Patents

Literature

633 results about "Biomass combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Essentially, biomass energy is a form of energy created from the combustion of carbon-based biological materials such as wood, vegetables or animal waste. The combustion of biomass materials usually takes place in a wood combustion system such as a biomass boiler, where the fuel is burnt to create the energy.

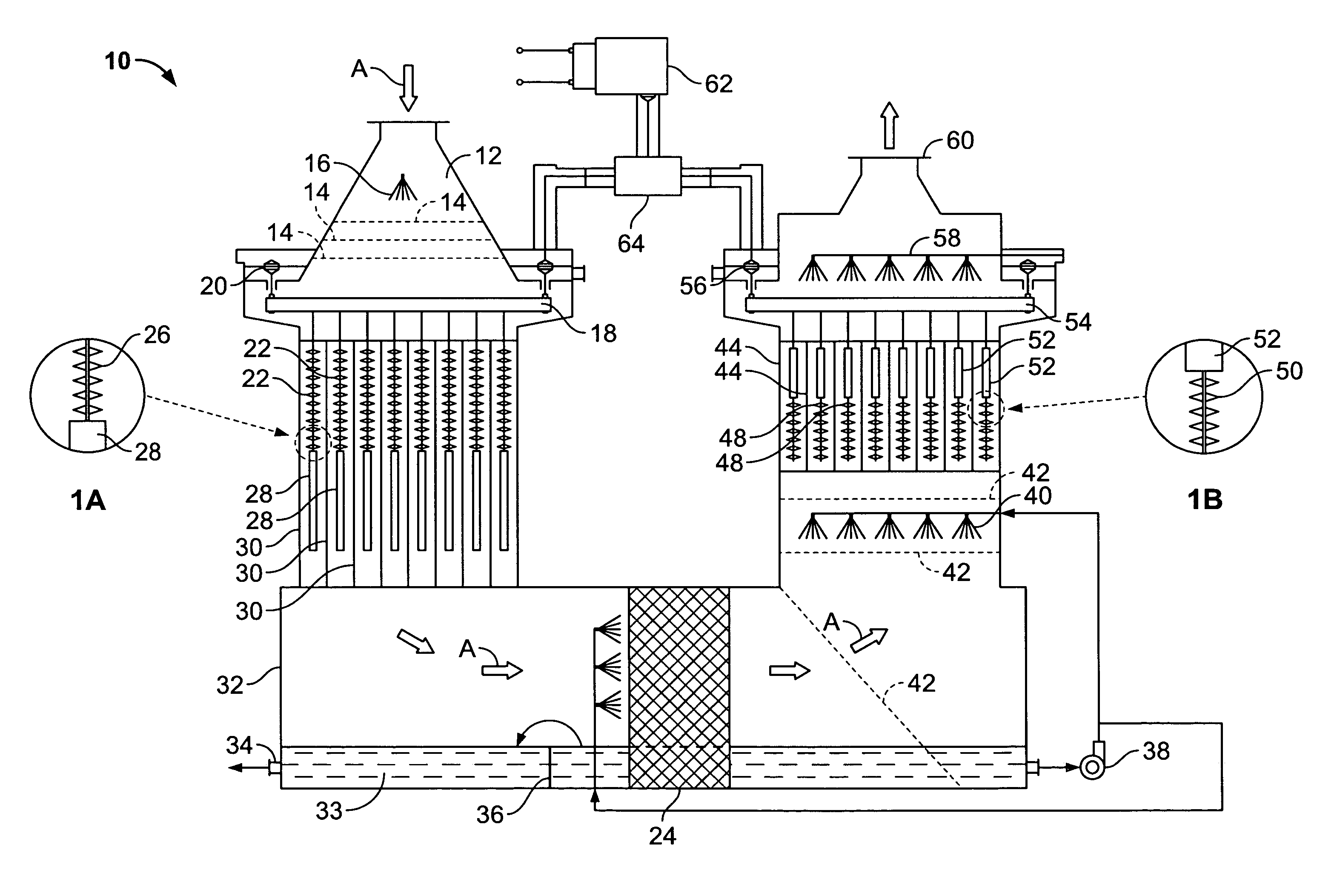

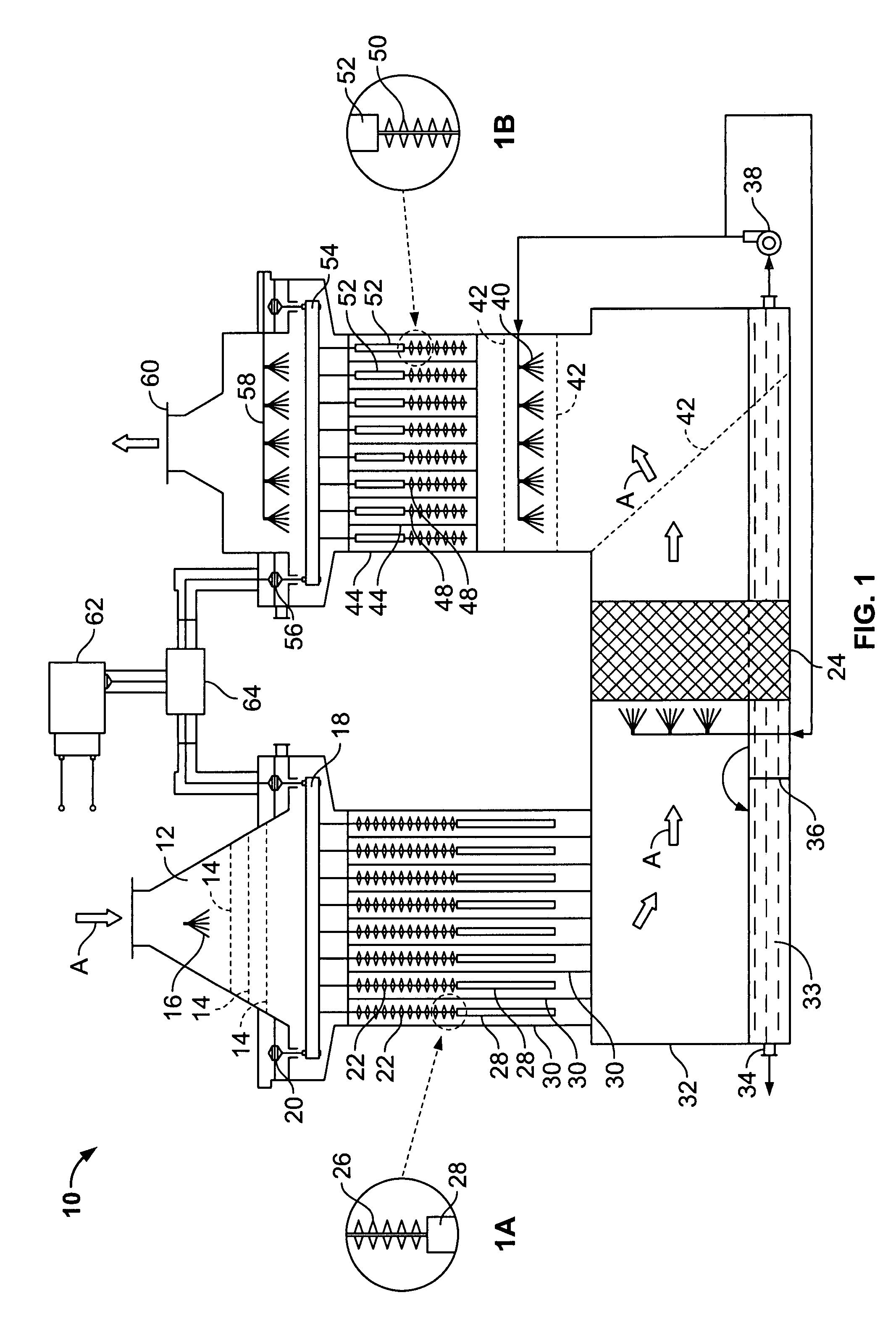

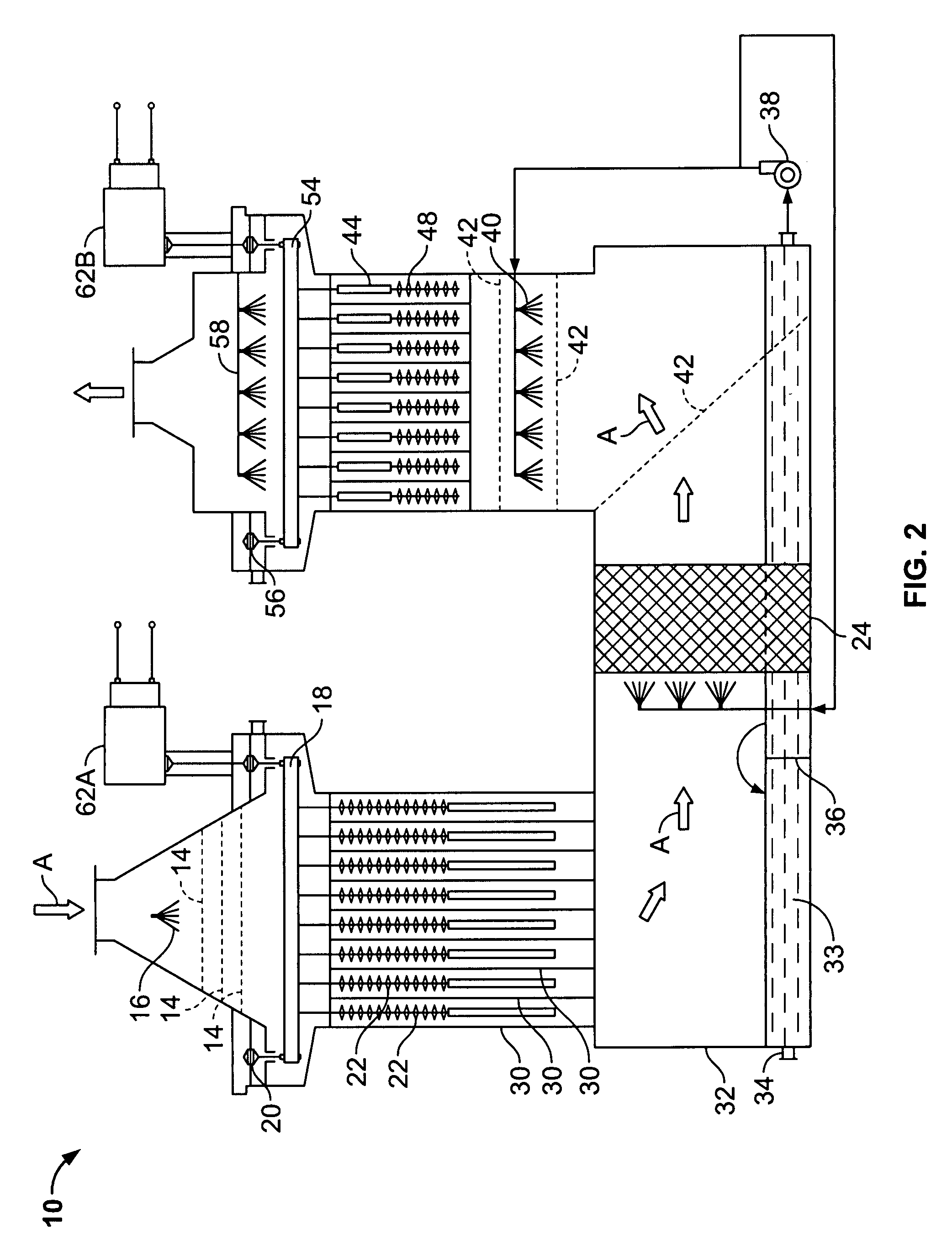

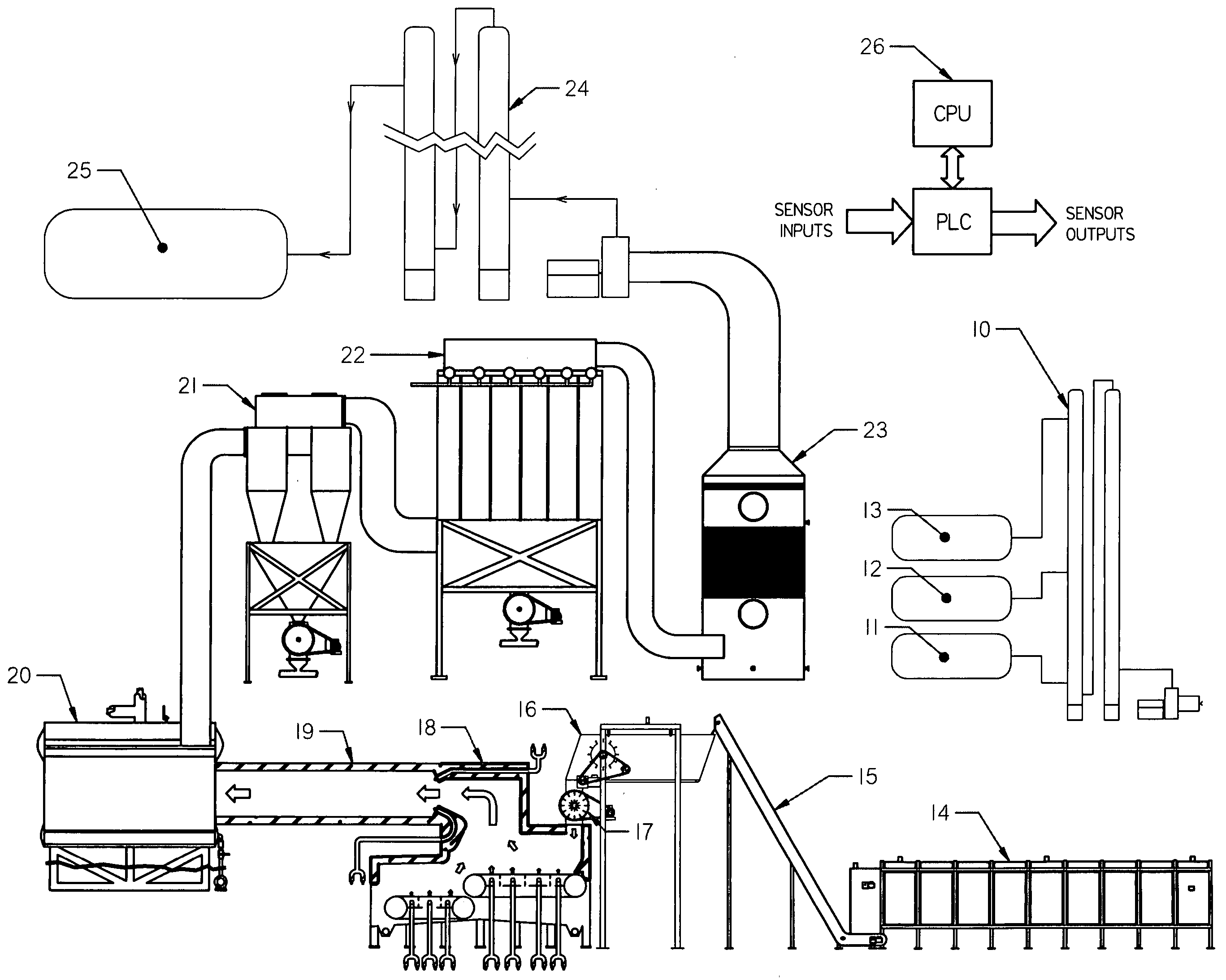

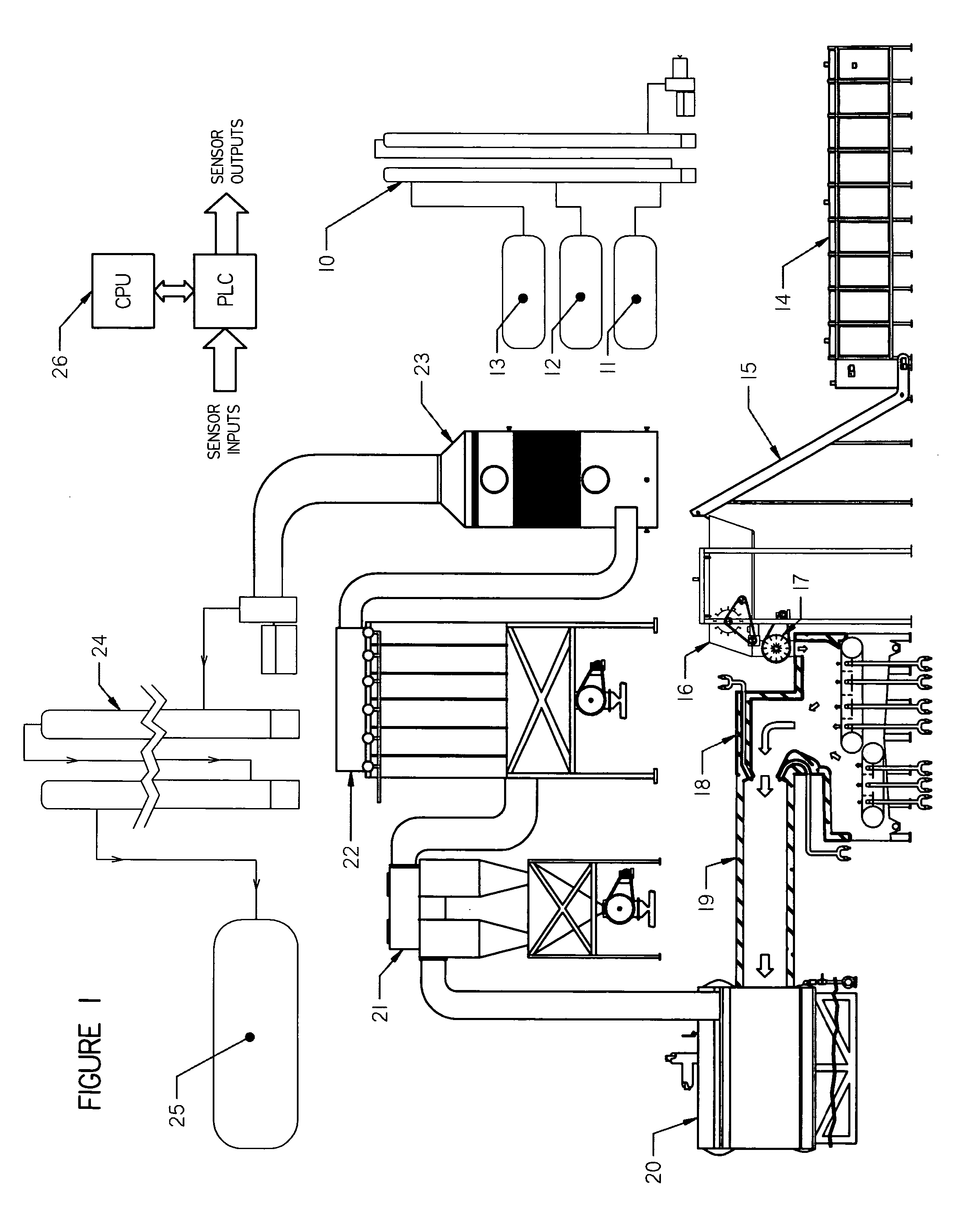

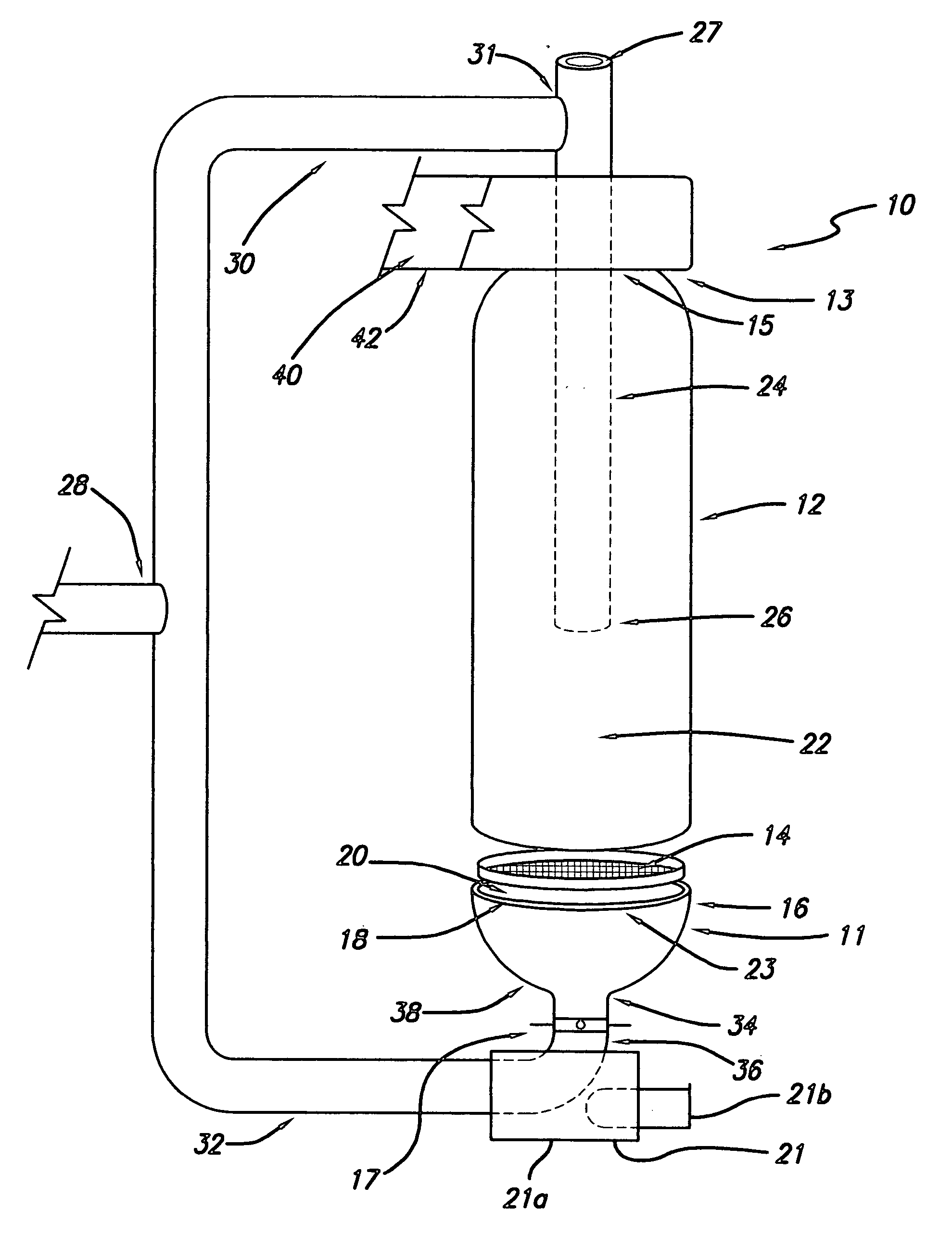

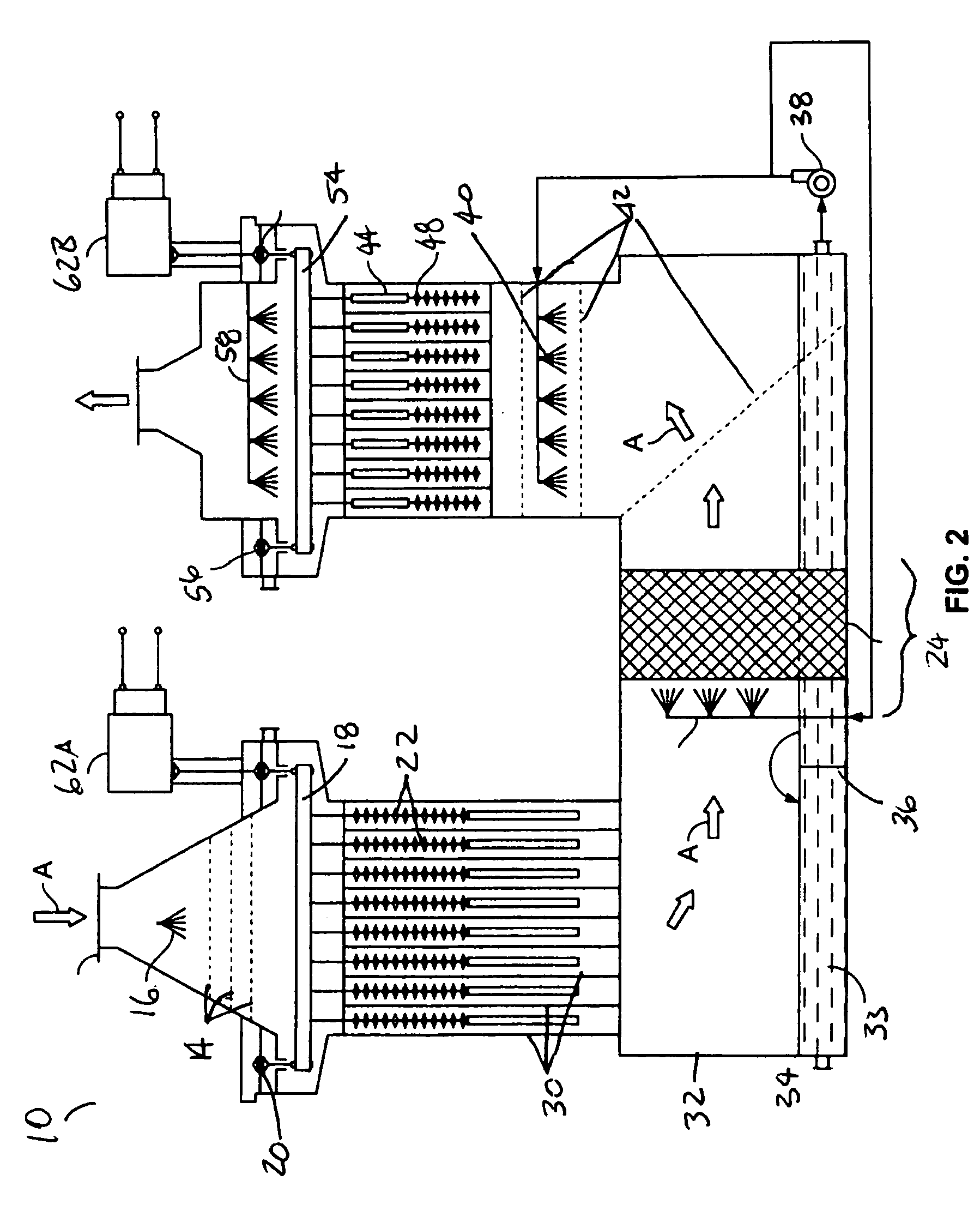

Wet electrostatic precipitator for treating oxidized biomass effluent

ActiveUS7297182B2Material analysis using wave/particle radiationElectric discharge tubesParticulatesProcess engineering

An apparatus for removing particulate matter from a biomass combustion gas stream, the apparatus having a mist-producing element that mixes a gas stream entering the apparatus with liquid droplets; a Wet Electrostatic Precipitator (WESP) section that includes ionizing electrodes that electrically charge the particulate matter and the intermixed liquid droplets and collecting surfaces under the influence of an electrical field which attract and remove electrically-charged particulate matter and intermixed liquid droplets from the gas stream; and a scrubbing section that provides for additional scrubbing of the gas.

Owner:ZENVIRO TECH HLDG INC

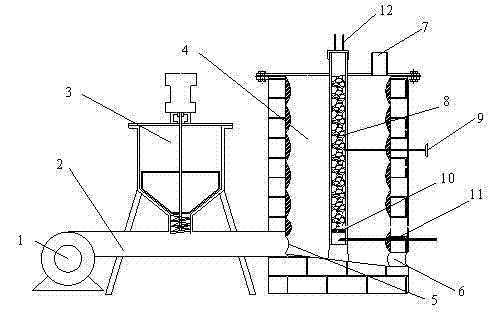

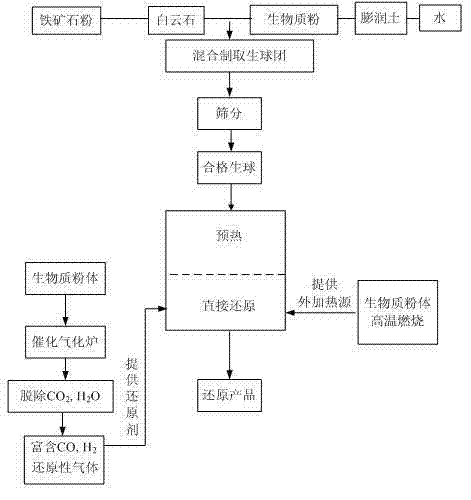

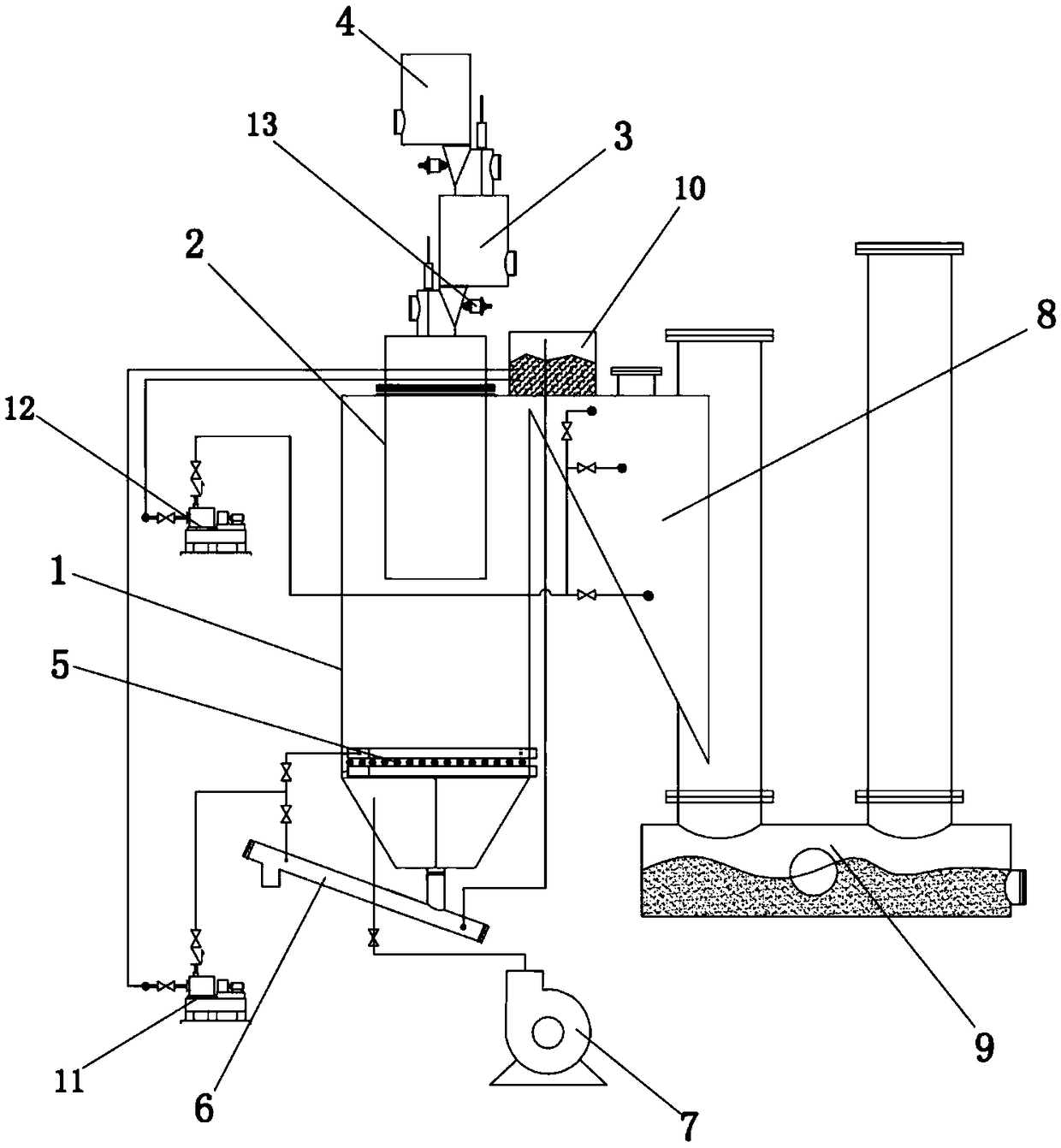

Biomass-based direct-reduction ironmaking device and method

InactiveCN102392093AIncrease volumeReduce manufacturing costGas emission reductionSyngasCombustion chamber

