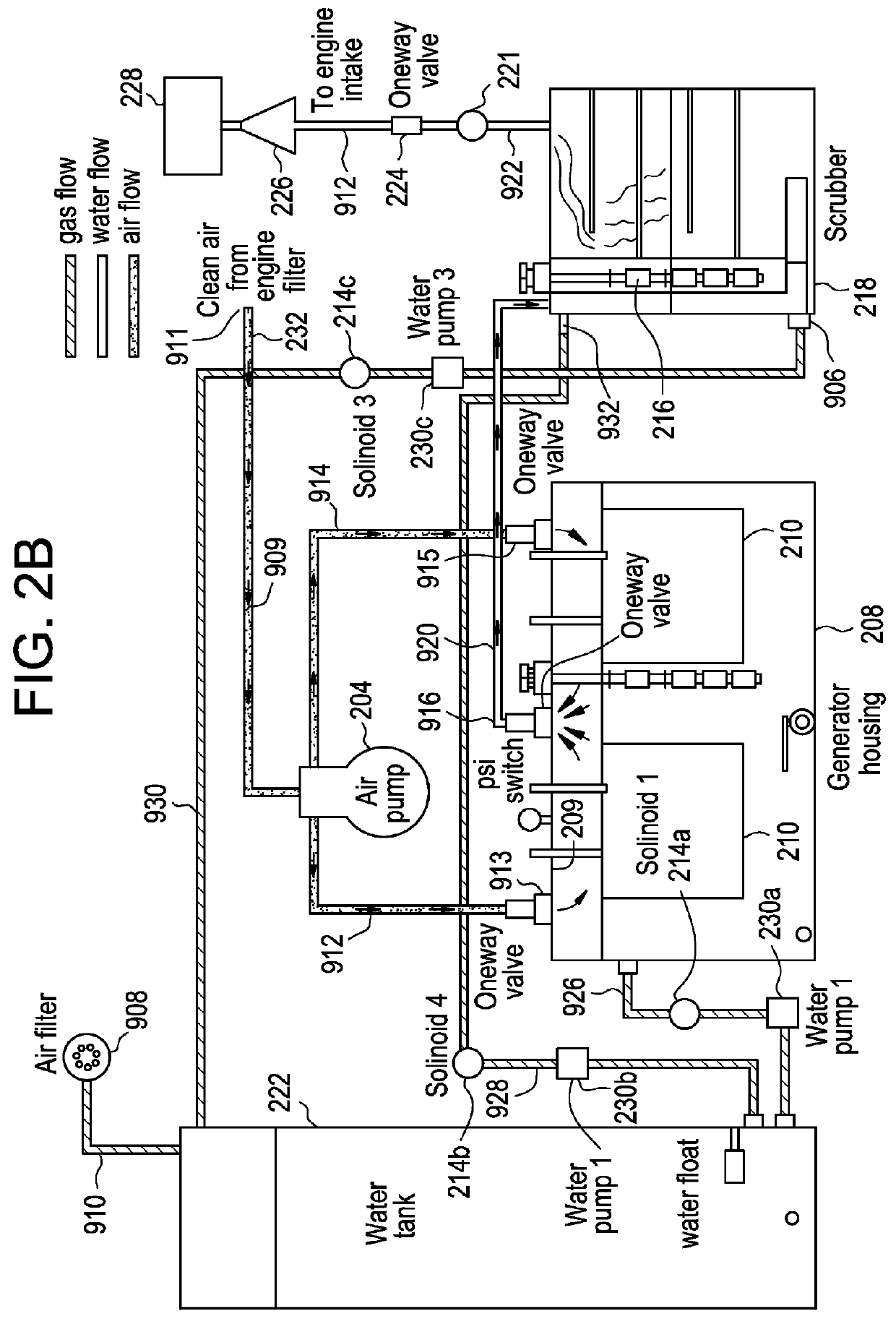

Hydrogen/oxygen on-demand system, high speed efficient hydrogen reactor system and methods therefor

ActiveUS20150159284A1Emission reductionReduce NOx emissionsCellsInternal combustion piston enginesHydrogenReactor system

A system for improving efficiency in which water or aqueous solution is broken into its core molecules of hydrogen and oxygen using a 12 volt power source, and of which this gas vapor can improve the efficiency of an engine of a vehicle in a catalytic fashion once combining with a fossil fuel, and includes a reactor housing containing at least one reactor unit having electrodes slotted in an insulated container, a solution supply system that regulates the aqueous solution in the system; and an air handling system that regulates the decomposed hydrogen and oxygen gas in the system. The reactor unit being immersed in an liquid or aqueous solution produces hydrogen and oxygen through electrolysis.

Owner:PACKER DAVID

Method for purging condensate from a charge air cooler

ActiveUS20140102424A1Increase powerHigh densityInternal combustion piston enginesCarburettorsChillerAerospace engineering

