Power generation system and power generation method for biomass gasification coupled coal-fired boiler

A technology for coal-fired boilers and power generation systems, which is used in gasification process, granular/powder fuel gasification, chemical industry, etc. complex problems, to achieve the effect of easy large-scale amplification, preventing low-temperature ash accumulation and slagging, and saving coal combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with specific embodiment, further illustrate the present invention.

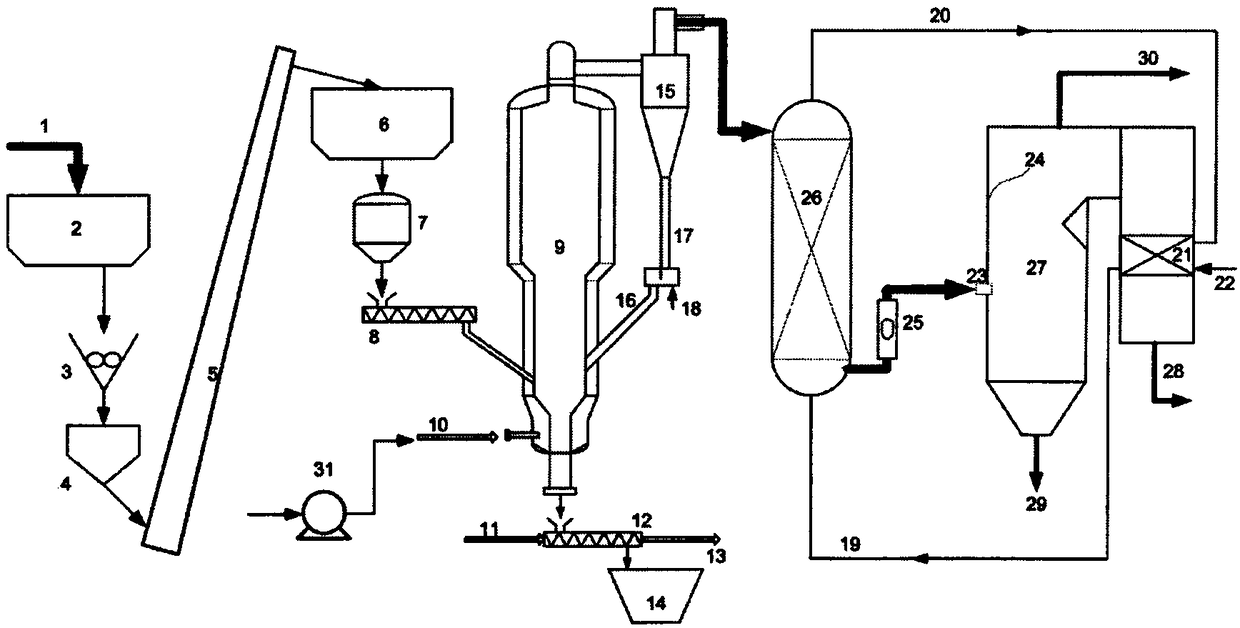

[0038] figure 1 A schematic diagram of a biomass gasification coupled coal-fired boiler power generation system provided for this example, said biomass gasification coupled coal-fired boiler power generation system mainly includes a biomass storage and delivery unit, a biomass circulating fluidized bed gasification unit, a biomass Material high temperature gas waste heat recovery unit, crude gas metering air supply unit and supporting combustion unit and other equipment.

[0039] Such as figure 1 As shown, the biomass storage and transportation unit mainly includes biomass storage bin 2, cutting crusher 3, hopper 4, conveyor belt 5, raw material bin 6, feeding bin 7, frequency conversion screw feeder 8 and supporting pipeline instruments. The cutting and breaking machine 3 is set under the biomass storage bin 2, the hopper 4 is set under the cutting and breaking machine 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com