The invention provides a biomass-based direct-reduction ironmaking device and a method thereof. The device provided by the invention comprises a blower fan, an air / pulverized coal premix pipe, a biomass feeder and a combustion chamber, wherein the biomass feeder is connected with the air / pulverized coal premix pipe; one end of the air / pulverized coal premix pipe is connected with the blower fan and the other end is connected with the combustion chamber; the bottom of the combustion chamber is provided with a slag removal outlet, the top is equipped with a flue gas outlet, and the intermediate part is provided with a reactor for direct-reduction ironmaking. The direct-reduction ironmaking method comprises green pellet preparation, preheating and direct reduction. The heat source needed for the preheating and reduction is provided by biomass combustion. Synthetic gas prepared by biomass catalysis and gasification is used as a reducing agent needed during the reduction process. According to the invention, coal and natural gas are replaced with biomass for direct-reduction ironmaking, thus reducing the dependence on fossil energy in the ironmaking industry, improving the quality of direct-reduction iron products, minimizing the harm to the environment, and fundamentally solving technological and equipment problems in the green ironmaking industry.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Oxygen-based biomass combustion system and method

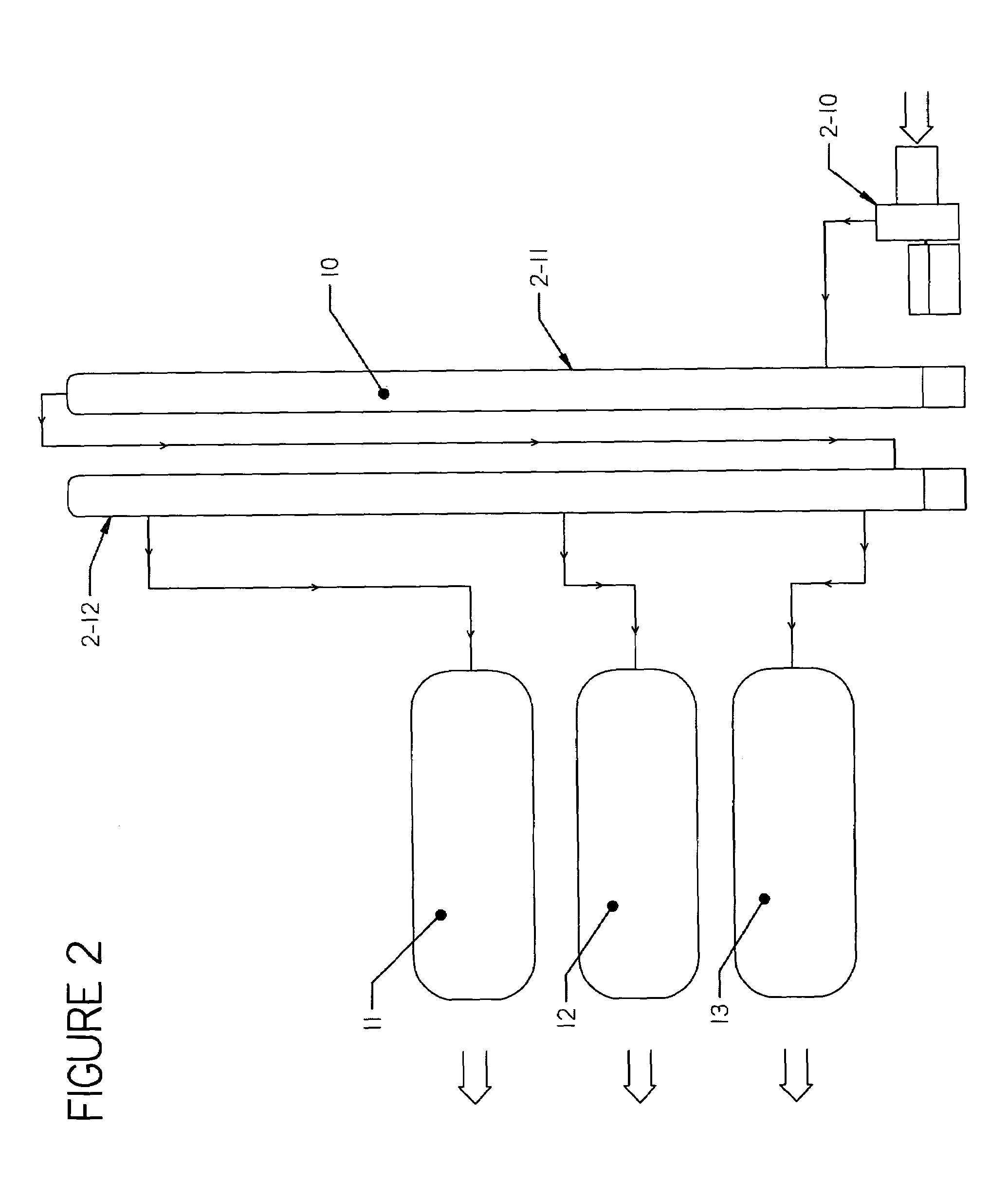

InactiveUS7007616B2Heat loss from heating unnecessary oxidant is minimizedReduce heat lossSolidificationLiquefactionCombustion chamberOxygen

An oxygen-based biomass solid fuel combustion system and method has an air separator for separating oxygen from air providing a supply of oxygen for feeding oxygen to a solid fuel combustion chamber. An airlock feeds a metered amount of solid fuel to the solid fuel combustion chamber. A burner stage having a firetube for collecting fuel gases from the solid fuel combustion chamber combusts the collected fuel gases with further oxygen from the separator and heats a boiler to generate steam. A heat utilization device (e.g. an electrical generator) may be connected to the steam boiler. Nitrogen-free diluent gases (e.g. argon and carbon dioxide) are used to control combustion process temperatures. The usable heat energy and useful byproducts are extracted from the different stages of the process.