Owner:FORD GLOBAL TECH LLC

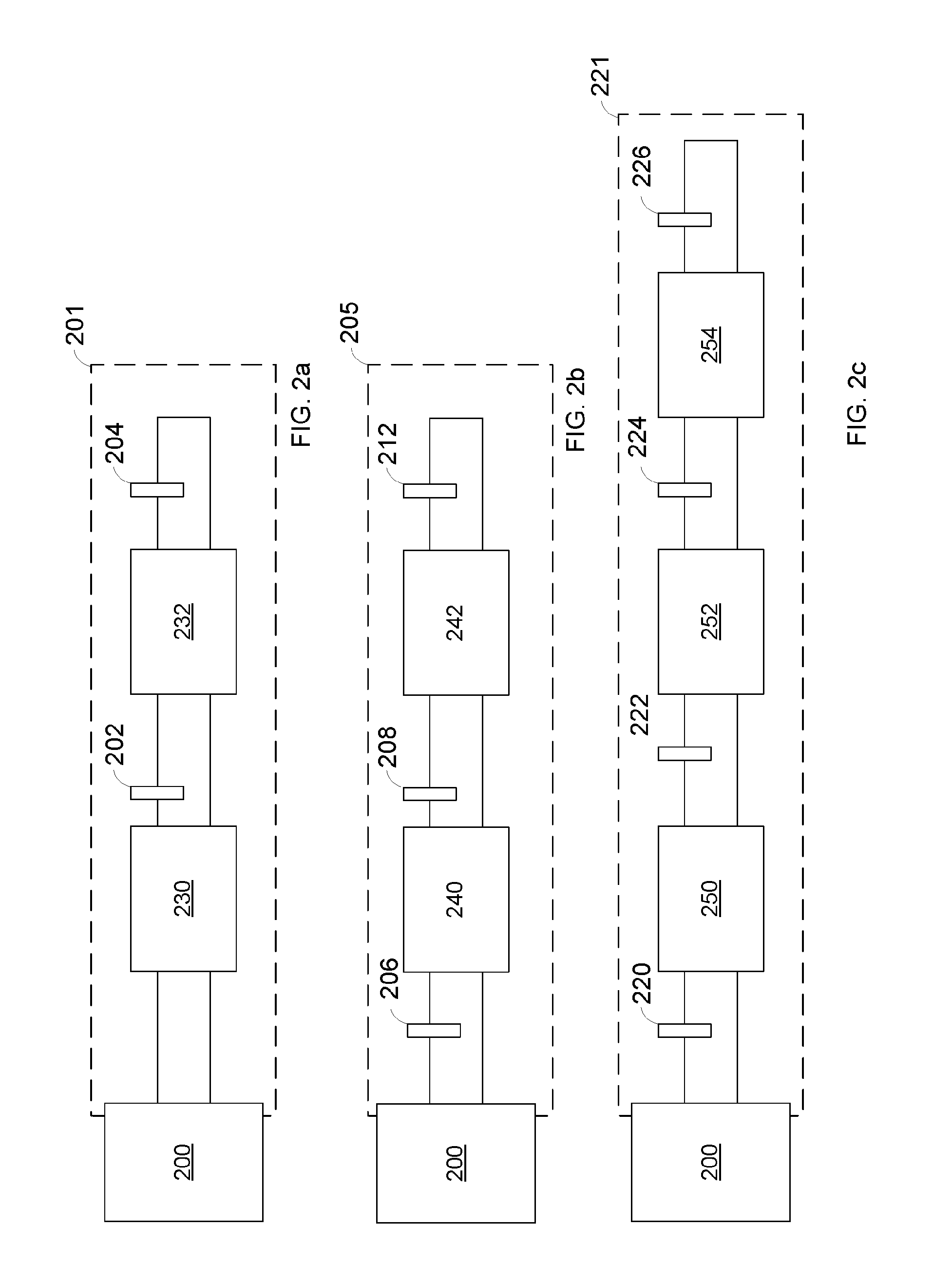

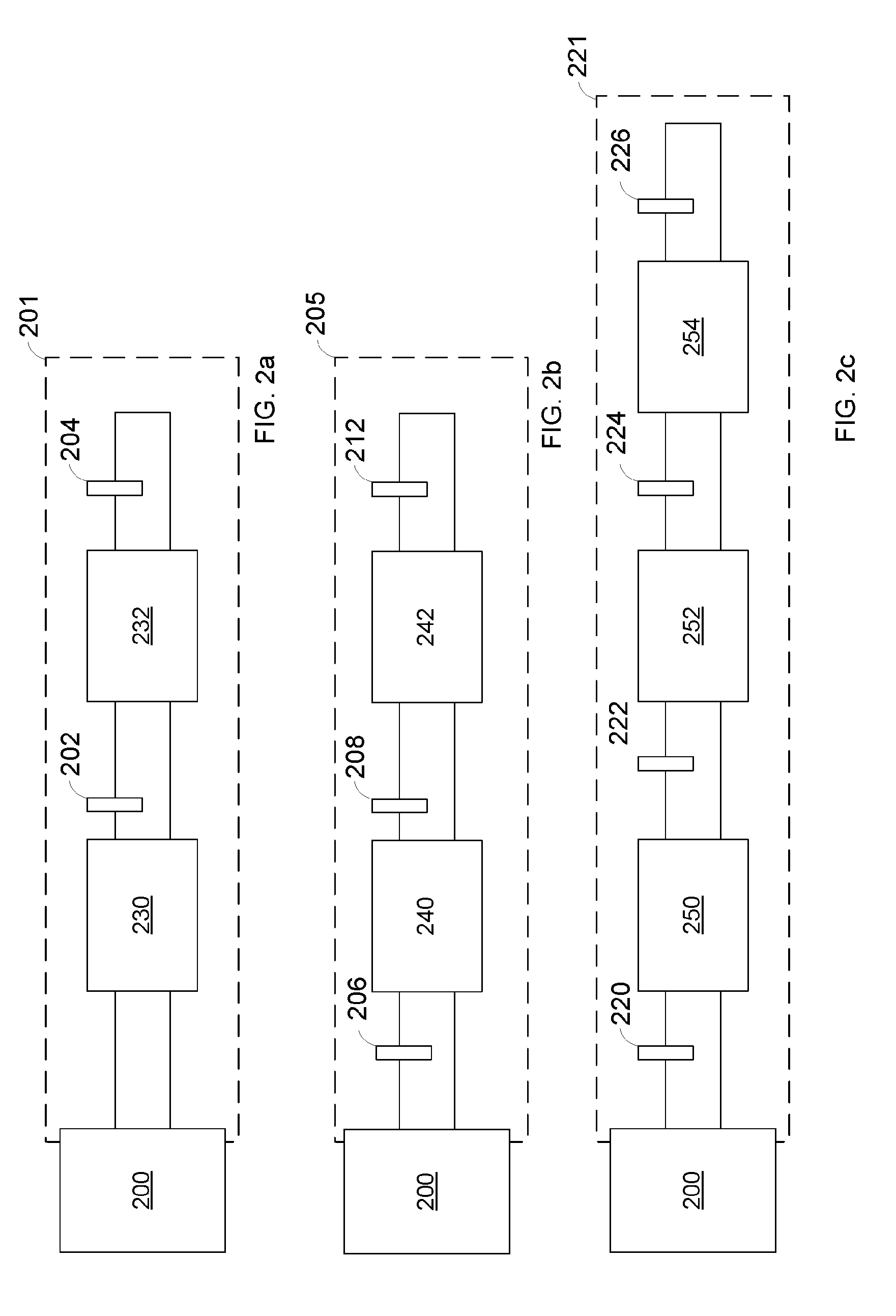

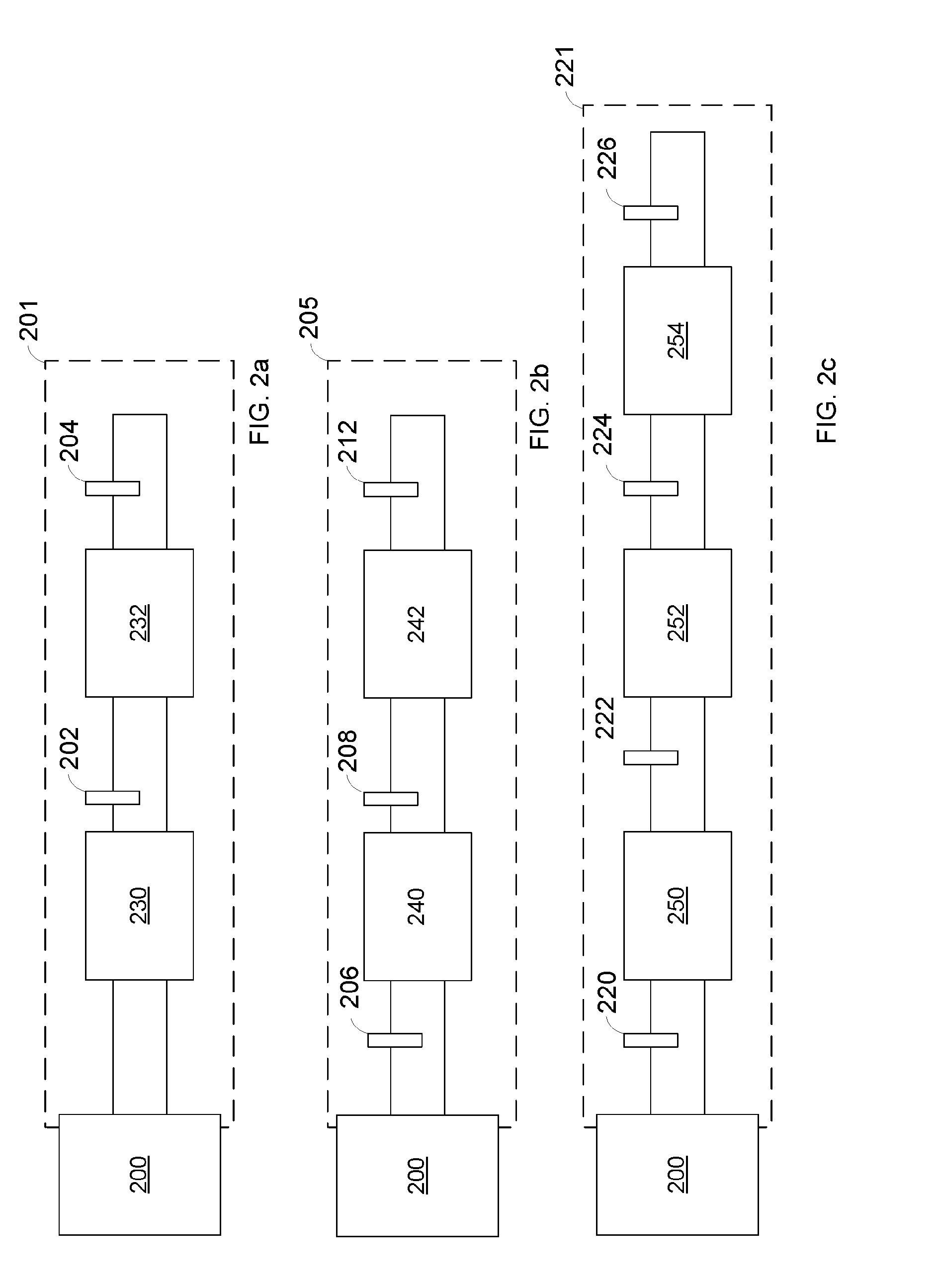

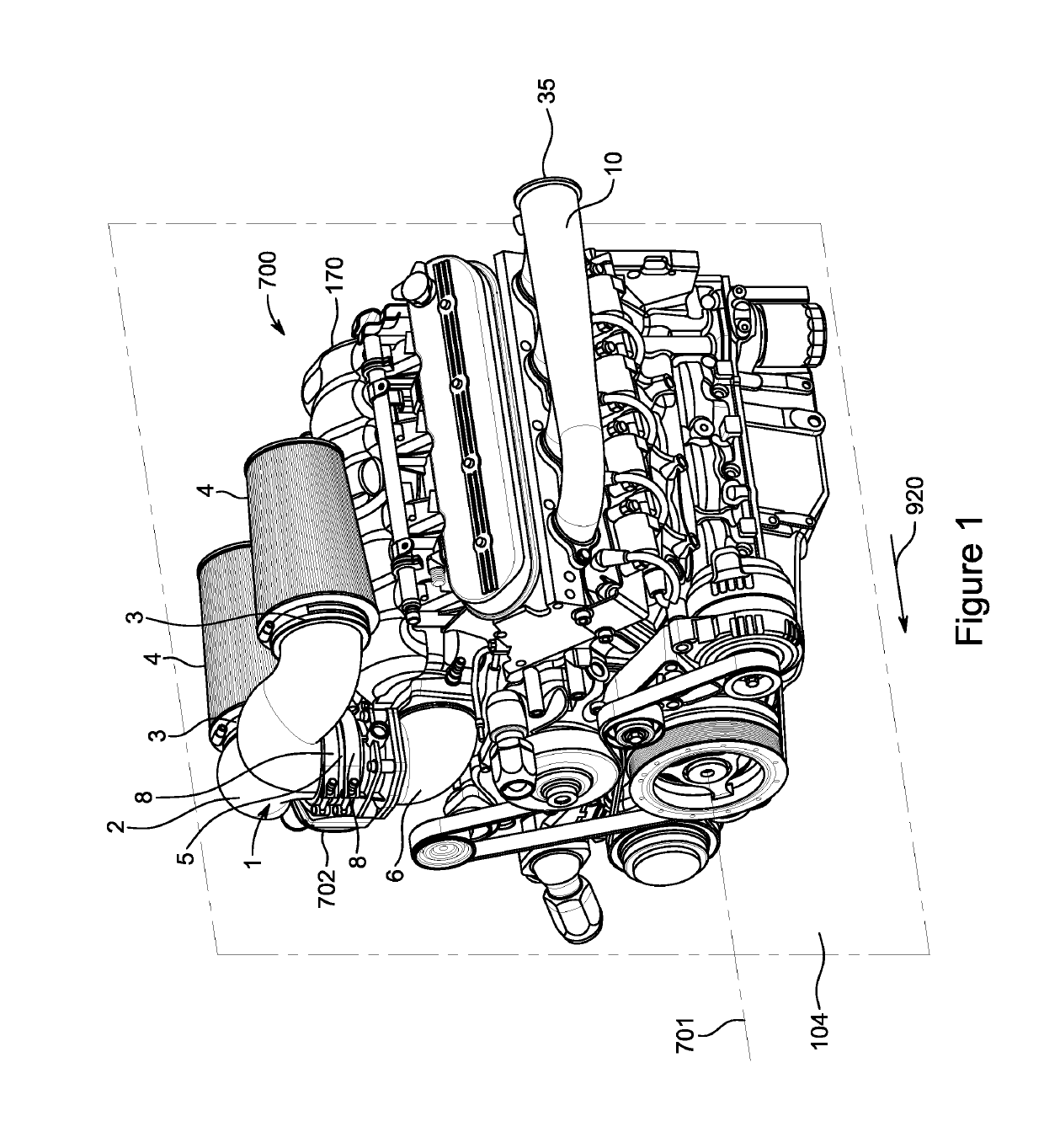

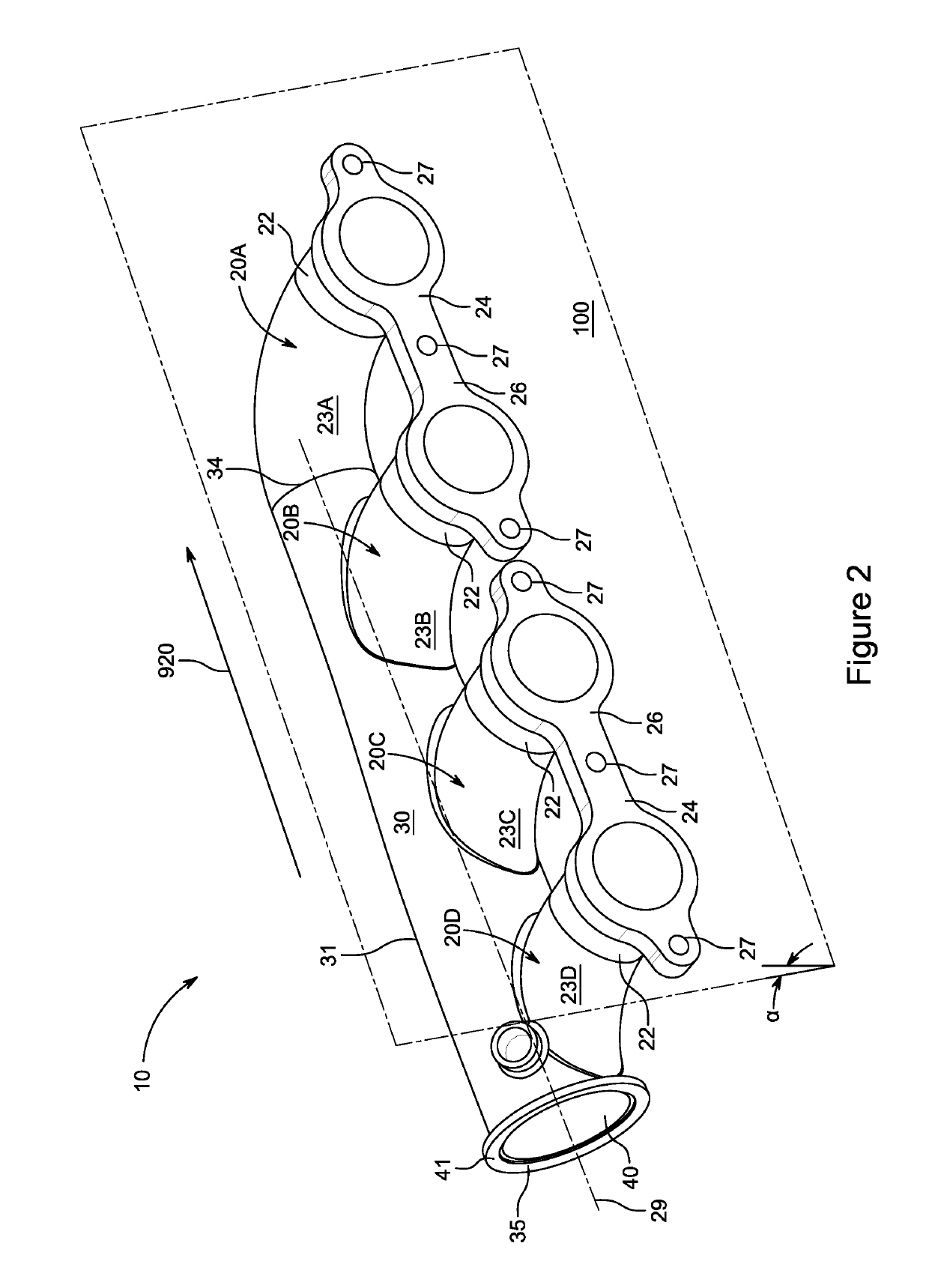

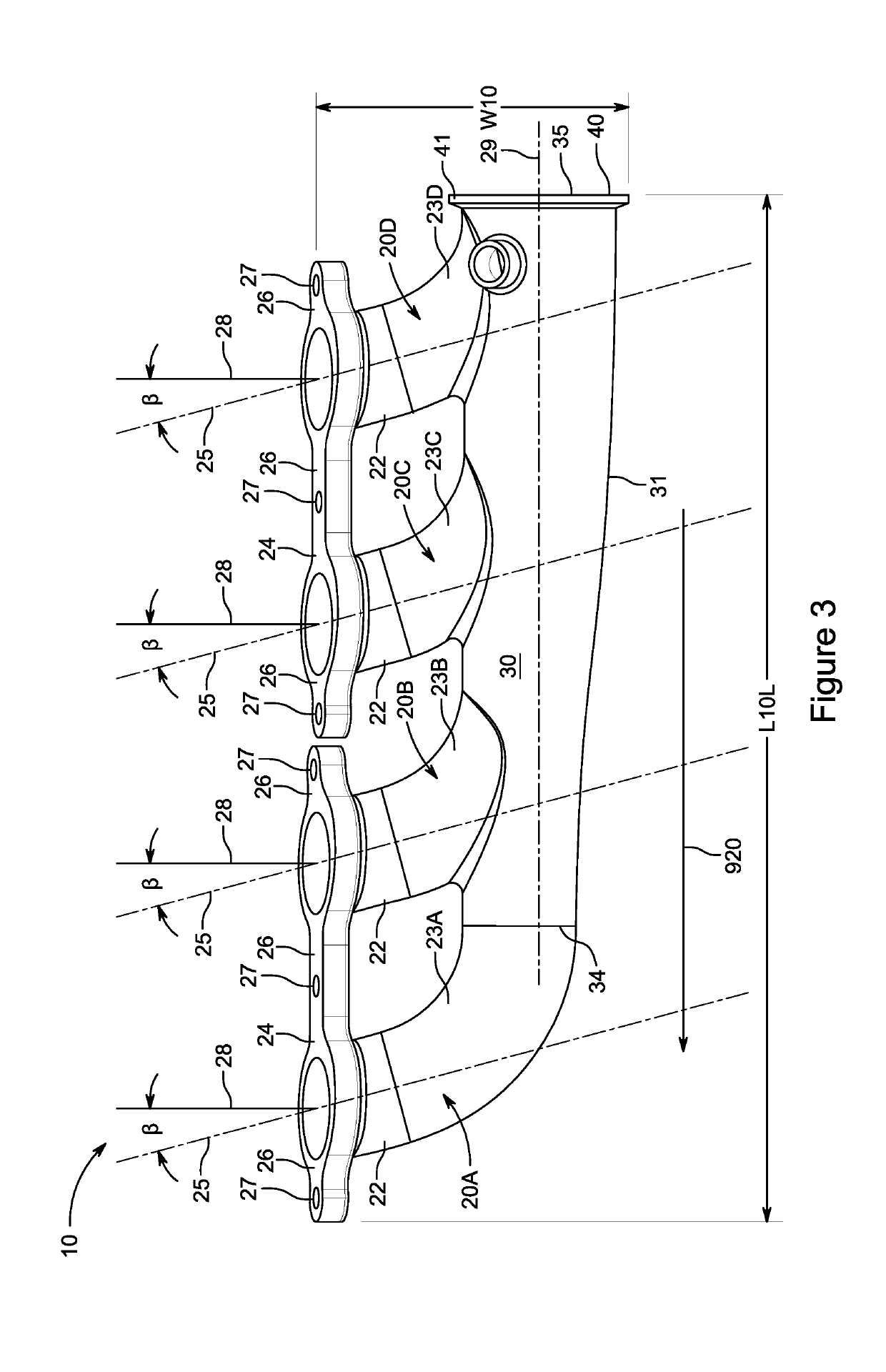

Customizable Engine Air Intake/Exhaust Systems

ActiveUS20190128221A1Improve performanceIncrease engine powerSilencing apparatusMachines/enginesVertical planeCombustion

