Patents

Literature

56results about How to "Reduce NOx emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen/oxygen on-demand system, high speed efficient hydrogen reactor system and methods therefor

ActiveUS20150159284A1Emission reductionReduce NOx emissionsCellsInternal combustion piston enginesHydrogenReactor system

A system for improving efficiency in which water or aqueous solution is broken into its core molecules of hydrogen and oxygen using a 12 volt power source, and of which this gas vapor can improve the efficiency of an engine of a vehicle in a catalytic fashion once combining with a fossil fuel, and includes a reactor housing containing at least one reactor unit having electrodes slotted in an insulated container, a solution supply system that regulates the aqueous solution in the system; and an air handling system that regulates the decomposed hydrogen and oxygen gas in the system. The reactor unit being immersed in an liquid or aqueous solution produces hydrogen and oxygen through electrolysis.

Owner:PACKER DAVID

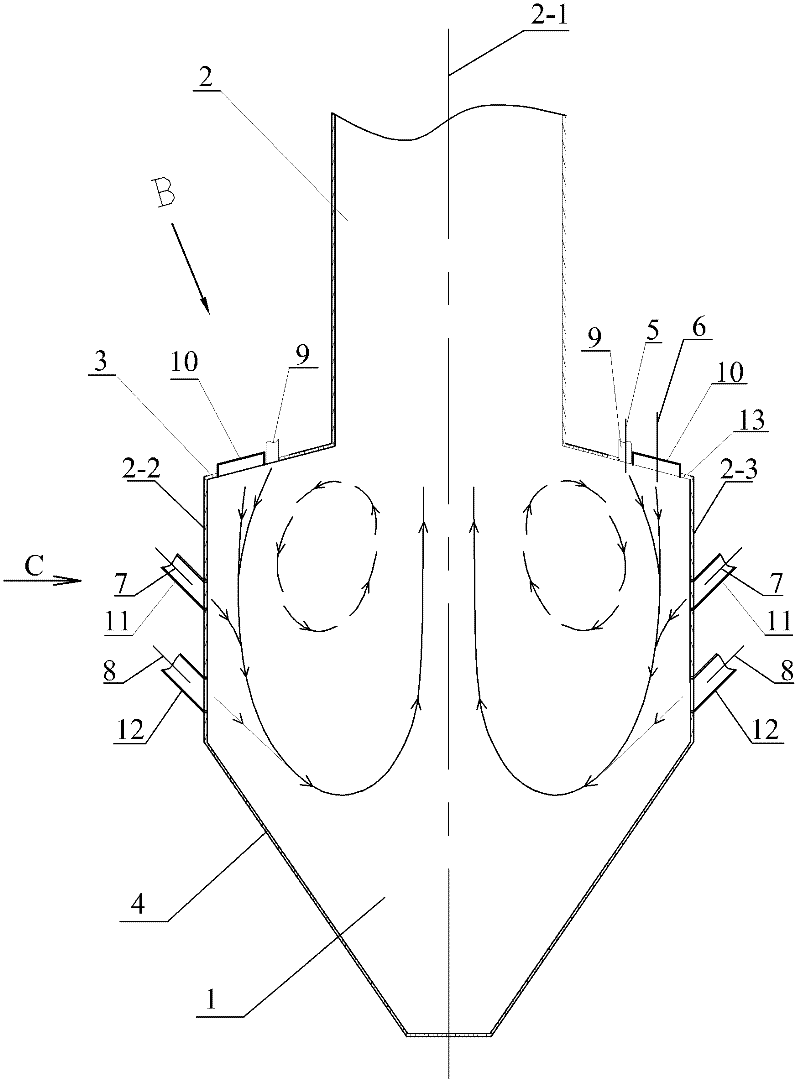

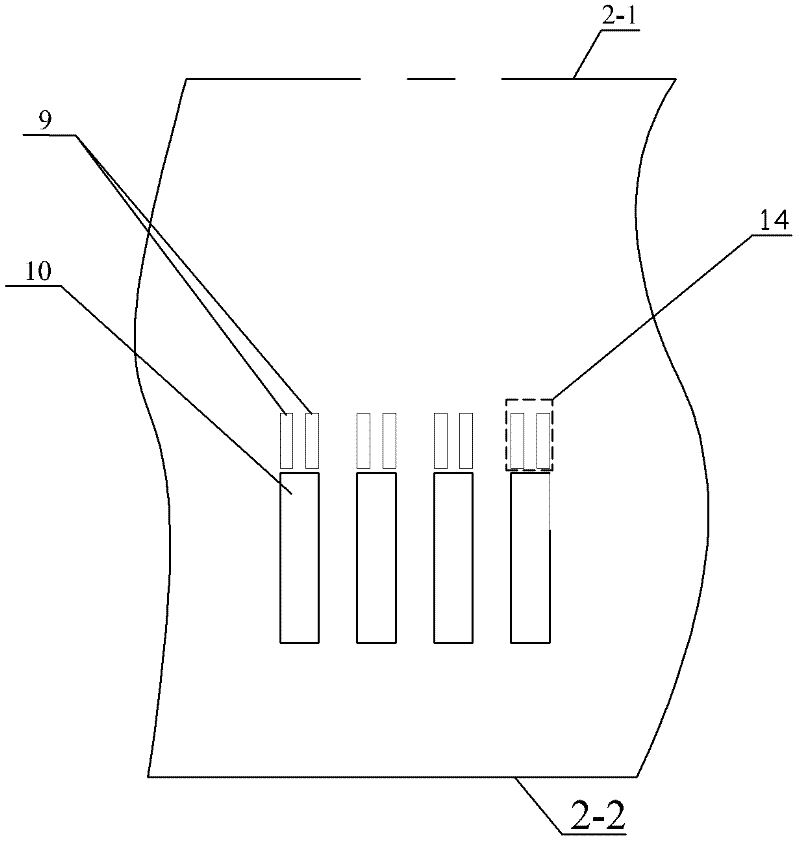

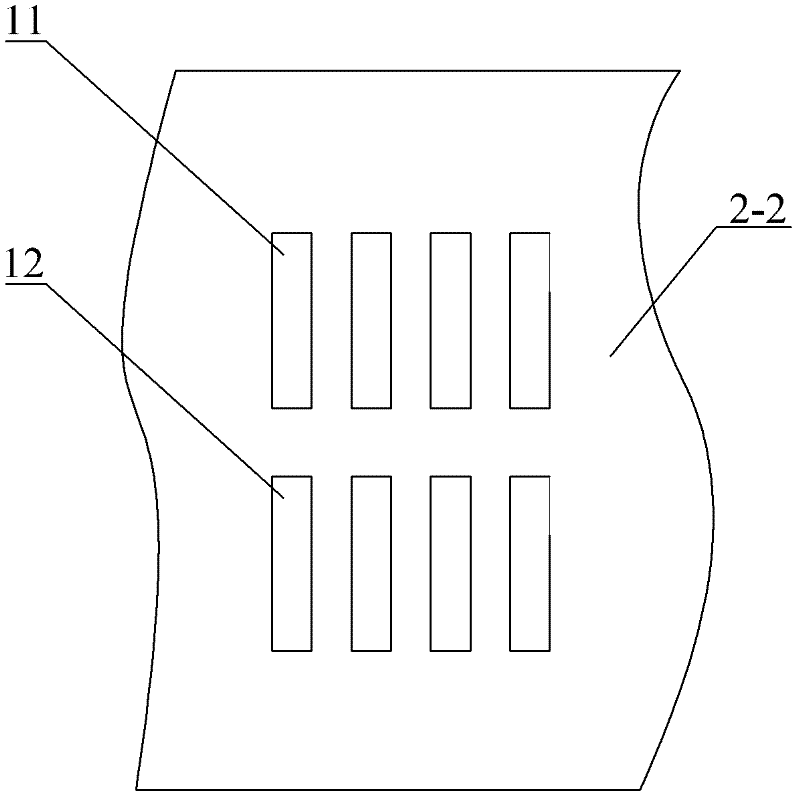

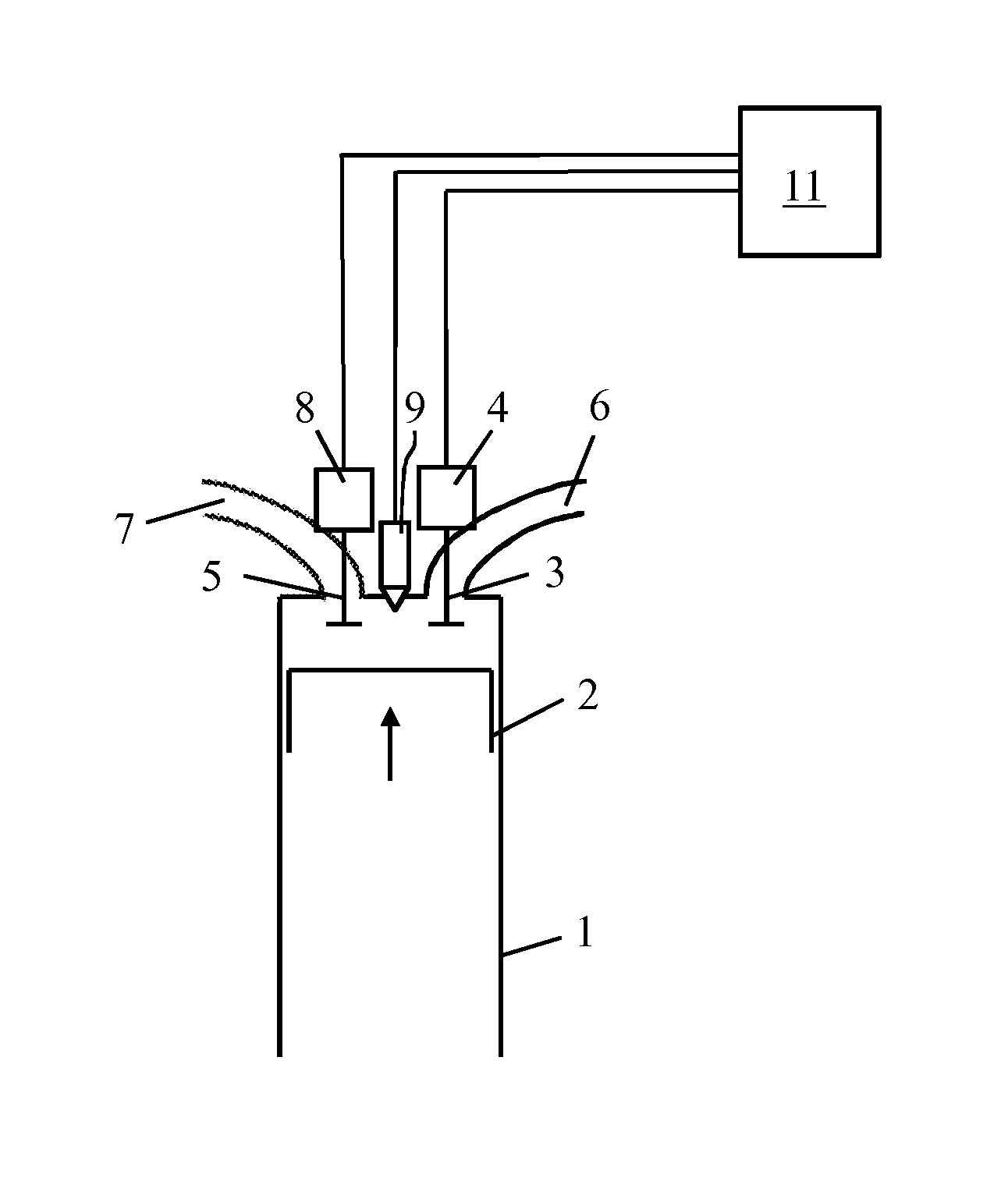

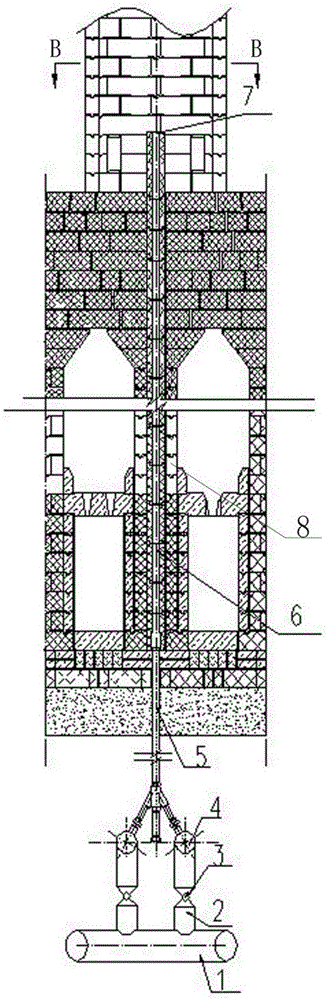

A kind of exhaust gas under the ejection stage combustion w flame boiler

InactiveCN102297420AReduce NOx emissionsSuppresses NOx formationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCoalAirflow

The utility model relates to a W-flame boiler with ejection and staged combustion under the exhaust gas, which relates to a W-flame combustion boiler. The invention solves the problem that the NOx emission is still relatively high during the operation of the W-flame boiler with the single-stage ejection staged combustion technology on the arch. The plurality of fresh pulverized coal airflow nozzles on the water-cooling wall of the front wall are symmetrically arranged with the plurality of fresh pulverized coal airflow nozzles on the water-cooling wall of the rear wall. The upper part is arranged in a straight line and at equal intervals along the width direction of the furnace. The multiple dense pulverized coal airflow nozzle groups on the front furnace arch correspond to the multiple thin coal powder airflow nozzles on the water wall of the front wall one by one. The multiple dense pulverized coal airflow nozzle groups are in one-to-one correspondence with the multiple fresh pulverized coal airflow nozzles on the water-cooled wall of the rear wall, and the angle between the centerline of each fresh pulverized coal airflow nozzle and the horizontal plane is 25°~45° . When the invention is used in W-flame boilers, the NOx emission can be greatly reduced and the combustible content of fly ash can be reduced.

Owner:HARBIN INST OF TECH

Method for reducing nitrogen oxide emissions in industrial process

InactiveUS20040143149A1Reduce nitrogen oxide emissionsReduce NOx emissionsDispersed particle separationStationary tubular conduit assembliesNitrogen oxidesWaste stream

One embodiment of the invention provides novel methods for reducing the generation of NOx emissions in industrial processes. These methods include the steps of: feeding a reaction feed mixture to a reaction vessel having an inlet and an outlet; producing a reaction product including a hot mixed gas stream in the reaction vessel; producing a cooled mixed gas stream by directing the hot mixed gas stream to a heat exchanger system; separating the cooled mixed gas stream into a cooled crude product stream and a cooled waste stream; producing a preheated waste stream by directing the cooled waste stream to a heat exchanger system; and incinerating the preheated waste stream by directing it to an incinerator. Upon incineration of the preheated waste stream, a decreased amount of NOx emissions is produced when compared to the amount of NOx emissions which would have been produced by incinerating the cooled waste stream.

Owner:DECOURCY MICHAEL STANLEY +1

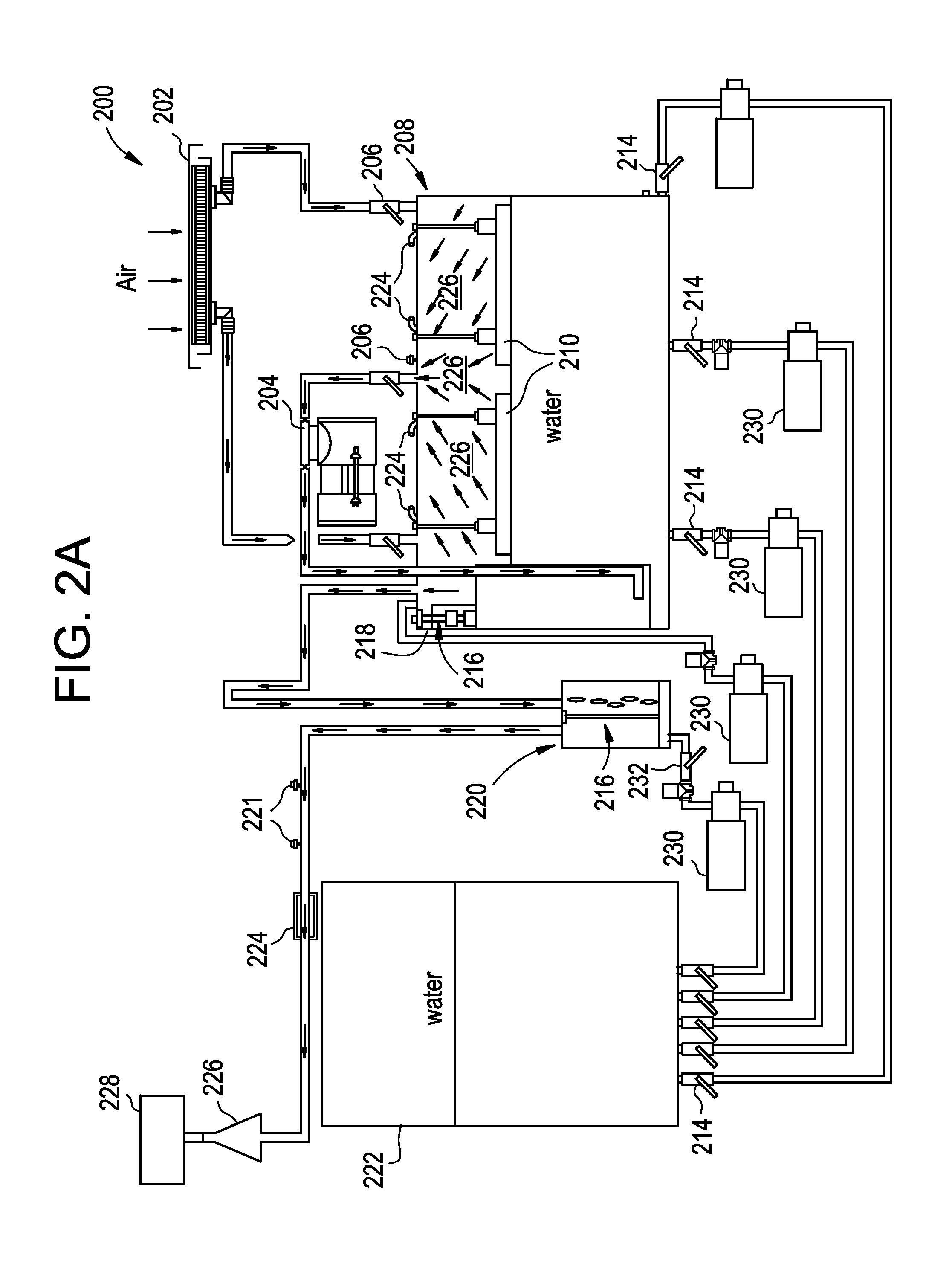

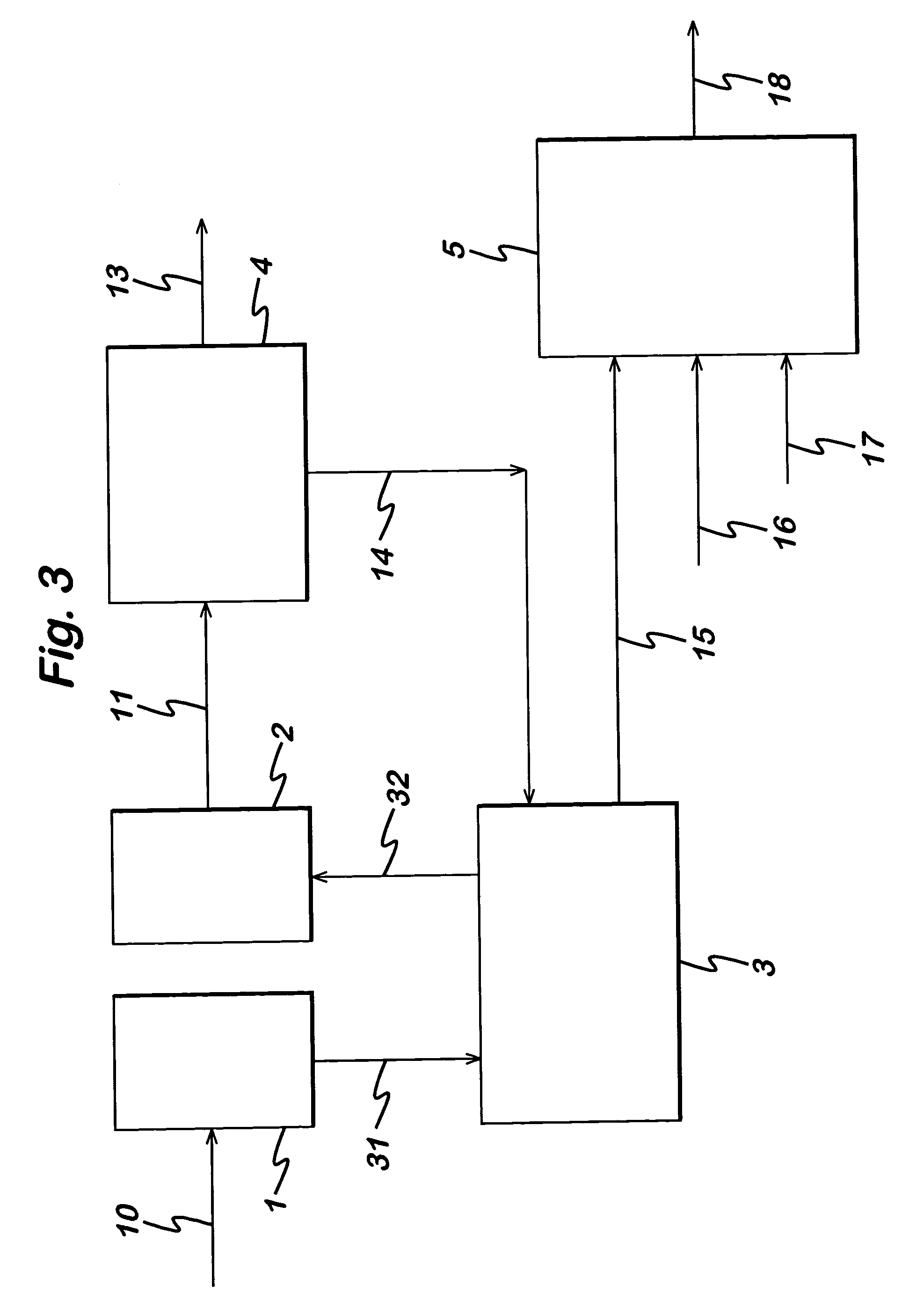

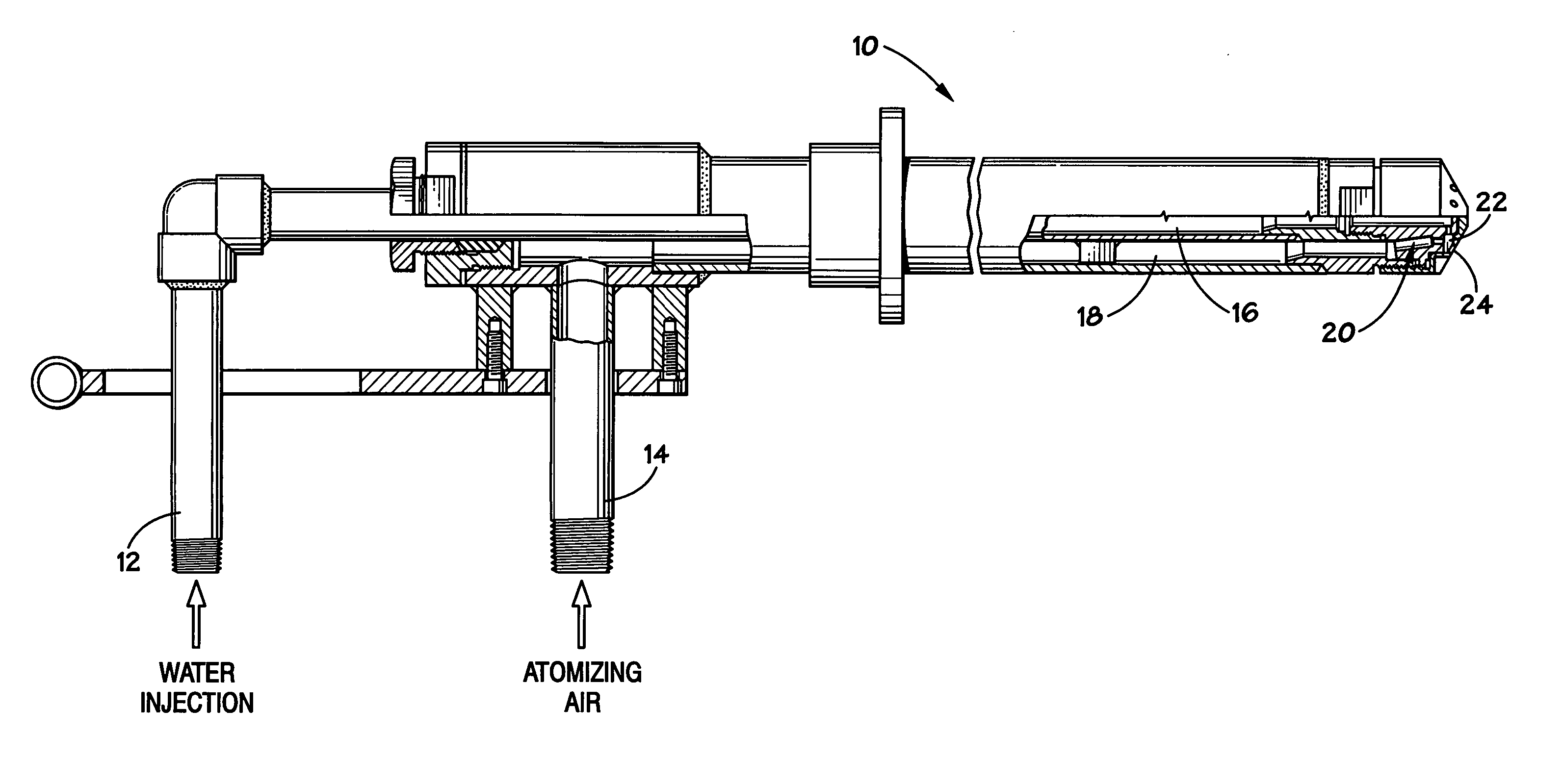

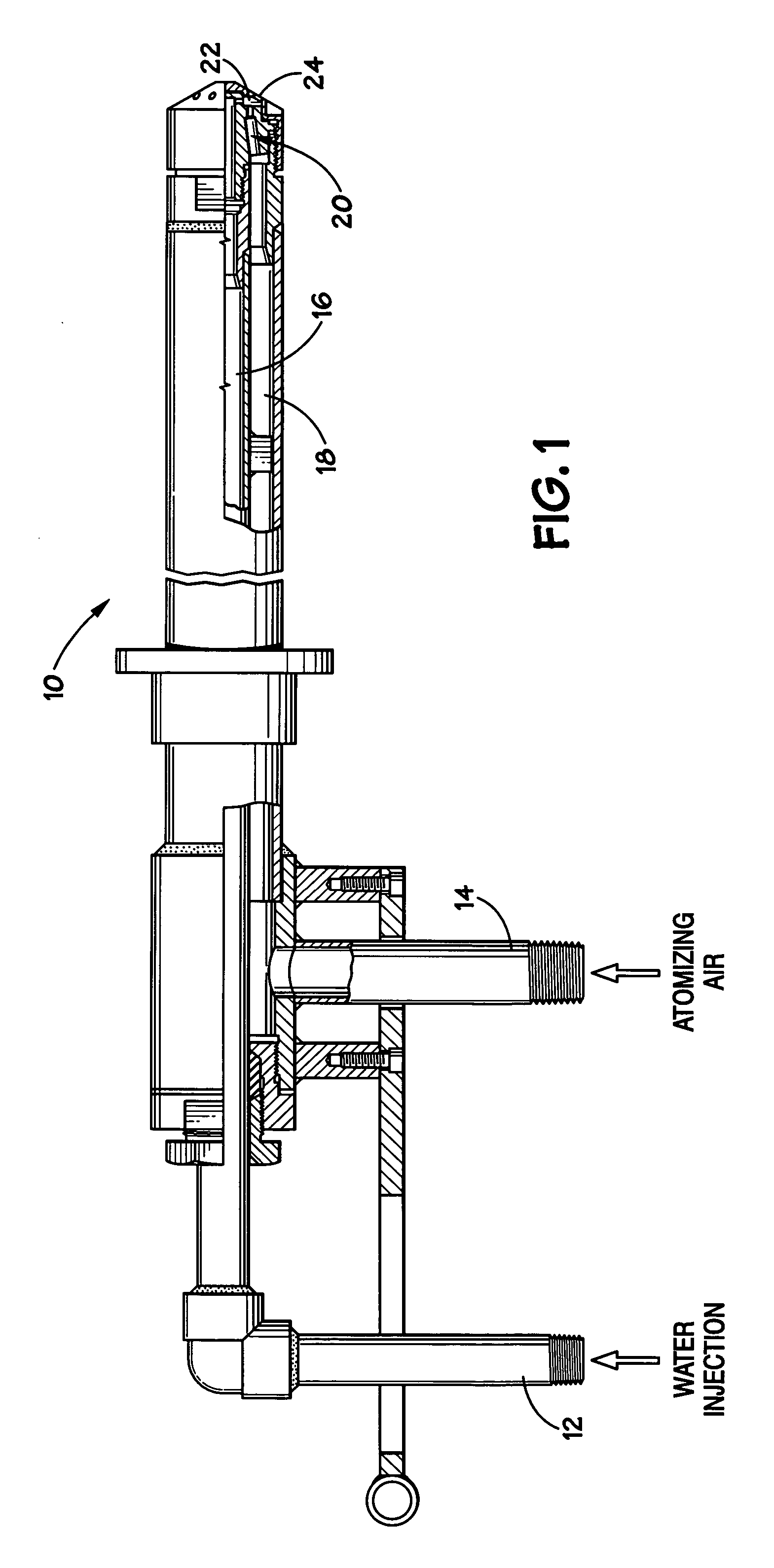

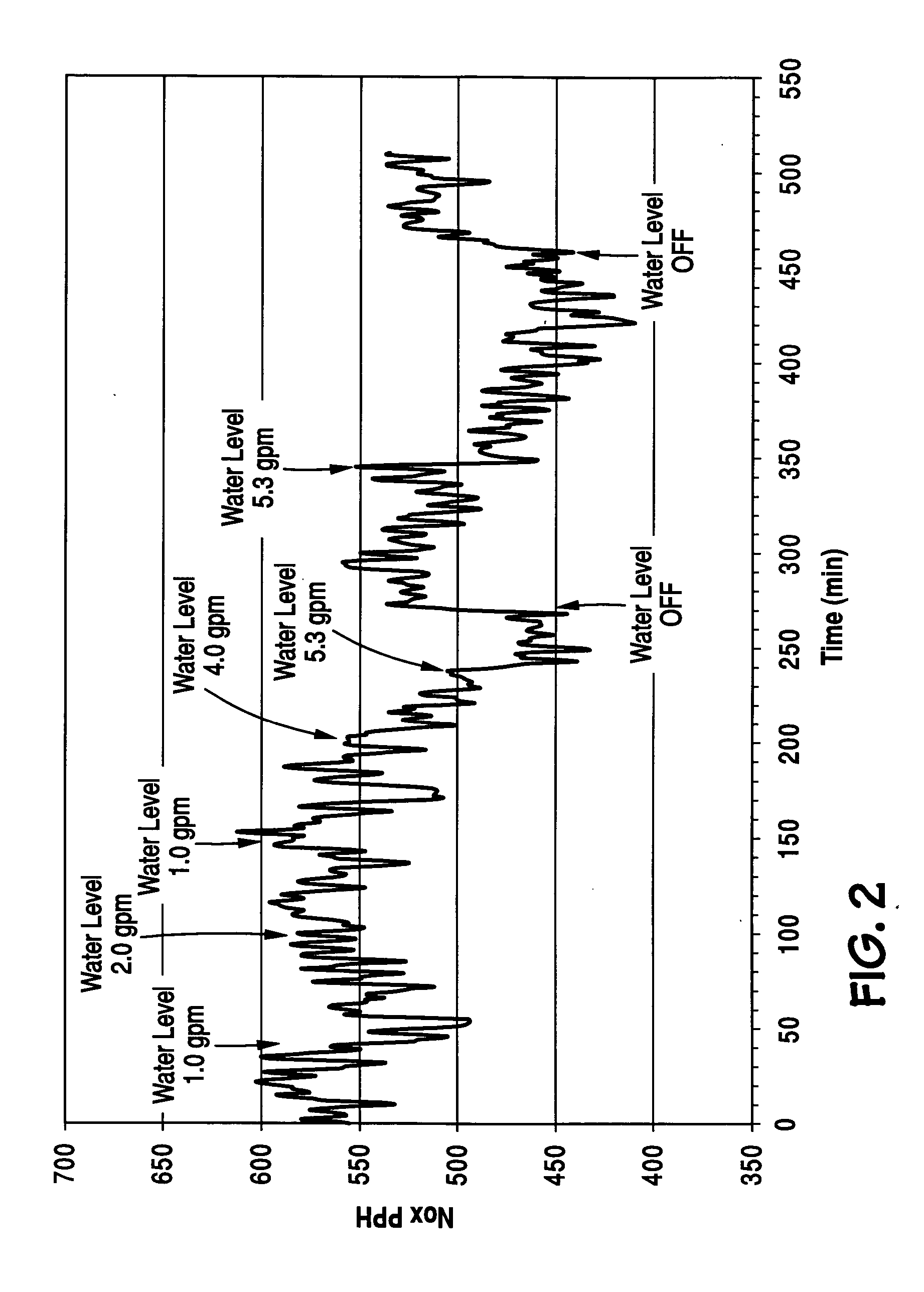

Method of reducing cement kiln NOx emissions by water injection

InactiveUS20050284347A1Reduce NOx emissionsReduce nitrogen oxide emissionsMaintainance of heating chambersFluidised-bed furnacesNitrogen oxidesProcess engineering

A method and apparatus are disclosed for reducing total NOx emissions from a cement kiln. The method includes the step of injecting water into the flame of the kiln at a point proximate the initial ignition point of the burner. The apparatus includes an injection nozzle for injecting water into the burner flame. Also disclosed is an improved process for making cement clinker. The process includes the steps of burning fuel to generate a flame within a kiln, injecting water into the flame to control formation of nitrogen oxides within the kiln, introducing a mixture of cement raw materials into the kiln, and reacting the raw materials to form cement clinker.