Owner:MUNIZ CESAR A

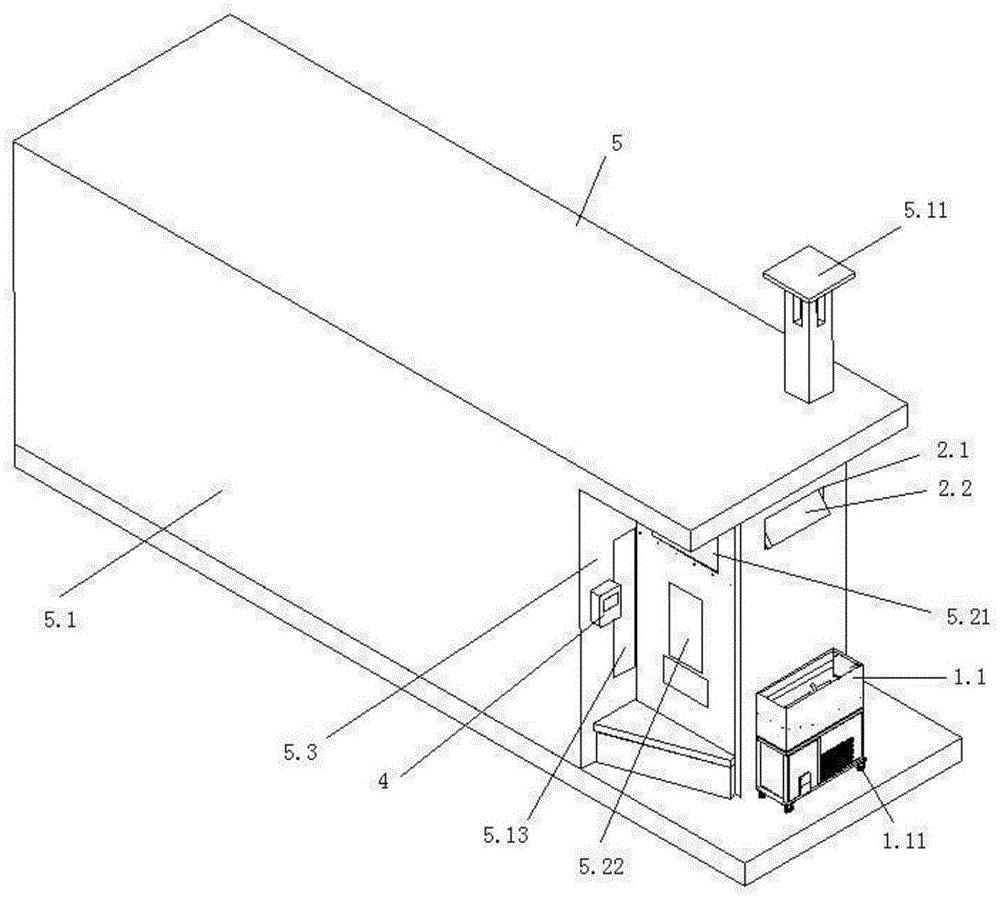

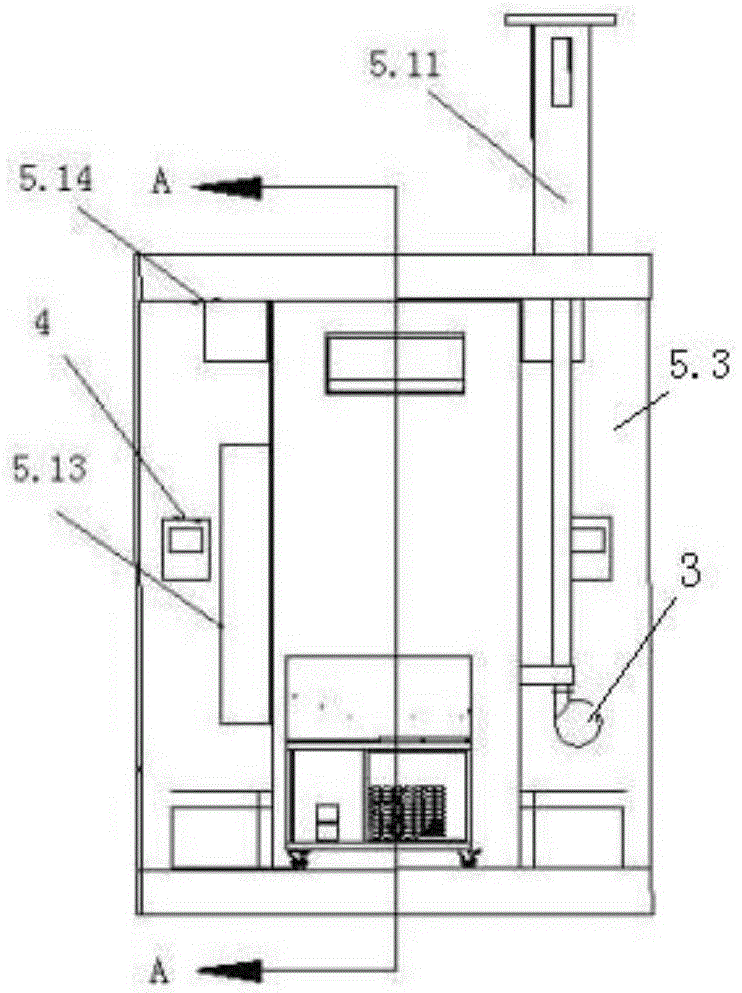

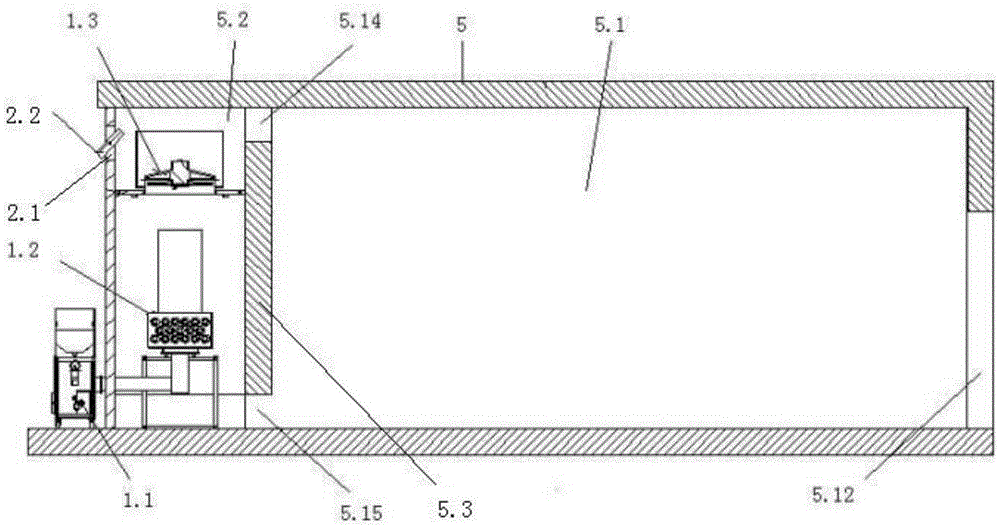

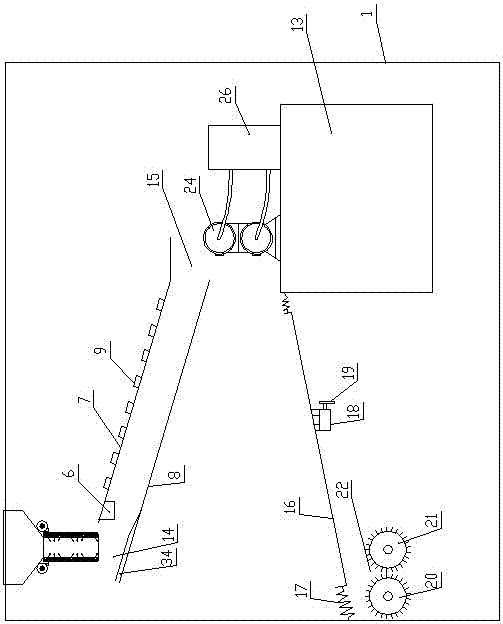

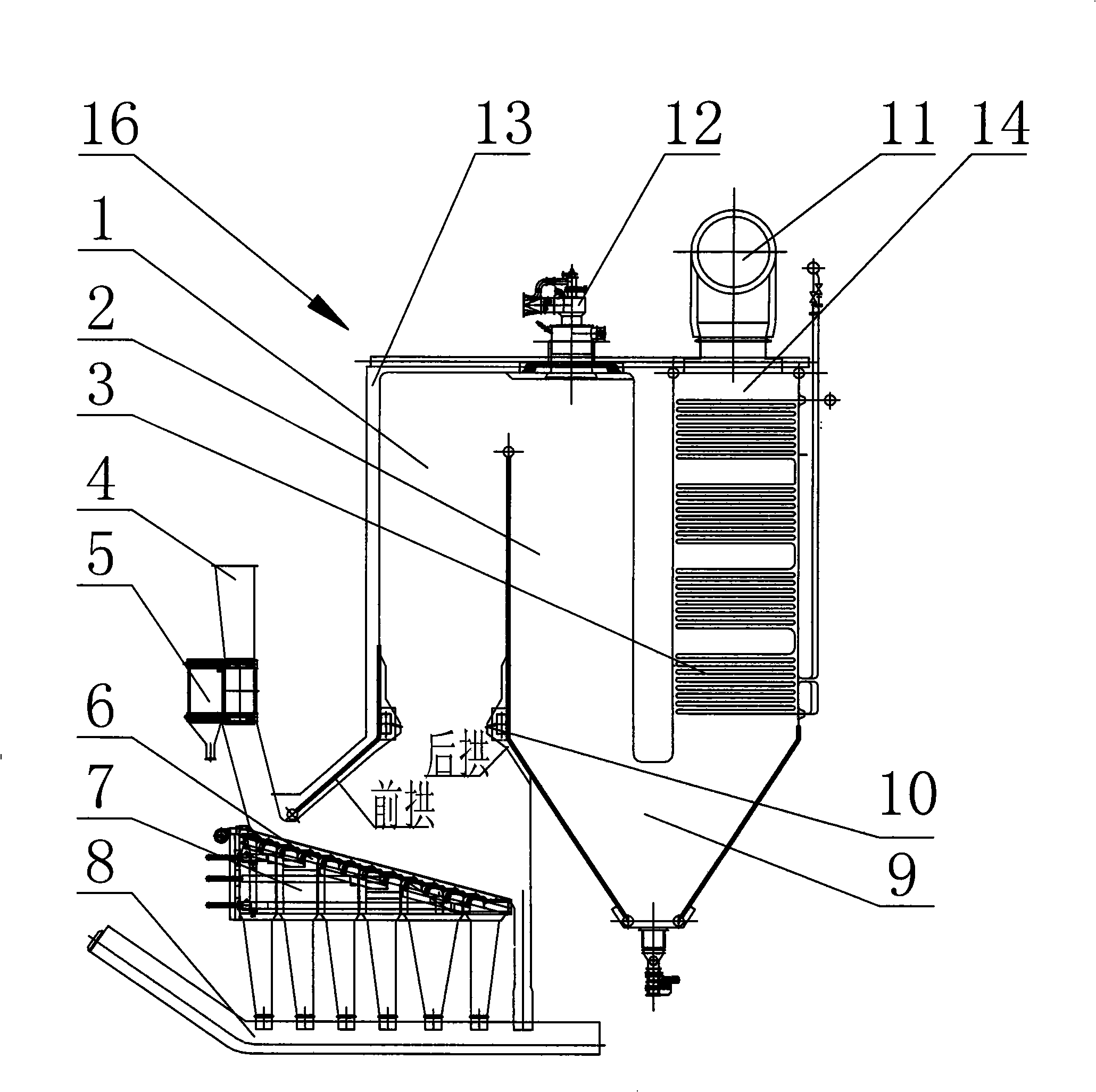

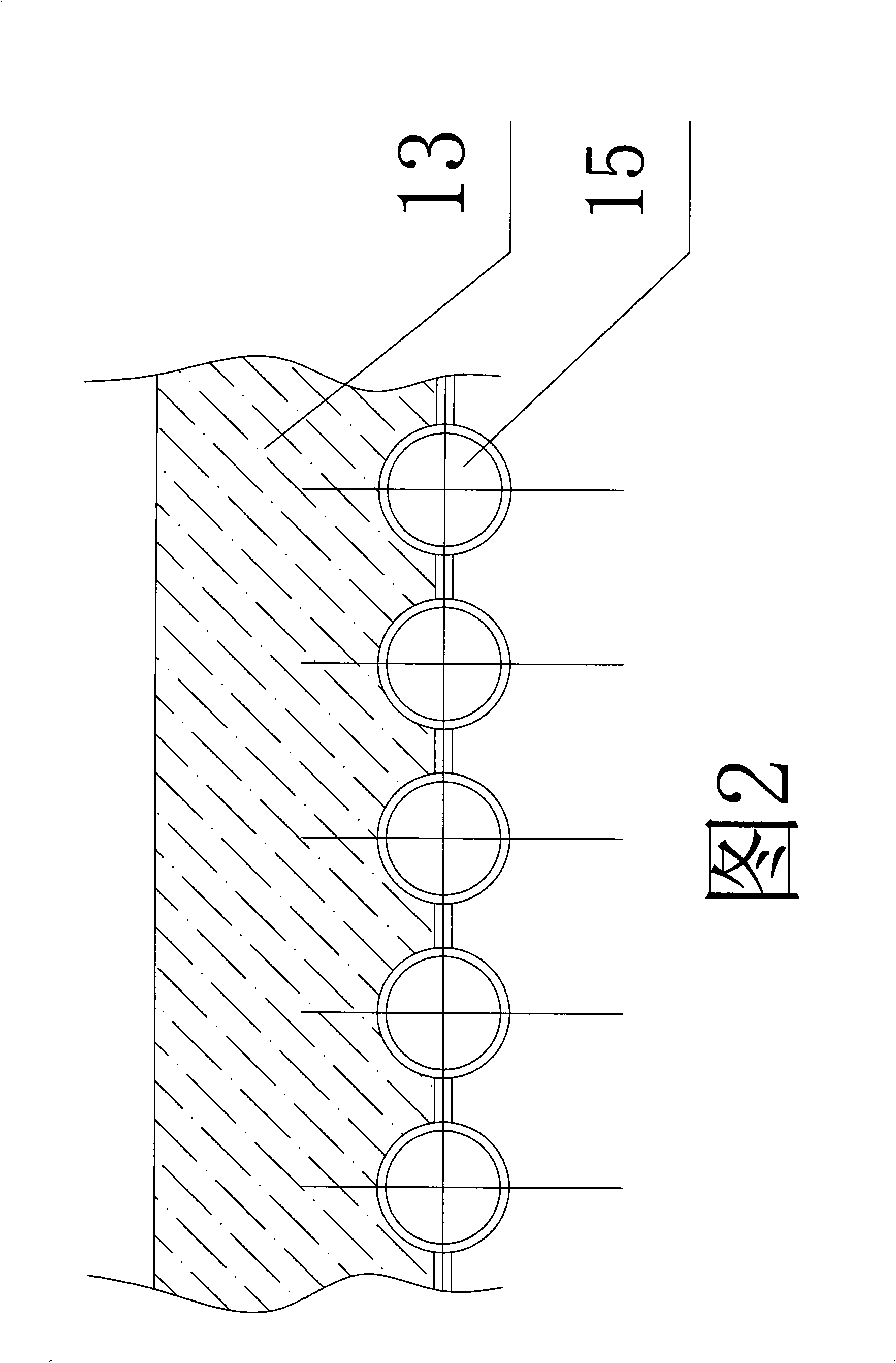

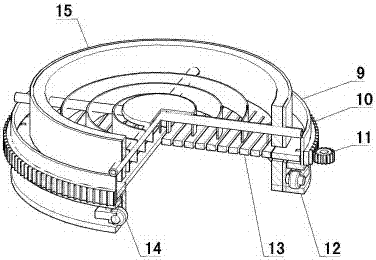

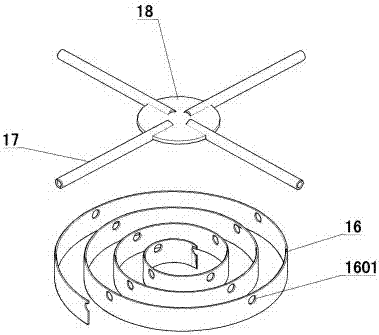

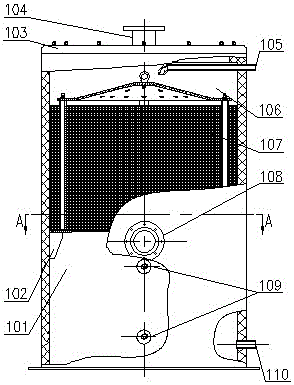

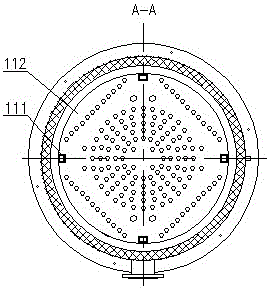

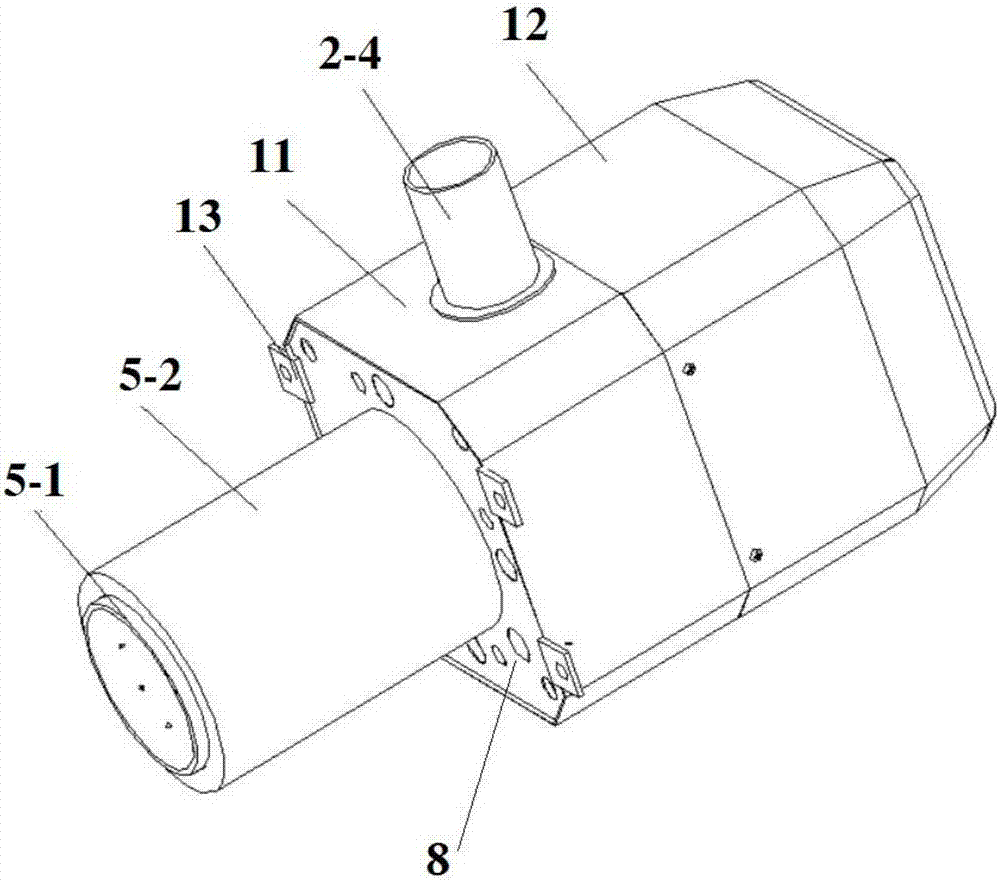

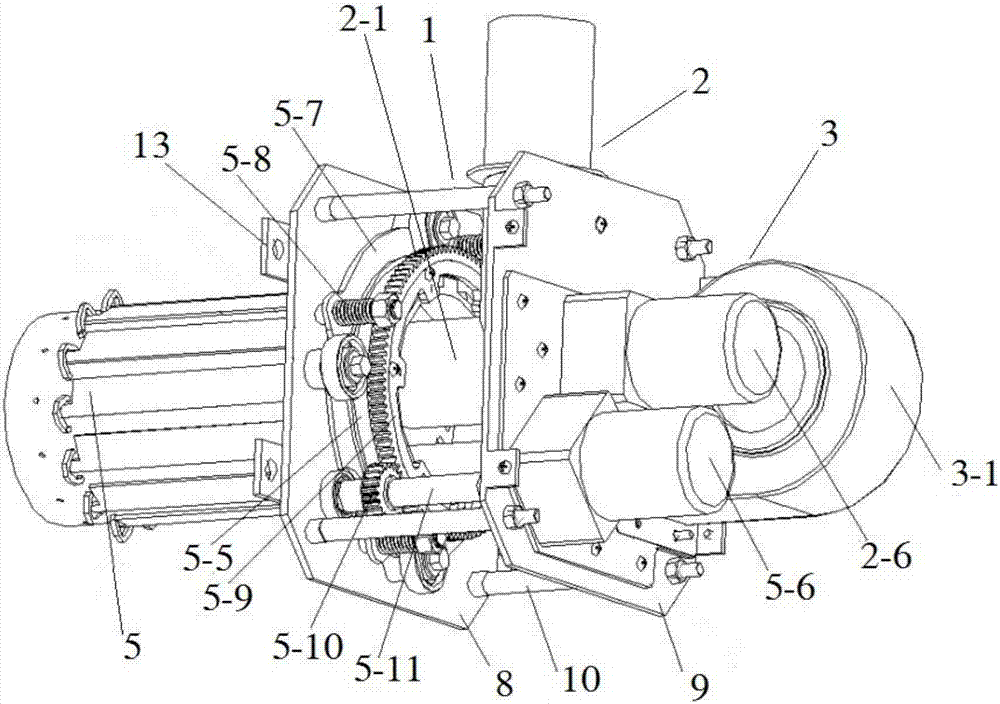

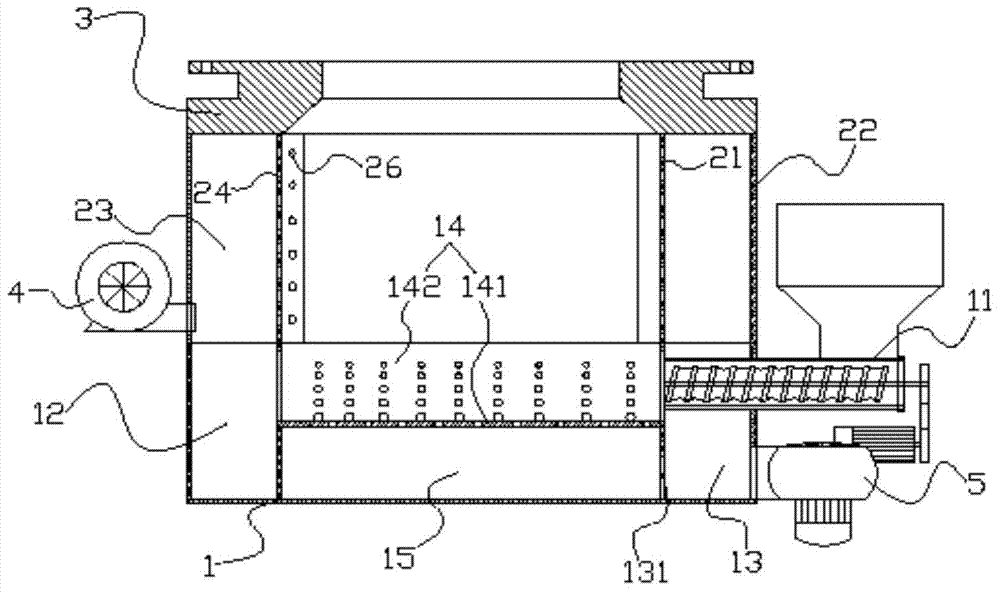

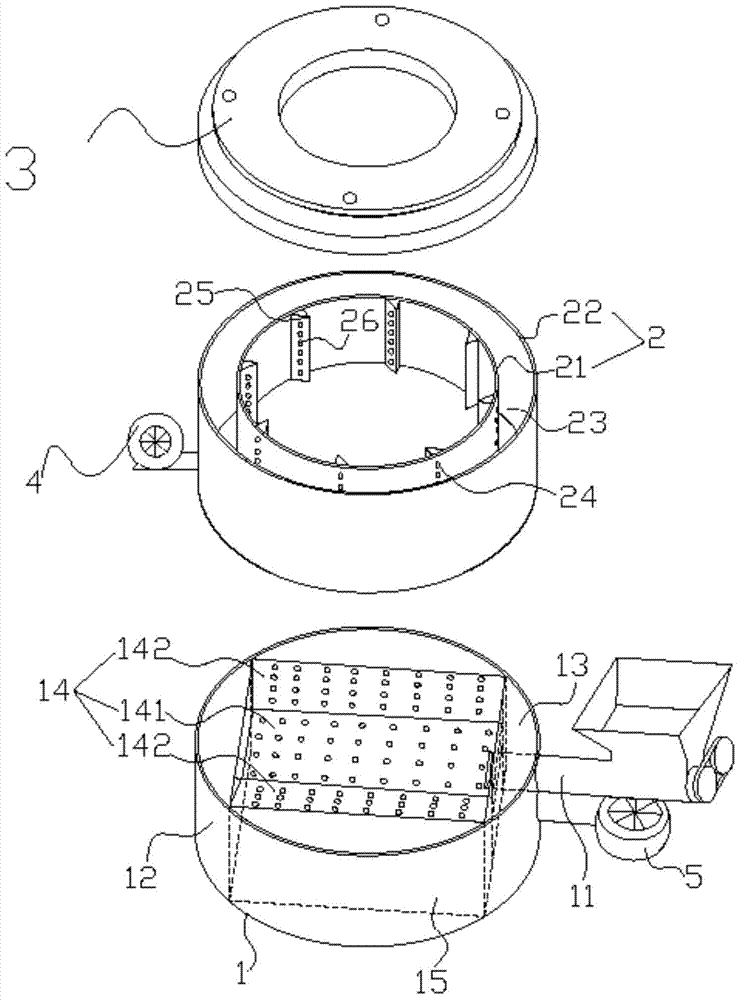

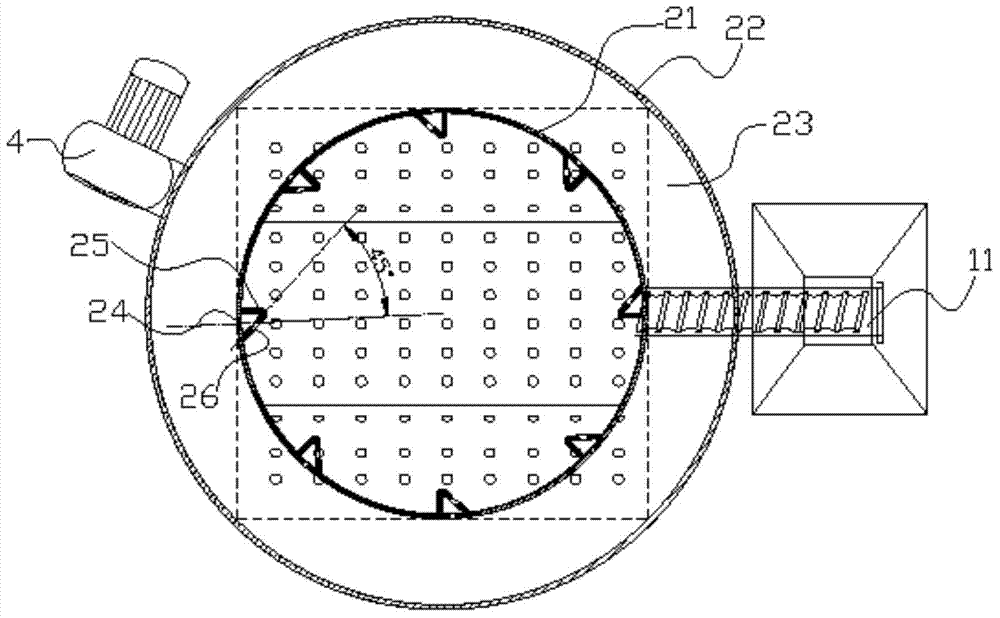

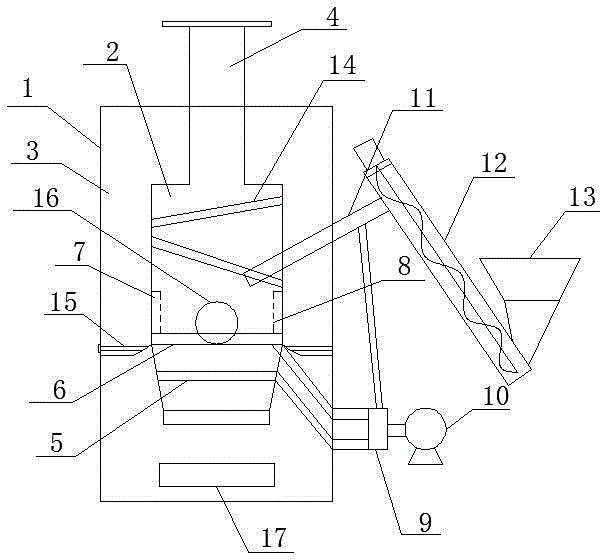

Tobacco leaf baking equipment

InactiveCN105520185AShort cycleSimple structureTobacco preparationBiomass combustionProcess engineering

The invention aims to provide tobacco leaf baking equipment. The tobacco leaf baking equipment comprises a heating apparatus, a humidity discharging apparatus and a controller, wherein the heating apparatus comprises a biomass combustion furnace, a heat exchanger connected with an exhaust gas outlet pipe of the biomass combustion furnace, a circulating fan used for conveying hot air, and a feeding apparatus used for feeding to the biomass combustion furnace; the feeding apparatus comprises a hopper and a helical conveying part for conveying the material in the outlet of the hopper to the material inlet of the biomass combustion furnace; the humidity discharging apparatus comprises a humidity discharging opening and a humidity discharging window formed in the humidity discharging opening; and an oxygen supplying device, the circulating fan and the helical conveying part in the biomass combustion furnace are all connected with the controller. By adoption of the technical scheme, the tobacco leaf baking equipment has the advantages as follows: the overall tobacco leaf baking equipment is simple in structure; due to the integrated design of the heating apparatus, the humidity discharging apparatus and the controller, the tobacco leaf baking equipment is high in practicability; and the biomass combustion furnace is adopted for providing heat energy, so that the tobacco leaf baking equipment is green and environment friendly.

