Combustion engine waste heat powered air-conditioning system

a technology of air-conditioning system and combustion engine, which is applied in the field of air-conditioning system, can solve the problems of increasing the cost of fuel consumption of vehicles, contributing to vehicle exhaust emission, and needless use of world fuel supply, so as to save 0.5 hp of engine power, improve the reliability of the overall system, and eliminate the cost of electric driven pump or belt driven pump system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

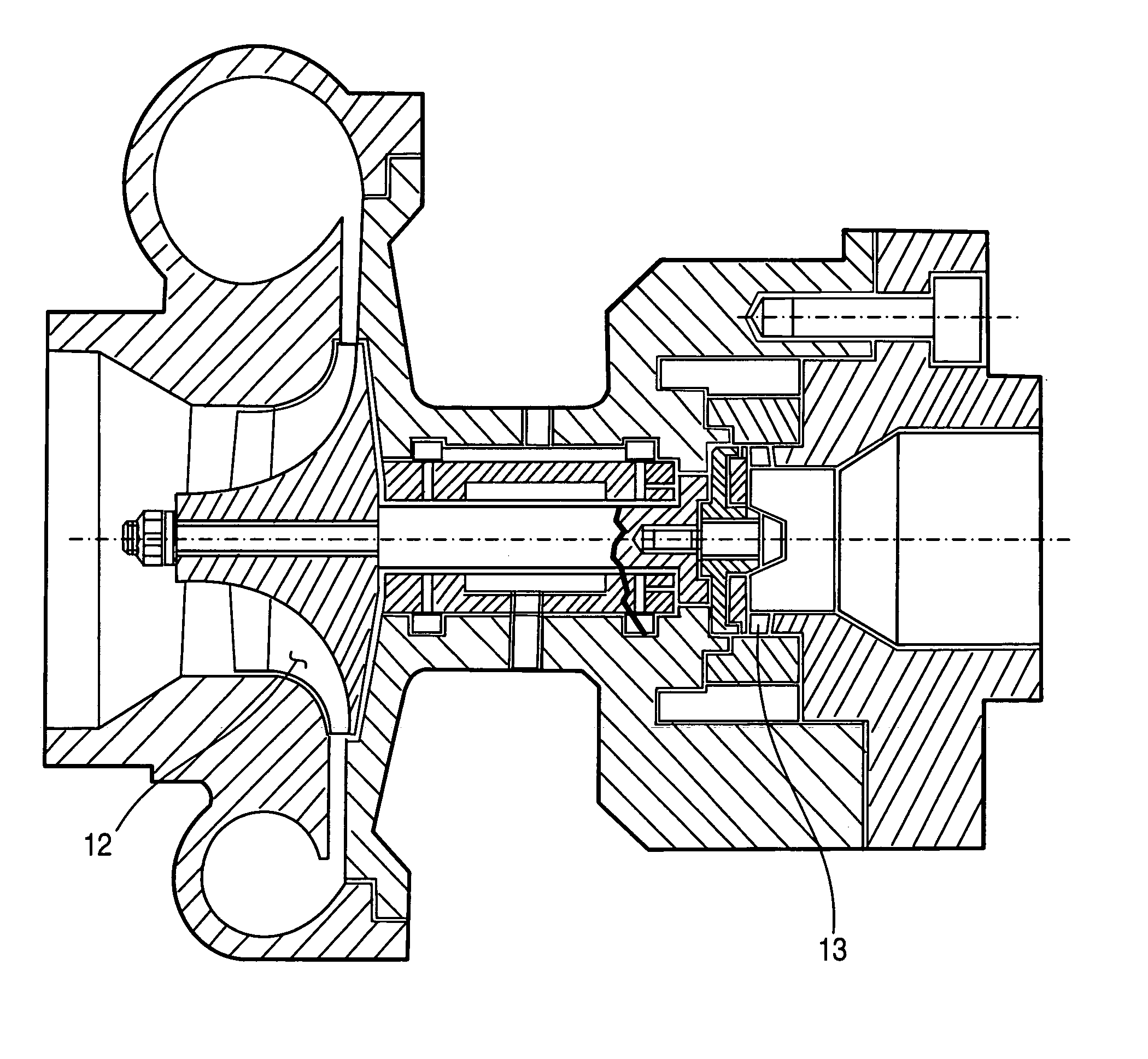