Owner:CEMEX

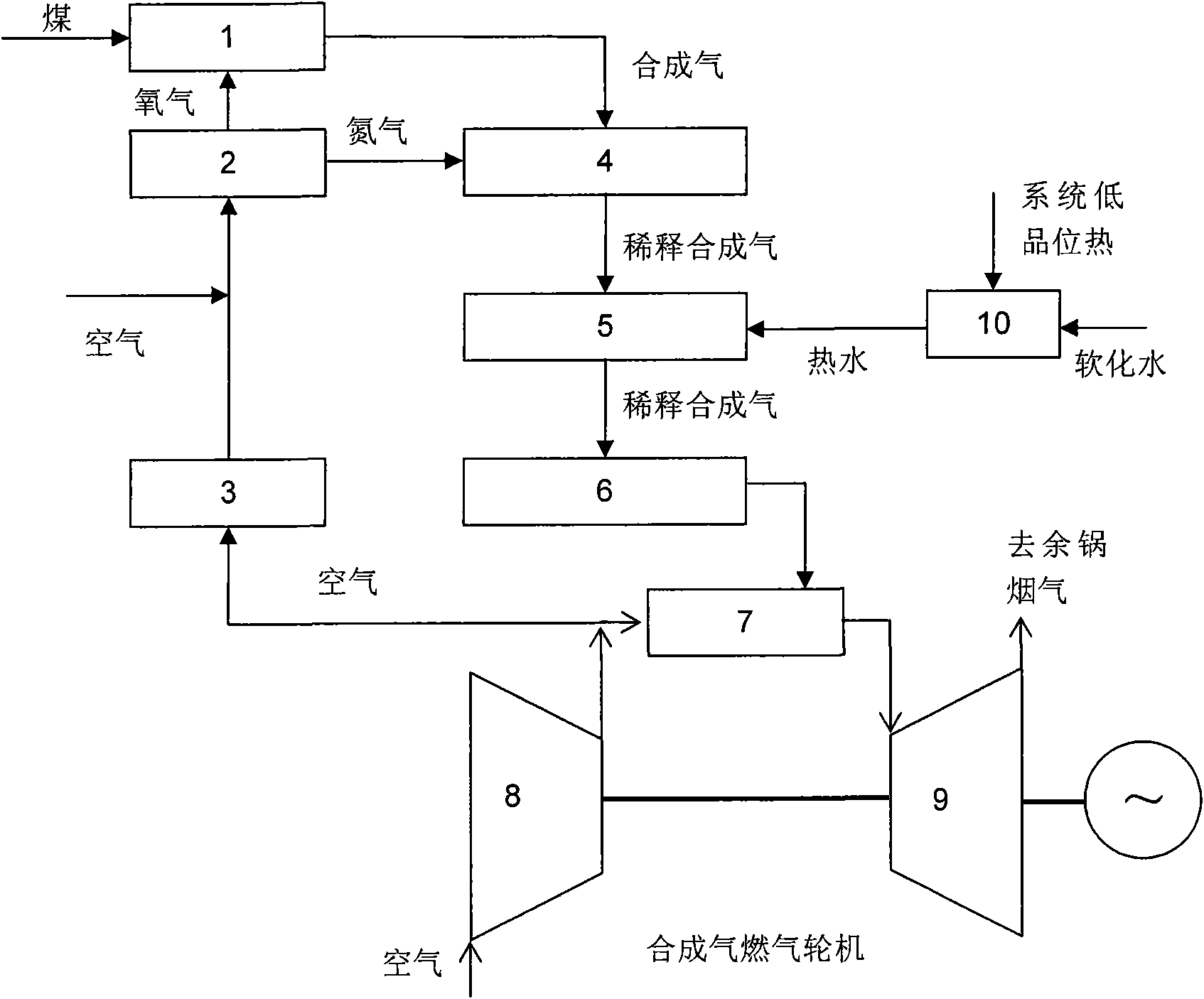

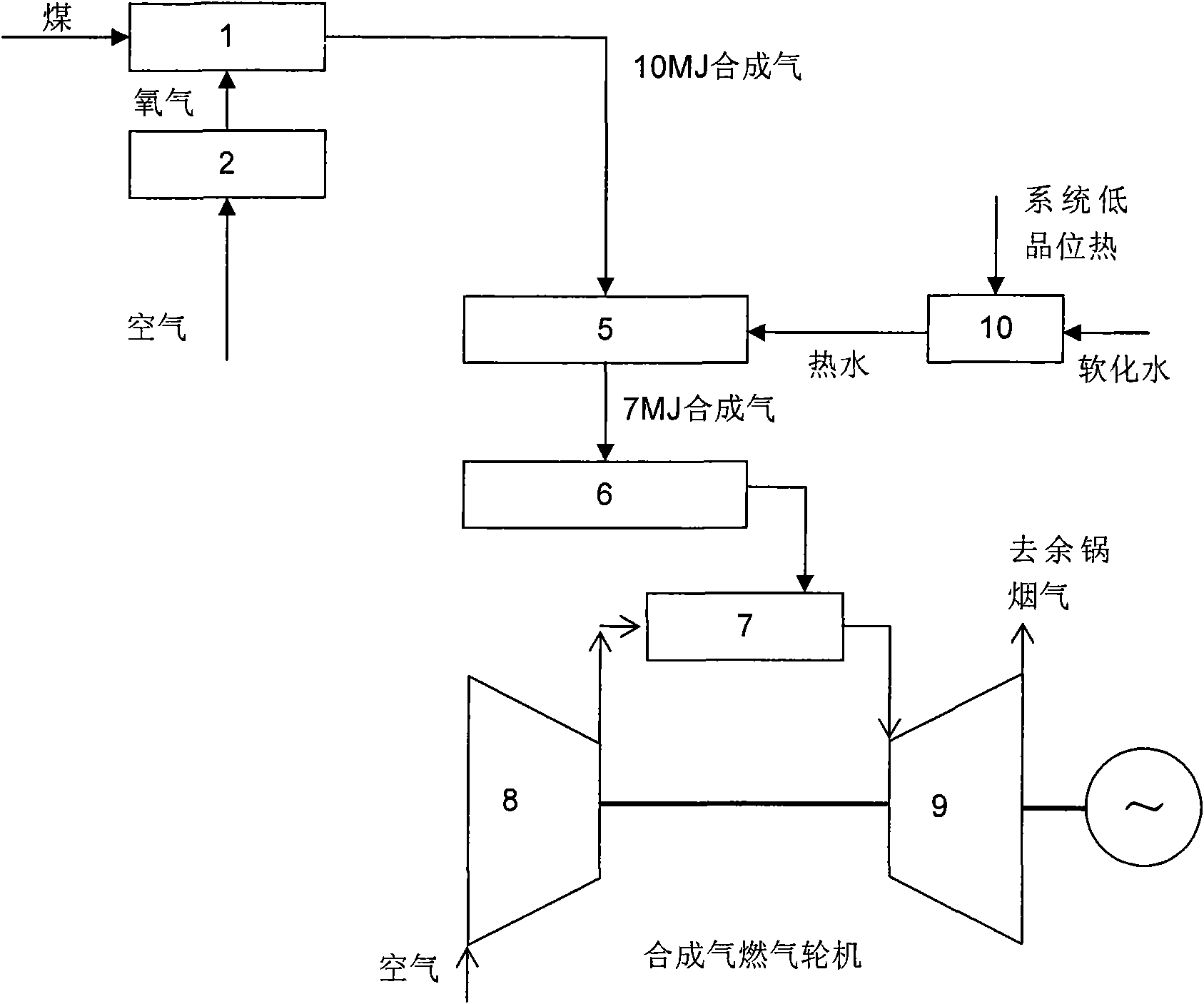

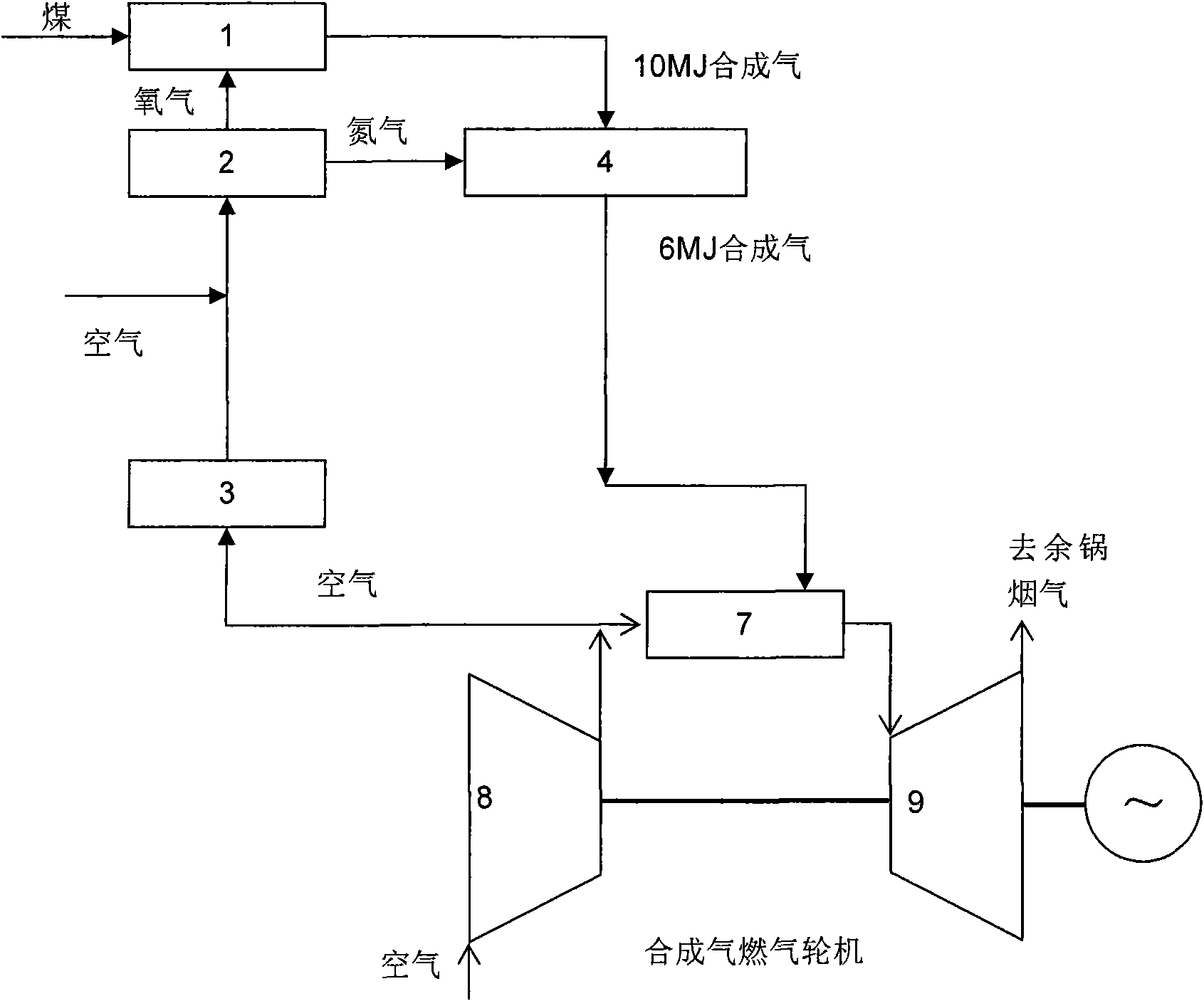

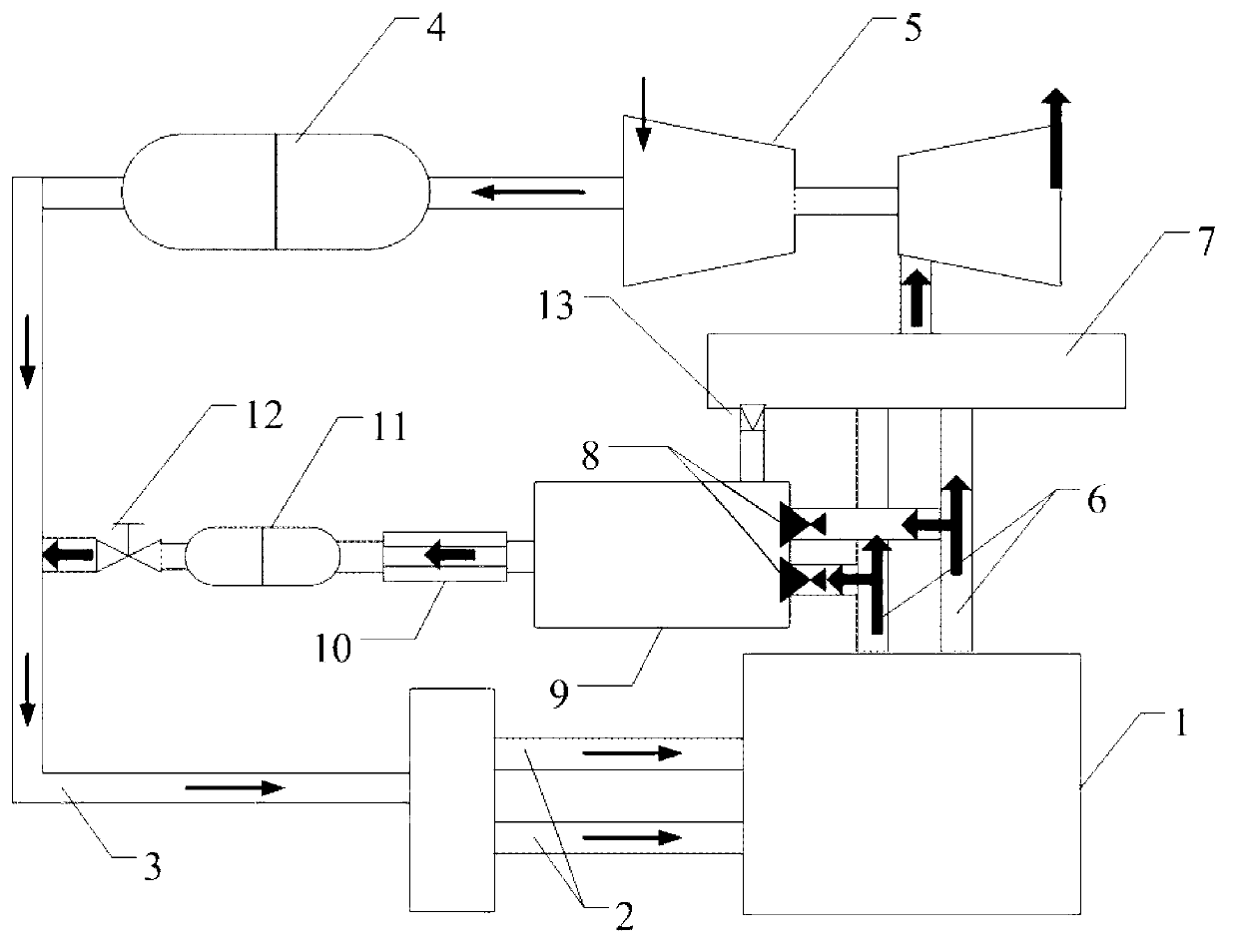

Combustion engine island technique

InactiveCN101555834AReduce NOx emissionsReduce power consumptionTurbine/propulsion fuel supply systemsGaseous fuelsAutomotive engineeringOil production

The invention relates to a combustion engine island technique which is used for power production of coal joint production and IGCC. By optical matching of a combustion engine and a system, a synthesis gas combustion engine achieves stable, high-efficient and low-pollution operation in the joint production and the IGCC, reaches the performance index of the system and ensures the economy of the system, wherein the technique comprises the use of a synthesis gas turbine, a synthesis gas dilution supply scheme and a suction gas utilization scheme of a gas turbine compressor, and the suction gas utilization scheme of the gas turbine compressor solves the problem of through flow matching of the compressor and the turbine and simultaneously improves the efficiency of the system.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

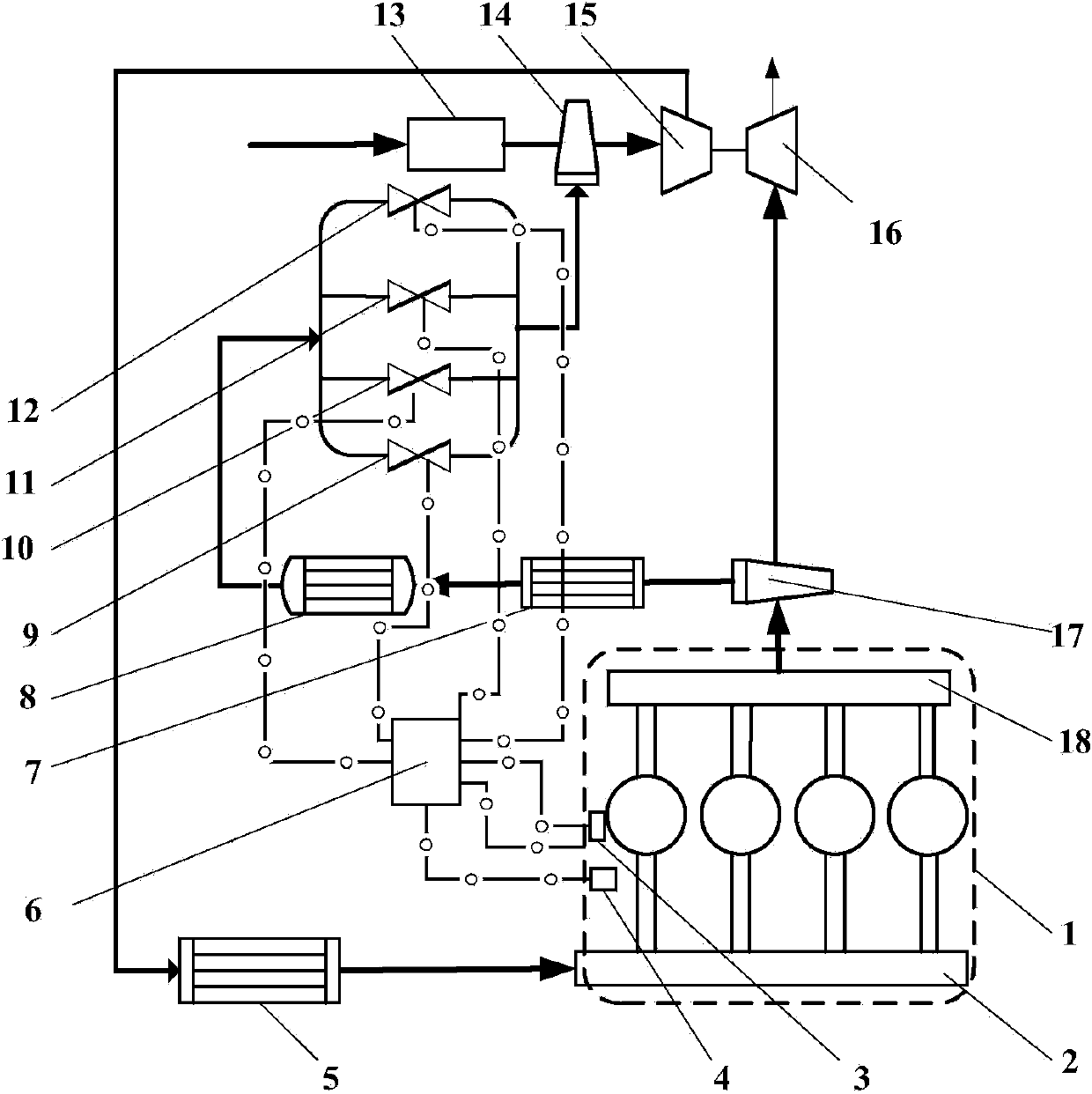

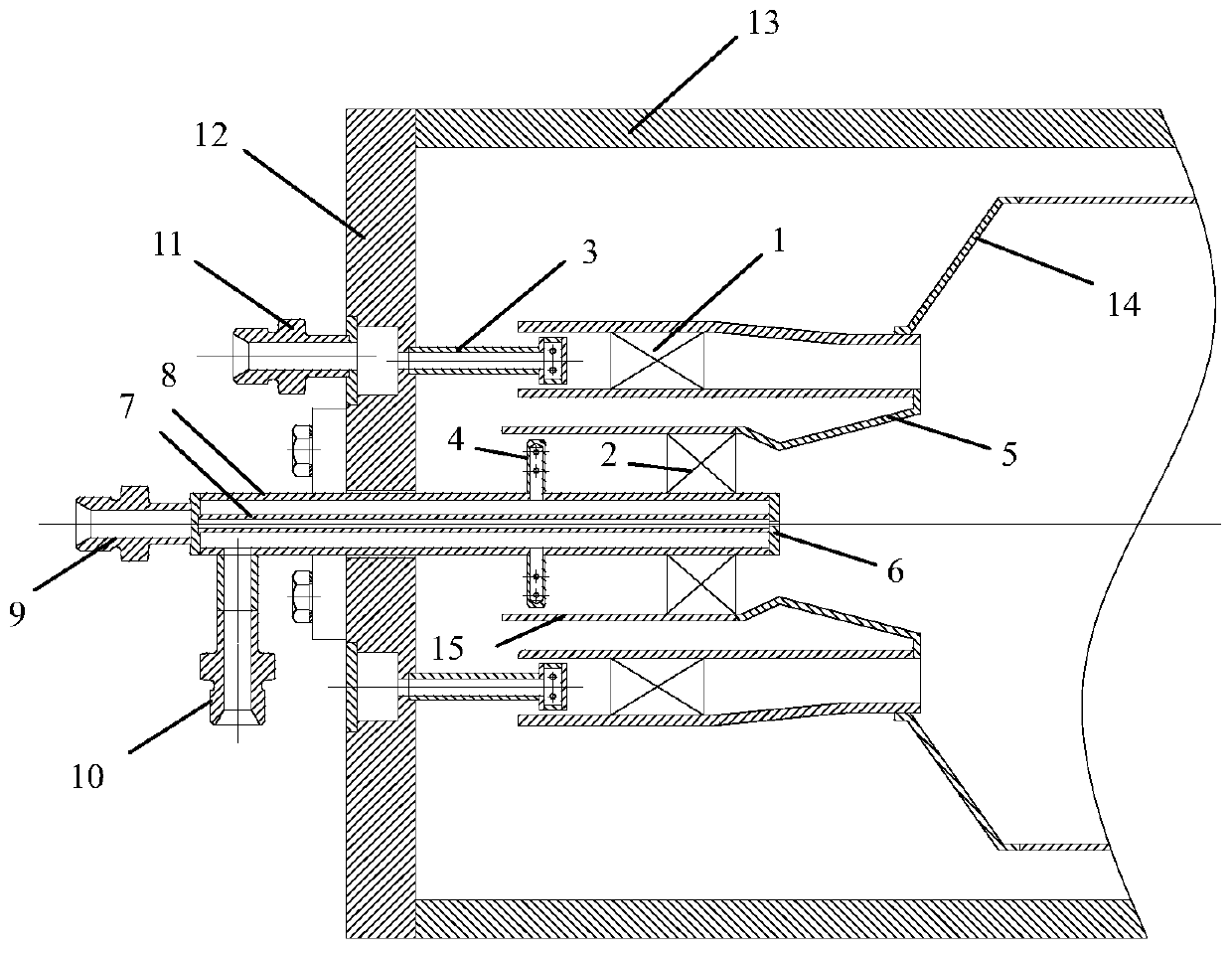

Supercharged diesel engine system based on EGR (exhaust gas recirculation) high pressure chamber

InactiveCN102996289AReduce NOx emissionsConstant pressureNon-fuel substance addition to fuelInternal combustion piston enginesHigh pressure chamberHigh pressure

The invention aims to provide a supercharged diesel engine system based on an EGR (exhaust gas recirculation) high pressure chamber. The supercharged diesel engine system comprises a diesel engine and a turbosupercharger, wherein a turbine of the turbosupercharger is connected with an exhaust manifold of each steam cylinder of the diesel engine, and a compressor of the turbosupercharger is connected with an air inlet manifold of each steam cylinder through an air inlet main pipe; and the supercharged diesel engine system also comprises the EGR high pressure chamber and an EGR valve, wherein the EGR high pressure chamber is communicated with each exhaust manifold through a one-way stop valve, the EGR high pressure chamber is communicated with an exhaust main pipe through a discharge valve and is communicated with an air inlet main pipe through the EGR valve. The supercharged diesel engine system provided by the invention effectively utilizes the exhaust pulse energy, high pressure waste gas opens up a one-way isolating valve, waste gas is injected into the high pressure chamber, so the waste gas pressure in an EGR chamber is improved, and meanwhile, the discharge valve of the high pressure chamber guarantees a constant pressure in a cavity body, and finally the waste gas can smoothly return to the air inlet main pipe, and the NOx discharge of the diesel engine is lowered.