Owner:CHANGSHA XINDI ELECTRONICS TECH

Biomass combustion device with low NOx emission and combustion method thereof

InactiveCN1789807AMitigate the conflict of oxygen grabbing combustionReduce high emissionsSolid fuel combustionCombustion apparatusCombustion chamberBiomass combustion

This invention relates to biomass low NOx burst device and its method, wherein, the device comprise the following parts: stand burst furnace with smoke channel exit with its inside isolation board as bottom heat chamber and burst chamber and connection hole; the material bin on the heat chamber; inclined furnace row and rotation reside device down the burst chamber; reducing zone and burst zone inside the burst chamber located with once, secondary and third wind-in mouth. The method combines the biomass characteristics of fully burst and coke burst to form different burst environment to reduce black smoke.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

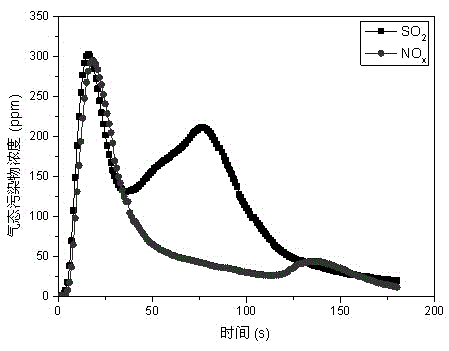

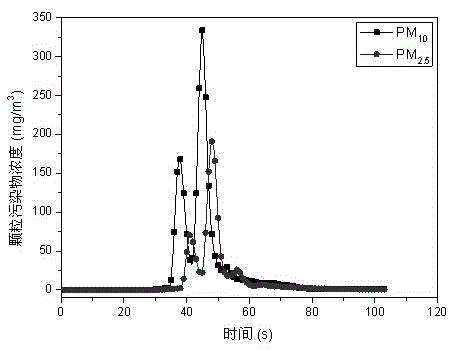

Comprehensive test apparatus for coal or biomass combustion flue gas pollutants, and method thereof

InactiveCN105043952AReduce investmentShort experiment cycleFurnace typesParticle suspension analysisChemical industryTemperature resistance

The present invention relates to a comprehensive test apparatus for coal or biomass combustion flue gas pollutants, and a method thereof. The comprehensive test apparatus comprises a combustion-supporting gas supply and regulation system, a high-temperature tube type furnace system, a pipeline system and a flue gas pollutant analysis system, wherein the combustion-supporting gas supply and regulation system is connected with the high-temperature tube type furnace system through a high temperature resistance detachable flange on the front end of the pipeline system, and the high-temperature tube type furnace system is connected with the flue gas pollutant analysis system through a high temperature resistance detachable flange on the rear end of the pipeline system, such that the integrated test on the discharge characteristics of the gas-state pollutants and the particle pollutants during the coal combustion process, the biomass combustion process or the coal and biomass mixed combustion process can be simultaneously achieved. With the apparatus and the method of the present invention, the discharge characteristics of various pollutants in the coal or biomass combustion flue gas can be completely and comprehensively measured in one time, the advantages of economy and efficiency are provided, the error caused by the multiple measurements can be reduced, and the apparatus and the method can be widely used in energy sources, environments, chemical industry and other science and engineering fields.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Compound biomass granular fuel

InactiveCN102010770ADiversification of income sourcesDiversified sources of incomeBiofuelsSolid fuelsBiomass combustionMaterials science

The invention relates to a compound biomass granular fuel. The invention aims at overcoming the problems of low ash melting point, serious coking and the like of the existing maize straw biomass granular fuel and providing a novel compound biomass granular fuel. The formula of the fuel comprises the following components by weight percent: 70-75% of maize straw powder, 24-30% of rice hull powder and 0.5-1% of calcium oxide powder. The manufacturing method comprises the following steps: firstly processing maize straws and rice hulls into fine powder by using a smashing machine; then adding the calcium oxide powder, uniformly mixing according to the stipulated weight percent; and sending into a particle forming machine for extruding the mixture into the cylindrical granular fuel with the diameter of 6-10mm. The biomass fuel is the compound biomass granular fuel with excellent combustion characteristic, high ash melting property and low fluxing trend, and can be widely applied in various biomass combustion devices.

Owner:JILIN UNIV

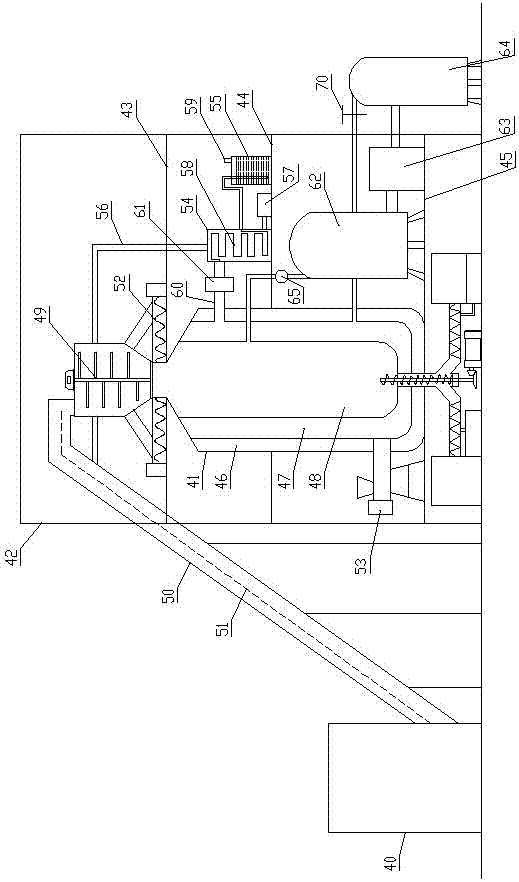

Household garbage low-temperature pyrolysis treatment system

ActiveCN107127205AImprove performanceFull recoveryGas current separationTransportation and packagingSocial benefitsBiomass combustion

A household garbage low-temperature pyrolysis treatment system comprises garbage specific gravity separation equipment, a pyrolysis furnace and an installation frame. The installation frame is provided with a first installation platform, a second installation platform and a third installation platform from top to bottom. The pyrolysis furnace penetrates through the second installation platform and is installed on the third installation platform. The furnace wall of the pyrolysis furnace is of a three-layer structure. An inner cavity of the pyrolysis furnace is divided into a heat preservation cavity, a heating cavity and a pyrolysis cavity from outside to inside through the furnace wall of the three-layer structure. The heat preservation cavity is filled with a heat preservation medium. In conclusion, the household garbage low-temperature pyrolysis treatment system conducts low-temperature pyrolysis on household garbage, energy sources in the garbage can be sufficiently recycled through the advanced biomass combustion and smoke waste heat utilization technologies, purposes of reduction, harmlessness and reclamation of garbage treatment are achieved, the requirement of urbanization in China for continuous development is met, and the urban household garbage low-temperature pyrolysis technology has broad market potential and the development space on the analysis of economic and social benefits.

Owner:武汉弘信兴然环保技术有限公司

Method for forming biomass fuel

The invention discloses a method for forming a biomass fuel and particularly relates to a method for forming a biomass fuel by using plant straw, wood flour, shrub, grass and the like as raw materials. In the method, biomass, coal dust and kieselguhr are used as raw materials and are crushed, mixed and compressed to be formed. The stable calorific value of biomass of different types and from different places can be obtained by adjusting the mixing ratio of coal to the biomass; under the condition of rated stable working conditions of a boiler, the influences of alkaline corrosion on the biomass are eliminated, the bonding forming of the crushed biomass particles is promoted effectively, the formed particles have high physical quality and properties, the compression forming rate is improved and energy consumption for forming is reduced. The biomass fuel of the invention can make full use of the straw, wood flour, shrub and grass and other wastes, and helps to reduce the demands for coal, natural gas and other non-renewable energy resources and relieve environmental pollution caused by combustion; and the biomass fuel has the advantages of improving volumetric heat release rate of the boiler and furnace temperature, improving thermal efficiency of the boiler, along with stable calorific value, alkaline corrosion resistance, quick ignition, high combustion efficiency, and the like. The biomass fuel can be used in biomass combustion power generation, and thus, the problem caused of lack of regional biomass that at present biomass power generation cannot be performed continuously and stably.

Owner:邢淦琛

Novel organic heat carrier furnace of biomass combustion membrane type wall

The invention relates to an organic heat transfer material heater of a novel biomass combustion film-typed wall, and pertains to incinerator equipment in the mechanical equipment field, in particular to a biomass combustion furnace taking waste wood, wood chips, straw and the like as fuels. The organic heat transfer material heater comprises a furnace body which is provided with burning equipment, a hearth, a reburning chamber and a tail smoke channel; the internal side of the furnace body is provided with a heat conducting oil pipe, the burning equipment is provided with a grate arranged under the furnace body and a feeding device correspondingly arranged at one end of the grate, the hearth is arranged at the other end of the grate, the top of the hearth is communicated with the top of the reburning chamber adjacently arranged, the reburning chamber is communicated with the tail smoke channel provided with a convective heating surface formed by the heat conducting oil pipe, and a smoke outlet is arranged above the top of the furnace body. The organic heat transfer material heater, effectively integrating an adiabatic combustion furnace and a conducting oil heat exchanger in one body, can not only reduce investment and occupied area, but also improve combustion efficiency, decrease maintenance cost of equipment operation, and prolong service life of the equipment.

Owner:常州联合锅炉容器有限公司

Biomass Combustion Chamber and Refractory Components

InactiveUS20090293786A1Improve combustion efficiencyImprove thermal efficiencyLiquid surface applicatorsGlass/slag layered productsColloidal silicaEmissivity

A combustion chamber has refractory walls, with an input feeding biomass into the chamber, and an ignition source to ignite the biomass. Each refractory wall component, refractory brick, panel or castable, has a surface exposed to heat generated within the chamber with a thermal protective layer consisting of a thermal enhancing high emissivity coating disposed on the exposed refractory surface. The coating contains from about 5% to about 35% of colloidal silica, colloidal alumina, or combinations thereof, from about 23% to about 79% of a filler, and from about 1% to about 20% of one or more emissivity agents.

Owner:FUJITSU LTD

Method for reducing slag in biomass combustion

ActiveUS20120312206A1Improve brittlenessReduce fouling rateSolid fuel pretreatmentSolid fuelsPtru catalystCapital equipment

Biomass is quickly becoming an important feedstock for energy generation in power plants. Due to their composition and nature, certain biomass fuels contribute to slagging, fouling, and corrosion. This invention provides a novel method of reducing or suppressing slag deposition and / or cleaning deposited slag in energy production processes in which potassium-containing solid fuels are combusted. Besides acting as a slag suppressant, further advantages of this invention are that the additive has no detrimental side-effects on capital equipment, increases slag friability, decreases slag fouling rate, reduces heat transfer corrosion as well as increasing the lifetime of the selective catalytic reduction catalyst.

Owner:ECOLAB USA INC

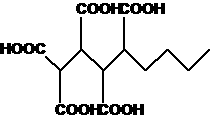

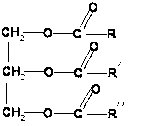

Method for preparing nonane diacid and biomass diesel from tung oil

InactiveCN102795988ASuitable for large-scale industrial productionSimple methodFatty acid chemical modificationFatty acids production/refiningBiodieselPtru catalyst

The invention relates to a method for preparing nonane diacid and a fine chemical engineering intermediate thereof and a byproduct diesel from tung oil, belonging to the technical fields of organic acids and biological energy sources. The method is characterized by comprising the following steps: directly carrying out Diels-Alder addition reaction on tung oil and dienophile monomer M under the action of a catalyst; and directly carrying out catalytic oxidation cracking, hydrolysis or methanol decomposition and separation to obtain nonane diacid, pelargonic acid, propandioic acid, hexanoic acid and 1,1,2,3,4-octanepentaacid or 1,1,2,3-octanetetracid. The yield of the organic acid and byproduct diesel is 60-90.5%. The invention can be used for obtaining abundant nonane diacid; and the method is simple, has the advantages of environment-friendly oxidation form, no pollution and high product yield, and is suitable for large-scale industrial production for developing tung oil renewable recourses.

Owner:重庆油桐产业研究中心

Carbon matrix fertilizer production resource comprehensive utilization method based on updraft carbon gas co-production furnace

InactiveCN108728165ARealize comprehensive utilizationImprove utilization efficiencyAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersLow nitrogenCrusher

The invention discloses a carbon matrix fertilizer production resource comprehensive utilization method based on an updraft carbon gas co-production furnace. The carbon matrix fertilizer production resource comprehensive utilization method comprises following steps: a, agriculture and forestry waste is crushed using a crusher, an obtained crushed material is introduced into a roller dryer for rawmaterial drying pretreatment; b, after drying, the material is introduced into the updraft carbon gas co-production furnace for pyrolysis gasification reaction to produce biomass charcoal and biomasscombustible gas; and c, the produced biomass charcoal is subjected to milling, obtained biomass charcoal powder is subjected to spraying treatment with pyroligneous liquor, an inorganic fertilizer anda binding agent are added into the biomass charcoal after spraying treatment so as to obtain a carbon matrix fertilizer, and the carbon matrix fertilizer is subjected to granulation so as to obtain carbon matrix fertilizer particles. The carbon matrix fertilizer production resource comprehensive utilization method is capable of realizing resource comprehensive utilization, and increasing energy utilization efficiency; and in addition, biomass combustion gas is subjected to low nitrogen combustion to produce steam, fire coal boilers can be replaced partially, environment protection discharge is realized, exhaust-heat boiler tail gas is further adopted in a drying system, and energy utilization optimization is realized.

Owner:FUJIAN SINOCHEM ZHISHENG FERTILIZER +1

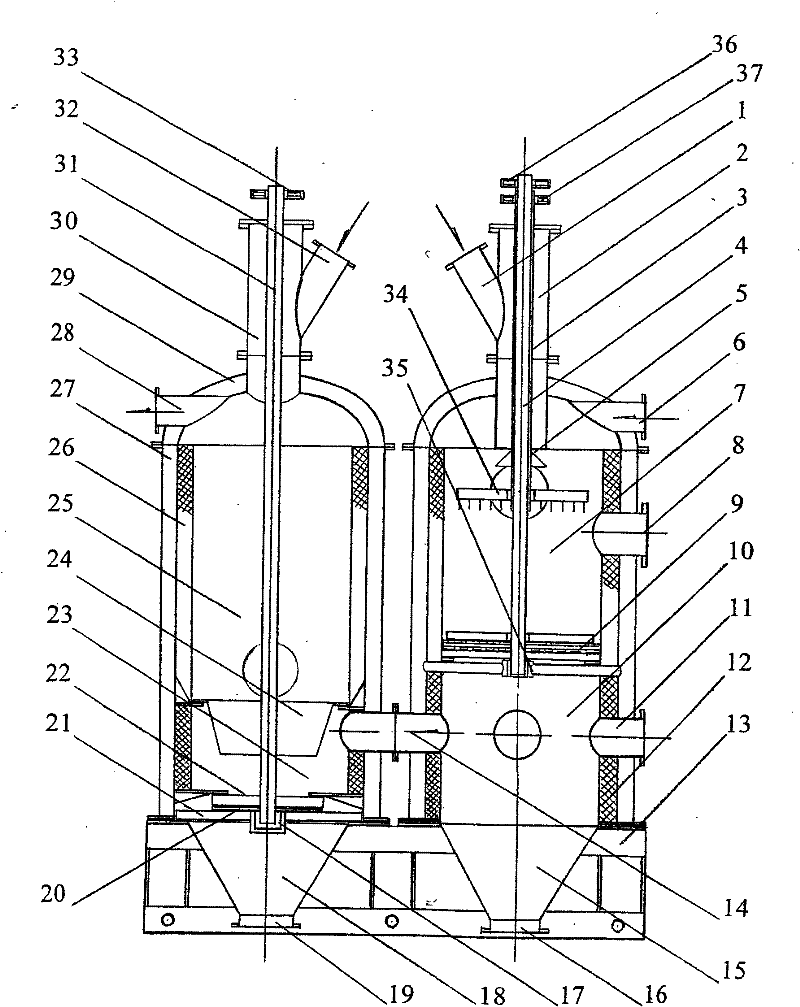

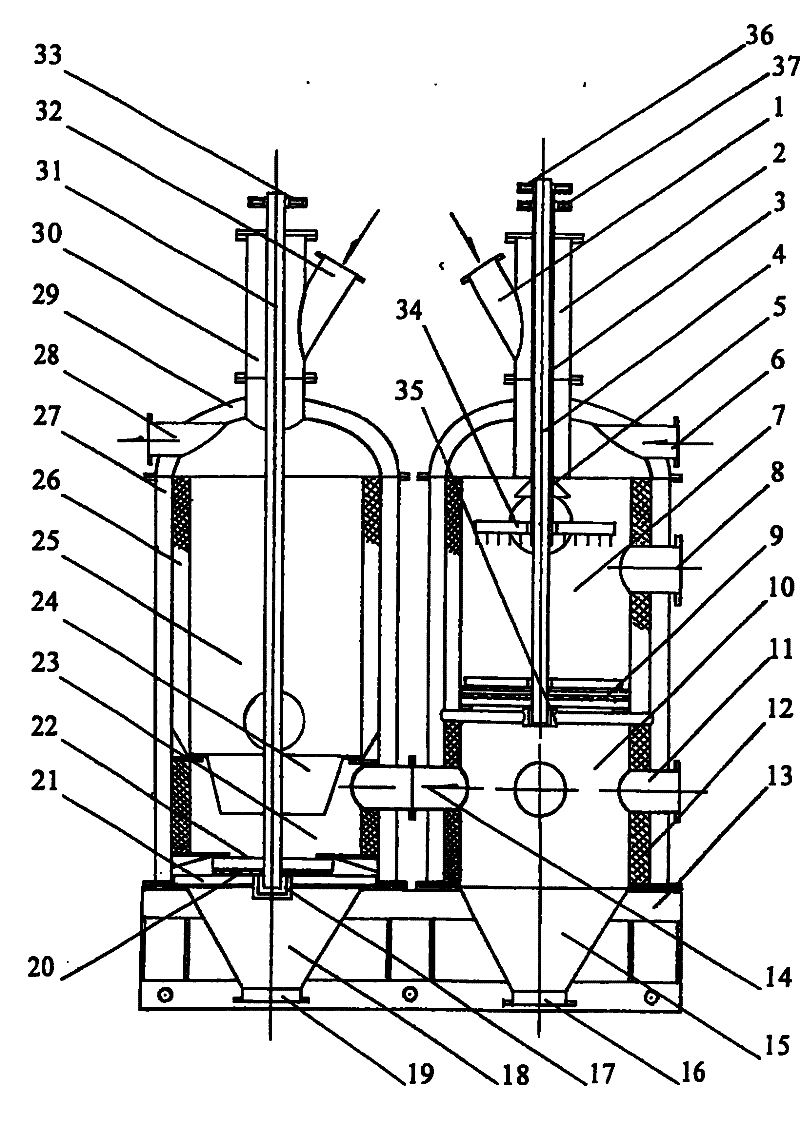

H-shaped carbonization furnace and method for producing biomass activated carbon and carbonized combustion gas by using same

InactiveCN102191067ASuitable for energy saving and emission reductionImprove the use of economic valueCarbon compoundsChemical industryThermal energyEnergy conservation

The invention relates to an H-shaped carbonization furnace and a method for producing biomass activated carbon and carbonized combustion gas by using the same. The H-shaped carbonization furnace comprises a charge pipe port, a charge pipe, a rotating sleeve, a rotating shaft, a distributing device, an air inlet pipe port, a gasification chamber, a carbonization chamber, an ignition furnace door, a dump grate, a furnace body water jacket, a lower deashing furnace door, a refractory liner, an integrated furnace seat, high-temperature carbon dioxide, a conical ash dump bucket, an ash discharge pipe port, a support shaft sleeve, a conical carbon discharge bucket, a carbon outlet pipe port, a support plate, a lower support, a carbon scraper, a combustion gas suction loop, a combustion gas suction pipe port, a furnace roof, rotating gears, an inside rake and a water cooling support. The high-temperature heat of the carrier in the produce combustion gas is used for producing the biomass activated carbon in a dry distillation carbonization mode, thereby saving the energy and increasing the heat value of the biomass combustion gas; and wood tar in the combustion gas is collected in the dry purification technology of combustion gas, wood vinegar is used as an industrial chemical raw material, and thus, agricultural waste resources are converted into industrial chemical raw materials.