A multi-stage reconfigurable air intake and exhaust system for an internal combustion piston engine having a first row of at least two cylinders inclined relative to a vertical plane, a second row of at least two cylinders inclined relative to the vertical plane, and the two rows of cylinders form a V configuration with the vertical plane being approximately equidistant between the two rows. The system comprises a Stage 1 package and a Stage 2 package. The Stage 1 package includes a first exhaust manifold adapted to be secured to the first row of cylinders for receiving and collecting in a plenum exhaust gases from the first row of cylinders, where the first exhaust manifold includes a first exhaust gas discharge aperture for discharging exhaust gases, the first exhaust gas discharge aperture is located at a first fixed spatial position when the first exhaust manifold is secured to the first row of cylinders, and there is provided first connecting means proximate the first exhaust gas aperture. The Stage 1 package additionally includes a second exhaust manifold adapted to be secured to the second row of cylinders for receiving and collecting in a plenum exhaust gases from the second row of cylinders, where the second exhaust manifold includes a second exhaust gas discharge aperture for discharging exhaust gases, the second exhaust gas discharge aperture is located at a second fixed spatial position when the second exhaust manifold is secured to the first row of cylinders, and there is provided second connecting means proximate the second exhaust gas aperture. The Stage 2 package includes a first turbo exhaust manifold adapted to be secured to the first row of cylinders for receiving and collecting in a plenum exhaust gases from at least from the first row of cylinders, where the first turbo exhaust manifold includes a first turbocharger connection aperture adapted for mounting a turbocharger and for delivering to the turbocharger exhaust gases from either the first row of cylinders or the first row of cylinders and the second row of cylinders, a first exhaust gas passage aperture and third connecting means proximate the first exhaust gas passage aperture, the first turbo exhaust manifold being dimensioned so that the first exhaust gas passage aperture is located at about the first fixed spatial position when the first turbo exhaust manifold is secured to the first row of cylinders in lieu of the first exhaust manifold, and a crossover pipe assembly having a second exhaust gas passage aperture and fourth connecting means proximate the second exhaust gas passage aperture, and having a third exhaust gas passage aperture and fifth connecting means proximate the third exhaust gas passage aperture, where the fourth and fifth connecting means are each adapted for coupling to any two of the first, second and third connecting means

Owner:AUTO IP LLC

System and methods for reducing particulate matter emissions

ActiveUS20170298850A1Reduce smoke and dust emissionsIncrease drivetrain costElectrical controlInternal combustion piston enginesParticulatesHigh pressure

A method may comprise: positioning a pressure control valve (PCV) at an outlet of a fuel rail; positioning a volume control valve (VCV) at an inlet of a high pressure pump; and in response to an exhaust particulate matter (PM) level deviating from a target PM level, adjusting a fuel ratio of a first fuel and a second fuel delivered to an engine, and opening one of the PCV and the VCV. In this way, the fuel oxygen content may be adjusted to maintain a PM at or below a target level without a DPF over a broad range of engine designs and operating conditions, while maintaining fuel economy.

Owner:FORD GLOBAL TECH LLC

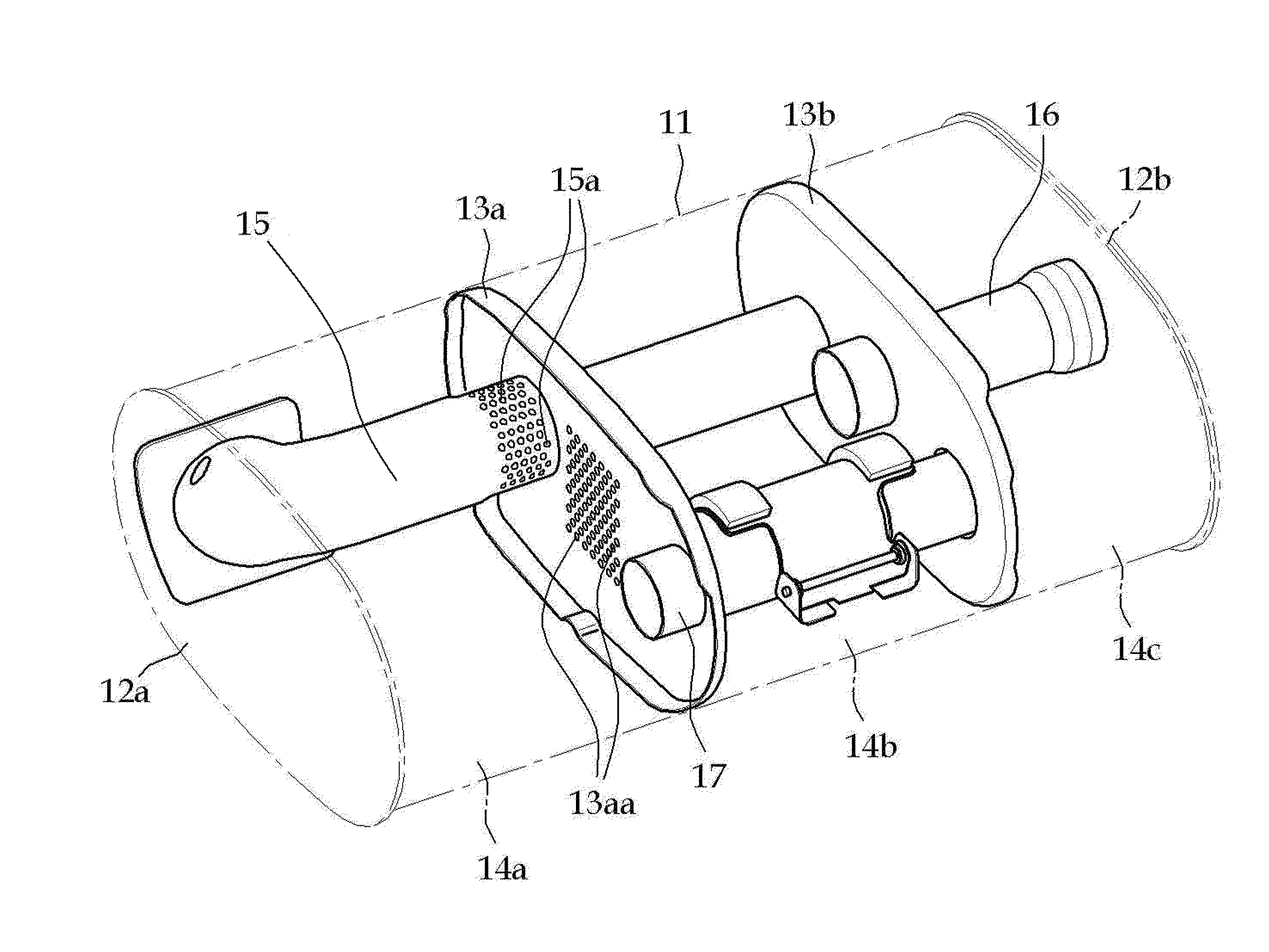

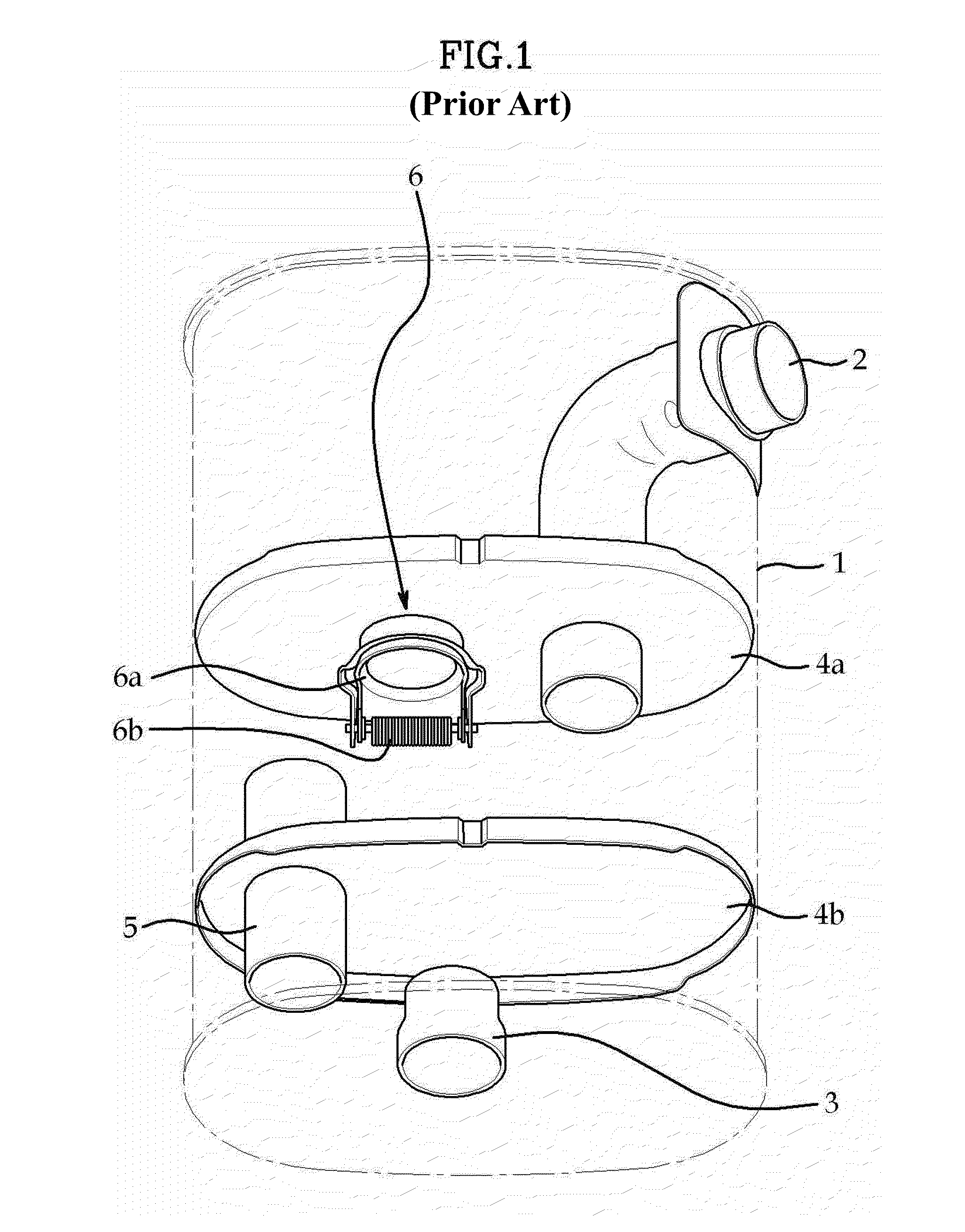

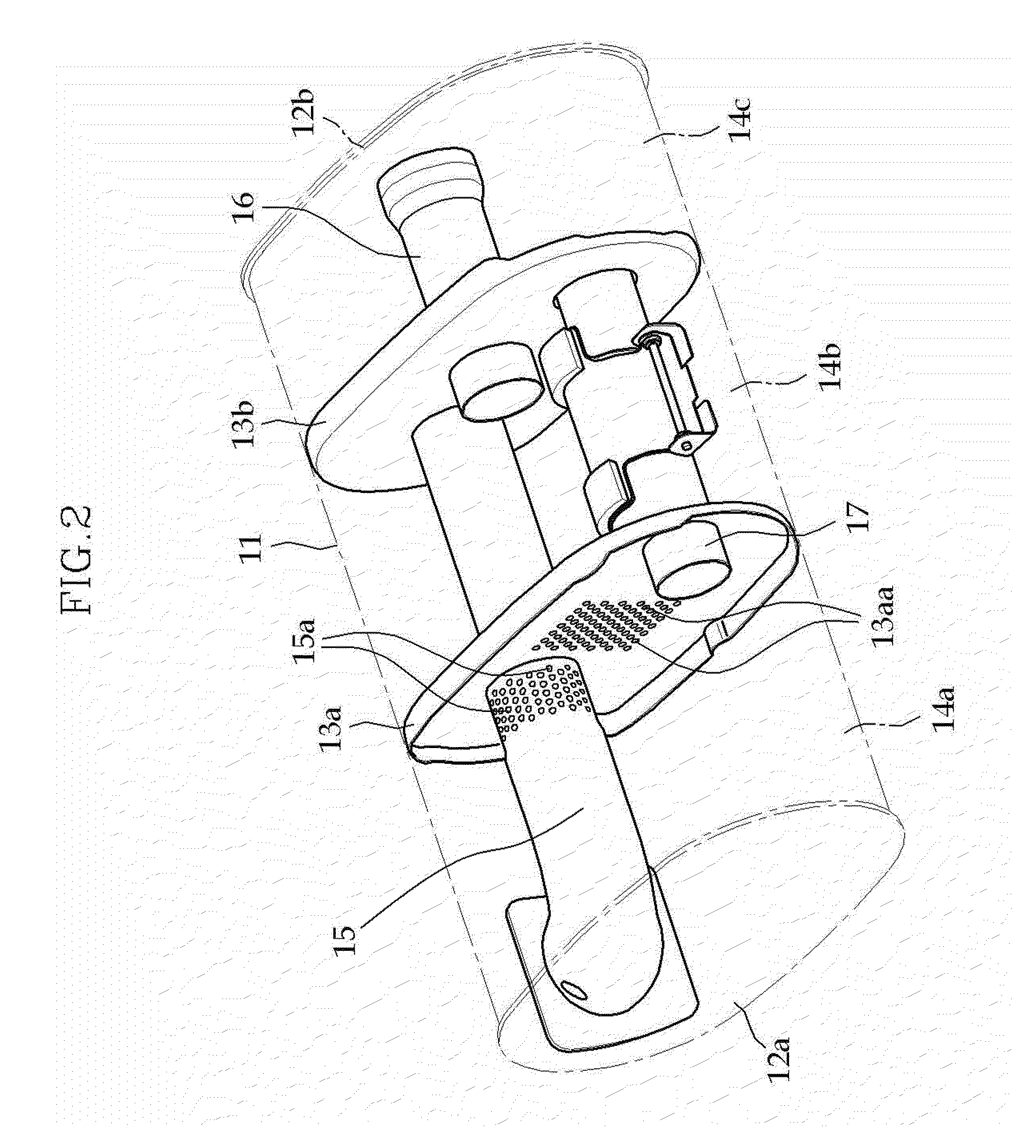

Flow Passage Control Valve for Muffler

InactiveUS20100140014A1Discharge noise is reducedEasy to controlSilencing apparatusEqualizing valvesEngineeringControl valves

A flow passage control valve for a muffler may include an opening formed through a guide pipe, which forms an exhaust gas channel in the muffler, to form another exhaust gas channel, and a valve body adjusts an open amount of the opening by using a difference between an exhaust gas pressure exerted through the opening and a weight of the valve body.

