Circulating fluidized bed boiler

A circulating fluidized bed and boiler technology, applied in the field of boiler manufacturing, can solve the problems of not being able to effectively reduce NOx emissions, increase the cost of boiler manufacturing and installation, and the heating surface of the superheater of the boiler is huge, so as to increase the cost of manufacturing and installation, and the cost of manufacturing Small, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

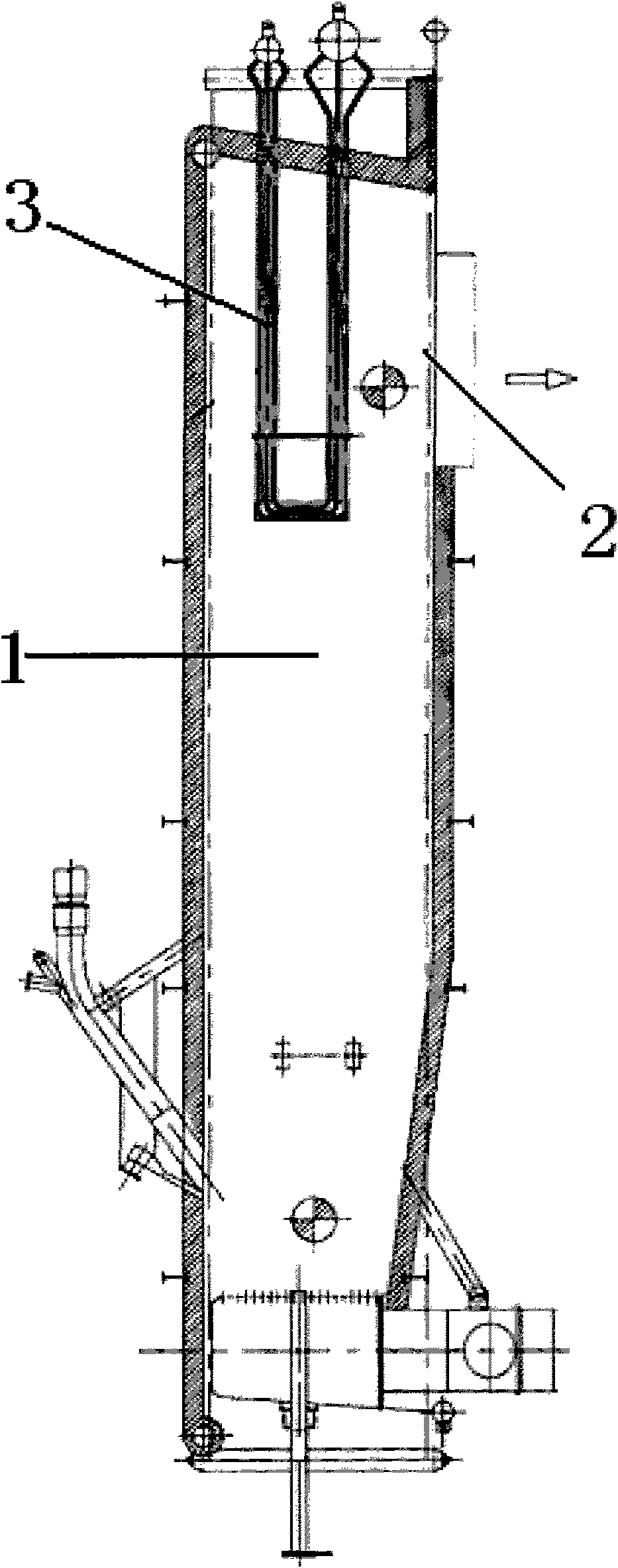

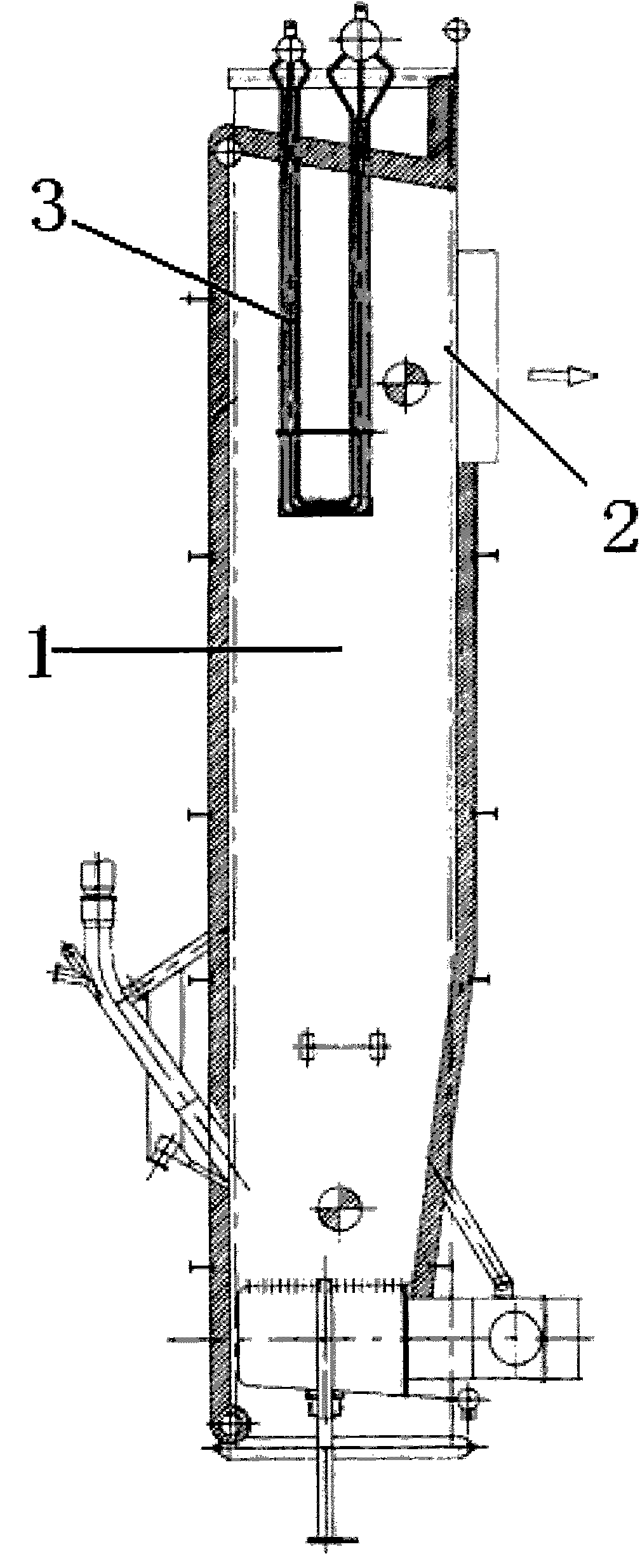

[0022] Structural brief introduction of the present invention:

[0023] The 3 tubes of the high-temperature superheater are arranged above the boiler furnace 1, and the horizontal pitch is evenly arranged according to the depth of the boiler furnace 1. 21 pieces are arranged in parallel, and each piece is connected in parallel with 3 sets, passing through the wall on the top of the membrane water wall. Due to the large radiation heat load in the furnace 1 and the heat that may be generated unevenly, the superheater tube specification adopts φ42×5, and the high-temperature steam flow rate in the design tube is above 24 m / s, and the tube material is selected 12Cr1MoVG / GB5310 (alloy steel pipe) This ensures that the metal wall temperature of the superheater tube is within the allowable value of the material.

[0024] The concentration of solid particles in the flue gas in furnace 1 is relatively high, but the flue gas flow direction is stable, so it is only necessary to add a wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com