Owner:孙青萍

Anti-slagging biomass cascade conversion combustion device

ActiveCN106594713APrevent slaggingThermochemical conversion achievedSolid fuel combustionIndirect carbon-dioxide mitigationAir preheaterWater vapor

The invention provides an anti-slagging biomass cascade conversion combustion device and relates to a biomass combustion device. The anti-slagging biomass cascade conversion combustion device aims at solving the technical problem that slagging happens easily when straw is combusted through an existing chain furnace. The anti-slagging biomass cascade conversion combustion device is composed of a chain furnace, a steam generator, an air blower, a high-temperature induced draft fan and an air preheater. A secondary air nozzle is arranged on the front wall below a front arch. An overfire air nozzle is arranged on the front arch. A circulating flue gas chamber communicates with a flue opening in the tail of the chain furnace through the high-temperature induced draft fan. A weak primary air chamber communicates with the air blower through the air preheater. A steam-circulating flue gas chamber communicates with the steam generator and the high-temperature induced draft fan. A strong primary air chamber communicates with the air blower through the air preheater. The secondary air nozzle communicates with the air blower. The overfire air nozzle communicates with the air blower. The anti-slagging biomass cascade conversion combustion device effectively solves the problem of slagging of biomass combustion chain grates.

Owner:HARBIN INST OF TECH

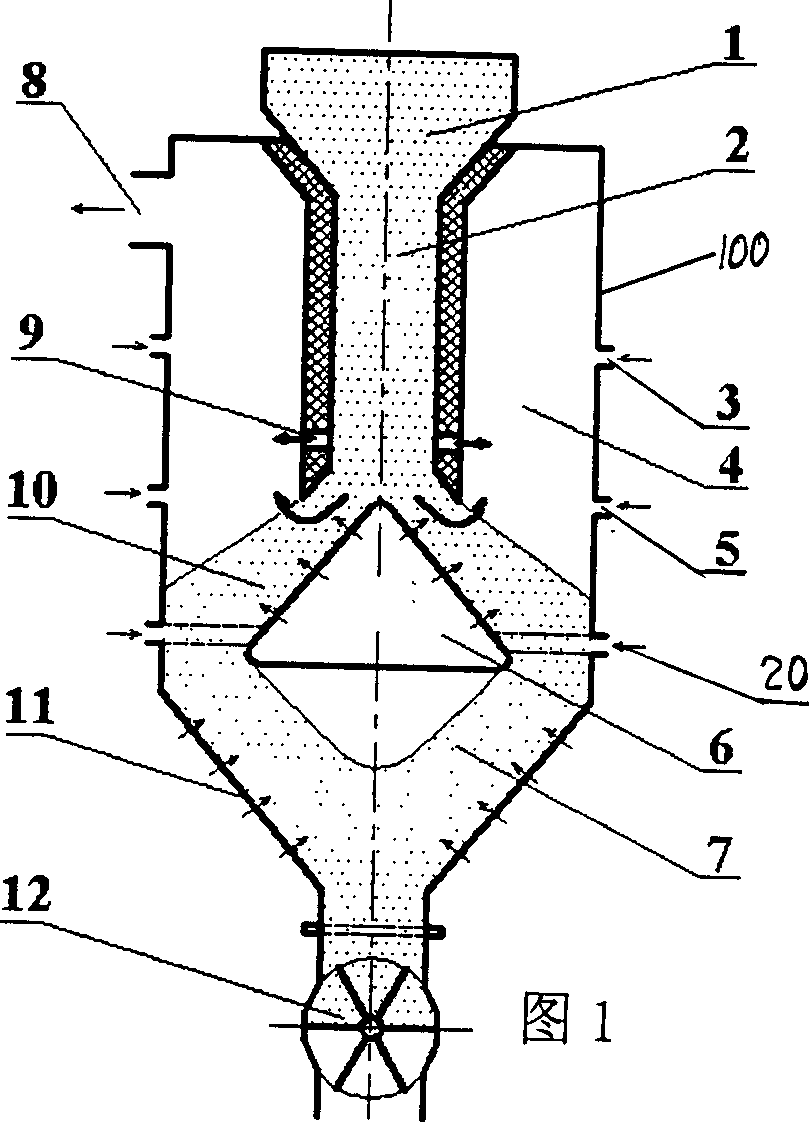

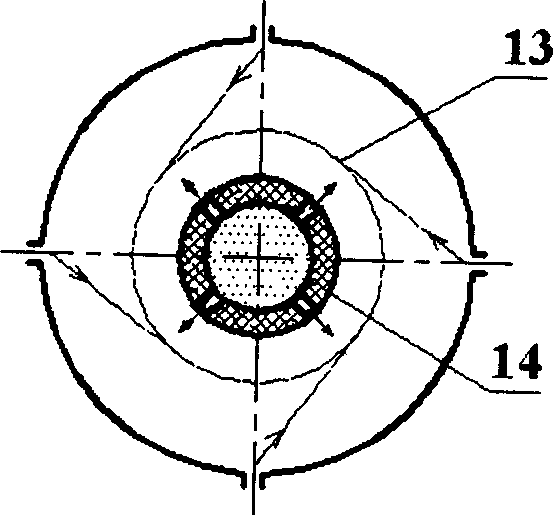

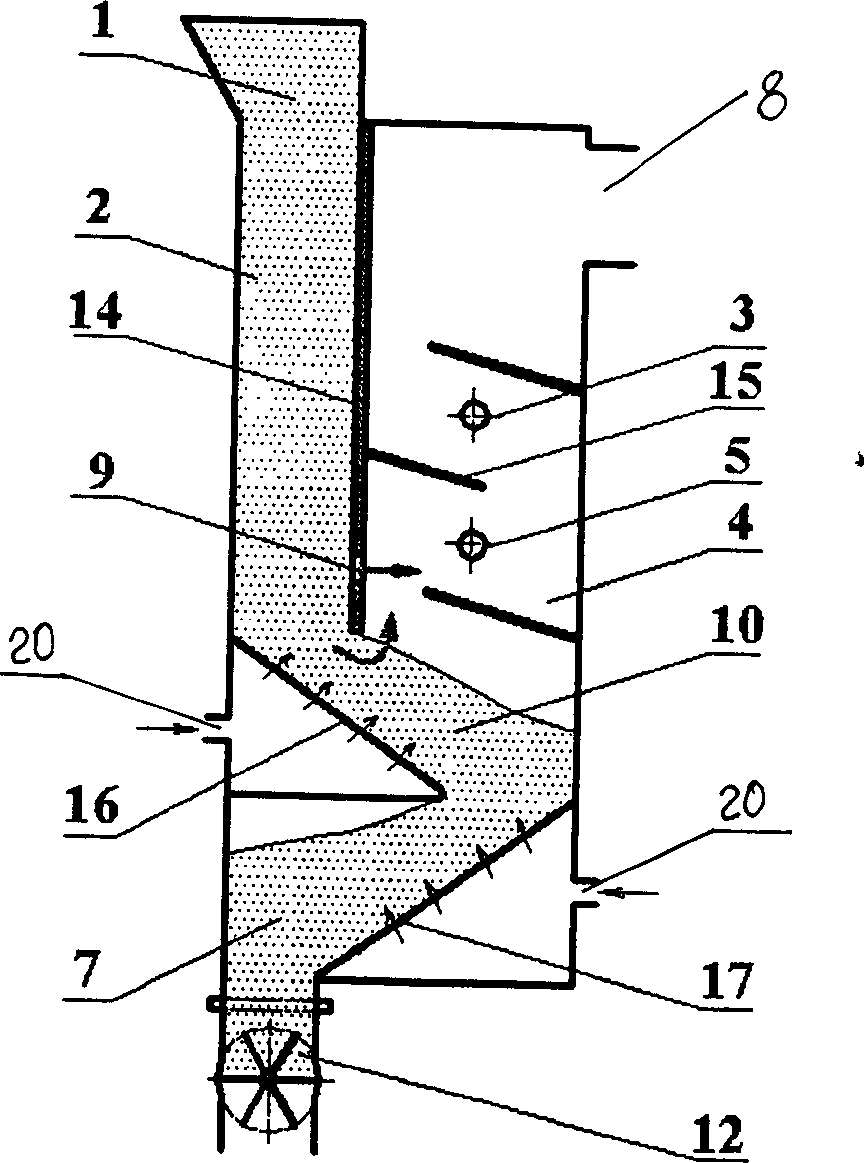

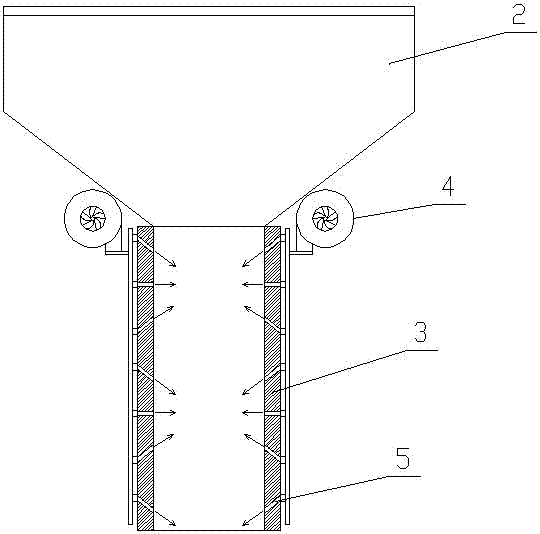

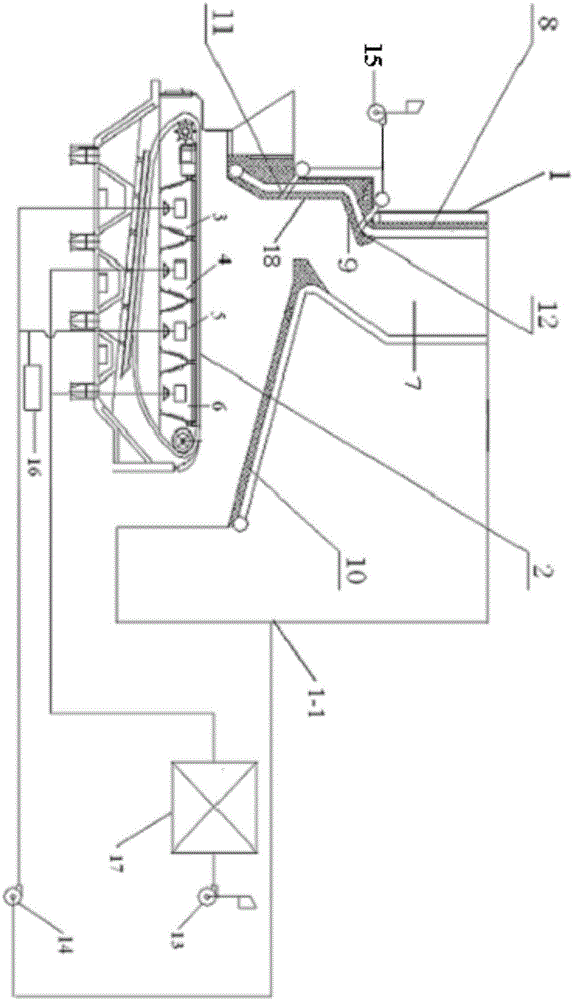

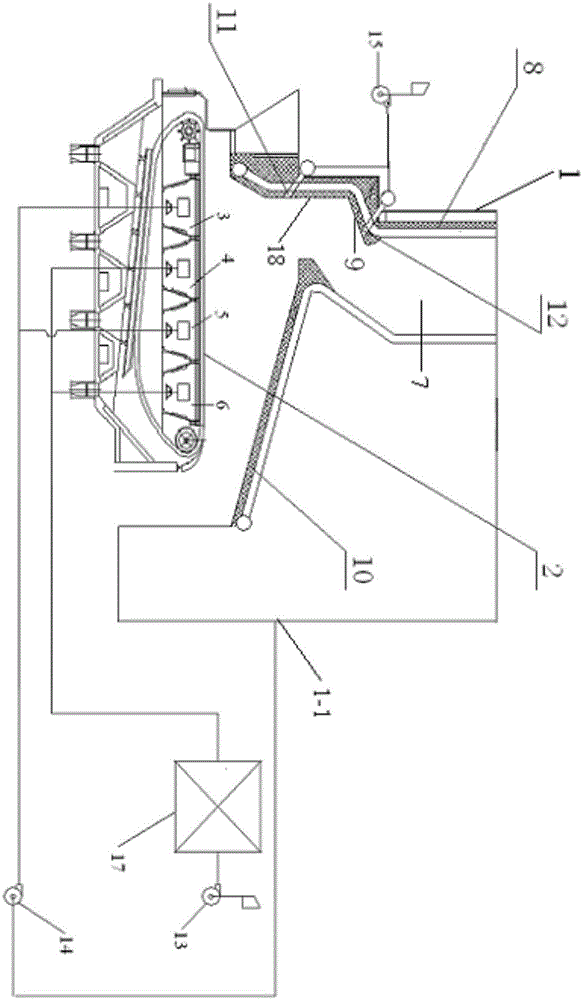

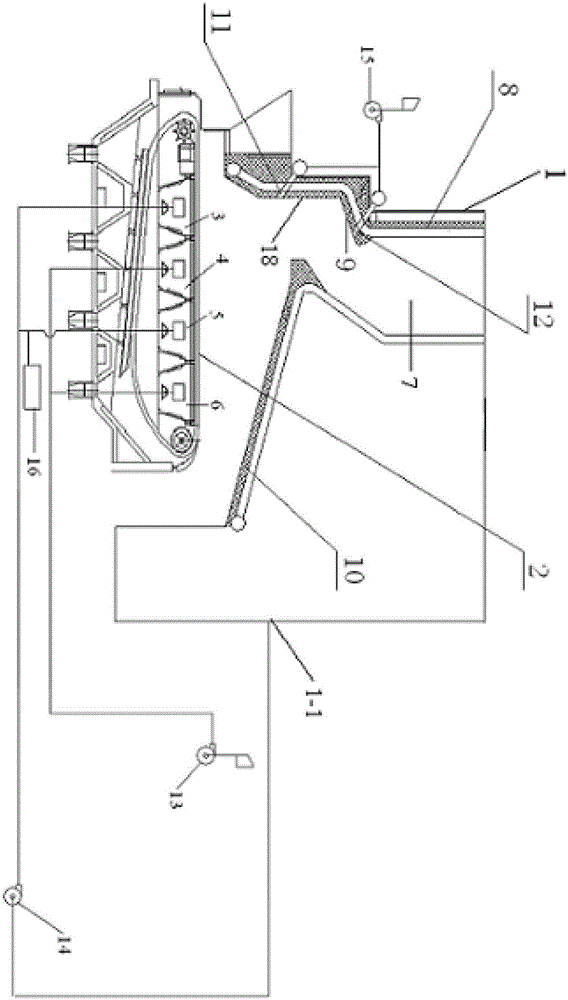

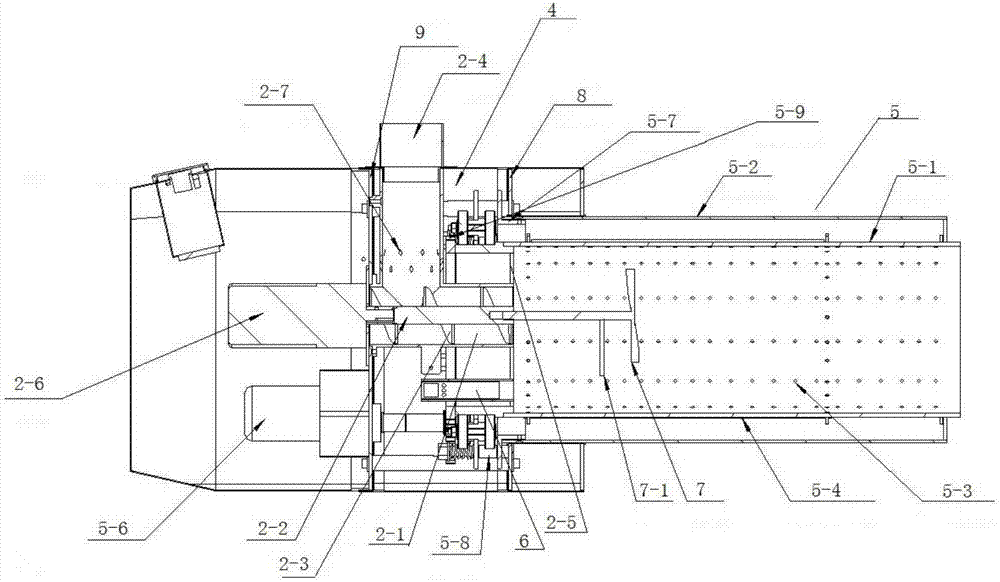

Biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device

ActiveCN106918039ASolve cokingSolve slaggingSolid fuel combustionLump/pulverulent fuel feeder/distributionGas solidSlag

The invention provides a biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device and belongs to the technical field of biomass combustion. The biomass-forming fuel solid-phase low-temperature gas-phase high-temperature combustion device is characterized in that a feeding opening of a smoldering region (3) communicates with a discharging opening of a hearth (1), a discharging opening of the smoldering region (3) communicates with a cooling region (4), a furnace grate (13) is arranged on the lower portion of the hearth (1), a crushing mechanism (2) for crushing materials is arranged on the furnace grate (13), the furnace grate (13) is connected with a rotating mechanism for disturbing biomass fuel so that carbon powder can fall into the smoldering region (3) to be smoldered, meanwhile the block-shaped biomass fuel is made to move to the middle of the furnace grate (13), and the crushing mechanism (2) is used for crushing the block-shaped biomass fuel into the carbon powder and then enabling the carbon powder to fall into the smoldering region (3) to be smoldered. By the adoption of the biomass forming fuel solid-phase low-temperature gas-phase high-temperature combustion device, the problems of coking, slag bonding, the high gas-solid pollutant emission and invalid ash fertilizer existing in combustion equipment for agricultural waste such as straw are solved fundamentally.

Owner:SHANDONG UNIV OF TECH

Biomass boiler for boiler front flue gas drying and continuous bale combustion

ActiveCN106369591AReduce moisturePromote combustionSolid fuel pretreatmentSolid fuel combustionAir preheaterHearth

The invention discloses a biomass boiler for boiler front flue gas drying and continuous bale combustion, and belongs to the technical field of biomass combustion. By adoption of the biomass boiler, problems of an existing biomass bale combustion technology are solved. The biomass boiler comprises a biomass boiler body. A drying area is arranged in front of a feed inlet of the biomass boiler body. Baled biomass is fed into the feed inlet after passing through the drying area. A water-cooling reciprocating grate is arranged at the bottom of a hearth of the biomass boiler body. A flue gas suction port is formed in a tail flue of the biomass boiler body and connected with a flue gas inlet device arranged at the bottom of the drying area. A coal economizer, an air pre-heater, a bag type dust collector, a second induced draught fan and a condensing heat exchanger are sequentially distributed in the tail flue of the biomass boiler body, wherein the air pre-heater is connected with and provides pre-heated air for an air chamber at the bottom of the hearth and secondary air ports formed in the two sides of a front arch of the hearth; and the condensing heat exchanger is sequentially connected with the water-cooling reciprocating grate, the coal economizer and a steam pocket of the biomass boiler body. The biomass boiler for boiler front flue gas drying and continuous bale combustion is used for combustion of baled biomass.