Owner:HYUNDAI MOTOR CO LTD

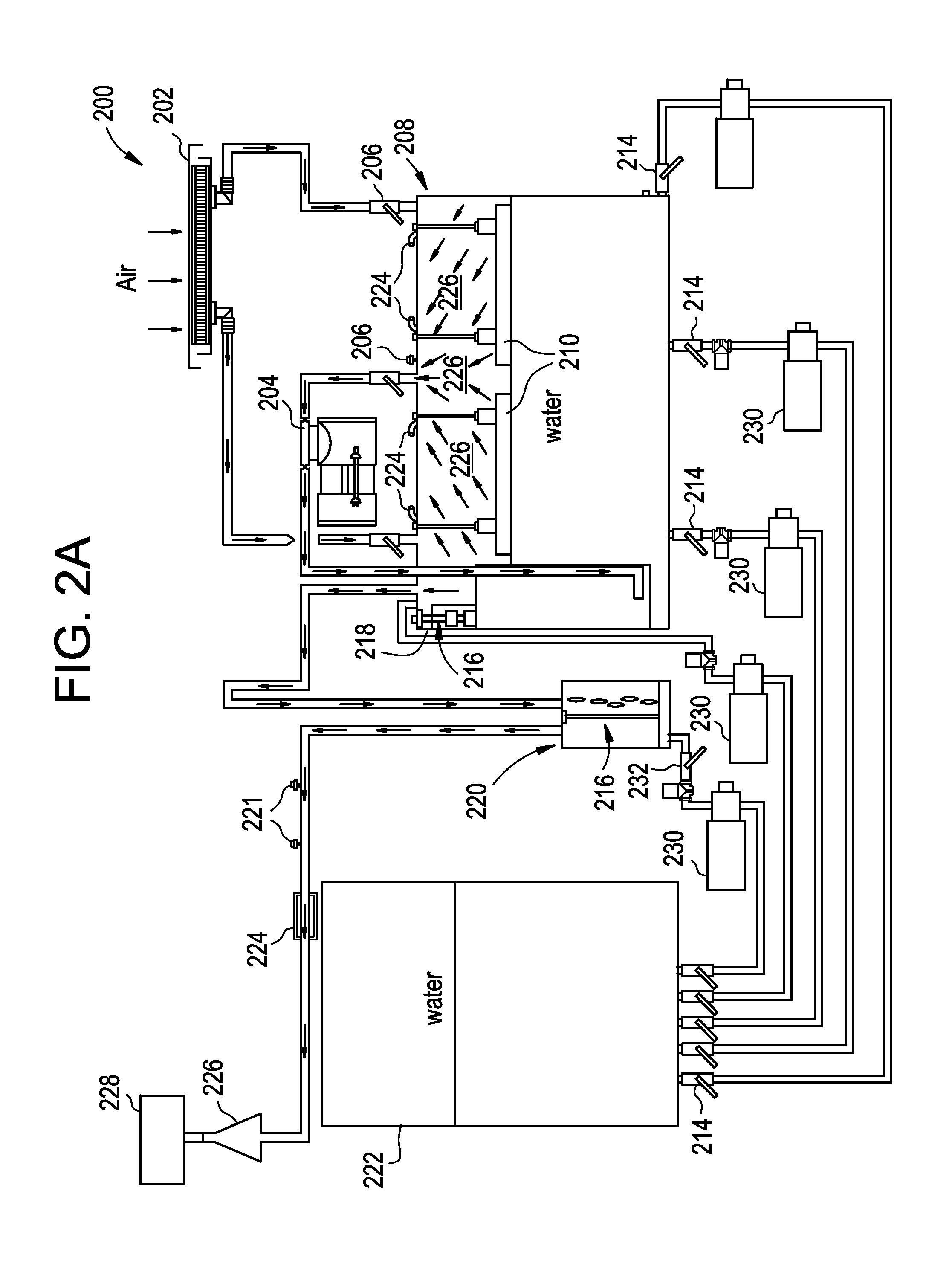

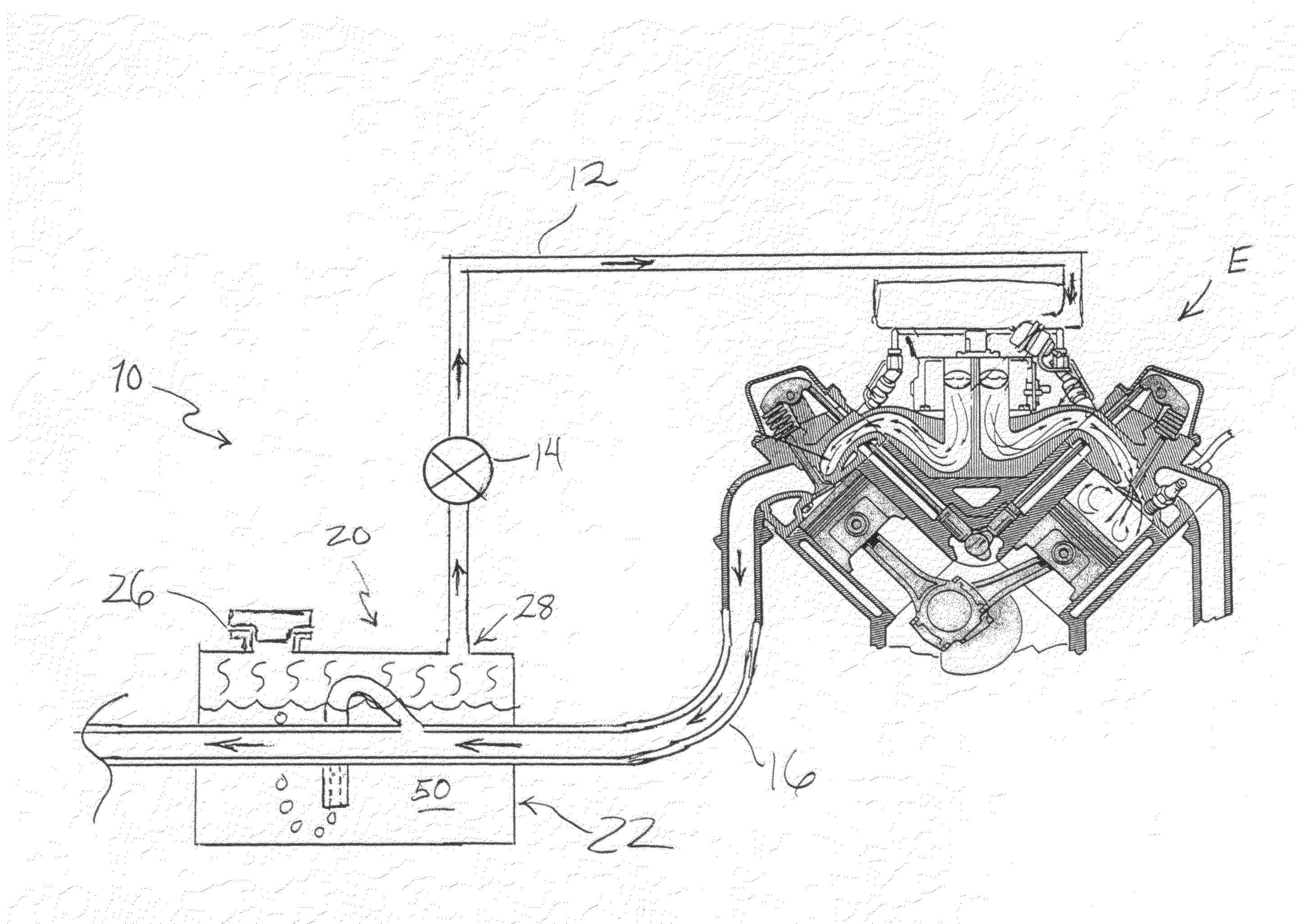

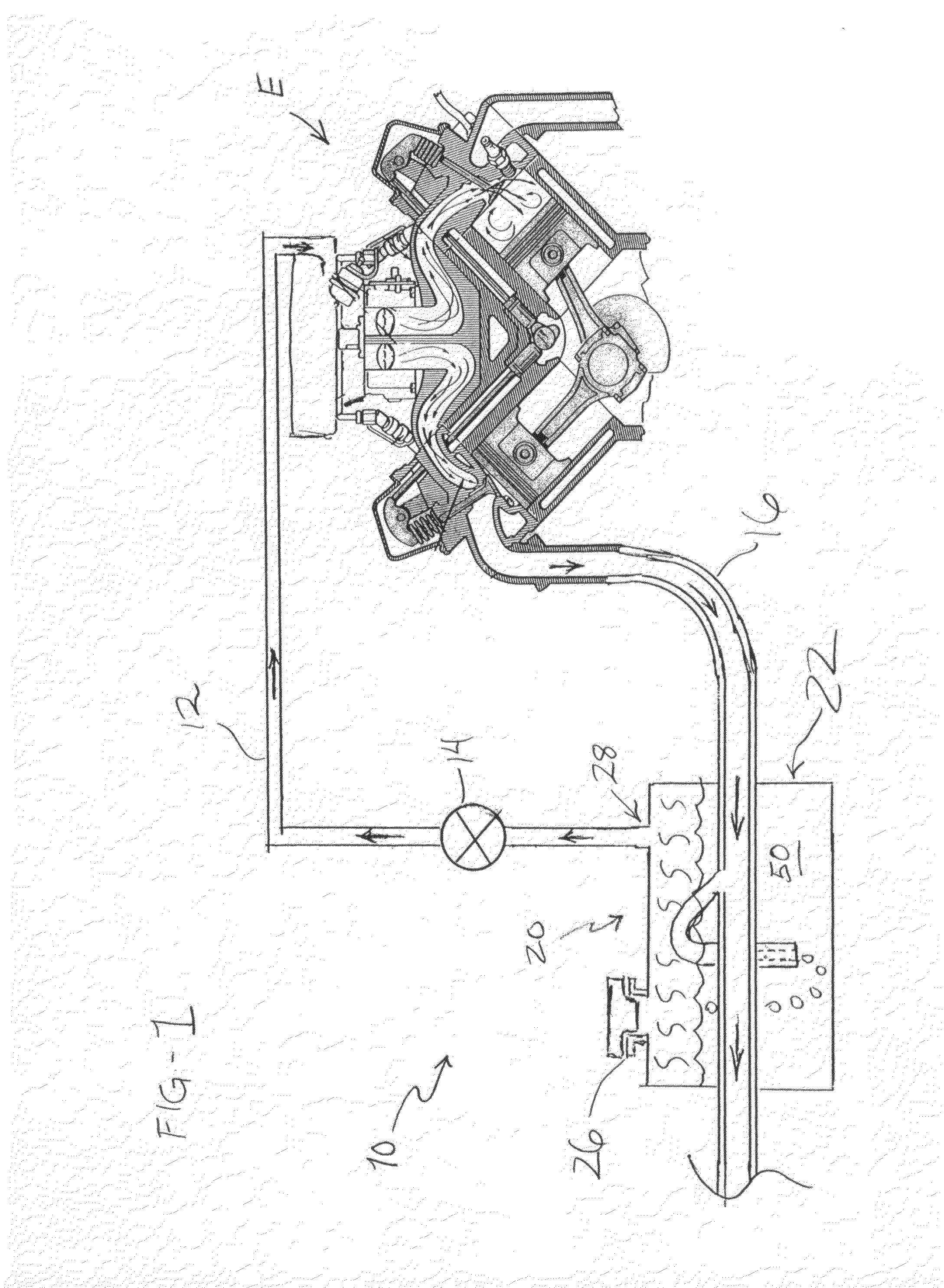

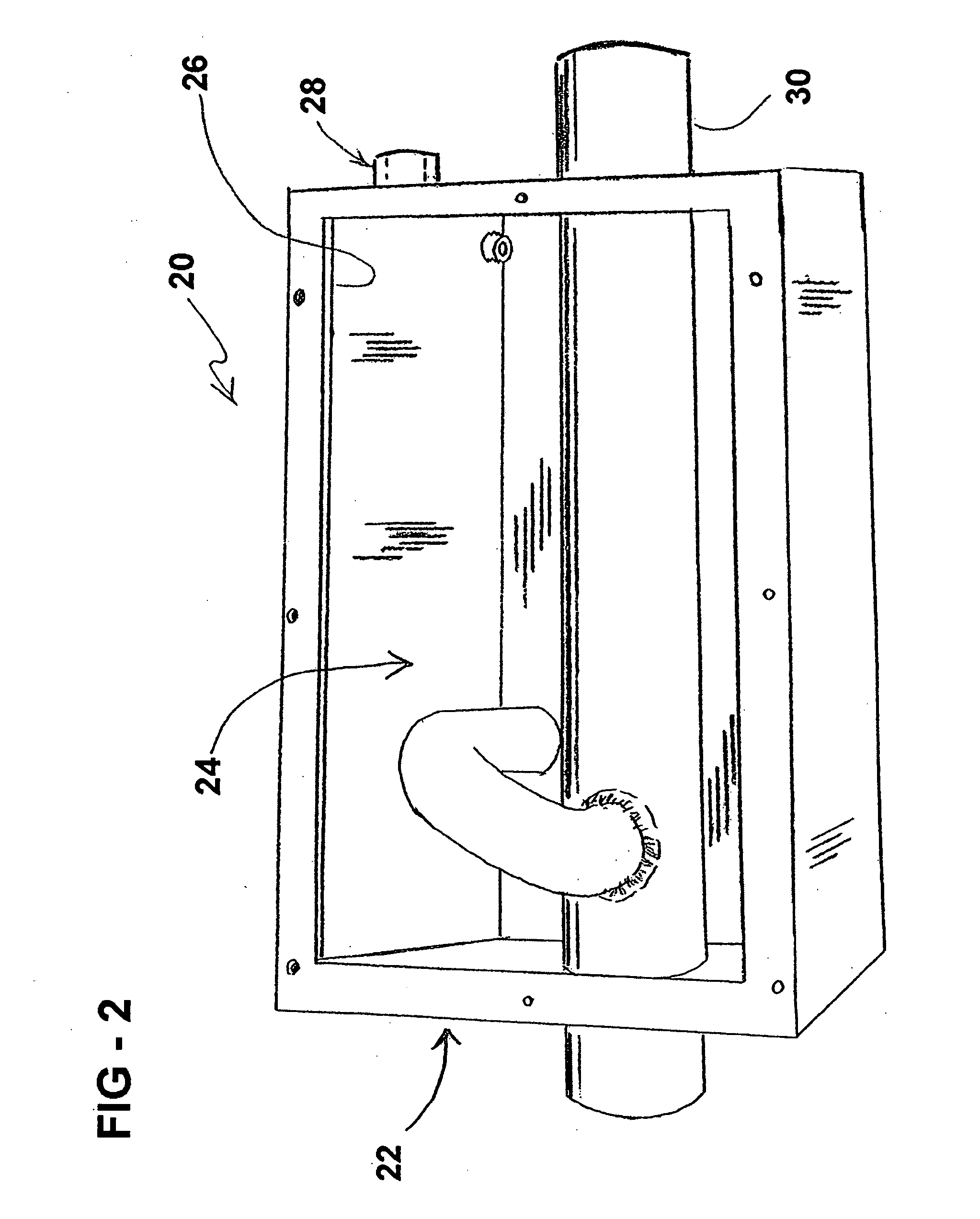

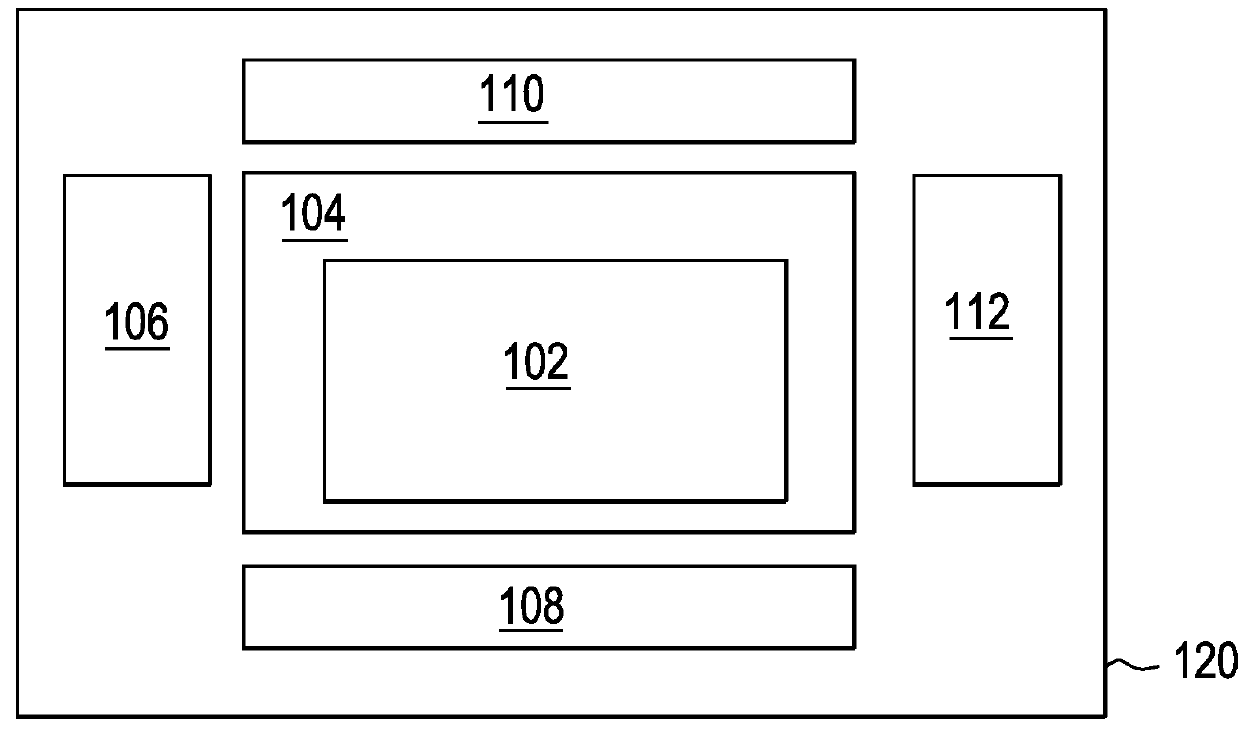

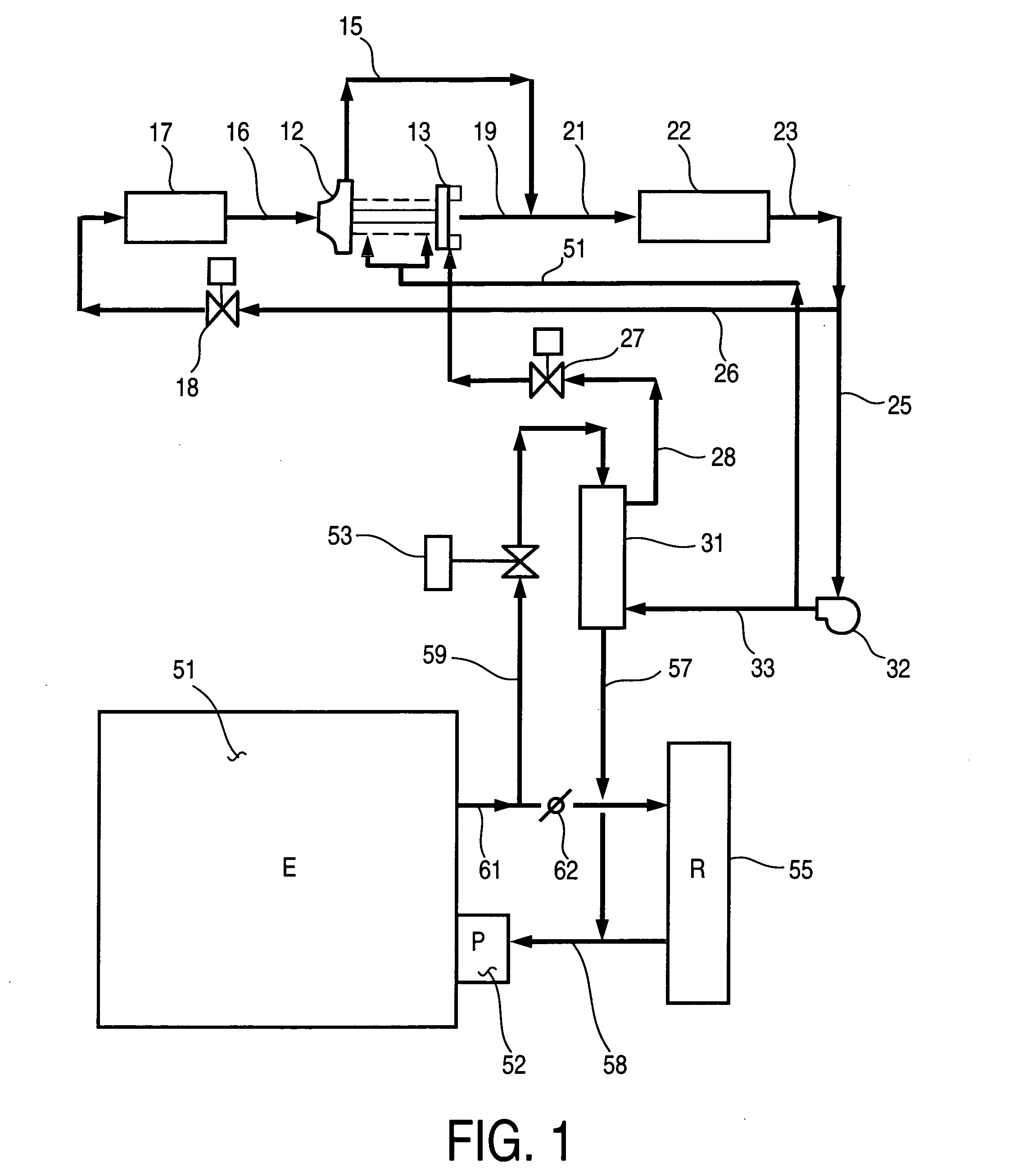

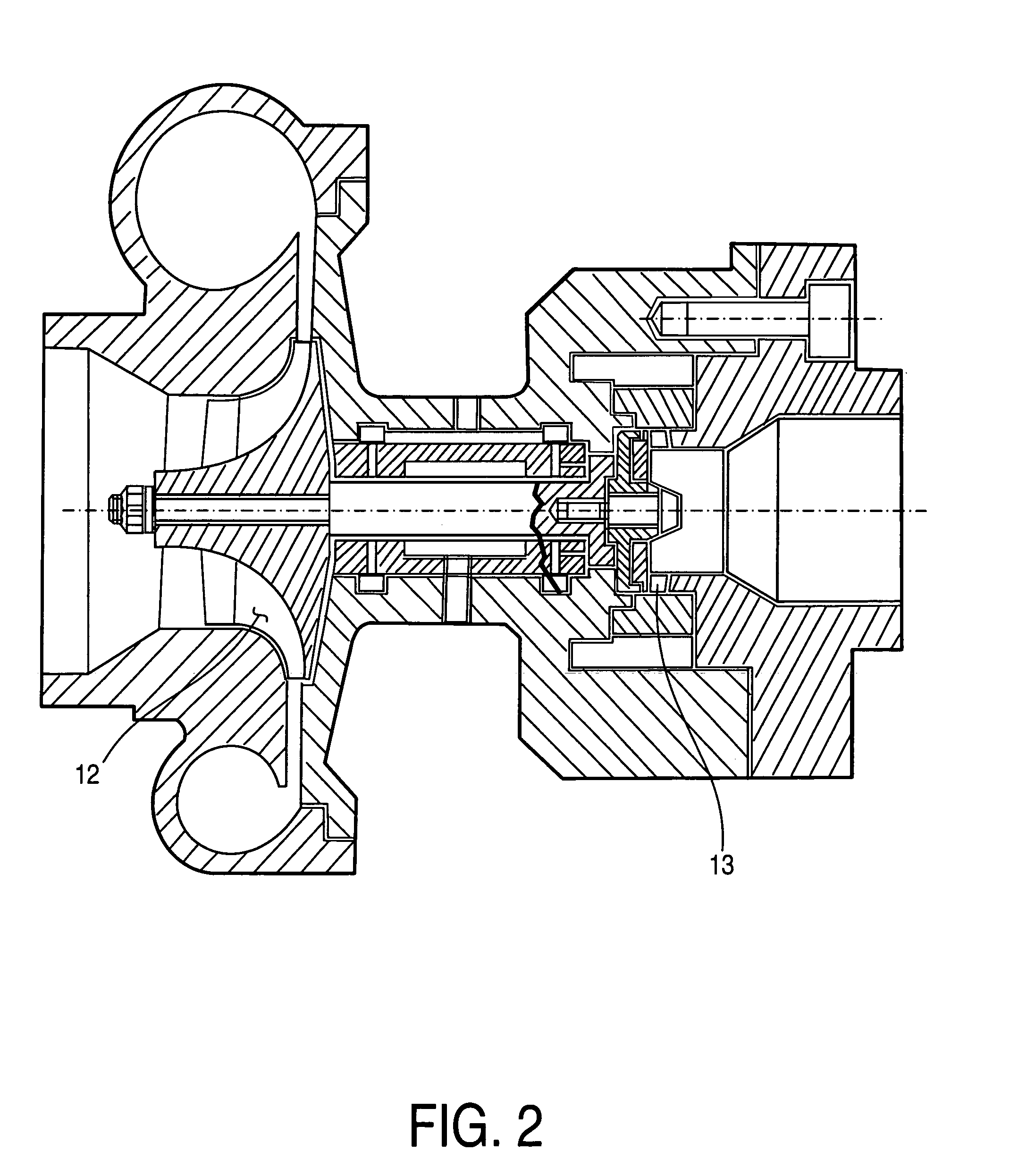

Hydrated EGR system, method and apparatus for reducing harmful exhaust emissions and improving fuel economy

ActiveUS20090032000A1Reduce harmful exhaust emissionsImprove engine performanceInternal combustion piston enginesNon-fuel substance addition to fuelWater vaporExhaust fumes

A hydrated EGR system, method and apparatus for a vehicle, in which heat from an exhaust pipe is used to heat an aqueous fluid solution in a water tank. A portion of the hot exhaust gas is diverted from the main exhaust flow, and the diverted portion is bubbled through the heated aqueous fluid solution to form a hydrated EGR mixture containing water vapor. The hydrated EGR mixture is then fed back to an intake portion of the engine, is mixed with an incoming fuel / air mixture, and is burned with the fuel air mixture inside the engine. The use of the hydrated EGR mixture, including heated water vapor, as part of the intake charge simultaneously reduces harmful exhaust emissions, improves engine performance, and improves fuel economy of the vehicle.

