Variable valve timing and variable valve lift control system for automobile engine

An automotive engine and valve phasing technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problem that the variable valve phase and the variable valve lift are not continuously changing, and achieve the goal of reducing NOX emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

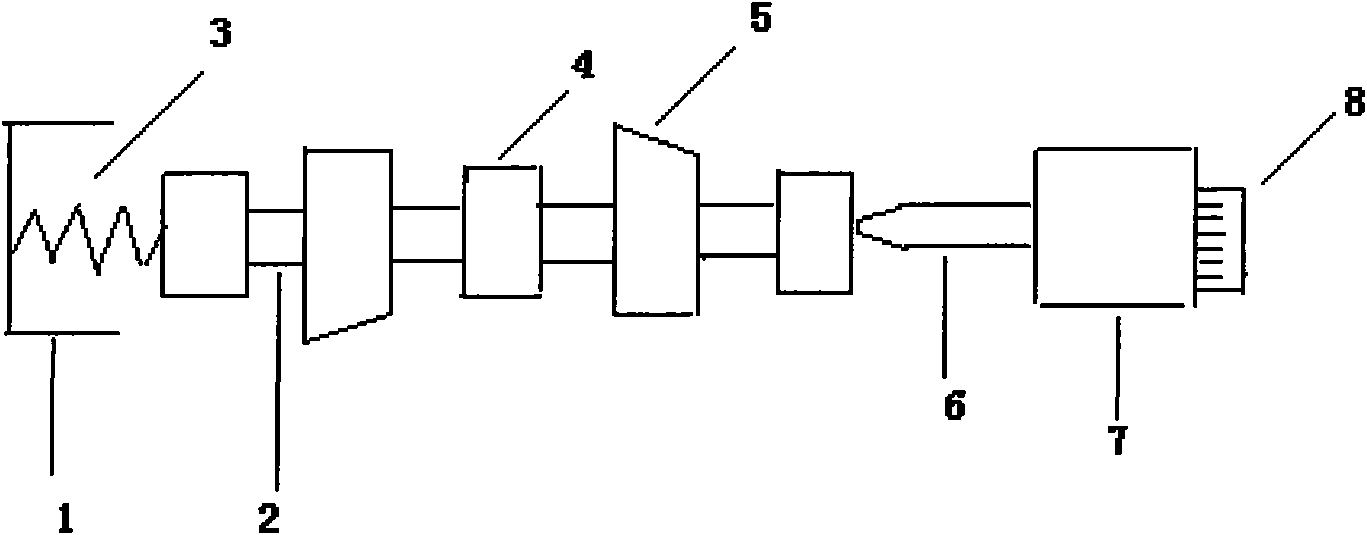

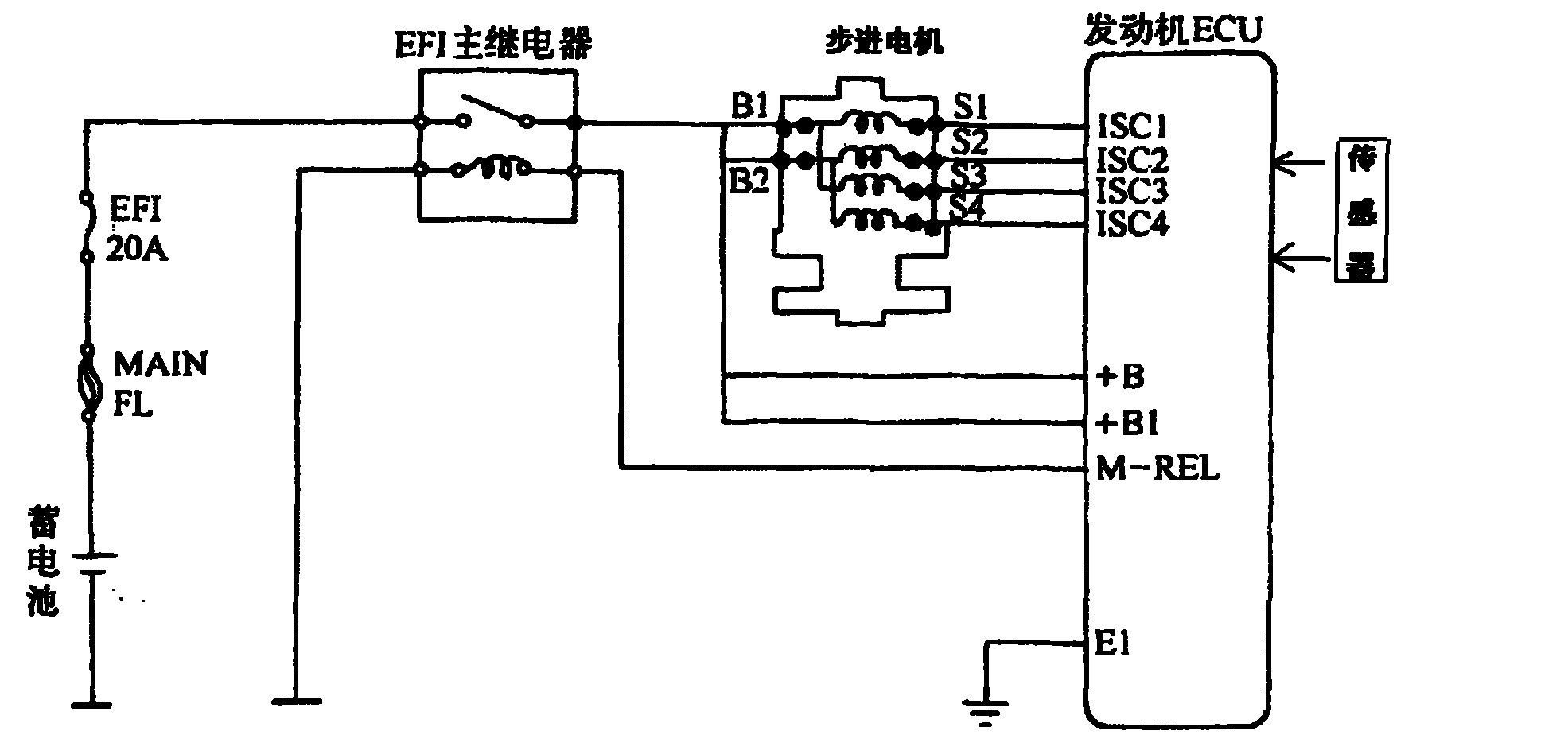

[0009] The principle of this control system is as follows figure 1 shown. The camshaft cam curve is a continuously changing curve of valve timing and valve lift that can meet the requirements of all engine working conditions. The axial position of the camshaft is driven by a stepping motor, which is controlled by the engine computer (ECU). Stepper motor control principle such as figure 2 shown. The engine computer mainly analyzes and calculates comprehensively based on signals such as speed, load, water temperature, and throttle opening. By controlling the grounding sequence and times of ISC1, ISC2, ISC3, and ISC4, the rotation direction and number of steps of the stepping motor can be controlled. And then precisely control the length of screw rod extension or shortening, the screw rod stretches out, pushes the cam shaft to move leftward, changes the contact position between the cam and the valve lifter, and also changes the valve timing and valve lift of the valve. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com