Owner:HAILUN LIMIN ENERGY SAVING BOILER MFG

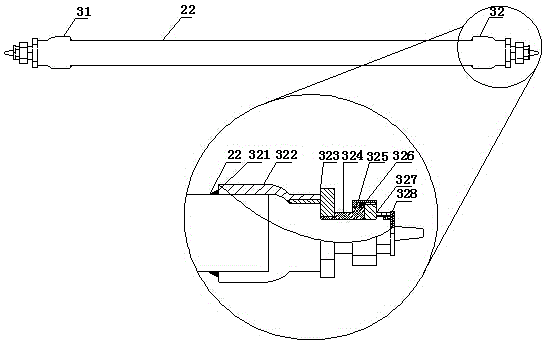

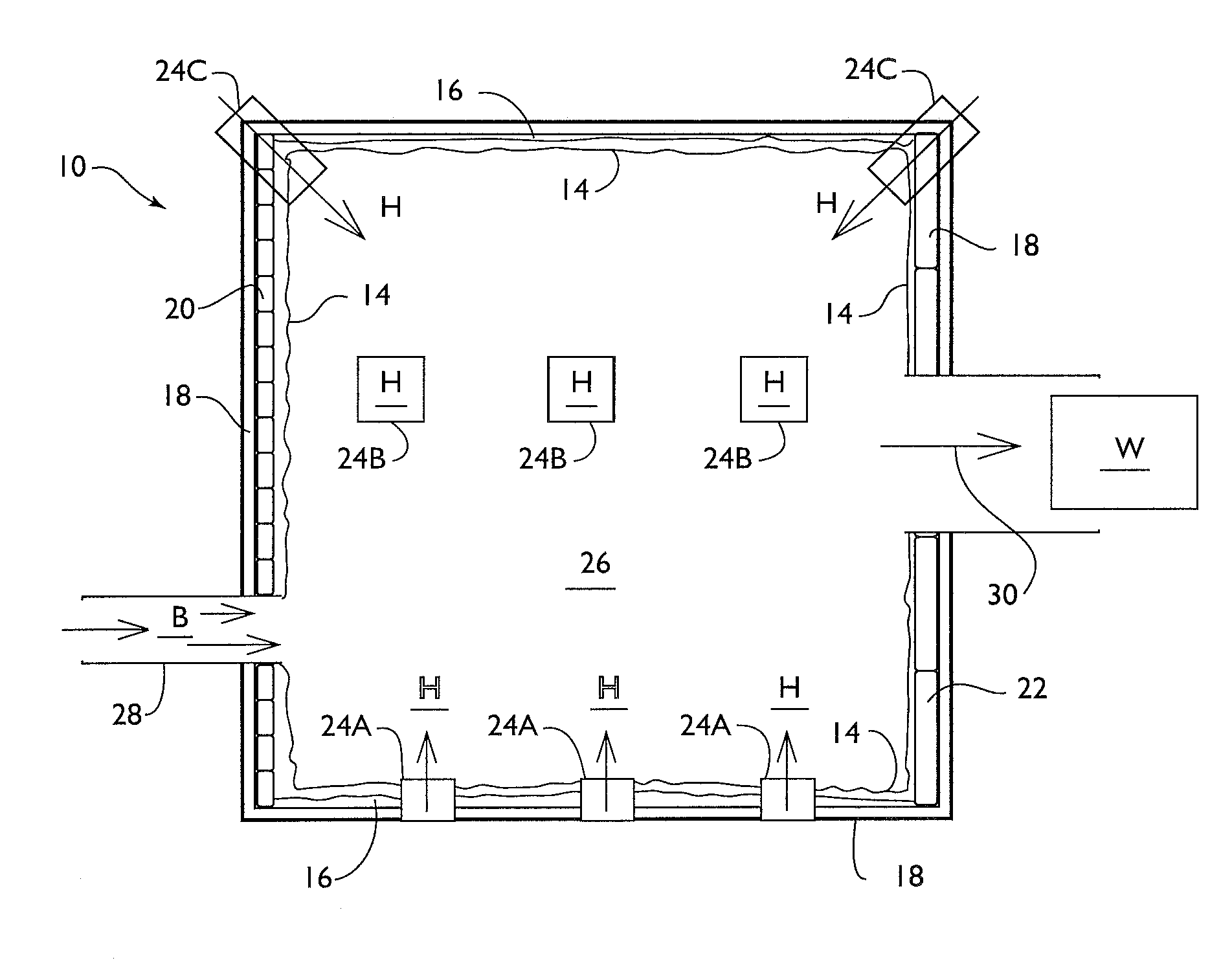

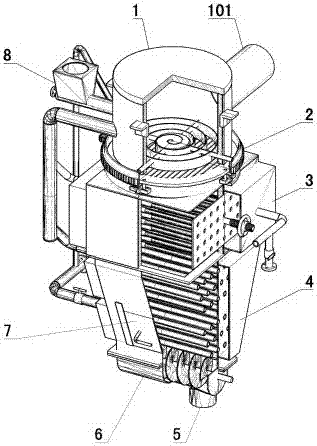

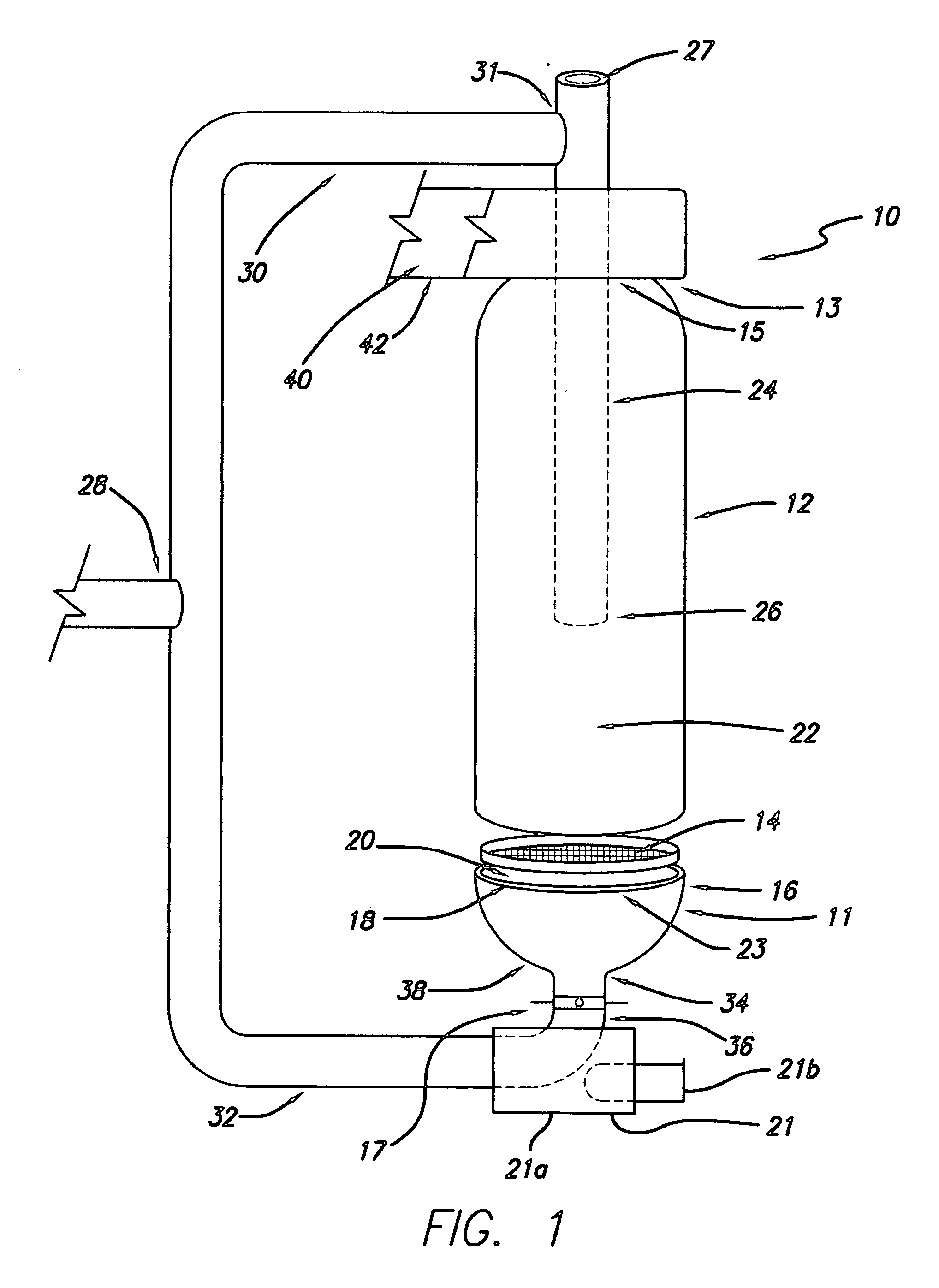

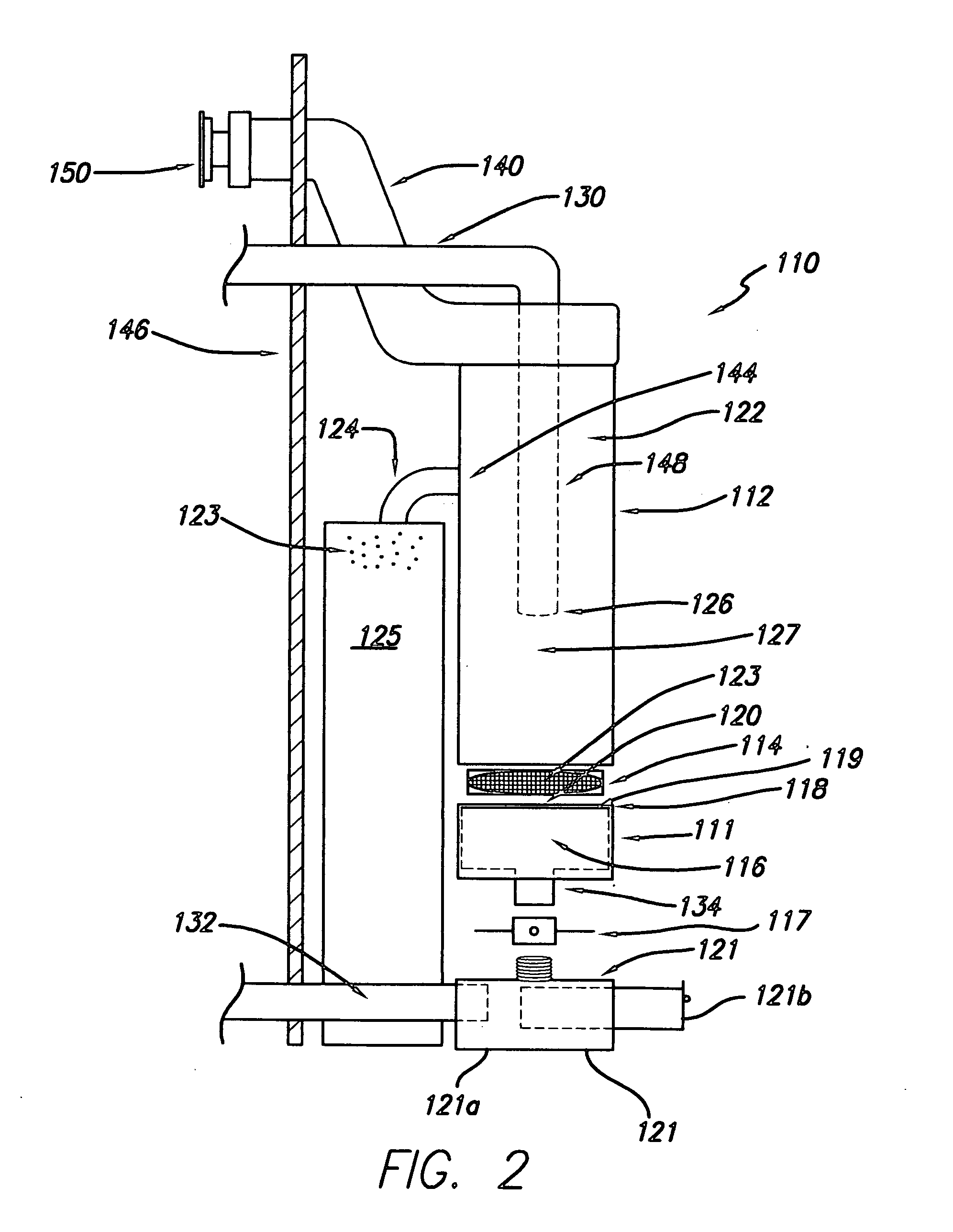

Biomass pellet fuel heating device, system and method

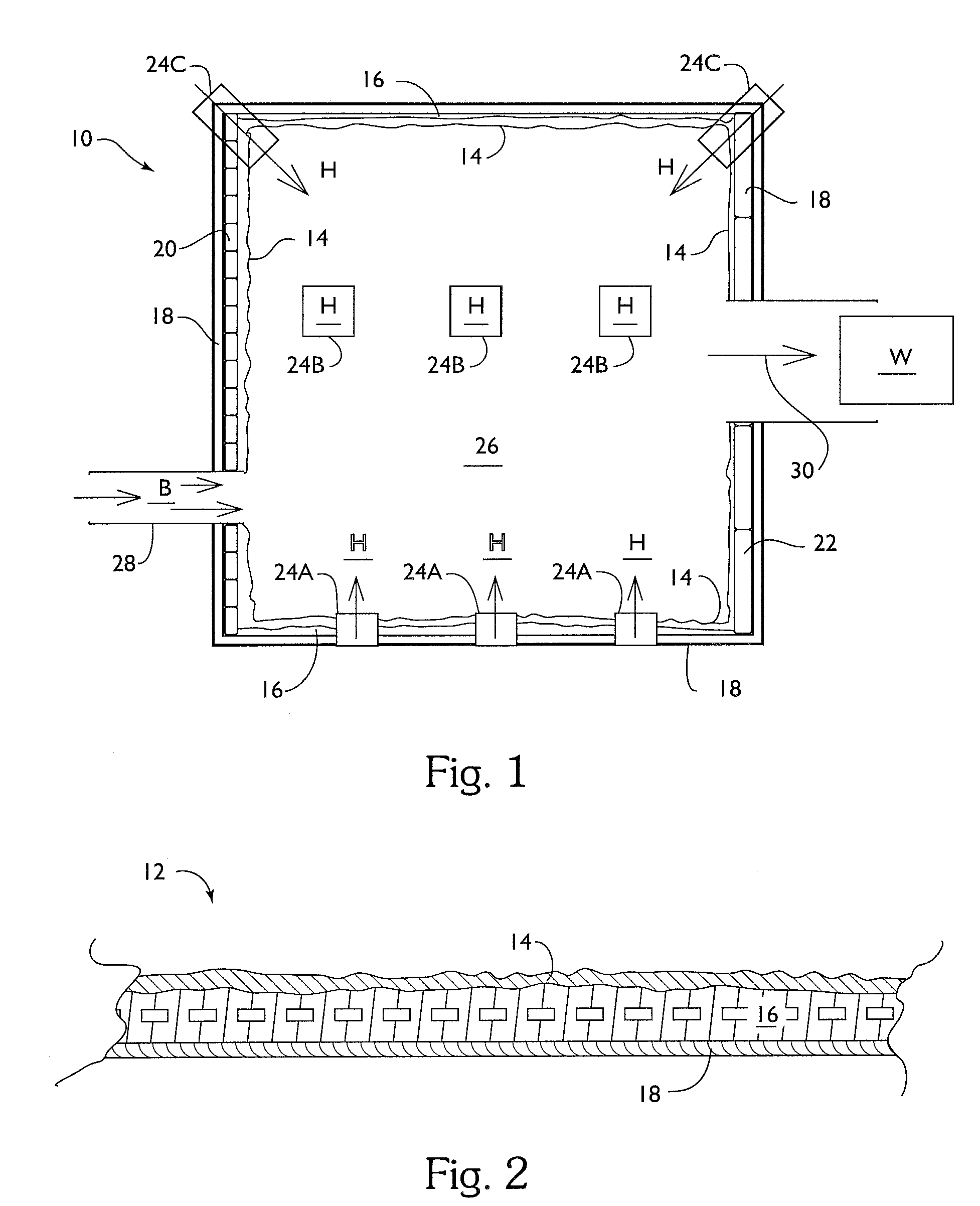

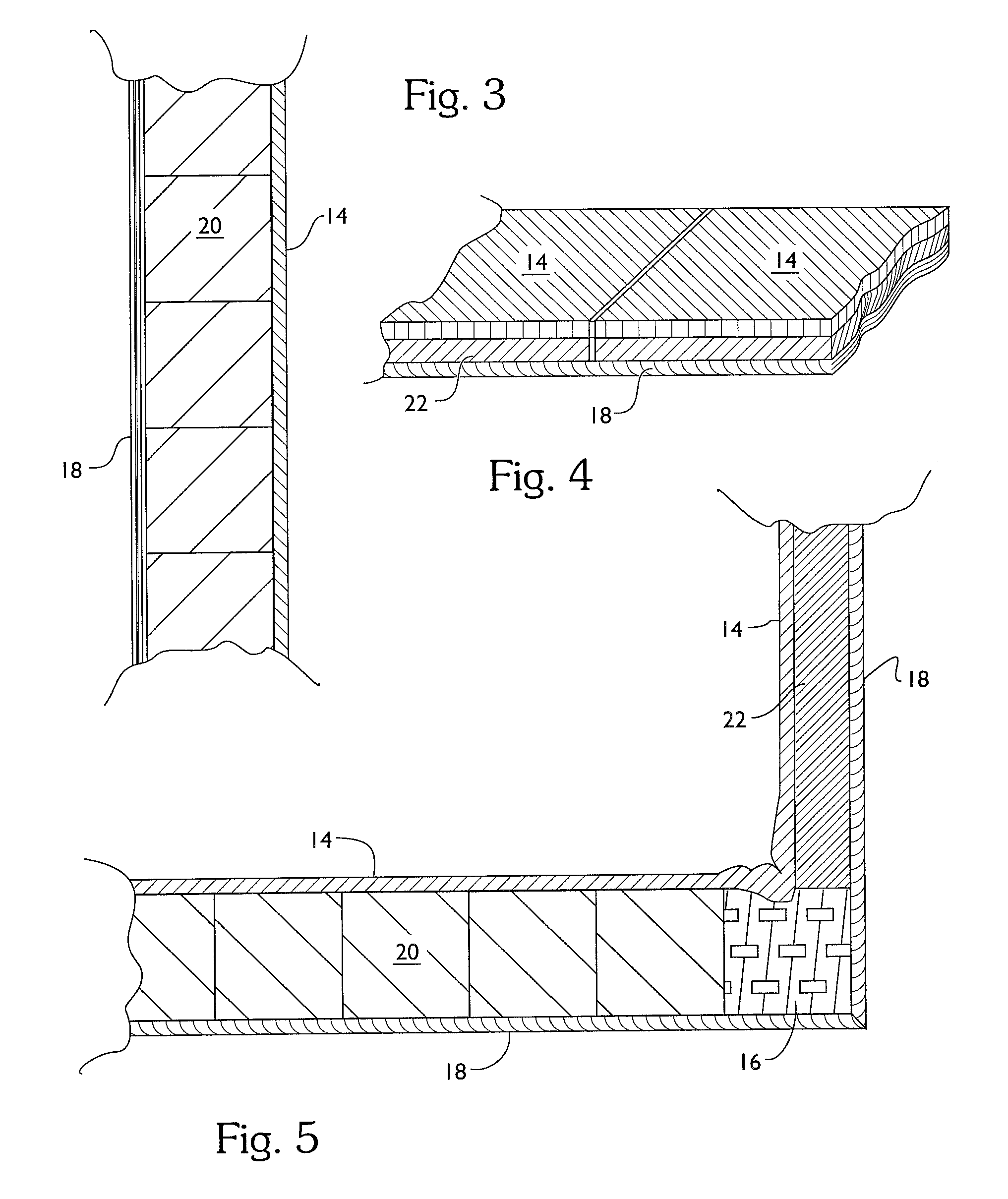

InactiveUS20080066731A1Improve thermal efficiencyReduce particulate emissionsDomestic stoves or rangesSolid fuel combustionFlue gasBiomass combustion

There is provided a pelletized-biomass combustion device comprising: (a) an elongate upright combustion capsule; (b) a grate element disposed within and bisecting the combustion capsule, (i) the grate element having a first side and a second side and (ii) the grate element open to fluid communication between the first side and the second side; (c) a first combustion air inlet facing the first side of the grate; (d) a second combustion air inlet facing the second side of the grate; (e) a fuel-feed inlet; and (f) a flue-gas exhaust outlet. The combustion capsule can be formed of two mated components such as a chamber housing mated with a burn pot member, or instead it can be formed as a single unit such as the chamber housing bisected by the grate. In any event, the grate element has two sides, and there are two combustion air inlets, each facing opposite sides of the grate. The combustion device is preferably an induced-draft system wherein the exhaust fan is positioned at the distal end of the stove pipe.