Owner:RIM JULIUS J

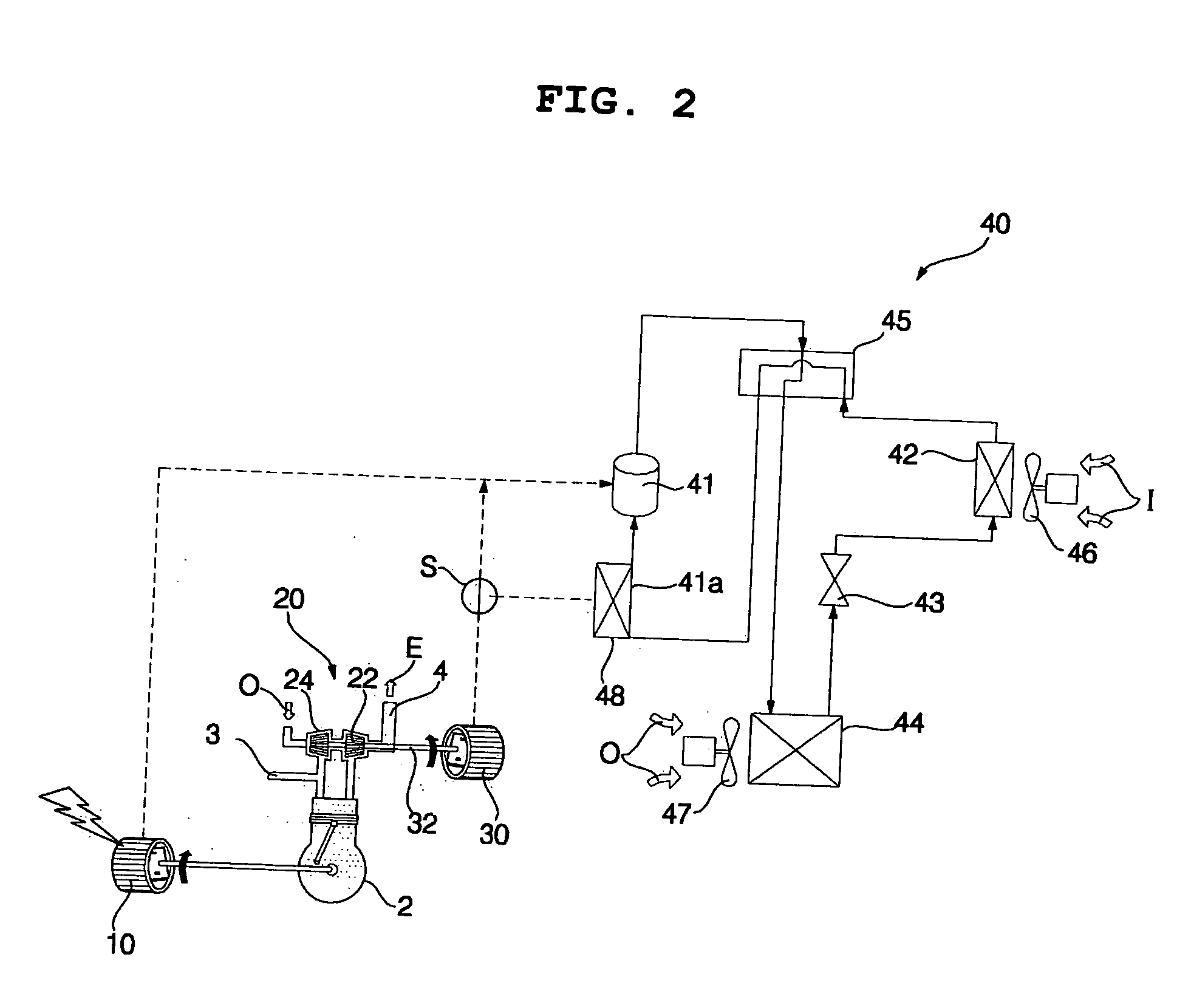

Electricity generating and air conditioning system

InactiveUS20060037347A1Improve energy efficiencyIncrease engine powerClimate change adaptationCompression machines with non-reversible cycleElectricityTurbocharger

An electricity generating and air conditioning system including a first generator coupled to the output shaft of the engine to generate electricity, a turbo charger to be operated by exhaust gas discharged from the engine, and thus, to enhance the power of the engine, and a second generator coupled to the turbo charger to generate electricity, so that it is possible to achieve an enhancement in energy efficiency.

Owner:LG ELECTRONICS INC

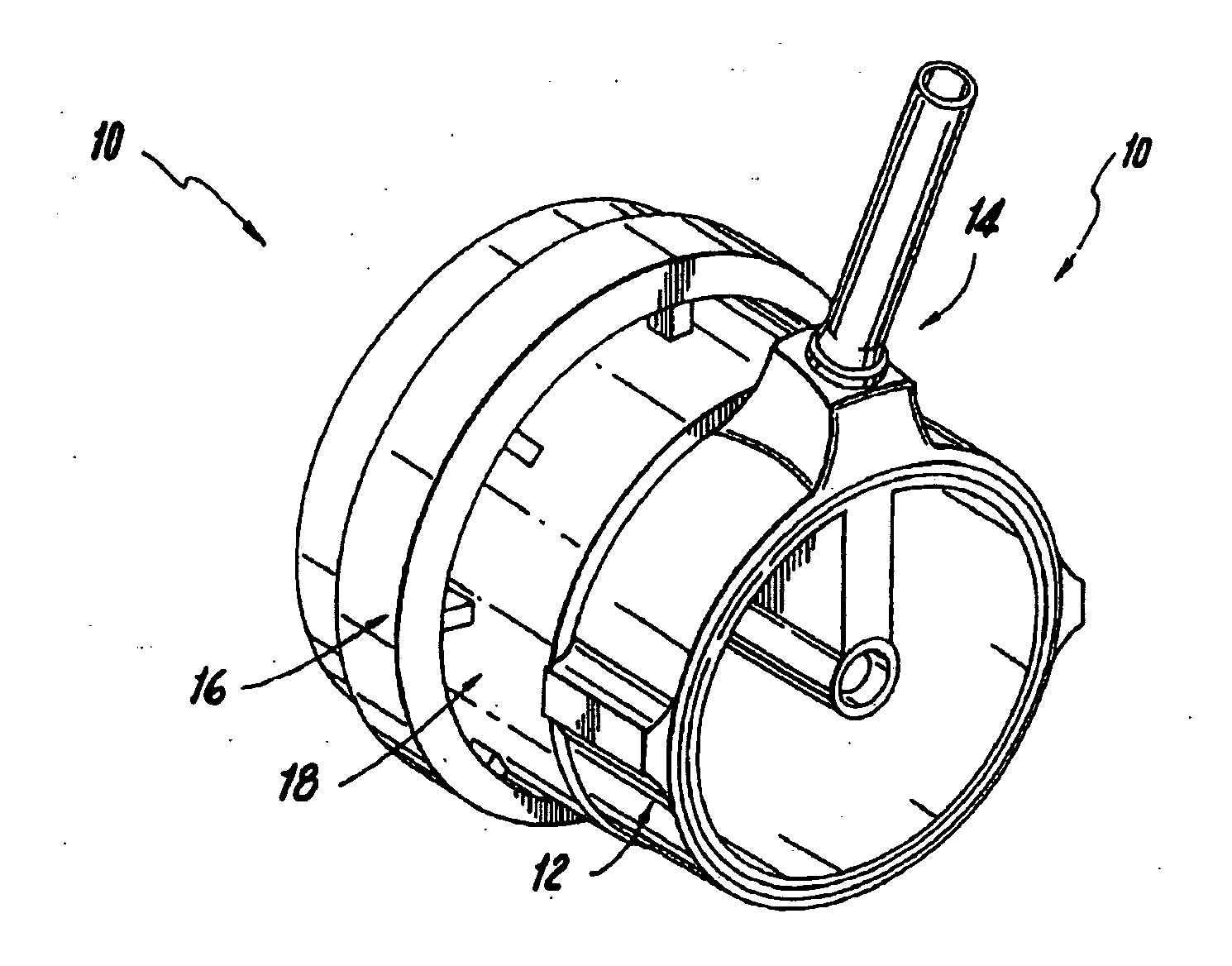

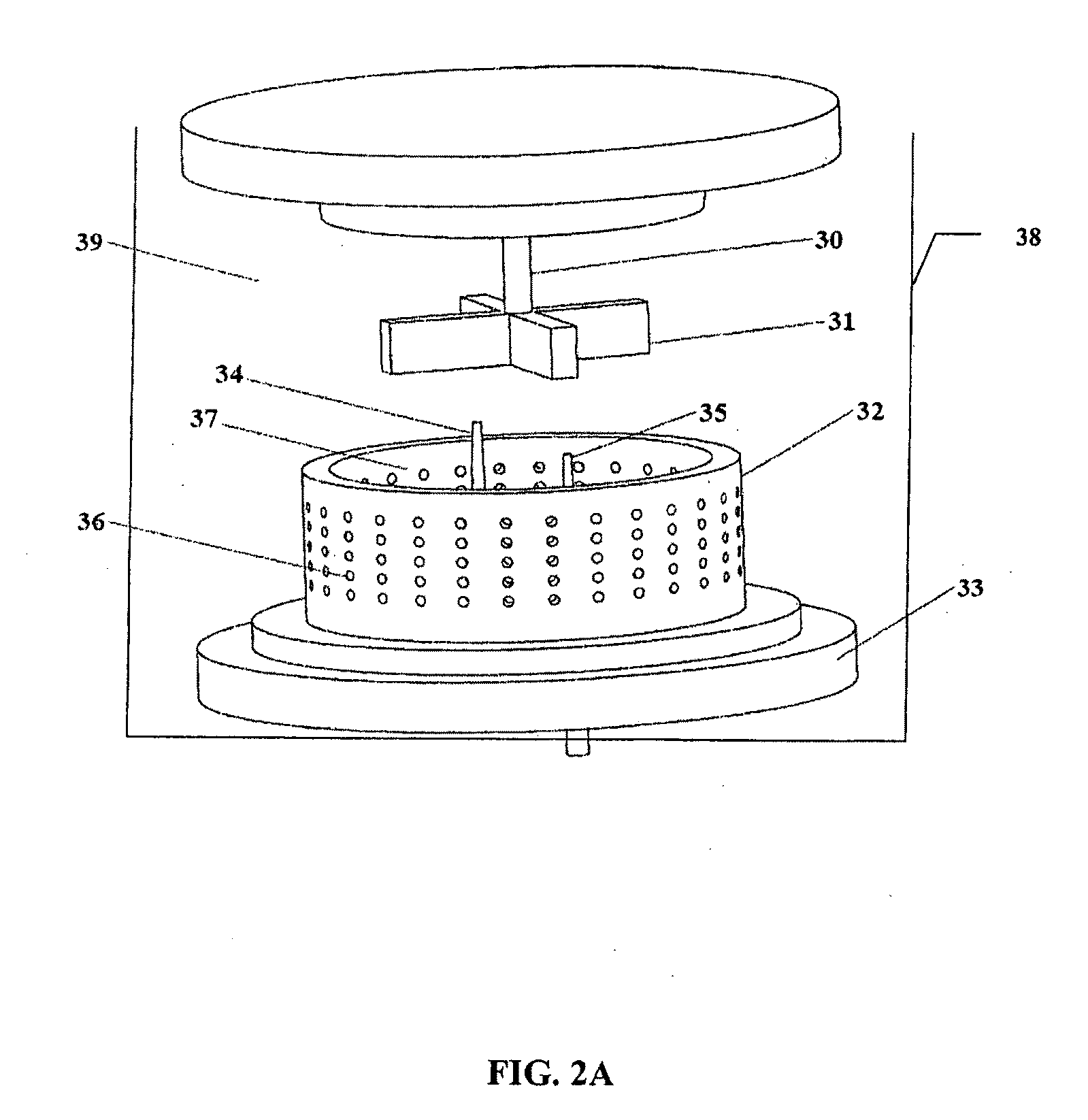

Hydrogen/oxygen on-demand system, high speed efficient hydrogen reactor system and methods therefor

ActiveUS9340881B2Improve efficiencyMore combustion dynamicCellsNon-fuel substance addition to fuelReactor systemHydrogen

A system for improving efficiency in which water or aqueous solution is broken into its core molecules of hydrogen and oxygen using a 12 volt power source, and of which this gas vapor can improve the efficiency of an engine of a vehicle in a catalytic fashion once combining with a fossil fuel, and includes a reactor housing containing at least one reactor unit having electrodes slotted in an insulated container, a solution supply system that regulates the aqueous solution in the system; and an air handling system that regulates the decomposed hydrogen and oxygen gas in the system. The reactor unit being immersed in an liquid or aqueous solution produces hydrogen and oxygen through electrolysis.