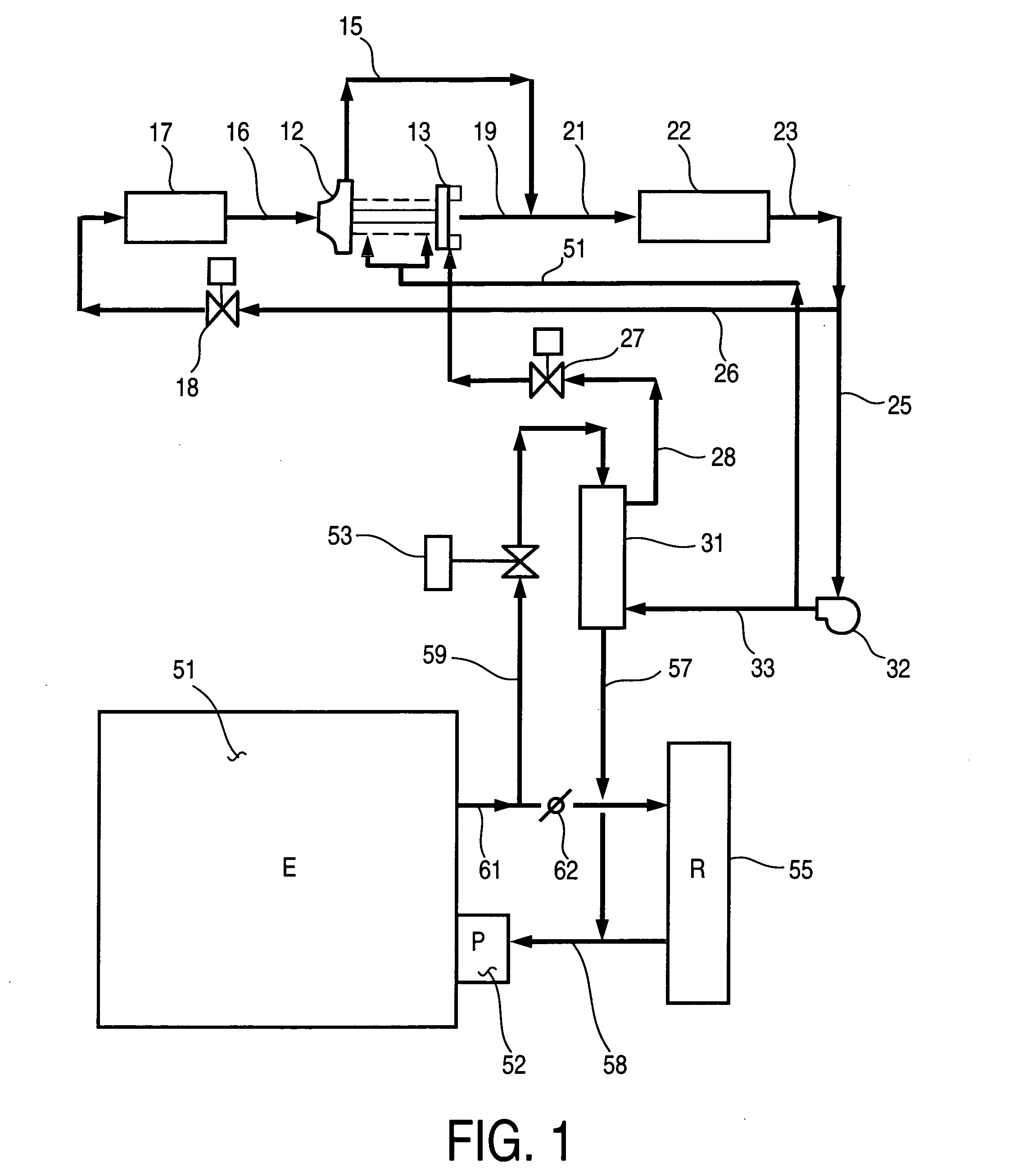

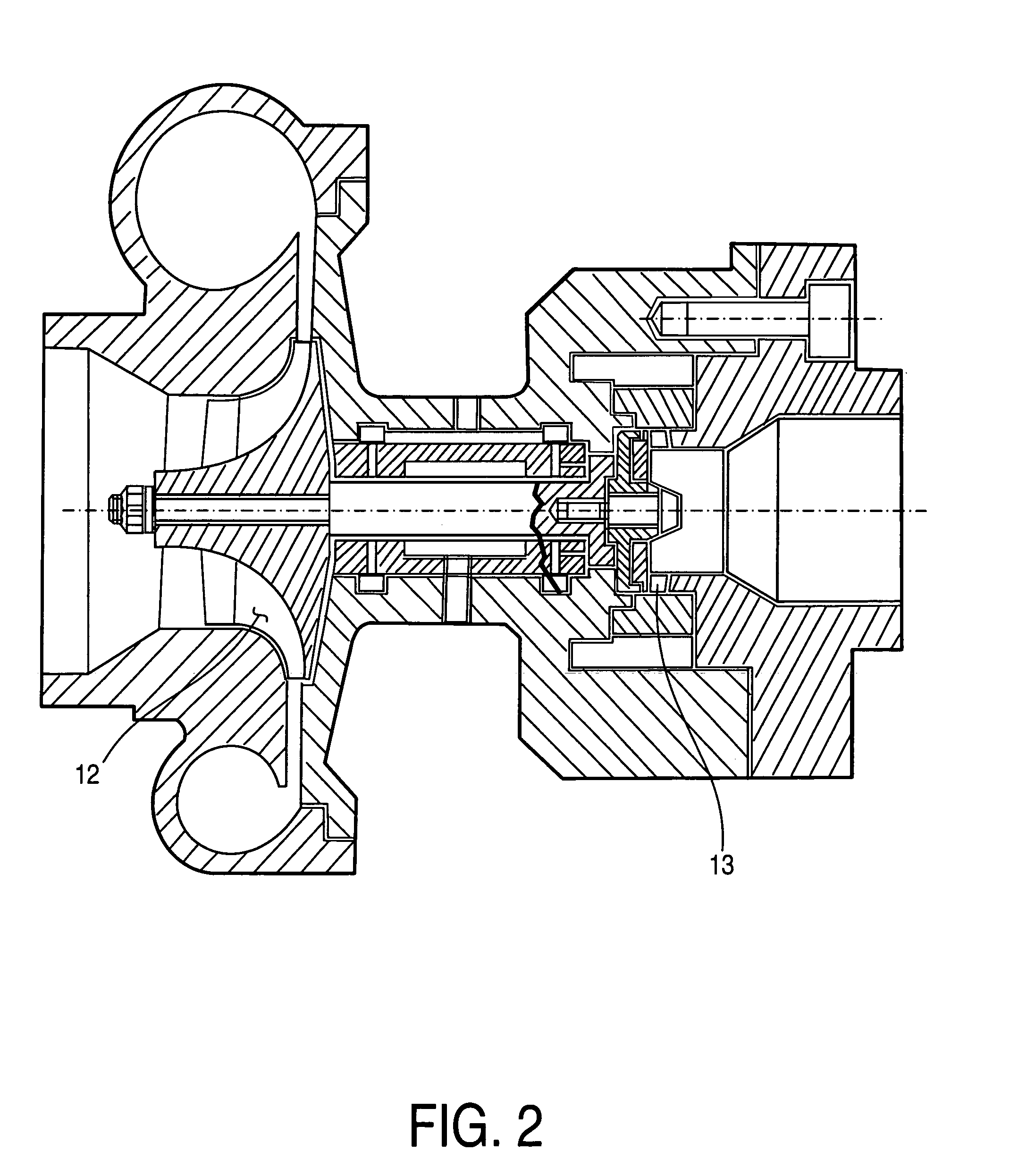

second preferred embodiment

[0031]FIG. 7 shows second preferred system embodiment which is similar to the first preferred embodiment shown in FIG. 1 with exception that refrigerant pump 32 which is electric driven or belt driven by the engine shown in FIG. 1 is being replaced by high speed refrigerant pump 81 that is driven by refrigerant vapor turbine 82 as shown in FIG. 7. Refrigerant pump 81 and refrigerant vapor turbine 82 rotor is supported on liquid refrigerant hydrostatic journal bearings in the same fashion as refrigerant turbo-compressor 12 rotor shown in FIG. 3, thus avoiding need for oil lubrication.

[0032]Thermal analysis of engine coolant and refrigerant system has shown that amount of engine coolant waste heat available in typical heavy duty diesel engine is more than sufficient to generate refrigerant vapor in refrigerant boiler 31 to drive both compressor drive turbine 13 and refrigerant pump drive turbine 82.

[0033]In case of 4 ton air conditioning system the compressor drive turbine 13 produces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com