Owner:JOHNSON GEOFFREY W A

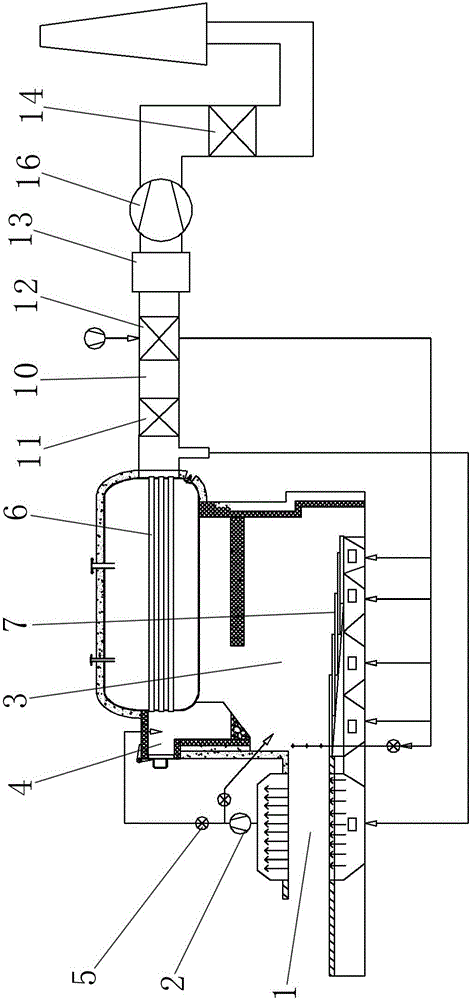

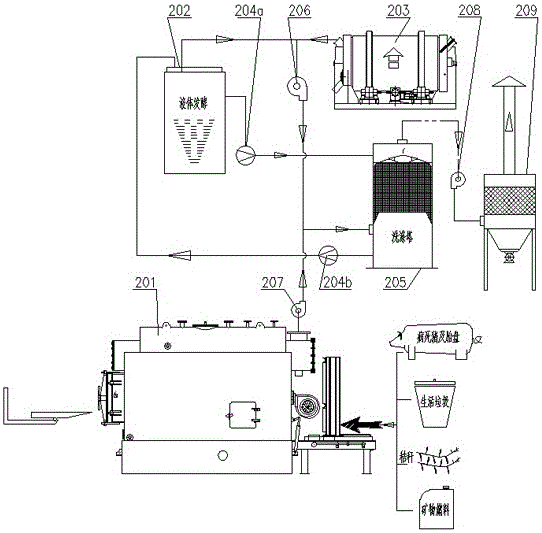

Washing governing system and method for fermentation odor and combustion smoke

ActiveCN106039982ALower pHHigh in nutrientsBio-organic fraction processingGas treatmentProcess engineeringBiomass combustion

The invention discloses a washing governing system and method for fermentation odor and combustion smoke. The system comprises an odor and smoke washing tower, a biological deodorization filtering tower, a multifunctional biomass combustion boiler, a liquid fermentation reactor, a solid fermentation reactor, a circulating pump, an exhaust fan and an induced draft fan; a top end cover of the odor and smoke washing tower is provided with an exhaust port, the side wall of a tank body is provided with a liquid inlet, a gas inlet and a liquid outlet, a lifting basket is placed in the tank body, organic filler and / or inorganic filler are / is placed in the lifting basket, an inner cavity of the washing tower is divided into an inflow liquid dividing cavity, a filler layer, a gas cavity and an accumulated liquid cavity from top to bottom, and supernate on the upper portion in the liquid fermentation reactor is connected with the liquid inlet of the washing tower; smoke of the multifunctional biomass combustion boiler is connected with the gas inlet of the washing tower, and exhaust of the washing tower is connected with the biological deodorization filtering tower; exhaust of the liquid fermentation reactor and exhaust of the solid fermentation reactor are connected with the washing tower; discharged liquid of the washing tower is connected with the liquid fermentation reactor. Through the washing governing system and method, problems concerning fermentation odor and combustion smoke are effectively solved, and environment protection and energy conservation are achieved.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

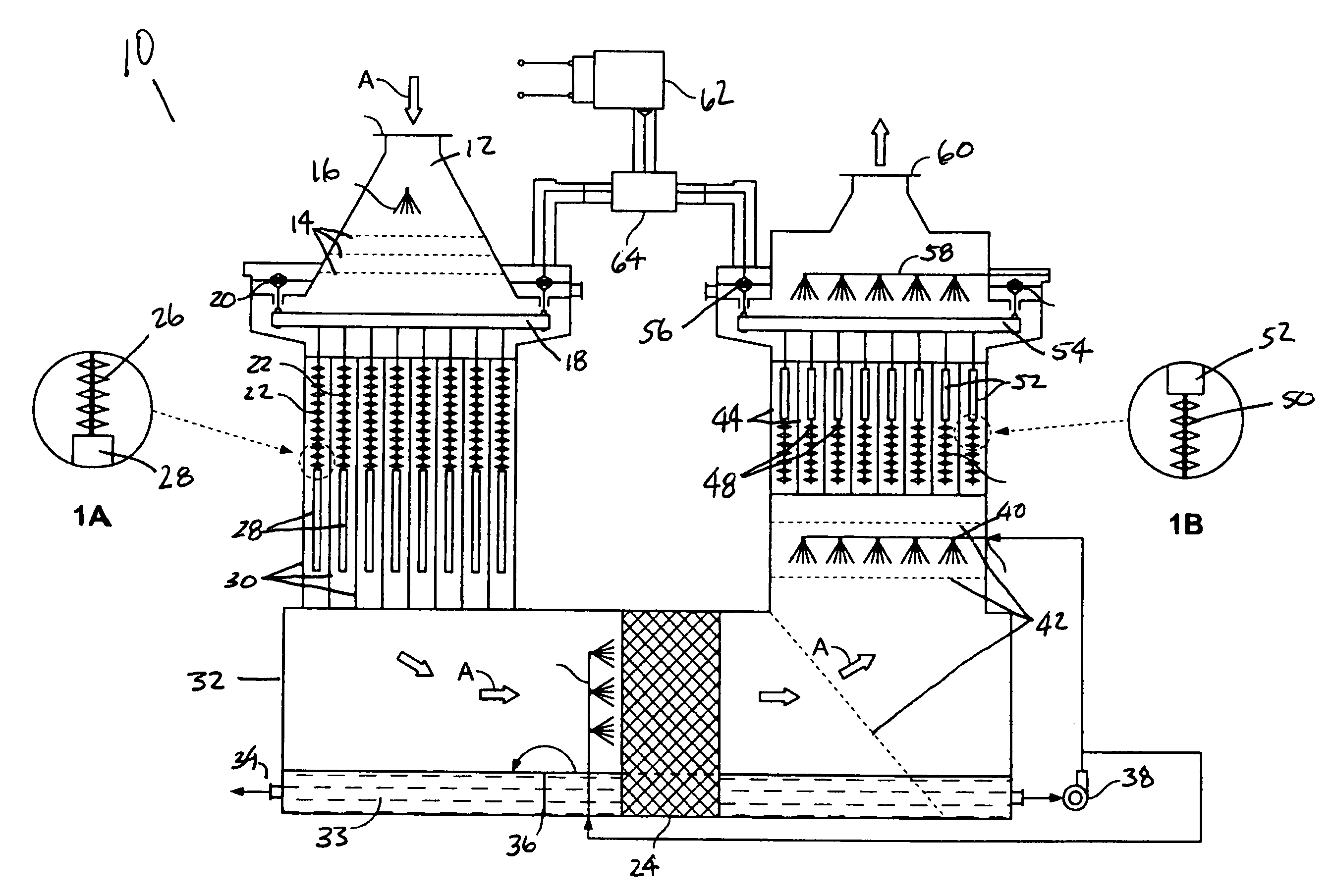

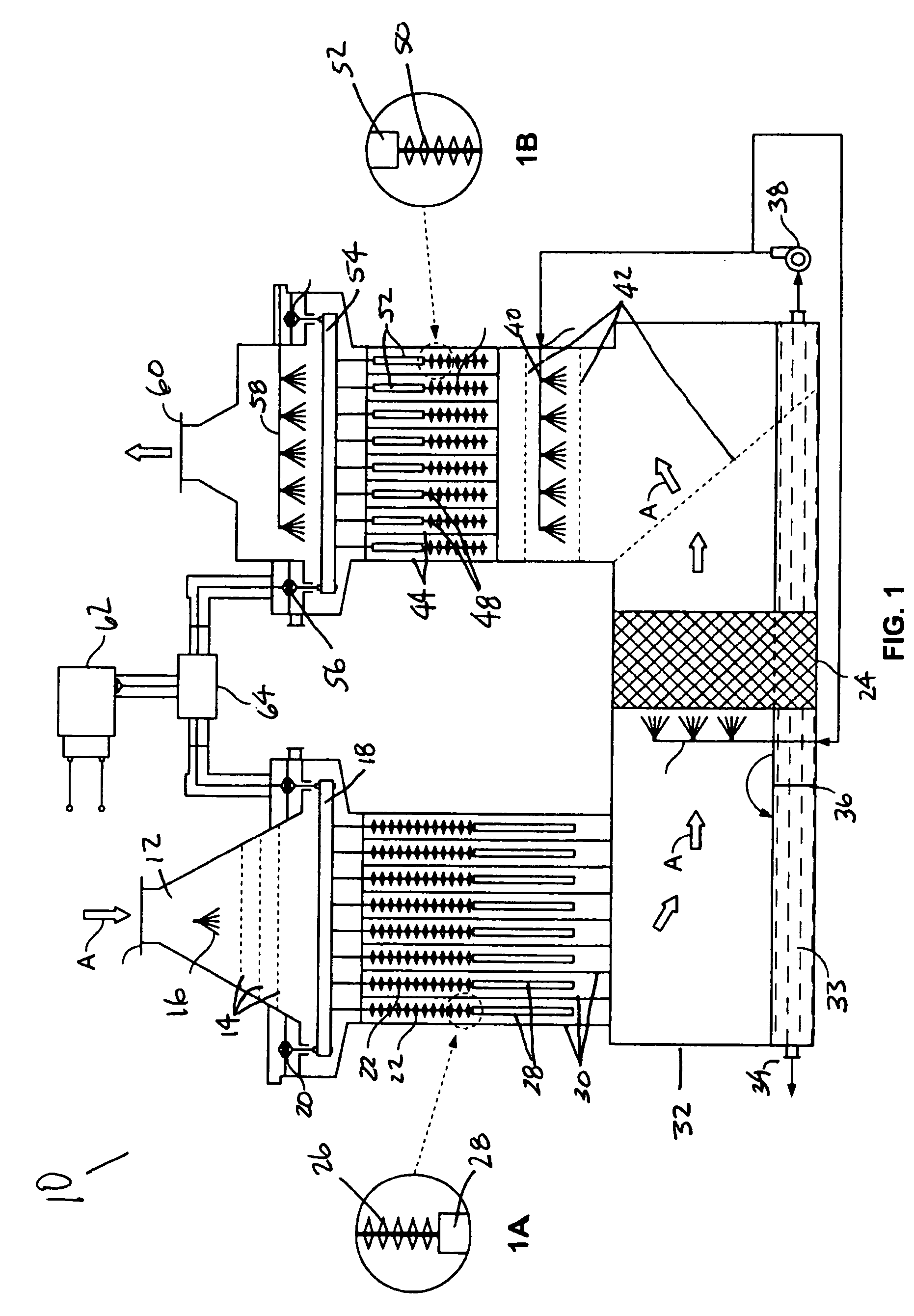

Wet electrostatic precipitator for treating oxidized biomass effluent

ActiveUS20060226373A1Material analysis using wave/particle radiationElectric discharge tubesParticulatesProcess engineering

An apparatus for removing particulate matter from a biomass combustion gas stream, the apparatus having a mist-producing element that mixes a gas stream entering the apparatus with liquid droplets; a Wet Electrostatic Precipitator (WESP) section that includes ionizing electrodes that electrically charge the particulate matter and the intermixed liquid droplets and collecting surfaces under the influence of an electrical field which attract and remove electrically-charged particulate matter and intermixed liquid droplets from the gas stream; and a scrubbing section that provides for additional scrubbing of the gas.

Owner:ZENVIRO TECH HLDG INC

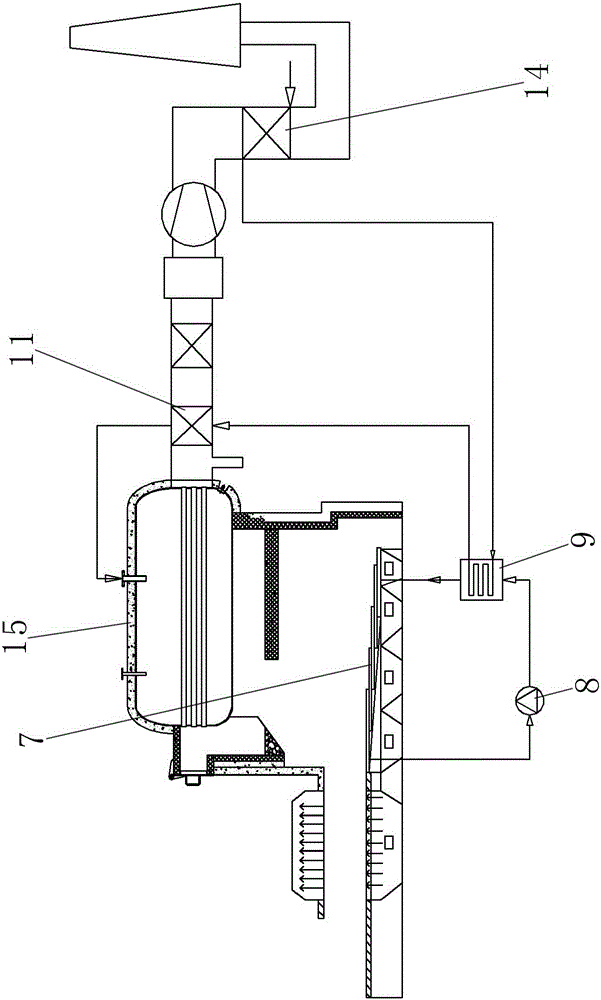

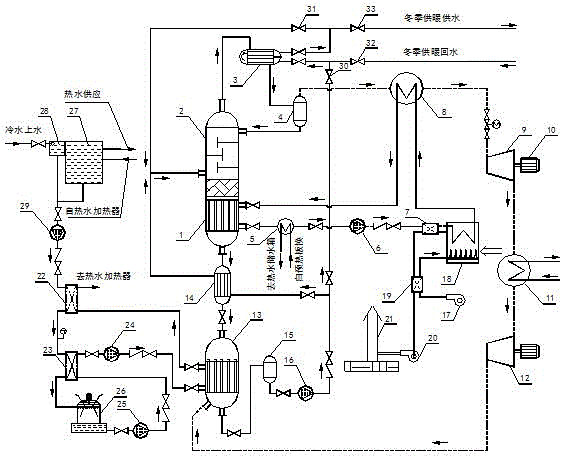

Biomass-combustion-heat-driven absorption type Organic Rankine Cycle distributed combined cooling, heating and power system

ActiveCN106091380AIncrease profitReduce outlet pressureSolidificationLiquefactionThermal energyOrganic Rankine cycle

The invention relates to a biomass-combustion-heat-driven absorption type Organic Rankine Cycle distributed combined cooling, heating and power system and belongs to the technical field of resource and environment. The biomass-combustion-heat-driven absorption type Organic Rankine Cycle distributed combined cooling, heating and power system comprises a biomass boiler equipment pipeline, an absorption type Organic Rankine Cycle circuit, a domestic hot water pipeline, a heating and water supply pipeline, a cooling closed-loop cycle circuit and a cooling water cycle circuit. According to the system, the absorption type refrigeration and the Organic Rankine Cycle are combined organically and the biomass combustion heat is utilized effectively, so that the electric energy can be supplied and the heat capacity and the cooling capacity can be supplied at the same time, the energy source utilization rate can be improved and the gradient utilization of energy can be realized at the same time, and the problem can be solved that the conventional biomass combustion heat is low in utilization rate.

Owner:KUNMING UNIV OF SCI & TECH

Sectionalized biomass combustion device

PendingCN106918040AReduce lossesHigh thermal efficiencySolid fuel combustionCombustion apparatusCombustion chamberEngineering

The invention provides a sectionalized biomass combustion device. The sectionalized biomass combustion device comprises a rack. A feeding device, an air supply device, a combustion chamber and an igniter are arranged on the rack. The feeding device communicates with the combustion chamber. An ignition port is formed in the combustion chamber. The air supply device is used for blowing air into an air chamber. The air chamber communicates with the feeding device and the combustion chamber. A flow disturbing plate is arranged in the combustion chamber. The sectionalized biomass combustion device has the beneficial effects that flow disturbing plates with different sizes can be adopted to change the primary tangent air direction according to the power of a combustion machine and the diameter of a combustion cylinder, so that slight reversal combustion is formed, sectionalized combustion is formed by properly increasing the combustion temperature of the rear section of the combustion cylinder, the rear section is a thermal decomposition section, and the front section is a high-temperature gasification section; and by widening the combustion temperature adjustment range, high-temperature biomass raw materials can be combusted and decomposed, and the adaptability of the device is improved, so that fuel is combusted sufficiently, the loss caused by insufficient combustion is reduced, and the heat efficiency is greatly improved.

Owner:XIAN SENWAS AGRI SCI & TECH

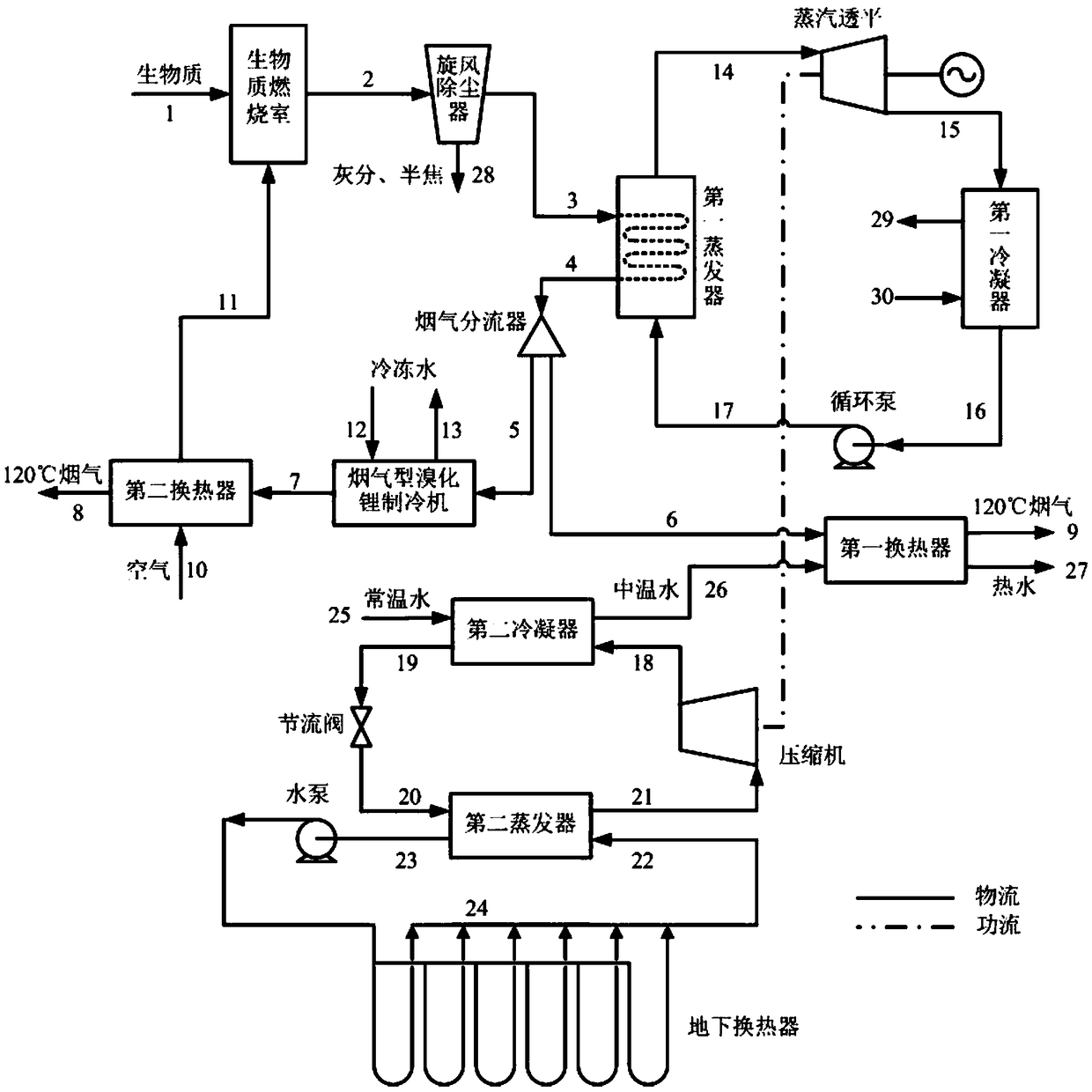

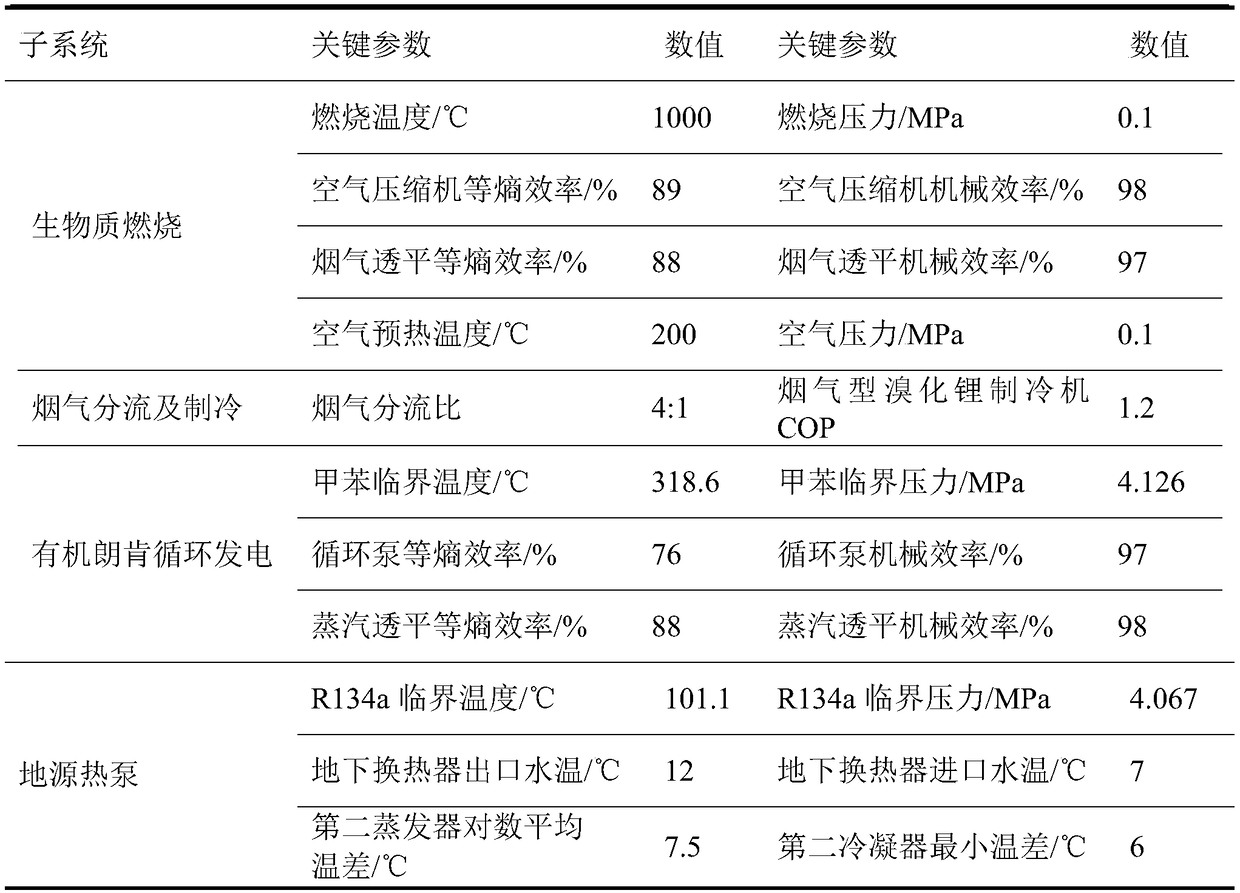

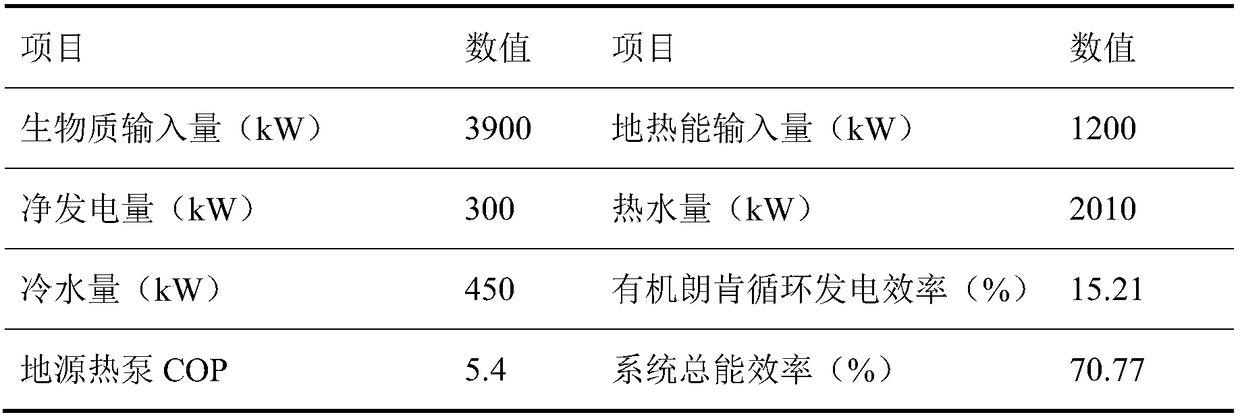

Biomass and geothermal energy complementary organic Rankine cycle distributed energy system