Owner:HARBIN ENG UNIV

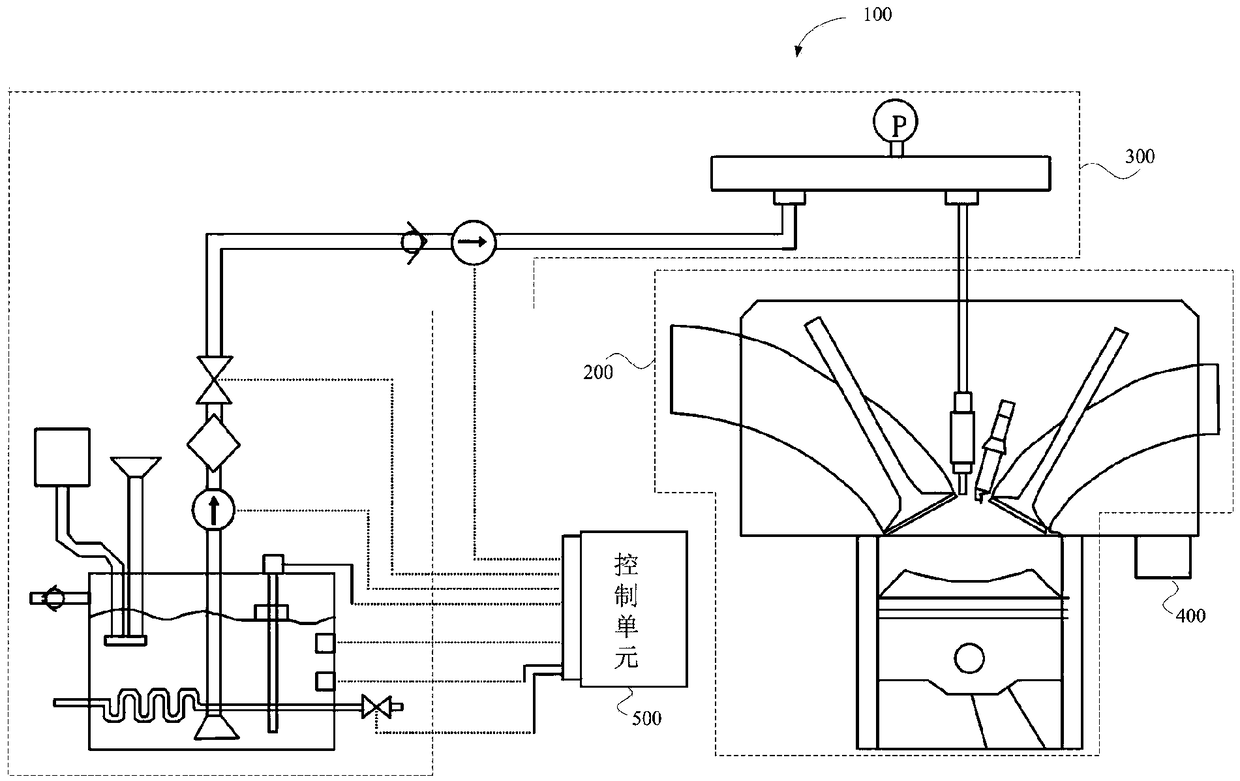

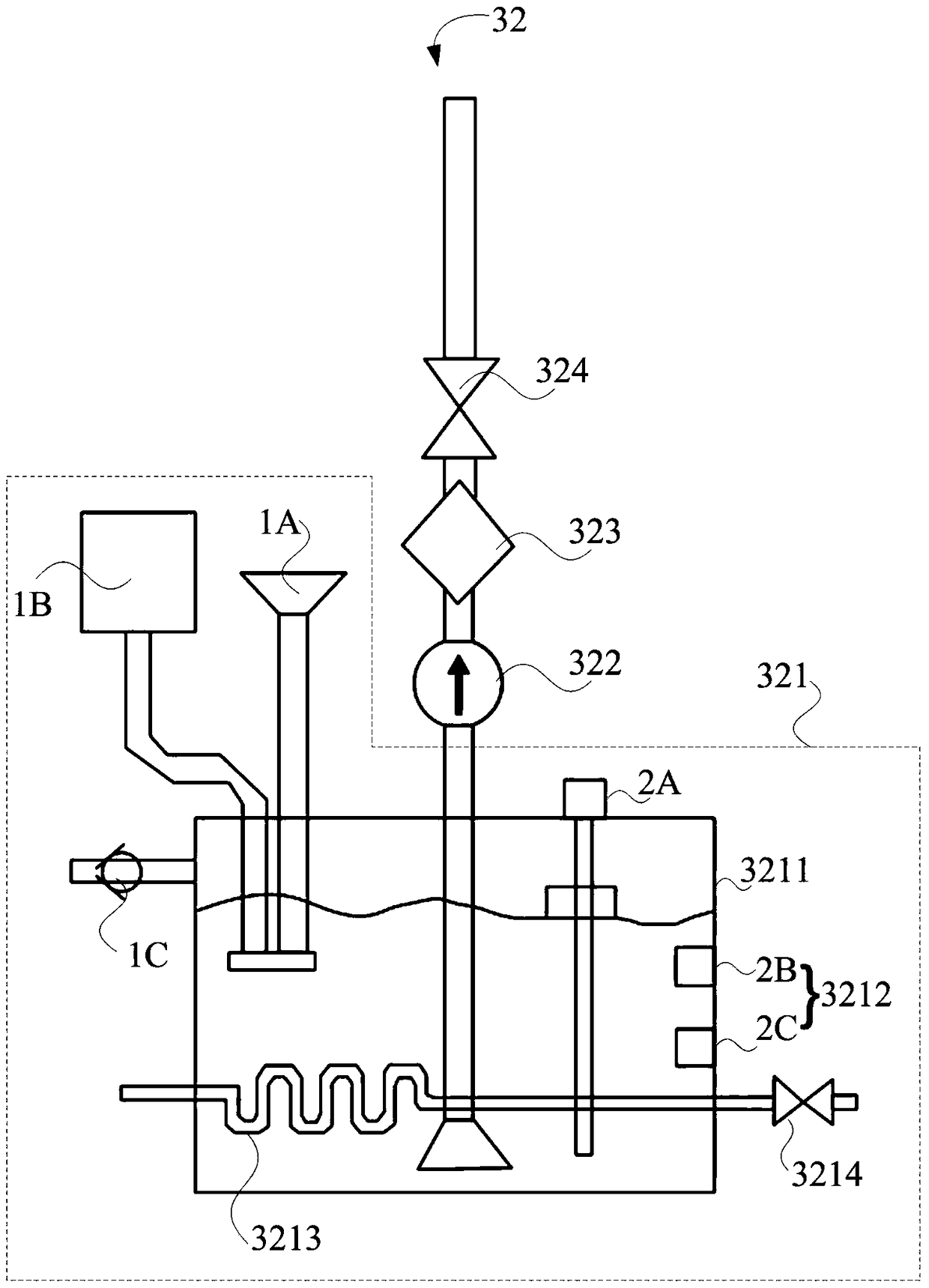

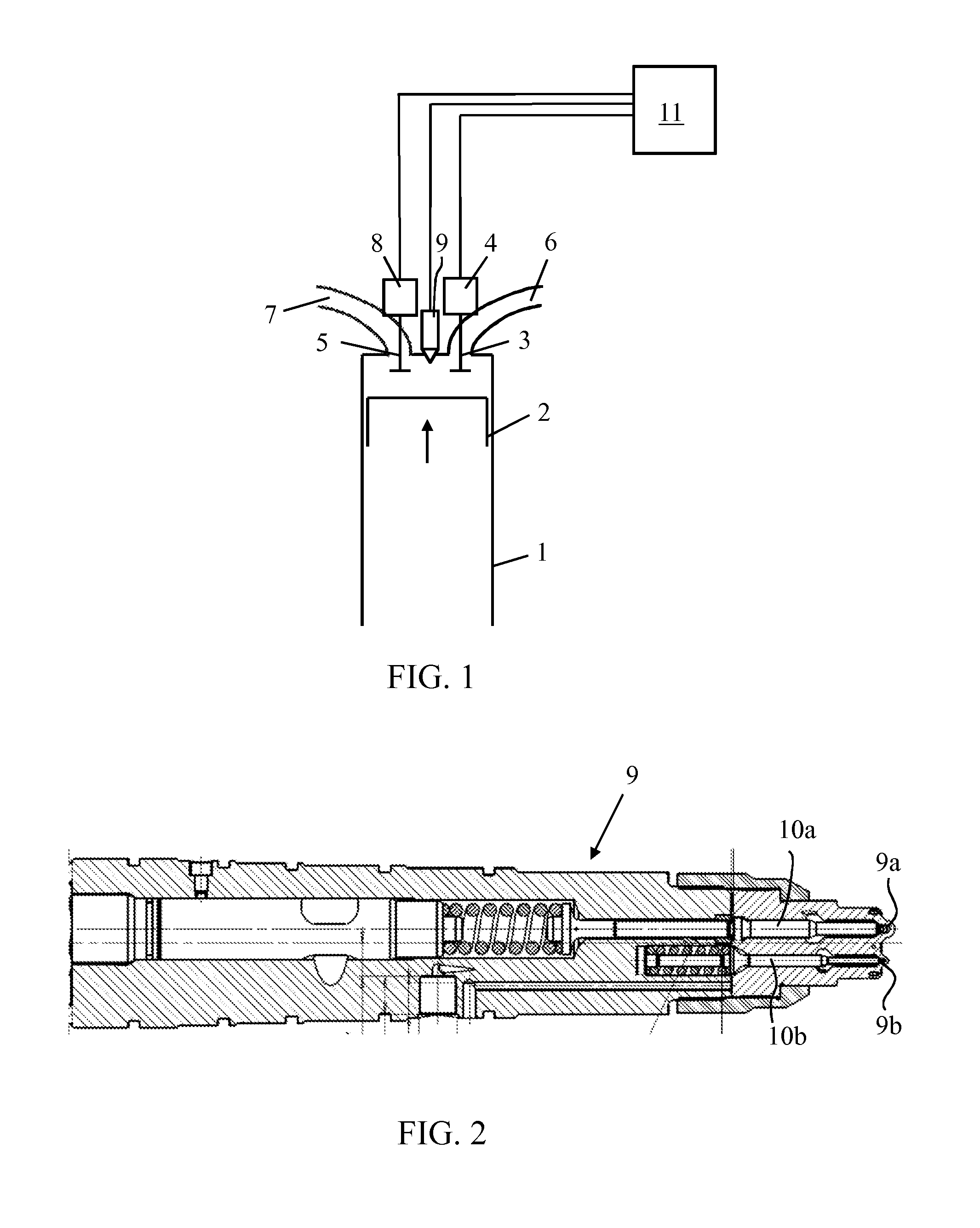

Engine water spraying system

InactiveCN108869105ALower cylinder temperatureReduce NOx emissionsElectrical controlNon-fuel substance addition to fuelValve openingCombustion chamber

The invention relates to the technical field of automobile manufacturing, in particular to an engine water spraying system. The engine water spraying system comprises an engine, a water spraying unit,a collecting unit and a control unit. The engine comprises a combustion chamber. The water spraying unit comprises a water spraying outlet, and the water spraying outlet of the water spraying unit isformed in the combustion chamber. The collecting unit is used for collecting the work load or the exhaust temperature of the engine. The control unit is connected with the water spraying unit and thecollecting unit and used for controlling water spraying of the water spraying unit according to the work load or the exhaust temperature of the engine. Thus, since the water spraying outlet is located in the combustion chamber, the water spraying atomization effect is good, water spraying time control is flexible, and limitation from valve opening and closing is avoided; meanwhile, the compression final temperature can be effectively reduced through the cylinder interior water spraying technology, on one hand, denotation limitation can be broken, the compression ratio is increased, and the heat efficiency is improved; and on the other hand, the cylinder interior temperature is reduced, and NOx emission can be reduced.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

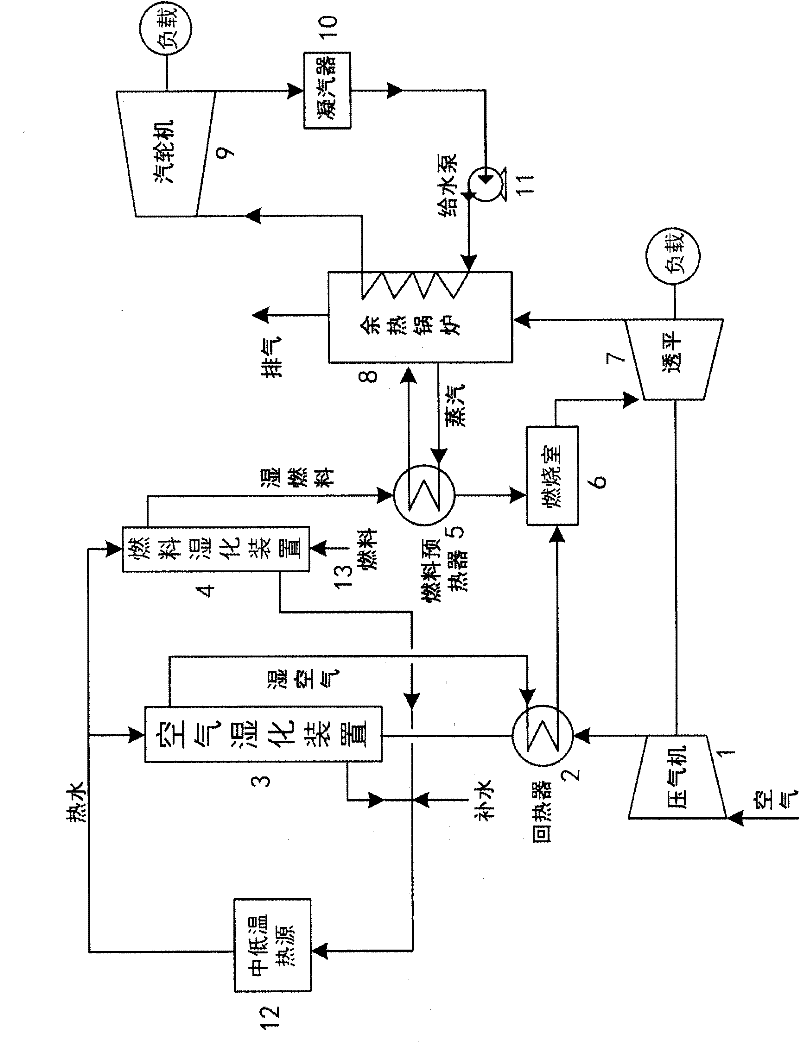

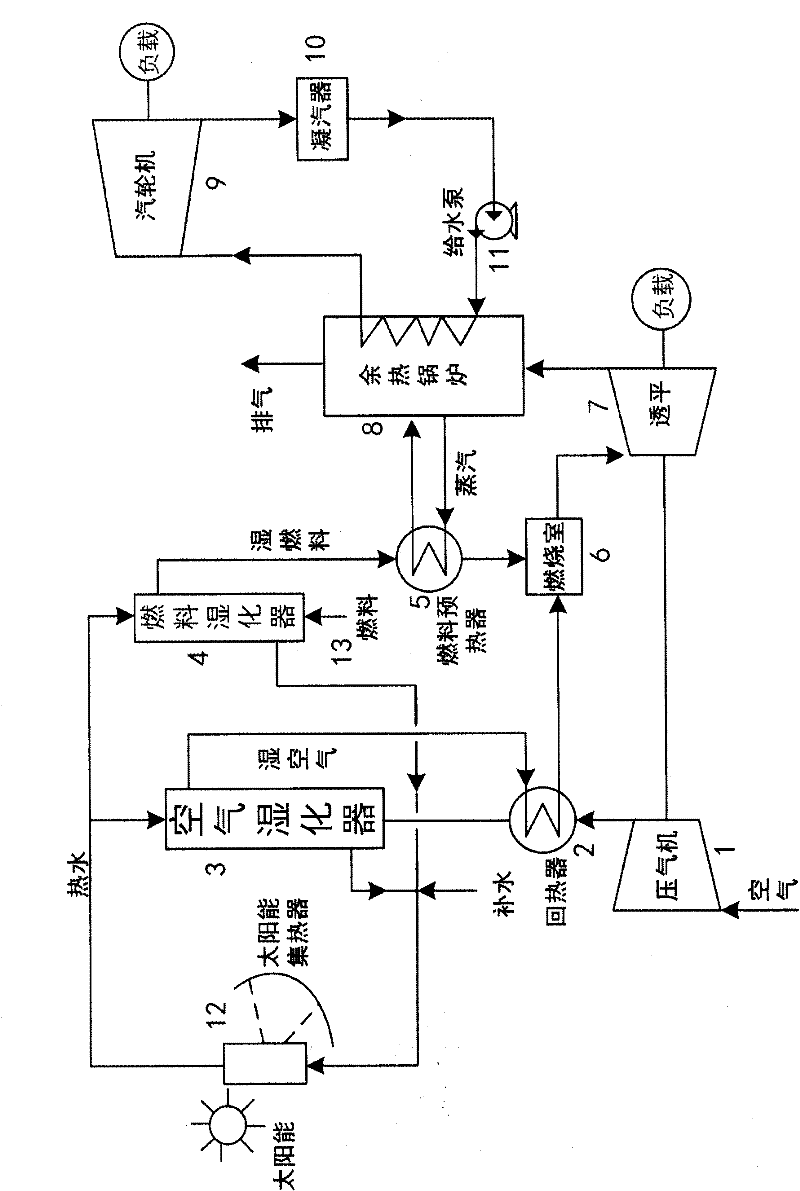

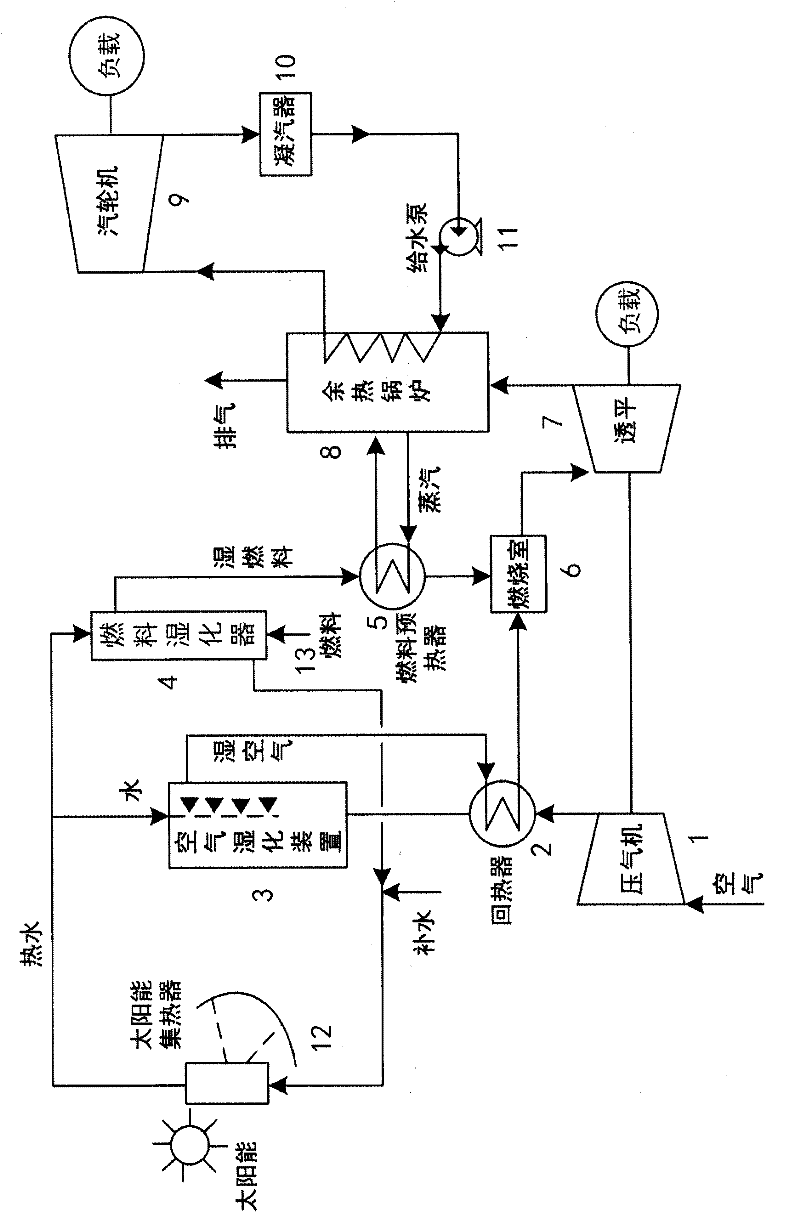

Distributed Air and Fuel Humidification Gas Turbine Combined Cycle Approach

InactiveCN102278205AReduce NOx emissionsImprove efficiencyTurbine/propulsion fuel supply systemsFrom solar energyInlet temperatureAutomotive engineering

The invention discloses a gas turbine combined cycle method which can be used for distributed air and fuel humidification, and relates to gas turbine technology. An air humidification device is arranged between the gas turbine compressor outlet and a combustion chamber, and the compressed air is humidified by the humidification system and then The preheating enters the combustion chamber, and the heat source for air humidification is provided by the external medium and low temperature heat source; the fuel is also humidified and preheated by the humidifier before entering the combustion chamber. The gas turbine combined cycle method of the present invention can make full use of low-grade heat to improve the performance of the gas turbine combined cycle. Under the same conditions as the temperature before the turbine, the compressor pressure ratio and the component efficiency, the thermal efficiency index of the conventional gas turbine combined cycle can be improved by about 10%. %-15%, the output power index per unit air flow is increased by 20%-30%.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