Owner:PACKER DAVID

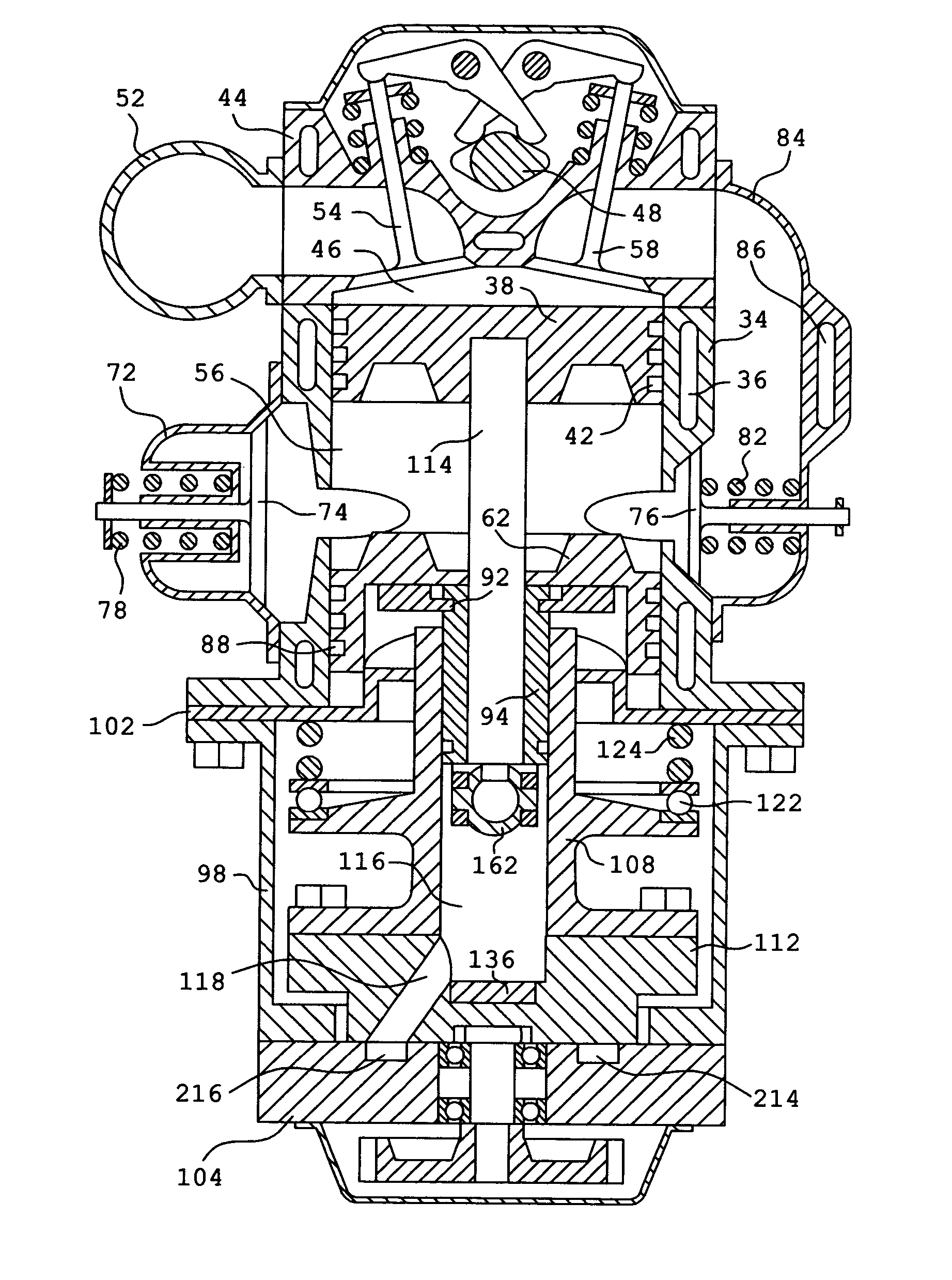

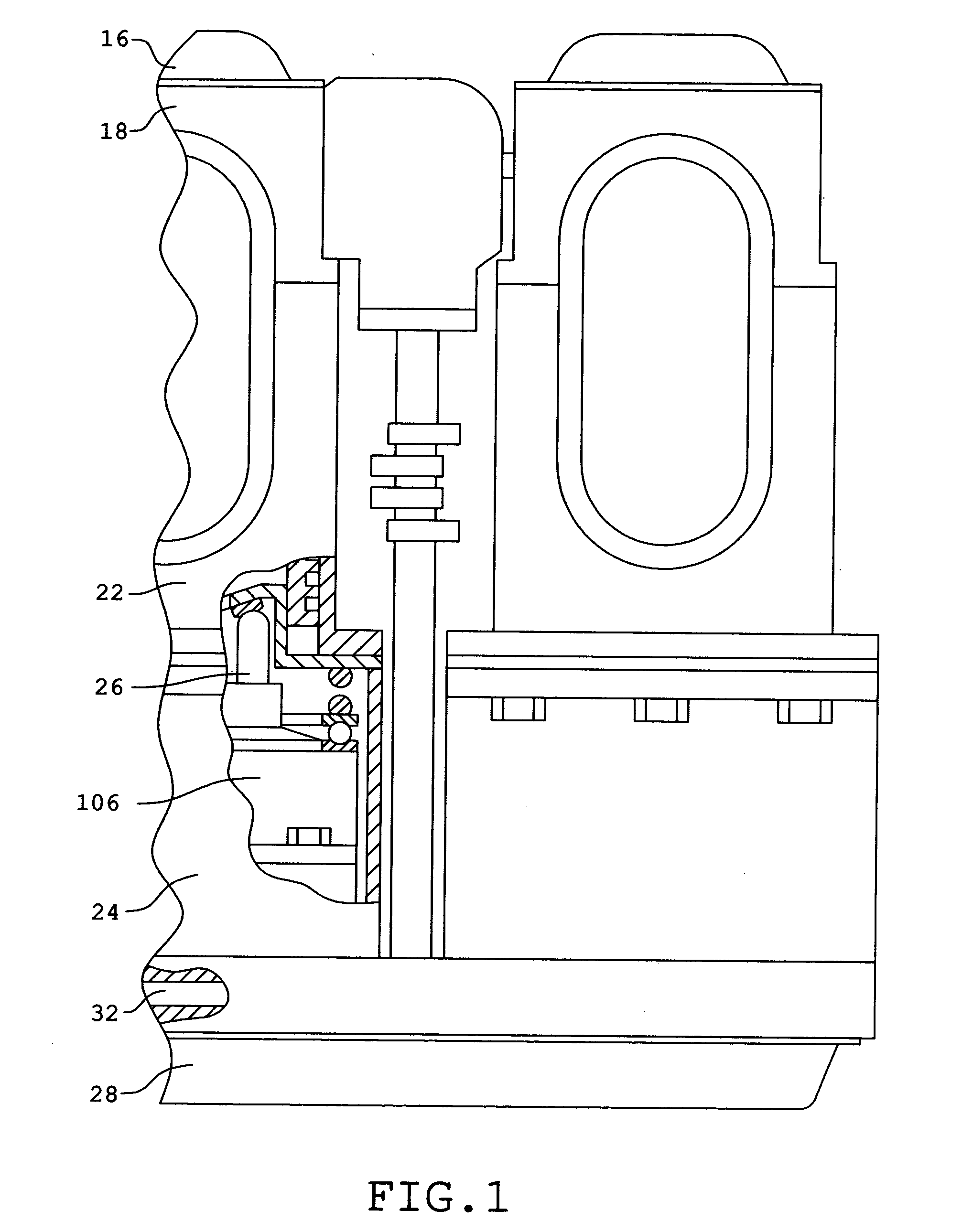

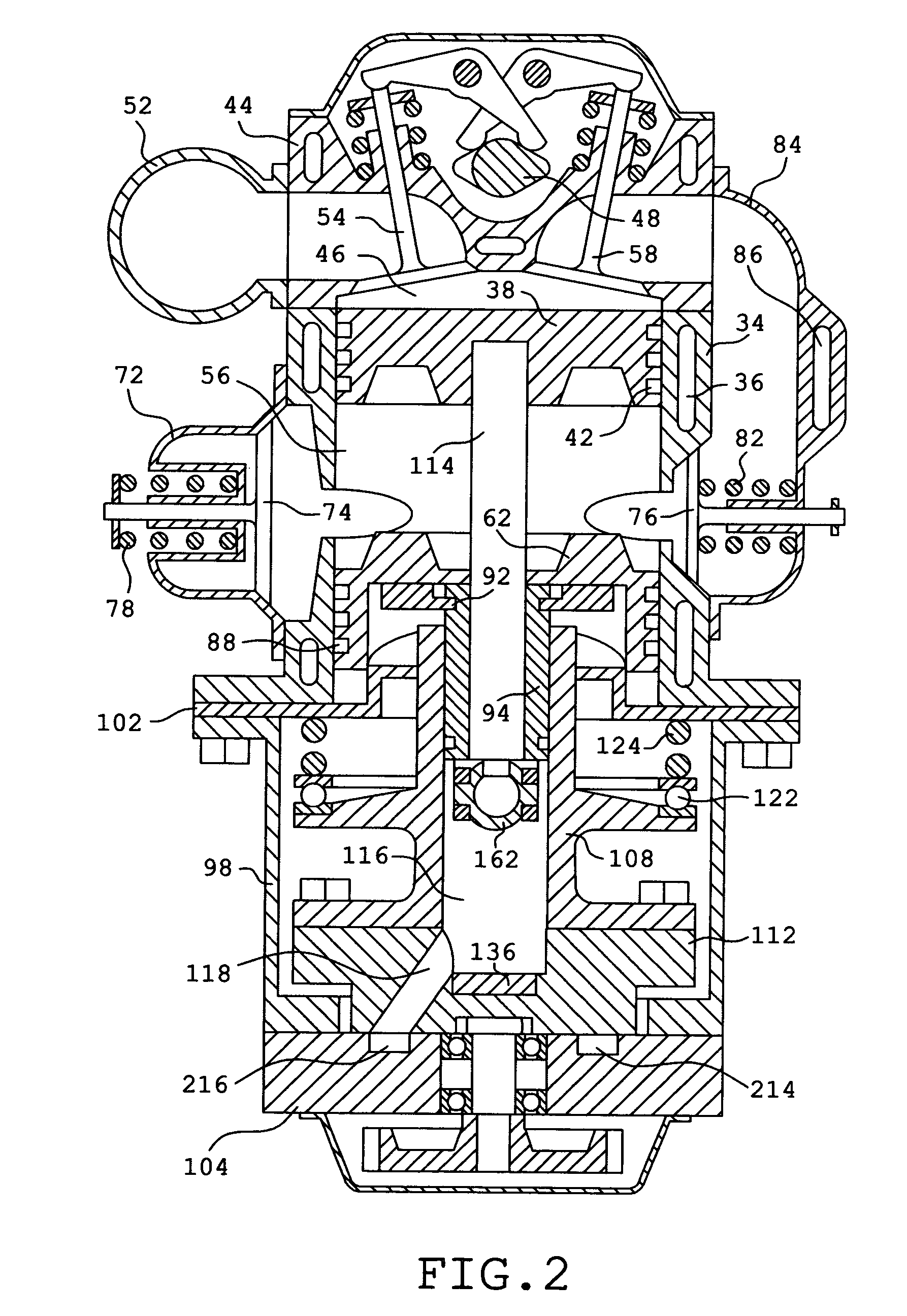

Hybrid two cycle engine, compressor and pump, and method of operation

InactiveUS20050028759A1Easy and efficient to manufactureLow priceFluid couplingsPlural diverse prime-mover propulsion mountingHydraulic pumpEngineering

The hybrid (16) comprises a two cycle engine (18), boosted by the engine power compressor (22) and a hydraulic pump (24). The pump plunger (114) fastened to engine piston (38) and located coaxially with the compressor piston (62) and pump (24) rotor (106), provide direct energy transmission to the compressor and pump. The plunger (114) and compressor piston (62), each connected to one of two diametrically opposite axial push rods (138), (142) of the rotor (106). The push rods synchronize and balance the pistons (38), (62) which move opposite directions into underside of the engine piston space. The rotor canals (118), (226) interact with the valve plate (104) and communicate fluid flow from a pumps of separate rotors. The reducer (28) synchronizes the motion of the separate rotors, activate engine and compressor camshafts (48), (64) and conventional accessory units. The engine can be high power started and restarted irrespective of parking time, since the start, idling and work modes provide a hydraulic distributor (272), pneumohydraulic accumulator (296) and starter pump (298) with pedal (302). Because of direct energy transmission the hybrid increases efficiency and specific power, while minimizing the weight, installation space and fuel consumption necessary in particular for automobile hydrostatic transmission.

