Coupled superfine biomass and coal-fired power generation system and method with flue gas drying and power feeding functions

A power generation system, biomass fuel technology, applied in the combustion method, dry gas arrangement, solid fuel combustion and other directions, can solve the problems of easy entanglement of fuel, unfavorable ignition and burnout, spontaneous combustion and even explosion, etc., to avoid the heating surface. The effect of coking, protecting the environment, improving reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

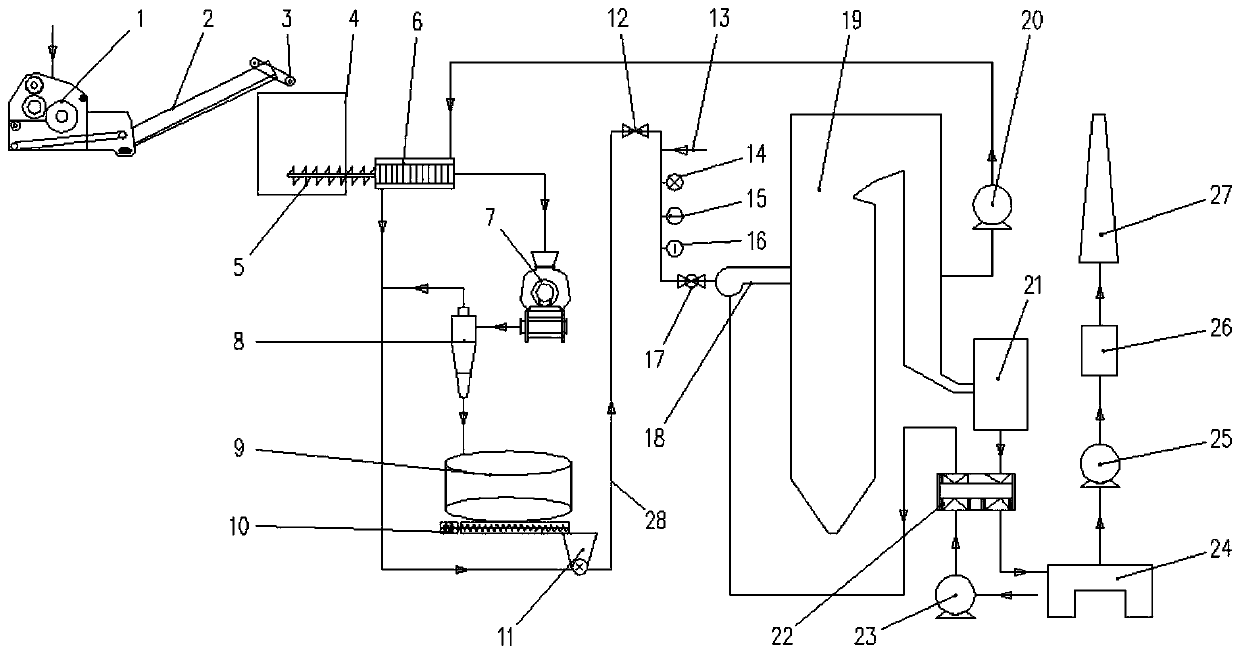

[0027] Specific implementation mode one: combine figure 1 Describe this embodiment, an ultrafine biomass and coal-fired coupled power generation system for flue gas drying and powder feeding in this embodiment, including a biomass particle preparation system, a biomass particle delivery system, and a biomass particle combustion and flue gas purification system The biomass particle preparation system is used to process and store the collected biomass raw materials; the biomass particle delivery system transports the formed ultrafine biomass fuel to the coal-fired boiler 19; the biomass particle combustion and flue gas purification system is used For the combustion of biomass particles and the purification of flue gas after combustion, the ultra-fine biomass fuel prepared by the biomass particle preparation system is transported to the coal-fired boiler 19 through the biomass particle delivery system, and part of the flue gas from the coal-fired boiler 19 is transported to The b...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination figure 1 This embodiment is described. In this embodiment, an ultrafine biomass and coal-fired coupled power generation system for flue gas drying and powder feeding, the biomass particle preparation system includes a biomass crusher 1, a belt conveyor 2, Buffer silo 4, screw conveyor 5, flue gas dryer 6, ultrafine biomass pulverizer 7, rotary separator 8 and ultrafine biomass silo 9, both ends of belt conveyor 2 are respectively connected to biomass Crusher 1 and buffer silo 4, screw conveyor 5 is arranged under buffer silo 4, screw conveyor 5 is connected with buffer silo 4 and flue gas dryer 6, and flue gas dryer 6 is connected with ultrafine biomass Pulverizer 7, ultrafine biomass pulverizer 7 communicates with ultrafine biomass material bin 9 through rotary separator 8, and described biomass particle delivery system transports the ultrafine biomass fuel stored in ultrafine biomass material bin 9 to Inside the coal-fire...

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 This embodiment is described. In this embodiment, an ultrafine biomass and coal-fired coupled power generation system for flue gas drying and powder feeding, the belt conveyor 2 is equipped with a magnetic drum 3 . So set, the material enters the buffer bin 4 after passing through the magnetic roller 3 at the outlet end of the belt conveyor 2 to remove the fine iron products doped in the material.

[0031] Specific implementation mode four: combination figure 1 Describe this embodiment, a flue gas drying and powder feeding ultrafine biomass and coal-fired coupled power generation system in this embodiment, the biomass particle conveying system includes a screw powder feeder 10 and a conical powder hopper 11, the screw The powder conveying machine 10 is connected with the superfine biomass material bin 9 and the conical powder hopper 11, and the screw powder conveying machine 10 transports the formed ultrafine bio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com