Supercharged diesel engine system based on EGR (exhaust gas recirculation) high pressure chamber

A high-pressure cavity and diesel engine technology, applied in the direction of charging system, mechanical equipment, engine components, etc., can solve the problems of lower pressure than the intake pressure, intake pressure back into the exhaust pipe, increase fuel consumption, etc., to reduce NOx The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

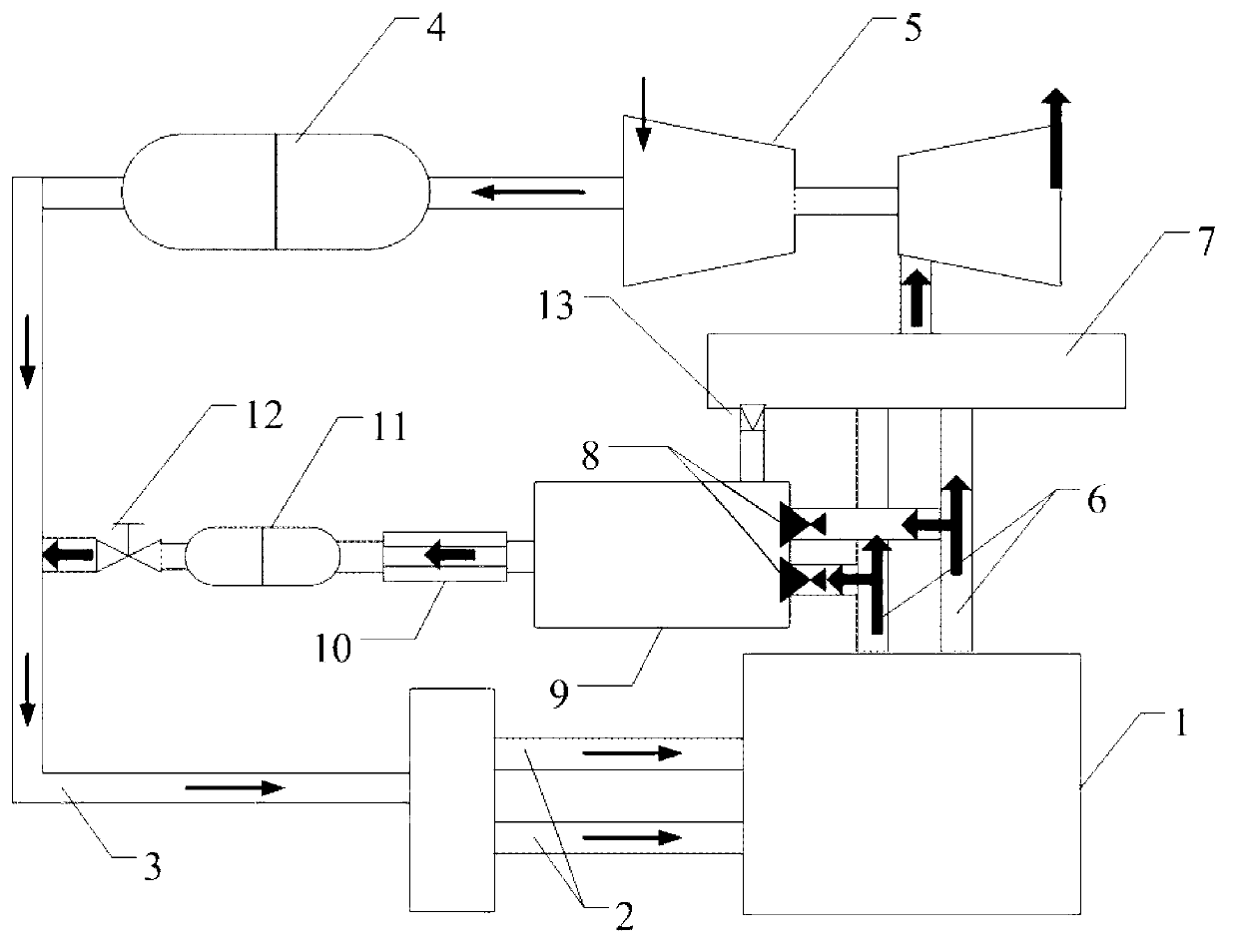

[0012] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0013] combine figure 1 , the technical scheme of the present invention is realized like this, and the present invention comprises: diesel engine 1, intake manifold 3, intake manifold 2, exhaust manifold 7, exhaust manifold 6, turbocharger 5, air intake intercooler 4, exhaust gas intercooler 11, EGR valve 12, EGR high-pressure chamber 9, one-way stop valve 8 and discharge valve 13 and other structures. A one-way stop valve 8 is installed at the inlet end of the EGR high-pressure chamber 9 connected to the exhaust manifold 6. One end of the outlet of the EGR high-pressure chamber 9 is connected with the exhaust gas filter 10, and the other end is connected with the exhaust main pipe 7. A discharge valve 13 is installed at the outlet end where the main pipe 7 is connected.

[0014] When the diesel engine normally works stably in each load area, since the intake pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com