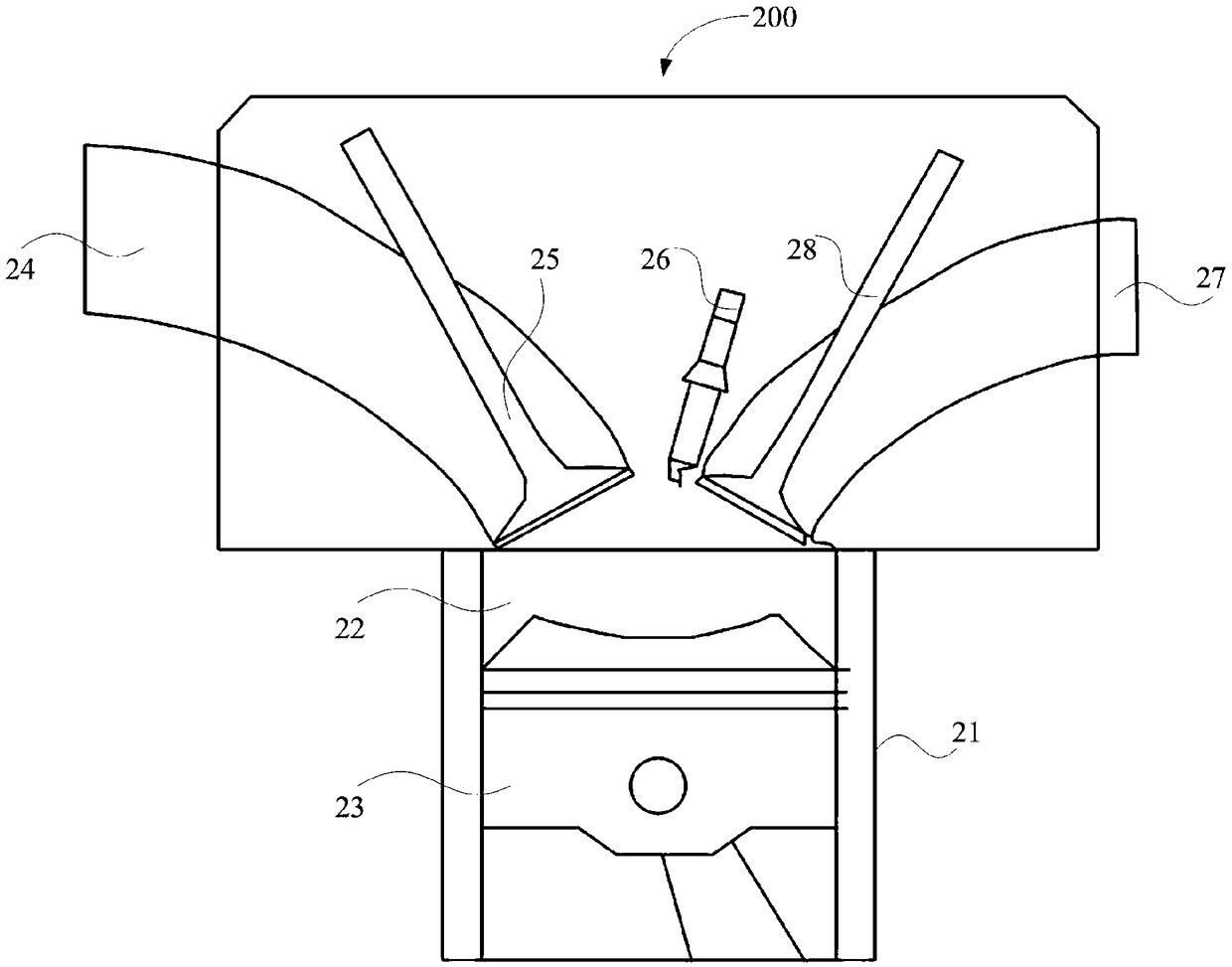

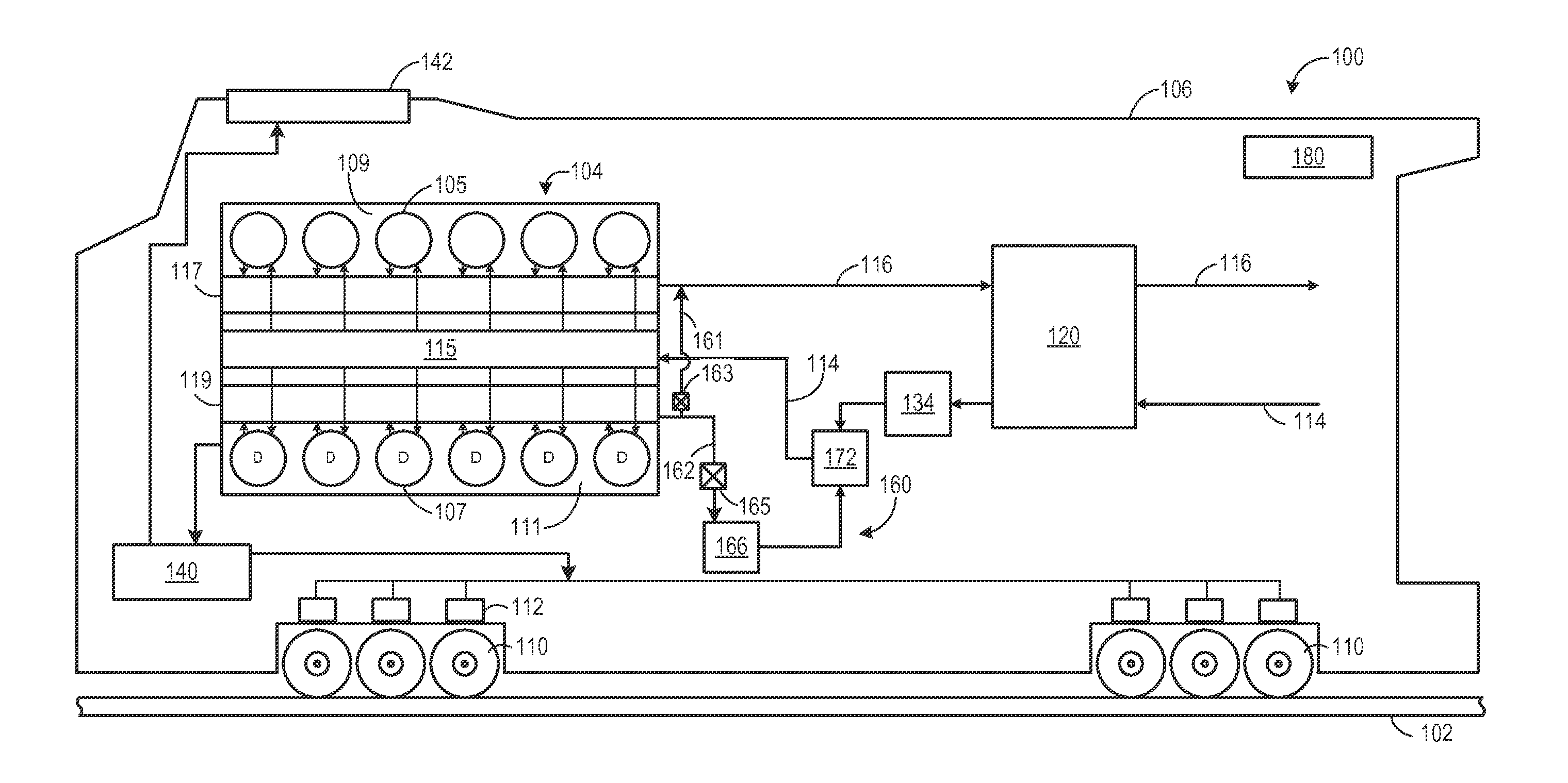

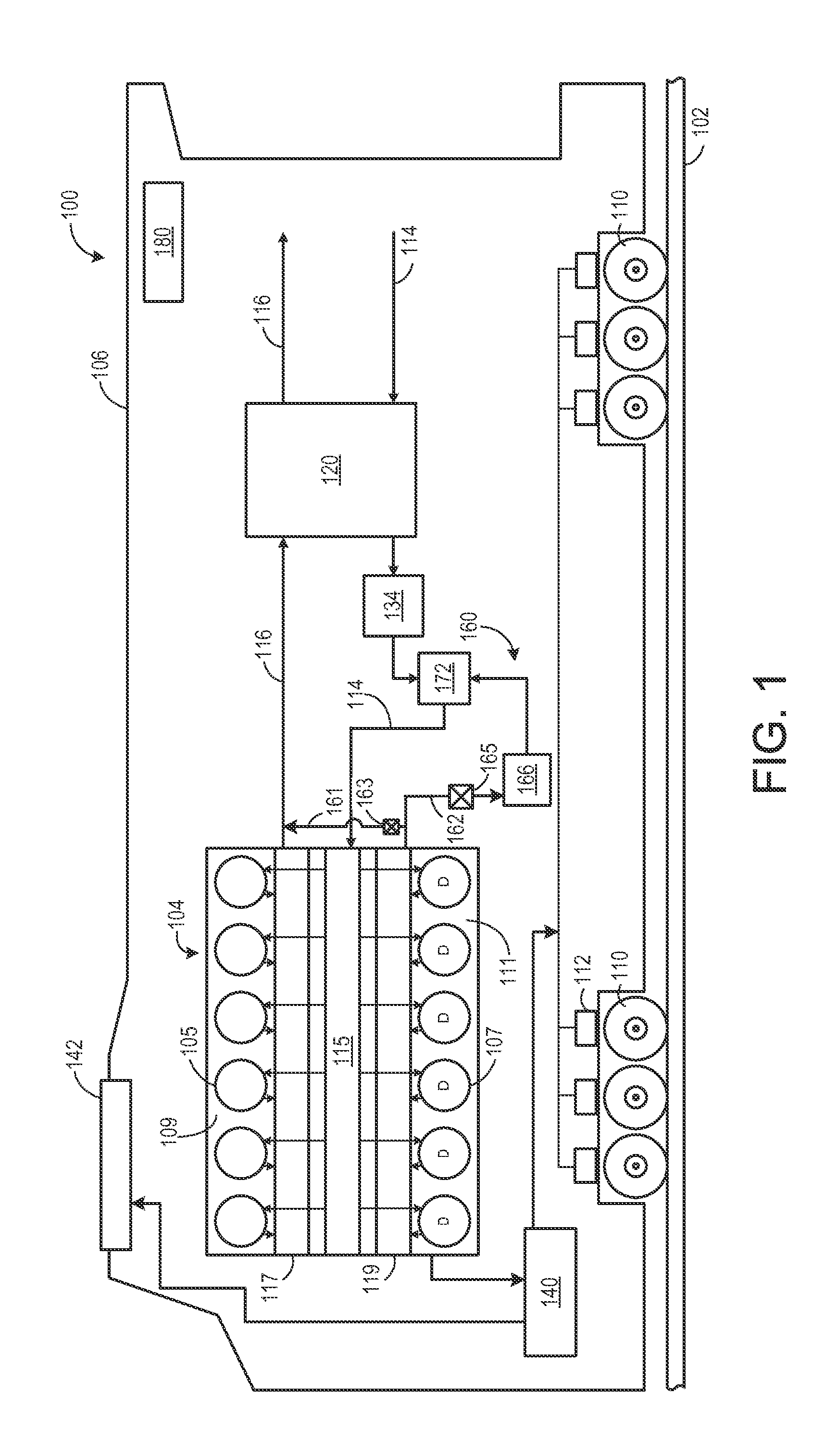

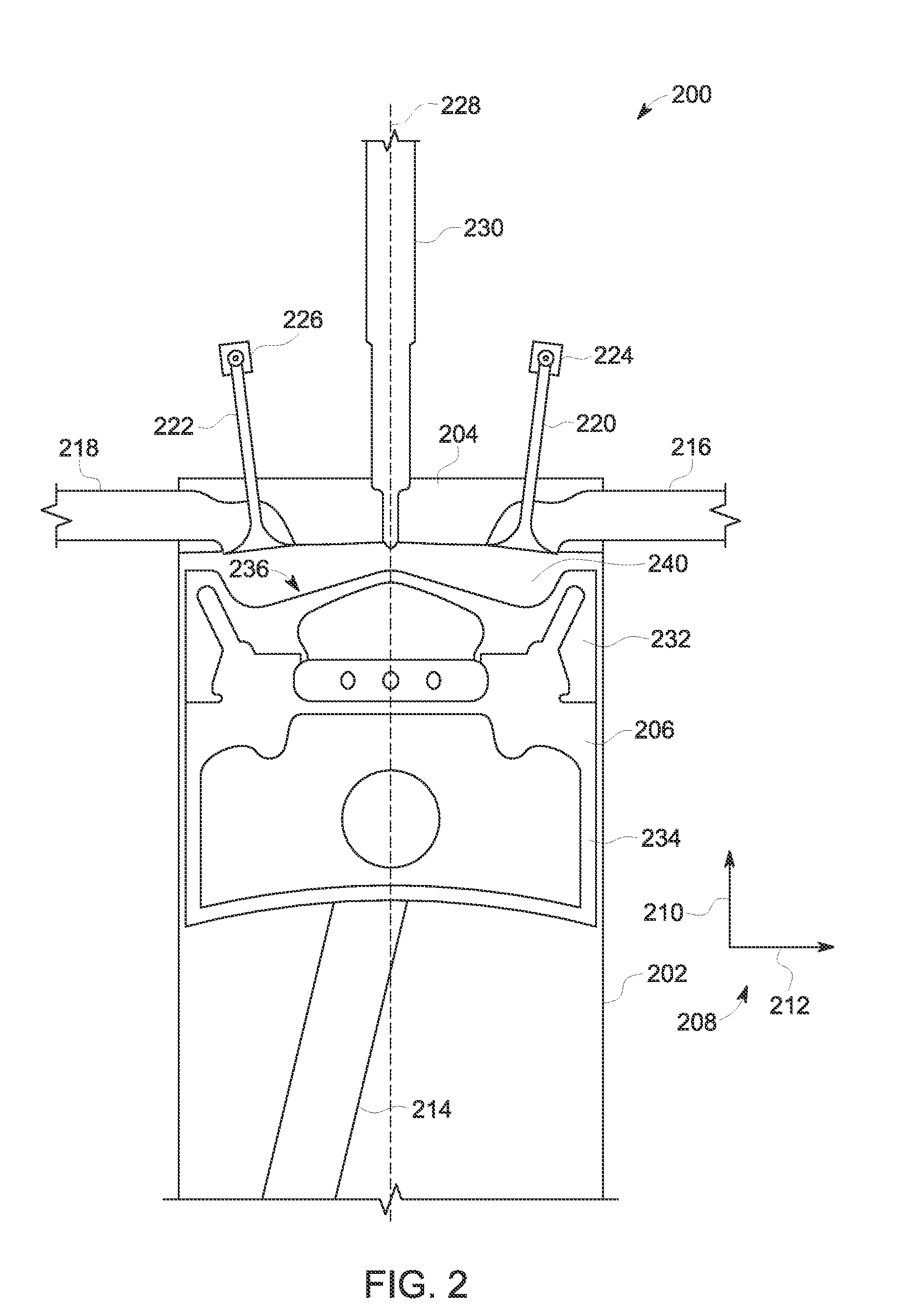

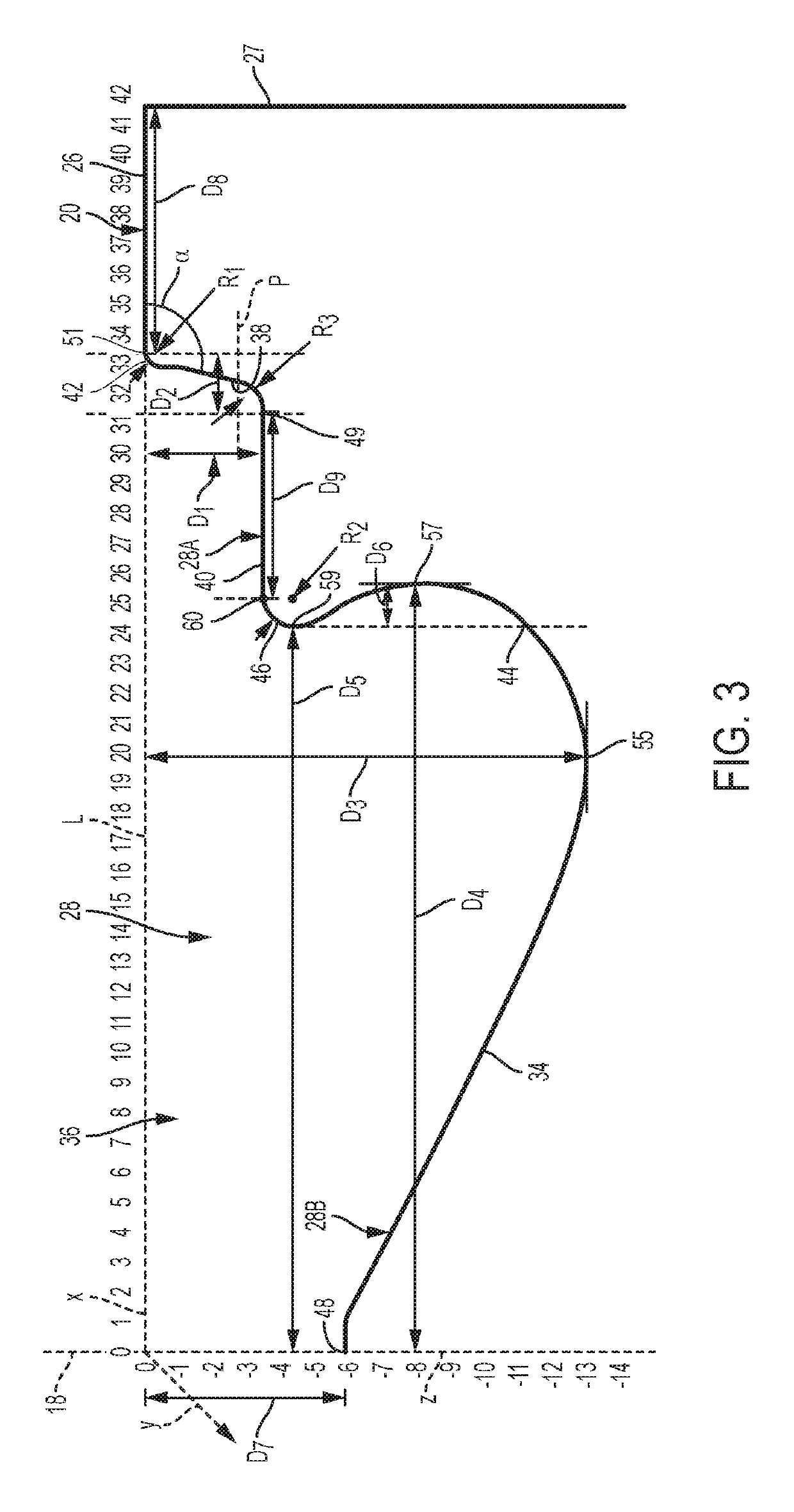

Combustion system including a piston crown and fuel injector

ActiveUS20150198070A1Reduce engine emissionsMaintaining engine performanceExhaust apparatusSilencing apparatusCombustion systemCombustion chamber

Various methods and systems are provided for a combustion system of an engine. In one example, a combustion system comprises a piston crown bowl with a central apex, a combustion chamber operable at a compression ratio in a range of from about 13:1 to about 17:1, the combustion chamber formed at least partially by the piston crown bowl, and a fuel injector with a nozzle extending into a central portion of the combustion chamber that is operable to inject fuel directly into the combustion chamber, the nozzle defining a number of apertures that is in a range of from six to ten.

Owner:GE GLOBAL SOURCING LLC

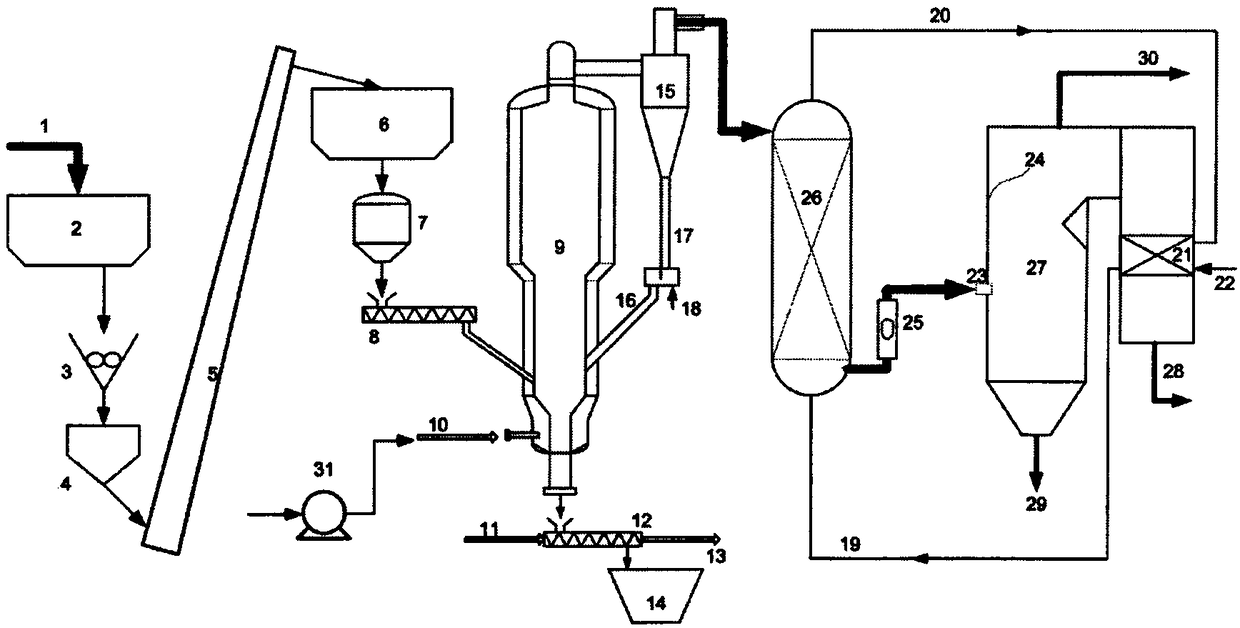

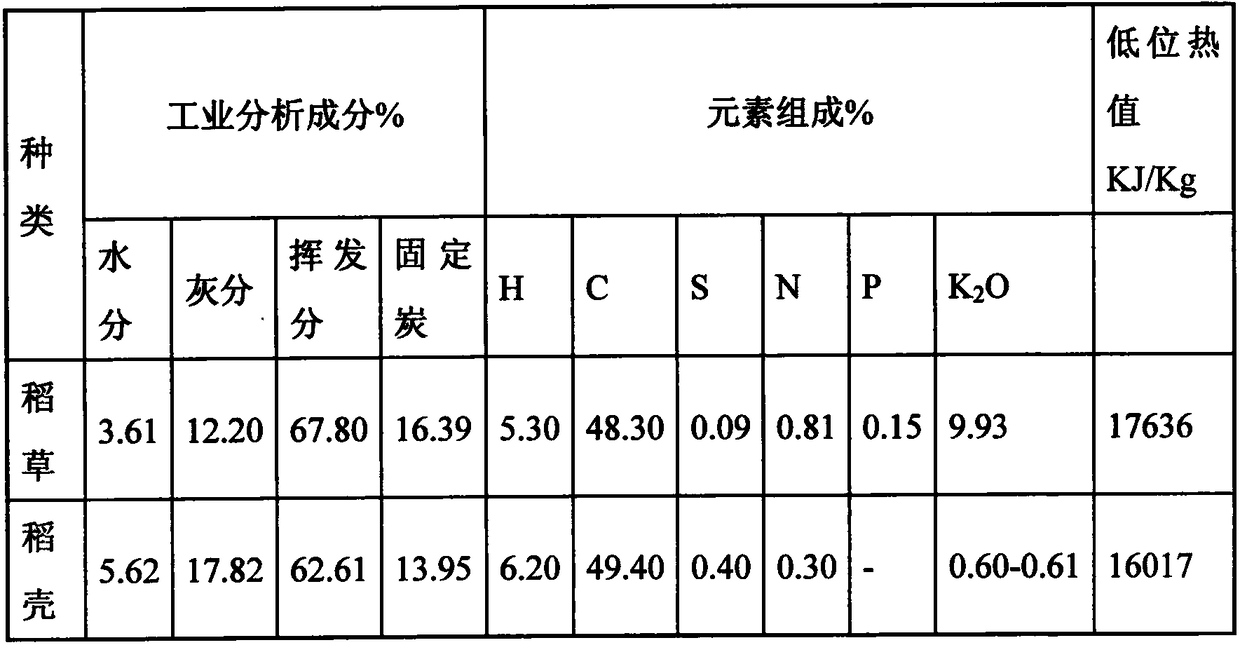

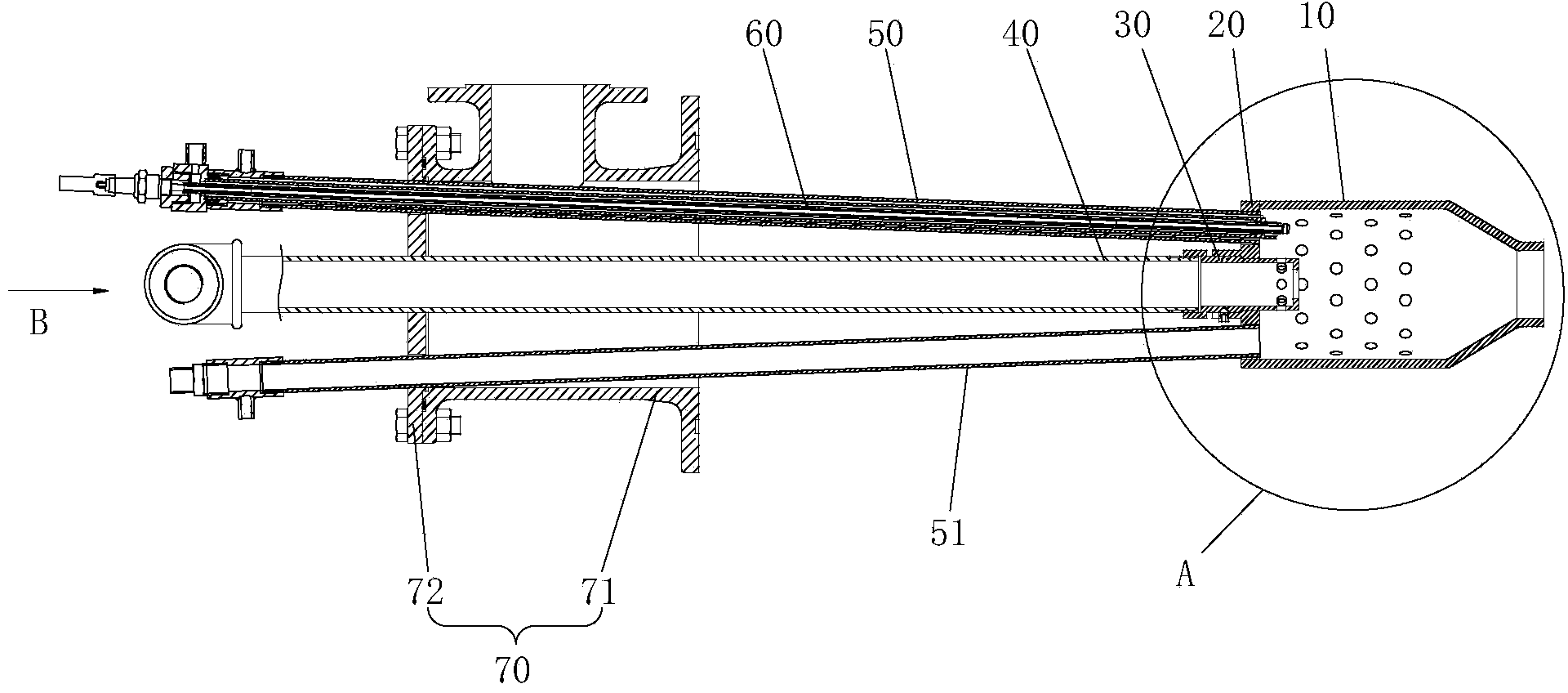

Power generation system and power generation method for biomass gasification coupled coal-fired boiler

PendingCN108456556ASave coalReduce NOx emissionsEnergy inputGasification processes detailsEconomizerBoiler feedwater

The invention provides a power generation system for a biomass gasification coupled coal-fired boiler. The power generation system comprises a biomass storage conveying unit, a biomass circulating fluidized bed gasification unit, a biomass high-temperature fuel gas waste heat recovering unit, a crude gas metering air supply unit and a matched combustion unit, wherein the biomass storage conveyingunit is used for finishing and storing collected biomass raw materials, as well as cutting, breaking and discharging the biomass raw materials; the biomass circulating fluidized bed gasification unitis used for gasifying cut and broken biomass particles into crude gas; the biomass high-temperature fuel gas waste heat recovering unit is used for adopting boiler feed water from a high-temperature economizer of a coal-fired boiler as a cooling medium and cooling the crude gas; the crude gas metering air supply unit and the matched combustion unit are used for feeding the cooled crude gas into the coal-fired boiler for combusting in a metering manner. The invention also provides a power generation method for the biomass gasification coupled coal-fired boiler. By coupling biomass gasification,waste heat recovery and combustion, the power generation system and the power generation method disclosed by the invention have the advantages that indirect power generation of biomass is realized, the biomass is efficiently utilized while fire coal is saved, NOx emission of the coal-fired boiler is reduced and a broad application prospect is realized.

Owner:SHANGHAI BOILER WORKS

Control method for an internal combustion engine and internal combustion engine

ActiveUS20140041637A1Reduce nitrogen oxide emissionsHigh smoke emissionElectrical controlInternal combustion piston enginesExternal combustion engineInlet valve

The method for controlling the operation of an internal combustion engine comprises at least two operating modes. In a first operating mode, the intake valve is closed at a first predetermined crank angle, in accordance with the Miller cycle, before the piston reaches bottom dead center during the intake stroke for reducing pressure in the cylinder, and fuel is injected using first fuel injection means optimized for large amounts of fuel. In a second operating mode the intake valve is closed at a second predetermined crank angle, in accordance with conventional intake valve closing timing, after or slightly before the piston has passed bottom dead center, and fuel is injected using second fuel injection means optimized for small amounts of fuel. The invention also concerns an internal combustion engine.

Owner:WARTSILA FINLAND OY

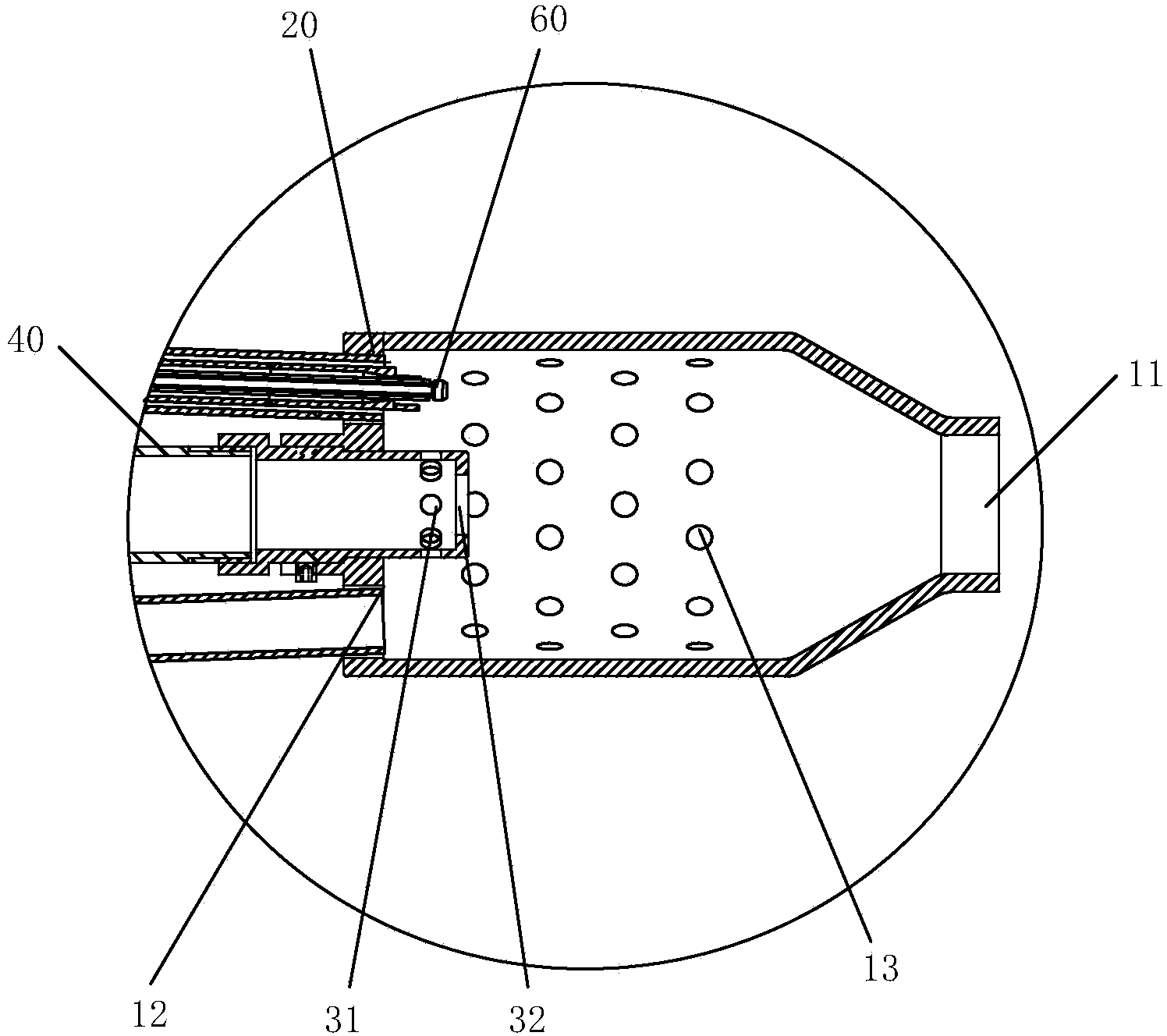

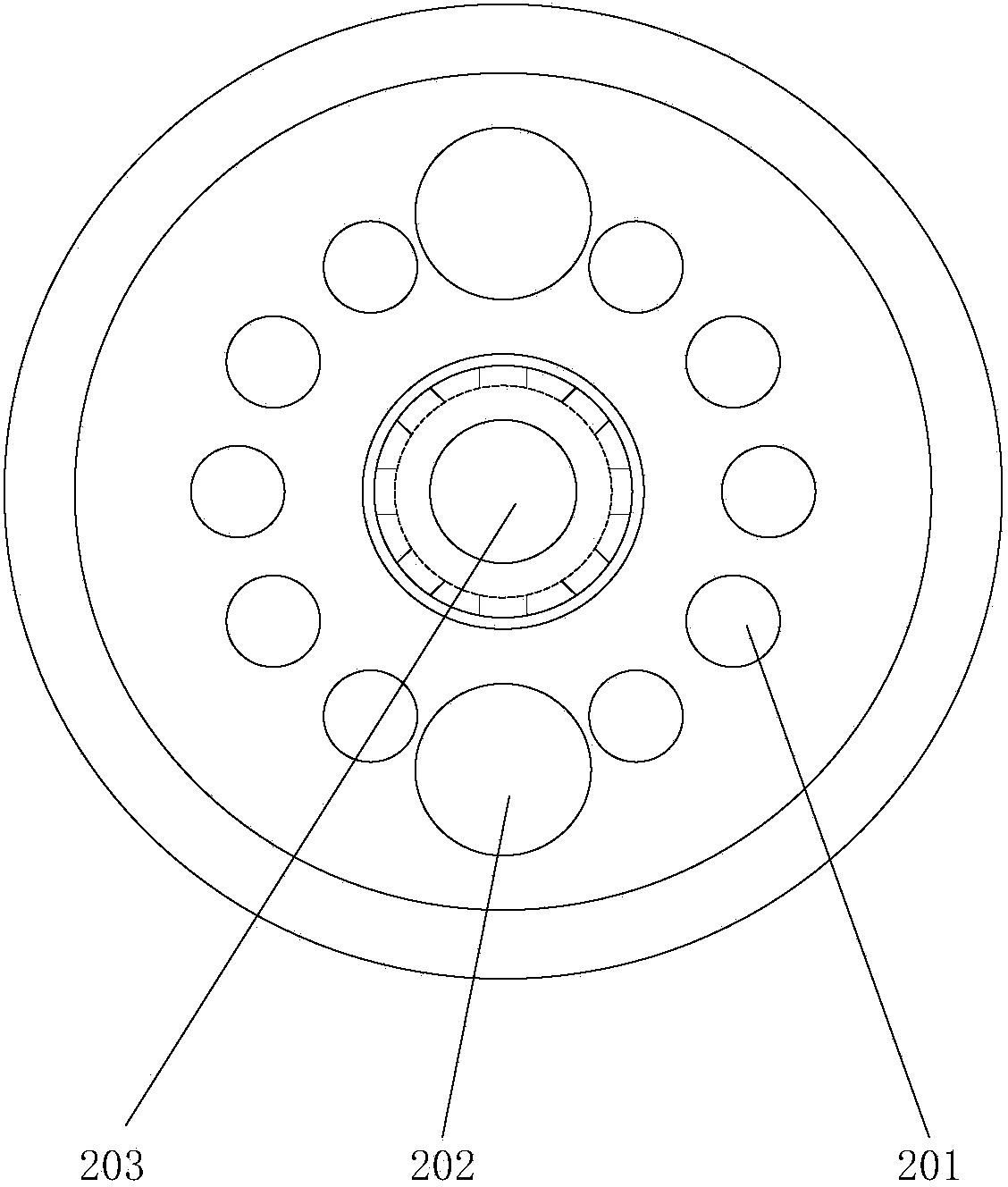

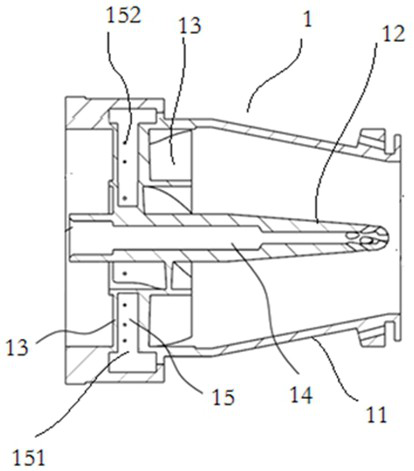

Low-calorific-value gas radiating tube burner and control method thereof

ActiveCN104266189AReduce NOx emissionsImprove temperature distribution uniformityGaseous fuel burnerSpray nozzlePollutant

The invention discloses a low-calorific-value gas radiating tube burner. The low-calorific-value gas radiating tube burner comprises a combustion chamber, an air distribution plate, a gas spraying nozzle, a gas guide tube, a first electrode guide tube, an ignition electrode and a fixing device; an inlet of the combustion chamber is provided with the air distribution plate; a combustion cavity of the combustion chamber is communicated with a radiating tube through an outlet of the combustion chamber; the air distribution plate is provided with an air inlet; the first electrode guide tube sleeves the ignition electrode; the first electrode guide tube penetrates the fixing device and the air distribution plate; the gas guide tube penetrates the fixing plate and the air distribution plate; the gas spraying nozzle is arranged at one end of the gas guide tube, wherein the end of the gas guide tube is close to the air distribution plate; the fixing device is used for fixing the low-calorific-value gas radiating tube burner into the radiating tube; the fixing device is provided with a combustion-supporting opening. The invention also provides a control method of the low-calorific-value gas radiating tube burner. According to the low-calorific-value gas radiating tube burner, the ignition stability of the burner during the application of the low-calorific-value gas is improved and meanwhile the emissions of pollutants are reduced.