Owner:EPSHTEYN GRIGORIY

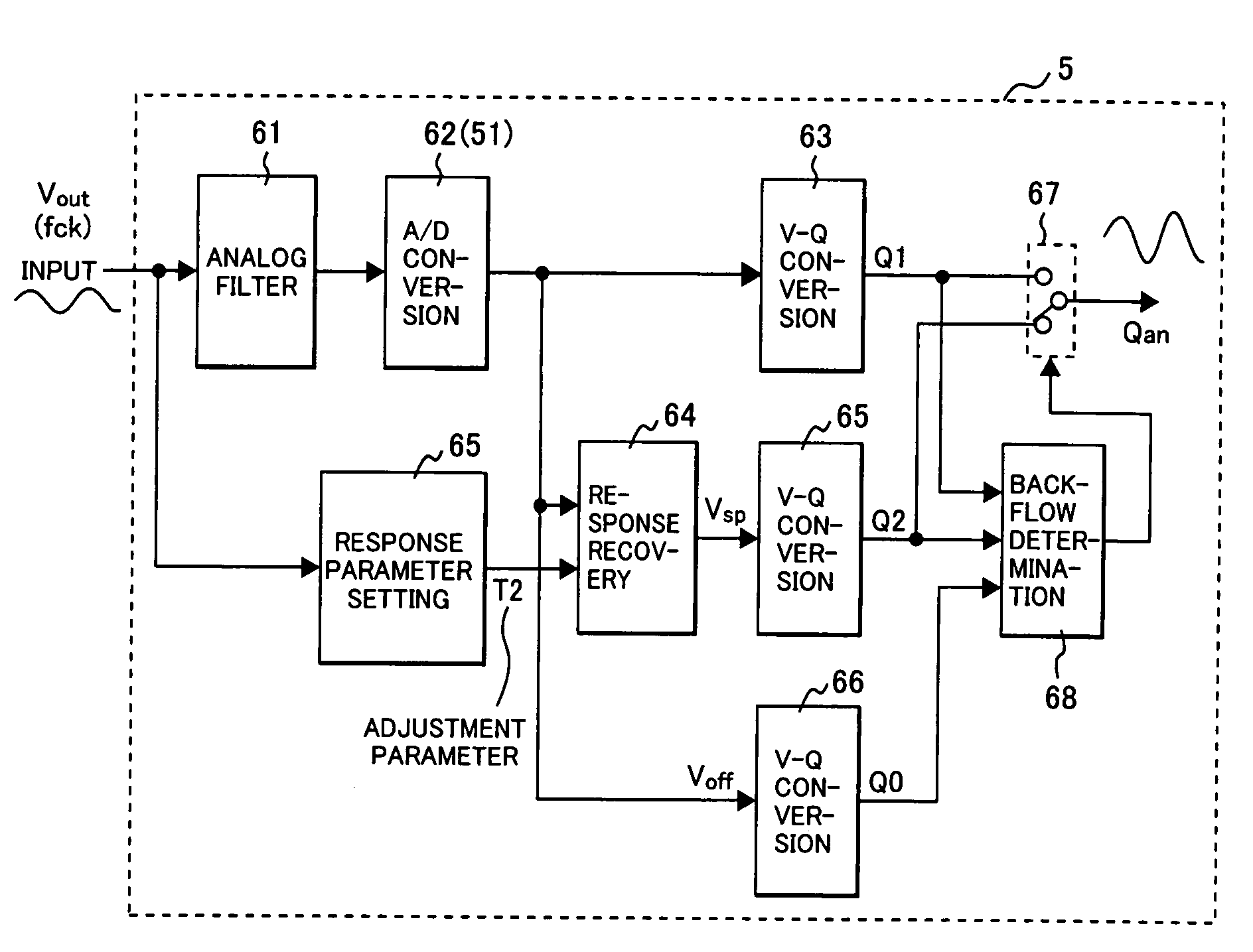

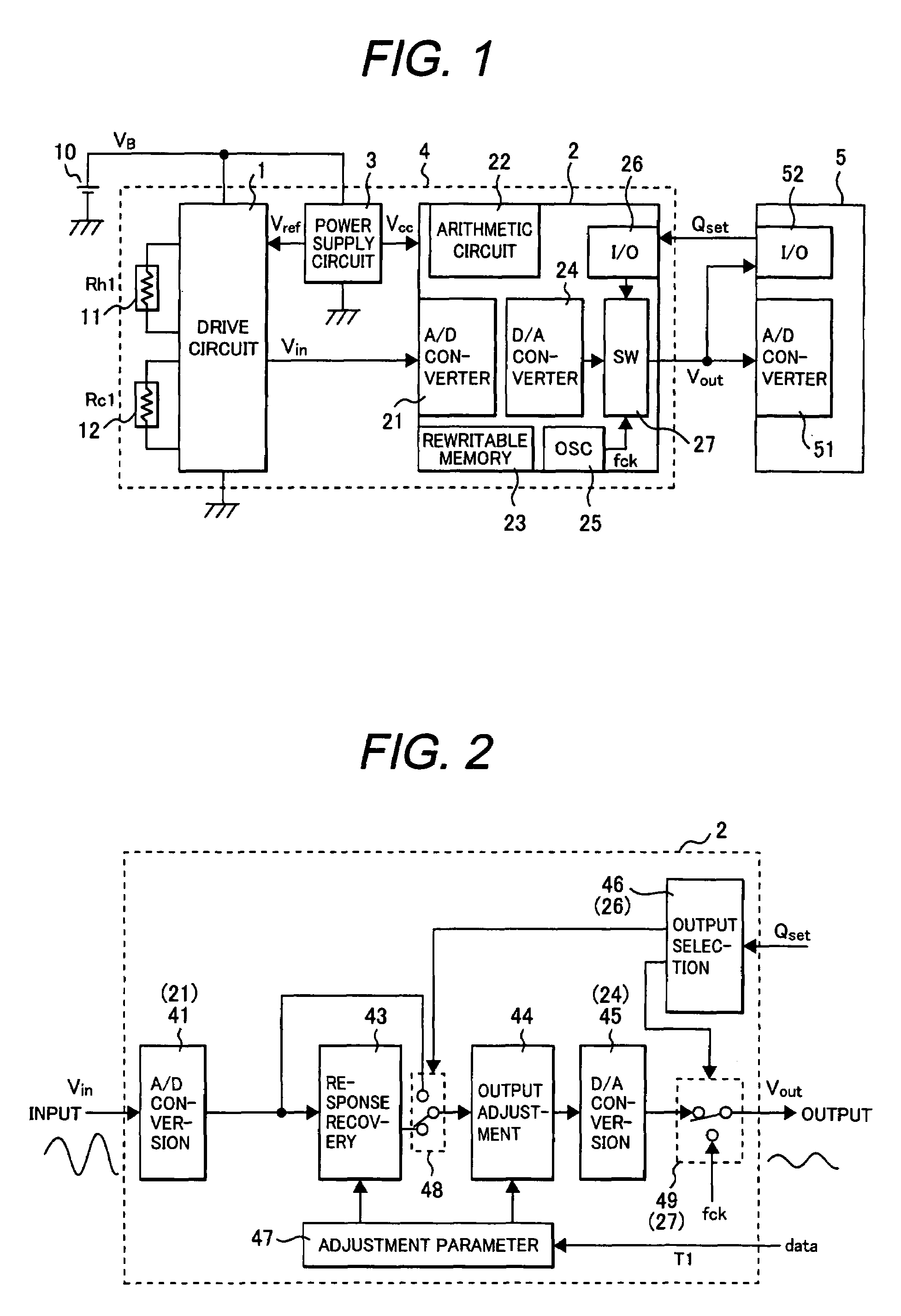

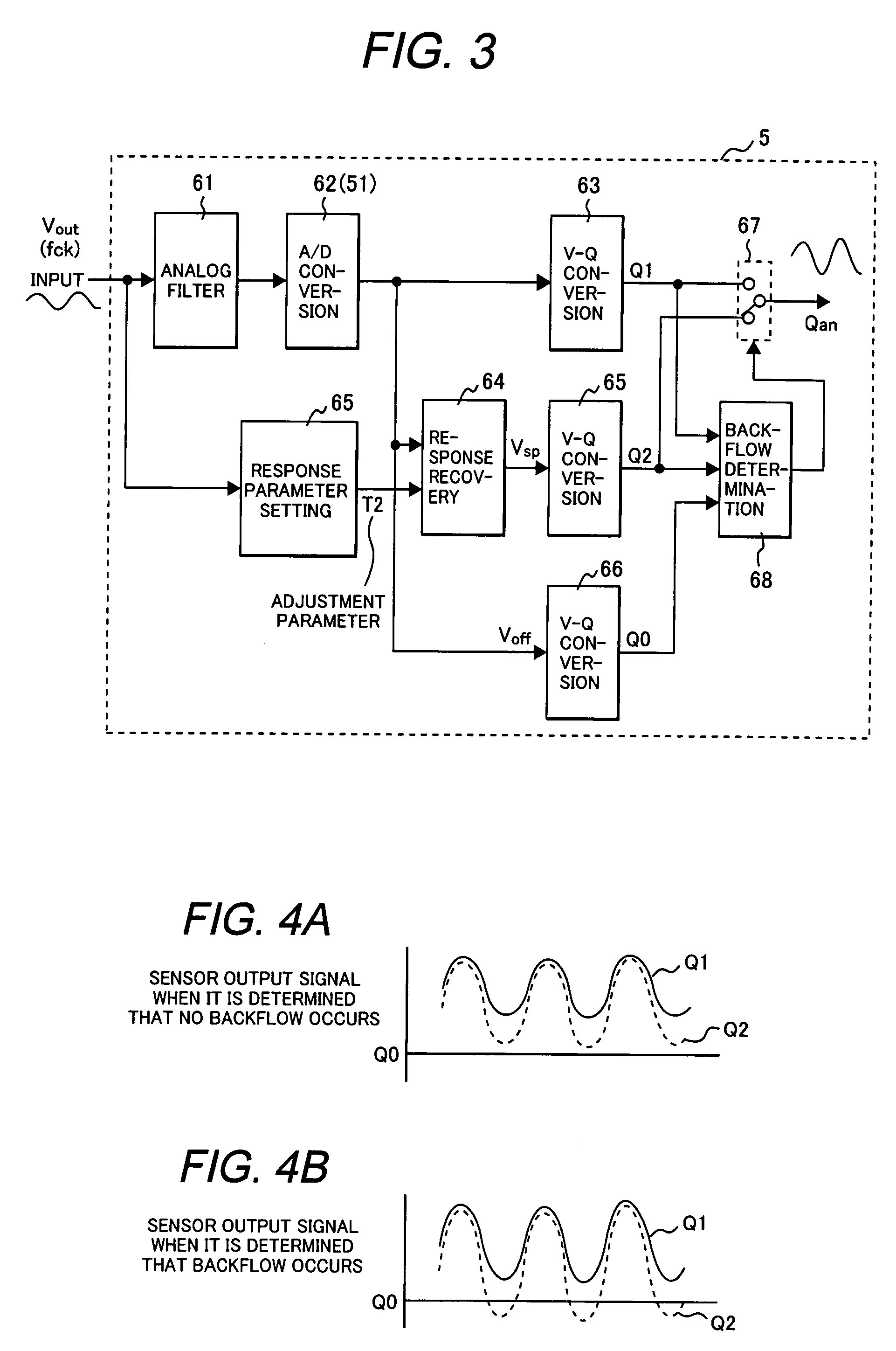

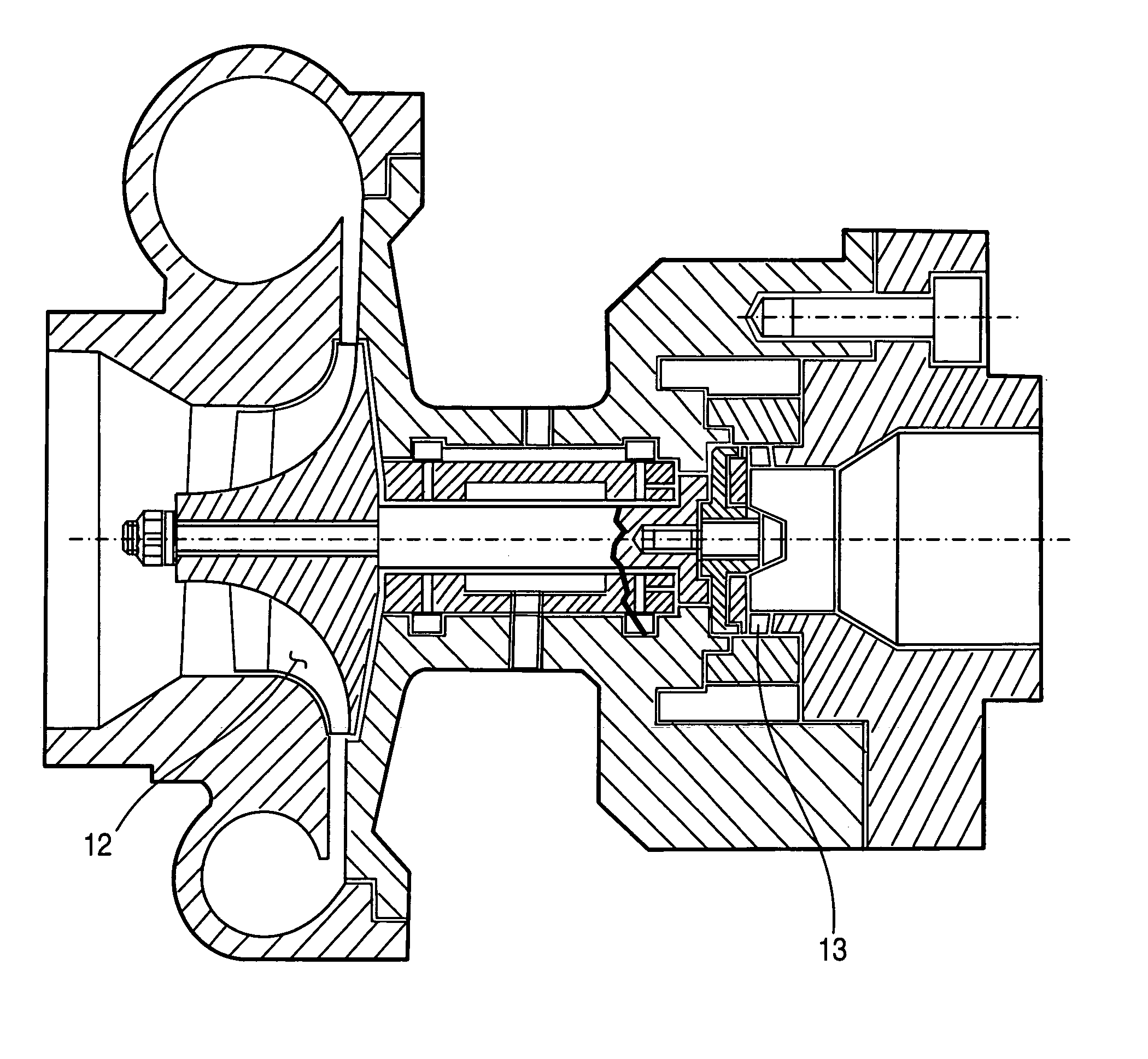

Thermal type flow rate measurement apparatus

ActiveUS7613582B2Increase pulsationImprove responseElectrical controlTesting/calibration apparatusEngineeringMotorized vehicle

Thermal type flow rate meters for measuring the flow rate of intake air of an internal combustion engine of a motor vehicle or the like have encountered a problem of an increase in pulsation errors during high engine speed and high pulsation. Meanwhile, digitally recovering responses has posed a problem in which pulsation performance is liable to become worse, affected by variation in a clock or the like. The sensor is provided with means for transferring a response variation factor to the engine control unit. The engine control unit is provided with logics for automatically determining the variation factor and correcting a response. Means for detecting a backflow occurrence is provided and a parameter for a response recovery is changed before and after a backflow occurrence. The sensor is provided with a selecting means by which a sensor response can be selected and obtained and the engine control unit is provided means for allowing selection of a response.

Owner:HITACHI ASTEMO LTD

Combustion engine waste heat powered air-conditioning system

InactiveUS20130263619A1Increase savingsImprove reliabilityCompression machines with non-reversible cycleClimate change adaptationEngineeringInternal combustion engine

An air conditioning system in which a high-pressure refrigerant vapor turbine is driving a low-pressure high-speed centrifugal compressor both supported on liquid refrigerant hydrostatic journal bearings. Due to required turbine miniaturization, the turbine blades surface finish and blade accuracy are of critical importance in order to produce high turbine adiabatic efficiency.

Owner:KAPICH DAVORIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com