InactiveCN108954907AReduce dependenceAchieve sustainable developmentFluid heatersHeat pumpsOrganic Rankine cycleLithium bromide

The invention discloses a biomass and geothermal energy complementary organic Rankine cycle distributed energy system which comprises a biomass combustion subsystem, an organic Rankine cycle power generation subsystem, a flue gas distribution and refrigeration subsystem and a ground source heat pump subsystem. Main equipment comprises a biomass combustion chamber, a cyclone dust collector, a second heat exchanger, a first evaporator, a steam turbine, a first condenser, a circulation pump, a flue gas distributor, a flue gas type lithium bromide refrigerator, a water pump, an underground heat exchanger, a second evaporator, a compressor, a second condenser, a throttling valve and a first heat exchanger. Two kinds of energy technologies of biomass organic Rankine cycle and the ground source heat pump are integrated, and two kinds of energy are efficiently utilized through system complementary integration. The total energy efficiency of the system reaches up to 70% or more, and a great significance is achieved for energy system structure optimization, output of various kinds of energy products and environmental and sustainable development.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

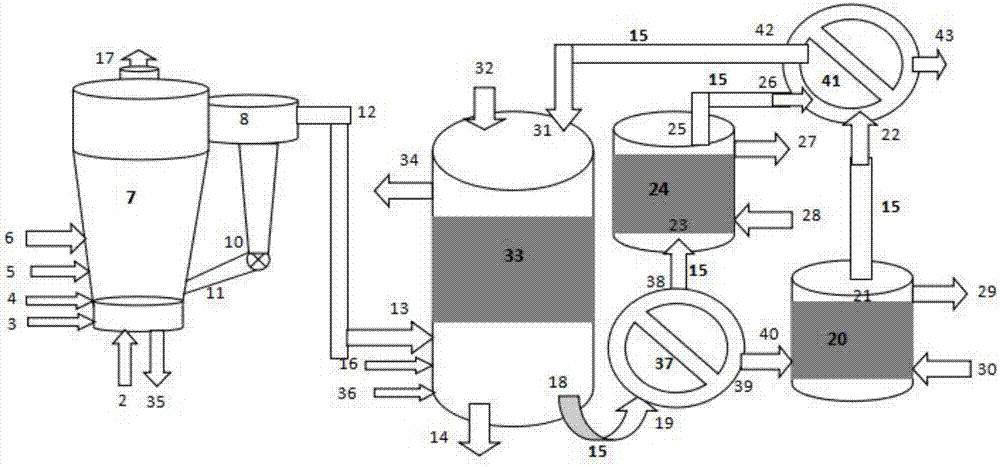

Process for producing hydrogen by combining biomass gasification in circulating fluidized bed with H2 adsorption enhanced water vapor transformation

ActiveCN107142128AImprove adaptabilityAvoid impact damageGas treatmentDispersed particle separationWater vaporIn situ adsorption

The invention provides a process for producing hydrogen by combining biomass combustion gasification and furnace internal calcium spraying in a circulating fluidized bed with H2 in-situ adsorption enhanced water vapor transformation. The process comprises the following steps: gradually enlarging a conical circulating fluidized bed of a hearth, and enabling biomass to carry out partial air combustion at the bottom of the circulating fluidized bed; releasing heat for water vapor gasification of most biomass raw materials; moreover, spraying quicklime into the furnace for catalytic synergism, enabling synergic gas generated by the circulating fluidized bed to enter a moving-bed reactor, and carrying out H2 in-situ adsorption enhanced water vapor transformation reaction to produce hydrogen at the temperature of 250 to 350DEG C; at the same time, adsorbing produced hydrogen and storing the adsorbed hydrogen in a hydrogen absorption material; separating the hydrogen absorption material for regenerating to release pure hydrogen; arranging a water vapor transformation moving bed reactor, a solid separator, a regenerator and a solid mixer for H2 adsorption enhanced water vapor transformation, and enabling a water vapor transformation catalyst and the hydrogen absorption material for adsorbing H2 to continuously and simultaneously move, react and regenerate, so as to obtain pure hydrogen with the content of 100 percent.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

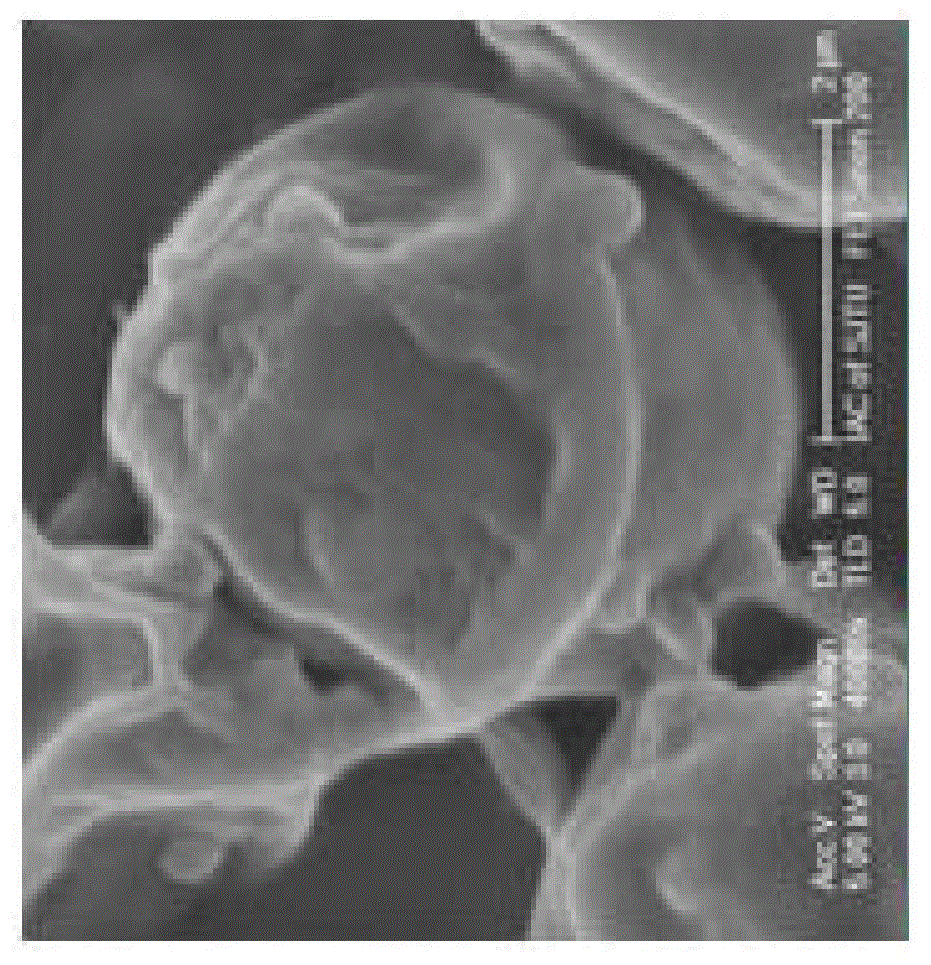

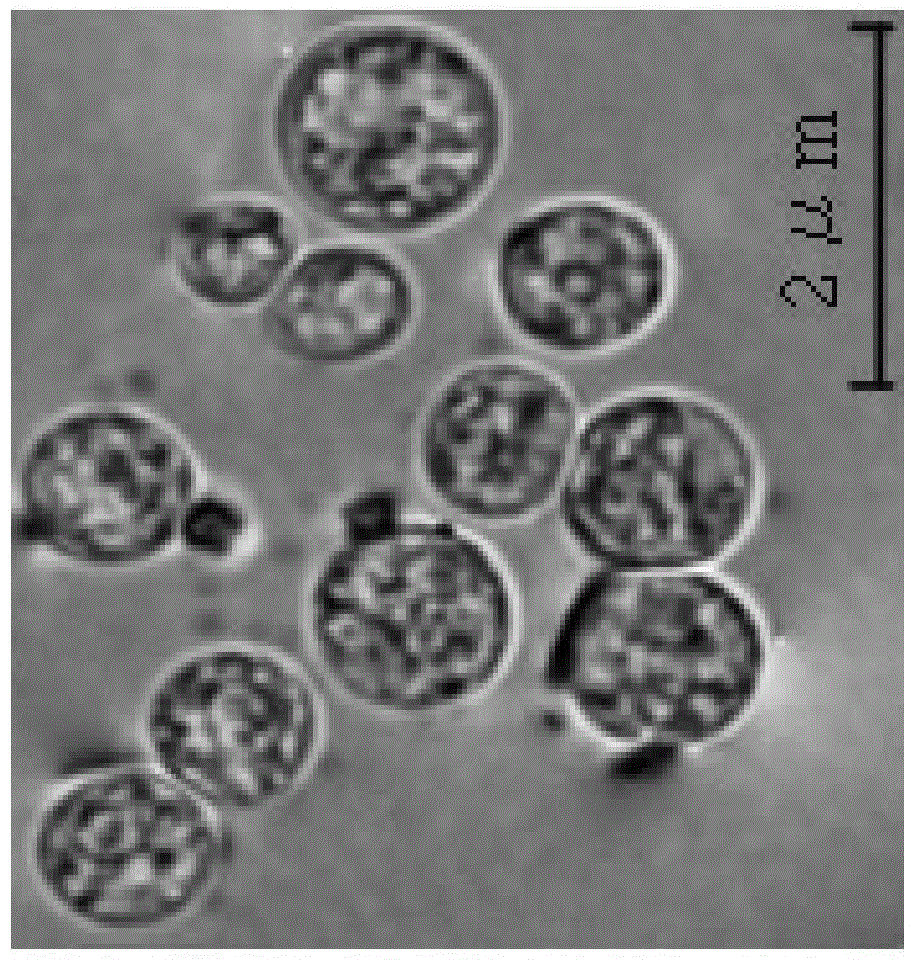

Freshwater Chlorella sorokiniana GS30 and application thereof

InactiveCN103952312AEfficient emission reductionEffectively fixedUnicellular algaeBiofuelsBiodieselEngineering

The invention relates to the technical field of biomass energy, and in particular to a freshwater chlorella strain (i) Chlorella sorokiniana ( / i) GS03 and application thereof to industrial flue gas CO2 fixation and production of microalgae biodiesel. The chlorella strain (i) C.sorokiniana ( / i) GS03 provided by the invention has a preservation number of CCTCC M2013607, and higher CO2 tolerance, higher fixation efficiency of high-concentration carbon dioxide and higher biomass yield and oil yield compared with the reported microalgae strains. Therefore, the invention can greatly reduce microalgal oil production cost, and provides a good production strain for algae for efficient fixation of CO2 in typical industrial flue gas environment and biodiesel production from microalgae oil, and shows great application prospect in the field of biomass energy.

Owner:SHANGHAI JIAO TONG UNIV

Biomass combustion furnace

ActiveCN103591573AIncrease profitThe ignition process is smooth and fastAir supply regulationSolid fuel combustionCombustion chamberAir blower

The invention relates to combustion furnaces and provides a biomass combustion furnace which is suitable for heating heat transfer oil furnaces, superheated steam furnaces, air heating furnaces, water heaters and the like. Through the biomass combustion furnace, biomass can be enabled to be combusted sufficiently, utilization rate of biomass combustion is increased, combustion ash can be removed timely during combustion, and pollution due to the fact that air flow is discharged into air is avoided. The biomass combustion furnace comprises a combustion base, a combustion chamber arranged on the combustion base and a flange arranged on the combustion chamber, the combustion base comprises a combustion base body, a feed device and a second air blower, an ash storage box is arranged at one end of the combustion base body, an air inlet box is arranged at the other end of the combustion base body, a combustion tank which is communicated with the ash storage box and the air inlet box is arranged on the upper portion of the combustion base body, air vents are formed in the combustion tank, the combustion tank, the bottom surface and the lateral surface of the combustion base body, the ash storage box and the air inlet box form a cavity jointly, an air inlet communicated with the air inlet box is formed in the lateral surface, connected with the air inlet box, of the cavity, the feed device is arranged outside the combustion base body and passes through the air inlet box to be led to the combustion groove, and the second air blower is communicated with the air inlet box.

Owner:泉州恒灼热力机械科技有限公司

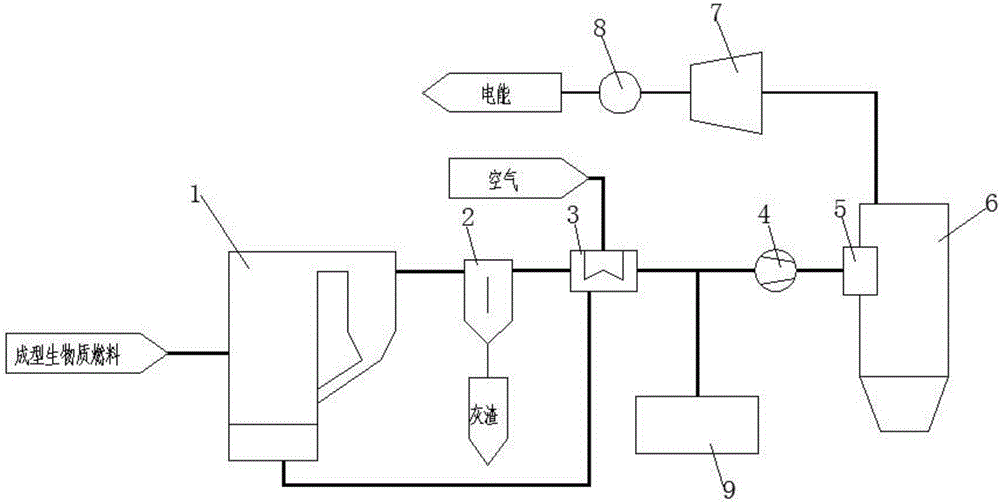

Power generation system and method by mixing fuel gas generated in molded biomass fuel burning with pulverized coal

InactiveCN106221816AReduce storage footprintEasy to transportSteam generation using pressureGasification processes detailsLow loadHeat energy

The invention discloses a power generation system and method by mixing fuel gas generated by molded biomass fuel burning with pulverized coal. Burning molded biomass fuel for a circulating fluidized bed is adopted, biomass energy is converted into high-temperature biomass gas, after high-temperature dust removal and heat exchange and cooling, the biomass gas is sent into a gas burner arranged on a pulverized coal boiler through a booster fan and has mixed combustion with the high-temperature pulverized coal in the boiler through the gas burner, so as to improve the utilization efficiency of the biomass energy and utilize an efficient coal-fired power generation unit to conduct combined power generation by the biomass and the fire coal. According to the system, a biomass gas energy on-line measuring device is arranged, so as to realize real-time effective online biomass gas heat energy detection. According to the power generation system and method, the problems that a biomass power plant is difficult in storage, large in land occupation and low in burning power generation efficiency are better solved, the system takes full use of the existing coal-fired power generation unit device to efficiently conduct power generation by molded biomass fuel, meanwhile the fire coal consumption of the existing coal-fired power generation unit is also reduced, and the low-load stable burning property, the low-load capacity and the low-load boiler efficiency of the existing coal-fired unit are improved.

Owner:浙江百能科技有限公司

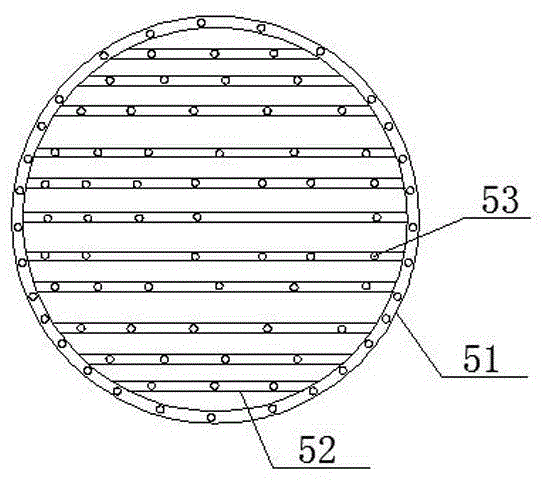

Biomass combustion boiler

ActiveCN104654285AIncrease profitThorough heat exchangeFluidized bed combustionWater heatersCombustion chamberBiomass combustion

The invention discloses a biomass combustion boiler. The biomass combustion boiler comprises an outer shell and an internal combustion chamber, wherein a water storage chamber is arranged between the shell and the combustion chamber; the lower part of the combustion chamber is provided with a fire grate; the fire grate comprises a fist round support pipe fit with the inner wall of the combustion chamber and a plurality of rib pipes which are horizontally arranged on a first round support pipe side by side; the first round support pipe and the rib pipes are provided with a plurality of upper air exhaust holes which exhaust air upwards; a second round support pipe close to the inner wall of the combustion chamber is arranged above the fire grate, and is provided with a plurality of vertical air blowing pipes communicated with the second round support pipe; the second round support pipe and the vertical air blowing pipes are provided with a plurality of radial air exhaust holes; the first round support pipe and the second round support are both communicated with an air outlet of the fan via connecting pipelines; the side surface of the shell is provided with a fuel charge pipe communicated with a packing auger outlet which is communicated with a fuel charge hopper. According to the biomass combustion boiler, by changing the structure of the fire grate and the air supplying mode of combustion supporting air, fuels are combusted fully, and the combustion efficiency is improved.

Owner:安徽长城锅炉制造有限公司

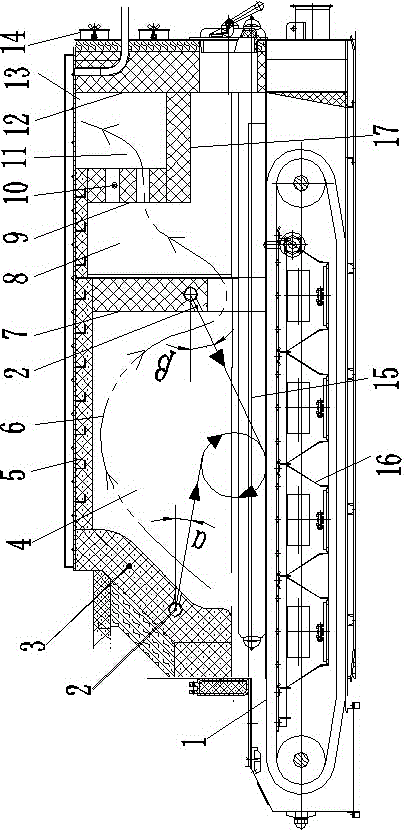

Novel hearth structure of biomass chain boiler

InactiveCN104566337AExtended stayOptimize thermal fieldSolid fuel combustionAir/fuel supply for combustionCombustion chamberSlag

The invention discloses a novel hearth structure of a biomass chain boiler. The novel hearth structure of the biomass chain boiler comprises a chain grate, wherein a front arch, a middle arch and a rear arch are sequentially arranged above the chain grate from front to back; the middle arch consists of a vertical flame turning wall; the rear arch comprises a vertical decorated wall and a transverse wall; the transverse wall is arranged on the rear side of the bottom of the decorated wall and transversely extends front and back; an arch top is arranged between the front arch and the middle arch, and an arch top is arranged between the middle arch and the rear arch; a first combustion chamber is formed between the front arch and the middle arch; a second combustion chamber is formed between the middle arch and the rear arch; a vertical rear boiler wall is arranged on the rear side of the rear arch; the decorated wall, the transverse wall and the rear boiler wall enclose a third combustion chamber. According to the novel hearth structure of the biomass chain boiler, a hearth can be effectively matched with the chain grate, an air power field in the boiler is organized, the combustion efficiency is improved, and the problems of ash deposition and slag formation in the biomass combustion process are mitigated.

Owner:HENAN AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com