Owner:WISDRI WUHAN WIS IND FURNACE

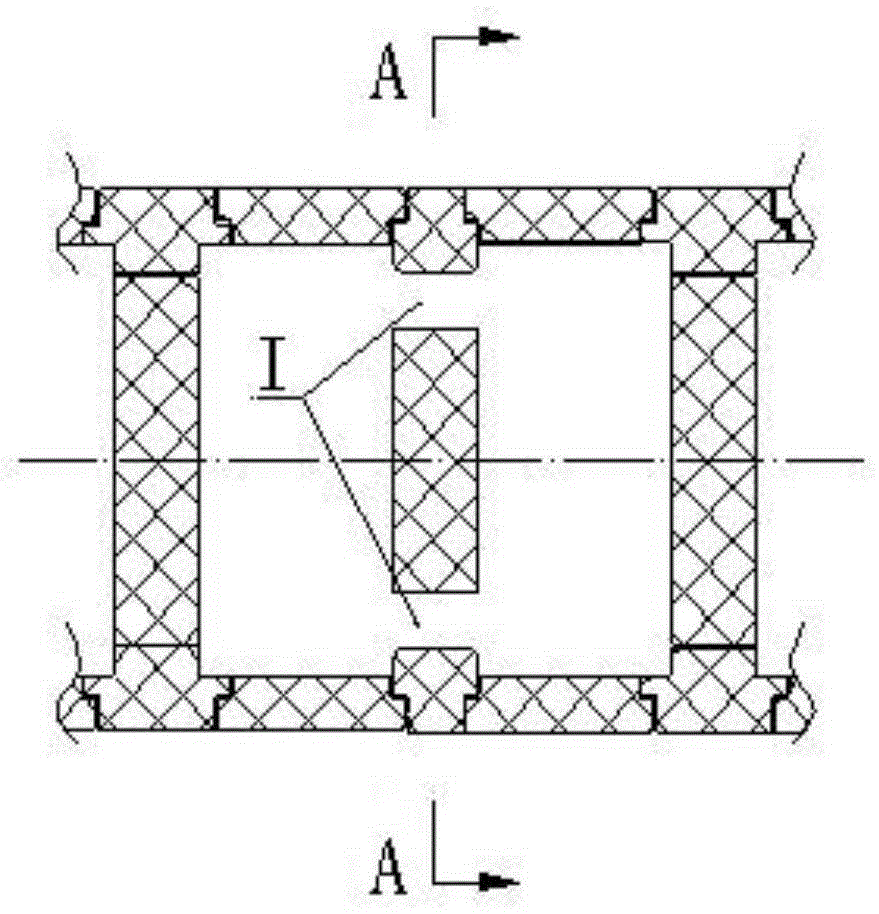

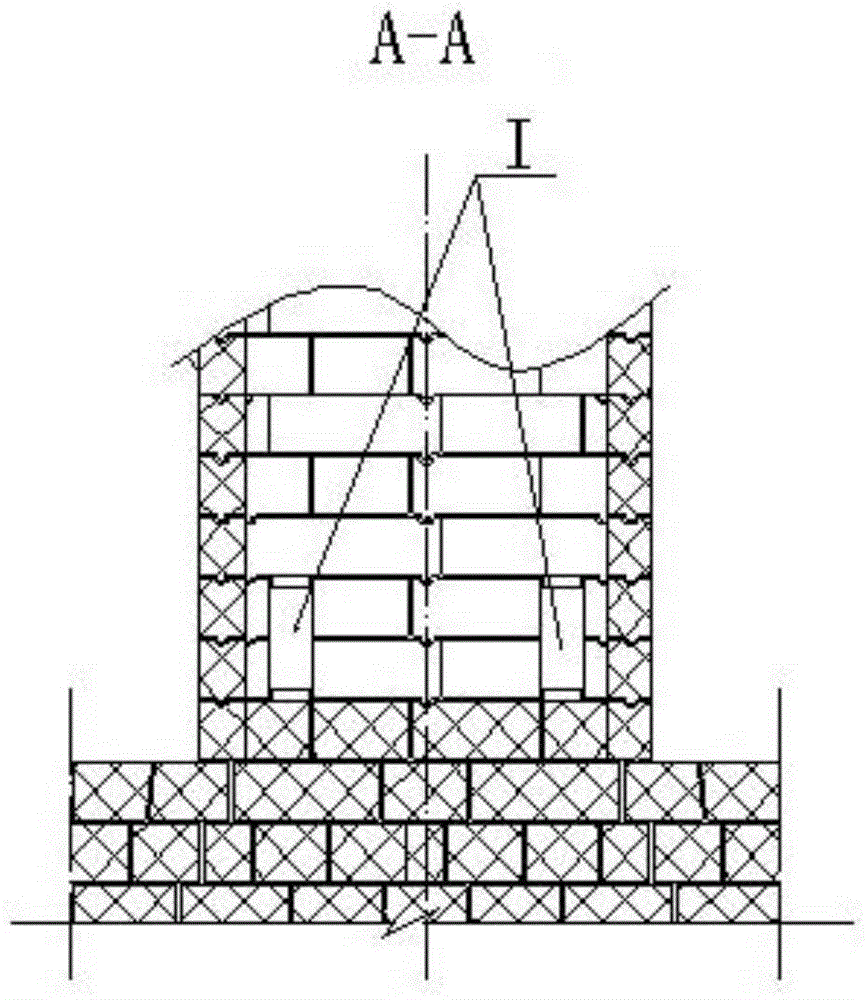

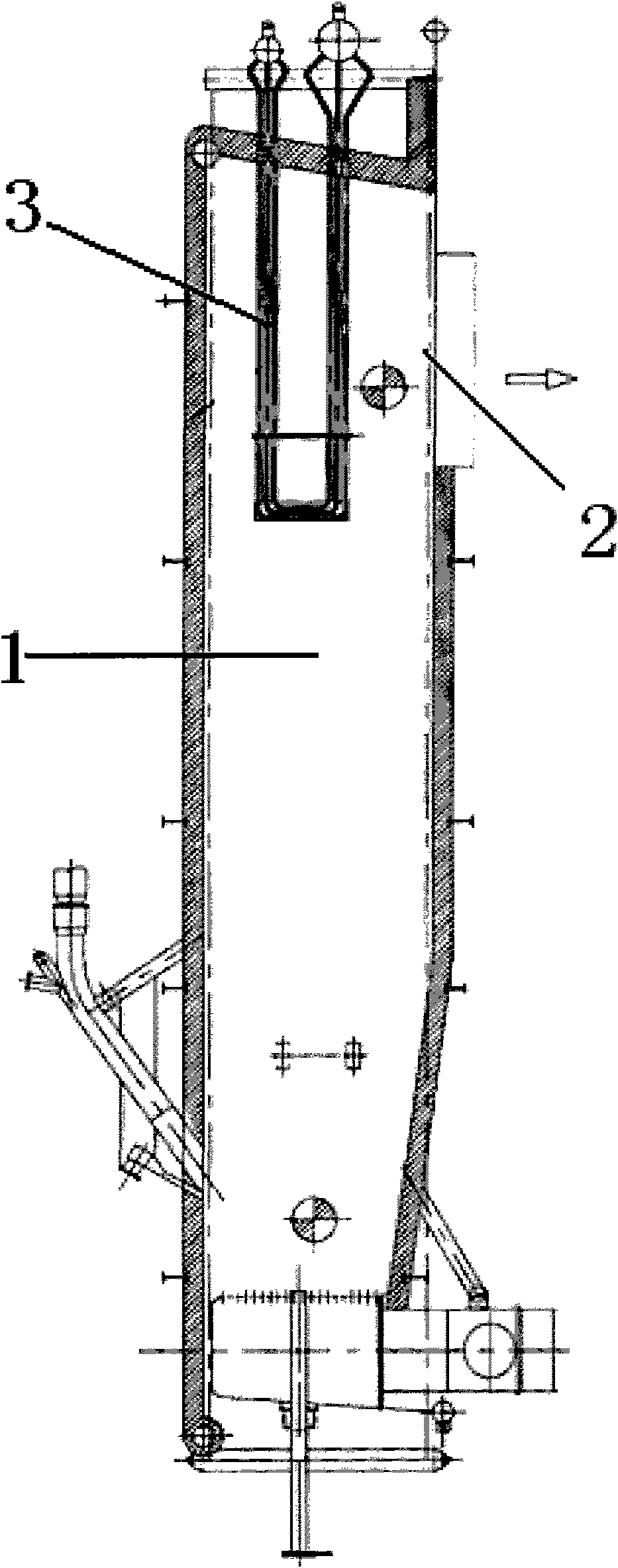

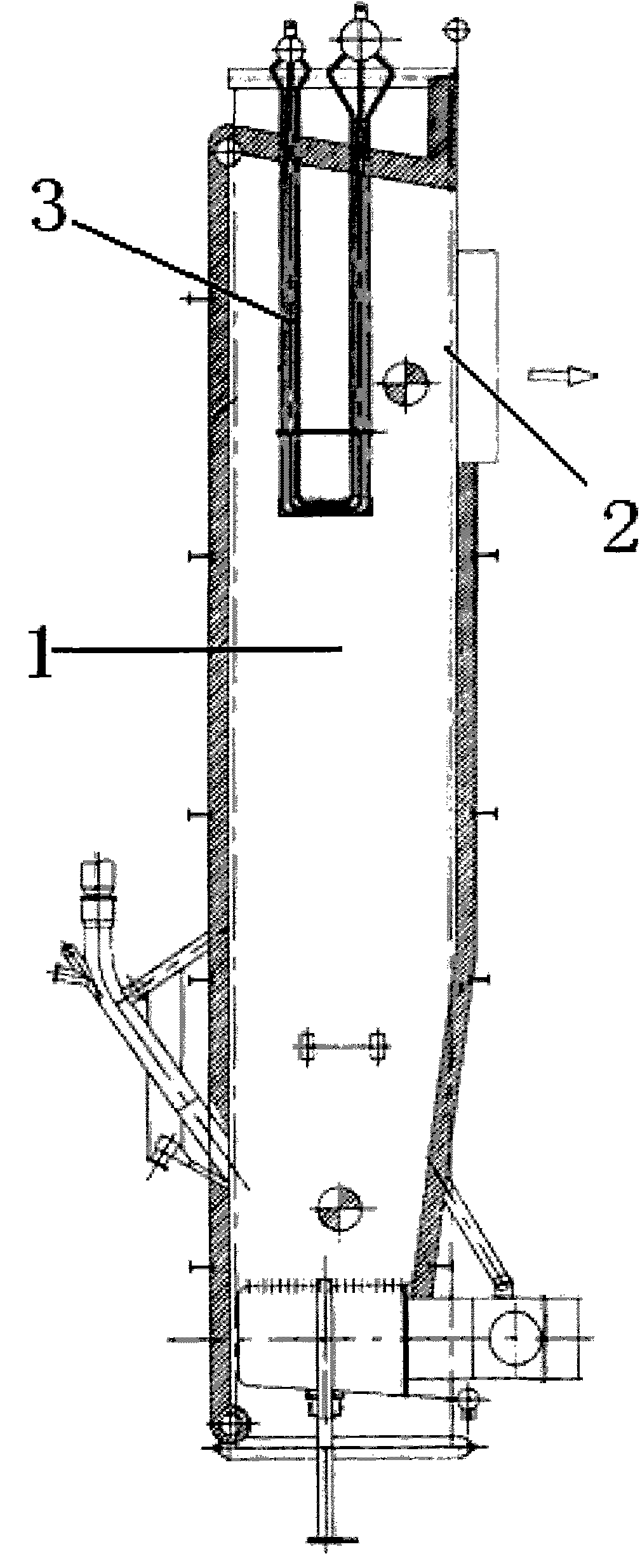

Circulating structure and method for exhaust gas of coke oven

InactiveCN105385460AIncrease exhaust gas circulationReduce NOX emissionsCombustible gas coke oven heatingAutomatic controlCombustion chamber

The invention relates to a circulating structure and method for exhaust gas of a coke oven. The circulating structure comprises a main exhaust gas pipe, a connecting pipe, an automatic flow controller, a basement horizontally-arranged pipe, a lower jet pipe and brick exhaust gas channels which are successively connected, wherein the main exhaust gas pipe is connected with an exhaust gas source via an external variable-frequency fan, the basement horizontally-arranged pipe is horizontally arranged along the coke oven, the upper part of the basement horizontally-arranged pipe is provided with the lower jet pipe which is connected with the brick exhaust gas channels built in the wall of each heat storage chamber, and brick exhaust gas channel outlets located at the top of the brick exhaust gas channels are arranged in a vertical flue of a combustion chamber. The circulating structure and method are applied to a compound heating coke oven using lean gas for heating and can increase the circulation volume of exhaust gas, reduce the discharging amount of NOX in coke oven flue gas and improve uniformity of high heating of the vertical flue; and the circulating structure is simple in structure and convenient and accurate to adjust, can be in automatic control, and is beneficial for improving an operation environment, mitigating labor intensity and improving work efficiency and security.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

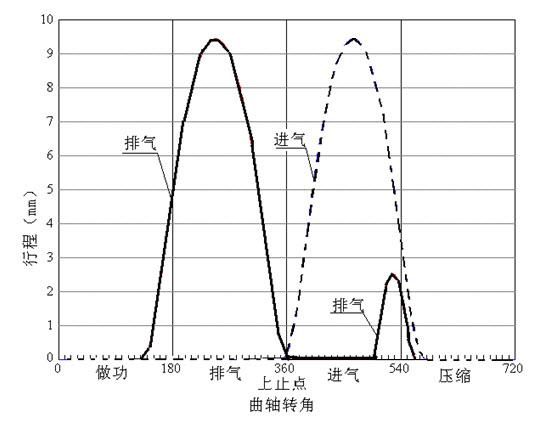

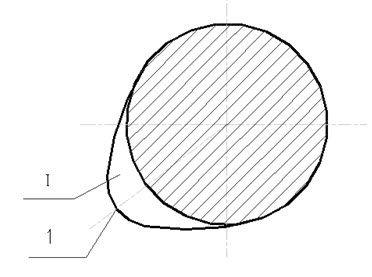

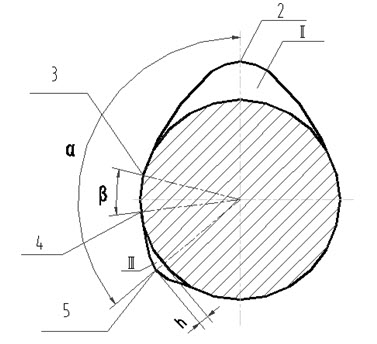

Dual-peak exhaust camshaft

InactiveCN101943037AReduce NOx emissionsAvoid wear and tearNon-fuel substance addition to fuelInternal combustion piston enginesExhaust valvePulp and paper industry

The invention discloses a camshaft with a dual-peak exhaust cam, which is used for recycling the internal waste gas. The camshaft comprises an intake cam and two exhaust cams; and the two exhaust cams include an exhaust cam and an EGR cam. The exhaust cam and the EGR cam share the same base circle; the maximum lift of the intake and exhaust cams is 5.5 to 9.5 mm; and the maximum lift h of the EGR cam is 0.5 to 2.5 mm. The included angle between the centre lines of the intake cam and the exhaust cams is 90 to 140 degrees; and the included angle alpha between the two centre lines of the exhaust cam and the EGR cam is 90 to 150 degrees. The included angle beta between the two end points of the exhaust cam travel and the EGR cam travel is 0 to 50 degrees. When the suction of a piston approaches the lower stop point of intake, the EGR cam makes an exhaust valve re-opened so that partial waste gas is sucked back to the cylinder by using the vacuum degree in the cylinder and the recycling of the waste gas is realized. The invention can effectively reduce NOx emission and avoid valve abrasion.

Owner:TIANJIN UNIV

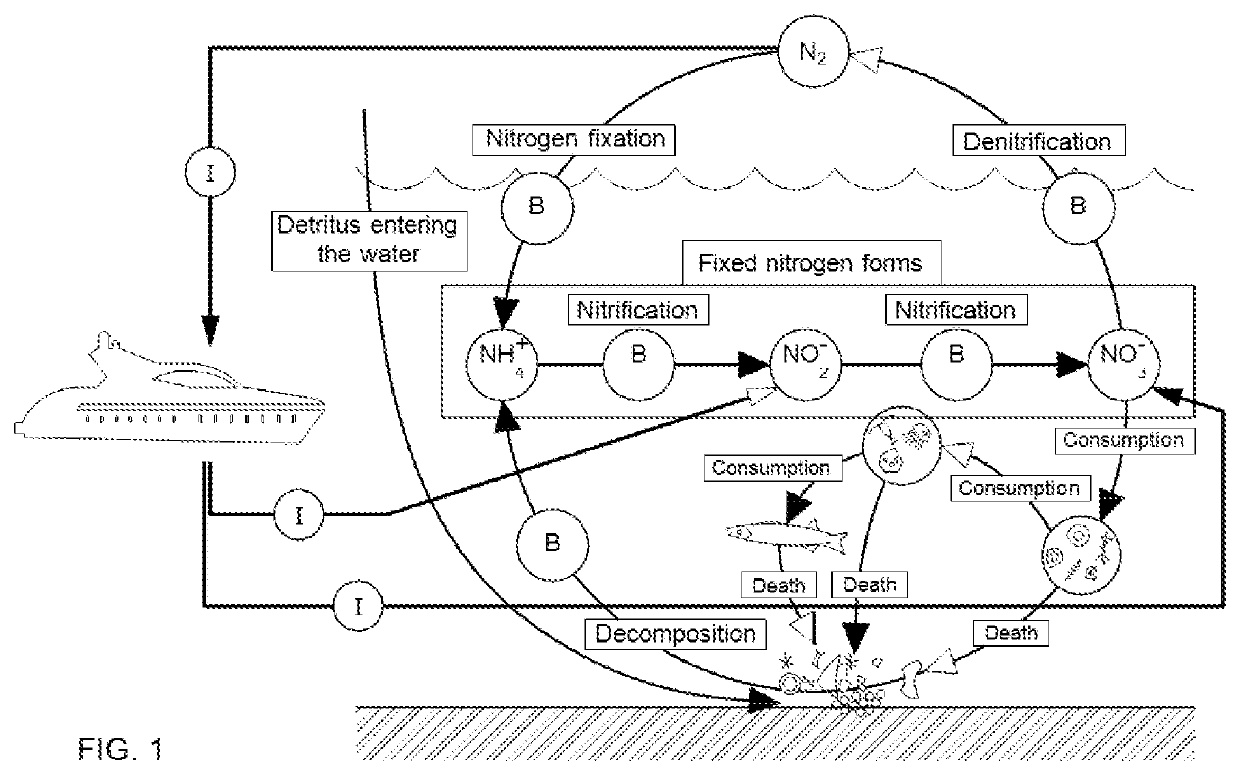

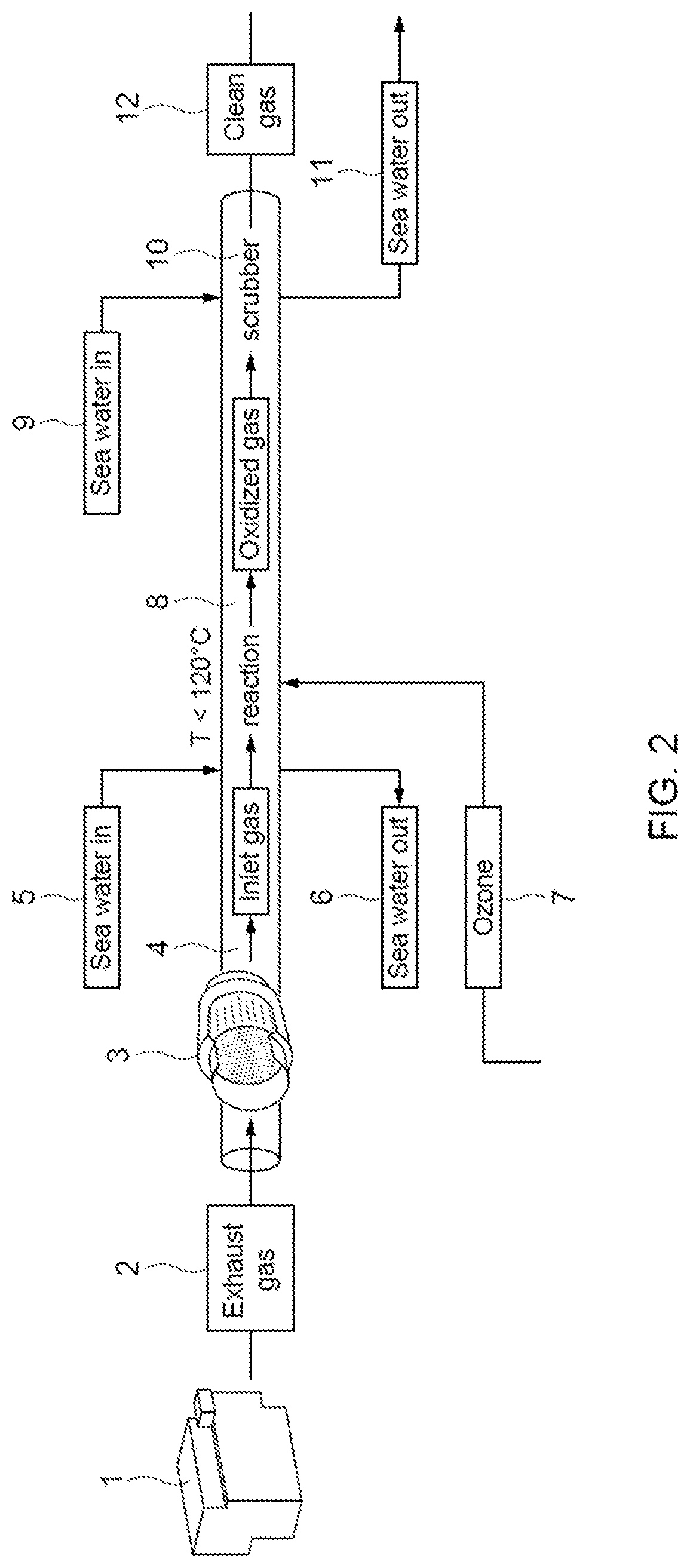

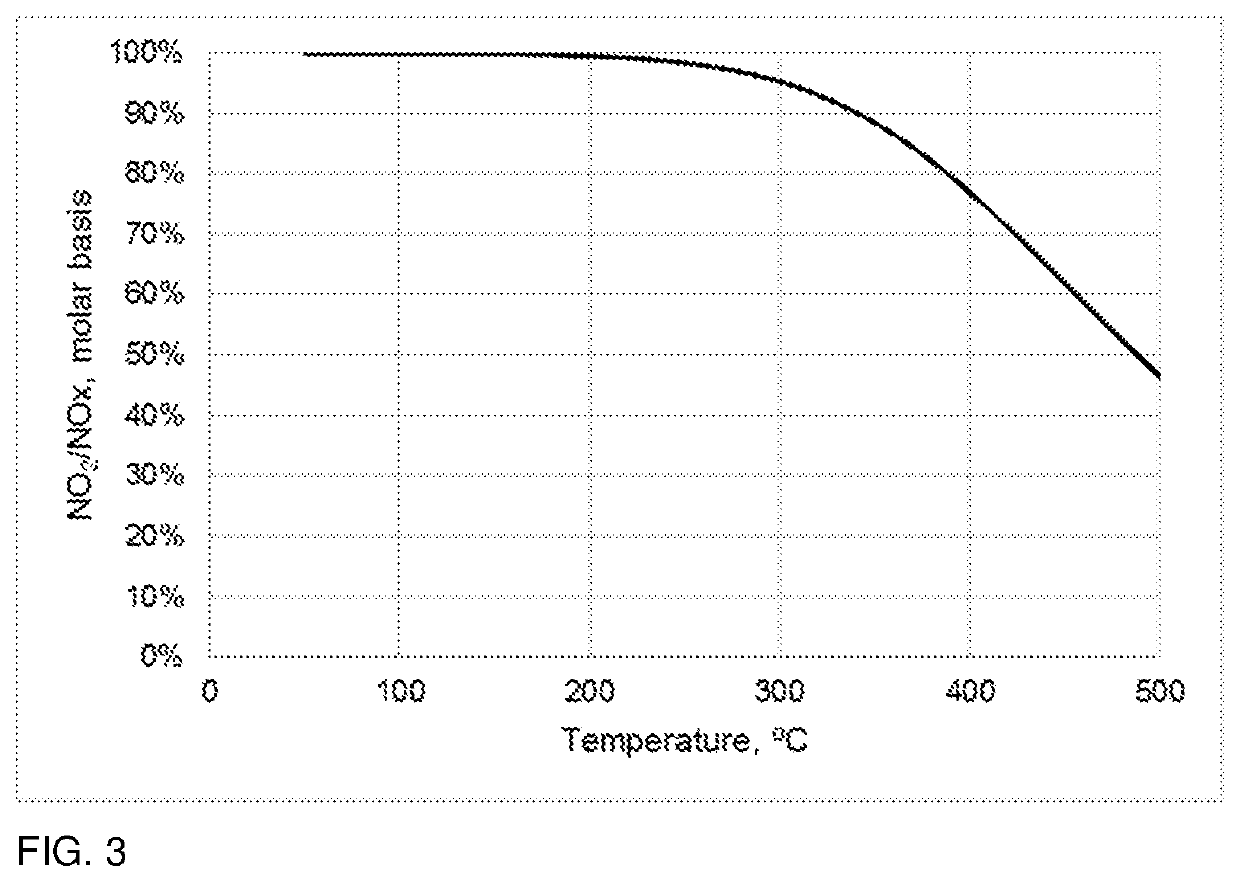

Process and Apparatus for Reducing Nox Emissions

ActiveUS20200116062A1Without sacrificing too much valuable spaceLose weightGas treatmentInternal combustion piston enginesNitrogen oxidesOn board

The invention is directed to a process and apparatus for treating an off-gas from a lean burn engine comprising contacting said off-gas with an oxidizing compound, thus producing oxidized NOx compounds, followed by contacting the oxidized NOx compounds with water, by which at least part of said oxidized NOx compounds dissolves in said water. The process of the invention provides for a very efficient means of reducing NOx emission. The equipment for carrying out the process of the invention can be compact, so that it can be used on board without sacrificing too much valuable space and without increasing the weight of the ship too much.

Owner:KONINK DE VRIES SCHEEPSBOUW BV

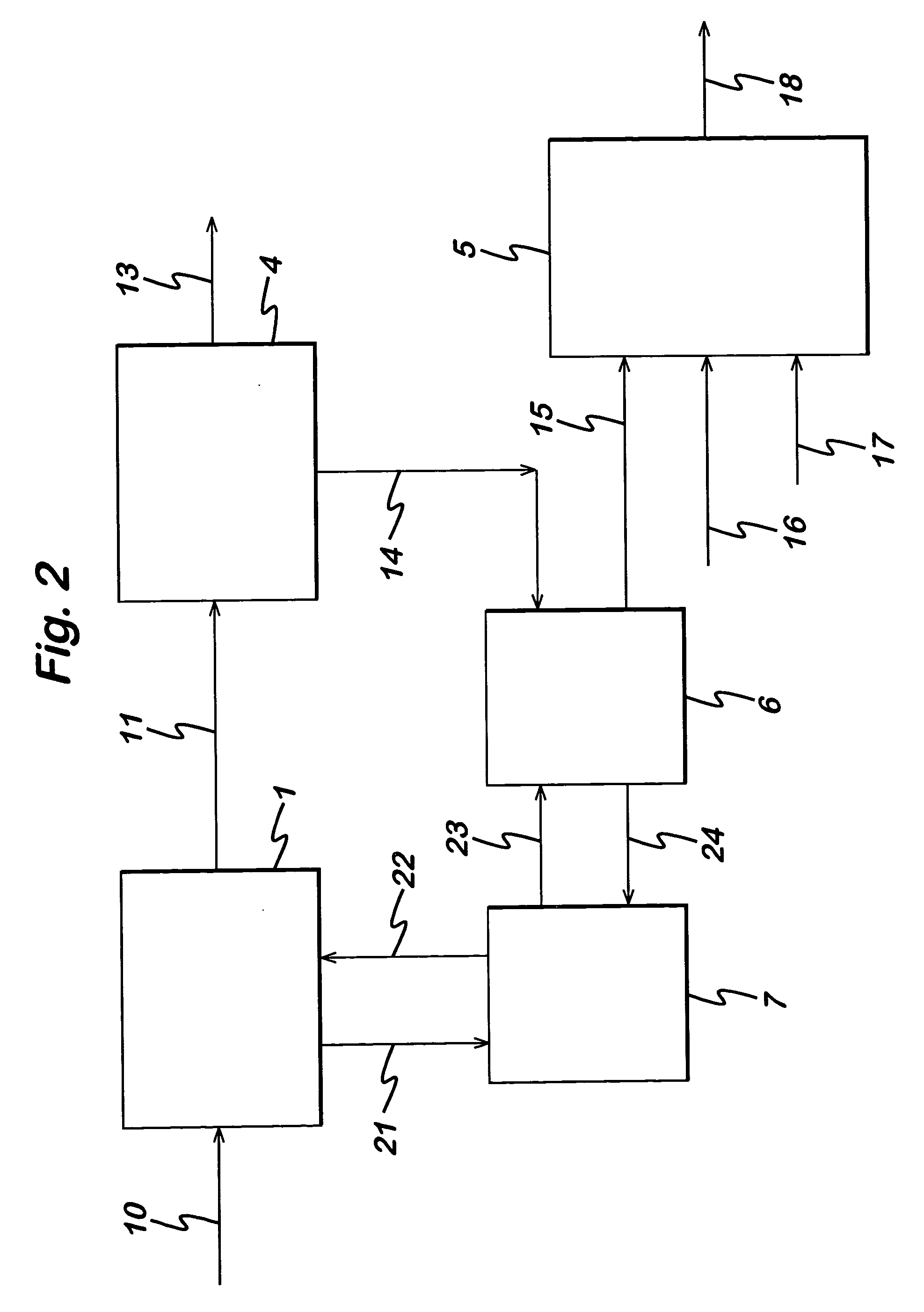

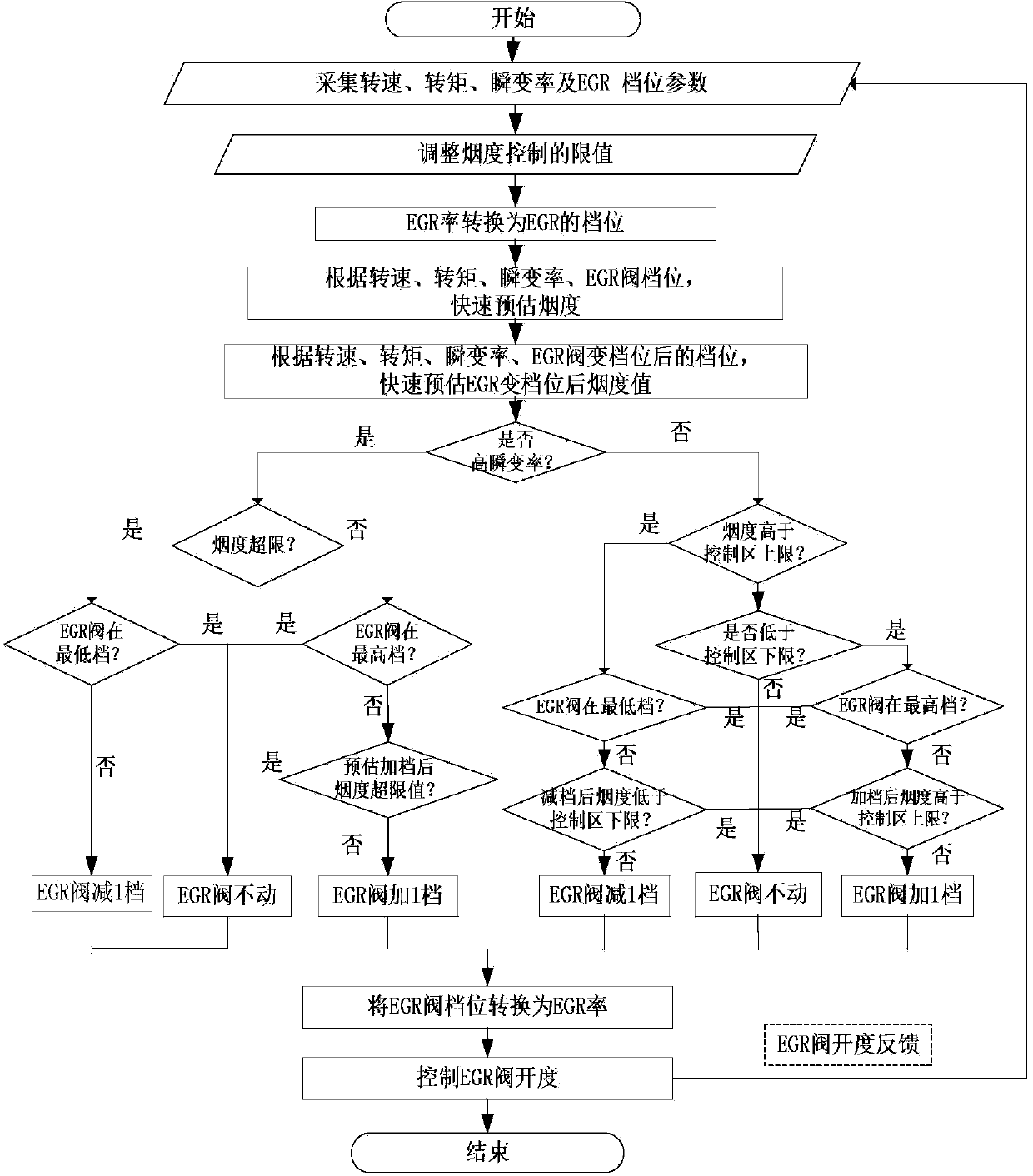

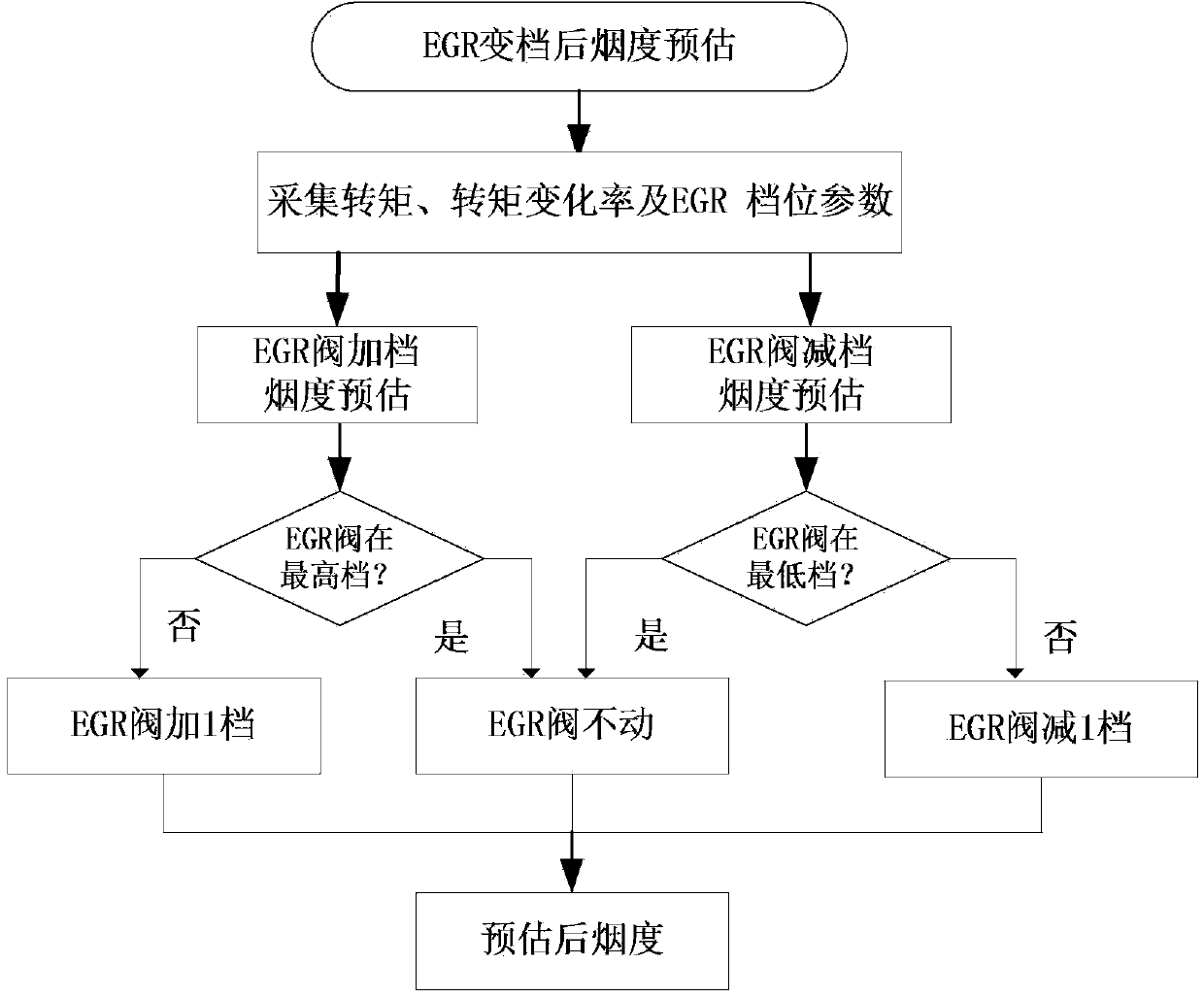

EGR control system for internal combustion engine instantaneous conditions

InactiveCN103758646AReduce NOx emissionsImprove trade-off relationshipEngine controllersMachines/enginesTorque sensorIntensity control

The invention relates to an EGR control system for internal combustion engine instantaneous conditions, and belongs to the field of emission control over the internal combustion engine instantaneous conditions. A high speed revolution speed sensor, a high speed torque sensor, four high response electronic control EGR valves and an ECU with smoke intensity control MAP are additionally arranged on the basis of an existing EGR control system, the four high response electronic control EGR valves are connected to an outlet of a filter and one inlets of three air inlet three-way tubes through pipes in parallel, and the ECU is respectively and elastically connected with an internal combustion engine, a high response revolution speed sensor, a high response torque sensor and the four high response electronic control EGR valves. According to the EGR control system, carbon smoke emission under the internal combustion engine instantaneous conditions can be effectively controlled, NOx emission is reduced to the greatest extent, and noxious substance emission of the internal combustion engine is reduced.

Owner:JILIN UNIV

Multi-stage partitioned combustion structure for gas turbine

ActiveCN113251440AEfficient and stable combustionReduce NOx emissionsContinuous combustion chamberFuel supplyNitrogen oxides

The invention belongs to the technical field of gas turbines, and particularly relates to a multi-stage partitioned combustion structure for a gas turbine. The multi-stage partitioned combustion structure for the gas turbine comprises a combustion chamber casing, a flame tube, a plurality of cyclones and a diverter. The cyclones are divided into an on-duty cyclone, a flame transfer cyclone, a first main combustion cyclone and a second main combustion cyclone, each cyclone is provided with a first fuel gas channel, and the first fuel gas channels convey fuel gas used for premixed combustion. A second fuel gas channel is further arranged at the on-duty cyclone, and the second fuel gas channel is used for conveying fuel gas for diffusive combustion. The installation angles of blades of the cyclones are different, and the flow fields of rotating airflow generated by the cyclones are relatively independent, so that the cyclones participate in independent partitioned combustion. According to the multi-stage partitioned combustion technology in the scheme, the four stages of different cyclones are combined with the diverter, multi-stage partitioned organization combustion is formed in a staged fuel supply mode, the requirements of all working conditions are met, the ignition and flameout performance and combustion stability of a combustion chamber are guaranteed, and the requirement for low emission of nitric oxide is met.

Owner:成都中科翼能科技有限公司

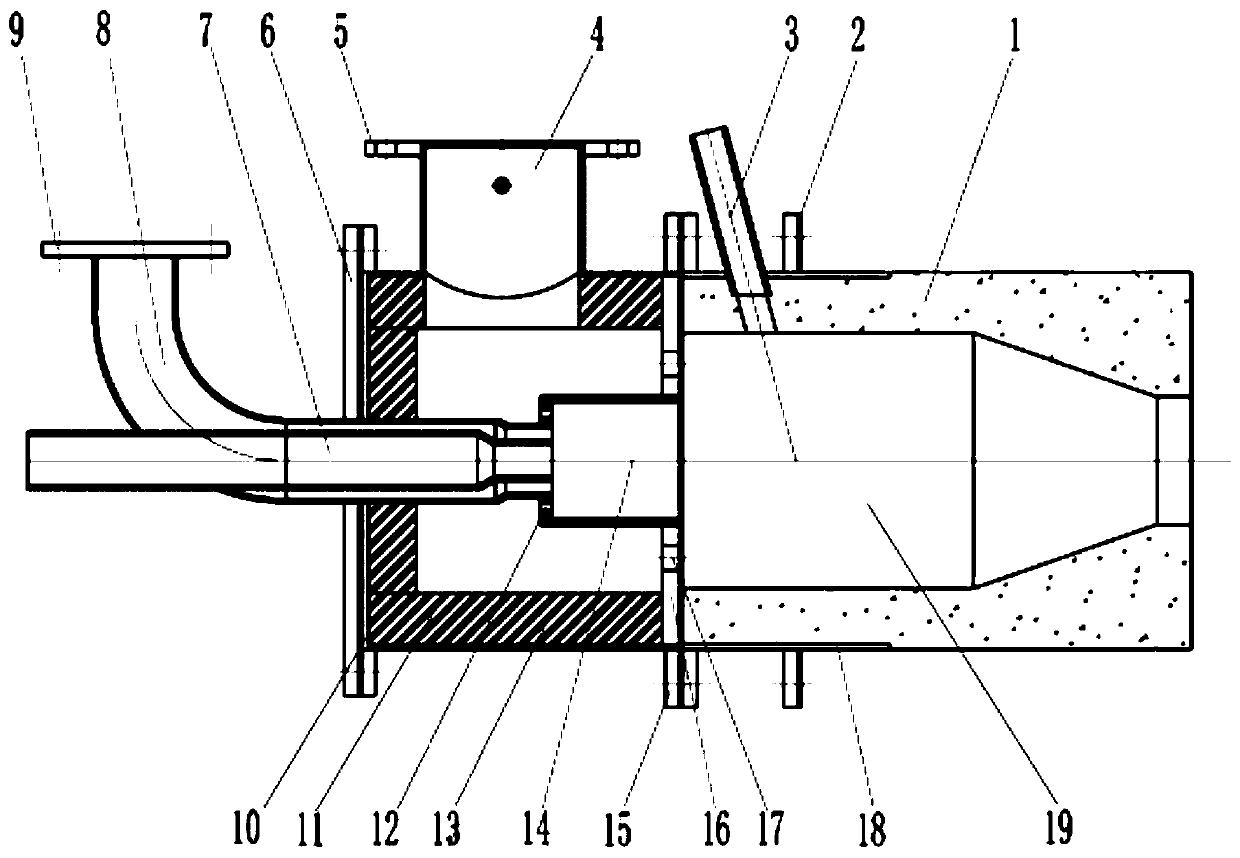

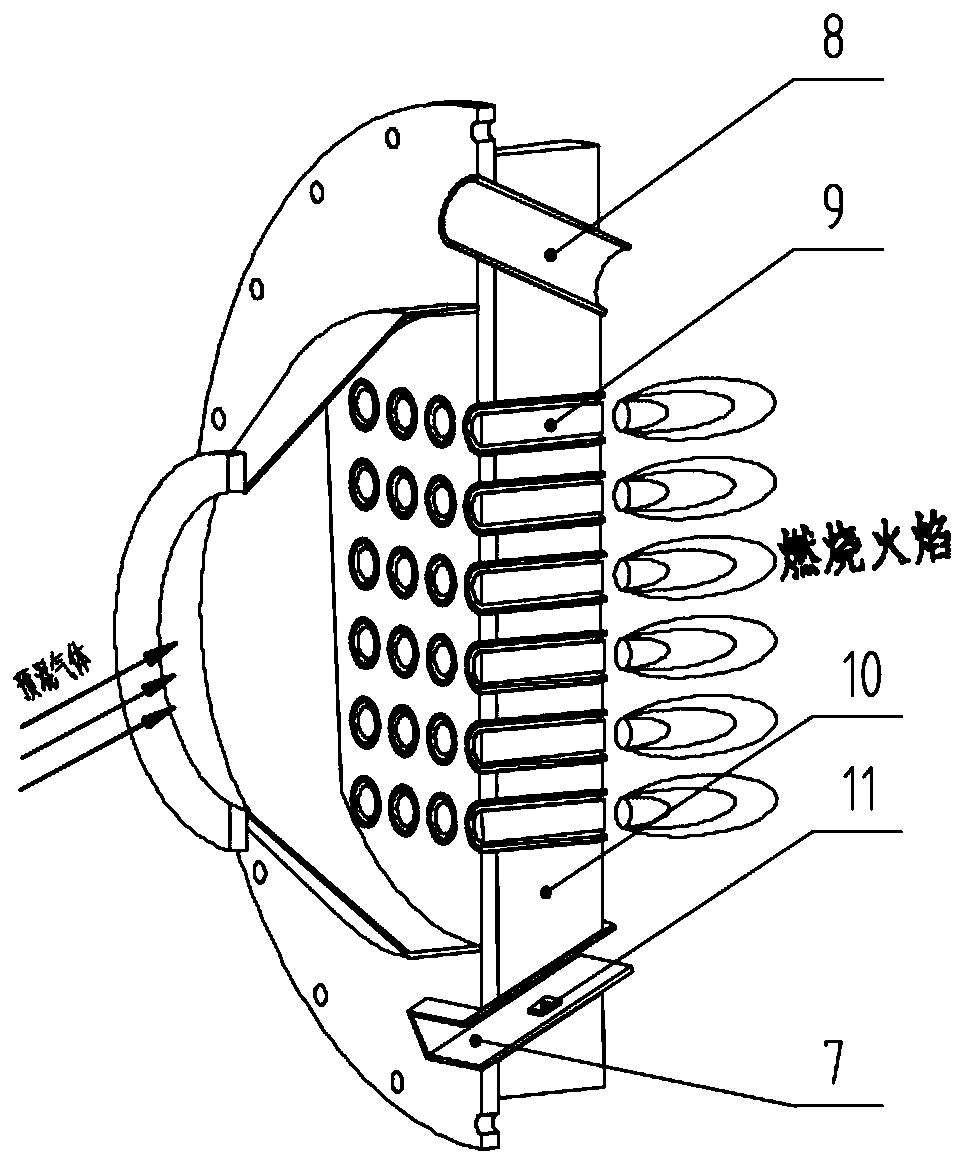

Large-speed-difference flue gas circulation and ultralow nitrogen oxide high-speed burner and control method thereof

PendingCN111457377AReduce NOX emissionsReduce gas calorific valueIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyNitrogen oxidesCombustion chamber

The invention relates to a large-speed-difference flue gas circulation and ultralow nitrogen oxide high-speed burner and a control method thereof. The burner is provided with a burner brick, an air, fuel gas and circulating flue gas inlet tube, a burner housing and a pre-combustion chamber, wherein the inner cavity of the burner brick is a combustion chamber; a fuel gas inlet end of the pre-combustion chamber is provided with a primary air inlet channel; the outlet of the pre-combustion chamber is provided with an air distributing disc; and a secondary air inlet channel is arranged on the airdistributing disc. While the burner works, fuel gas and flue gas is pre-mixed and combusted in the pre-combustion chamber. Through a two-stage air distribution way, a gas mixture sprayed out by the pre-combustion chamber and flow speed of combustion-supporting air sprayed out through the secondary air inlet channel define large speed difference, so that an air flow reflow region is made in the outlet area of the pre-combustion chamber; and the airflow reflow region guarantees stable fuel gas and complete combustion in a furnace kiln. According to the control method, circulating flue gas is notinput into the burner while the furnace temperature is lower than a temperature of 900 DEG C, circulating flue gas is input into the burner to participate in combustion while the furnace temperatureis higher than the temperature of 900 DEG C, the circulating flue gas reduces a fuel gas heat value and a high temperature point of combustion flames, and ultralow NOX emission is realized.

Owner:WUHAN UNIV OF SCI & TECH

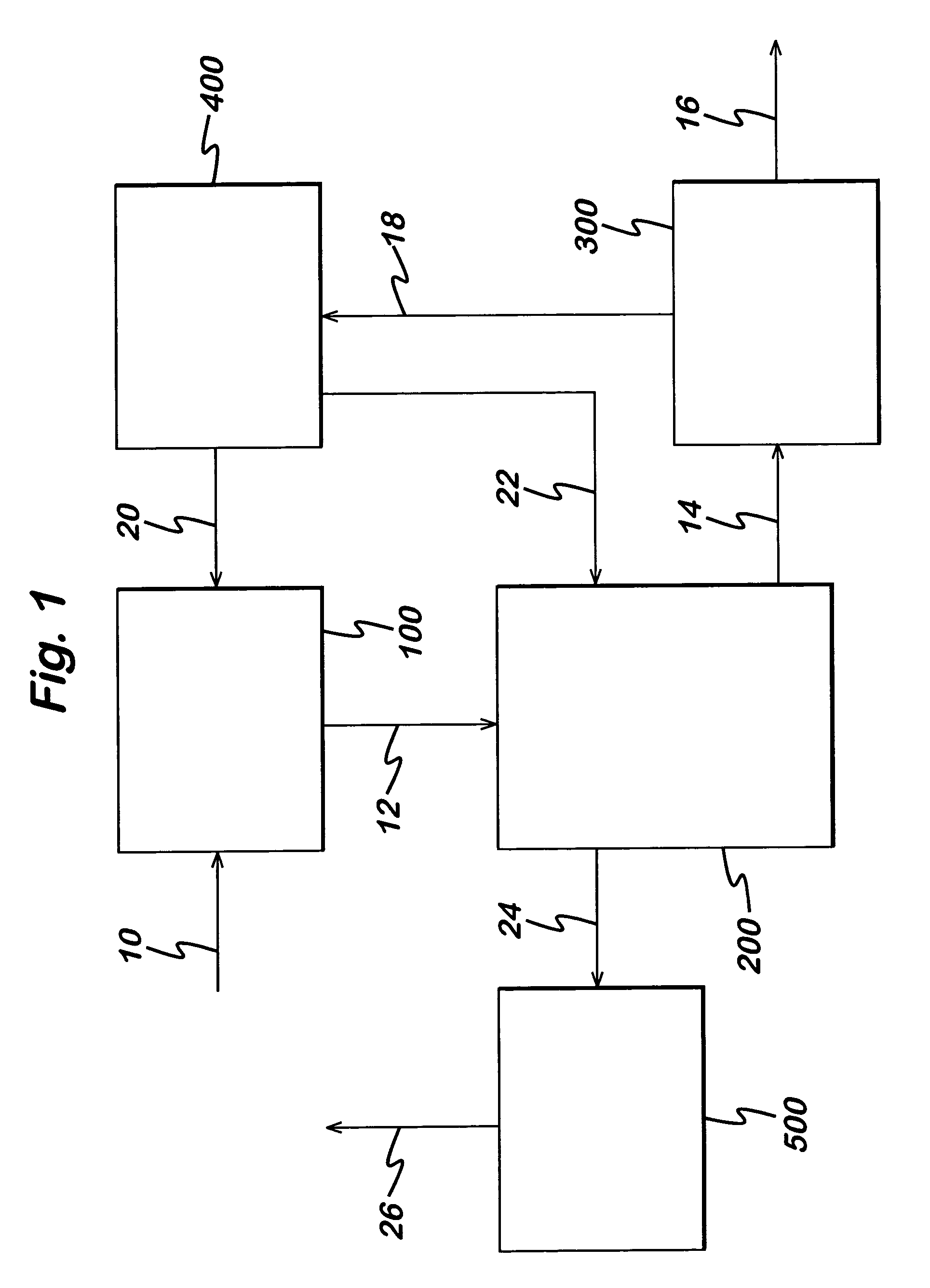

Combustion and denitration running comprehensive optimization system of coal-fired unit boiler

InactiveCN106556028AReduce NOx emissionsReduce the cost of denitrificationCombustion regulationAutomotive engineeringParameter control

The invention relates to a combustion and denitration running comprehensive optimization system of a coal-fired unit boiler. The system comprises a combustion unit load obtaining module, a NOx emission load calculation module, an optimal result output module, a combustion wind amount control module and a running oxygen amount control module; the combustion unit load obtaining module is used for receiving loads of a combustion unit to be optimized; the NOx emission load calculation module is used for calculating the corresponding NOx emission loads according to the loads of the combustion unit to be optimized and the set multiple sets of combustion wind amounts and running oxygen amounts, and a combustion parameter control table is formed; the optimal result output module is used for obtaining the lowest NOx emission loads under the current load and outputting the corresponding combustion wind amount and the corresponding running oxygen amount; the combustion wind amount control module is used for receiving the combustion wind amount output by the optimal result output module and generating a first control signal for controlling the opening degree of a combustion air door; the running oxygen amount control module is used for receiving the running oxygen amount output by the optimal result output module and generating a second control signal used for controlling the running oxygen amount entering the combustion unit; compared with the prior art, the system has the beneficial effects of reducing the emission loads of the NOx, reducing the denitration cost and the like.

Owner:SHANGHAI SHANGDIAN CAOJING POWER GENERATION

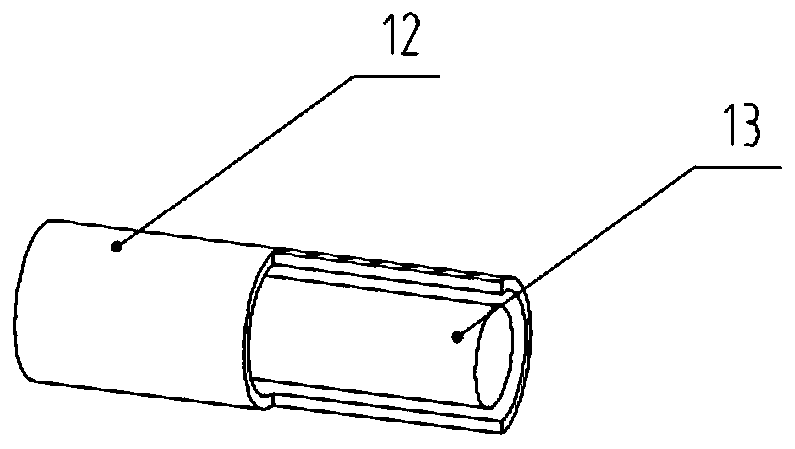

Ultra-low nitrogen premixed gas burner and combustion method thereof

PendingCN110566947AReduce NOx emissionsEasy to installGaseous fuel burnerGas burnerProcess engineering

The invention relates to the technical field of gas combustion devices, in particular to an ultra-low nitrogen premixed gas burner and a combustion method thereof. The ultra-low nitrogen premixed gasburner comprises a plurality of nozzles arranged at the tail end of the burner, and premixed gas in the burner enters a hearth after being uniformly distributed through the nozzles; after the premixedgas is ignited at the outlet ends of the nozzles, the premixed gas is subjected to blowoff combustion in the hearth; and the nozzles comprise hollow shells and solid blunt bodies, the blunt bodies are sleeved with the shells, and channels for premixed gas to flow are formed between the shells and the blunt bodies. According to the ultra-low nitrogen premixed gas burner, a full premixing combustion mode is adopted, and the plurality of nozzles are arranged at the tail end of the burner, so that the premixed gas flows in the nozzle channels and is blowoff combusted at the outlets of the nozzles, and low nitrogen oxide (NOx) emission is realized without reducing the combustion efficiency.

Owner:ZHEJIANG UNIPOWER BOILER CO LTD

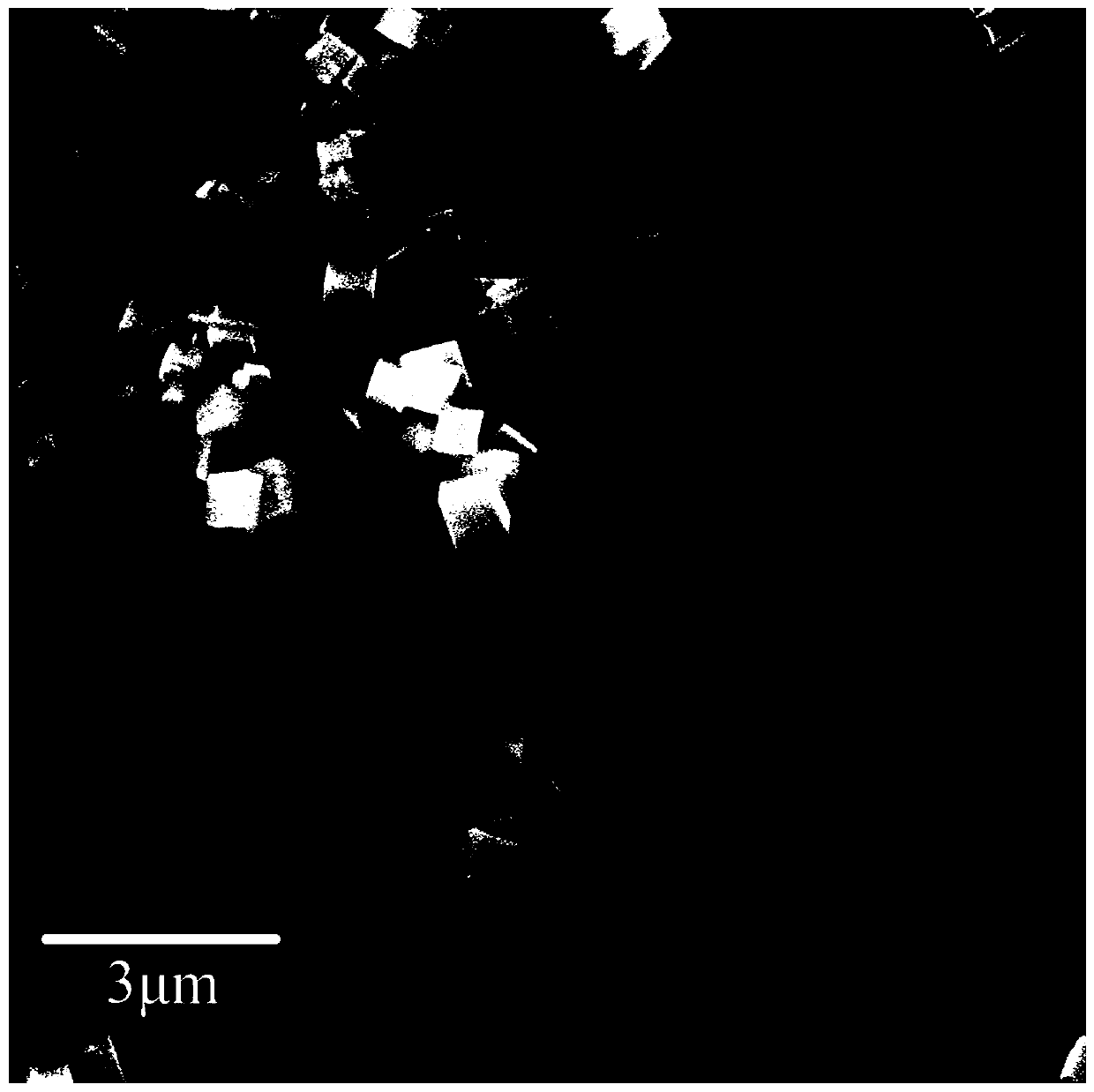

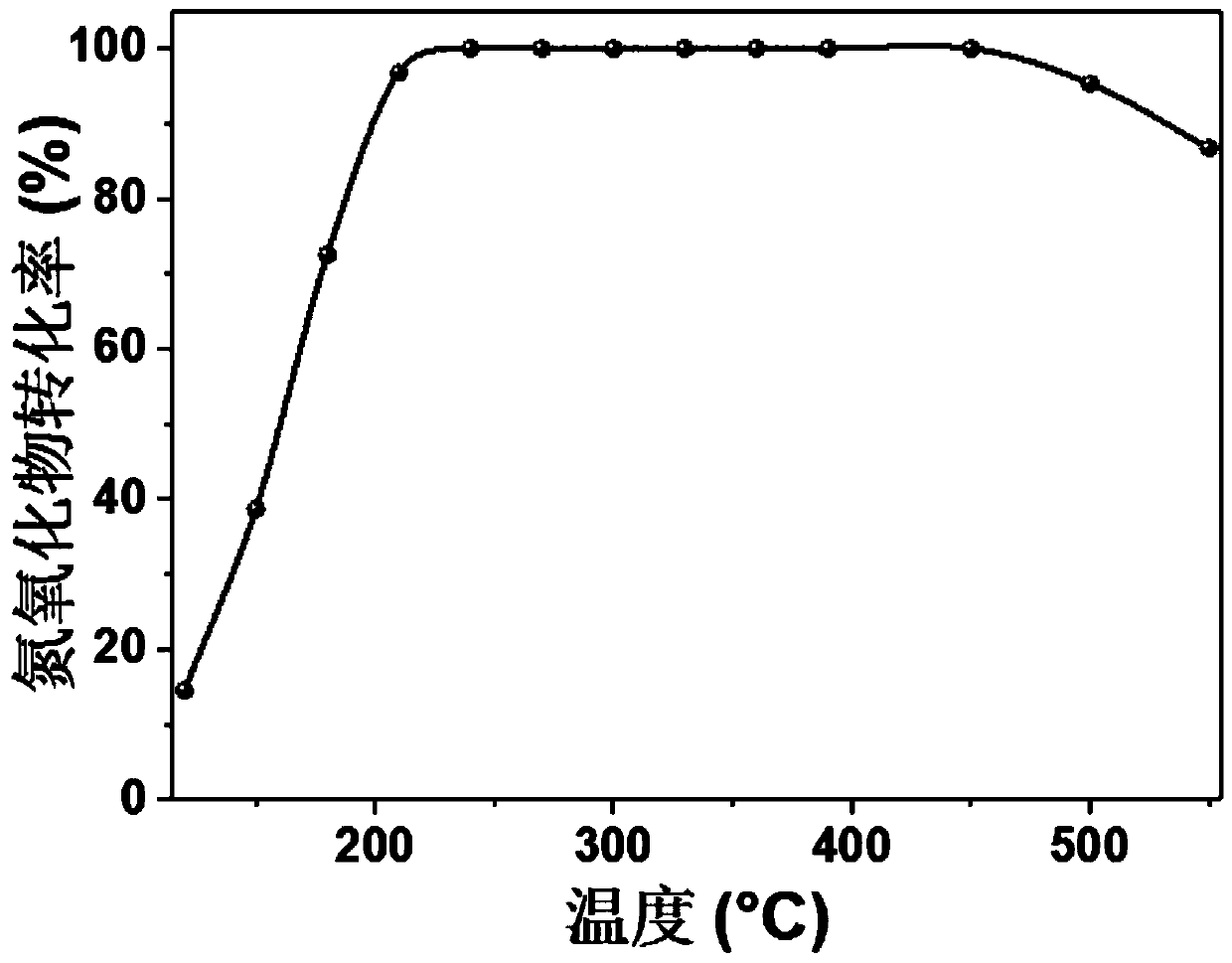

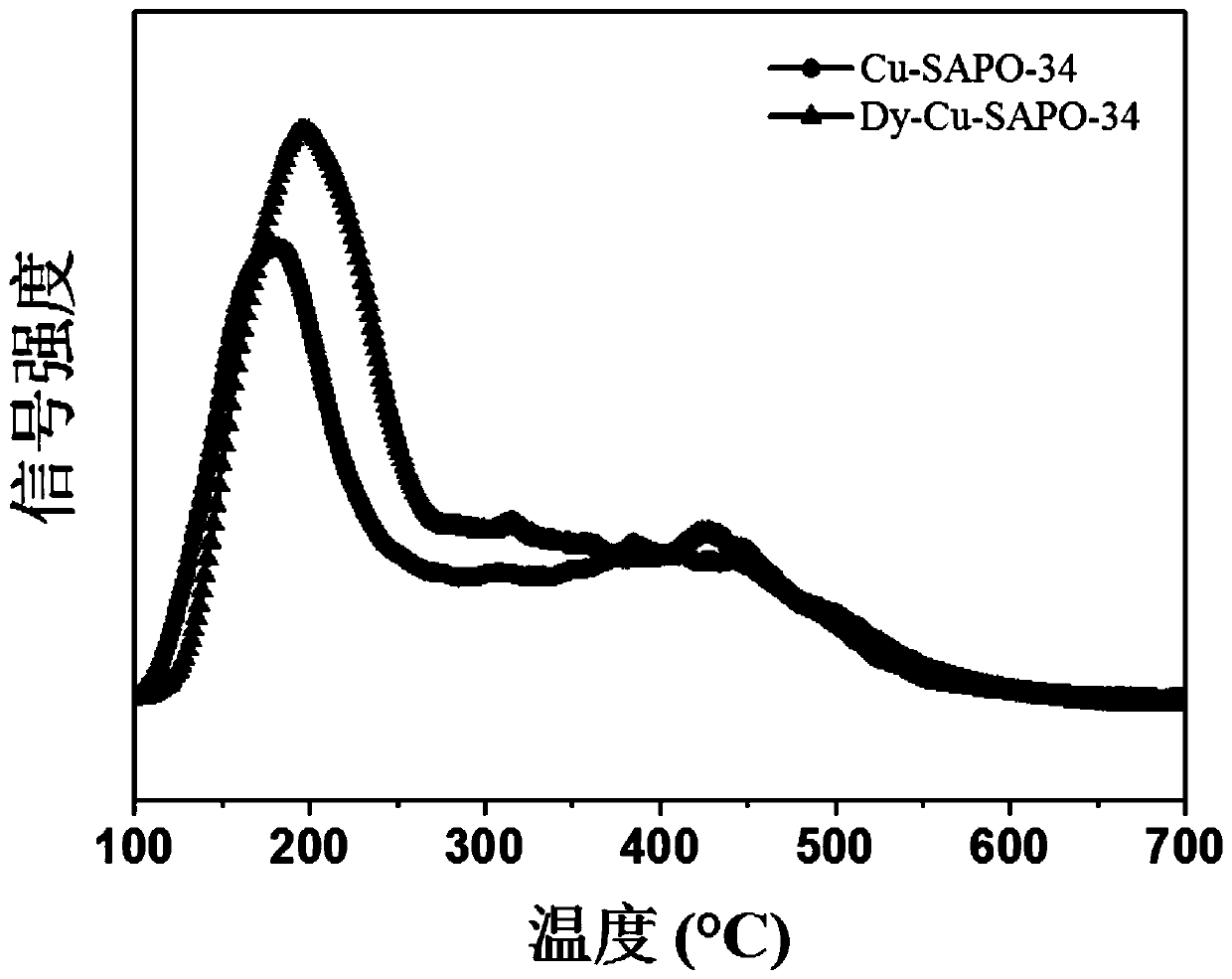

Dysprosium-modified Cu-SAPO-34 molecular sieve denitration catalyst and preparation method thereof

PendingCN110479358AHigh reactivityReduce NOx emissionsMolecular sieve catalystsMolecular sieveDysprosium nitrate

The invention discloses a dysprosium-modified Cu-SAPO-34 molecular sieve denitration catalyst and a preparation method thereof. The preparation method comprises the steps that: 1, weighing an aluminumsource, a silicon source, phosphoric acid, a template agent, copper nitrate, dysprosium nitrate and deionized water, and preparing a homogeneous aqueous solution A; 2, carrying out a hydrothermal reaction on the aqueous solution A obtained in the step 1, and aging the reaction product at 160-200 DEG C to obtain a reaction product B; and 3, washing and drying the reaction product B obtained in thestep 2, and calcining the reaction product B at the temperature of 450 DEG C or above to obtain the dysprosium-modified Cu-SAPO-34 molecular sieve denitration catalyst. The preparation method disclosed by the invention can be used for preparing the dysprosium modified Cu-SAPO-34 molecular sieve denitration catalyst disclosed by the invention; the dysprosium-modified Cu-SAPO-34 molecular sieve denitration catalyst provided by the invention can be used for selective catalytic reduction removal of nitrogen oxides in diesel vehicle tail gas, and has certain sulfur dioxide poisoning resistance andgood low-temperature catalytic performance.

Owner:XI AN JIAOTONG UNIV

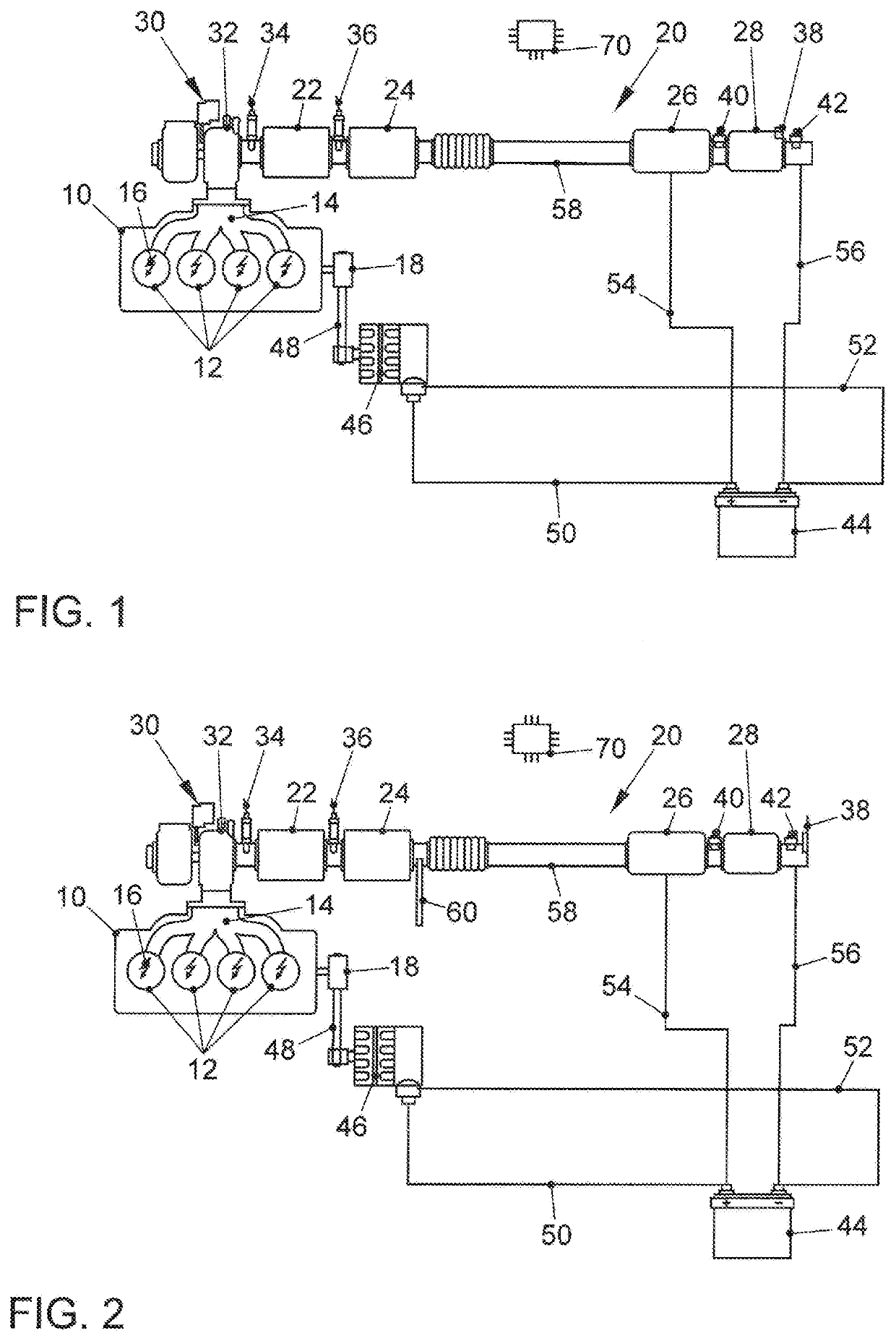

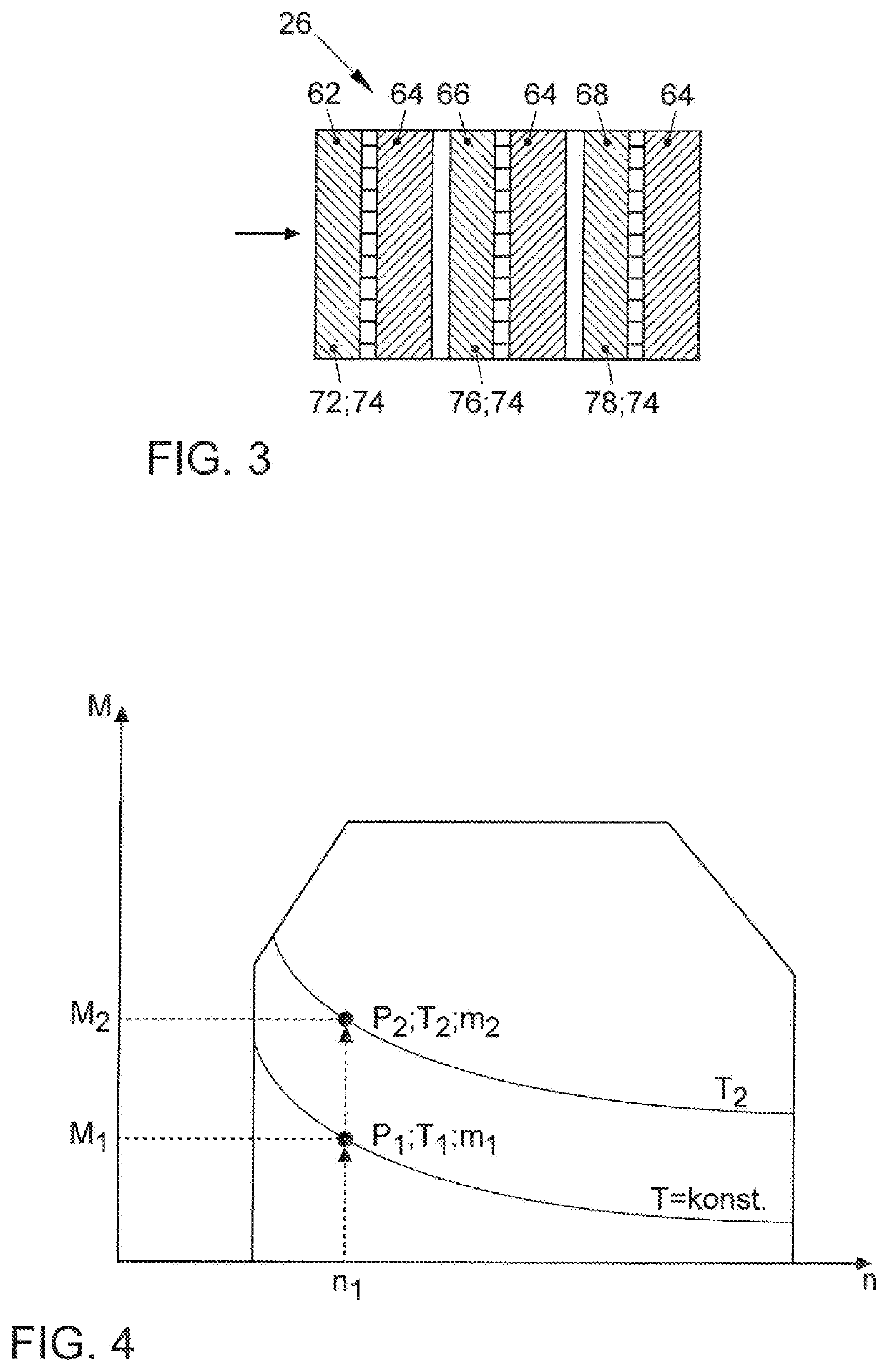

Exhaust aftertreatment system and method for regenerating a particulate filter

ActiveUS20190376432A1Achieve regenerationHigh exhaust temperatureGas treatmentInternal combustion piston enginesElectricityParticulates

The invention relates to an exhaust aftertreatment system for an internal combustion engine (10). The exhaust aftertreatment system comprises an exhaust system (20) having at least one three-way catalyst (22, 24) near the engine, wherein a particulate filter (28) is arranged downstream from the three-way catalyst, preferably in an underbody installation in a motor vehicle. A heated catalyst (26), which has at least one heating stage (62, 66, 68) that can be heated by means of an electric heating element (72, 74, 76, 78), is provided upstream from the at least one three-way catalyst (22, 24) and downstream from the particulate filter (28). It is provided that the at least one electrically heatable heating stage (62, 66, 68) is supplied with electric power directly from a generator (46) that is operatively connected to the internal combustion engine (10), so that heating of the heated catalyst (26) takes place essentially independently of the charge status of the vehicle battery (44). The invention also relates to a method for regeneration of a particulate filter (28) in the exhaust system (20) of an internal combustion engine (10) by means of such an exhaust aftertreatment system.

Owner:VOLKSWAGEN AG

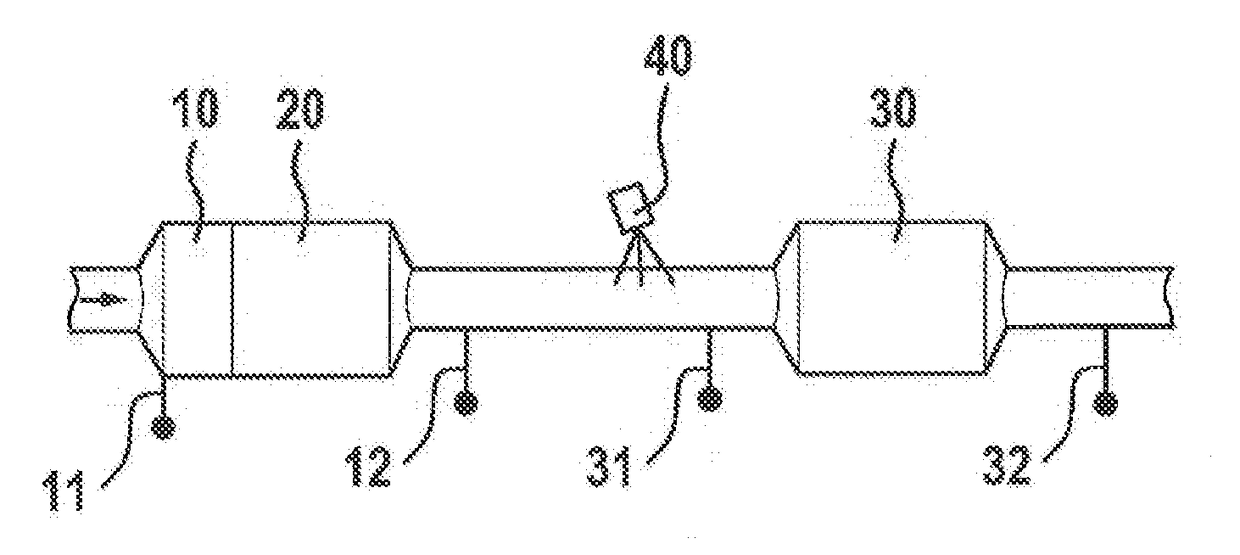

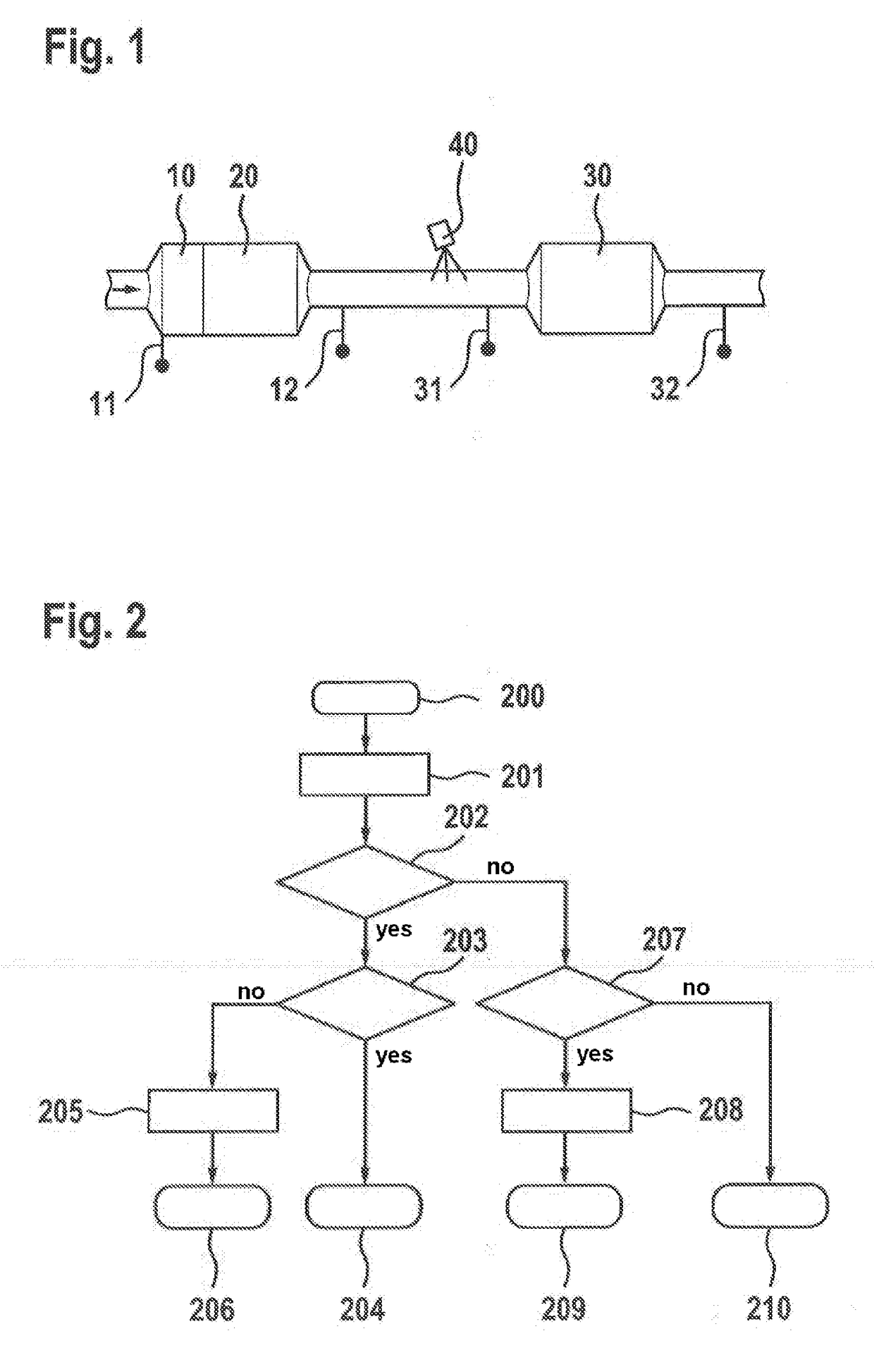

Method for operating an exhaust gas aftertreatment system of a motor vehicle

ActiveUS20170248052A1Increased NOx emissionIncrease capacityInternal combustion piston enginesExhaust apparatusMotorized vehicleTreatment system

In the case of a method for operating an exhaust gas aftertreatment system of a motor vehicle, the exhaust gas aftertreatment system comprises at least one NOx storage catalyst (10) and at least one SCR catalyst (30). According to the invention, when an inadequate function of the NOx storage catalyst (10) or of the SCR catalyst (30) is identified, at least one auxiliary measure is initiated which leads to a reduction of the NOx emissions of the motor vehicle.

Owner:ROBERT BOSCH GMBH

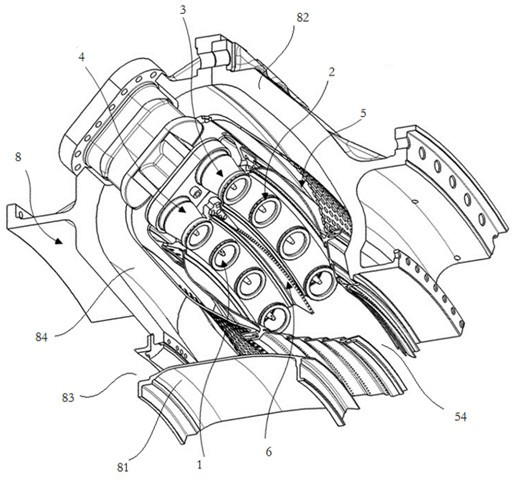

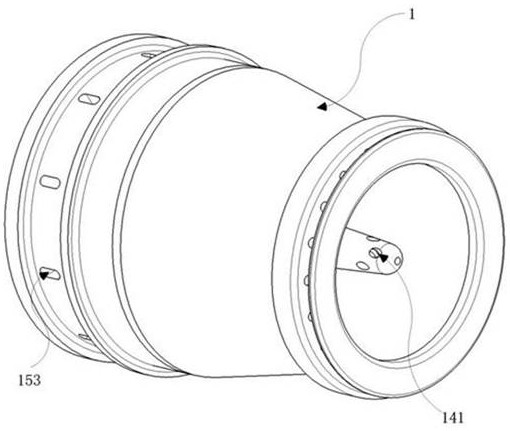

Combustion chamber combustor of gas turbine

ActiveCN110440292AImprove gradingReduce NOx emissionsContinuous combustion chamberGas turbinesFuel gas

The invention belongs to the technical field of aero-engine design, and relates to a combustion chamber combustor of a gas turbine. A fuel delivery pipeline of the combustion chamber combustor comprises an auxiliary-stage fuel gas pipe at the innermost layer, an auxiliary-stage sleeve, an inner pipe and an outer pipe, wherein the auxiliary-stage sleeve, the inner pipe and the outer pipe are sequentially connected in the radial direction in a sleeve mode, a primary mixing channel is formed between the inner pipe and the outer pipe, and a main-stage swirler is arranged in the main mixing channel; the auxiliary-stage sleeve is connected to the inner wall of the inner pipe through a venturi pipe in a connecting mode, a secondary mixing channel is formed between the auxiliary-stage sleeve and the auxiliary-stage fuel gas pipe, an auxiliary-stage swirler is arranged in the secondary mixing channel, and an auxiliary-stage fuel injection rod extends towards the secondary mixing channel by theauxiliary-stage fuel gas pipe; and a duty-stage fuel gas pipe is arranged in the auxiliary-stage fuel gas pipe in a sleeve mode, and fuel is sprayed in a combustion chamber flame pipe through a duty-stage fuel spraying nozzle. According to the combustion chamber combustor, the two stages axial swirlers, the three stages fuel nozzles and a venturi structure are arranged to realize premixed combustion of the fuel, the grading effect of the head part of the combustion chamber is optimized, the ignition performance of the combustor is improved while low NOx emission is realized, and the complexityof a fuel system is reduced.

Owner:AECC SHENYANG ENGINE RES INST

Circulating fluidized bed boiler

InactiveCN101943395AIncreased manufacturing and installation costsReduce NOx emissionsFluidized bed combustionSteam superheatersFlueSuperheater

The invention discloses a circulating fluidized bed boiler which comprises a hearth, a hearth outlet arranged at the upper part of the hearth, a membrane wall arranged in the hearth and a convection flue gas pass connected with the hearth outlet, wherein a high-temperature superheater is arranged in the hearth, the high-temperature superheater is arranged and fixed above the hearth, the high-temperature superheater extends into the hearth, and the extension height is higher than the height of the hearth outlet. The invention can greatly reduce the manufacturing and installation cost of the boiler, and can effectively solve the technical problems that repeated low-temperature burning and desulfuration reaction can not be effectively promoted at the same time, the emission of NOx can not be effectively reduced, etc. At the same time, the invention has the characteristics of small manufacturing cost, high vulcanizing efficiency, long service life and the like.

Owner:ANHUI JINDING BOILER

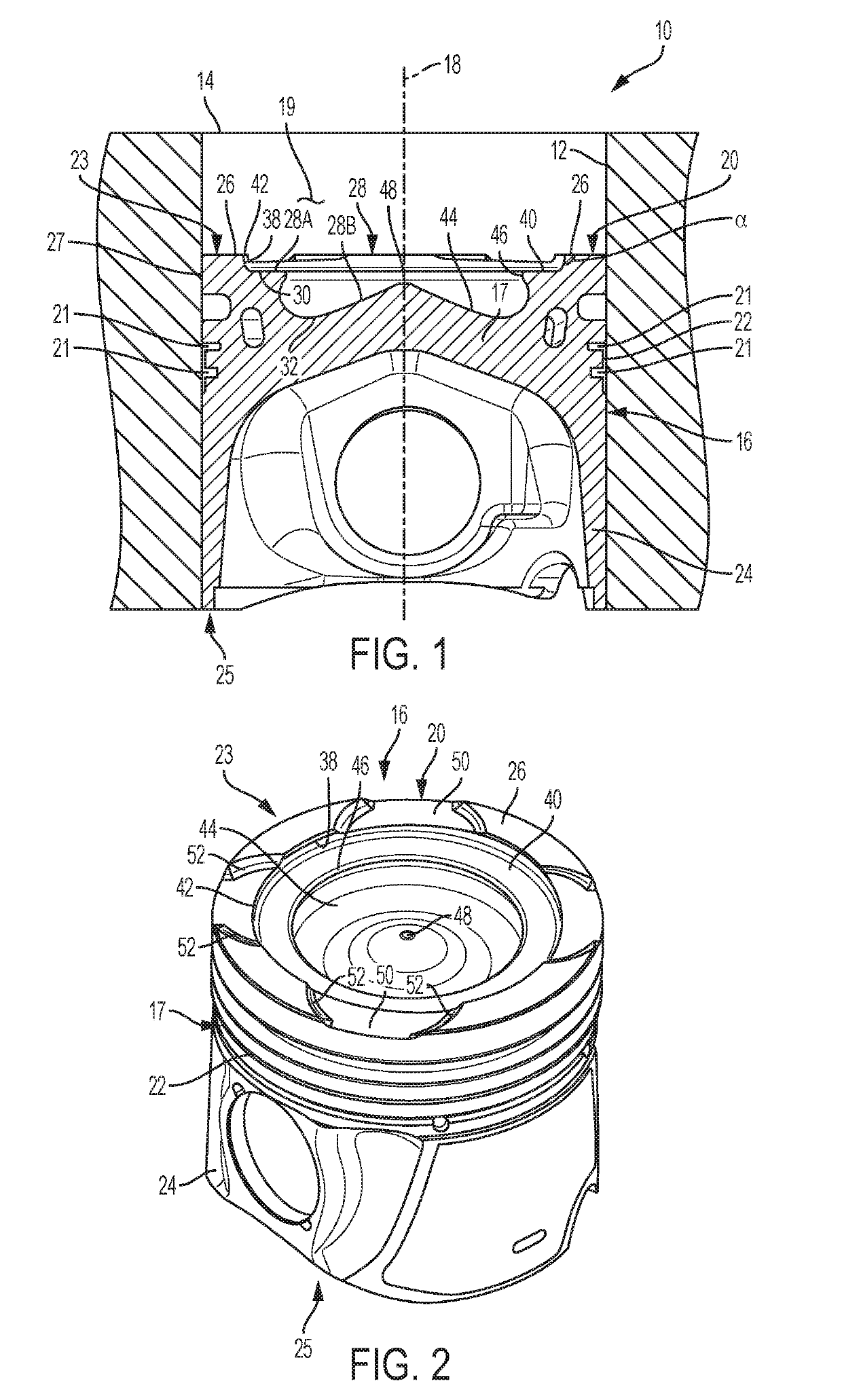

Diesel piston with sharp-step profile

ActiveUS20190178203A1Well mixedReduce sootInternal combustion piston enginesPistonsCombustionEngineering

A piston for a diesel engine includes a piston body having a skirt and crown. The piston body has portions defining an outer combustion bowl and an inner combustion bowl within the piston body through the crown. The outer combustion bowl has a curved annular side wall extending from the crown surface and an annular flat shelf extending from the curved annular side wall. The new stepped bowl design integrates a bottom profile with smoothly varying curvature and a sharp step at the top. The annular flat shelf is recessed a distance in the range of 2.5-4.5 millimeters from a line coplanar with the crown surface. The piston body defines an outer convex curved surface connecting the curved annular side wall to the crown surface. The outer convex curved surface has a radius of curvature in the range of 0.25-0.75 millimeter.

Owner:GM GLOBAL TECH OPERATIONS LLC

Burner arrangement method and arrangement structure for power station boiler

ActiveCN102777892AReduce NOx emissionsImprove combustion efficiencyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCoalHigher Power

The invention discloses a burner arrangement method and arrangement structure for a power station boiler. The method disclosed by the invention is characterized in that a pulverized coal burner is arranged by adopting a manner of combining tangential combustion and opposed combustion. The burner arrangement method and arrangement structure disclosed by the invention have the beneficial effects that combustion stability and economy problems of a boiler are solved firstly and less NOx is discharged. By virtue of massive research and calculation by the inventor, results show that the tangential combustion manner has better economy and less NOx discharge but has poor combustion stability, if the combustion stability is better and a flame is used for supporting combustion, the characteristics of the tangential combustion can be fully played. A symmetric combustion manner has better whole combustion stability as a single burner has stronger combustion stabilizing capability and has poor combustion economy as a combustion stroke is shorter, and NOx discharge is higher as a local high temperature region is formed by higher power of the single burner. Thus, if the advantages of the two combustion manners are combined to form a new combustion manner, better combustion effects can be achieved.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

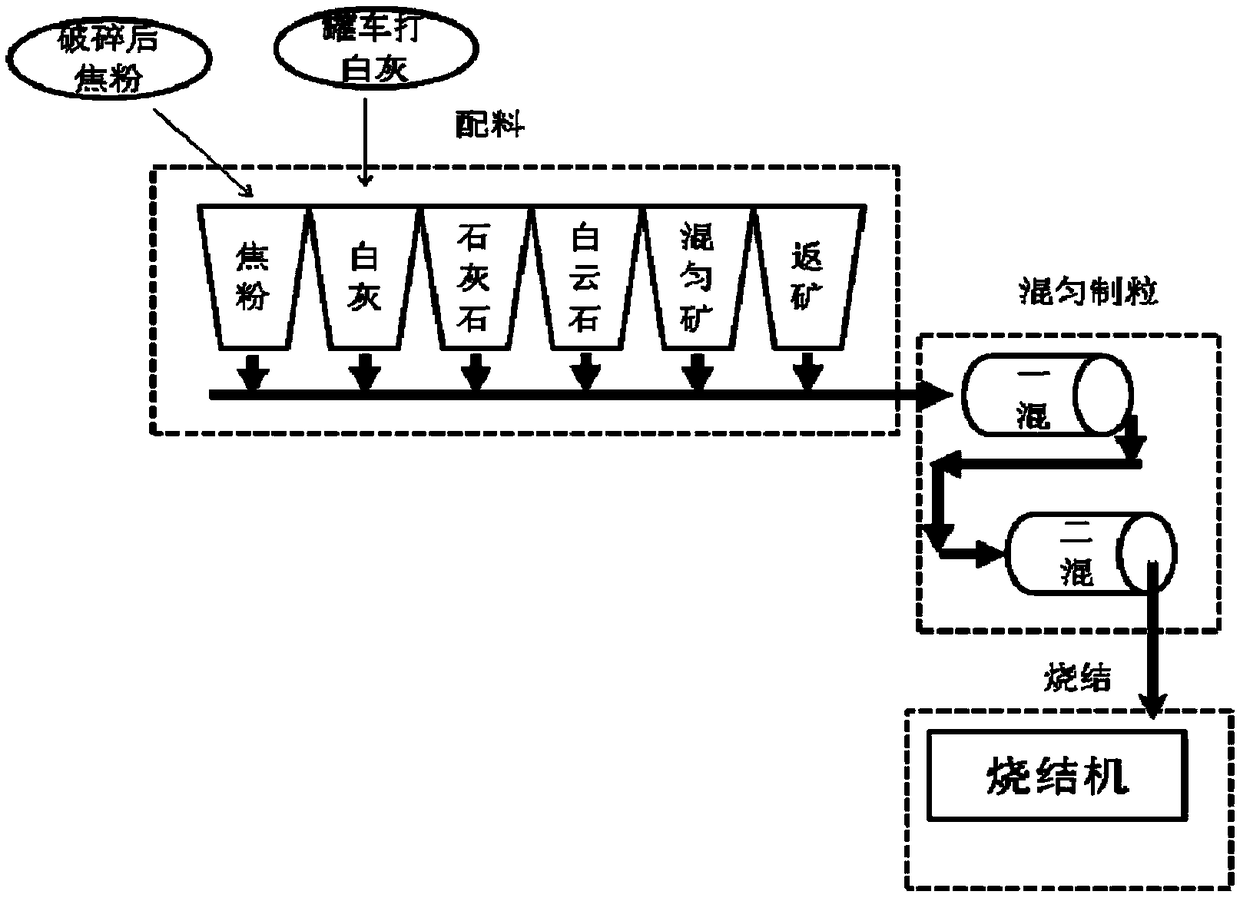

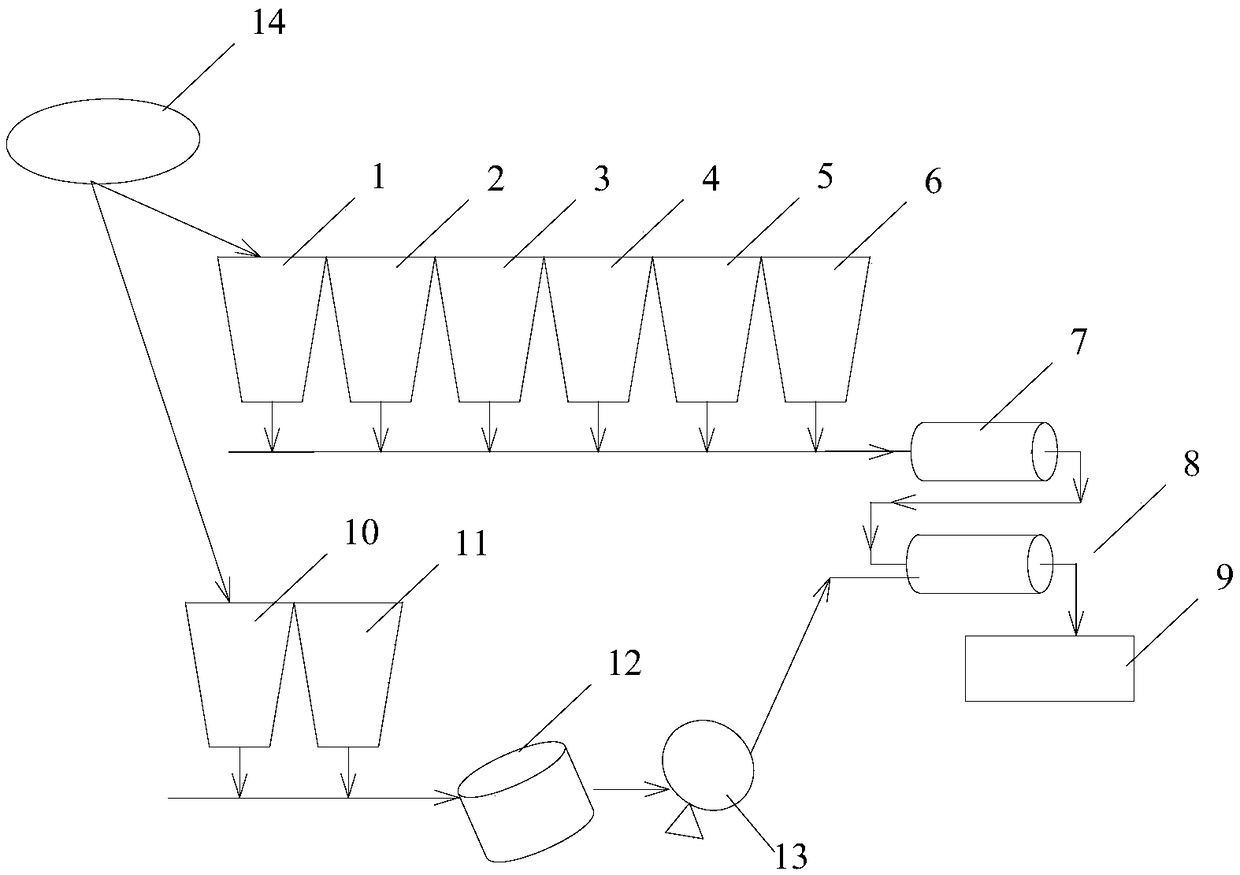

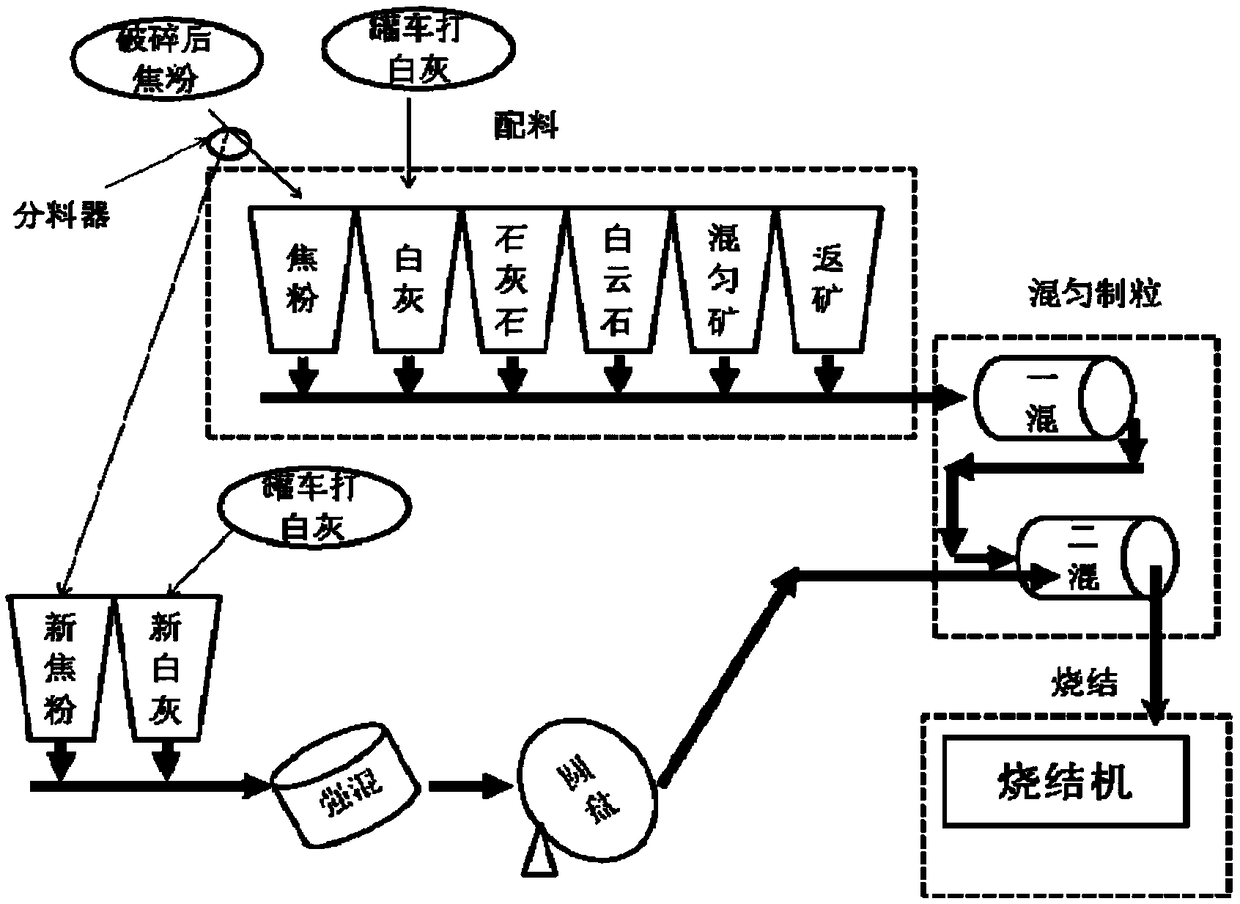

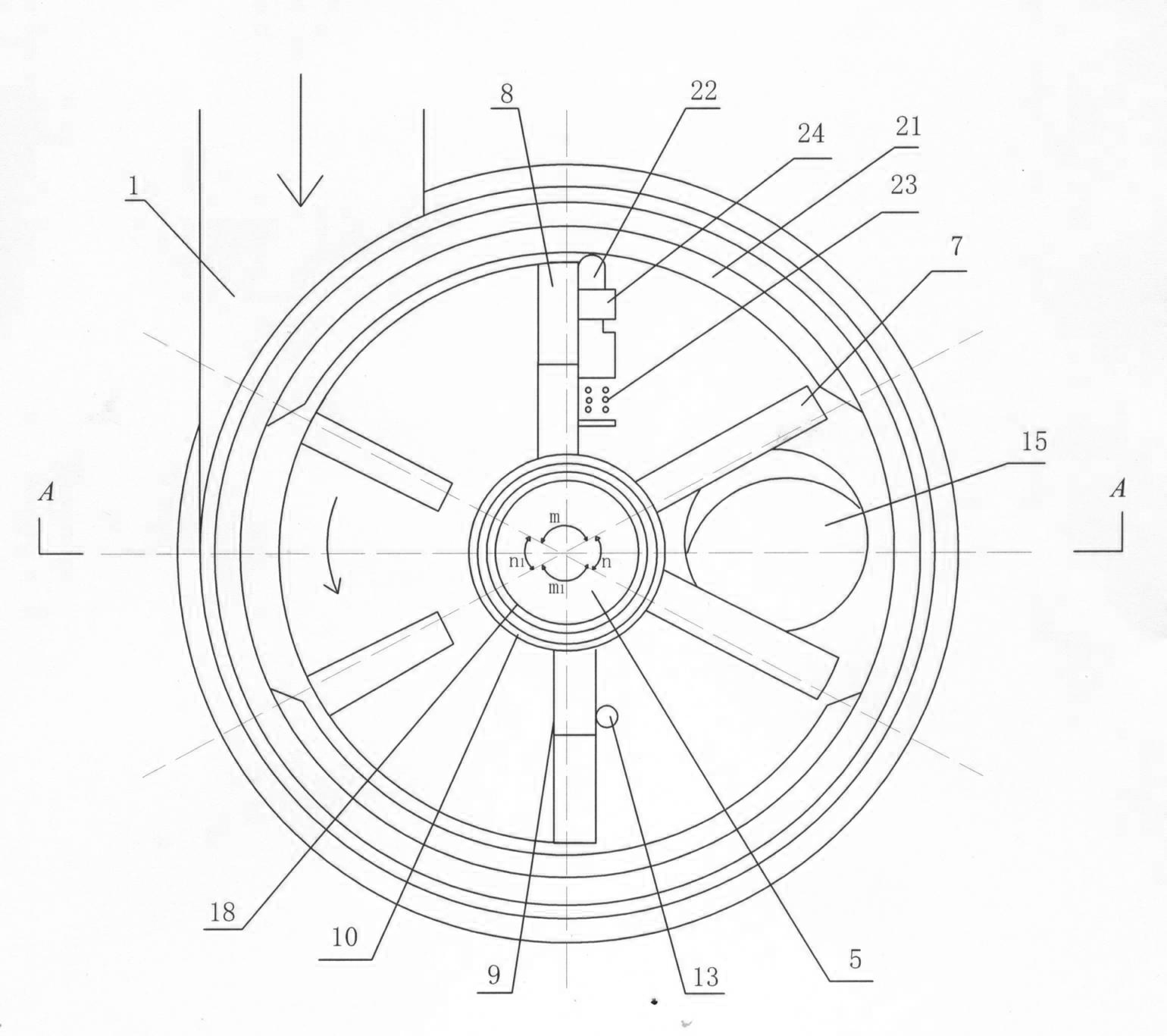

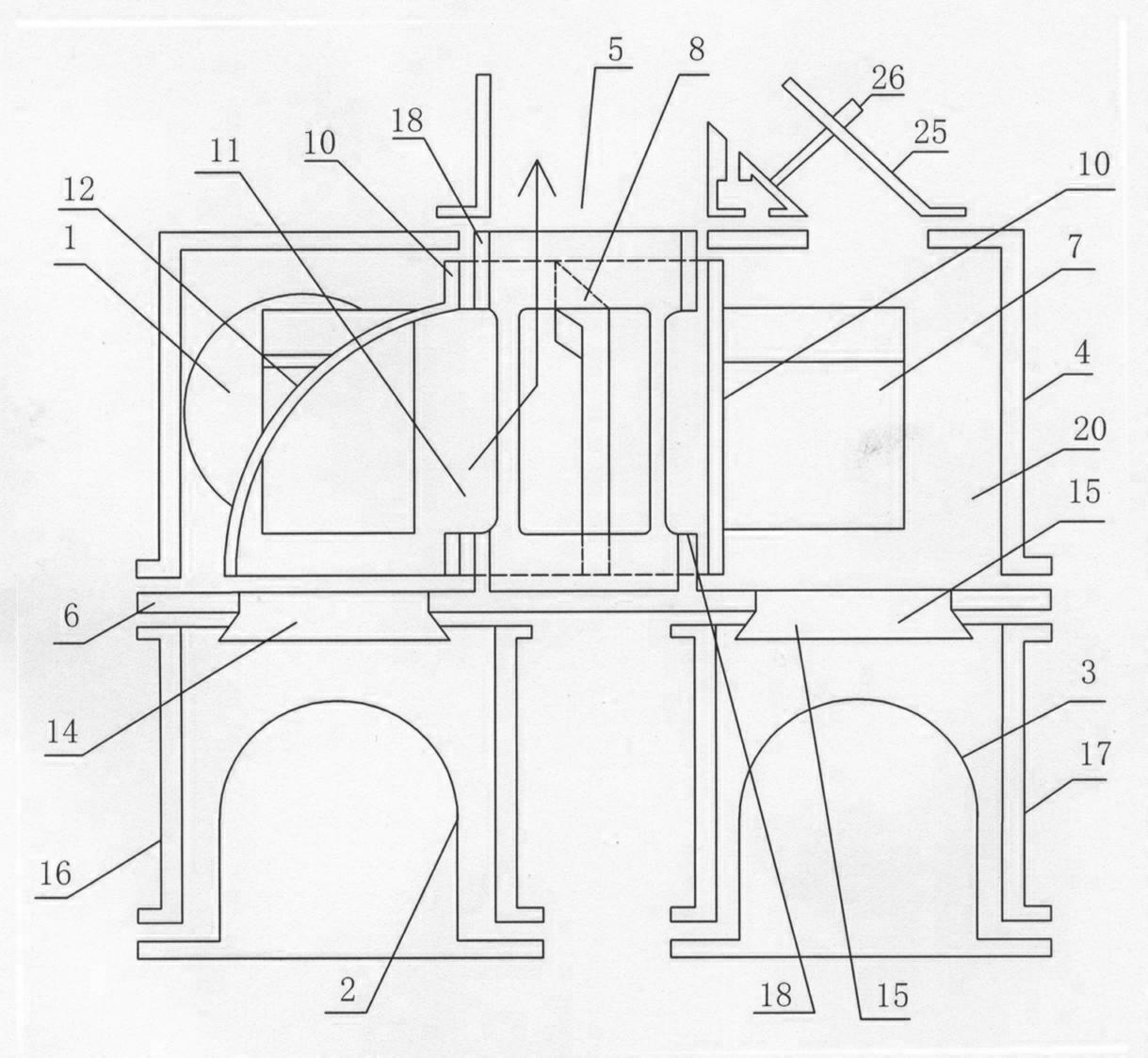

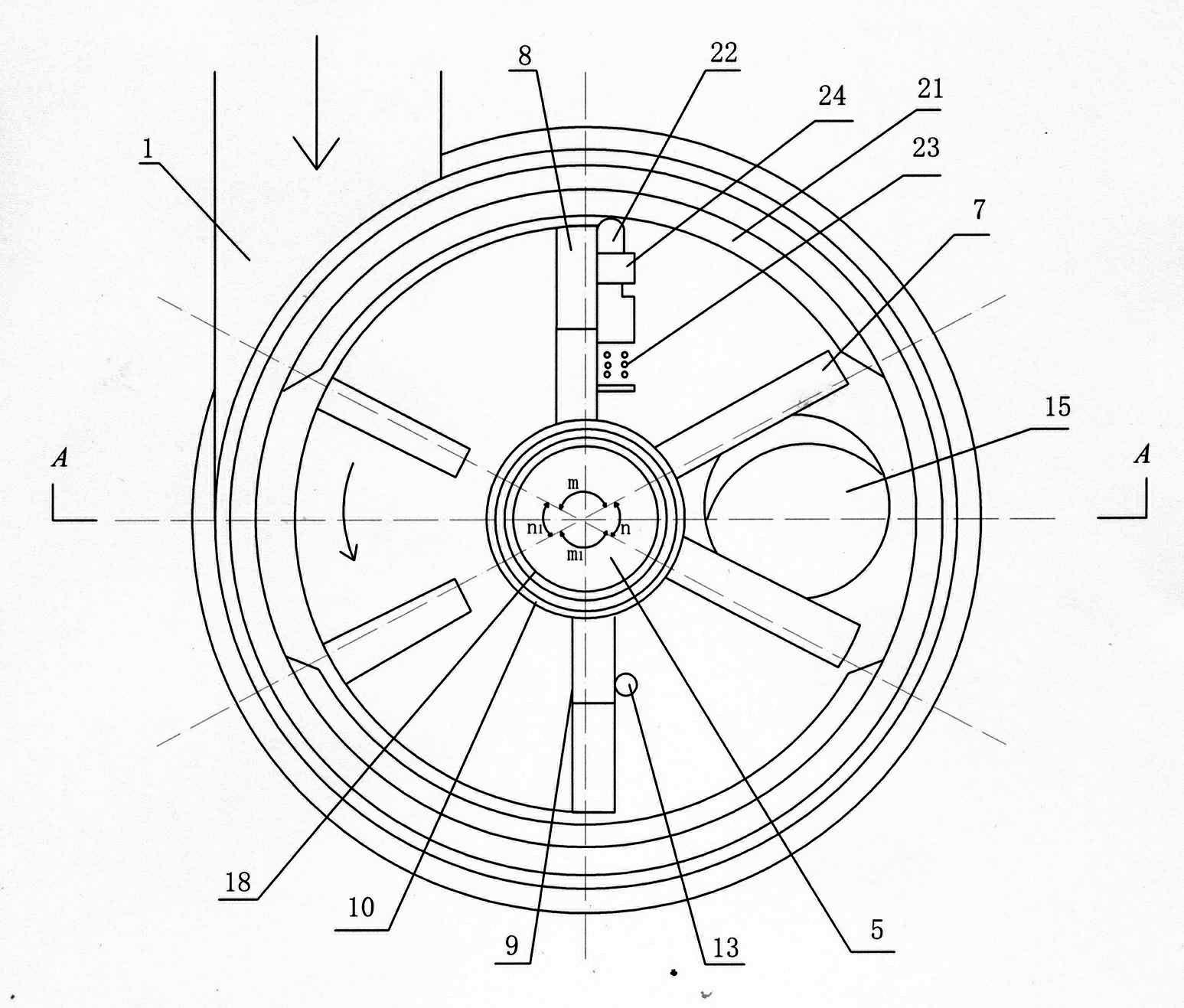

Emission reduction and device for NOx generated in sintering process

The invention discloses an emission reduction and device for a NOx generated in a sintering process. The method comprises the three main steps of material preparation, mixing and granulation and sintering. According to the NOx emission reduction scheme, a new coke powder bin and a new lime bin are built, coke powder and some lime do not pass through a coke powder bin and a lime bin of a traditional material preparation chamber, directly enter the new coke powder bin and the new lime bin, enter a strong mixing machine to be mixed evenly, and are pelletized in a pelletizing disc to form a mixture, and the mixture is transferred into the certain position in a secondary cylinder mixing machine. By means of the emission reduction and device for the NOx generated in the sintering process, the purpose that NOx generated in the sintering process is reduced is achieved by adjusting the wrapping state of coke powder without greatly changing the current sintering technology.

Owner:ZENITH STEEL GROUP CORP

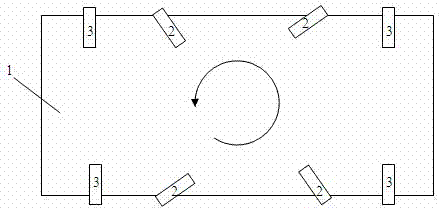

PM (particle matter) trapping and back-flushing circulator

ActiveCN102588162AReduce NOx emissionsPurify the environmentInternal combustion piston enginesNon-fuel substance addition to fuelParticle trappingExhaust gas

The invention discloses a PM (particle matter) trapping and back-flushing circulator, comprising a current converting chamber (20) enclosed by a substrate (6) and a shell (4), wherein inside the current converting chamber (20), a rotary air inlet passage (11) is integrated by uniformly distributed paddles (7) (8) (9), a curve cover plate (12) and a shaft sleeve (10); the both ends of the sleeve (10) are connected with a tubular shaft (18) that is integrated with the substrate (6); the paddles (8) (9) on the rotary air inlet passage (11) touch with the spool connecting element (13) of time-control solenoid valve; and the substrate (6) is provided with at least two correspondingly arranged guiding through holes (14) (15), the upper segment of which is connected with the current converting chamber (20), while the lower segment is opened like a horn and connected with the alternate air inlet and outlet tubes (16) (17) and corresponding filter bag assembly (2) (3). The PM particle trappingand back-flushing circulator manufactured according to the subject of the invention can trap over 90% of harmful particles (including PM2.5) discharged from diesel motors and re-combust them to reduce the emission of NOx (nitrogen oxides), which effectively purifies the environment from the source and makes positive contribution to human health. At the same time, the PM particle trapping and back-flushing circulator of the invention also achieves the beneficial effect of energy saving and emission reduction.

Owner:浙江瑞孚电气有限公司

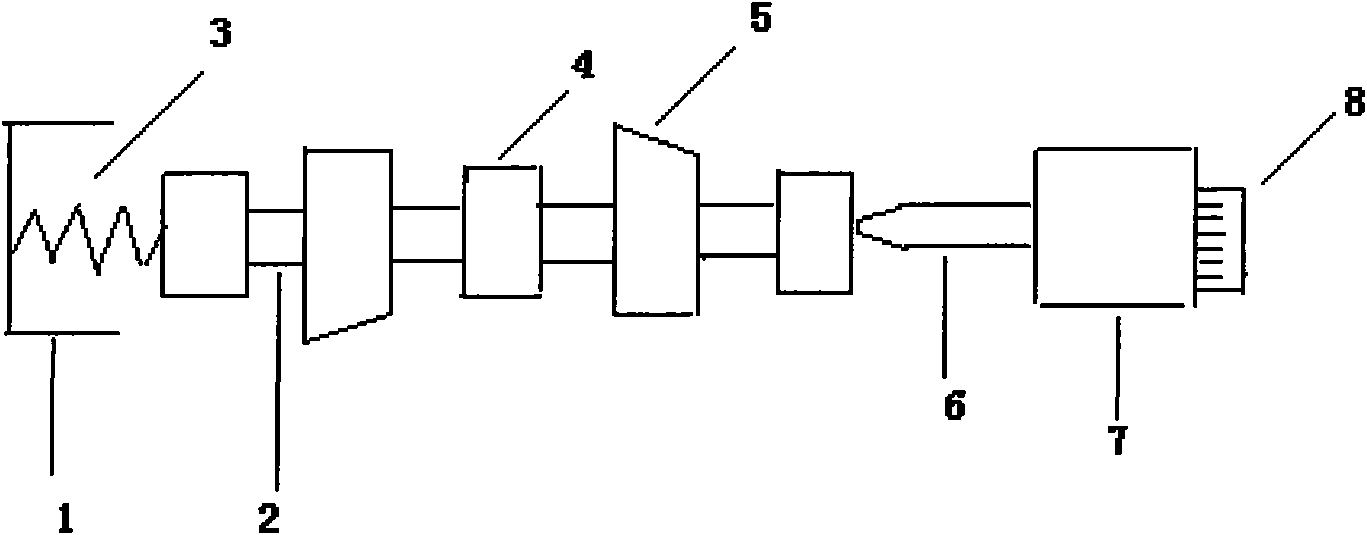

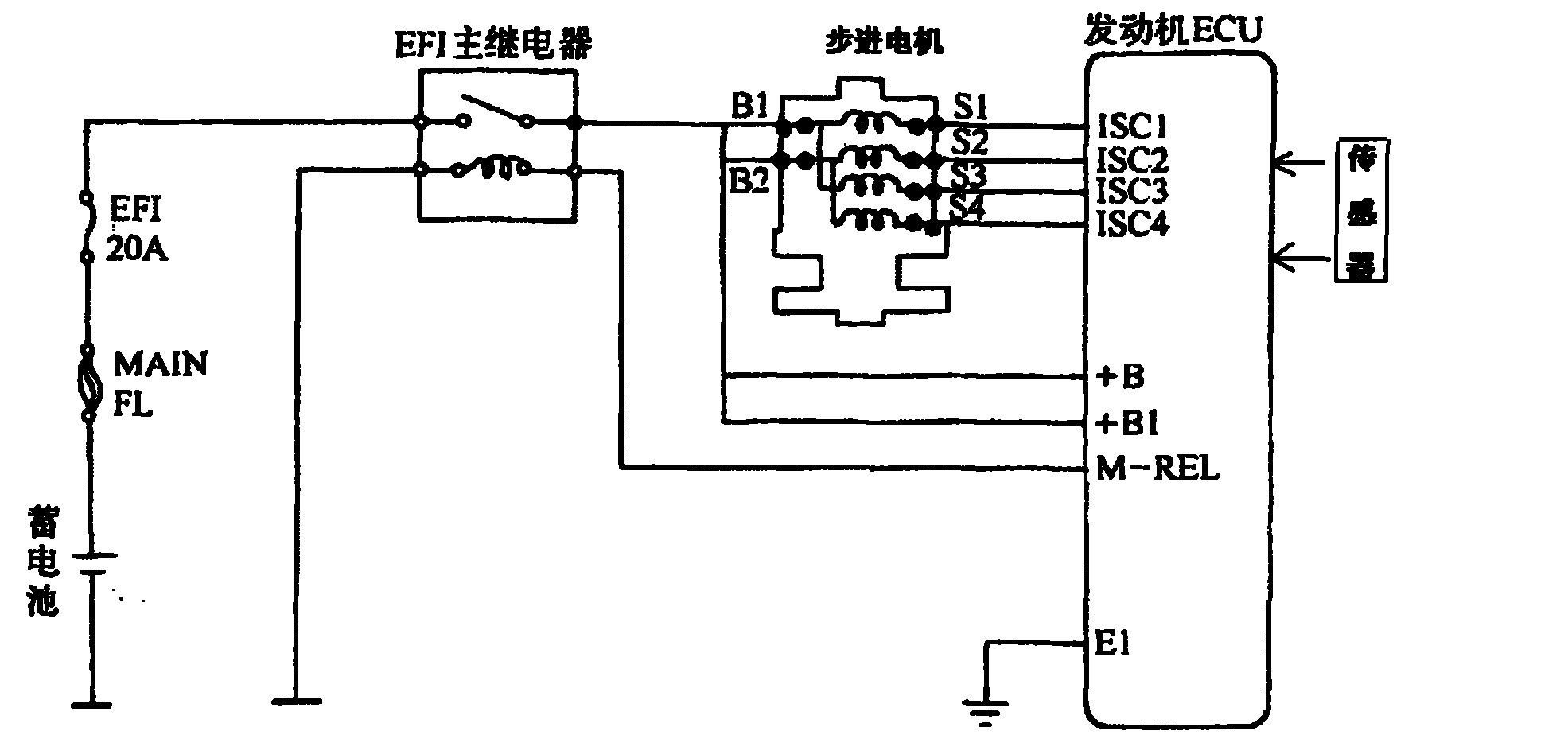

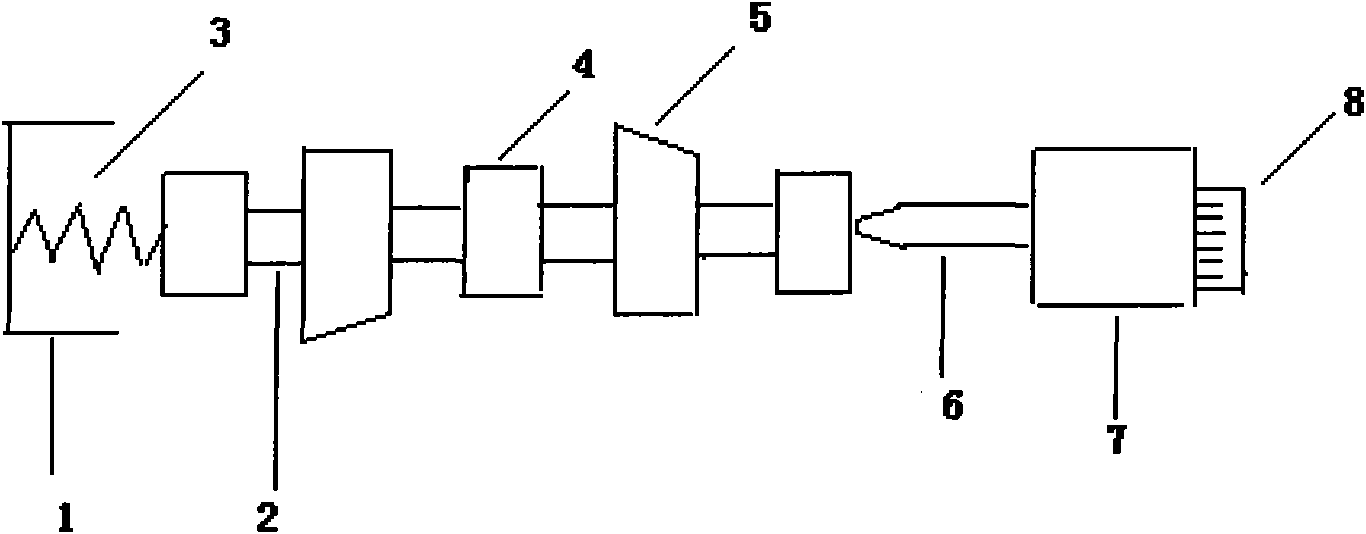

Variable valve timing and variable valve lift control system for automobile engine

InactiveCN101886562AReduce NOX emissionsEmission reductionMachines/enginesNon-mechanical valveEngineeringCam

The invention discloses a variable valve timing and variable valve lift control system for an automobile engine, which comprises a return spring bracket 1, a cam shaft 2, a return spring 3, a shaft neck 4, a cam 5, a lead screw 6, a stepping motor 7 and a plug 8, wherein the return spring 3 is arranged in the return spring bracket 1; the return spring 3 is connected with the cam shaft 2; the shaft neck 4 is connected with the cam 5; the stepping motor 7 is connected with the cam 5 through the lead screw 6; and the plug 8 is arranged on the stepping motor 7 and is used for connecting an external power source. The system of the invention can be formed by direct expansion on an engine computer and does not need an individual control system. Moreover, by controlling an intake valve and an exhaust valve, exhaust gas recirculation (EGR) of an engine can be realized very conveniently, and emission of NOX is greatly reduced.

Owner:龚文资

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com